Patents

Literature

1706 results about "Riveting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A riveting machine is used to automatically set (squeeze) rivets in order to join materials together. The riveting machine offers greater consistency, productivity, and lower cost when compared to manual riveting.

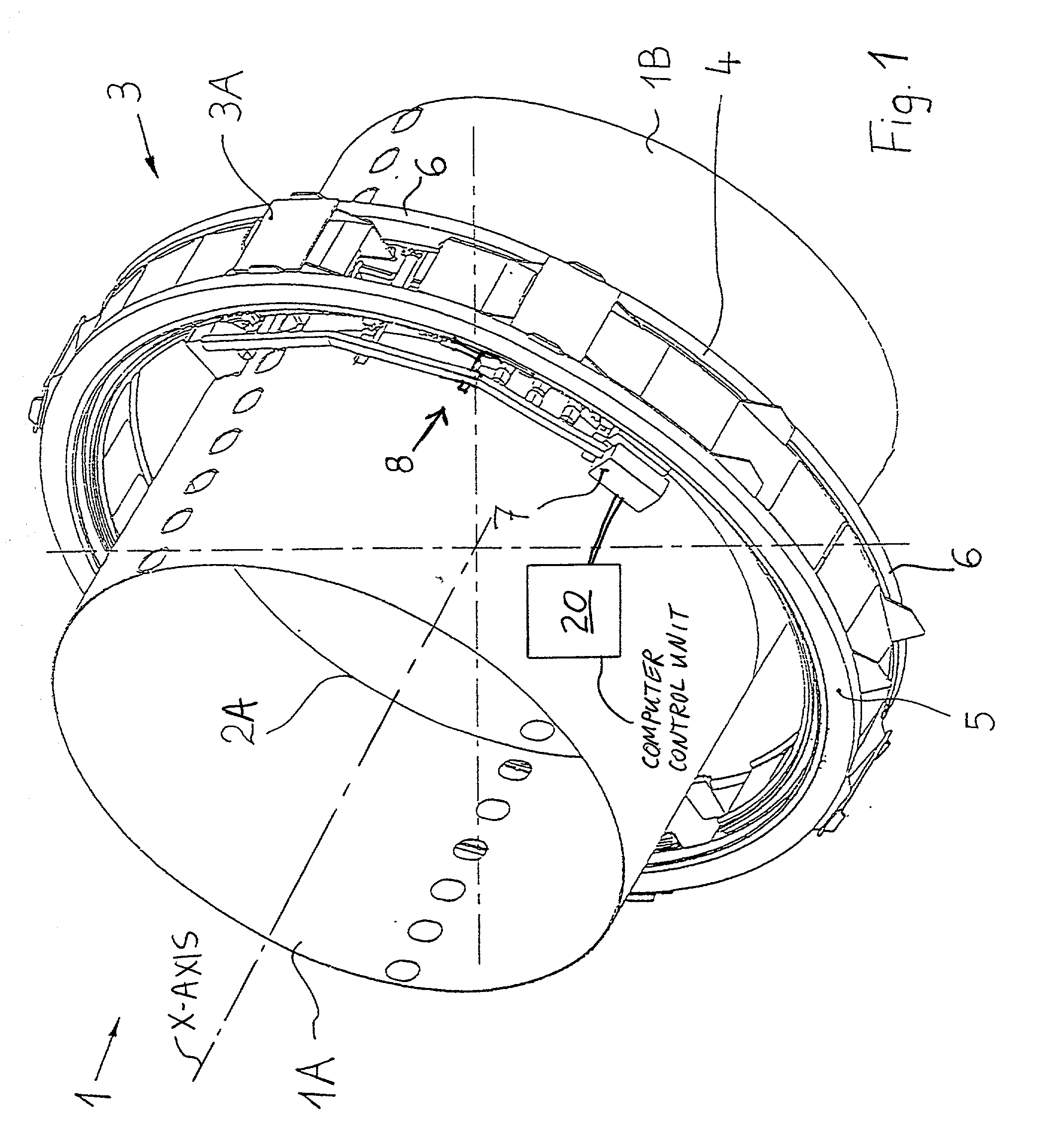

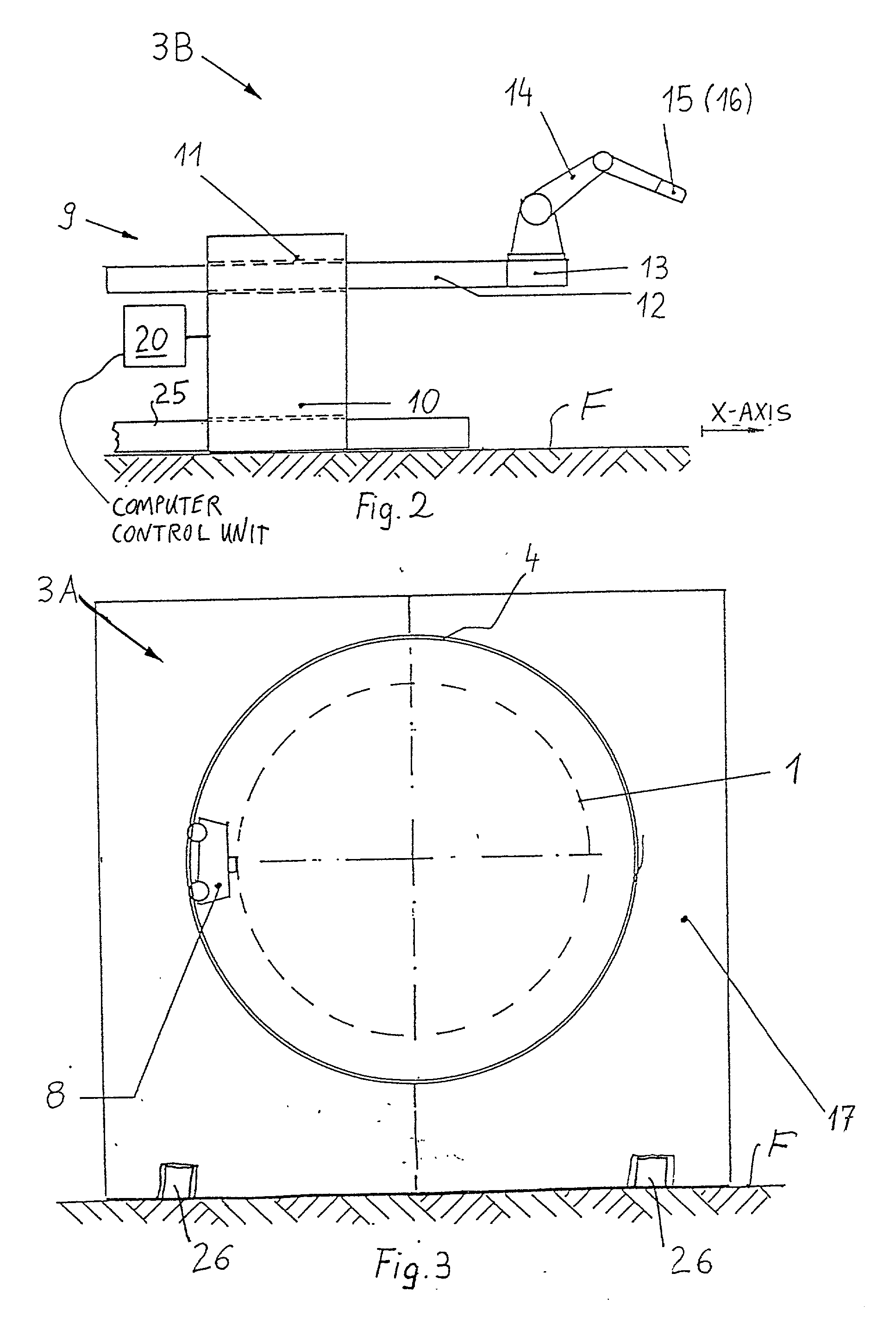

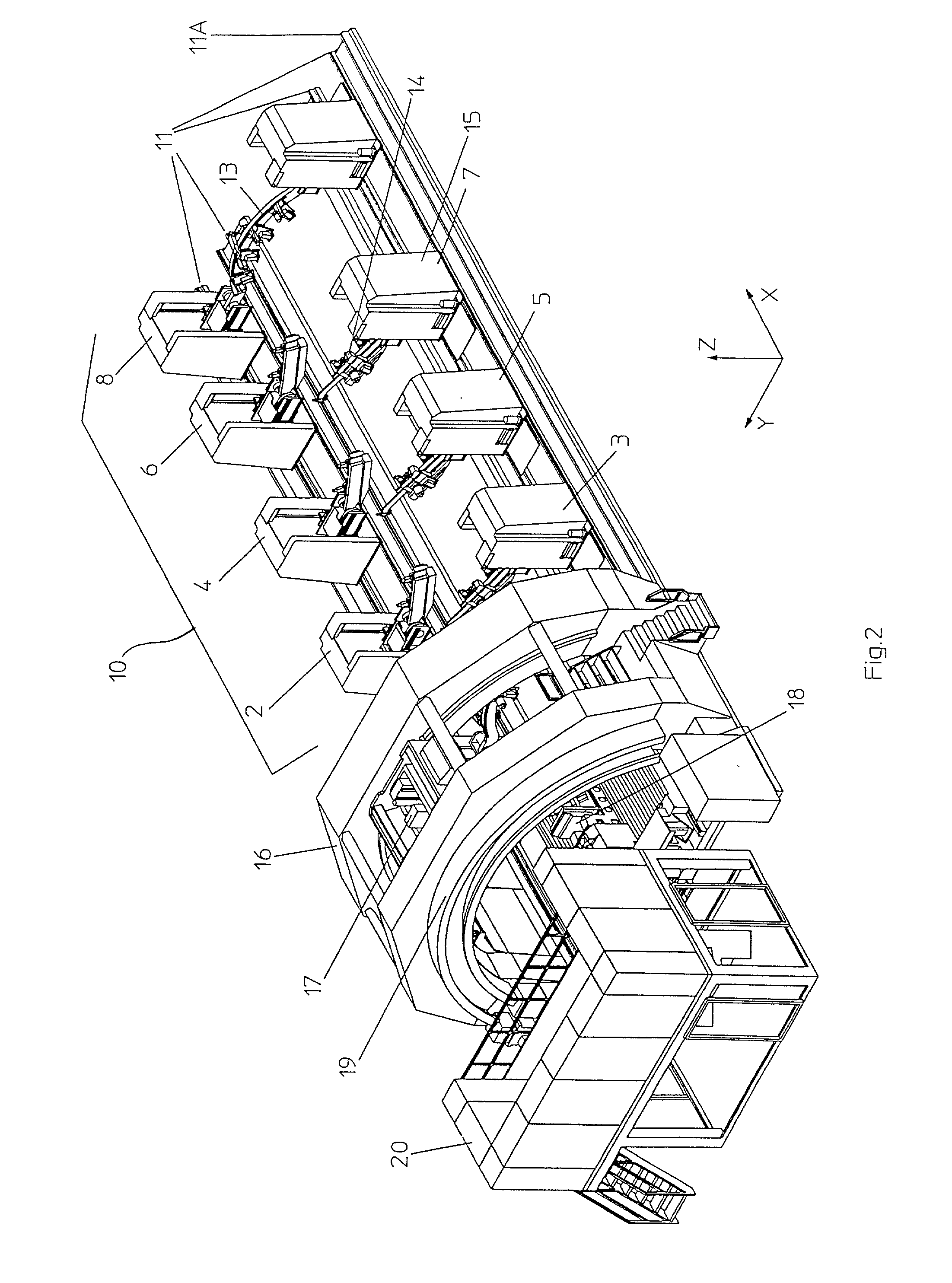

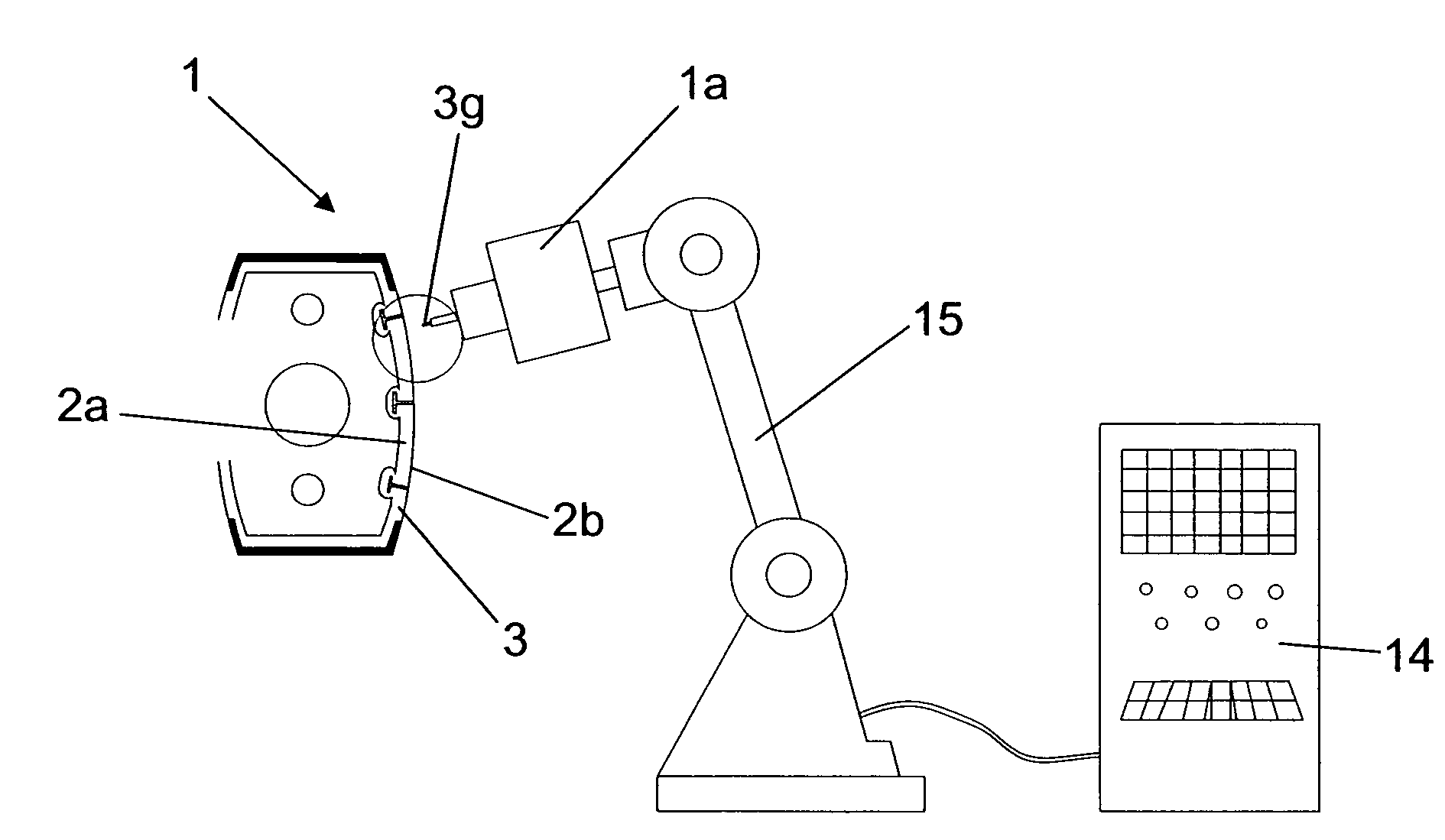

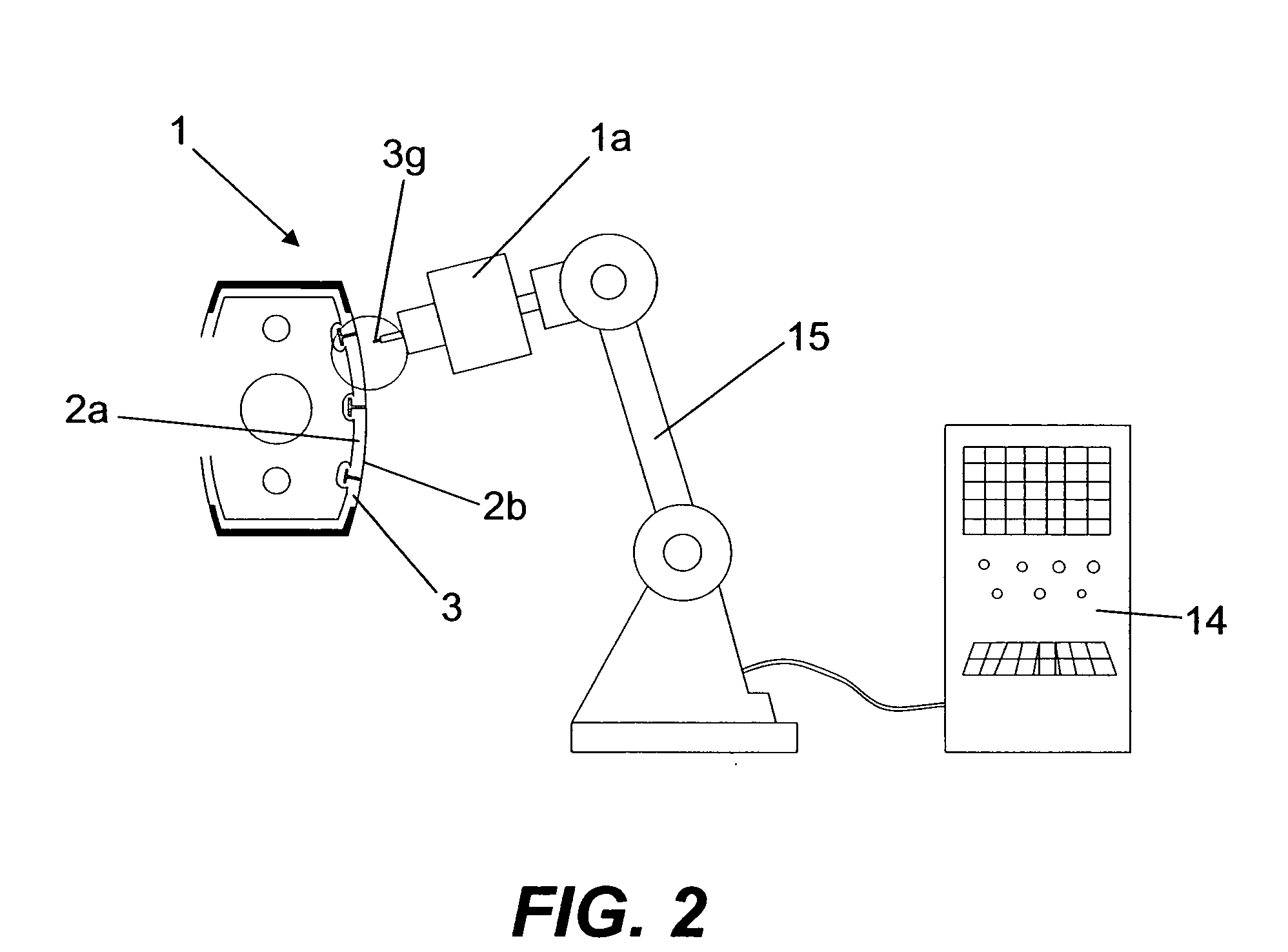

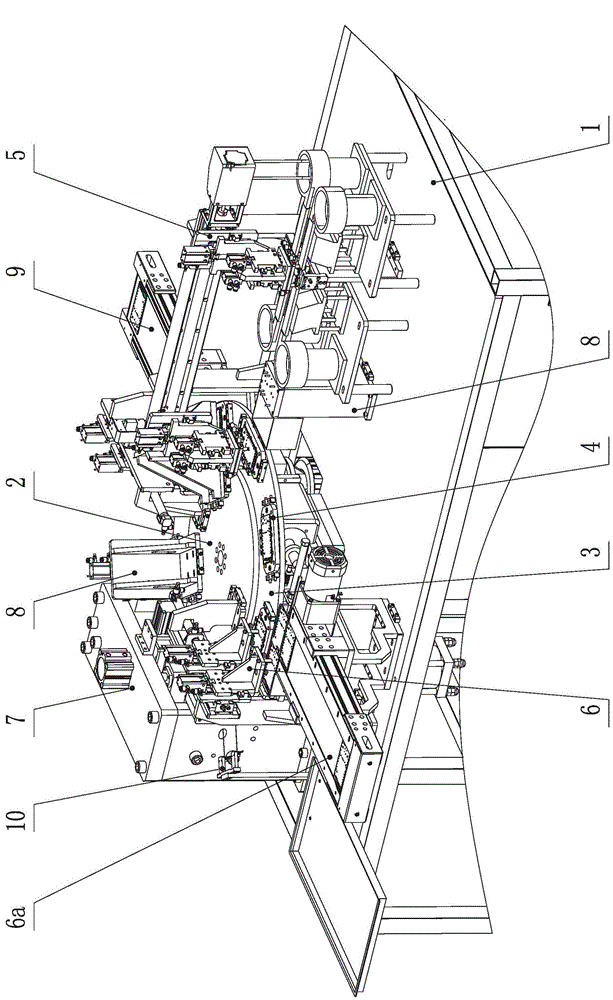

Two-part riveting apparatus and method for riveting barrel-shaped components such as aircraft fuselage components

InactiveUS6505393B2Effective movementEfficiently reachAutomatic control devicesAssembly machinesControl signalBarrel Shaped

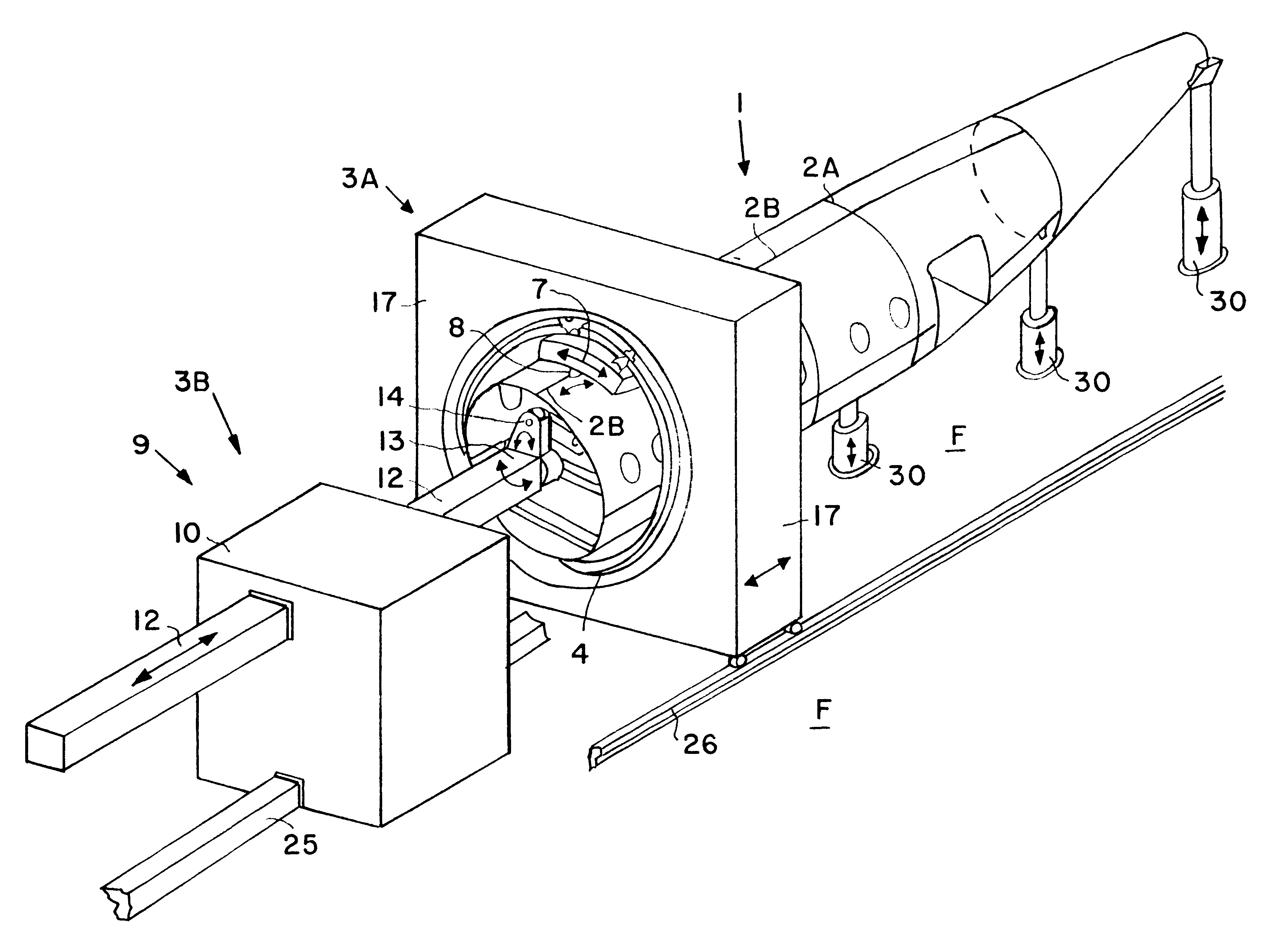

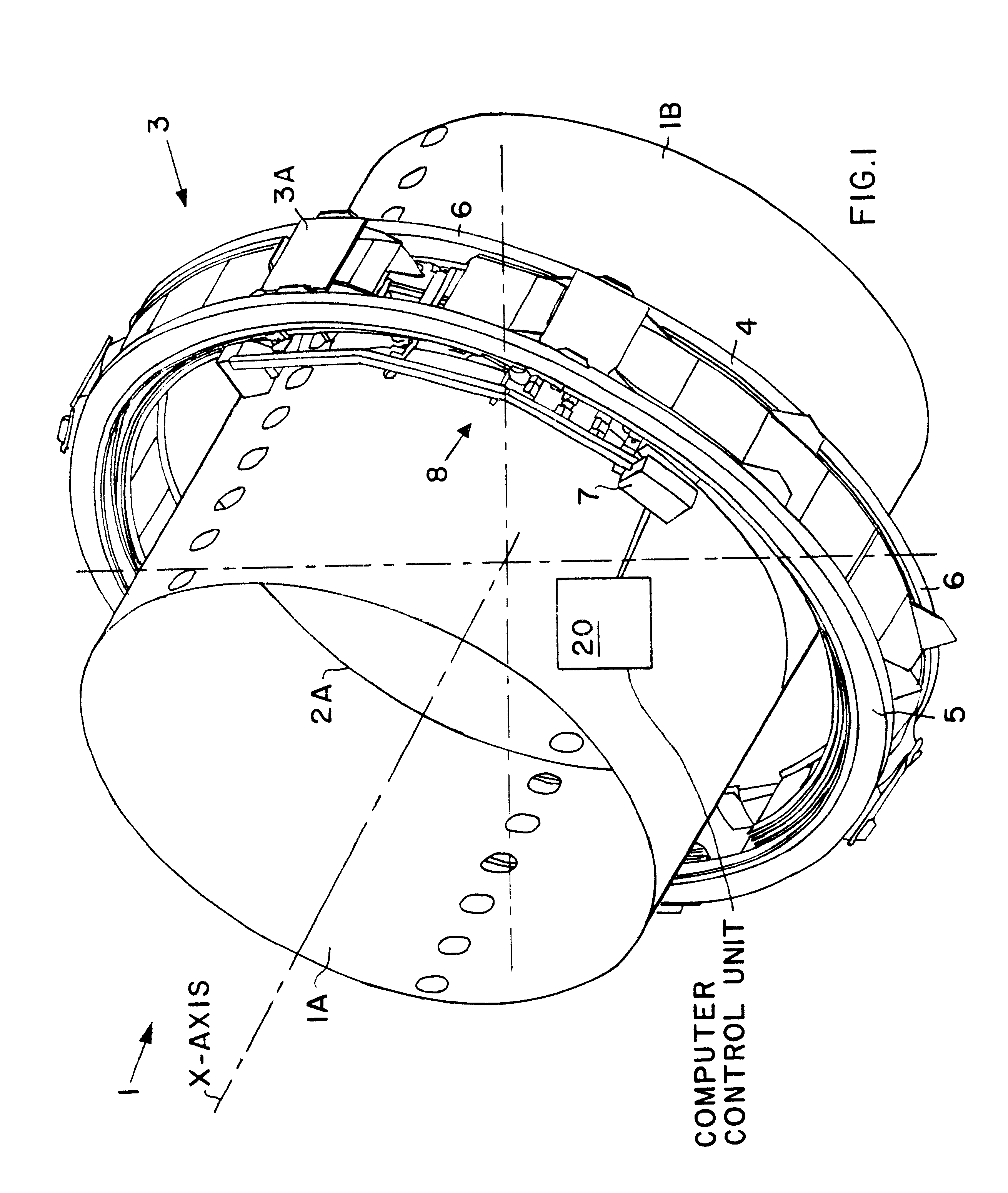

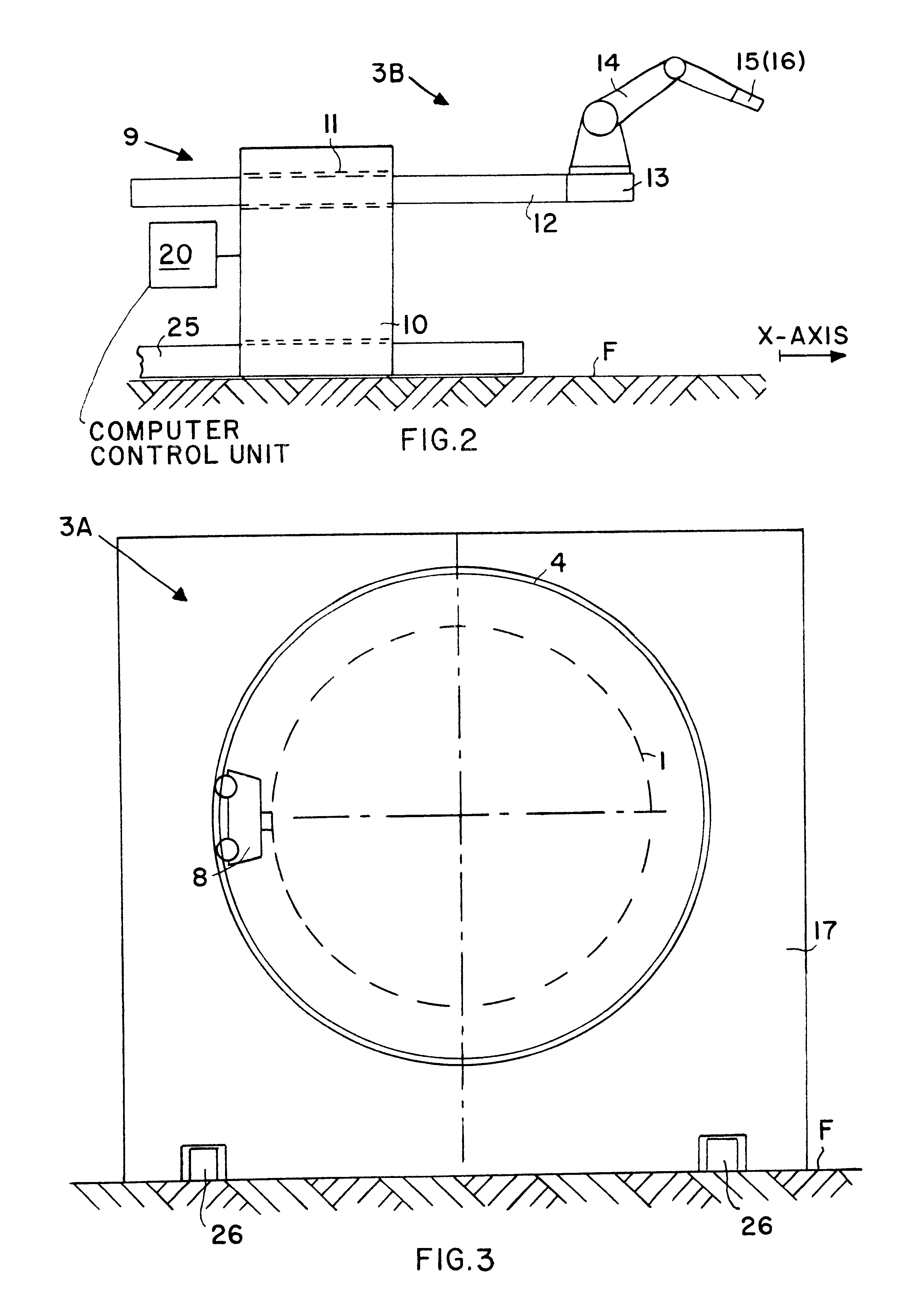

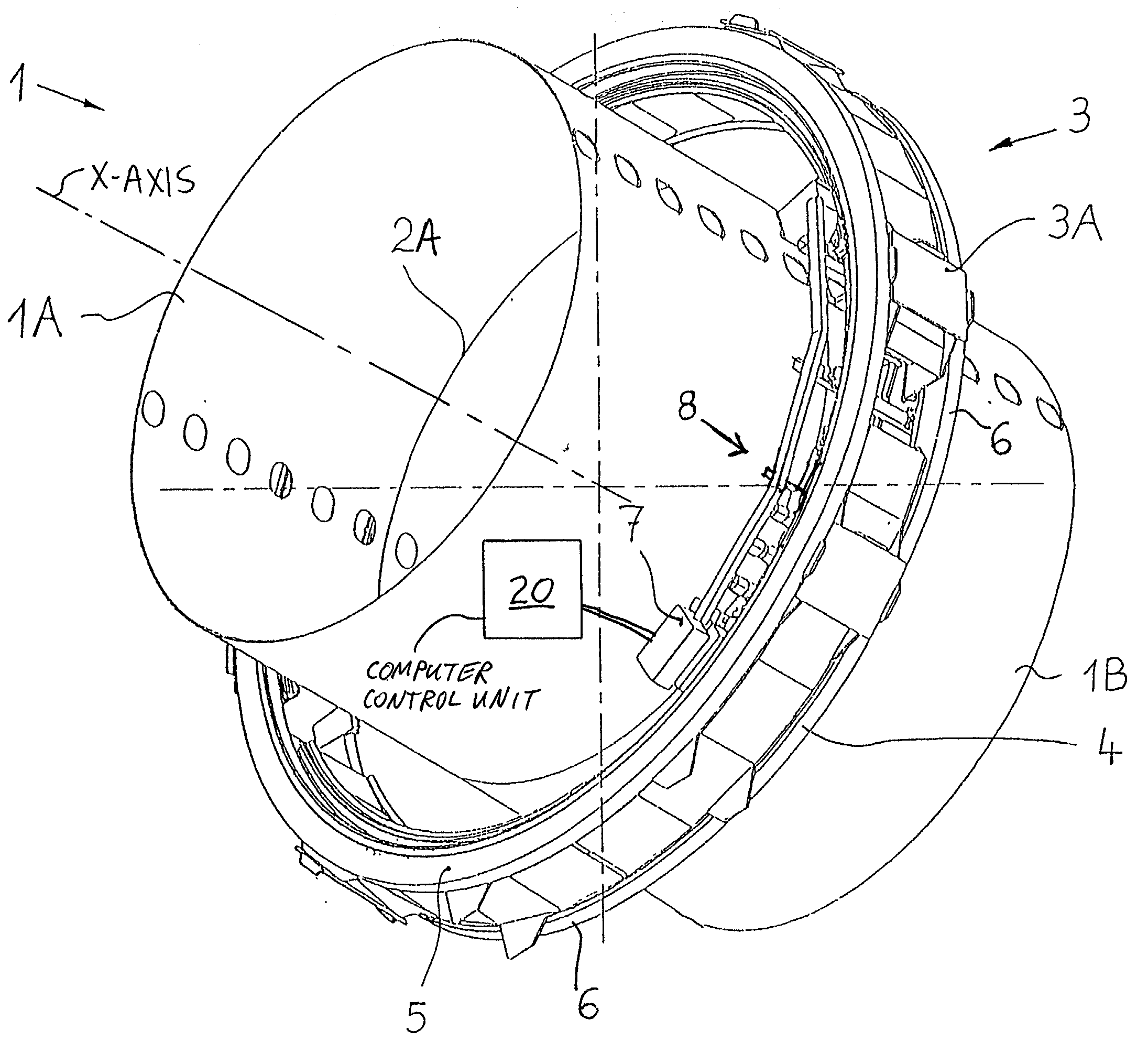

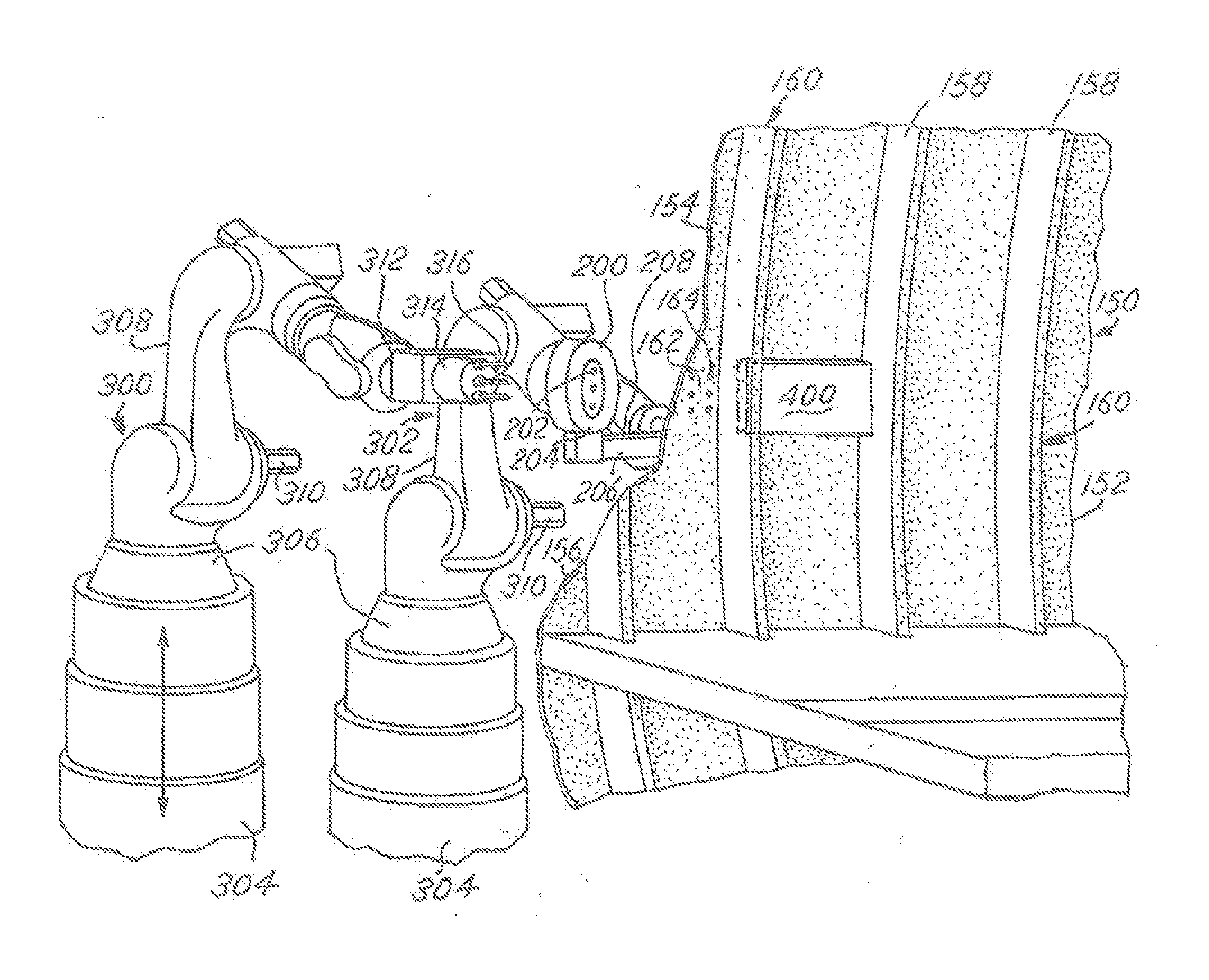

An apparatus for riveting shell components to form a barrel-shaped structure such as an aircraft fuselage includes an outer part and an inner part that operate coordinated with each other under computer control. The outer apparatus part includes a riveting machine system movably carried on an annular machine guide that is supported on a stand that is movable in a length-wise X-direction. The inner apparatus part includes a multi-axis riveting robot mounted on a mounting frame that is movable along the X-direction. Instead of moving the inner and outer apparatus parts in the X-direction, it is alternatively possible to move the fuselage while keeping the apparatus parts stationary. A computer control unit provides control signals to achieve a coordinated and concurrent positioning of the inner and outer apparatus parts, and to carry out a coordinated sequence of riveting steps. Rivets can be automatically fastened even at difficult to access locations, while avoiding structural obstacles inside the aircraft fuselage. The apparatus parts are supported independently of the fuselage on the floor of the assembly hall.

Owner:AIRBUS OPERATIONS GMBH

Two-part riveting apparatus and method for riveting barrel-shaped components such as aircraft fuselage components

InactiveUS20020007548A1Effective movementEfficiently reachAutomatic control devicesAssembly machinesControl signalBarrel Shaped

An apparatus for riveting shell components to form a barrel-shaped structure such as an aircraft fuselage includes an outer part and an inner part that operate coordinated with each other under computer control. The outer apparatus part includes a riveting machine system movably carried on an annular machine guide that is supported on a stand that is movable in a lengthwise X-direction. The inner apparatus part includes a multi-axis riveting robot mounted on a mounting frame that is movable along the X-direction. Instead of moving the inner and outer apparatus parts in the X-direction, it is alternatively possible to move the fuselage while keeping the apparatus parts stationary. A computer control unit provides control signals to achieve a coordinated and concurrent positioning of the inner and outer apparatus parts, and to carry out a coordinated sequence of riveting steps. Rivets can be automatically fastened even at difficult to access locations, while avoiding structural obstacles inside the aircraft fuselage. The apparatus parts are supported independently of the fuselage on the floor of the assembly hall.

Owner:AIRBUS OPERATIONS GMBH

Versatile adaptable holding apparatus for holding large format workpieces

InactiveUS20020092149A1Precise positioningReduce usageLarge fixed membersPositioning apparatusRiveting machinesMachine

An apparatus for holding a large format workpiece includes first and second sets of support units on opposite sides of the workpiece. Each support unit includes a support arm carrying individual mounting fixtures such as suction units for suction-holding the workpiece. The support arm is pivotably mounted on a support column, which in turn is movable along a floor-mounted rail. A riveting machine includes an upper tool and a lower tool that are movable parallel to the floor-mounted rail. To make space for the machine to set rivets in the area that is supported by a given support arm, that support arm is released from the workpiece and moved away to allow the machine to carry out its riveting cycle at that area, while the greatest possible number of the other support units simultaneously remain in place and continue to support the workpiece.

Owner:AIRBUS OPERATIONS GMBH +1

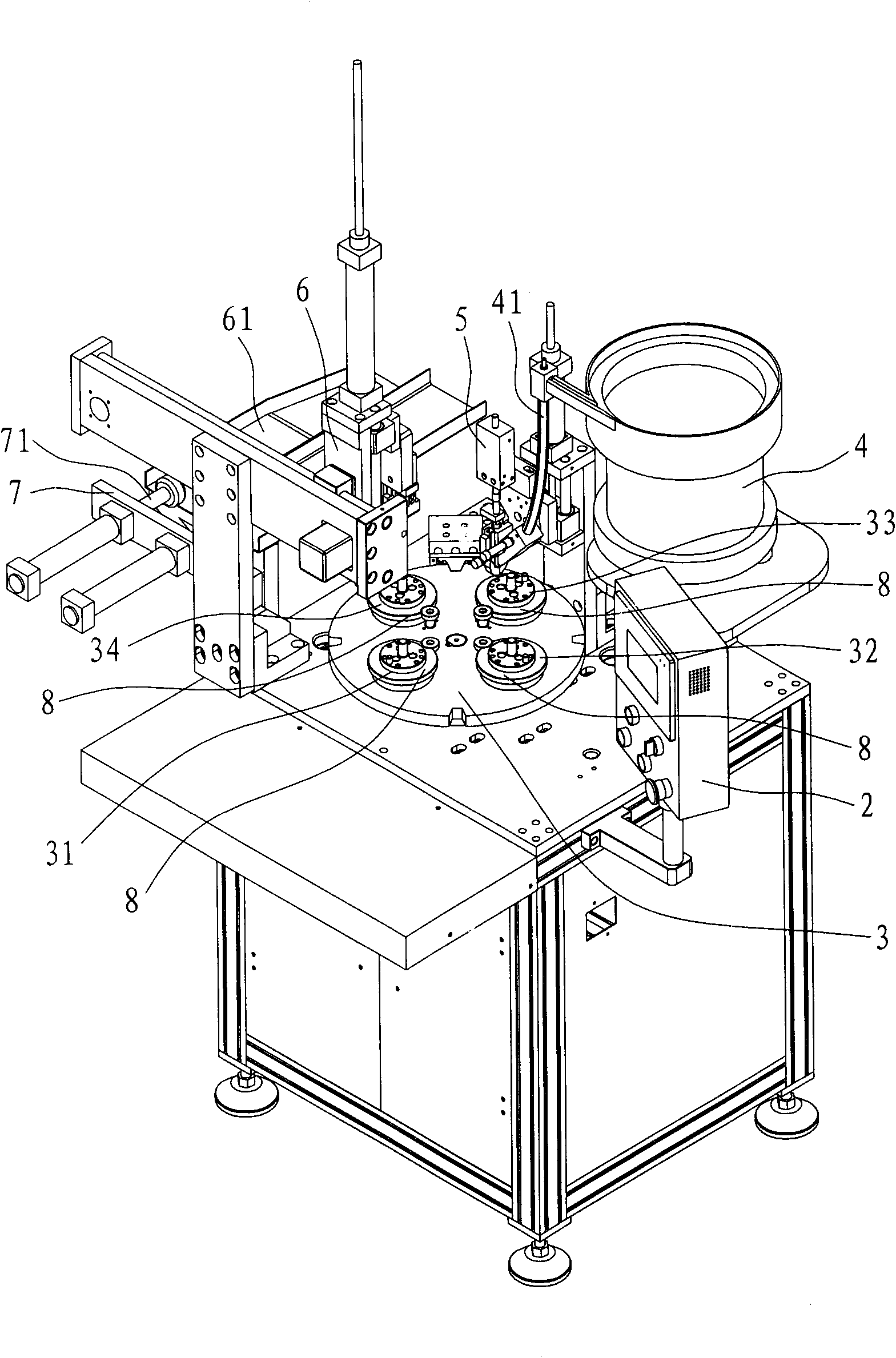

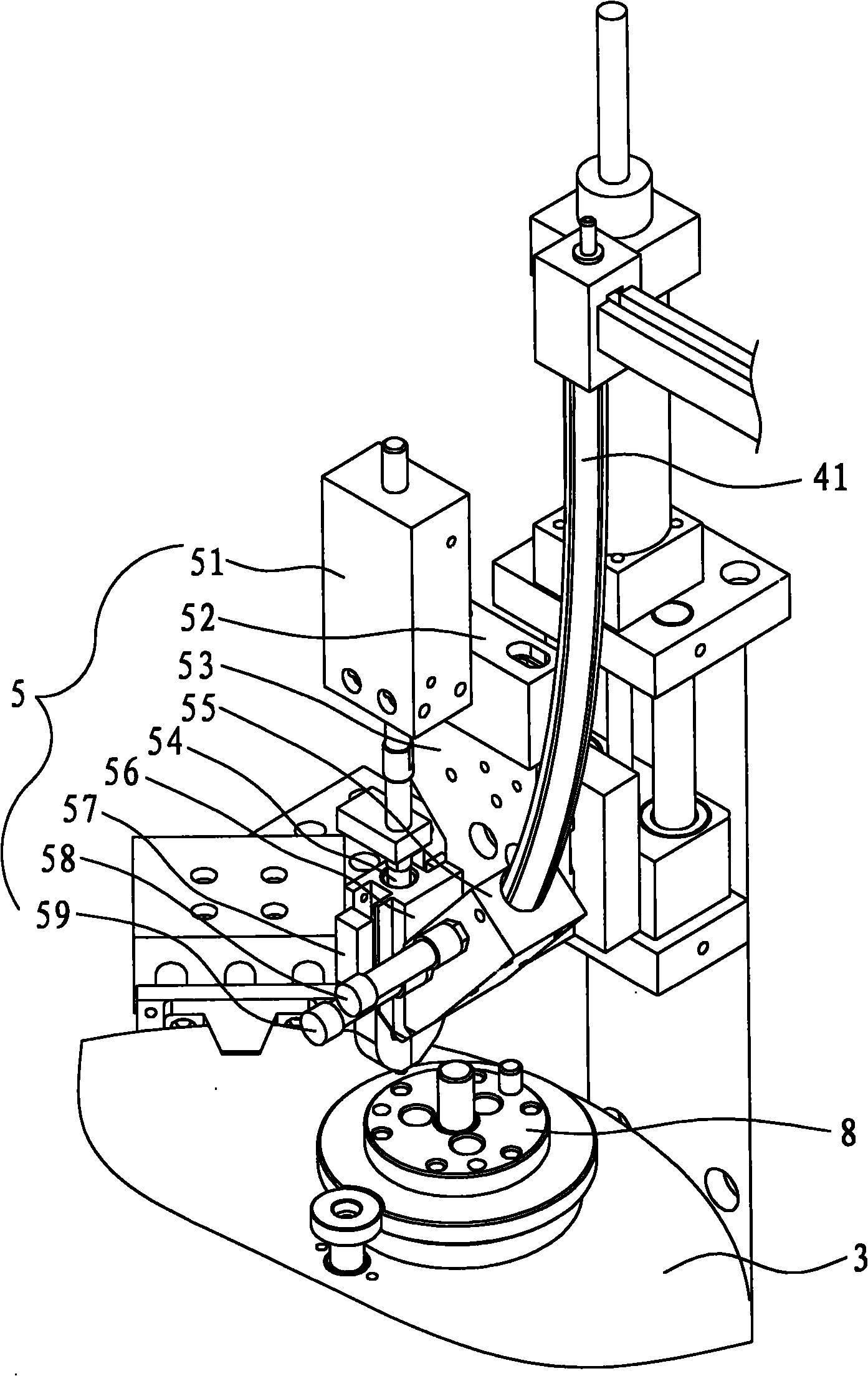

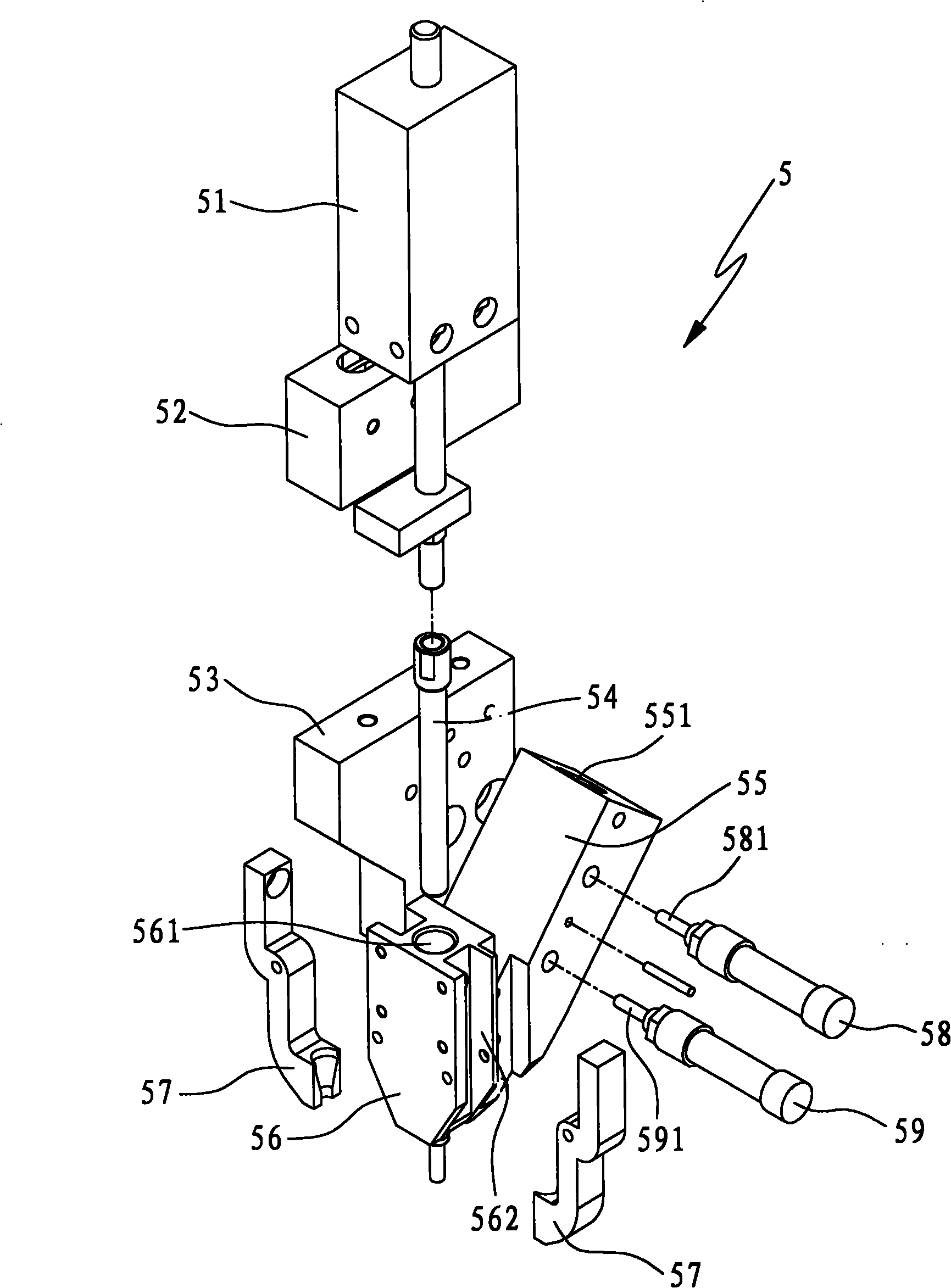

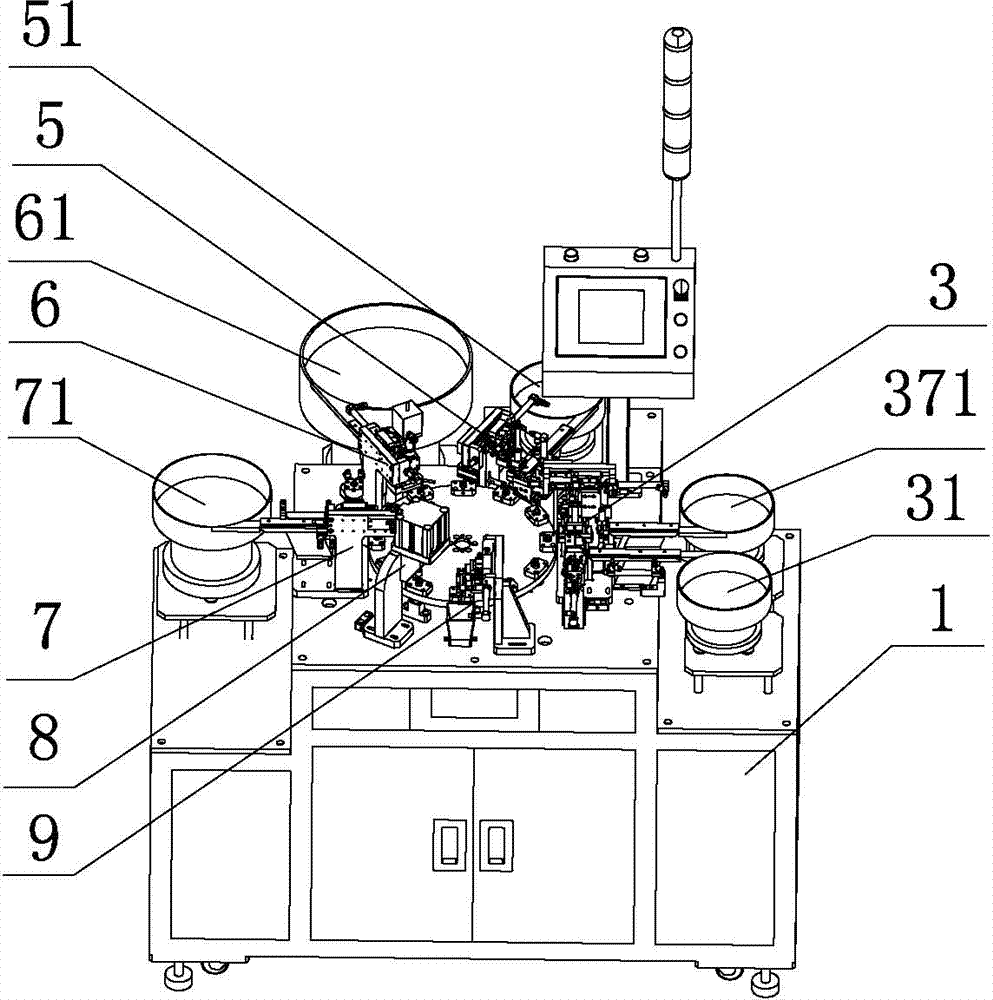

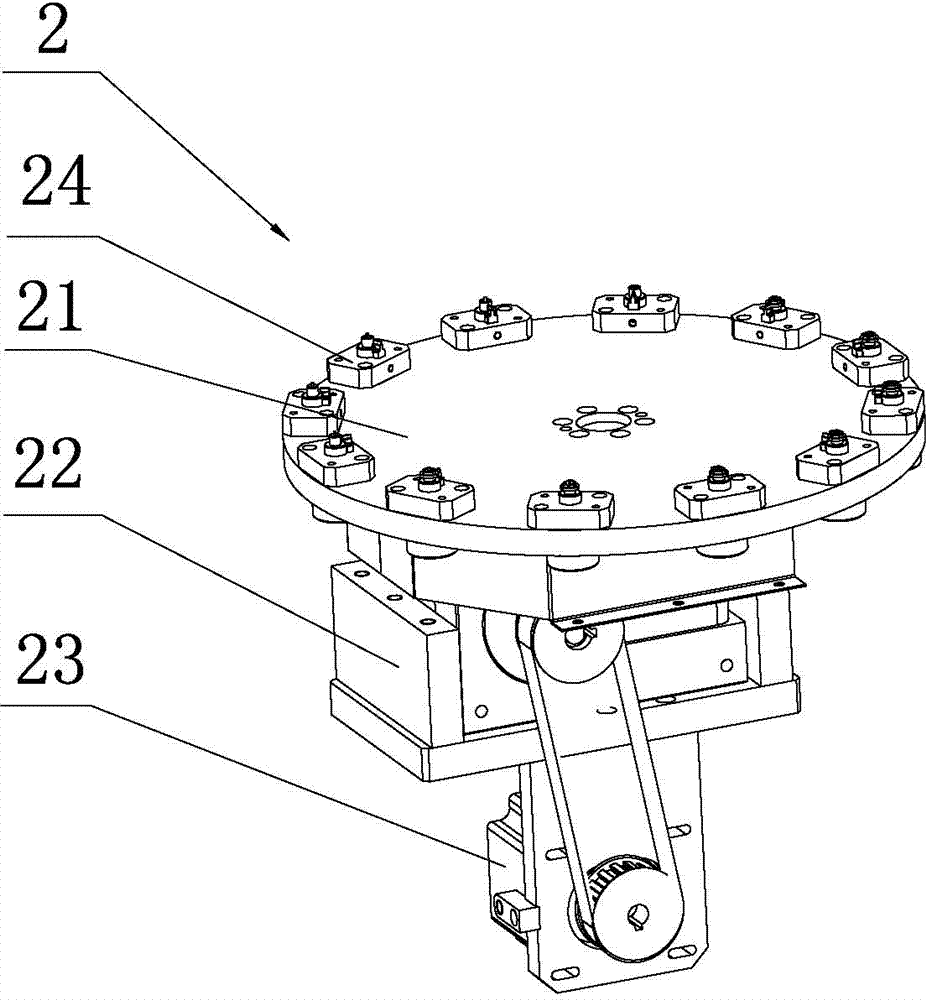

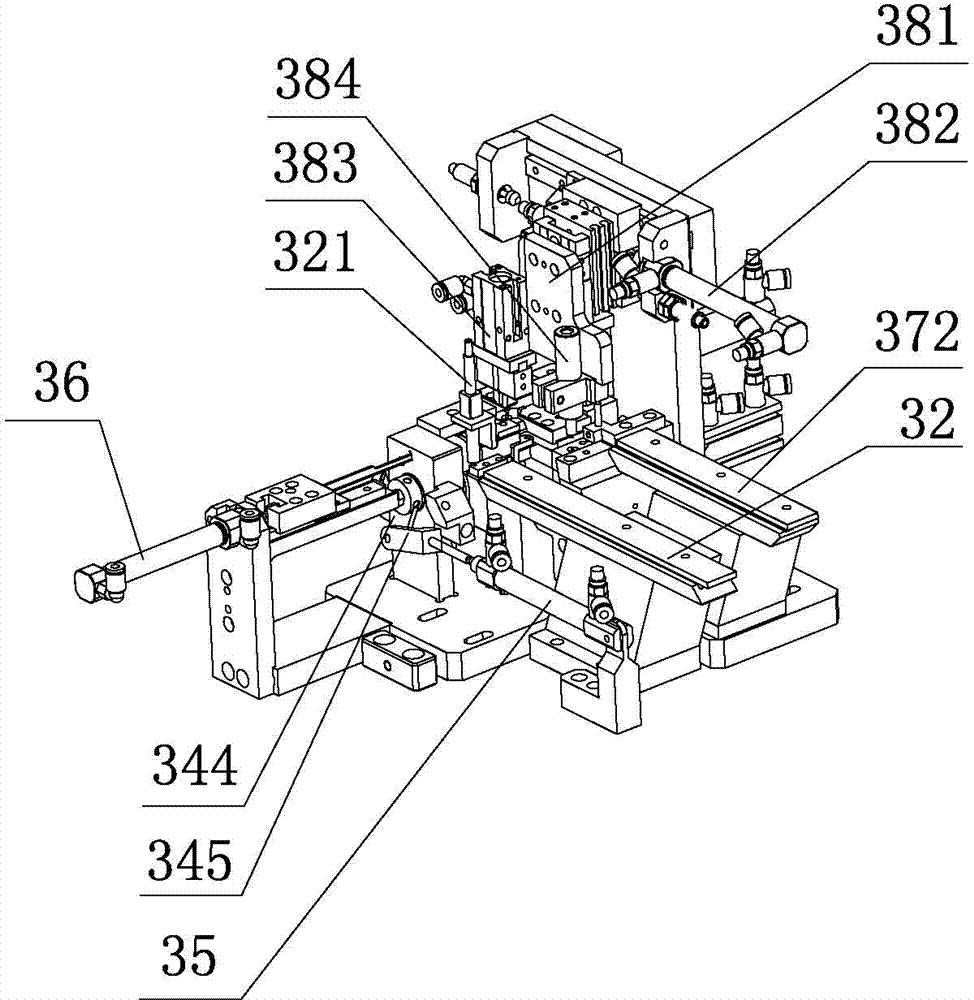

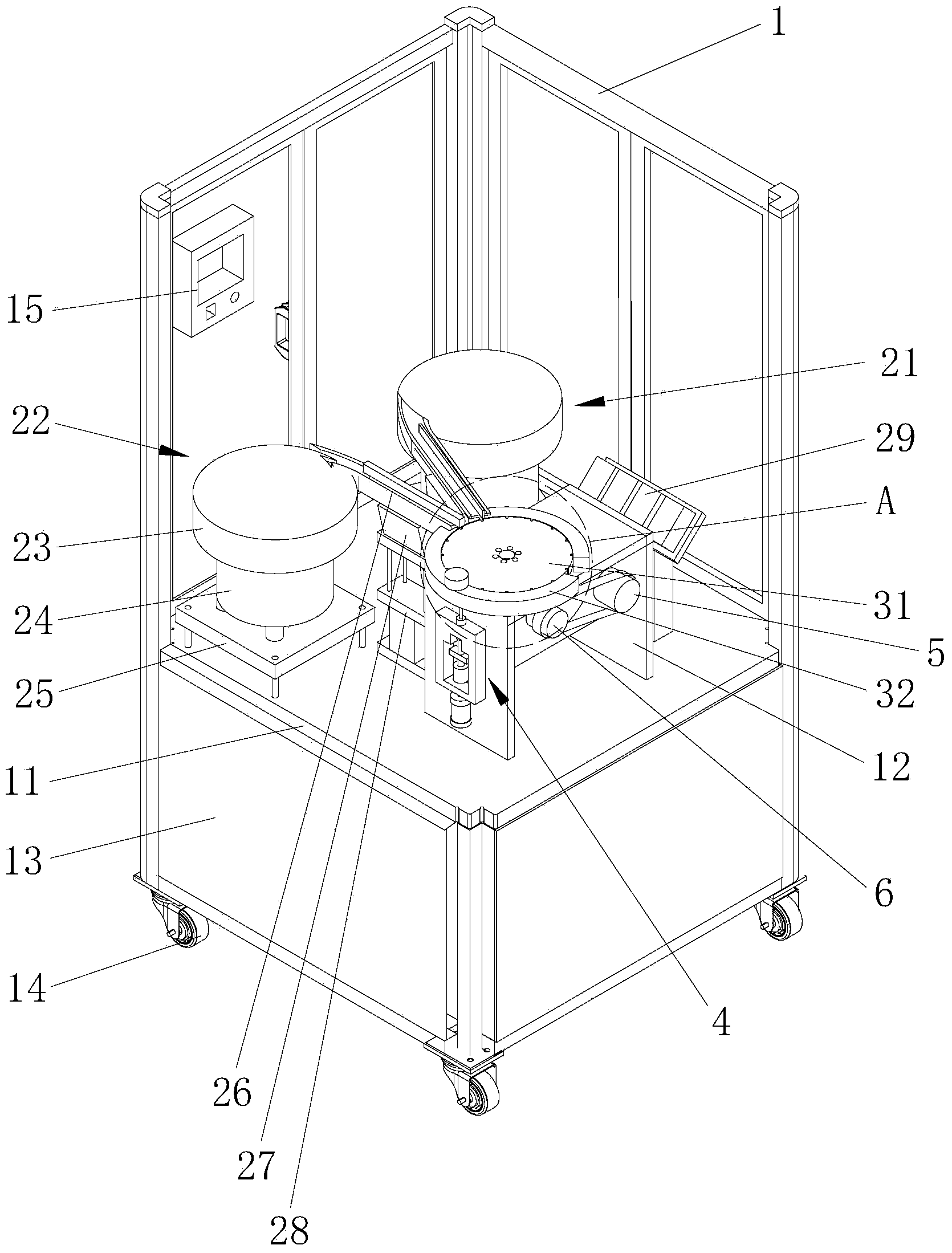

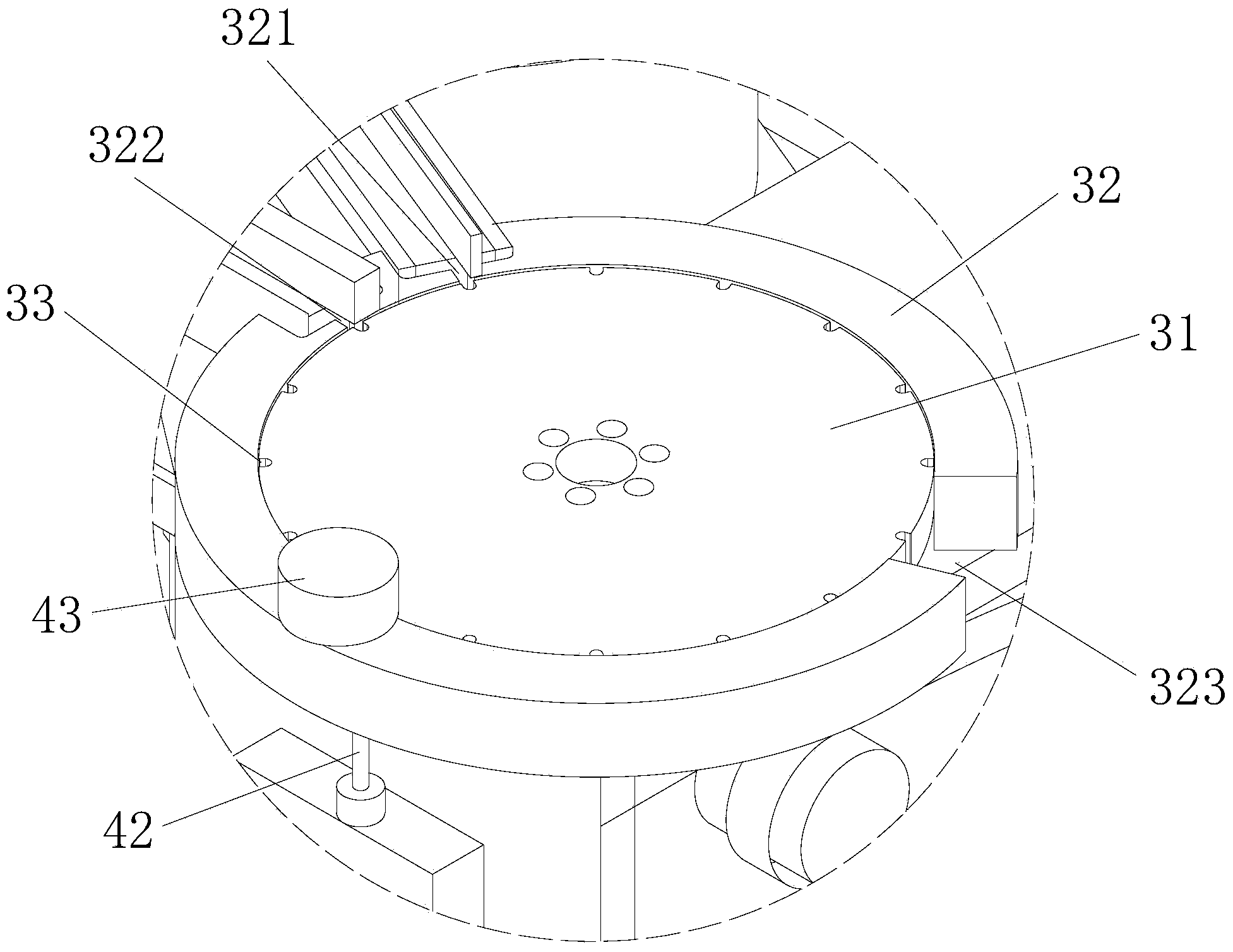

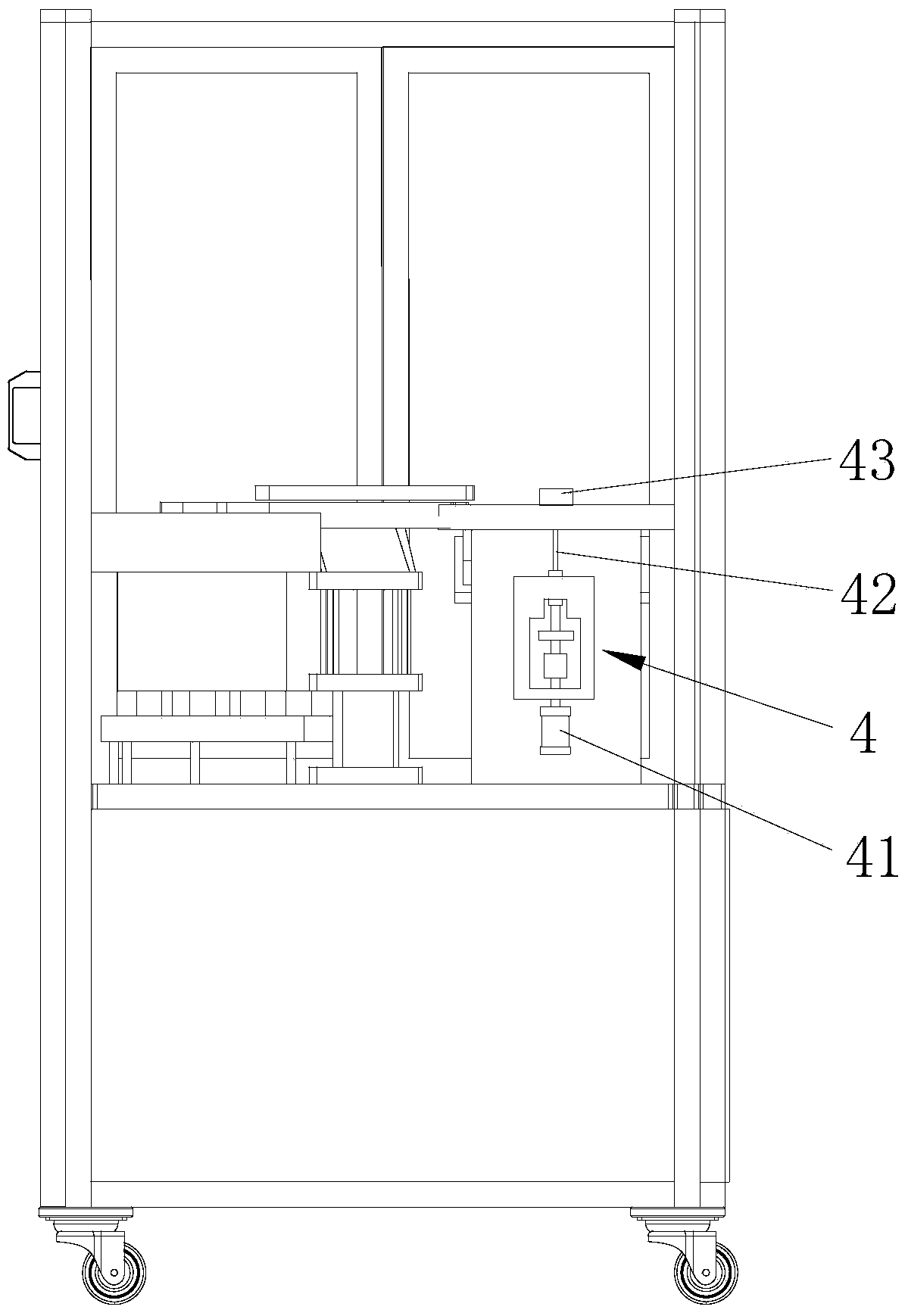

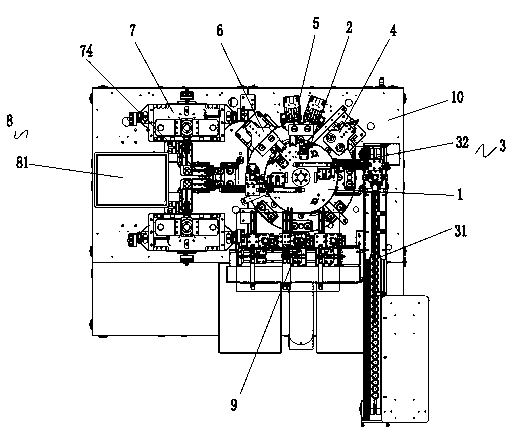

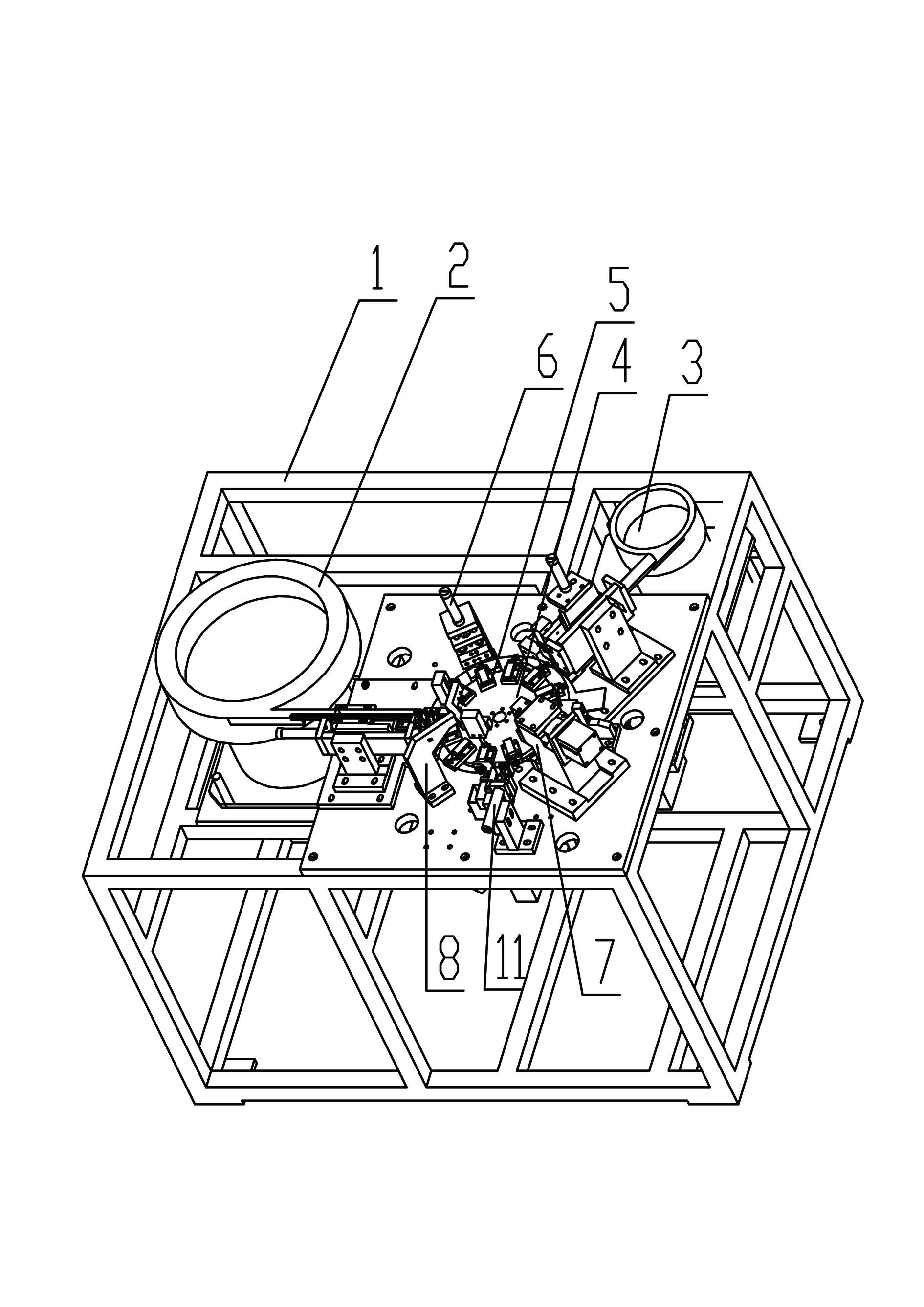

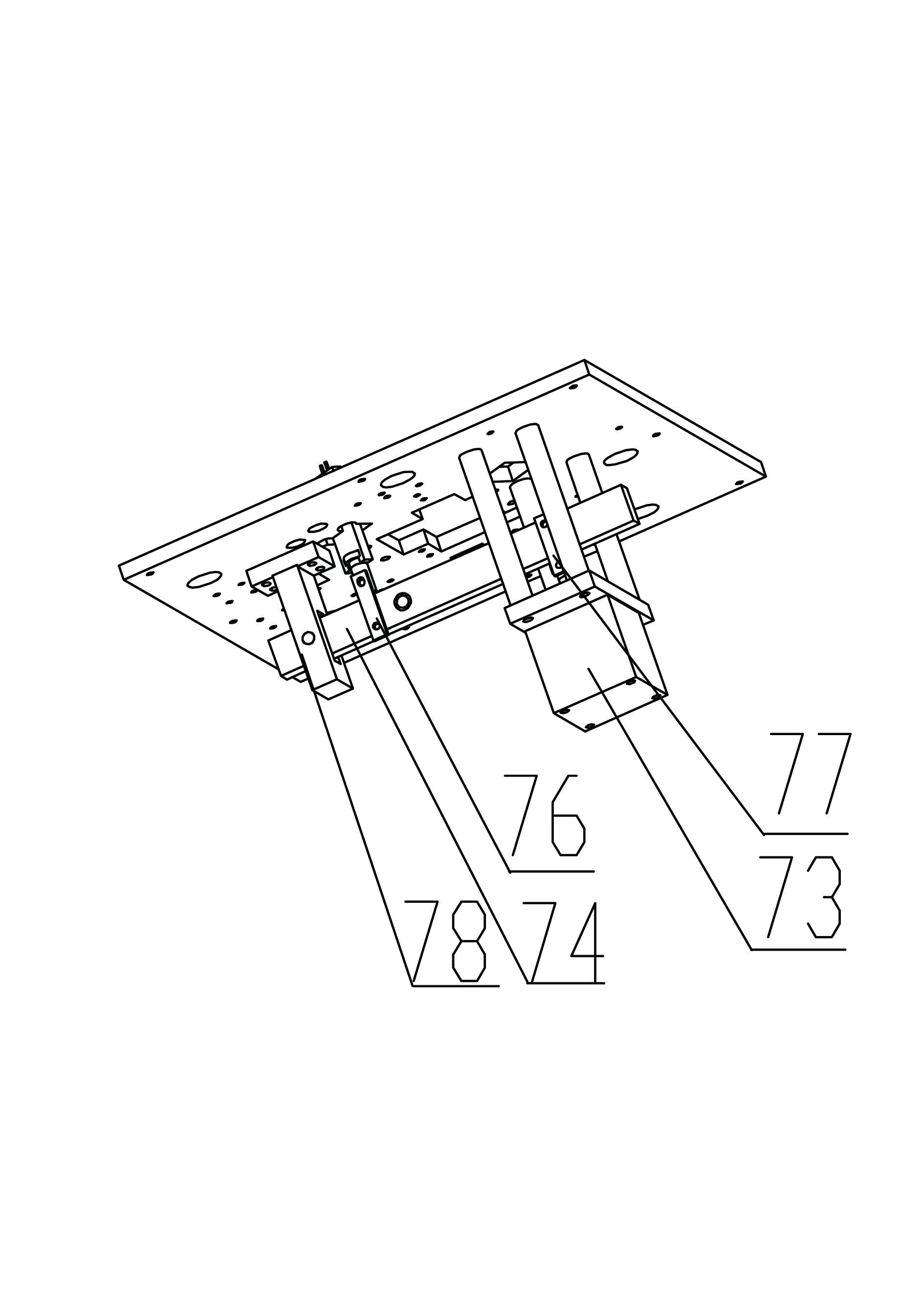

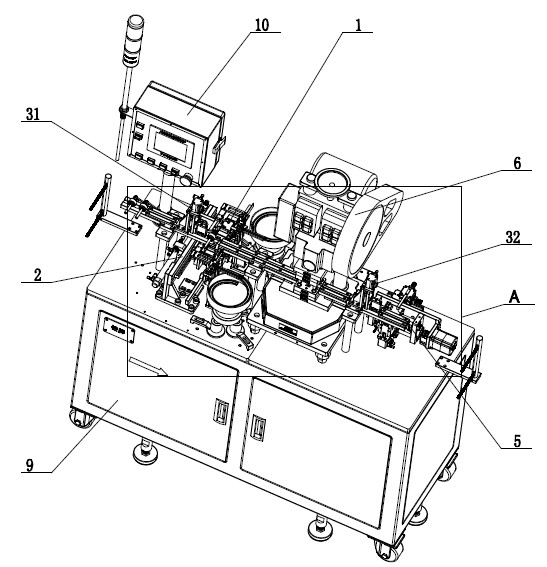

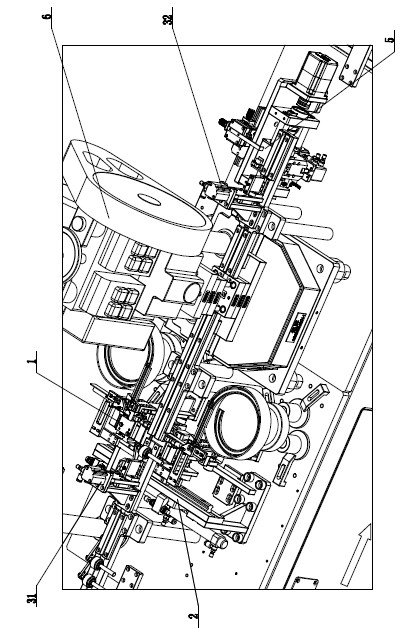

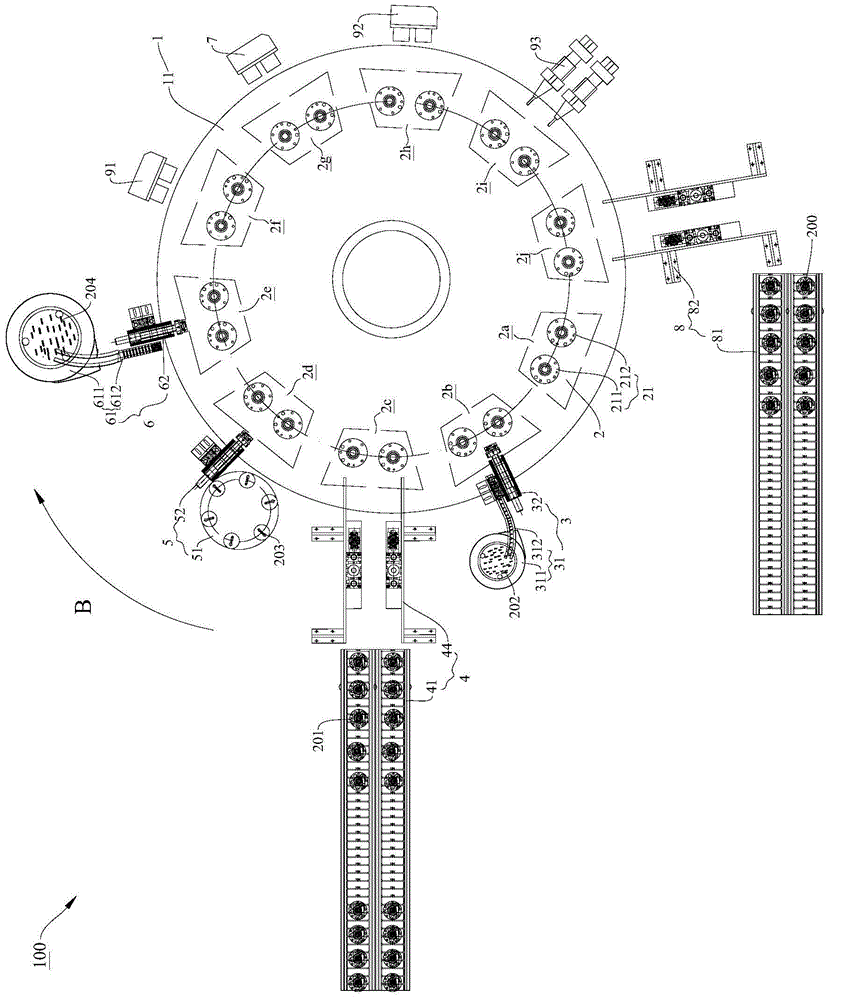

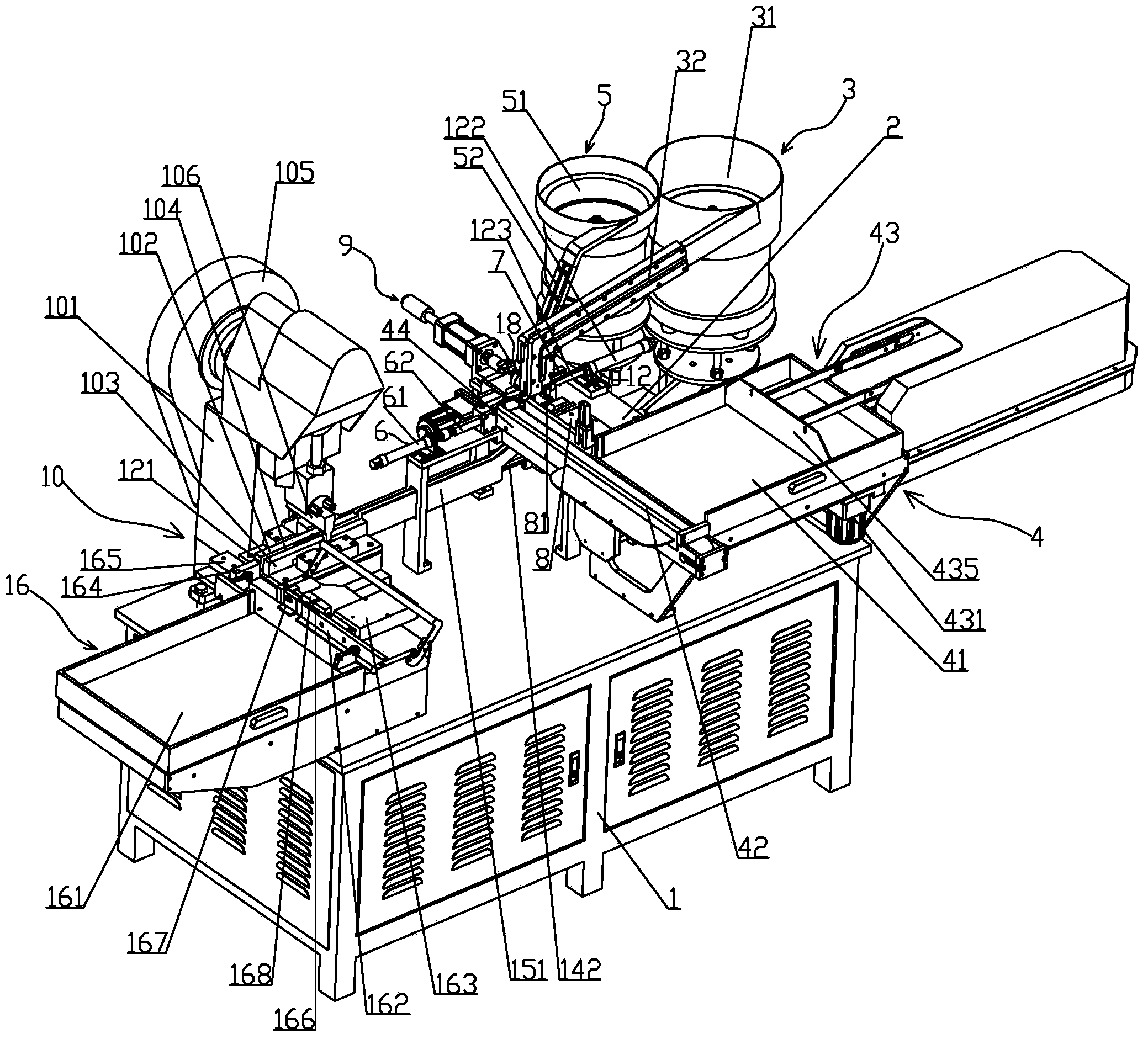

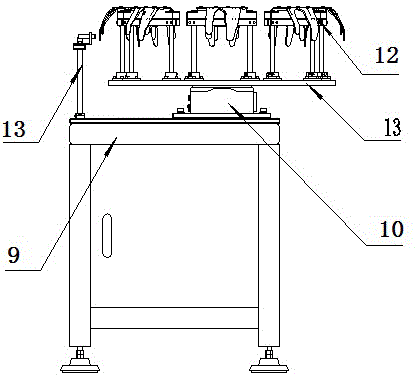

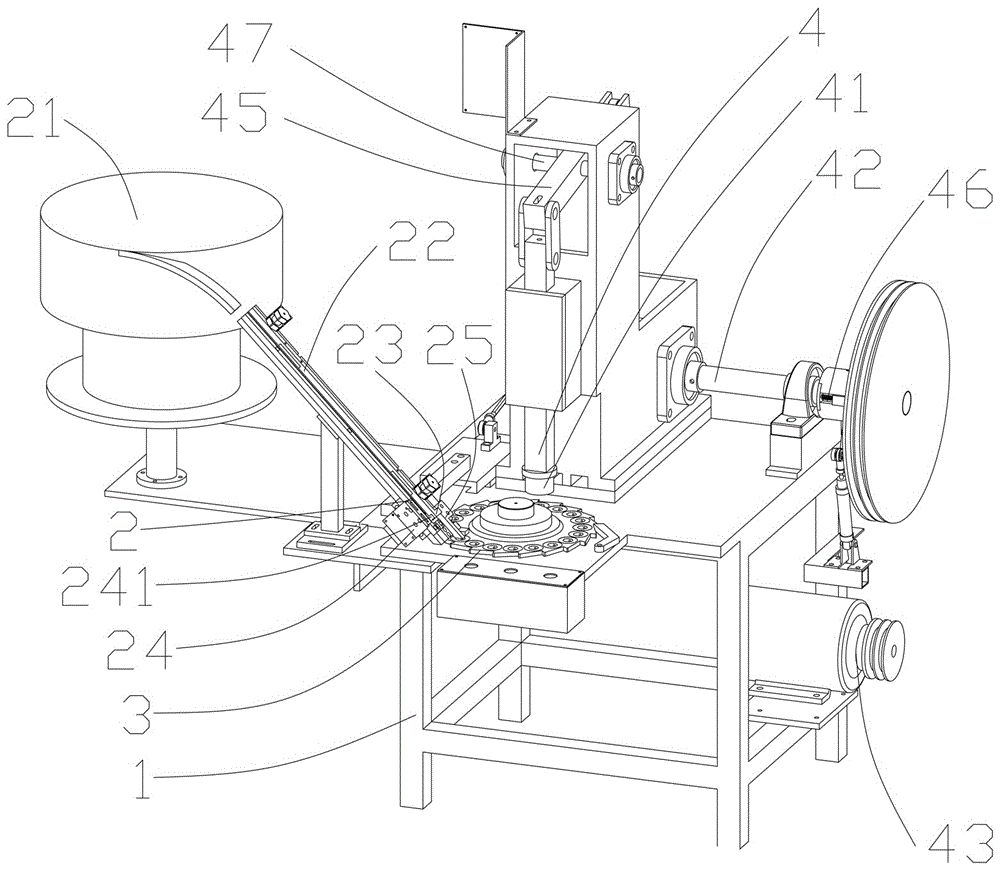

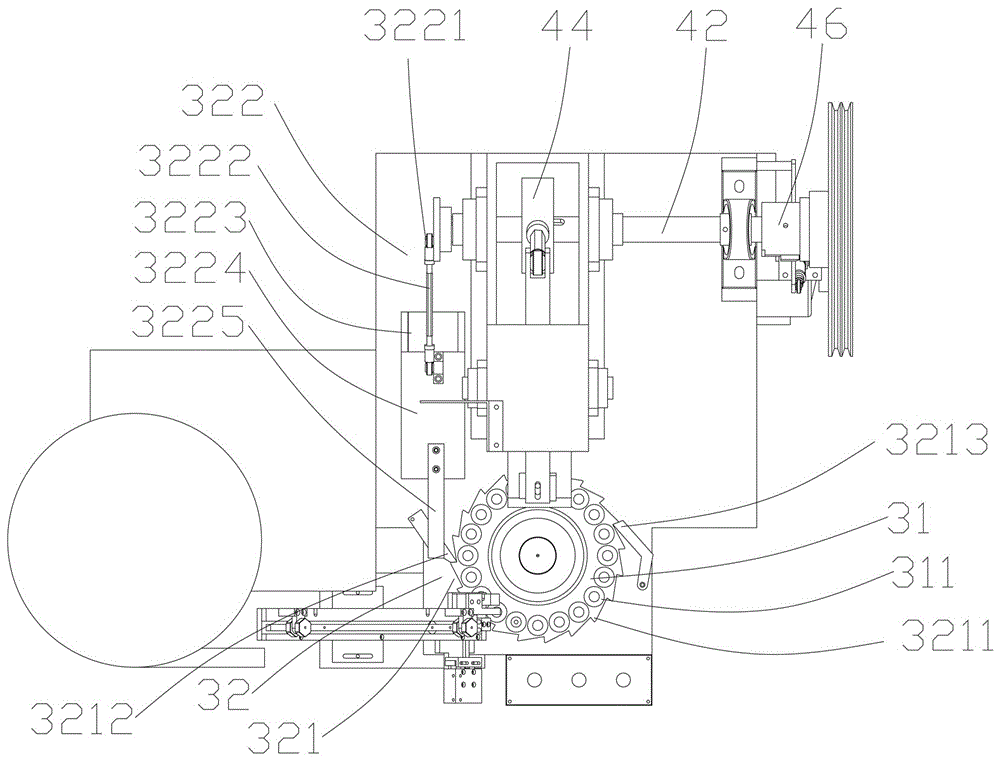

Riveting machine

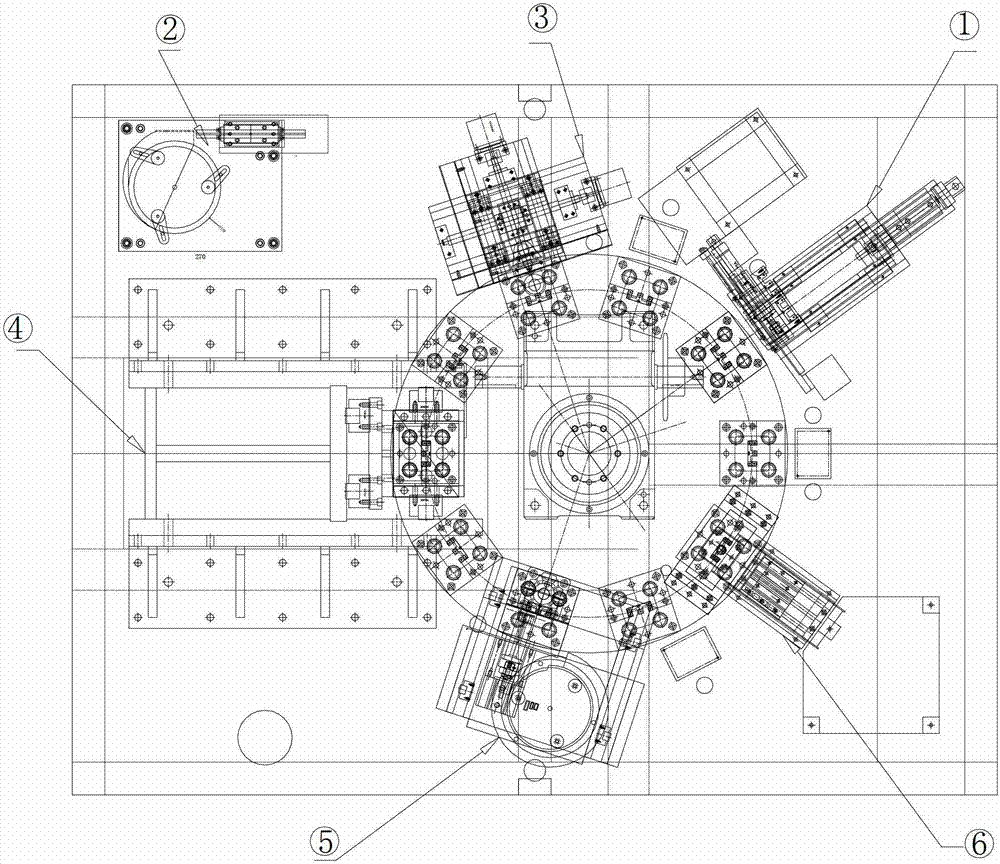

The invention discloses a riveting machine which comprises a machine frame, a control panel, a station turntable, a material-vibrating mechanism, a rivet punching mechanism, a blanking mechanism and a material-pushing mechanism, wherein the station turntable is mounted on the machine frame and is provided with fixtures for holding workpieces; the material-vibrating mechanism equipped with a rivet, the rivet punching mechanism and the blanking mechanism are sequentially encircled on one side of the station turntable; the material-vibrating mechanism is connected to the rivet punching mechanism through a feeding pipe and used for feeding the rivet to the rivet punching mechanism; and the material-pushing mechanism is mounted on one side of the blanking mechanism and the moving direction of a pushing rod of the material-pushing mechanism is aligned with a guide channel on the blanking mechanism. In the riveting machine, four fixtures are arranged on the station turntable according to different stations, thereby finishing all the processes of rivet dropping, riveting and blanking on the station turntable and requiring no manual operation. The riveting machine has the advantages of high assembling efficiency, high yield, safety, reliability, and the like.

Owner:厦门义胜自动化设备有限公司

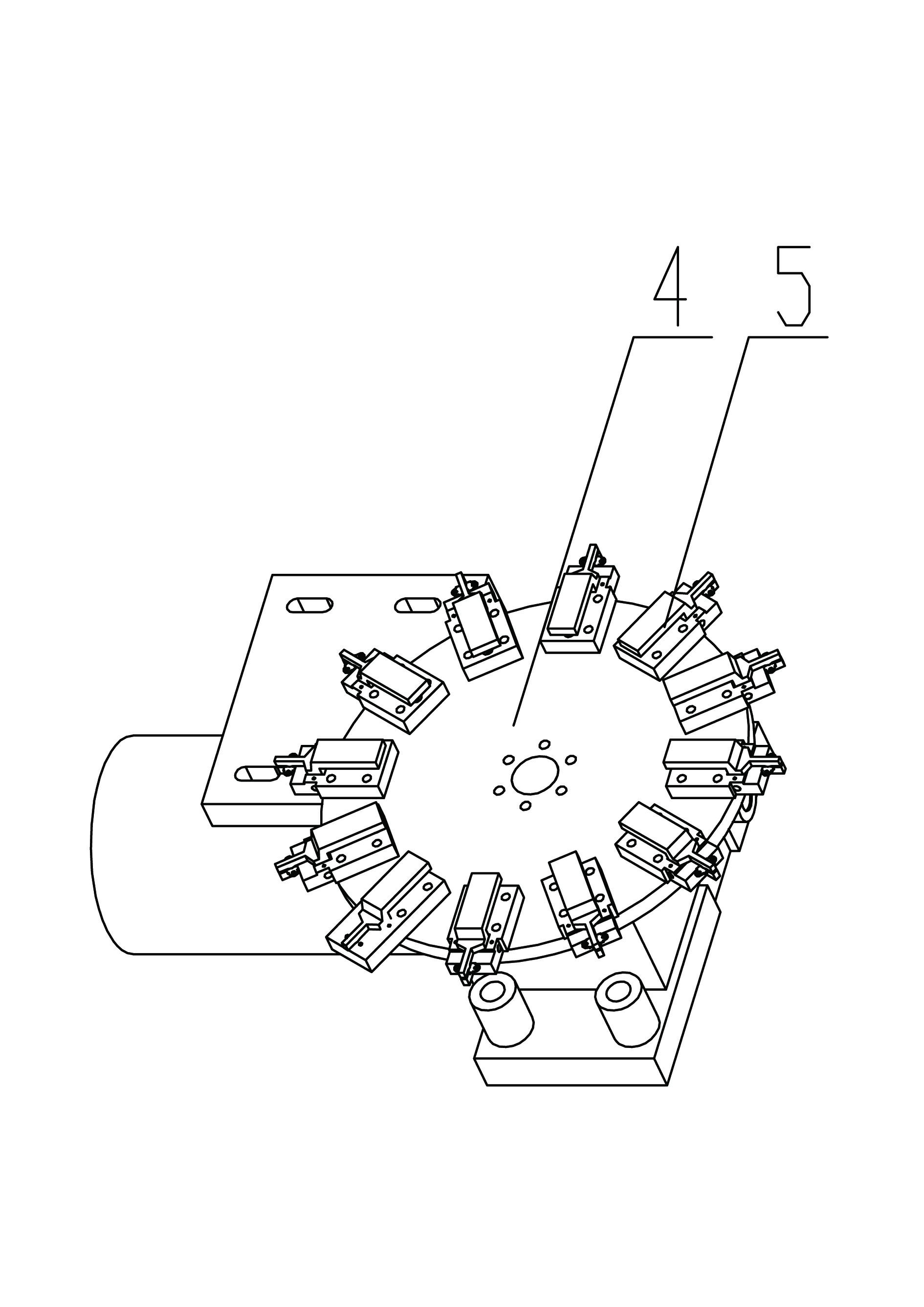

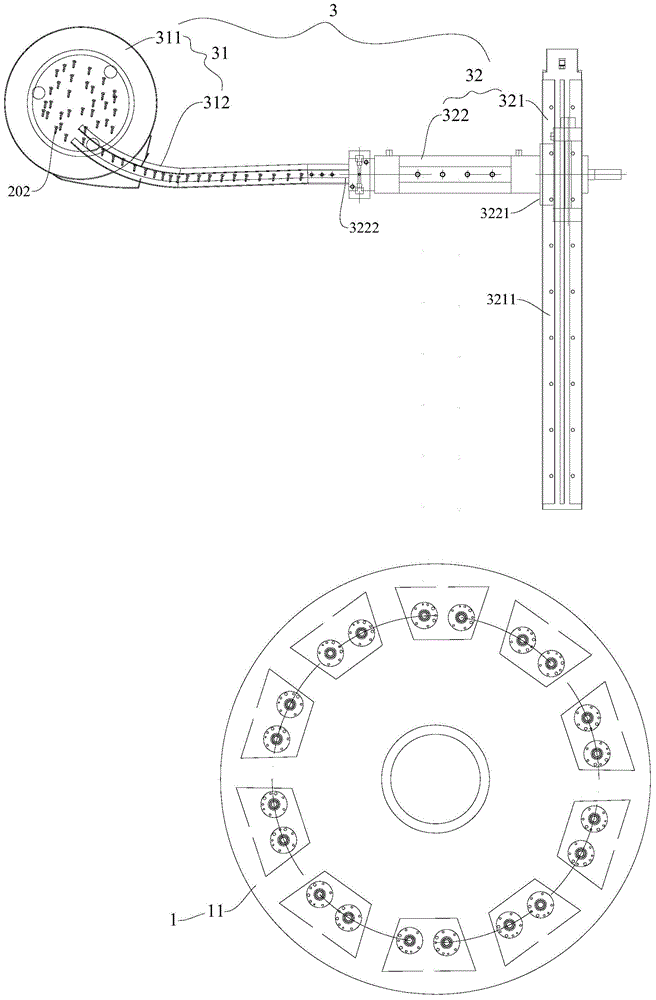

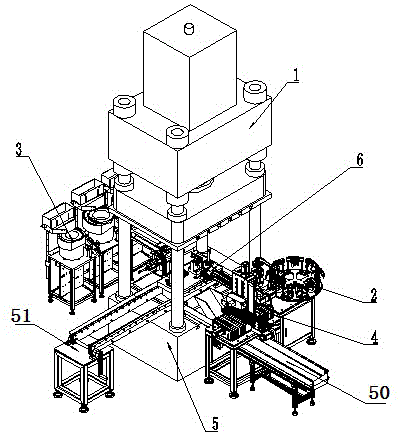

Fully-automatic rivet magnetic circuit assembly machine

ActiveCN103707055AAvoid wrong loadingAvoid leakage and other phenomenaAssembly machinesAutomatic test equipmentEngineering

The invention relates to the technical field of automatic assembly equipment, in particular to a fully-automatic rivet magnetic circuit assembly machine comprising a table and a turntable device. The turntable device is arranged at the upper end of the table. According to rivet receiver assembly procedures, the table is sequentially provided with a rivet feeding device, a rivet correcting device, a magnet assembling device, an iron box assembling device, a PCB assembling device, a riveting machine and a discharging device in an annular form. The fully-automatic rivet magnetic assembly machine is available for assembly and processing in a fully-automatic manner, situations of wrong assembly and missing assembly are avoided, one worker can be in charge of a plurality of machines, labor investment is reduced, and labor cost is reduced; and the fully-automatic rivet magnetic assembly machine is small in size, occupation space is saved, and a limit of the size of plant space can be avoided.

Owner:东莞市昱华智创科技有限公司

Automatic riveting machine

The present invention relates to a riveling press, in particular, it relates to an automatic riveling press. It includes a working platform, over the working platform a die for placing fivet and a power device for pressing rivet are set; the described die is composed of upper die table and lower die table, said upper die table is connected with the ram of cylinder, and the lower die table is fixedly set on the working platform, between the upper plate and working platform an upper die table guide column is fixedly set, two ends of said upper die table are cover-mounted on the upper die table guide column and are slide-connected with said upper die table guide column; on the working platform positioned in the rear portion of die a robot for feeding rivet is set, and on the working platform positioned in the front portion of die a material-placing mechanism for placing piece to be machined is set.

Owner:昆山精亿杰精密技术有限公司

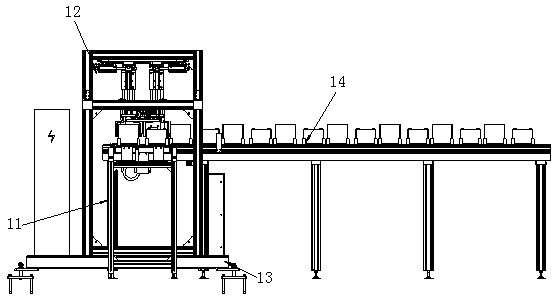

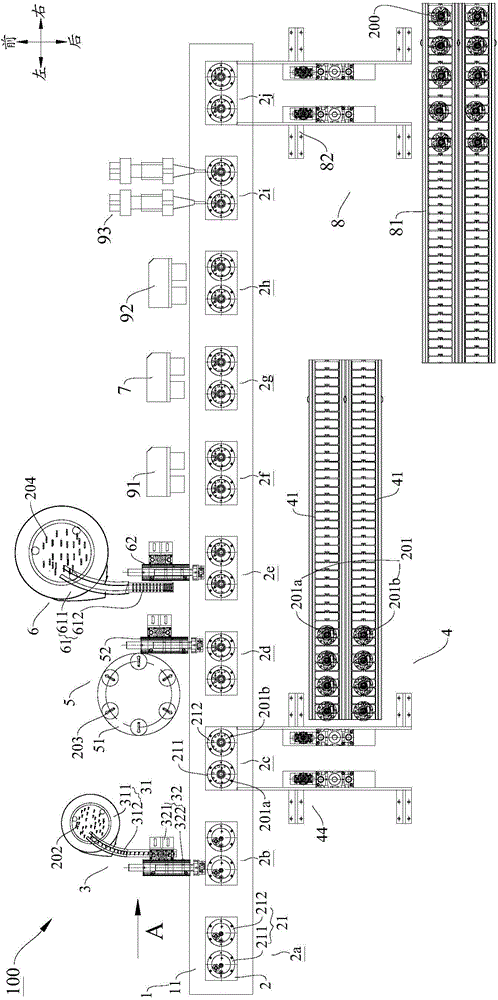

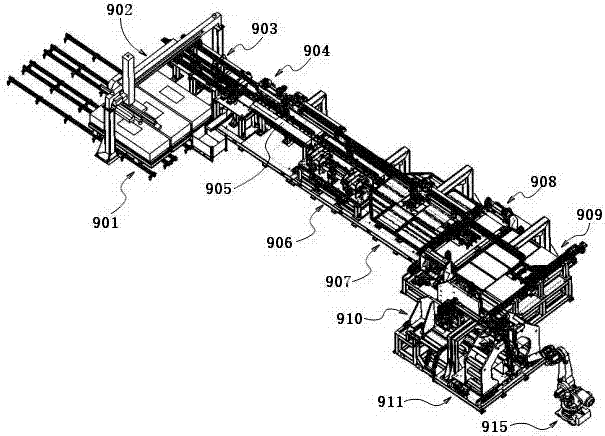

New energy power module assembling line

ActiveCN107819134ARealize the assemblyRealize automatic assemblyPrimary cell manufactureAssembling battery machinesNew energyBattery cell

The invention discloses a new energy power module assembling line relating to the technical field of tools for battery modules. A battery cell detection station is arranged on one side of a battery cell loading assembly, a automatic battery cell frame mounting station is arranged on one side of the battery cell detection station, a battery cell splicing station is arranged on one side of the automatic battery cell frame mounting station, a side loading line of the battery cell splicing station is arranged on one side of the battery cell splicing station, a battery cell module transplanter is arranged on one side of the side loading line of the battery cell splicing station, and a riveting machine is mounted on the battery cell module transplanter. The new energy power module assembling line can achieve assembly of a new energy battery module and can achieve automatic assembling, so that the labor and the time are saved and the efficiency is high.

Owner:丁琛琦

Automatic silver point riveting machine

InactiveCN101345147AReduce labor intensityReduce labor costsElectric switchesRelaysEngineeringMechanical engineering

The invention relates to an automatic silver-point riveting machine, which is characterized in that the automatic silver-point riveting machine comprises an automatic silver-point screening and conveying mechanism, and a silver-point receiving mechanism and a silver-point riveting mechanism which are connected with the automatic silver-point screening and conveying mechanism; as the automatic silver-point screening and conveying device, the automatic silver-point receiving device and the riveting mechanism are adopted, a plurality of silver points can be screened, conveyed, received and riveted simultaneously; therefore, the automatic silver-point riveting is really realized, the work benefits are greatly improved, and the labour intensity of the workers and the manpower cost are effectively reduced during the production process of an enterprise.

Owner:方安林

Full-automatic riveting machine

InactiveCN103433410ARealize full automationNo manual operationPinsNailsMechanical engineeringRiveting machines

The invention relates to the technical field of riveting machines, in particular to a full-automatic riveting machine. The full-automatic riveting machine comprises a machine frame, and the machine frame is provided with two vibration feeding devices and a disc device. The two vibration feeding devices comprise a first vibration feeding device used for conveying female screws and a second vibration feeding device used for conveying male screws respectively. The disc device comprises an inner disc and an annular outer disc, and the inner disc is rotatably mounted inside the outer disc. The inner disc comprises an upper layer and a lower layer, the edge of the upper layer and the edge of the lower layer are respectively provided with a plurality of placing holes, the placing holes in the upper layer are used for placing the female screws, and the placing holes in the lower layer are used for placing the male screws. The circumference of the outer disc is provided with an ejection device which is used for press fitting and assembling of the female screws and the male screws in the placing holes. In the working process, the full-automatic riveting machine can achieve automatic feeding of the female screws and the male screws and automatic assembling of the female screws and the male screws, the whole process is automatic, manual operation is needless, thus, production efficiency can be improved, and assembling quality can be guaranteed.

Owner:GANZHOU HEYING AUTO PARTS +1

Automatic assembly production line of bulb lamps

InactiveCN103624543AShorten production timeEasy to produceAssembly machinesMetal working apparatusProduction lineControl system

The invention relates to an automatic assembly production line of bulb lamps. The automatic assembly production line comprises a control system, a rack arranged beside the control system, a lamp holder cup assembling machine and an automatic lamp source connecting plate loading and unloading machine, wherein an indexing plate, a four-axis robot and an automatic cup overturning machine are arranged on the rack; an automatic lampshade assembling mechanism, an integrating sphere tester and an automatic lamp source assembling mechanism are arranged beside the rack; an automatic rivet assembling mechanism, an automatic lamp holder assembling mechanism and an automatic cup assembling mechanism are assembled beside the lamp holder cup assembling mechanism; a carrying tray is arranged on the automatic lamp source connecting plate loading and unloading machine; a waste transferring mechanism is arranged beside the integrating sphere tester; a riveting machine is arranged beside the waste transferring mechanism. The automatic assembly production line has the advantages that the manufacturing time of LED (Light Emitting Diode) products is shortened in the process of manufacturing the LED products, the production efficiency is improved, and further, the cost of the products is reduced; the automatic assembly production line can be used for conveniently producing the LED products in an industrial assembly line manner and in a large scale.

Owner:滕州天一光电科技有限公司

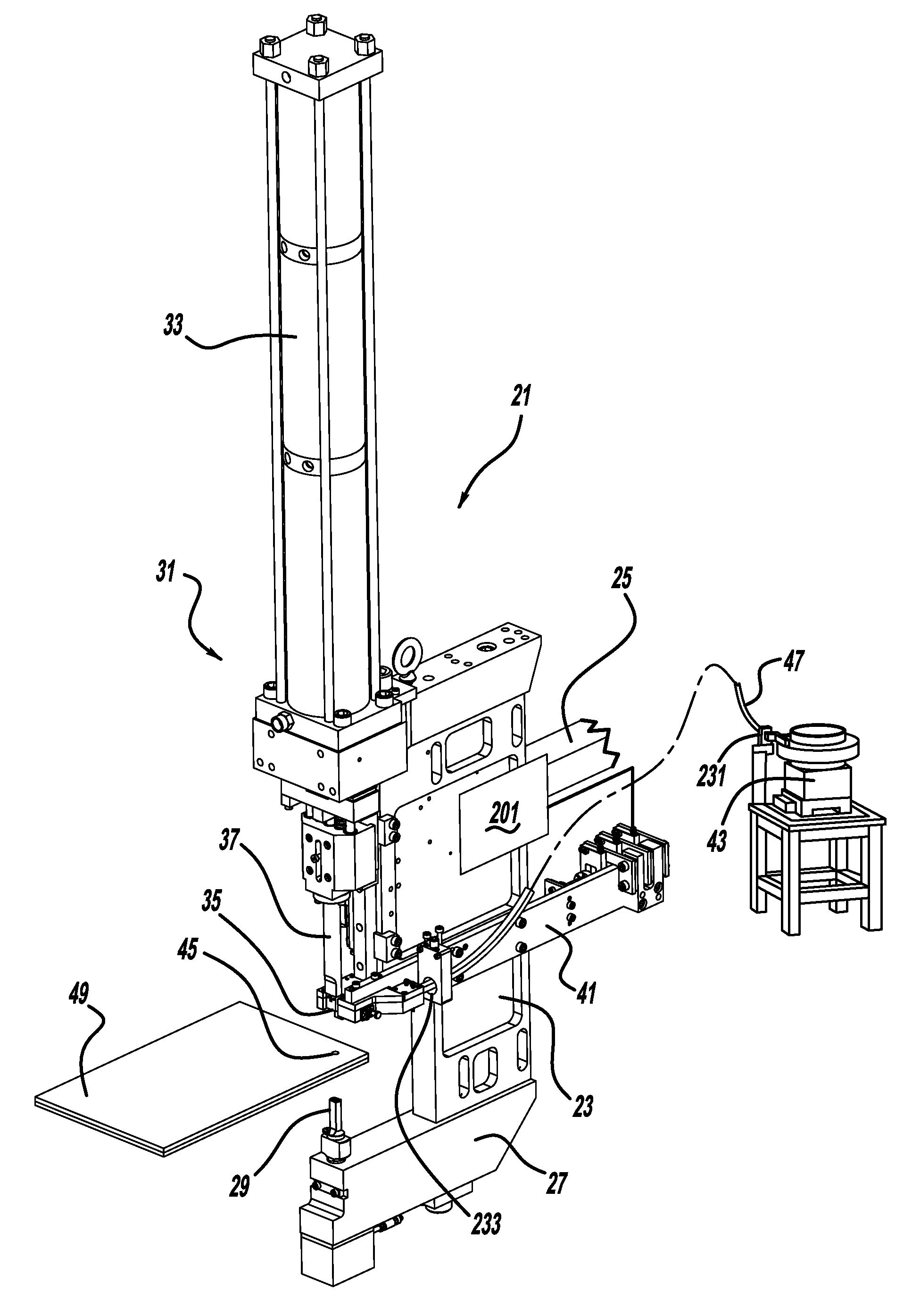

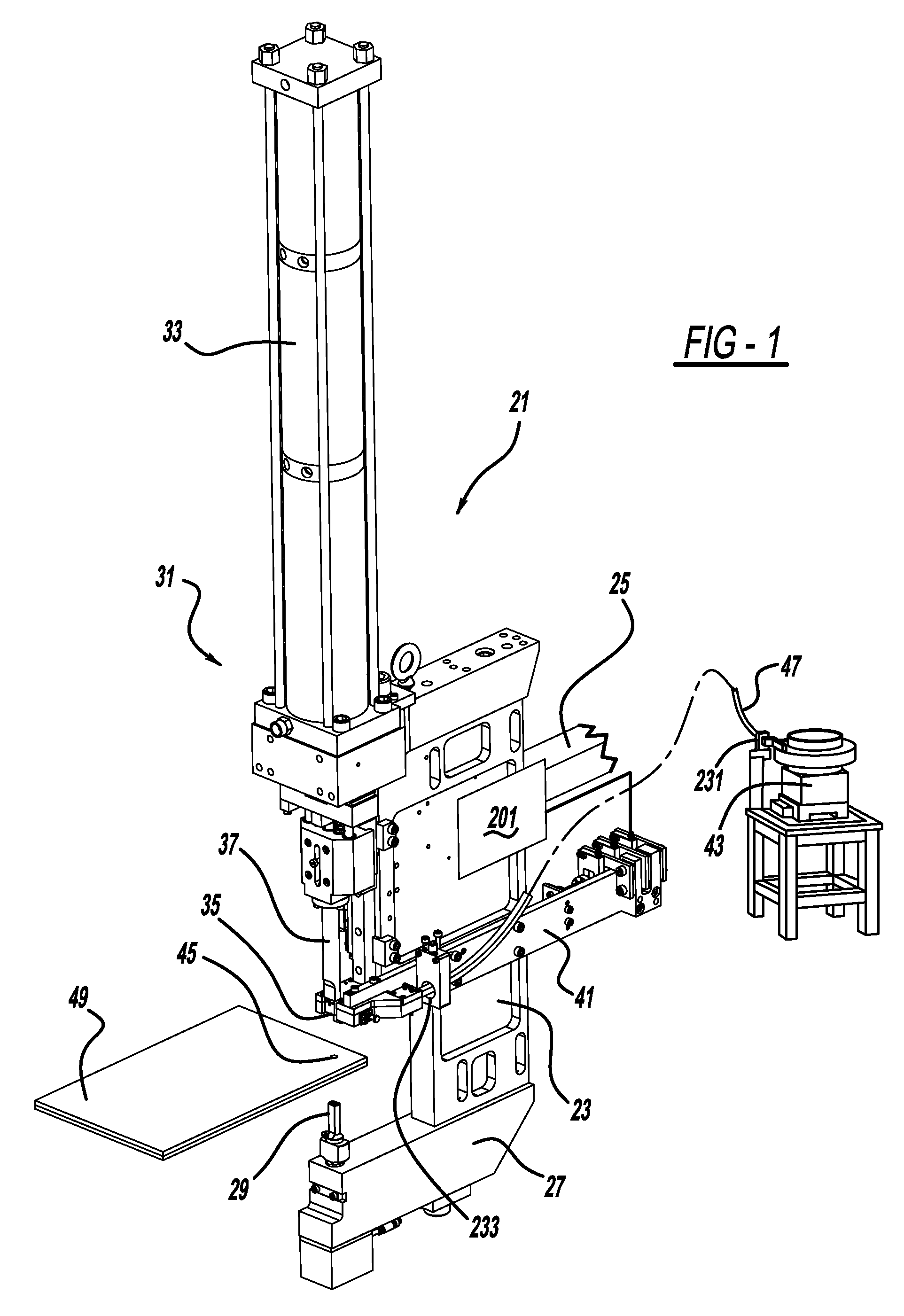

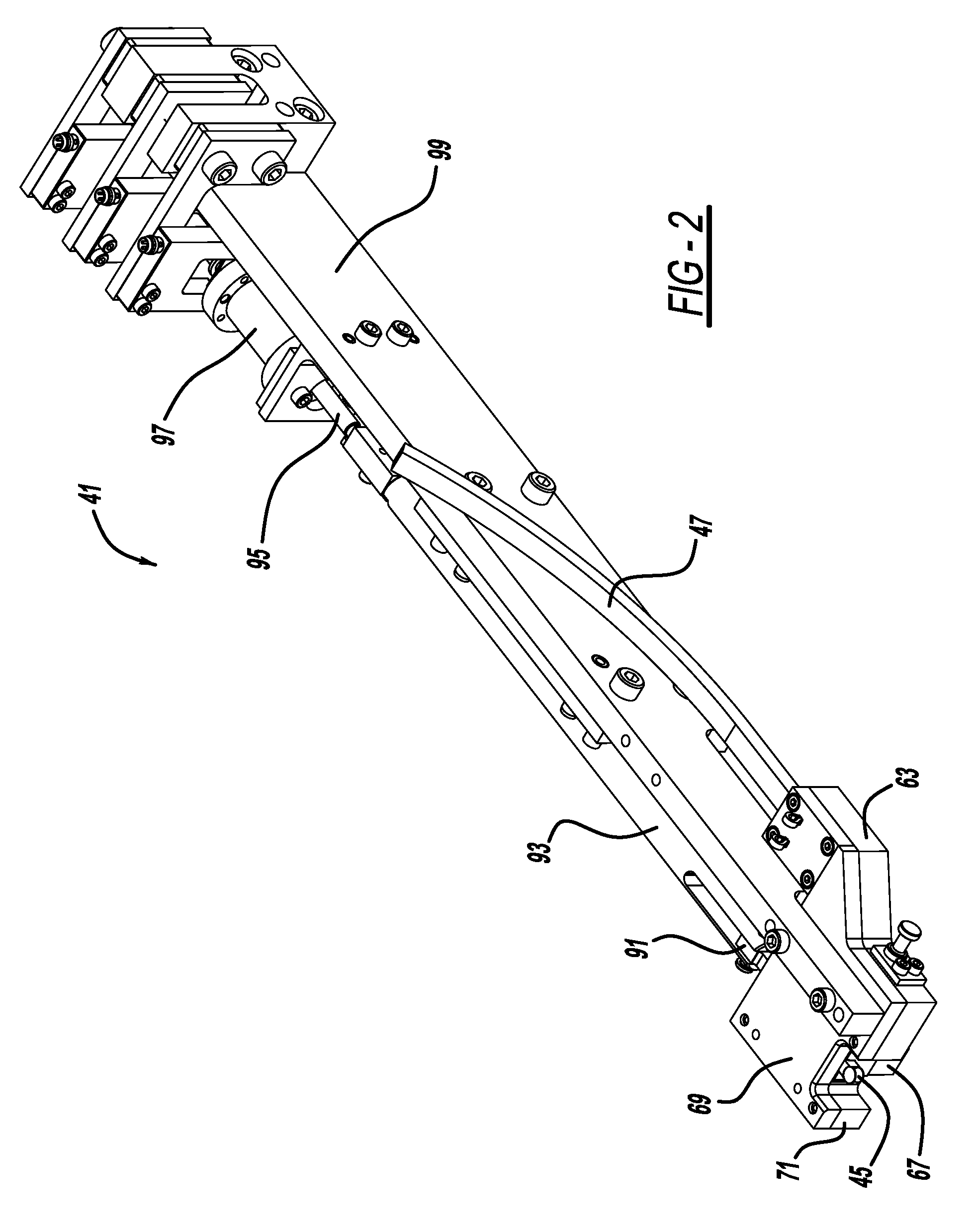

Rivet machine

A fastener machine is provided. In another aspect, a rivet machine employs a rivet feeding mechanism. A further aspect includes a guide located at an intersection between a feed track and a feed rail with the guide having an angular offset orientation relative to both in order to deter ricocheting of the rivet back into the feed track when the rivet enters the feed rail. Moreover, an aspect of the present machine employs a rocker arm.

Owner:BTM COMPANY

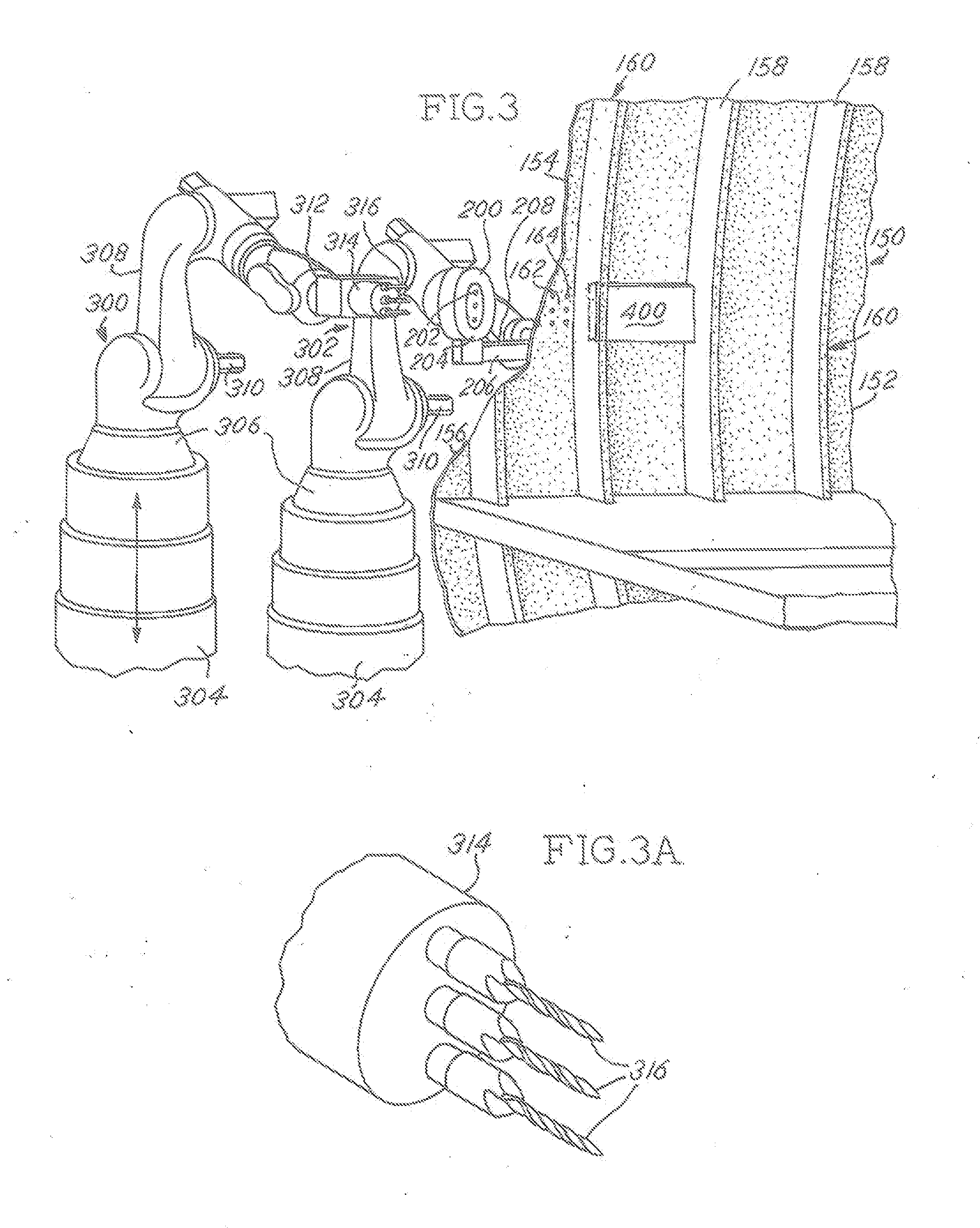

Method and Apparatus for Automated Multi-Drilling and Multi-Rivet Machine

Method and apparatus for assembling, with fasteners, components of a structure having an outboard side, an inboard side, and a supporting frame. The components are placed together on the frame. An electromagnet having a core with multiple openings is positioned on the outboard side. A magnetically attractive member is placed against the inboard side opposite and aligned with the electromagnet. When activated, the electromagnet is attracted towards the magnetically attractive member and the two hold the components together. Multiple drill members pass through the openings in the core of the electromagnet and multiple openings are drilled simultaneously through the components. Subsequently, multiple rivets or huck bolts are simultaneously inserted into the drilled openings. Finally, fasteners are hammered through the drilled openings and rivets are secured by bucking bars provided on the magnetically attractive member. Alternatively, openings are provided in the magnetically attractive member for manually securing huck bolts to the components.

Owner:THE BOEING CO

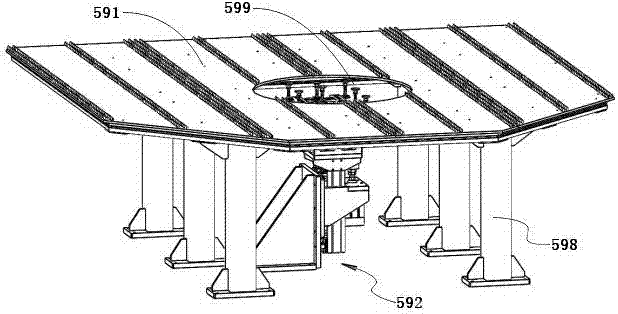

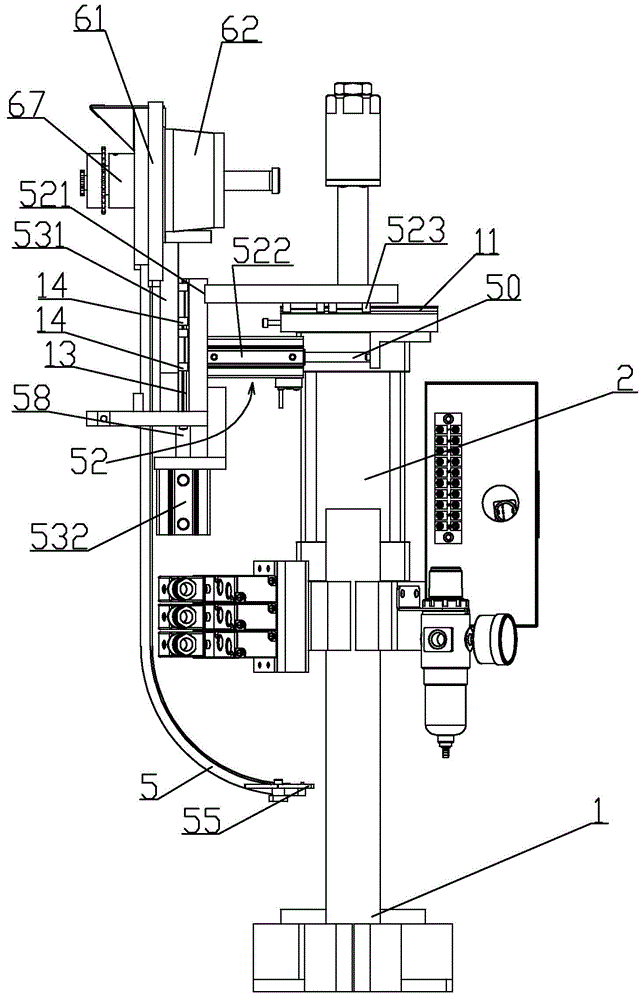

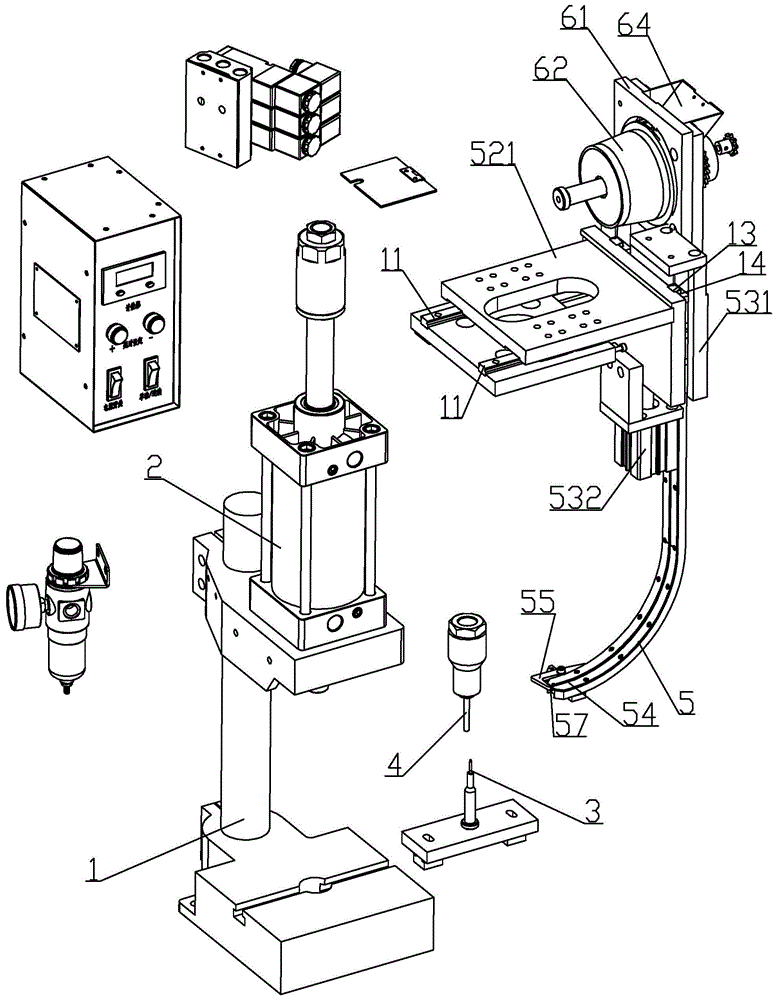

Semi-automatic assembly equipment of fire extinguisher pressure gauge

InactiveCN102990356AReasonable structural designReduce labor intensityAssembly machinesElectrical controlSemi automatic

The invention relates to semi-automatic assembly equipment of a fire extinguisher pressure gauge, comprising a frame and a worktable arranged on the frame, wherein a turntable is arranged on the worktable; a clamp for arranging the pressure gauge is arranged on the turntable; a pressure gauge conveying mechanism for transporting the pressure gauge to the clamp of the turntable, a riveting mechanism for riveting the pressure gauge and a good product unloading mechanism are further arranged on the worktable; and the mechanisms are respectively connected with and controlled by the main control circuit. The semi-automatic assembly equipment of the fire extinguisher pressure gauge provided by the invention is reasonable in structural design, and employs electric power to control automatic feeding, detection, riveting and unloading of the pressure gauge, so that the production efficiency and the product quality are improved, the labor intensity of workers is greatly reduced and the production cost is saved; and therefore, the semi-automatic assembly equipment is especially suitable for meeting the need of large-batch production of the fire extinguisher pressure gauge; and the market competitiveness of the enterprise is improved.

Owner:周俊雄

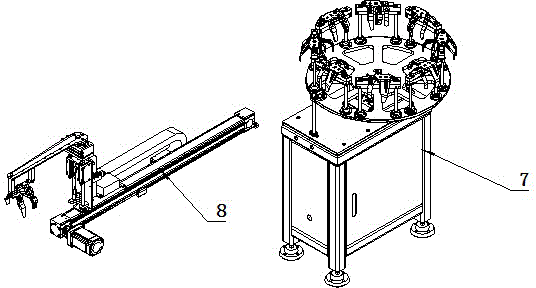

Automatic riveting machine

The invention relates to an automatic riveting machine. A plurality of elastic clamping devices are uniformly arranged on the outer circumference of a rotary feeding table; the rotary feeding table is arranged on a rack; a component vibration feeder, a component guiding device, a silver point vibration feeder, a double-end riveting device and a component stirring device are arranged at the periphery of the rotary feeding table in sequence; a component carrying mechanical arm is arranged between the component vibration feeder and the rotary feeding table; a silver point carrying mechanical arm is arranged between the silver point vibration feeder and the rotary feeding table; and a discharging mechanical arm is adjacent to the rotary feeding table and the double-end riveting device. The automatic riveting machine can realize full automation in the whole riveting process, the positions of components can be adjusted, the riveting quality is good, the working efficiency is improved and the automatic riveting machine is applicable to large-scale production in batches.

Owner:WENZHOU TIANJI ROBOT AUTOMATION

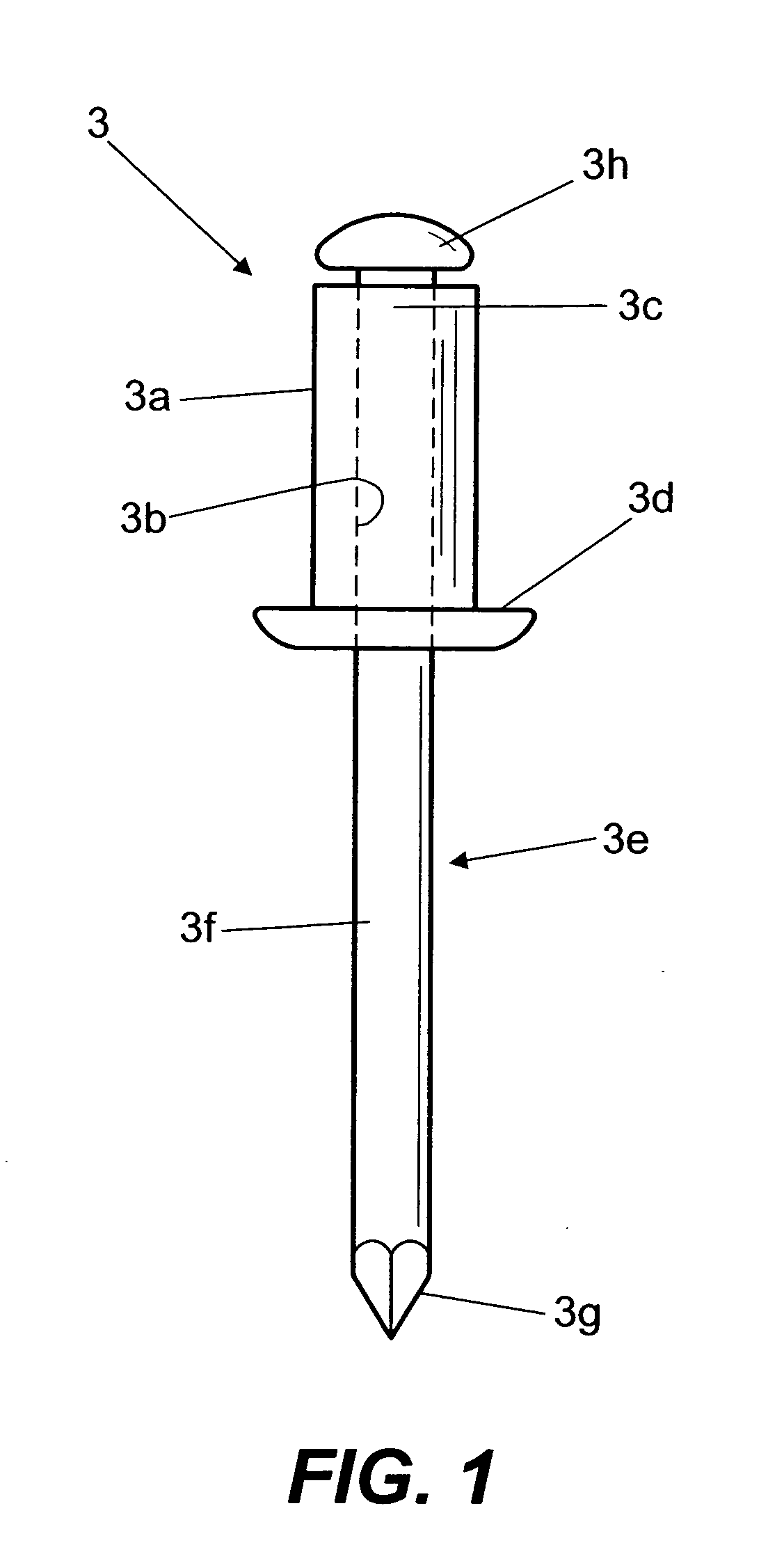

Dynamic verification method for a riveting process with blind rivets carried out with an automatic riveting apparatus, and verifying device for carrying out the verification

InactiveUS20080250832A1Shaping safety devicesMeasurement/indication equipmentsClassical mechanicsTractive force

A method and device are provided for verification of the quality of placing of blind rivets. The verification method involves successively carrying out, during the application of traction force to a stem, initial measurements in an initial state of the application of the traction force to obtain an initial traction force and an initial displacement of the rivet stem relative to the rivet body, intermediate measurements in an intermediate stage of the application of the traction force to obtain an intermediate traction force and an intermediate displacement, and terminal measurements in a terminal stage of the application of the traction force to obtain a terminal traction force and a terminal displacement. The obtained values are compared to acceptable values in an assignment table.

Owner:AIRBUS OPERATIONS SL

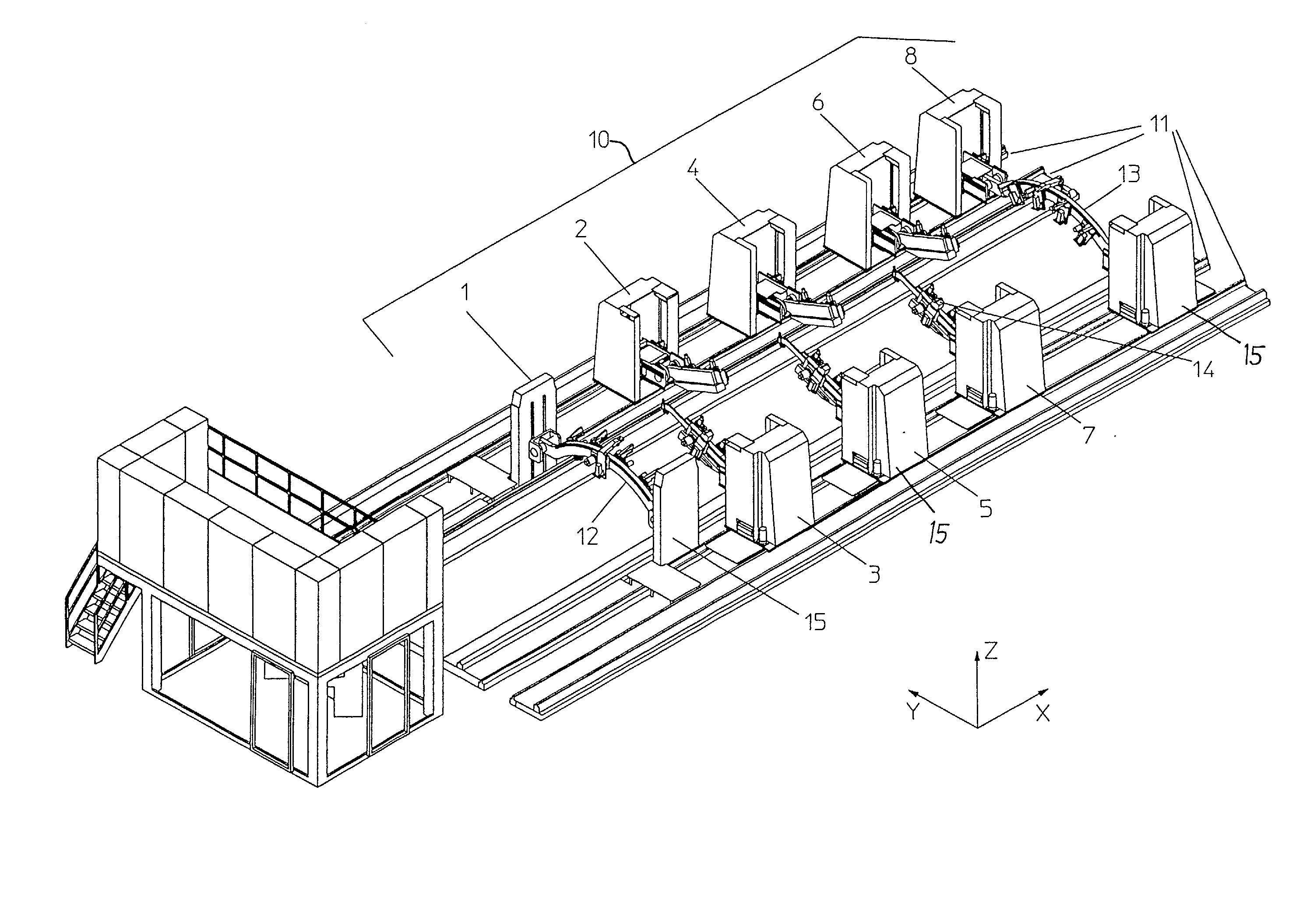

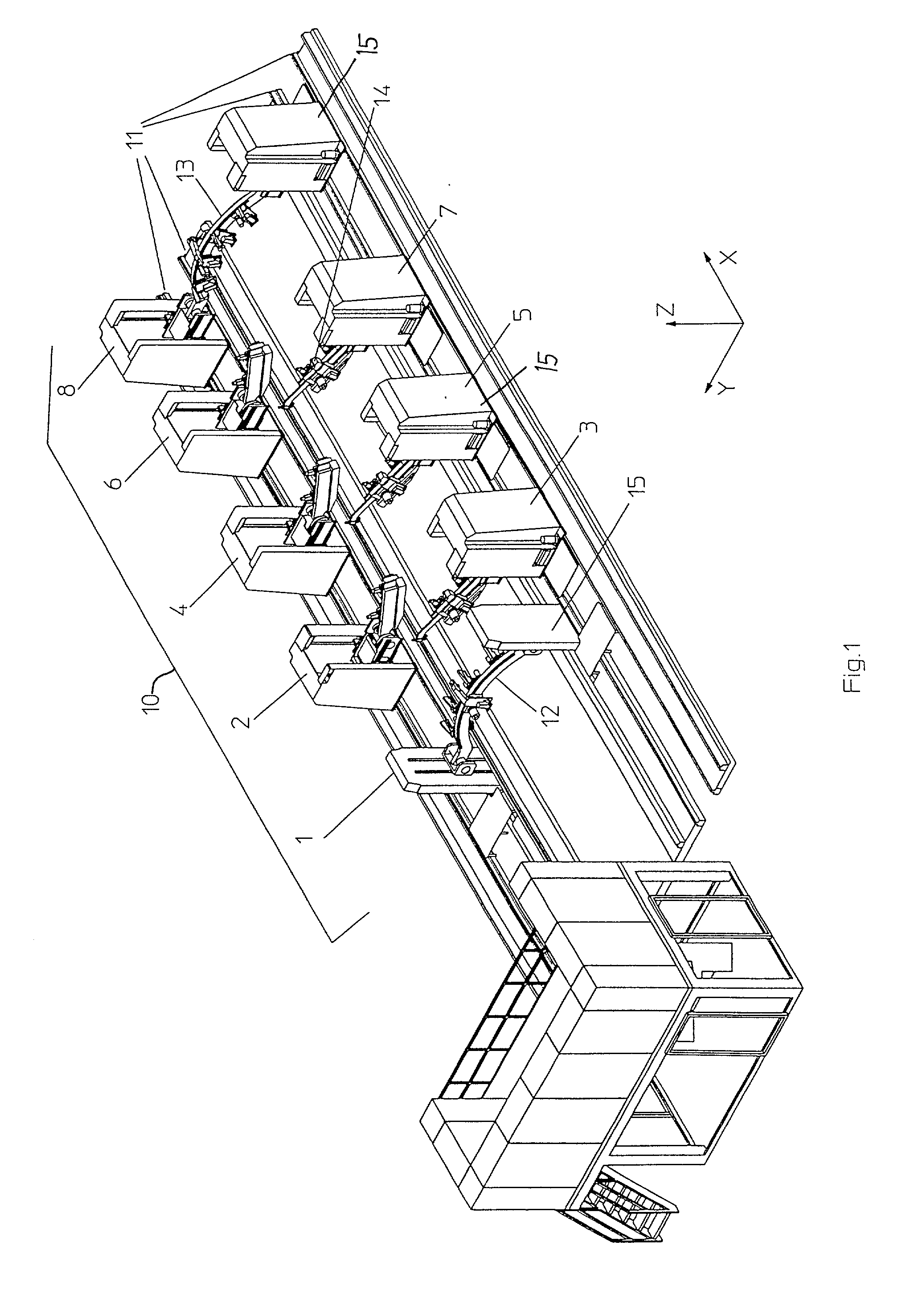

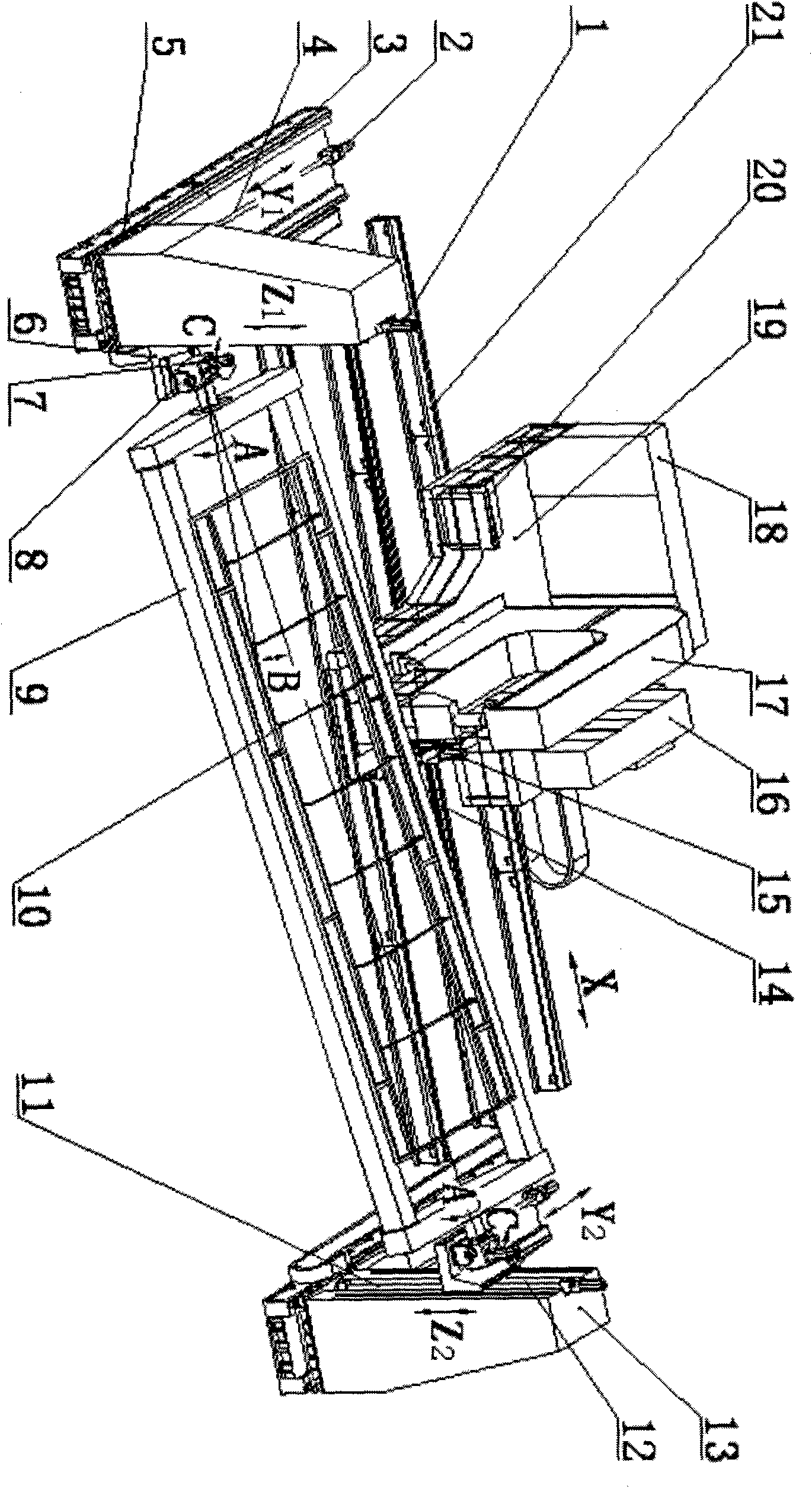

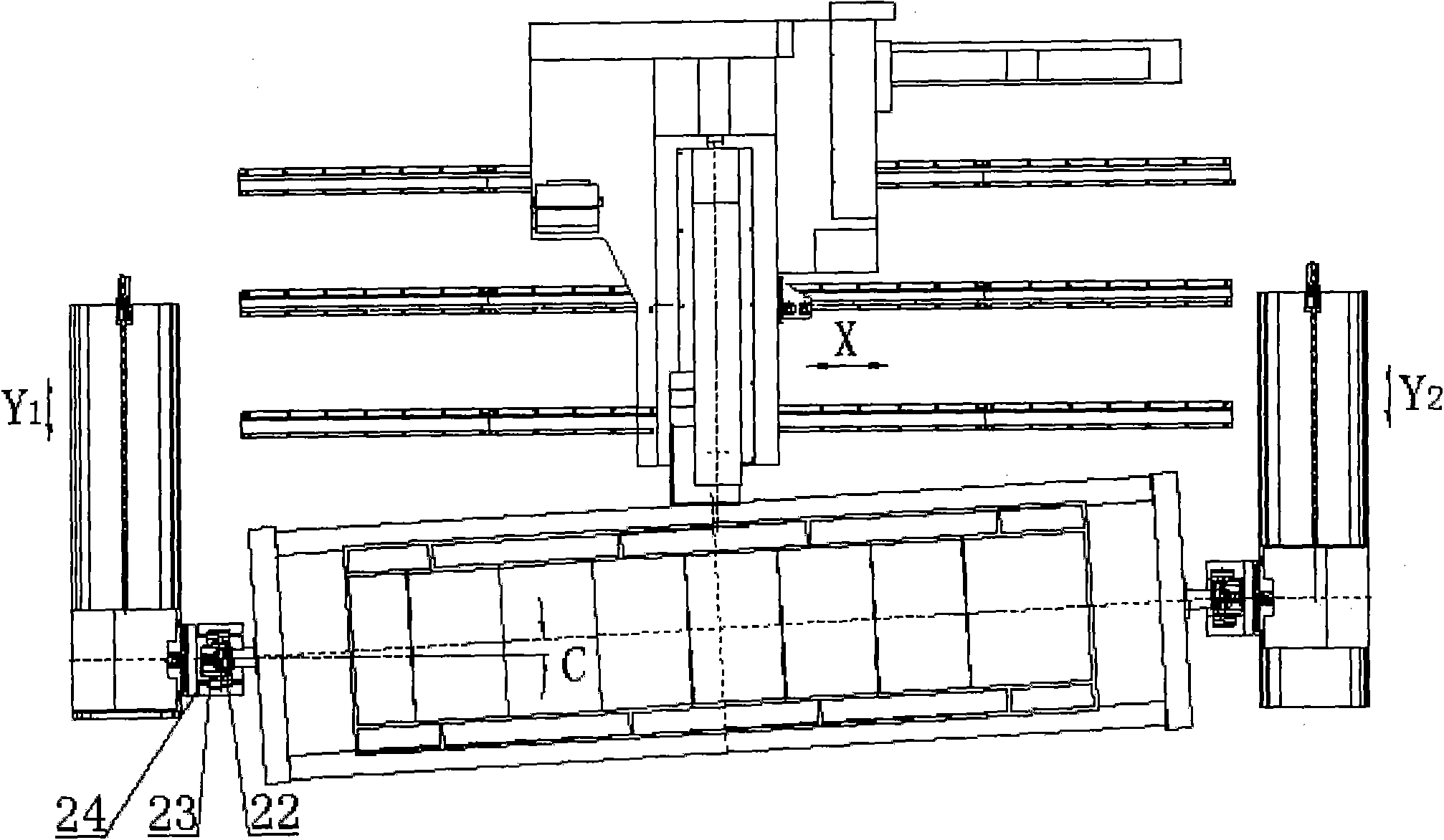

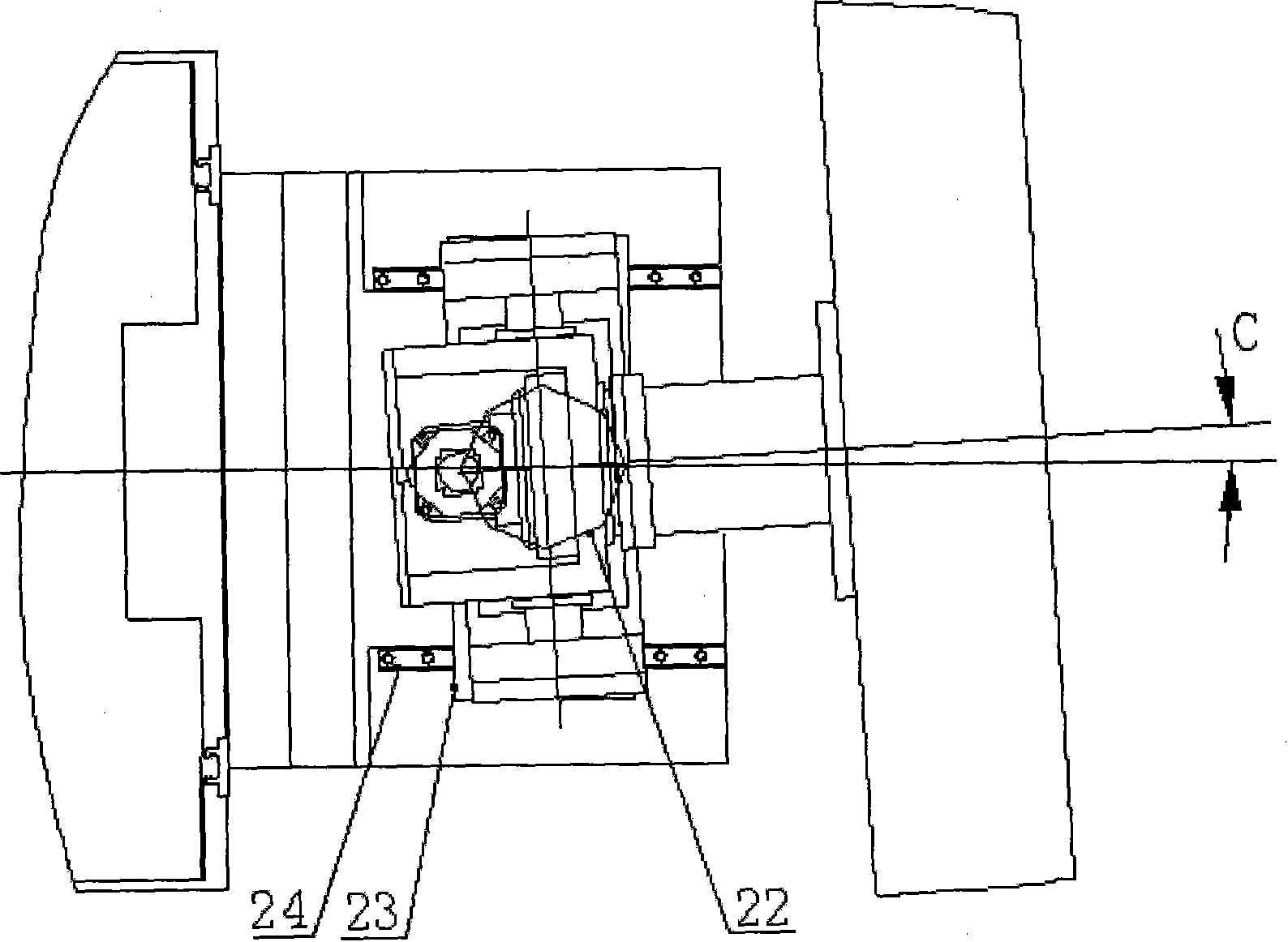

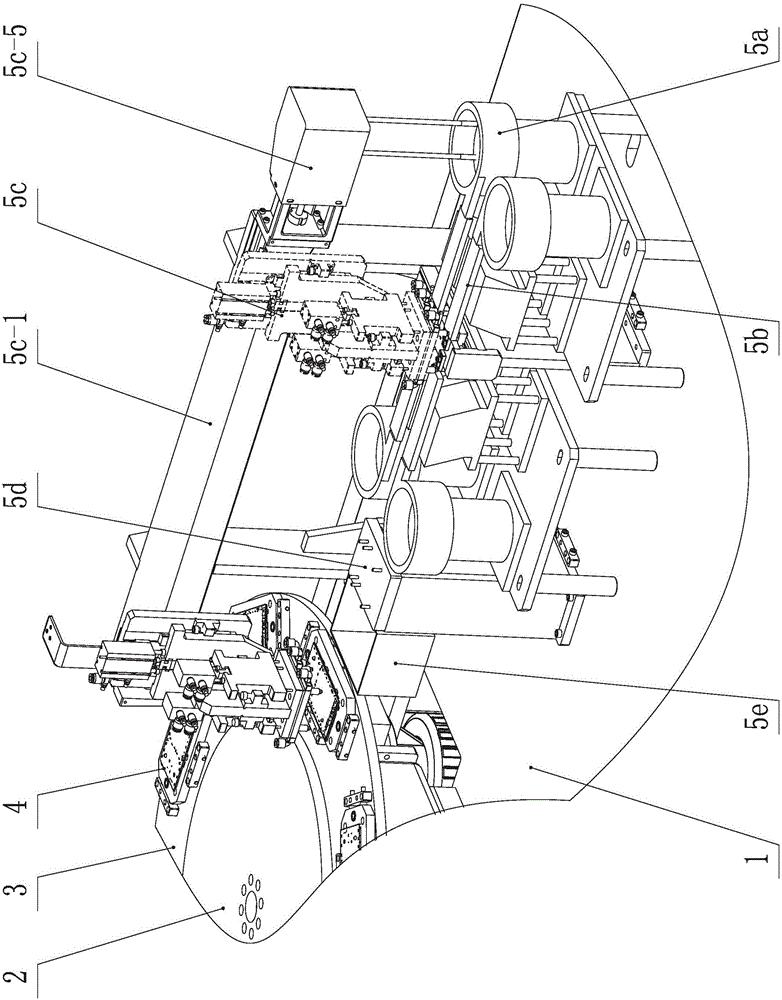

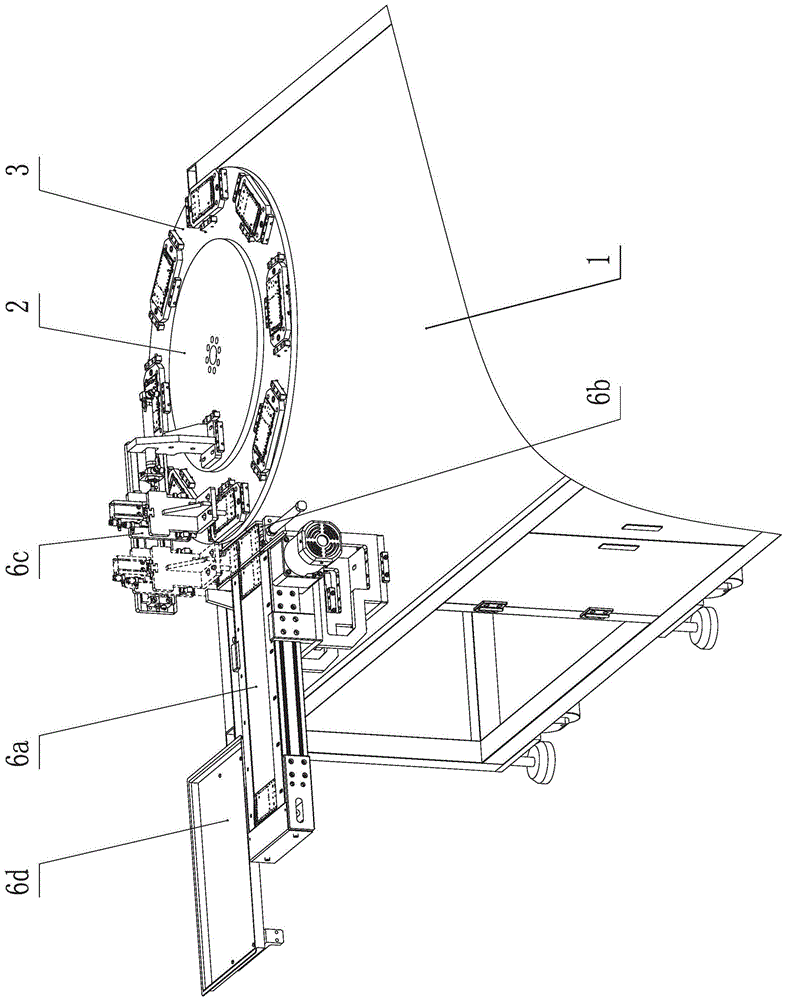

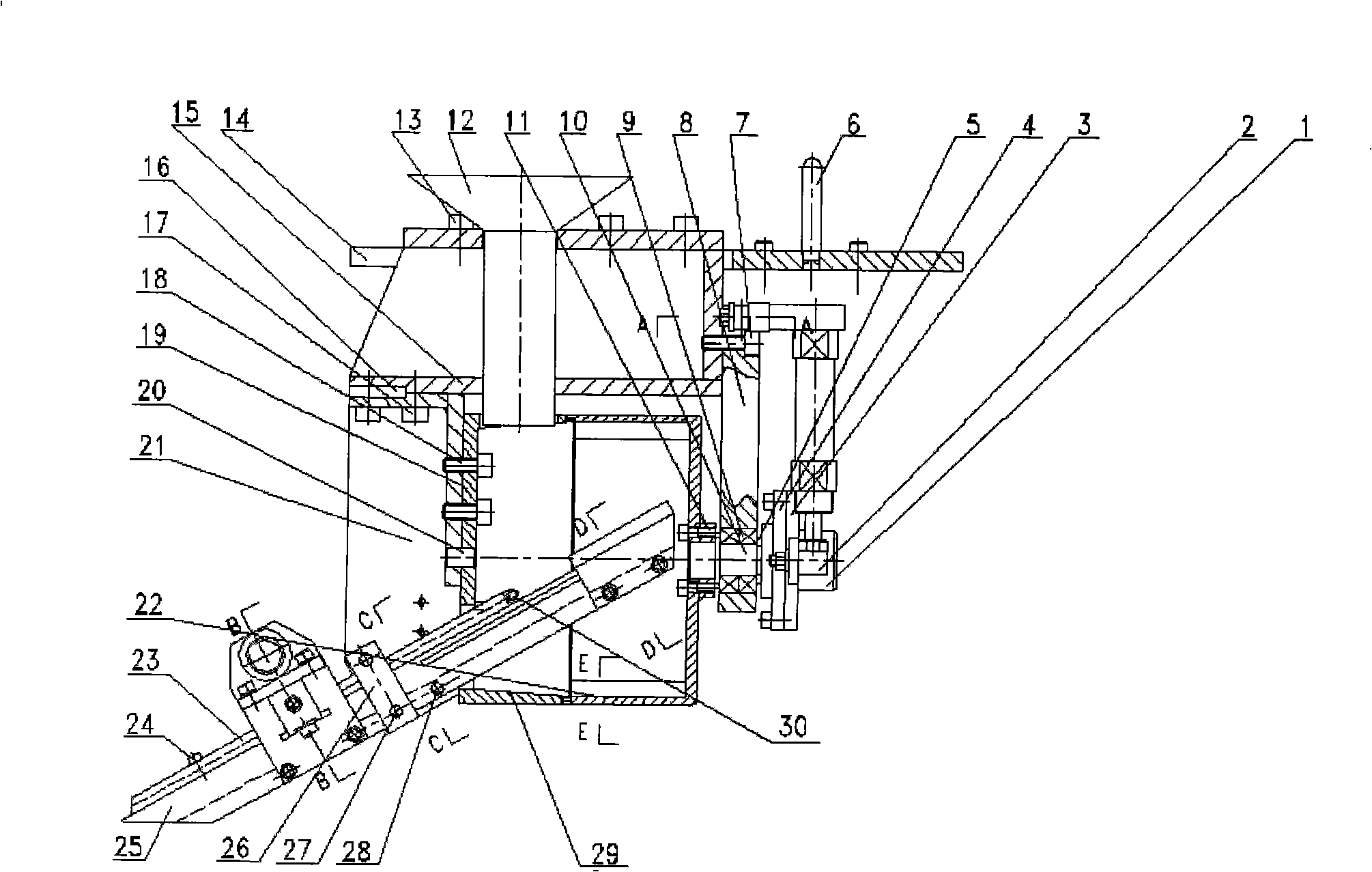

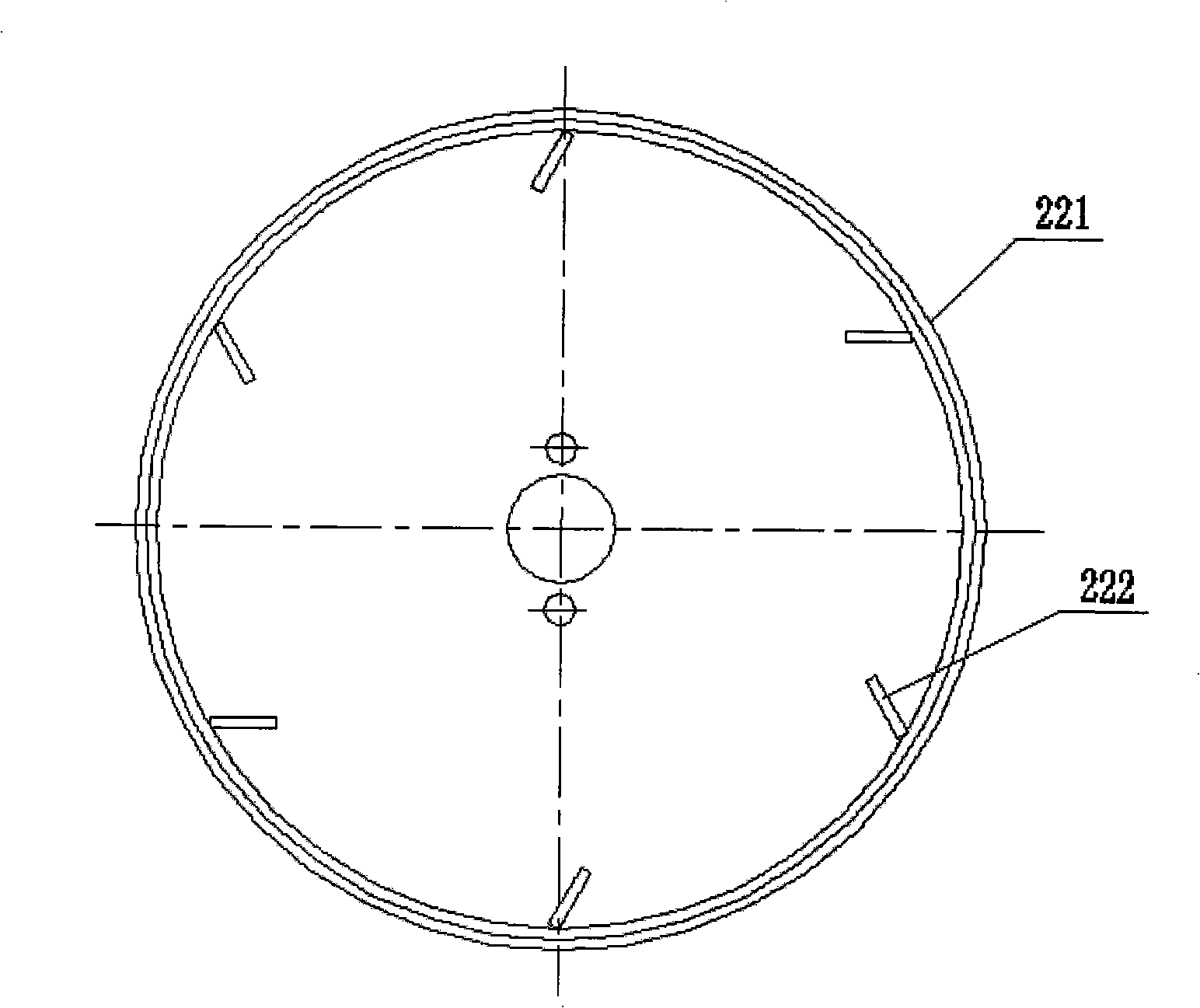

Separated full-automatic drilling and riveting bracket system

InactiveCN101817146AAchieve productionResolve center of gravity shiftOther manufacturing equipments/toolsLarge fixed membersEngineeringMachining

The invention relates to a s full-automatic drilling and riveting bracket system, comprising a lateral X-axis guide rail , a slipway X, a drilling and riveting machine, a console, a longitudinal Y-axis guide rail, a left-right slipway Y, a Z pillar arranged on the slipway Y, a Z slipway, a bracket frame arranged on the slipway Z, a working frame fixed on the bracket frame and on the like. The motion of an axis A is achieved by the rotation of the bracket frame, the motion of an axis B is achieved by a differential motion of Z1 and Z2, and the motion of an axis C is achieved by a differential motion of Y1 and Y2. The location and normal adjustment of parts are realized by the together motion of six coordinate axis including an X-axis, a Y-axis, a Z-axis, an A-axis, a B-axis and a C-axis. The invention has simple structure, stable quality of riveting and high precision of positioning, can produce different kinds of parts on the same bracket system; the operation of clamping and adjusting a product is very convenient because the bracket frame can be lowered to a lower height. The invention can realize cross-stringer automatic drilling and riveting; has good production continuity, high degree of automation, small occupation area and low manufacture cost, and the machining efficiency reaches the most advanced world level.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

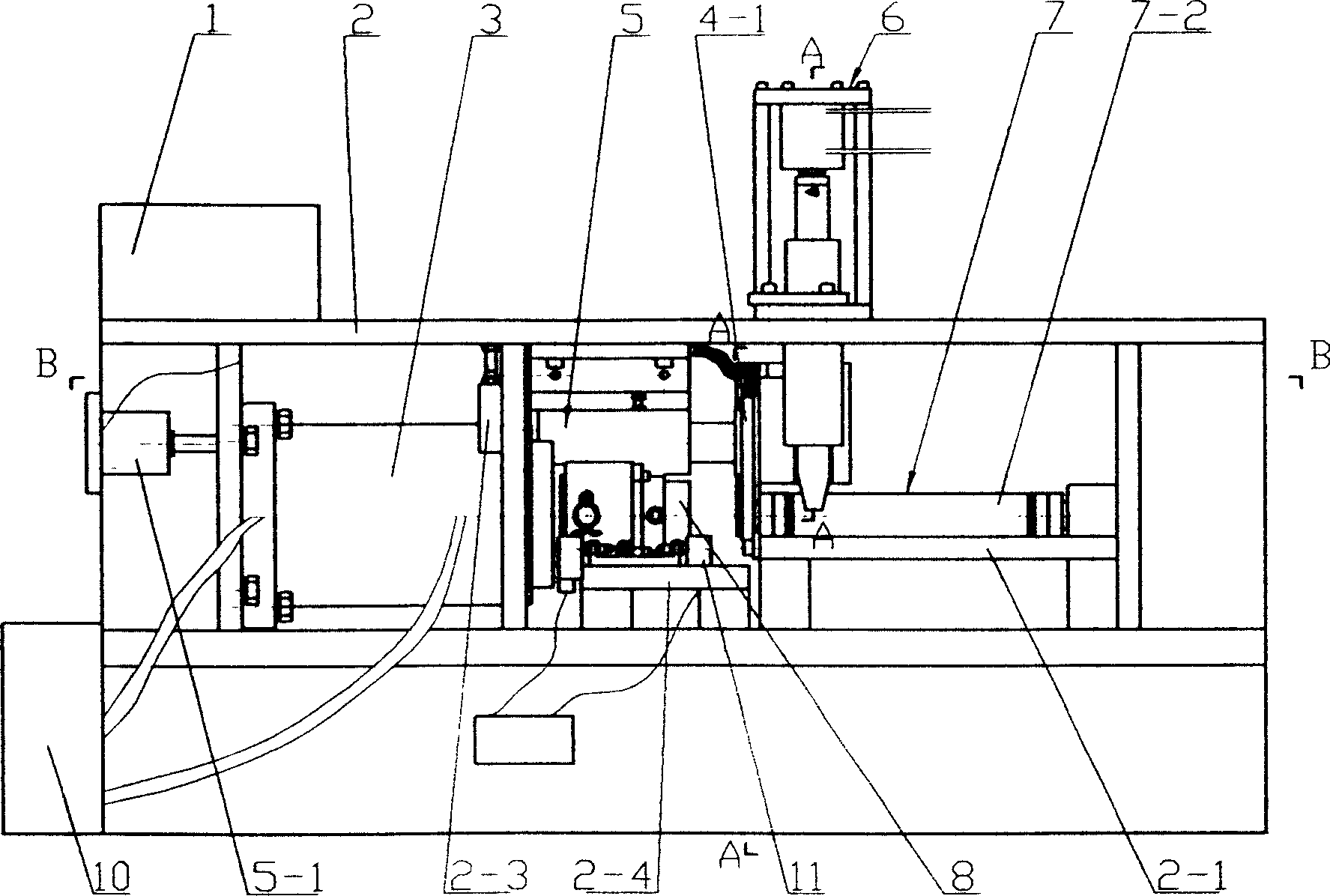

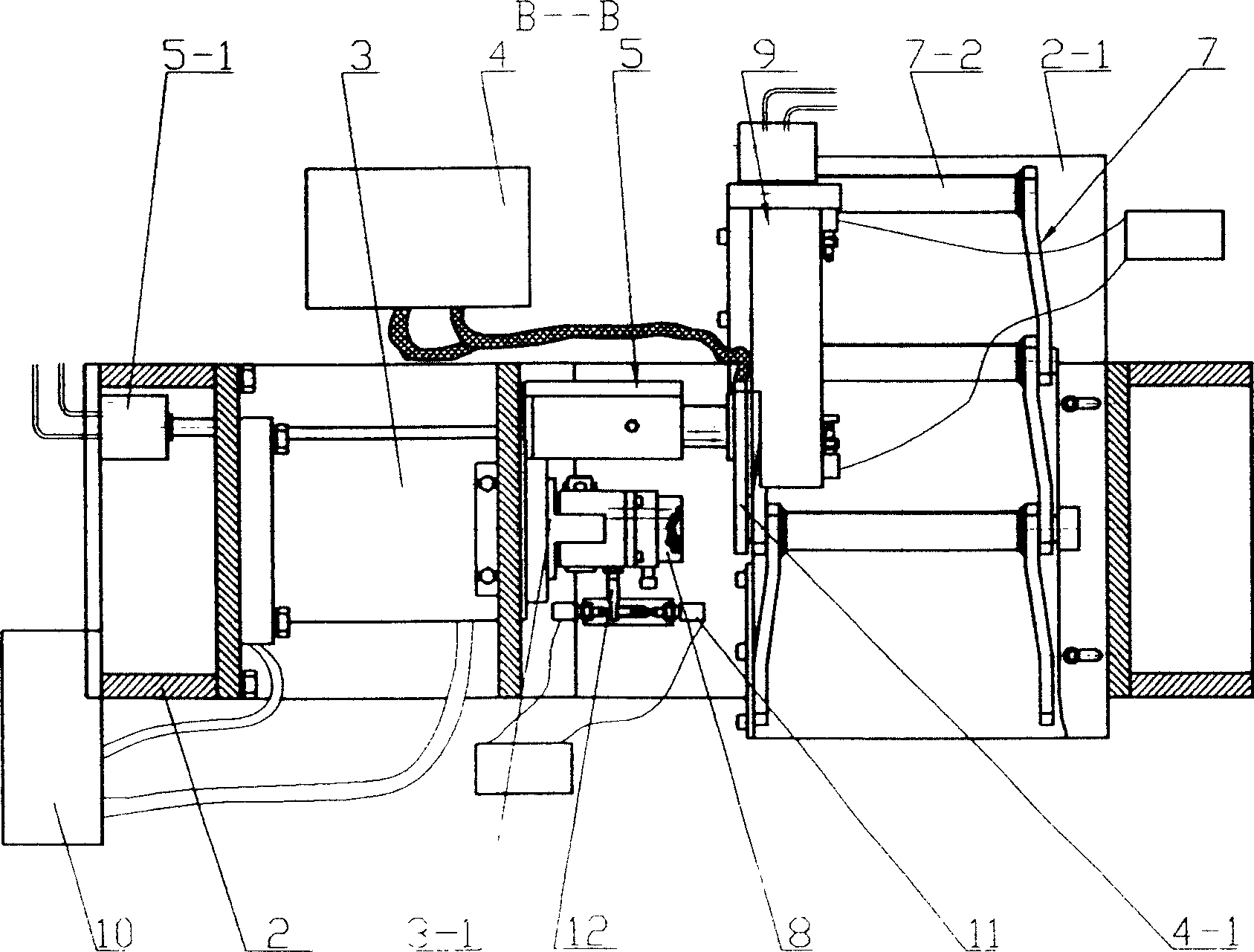

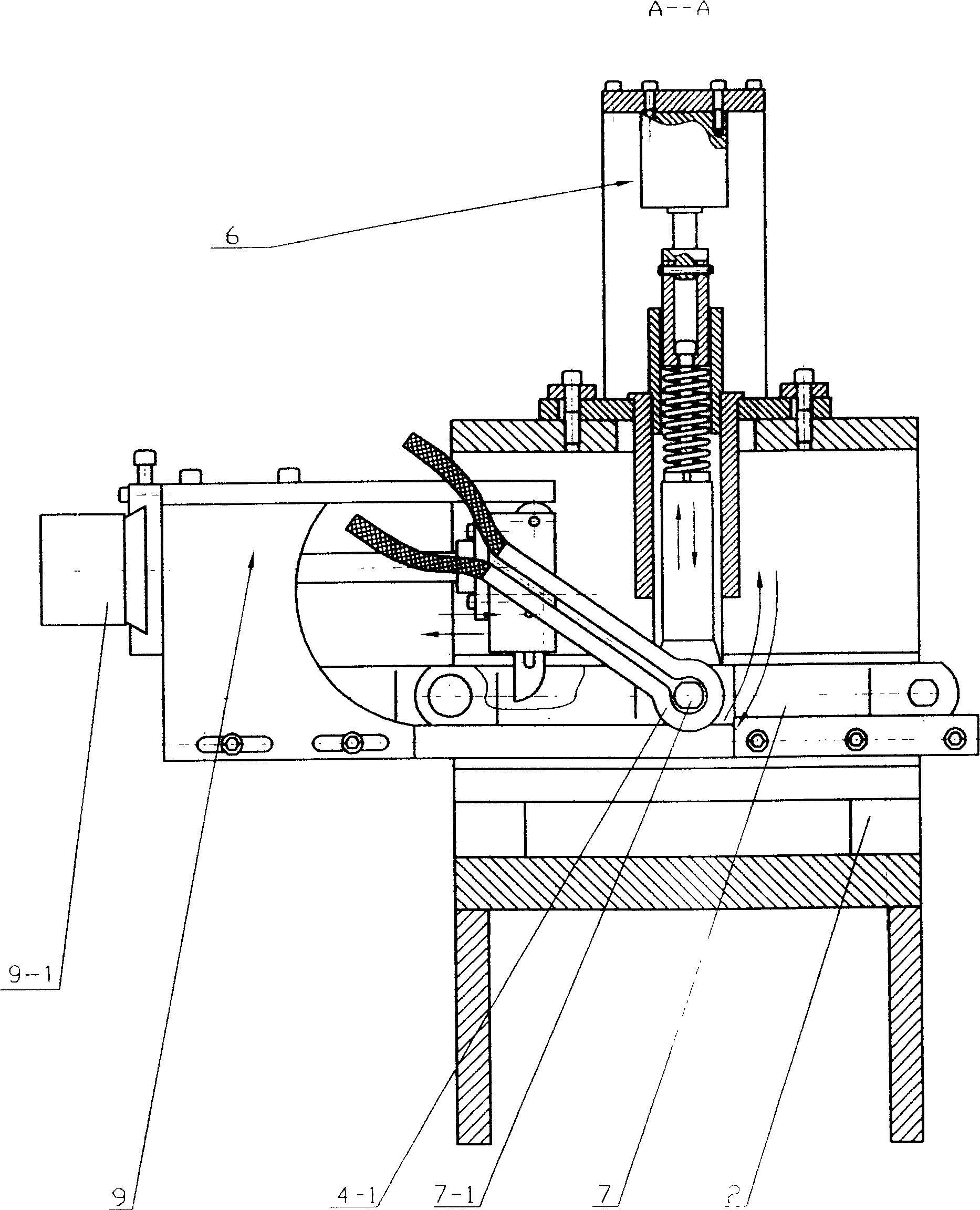

Contact riveter

InactiveCN102120245ASolve the speed problemSolve efficiency problemsMetal-working feeding devicesPositioning devicesCamControl circuit

The invention belongs to the technical field of riveters and particularly discloses a contact riveter, which comprises a machine body, a first material band positioning and pressing device, a contact feeding device, a contact riveting device, a second material band positioning and pressing device, a material band feeding device, a cam ejecting device, a material band feeding track, wherein the first material band positioning and pressing device, the contact feeding device, the contact riveting device, the second material band positioning and pressing device and the material band feeding device are arranged on the machine body in turn; the cam ejecting device is arranged below the contact feeding device; all devices are connected with and controlled by a main control circuit arranged on one end of the machine body; and the material band feeding track carries a material band, runs through the middle of the first material band positioning and pressing device and the contact feeding device and extends to the contact riveting device, the second material band positioning and pressing device and the material band feeding device. In the invention, the low speed and low efficiency problemsof a riveting process combining a working mechanism and manual operation, the contact riveter adopting a fully automatic flow has the advantages of high assembly quality and high efficiency, and operation environment is improved.

Owner:周俊雄

Automatic riveting machine

The invention discloses an automatic riveting machine, which solves the technical problem that the automation degree of the riveting machine in the prior art is low. The automatic riveting machine comprises a workbench, an intermediate base, a riveting piece loading rotary plate and a loading rotary plate driving mechanism, wherein the intermediate base is fixed on the workbench, the riveting piece loading rotary plate is arranged around the intermediate base, and the loading rotary plate driving mechanism is in signal connection with an upper computer; riveting piece carriers are arranged on the loading rotary plate, and rivet locating holes are formed in the riveting piece carriers; a rivet loading mechanism, a riveting piece loading mechanism, a riveting mechanism, a riveting piece column leakage detecting mechanism and a riveting piece output mechanism are sequentially arranged on the workbench in a rotation direction of the riveting piece loading rotary plate, and are respectively in signal connection with the upper computer. According to the automatic riveting machine, full automatic production from loading, riveting and unloading is achieved, the labor cost is reduced, the working efficiency is improved, and the automatic riveting machine is suitable for large-scale batch production.

Owner:昆山湘北精密金属有限公司

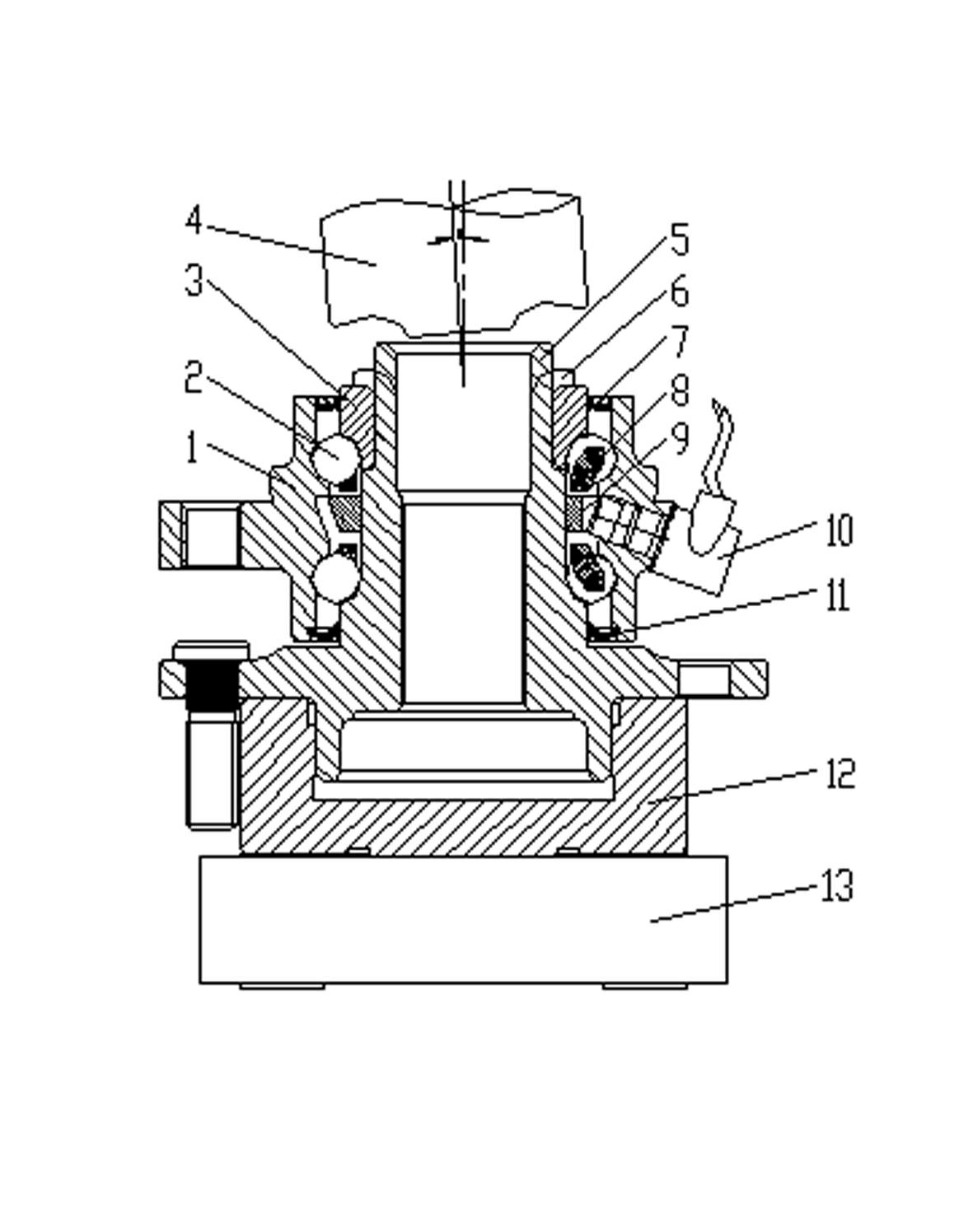

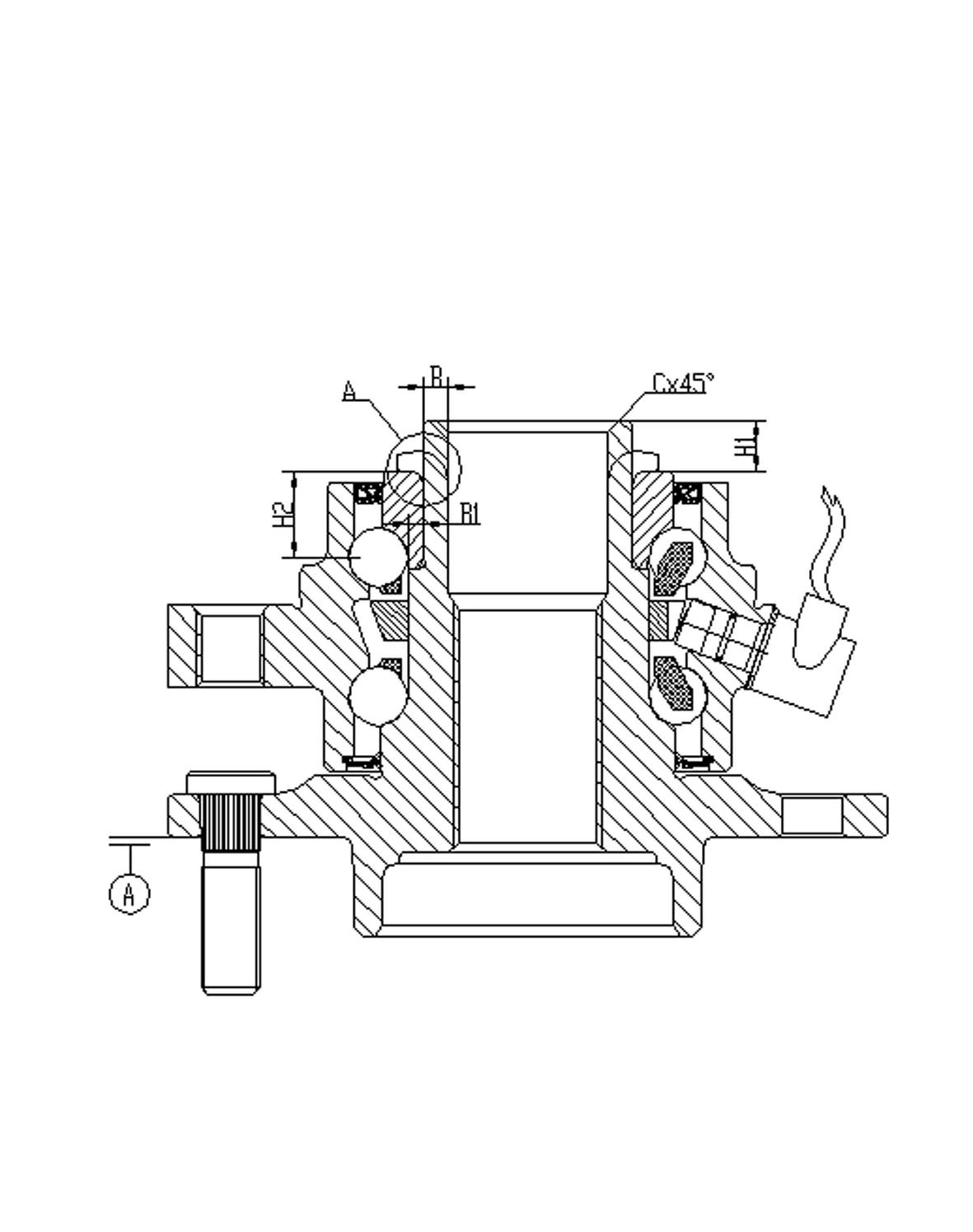

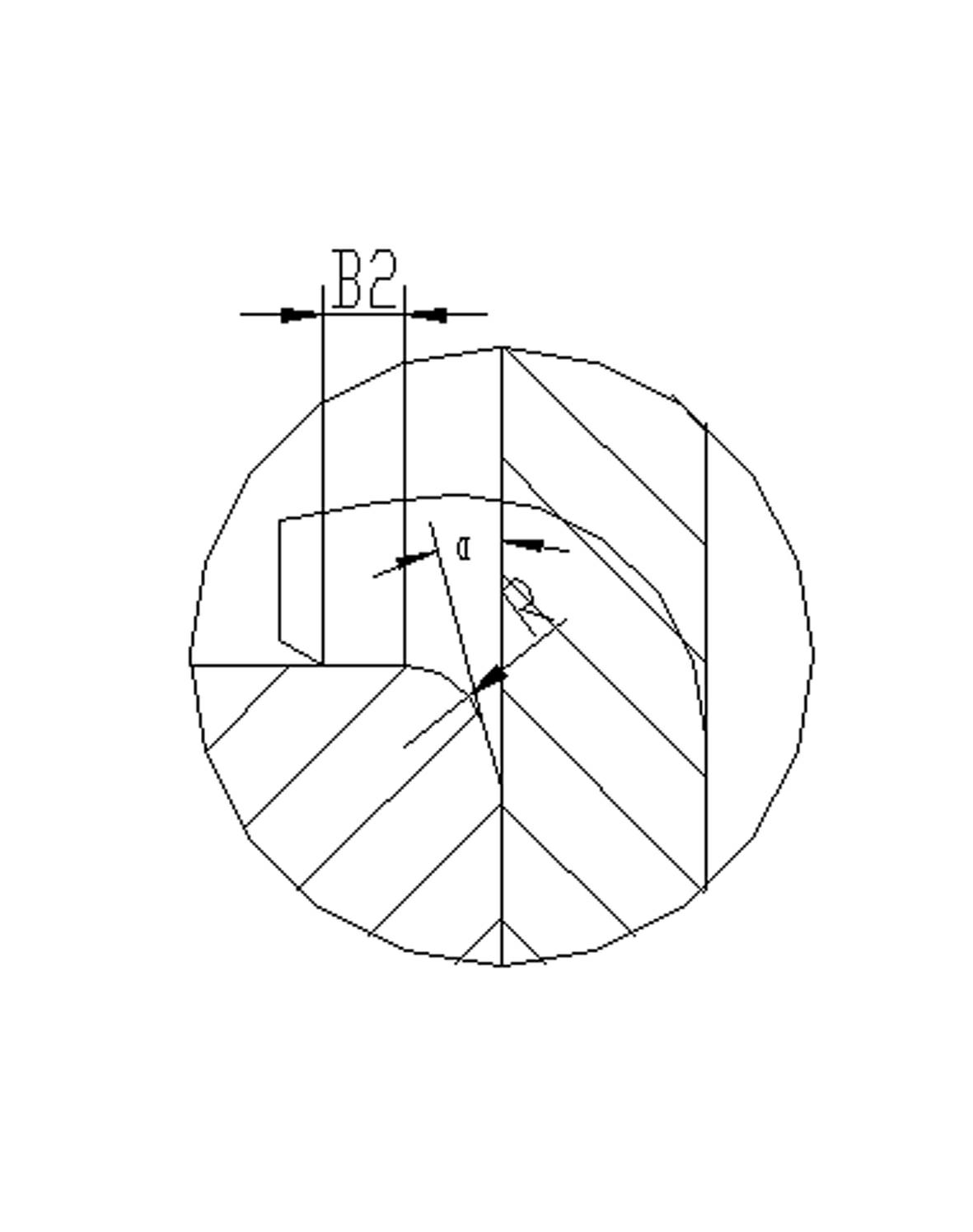

Spinning riveting assembly and manufacturing method of automobile hub bearing unit

The invention relates to a spinning riveting assembly and manufacturing method of an automobile hub bearing unit. The method comprises the following steps: firstly machining a hub bearing; assembling an outer flange, steel balls, a small inner ring and a hub shaft according to the requirements of being approximate to zero end play, and assembling the bearing unit into a state before riveting according to a certain process; placing the assembled bearing unit on a worktable of a riveting machine tool for spinning deformation; and finally inspecting. The spinning riveting assembly and manufacturing method has the beneficial effects that assembly quality and assembly efficiency of the automobile hub bearing unit can be greatly improved, the assembled automobile hub bearing unit becomes a whole body, axial load (clamping force) of the small inner ring can be accurately controlled, reliability, safety and service life of the hub bearing are greatly improved, and production efficiency is very high and up to 20-30sec / unit; and according to product structure design provided by the invention, smooth implementation of spinning riveting assembly can be ensured, loss of raw materials can be effectively reduced, and remarkable effect of saving energy and materials is achieved.

Owner:SHAOGUAN SOUTHEAST BEARING CO LTD

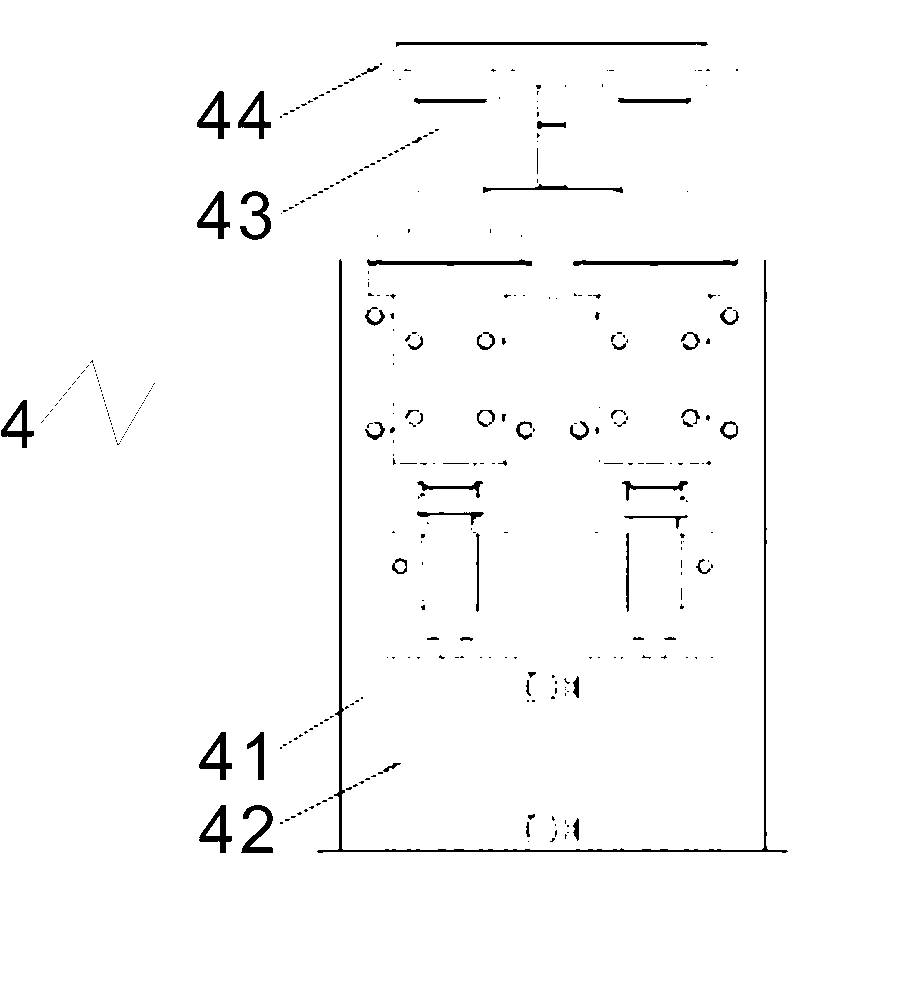

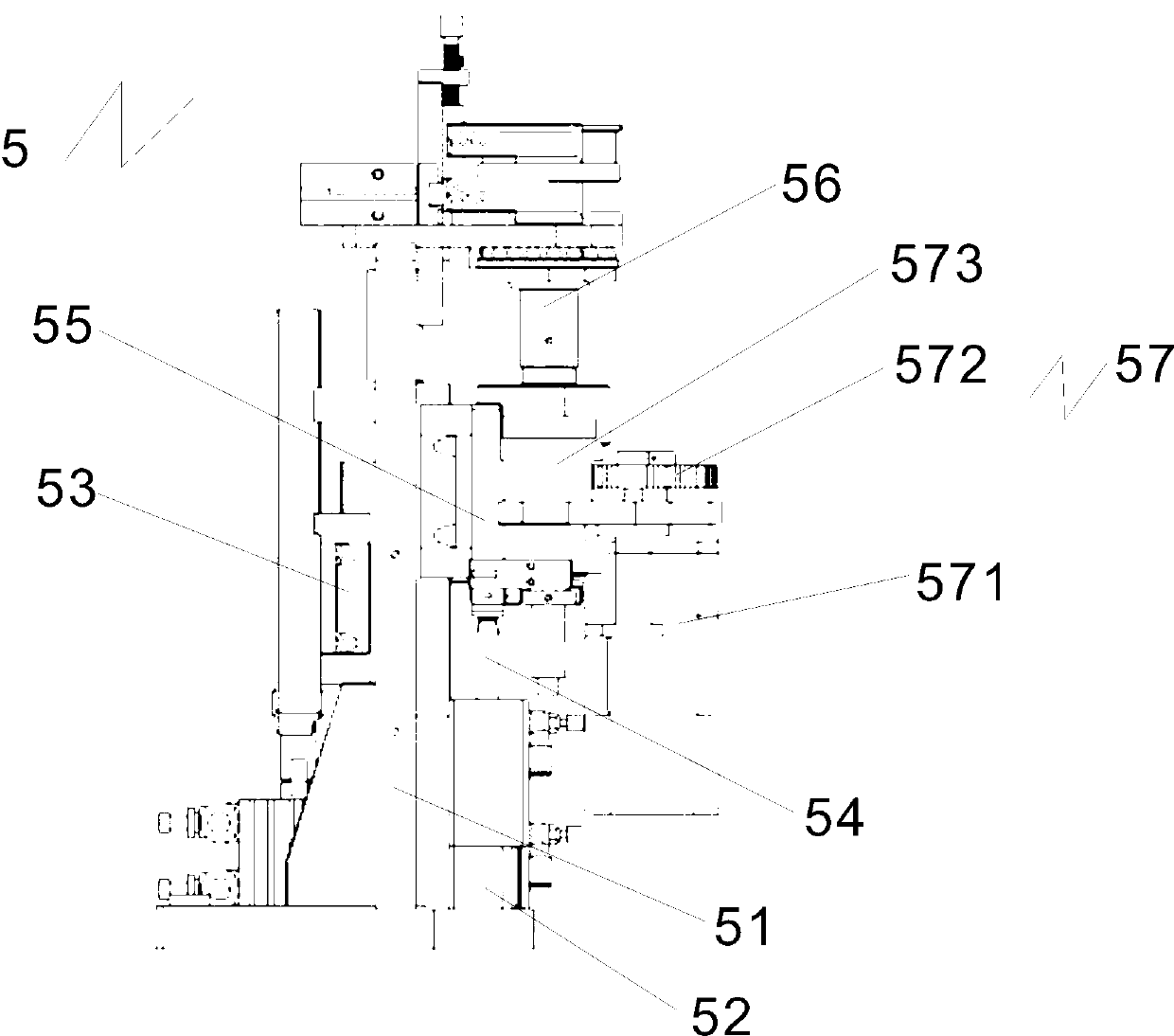

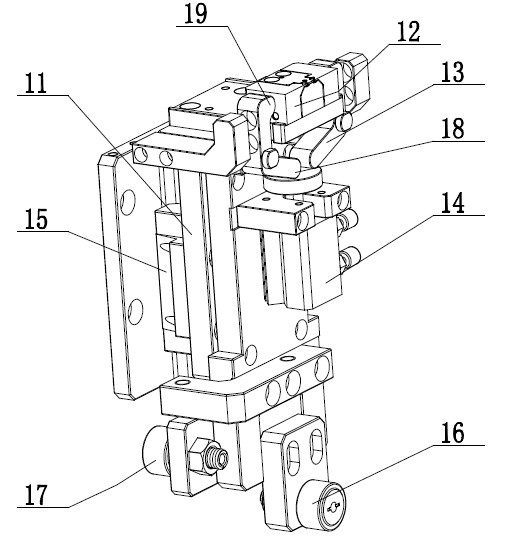

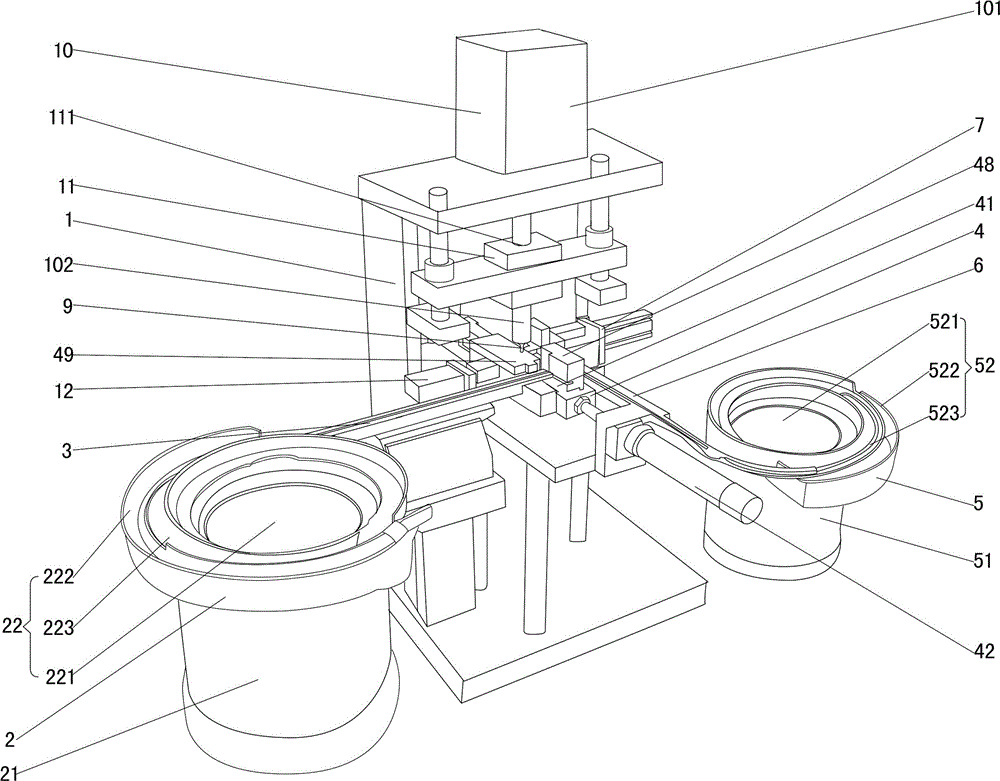

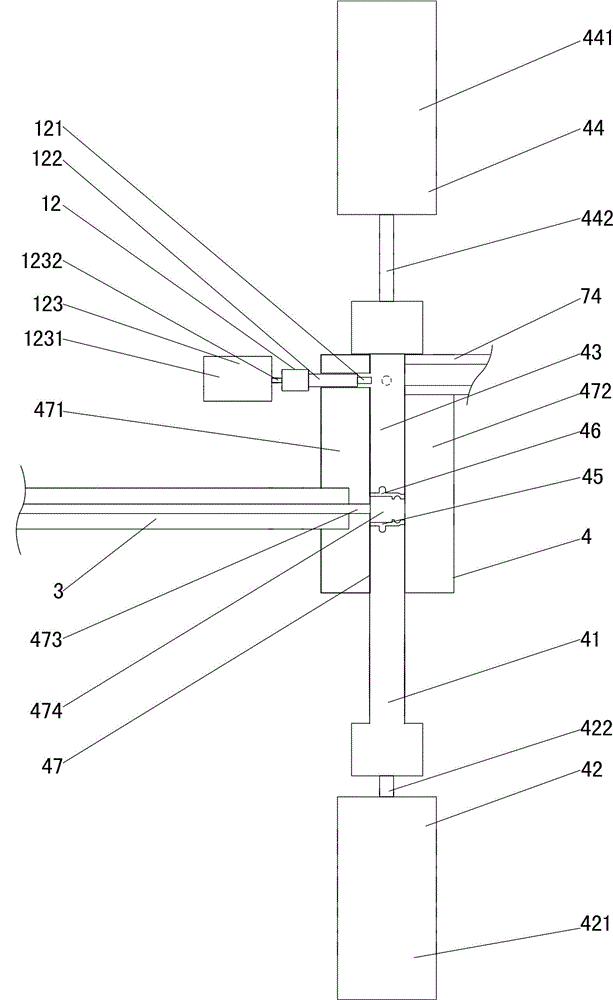

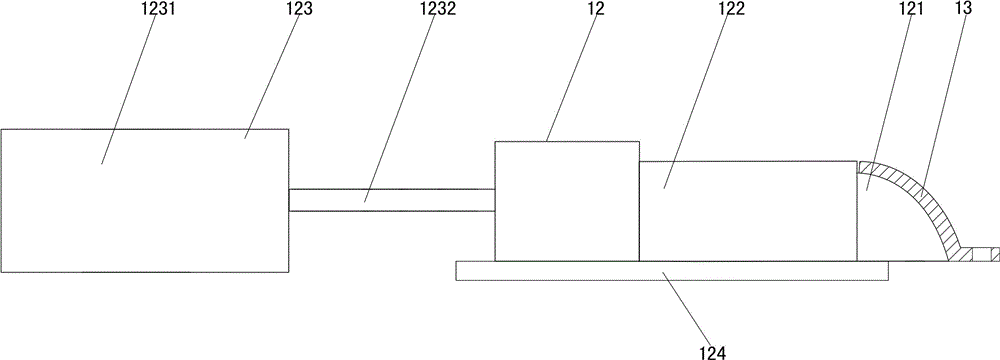

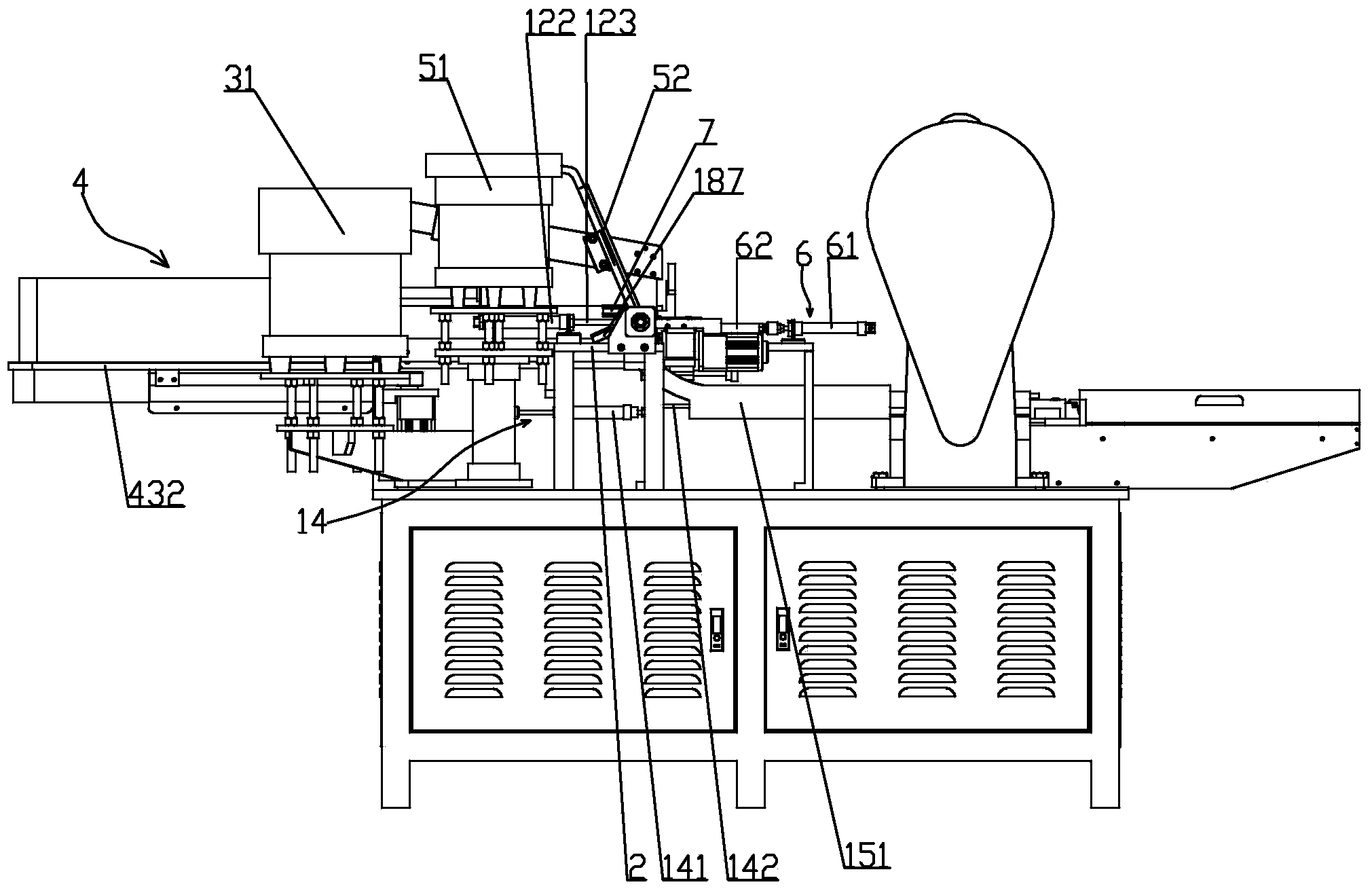

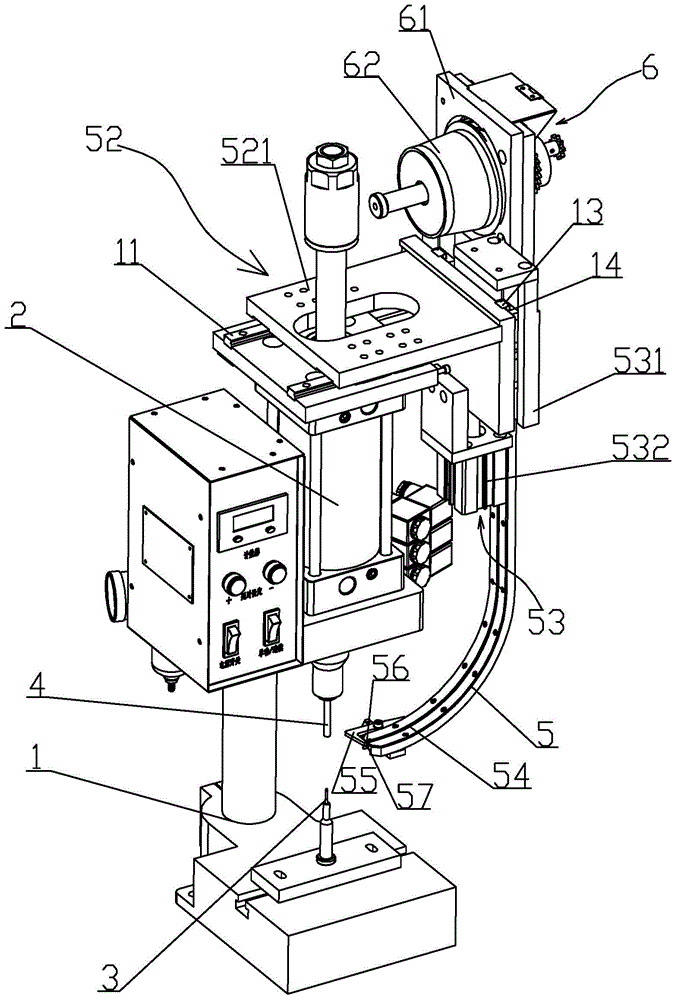

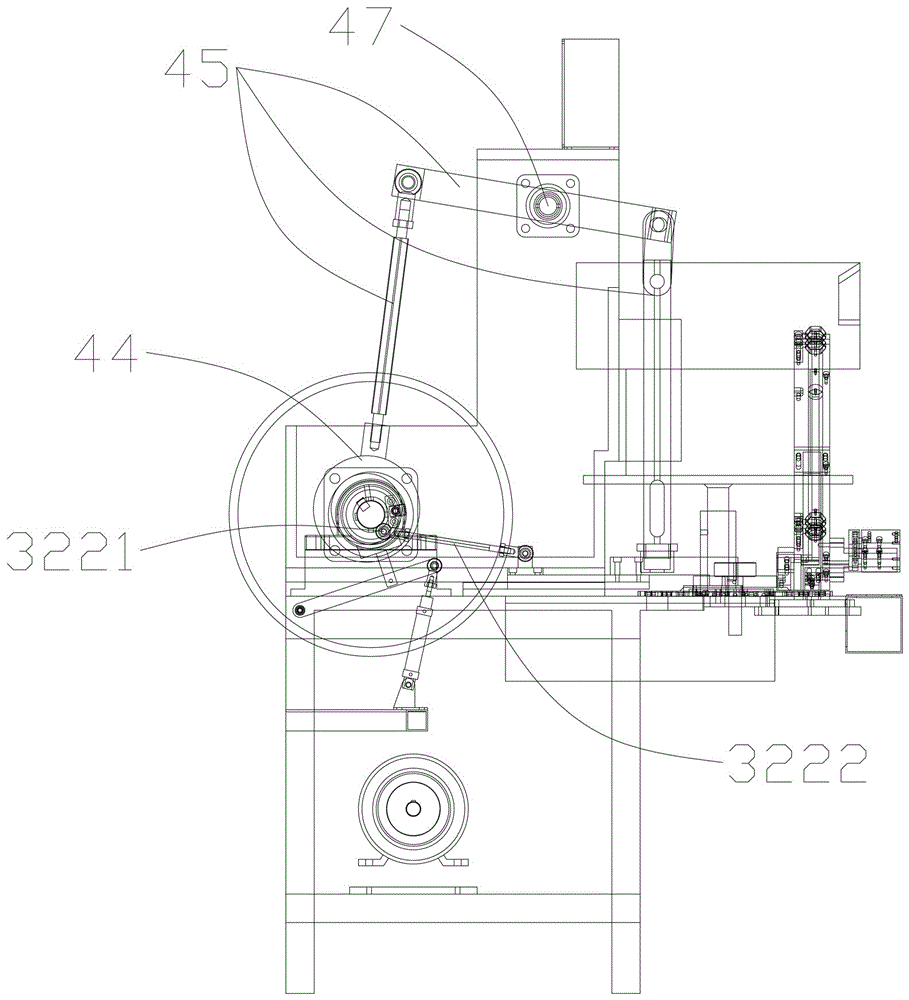

Riveting machine

InactiveCN104785647AReduce labor intensityHigh degree of automationMetal-working feeding devicesPositioning devicesEngineeringAutomation

A riveting machine comprises a machine frame, a sheetmetal vibration disc, a sheetmetal output rail, a sheetmetal clamping and horizontally-moving mechanism, a contact vibration disc, a contact output rail, a contact horizontally-moving mechanism, a contact ejecting mechanism, a riveting punch, a riveting punch lifting control mechanism and a collection sliding groove, wherein the contact ejecting mechanism comprises a supporting cushion block and a supporting cushion block lifting control mechanism, a contact accommodating groove is formed in the top of the supporting cushion block, the riveting punch is connected with the power output end of the riveting punch lifting control mechanism, and the riveting punch is located over the contact accommodating groove; the sheetmetal clamping and horizontally-moving mechanism is used for clamping sheetmetal output through the outlet end of the sheetmetal output rail and horizontally moving the sheetmetal to the space under the riveting punch, and the contact horizontally-moving mechanism is used for horizontally moving a contact output through the outlet end of the contact output rail to the contact accommodating groove. According to the riveting machine, the contact and the sheetmetal can be riveted automatically, automation degree is high, operation is easy and safe, production efficiency is high, and riveting quality is stable.

Owner:汕头市潮阳区骏达实业有限公司

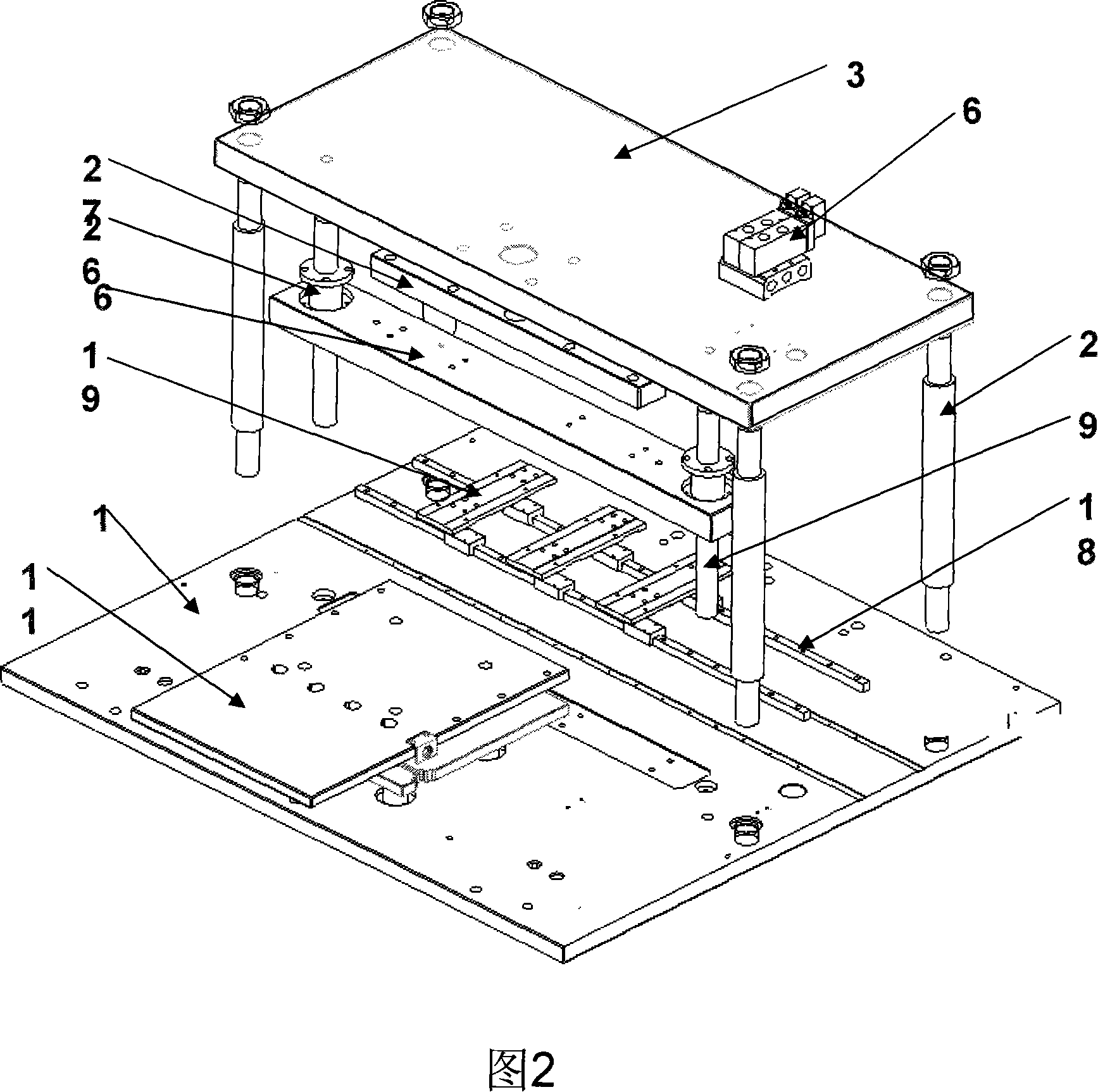

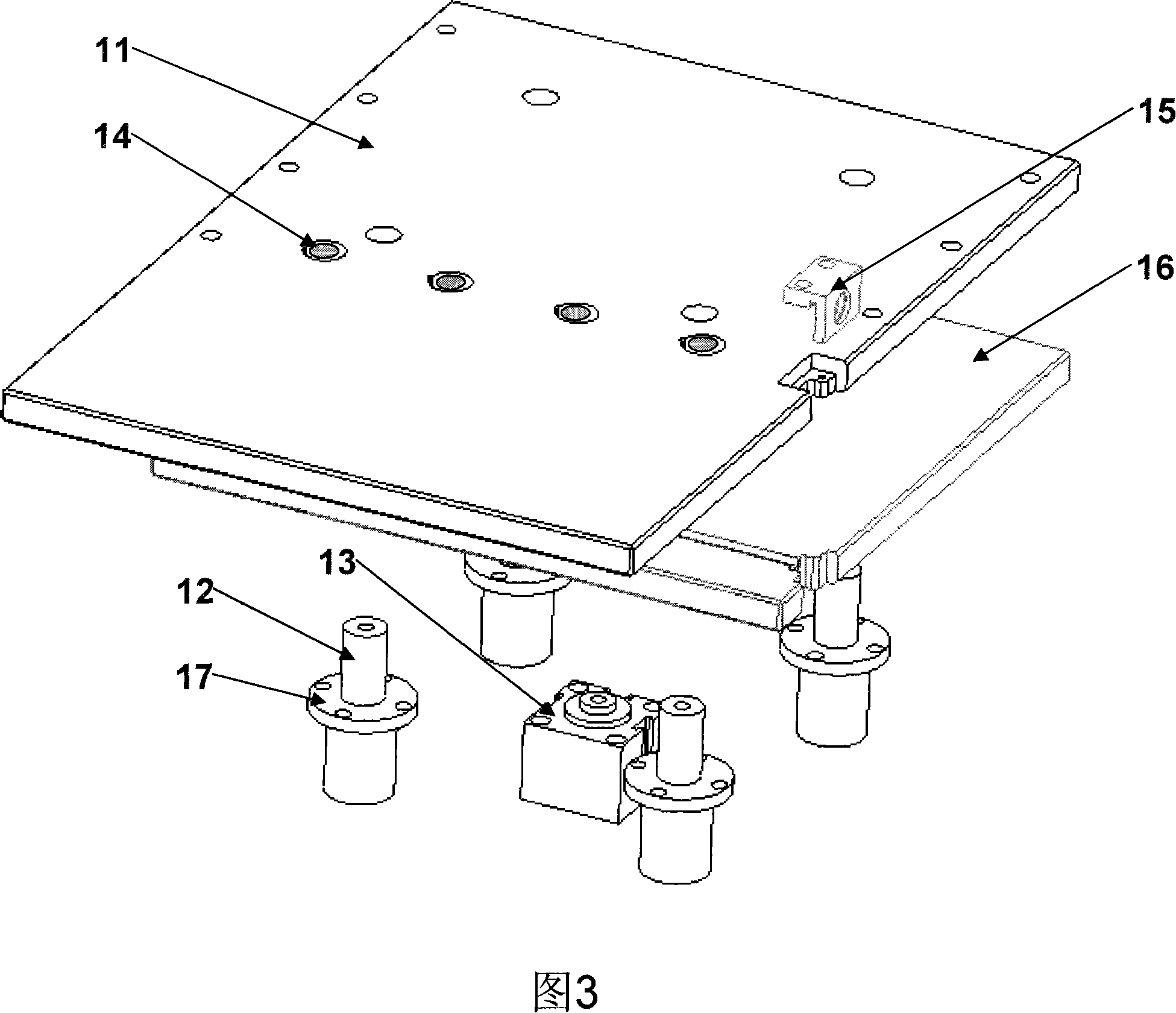

Riveting machine device

The invention discloses a riveting machine device which comprises a main line body, a tool tray, a rivet feeding mechanism, a bearing feeding mechanism, an exhaust valve plate feeding mechanism, a limiting stopper feeding mechanism and a bearing riveting mechanism. The tool tray, the rivet feeding mechanism, the bearing feeding mechanism, the exhaust valve plate feeding mechanism, the limiting stopper feeding mechanism and the bearing riveting mechanism are arranged on the main line body. At least two locating seats are carried on the tool tray. The rivet feeding mechanism is used for conveying rivets to the locating seats. The bearing feeding mechanism is used for conveying bearings to the locating seats. The exhaust valve plate feeding mechanism is used for conveying exhaust valve plates to the bearings. The limiting stopper feeding mechanism is used for conveying limiting stoppers to the bearings. The bearing riveting mechanism is arranged on the down stream of the limiting stopper feeding mechanism so that the rivet can be used for riveting the bearings, the exhaust valve plates and the limiting stoppers into finished products. According to the riveting machine device, the production mode of automatic conveying, automatic feeding, multi-position synchronous operation and multi-workpiece simultaneous riveting is achieved, so that personnel input is reduced, and single-machine operation efficiency and the utilization rate of equipment are improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

Automatic thermal riveting method and automatic thermal riveting machine for chain pin shaft

The invention relates to an automatic hot rivet method of chain pin axle and a relative rivet machine, wherein said method comprises: arranging several chain sections on the work bench; positioning the chain section of riveted pin axle, to aim the end of pin axle to the rivet mould and aim the tail of pin axle axially; then moving the electromagnetic induction heating coil to be end of pin axle, to heat the end; heating to the rivet temperature, removing the electromagnetic induction heating coil; riveting the pin axle end with rivet mould; returning the rivet mould; loosing the chain section; then moving the chain section to make the next pin axle on site. The heat riveter comprises a frame, a hydraulic cylinder, a controller, an electromagnetic induction heating coil feeder and a chain positioning device. And the invention has high rivet speed and high working efficiency.

Owner:JIANGSU SHUANGLING CHAIN TRANSMISSION

Production line of square coaming of freezer liner

The invention discloses a production line of square coaming of a freezer liner. The production line comprises a plate bin, a charging platform, a die cutting unit, a first transition platform, a long edge folding machine, a 90 DEG steering platform, a flanging machine with two ends in different directions, a second transition platform, a first bending machine and a second bending and riveting machine. A first sucker manipulator is arranged between the plate bin and the charging platform. Gripper manipulators are arranged among the charging platform, the die cutting unit and the first transition platform. First duplex sucker manipulators are arranged among the first transition platform, the long edge folding machine and the 90 DEG steering platform. Second duplex sucker manipulators are arranged among the 90 DEG steering platform, the flanging machine with the two ends in different directions and the second transition platform. A second sucker manipulator is arranged between the second transition platform and the first bending machine. A third sucker manipulator is arranged between the first bending machine and the second bending and riveting machine. Plates are bent to U-shaped coaming by the first bending machine. The U-shaped coaming is bent to the square coaming and riveted by the second bending and riveting machine.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

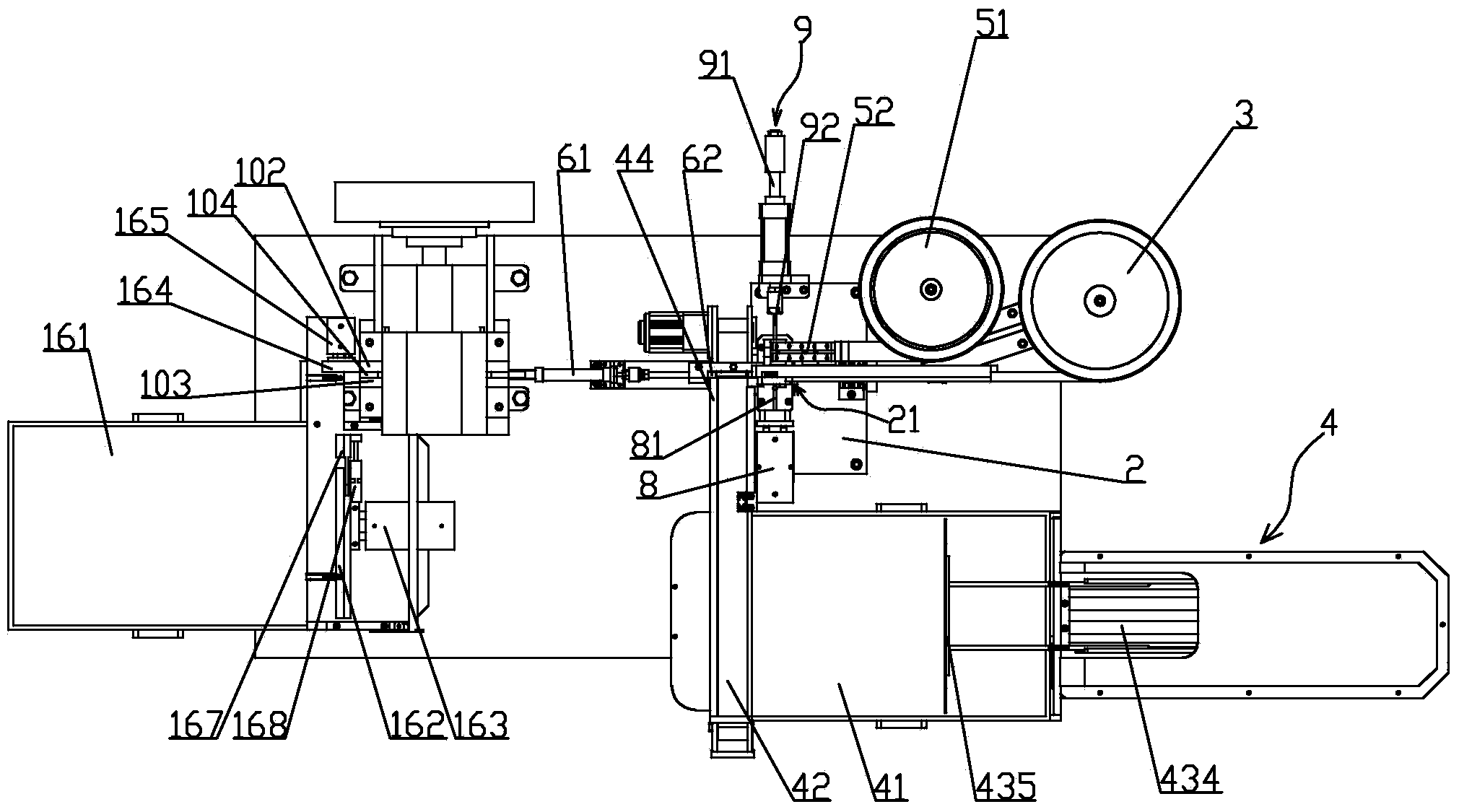

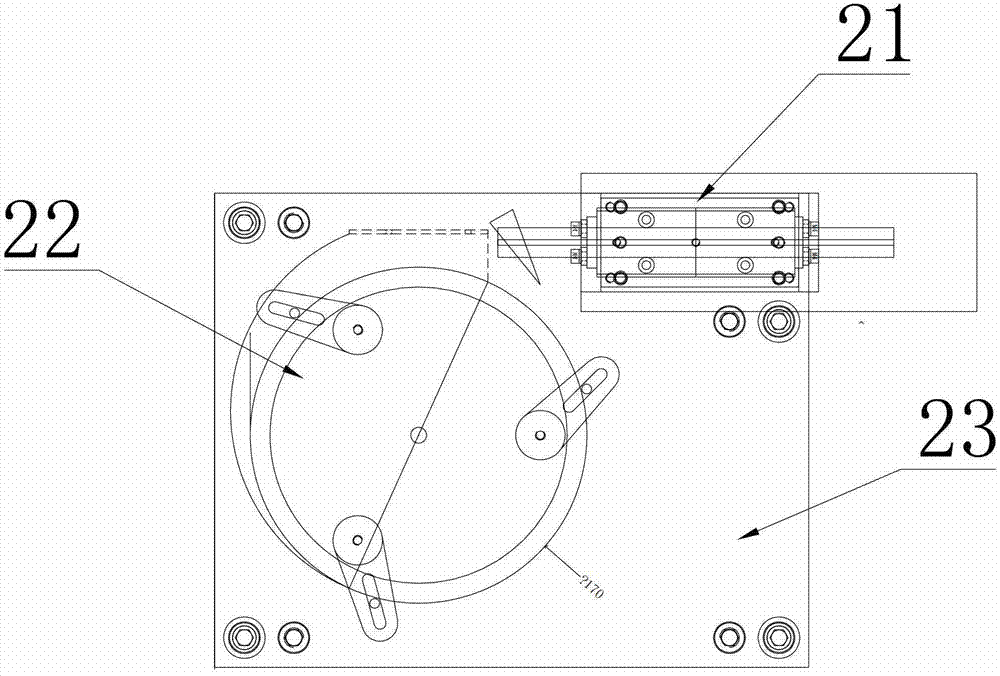

Automatic assembling pulley riveting machine

The invention relates to an automatic assembling pulley riveting machine which comprises a base and a support platform on the base. According to the technical scheme, a pulley assembling part is disposed on the support platform, a rotary wheel feed device, a pulley frame feed device and rivet feed device are disposed on the base, a pulley frame pushing device is disposed on the pulley frame feed device, a rotary wheel control device is disposed on the pulley assembling part, a penetrating device is disposed on the support platform, a rivet control device is disposed on the rivet feed device, a rivet pushing device is disposed on the support platform, a riveting device is further disposed on the base, a discharge device is disposed on the pulley assembling part which is connected with the guide groove, a pushing device is further disposed on the support platform, and a finished product loading device is disposed on one side of the finished product discharge outlet of the riveting device on the base. The automatic assembling pulley riveting machine has the advantages that automatic riveting of rotary wheels and pulley frames can be achieved, automation is achieved, manpower is saved, and production efficiency is increased.

Owner:许姜德

Automatic hydraulic riveting machine

InactiveCN101288895ASolve labor intensitySolve efficiency problemsHydraulic cylinderControl engineering

The invention discloses an automatic hydraulic riveter with an automatic feeding mechanism, comprising a base, a frame, a lower die, a hydraulic system, an automatic feeding mechanism and a clamping nozzle; the frame is fixed on the base; the hydraulic system comprises a hydraulic station and a hydraulic cylinder; the hydraulic station is fixed on the base; the hydraulic cylinder is fixed on the upper part of the frame; the automatic feeding mechanism is obliquely fixed on the frame; the clamping nozzle is fixed on the frame by an adjustable connecting rod; the clamping nozzle can clamp and position the rivets which are delivered by the automatic feeding mechanism; the lower die used for positioning sheet metal parts is fixed on the frame of the riveter by bolts and is corresponding to the position of the clamping nozzle. The automatic hydraulic riveter solves the problems in the prior art such as high labour intensity, low production efficiency and more energy resource loss; the production efficiency is improved by 300% compared with manpower operation, the power resource is saved, and stable impact force provided by the hydraulic pressure ensures the quality of the product.

Owner:范耀光 +1

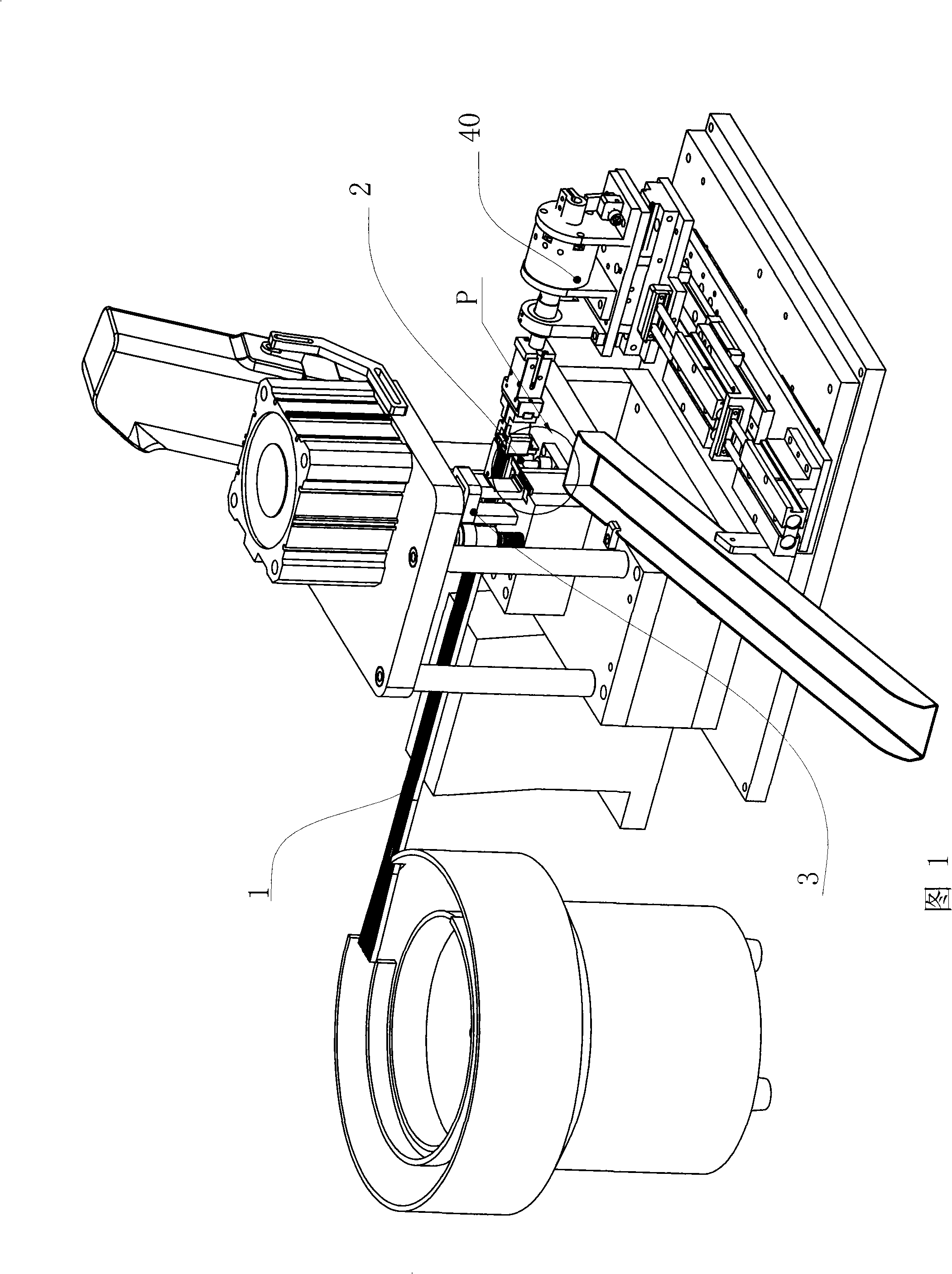

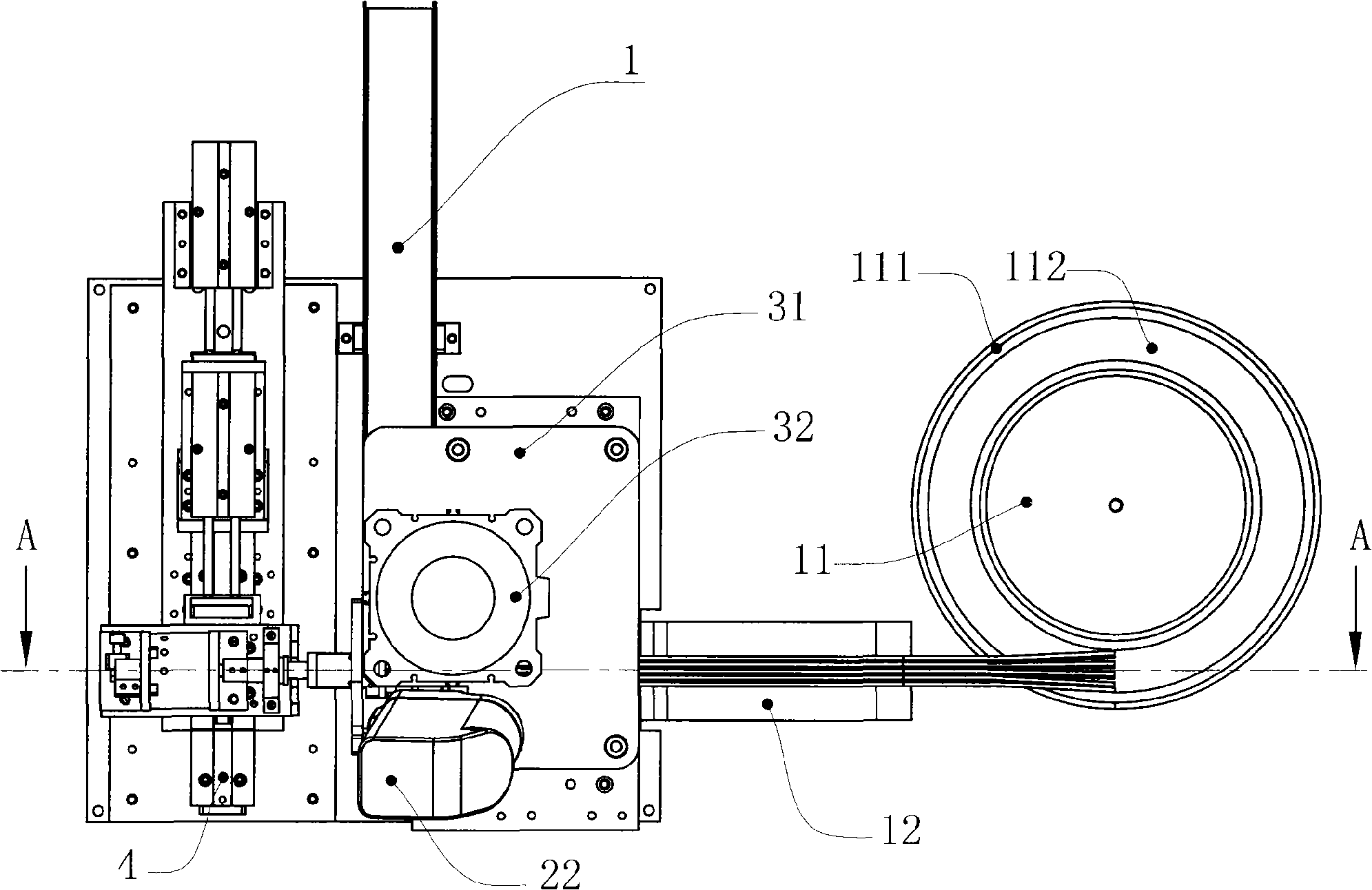

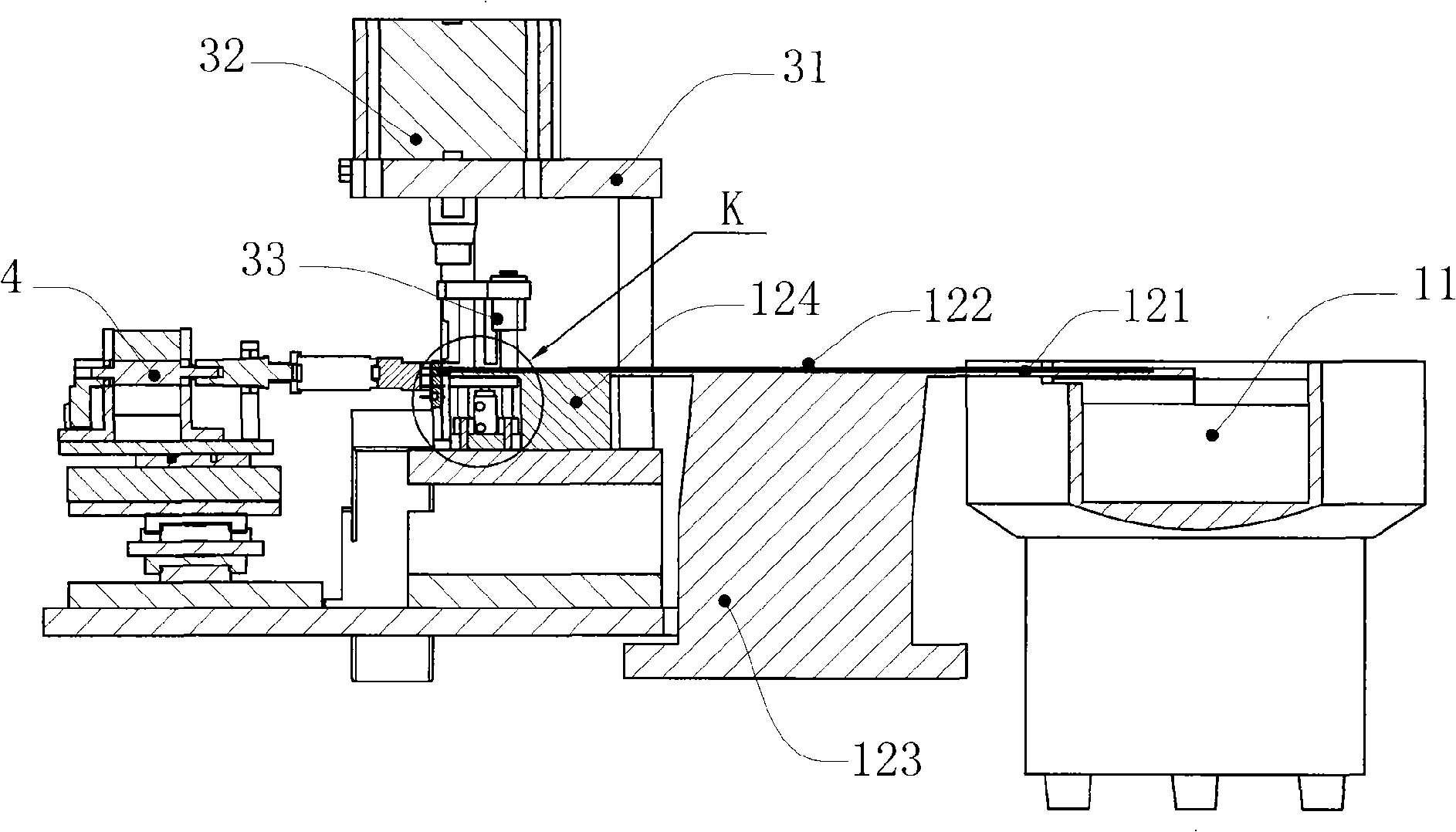

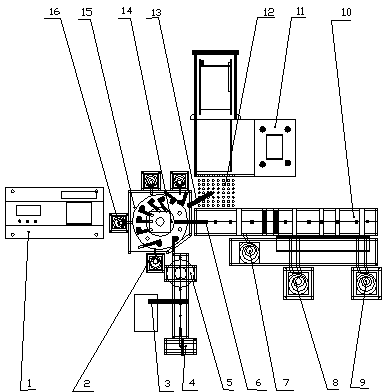

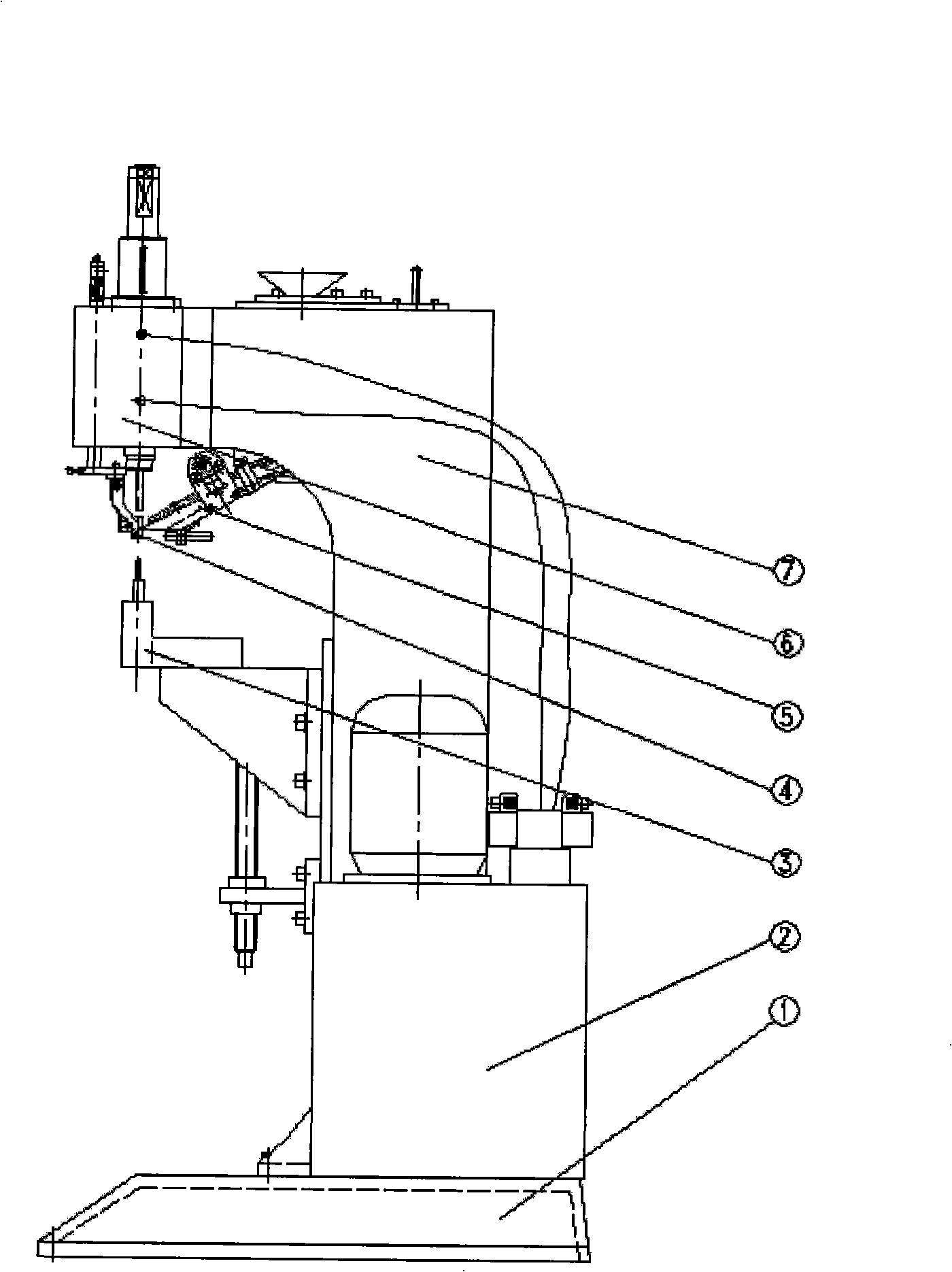

Riveting machine

ActiveCN104439020AHigh precisionQuality improvementProgramme-controlled manipulatorIndustrial engineeringAutomation

The invention discloses a riveting machine. The riveting machine comprises a press (1), a material loading device (2), a rivet placing device (3) and a material taking device (4), wherein the press (1) is provided with a base (5) on which a riveting station (6) is arranged; the material loading device (2), the press (1) and the rivet placing device (3) are transversely arranged in parallel; the material taking device (4) and the material loading device (2) are longitudinally arranged in parallel. According to the riveting machine, material loading automation, rivet loading automation and material taking automation during riveting are realized, and the effects of automatic riveting and high efficiency are achieved; due to the fact that artificial errors are avoided, the riveting accuracy and the riveting quality are improved; in addition, the labor cost can be reduced.

Owner:CHONGQING LANGZHENG TECH

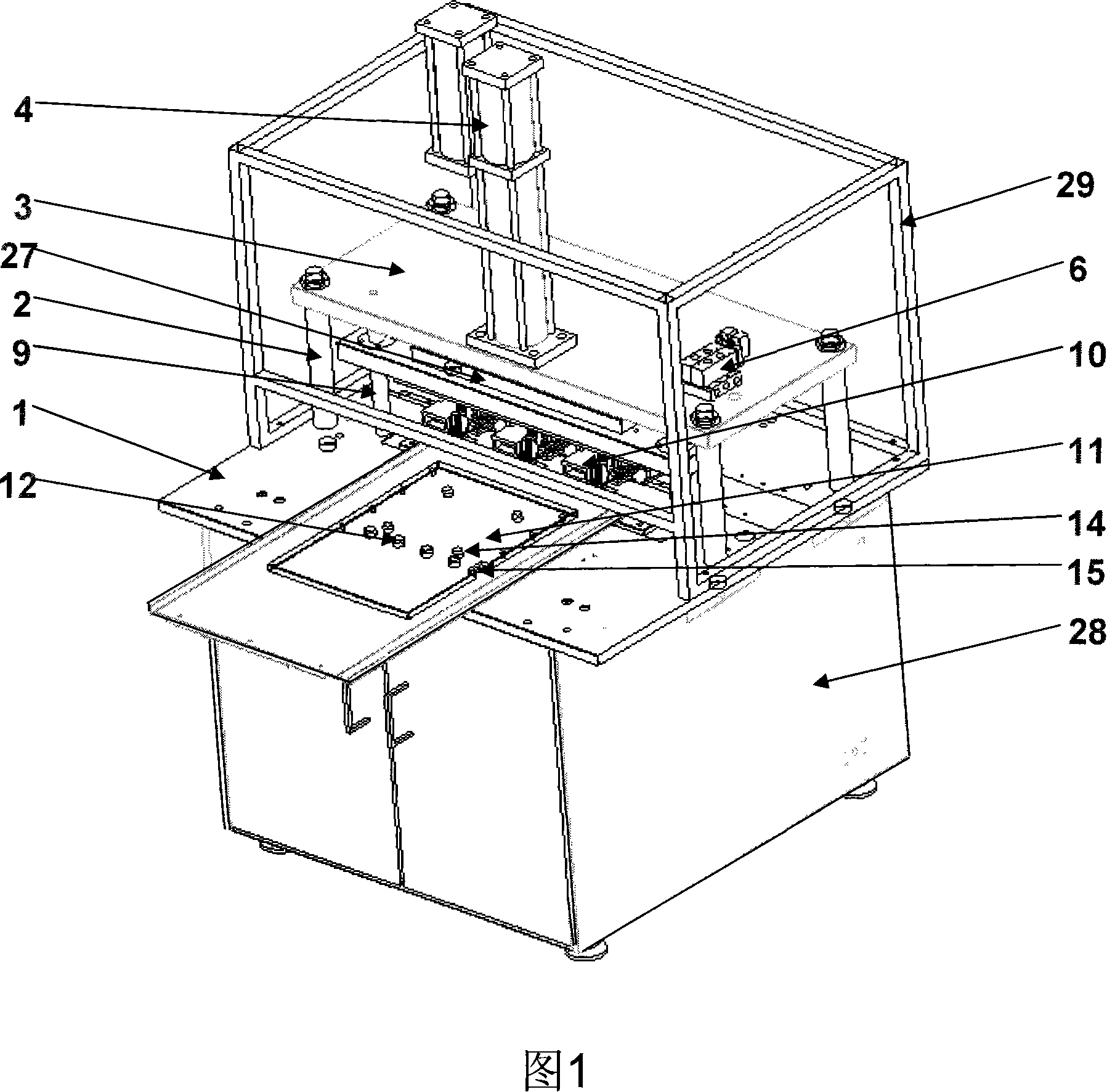

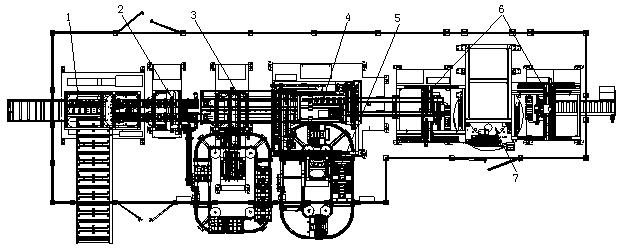

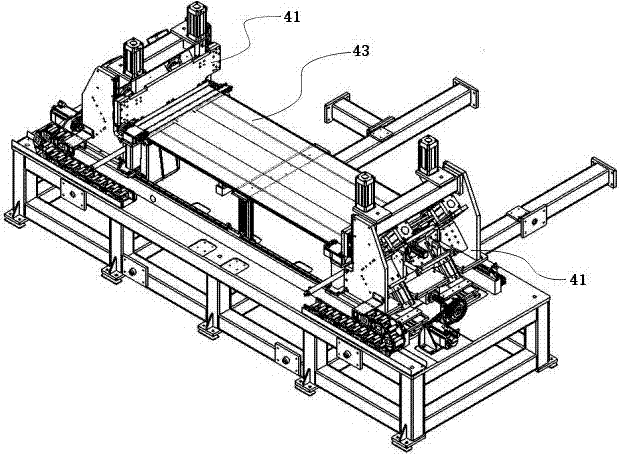

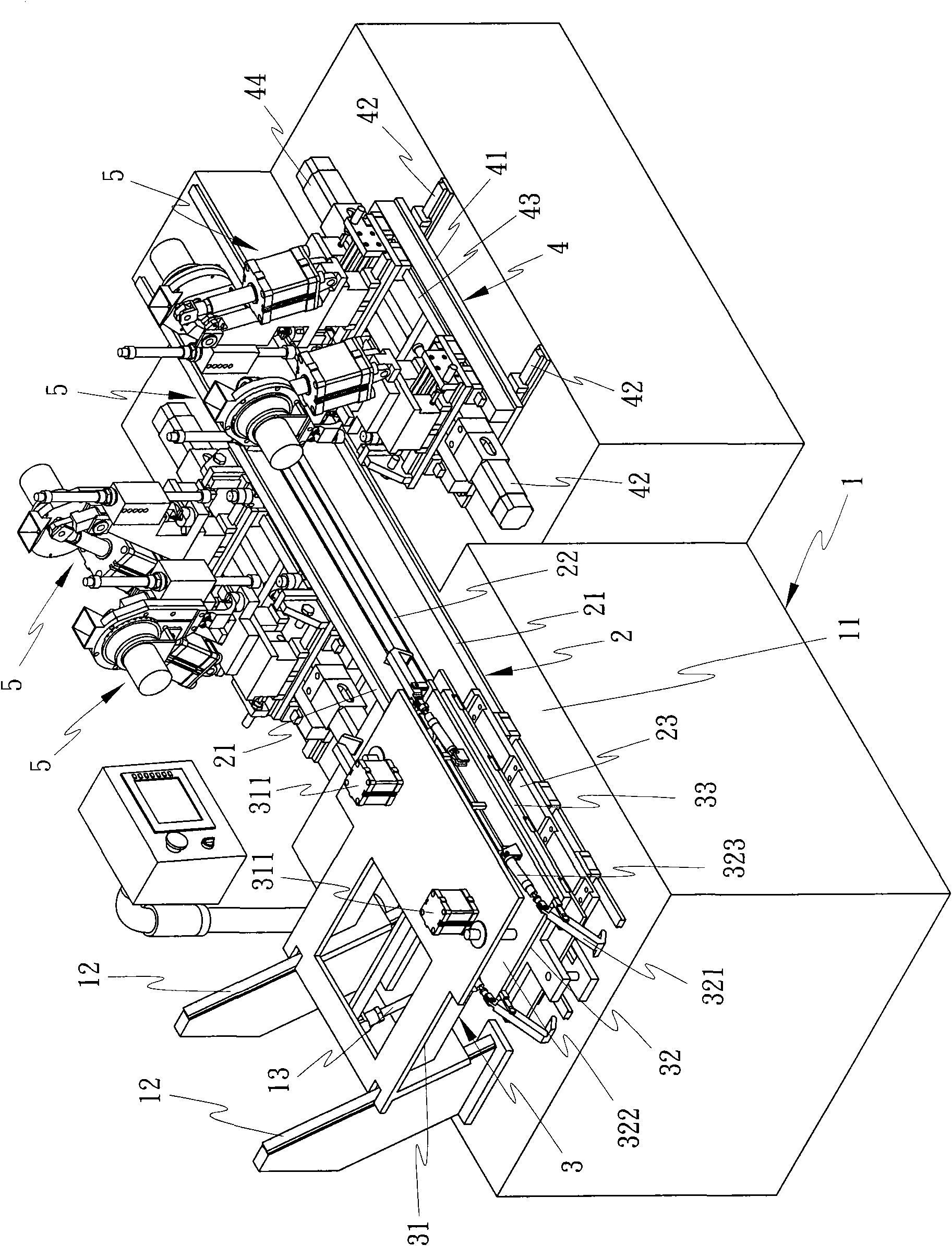

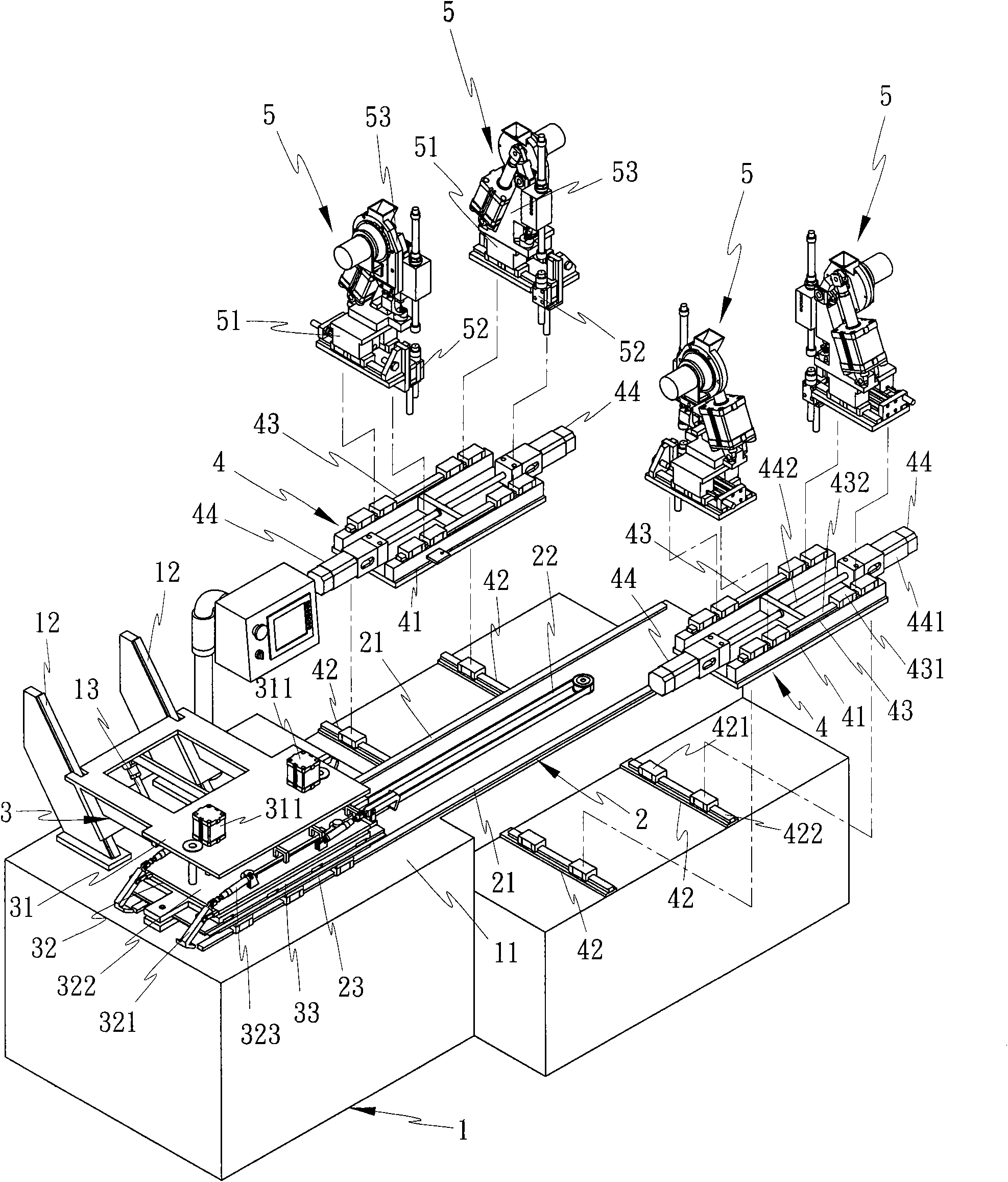

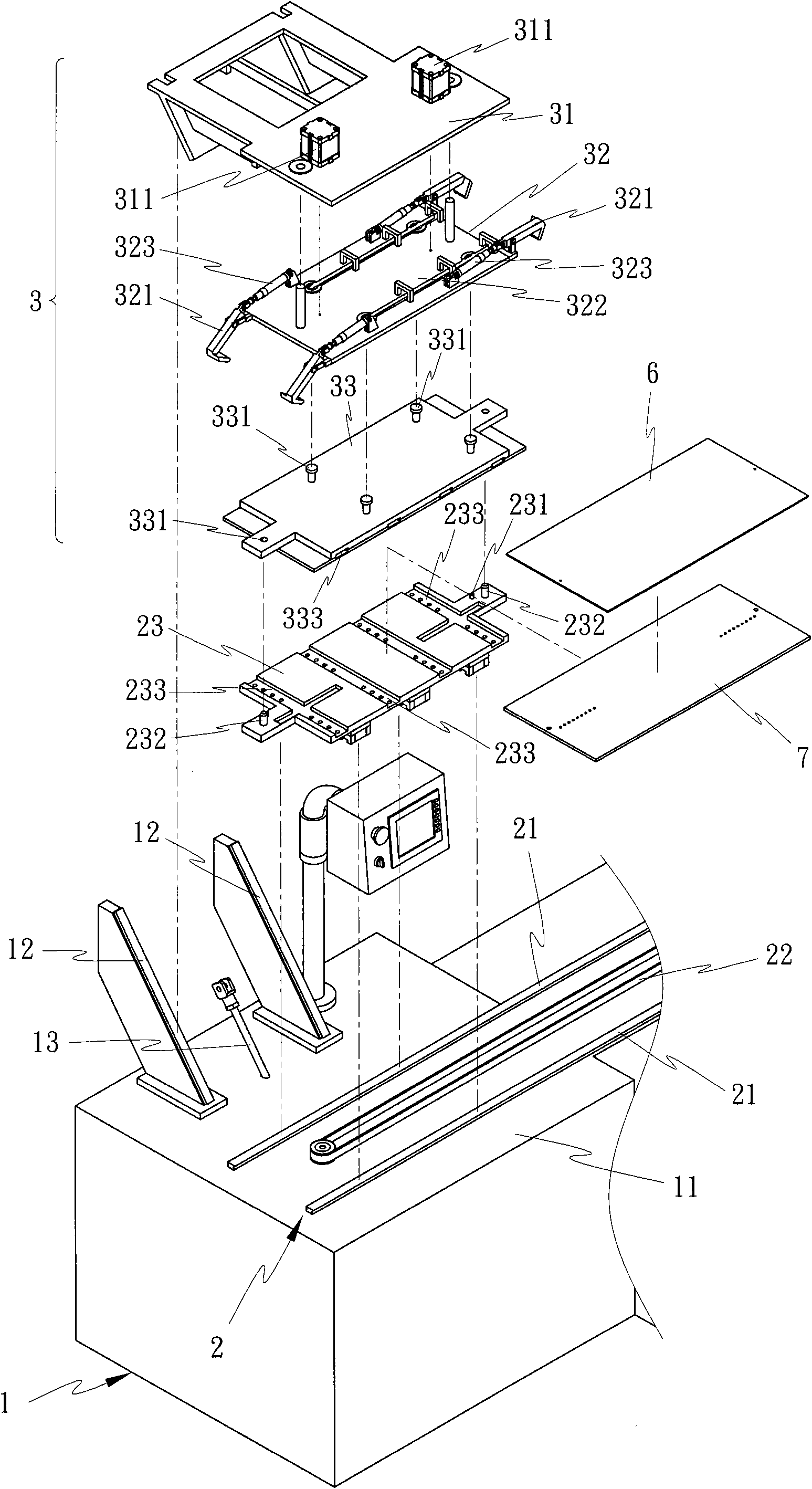

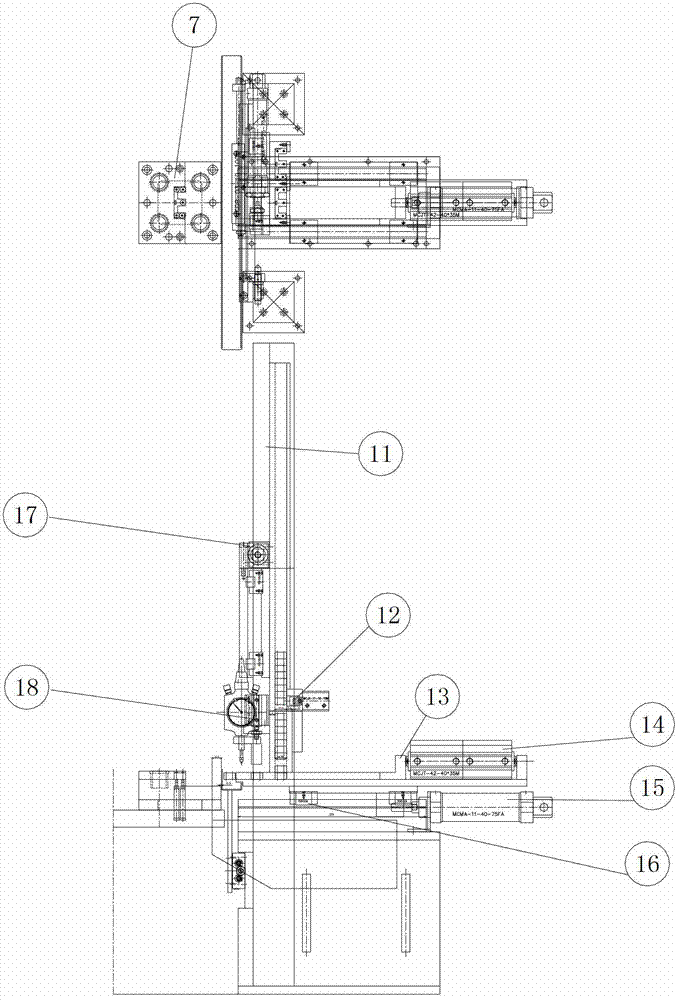

Automatic riveting machine for multi-layer circuit board

InactiveCN101850514AImprove precisionLow costOther manufacturing equipments/toolsLarge fixed membersEngineeringMechanical engineering

The invention discloses an automatic riveting machine for a multi-layer circuit board, which comprising a machine platform, a conveying mechanism, a grabbing mechanism, a bidirectional sliding mechanism and a drilling and riveting mechanism. A plurality of circuit boards can be placed on a holding disc, the holding disc is fixed on a conveying platform of the conveying mechanism, the conveying platform is used for conveying the circuit boards to the drilling and riveting mechanism at the other end of the machine platform, so that the drilling and riveting mechanism automatically makes bidirectional movement and feeding to carry out hole-drilling and riveting operations on the edges of the circuit boards; the conveying platform is used for sending the riveted circuit boards back to the space below the grabbing mechanism, which ensures that the grabbing mechanism lifts the circuit boards and the holding disc to complete the full automatic hole-drilling and riveting process. By using the full automatic riveting machine for a multi-layer circuit board, the bidirectionally-moving hole-drilling and riveting mechanism can automatically complete the hole-drilling and riveting operation of an entire row after the multi-layer circuit board is moved in place so as to complete high-precision and high-efficiency hole drilling and riveting.

Owner:李富祥

Fully automatic iron core riveting machine

The invention discloses a fully automatic iron core riveting machine which comprises a working table surface and a riveting jig table. The fully automatic iron core riveting machine is characterized by comprising a silicon steel sheet material separation mechanism, an iron rivet vibrating disk mechanism, an iron rivet material delivery mechanism, an oil pressure riveting mechanism, a short circuit ring riveting mechanism and a material returning mechanism, wherein the silicon steel sheet material separation mechanism delivers silicon steel sheets to the riveting jig table, the iron rivet vibrating disk mechanism and the iron rivet material deliver mechanism deliver rivets to the position of the silicon steel sheets in the riveting jig table, the oil pressure riveting mechanism rivets the silicon steel sheets and the rivets, the short circuit ring riveting mechanism put a short circuit ring into the riveted silicon steel sheets and assemblage parts of the rivets to be rivet again, and the material returning mechanism returns the riveted work pieces. The fully automatic iron core riveting machine has the advantage of being convenient to operate, high in precision rate of material delivery, good in consistency of products, and capable of greatly improving production efficiency comparing with the prior art.

Owner:建宏金属材料(苏州)有限公司

Automatic riveting machine

The invention relates an automatic riveting machine. The automatic riveting machine comprises a base frame and is characterized in that an upper die driving device and a lower die rod where a rivet can be installed in a penetrating mode are arranged on the base frame, an upper die rod is arranged on the upper die driving device and driven by the upper die driving device to move towards the lower die rod so as to rivet the rivet installed on the lower die rod in the penetrating mode, a rivet conveying device used for conveying the rivet onto the lower die rod is further arranged on the base frame and comprises a guiding block, a horizontal movement driving mechanism and a vertical movement driving mechanism, the guiding block can guide the rivet to the lower die rod, the horizontal movement driving mechanism controls the guiding block to move in the horizontal direction and can convey the rivet to the position above the lower die rod, and the vertical movement driving mechanism controls the guiding block to move vertically so as to install the rivet on the lower die rod in the penetrating mode. The automatic riveting machine is simple in structure and capable of conveying the rivet automatically, easily and conveniently.

Owner:中山市协展机械有限公司

Automatic riveting machine for metal button surfaces

InactiveCN105798179AAutomatic riveting realizationSave manpower and material resourcesMetal-working feeding devicesClothes buttonsMaterial resourcesPlunger

The invention discloses an automatic riveting machine for metal button surfaces. The automatic riveting machine comprises a machine body, a feeding mechanism, a charging mechanism, a riveting mechanism and a controller. The riveting mechanism and the charging mechanism are arranged on the machine body. The riveting mechanism is provided with a riveting plunger chip and a plunger chip drive mechanism driving the riveting plunger chip to conduct riveting. The charging mechanism is provided with a charging rotary table and a rotary table drive mechanism. The charging rotary table is arranged below the riveting plunger chip and provided with one or more supplying grooves. The feeding mechanism conveys buttons into the supplying grooves. The rotary table drive mechanism drives the charging rotary table to rotatably conduct supplying. The controller controls the plunger chip drive mechanism, the charging mechanism and the feeding mechanism to work. The controller on the automatic riveting machine for the metal button surfaces controls the feeding mechanism to automatically conduct feeding, controls the charging mechanism to automatically conduct charging and controls the plunger chip drive mechanism to drive the riveting plunger chip to conduct riveting, then, automatic riveting is achieved, and manpower and material resources are saved.

Owner:深圳市联星服装辅料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com