Patents

Literature

900results about "Wood slotting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

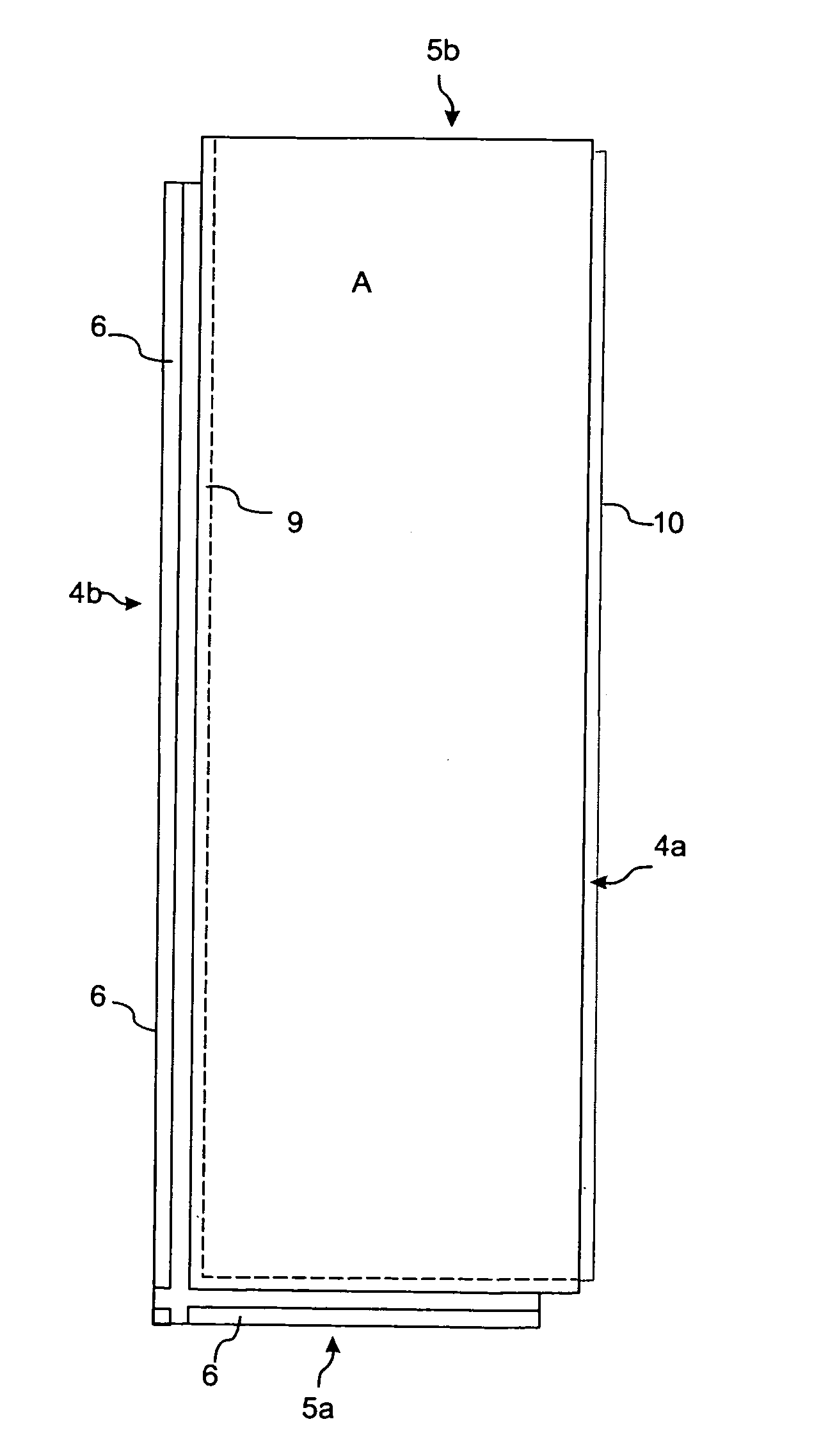

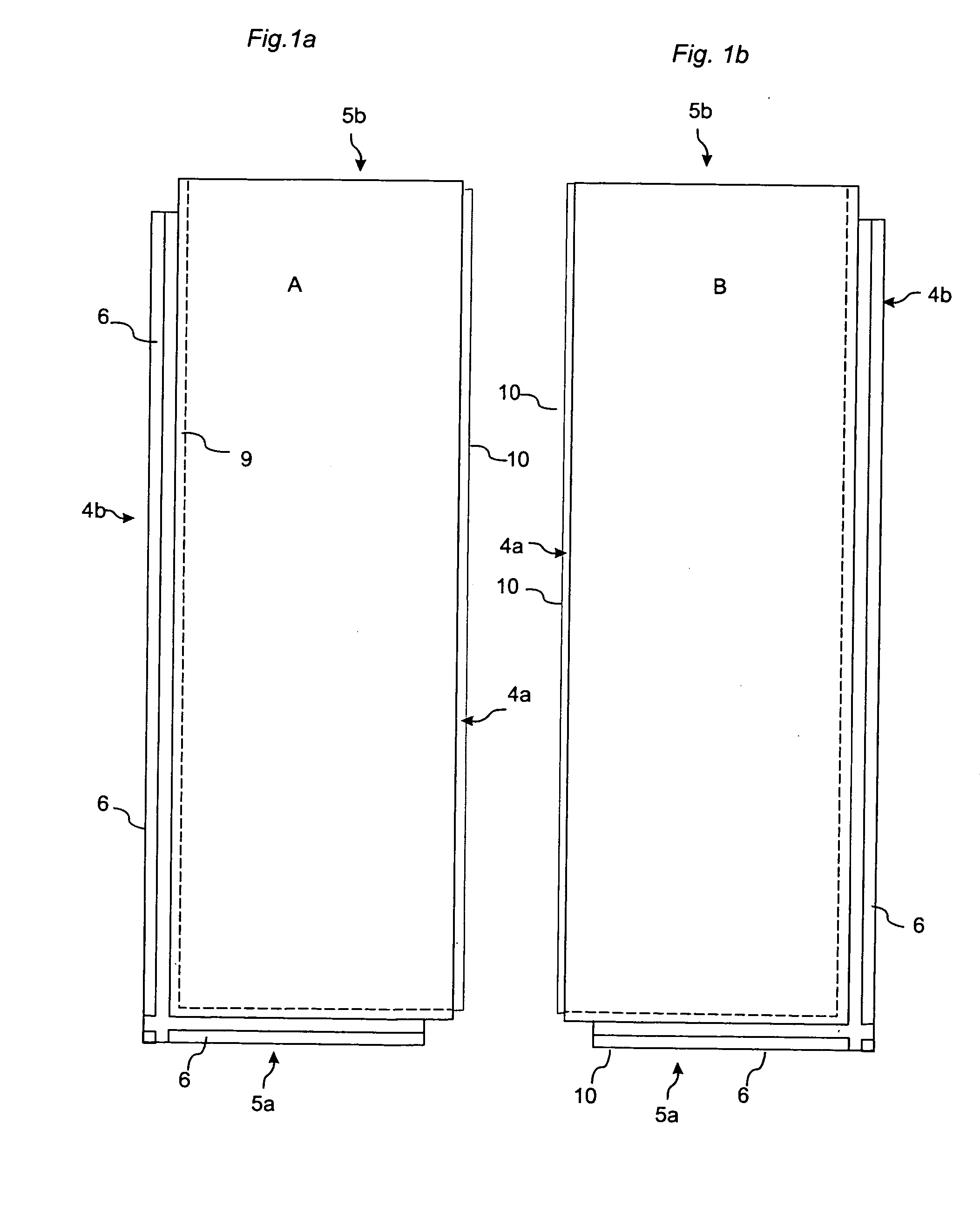

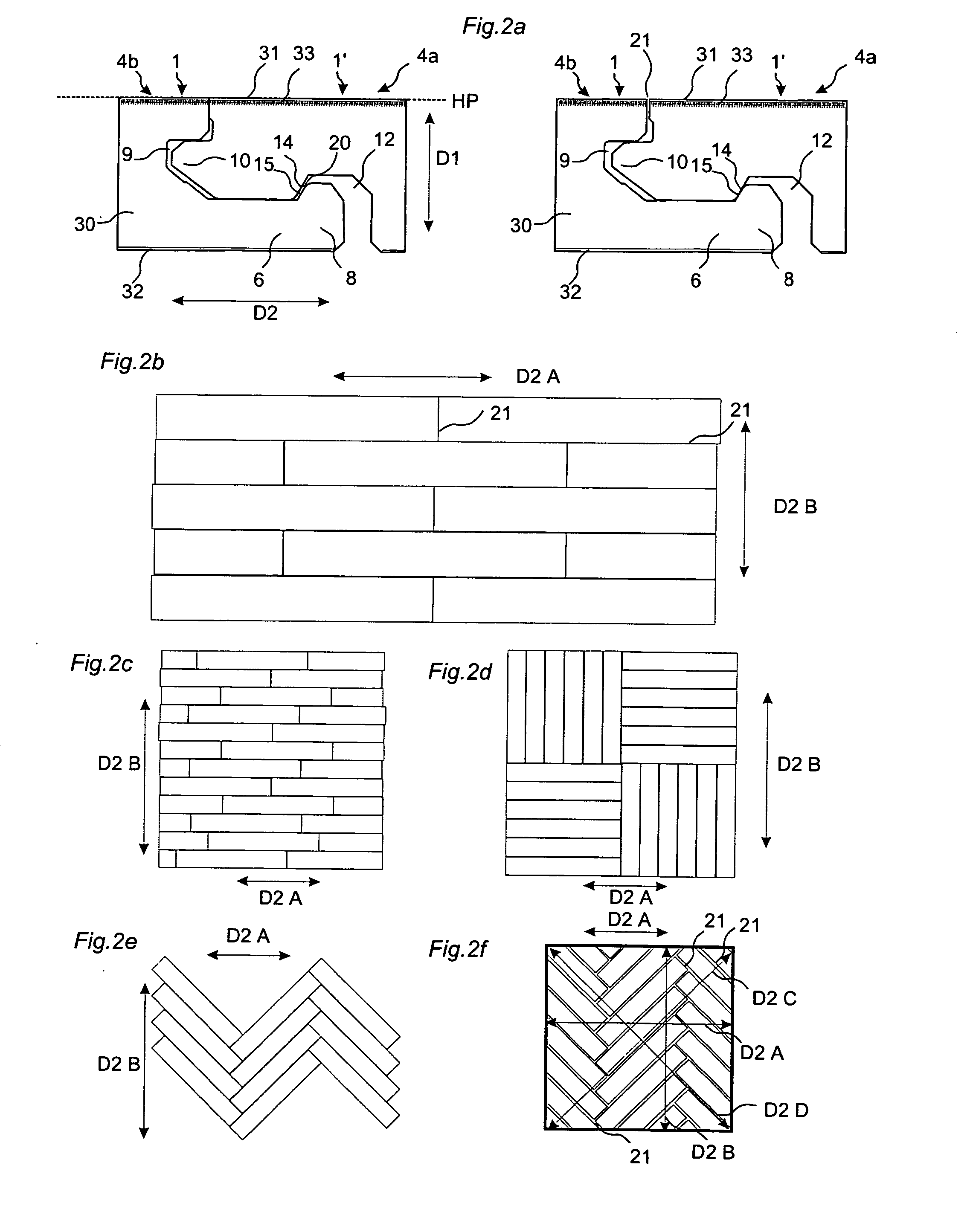

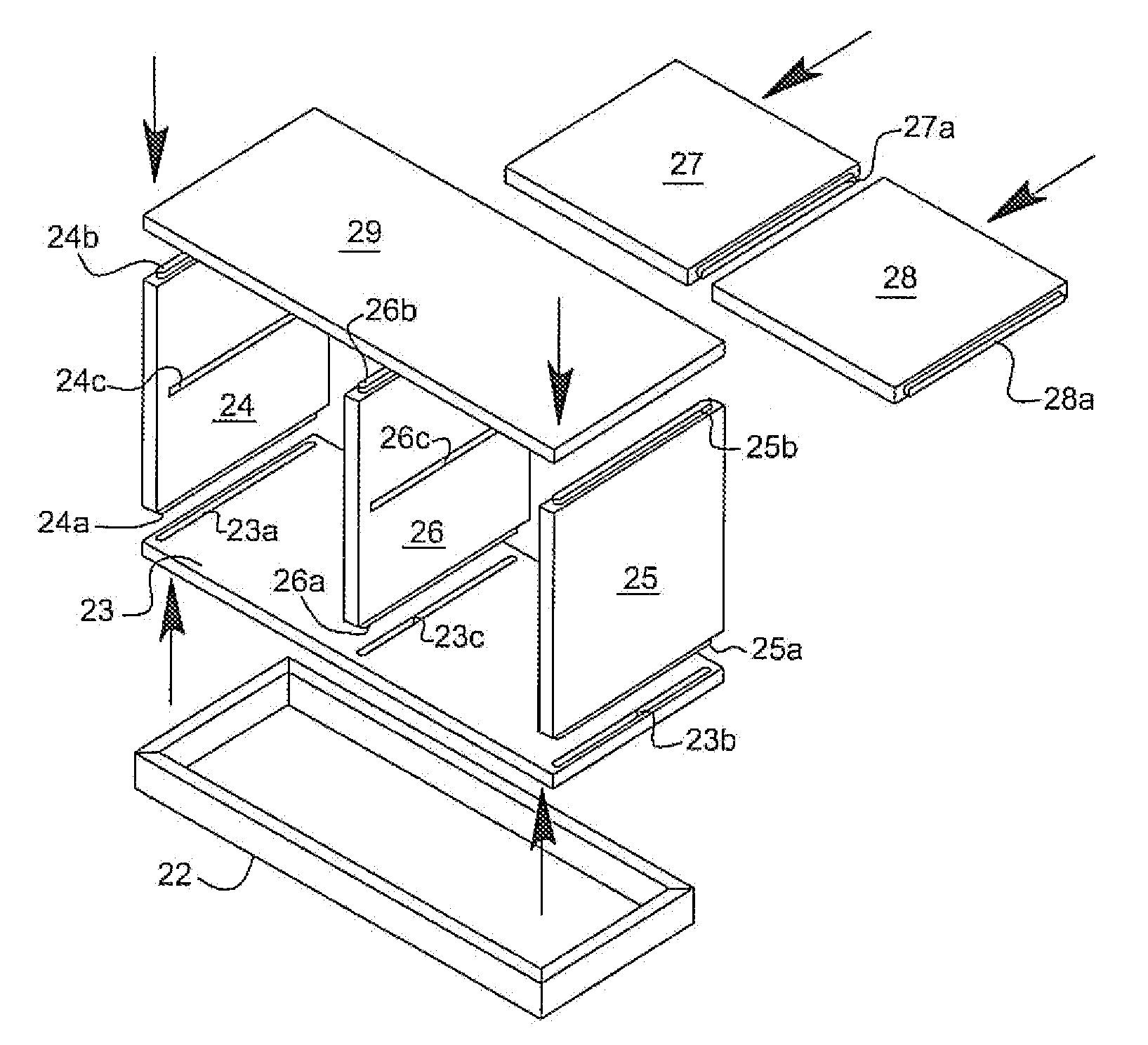

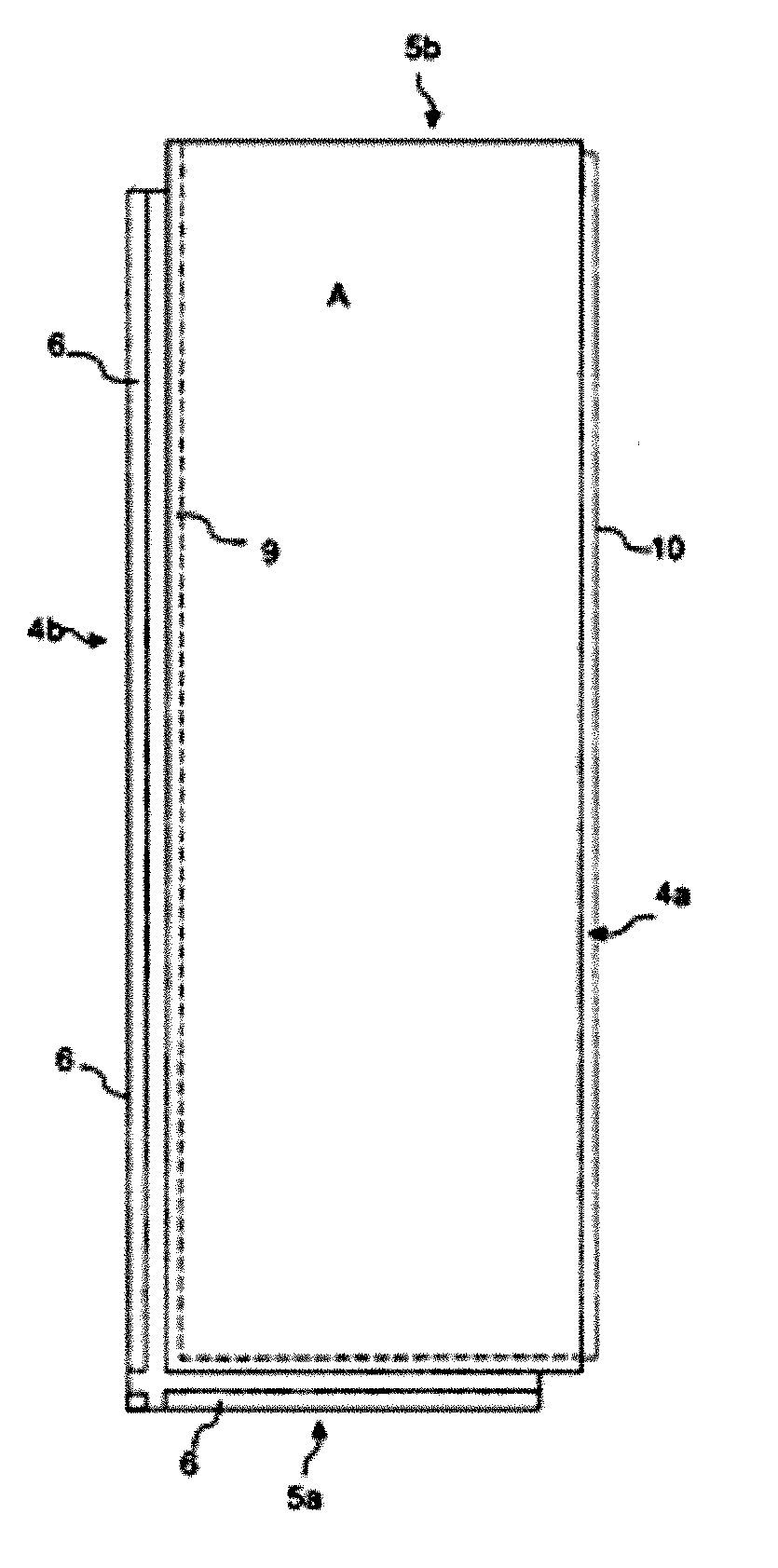

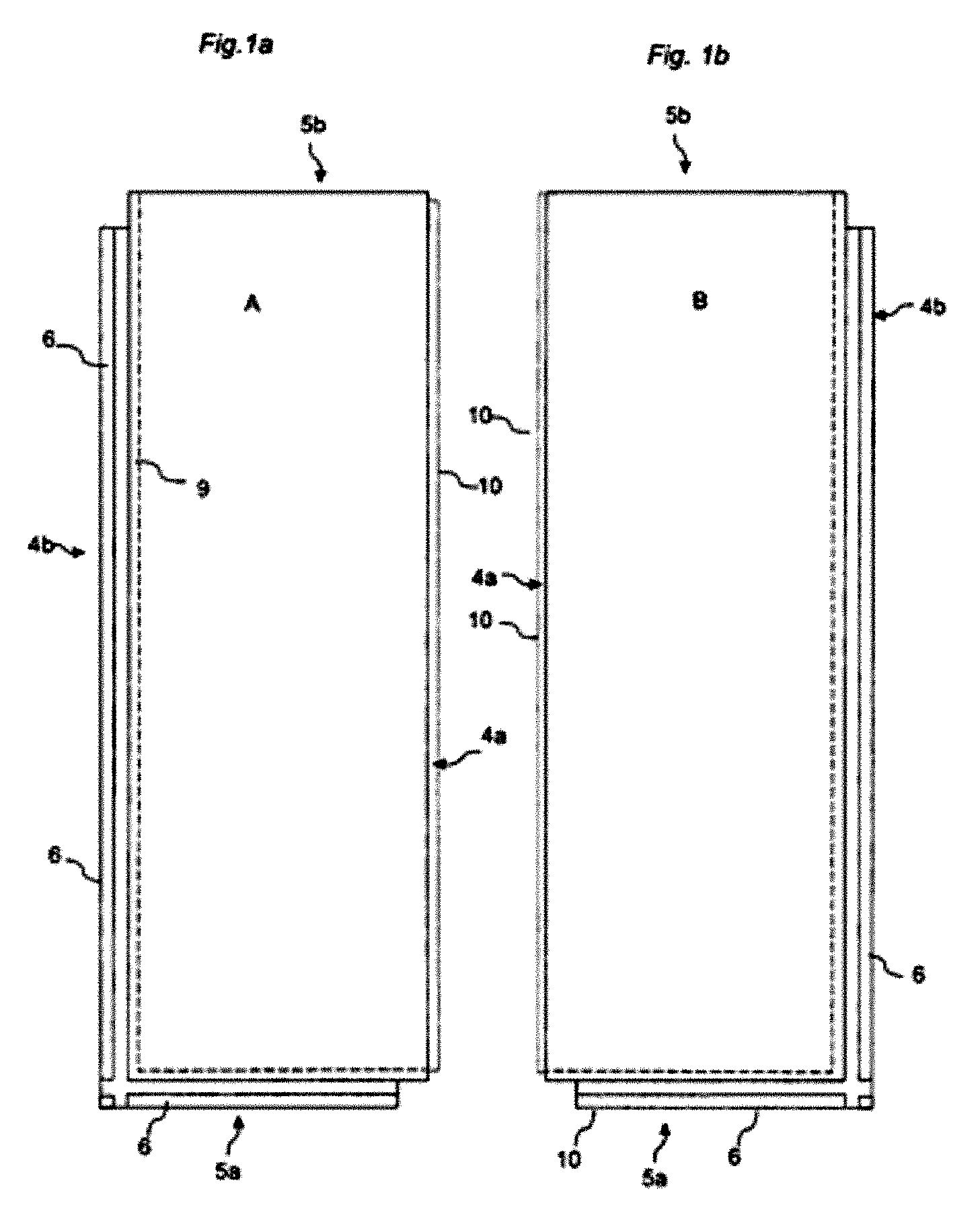

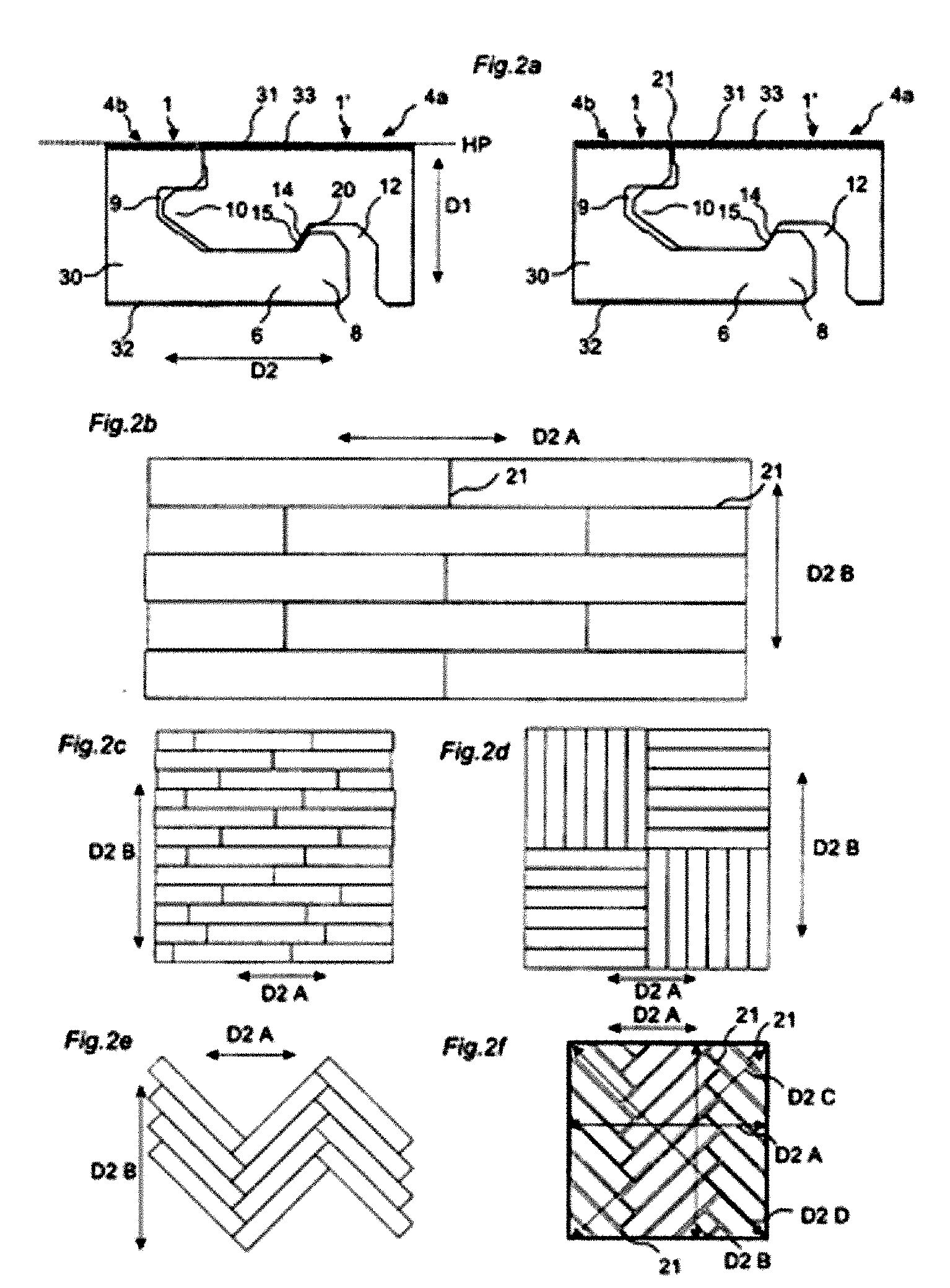

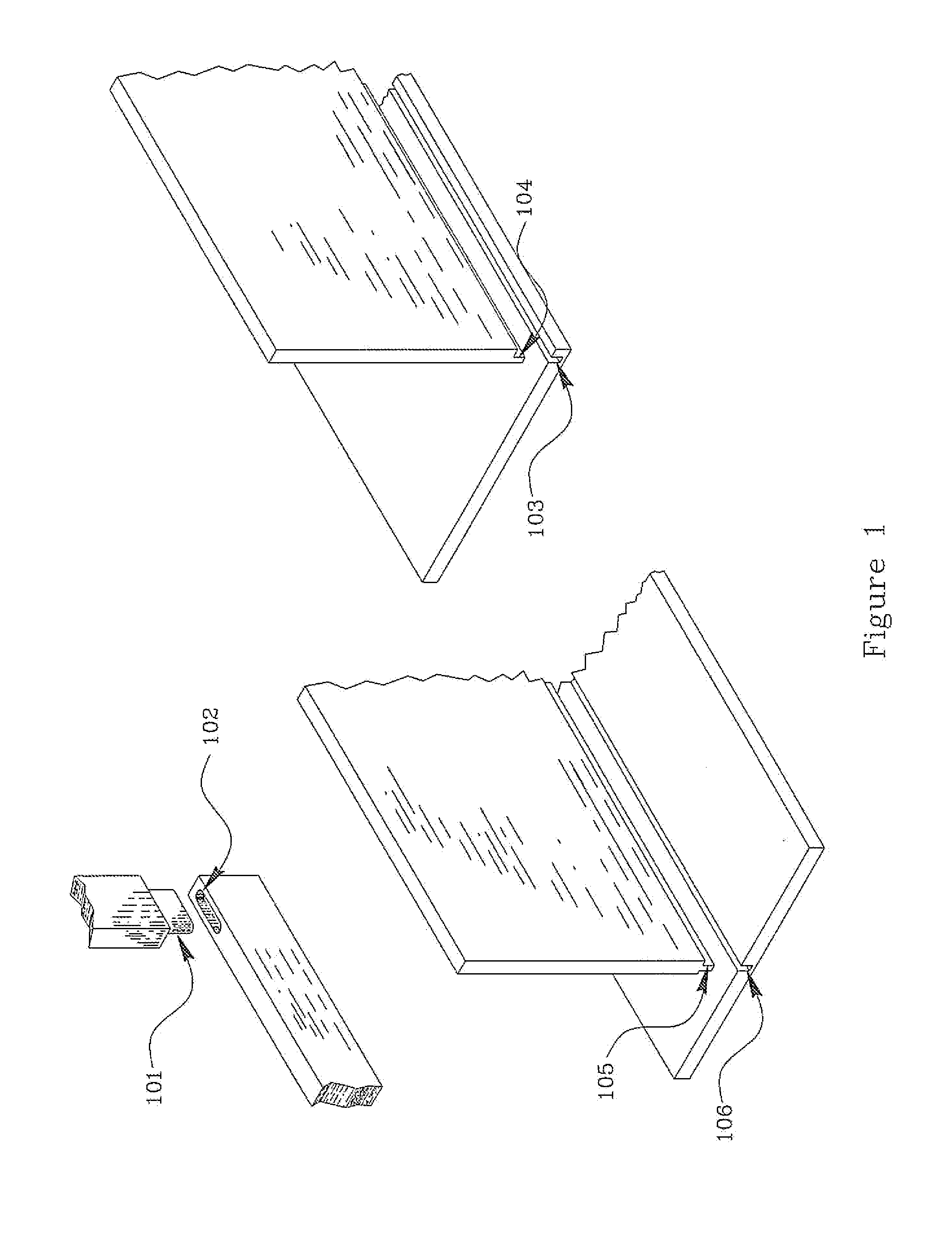

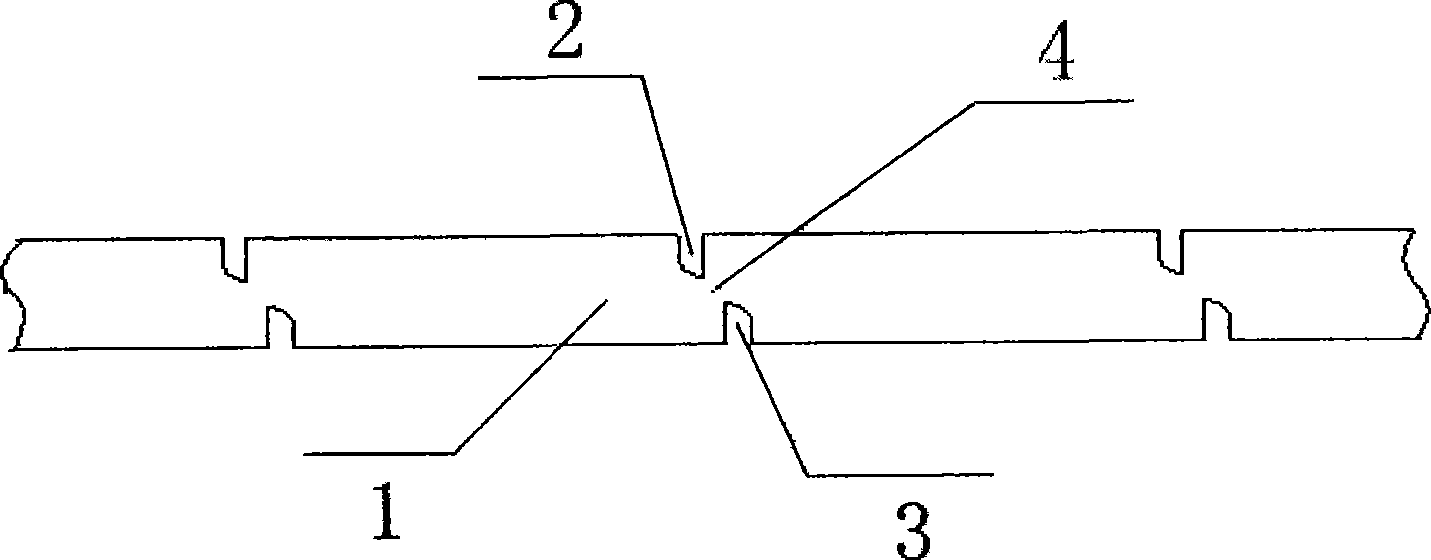

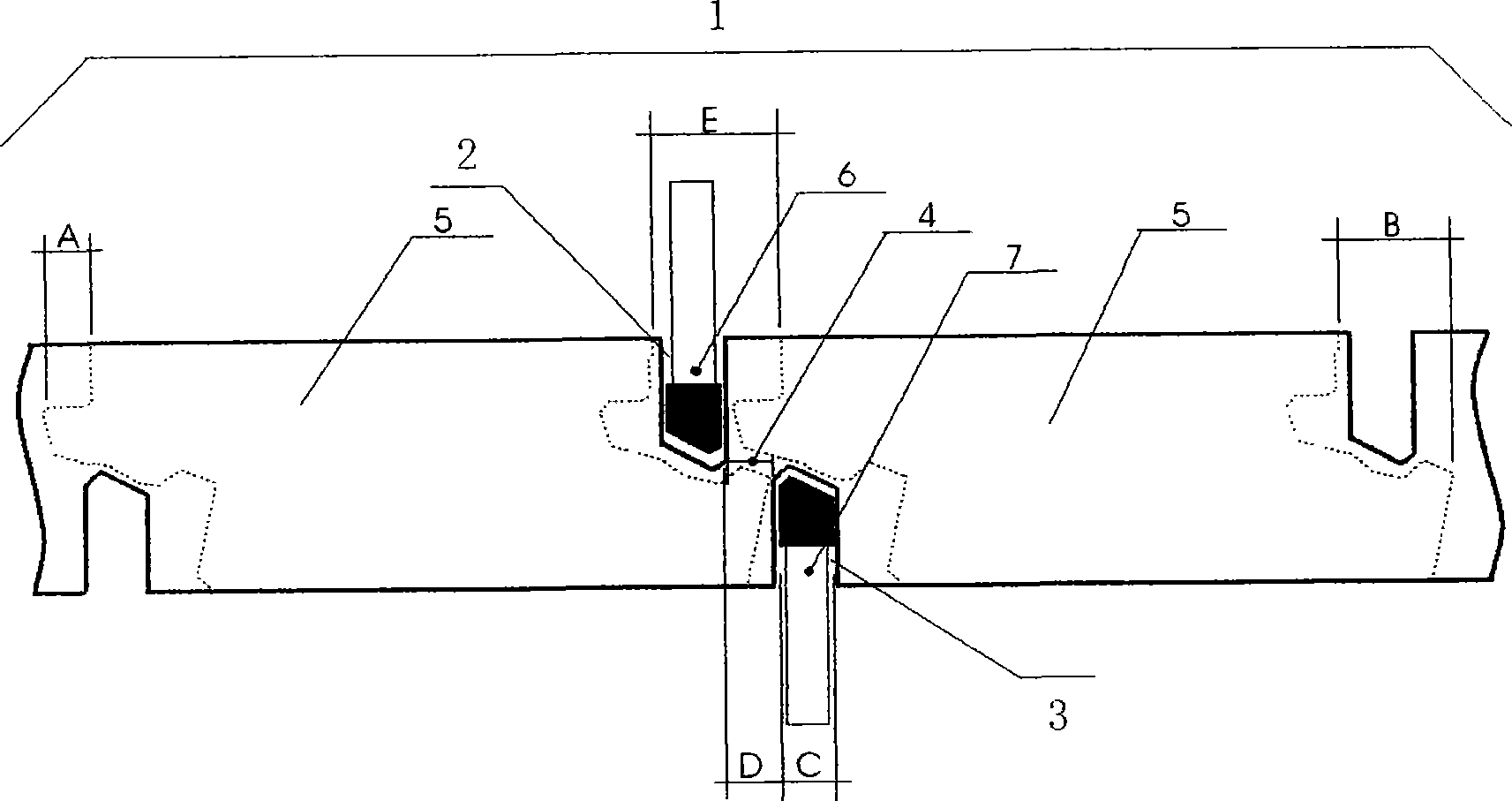

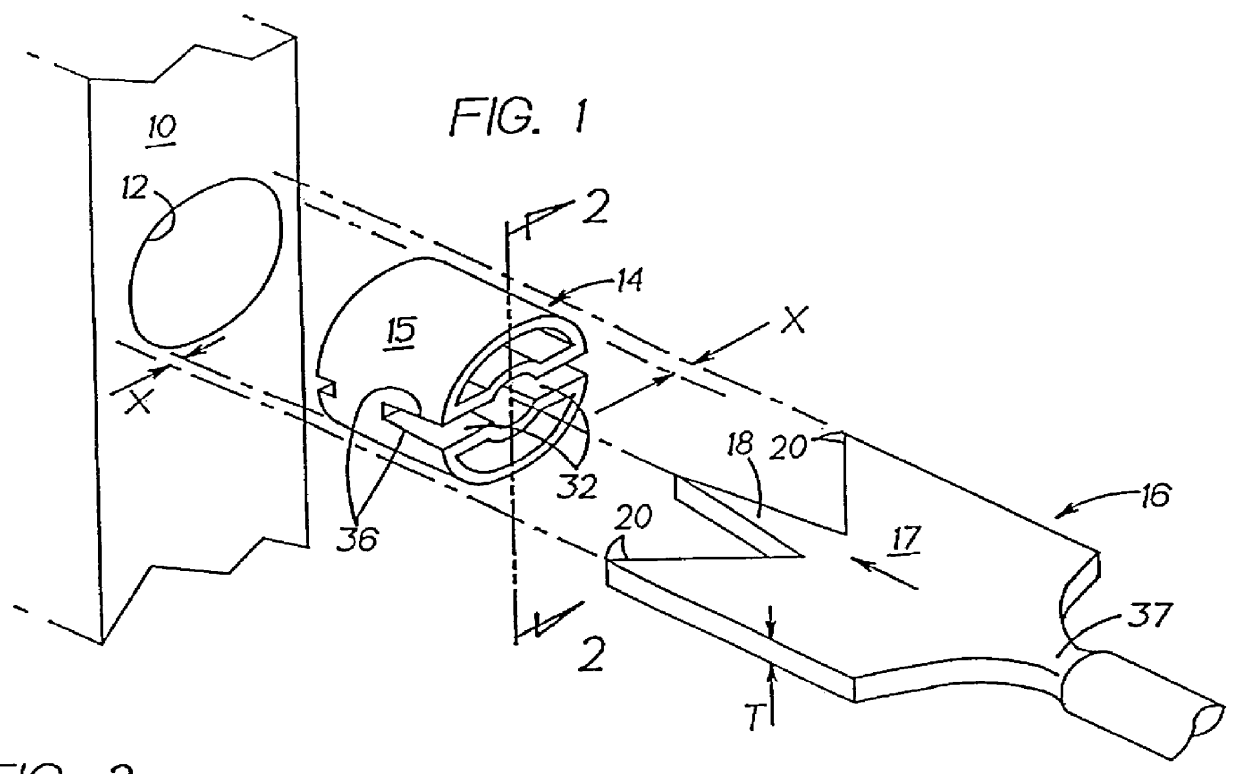

Floor covering and locking systems

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

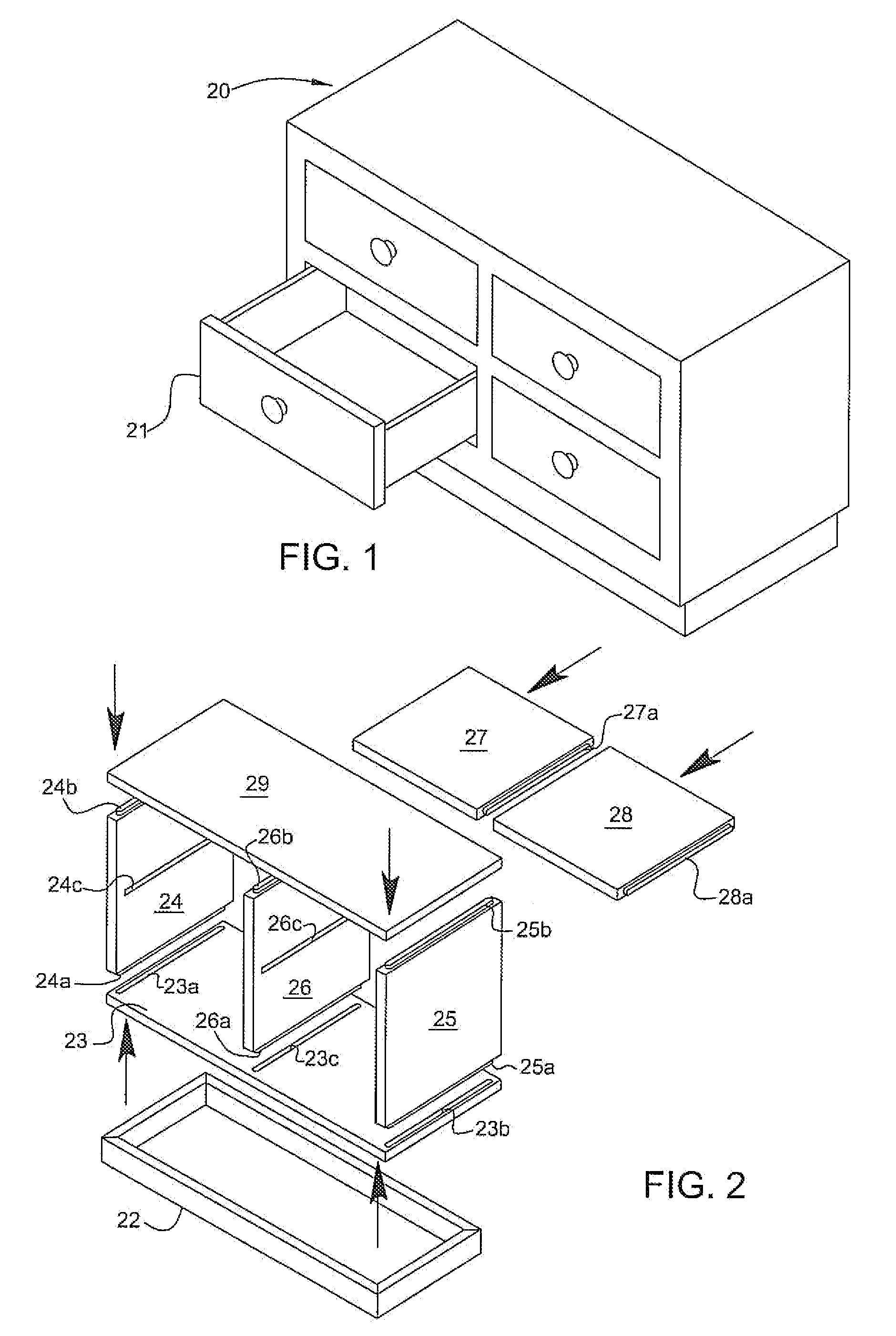

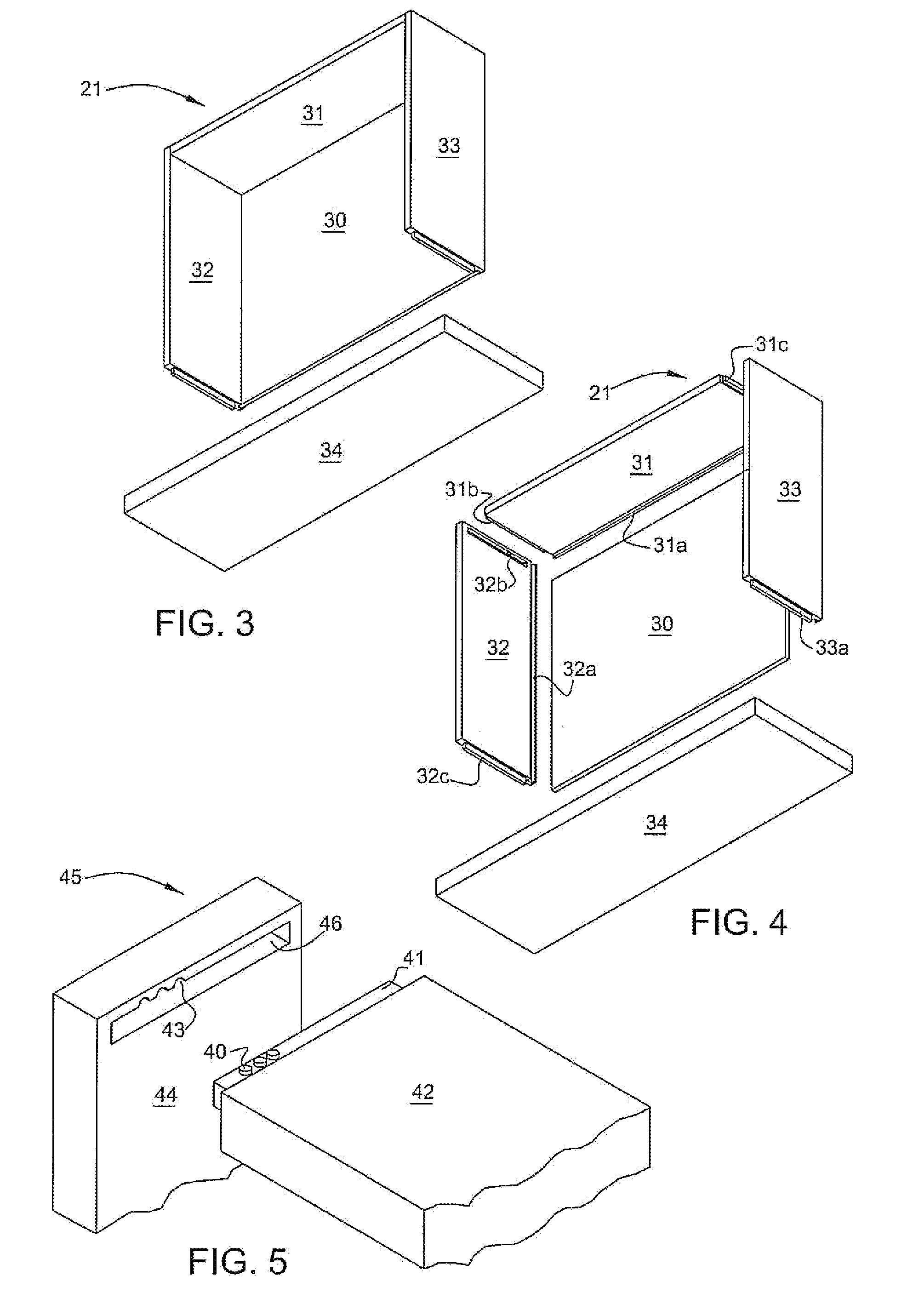

Structure and method of assembly thereof

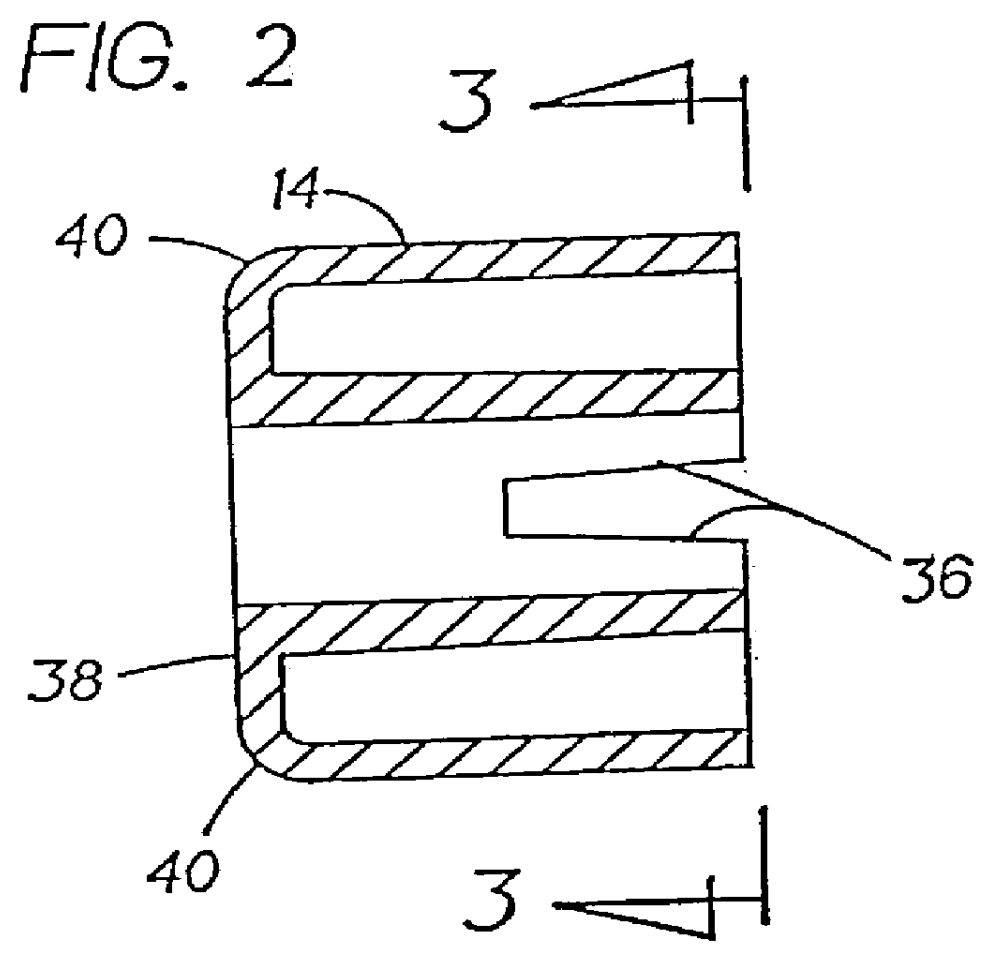

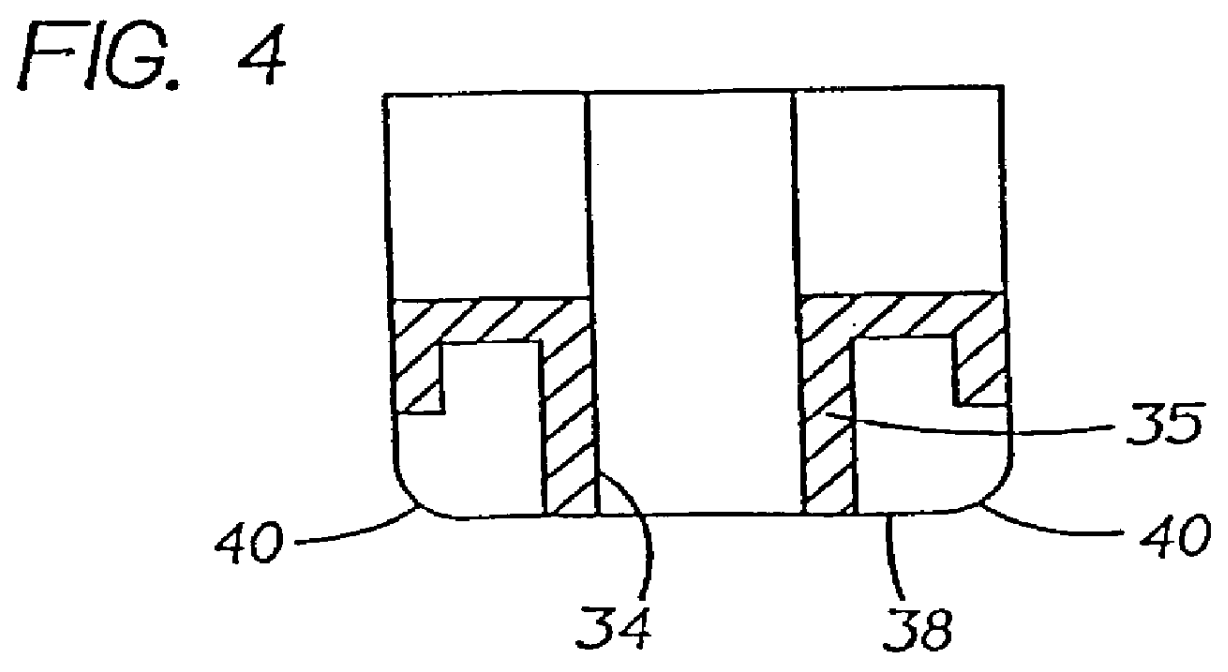

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

Floor Covering And Locking Systems

Abstract of the DisclosureFloorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

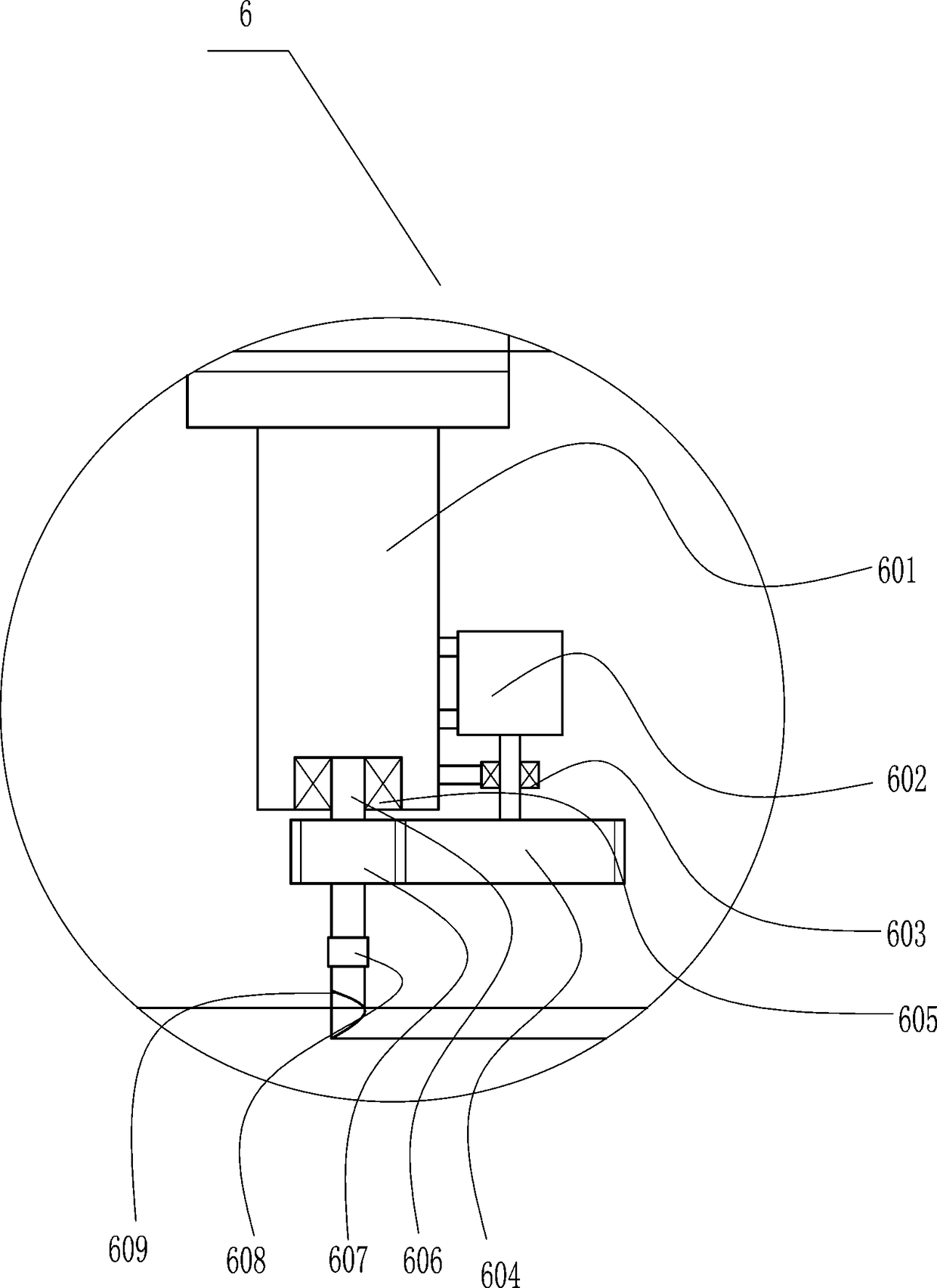

Processing device for wood notches of furniture

ActiveCN106182229AMaintain personal safetyEasy to operateWood mortising machinesWood slotting machinesElectricitySemi automatic

The invention discloses a processing device for wood notches of furniture. The processing device comprises a workbench, wherein a rectangular groove is formed in the upper surface of the workbench; a group of circular grooves are formed in the surface on each of the opposite sides inside the rectangular groove; micro linear motors of which telescopic ends are horizontal are arranged in the circular grooves; top plates matched with the circular grooves are arranged at the telescopic ends of the micro linear motors; a controller is arranged on the surface of one side of the workbench; a PLC programming system is arranged inside the controller; a mains supply interface is arranged on one side of the controller; a supply terminal of the controller is connected with the controller through a conducting wire; and an input end of the controller is connected with a linear motor, an electric push rod, an electric trolley, a No.2 linear motor, the PLC programming system, a No.3 linear motor and a rotating motor through a conducting wire. The processing device has the beneficial effects that mechanical semi-automatic processing treatment is adopted, the working efficiency is high, the personal safety of staff is maintained, the speed is high, and the maintenance cost is low.

Owner:惠州市欧陆家具有限公司

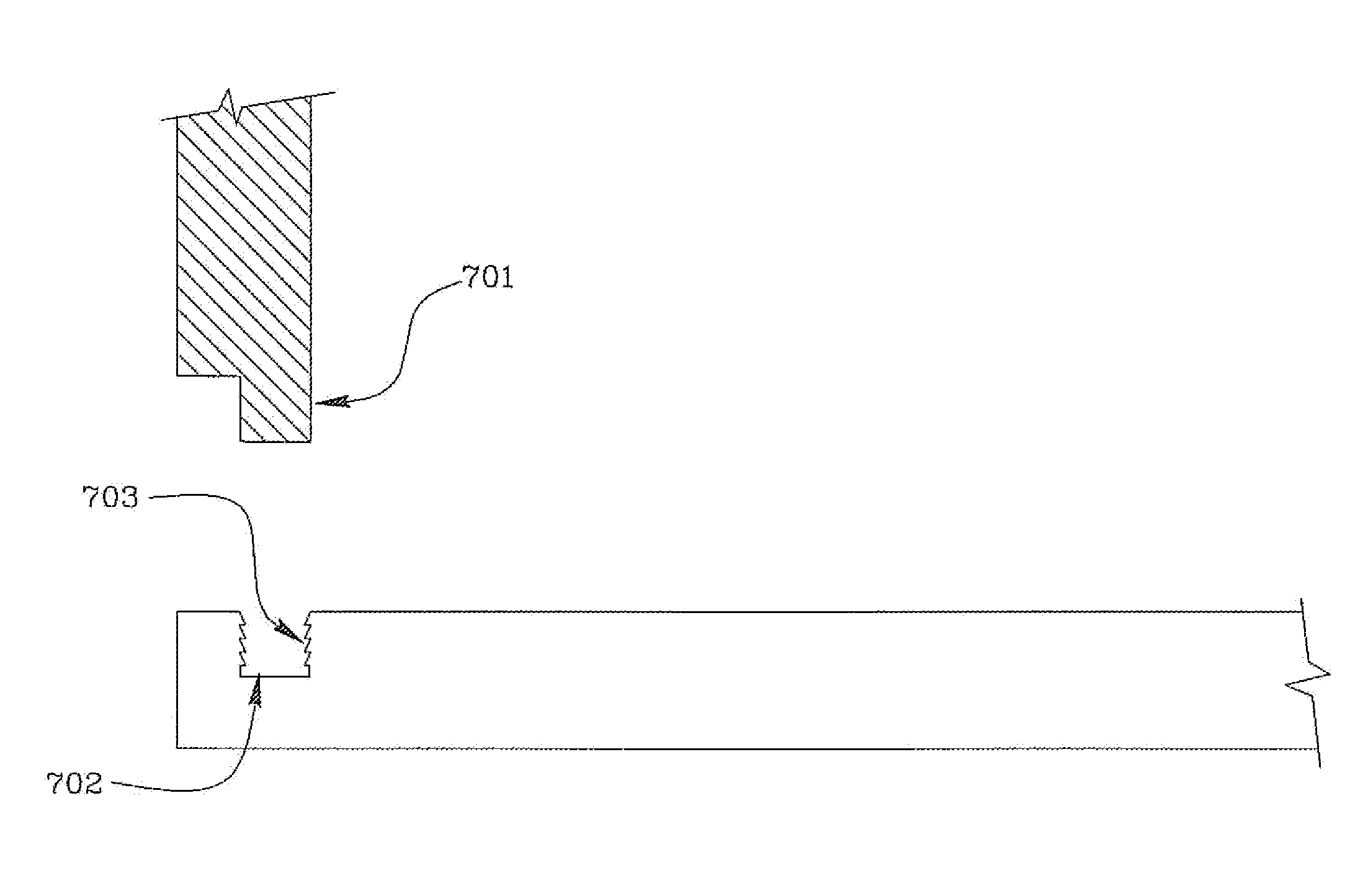

Method for Joining Workpieces Together and Product Made Thereby

A method of forming a joint between first and second workpieces generally consisting of forming a recess in one of such workpieces, provided with at least one side wall having a serrated cross-sectional configuration with inwardly projecting, distortable segments; providing a portion in the other of such workpieces, insertable into such recess, having a cross-sectional configuration sufficient to engage and distort such segments as such portion is inserted into such recess; and inserting such portion of the other workpiece into such recess, causing the segments to distort and thus provide an interference fit between such workpieces.

Owner:THERMWOOD CORPORATION

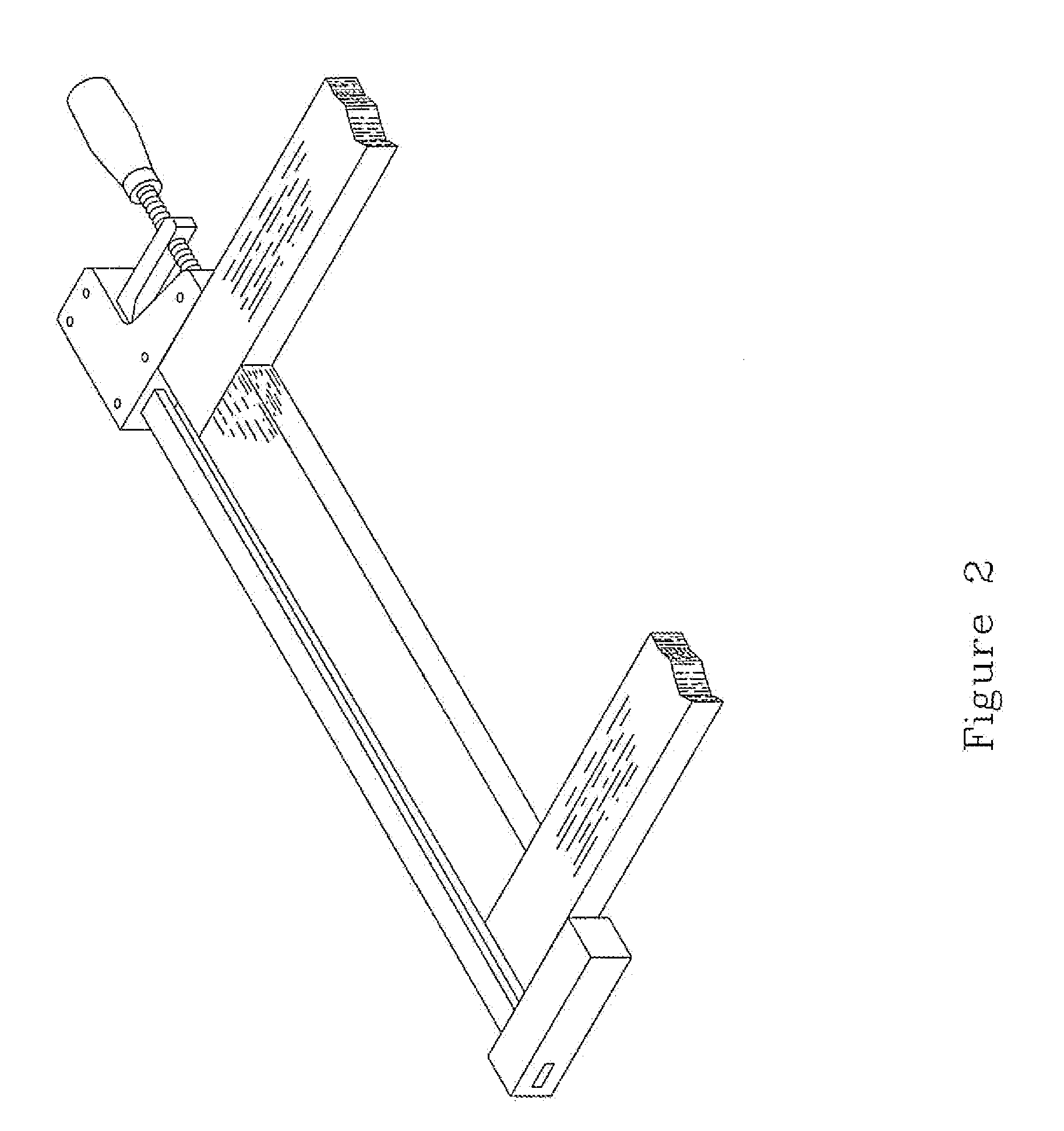

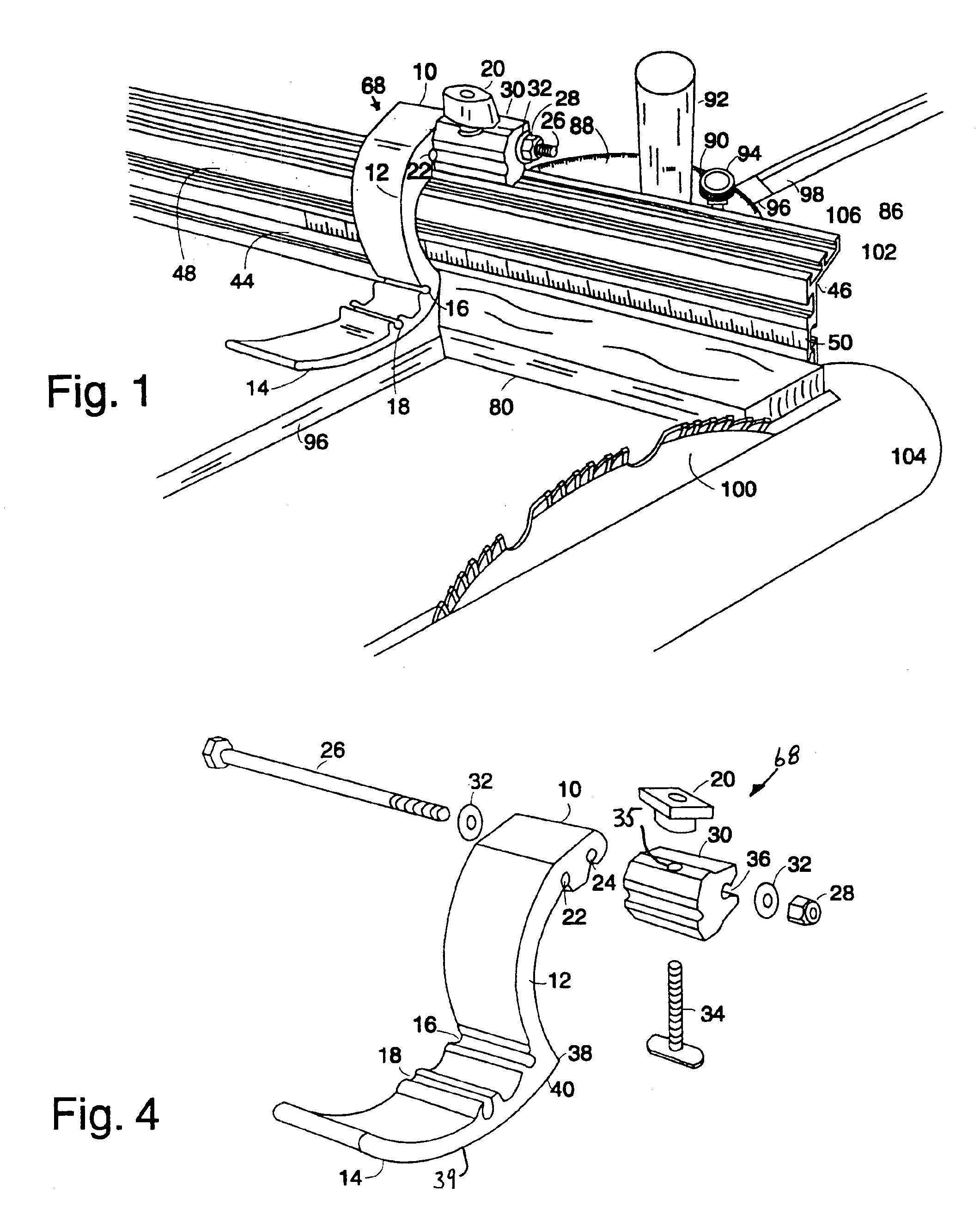

Woodworking machinery jig and fixture system

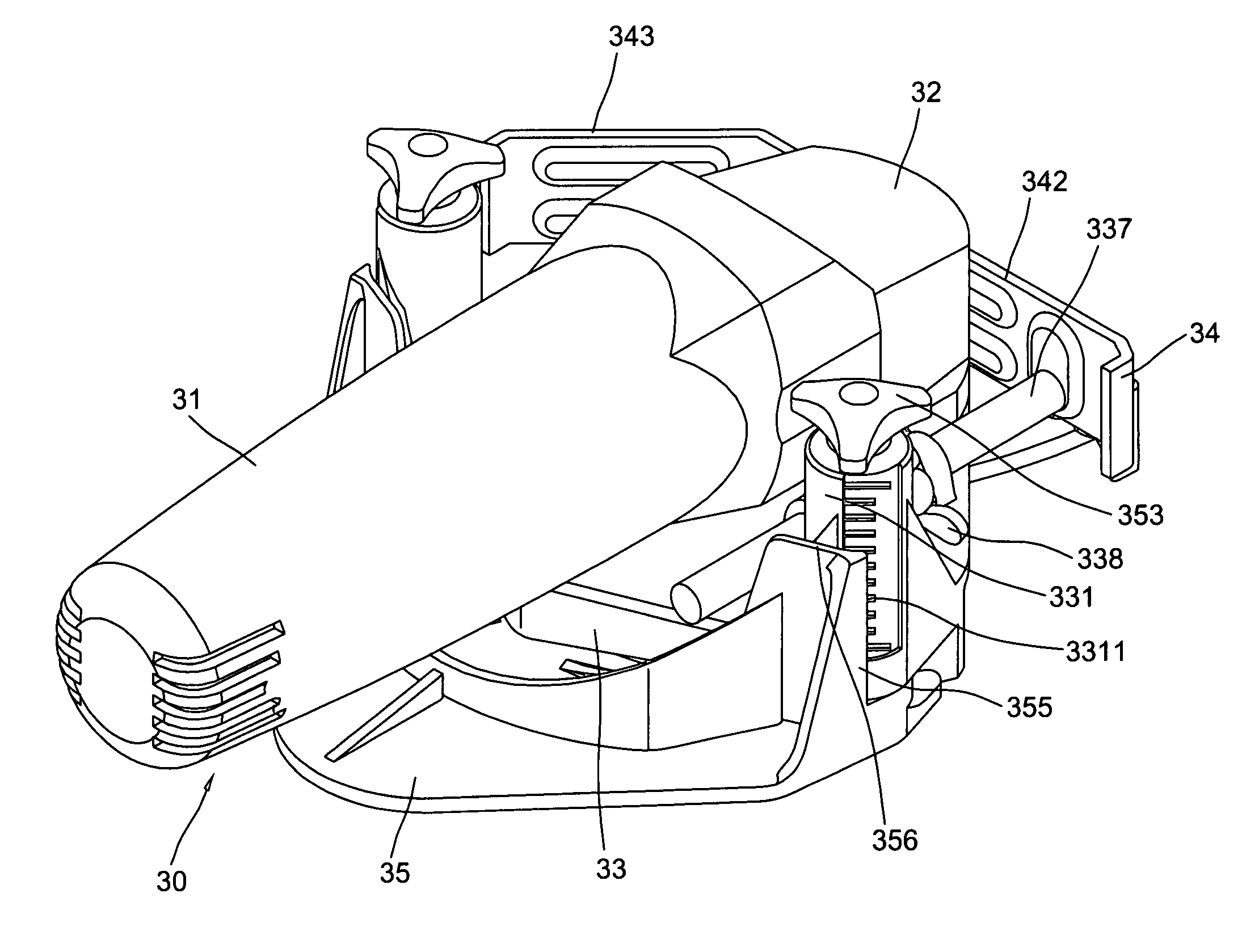

A woodworking machinery jig and fixture system includes a track which is or may be attached to a fence, a convex-concave curved flip stop and a base which mounts the stop to the track. The stop has a projecting portion which penetrates the plane of the fence so the stop isn't lifted by the point of a mitered board. The stop also has a lower convex surface which faces the work support surface and curves up at both ends. The top leg of the stop is concave toward the fence to allow clearance for a zero-clearance board and make the stop adaptable to different track and fence configurations. The base has opposite sides of different widths bordered by steps on one side and a ramp on the other side so the base can be used in a large range of T-track slot widths. The arm mounting hole of the base is offset from the base mounting so as to provide an offset to accommodate a ¾″ zero clearance board by turning the base a half turn relative to the slot. A two slot track is provided in which one of the slots can mount a sliding measurement tape or a base, and the other slot can also mount a base. In another track, a sidewall flange is provided which can be filed to accurately fit into a miter gauge slot of a cutting tool table.

Owner:KREG ENTERPRISES

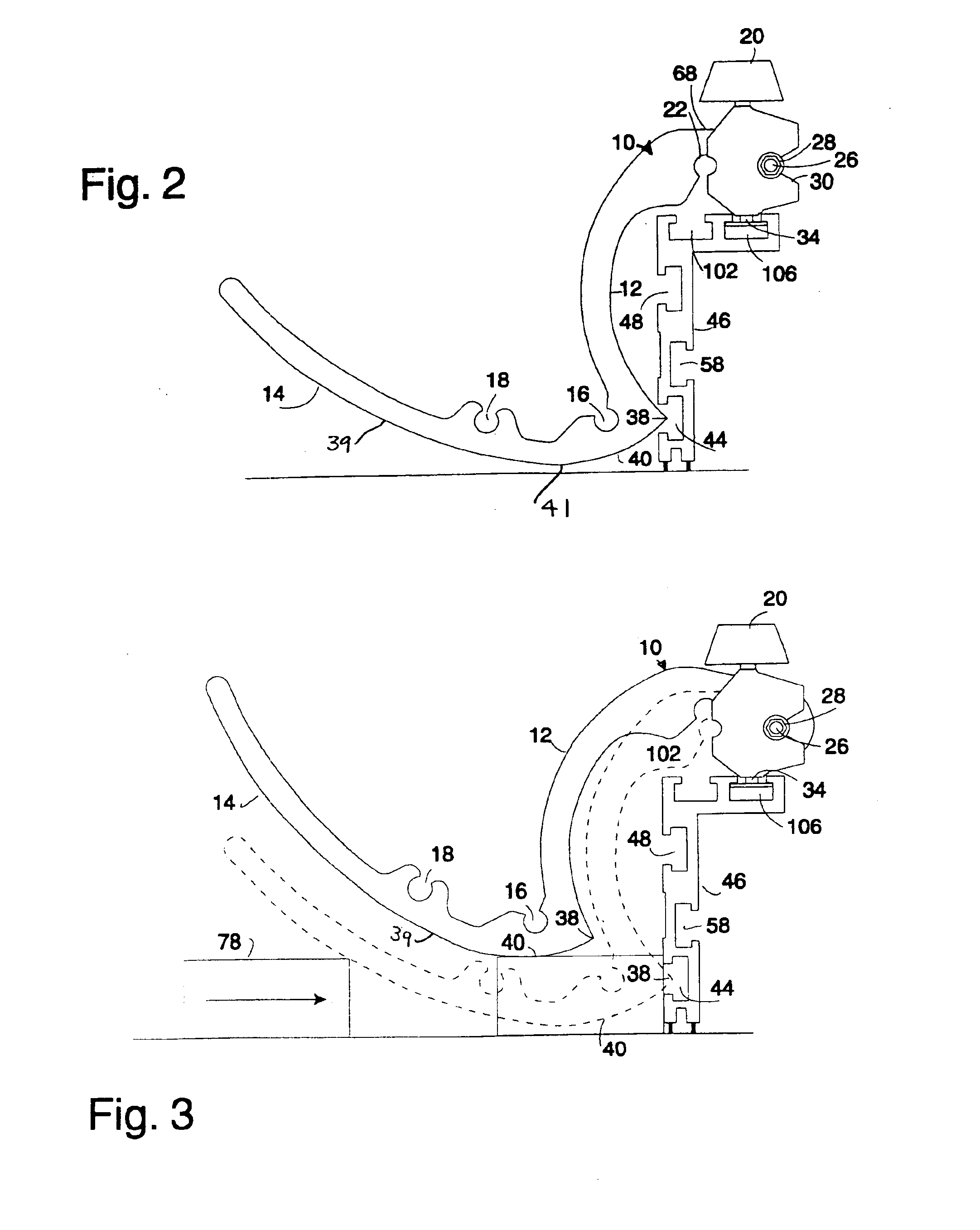

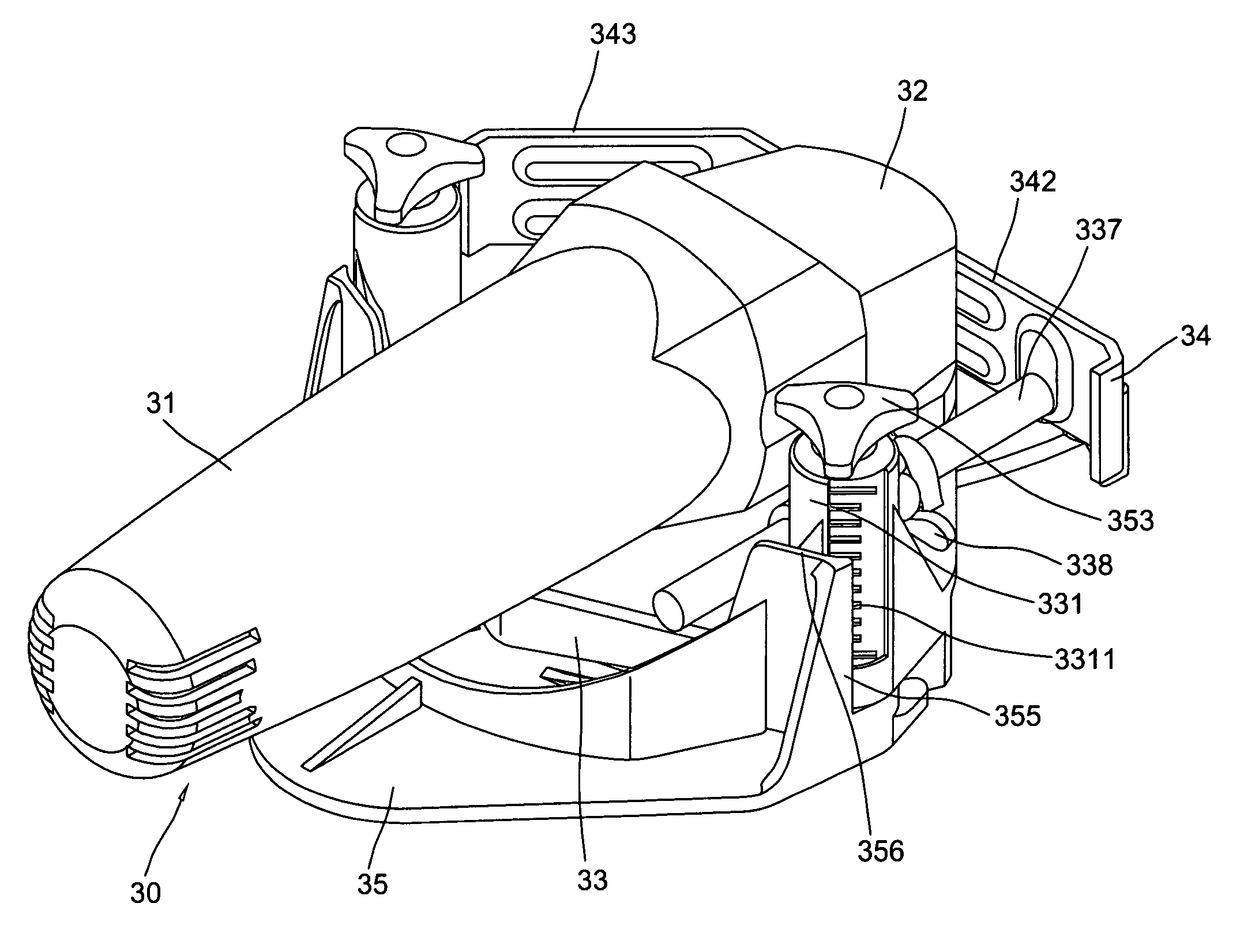

Jig for fitting locks to doors

InactiveUS6343632B1Eliminate damageEasy alignmentDrilling/boring measurement devicesThread cutting machinesLocking mechanismEngineering

A jig (11) for removable fitment along the edge of a door (19) which provides a suitable combination of guides and stops to allow the location and operation of suitable cutting tools such as drills or routers. The jig comprises a pair of parallel guide plates (26) the distance between which is adjustable for removable fitment to opposing surfaces of the door. Guide holes (30, 31, 32) are located in the guide plates through which a drill or other suitable tool may be inserted. The jig has guide means (12) associated therewith for allowing location of a suitable tool at the edge of the door for making a cylindrical hole or for machining a mortise therein for receiving the body of a mortise lock or a rebate for receiving the face plate of the lock mechanism. A guide block (50) to facilitate accurate drilling is also disclosed.

Owner:ZIVOJINOVIC ZARKO

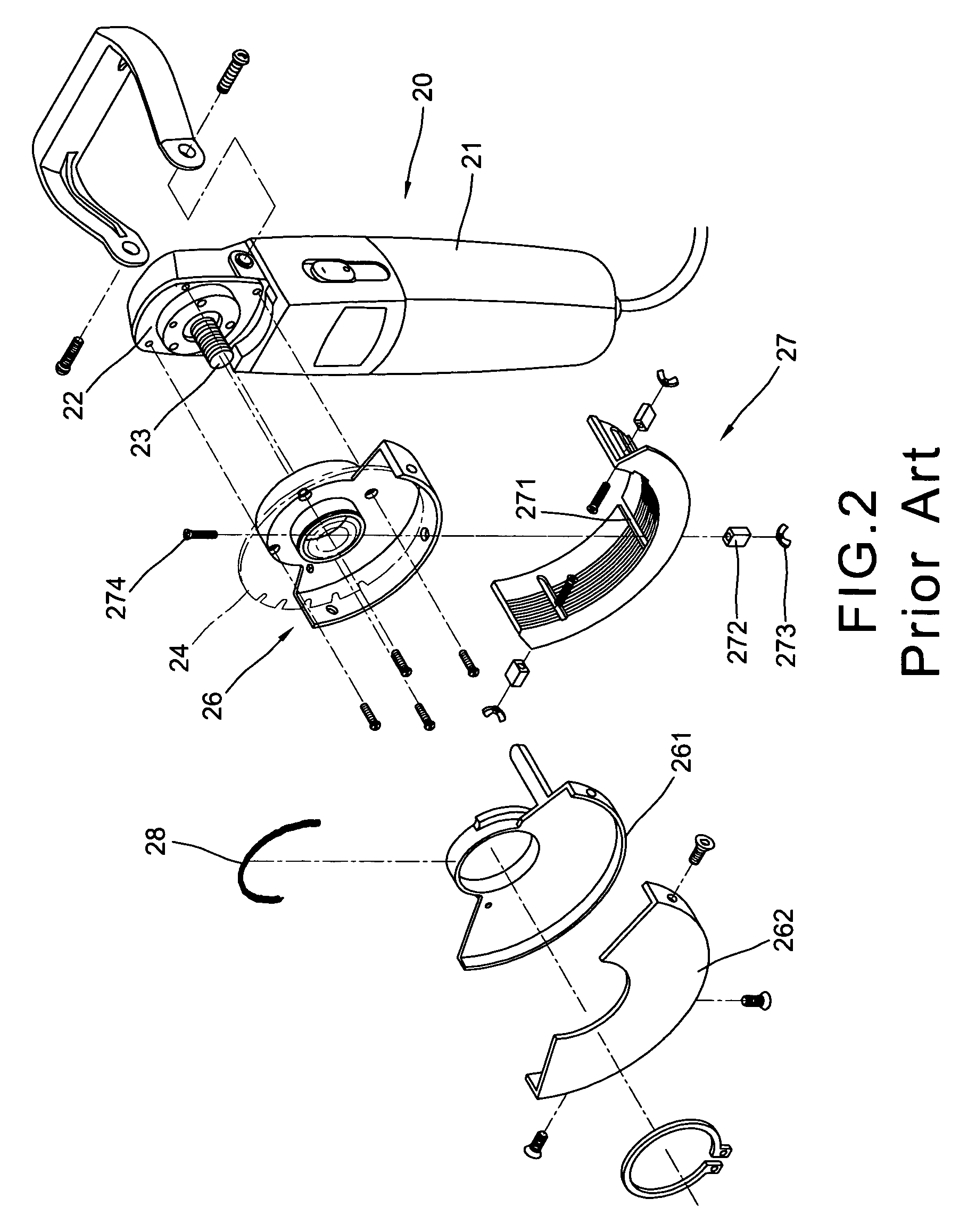

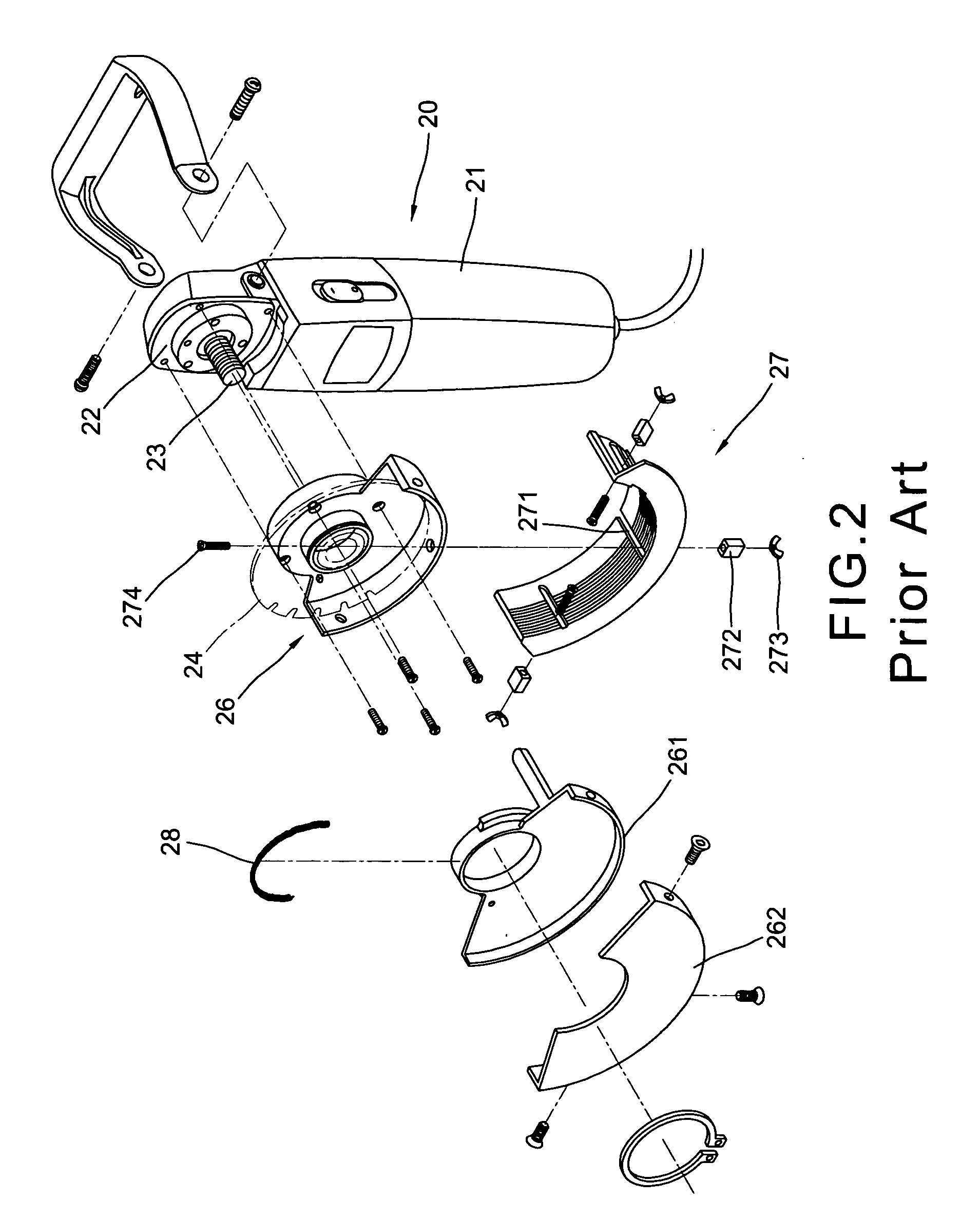

Hand-operated circular saw having blade cutting depth adjustment device

InactiveUS7047650B2Easy to operateEasy and convenient and preciseMetal sawing devicesMetal sawing accessoriesHand graspCircular saw

Owner:CHEN YUEHTING

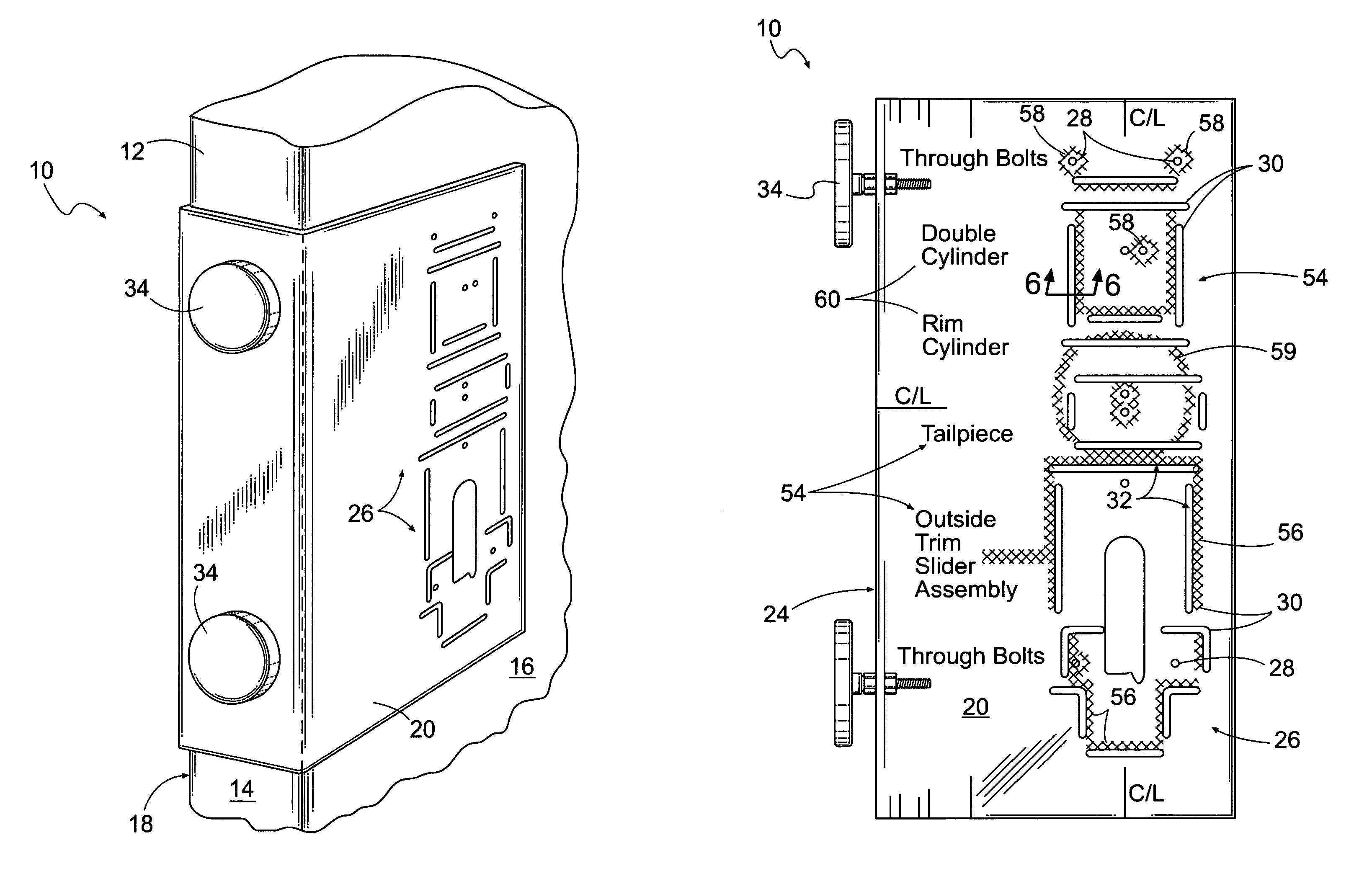

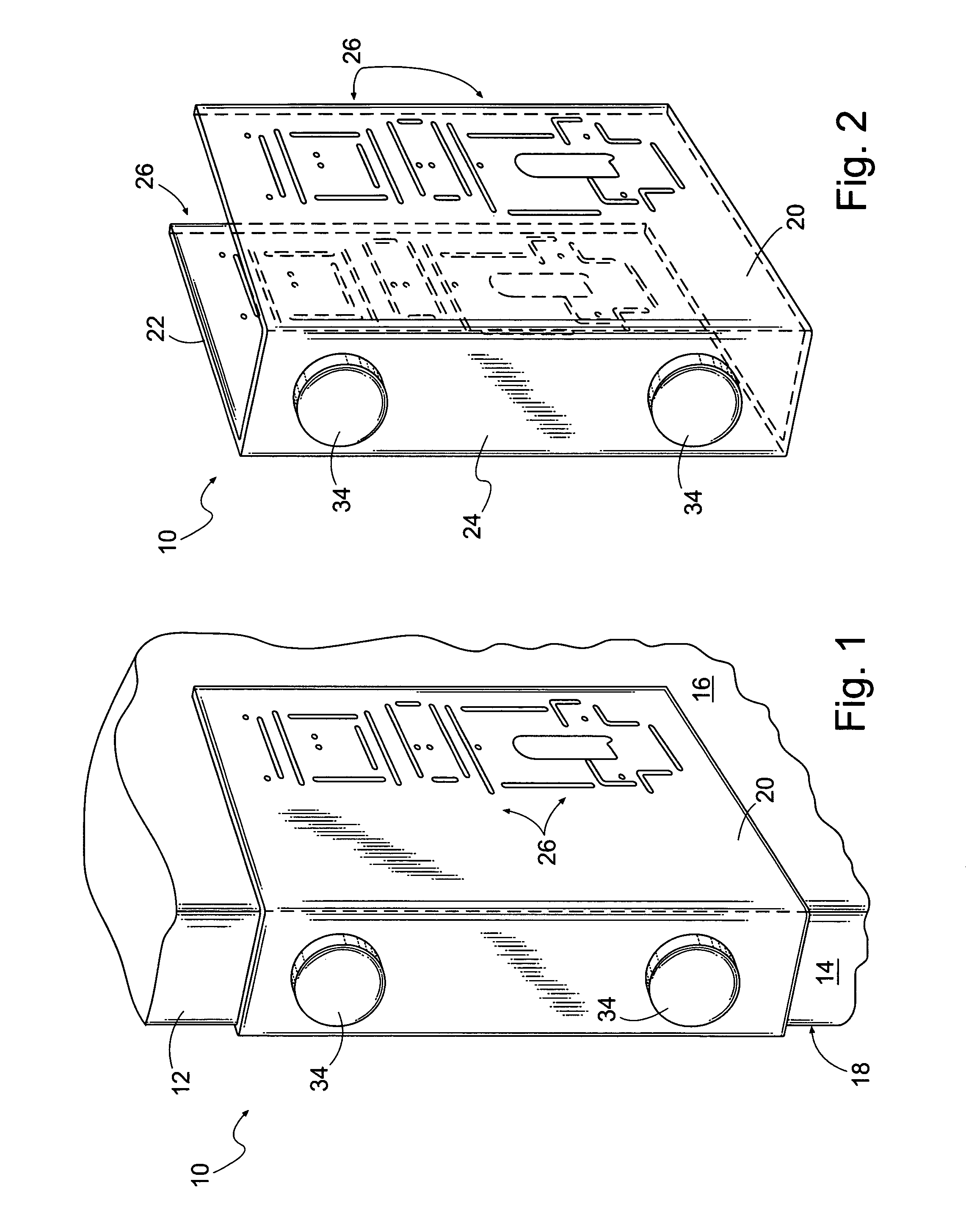

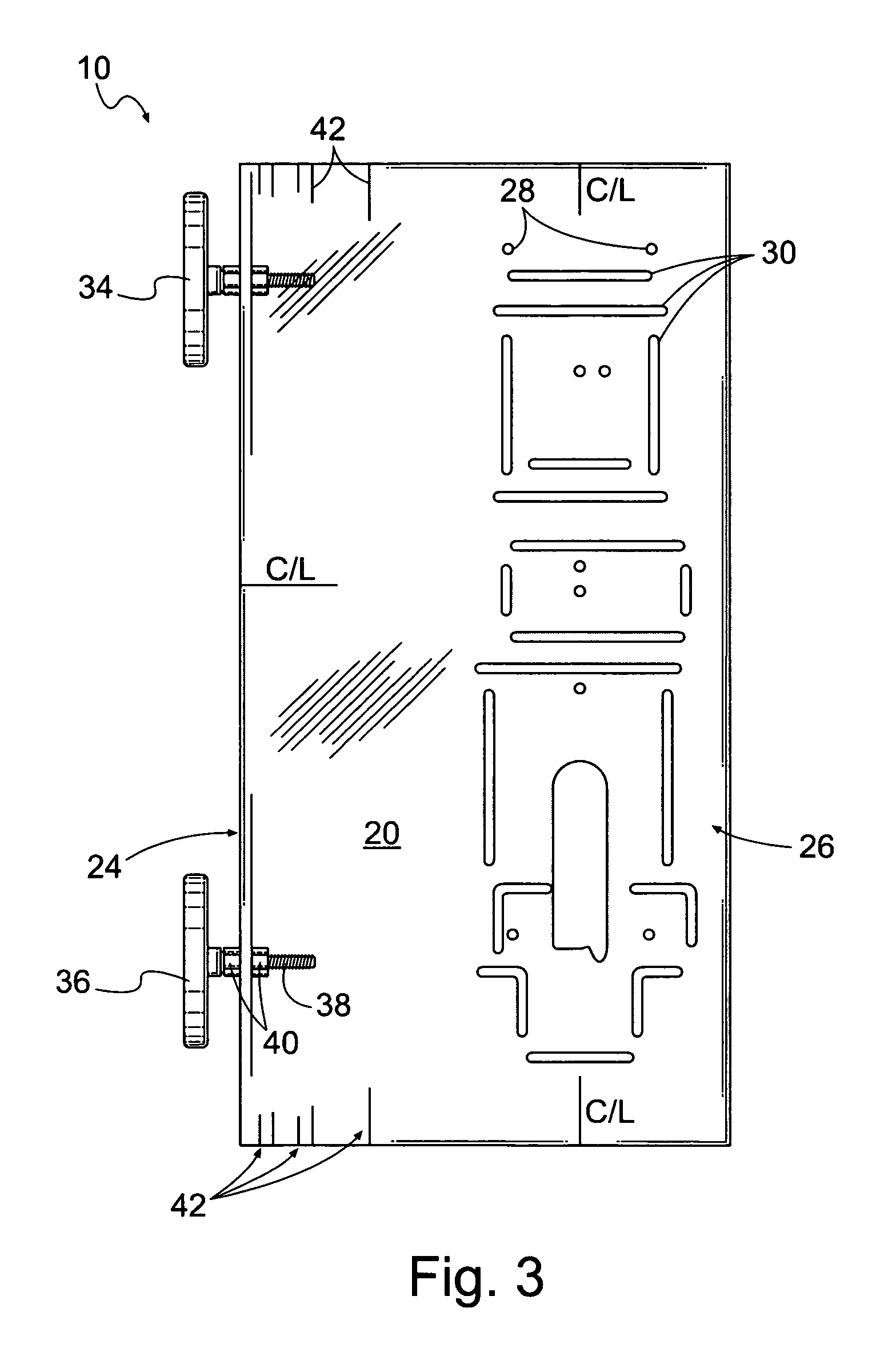

Template for fitting exit hardware on a door

InactiveUS7003889B1Easy to useQuickly and accurately installAngles/taper measurementsDoors/windowsEngineeringMechanical engineering

A template for cutting a door has a first sidewall having a plurality of through holes through the first sidewall indicating centers of proposed mounting holes, and a plurality of through slots, each having first and second edges separated by a width. Both the first and second edges indicate proposed cutting lines with the width operably spacing the first and second edges. First and second indicia printed on the first sidewall for indicating the through holes and the edges that together operate to indicate the holes and cuts necessary for first and second cutting operations, respectively.

Owner:LUCIANI MICHAEL

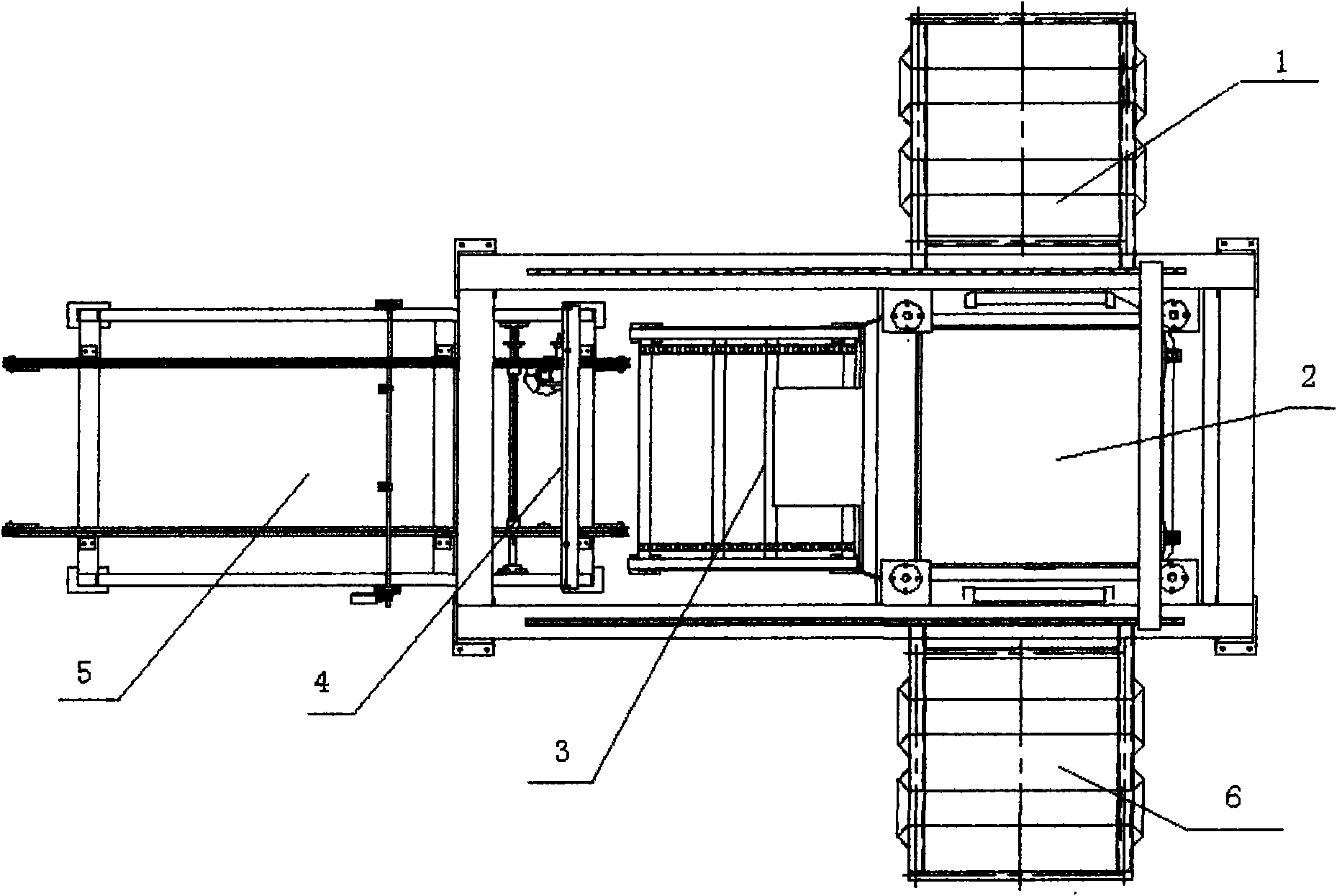

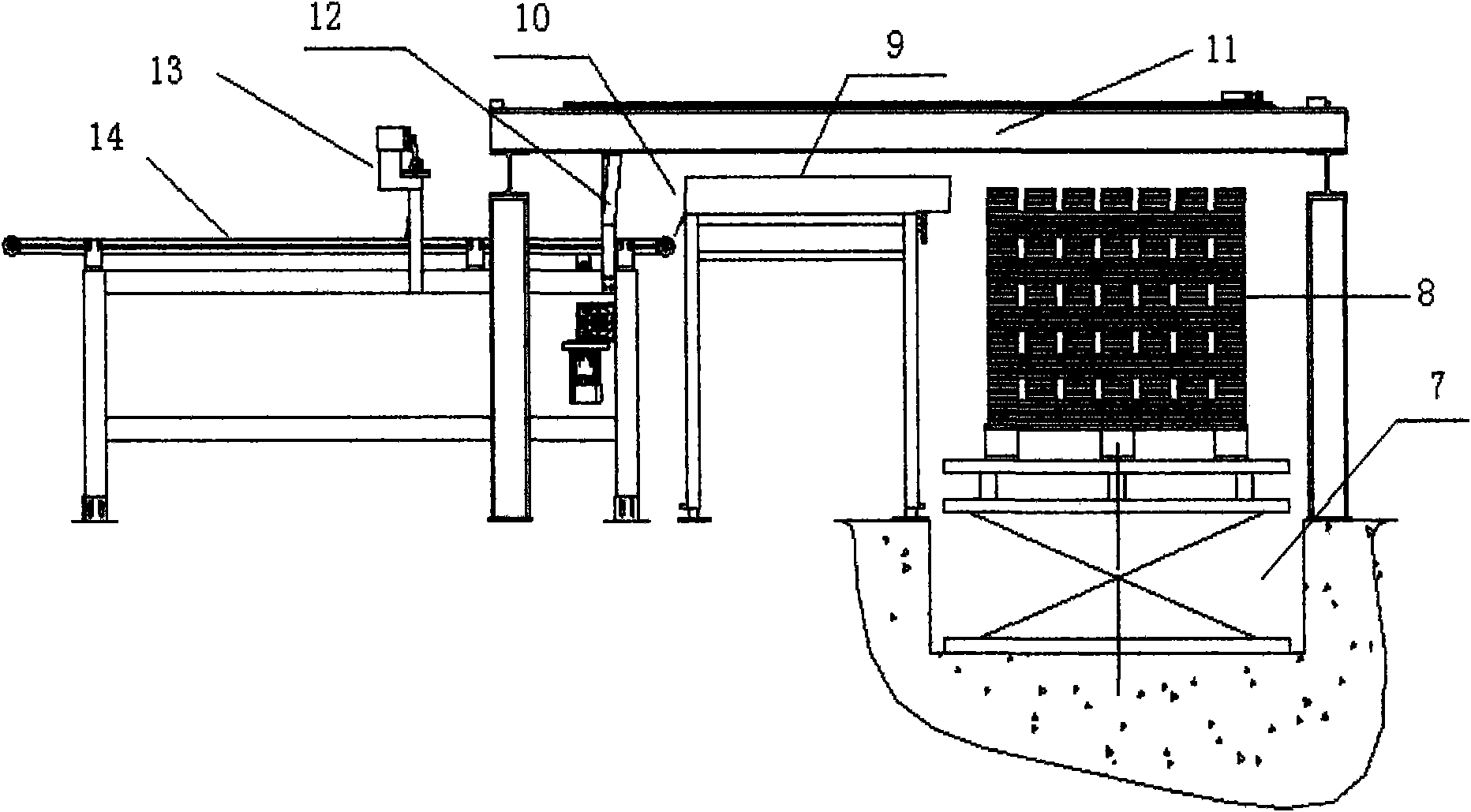

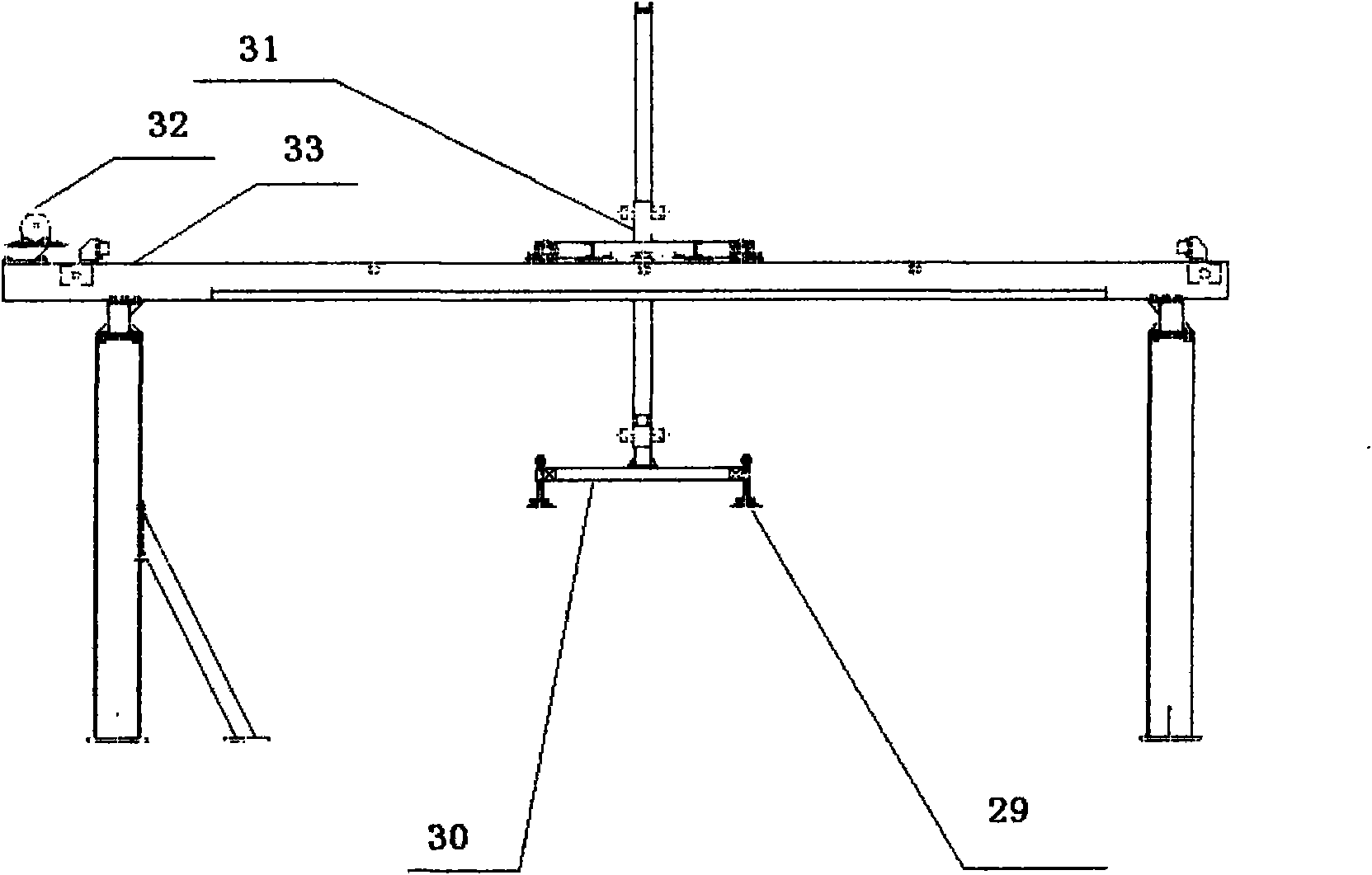

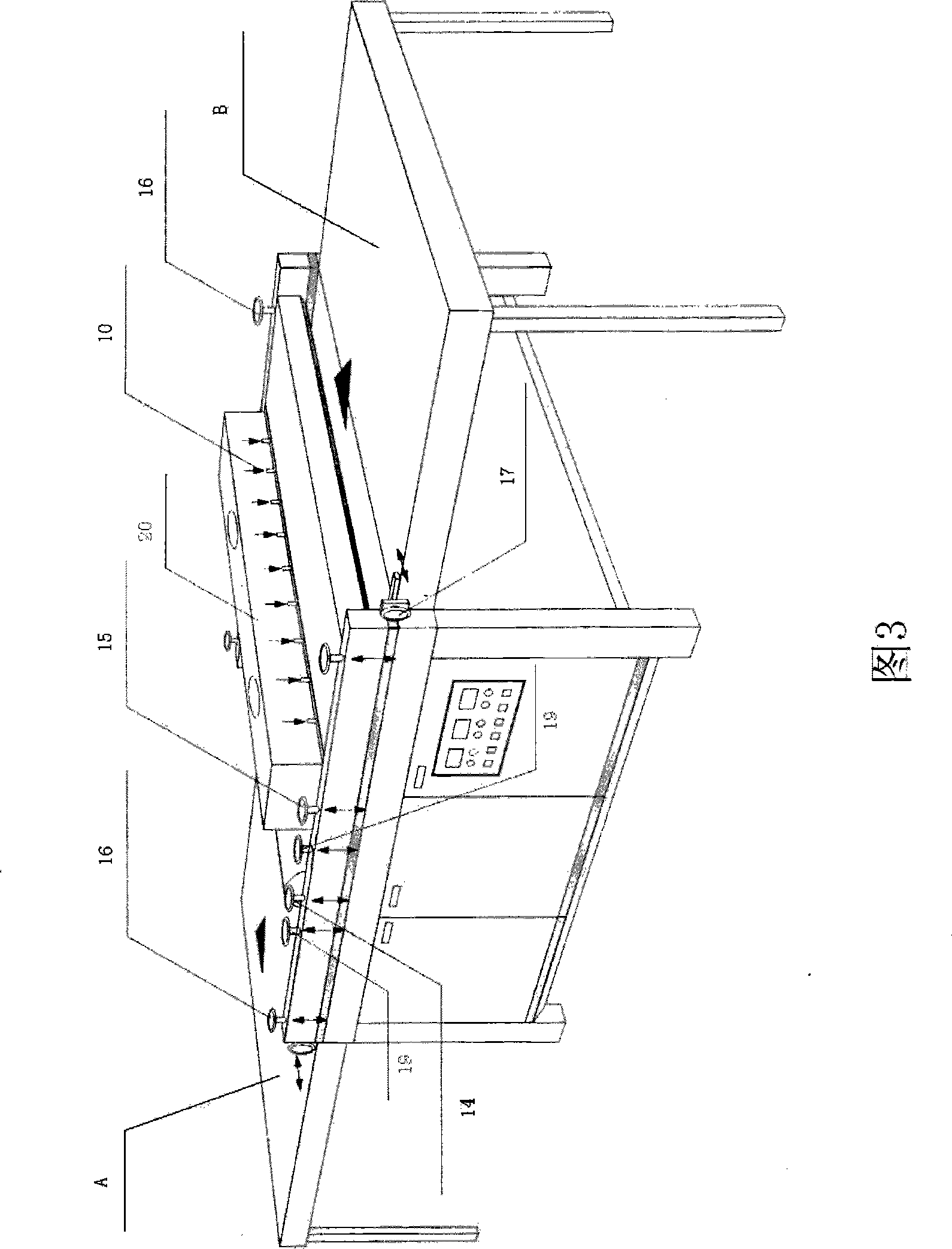

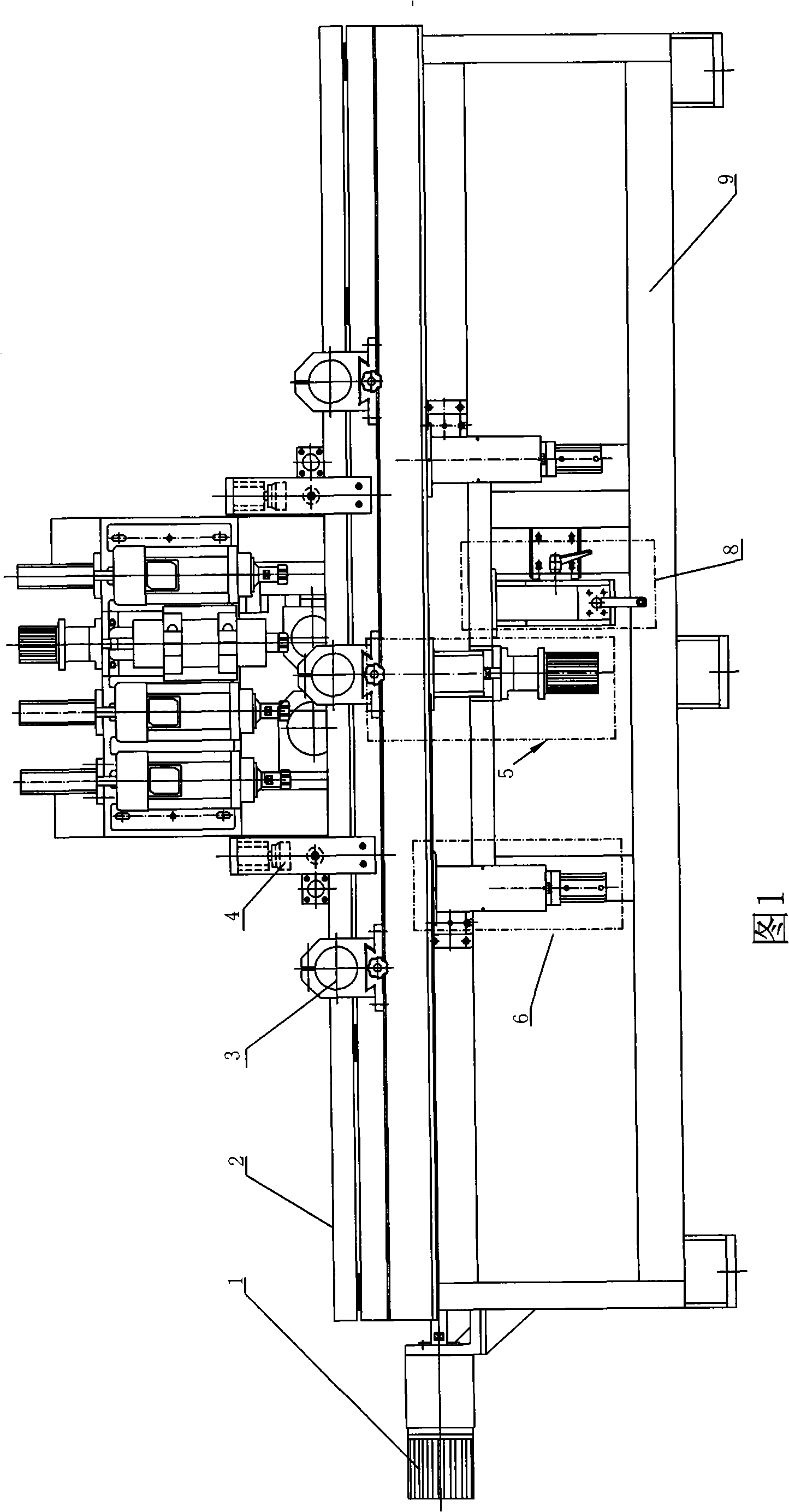

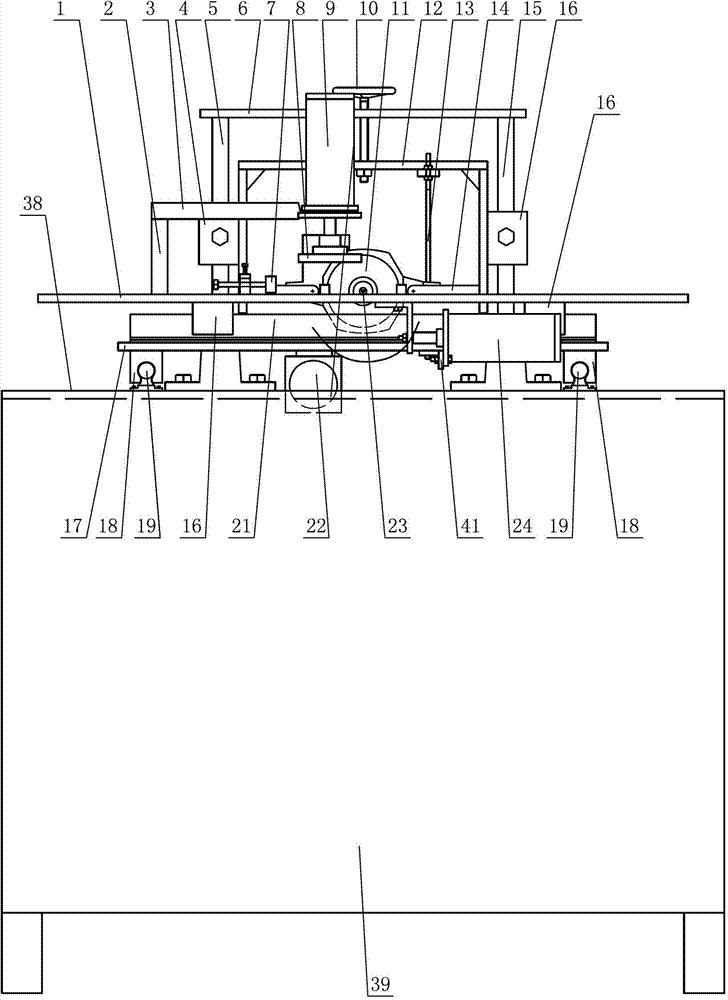

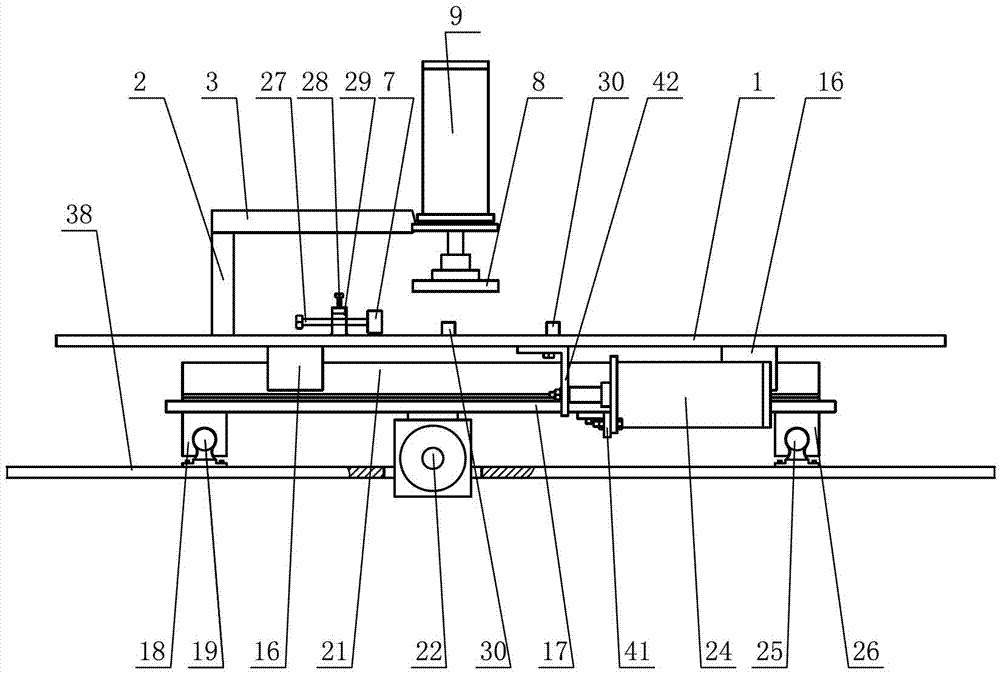

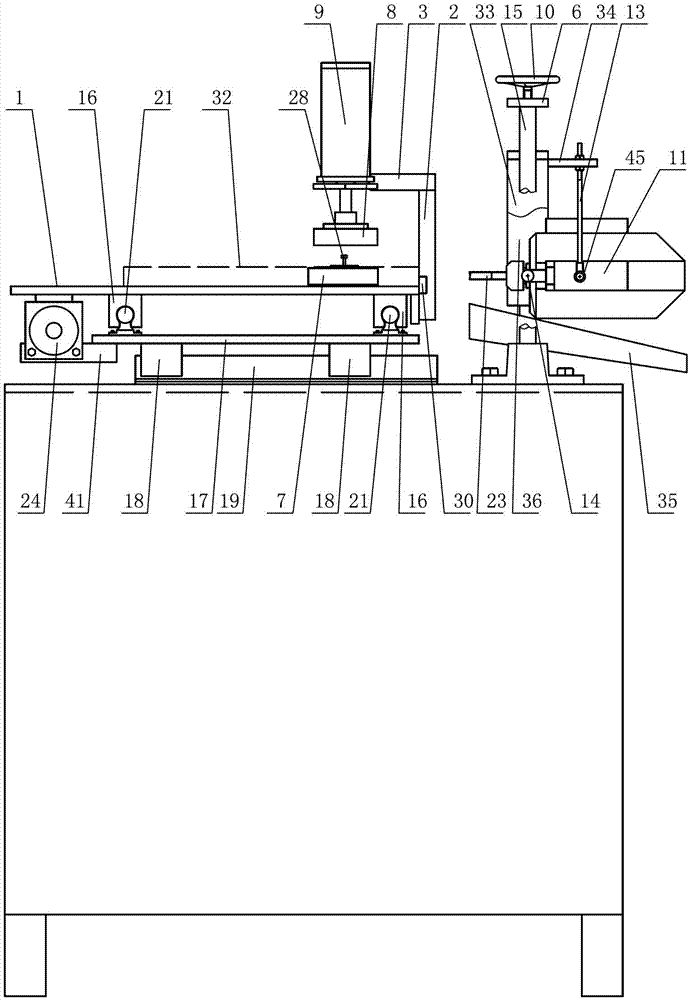

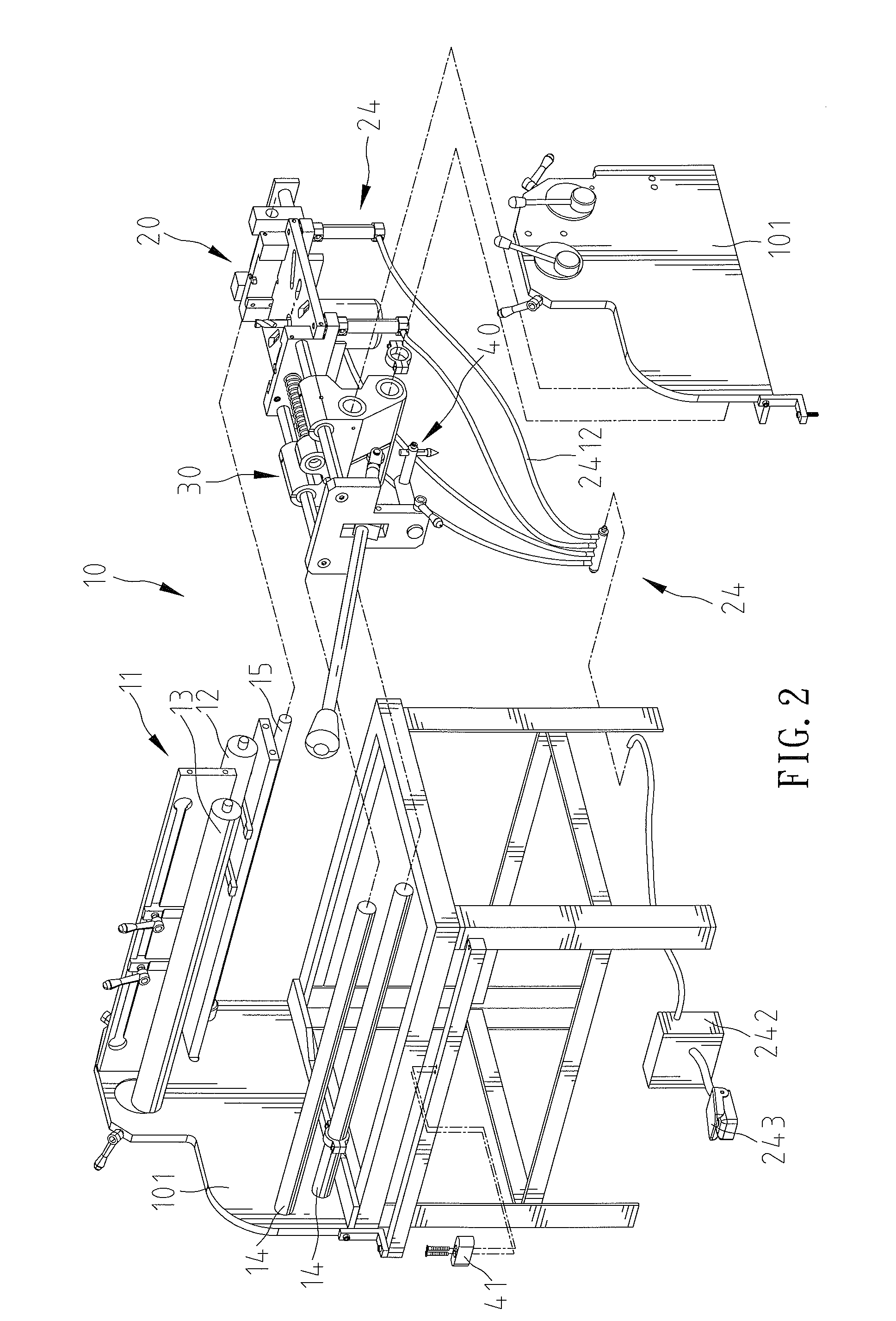

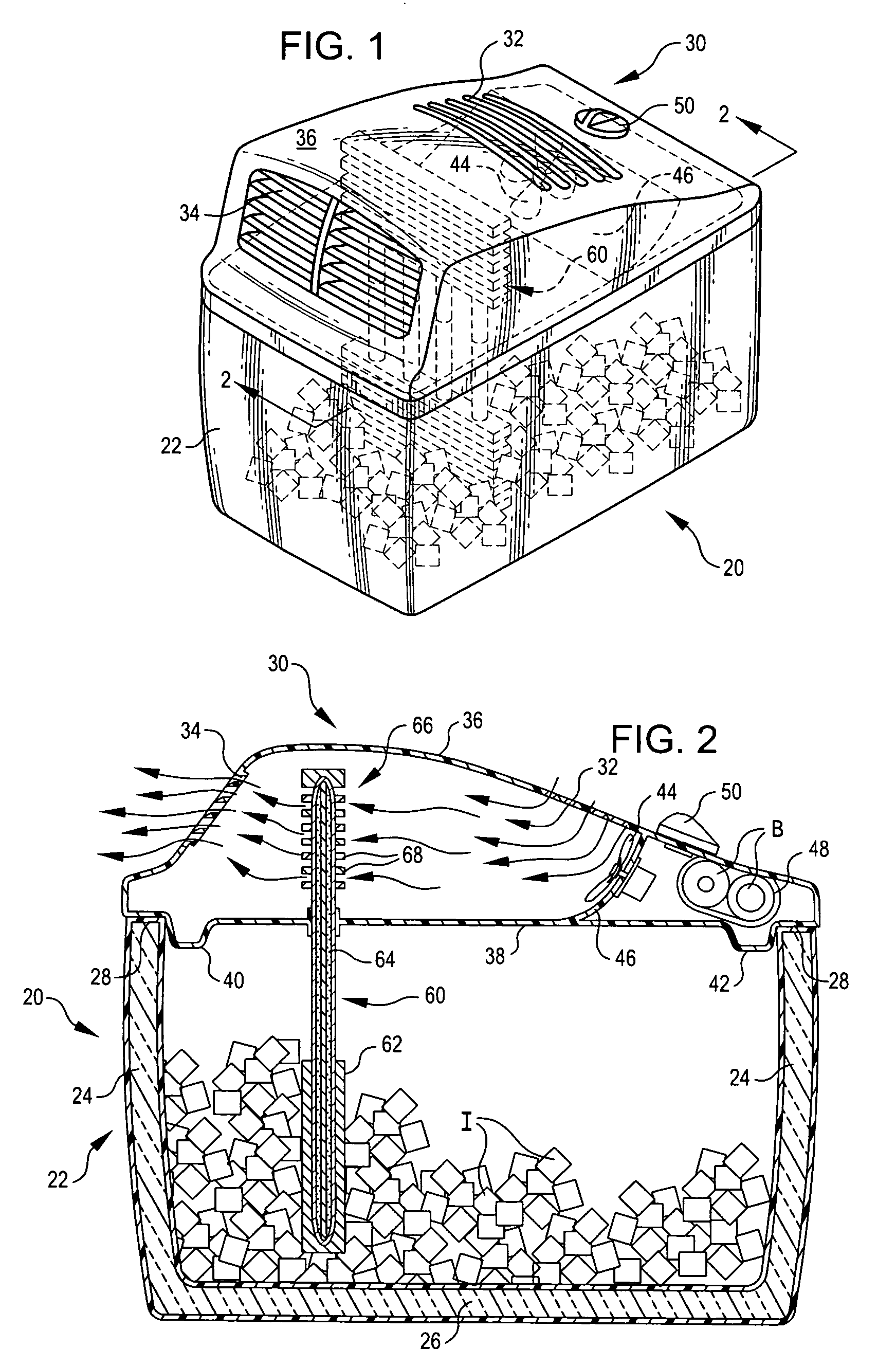

Automatic loading device for plates to be milled and loading material method thereof

InactiveCN101830013AAchieve mechanical propertiesFully automatedWood mortising machinesWood slotting machinesAutomatic controlEngineering

The invention discloses an automatic loading device for plates to be milled, which is suitable for delivering wood floor strips in a production process. The device consists of a feeding and discharging conveyor, a hydraulically lifted steering platform, a plate pusher or a plate absorbing carriage system, a lift-up roller and a turning and conveying mechanism, wherein the feeding and discharging conveyor is used for conveying a tray inside and outside; the hydraulically lifted steering platform is used for lifting the tray and steering the tray at an right angle horizontally; the plate pusher is used for pushing a plate blank onto the lift-up roller; the plate absorbing carriage system absorbs the plate blank and transfers the plate blank to the turning and conveying mechanism; and the turning and conveying mechanism turns the designated plate blank. The invention also discloses an automatic loading method for the plates to be milled, which comprises the following steps of: conveying the tray to the feeding and discharging conveyor; transferring the plate blank (lapped in a single manner) on the top layer onto the lift-up roller by using the plate pusher and conveying the plate blank onto the turning and conveying mechanism; or absorbing the plate blank and transferring the plate blank on the turning and conveying mechanism by using the plate absorbing carriage system; and turning over the designated plate blank by using a turning hook and conveying the designated plate blank into a two-end mill. The automatic loading device and the automatic loading method thereof adopt automatic control, are convenient to operate, reduce labor intensity and save materials.

Owner:苏州伍得人造板设备有限公司

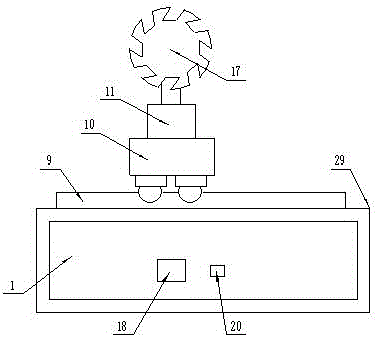

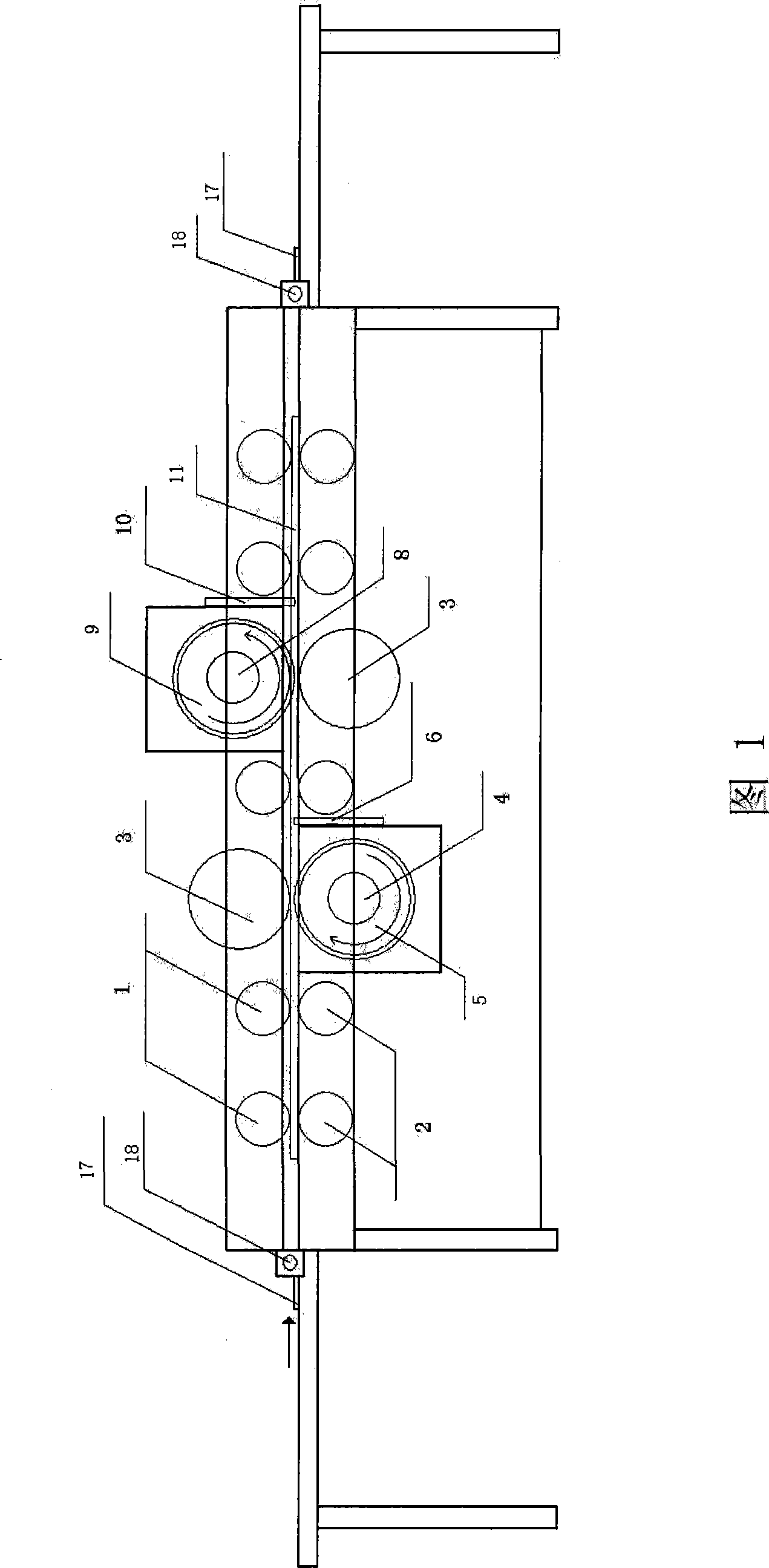

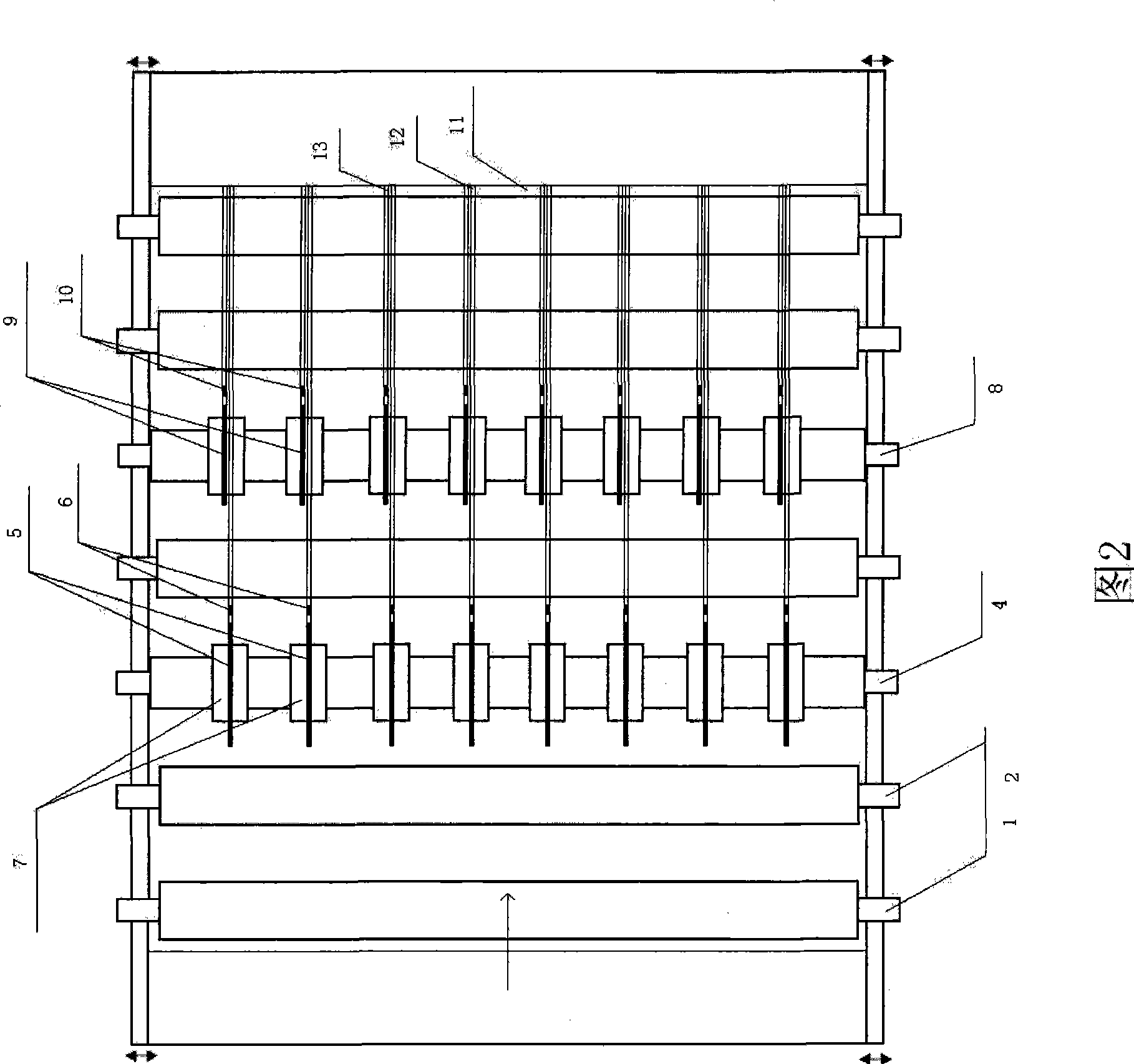

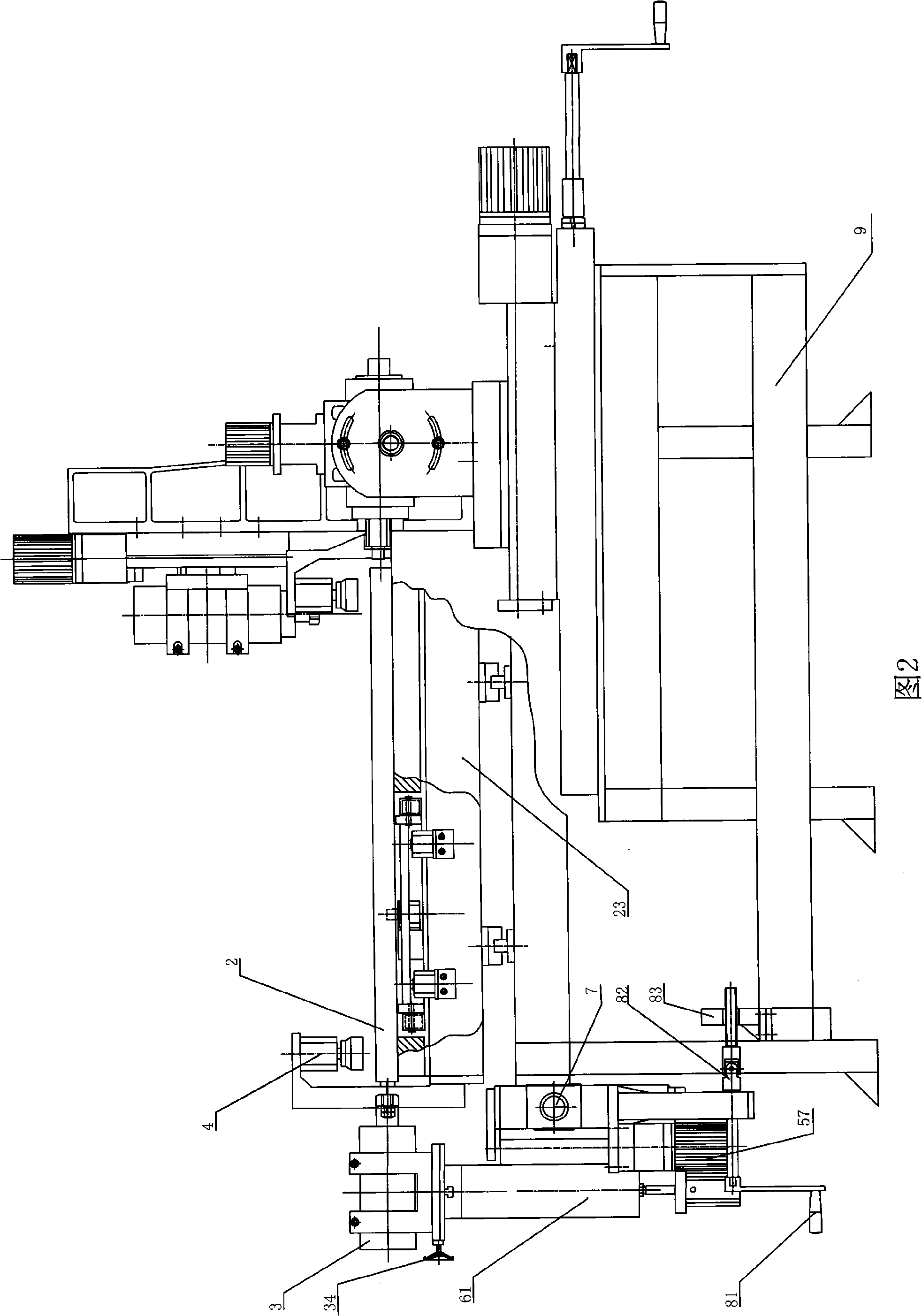

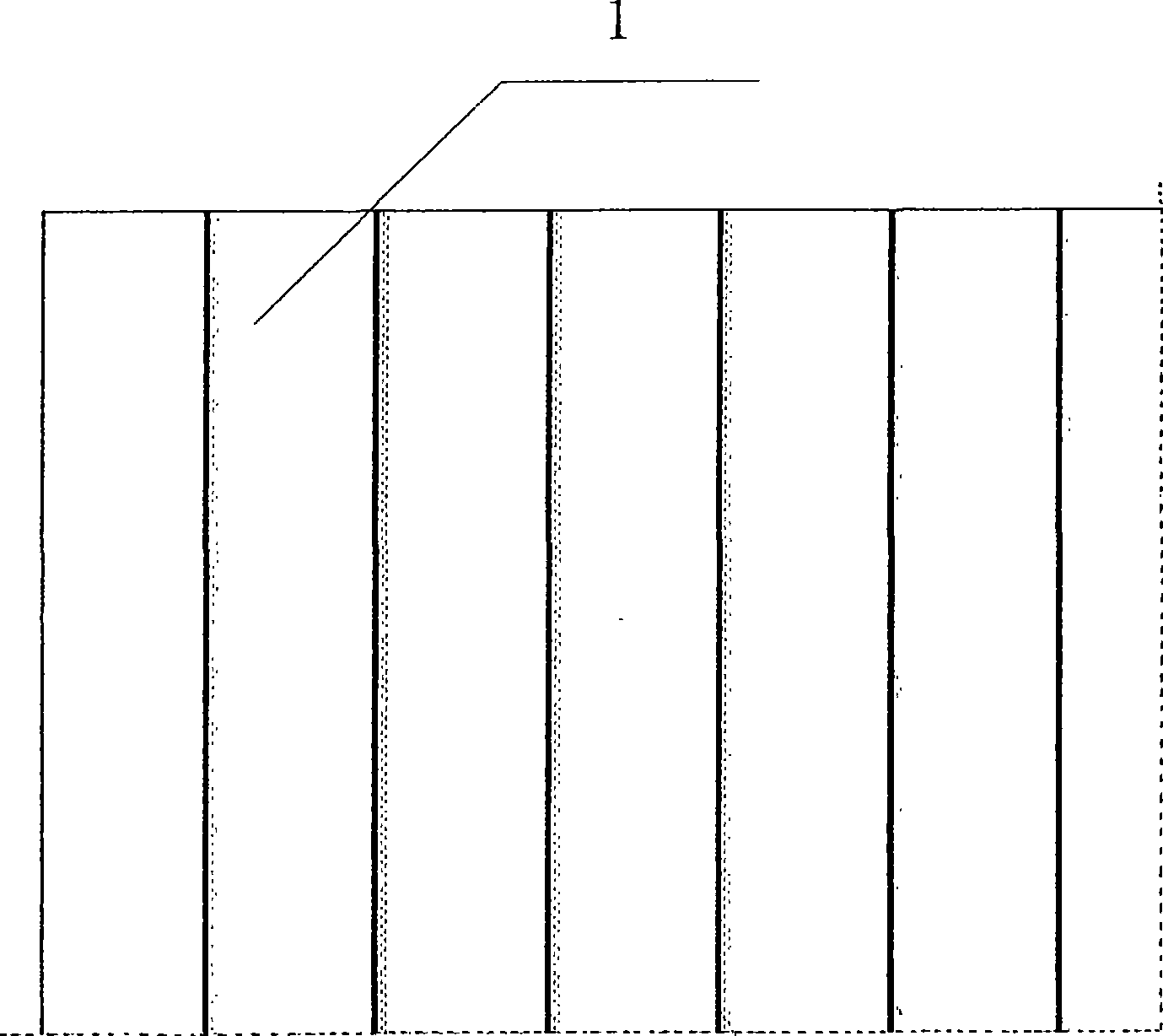

Full-automatic profiling cutter for wooden floor substrate

InactiveCN101412228ASolve the upper slotSolve the problem of cutting and grooving at the same timeWood mortising machinesCircular sawsEngineeringFully automatic

The invention relates to a fully-automatic shape cutting machine for cutting a wood floor base board, which is applicable to an energy-saving shape cutting method for composite floor boards. The fully-automatic shape cutting machine is characterized in that the shape cutting of the wood floor base board is achieved through using a plurality of upper groove cutting saw blades and a plurality of lower groove cutting saw blades which are arranged on a cutting tool to cut and open grooves on the front side and the back side of the wood floor base board from the upper side and the lower side simultaneously, and performing no loss cutting on the connecting parts between upper grooves and lower grooves by using an upper groove cutting knife and a lower groove cutting knife after a plurality of staggered and parallel upper grooves and lower grooves are opened on the wood floor base board so as to cut the wood floor base board into a plurality of semi-finished wood floor strips.

Owner:沈冬良

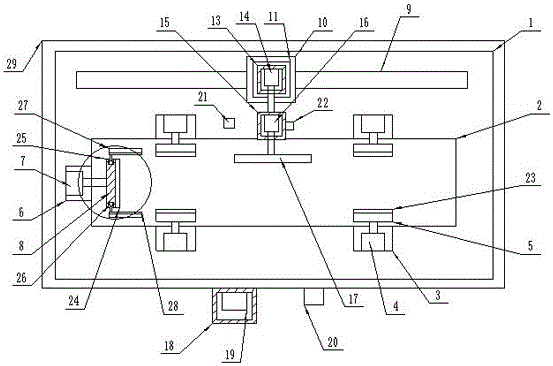

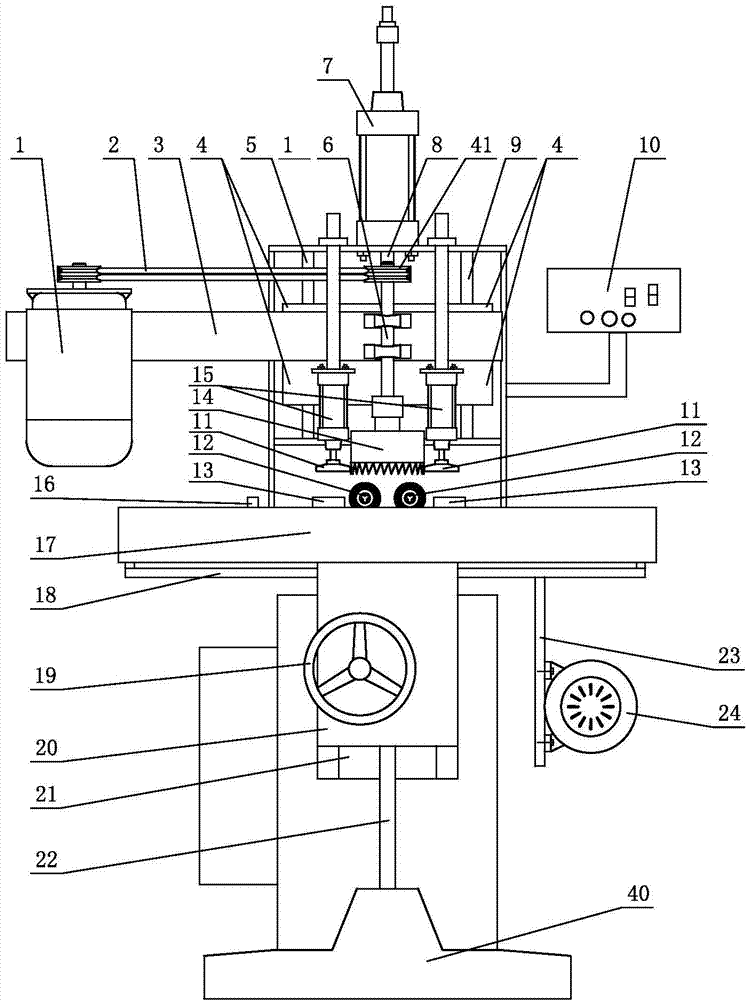

Full-automatic wood door lock, hinge groove and hole processor

InactiveCN101279454ASolve processing problemsImprove processing efficiencyDrilling machinesWood mortising machinesMilling cutterEngineering

The invention relates to a wood processing device, in particular to a full-automatic lock for wooden door, the groove of a hinge and a hole processing machine, which comprises a frame. The invention is characterized in that: a working table which is controlled by a motor to move horizontally and used for placing a wooden door forms a sliding fitting with the frame, and a clamping device for wooden door is arranged at the side edge of the frame; an electric milling cutter device for hinge which can horizontally move along the X direction relative to the frame is arranged at the front side of the frame, an electric drilling and milling device for fade lockhole which can move in the Y direction is arranged at the rear side of the frame and an electric drilling and milling device for door side lock groove which can move along the Y direction is arranged below the electric drilling and milling device for fade lockhole. Various motors and cylinders of the wood processing device are controlled by a computer chip controller, thus ensuring that the drills, and milling knives lift and prone automatically according to the program or simultaneously sequentially complete a plurality of cutting and manufacturing of holes and grooves required for arrangement of locks or hinges on the fade or at the side of a door. The problem of processing the inclined plane groove is solved, and the processing efficiency, the slotting quality and the processing precision are significantly enhanced. Furthermore, the wood processing device can process an inclined plane groove, thus solving the problems of processing of inclined plane grooves and significantly enhancing the processing efficiency, the grooving quality and the processing precision.

Owner:TAIZHOU EVOK MASCH CO LTD

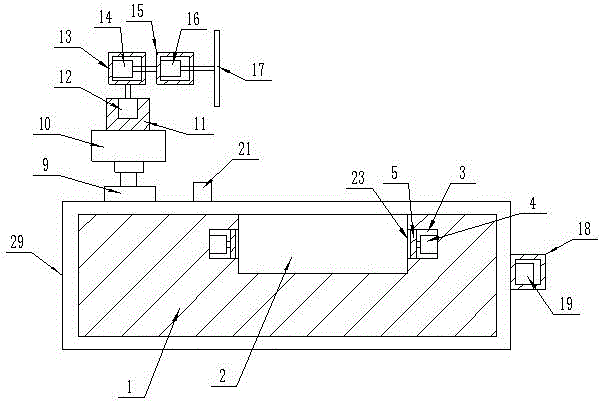

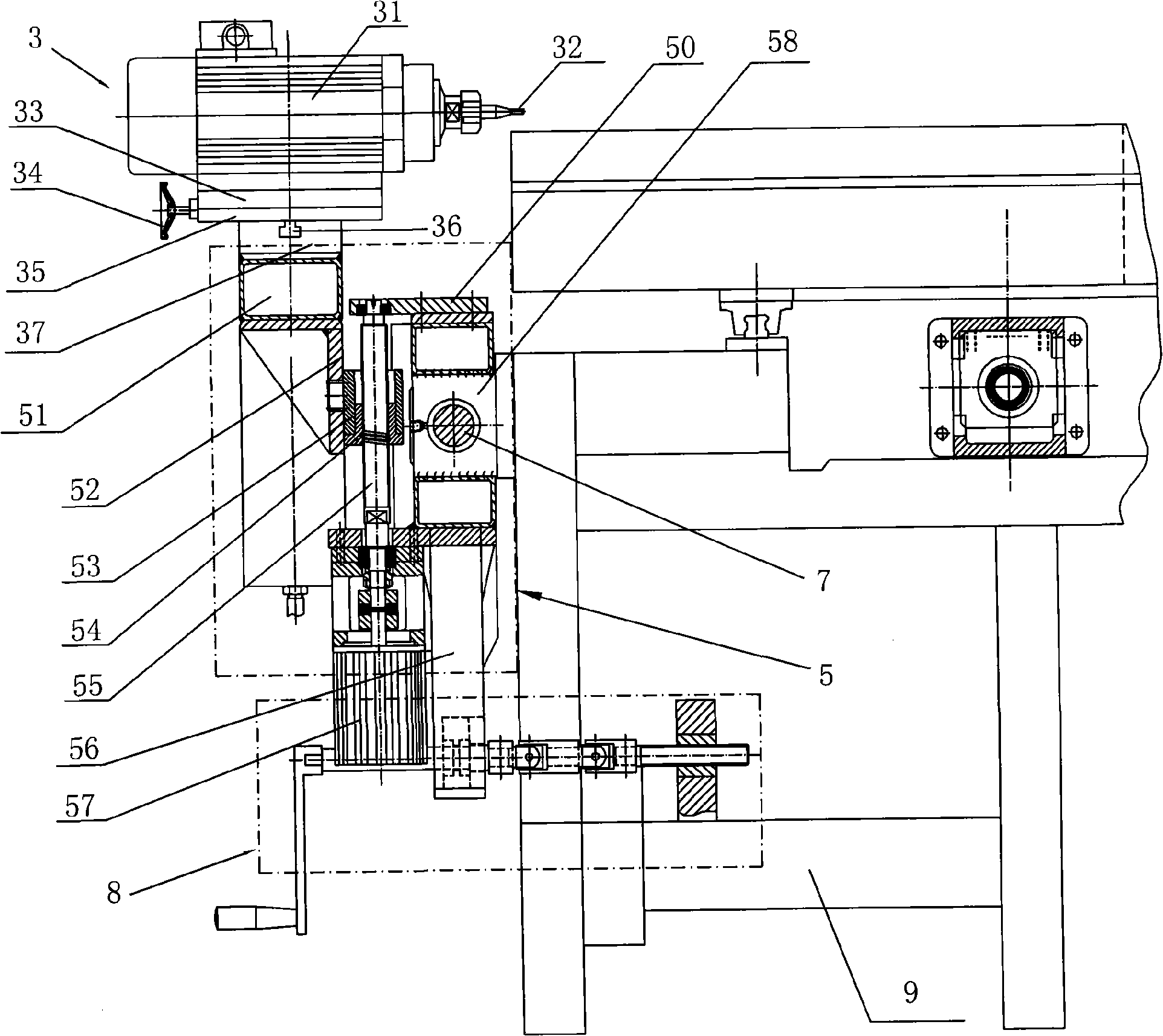

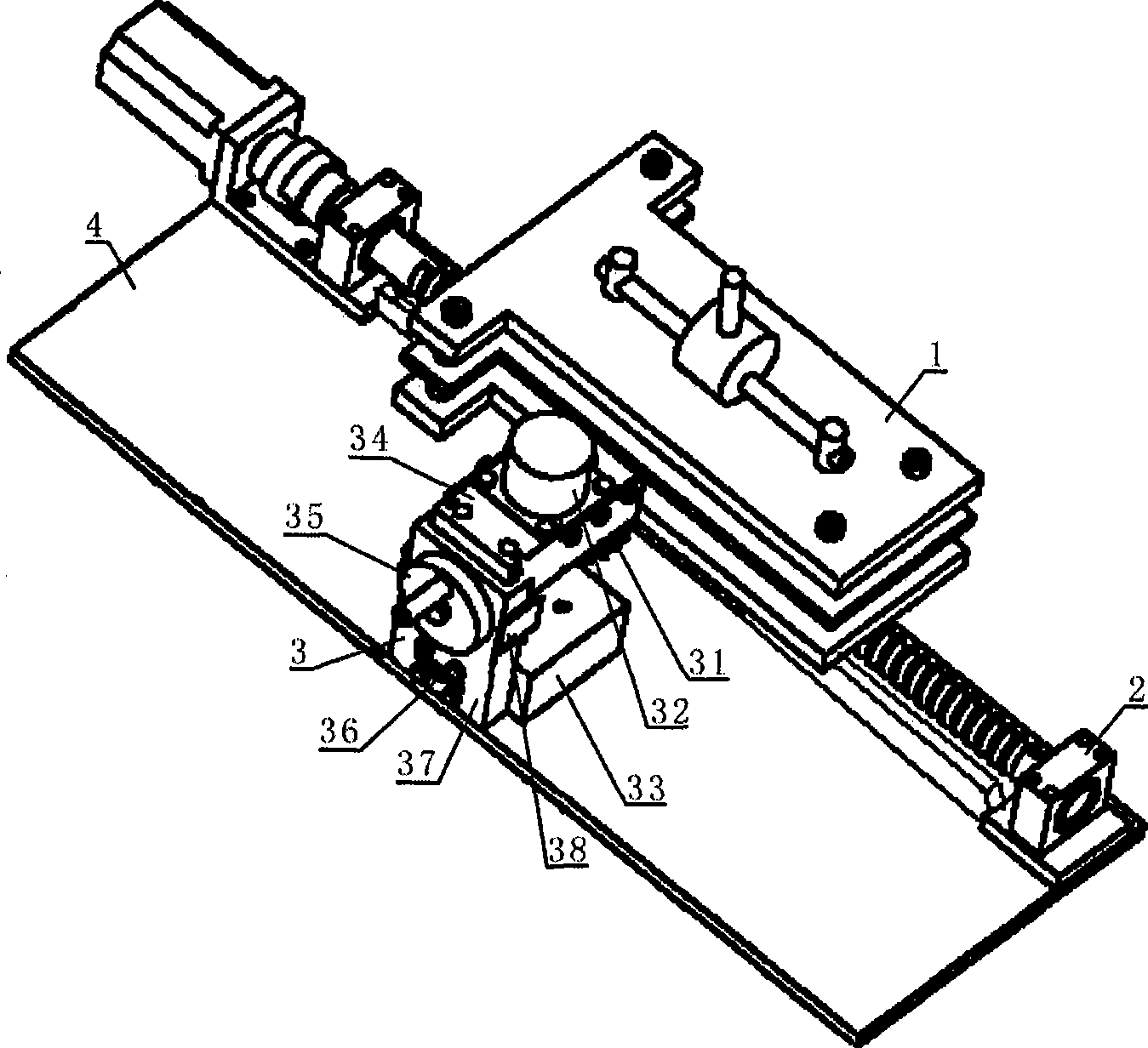

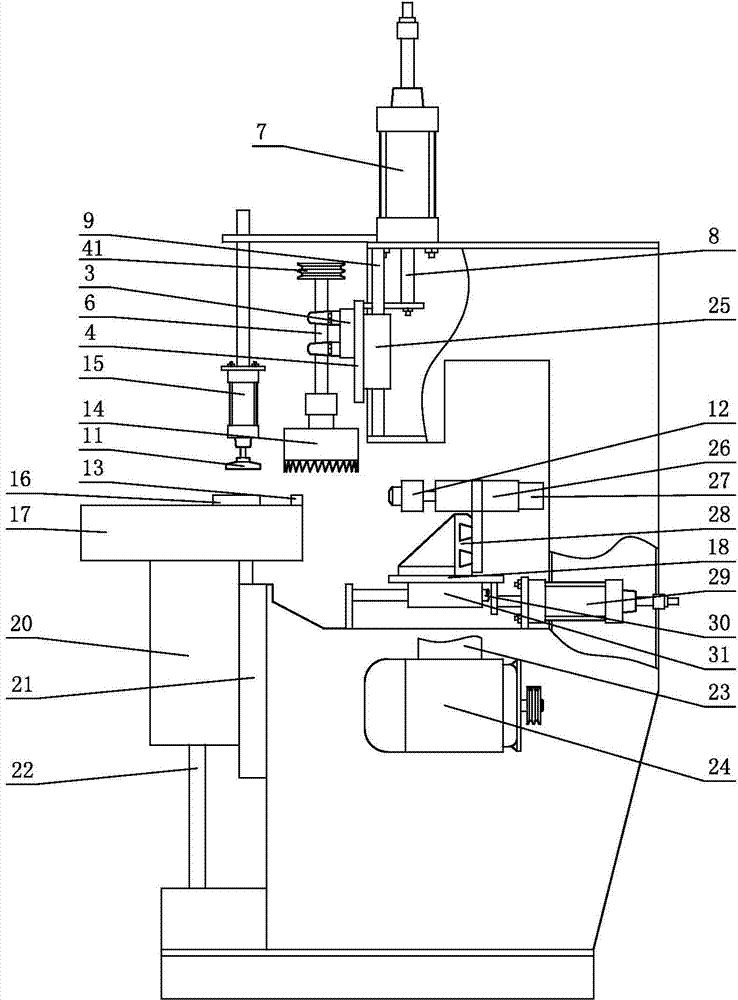

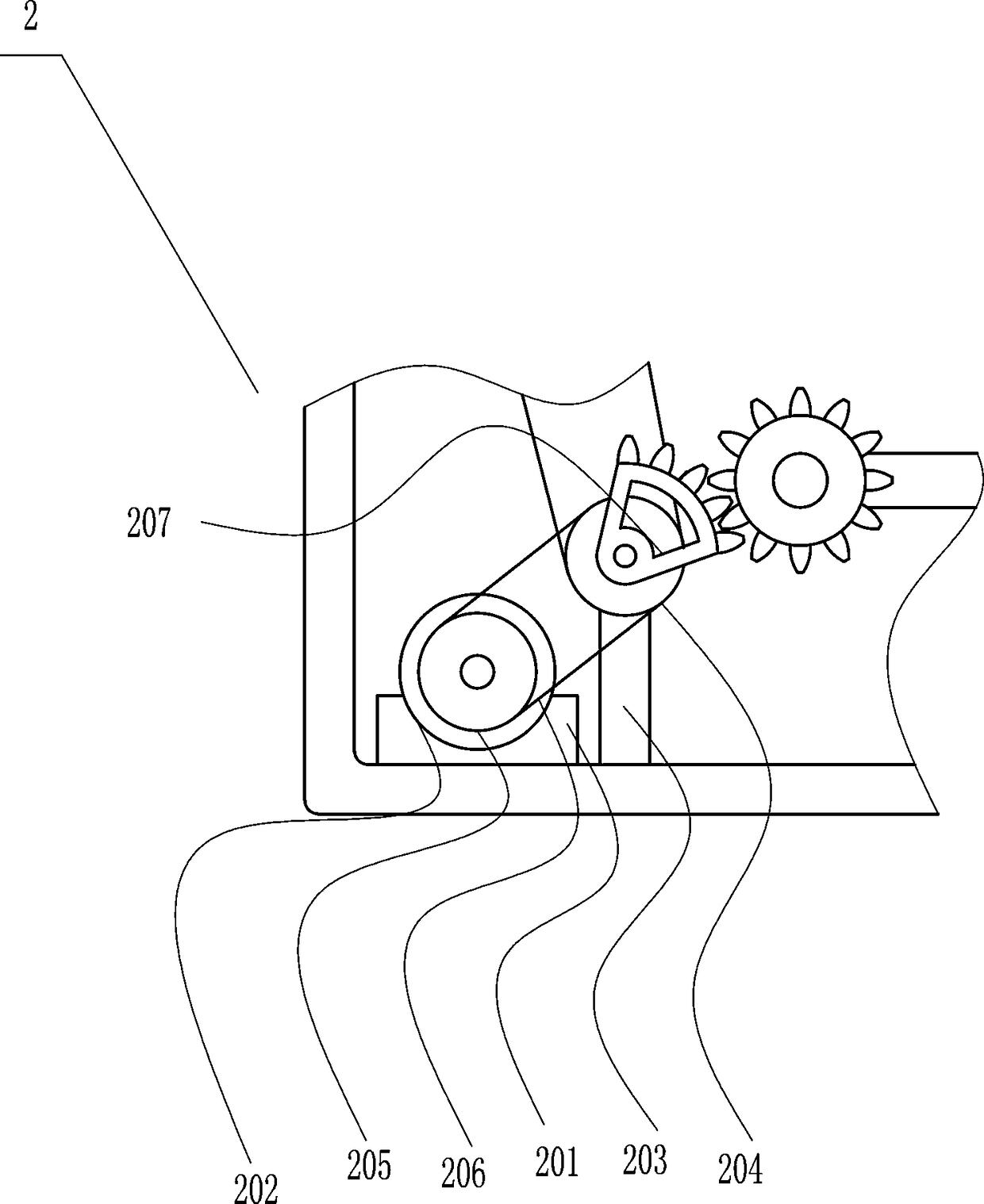

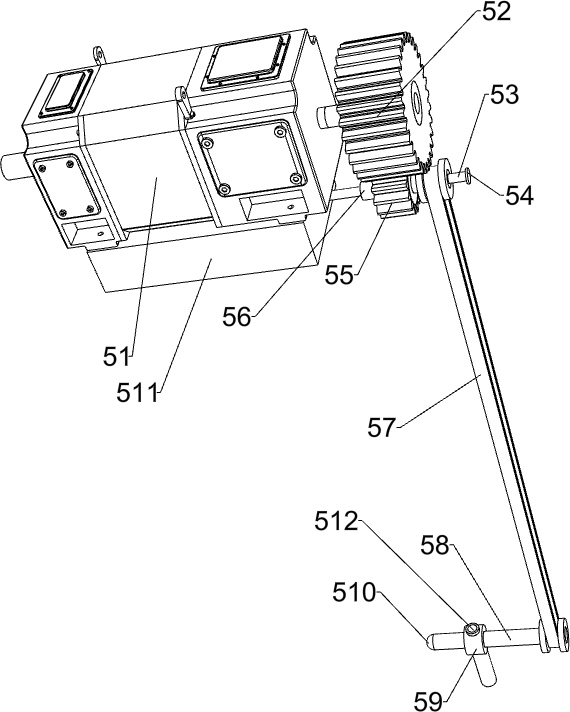

Portable wooden floor groove cutting machine

InactiveCN101474811ASimple structureLow costProfiling/shaping machinesWood mortising machinesCouplingReciprocating motion

The present invention provides a portable wood floor grooving machine which is characterized by comprising a milling cutter device, a feeding device, a clamping positioning device and a frame. The milling cutter device and the feeding device are installed on the frame. The clamping positioning device is installed on the feeding device. The milling cutter of milling cutter device rotates in a horizontal plane. The clamping positioning device executes linear reciprocating motion under the driving of feeding device. The clamping feeding device is mainly composed of an eccentric wheel, an eccentric wheel handle, a tension rod shaft, a tension rod, a supporting plate, an upper splint, a lower splint, a spring and a guiding lever. The feeding device is mainly composed of a feeding motor, a feeding motor support, a coupling, a front support of guide screw, a guide screw, a feed screw nut, a straight slide way, a sliding block and a back support of guide screw. The milling cutter device is mainly composed of the milling cutter, a support, a cutter base, a base frame, a milling cutter motor, a regulating knob, an ejector rod, a regulating wheel and a clamping sheet. The wood floor grooving machine of the invention has the advantages of light weight, excellent portability, simple structure, convenient operation and low fabricating cost.

Owner:WUHAN TEXTILE UNIV

Energy-saving shape cutting method of composite floor

InactiveCN101391427AReduce wasteReduce lossTongue/grooves making apparatusWood mortising machinesEnvironmental resistanceHigh density

The invention belongs to a base plate cutting method of a wood-based panel lock-catch composite floor, which is used to improve the usage rate of a wood floor base plate and reduce the loss. The cutting method uses an non-corresponding upper and lower slotting and cutting as well as cutting saw blade copying technique, the cutting method is determined according to the shape of a wood floor lock catch, the cutting position is selected reasonably, the practical usable area of the wood floor base plate is increased, the method is particularly applicable to a high density impregnated paper lamination strengthening composite floor, the floor commonly uses the method of the lock catch assembling. Using the technique of the composite floor energy saving copying cutting method can save the loss by 3 to 7% under the situation that the original structure of the wood floor base plate is not changed, the width of the wood board strip produced after the cutting of the wood floor base plate before shape milling is more than or equal to the practical calculating width of the wood floor base plate being equally divided corresponding to the required specification of the finished wood floor, the method really plays the effects of saving the wood resources, reducing the cost, saving the energy and protecting the environment; the competitive advantage of the floor production enterprises is increased.

Owner:沈冬良

Equipment for processing tag slot on side edge of chopping board

ActiveCN102950626AMechanizationAccurate locationProfiling/shaping machinesWood mortising machinesMilling cutterEngineering

The invention belongs to the technical field of chopping board processing, and particularly discloses equipment for processing a tag slot on the side edge of a chopping board. The equipment mainly comprises a chopping board clamping mechanism, a tool rest mechanism and a controller, wherein the tool rest mechanism is used for arranging a milling tool; the chopping board clamping mechanism comprises a clamping bottom plate and a clamping support plate; the clamping bottom plate is arranged on a stand in a front-and-back sliding way, and the clamping support plate is arranged on the clamping bottom plate in a right-and-left sliding way; a pressure plate is arranged above the region, which is used for clamping the chopping board, of the clamping support plate in a suspending way; the tool rest mechanism is arranged at rear of the chopping board clamping mechanism; the head of the milling tool horizontally corresponds to the side edge of the chopping board clamped on the clamping support plate; and the controller controls the actions of a bottom plate driving cylinder, a support plate driving cylinder and a pressing cylinder through air valves. The equipment disclosed by the invention can be used for completing the various actions in the manually operating process in a simulating way by designing the special chopping board clamping mechanism and using a cylinder device, thereby realizing the mechanization of tag slot processing; and compared with manual operation, the equipment disclosed by the invention has the advantages of high processing efficiency, reduced labor intensity of workers and labor cost saving.

Owner:SUNCHA TECH CO LTD

Equipment for grooving and drilling on side of cutting board

ActiveCN103692499AReduce labor intensityRealize mechanical automationDrilling machinesMulti-purpose machinesEngineeringMachining

The invention belongs to the technical field of machining of cutting boards, and discloses equipment for grooving and drilling on the side of a cutting board. The equipment comprises a cutting board clamping table, a drilling device, a grooving device and a controller, wherein the drilling device is arranged behind the cutting board clamping table and comprises a drill bit and a drilling motor which drives the drill bit to rotate, and the forward projection point of the drill bit is located in a pre-drilling position of the cutting board which is positioned and clamped on the cutting board clamping table. The grooving device is arranged above the drilling device and comprises a cylindrical saw web and a grooving motor which drives the saw web to rotate around a cylinder axis. The downward projection of the cutting line of the cylindrical saw web is overlapped with an arc-shaped contour of a pre-cutting arch-shaped groove of the cutting board which is positioned and clamped on the cutting board clamping table. According to the equipment disclosed by the invention, the special cutting board clamping mechanism is designed, and an air cylinder device is selected to simulate actions in a manual operation process, so that mechanization and automation of the arch-shaped grooving and drilling are realized. Compared with manual operation, the mechanical and automatic operation has the advantages that the machining efficiency is high, the labor intensity of workers is reduced, and the labor cost is reduced.

Owner:ZHEJIANG SHUANGQIANG BAMBOO & WOOD CO LTD

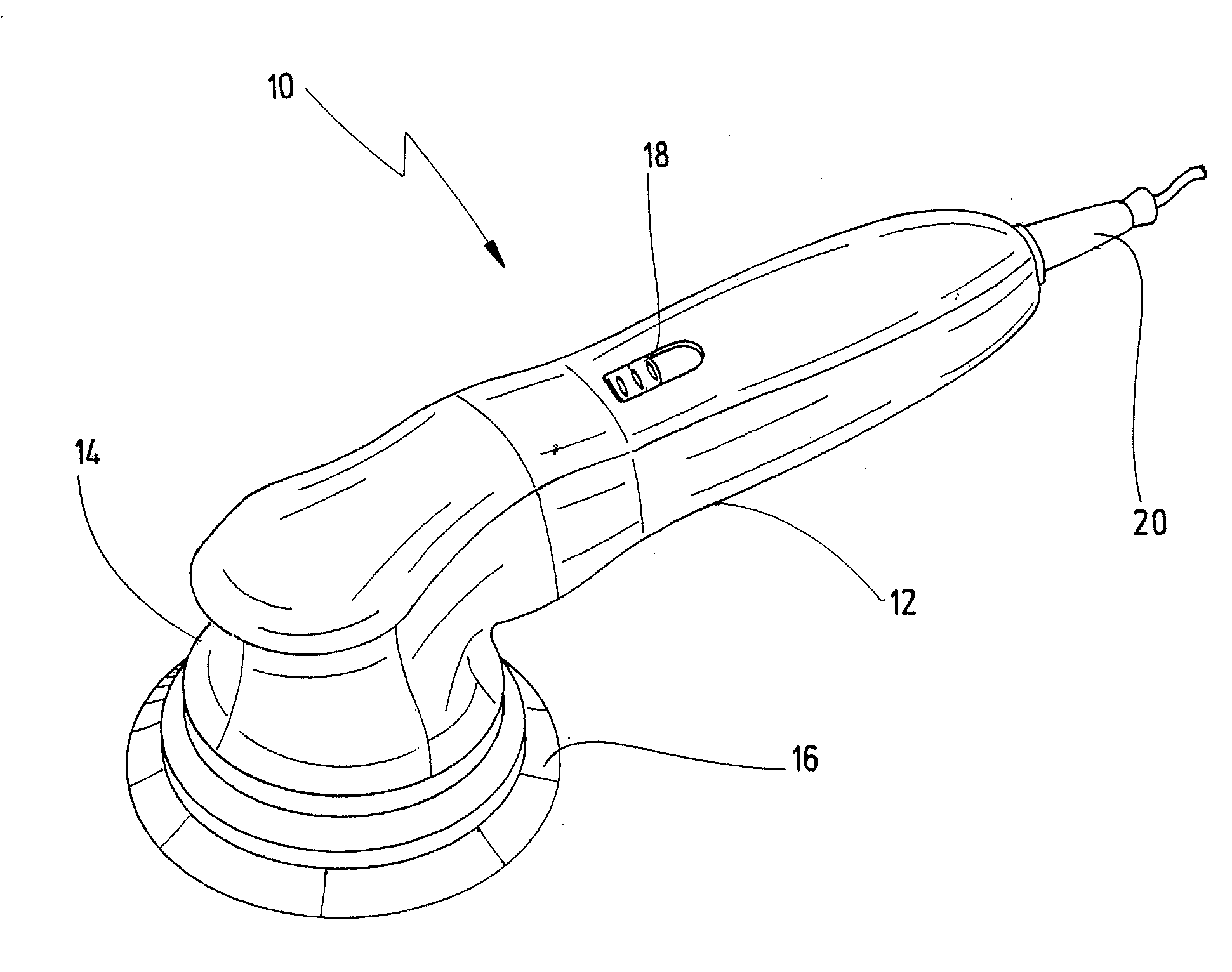

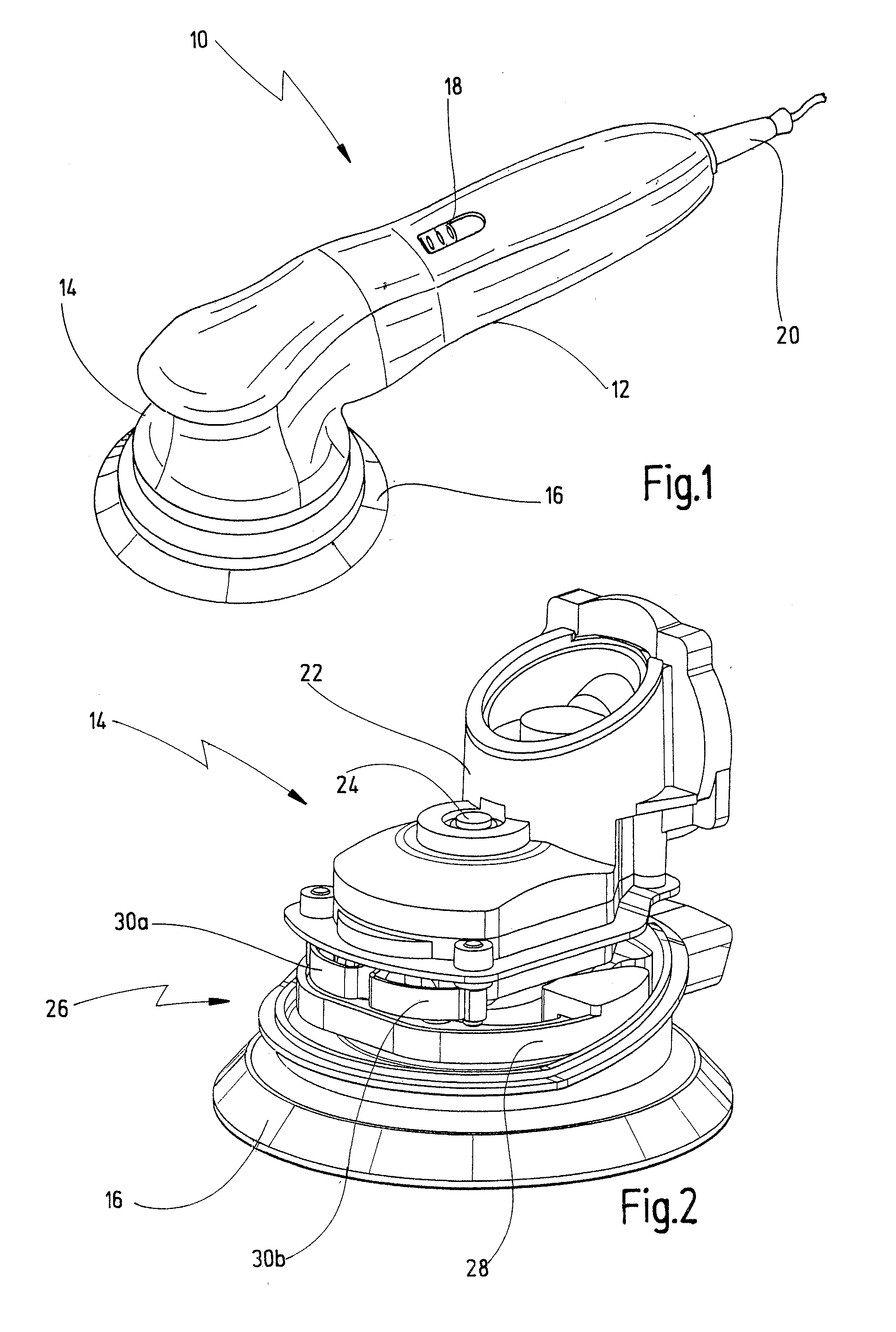

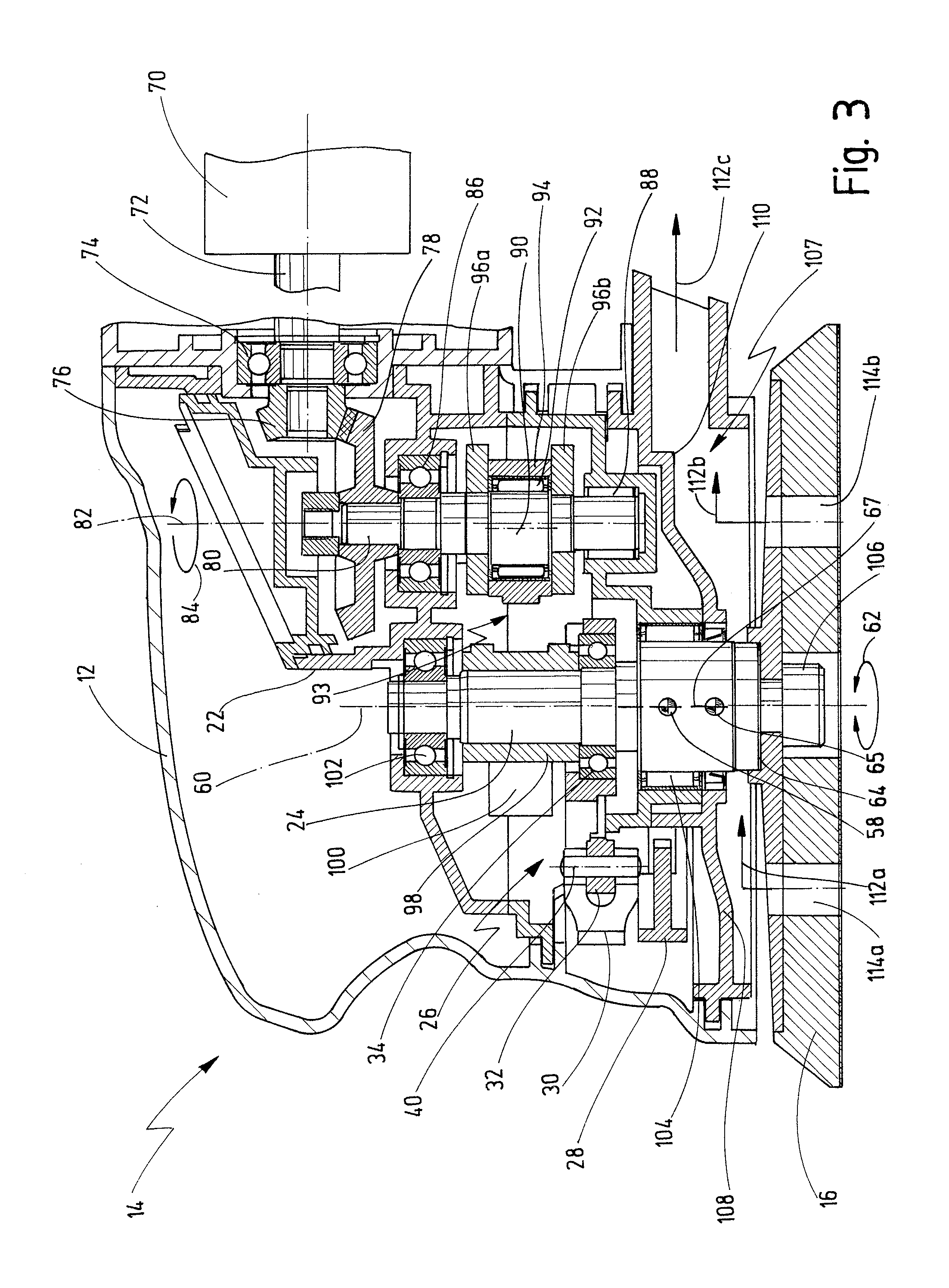

Portable Tool

InactiveUS20120037391A1Improve performanceEfficient extractionGrinding machine componentsPortable percussive toolsDrive shaftCoupling

The invention relates to a The portable tool, in particular a tool for grinding or cutting, having a housing with a gear head, having a drive shaft which can be rotationally driven by a motor and can be coupled via a coupling drive to a tool spindle for the drive thereof, wherein the tool spindle can be driven rotatingly oscillating about the longitudinal axis thereof and is configured for receiving a tool wherein a vibration absorber is provided at the tool spindle, the vibration absorber having an absorption mass which encloses the tool spindle. Preferably the absorption mass is configured substantially in a ring segment shape and encloses the tool spindle by at least 180°, or even by 360°.

Owner:C & E FEIN GMBH & CO KG

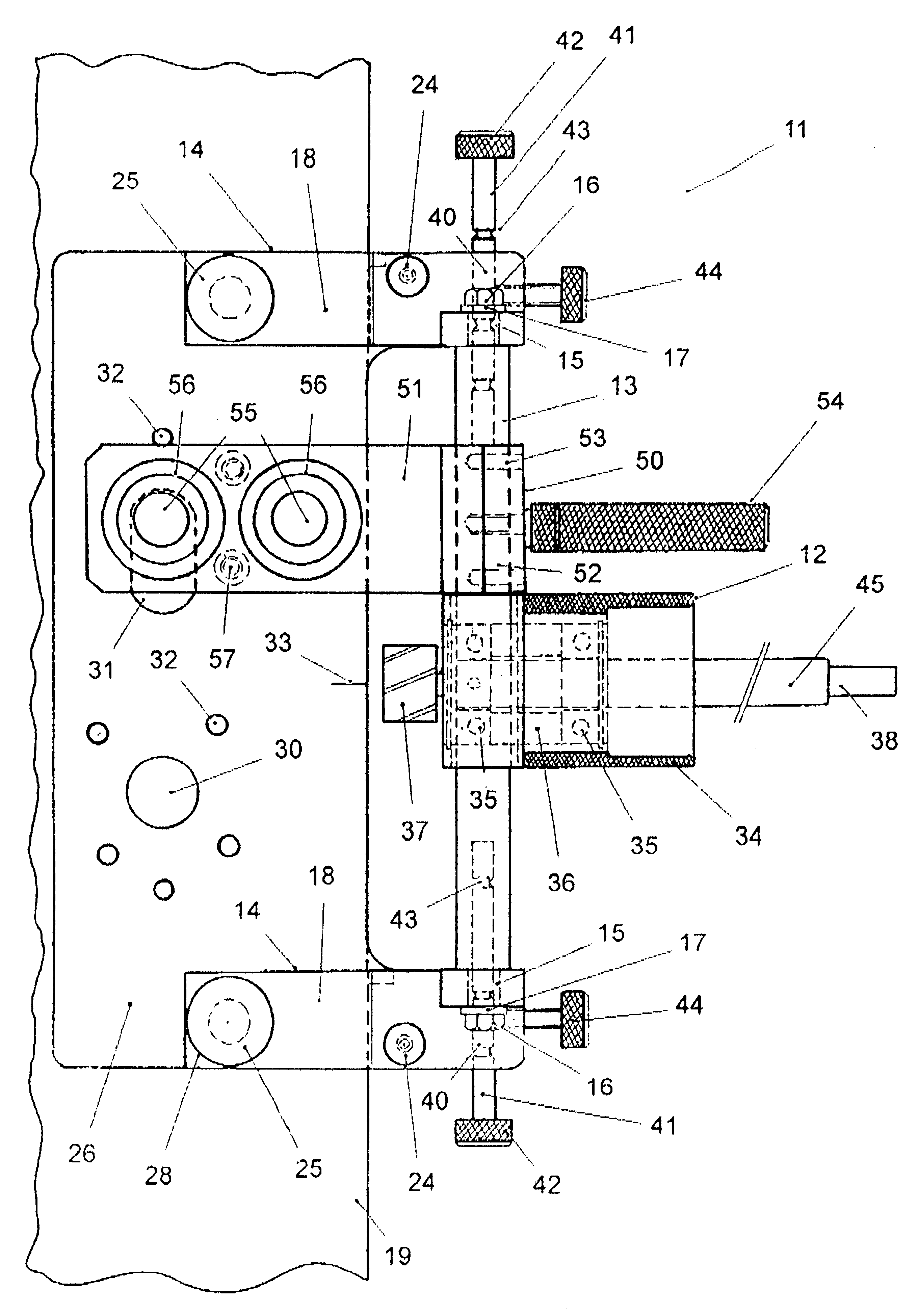

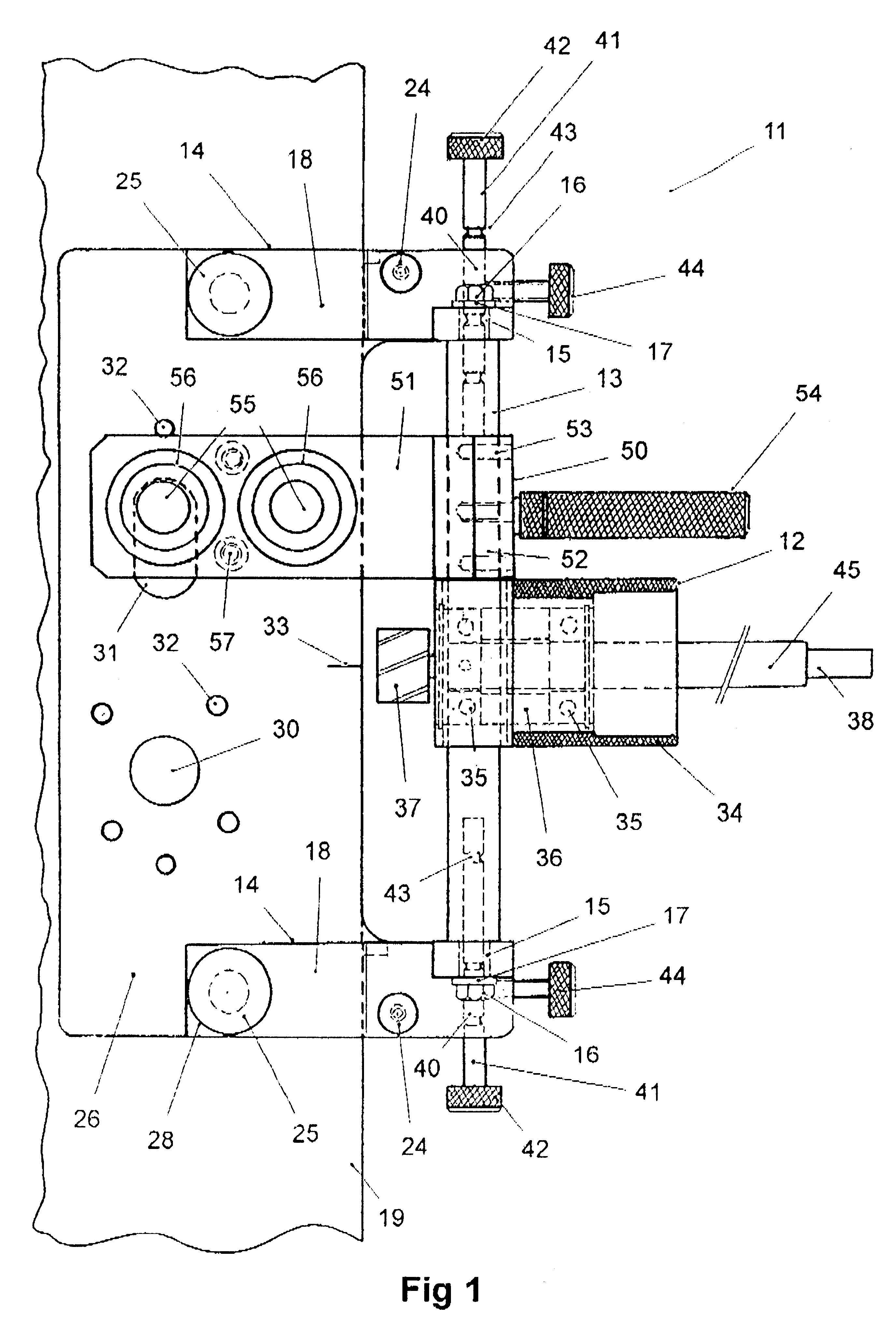

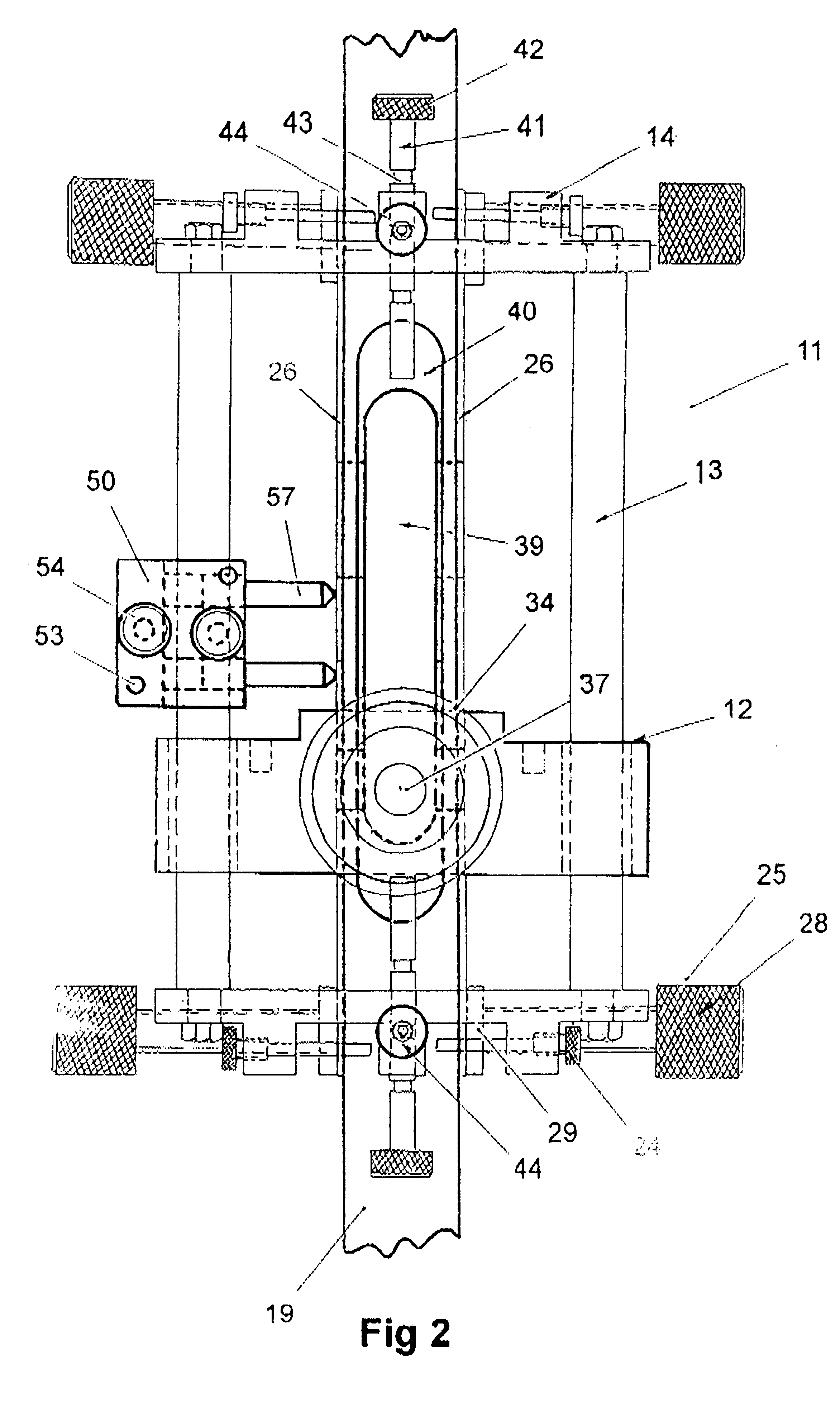

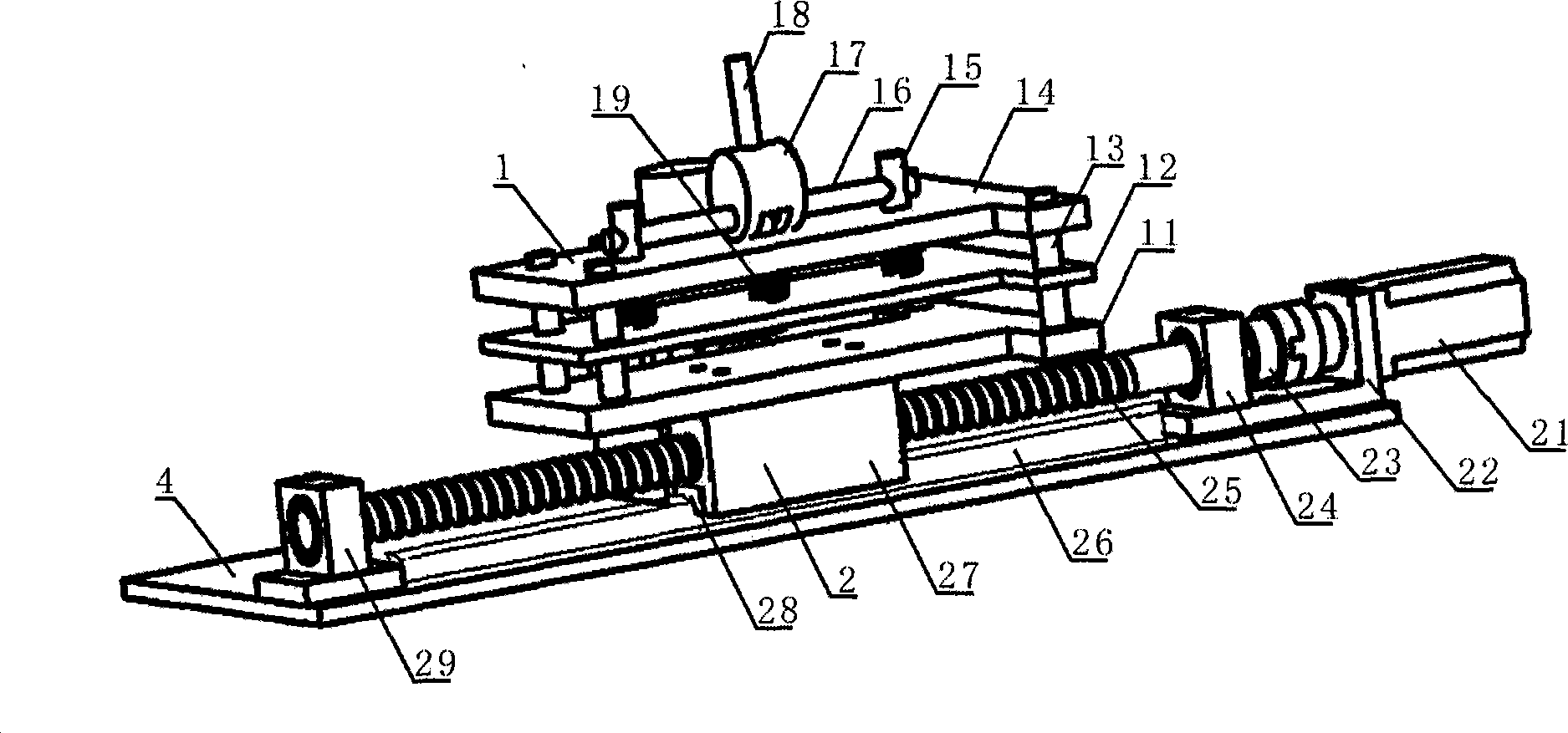

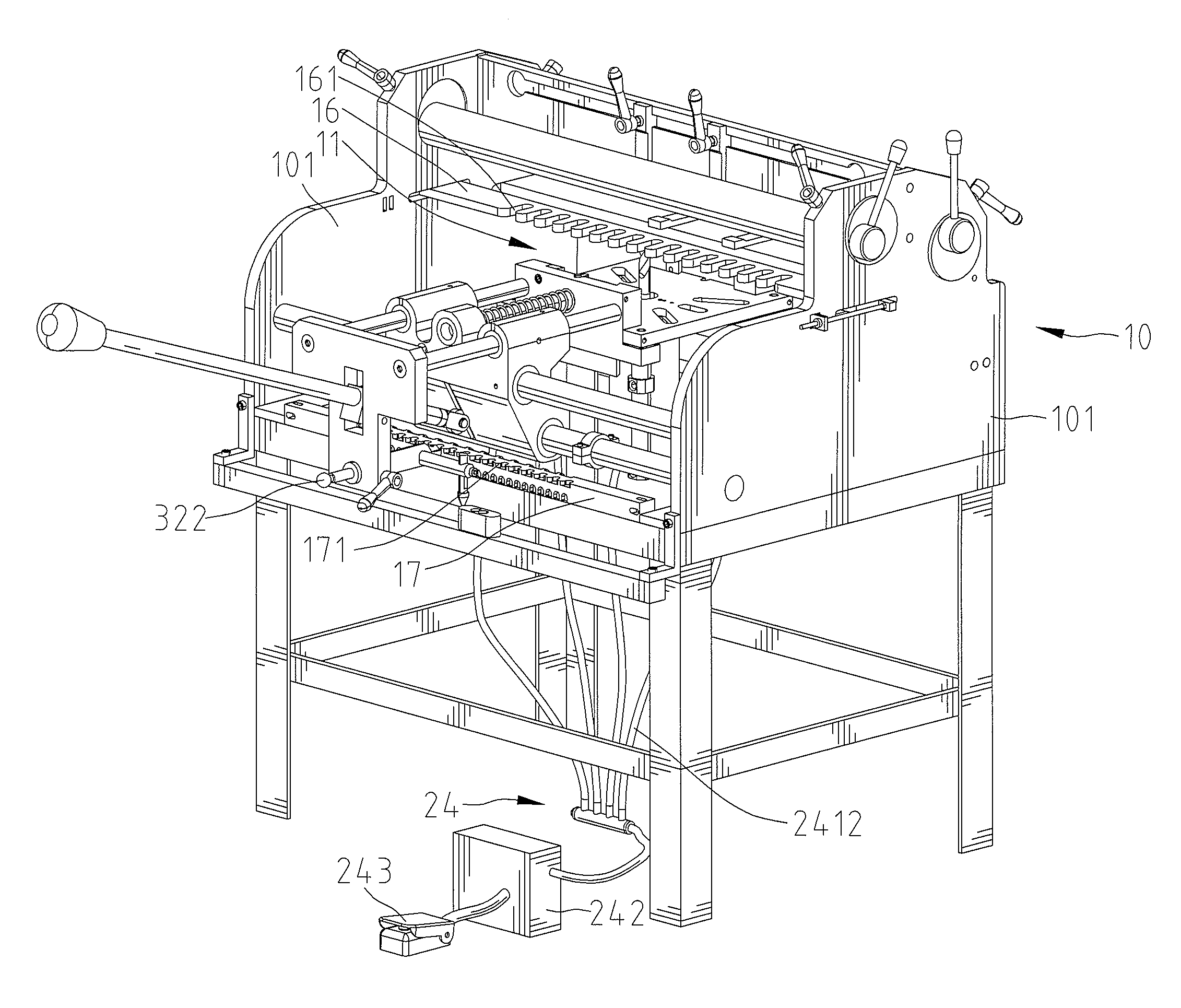

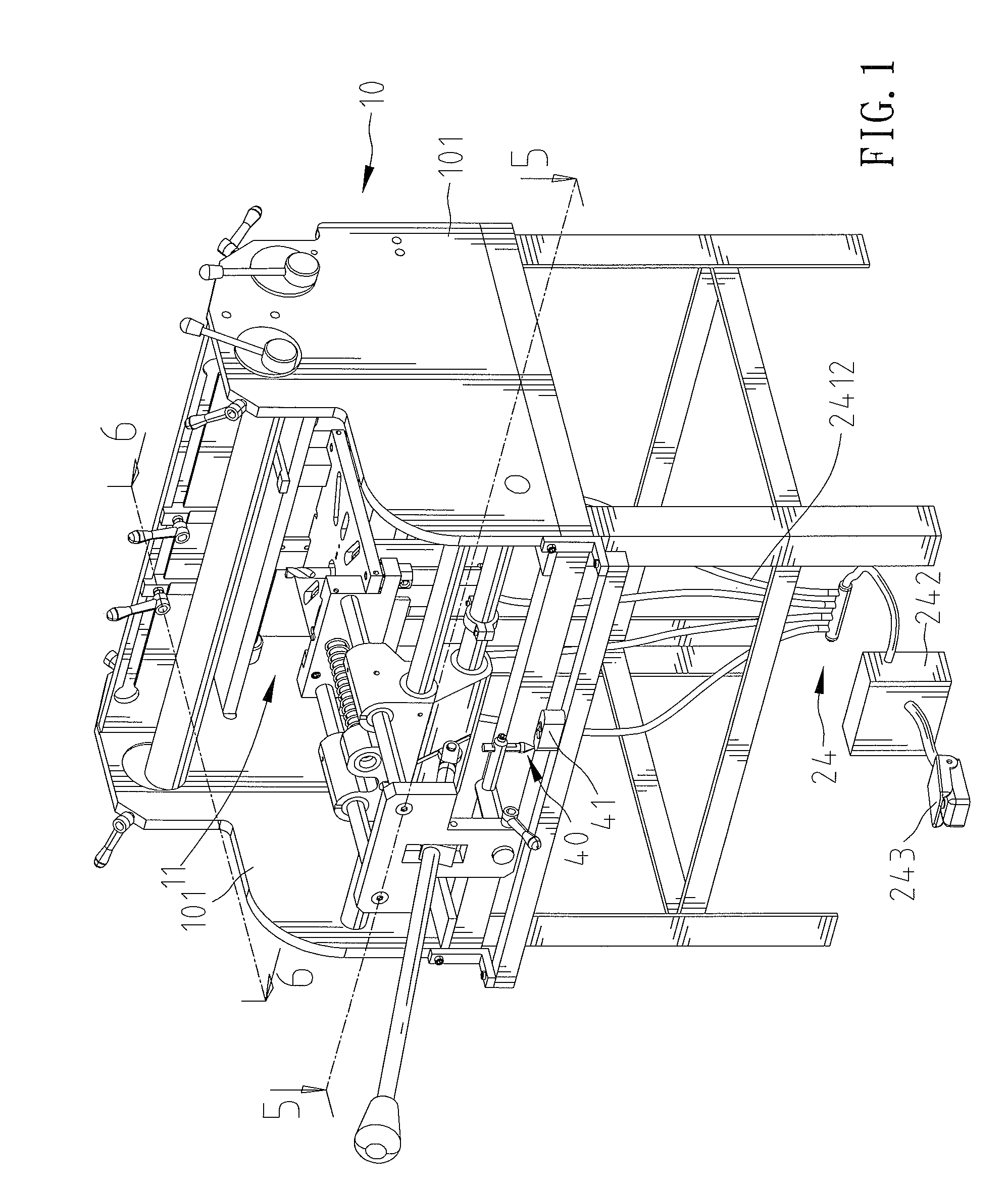

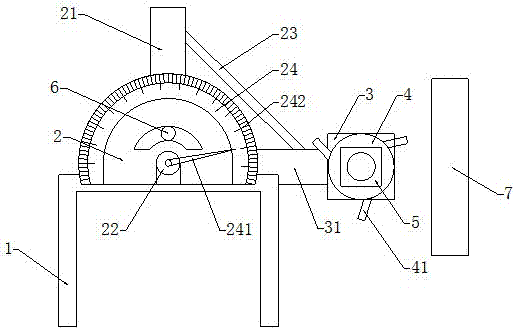

Multi-Function Mortise/Tenon Apparatus

A multi-function mortise / tenon apparatus, the apparatus comprises a chassis including a placement portion for placing a work piece horizontally / vertically and at least one transverse sliding rod; a work table including a first base member, a second base member and a lift / lower platform provided between the first and second base members; wherein the lift / lower platform and the first and second base members are driven to slide with respect to the chassis transversely / longitudinally; wherein the lift / lower platform is driven to lift / lower with respect to the chassis; and a guiding device installed to the at least one first sliding rod slideably and transversely and coupled to the work table which is driven by the guiding device to slide with respect to the chassis transversely / longitudinally.

Owner:YANG JACK

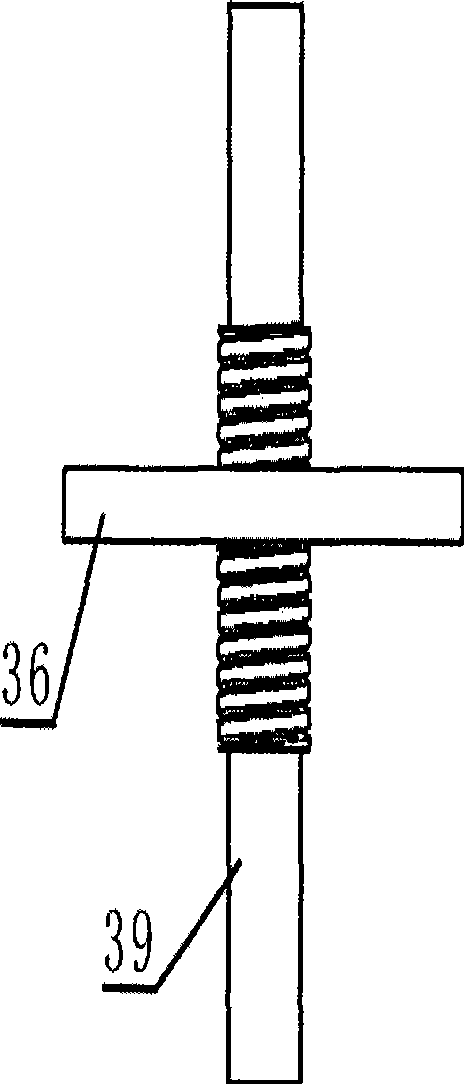

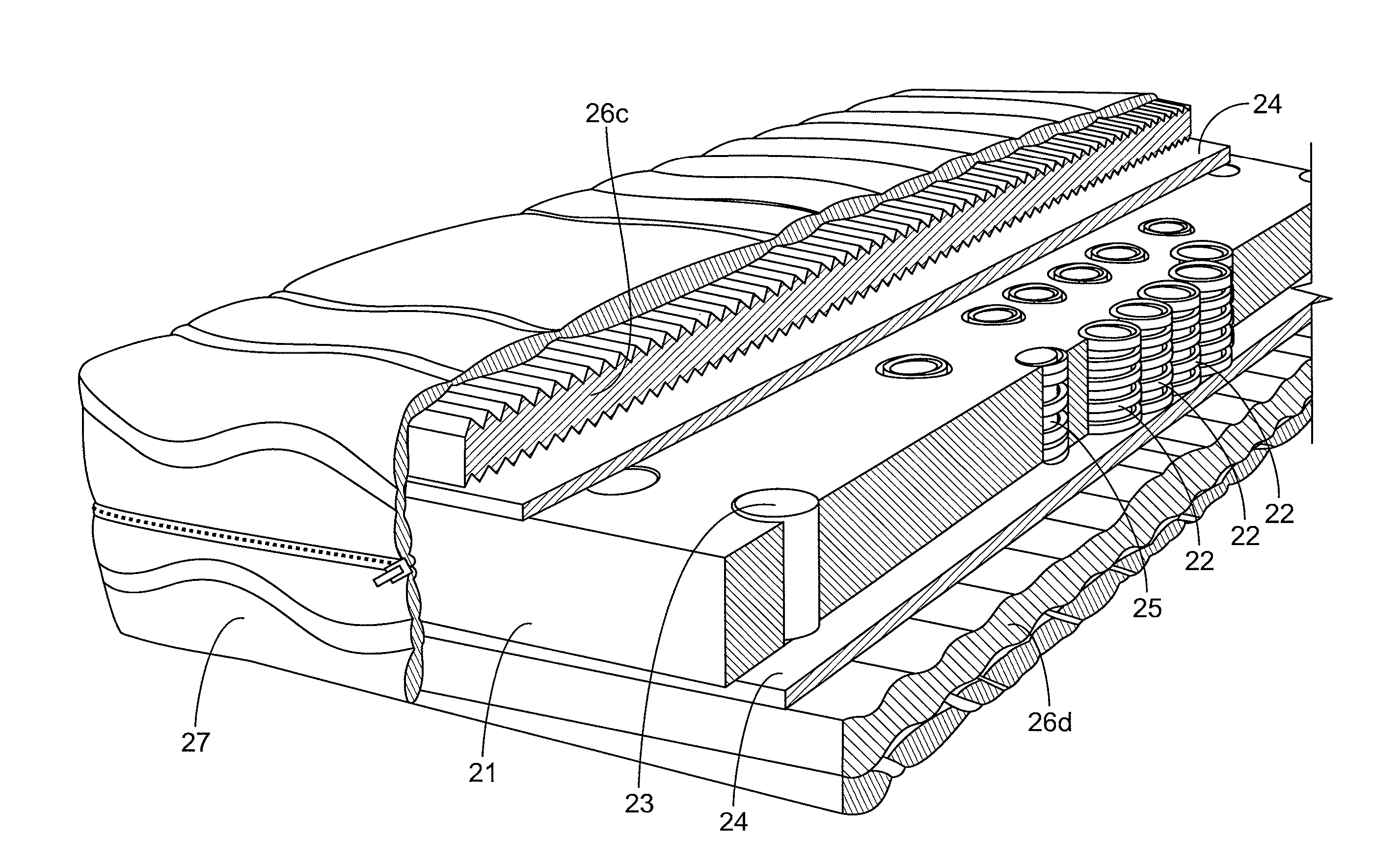

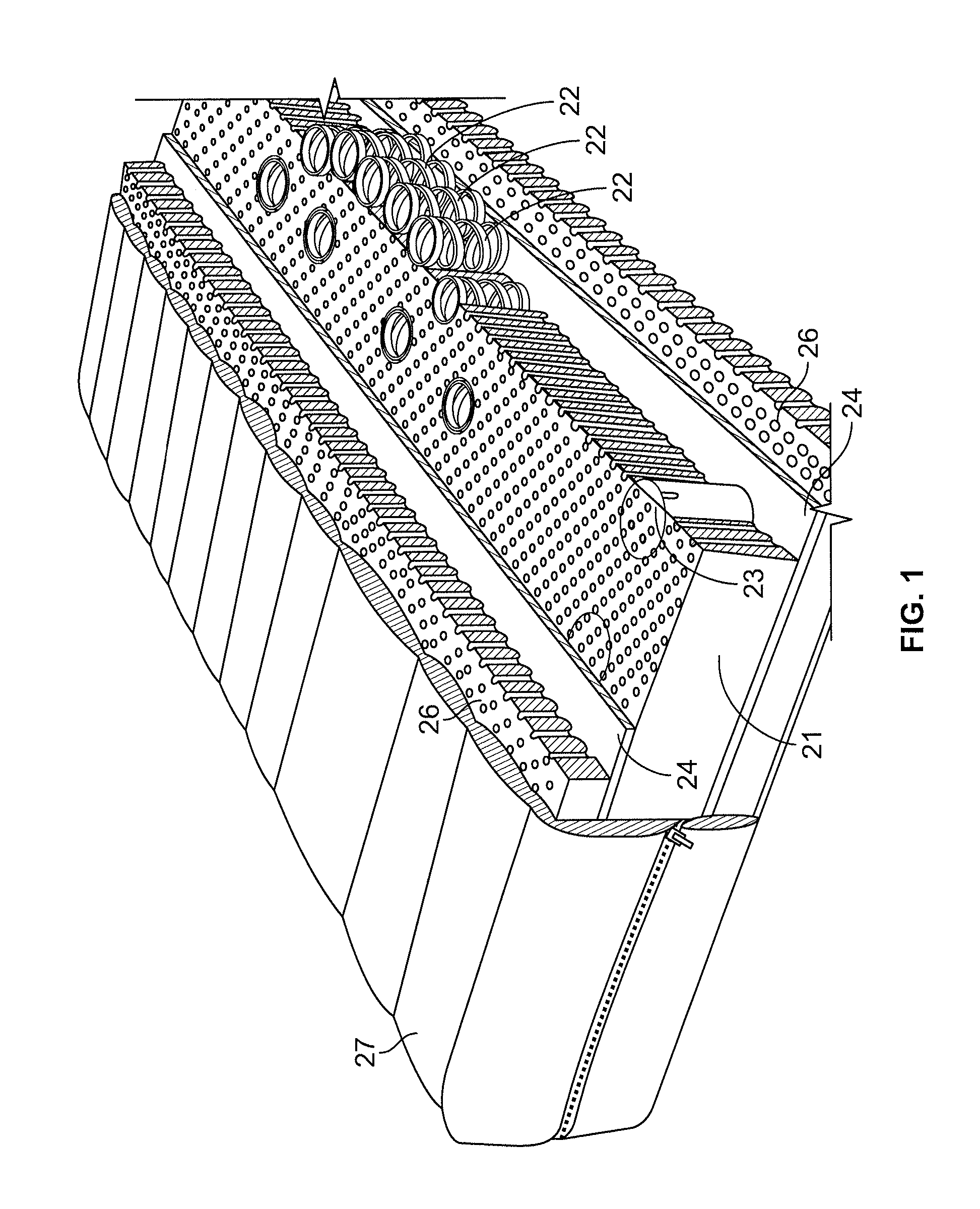

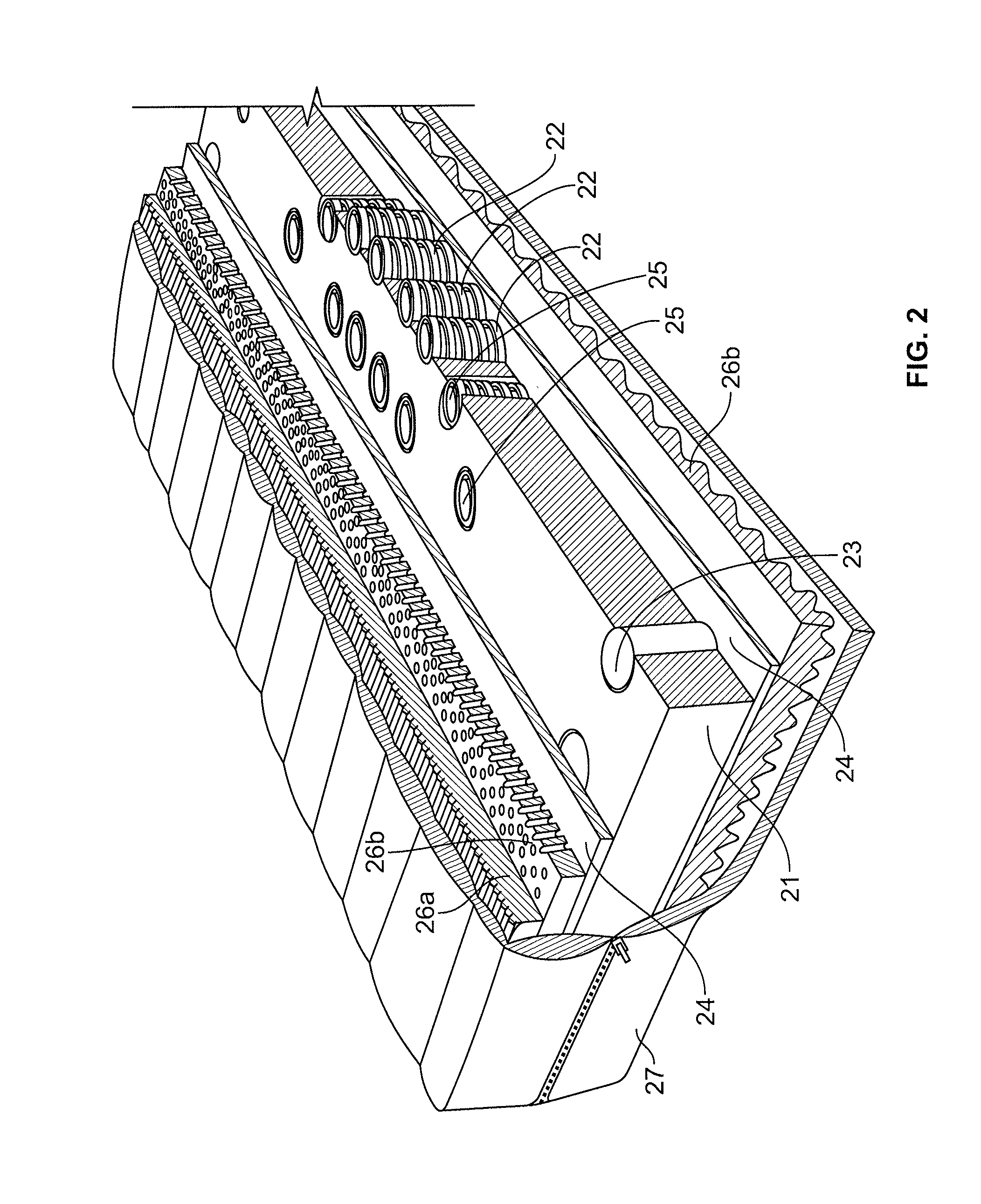

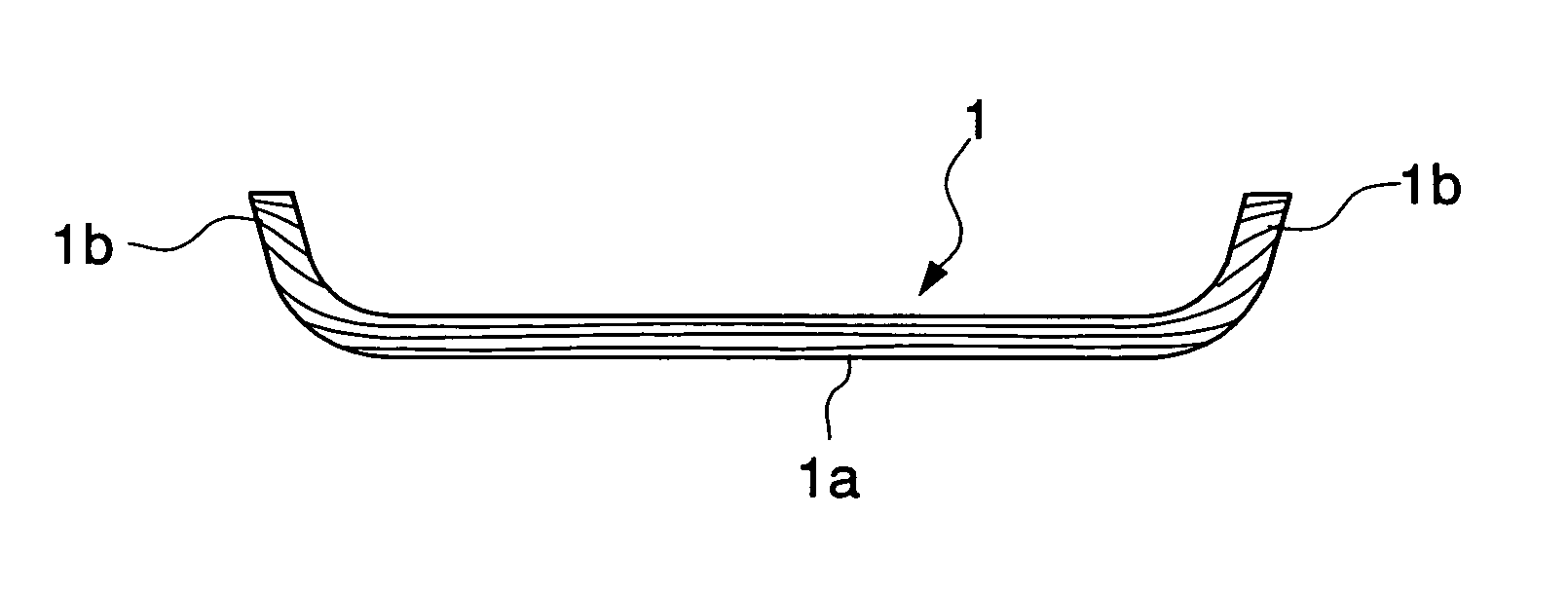

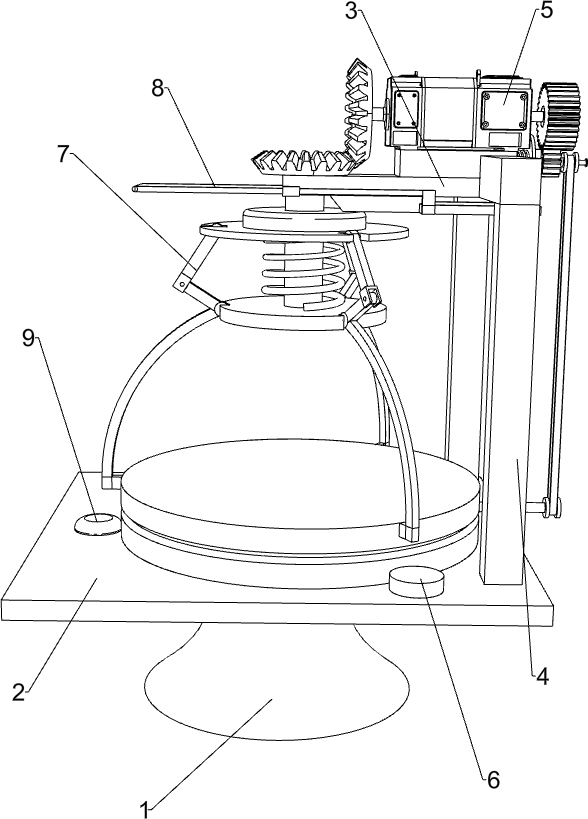

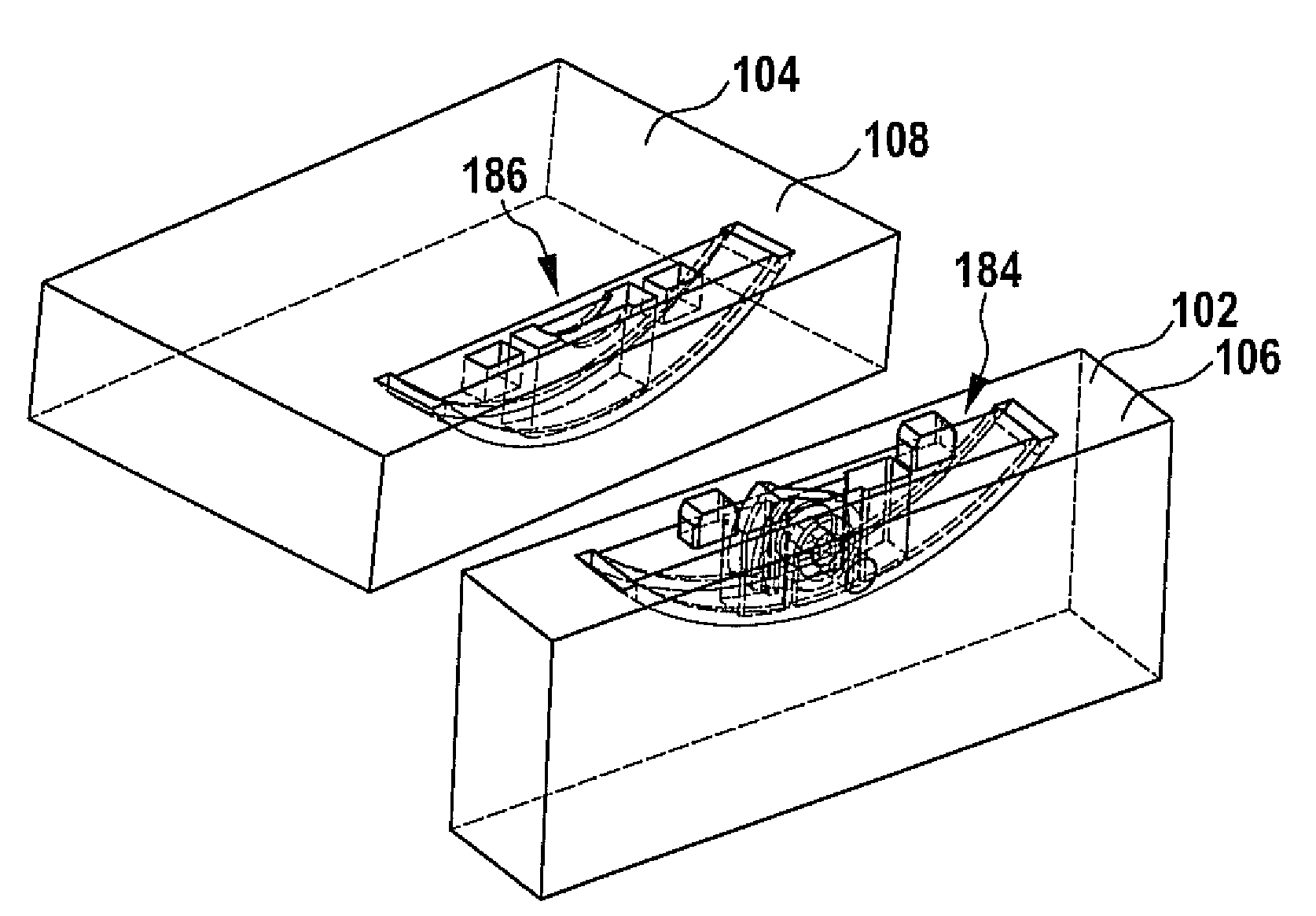

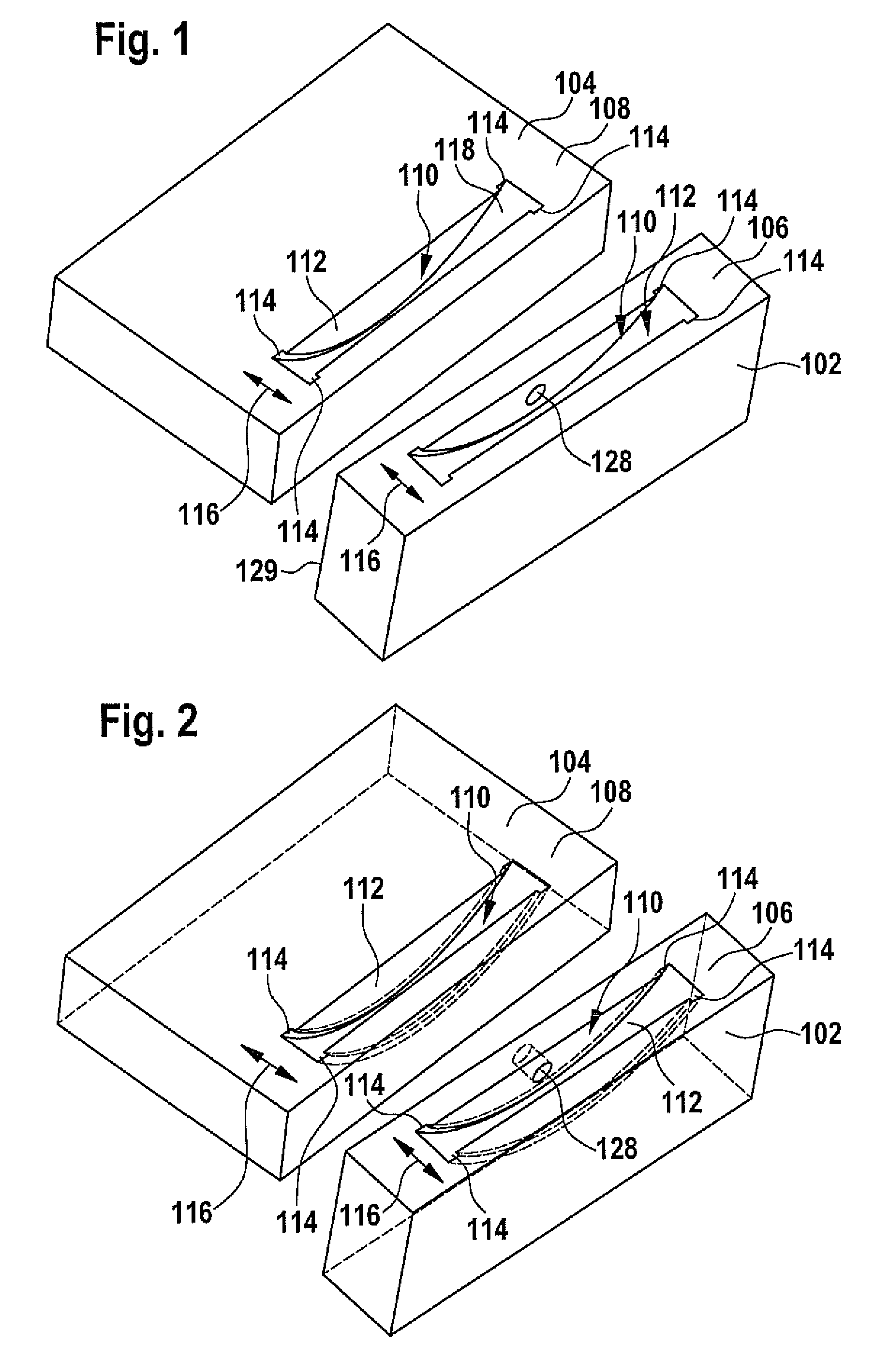

Wooden spring and mattress manufactured with wooden springs

Described are wooden coil springs, including those made of non-compressed wood, and mattresses with such coil springs. Also described is a method of producing a coil spring made of non-compressed wood, which includes winding a slat on reel, steaming and drying to produce the wooden coil spring. Such a coil spring may have a cylindrical shape, a cone shape or a truncated cone shape, and may have a substantially perpendicular end turn with respect to the longitudinal axis of the coil spring.

Owner:VOROS GABOR

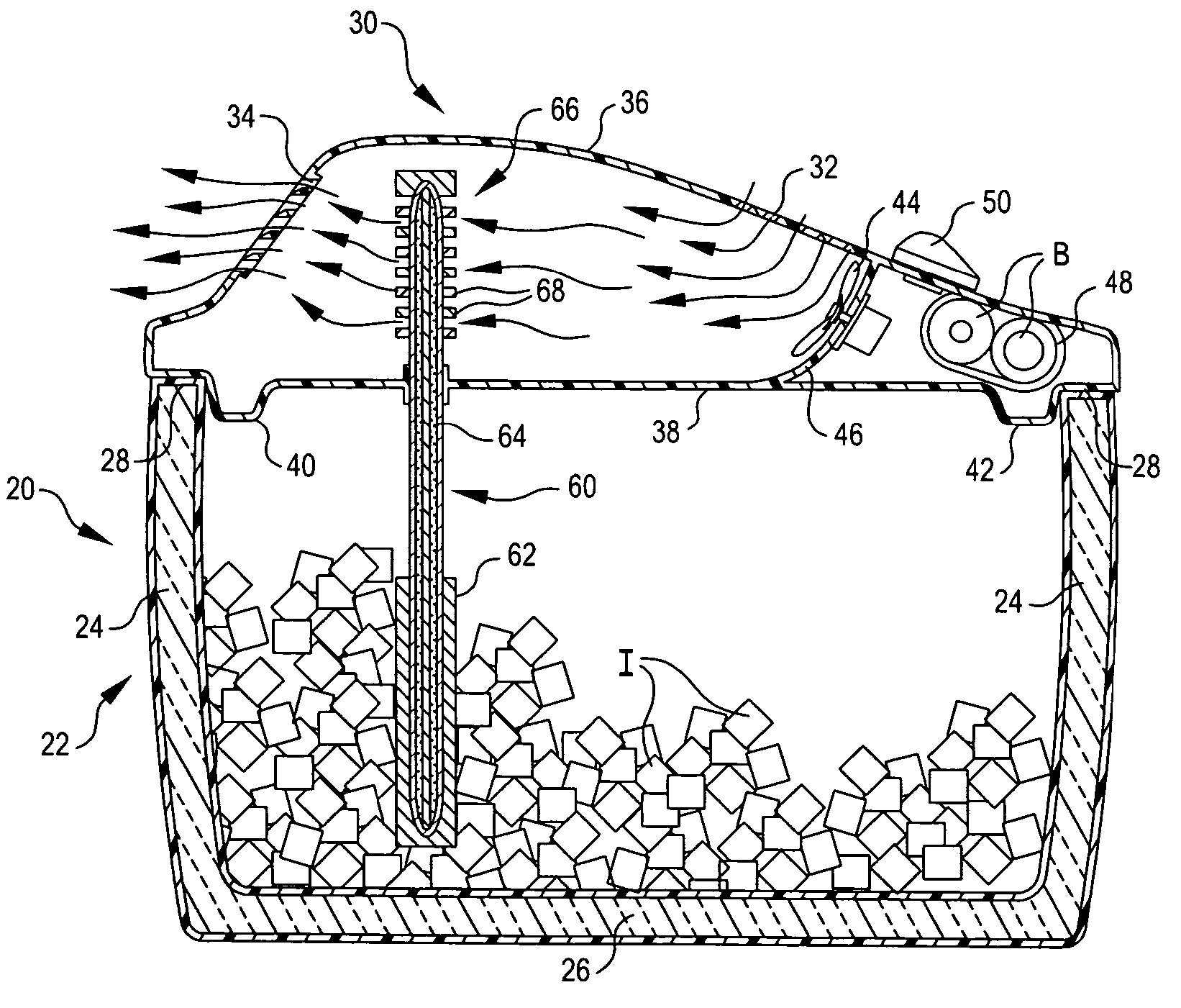

Personal air conditioning system

InactiveUS20050150251A1Domestic cooling apparatusMachines using electric/magnetic effectsEngineeringAir conditioning

A personal air conditioning system that may be used, for example, to cool a tent. The personal air conditioning system includes a cooling lid that fits over a typical insulated cooler. The cooling lid includes a heat transfer tower that is configured to transfer heat from a cold medium, such as ice, that is located within the cooler to an area within the cooling lid. A heat sink is provided at the top of the heat transfer tower and at least partially within the cooling lid. A fan is configured to draw air into the cooling lid, across the heat sink, and out of the cooling lid. The cooled air may then be used for cooling of a tent or other compartment, for example, or may be directed to blow on an individual.

Owner:THE COLEMAN CO INC

Combined process for manufacturing door

InactiveCN101797763AReduce areaReduce consumptionWood mortising machinesFlat articlesConnection formOil paint

The invention relates to the technical field of wood doors and metal (plastic) doors outside which wooden materials are wrapped, in particular to a combined process for manufacturing a door, which is characterized by comprising the following process steps: a, a door frame manufacturing process; b, a surface board or door core manufacturing process; c, an edge strip manufacturing process; and d, a door assembling process. Compared with the prior art, the invention has the key of changing the production process of a surface material, firstly, the surface material and an economically suitable lining material (thickness is determined by design) are compounded (hot pressing) in advance, and then cutting and machining (plain end, rabbet, V-shaped and other plug connection forms) are carried out to obtain designed width or length dimensions and painting is carried out. The whole production process has high degree of mechanization, high production efficiency, esthetic exterior appearance, little manual work and reduction of dependence on people. The production factory area is reduced and the consumption of oil paint (process waste part) is reduced. The concave and convex phenomena of finished product appearances of the existing wood doors can be avoided.

Owner:张建岩

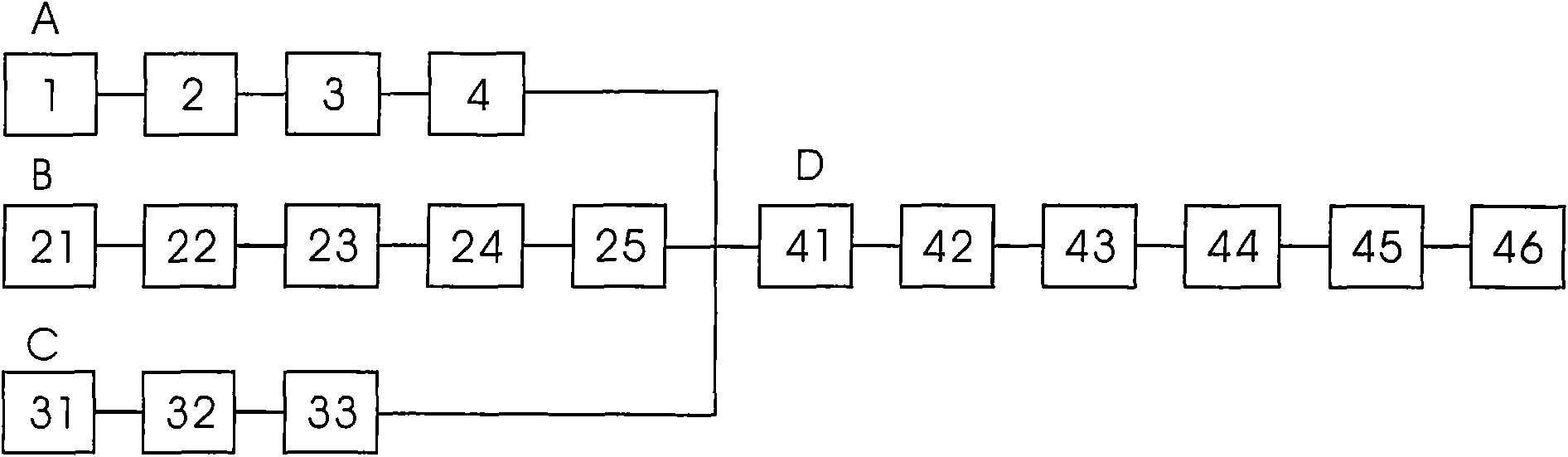

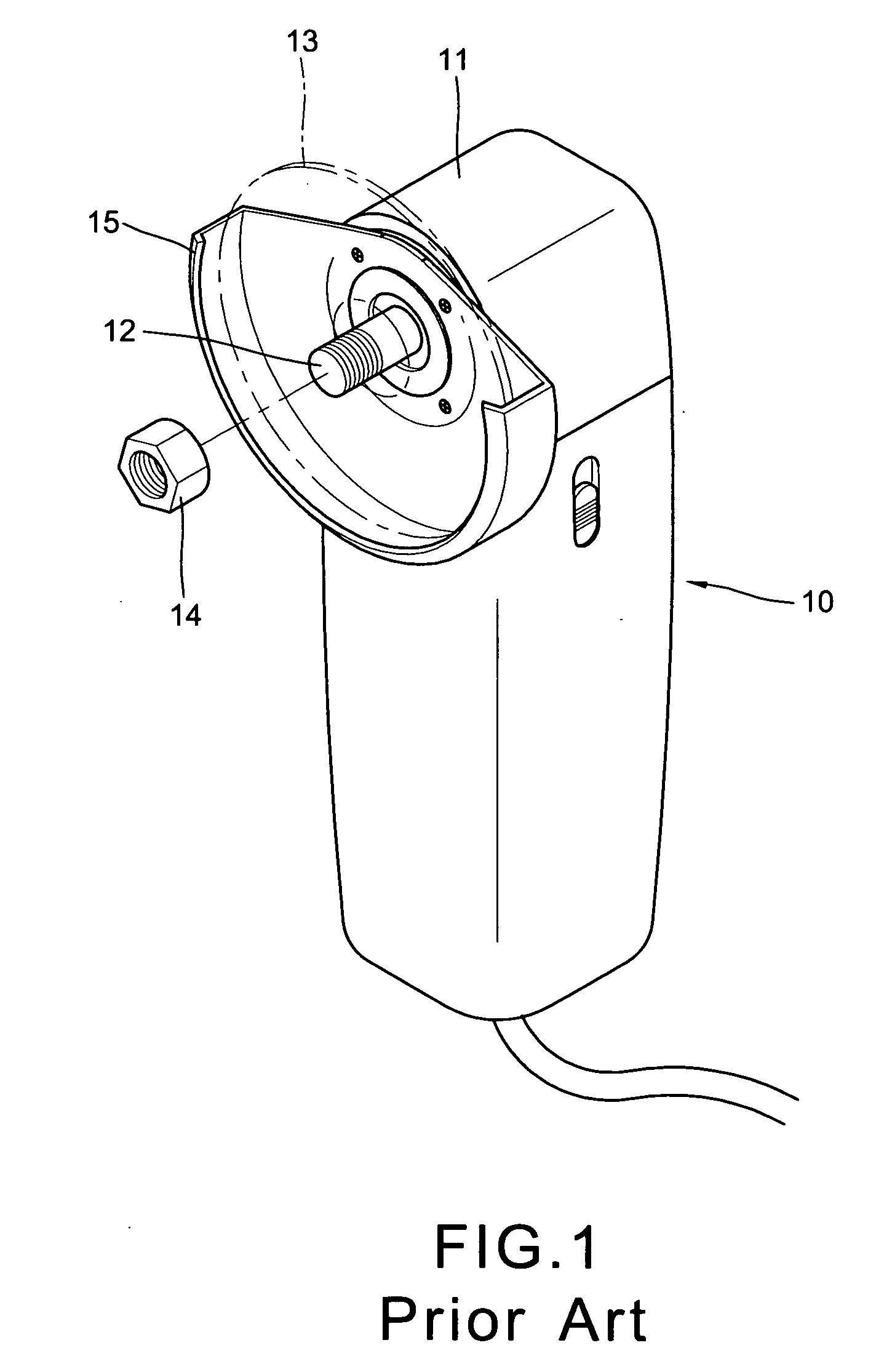

Tool for enlarging hole

A tool for enlarging the size of an existing bore to a selected enlarged size. The tool has a drill sized to define the enlarged bore, and a guide having a cylindrical body sized so that the guide can be rotated in the existing bore. The guide and drill including cooperating structures for releasably interconnecting the guide and the drill with the guide and drill coaxially aligned whereby, with the guide releasable secured to the drill, the guide can be located within the original hole to guide the cutting action of the drill as it enlarges the original hole.

Owner:NEWFREY

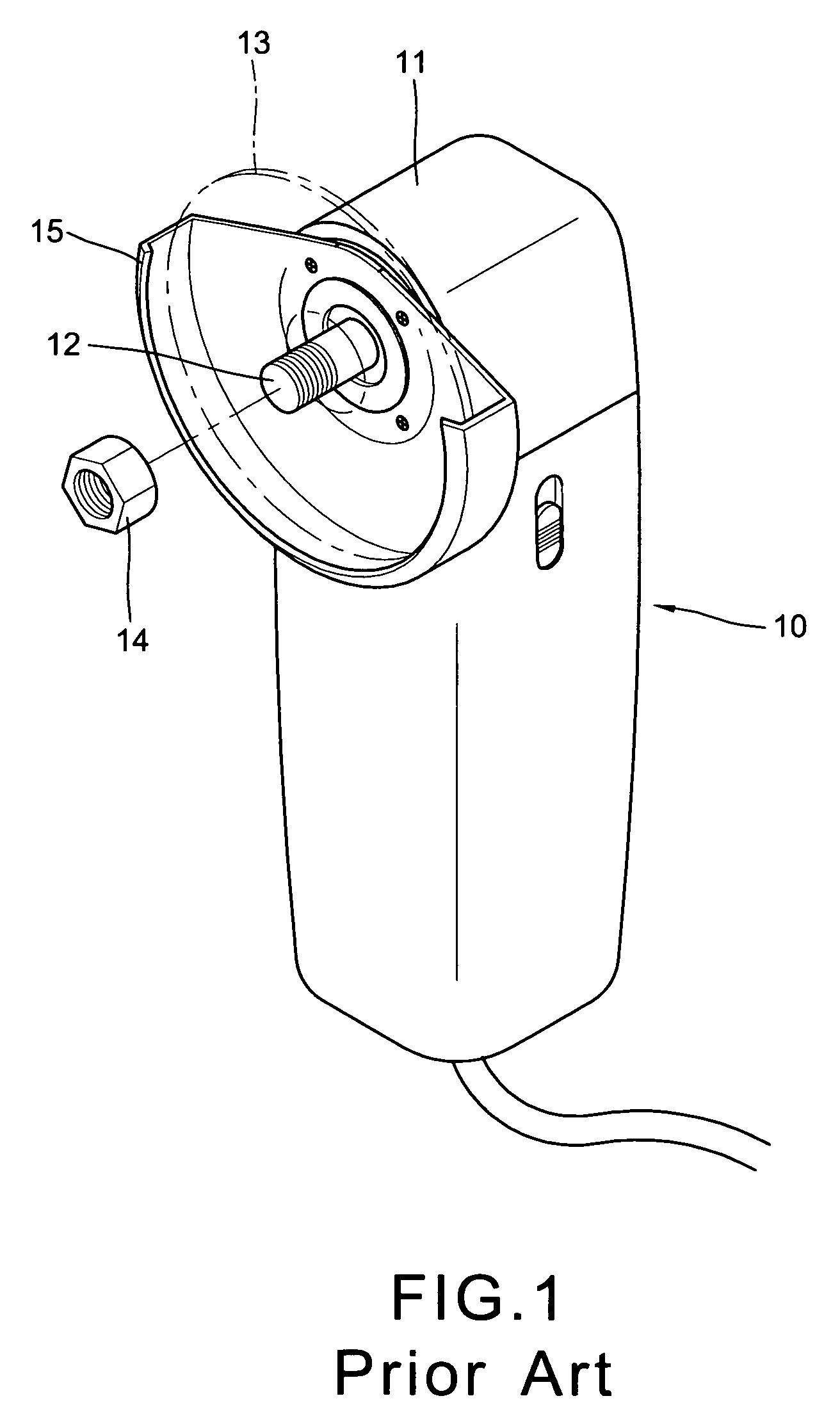

Hand-operated circular saw having blade cutting depth adjustment device

InactiveUS20050155233A1Easy to operateEasy and convenient and preciseMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

Owner:CHEN YUEHTING

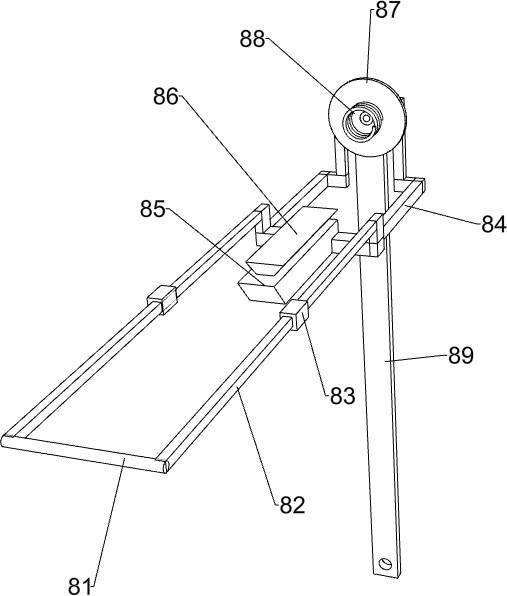

Arc-shaped-groove machining device for wood packages

InactiveCN107379149AQuick slotSlot implementationWood mortising machinesWood slotting machinesMilling cutterEngineering

The invention relates to an arc-shaped-groove machining device for wood packages and belongs to the field of wood package machining. The arc-shaped-groove machining device comprises a frame and is characterized in that an angle adjusting device is connected to the frame, a tool mounting rack is connected to the angle adjusting device, a tool mounting plate is arranged on the tool mounting rack, a plurality of milling tools are mounted on the tool mounting plate, a drive motor for driving the tool mounting plate to rotate is fixedly connected to the tool mounting rack, the angle adjusting device comprises an L-shaped support rod, a rotary shaft is connected to the L-shaped support rod in a communicated manner, the rotary shaft is connected to the frame, and the tool mounting plate is fixedly connected to one end of the L-shaped support rod. The arc-shaped-groove machining device has the advantages that fast grooving of the wood packages of different materials and sizes can be achieved, grooving efficiency can be increased, high grooving efficiency is achieved, angles can be adjusted according to the fixing positions of the wood packages, grooving of the wood packages with inclined surfaces can be achieved, and the device is widely applicable.

Owner:苏州卫刚木包装制品有限公司

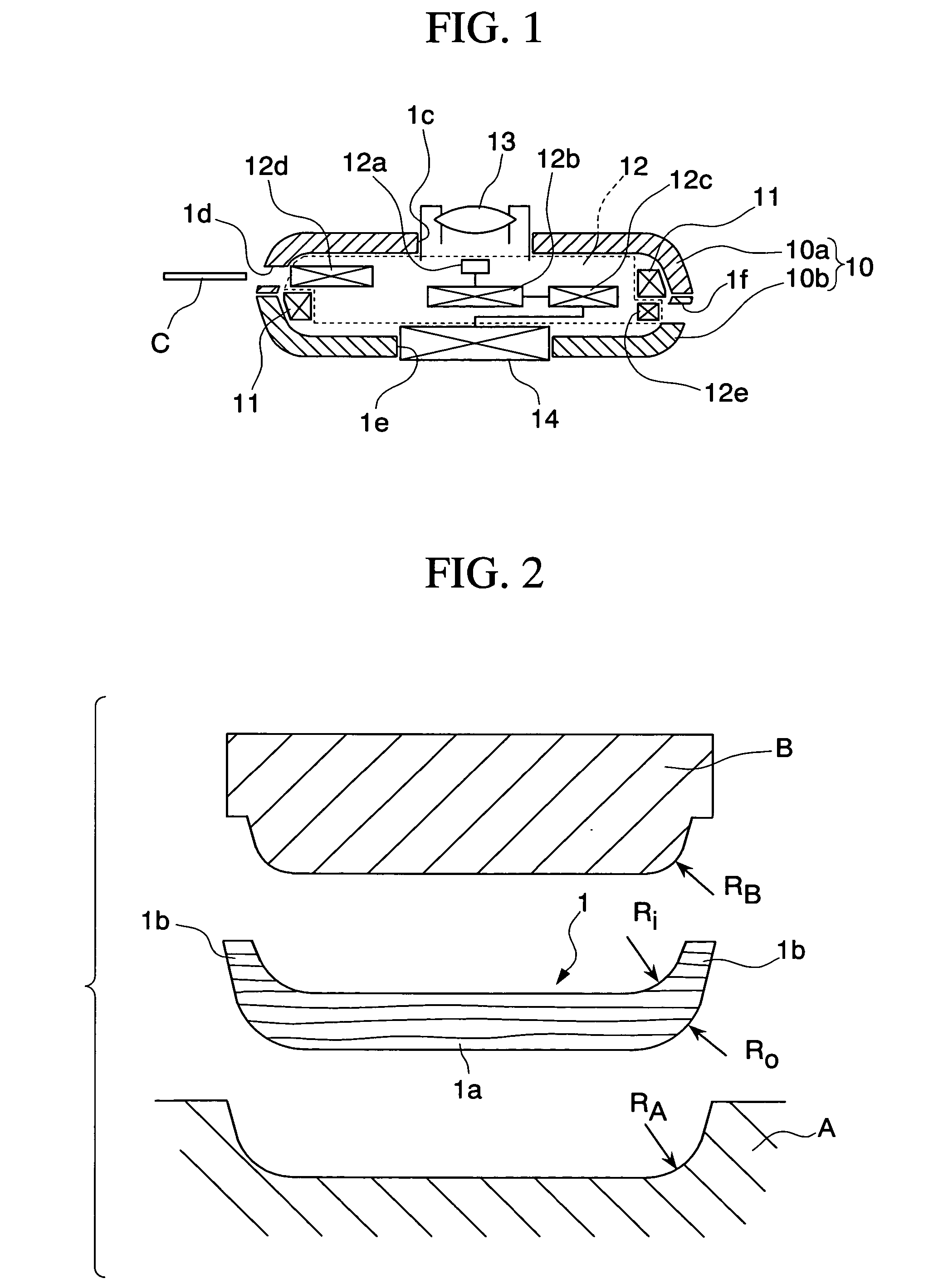

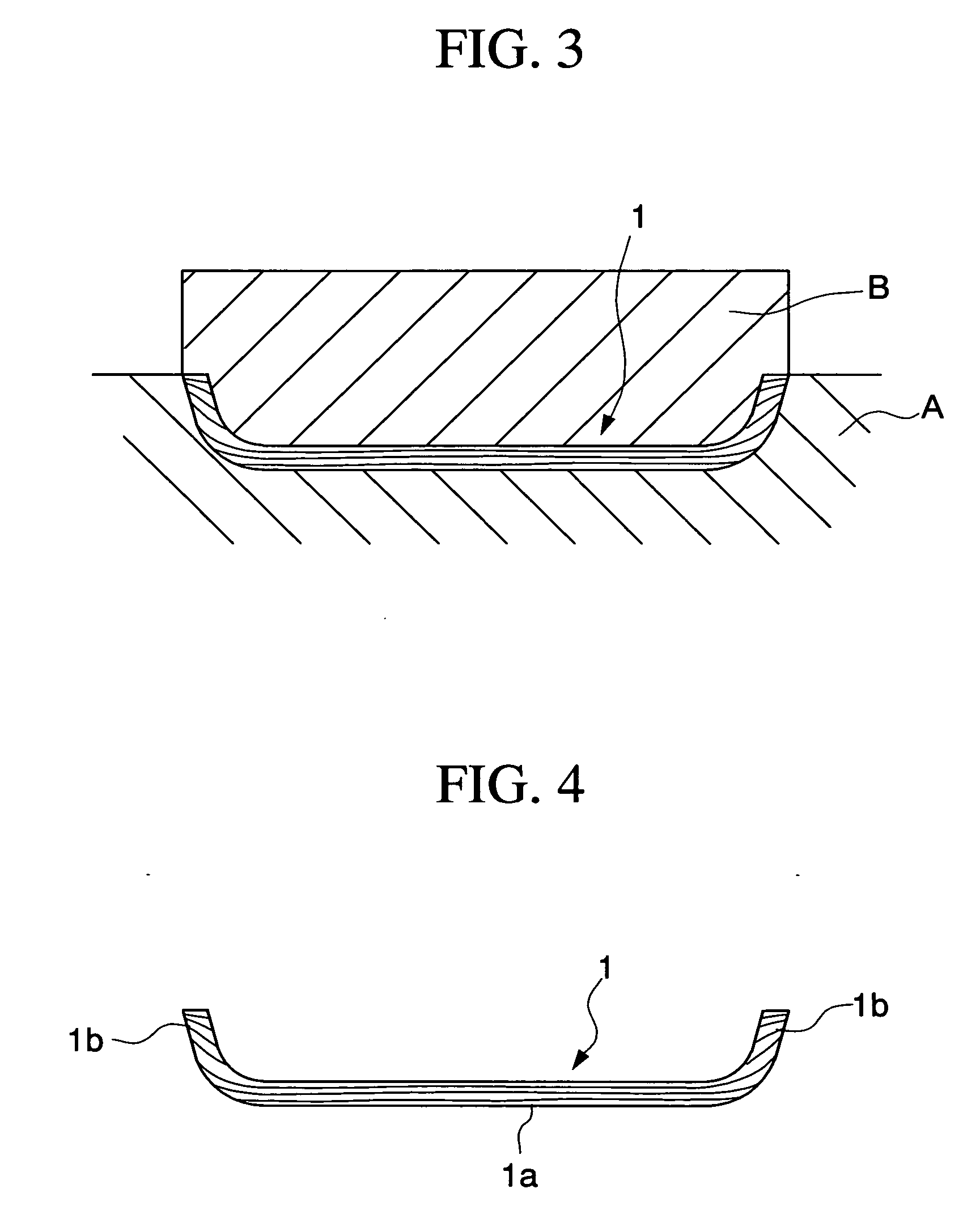

Electronic device

Owner:OLYMPUS CORP

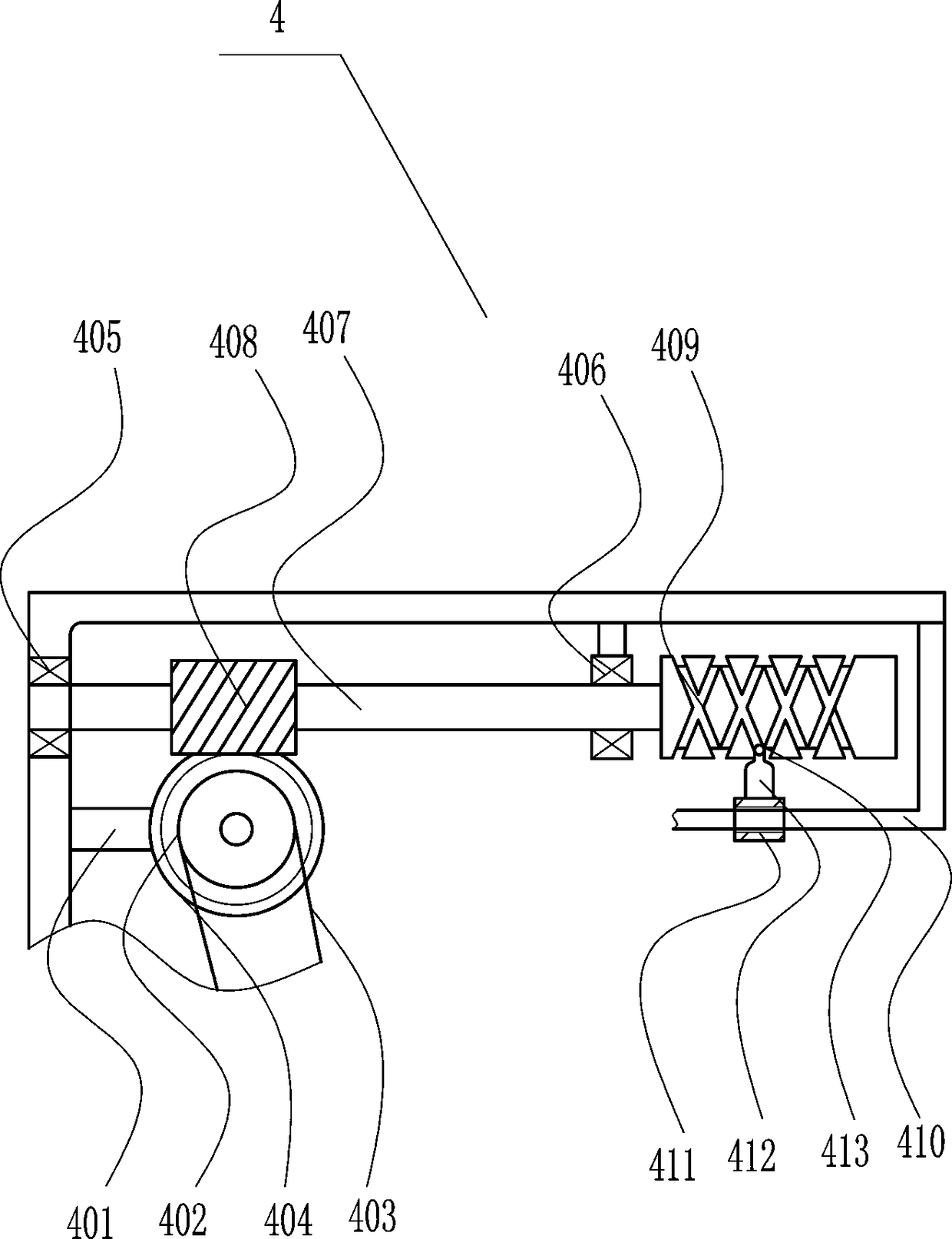

Wood slotting device capable of achieving automatic discharge

ActiveCN108162101APlay the role of cuttingReach the function of feeding switchStationary drilling machinesWood mortising machinesEngineeringCam

The invention relates to a slotting device, particularly to a wood slotting device capable of achieving automatic discharge, and provides the wood slotting device capable of achieving automatic discharge, which utilizes machinery to replace manual work. The wood slotting device capable of achieving automatic discharge provided to solve the technical problem comprises a rack, a driving device, a conveying device, a cam device, a discharge device, and the like, wherein the driving device is arranged on the rack; the conveying device is arranged on the right side of the driving device; the cam device is arranged above the driving device; the discharge device is arranged below the cam device; a slotting device is arranged below the cam device; and a switch device is arranged below the right side of the discharge device. According to the wood slotting device, an automatic slotting function is achieved, an automatic conveying function is achieved, and the wood slotting device has the characteristics that the slotting speed is high, operation is convenient, manufacturing is simple, manufacturing cost is low, popularization is facilitated, and the like.

Owner:成都千川门窗有限公司

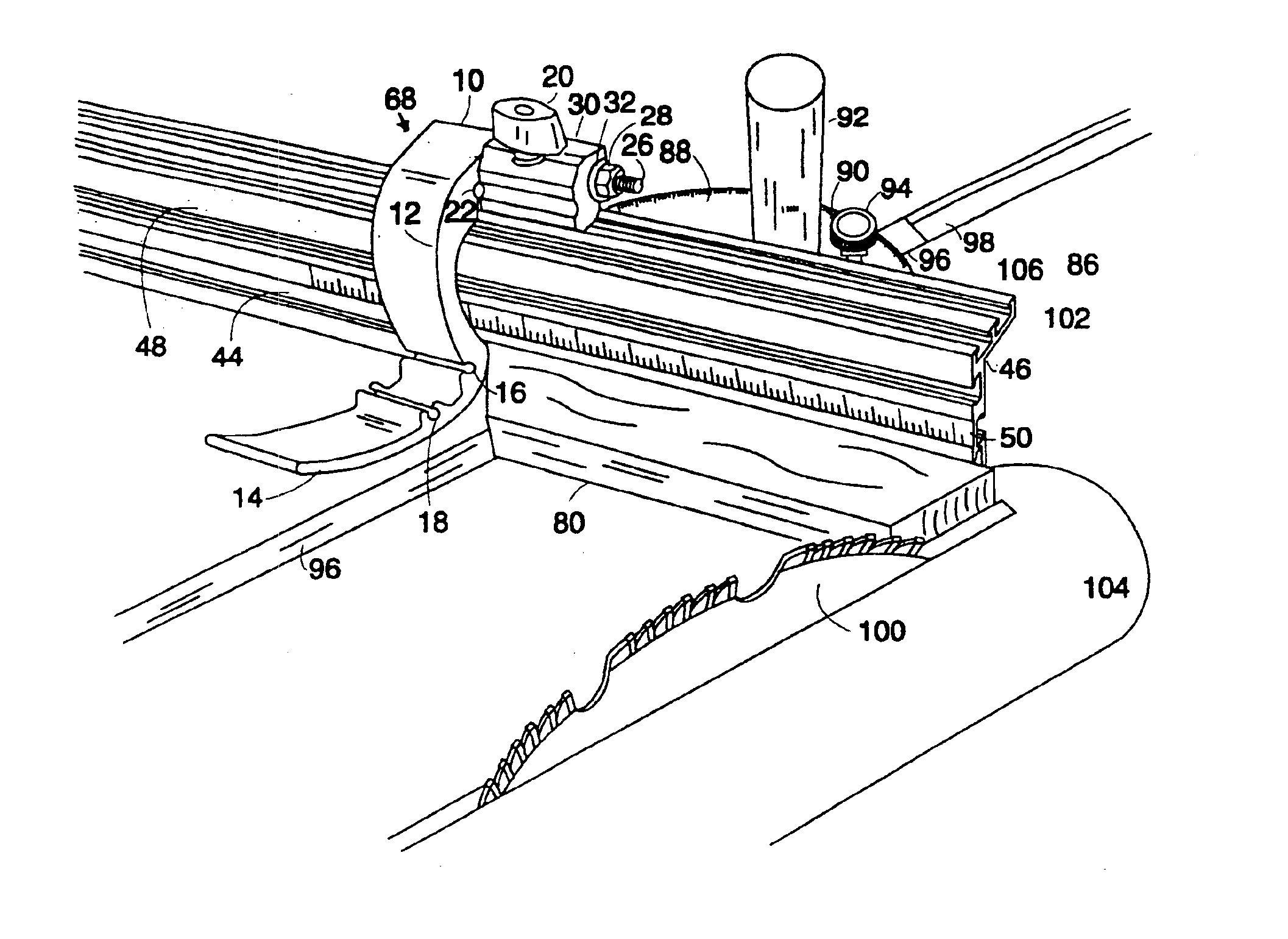

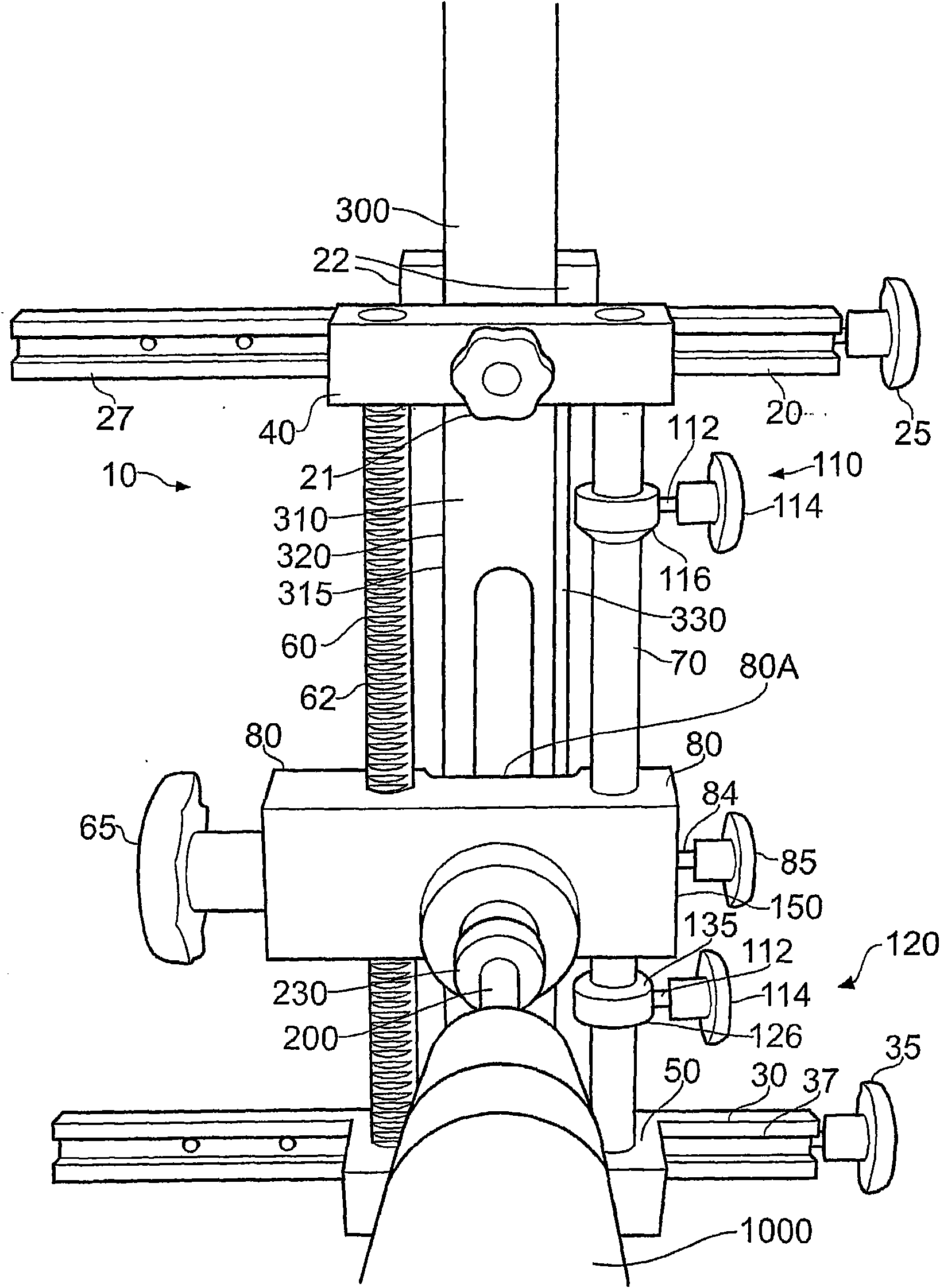

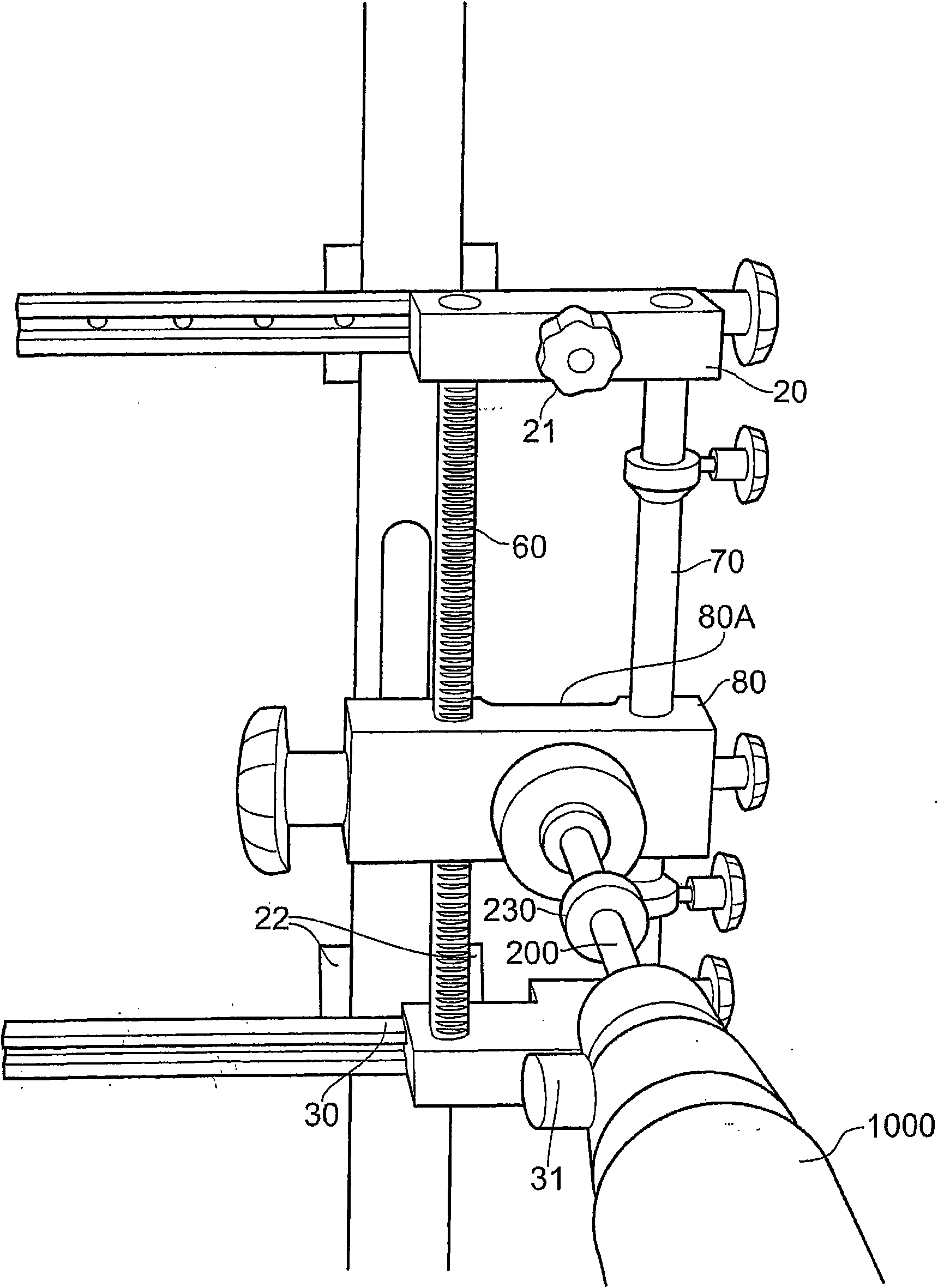

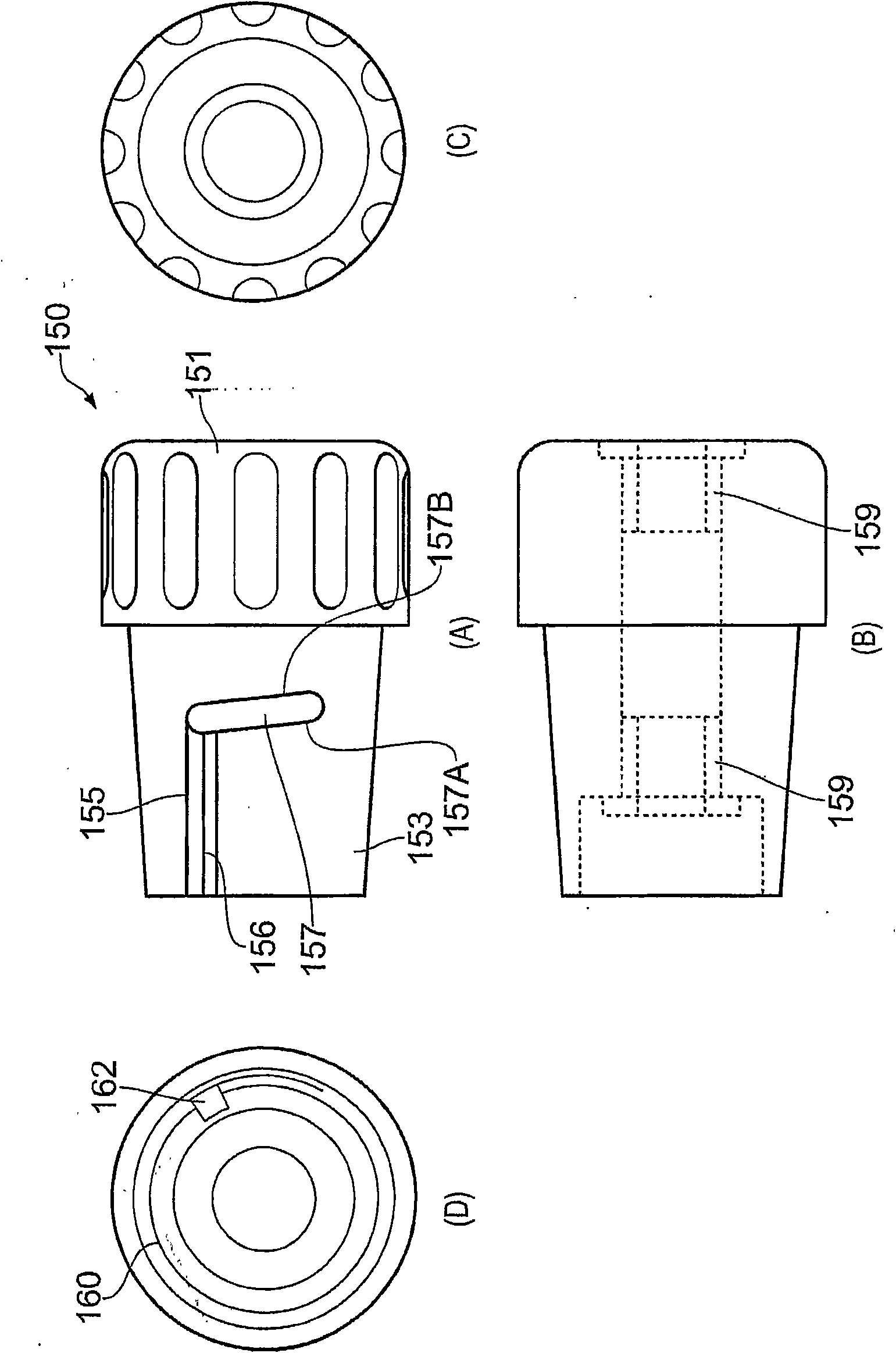

Cutting apparatus and method

InactiveCN101610880AEfficient cuttingDrilling/boring measurement devicesRotary cutting toolsLeading edgeEngineering

An apparatus for use in cutting a mortice pocket in a leading edge of a door in-situ, the apparatus comprising: at least one elongate guide means (60, 70); clamping means (22) for clamping the elongate guide means to a door (300) or other workpiece; a drill guide means mounted on the elongate guide means; and translating means (20, 30); wherein the drill guide means comprises a bearing block (150) and a saddle member(80), the saddle member(80) having a bearing block aperture (160) formed therethrough arranged to releasably receive the bearing block therein, the bearing block (150) having a hole therethrough adapted snugly to receive a drill shaft (200) such that the drill shaft is supported, directly or indirectly, by the bearings of the bearing block and is rotatable therein, and wherein at least one of the bearing block aperture (160) and the bearing block (150) is tapered.

Owner:W S NORMAN ENG IOM

Cutting board slotting equipment

InactiveCN111605005ATo achieve the effect of slottingSave human effortStationary drilling machinesWood mortising machinesWorkbenchIndustrial engineering

The invention relates to slotting equipment, in particular to cutting board slotting equipment, and aims at solving the technical problem about how to design cutting board slotting equipment simple inoperation and capable of improving work efficiency and saving manpower. The cutting board slotting equipment is provided and comprises a landing leg with the top connected with a workbench, a supportconnected to one side of the top of the workbench, and a slotting assembly, wherein the top of the support is connected with a transverse plate, and the slotting assembly is arranged between the transverse plate and the support. The slotting assembly is used for slotting a cutting board, and accordingly the effect of cutting board slotting is achieved. The slotting assembly is assisted in runningand rotating the cutting board through cooperation of a clamping assembly and a downward pressing assembly, manual cutting board rotation is not needed, and manpower is effectively saved.

Owner:南京科信磁业有限公司

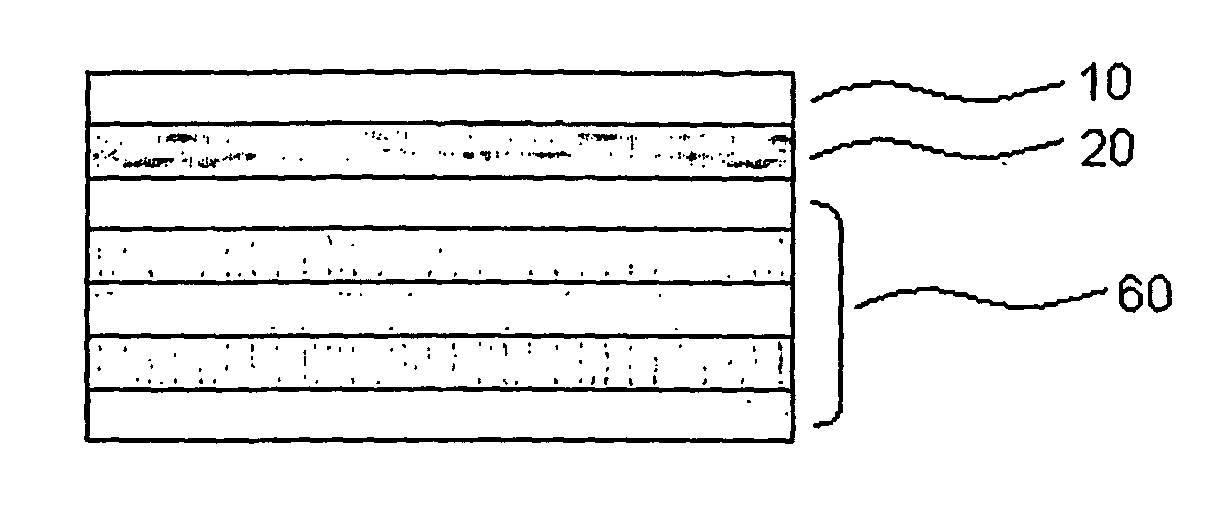

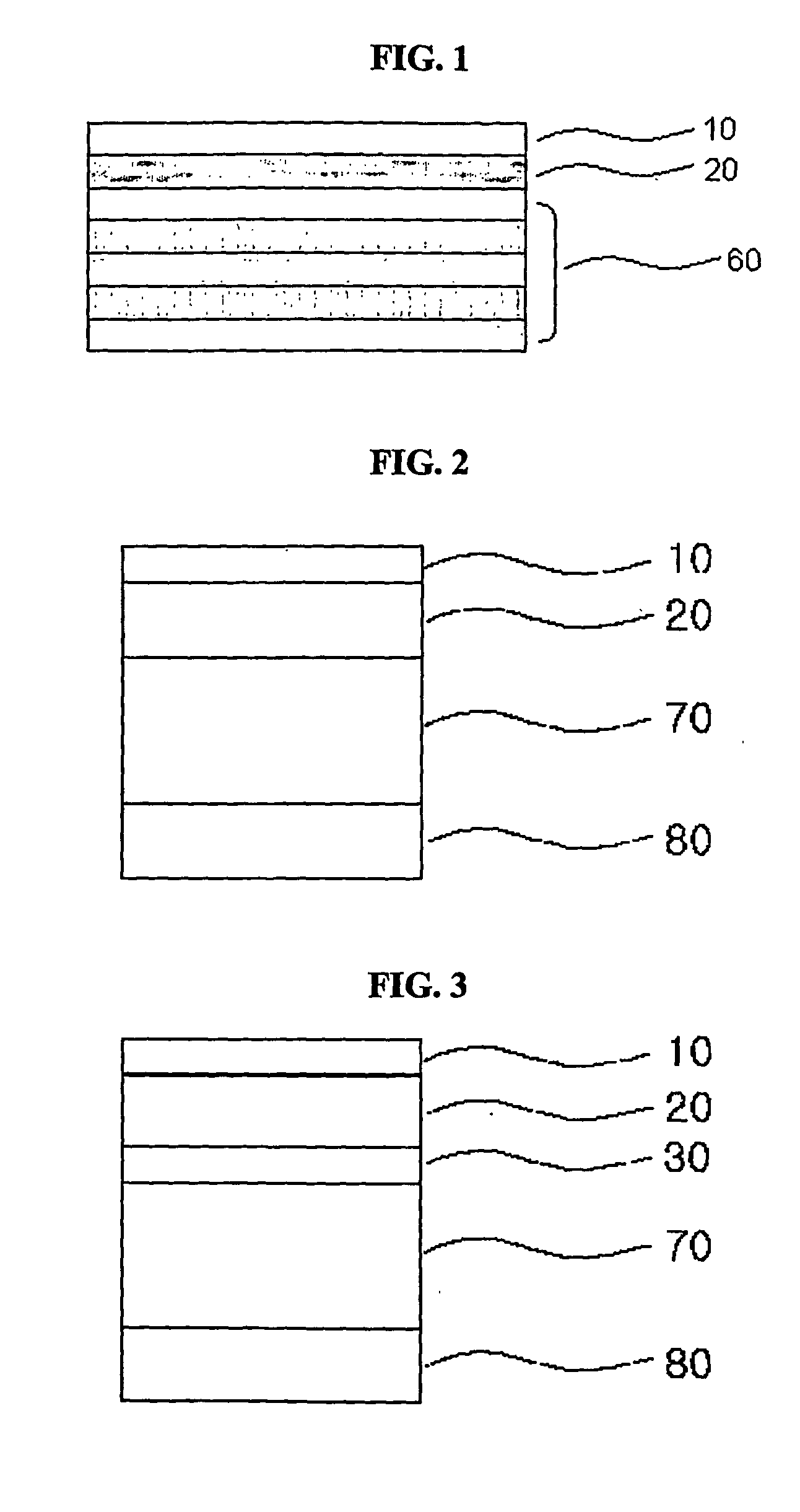

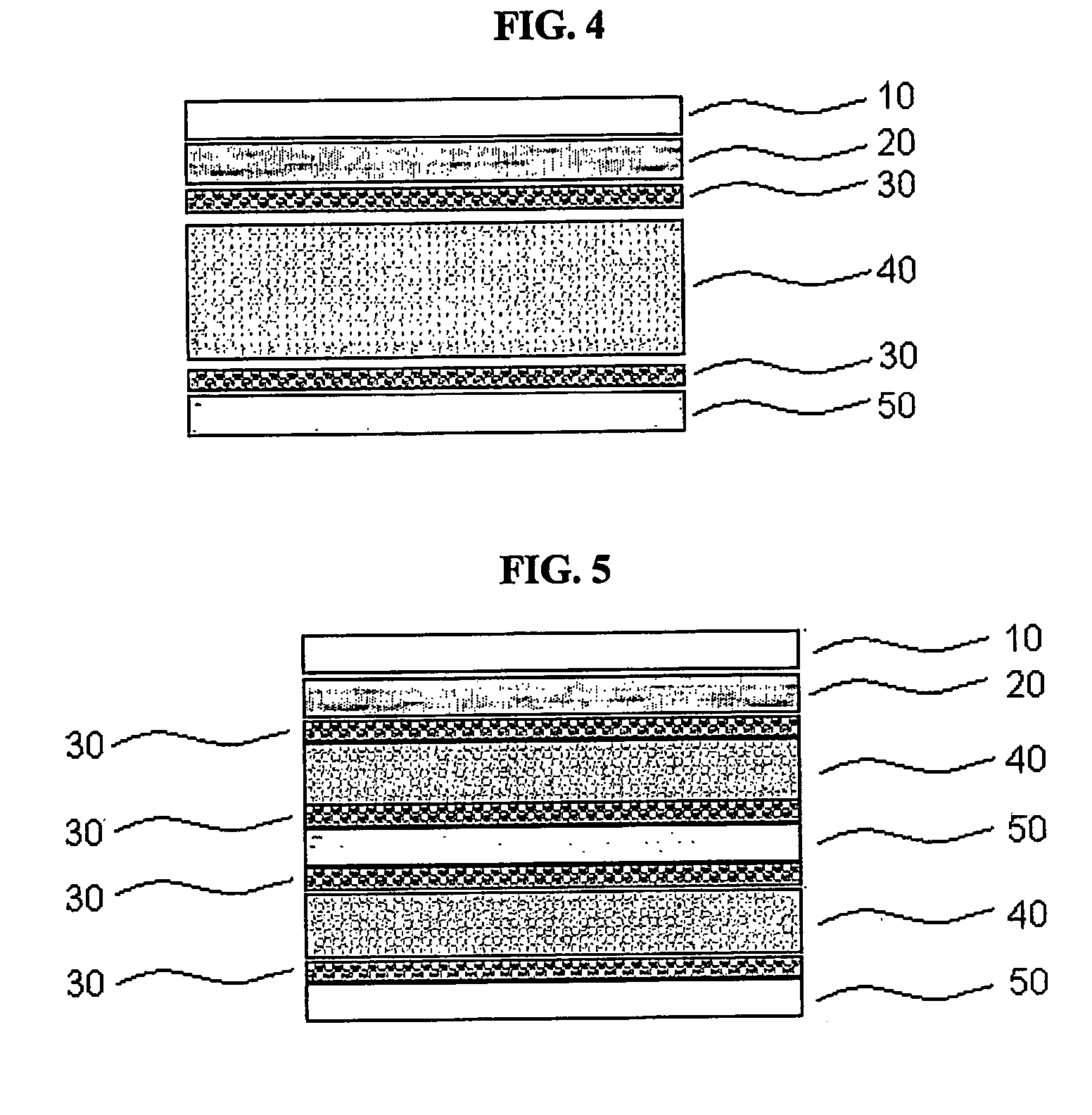

Wood flooring with laminated wood and plastic layers using symmetric structure and method of manufacturing the same

InactiveUS20050227104A1Deformation MinimizationGood dimensional stabilityStapling toolsDovetailed workEngineeringSymmetric structure

It is provided a wood flooring laminated wood and plastic layers symmetric to each other and method of manufacturing the same. The wood flooring has an upper layer including laminated wood, a core layer including plastic sheets manufactured by calendaring, and a lower layer including veneer board, the lower layer being made of the same material as the upper layer, which are piled up symmetrically in order to keep the balance between the upper layer and lower layer, and then integrated under a constant temperature and pressure to form a suitable layers made by wood and plastic, thereby providing natural feeling in surface and solving the problem of distortion according to the change of environment.

Owner:LG CHEM LTD

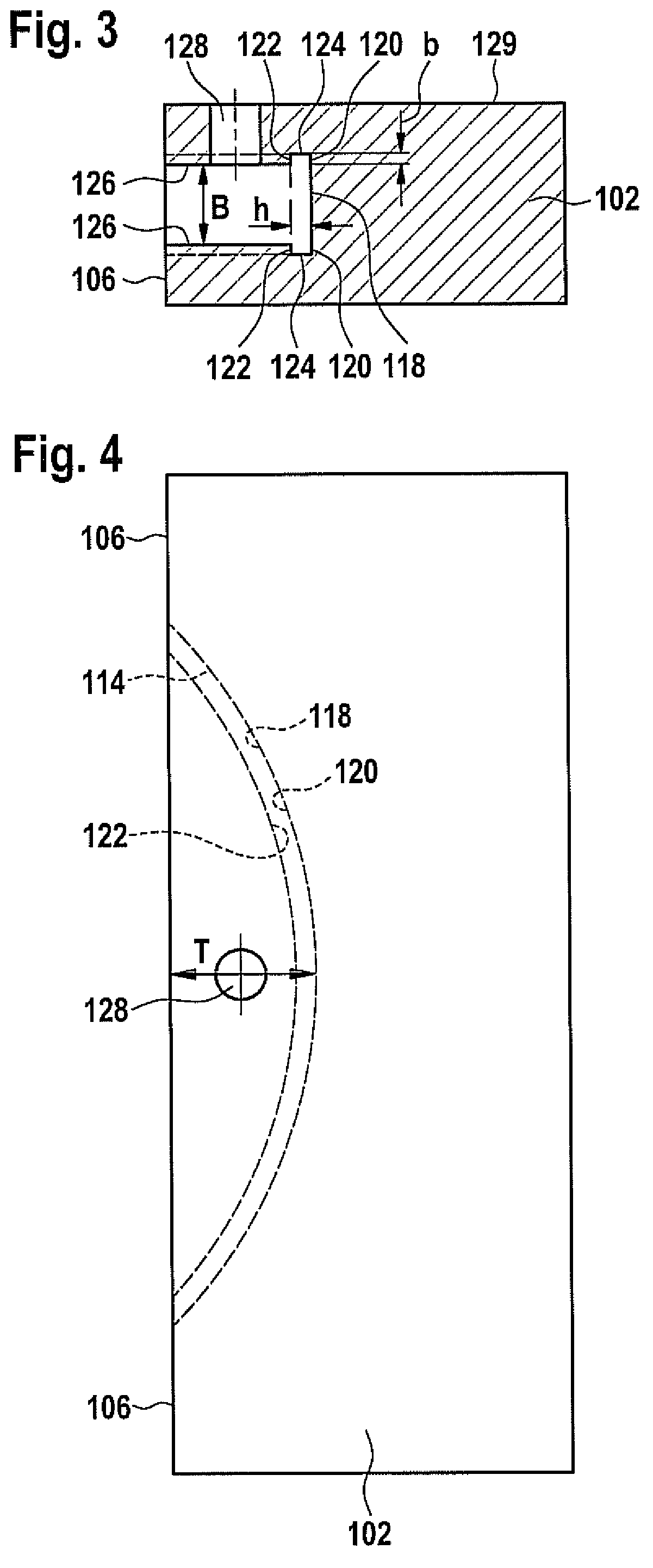

Connecting means and method of producing a connection between a first component and a second component

In order to produce a connecting means for connecting a first component and a second component and especially for connecting furniture parts or machine parts which will enable two components consisting of a multiplicity of materials to be securely connected to one another without giving rise to the danger of damaging the two components during the assembly process, wherein the device comprises a first connecting element that it arranged on the first component in the connected state of the components and a second connecting element that is arranged on the second component in the connected state of the components, it is proposed that at least one of the connecting elements should comprise a non self-cutting holding projection which has a curved support surface that is in the form of an arc of a circle in longitudinal section, wherein the holding projection can be inserted into a groove which is provided in one of the components and has a curved undercut surface that is in the form of an arc of a circle in longitudinal section.

Owner:BAUR FRANZ +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com