Machine tool for processing inclined iron

A technology of machine tools and inclined irons, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of slow processing speed, severe tool loss, and difficult operation of milling machines, so as to avoid random flying of iron filings and improve work efficiency. The effect of improving and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it should not be understood as a limitation on the technical solution, and the adaptive improvements on this basis all belong to the protection scope of the present invention.

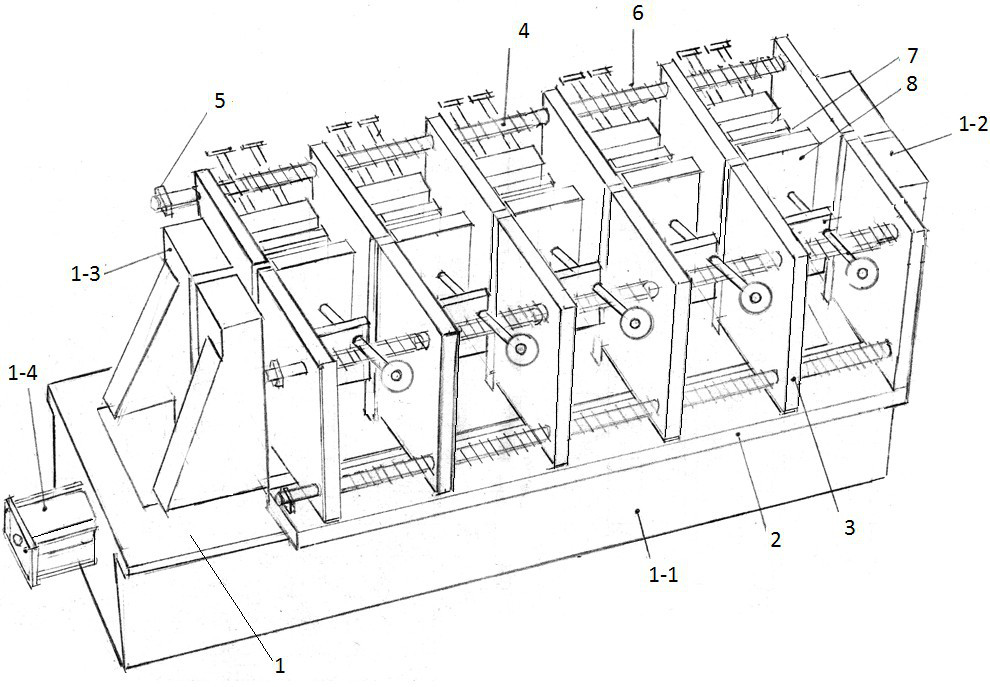

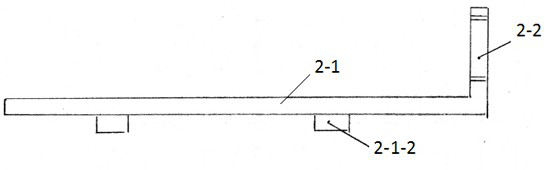

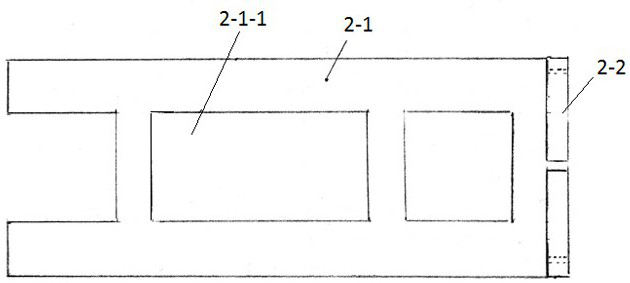

[0033] Such as figure 1 As shown, the machine tool for processing inclined iron includes a sawing machine, which is characterized in that a clamp is installed at the jaws of the sawing machine, and the clamps include a hydraulic clamp 1, a station seat 2 and a station clamp 3, and at the jaws of the sawing machine The hydraulic tongs 1 are installed, the station seat 2 is installed in the hydraulic tongs 1, and several station clips 3 are neatly installed on the station seat 2 through four guide rods 4, forming a machine tool for processing inclined iron as a whole.

[0034] Furthermore, several station clamps 3 are neatly installed on the station seat 2 through four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com