Patents

Literature

142results about How to "Cut surface smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

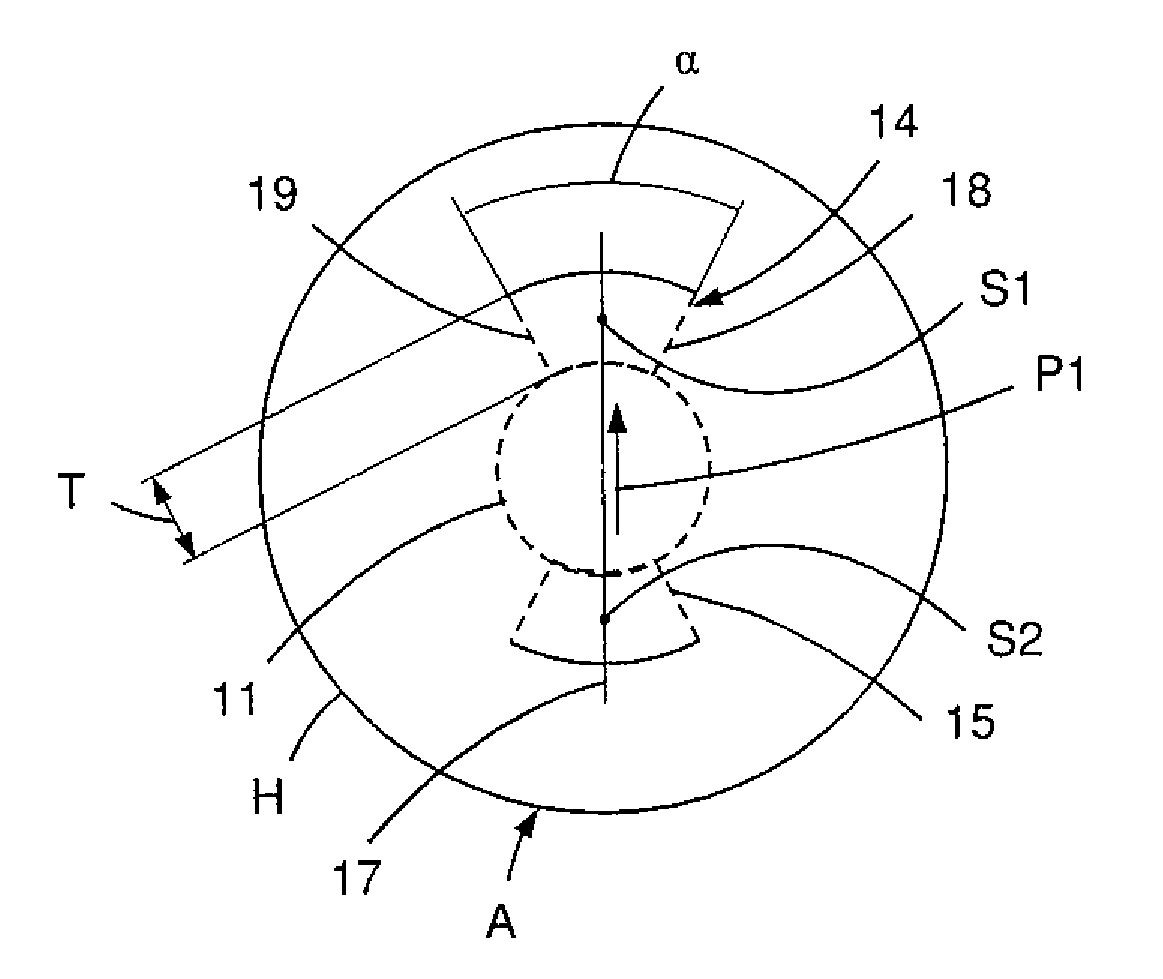

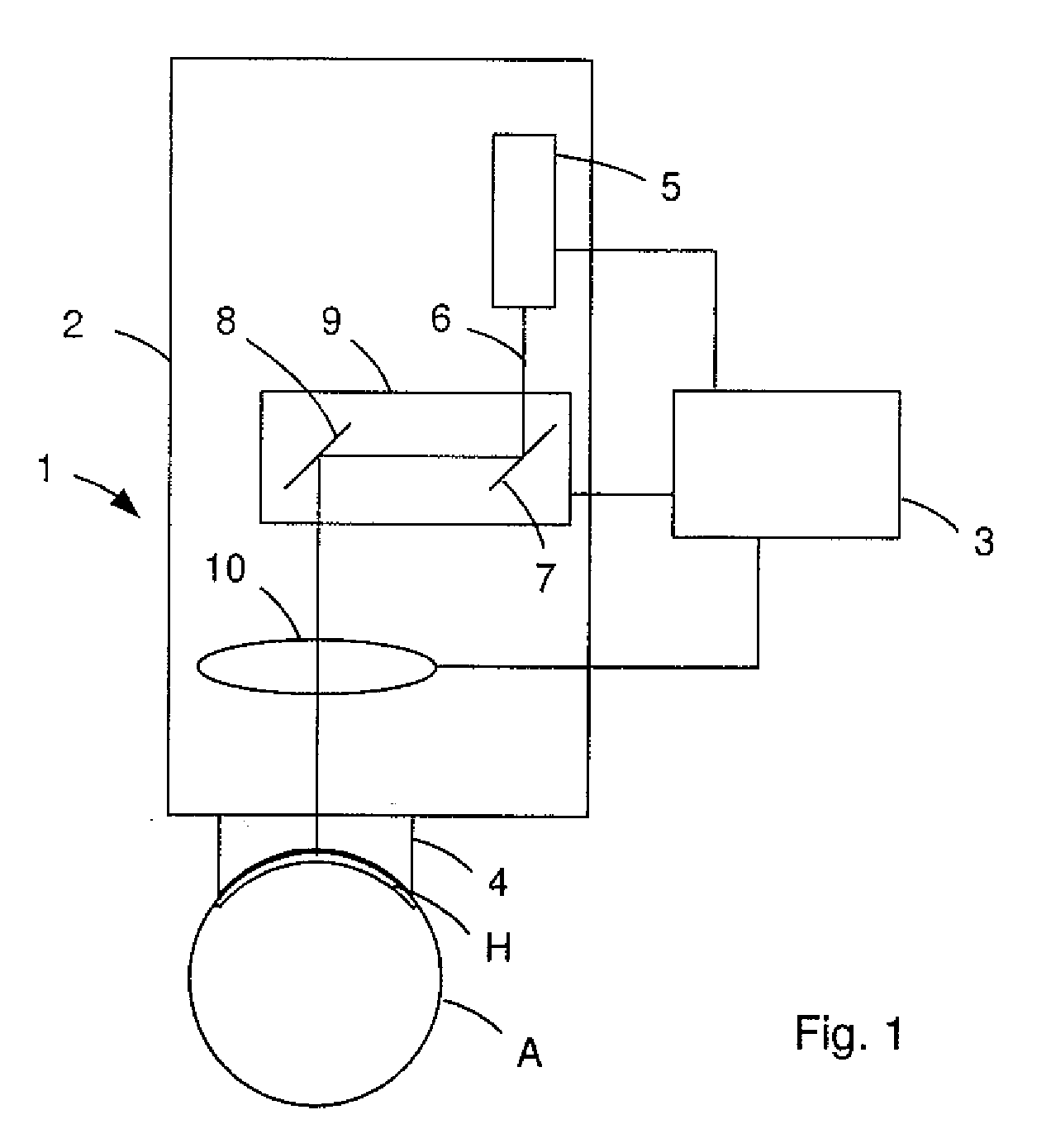

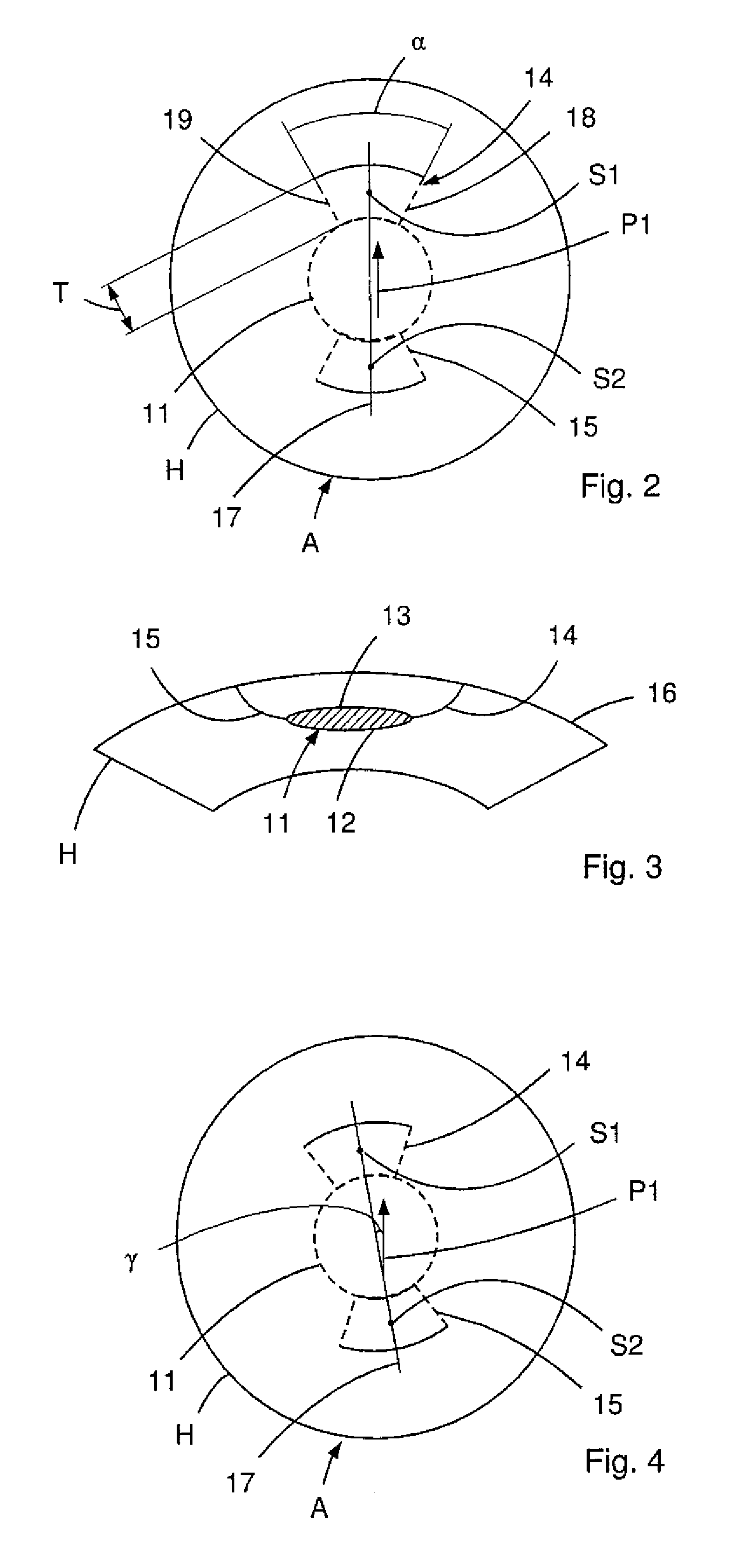

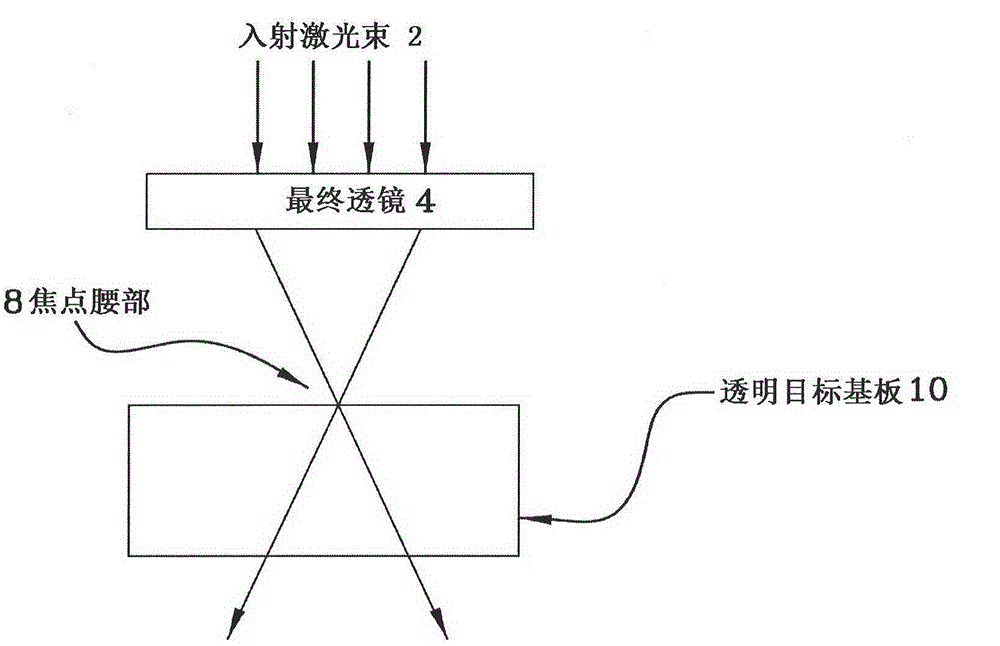

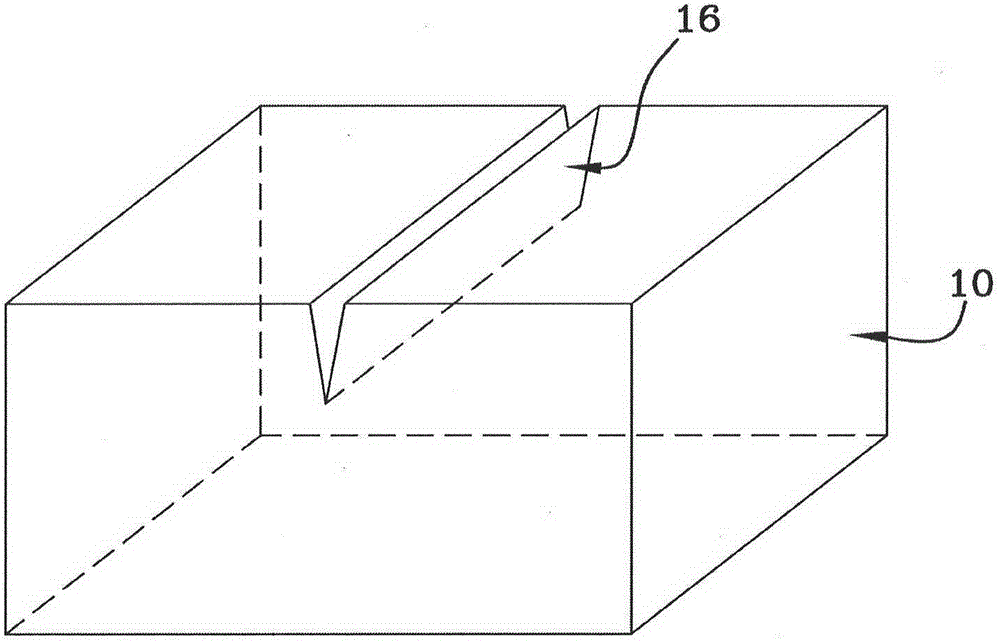

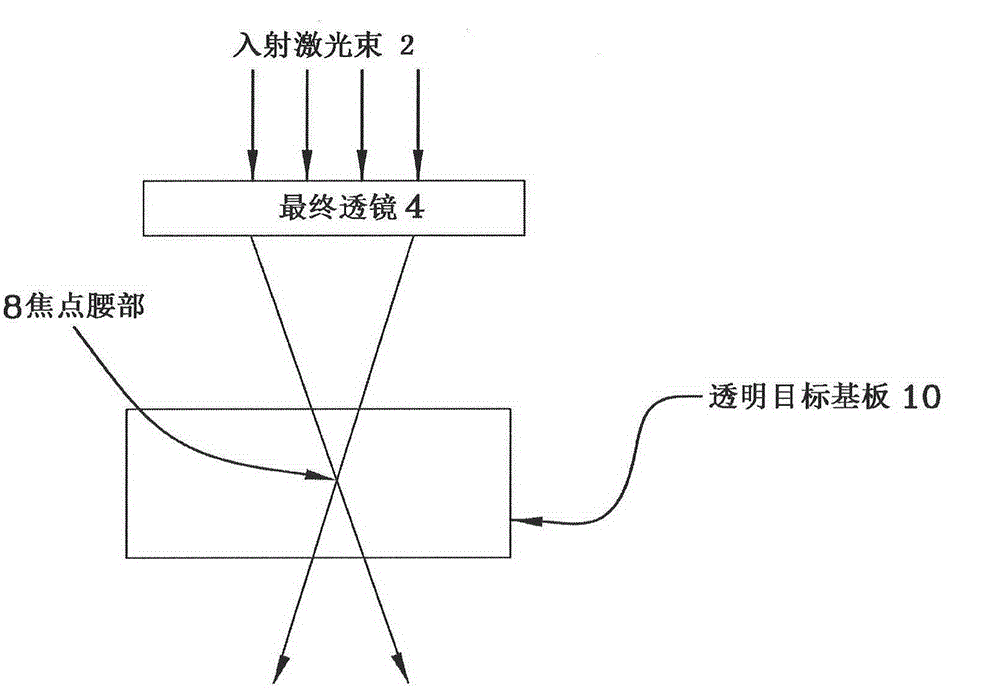

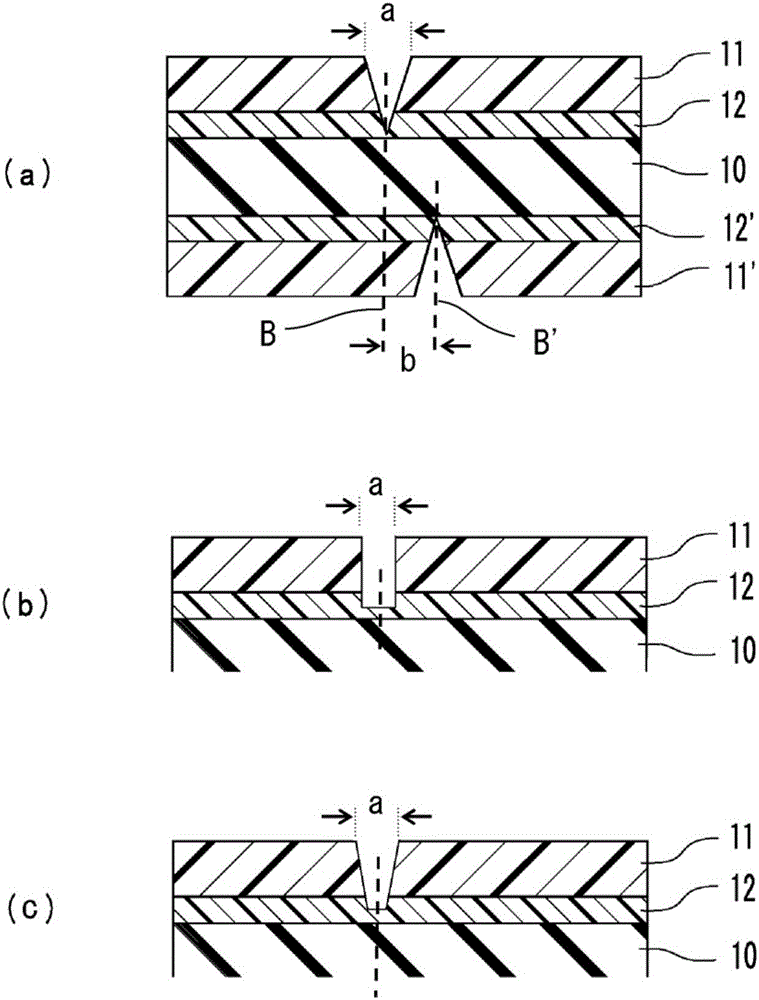

Apparatus and method for generating cut surfaces in the cornea of an eye for correction of ametropia

ActiveUS20080275433A1Cut surface smoothOpening cuts can be preventedLaser surgerySurgical instrument detailsCorneal surfaceRefractive error

An apparatus for generating cut surfaces in the cornea of an eye in order to correct ametropia is provided, said apparatus comprising a laser unit, which can focus pulsed laser radiation into the cornea and move it therein in order to generate cut surfaces, and a control unit, which controls the laser unit for generating cut surfaces such that a predetermined lenticle to be removed is separated from the surrounding corneal material in the cornea by at least one cut surface, and that at least two mutually spaced apart cut surfaces are formed as opening cuts, each extending from the lenticle to the anterior corneal surface, the position and shape of the opening cuts being selected such that the opening cuts contribute to the correction of the ametropia of the eye or do not counteract the correction of the ametropia of the eye.

Owner:CARL ZEISS MEDITEC AG

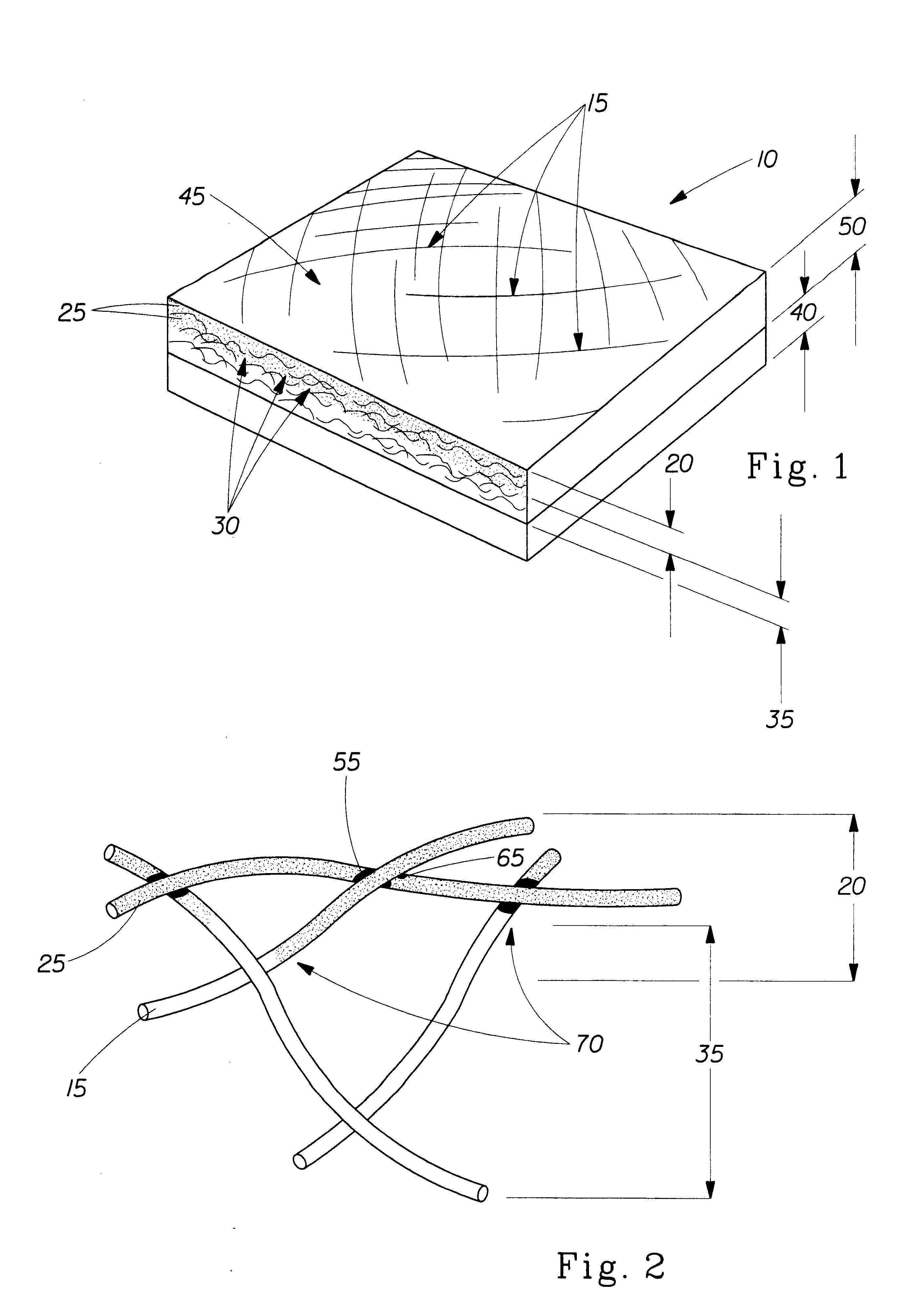

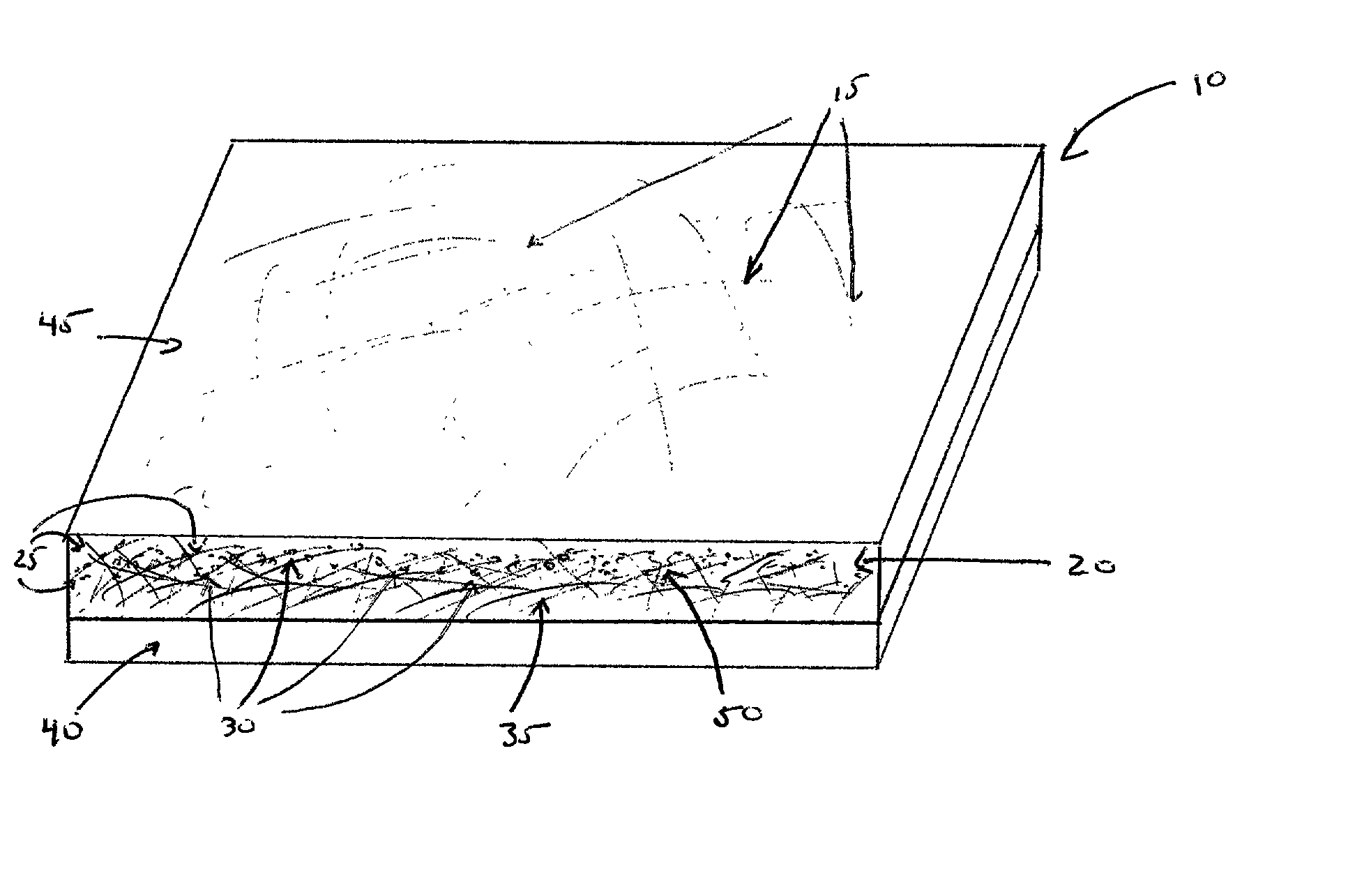

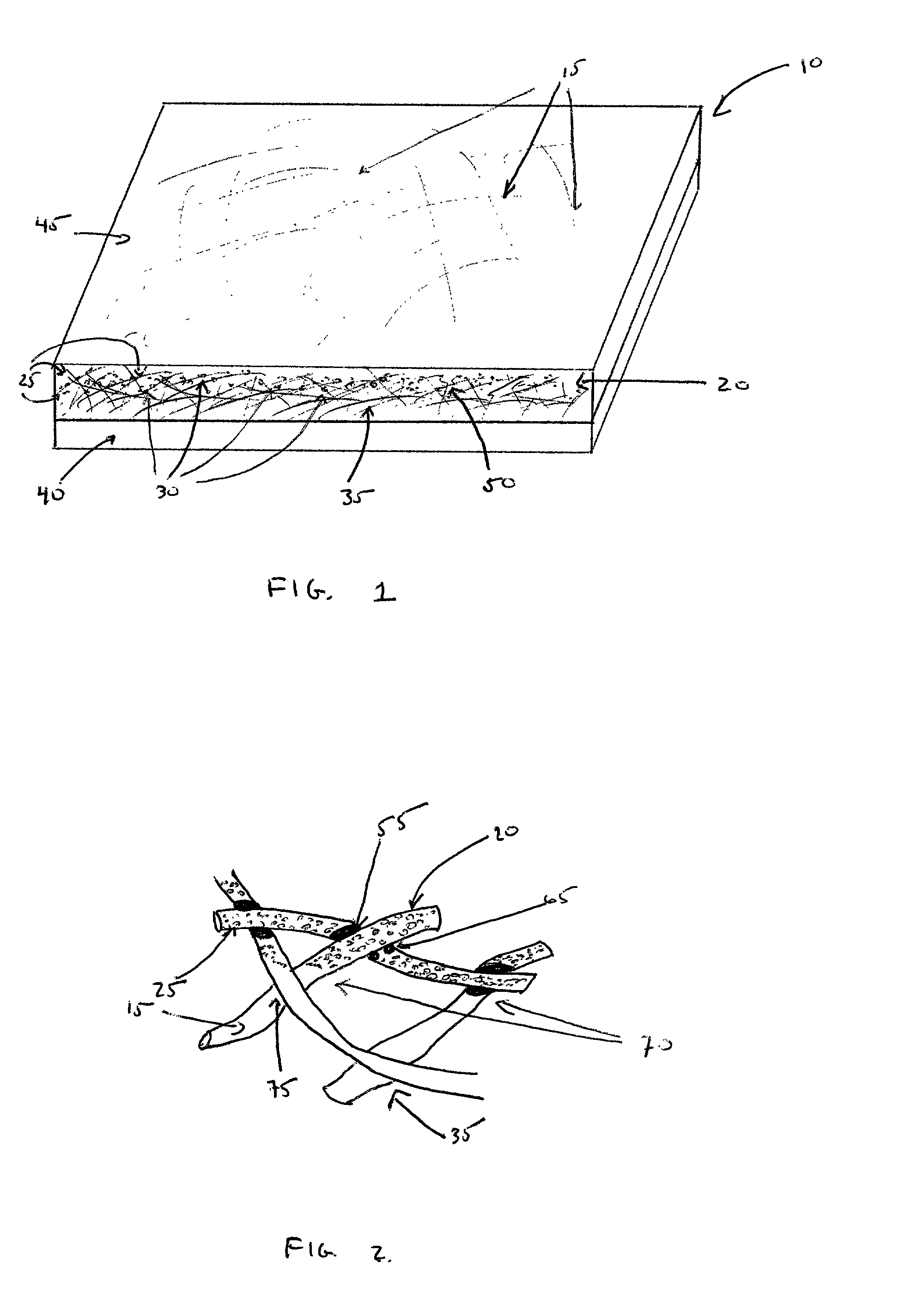

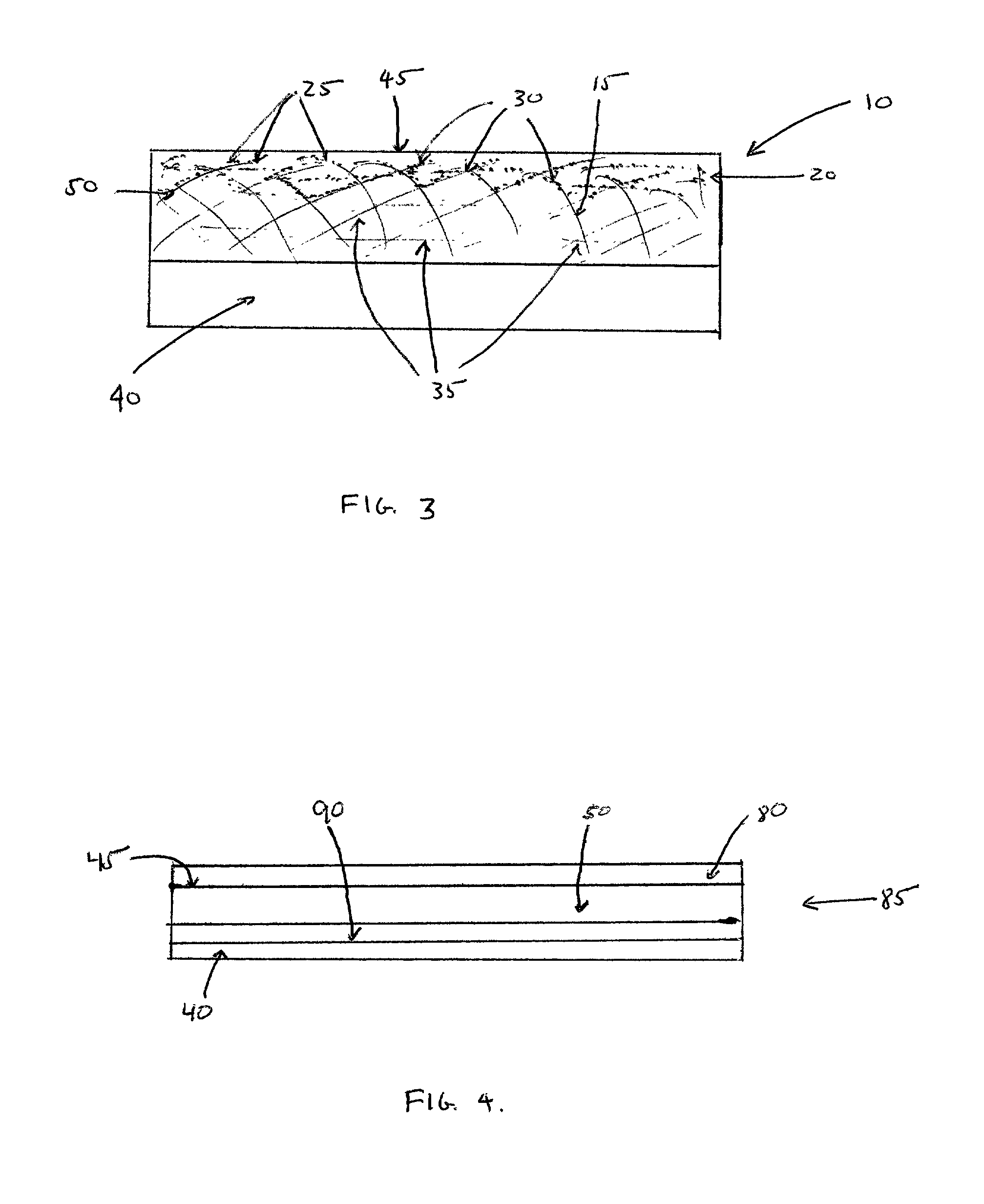

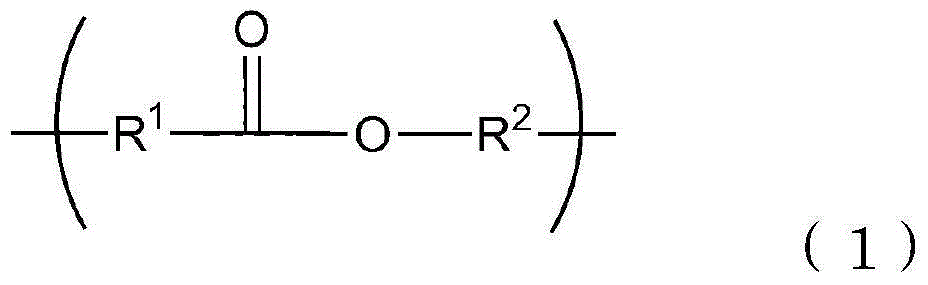

Multi-purpose absorbent and shred-resistant sheet material

InactiveUS6579816B2Cut surface smoothImprove propertiesReinforcing agents additionPaper/cardboardEngineeringAverage size

A shred-resistant and cut-resistant absorbent sheet material including an absorbent substrate and cut-resistant particles discontinuously distributed through the substrate. The absorbent substrate can comprise cellulosic material and the particles comprise polymeric materials having an average size of at least about 100 nanometers, and most preferably between 100 nanometers and 1000 nanometers. In one embodiment, the particles are provided in an amount of between about 10 percent to about 50 percent by weight of the sheet. The sheet material can be made using typical paper making processes. Heat and / or pressure are applied to the sheet material to cause the particles to at least partially flow, so as to bond to the absorbent substrate. The sheets can be provided as a layered structure with a slip-resistant base for home use in the preparation of foodstuffs.

Owner:PROCTER & GAMBLE CO

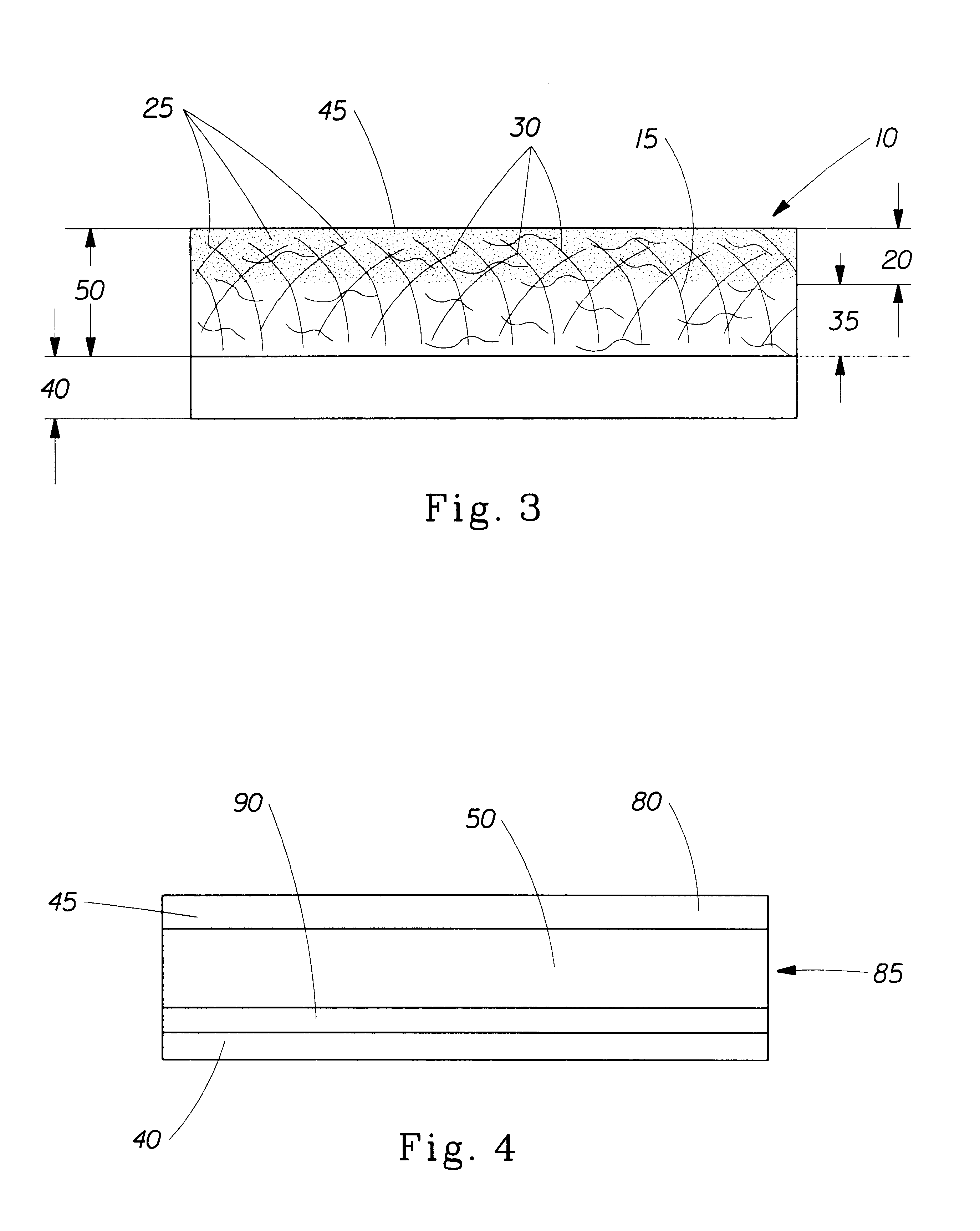

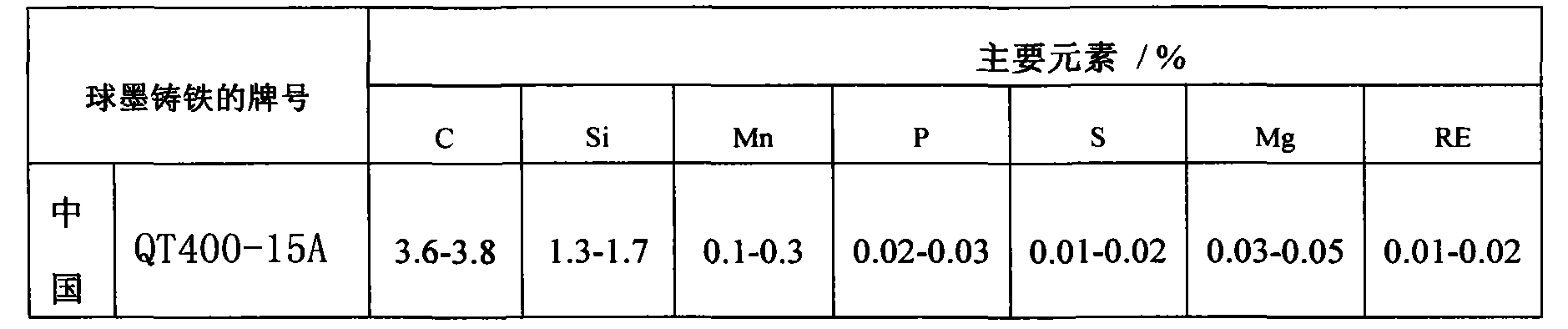

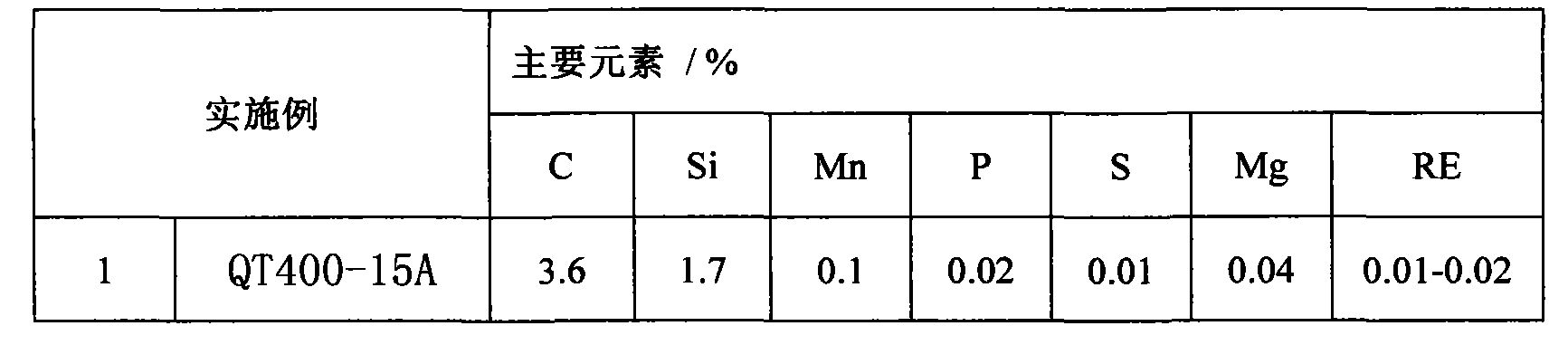

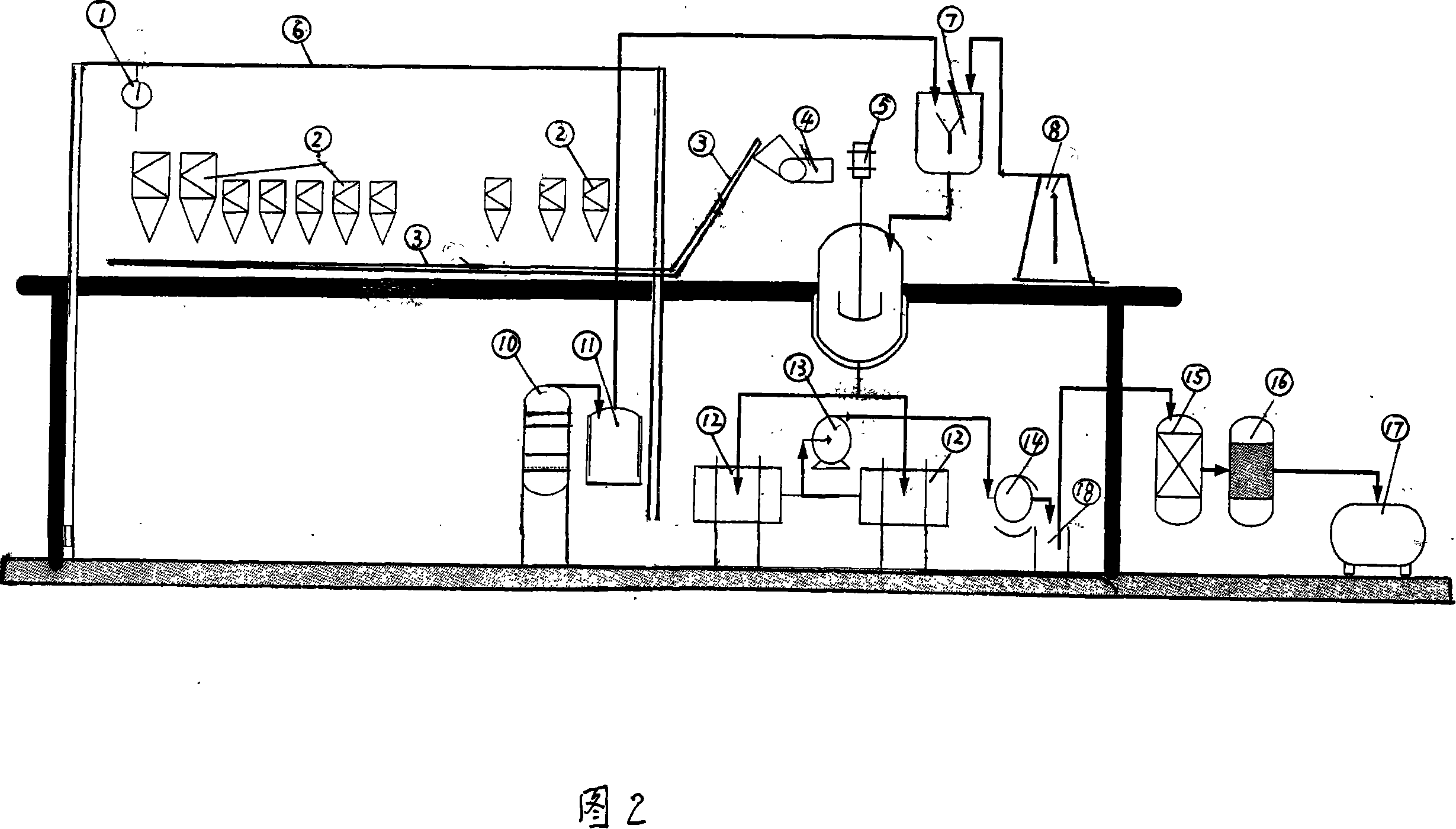

Method for integrally casting large-sized V-shaped diesel engine body by utilizing nodular cast iron

The invention discloses a method for integrally casting a more-than-25-ton large-sized diesel engine V-shaped body by utilizing nodular cast iron. The method comprises the following steps of A1, smelting the nodular cast iron in a smelting furnace, and adding bariumsili and metallurgical carborundum pretreatment agent after the smelting; A2, placing a spheroidizing agent into a bottommost layer of a dam-type spheroidizing ladle, utilizing a nucleating agent to cover a second layer, and utilizing a low-maganese low-alloy broken steel sheet to completely cover and compact a third layer; A3, adding a calcium-barium nucleating agent, charging the melted iron in one step to carry out the tapping metal-stream inoculation, realizing the nucleating effect while carrying out the spheroidizing treatment on charged melted iron, and carrying out the pouring pretreatment on the melted iron in the ladle; A4, placing the metal-stream inoculation agent into a funnel to carry out the pouring metal-stream inoculation; and A5, finally pouring the melted iron with the temperature being more than or equal to 1400 DEG C into a sand box, forming a cast by mold filling and solidifying the melted iron under the feeding of the feeder head liquid metal, and carrying out the heat treatment by utilizing the waste heat of the cast.

Owner:宜宾普什联动科技有限公司

Tomato grafting method capable of improving survival rate

InactiveCN104303851APrevent the occurrence of virusesImprove survival rateGraftingTomato graftingRootstock

The invention discloses a tomato grafting method capable of improving the survival rate. The tomato grafting method comprises the steps of variety selecting, strong stock culturing, scion forming, grafting and managing after grafting. High-quality seeds are selected and sterilized, a strong stock and scion are cultured, a W-shaped staggered grafting way is adopted, the contact area is enlarged, the rigorous and scientific later period maintenance is conducted, the resistance of a plant is improved, the cell division is promoted, the wound healing is accelerated, and the grafted young plant can recover and grow quickly. The survival rate of the grafted tomato young plant cultured according to the grafting method reaches more than 98%.

Owner:定远县金胜农业开发有限公司

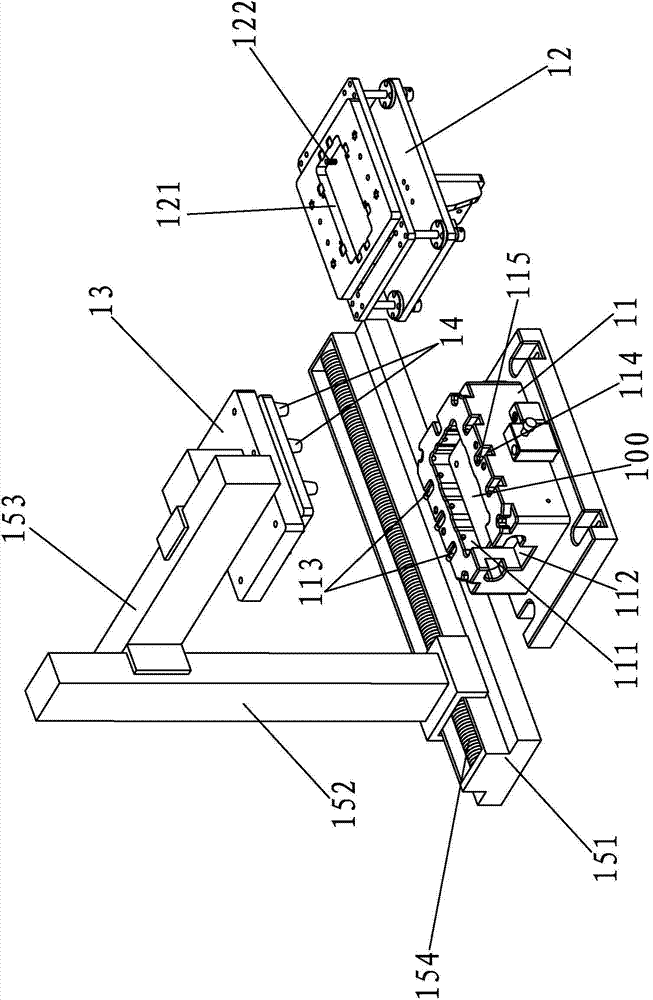

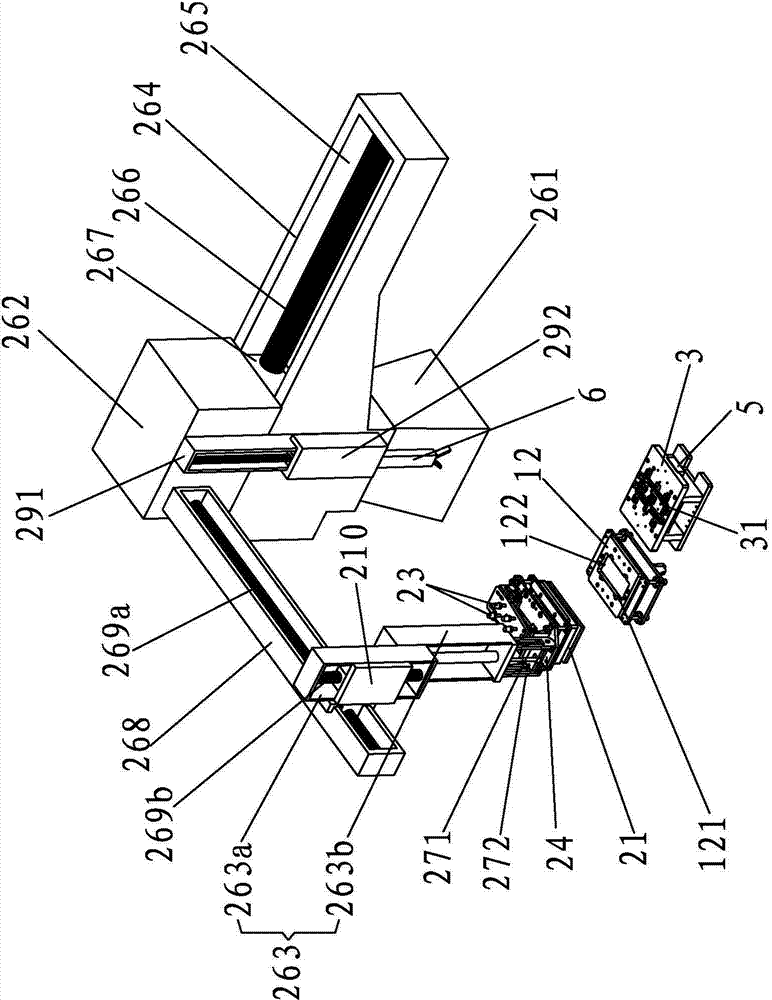

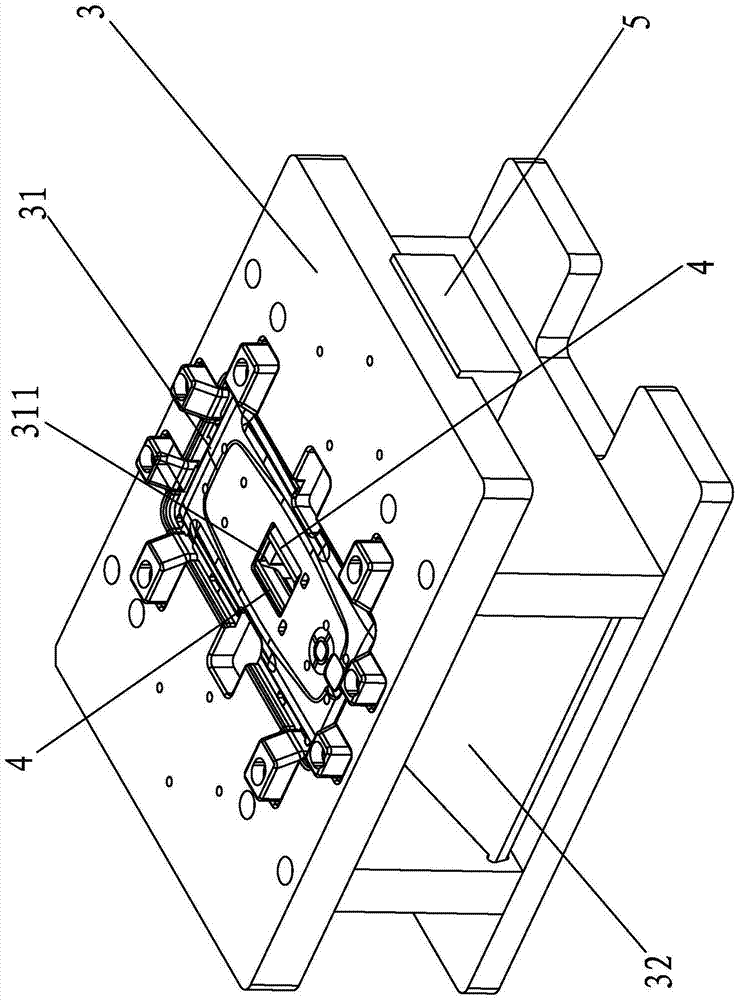

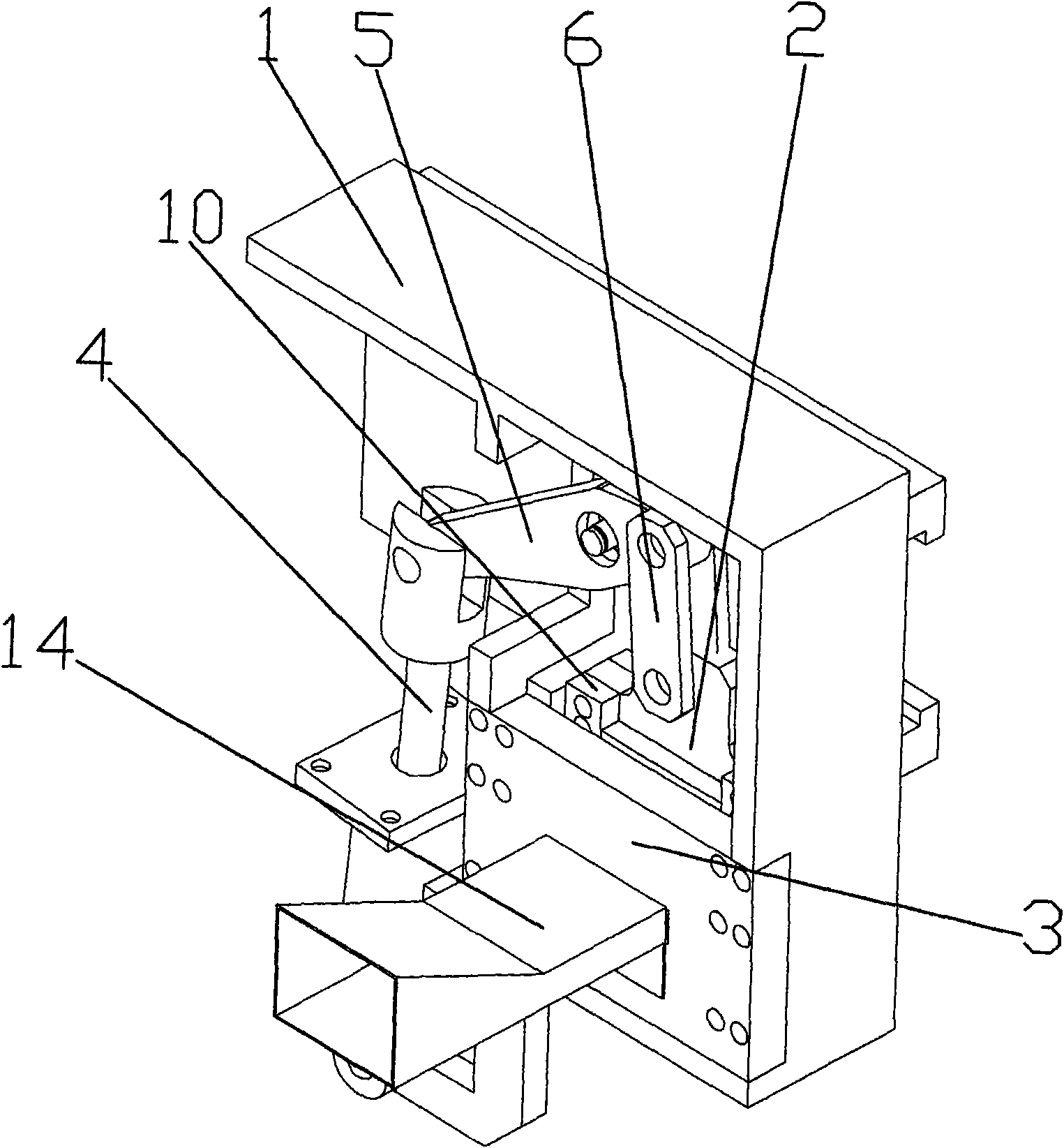

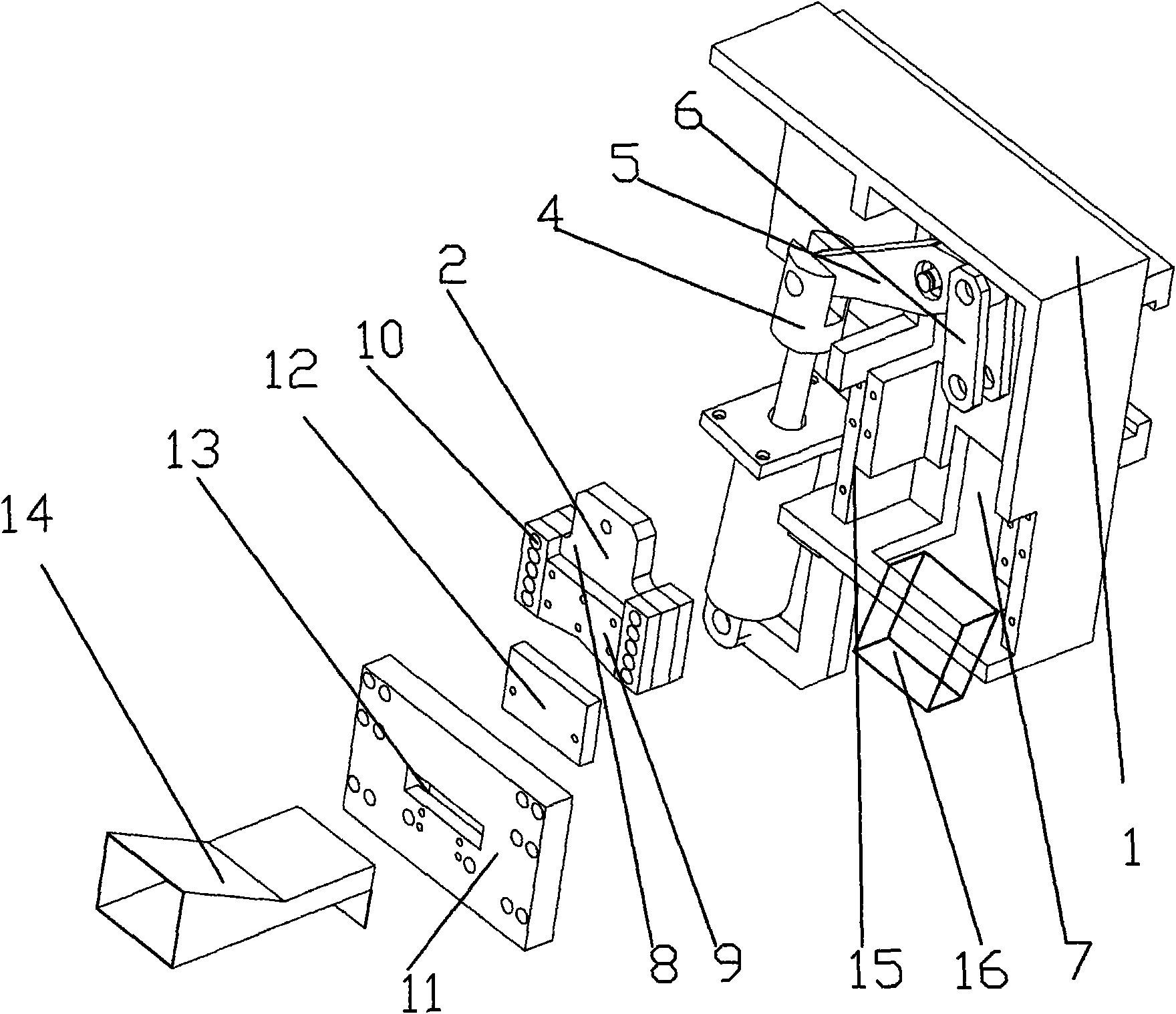

Automatic system for IML injection molding

The invention discloses an automatic system for IML injection molding. The automatic system comprises a sheet storage mechanism, a sheet transfer mechanism and an orifice cutting seat, wherein the sheet storage mechanism comprises a sheet storage and taking seat for storage of a stack of film sheets, a sheet storage and placement seat for placement of the single film sheet and a sheet suction seat for sucking away the film sheets in the sheet storage and taking seat and placing the film sheets in the sheet storage and placement seat; the sheet transfer mechanism comprises a sheet transfer seat for sucking the film sheets in the sheet storage and taking seat, placing the film sheets in an injection mold, and sucking IML decorating parts in the injection mold out of the injection mold; the orifice cutting seat comprises a positioning placement groove for placement of the IML decorating parts, blades used for cutting off orifices of the IML decorating parts, and a waste conveying channel. Compared with the prior art, the automatic system has the advantages as follows: full-automatic consecutive operation is adopted, and unmanned production is achieved, so that the whole working efficiency is improved greatly, the advantages of precision in taking out and high safety system are achieved, that the cutting surfaces of the IML decorating parts are relatively smooth is ensured, and appearance quality is not influenced.

Owner:通达(石狮)科技有限公司

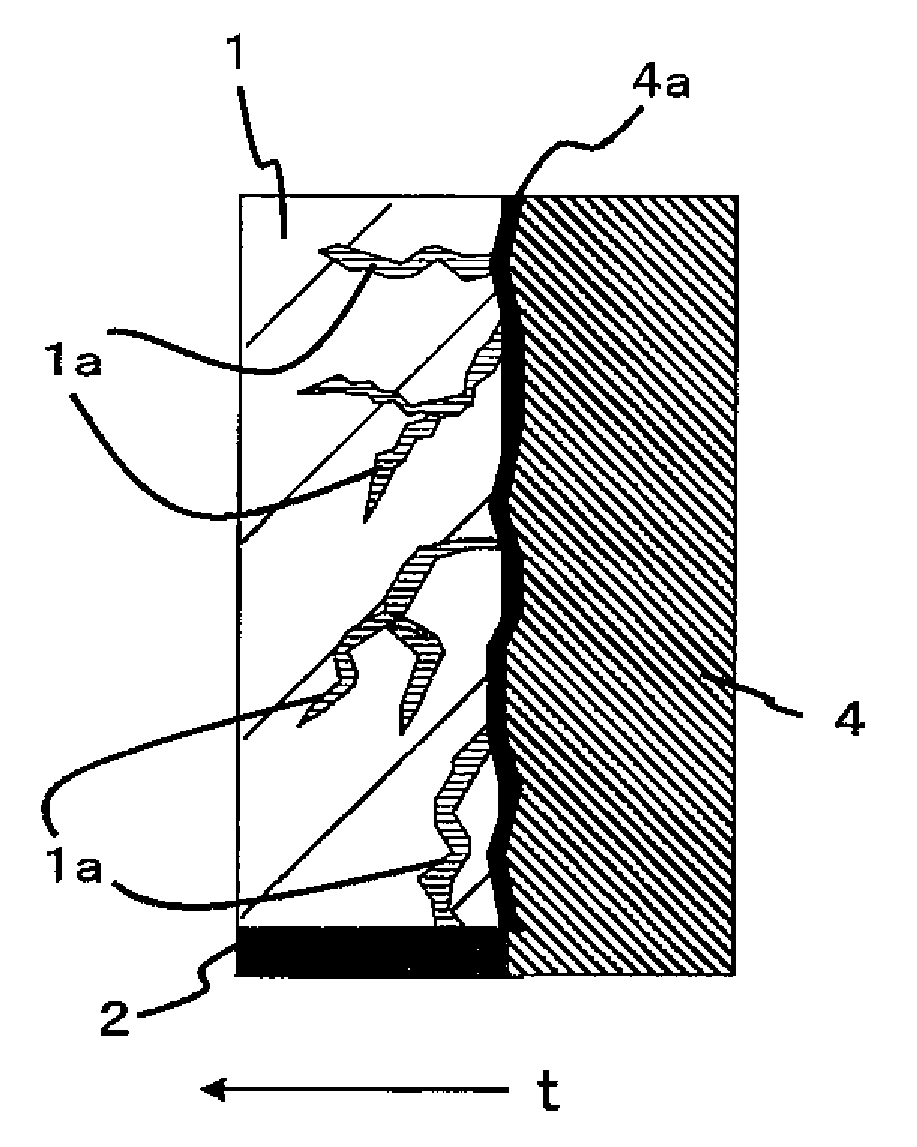

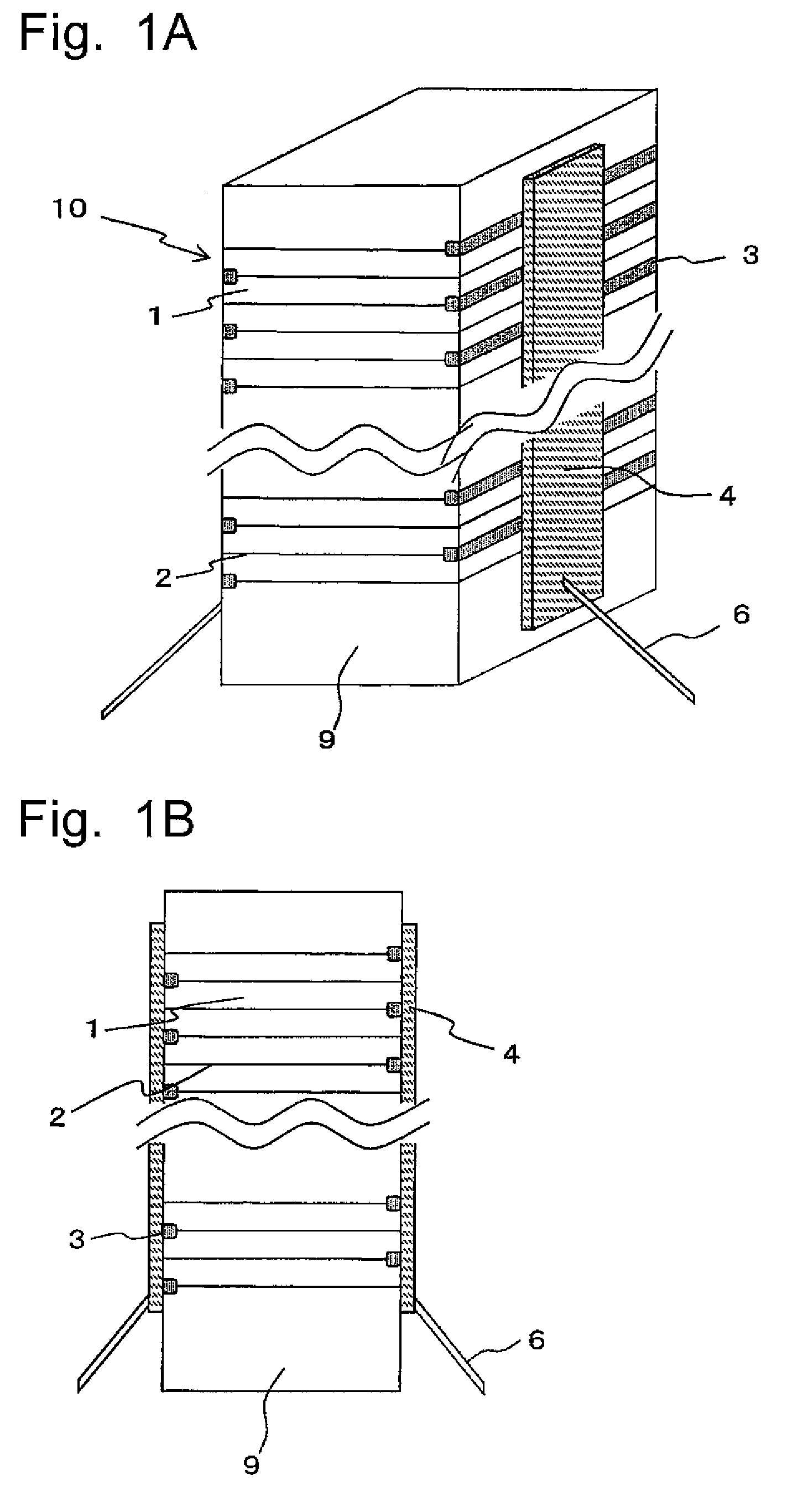

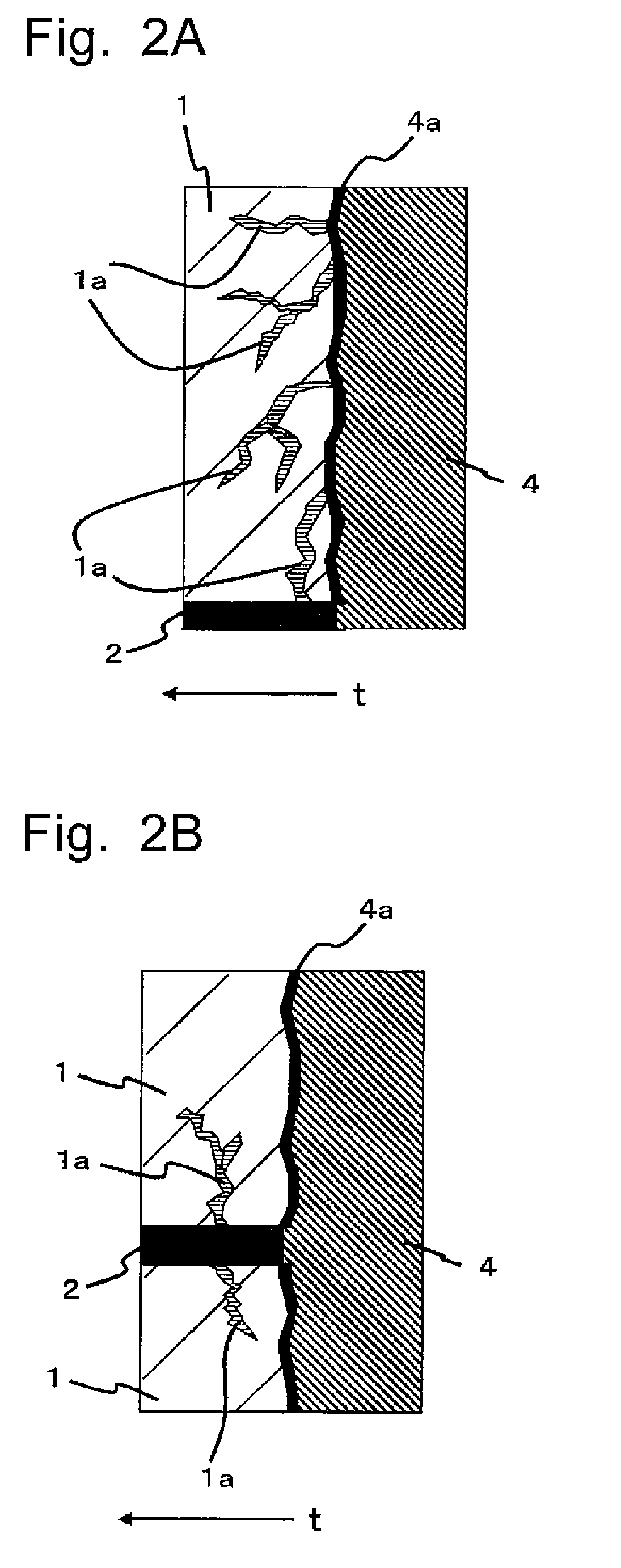

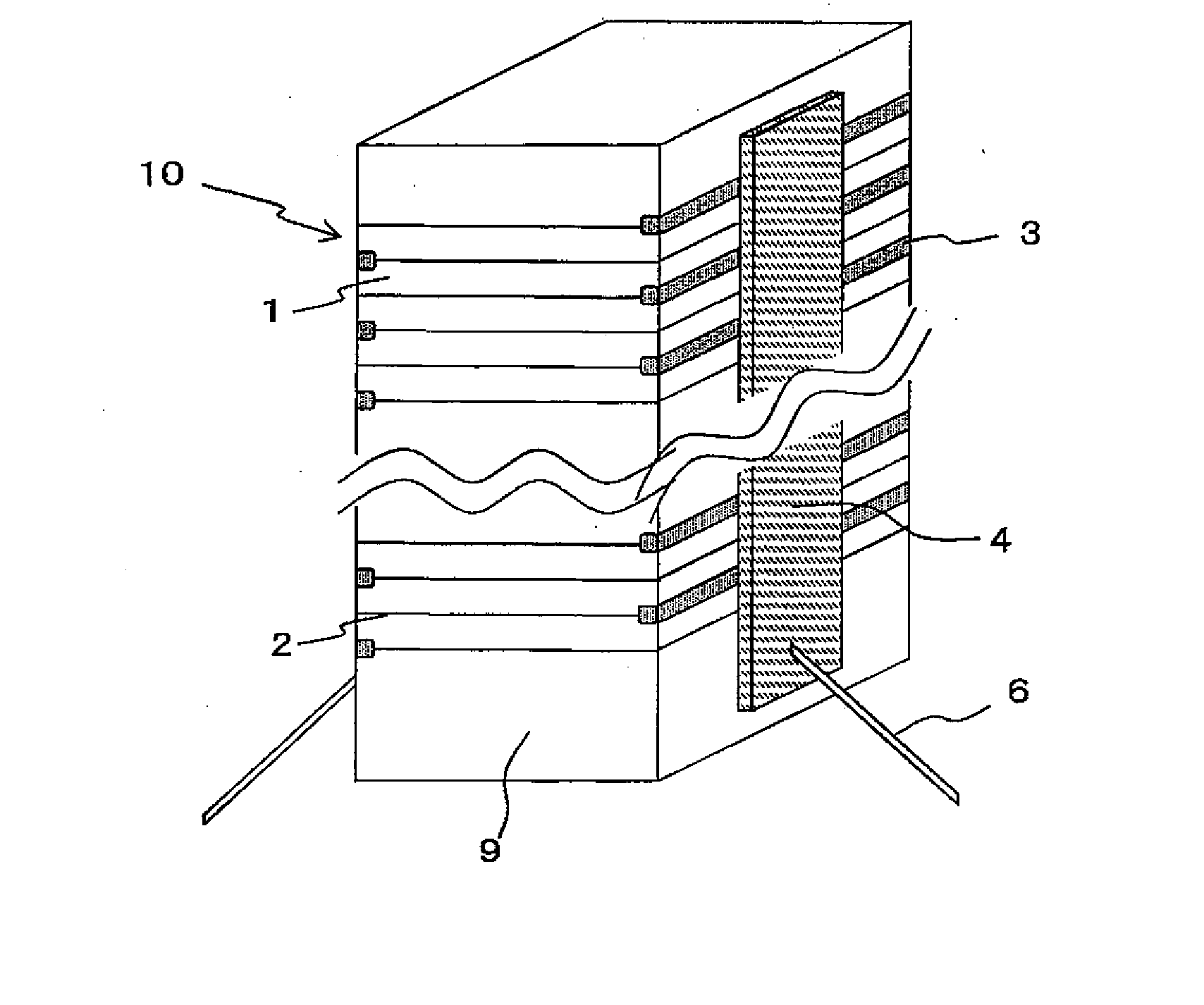

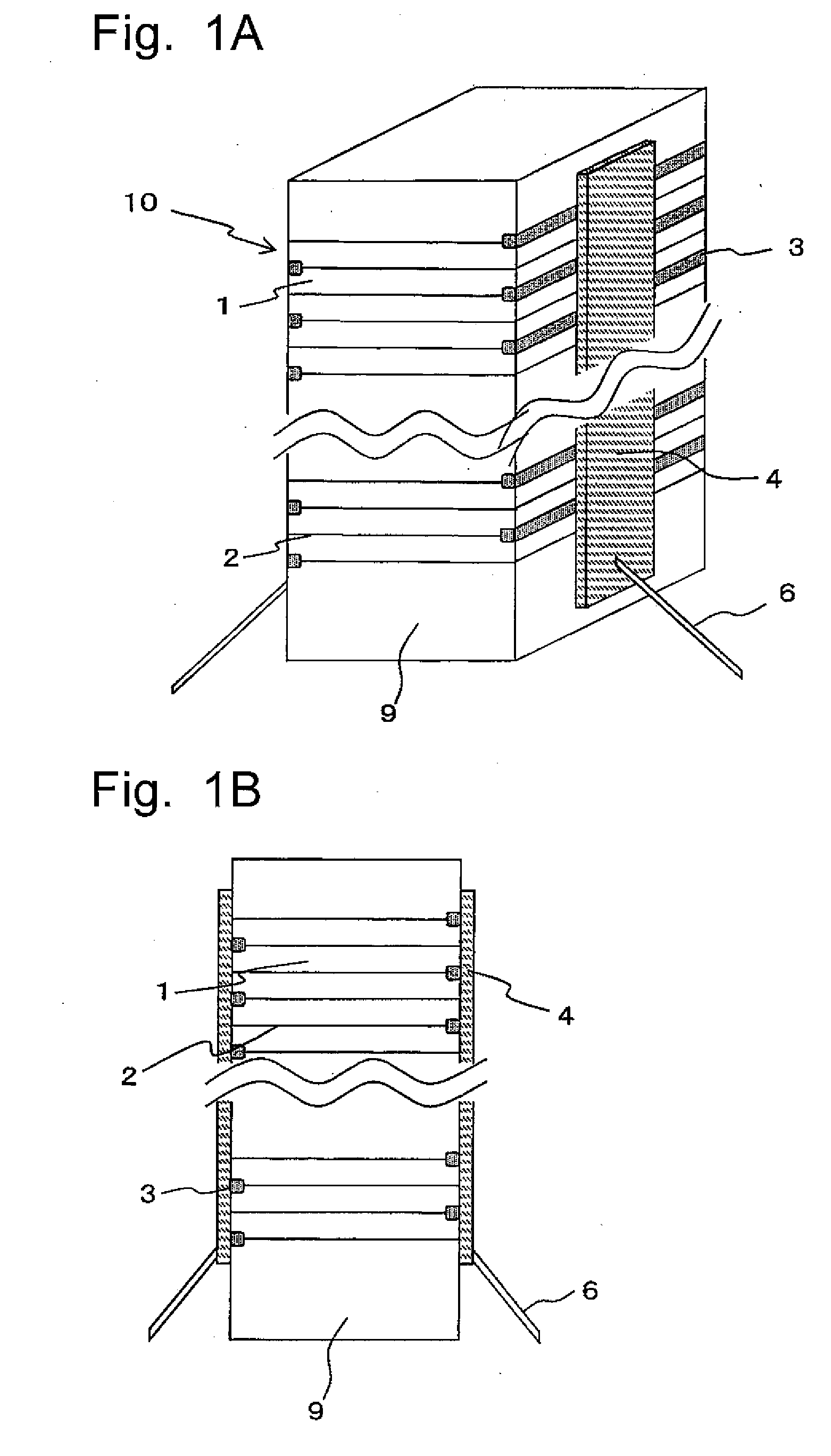

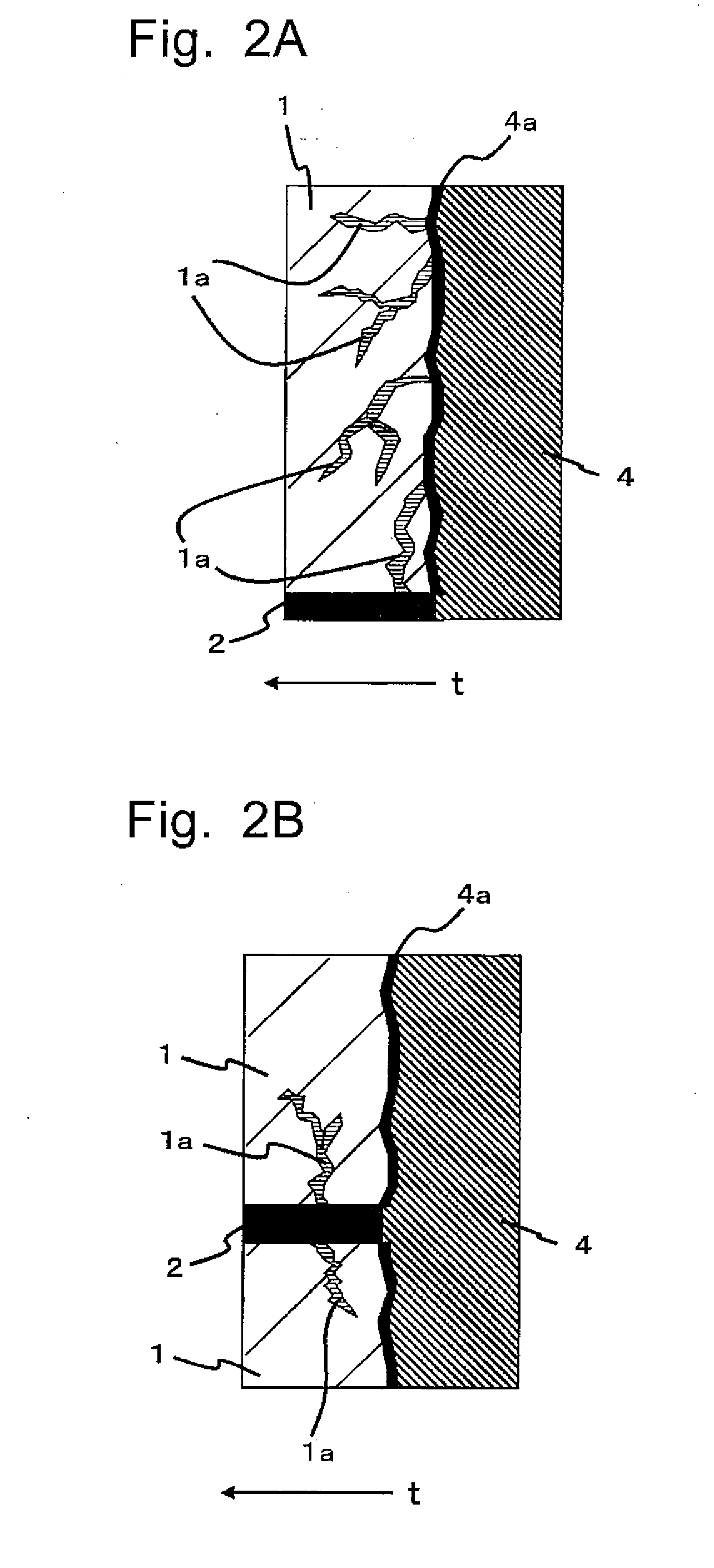

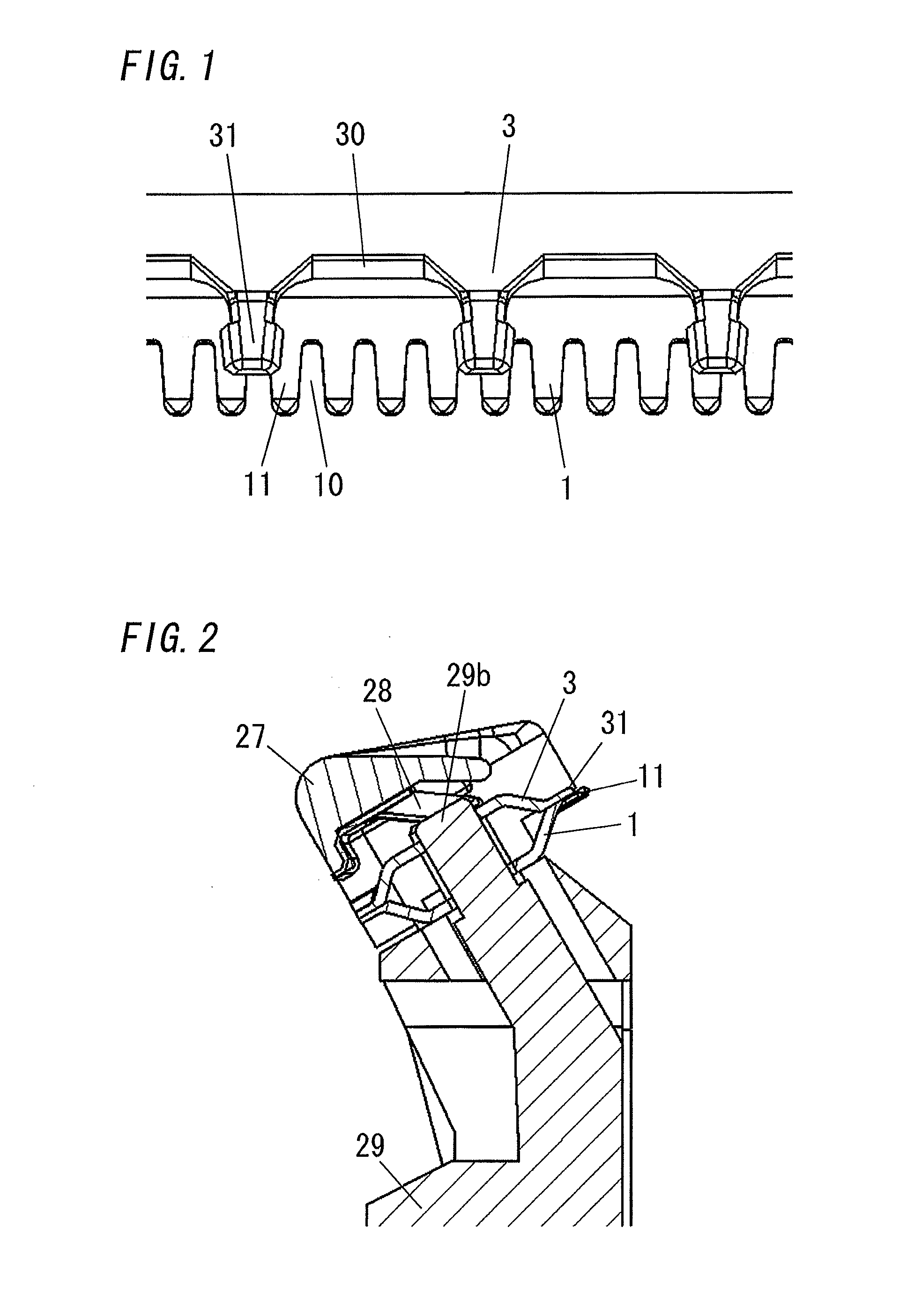

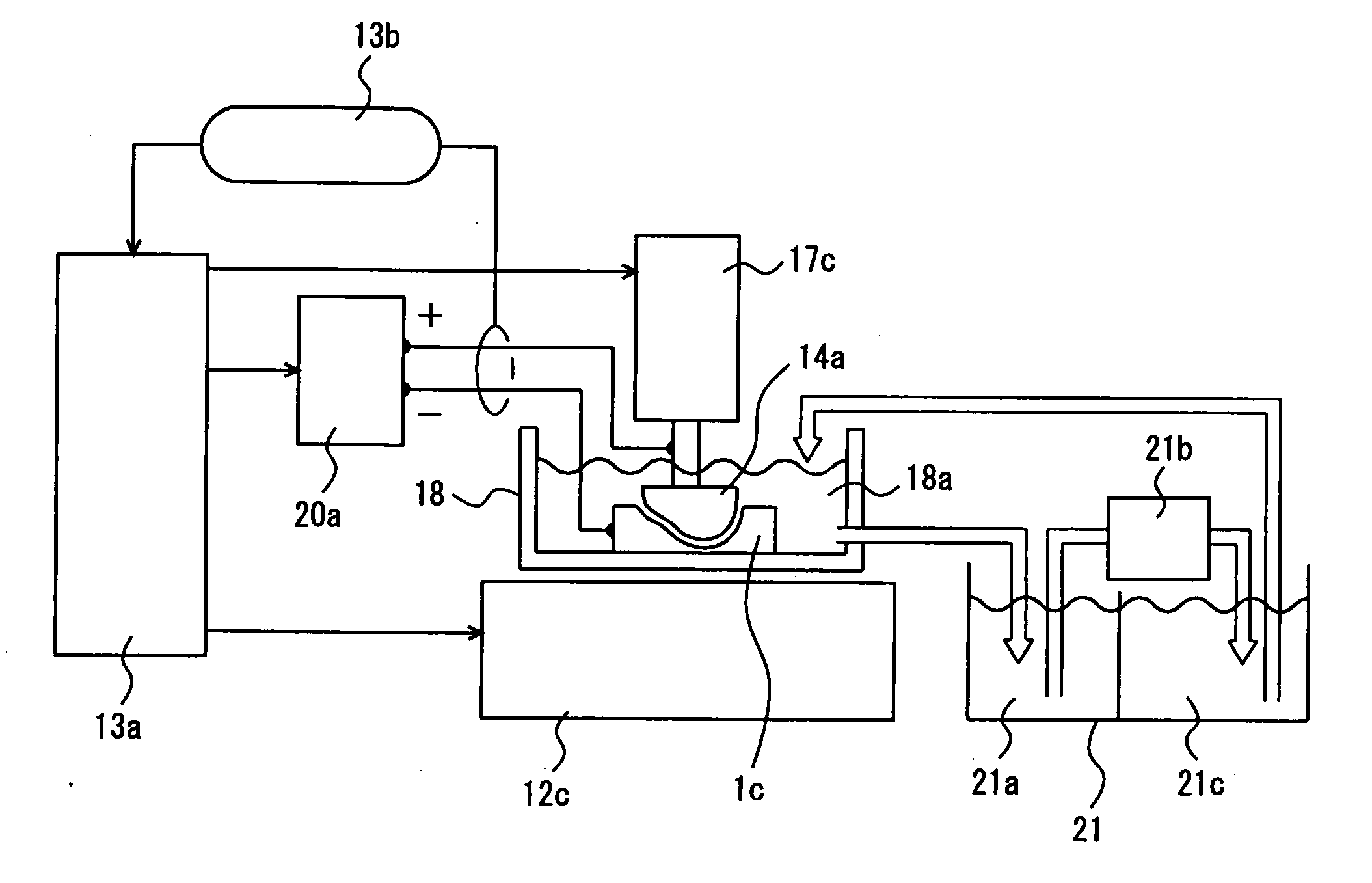

Multi-layer piezoelectric element and method for manufacturing the same

ActiveUS7498727B2High bonding strengthBonded firmlyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesConductive materialsHigh pressure

A multi-layer piezoelectric element having high durability wherein the internal electrodes and the external electrodes do not break even when operated continuously over a long time under high electric field and high pressure is provided.The multi-layer piezoelectric element comprises a stack formed by stacking at least one piezoelectric layer and internal electrodes consisting of first and second internal electrodes one on another, and external electrodes formed on two side faces of the stack with one of which being connected to the first internal electrode and the other external electrode being connected to the second internal electrode, wherein the external electrodes contain a conductive material and glass, the side whereon the external electrode is formed has cleft which has a wedge which contains glass formed therein, and the cleft is filled with the glass contained in the wedge and glass contained in the external electrode.

Owner:KYOCERA CORP

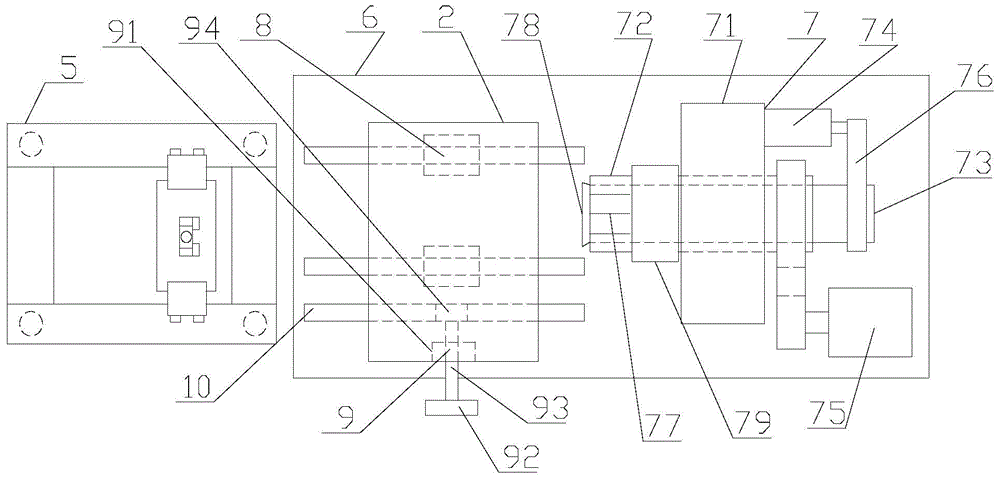

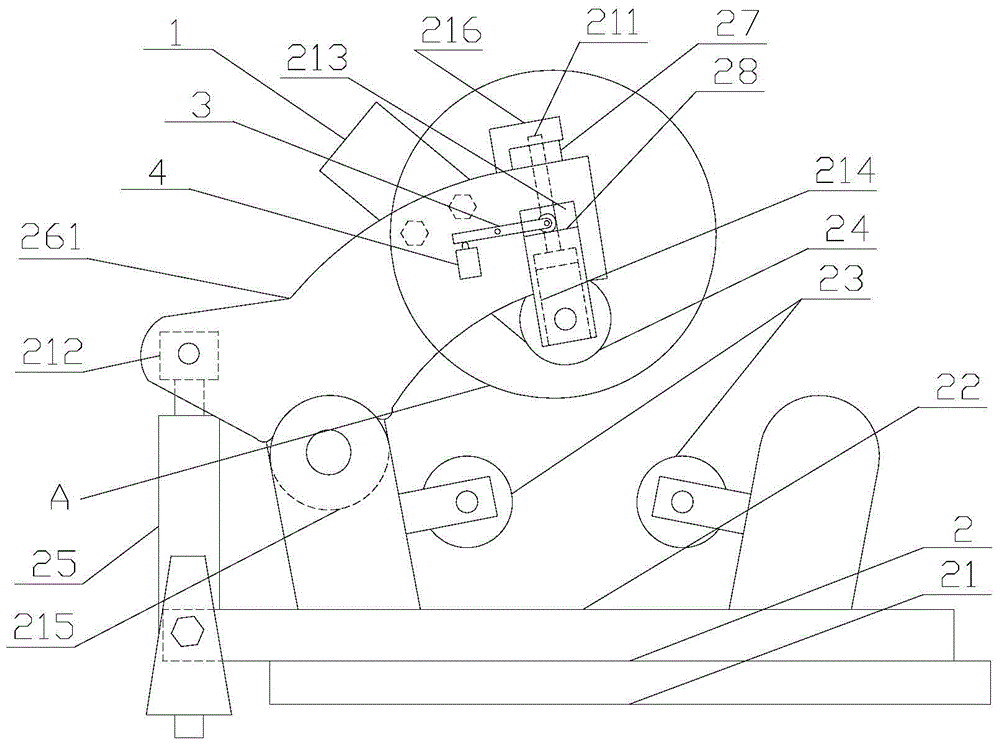

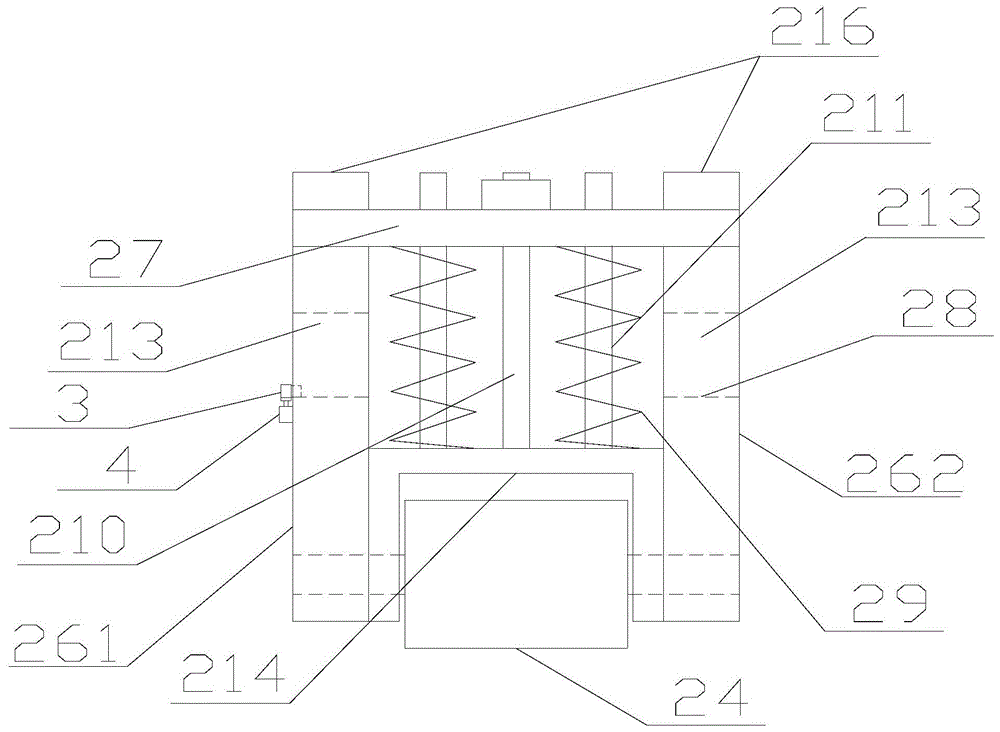

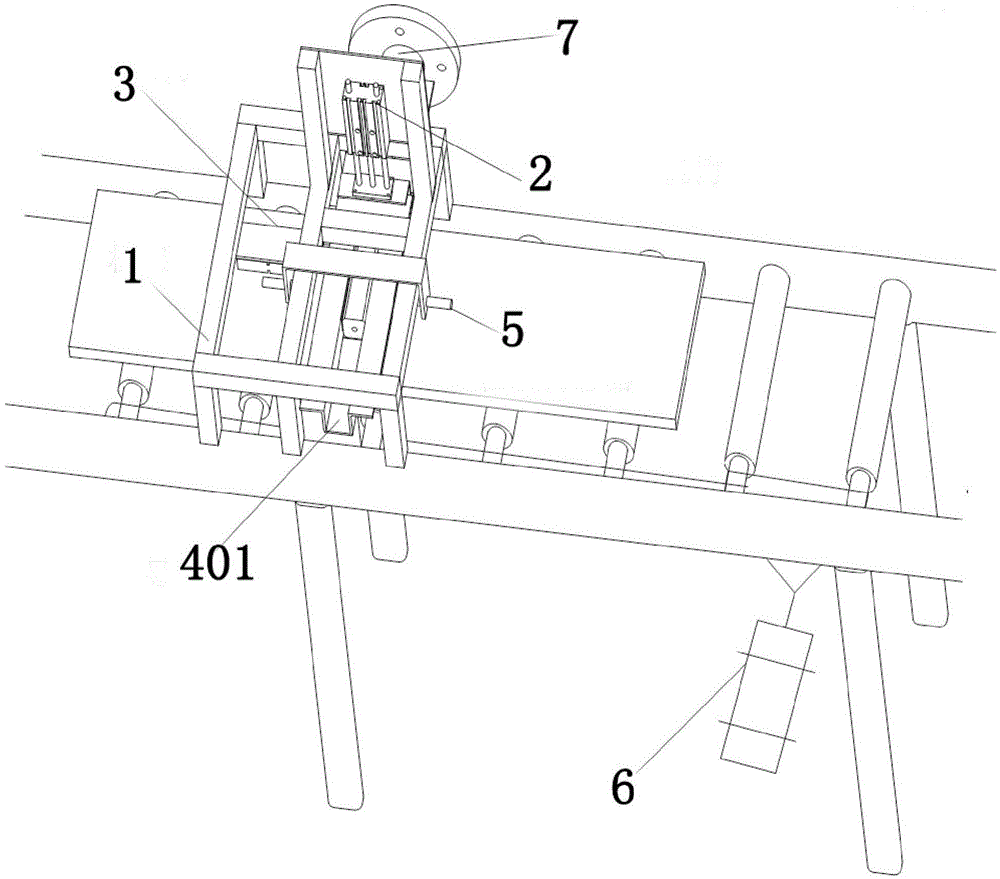

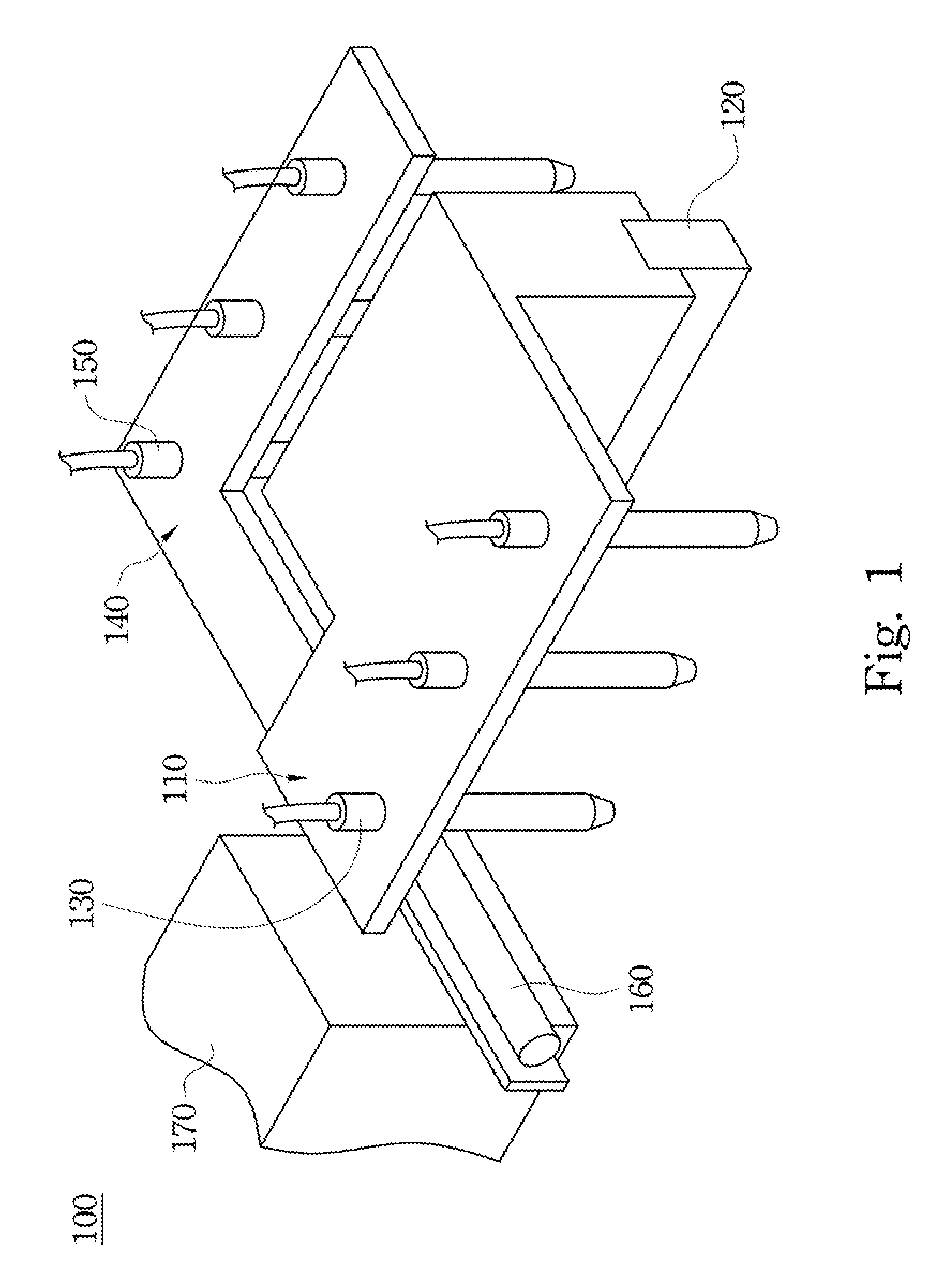

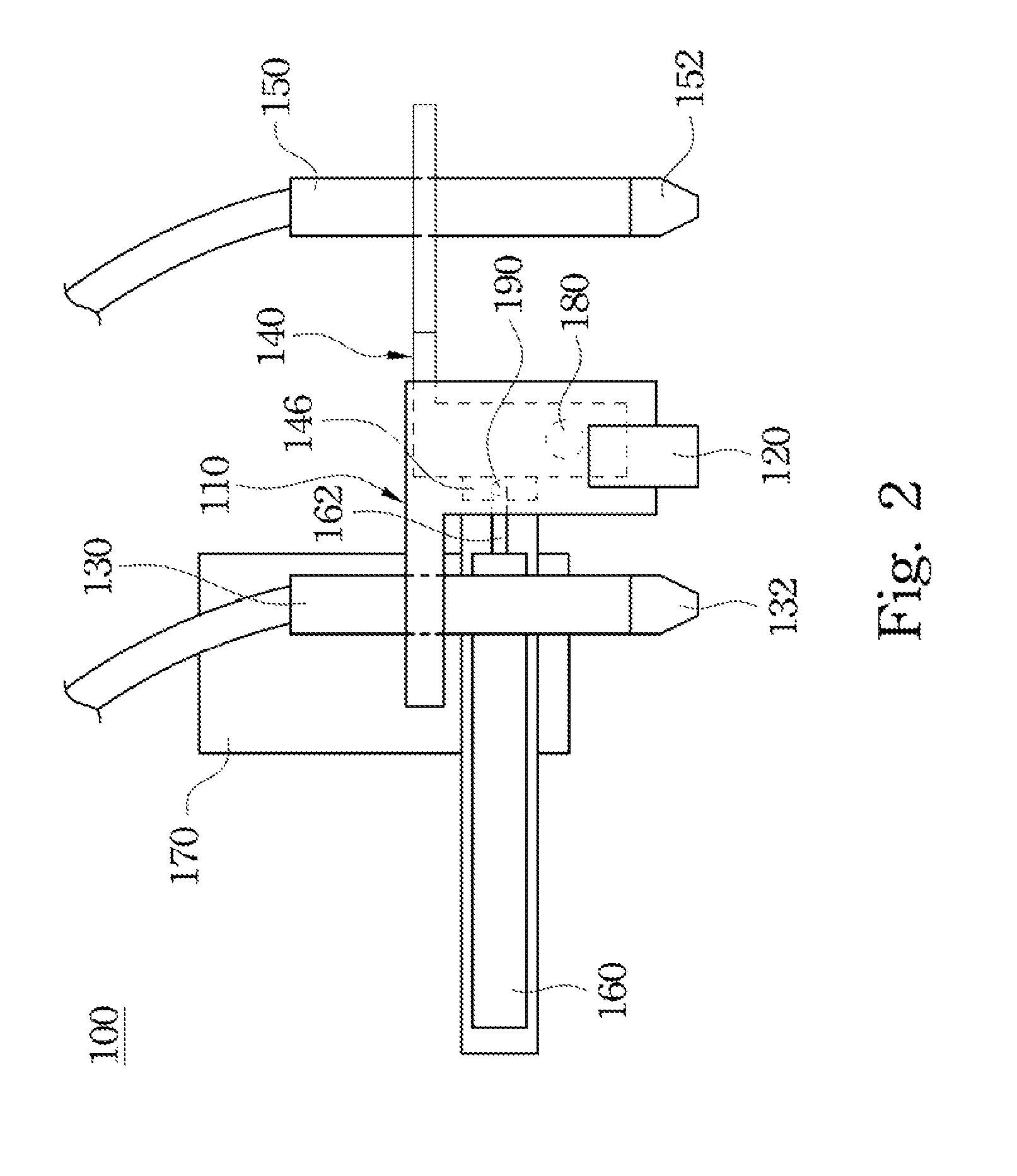

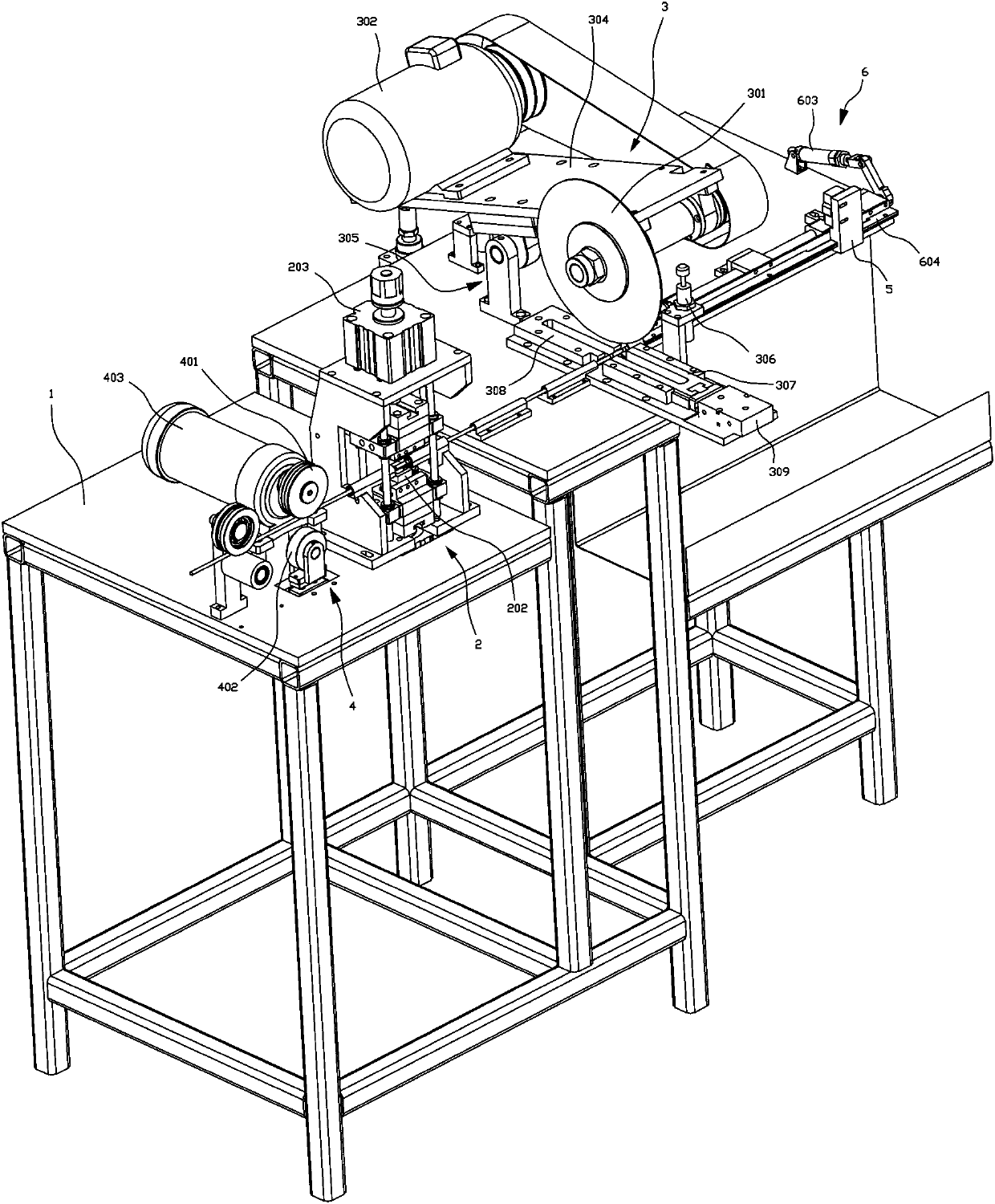

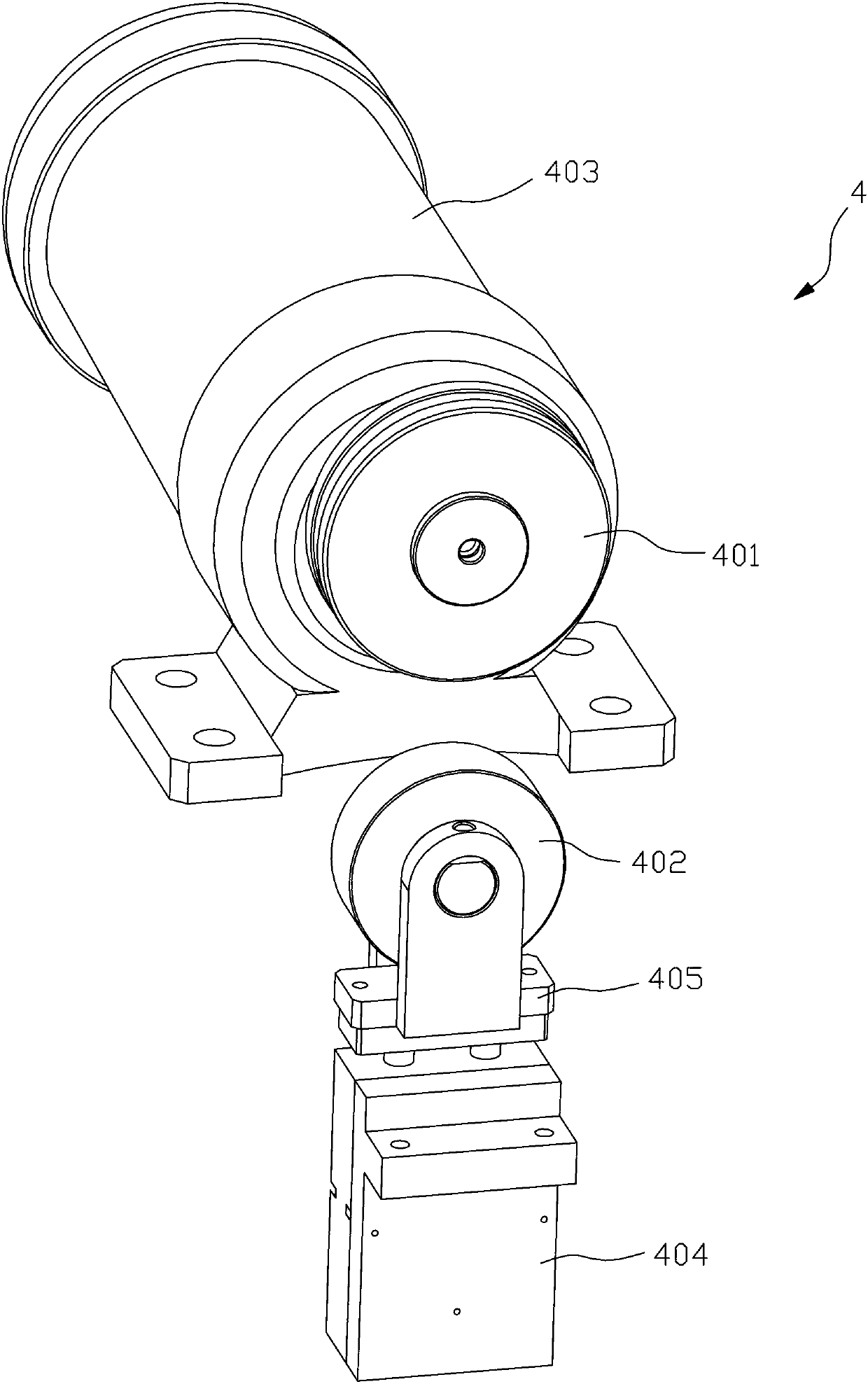

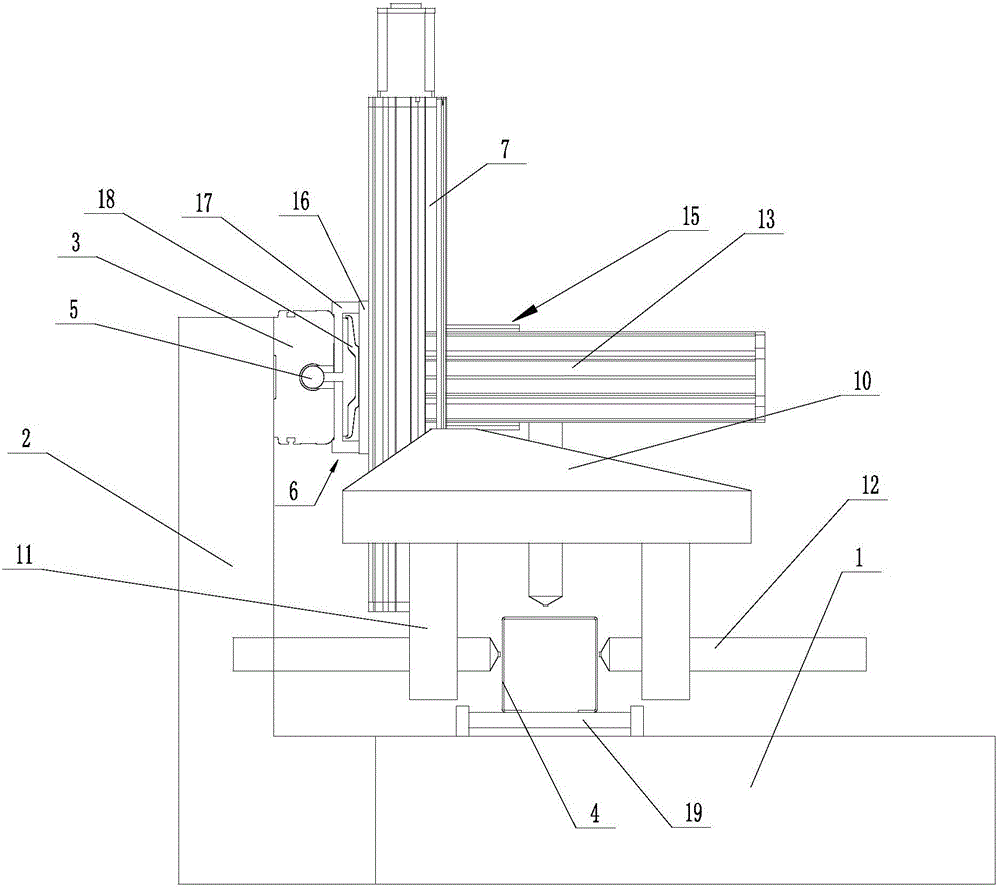

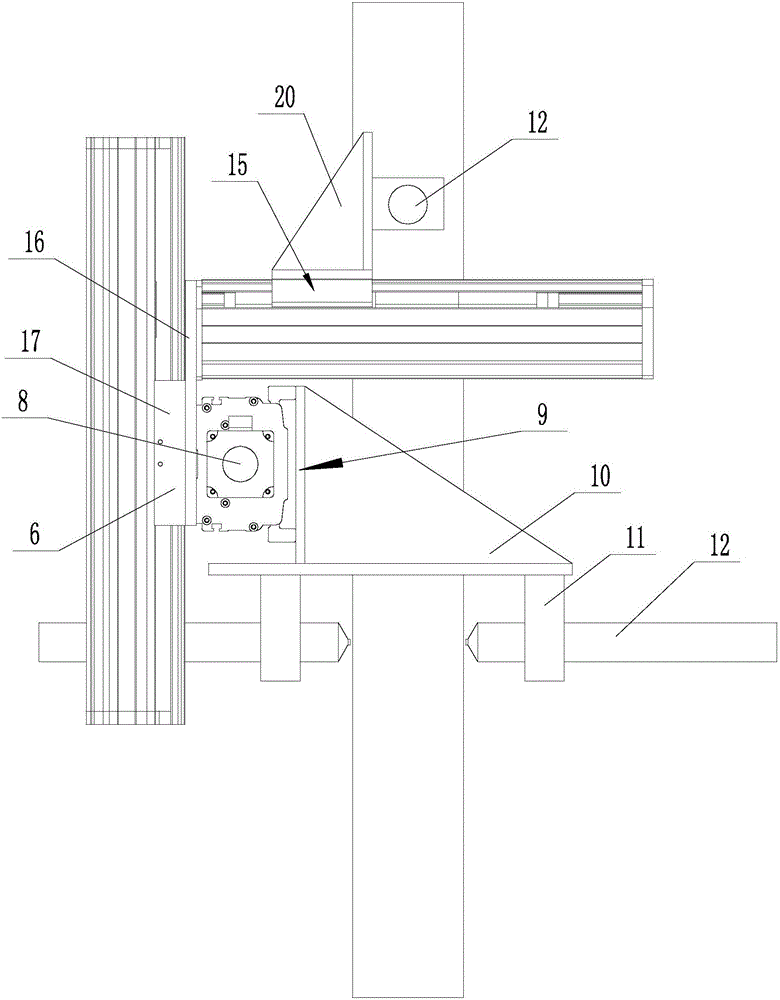

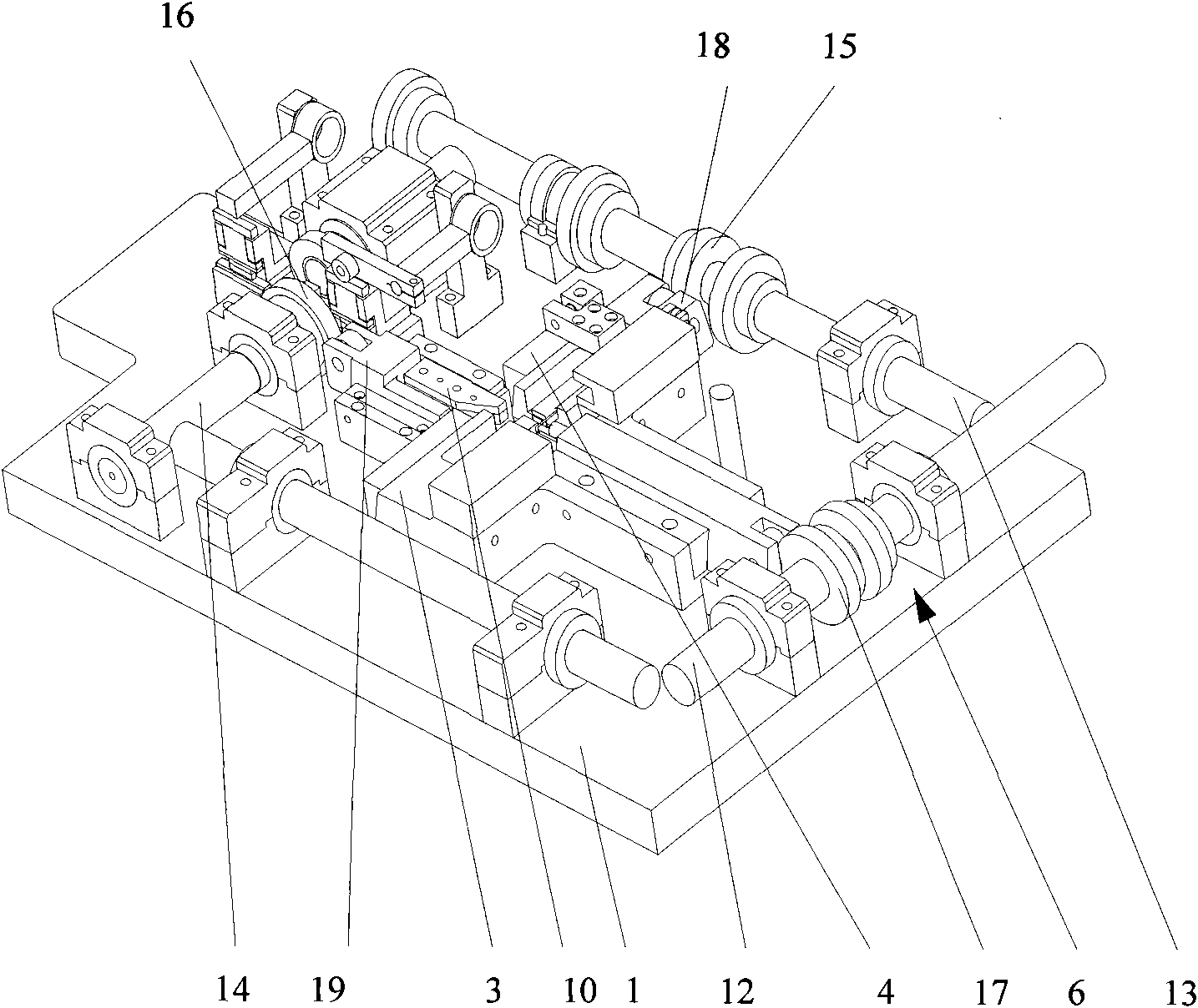

Circumferential cutting machine for circular tube

ActiveCN104907626AImprove cutting efficiencyCut surface smoothMetal sawing devicesMechanical engineeringEngineering

The invention discloses a circumferential cutting machine for a circular tube. The circumferential cutting machine comprises a cutting device, a material placing device, a stand, a transmission device, a slide rail, an adjusting device and a first rack, wherein the transmission device, the slide rail and the first rack are arranged on the stand; the slide rail and the first rack are arranged in the front of the transmission device; the cutting device is arranged on the slide rail; the adjusting device is arranged at the bottom of the cutting device and is connected with the first rack; the material placing device is arranged in the front of the stand; the cutting device comprises a cutting mechanism and a clamping mechanism, and the cutting mechanism is arranged on the clamping mechanism. Compared with the prior art, the invention has the advantages that the cutting efficiency can be improved, cut surfaces are flat and the use is convenient.

Owner:ZHUJI JIAERDA MACHINERY

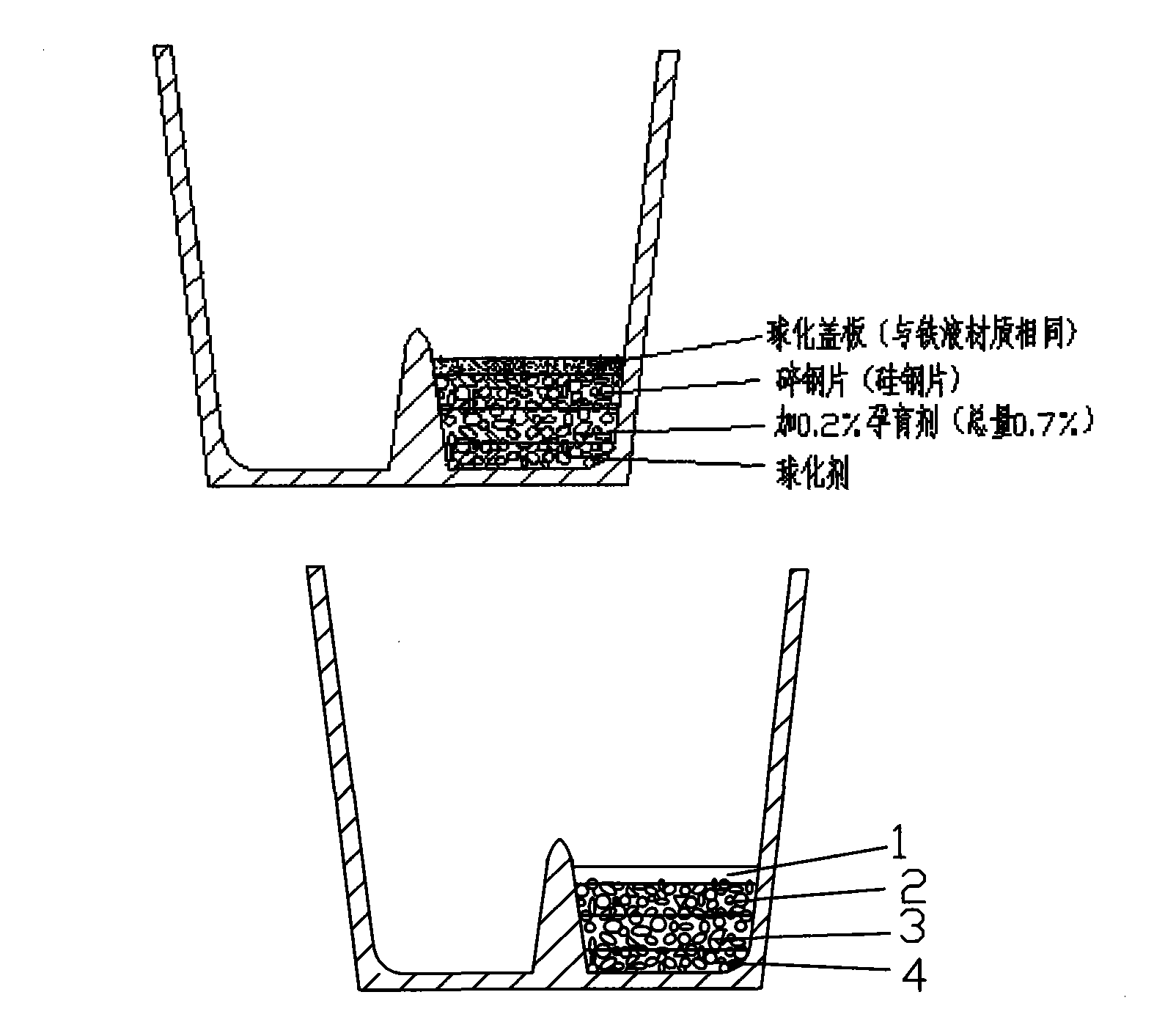

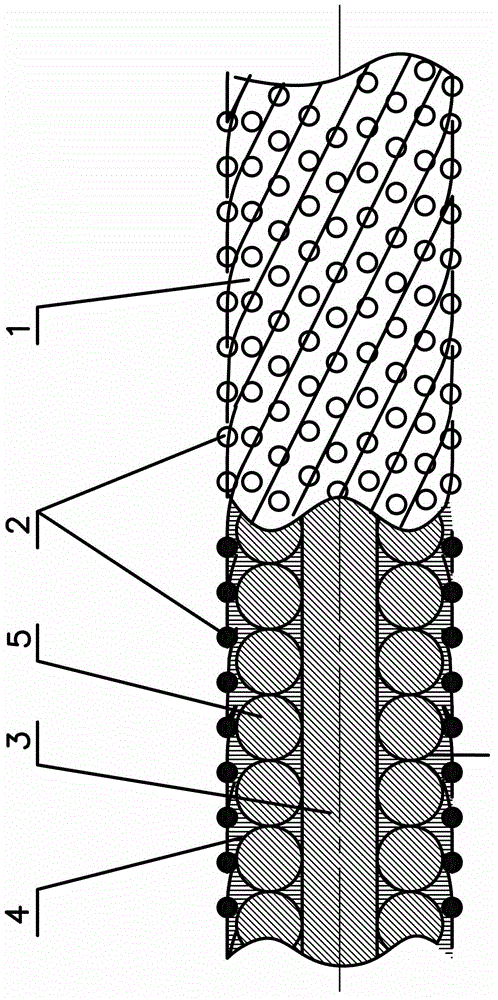

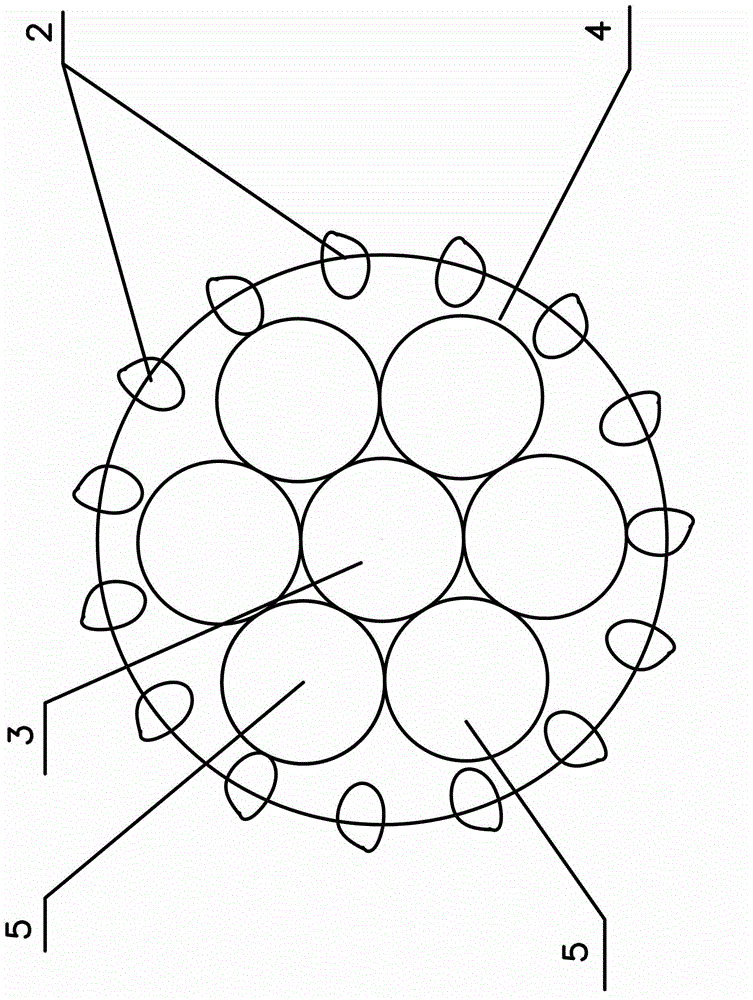

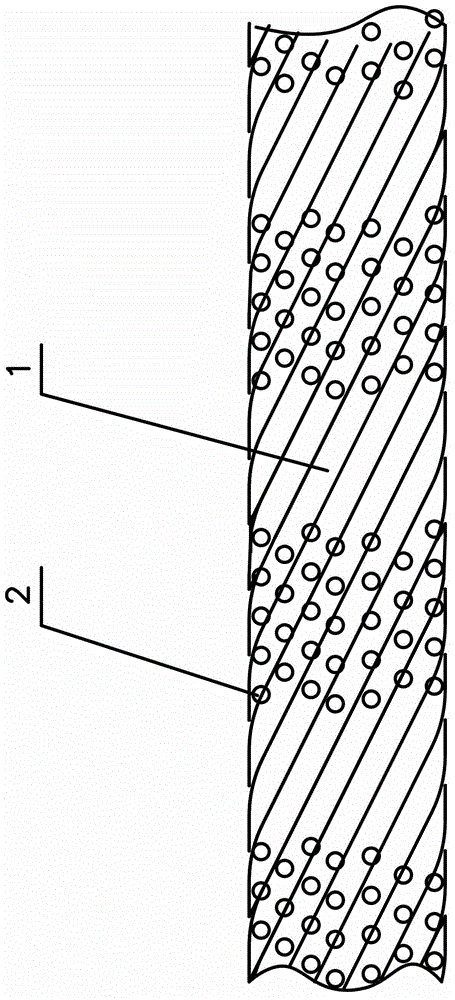

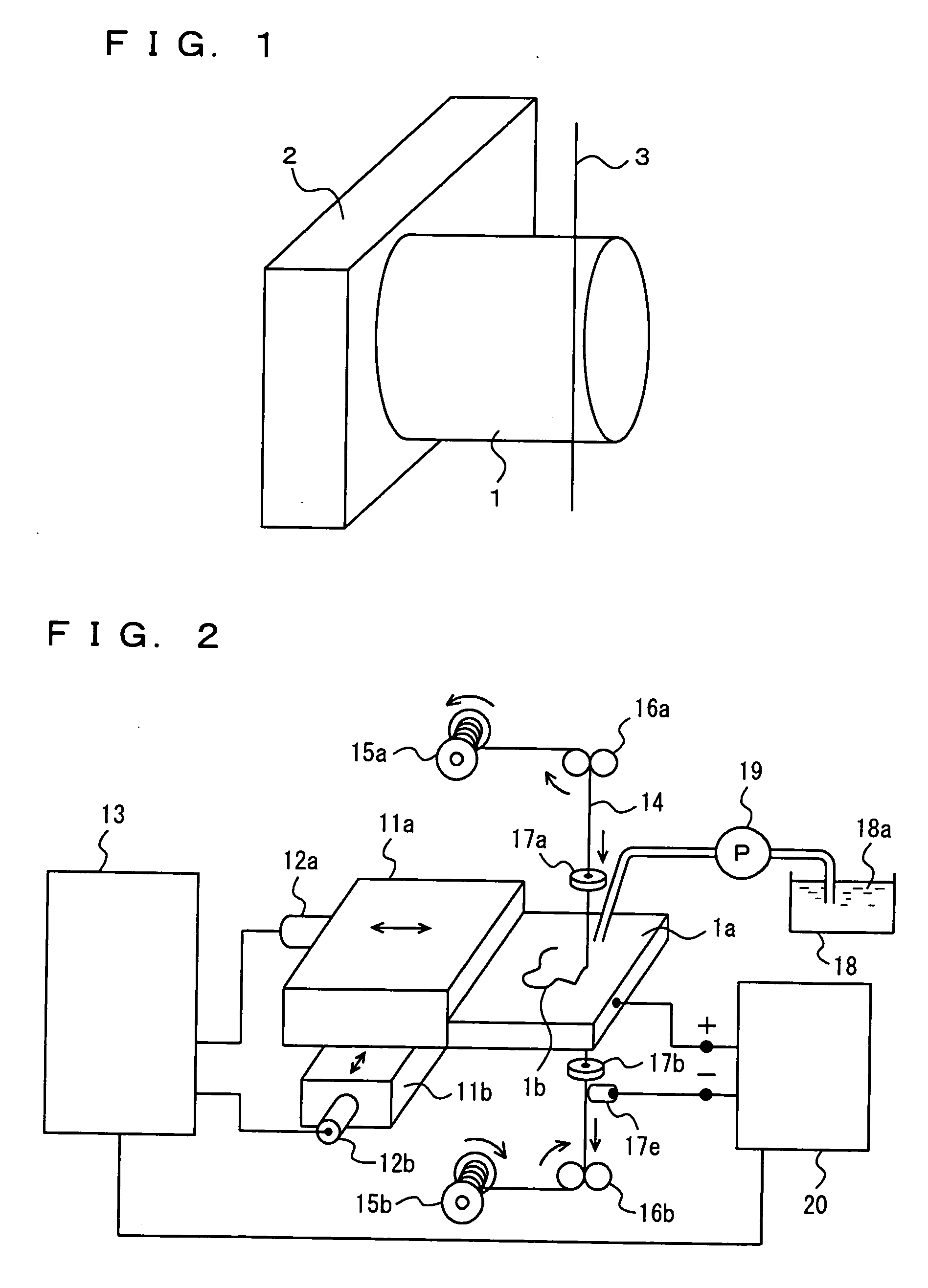

Annular super-hard abrasive wire and method for manufacturing same

ActiveCN102873401AUniform thicknessUniform distribution of superabrasive particlesMetal sawing tool makingHigh intensityElectrical conductor

The invention discloses an annular super-hard abrasive wire and a method for manufacturing the same. The annular super-hard abrasive wire comprises a rope, super-hard abrasive particles and a coating, wherein the size of the rope ranges from 0.1mm to 6mm, the super-hard abrasive particles are solidified on the surface of the rope, and the coating is used for solidifying the super-hard abrasive particles. The method for manufacturing the annular super-hard abrasive wire includes braiding the thin rope to form a ring with an optional perimeter; and then solidifying the super-hard abrasive particles on the surface of the annular rope by means of coating to form the high-strength annular super-hard abrasive wire with the uniform outer diameter and a long service life. The annular super-hard abrasive wire is low in cost, high in fatigue strength, long in service life, good in cutting quality and high in cutting efficiency, and a cutting machine with the annular wire can be used for cutting conductors, semiconductors and non-conductor materials.

Owner:中国有色桂林矿产地质研究院有限公司

Multi-Layer Piezoelectric Element and Method for Manufacturing the Same

ActiveUS20080007143A1High bonding strengthBonded firmlyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesConductive materialsEngineering

A multi-layer piezoelectric element having high durability wherein the internal electrodes and the external electrodes do not break even when operated continuously over a long time under high electric field and high pressure is provided. The multi-layer piezoelectric element comprises a stack formed by stacking at least one piezoelectric layer and internal electrodes consisting of first and second internal electrodes one on another, and external electrodes formed on two side faces of the stack with one of which being connected to the first internal electrode and the other external electrode being connected to the second internal electrode, wherein the external electrodes contain a conductive material and glass, the side whereon the external electrode is formed has cleft which has a wedge which contains glass formed therein, and the cleft is filled with the glass contained in the wedge and glass contained in the external electrode.

Owner:KYOCERA CORP

Wax emulsion for treating pencil wood

ActiveCN1611334AFine and uniform particlesImprove stabilityWood impregnation detailsMINERAL WAXPolymer science

The present invention discloses a wax emulsion for treating board for making pencil. Said wax emulsion is made up by using mineral wax, sterilizing agent, adjuvant, emulsifier, preservative and water according to a certain mixing ratio. The cutting face of the pencil made of the board treated by said wax emulsion is smooth and clean, and said invented wax emulsion can greatly raise quality of the product. As compared with dry board-baking wax-impregnating method said invented method can reduce consumption of wax-like material, also can reduce environmental pollution due to dry baking wax-impregnating method.

Owner:CHINA PETROLEUM & CHEM CORP +1

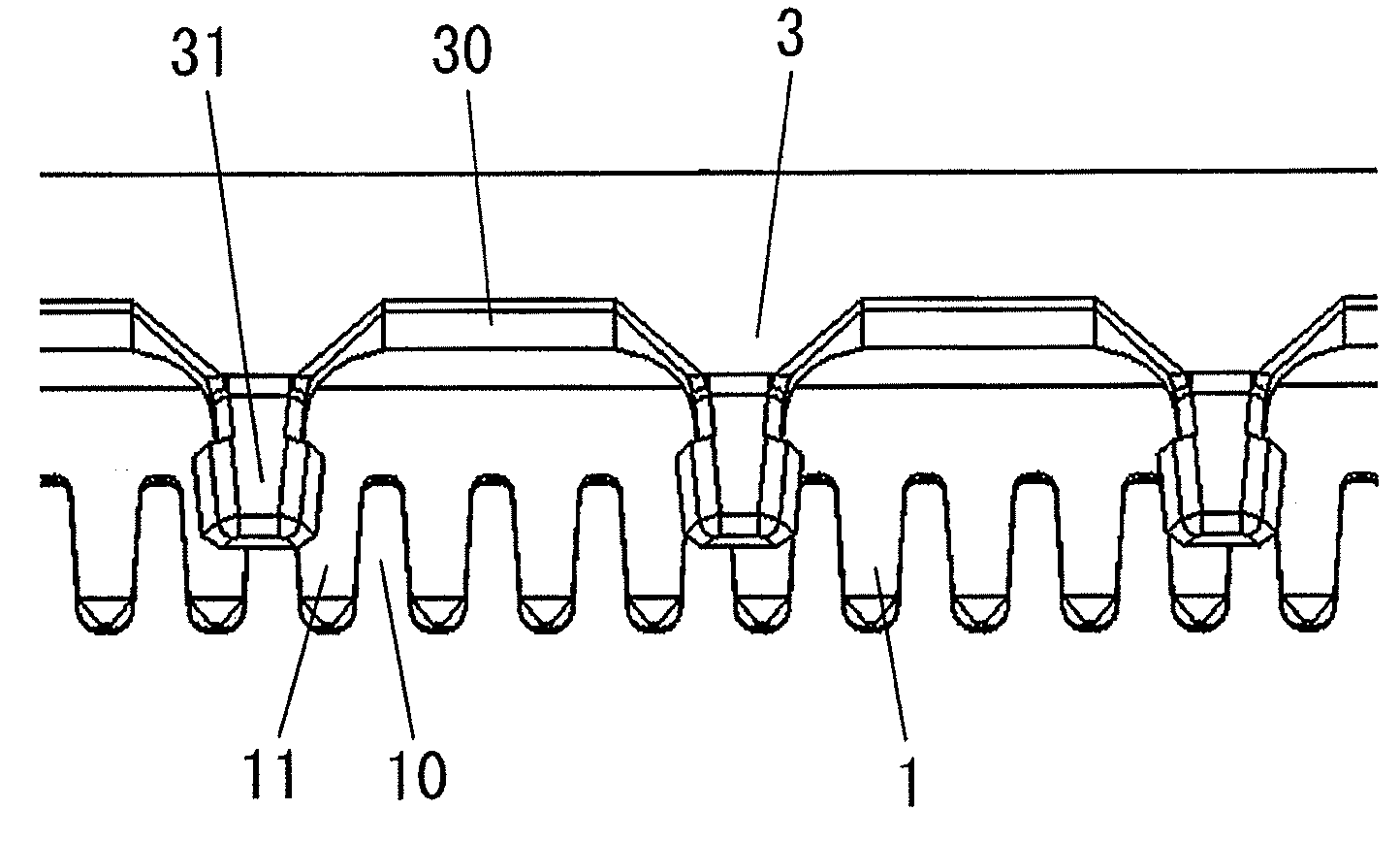

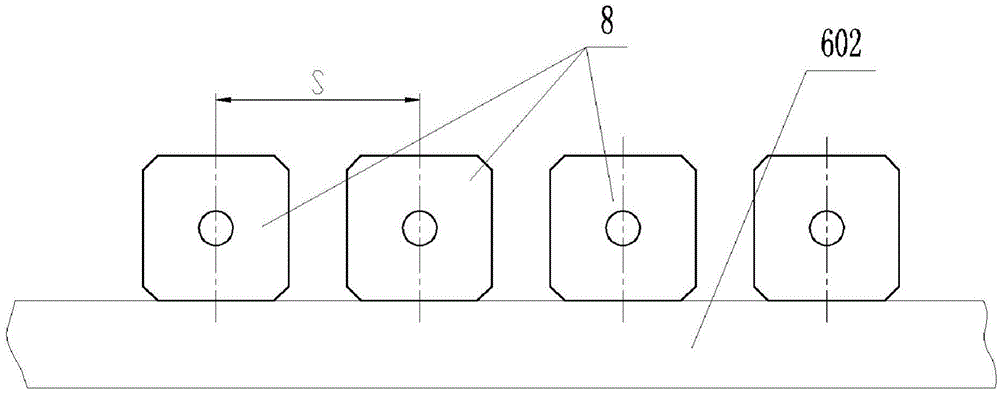

Trimmer blade

InactiveUS20120240409A1Increase insertion efficiencyImprove cutting efficiencyMetal working apparatusReciprocating motionEngineering

A trimmer blade comprises a fixed blade unit and a movable blade unit. Then, said fixed blade unit comprises a comb-shaped blade section having a plurality of blades and a plurality of gullets, and said plurality of blades are arranged alternately with said plurality of gullets. Then, said movable blade unit comprises a comb-shaped blade section having a plurality of blades and a plurality of gullets, and said plurality of blades are arranged alternately with said plurality of gullets, and said movable blade unit is configured to slide on said fixed blade unit while reciprocating. A width of each gullet of said movable blade unit is set so that at least two gullets of said fixed blade unit fall inside each gullet of said movable blade unit, as viewed from a direction perpendicular to a sliding surface between said movable blade unit and said fixed blade unit.

Owner:PANASONIC CORP

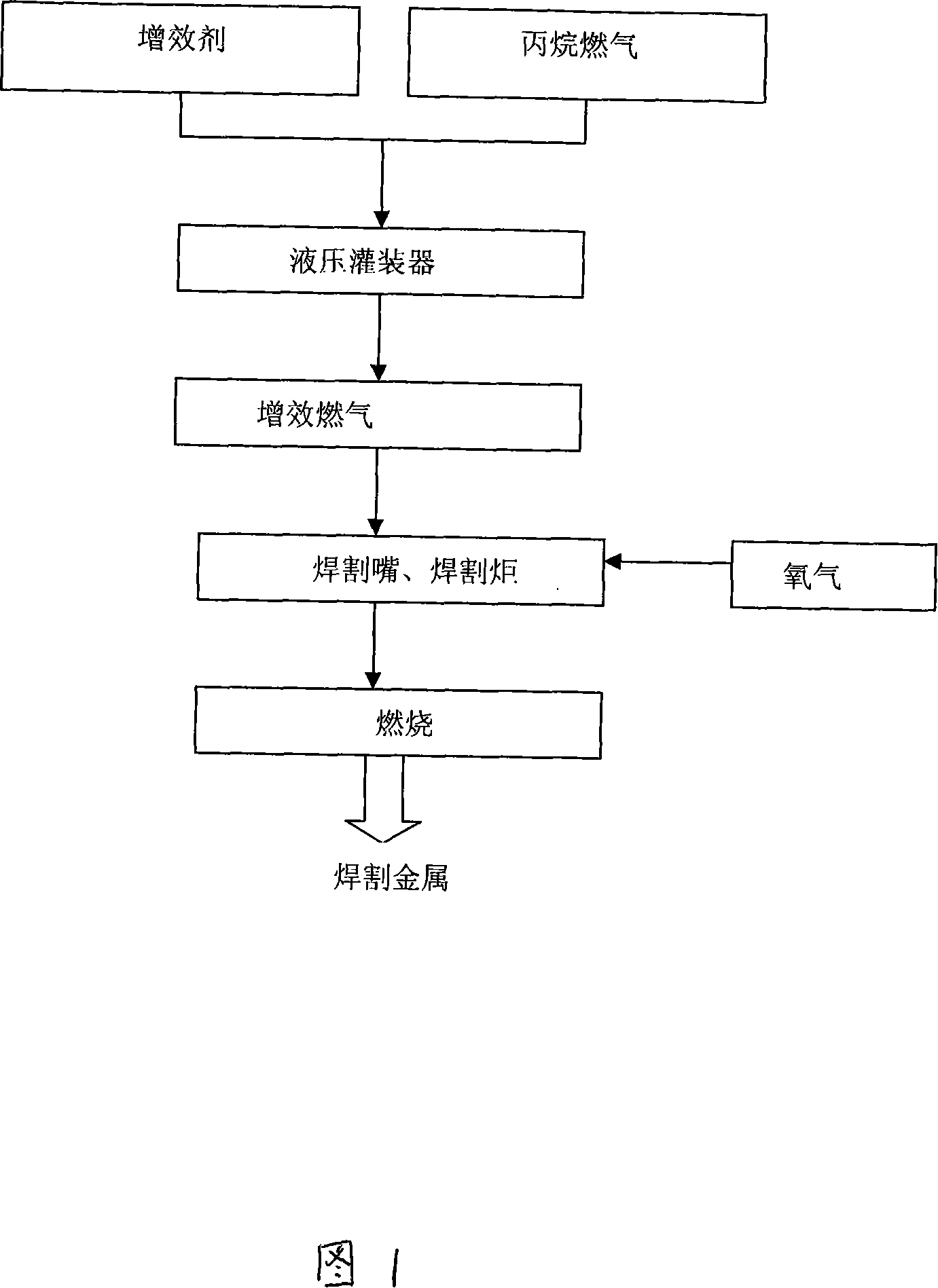

Environment-protection energy-saving gas for welding and cutting

InactiveCN101139535ARaise the combustion temperatureBurn fasterGaseous fuelsForeign matterEngineering

The invention relates to a fuel gas for welding cut that is environmental friendly and energy saving, in particular to a fuel gas that can substitute acetylene gas. The fuel gas comprises a propane gas, which is characterized in that synergist is added in certain proportion in the propane gas; the content of the propane gas is 97-99%; the content of the synergist is 5 per mill-1%, the content of the liquefiable foreign matter of gas is less than 2.5% by weight; the synergist is a mixed solution comprising combustion catalyst, smoke-removing agent, polymer degrading agent, solvent, solution assistant, and combustion assistant, etc.; the fuel gas is used as combustion gas in place of acetylene gas to weld and cut metals. The flame of the fuel gas is of high temperature, is free from reverse (return) combustion; the fuel gas is of very low explosion limit and low toxicity, free from harm to human bodies, of low comprehensive cost, high efficiency, is safe, environmental friendly and energy saving.

Owner:周尧

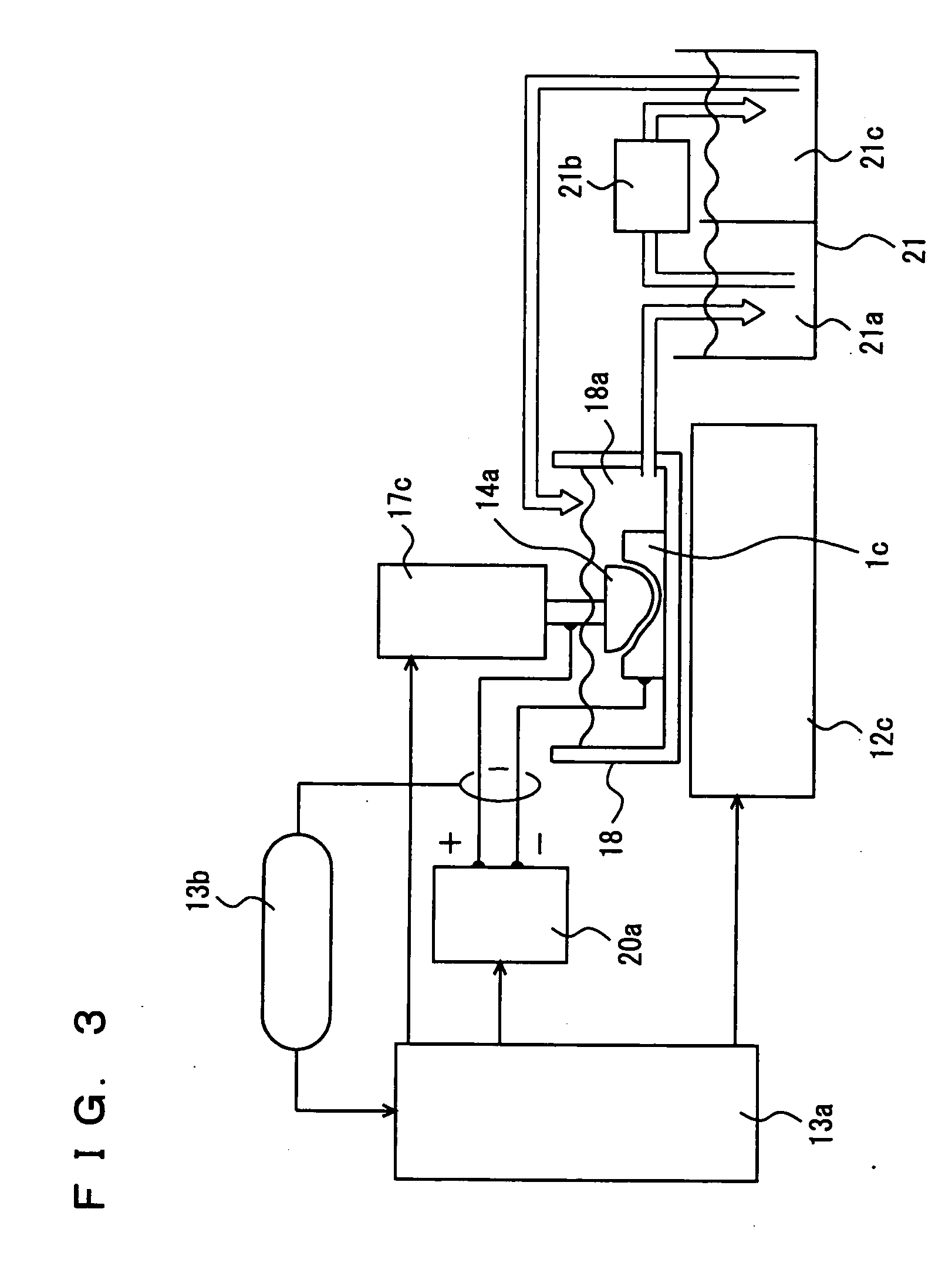

Method of working nitride semiconductor crystal

InactiveUS20060292832A1Simple and efficient mannerLow costGrinding drivesSemiconductor/solid-state device manufacturingNitride semiconductorsVoltage

Owner:SUMITOMO ELECTRIC IND LTD

Electro/mechanical microchips and method of making with burst ultrafast laser pulses

ActiveCN104646837AReduce wasteCheap manufacturingSolid-state devicesForming microstructural systemsEngineeringLaser

A method for making an electromechanical chip using a plurality of transparent substrates, comprising the steps of: machining, using photoacoustic compression, full or partial voids in at least one of the plurality of substrates. The plurality of transparent substrates are stacked and arranged in a specific order. The transparent substrates are affixed and sealed together. The chip may be sealed by laser welding or adhesive.

Owner:ROFIN SINAR TECH

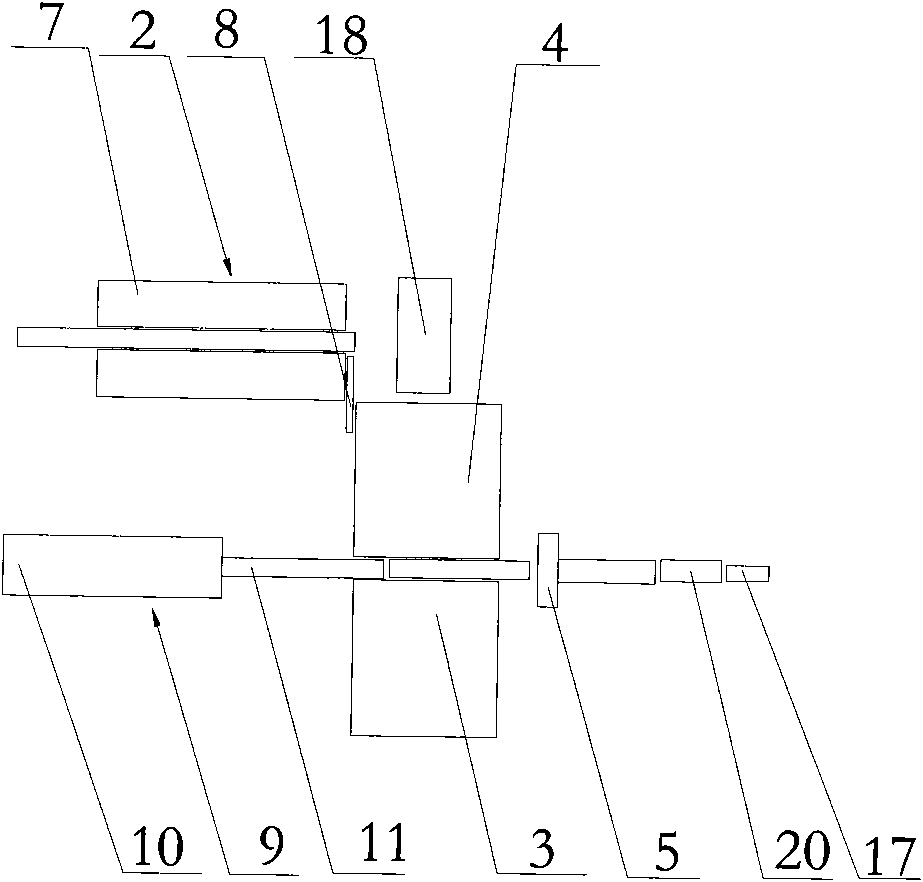

Automatic cutting equipment for bar type material continuous discharging system

ActiveCN103552103AAchieve neat placementUniform and stable lengthMetal working apparatusControl systemElectrical control

The invention discloses automatic cutting equipment for a bar type material continuous discharging system. The automatic cutting equipment is mainly used for the bar type material continuous discharging system and is structurally characterized by being arranged at the material outlet of the bar type material continuous discharging system, wherein a supporting mechanism is arranged in front of the material outlet, and a guide slot is fixedly arranged above the supporting mechanism; a position sensor is arranged at the periphery of the guide slot; a transmission mechanism is positioned below the supporting mechanism; a material moves forward along the guide slot on the supporting mechanism by virtue of the material outlet; when the material reaches at a set length, the position sensor sends out an effective signal, an electrical control system drives the automatic cutting mechanism to cut off the material; meanwhile, supporting plates on the supporting mechanism move back to perform blanking, so that the material is regularly discharged on a blanking plate, and the transmission mechanism drives the blanking plate to discharge the material, by parity of reasoning, so that the automatic cutting and discharging of the material can be realized. By utilizing the high degree of automation and low manufacturing cost of the equipment, the defects of low efficiency and low cutting precision of existing manual operation can be improved.

Owner:吴德会

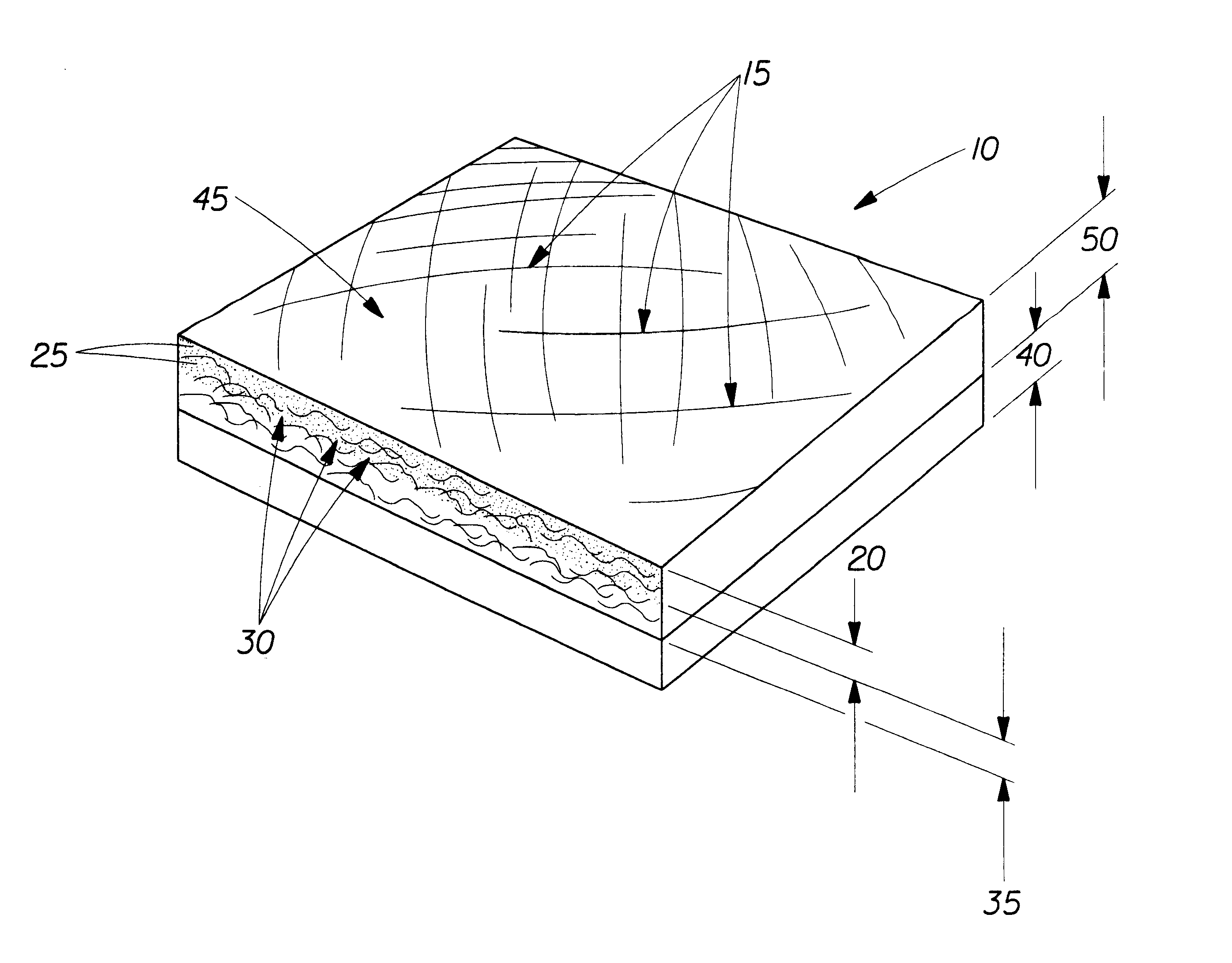

Multi-purpose absorbent and shred-resistant sheet material

InactiveUS20020136871A1Avoid pollutionIncrease coefficient of frictionReinforcing agents additionPaper/cardboardEngineeringAverage size

A shred-resistant and cut-resistant absorbent sheet material including an absorbent substrate and cut-resistant particles discontinuously distributed through the substrate. The absorbent substrate can comprise cellulosic material and the particles comprise polymeric materials having an average size of at least about 100 nanometers, and most preferably between 100 nanometers and 1000 nanometers. In one embodiment, the particles are provided in an amount of between about 10 percent to about 50 percent by weight of the sheet. The sheet material can be made using typical paper making processes. Heat and / or pressure are applied to the sheet material to cause the particles to at least partially flow, so as to bond to the absorbent substrate. The sheets can be provided as a layered structure with a slip-resistant base for home use in the preparation of foodstuffs.

Owner:THE PROCTER & GAMBLE COMPANY

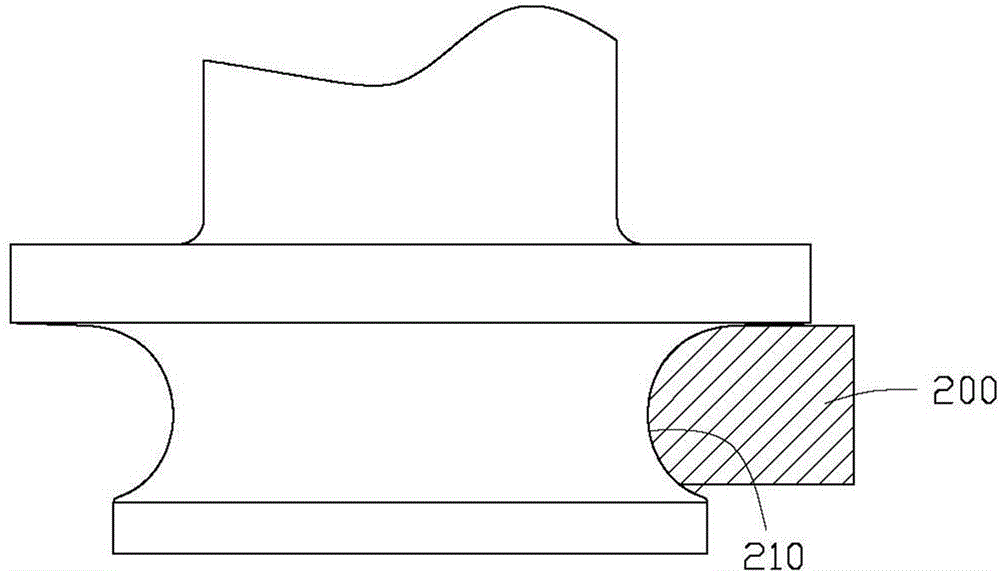

Edge material shearing device for plastic sheets

The invention discloses an edge material shearing device for plastic sheets. The edge material shearing device comprises an engine base, an upper cutter device and a lower cutter device. The inventionis characterized in that the a cylinder is arranged on the engine base, a push rod of the cylinder is connected with a hinge mechanism, the engine base is provided with a concave cavity, the hinge mechanism is fixed in the concave cavity, a connection rod of the hinge mechanism is fixedly connected with the upper cutter device, the blade of the upper cutter device is in the shape of a dovetail, the lower cutter device is arranged below the upper cutter device, and the blade of the lower cutter device is rectangular. The invention can be used for directly shearing edge materials and has high operation efficiency. Besides, the shear plane is smooth and clean; and the shearing device is especially safer and more reliable for shearing splintery materials.

Owner:CHANGZHOU BOSHUANG PLASTICS

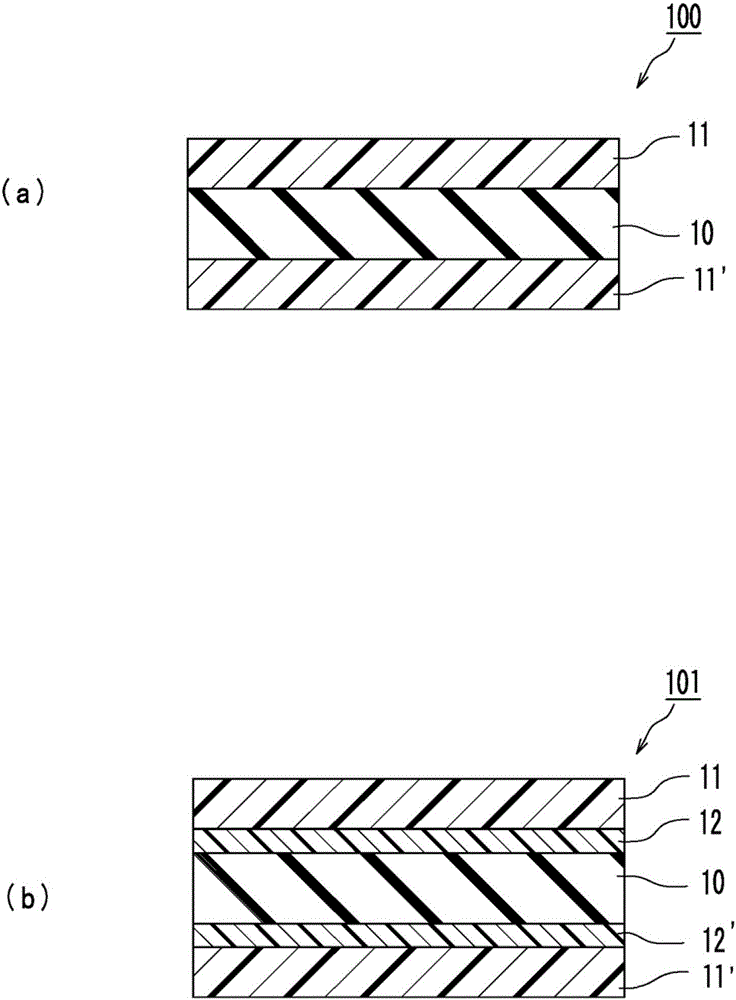

Method for producing flexible film

InactiveCN105073660ACut surface smoothAvoid breakingLamination ancillary operationsLayered product treatmentThin glass

Provided is a method for producing a flexible film (a diced laminate) that has a smooth torn surface and does not undergo the breakage of a thin glass contained therein by cutting a laminate comprising the thin glass and a resin layer. The method for producing a flexible film according to the present invention comprises cutting a laminate which comprises a thin glass having a thickness of 100 μm or less and a resin layer arranged on one surface or both surfaces of the thin glass. The method comprises the steps of: forming a groove on the outer surface side of the resin layer; and cutting the laminate along the groove.

Owner:NITTO DENKO CORP

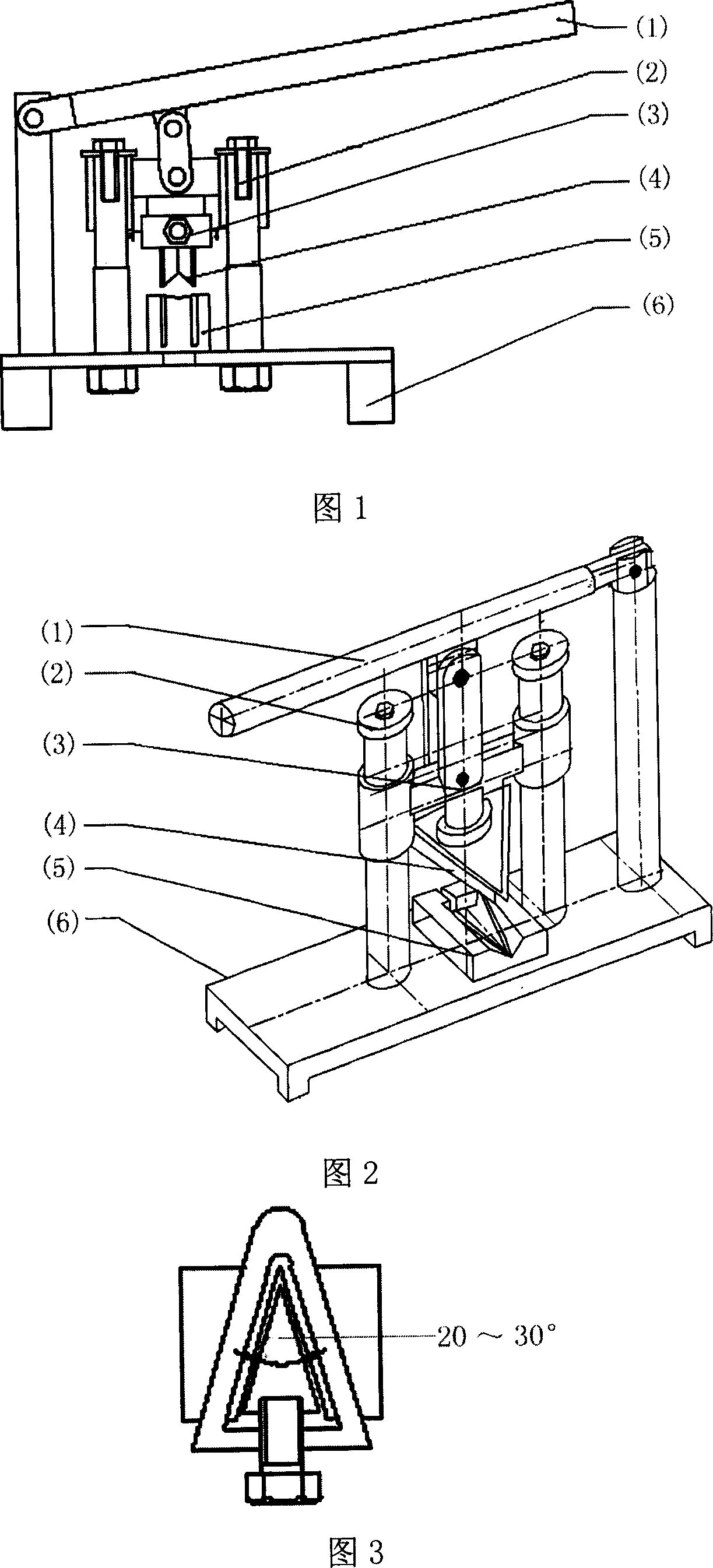

Fruit-tree grafting machine

The present invention discloses a fruit tree grafting tool. It is composed of handle, guide column, upper cutter carriage, cutter body, lower cutter groove and base seat. It is characterized by that the horizontal cross-section of said cutter body is 'V' form, on the cutter seat a cutter groove is set, said cutter groove can be engaged with said 'V'-shaped cutter body.

Owner:SHANDONG INST OF POMOLOGY

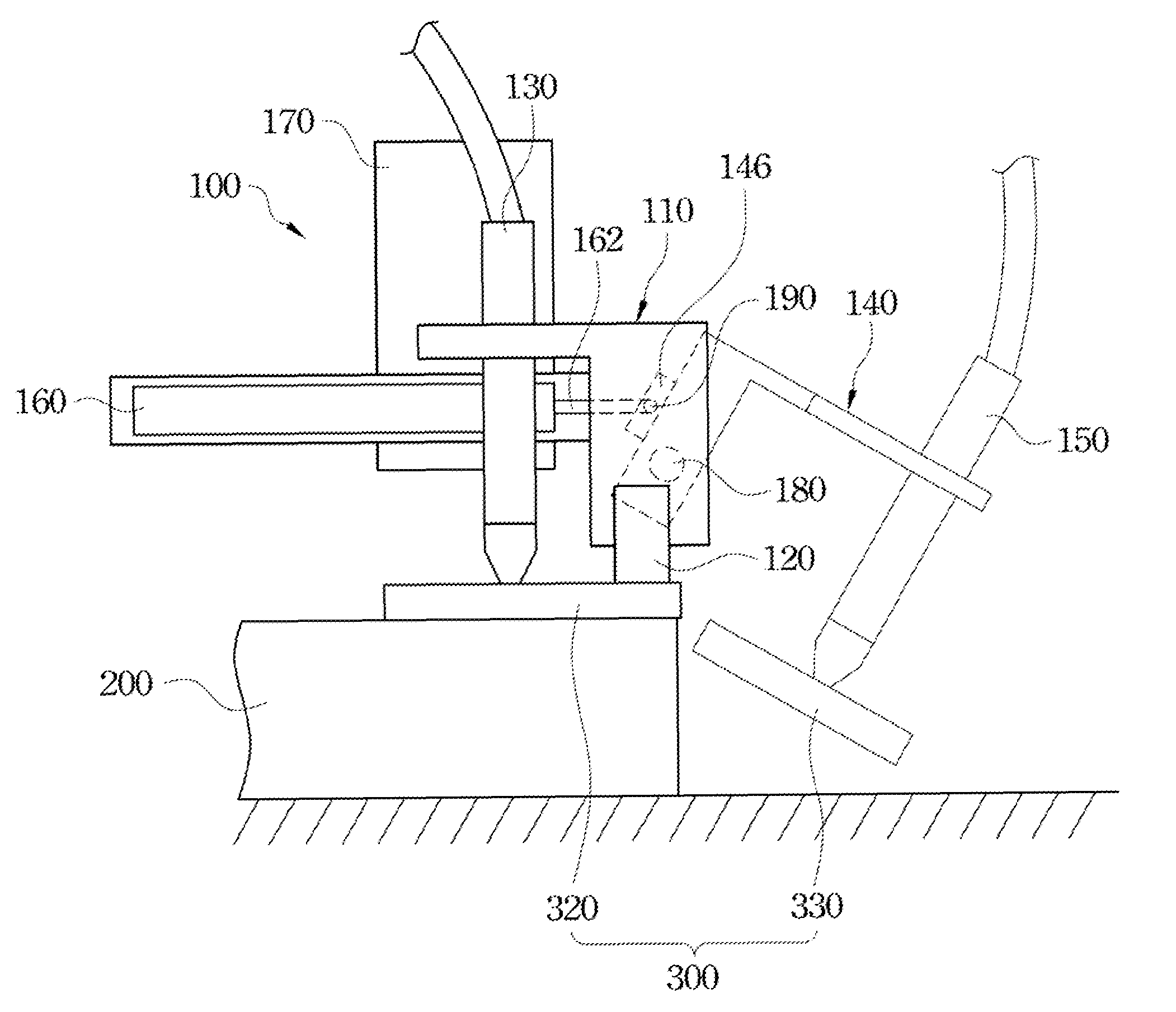

Fracturing apparatus

InactiveUS8584918B2Easy qualityYield easilyMetal working apparatusArticle deliveryEngineeringMechanical engineering

A fracturing apparatus is provided. The fracturing apparatus includes a first board portion, a pressing element, a first suction device, a second board portion, a second suction device, and a cylinder. The first suction device is secured to the first board portion. The second board portion is rotatably connected to the first board portion. The second suction device is secured to the second board portion. The pressing element is secured to the first board portion and disposed between the first board portion and the second board portion. The cylinder is located on the first board portion and includes a piston rod rotatably connected to the second board portion. When the piston rod extends, the second board portion is pressed by the piston rod and swiveled about the first board portion.

Owner:RYTEC CORP

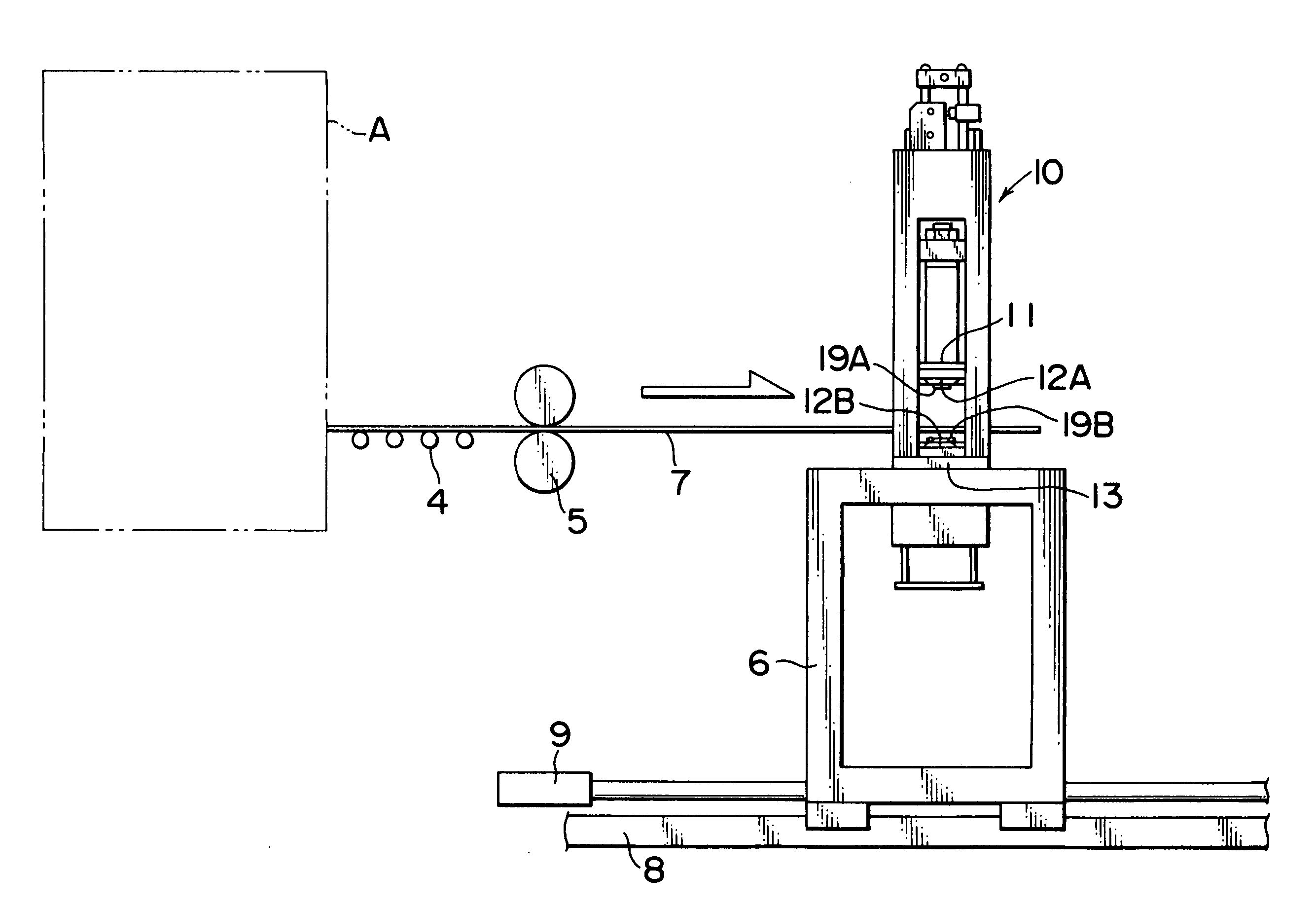

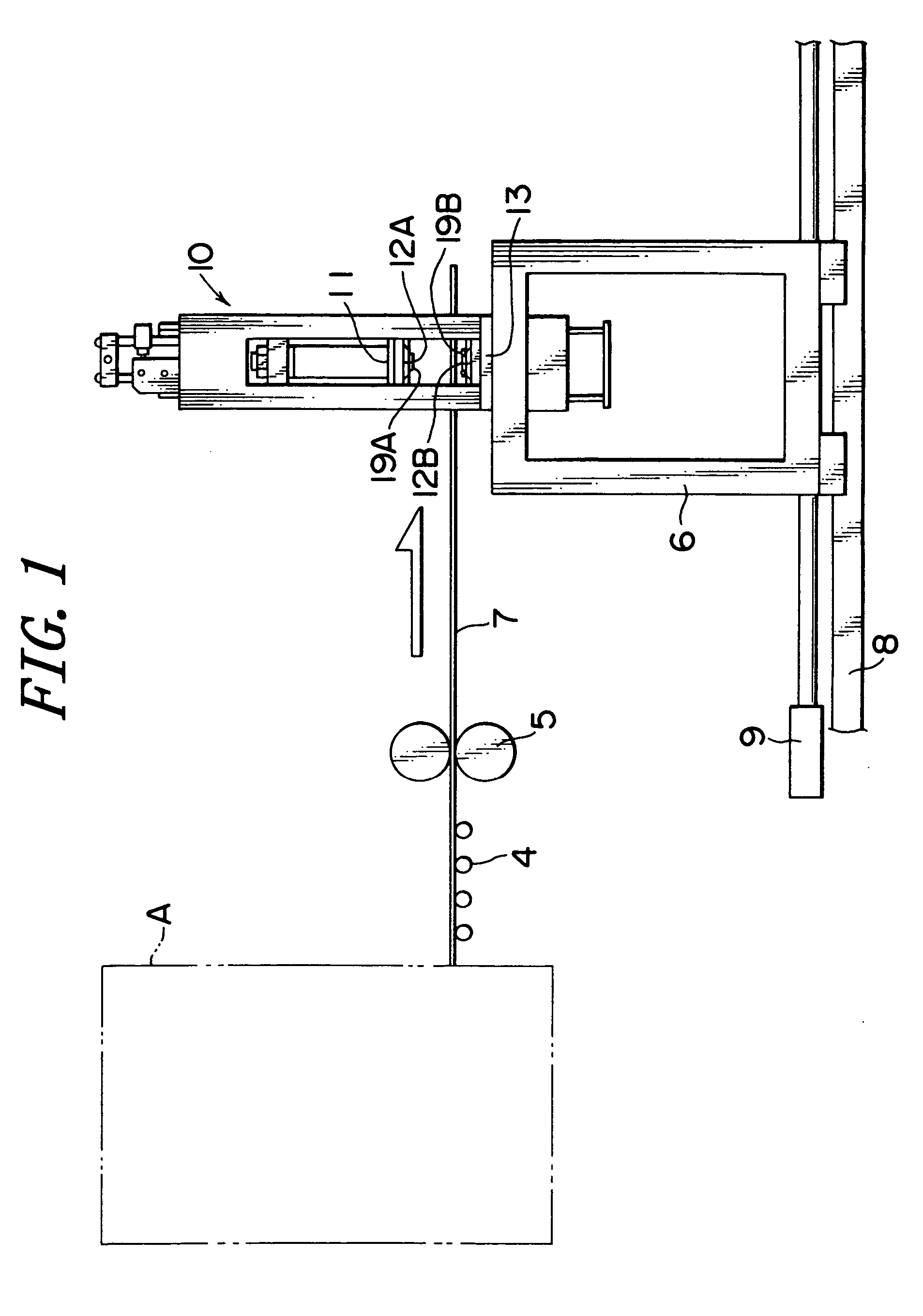

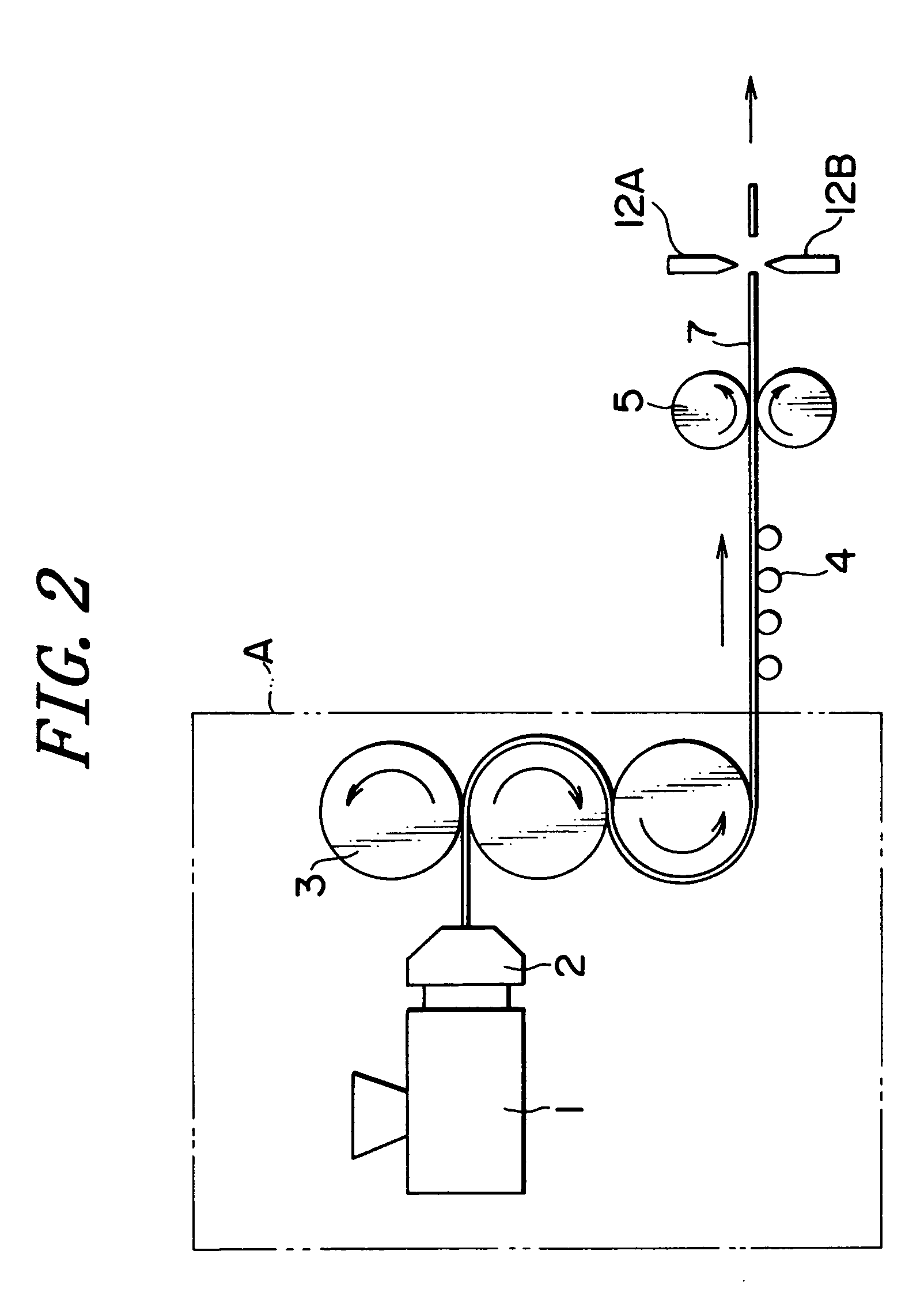

Cutting machine and manufacturing system for fixed size sheet

InactiveUS20060075863A1High precision cuttingShort cutting timeMetal working apparatusEngineeringHardness

A cutting machine 10 includes an upper blade 12A and a lower blade 12B installed at upper and lower positions, and resilient members 19A, 19B installed on both sides of the blades and protruding more than the blades for supporting a hard plastic sheet 7 during cutting. The resilient members installed on both sides of either of the upper and lower blades include a resilient member at a section near the blade and a resilient member at a section far from the blade, and the hardness of the resilient member at a section near the blade is different from the hardness of the resilient member at a section far from the blade.

Owner:TEIPI THERMAL ENG +2

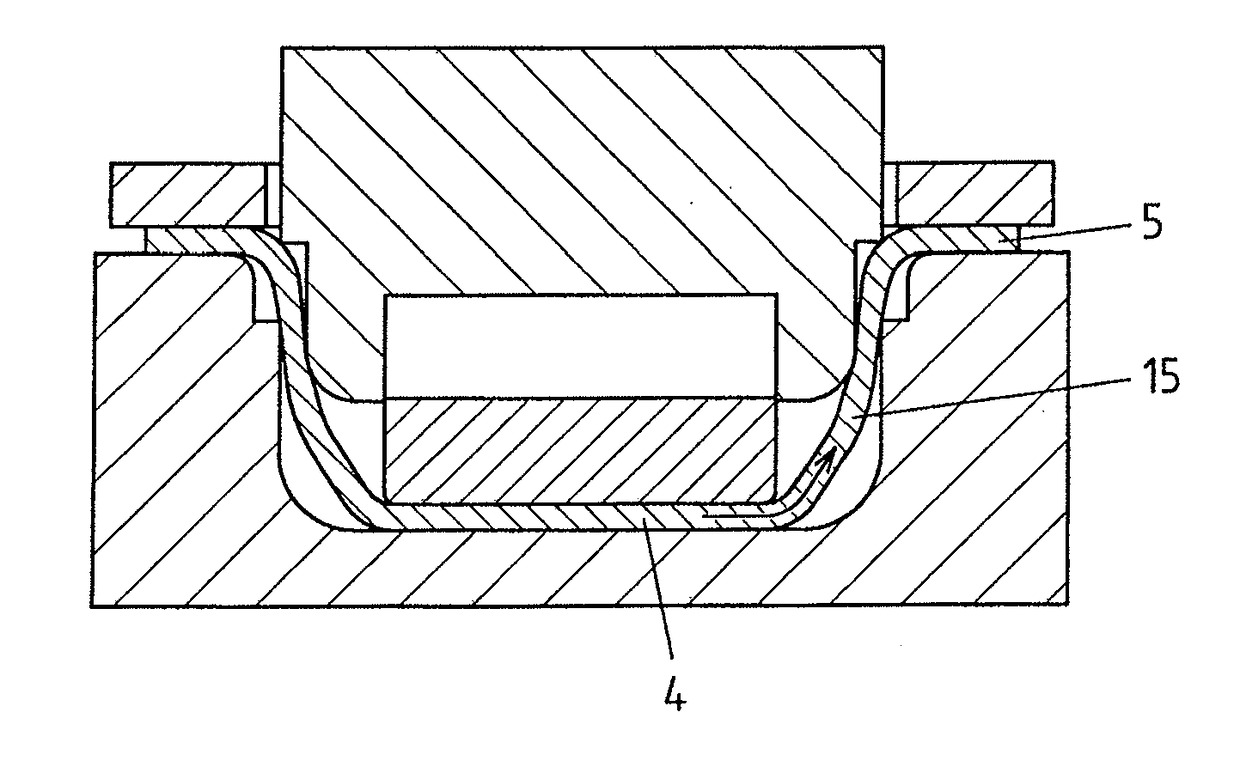

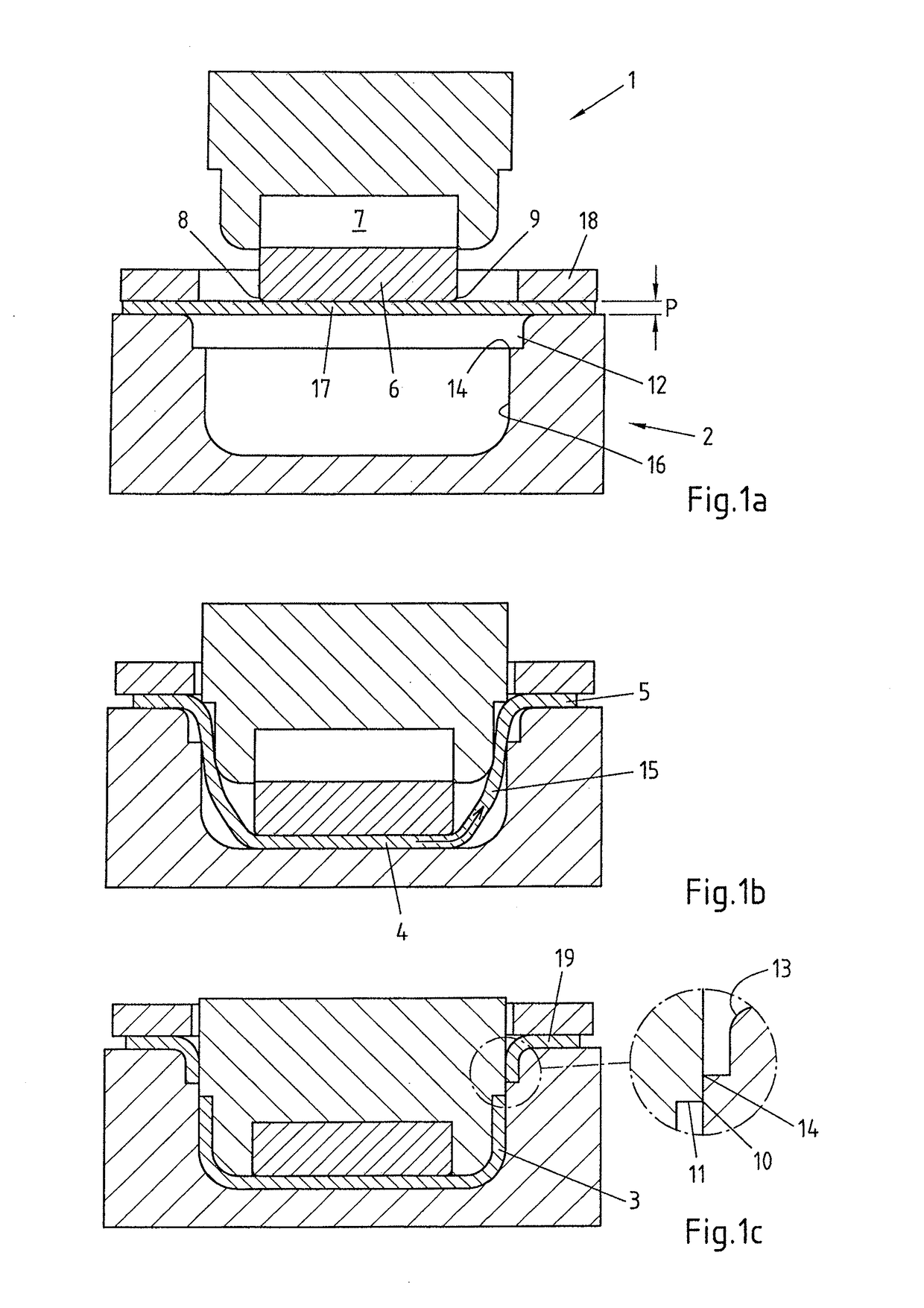

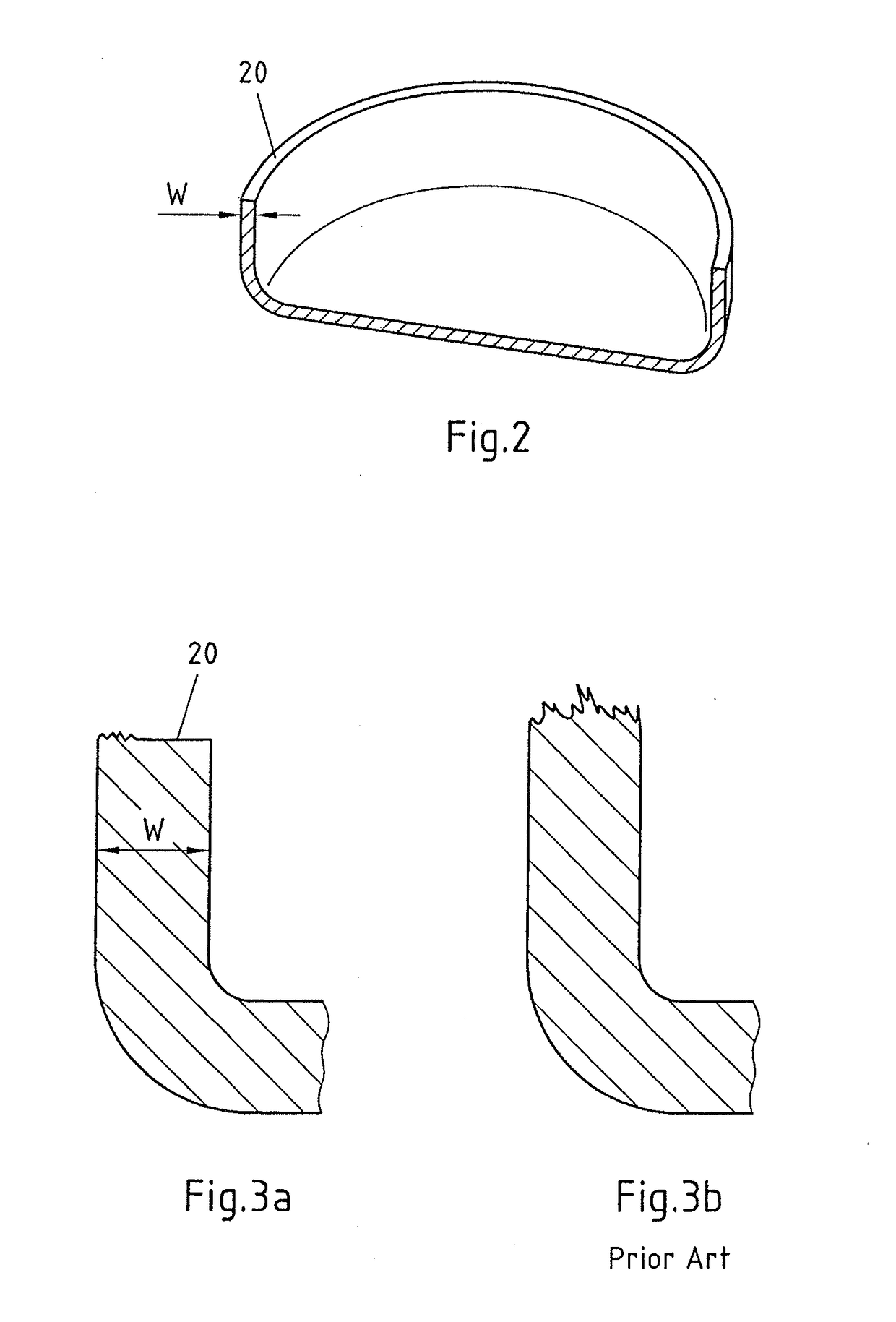

Method and device for producing a half-shell part

InactiveUS20170225216A1Elastic recovery after deep drawing is reduced or suppressedGood dimensional stabilityShaping toolsThin material handlingEngineeringFlange

The invention relates to a method for producing a half-shell part with a drawing punch and a drawing die. The object of providing a method for the process-reliable and cost-effective production of highly dimensionally stable half-shell parts is achieved in that, in a single work step, the drawing punch is advanced into the drawing die, a sheet metal blank is preformed into a sheet metal raw part with at least one base section, at least one frame section and optionally a flange section, wherein during the preforming with the drawing punch a material excess is introduced either into the base section and the frame section or into the optional flange section of the sheet metal raw part, and the sheet metal raw part is finished to form a half-shell part and calibrated.

Owner:THYSSENKRUPP STEEL EURO AG

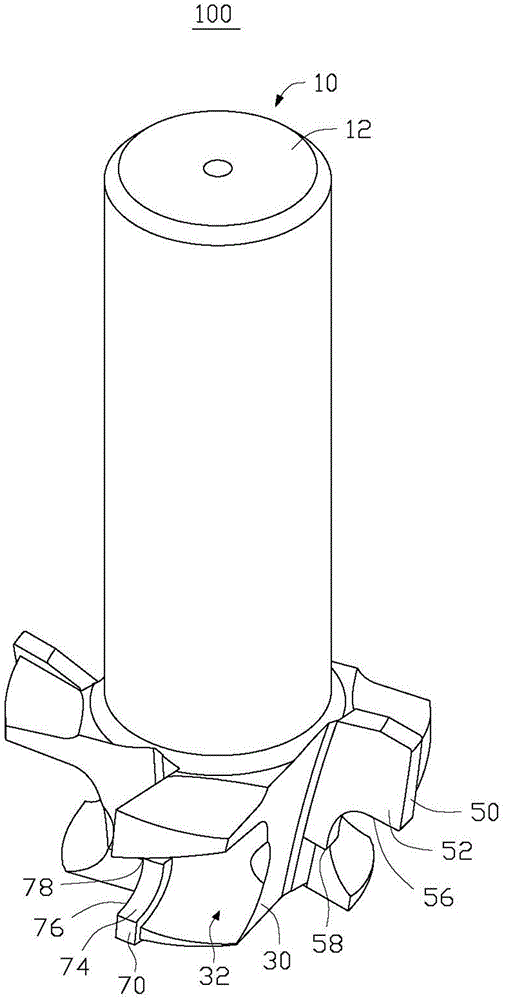

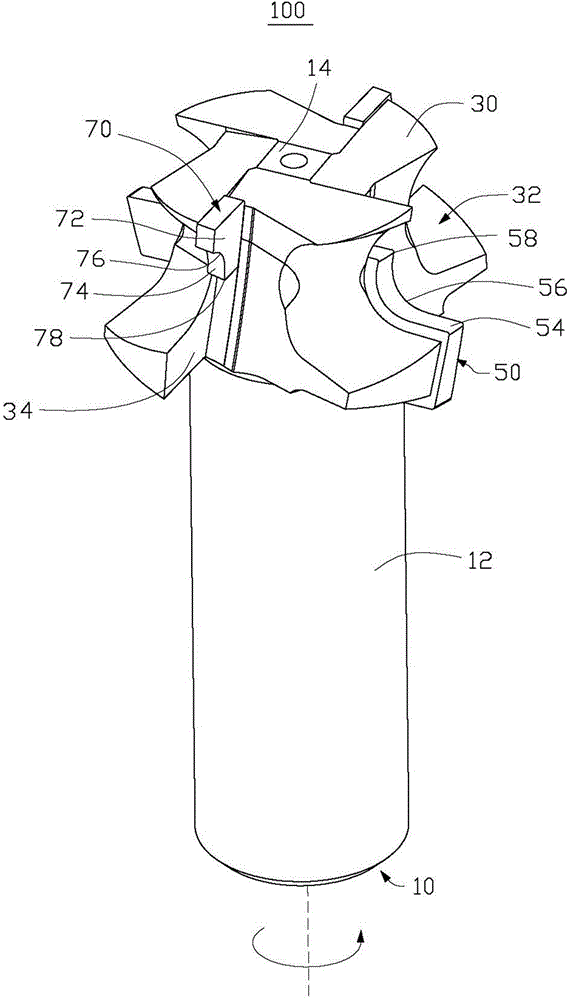

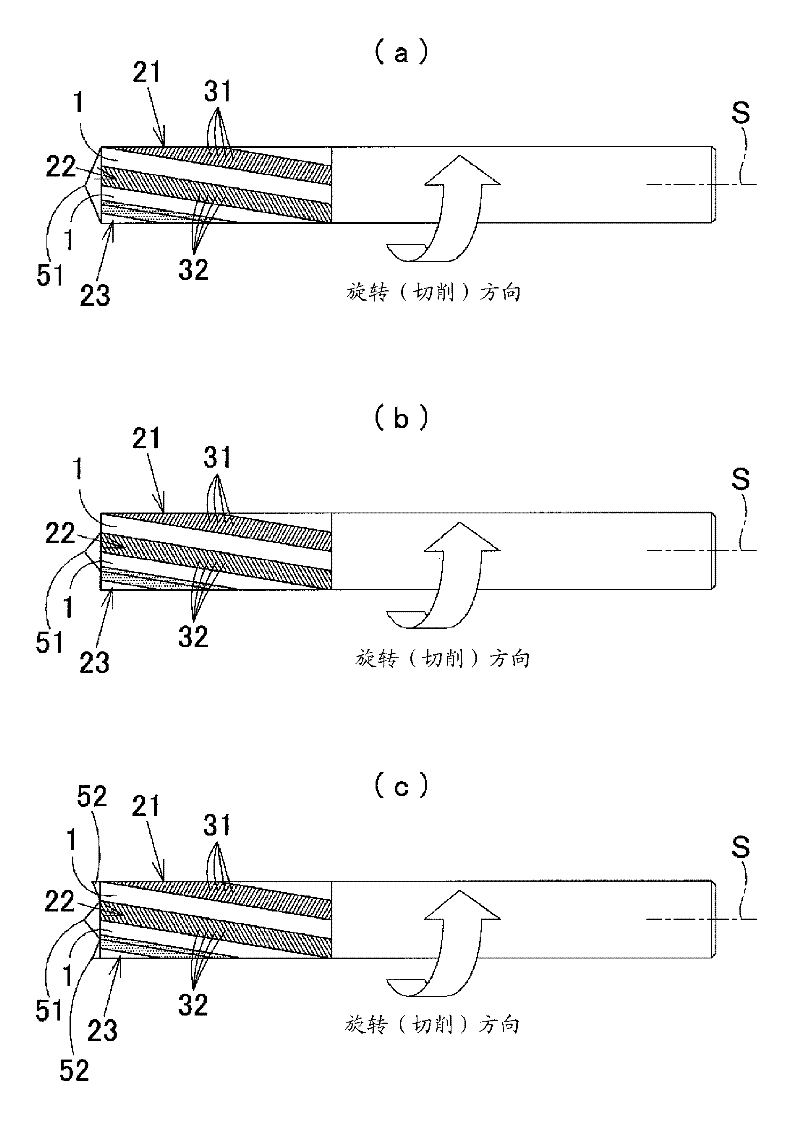

Milling cutter

InactiveCN105562801AExtended service lifeNot easy to roll the bladeMilling cuttersMilling equipment detailsMilling cutterMechanical engineering

The invention provides a milling cutter used for machining a workpiece to obtain a predetermined contour line. The predetermined contour line comprises a first part and a second part connected with the first part. The milling cutter comprises a cutter handle provided with a center shaft and further comprises a plurality of first cutting edges and a plurality of second cutting edges, wherein the first cutting edges and the second cutting edges are arranged in a stagger mode, the first cutting edges are used for rotating around the center shaft to form a first rotation track to machine the first part of the predetermined contour line of the workpiece, the second cutting edges are used for rotating around the center shaft to form a second rotation track different from the first rotation track to machine the second part of the predetermined contour line of the workpiece, and the first rotation track is connected with the second rotation track. The milling cutter is relatively low in cutting resistance and long in service life.

Owner:JIZHUN PRECISION IND HUIZHOU

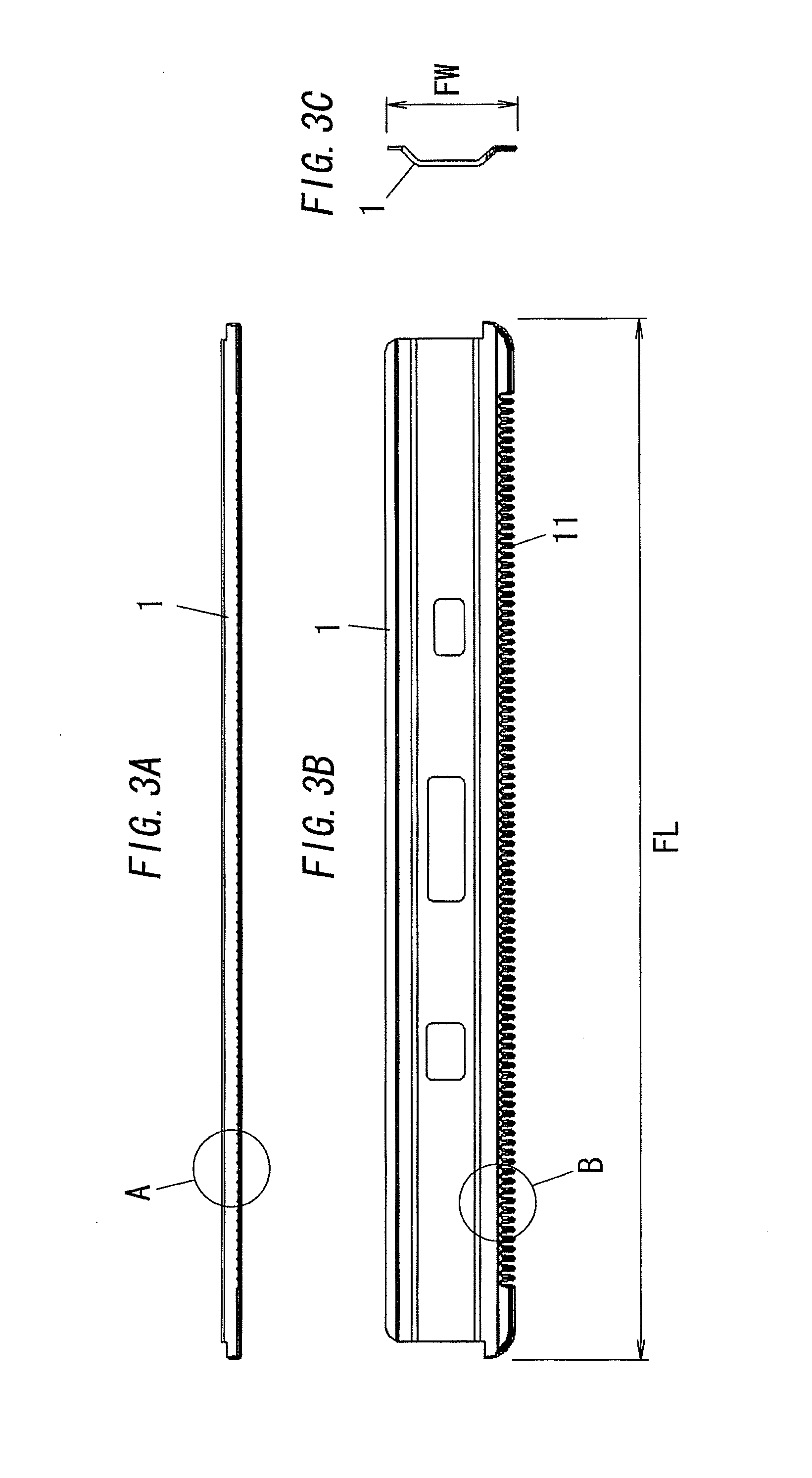

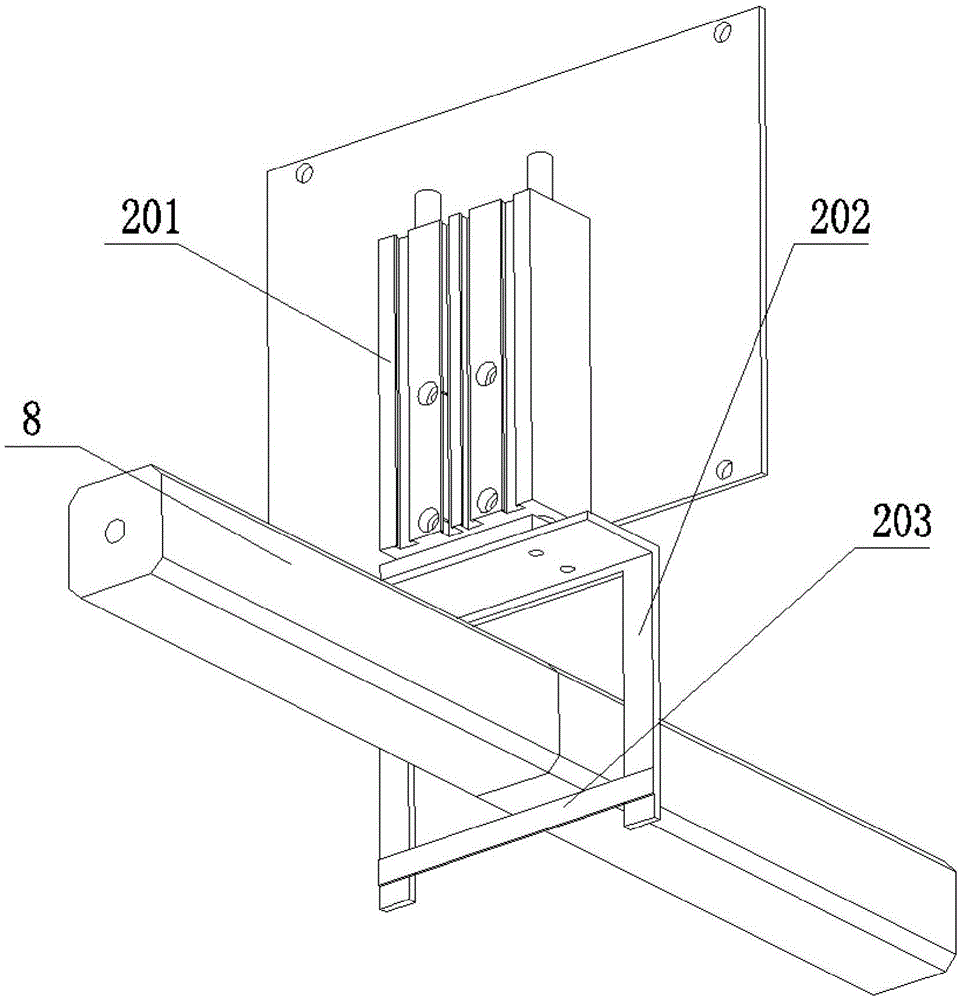

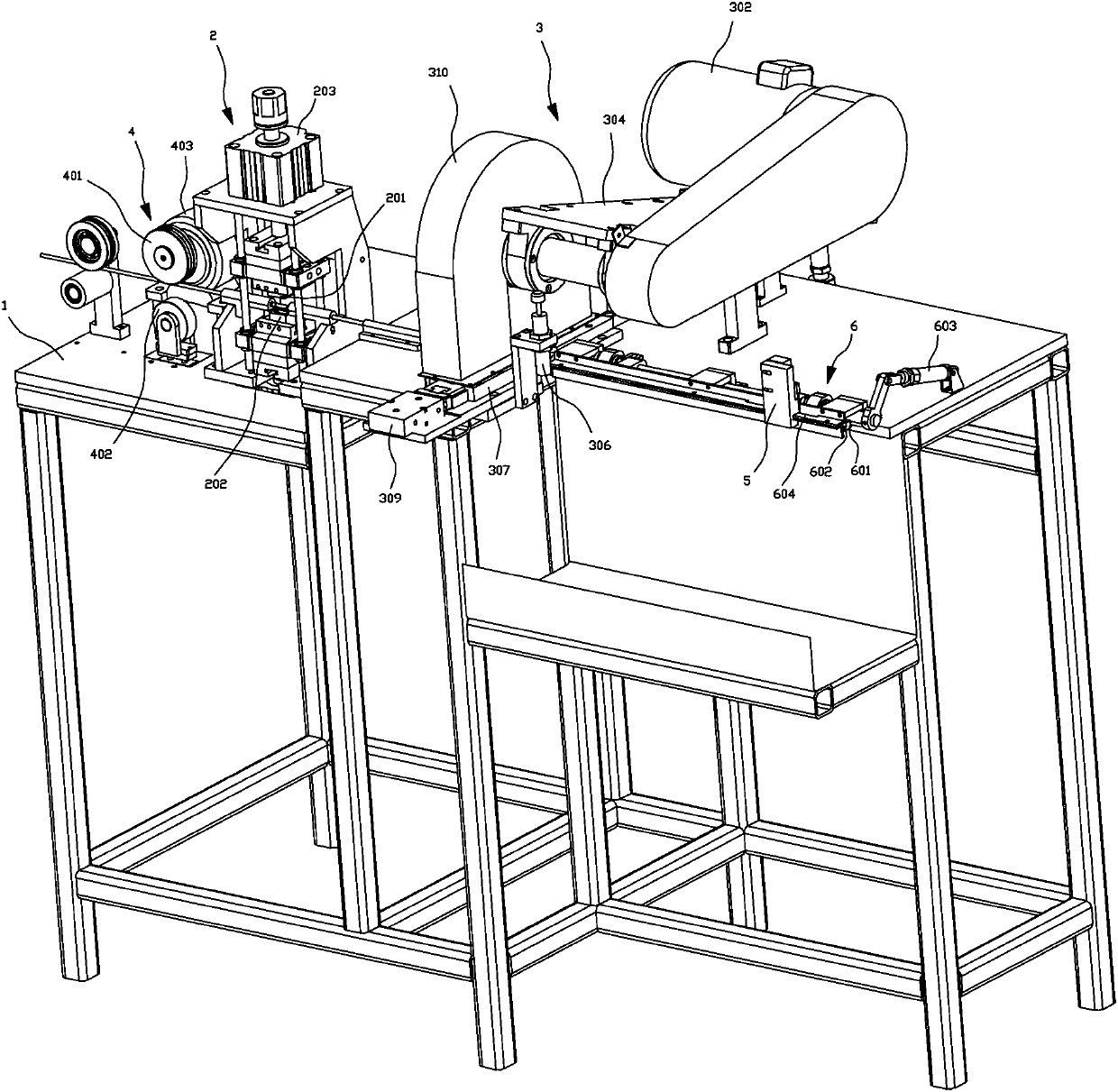

Hose embossing cutting-off machine

The invention discloses a hose embossing cutting-off machine. The hose embossing cutting-off machine comprises a worktable (1) which is horizontally and sequentially provided with a feeding device (4), an embossing device (2) and a cutting-off device (3), wherein electric control parts on the feeding device (4), the embossing device (2) and the cutting-off device (3) are all electrically connected with a same main controller; the embossing device (2) comprises an upper mould (201) and a lower mould (202), which are matched with each other and are used for embossing and molding a hose; the hose is located between the upper mould (201) and the lower mould (202); the two ends of the upper mould (201) and the lower mould (202), which extend along the direction of the hose, are respectively provided with embossing parts (205) which are matched with each other and are used for pressing two adjacent sections of threads; and the cutting-off device (3) comprises a cutting wheel capable of cutting off the hose from the two adjacent sections of threads. The hose embossing cutting-off machine disclosed by the invention is high in hose machining efficiency; and meanwhile, the labor cost is low.

Owner:NINGBO AUTO CABLE CONTROLS

Active ion welding gas

This invention relates to an active ionic welding and cutting gas including the following components: potassium permanganate 1-3, toluol 0.5-55, aether substances 4-40, acetone 20-60, burning gas 2000-3000 and also includes the following weight shares: baking soda 0.2, deionized water 0-150, xylene 0-30, toluol 0-30, p-toluene-phenol 0-50 and ring ethane 0-20.

Owner:杨向东

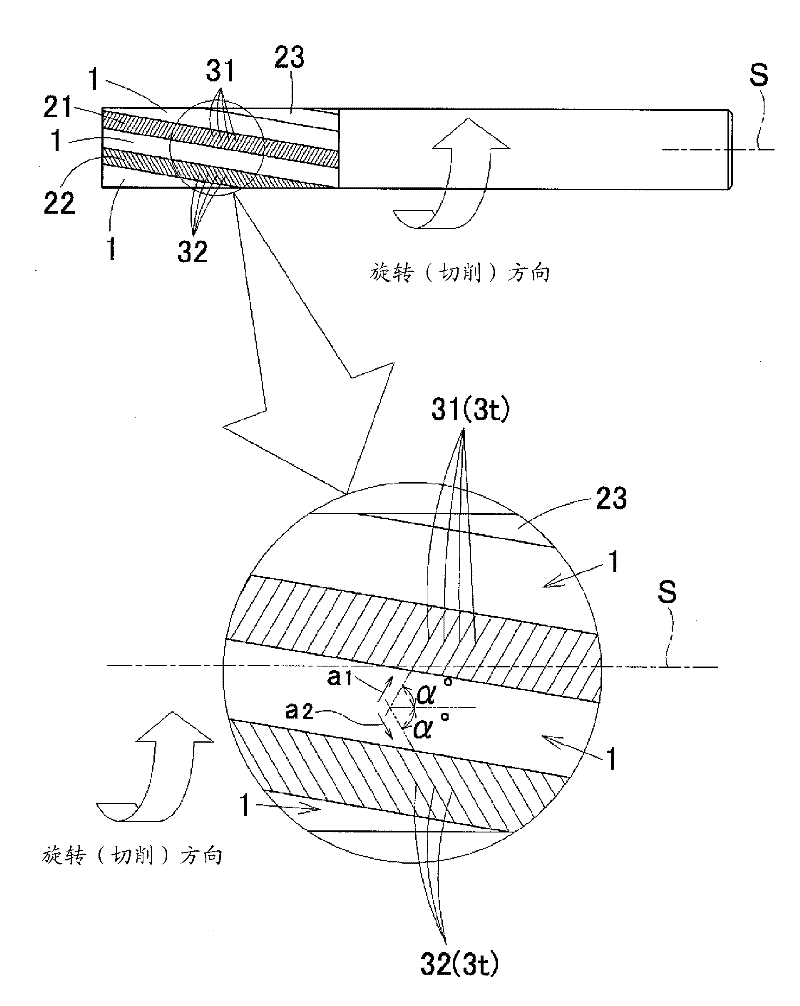

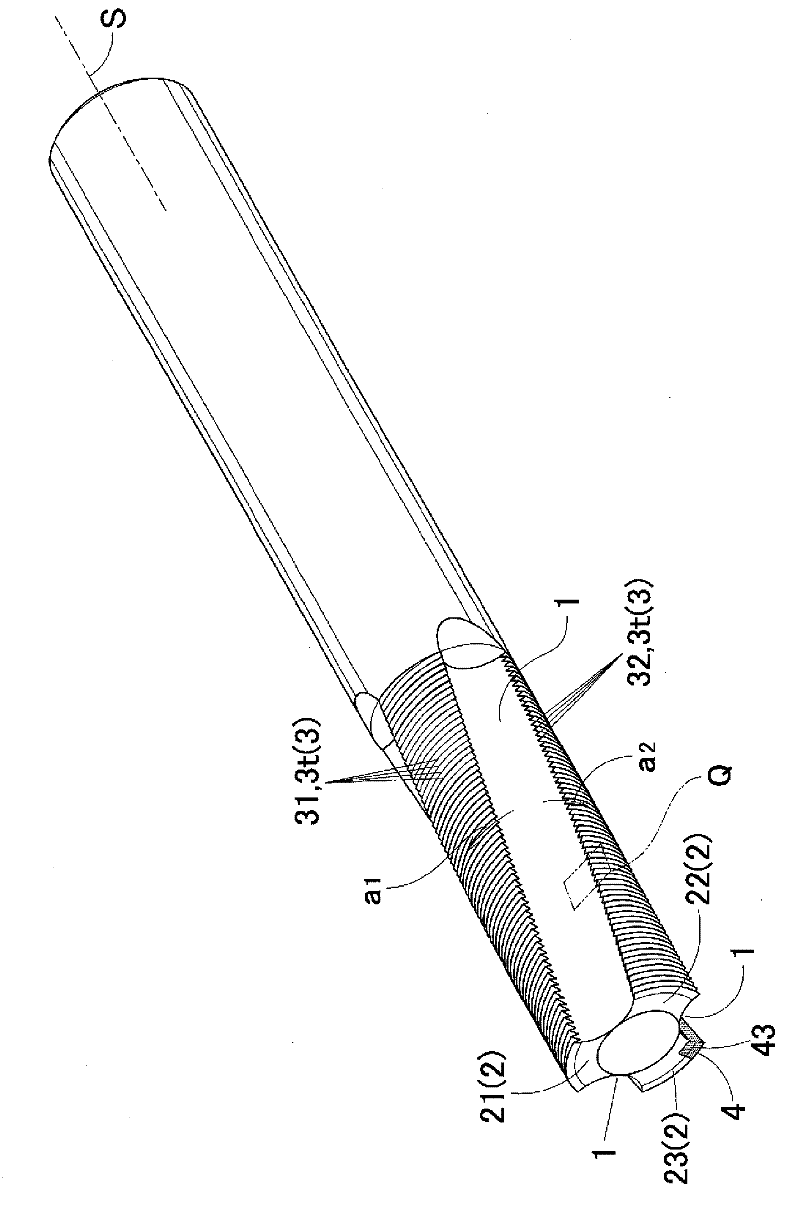

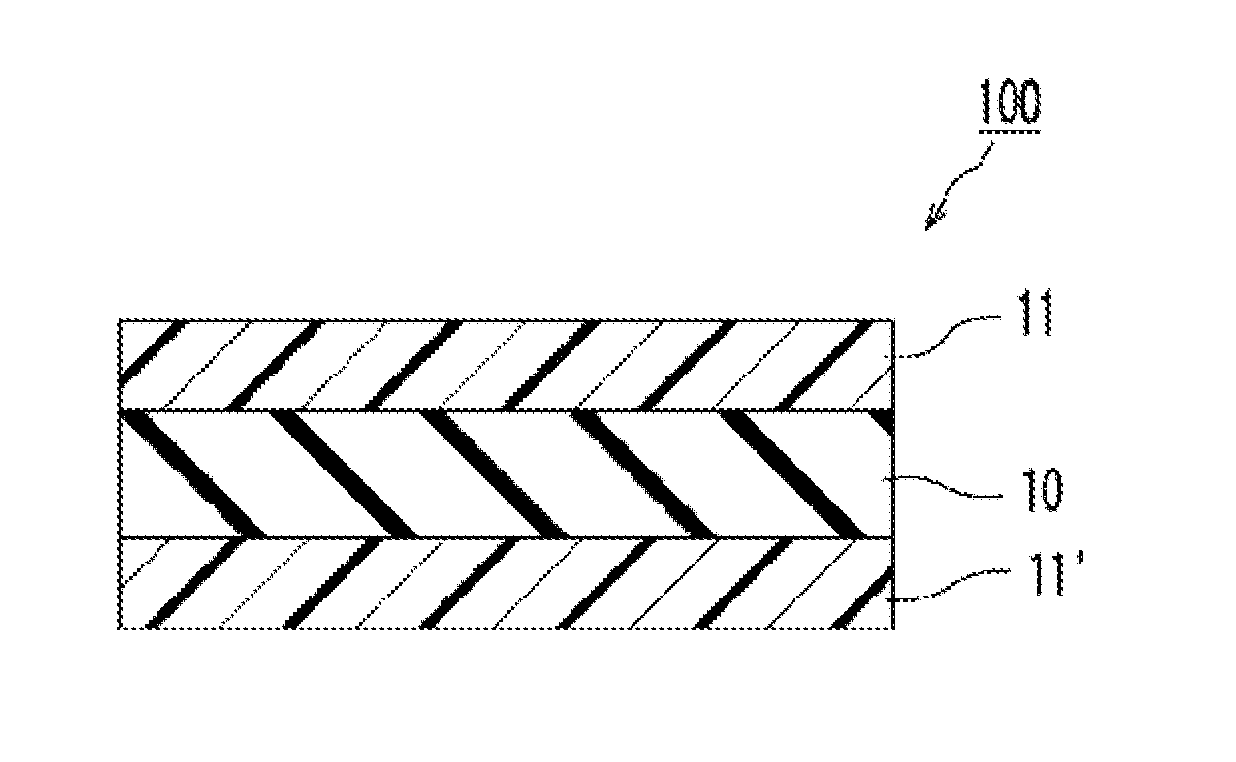

End mill

InactiveCN102227279AInhibition of bleachingEasy to cutMilling cuttersWorkpiecesMilling cutterEngineering

Disclosed is a router end mill which enables prevention of whitening of the cut surface, interlayer separation, and resin fusion during the milling, enables milling of FRP resin by fast rotation for a long time, and has an excellent durability. An odd number of lands (2) extending while meandering are formed by meandering grooves (1) between neighboring meandering grooves (1). First and second nicks (31, 32) forming apexes and arranged across the land width along a predetermined first direction (a1) are formed in each land of at least one pair of neighboring lands out of the odd number of lands (2). Finishing blades are formed on the other land (23) than the pair of lands out of the odd number of lands (2).

Owner:G N TOOL

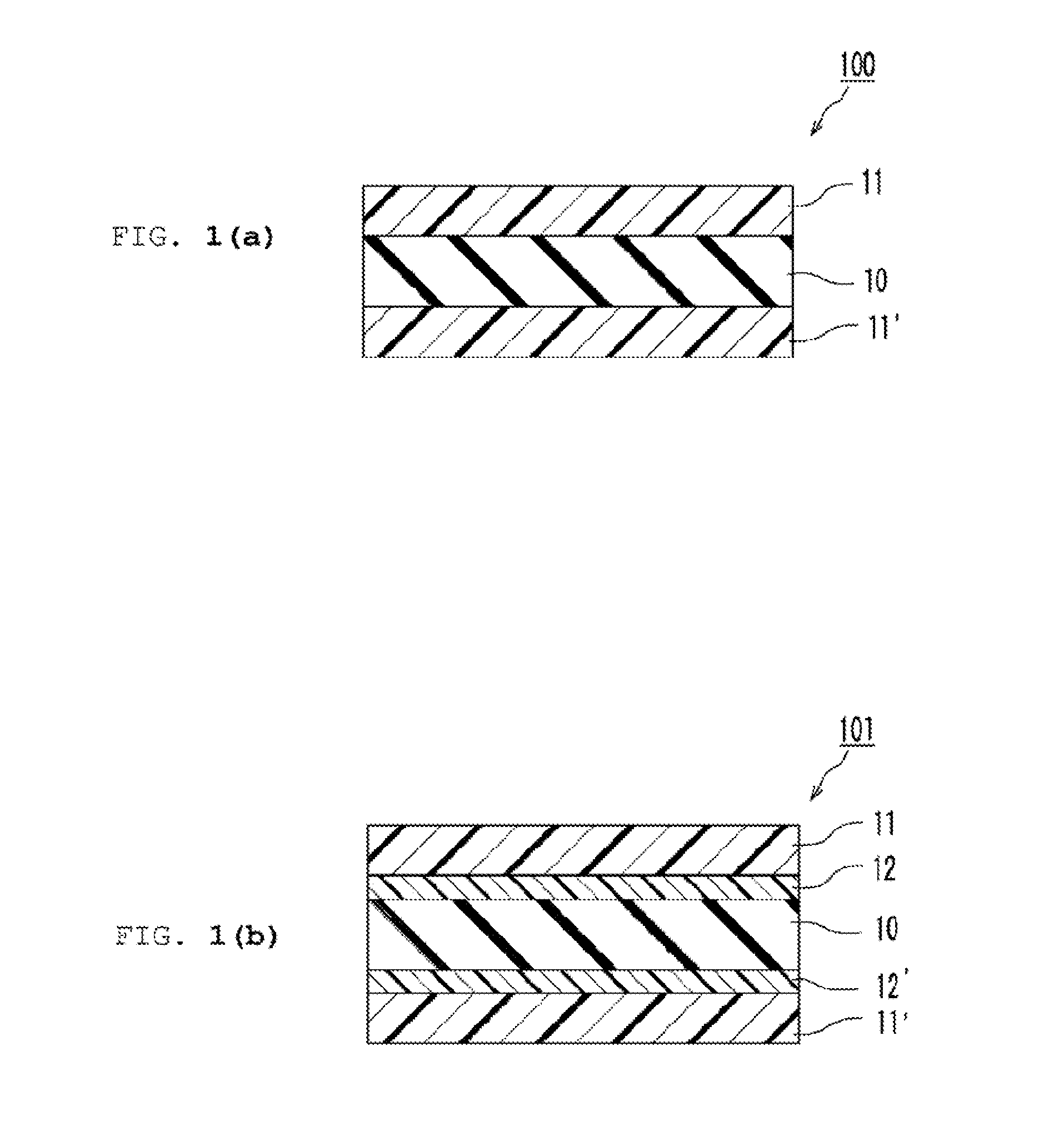

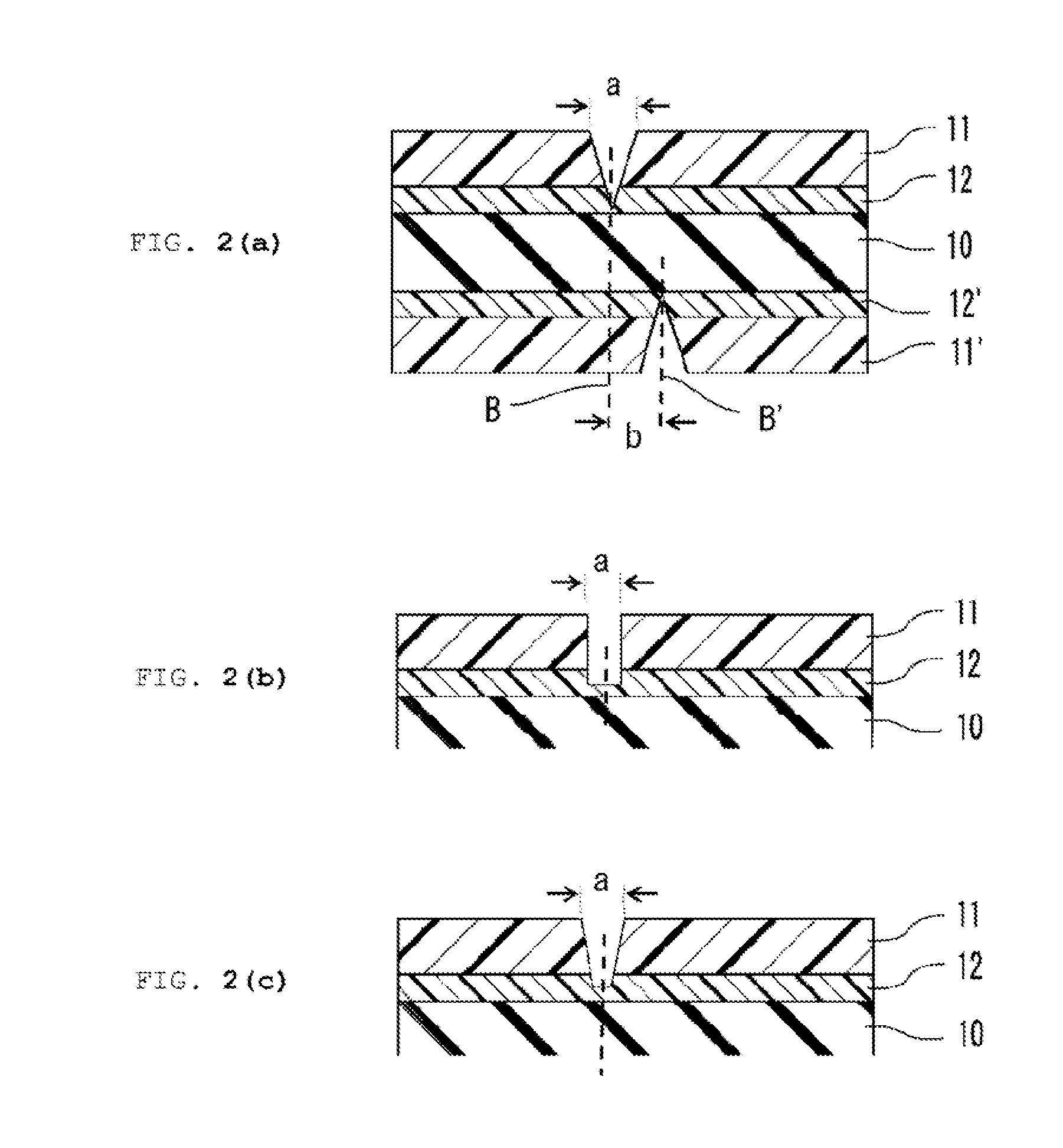

Method for producing flexible film

InactiveUS20150367621A1Smooth cutting surfaceCut surface smoothLamination ancillary operationsLayered product treatmentEngineeringPolyresin

There is provided a method of producing a flexible film (fragmented laminate) which has a smooth cut surface and is suppressed in breakage of a thin glass, the method including cutting a laminate having the thin glass and a resin layer. The method of producing a flexible film of the present invention includes cutting a laminate including a thin glass having a thickness of 100 μm or less and a resin layer arranged on one side, or each of both sides, of the thin glass. The method of producing a flexible film includes the steps of forming a groove from an outer surface side of the resin layer and cutting the laminate along the groove.

Owner:NITTO DENKO CORP

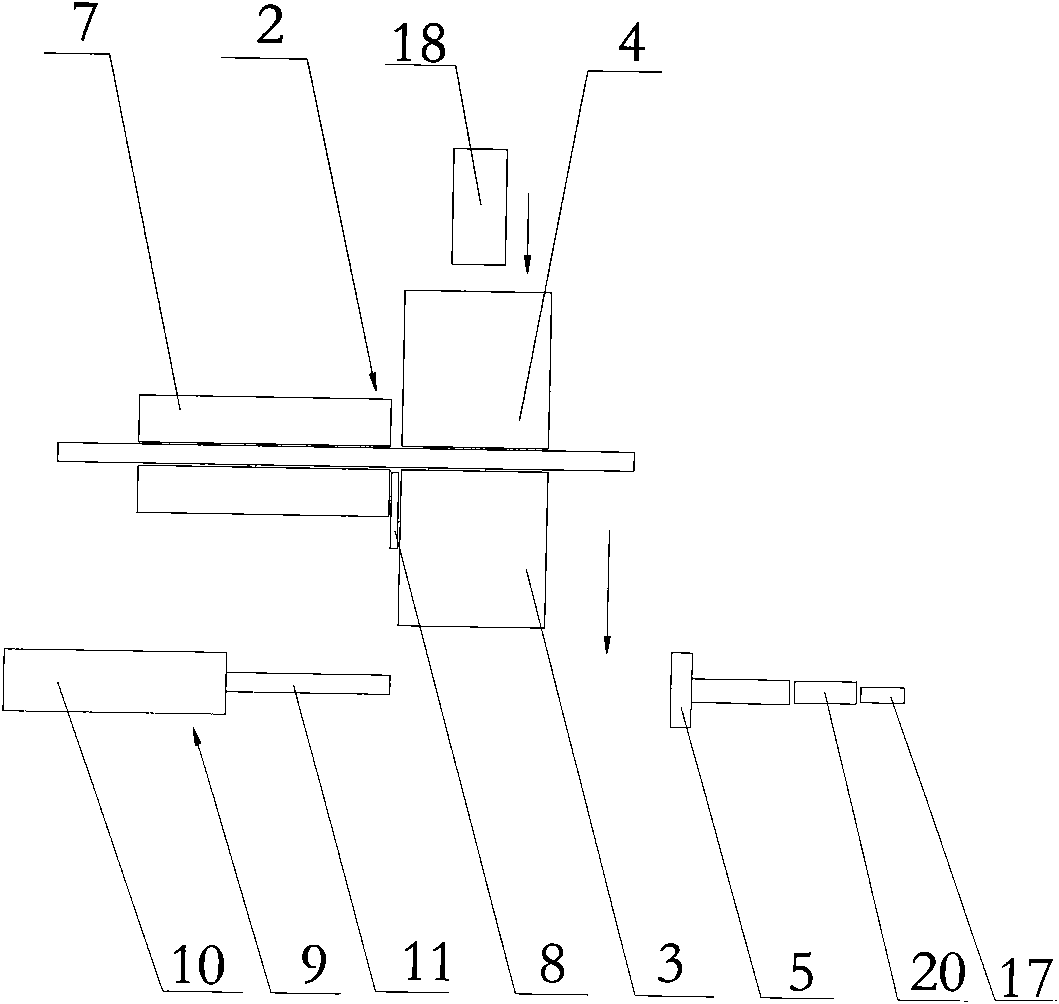

Plasma hole cutting equipment

ActiveCN105798443AFast cutting speedSmooth cutting surfaceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPlasma cutting

The invention discloses plasma hole cutting equipment capable of machining holes in such profiles as square pipes without using molds and punches. The plasma hole cutting equipment comprises a base; a bracket is arranged on one side of the base; an X support column is arranged on the bracket; an X axle is arranged in the X support column; an X slide block is arranged on the outer side of the X support column; the X axle is fixedly connected with the X slide block; a Y support column is fixed on the X slide block in the vertical direction; a Y axle is arranged in the Y support column; a Y slide block is arranged on the outer side of the Y support column; the Y axle is fixedly connected with the Y slide block; a fixed plate is arranged on the Y slide block; a Z support column is fixed on the X slide block; a Z axle is arranged in the Z support column; a Z slide block is arranged on the outer side of the Z support column; the Z axle is fixedly connected with the Z slide block; and a plasma cutting head is clamped on the Z slide block in the vertical direction. The plasma hole cutting equipment has the following advantages: the hole machining in the positions of two side surfaces and upper surfaces of workpieces is realized by combining a three-dimensional movement structure with the plasma cutting head; the cutting speed is fast; and the cutting surface is smooth.

Owner:张家港奥得森机电设备有限公司

Forming machine for conducting wire of glass-sealed diode

ActiveCN101656390AHigh dimensional accuracyFlat surfaceLine/current collector detailsSolid-state devicesState of artMolding machine

The invention relates to a forming machine for a conducting wire of a glass-sealed diode. The forming machine comprises a station, a thread cutting mechanism, a front mold, a rear mold and a ram whichare arranged on the station, a pushing mechanism for driving the components, and a thread ejection mechanism, wherein the front mold and the rear mold can be closed to form a mold cavity; the threadcutting mechanism comprises a threading block provided with a threading hole; an outlet end of the threading block is adjacent to an inlet end of a mold cavity; a cutting knife is arranged at the adjacent position; and the thread ejection mechanism is arranged on the front side of the threading block, and comprises a thimble fixture and a thimble fixed on the thimble fixture. Compared with the prior art, a product produced by the forming machine has higher dimensional precision and smooth surface, completely improves the defects such as clamp marks, scratches, burrs and the like, has a fully smooth incision surface, and not only has qualitative change of the product quality, but also greatly improves the production efficiency from the original 120 counts / min to the current 180 counts / min.

Owner:光路新能源材料(上海)有限公司

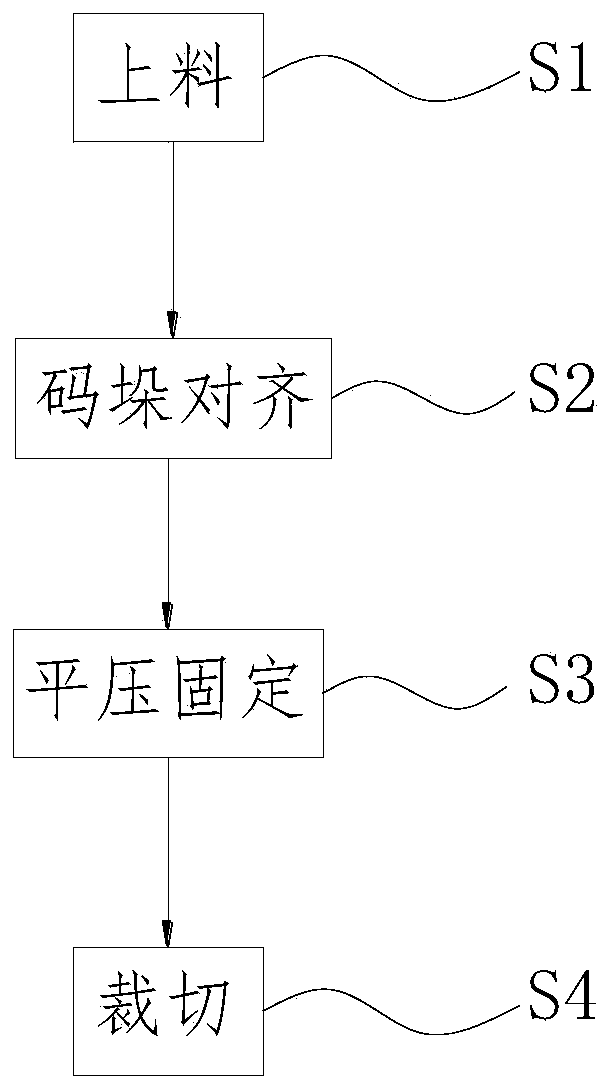

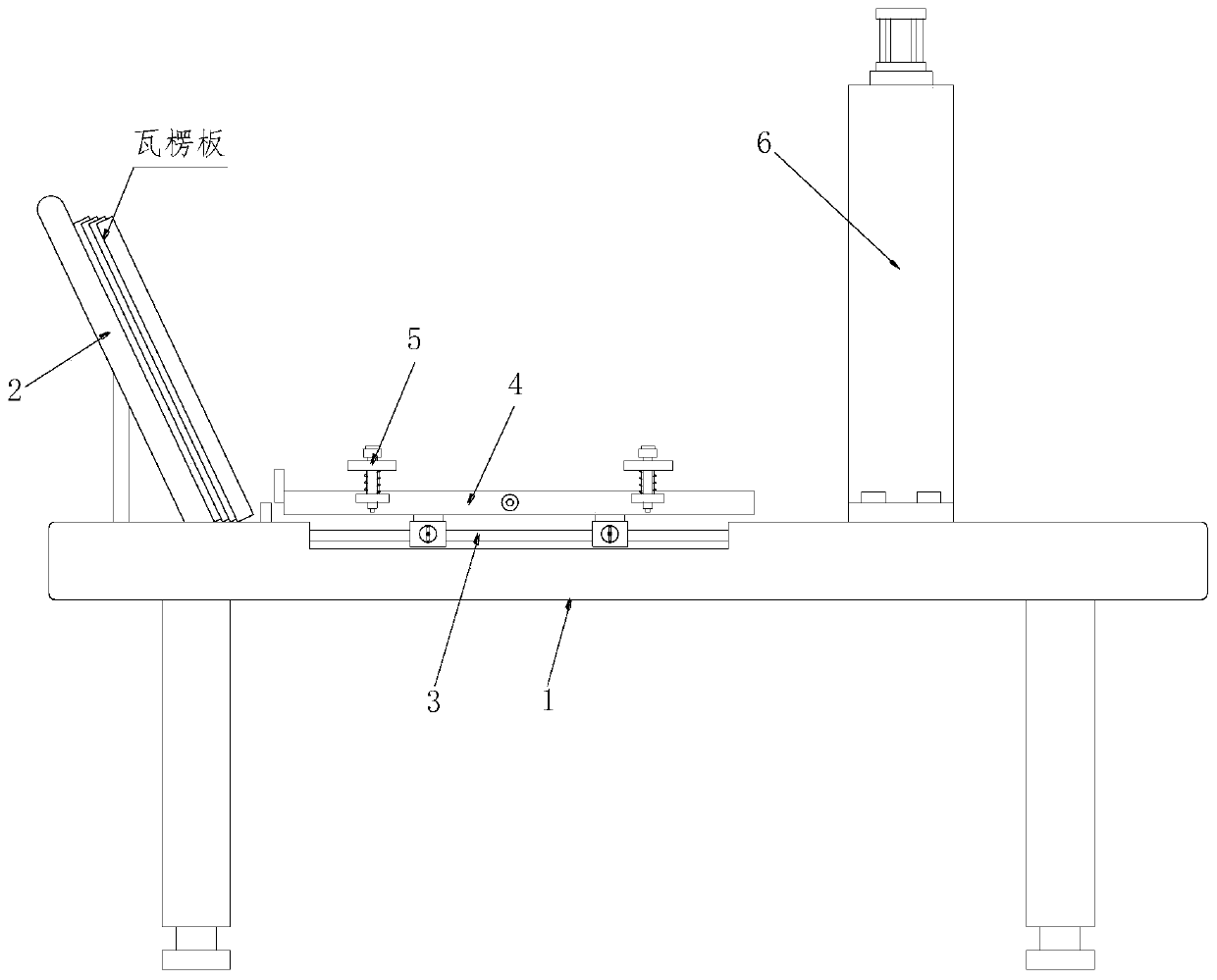

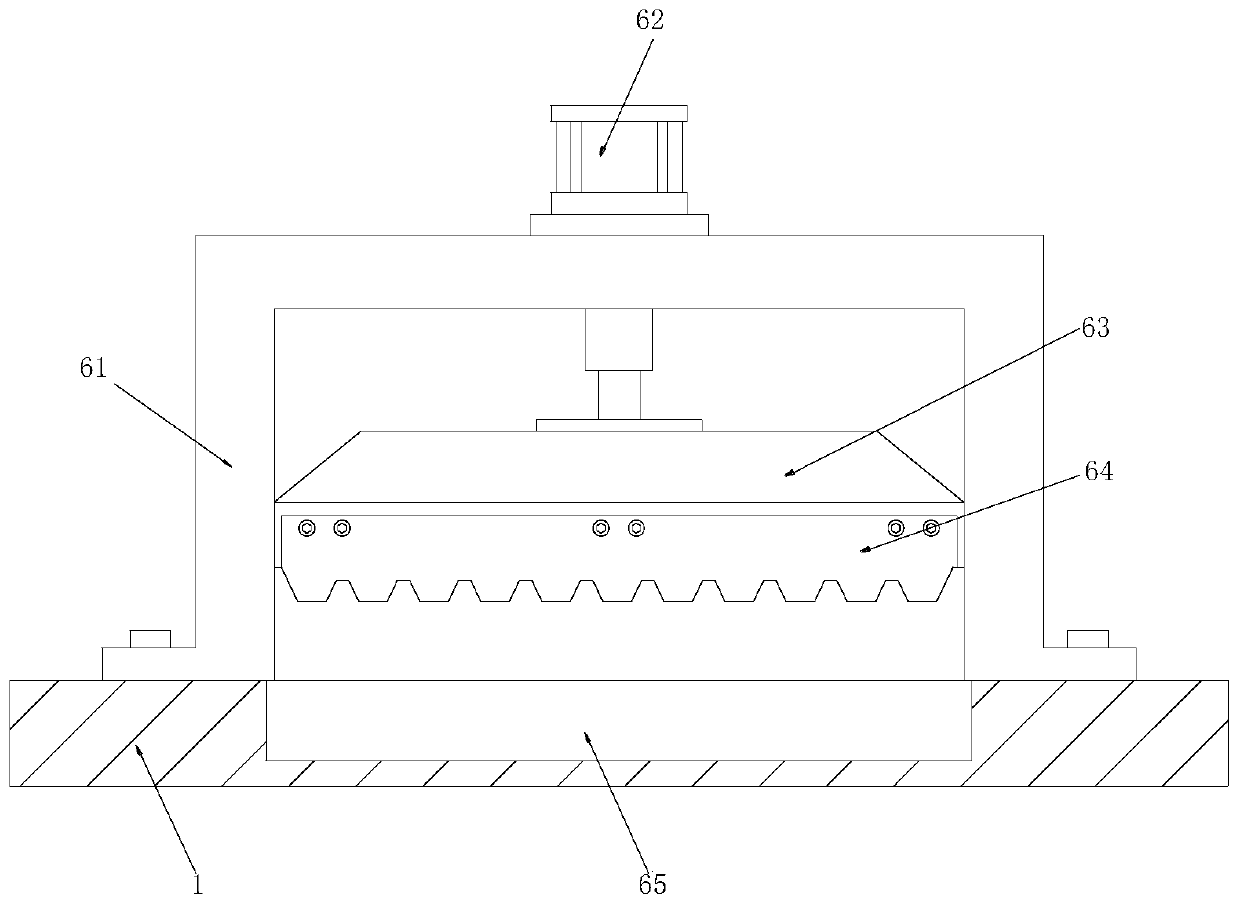

Processing and cutting process for corrugated board

InactiveCN111299680ASmooth cut surfaceGuaranteed service lifeShearing machinesMaintainance and safety accessoriesKnife bladesHydraulic pressure

The invention relates to a processing and cutting process for a corrugated board. The process comprises a support table, an inclined discharging plate, a sliding rail, a placing plate, a fixing mechanism and a cutting mechanism, wherein a fixing frame is fixed at the top of the support table by bolts, the top of the fixing frame is provided with a hydraulic pushing rod, the bottom of the hydraulicpushing rod is connected with a blade fixing frame, a cutting blade is installed at the bottom of the blade fixing frame, a lubricating assembly is arranged below the cutting blade, and the lubricating assembly is embedded into the top of the support table, a sealing shell is embedded into the top of the support table, the top of the sealing shell is provided with a cutting edge, a support frameis installed in the sealing shell, a sliding groove is formed in the support frame, a rectangular sliding block is matched and installed in the sliding groove, a wiping roller is installed in the rectangular sliding block by a bearing, and the outer wall of the wiping roller is wrapped with an oil-absorbing sponge; according to the invention, during the process of cutting the corrugated board, thesmooth cutting surface of the corrugated board is effectively ensured, the cutting amount is higher, and the cutting blade is not easy to rust.

Owner:广州市同泰纸品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com