Automatic hydraulic riveting machine

A riveting machine and hydraulic technology, applied in the field of automatic hydraulic riveting machines, can solve the problems of high labor intensity, low production efficiency, limited special products, etc., and achieve the effect of solving high labor intensity, improving production efficiency and saving power resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited to the scope described in the embodiments.

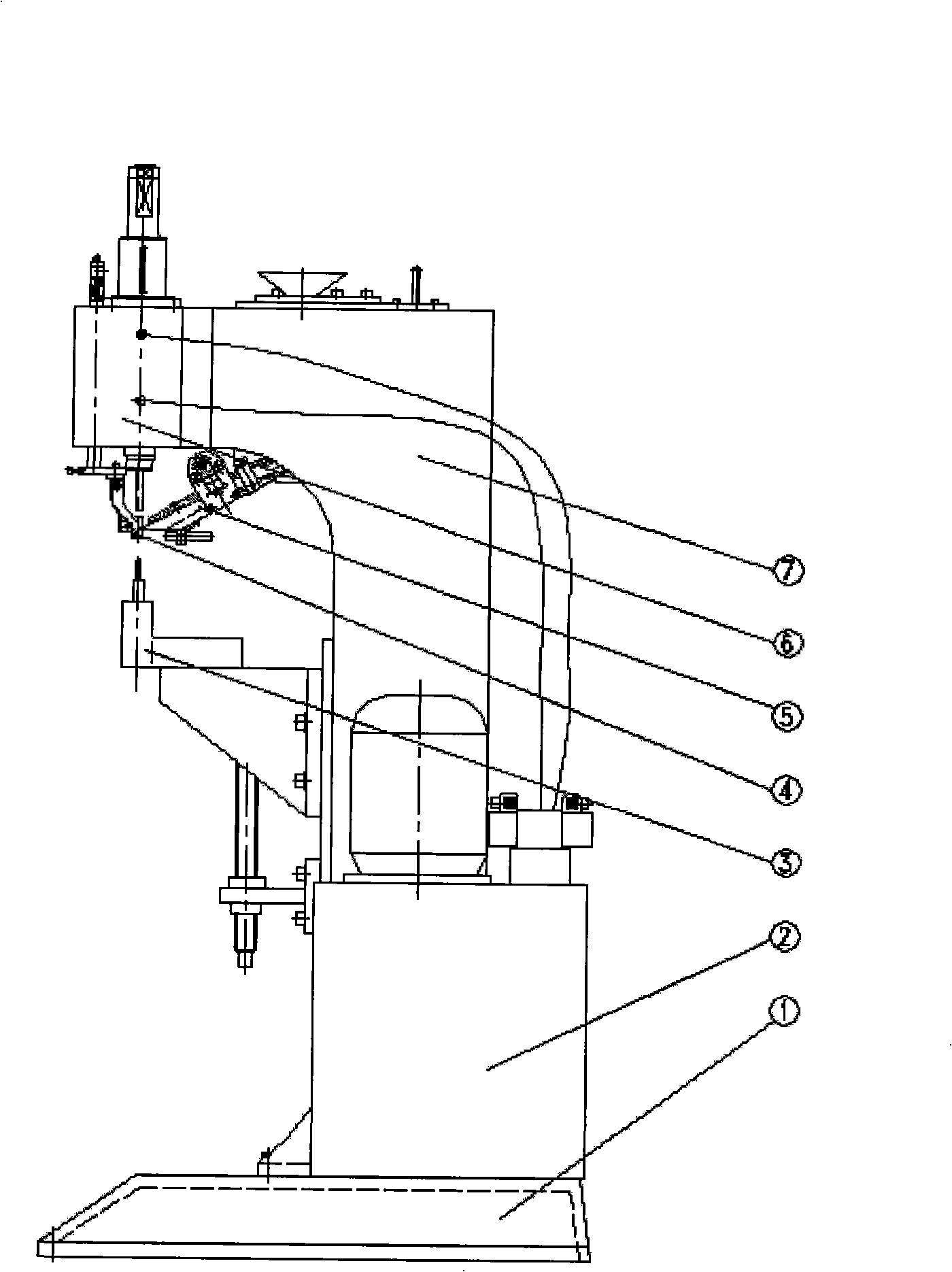

[0034] figure 1 It is the overall assembly drawing of the automatic hydraulic riveting machine of the present invention.

[0035] ① is the base, made of cast iron, which has the advantages of low price, easy cutting and processing, energy absorption and shock absorption, etc.

[0036] ② is a hydraulic station, which is composed of hydraulic pumps, liquid tanks, electric motors and other components, and its function is to provide high-pressure liquid to drive hydraulic cylinders ⑥.

[0037] ③It is the lower mold, which is fixed on the riveting machine frame by bolts. Its function is to position the sheet metal parts. According to different sheet metal parts, different lower molds can be replaced and its relative position to the upper mold can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com