Patents

Literature

321results about "Dovetailed work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

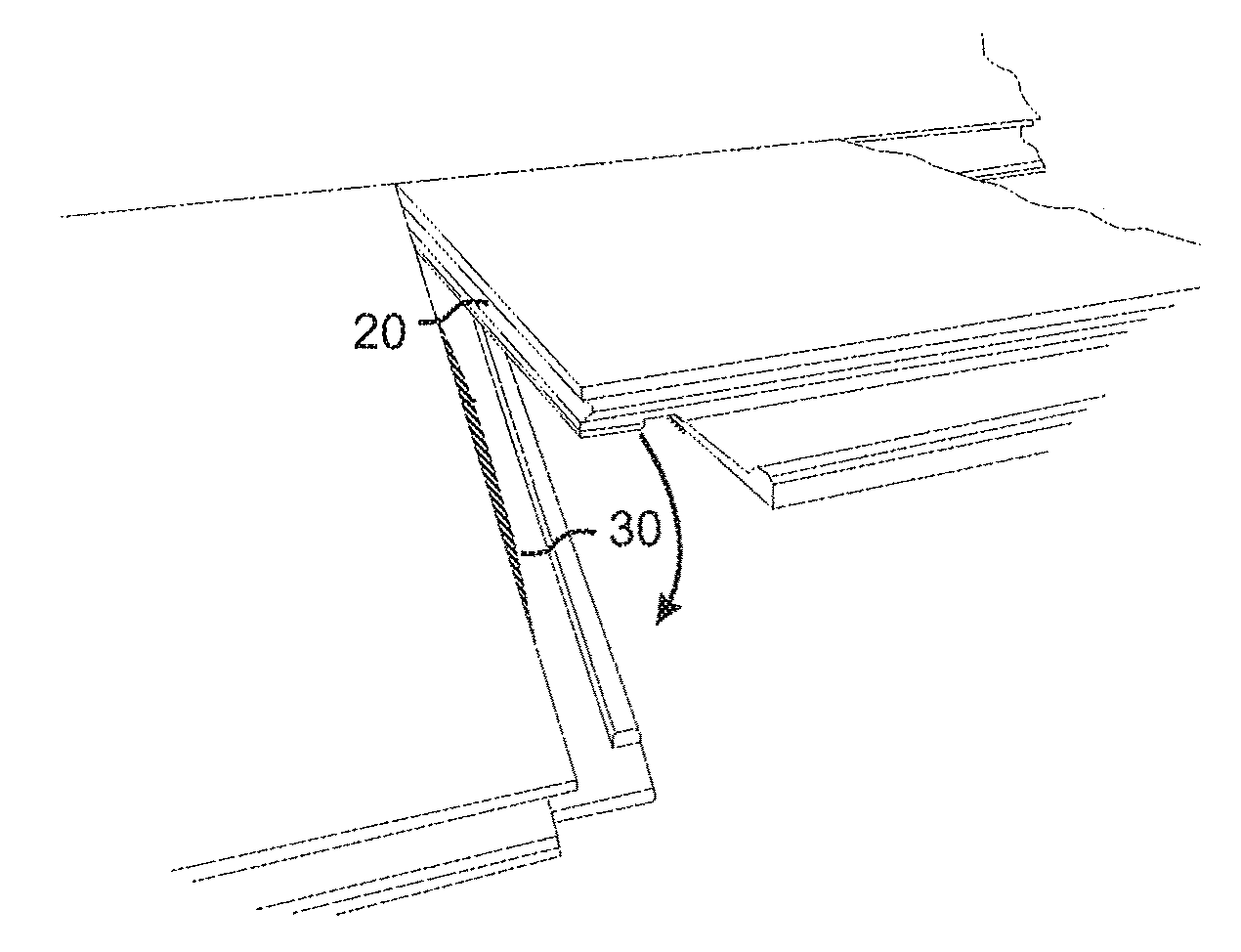

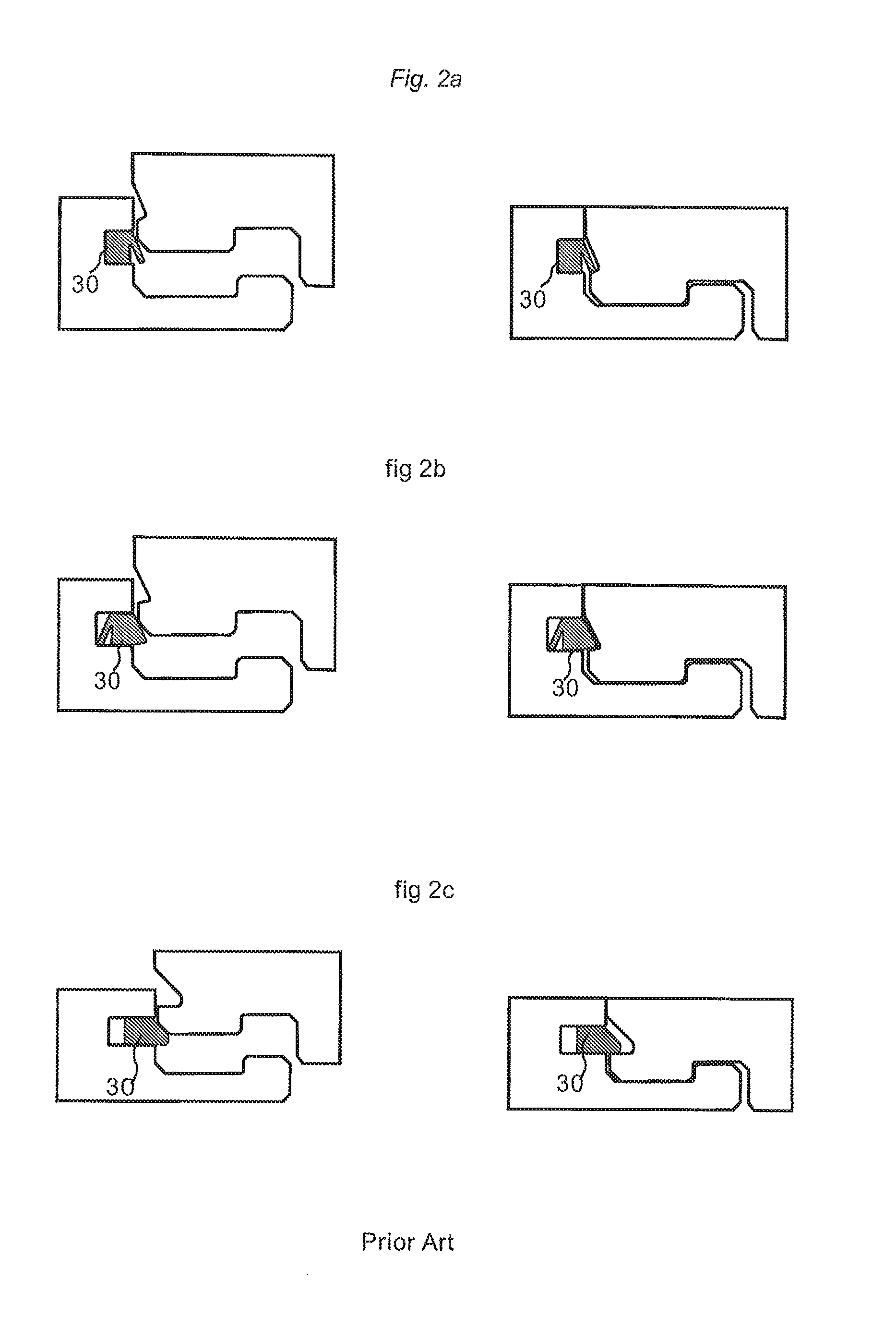

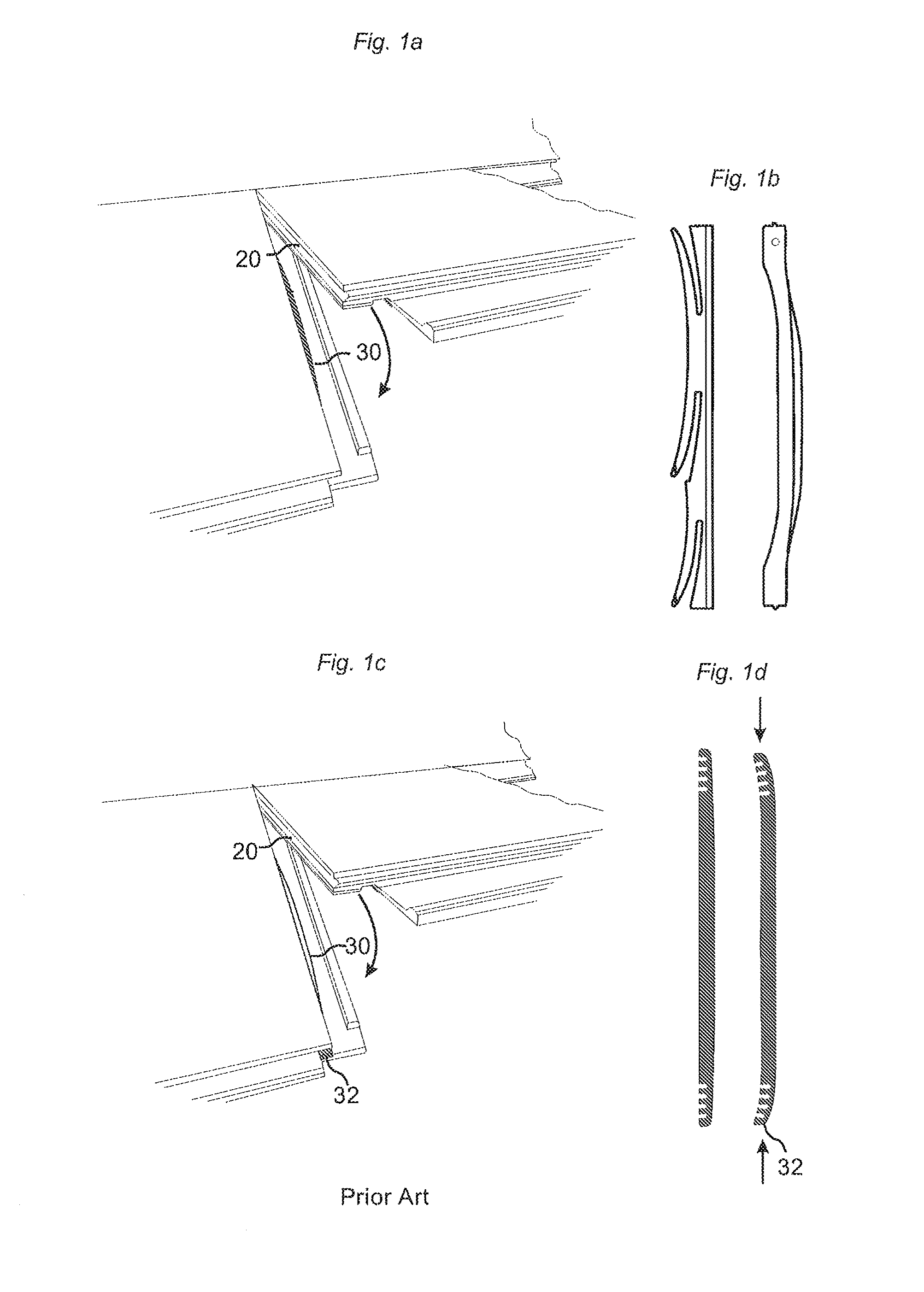

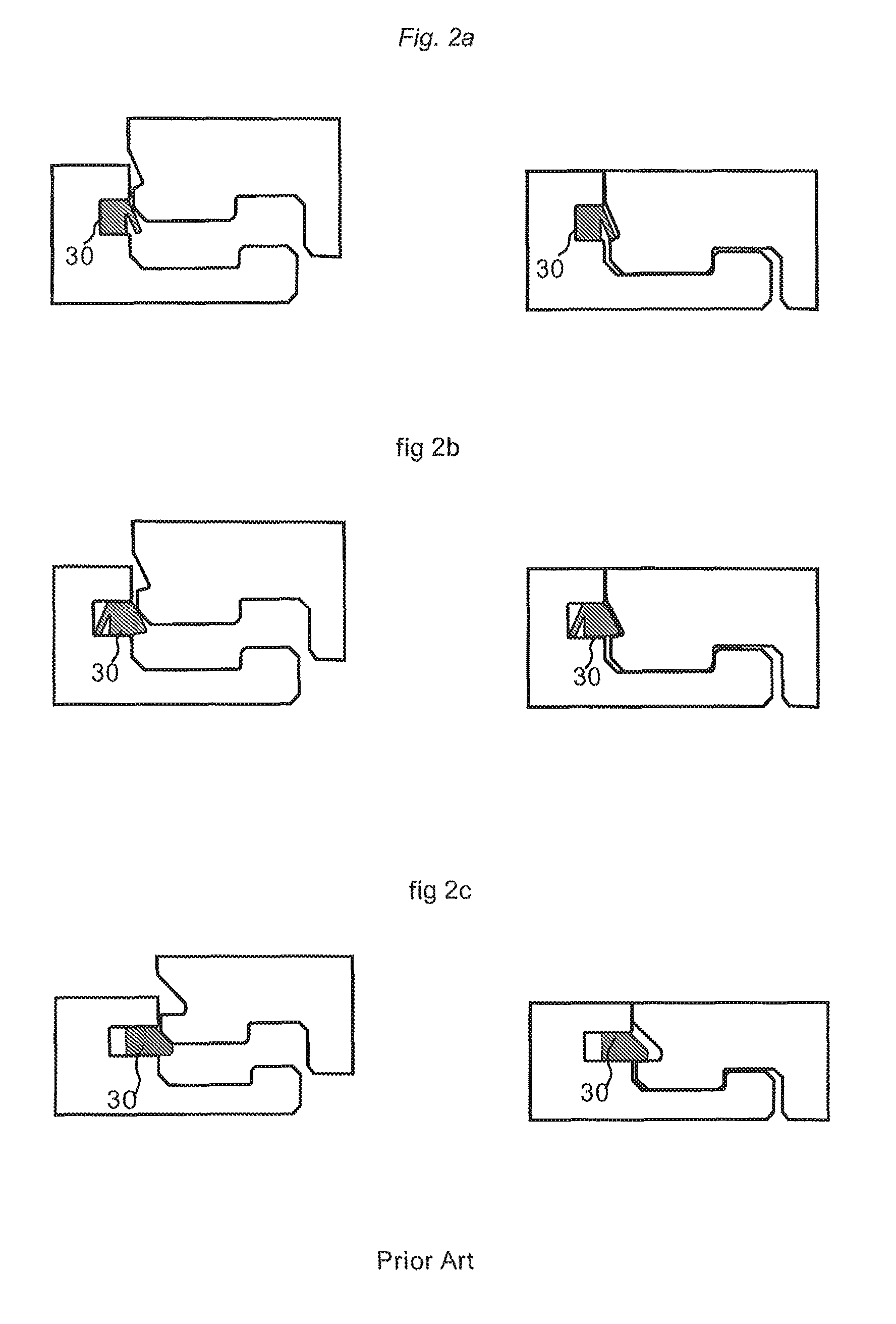

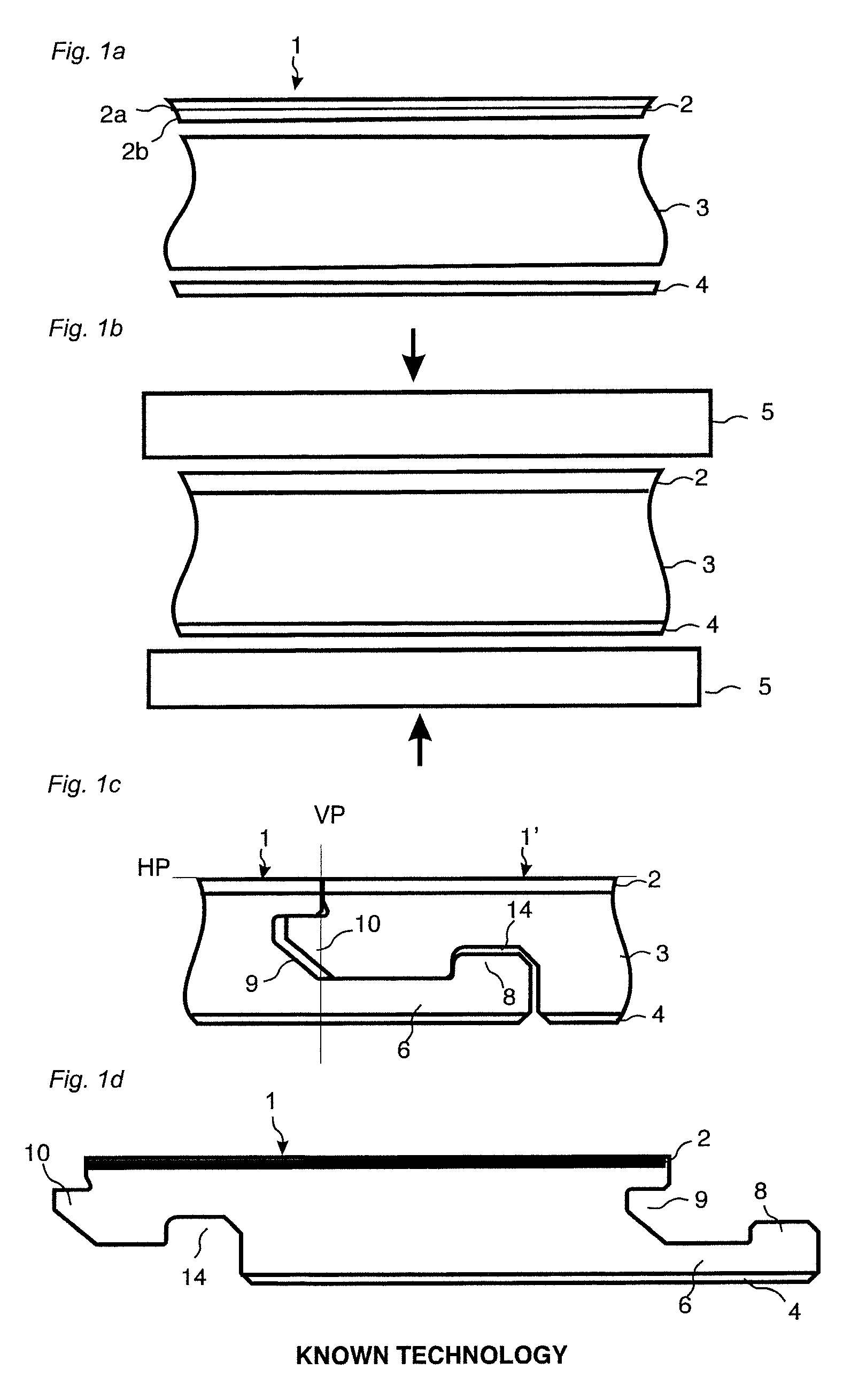

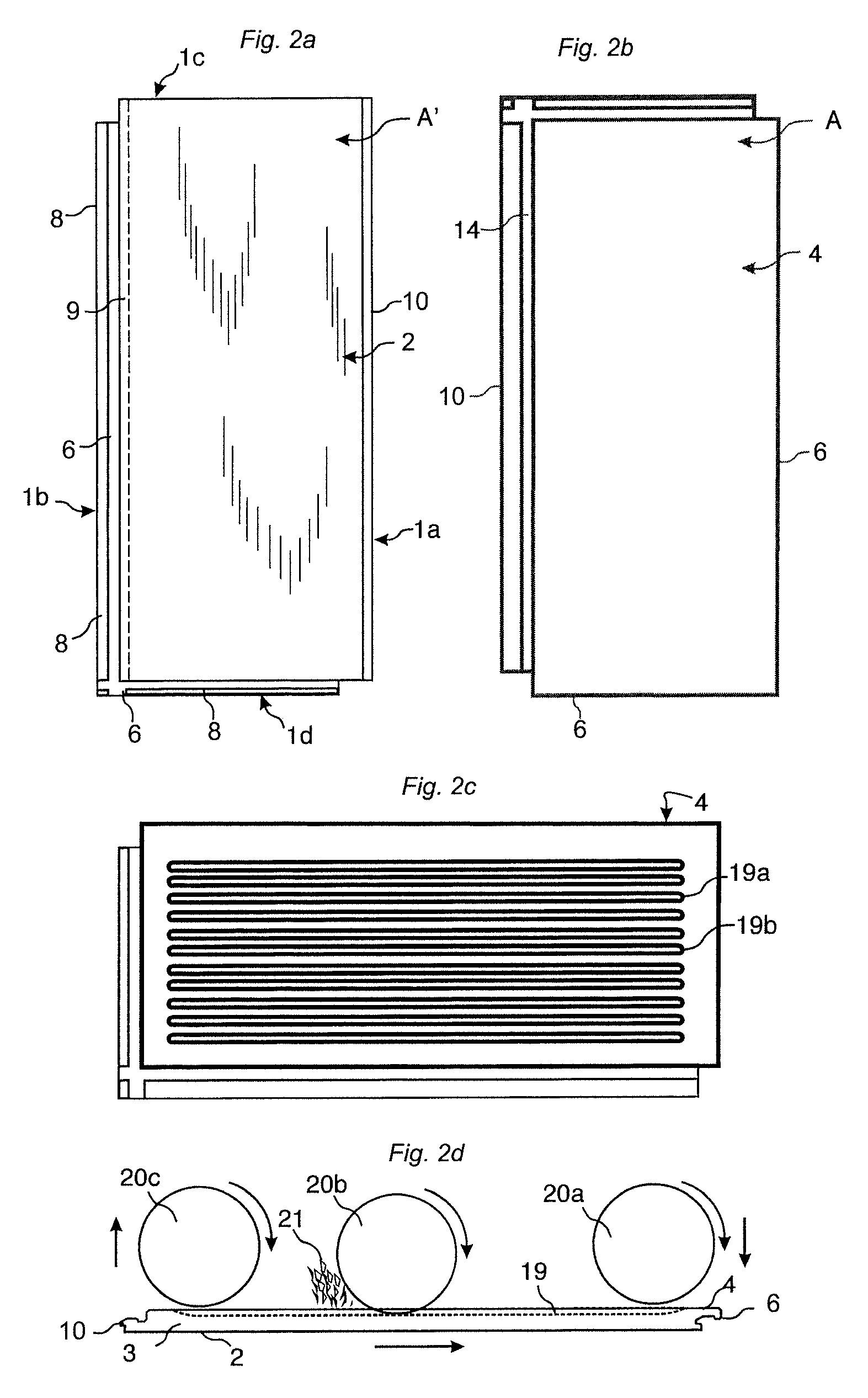

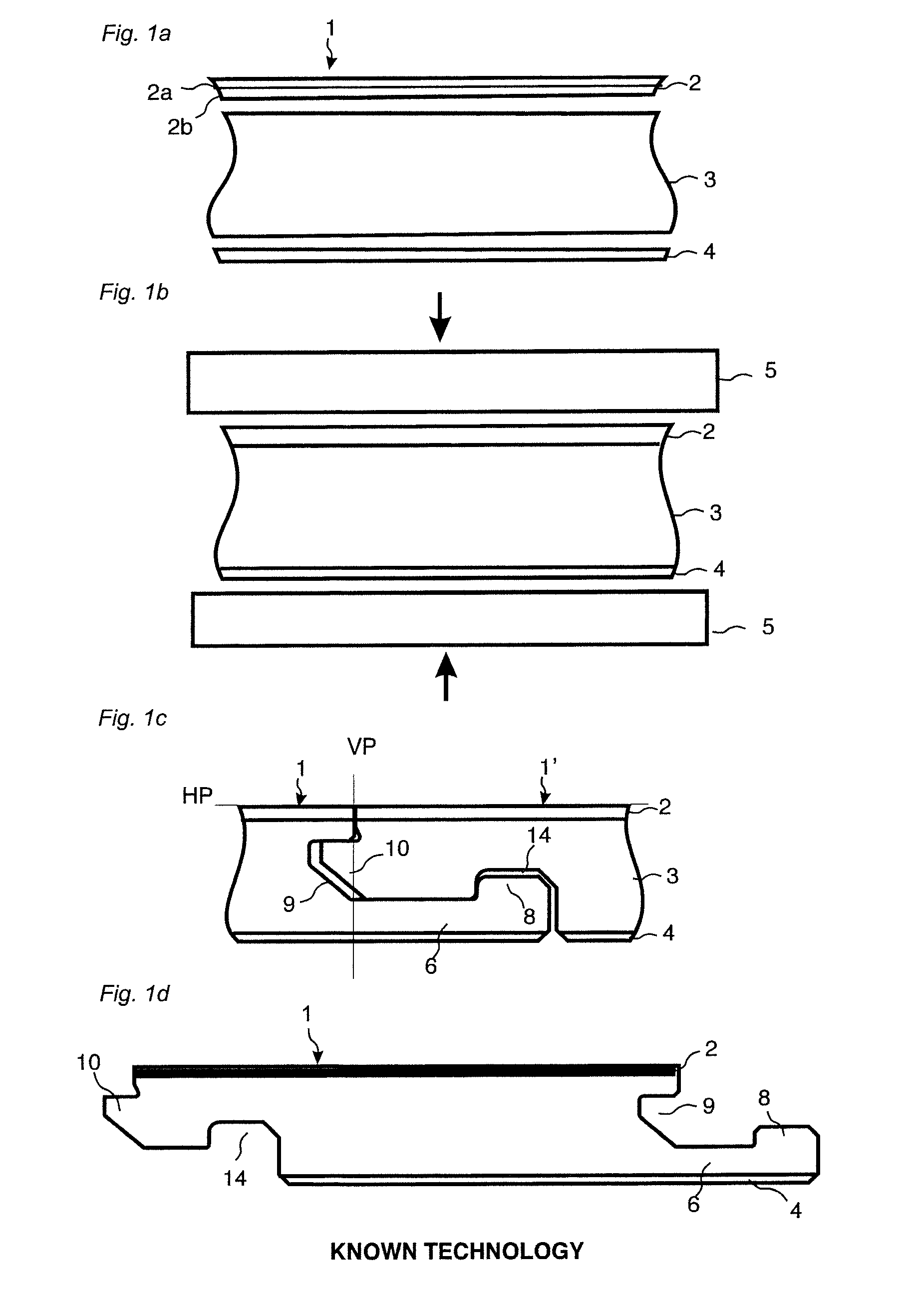

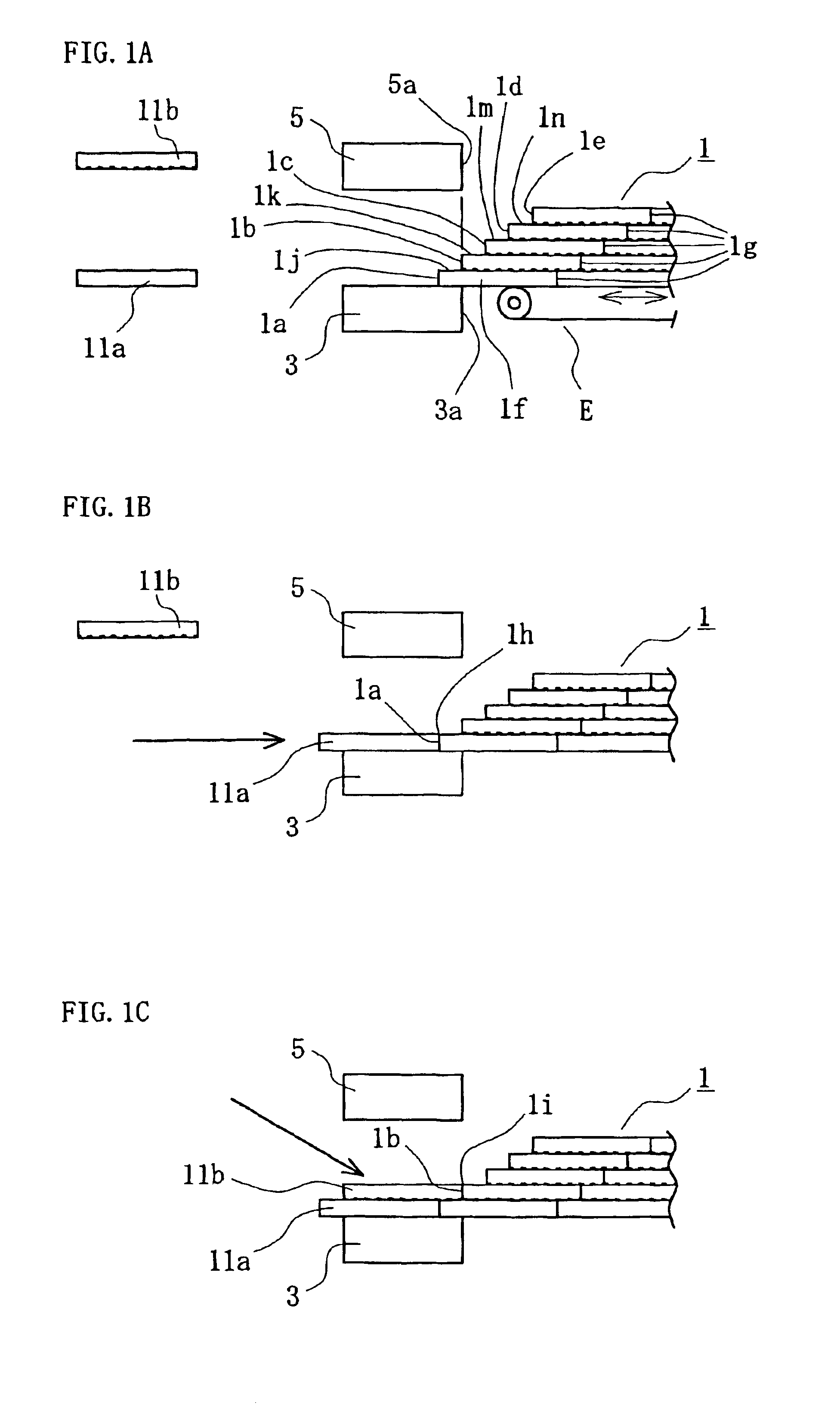

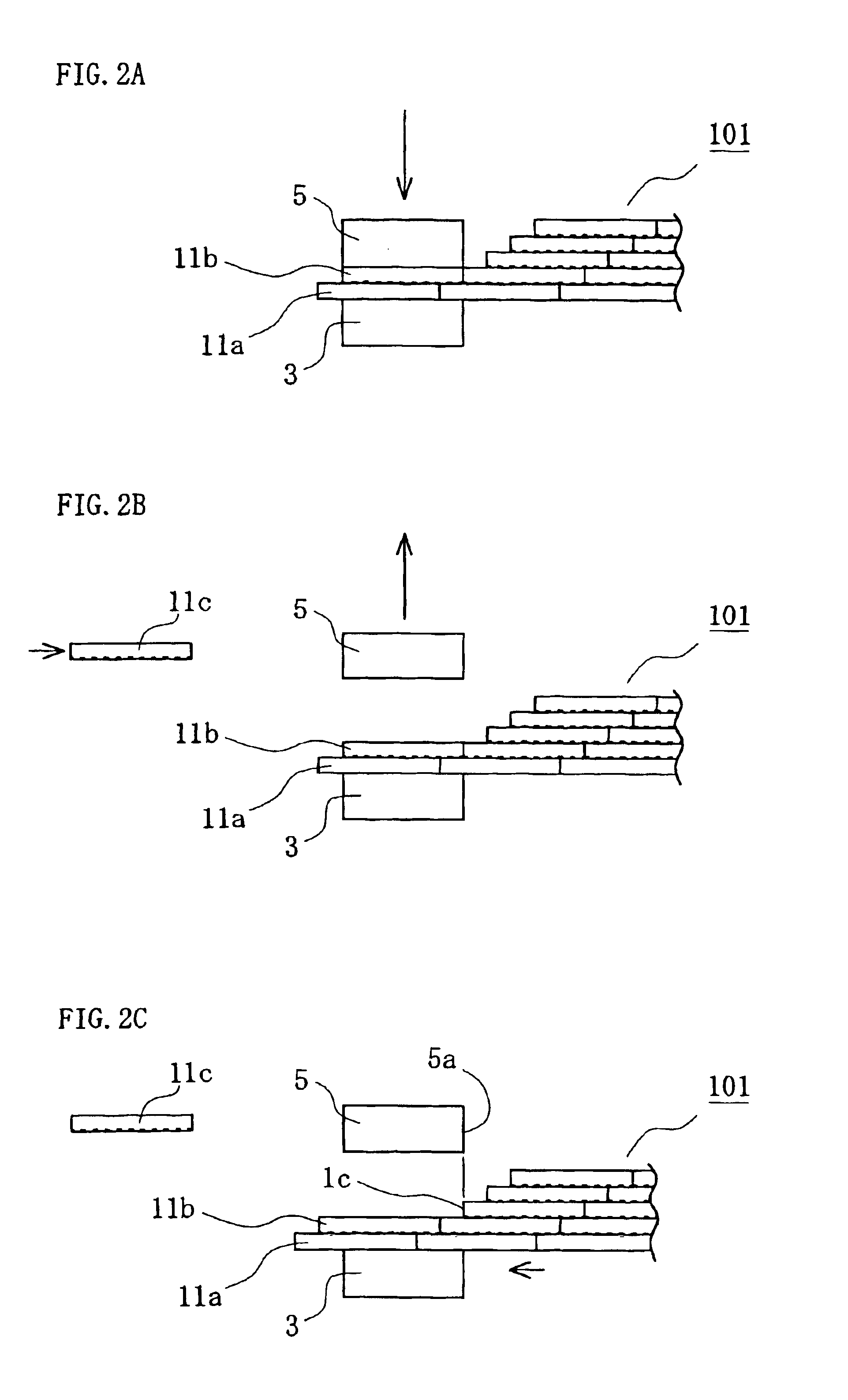

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

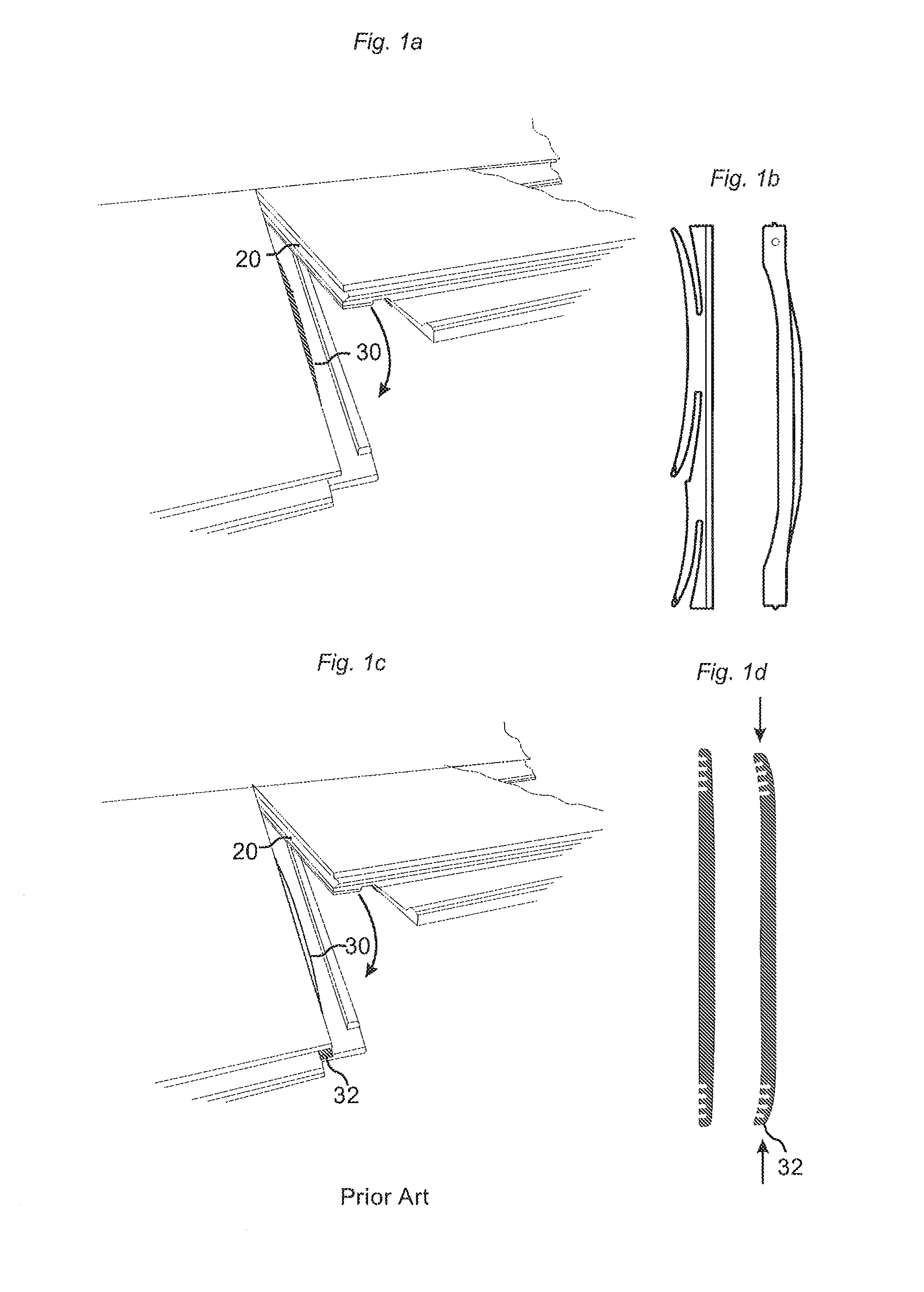

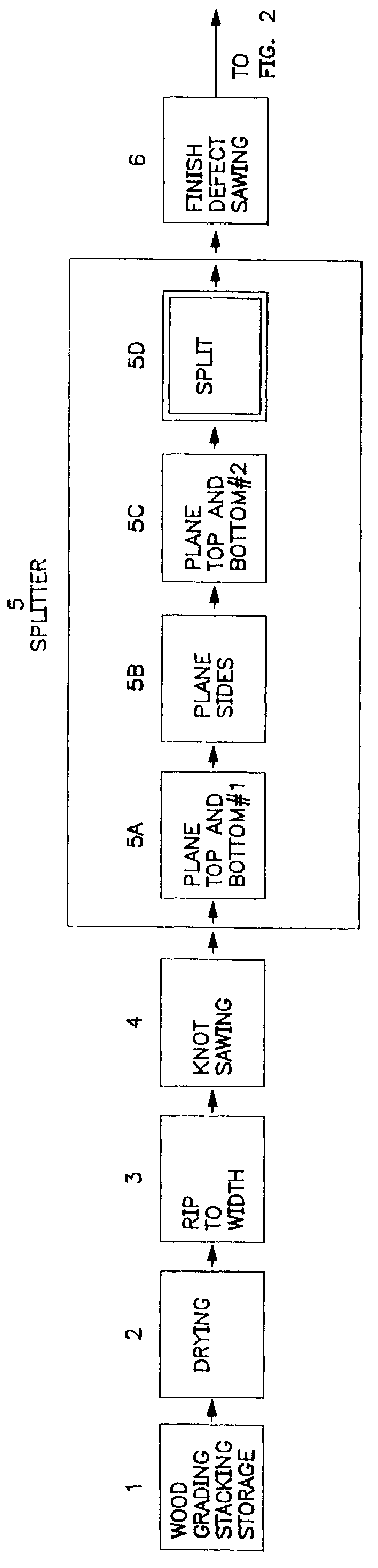

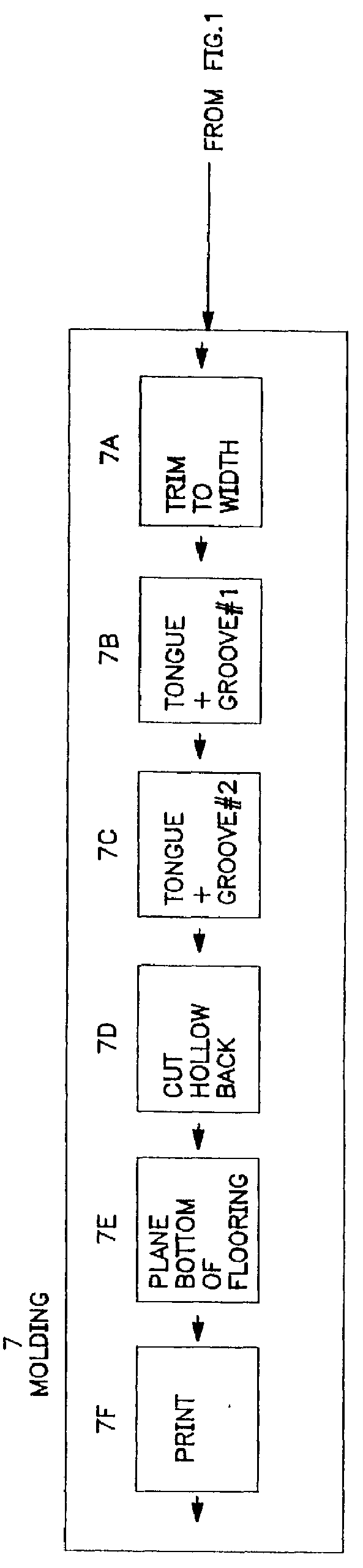

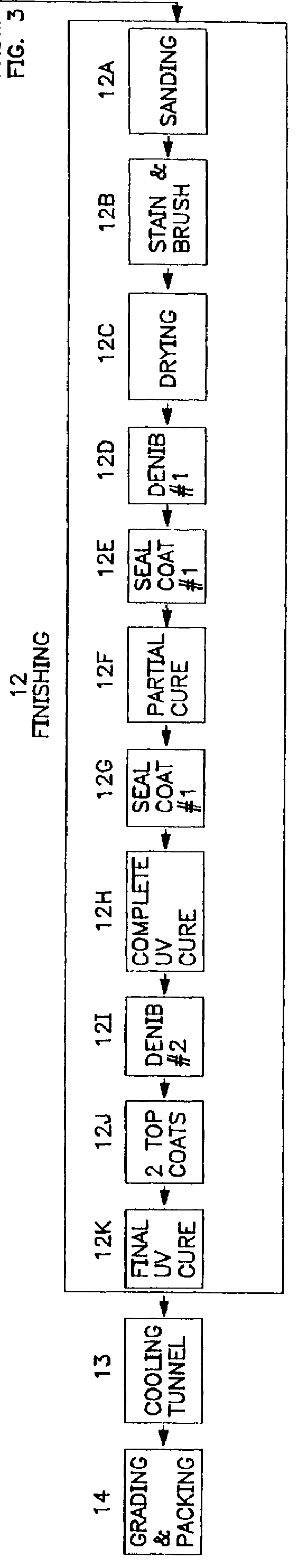

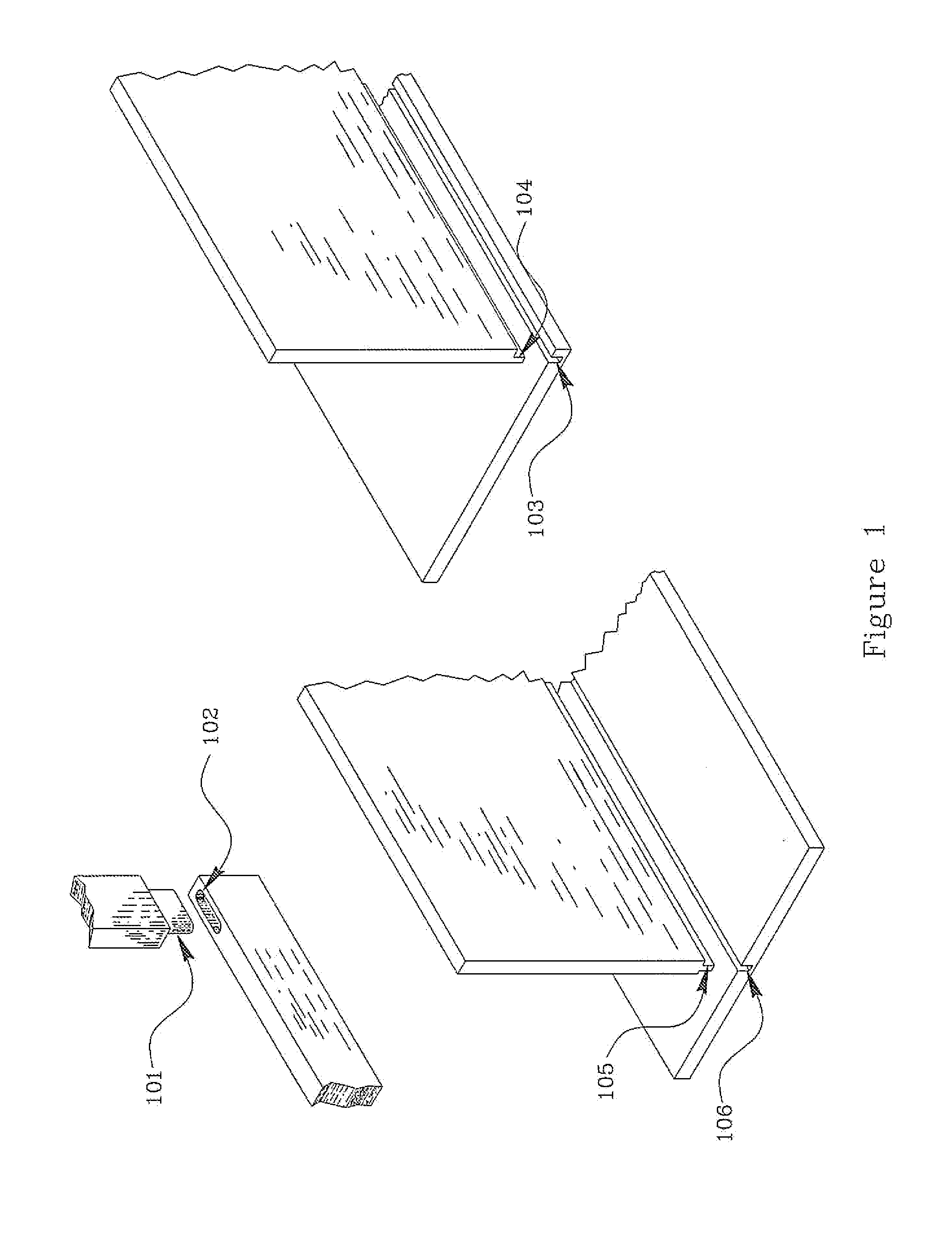

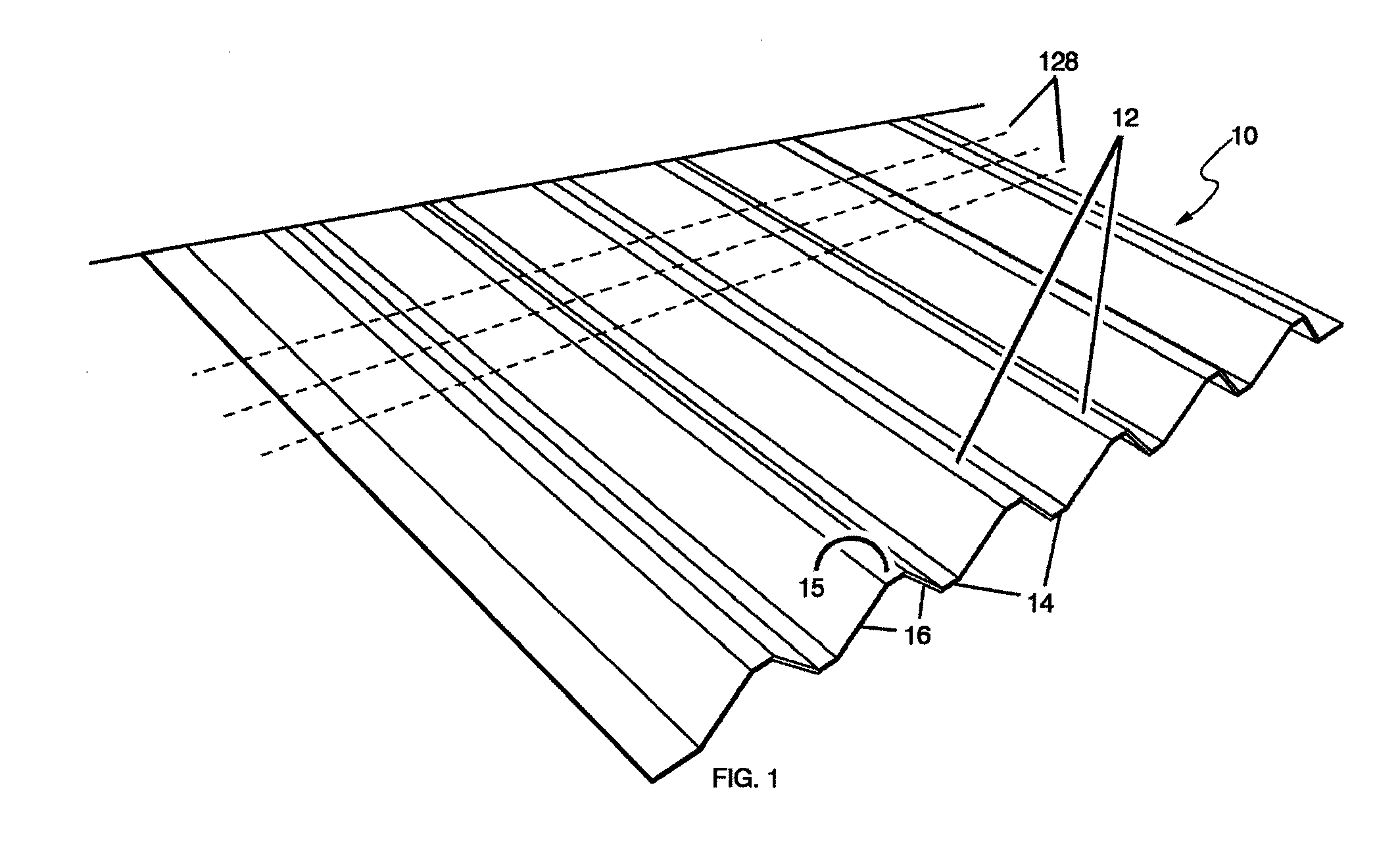

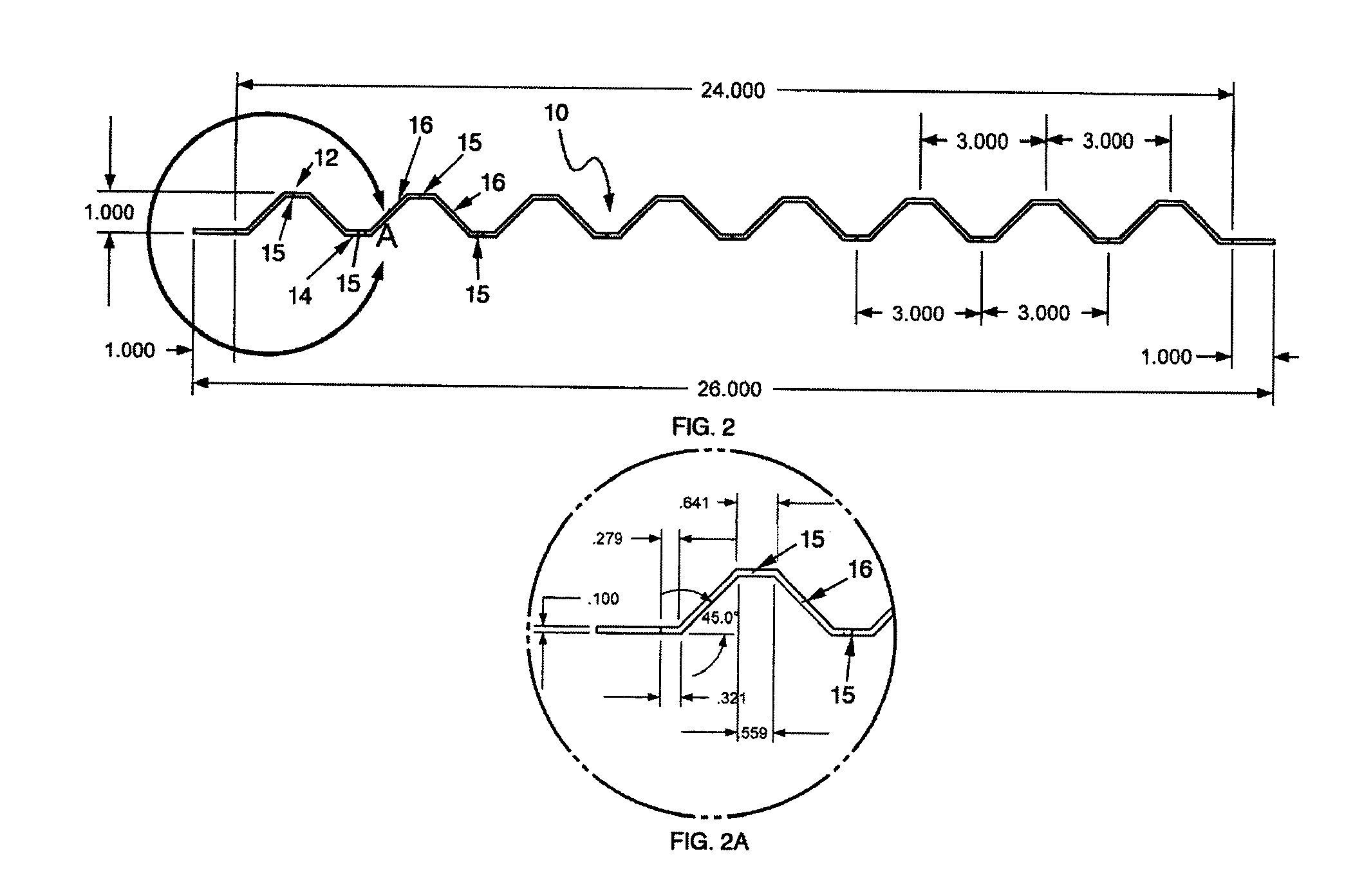

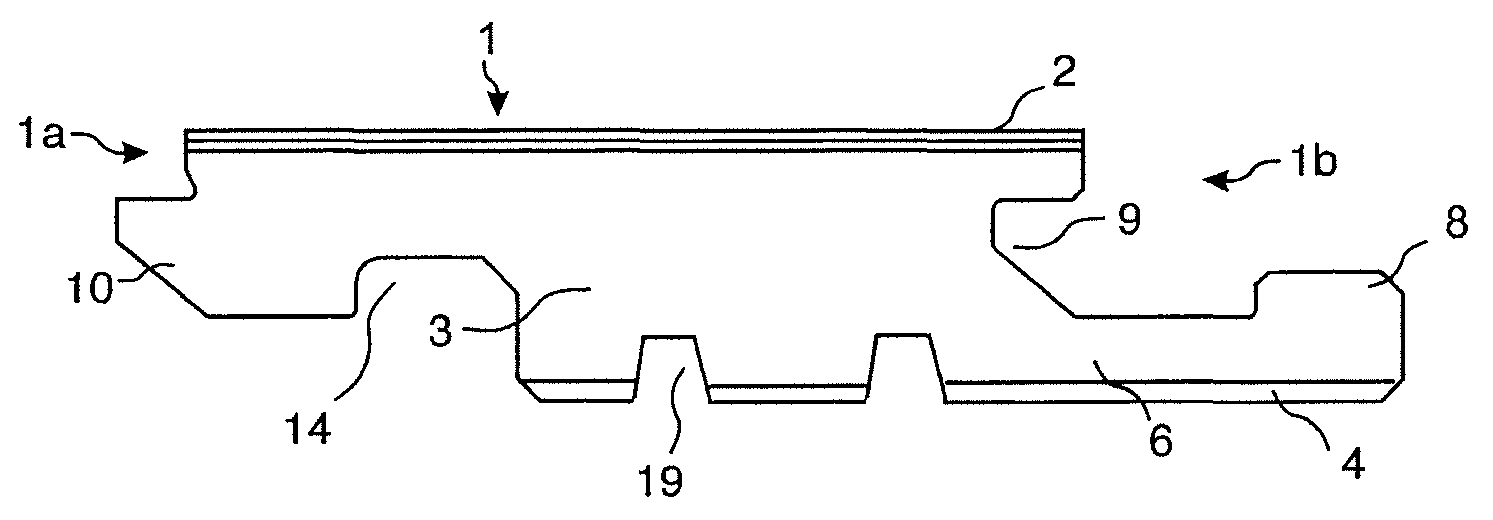

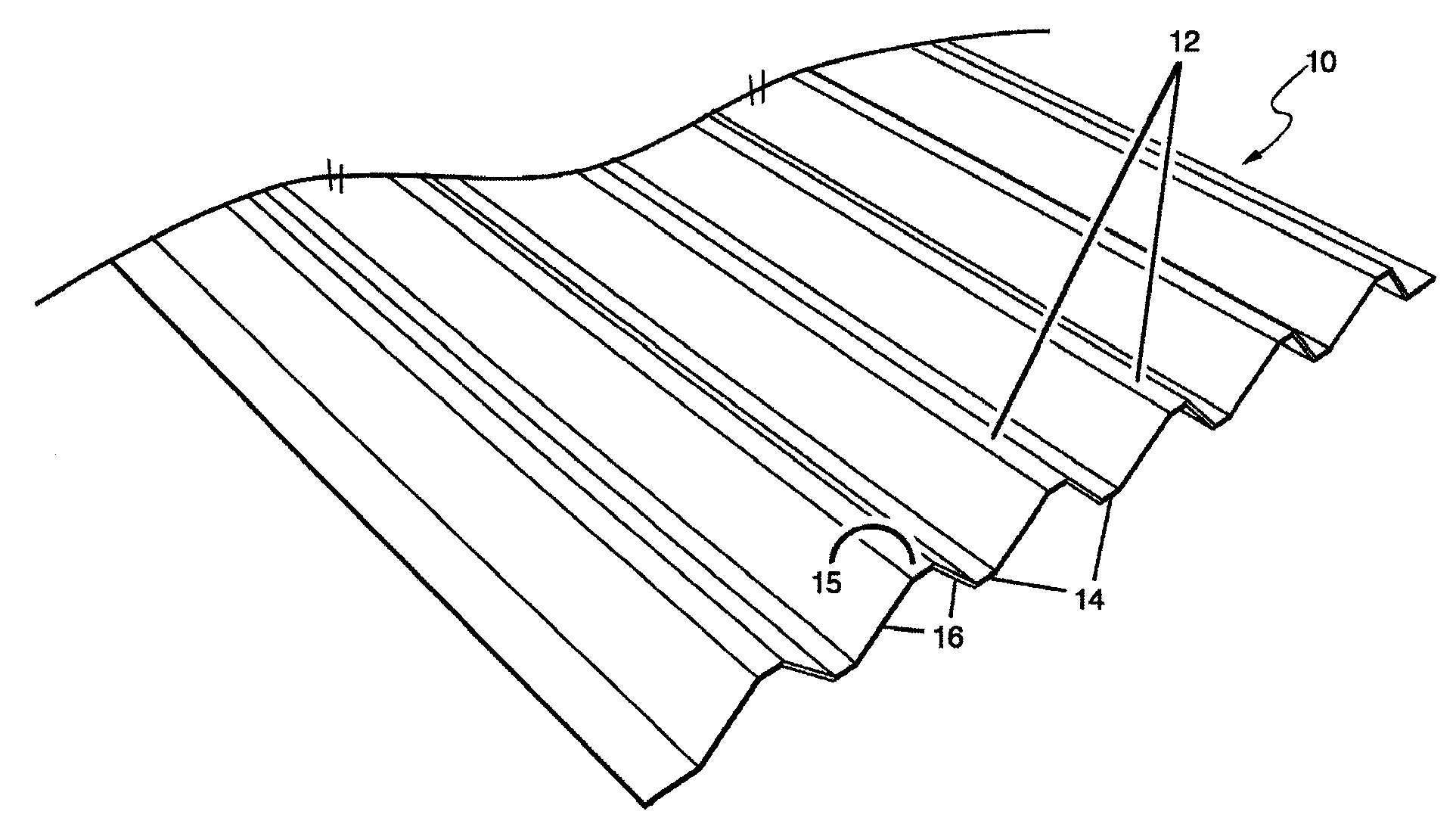

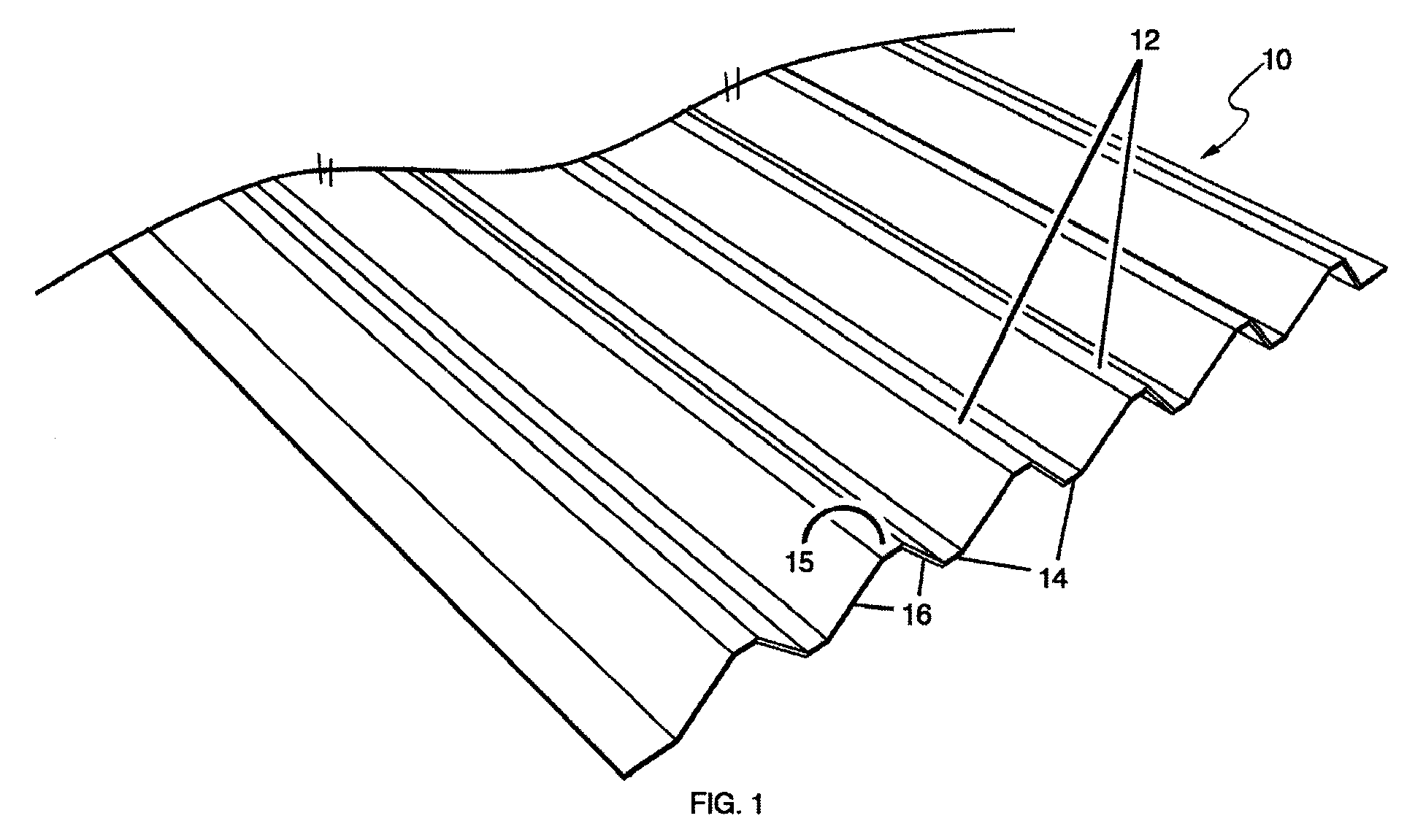

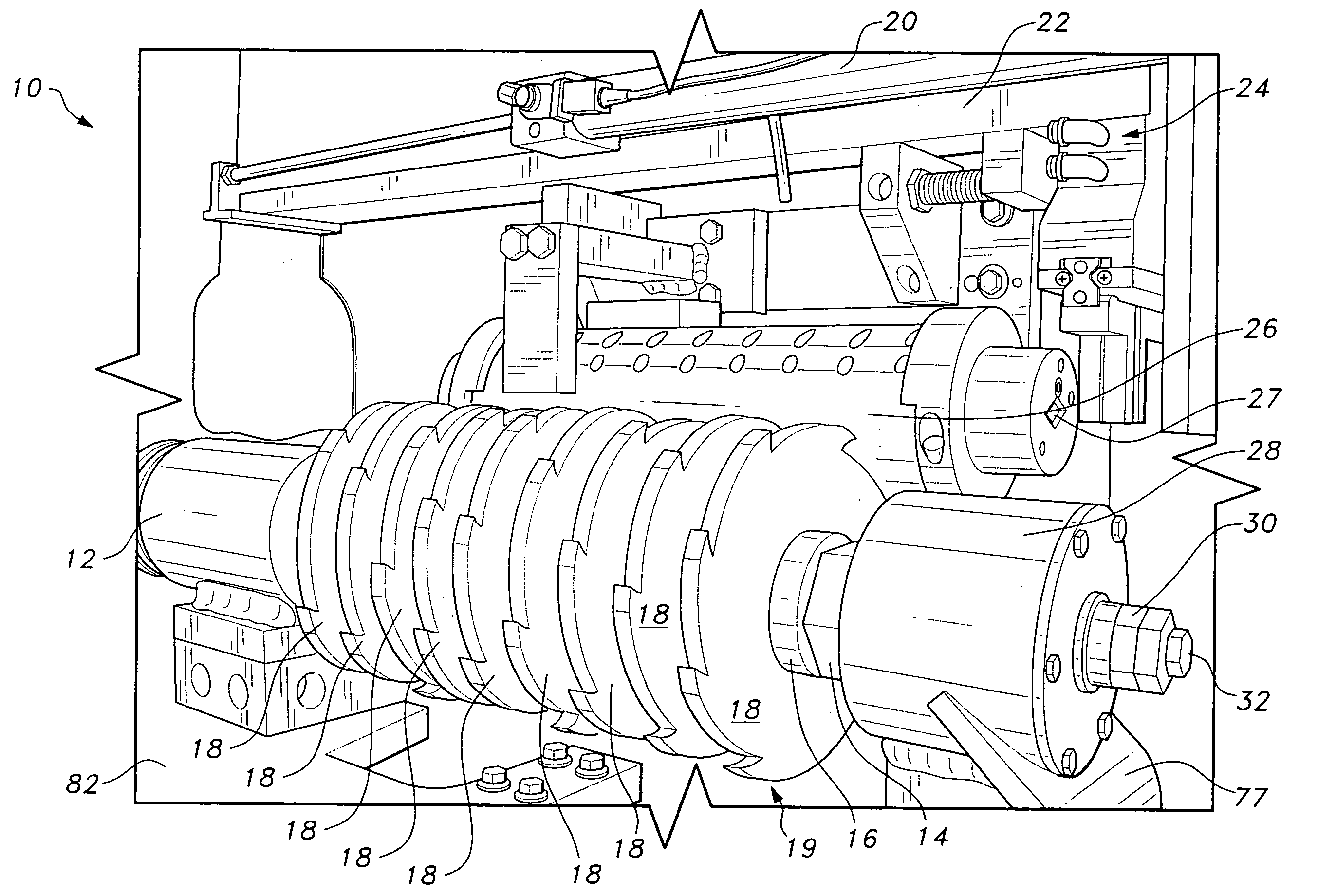

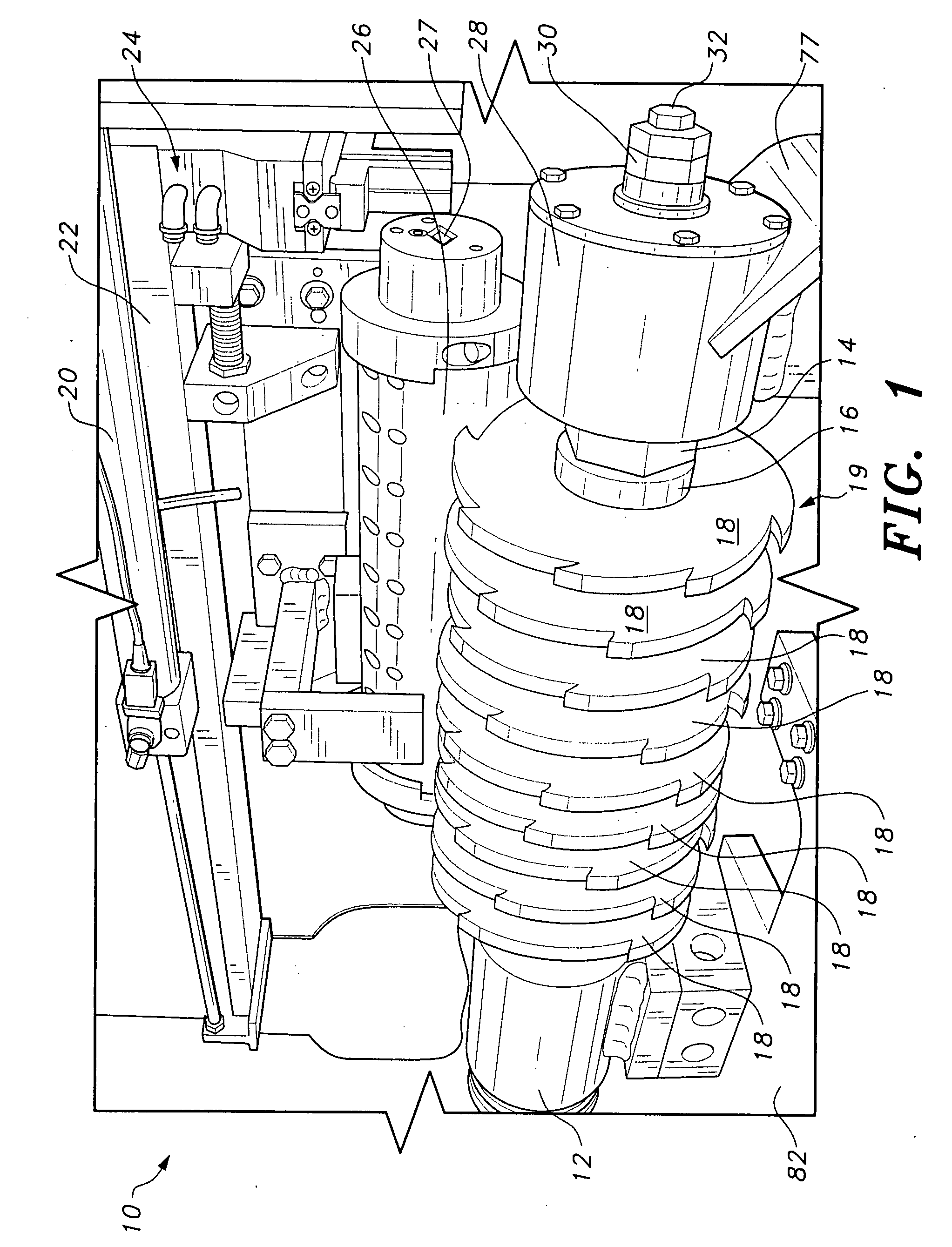

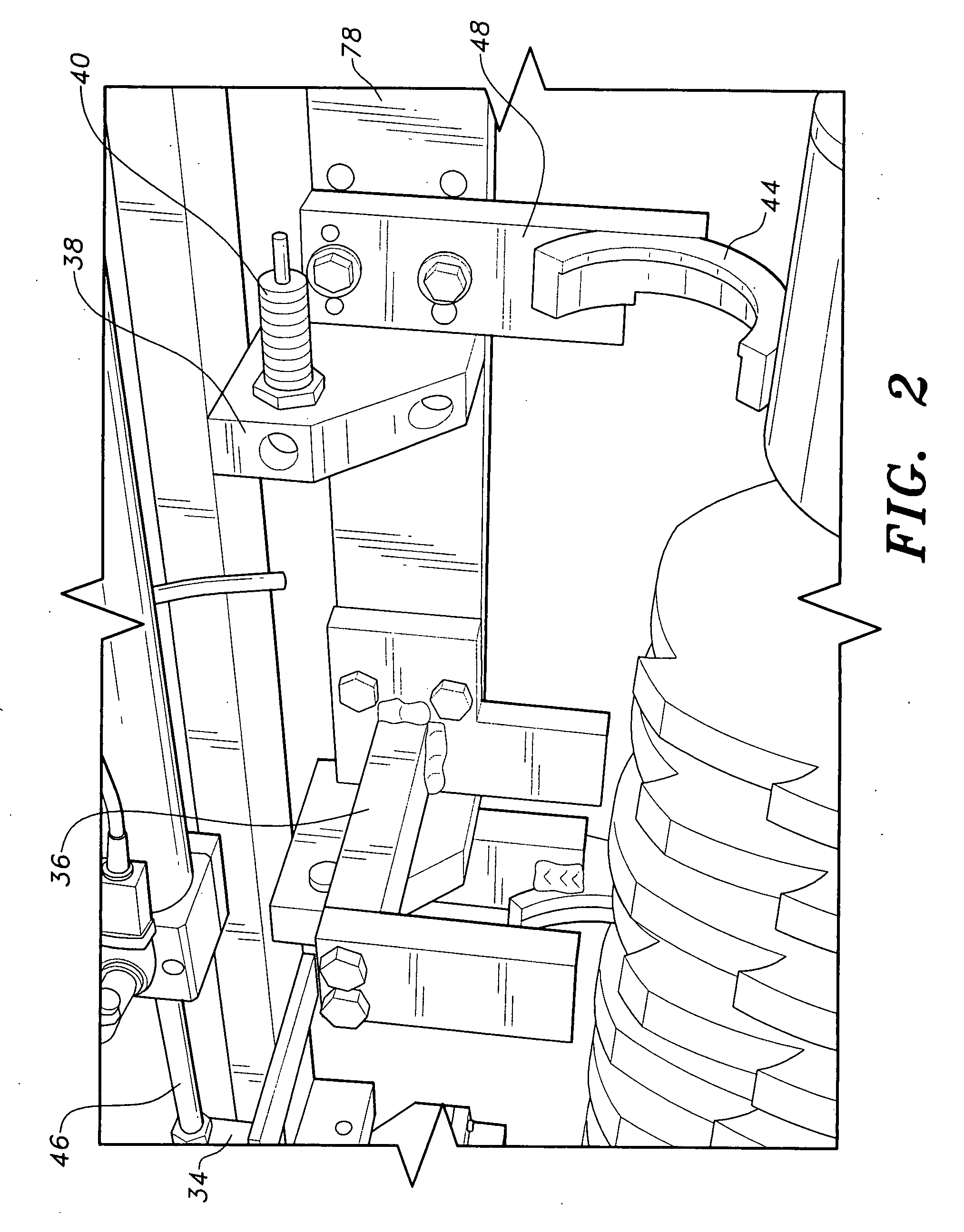

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

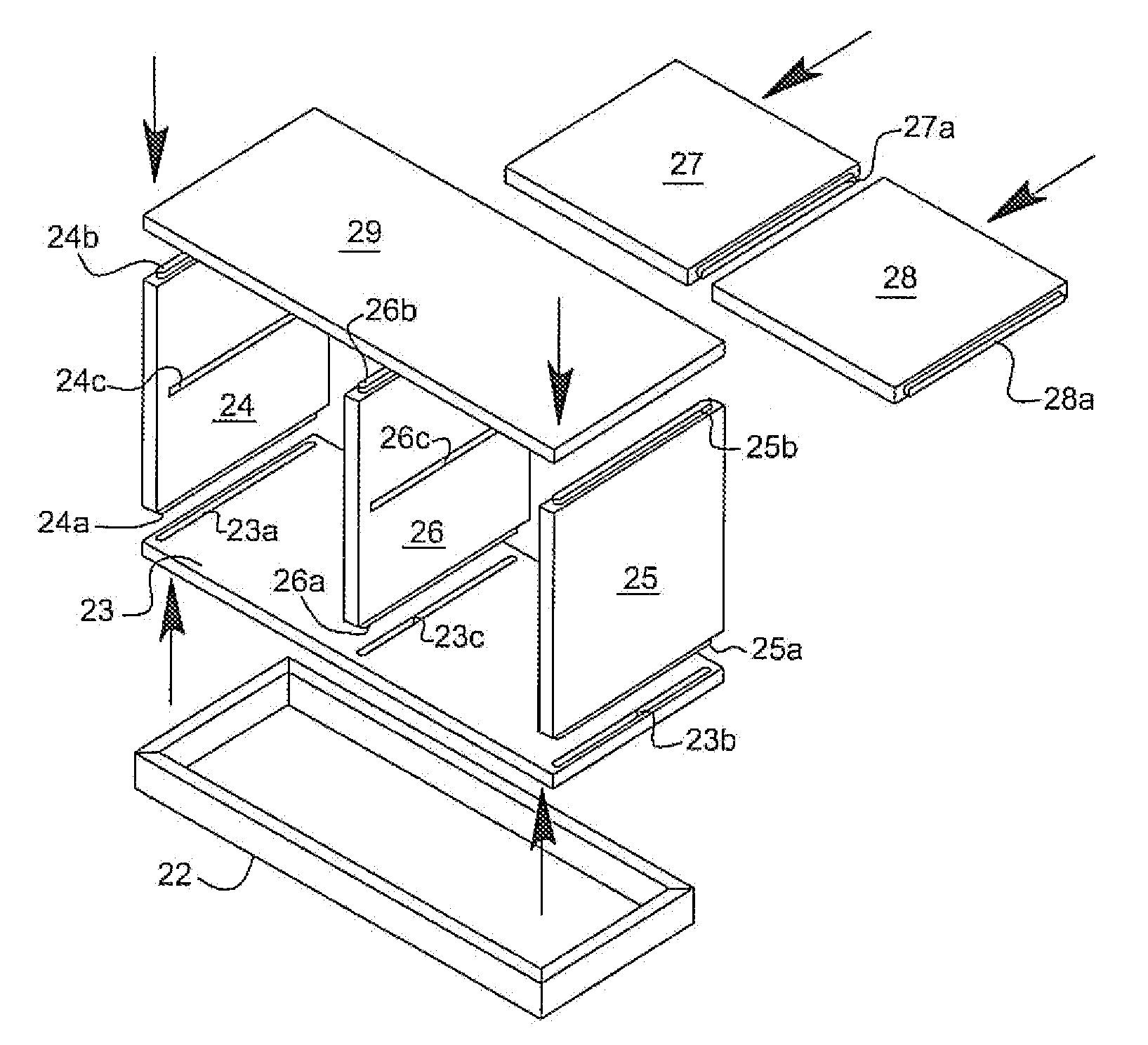

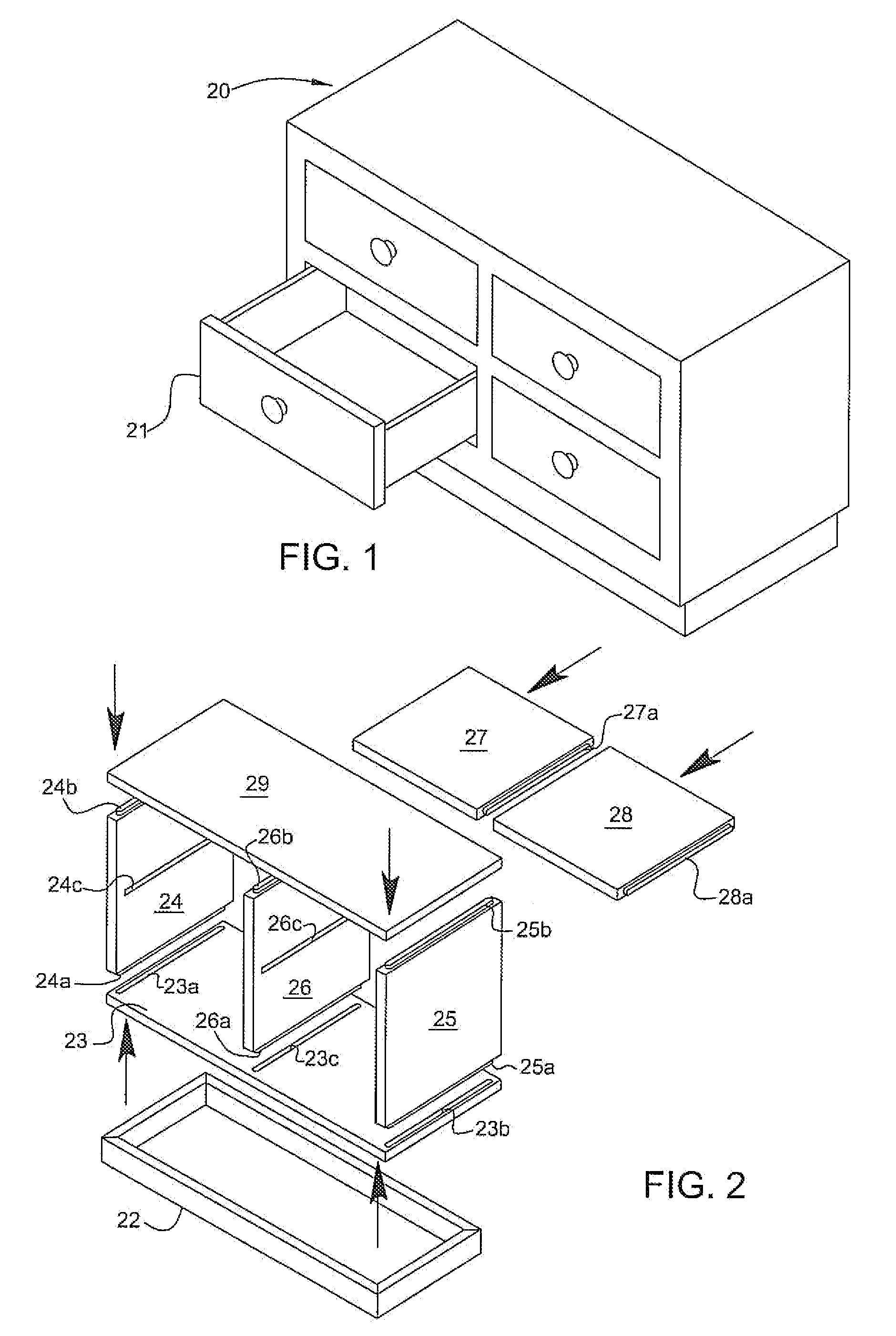

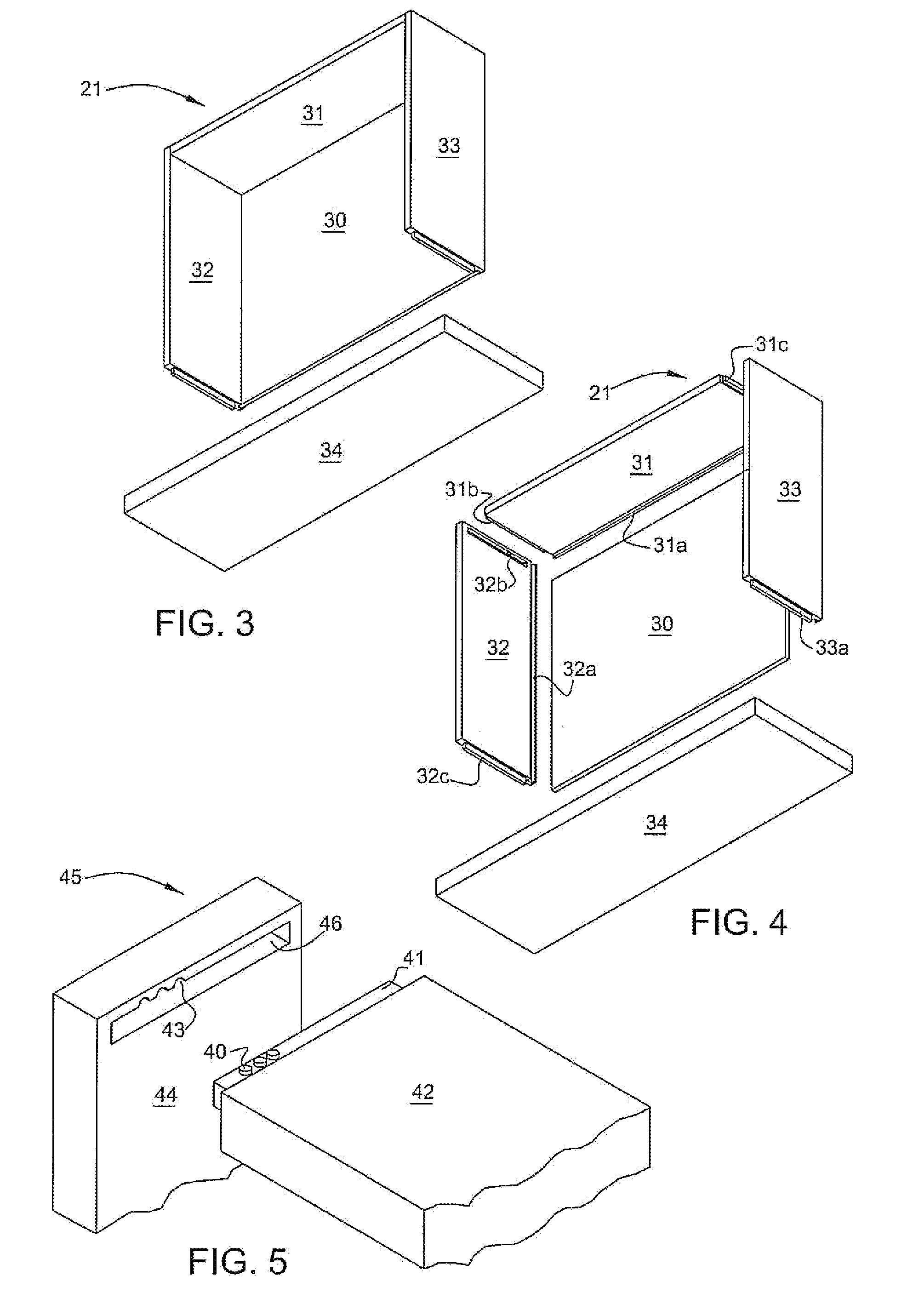

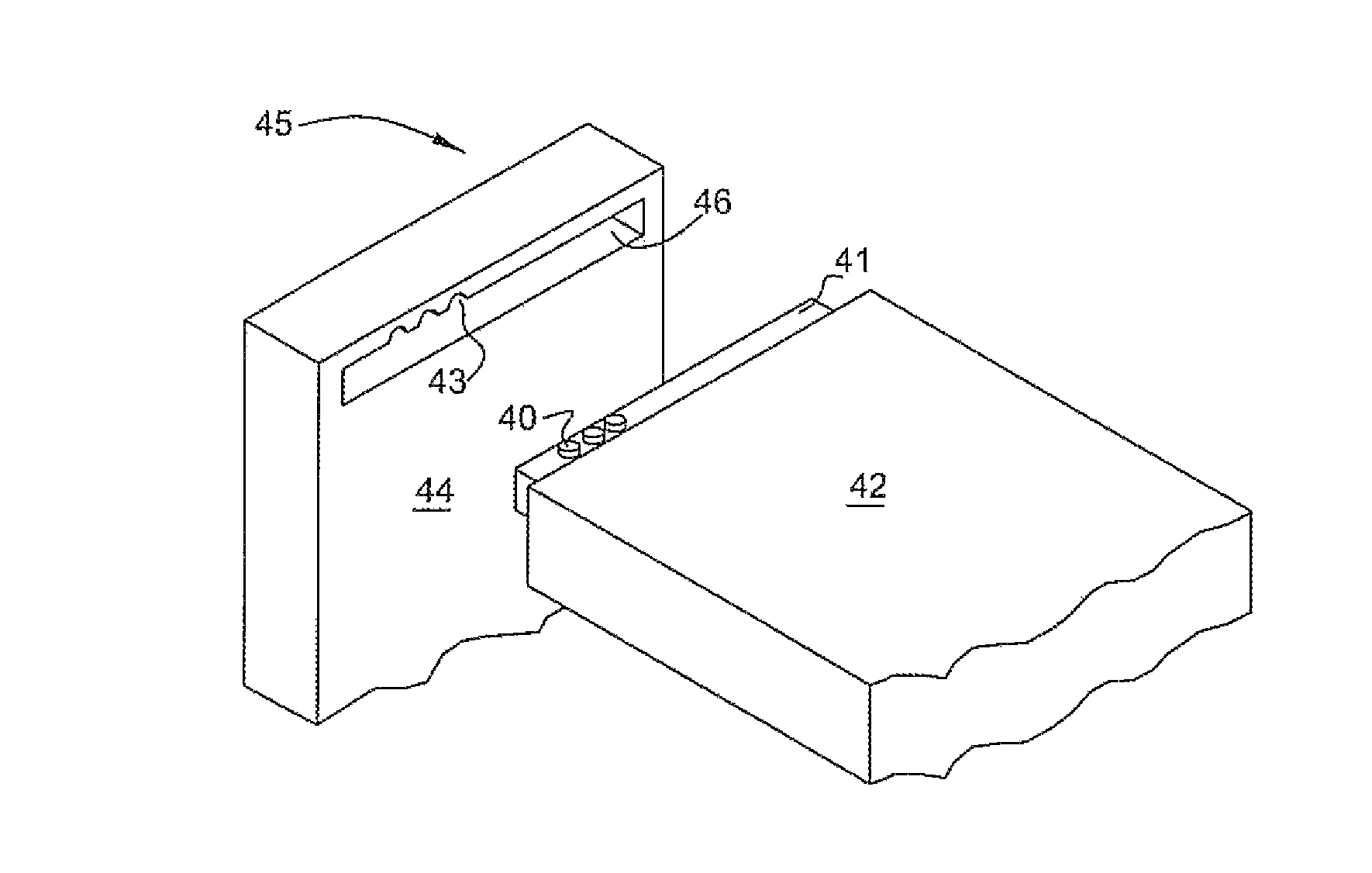

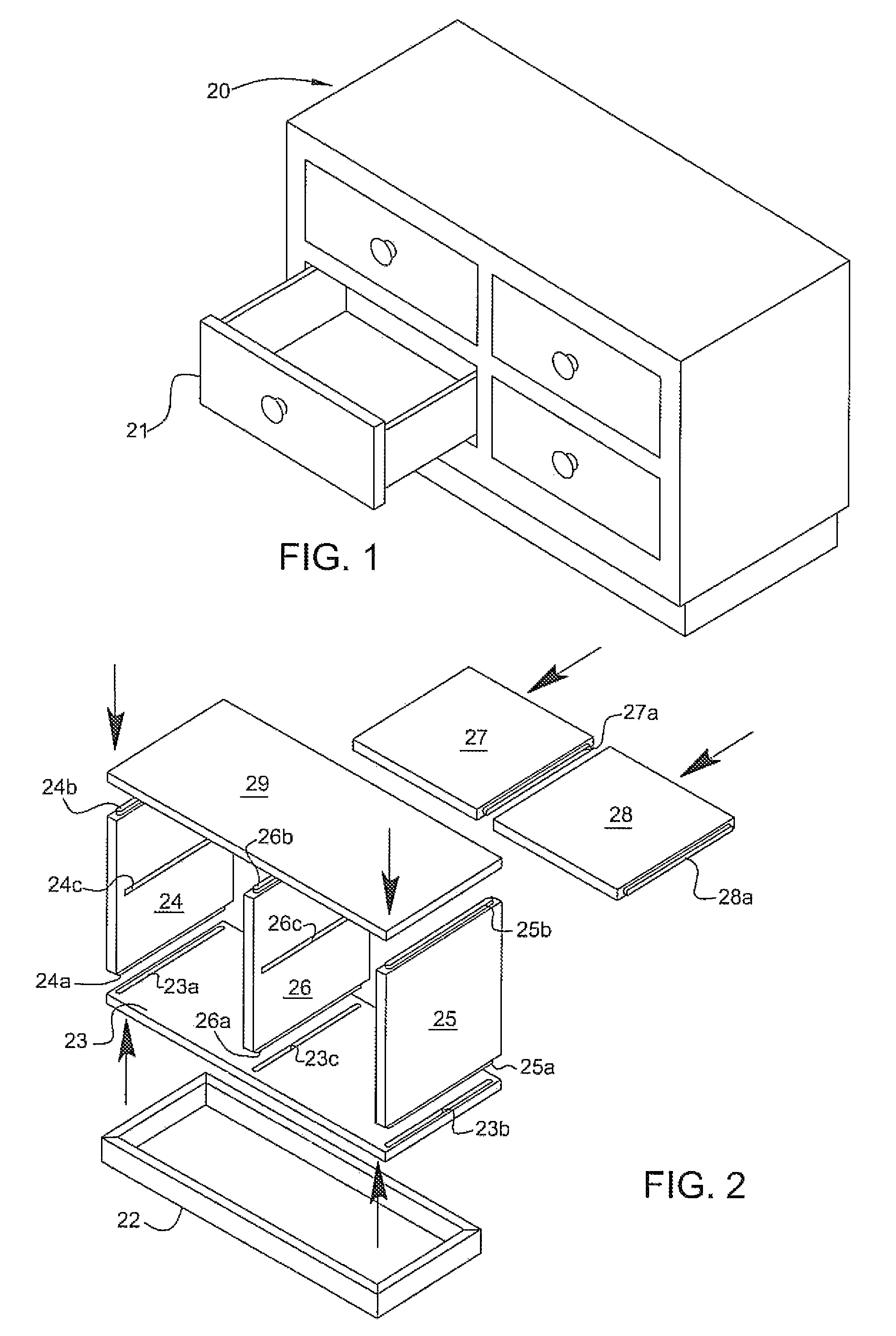

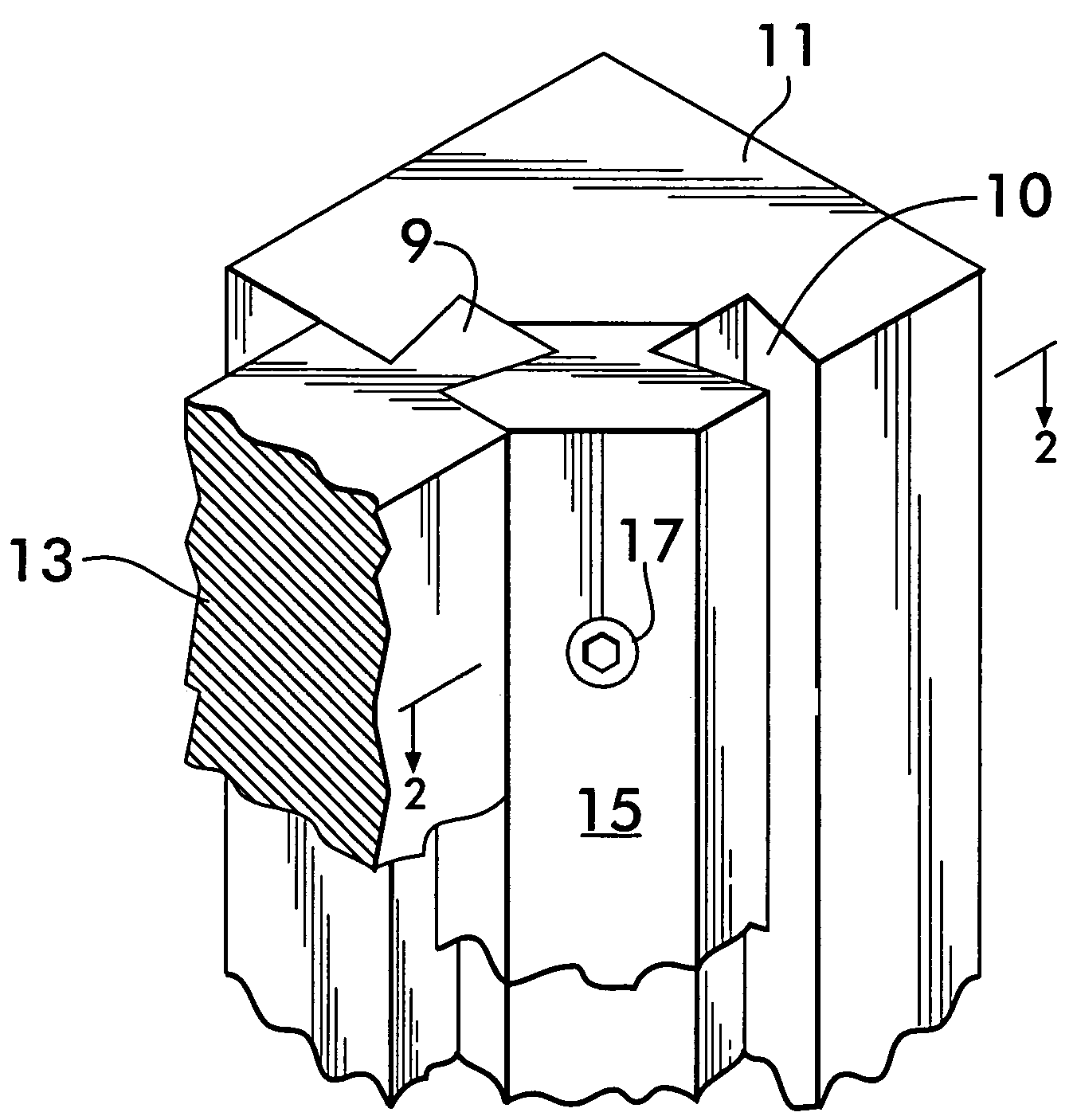

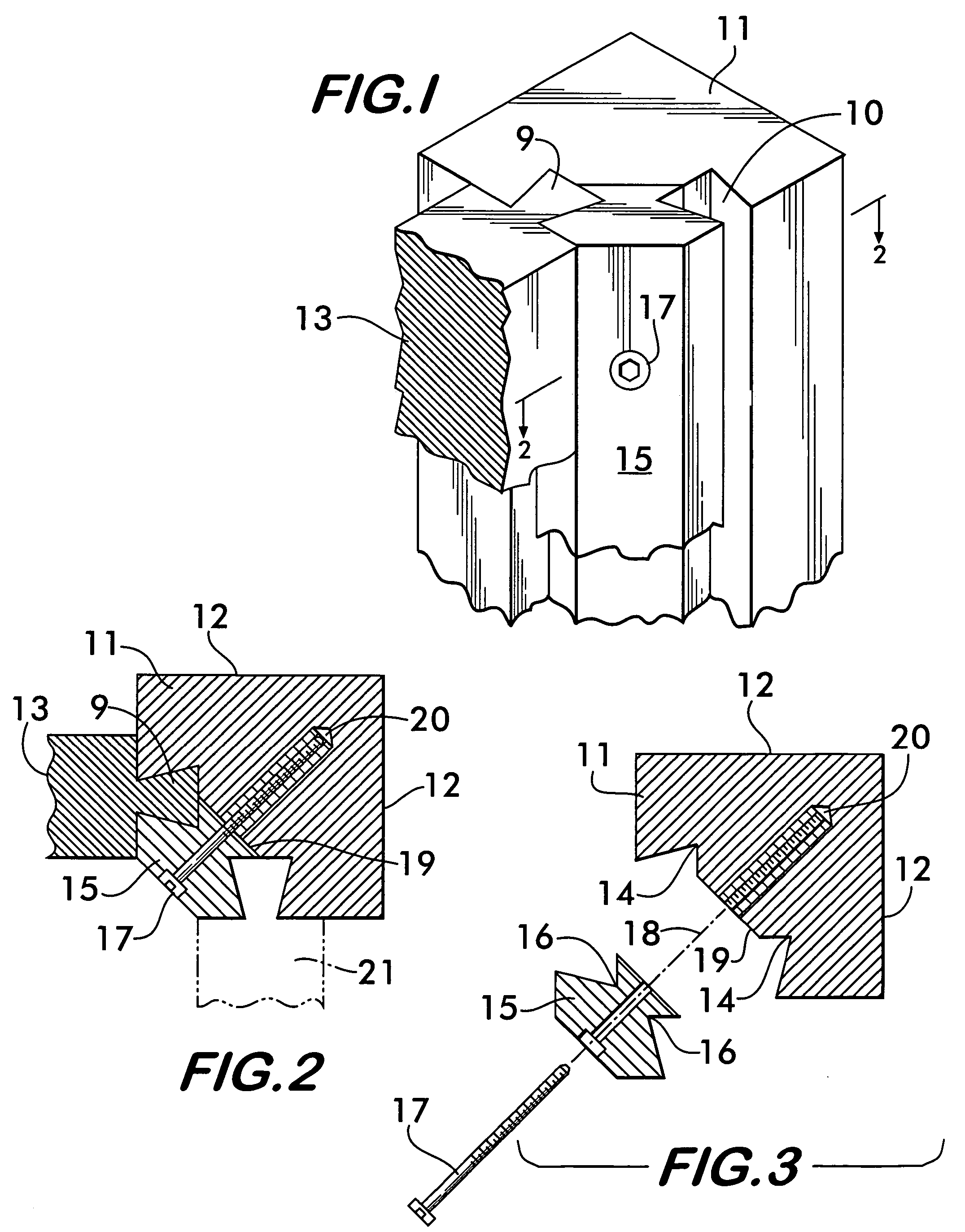

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

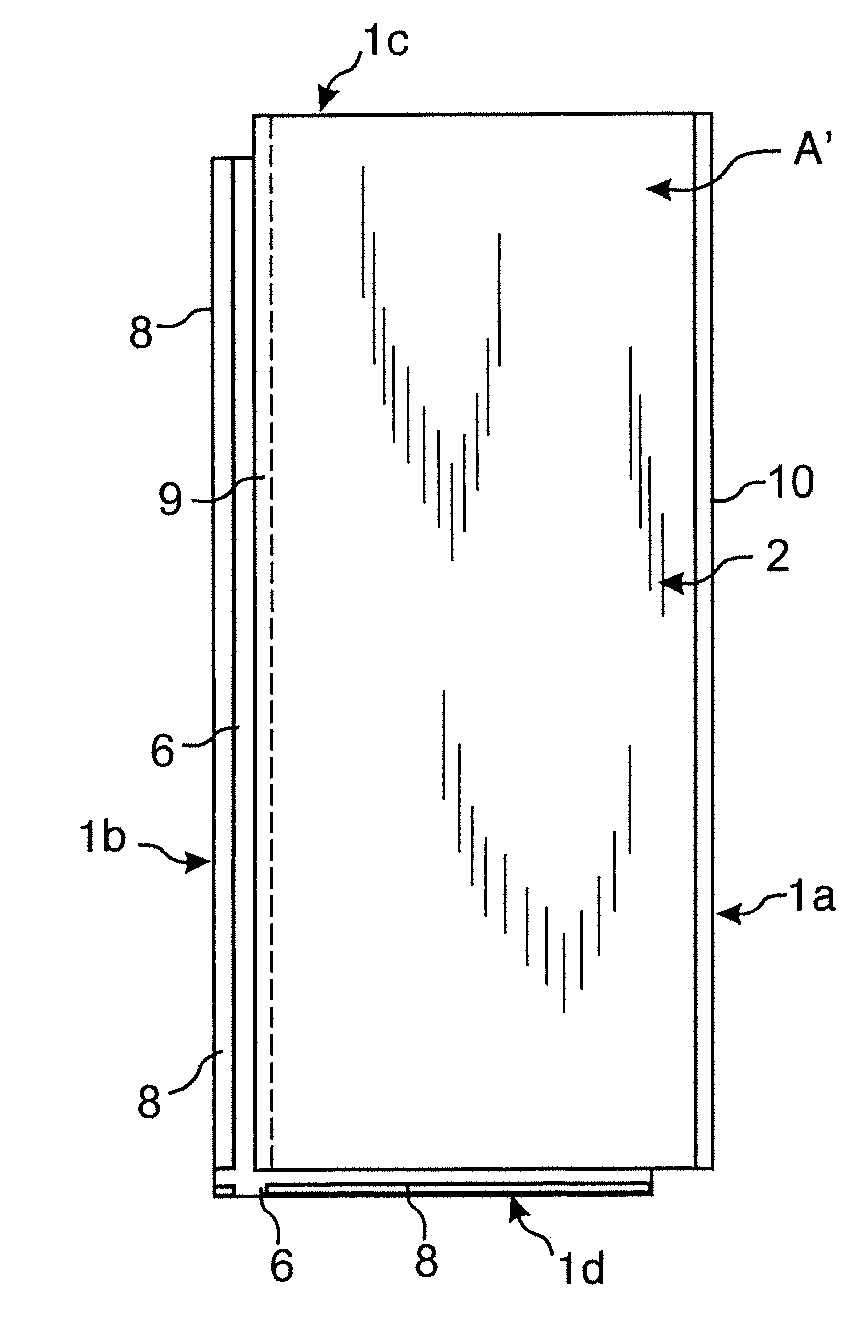

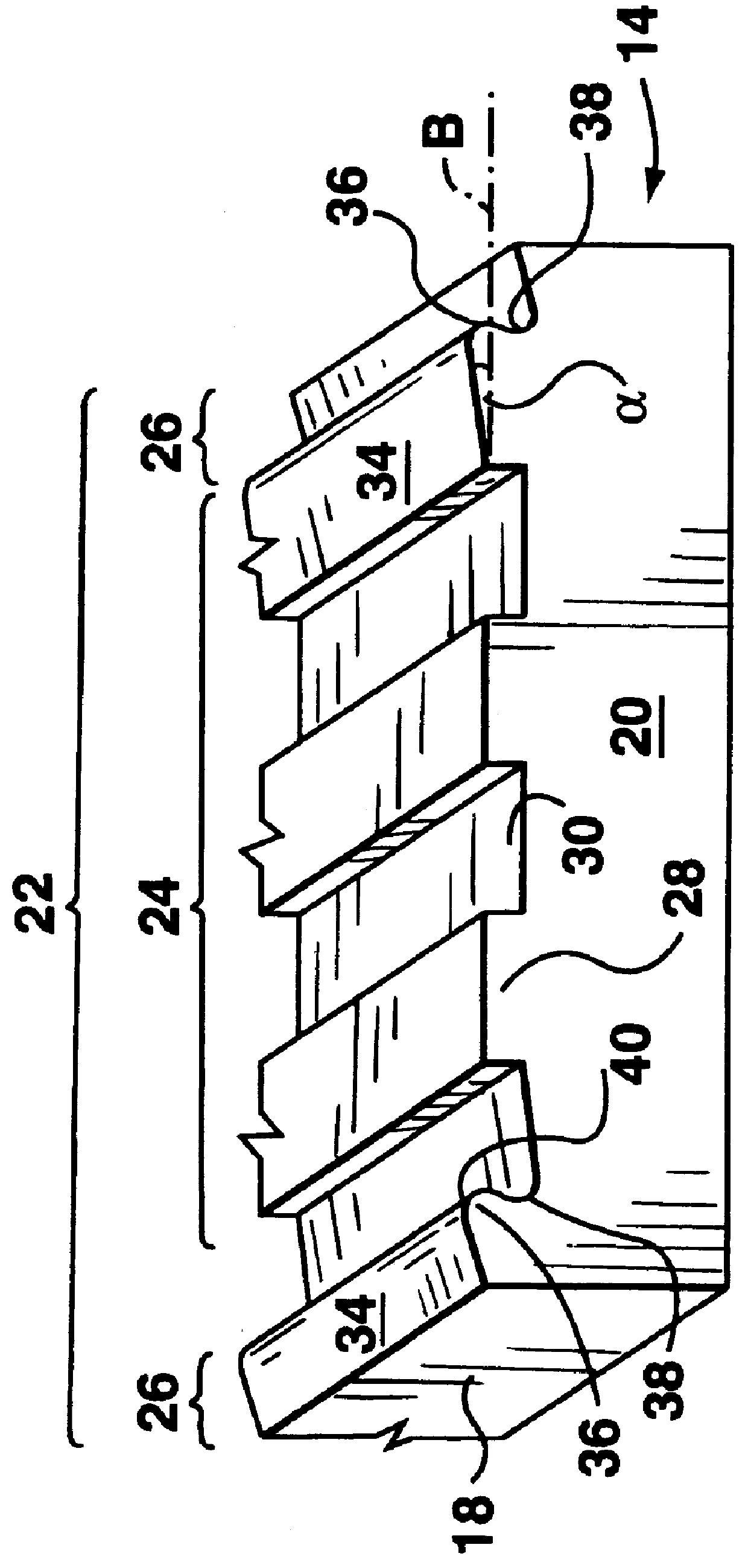

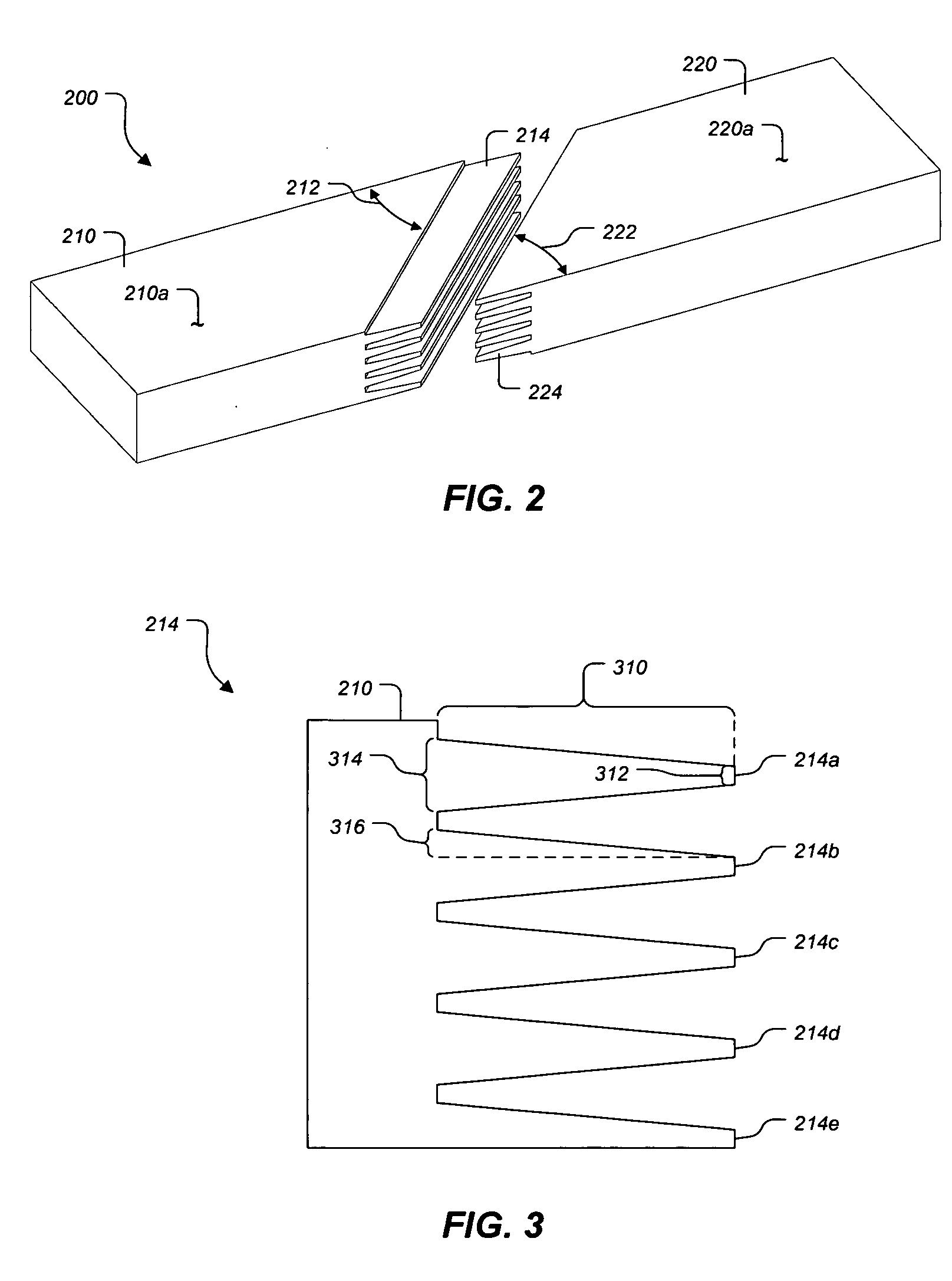

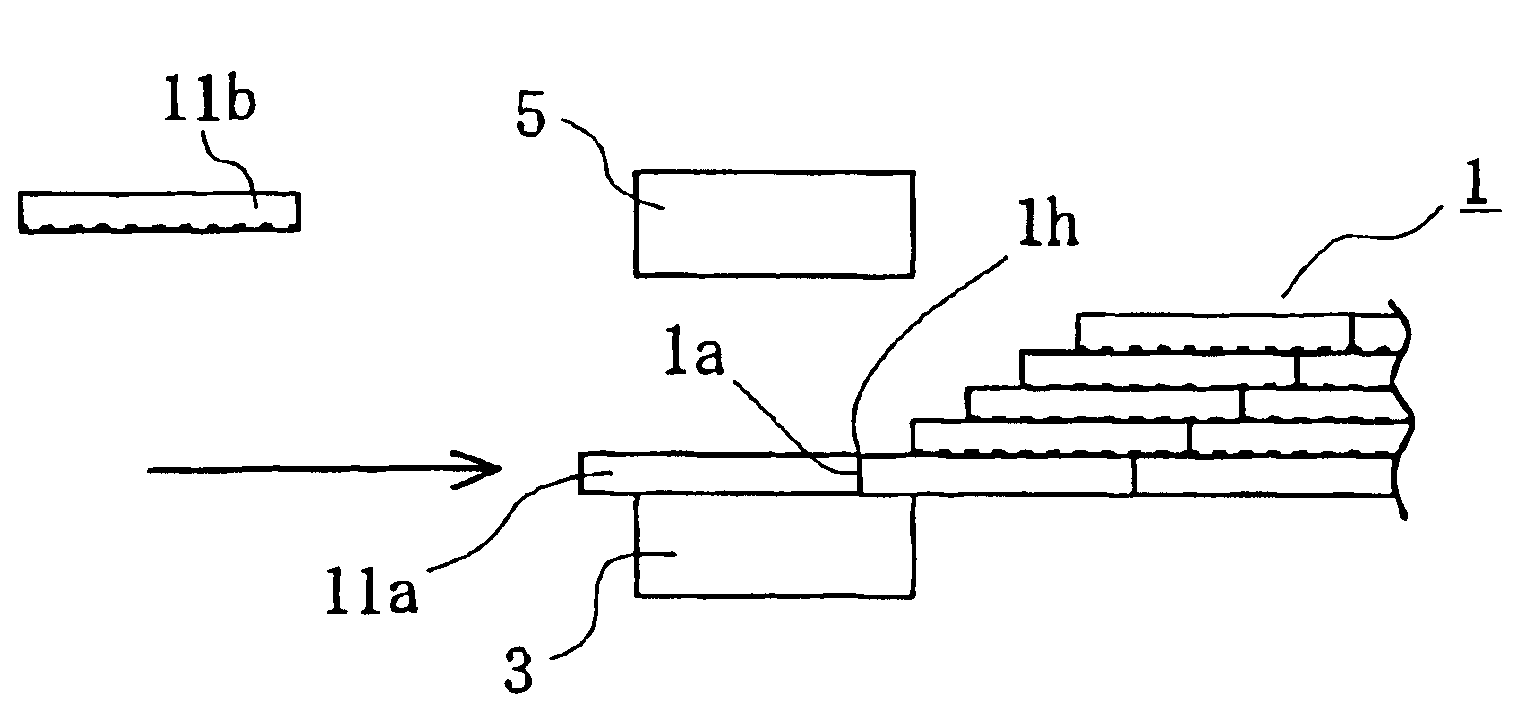

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

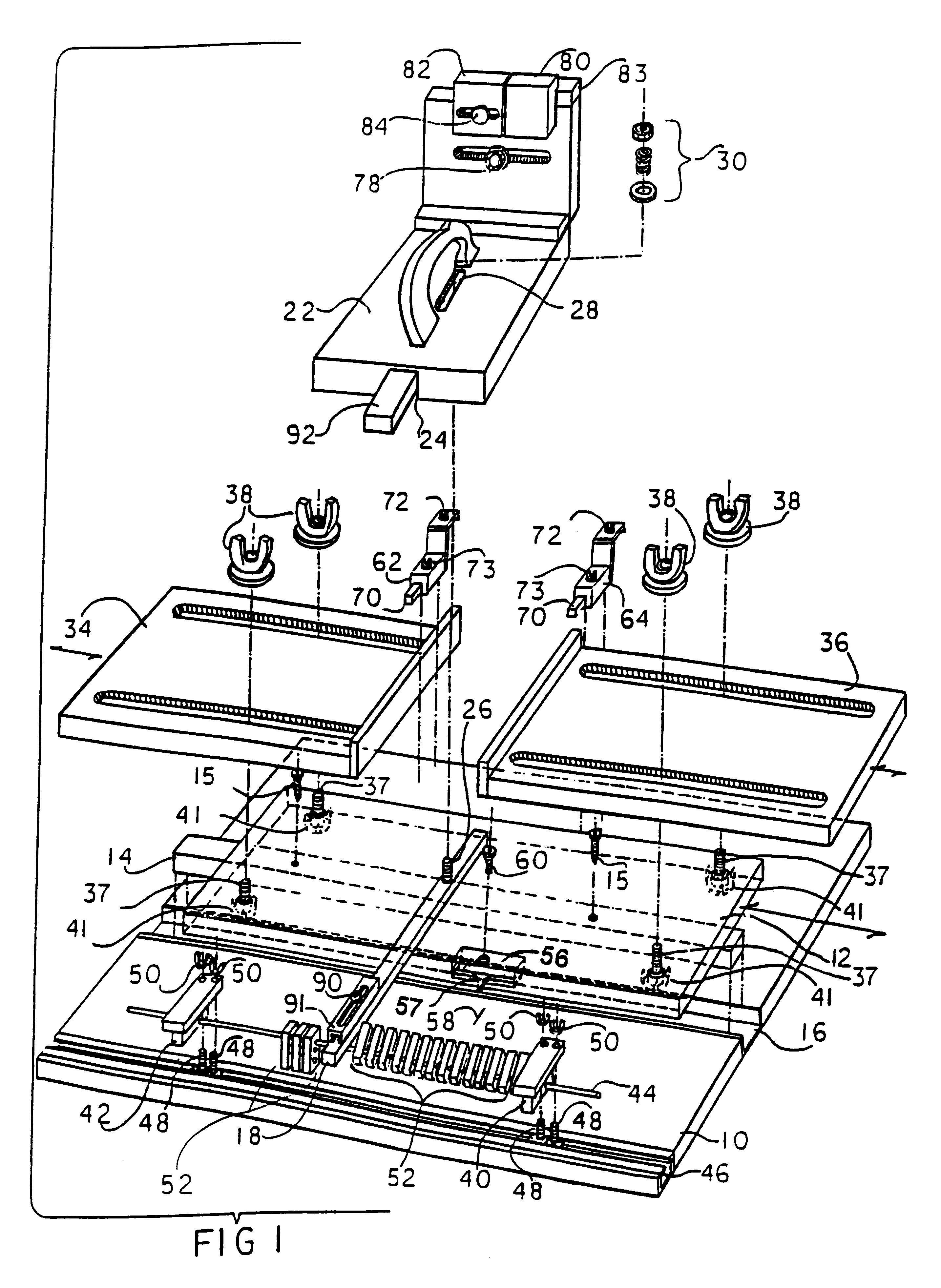

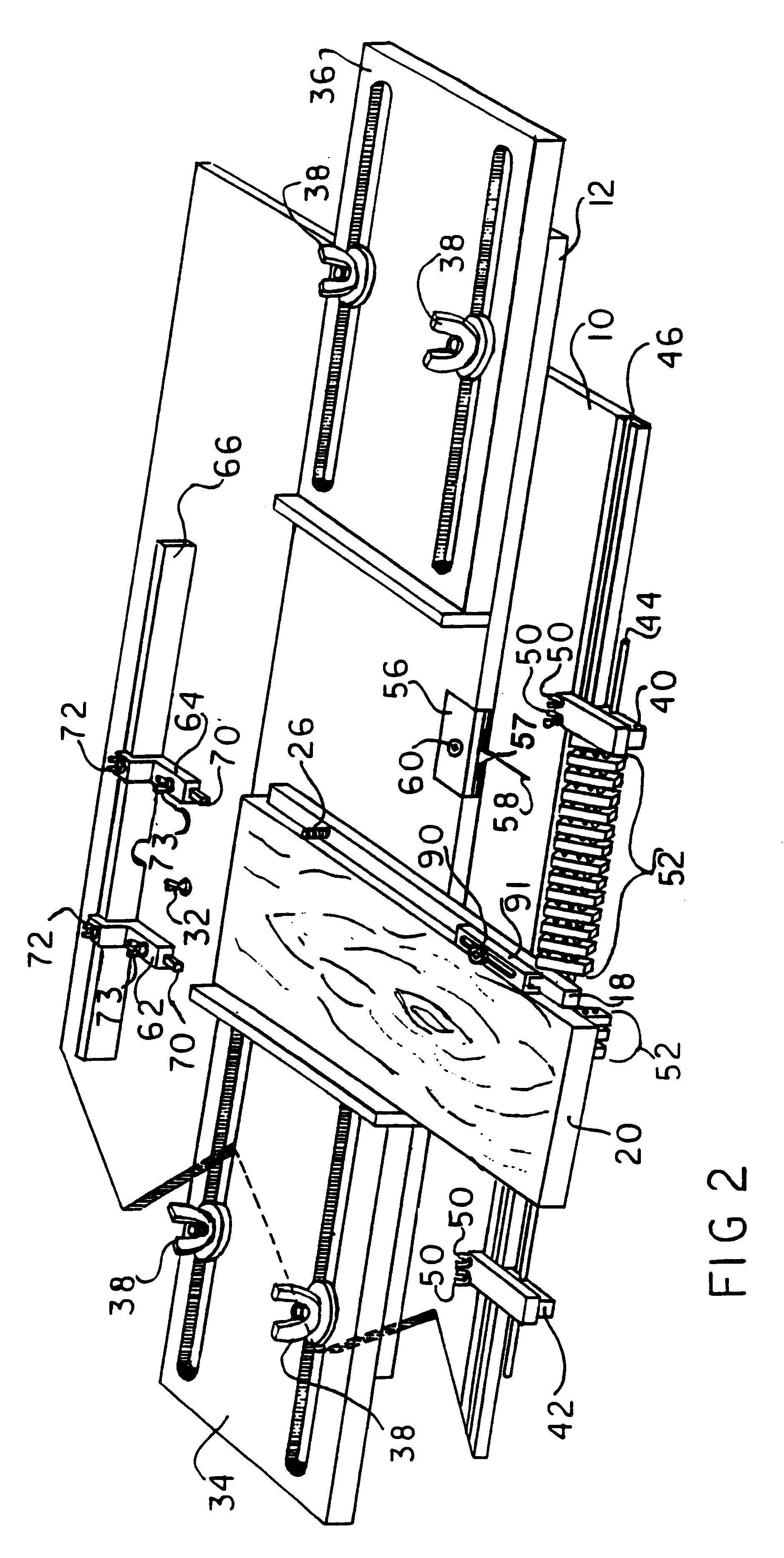

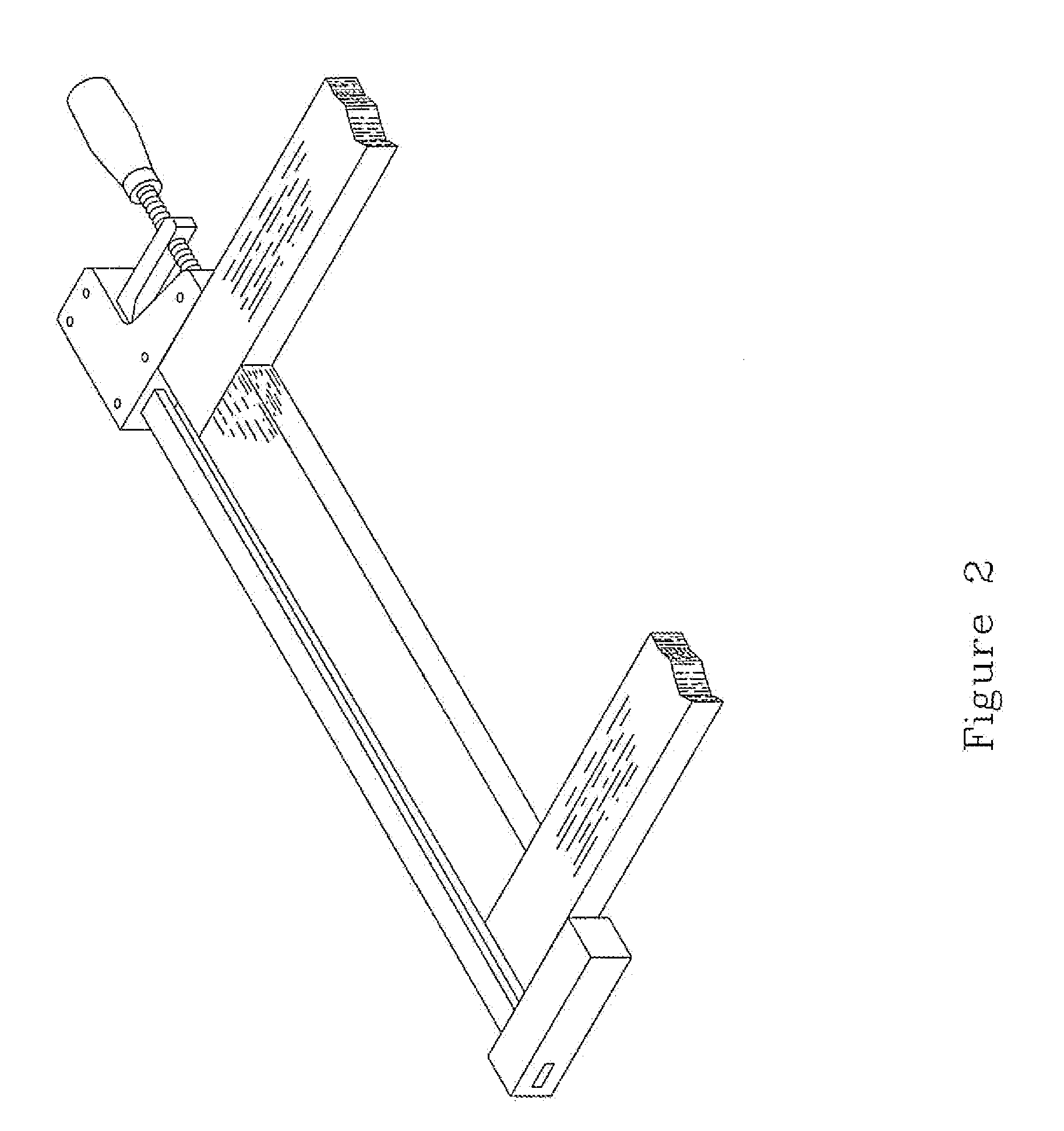

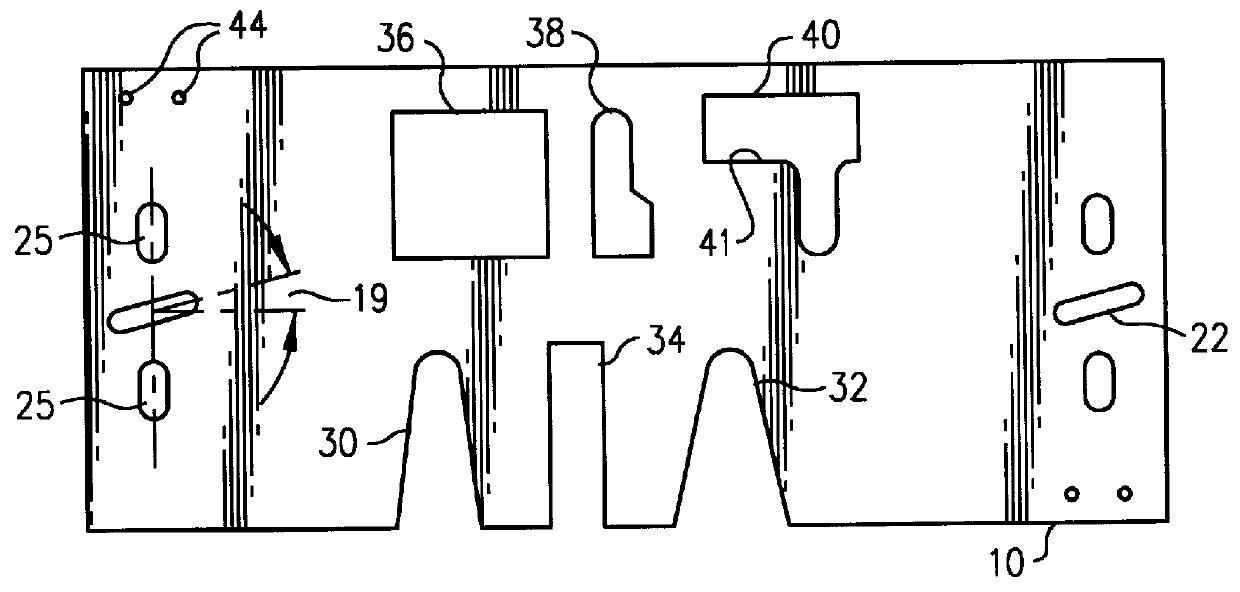

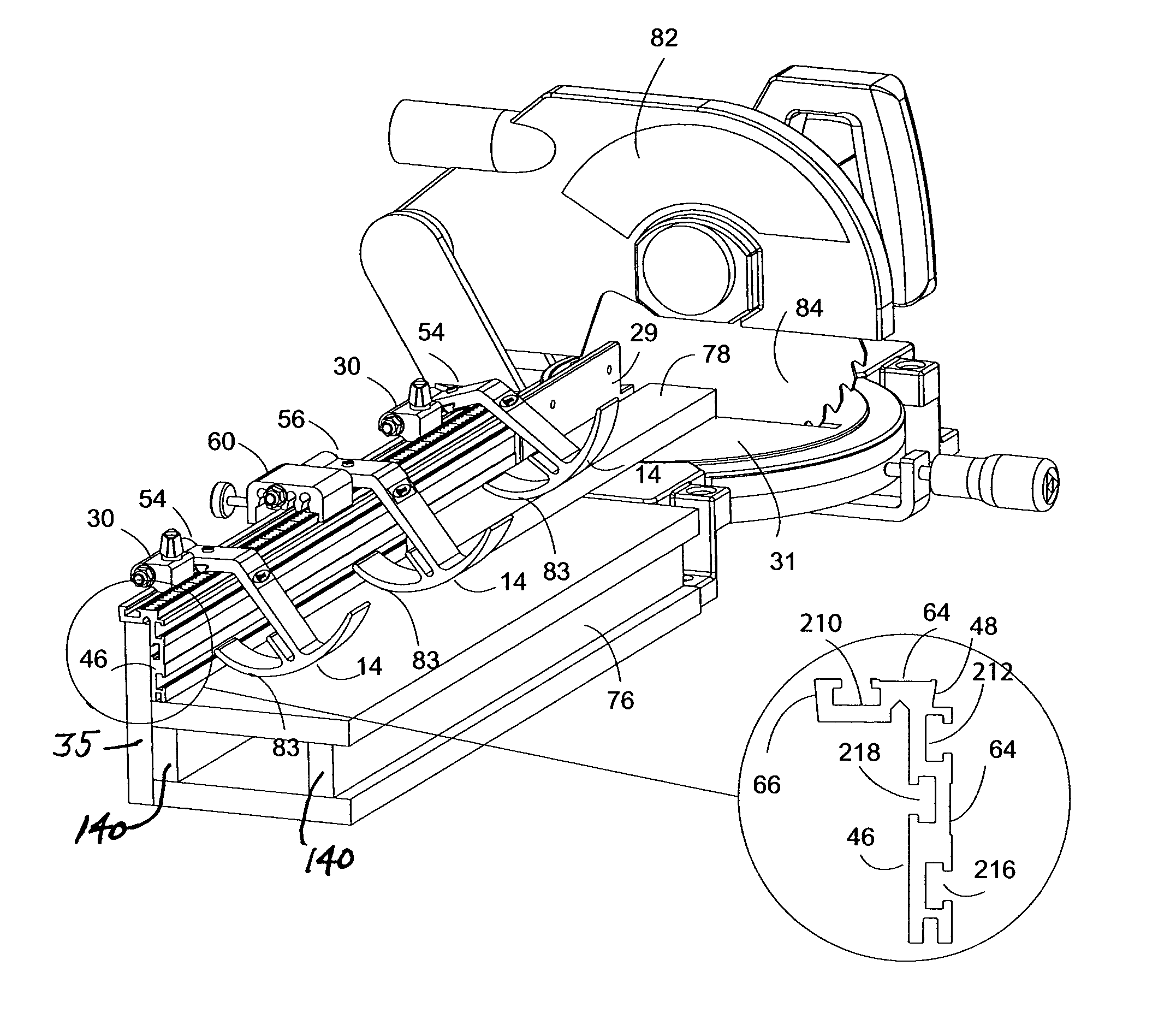

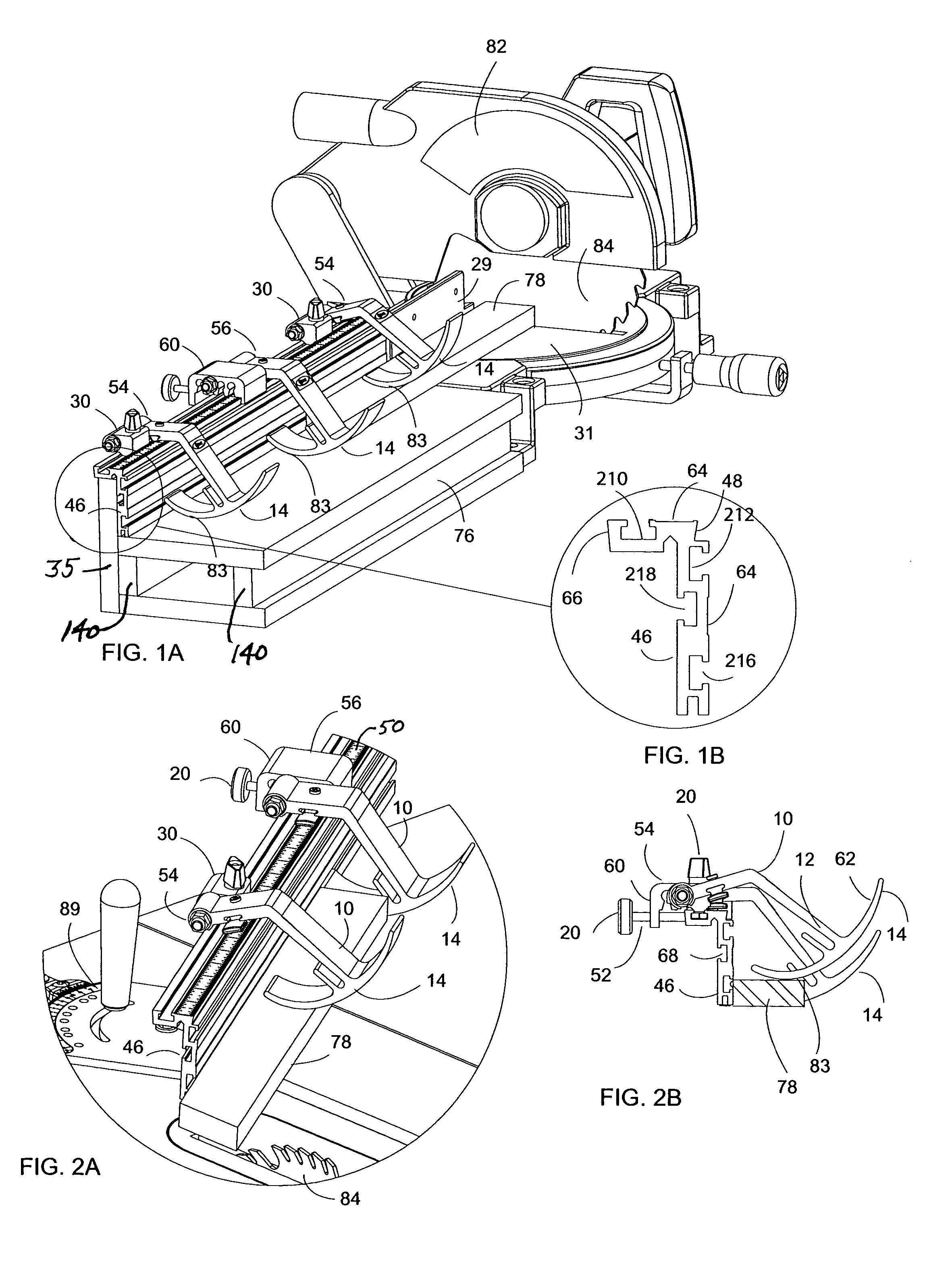

Jig system for positioning the placement of multiple cuts in a workpiece

InactiveUS6206060B1Reduce lateral movementGreat accuracy positioningDrilling/boring measurement devicesTongue/grooves making apparatusEngineeringDovetail joint

The present invention is a jig system for precisely positioning the placement of multiple cuts such as in the placement of dovetail or box joints cut in a wood panel. A row of multi-use adjustable spacers controls the indexing of a workpiece and can be used with a stationary and / or a portable cutting tool. The movability of the spacers permits a workpiece to be cut on both sides of a guide bar fence thereby assuring that the first cut will always be made on the same side of a drawer and will be esthetically pleasing regardless of the width of the workpiece. Additionally, the adjustability of the spacers accommodates any desired cutting tool height, angle and / or size. The jig system comprises: a stationary fixture; a spacer bar; a plurality of spacers engaged with the spacer bar, the spacers are adapted for lateral and rotational movement along the spacer bar thereby providing an engaged and non-engaged working mode; a sliding member adapted for lateral movement on the stationary fixture and for engaging at least one of the spacers in the engaged working mode; and means for holding the spacer bar and connecting the spacer bar to the stationary fixture while engaging with at least one of the spacers during the engaged working mode.

Owner:BLAKE F RICHARD

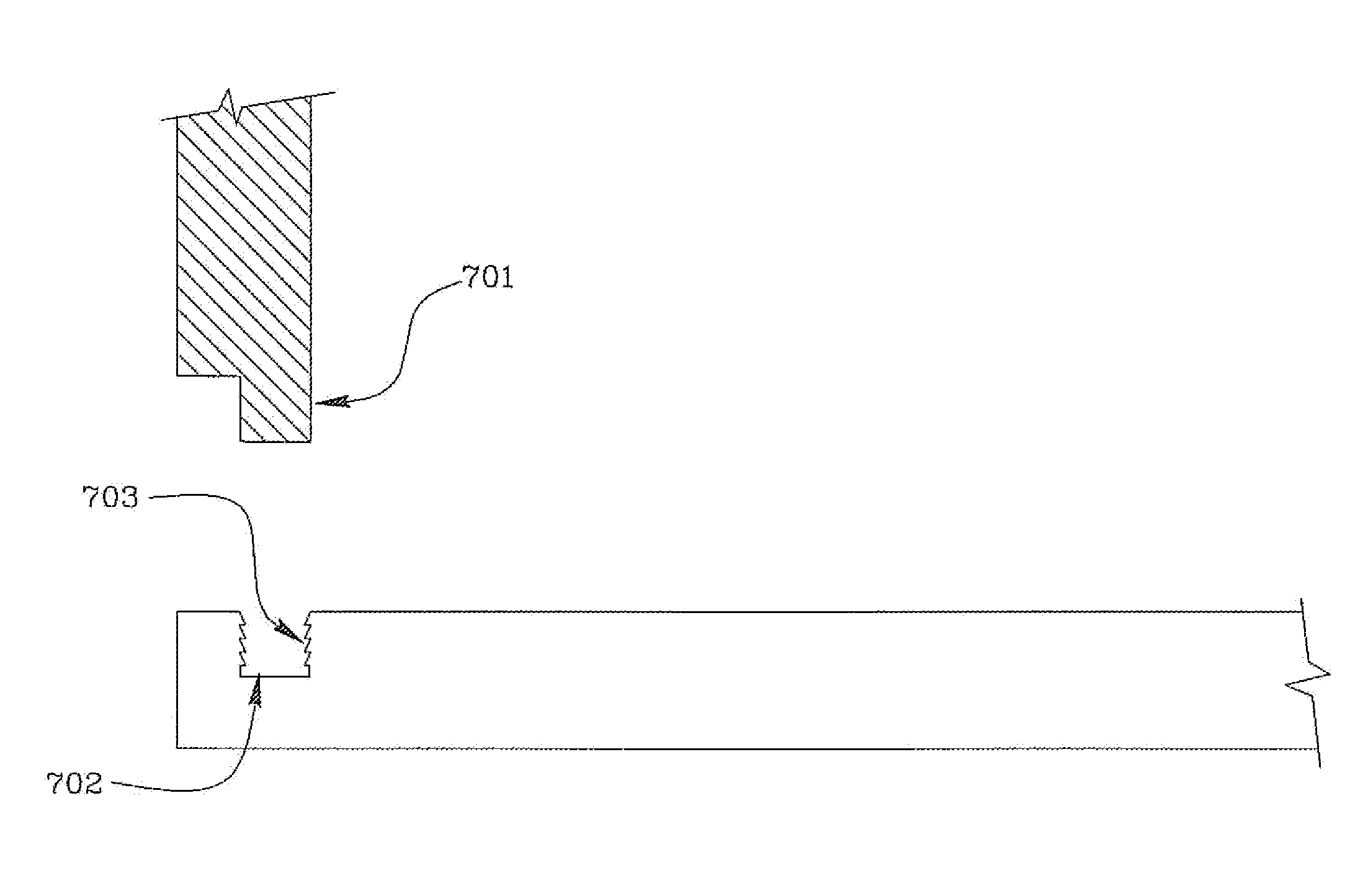

Method for Joining Workpieces Together and Product Made Thereby

A method of forming a joint between first and second workpieces generally consisting of forming a recess in one of such workpieces, provided with at least one side wall having a serrated cross-sectional configuration with inwardly projecting, distortable segments; providing a portion in the other of such workpieces, insertable into such recess, having a cross-sectional configuration sufficient to engage and distort such segments as such portion is inserted into such recess; and inserting such portion of the other workpiece into such recess, causing the segments to distort and thus provide an interference fit between such workpieces.

Owner:THERMWOOD CORPORATION

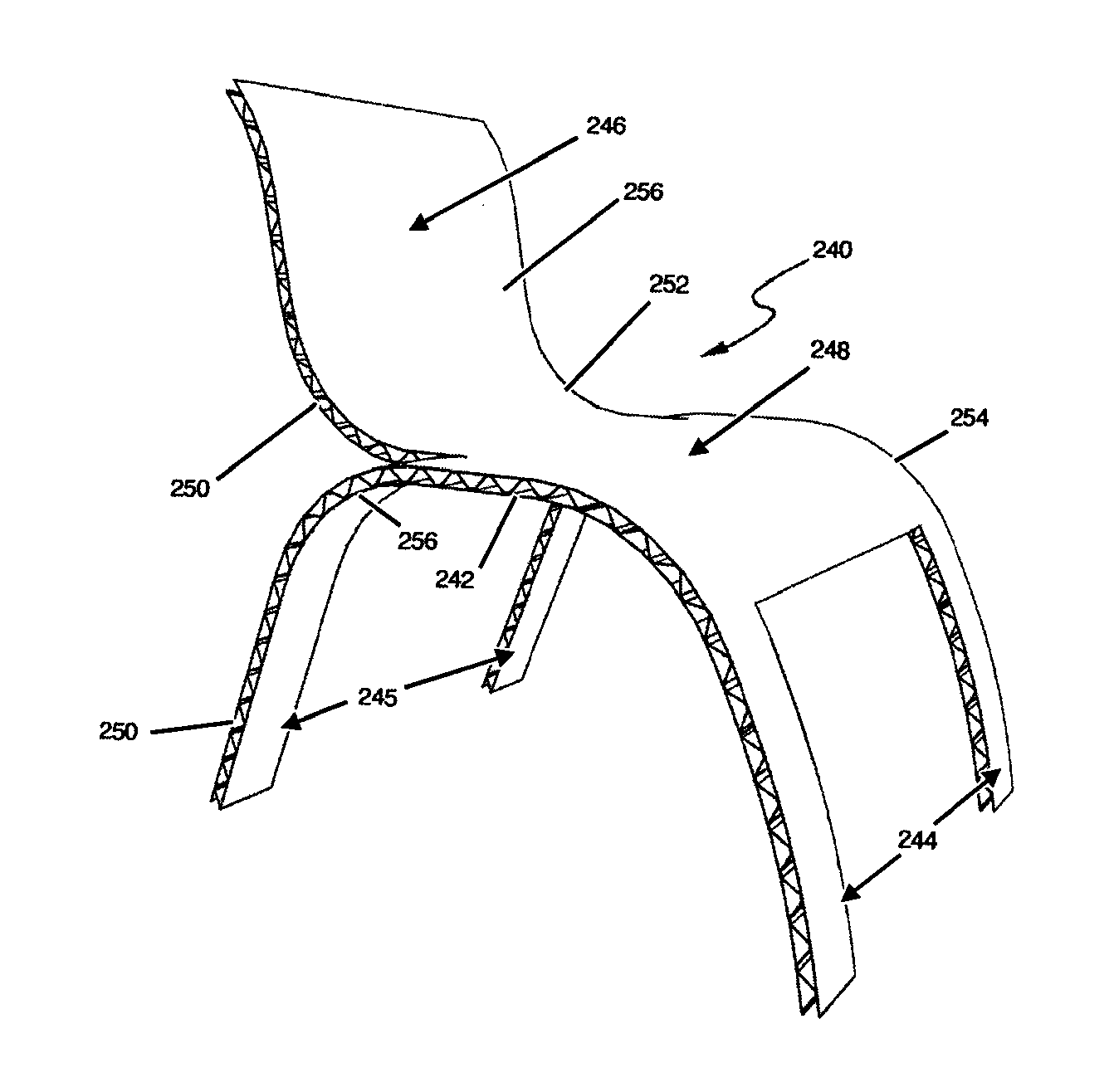

Engineered Molded Fiberboard Panels. Methods of Making the Panels, and Products Fabricated From the Panels

A honeycomb-shaped panel is formed from a plurality of generally sinusoidally shaped strips of molded fiberboard material each having spaced, oppositely directed flat peaks, the peaks of adjacent strips being secured together to form a plurality of hexagonally shaped cells extending perpendicular to the surfaces of the sheet. The strips may be cut from a single sheet of corrugated fiberboard sheet material and then secured together to form the honeycomb panel, or a plurality of such panels may be secured together face to face with their ribs aligned to form a stack, and selected cuts may be made through the secured, stacked panels to form a plurality of honeycomb panels of desired surface shape and height dimensions. The strips forming the cells are substantially rigid and resistant to collapse of the cells, and form a substantially rigid core when assembled between two flexible fiberboard skins, while the panel is bendable to adopt a desired panel curvature.

Owner:US SEC AGRI +1

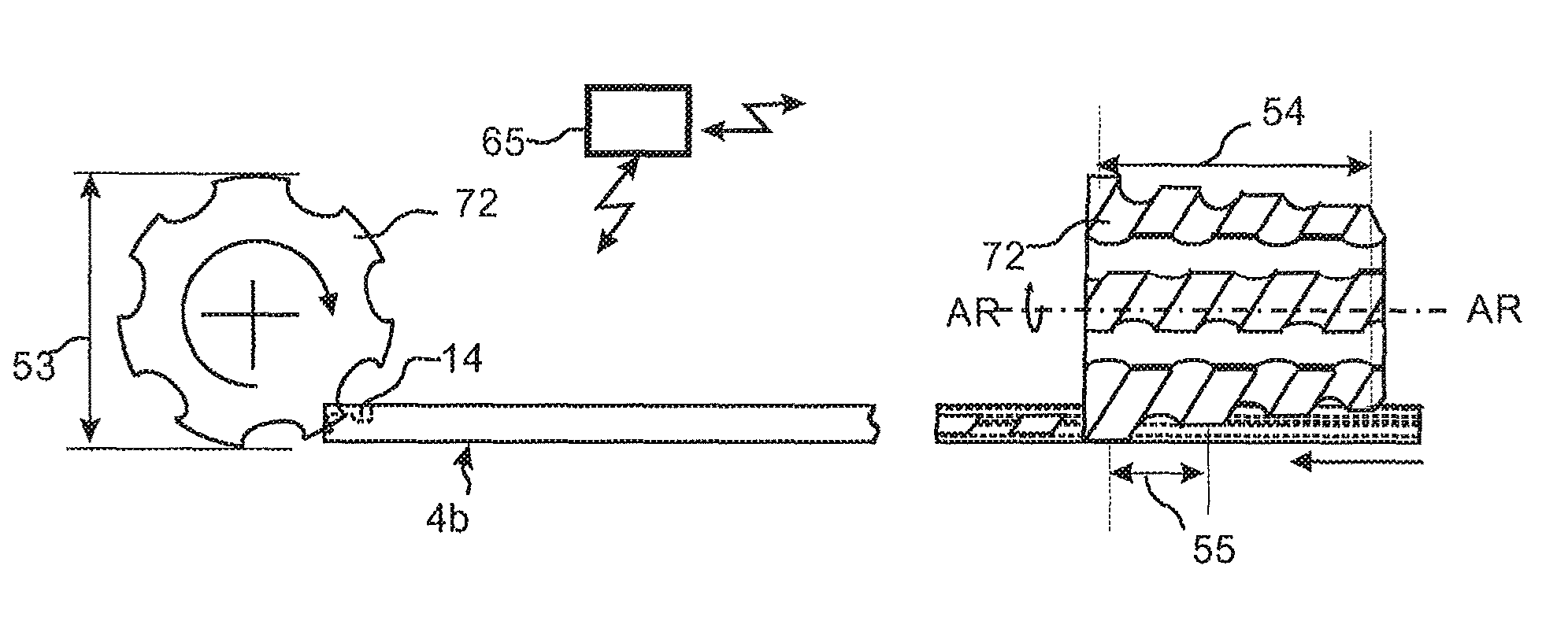

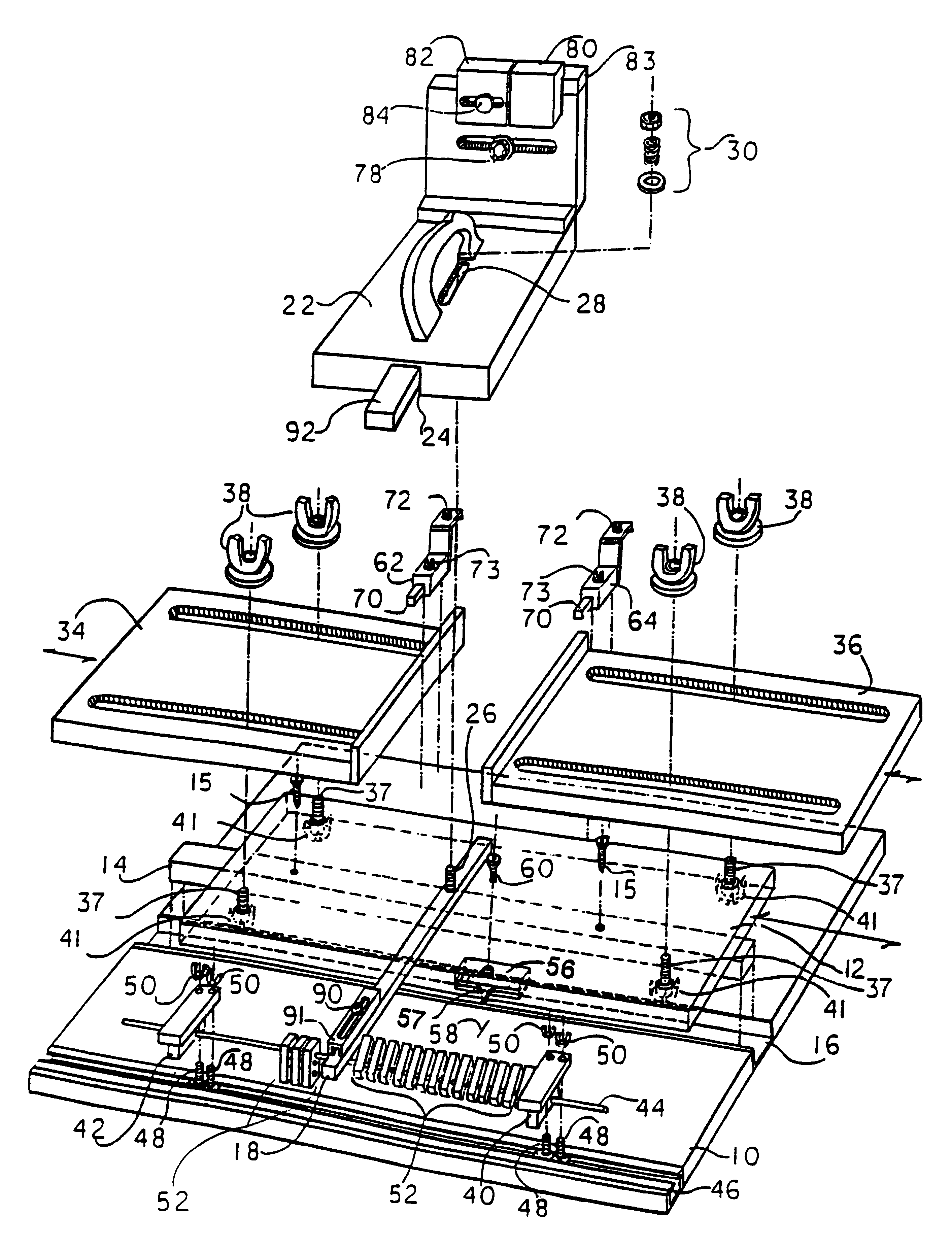

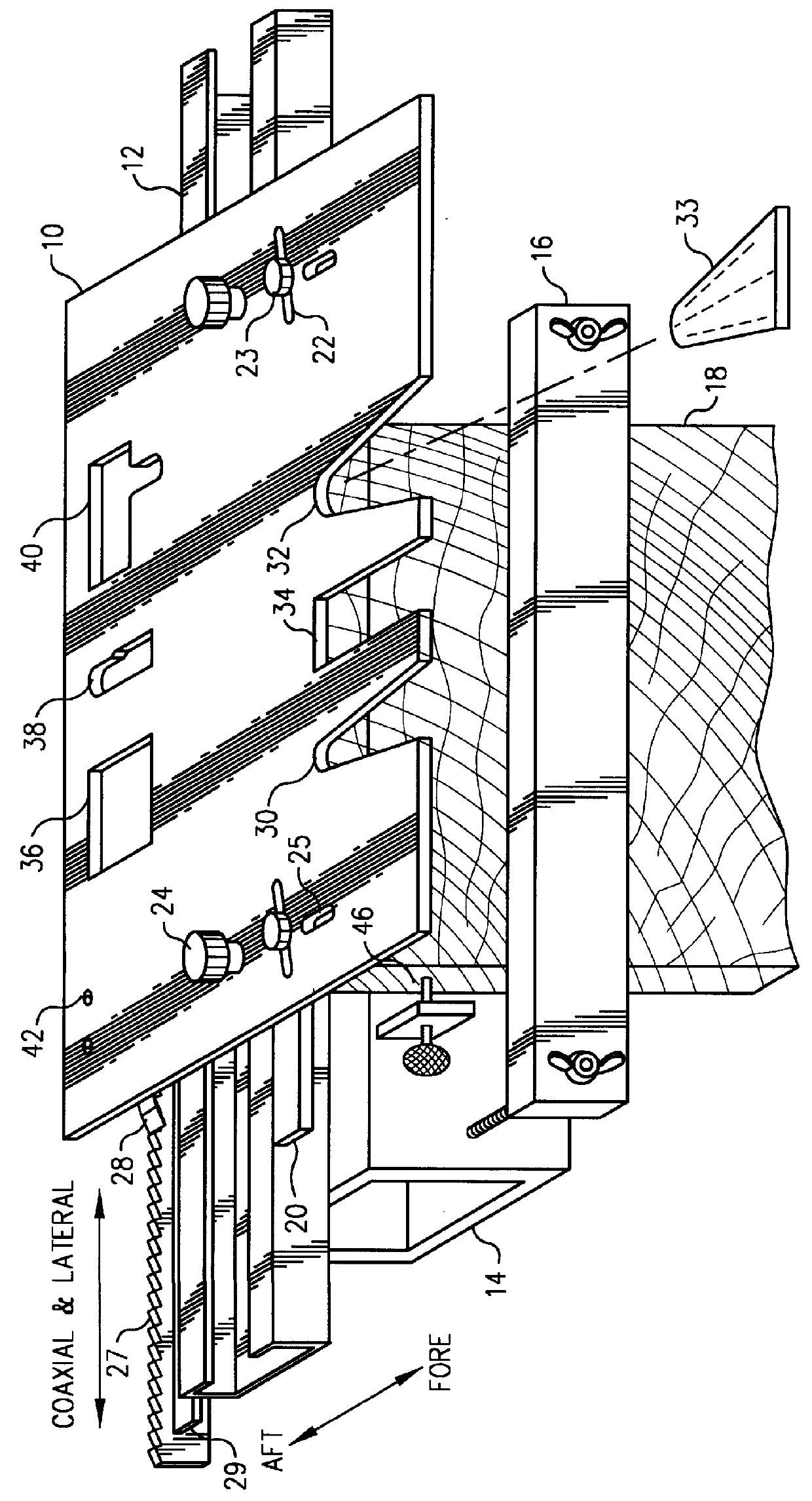

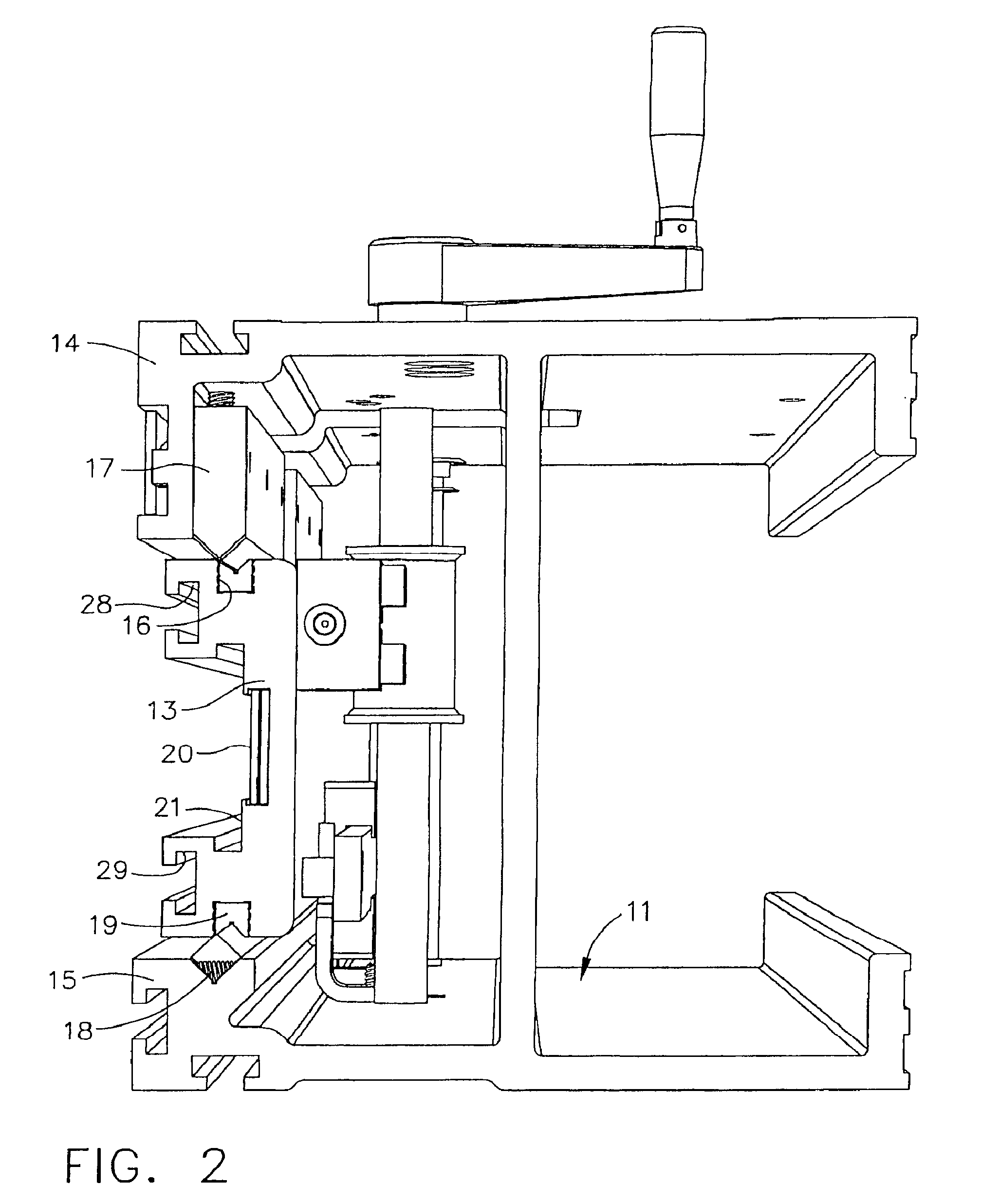

Apparatus for forming dovetail, box and related joints

InactiveUS6076575APrecise positioningGood precisionTongue/grooves making apparatusDovetailed workEngineeringMechanical engineering

A jig used to support and guide a router has a support base to which the workpiece is clamped as well as a moveable template containing guiding surfaces for a router. The template is attached to the support base via an elongated support channel. The support channel is permanently attached to the support base and captures two square nuts used to clamp the template to said channel while cutting but allowing the template to be loosened and repositioned between cuts. A bar clamped to the underside of the template is pressed against the channel to align both in parallel and, by virtue of being attached to the template via angled slots, can be used to adjust the position of guiding surfaces in the template relative to the workpiece. The template has a variety of slots and cutouts whose sides guide the router in the making of specific cuts for dovetail, box and related joints. The template is indexed from one cutting position to another by means of a ratchet or equivalent which engages the teeth of a saw tooth rack. The pitch or distance between teeth is precise and carefully chosen in regard to a variety of factors. The jig essentially cuts tails or pins one at a time. Its adjustable nature allows wide variation in joint design including the size and spacing of joint elements.

Owner:HARKNESS RICHARD C

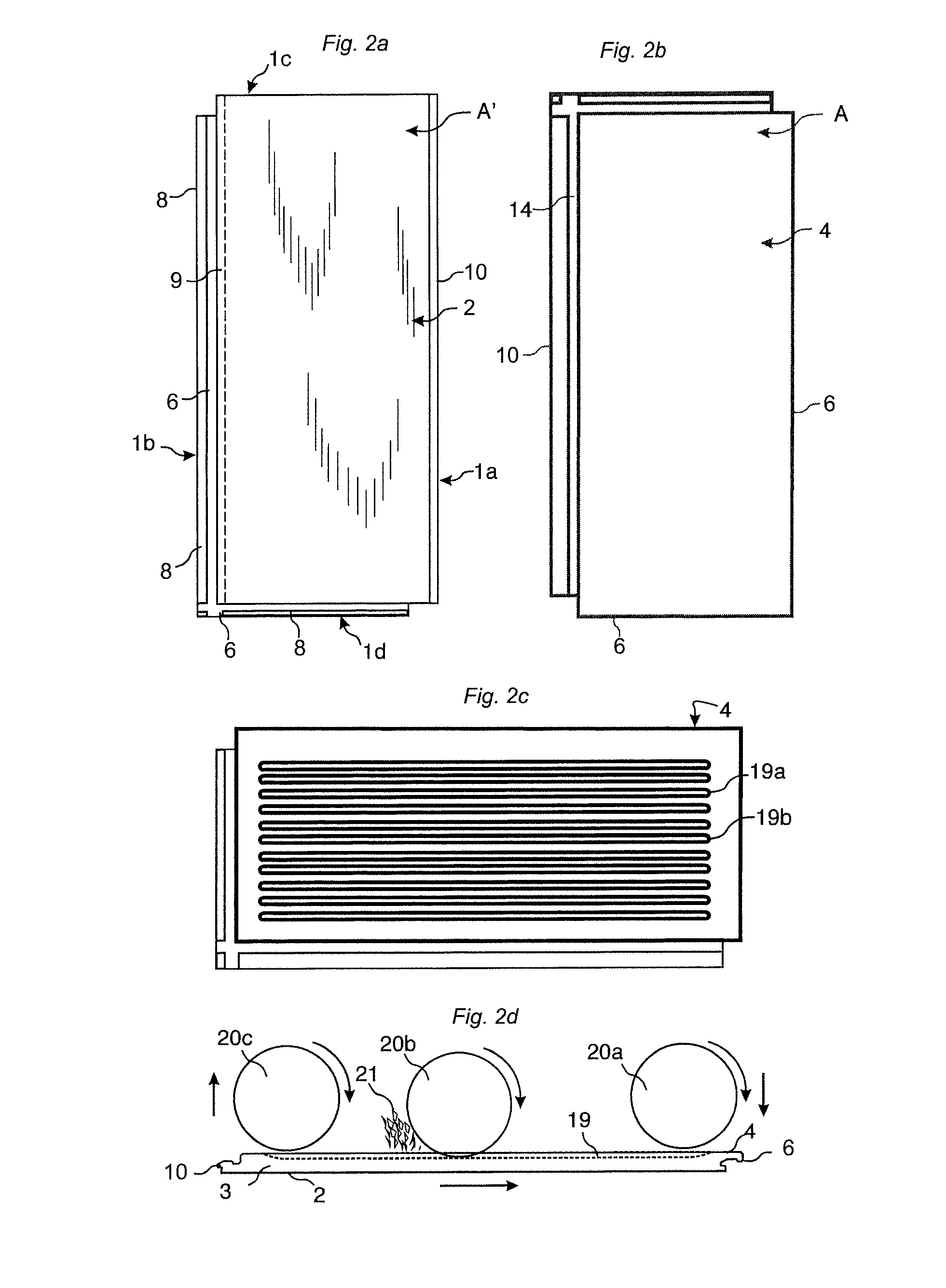

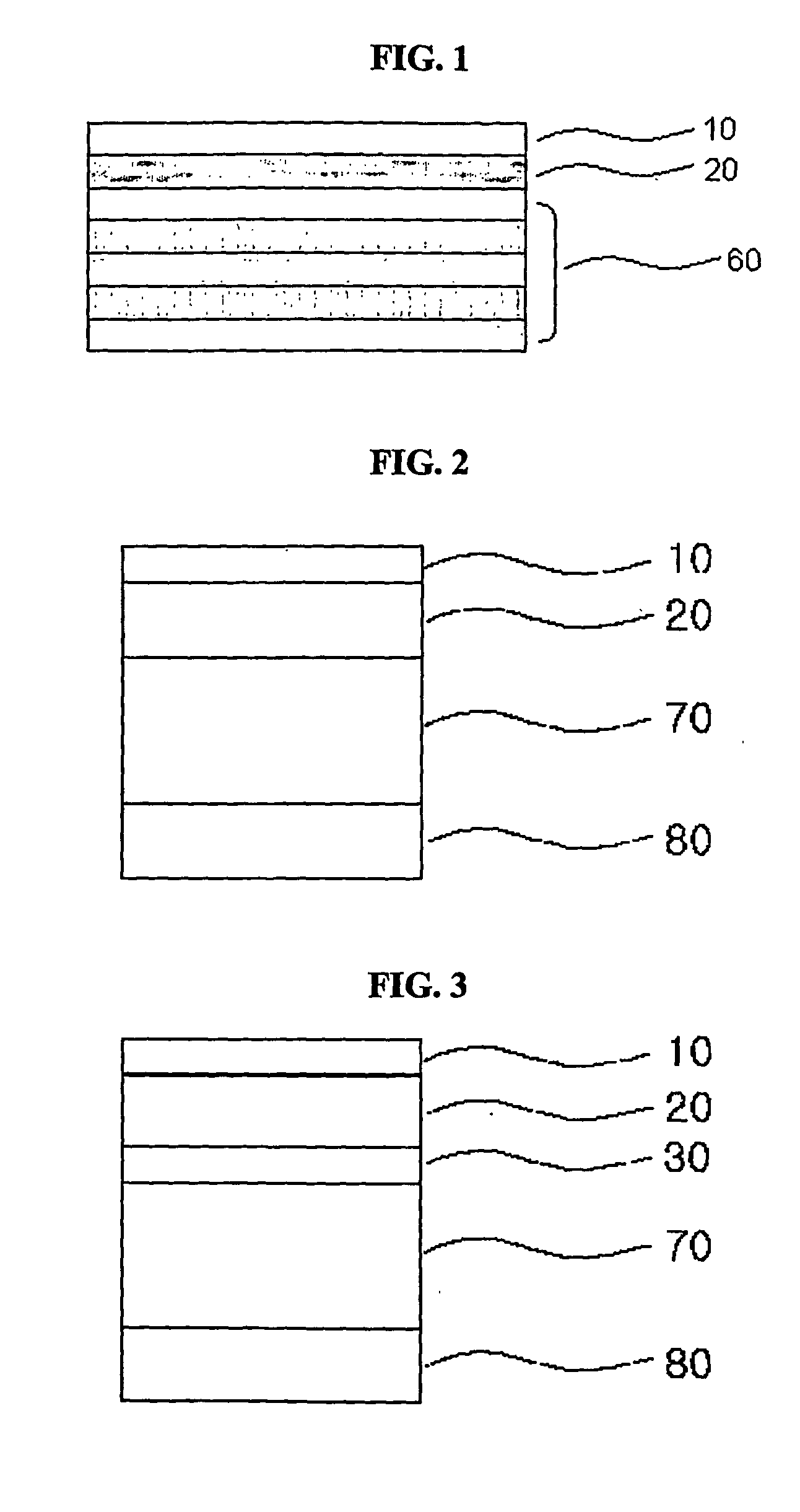

Panel forming

ActiveUS9140010B2Reduce contentReduce weightCovering/liningsTongue/grooves making apparatusDecrease weightEngineering

Building panels, especially laminated floor panels are shown, which are provided with a locking system and several core grooves at the rear side in order to save material and decrease weight.

Owner:CERALOC INNOVATION AB

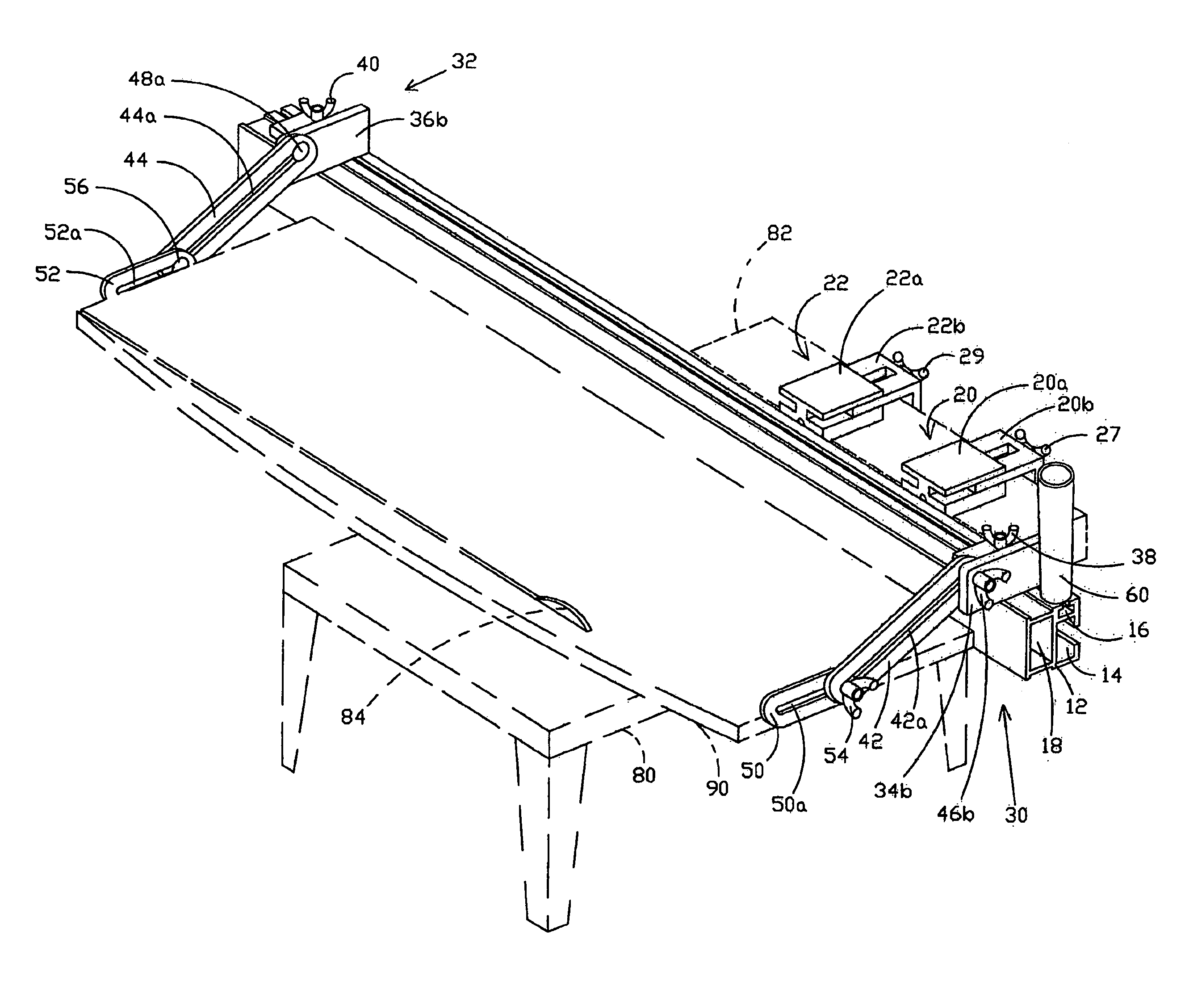

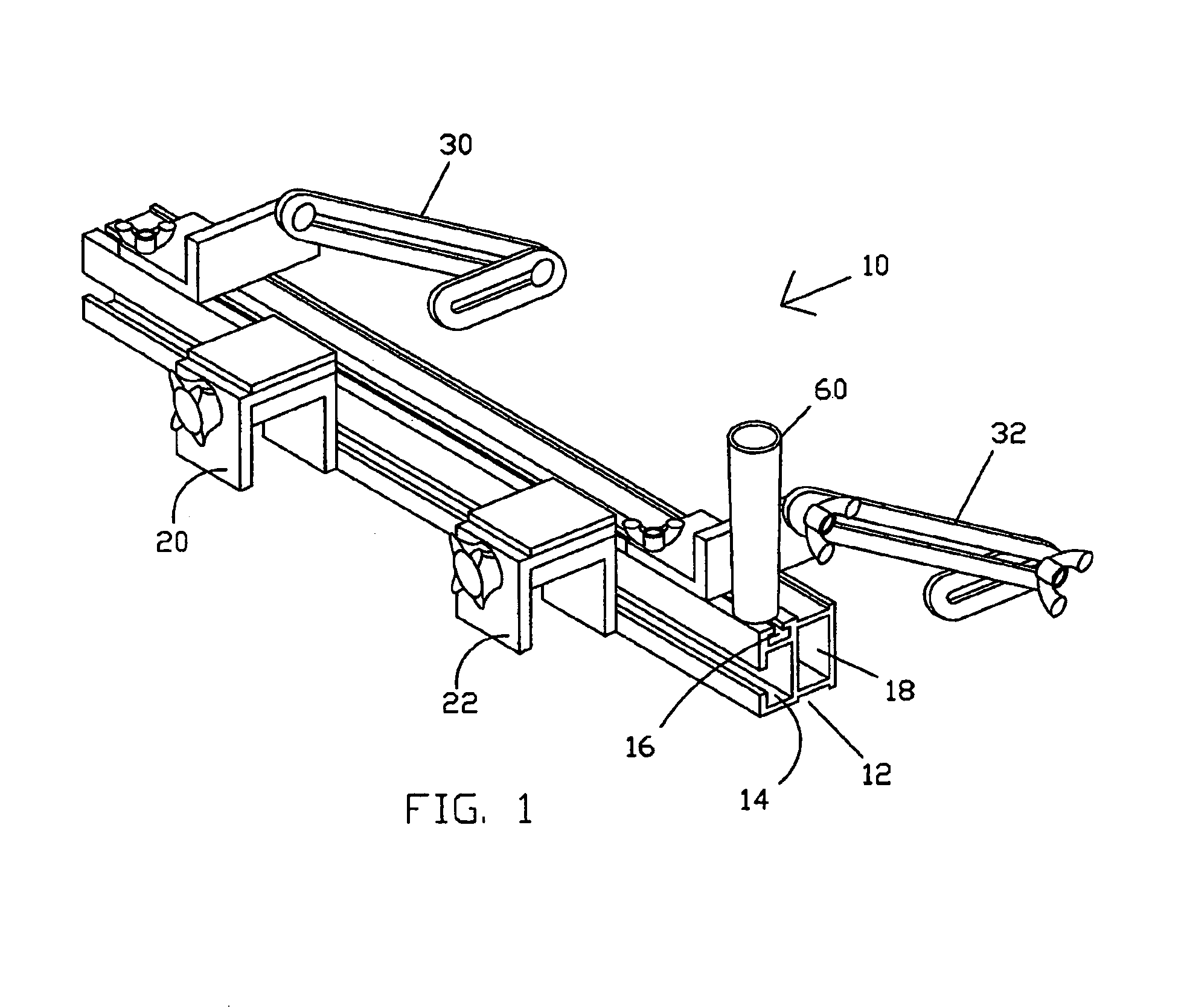

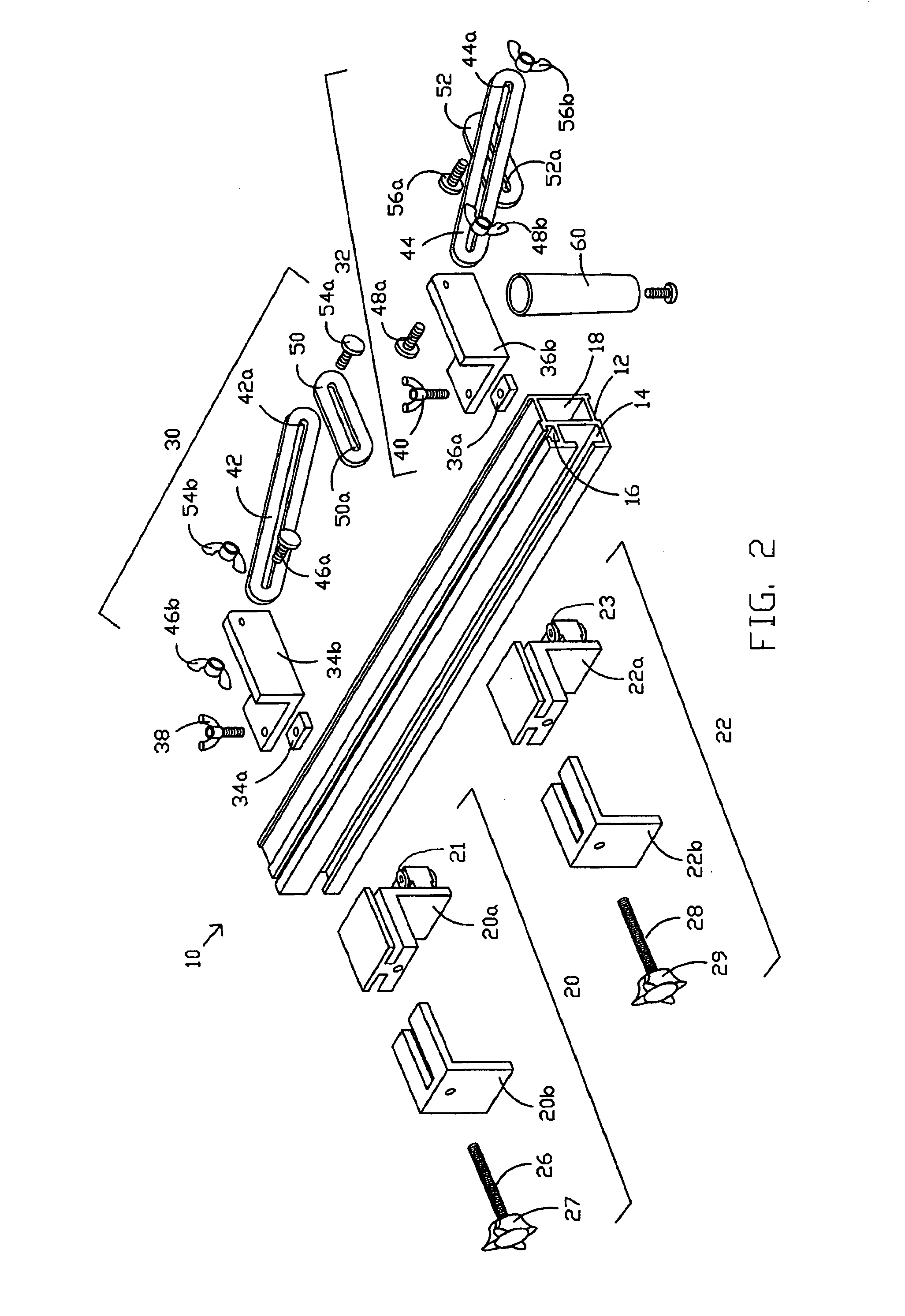

Woodworking machinery stop and track system

Owner:KREG ENTERPRISES

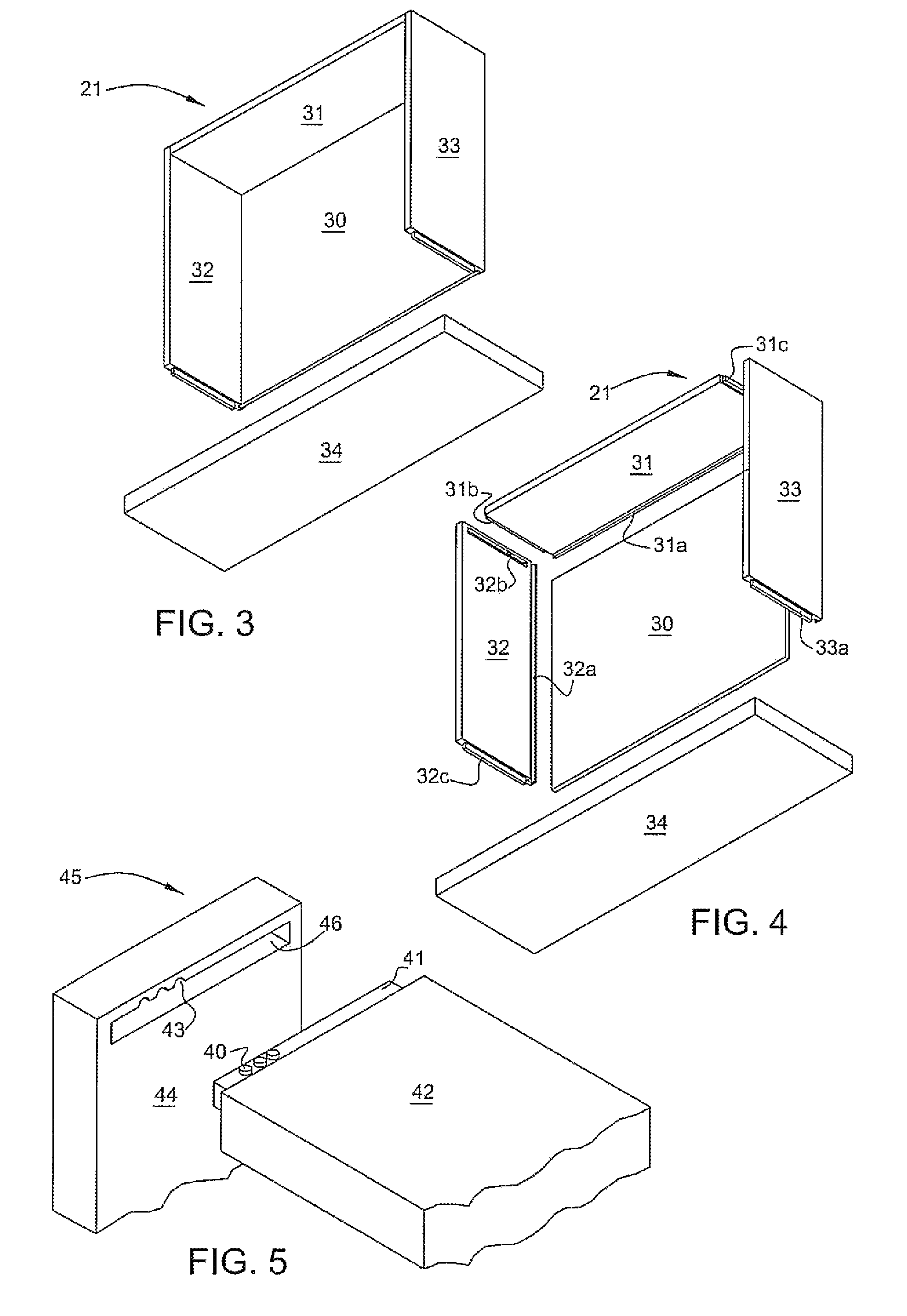

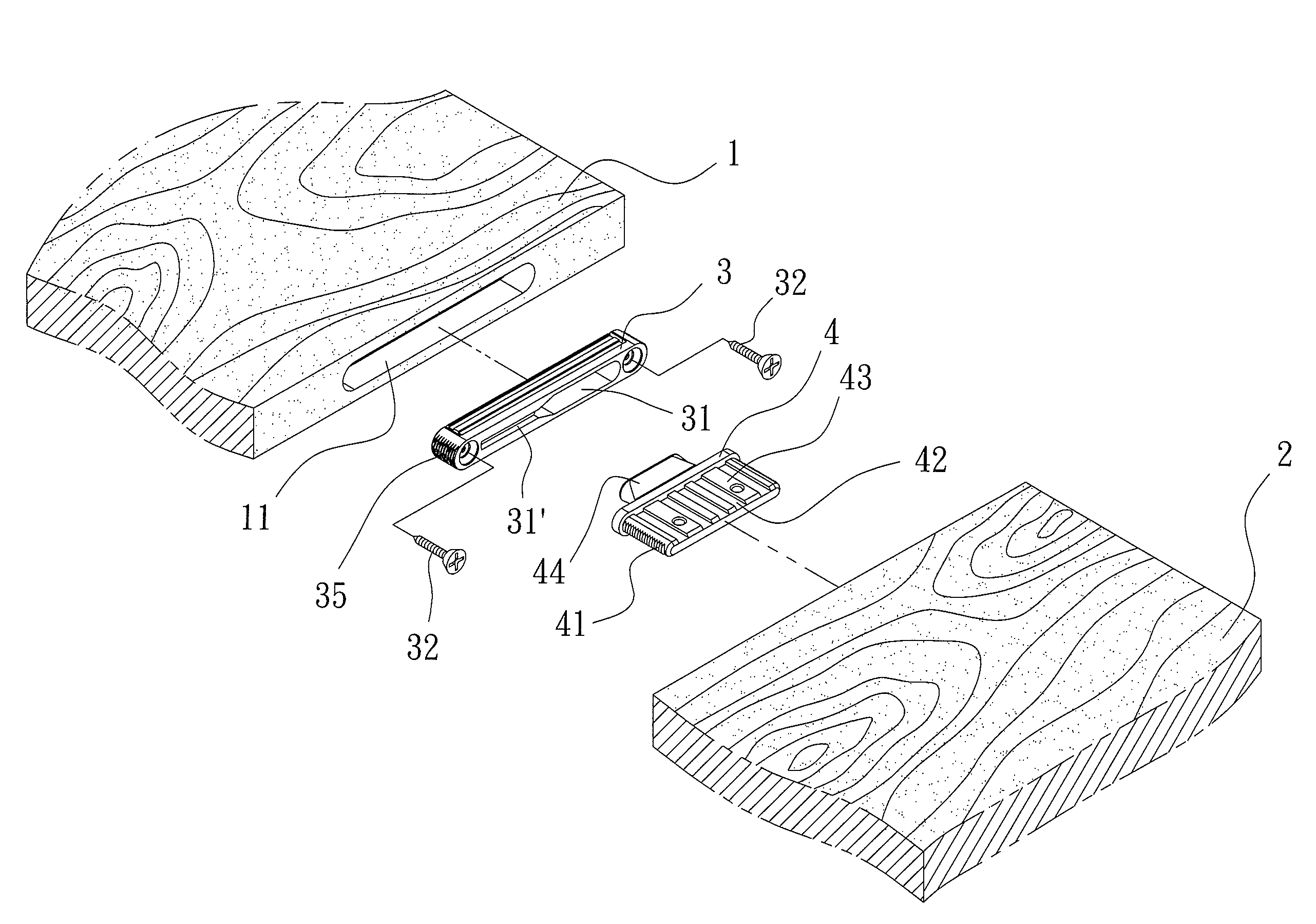

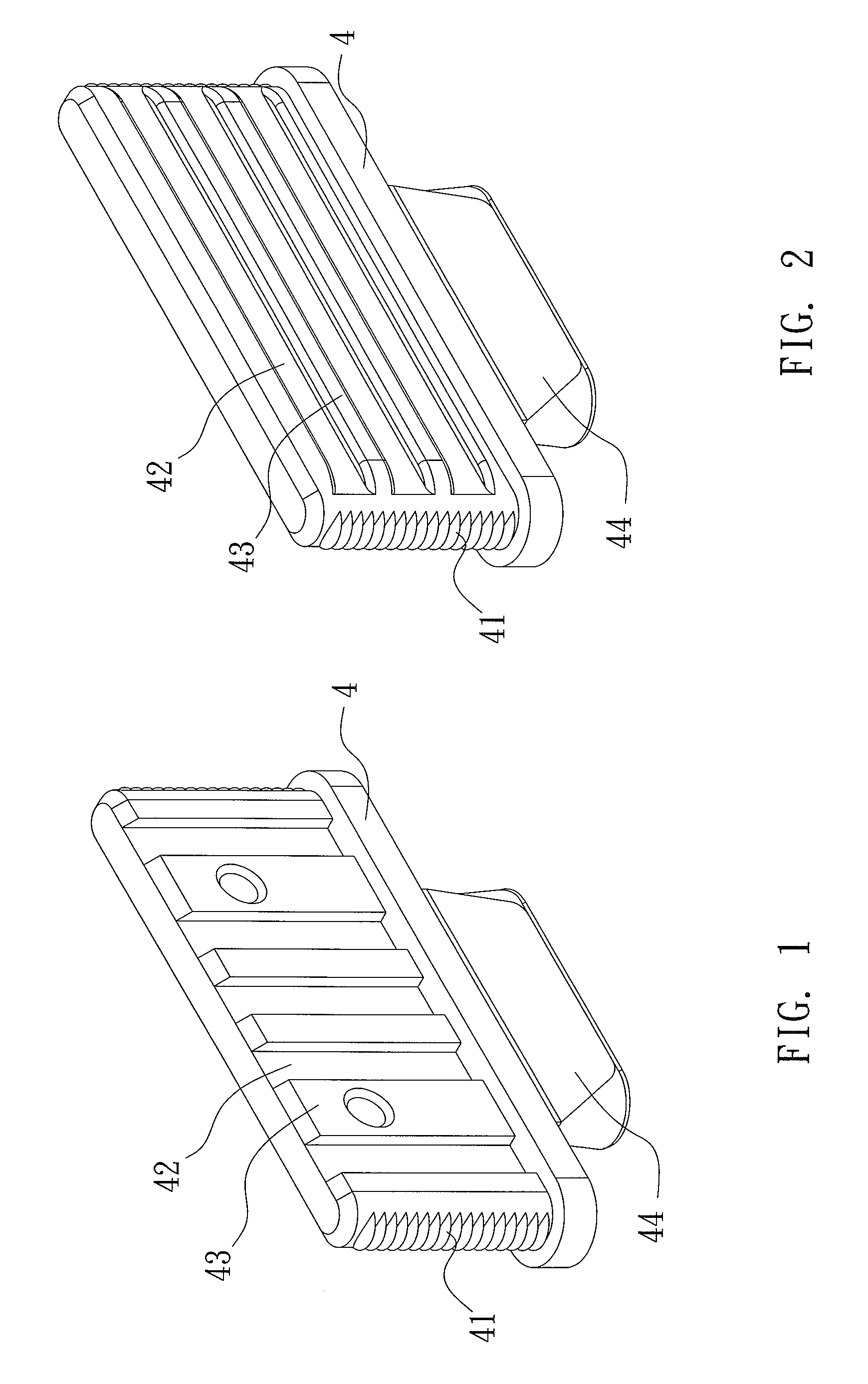

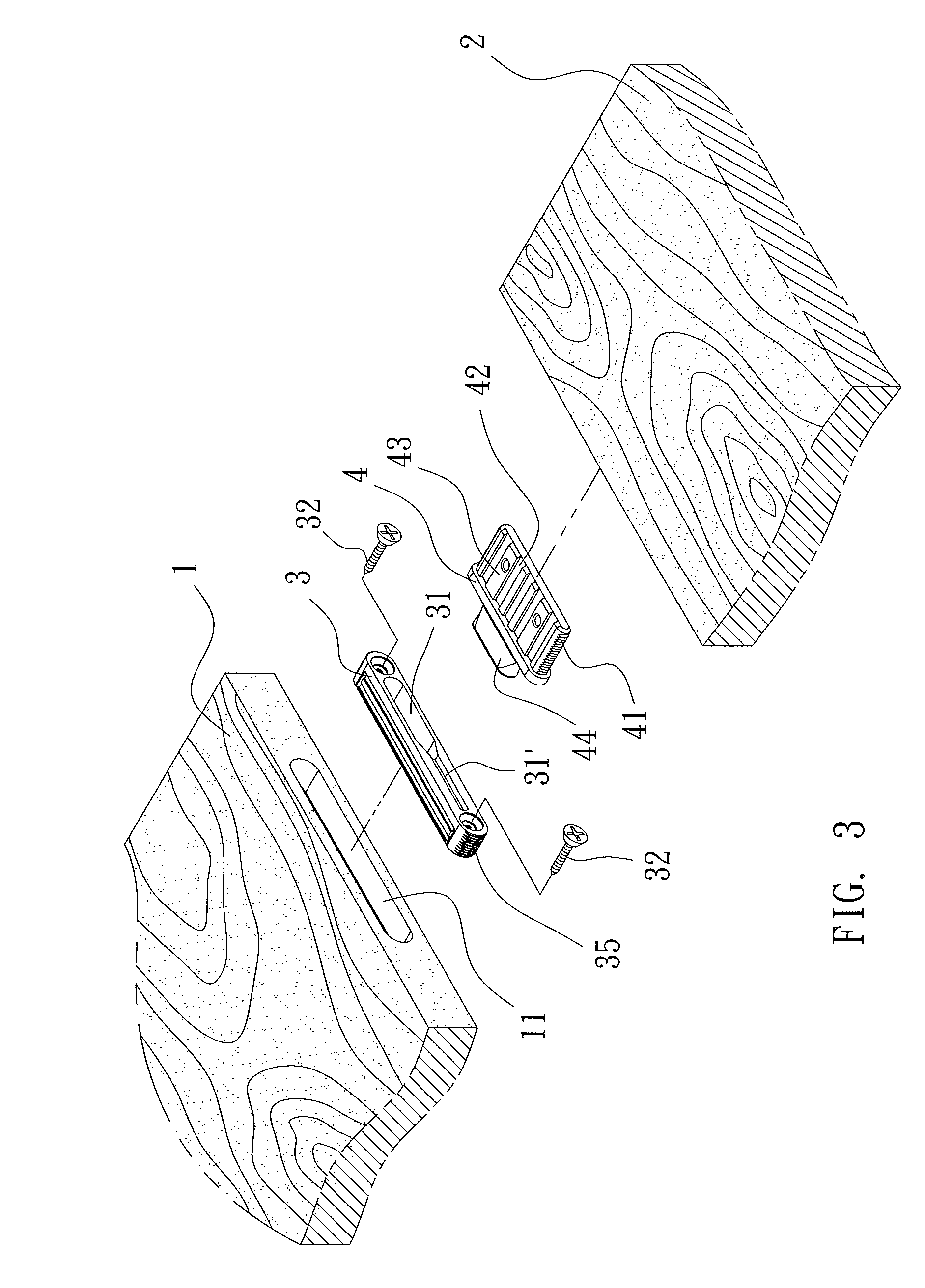

Retaining Structure

ActiveUS20110085853A1Easy to fixRopes and cables for vehicles/pulleyDovetailed workEngineeringMechanical engineering

A retaining structure is used to retain a wooden first part with a wooden second part together and comprises a retainer fitted to a recess of the first part, and a fastening member to be engaged to the second part, wherein the fastening member has a plurality of wings formed on two sides of an acting end thereof, a number of recessed portions mounted between front and rear sides thereof and spaced apart from each other, and a plurality of raised portions; the recessed and raised portions are arranged longitudinally or horizontally between the front and rear sides of the acting end of the fastening member.

Owner:LIU MIN SHENG +3

Panel forming

ActiveUS20140000197A1Reduce contentReduce weightCovering/liningsTongue/grooves making apparatusDecrease weightEngineering

Building panels, especially laminated floor panels are shown, which are provided with a locking system and several core grooves at the rear side in order to save material and decrease weight.

Owner:CERALOC INNOVATION AB

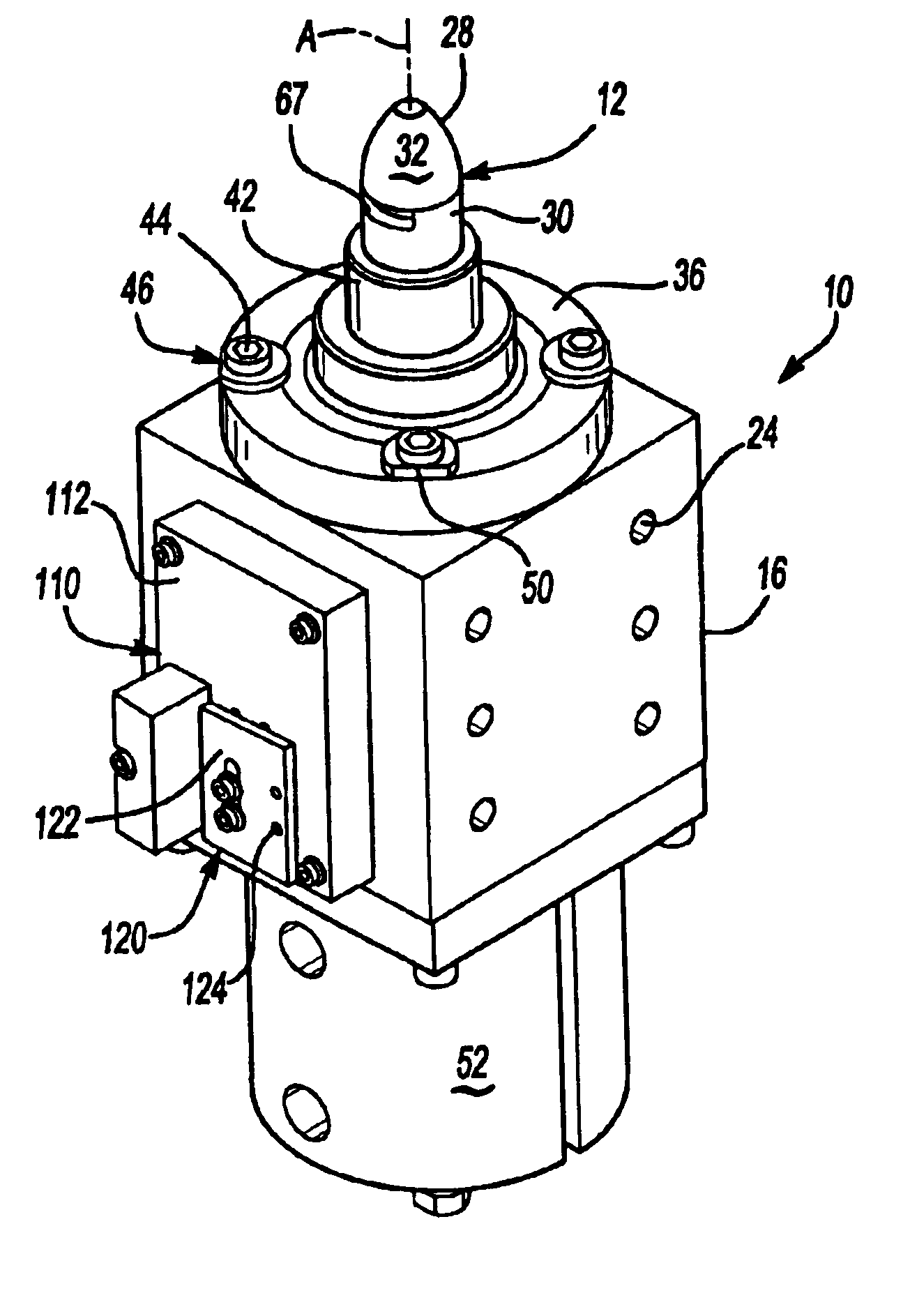

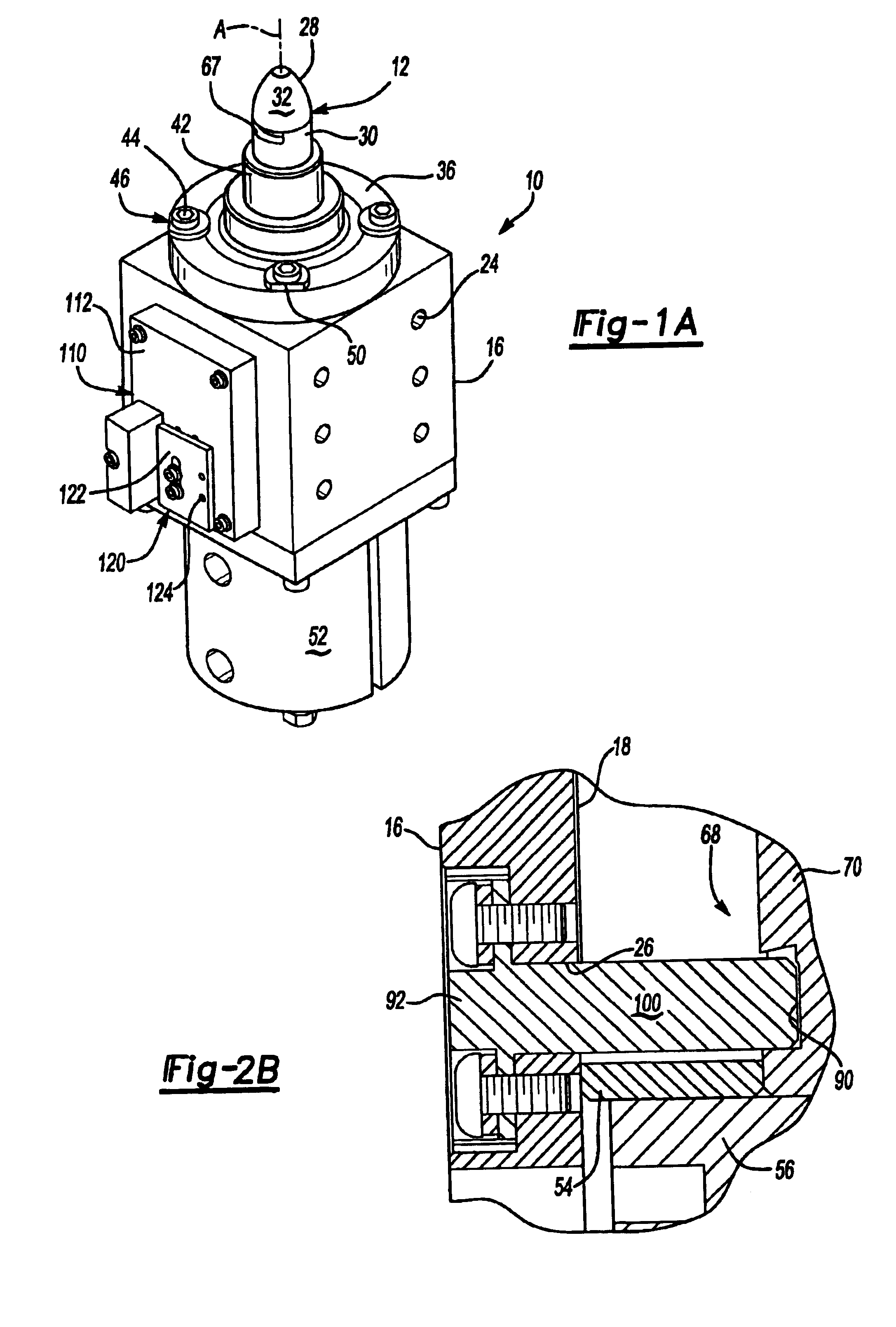

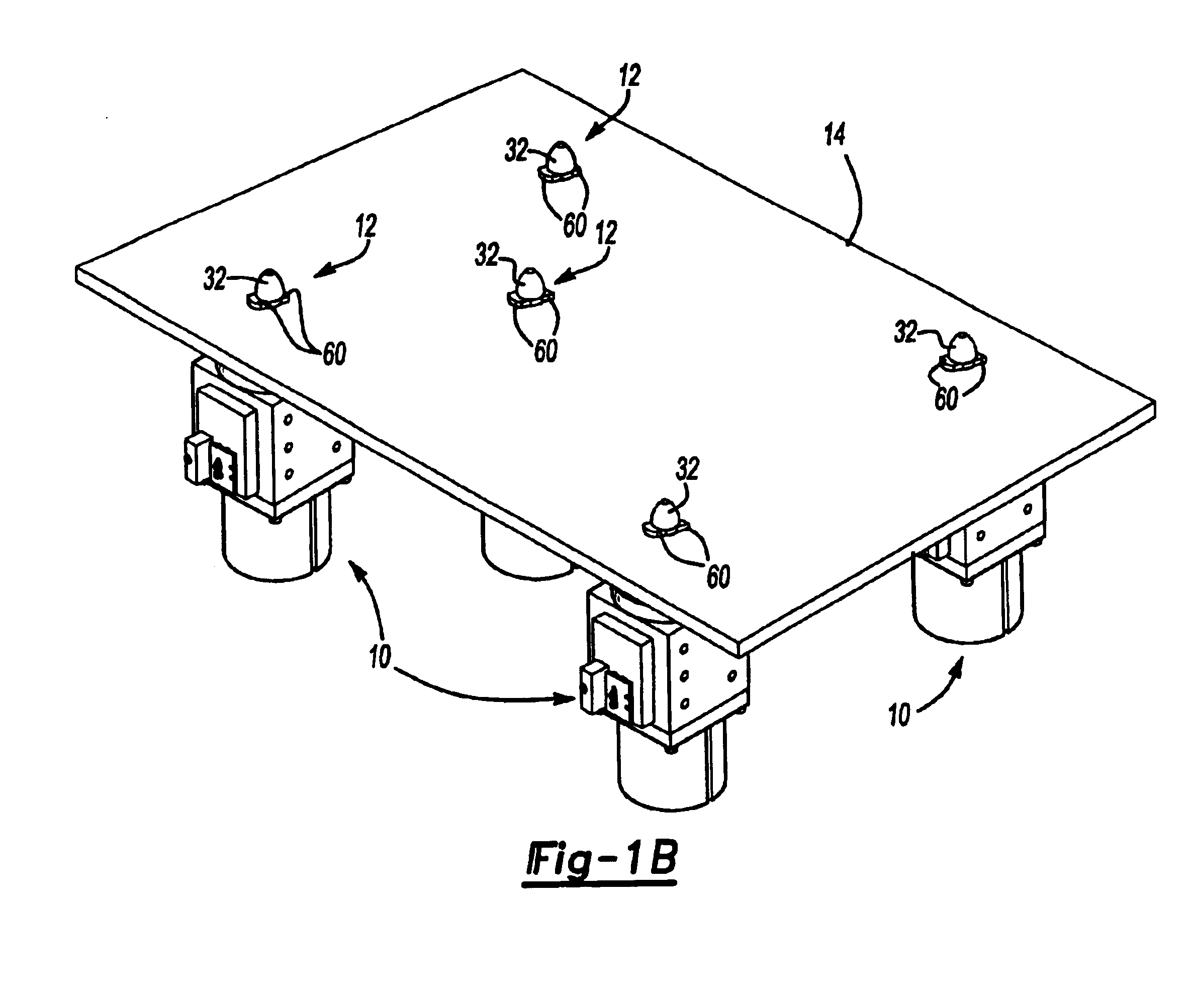

Locating assembly having an extendable clamping finger

InactiveUS6913254B2Work faster and moreEasy to operatePrecision positioning equipmentDovetailed workEngineeringActuator

The subject invention provides a locating assembly for centering and securing a work piece. The locating assembly includes a body. The body defines an internal cavity and an opening from the cavity to the exterior of the body. A locating pin is disposed in the cavity and extends along an axis out of the opening. An actuator moves the locating pin rectilinearly along the axis. A pair of fingers are supported by the locating pin and move radially into and out of the locating pin, transversely to the axis. A central post rotates in response to the rectilinear movement of the locating pin. A dowel extends from an end of the central post into a slot in the finger. The central post moves the dowel in an arcuate path through the slot to radially move the finger simultaneous with the rectilinear movement of the locating pin.

Owner:WELKER BEARING

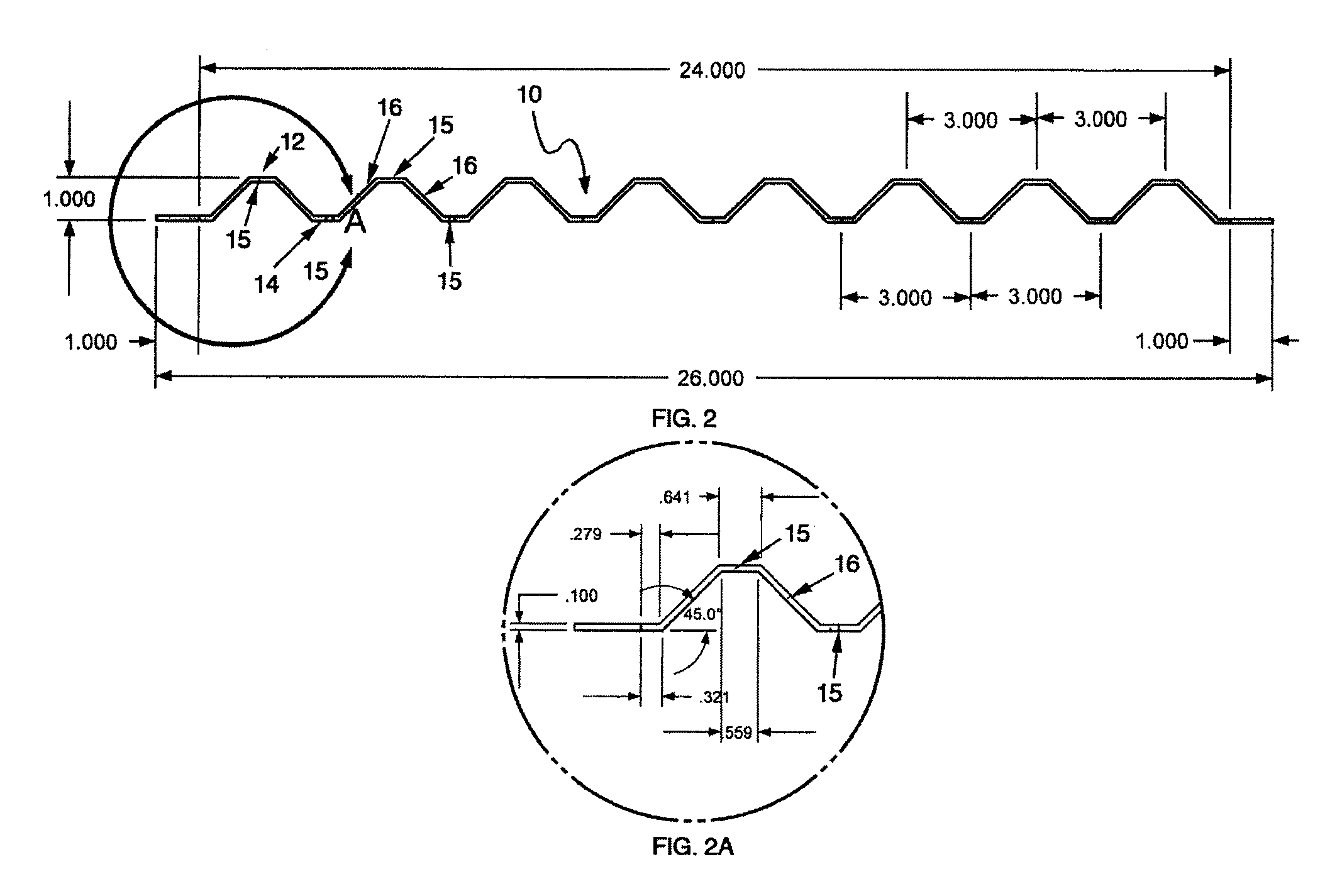

Engineered Molded Fiberboard Panels and Methods of Making and Using the Same

A fiberboard panel is formed from at least one corrugated sheet of molded cellulose fiber material having alternating ribs and grooves. Spaced slits are cut through the ribs on one face of the sheet and terminate short of the opposite face so as to form at least one slotted portion of more flexibility which may be bent to form a curve. The corrugated sheet is sandwiched between two flat sheets of the same material to form a composite panel. The corrugated sheet or panel is formed by a wet processing method including successive cold and hot press steps in which a wet mat is pressed between an opposing perforated platen and non-perforated, elastomeric material platen of cross-sectional shape substantially matching the desired panel shape and dimensions.

Owner:NOBLE ENVIRONMENTAL TECH CORP +1

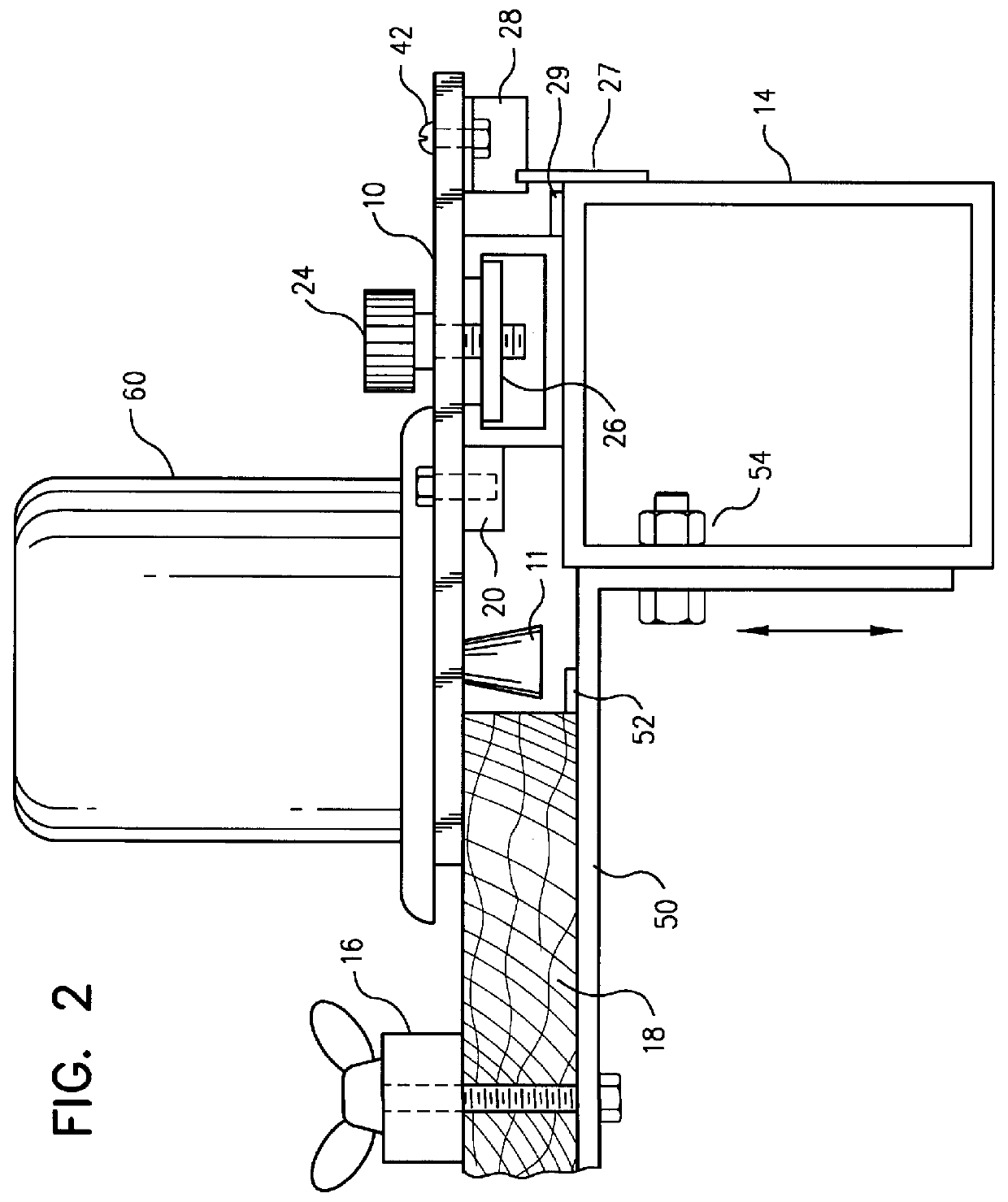

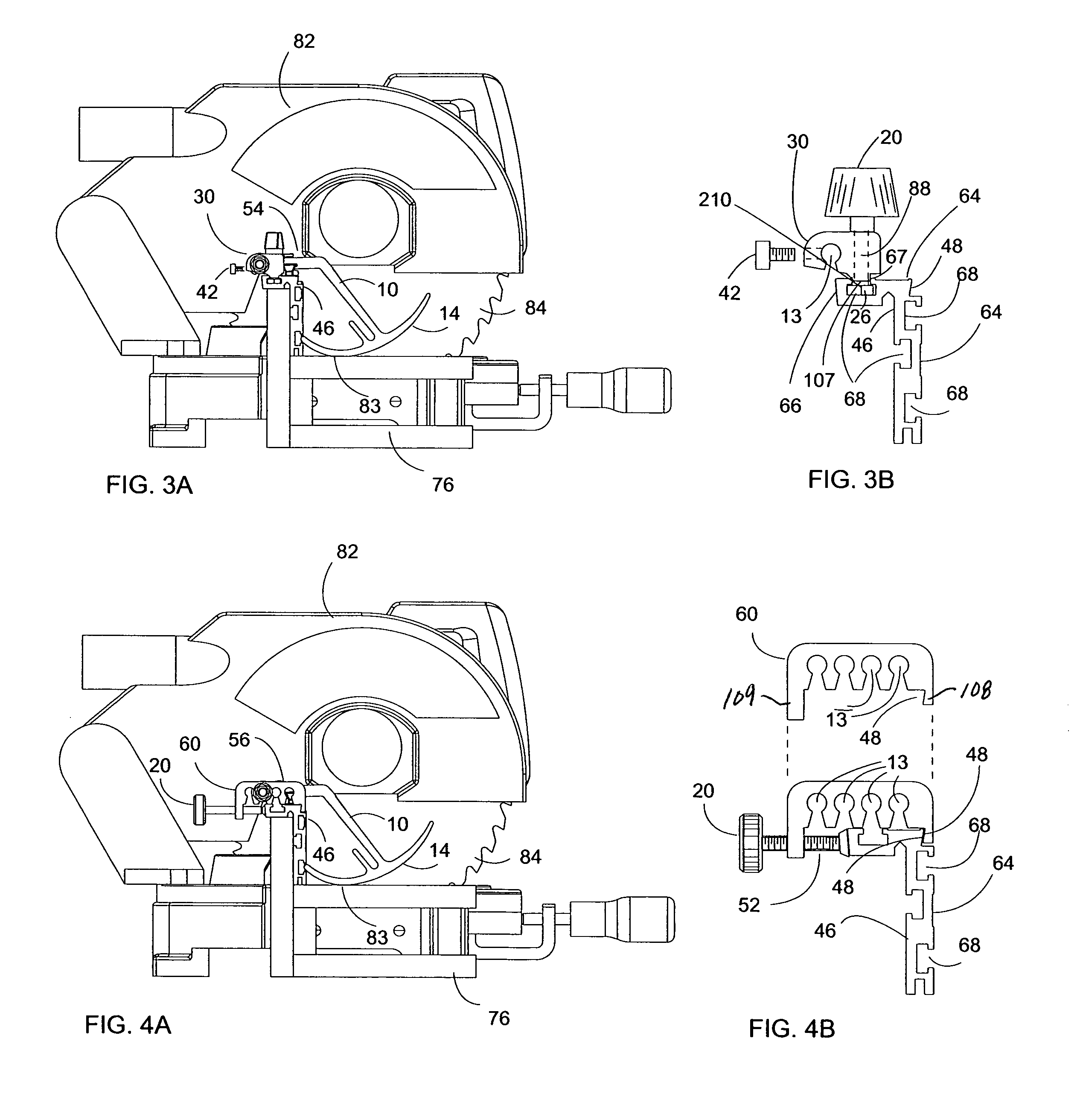

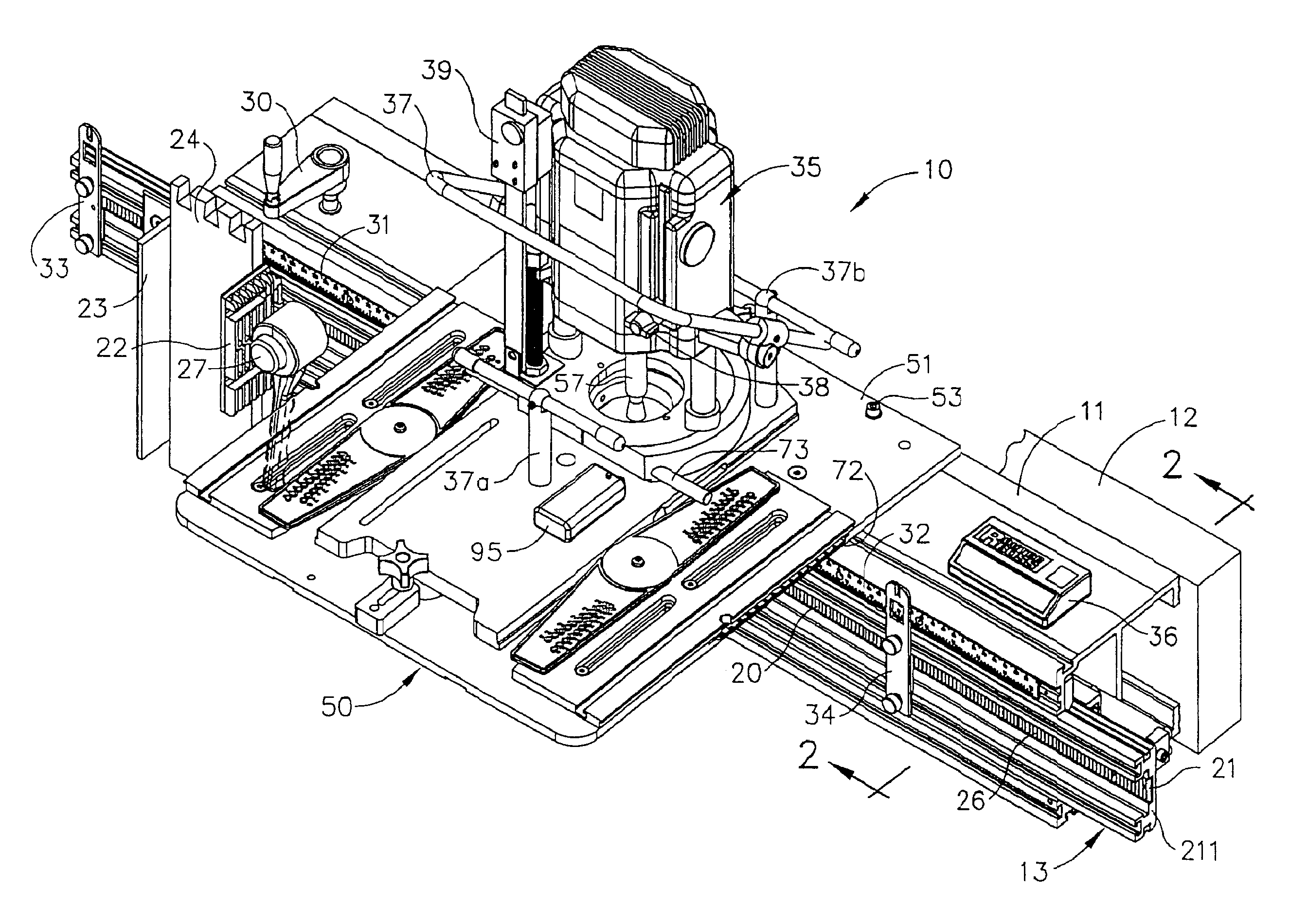

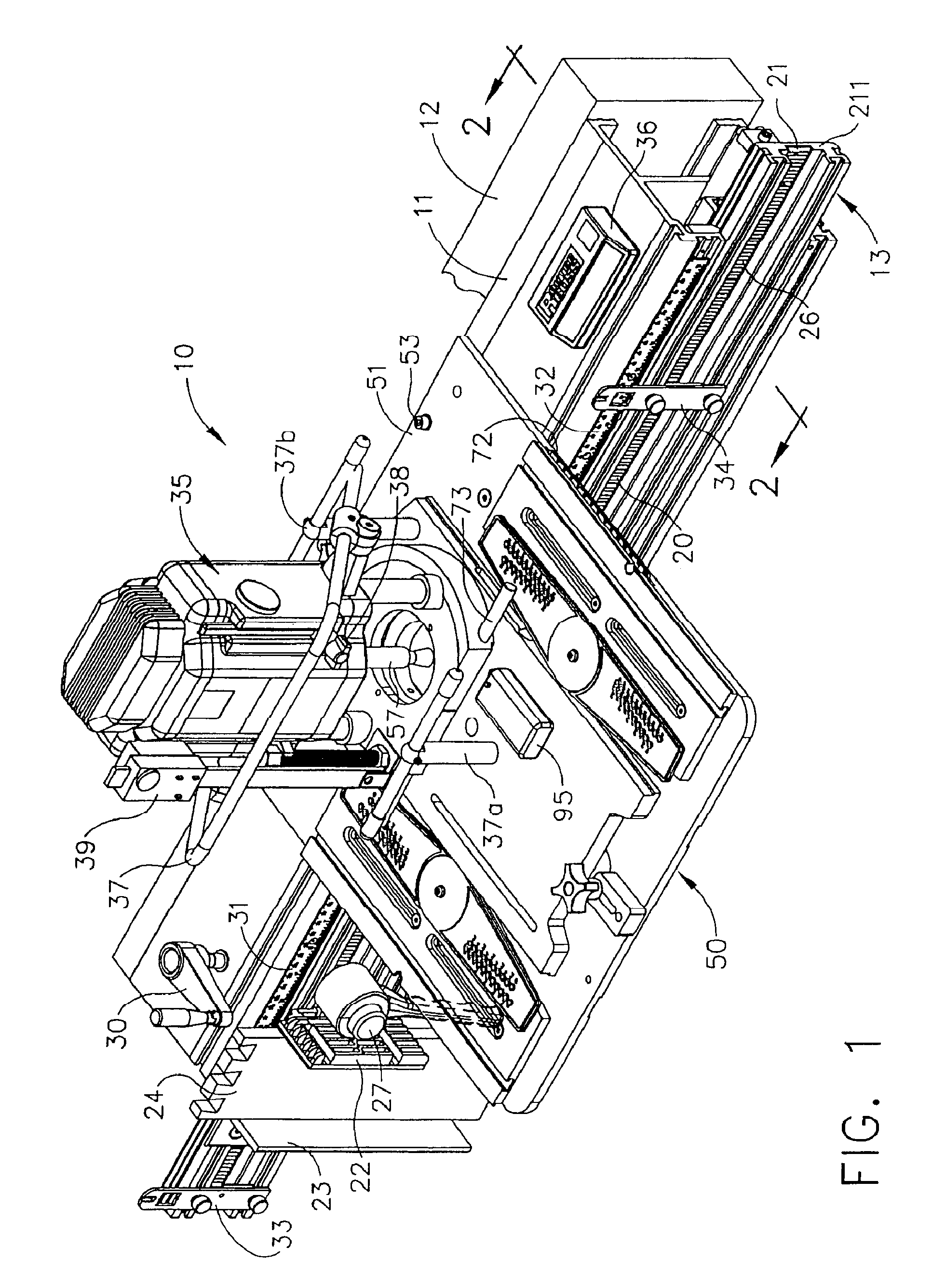

Wood Working Machine

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

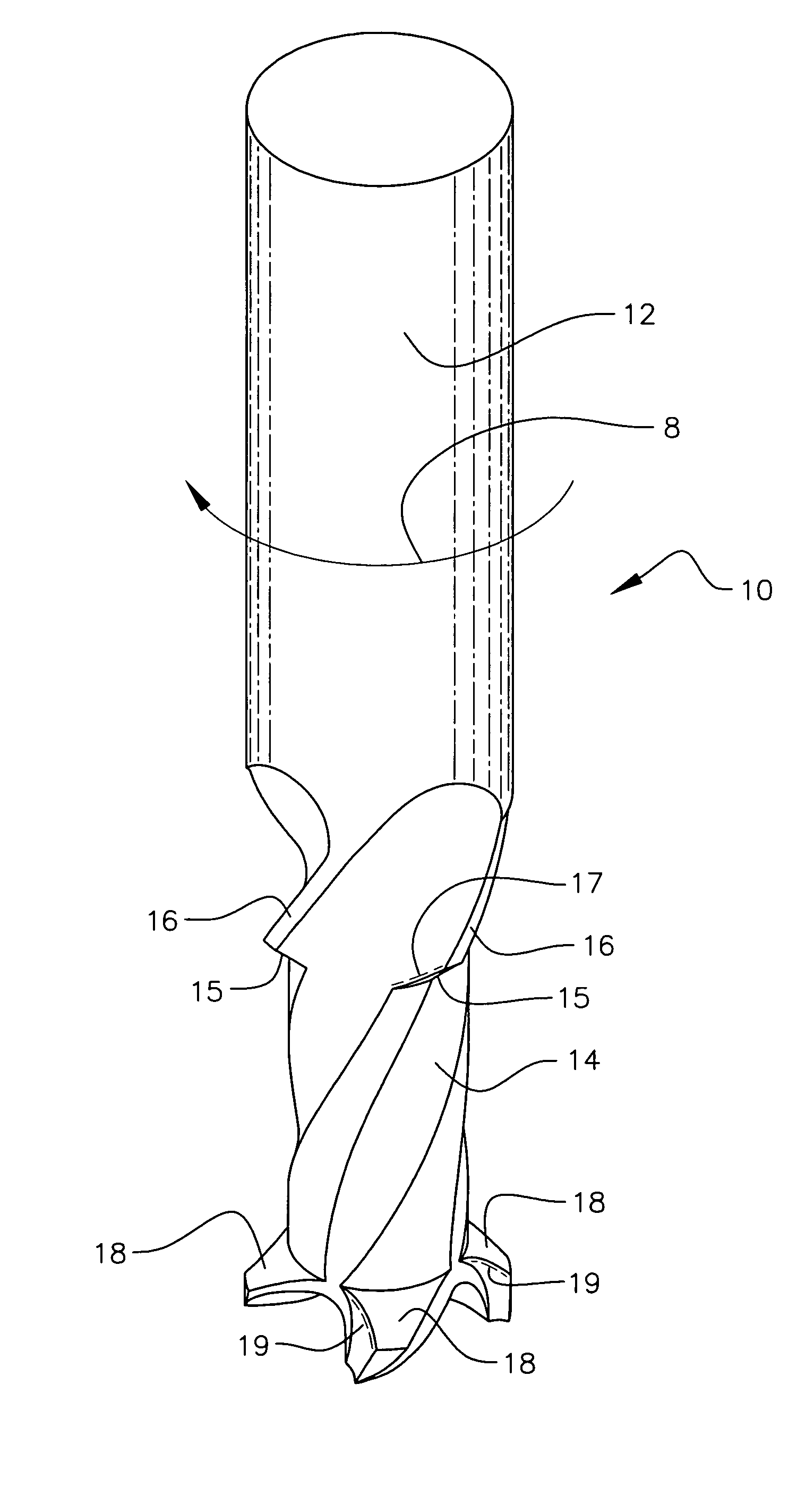

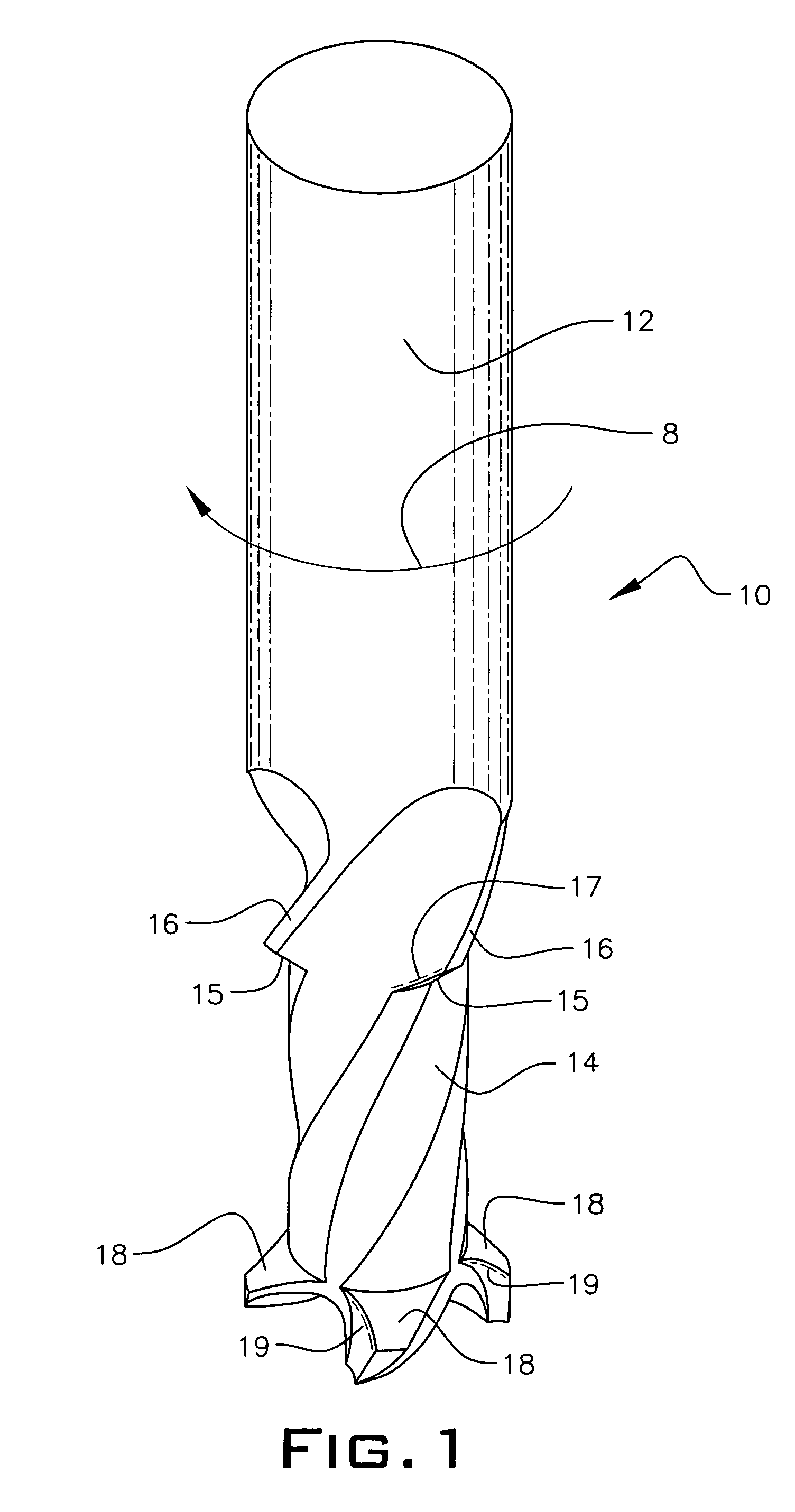

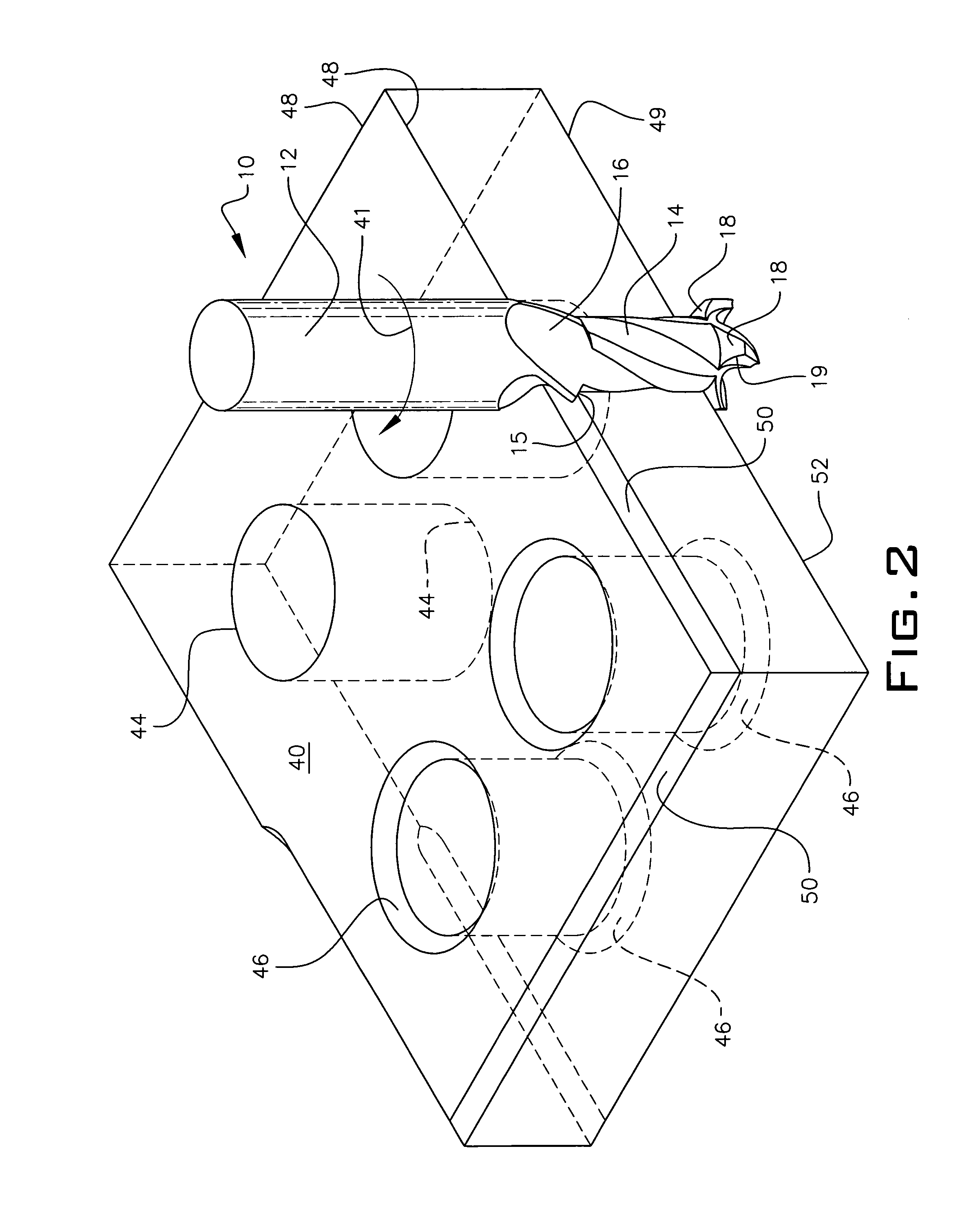

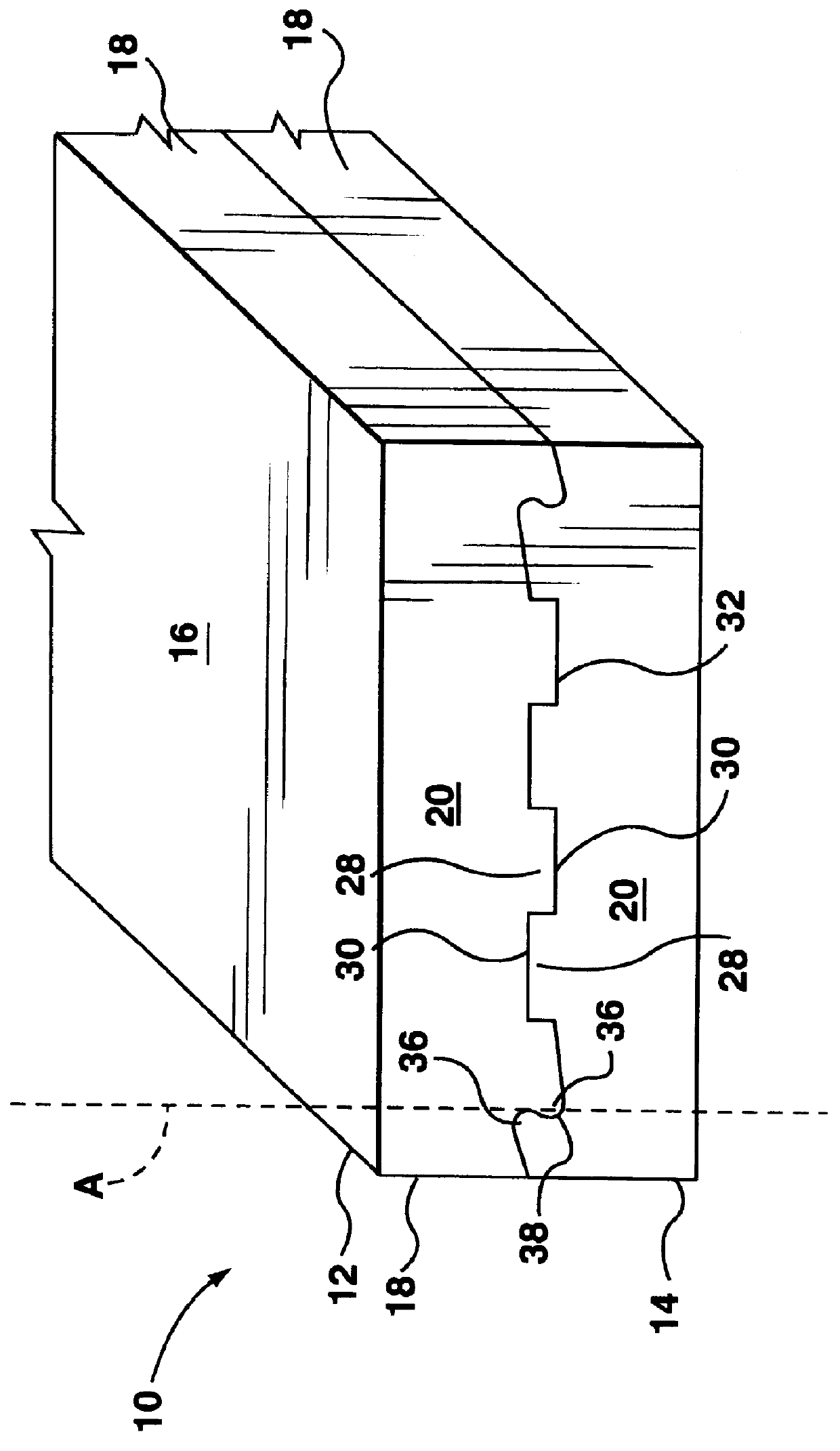

Two edge deburring tool

Owner:CLAYTON STEPHEN D

Wood article and method of manufacture

InactiveUS6125607ALow costElement becomes smallTongue/grooves making apparatusWallsAdhesiveEngineering

A wood member comprises first and second opposed members made of wood and secured together. Each of the first and second members has spaced sides and a surface extending between the sides. The surfaces include a first portion contoured to define a contact surface which extends in more than one plane, the first portions defining a space therebetween for receiving an adhesive for securing the first and second members together; a second portion contoured to restrict the flow of the adhesive to a position outward from the sides when the first and second members are brought into engagement; and, opposed engagement members configured to lockingly engage without substantial deformation of the engagement members and secure the first and second members together as the adhesive dries.

Owner:POCE JOHN DI

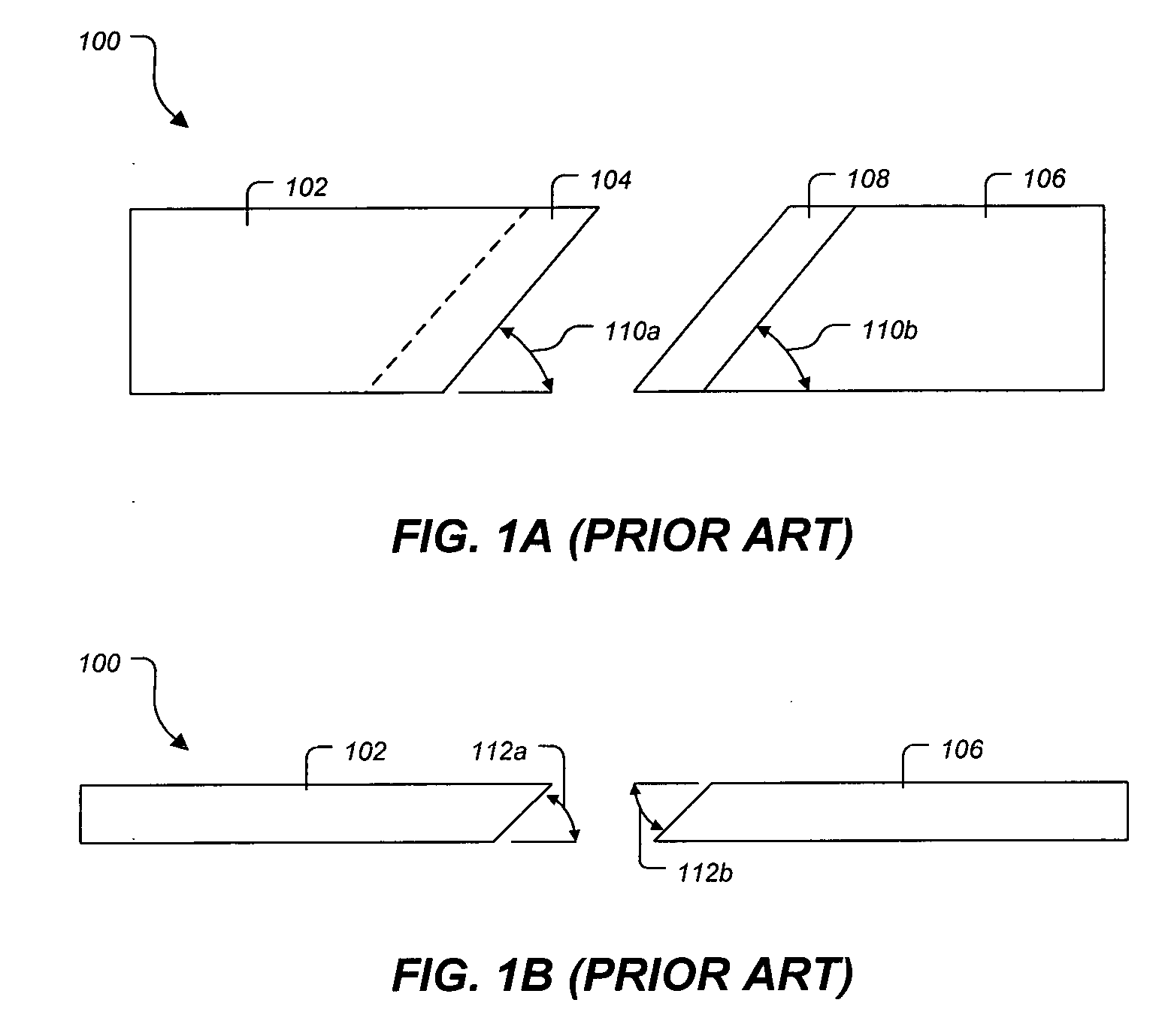

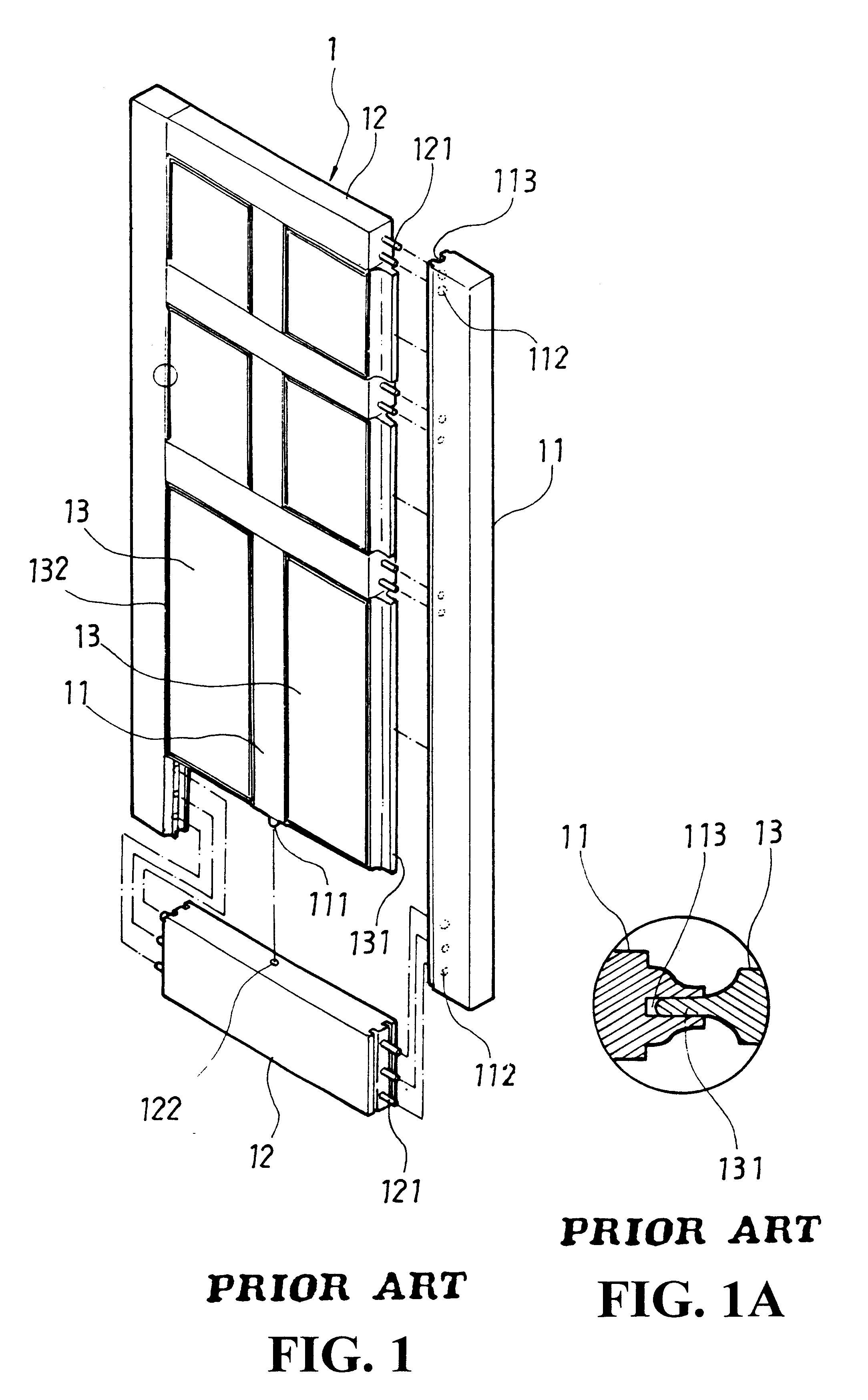

Releasable dovetail corner joint

InactiveUS7255511B2Facilitates adjustment and assemblyIncrease spacingScaffold connectionsDoors/windowsEngineeringMirror image

Owner:DOLAN KEVIN P

Guide for a cutting tool

InactiveUS7127976B1Cutting and similar operationEasy to cutDovetailed workMulti-purpose machinesEngineeringKnife blades

A guide comprises one or more brackets for securing the guide to a cutting tool, a horizontal support member secured to and moveable with respect to the brackets, and one or more arm assemblies secured to the horizontal support member and adapted to secure a working piece relative to the horizontal support member. With the working piece secured to the guide in this manner, the working piece may be readily advanced over a blade of the cutting tool by grasping and moving the horizontal support member relative to the brackets, thus ensuring a precise cutting of the working piece while also allowing a user to keep their hands away from the blade.

Owner:FITZSIMMONS GEORGE

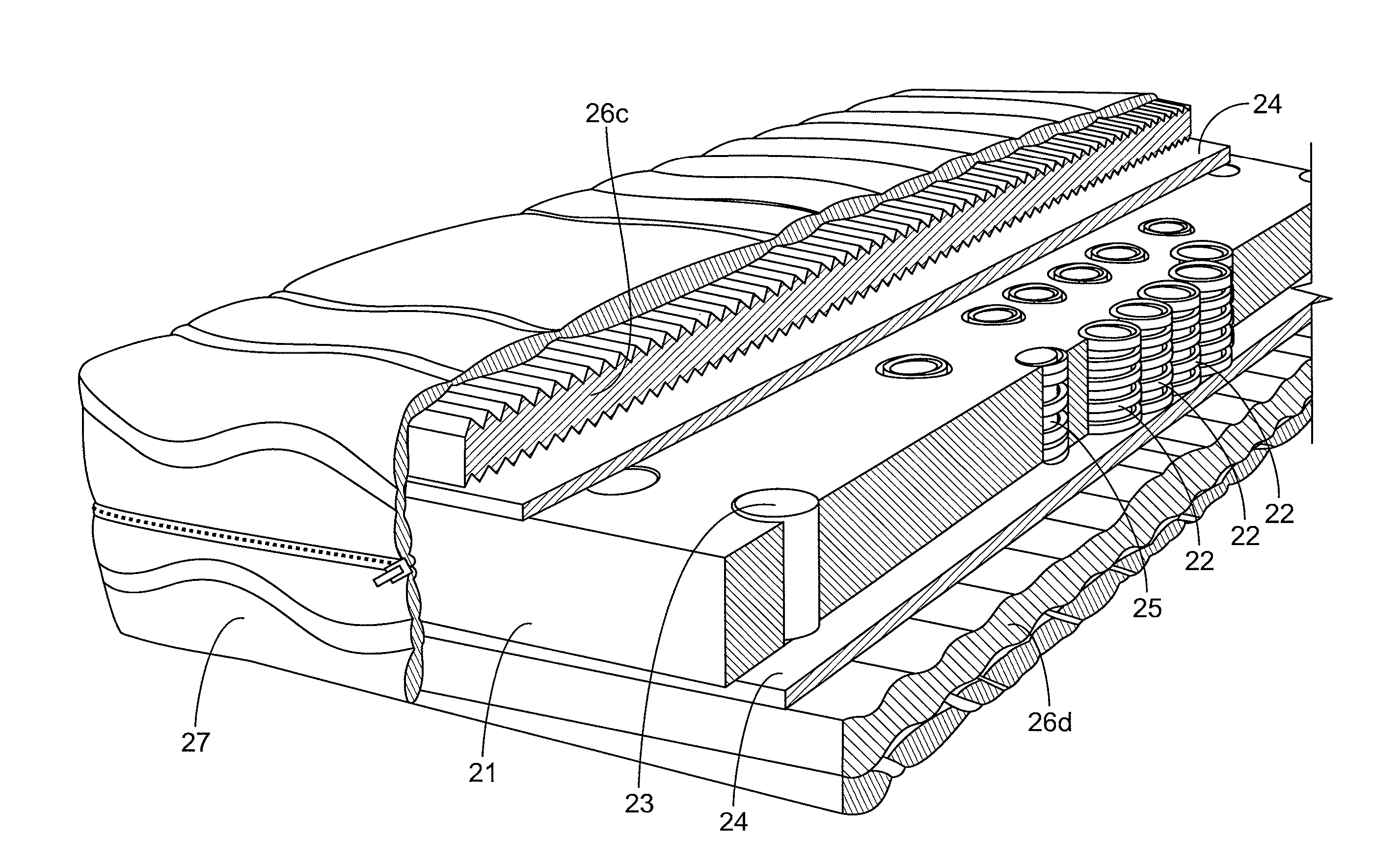

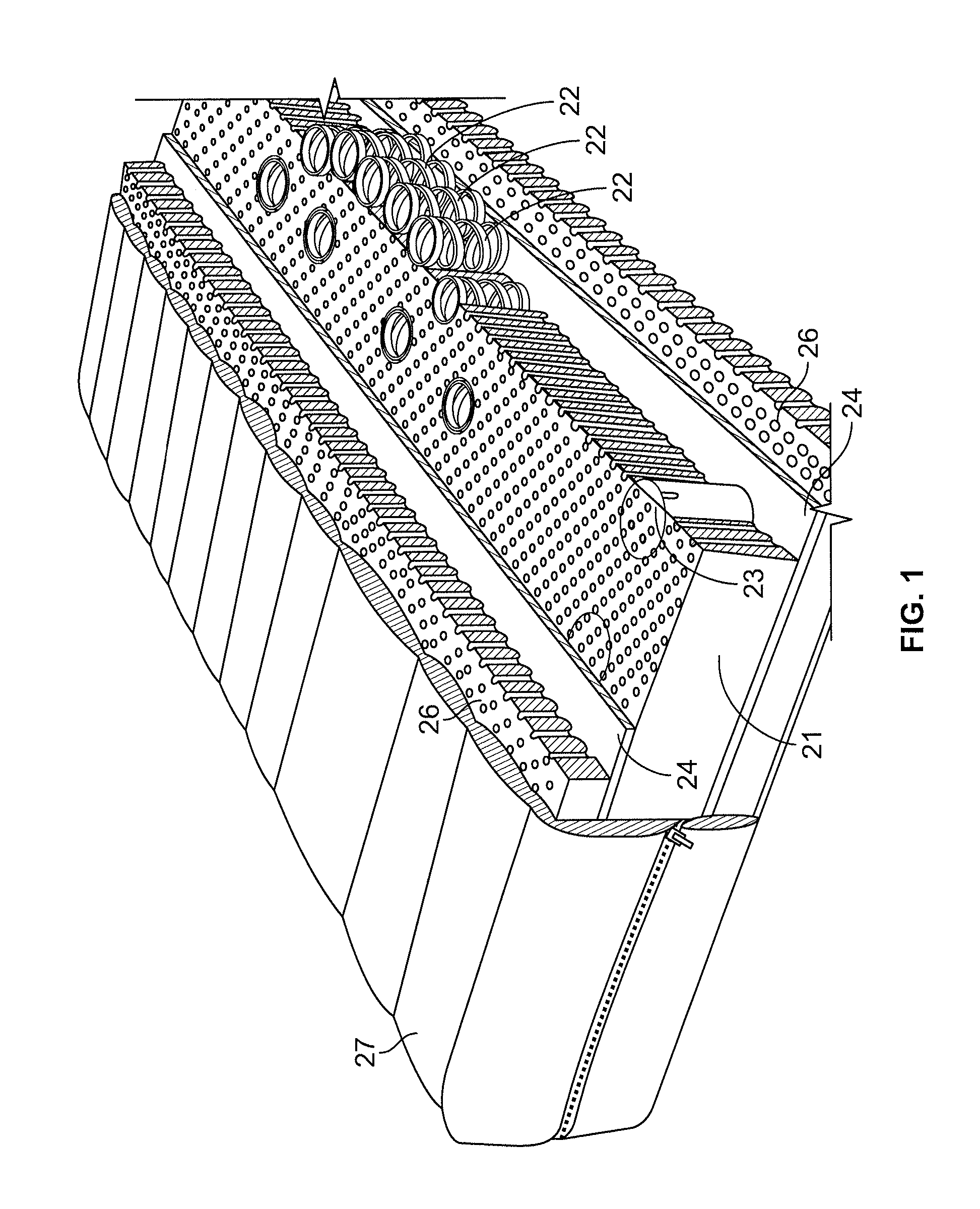

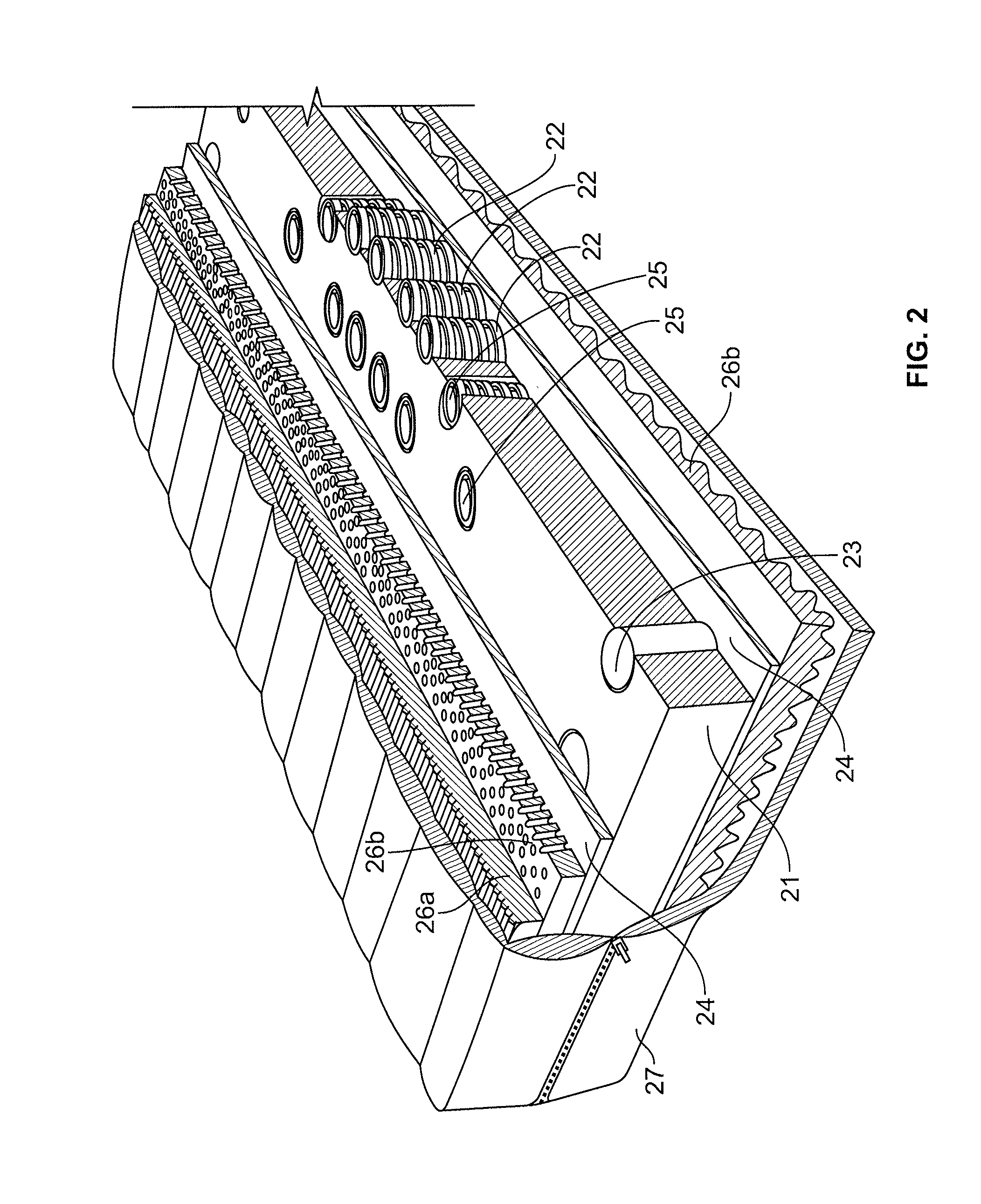

Wooden spring and mattress manufactured with wooden springs

Described are wooden coil springs, including those made of non-compressed wood, and mattresses with such coil springs. Also described is a method of producing a coil spring made of non-compressed wood, which includes winding a slat on reel, steaming and drying to produce the wooden coil spring. Such a coil spring may have a cylindrical shape, a cone shape or a truncated cone shape, and may have a substantially perpendicular end turn with respect to the longitudinal axis of the coil spring.

Owner:VOROS GABOR

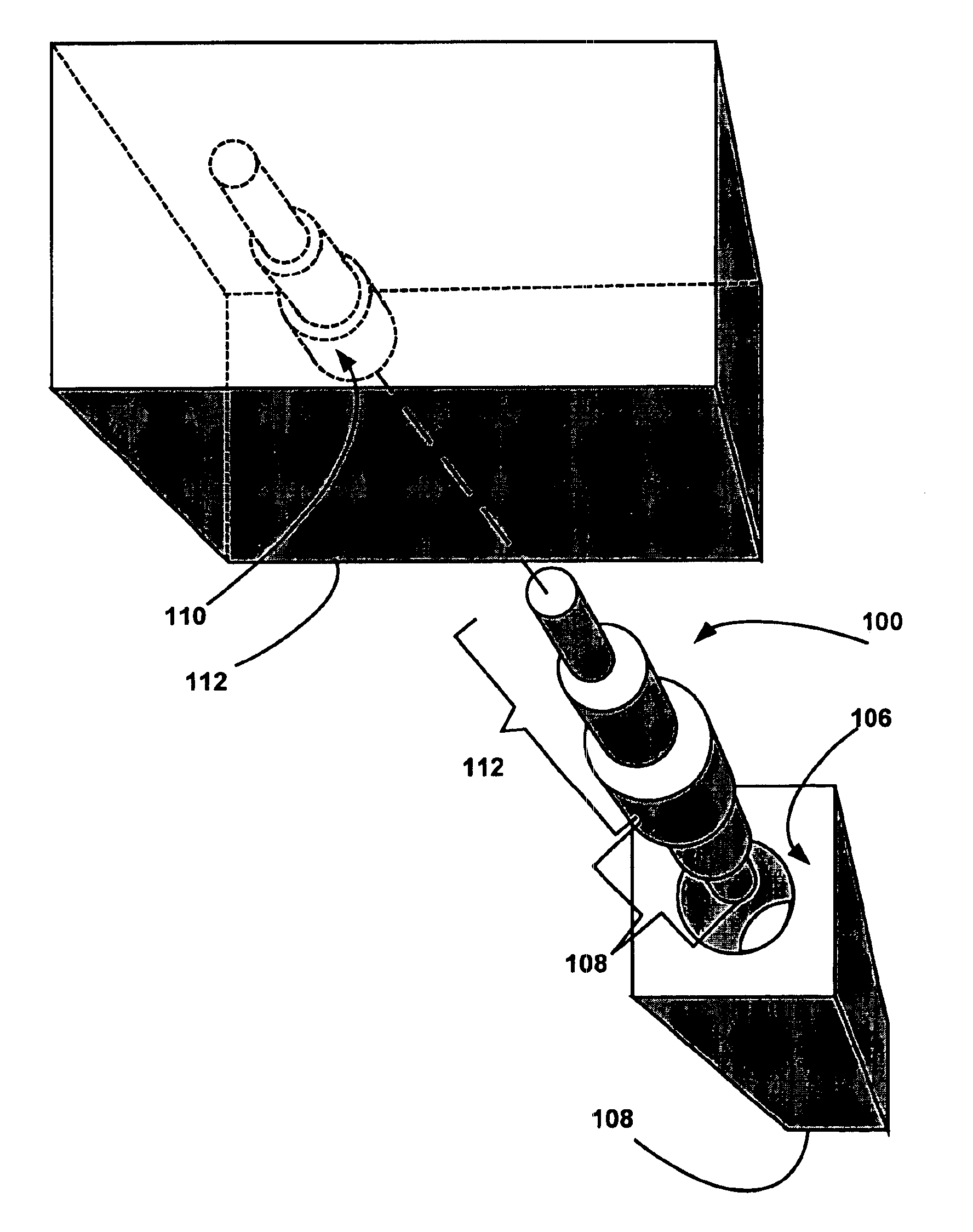

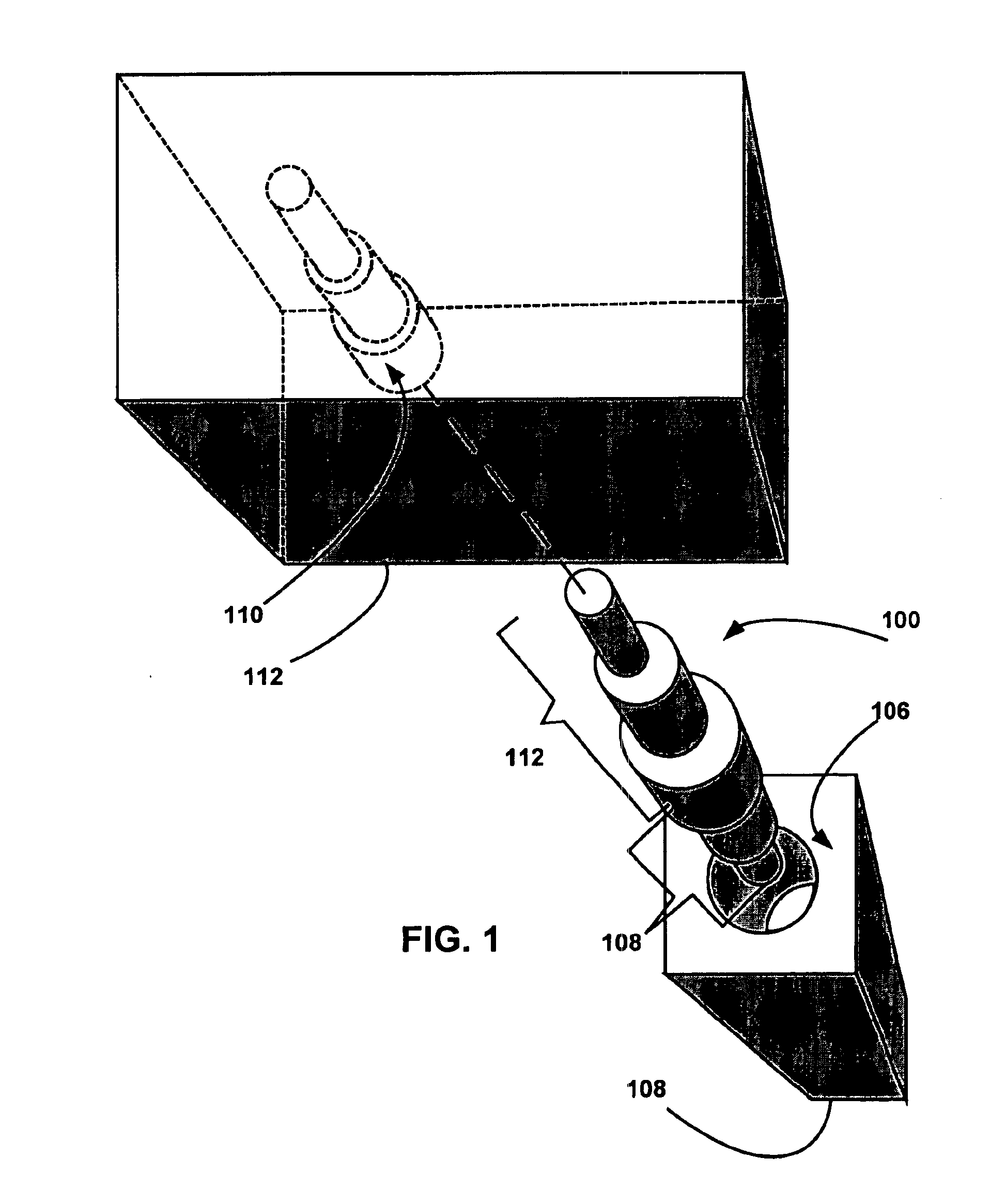

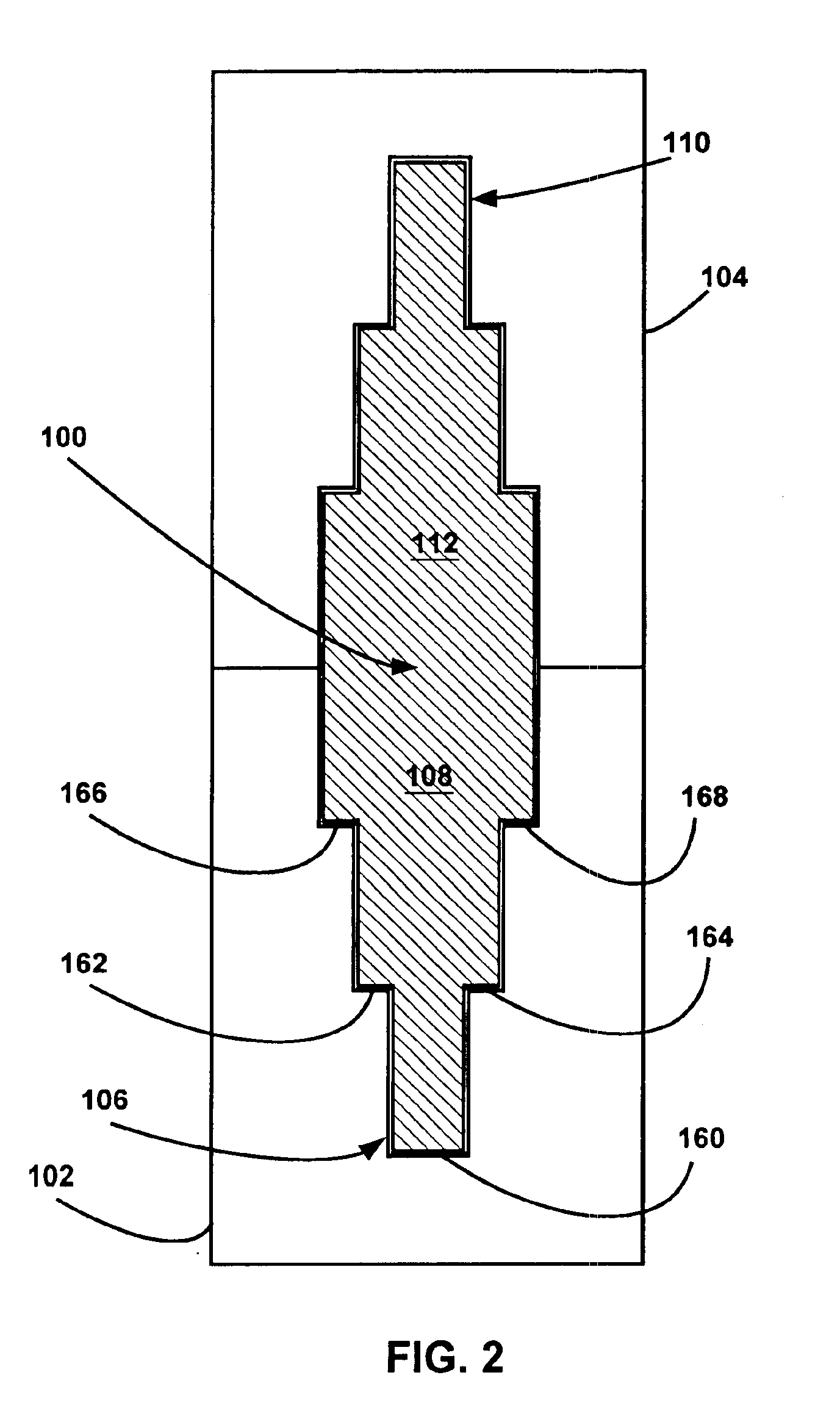

Dowel connection system and method

An embodiment of the connection system is for connecting a plurality of components together. One embodiment of a method of the system provides a dowel having first and second portions. Each of the portions has first and second ends, the first and second portions being connected to one another at their second ends. At least one portion of the first and second portions has at least three dowel sections of successively decreasing diameters. One of these dowel sections has a side wall and an end wall that forms the first end of the at least one portion and each of the other dowel sections has a side wall and step wall. A first component has a first opening configured to substantially fit the first portion, and a second component has a second opening configured to substantially fit the second portion. An adhesive material is then applied on at least part of the first portion, and the first portion is inserted into the first opening in the first component. Adhesive material is then also applied on at least a part of the second portion, and the second portion is inserted into the second opening in the second component, thereby connecting together the two components.

Owner:MILLER DOWEL

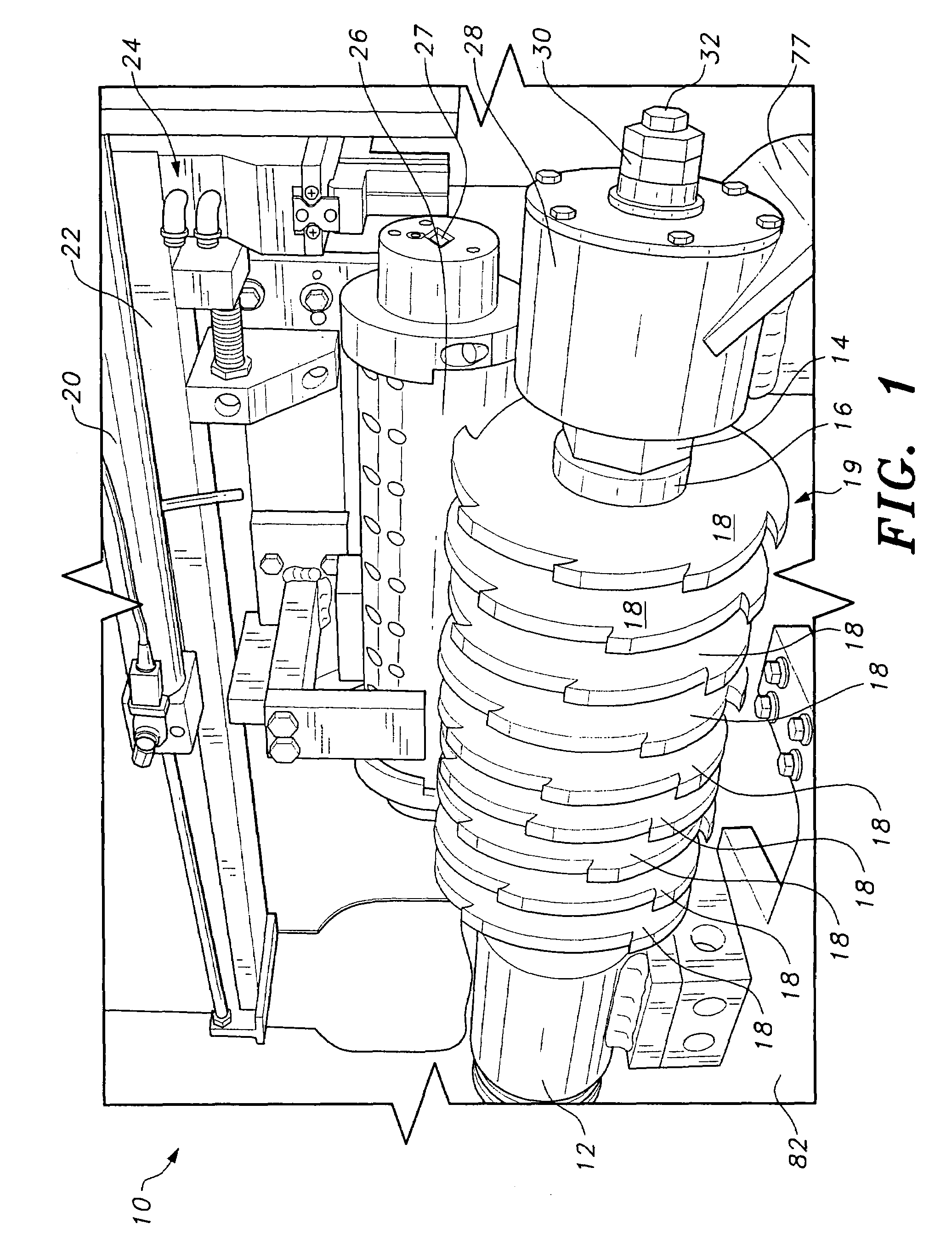

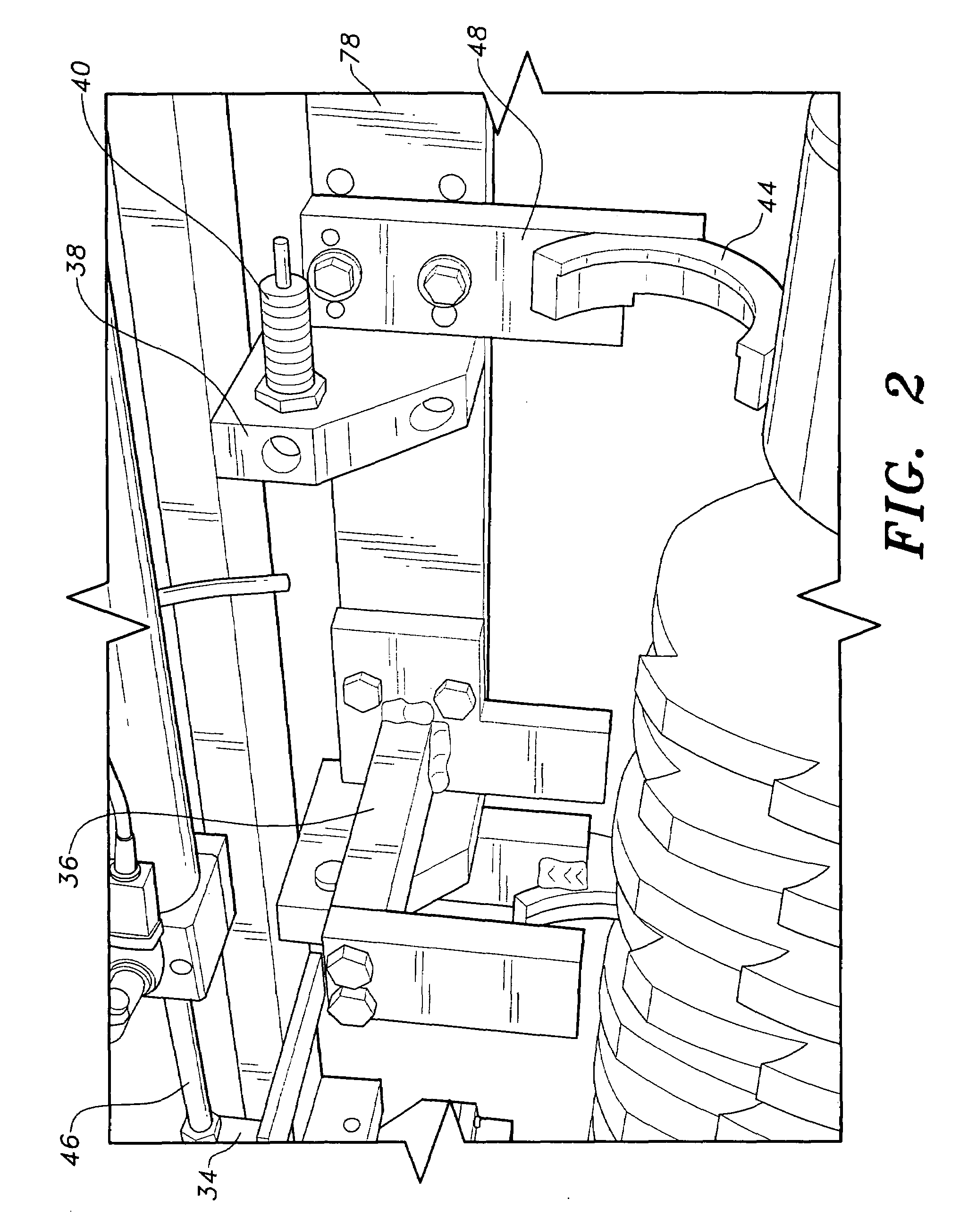

Woodworking machine for shaping molding

The woodworking machine for shaping molding has a hollow cylindrical cartridge with end caps having openings defined therein adapted for inserting a blank strip of molding through the cartridge. Robotic grippers advance the molding strip through the cartridge in indexed increments. A cutter assembly is mounted on a movable table, the cutter assembly having a plurality of spaced apart cutters. An electronic control system, preferably including a programmable logic controller, causes the grippers to grip the blank molding, insert the blank through the cartridge, actuate the cutter assembly and move the table so that the cutters simultaneously cut a plurality of notches in the molding, retract the cutter assembly, advance the molding the indexed distance, and automatically repeat the cycle, ejecting the strip when notches have been formed in the entire length of the molding. The machine may be used to form dental molding.

Owner:BURKHOLDER LEON R

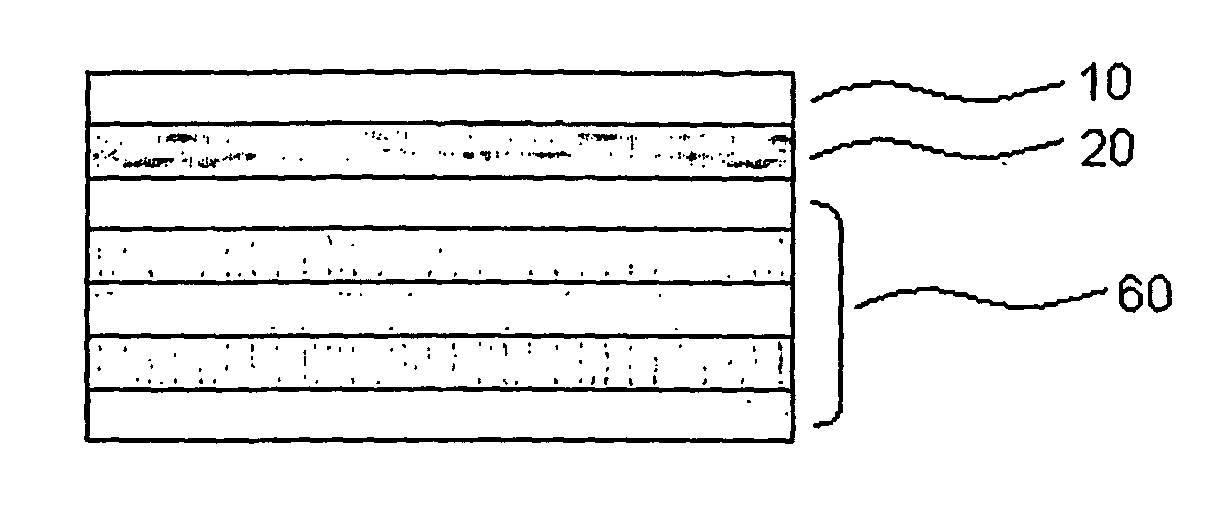

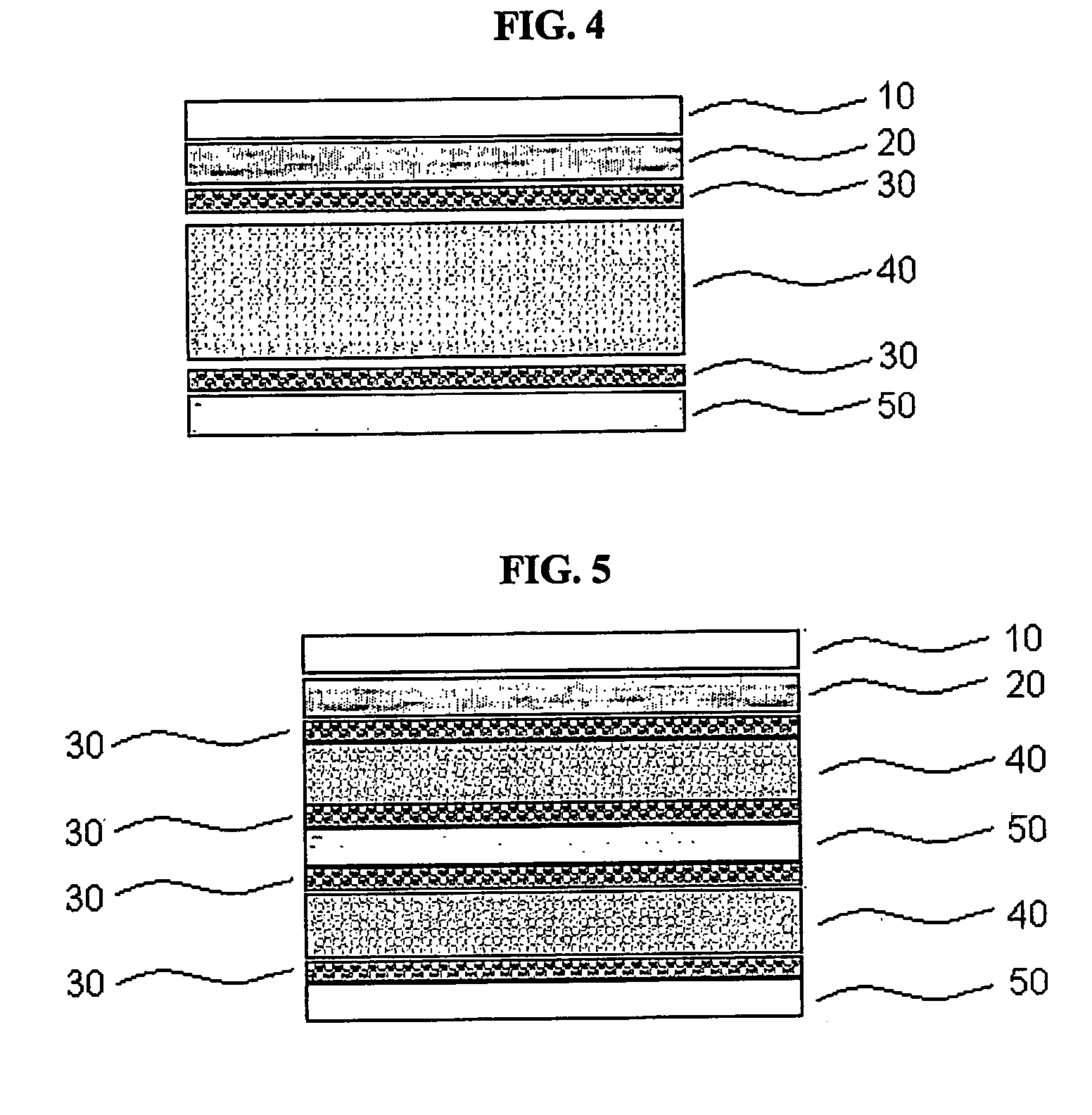

Wood flooring with laminated wood and plastic layers using symmetric structure and method of manufacturing the same

InactiveUS20050227104A1Deformation MinimizationGood dimensional stabilityStapling toolsDovetailed workEngineeringSymmetric structure

It is provided a wood flooring laminated wood and plastic layers symmetric to each other and method of manufacturing the same. The wood flooring has an upper layer including laminated wood, a core layer including plastic sheets manufactured by calendaring, and a lower layer including veneer board, the lower layer being made of the same material as the upper layer, which are piled up symmetrically in order to keep the balance between the upper layer and lower layer, and then integrated under a constant temperature and pressure to form a suitable layers made by wood and plastic, thereby providing natural feeling in surface and solving the problem of distortion according to the change of environment.

Owner:LG CHEM LTD

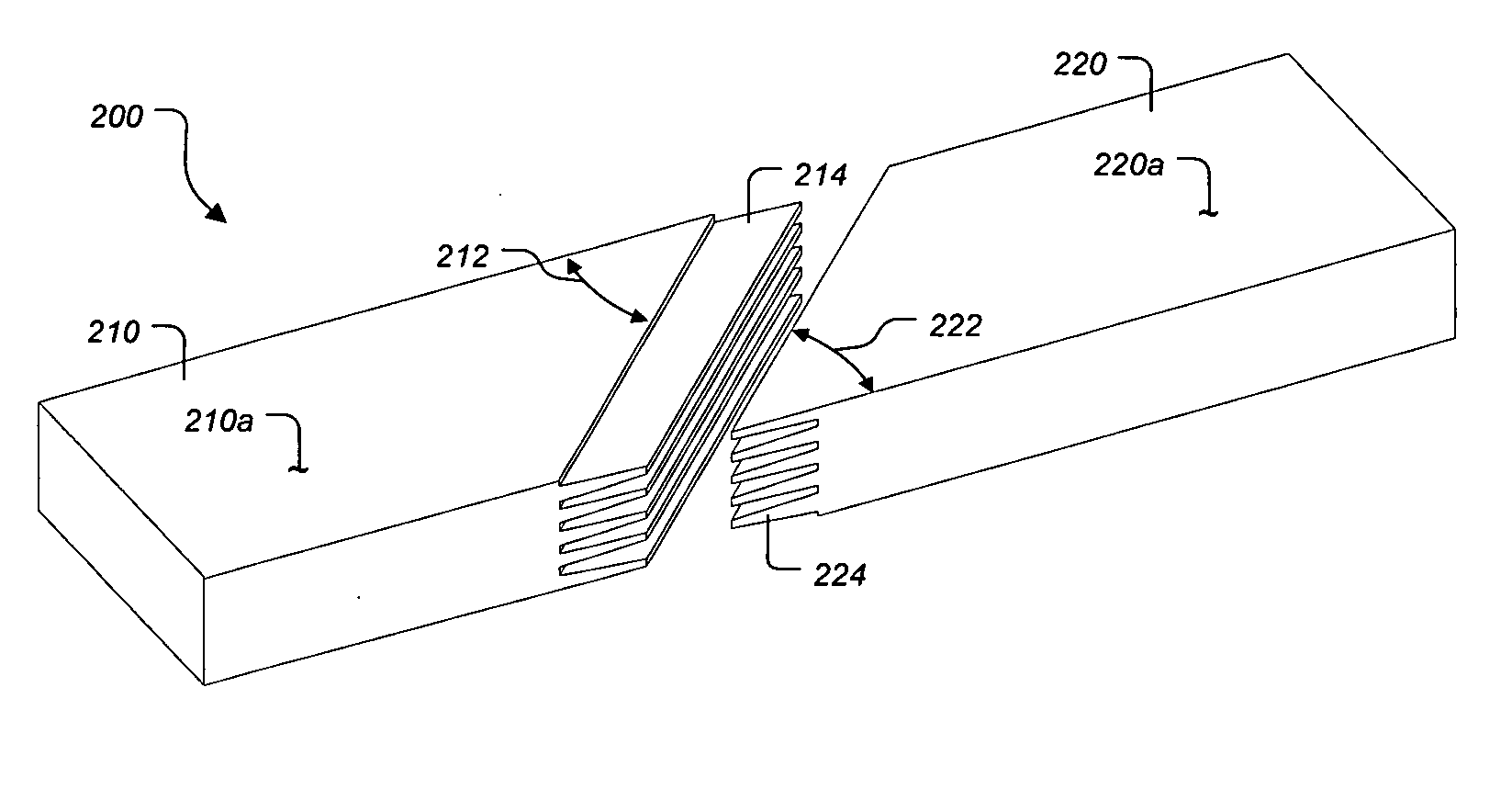

Assembly and method for providing an interlocking angular end joint

InactiveUS20070125448A1High strengthEasy to assembleDovetailed workMulti-purpose machinesEngineering

An assembly and method is disclosed for providing an interlocking angular end joint. The interlocking angular end joint is capable of providing a virtually invisible end joint and comprises at least a first board capable of being longitudinally ripped from lumber to a predetermined width, at least a first angle cut at a predetermined angle into at least one end portion relative to the longitudinal length of the first board, and at least a first interlocking member capable of being machined into at least one end portion of the first board.

Owner:ABBOTT RICHARD T

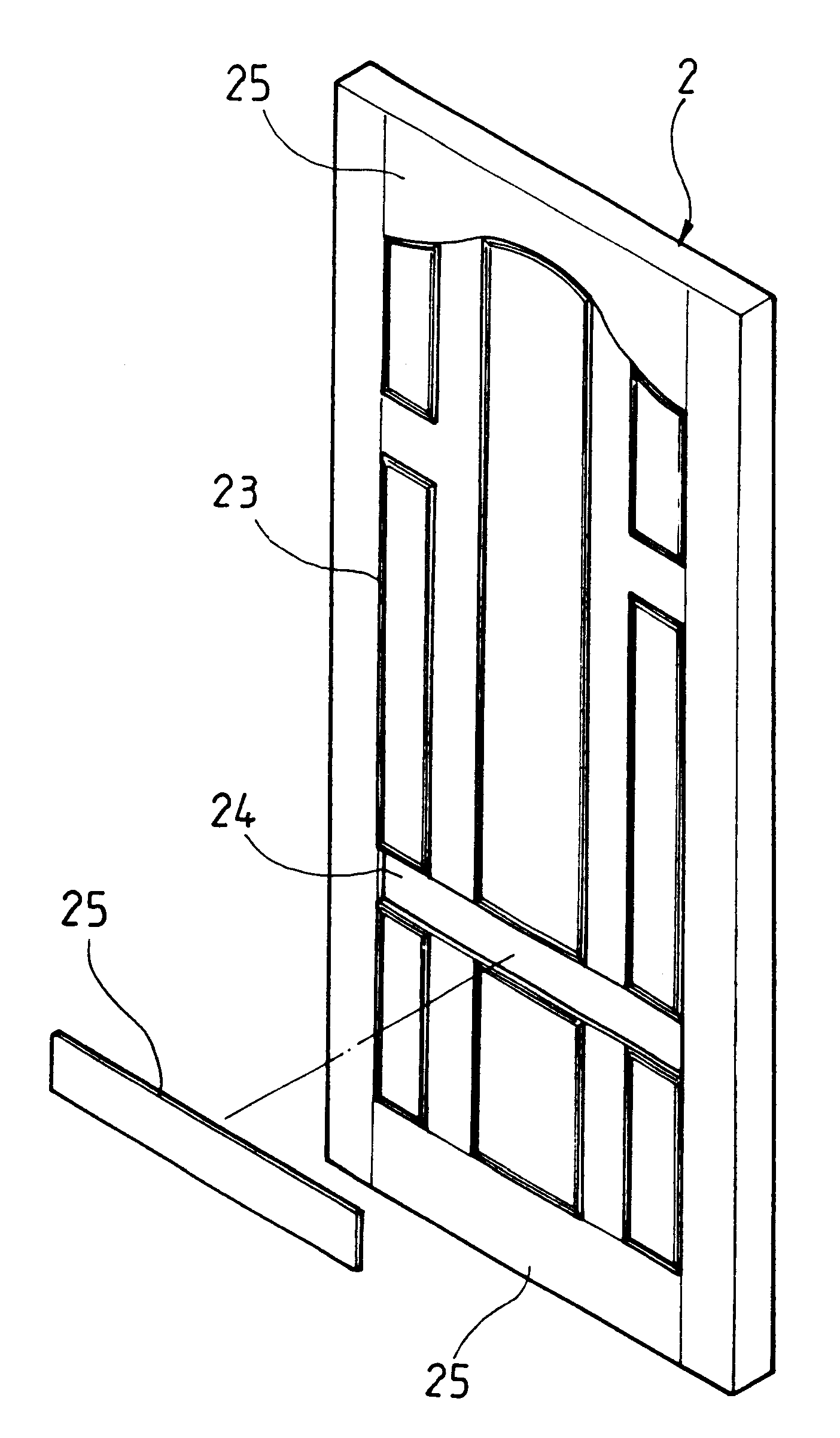

Method of manufacturing carved wooden doors

A method of manufacturing carved wooden doors includes the steps of forming wooden blocks with different width but same height and joining them together at a vertical lateral side thereof, joining said wooden blocks together to form a rectangular member for carving, carving desired patterns on said rectangular member, and carving a transverse recess on said rectangular member and affixing a panel in said transverse recess to form a complete carved wooden door, whereby carved wooden doors can be manufactured at a faster speed than the conventional and joint connections of said wooden doors can be prevented from becoming loose thereby prolonging service life thereof.

Owner:CHENG TA WOOD IND

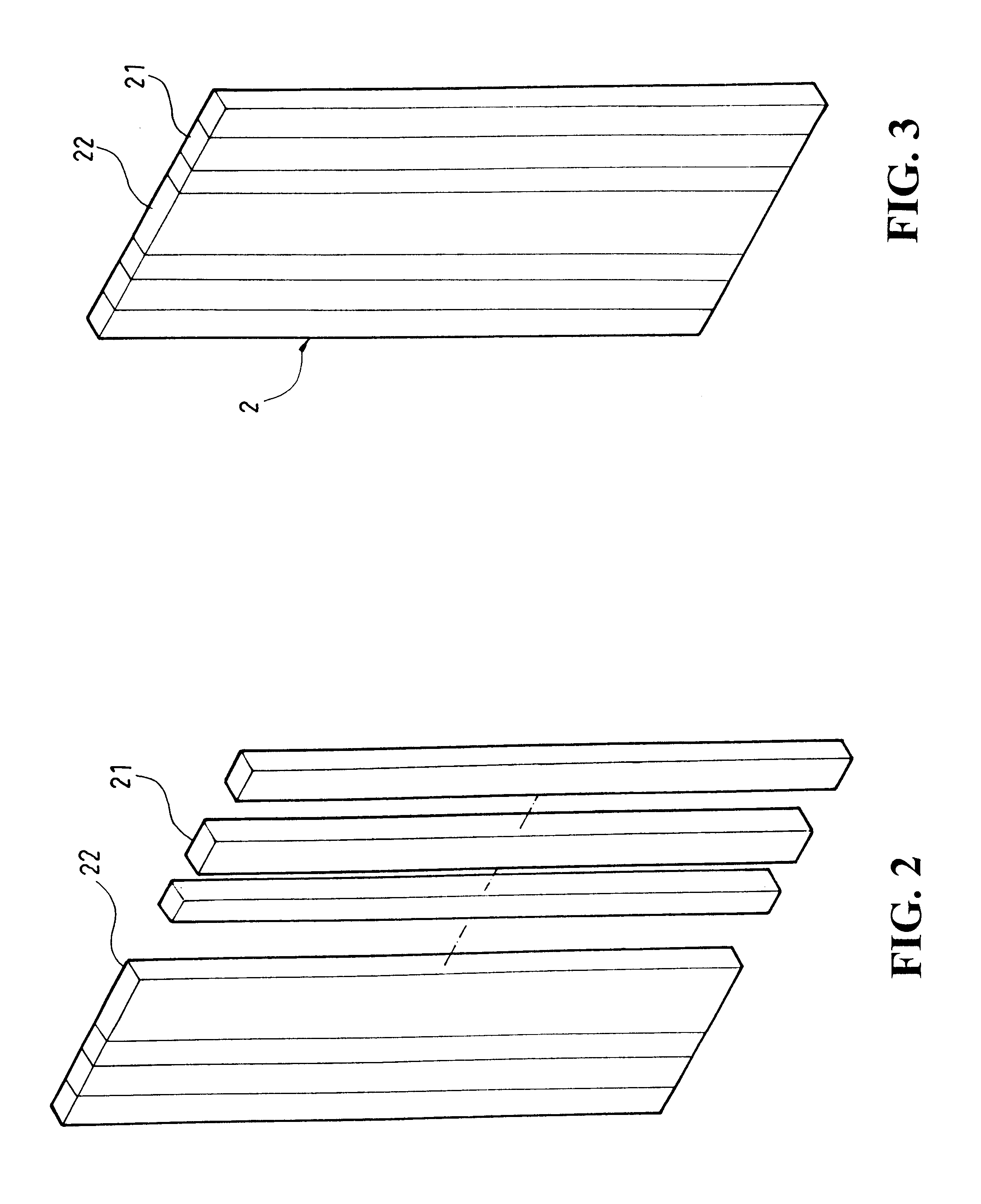

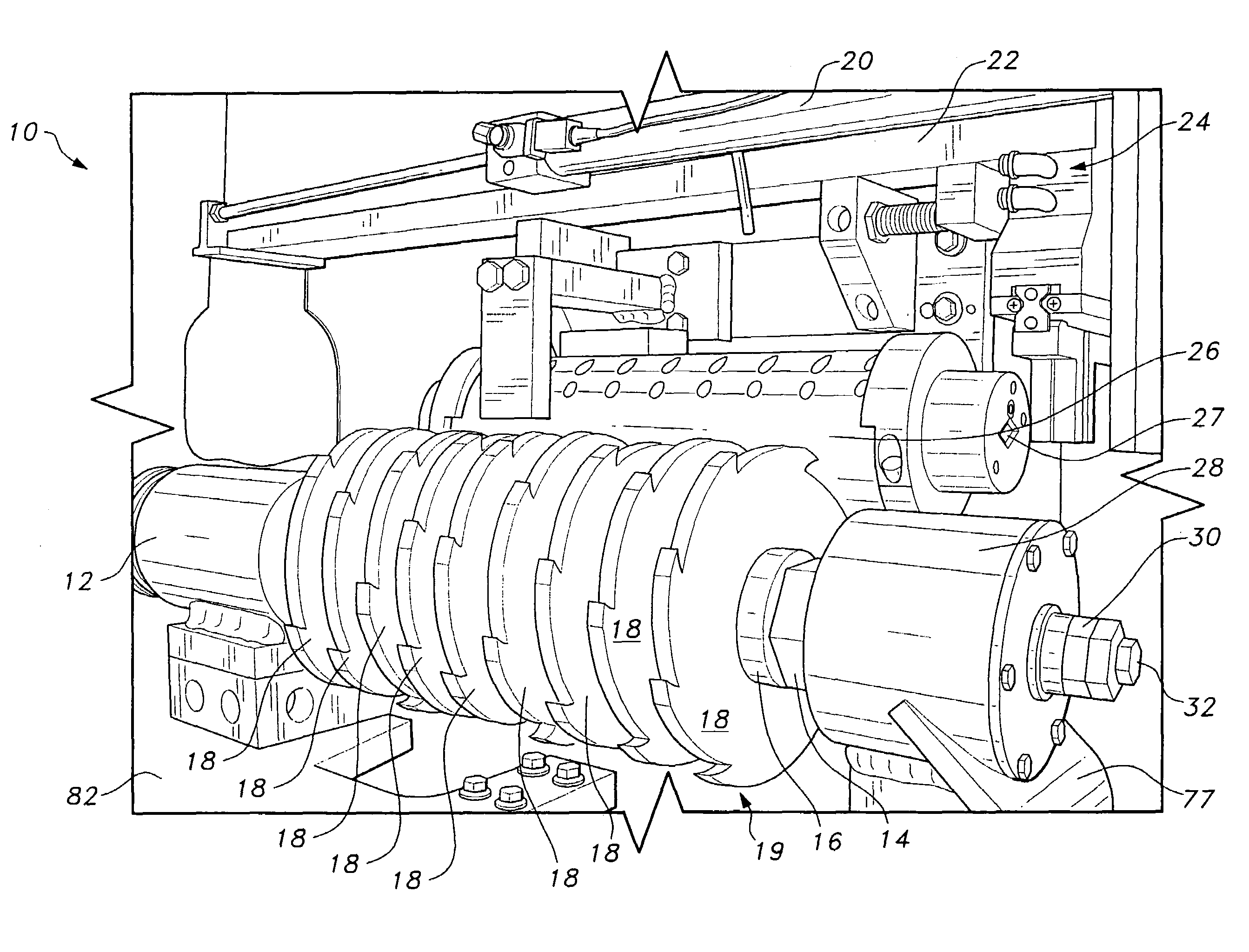

Method of manufacturing glued laminated wood

A method of manufacturing glued laminated wood such as laminated veneer lumber (LVL) is disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board wherein the end joints of the wood sheets are disposed in a staggered array. There is provided an initial base material having an end which is shaped in the form of a flight of steps including a series of alternate horizontal surface having a lengthwise dimension smaller than the length of the wood sheet and a vertical surface having a height corresponding to the wood sheet thickness, and the glued laminated wood board is formed extending from the end of such initial base material. The hot press includes a pair of heat plates each having an effective pressing area capable of covering the entire surface of the wood sheet. In hot pressing a wood sheet having on one surface thereof coated with adhesive, a board of the glued laminated wood in progress is placed and maintained for a predetermined length of time at a position where the entire top surface of the wood sheet is kept to be pressed from the top by one of the plates while the entire lower surface of the wood sheet is supported from the bottom by the other plate.

Owner:MEINAN MASCH WORKS INC

Woodworking machine for shaping molding

The woodworking machine for shaping molding has a hollow cylindrical cartridge with end caps having openings defined therein adapted for inserting a blank strip of molding through the cartridge. Robotic grippers advance the molding strip through the cartridge in indexed increments. A cutter assembly is mounted on a movable table, the cutter assembly having a plurality of spaced apart cutters. An electronic control system, preferably including a programmable logic controller, causes the grippers to grip the blank molding, insert the blank through the cartridge, actuate the cutter assembly and move the table so that the cutters simultaneously cut a plurality of notches in the molding, retract the cutter assembly, advance the molding the indexed distance, and automatically repeat the cycle, ejecting the strip when notches have been formed in the entire length of the molding. The machine may be used to form dental molding.

Owner:BURKHOLDER LEON R

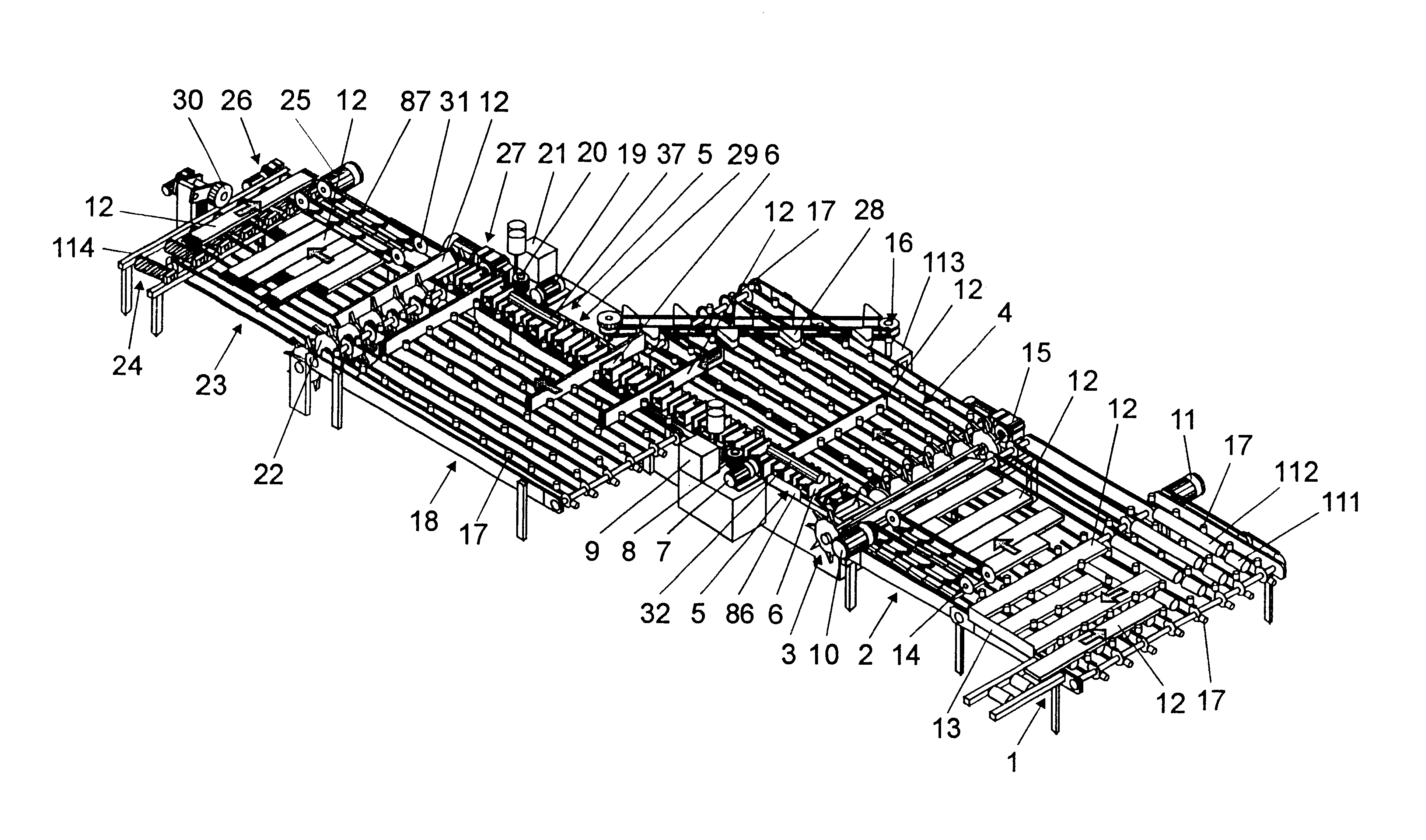

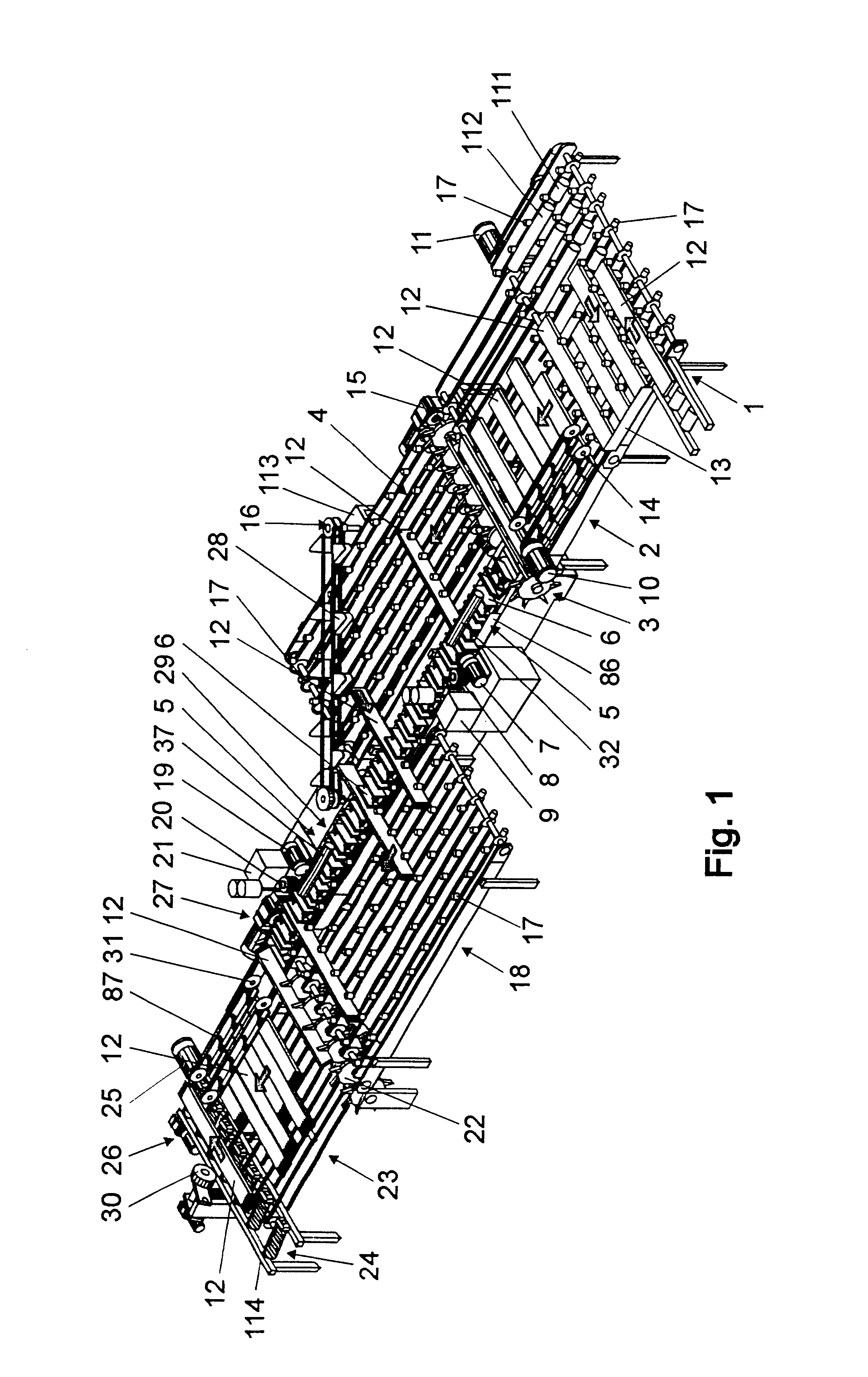

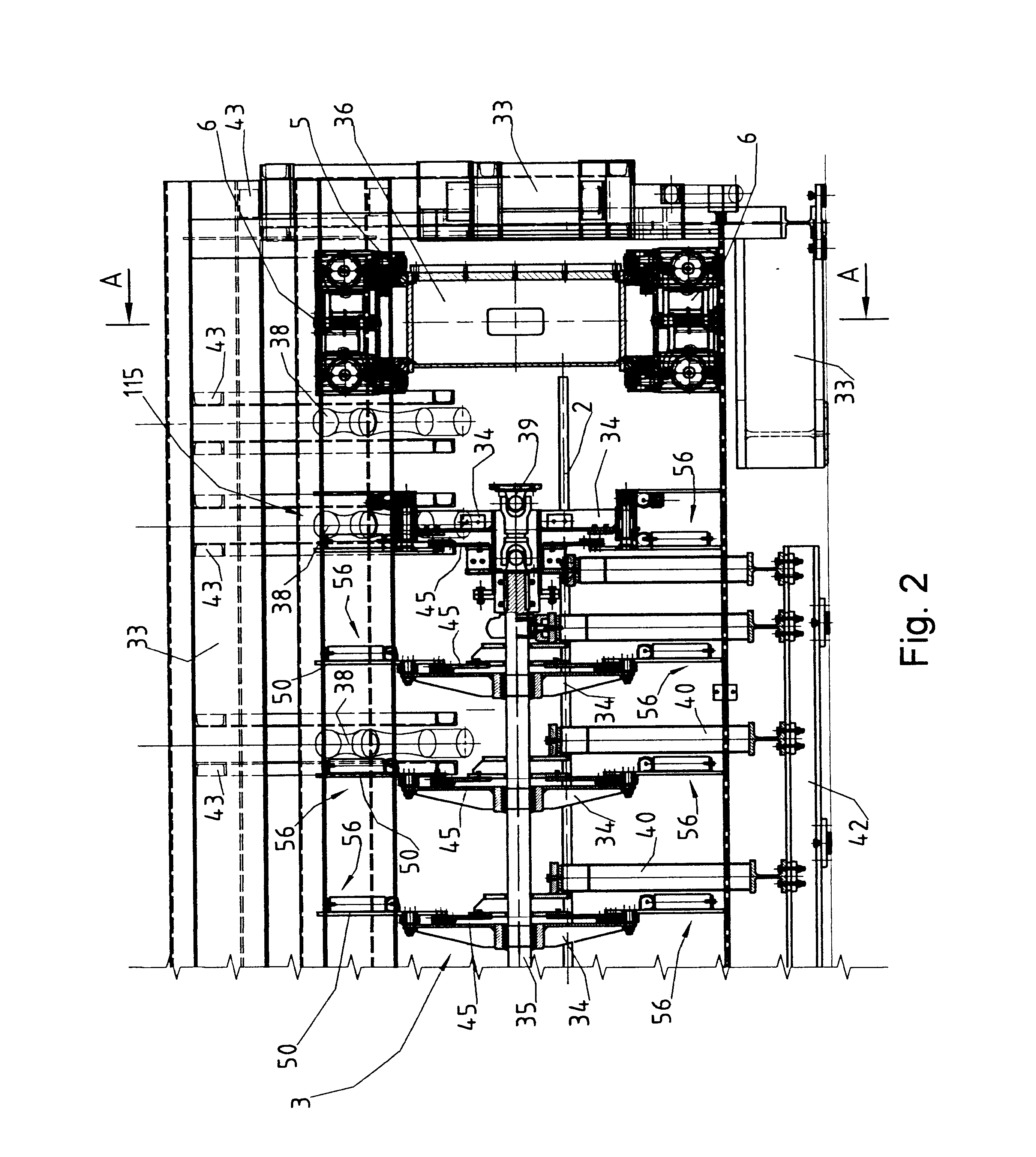

Machine for profile working of front surfaces on oblong wood workpieces

Machine for profile working of front surfaces on oblong wood workpieces resolves the problem of simple, accurate and fluent or continued working of workpieces front surfaces of various lengths and intersections, and the machine is of a compact construction. It is characteristic by the construction of the entrance turnover device transversely placed between longitudinal conveyors with carriers, which has on the periphery of rotating wheels constructed movable bearing couplings, and by them fixed guiding plates with the groove inside which there are movably inserted guided bearings of bearing couplings. In the area of the entrance turnover device there are placed under an optional angle the oblique roller conveyors, inside which there are flexibly and circularly movably inserted rolls. Between the longitudinal conveyors there is placed the endless conveying chain, which has to its entire extent fastened clamping units that have inside the fixed housing inserted the clamping mechanism, the operation of which is regulated by the control field and control indicator. Over the free corner of the longitudinal conveyor there runs the oblique conveyor with carriers tilted to the longitudinal conveyor. Between longitudinal conveyors there is transversely placed the exit turnover device, which has on the periphery of rotating wheels constructed movable bearing cranks, being through the chain connected with the control chain wheel and control panel, the guided bearing of which is movably inserted inside the channel guide fixed on the rotating wheels.

Owner:LEDINEK PAVEL +1

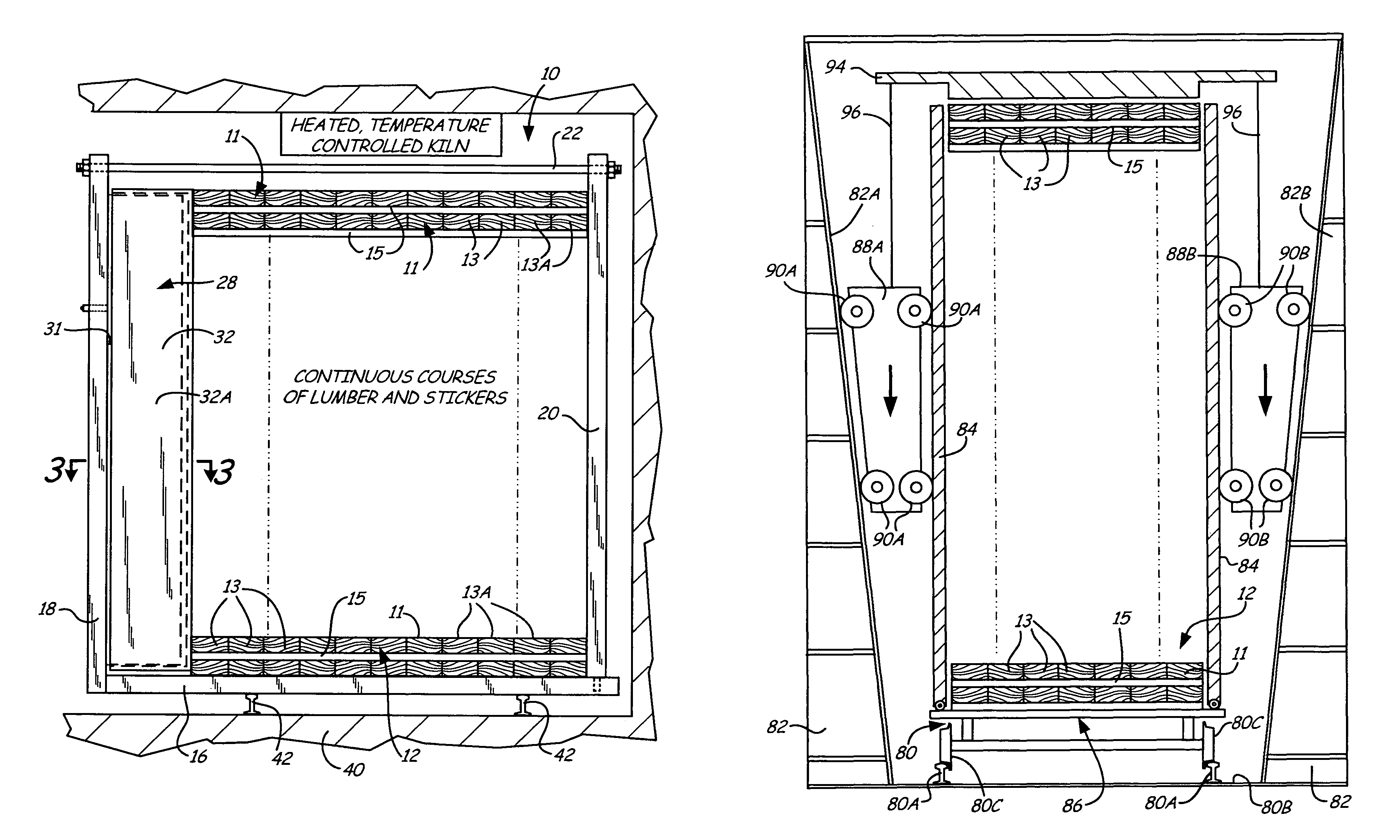

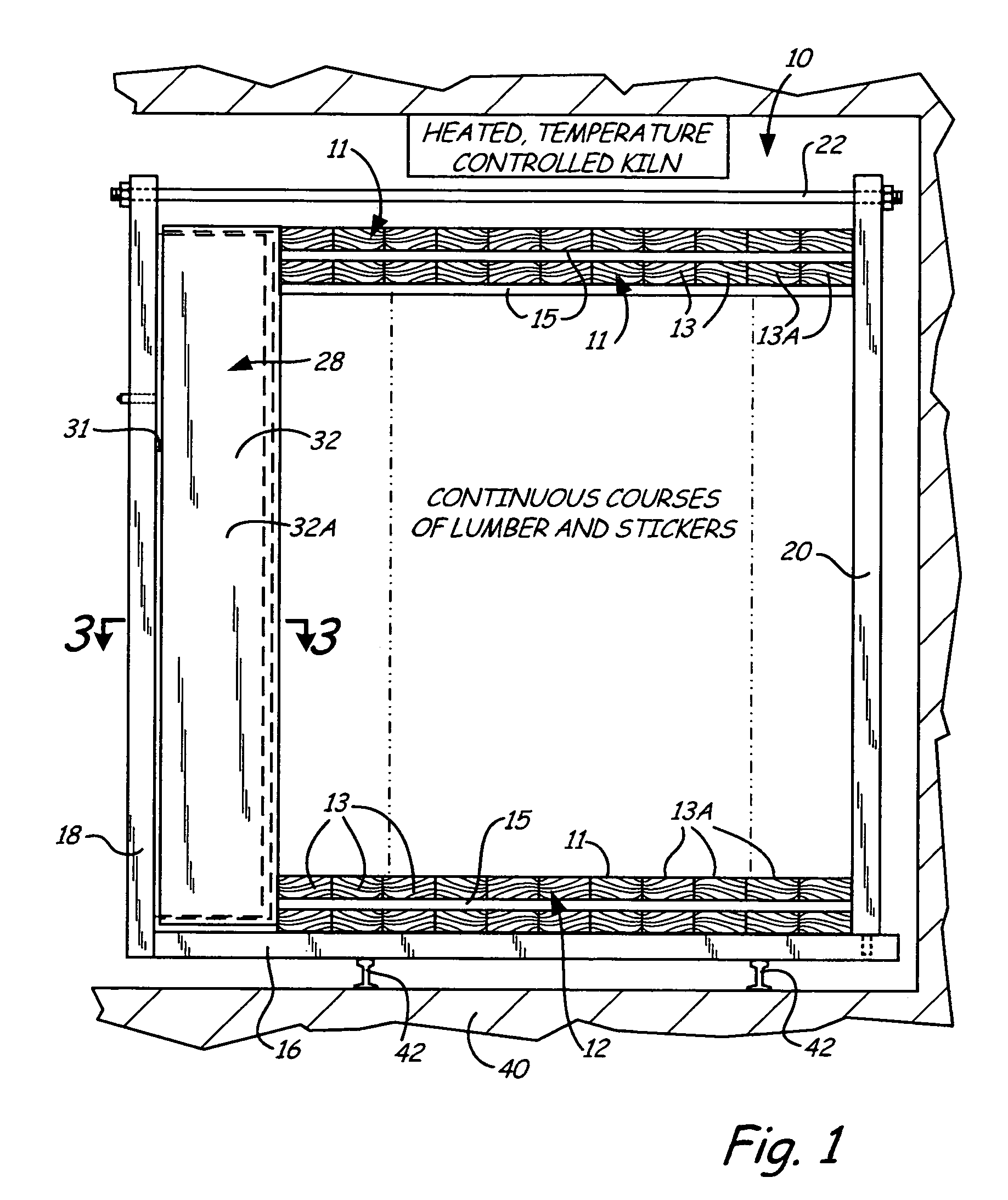

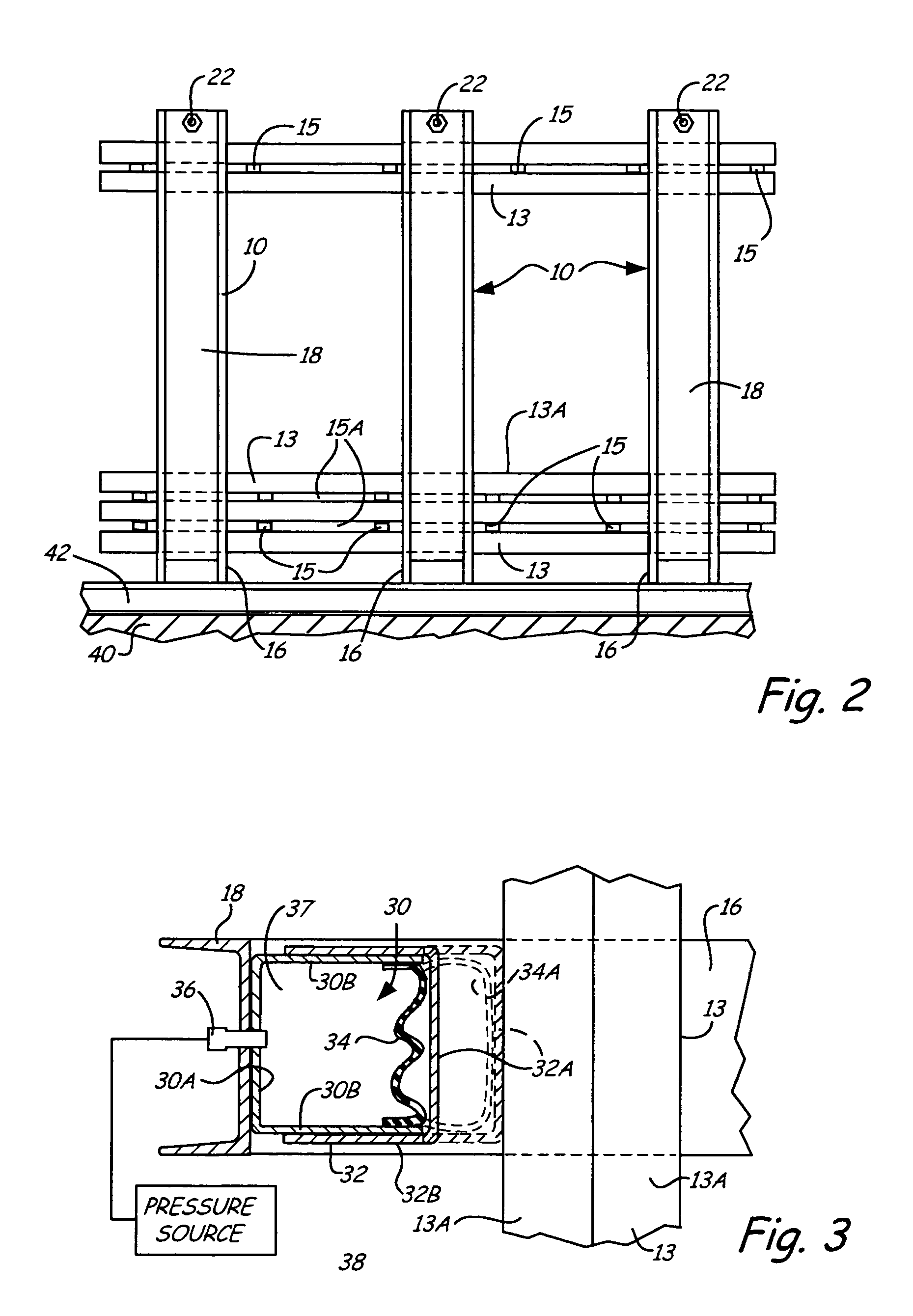

Restraining device for reducing warp in lumber during drying

The present invention relates to an apparatus and processing method for drying lumber, for example two-by-four studs in an environment in a kiln in a manner to avoid warping, including crook, bow, cup and twist. The lumber pieces are stacked in a normal manner with stickers for providing air flow between courses of the lumber pieces, and the stack is dried while a horizontal force is provided to the respective courses of lumber in the stack to hold the individual pieces of lumber in edge to edge contact throughout the drying, equalizing, conditioning and cooling process for first drying of lumber, redrying of lumber or in a treatment process for removing warp from previously dried lumber. A vertical force comprising a weight or other force generating device can be also applied to the stack of lumber to augment the overall reduction in warpage if so evidenced.

Owner:ERICKSON ROBERT W

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com