Patents

Literature

162results about "Tenon making apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

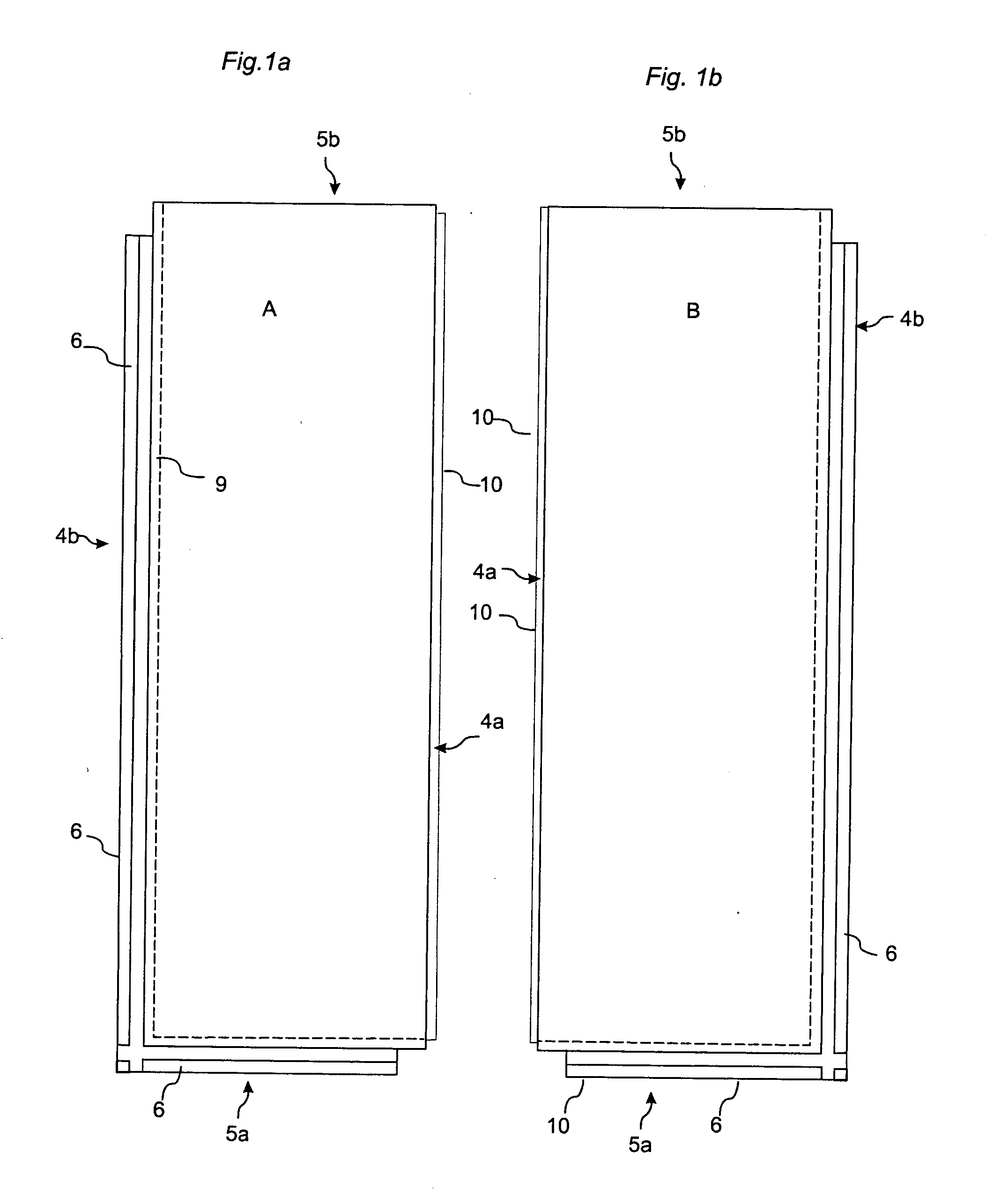

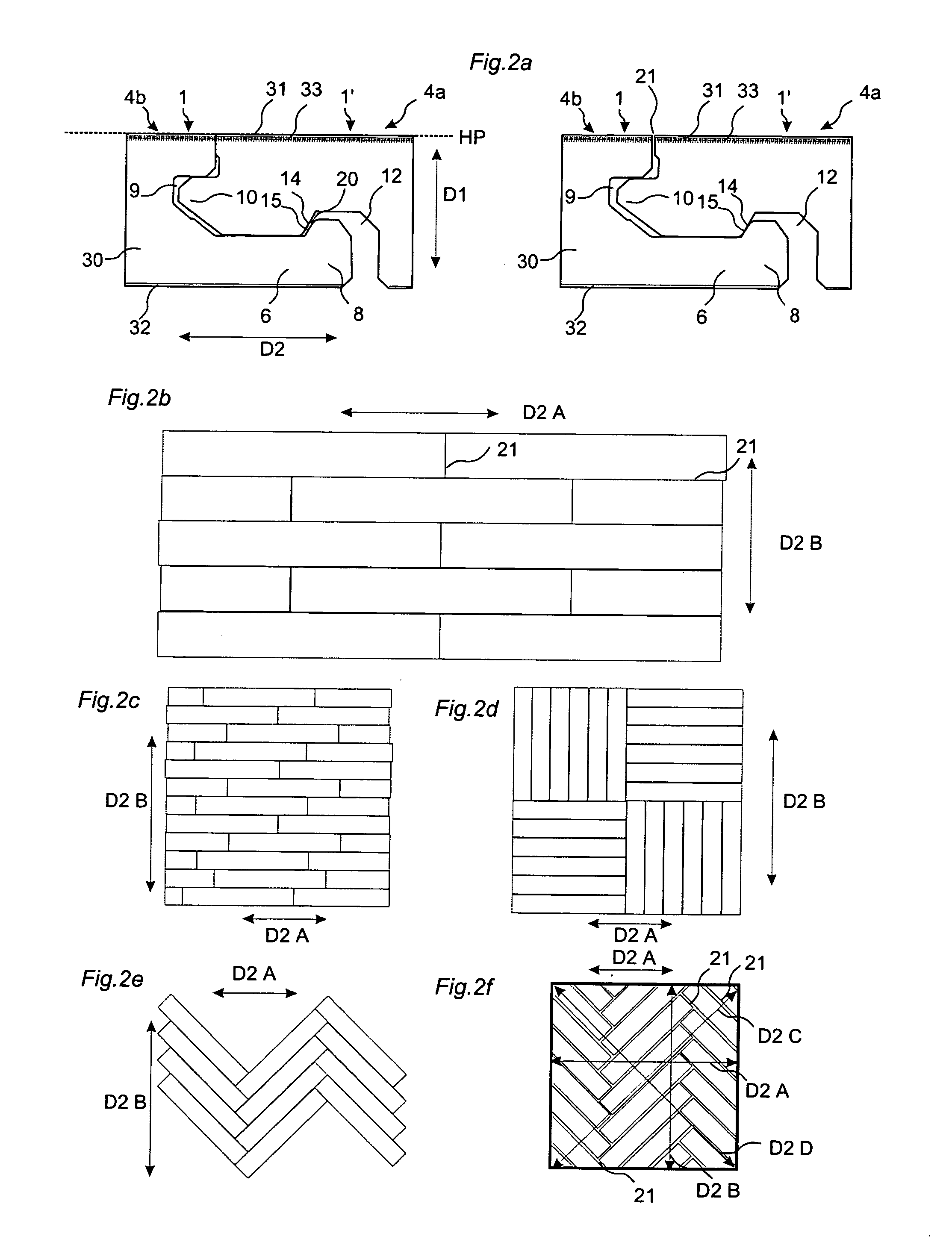

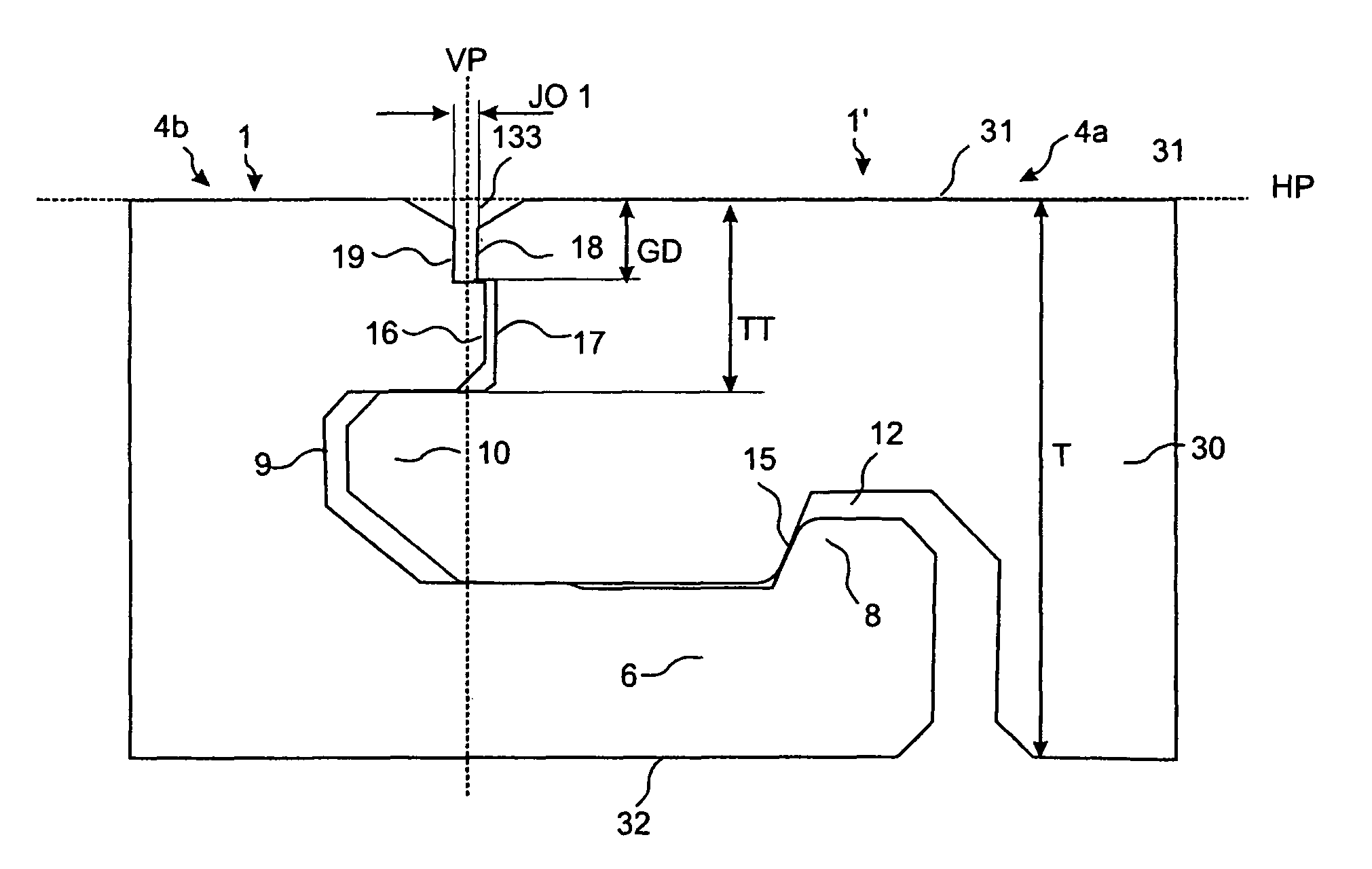

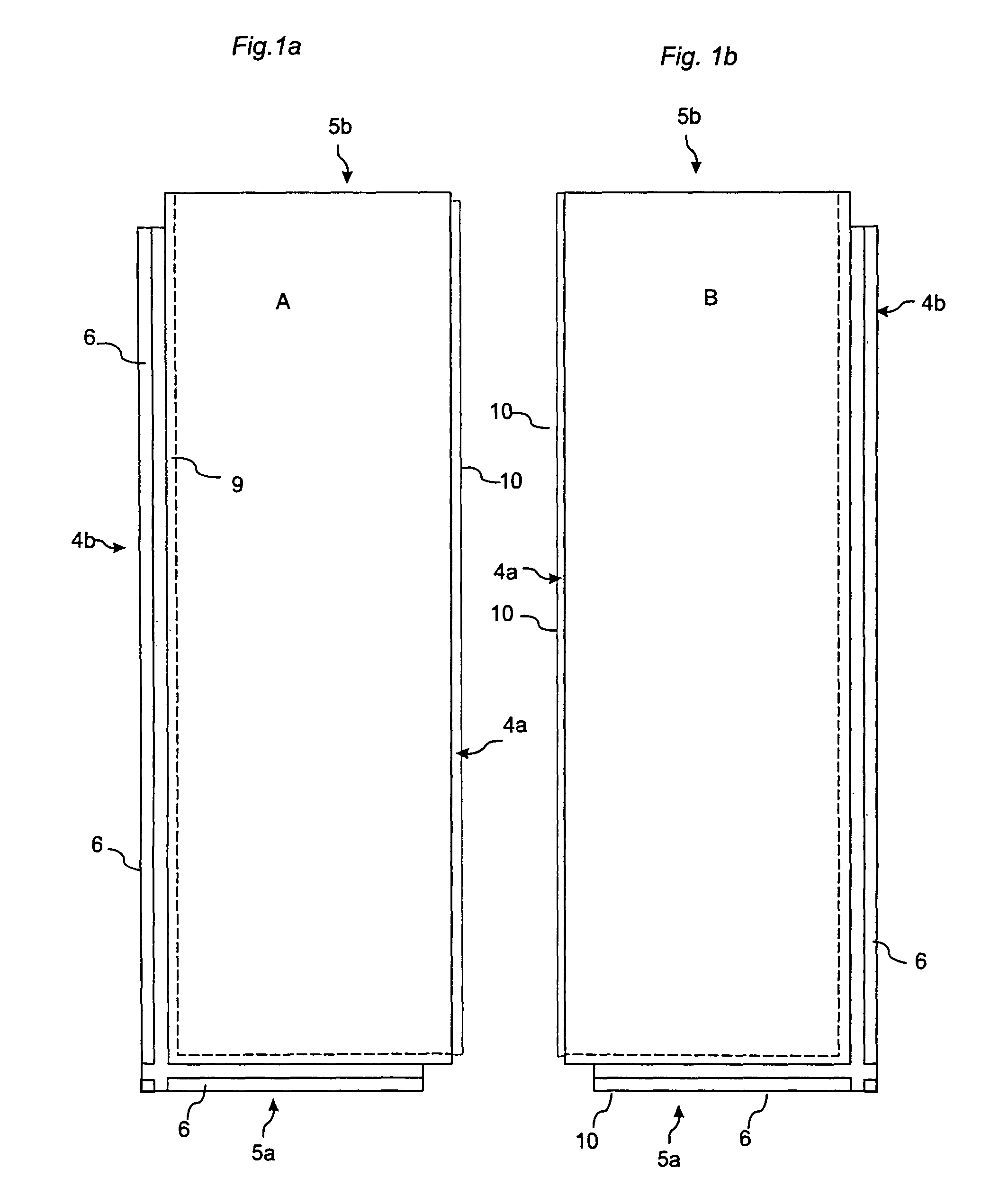

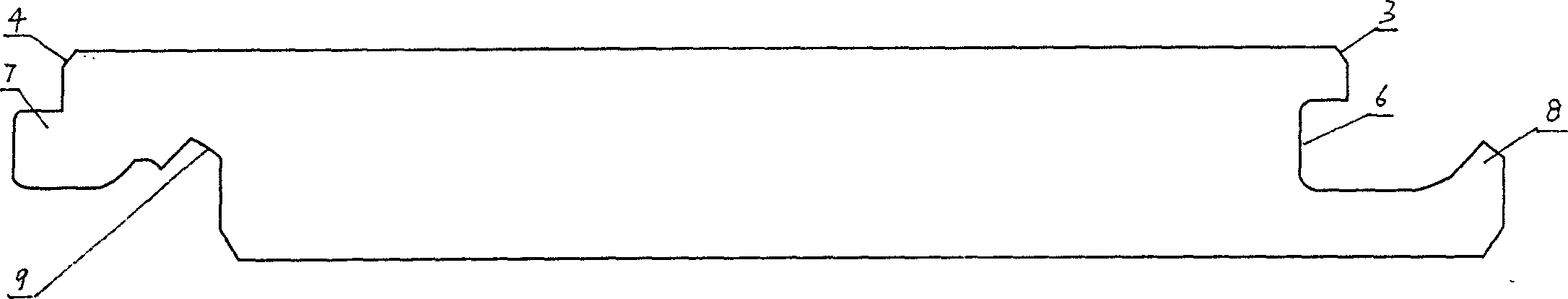

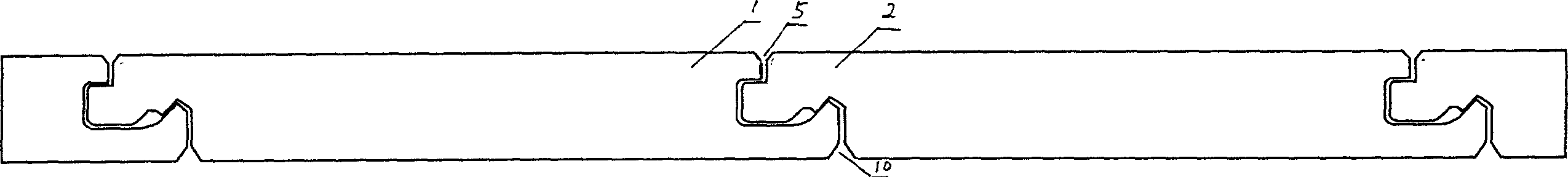

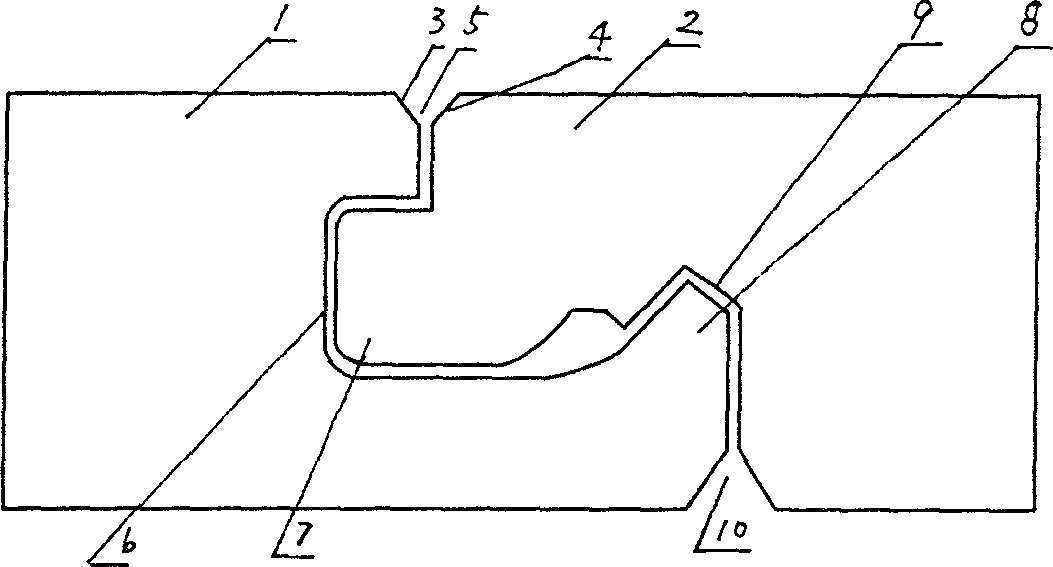

Mechanical locking of floor panels

ActiveUS20090193748A1Avoid vertical displacementReduce vertical frictionTongue/grooves making apparatusWallsEngineeringTongue and groove

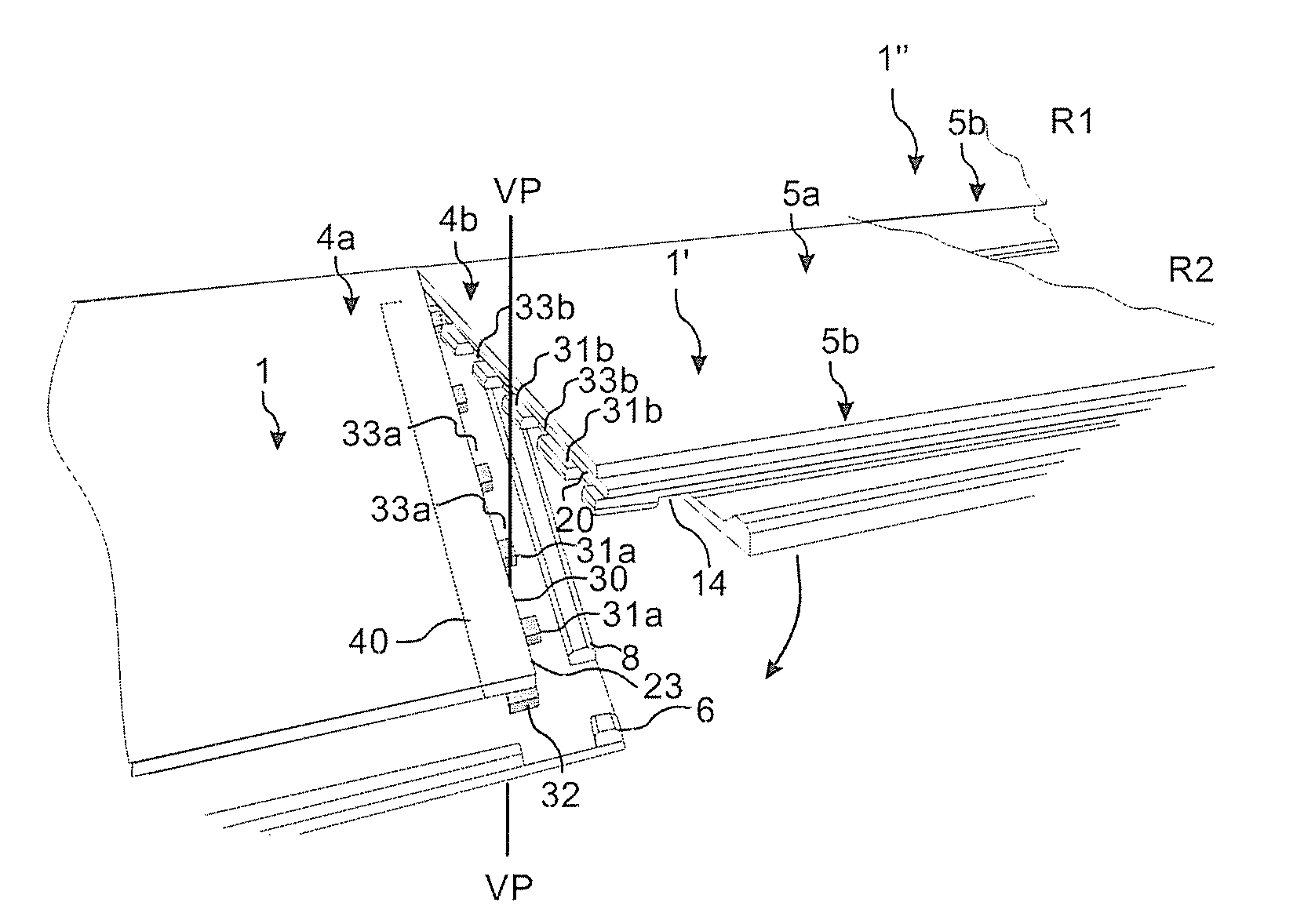

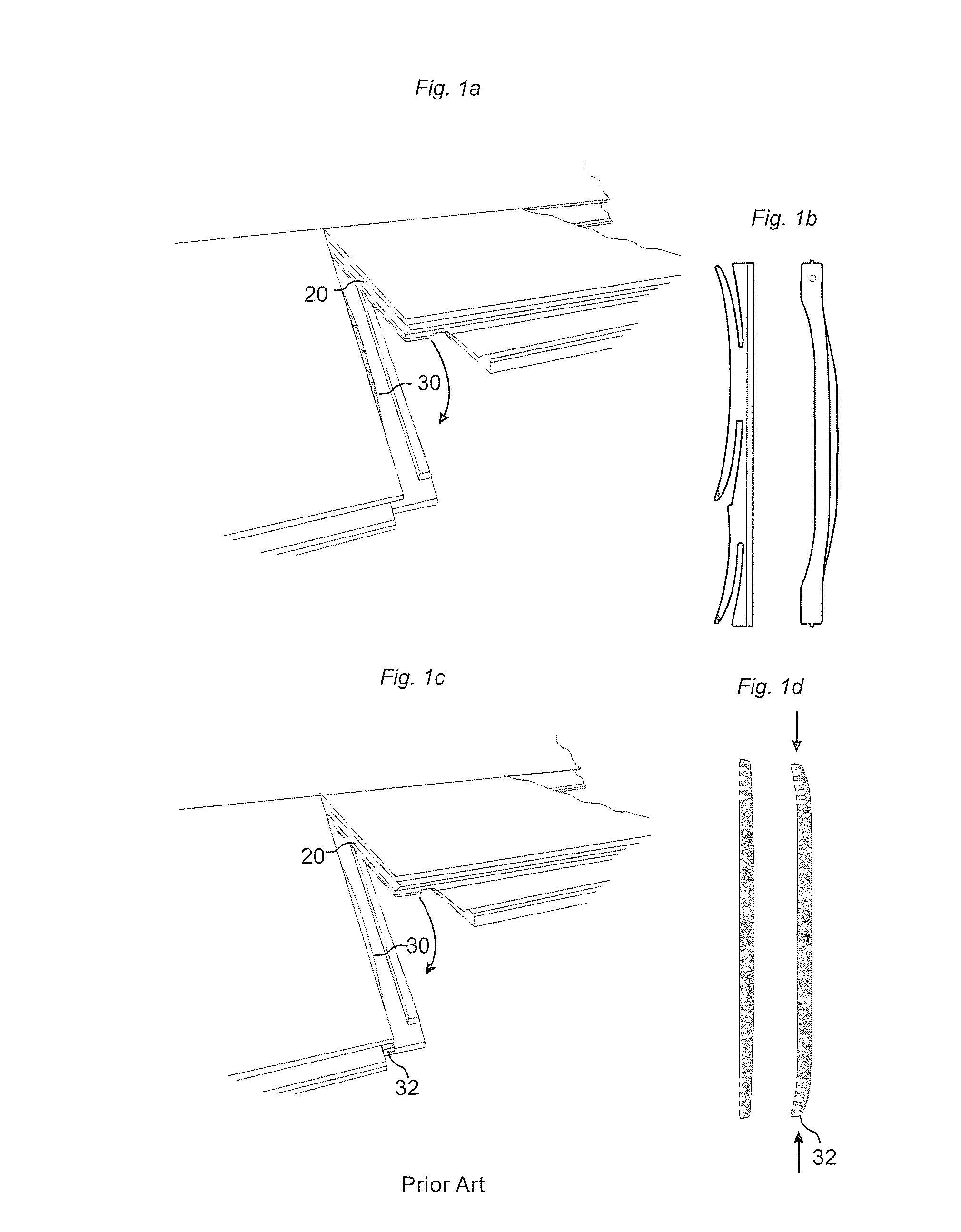

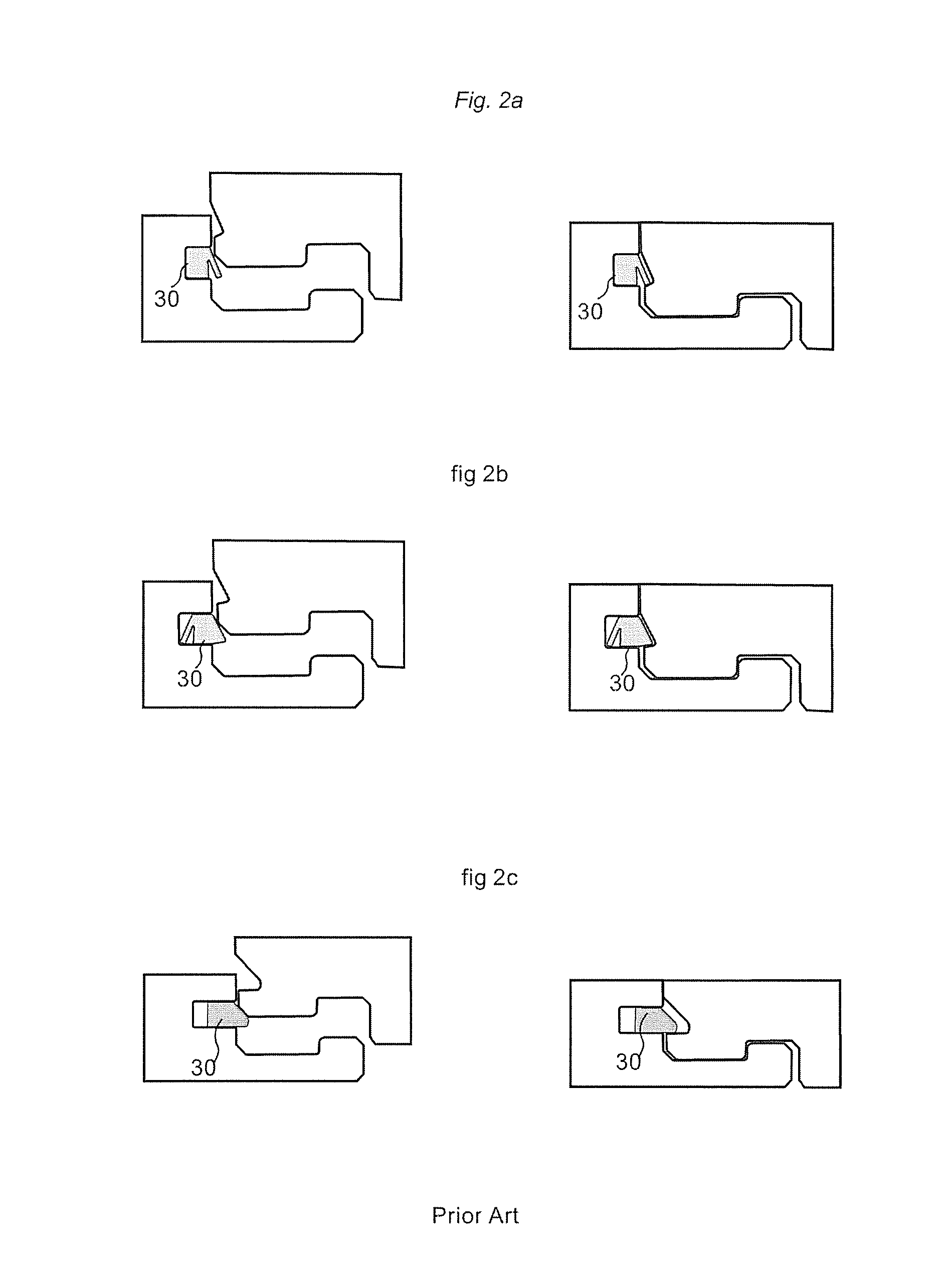

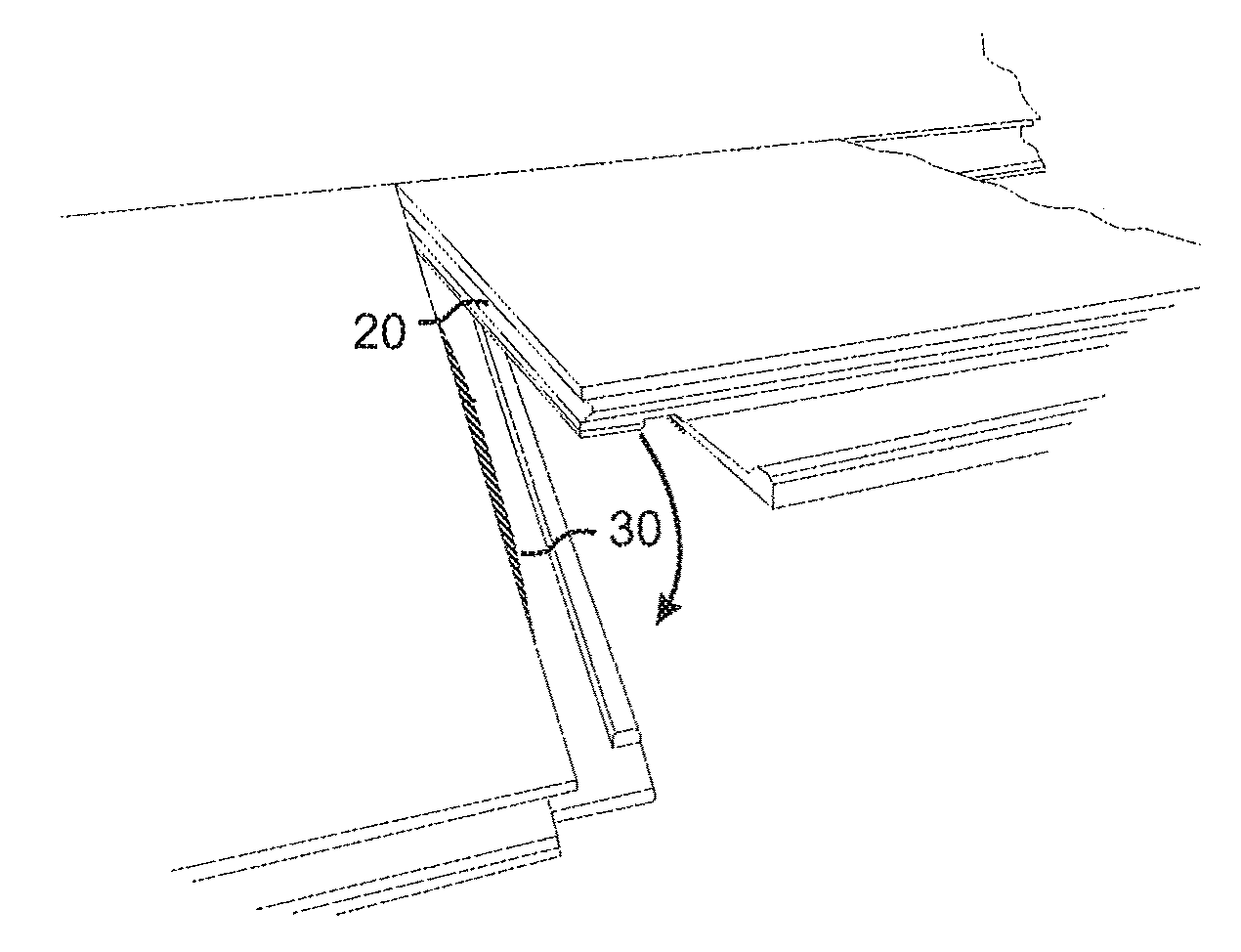

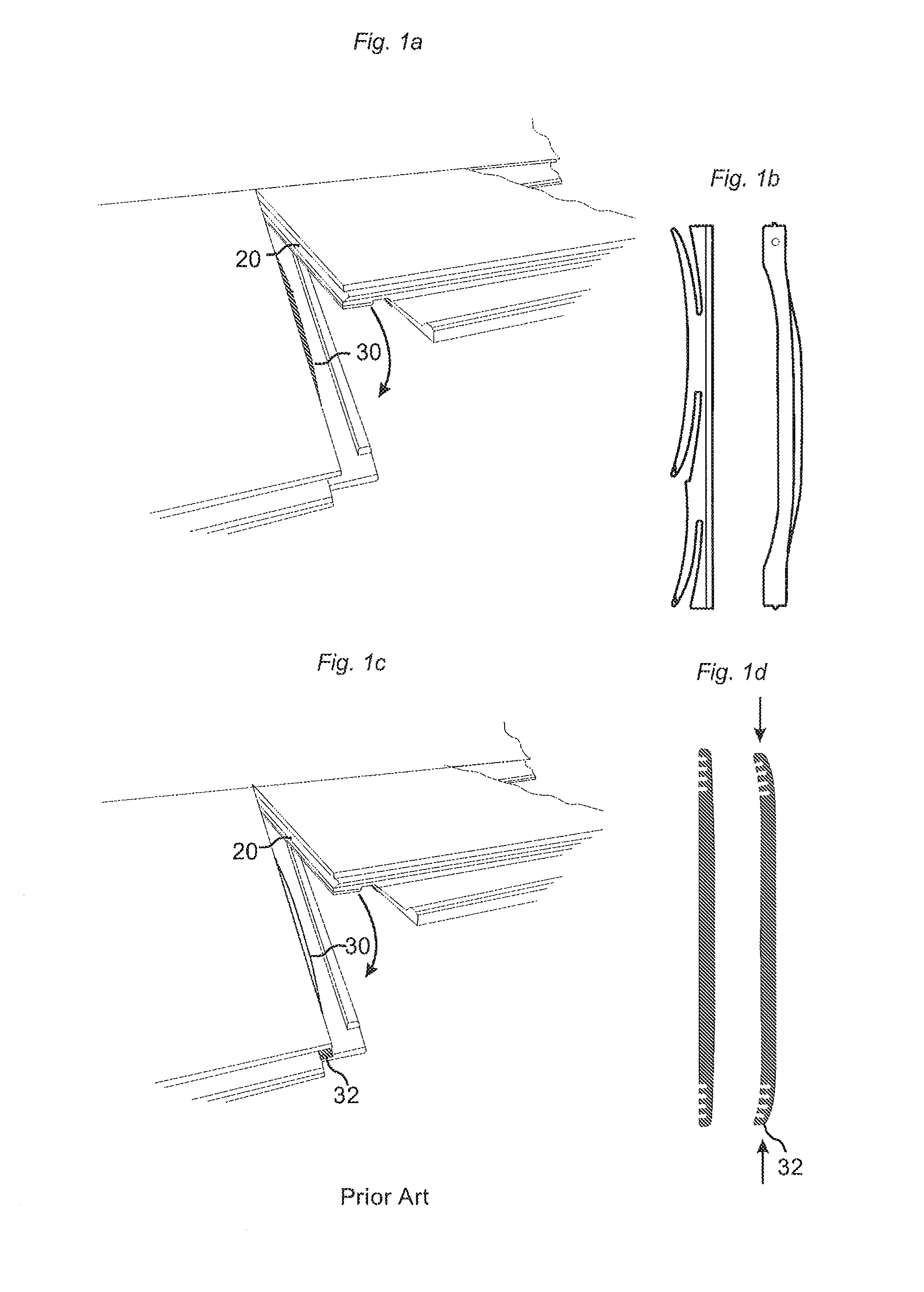

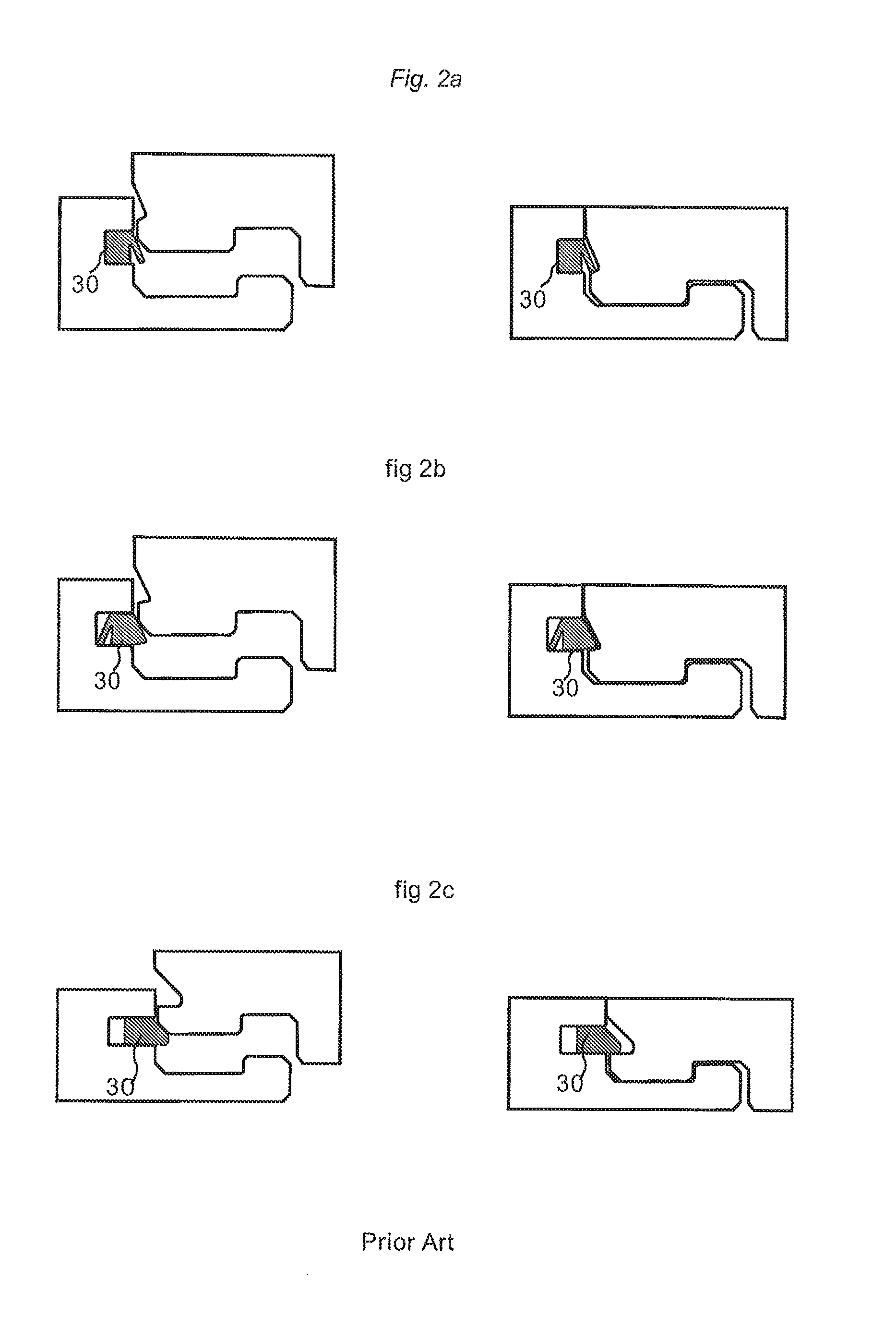

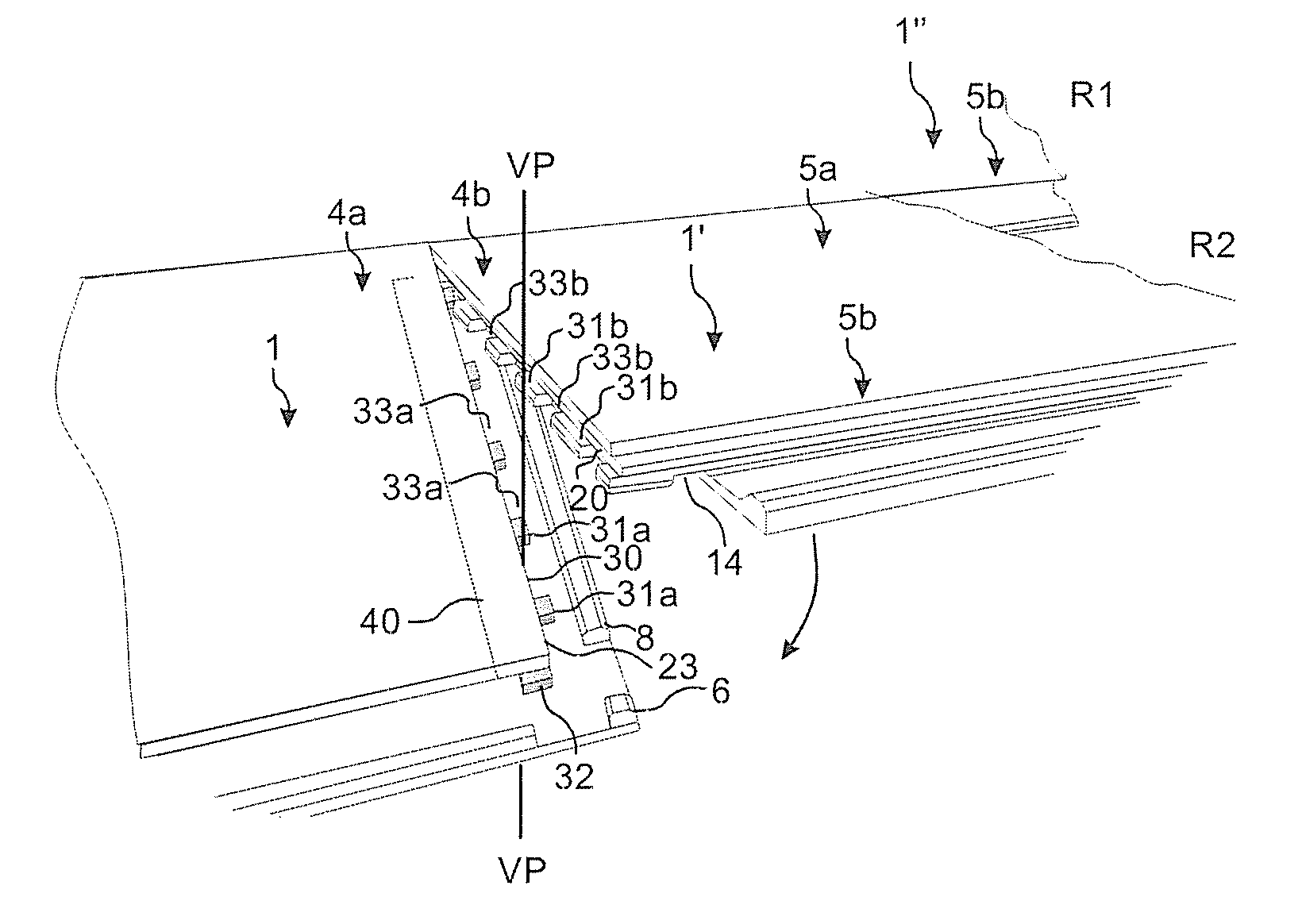

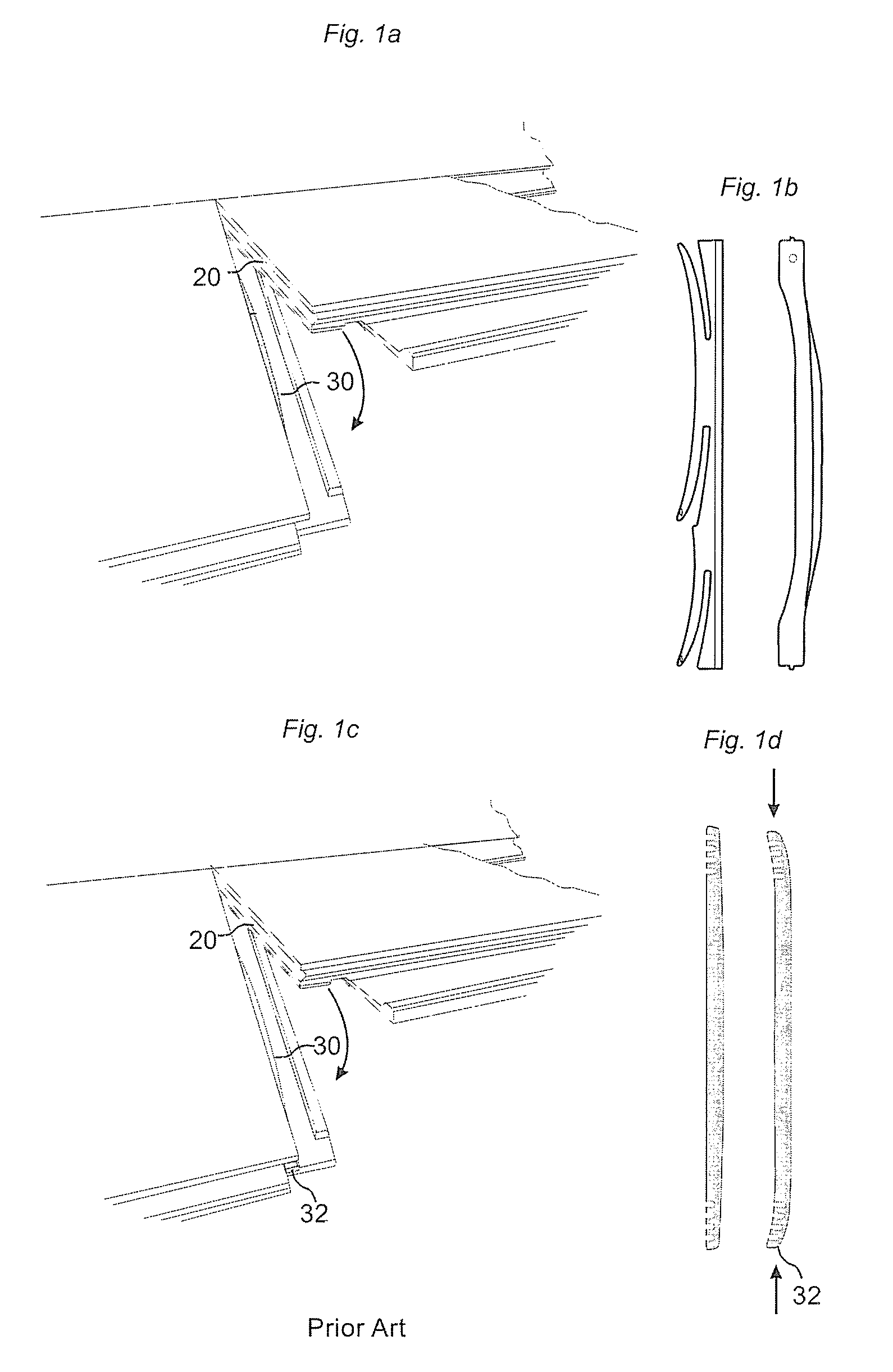

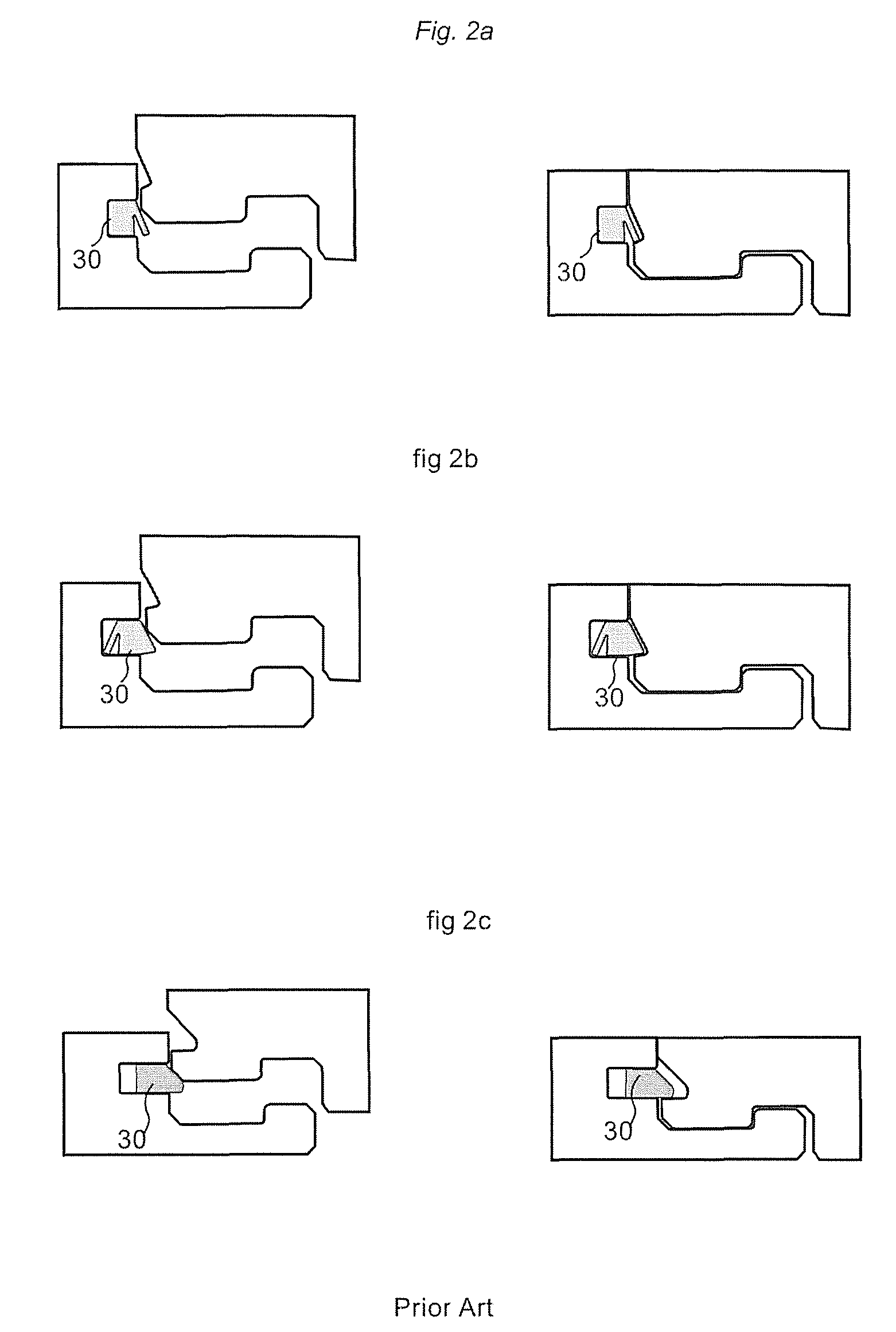

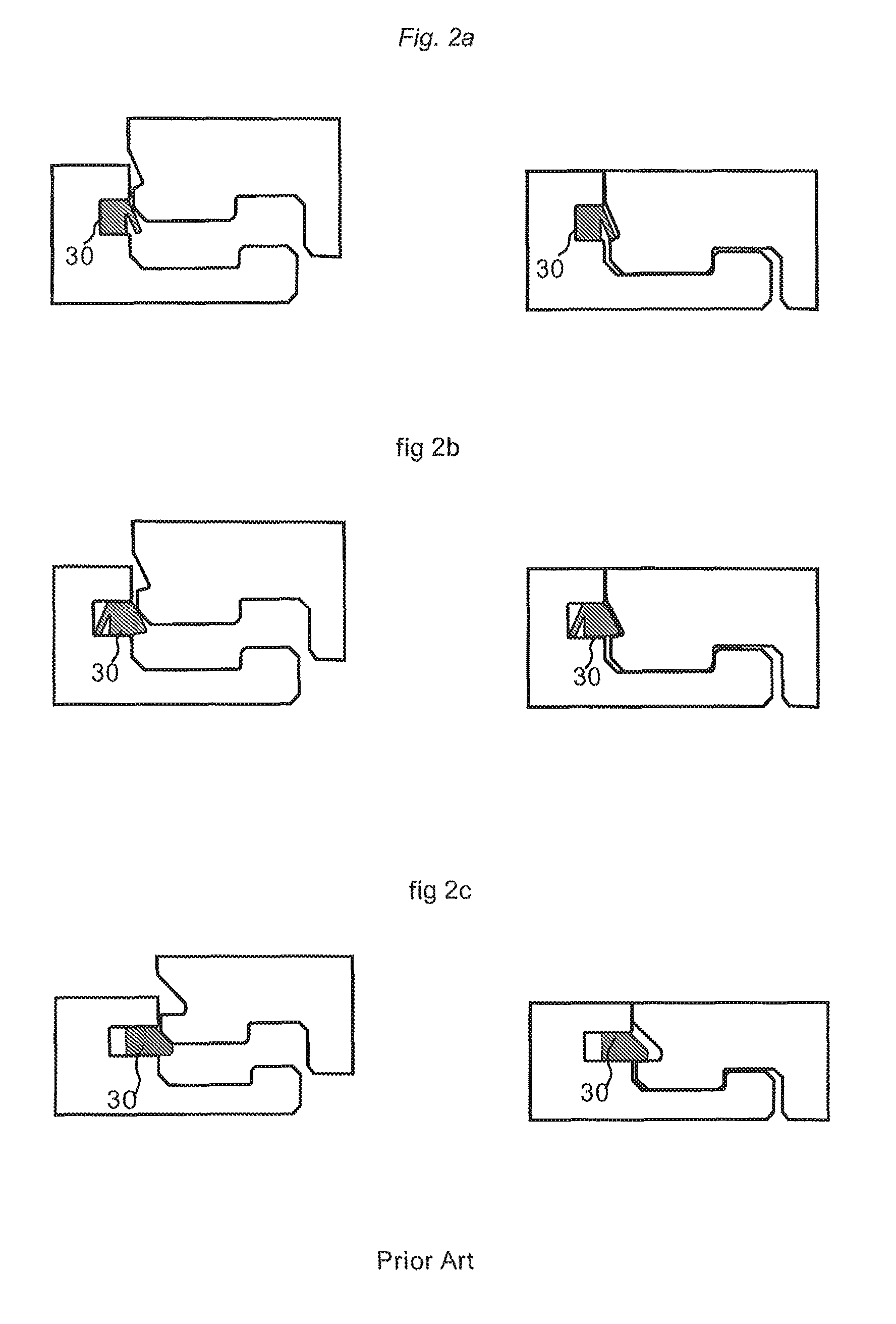

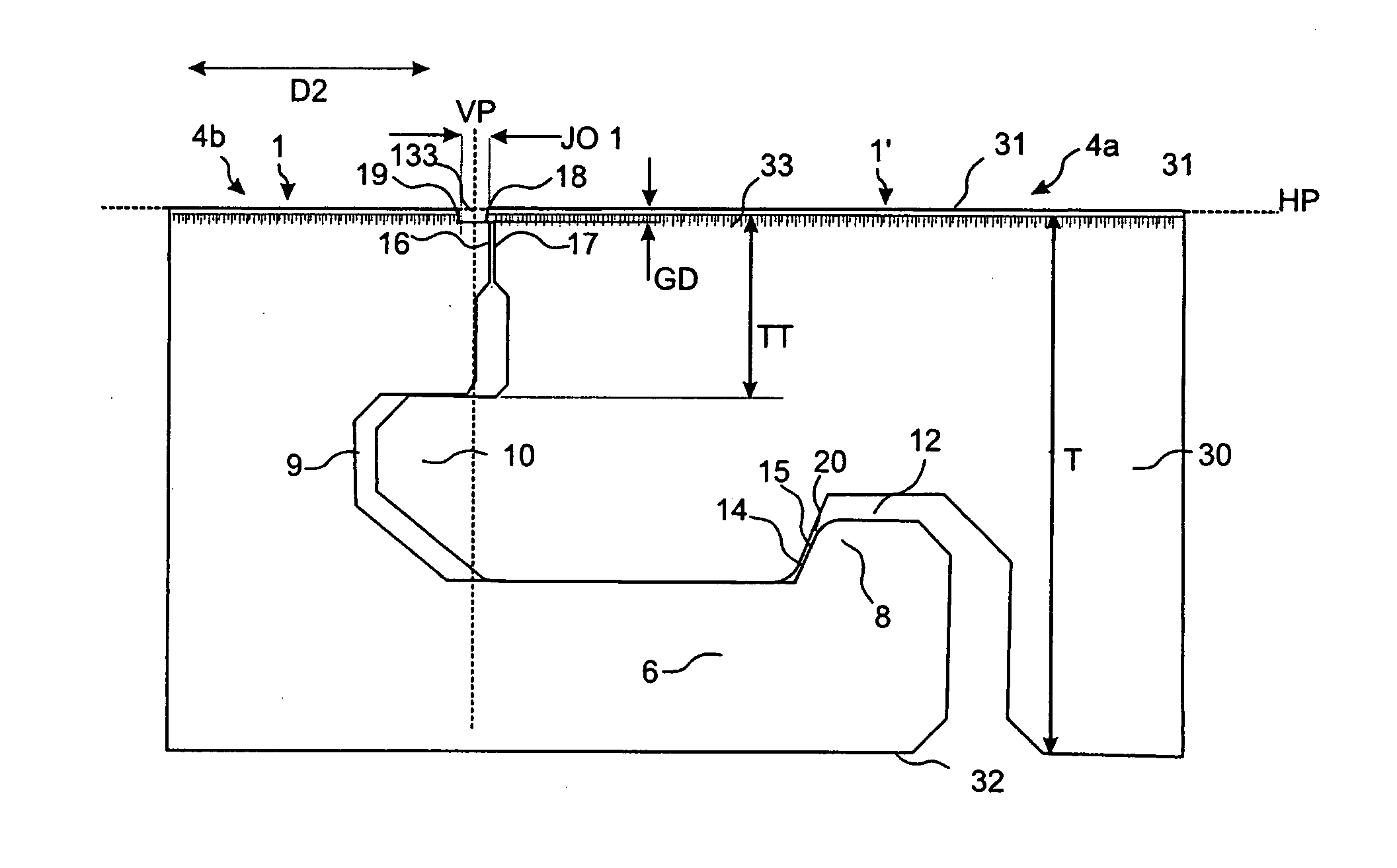

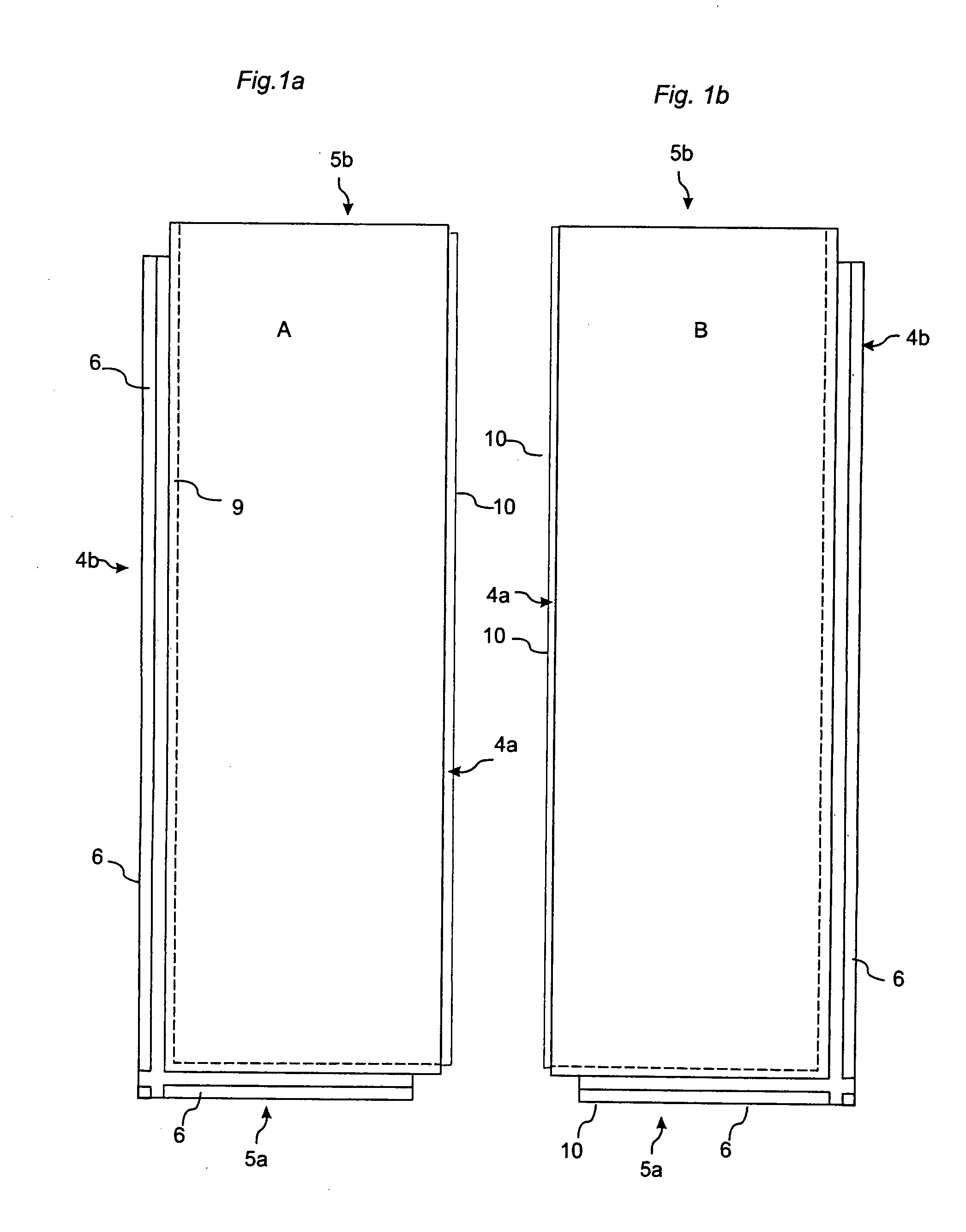

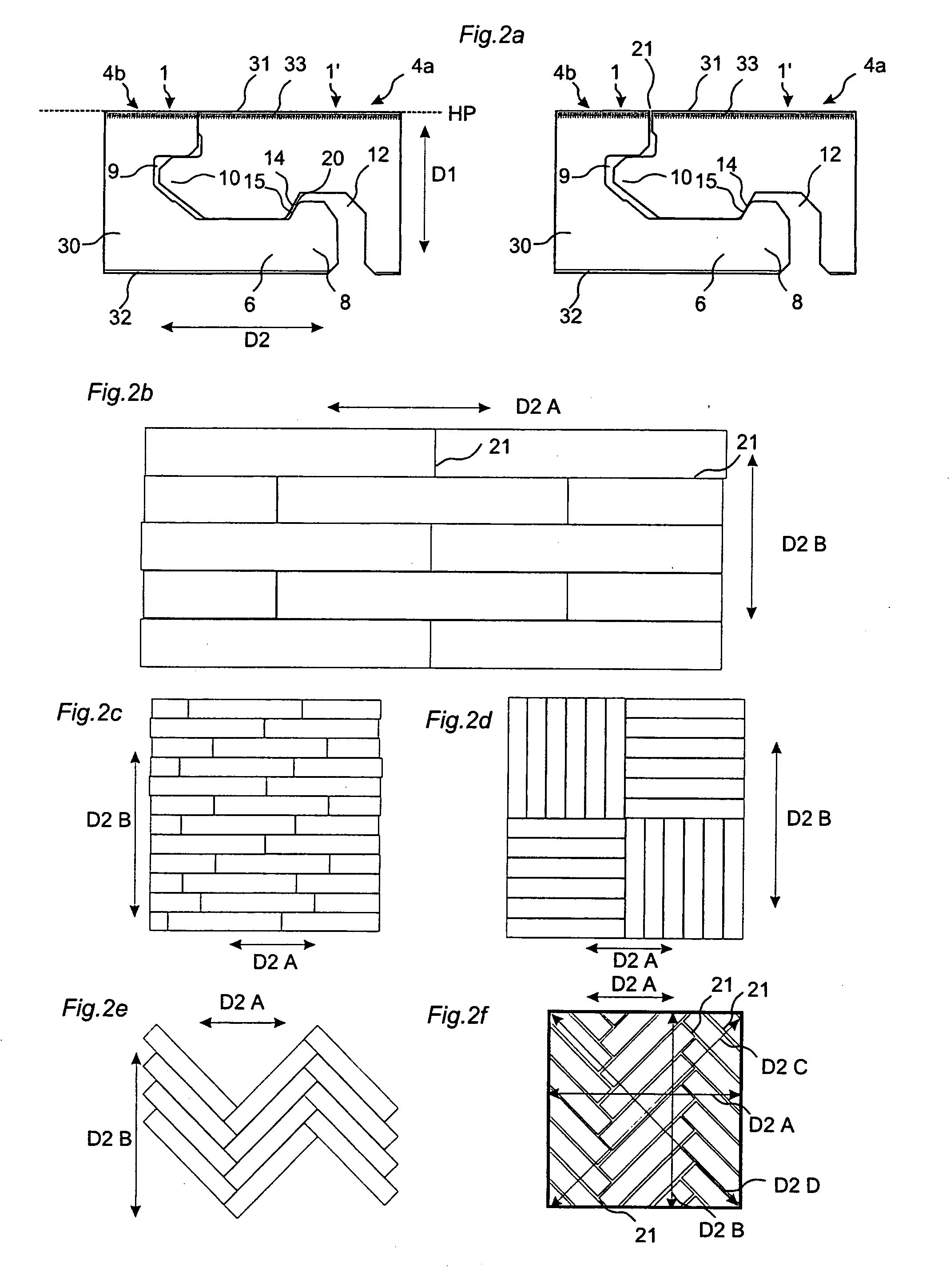

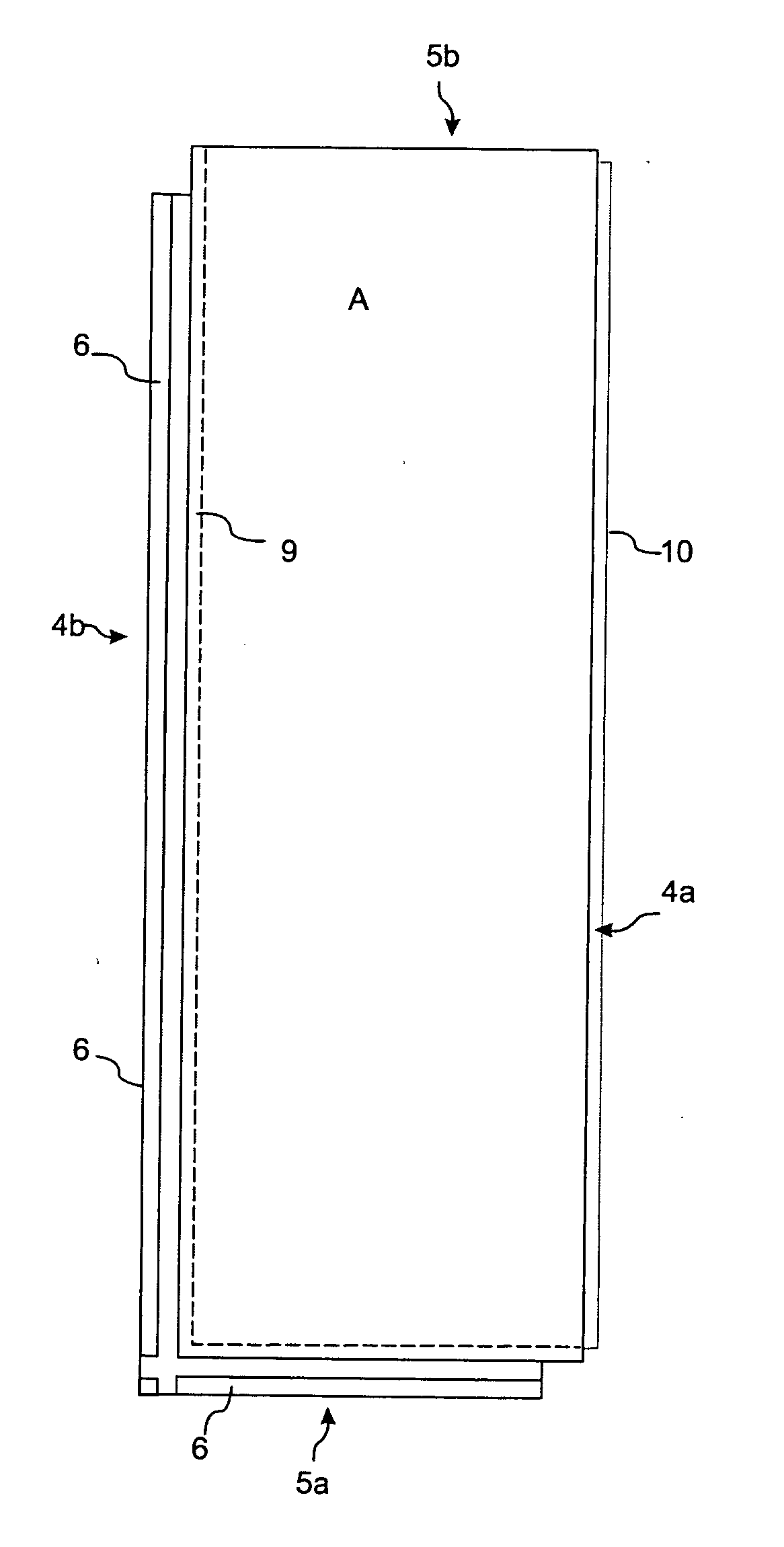

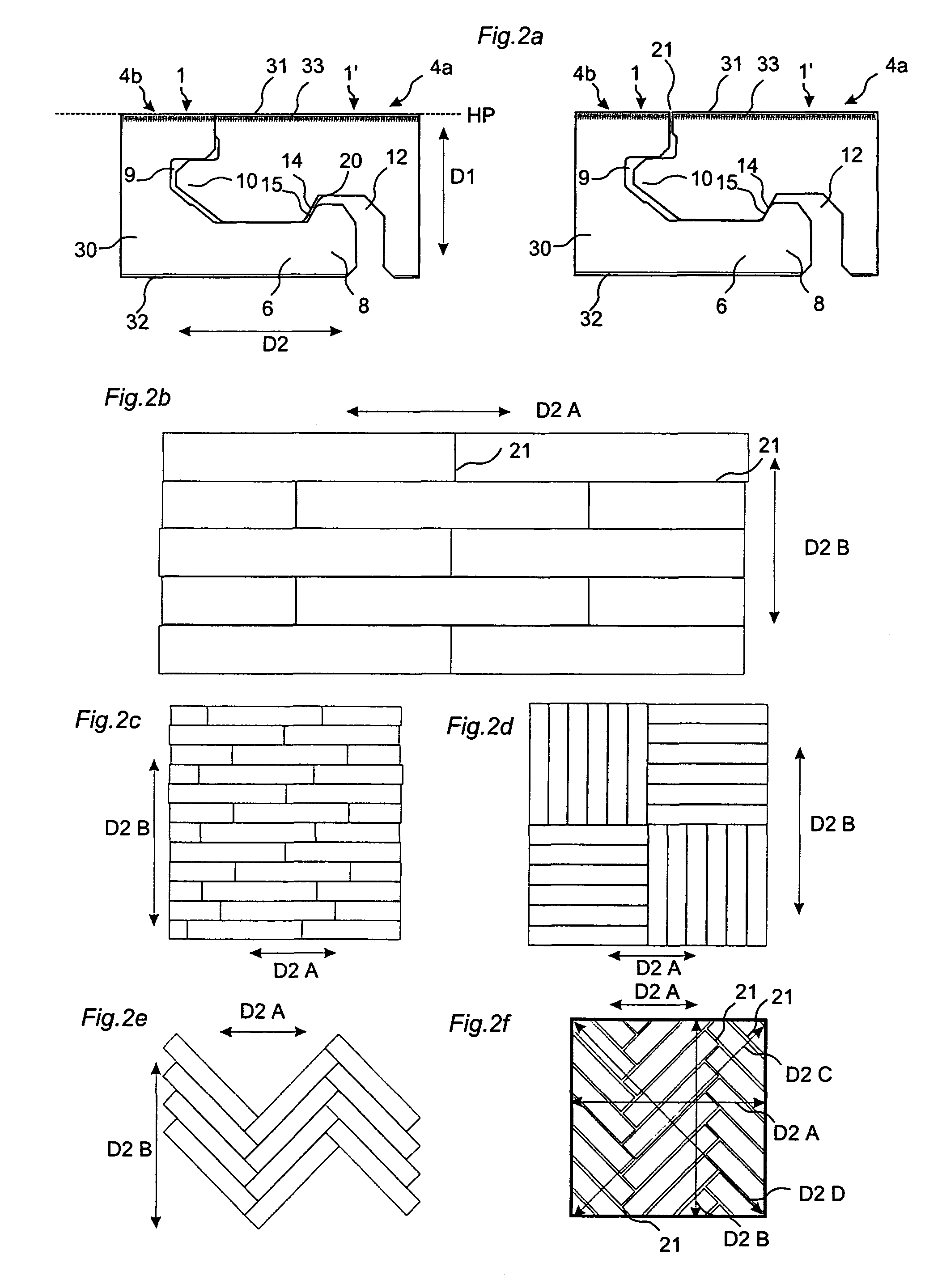

Floor panels are shown, which are provided with a mechanical locking system having tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels

ActiveUS8505257B2Easy to installImprove installation and strength and quality and production costTongue/grooves making apparatusWallsTongue and grooveEngineering

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Floor covering and locking systems

ActiveUS20080168737A1Remove changeChange shapeTongue/grooves making apparatusWallsEngineeringMechanical engineering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Floor covering and locking systems

InactiveUS20050166516A1Remove changeChange shapeTongue/grooves making apparatusWallsEngineeringMechanical engineering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Floor covering and locking systems

ActiveUS8495849B2Remove changeChange shapeTongue/grooves making apparatusWallsMechanical engineeringFloor covering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

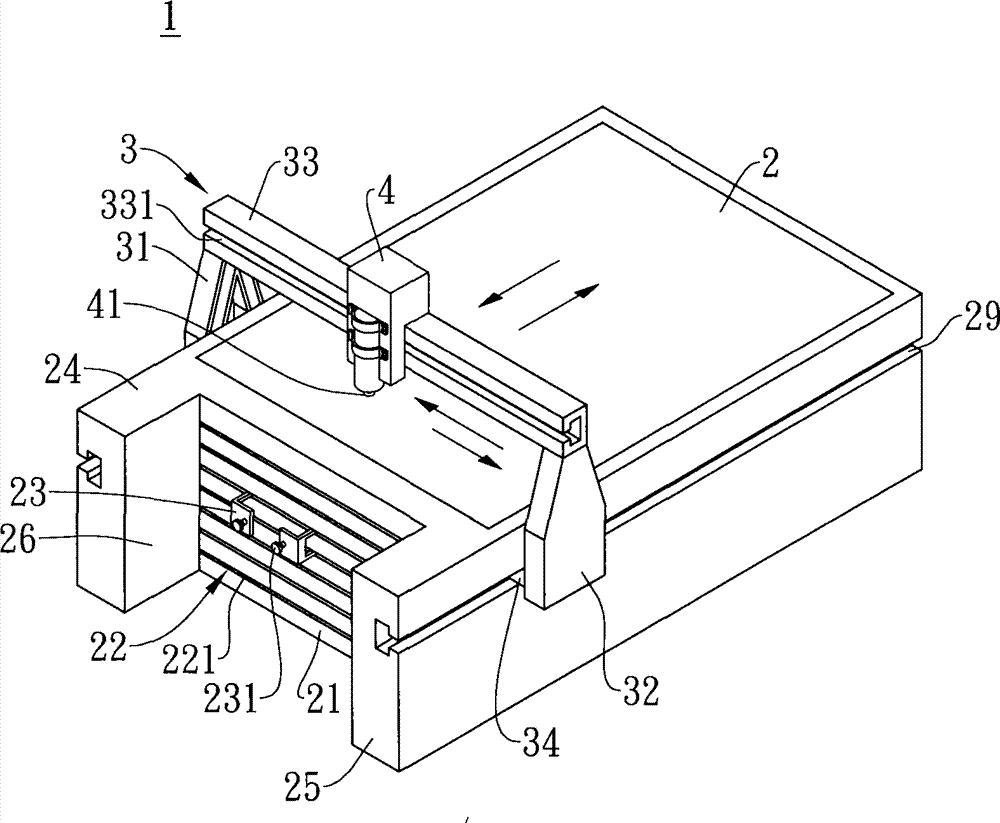

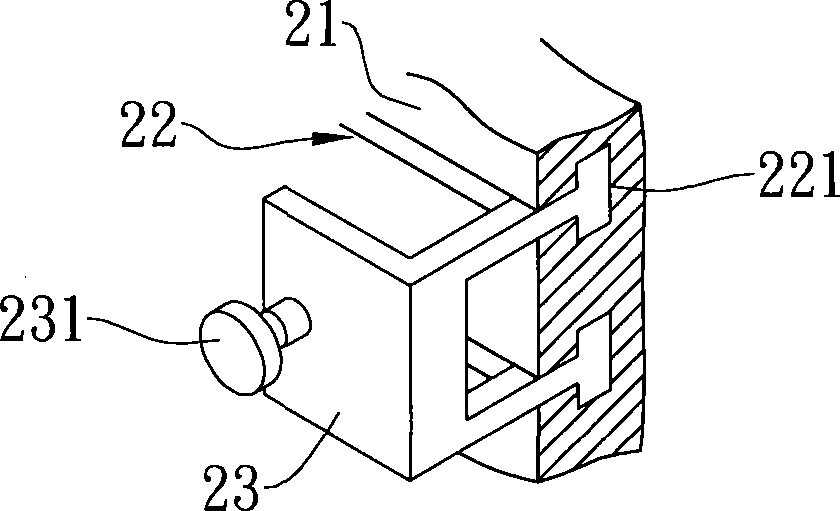

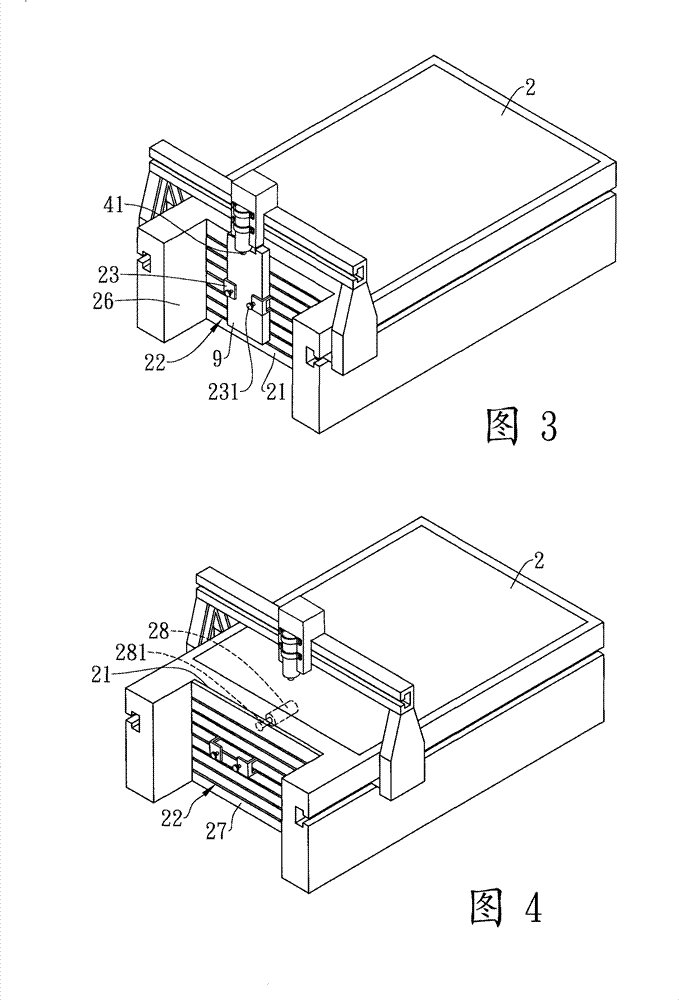

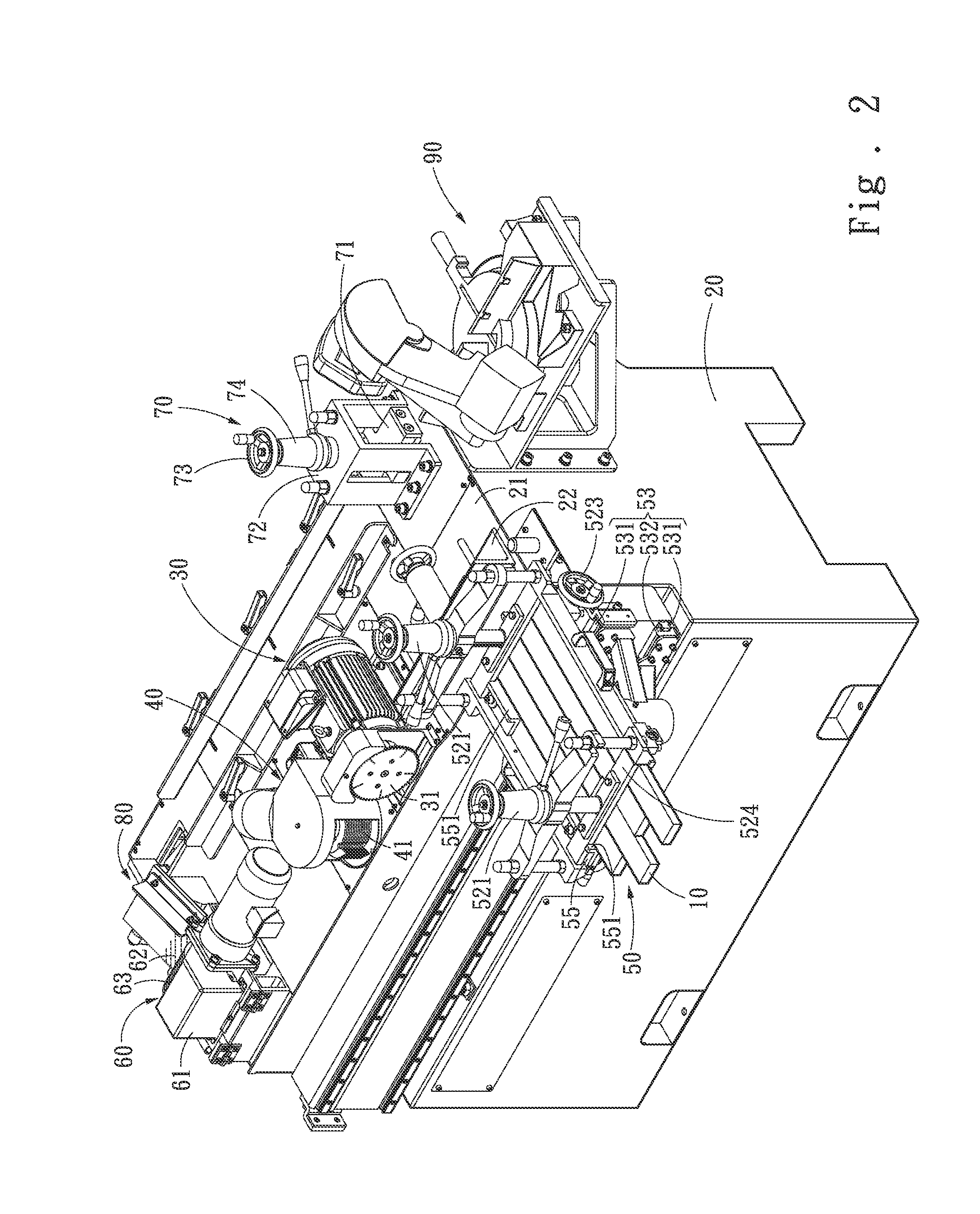

Numerical control five-axis tenon machining machine tool

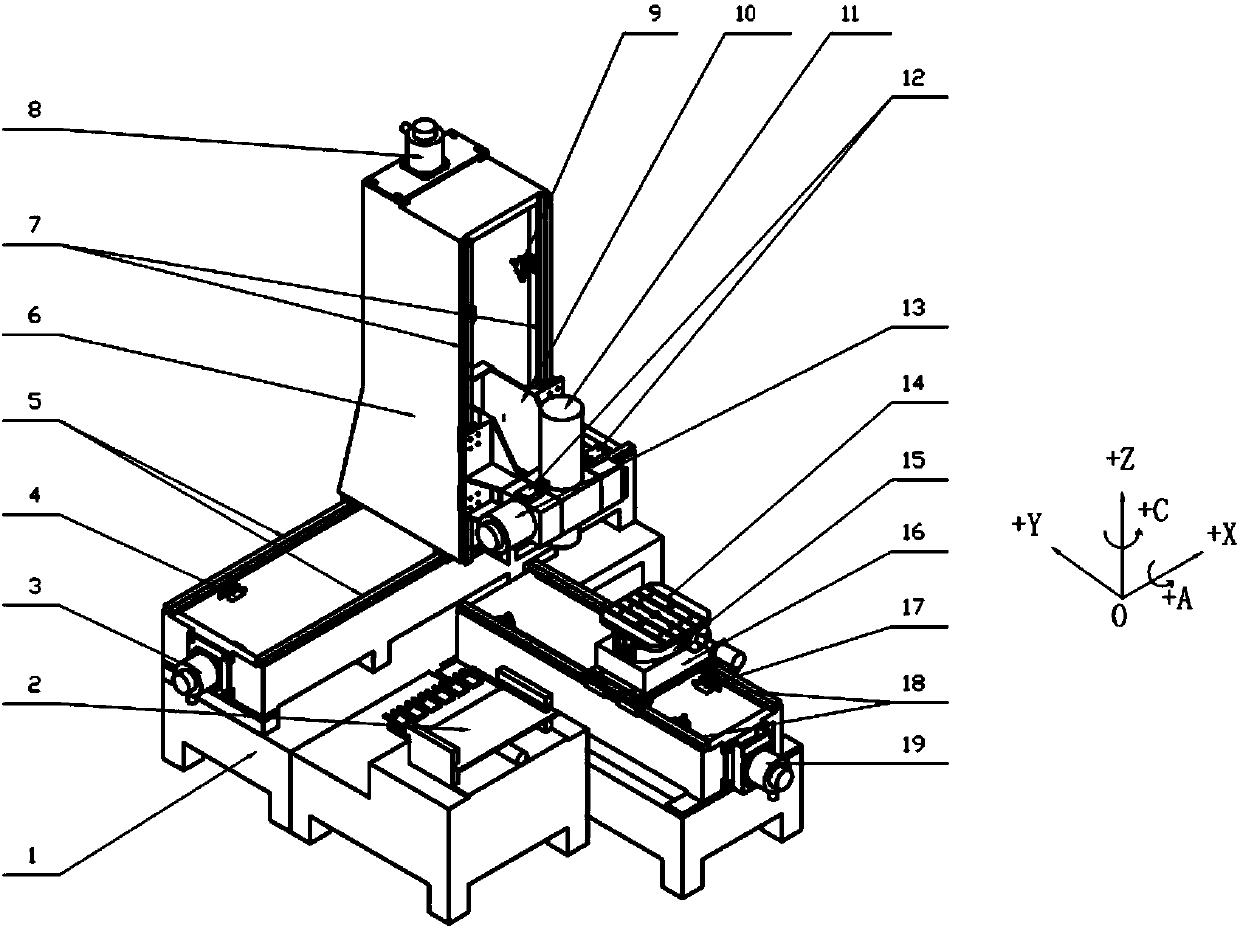

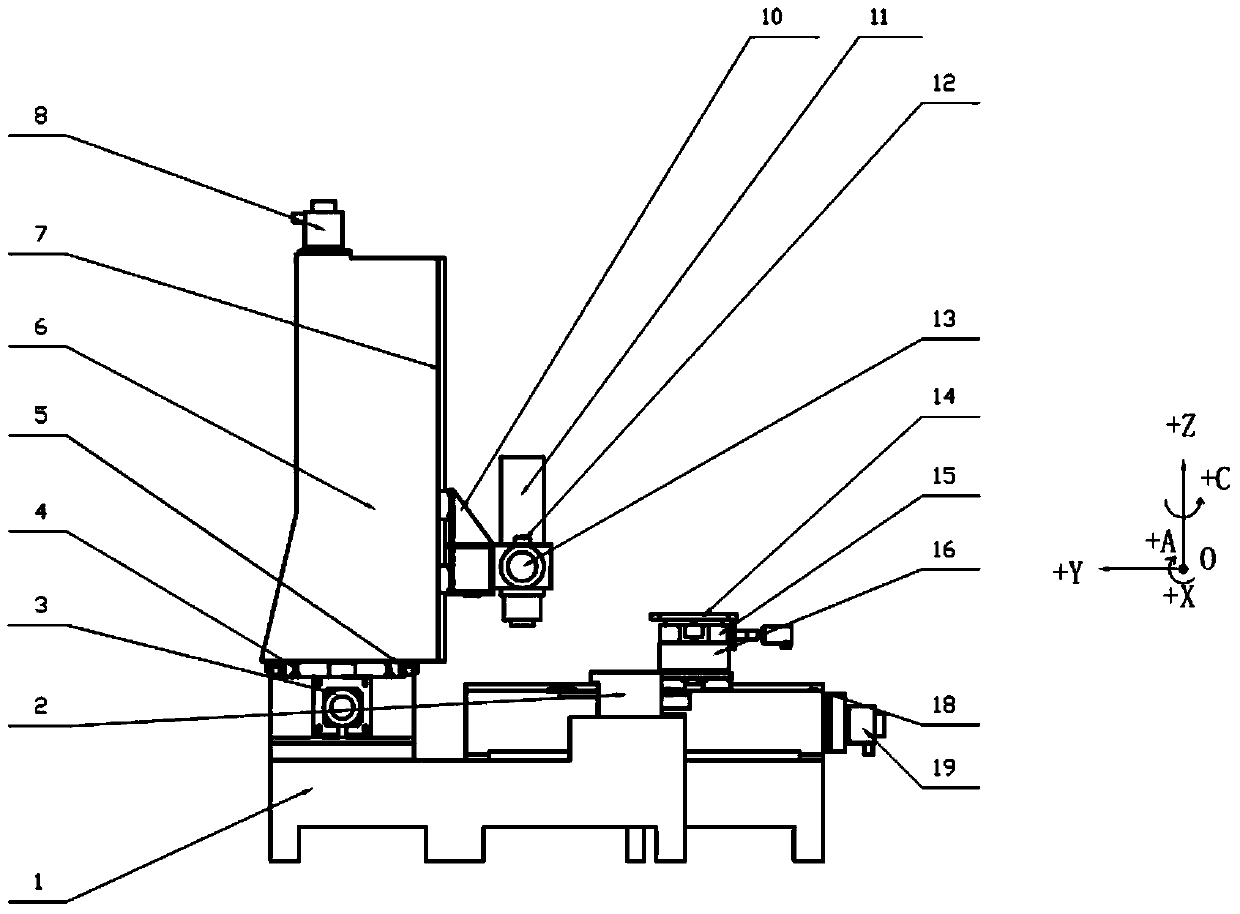

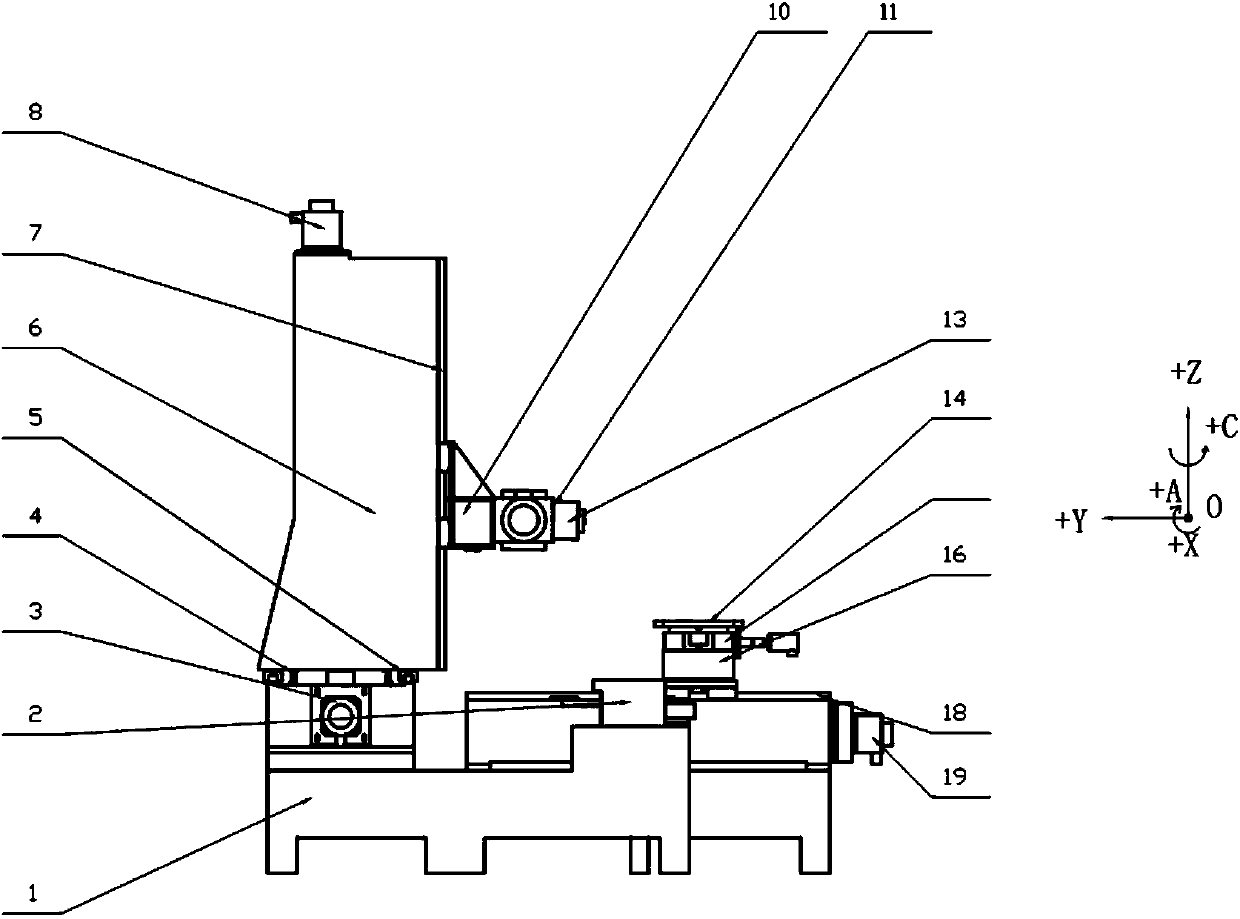

InactiveCN103802180AImprove machining accuracyPracticalTongue/grooves making apparatusTenon making apparatusNumerical controlMortise and tenon

The invention discloses a numerical control five-axis tenon machining machine tool, and belongs to the technical field of machining machine tools. The numerical control five-axis tenon machining machine tool comprises a machine tool body, upright posts, a rotary positioning turntable, a main shaft component, a tool magazine and a control card used for controlling the machine tool, wherein the upright posts are connected with the machine tool body through X-axial guide rails and move along the X axes under the drive of a drive device; the rotary positioning turntable is connected with the machine tool body through a Y-axial guide rail and moves along the Y axis under the drive of the drive device; the main shaft component is connected with the upright posts through Z-axial guide rails and move along the Z axis under the drive of the drive device; an X-axial guide rail is placed on each of the two cross beams of the machine tool; the upright posts and the cross beams of the machine tool body form guide rail connection; a Y-axial guide rail is placed on each of the two longitudinal beams of the machine tool body; a Y-axial sliding plate and the longitudinal beams of the machine tool body form guide rail connection. The numerical control five-axis tenon machining machine tool can implement the three-dimensional five-axis cutting machining on a complex tenon structure, and the machining level of the machine tool is higher. According to the machine tool, the self gravity of the machine tool is greatly reduced without influencing the use precision of the machine tool.

Owner:刘岩松

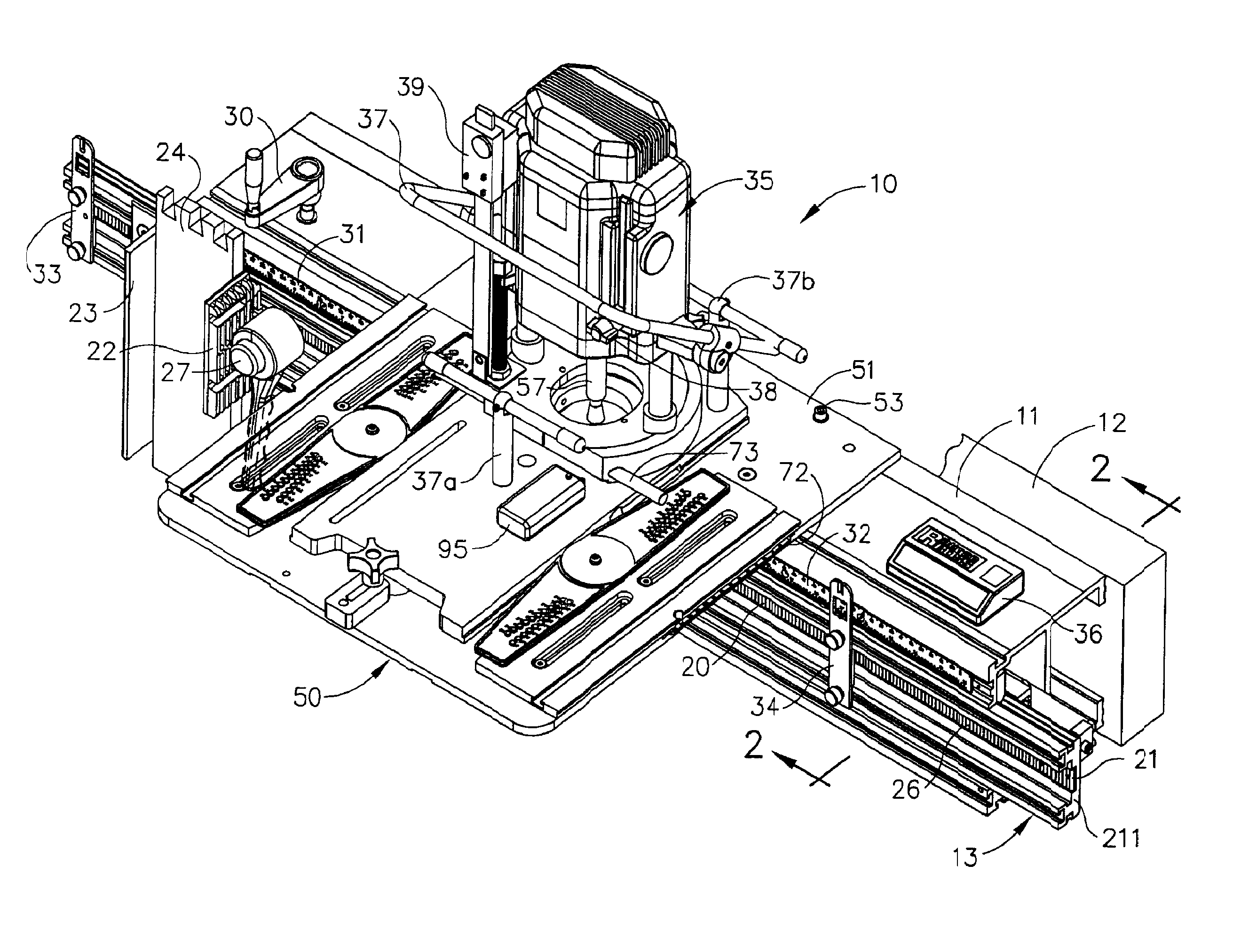

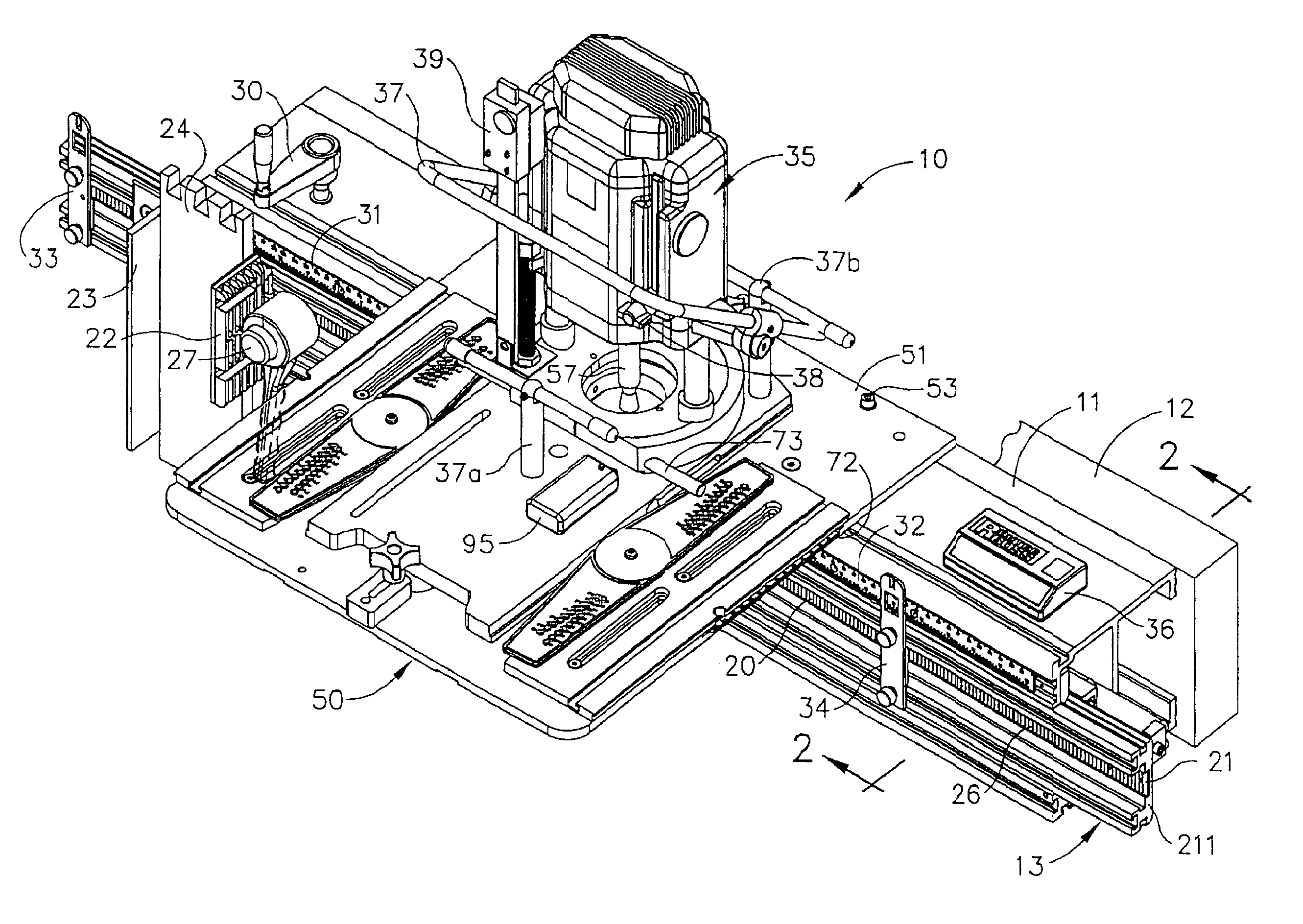

Wood Working Machine

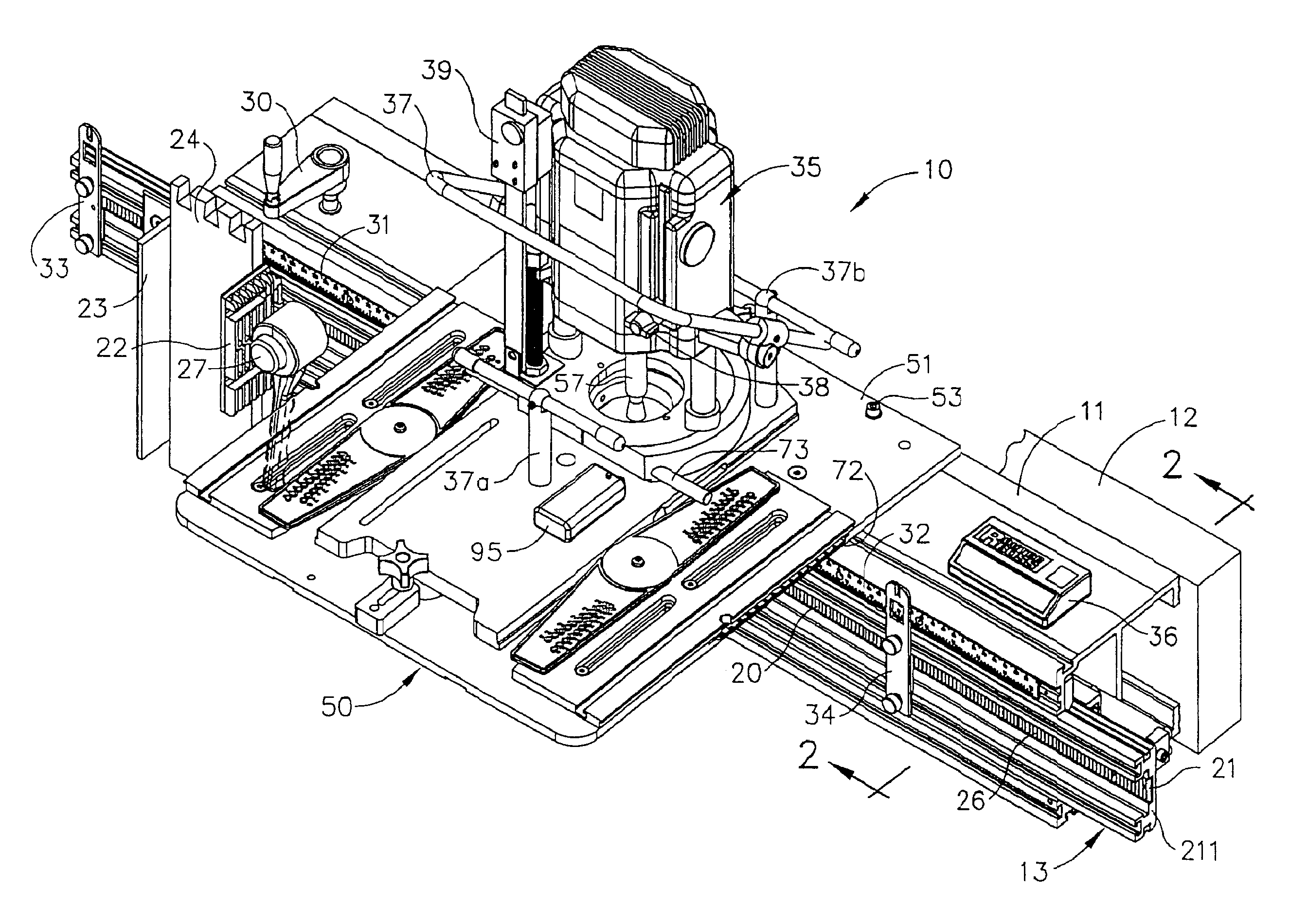

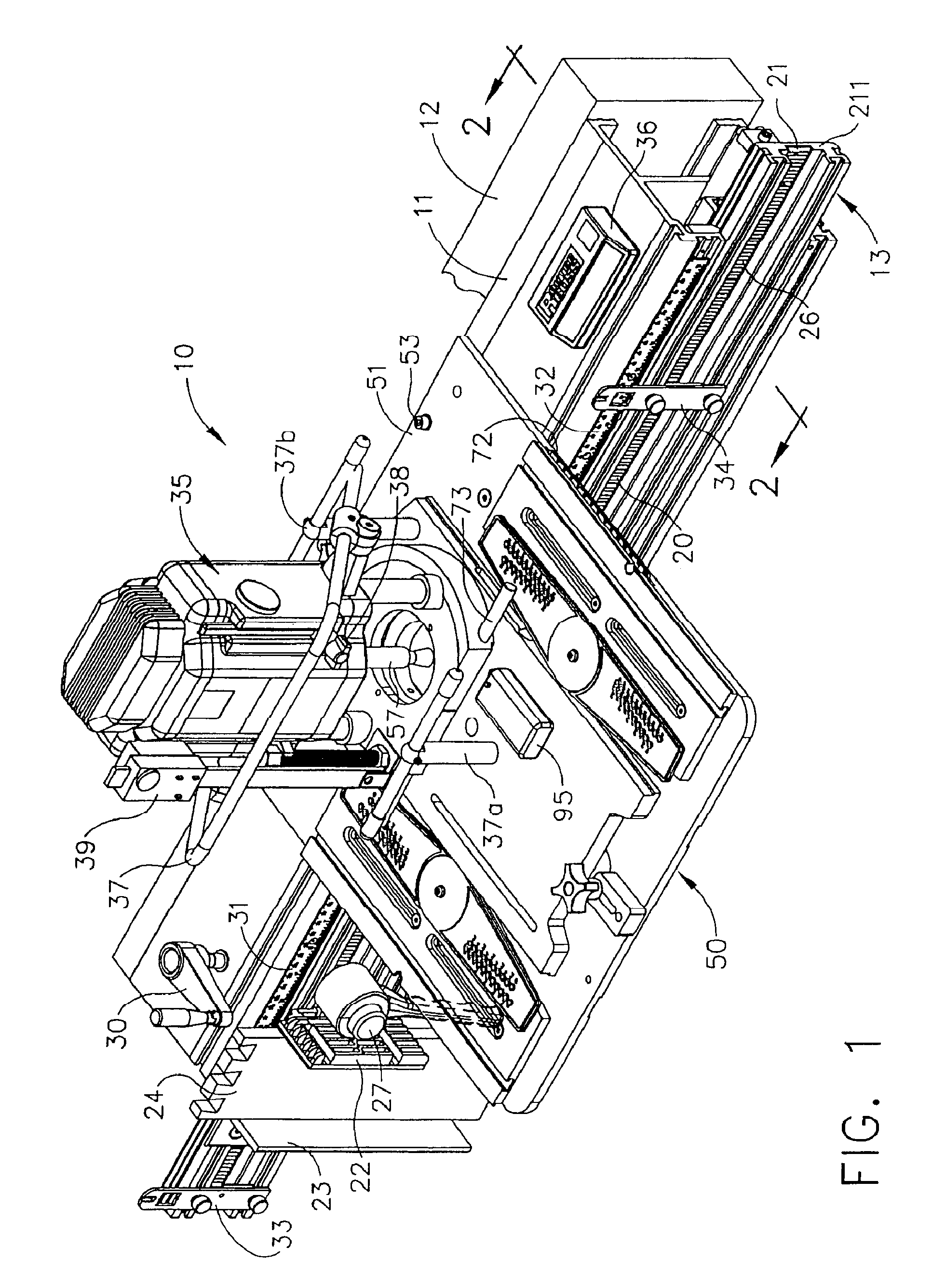

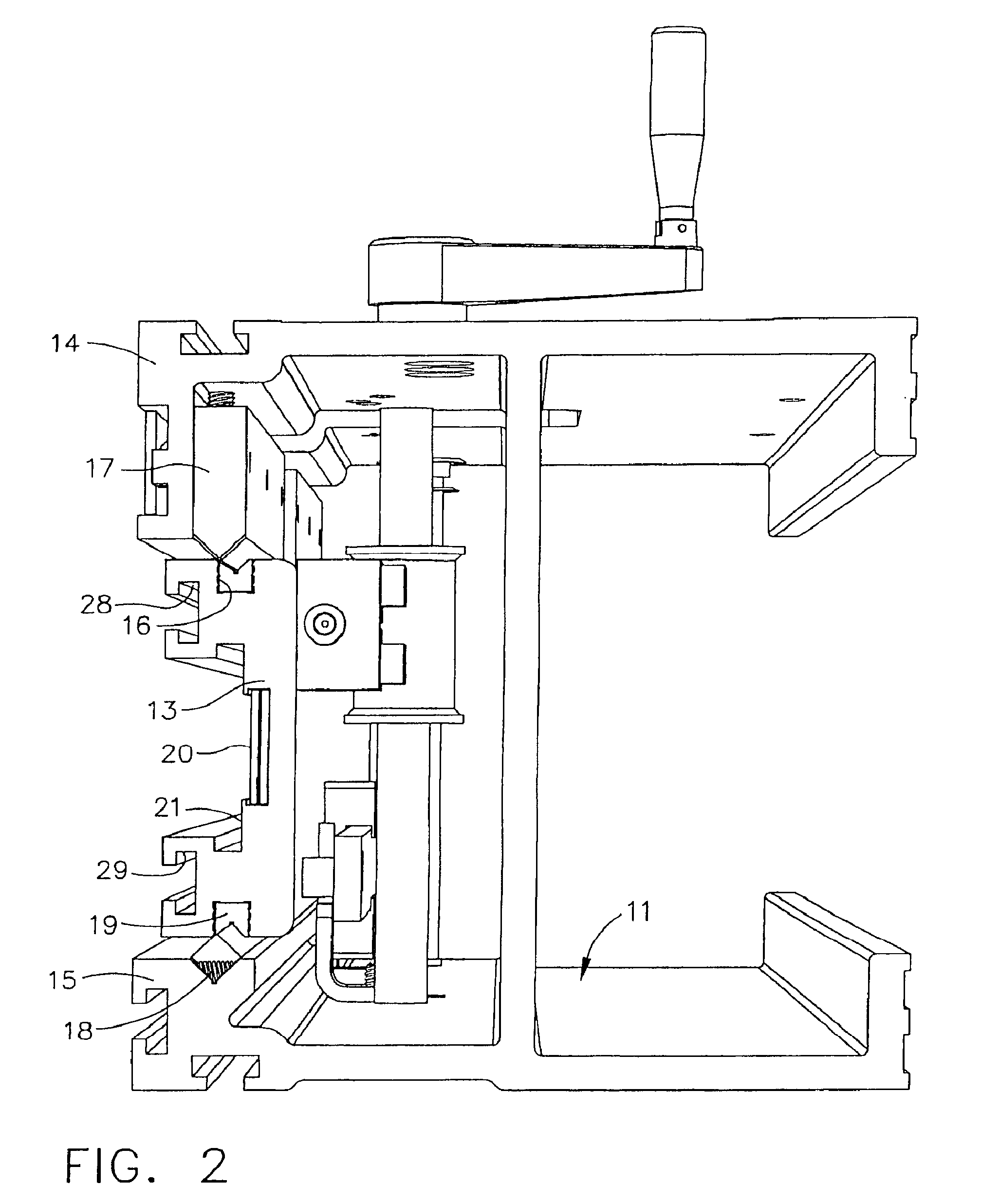

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

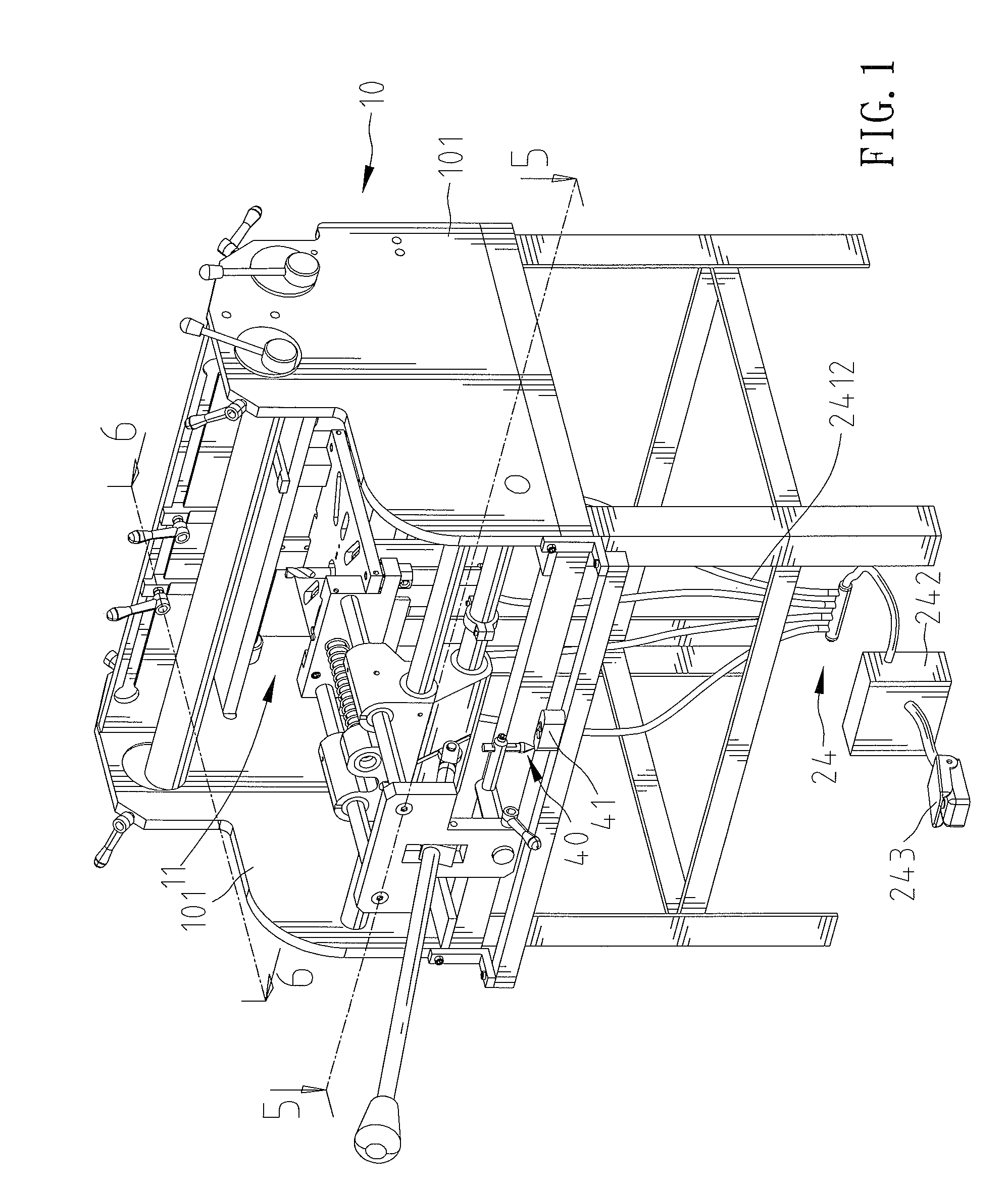

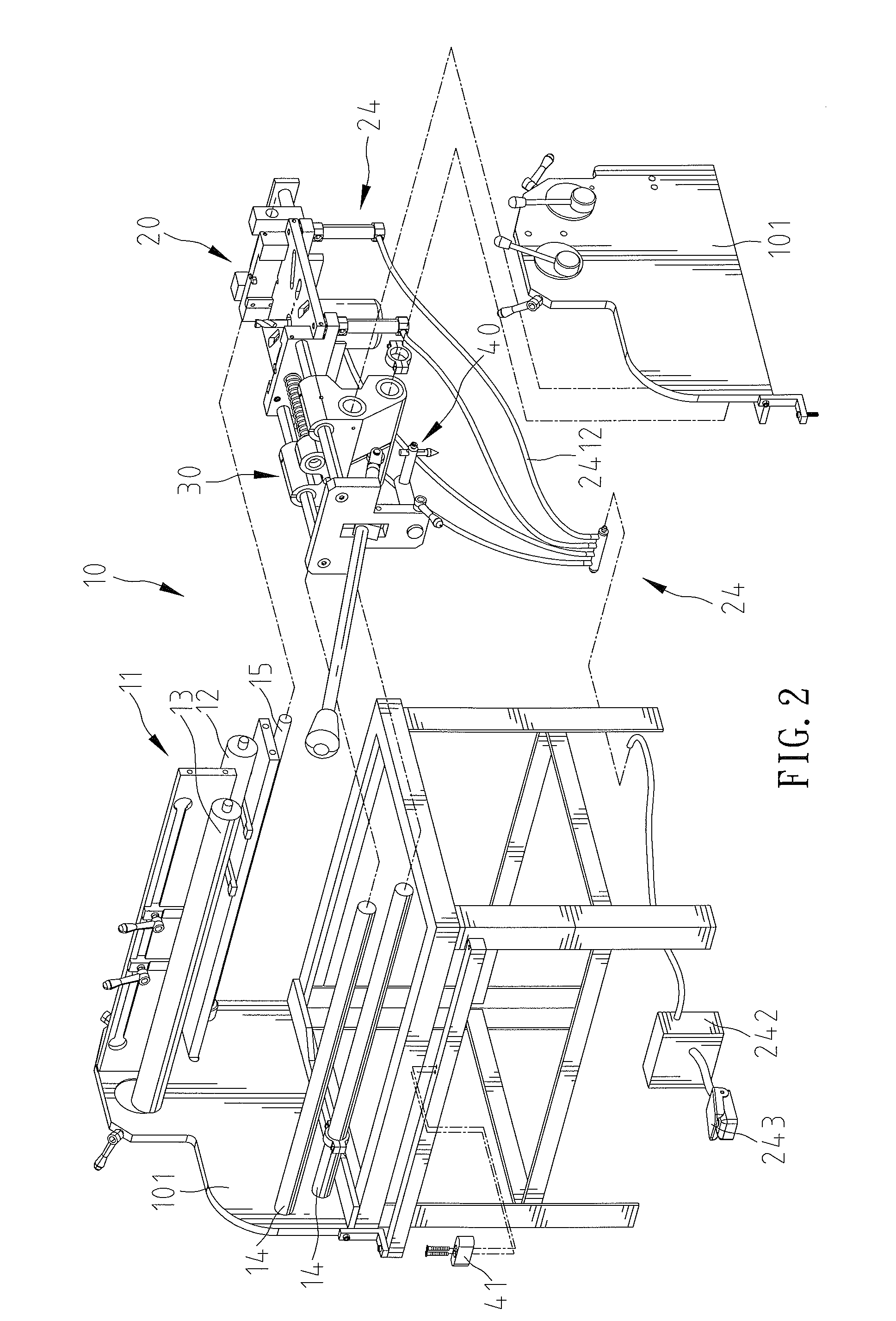

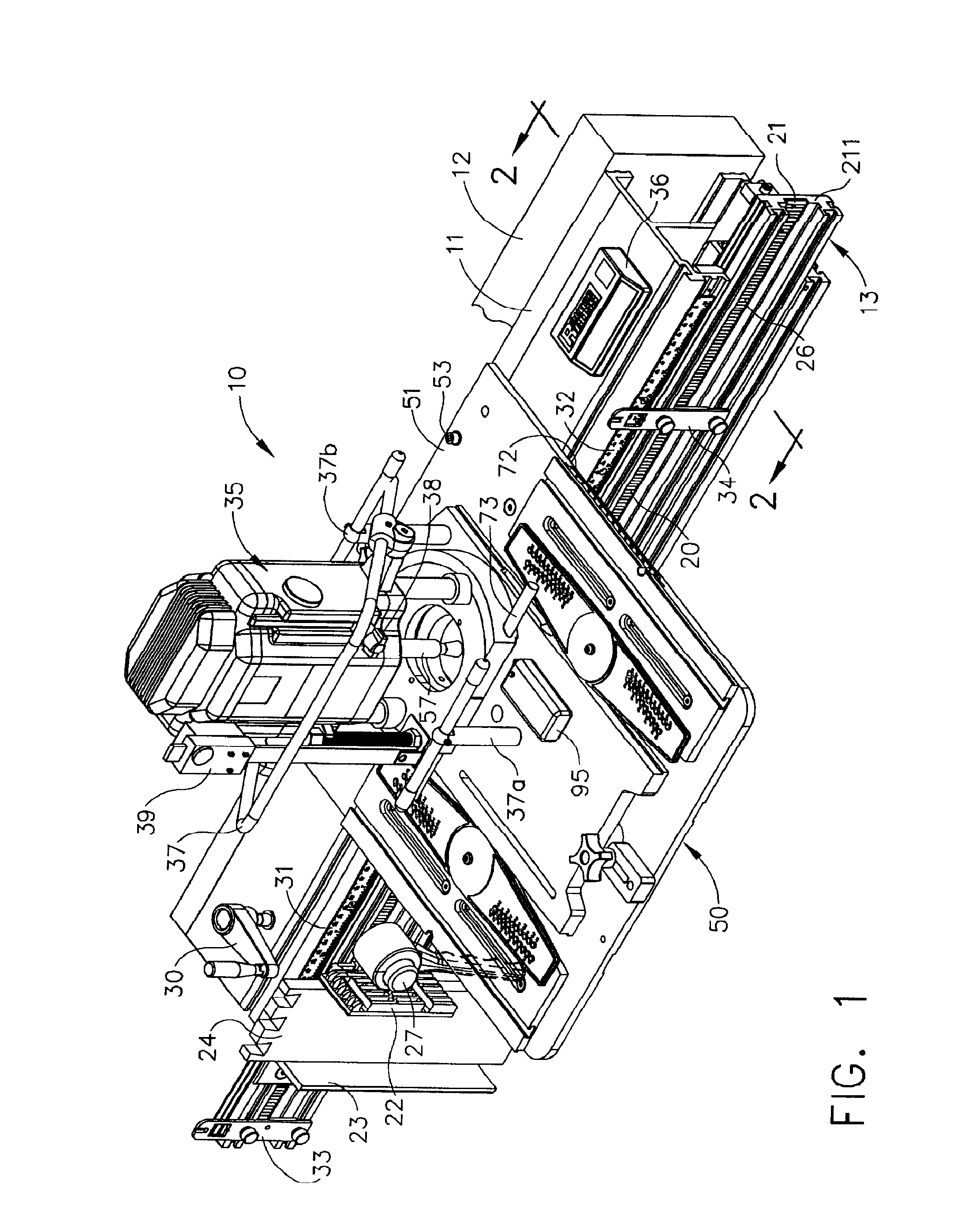

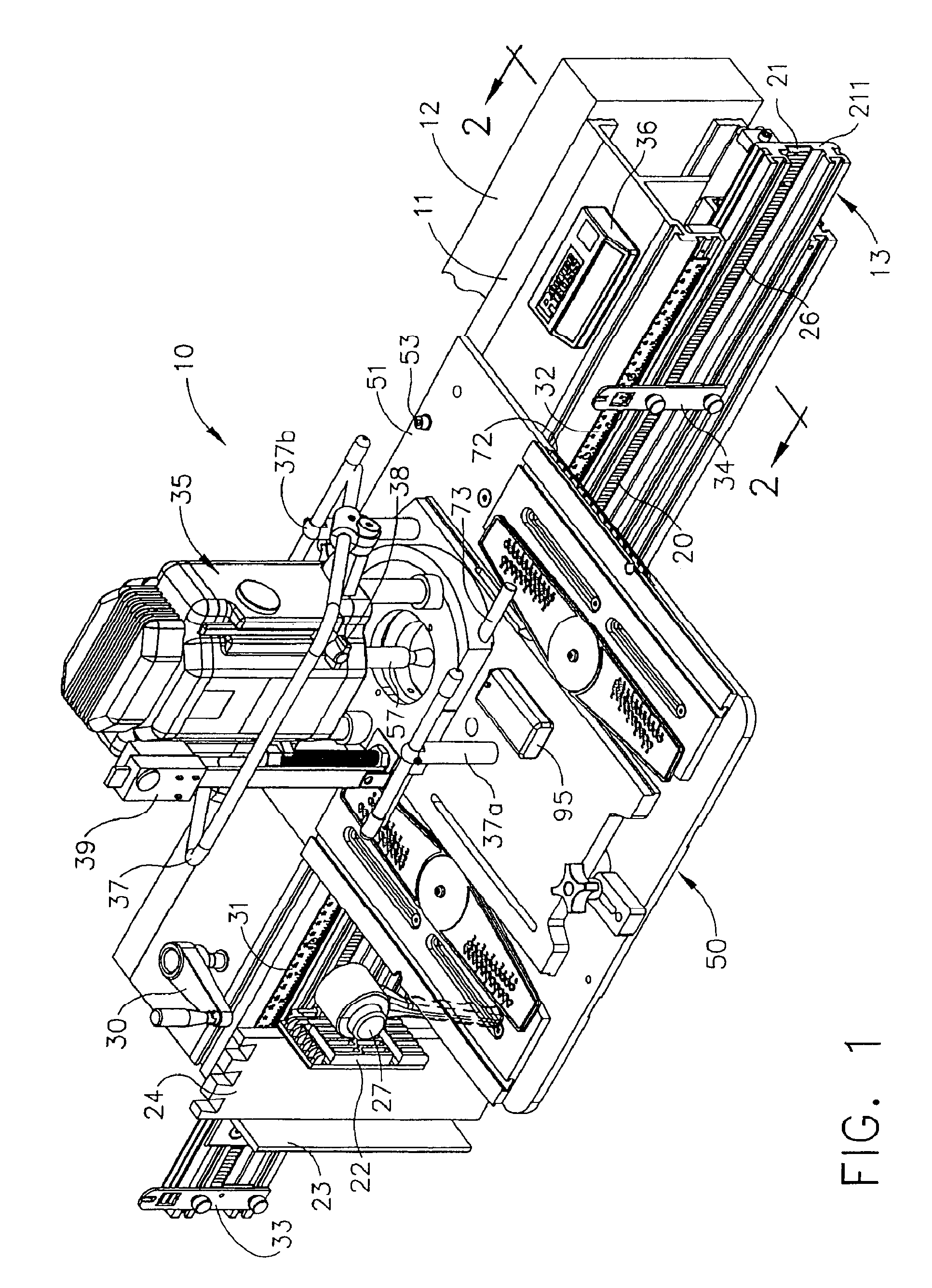

Multi-Function Mortise/Tenon Apparatus

A multi-function mortise / tenon apparatus, the apparatus comprises a chassis including a placement portion for placing a work piece horizontally / vertically and at least one transverse sliding rod; a work table including a first base member, a second base member and a lift / lower platform provided between the first and second base members; wherein the lift / lower platform and the first and second base members are driven to slide with respect to the chassis transversely / longitudinally; wherein the lift / lower platform is driven to lift / lower with respect to the chassis; and a guiding device installed to the at least one first sliding rod slideably and transversely and coupled to the work table which is driven by the guiding device to slide with respect to the chassis transversely / longitudinally.

Owner:YANG JACK

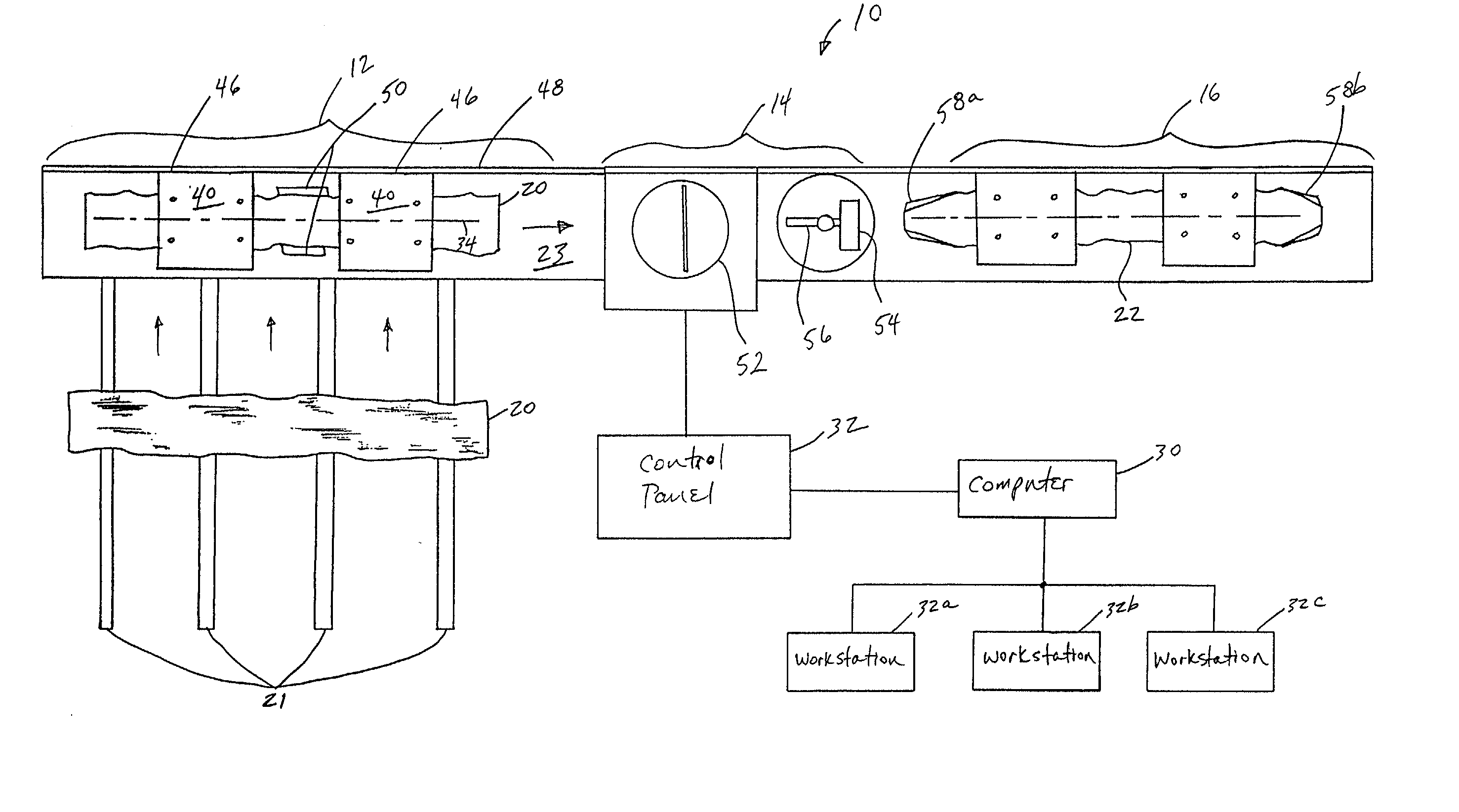

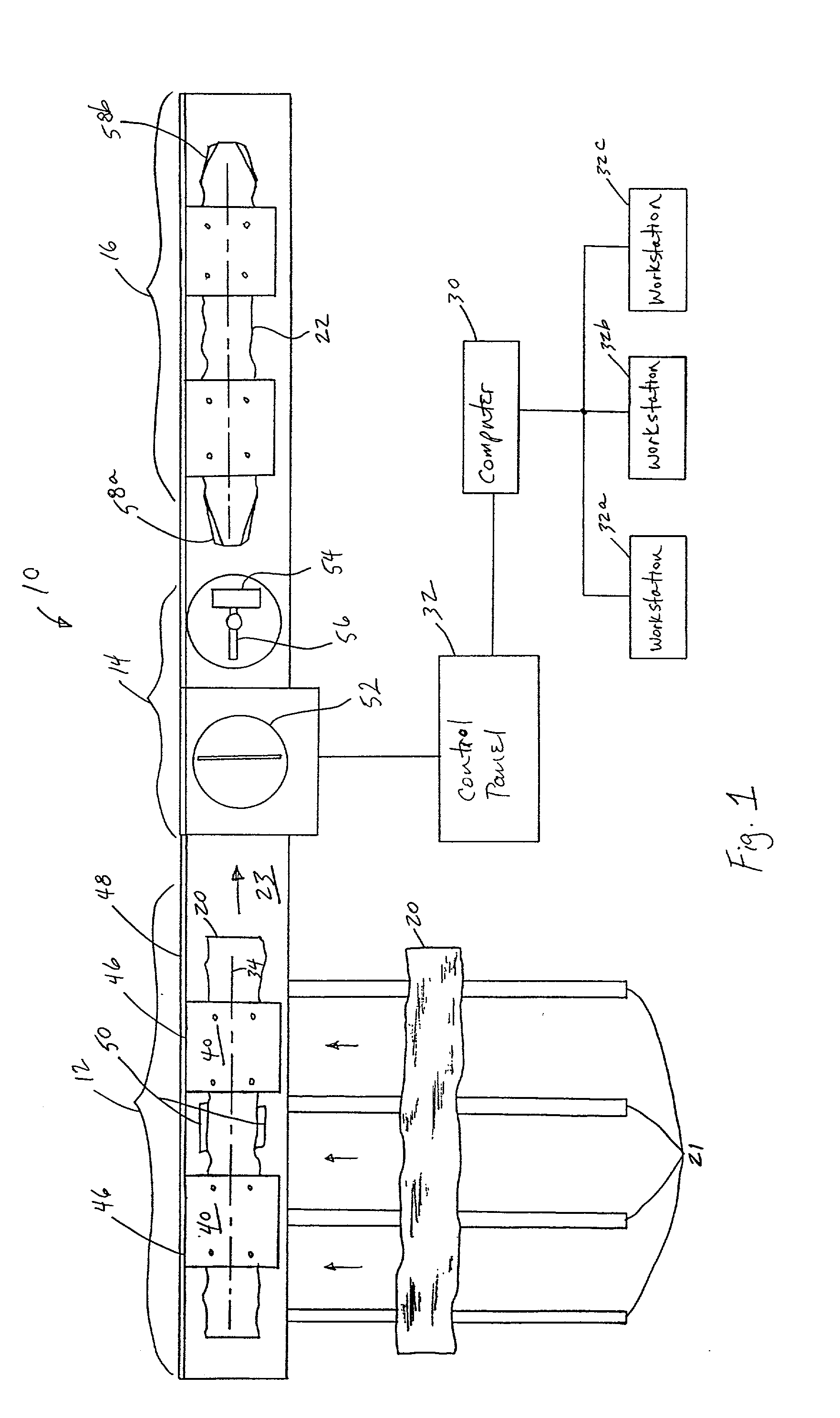

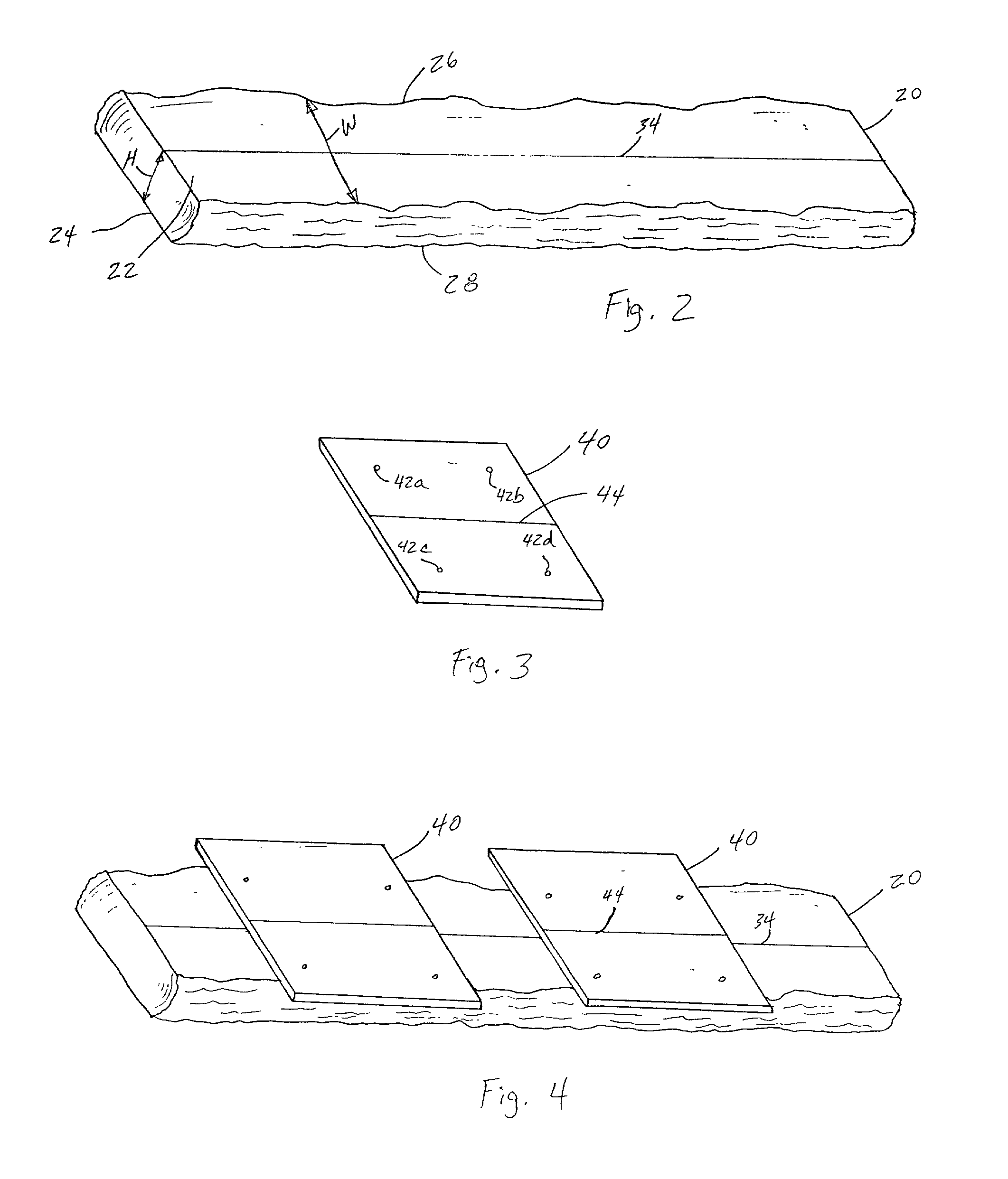

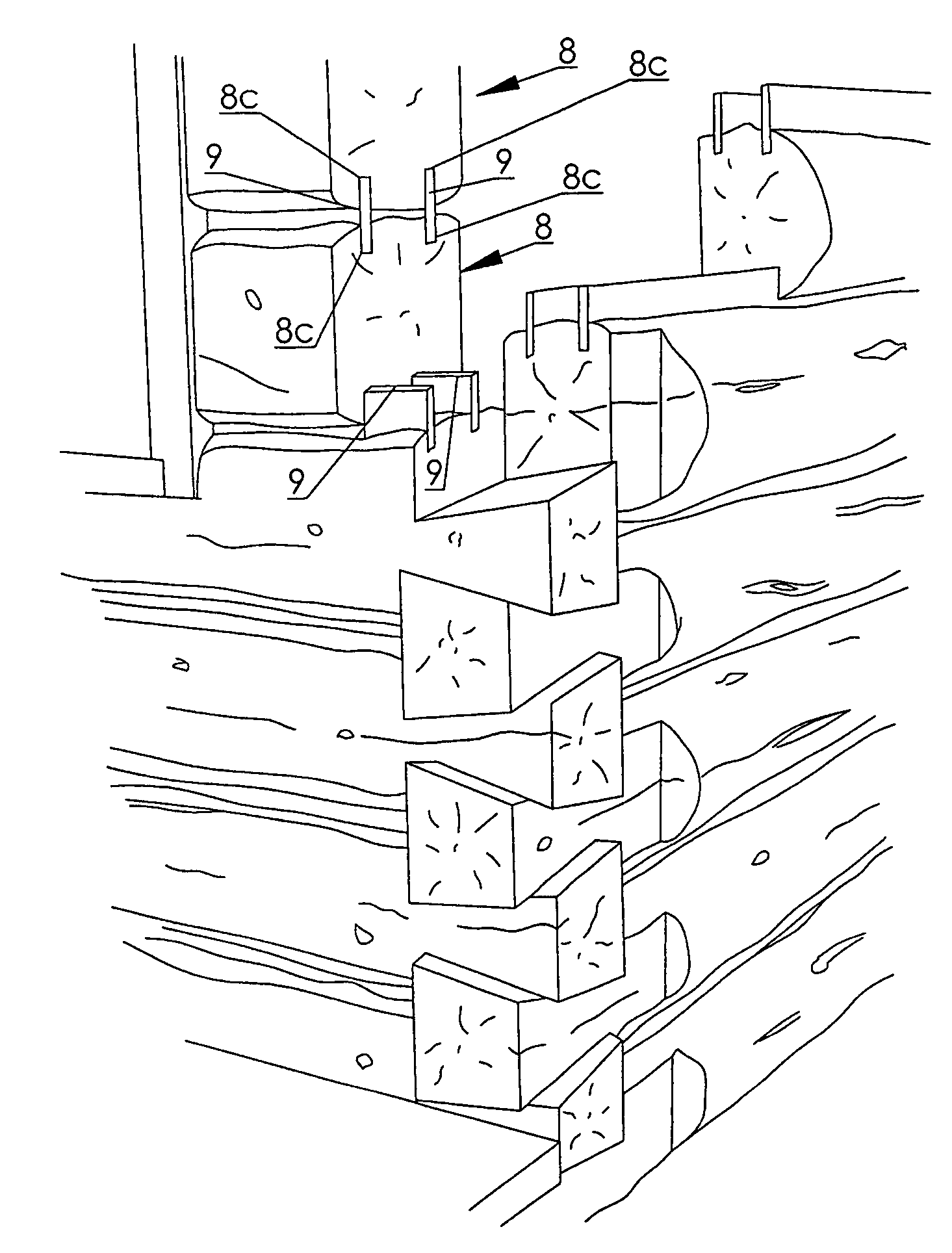

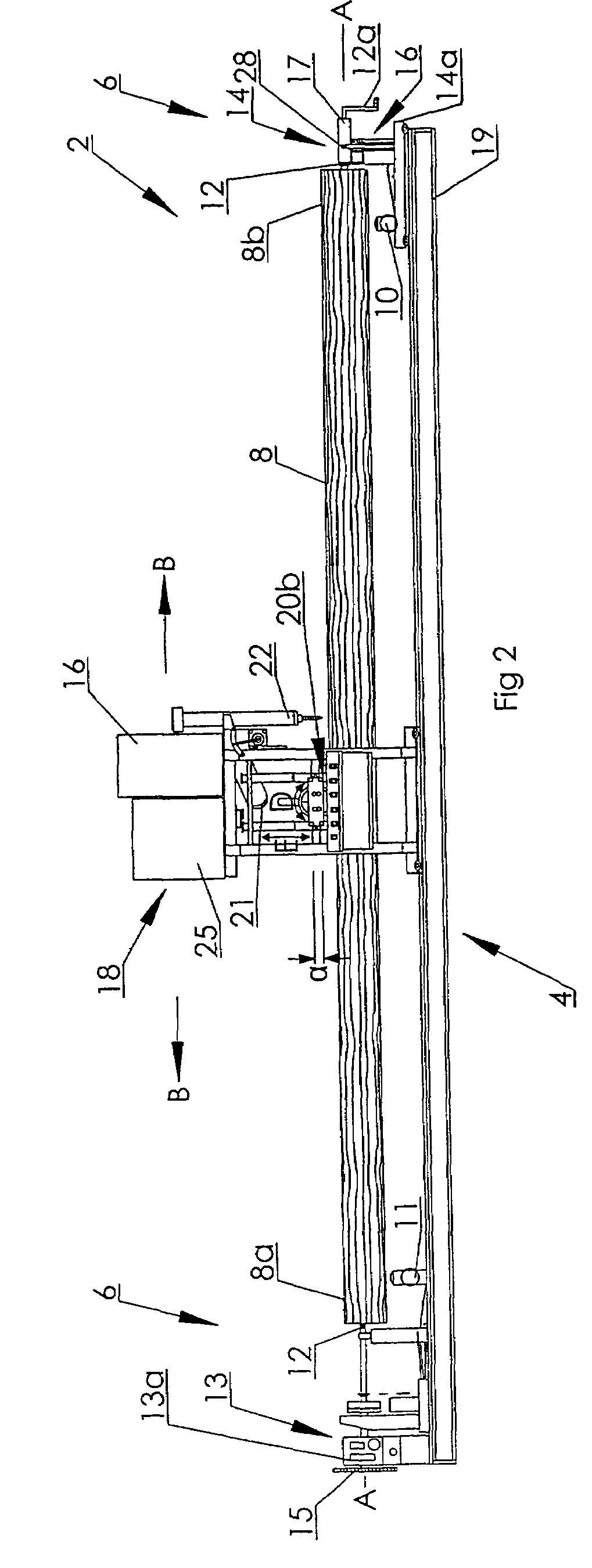

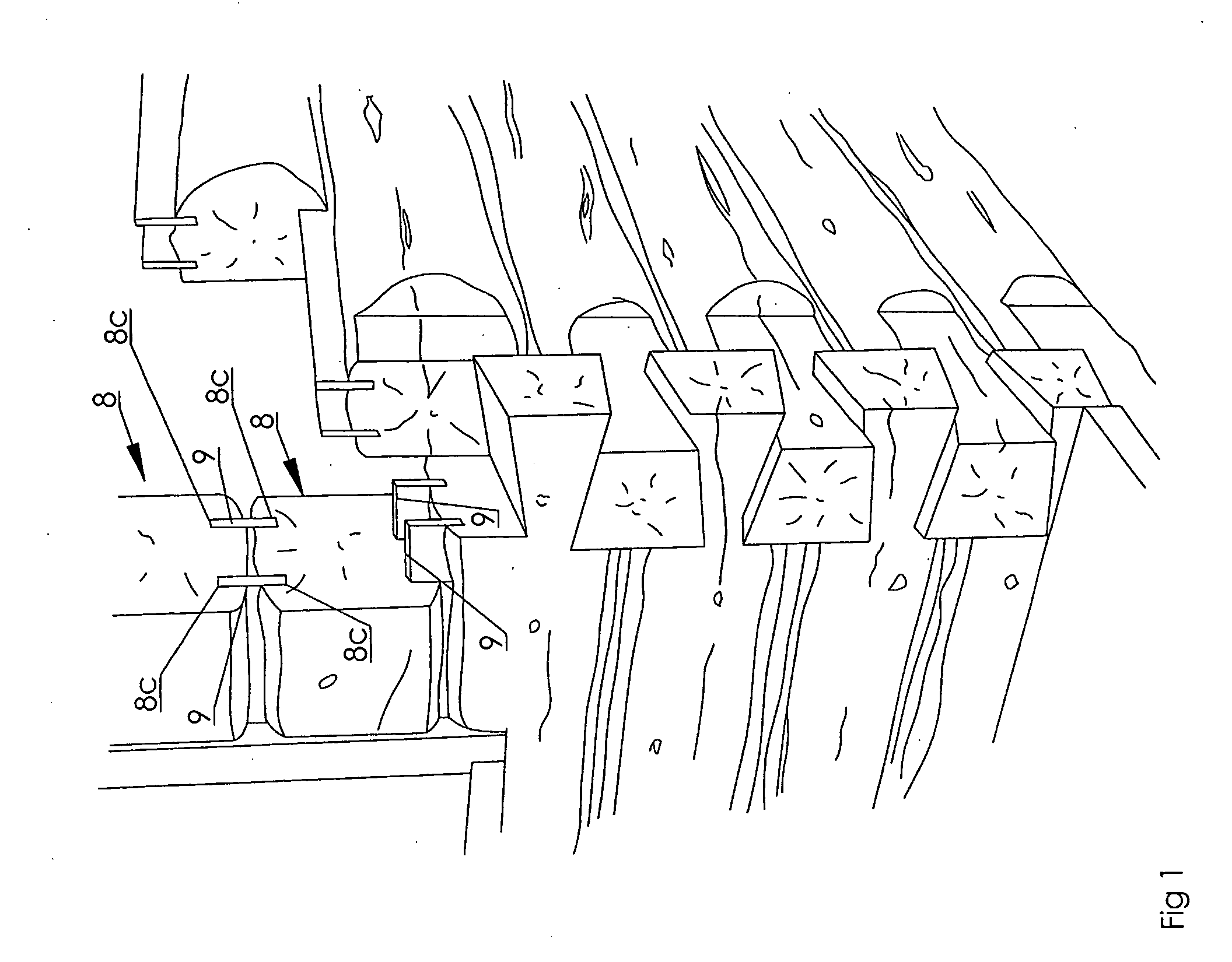

Log home fabrication process and associate log cutting machine

InactiveUS20030041919A1Tongue/grooves making apparatusMulti-purpose machinesComputer scienceComputer control

A log processing machine and associate method employs one or more log guides to make joinery cuts in a processed log which has at opposed edges of the processed log the raw log's natural external contour. In a preferred embodiment of the invention, each log guide includes a straight edge and is attached to the processed log to create an artificial straight edge for guiding the processed log through the joinery machine. Prior to attachment, centerlines are marked on the log guide and the processed log, and the centerlines are aligned when the log guide is attached to the processed log. The processed log, with the log guide attached, is then moved through the machine with the aid of computer control while the straight edge of the log guide follows a fence. In this manner, the position of the processed log and its centerline are always known so that the computer can make the programmed joinery cuts with high precision. An alternate embodiment of the invention employs one or more fence extensions as log guides. The fence extensions are positionable in guide channels formed in the contoured edges of the processed log. A further embodiment of the invention employs an opposed pair of clamping / alignment elements which are controlled by a computer to align and guide the log through the joinery machine.

Owner:HEARTHSTONE

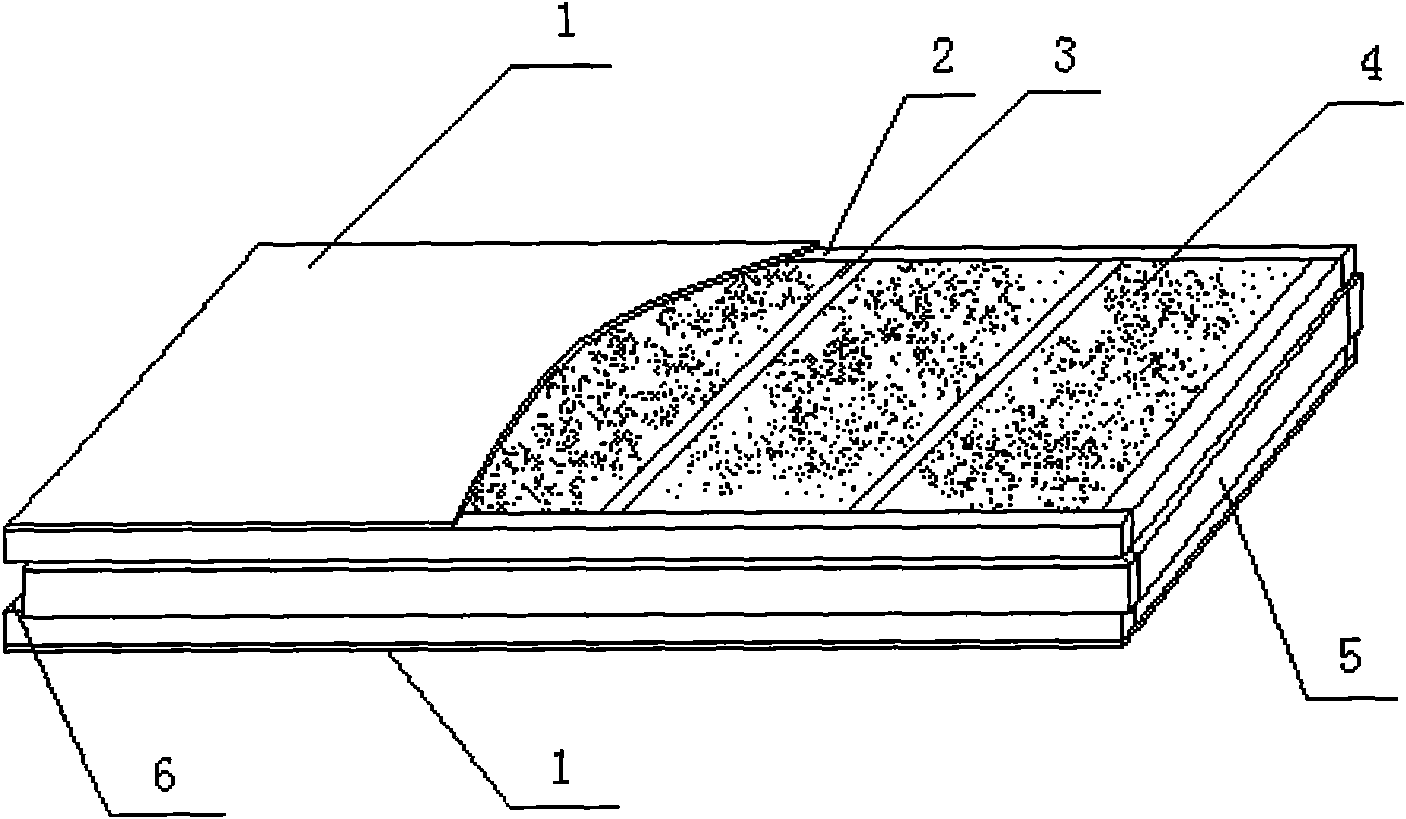

Rapid installing connection structure and manufacturing method of insulation board compounded by wood and foamed plastics

InactiveCN102001111AOther plywood/veneer working apparatusTongue/grooves making apparatusManufacturing technologyThermal insulation

The invention relates to the technical field of a composite material manufacturing in a wood processing industry. In the structure, wood or a woody material is used as frames. First, a matcher is used for processing one outward side of the wood frame material into the structure that two adjacent frames are tenons and another two frames are grooves. The middle part of the wood frame uses battens as middle parting stops, the space between each two parting stops is filled with a foamed plastic board which is cut into the size same with the size of the space, and the thickness of the foamed plastic board is slightly larger than the thickness of the wood frame. Two layers to a plurality of layers of plywood or woody sheets or decorative sheets are covered on two surfaces of the wood frame, and the structure subjected to compregnate is processed into an insulation board compounded by wood and foamed plastics. The area of the insulation board is increased by inserted connection of the tenons and the grooves, and the insulation board is just fixed on the ground or a roof in installation. The insulation board is a thermal-insulation material of an interior wall integrating thermal insulation, sound insulation and decoration in a whole, can be directly stuck on the interior wall, and can also be used as an indoor partition board. Moreover, the interior partition wall of a house can be rapidly and conveniently installed.

Owner:NANJING FORESTRY UNIV

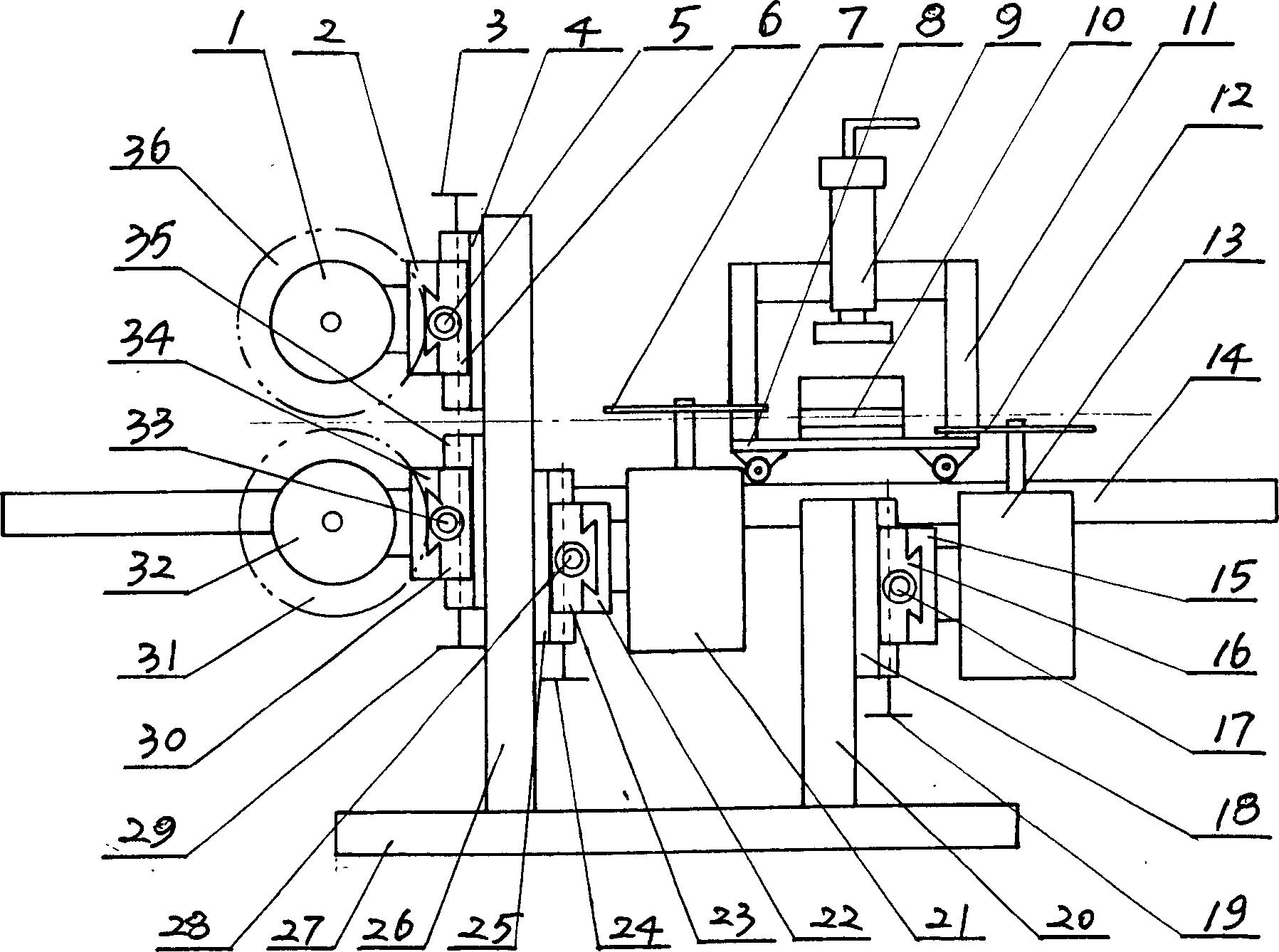

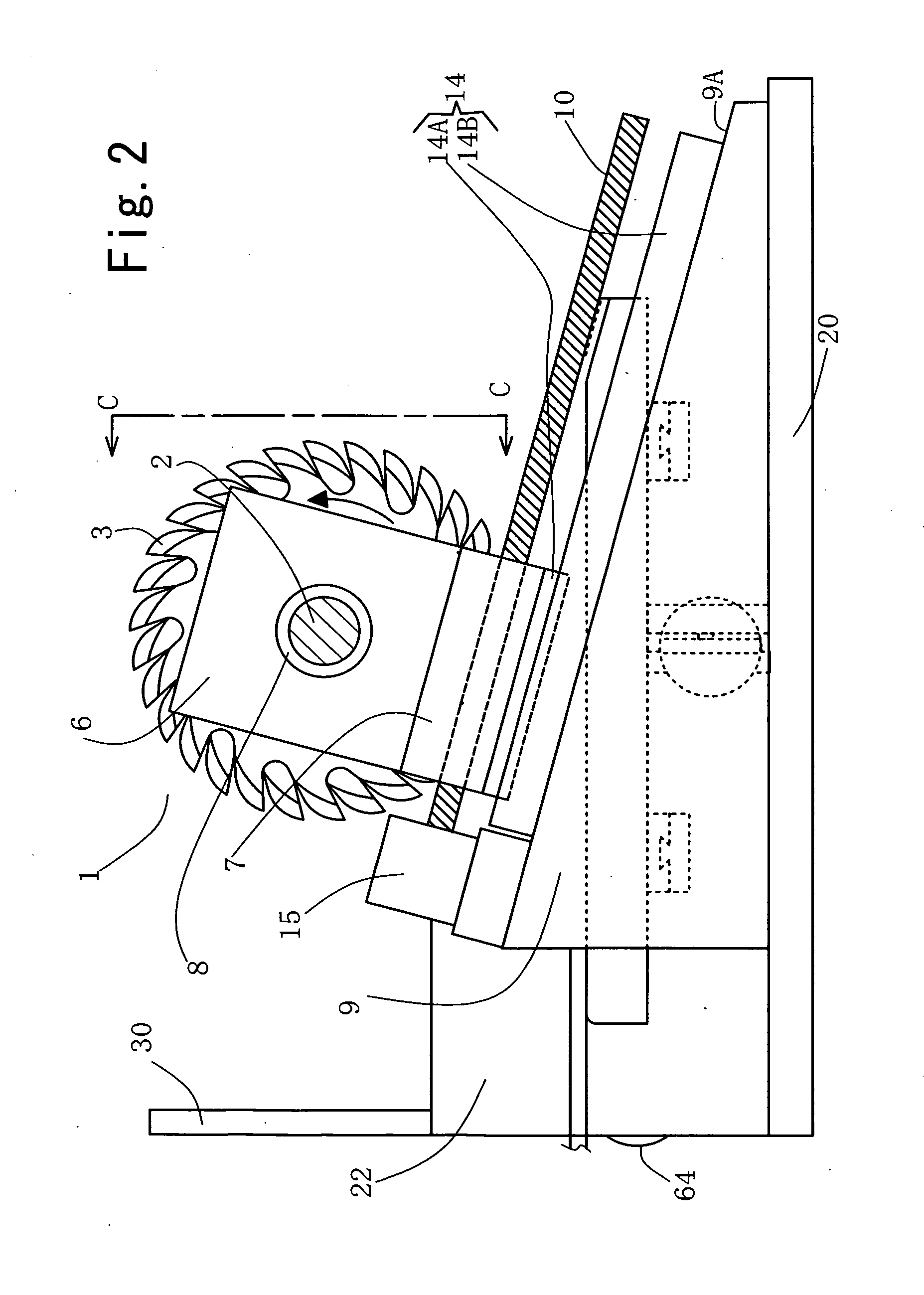

High speed timber tenon-making machine

InactiveCN1836856ASimple structureLow priceTongue/grooves making apparatusCircular sawsCircular sawEngineering

The present invention is one timber tenoning machine. The timber tenoning machine has vertical frame, fixed seat, elevating seat, transverse seat, motor connected to the transverse seat and with circular saw blades for vertical cutting and horizontal cutting, rail frame, sliding timber carrying tackle with working platform and pneumatic cylinder for fixing timber. It is used in tenoning timber. It has simple structure, low cost, convenient use, and high tenoning precision and speed.

Owner:夏洪杰

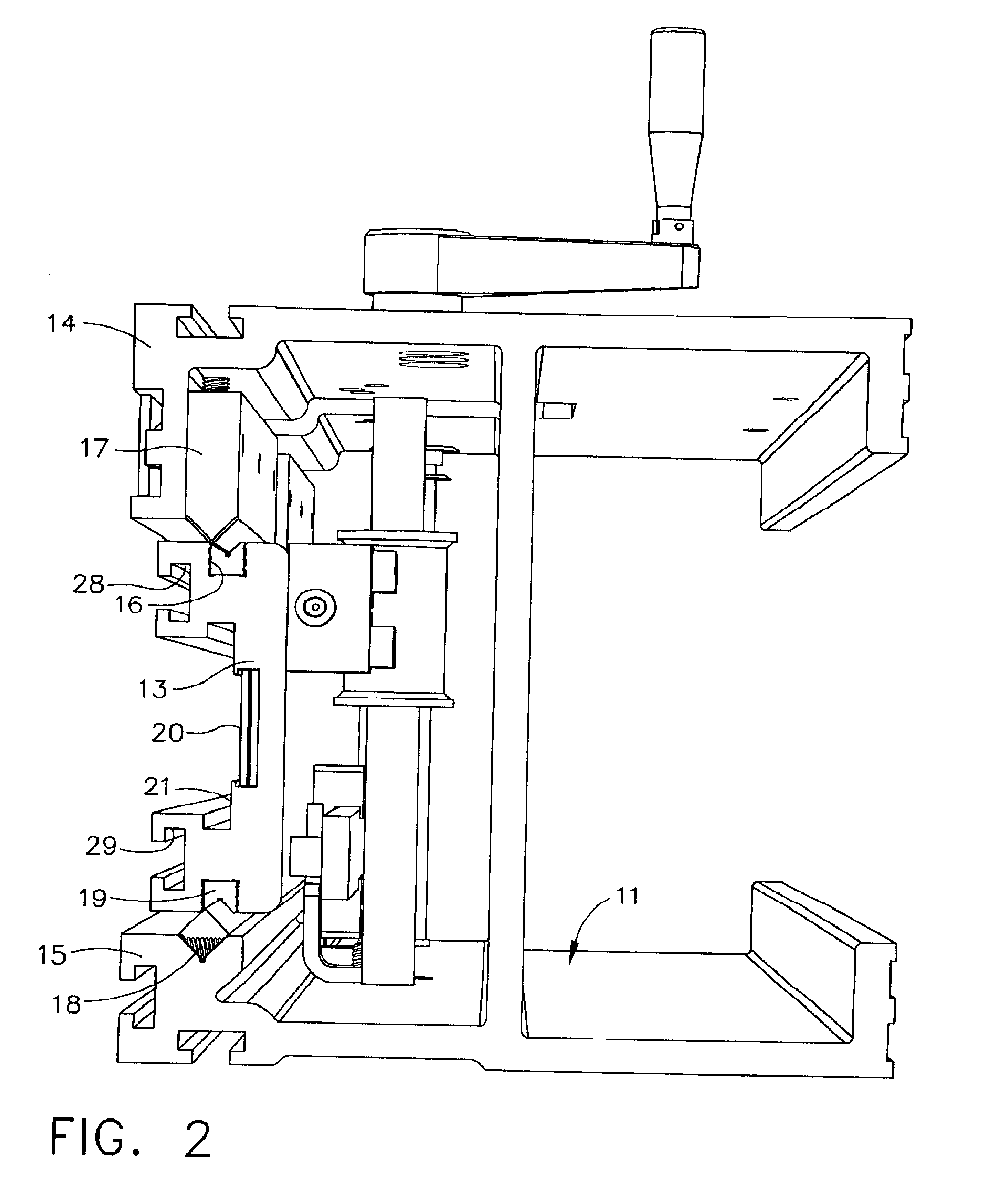

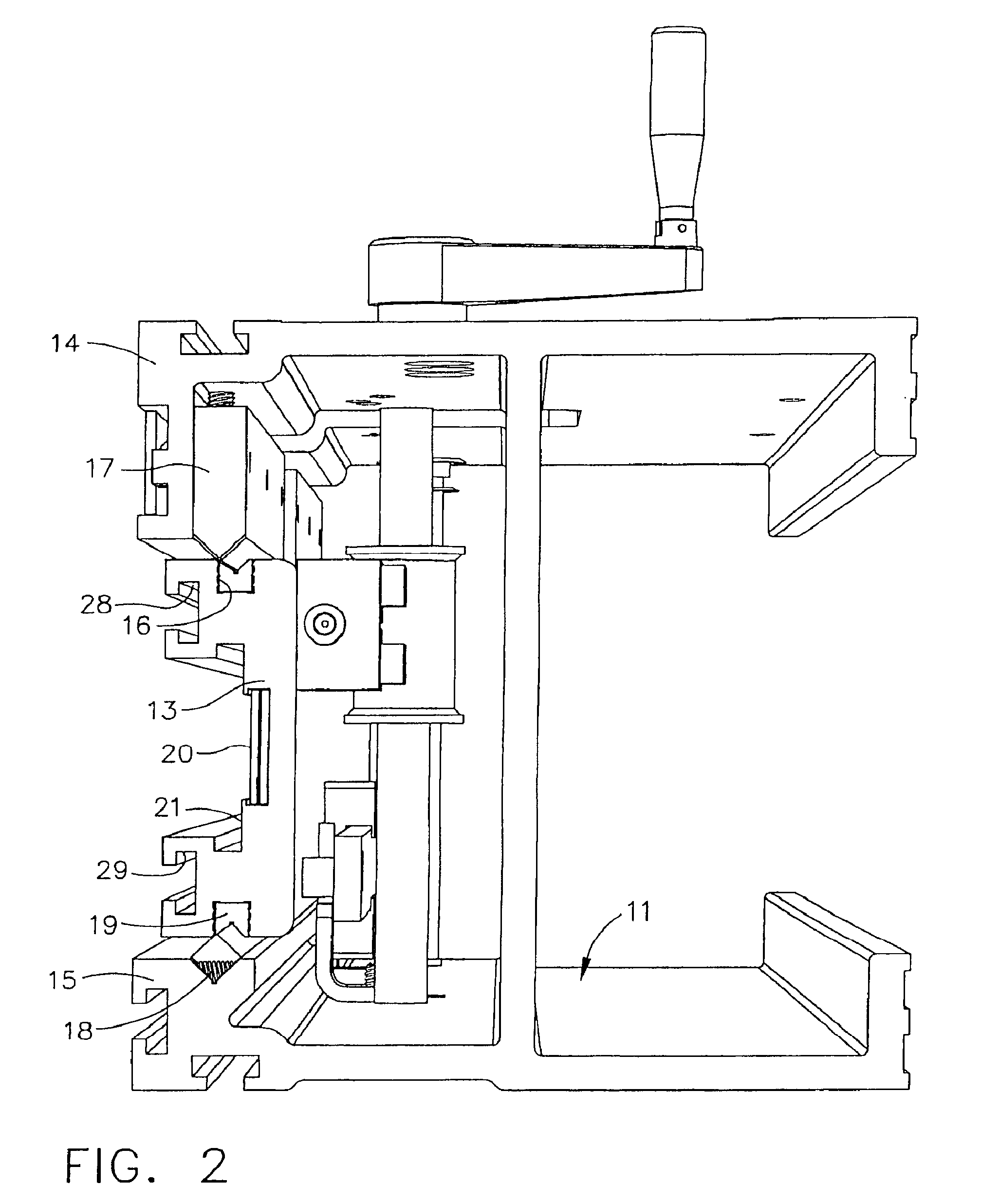

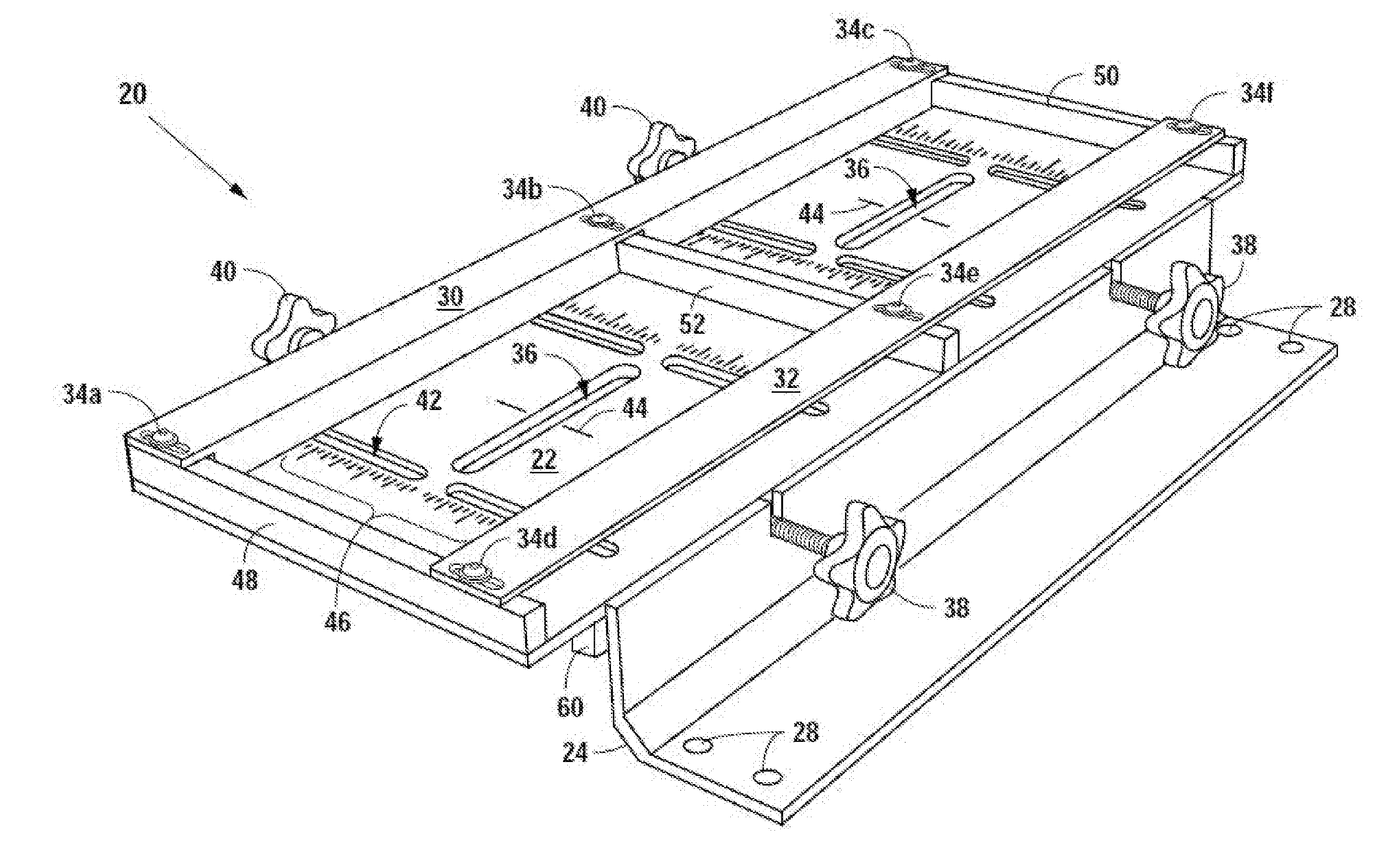

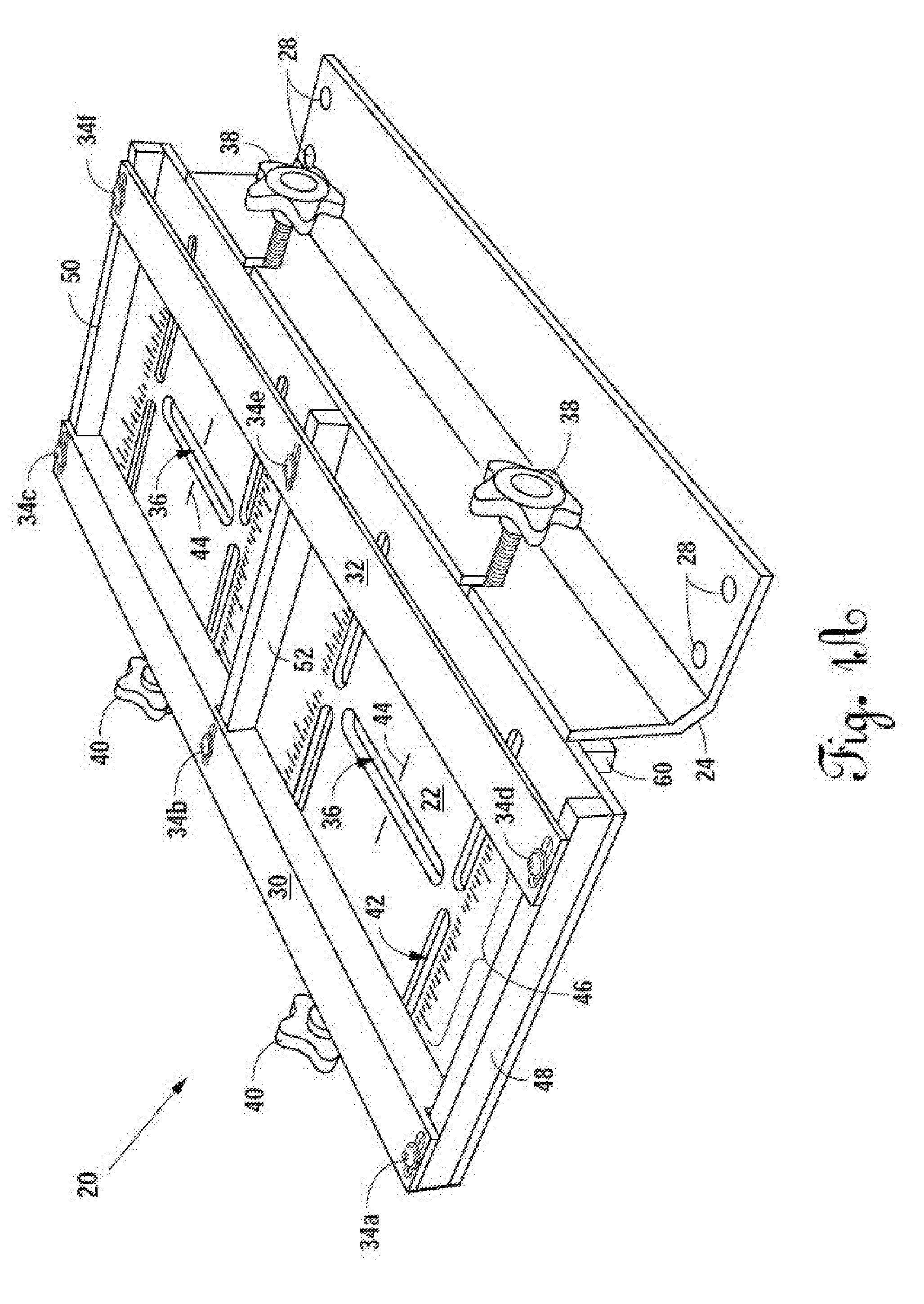

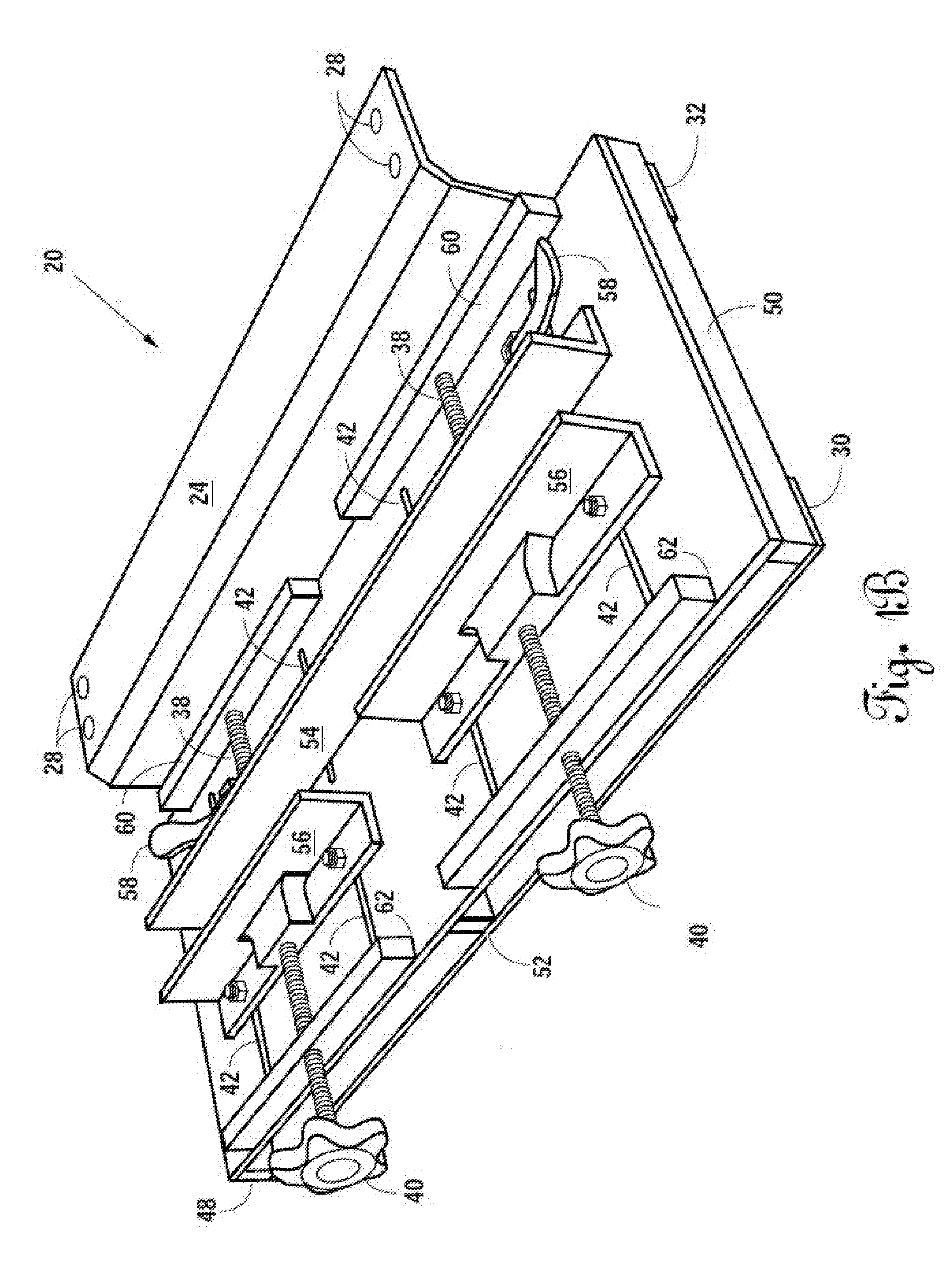

Combination mortise and tenon jig

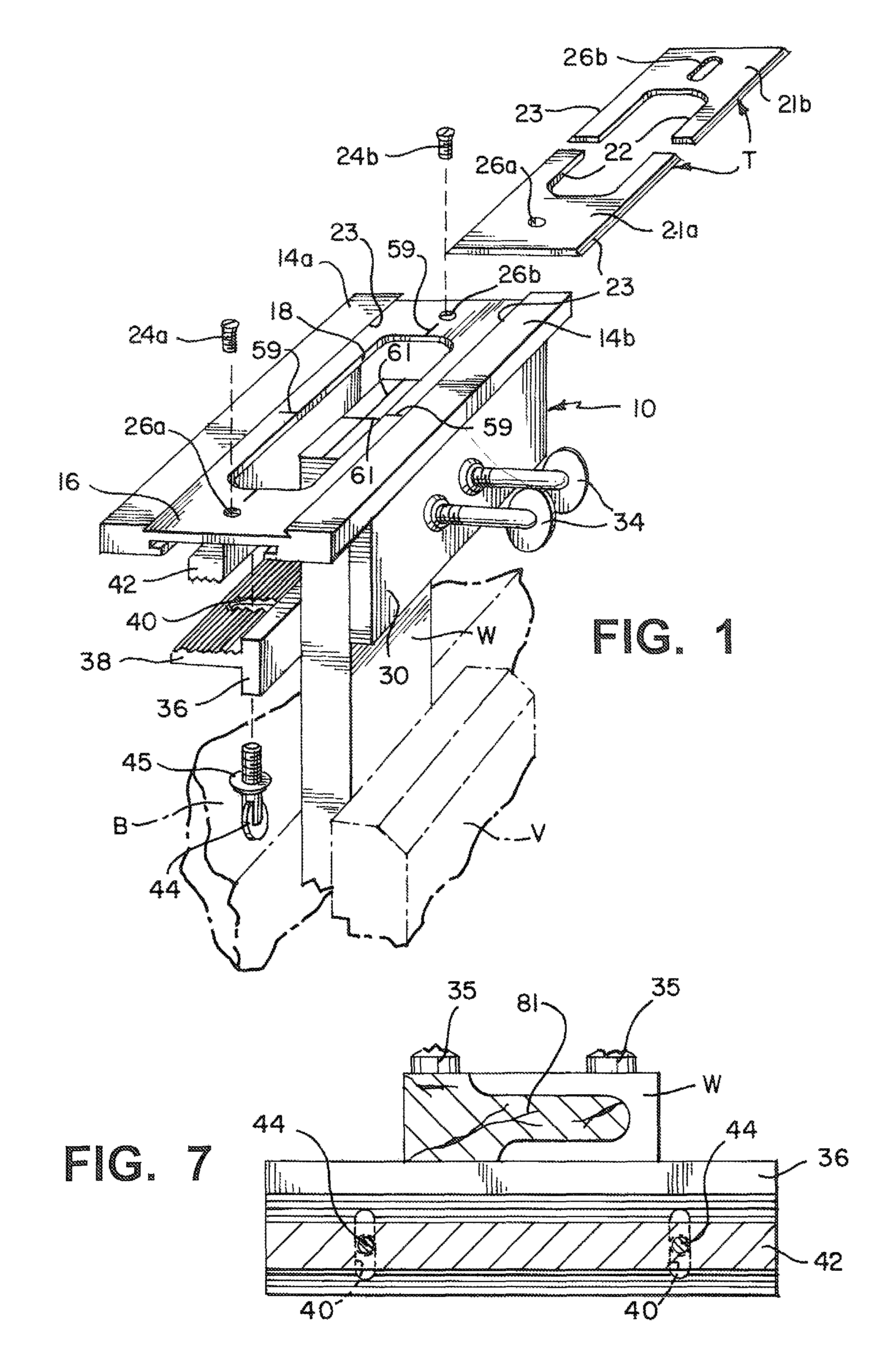

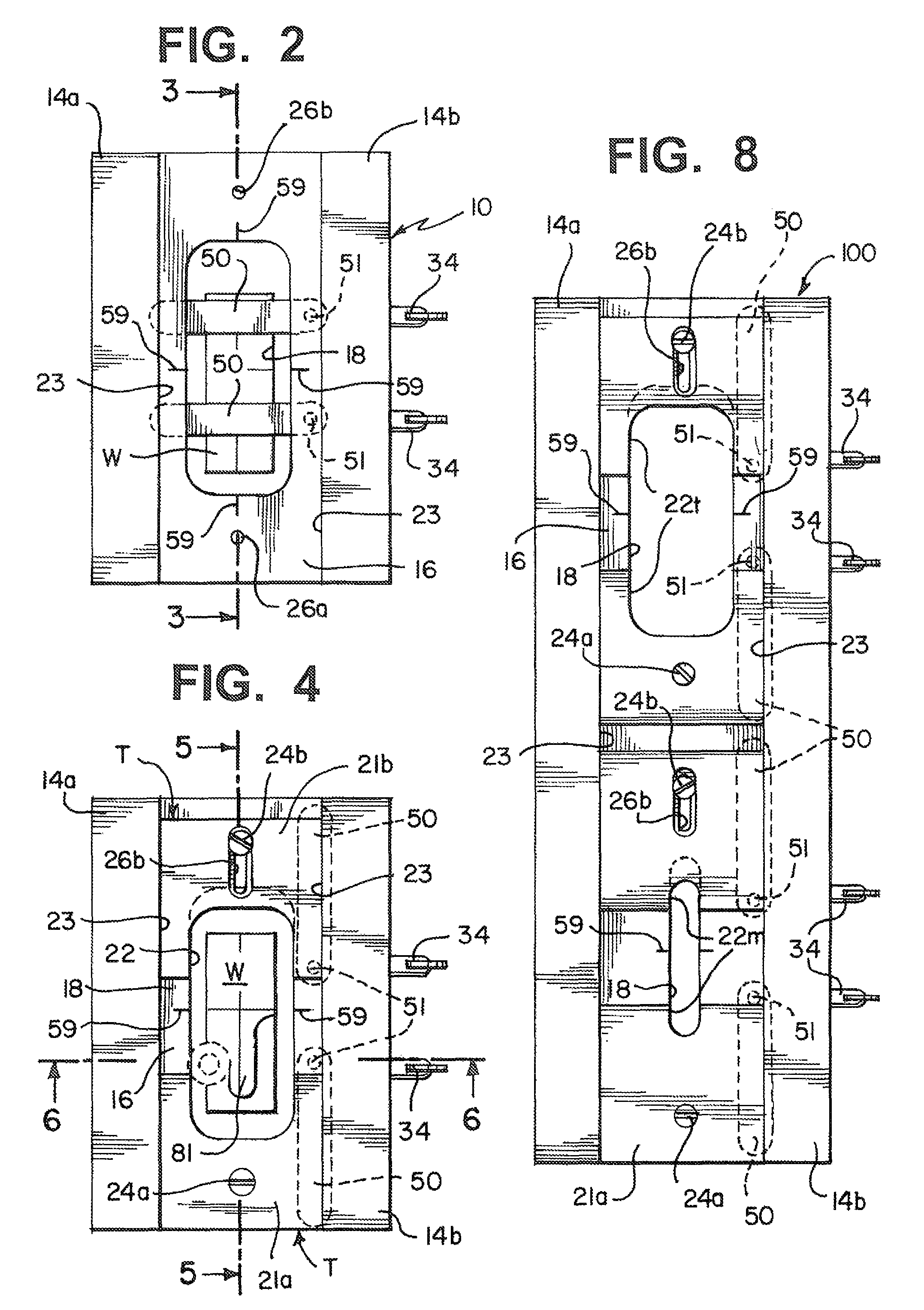

InactiveUS8016005B1Quickly relatively easilyMade preciselyTongue/grooves making apparatusMulti-purpose machinesMortise and tenonEngineering

A combination mortise and tenon jig has a body including a platform having an open section with first and second clamp legs on opposite sides for holding a workpiece therebetween with the workpiece part in which a mortise or tenon is to be cut facing toward the open section. A plurality of adjustable members extend from the first clamp leg to engage a workpiece face and the second clamp leg is movable relative to the open section with the extending members and the second clamp leg holding the workpiece at a selected position in the open section. A pair of guide arms pivotally mounted below the platform swing across the platform open section to engage the workpiece part and make it parallel to the platform and a template having a cutout pattern of one of a mortise or tenon overlies the platform open section to guide a router bit to cut the mortise or tenon in the workpiece end.

Owner:GEN TOOLS & INSTR

Tenon engraving machine

InactiveCN101879727BIncreased tenoning speedReduce human production costsTongue/grooves making apparatusTenon making apparatusRight convexEngineering

The invention relates to a tenon engraving machine. A left convex part is arranged at the left side of the front end surface of a stand, a right convex part corresponding to the left convex part is arranged at the right side of the front end surface of the stand, and a groove is formed among the front end surface, the left convex part and the right convex part of the stand; the front end surface of the stand is provided with a positioning part; and in addition, an inverted U-shaped hanging bracket which can move back and forth and oppositely parallel to the stand is arranged on the stand, a cutter seat which can slide left and right opposite to the hanging bracket is arranged on the hanging bracket, and a cutter is arranged below the cutter seat. Thus, when an article to be processed is located on the positioning part at the front end of the stand, a tenon joint on the article to be processed can be cut by moving the cutter.

Owner:李尚民

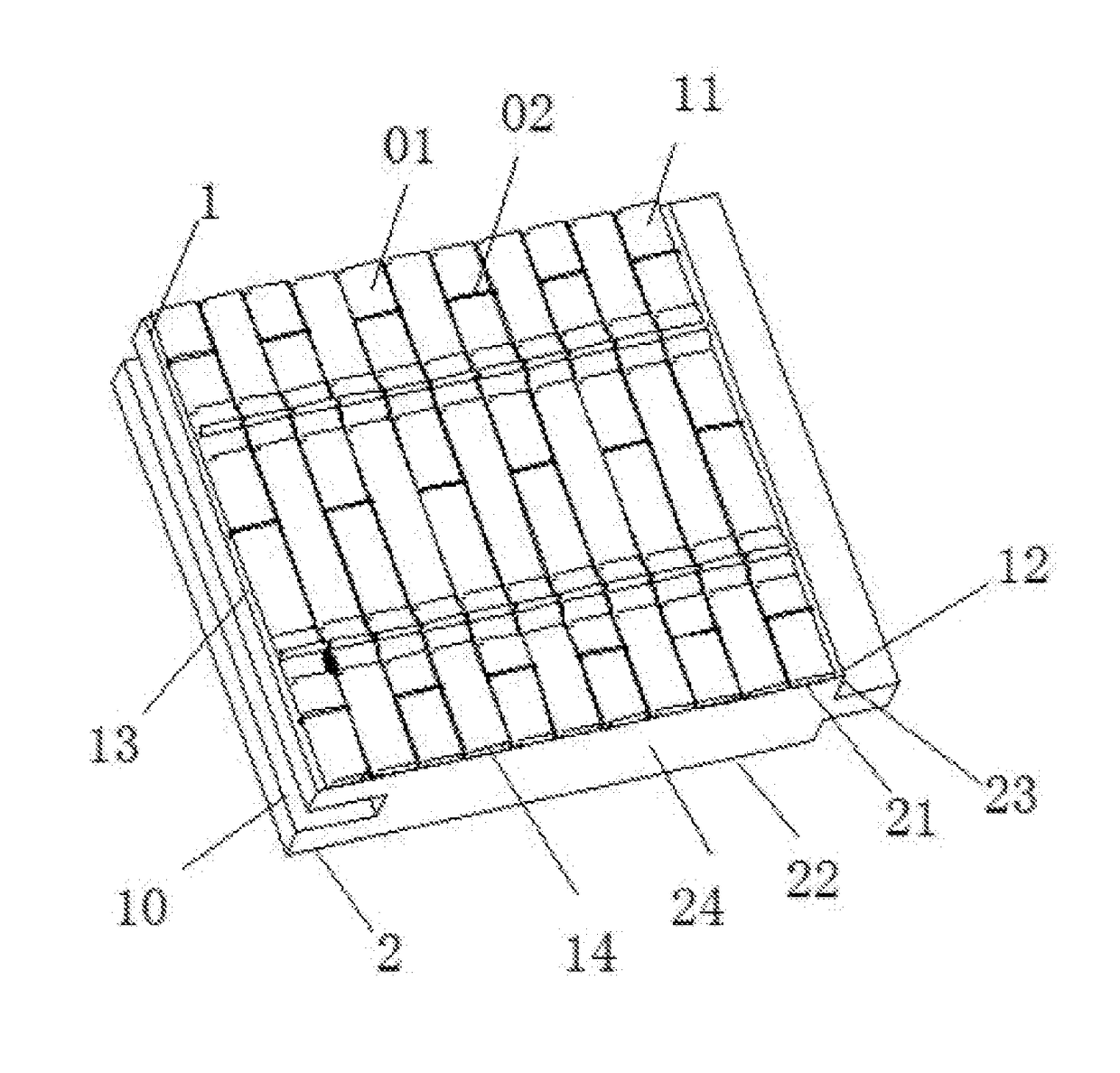

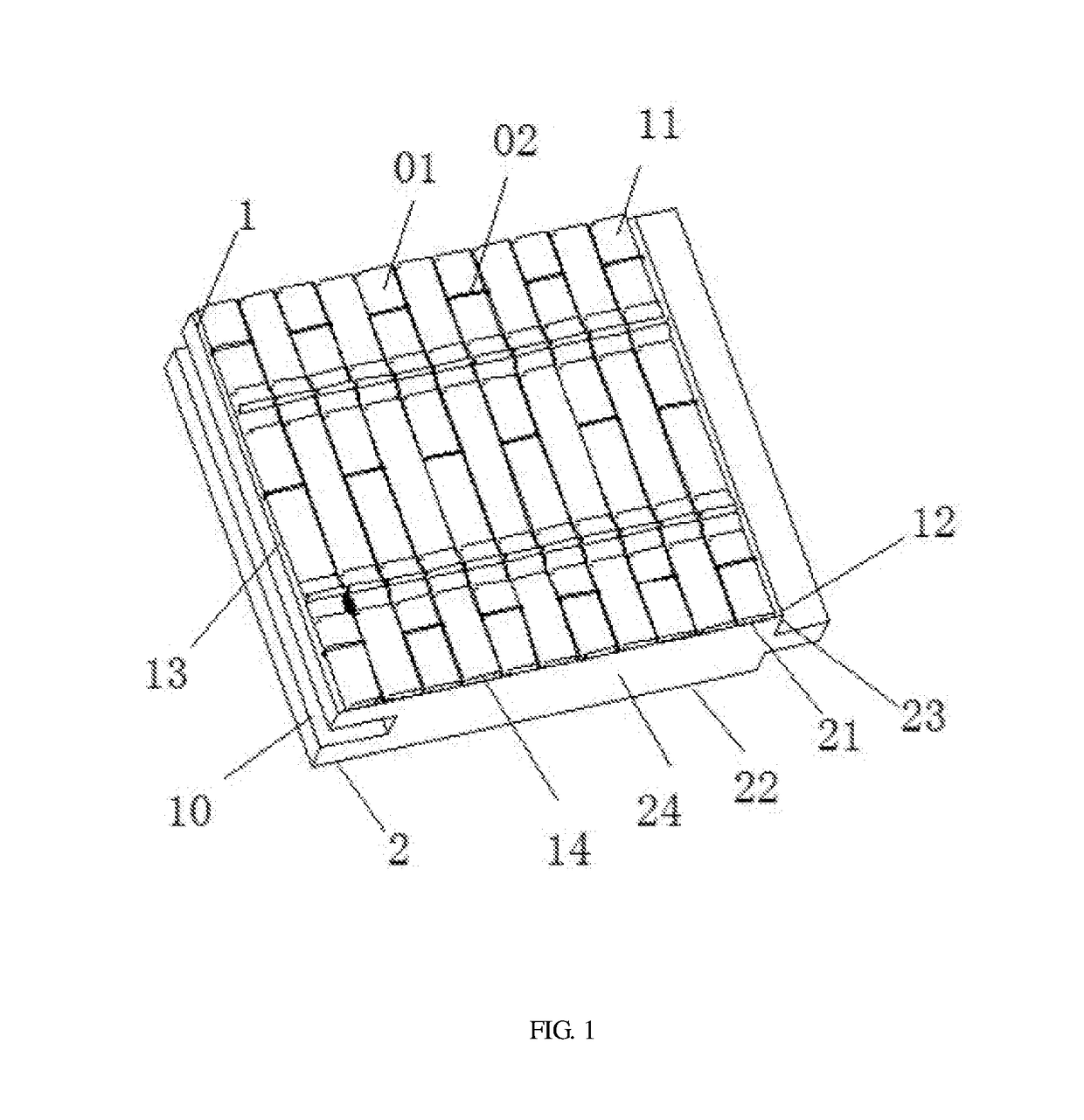

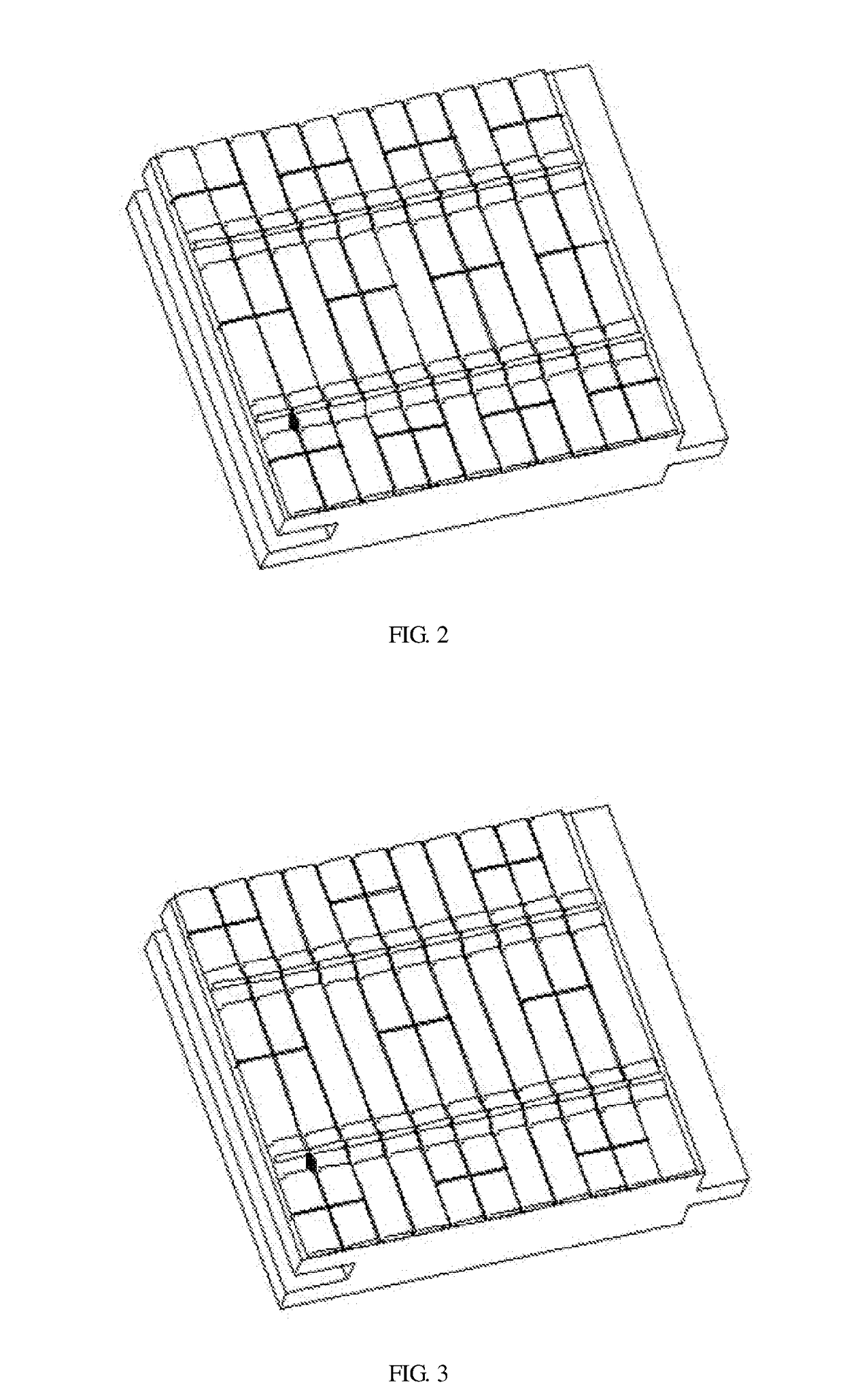

Composite bamboo floor and manufacturing method thereof

ActiveUS20170356193A1Improve stabilityShort processing timeTongue/grooves making apparatusCane mechanical workingEngineeringBamboo floor

The invention relates to a bamboo floor, in particular to a composite bamboo floor. The composite bamboo floor comprises a floor surface board provided with a body, a pressed surface, a connecting surface connected with the core board, at least one cut surface board side face and surface board end faces, and the core board arranged under the floor surface board and provided with a core board surface connected with the floor surface board, a core board bottom surface, core board side faces and core board end faces, and the positions of the core board side faces or the core board side faces and the surface board side faces are provided with notch structures processed in two sides in the length direction of the composite bamboo floor. The composite bamboo floor is high in strength, high in processing efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

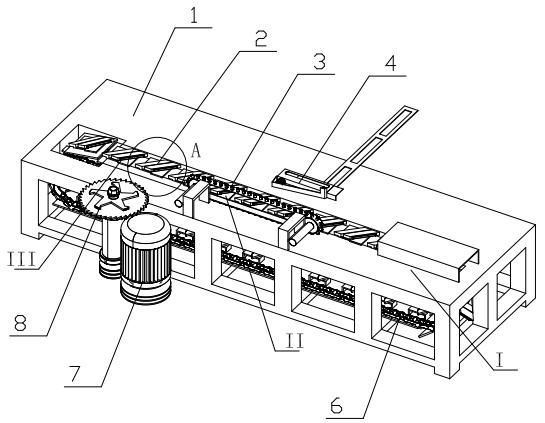

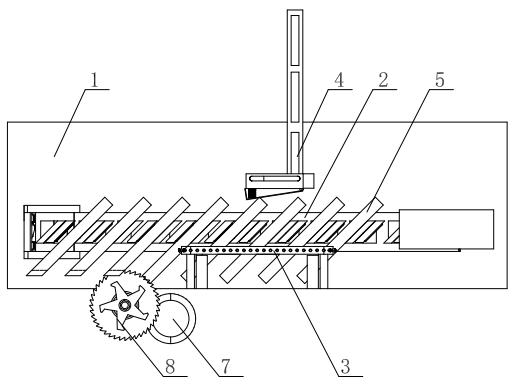

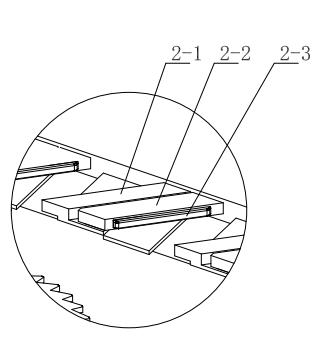

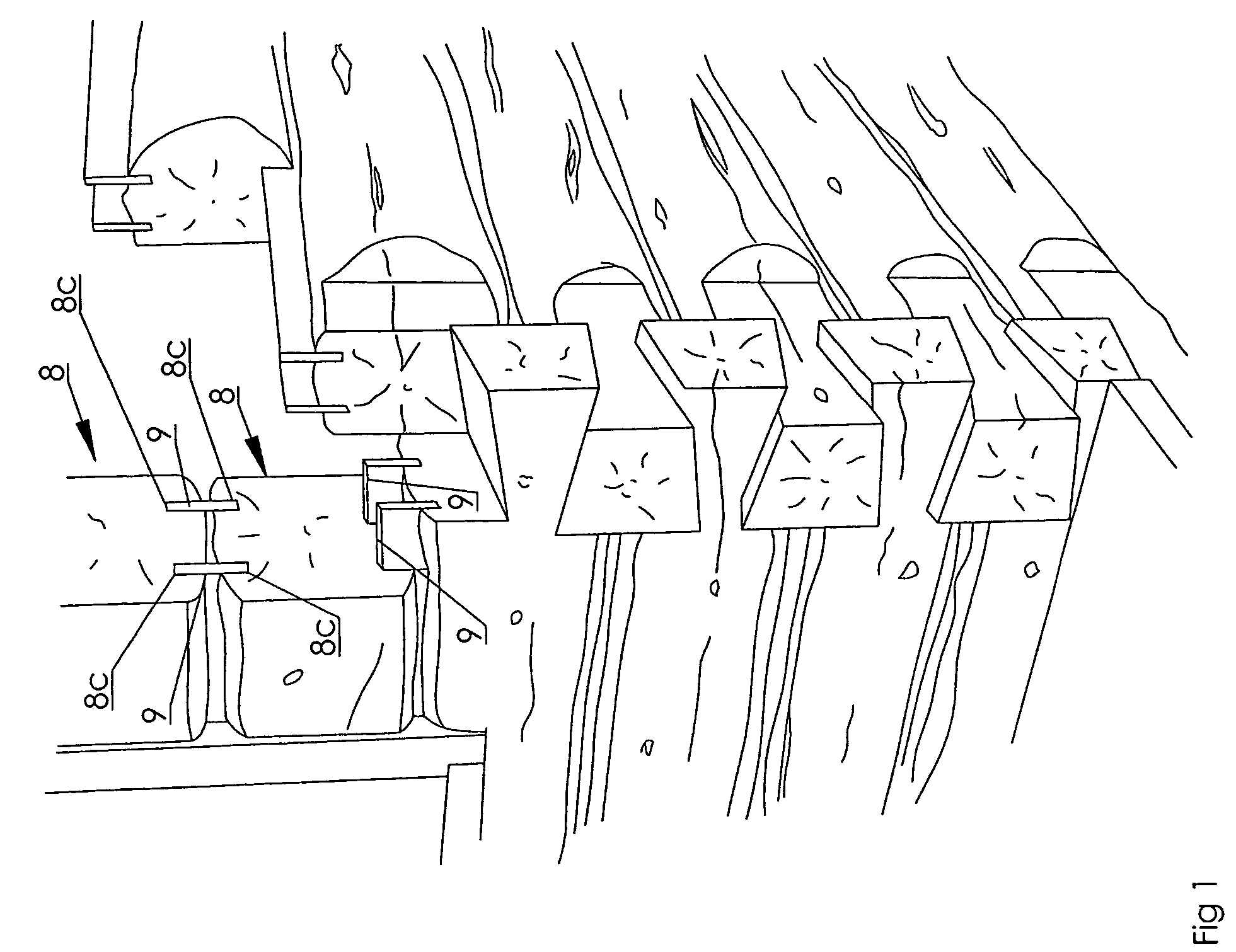

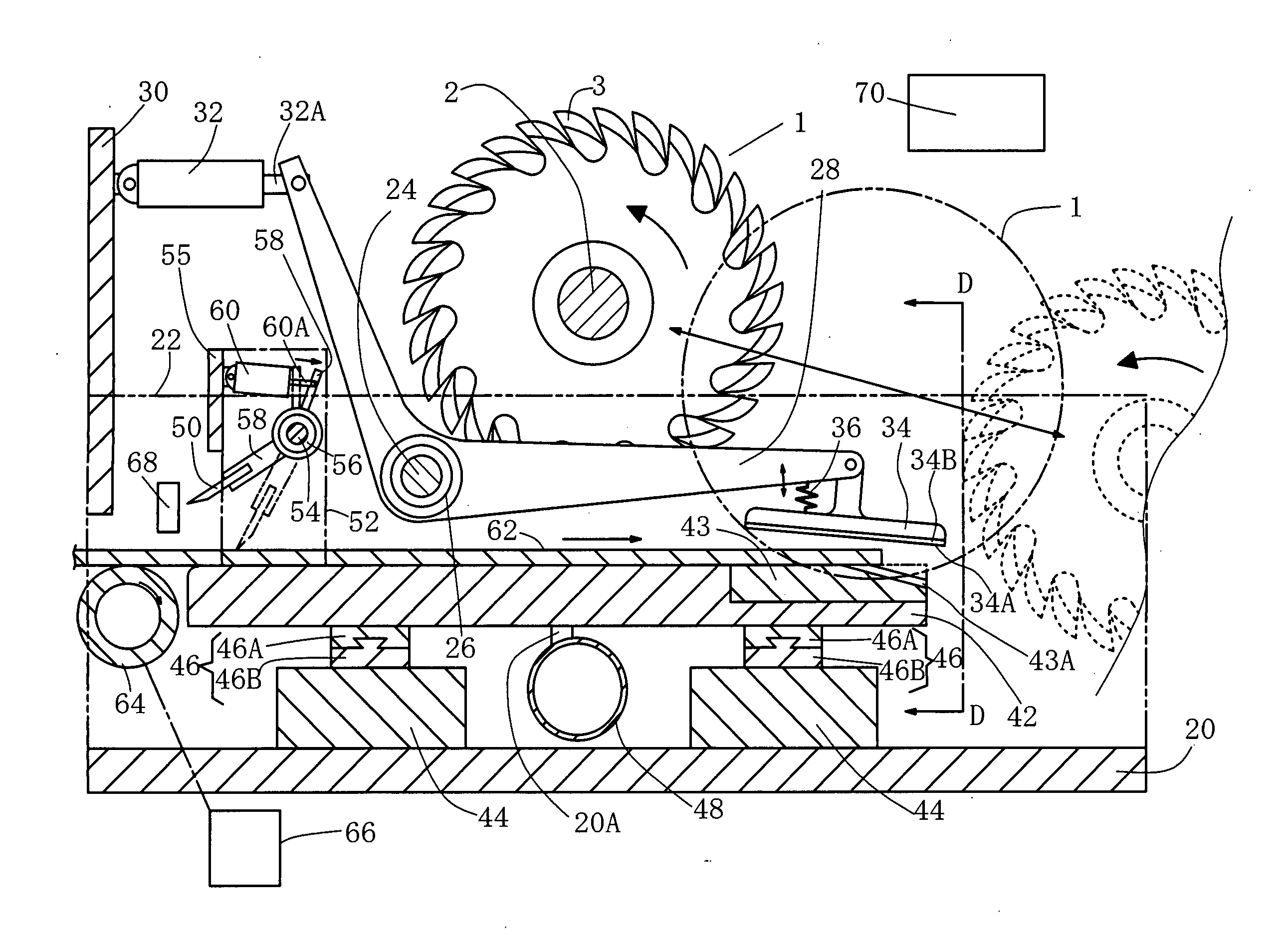

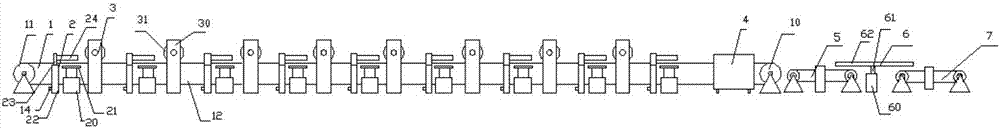

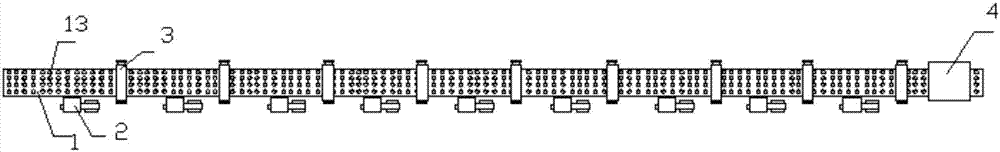

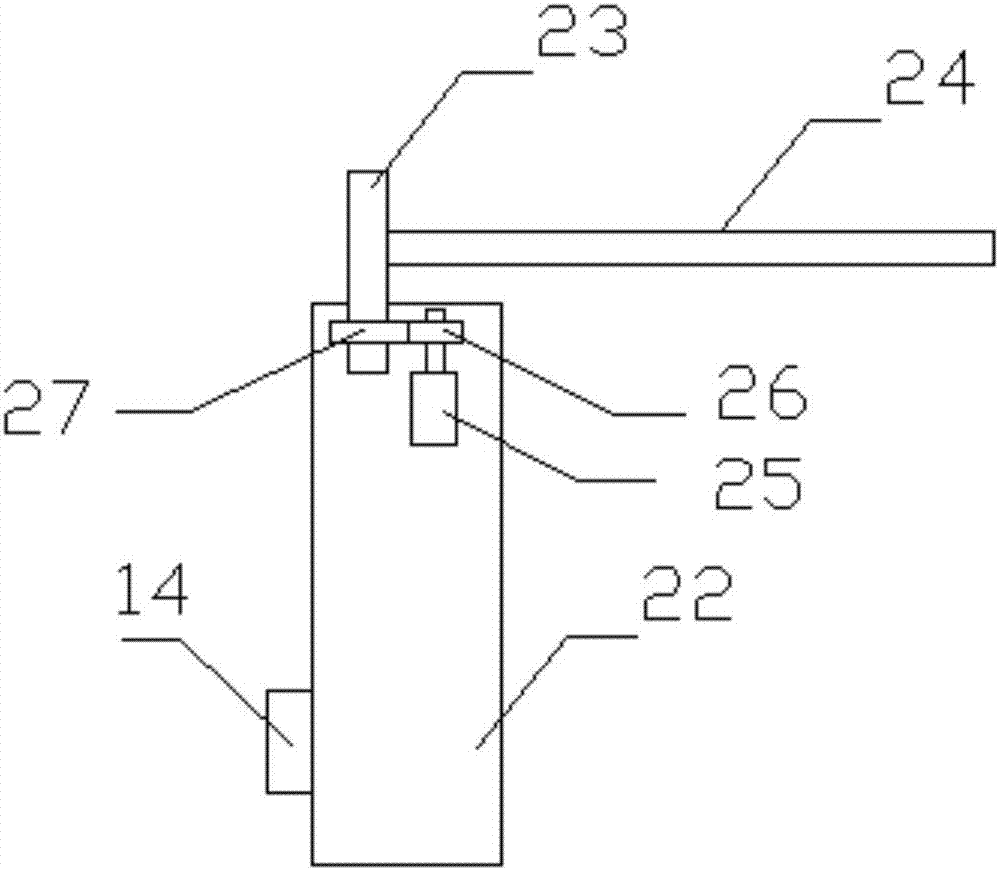

Automatic processing machine for timber tenon

ActiveCN102490221AProtect personal safetyPrecise positioningTongue/grooves making apparatusTenon making apparatusDrive motorOperation mode

The invention discloses an automatic processing machine for a timber tenon. The edge side of a rack is provided with a motor and a saw blade; the rack is provided with a rotary clamping block caterpillar track; the rotary clamping block caterpillar track is driven by a driving motor and a chain and is composed of multiple groups of fixed blocks and movable blocks forming an inclined angle of 45 degrees with the transmission direction; and a vertical clamping belt and a pushing elastic rack are respectively arranged on two sides of the rotary clamping block caterpillar track. According to the automatic processing machine for the timber tenon, the dangerous operation mode of mutually feeding and cutting gradually at present can be changed, only one operation person needs to be arranged to feed on the caterpillar track at low intensity on the safe position far away from the saw blade so as to greatly lower the labor danger and protect the personal safety; and the output within the unit time is greatly improved. The relative movement of the fixed blocks and the movable blocks is utilized to clamp and release the timber, the vertical clamping belt and the pushing elastic rack are arranged in front of the clamping point to accurately position and locate the timber before the timber is clamped, and the machining precision and the consistency of the product are reliably guaranteed.

Owner:WUXI PHOENIX ARTIST MATERIALS

Wood working machine

ActiveUS20100108194A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWood processorEngineering

Owner:STEPP LEWIS E

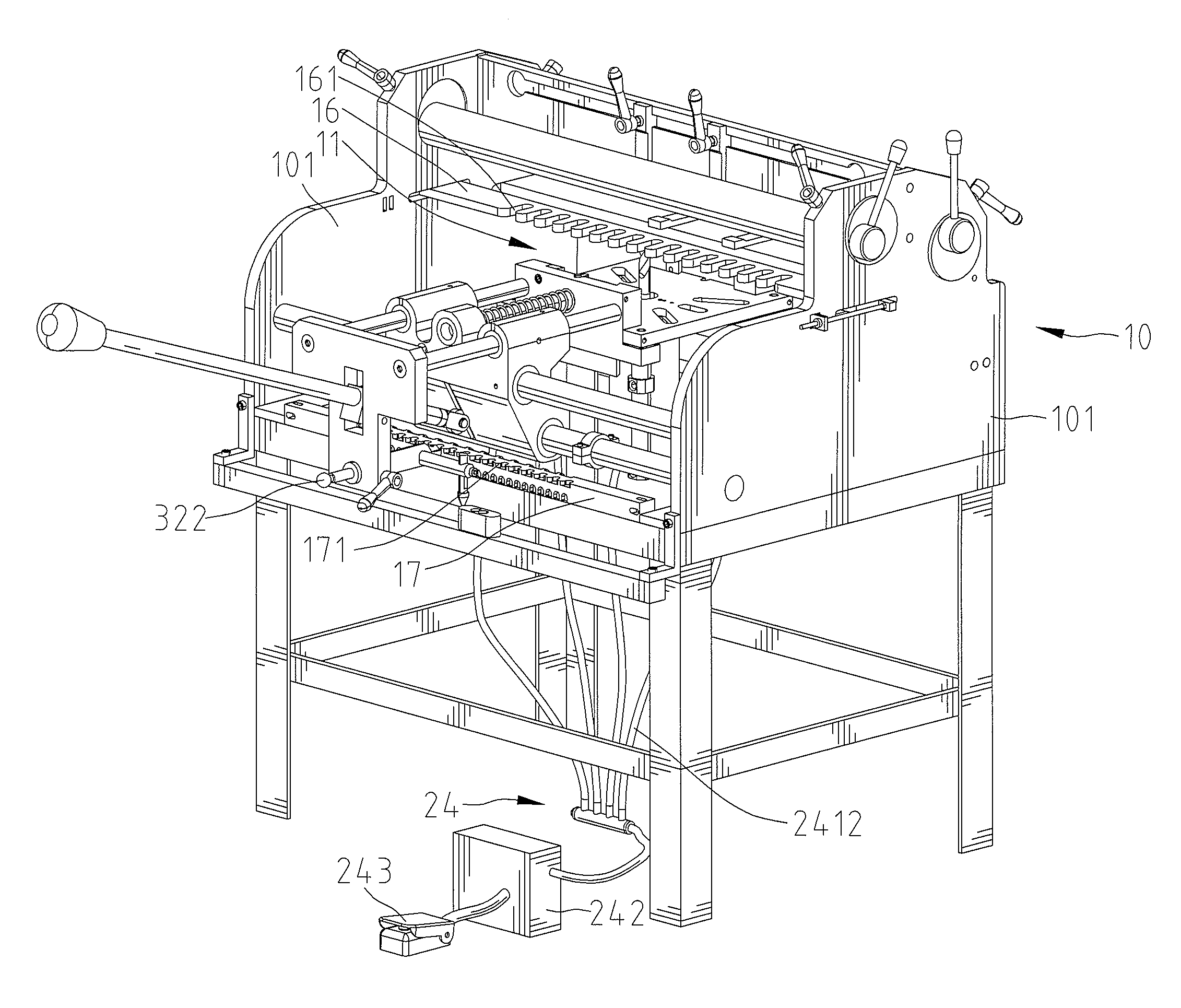

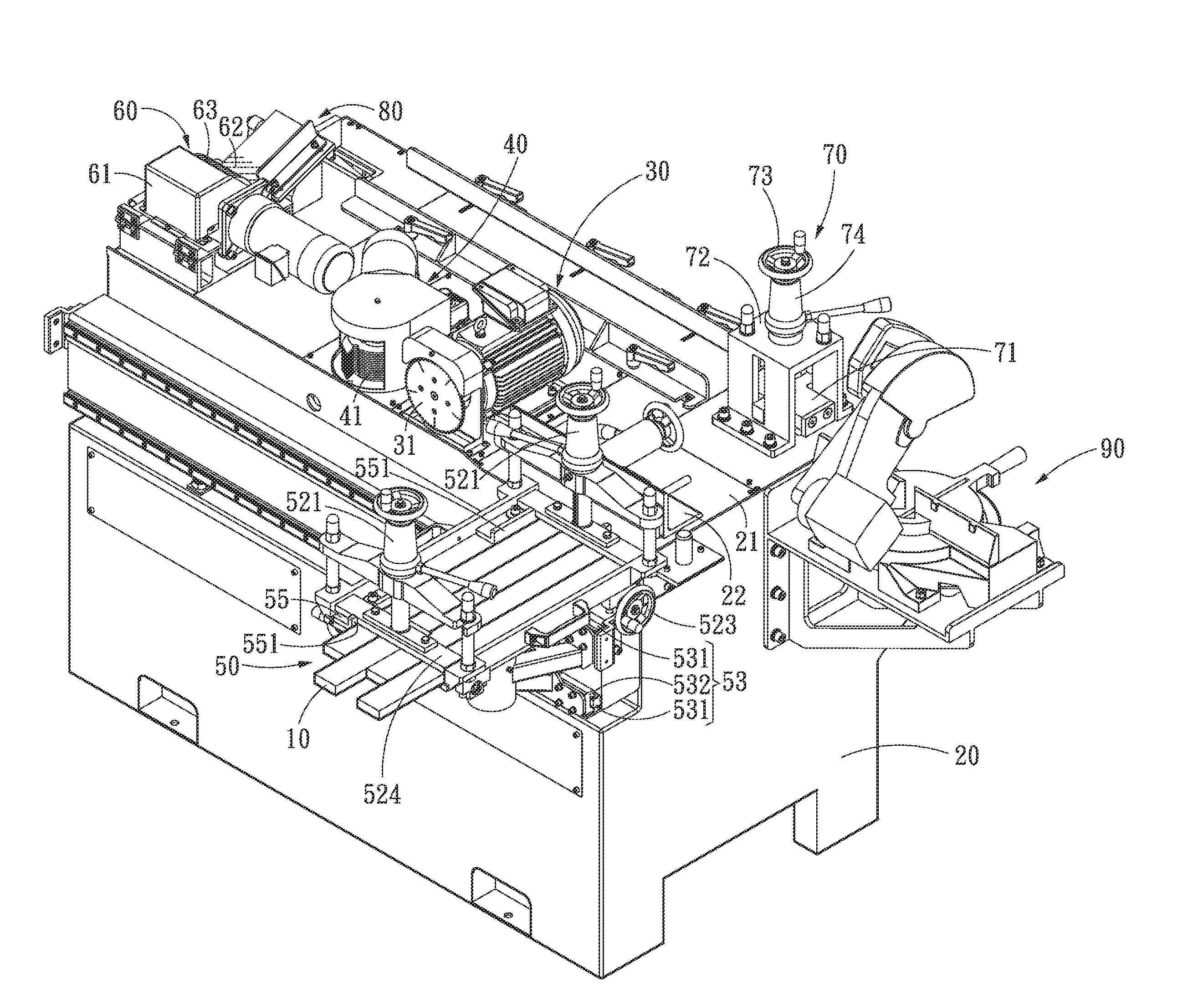

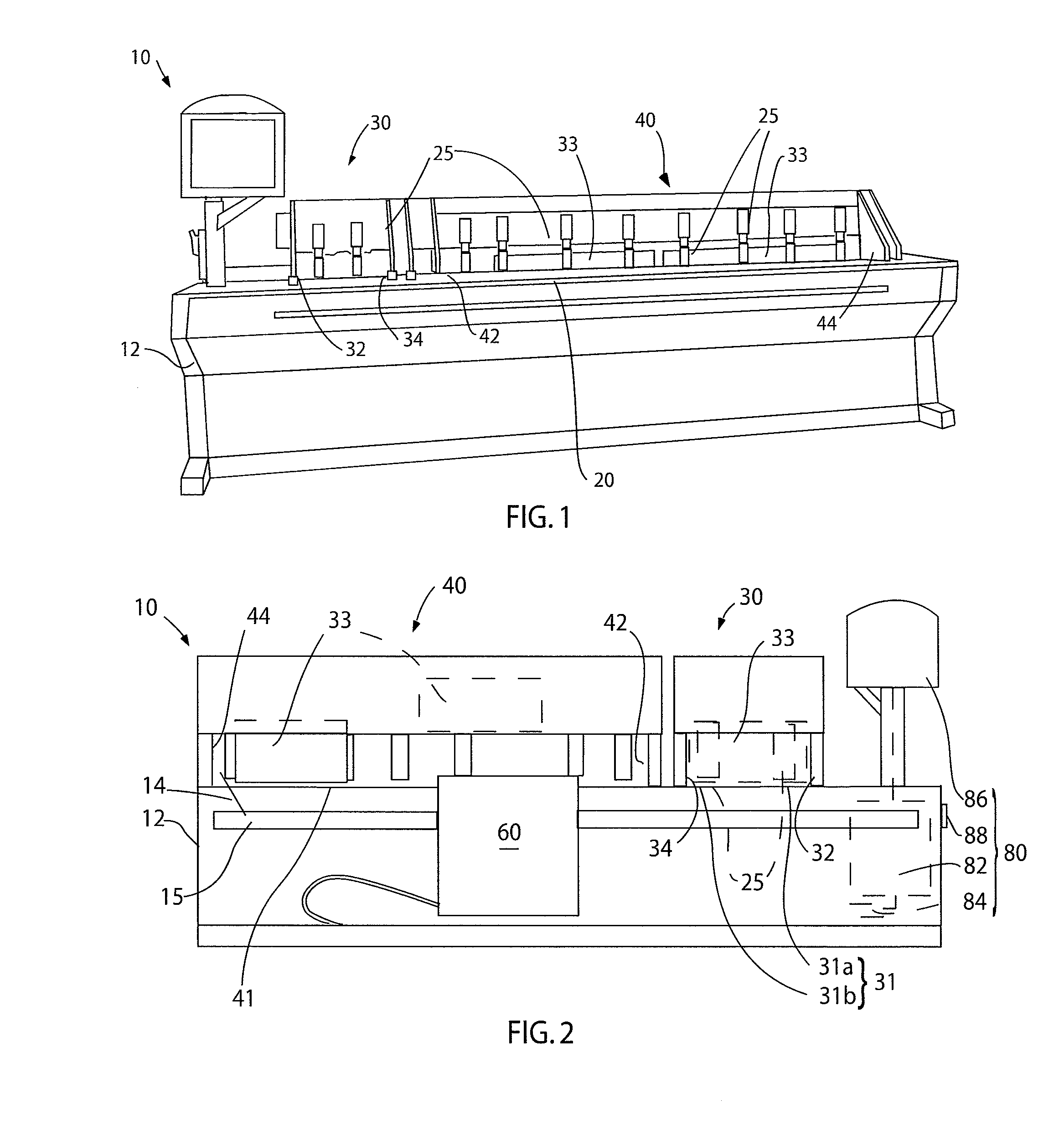

Wooden tenon press and connection machine

InactiveUS20160288360A1Increase the lengthLow costTongue/grooves making apparatusMulti-purpose machinesEngineeringMechanical engineering

A wooden tenon press and connection machine for coupling a plurality of wooden strips includes a station and a slide deck located on the station, a plane cutting device, a sawtooth cutting device, a gluing device, a thrust device and a press device that are located on the station. The slide deck carries the wooden strips sliding so that end surfaces at two sides of the wooden strips can pass through respectively a plane cutter of the plane cutting device and a sawtooth cutter of the sawtooth cutting device to form a wooden tenon on each of the end surfaces at two sides of the wooden strips. The two wooden tenons are daubed with a glue through the gluing device, and pressed through the press device and pushed and moved through the thrust device so that corresponding tenons of the wooden strips are tightly coupled together.

Owner:CHENG KUANG WOOD MACHINERY WORKS

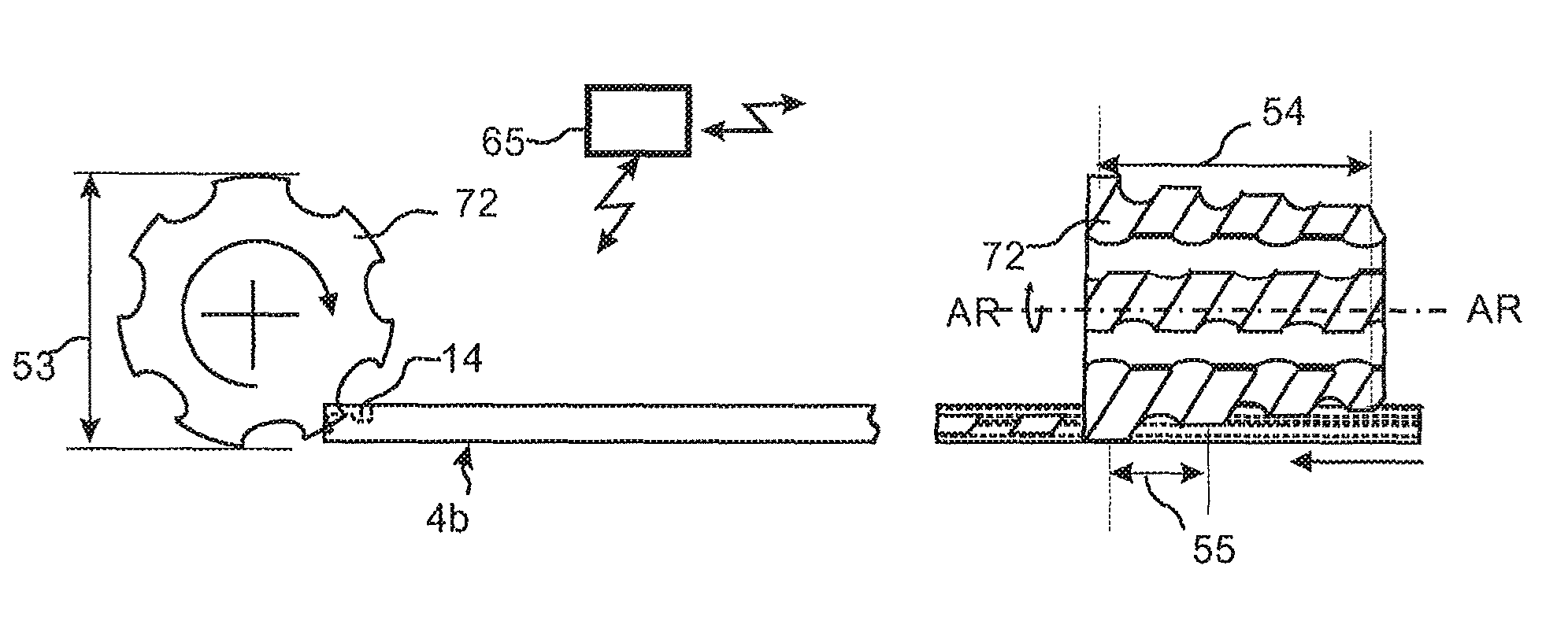

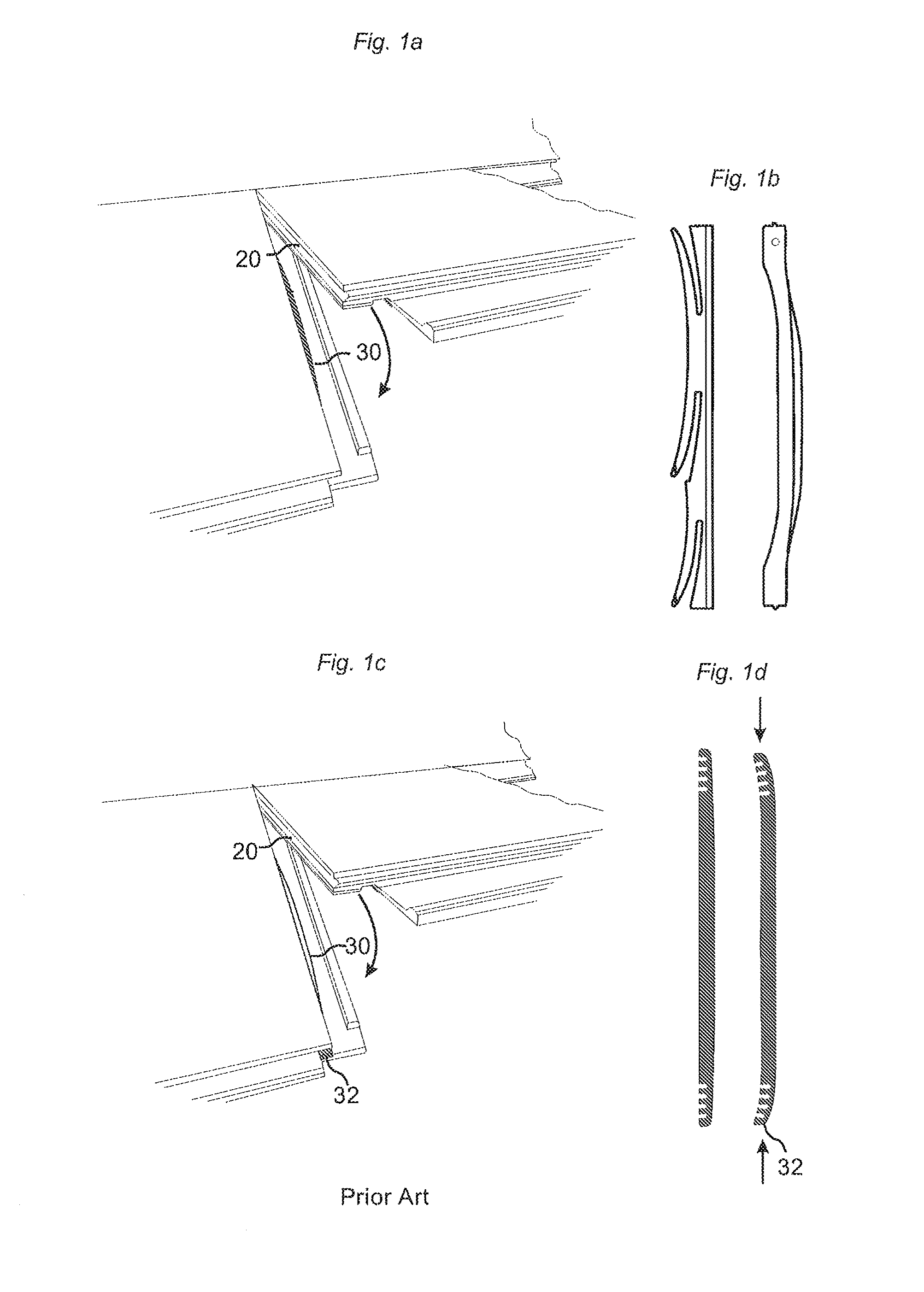

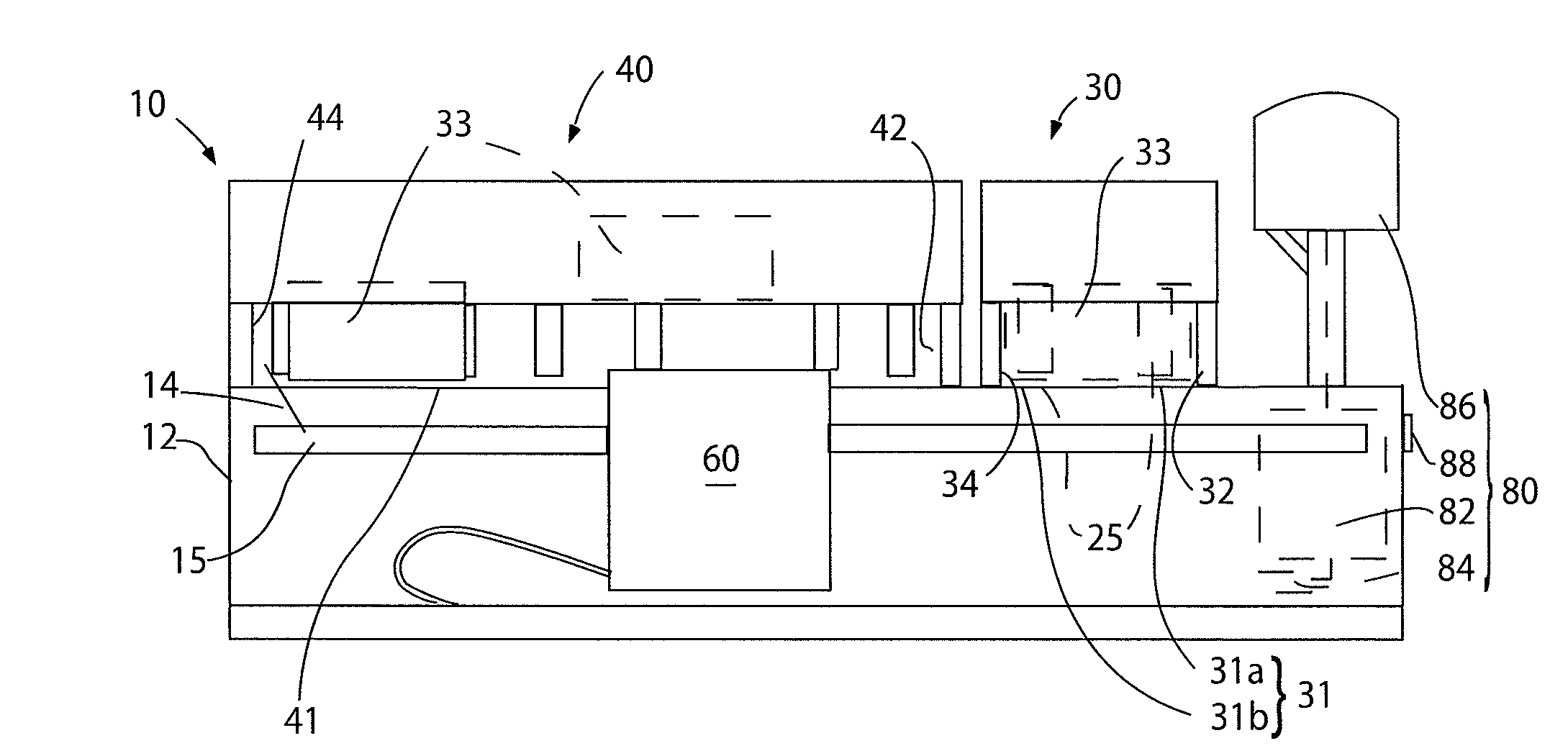

Apparatus and methods for shaping and machining elongate workpieces

InactiveUS20100154934A1Avoid badMinimize visibilityTongue/grooves making apparatusMulti-purpose machinesWoodworking machineVisible surface

The present invention includes methods in which work pieces are machined based upon the appearance of their surfaces. The work piece may be processed in such a way that surfaces with desirable features may be oriented so as to form visible surfaces of a finished part. In addition, the present invention includes woodworking machines that define joint features in and shape surfaces of rough work pieces.

Owner:HATCH JR J MELVON +1

Colour combination V-groove composite floor block and mfg. method thereof

InactiveCN1752374ARich in colorImprove visual effectsTongue/grooves making apparatusWood mortising machinesSolid woodEngineering

The present invention relates to a color-matched V-type groove composite floor board and its production method. It is characterized by that on two sides of top surface of a rectangular composite floor board an oblique angle toward outside is chamfered respectively, so that two edges of top surface of spliced adjacent rectangular composite floor boards are formed into a V-type chamfered groove, on the surface of V-type chamfered groove a color-matched layer whose color is different from that of composite floor board self-body is set. Besides, said invention also provides the concrete steps of its production method.

Owner:李卫

Wood working machine

InactiveUS7997308B2Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workTool bitEngineering

Owner:STEPP LEWIS E

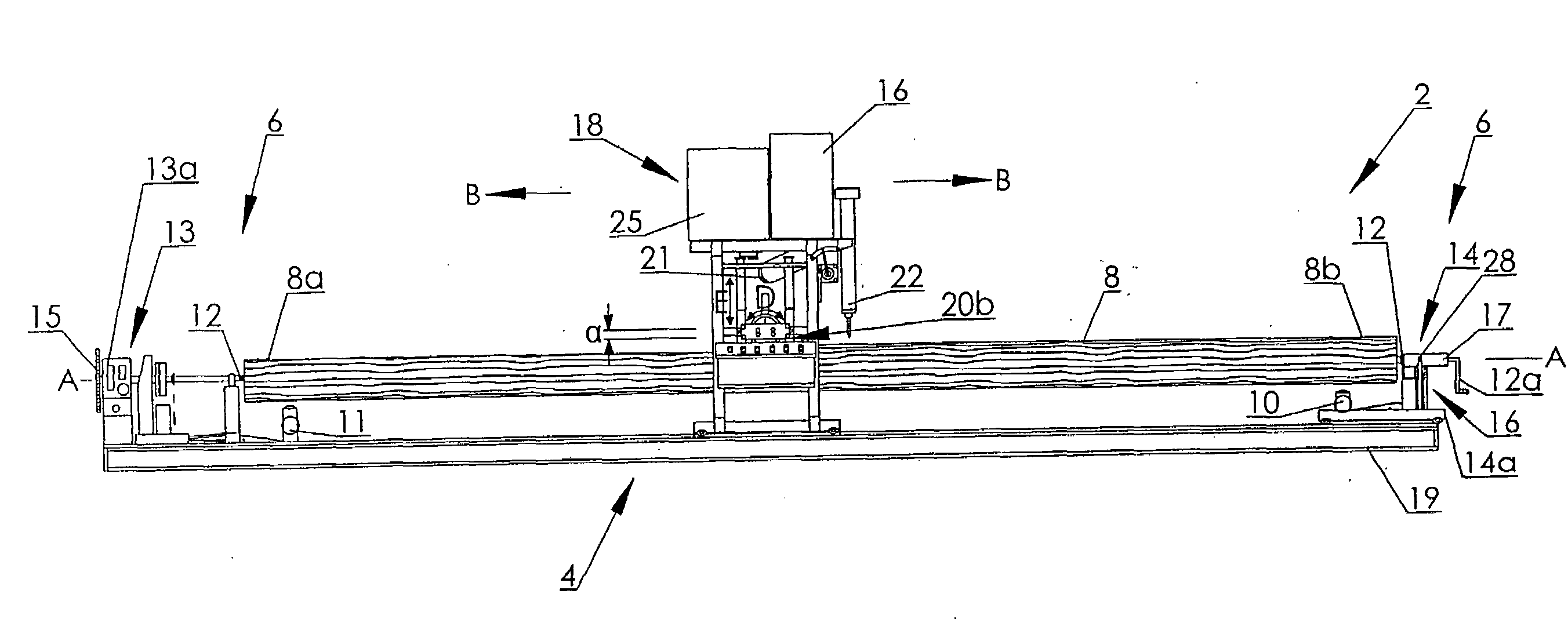

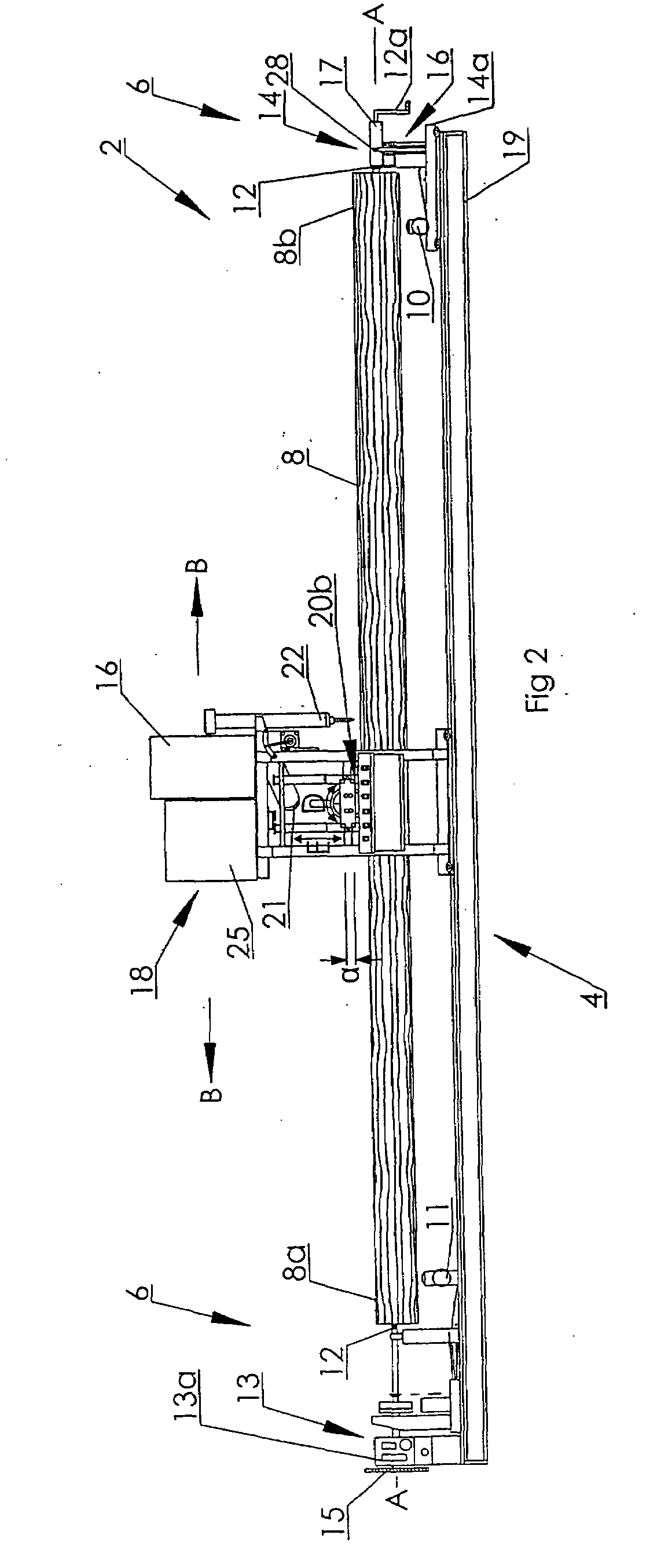

Method and apparatus for profiling a log for use in building timber or log homes

A log profiler for sawing surfaces into and along the length of a log may be characterized as including a saw carriage selectively translatable along a track, a pair of log holders on the track for holding the log suspended over and along the track and adapted to selectively rotate the log about its long axis, a linear double-acting saw blade mounted on a blade carriage, the blade translatable linearly along the blade carriage relative to both the blade carriage and saw carriage, the blade carriage selectively rotatable and selectively elevatable relative to the saw carriage.

Owner:JANZEN MARTIN

Method and apparatus for profiling a log for use in building timber or log homes

A log profiler for sawing surfaces into and along the length of a log may be characterized as including a saw carriage selectively translatable along a track, a pair of log holders on the track for holding the log suspended over and along the track and adapted to selectively rotate the log about its long axis, a linear double-acting saw blade mounted on a blade carriage, the blade translatable linearly along the blade carriage relative to both the blade carriage and saw carriage, the blade carriage selectively rotatable and selectively elevatable relative to the saw carriage.

Owner:JANZEN MARTIN

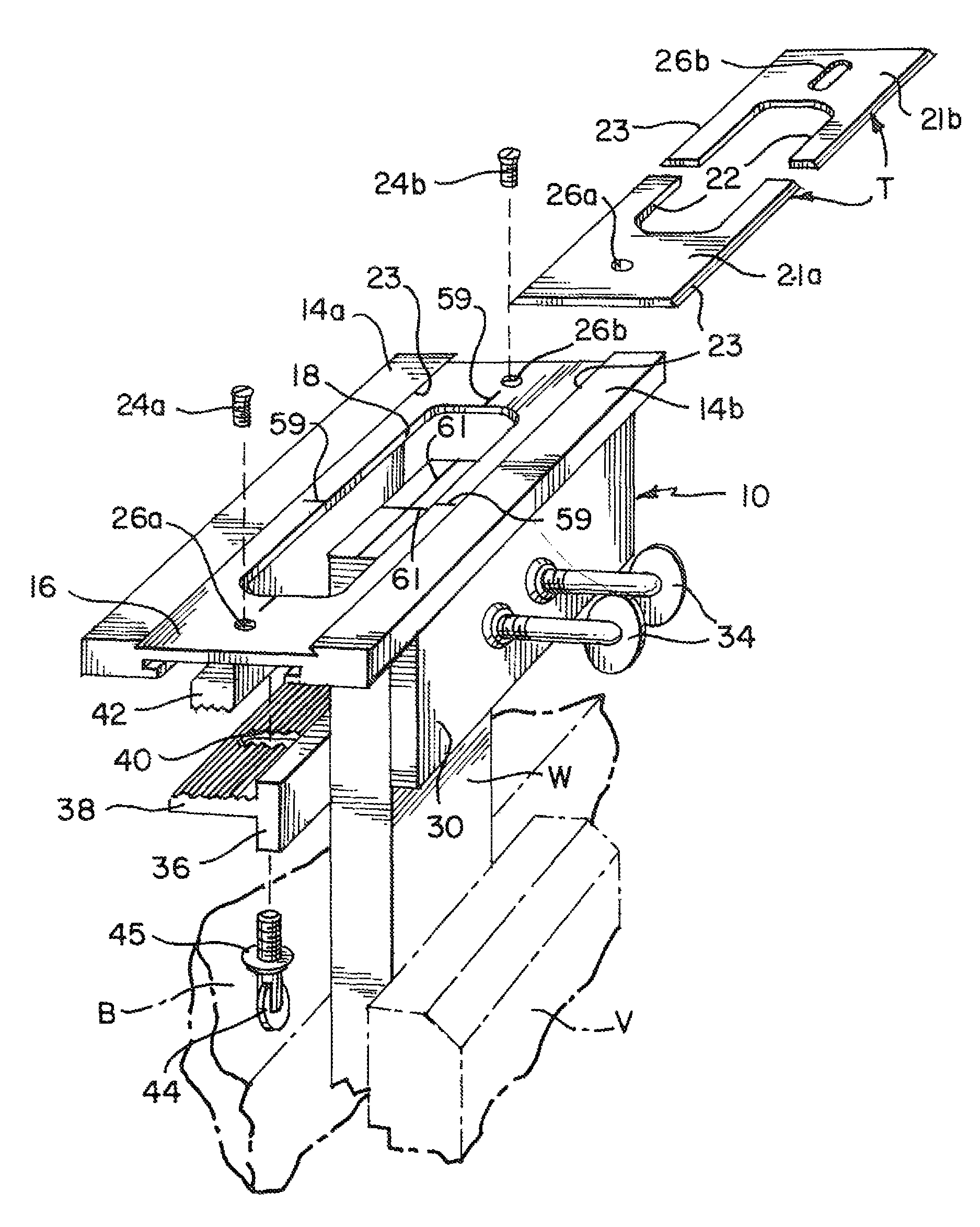

Mortise Jig for a Plunge Router

A mortise and dowel hole jig for ensuring timely and consistent cuts with a plunge router. The jig mounts to a work table and includes slot(s) to confine the router bit while cutting horizontally and holding the router in place vertically by two router guides. The jig also includes a rear clamp to lock-in-place and serve as a face for one or more pieces of wood; front clamp(s) to secure each piece of wood while making cuts; and a centering tool that enables a woodworker to quickly line up the center point of the piece of wood and determine where to make the desired cut.

Owner:MORTISE PRO PLUS LLC

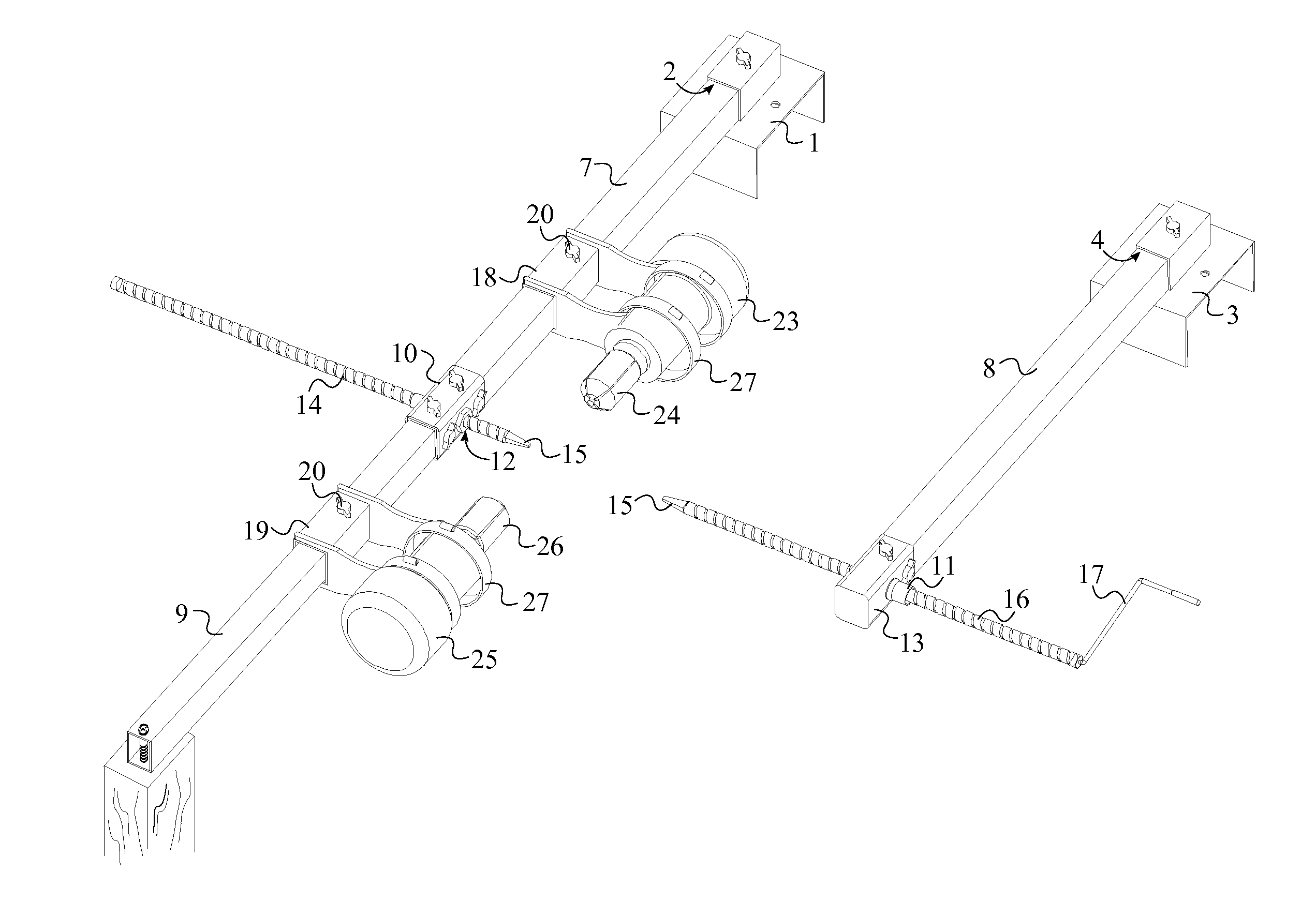

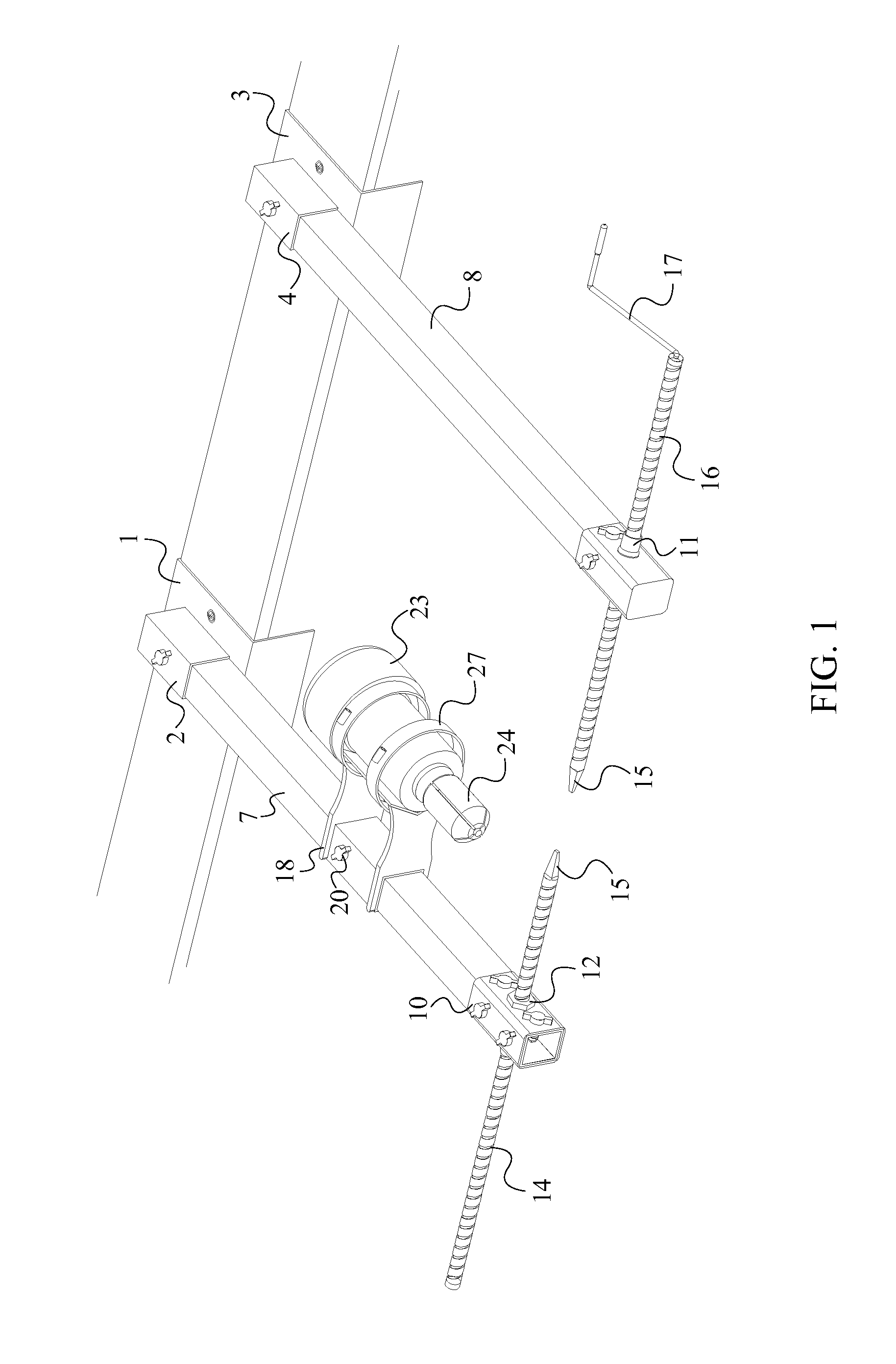

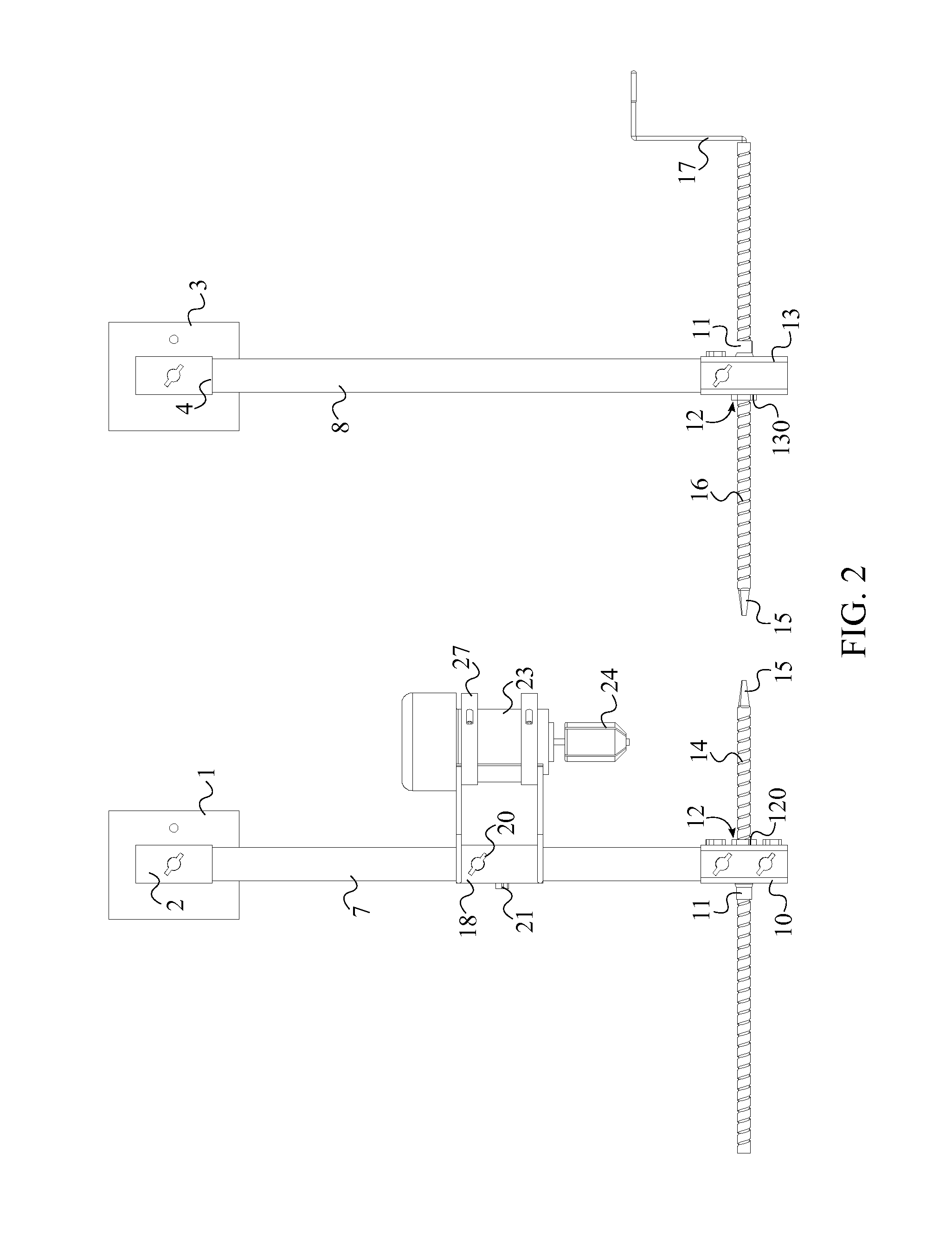

Router Jig for Producing Tenons

An apparatus used for cutting tenons consists of a plurality of mounting brackets, a plurality of arms, a motor, and a pair of threaded rods. The plurality of mounting brackets attaches the apparatus to an external platform. The motor is mounted onto one of the plurality of arms allowing the motor to slide along the length of the arm. The log in which the tenon is to be cut is placed in between the pair of threaded rods. By rotating the log with the use of one of the threaded rods or with the use of a drill, the log makes contact with the motor. The rotating motion of both the log and also the motor, results in a tenon being cut on the log. Additionally, two motors can also be used in tenon cutting such that a tenon with different diameters can be cut simultaneously.

Owner:SMITH LESLIE G

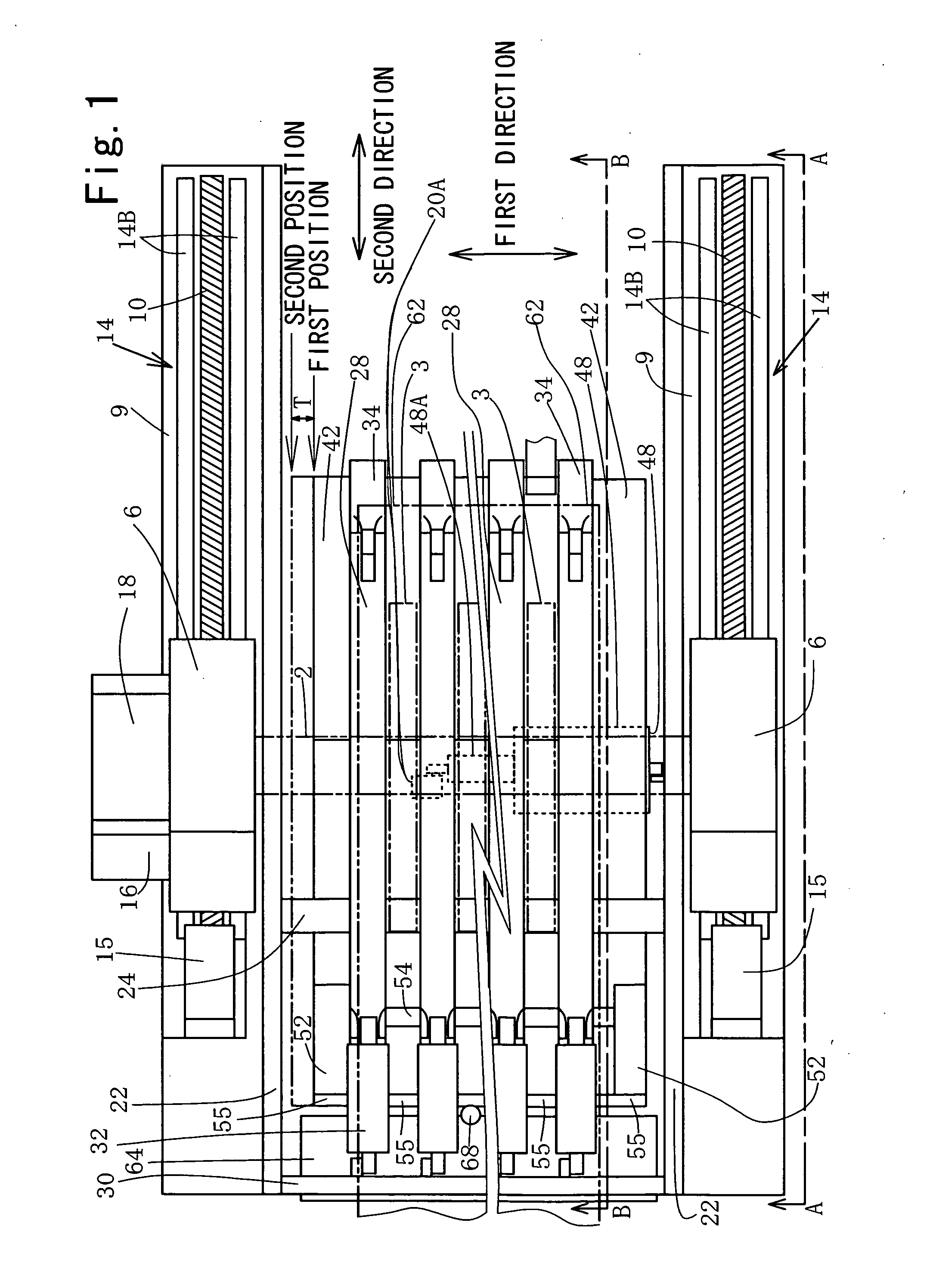

Method for forming a bevel cut at an end of a wood member

ActiveUS20110203703A1Tongue/grooves making apparatusProfiling/shaping machinesRelative motionEngineering

A method for forming a bevel cut at an end of a wood member is disclosed. A wood member is placed on a support table and a plurality of cutters mounted on and spaced along a shaft extending in parallel to the end of the wood member on the table is moved relative to the table in a direction inclined with respect to the wood member thereby to make a first cutting to form a plurality of bevel cuts. The support table is shifted in the direction parallel to the end of the wood member and a second cutting is made by the relative movement between the cutters and the table. During the first and second cutting, the wood member is pressed against the support table by a pressing member at a position adjacent to the end of the wood member and between any two adjacent cutters.

Owner:MEINAN MASCH WORKS INC

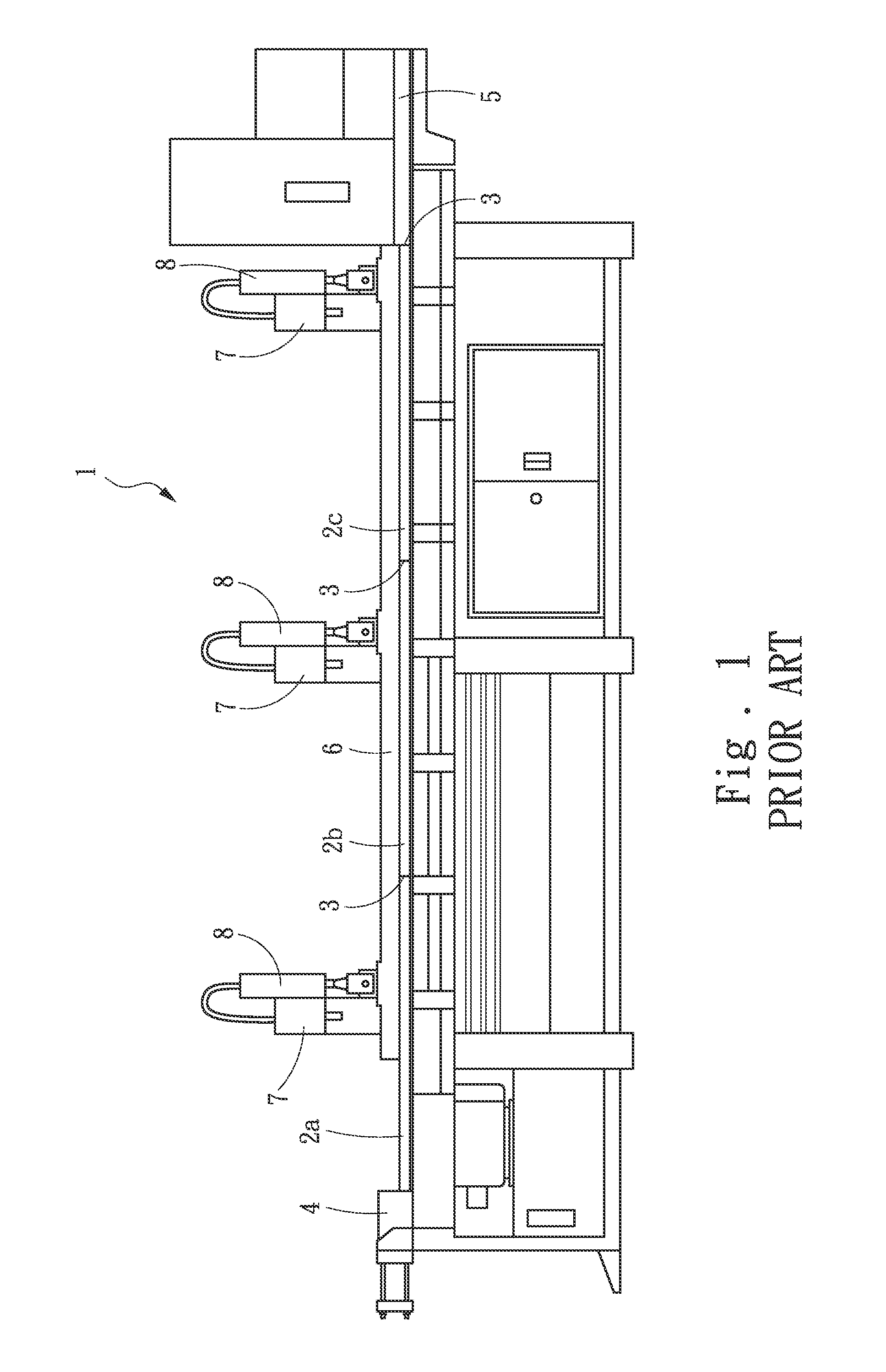

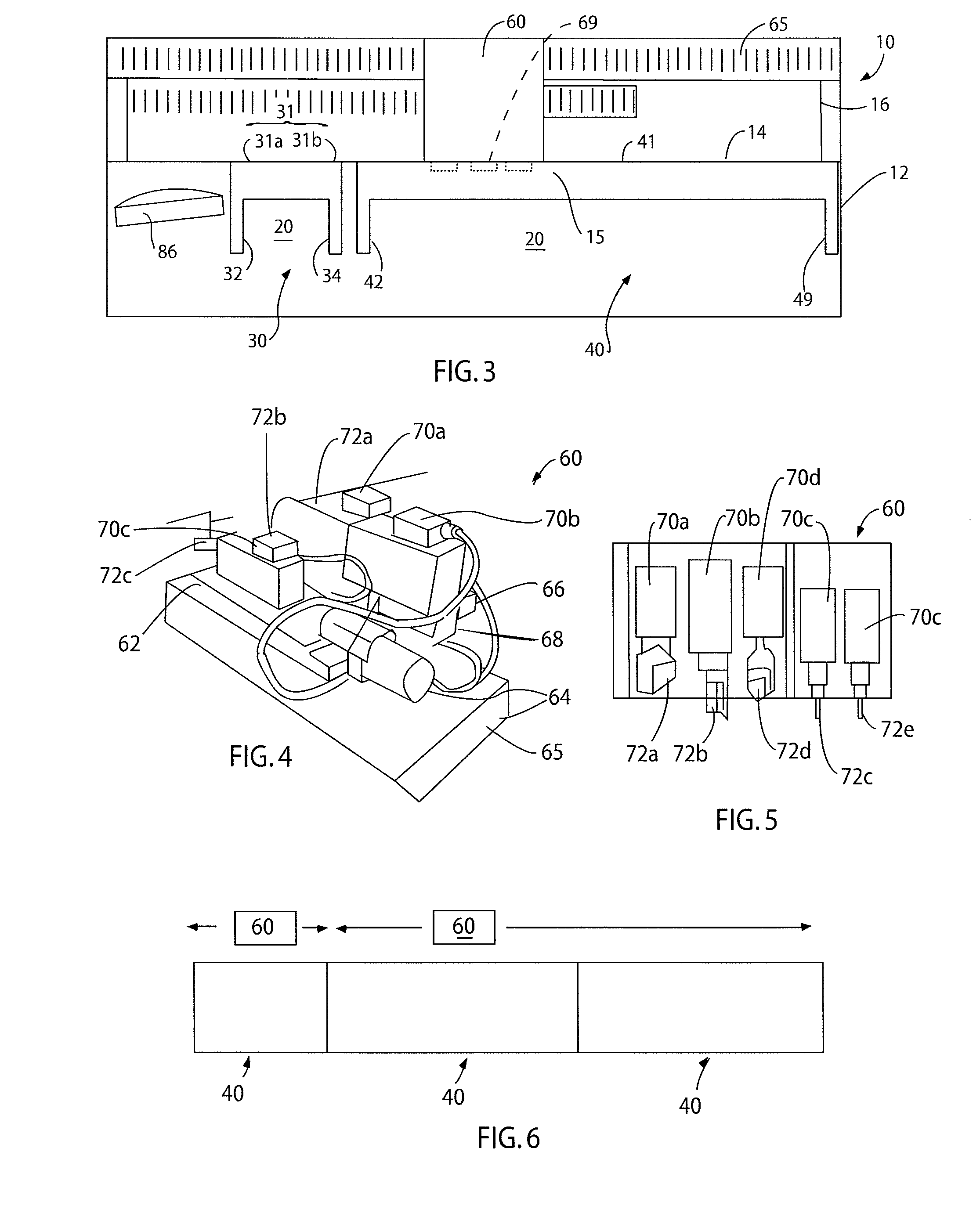

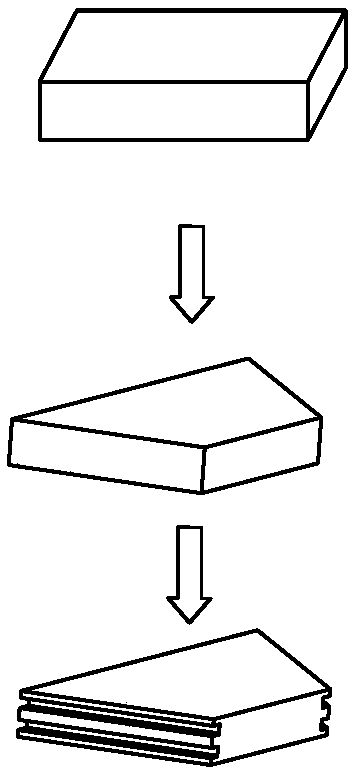

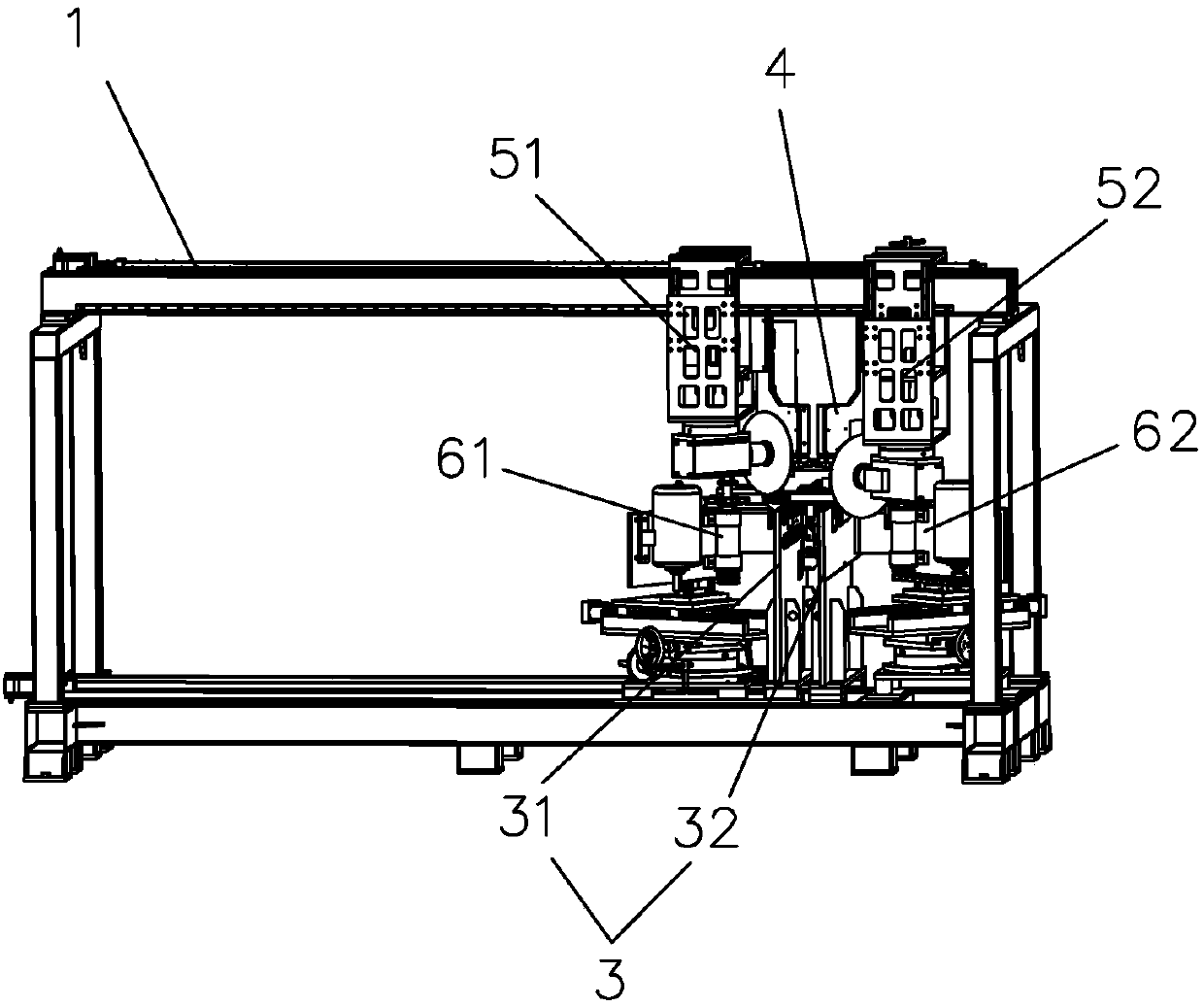

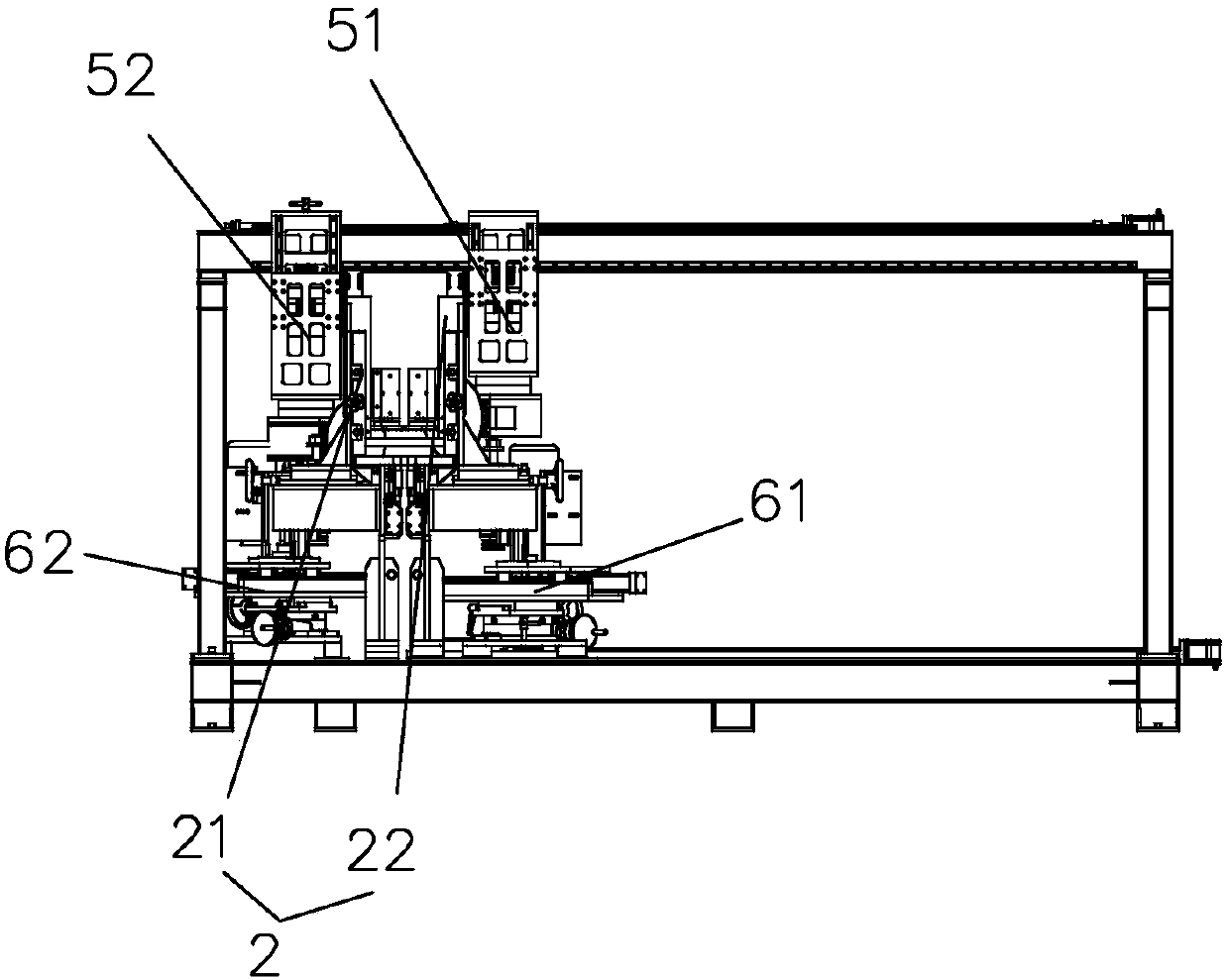

Double-headed automatic oblique tenoning machine

ActiveCN107803892AHigh degree of automationIncrease productivityTongue/grooves making apparatusTenon making apparatusStructural engineeringMachine

The invention discloses a double-headed automatic oblique tenoning machine. The double-headed automatic oblique tenoning machine comprises a rack, a timber storing mechanism, a timber pushing mechanism, a positioning mechanism, a first cutting mechanism, a second cutting mechanism, a first mill-tenoning mechanism and a second mill-tenoning mechanism, wherein the timber storing mechanism is used for storing a plurality of timbers arranged in a stacking mode, the timber pushing mechanism is used for pushing bottom timbers in the timbers arranged in a stacking mode to a machining area, the positioning mechanism is used for fixing the timbers when the timbers are located at the machining position, and the first cutting mechanism, the second cutting mechanism, the first mill-tenoning mechanismand the second mill-tenoning mechanism are used for conducting cutting operation and mill-tenoning operation on the two sides of the timbers respectively; and the first cutting mechanism and the second cutting mechanism are located over the first mill-tenoning mechanism and the second mill-tenoning mechanism and arranged on the left side and the right side of the timbers respectively, and the first mill-tenoning mechanism and the second mill-tenoning mechanism are arranged on the left side and the right side of the timbers respectively. Compared with the prior art, the double-headed automaticoblique tenoning machine achieves the purpose of automatically machining the long-strip-shaped timbers into needed standard parts and has the characteristics of being high in automation degree and production efficiency, the product production efficiency is greatly improved, and the labor intensity is reduced.

Owner:福建省富尔邦自动化设备有限公司

Multi-layer solid wood floor forming device

InactiveCN107081835AImprove molding efficiencyApply evenlyOther plywood/veneer working apparatusTongue/grooves making apparatusSolid woodTransverse groove

The invention discloses a multi-layer solid wood floor forming device, which is characterized in that it comprises a conveying mechanism, a plate feeding mechanism, a glue brushing mechanism, a drying mechanism, a vertical groove cutting mechanism, a steering mechanism and a transverse groove cutting mechanism There are nine sets of plate mechanisms, and eight sets of the glue brushing mechanism. The plate feeding mechanism and the glue brushing mechanism are arranged at intervals. According to the conveying direction of the conveying mechanism, the first set of plate feeding mechanisms is located in front of the first set of glue brushing mechanisms. The plate feeding mechanism is installed on the side of the conveying mechanism, the glue brushing mechanism spans above the conveying mechanism, the drying mechanism is located behind the last set of plate conveying mechanism, and the vertical grooving mechanism is located behind the dryer , the steering mechanism is located behind the vertical grooving mechanism, the transverse grooving mechanism is located behind the steering mechanism, and a heater is installed inside the rubber brushing roller of the gluing mechanism. The invention bonds multiple layers of solid wood together without air bubbles at the bonding place, and the glue is evenly applied to prevent the floor from warping, and can operate continuously, thereby improving the forming efficiency.

Owner:湖州红树叶木业有限公司

Method for processing lock catch of lock catch floor

InactiveCN101314231AAvoid or reduce sawing road lossSimple processTongue/grooves making apparatusCircular sawsMilling cutterTongue and groove

The invention relates to a method for processing a lock catch of a lock catch floor. The method comprises the following steps that: 1. sawing is performed at a position which is close to a boundary of two adjacent floors of a large-area floor blank and needs to be milled and removed, and two adjacent floor blanks are separated; and 2. the edge of the floor blank is milled into a tenon groove or a male dovetail by a milling cutter; therefore, the method avoids or reduces the loss of kerfs and has simple process.

Owner:湖北燕加隆木制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com