Production jig of optical fiber rapid connector and production method of optical fiber rapid connector

A production method and connector technology, applied in the coupling of optical waveguides, etc., can solve problems such as low work efficiency and high labor intensity, and achieve the effect of improving production efficiency and solving high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] The invention provides a production jig for an optical fiber quick connector and a method for manufacturing an optical fiber quick connector by using the production jig, which is mainly used to solve the problems of high labor intensity and work The problem of low efficiency.

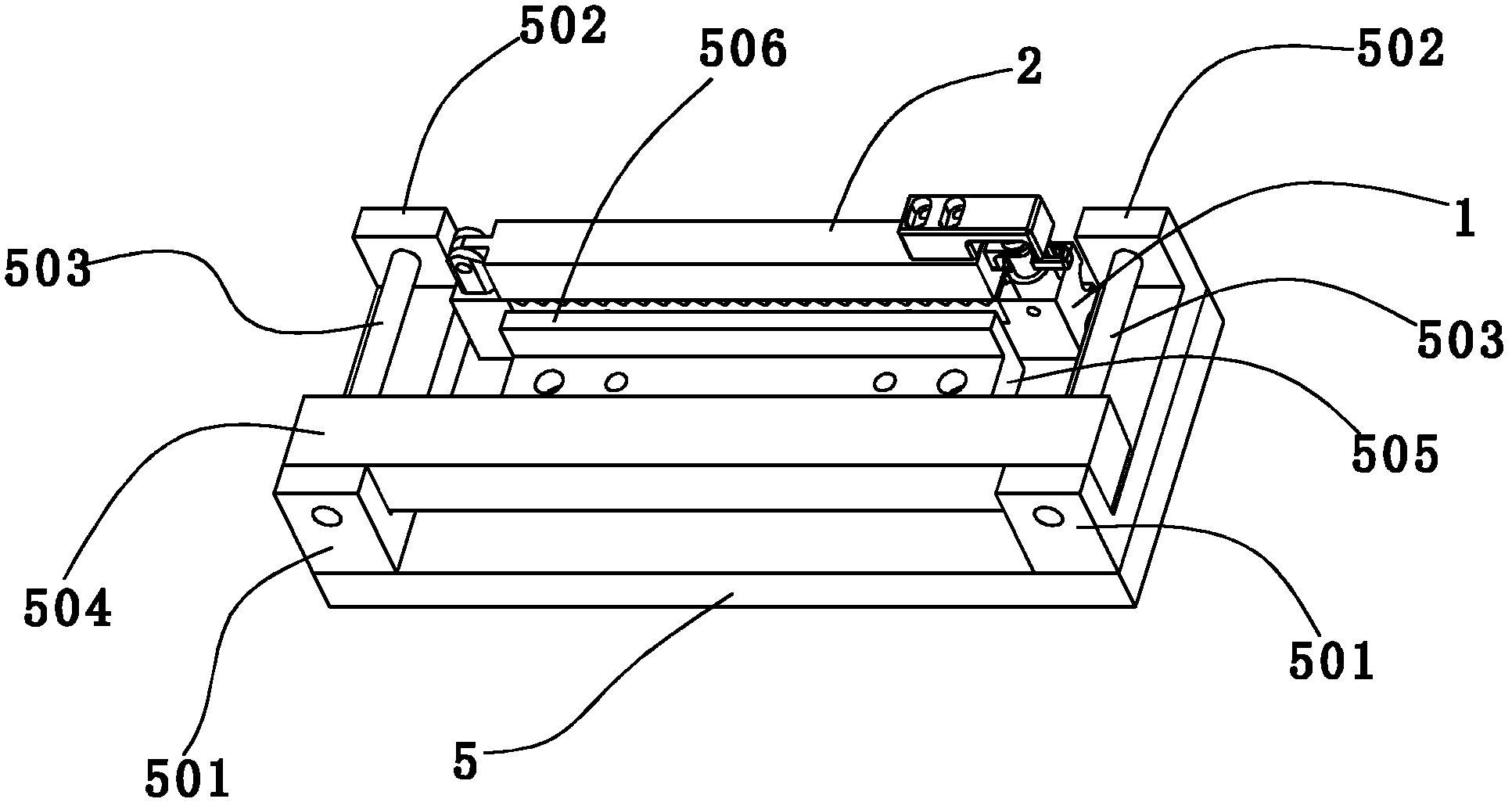

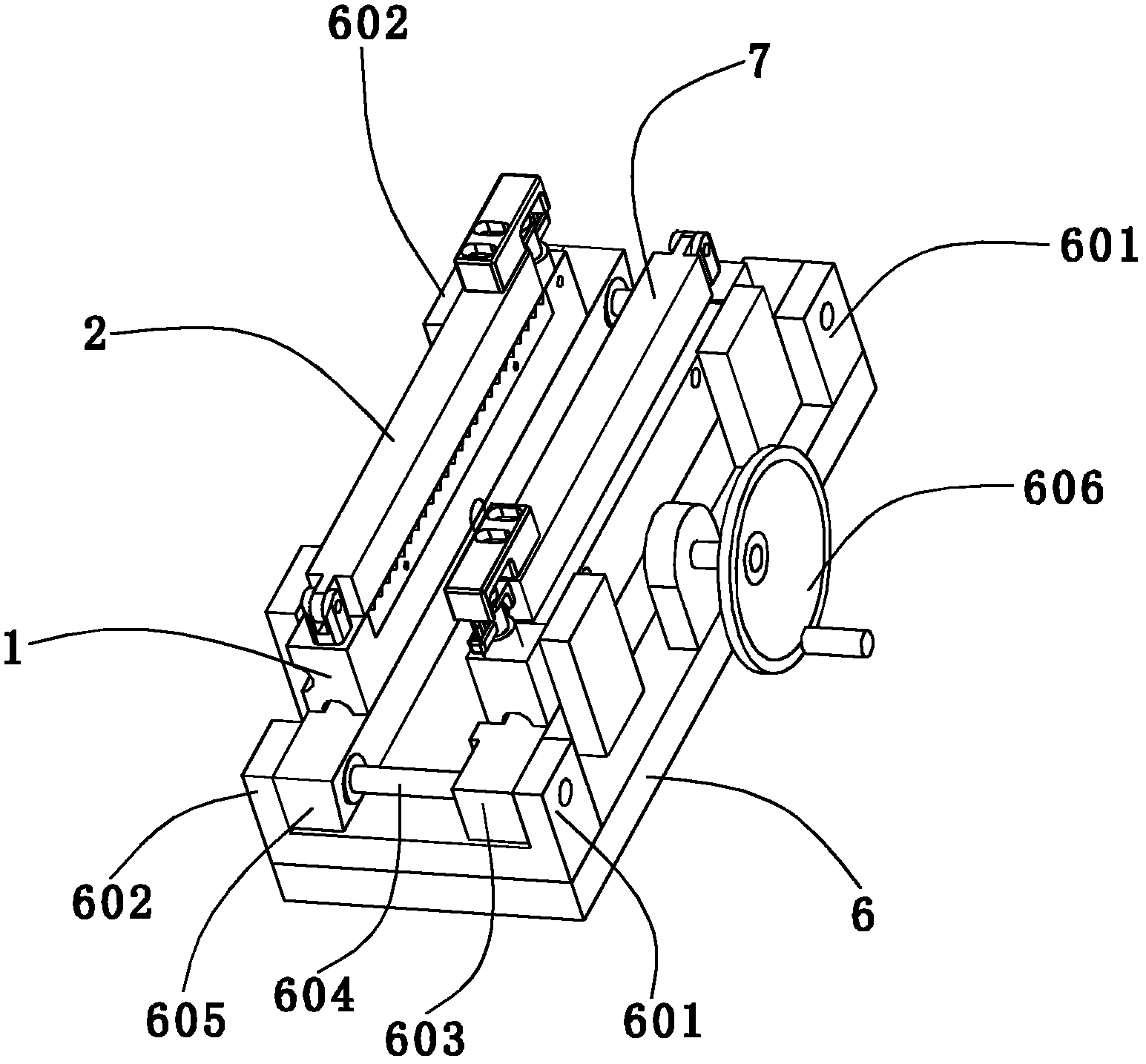

[0037] The jig for producing optical fiber quick connectors according to the present invention mainly includes a ferrule positioner, an optical fiber length fixer, a curing furnace and a protective sleeve fixture.

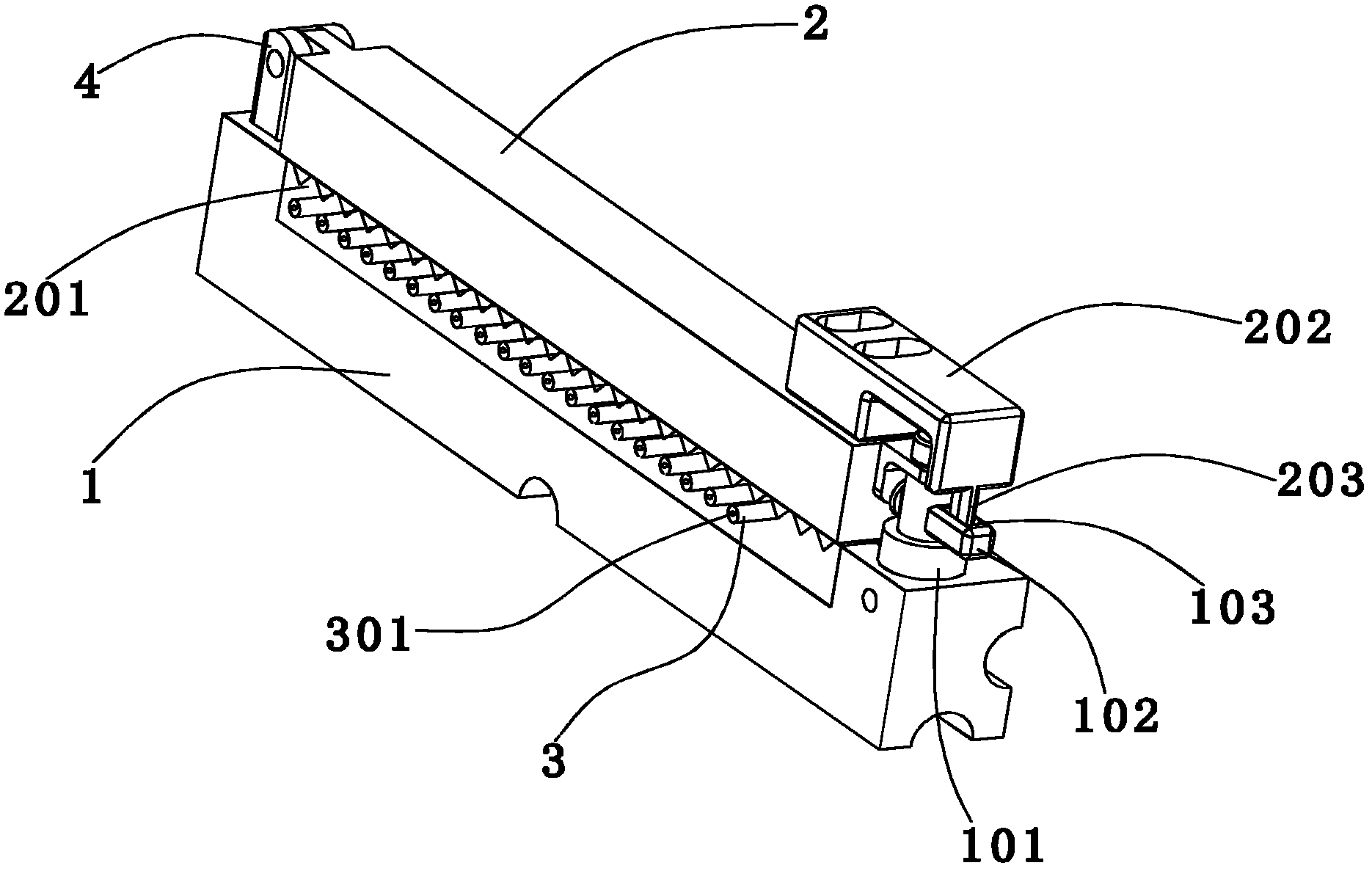

[0038] See figure 1 as shown, figure 1 It is a structural schematic diagram of the ferrule positioner of the present invention. The ferrule positioner described therein is used to fix the ferrule 3, and insert the optical fiber into the socket 301 in the ferrule 3 after the glue i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com