Patents

Literature

38results about How to "Avoid random flying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

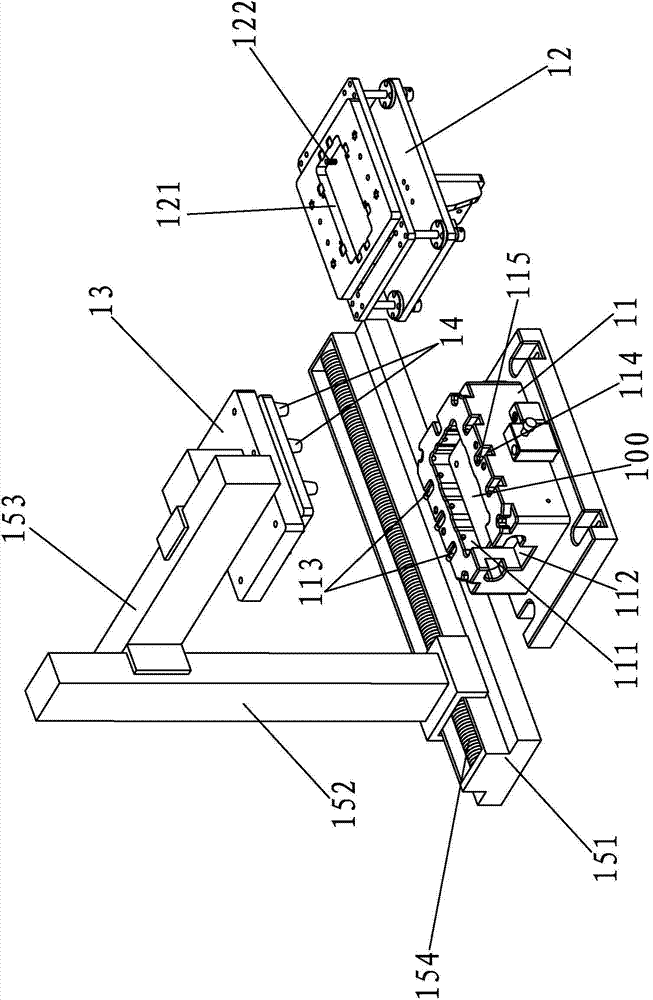

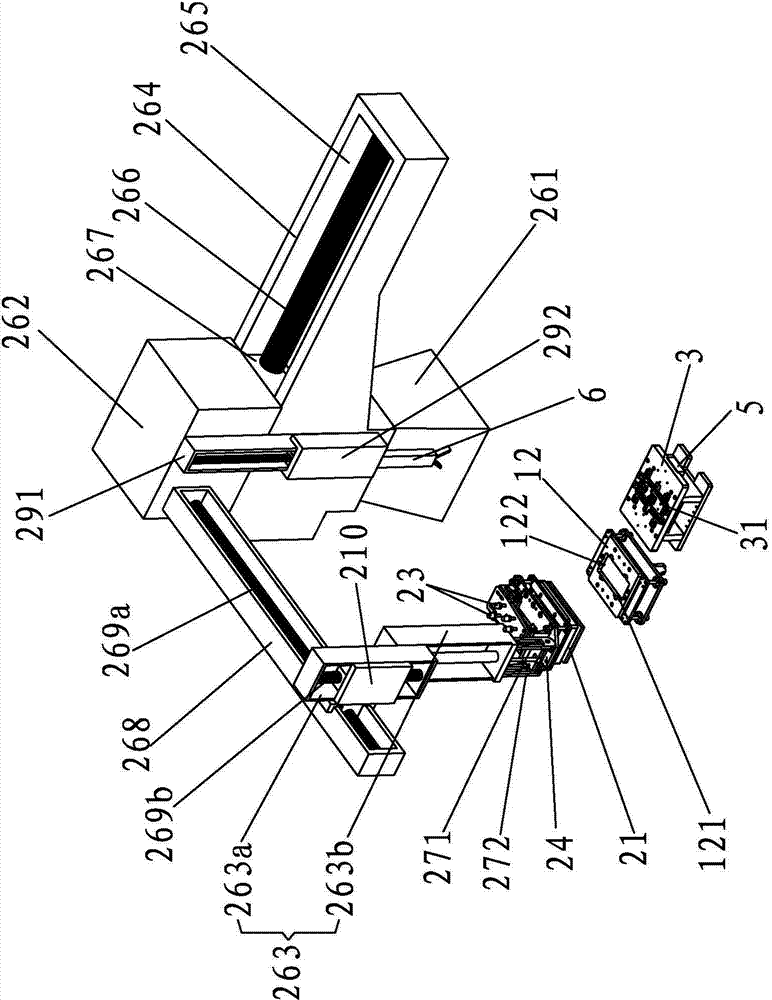

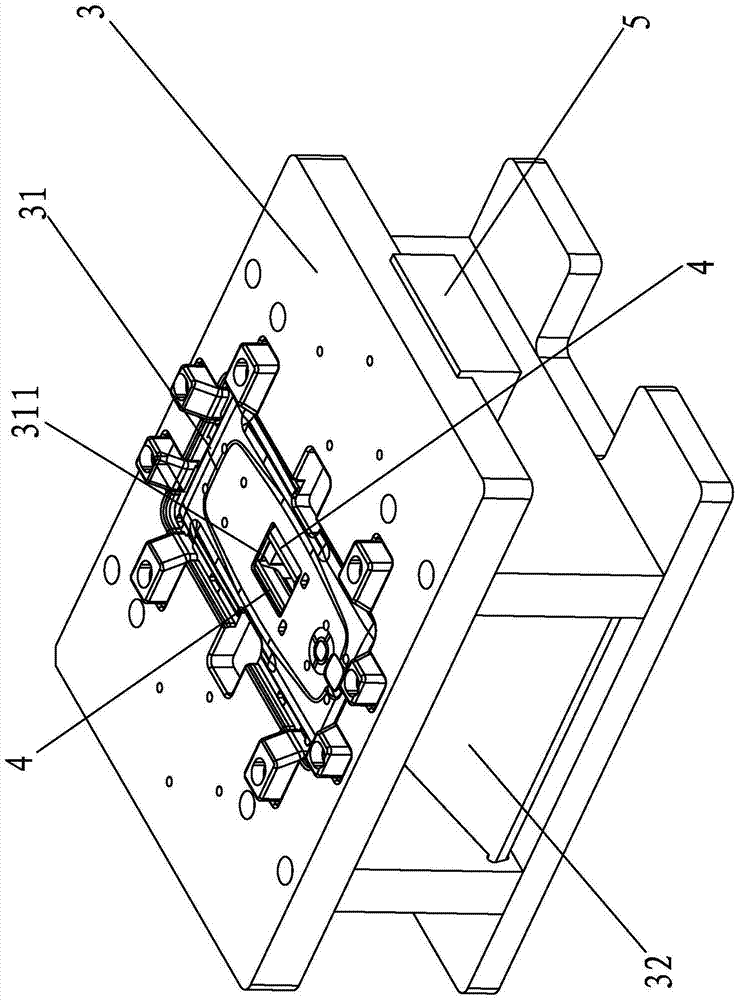

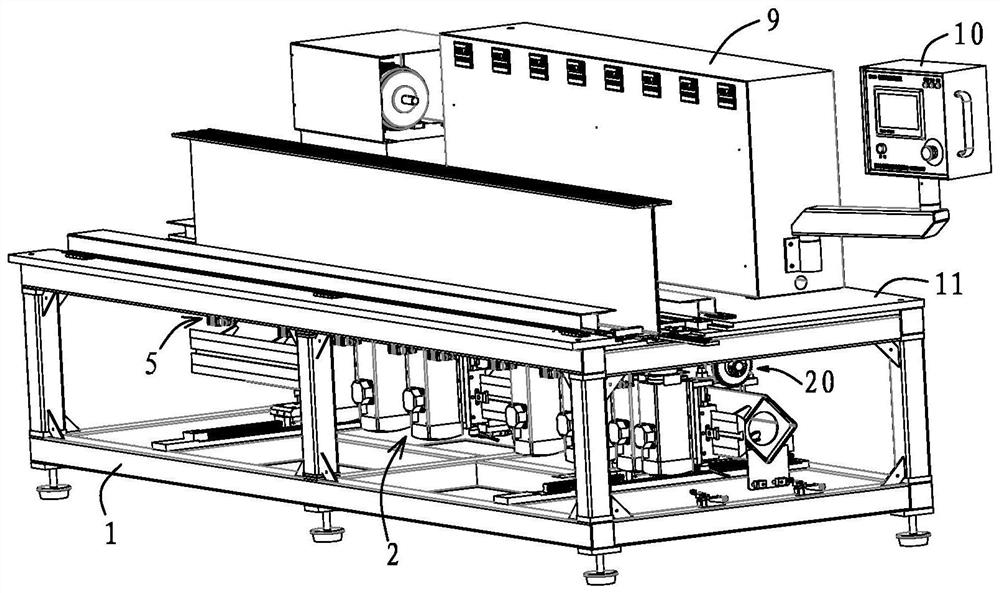

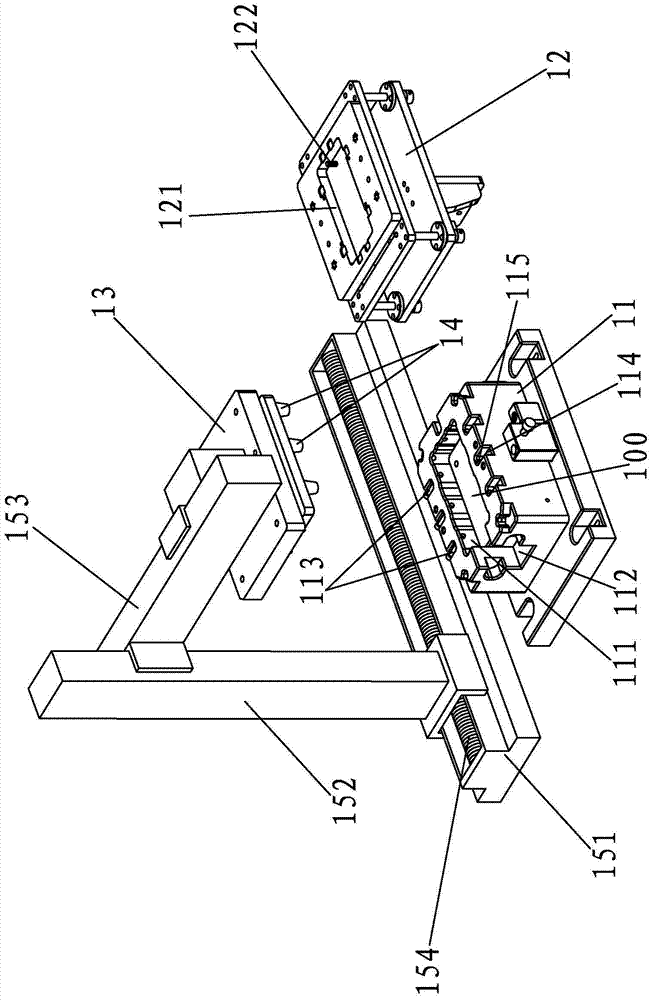

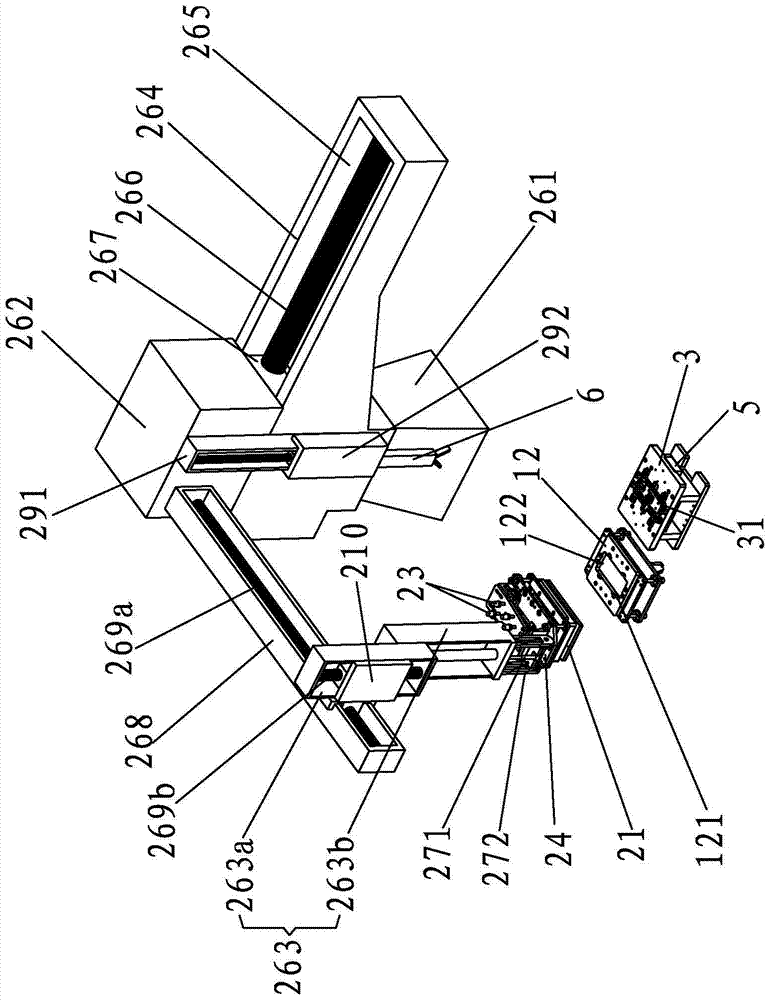

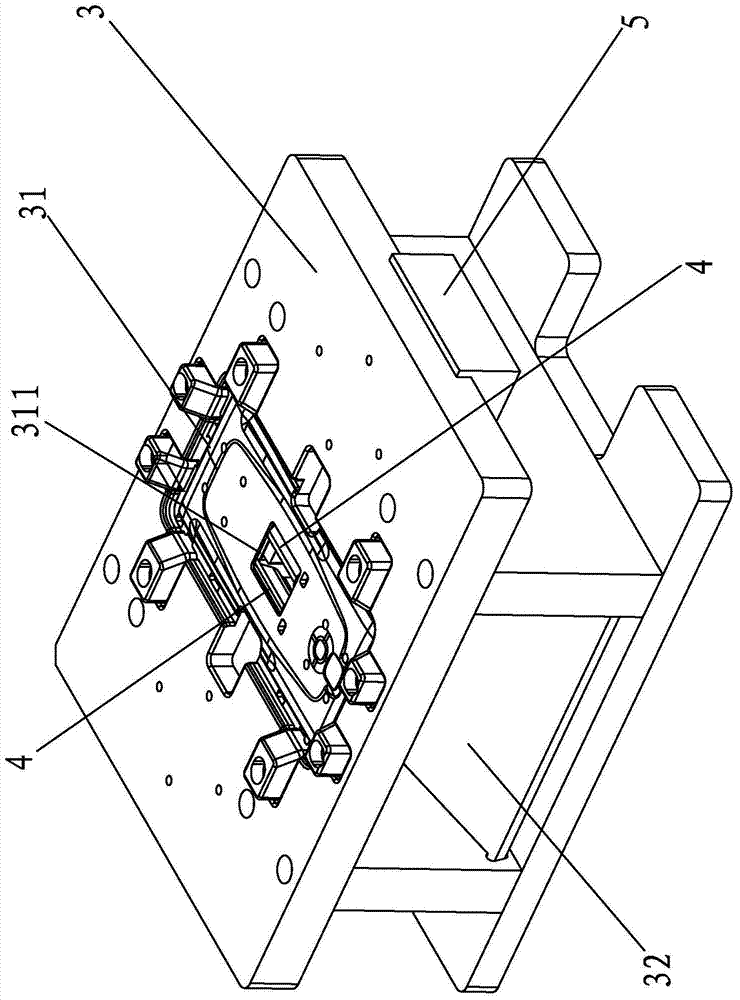

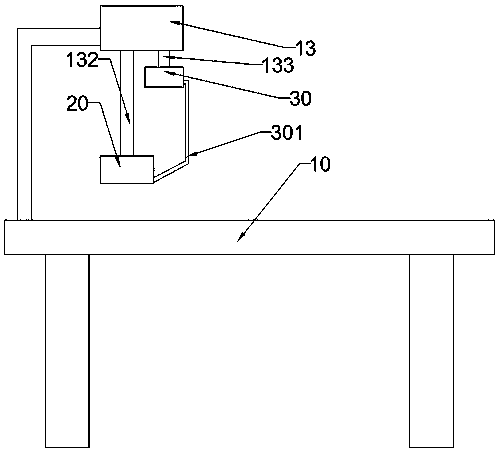

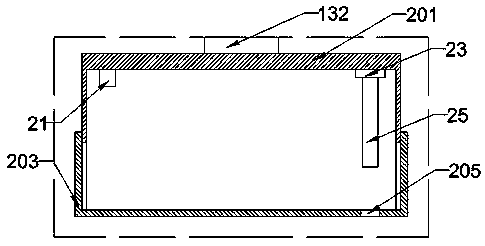

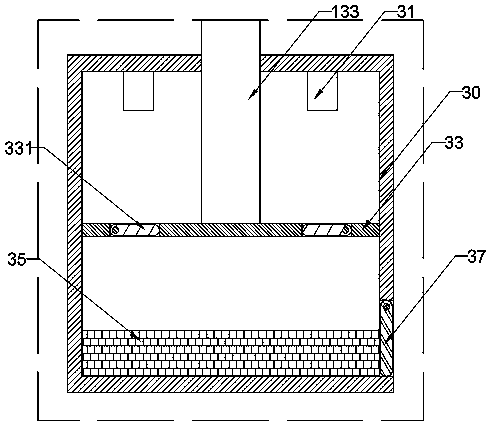

Automatic system for IML injection molding

The invention discloses an automatic system for IML injection molding. The automatic system comprises a sheet storage mechanism, a sheet transfer mechanism and an orifice cutting seat, wherein the sheet storage mechanism comprises a sheet storage and taking seat for storage of a stack of film sheets, a sheet storage and placement seat for placement of the single film sheet and a sheet suction seat for sucking away the film sheets in the sheet storage and taking seat and placing the film sheets in the sheet storage and placement seat; the sheet transfer mechanism comprises a sheet transfer seat for sucking the film sheets in the sheet storage and taking seat, placing the film sheets in an injection mold, and sucking IML decorating parts in the injection mold out of the injection mold; the orifice cutting seat comprises a positioning placement groove for placement of the IML decorating parts, blades used for cutting off orifices of the IML decorating parts, and a waste conveying channel. Compared with the prior art, the automatic system has the advantages as follows: full-automatic consecutive operation is adopted, and unmanned production is achieved, so that the whole working efficiency is improved greatly, the advantages of precision in taking out and high safety system are achieved, that the cutting surfaces of the IML decorating parts are relatively smooth is ensured, and appearance quality is not influenced.

Owner:通达(石狮)科技有限公司

Wood chip collecting device for wood cutting

InactiveCN108656257AEasy to collectSolve the problem of inconvenient collection of sawdustBark-zones/chip/dust/waste removalPulp and paper industryKnife blades

The invention discloses a wood chip collecting device for wood cutting. The wood chip collecting device for wood cutting comprises a base plate. A connection plate is fixedly connected with the left side of the top of the base plate. The top of the right side of the connection plate is fixedly connected with a supporting plate. A blade shell is fixedly connected with the right side of the bottom of the supporting plate. The bottom of the inner wall of the blade shell is movably connected with a cutting blade. The bottom of the cutting blade penetrates through the blade shell and extends to theoutside of the blade shell. Through mutual cooperation of a rotation motor, a rotation rotating shaft, a rotating disk, a first connection shaft, a connection rod, a second connection shaft, a supporting block, a moving plate, telescopic rods, a limiting plate, a sliding groove, a second fixing block, a second rotating shaft, an adjusting rod, a third rotating shaft, a third fixing block, a firstfixing block, a first rotating shaft, an adjusting plate and a wood chip box, the effect that wood chips are conveniently collected is achieved, the problem that by the adoption of a wood cutting device, the wood chips are inconvenient to collect is solved, the work efficiency is improved, the influence on the environment is reduced, the service life of equipment is prolonged, and great convenience is brought to a user.

Owner:安徽云帆科技咨询有限公司

Sand blasting equipment for motorcycle accessories

InactiveCN107498475AImprove practicalityImprove recycling effectAbrasive machine appurtenancesAbrasive blasting machinesUser needsSand blasting

The invention discloses a sandblasting equipment for motorcycle parts, which comprises a workbench. The top of the workbench is symmetrically fixedly connected with uprights, the top of the uprights is fixedly connected with a support plate, and the left side of the top of the workbench is fixedly connected with a sand storage box. , the left side of the bottom of the support plate is fixedly connected with an air compressor. The present invention solves the problem of existing spraying problems through the cooperative use of a recovery device, a box body, a fan, a recovery box, a first fixed frame, a movable plate, a fixed block, a motor, a turntable, a movable rod, a second fixed frame, a spring and a fixed plate When the sand device performs sandblasting on motorcycle accessories, the sand body may stay on the recovery device, which is not conducive to the recovery of the sand body, resulting in the problem that the user needs to spend a long time cleaning the recovery device. The motorcycle The sandblasting device for accessories processing has the advantages of good sand recovery effect, which is convenient for users and improves the practicability of the sandblasting device.

Owner:长兴运达汽车配件有限公司

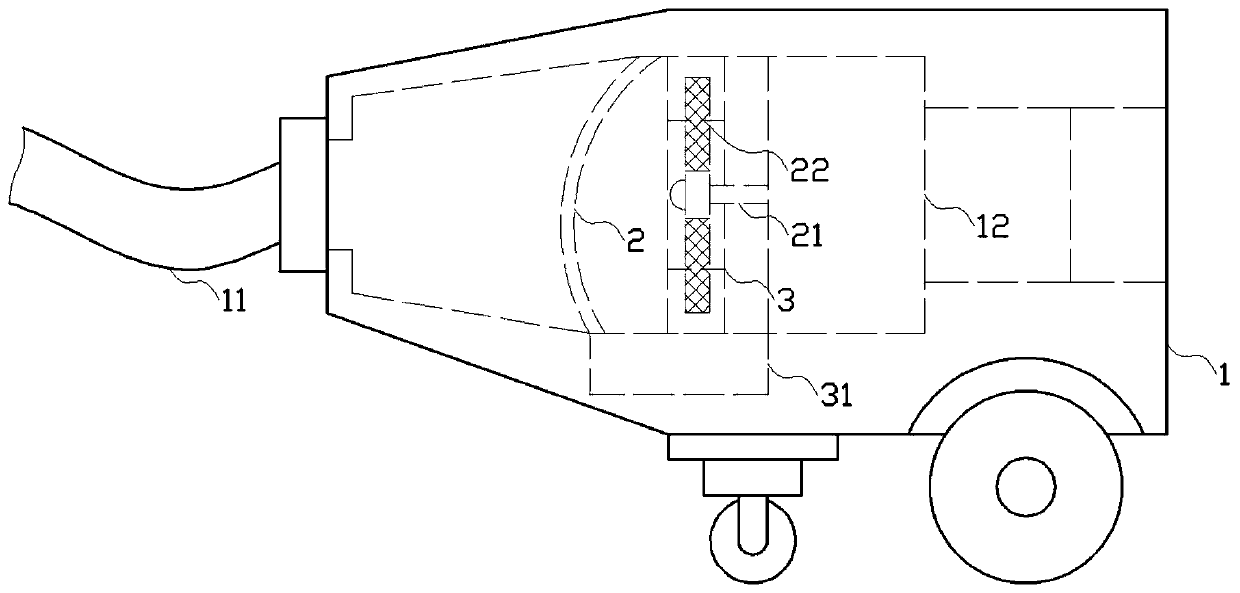

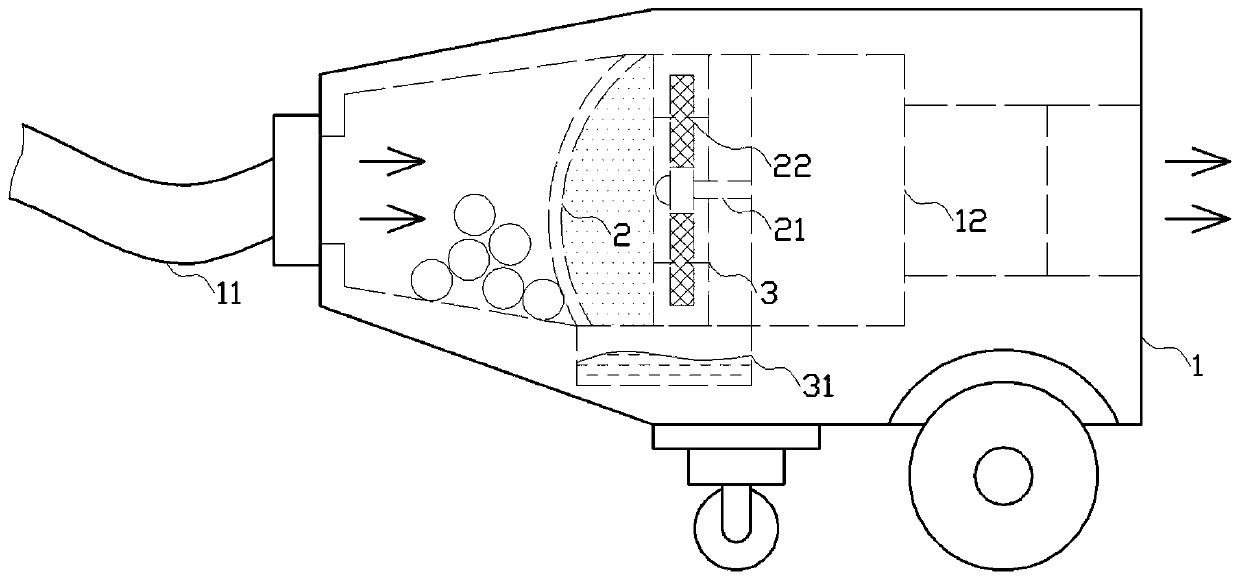

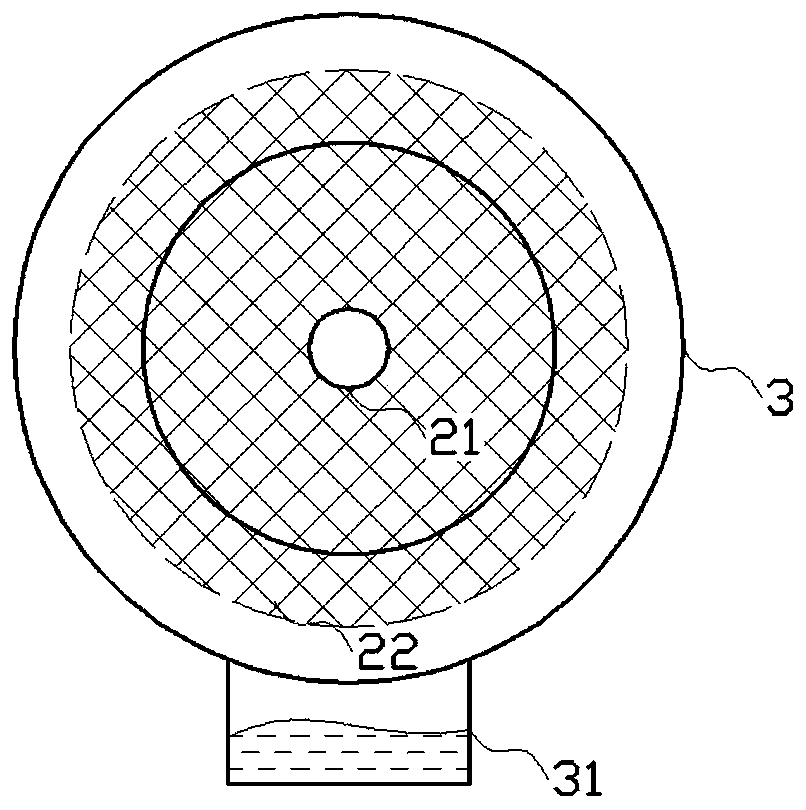

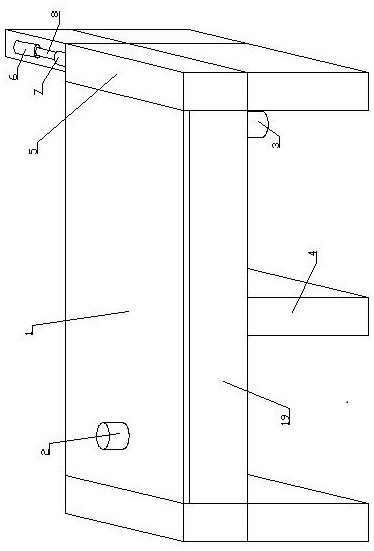

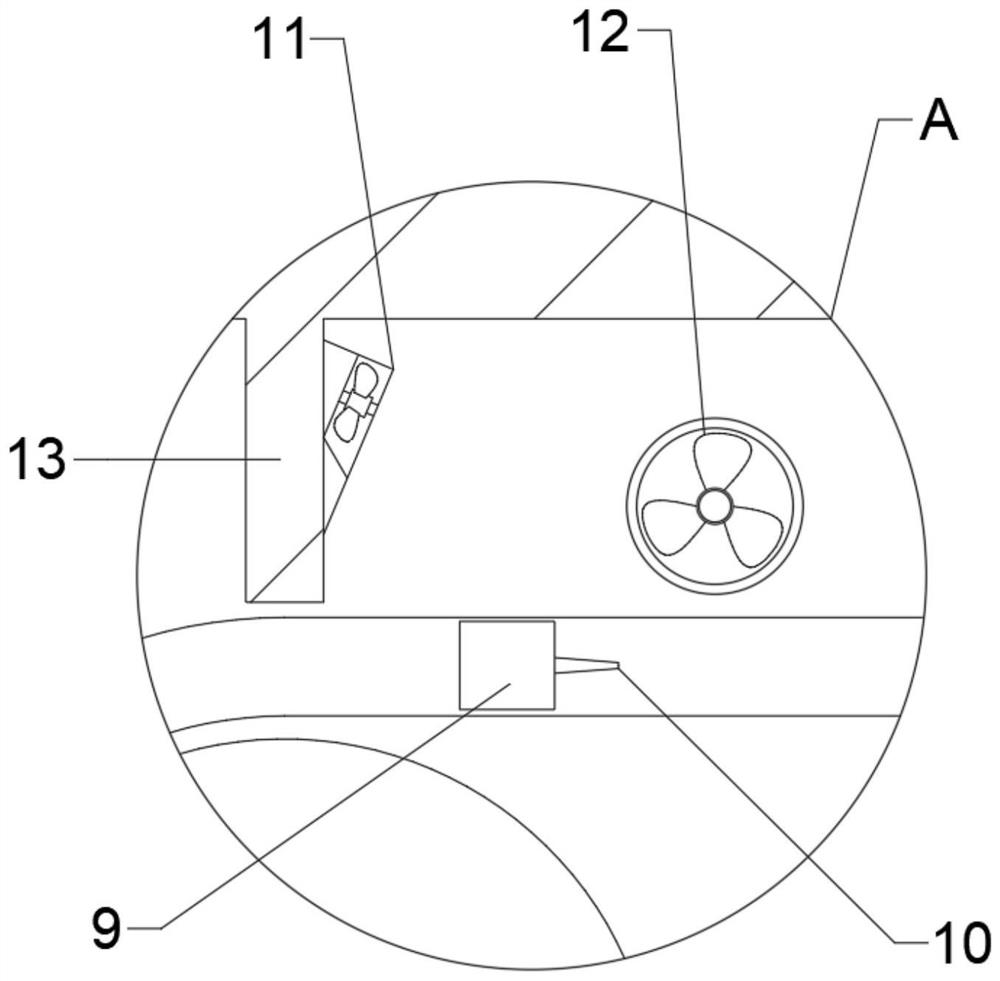

Centrifugal water removal automatic cleaning and dust removal device

ActiveCN110664314AAchieve preliminary separationTo achieve the function of automatic drainageCombination devicesSuction filtersWater storageDust control

The invention provides a centrifugal water removal automatic cleaning and dust removal device comprising a dust collector body, a filtering module and a separation module; the dust collector body comprises the filtering module, and the filtering module comprises a filtering net; the filtering module comprises a rotating shaft; a water absorbing layer is arranged on the rotating shaft; the separation module is arranged in a separation cavity, and the separation module comprises a drainage ring; the separation module comprises a water storage cavity; and a drainage hole is formed in a drainage groove. The centrifugal water removal automatic cleaning and dust removal device is such a device that dust and accumulated water are sucked into the dust collector through a fan, and the dust and theaccumulated water are separated from sundries through a filtering layer, so that the dust and the accumulated water are subjected to secondary filter; then, the accumulated water is absorbed through the water absorbing layer and discharged to a water storage box under the centrifugal action, such that the dust is separated from the accumulated water; and after the device is closed, the dust fallsinto the water storage box under the action of gravity and is fused with the accumulated water, thereby facilitating cleaning.

Owner:山东华歌建筑设计有限公司

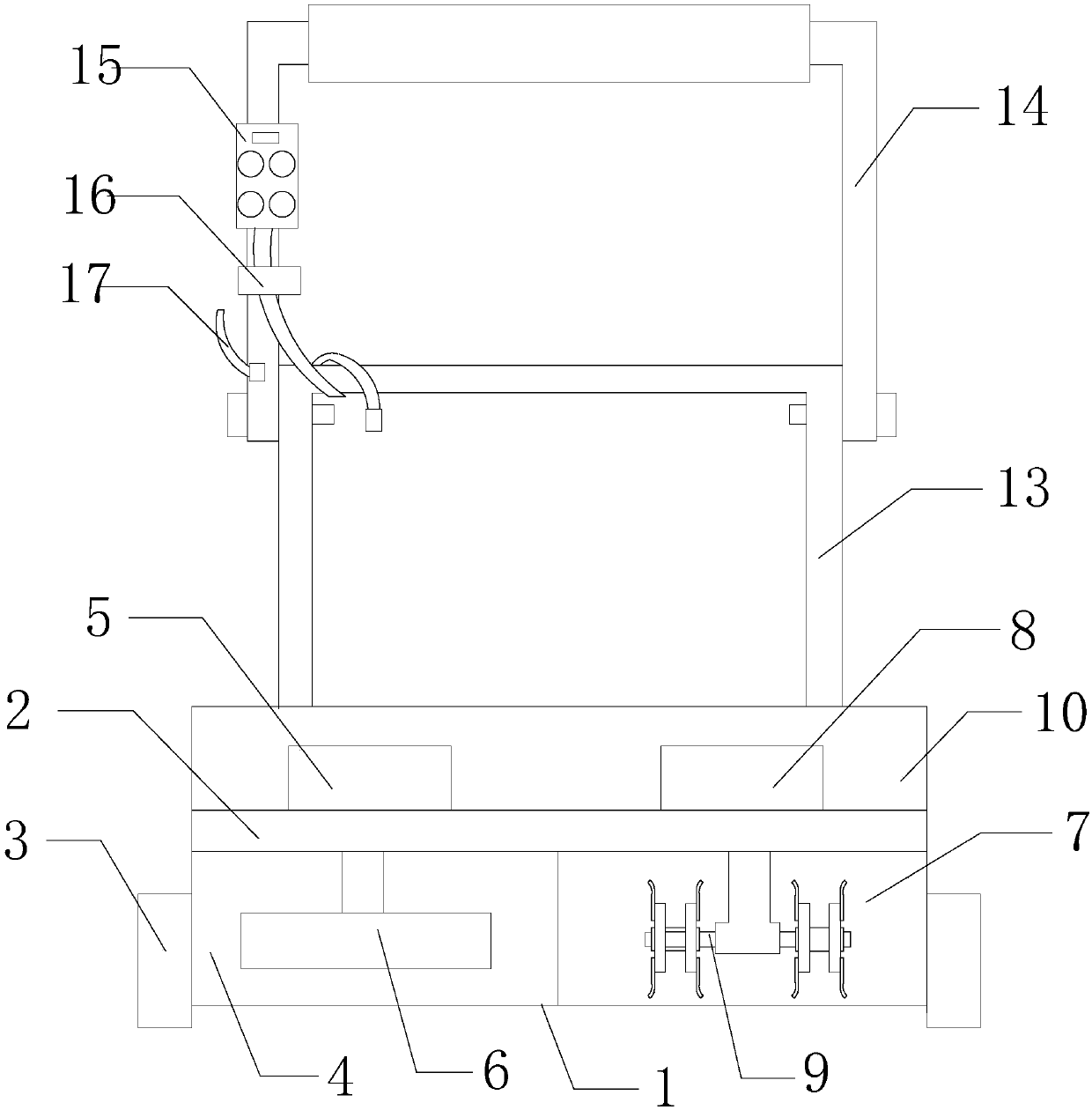

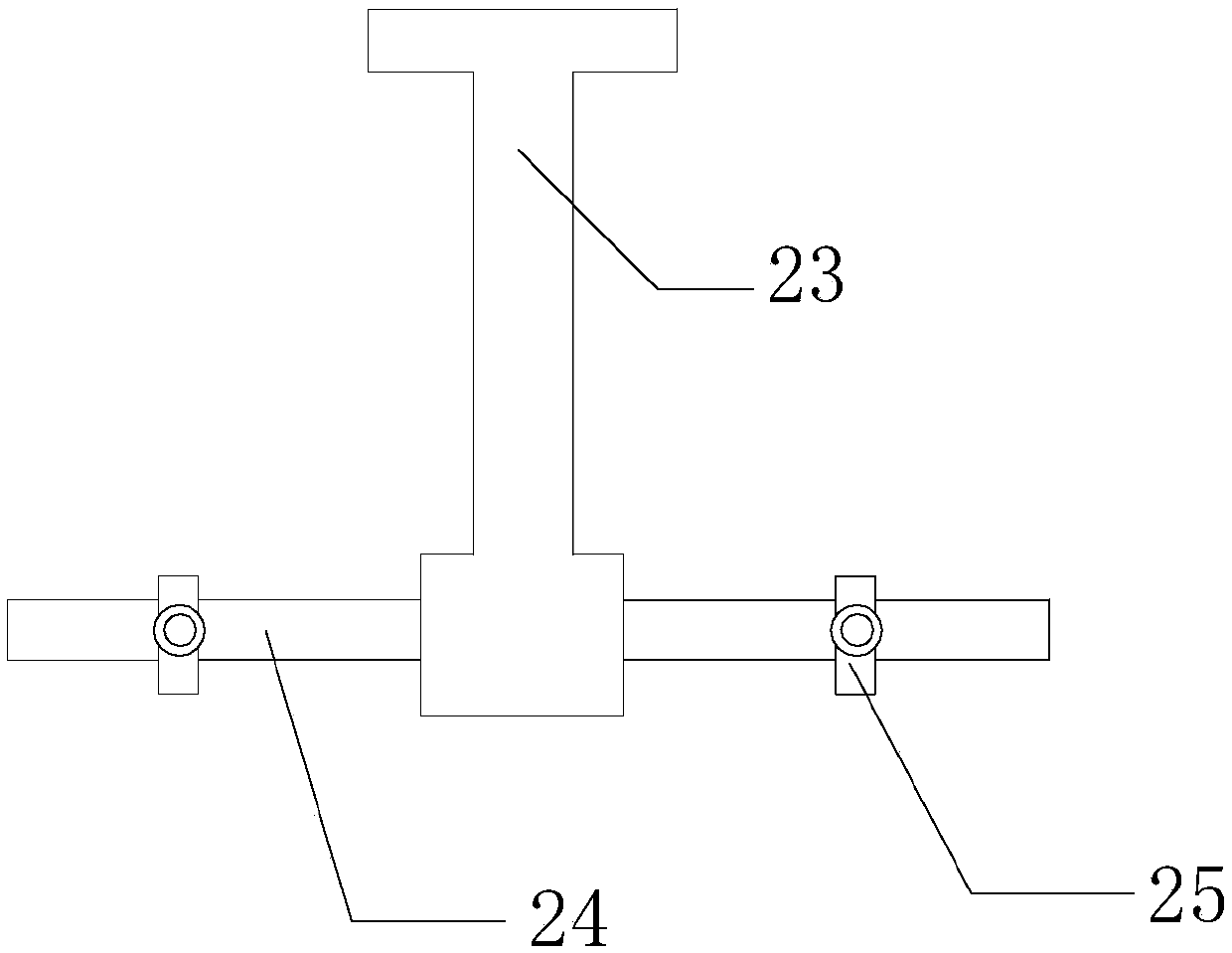

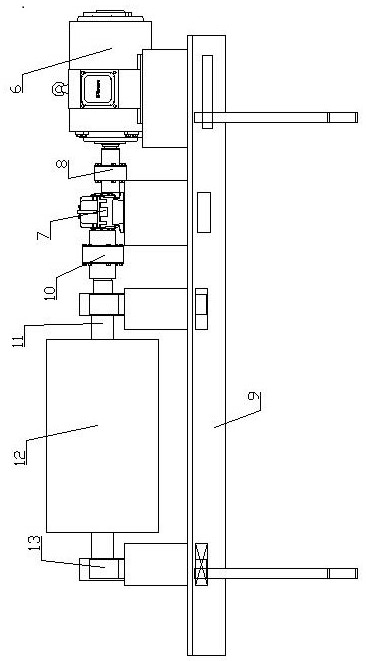

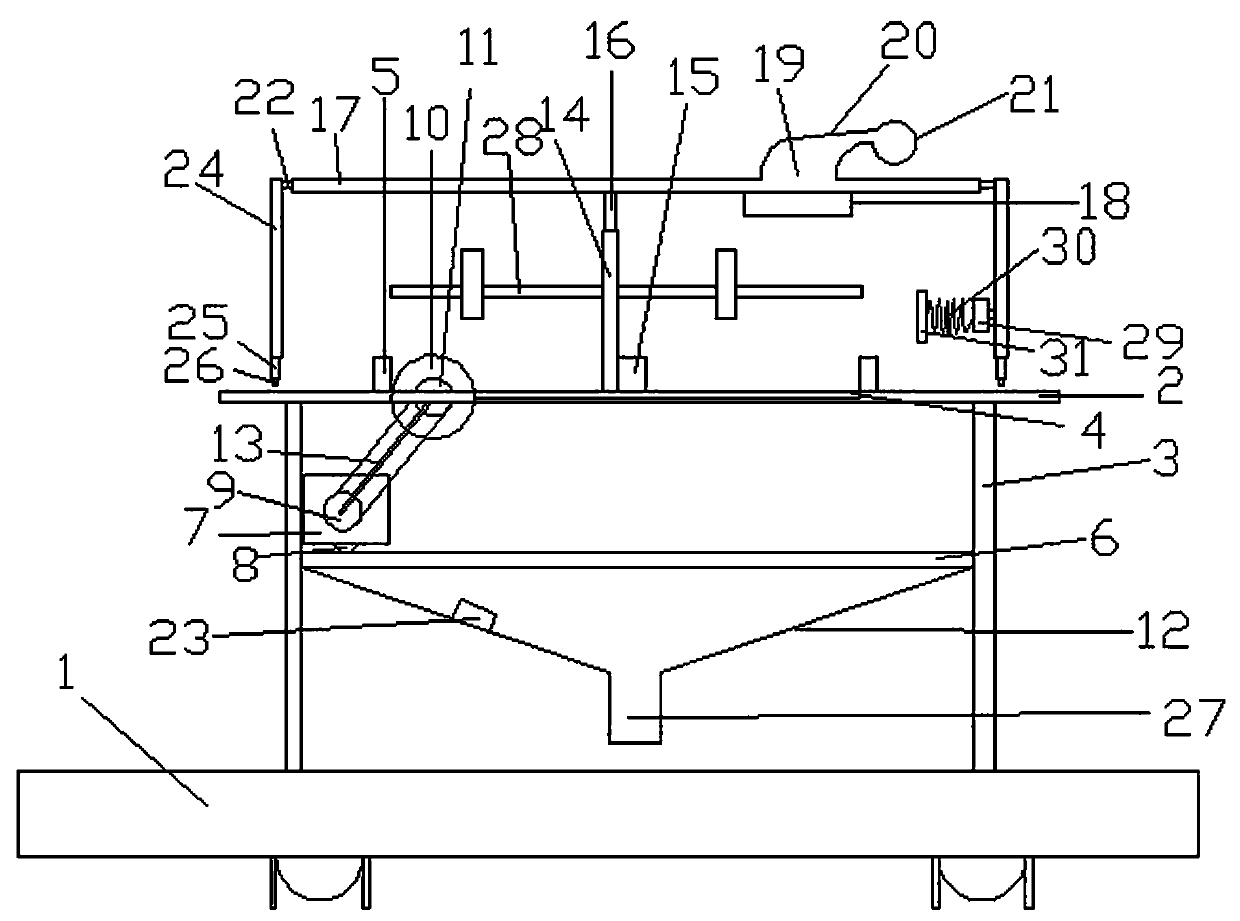

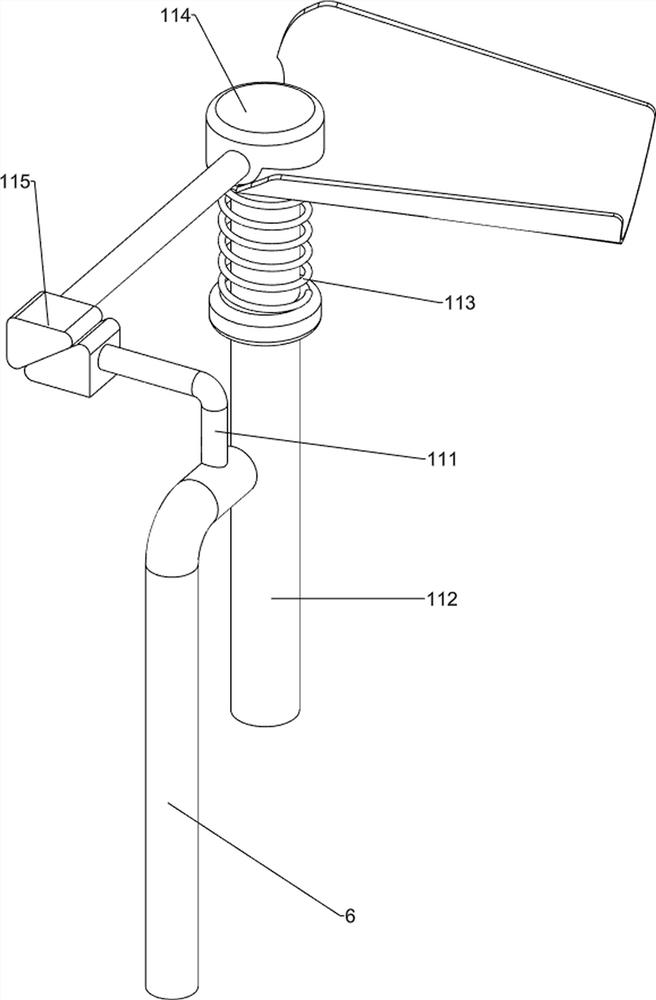

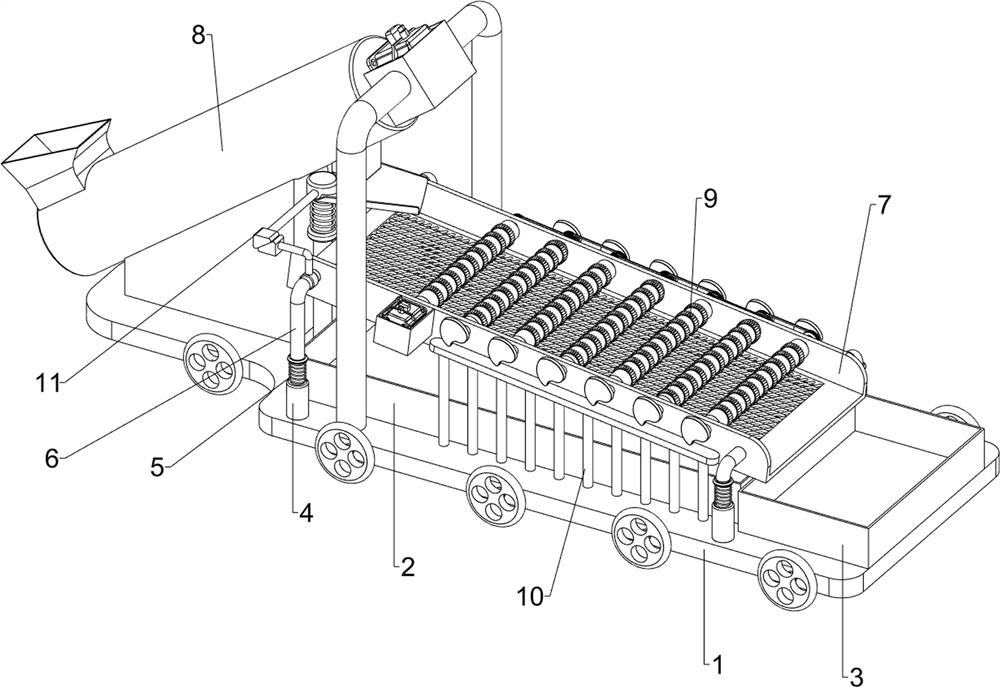

Drilling machine feeding device based on Internet of things

InactiveCN110757590AAvoid random flyingKeep healthyStationary drilling machinesBark-zones/chip/dust/waste removalTool bitControl engineering

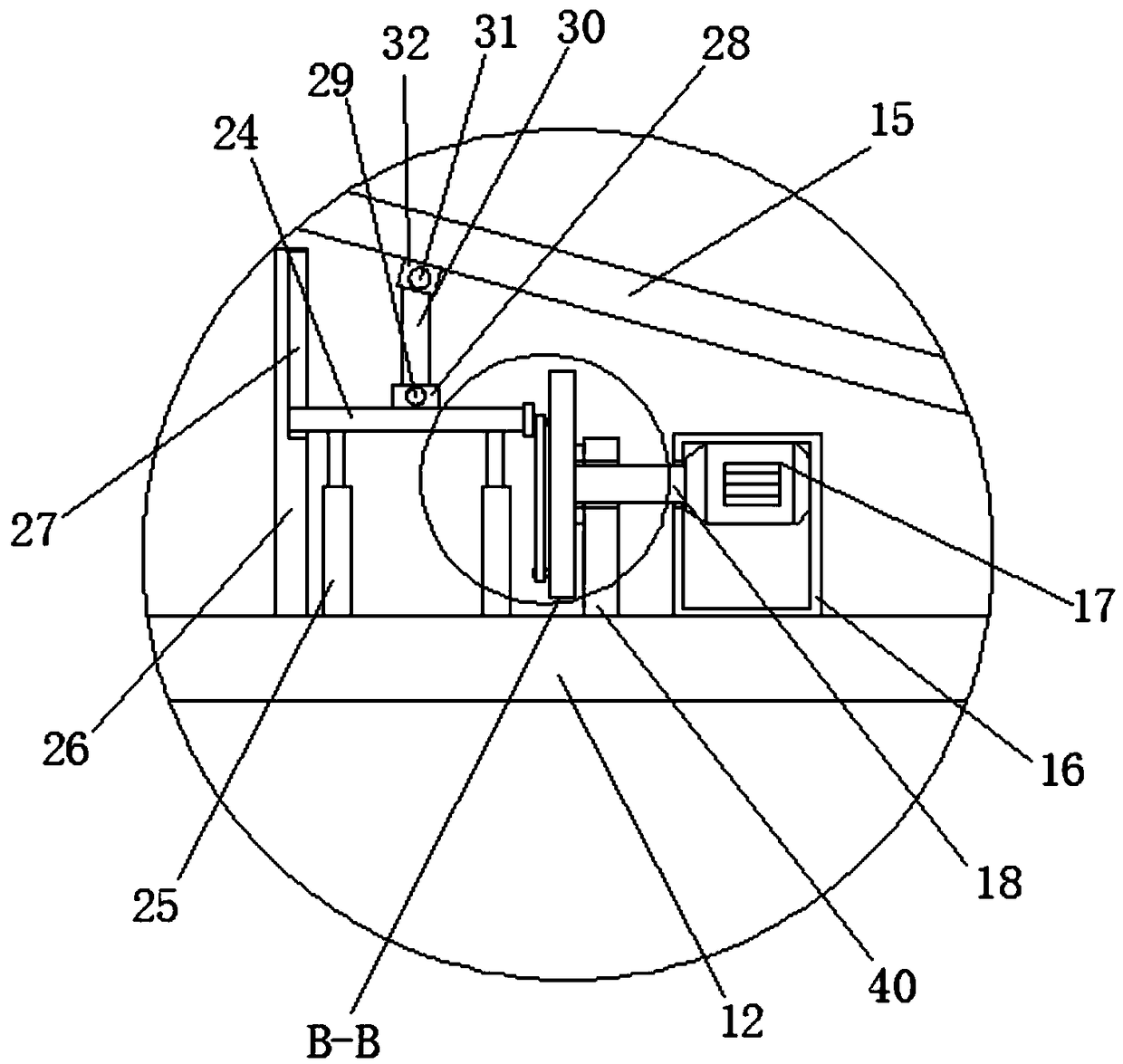

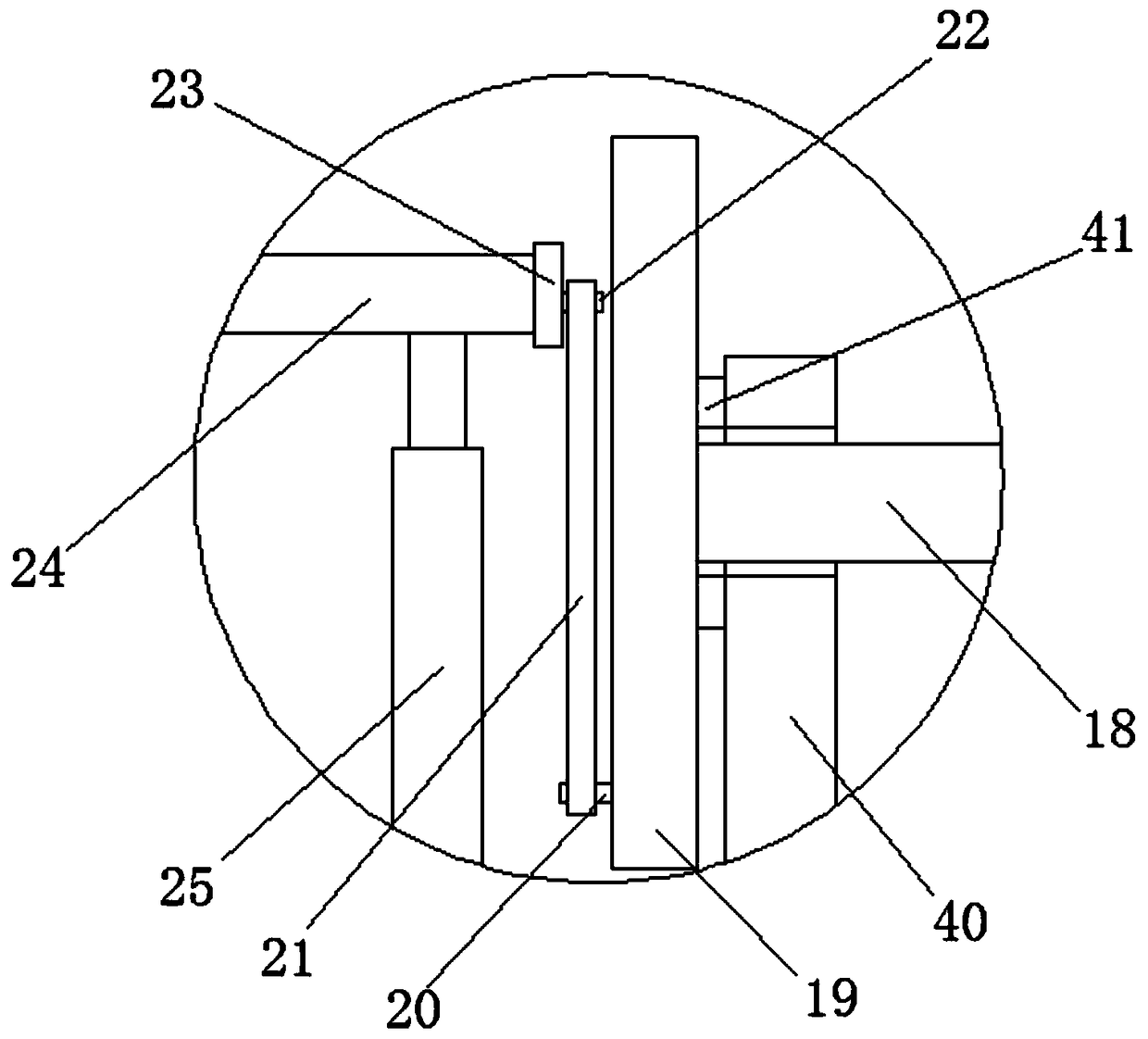

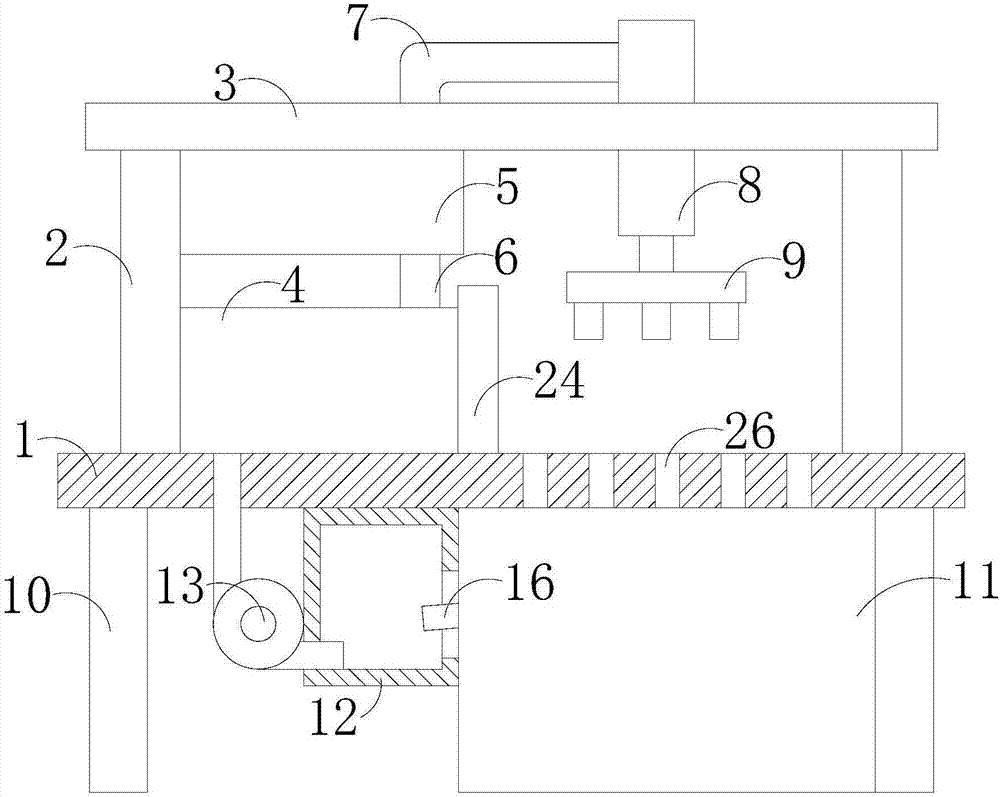

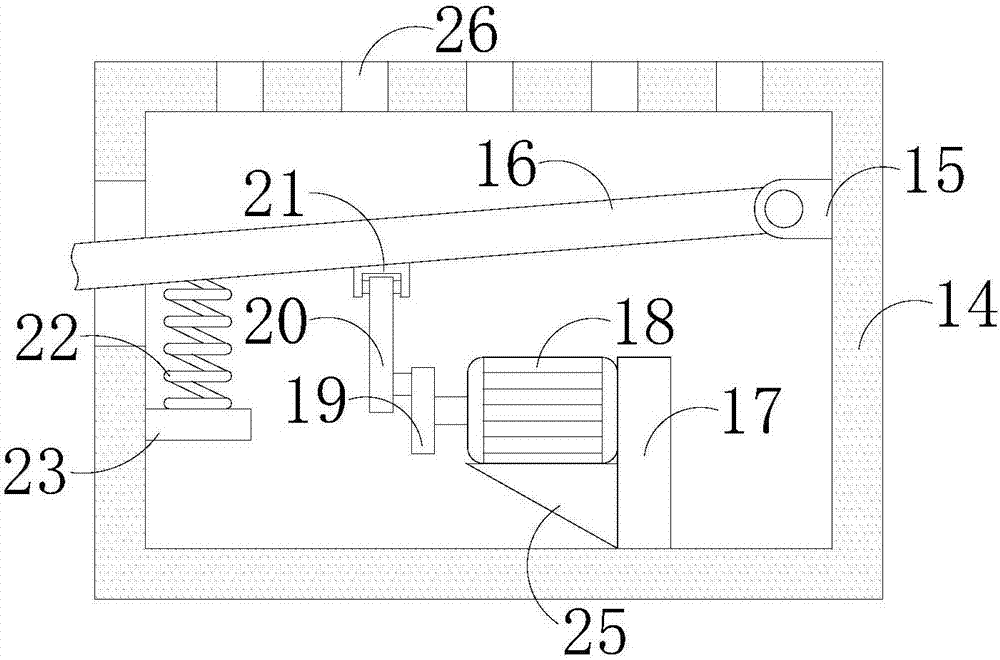

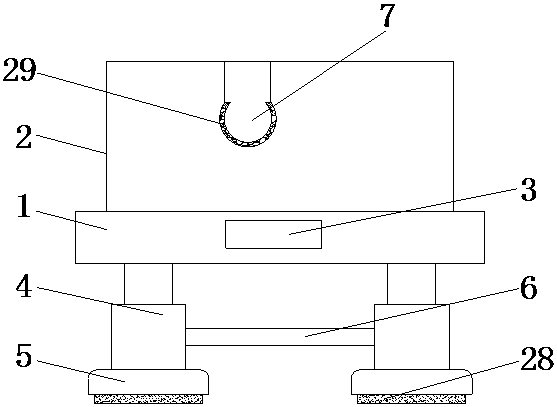

The invention discloses a drilling machine feeding device based on Internet of things. The drilling machine feeding device comprises a fixing plate, wherein a feeding pipe is arranged on the fixing plate; the periphery of the lower part of the feeding pipe is sleeved with a linear bearing; the linear bearing penetrates through the middle of the fixing plate, and the outer ring of the linear bearing is connected with the fixing plate; a first electric telescopic rod, an air inlet device, a first fan, a second electric telescopic rod, a first power device and a second power device are connectedwith a controller and a power source correspondingly; and the controller is connected with the power source and a network. According to the drilling machine feeding device, the mode that an annular groove is drilled through a drilling barrel and drilling teeth firstly, and then a drilling tool bit is driven by a telescopic shaft to conduct drilling is adopted, wood drilling operation is conductedin two steps, the phenomenon that wood chips fly around during drilling can be effectively avoided, a good working environment is created for wood drilling, and the health of drilling workers is ensured; and meanwhile, wood drilling is conducted through full-automatic operation, the workload of the drilling workers is reduced, the labor cost is saved, the drilling precision is further ensured, andthe drilling quality is improved.

Owner:唐健豪

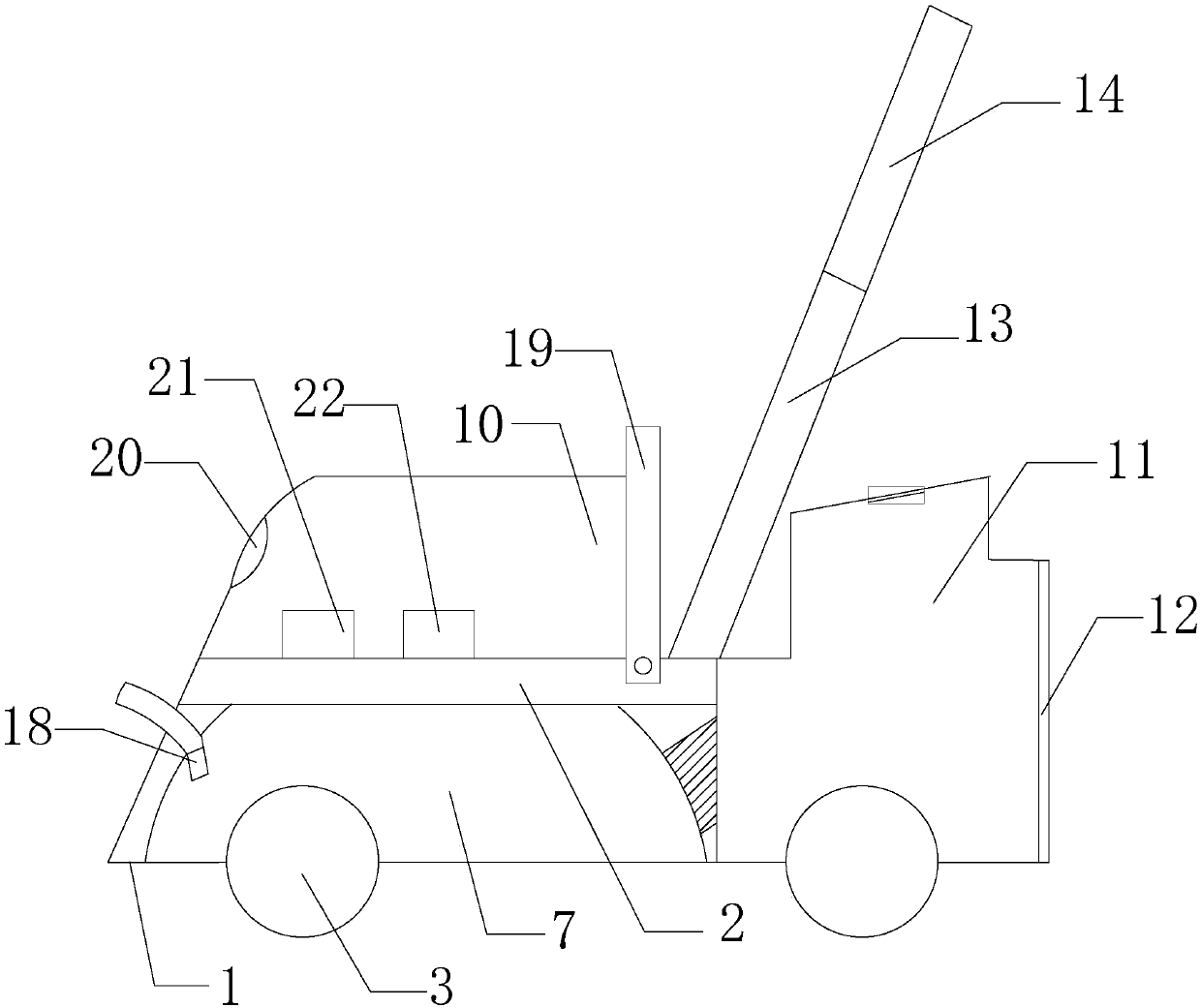

Novel mower

The invention discloses a novel mower. The mower comprises a mower body, the mower body is provided with a support, traveling mechanisms are arranged on both sides of the lower portion of the support,a cutter is arranged in the support, a first motor is mounted on the cutter, a blade is mounted on the output shaft of the first motor, a chassis is arranged on one side of the cutter, a second motoris mounted on the chassis, and weeding wheels are mounted on the output shaft of the second motor; water spraying nozzles are arranged on the inner wall of the cutter and the inner wall of the chassis, and the water spraying nozzles are connected with hoses; the mower body is provided with an infrared sensor, the infrared sensor is connected with a controller, the controller is arranged in a motor hood, the controller is connected with a direction device, and the controller is connected with the traveling mechanisms, the first motor and the second motor separately. By means of the novel mower, manual mowing and automated mowing can be achieved, meanwhile the mower has various functions such as water spraying, low noise, ripping and the like, the mowing process is simplified, the working efficiency is improved, and the working time is shortened.

Owner:徐应盈

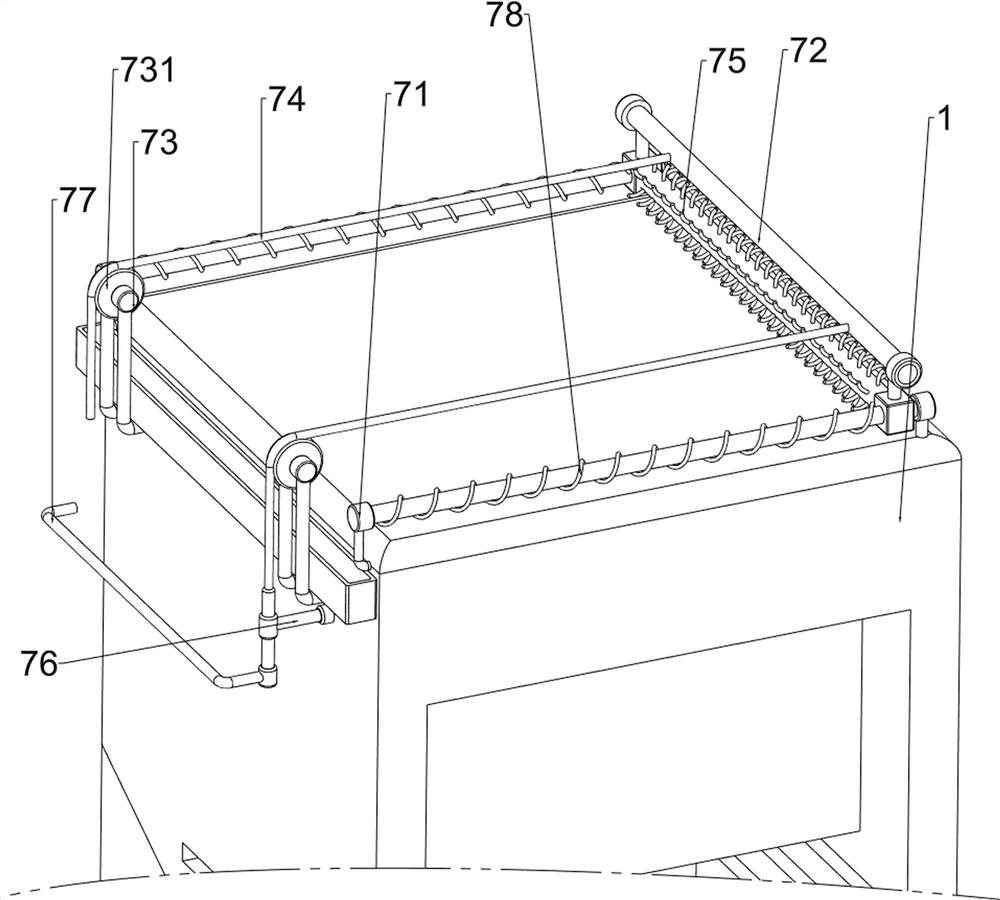

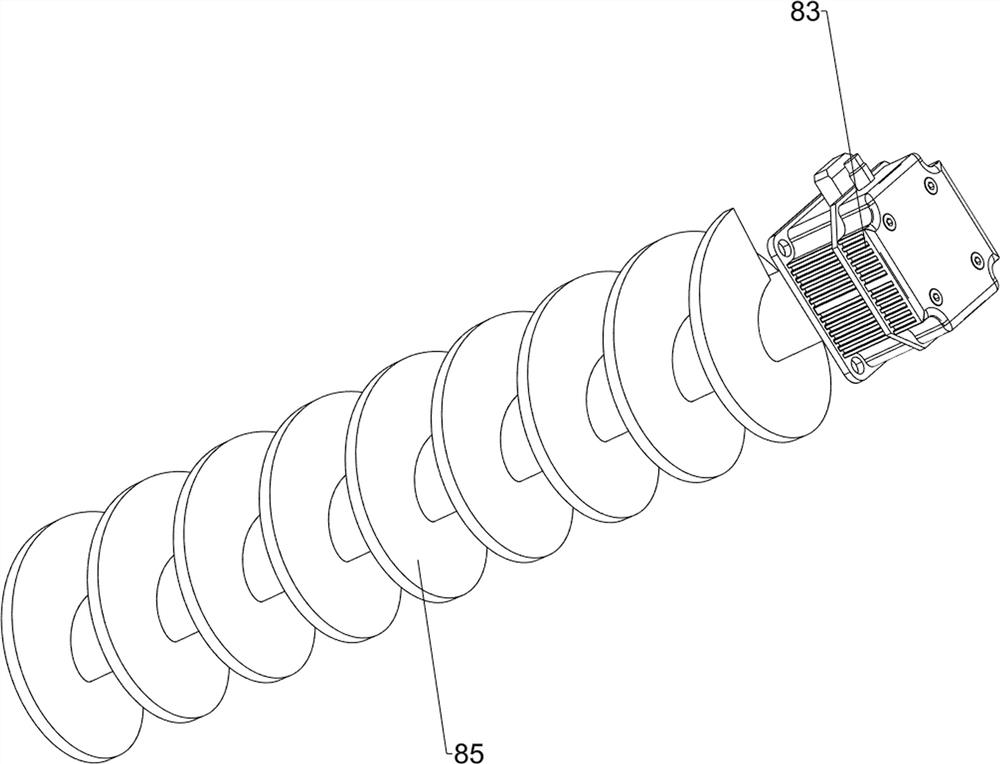

Agricultural automatic corn threshing equipment

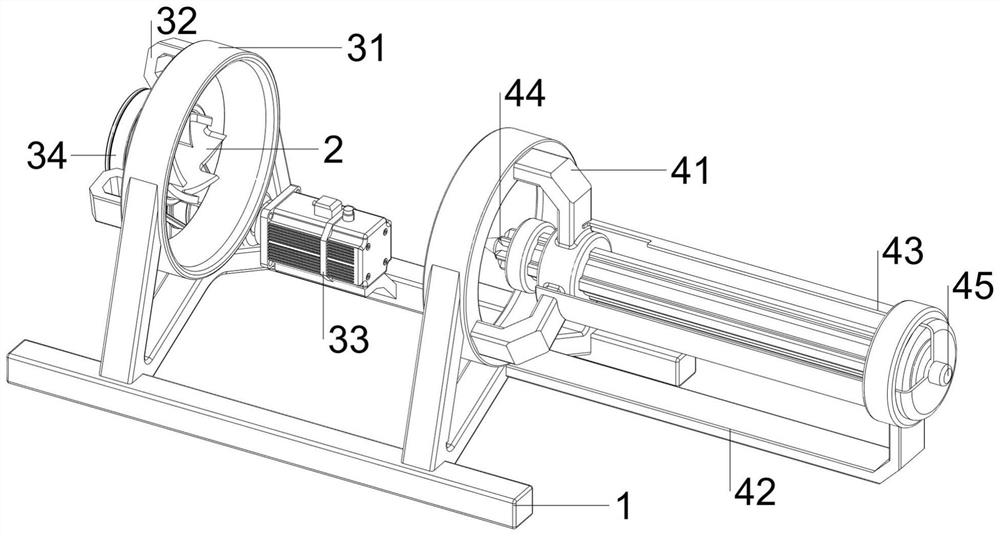

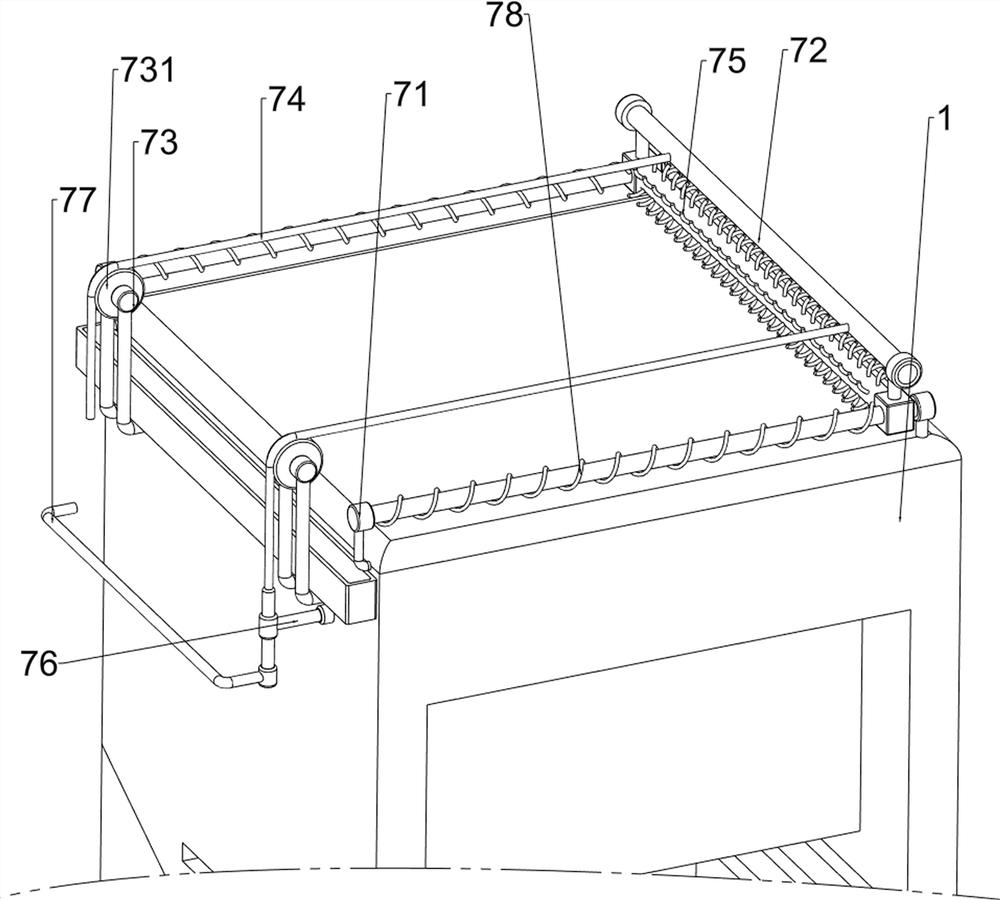

InactiveCN113196957AThreshing automaticAutomatic push and threshingThreshersAgricultural scienceAgricultural engineering

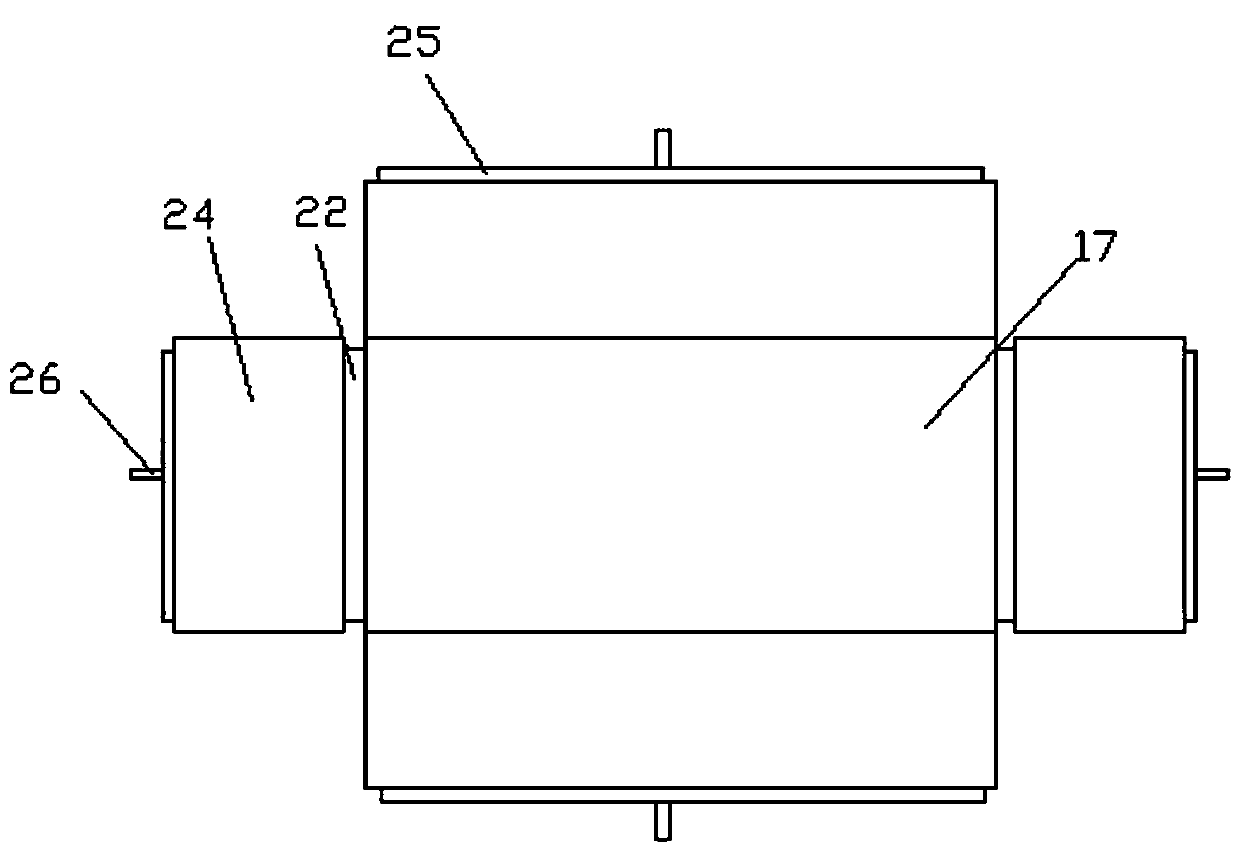

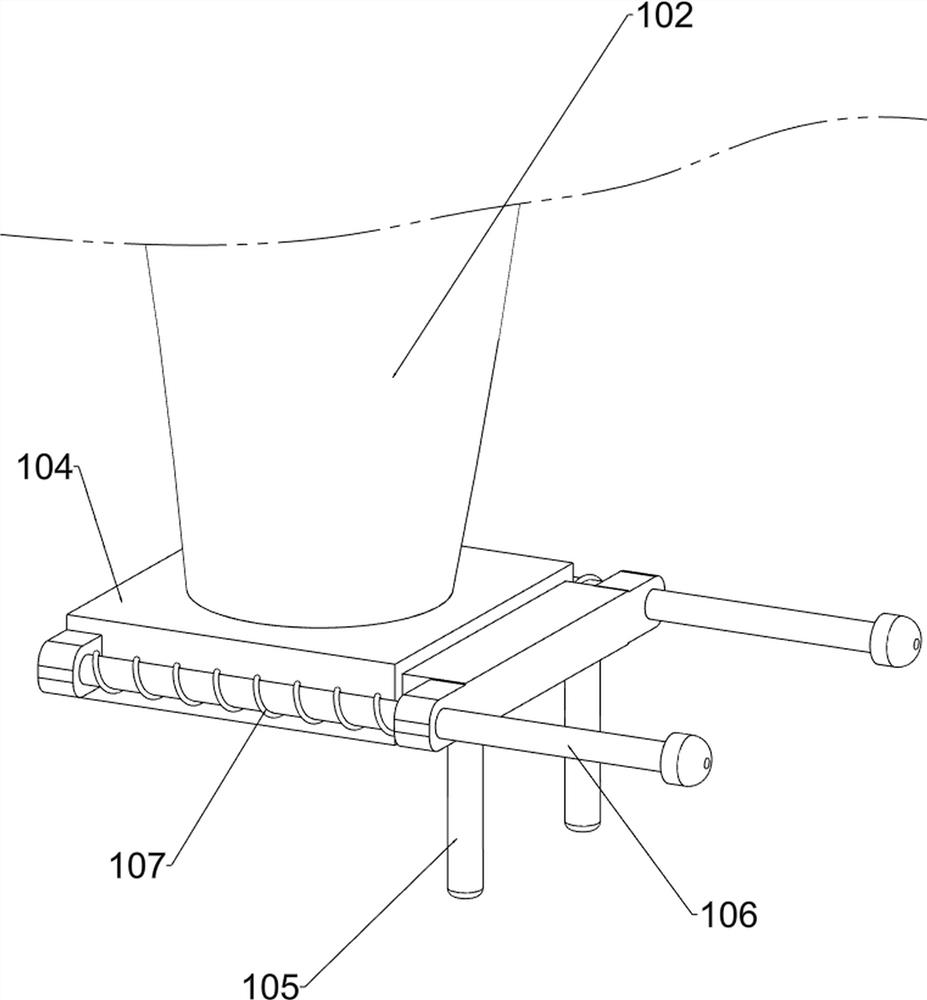

The invention relates to threshing equipment, in particular to agricultural automatic corn threshing equipment. The technical problem of the invention is to provide the agricultural automatic corn threshing equipment which is high in working efficiency and facilitates collection of corn kernels. The agricultural automatic corn threshing equipment comprises bases and a threshing mechanism, a rotating wheel and a pushing mechanism. The threshing mechanism is arranged between the tops of the bases on the two sides; the rotating wheel is rotationally arranged on the threshing mechanism; and the pushing mechanism is arranged on the threshing mechanism. Through cooperation of the rotating wheel, the threshing mechanism and the pushing mechanism, corn can be automatically pushed and threshed, and the working efficiency is high. Through cooperation of a storage mechanism and a discharging mechanism, the intermittent feeding function of the corn can be automatically completed, and time and effort are saved. Through the limiting mechanism, threshed corn cobs can be automatically discharged, and subsequent treatment by people is facilitated.

Owner:赣州康瑞农产品有限公司

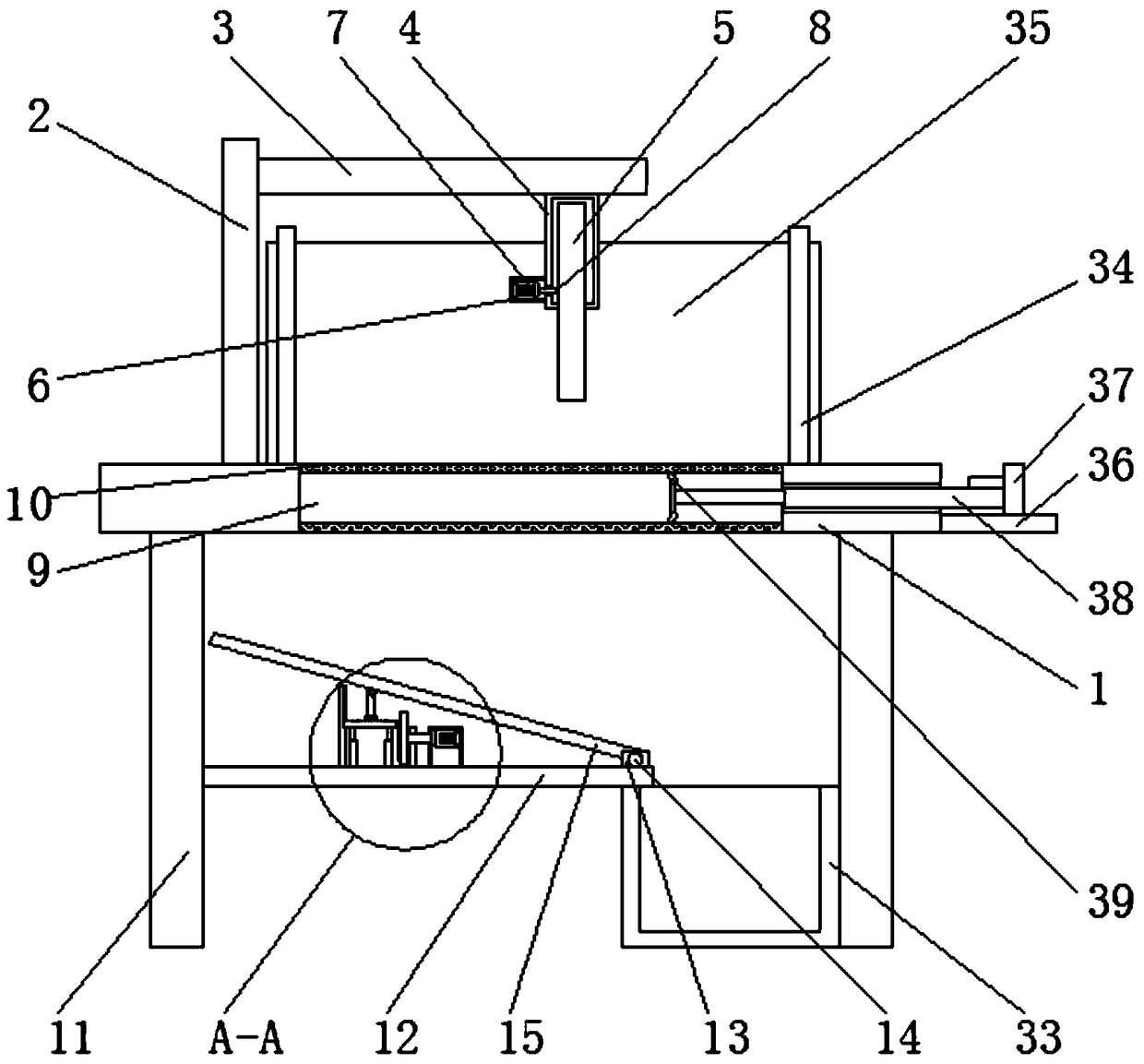

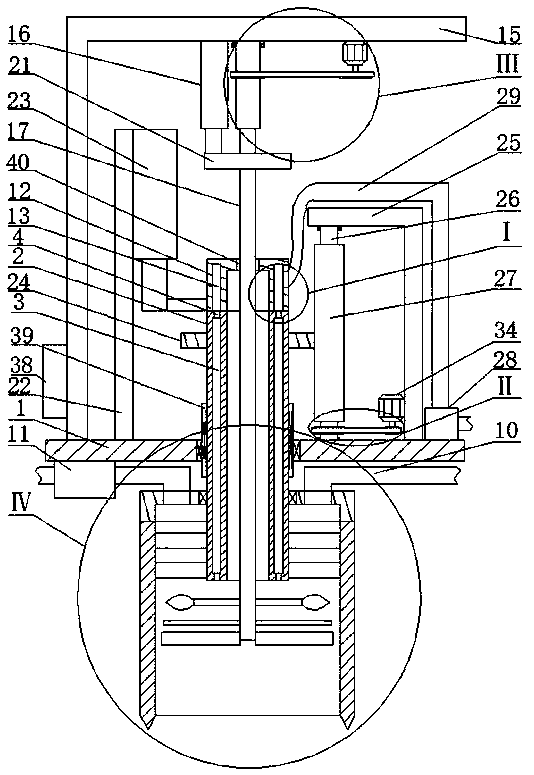

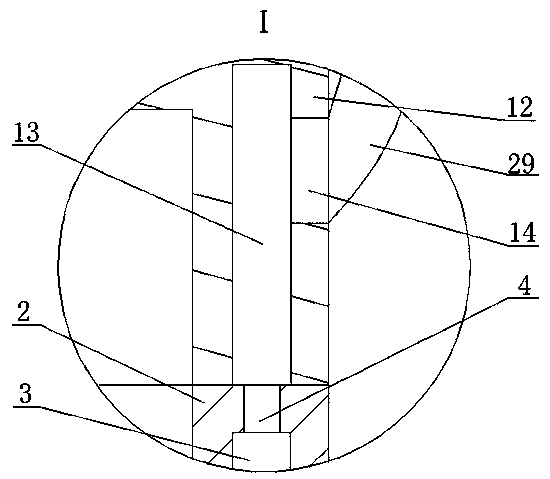

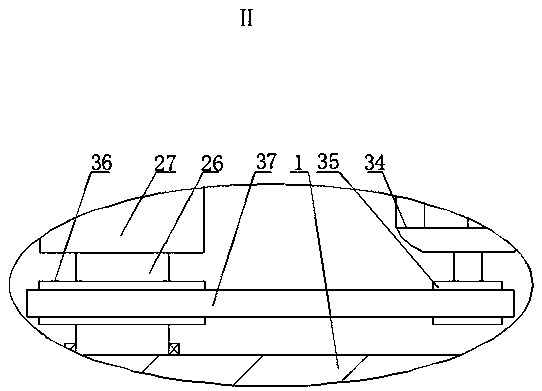

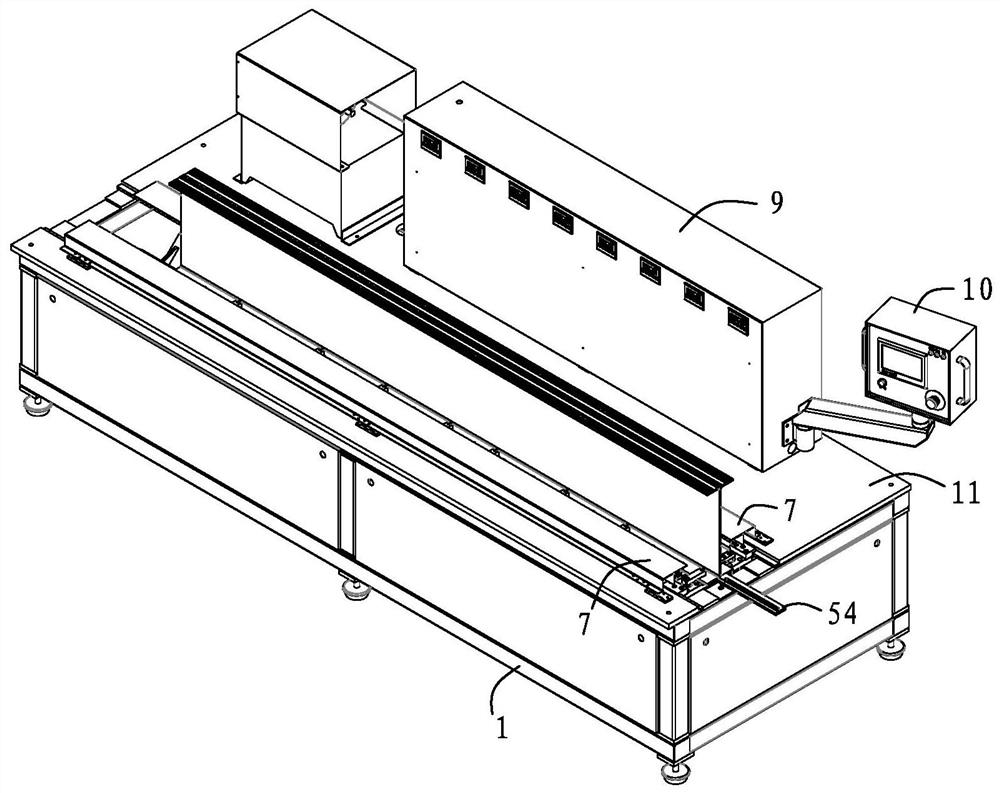

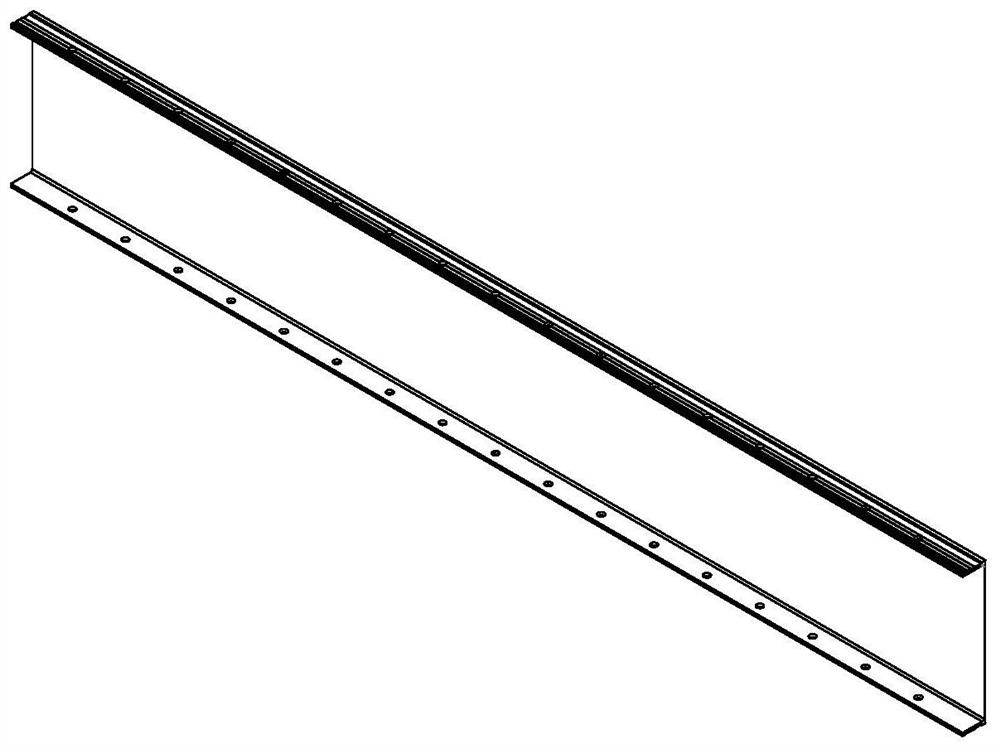

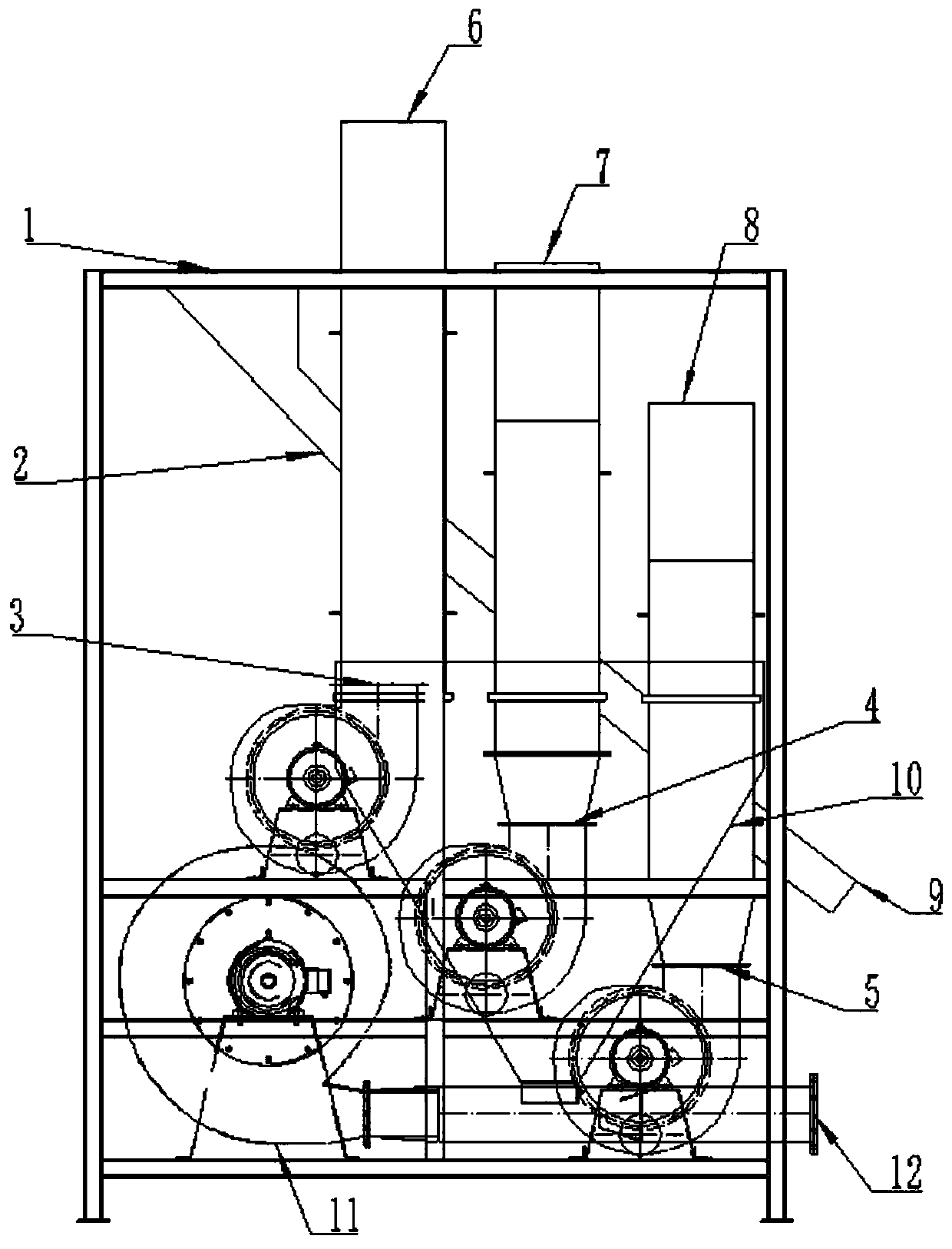

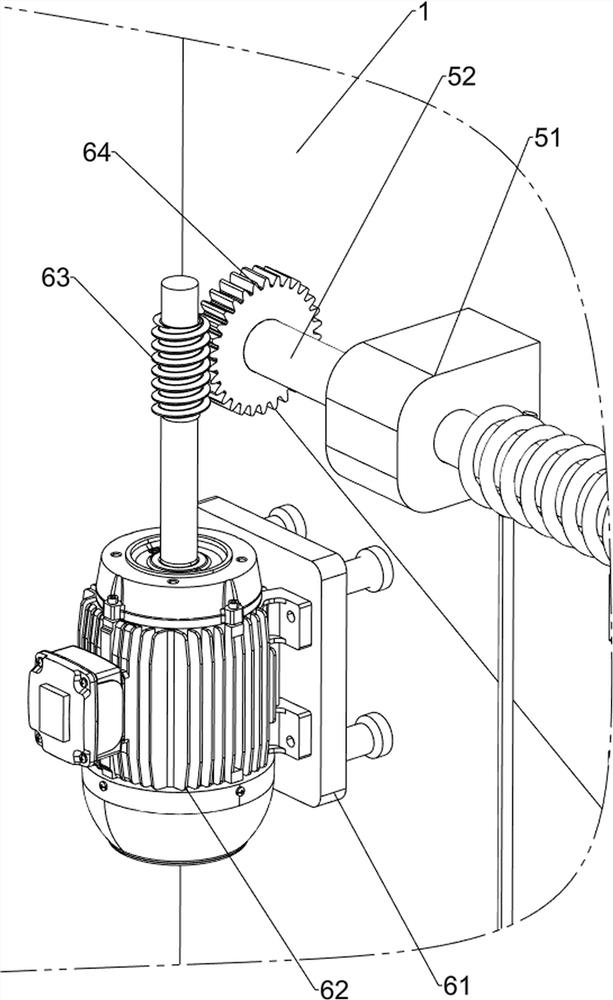

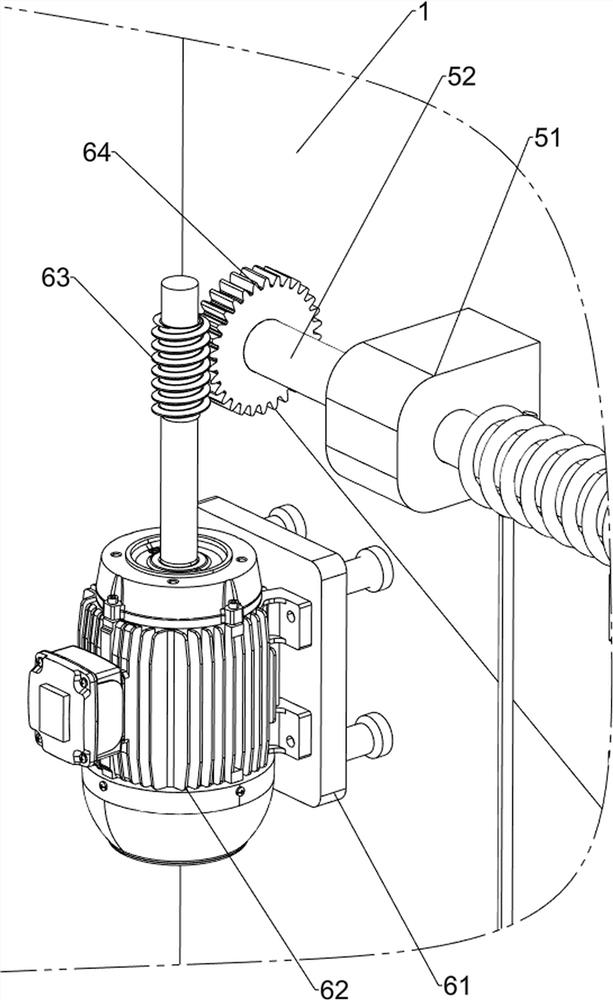

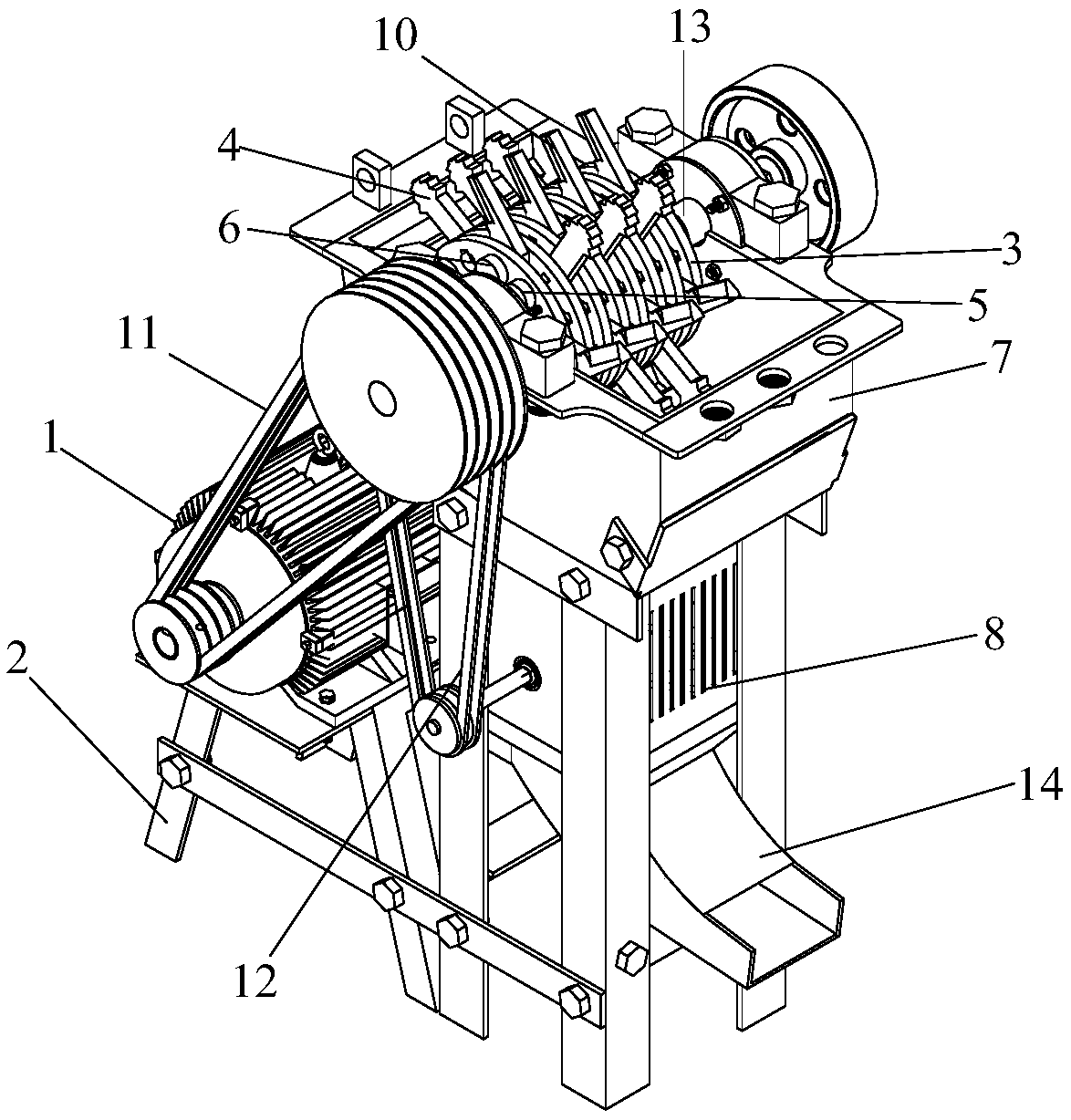

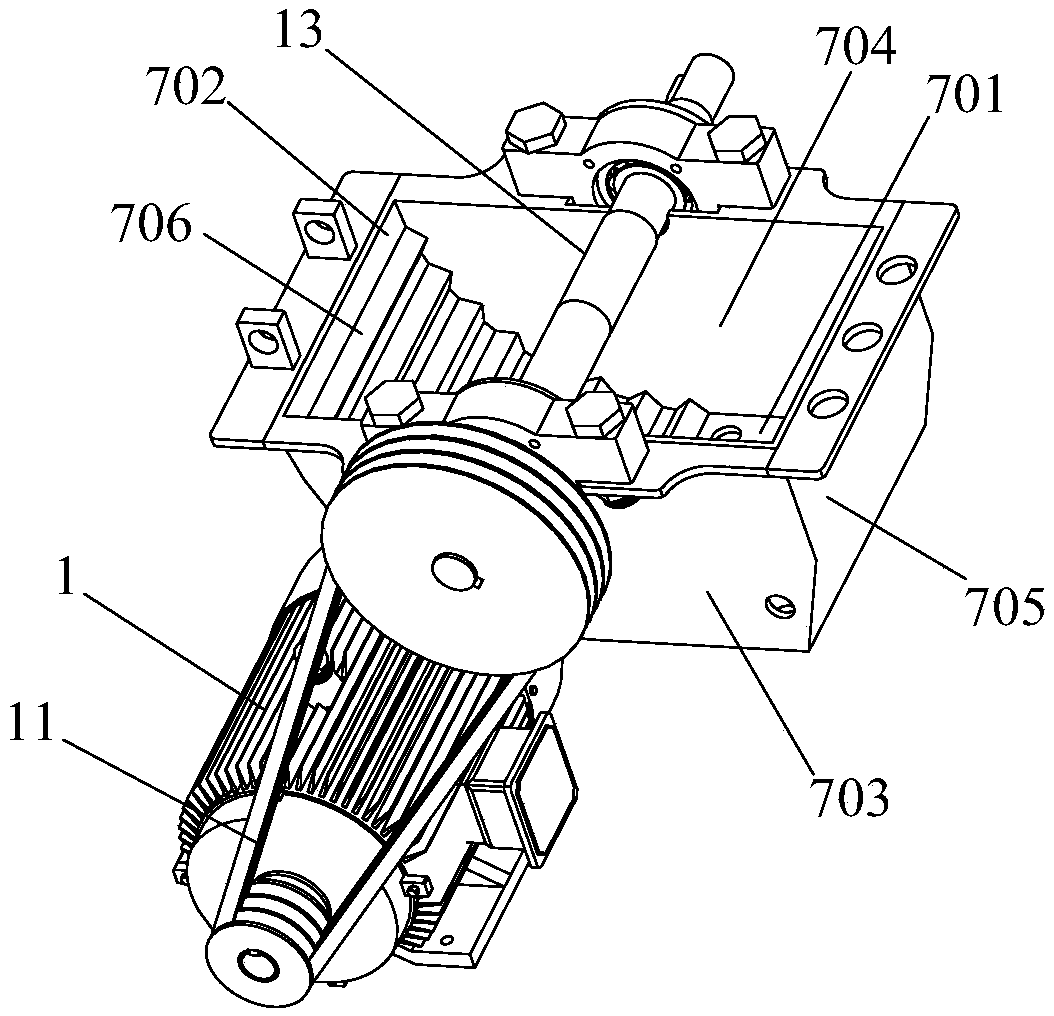

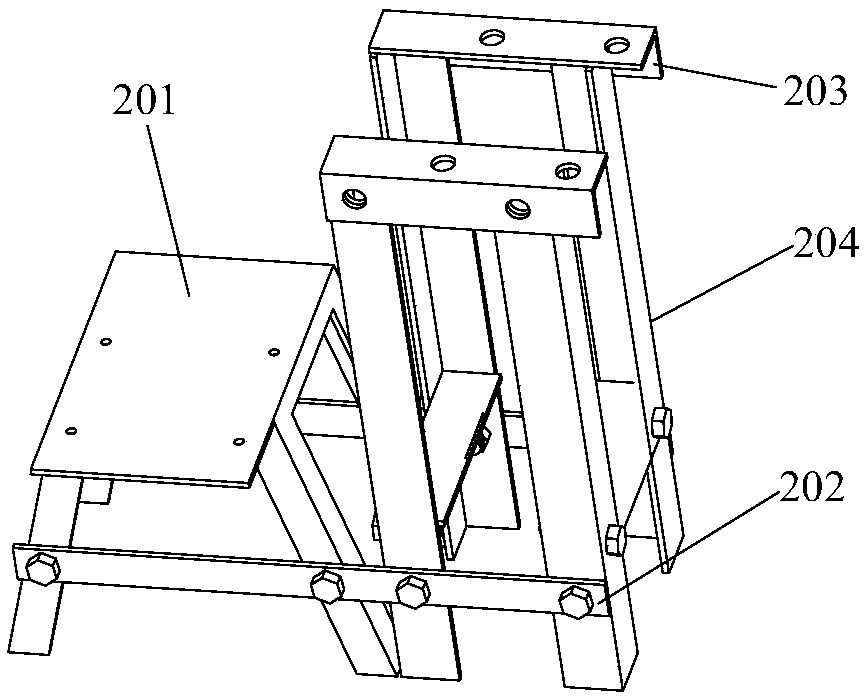

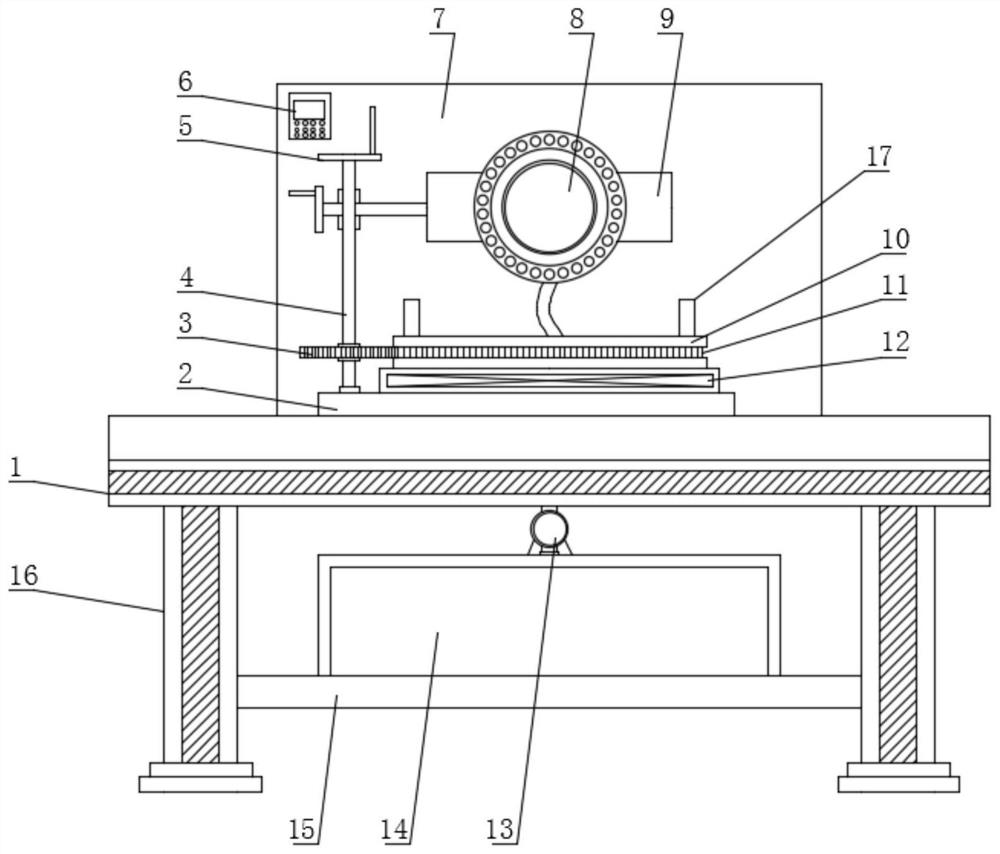

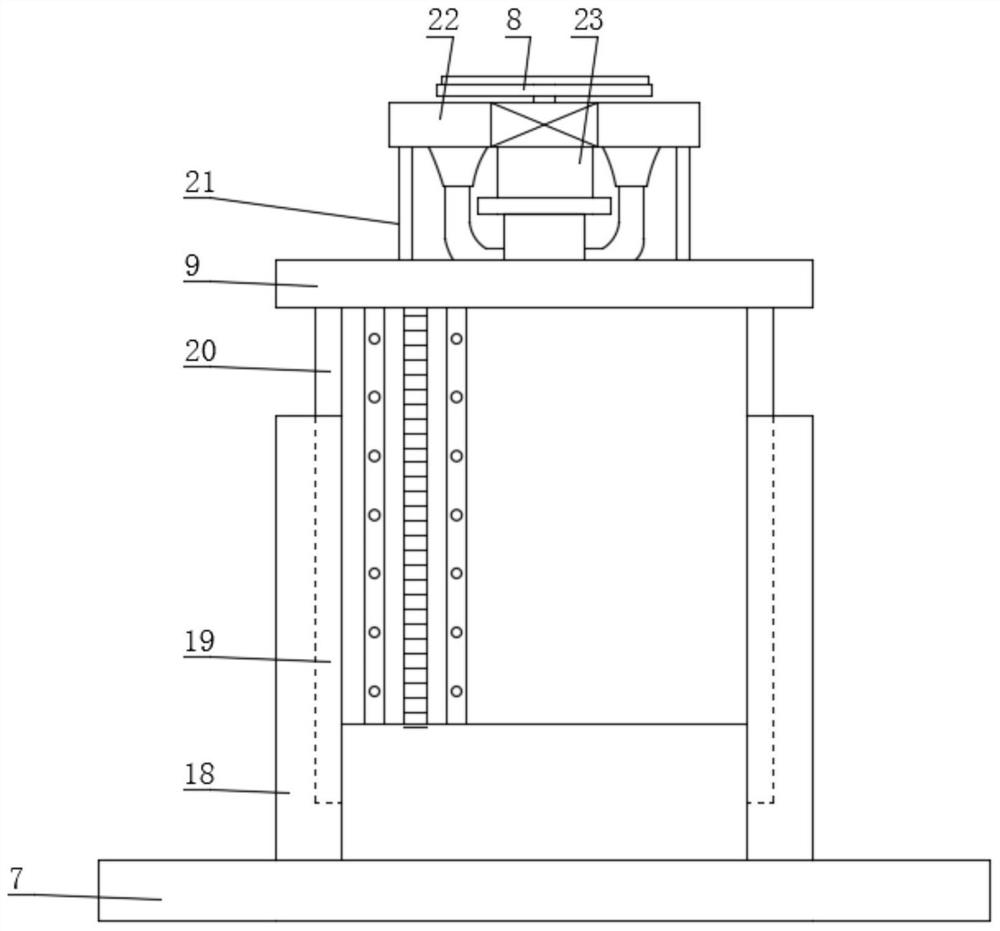

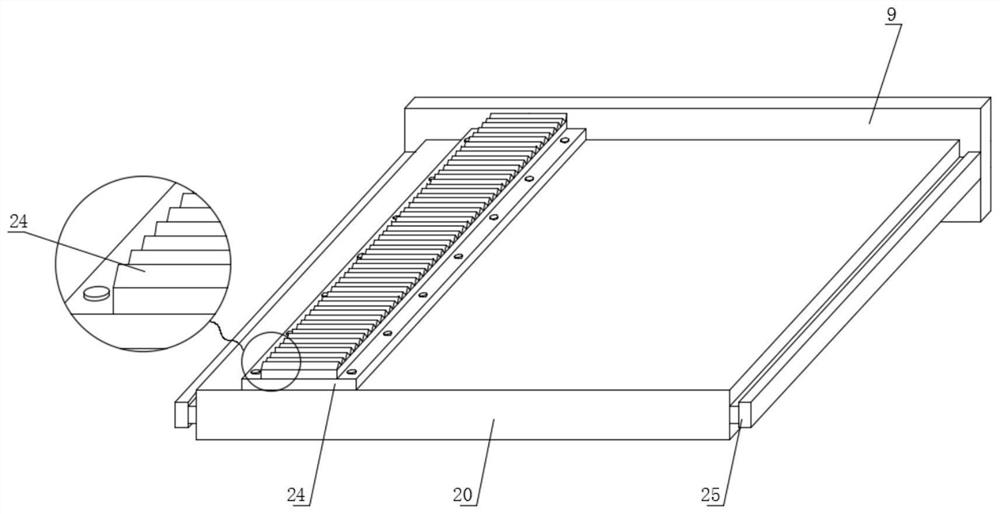

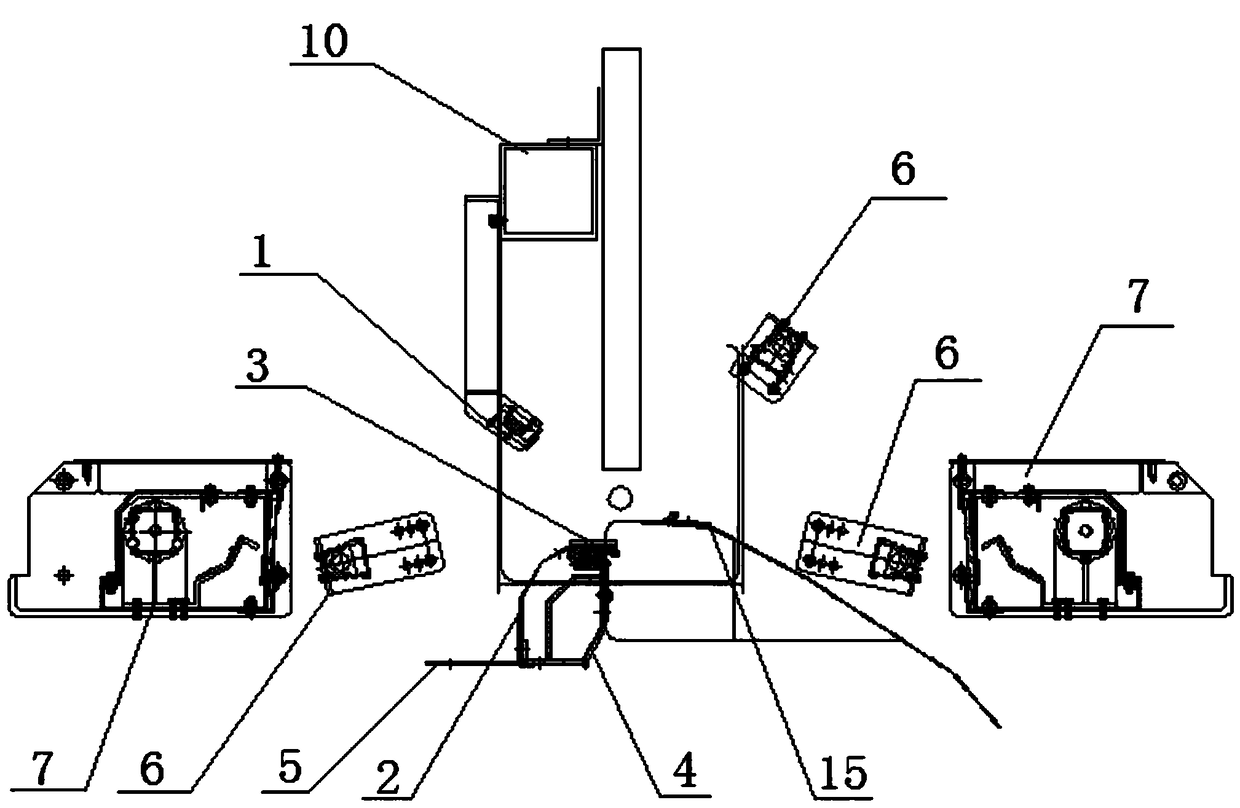

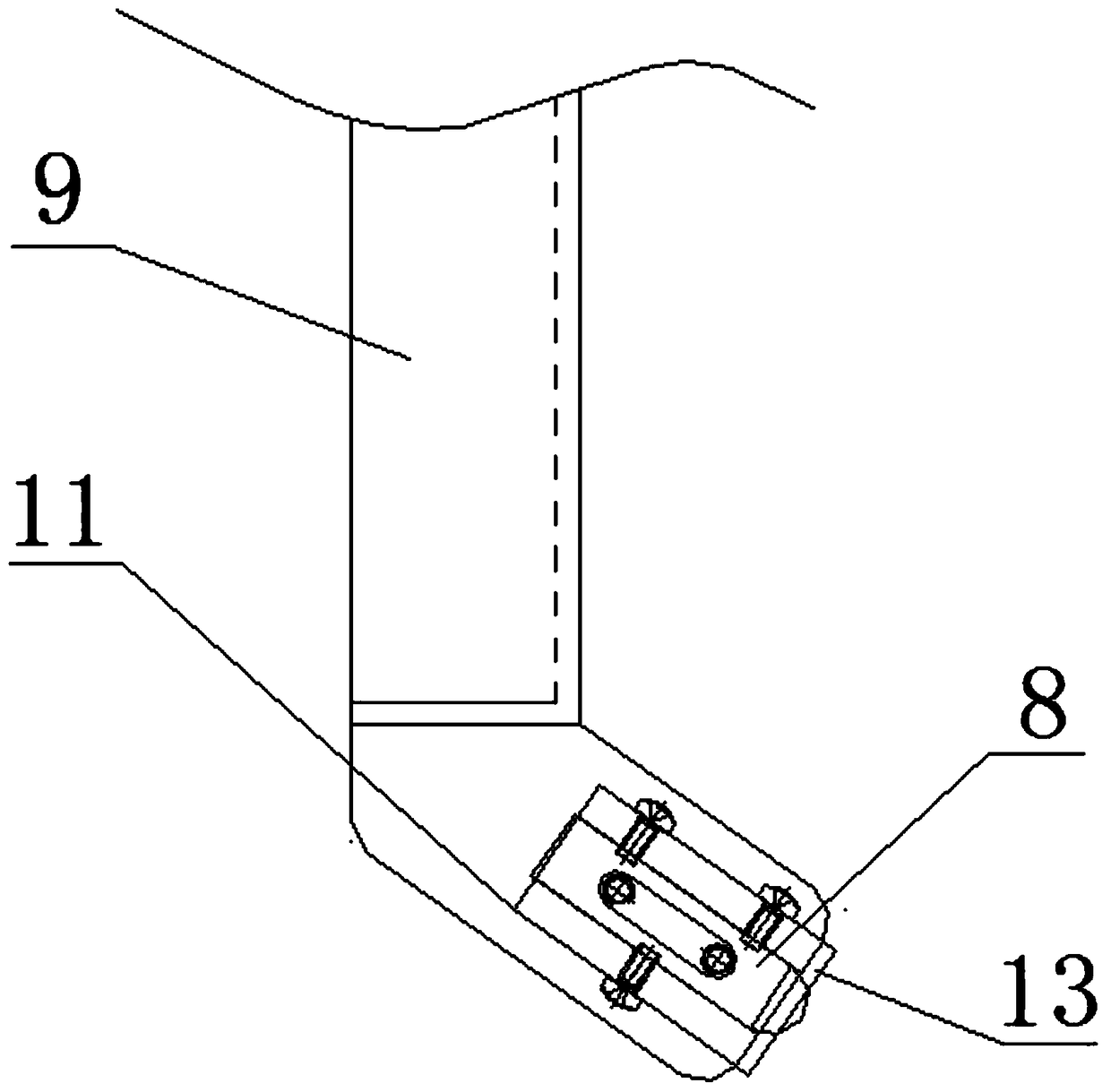

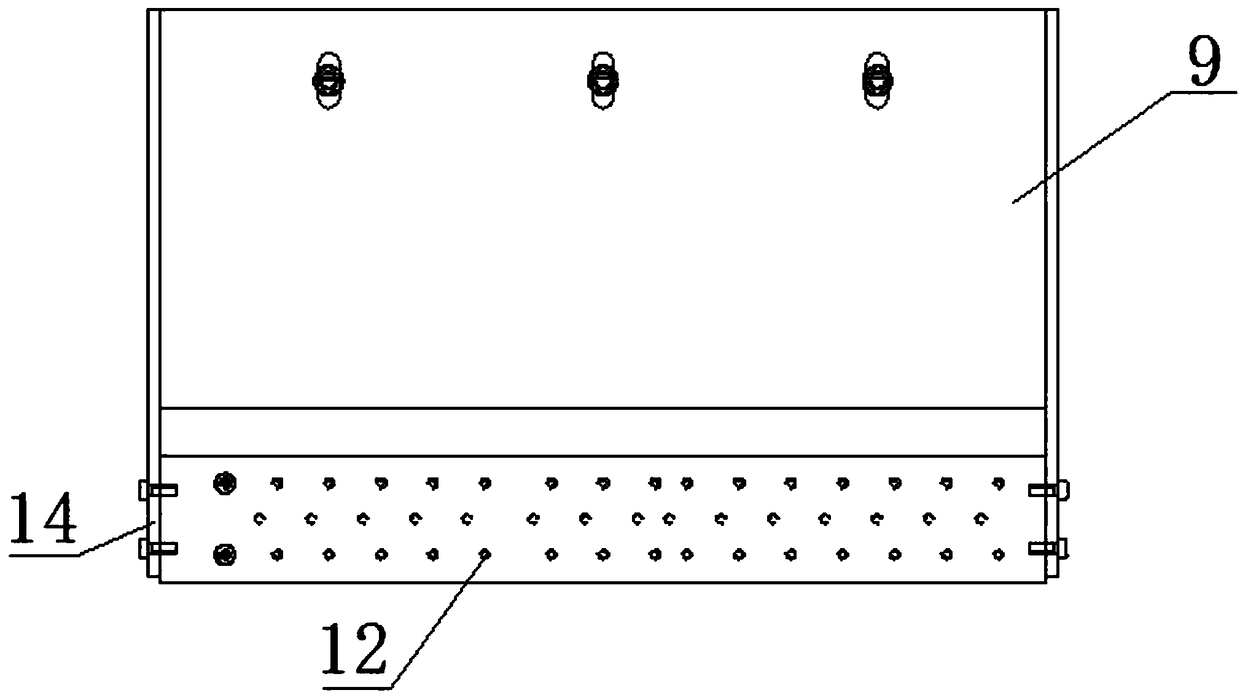

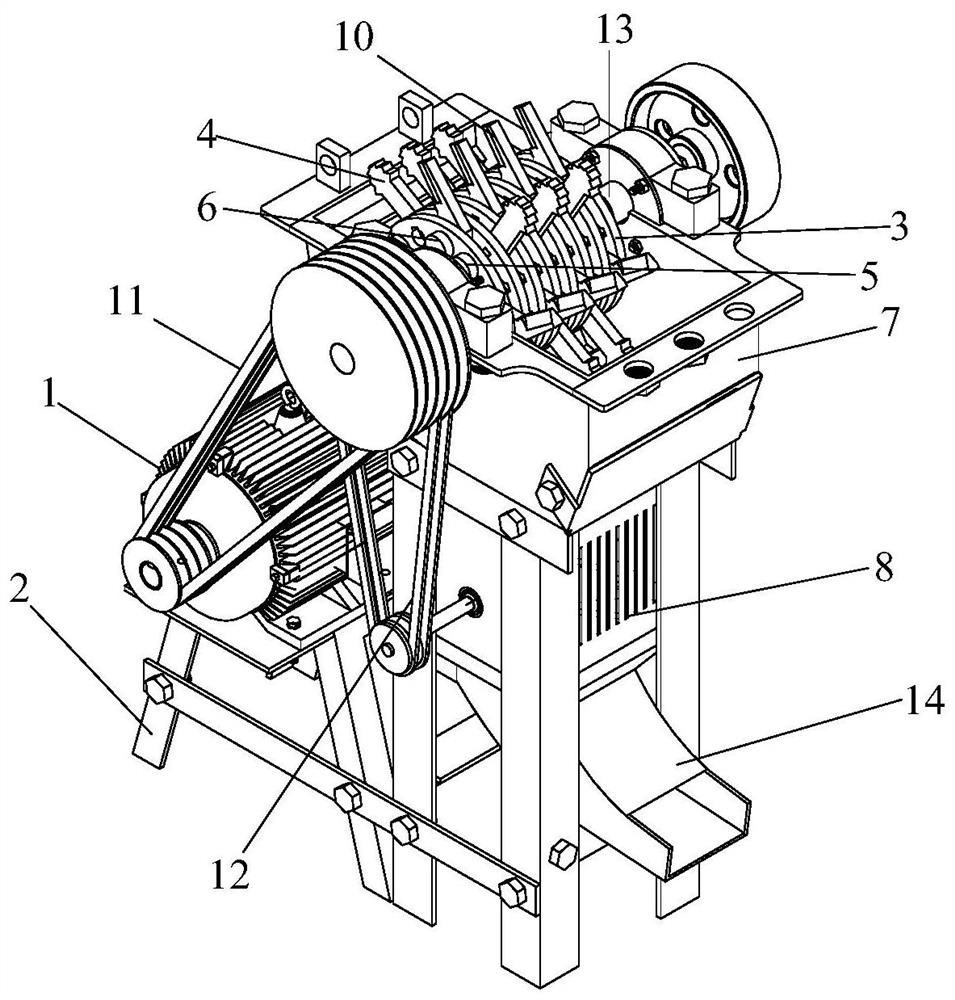

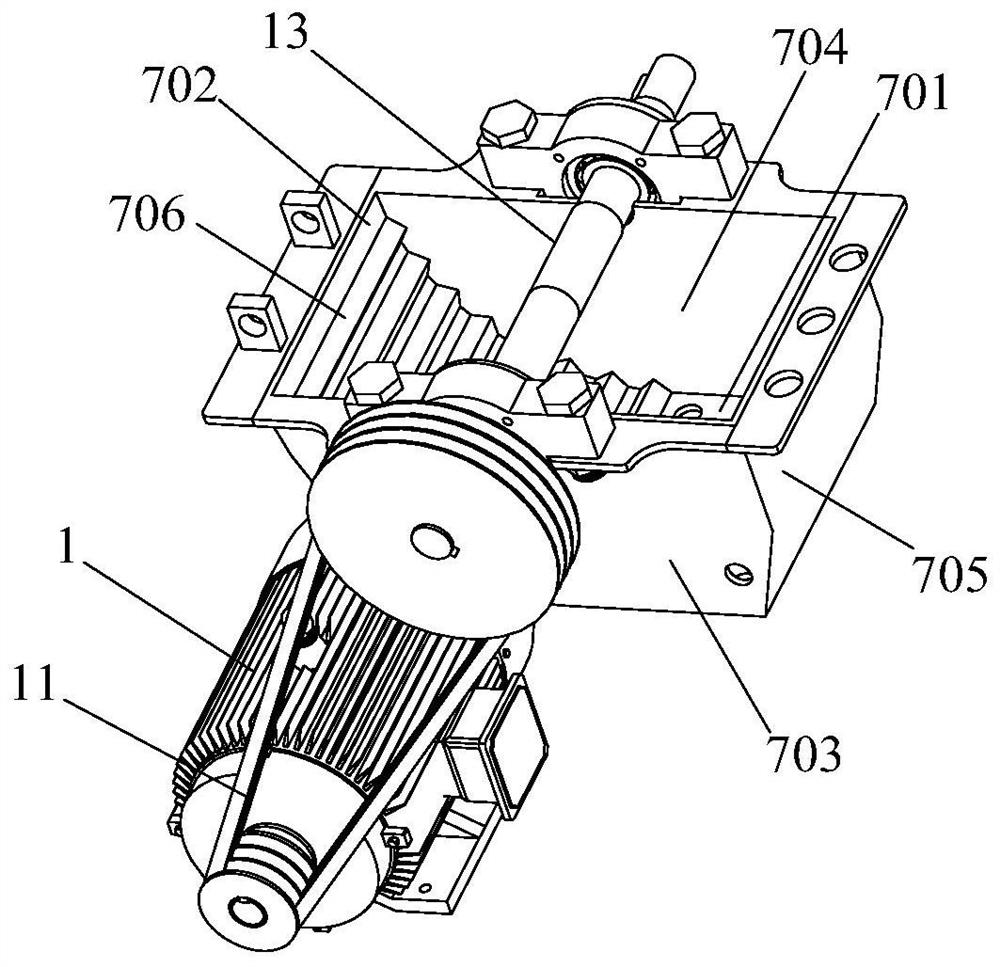

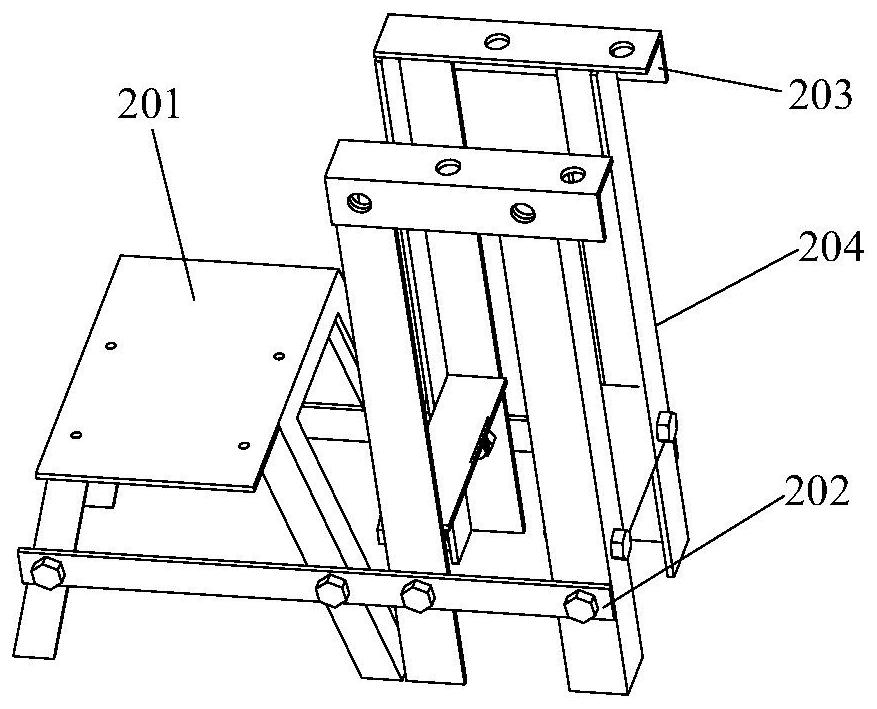

Vertical double-workpiece multi-head slot milling machine

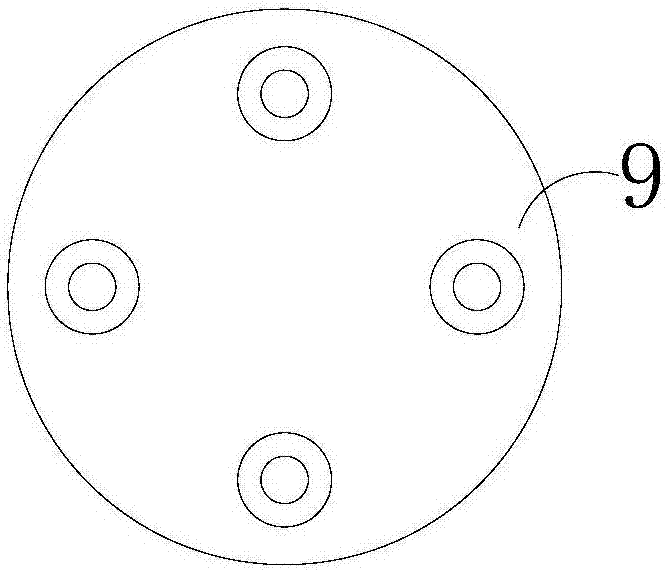

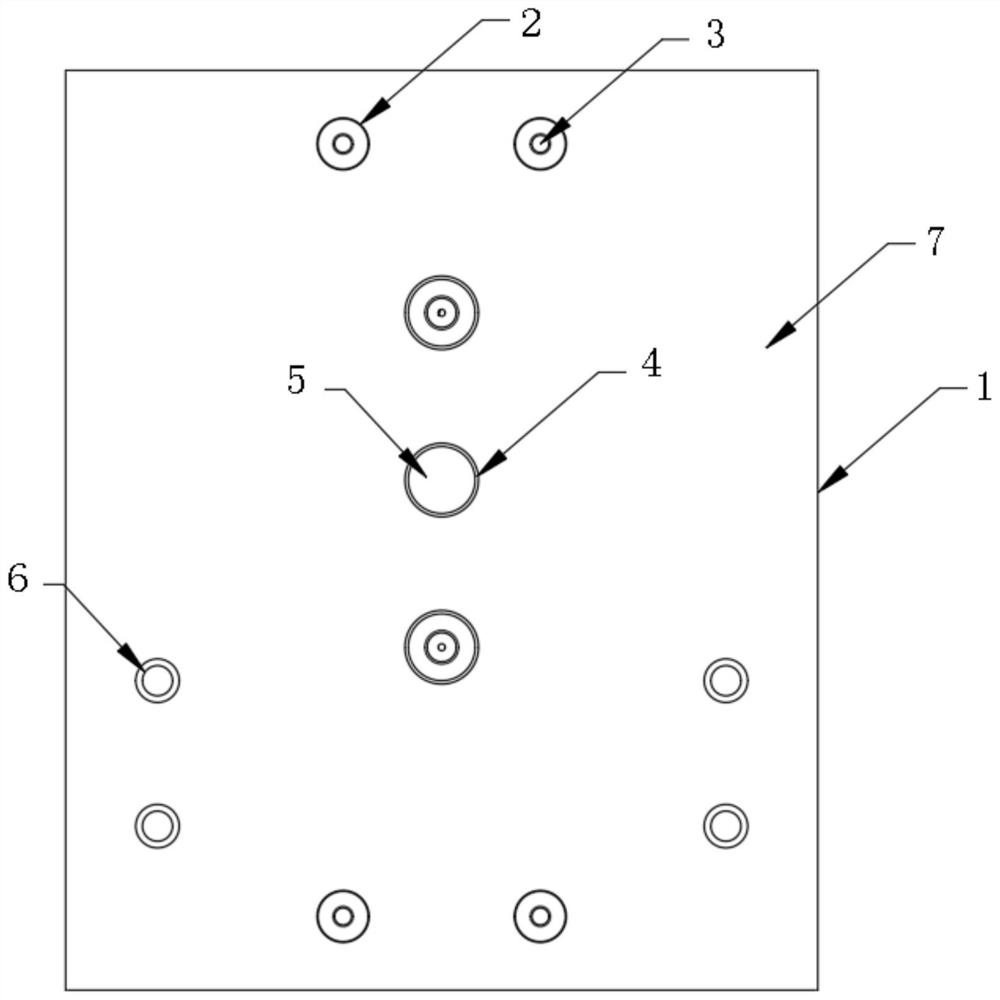

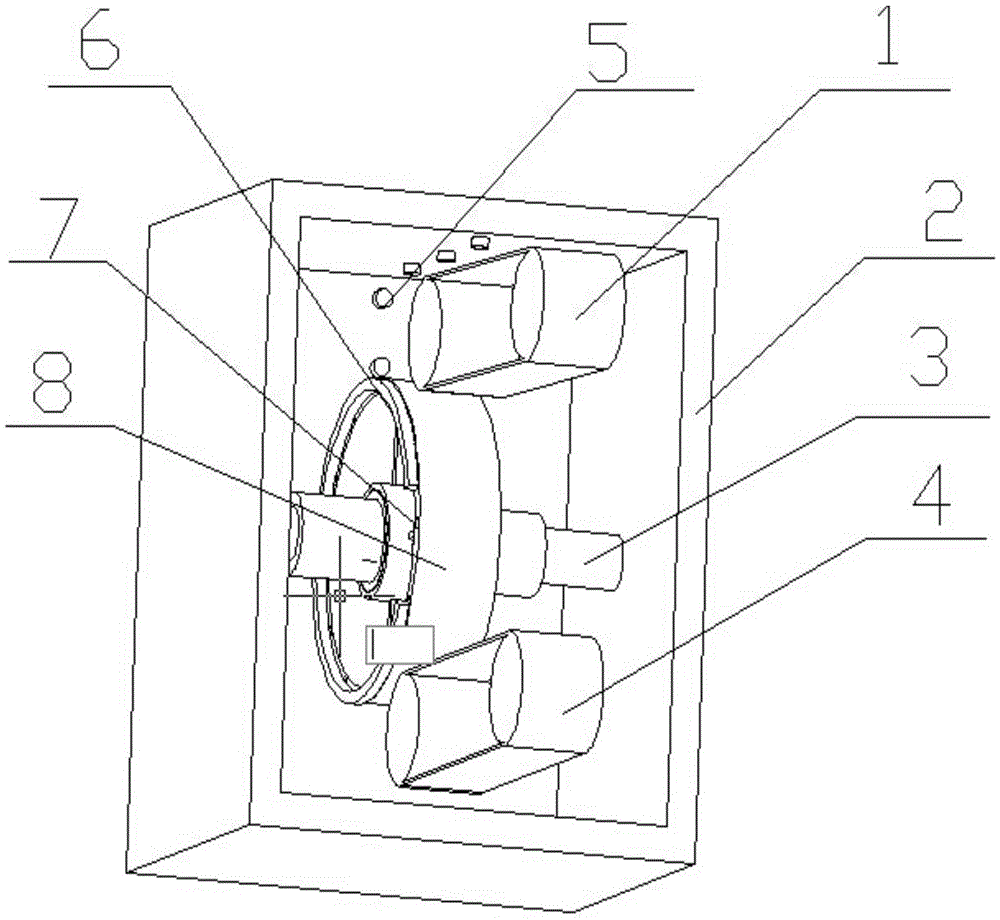

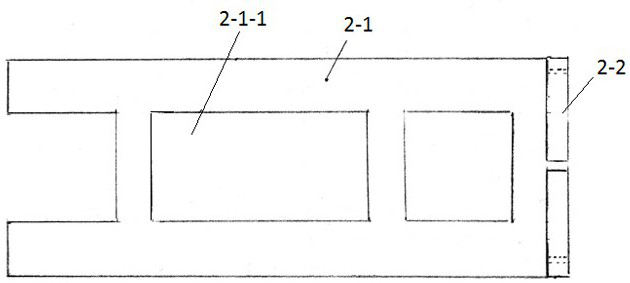

PendingCN113814454AEasy to fixQuick fixWork clamping meansFeeding apparatusMilling cutterEngineering

The invention discloses a vertical double-workpiece multi-head slot milling machine. The vertical double-workpiece multi-head slot milling machine is suitable for the building aluminum template manufacturing industry. The vertical double-workpiece multi-head slot milling machine is special equipment for groove milling of aluminum templates of a pull tab system. The vertical double-workpiece multi-head slot milling machine comprises a machine frame, milling cutter power devices, a front-back driving device, an up-down driving device and a pneumatic clamping device, wherein a workbench is arranged on the machine frame, the milling cutter power devices are arranged below the workbench and workpieces, suspensions of the milling cutter power devices and the front-back driving device are arranged on the machine frame, and the up-down driving device is connected with the milling cutter power devices; and the pneumatic clamping device is arranged on the workbench and located below the workpieces, and the pneumatic clamping device is correspondingly matched with the milling cutter power devices. The workpieces are placed on the pneumatic clamping device, the workpieces can be clamped and fixed by taking a machining surface as a reference, the workpieces can be conveniently and quickly fixed, and the machining surfaces of the workpieces face downwards; and the workpieces are positioned above milling cutters. When the other faces of the workpieces are machined, only the workpieces need to be overturned up and down, clamping is convenient, the workload is reduced, and the machining efficiency is improved.

Owner:佛山市银弧机电设备有限公司

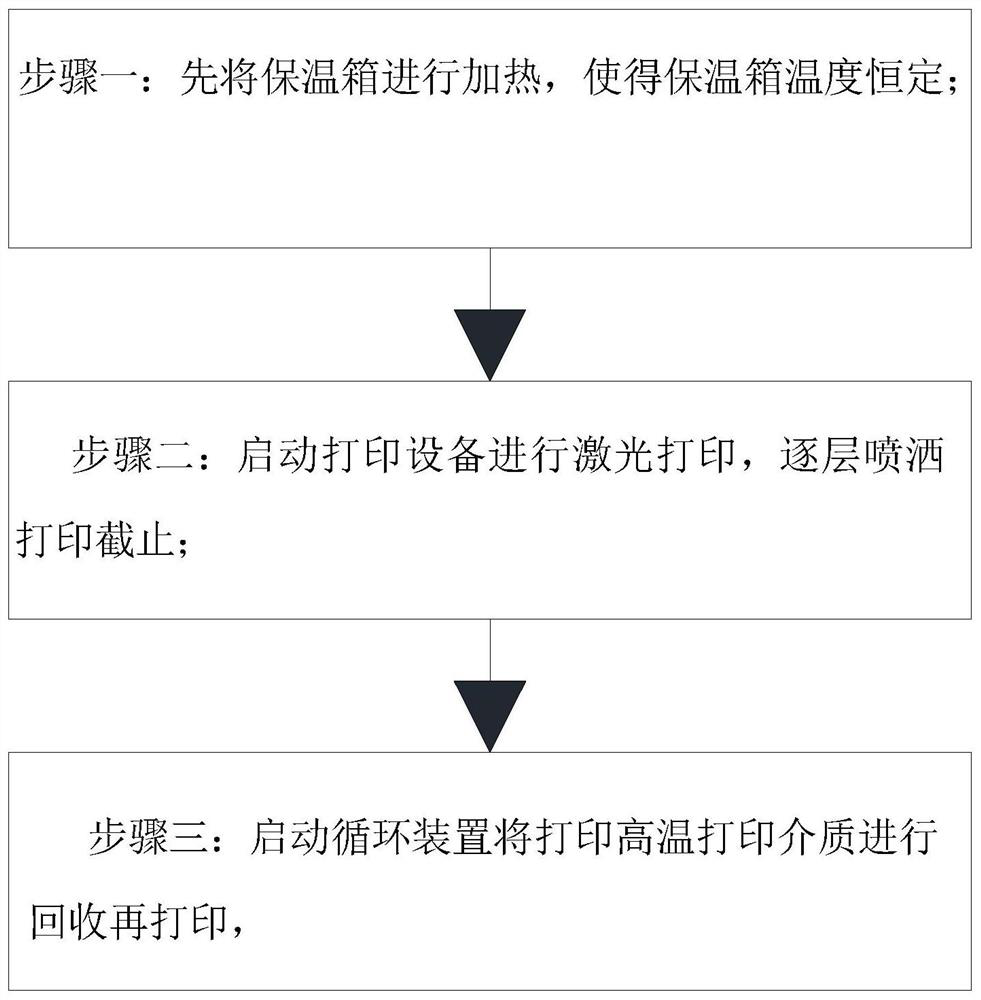

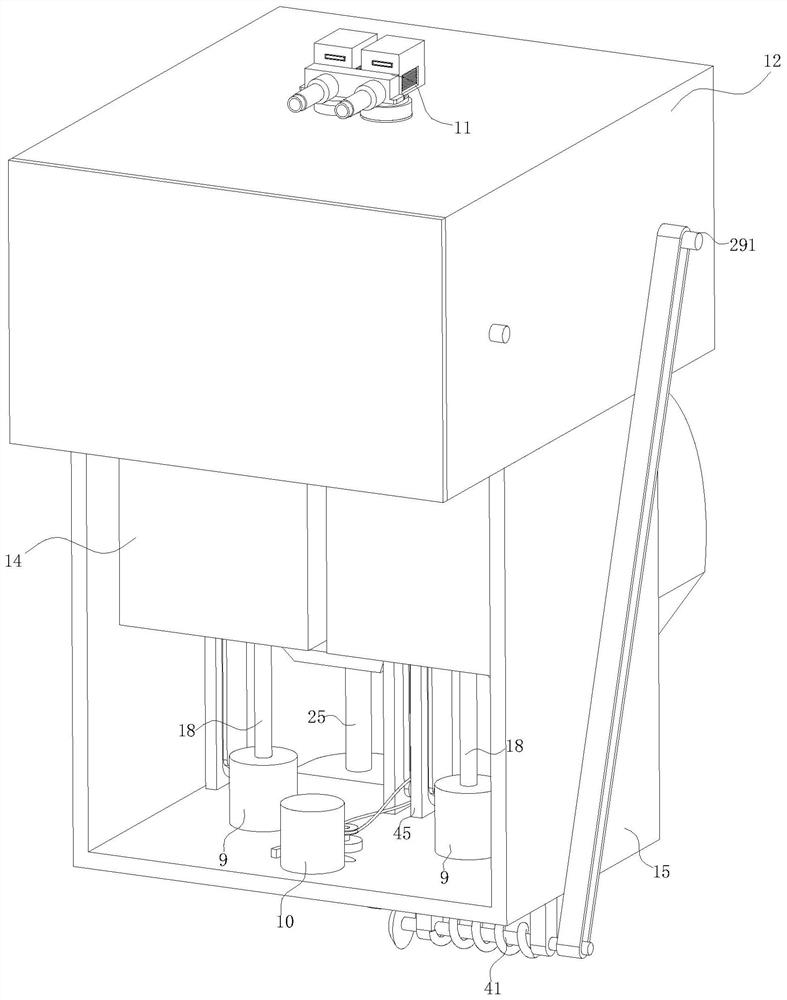

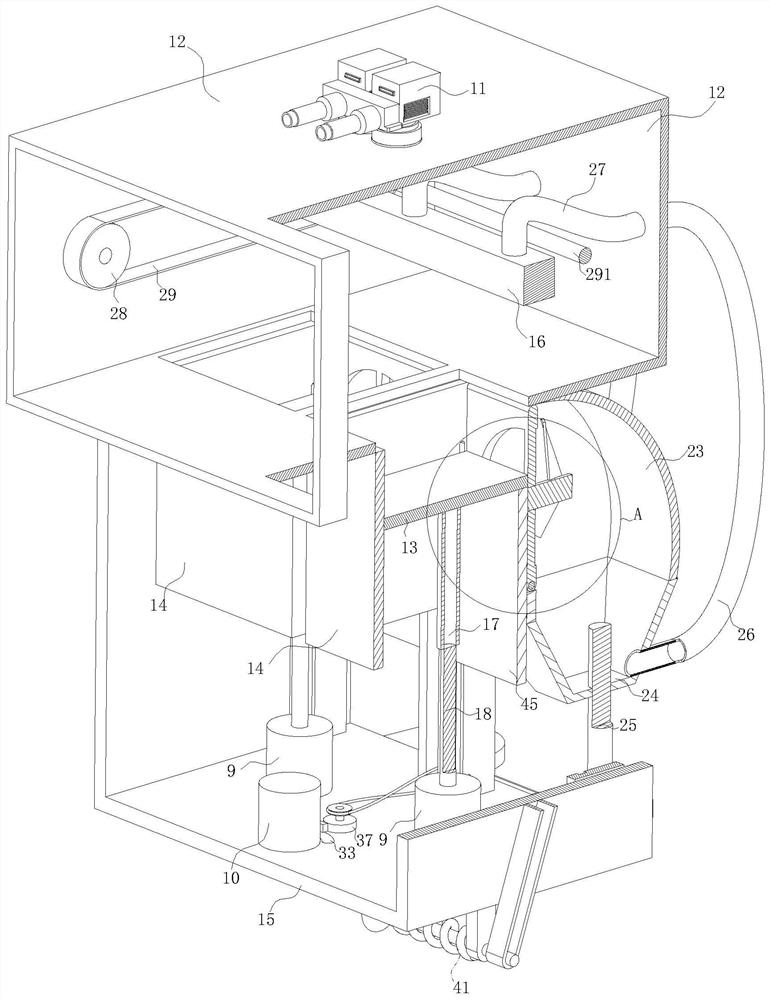

Laser heat recycling method for double-laser printing

ActiveCN113523305AAvoid wastingAvoid random flyingAdditive manufacturing apparatusIncreasing energy efficiencyThermodynamicsComputer printing

The invention discloses a laser heat recycling method for double-laser printing in the technical field of laser printing. The method comprises the specific implementation steps that firstly, a heat preservation box is heated, and the temperature of the heat preservation box is constant; printing equipment is started for laser printing, and layer-by-layer spraying printing is stopped; and a circulating device is started to recycle a printing high-temperature printing medium for reprinting. The problems that when an existing printer is used, the interior of equipment needs to be heated, the equipment is located at the constant temperature for efficient printing, but in the laser printing process, heat on unprinted powder is radiated, when parts are finally taken out, the parts are recycled at a time for reprinting, and consequently heat losses of the laser printer are caused are solved.

Owner:山东创瑞激光科技有限公司

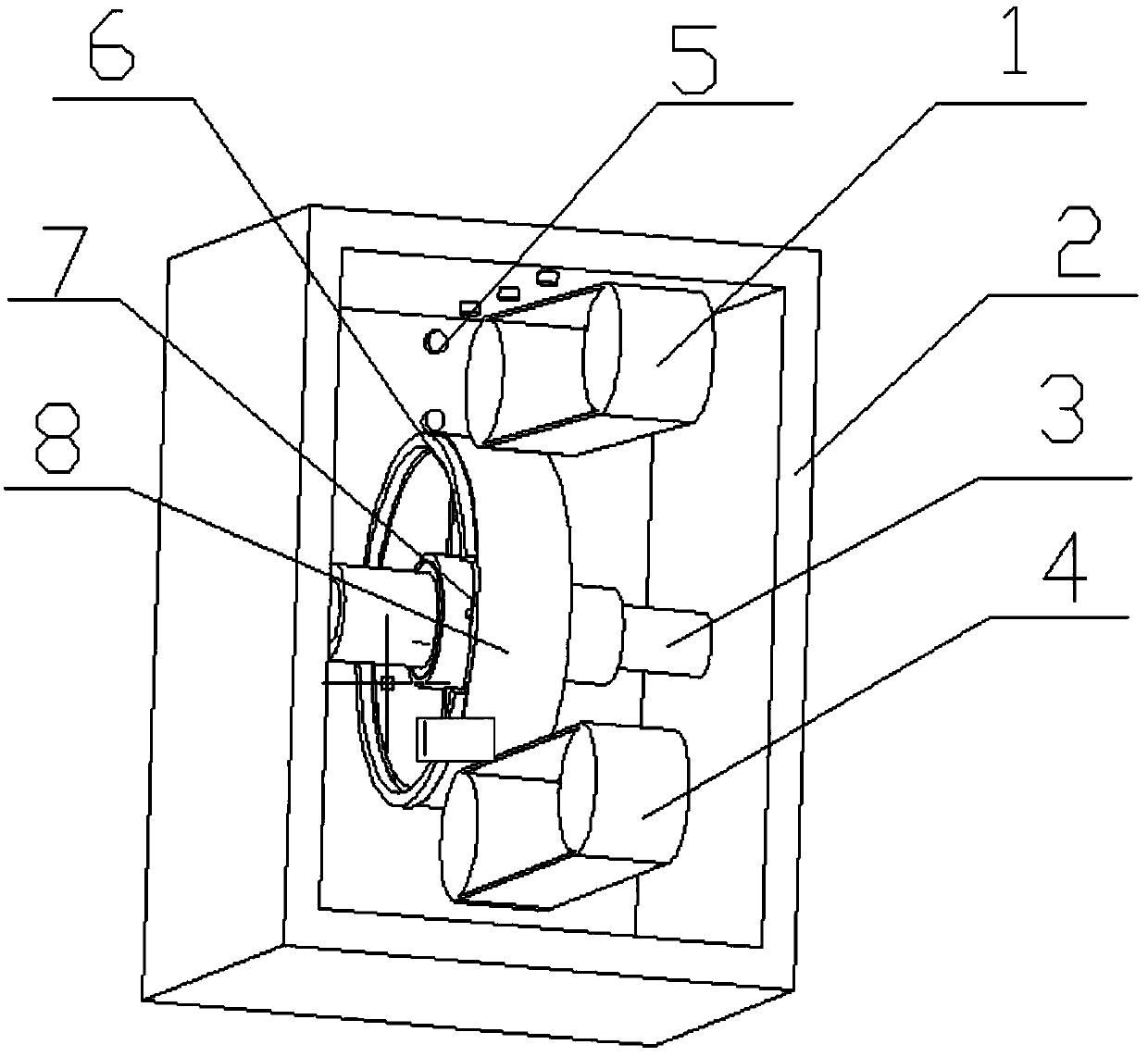

Automatic cleaning device for mandarin duck hotpot

InactiveCN104043607AEasy to cleanAvoid random flyingHollow article cleaningCleaning using liquidsMechanical engineeringElectromagnet

The invention relates to an automatic cleaning device for a mandarin duck hotpot, and belongs to the field of cleaning devices. The automatic cleaning device for the mandarin duck hotpot is composed of a feeding belt, a discharging belt, a large roller, an electromagnet, spraying heads, an electric brush, a box body and a main shaft. The automatic cleaning device for the mandarin duck hotpot is characterized in that the large roller is installed on the main shaft, the main shaft is installed inside the box body, the spraying heads are installed on the two sides inside the box body, the electromagnet is installed on the large roller, the electric brush abuts against the electromagnet, the feeding belt is placed at the upper portion outside the box body, and the discharging belt is arranged at the lower portion outside the box body. The automatic cleaning device for the mandarin duck hotpot has the advantage of being capable of automatically cleaning the mandarin duck hotpot.

Owner:李丽

Crushed plastic sheet sorting device

PendingCN110722712AAvoid random flyingSolve the separation efficiencyPlastic recyclingEngineeringStructural engineering

The invention belongs to the technical field of sorting devices, and particularly relates to a crushed plastic sheet sorting device. The upper end of a machine case is provided with a feeding port, the bottom of the feeding port is connected to a discharging barrel, a first fan, a second fan, a third fan and a fourth fan are arranged in the machine case, the first fan, the second fan and the thirdfan are correspondingly connected to a first light material outlet, a second light material outlet and a third light material outlet, the first fan, the second fan and the third fan are sequentiallyarranged from high to low and from left to right, and the first light material outlet, the second light material outlet and the third light material outlet are correspondingly arranged from high to low and from left to right; and an air outlet of the fourth fan is horizontally connected to outlets of collecting bins, the exteriors of the lower ends of the first light material outlet, the second light material outlet and the third light material outlet are provided with the collecting bins, and the discharging barrel is inclined downwards to sequentially pass through the first light material outlet, the second light material outlet and the third light material outlet.

Owner:东莞市绿丰环保机械有限公司

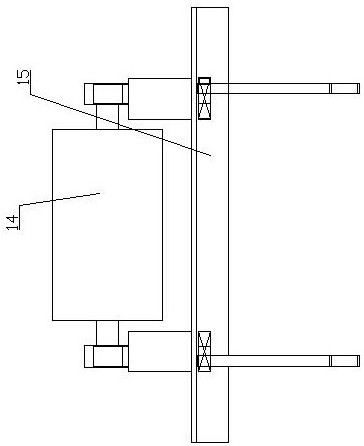

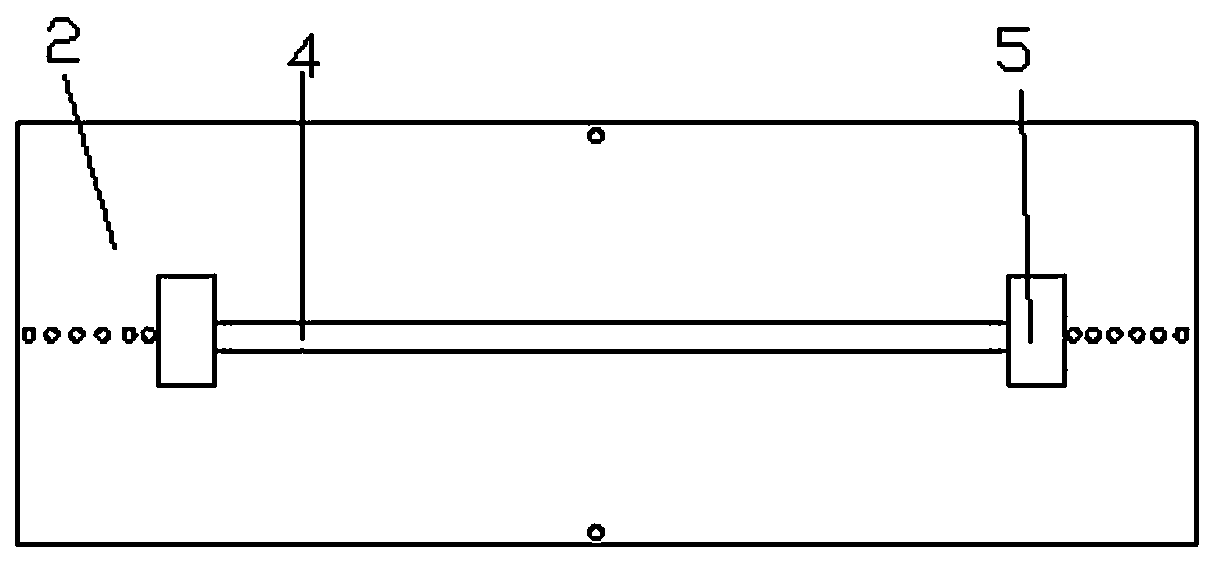

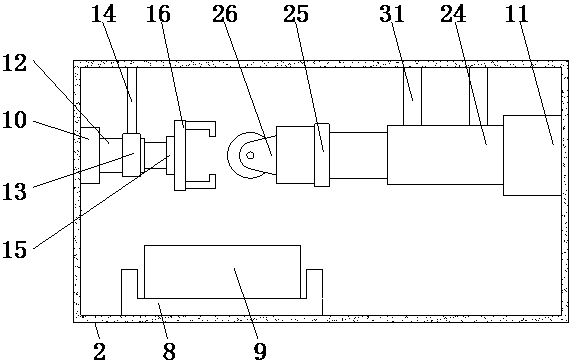

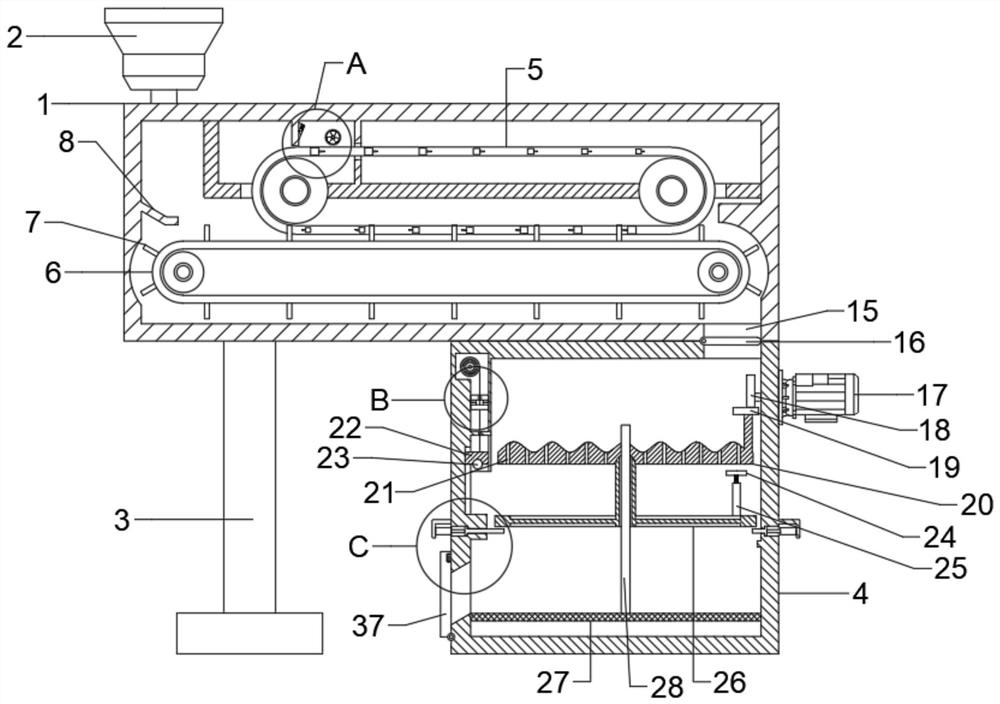

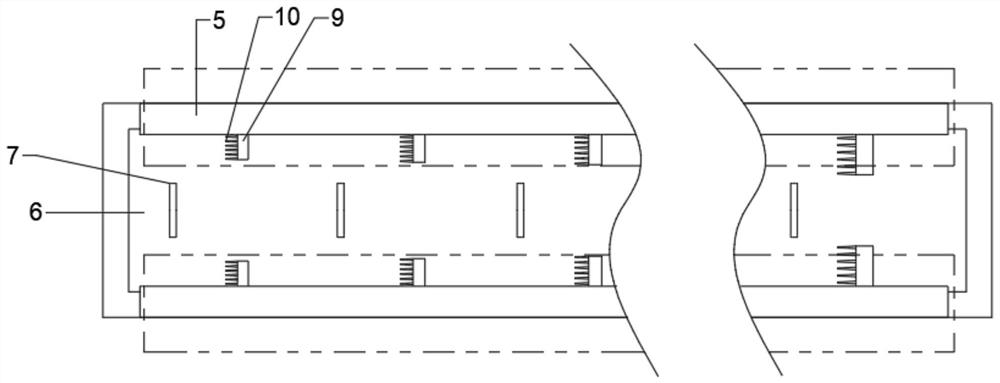

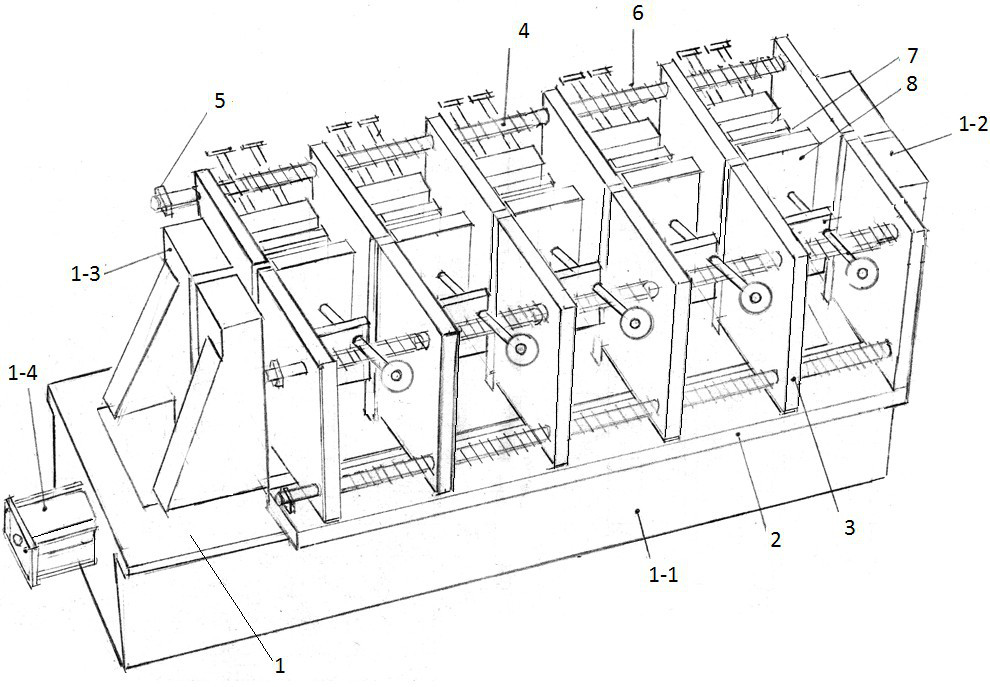

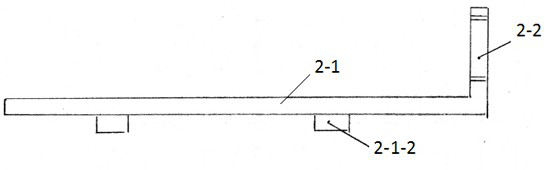

Powdery material belt conveyor and conveying method thereof

InactiveCN111646119ARealize deliverySimple structureConveyorsCleaningElectric machineryStructural engineering

The invention discloses a powdery material belt conveyor and a conveying method thereof. The belt conveyor comprises a conveyor belt, a feeding port is formed in the front end of the conveyor belt, adischarging port is formed in the rear end of the conveyor belt, and the belt conveyor further comprises a transmission mechanism, a protective mechanism and a slip detection mechanism; the transmission mechanism comprises a motor, a driven roller and a transmission roller connected with an output shaft of the motor in a transmission mode, and the conveyor belt is arranged between the driven roller and the transmission roller in a transmission mode; the protective mechanism comprises a protective groove, a protective cover is arranged at the top of the protective groove, and the conveyor beltis arranged in the protective groove; and the slip detection mechanism comprises flow detection devices arranged at the feeding port and the discharging port. According to the powdery material belt conveyor and the conveying method thereof, the conveying of powdery materials can be achieved, the phenomenon of powder material flying disorderly is effectively avoided, meanwhile reminding is timely conducted when the conveyor belt slips, and in addition, the transmission mechanism has high transmission efficiency, stable transmission process and low energy consumption.

Owner:PINGDINGSHAN UNIVERSITY

Method for cleaning waste during die punching

The invention relates to the technical field of hardware, in particular to a method for cleaning waste through die punching, which comprises a die main body, an integrally formed waste discharge hole is formed in the center of the surface of the die main body, a rubber ring is arranged at the edge of the waste discharge hole, rubber is reserved on the surface of the rubber ring, and a bottom film is arranged on the surface of the die main body. The use method comprises the following steps: 1, comprehensively rubberizing the surface of the die main body; 2, remaining rubber in the middle of the rubber ring at the waste discharge hole; 3, pasting a rubber ring on the waste discharge hole to the bottom film; 4, directly sticking release paper on the surface of the die main body; and 5, aligning a drilling tool to the release paper for punching, arranging punching rings on the two sides of the waste discharge hole, and an integrally formed positioning ring is arranged on the surface of the punching ring. The method has the beneficial effects that the punching ring is arranged, so that the whole die can be conveniently fixed by a punching part through the punching ring, and the phenomenon that the die deviates during punching is prevented.

Owner:SUZHOU TIANLIDA ADHESIVE PROD CO LTD

An automatic cleaning device for mandarin duck hot pot

InactiveCN104043607BEasy to cleanAvoid random flyingHollow article cleaningCleaning using liquidsEngineeringMechanical engineering

The invention relates to an automatic cleaning device for a mandarin duck hotpot, and belongs to the field of cleaning devices. The automatic cleaning device for the mandarin duck hotpot is composed of a feeding belt, a discharging belt, a large roller, an electromagnet, spraying heads, an electric brush, a box body and a main shaft. The automatic cleaning device for the mandarin duck hotpot is characterized in that the large roller is installed on the main shaft, the main shaft is installed inside the box body, the spraying heads are installed on the two sides inside the box body, the electromagnet is installed on the large roller, the electric brush abuts against the electromagnet, the feeding belt is placed at the upper portion outside the box body, and the discharging belt is arranged at the lower portion outside the box body. The automatic cleaning device for the mandarin duck hotpot has the advantage of being capable of automatically cleaning the mandarin duck hotpot.

Owner:李丽

High-efficient wood cutting device

InactiveCN107627402AImprove practicalityExtended service lifeProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringPulp and paper industry

The invention discloses a high-efficient wood cutting device, which comprises a supporting table. A cutting table is located on the supporting table; supporting columns are fixedly connected to the bottom part of the cutting table; the other ends of the supporting columns are fixedly connected to the top part of the supporting table; a sliding chute is formed in the cutting table; baffle plates are arranged at two ends of the sliding chute; the bottom ends of the baffle plates are fixedly connected with the cutting table; a gear is arranged on the cutting table; a rotating wheel is fixedly connected onto the gear; a supporting plate is fixedly connected in the middle parts of the supporting columns; a motor is arranged on the supporting plate; and the rotating wheel is arranged at the bottom end of the motor, and is movably connected with the supporting plate. The high-efficient wood cutting device has the beneficial effects that through the arrangement of a cover top, a cover body, aninner-layer cover top and an inner-layer cover body, the working table has a sealing space with a changeable size, so that the practicability of the cutting device is improved; when woods are cut, the occurrence of the phenomenon that wood bits fly disorderly is avoided, so that the cleanliness of a workplace is better maintained; and with actions of a suction machine and an air blower, the woodbits at corners of the working table are collected.

Owner:罗院昌

A steel bar cutting device with stable clamping function

Owner:佛山市顺德区海众金属制品有限公司

An iml injection molding automation system

The invention discloses an IML injection molding automation system, which includes a sheet storage mechanism, a sheet transfer mechanism and a material opening cutting seat. The sheet storage mechanism has a sheet access seat for storing a stack of film sheets, and a single film The sheet storage seat where the sheet is placed and the sheet suction seat that sucks the film sheet in the sheet storage seat and places it in the sheet storage seat; the sheet transfer mechanism has a The film sheet is sucked and placed in the injection mold, and the formed IML decorative parts in the injection mold are sucked out of the sheet transfer seat outside the injection mold; the cutting seat of the material port has a positioning slot for the placement of the IML decorative parts, and the IML decorative parts The cutting blade and waste conveying channel of the material port. Compared with the existing technology, it adopts fully automatic continuous operation and unmanned production, which greatly improves the overall work efficiency, has the advantages of accurate removal and high safety system, and can ensure that the cut surface of IML decorative parts is relatively smooth without affecting Appearance quality.

Owner:通达(石狮)科技有限公司

Fault alarm device for intelligent manufacturing

ActiveCN112452924AAutomatic rotationReduce stepsUsing liquid separation agentDirt cleaningSmart manufacturingAlarm device

The invention relates to an alarm device, in particular to a fault alarm device for intelligent manufacturing. The fault alarm device for intelligent manufacturing can automatically clean a fault alarm device body and can sensitively give an alarm. The fault alarm device for intelligent manufacturing comprises an alarm cabinet, a fan arranged on the alarm cabinet, a dust collector arranged on thealarm cabinet, a dust collection frame arranged on the alarm cabinet in a sliding manner, a covering mechanism arranged on the alarm cabinet, and a rotating mechanism arranged on the alarm cabinet. Through the arrangement of the covering mechanism, the covering mechanism divides the device into an upper layer and a lower layer, so that an operator cleans dust on the lower layer conveniently; and by arranging the rotating mechanism, the rotating mechanism can automatically drive a winding wheel to rotate, and the winding wheel does not need to be rotated manually.

Owner:广州市丰兆电子科技有限公司

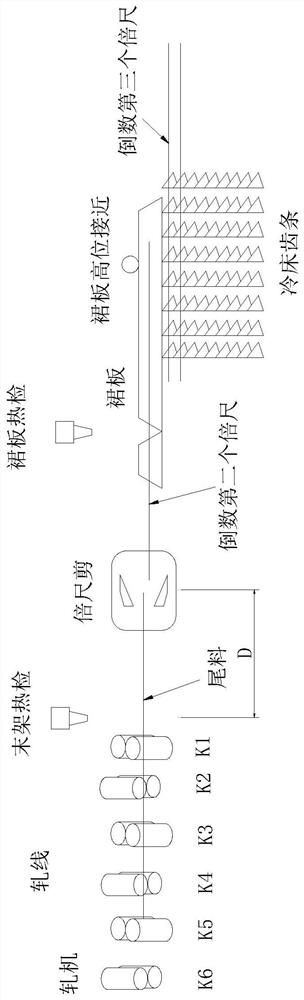

Cooling bed rack control method

ActiveCN111672914BIncrease production capacityIncrease productivityRare end control deviceCooling bedsThermodynamicsTime control

The invention discloses a cooling bed rack control method, comprising the following steps: a. obtaining the length L of the steel bar tail when the steel bar tail hits the rack; b. obtaining the length L of the steel bar tail, and the steel bar tail at position S on the rolling line; c, collect the shear signal and the steel bite signal at position S, and send it to the cooling bed PLC; d, the cooling bed PLC judges the size between the length l and L of the actual steel bar tailings, if If the length l of the actual rebar tail is less than L, a signal X is generated and the delay time TL is input; e. When the signal X is generated, the delay TL time controls the cooling bed rack to stop until the rebar tail reaches the cooling bed rack , the cooling bed rack is allowed to continue to move, so as to avoid the steel tailings hitting the cooling bed rack. The tailings of steel bars in the invention will not collide with the cooling bed rack, which has the characteristics of reducing product loss, increasing income, reducing the incidence of safety accidents, and reducing labor intensity of workers.

Owner:浙江富钢集团有限公司

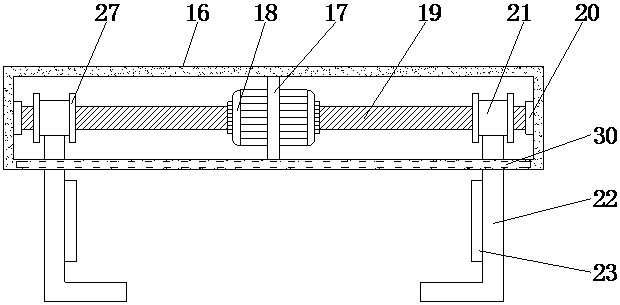

Wool processing device for textile industry

InactiveCN112251853AAvoid getting stuckAvoid random flyingFibre cleaning/opening by toothed membersWool fibre washing/scouringWoolManufacturing engineering

The invention relates to the technical field of textile devices, in particular to a wool processing device for textile industry. The wool processing device for textile industry comprises a conveying box, a support column and a cleaning box, wherein the support column is fixedly mounted on the conveying box, the conveying box and the cleaning box are fixedly mounted, the conveying box is provided with a feed inlet, a loosening mechanism is arranged in the conveying box, the loosening mechanism comprises a set of first conveying belts and a set of second conveying belts, the first conveying belts and the second conveying belts are rotationally installed in the conveying box, the first conveying belts are longitudinally and symmetrically distributed on two sides of the second conveying belts,conveying plates are arranged on the second conveying belts at equal intervals, comb plates are symmetrically and fixedly installed on the first conveying belts at equal intervals, comb tips matchedwith the comb plate are fixed to each comb plate, a baffle is fixedly installed on the conveying box, and a main fan used for removing wool on the comb tips is fixedly installed on the baffle.

Owner:蒋秀兰

A fault alarm device for intelligent manufacturing

ActiveCN112452924BAutomatic rotationReduce stepsUsing liquid separation agentDirt cleaningSmart manufacturingAlarm device

The invention relates to an alarm device, in particular to a failure alarm device for intelligent manufacturing. The invention provides a fault alarm device capable of automatic cleaning and a fault alarm device for intelligent manufacturing capable of sensitive alarm. A failure alarm device for intelligent manufacturing, comprising: an alarm cabinet and a fan, the alarm cabinet is provided with a fan; a vacuum cleaner, the alarm cabinet is provided with a vacuum cleaner; a dust collection frame, the alarm cabinet is slidingly provided with a dust collection frame; a covering mechanism , the alarm cabinet is provided with a covering mechanism; the rotating mechanism is provided with a rotating mechanism on the alarm cabinet. The present invention is provided with a covering mechanism, which will separate the present invention into two parts, the upper layer and the lower layer, so that the operator can clean up the dust on the lower layer; the present invention is provided with a rotating mechanism, which can automatically drive the reel to rotate, without It is necessary to manually turn the reel by hand.

Owner:广州市丰兆电子科技有限公司

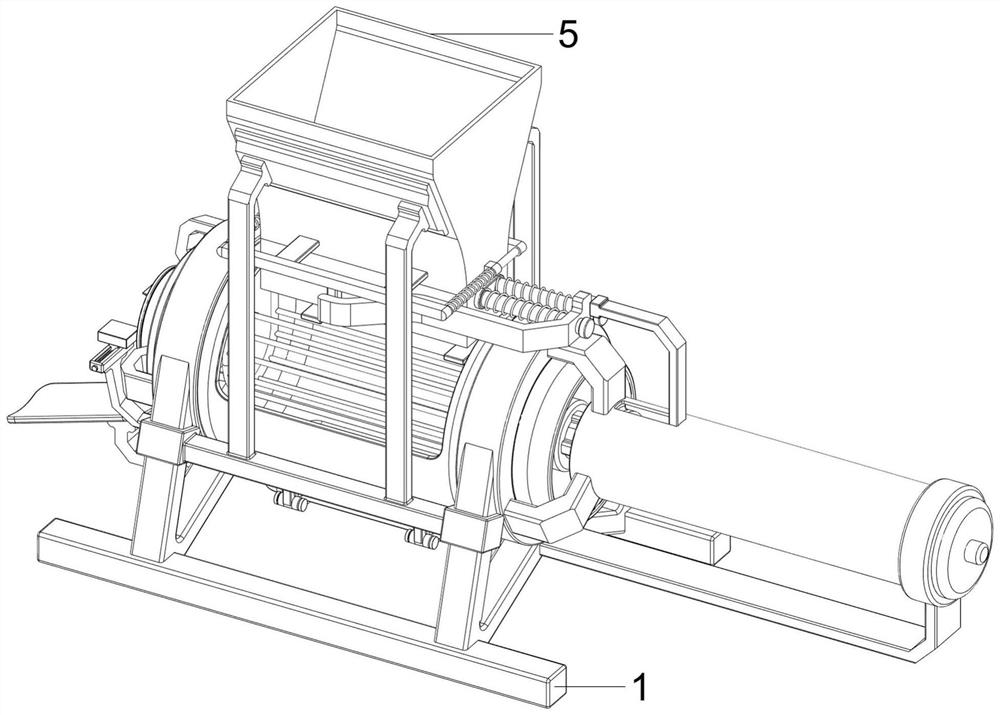

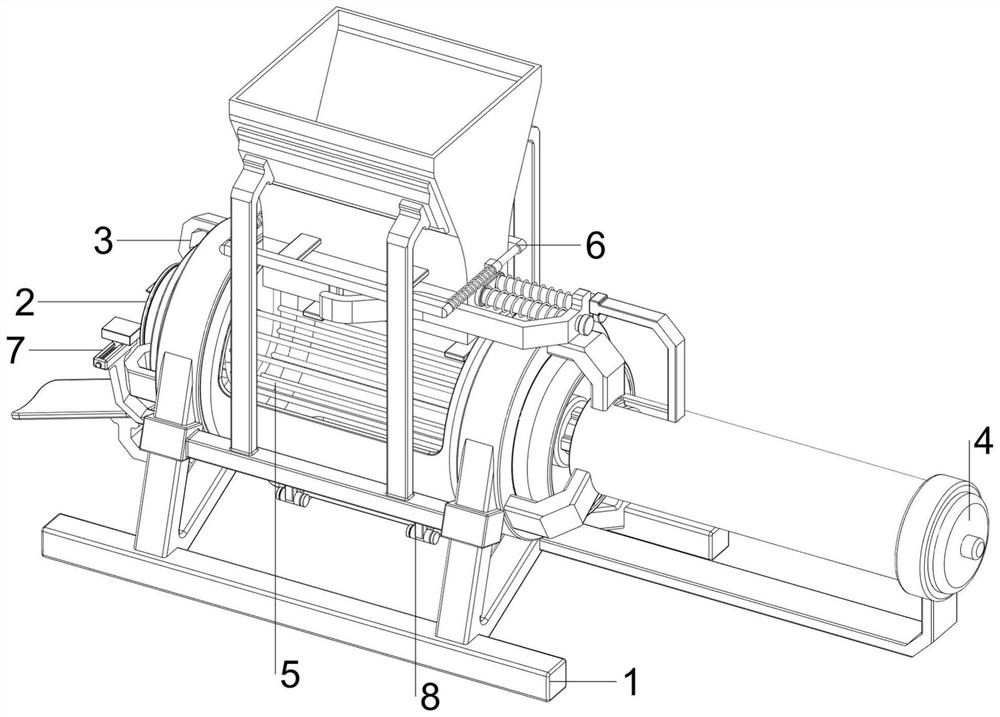

Hammer-type straw pulverizer

The invention discloses a hammer-type straw pulverizer, comprising a pulverizing chamber, a hammer rack rotationally arranged in the pulverizing chamber, a first pulverizing tool, a second pulverizingtool and a first quick change device allowing the first pulverizing tool to be releasably connected with the hammer rack and allowing the first pulverizing tool and the hammer rack to be relatively fixed when operating. The hammer-type straw pulverizer has the advantages that the pulverizing tools are convenient to change, so that tool changing efficiency is greatly improved; a vacuum device is used, pulverized particles can be sucked directly into a collecting device under air suction effect, and dusting can be well avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Platen wood cutting device for papermaking

ActiveCN107511886BAvoid cutting damageEasy to cutGuide fencesProfiling/shaping machinesPapermakingEngineering

The invention relates to the field of papermaking equipment, and provides a pressing plate type wood cutting device for papermaking in order to solve the problem that when a tree is cut with an existing cutting device, the tree deviates from the initial position due to the fact that vibration can be generated when a cutting knife makes contact with the tree, and the tree is wrongly cut. The pressing plate type wood cutting device for papermaking comprises a cutting platform and a cutting mechanism, the cutting mechanism comprises a cutting knife and an air cylinder, a pressing plate is connected to the lower end of a piston rod of the air cylinder, the cutting knife is connected to the pressing plate, and the tree is cut with the cutting knife after being pressed with the pressing plate. The pressing plate type wood cutting device for papermaking further comprises a collecting box, a partition plate is slidably connected to the interior of the collecting box, convex blocks are arranged on the inner wall of the upper end of the collecting box, and water outlet plates are arranged on the partition plate and can be opened downwards under the action of the convex blocks; water absorption parts are arranged on the bottom face of the collecting box, an outlet is formed in the bottom of the collecting box, a filter screen is installed in the outlet, a water outlet pipe is connected to the outlet, and a driving rod is arranged on the upper end face of the partition plate and connected with the piston of the air cylinder.

Owner:CHONGQING SAN HAO PAPER IND

Efficient grinding equipment for metal casting

InactiveCN113386022AEasy to operateReduce laborGrinding drivesGrinding machinesGear wheelEngineering

The invention discloses efficient grinding equipment for metal casting. The efficient grinding equipment for metal casting comprises a device body, wherein a back plate is vertically installed at the position, close to the edge, of the surface of the top of the device body, fixing blocks are symmetrically installed on the surface of the back plate, sliding rails are arranged on the surfaces of the fixing blocks, and an adjusting plate is arranged between the two fixing blocks; and sliding blocks are arranged at the two ends of the adjusting plate, the adjusting plate is slidably connected with the sliding rails through the sliding blocks, a spur rack is arranged on the surface of the bottom end of the adjusting plate, a supporting plate is arranged on the surface of the back plate, and a second rotating rod is movably connected to the surface of the supporting plate. According to the efficient grinding equipment, through the cooperative use of the back plate, the fixing blocks, the adjusting plate, the sliding rails, the sliding blocks, a mounting plate, the spur rack, the second rotating rod, a second adjusting wheel and a second driving gear, operation of a grinding mechanism is facilitated, the traditional mode that a worker manually picks up the grinding mechanism for grinding is changed, the labor amount of the worker is reduced, and the working efficiency of the device body is also improved.

Owner:江西维海机械设备有限公司

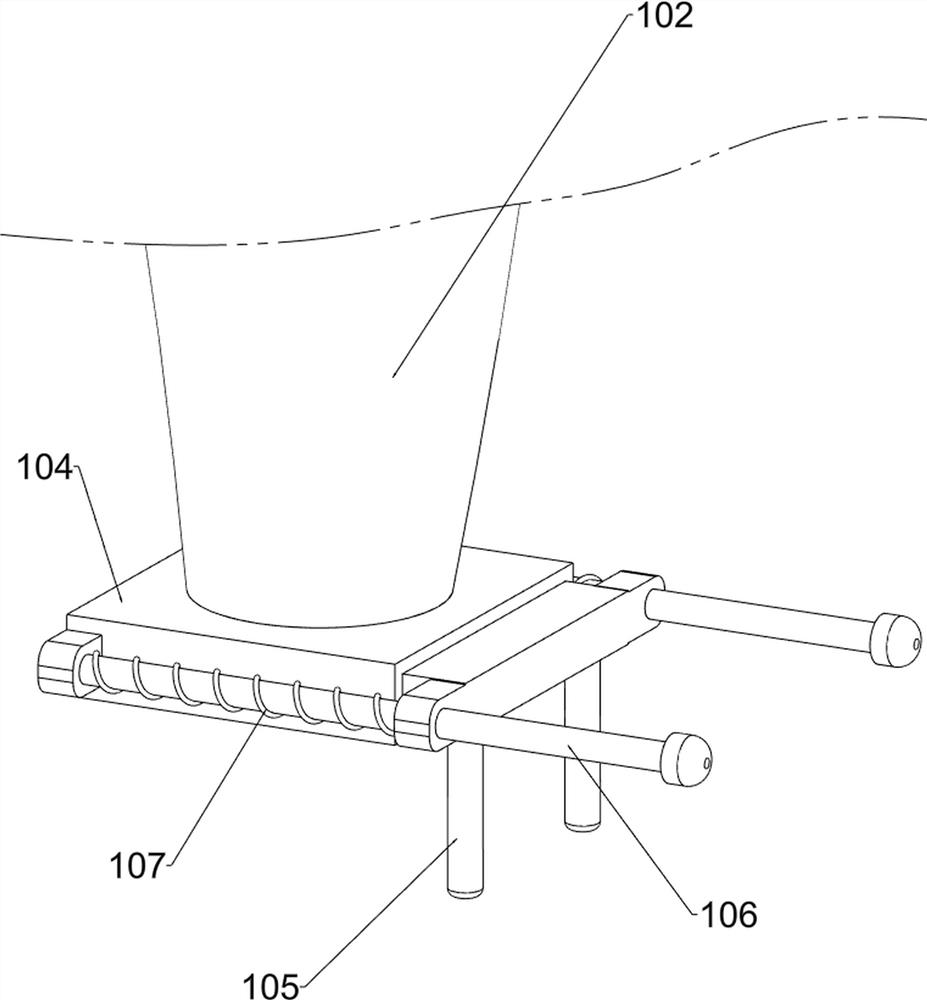

A kind of aggregate screening equipment for concrete

ActiveCN112320228BLabor saving effectImprove collection efficiencySievingScreeningArchitectural engineeringStructural engineering

The invention relates to screening equipment, in particular to an aggregate screening equipment for concrete. The invention provides time-saving and labor-saving aggregate screening equipment for concrete, which has high practicability, good screening effect and automatic aggregate transmission. A kind of aggregate screening equipment for concrete, comprising: a base, a collecting frame is arranged in the middle of the top of the base; , set on the base, the telescopic rod is slidingly connected with the hollow column; the first spring, the first spring is set on the lower part of the telescopic rod; the screening frame, the screening frame is arranged between the telescopic rods; There is a brushing mechanism; a feeding mechanism, and a feeding mechanism is provided on the base. The invention is provided with a screw rod, which can automatically transfer the concrete aggregate from the bottom to the top, and achieves the labor-saving effect.

Owner:兰溪市环城建材有限公司

Impurity identification and elimination structure on color sorter

The invention discloses an impurity identification and elimination structure on a color sorter. The impurity identification and elimination structure comprises a laser head assembly and a nozzle assembly used for eliminating impurities, wherein the nozzle assembly comprises a nozzle rear cover and a nozzle formed in the nozzle rear cover; the nozzle is connected to a nozzle installation cross beam; the nozzle installation cross beam is connected with a nozzle adjustment plate used for adjusting the angle of the nozzle; an illumination lamp and a background lamp are arranged at the two sides ofthe nozzle separately; the laser head assembly comprises a laser head and a laser head support; the upper end of the laser head support is connected with a color sorter rack; the lower end of the laser head support is connected with a laser head installation plate; a laser head installation hole used for placing the laser head is formed in the laser head installation plate; and a laser head coverplate is arranged at the outer end of the laser head. The impurity identification and elimination structure disclosed by the invention is capable of eliminating foreign matters such as peanuts or soybeans with interior mildew, and good in color sorting effect.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

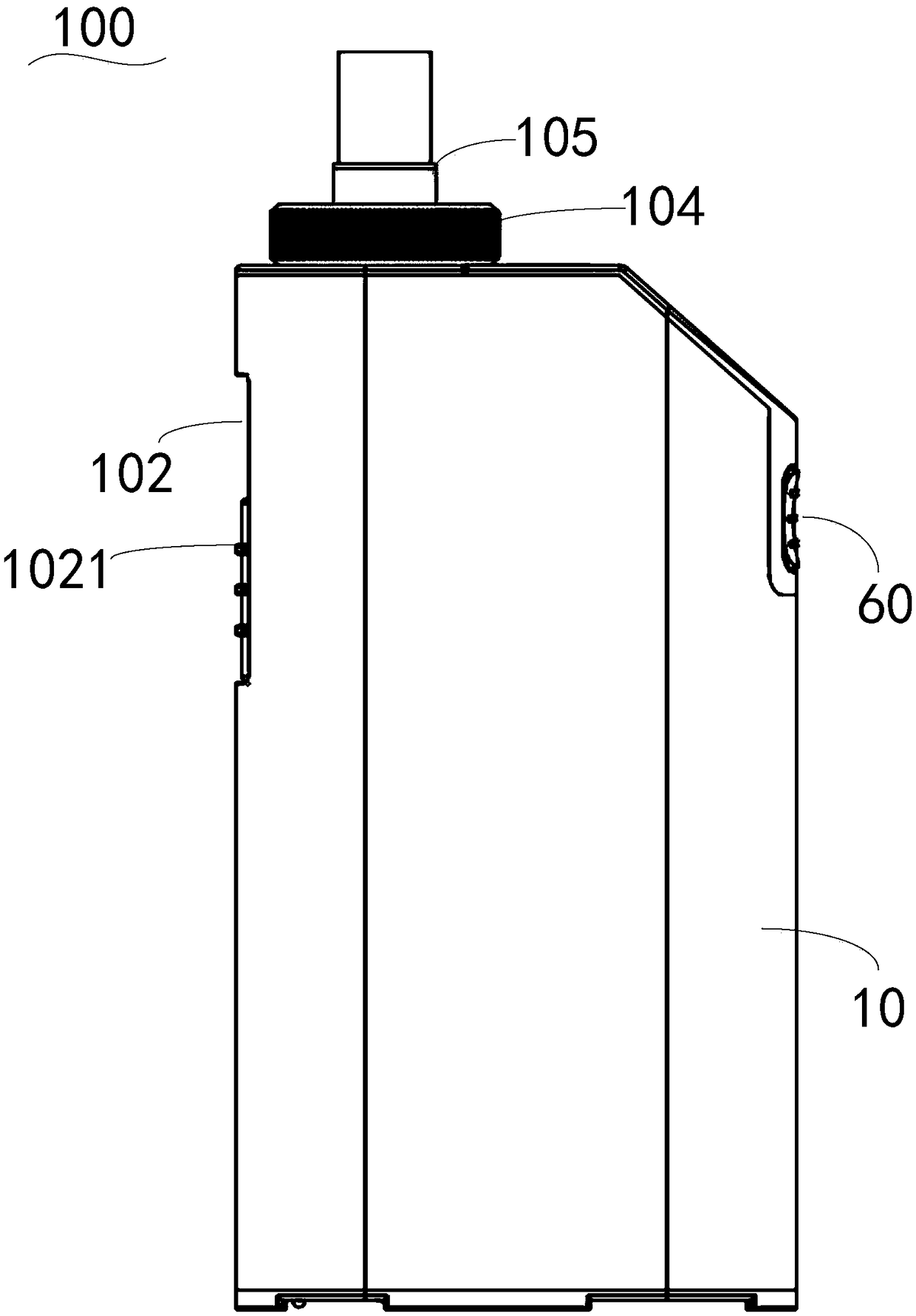

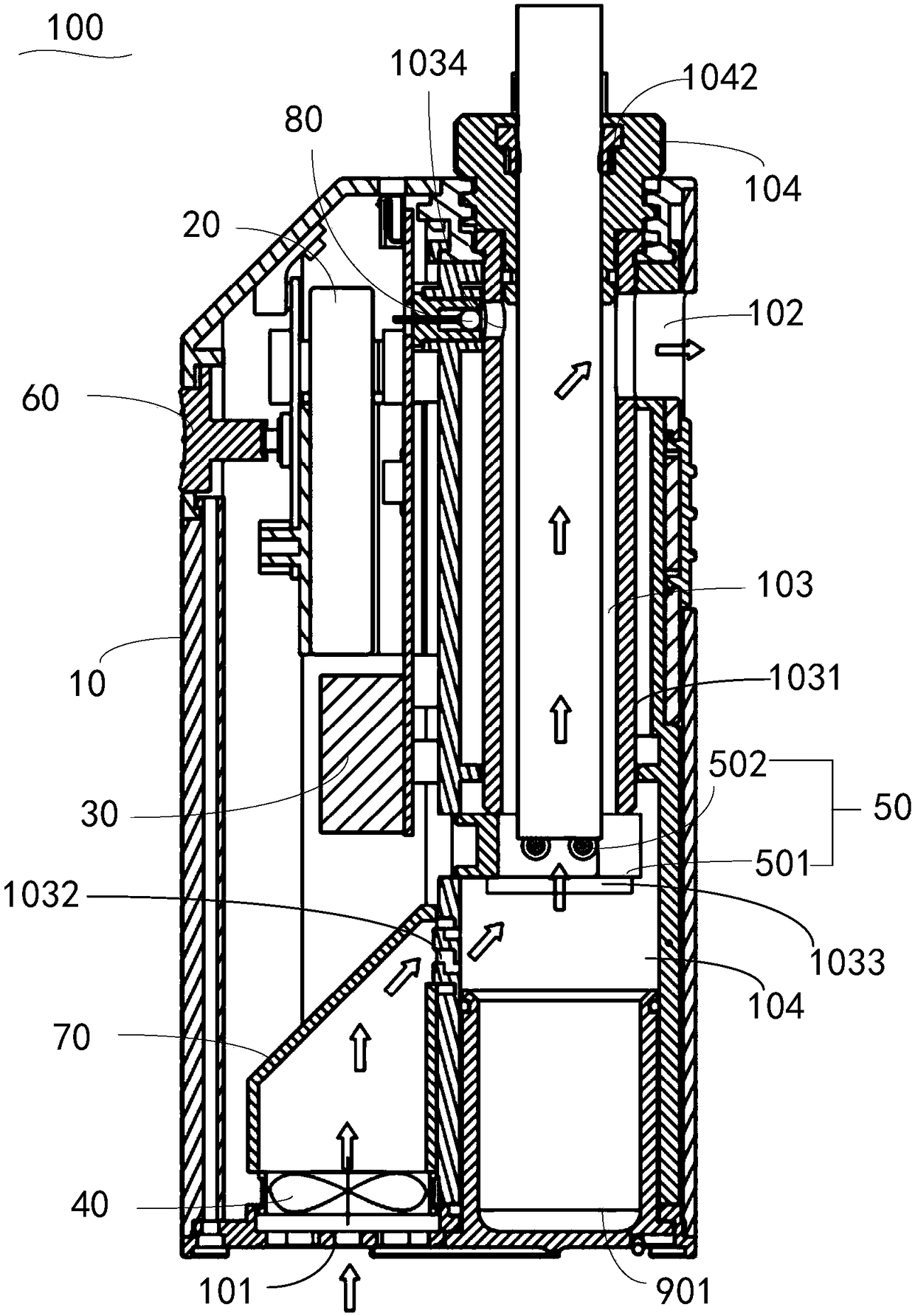

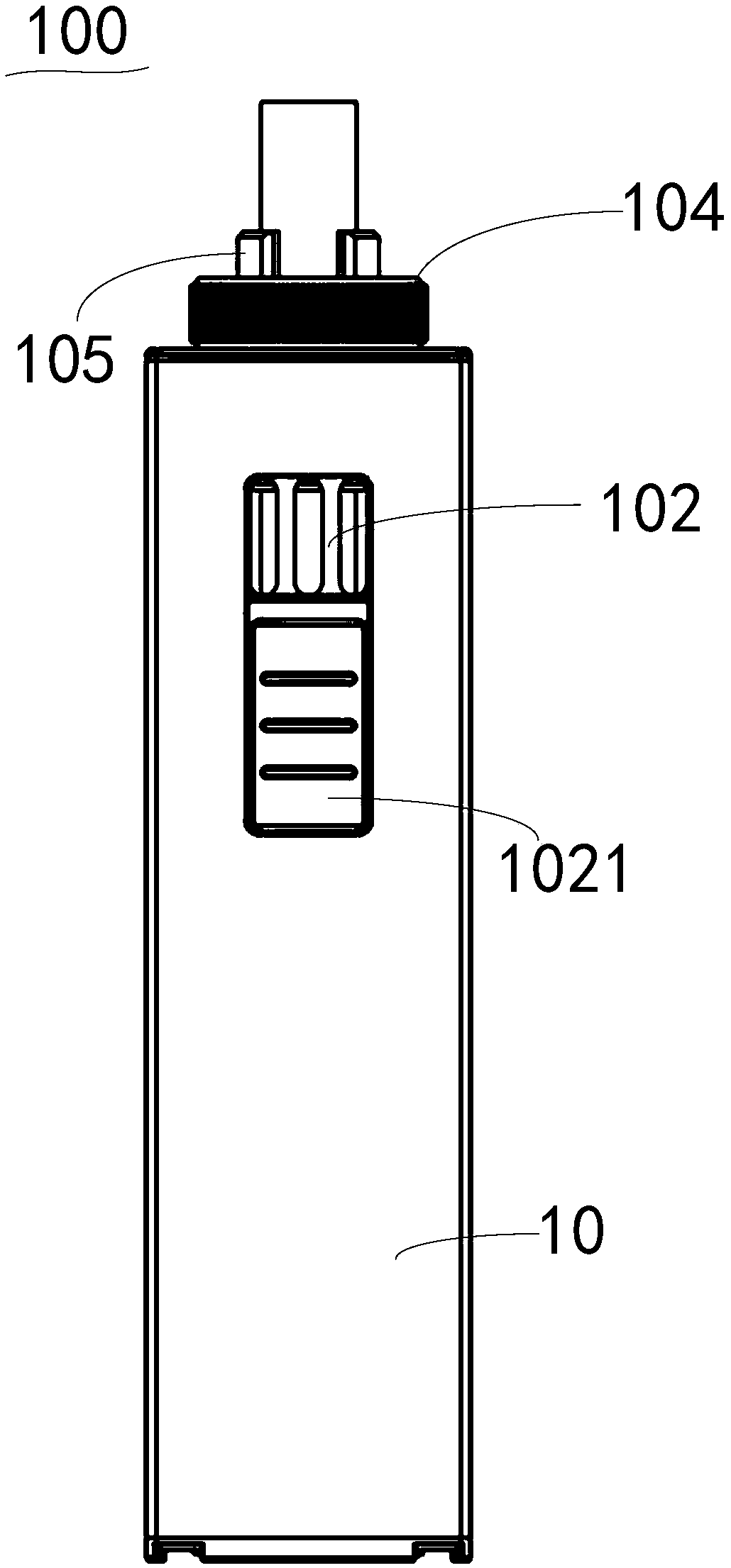

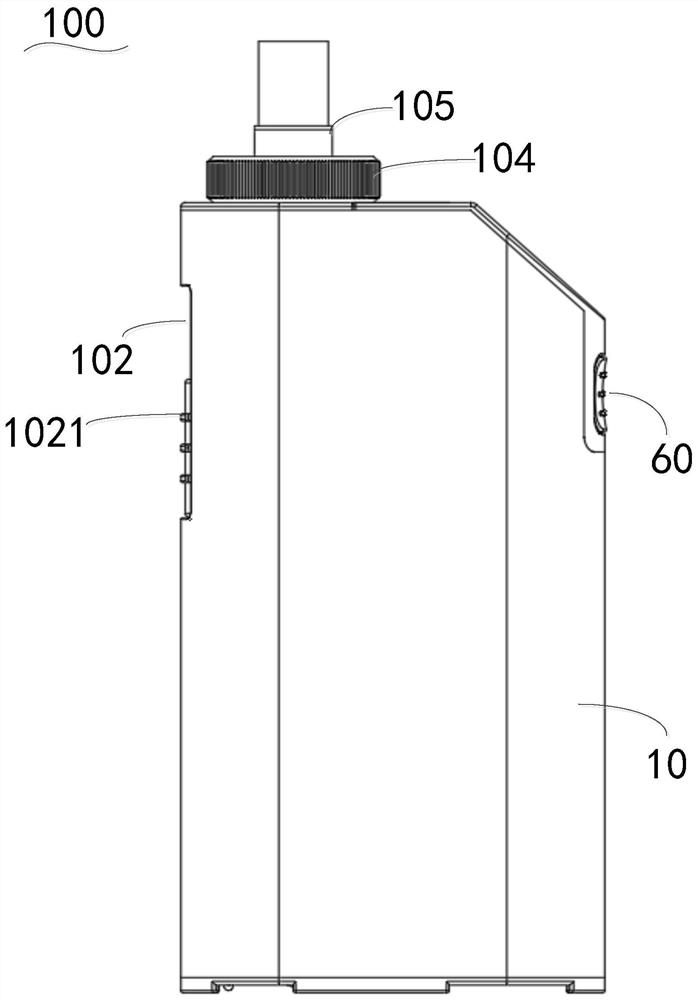

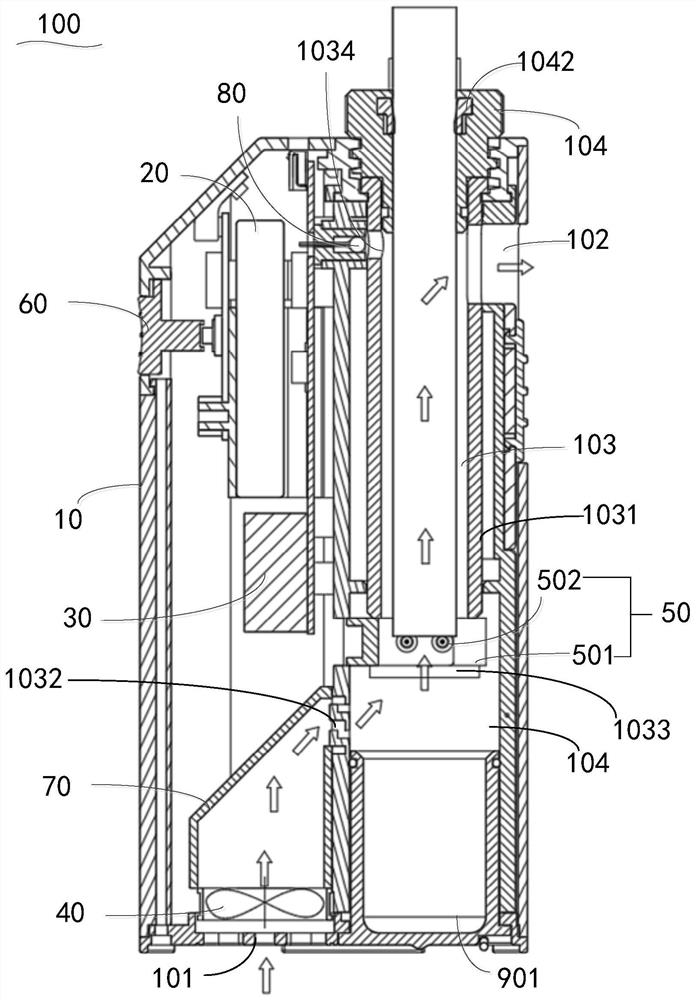

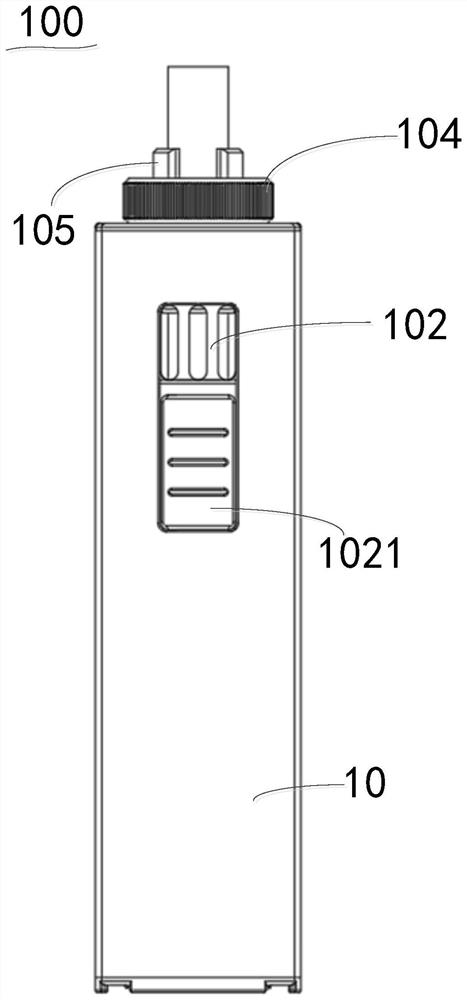

Electronic cigarette

ActiveCN108851241AAvoid random flyingAvoid environmental pollutionTobacco devicesElectronic cigaretteEngineering

The invention relates to field of cigarette utensils, and discloses an electronic cigarette, which comprises a box body, wherein the box body is provided with a smoke cavity, a cavity opening, an airinlet and an air outlet, the air outlet is arranged at the side wall of the box body and is communicated with the smoke cavity; the top end of the smoke cavity is communicated with the cavity opening;the bottom end of the smoke cavity is positioned at the bottom of the box body, the air inlet is arranged at the bottom of the box body, away from the smoke cavity, and the smoke cavity is used for containing real cigarettes; a vent pipe, wherein one end of the vent pipe is communicated with the air inlet, and the other end is communicated with the smoke cavity; a collecting box, wherein the collecting box is positioned at the bottom end of the smoke cavity, the opening of the collecting box is arranged towards the cavity opening, the joint where the vent pipe is connected with the smoke cavity is positioned above the collecting box, the collecting box is used for collecting cigarette ash, the cigarette ash can fall into the collecting box, the phenomenon that the cigarette ash flies randomly is solved when the real cigarettes are smoked, so that the technical problem that the cigarette ash falls on the body, which damages the cloths, is solved, and moreover, the cigarette ash is collected through the collecting box, so that the phenomenon of environmental pollution of the cigarette ash is avoided.

Owner:龙其壹

Straw crushing method

ActiveCN109479537BImprove crushing efficiencySpeed up the flowCuttersSuction forcePulp and paper industry

The invention discloses a straw pulverizing method, which adopts a hammer-type straw pulverizer, and comprises the steps of: S1, putting the straw into the hammer-type straw pulverizer; S2, pulverizing the straw by the hammer-type straw pulverizer, Forming granular materials; S3, bagging the materials; wherein, in step S2, a negative pressure is generated by the suction device of the hammer-type straw grinder, so that the materials enter the discharge hopper. The straw crushing method of the present invention adopts a hammer-type straw crushing machine with a negative pressure device, which can directly suck the crushed particles into the collecting device through the suction of the air, so as to ensure smooth material flow and improve the working efficiency of straw crushing , and can well avoid the phenomenon of dust flying.

Owner:ANHUI POLYTECHNIC UNIV

Machine tool for processing inclined iron

ActiveCN111112743BImprove ergonomicsEasy to operateMetal sawing accessoriesPositioning apparatusMachineMachine tool

Owner:陈学山

an electronic cigarette

ActiveCN108851241BAvoid random flyingAvoid environmental pollutionTobacco devicesTobaccoElectronic cigarettePolluted environment

The present invention relates to the field of smoking accessories, and discloses an electronic cigarette, comprising: a box body, which is provided with a smoke cavity, a cavity opening, an air inlet and an air outlet, and the air outlet is arranged on the side wall of the box body and connected to the cigarette The top of the smoke cavity communicates with the mouth of the cavity, the bottom of the smoke cavity is located at the bottom of the box body, the air inlet is set at the bottom of the box body and away from the position of the smoke cavity, the smoke cavity The cavity is used to hold real cigarettes; the ventilation pipe, one end of the ventilation pipe communicates with the air inlet, and the other end communicates with the smoke cavity; the collection box is located at the bottom of the smoke cavity, and the opening of the collection box It is arranged towards the mouth of the mouth, and the position where the ventilation pipe is connected with the smoke chamber is located above the collection box, which is used to collect soot, and the soot will fall into the collection box, avoiding the ash from being sucked when smoking real cigarettes. The phenomenon of flying randomly, thereby solving the technical problem of soot falling on the body and damaging clothes. Secondly, collecting soot through the collection box avoids the phenomenon of soot polluting the environment.

Owner:龙其壹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com