Method for producing flexible film

A manufacturing method and flexible thin film technology, applied in the direction of manufacturing tools, glass manufacturing equipment, chemical instruments and methods, etc., can solve the problems of inability to cut glass properly, decrease the smoothness of the cut-off surface, and poor smoothness of the cut-off surface, and achieve the purpose of suppressing The effect of thin glass breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

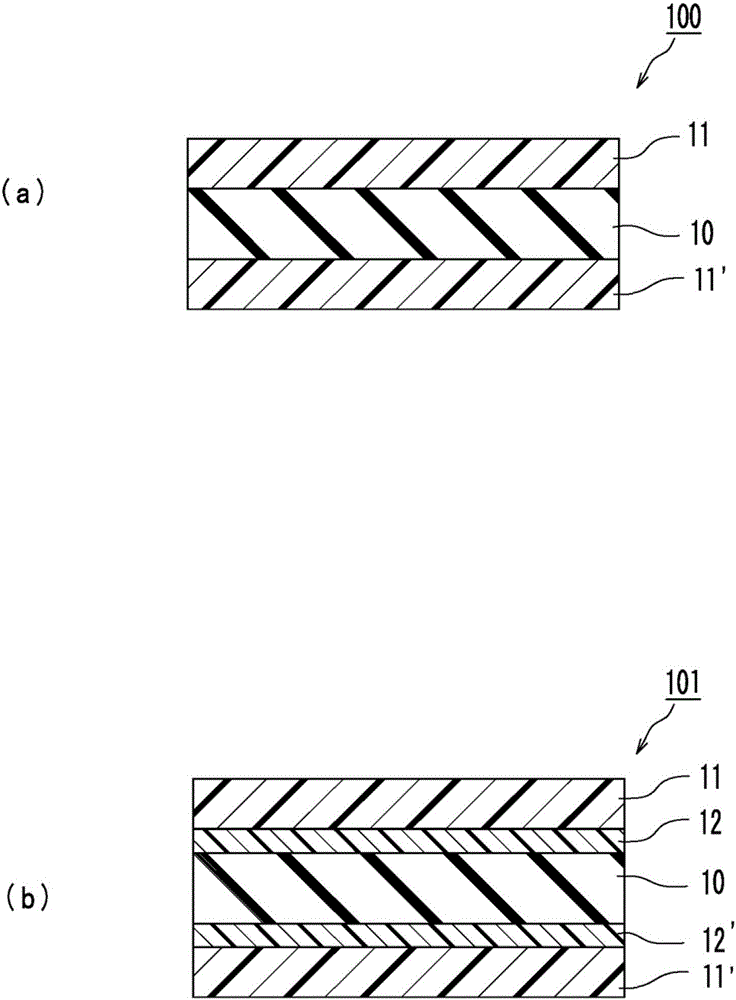

[0069] On PET film (manufactured by Toray Corporation, trade name "Lumil T60", thickness: 25 μm), an adhesive (epoxy resin-based adhesive manufactured by Teijin Chemical Industry Co., Ltd., 100 parts by weight of trade name A mixture of "CELLOXIDE2021P", 10 parts by weight of the product name "OXT221" manufactured by Toagosei Co., Ltd., 3 parts by weight of the product name "SP-170" manufactured by Adico Corporation, and 100 parts by weight of methyl ethyl ketone) This was dried to form an adhesive layer (thickness: 5 μm). A PET (resin layer) / adhesive layer film is attached to a thin glass (thickness: 30 μm) that has undergone coupling treatment on both sides with a coupling agent (manufactured by Shin-Etsu Chemical Co., Ltd., product name "KBM-403"). On both sides, using UV light (1000mJ / cm 2 above) to cure the bonding layer.

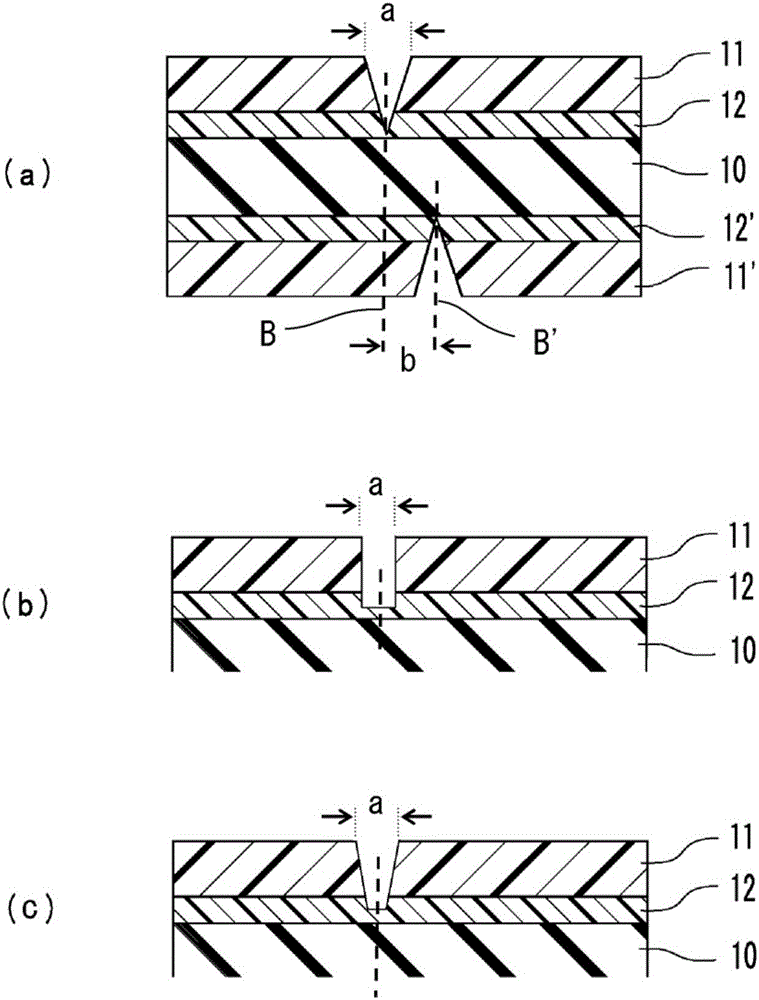

[0070]Grooves were formed in the resin layers on both surfaces of the thus obtained laminate using NT cutter (registered trademark). The width of t...

Embodiment 2

[0073] A flexible film was obtained in the same manner as in Example 1 except that thin glass with a thickness of 50 μm was used instead of the thin glass with a thickness of 30 μm. The cut surface of the flexible film was smooth, and no cracks were generated on the thin glass.

Embodiment 3

[0075] A flexible film was obtained in the same manner as in Example 1 except that thin glass with a thickness of 100 μm was used instead of the thin glass with a thickness of 30 μm. The cut surface of the flexible film was smooth, and no cracks were generated on the thin glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com