Patents

Literature

2741results about "Multi-purpose machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

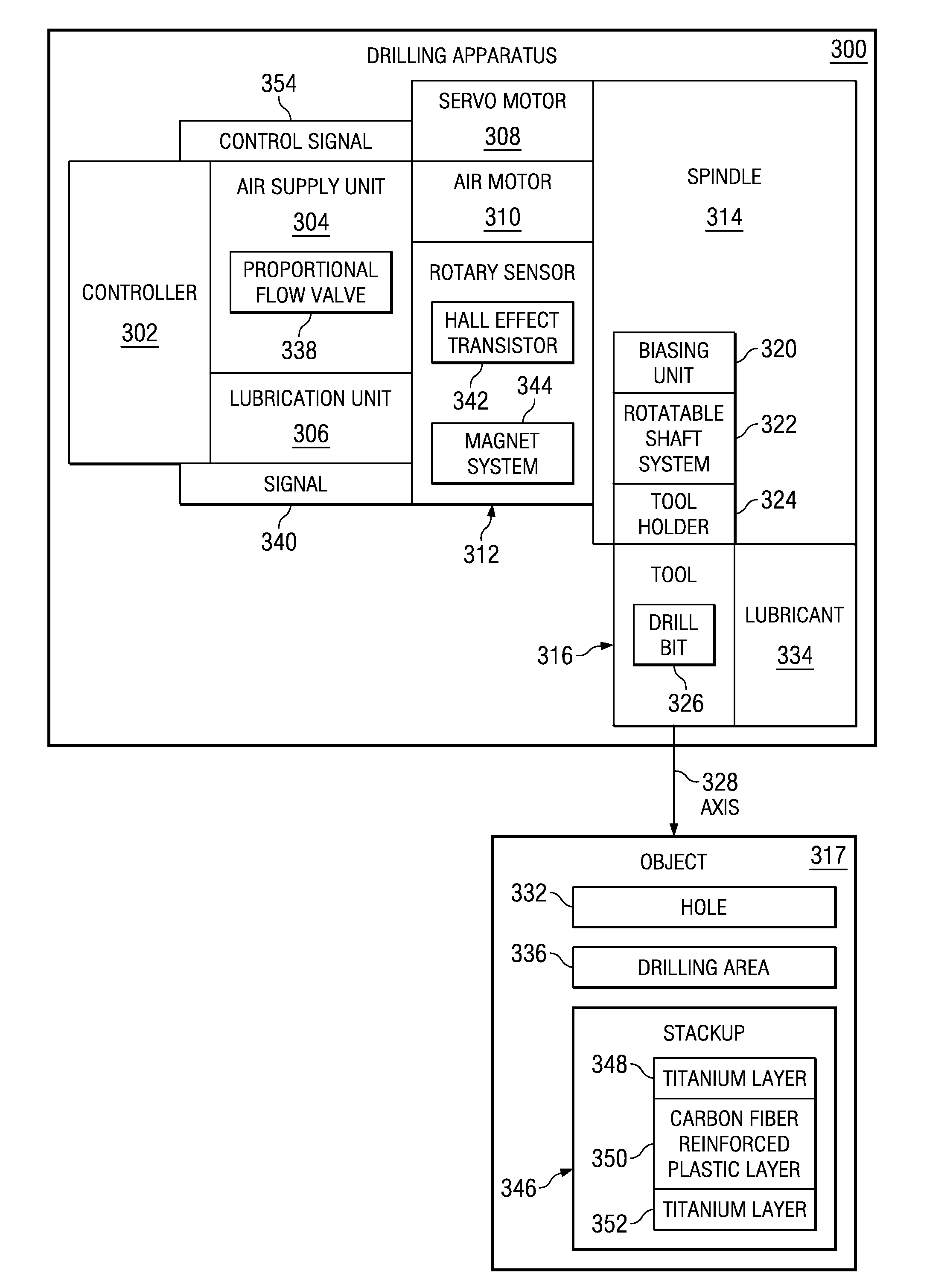

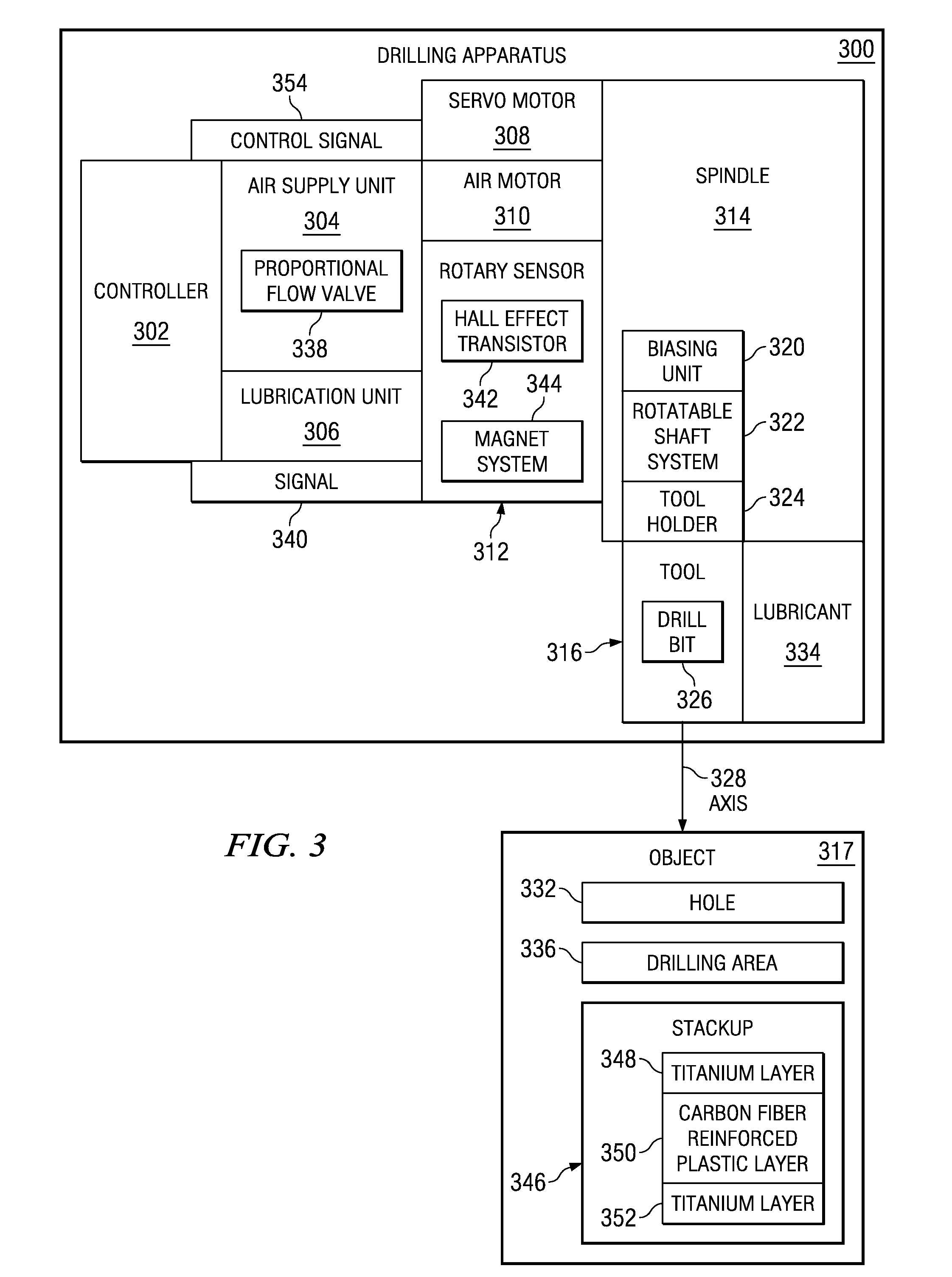

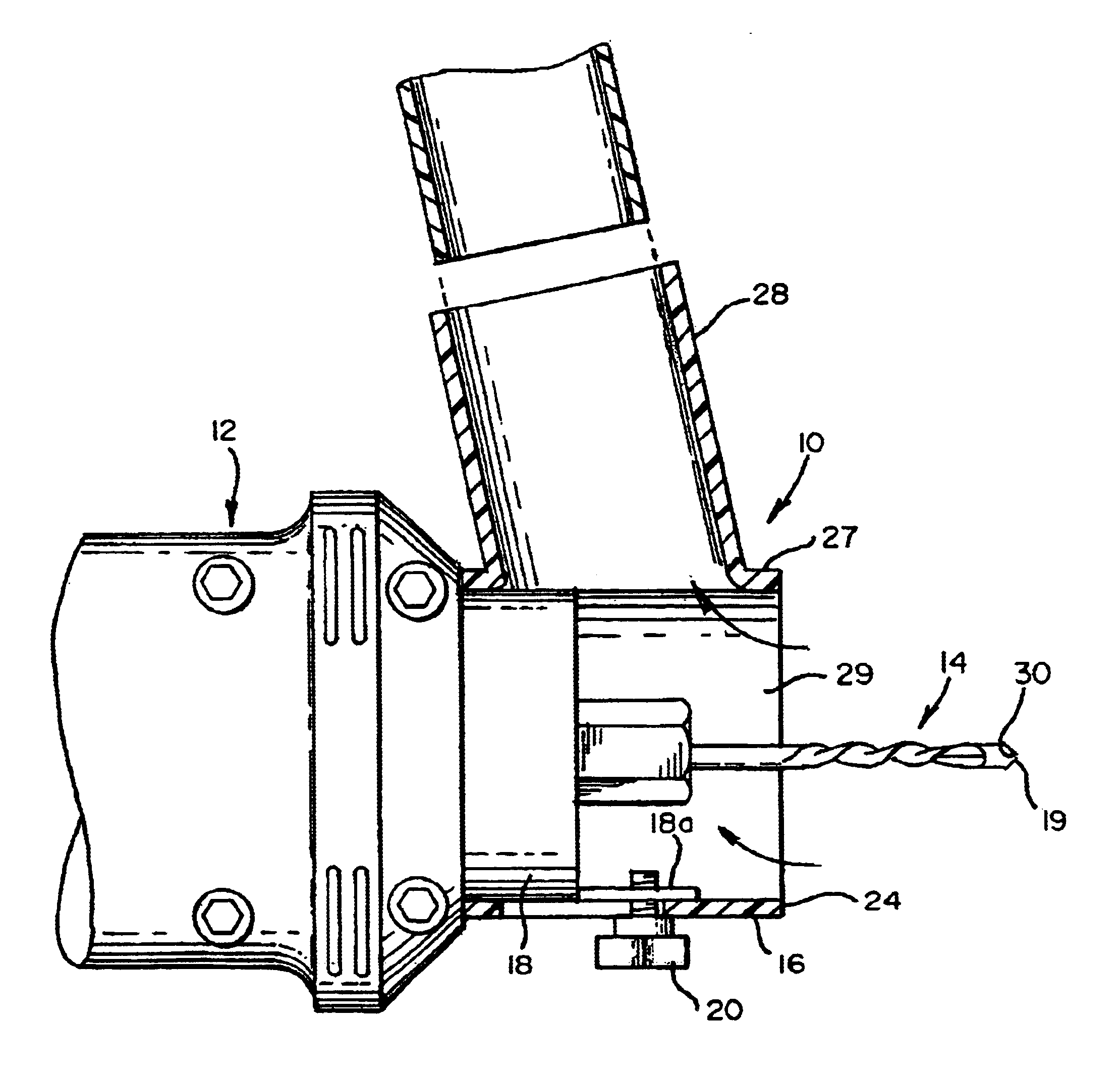

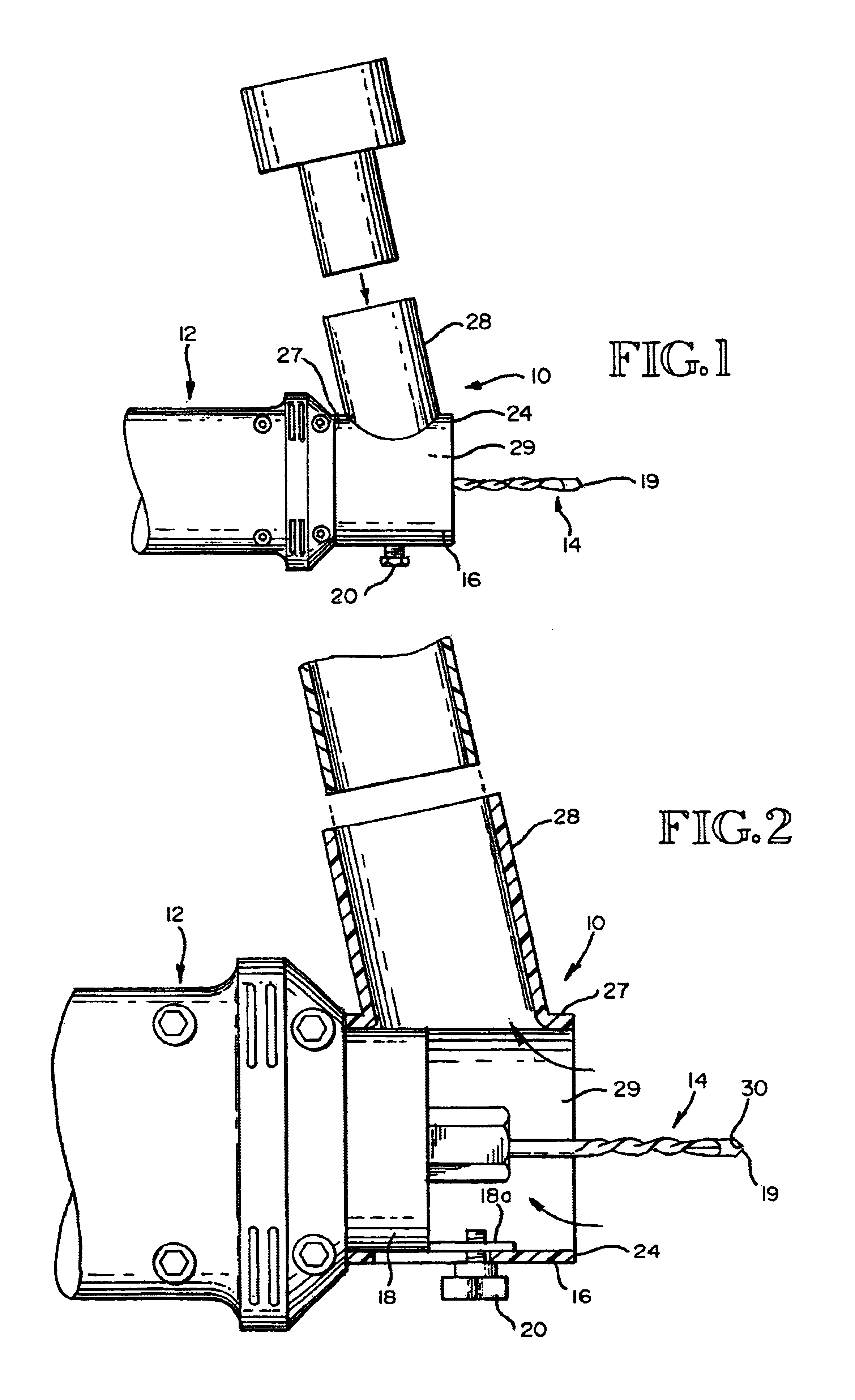

Adaptive positive feed drilling system

An apparatus for a drilling operation. In one advantageous embodiment, the drilling operation includes a motor, a rotary sensor, and a controller connected to the rotary sensor. The rotary sensor may be capable of generating a signal in response to rotary movement of the drill motor. The controller may be capable of monitoring a speed of the air motor from the signal generated by the rotary sensor and may be capable of identifying a change from a current layer in a stackup to a new layer in the stackup using the signal.

Owner:THE BOEING CO

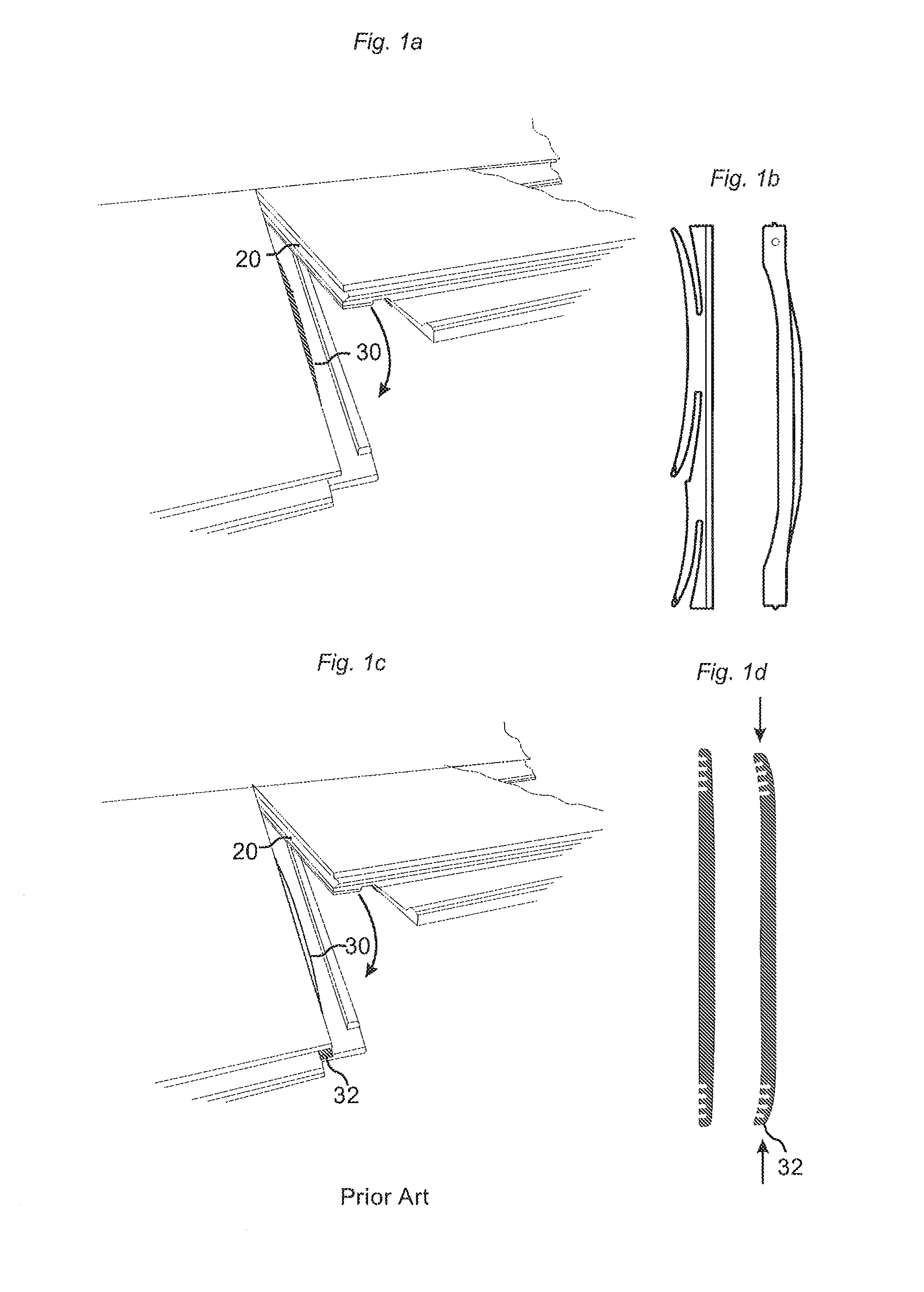

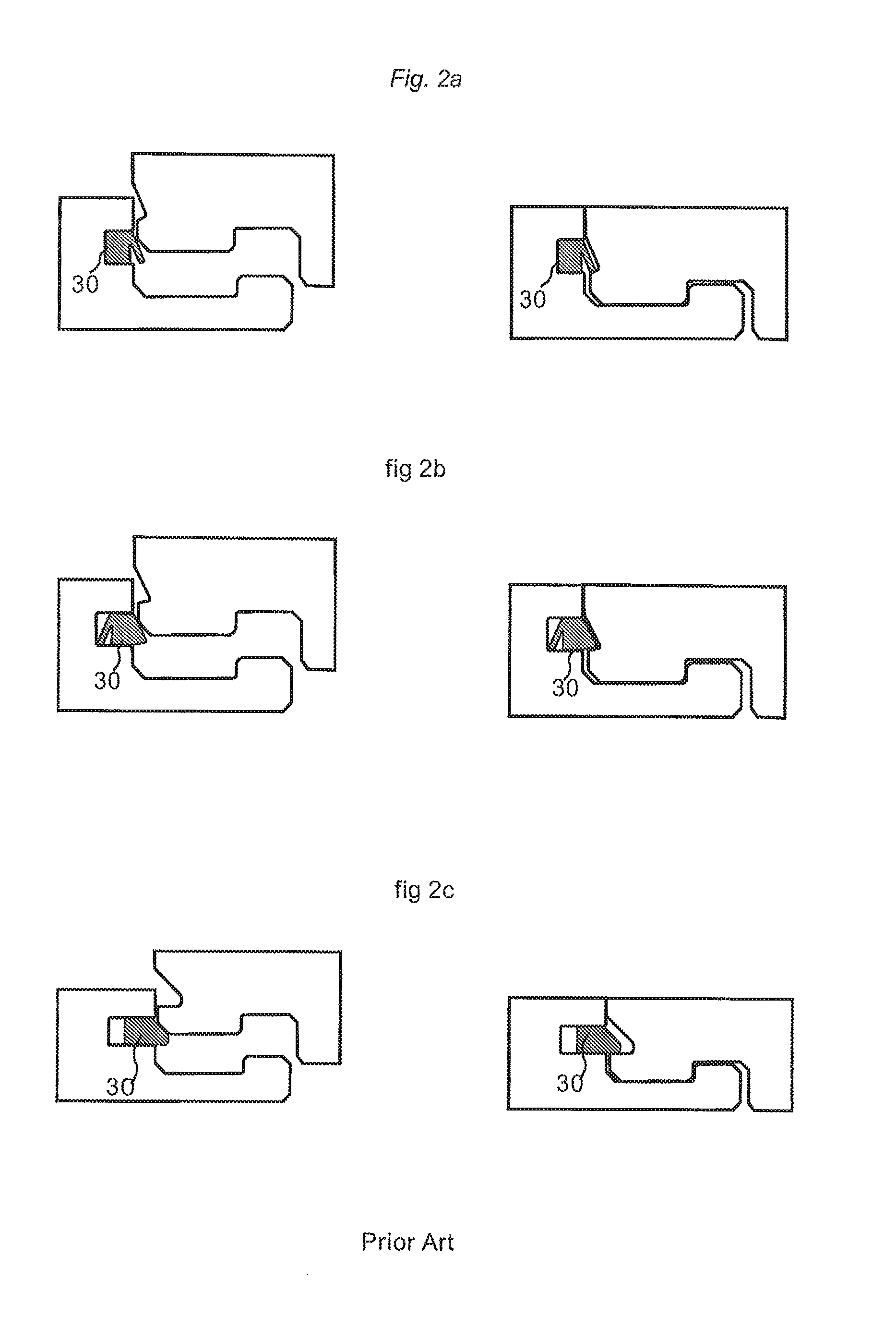

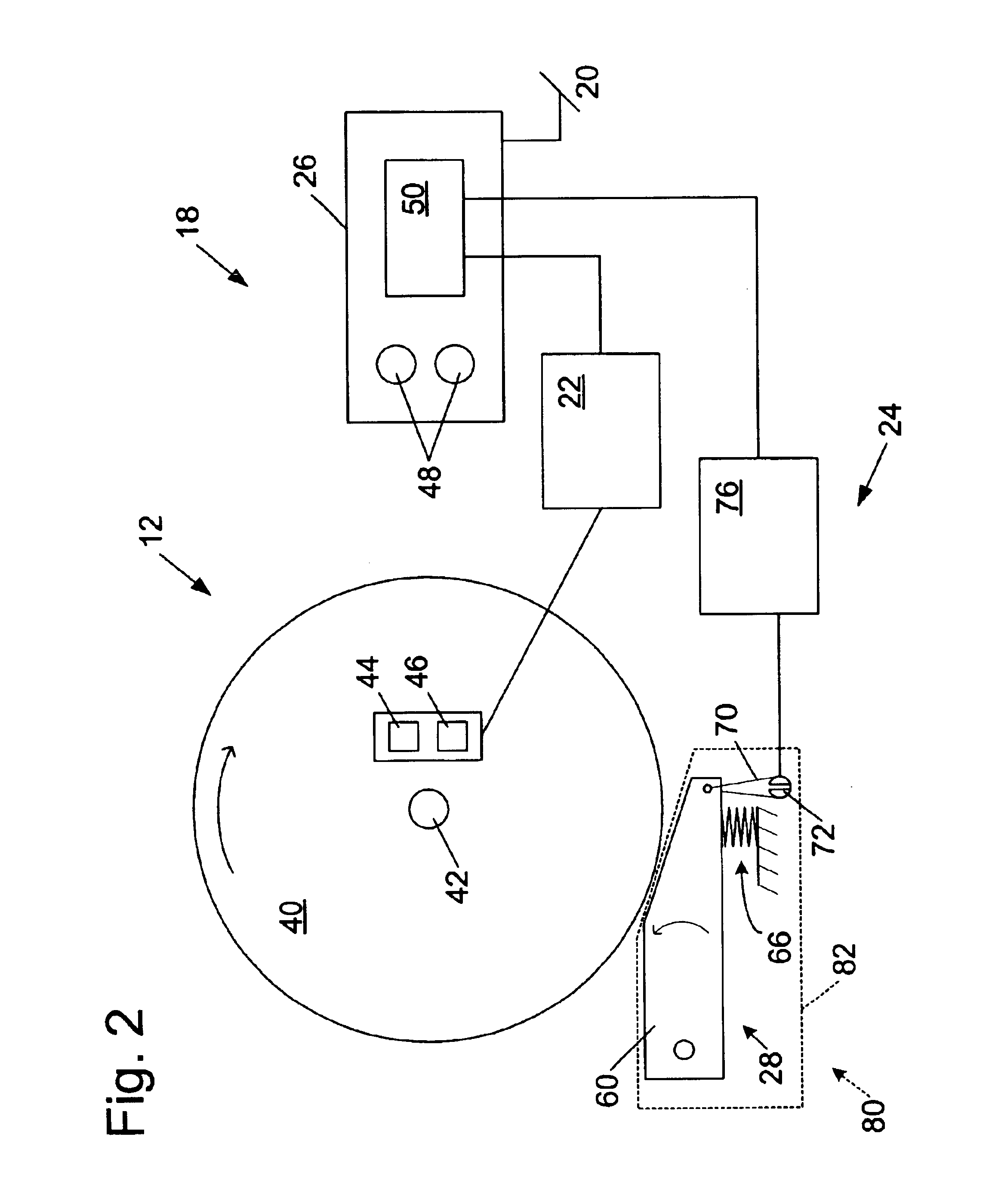

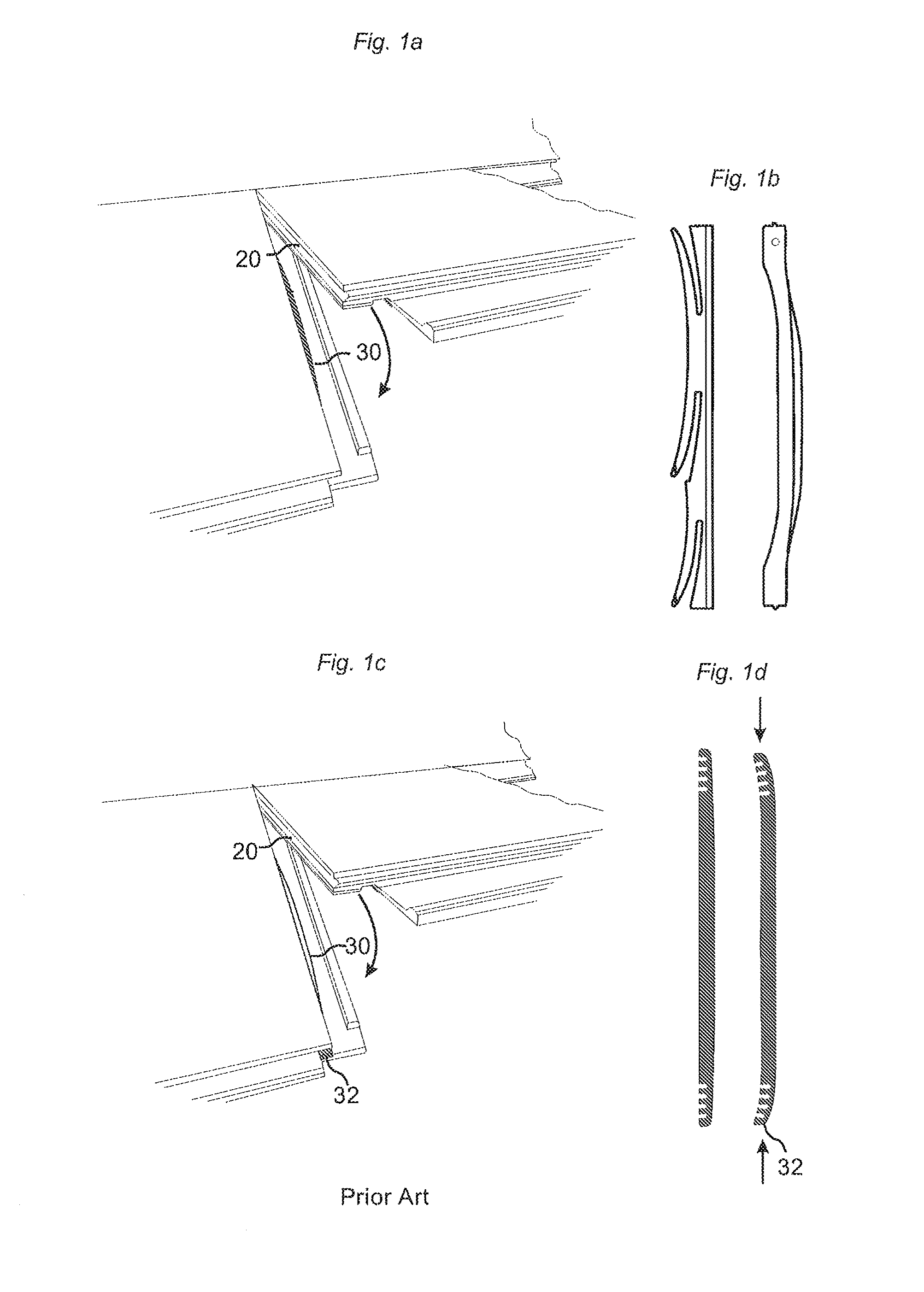

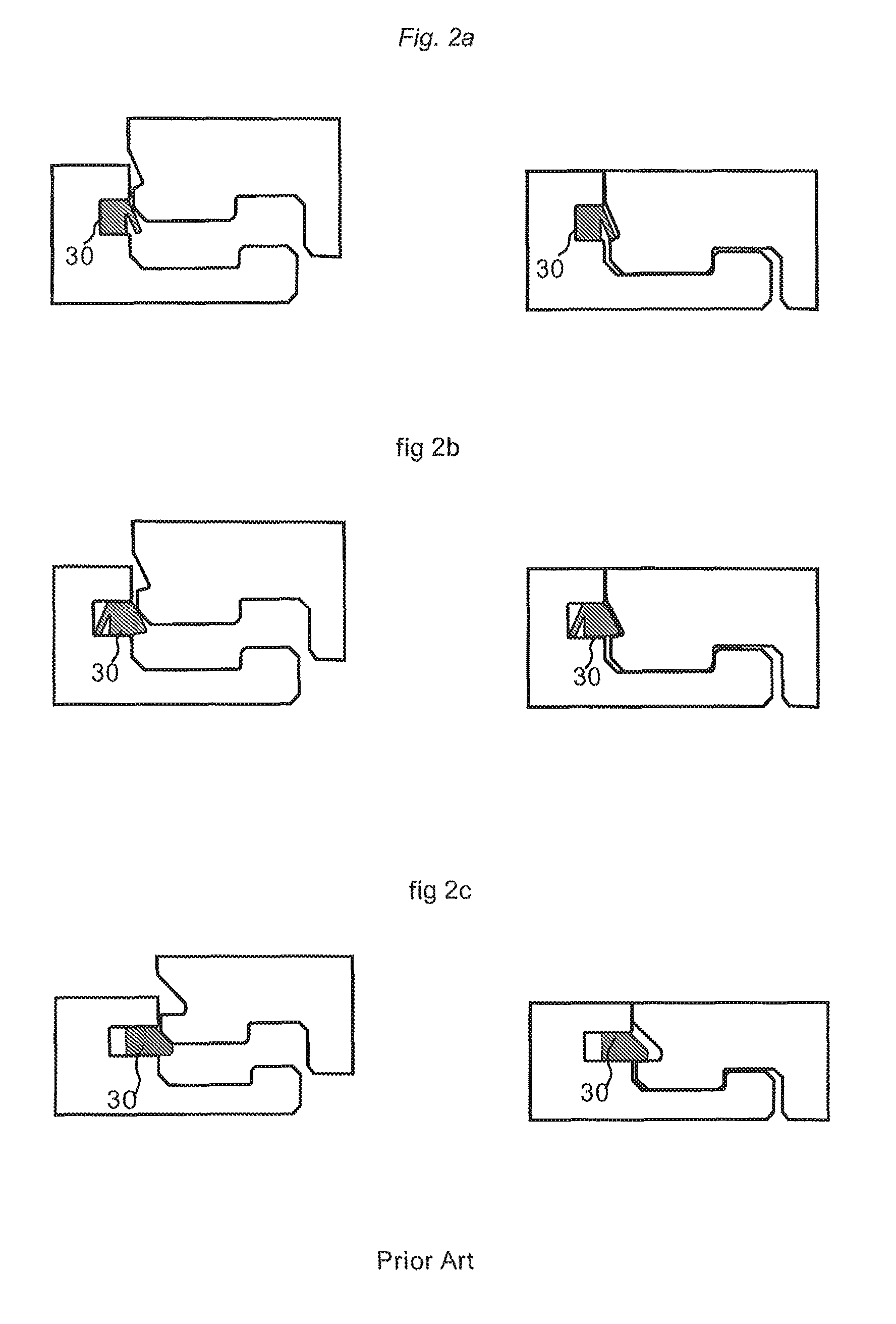

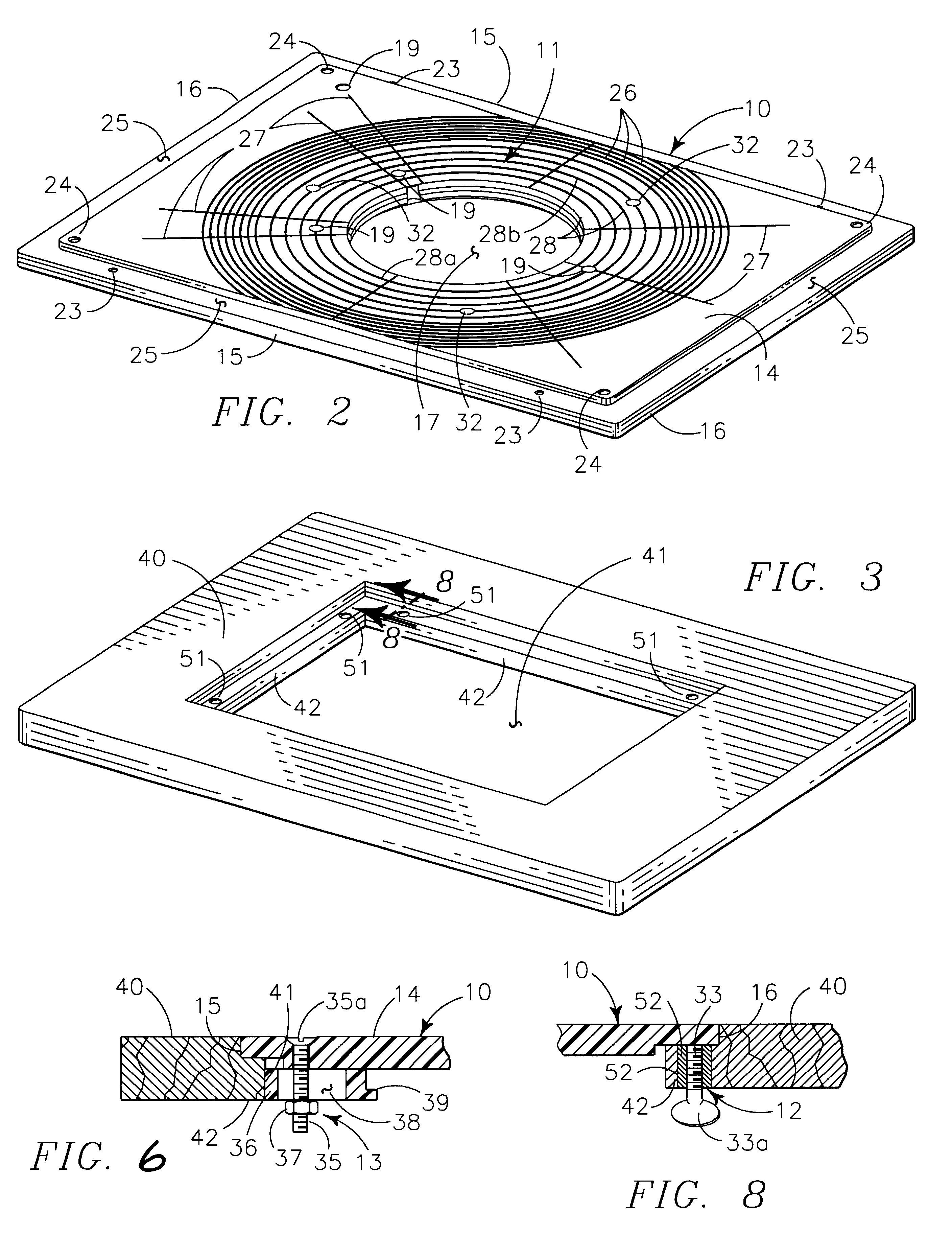

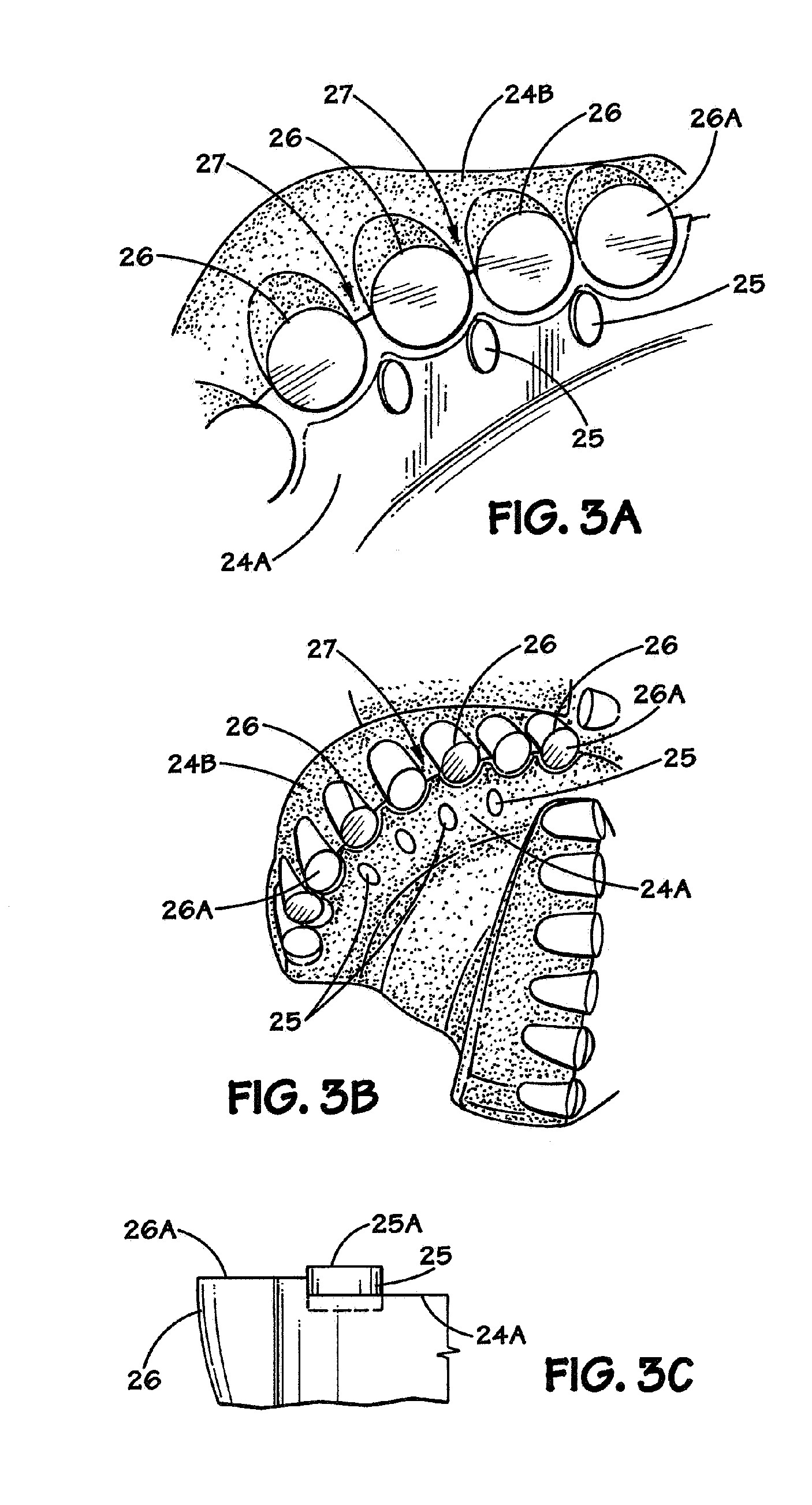

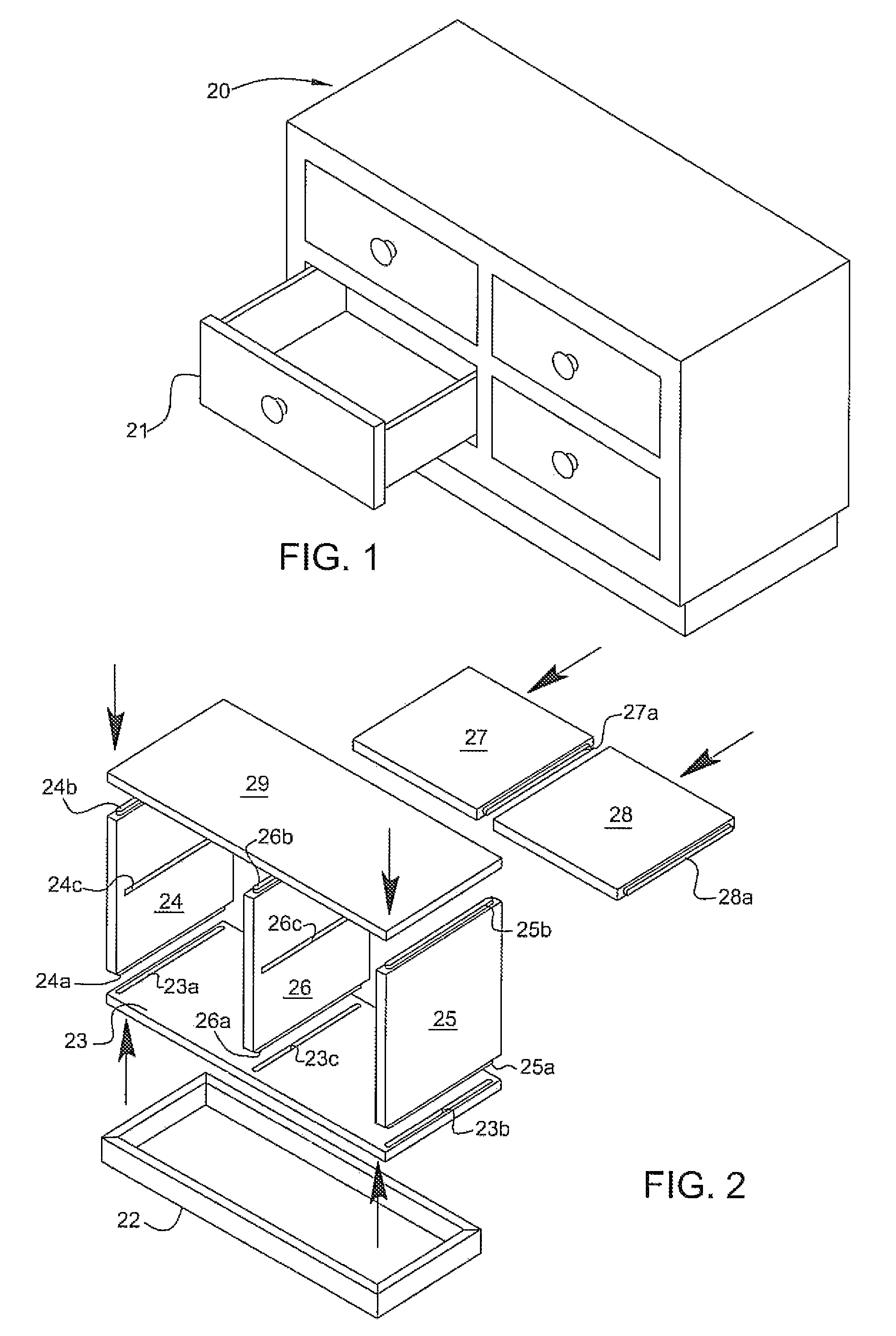

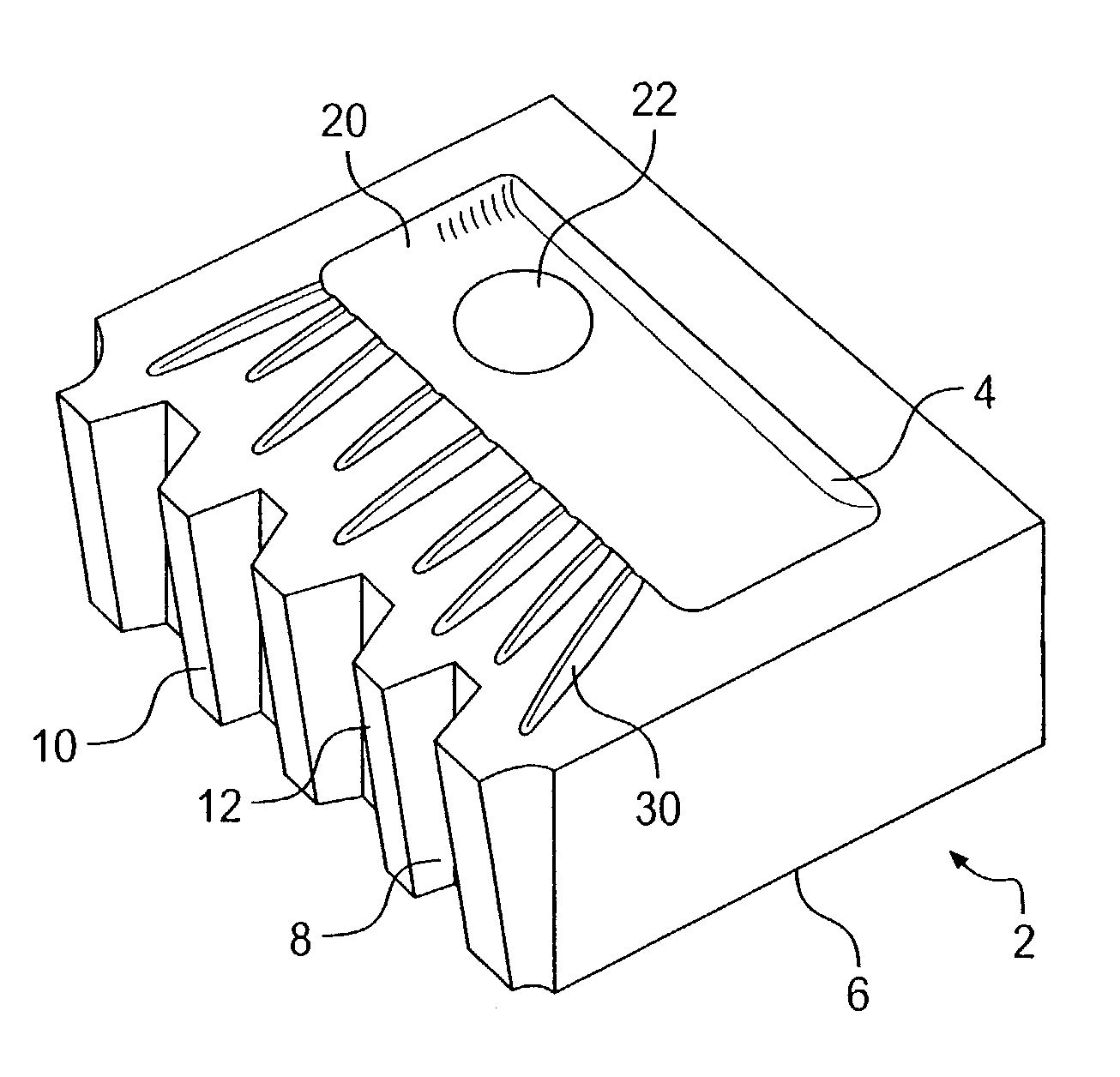

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

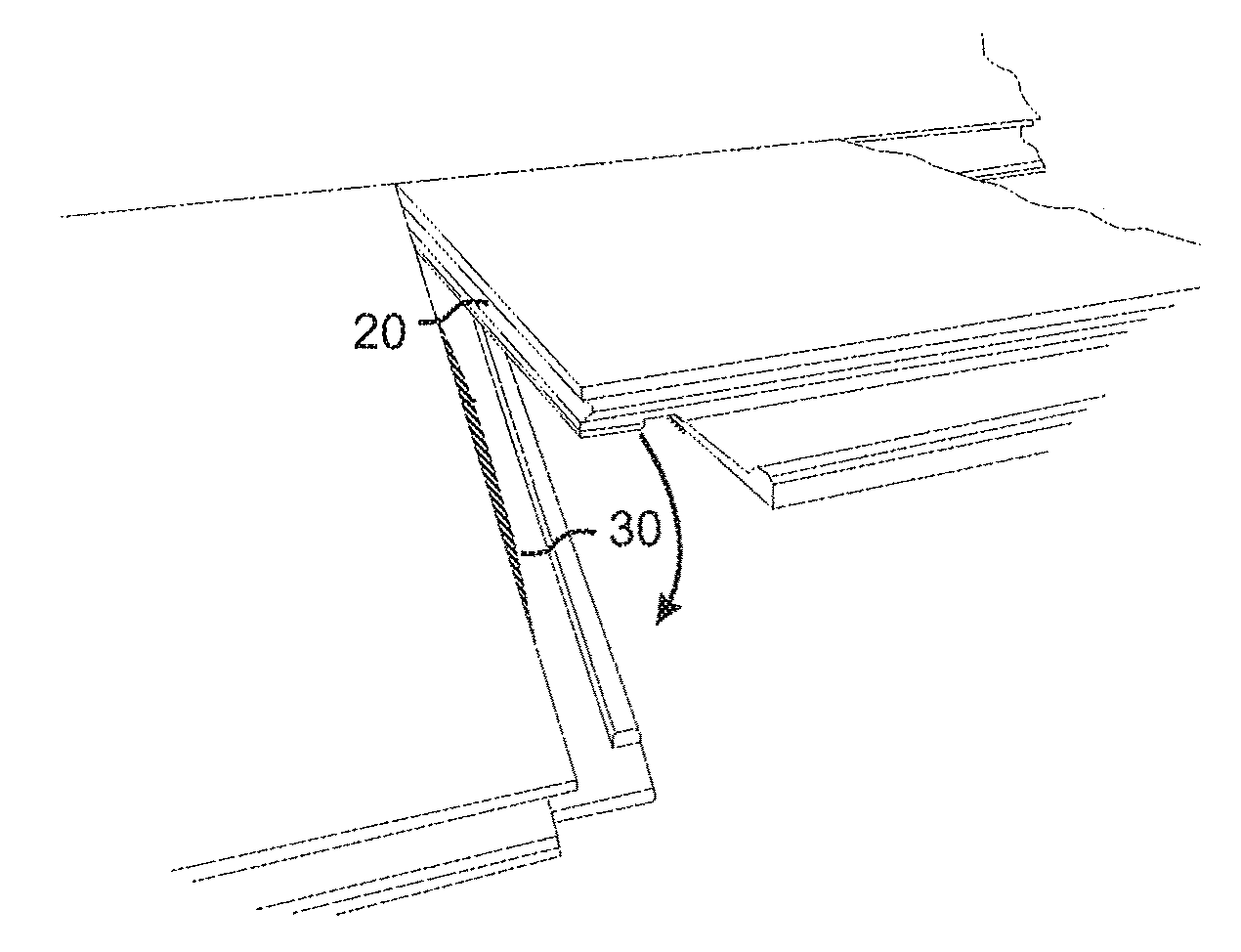

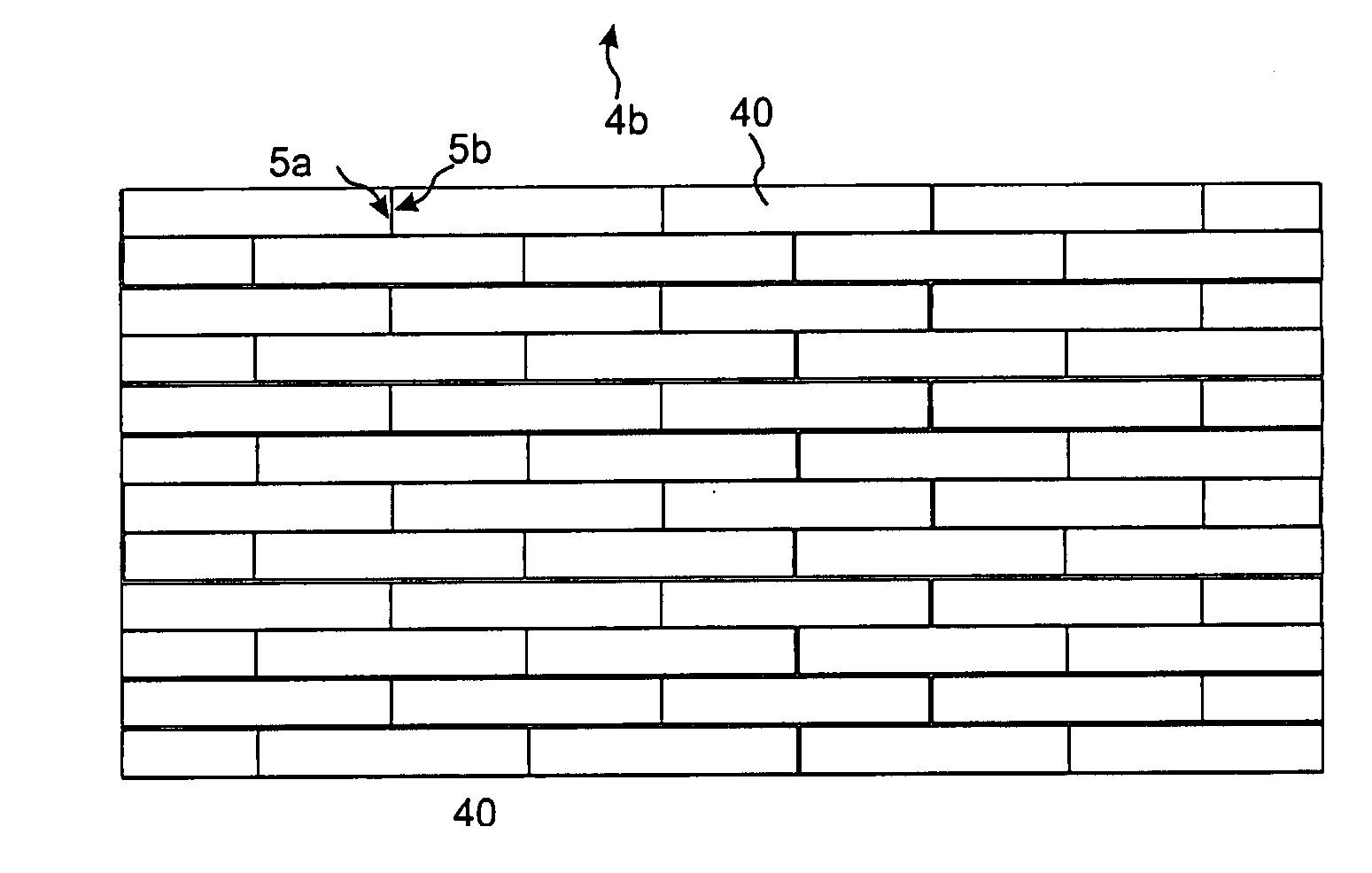

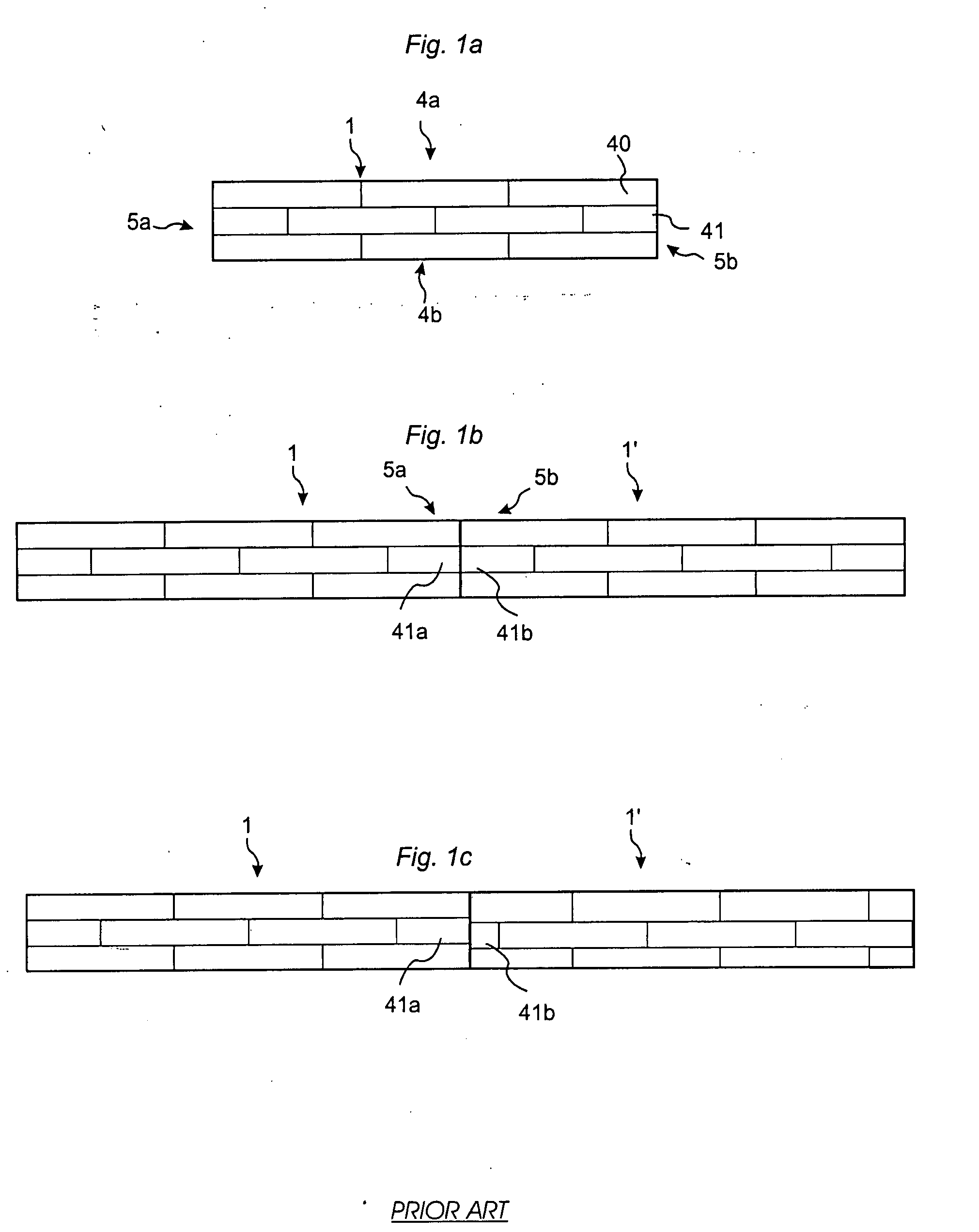

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

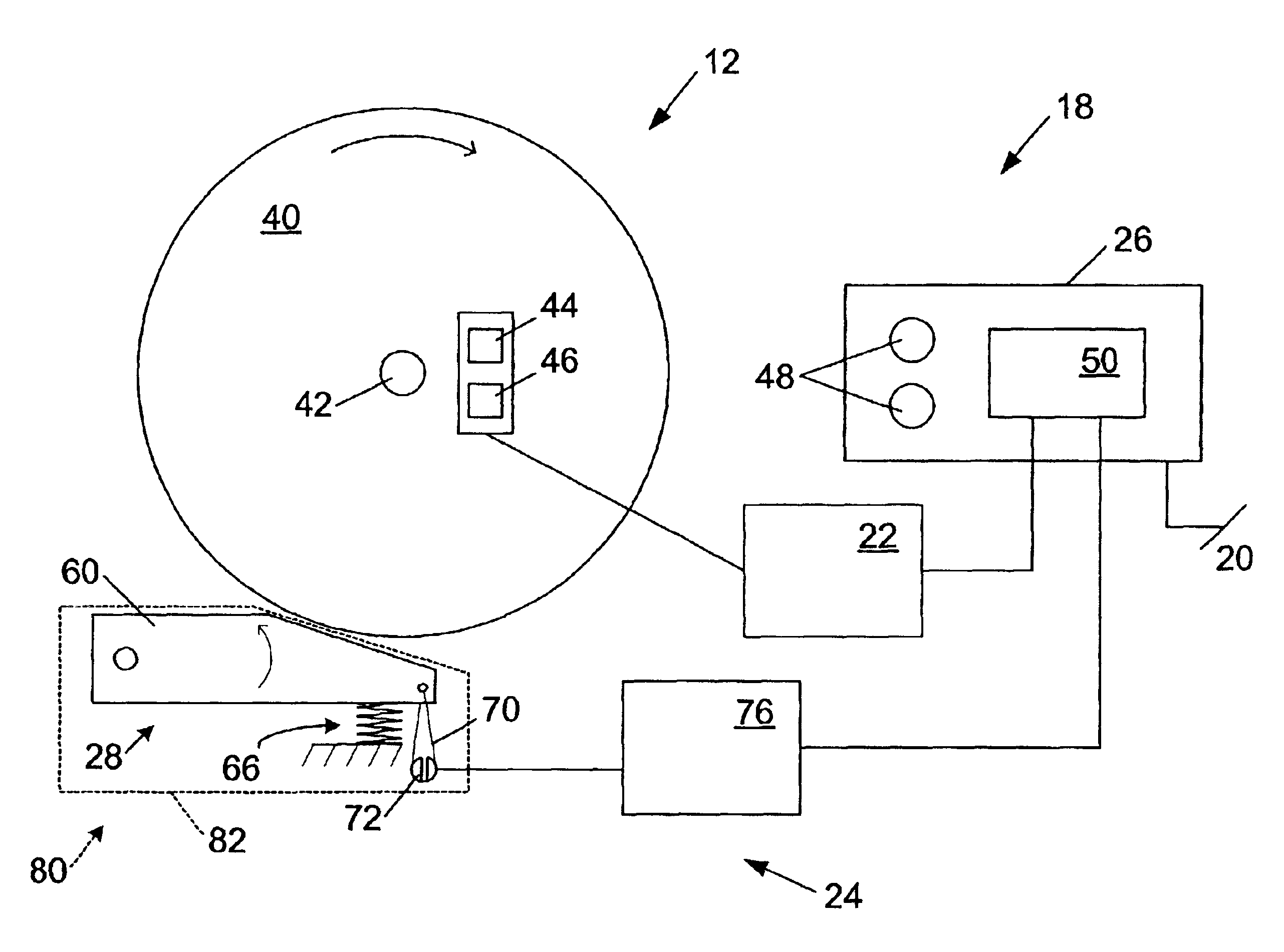

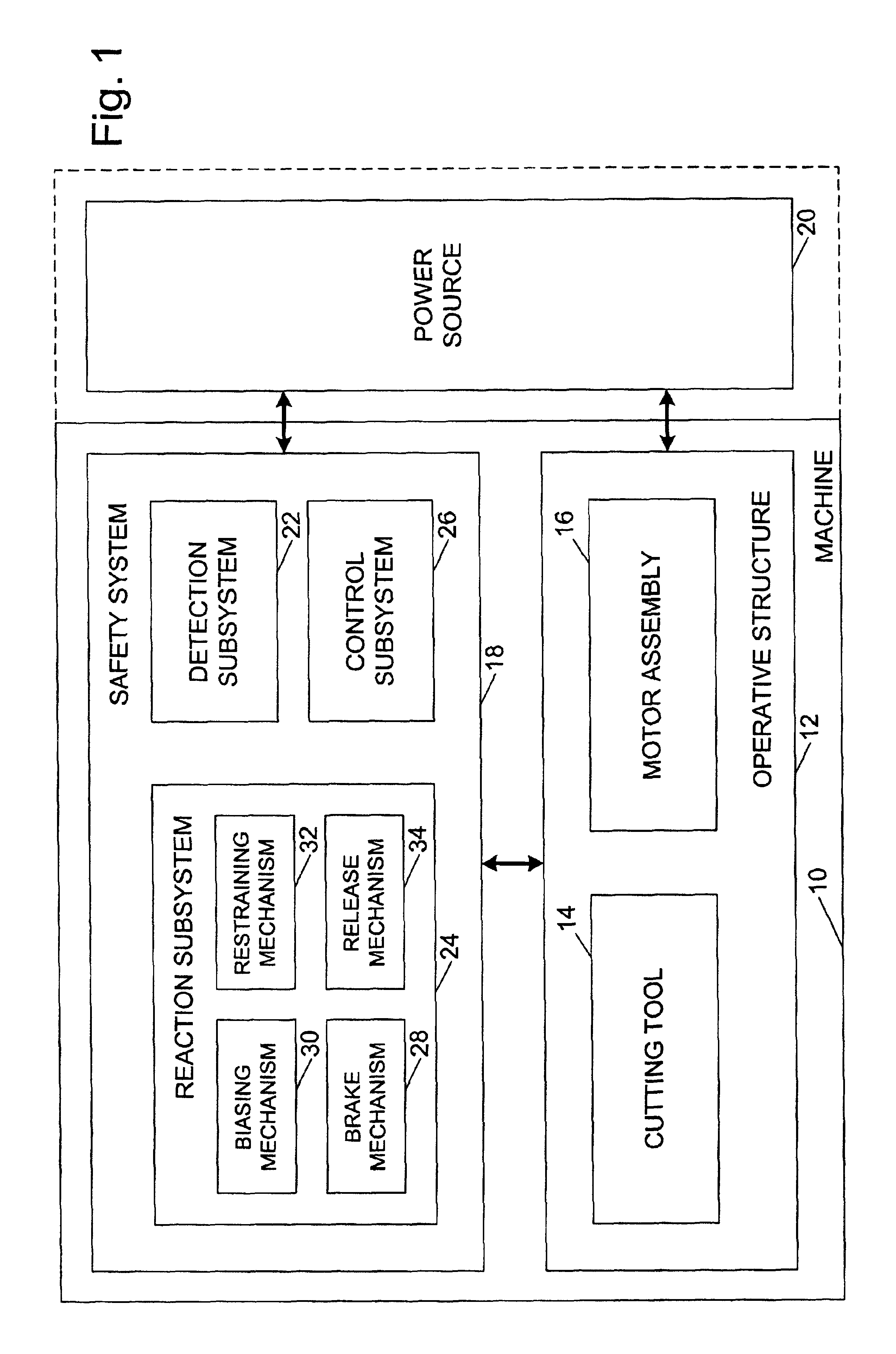

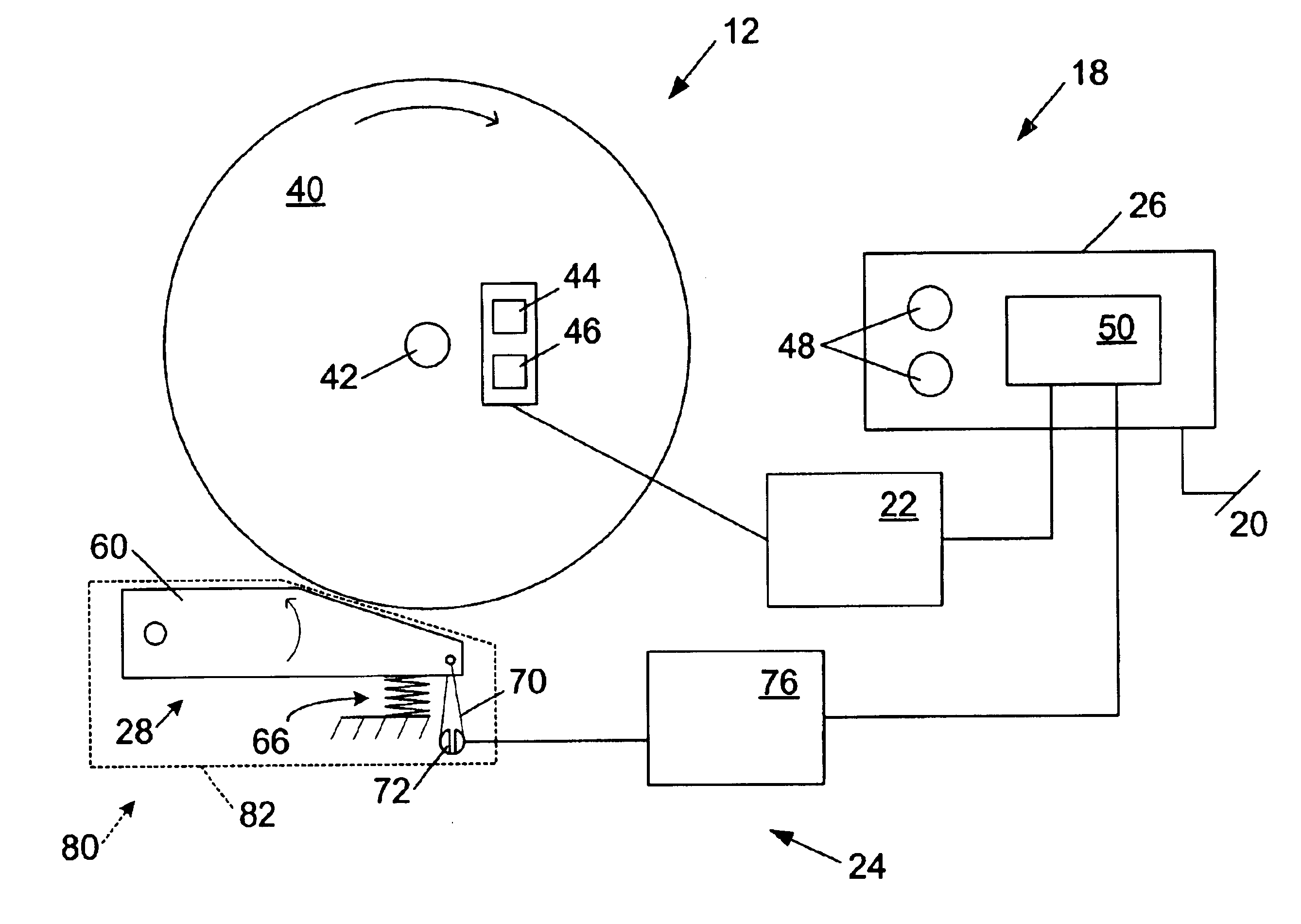

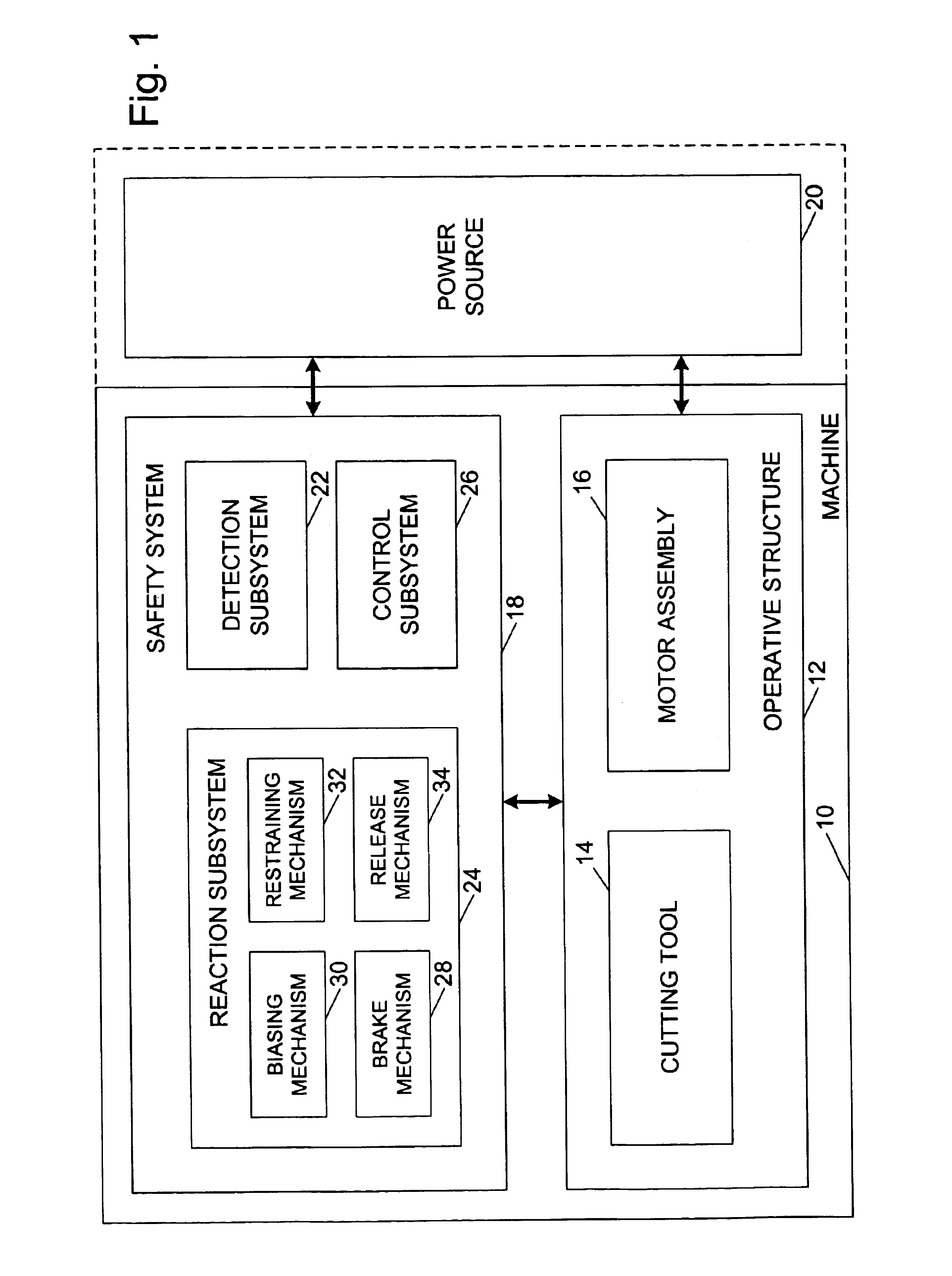

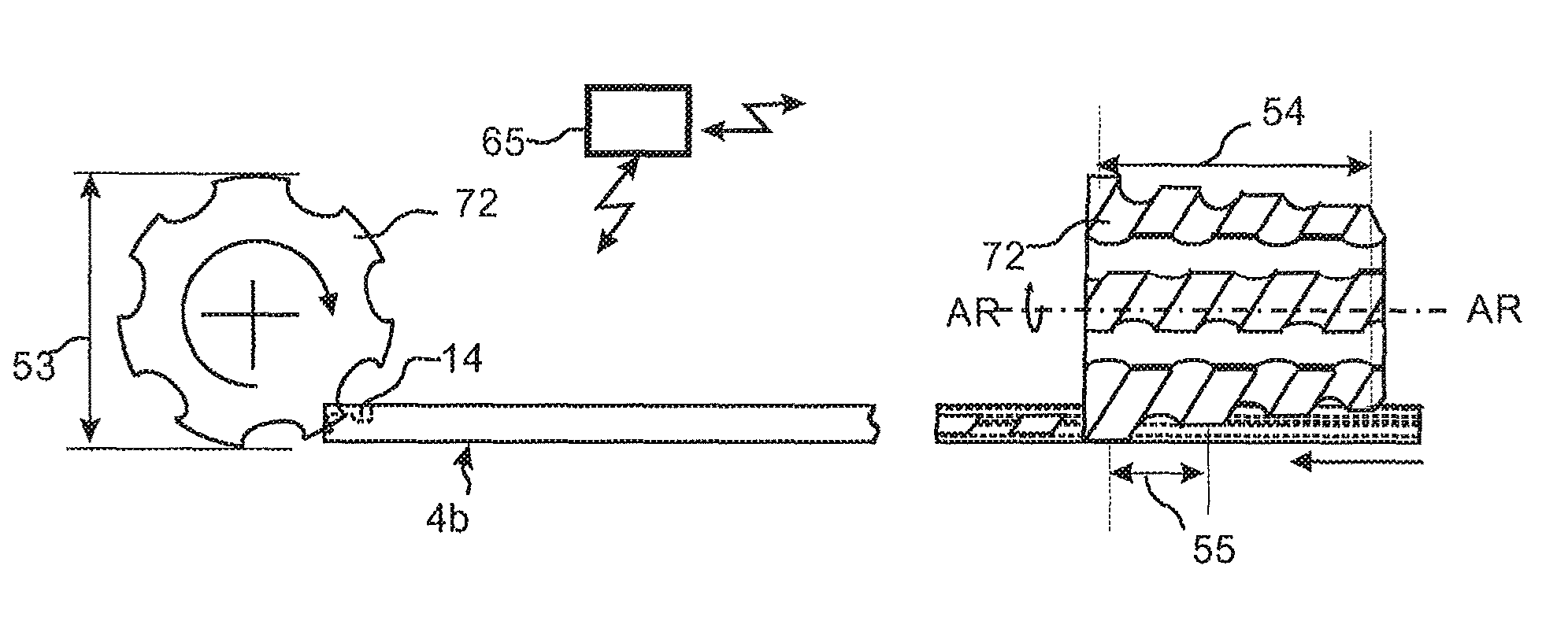

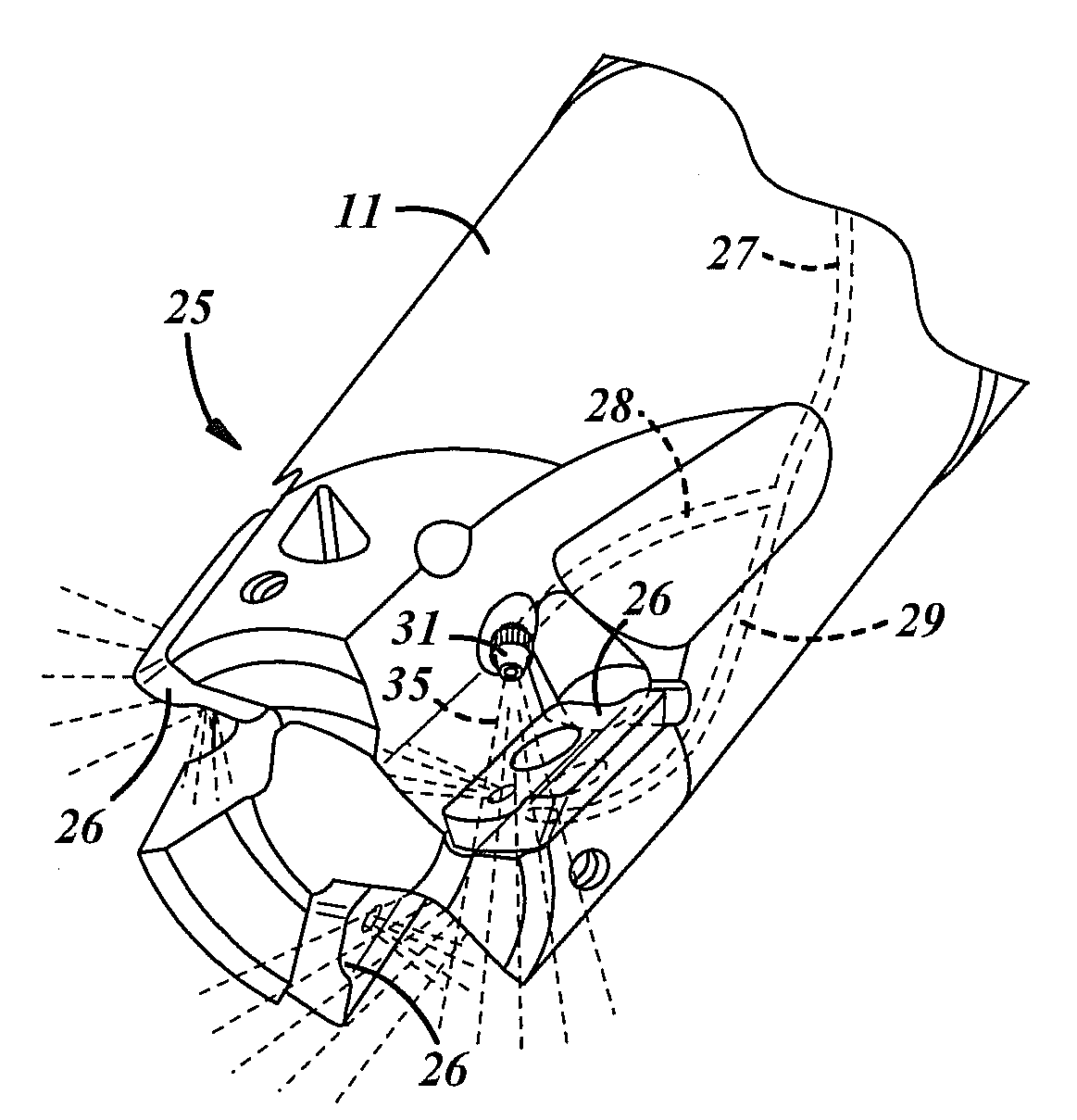

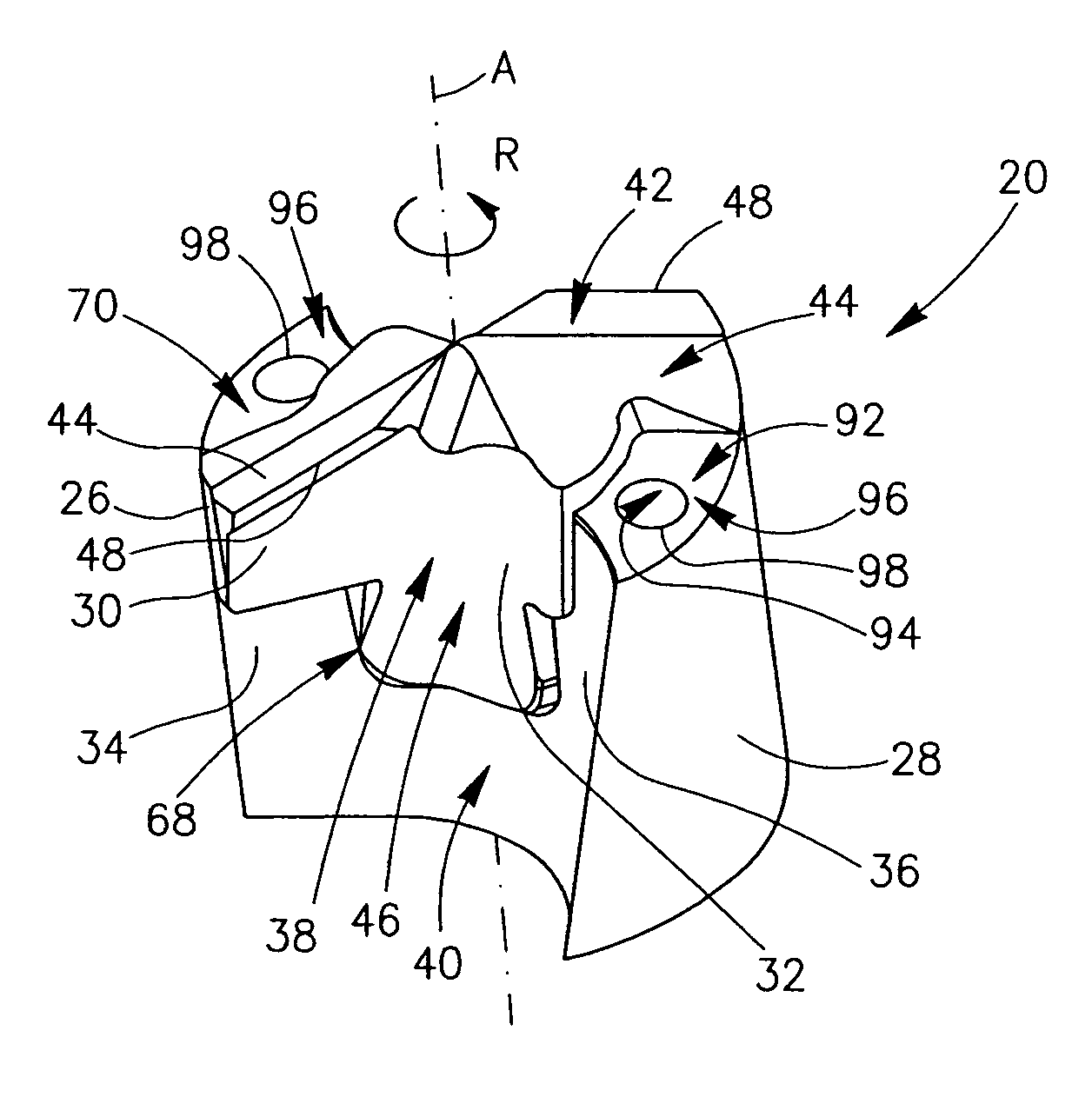

Brake positioning system

InactiveUS6857345B2Multi-purpose machinesEngineering safety devicesEngineeringMechanical engineering

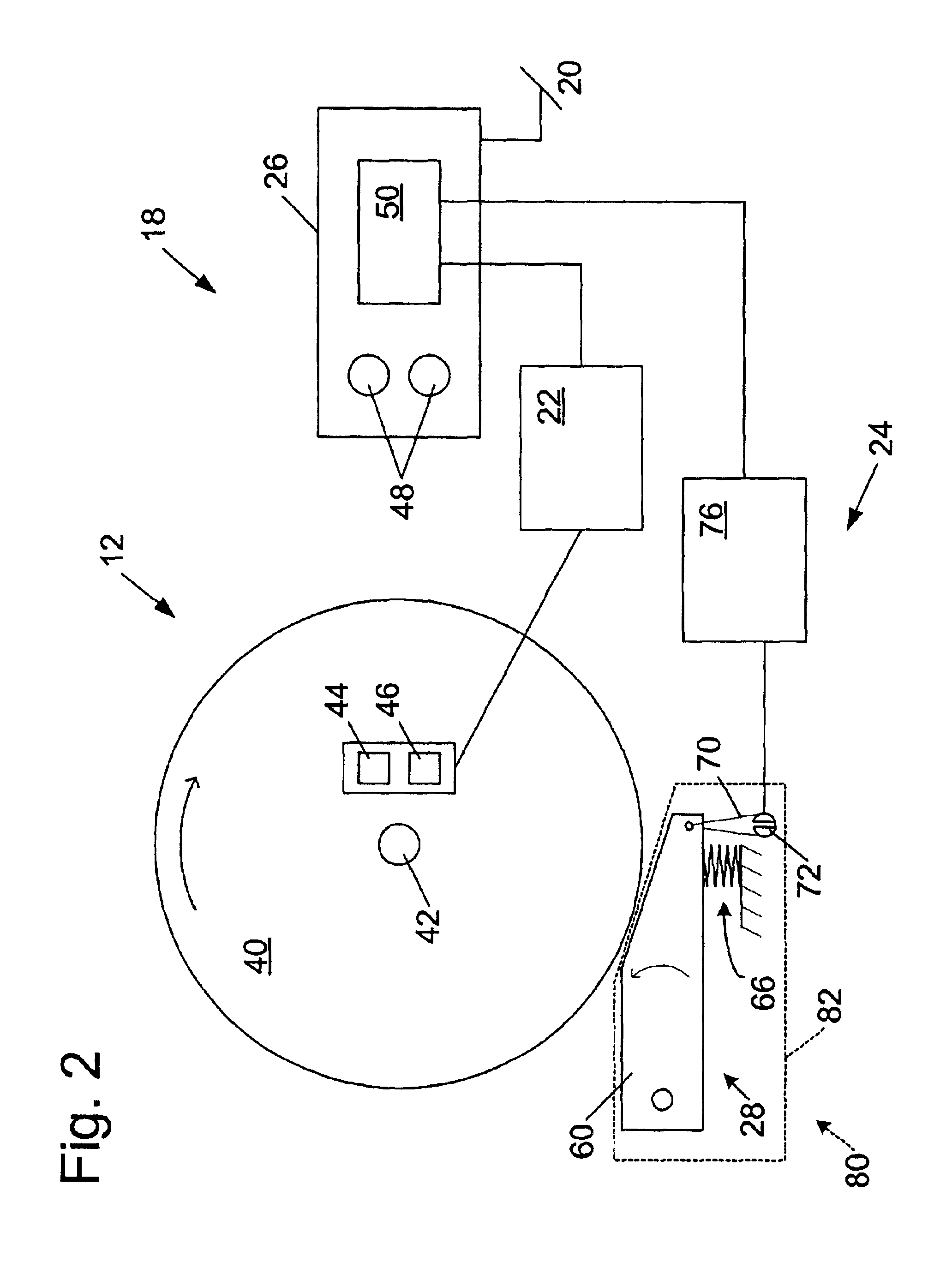

A saw is disclosed having a detection system adapted to detect a dangerous condition between a person and a saw blade, and a brake adapted to stop the saw blade in response to detection of the dangerous condition. The saw further includes a brake positioning system that allows the brake to be positioned in at least two different operable positions to accommodate at least two different blade diameters. The saw may include a system to detect brake-to-blade spacing.

Owner:SAWSTOP HLDG LLC

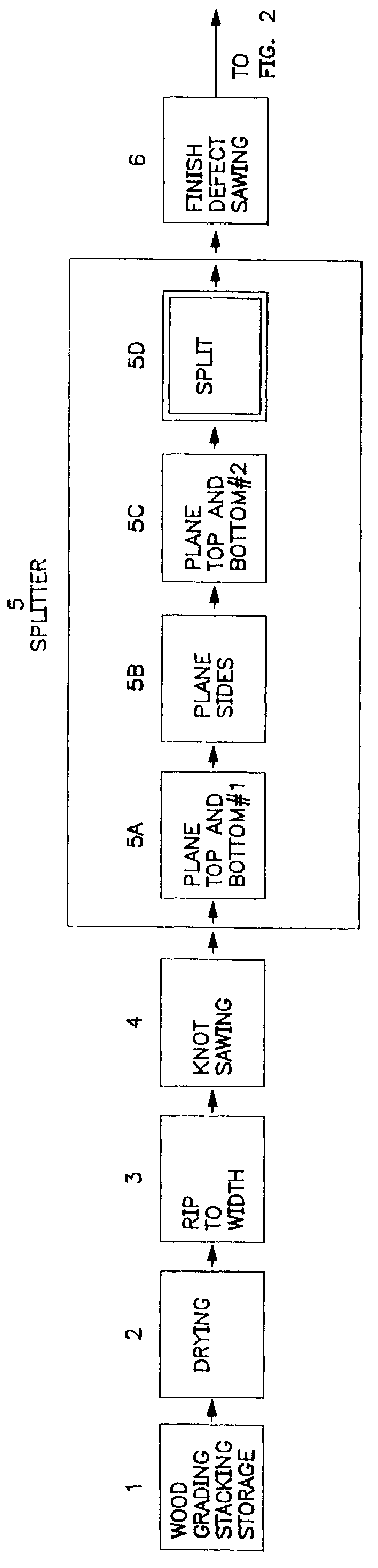

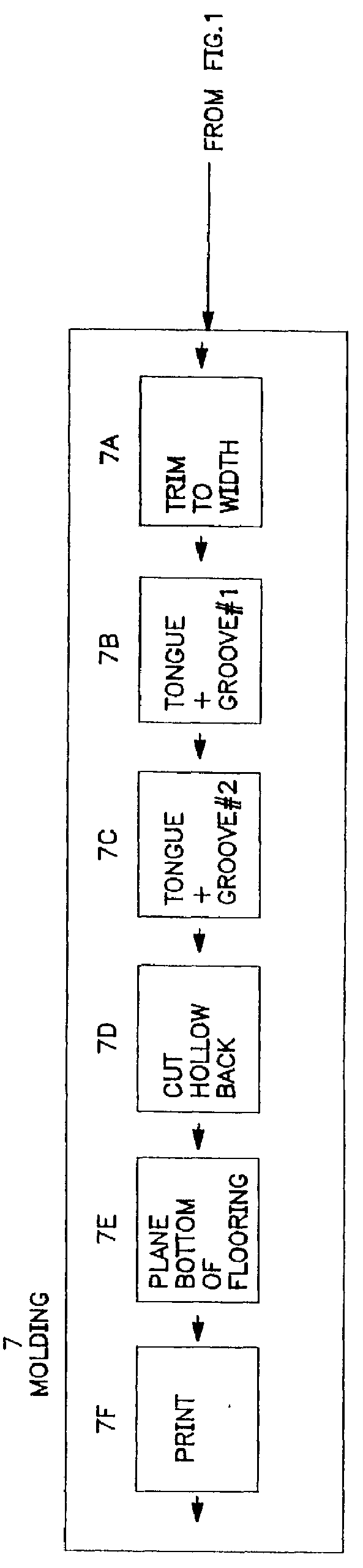

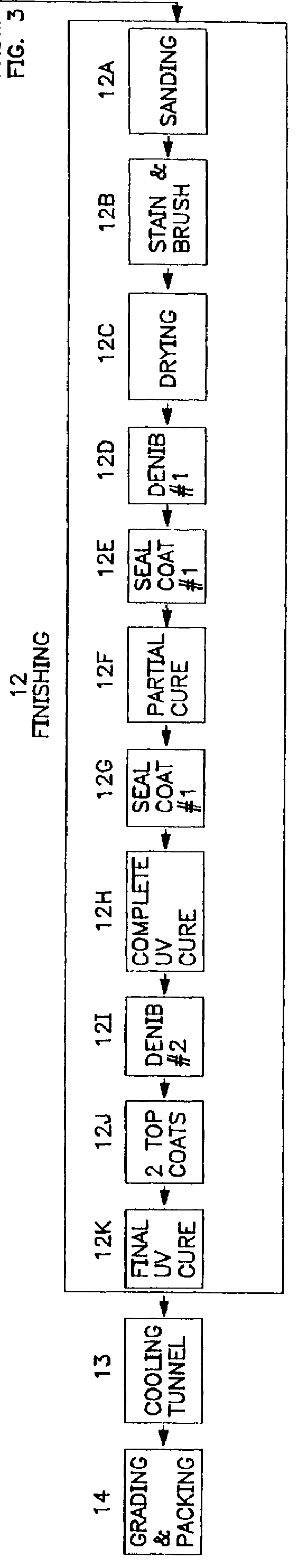

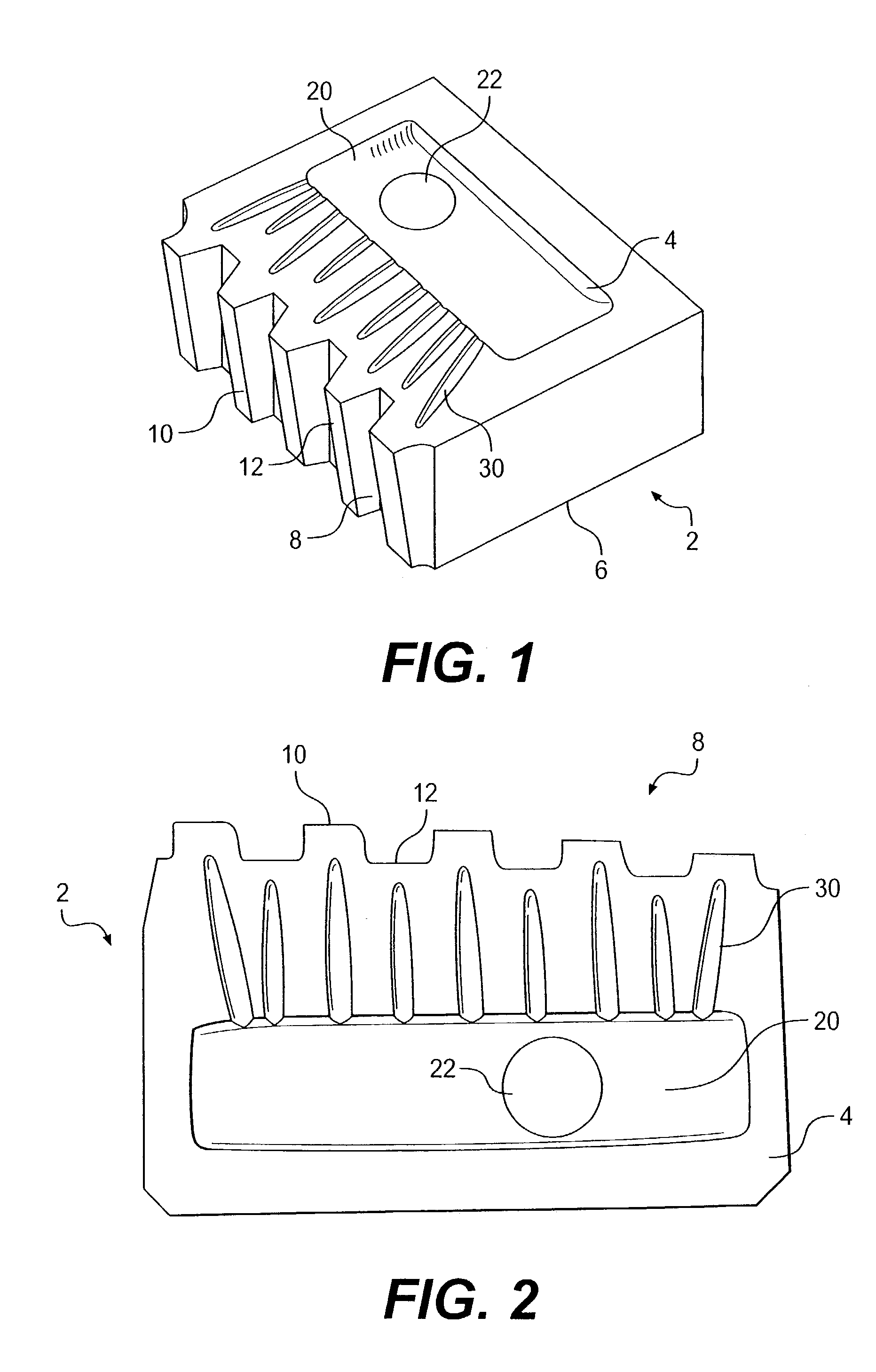

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

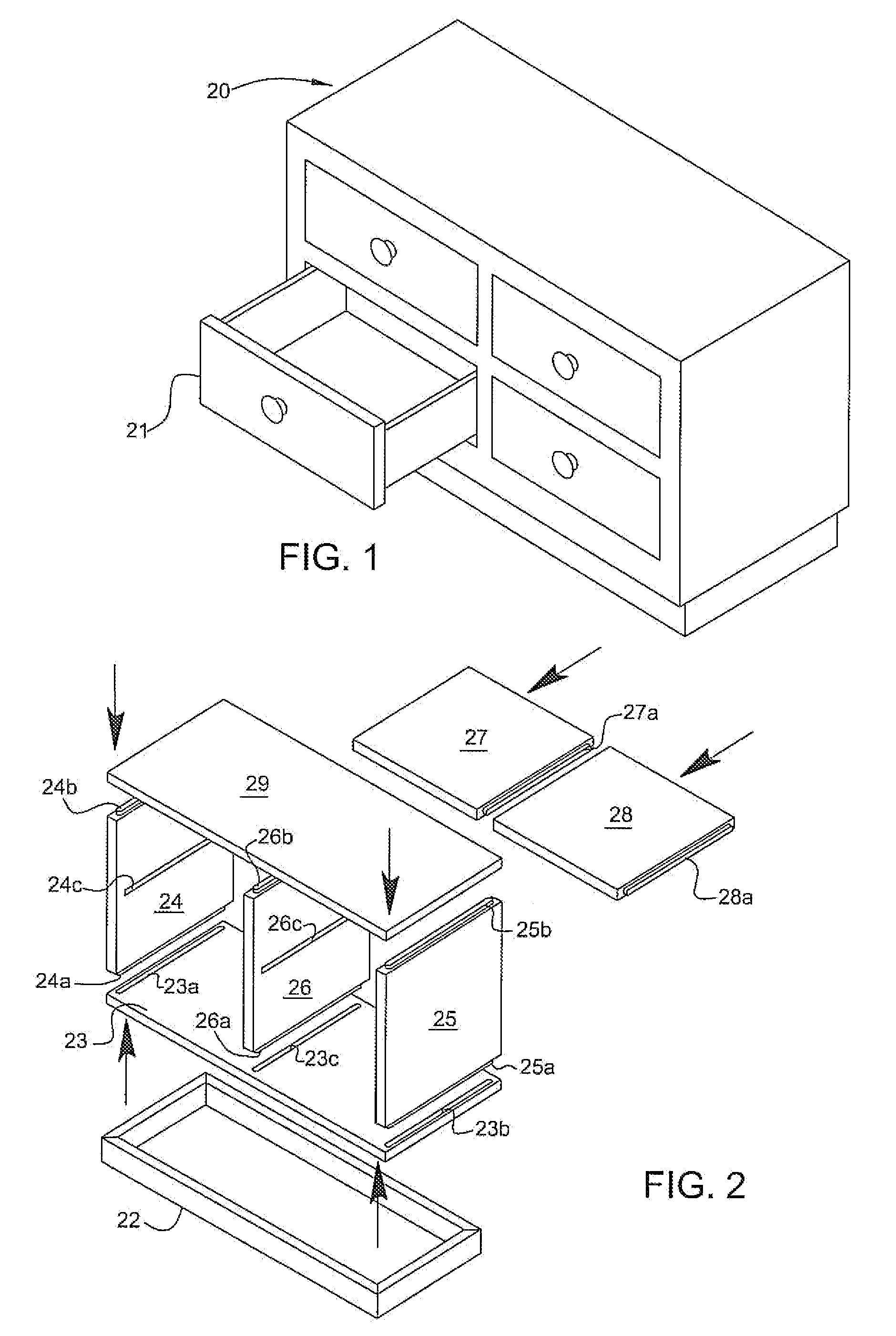

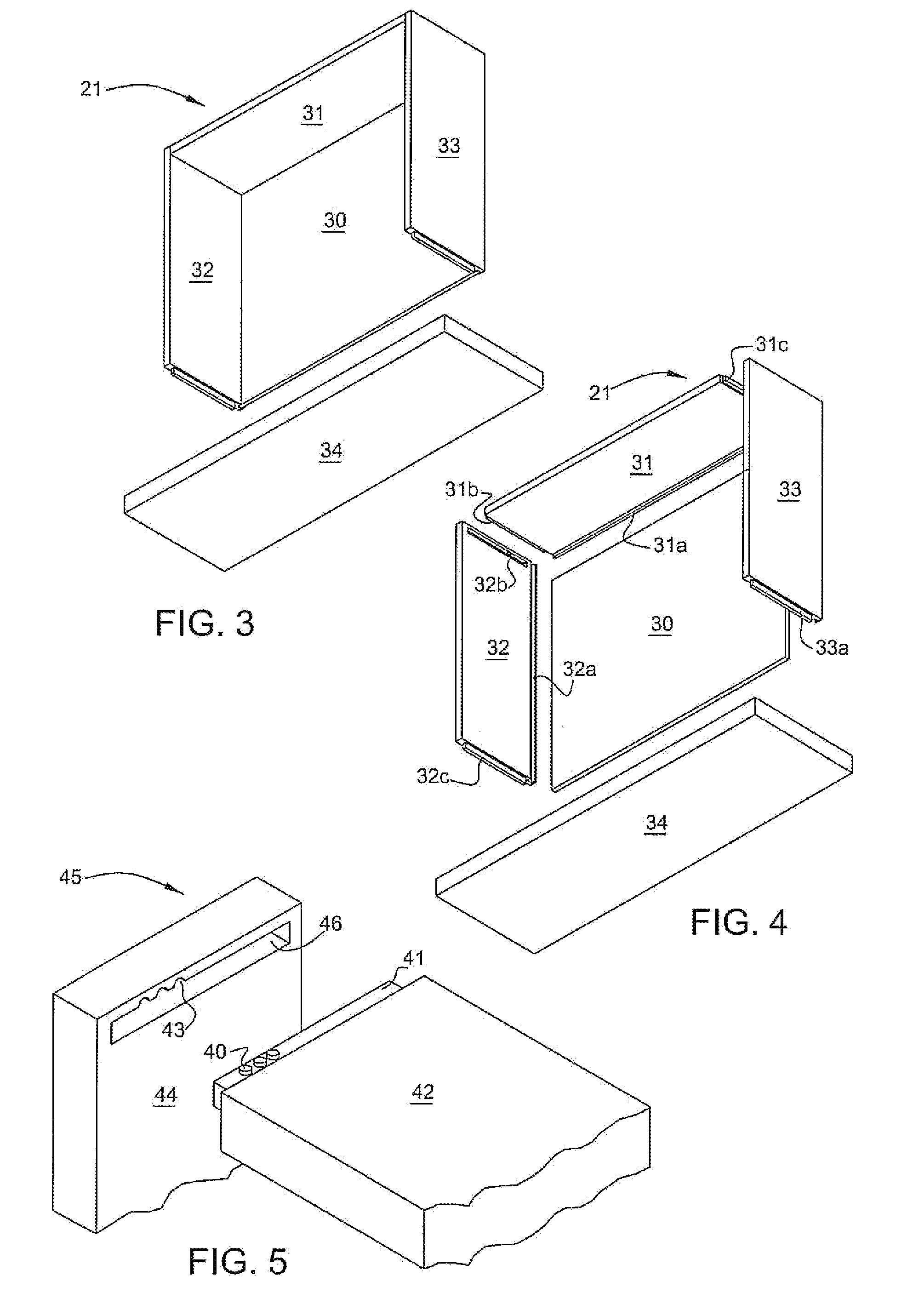

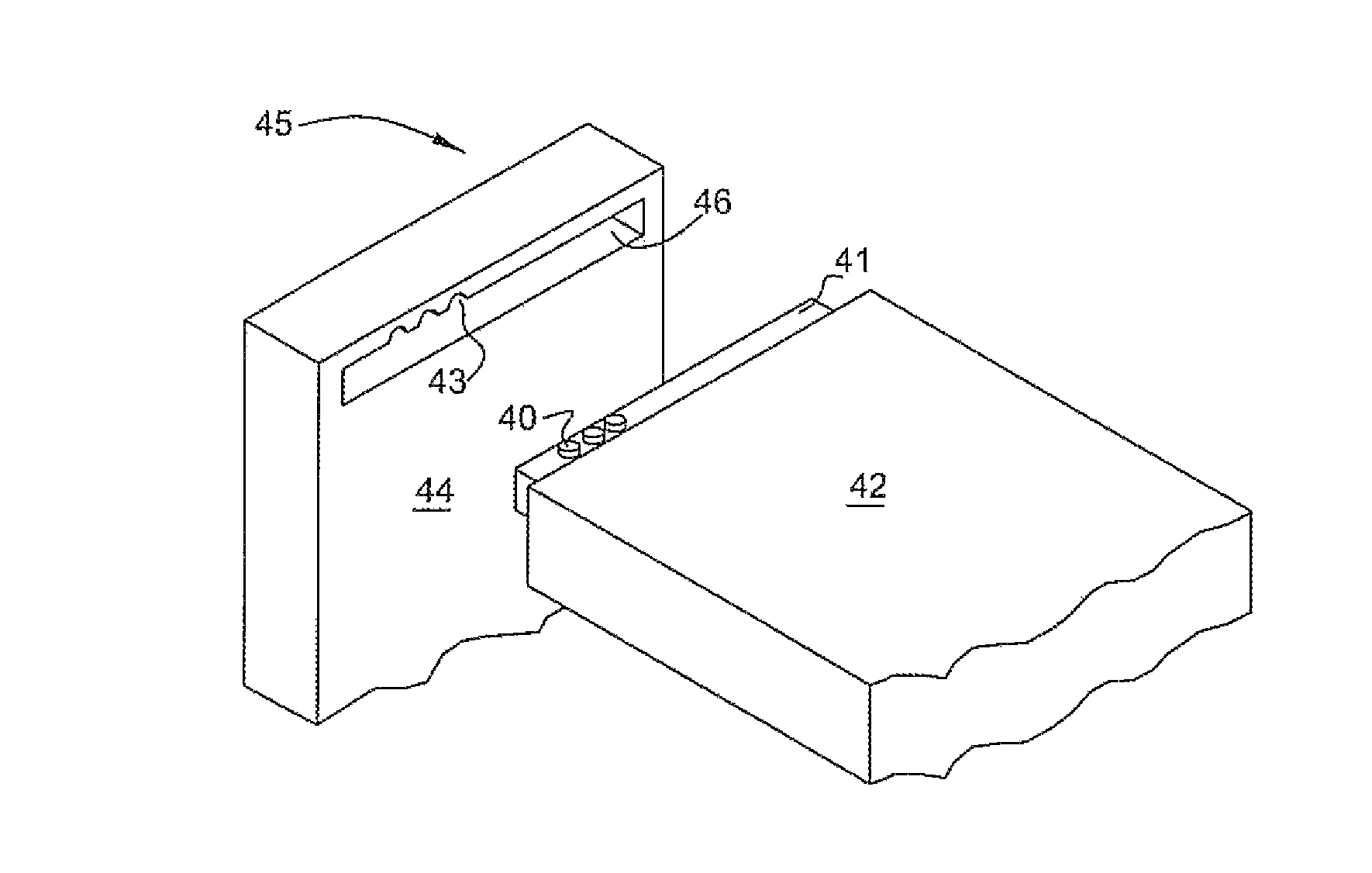

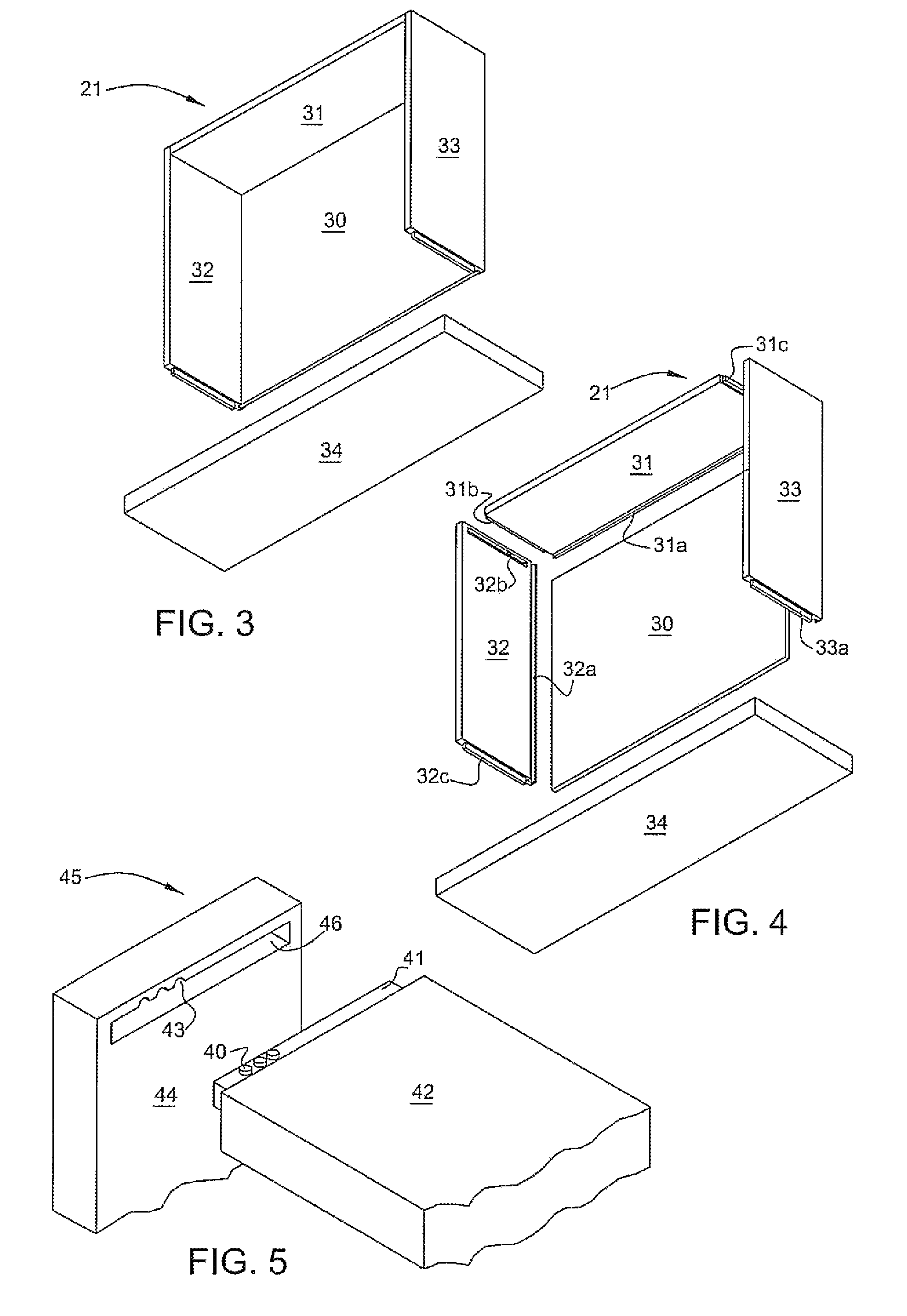

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

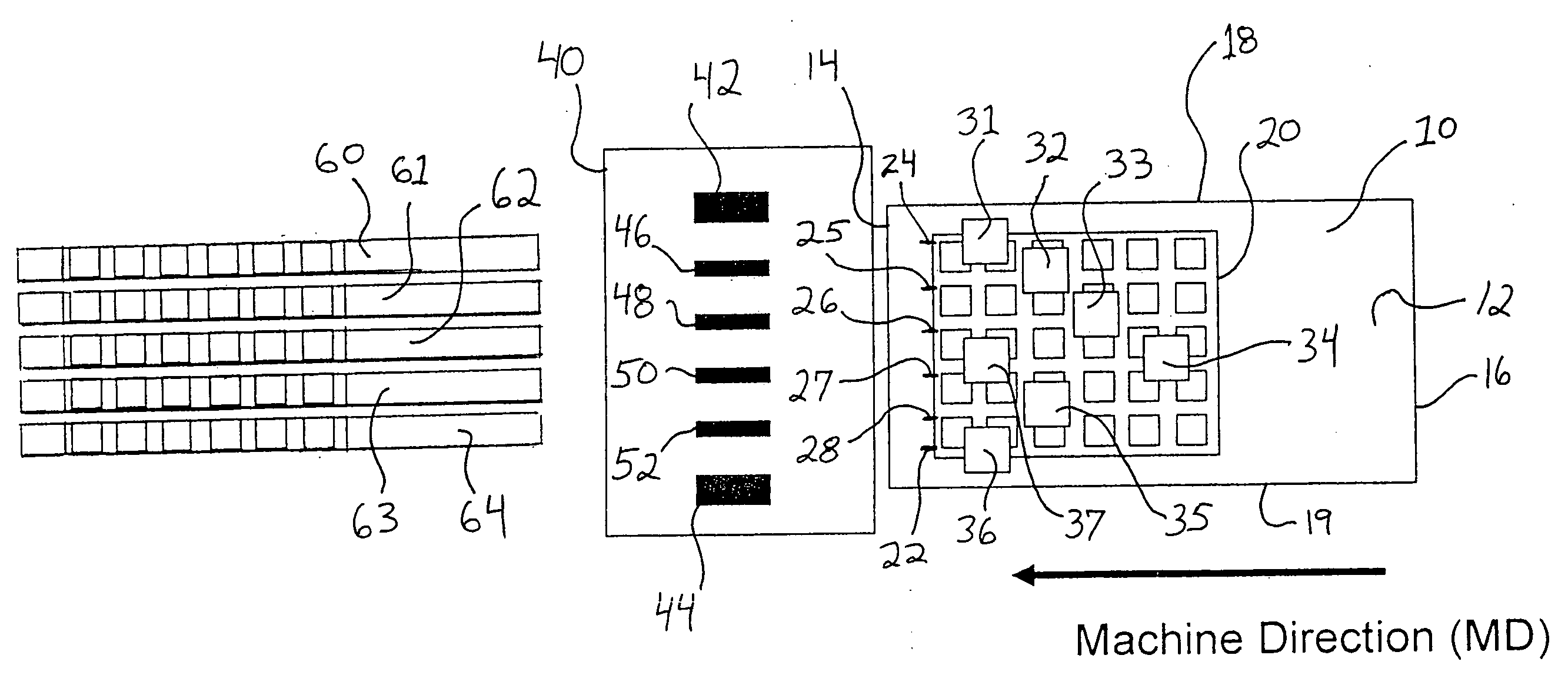

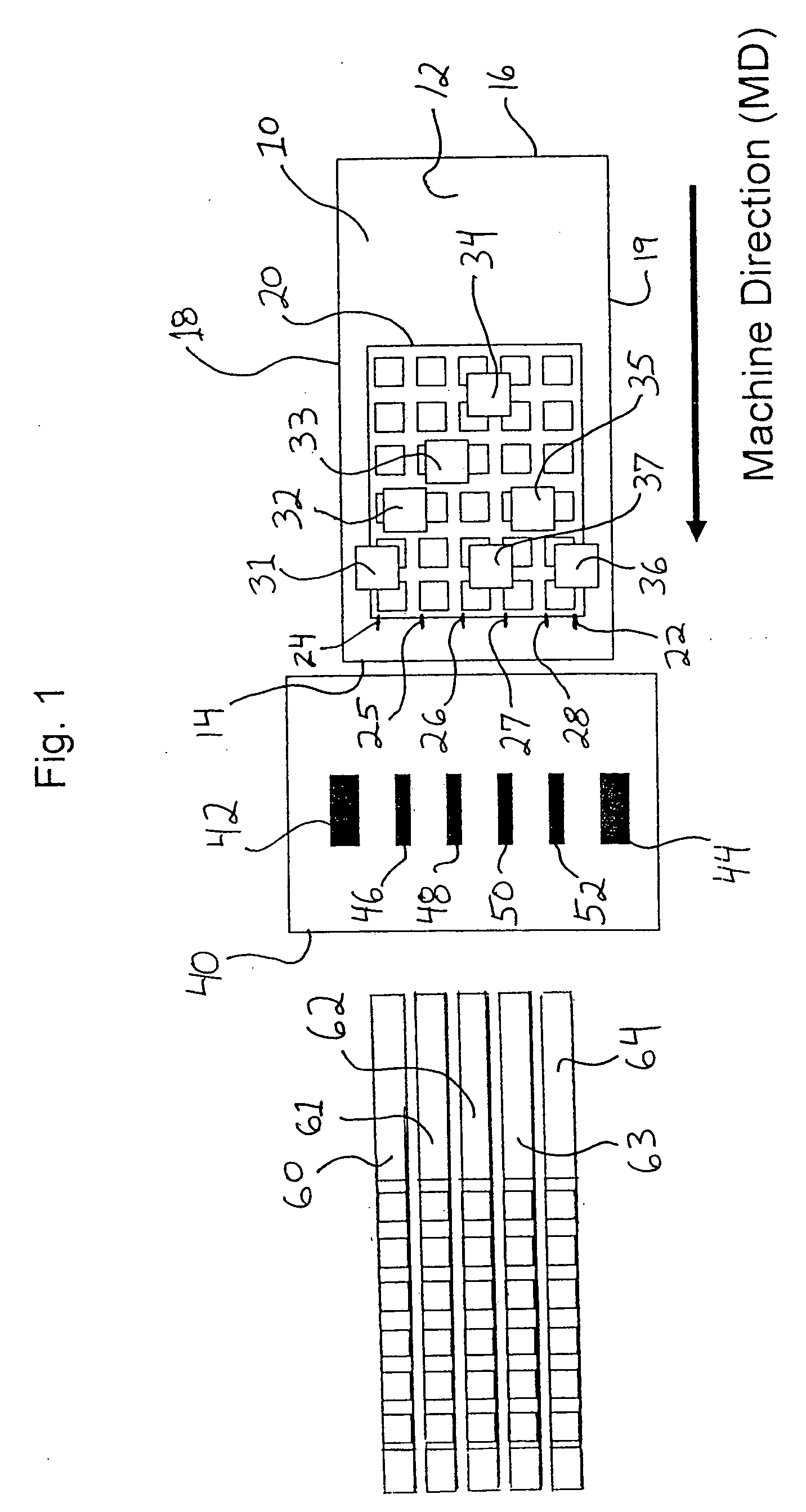

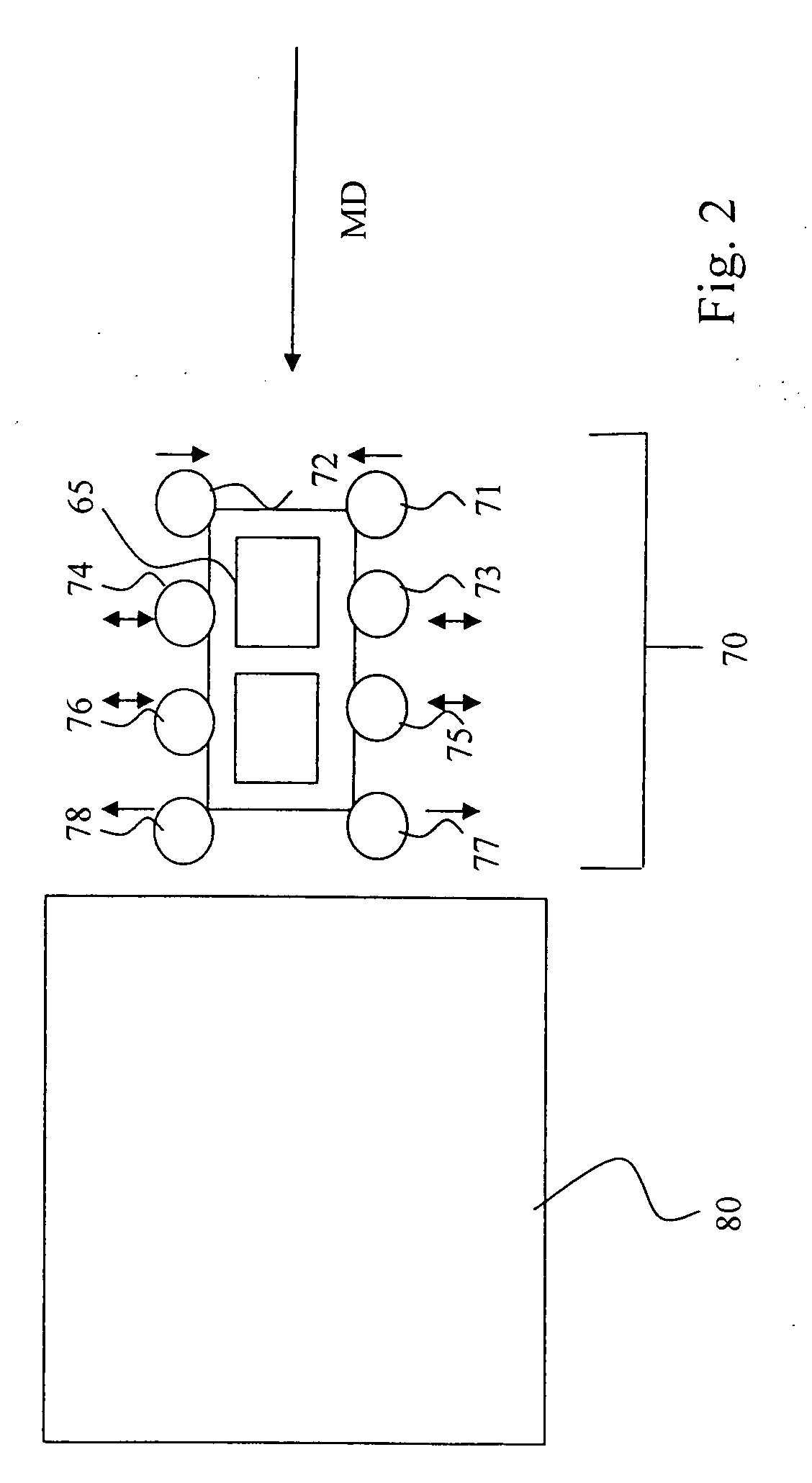

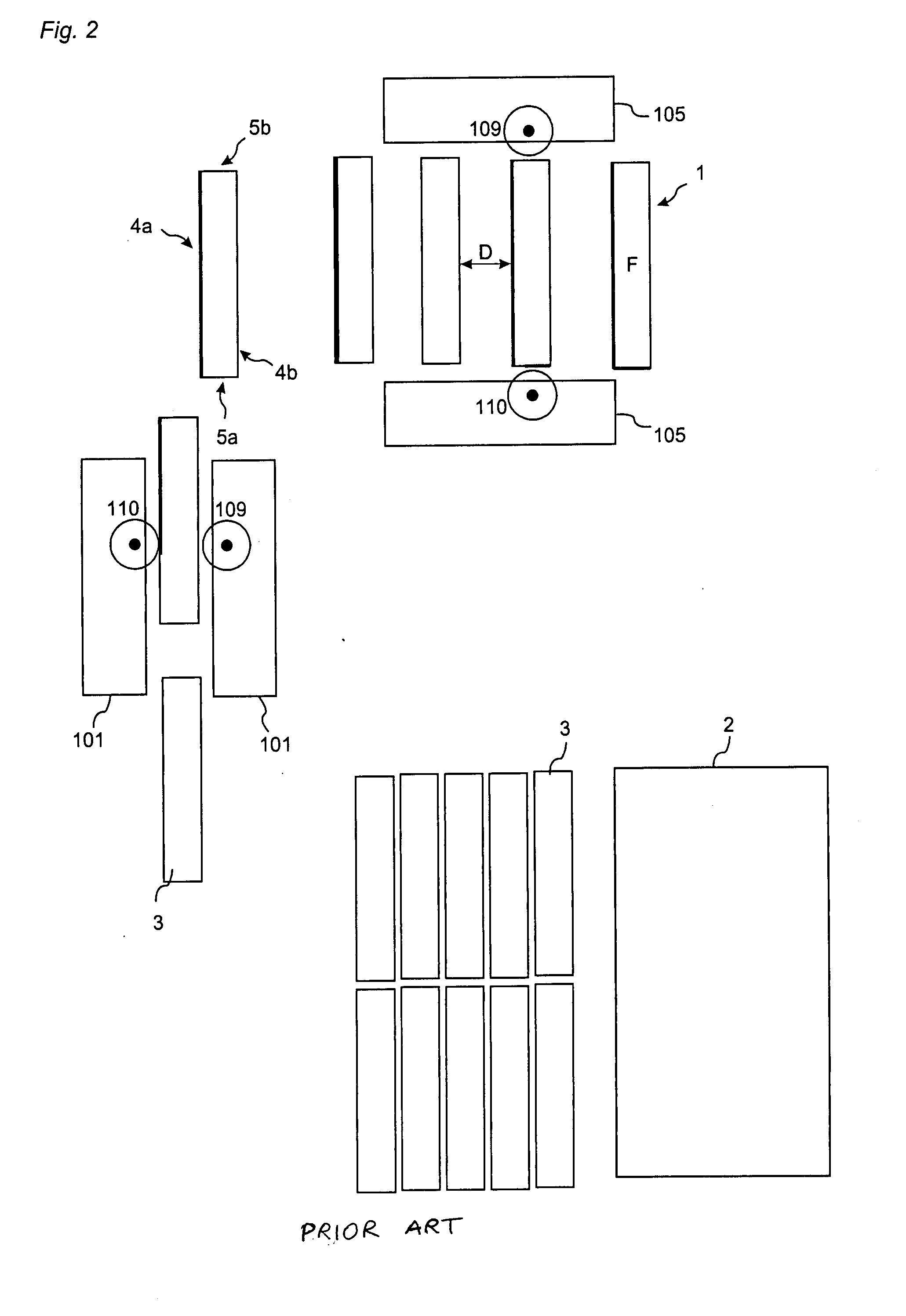

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

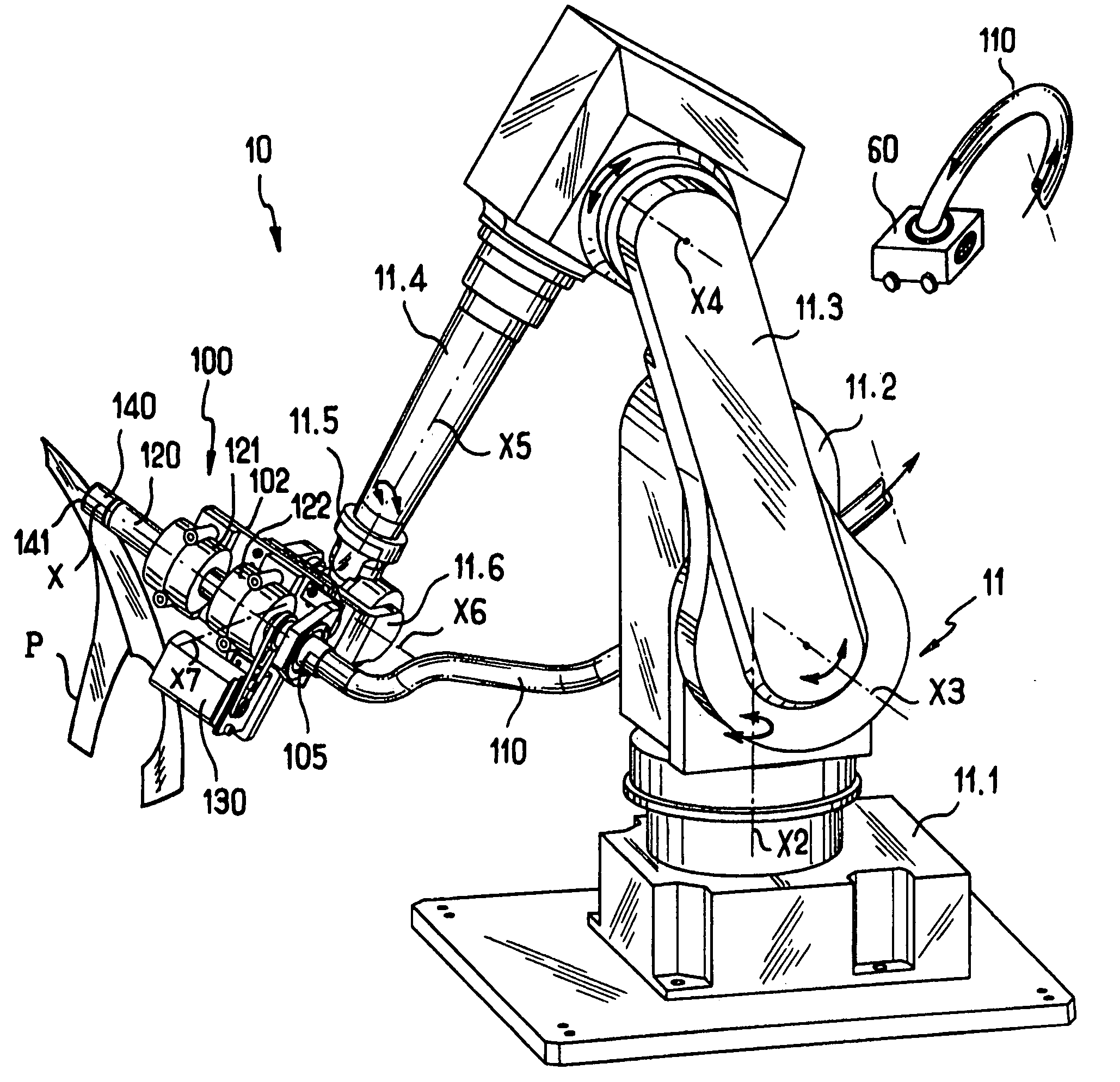

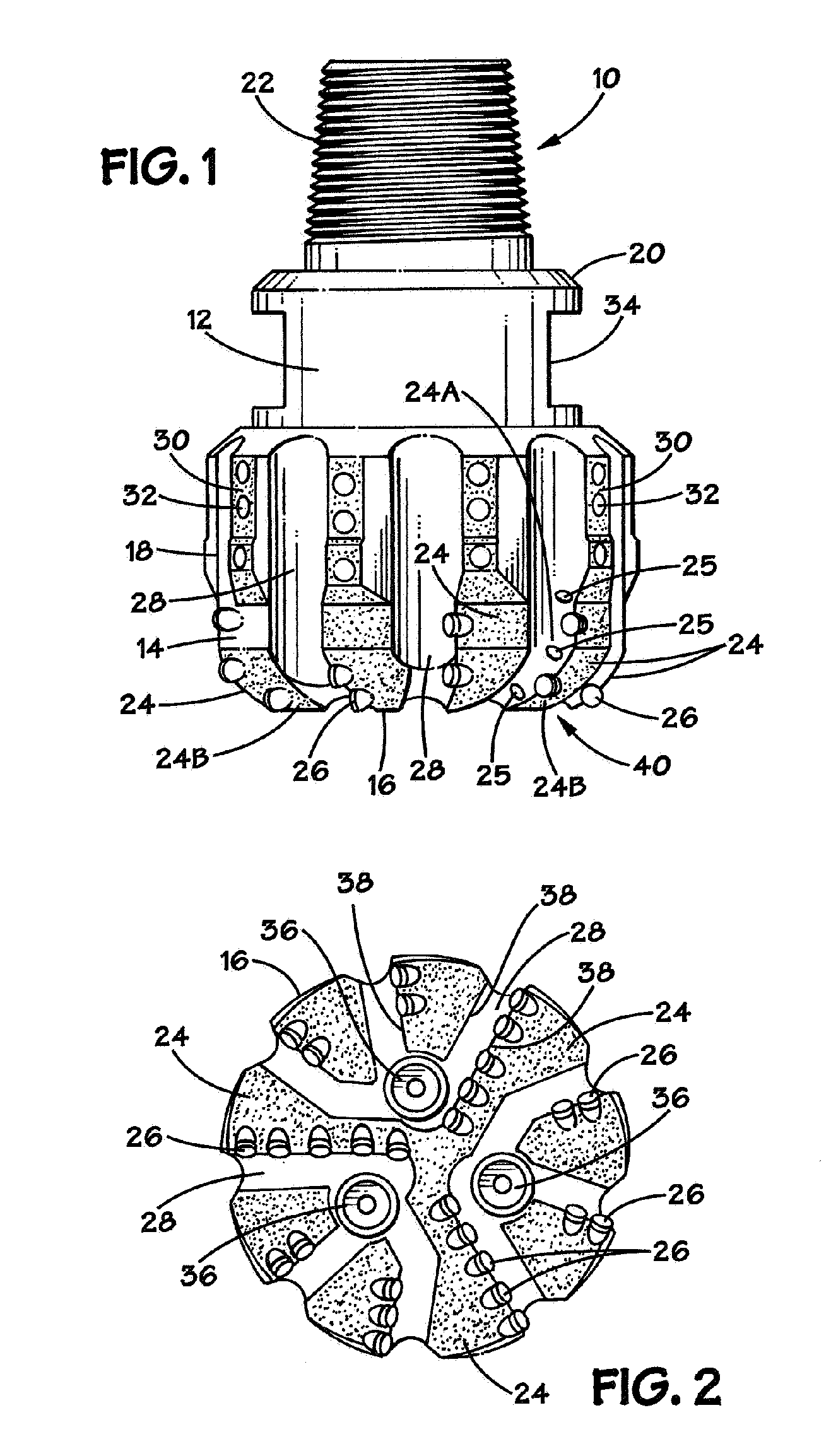

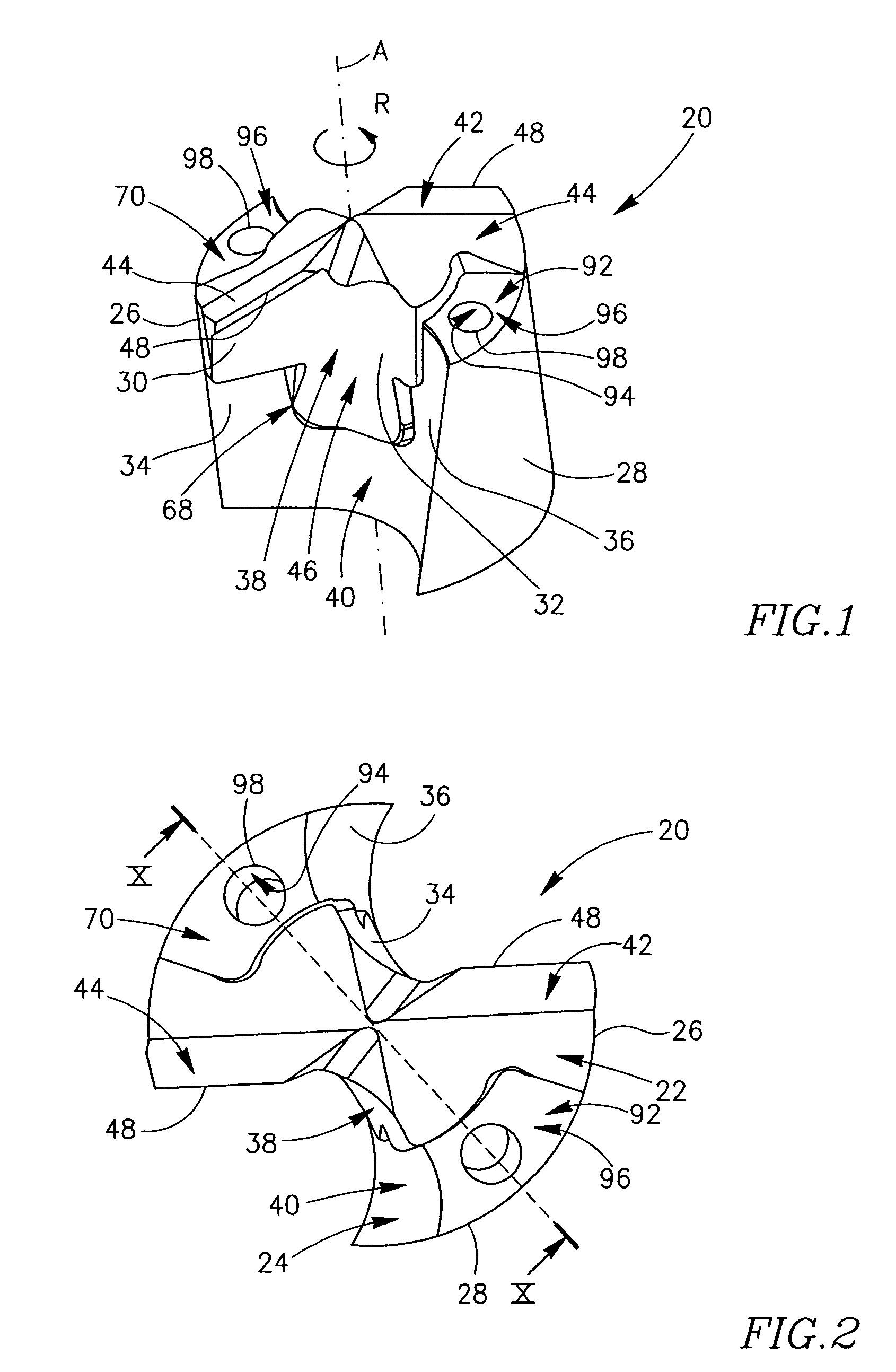

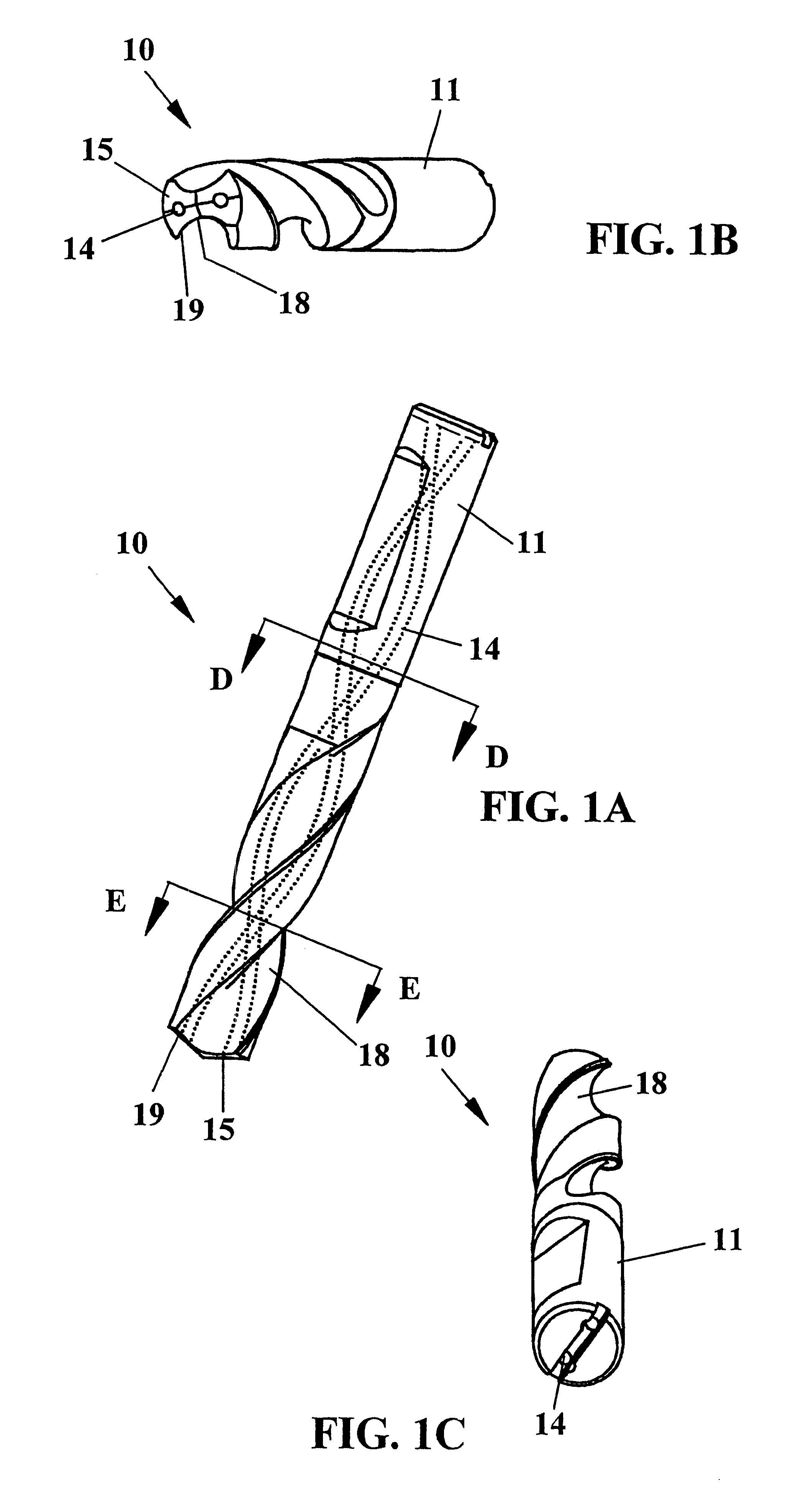

Indirect Cooling of a Rotary Cutting Tool

ActiveUS20100272529A1Dissipate energyMinimization requirementsTransportation and packagingMilling cuttersWorking fluidEngineering

An indirect cooling system for a rotating cutting tool uses a cryogenic coolant that is delivered to a cavity formed on the back surface of the cutting element, providing cooling near the cutting edge of the element. Because the total flow rate of the working fluid is low (less than 0.08 Liters / min / cutting edge), the fluid can be safely vented to atmosphere from the cavity, and as a result, no specialized coolant recovery or ventilation equipment is needed. The cavity may be formed with fins to enhance the heat transfer between the cutting element and the coolant, and coolant may additionally be sprayed directly onto the exterior surface of the element to cool the tool-chip interface. The indirect cooling system may be used for hard to machine metals and composites, as well as the machining of conventional materials without the use of traditional cutting fluids.

Owner:5ME LLC

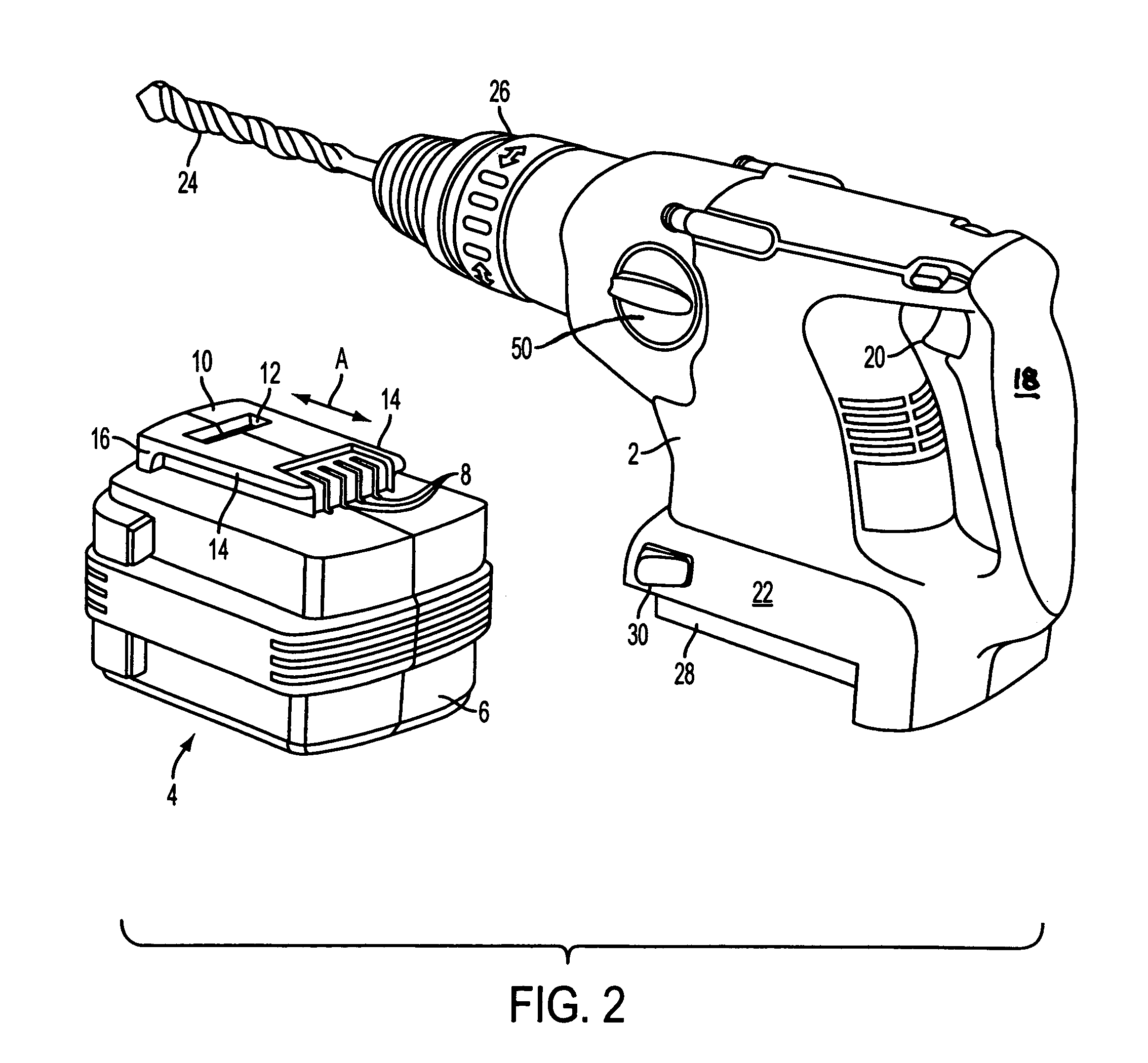

Cordless hand held power tool with powered accessory

Owner:BLACK & DECKER INC

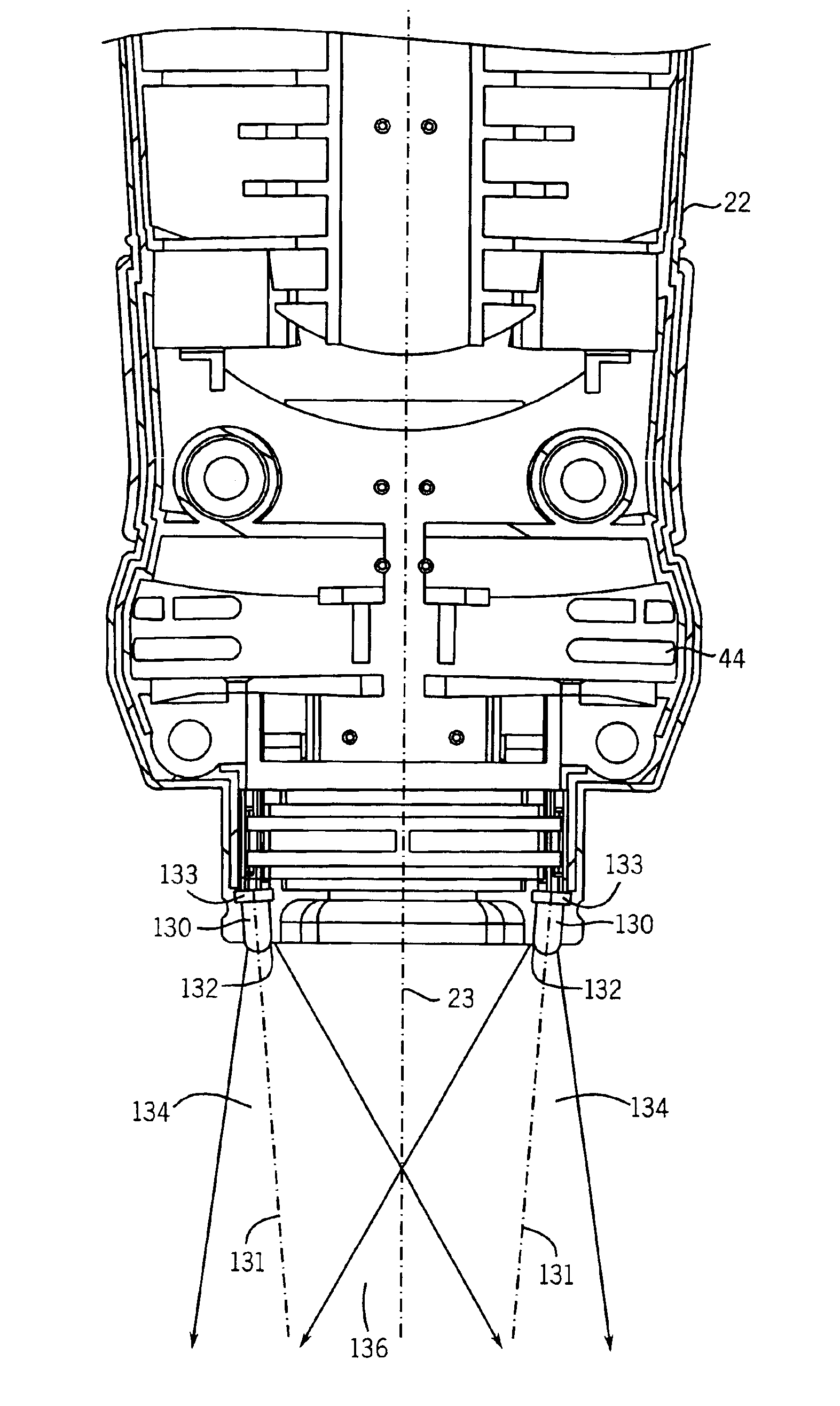

Power tool with light emitting diode

A rotary cutting tool includes a housing and a motor provided within the housing for rotating a cutting accessory coupled to the rotary cutting tool. The rotary cutting tool also includes a plurality of light emitting diodes for illuminating a point of cut of the rotary cutting tool. Each of the plurality of light emitting diodes have a central longitudinal axis, and at least one of the light emitting diodes is couple to the housing such that the central longitudinal axis of the light emitting diode is not parallel to a rotation axis of the cutting accessory.

Owner:CREDO TECH CORP

Floorboards, flooring systems and method for manufacturing and installation thereof

Floorboards with a format corresponding to a traditional parquet block for laying of mechanically joined floating flooring. Rectangular floorboards include a surface layer and a core with two long sides and two short sides, for making a floating flooring, which floorboards are mechanically lockable and which along their four sides have pairs of opposing connectors for locking similar, adjoining floorboards to each other both vertically and horizontally wherein the long sides have a length not exceeding 80 cm and the short sides have a width not exceeding 10 cm.

Owner:VÄLINGE INNOVATION AB

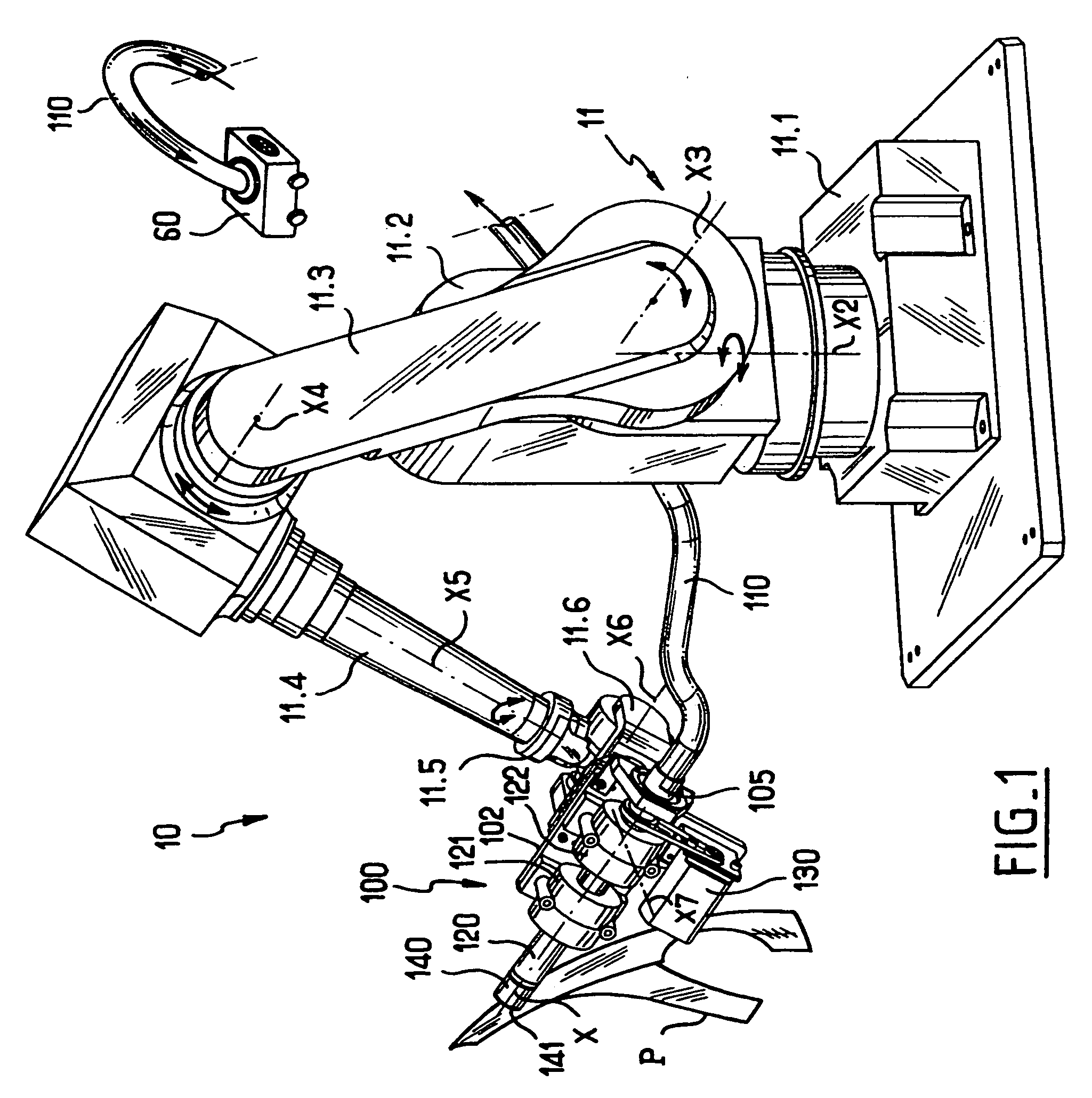

Machining mechanical parts with a hollow cylindrical tool

ActiveUS20060291970A1Simple processAvoid high frequency noiseThread cutting feeding devicesDrilling rodsWood shavingsMechanical components

The present invention relates to a device for machining mechanical parts by means of a hollow cylindrical tool presenting a distal end with a free edge that is shaped to perform machining when said tool is rotated about its axis. In accordance with the invention, the hollow cylindrical tool is fitted internally with a transverse member forming a shaving-breaker, and said hollow cylindrical tool is secured axially to a distal end of a hollow cylindrical spindle, said hollow cylindrical spindle being mounted to rotate about its own axis on a support plate, and being driven externally by rotary drive means mounted on said support plate, and said hollow cylindrical spindle having a proximal end facing and directly adjacent to a hollow cylindrical endpiece secured to said support plate and connected to a suction hose, such that the machining shavings can be evacuated internally by passing successively through the hollow cylindrical tool going round the transverse member forming a shaving-breaker, through the hollow cylindrical spindle, through the hollow cylindrical endpiece, and through the suction hose.

Owner:ROMER INC

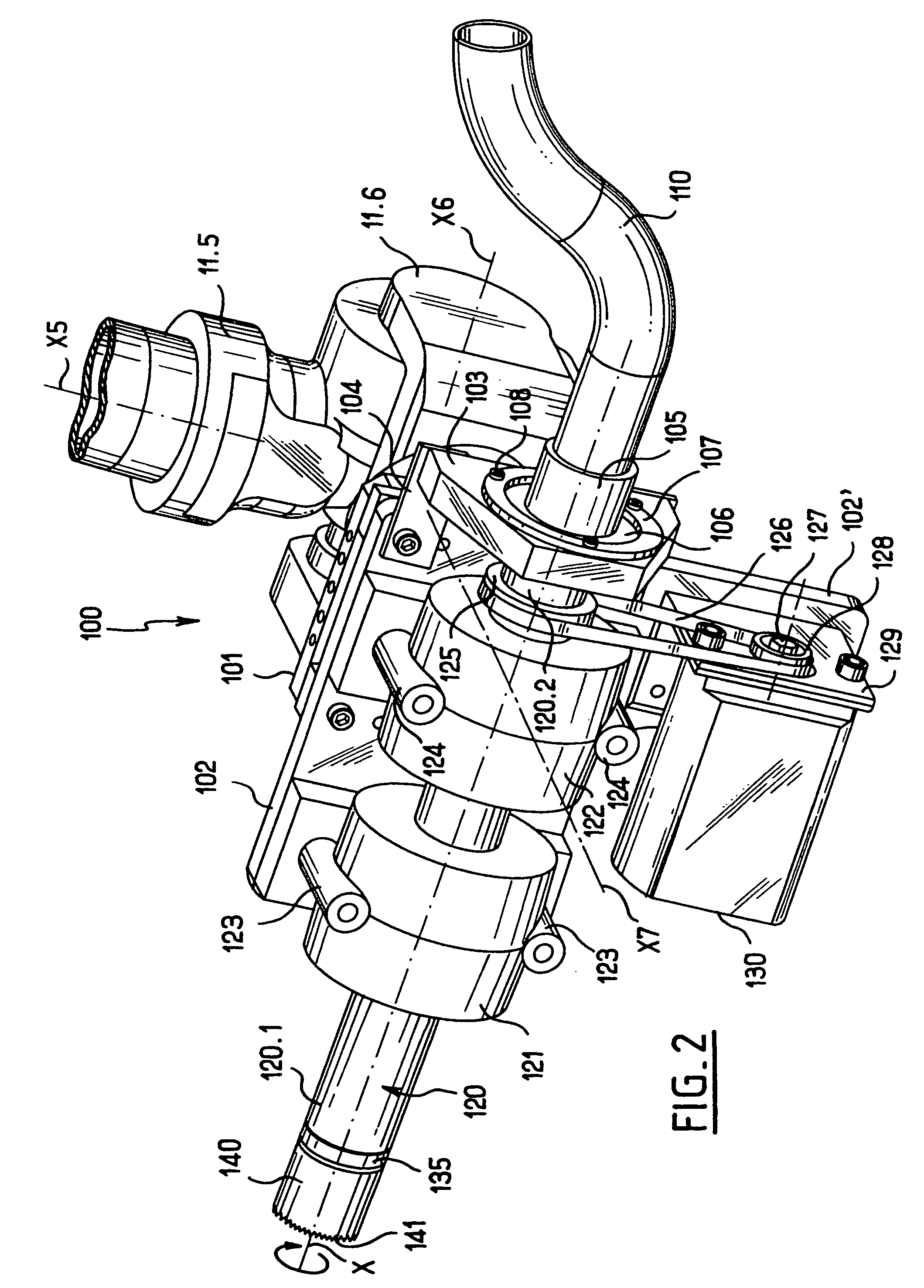

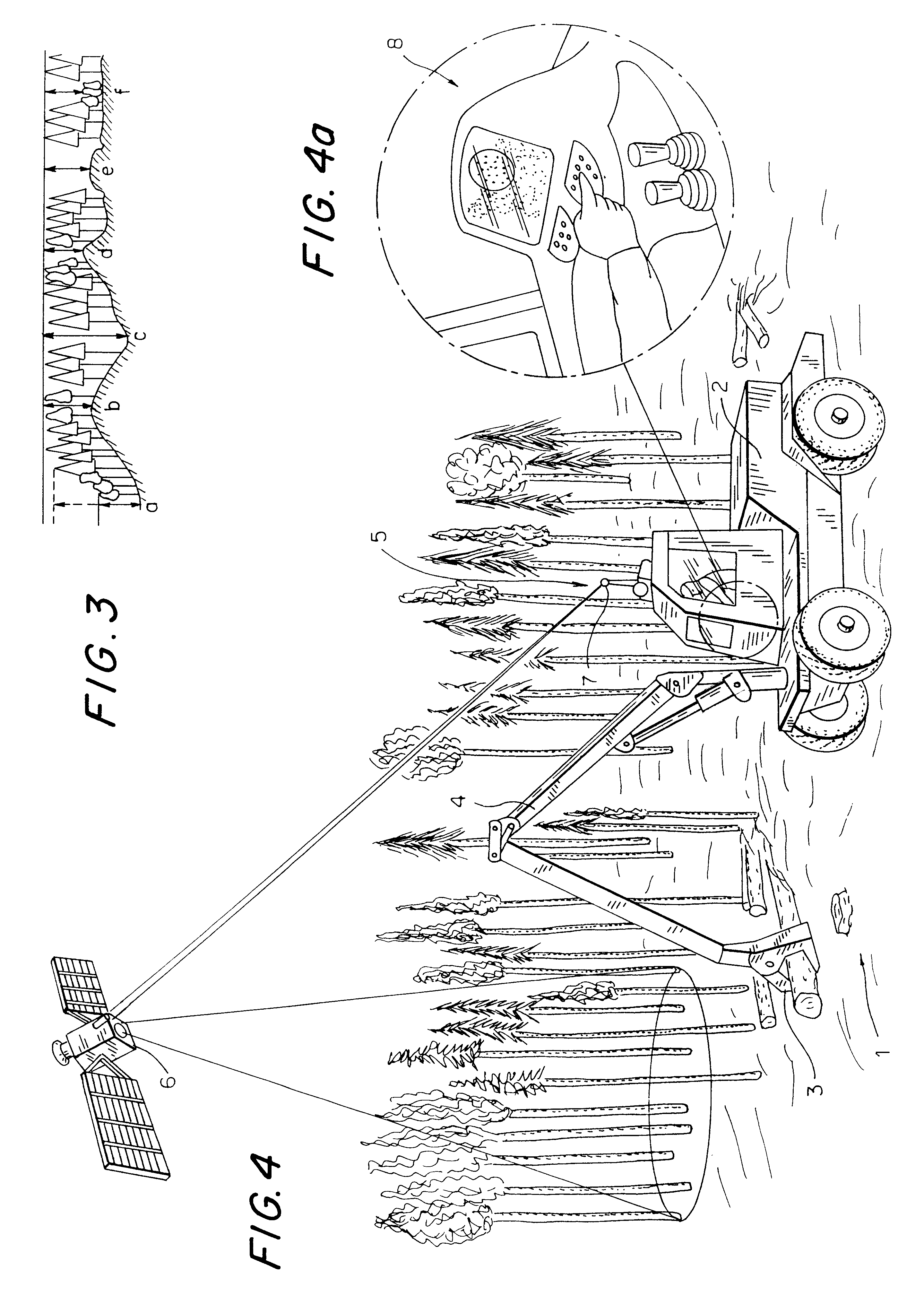

Method for timber harvesting and system for forestry

InactiveUS6182725B1Less-accurate resolutionSawing apparatusMulti-purpose machinesForest industryEngineering

A method and system for forestry, in particular harvesting by means of a harvesting machine comprising a vehicle and a harvesting arrangement mounted thereon, is based on the fact that at least one position determining device (5) capable of determining the positioning of the harvesting machine by means of external wirelessly receiveable signals is arranged on the harvesting machine (1). A marking device computer, is arranged on the harvesting machine to control the marking device to mark the piece of timber with position information by means of position information received from the position determining device (5).

Owner:SORVIK BENGT

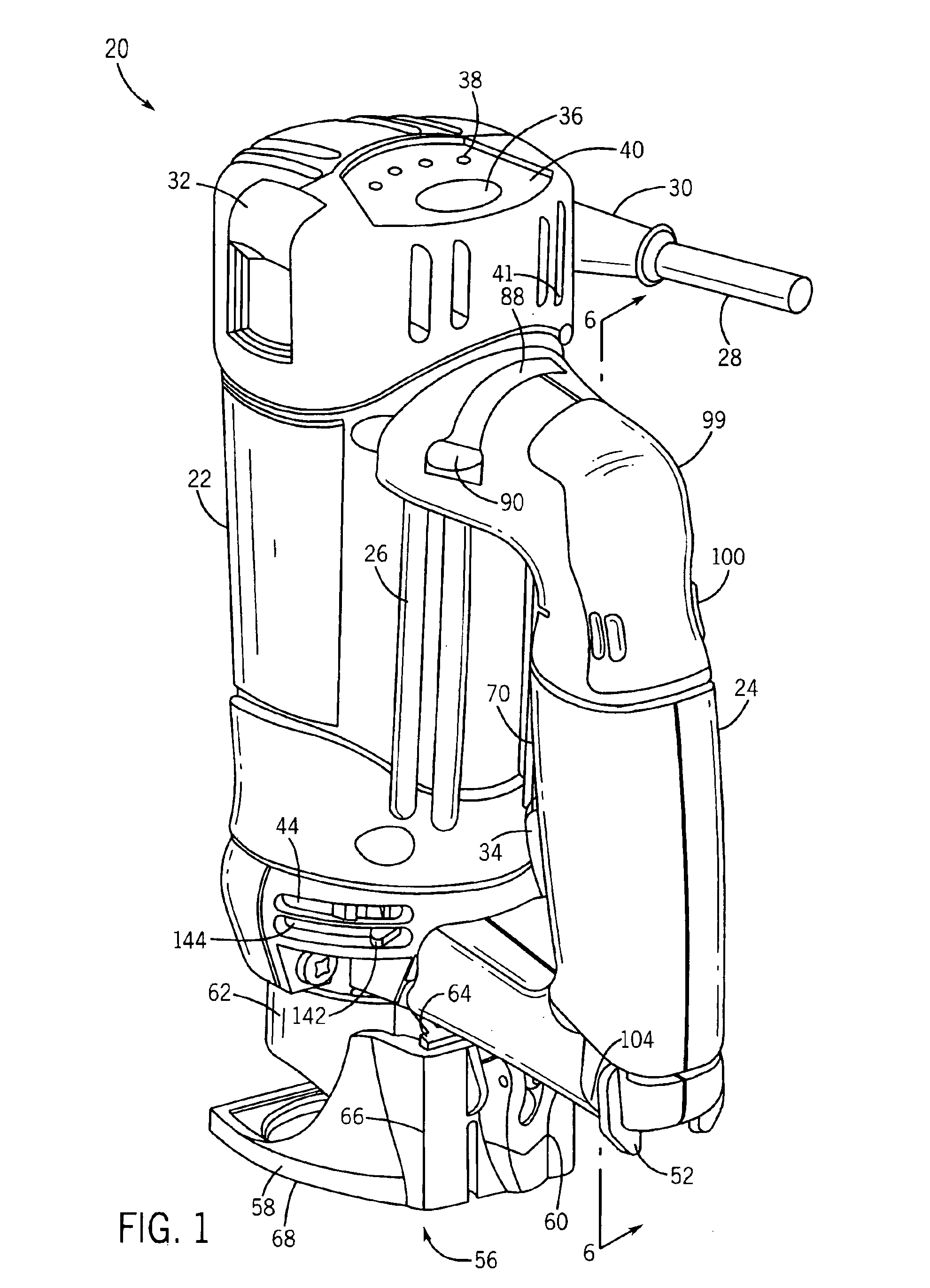

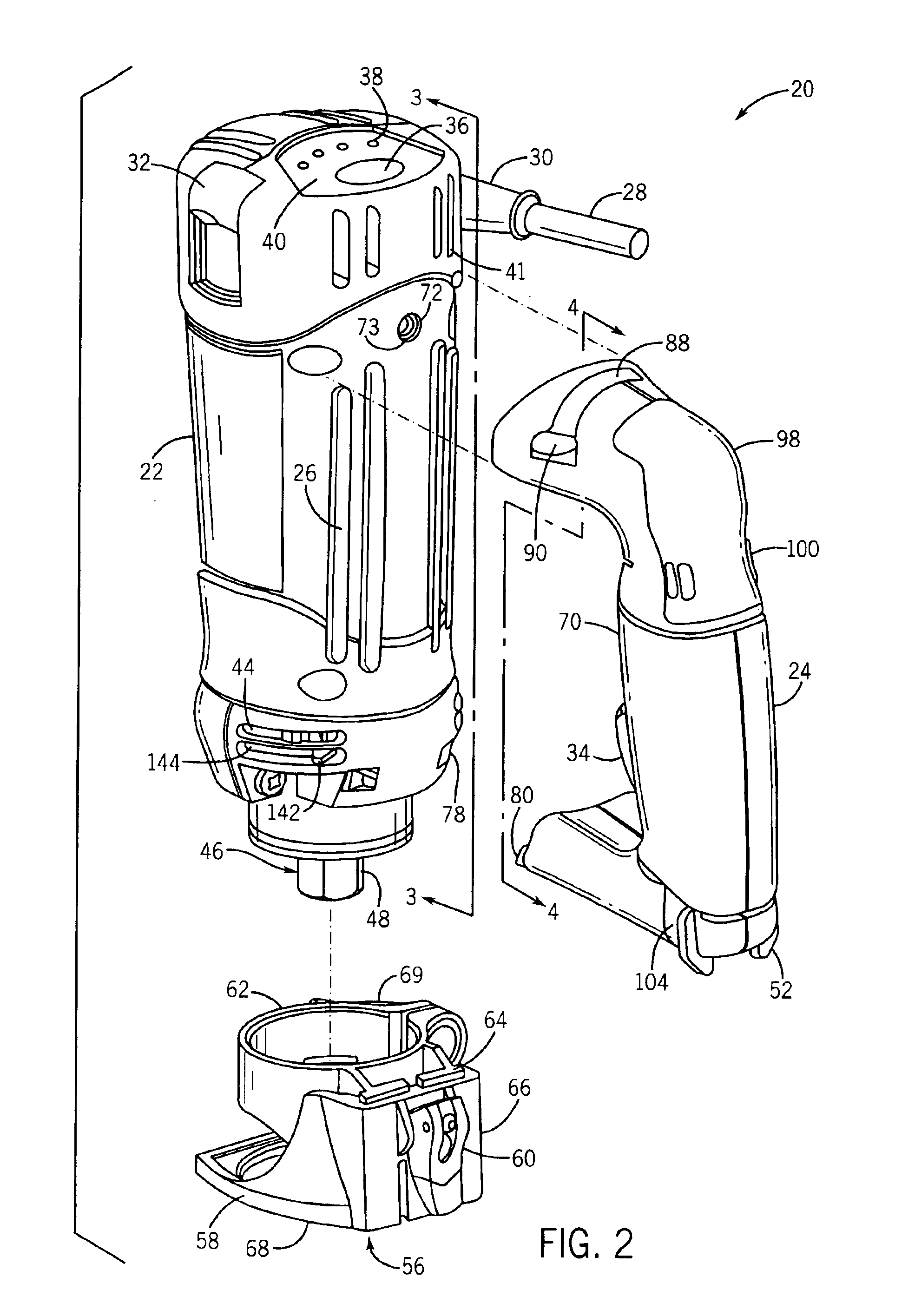

Dust extractor device for a router

ActiveUS7290967B2Maximum effectivenessSpace minimizationMulti-purpose machinesProfiling/shaping machinesEngineeringFoot boards

A dust extractor device of a router has rotatable dust trap part able to be connected with a foot plate of the router and arranged to the side of the routing tool underneath the foot plate, such dust trap part being open toward the routing tool. The foot plate has an access opening for the routing tool. The dust trap part is constituted by an extractor hood with a hood casing at least essentially centered on the axis of rotation and a hood floor. The hood casing and the hood floor extend in the peripheral direction through an angle equal to or less than 180°. The extractor hood is open at its top side and opens into the access opening. The top end region of the extractor hood is rotatably supported on a holder, which is detachably secured to the foot plate and in the position of use extends around the access opening. The top side of the access opening is provided with a covering means, which is detachably attached to the foot plate and covers the access opening, such covering means having in it an access opening for the routing tool. The connection means is, in the position of use, in open connection with the access opening.

Owner:FESTOOL GMBH

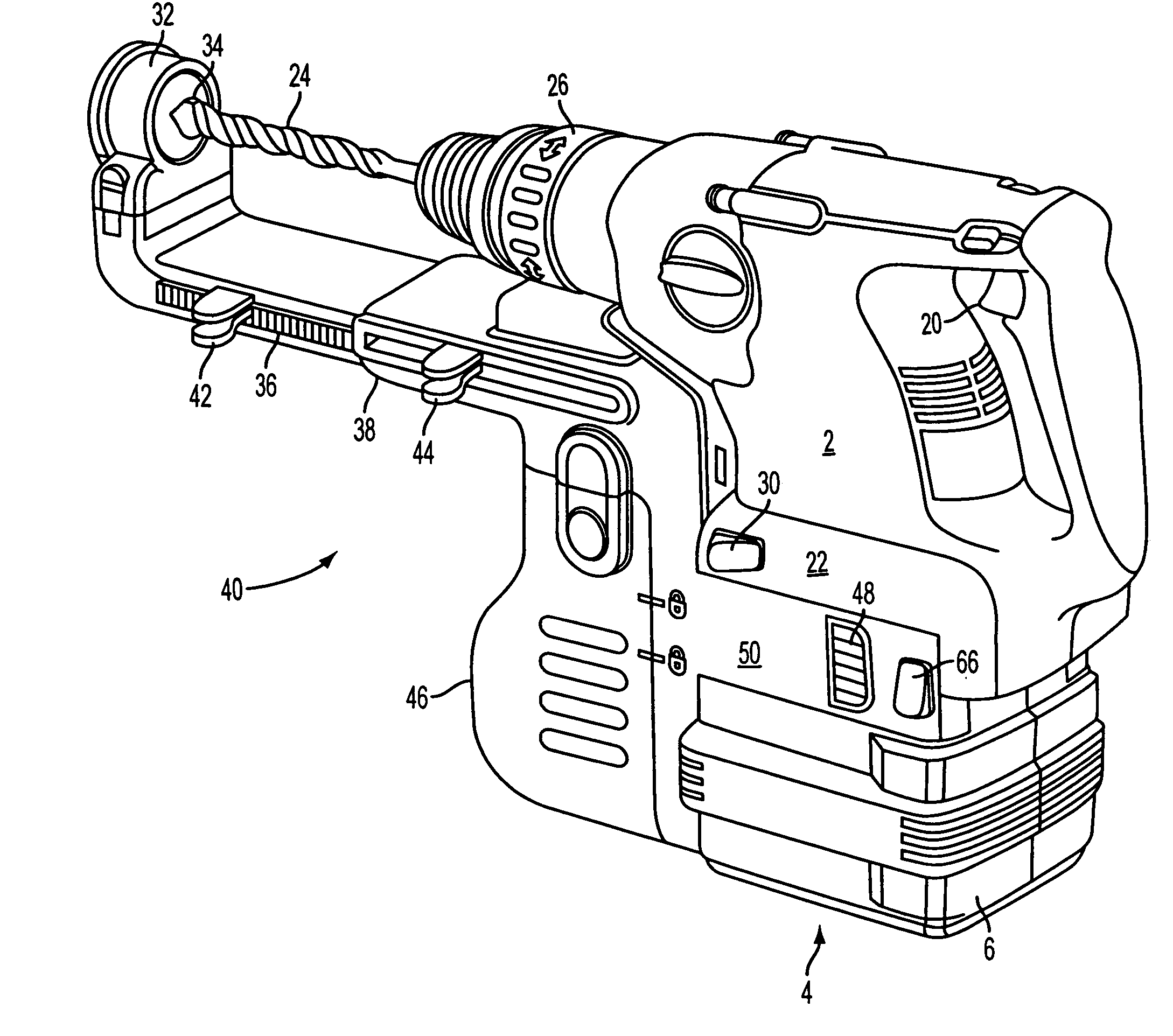

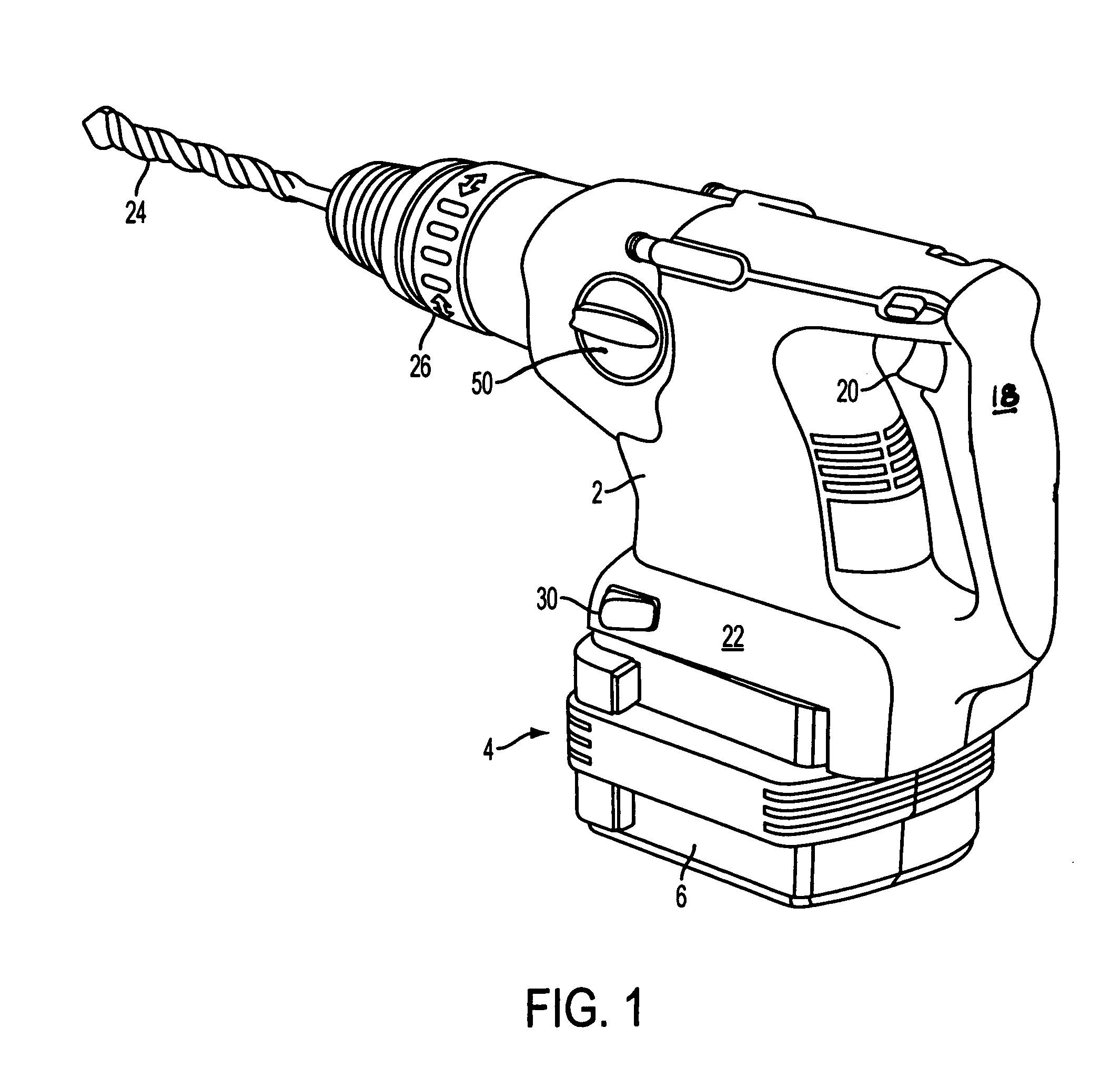

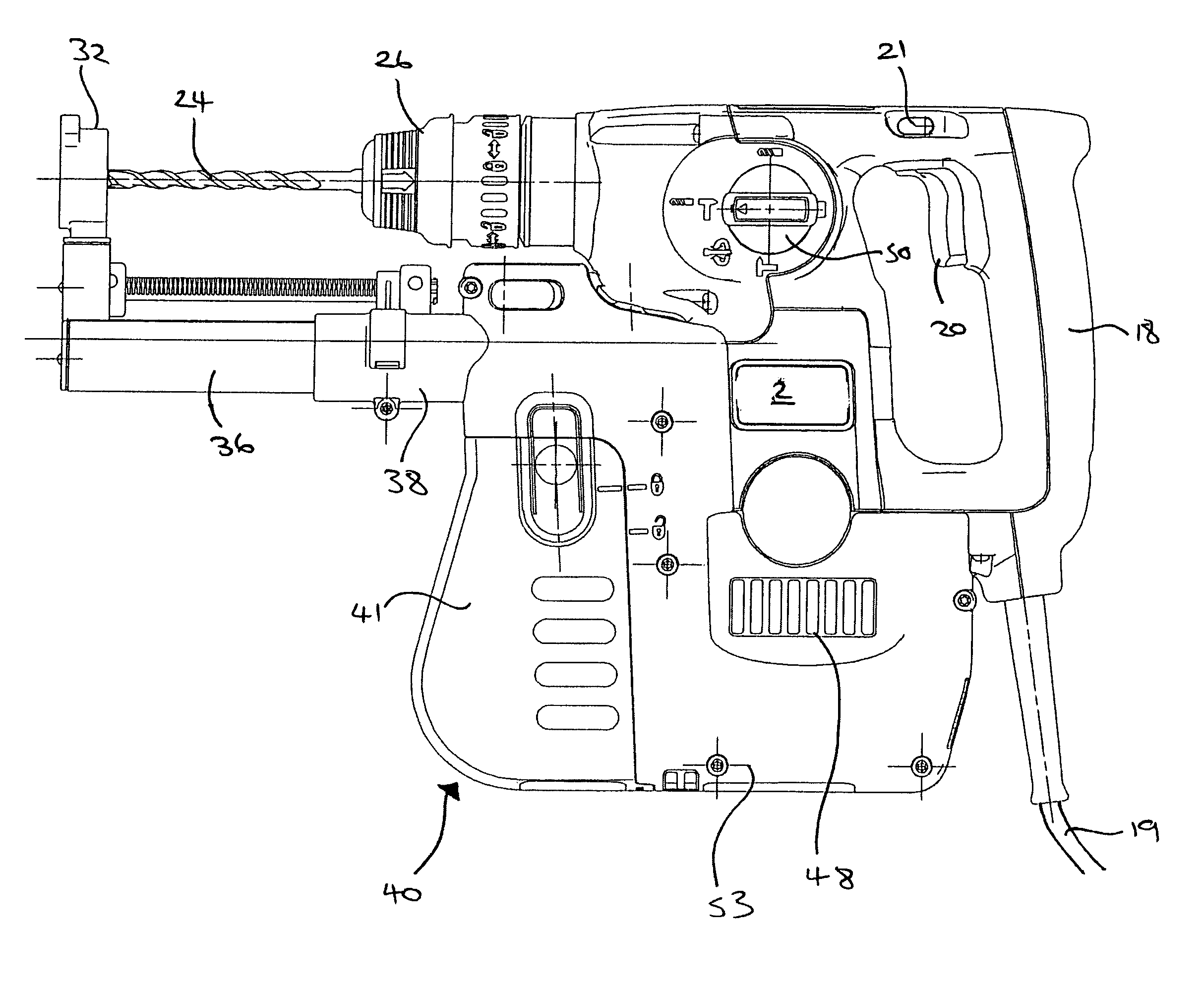

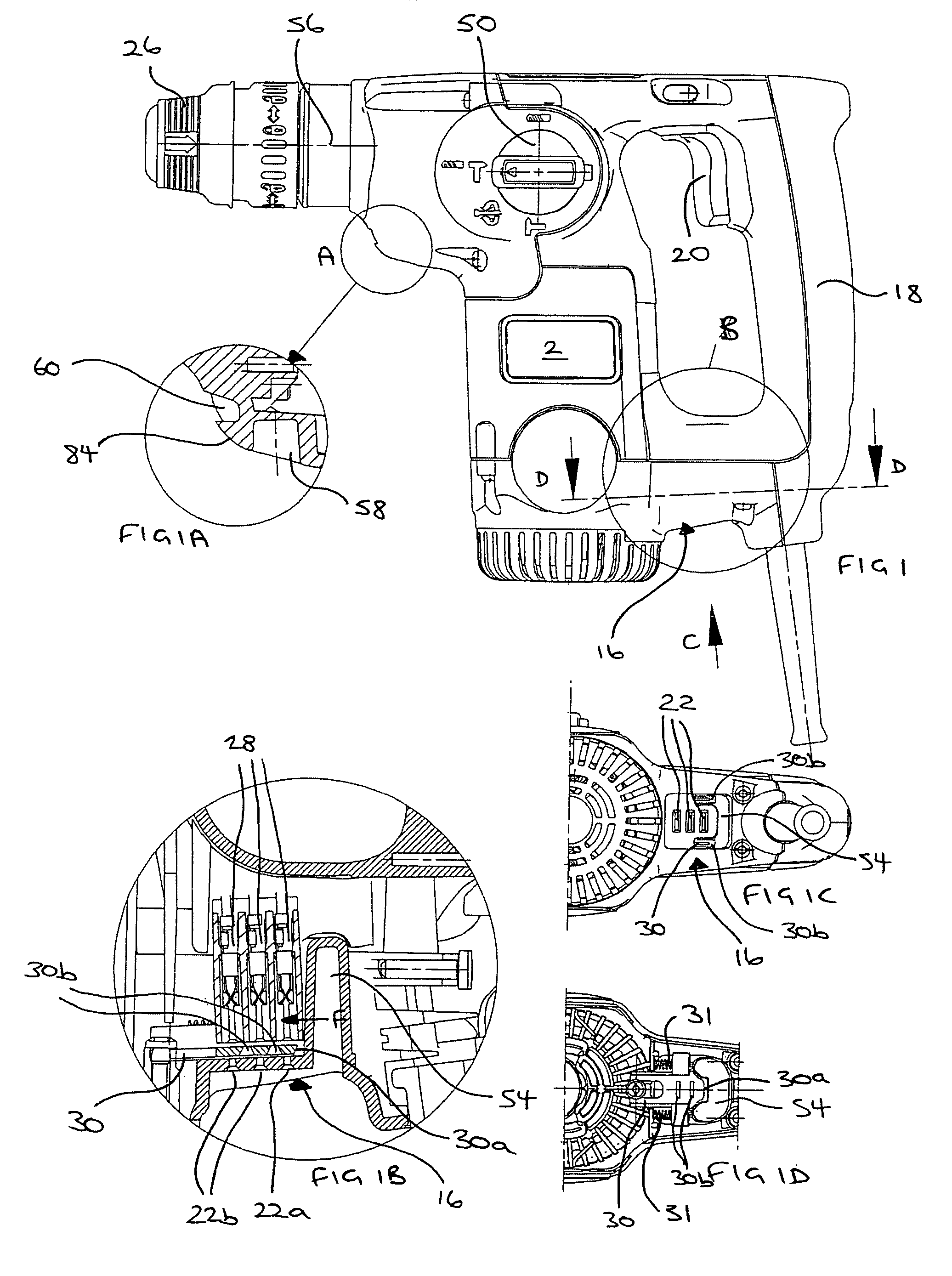

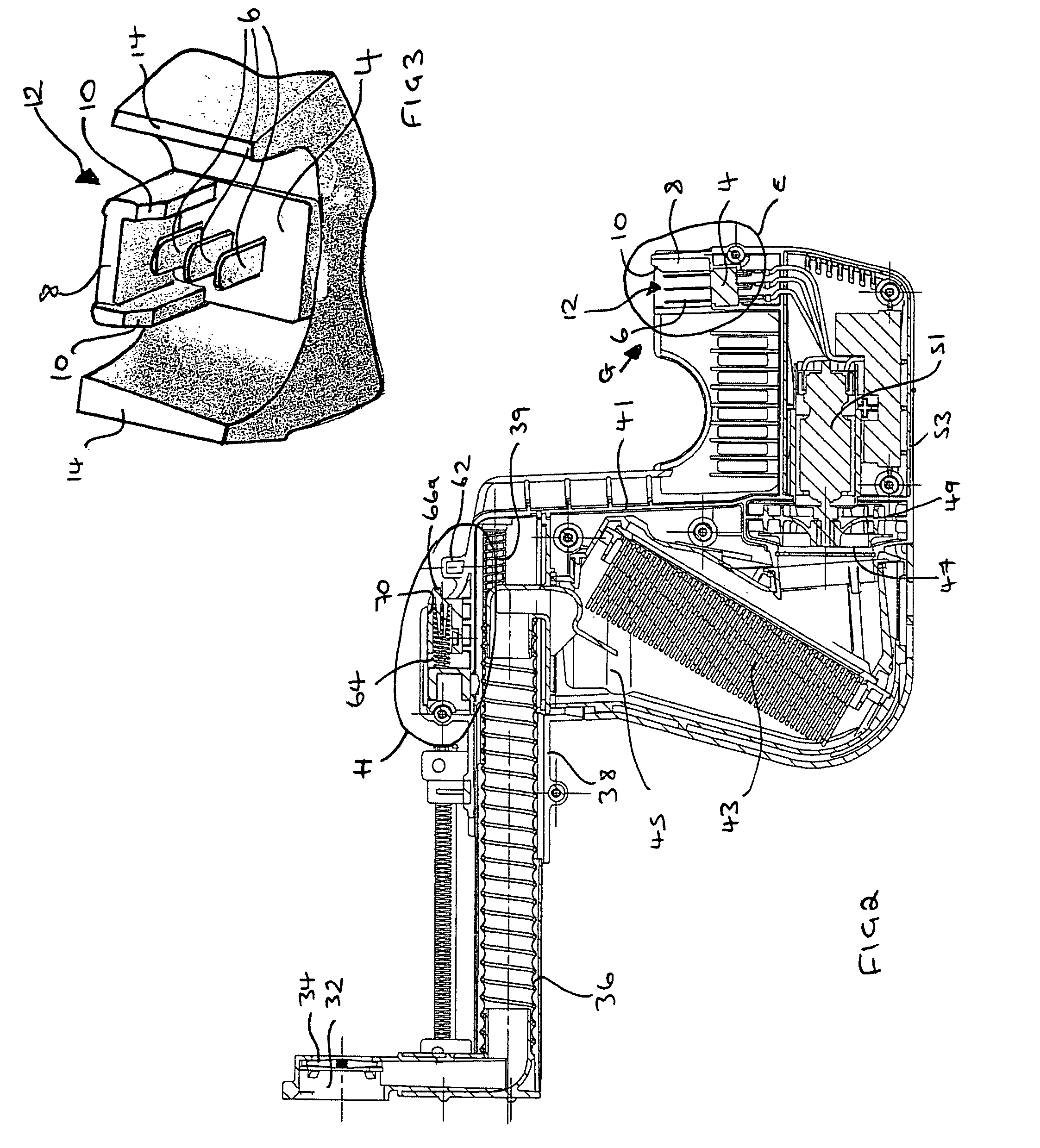

Hand held drilling and/or hammering tool with dust collection unit

InactiveUS7017680B2Efficient processEasy to installThread cutting feeding devicesDrilling rodsHand heldElectrical connection

Owner:BLACK & DECKER INC

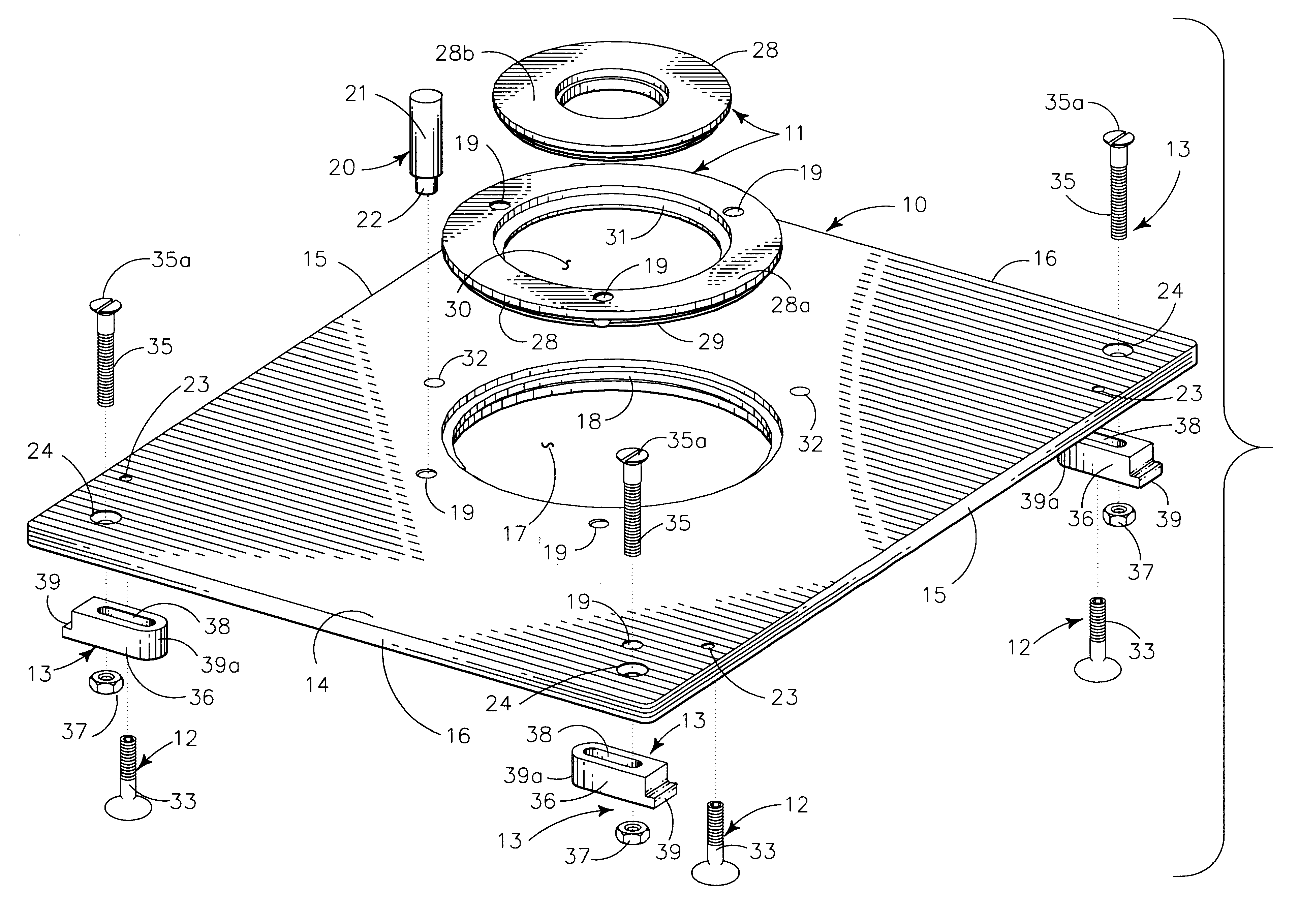

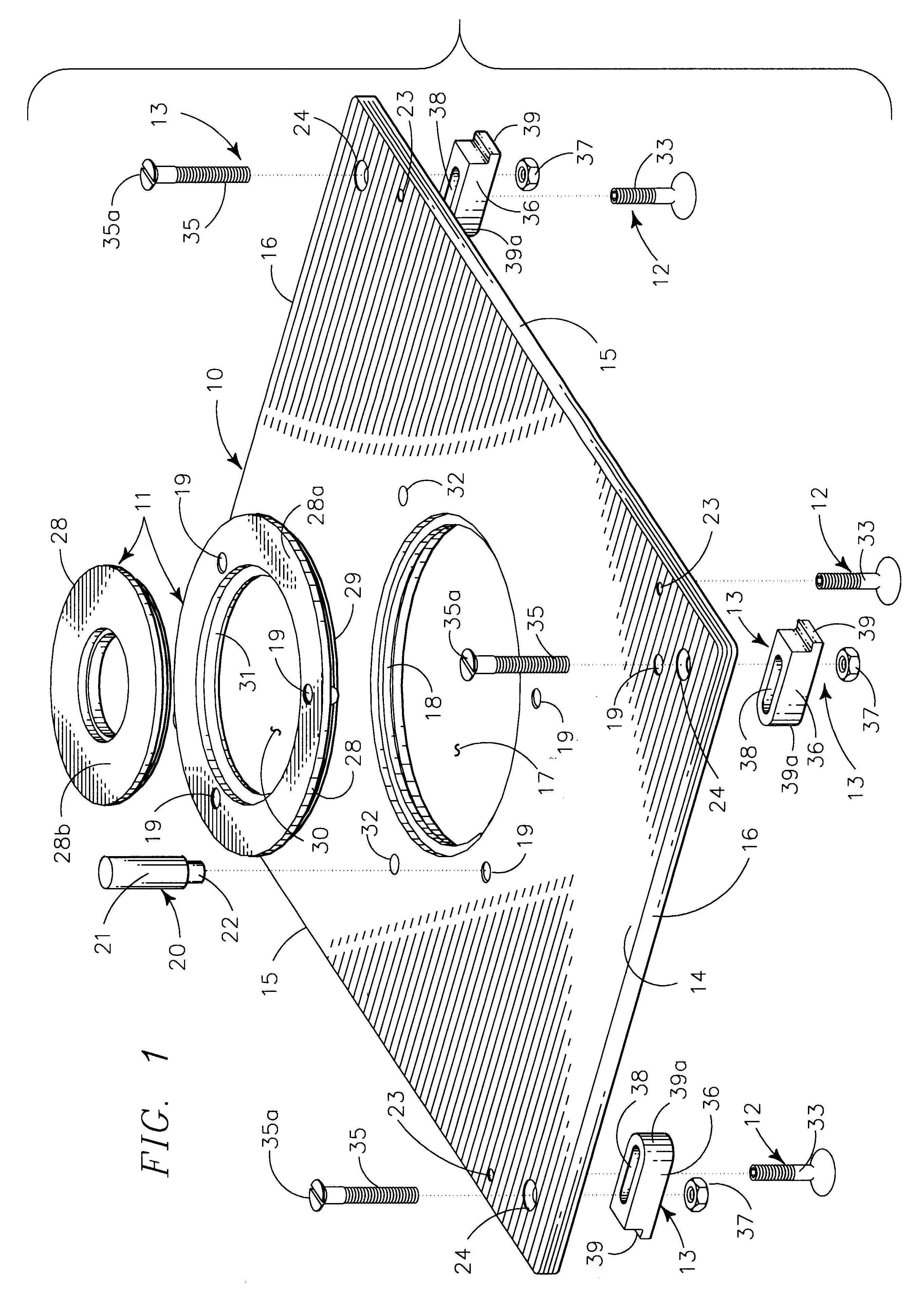

Base plate for mounting router in a support table

InactiveUS6305447B1Excessive damageExcessive wearMulti-purpose machinesProfiling/shaping machinesEngineeringSupport surface

A base plate for mounting a router in a support table provides a plate configured to fit in an orifice, having an inwardly extending ledge thereabout, defined in the support table with the router supported by the base plate to depend therefrom. The base plate defines a medial orifice for passage of the router shaft through the orifice for operative positioning of a cutter carried on the router shaft above the base plate. The base plate medial orifice releasably carries plural annular inserts to cover space between the router shaft and the support plate portion defining the medial orifice. Plural adjustment screws are carried in threaded engagement in the ledge of the support surface orifice for vertical motion to adjustably move adjacent portions of the base plate periphery upwardly from the ledge to create a coplanar relationship of adjacent portions of the base plate and support table. The base plate carries at least one releasably adjustable fastener to fasten the support plate on the ledge in the orifice defined in the support table.

Owner:ROUSSEAU TONY

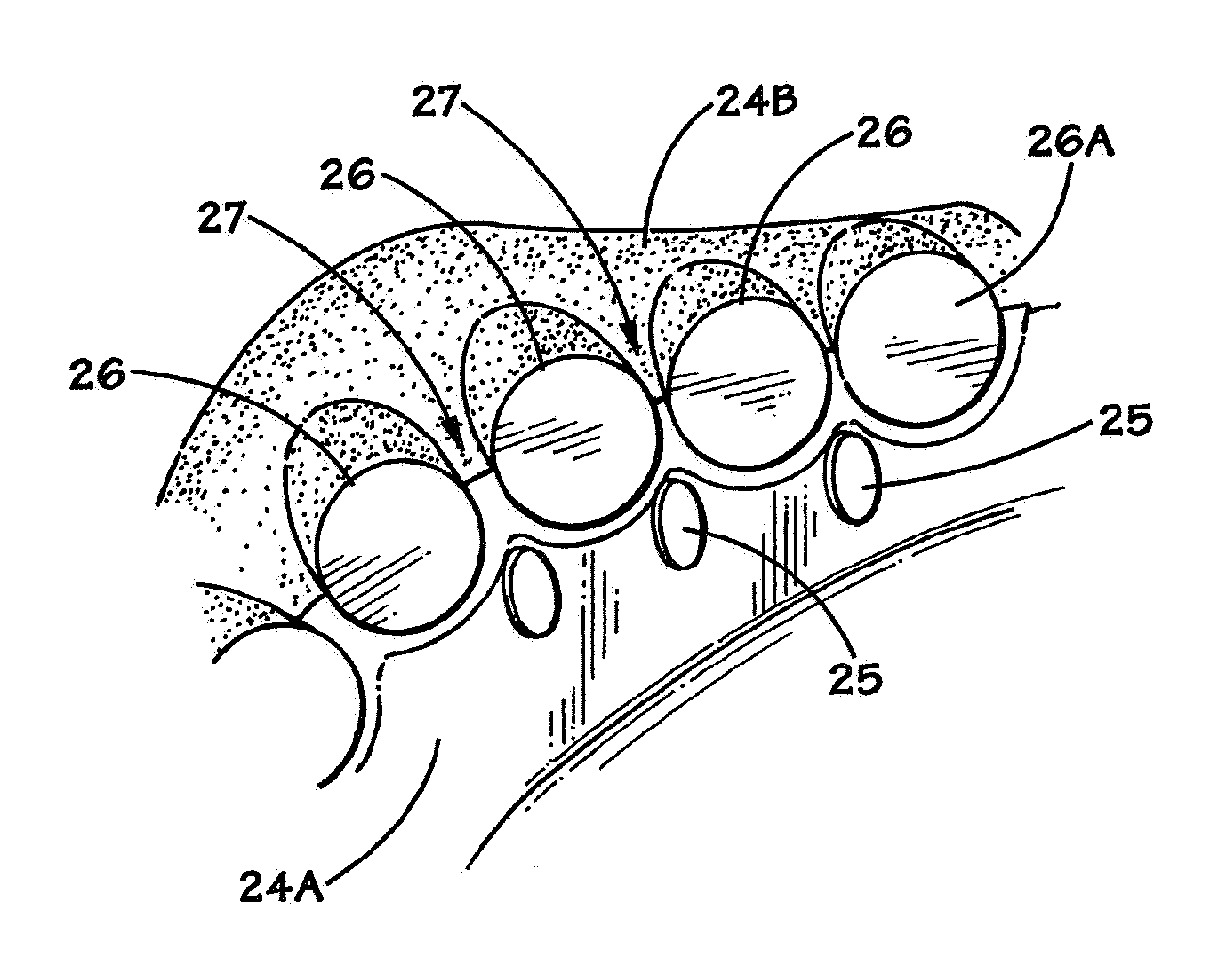

Fixed cutter drill bit with non-cutting erosion resistant inserts

The present invention is directed to a drill bit with non-cutting erosion resistant inserts. In one illustrative embodiment, the apparatus comprises a matrix drill bit body comprising a plurality of blades, a plurality of cutting elements positioned on each of the blades, the cutting elements defining a plurality of web regions, and a plurality of spaced apart, non-cutting erosion resistant inserts positioned along a face of at least one of the blades, at least a portion of each of the non-cutting erosion resistant inserts being positioned in front of one of the web regions.

Owner:GP USA HLDG LLC

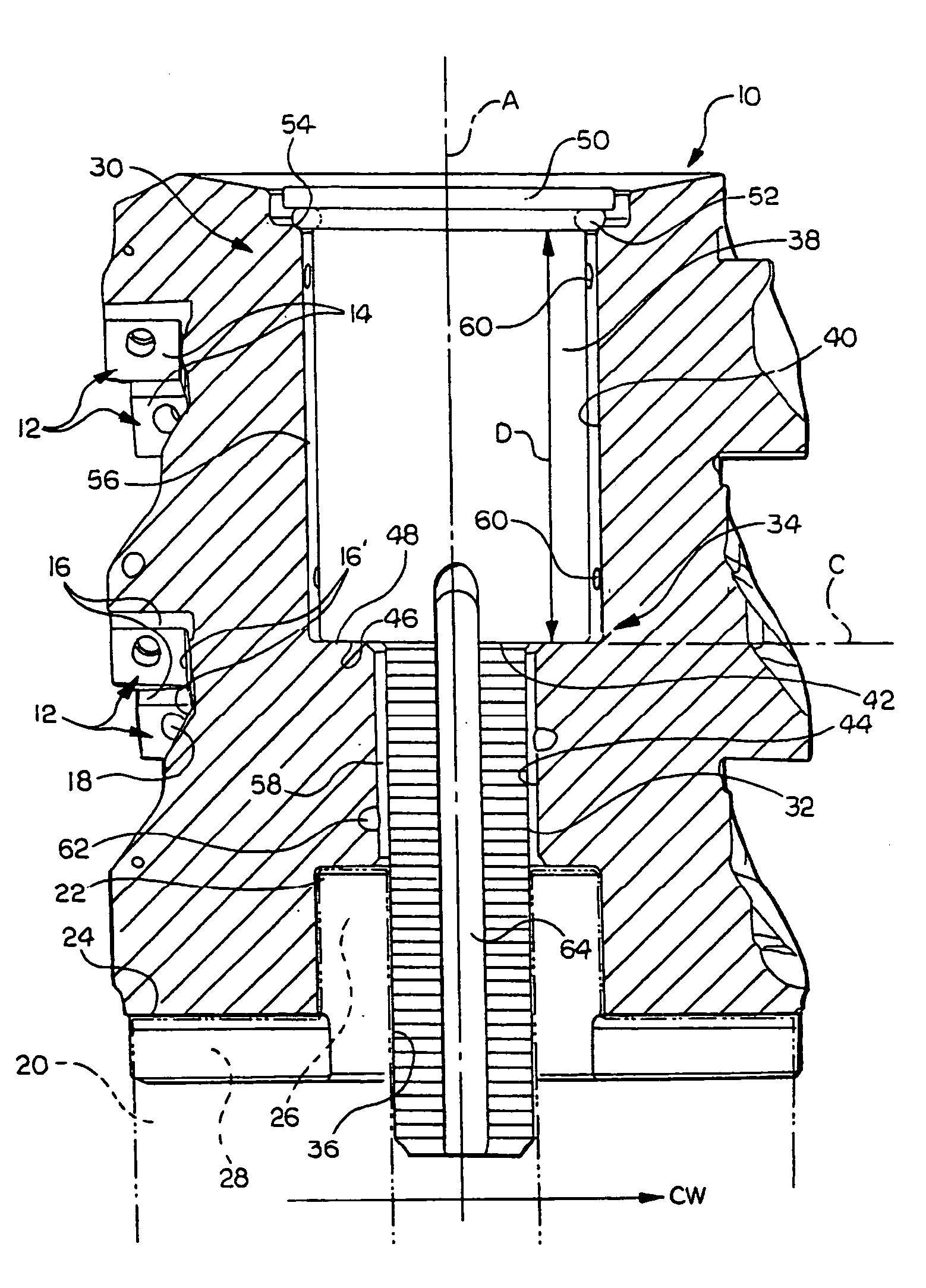

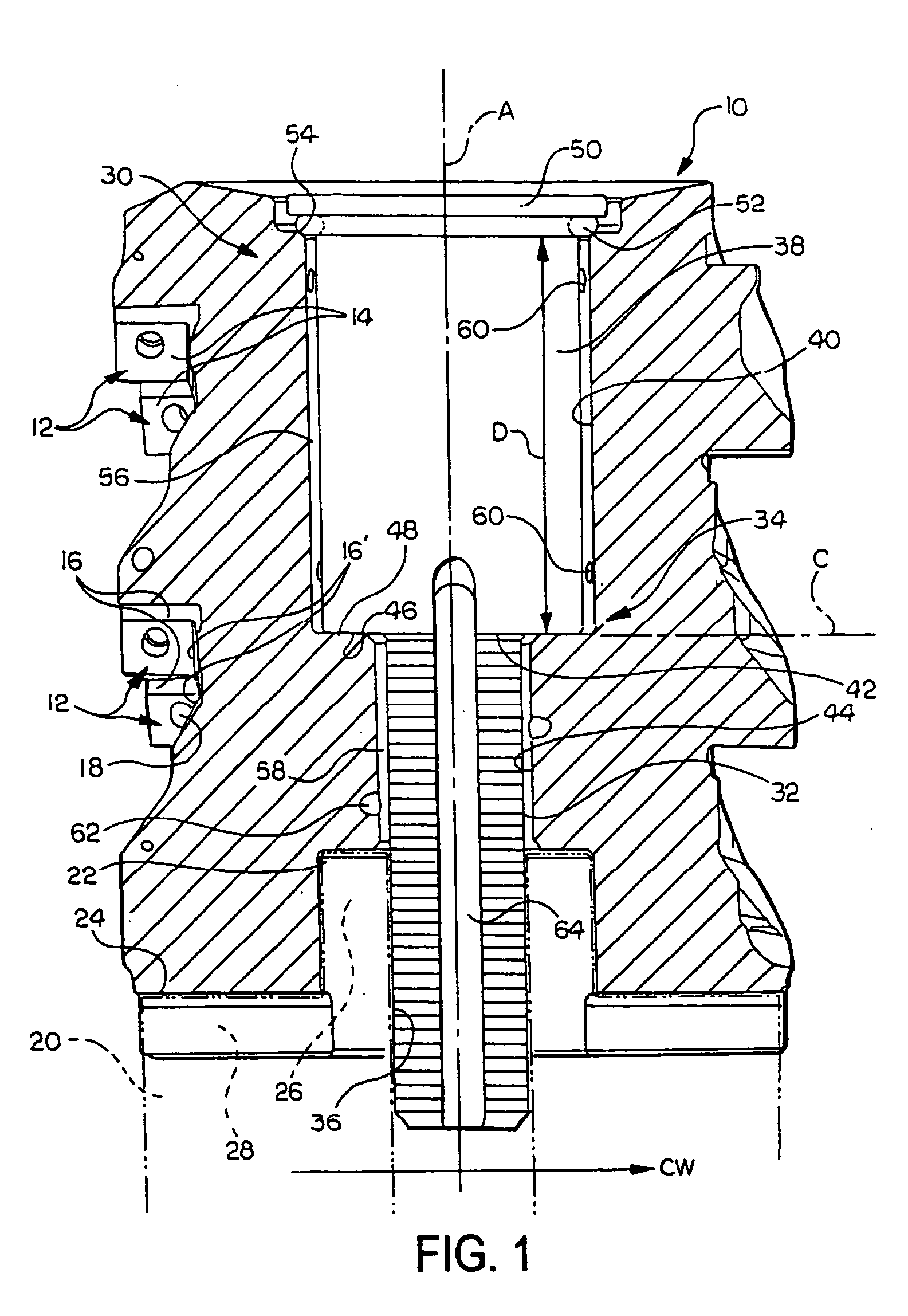

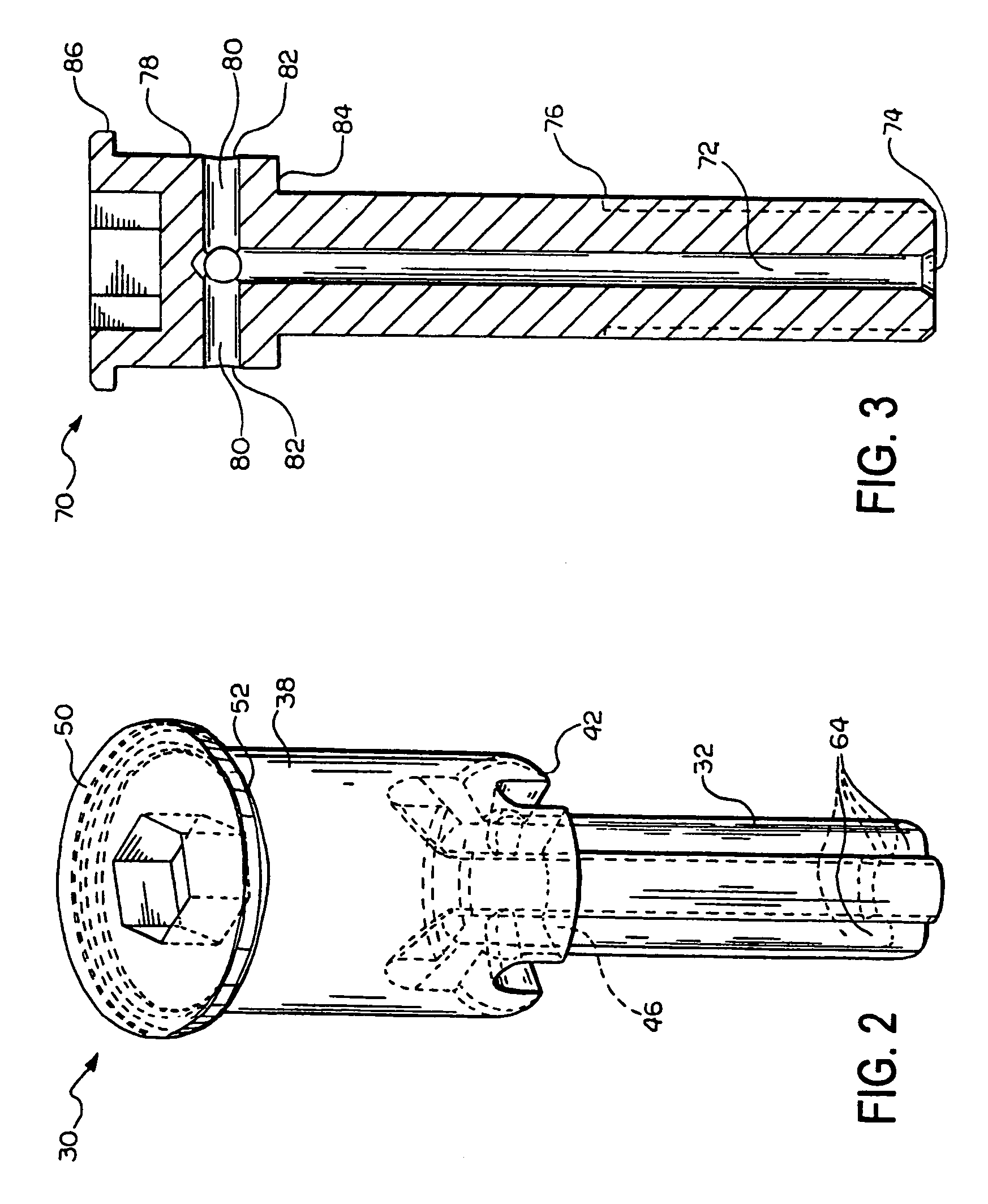

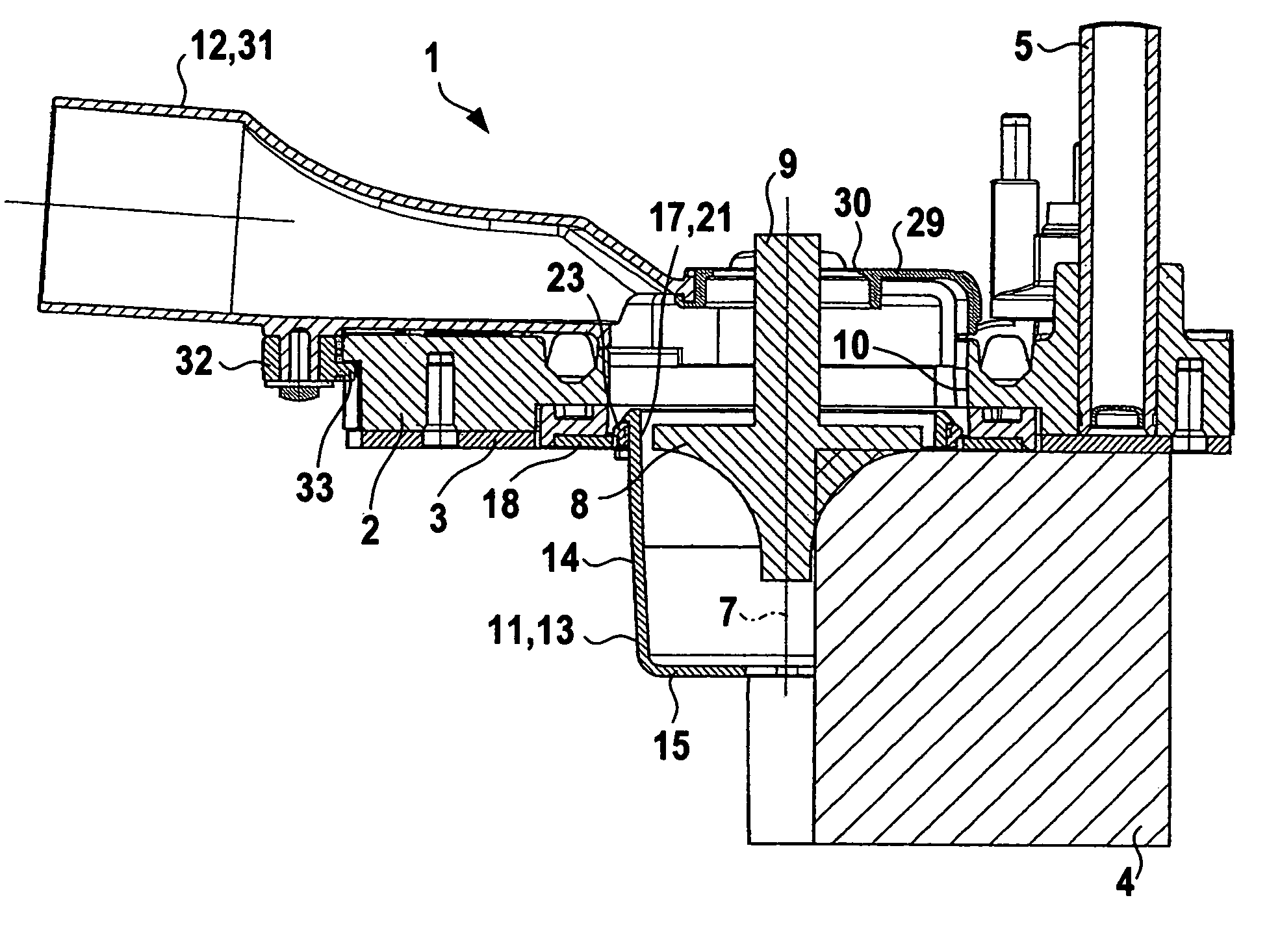

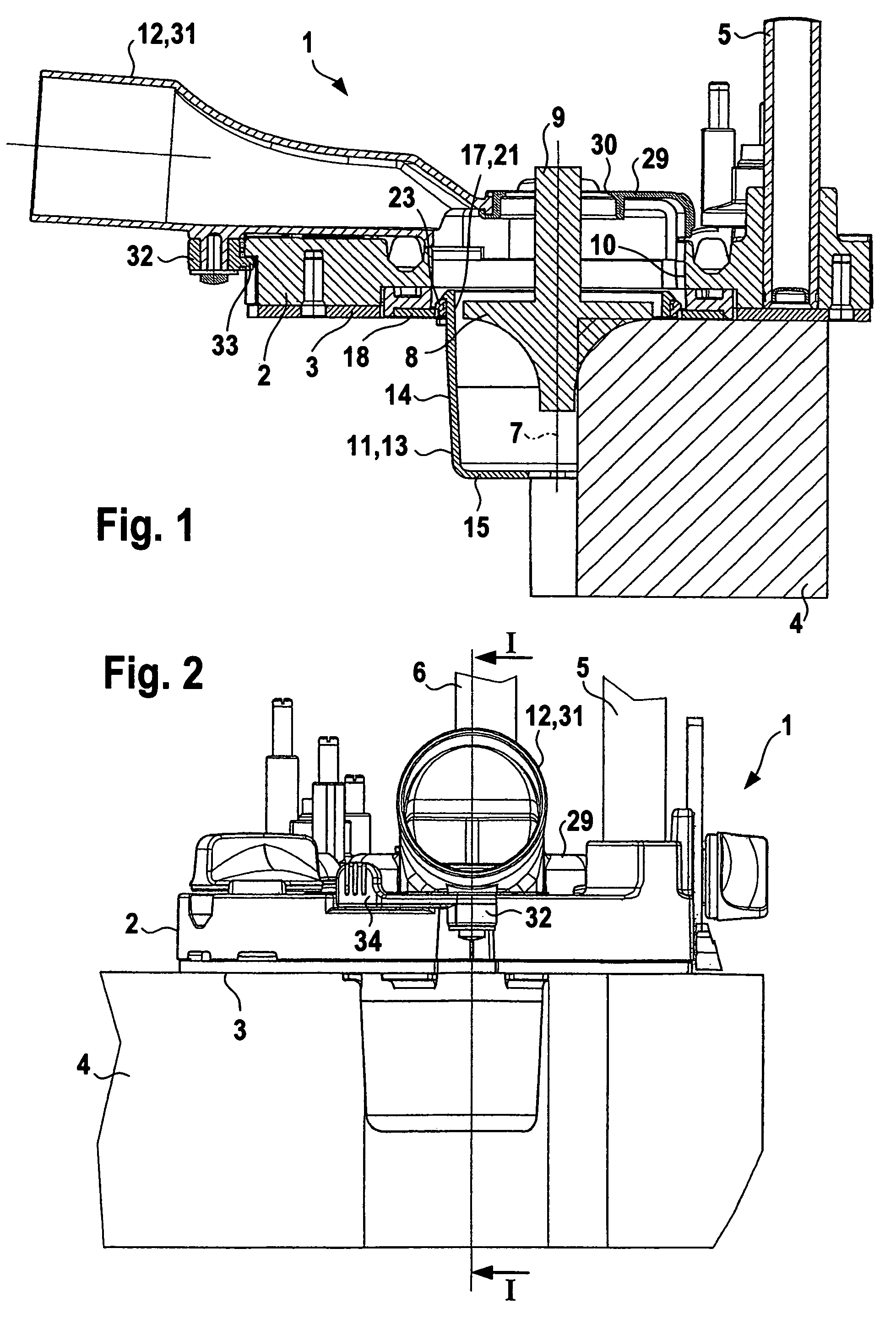

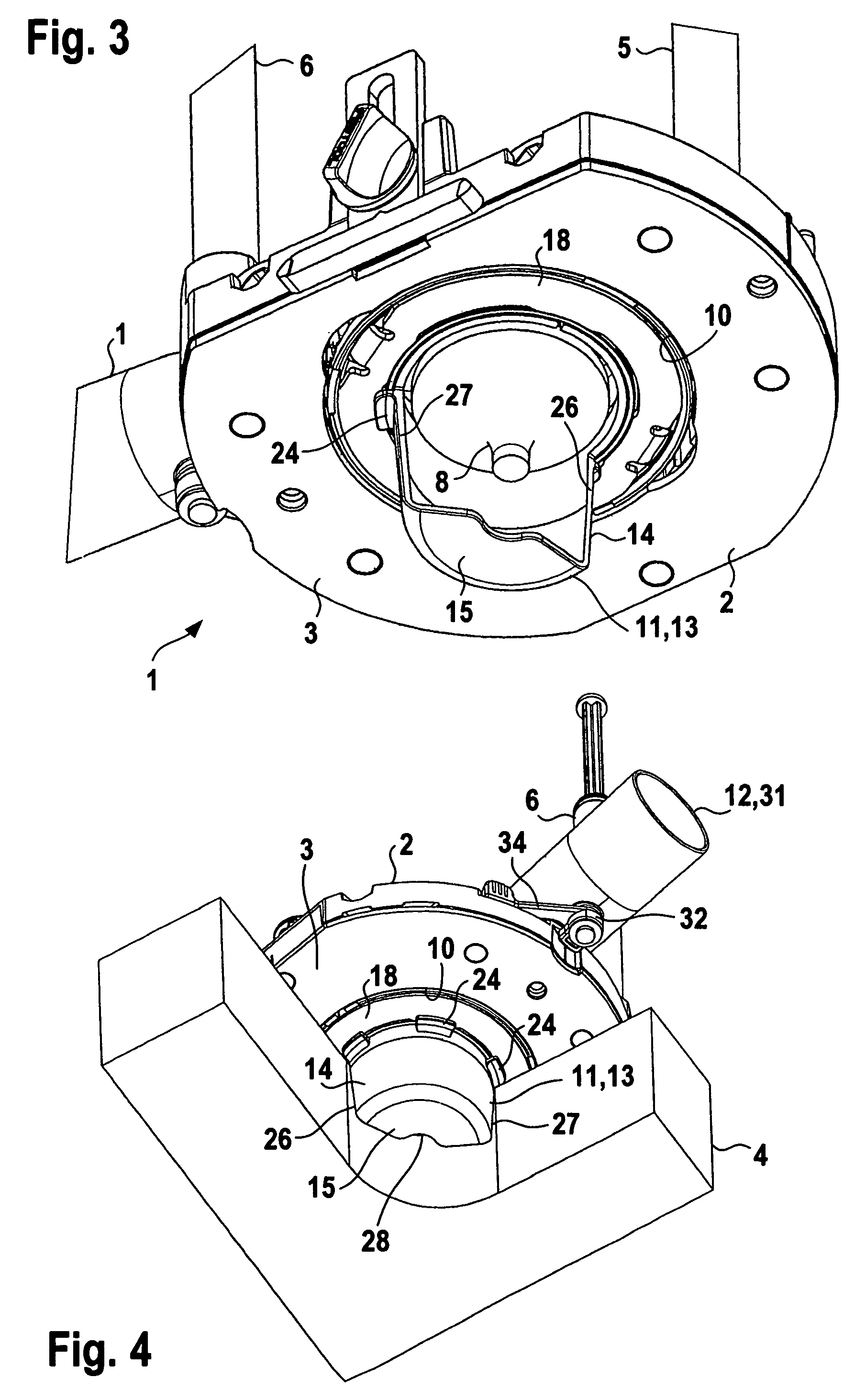

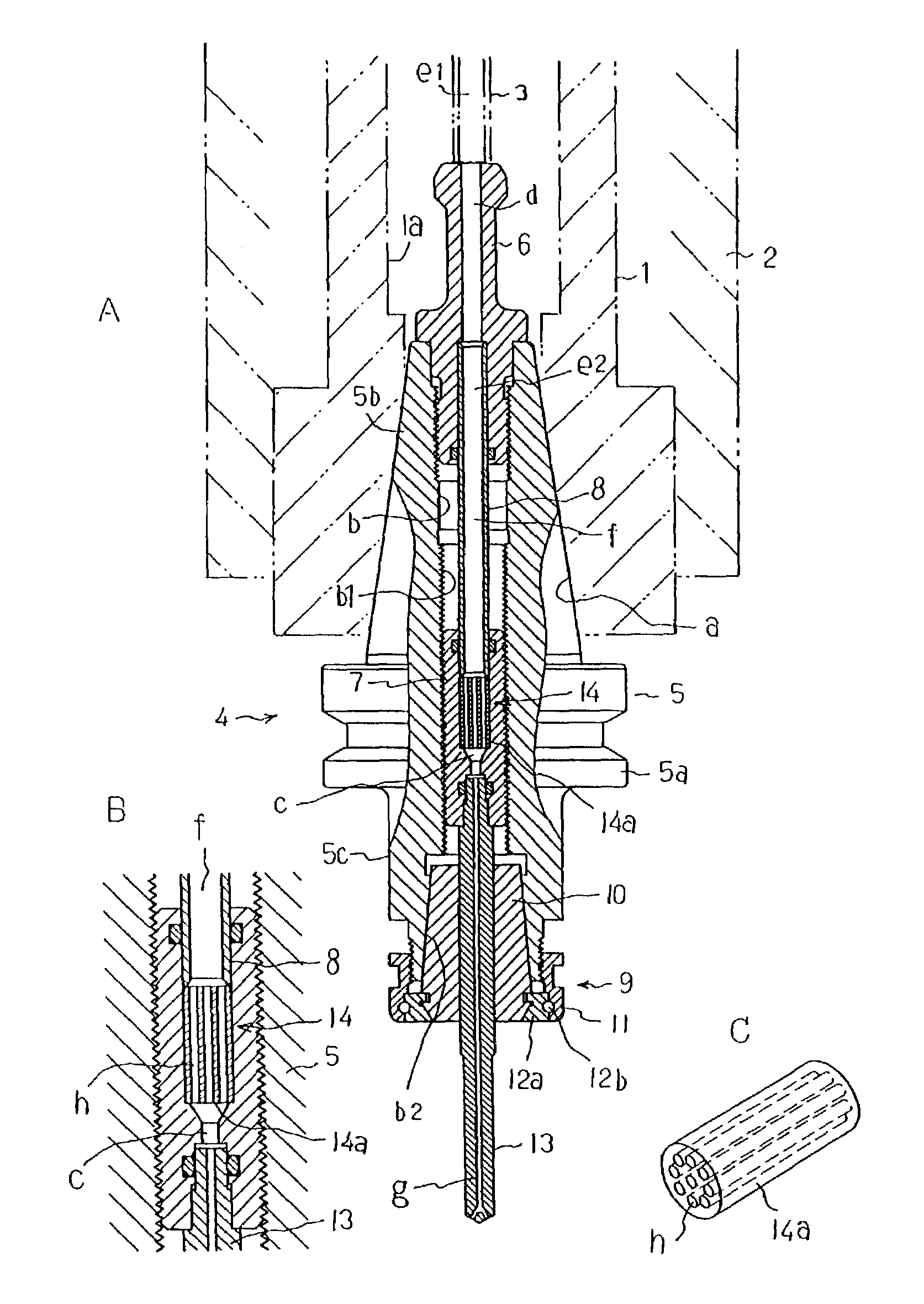

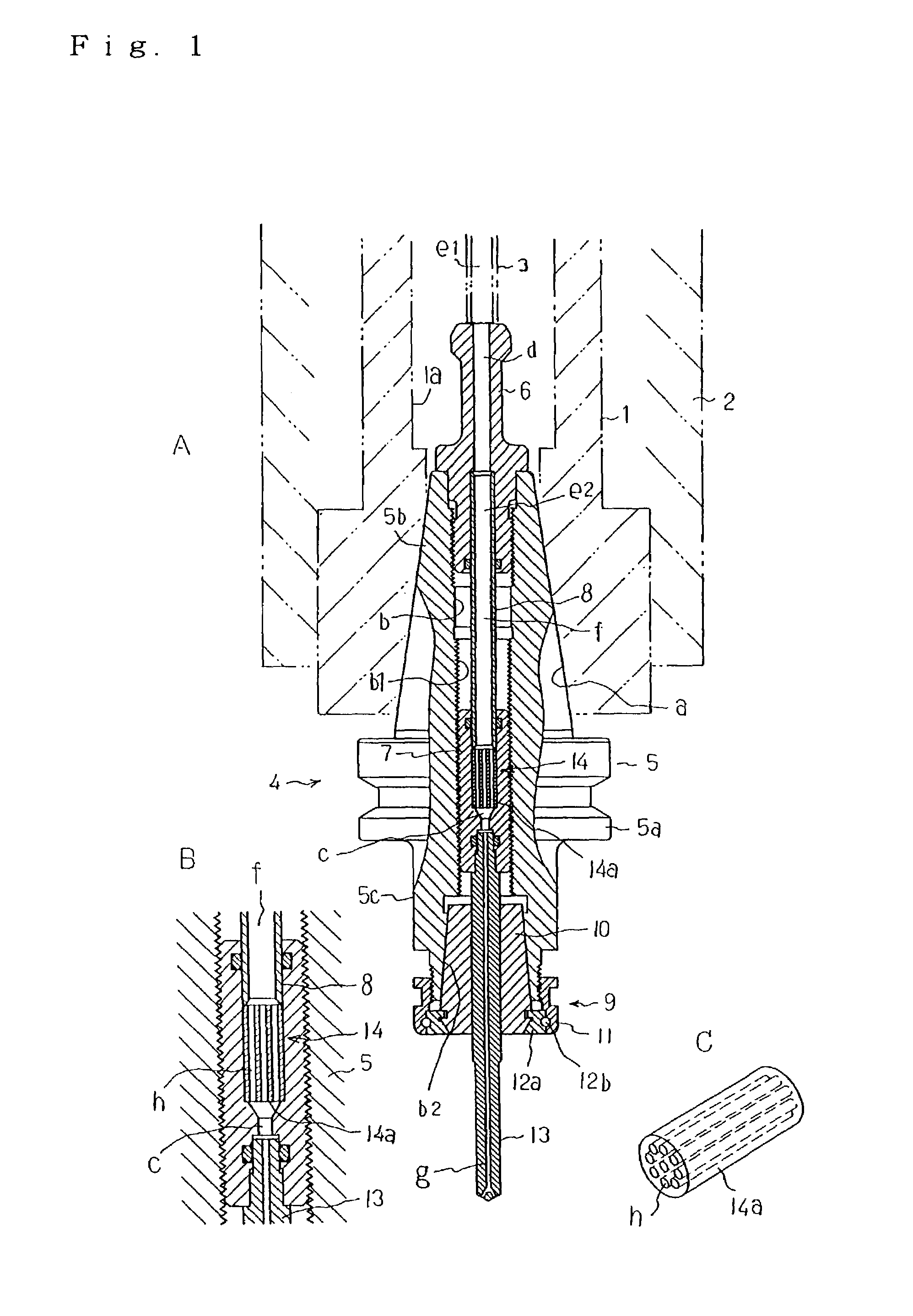

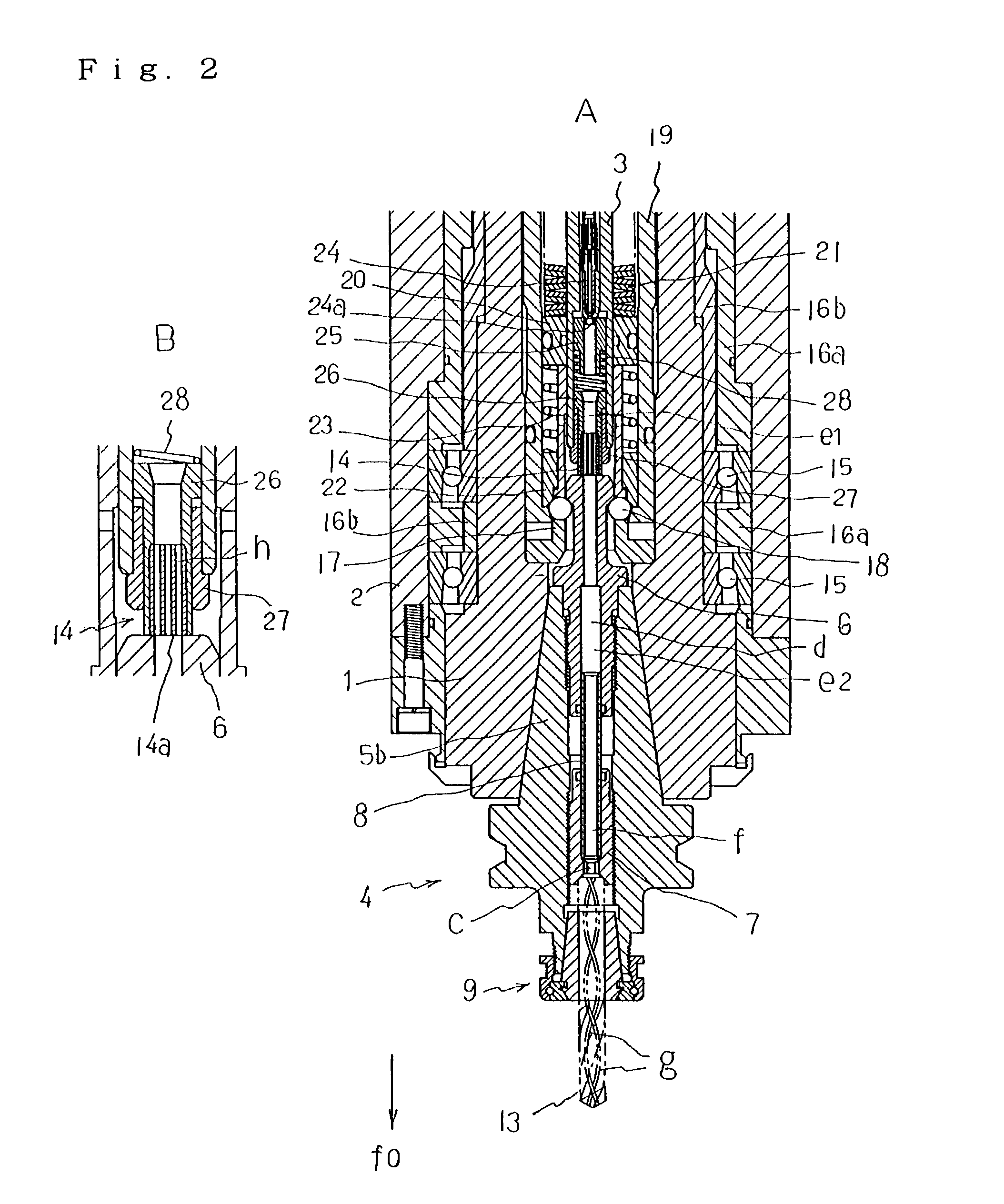

Cutting fluid device for a spindle of a machine tool

InactiveUS7048481B2Easy to producePrevent liquefactionTransportation and packagingMulti-purpose machinesMachine toolCutting fluid

A spindle device of a machine tool, which can prevent the liquefaction of atomized cutting fluid in atomized cutting fluid passage downstream of a straightening unit 14, enhance a responsiveness to an ejecting start or stop instruction, and prevent a waste of cutting fluid. The spindle device for a machine tool has atomized cutting liquid passage (e1, e2) each having a single-shape passage section and formed inside the device ranging from the spindle 1 to the tip end of a cutting tool 13 mounted thereto in one piece, and is operated so as to eject atomized cutting tool 13 via the atomized cutting fluid passages (e1, e2), wherein a straightening unit 14 formed with a plurality of small-diameter passages h are provided in the middle of the cutting liquid passages (e1, e2).

Owner:HORKOS

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

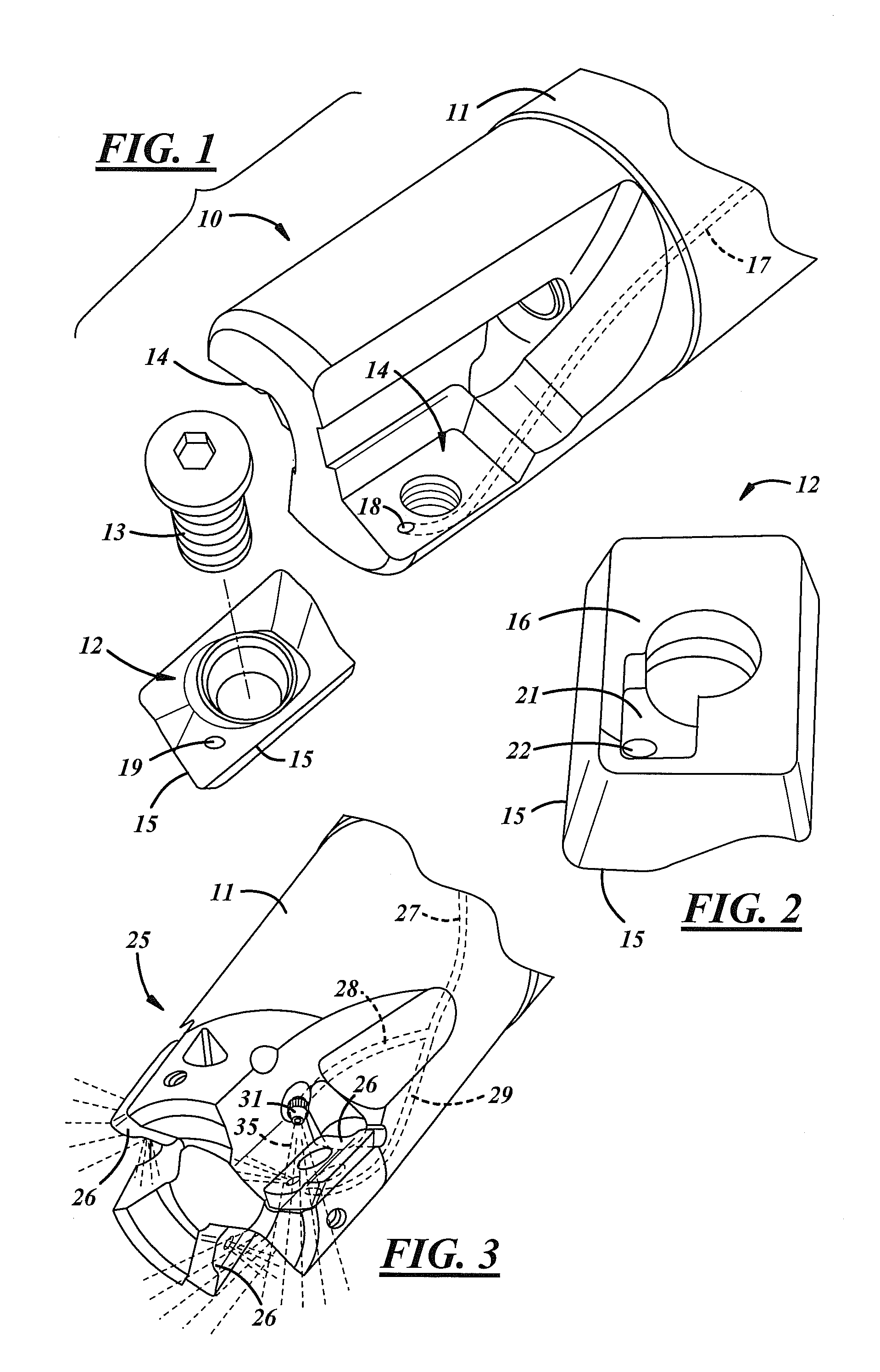

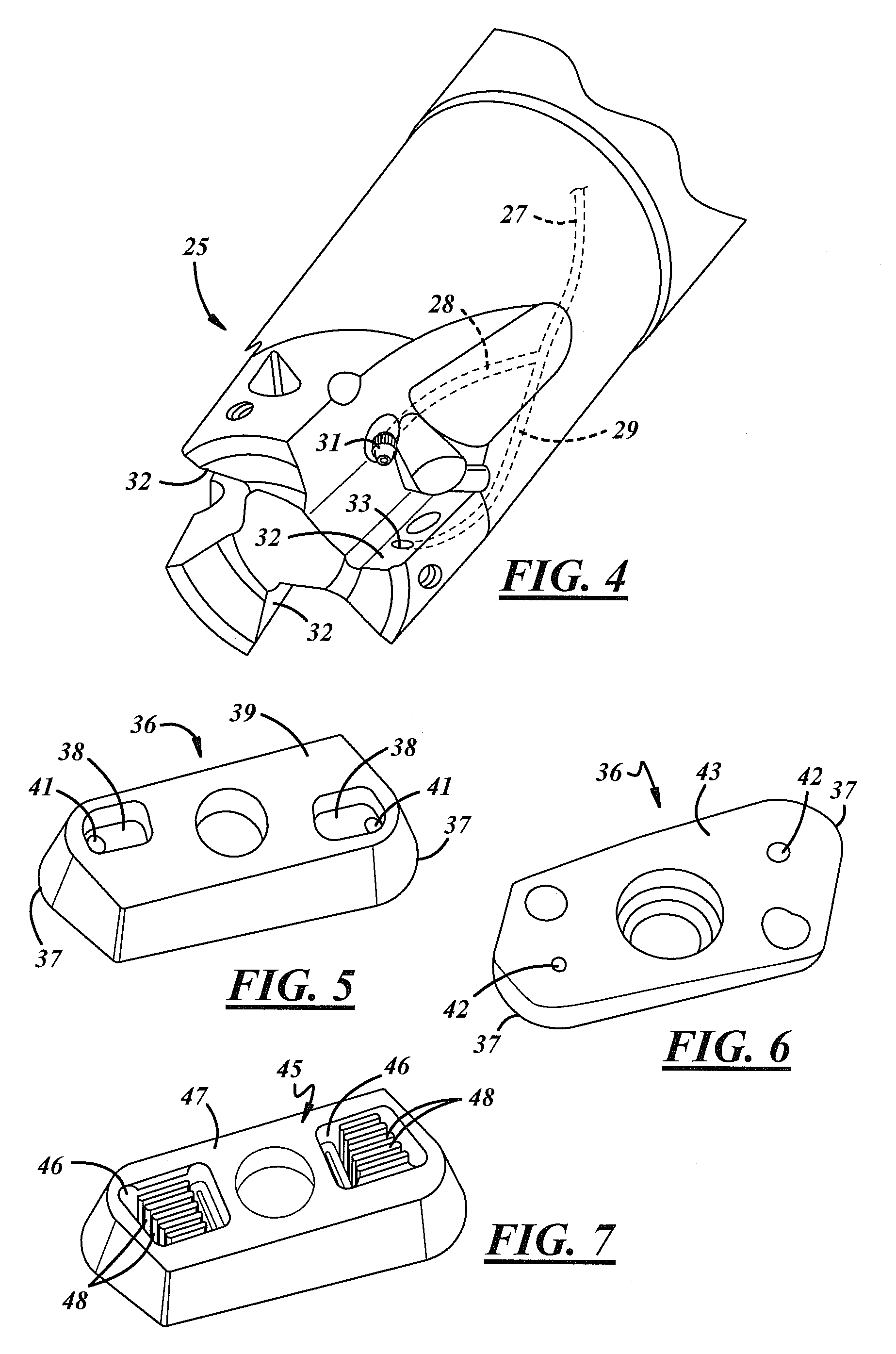

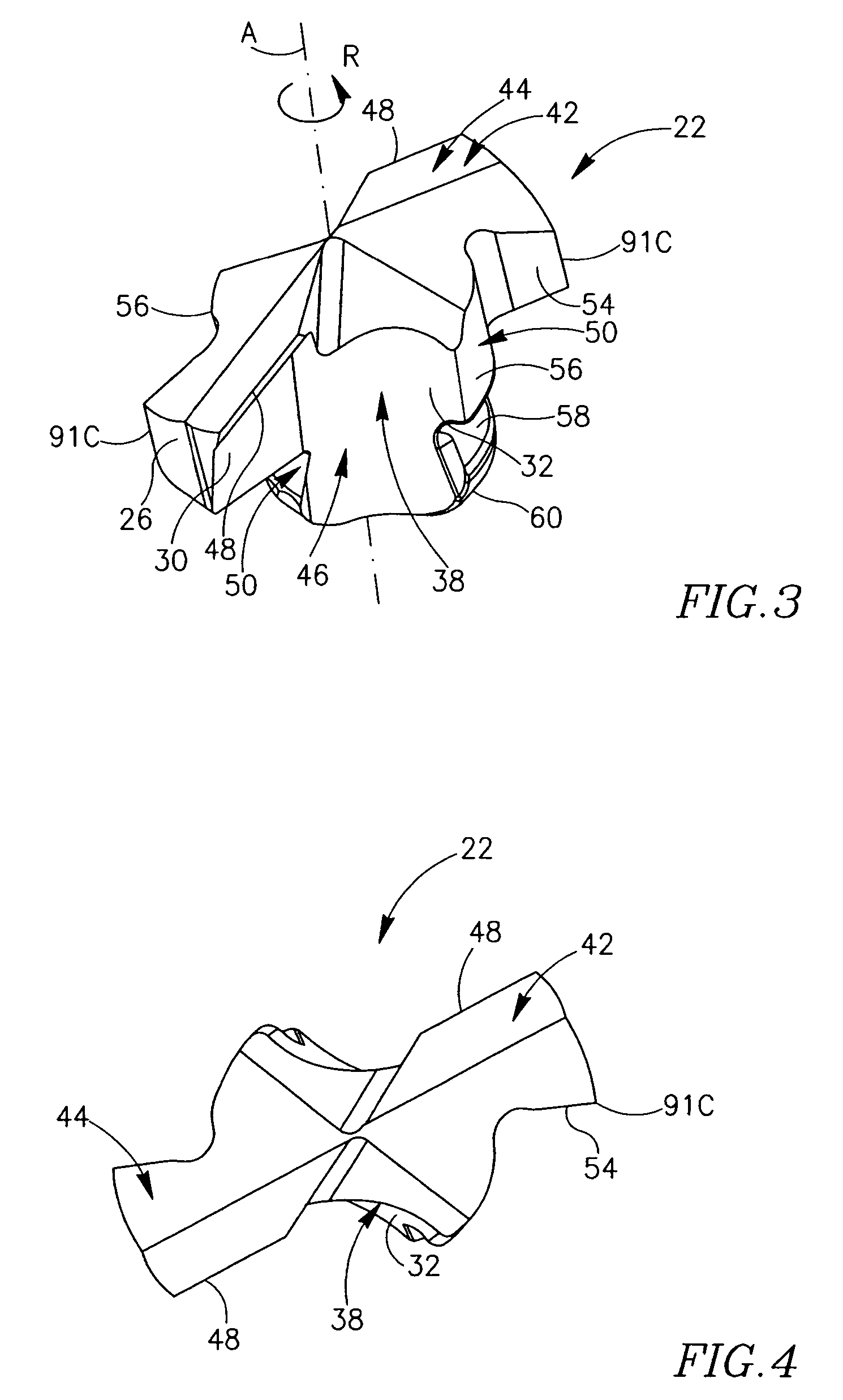

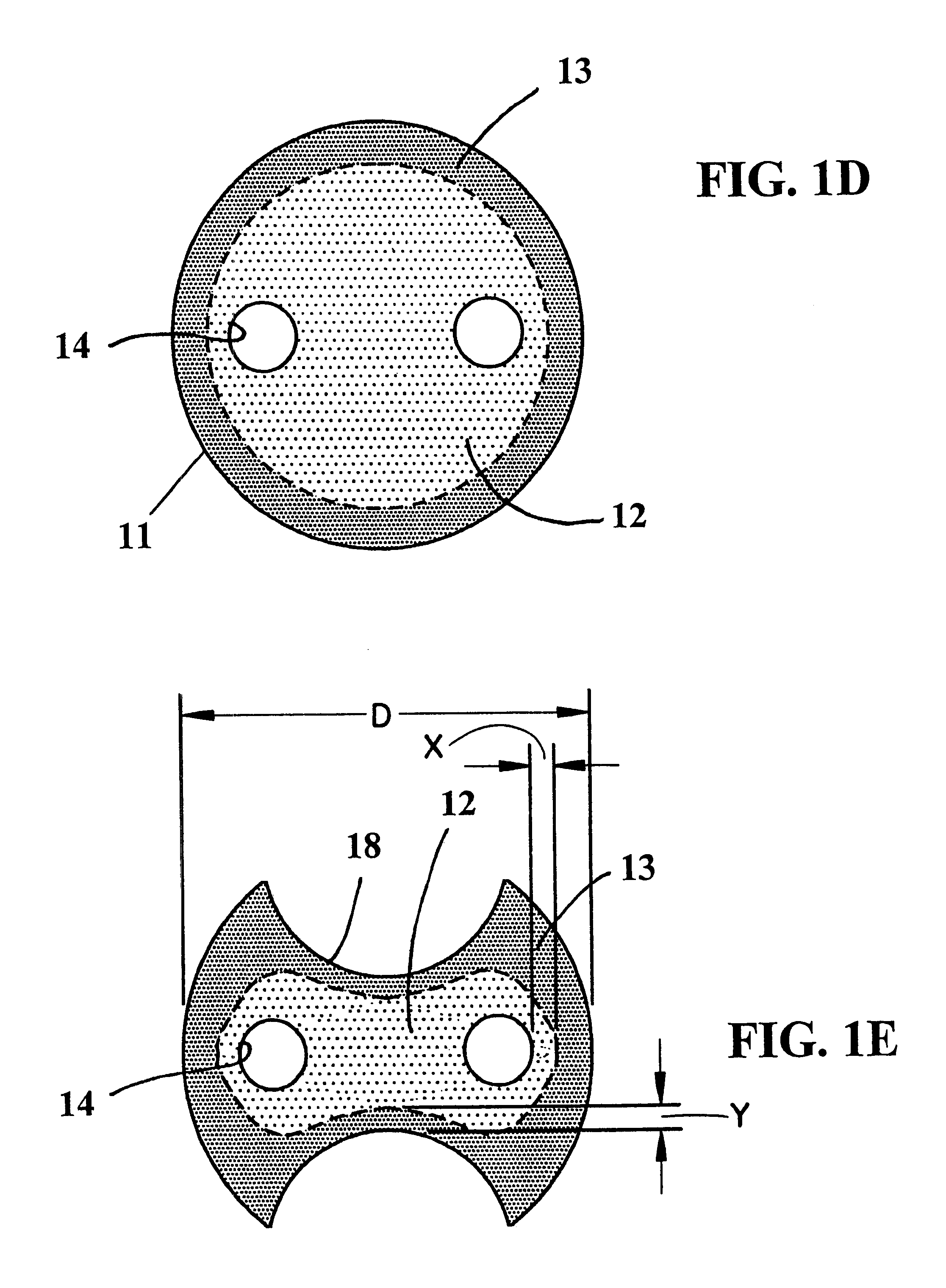

Cutting tool assembly and cutting head therefor

A rotary cutting tool comprising a solid cutting head mounted to a shank. The cutting head comprises a cutting portion adjacent a cutting head front face and a mounting portion integrally formed therewith and extending rearwardly therefrom. The shank comprises a receiving portion extending rearwardly from a shank front face. When the cutting head is secured to the shank, the mounting portion is received in the receiving portion, and the shank front face is forwardly exposed and adjacent the cutting head front face.

Owner:ISCAR LTD

Threading insert with cooling channels

A metalworking apparatus includes a threading insert with a channel-less chip breaker and a holder for holding the threading insert. The threading insert includes (i) one cooling channel disposed on the top side of the threading insert for each crest and each valley, which terminates near the cutting region, and (ii) a ceramic coating on at least the cutting region of crests and valleys, with each cooling channel being uncoated.

Owner:SIDERCA S A L C ARGENTINA

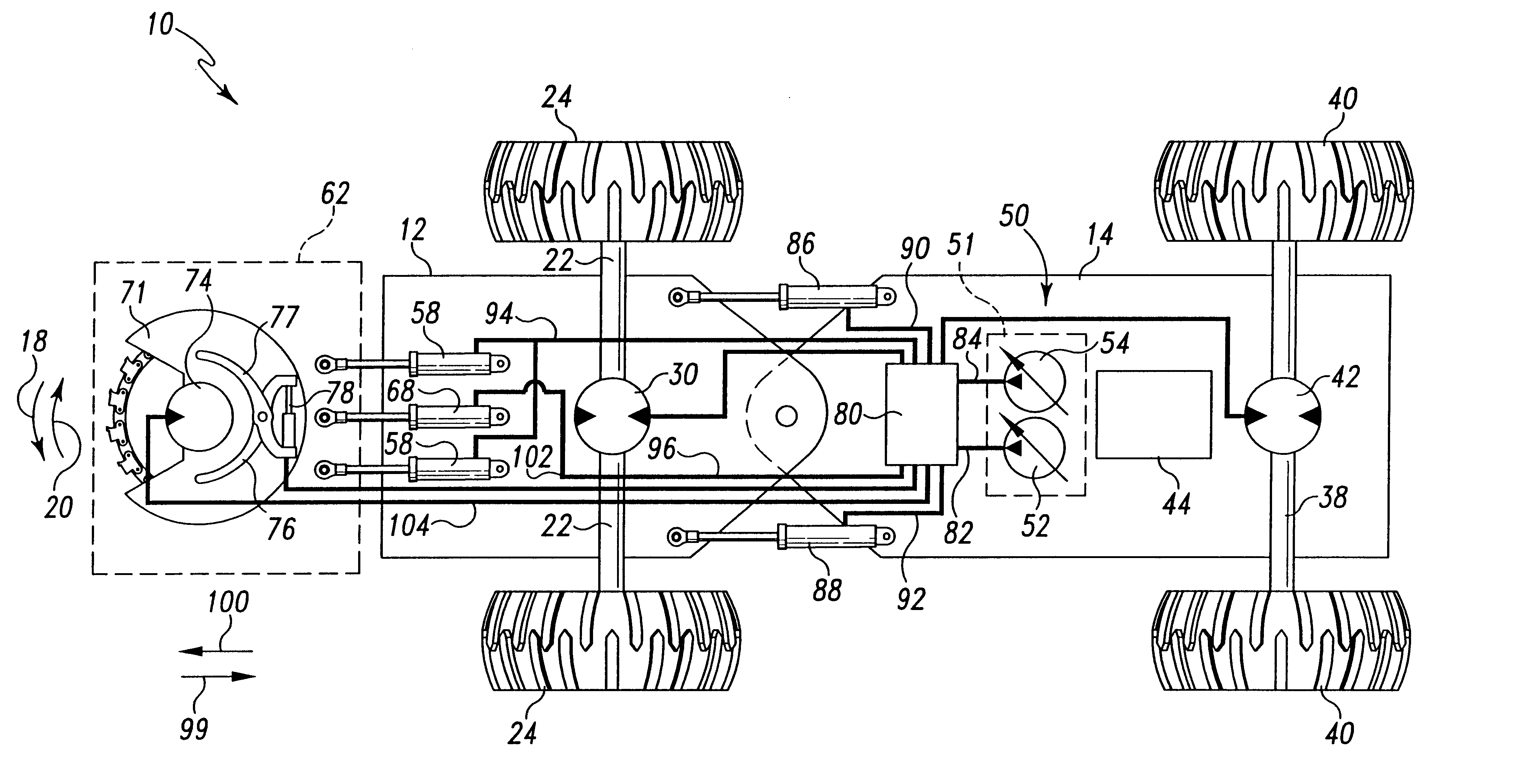

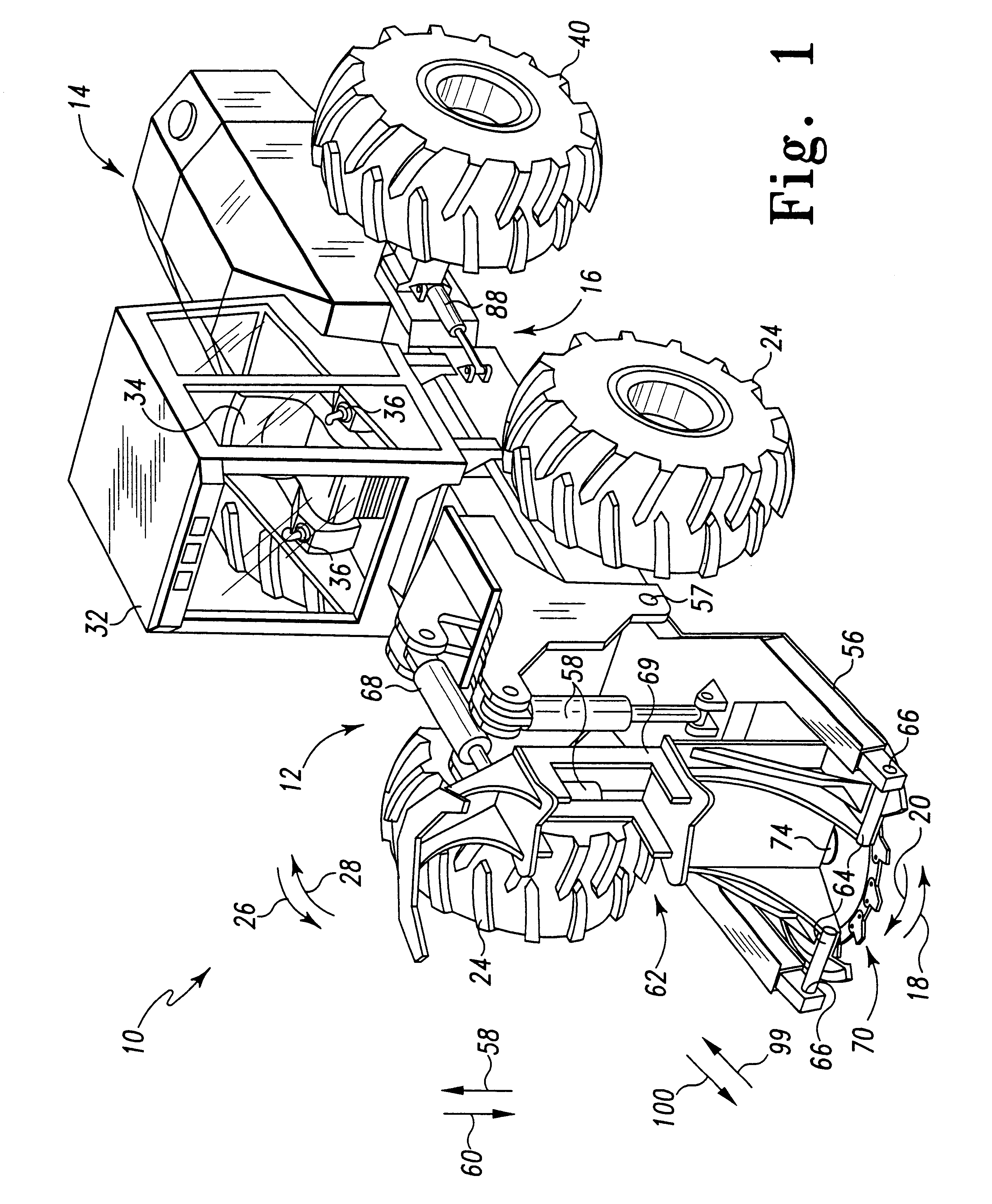

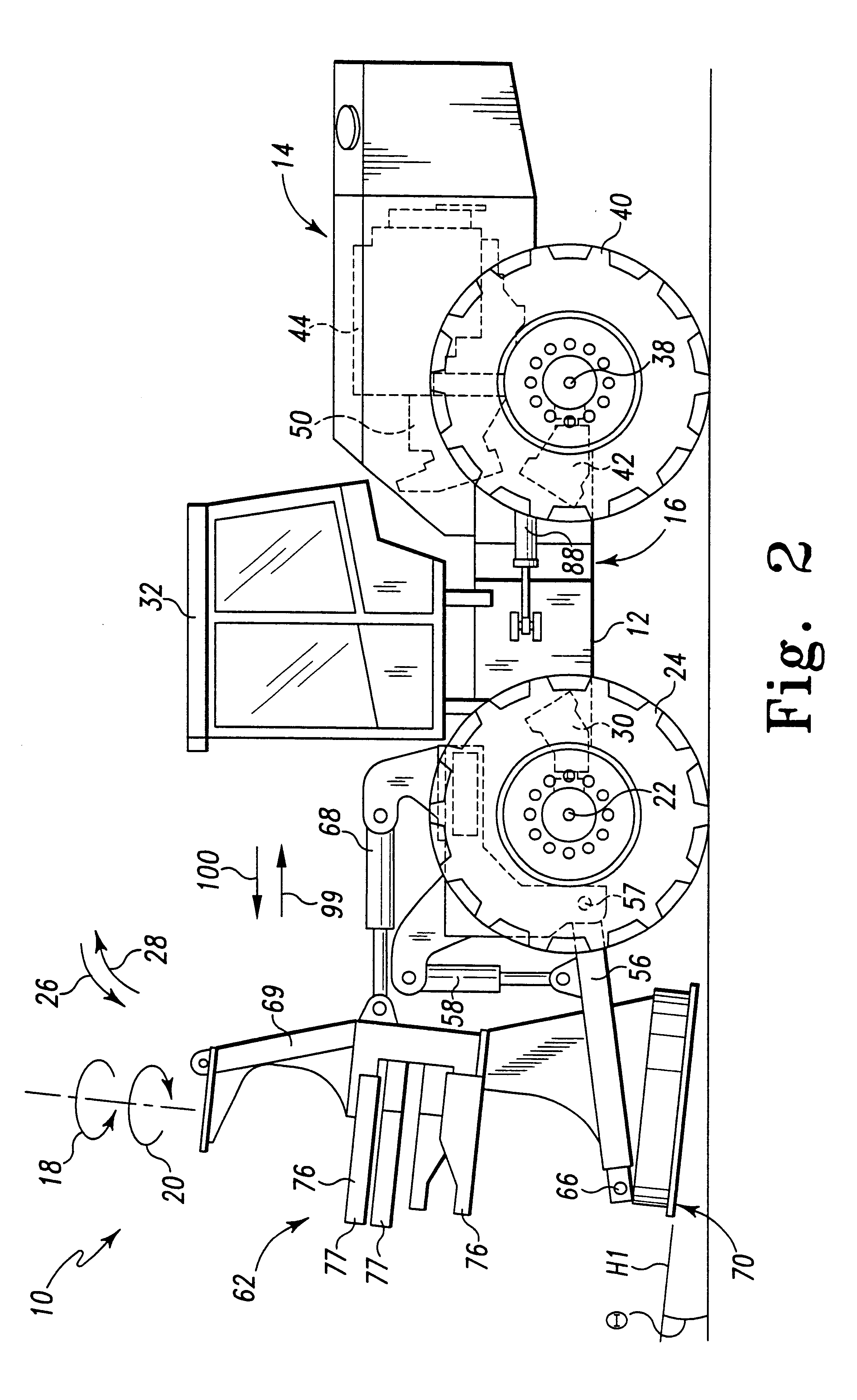

Method and apparatus for operating a hydraulic drive system of a feller-buncher

A feller-buncher includes a first axle having a number of first wheels attached thereto and a second axle having a number of second wheels attached thereto. The feller-buncher also includes a first hydraulic motor operable to rotate the first axle and a second hydraulic motor operable to rotate the second axle. The feller-buncher also includes a first hydraulic pump operable to supply pressurized hydraulic fluid. Yet further, the feller-buncher includes a first flow sharing valve fluidly coupled to each of the first hydraulic pump, the first hydraulic motor, and the second hydraulic motor. The first flow sharing valve is configured to distribute the pressurized hydraulic fluid from the first hydraulic pump evenly between the first hydraulic motor and the second hydraulic motor, whereby the first axle and the second axle are driven at a substantially equal speed relative to one another. A method of operating a feller-buncher is also disclosed.

Owner:CATERPILLAR INC

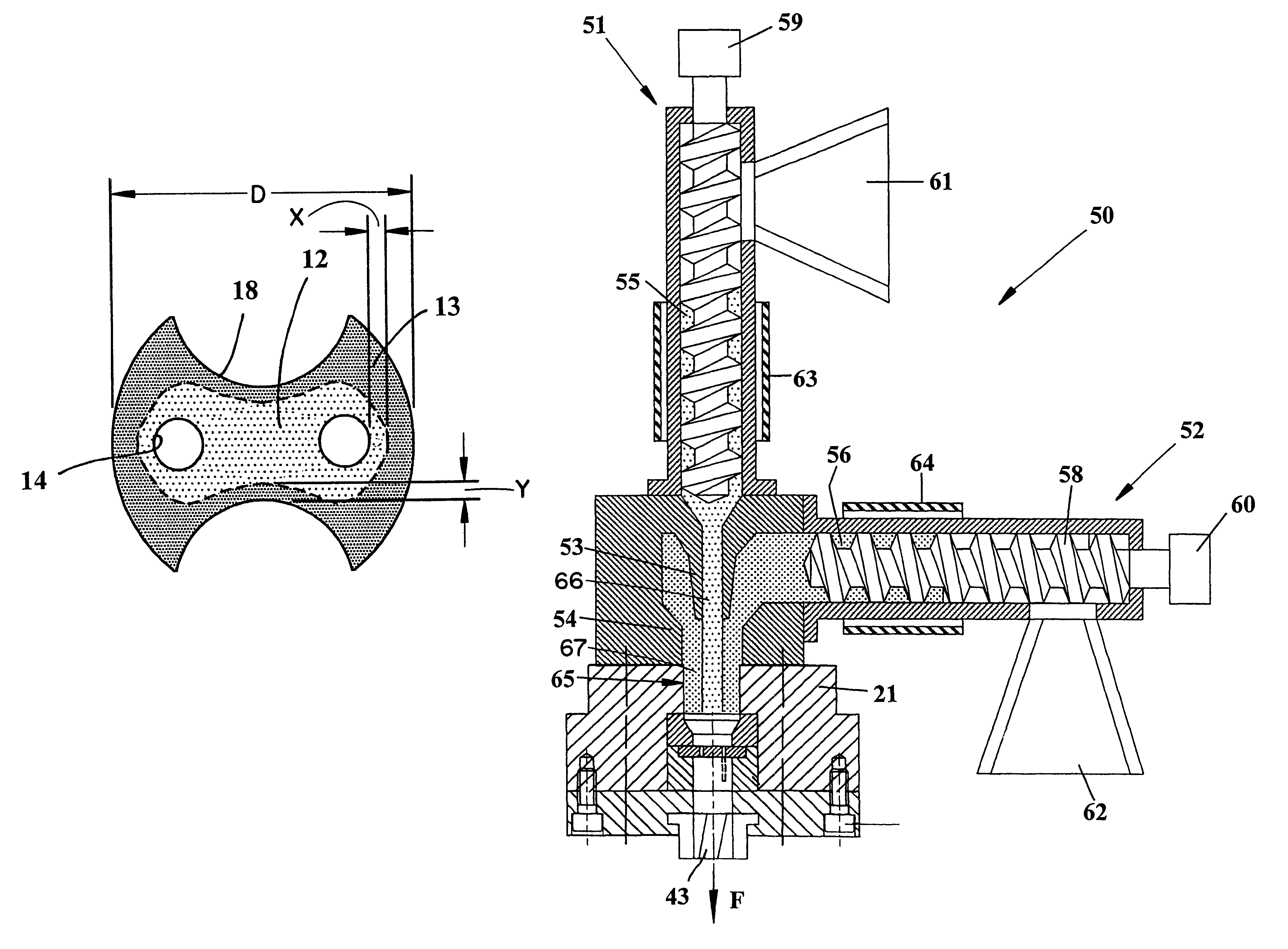

Tool for chip removing machining and methods and apparatus for making the tool

InactiveUS6450739B1Drawback can be obviatedDrawbacks of the known technique are eliminatedMetal-working drilling toolsTransportation and packagingWear resistantEngineering

A tool for chip-forming machining is made by passing first and second compounds through first and second coaxial dies, respectively, whereby the first material forms a center core of the tool, and the second material forms an outer rod of the material. The material of the core is tougher and less wear-resistant than the material of the outer rod. The coaxial first and second compounds are passed through a shaping die and then through a flute-forming structure which forms chip flutes in the outer rod.

Owner:SECO TOOLS AB

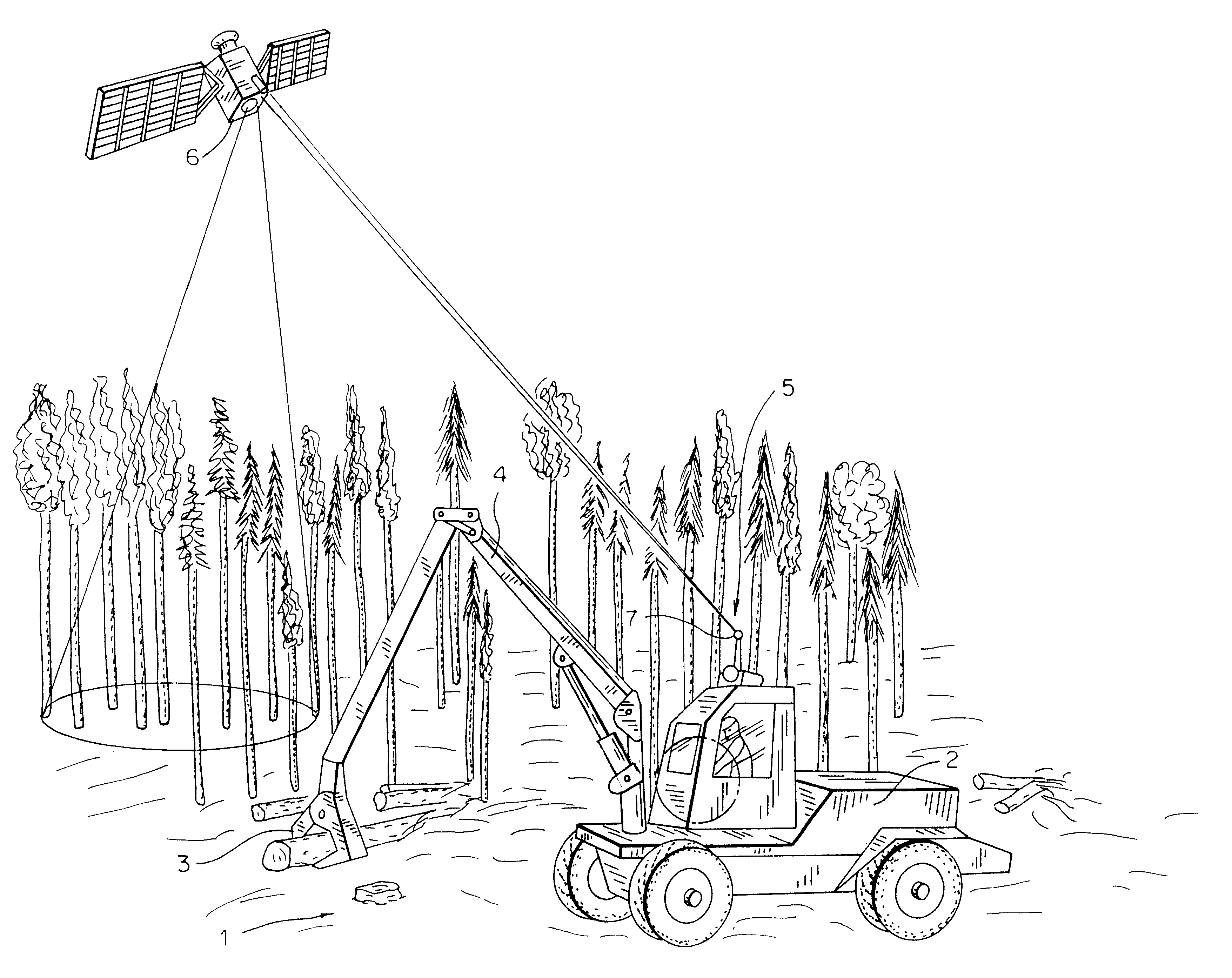

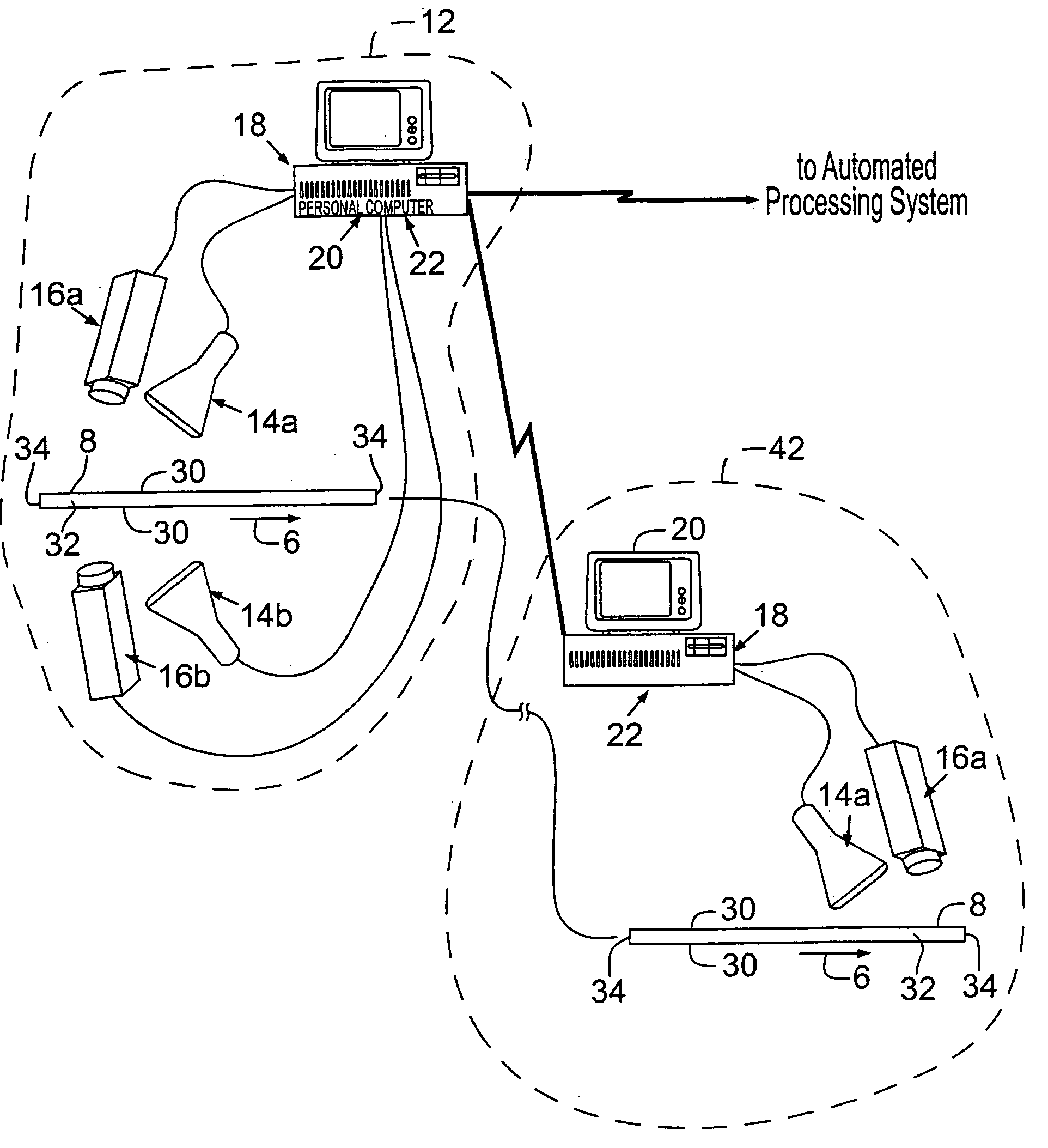

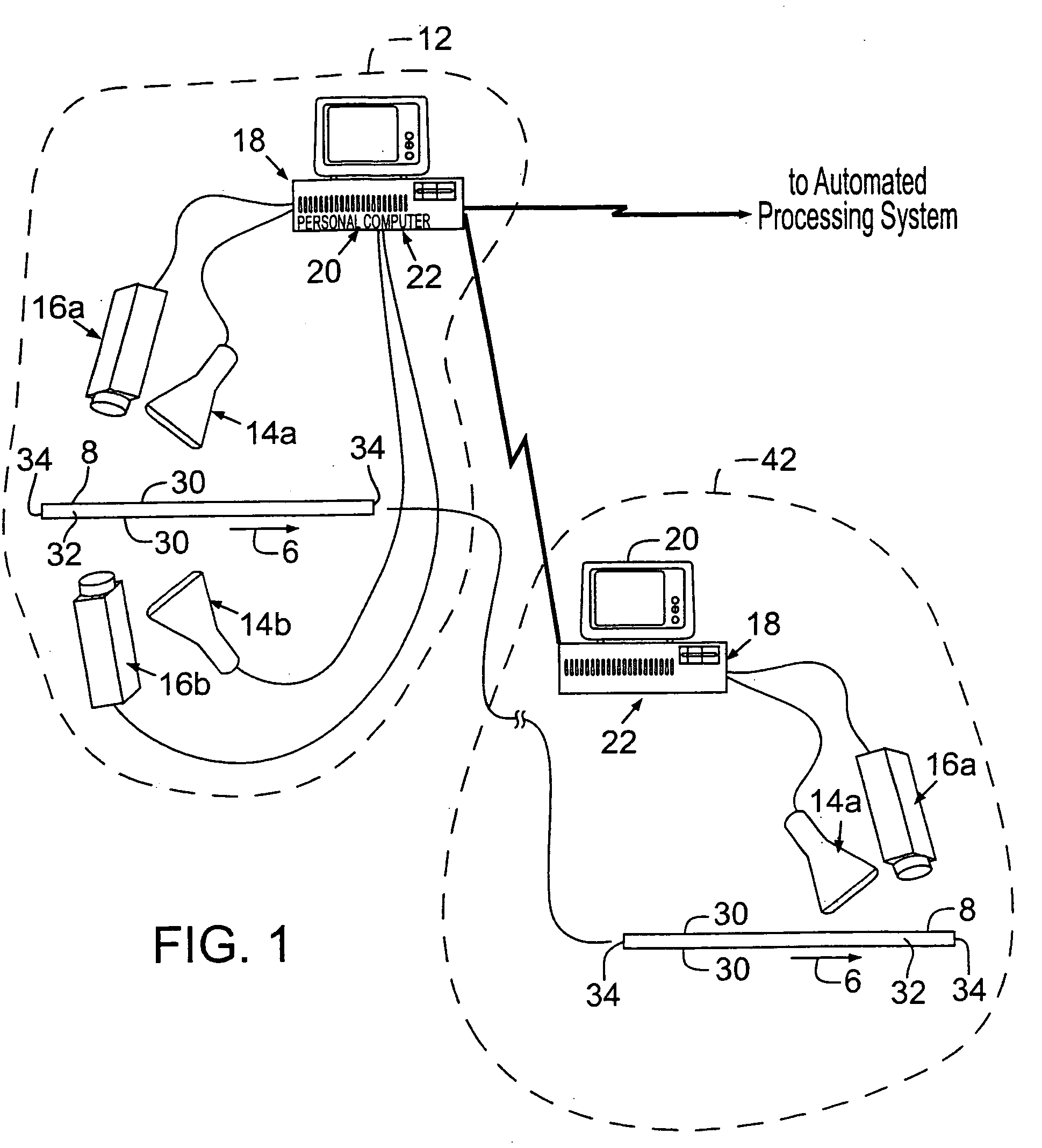

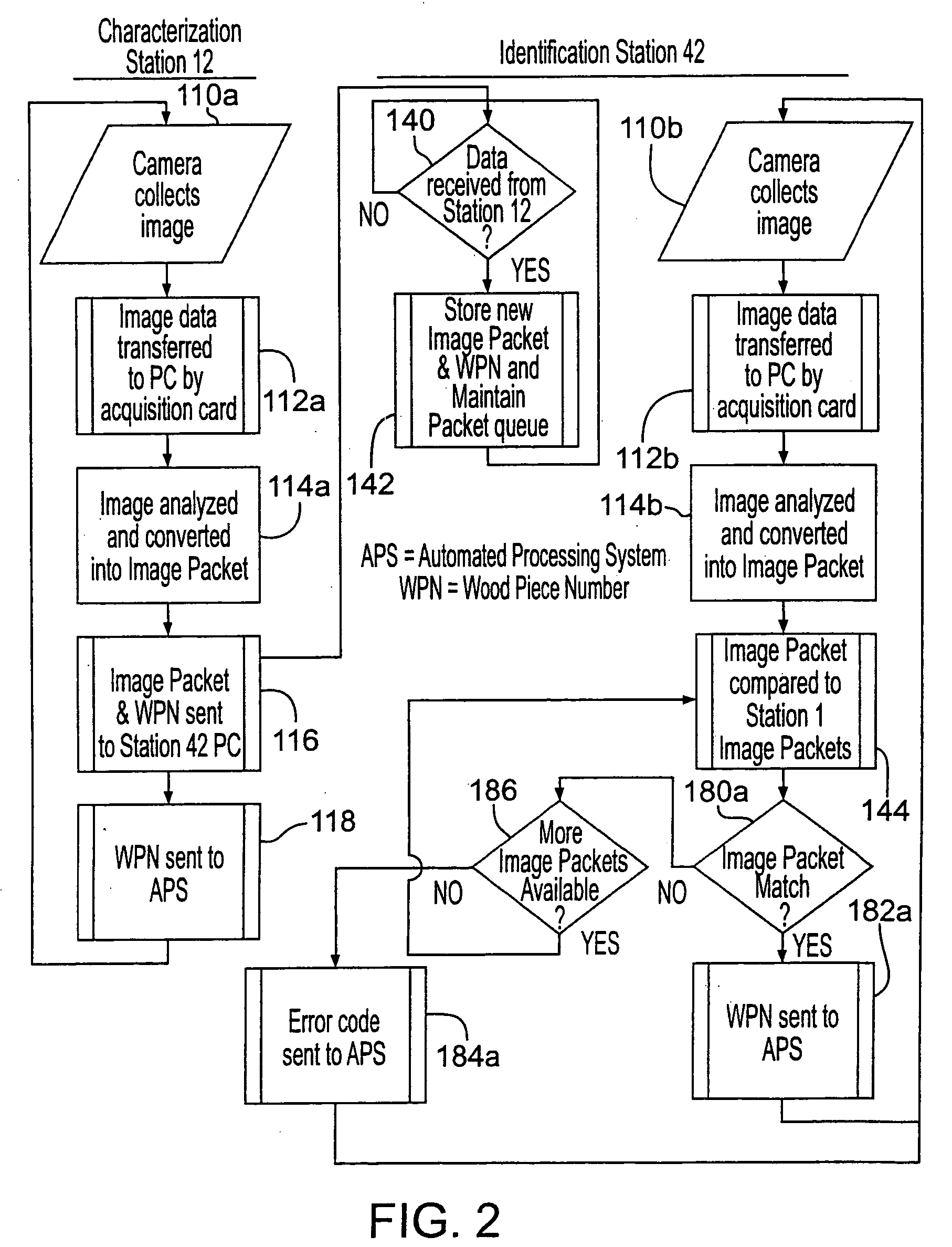

Wood tracking by identification of surface characteristics

ActiveUS20050161118A1Reduce impactCertain amountProgramme controlAutomatic control devicesComputer graphics (images)Image processing software

A “Woodprint™” characterization and identification technique employs cameras (16), lighting (14), camera interface hardware (18), a computer (20), and / or image processing software to collect and analyze surface characteristics of pieces of wood (8) to track them through an automated production process in real-time with information that is specific to each wood piece (8), such as what machining is required, its value, and / or its destination. When a wood piece (8) reaches a point in the production process where a decision is required, its unique identity is used to retrieve appropriate information previously determined and assigned to the wood piece (8).

Owner:LUCIDYNE TECH

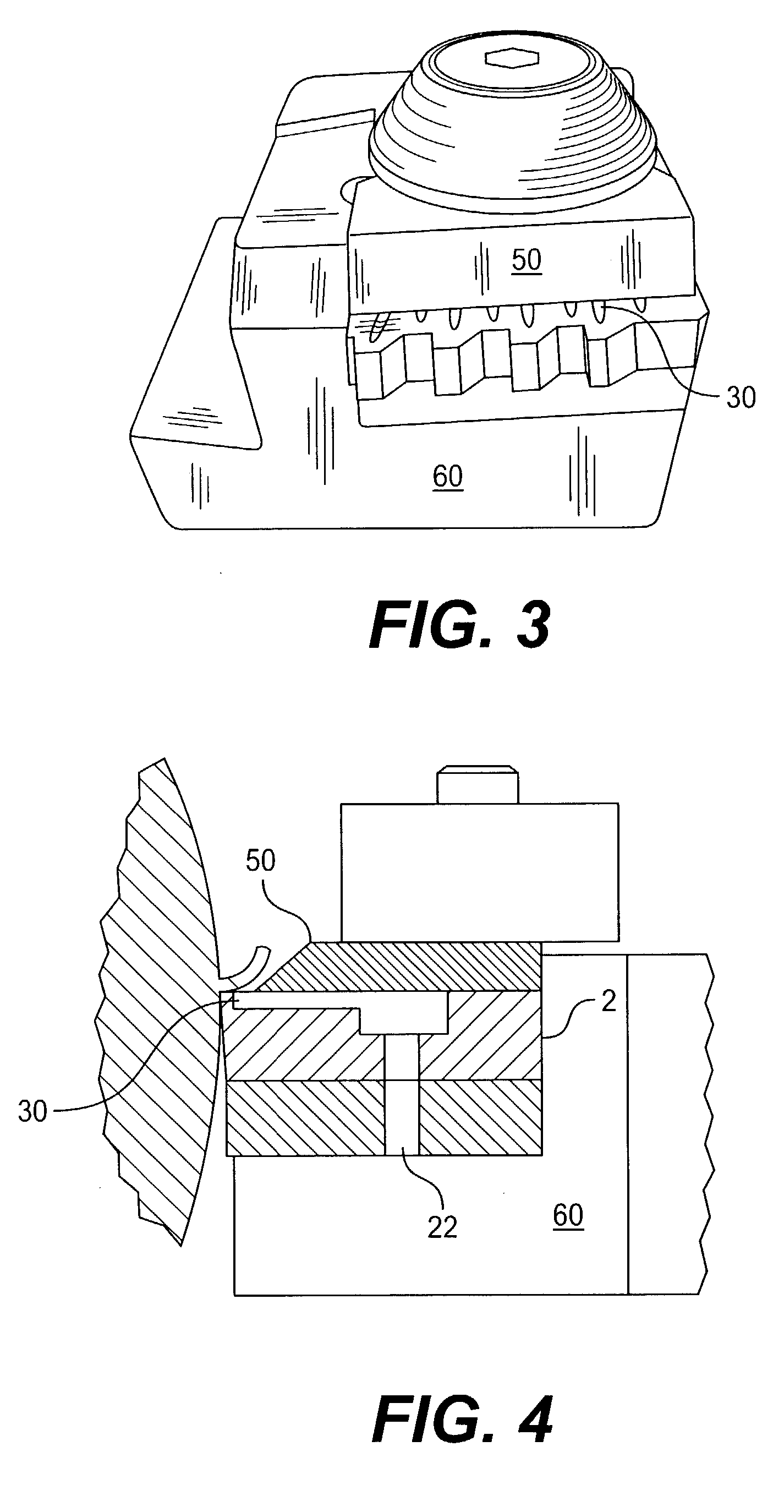

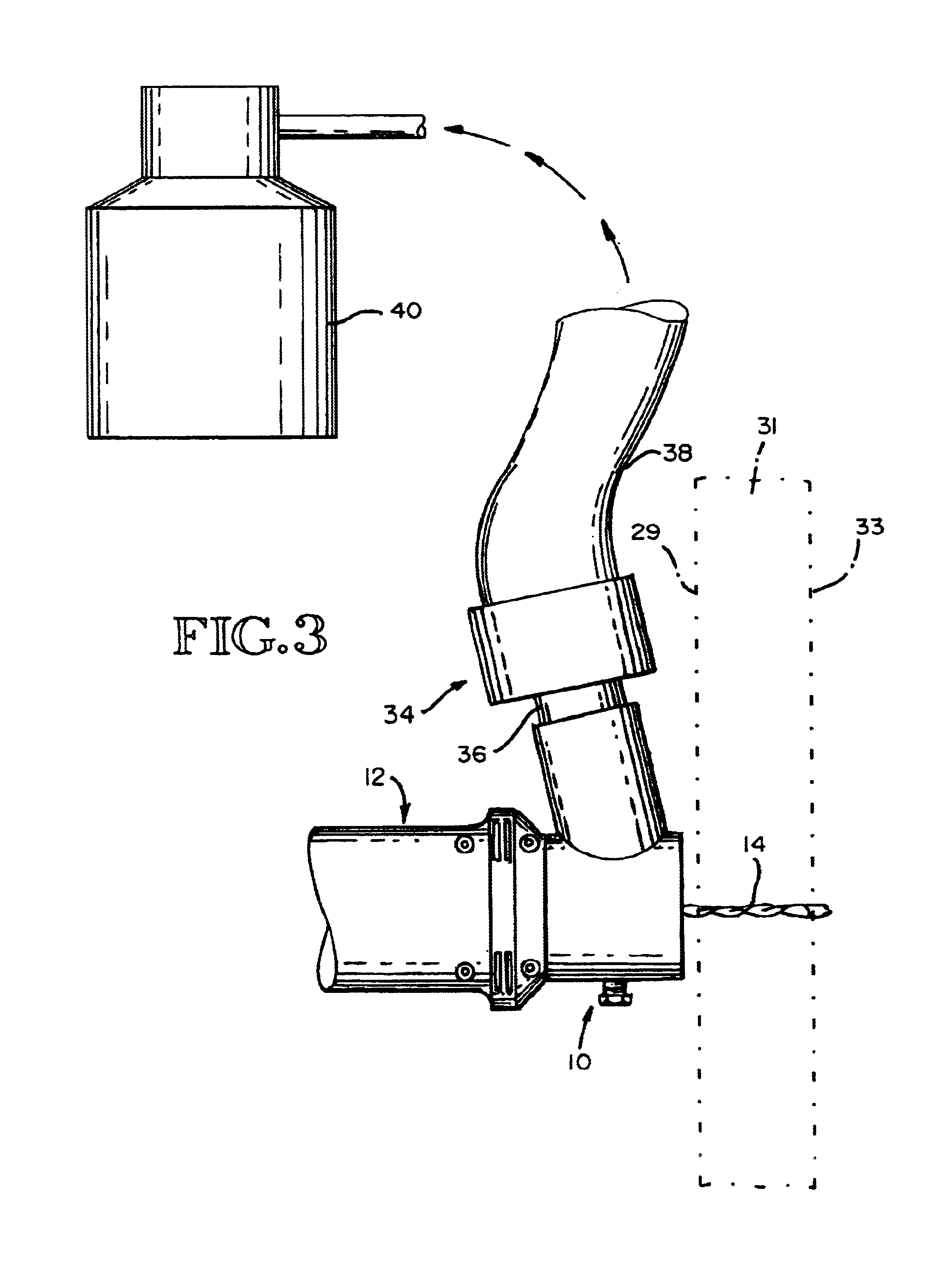

Dust collector attachment for a spiral power tool

The dust attachment which is used with a spiral saw power tool includes a first attachment portion which at a rear end has a substantially dust-tight fit with a mounting head portion of the tool. The other (forward) end extends beyond a forward edge of the mounting head portion, but such that the spiral saw bit extends beyond the forward edge of the attachment portion by a distance which is slightly greater than that of the thickness of the workpiece. An attaching member such as a screw secures the dust attachment portion to the tool. An dust exit tube extends from a side surface of the attachment portion and communicates with the interior of the attachment portion. The dust exit tube extends at an angle away from the attachment portion toward the rear end thereof.

Owner:WEISS STEPHEN F

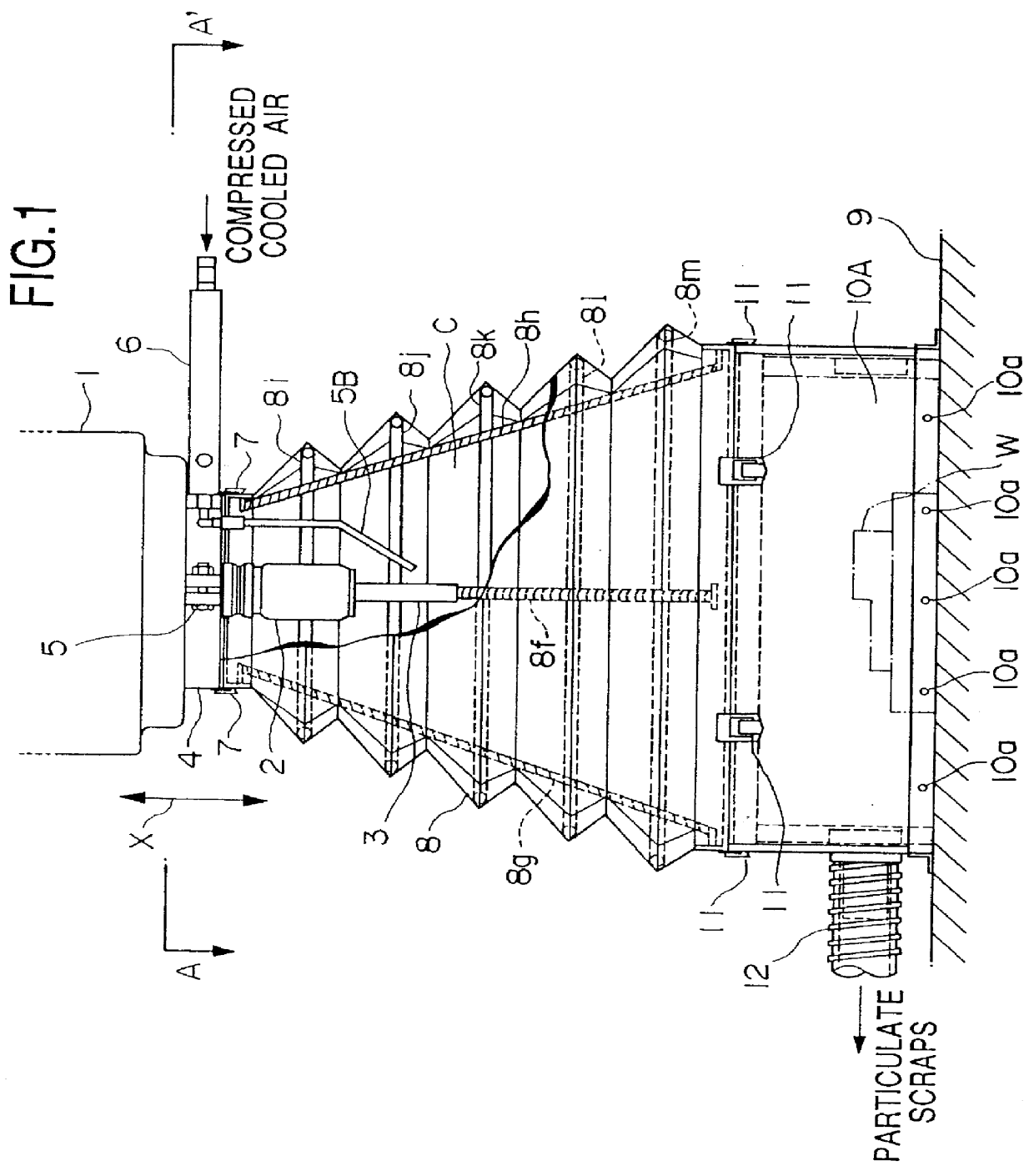

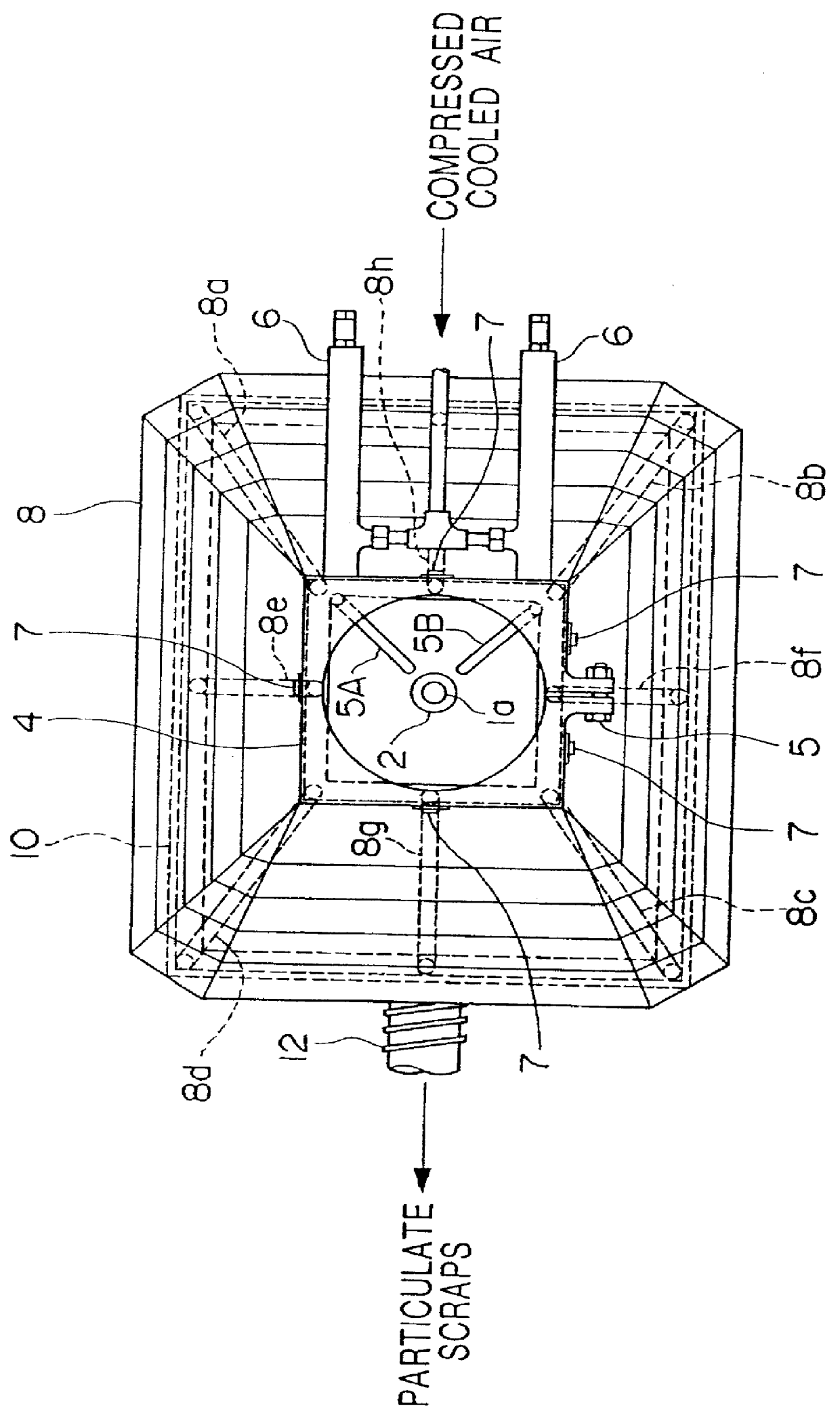

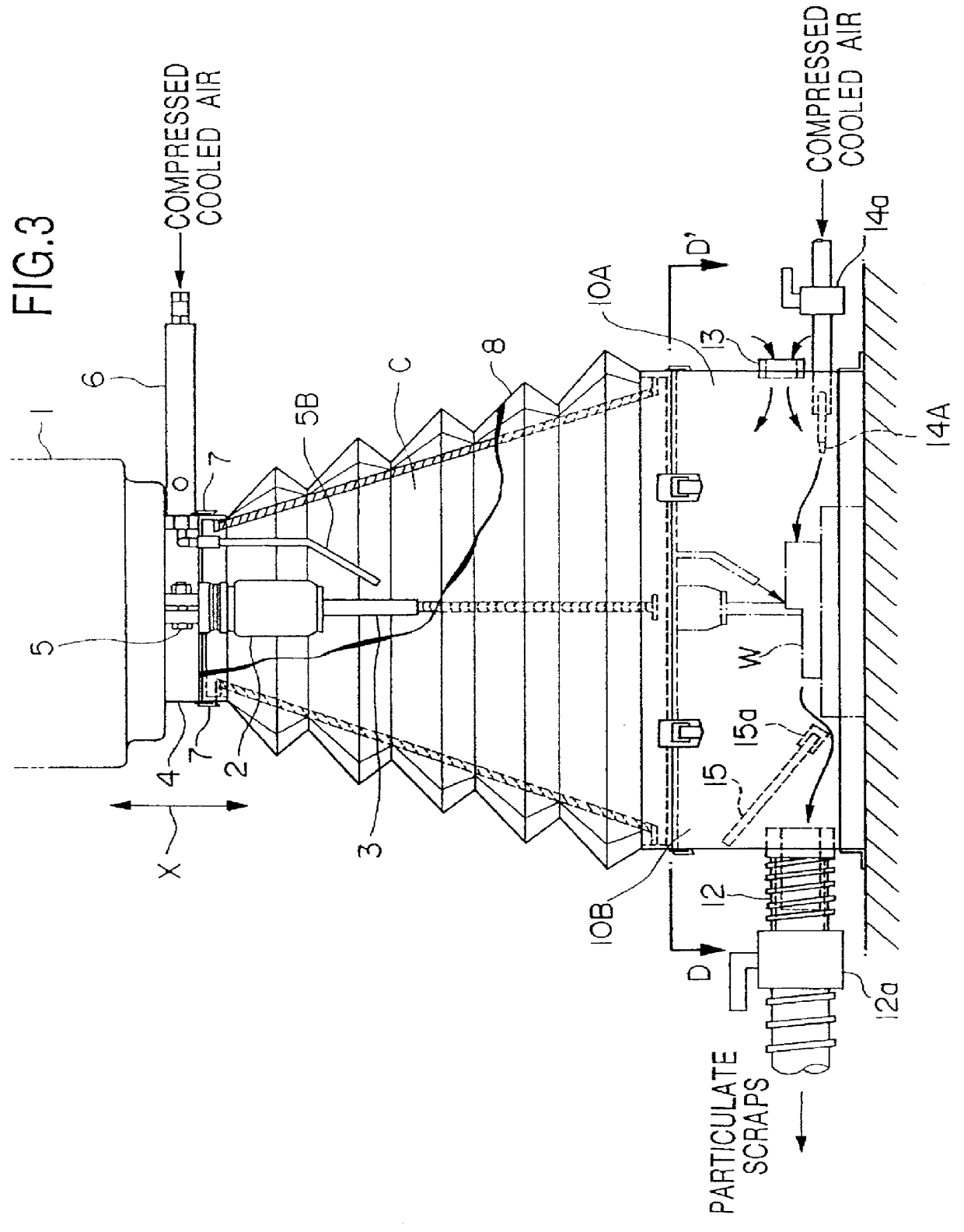

Machine tool

PCT No. PCT / JP97 / 02496 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Jul. 18, 1997 PCT Pub. No. WO98 / 03302 PCT Pub. Date Jan. 29, 1998In order to process a solid processed object with a simple construction, and to process a solid and flat work while effectively collecting particulate scraps, in a machine tool for processing work in which a working table on which the work is mounted and a spindle in which a cutter is installed move relatively to each other, a bellow which telescopes freely is provided, one open end of which connects to the spindle head so as to surround the spindle, and the other open end of which connects to a working table in such a manner as to surround the work.

Owner:TOKO KABUSHIKI KAISHA

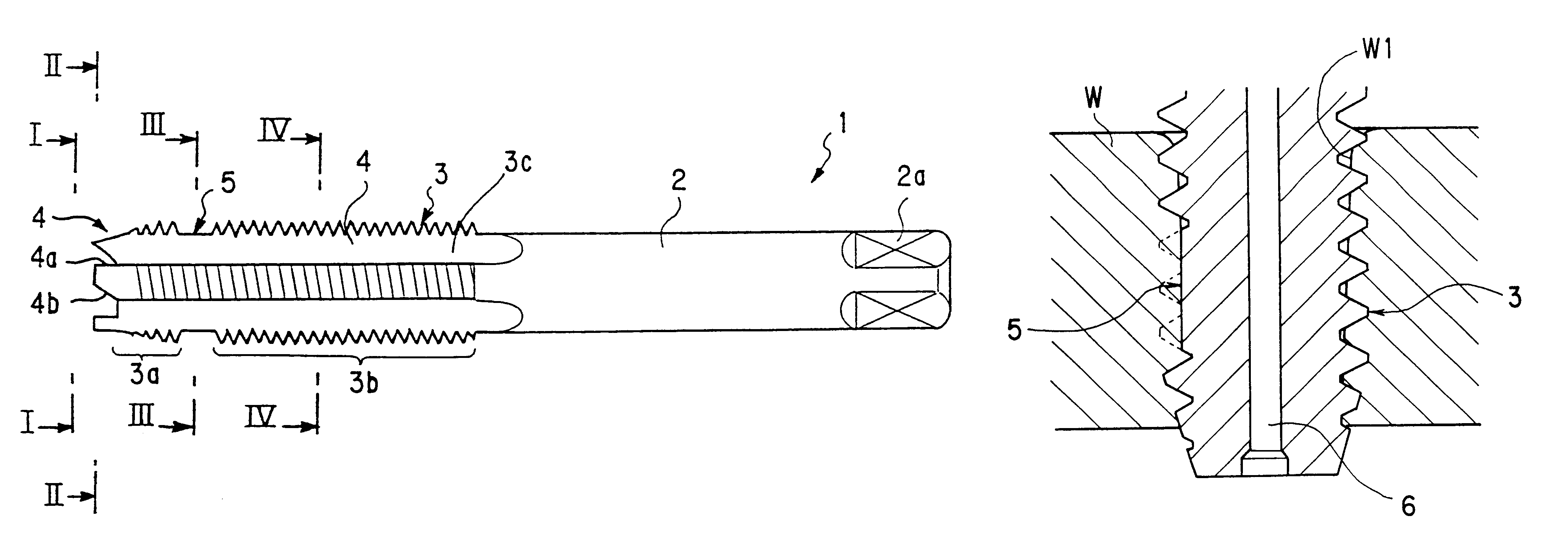

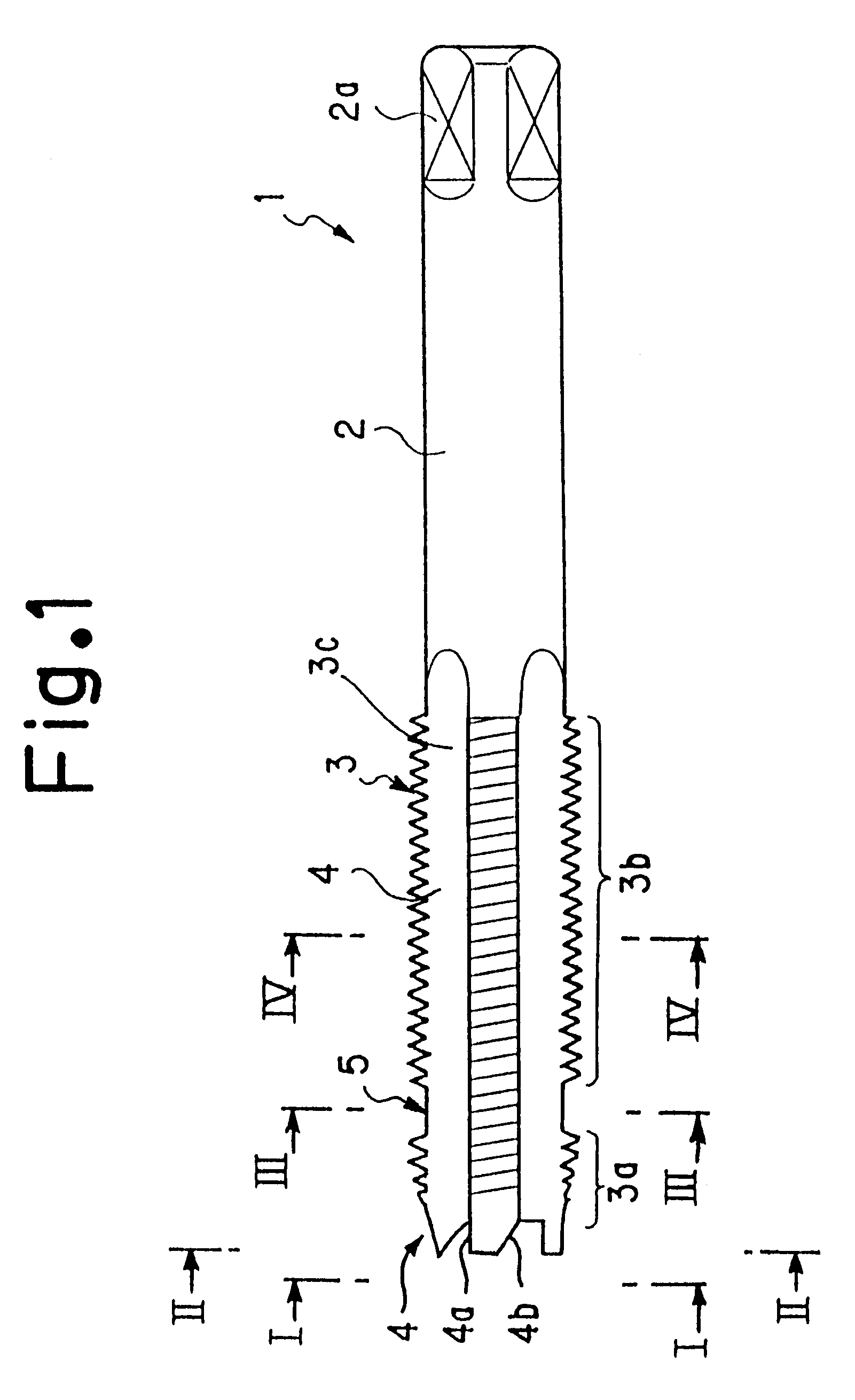

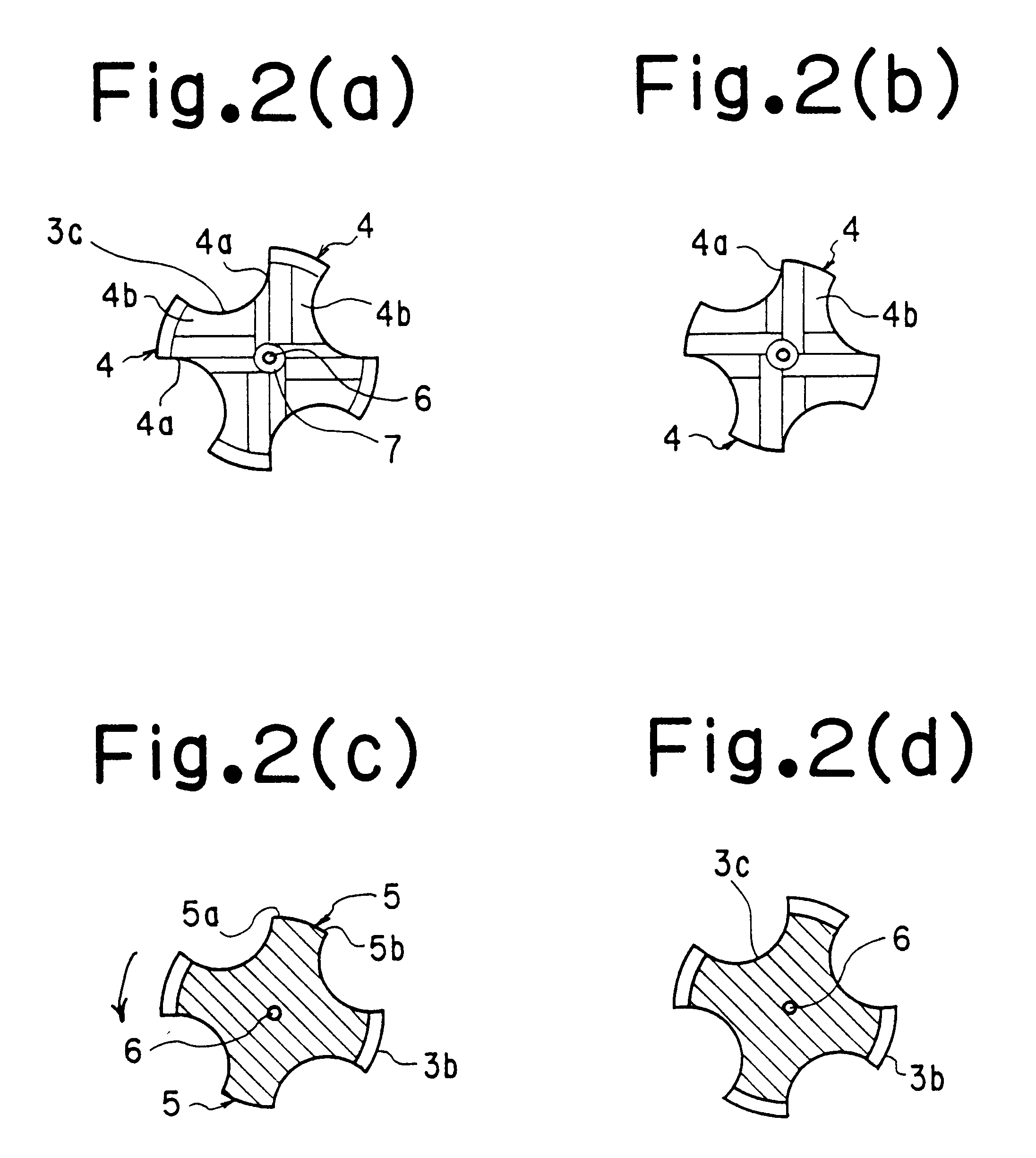

Tap

InactiveUS6499920B2Reduce processing timeImprove productivityThread cutting toolsWood turning toolsFluteEngineering

A cutting tap comprises a threaded portion including a lead whose thread diameter gradually decreases toward a front end of the lead, a complete thread portion continued from the lead, and four flutes arranged at equal intervals in a circumferential direction. In the cutting tap, a first cutting edge portion for processing a prepared hole is formed at a front end surface of the lead, and a second cutting edge portion for finishing a minor diameter of an internal thread is formed in a part of an outer periphery of the complete thread portion, the second cutting edge portion being one or more pitches long. The cutting tap can perform processing of a prepared hole, tapping, and finishing of a minor diameter by a single step, and can also perform tapping even if a prepared hole for an internal thread is a blind hole or the like and does not have enough space.

Owner:TANOI MFG CO LTD

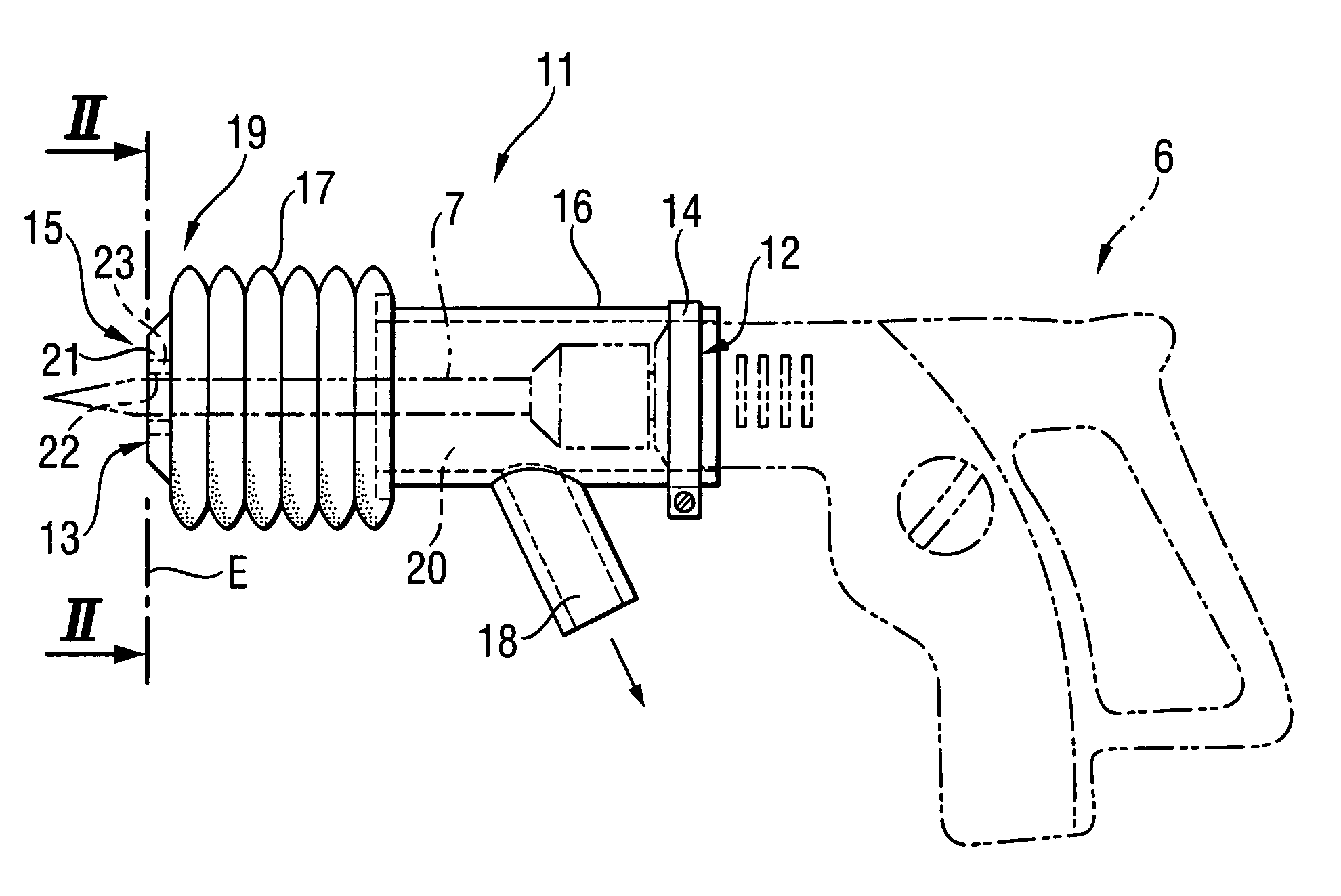

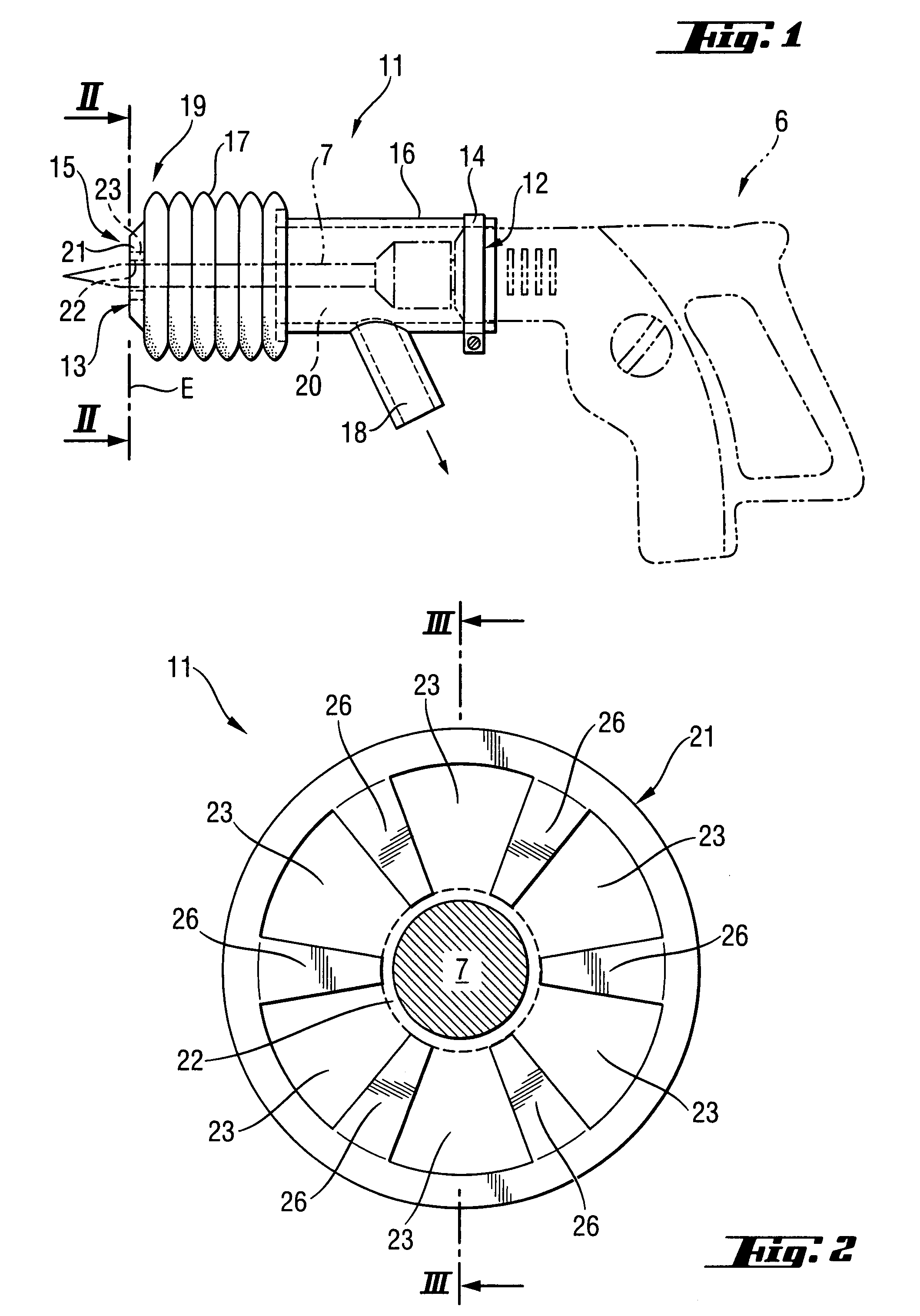

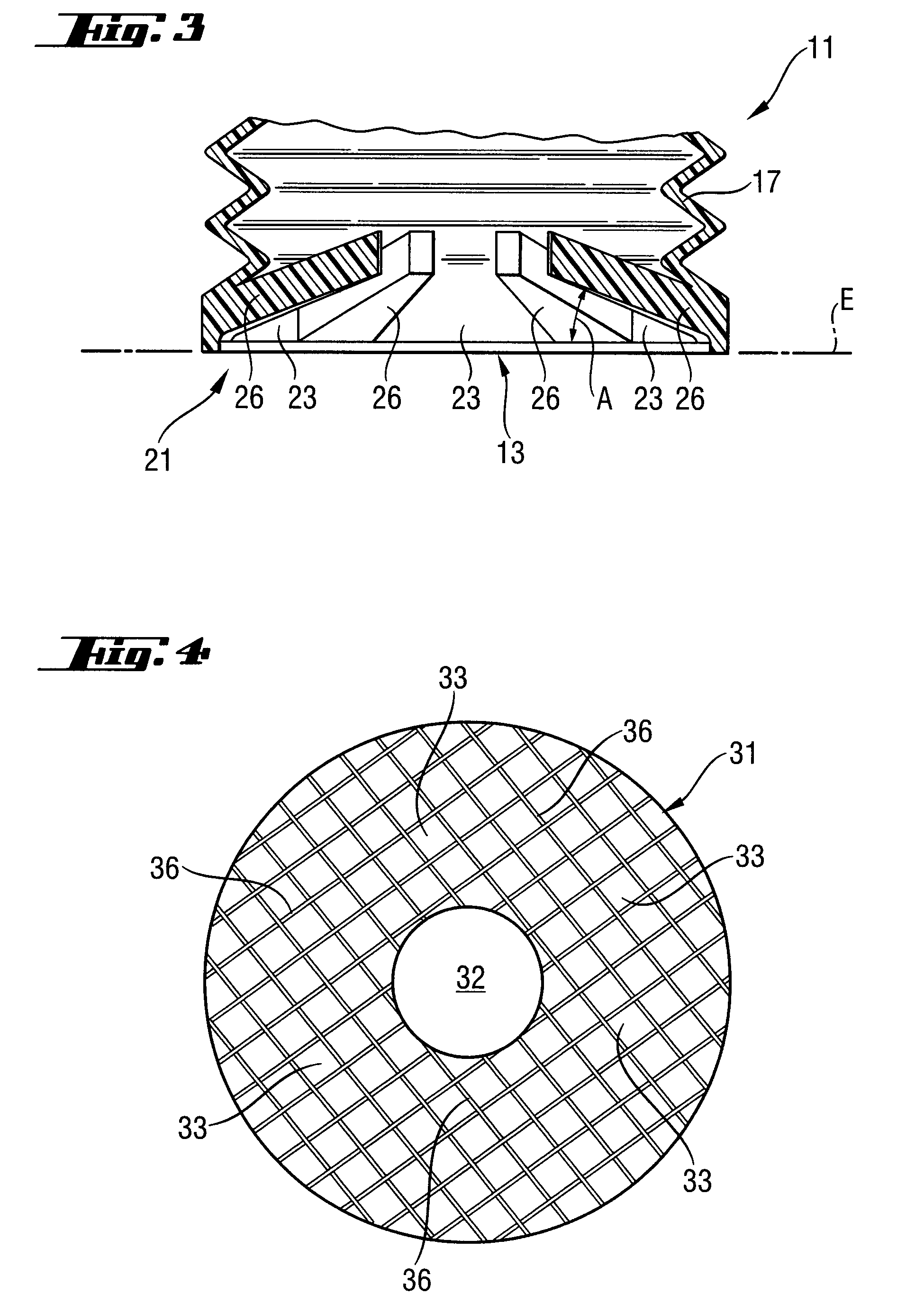

Suction device for a pick power tool

ActiveUS7740086B2Avoid cloggingGreat suctionTransportation and packagingMulti-purpose machinesClassical mechanicsPower tool

A suction device (11) for a hammer drill (6) has a first end (12) with a securing device (14) for securing the suction device (11) to the hammer drill (6) and a second end (13) opposite first end (12) and which has a contact area (15) with which the suction device (11) contacts a constructional component, the suction device (11) further having a receiving space (20) which at least partially encloses a working tool (7) of the pick power tool (6), and being provided with a connection device (18) for a vacuum source. A retaining element (21) having a through-opening (22) for the working tool (7) and a plurality of suction openings (23) is provided in an area (19) of the second end (13).

Owner:HILTI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com