Rapid installing connection structure and manufacturing method of insulation board compounded by wood and foamed plastics

A foam plastic board and technology of foam plastic, applied in the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve problems such as poor strength and inconvenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

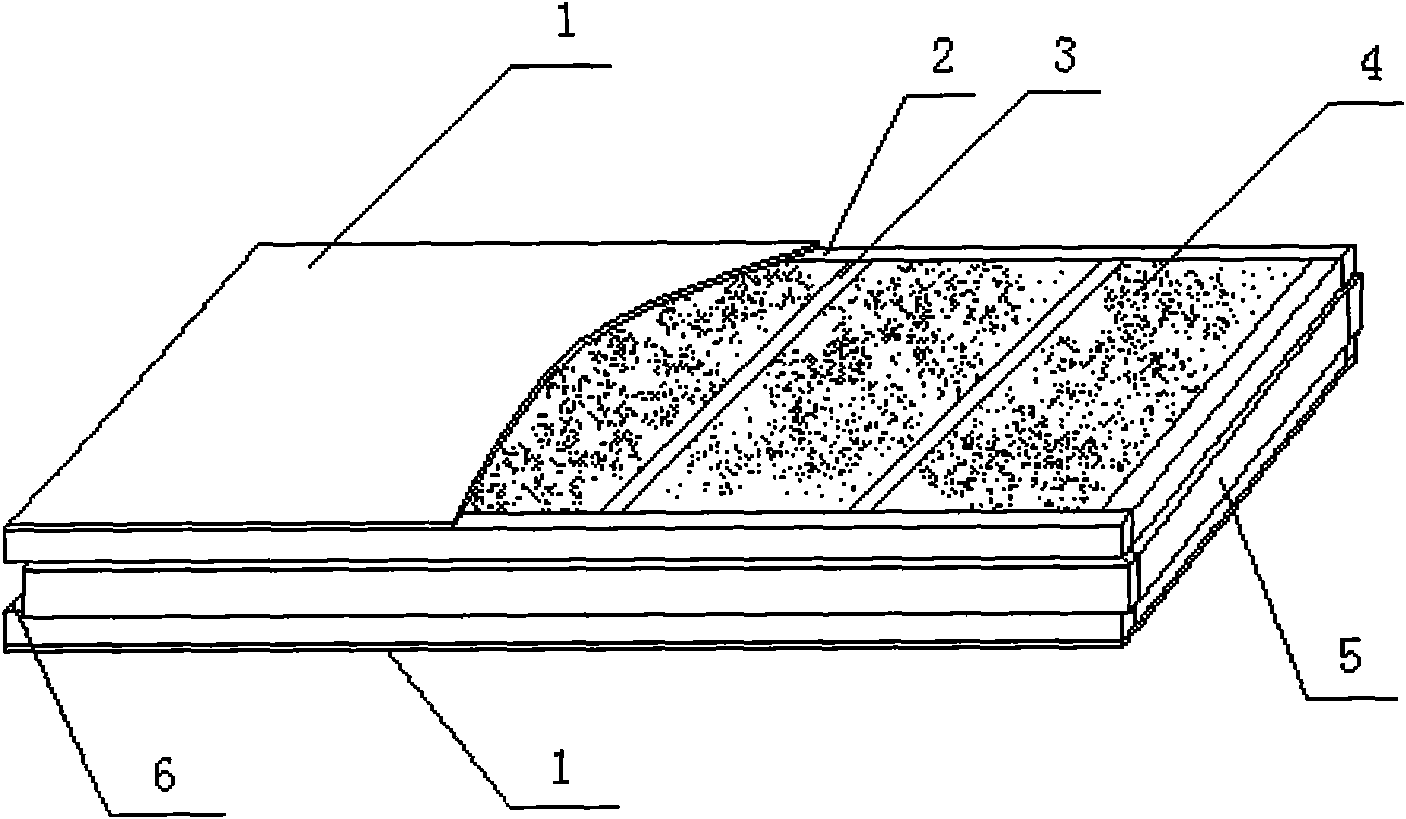

[0019] as attached figure 1 As shown, the surface layer is a 1.0mm thick two-layer poplar veneer with criss-cross textures, and is hot-pressed with urea-formaldehyde resin glue to form a plywood with a length of 2000mm and a width of 1000mm. The moisture content of the dried poplar board is 8-12%, processed into a wooden frame material with a width of 80mm and a surface finishing thickness of 22mm, and sawn into a wooden frame material with a length of 2000mm and a length of 960mm respectively. The outer side of the long frame material and one short frame material is processed into a tenon with a four-sided planer, the width of the tenon is 8mm, and the height is 7mm; the outer side of the other long frame material and one short frame material is processed into a groove with a four-side planer , the width of the groove is 9mm, and the depth is 8mm; the tongue and groove of the two long wooden frame materials and the two short wooden frame materials are nailed outward to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com