Patents

Literature

74results about How to "High cutting surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

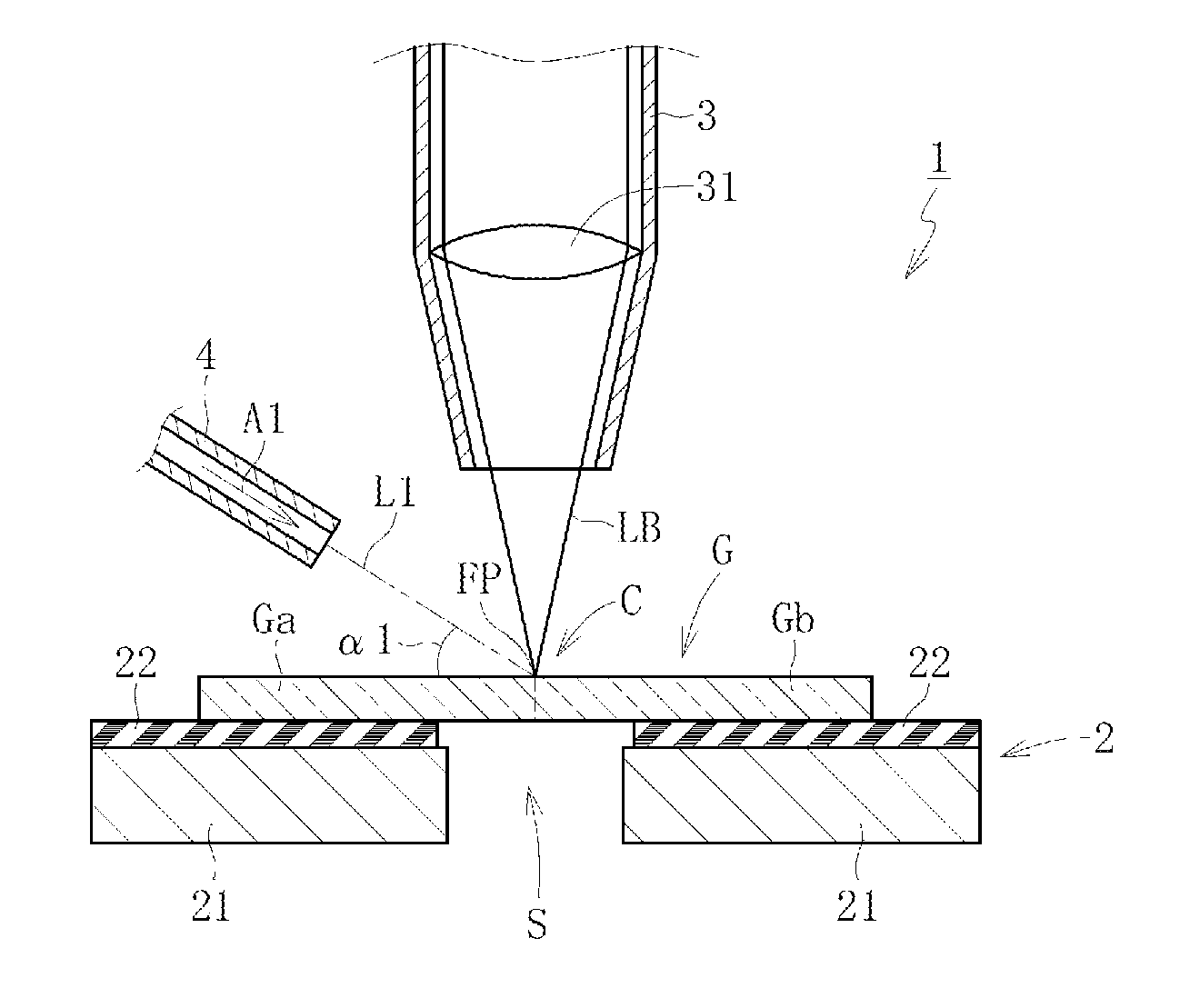

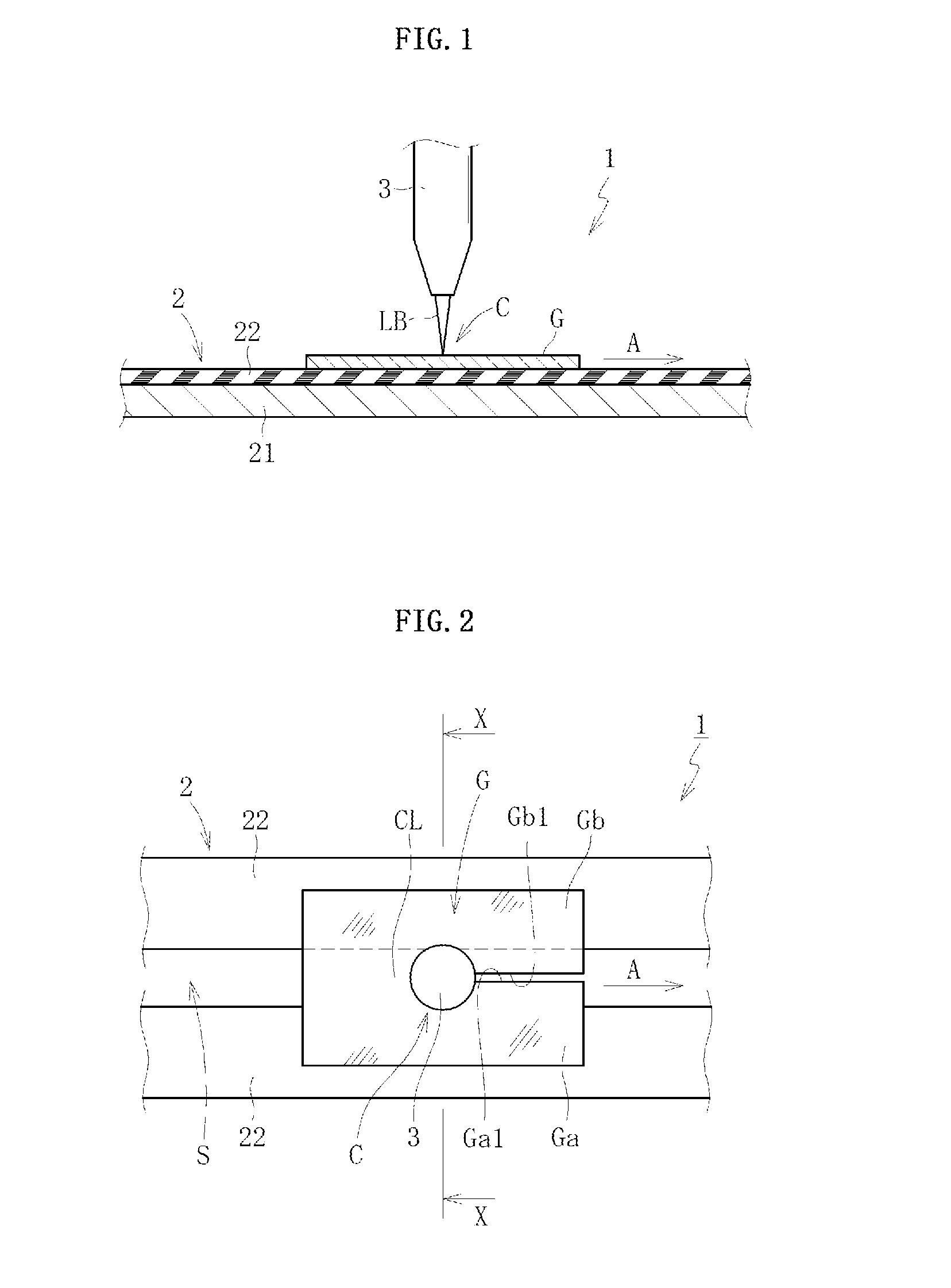

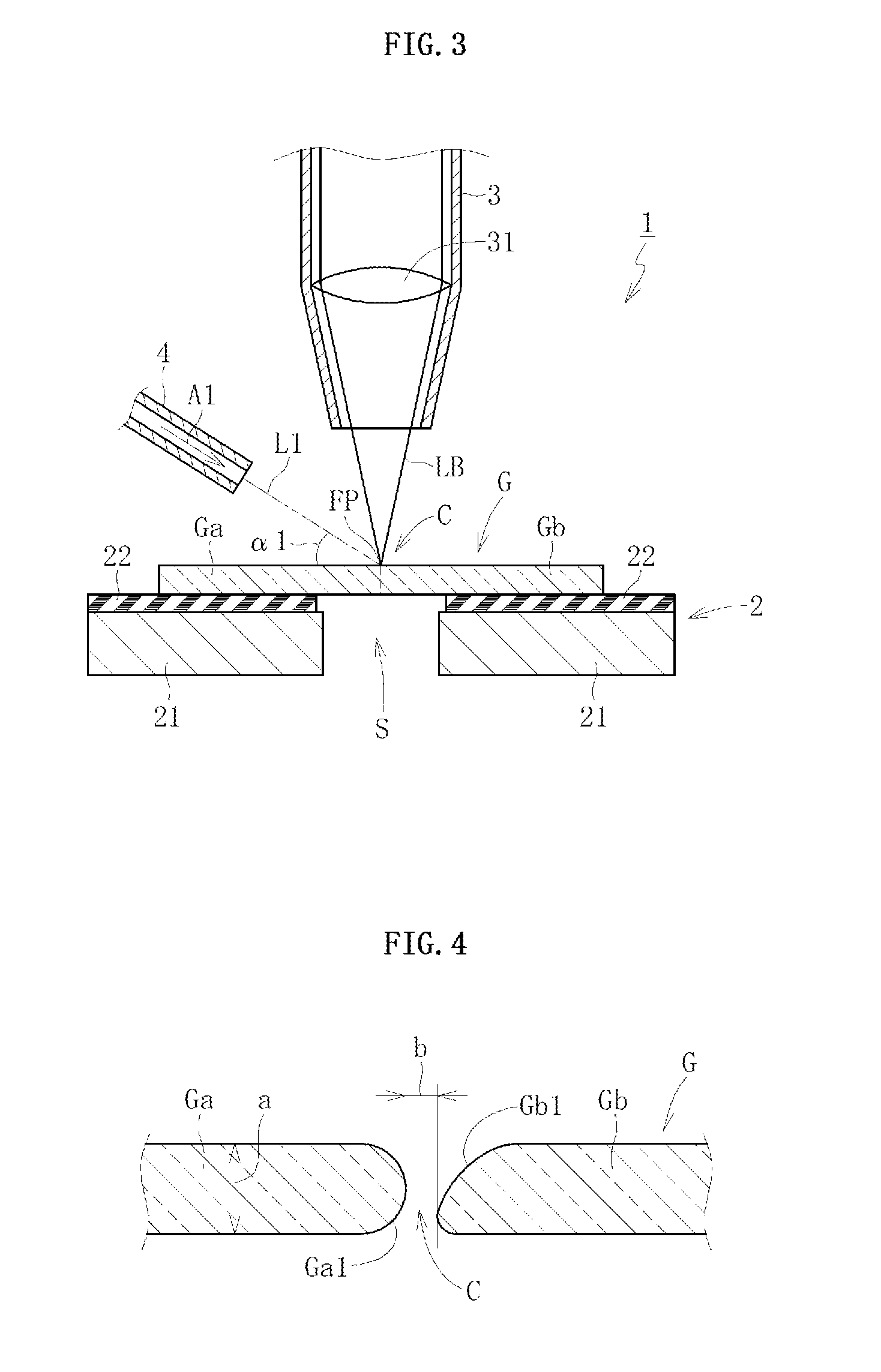

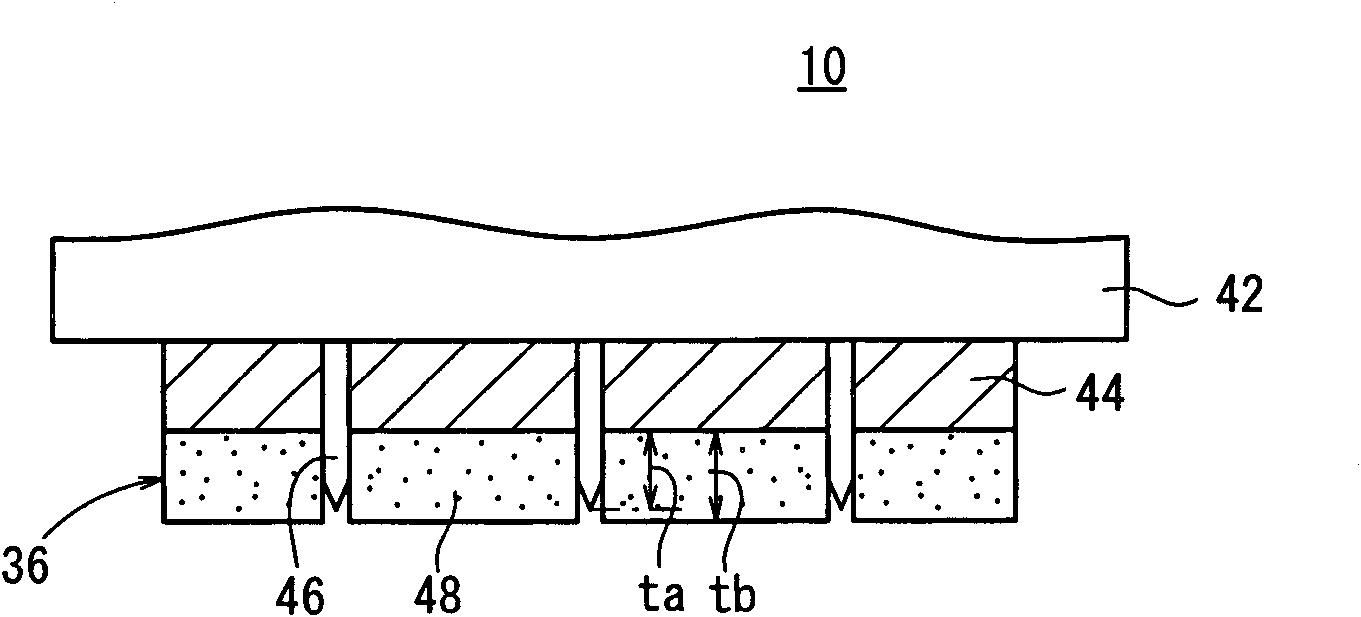

Cutting method for glass sheet and glass sheet cutting apparatus

ActiveUS20130122264A1Safe separationStrict managementGlass furnace apparatusCellulosic plastic layered productsLaser beamsGlass sheet

Provided is a cutting method for a glass sheet, comprising radiating a laser beam to a cutting portion (C) of a glass sheet (G) having a thickness of 500 μm or less to fuse the glass sheet (G), wherein a narrowest gap between fused end surfaces (Ga1 and Gb1) of the glass sheet (G), which face each other in the cutting portion (C), is managed to satisfy a relationship of 0.1≦b / a≦2, where “a” is a thickness of the glass sheet (G) and “b” is the narrowest gap.

Owner:NIPPON ELECTRIC GLASS CO LTD

Linear cutting emulsified liquid

InactiveCN1439698AEasy to demouldEasy to cleanLubricant compositionPotassium hydroxidePhosphoric acid

An emulsified soap as the working liquid of linear cutting is prepared through proportionally mixing machine oil, oleic acid and resin, heating to 70-95 deg.c, sequentially and proportionally adding potassium hydroxide, phosphate and additive, and heating to 120-130 deg.C. Its advantages are high power for cutting thick (300-500 mm) workpiece, easy demoulding and cleaning, and high cutting quality and efficiency.

Owner:金庆同 +2

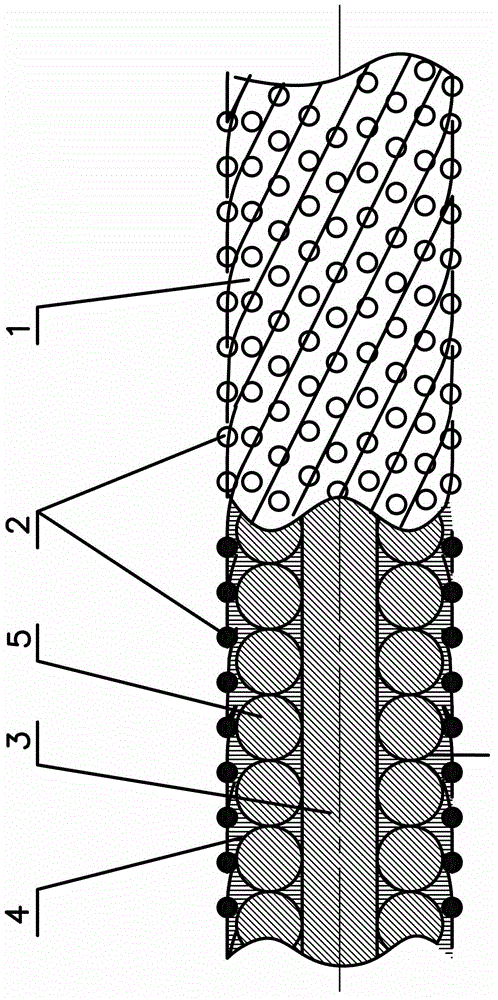

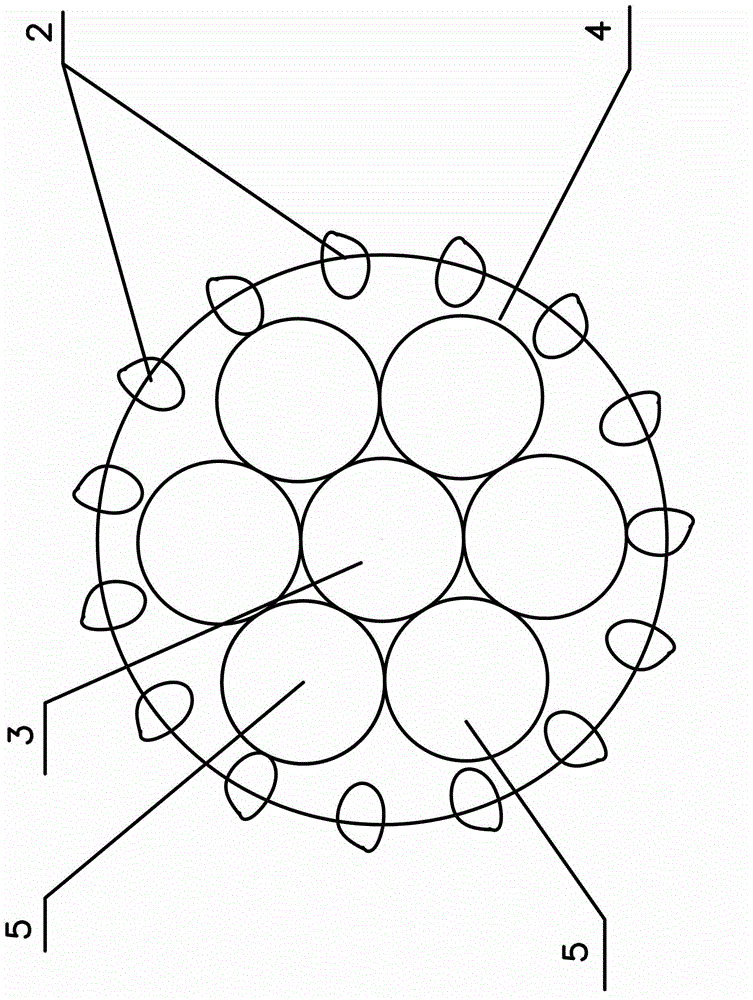

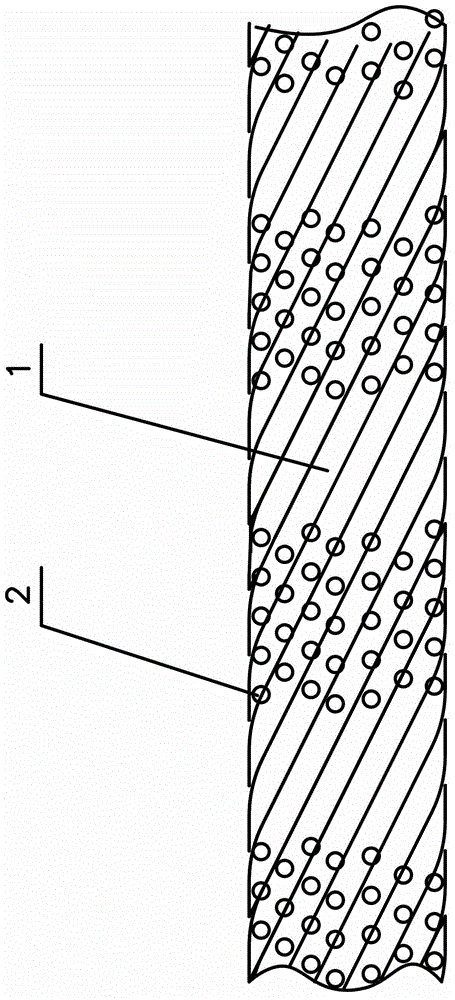

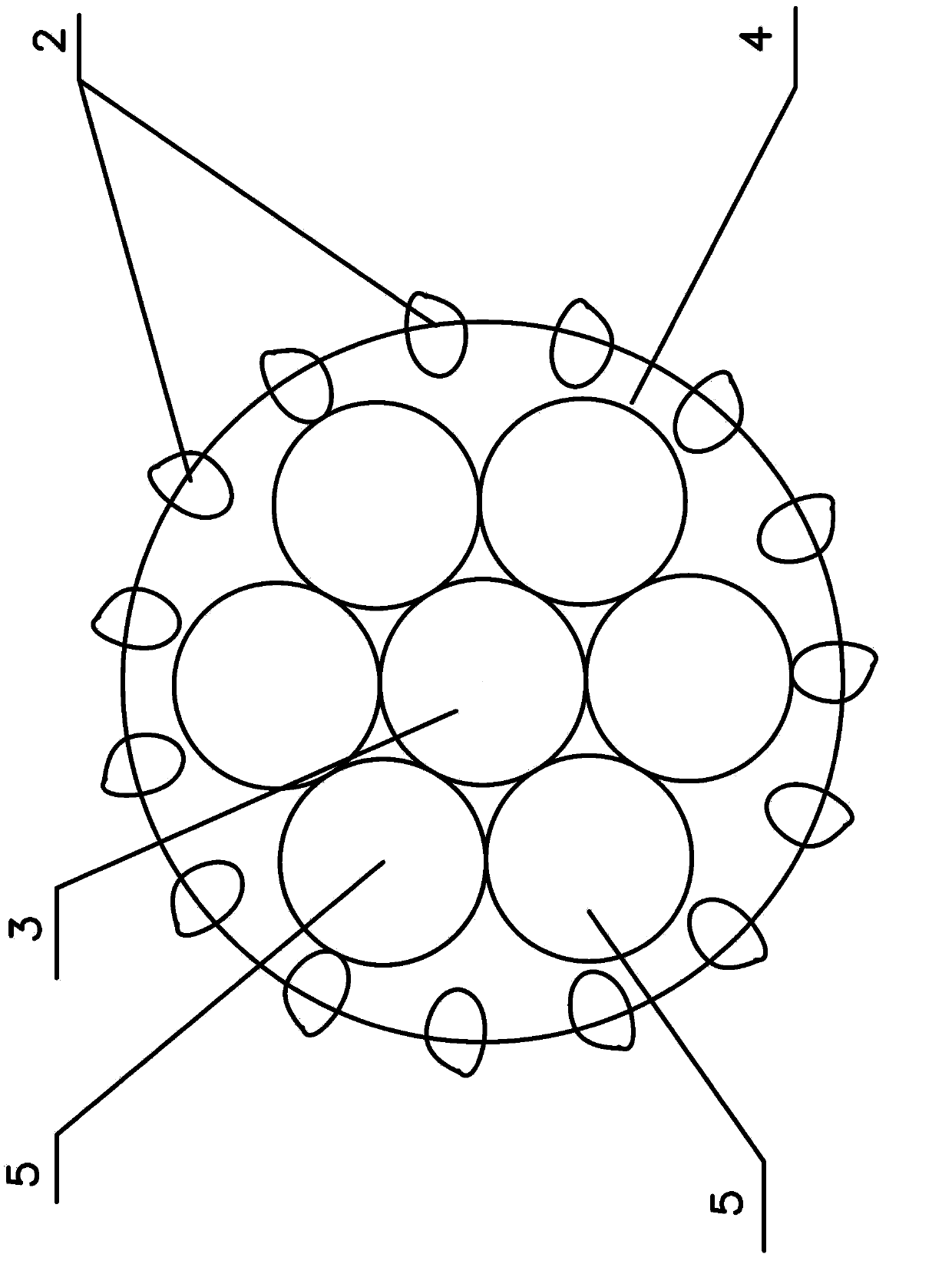

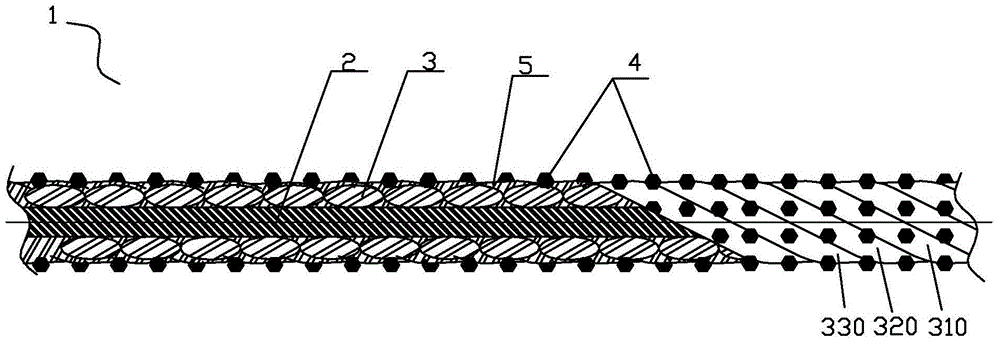

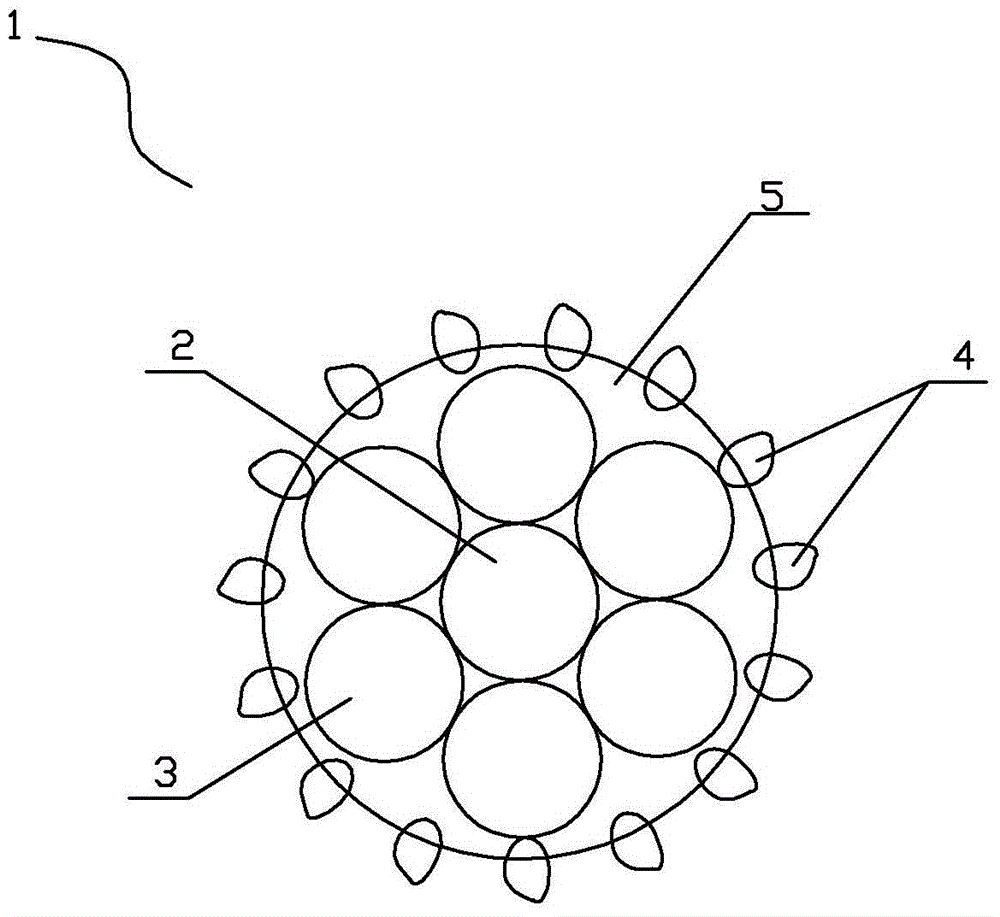

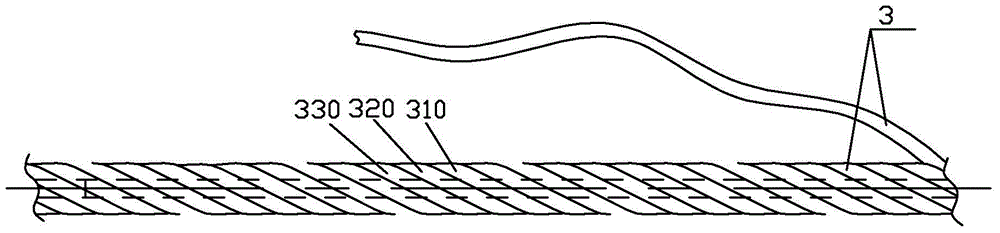

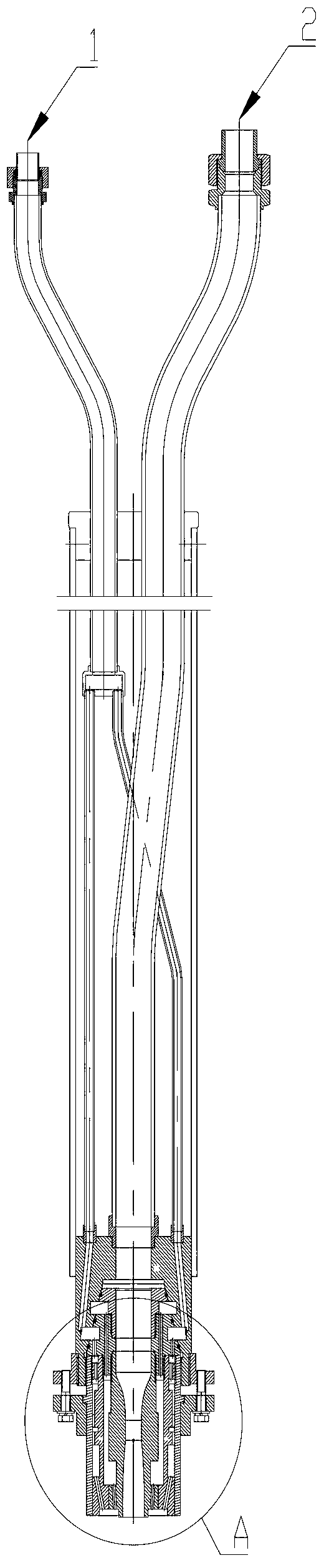

Annular super-hard abrasive wire and method for manufacturing same

ActiveCN102873401AUniform thicknessUniform distribution of superabrasive particlesMetal sawing tool makingHigh intensityElectrical conductor

The invention discloses an annular super-hard abrasive wire and a method for manufacturing the same. The annular super-hard abrasive wire comprises a rope, super-hard abrasive particles and a coating, wherein the size of the rope ranges from 0.1mm to 6mm, the super-hard abrasive particles are solidified on the surface of the rope, and the coating is used for solidifying the super-hard abrasive particles. The method for manufacturing the annular super-hard abrasive wire includes braiding the thin rope to form a ring with an optional perimeter; and then solidifying the super-hard abrasive particles on the surface of the annular rope by means of coating to form the high-strength annular super-hard abrasive wire with the uniform outer diameter and a long service life. The annular super-hard abrasive wire is low in cost, high in fatigue strength, long in service life, good in cutting quality and high in cutting efficiency, and a cutting machine with the annular wire can be used for cutting conductors, semiconductors and non-conductor materials.

Owner:中国有色桂林矿产地质研究院有限公司

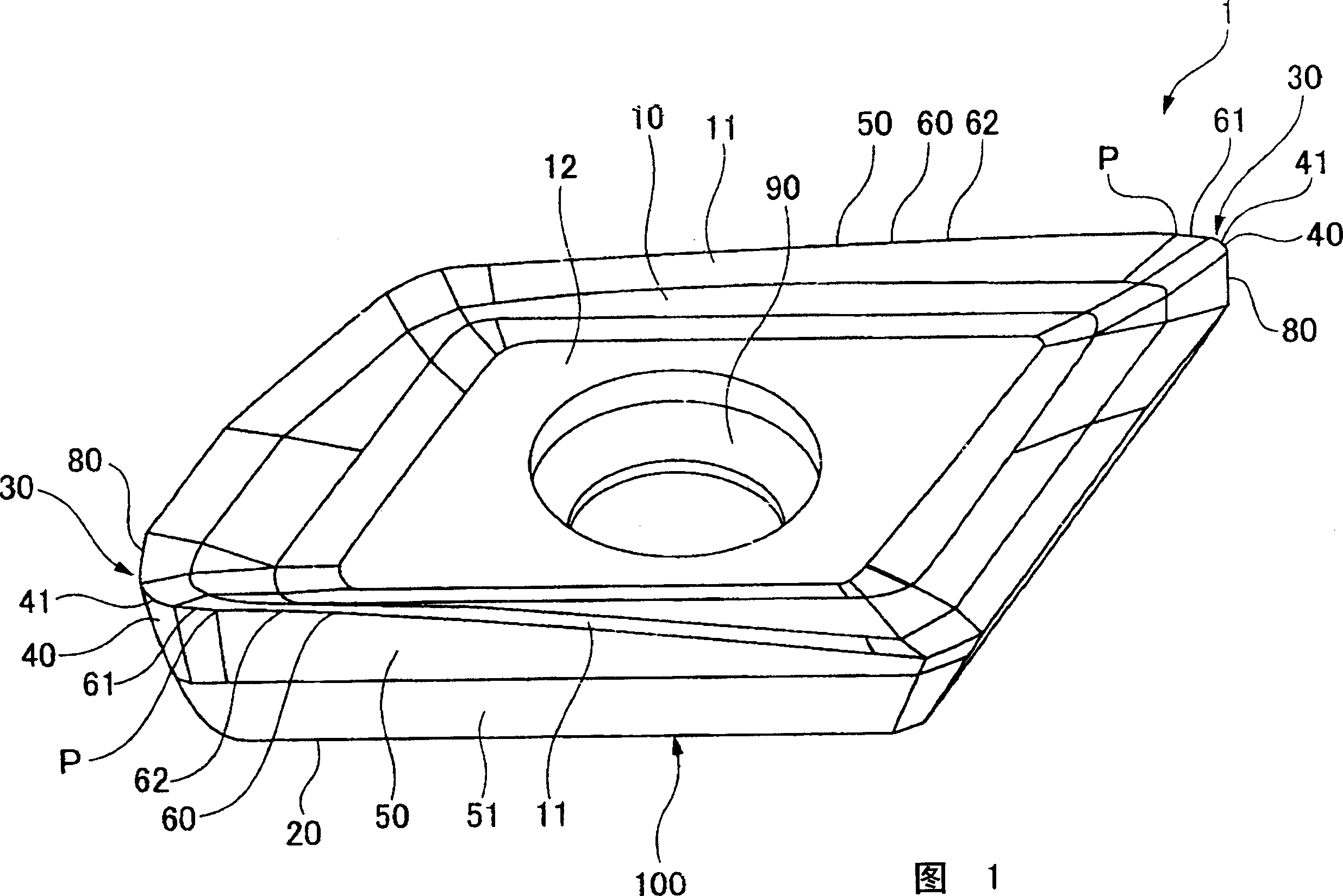

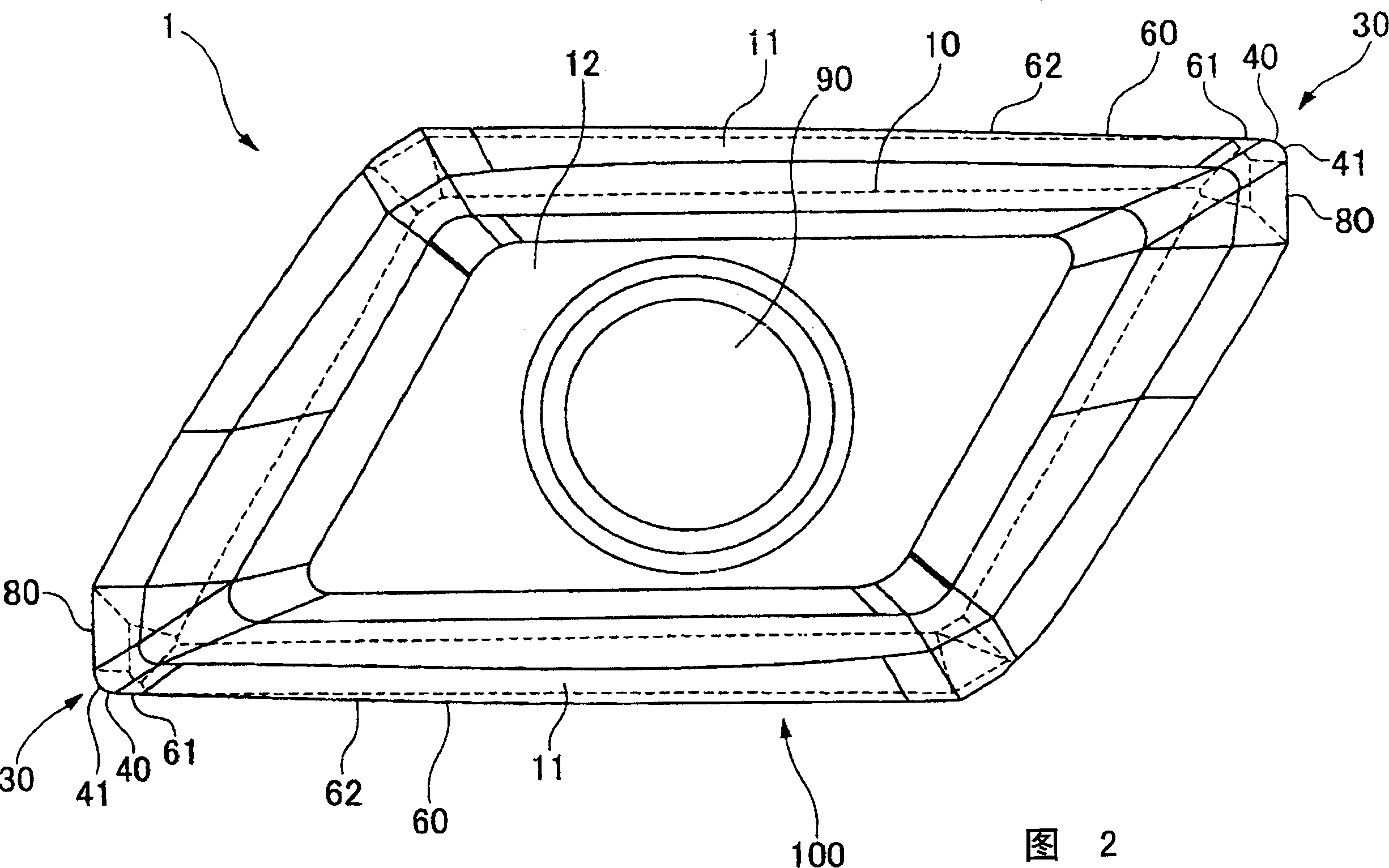

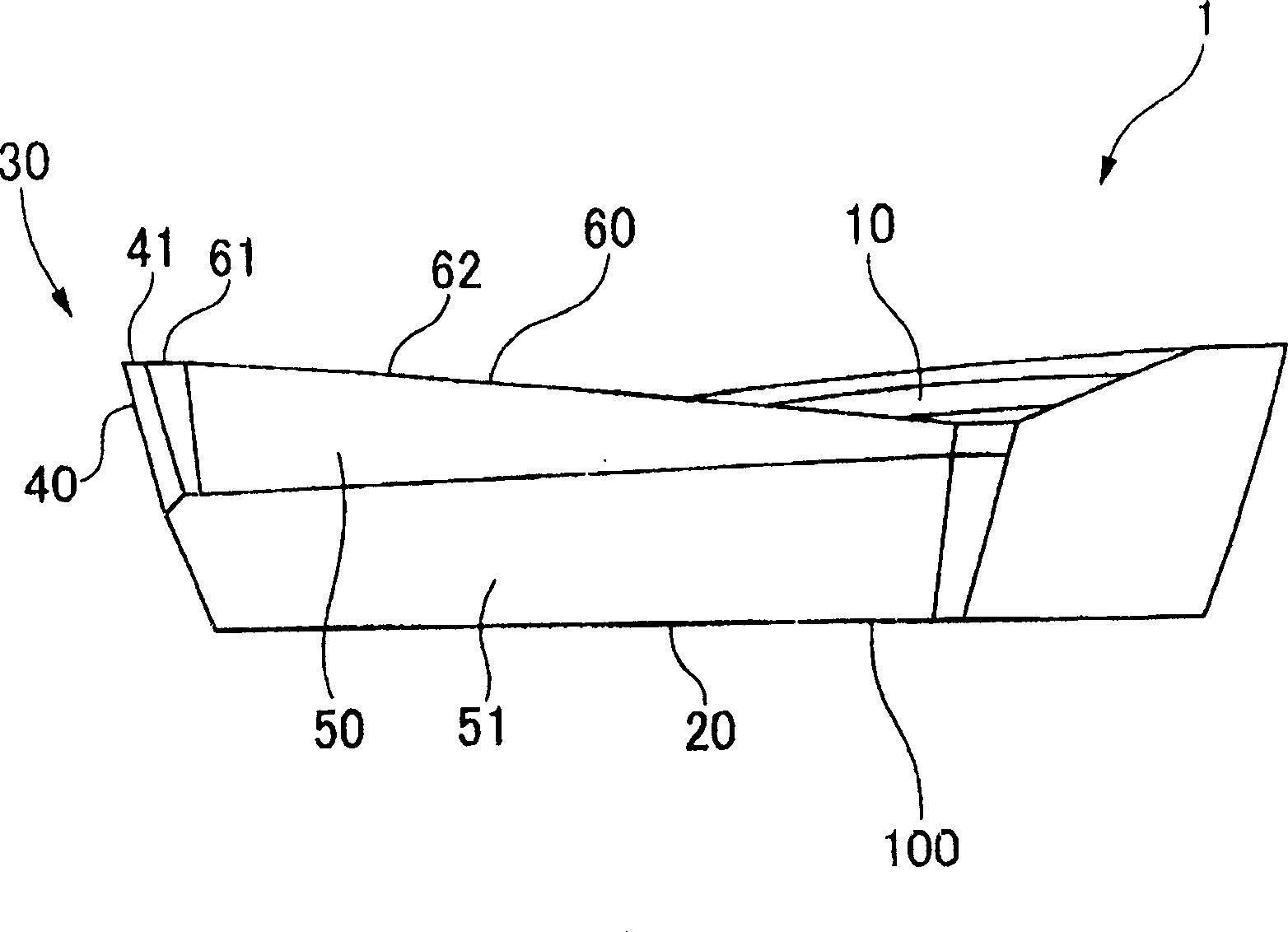

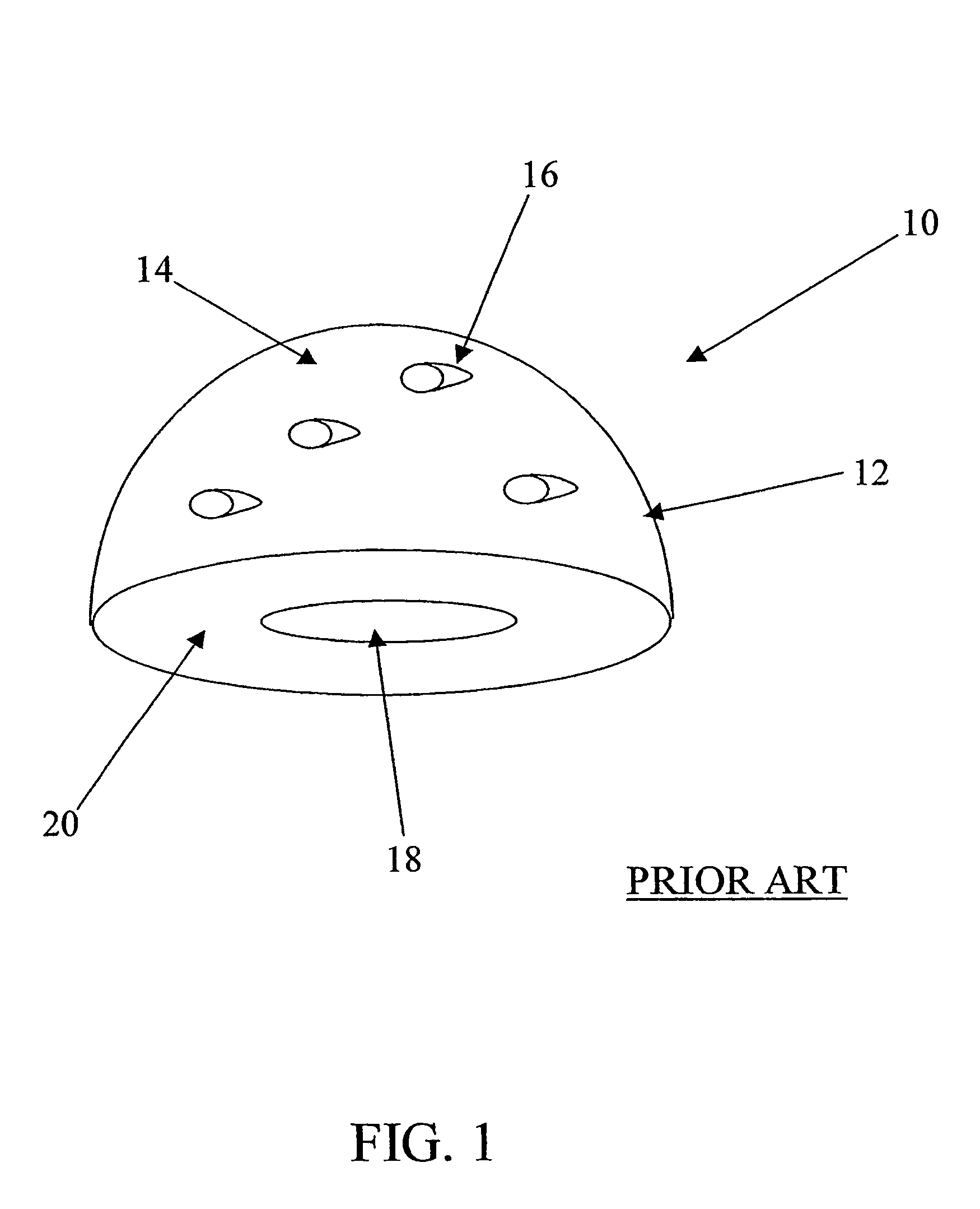

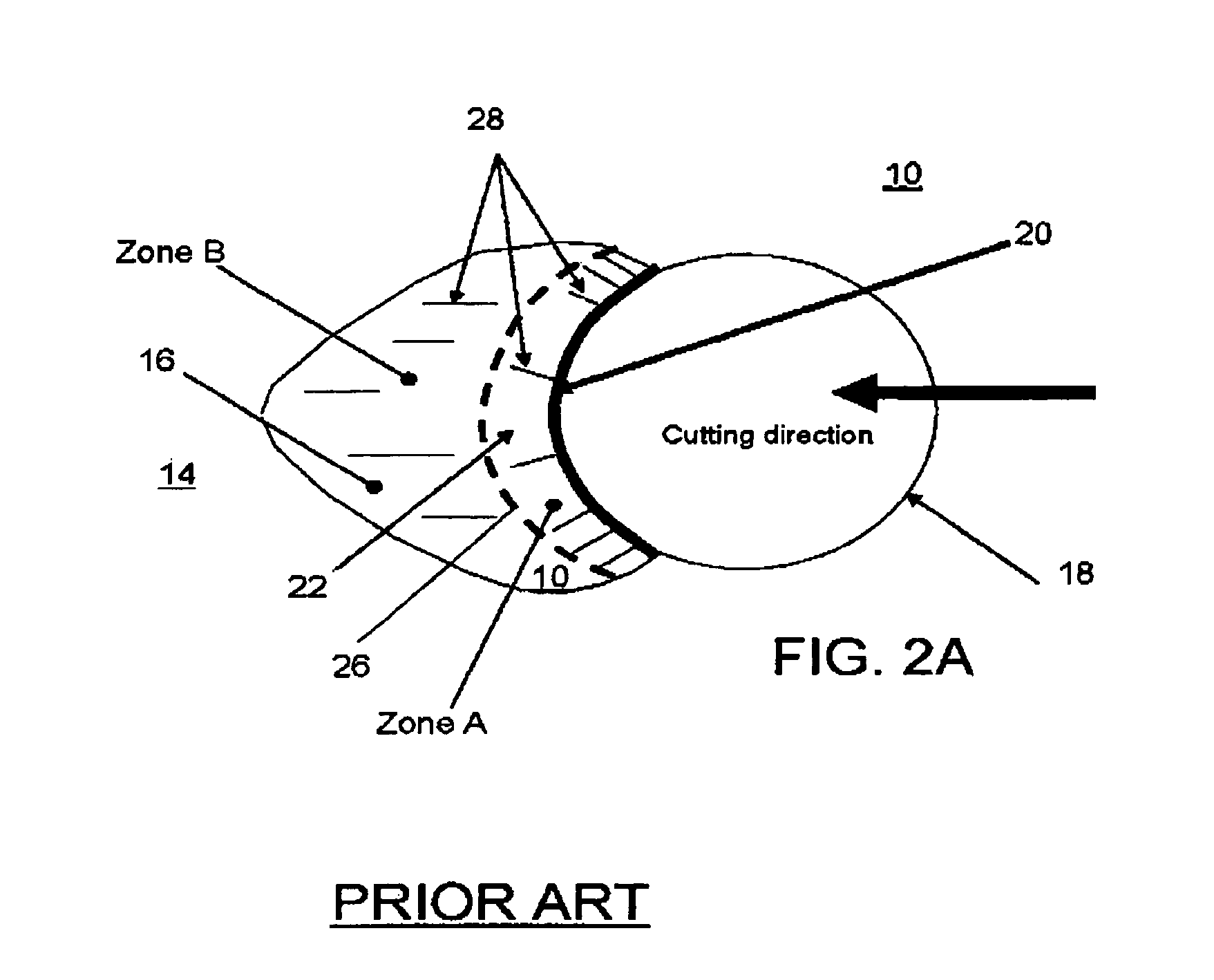

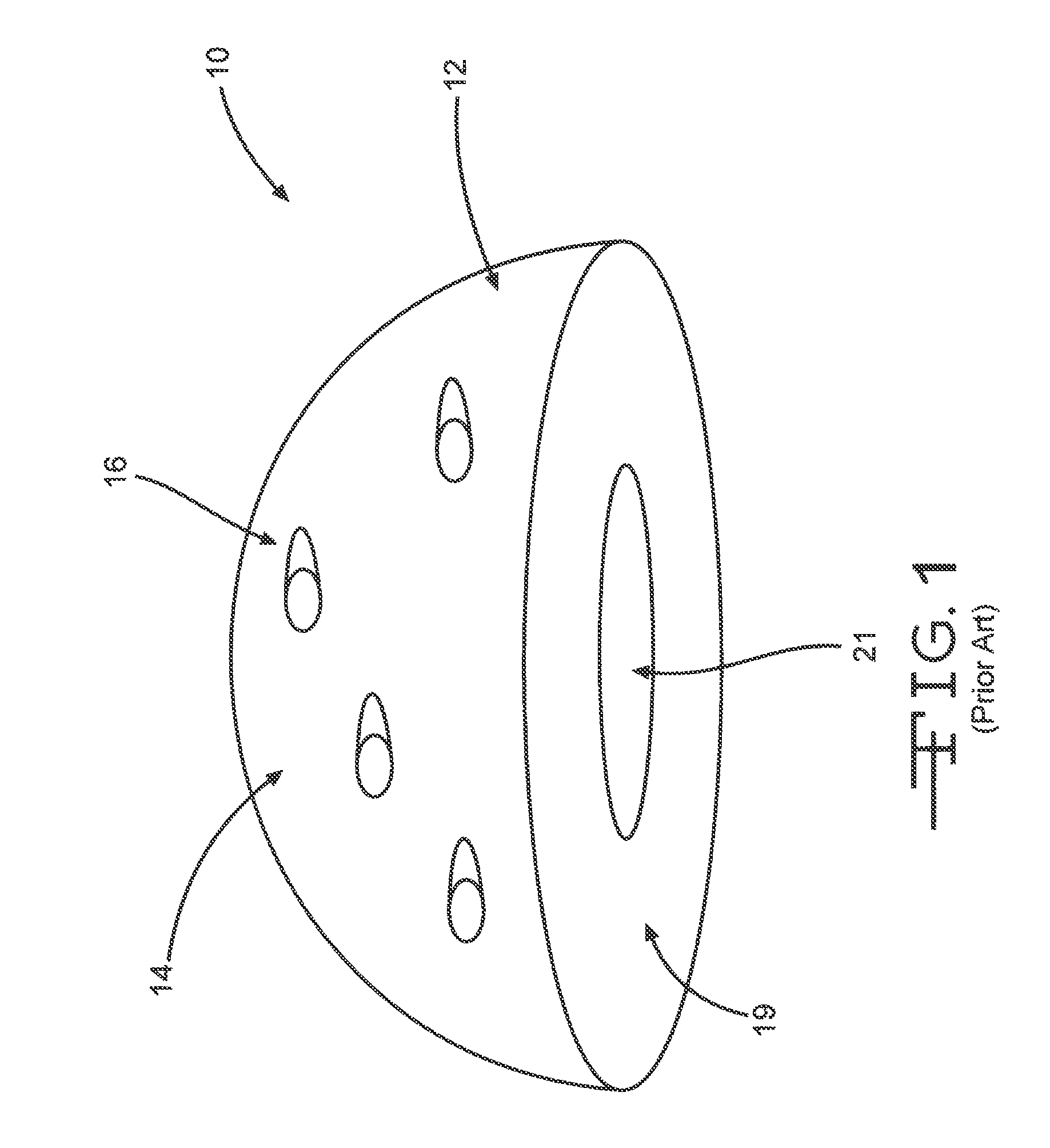

Multiple cutter blade and cutting tool

InactiveCN1443619AImprove machined surface qualityHigh speed cuttingMilling cuttersWorkpiecesRotational axisMachined surface

A throwaway insert and a cutting tool enable a high speed cutting operation for a metallic material having great ductility such as aluminum and obtaining a vertical wall with a high quality machined surface while improving chip control. The throwaway insert (1) comprises a major cutting edge (60) including a tapered cutting edge (61) connected to a cutting edge (41) of a nose portion (40), and a curved cutting edge (62) connected to an end of the tapered cutting edge (61) at a connection point (P). The curved cutting edge (62) is formed so as to extend along an imaginary cylindrical surface (S) whose center axis coincides with the axis of rotation of a tool main body (200), and tapered cutting edge (61) is formed so as to gradually curve from the imaginary cylindrical surface (S) toward the inside of the imaginary cylindrical surface (S) as the distance from the curved cutting edge (62) increases, and the distance from the nose portion (40) decreases. The throwaway insert (1) is attached to the tool main body (200) in which the surface of the distal end thereof is machined so that surface roughness thereof is less than 3.2 mu m when indicated by the Ry roughness. <IMAGE>A throwaway insert and a cutting tool enable a high speed cutting operation for a metallic material having great ductility such as aluminum and obtaining a vertical wall with a high quality machined surface while improving chip control. The throwaway insert (1) comprises a major cutting edge (60) including a tapered cutting edge (61) connected to a cutting edge (41) of a nose portion (40), and a curved cutting edge (62) connected to an end of the tapered cutting edge (61) at a connection point (P). The curved cutting edge (62) is formed so as to extend along an imaginary cylindrical surface (S) whose center axis coincides with the axis of rotation of a tool main body (200), and tapered cutting edge (61) is formed so as to gradually curve from the imaginary cylindrical surface (S) toward the inside of the imaginary cylindrical surface (S) as the distance from the curved cutting edge (62) increases, and the distance from the nose portion (40) decreases. The throwaway insert (1) is attached to the tool main body (200) in which the surface of the distal end thereof is machined so that surface roughness thereof is less than 3.2 mu m when indicated by the Ry roughness. <IMAGE>

Owner:MITSUBISHI MATERIALS CORP

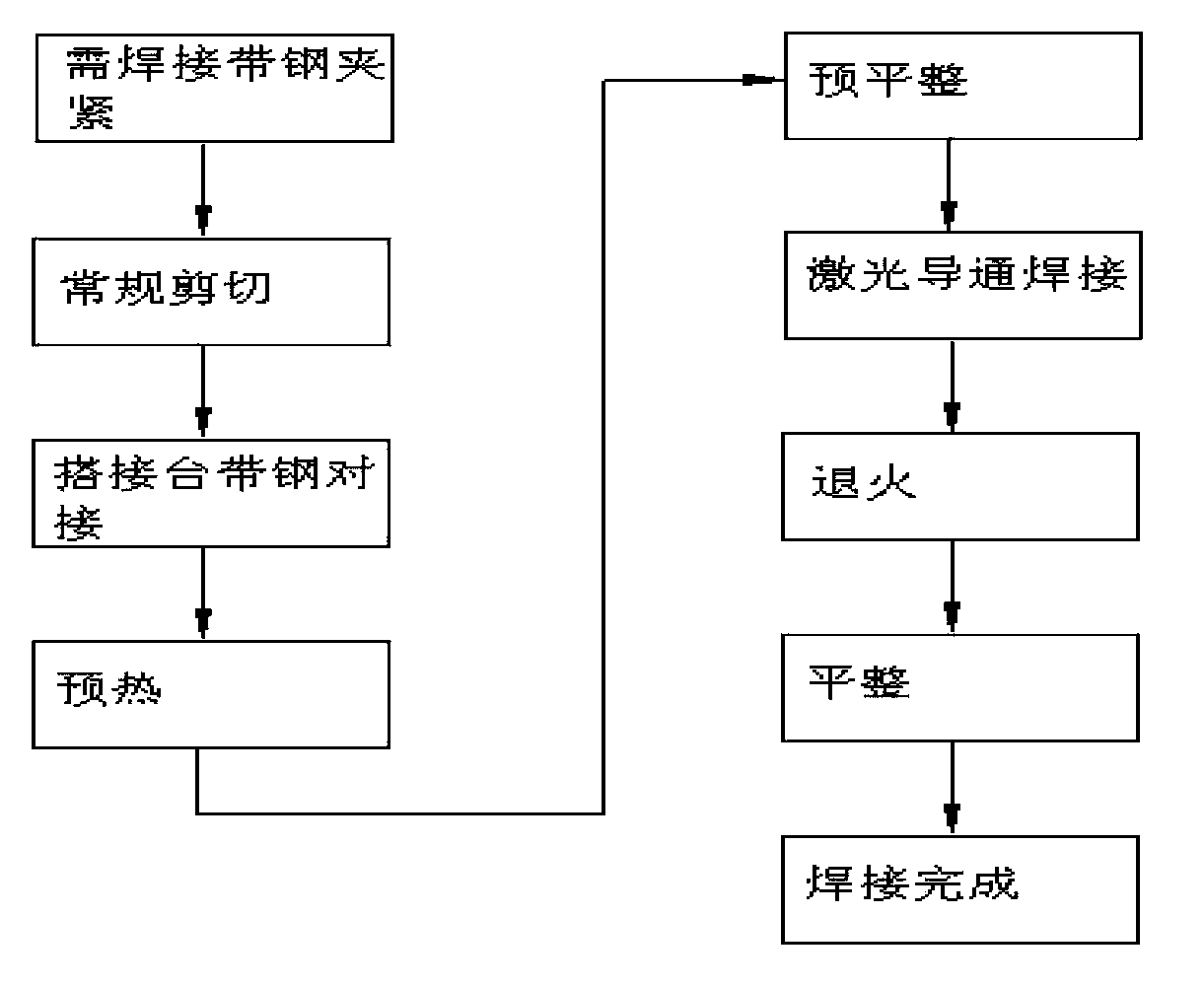

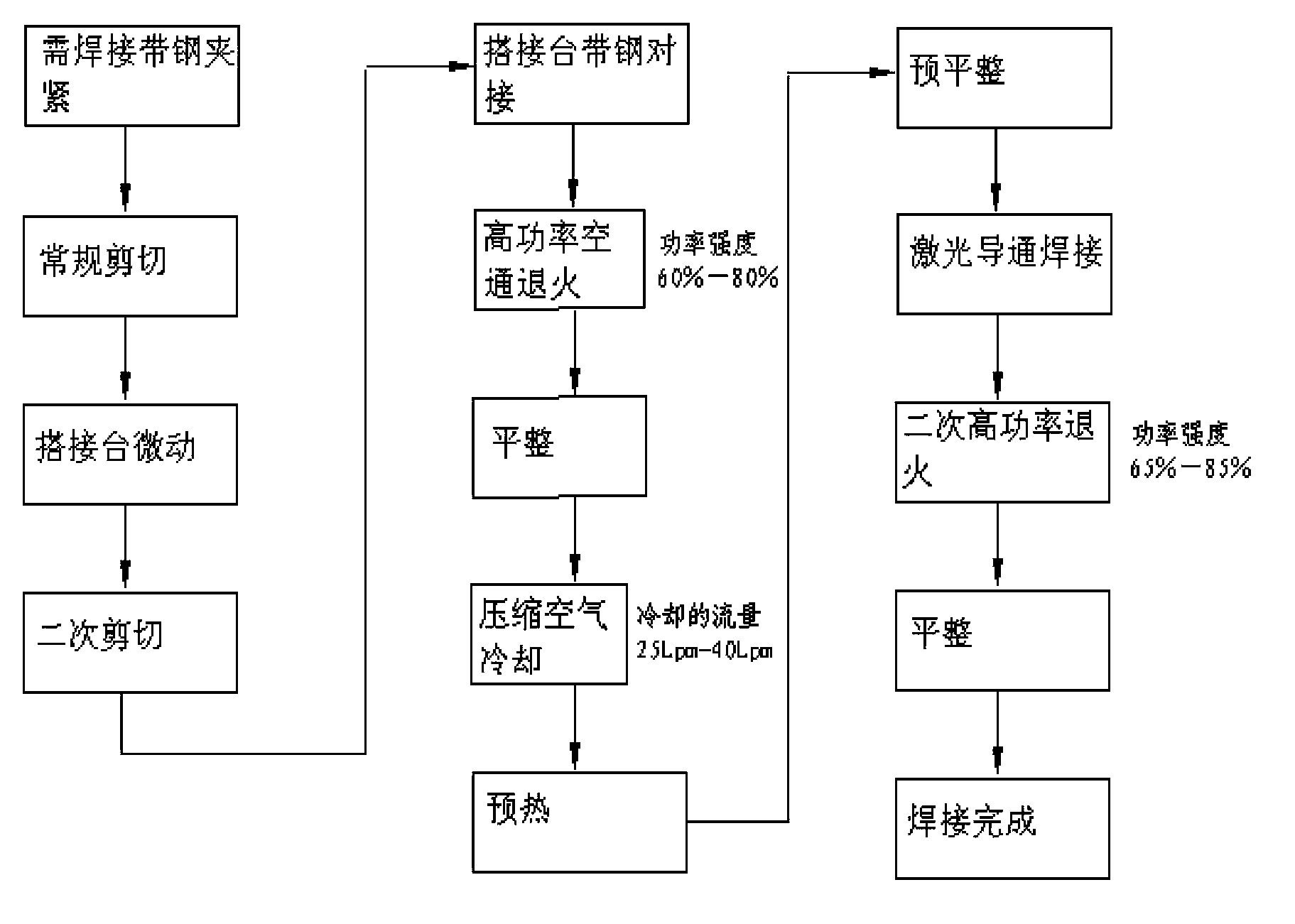

Method for welding high-strength steel through laser welding machine

ActiveCN103537880AHigh cutting surface qualityEasy to shapeLaser beam welding apparatusButt jointLap joint

The invention discloses a method for welding high-strength steel through a laser welding machine. The welding method includes the steps of clamping of strip steel to be welded, conventional shearing, slight moving of a lap joint platform to determine shear amount of secondary shearing, secondary shearing, butt-joint of the strip steel on the lap joint platform, high-power vacuum annealing, smoothening, compressed air cooling, preheating, pre-smoothening, laser connection welding, secondary high-power annealing, smoothening, welding finishing and the like. The quality of the shearing surface of the strip steel is improved through the secondary shearing; yield strength can be reduced through the high-power vacuum annealing, the plate form of the strip steel in the welding region can be effectively improved, and material grains can be improved; material of the strip steel in the welding region can be improved through the air cooling, and thus fracture of welding joints in a thermoinduction region can be effectively avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

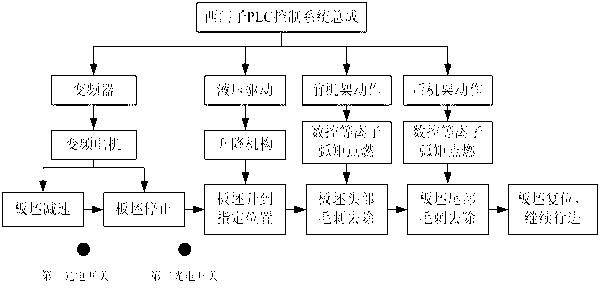

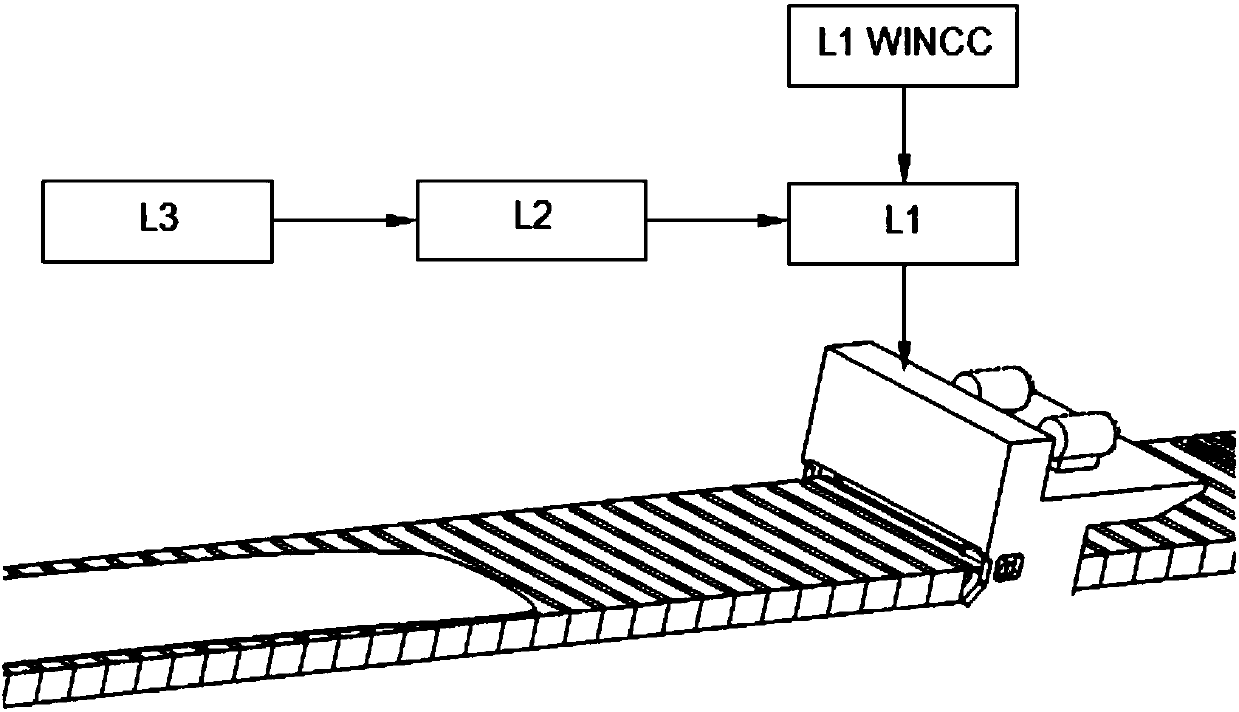

System for removing slab burrs

InactiveCN102935547AGood cutting surface qualityAcceleratePlasma welding apparatusProgrammable logic controllerFlame cutting

The invention discloses a system for removing slab burrs and belongs to the field of machining of a slab after flame cutting in a steel metallurgical industry. The system is composed of a numerical control plasma arc cutting device, a slab locating device and a siemens programmable logic controller (PLC) control system. The numerical control plasma arc cutting device is formed by two sets of identical components and comprises a plasma power supply, a control cabinet, a first servo motor, a plasma gun body and a traveling mechanism of the plasma gun body. The slab locating device is composed of a traveling mechanism of a front frame and a rear frame, a traveling mechanism of the slab and a lifting control system of the slab. The siemens PLC control system assembly comprises a siemens S7-300 system module, a frequency converter, a hydraulic driver, a servo driver of the front frame and rear frame, a second photoelectric switch, a first photoelectric switch and a communication port. The system integrates high speed of slab burr removing and high burr removing rate and has important application value on controlling rolling quality of the slab.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

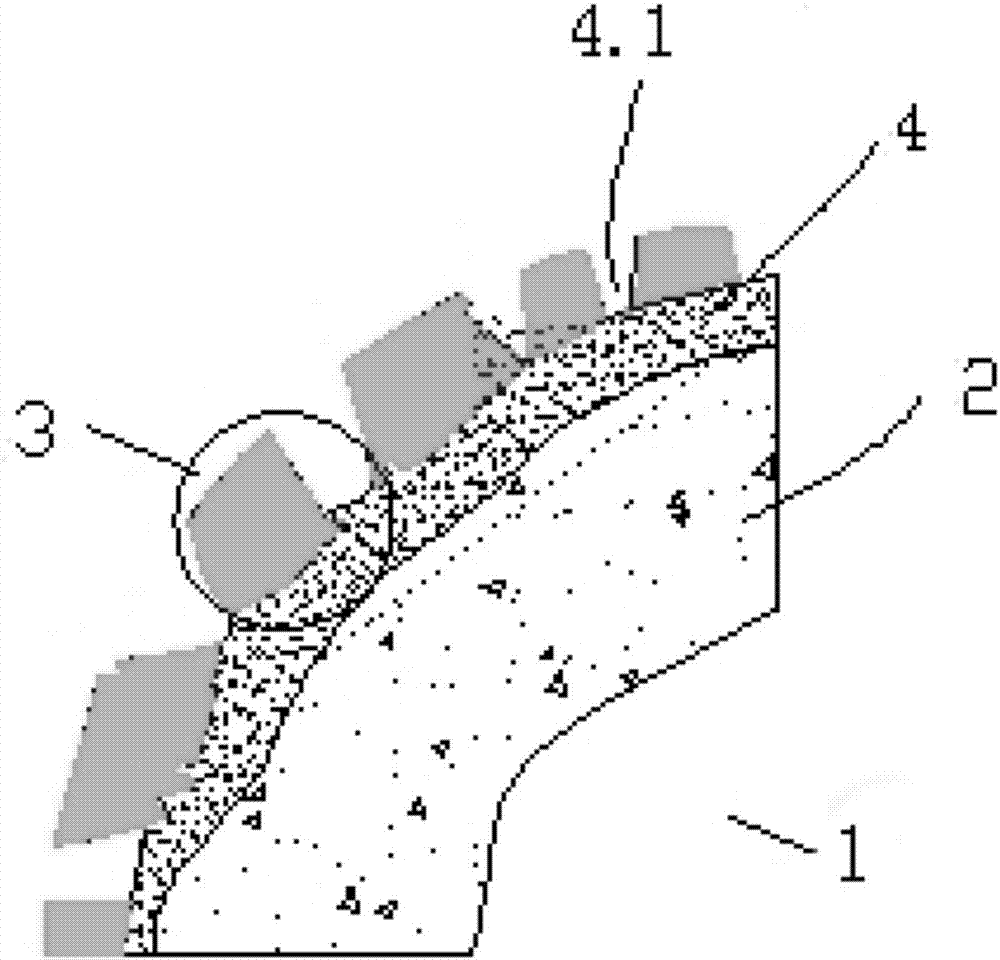

Low-loss oriented cutting method of large-size sapphire crystal blanks

InactiveCN102152420AImprove processing efficiencyReduce processing stepsFine working devicesSheet steelCrystal orientation

The invention provides a low-loss directional cutting method of large-size sapphire crystal blanks. The large sapphire crystal blanks are fed in a rotation manner in the method, and the processing efficiency of the method is improved by one time than that of a traditional band-saw cutting method. Before cutting, the end faces of the large-size sapphire crystal blanks are oriented, steel plates in corresponding angles are selected according to the crystal orientation deviation of the end faces for bonding, thereby the accurate orientation is finished in a cutting procedure. The method is greatly improved on the basis of the traditional band-saw cutting method, has the advantages of higher cutting efficiency, better cutting surface quality, high surface flatness, shorter follow-up processing time, lower unit production cost and the like, and can be used for correcting the crystal orientation of the end faces of the large sapphire crystal blanks.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

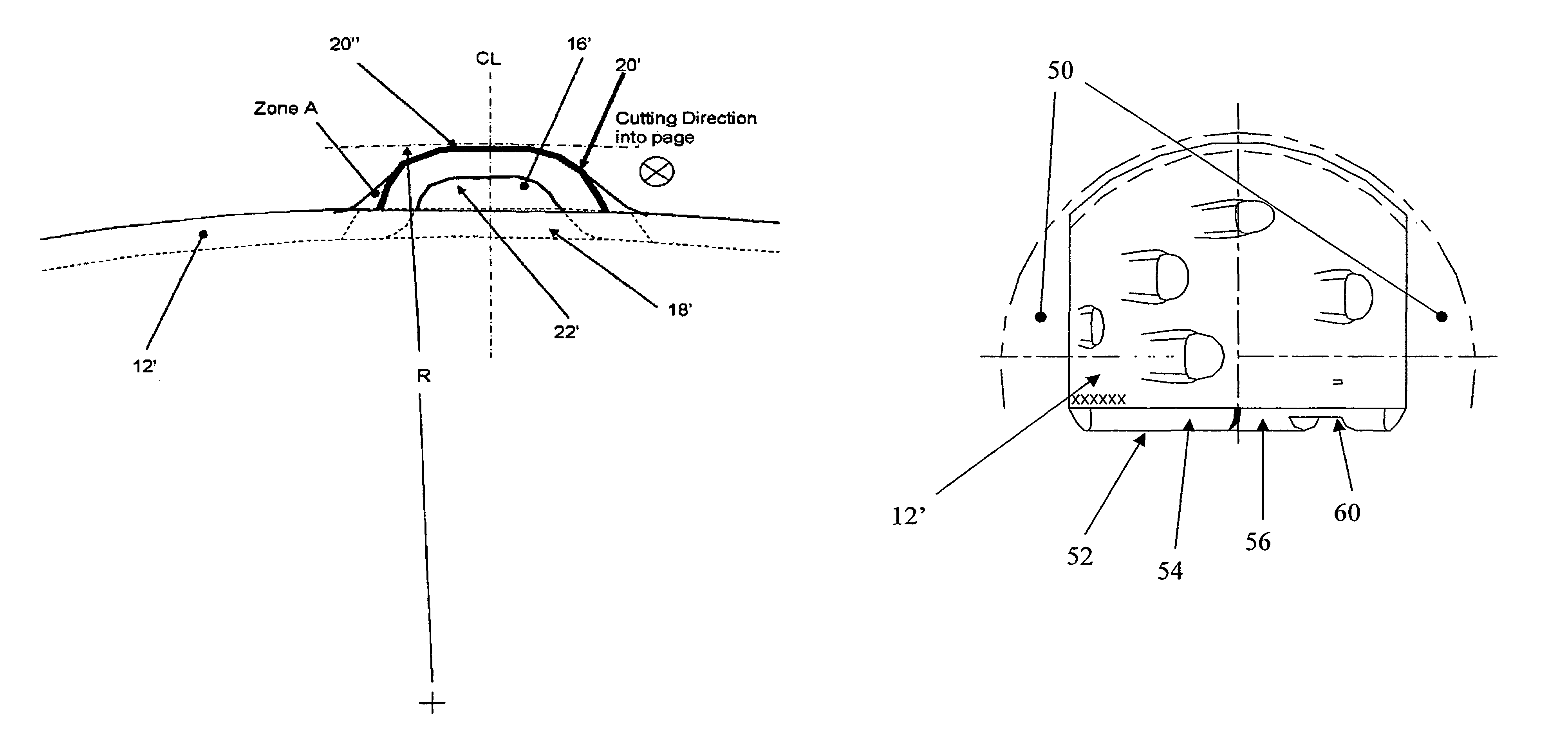

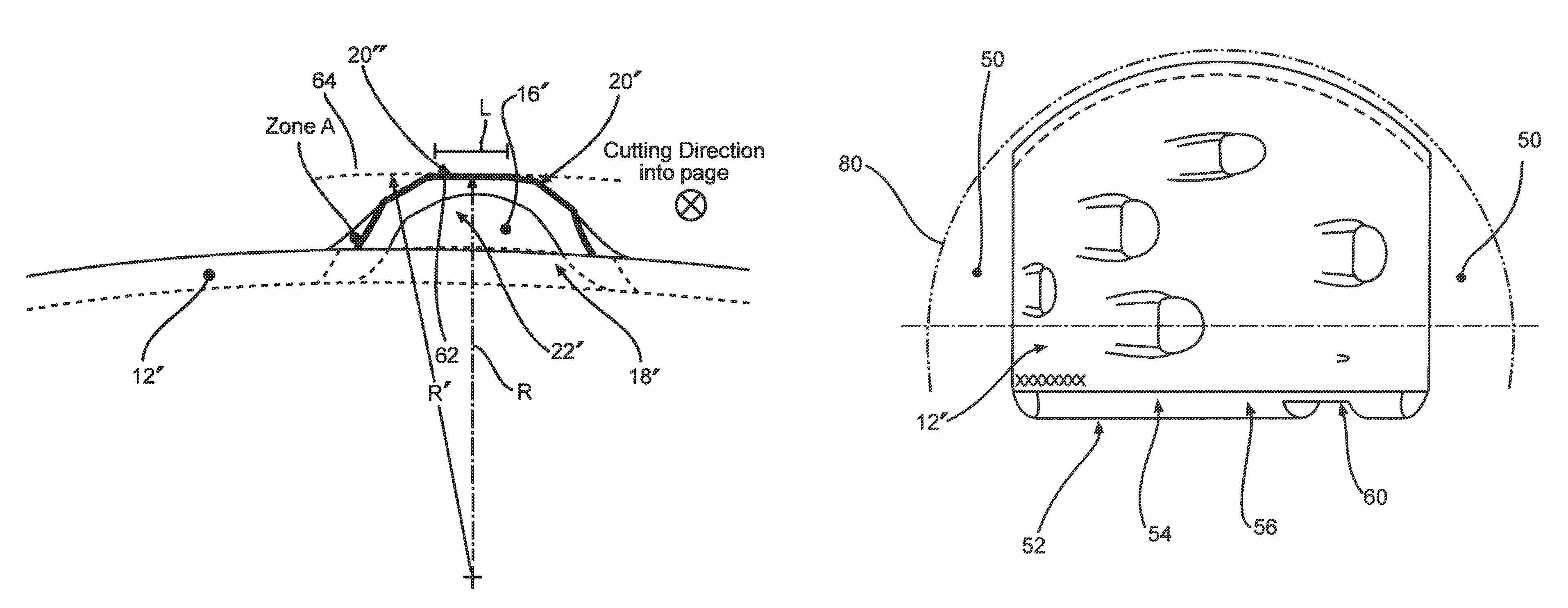

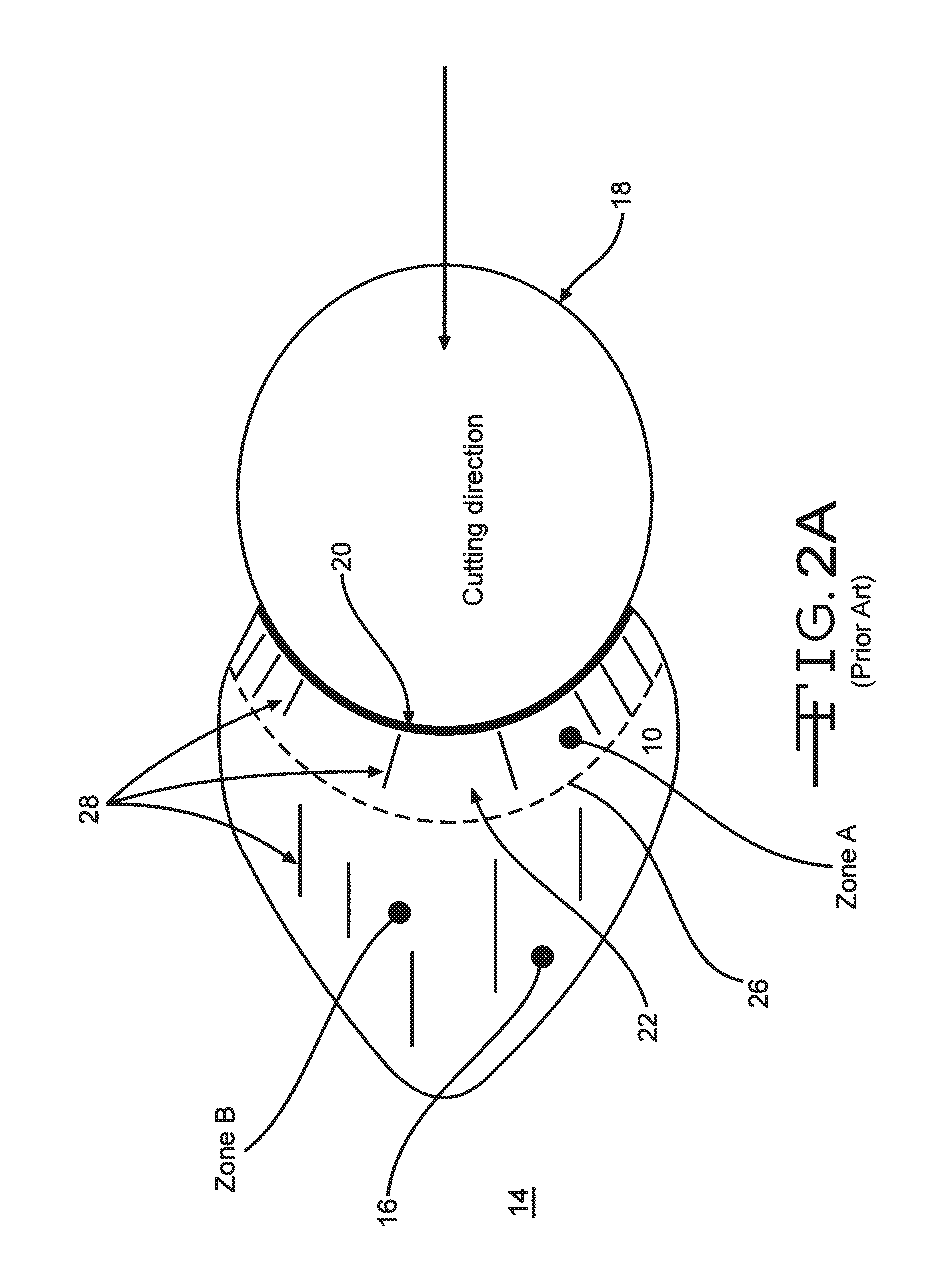

Contoured reamer teeth

An acetabular reamer (10′) for cutting a required cut shape. The reamer has a cutting shell (12′) having a series of doubly curved cutting teeth (16′) thereon of a quantity to substantially reduce a cutting pressure on each tooth as well as to reduce a size of a typical chip generated upon cutting. Substantially all the teeth each have a matched arc cutting edge (20′) of substantial length that has a cutting profile which substantially matches a profile of a shape to be cut. Such a configuration reduces the number of teeth required to cut the shape.

Owner:VIANT AS&O HLDG LLC

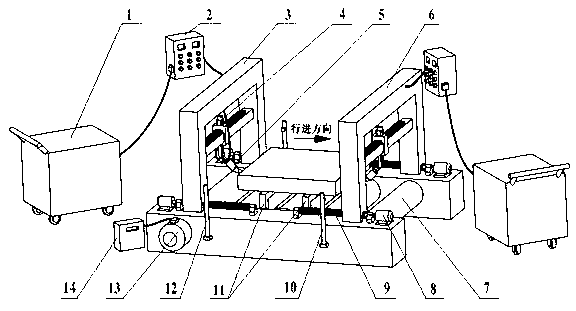

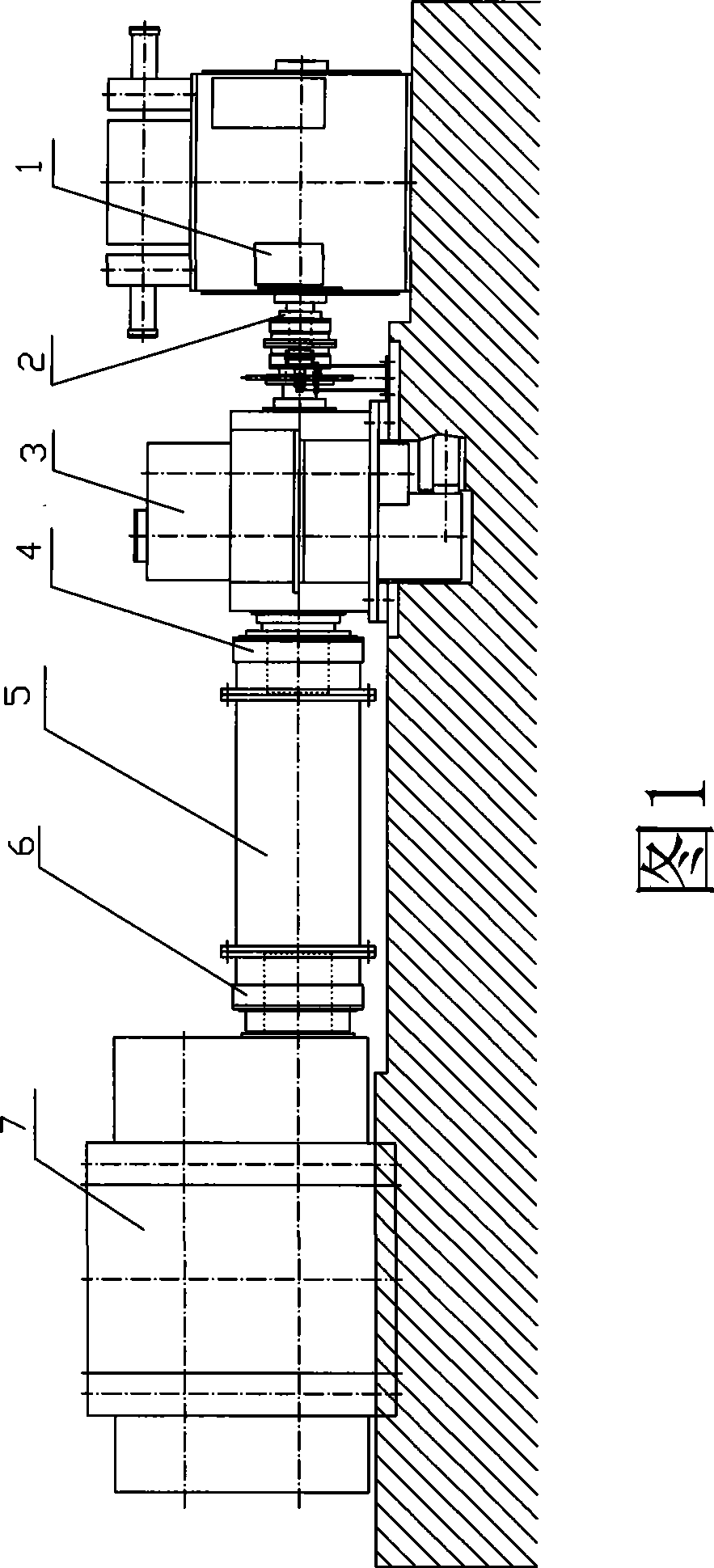

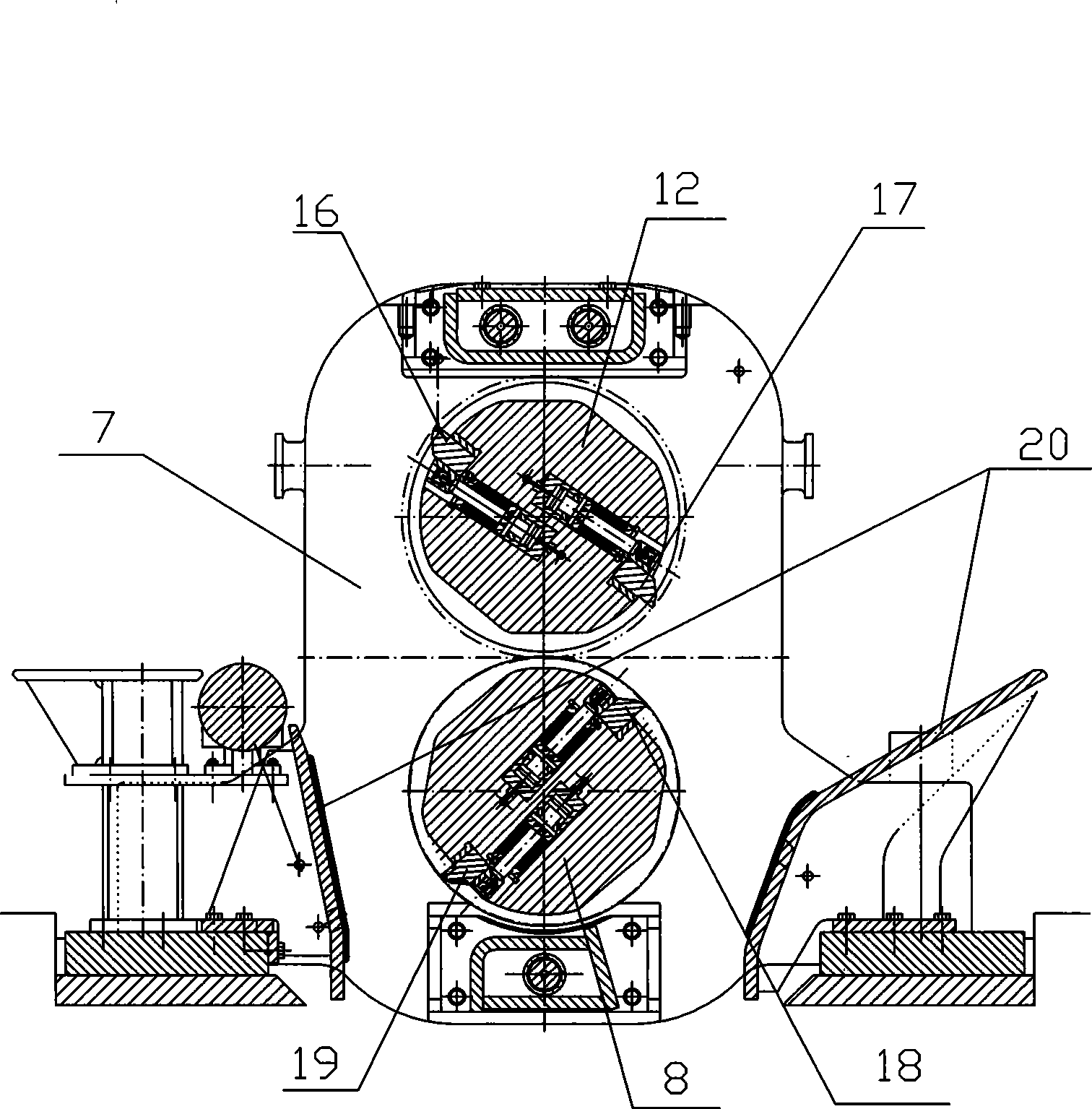

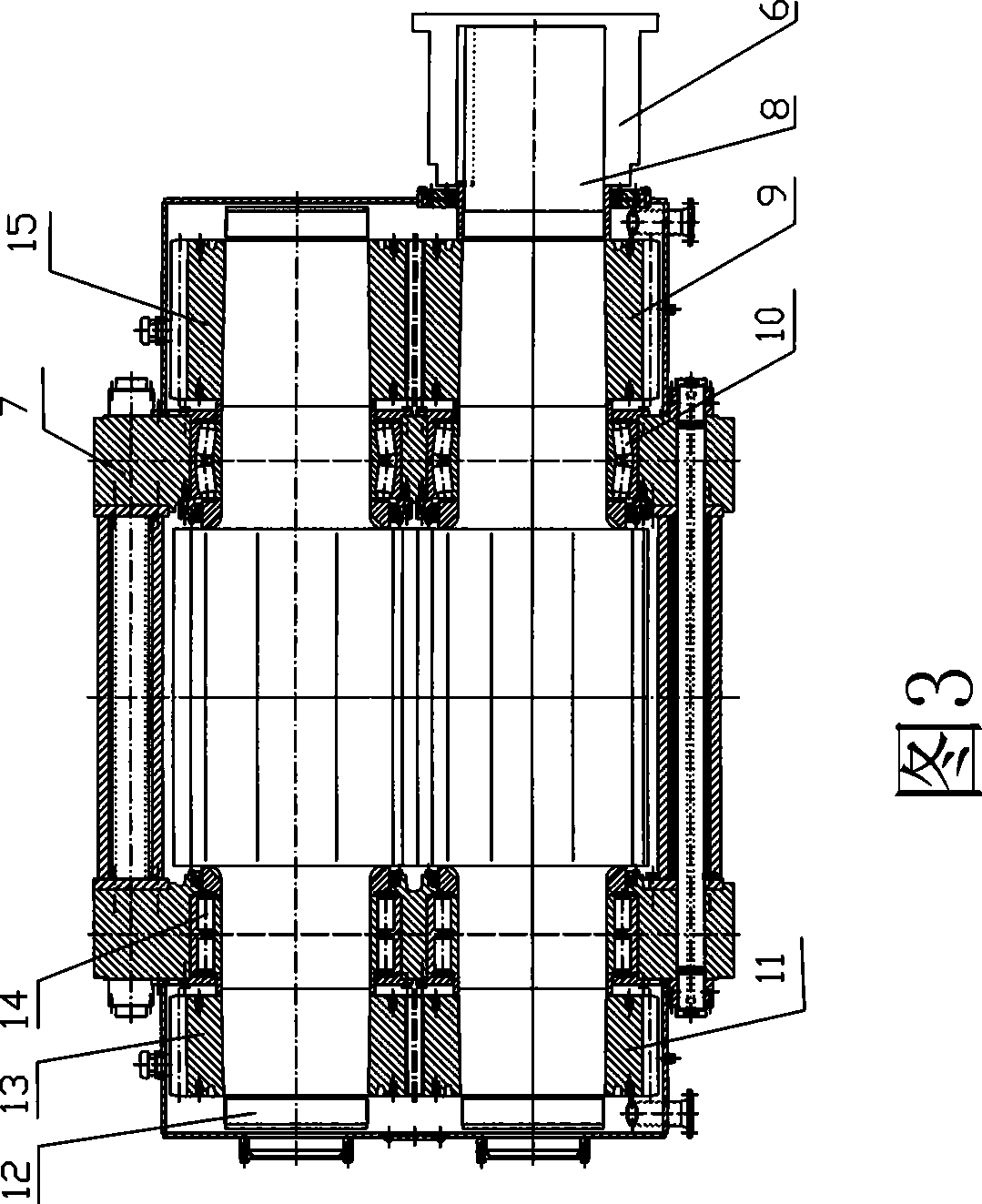

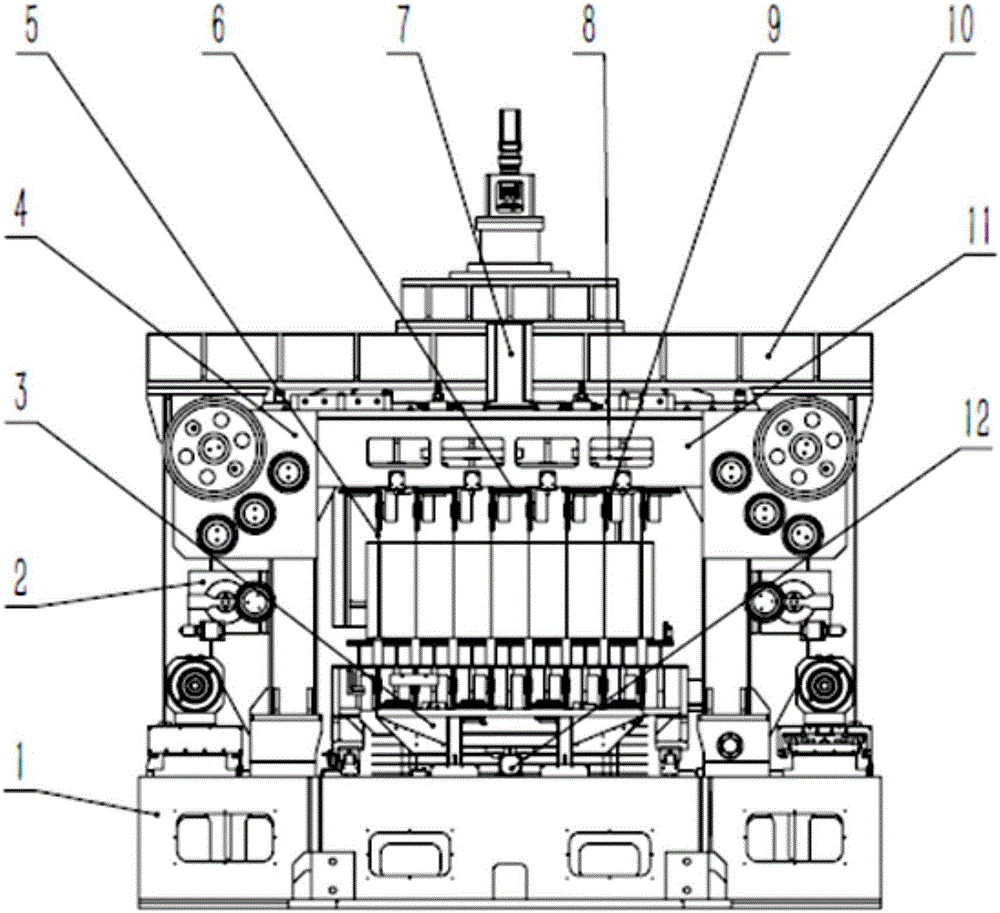

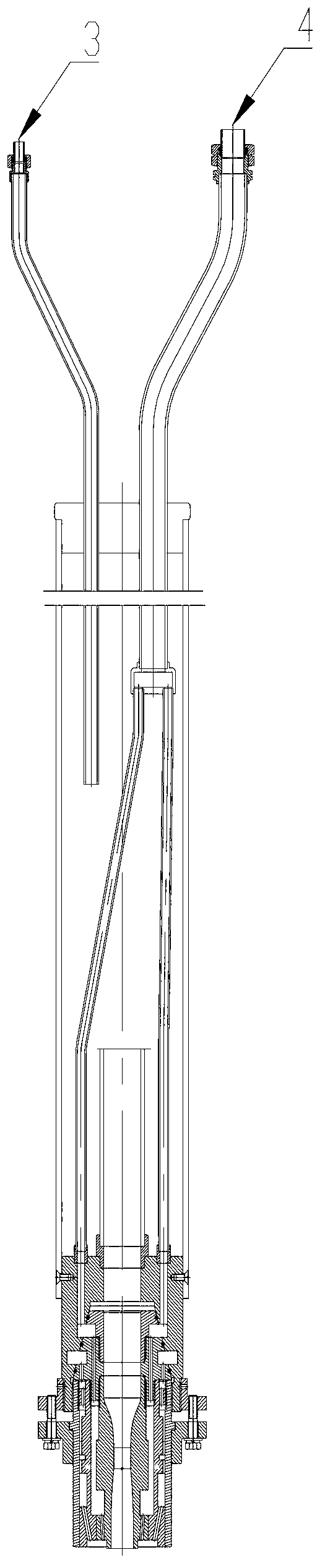

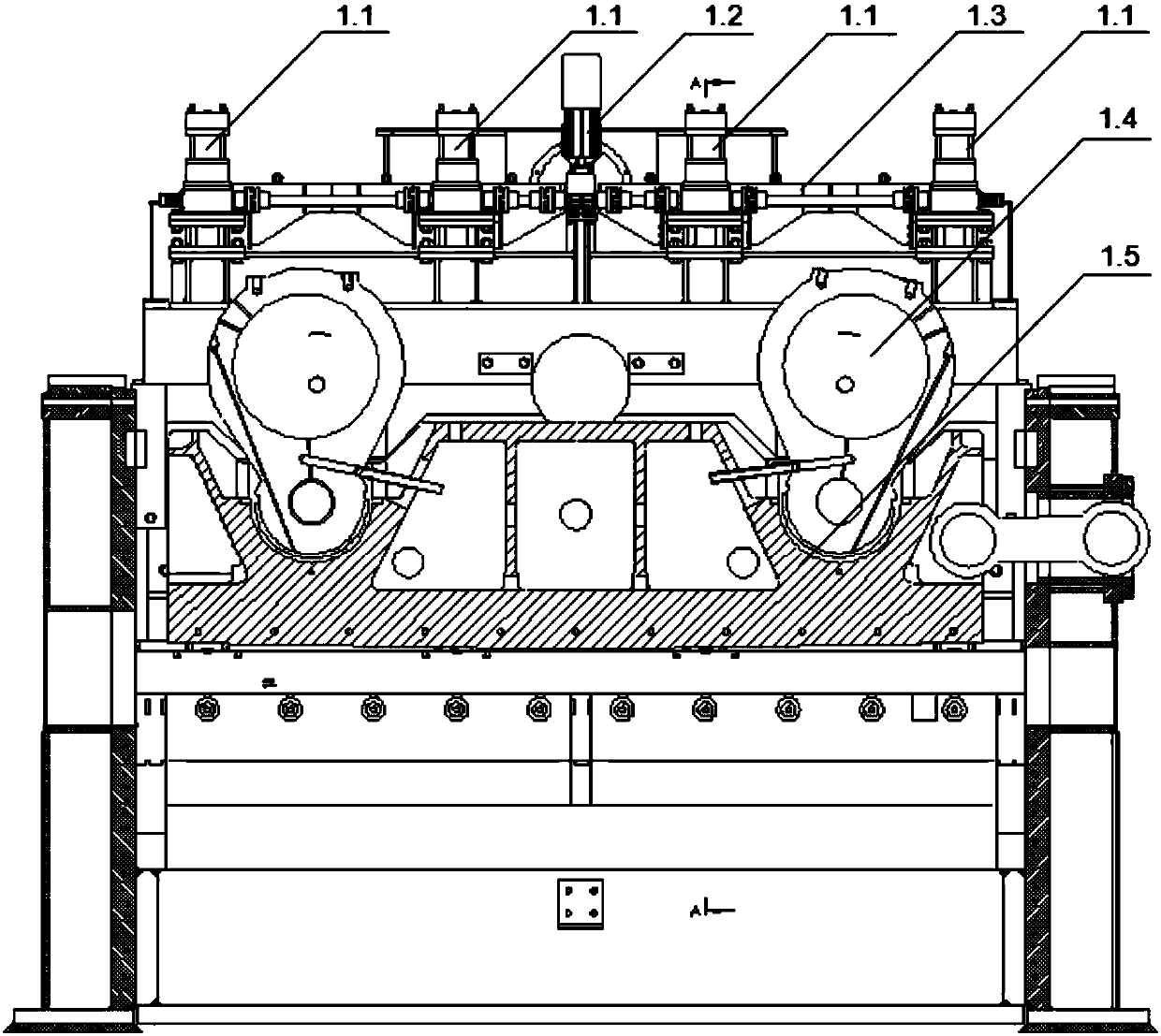

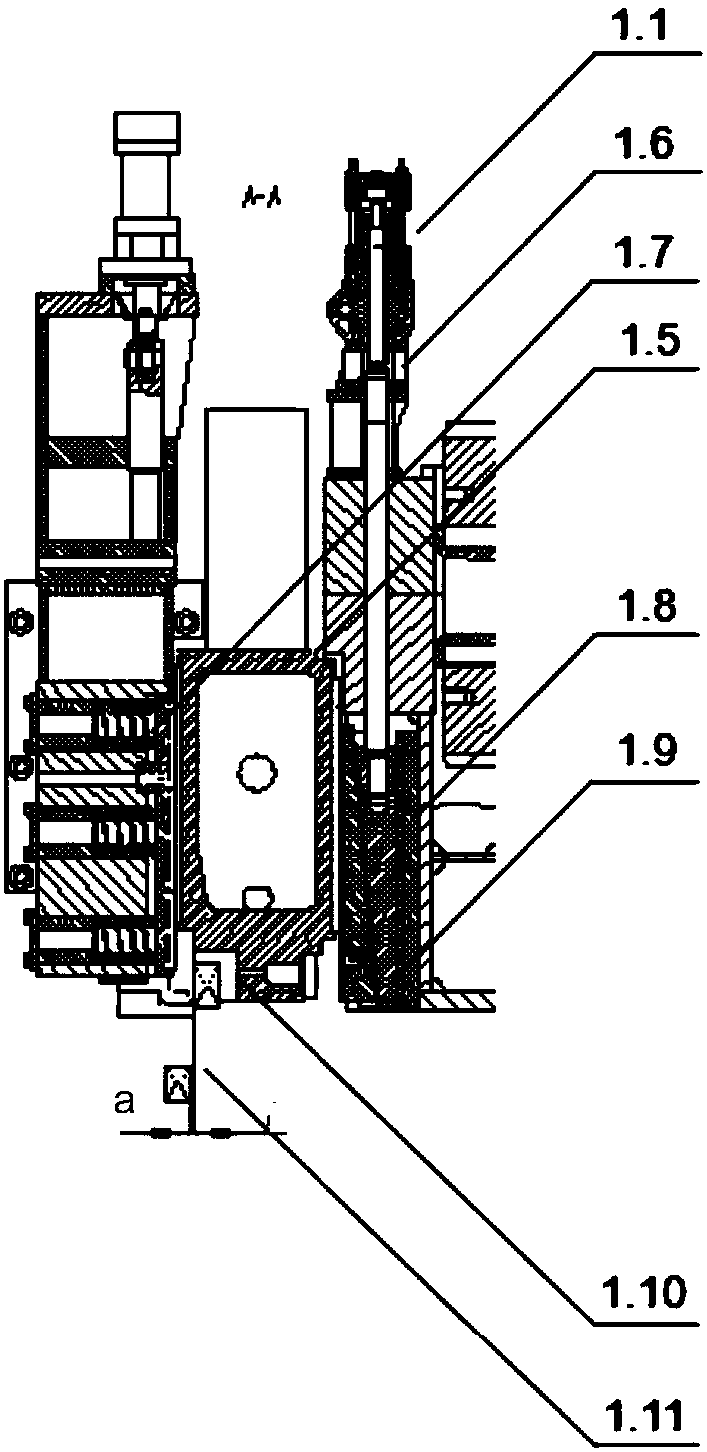

Drum type flying shears and gear pair return-clearance adjustment method

The invention discloses a rotary-drum type fly-shearing machine and a method for adjusting gear-pair return clearance. The rotary-drum type fly-shearing machine is shearing equipment used for shearing the head, tail, low-temperature and irregular parts of strip stock after rough rolling. The fly-shearing machine comprises a motor, a speed reducer, a transmission shaft, a fly-shearing machine body, a lower rotary drum, an upper rotary drum, a head-cutting upper shearing blade, a tail-cutting upper shearing blade, a tail-cutting lower shearing blade and a head-cutting lower shearing blade, wherein the motor is connected with the lower rotary drum through the speed reducer and the transmission shaft; a gear I, a gear II, a gear III and a gear IV are pressed and arranged on cone shafts at two ends of the upper rotary drum and the lower rotary drum through hydraulic oil respectively; and the upper rotary drum and the lower rotary drum are symmetrically provided with a pair of shearing blades respectively. A transmission side is in mesh transmission with a synchronous gear pair when the fly-shearing machine is in a started state, and an operation side is in mesh transmission with the synchronous gear pair when the fly-shearing machine is in a braked state, so that the prior master-minor gear structure and shearing-blade adjustment device which are complex in structure and difficult to adjust are cancelled, and the structure is simple. In addition, the gear-pair return clearance can be adjusted and eliminated through the repeated assembly of gear pairs and the rotary drums, so as to improve the utilization rate of equipment.

Owner:CHINA FIRST HEAVY IND +1

Preparation method for resin diamond wire capable of improving diamond holding force

InactiveCN106112839AImprove bindingImprove cutting effectGrinding devicesEpoxy resin coatingsFiberOrganic solvent

The present invention relates to the preparation method of the resin diamond wire which can improve the diamond holding force, comprising the following steps: (1) preparation of diamond powder treatment solution: 1-10% silane coupling agent, 85-92% organic solvent, 1- 10% water; (2) diamond treatment; (3) preparation of diamond wire resin liquid: 20-50% resin powder, 10-30% organic solvent, 10-30% silicon carbide powder, 1-10 % of nanofibers, 20-40% of diamond powder treated in step (2); (4) coating of steel wire; (5) curing: primary curing, curing temperature is 500-900°C, secondary curing, A stepwise heating process is adopted, and finally the temperature is naturally lowered to room temperature with the furnace to obtain the finished resin diamond wire. The method of the invention can improve the binding force between the resin liquid and the diamond, has low energy consumption, little environmental pollution and low production cost.

Owner:HENAN XINDAXIN SCI & TECH

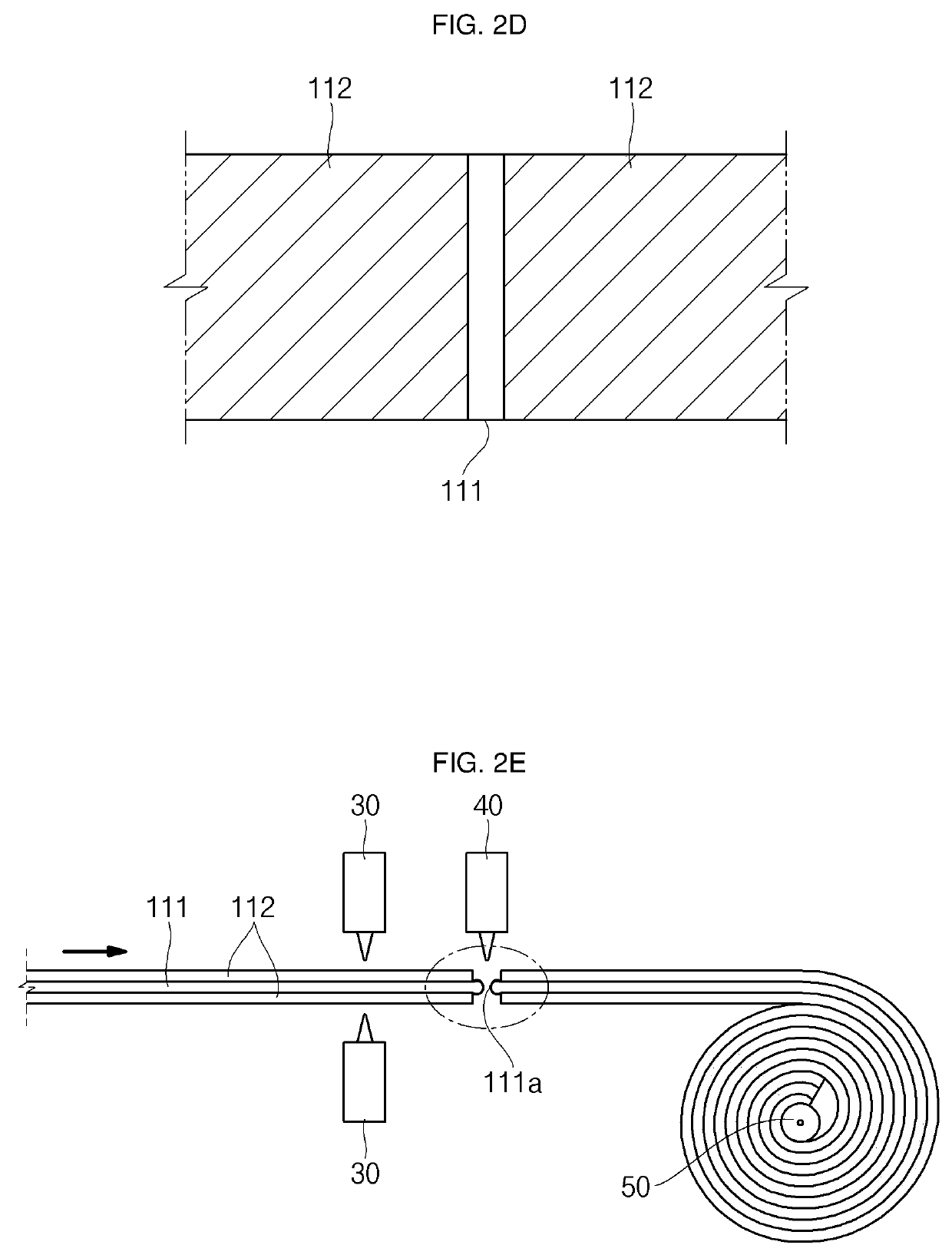

Liquid crystal glass substrate double-cutter wheel cutting device and method

ActiveCN104003610AHigh cutting surface qualityFlexibleGlass severing apparatusLiquid crystalEngineering

Owner:SOUTH CHINA UNIV OF TECH

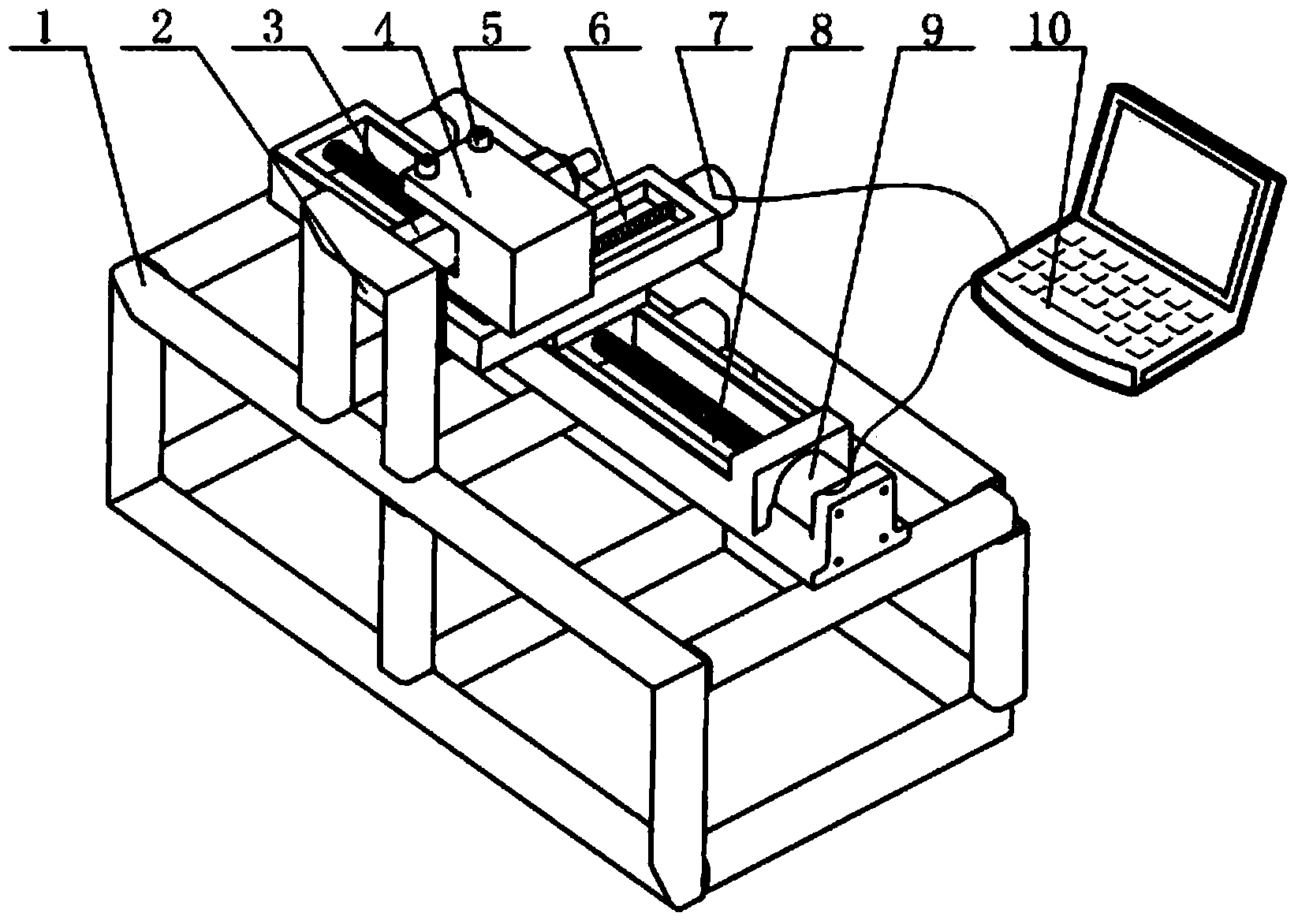

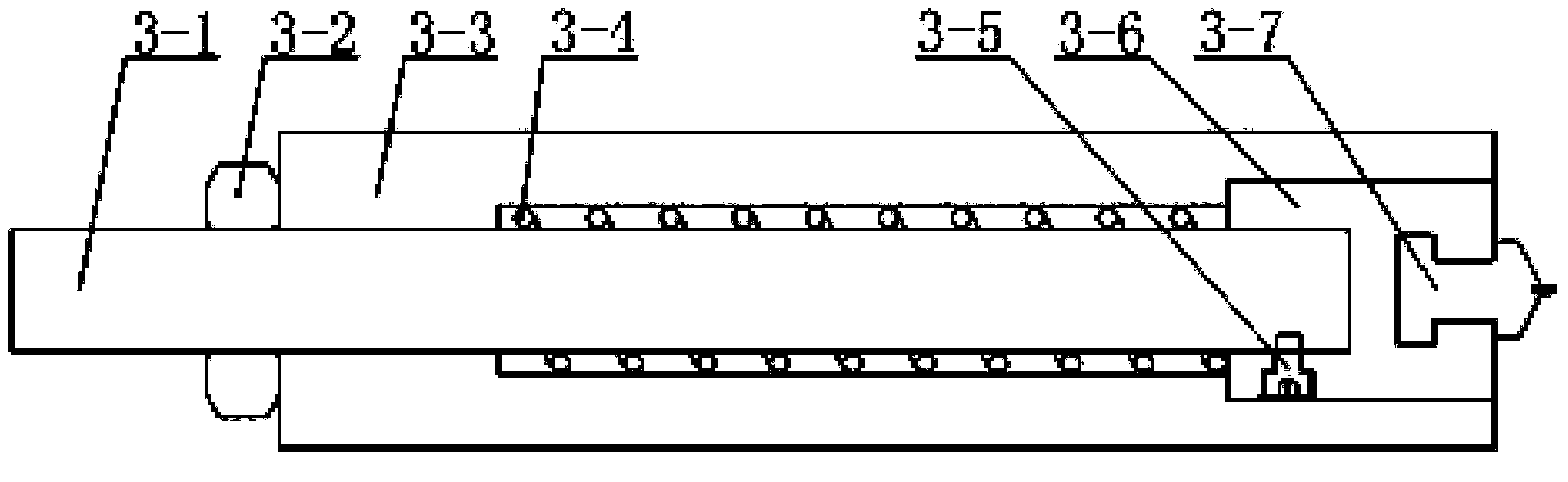

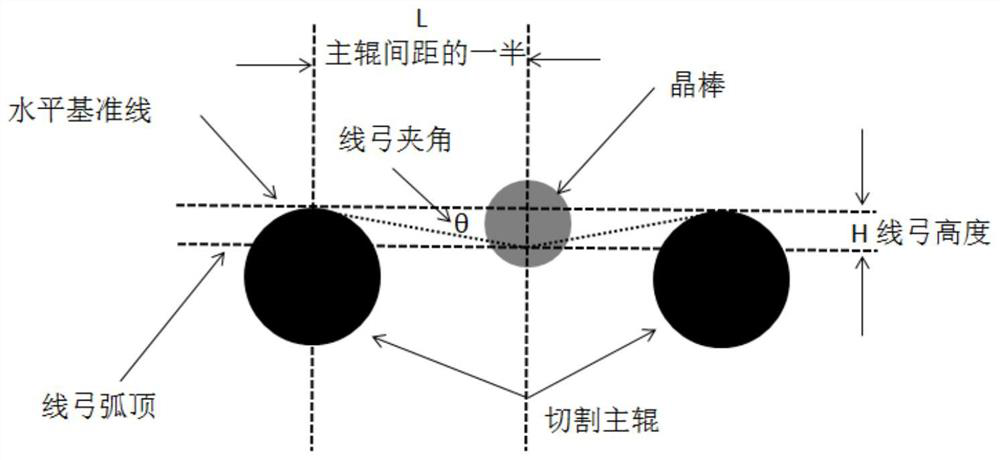

Control method and control system for cutting crystal bar by diamond wire

InactiveCN111923261AImprove the lubrication effectImprove cooling effectWorking accessoriesGrinding machinesControl systemCooling effect

The invention provides a control method and control system for cutting a crystal bar by a diamond wire. The diamond wire is arranged between two cutting main rollers with the same size and the same height, and the crystal bar is positioned on a central axis between the two cutting main rollers to cut in the direction perpendicular to a connecting line between the two cutting main rollers. The control method comprises the steps that whether an actual wire arch when the diamond wire cuts the crystal bar meets a backoff condition is judged, if so, the crystal bar or the diamond wire is retracteda first distance and then cutting continues, if not, no changes are made, that is, as long as the retreating condition is satisfied, the crystal bar or the diamond wire retreats the first distance, aslong as the retreating condition is satisfied, the crystal bar or the diamond wire retreats the first distance, so that the repetition can ensure that the actual contact surface of the diamond wire and the crystal bar is always at a distance around the arc top of the wire arch, the situation that the diamond wire and the crystal bar are cut by the a small wire arch is maintained more, the good cutting lubrication and cooling effect is achieved, and therefore, the better cutting surface quality is obtained.

Owner:苏州赛万玉山智能科技有限公司

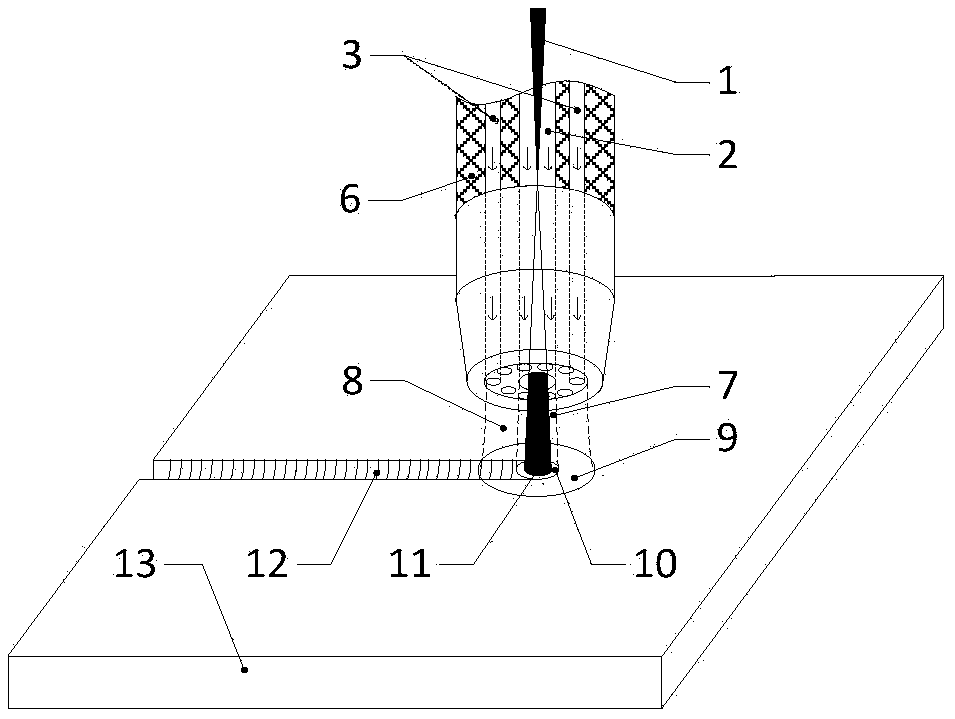

Laser-flame combination cutting method

ActiveCN103934582AImprove verticalityLarge cutting thicknessWelding/soldering/cutting articlesMetal working apparatusHeat-affected zonePunching

The invention provides a laser-flame combination cutting method, relates to a cutting method for integrating a laser heat source and a flame heat source, and belongs to the technical field of metal thermal cutting. The laser-flame combination cutting method solves the technical problems that in flame cutting, cutting efficiency of thick steel products is low, deformation is high, the upper edge of a kerf is prone to melting and collapsing, and adhering slag is easily formed on the lower edge of the kerf. The method comprises the following steps that a steel plate is fixed on a workbench, the steel plate is cut at a high speed in a laser and flame coaxial or non-coaxial combination mode, and namely laser-flame combination cutting is completed. The kerf obtained with the method is good in perpendicularity, the quality of the cutting surface is high, the cutting thickness is large, and an expensive hafnium electrode does not need to be replaced periodically. The laser-flame combination cutting method has the advantages that the cutting speed is high, the cutting efficiency is high, a heat affected zone is small, deformation is small, no hole needs to be formed in the steel plate in advance because lasers have the punching function, and a cutting process is directly started without the need for preheating. The laser-flame combination cutting method belongs to the field of steel-product cutting.

Owner:HARBIN WELDING INST LTD

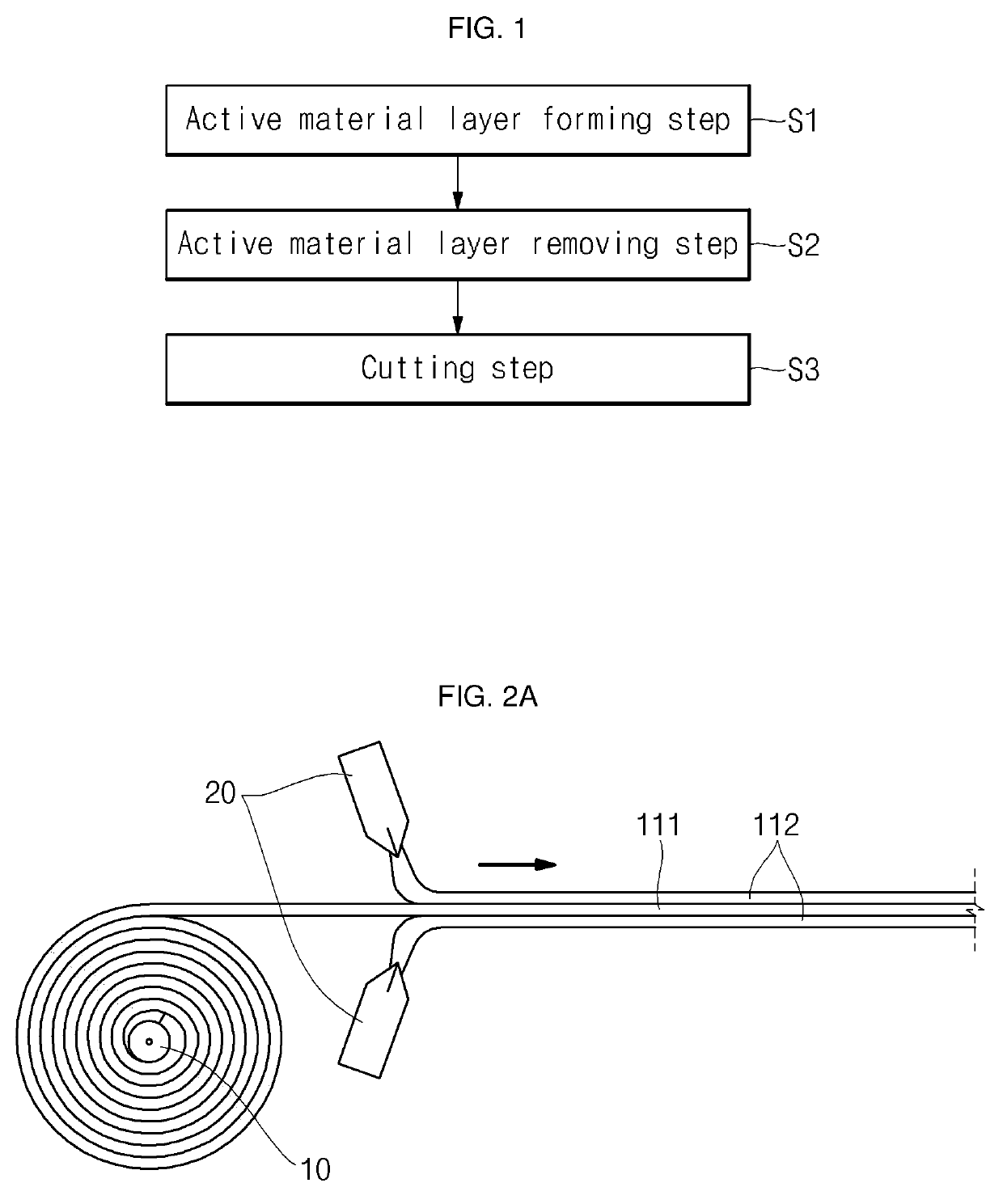

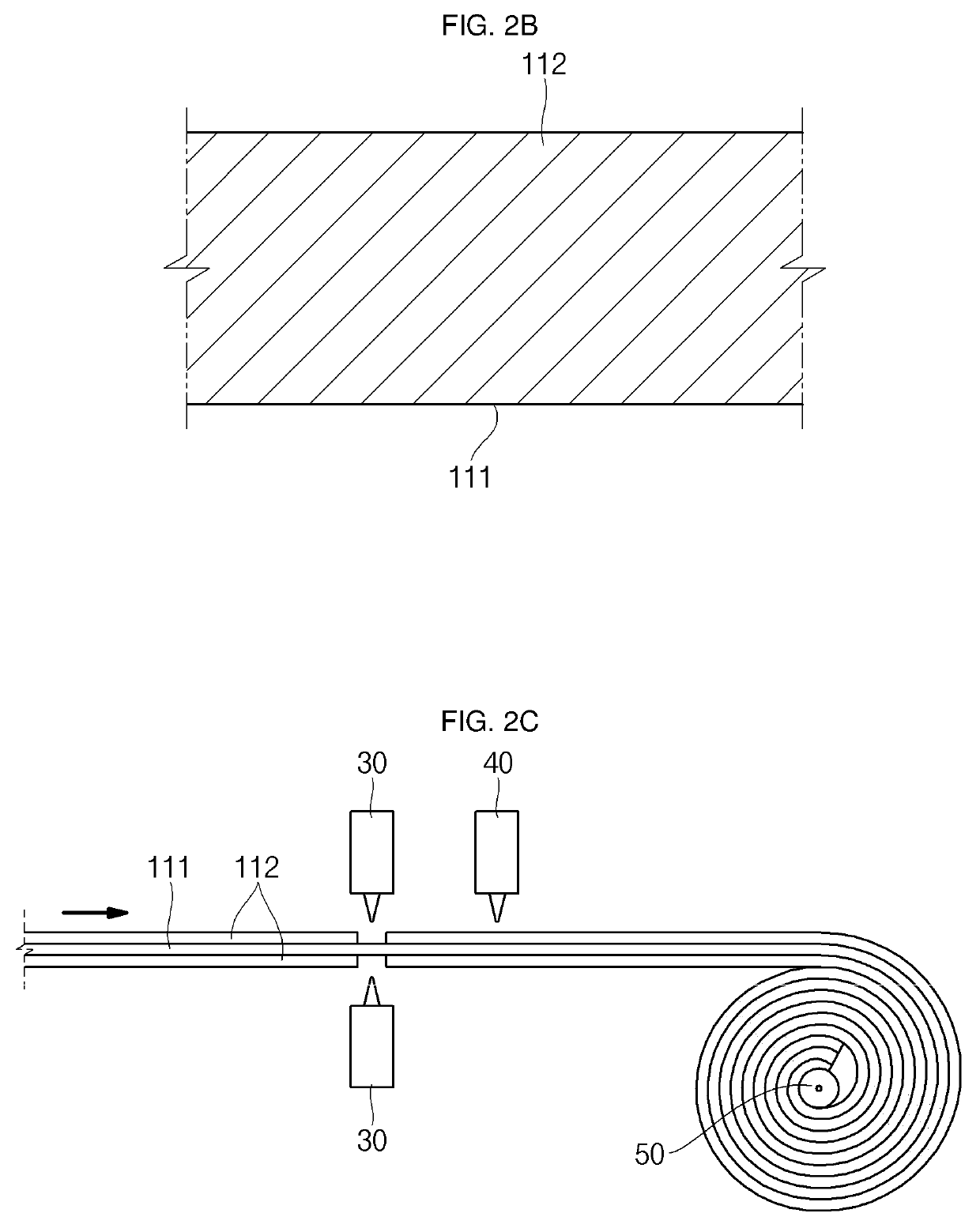

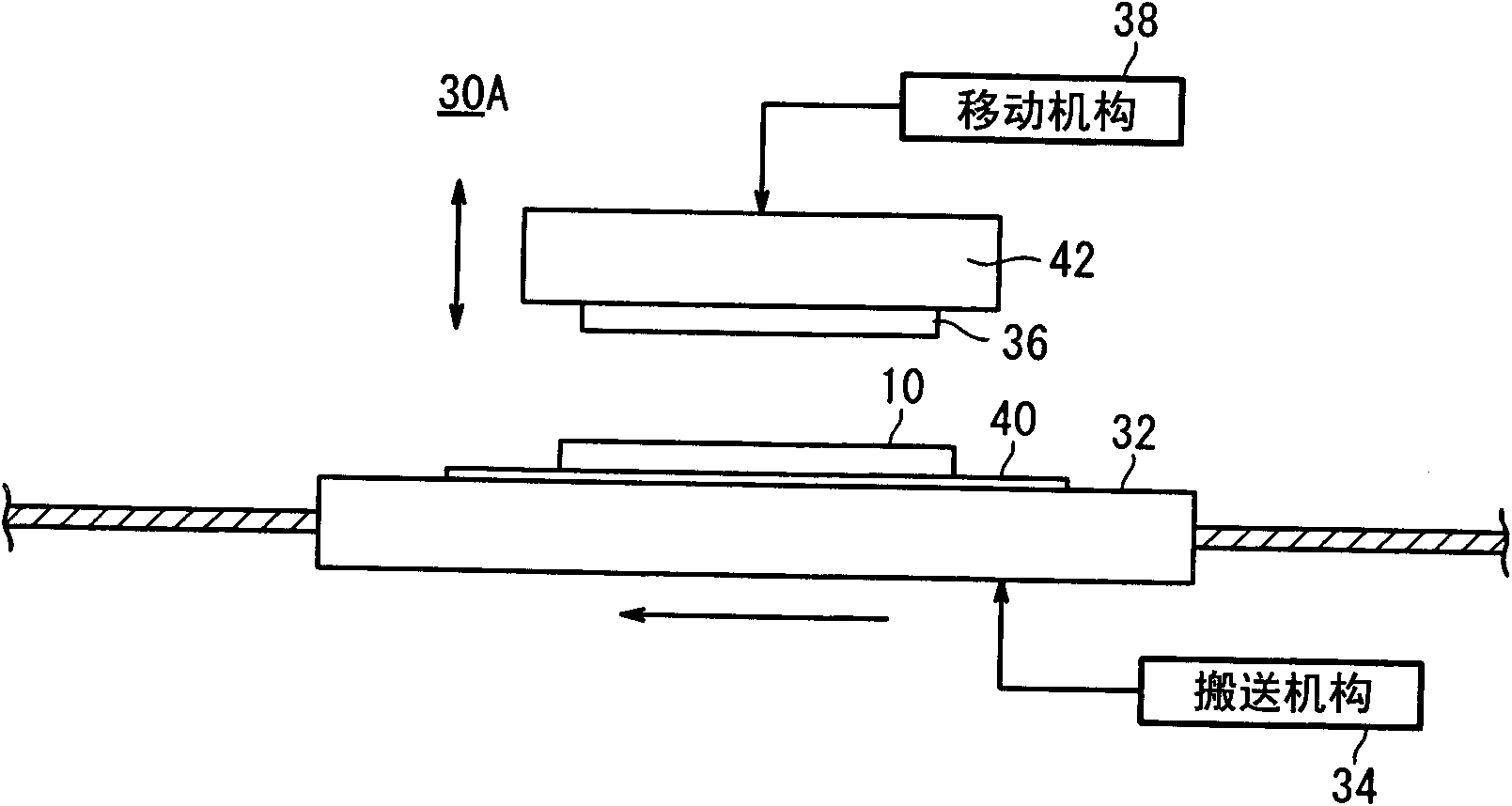

Method for manufacturing secondary battery and secondary battery using same

ActiveUS20190267608A1High cutting surface qualityAvoid pollutionElectrode thermal treatmentFinal product manufactureElectrical batteryEngineering

The present invention relates to a method for manufacturing a secondary battery and a secondary battery using the same, which can improve the quality of a cut surface of an electrode plate and improve the reliability of the secondary battery. For example, disclosed is a method for manufacturing a secondary battery, the method comprising: an active material layer forming step of forming an active material layer by coating an active material on both surfaces of a collector plate; an active material layer removing step of removing a part of the active material layer by irradiating a laser beam to the both surfaces of the collector plate; and a cutting step of cutting the collector plate by irradiating a laser beam onto the collector plate from which the active material layer has been removed in the active material layer removing step.

Owner:SAMSUNG SDI CO LTD

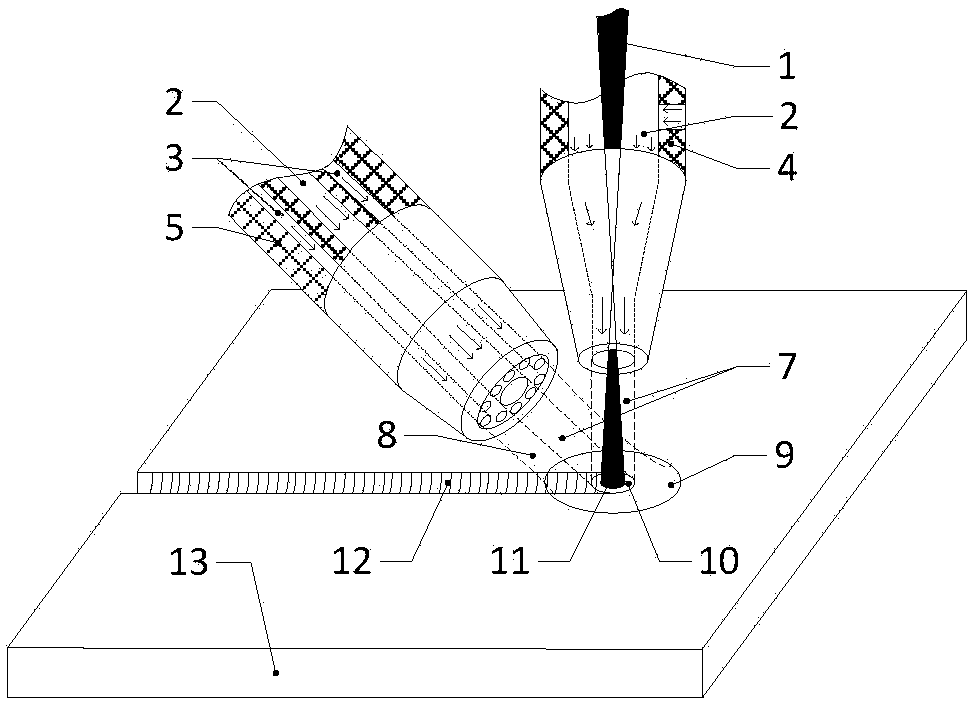

Metal Powder Processing Equipment

ActiveUS20150283649A1Improve cutting lifeHigh cutting surface qualityAdditive manufacturing apparatusArc welding apparatusMetallurgyMetal powder

In metal powder processing equipment where metal powder is sequentially laminated on a table inside a chamber and laser beam melting or electron beam melting, and shaping by a cutting tool subsequent to the melting are performed, unmolded powder remaining at the time of the melting and cut powder generated by the cutting can be scattered by generating air flow with respect to the cutting tool from either side of a main shaft or a tool holder. As a result, life of the cutting tool is prolonged and quality of a cut surface can be improved.

Owner:MATSUURA MACHINERY

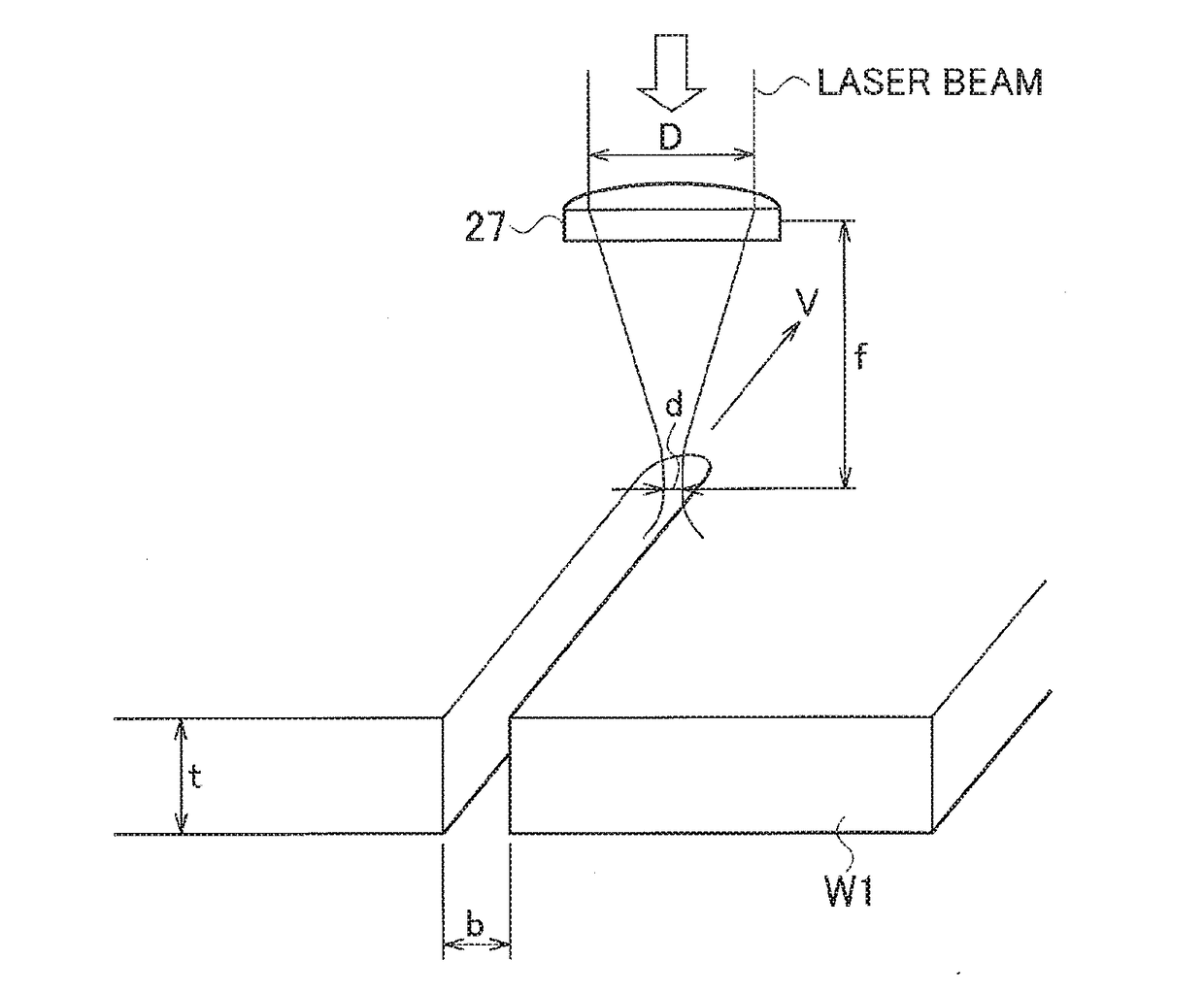

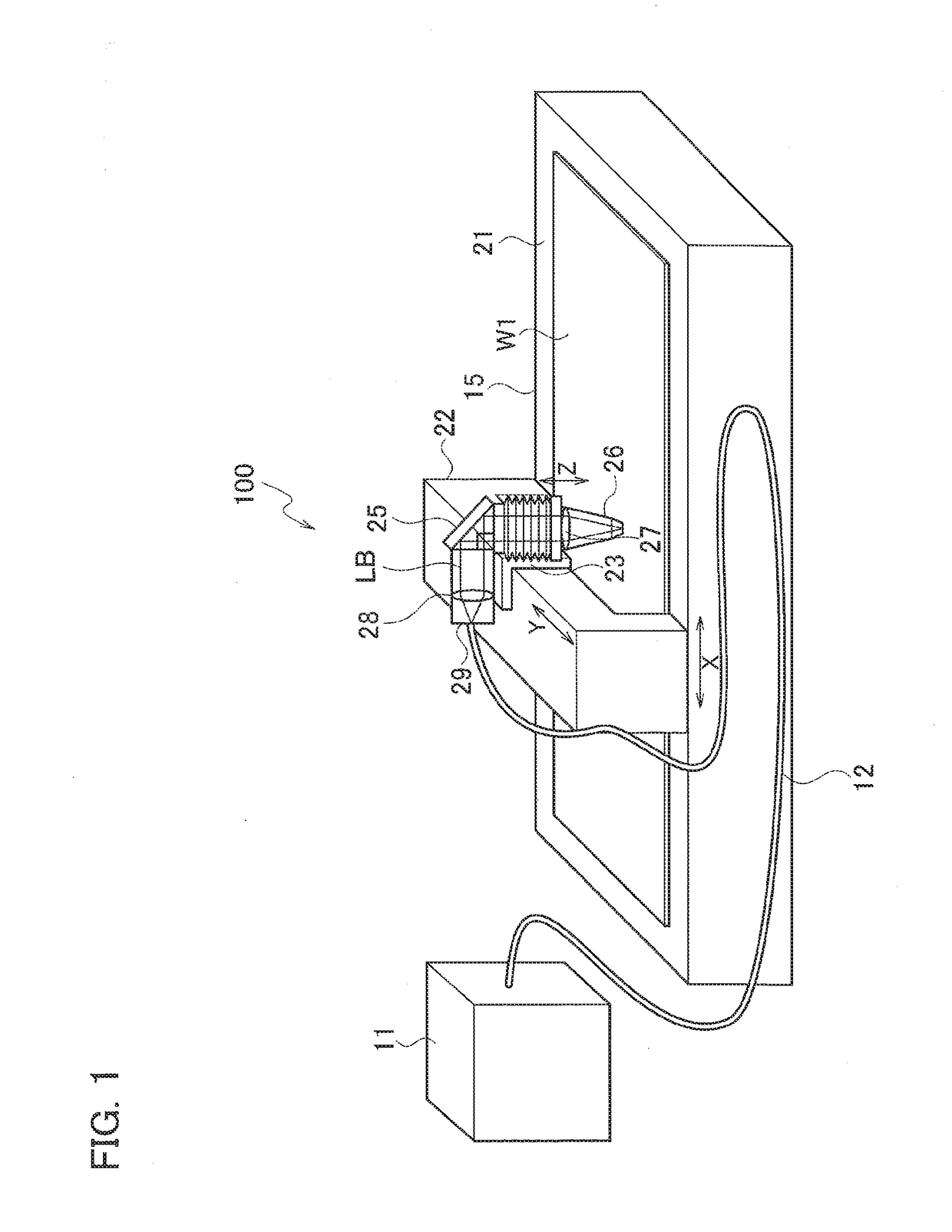

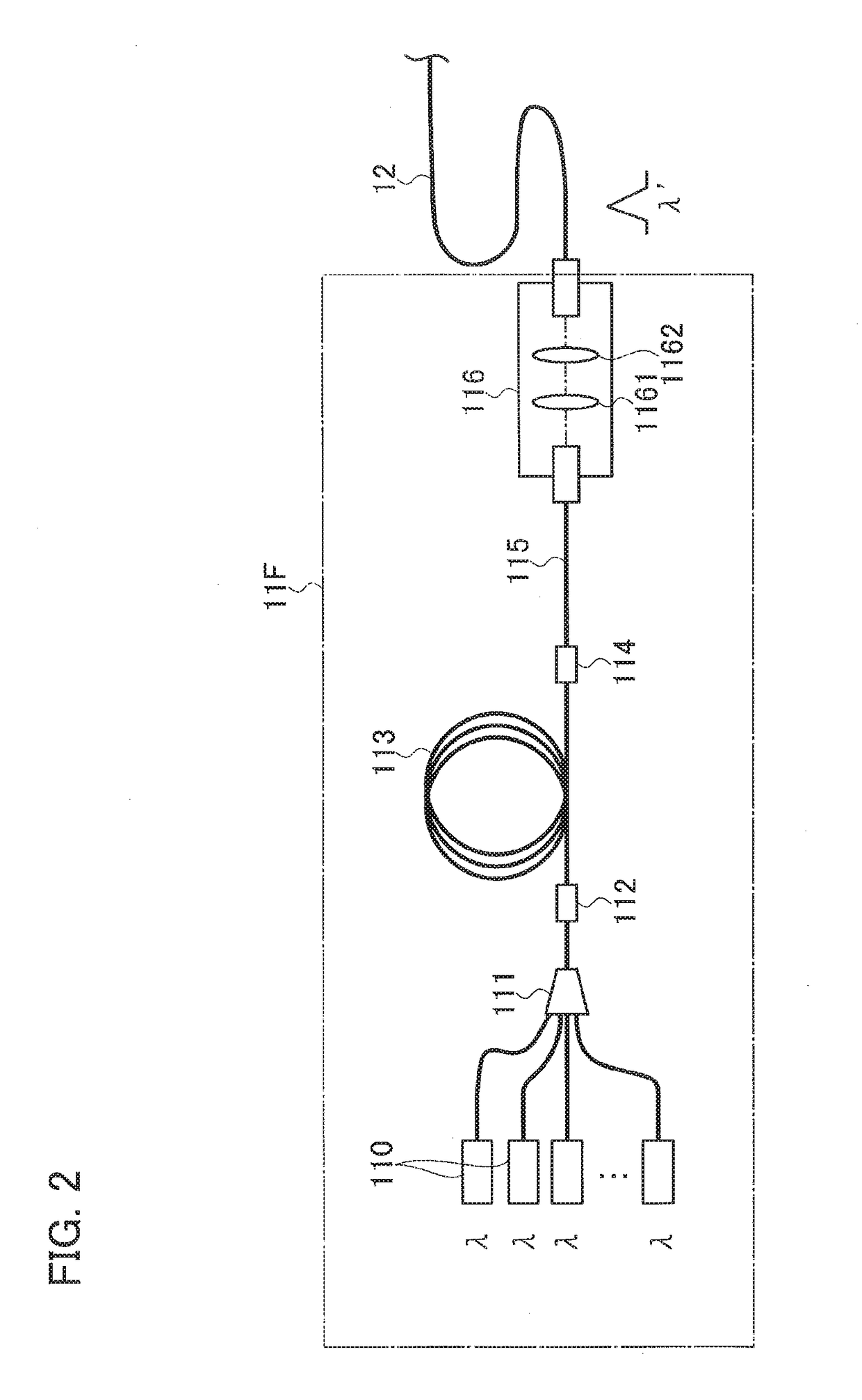

Laser processing machine and laser cutting method

ActiveUS20180169792A1High cutting surface qualityQuality improvementLaser beam welding apparatusLaser processingOptical axis

A laser processing machine includes a laser oscillator. The laser oscillator excites a laser beam having a wavelength in a 1 μm band or a shorter wavelength band. One process fiber transmits the laser beam emitted from the laser oscillator. A focusing optical element focuses, when a workpiece is irradiated with the laser beam emitted from the process fiber, the laser beam on a plurality of spots in a unit area within a unit time, the unit area having a radius of 0.5 mm of an optical axis of the laser beam, and the unit time being a time from when the workpiece starts to melt to when the melting of the workpiece ends.

Owner:AMADA HLDG CO LTD

Annular super-hard abrasive wire and method for manufacturing same

ActiveCN102873401BUniform particle distributionHigh tensile strengthMetal sawing tool makingElectrical conductorHigh intensity

The invention discloses an annular super-hard abrasive wire and a method for manufacturing the same. The annular super-hard abrasive wire comprises a rope, super-hard abrasive particles and a coating, wherein the size of the rope ranges from 0.1mm to 6mm, the super-hard abrasive particles are solidified on the surface of the rope, and the coating is used for solidifying the super-hard abrasive particles. The method for manufacturing the annular super-hard abrasive wire includes braiding the thin rope to form a ring with an optional perimeter; and then solidifying the super-hard abrasive particles on the surface of the annular rope by means of coating to form the high-strength annular super-hard abrasive wire with the uniform outer diameter and a long service life. The annular super-hard abrasive wire is low in cost, high in fatigue strength, long in service life, good in cutting quality and high in cutting efficiency, and a cutting machine with the annular wire can be used for cutting conductors, semiconductors and non-conductor materials.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

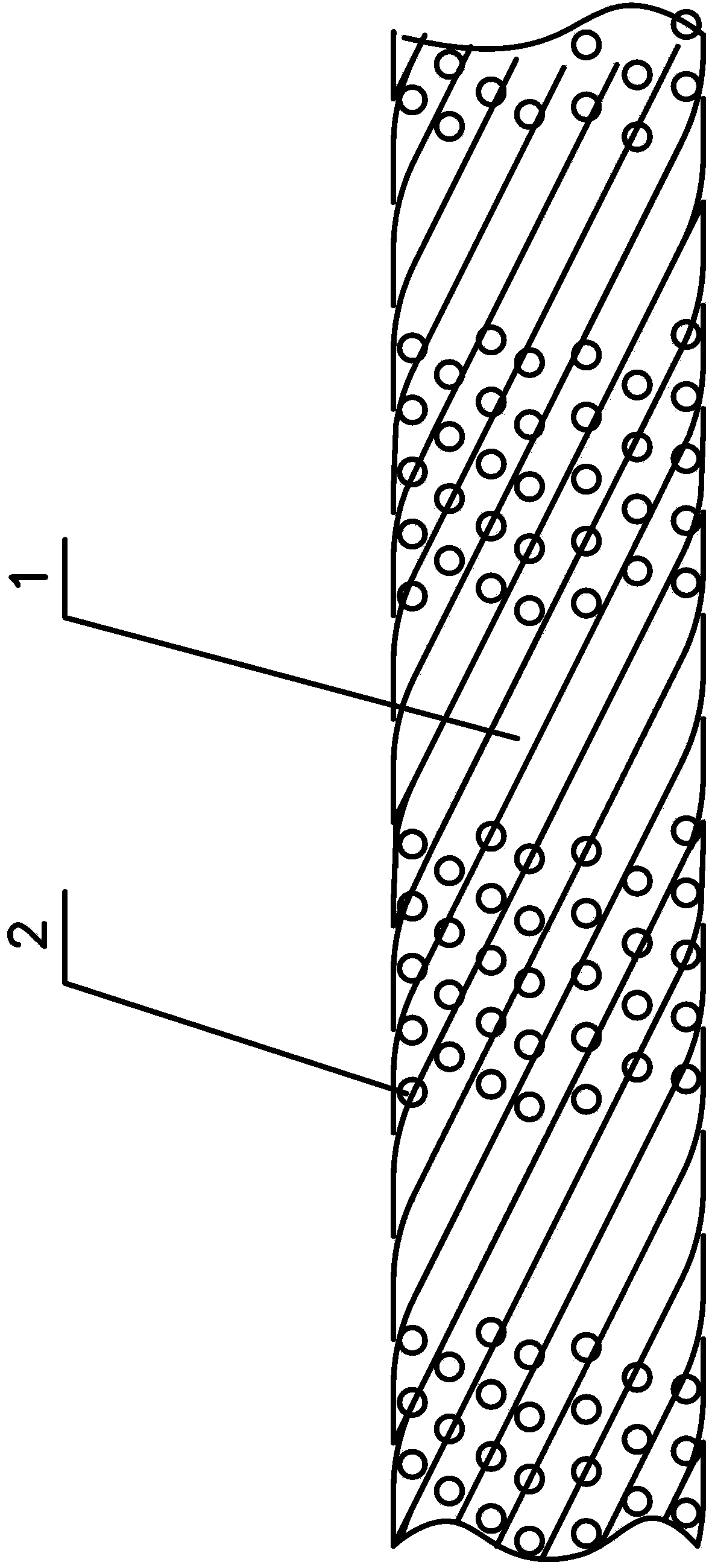

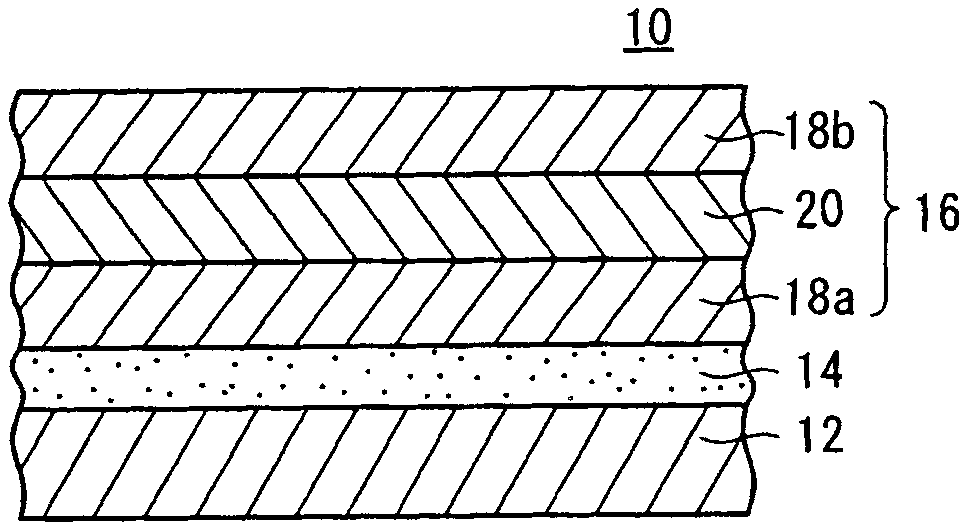

Method of cutting laminated body

InactiveCN101898366AHigh cutting surface qualityMetal working apparatusTectorial membraneEngineering

The present invention provides a method of cutting a laminated body, capable of obtaining good cutting surface quality without cost and labour hour even that a part (film) of the laminated body (10) has a low elongation rate, wherein the laminated body (10) is cut by a cutting knife (46). The laminated body (10) has a separation film (12) and a multilayer film (16) stacked on the separation film (12) through adhesive agent (14). The multilayer film (16) has a first protection film (18a) stacked on the adhesive agent (14), a polarization mirror (20) stacked on the first protection film (18a), and a second protection film (18b) stacked on the polarization mirror (20). Furthermore, a speed (cutting speed v) of the cutting knife (46) to the laminated body (10) is adjusted to more than 8mm / sec, preferably more than 10mm / sec to cut the laminated body (10).

Owner:FUJIFILM CORP

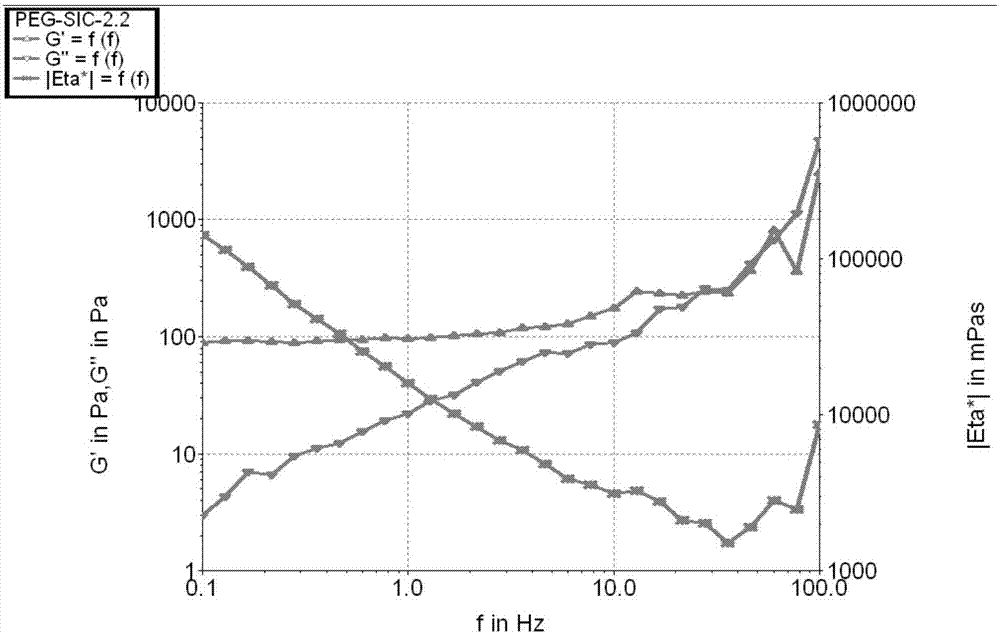

Solar silicon wafer cutting fluid based on shear thickening mechanism, and preparation method thereof

ActiveCN106957710AStirring does not affectDoes not affect flowLubricant compositionSilica particleSilicon dioxide

The invention provides a solar silicon wafer cutting fluid based on a shear thickening mechanism. The cutting fluid is prepared from micro / nano-silicon dioxide particles, dispersion media and SiC powder, wherein a certain part of micro / nano-silicon dioxide particles is dissolved in the dispersion media to form the cutting fluid with a shear thickening effect. The preparation method comprises the following main preparation steps: dissolving micro / nano particles into pretreatment dispersion media to obtain premixed liquid; further dispersing the premixed liquid in the dispersion media to obtain a micro / nano-silicon dioxide dispersion system; adding the SiC powder into the dispersion system to obtain the novel solar silicon wafer cutting fluid. Compared with traditional solar silicon wafer cutting fluid, the solar silicon wafer cutting fluid has the advantages of better dispersibility, stability and shear thickening performance, lower cutting cost and better cutting surface quality. The solar silicon wafer cutting fluid based on the shear thickening mechanism has the advantages of simple preparation technology, convenience in operation and easiness in realizing industrial production.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

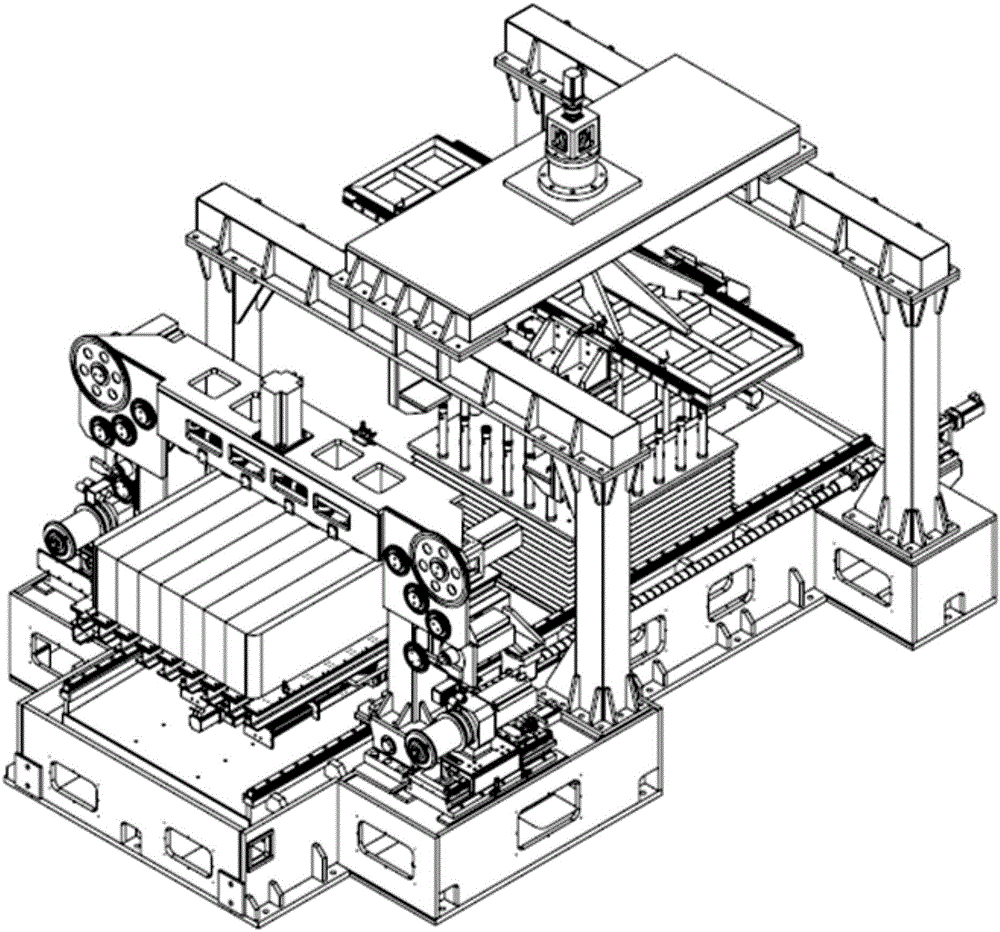

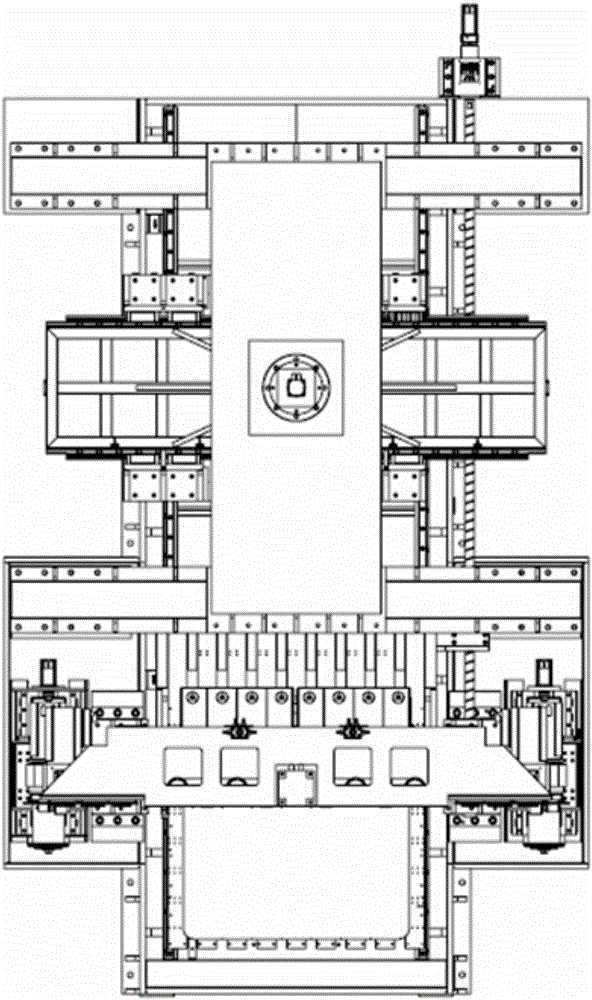

Diamond wire crystal ingot squarer

ActiveCN106182480AReduce lossSmall cutting marksFine working devicesDiamond wire sawWorking environment

The invention relates to cutting equipment special for polycrystalline silicon processing and aims to provide a diamond wire crystal ingot squarer. The diamond wire crystal ingot squarer comprises a large bottom frame, a workbench, a workbench horizontal moving motor, a speed reducer, a main screw, a manipulator part, a cutting chamber part, a lifting mechanism, a take-up and payoff part, a tension part and a bottom guide wheel part. According to the diamond wire crystal ingot squarer, a diamond wire saw is adopted for cutting, a cutting mark is small, a cutting face is high in quality, material loss is reduced greatly, and the work environment is improved. According to the diamond wire crystal ingot squarer, a novel rotary mechanism is adopted for decreasing the height of the workbench, and thus the axis distance of a cutting guide wheel is reduced. The wire arch is small, cutter feeding is fast, the cutting efficiency is high, and the cutting dimensional deviation caused by a hard point is avoided. According to the diamond wire crystal ingot squarer, a horizontal moving function is added to a bottom guide wheel, a cutting line is changed into an oblique line from a vertical line during second time of cutter feeding, only a cutting-in opening is cut in the upper portion of a crystal ingot, and thus the uncontrollable size and edge breakage are avoided.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

Method for cutting groove of U-rib steel plate by plasma cutting torches at double variable angles for one time

ActiveCN103302388AHighly stableRealize automatic joint controlPlasma welding apparatusPower flowProgrammable logic controller

The invention relates to a method for cutting a groove of a U-rib steel plate by plasma cutting torches at double variable angles for one time. The method comprises steps as follows: two sets of plasma batteries and two sets of the plasma cutting torches which can deflect angles are mounted on one plasma numerical control cutting machine; the two plasma cutting torches are configured with cutting torch initial height positioners, cutting torch arc voltage adjusting systems, numerical control systems and PLC (programmable logic controller) systems; a to-be-cut steel plate is placed on a cutting table, the two plasma cutting torches are aligned to the edge of the to-be-cut steel plate, the transverse distance between the two plasma cutting torches and the angles of the two plasma cutting torches are adjusted, and initial positioning values, cutting current and cutting speeds of the two plasma cutting torches are set in the numerical control systems; and a starting button of the cutting machine is pressed, and under the control of the numerical control systems, the two plasma cutting torches simultaneously start arc and cut the U-rib steel plate. According to the method, only one processing process is required, and the U-rib steel plate can be cut for one time, therefore, the operation is simple, automatic cutting is realized, and the straightness of the cut U-rib steel plate, the surface quality of the groove and the angle accuracy all meet the design requirements.

Owner:HAIOD HEAVY ENG TECH

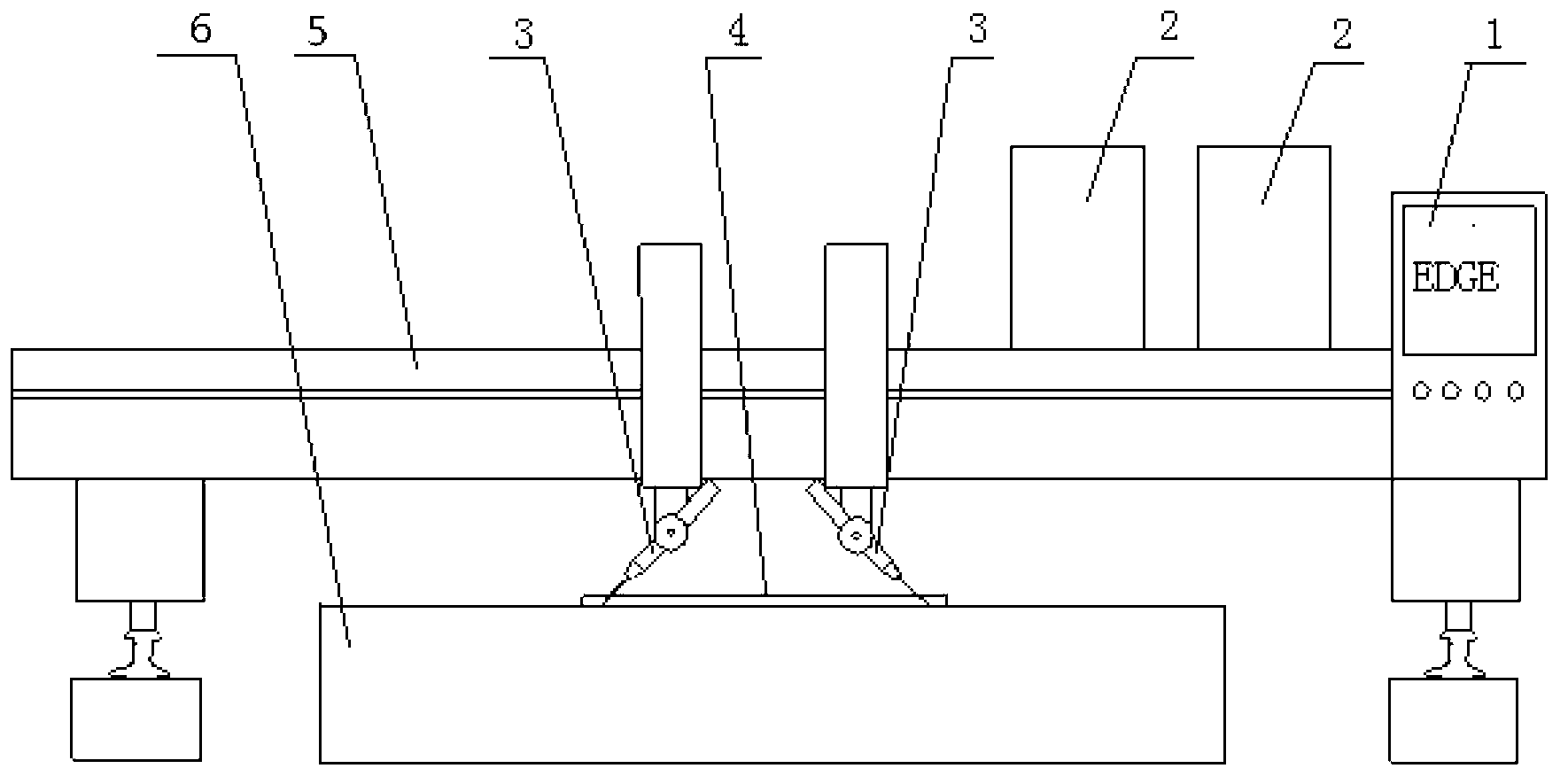

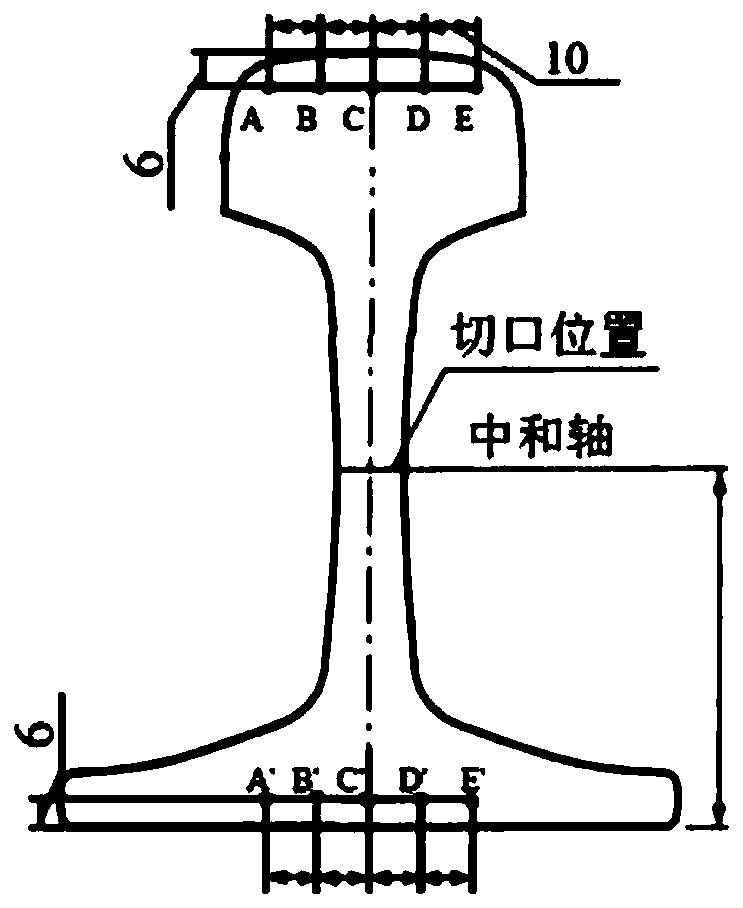

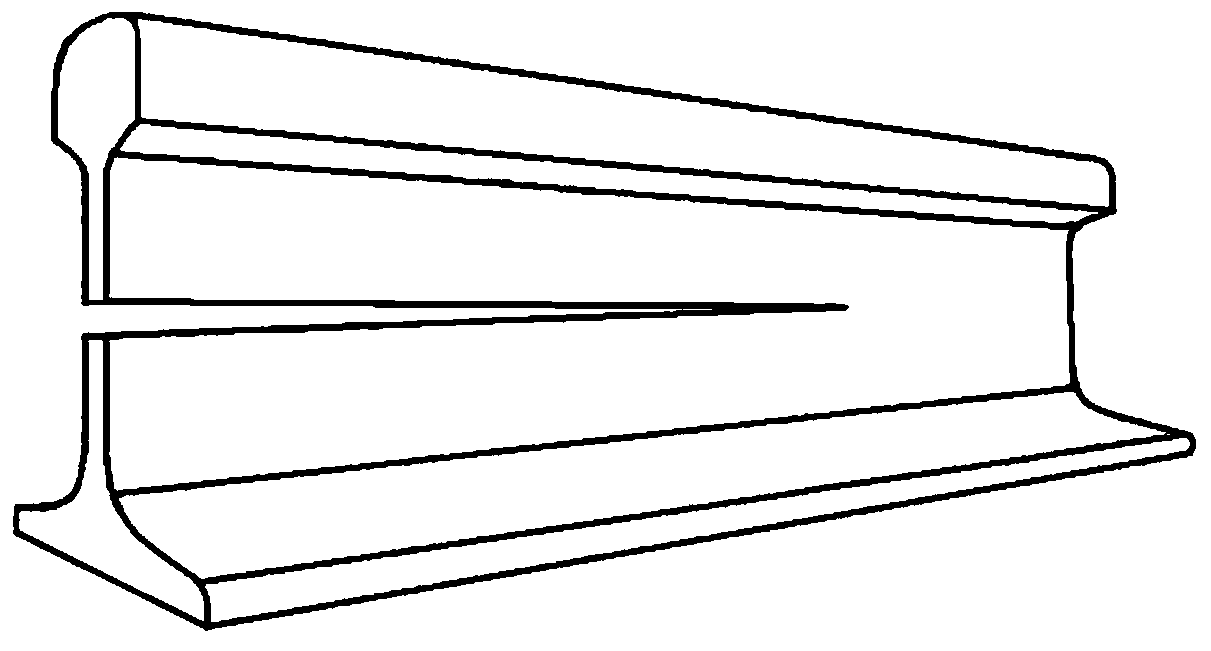

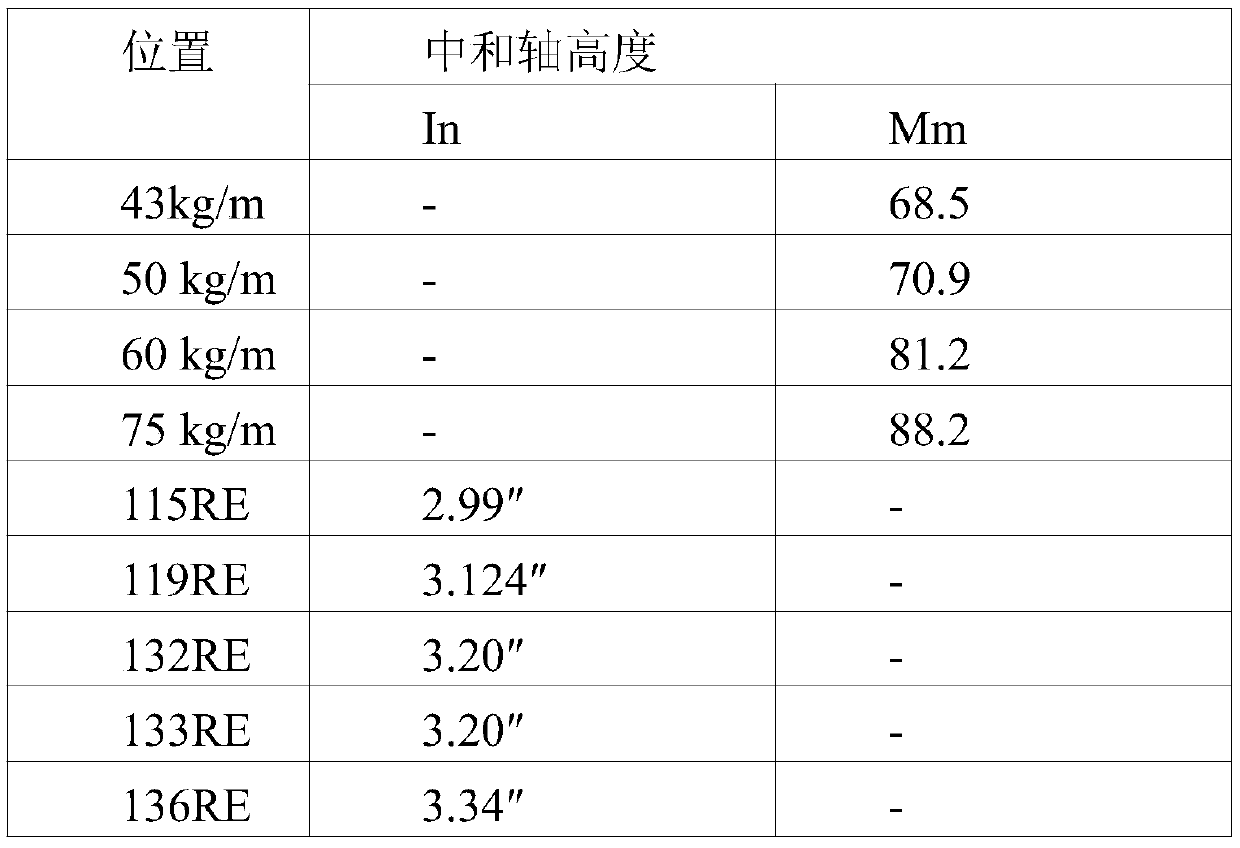

Steel rail residual stress testing method

InactiveCN110987261AHigh cutting surface qualityResidual stress release with little interferenceApparatus for force/torque/work measurementClassical mechanicsWire cutting

The invention discloses a test method for testing residual stress of a steel rail by adopting a rail web notching method. The test method comprises the following steps: 1) preparing a sample; 2) cutting a rail web; and 3) performing measuring. A linear cutting machine tool is used for cutting, the notch surface quality is good, and macroscopic cutting force in machining is avoided; the length of asample is 600 mm, a molybdenum wire is a molybdenum wire special for 0.18 mm linear cutting, the length of a notch is 400 mm, computer programming control is adopted in the cutting process, and the size precision of the notch is high. Residual stress displacement value measurement is performed by using an average value method so as to reduce measurement errors; a vernier caliper is used for measurement, and the displacement value (+ or-) is required to be smaller than or equal to 3.75 mm.

Owner:BAOTOU IRON & STEEL GRP

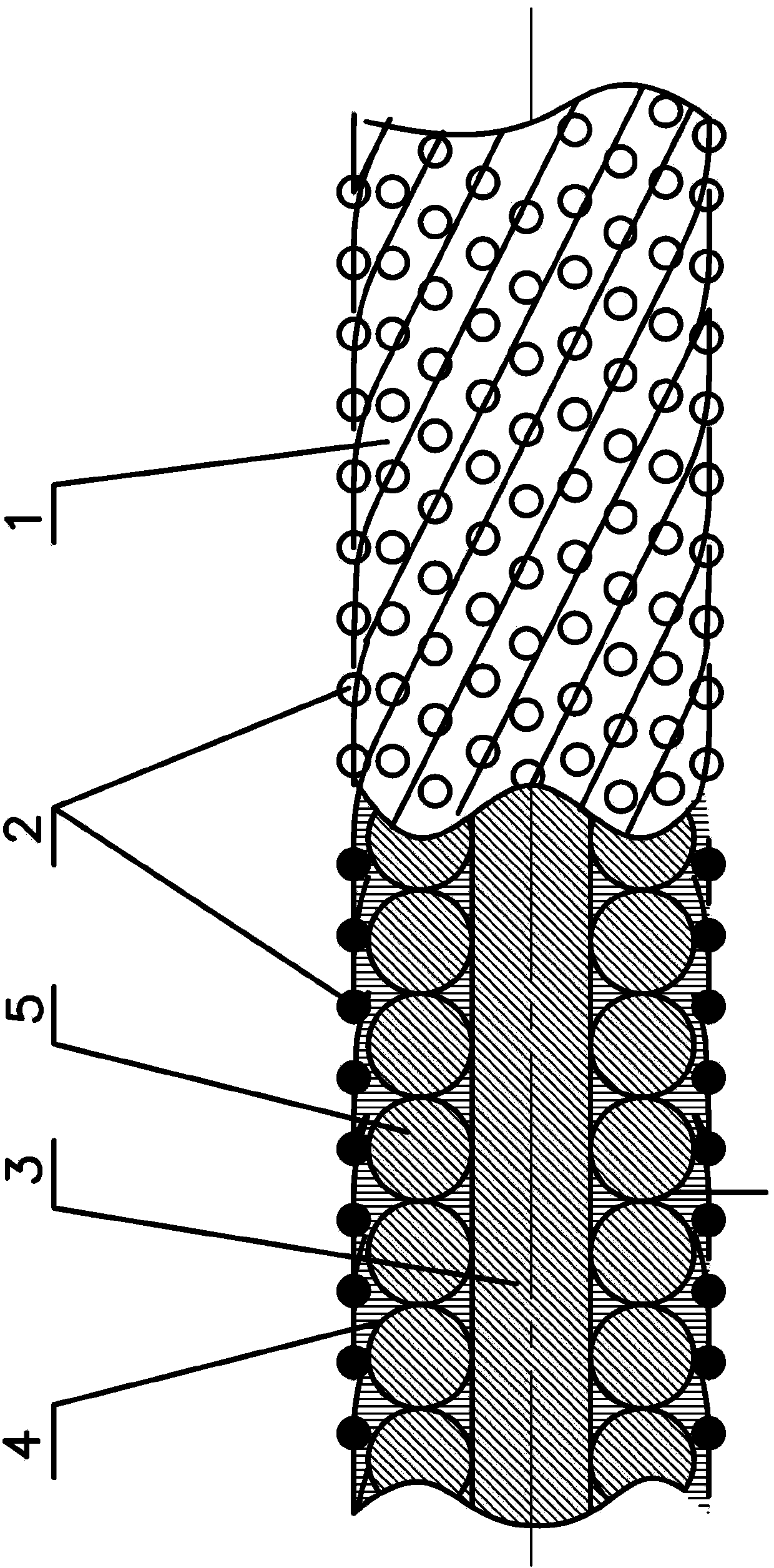

Annular superabrasive wire and manufacturing method thereof

ActiveCN104908166BReduce the numberNarrow kerfFine working devicesStone-like material working toolsYarnMaterials science

The invention discloses an annular superhard abrasive wire and a manufacturing method thereof. The base body of the annular superhard abrasive wire is a wire rope, the wire rope is connected in an end-to-end mode to form an annular shape, superhard abrasive particles are uniformly consolidated on the surface of the wire rope so as to form a superhard abrasive layer, the superhard abrasive layer is a single particle thickness layer, the wire rope comprises a core and compound yarns spirally wound on the core, the initial end and the tail end of the core are connected to form an annular shape, the length of the compound yarns wound on the core meets the requirement that the compound yarns can be wound on the core for six turns, after the compound yarns are wound on the core for six turns, the compound yarns are connected in an end-to-end mode, and joints of the compound yarns are disposed at one side of a core connecting point. The annular superhard abrasive wire is narrow in joint cutting, high in efficiency and good in cutting surface quality, and also has higher anti-fatigue strength.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

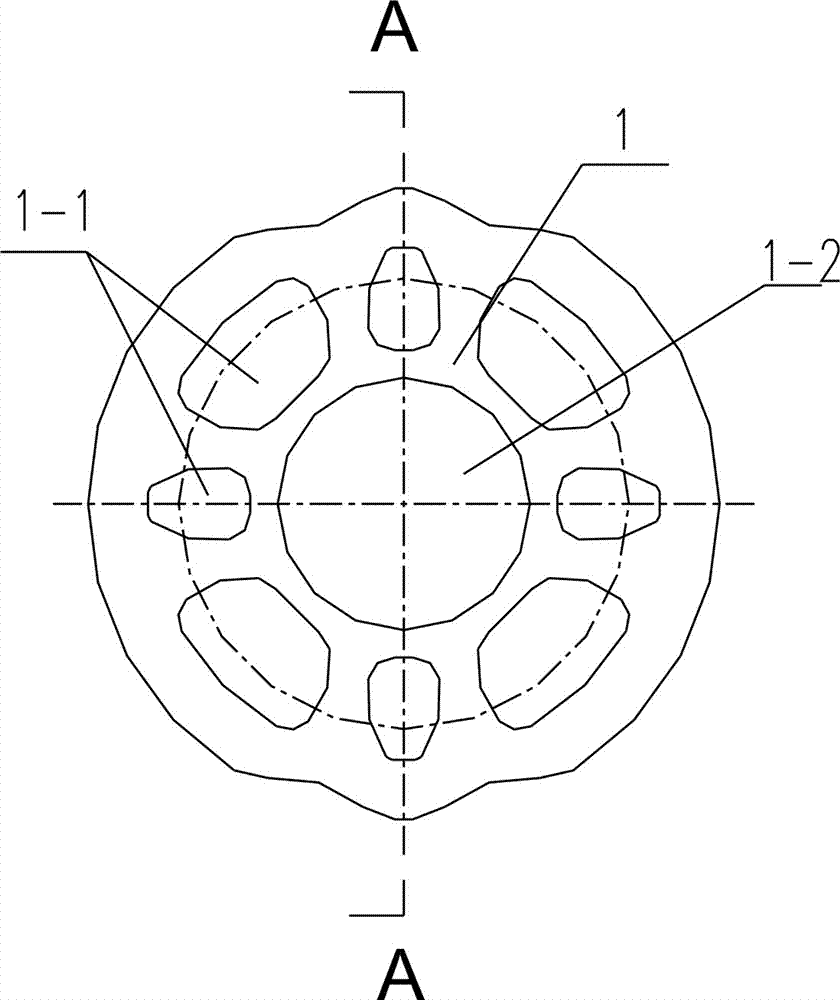

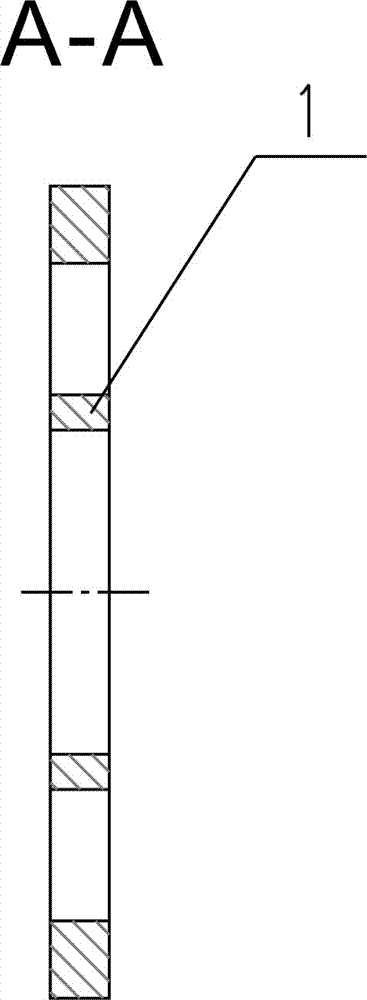

Once fine blanking forming method for thick plate disc

ActiveCN102756247AReduce punching forceGuaranteed dimensional accuracyThick plateHigh volume manufacturing

The invention provides a once fine blanking forming method for a thick plate disc. The method comprises the following steps of: 1) preparation of equipment, raw materials and upper and lower once fine blanking forming dies; and 2) once fine blanking forming. The step 2) comprises the following steps that: 1, the upper and lower once fine blanking forming dies are arranged on an upper tabletop and a lower tabletop of a fine blanking machine respectively, and when a fine blanking mold is at an opening position, a bar stock is fed to a fine blanking station; (2) the fine blanking machine is started, and a lower workbench of the fine blanking machine moves upwards to apply blanking force FS to a female die, a round hole male die and an irregularly-shaped hole male die, apply blank holding force FR to a dowel bar, a round knock-out pin and an irregularly-shaped knock-out pin and apply back pressure FG to the knock-out pins; and 3, a lower workbench of the fine blanking machine moves downwards, a pressure plate withdraws the cut bar stock from a punch die under the action of the blank holding force FR, and a pushing plate ejects a thick plate disc part from the female die under the action of the back pressure FG to obtain the formed thick plate disc part. The method is applied to batch production, and has the characteristics of operational simplicity, high efficiency, cost saving and stable quality.

Owner:武汉华夏精冲技术有限公司

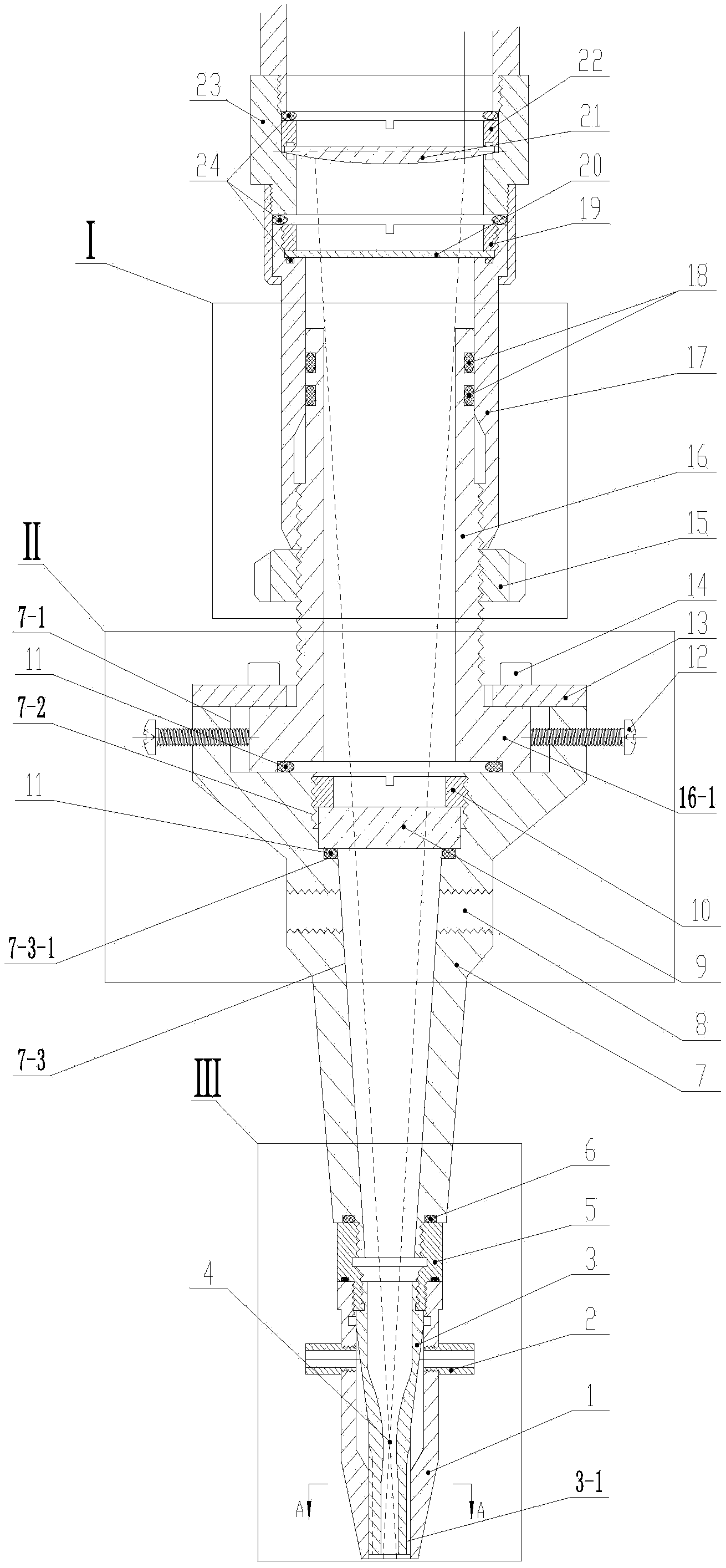

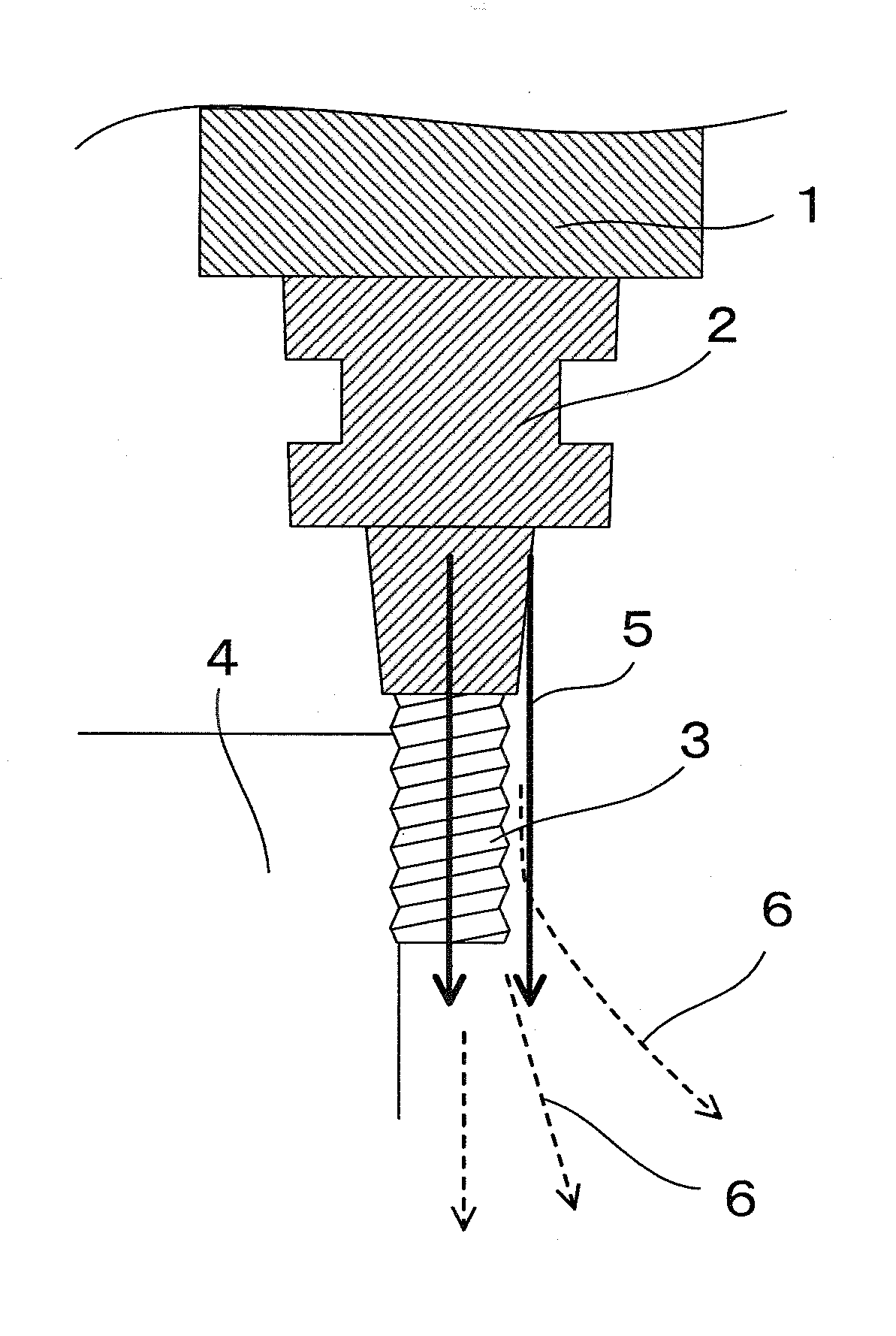

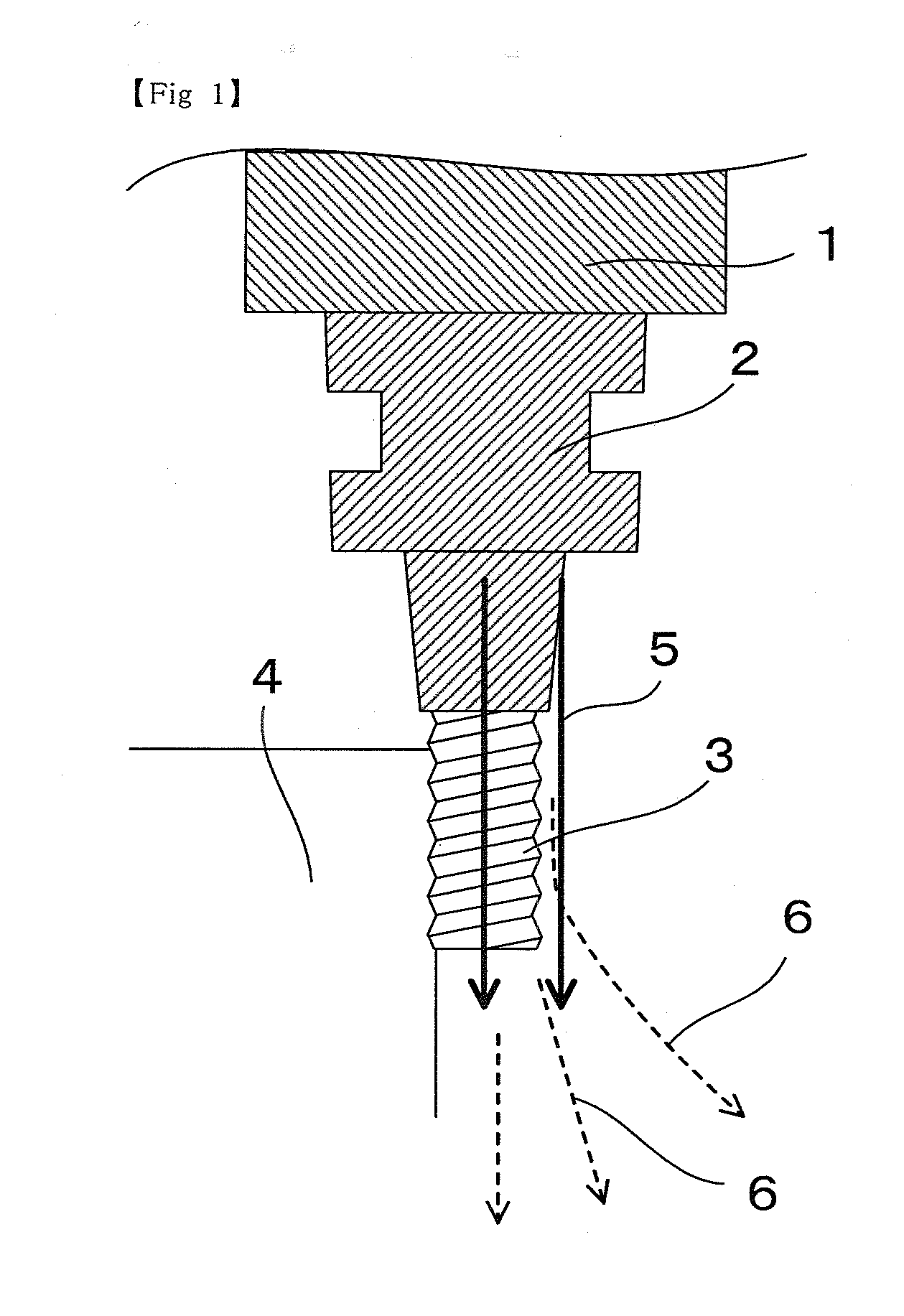

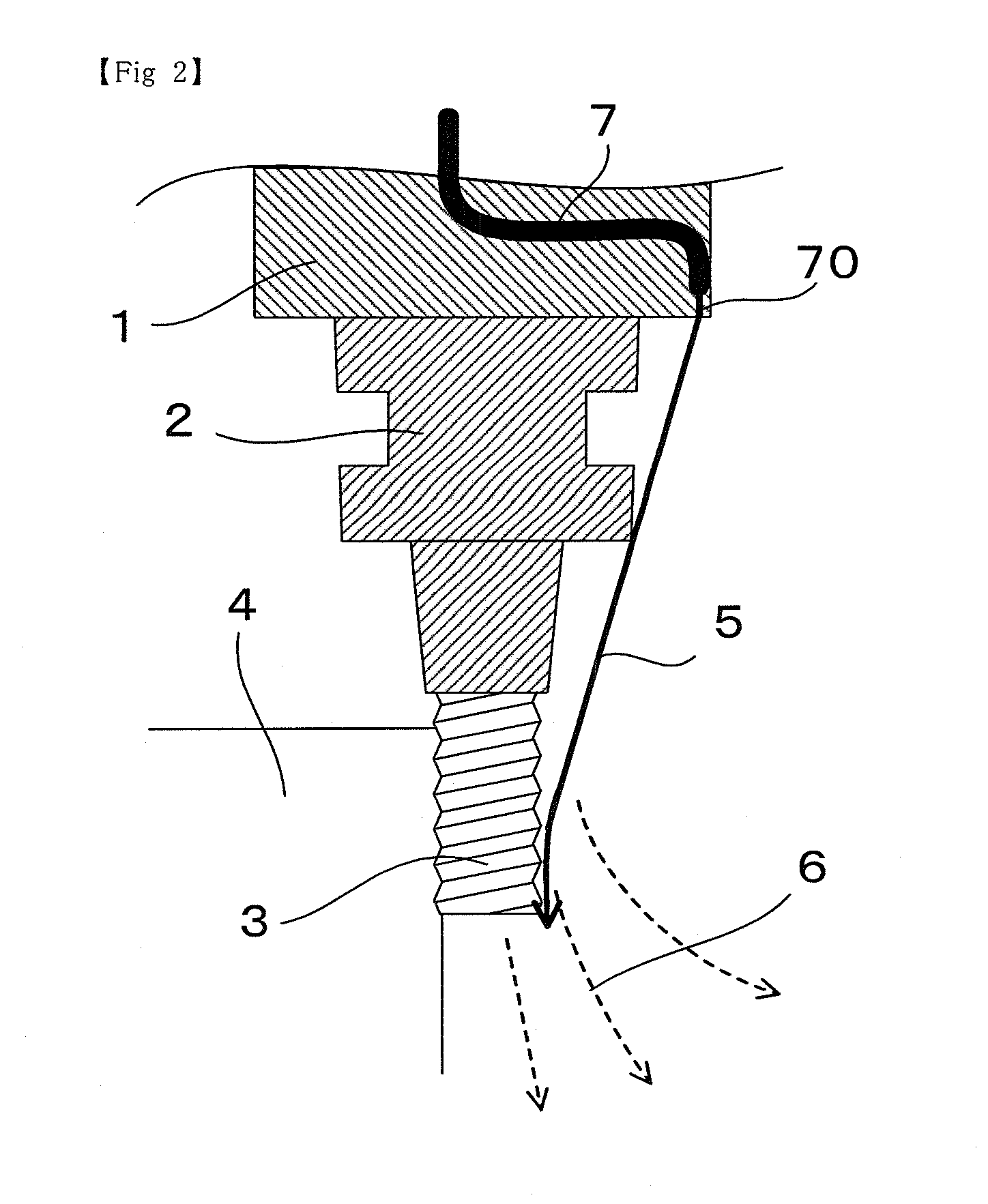

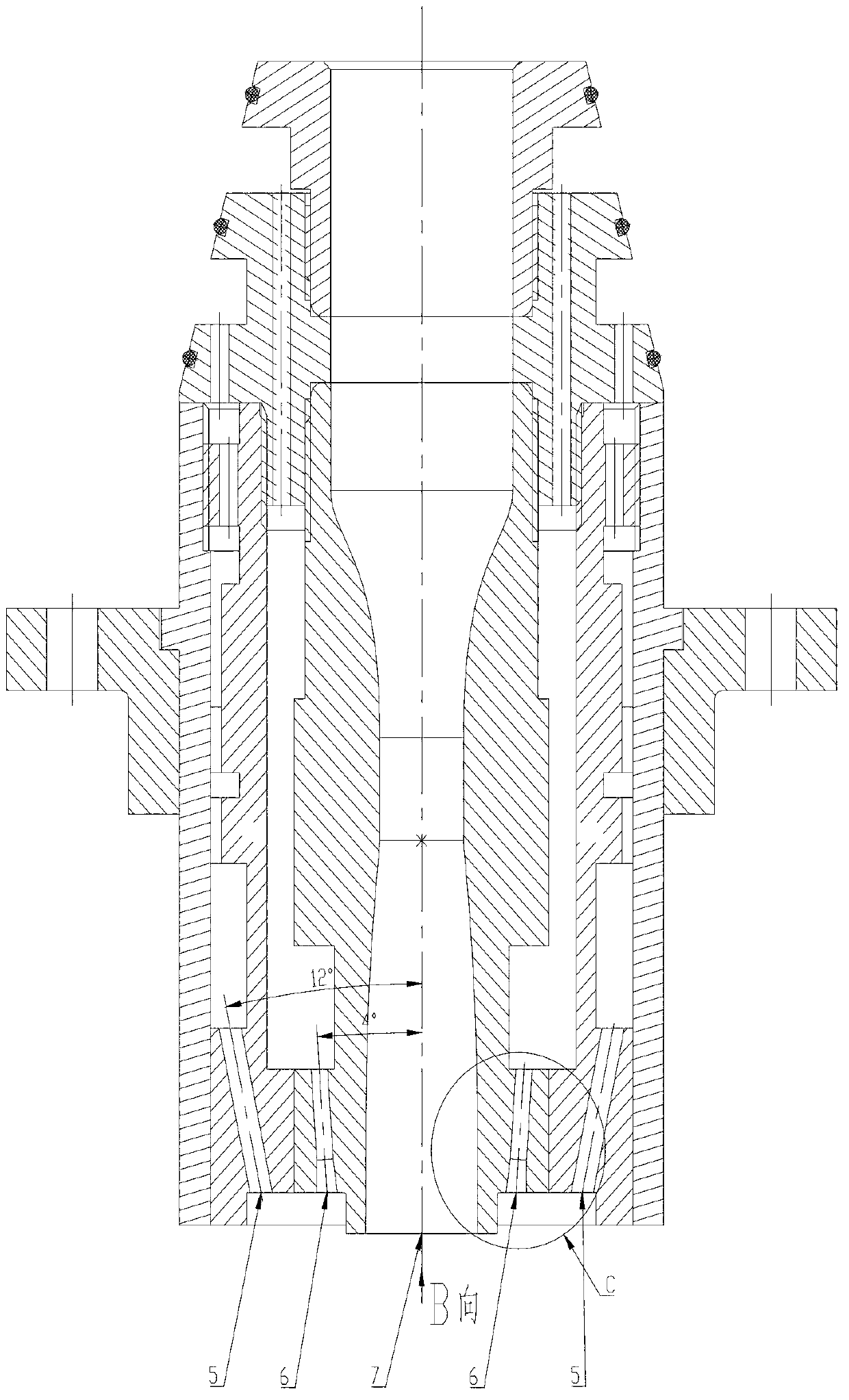

Cutting torch for cutting ultrahigh-thickness 2000-3500 mm low-carbon and low-alloy steel ingot

ActiveCN102997243AImprove the heating effectHigh cutting surface qualityGaseous fuel burnerTorchIngot

The invention provides a cutting torch for cutting an ultrahigh-thickness 2000-3500 mm low-carbon and low-alloy steel ingot and belongs to the technical field of the ultrahigh-thickness low-carbon steel ingot oxygen cutting device. The invention aims to solve the technical problem in the background art that the 2000-3500 mm ultrahigh-thickness low-carbon and low-alloy steel ingot cannot be cut at high efficiency and good quality. The cutting torch is mainly characterized in that preheating oxygen and propane gas are not mixed inside the cutting tip of the cutting torch at first, and mixed and burnt in atmosphere after being jet out of the cutting torch instead, a preheating oxygen duct (5) and a gas duct (6) both are inclined toward the axis of the cutting torch, the diameter of the throat part of a large-flow cutting oxygen cutting tip (7) is 17-22 mm, each gas duct (6) is designed into a structure with the lower part thereof slightly spread, and the diameter of the inlet thereof is 4.5 mm, the spreading taper angle is 1.146% and the length of the spreading section is 8 mm. The cutting torch provided by the invention is suitable for good-quality and high-efficiency cutting of the ultrahigh-thickness 2000-3500 mm low-carbon and low-alloy steel ingot.

Owner:HARBIN WELDING INST LTD

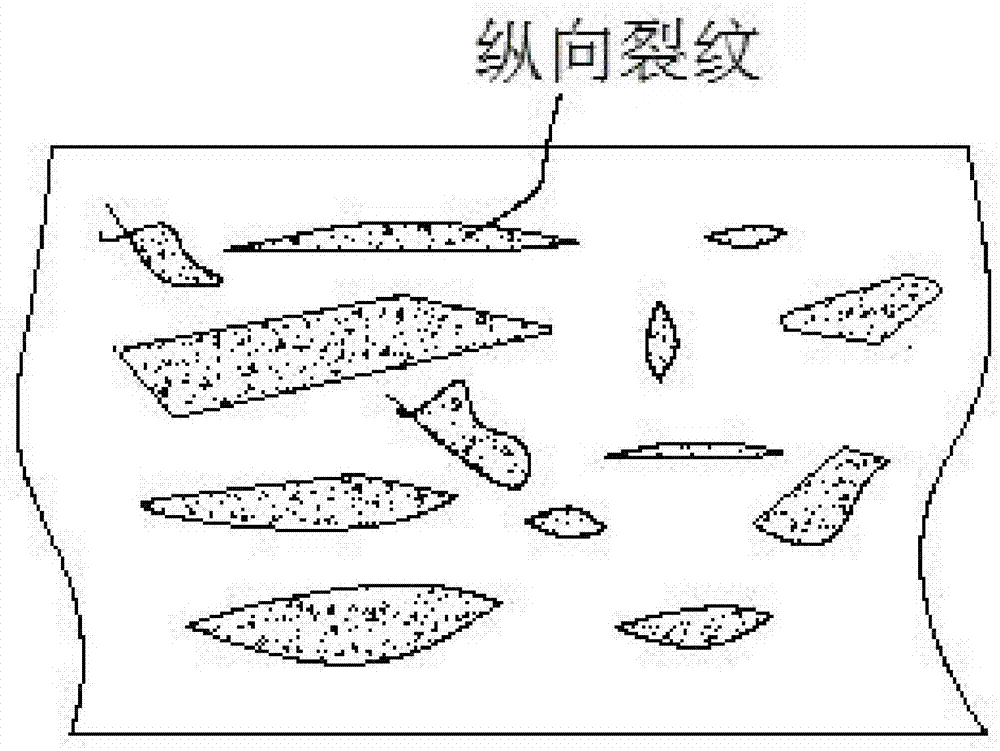

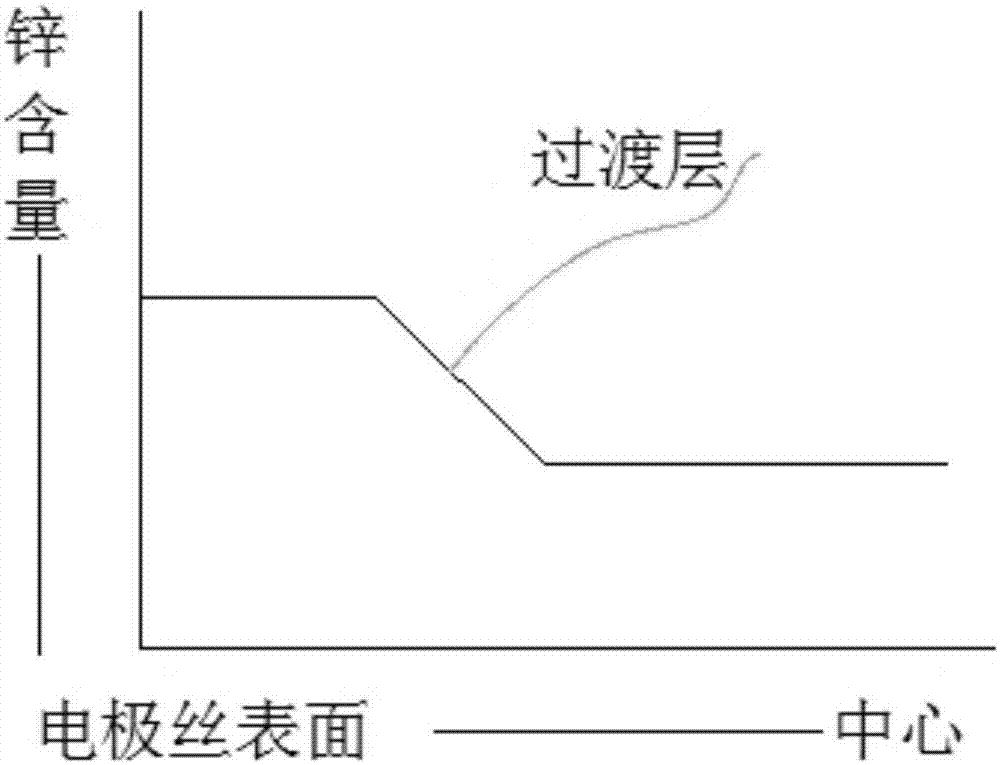

Electrode wire for slow wire EDM cutting

ActiveCN105834533BHigh cutting surface qualityLow cut surface qualityElectrical-based machining electrodesLow speedWire cutting

An electrode wire used for spark cutting of low-speed wire cutting comprises an electrode wire body. The electrode wire body is composed of a core material and a surface metal layer, wherein the core material is made of an alloying brass material, and the surface metal layer covers the core material. A transition layer is arranged between the core material and the surface metal layer. The alloying brass material is composed of, by weight, 58.0-65.0% of copper and the balance zinc, a small quantity of adding elements and inevitable impurities. The surface metal layer is composed of copper, zinc, adding elements and inevitable impurities, wherein the zinc content is larger than 52 wt% and smaller than 68 wt%, and the surface metal layer is distributed in a fracture shape longitudinally. Compared with the prior art, the electrode wire has the advantages that the manufactured electrode wire is stable in discharge performance, the cutting speed is increased, a wire feeding part and a guiding device of low-speed wire cutting equipment are prevented from being damaged, a machining technique of the electrode wire is simple, the application range is wide, the cost is low, and broad market prospects are achieved.

Owner:NINGBO BODE HIGHTECH CO LTD

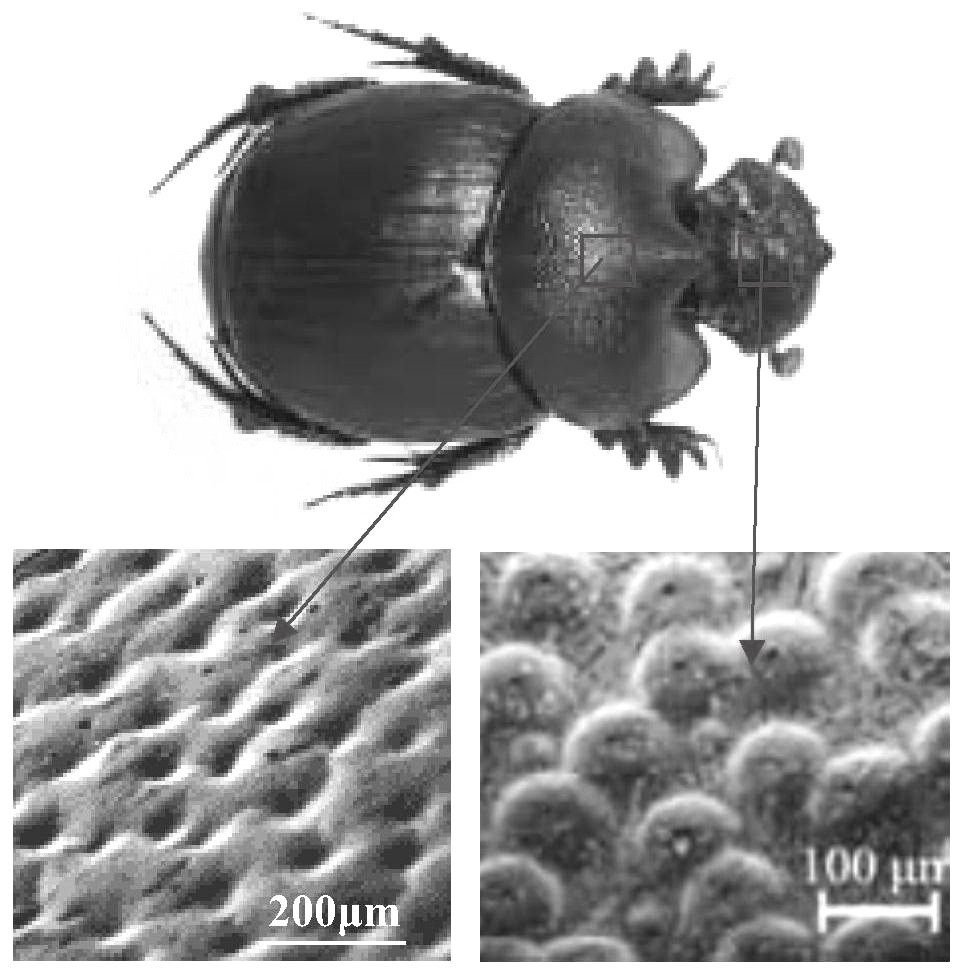

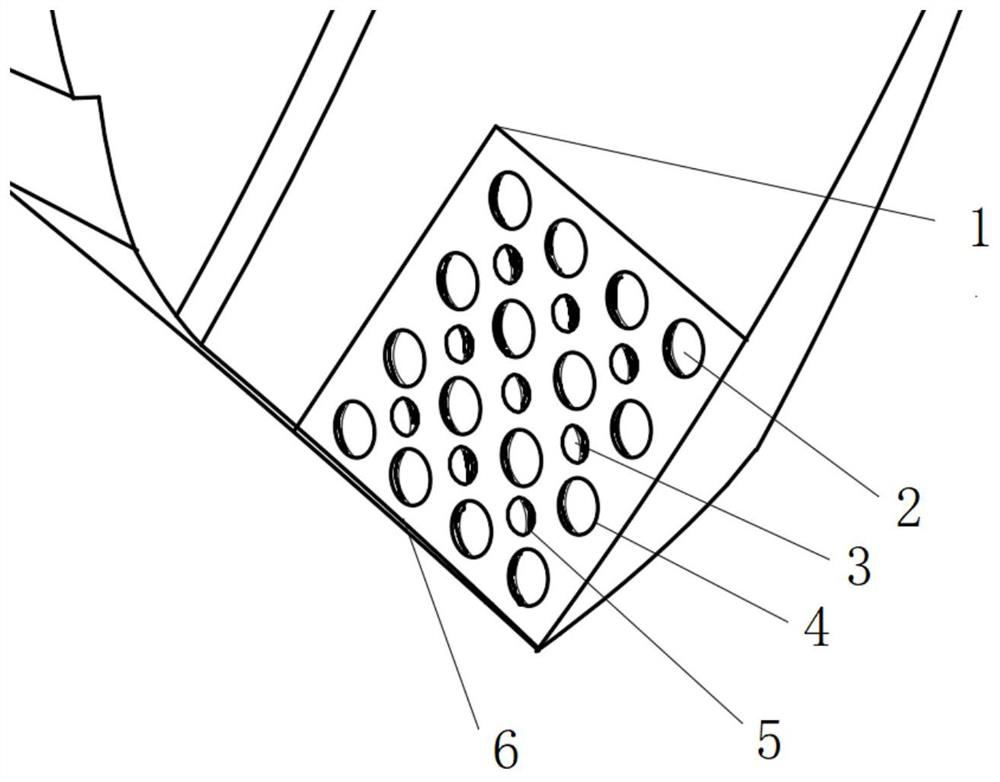

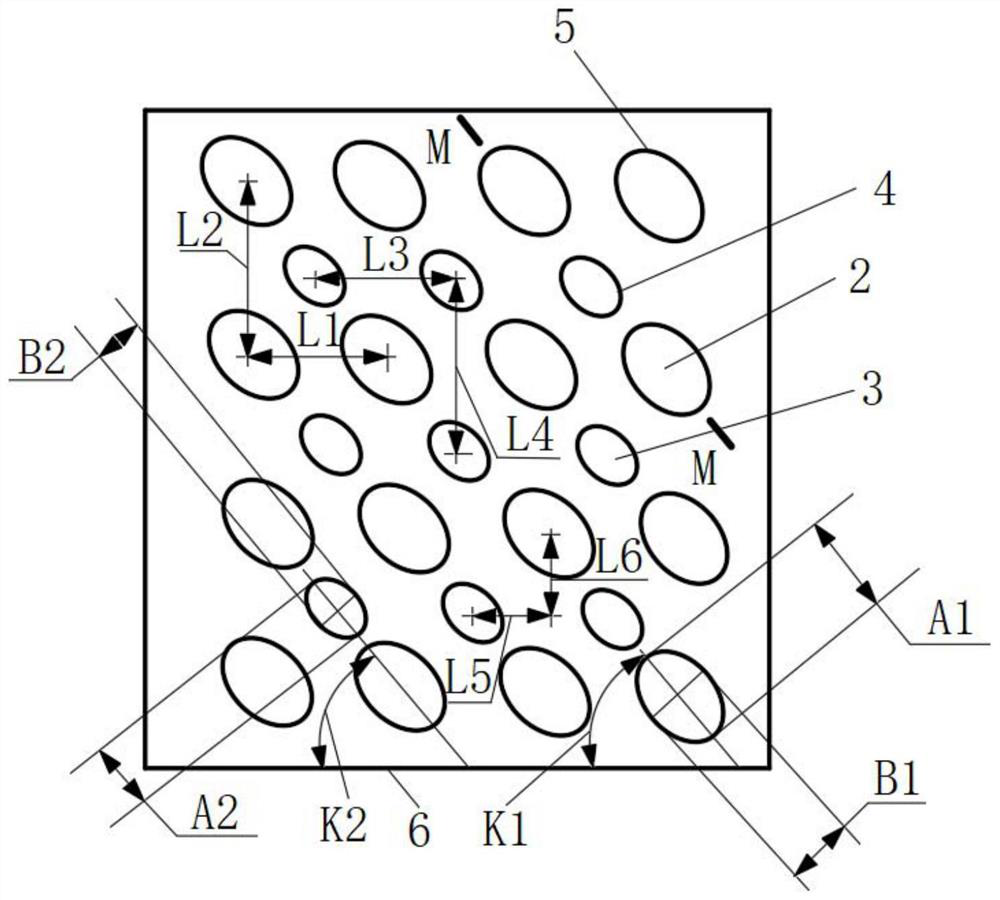

Bionic bone cutting tool based on dung beetle surface microstructure and preparation method of bionic bone cutting tool

The invention belongs to the technical field of manufacturing of bone cutting tools, and particularly relates to a bionic bone cutting tool based on a dung beetle surface microstructure and a preparation method of the bionic bone cutting tool. A texture array of an imitated dung beetle surface microstructure is processed in a cutting chip contact area, and comprises semi-ellipsoid protrusion microstructures distributed on the head of a dung beetle and semi-ellipsoid pit microstructures distributed on the back of the dung beetle, the cutting temperature in the process of cutting a bone materialby the tool can be reduced, the cutting process is more stable, cracks are inhibited, and the surface quality is improved. The bionic tool can be widely applied to a backbone cutting surgery, the cutting temperature can be reduced, moreover, cracks can be inhibited, so that the cutting surface quality of the bone material is improved, and secondary damage to a patient is avoided.

Owner:XIAMEN UNIV

Automatic control system for cross-cut shear blade gap

ActiveCN110181112ATargetedReduce biasAutomatic control devicesFeeding apparatusAutomatic controlSheet steel

The invention discloses an automatic control system for a cross-cut shear blade gap. A process automation computer calculates an optimal shear blade gap value by comprehensively considering the thickness and the tensile strength of a steel plate according to original data of the steel plate to be sheared sent by a production control computer, the optimal shear blade gap value is automatically sentto a base automation computer, and the base automation computer further considers a shear blade actual wear compensation dosage and then automatically sends a final optimal shear blade gap value to ashearing machine automation control programmable logic controller (PLC) for carrying out shearing. The automatic control system for the cross-cut shear blade gap has the advantages that the shear blade gap is scientific, reasonable and targeted, so that the quality of cut surfaces of various steel plates especially high-strength steel is effectively improved. In addition, a gasket for clearance adjustment is further cushioned on a top knife rest, so that the deviation of the gap in the shear blade length direction is reduced, a method is simple and easy to implement, and the remarkable effects on improving the overall quality of the cut surface and prolonging the service life of the shear blade are achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

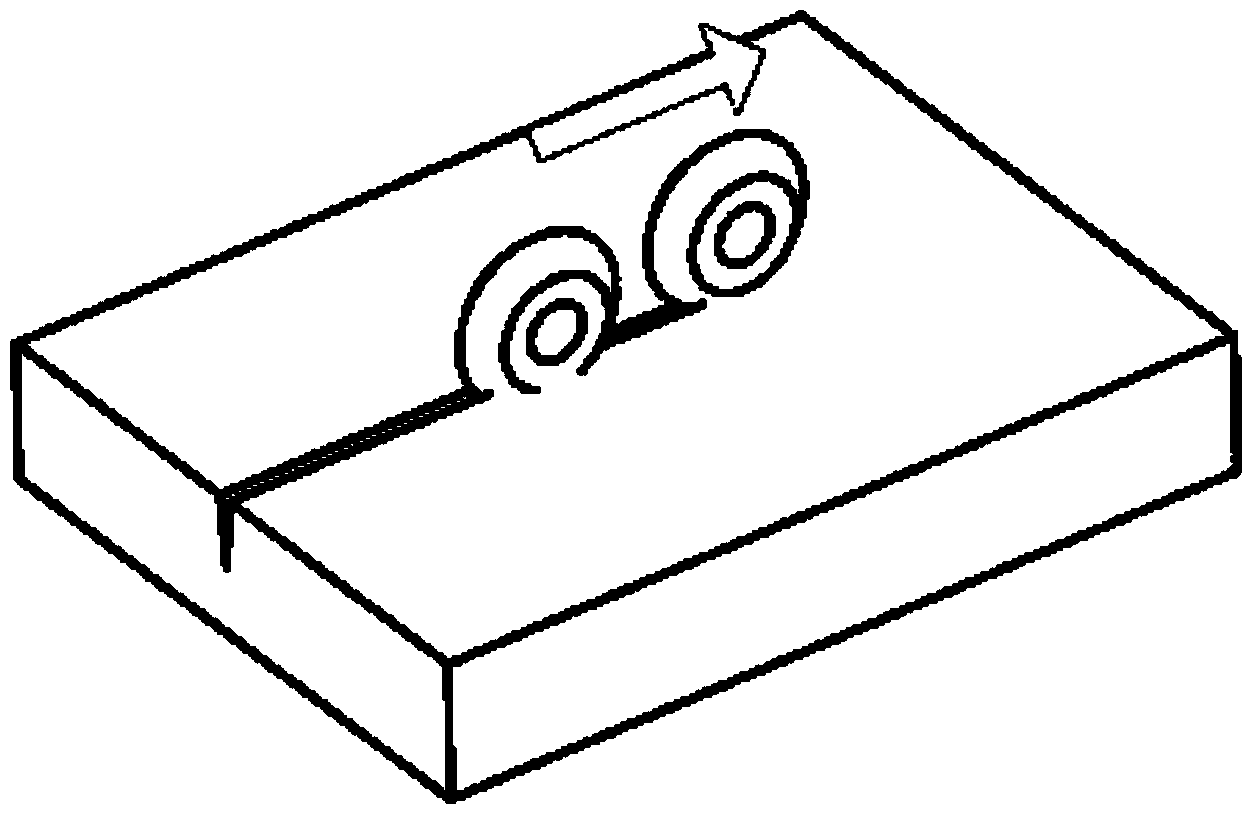

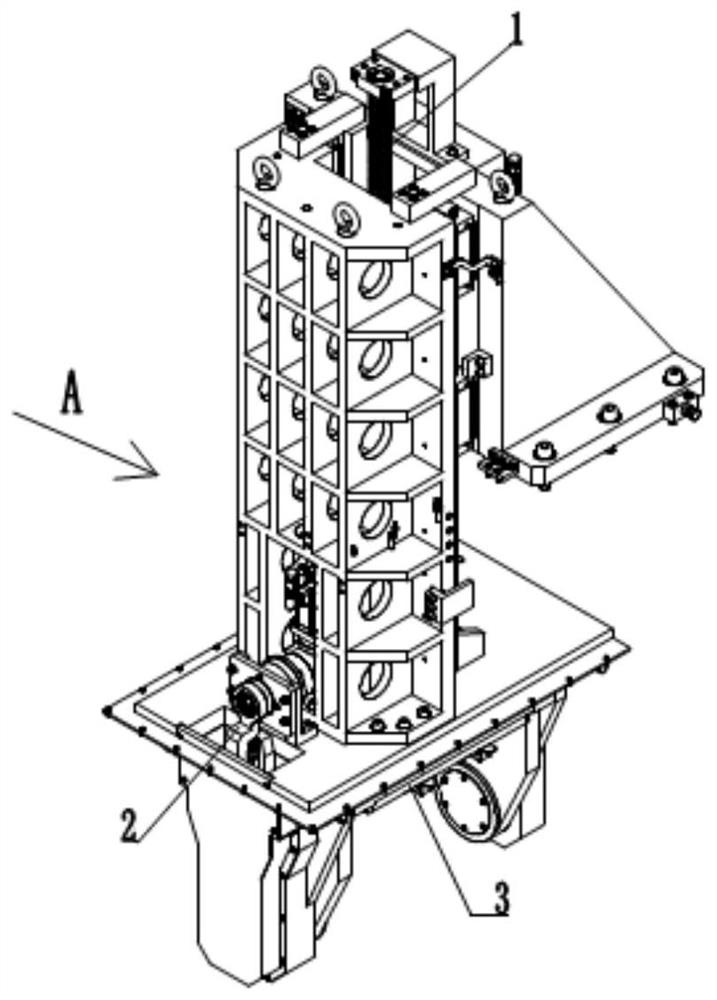

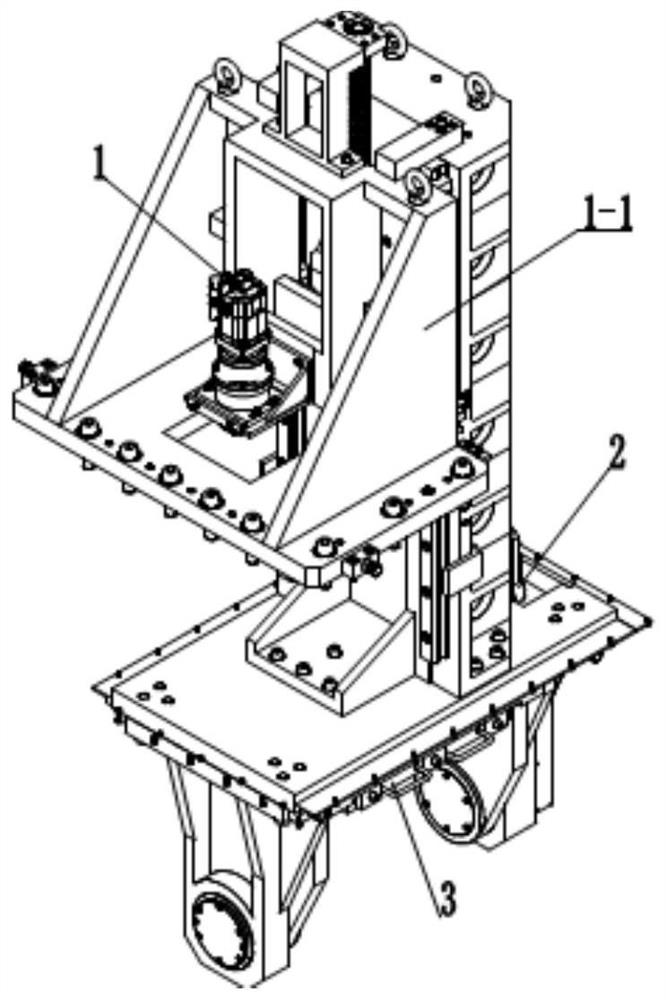

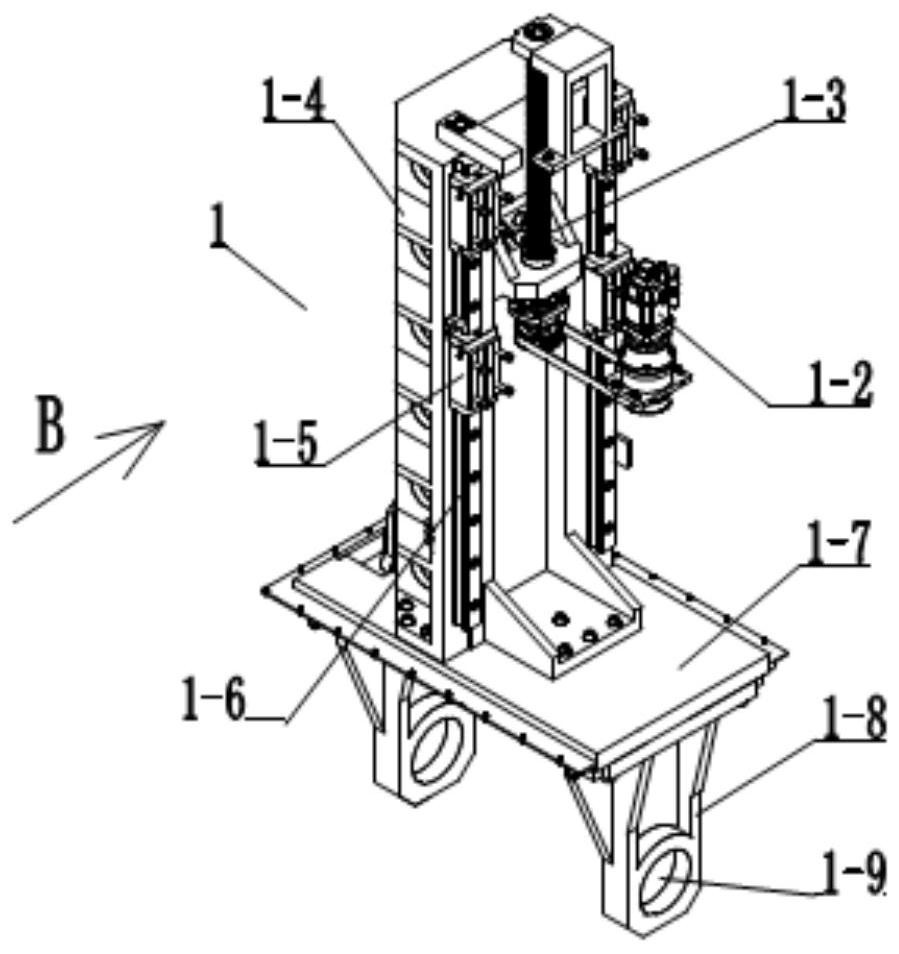

Inverted swing worktable of multi-line cutting machine

PendingCN111791381APrevent fallingEnsure cutting surface qualityWorking accessoriesGrinding machinesControl engineeringElectric machinery

The invention discloses an inverted swing worktable of a multi-line cutting machine, comprising a lifting mechanism, a swing mechanism and a worktable body. The lifting mechanism is provided with a fixed base, a lifting motor, a lifting base, a lifting substrate and a screw nut transmission component; the fixed base is mounted at the top of a main frame of the multi-line cutting machine; the lifting motor is mounted on the fixed base; an output shaft of the lifting motor is fixedly connected to a lead screw in the screw nut transmission component; a nut in the screw nut transmission componentis fixedly assembled with the lifting base; the lifting substrate is fixed at the bottom of the lifting base; vertical plates on both sides of the lifting substrate are provided with hinge holes matched with the swing mechanism; the swing mechanism is mounted on the lifting substrate; swing arms are provided on both sides of the worktable body; and the worktable body is assembled with the swing mechanism by means of the swing arms. By optimally designing the arrangement form and motion mode of the worktable, the purposes of improving the quality of workpiece cut surfaces, satisfying the processing requirements of high-precision workpieces and improving the working efficiency are achieved.

Owner:唐山晶玉科技股份有限公司

Contoured reamer teeth

An acetabular reamer (10′) for cutting a required cut shape. The reamer has a cutting shell (12′) having a series of doubly curved cutting teeth (16′) thereon of a quantity to substantially reduce a cutting pressure on each tooth as well as to reduce a size of a typical chip generated upon cutting. Substantially all the teeth each have a matched arc cutting edge (20′) of substantial length that has a cutting profile which substantially matches a profile of a shape to be cut. Such a configuration reduces the number of teeth required to cut the shape.

Owner:VIANT AS&O HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com