Method for Joining Workpieces Together and Product Made Thereby

a technology of workpieces and clamps, which is applied in the direction of manufacturing tools, furniture parts, flat surfacing machines, etc., can solve the problems of affecting the quality of finished joints,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

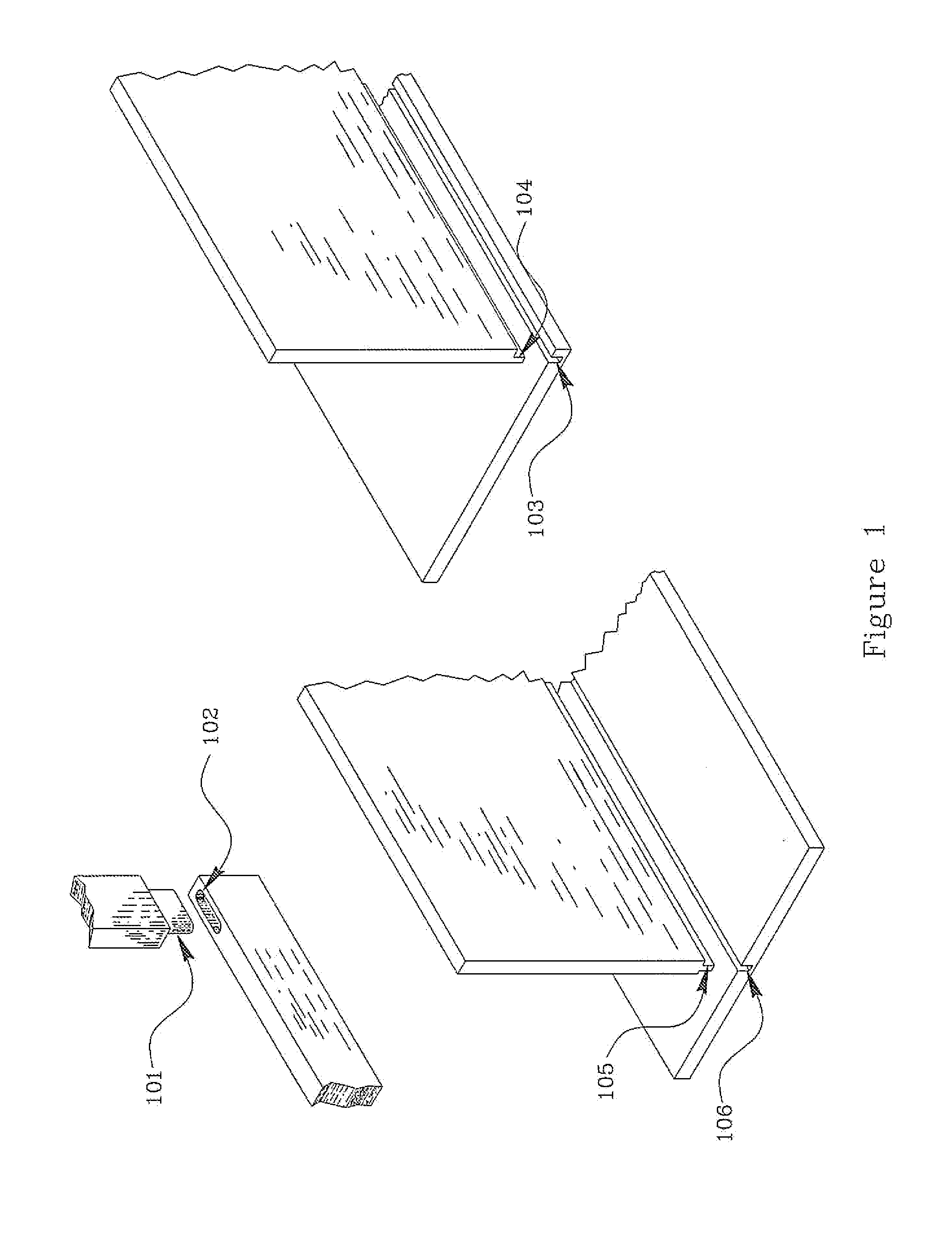

[0014]Generally, in the cabinet making trade, machining operations required for making mortise and tenon joints for joining panels together are performed on a CNC router. The various components comprising the main body of a kitchen cabinet, as an example, are generally machined on a flatbed CNC router, from full sized sheets of panel stock. The process also may be carried out using a handheld portable router, or by using ordinary cabinetmakers' hand tools, although the latter is considered more of an art than a craft.

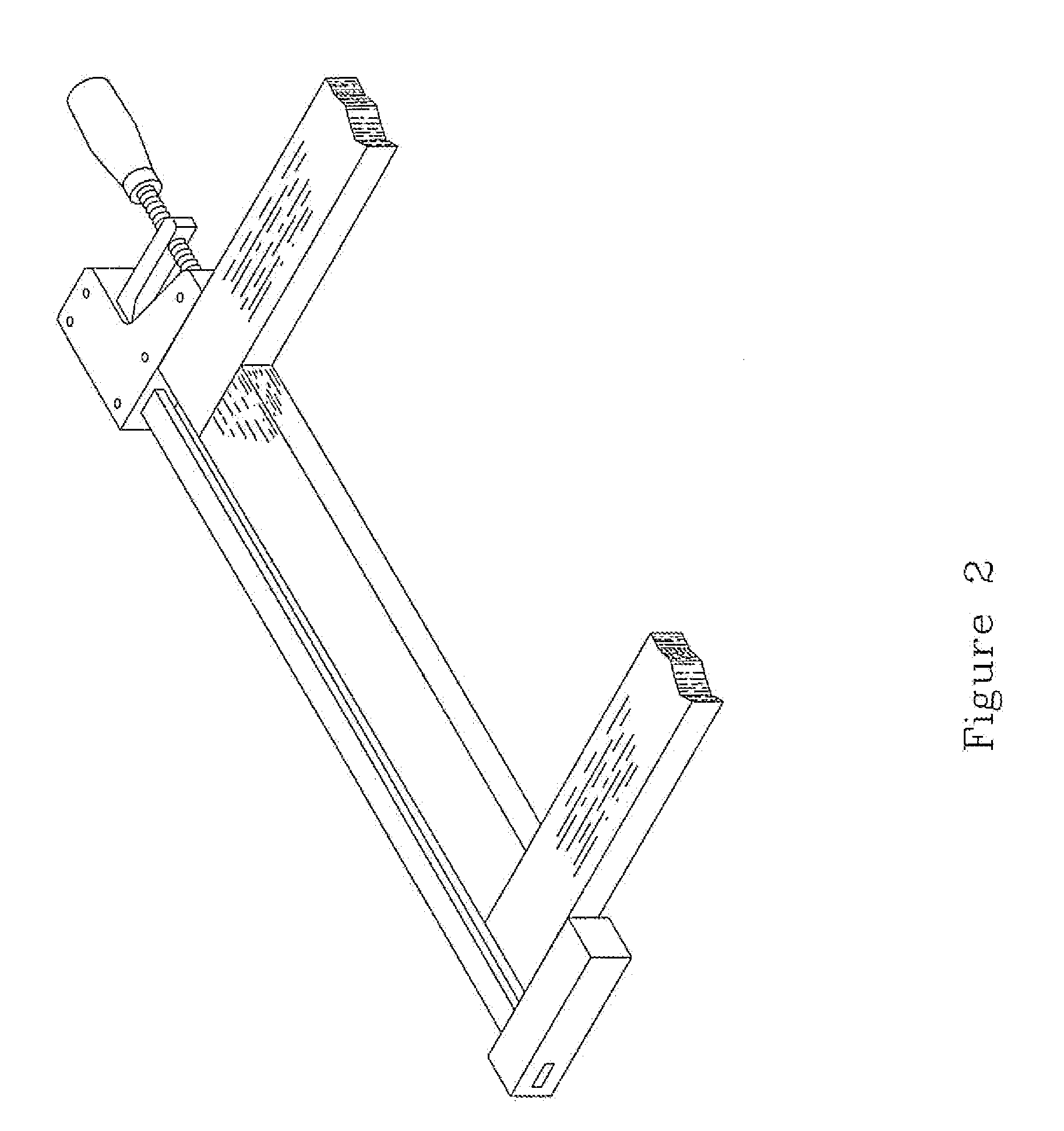

[0015]Referring to FIG. 3 of the drawings, in a typical manufacturing environment utilizing a CNC machine 301, components are manufactured by first loading a tool-path program into the machine control 302. Material in the form of full sized sheet stock is then placed upon worktable 302 of the CNC machine. The tool-path program through the computer component of the machine control 302 then guides the tool 304 through multiple program cut paths, producing components that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| axial length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com