Patents

Literature

1348results about "Thread cutting tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

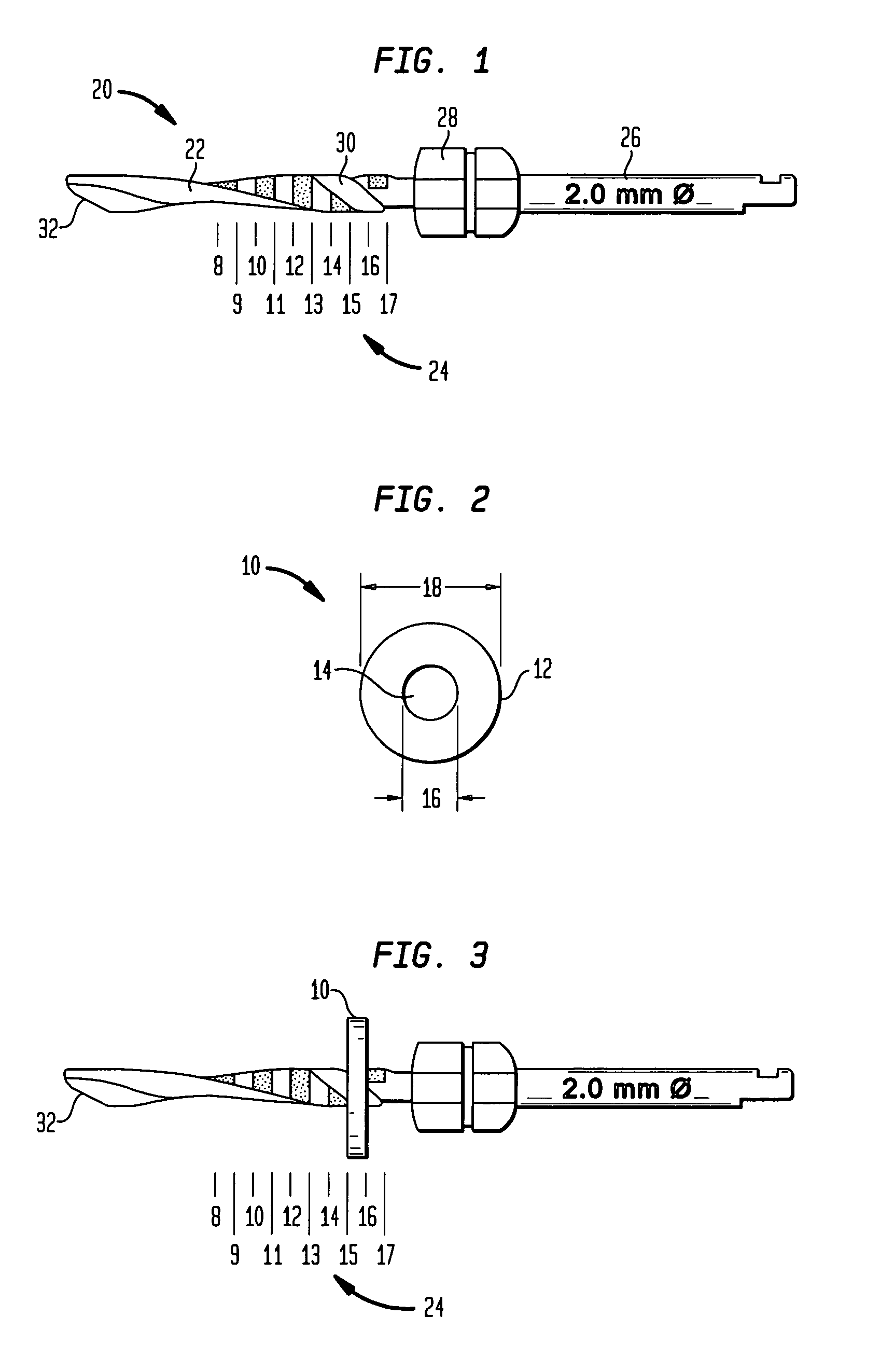

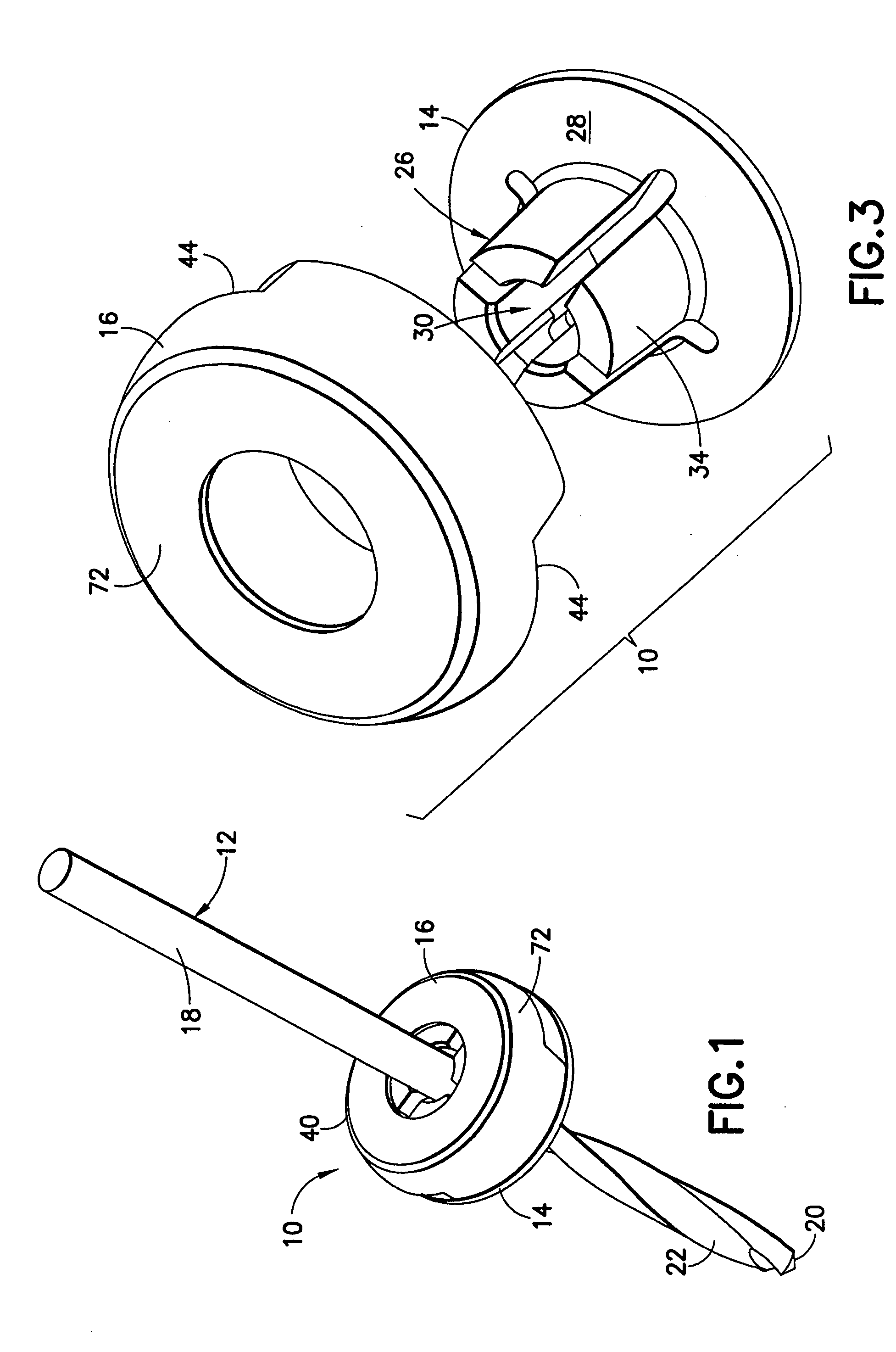

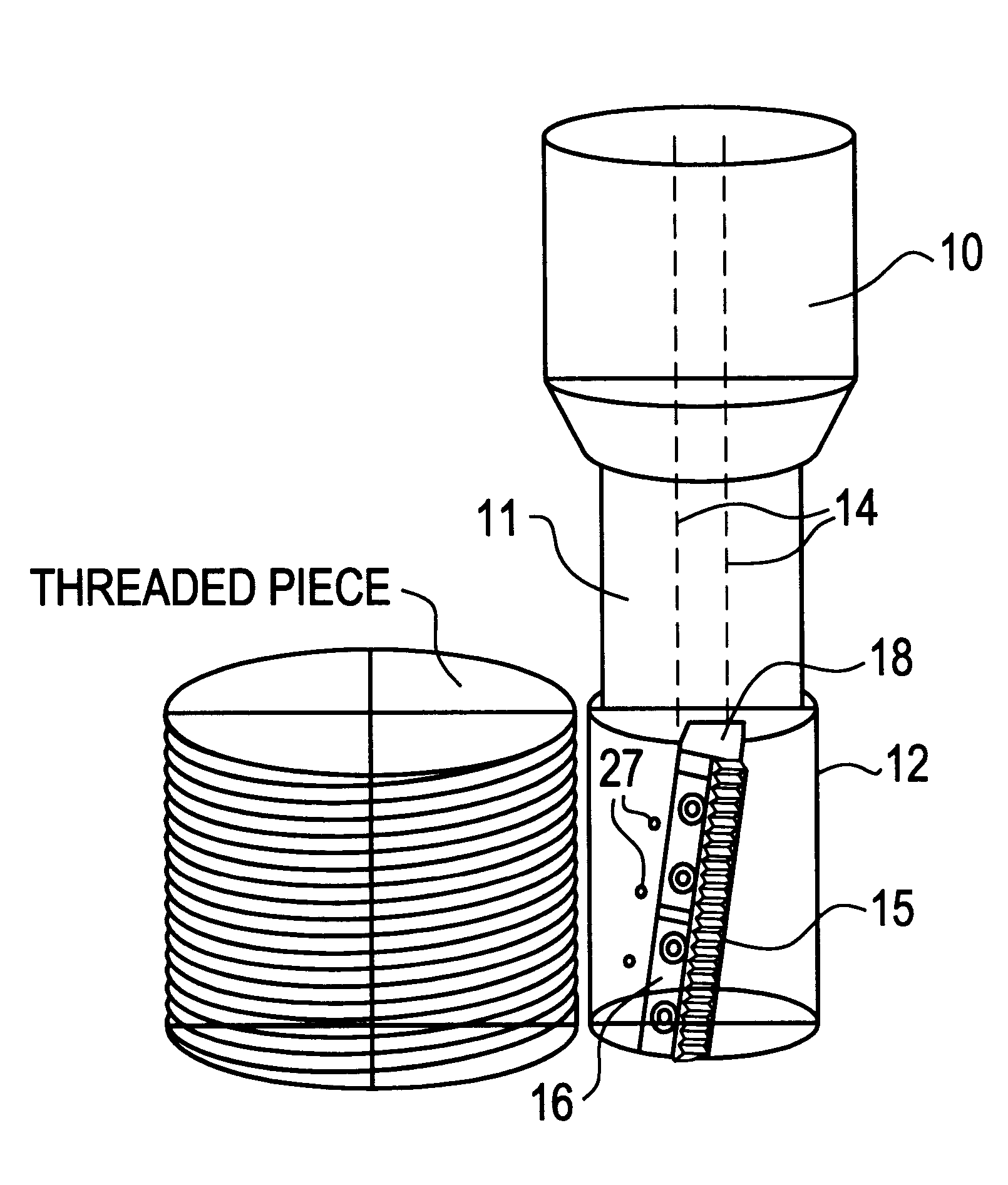

Sleeved stop for a drill bit

A stop for use with an electric drill bit, the stop having at least one threaded sleeve for positioning the stop relative to a surface into which the drill bit will extend. The stop may have both an inner and an outer sleeve. The sleeves are mounted coaxially, one inside the other about the drill bit. One of the sleeves, preferably the inner sleeve, provides coarse adjustment of the position of the shoulder relative to the tip of the bit, while the other, preferably the outer sleeve, provides fine adjustment of the position of the shoulder relative to the top of the bit.

Owner:3D SCAN GUIDE LLC

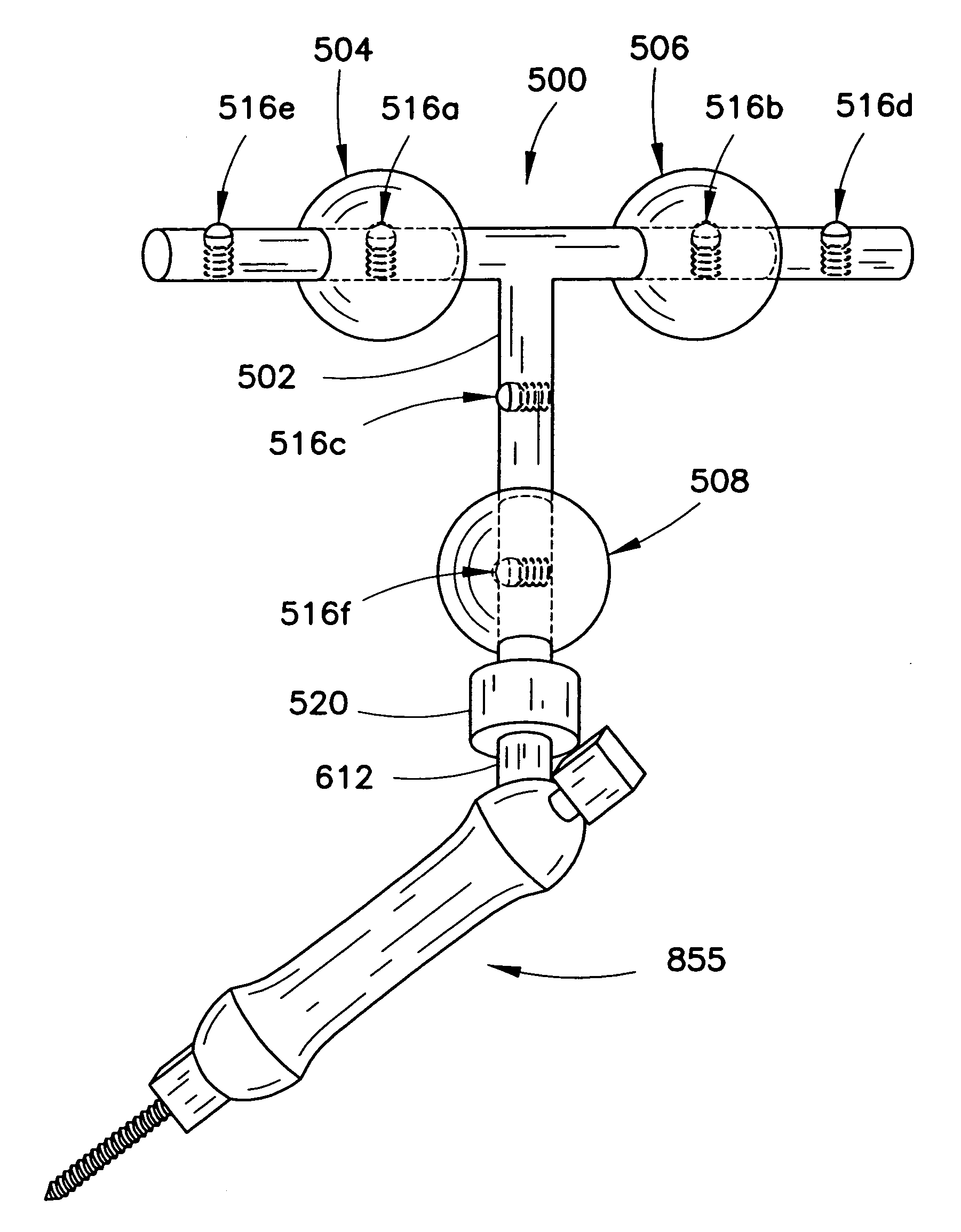

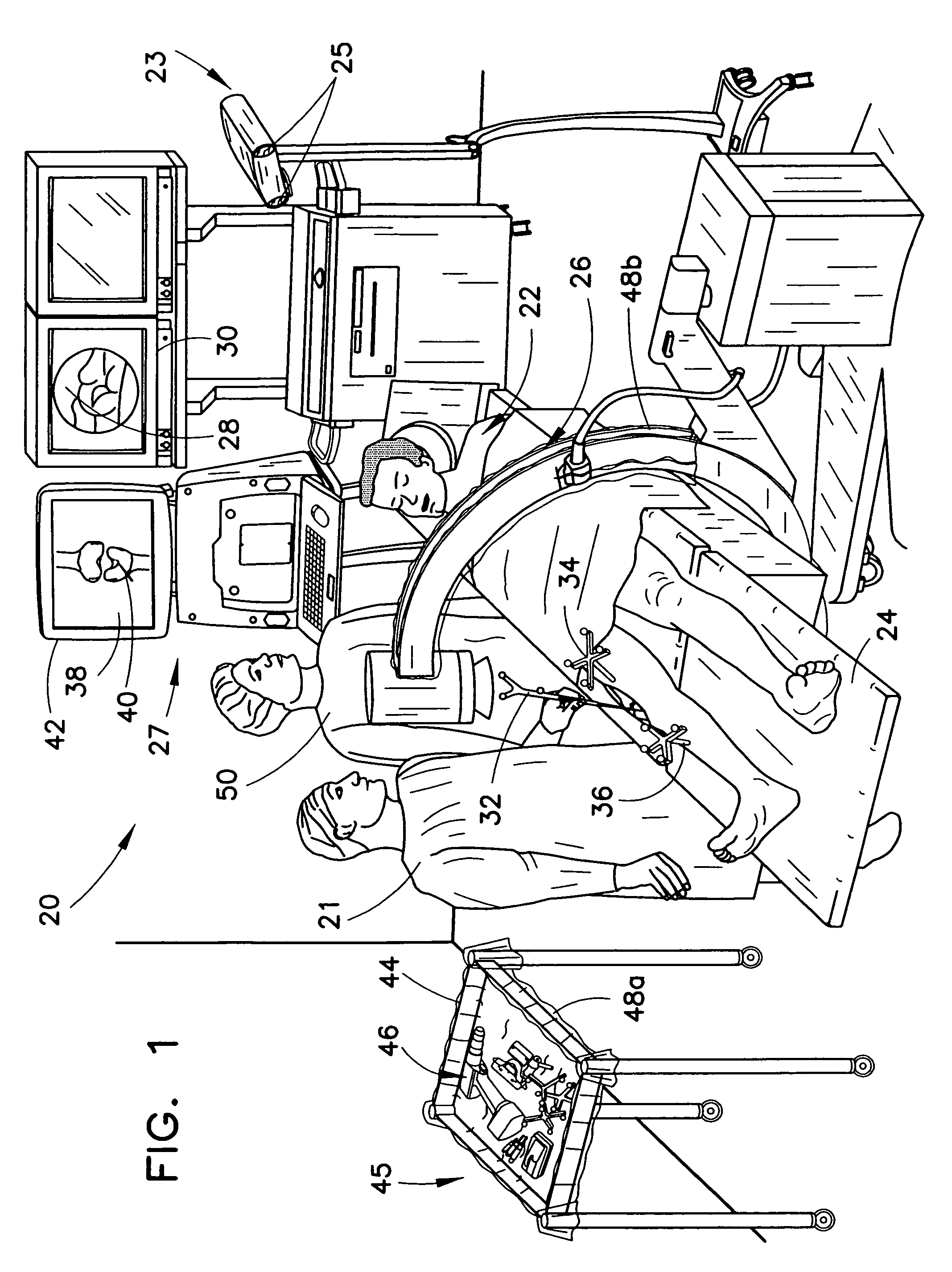

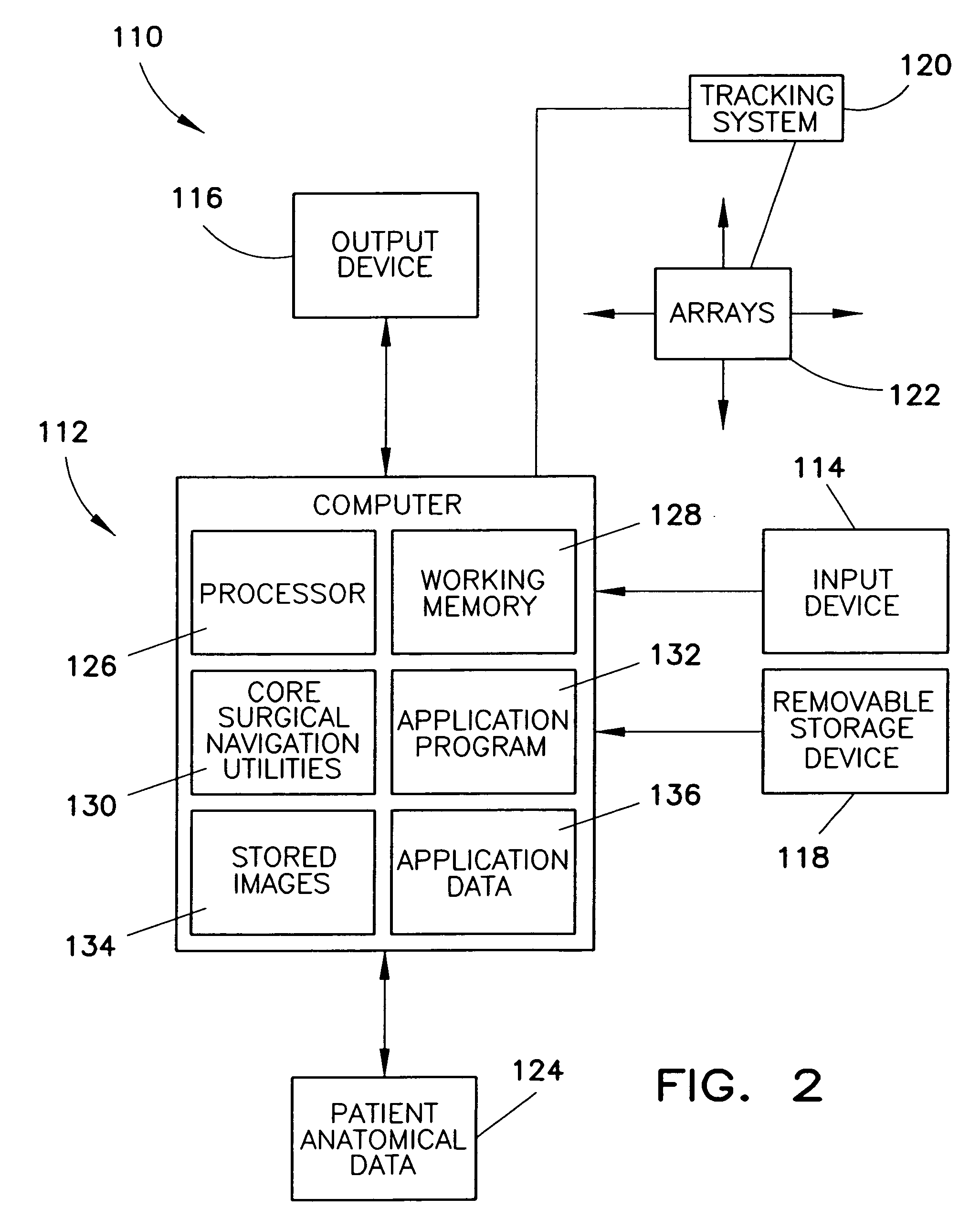

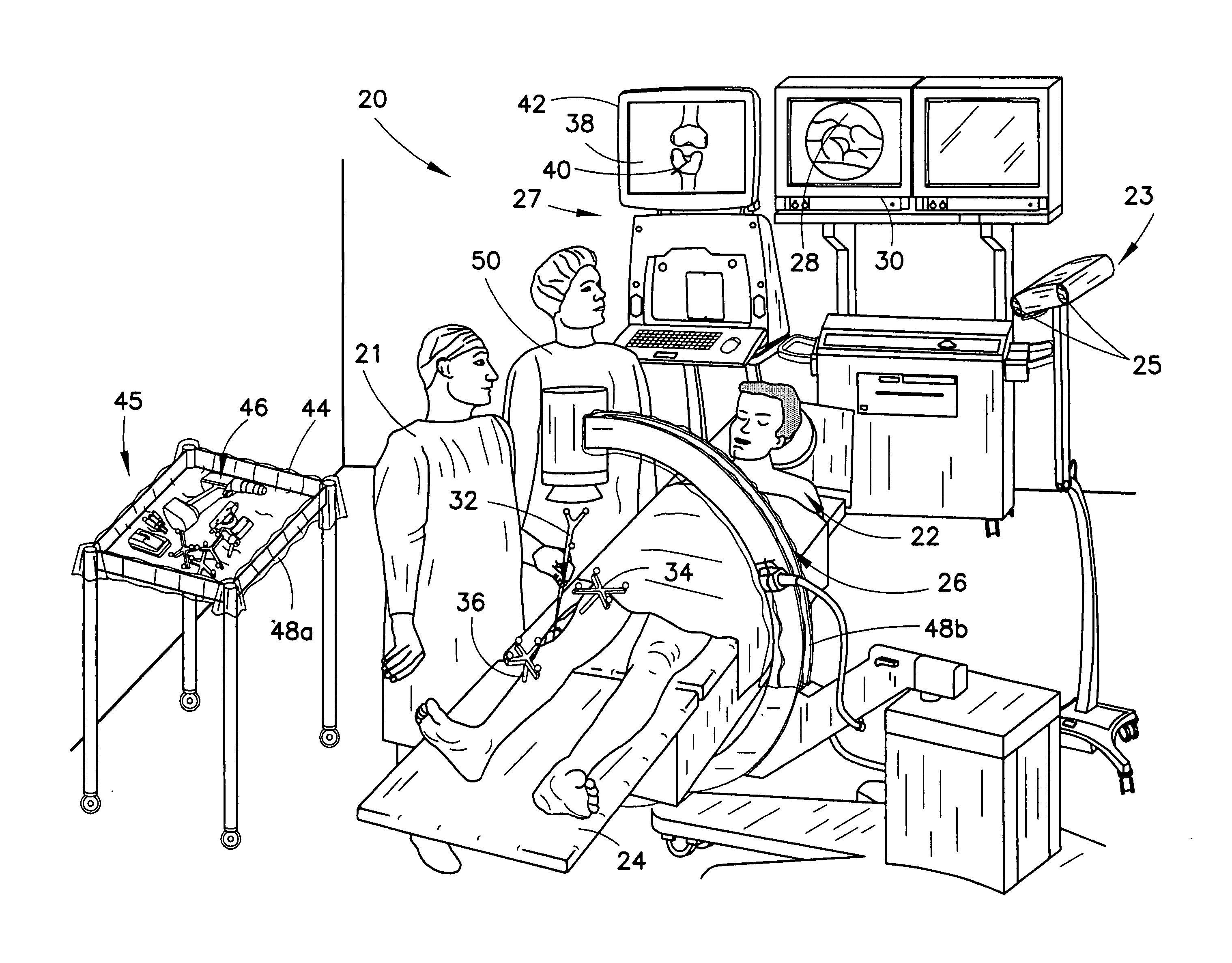

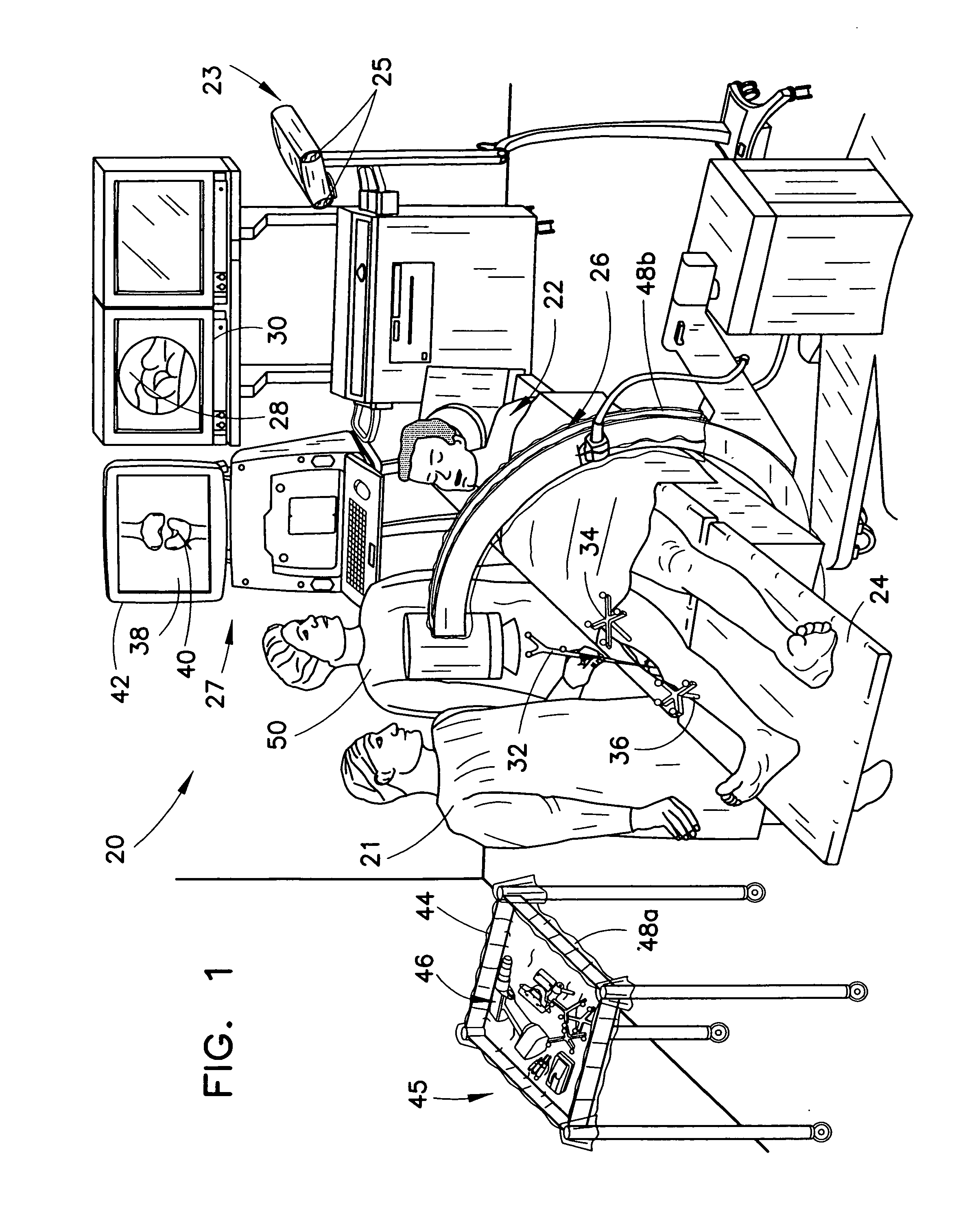

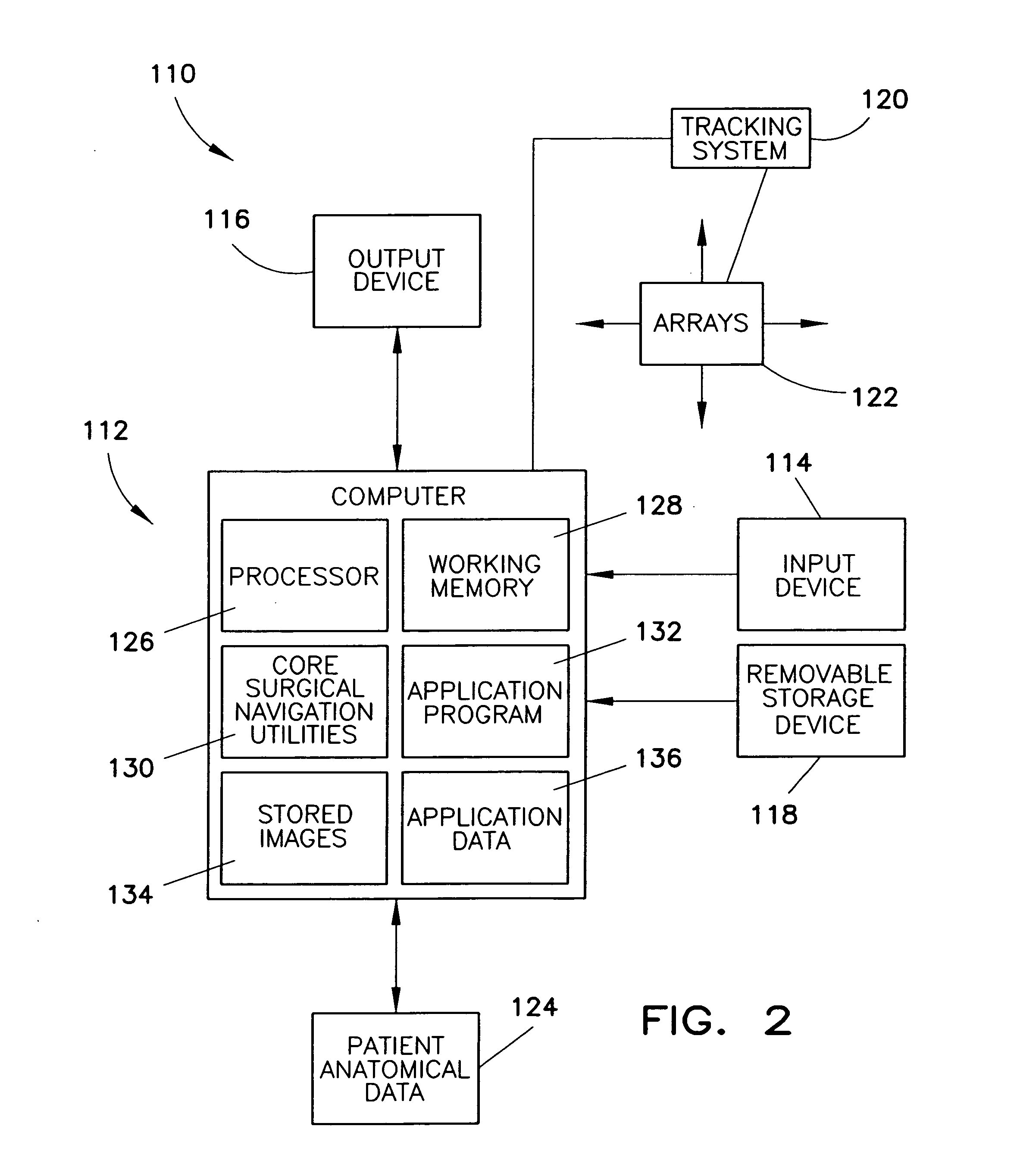

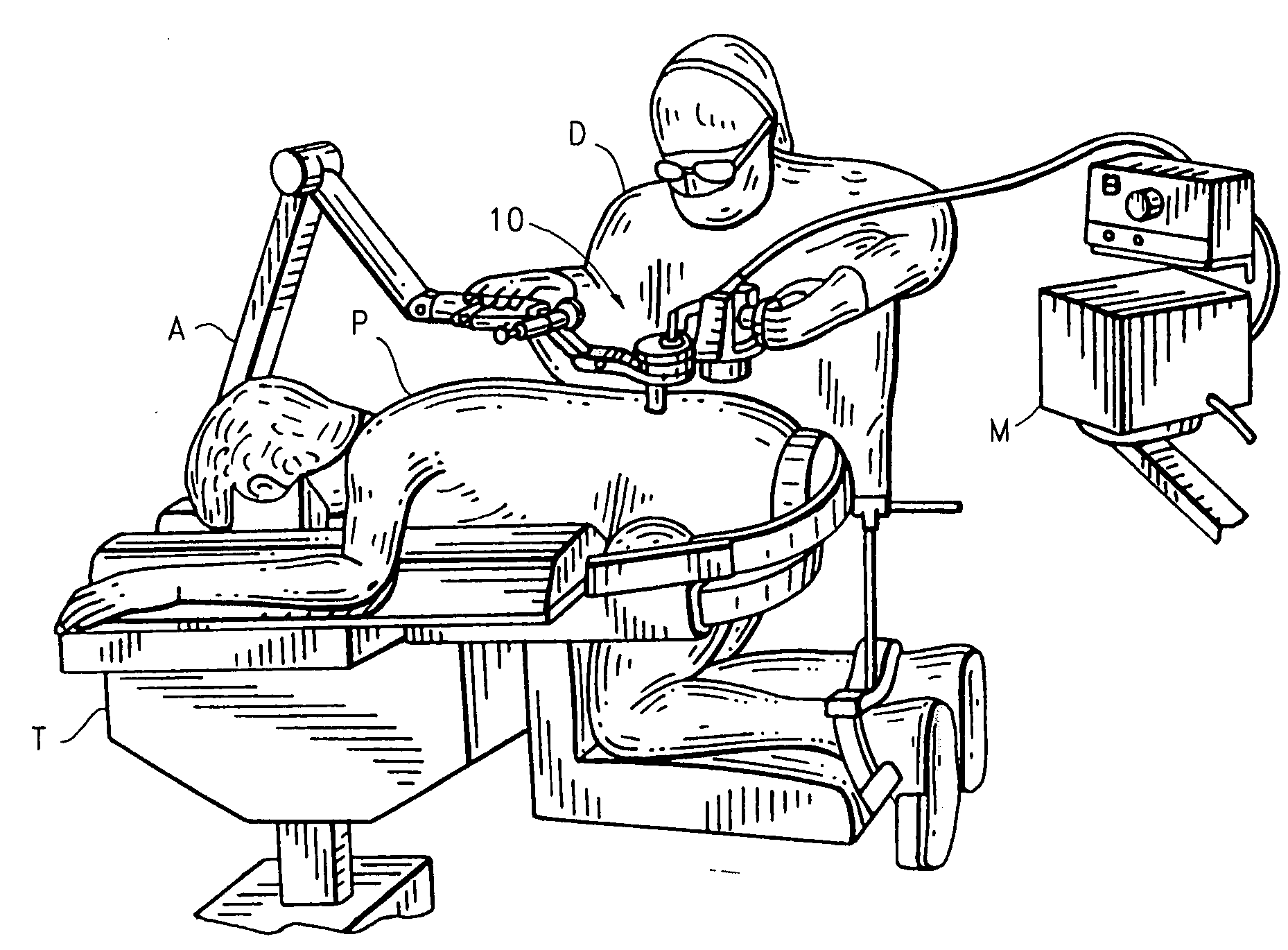

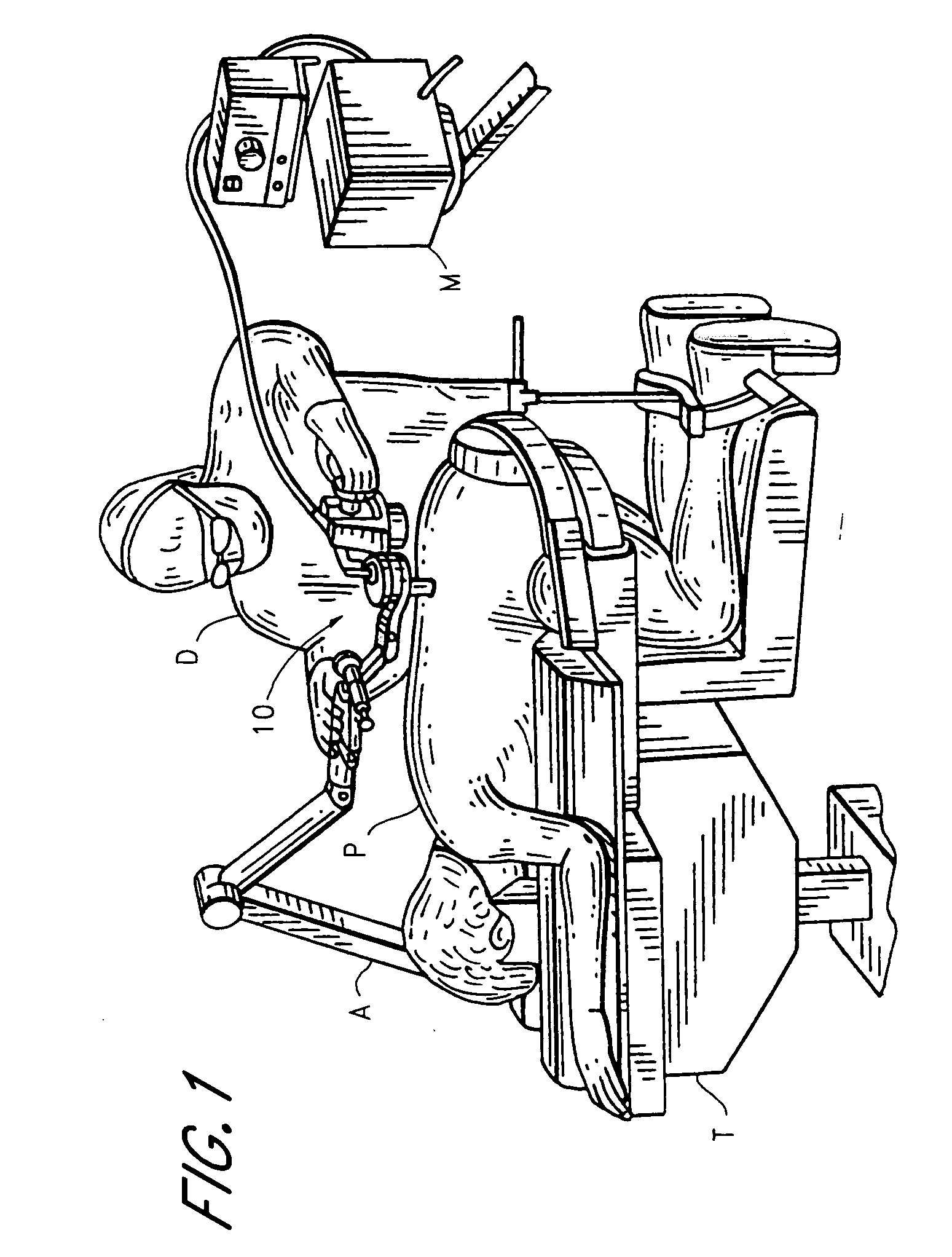

Image guided tracking array and method

ActiveUS7840256B2Reduce in quantityThread cutting toolsTransportation and packagingNavigation systemComputer science

Owner:BIOMET MFG CORP

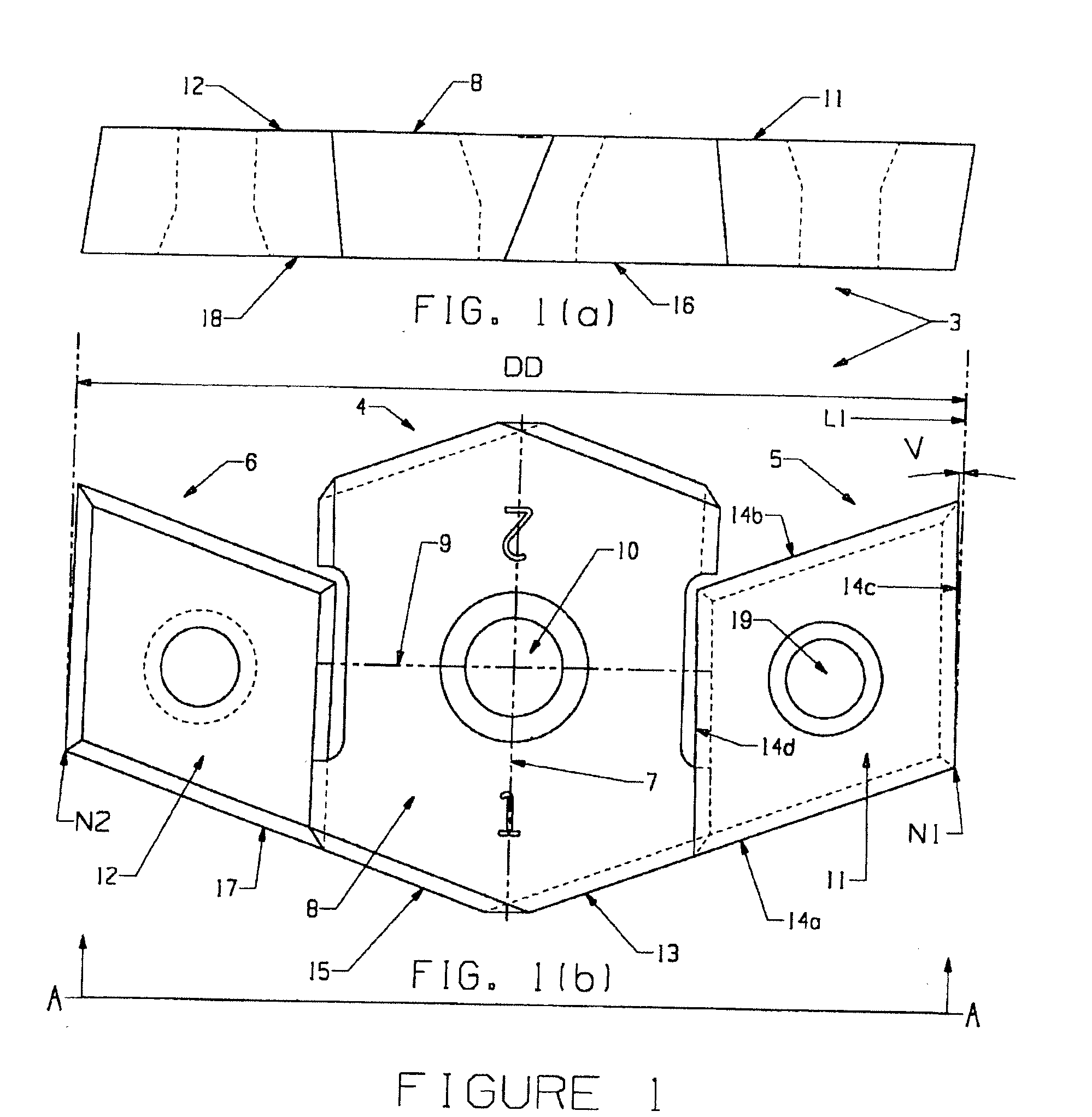

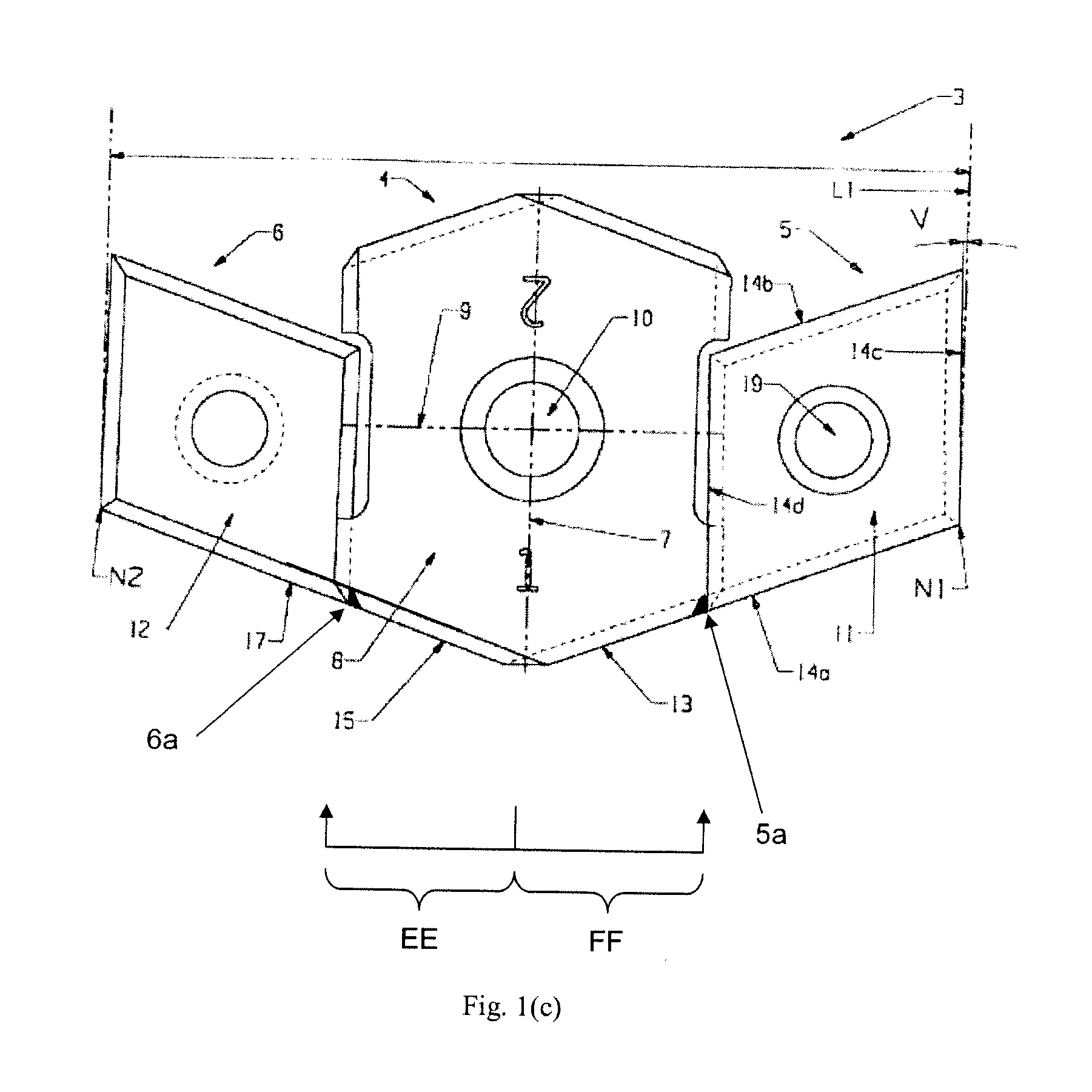

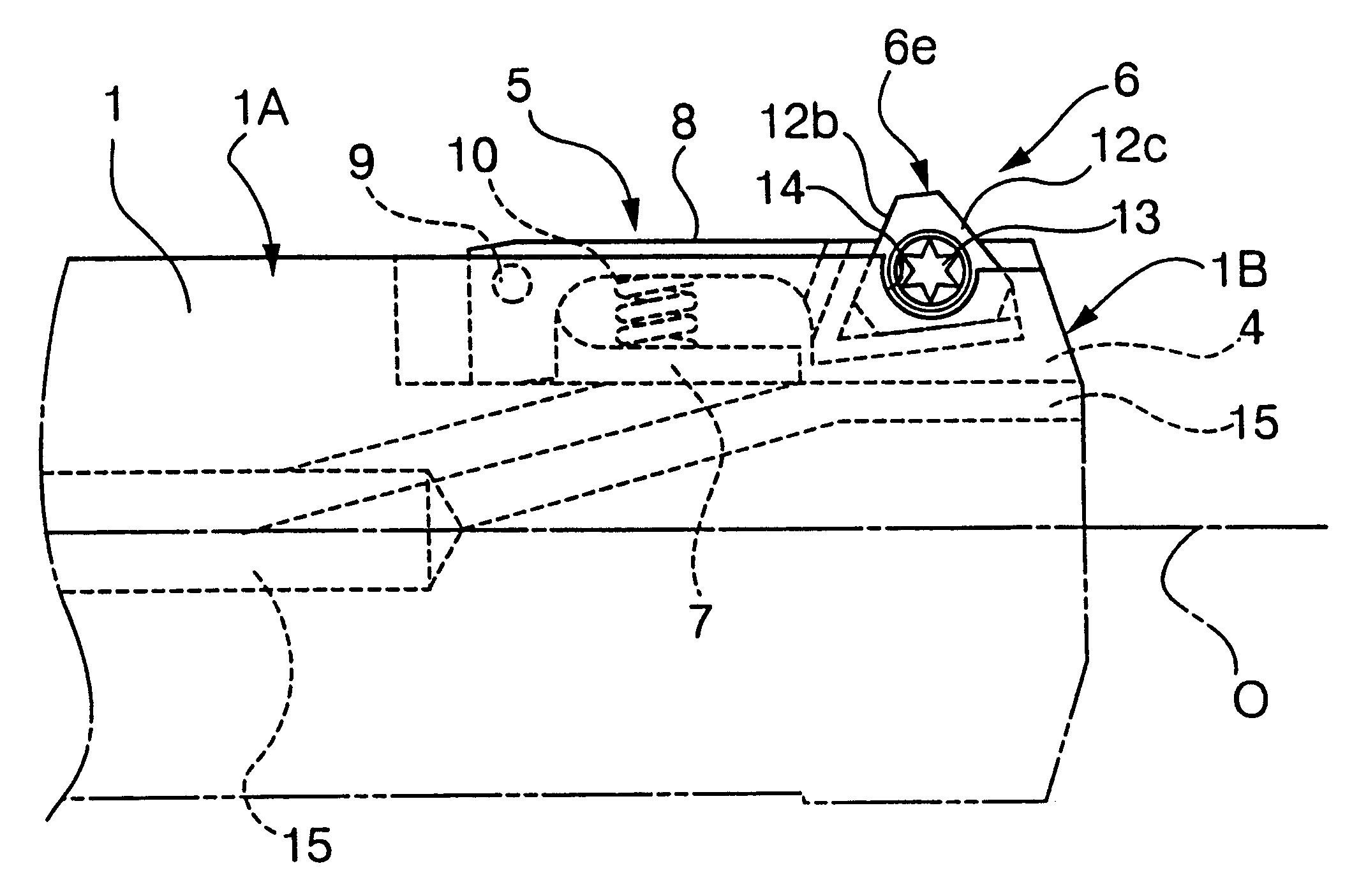

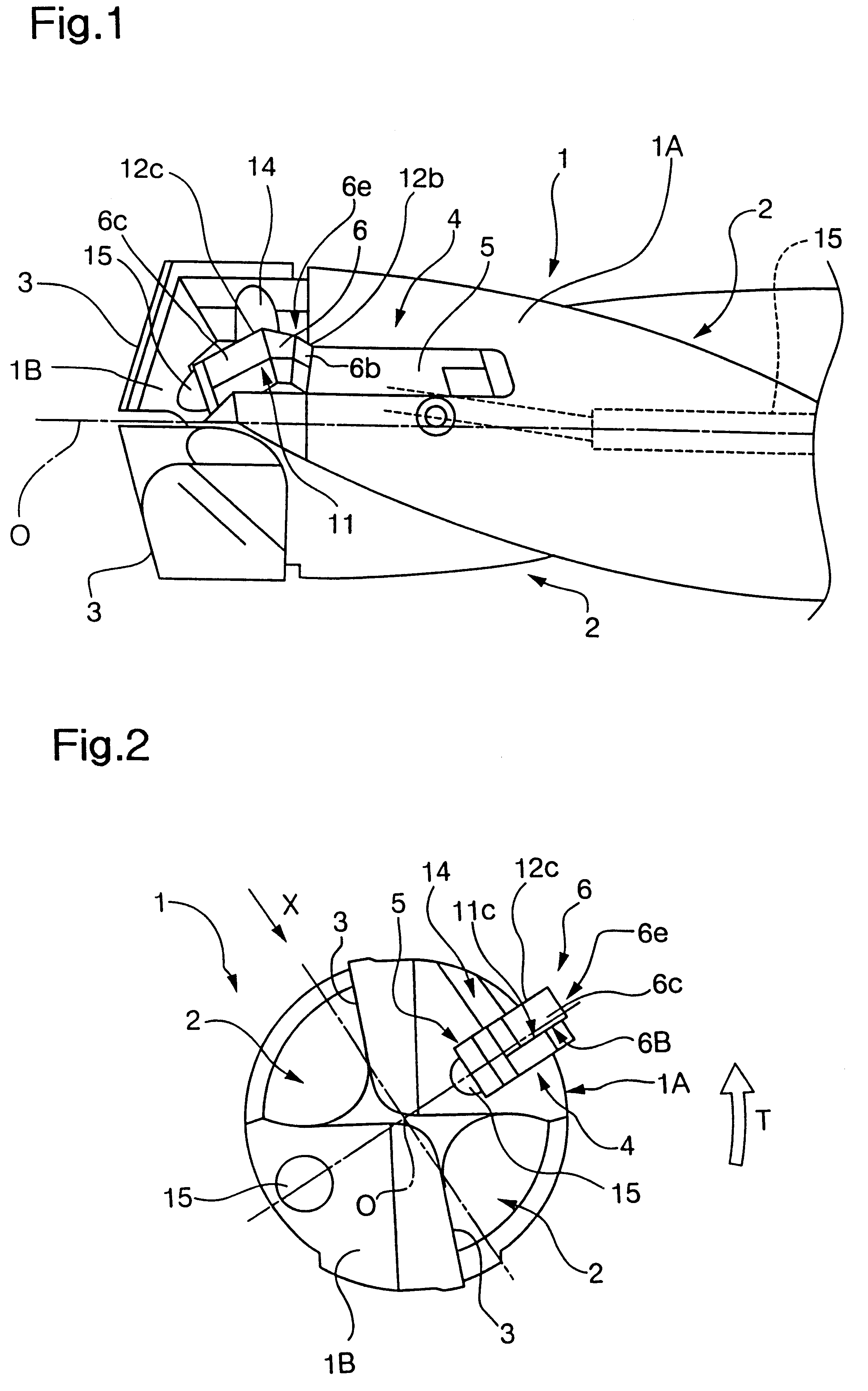

Image guided tracking array and method

ActiveUS20070016009A1Reduce in quantityThread cutting toolsTransportation and packagingNavigation systemComputer science

An array for use with a surgical navigation system is provided. The array comprises a frame and first, second and third markers attached to the frame. The first, second and third markers are detectable by a tracking system used in image guided surgery, and the first marker is movable relative to the frame. In one embodiment, at least one marker slides along the frame from a first position where it is held in place to a second position where it is also held in place. In another embodiment, one or more of the markers is removed from the frame at a first position and reattached to the frame at a second position. In still another embodiment, a portion of the frame itself moves with the moveable marker.

Owner:BIOMET MFG CORP

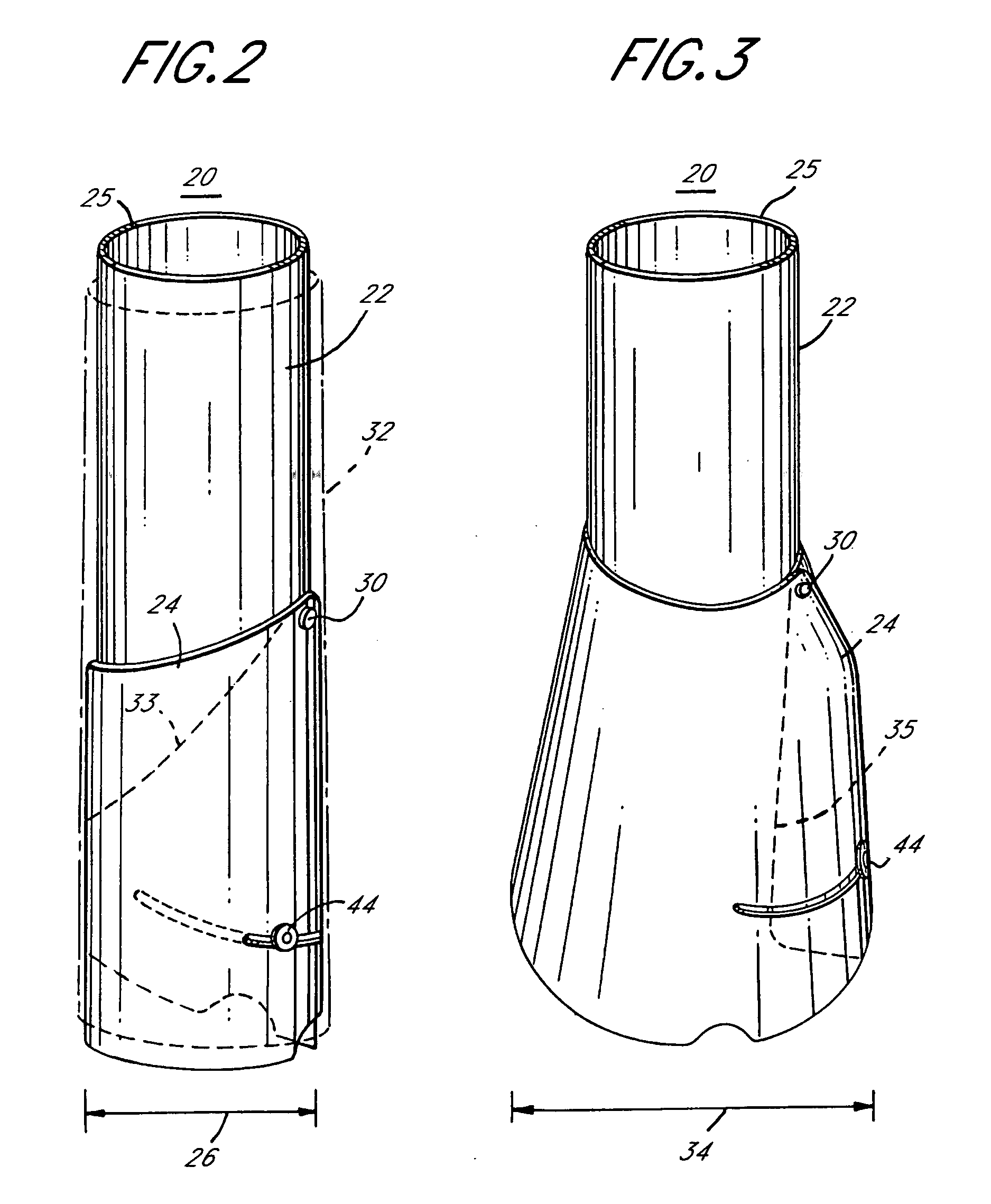

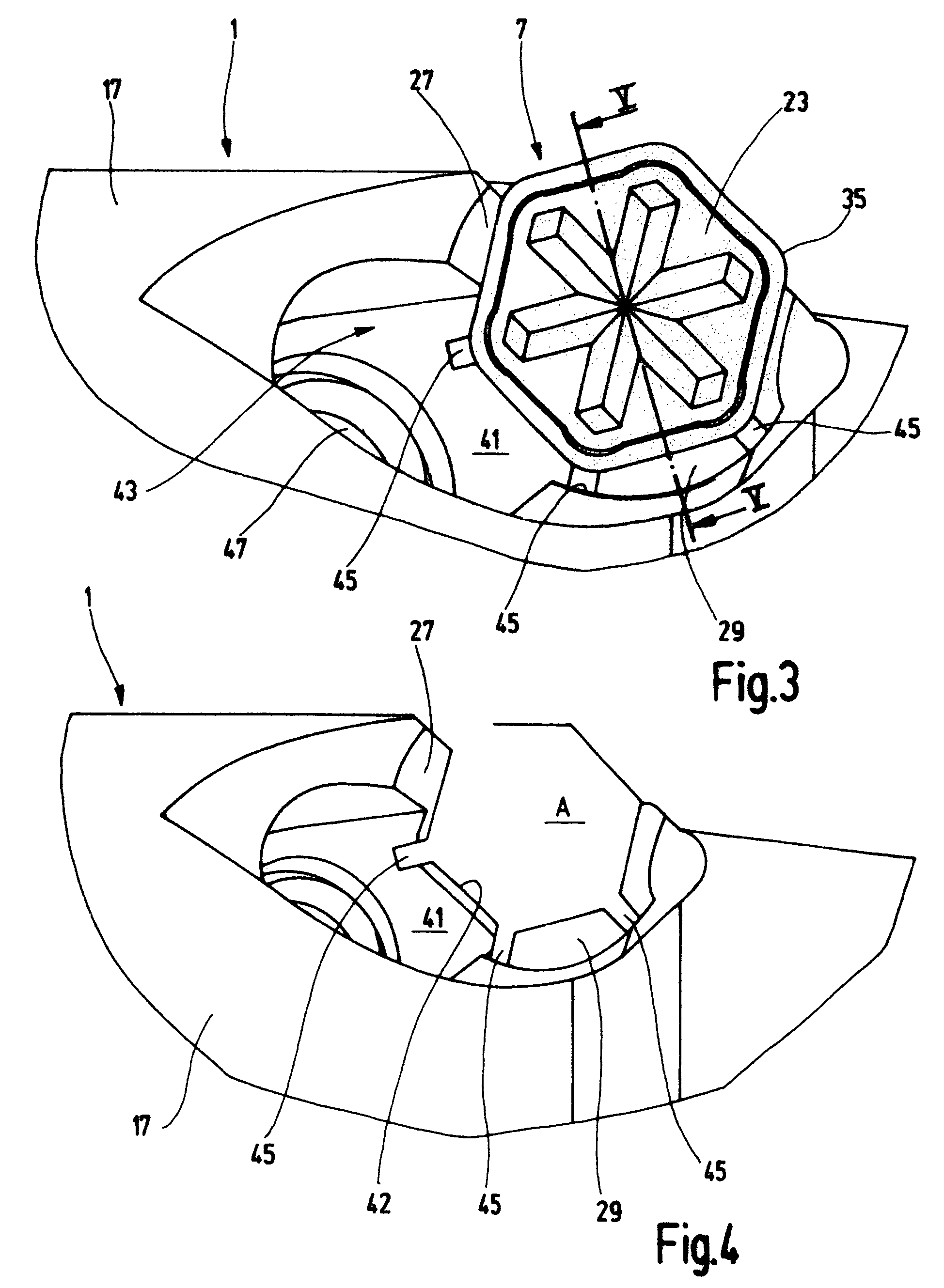

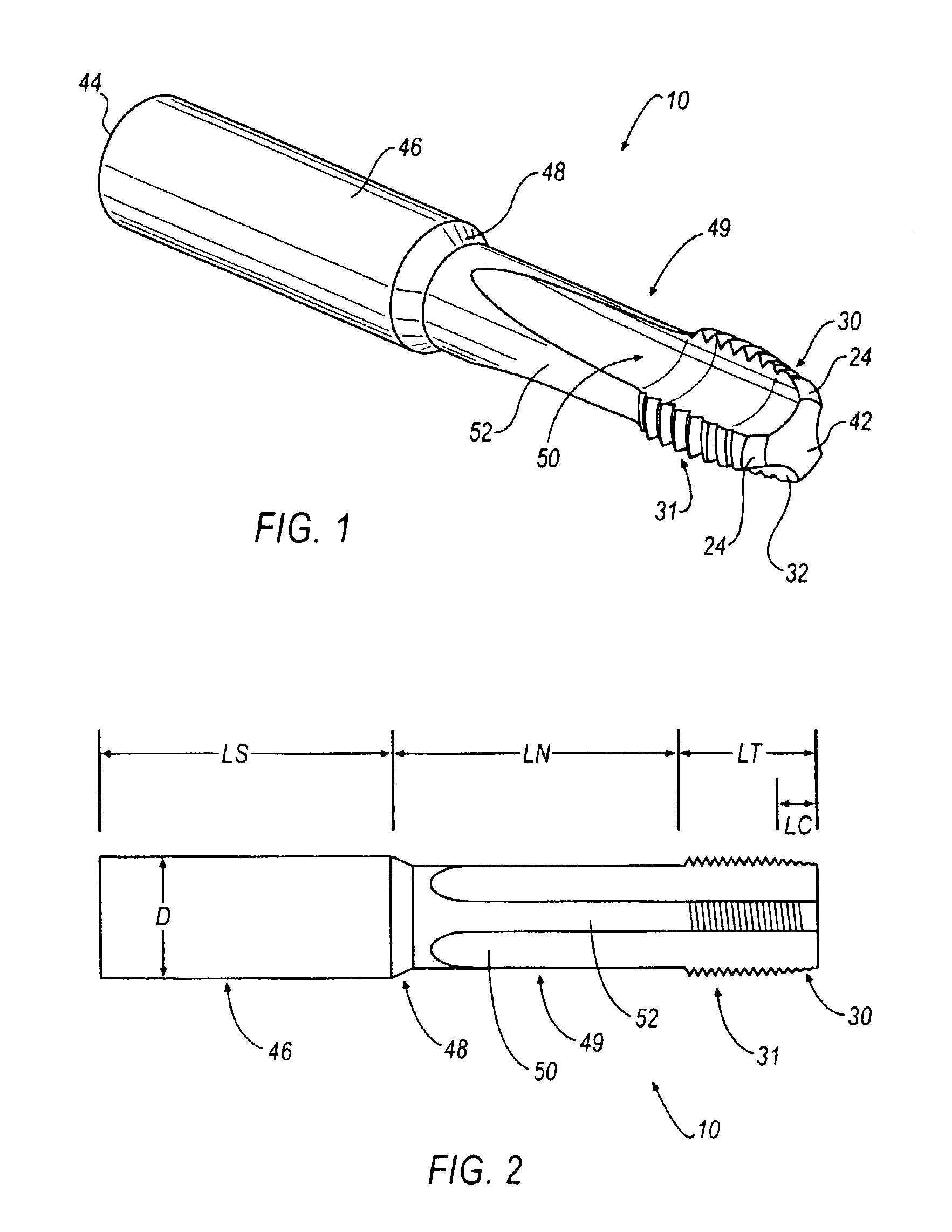

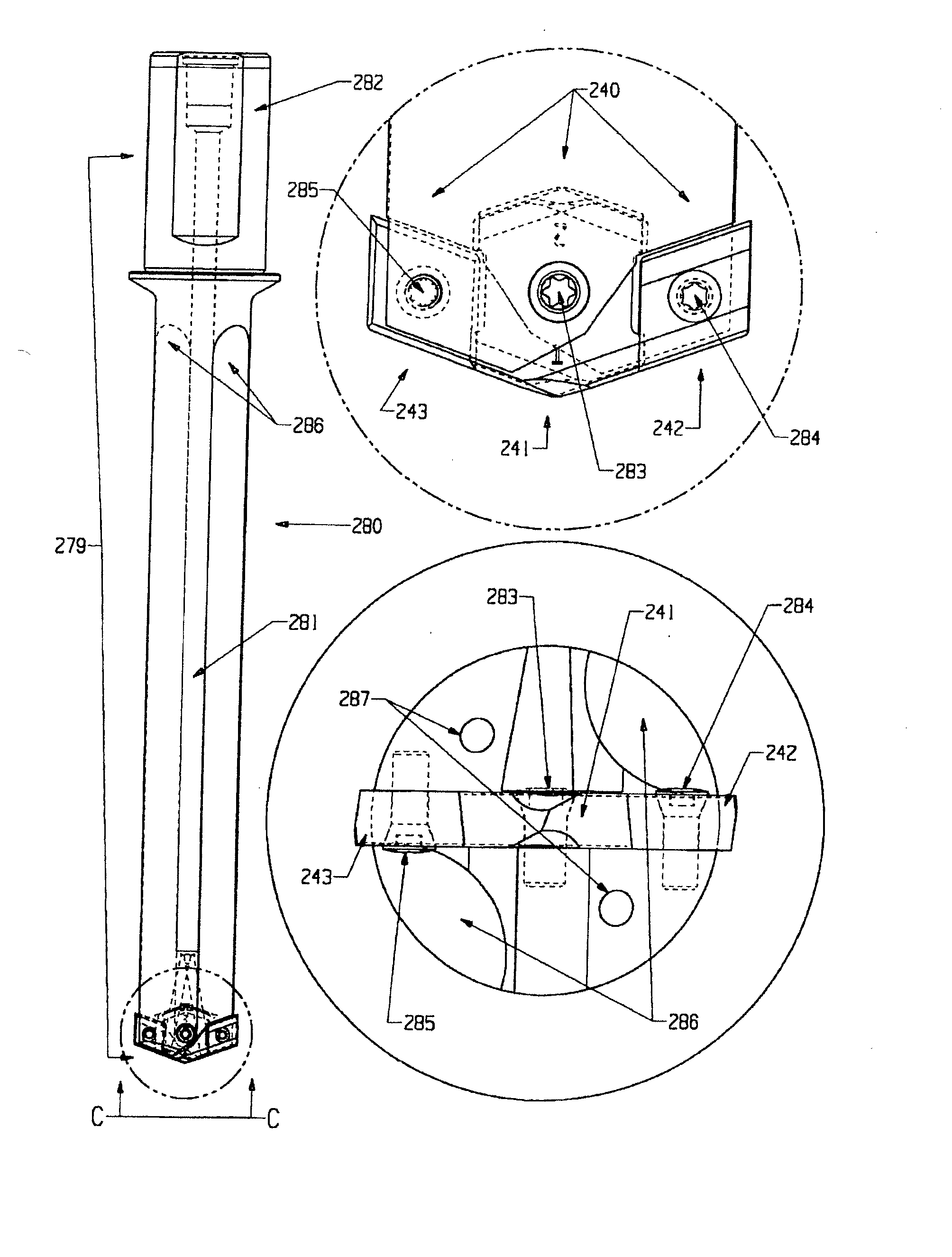

Instrument and method for preparing a bone to receive an implant

InactiveUS20050171551A1Expand accessPassage increaseThread cutting toolsInternal osteosythesisDistal portionBiomedical engineering

A device for preparing a pedicle to receive an implant comprises an elongated shaft having a proximal portion and a distal portion. An awl tip portion is near the distal portion. A probe portion is proximal to the awl tip portion. A threaded portion is proximal to the probe portion.

Owner:ZIMMER SPINE INC

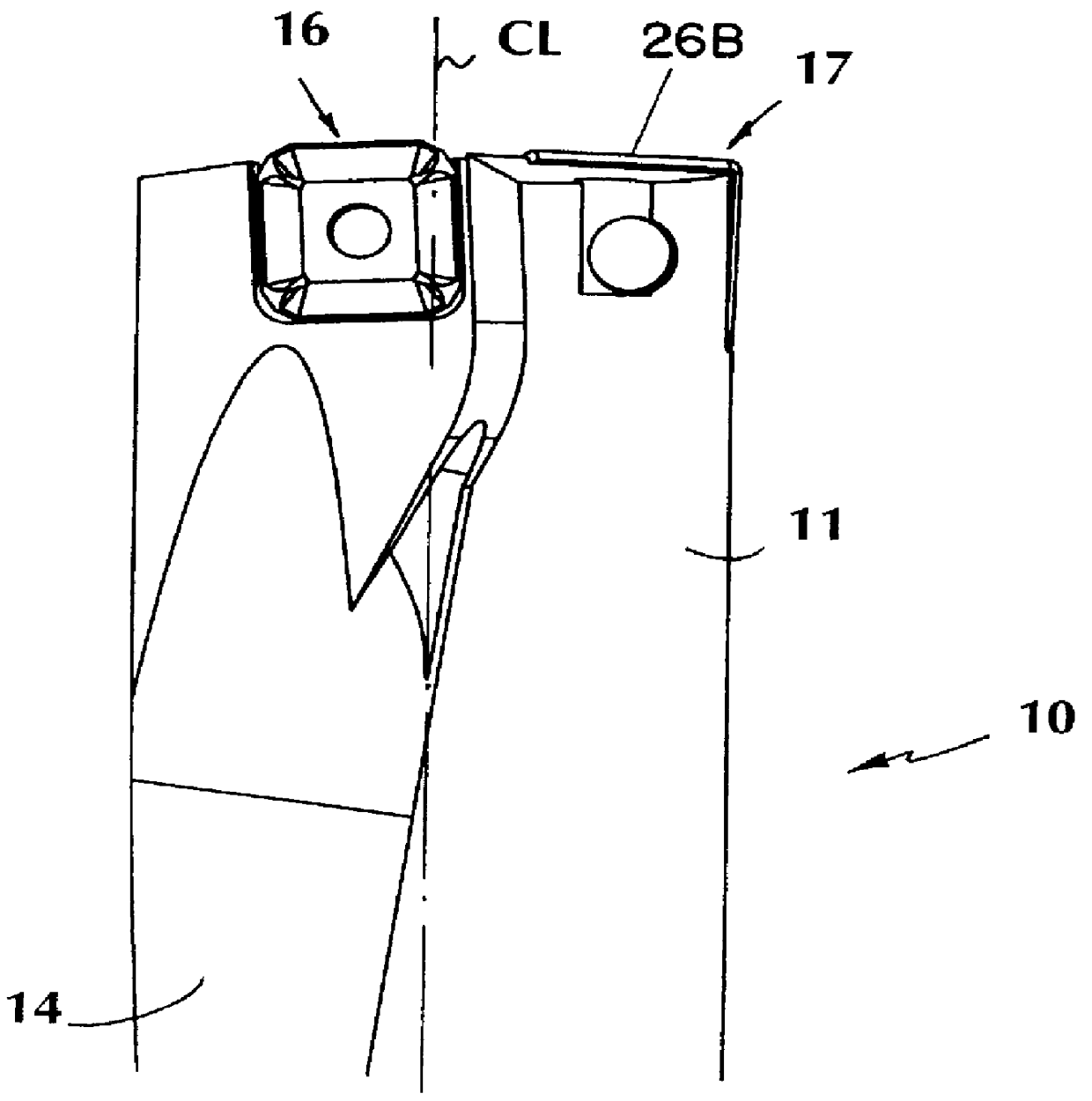

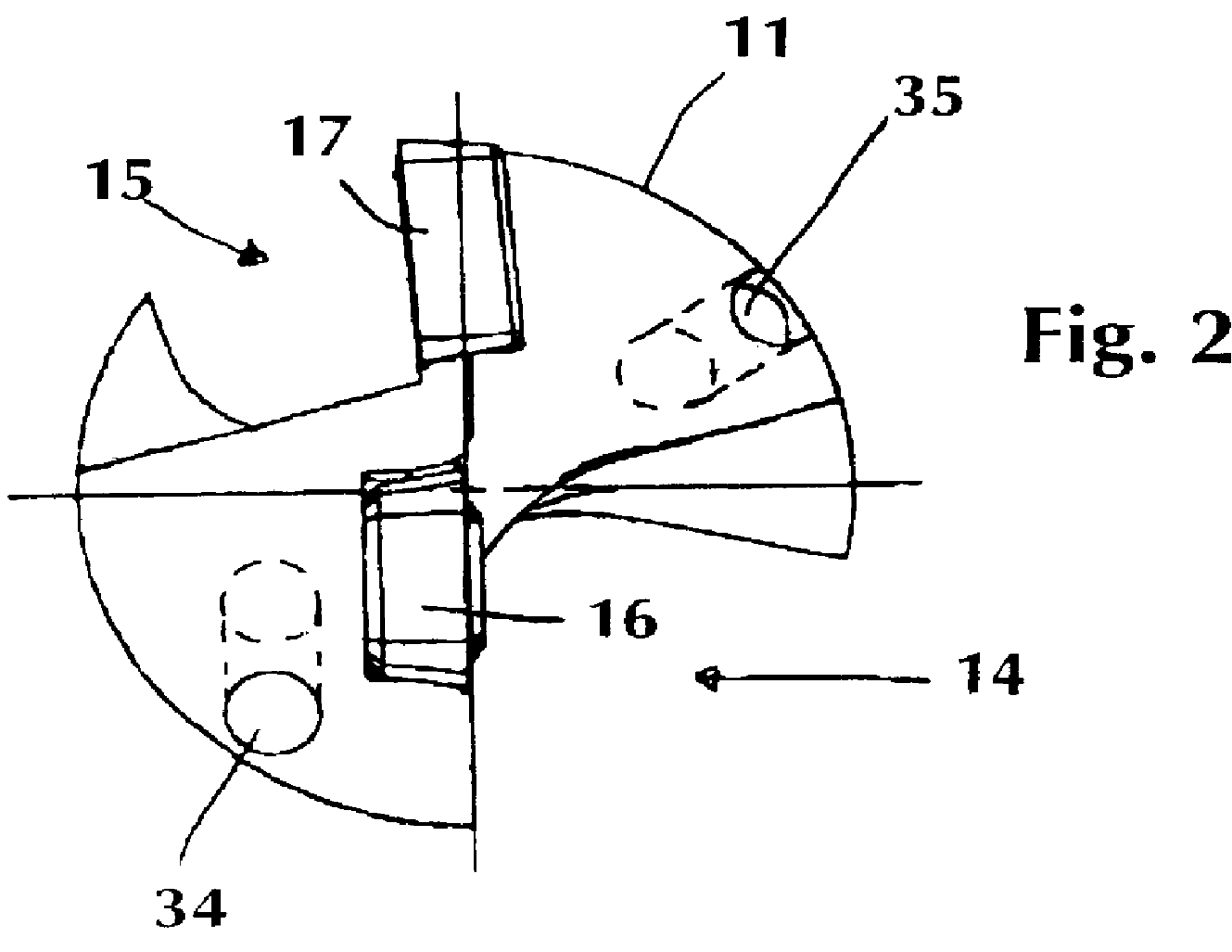

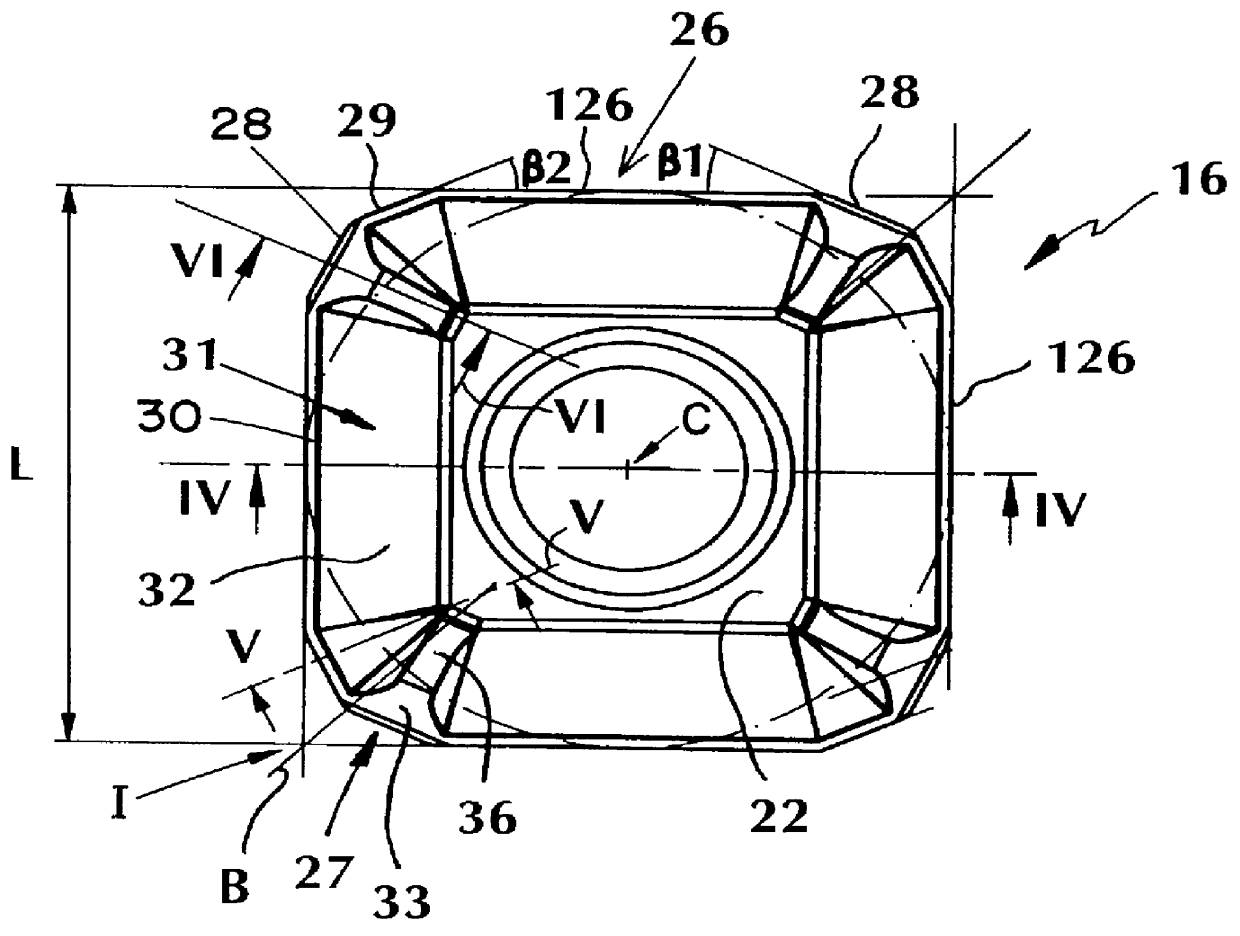

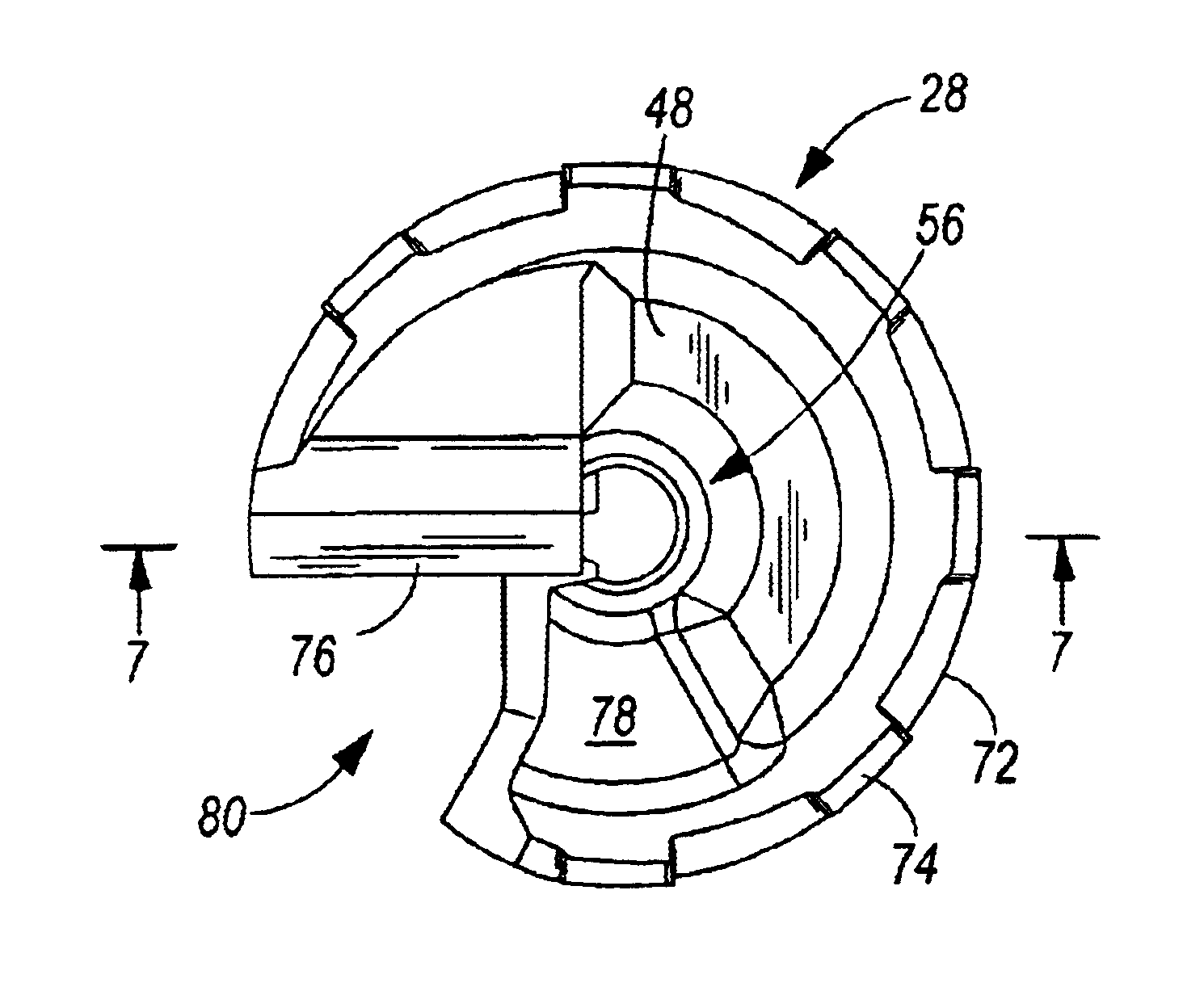

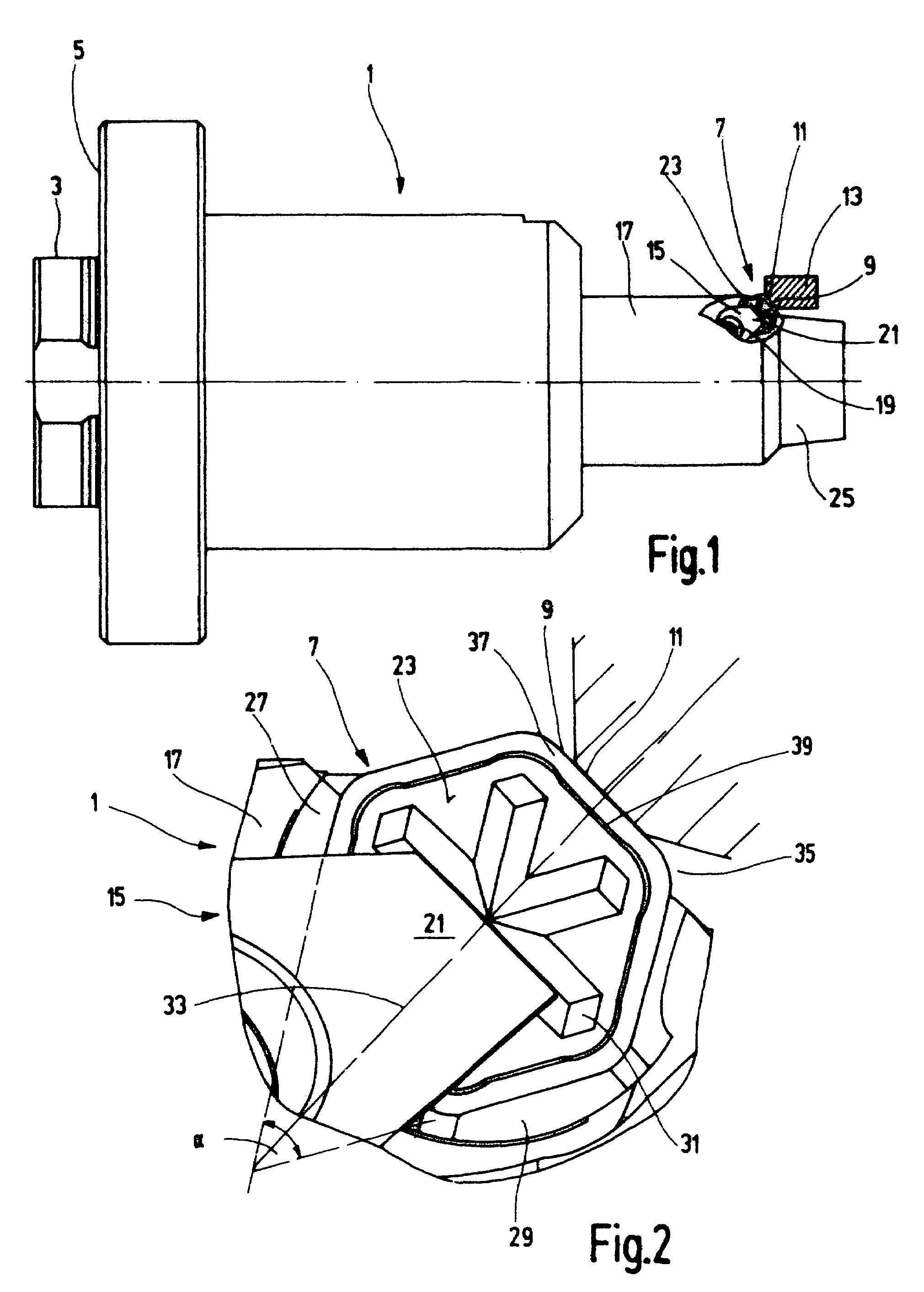

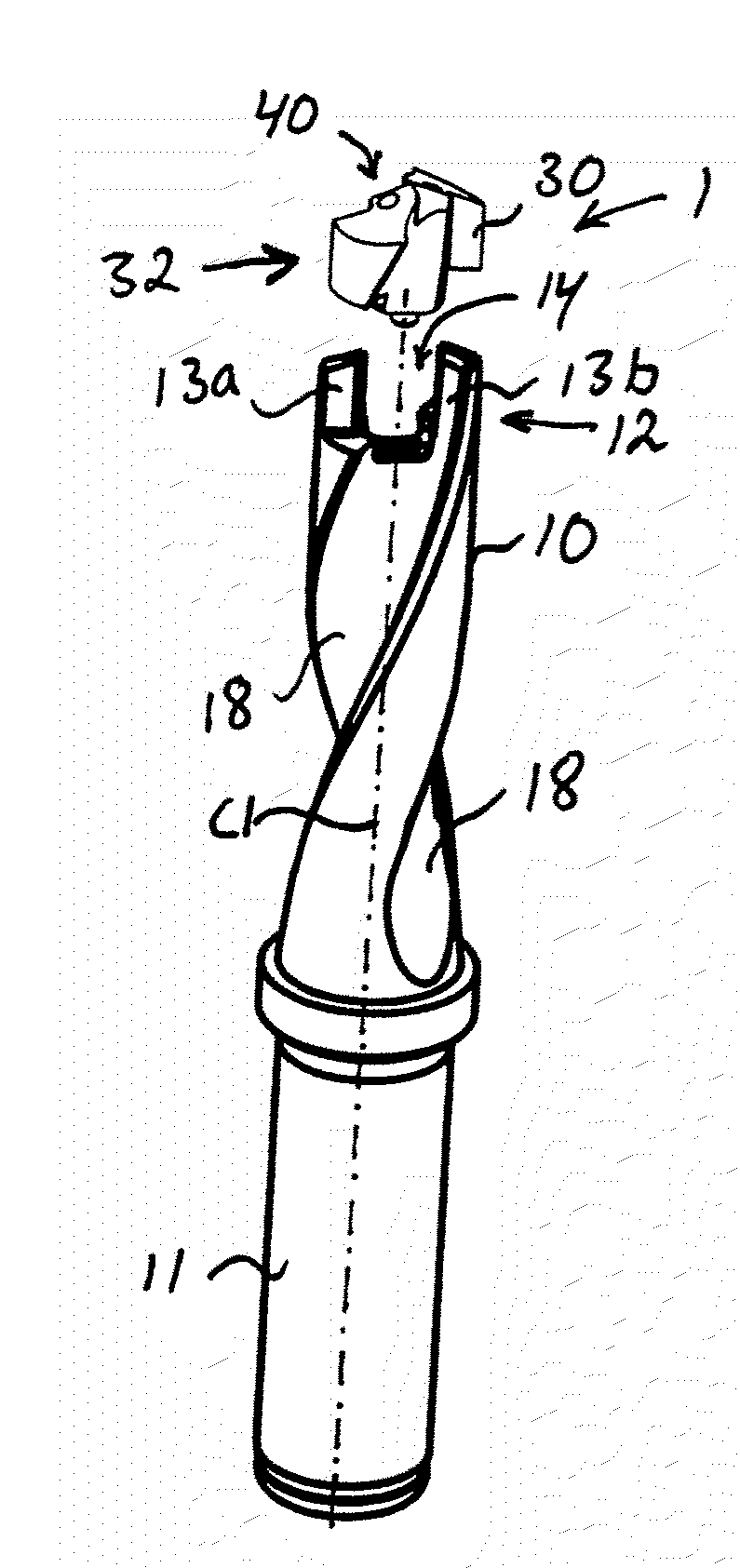

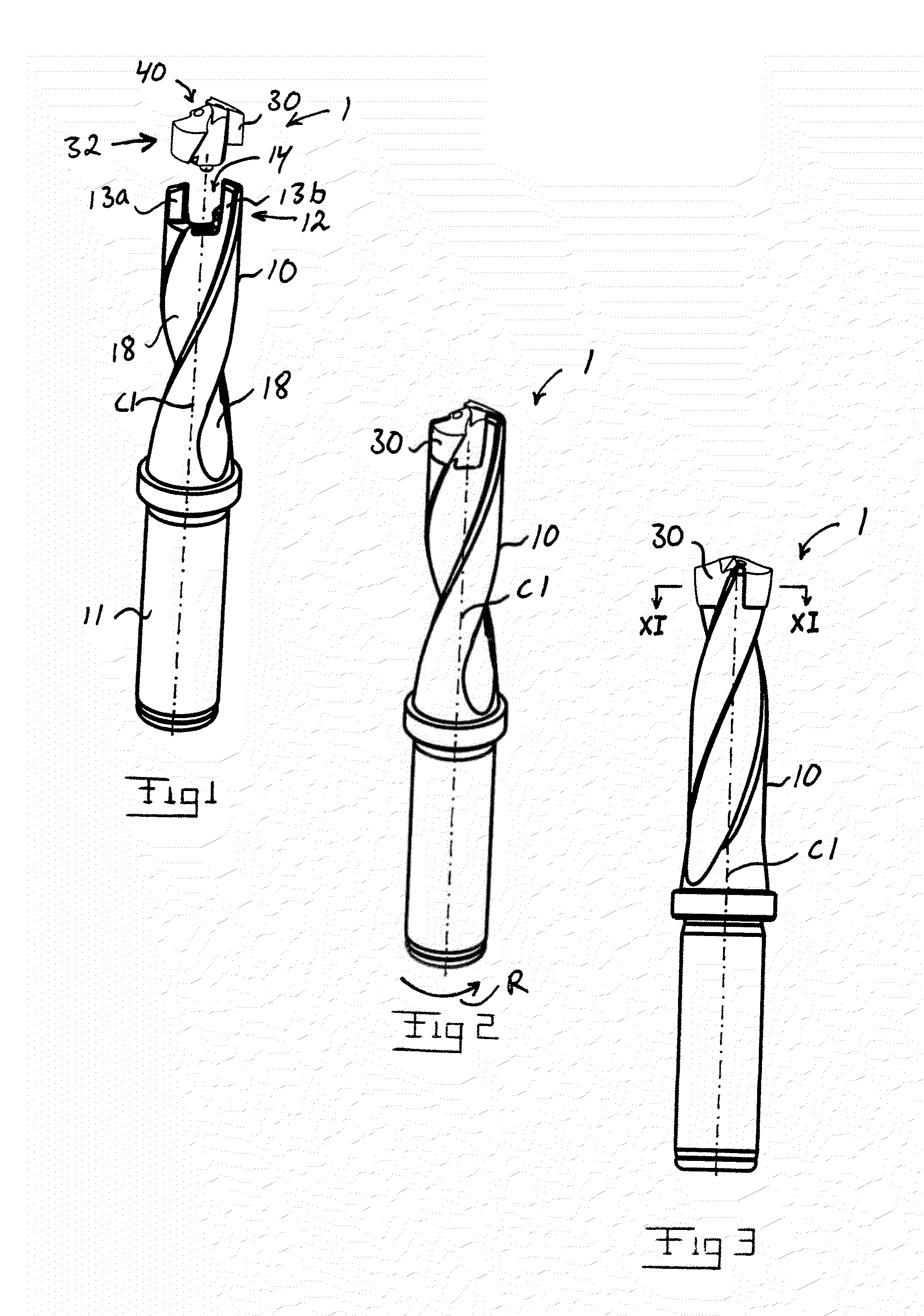

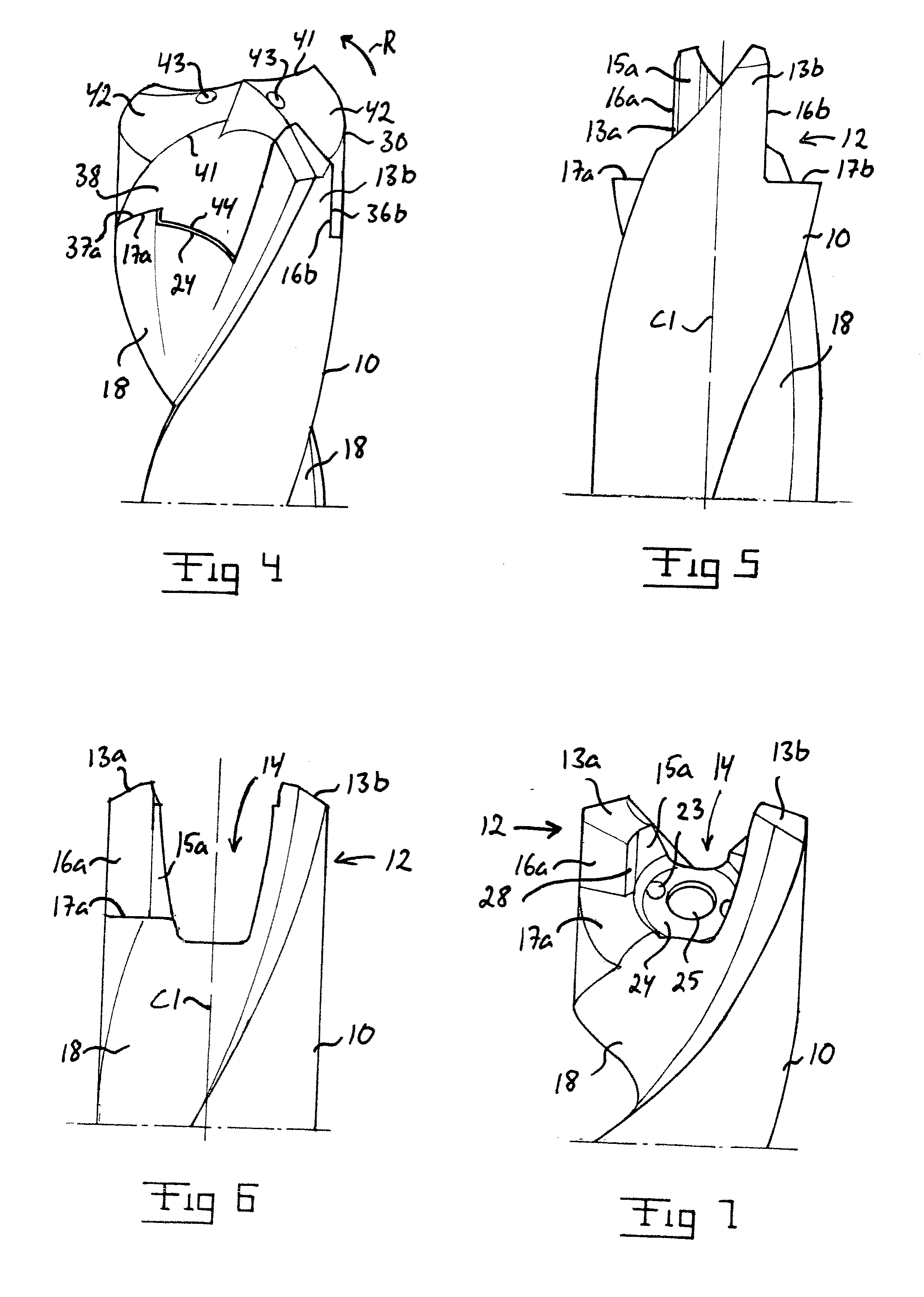

Drill having radially overlapping indexable cutting inserts

A drill includes a shank, a central insert and a peripheral insert. The shank defines a central axis of rotation and has pockets which carry the peripheral and central inserts. Chip flutes are formed in an outer periphery of the shank for conducting chips cut by the respective inserts. The peripheral insert includes a first operative cutting edge, and the central insert includes a second operative cutting edge which overlaps the first cutting edge at an overlap region. The central insert forms a rake surface adjacent to the second cutting edge. The rake surface includes a first portion disposed at the overlap region, and a second portion disposed at the axis of rotation of the shank. The first portion has a larger rake angle than the second portion.

Owner:SECO TOOLS AB

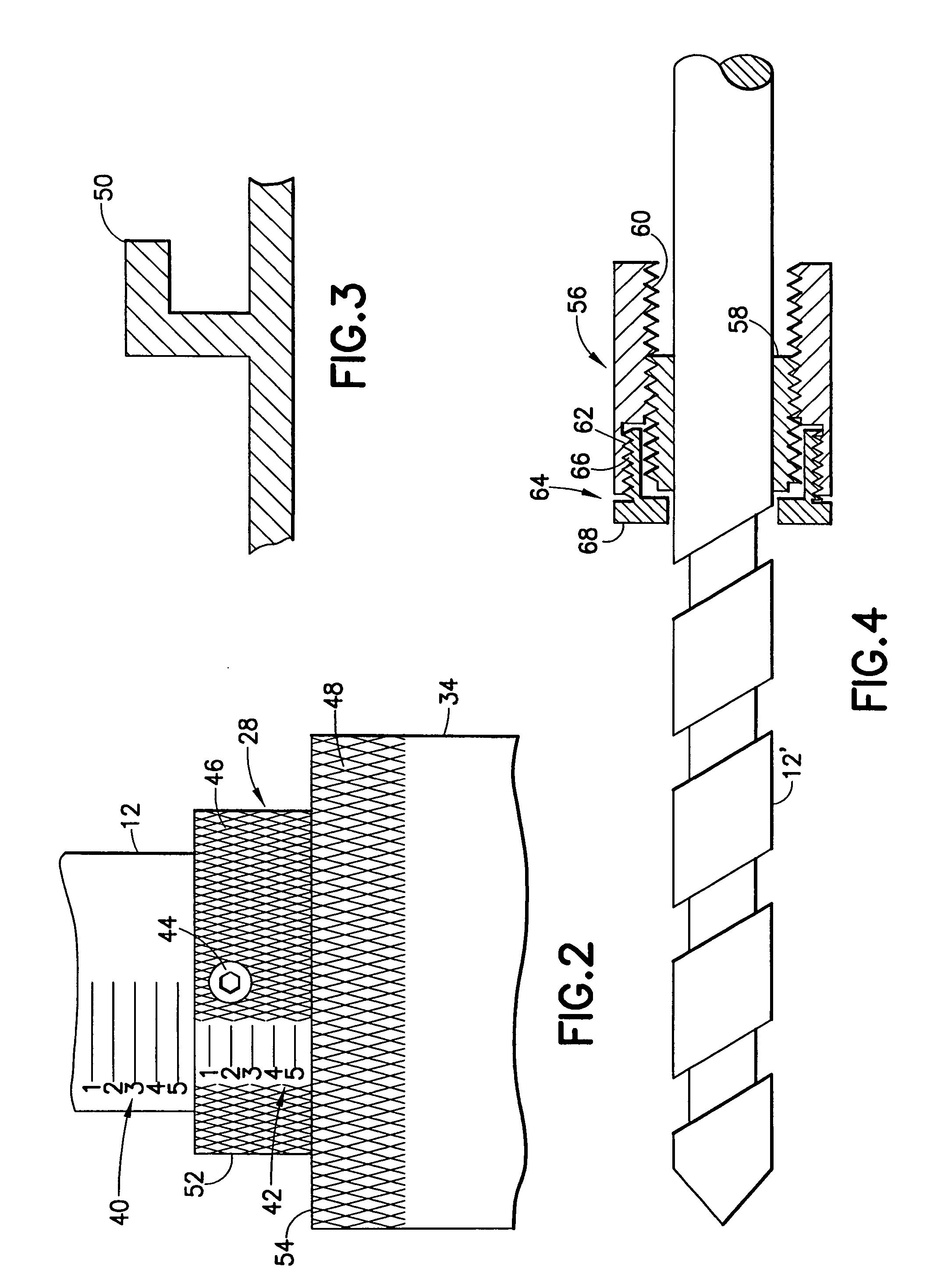

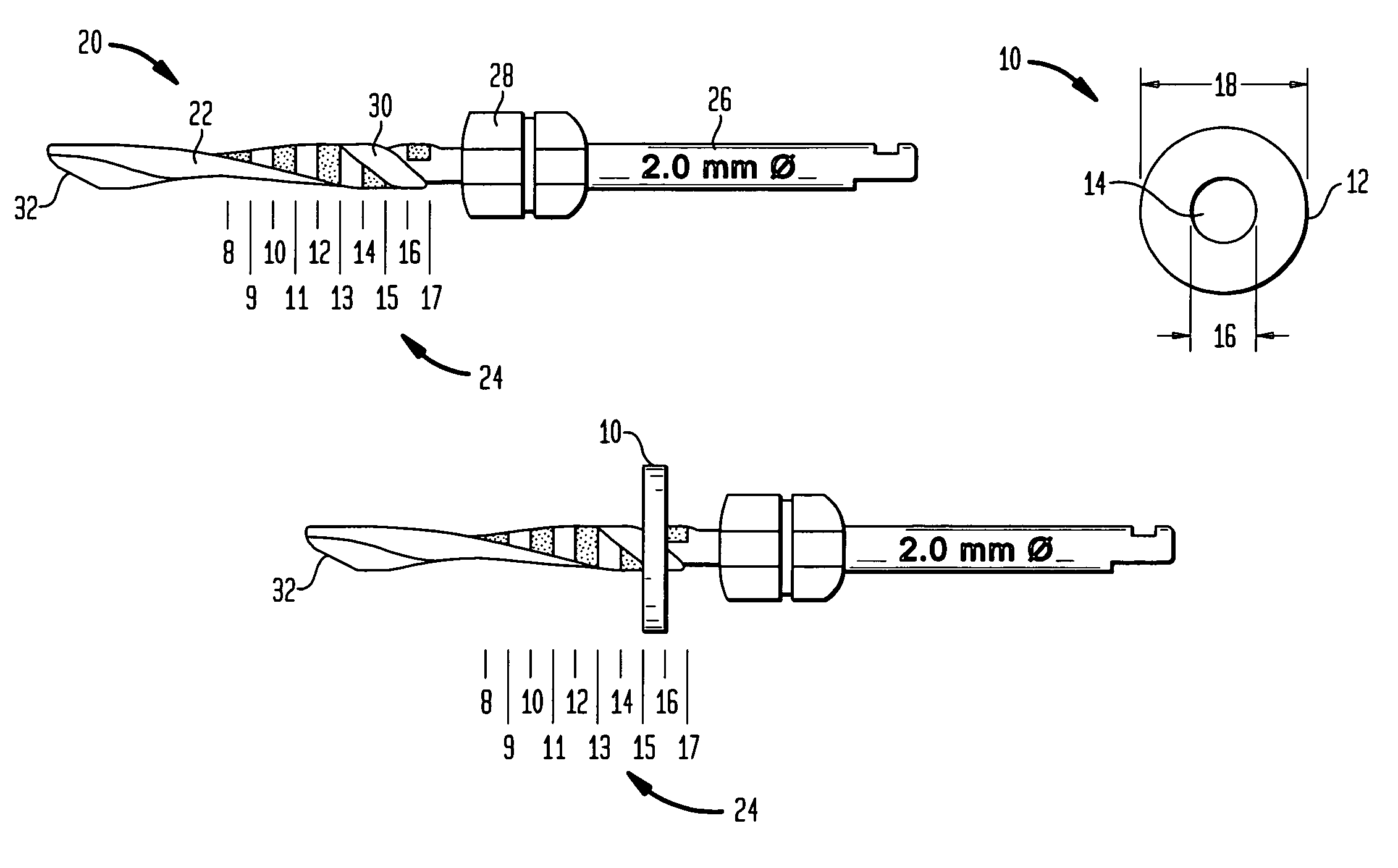

Drill measurement stops

InactiveUS7048477B2Easy to identifyReduce manufacturing costThread cutting toolsDental implantsEngineeringVisual perception

A depth stop for use with a drill bit comprises a tubular body having an opening therethrough. Used with a drill bit whose bit portion includes a cutting end, and a shank portion, the depth stop is frictionally positionable on the bit portion at a specified point from the cutting end, thereby indicating a specified depth. Depth stops are manufactured in different colors, each color corresponding to a specified range of drill bits that the depth stops will fit. The depth stops, manufactured from a sterilizable material, are intended for single use. The depth stop can be used with a drill bit and drill extender, where one or more depth stops provide multiple visual points of reference for the operator. The depth stops can be quickly mounted onto most any manufacturer's drill bits.

Owner:IDMS

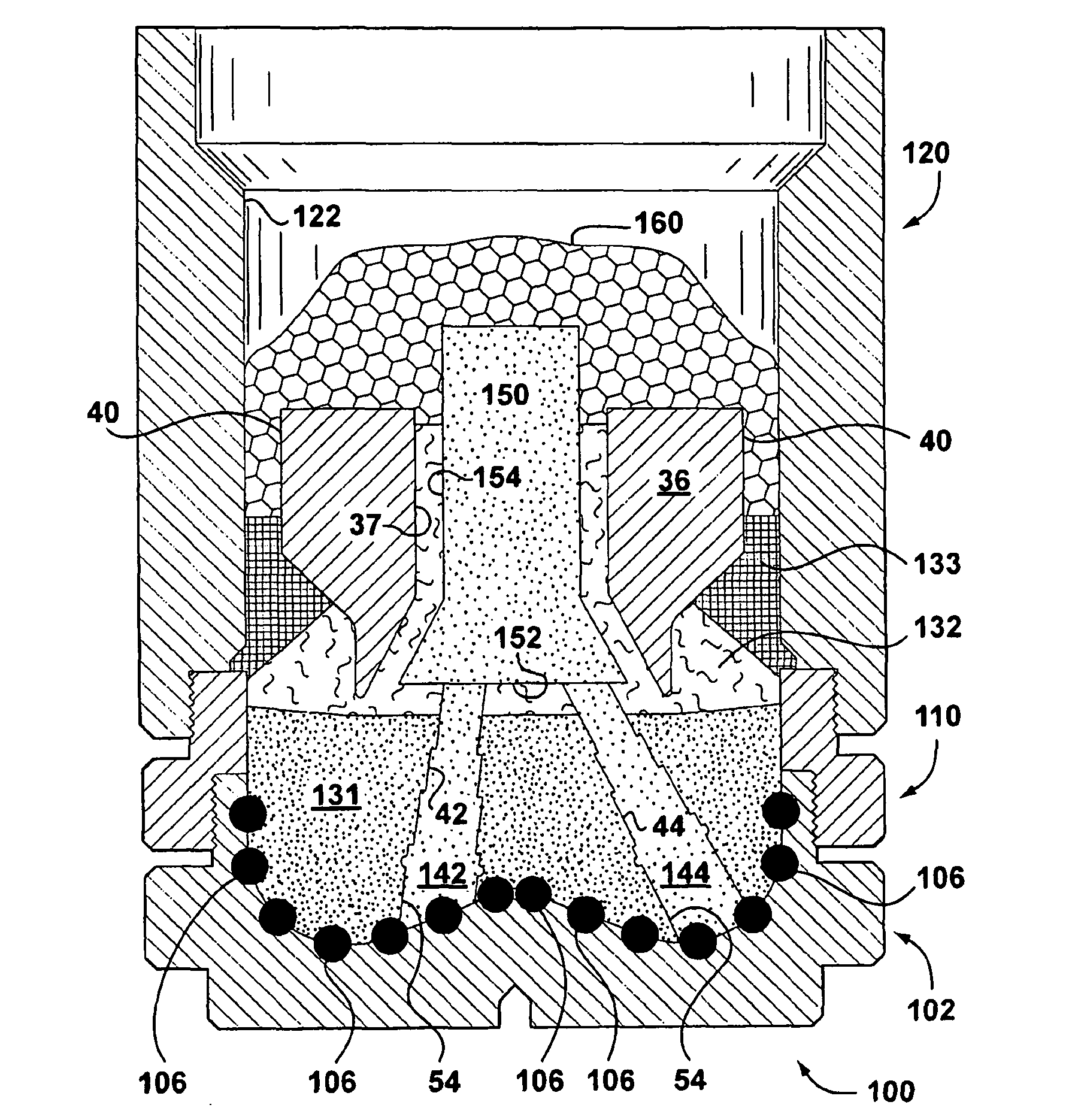

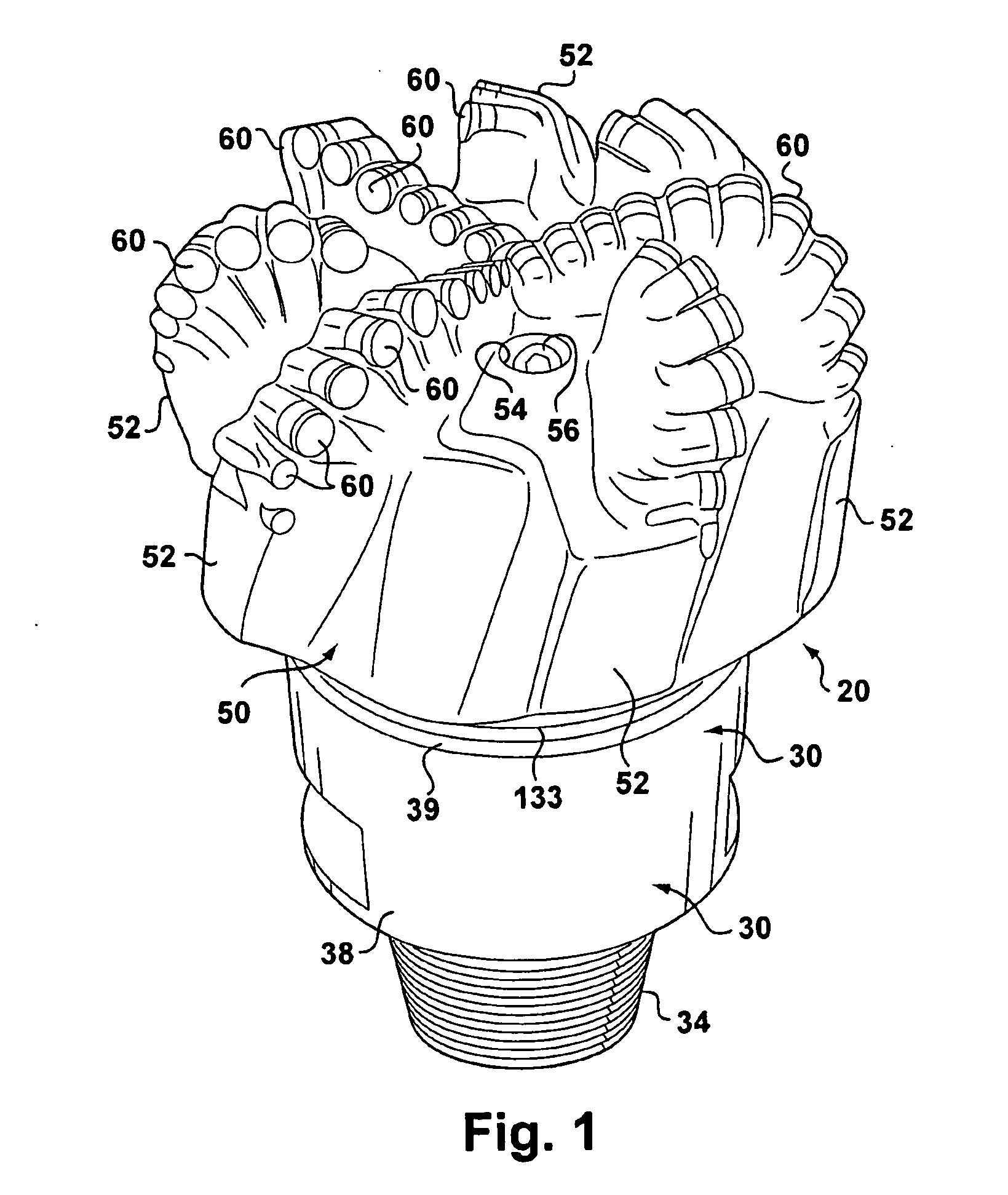

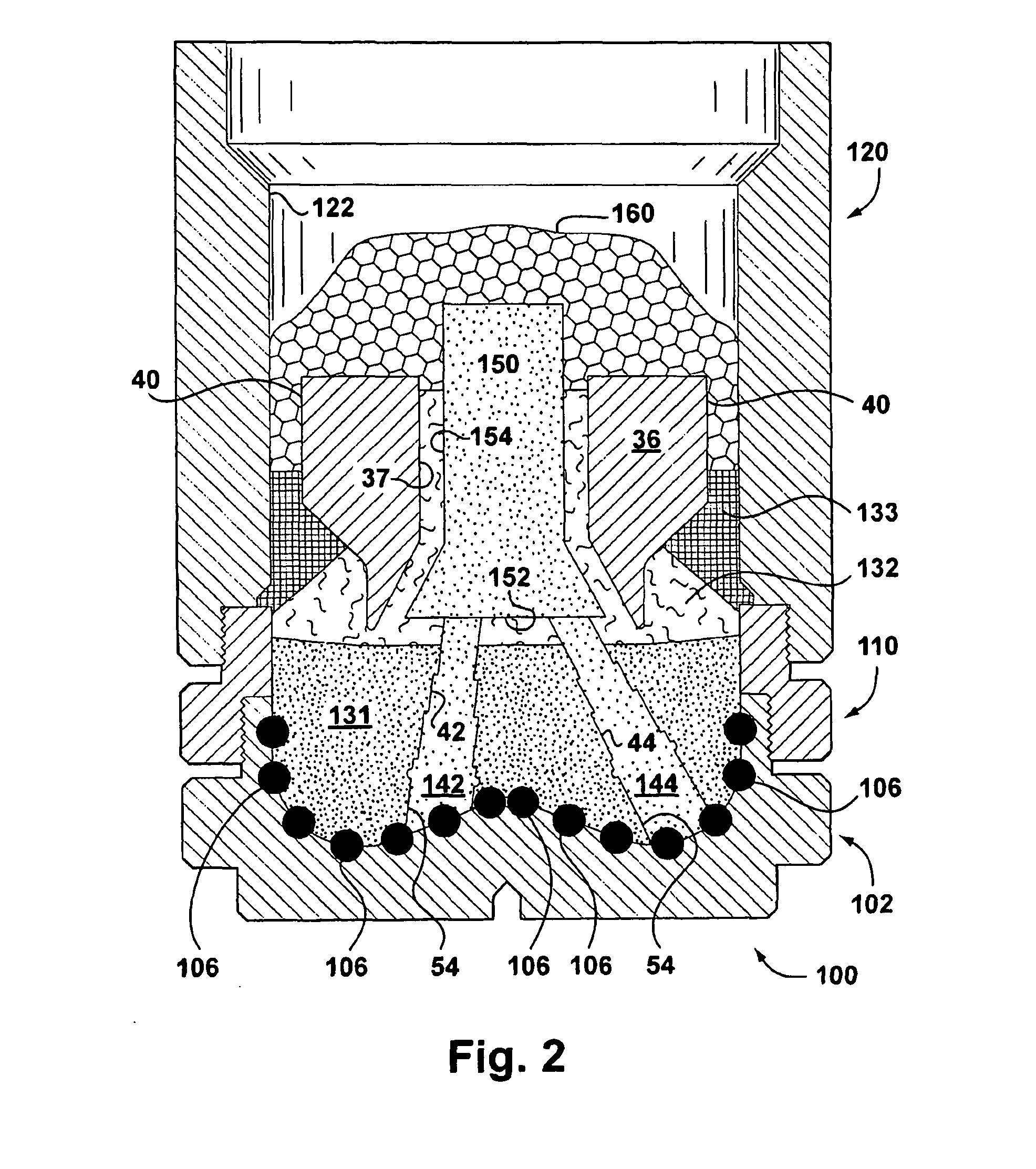

Casting of tungsten carbide matrix bit heads and heating bit head portions with microwave radiation

A method of making a drill bit having the following steps: placing matrix material in a bit body mold; placing a metal blank in the bit body mold; placing a binder material in the bit body mold with the binder material proximate the matrix material and the metal blank; and exposing hinder material to microwave radiation, whereby hinder material and other constituents is heated to a selected temperature to allow hinder material to melt and to infiltrate matrix material. A method of heating selected portions of a drill bit comprising: placing the drill bit in an insulative oven having a wave guide of microwave radiation from a microwave generator; positioning a portion of the drill bit to be heated proximate the wave guide; and exposing the portion of the drill bit to be heated to microwave radiation, wherein the portion of the drill bit is heated without overheating remaining portions of the drill bit.

Owner:HALLIBURTON ENERGY SERVICES INC

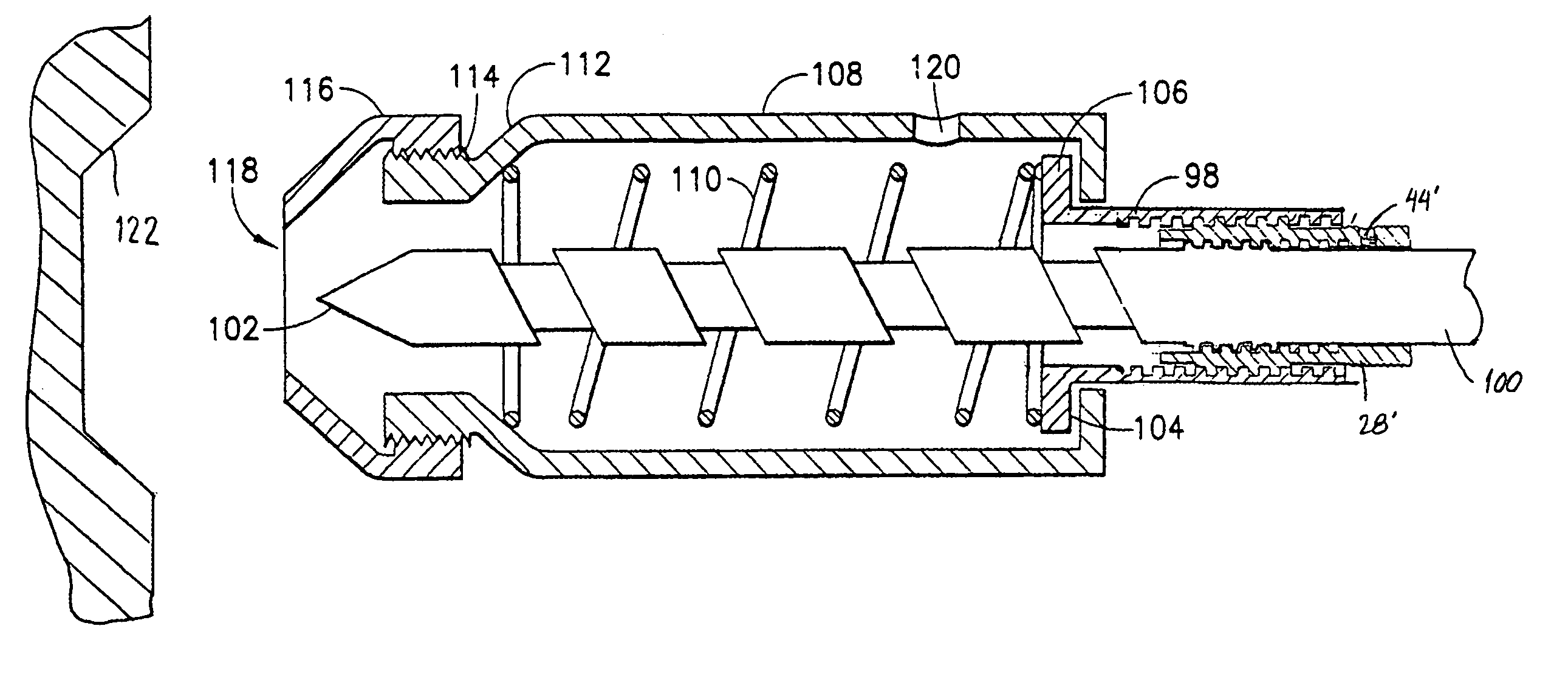

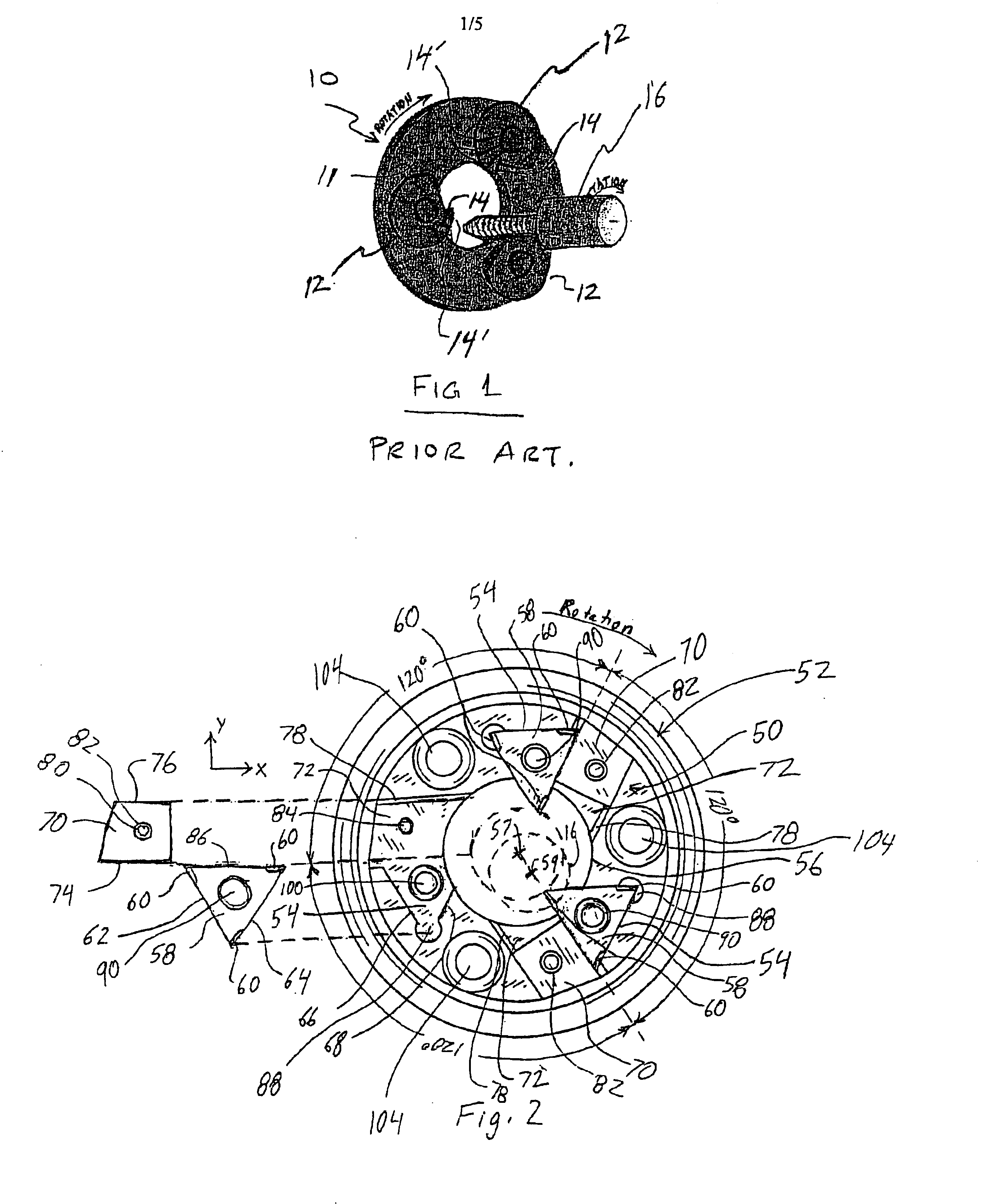

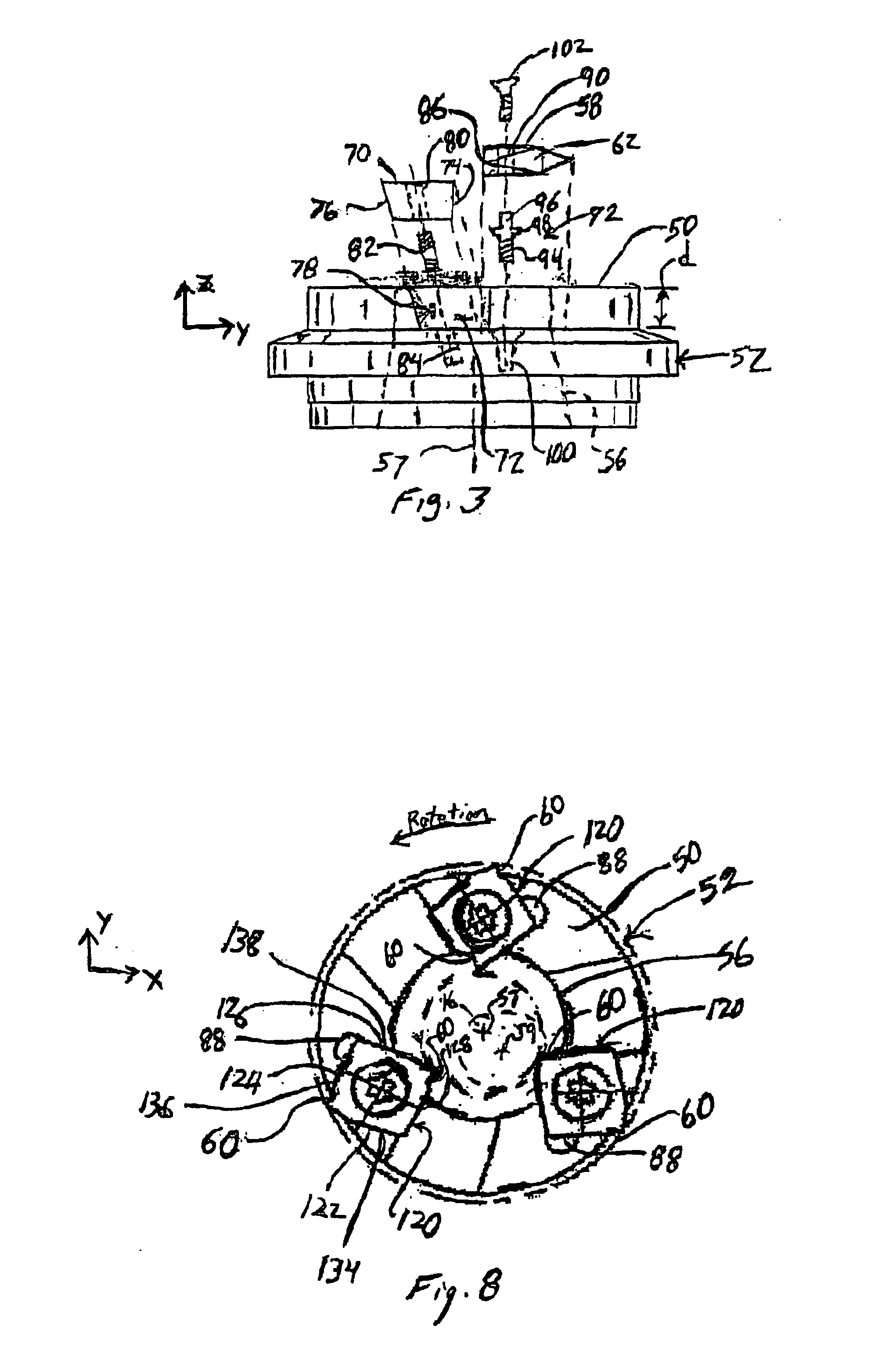

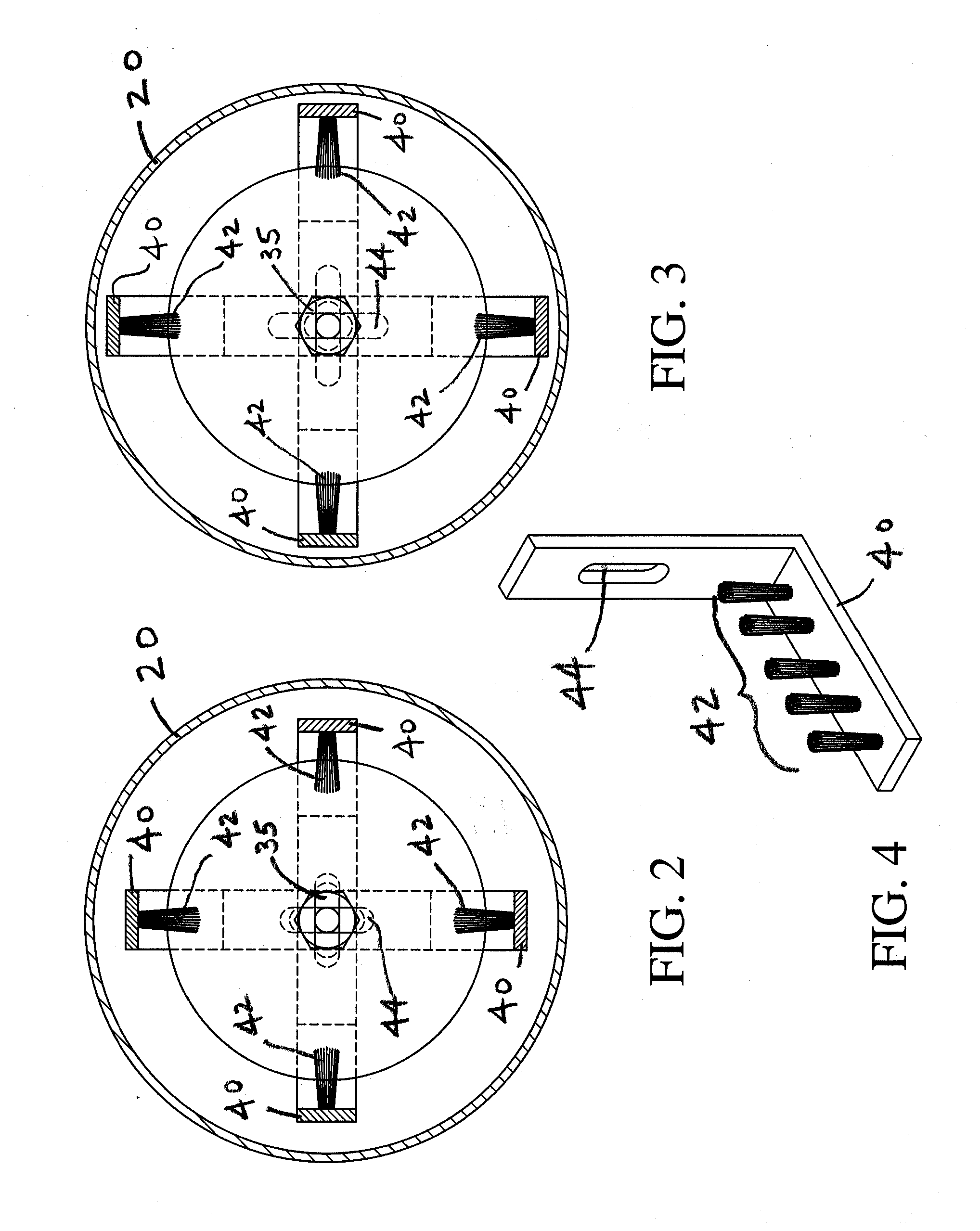

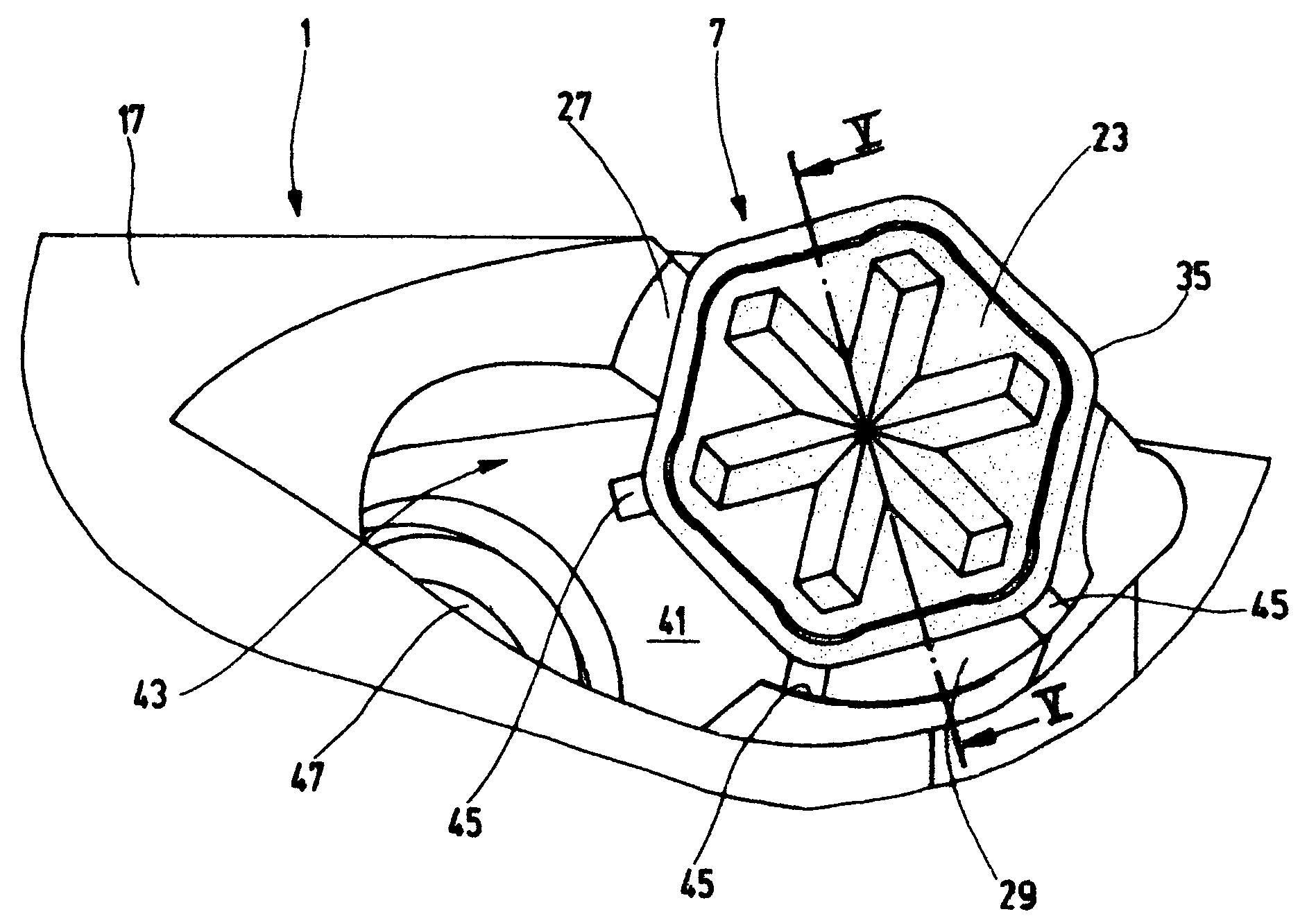

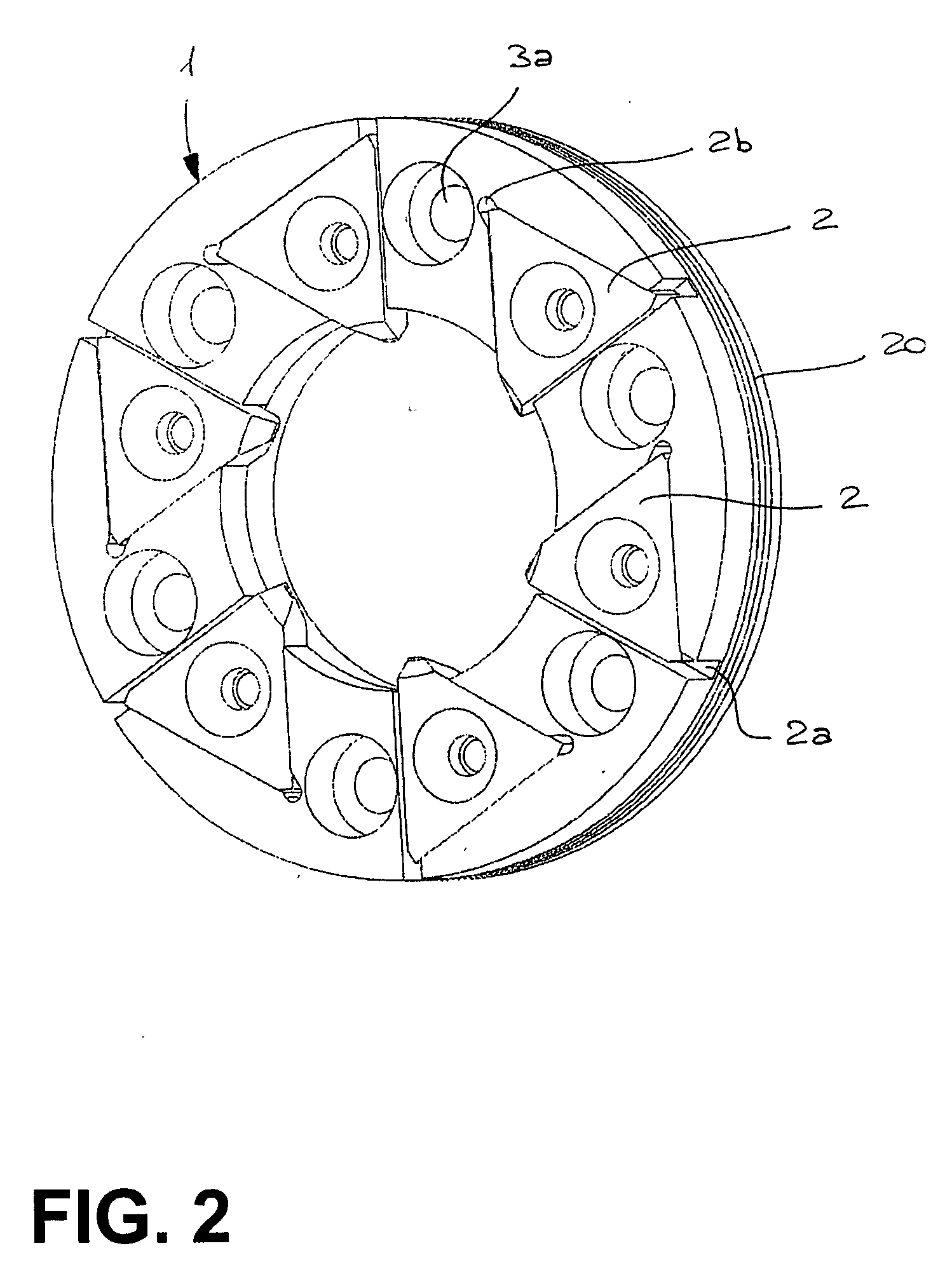

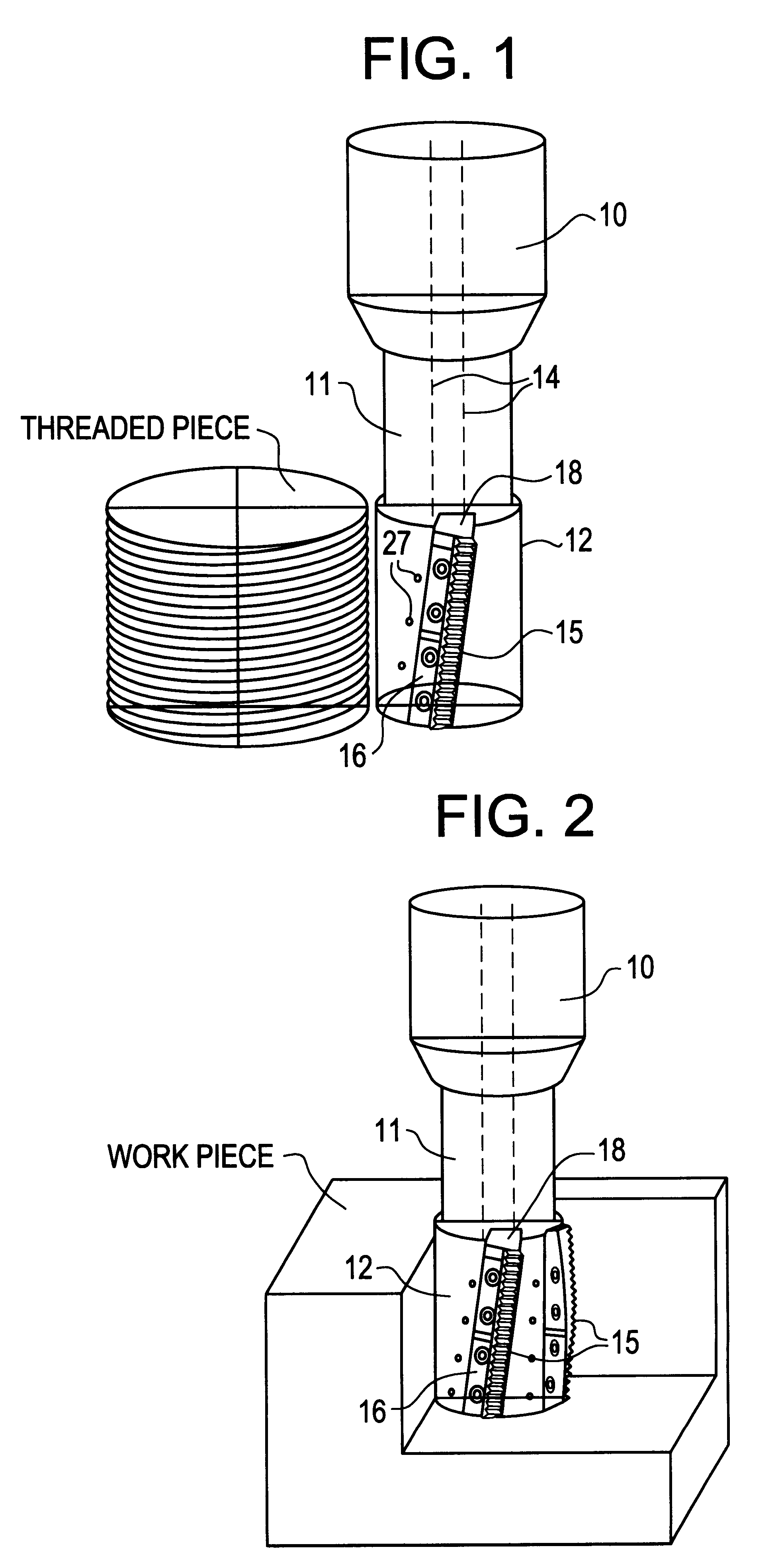

Milling head for thread whirling

A milling head for thread whirling, the milling head includes a plurality of cutting elements evenly disposed around a center hole, each cutting element in the plurality of cutting elements includes at least two cutting surfaces formed thereon. Any one of the at least two cutting surfaces is selectable to extend within the center hole for contacting a work-piece. Each cutting element in the plurality of cutting elements is disposed in a recess formed in a face of the milling head, with each recess defining at least two walls. Each of the at least two walls contacts a side of the cutting element to align the cutting element in a predetermined relationship with respect to the milling head. In one embodiment, the plurality of cutting elements include first and second sets of cutting elements. The first set of cutting elements is evenly disposed around the center hole and contact the work-piece to produce a thread form on the work-piece. The second set of cutting elements is evenly disposed around the center hole and contacts the work-piece to remove material proximate the outside diameter of the work-piece.

Owner:REM SALES

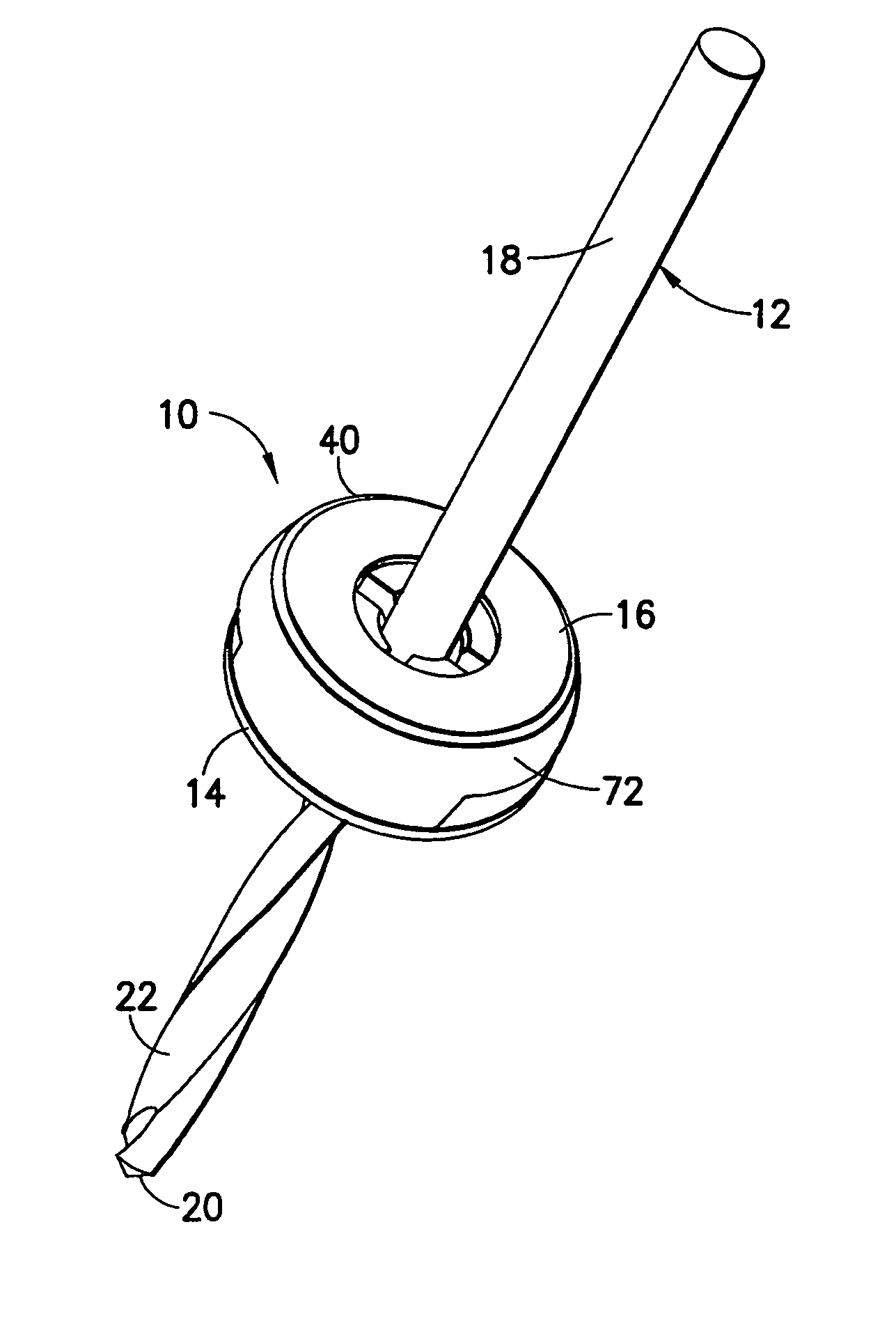

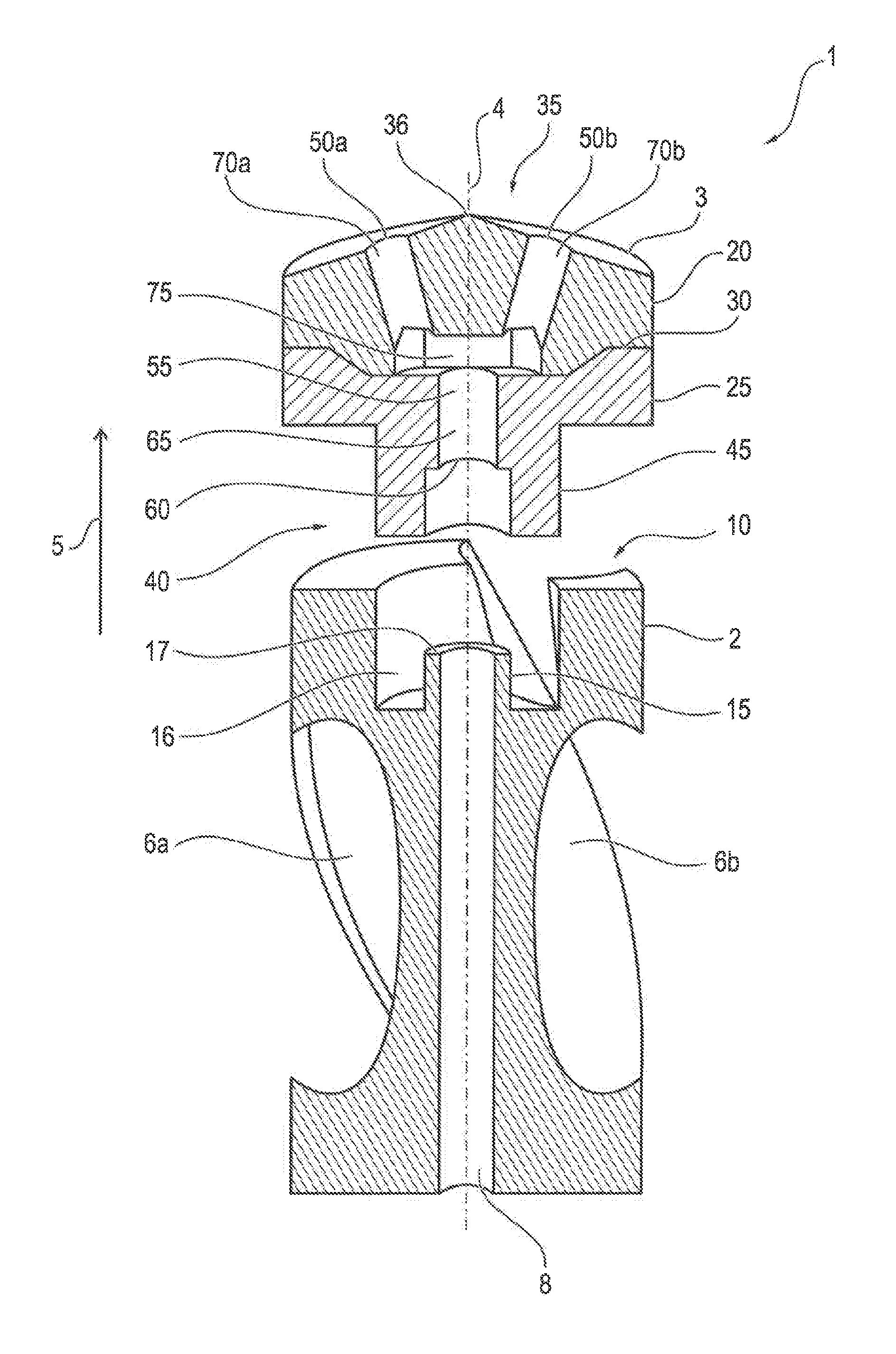

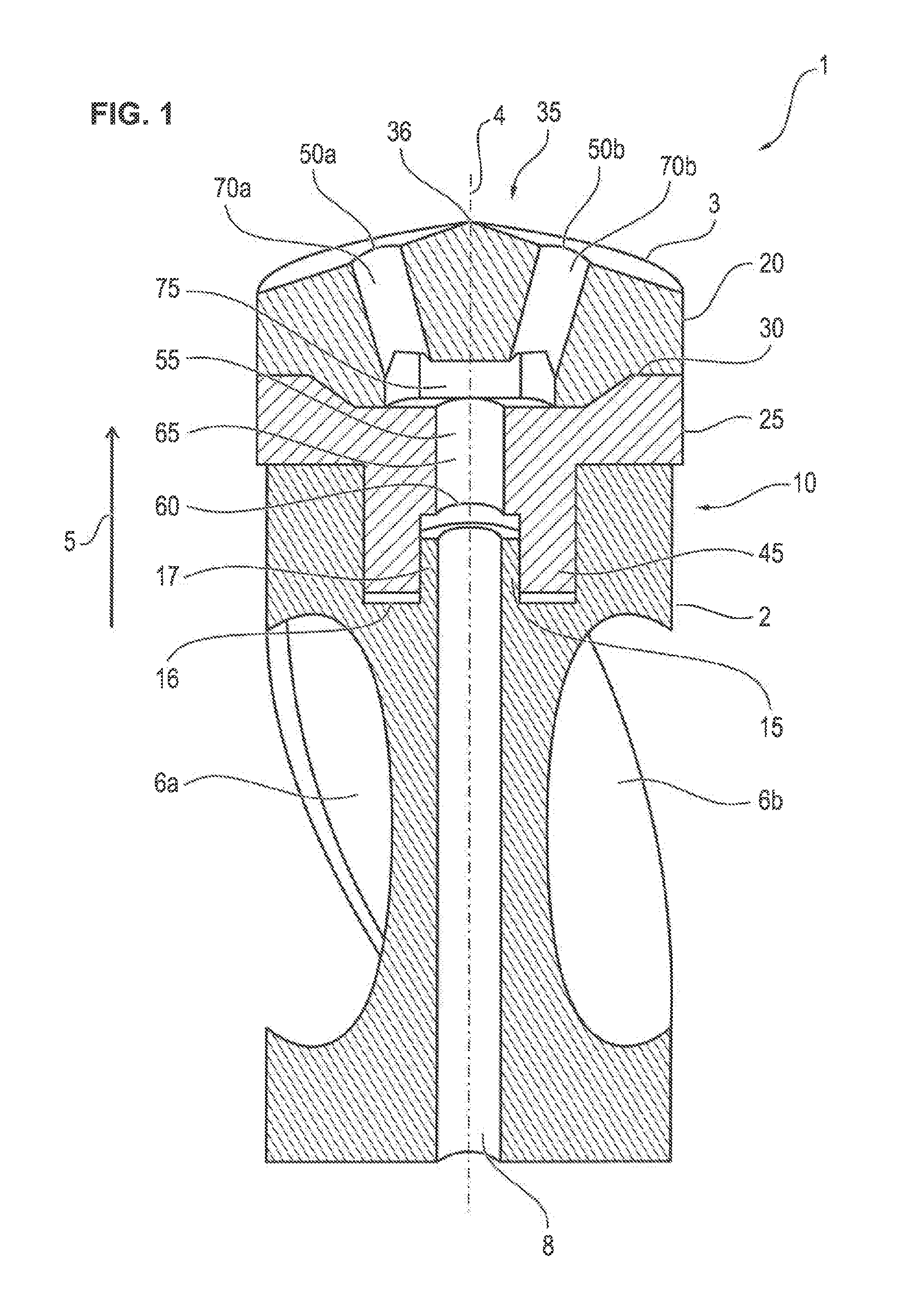

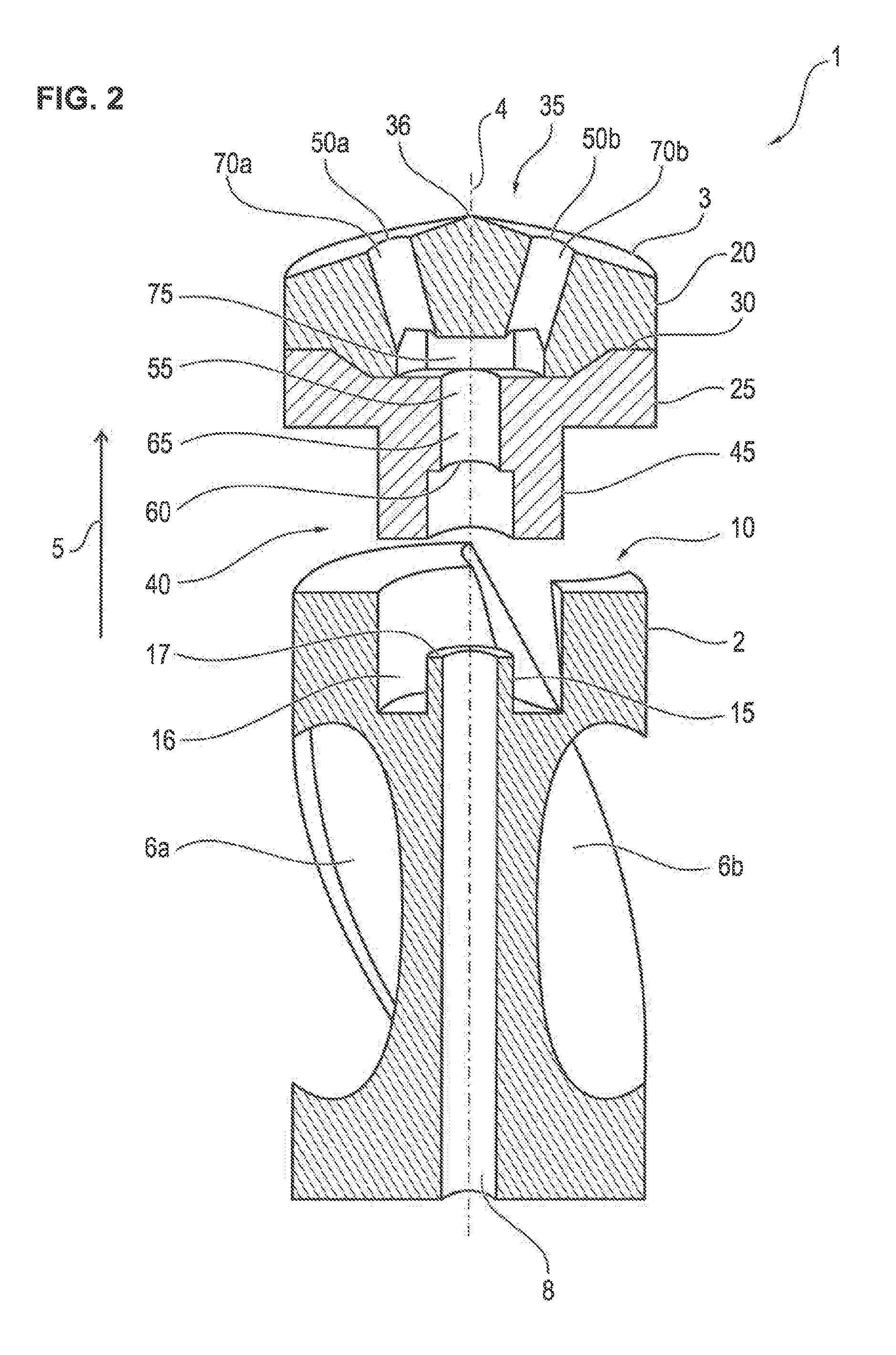

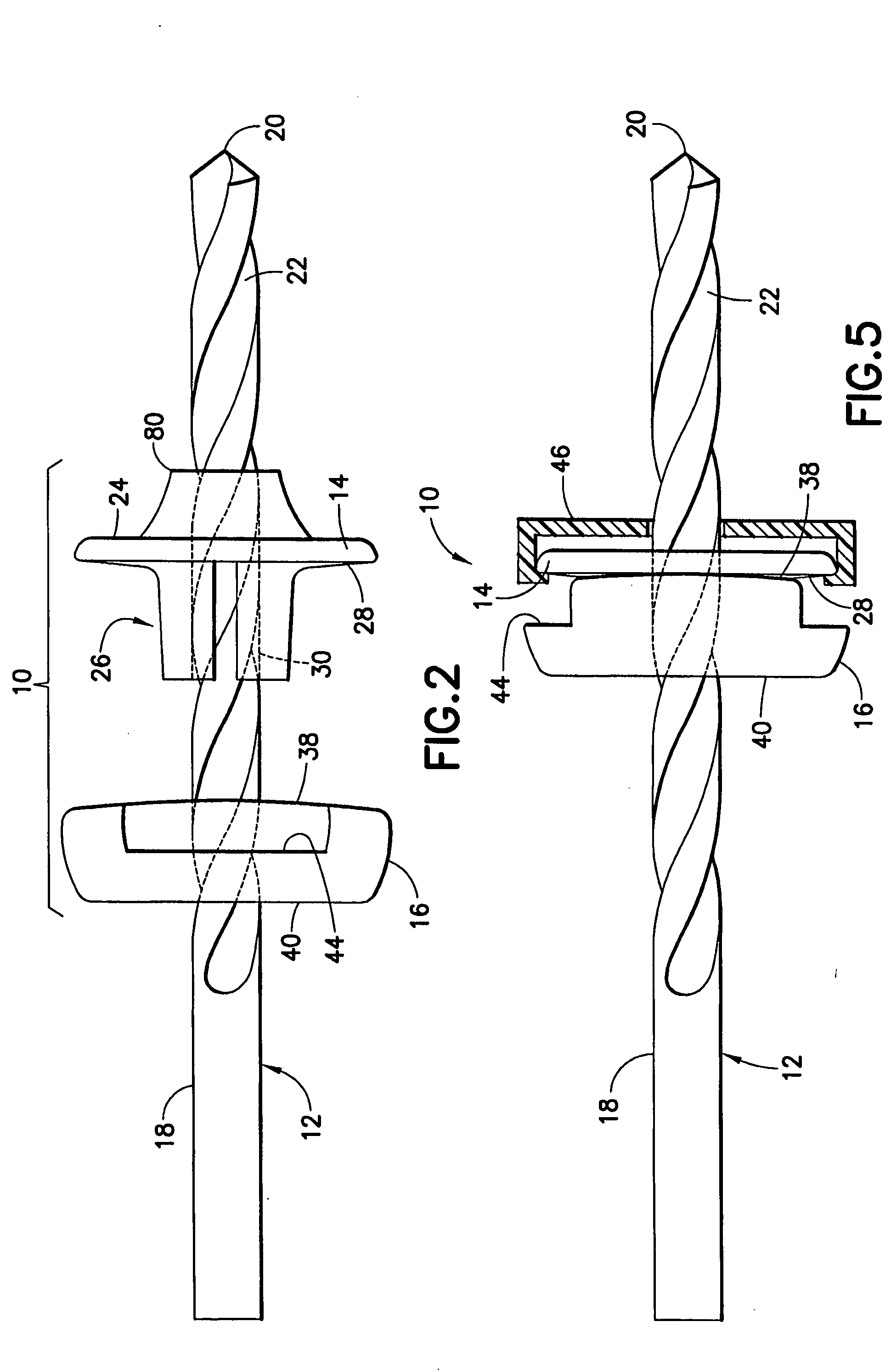

Depth limiting device and hole forming apparatus containing the same

ActiveUS7258513B2Facilitates and promotesAvoid damageThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

A depth limiting device includes a stop collar having a an open end portion and an workpiece engaging portion extending along the open end portion thereof for contacting a workpiece; a spindle extending axially through the shell, the spindle including a first end extending from the exterior of the stop collar for attachment to a hole forming apparatus, and an second end interior to the stop collar for attachment to a hole forming bit, wherein the attached hole forming bit projects through the open end portion of the stop collar at a predetermined length corresponding to the desired depth of the hole in the workpiece; and a bearing assembly operatively associated with the stop collar and the spindle for isolating the rotation of the spindle from the stop collar whereby the stop collar ceases to rotate when contacting the workpiece without generating sufficient frictional contact to mar or otherwise damage the workpiece.

Owner:FAR NORTH

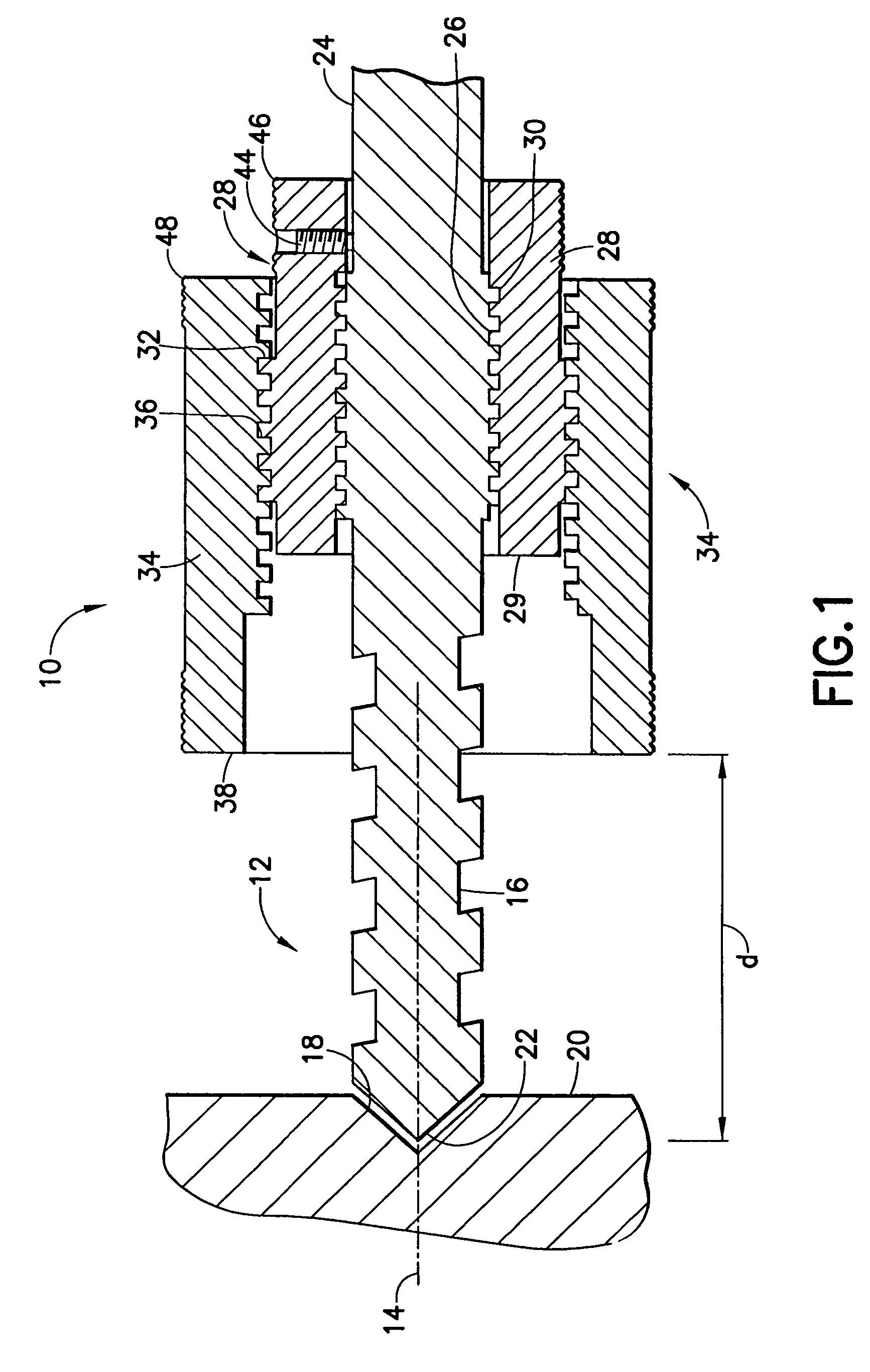

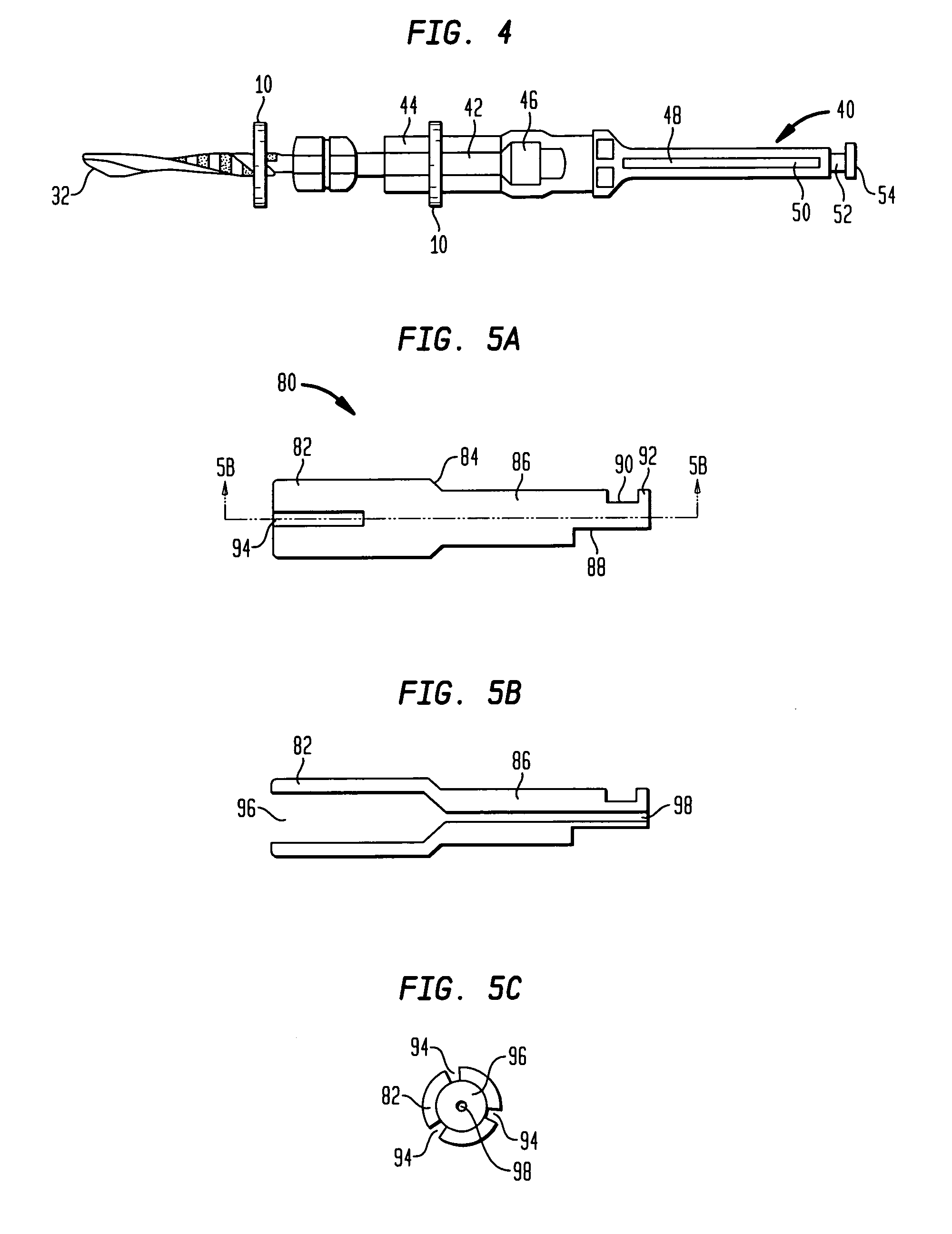

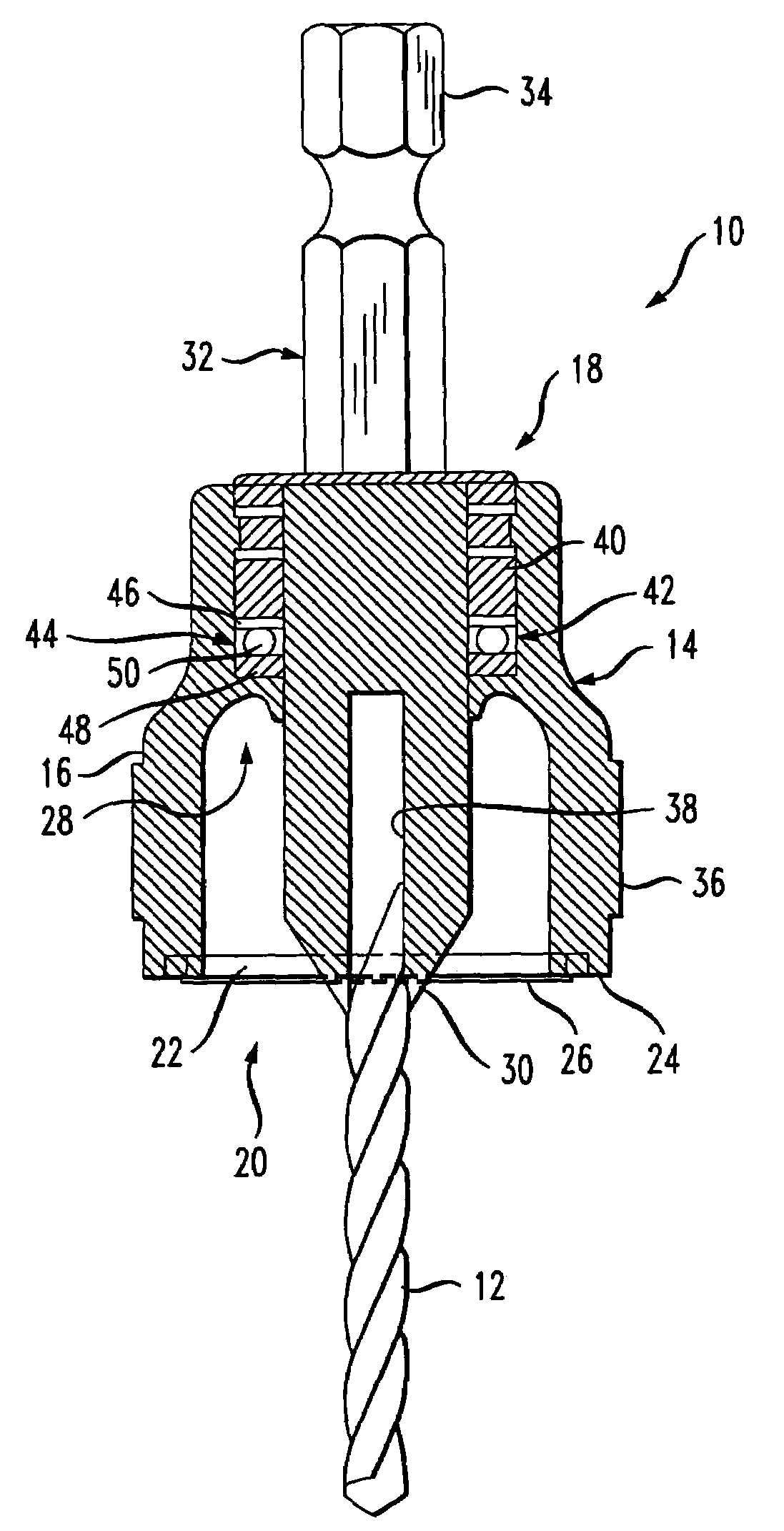

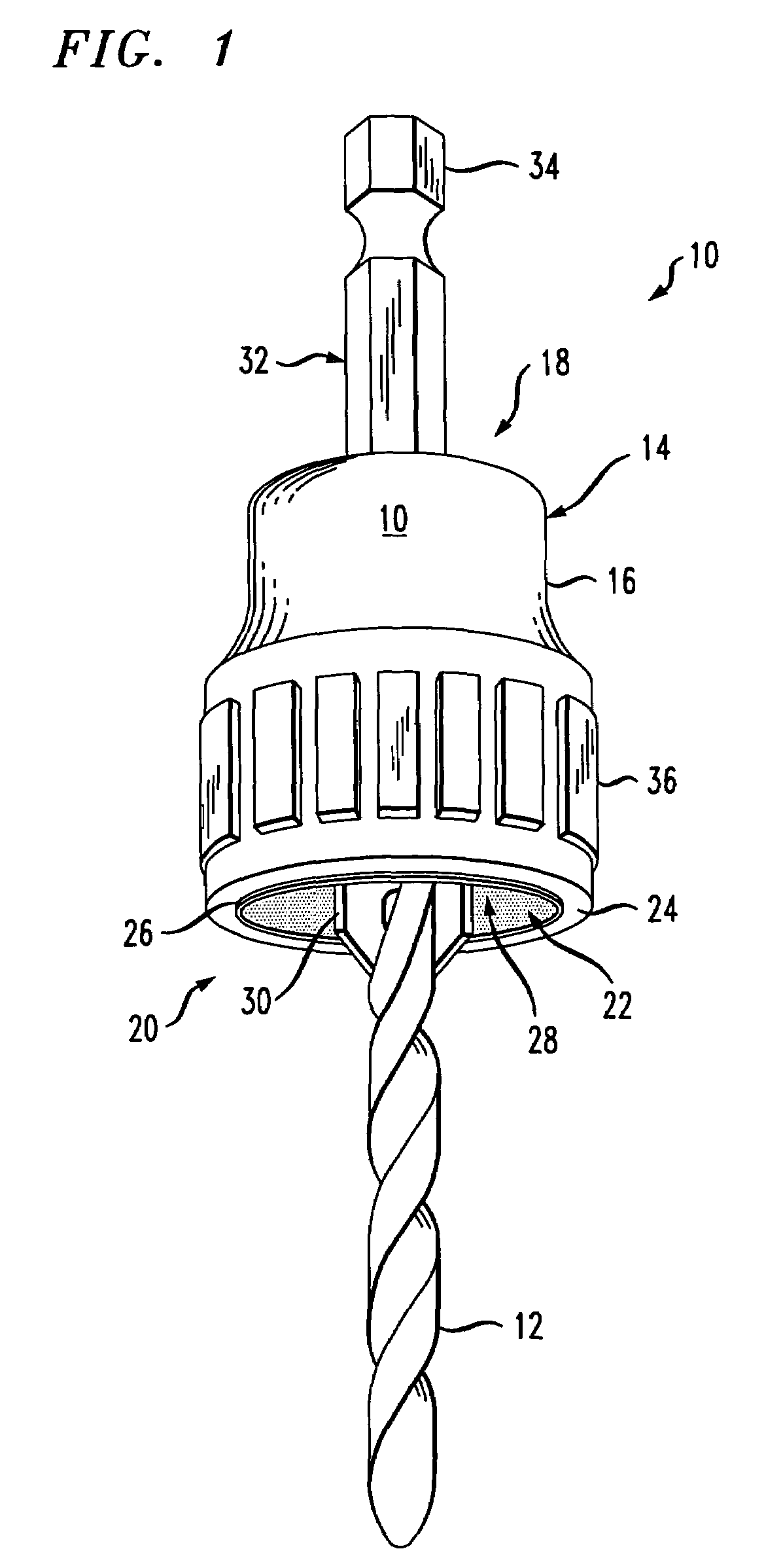

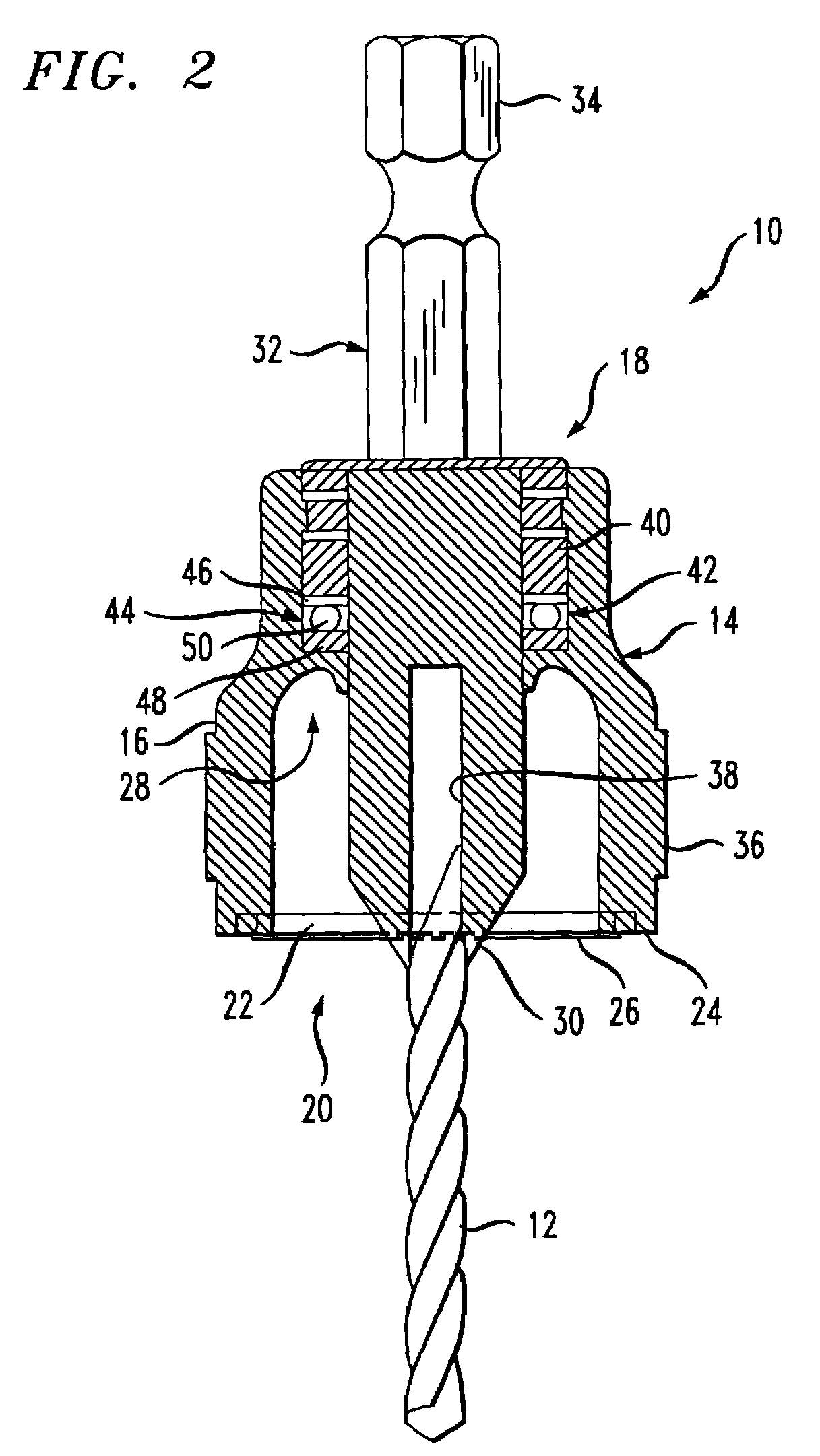

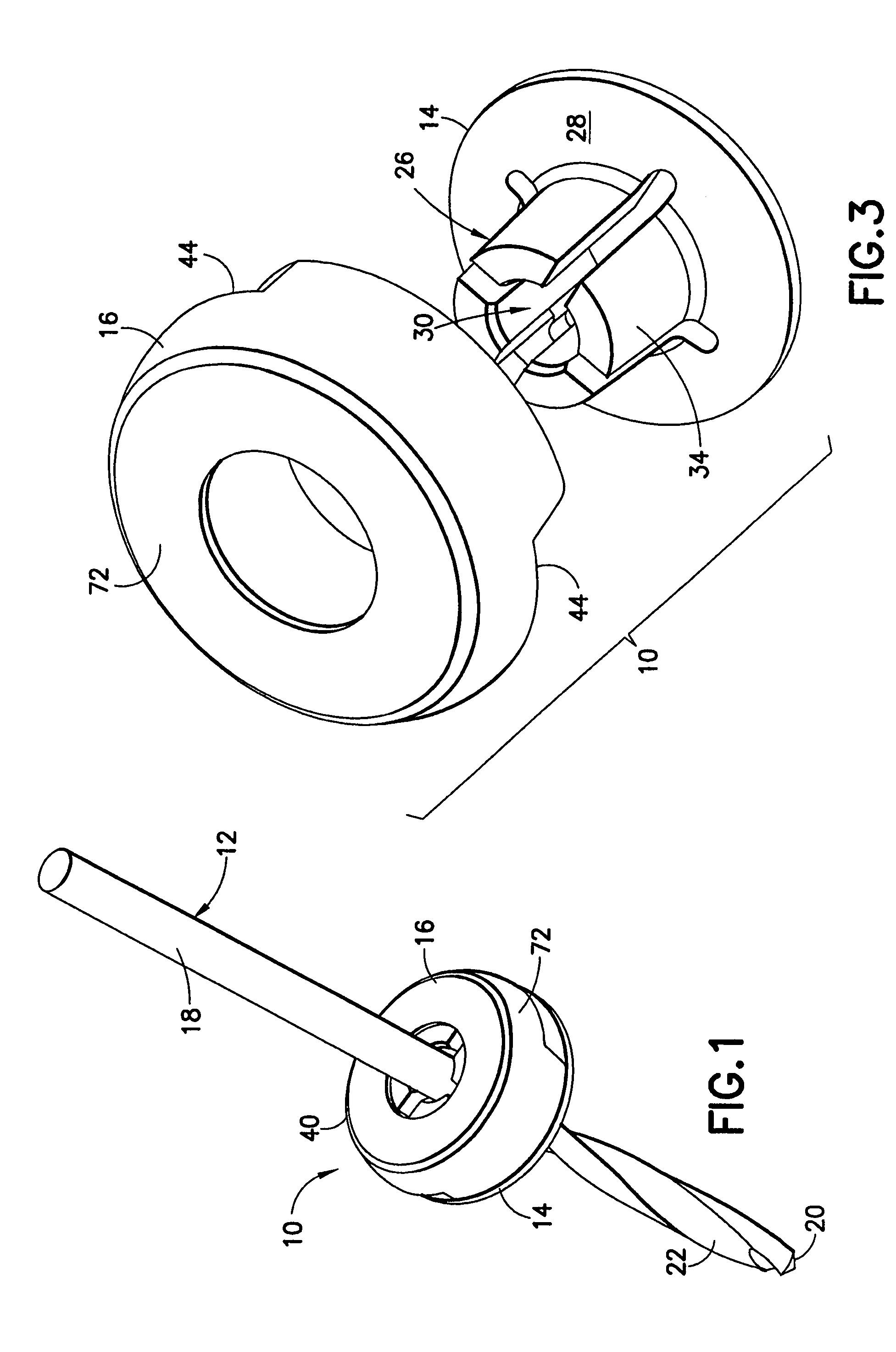

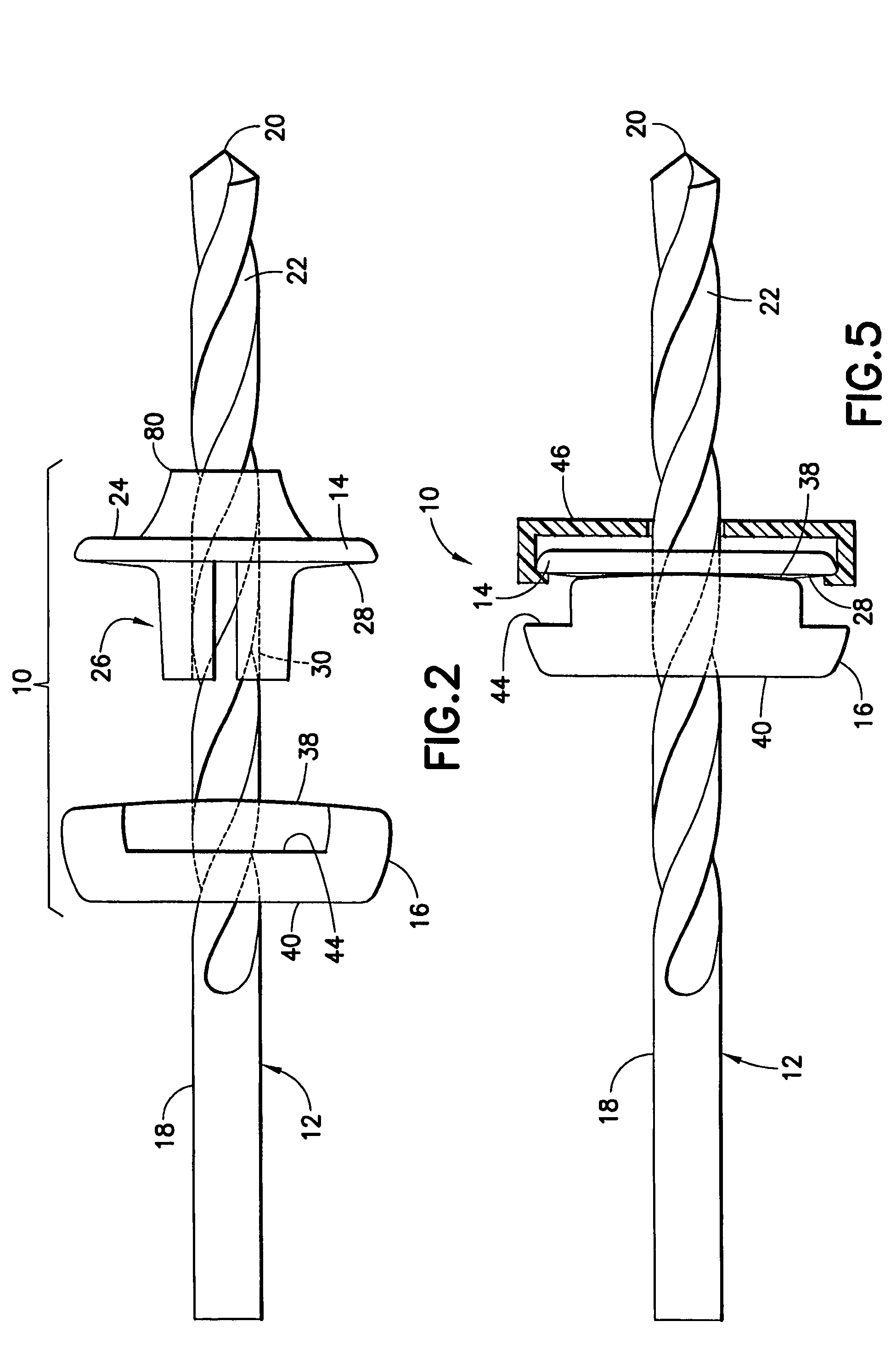

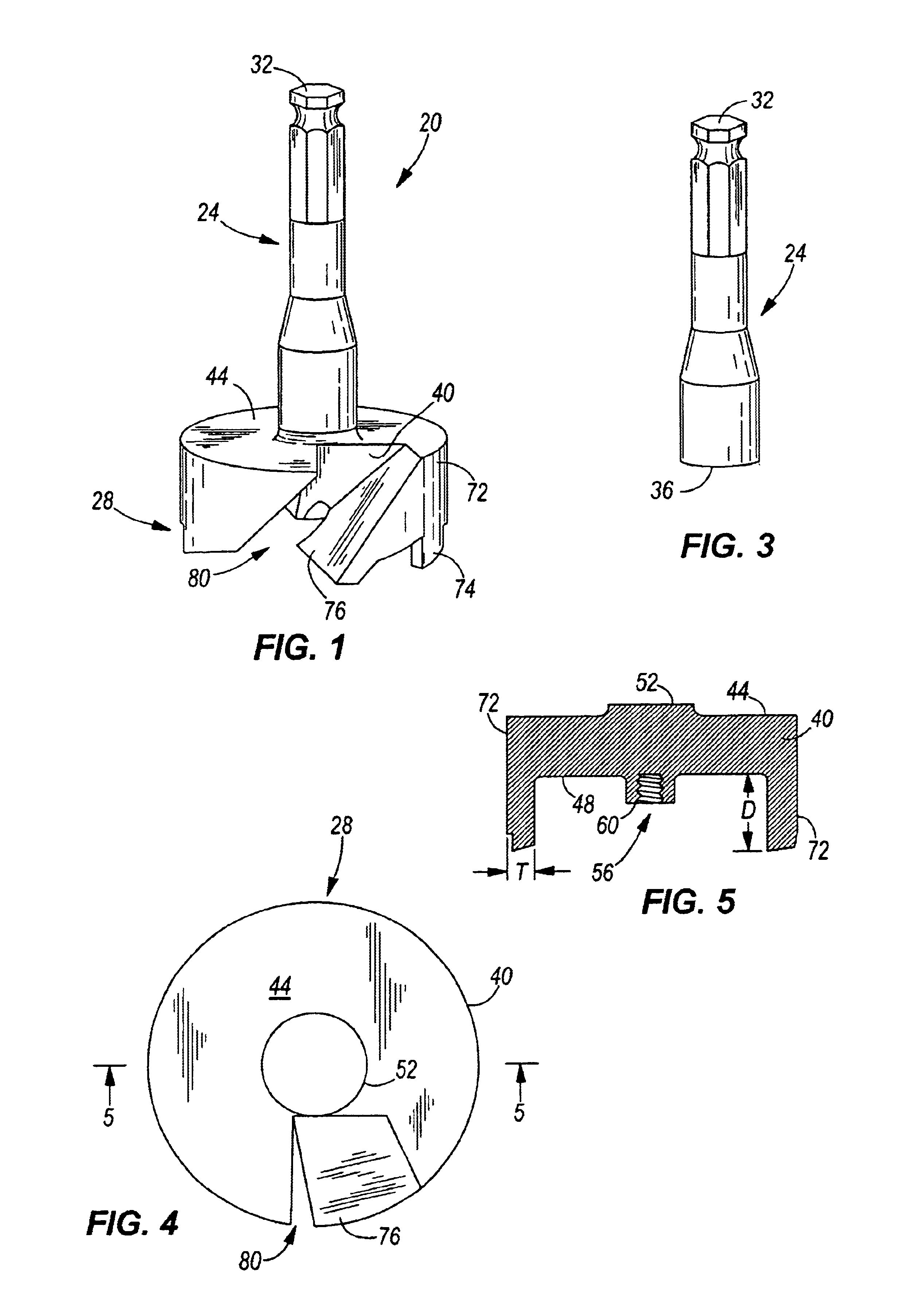

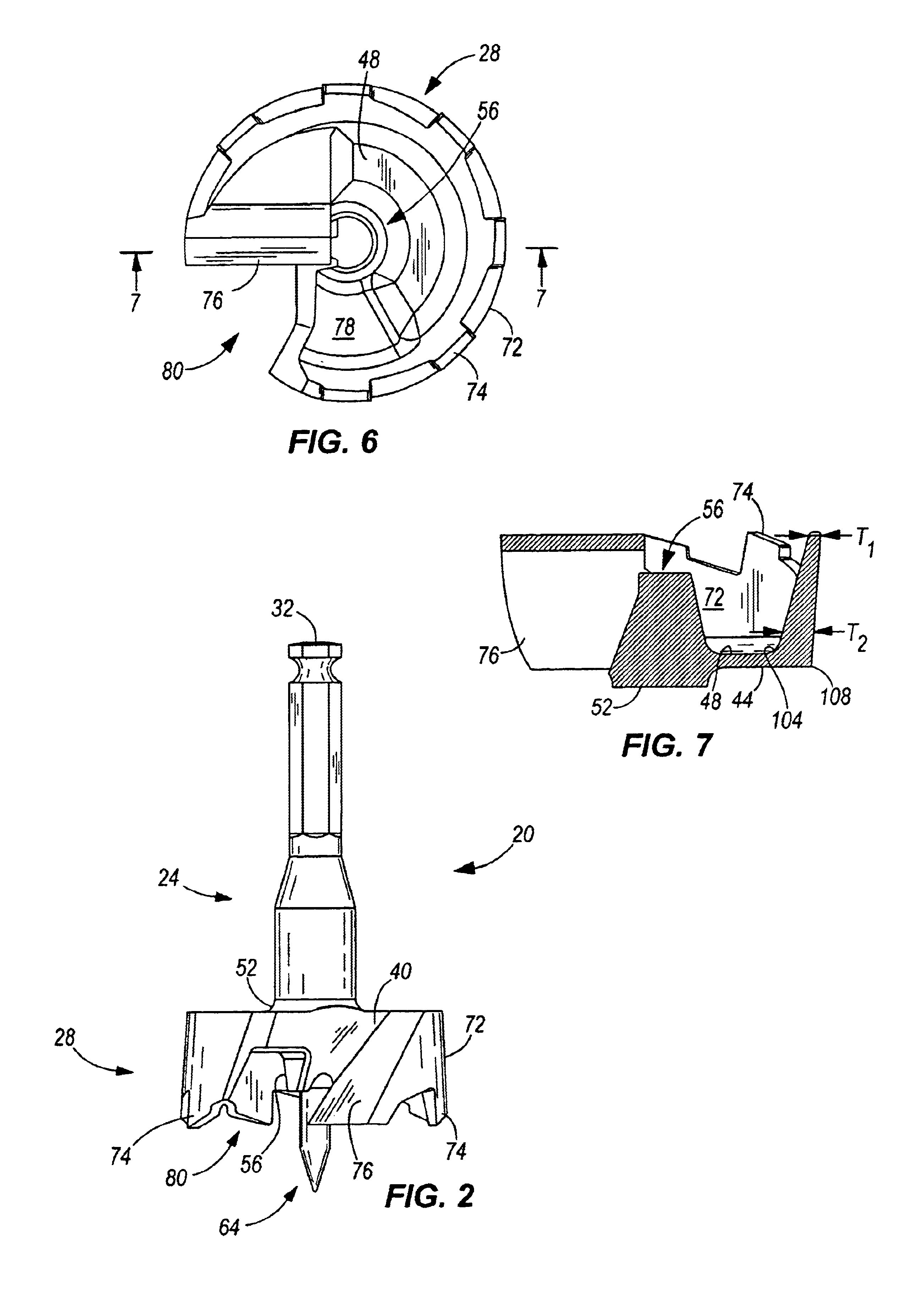

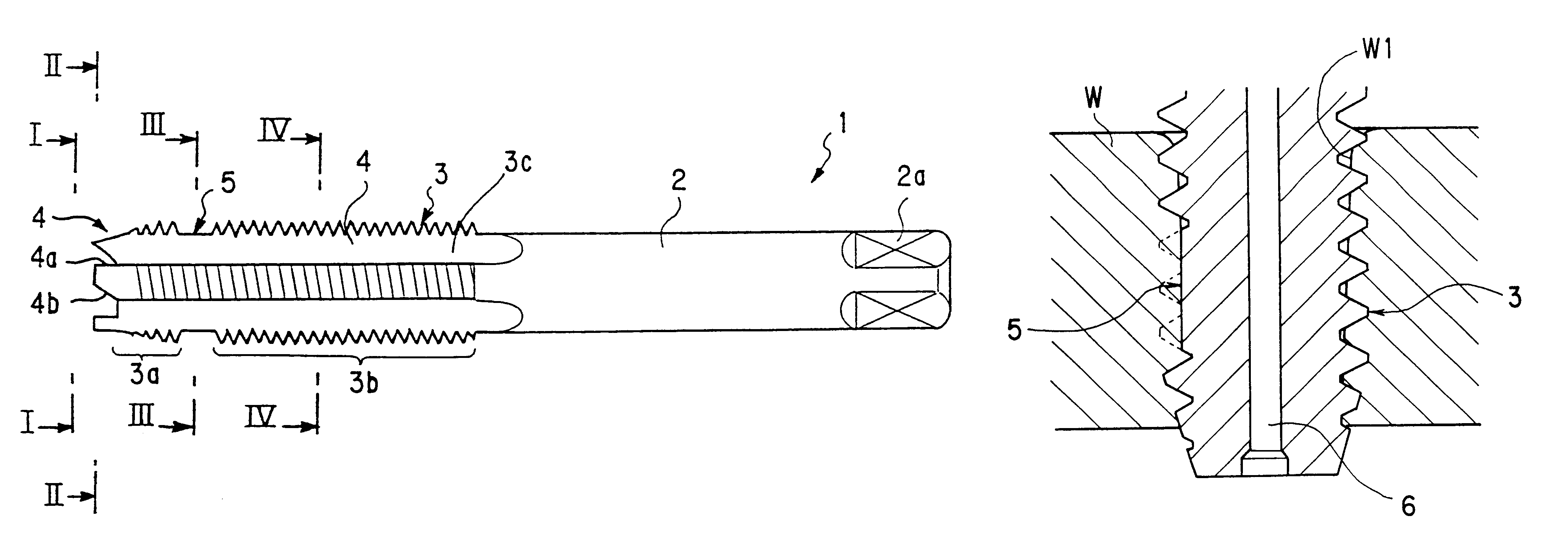

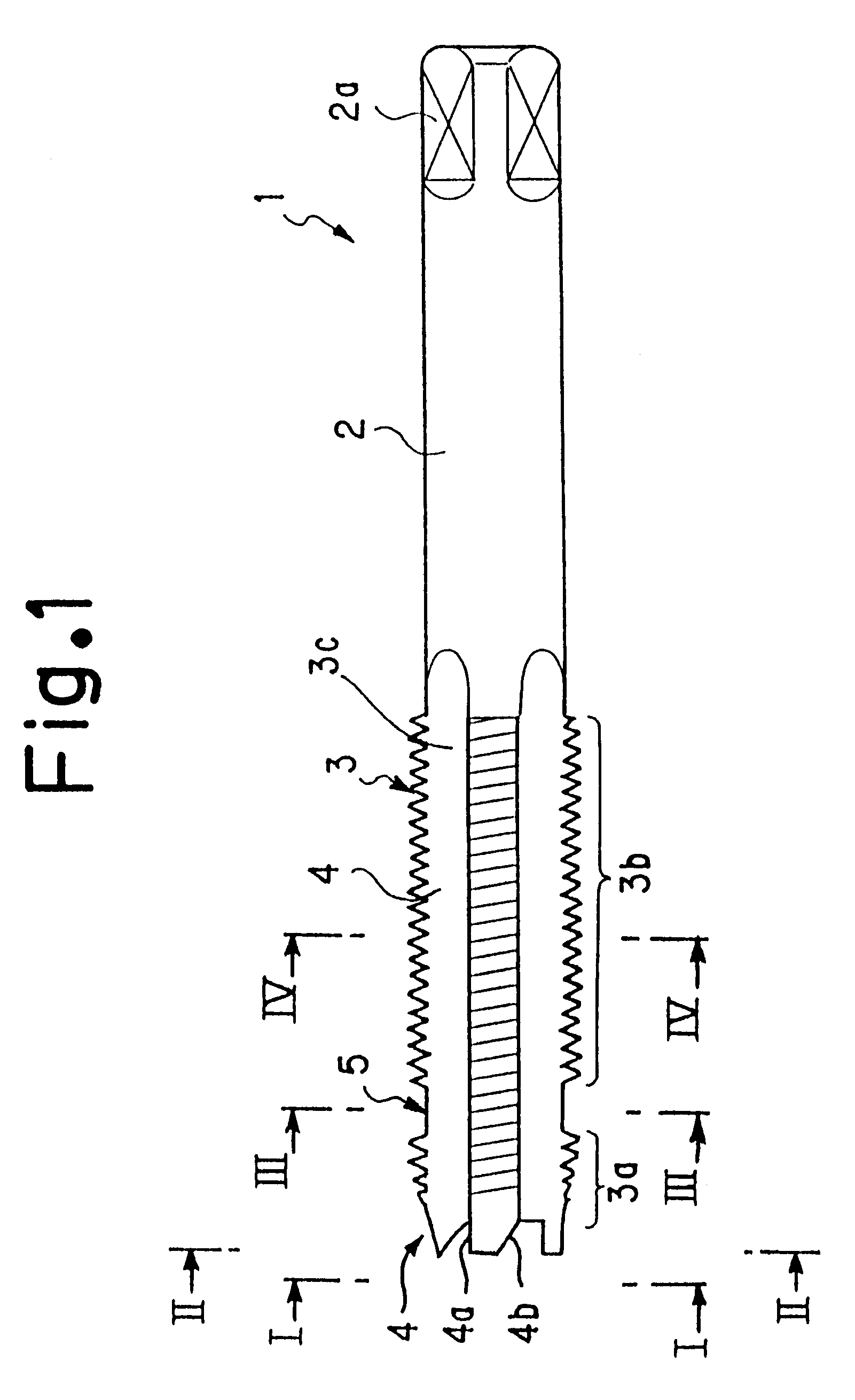

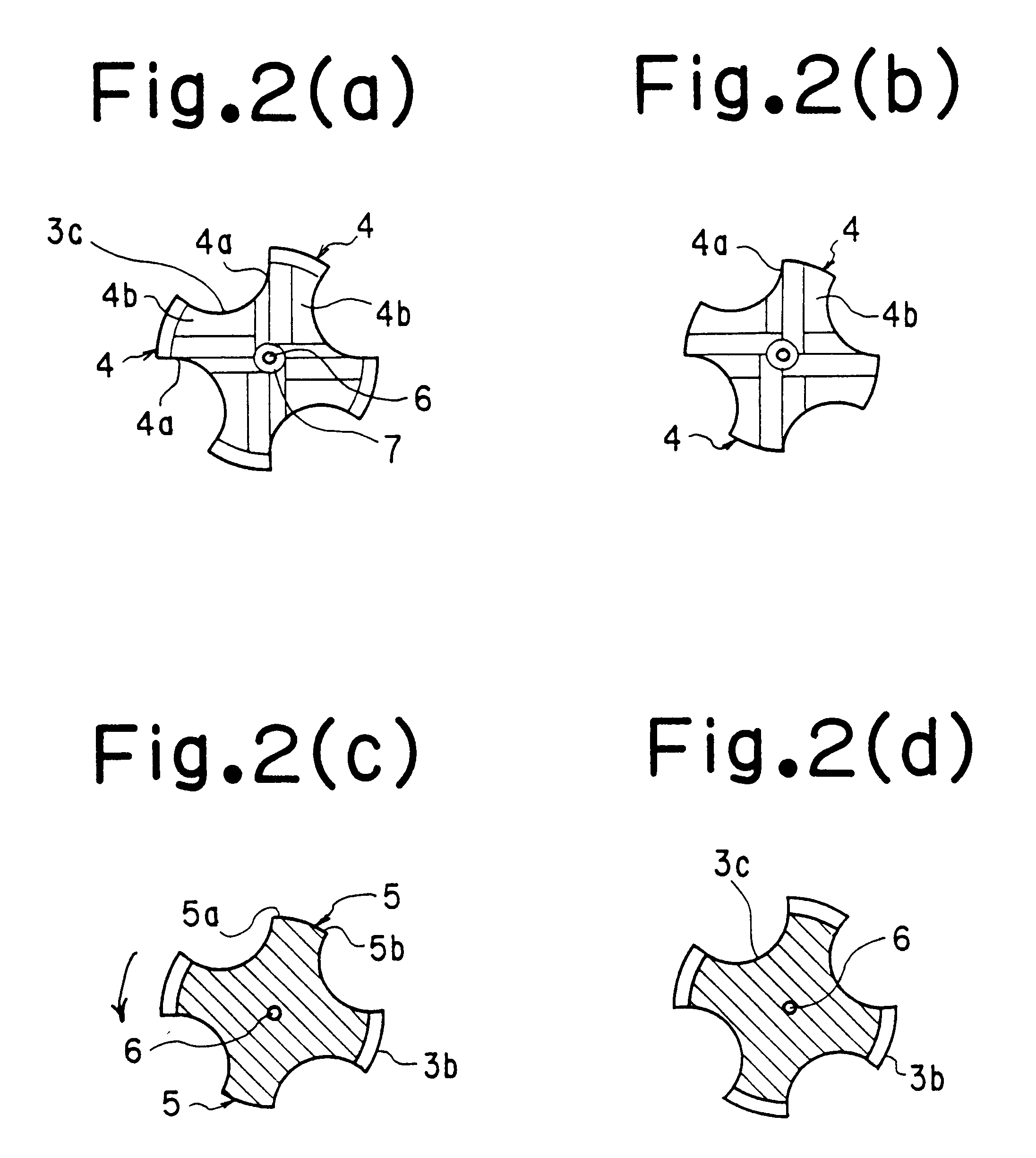

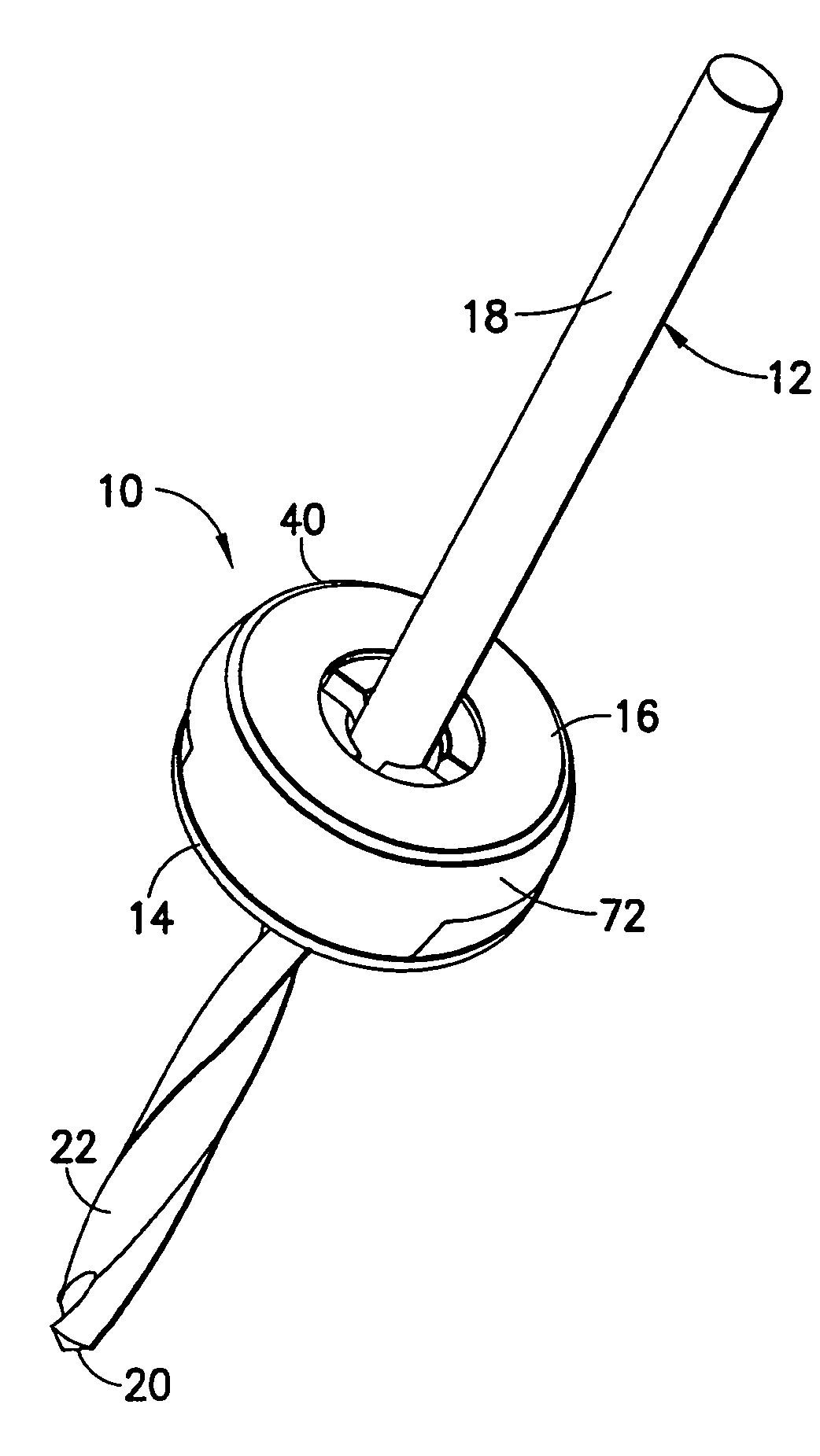

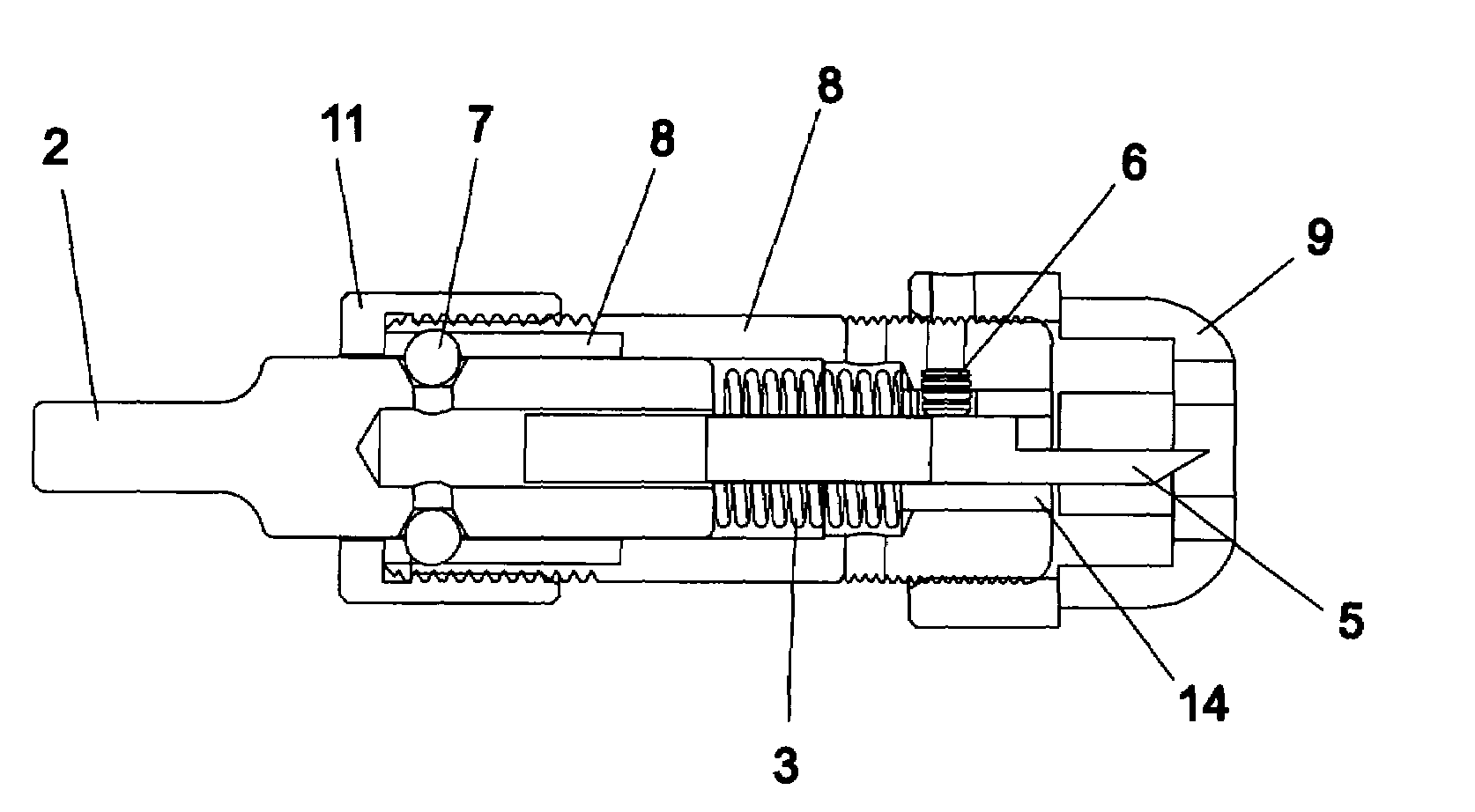

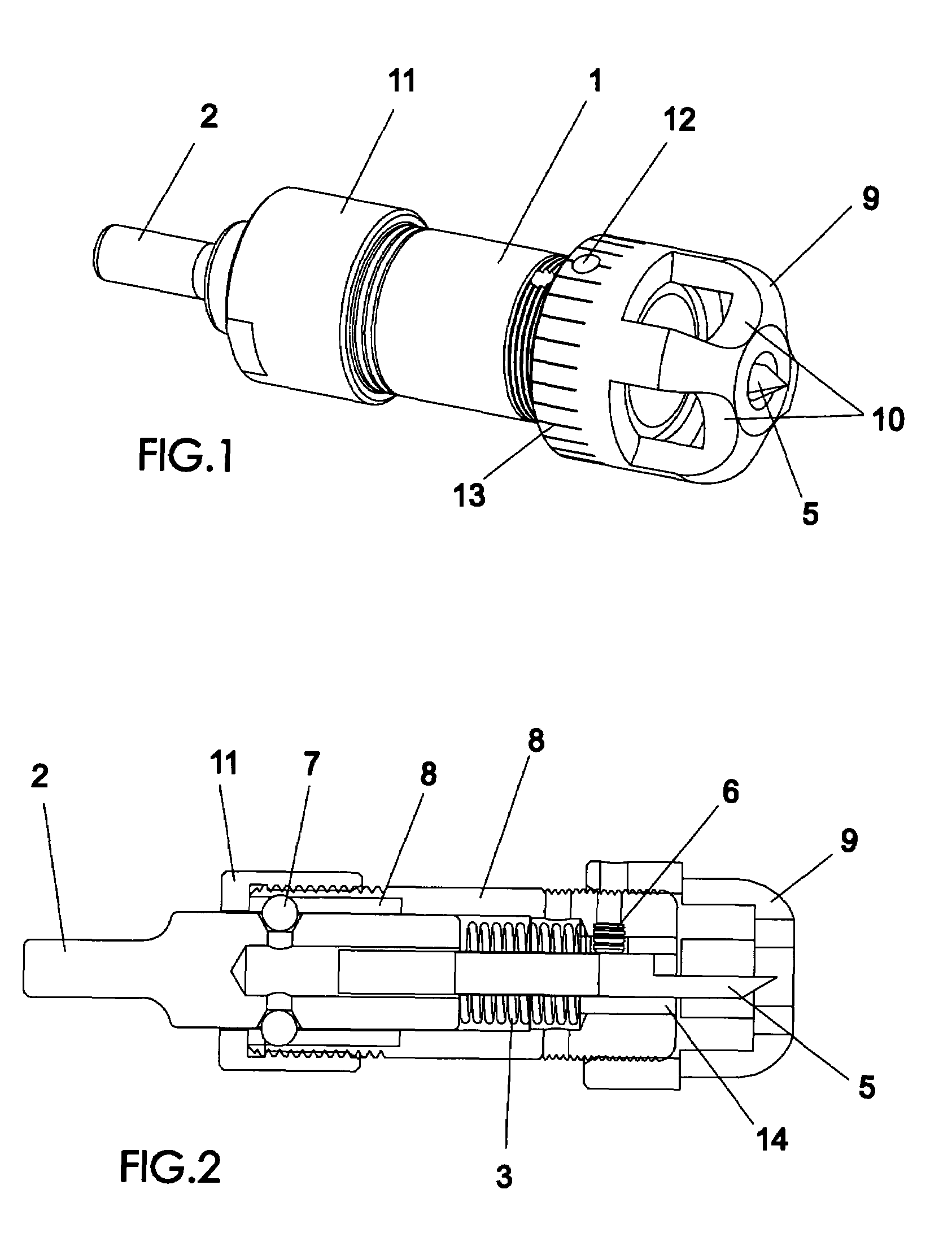

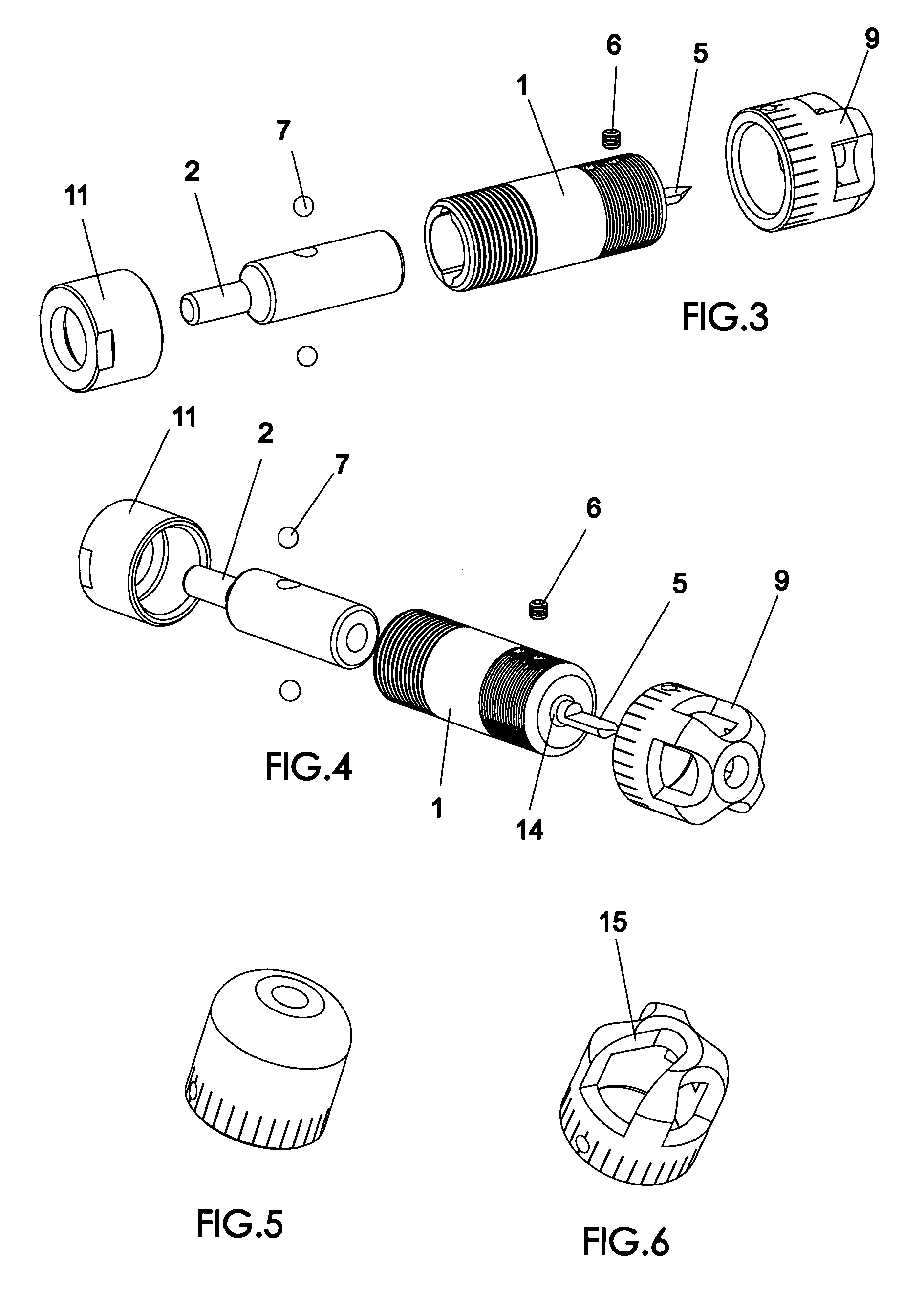

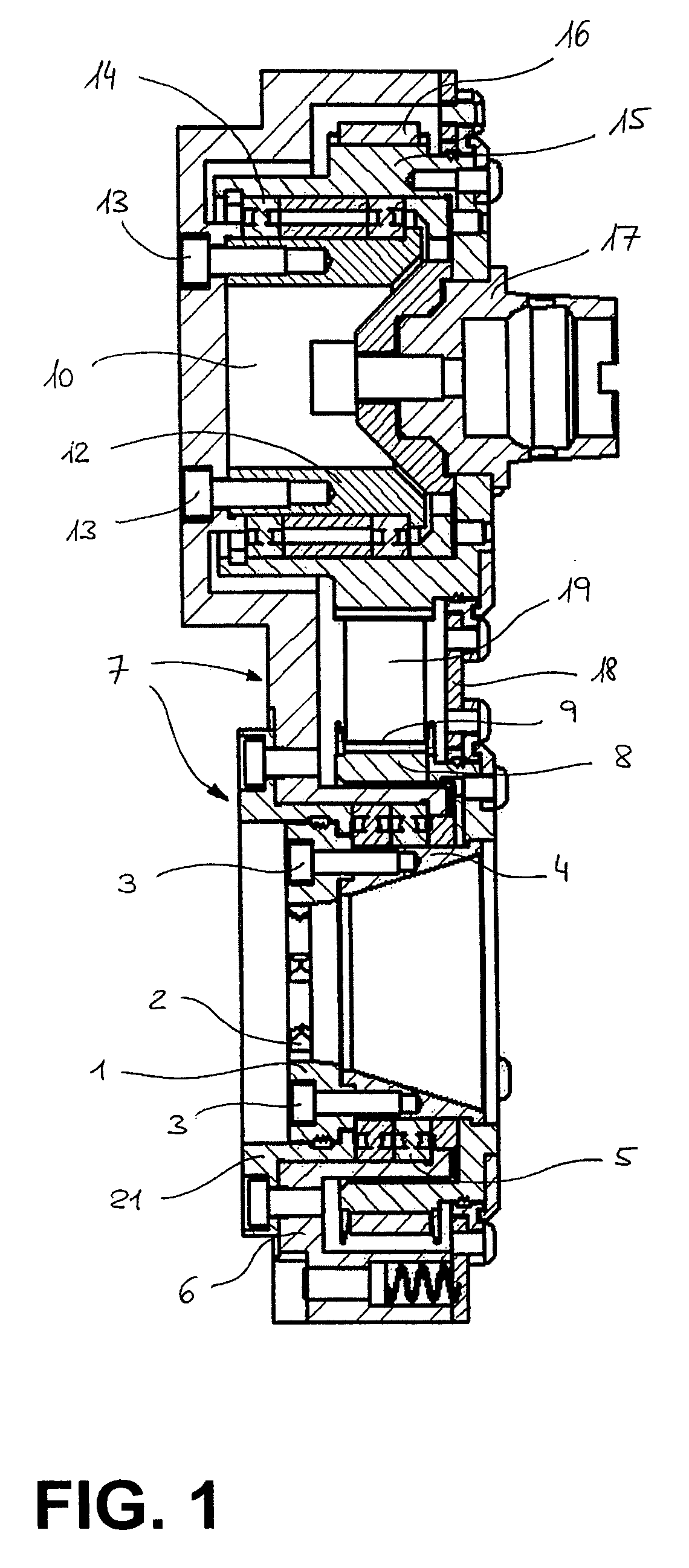

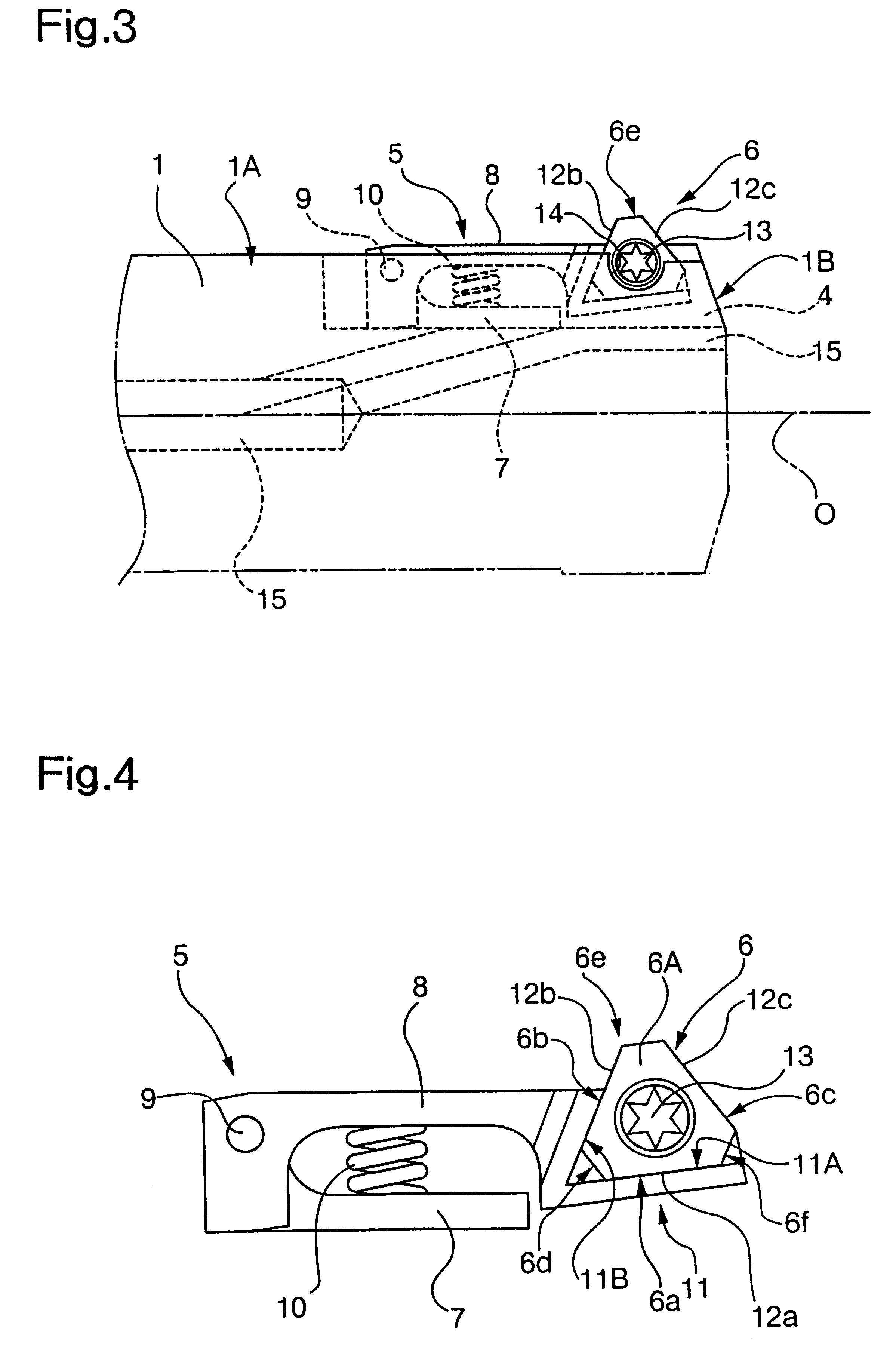

Collet collar stop for a drill bit

InactiveUS7513722B2Thread cutting toolsDrilling/boring measurement devicesDepth of penetrationEngineering

A stop for a drill bit having a shaft, the stop having a first member which includes a collet. The collet is configured to receive the shaft of the drill bit and is positionable along the shaft of the drill bit. The stop also has a second member which includes a clamp, for clamping the first member in a desired position along the shaft of the drill bit by securing the collet in a desired position along the shaft of the drill bit. The stop further has an abutment surface on one of the first and second members, for limiting the depth of penetration of the drill bit into an object, the abutment surface being disposed in a fixed position along the shaft of the drill bit by the clamping of the first and second members.

Owner:GREENBERG SURGICAL TECH

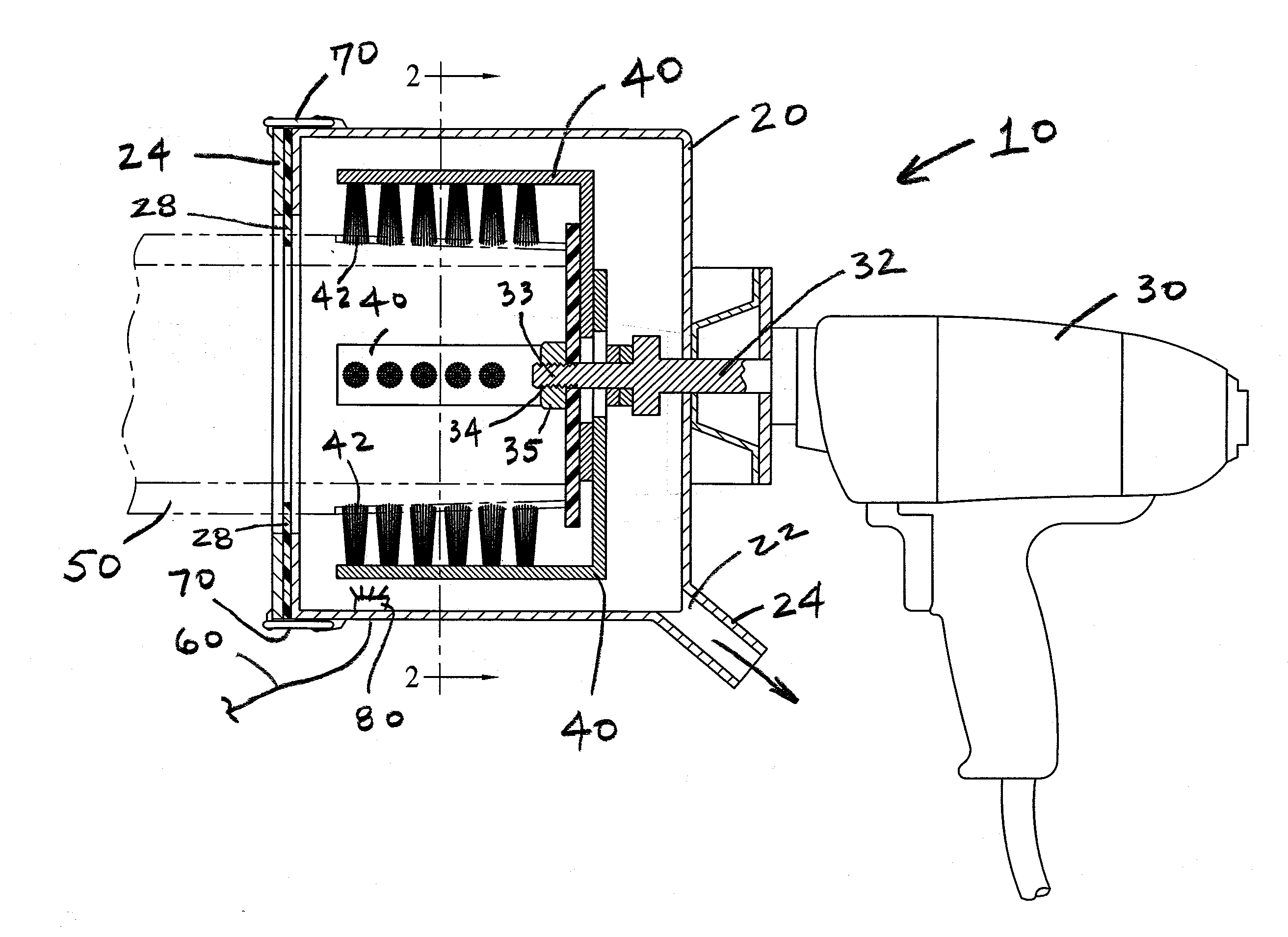

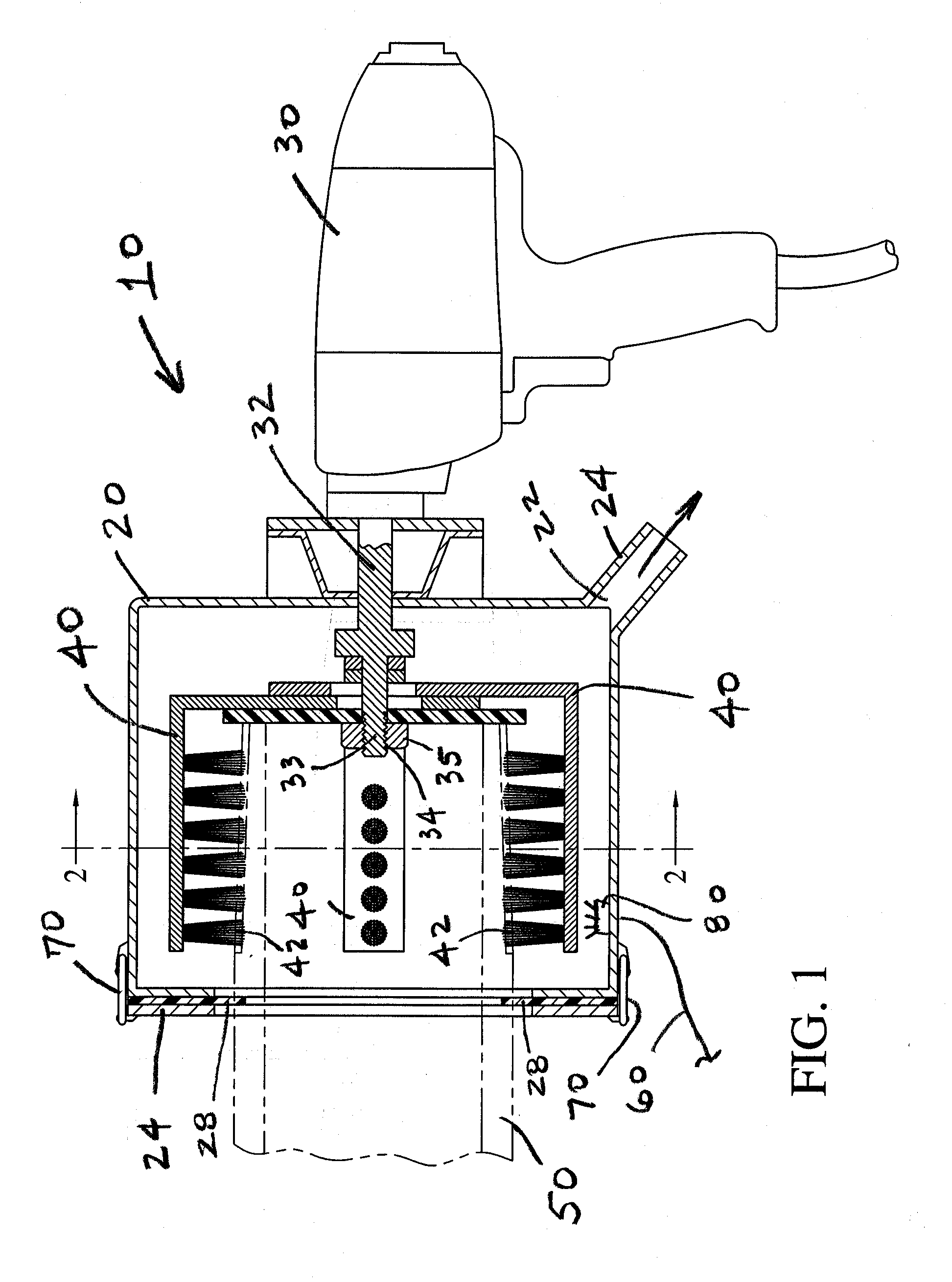

Thread Cleaning Apparatus Having Adjustable Diameter Brush Bases

An apparatus for cleaning of tubular threads having adjustable spacing brushes to accommodate tubulars of different diameters. A plurality of brushes are rotated in a drum, which fits over the tubular connection. The brushes are mounted on L-shaped brackets, which are in turn mounted to a rotary driver by a shaft extending through slots in the brackets. By loosening the attachment of the brackets on the rotary driver, the brackets can be slid radially inward or outward to the extent of the slots, thereby adjusting the diameter of the threads that can be cleaned. The front access plate and seal plate, through which the tubular extends into the drum, are preferably held to the drum by hand operable latches. Solvent may be injected into the drum and onto the threads by a hand pump, and captured in the drum and drained into a container for disposal or reuse.

Owner:SUBARU TECNICA INTERNATIONAL

Boring bit and methods for manufacturing boring bits

InactiveUS6874978B2Reduce extra spaceReduce spacingThread cutting toolsWood turning toolsEngineeringPower tool

Boring bits and methods for manufacturing boring bits. The method includes the acts of forming a shank including one end connectable to a power tool and an opposite end, molding a cutting head separate from the shank, the cutting head including a base wall and a side wall extending from the base wall, the base wall having an interior base surface and an exterior base surface, and bonding the shank and the cutting head as a unit including bonding the opposite end of the shank to the exterior base surface.

Owner:MILWAUKEE ELECTRIC TOOL CORP

Tap

InactiveUS6499920B2Reduce processing timeImprove productivityThread cutting toolsWood turning toolsFluteEngineering

A cutting tap comprises a threaded portion including a lead whose thread diameter gradually decreases toward a front end of the lead, a complete thread portion continued from the lead, and four flutes arranged at equal intervals in a circumferential direction. In the cutting tap, a first cutting edge portion for processing a prepared hole is formed at a front end surface of the lead, and a second cutting edge portion for finishing a minor diameter of an internal thread is formed in a part of an outer periphery of the complete thread portion, the second cutting edge portion being one or more pitches long. The cutting tap can perform processing of a prepared hole, tapping, and finishing of a minor diameter by a single step, and can also perform tapping even if a prepared hole for an internal thread is a blind hole or the like and does not have enough space.

Owner:TANOI MFG CO LTD

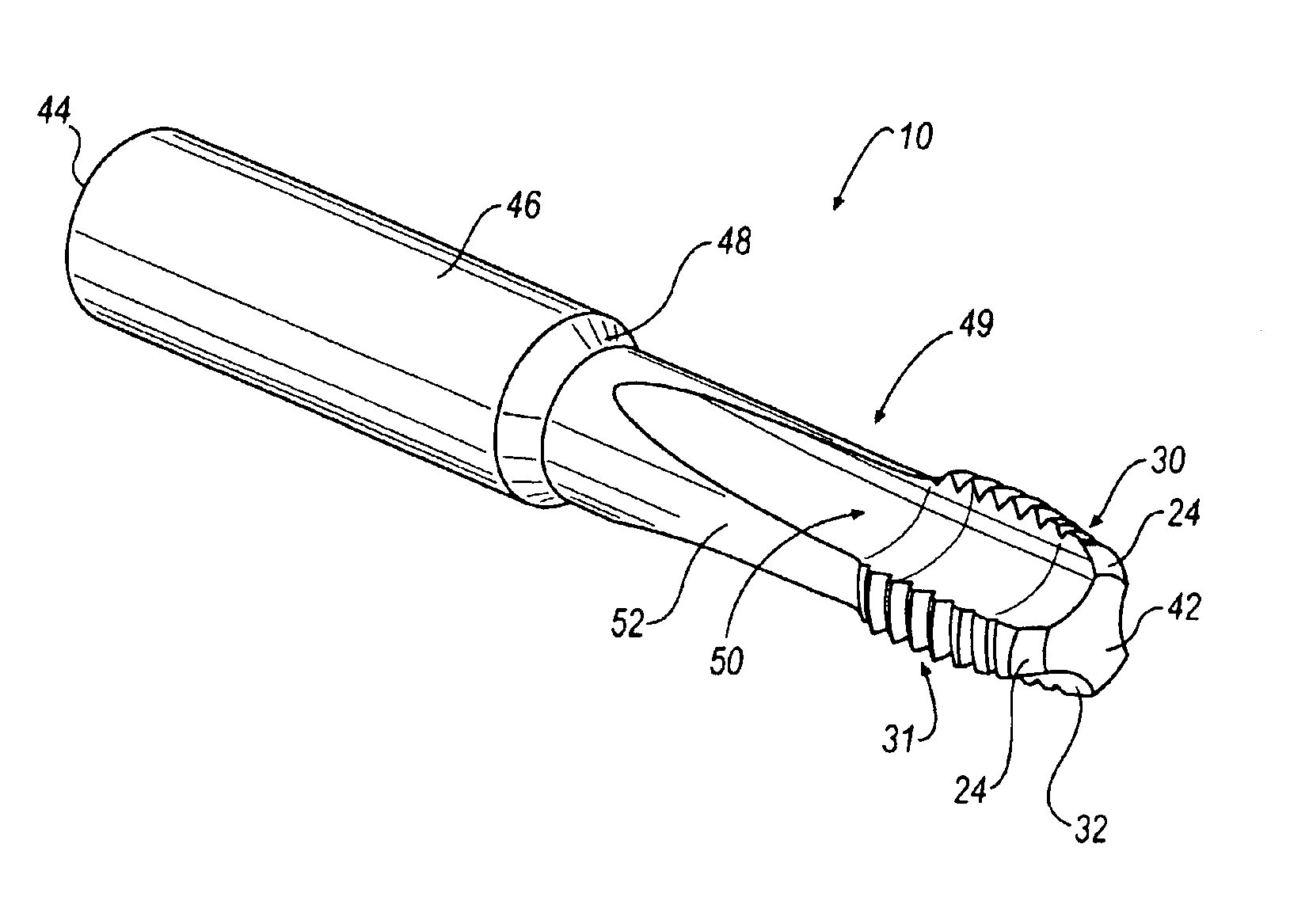

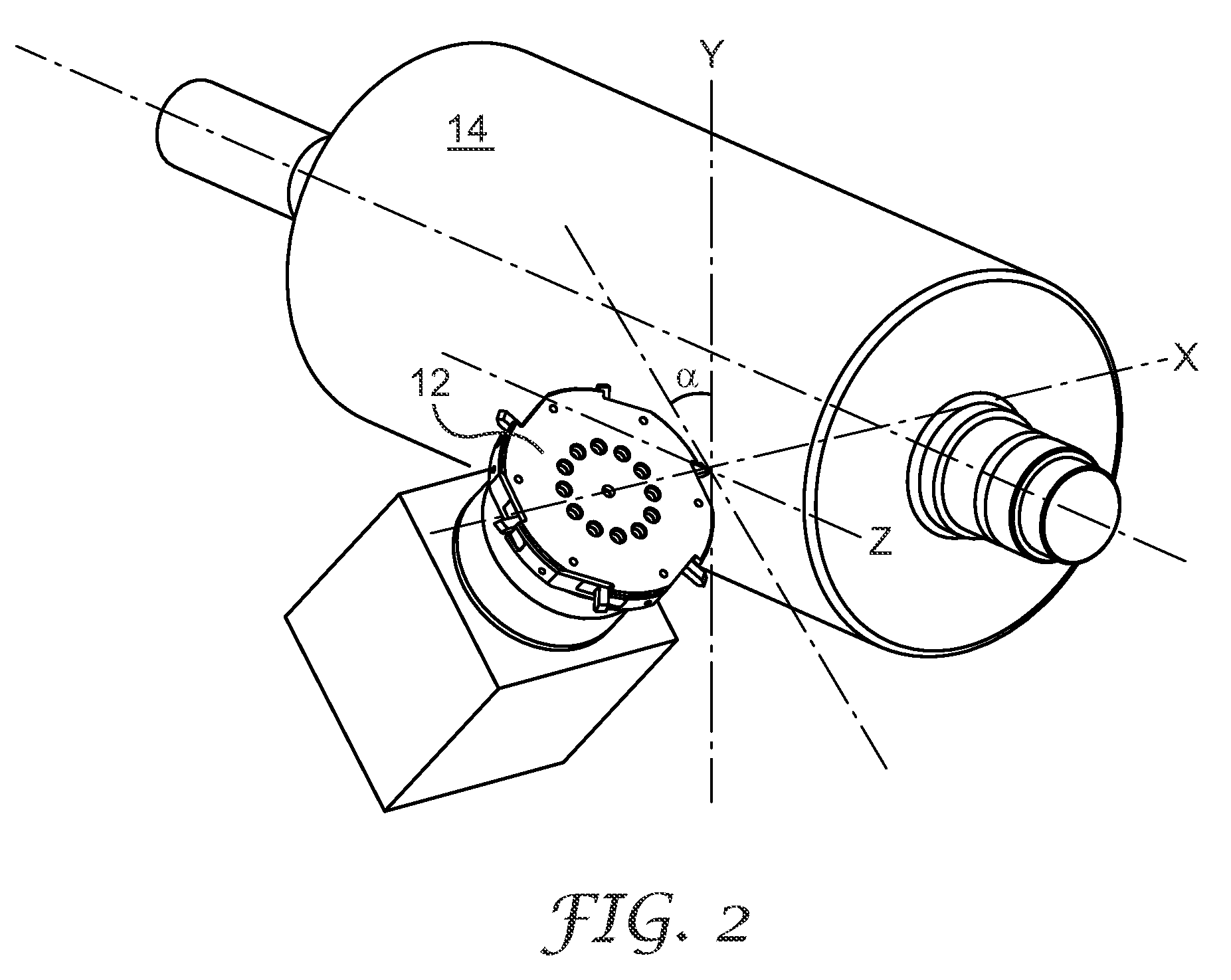

Tool for the metal cutting machining of valve seats

InactiveUS7530769B2Less-expensive solutionSimple methodThread cutting toolsTransportation and packagingCylinder headEngineering

A tool for metal-cutting machining of a surface of an opening particularly of a valve seat in a cylinder head of an internal combustion engines. The tool has a cutter tip with at least one geometrically defined cutting edge. The cutter tip rests on two supporting regions in the tool which are arranged at an angle α, and an angle-bisecting line runs essentially perpendicularly with respect to the active cutting edge which then is removing chips from the valve seat. A claw holds the cutting tip to the tool end. Coolant and lubricant are supplied through an outlet from the claw.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

Precision cemented carbide threading tap

InactiveUS7147413B2Improve accuracyIncrease speedThread cutting toolsWood turning toolsEngineeringCemented carbide

A precision cemented carbide threading tap is designed for use in precision tool holders in synchronous high speed tapping. The precision tap includes a fully cylindrical shank without the aid of squares, flats or other notches. The precision tap further includes a threaded body portion and a threaded cutting chamfer portion. The threaded body portion and the threaded cutting chamfer portion of the precision tap are concentric to the cylindrical shank of the tap within a runout of 10 microns. The precision cemented carbide threading tap improves the accuracy, life and speed by which internal screw threads are produced.

Owner:KENNAMETAL INC +1

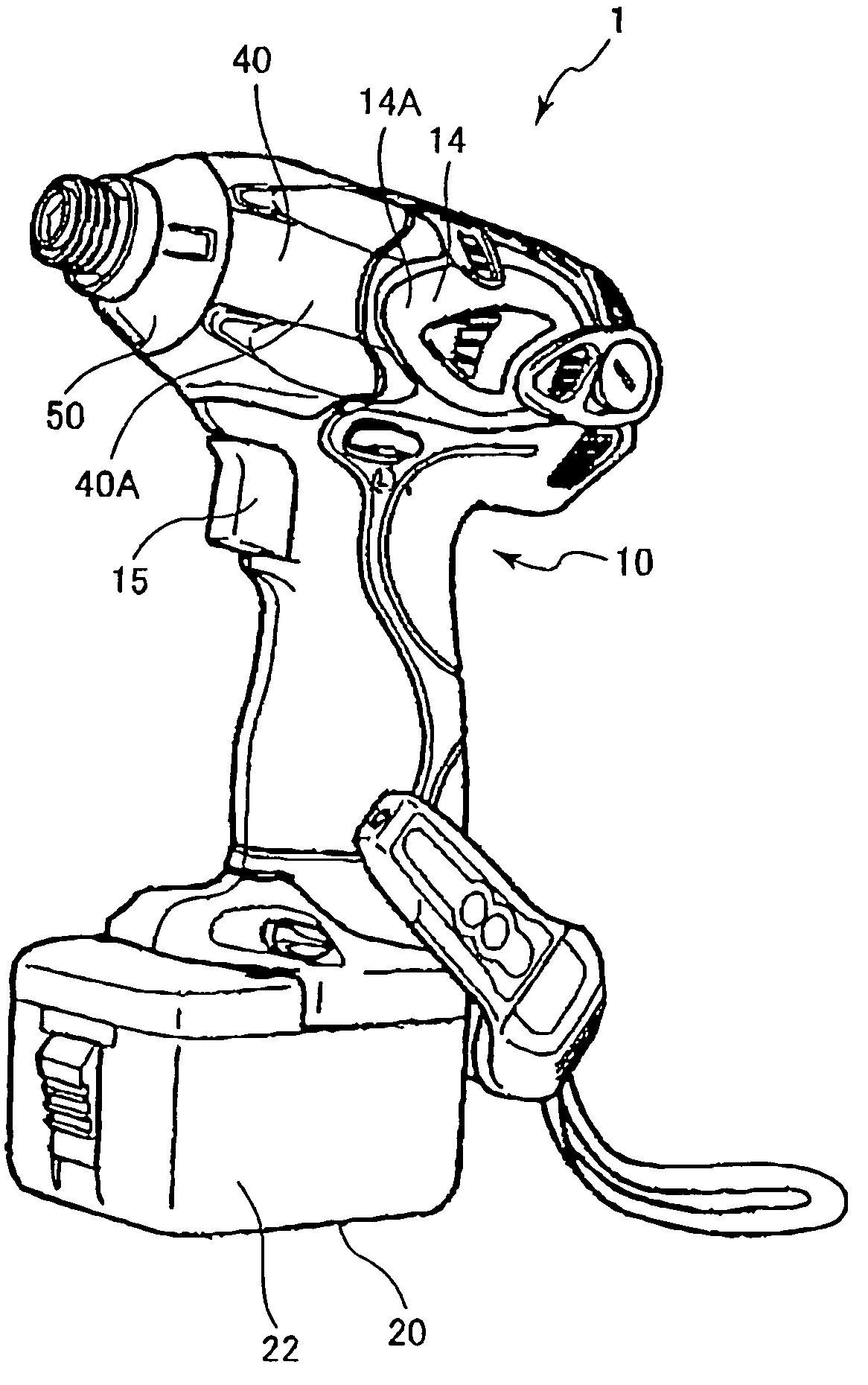

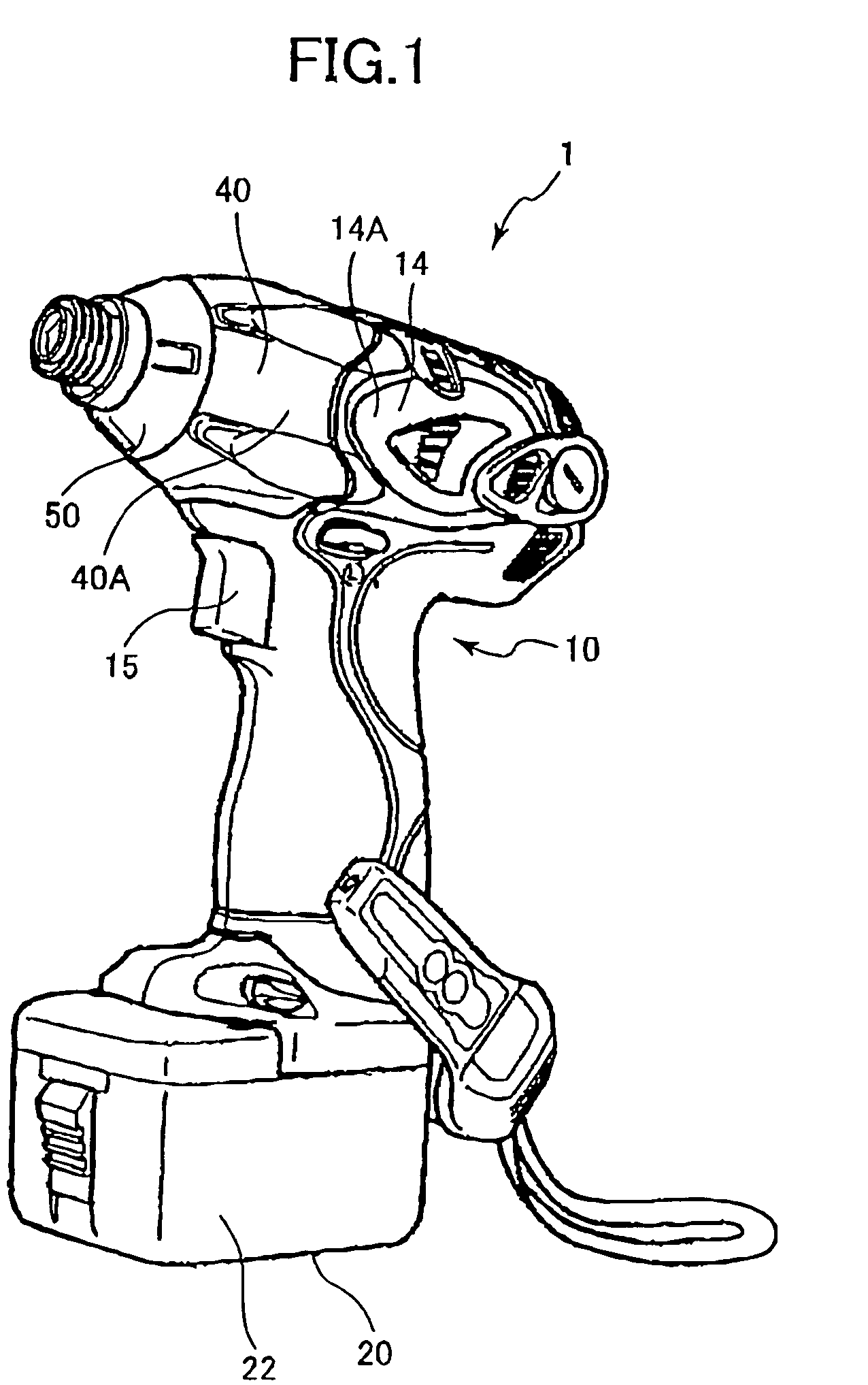

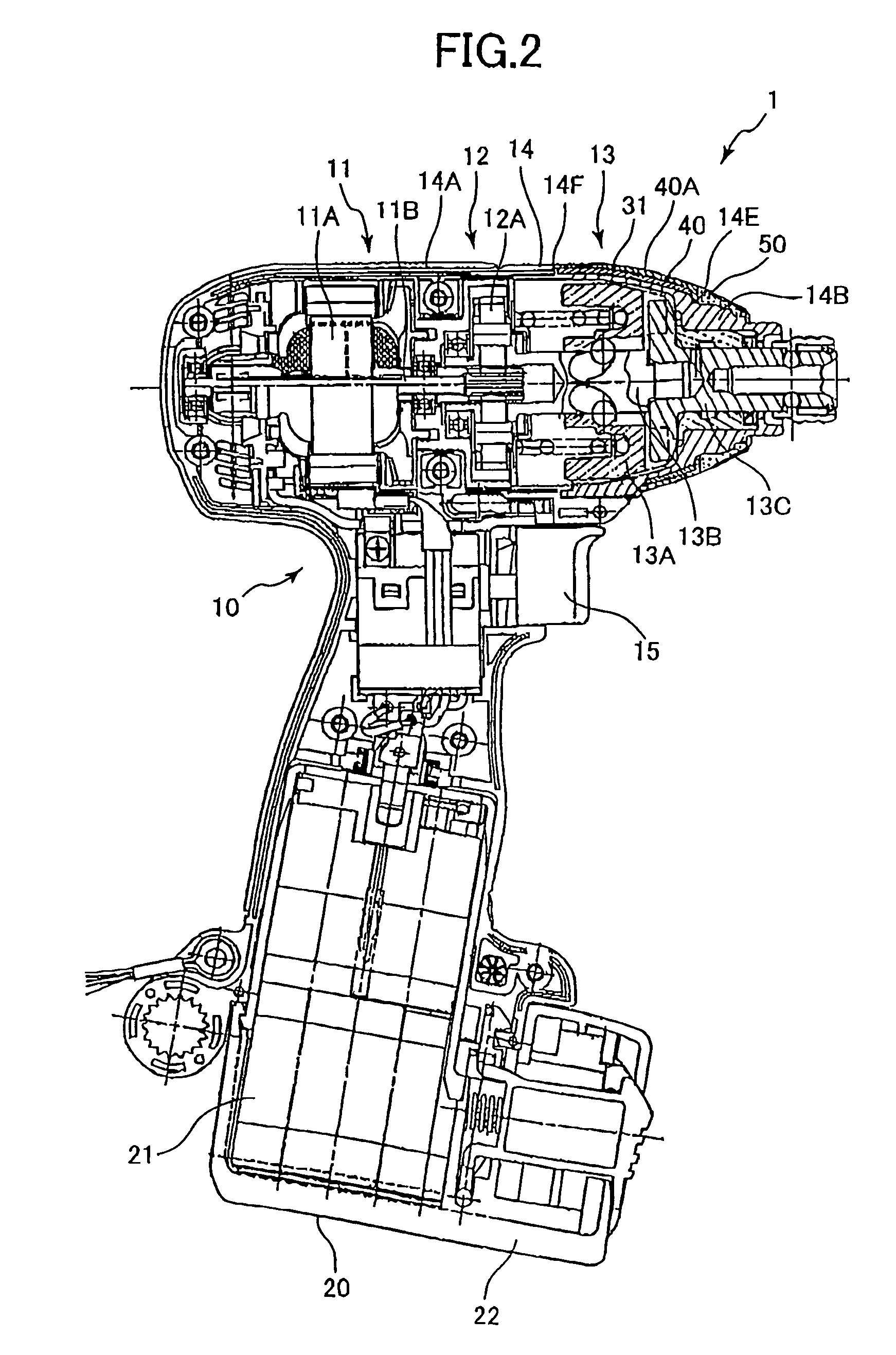

Portable tool having cover and label to be stuck on the portable tool for identification

InactiveUS7140451B2Low costThread cutting toolsStampsMotive powerElectrical and Electronics engineering

A portable tool includes a motive power section, a mechanical section driven by the motive power section, and an outer frame covering the motive power section and the mechanical section. A label or a sticker is affixed to an outer peripheral surface of the outer frame. The label contains specific pattern or specific color or specific character representing a specific user of the portable tool. The cover is made from a transparent resin and is removably disposed to the outer frame for protectingly covering the label. A sheet containing a plurality of labels having colors or pattern different from each other is provided. A user can select one of the labels.

Owner:KOKI HLDG CO LTD

Tool head for a modular shank tool

Owner:KENNAMETAL INC

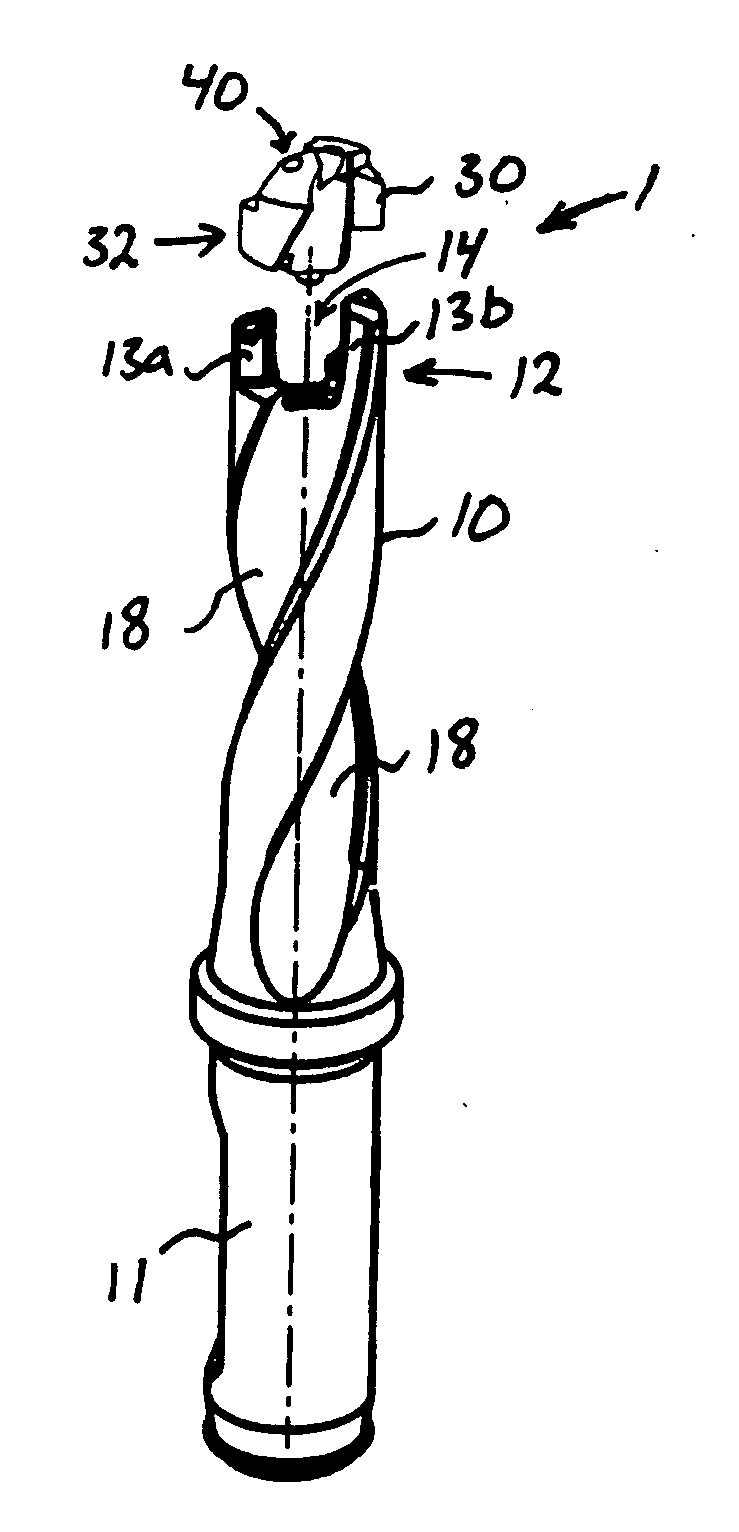

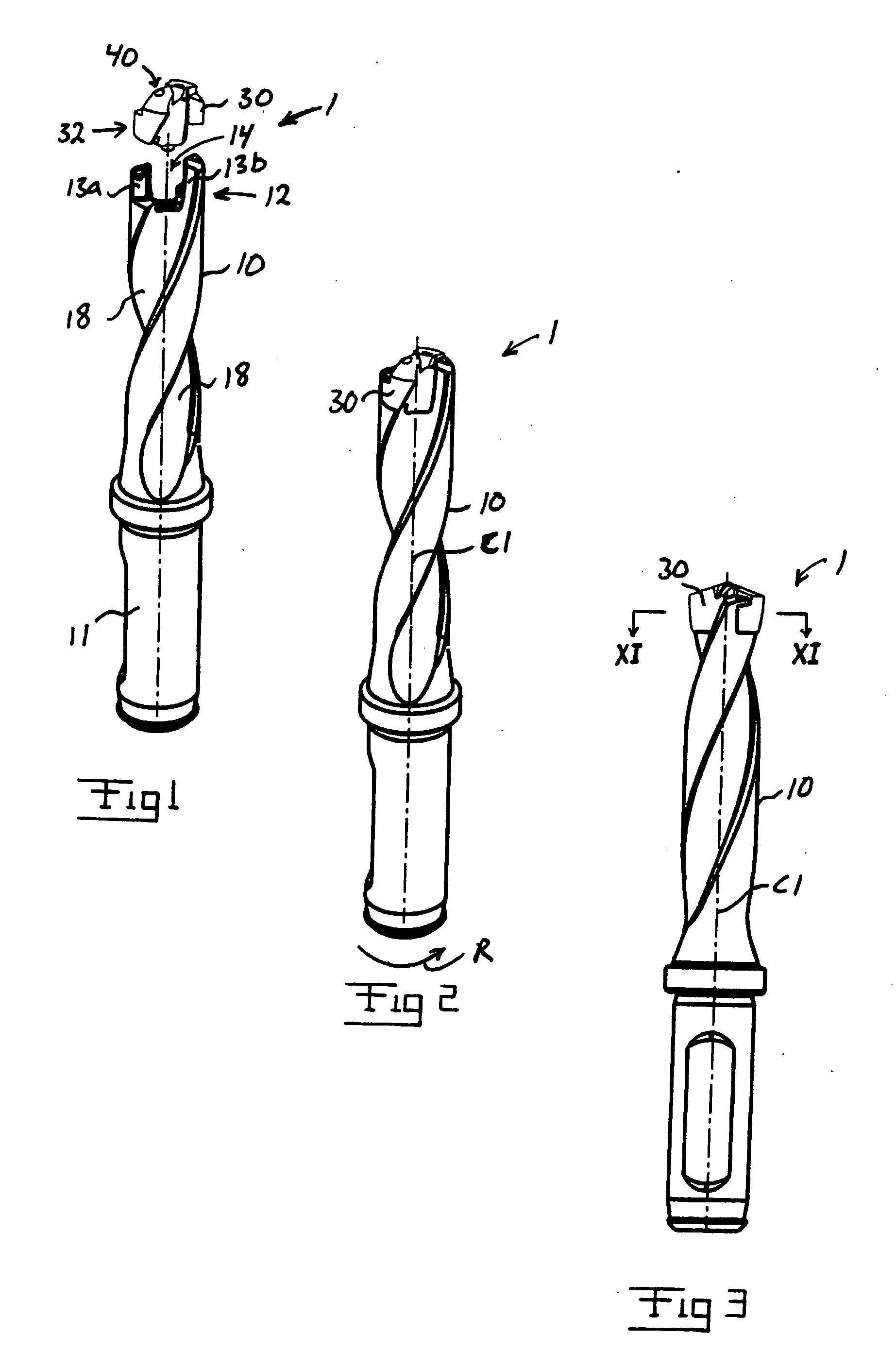

Cutting Tool Having Releasably Mounted Self-Clamping Cutting Head

A cutting tool has a tool shank and a replaceable cutting head resiliently secured to the tool shank by an interference fit between a male fixation member of the cutting head and a female fixation member of the tool shank. The male fixation member has a resilience slit. In each cross section of the cutting tool taken perpendicular to an axis of rotation of the cutting tool through mutual abutment regions, the cross sectional profiles of the mutual abutment regions are arcuate sectors.

Owner:ISCAR LTD

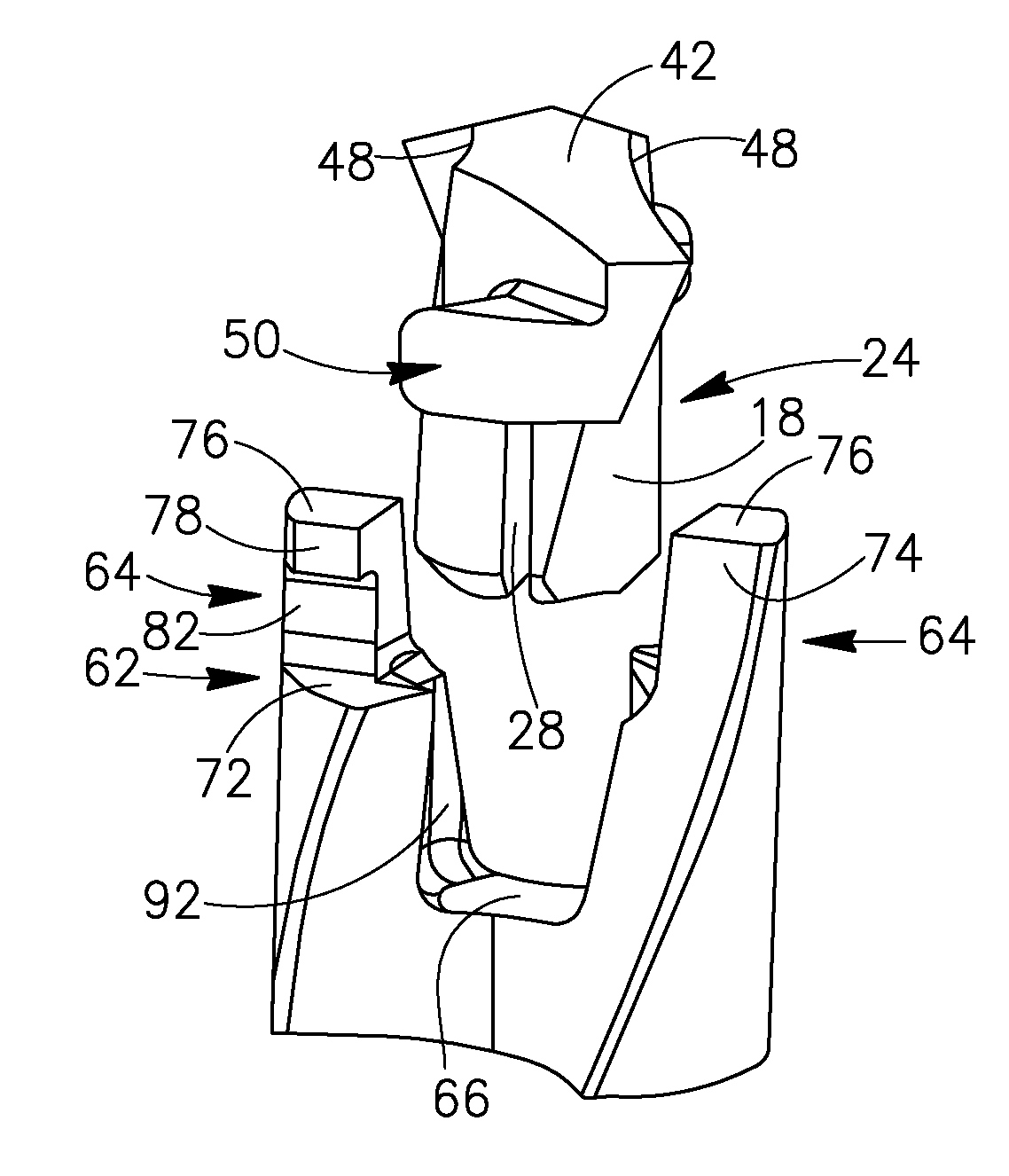

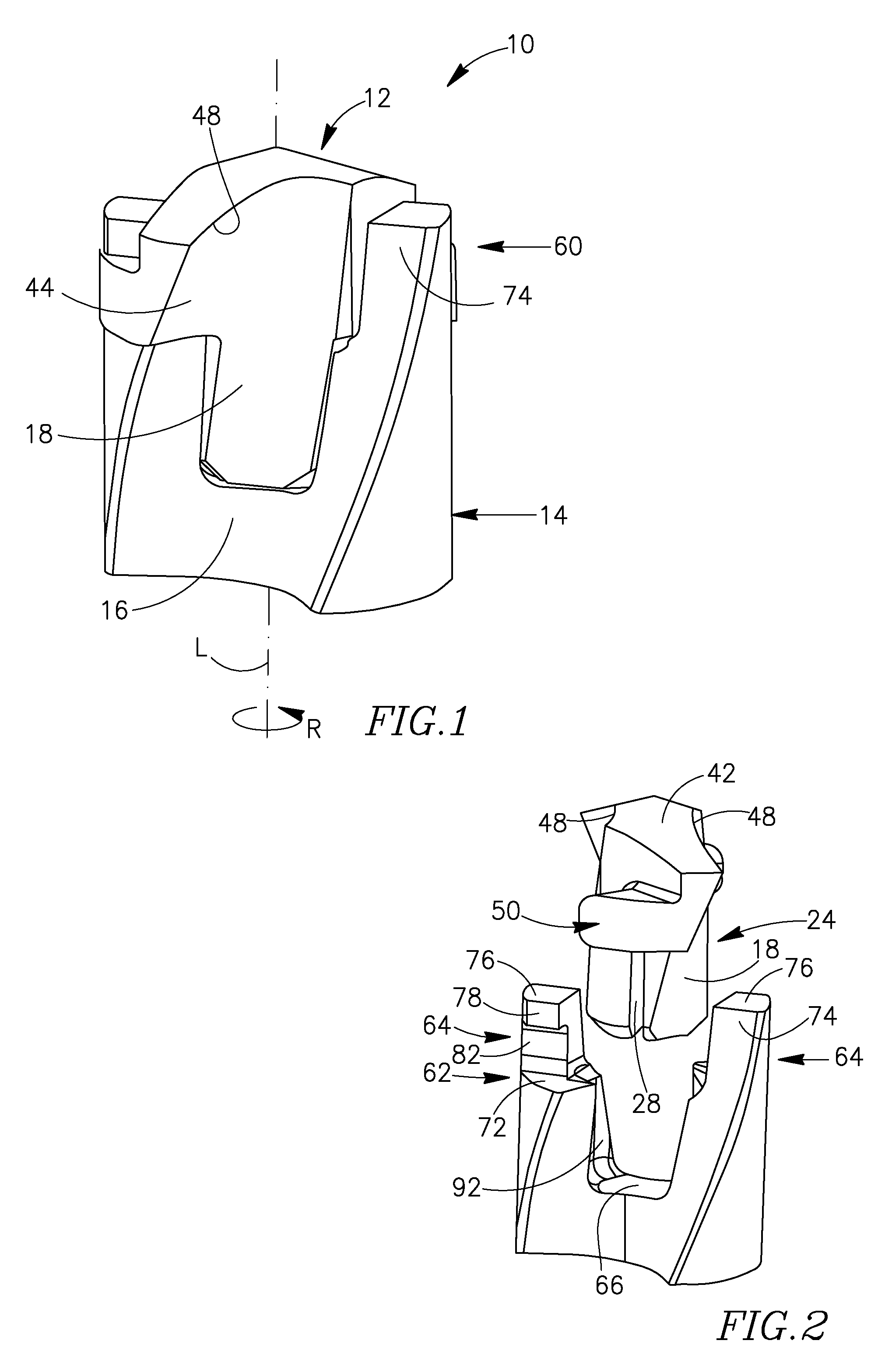

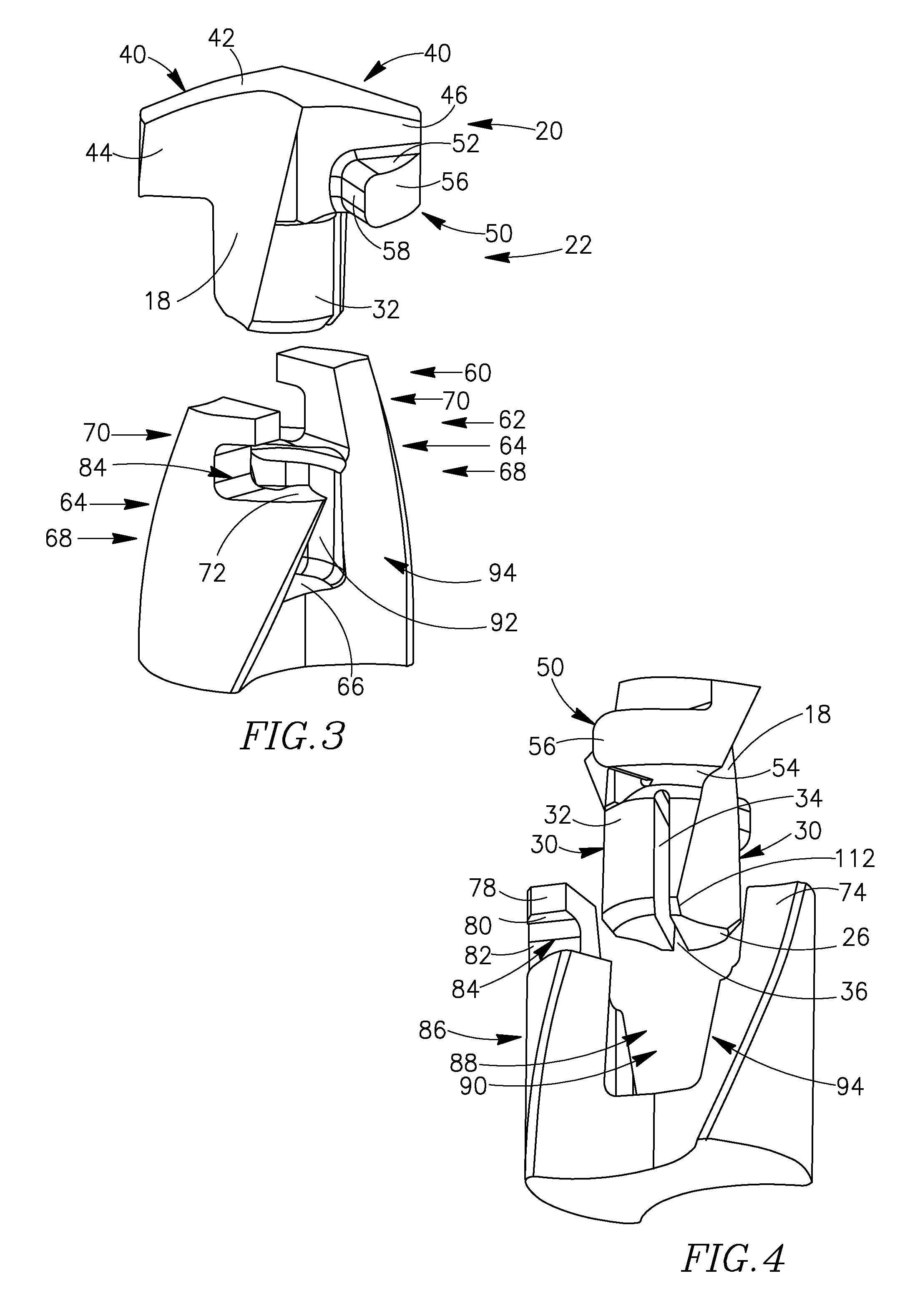

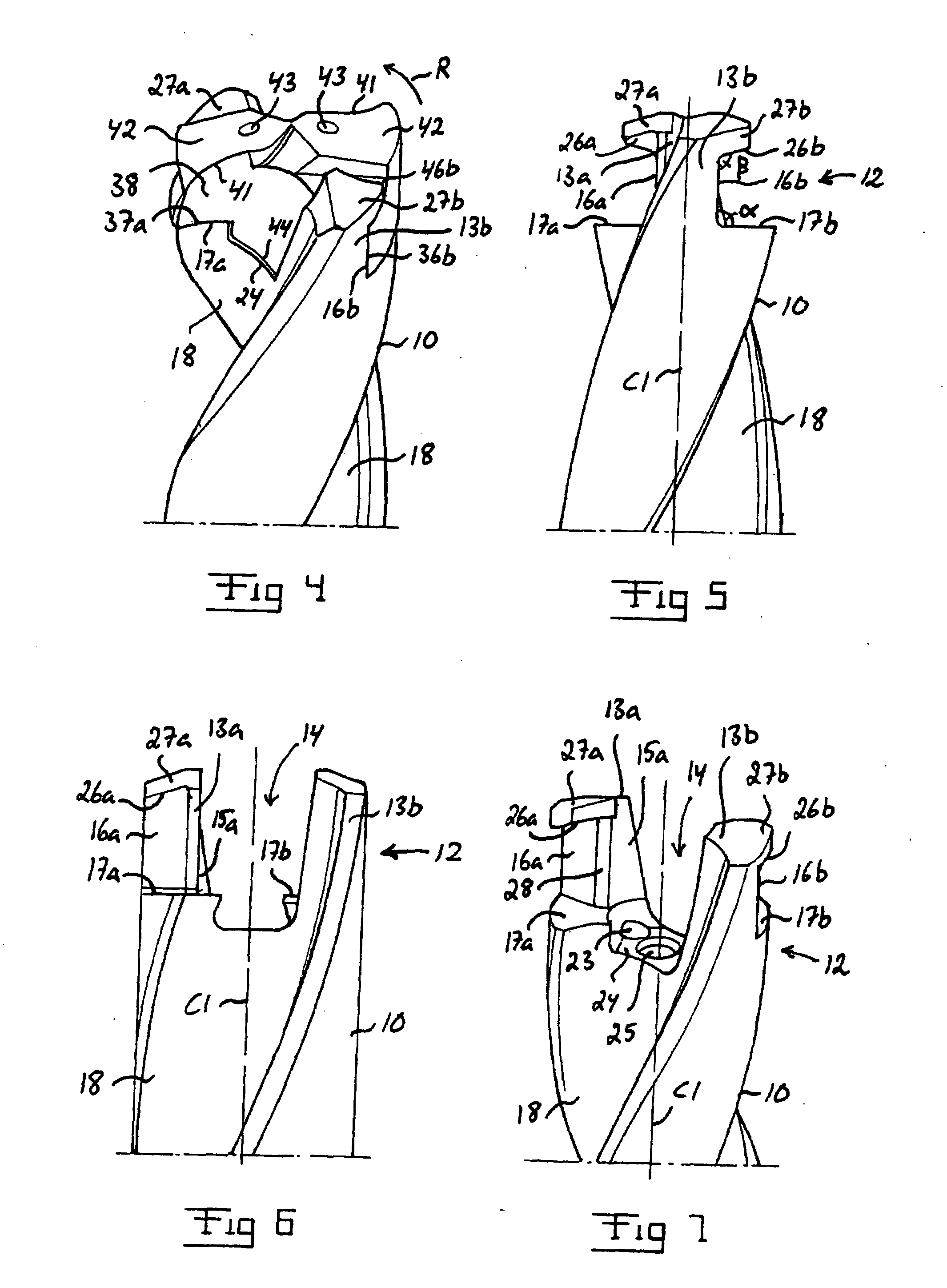

Collet collar stop for a drill bit

InactiveUS20060008332A1Thread cutting toolsDrilling/boring measurement devicesDepth of penetrationEngineering

A stop for a drill bit having a shaft, the stop having a first member which includes a collet. The collet is configured to receive the shaft of the drill bit and is positionable along the shaft of the drill bit. The stop also has a second member which includes a clamp, for clamping the first member in a desired position along the shaft of the drill bit by securing the collet in a desired position along the shaft of the drill bit. The stop further has an abutment surface on one of the first and second members, for limiting the depth of penetration of the drill bit into an object, the abutment surface being disposed in a fixed position along the shaft of the drill bit by the clamping of the first and second members.

Owner:GREENBERG SURGICAL TECH

Spring loaded tool with floating depth control for countersinking holes or engraving

ActiveUS7607871B1Avoid damageAvoid scratchesThread cutting toolsDrilling/boring measurement devicesTool bitSpray nozzle

A floating tool-bit depth controlling nosepiece for a spring loaded tool holder is used to countersink holes of equal size when the height of the work piece material changes. The floating tool-bit depth controlling nosepiece, driven by a cnc machine, is rigidly coupled to the floating portion of the tool holding element. The floating depth controlling nosepiece has a bearing on the end to allow an area of the nosepiece to stop rotating when the nosepiece is pressed against the work-piece surface. Since the area of the nosepiece that comes into contact with the work-piece is no longer spinning in relationship with the work-piece, the possibility of scratching the work-piece surface is reduced. Additionally, the nosepiece has cutouts therein to expel machined chips during countersinking of holes.

Owner:NELSON LANCE

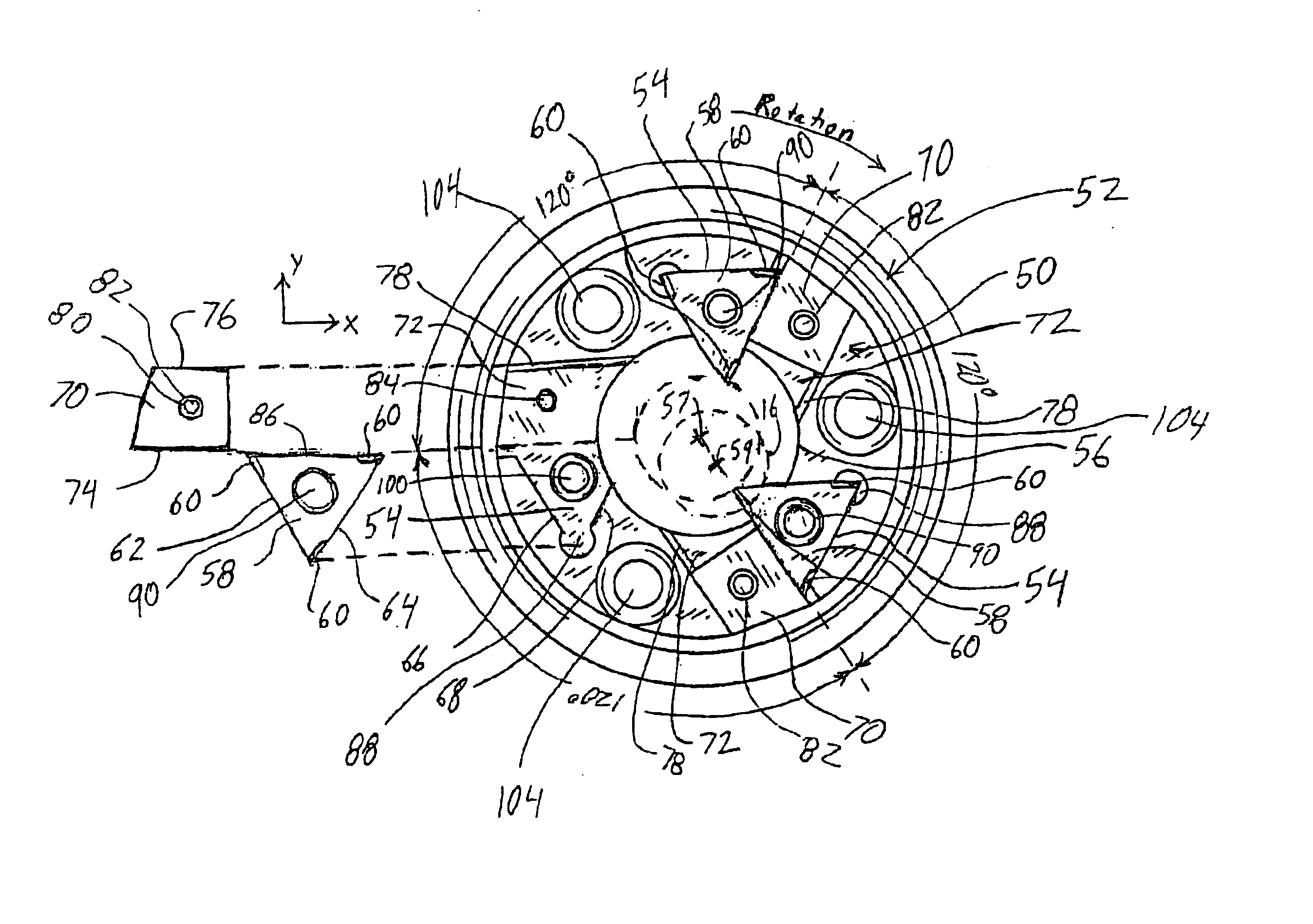

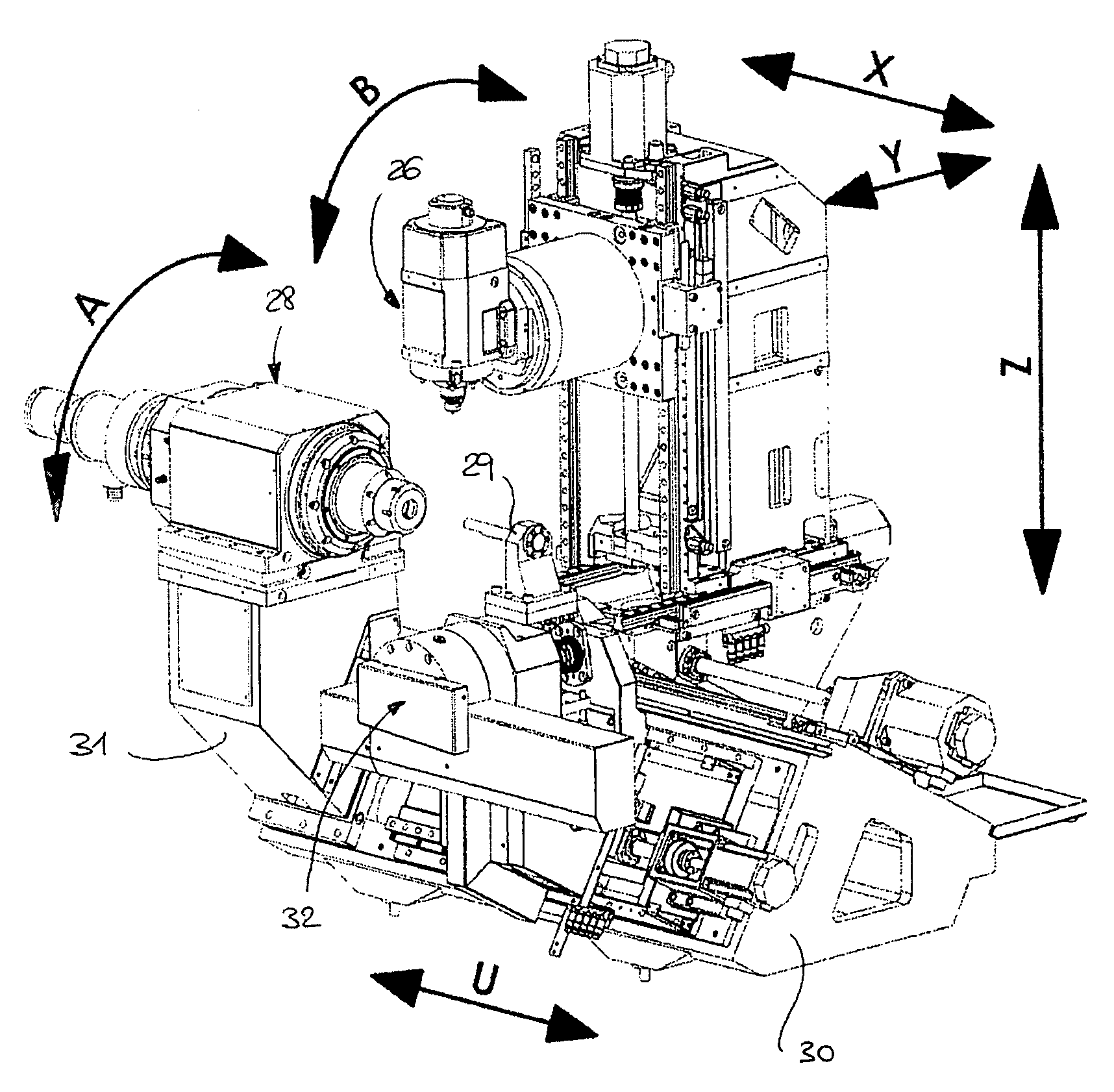

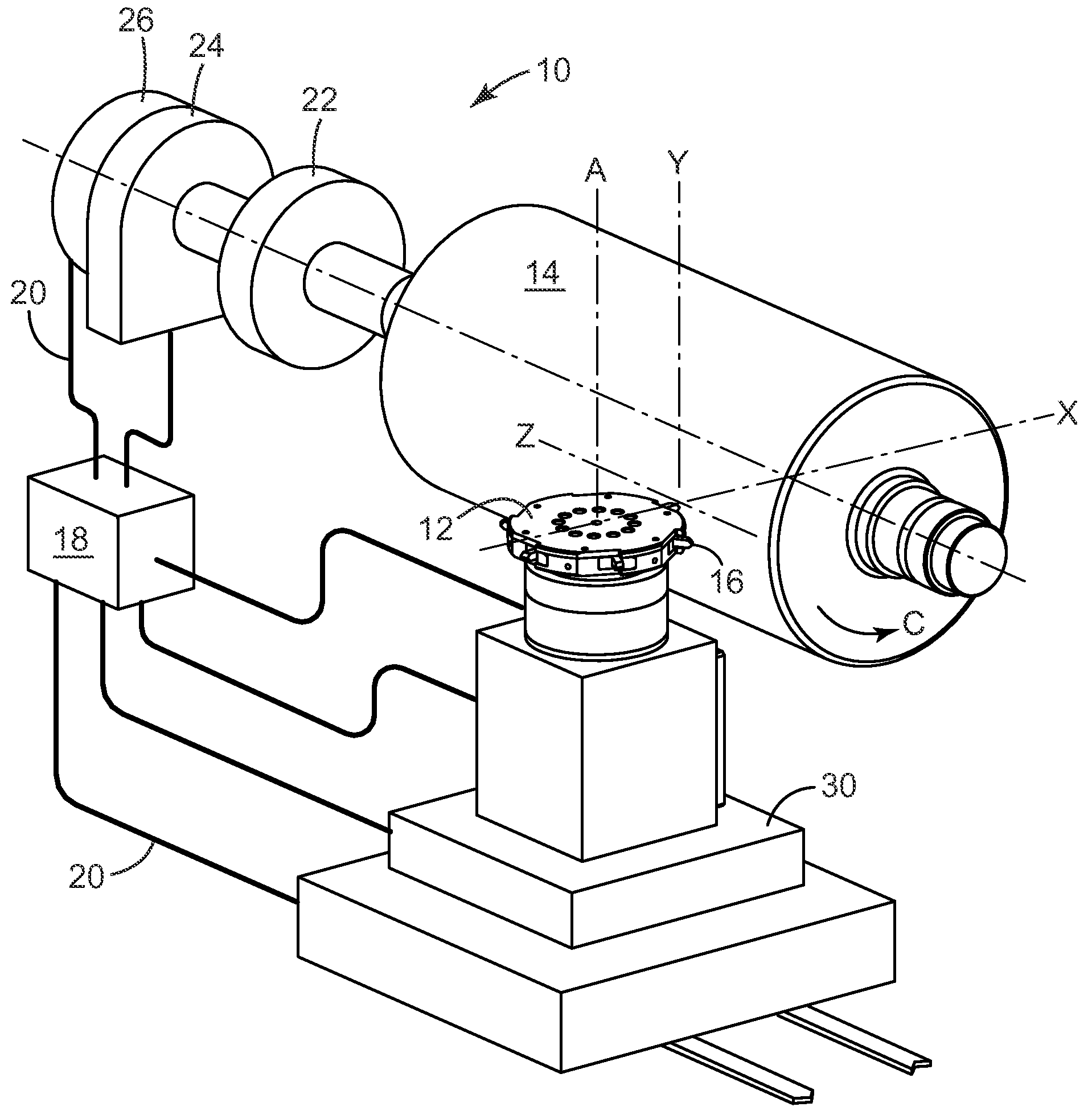

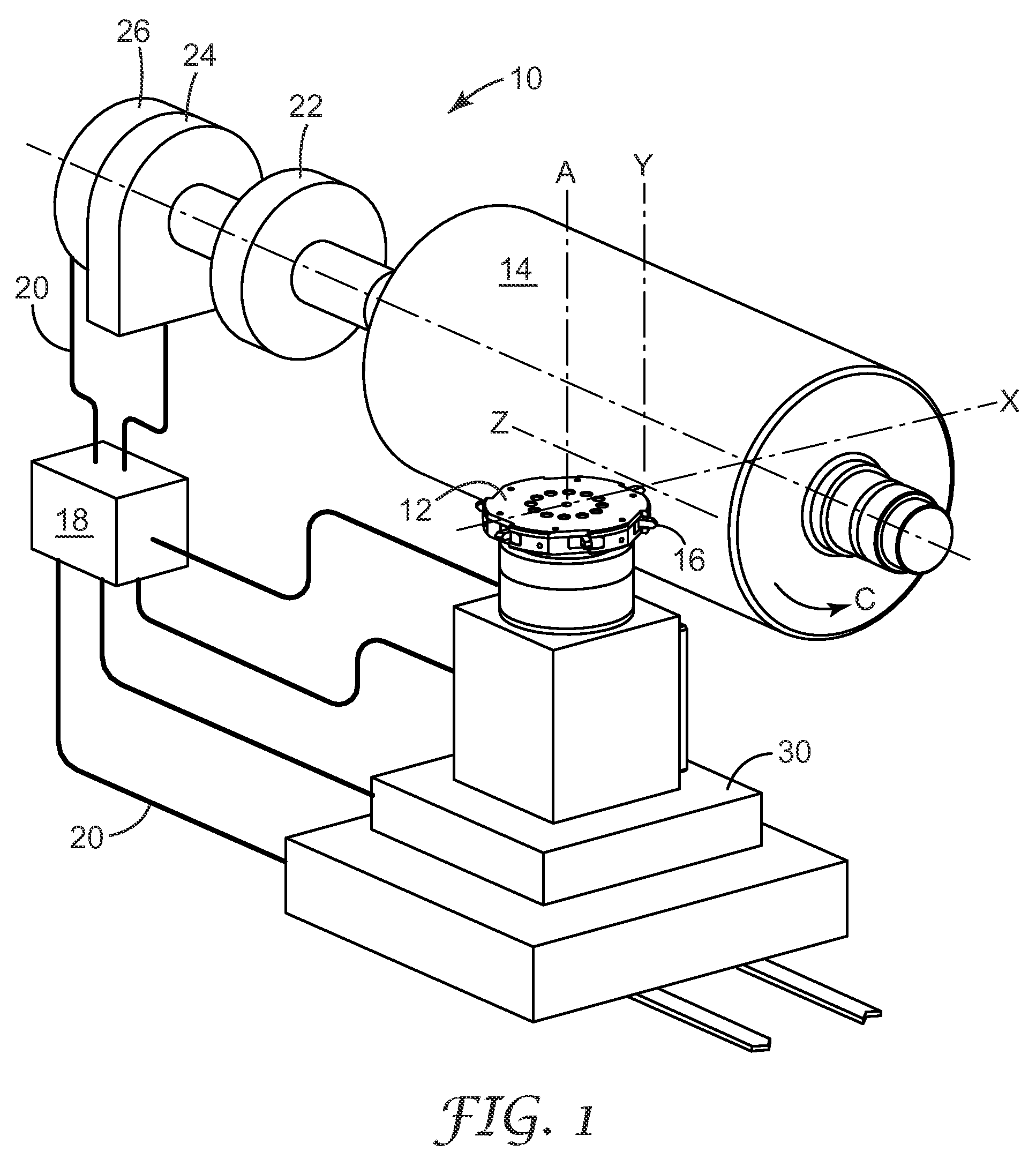

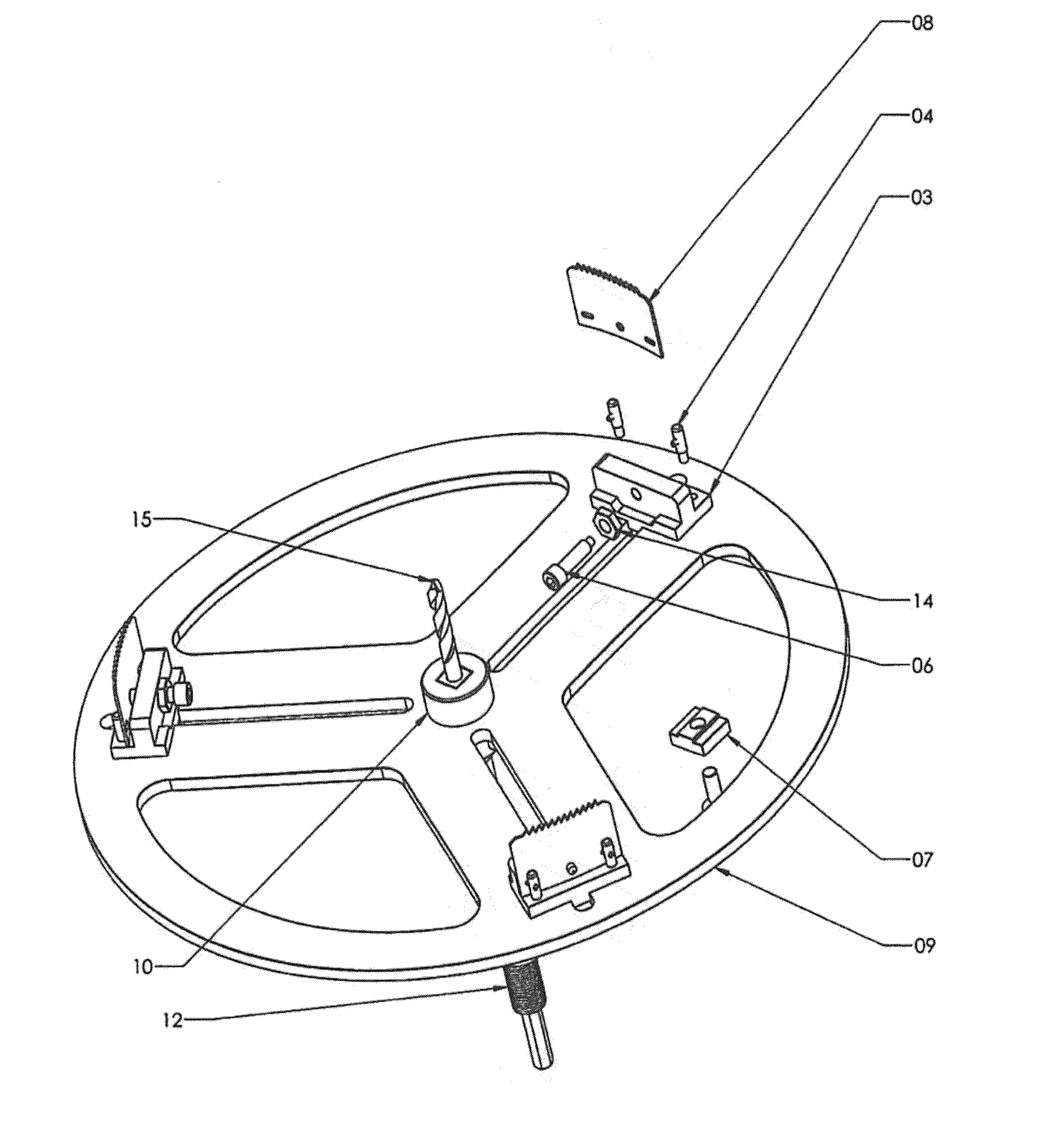

Whirling head and its use

The frame of the whirling head comprises the rigid casing (7), in which the part (10) contains the drive pulley (15) solidly attached to the coupling member (17) connected to the drive shaft of the spindle (26). By means of the belt (19), this pulley (15) drives the pulley (8) solidly attached to the connecting cone (4), which in turn comprises the internal milling cutter (1) which cuts the thread of the screw shaft (27) supported between the bar advance unit (28) and the tailstock centre (29). The latter is mounted as an exchangeable tool on the return unit (32).

Owner:WILLEMIN MACODEL

Fly-cutting head, system and method, and tooling and sheeting produced therewith

A fly-cutting system is disclosed, and in particular one that comprises a dynamically-controllable actuator for controlling the position, orientation, or both position and orientation of a cutting element carried by a fly-cutting head. In certain embodiments, the actuator can adjust the position or orientation of a cutting element, or both, hundreds or thousands of times per second, enabling precise control over the shape of features formed by the cutting element in a surface of a workpiece.

Owner:3M INNOVATIVE PROPERTIES CO

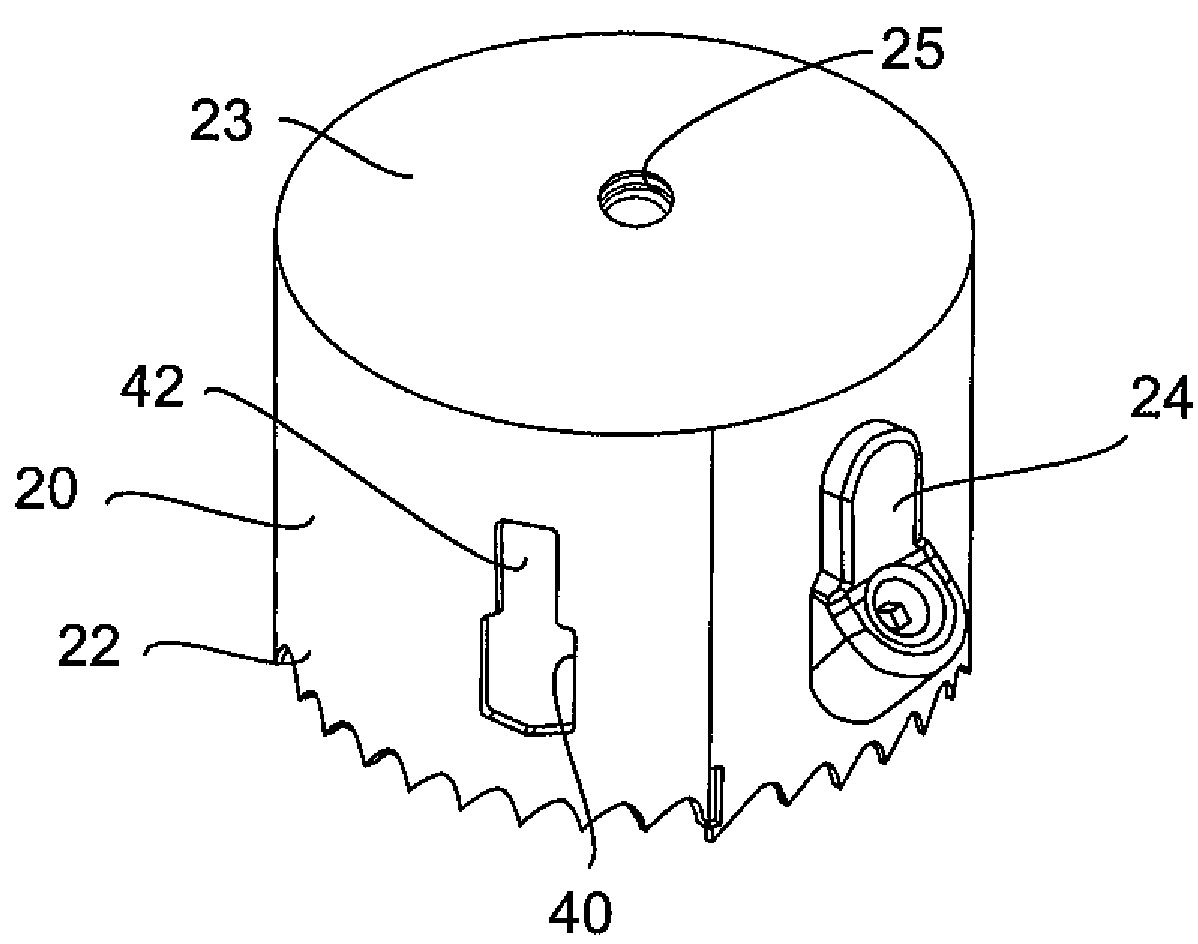

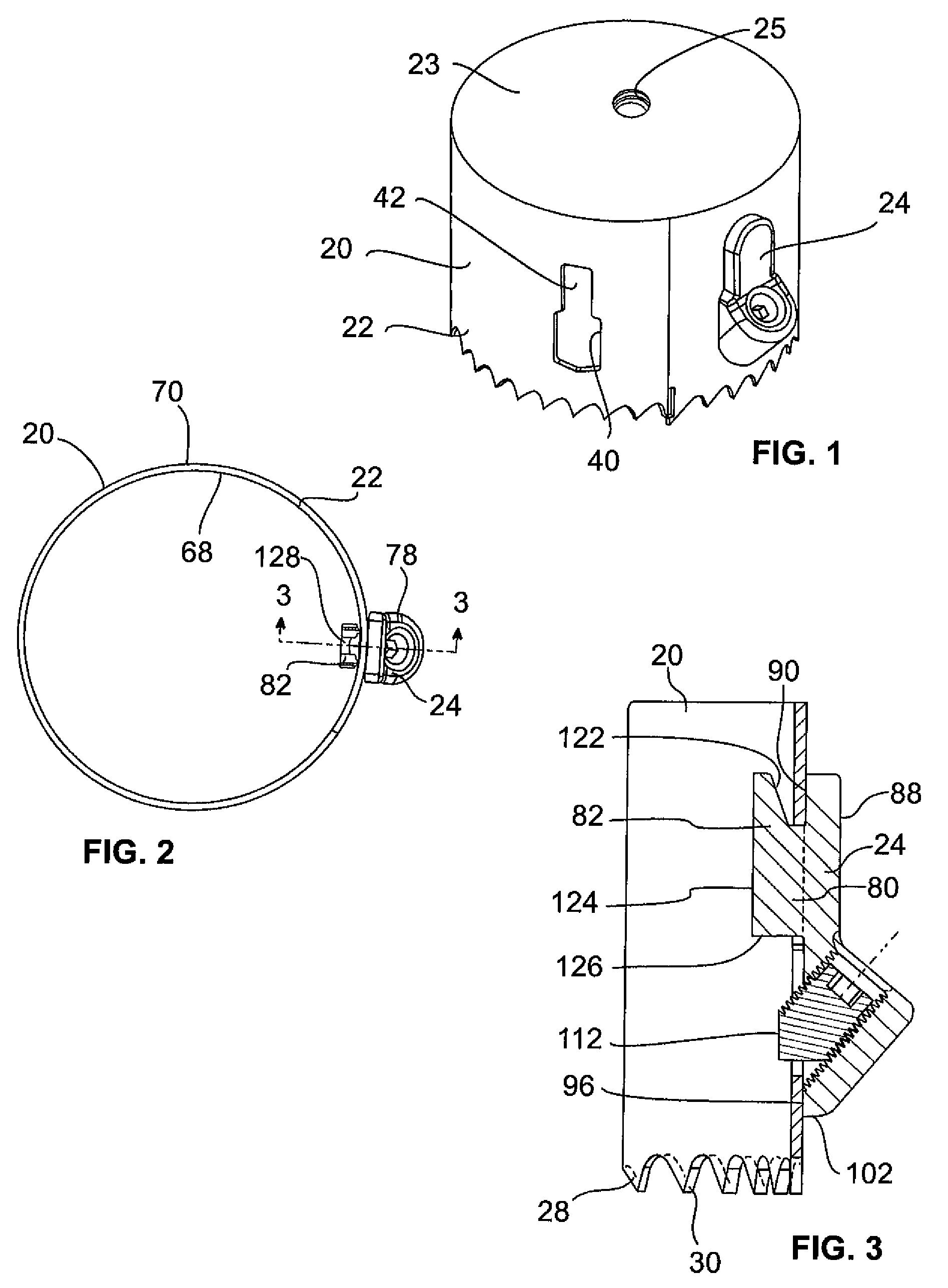

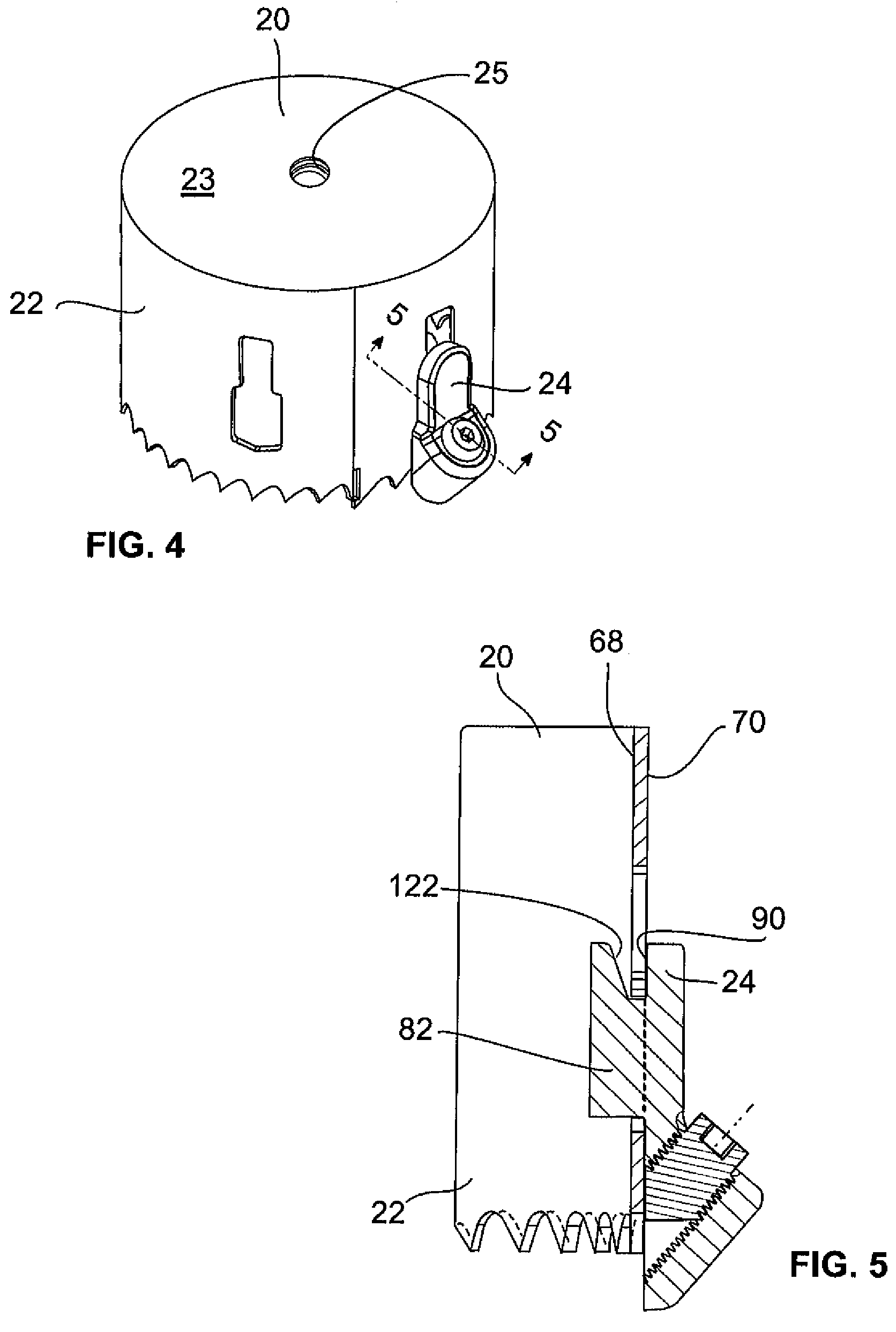

Hole saw with depth stop

InactiveUS7661913B2Prevent penetrationDeep penetrationThread cutting toolsDrilling/boring measurement devicesHole sawDepth of penetration

A hole saw includes a depth stop for limiting the depth of penetration of the hole saw into a workpiece. The blade of the hole saw includes a plurality of slots, one of which is used to receive the depth stop. The depth stop is mounted to the blade by positioning a portion of the depth stop within the slot and sliding the depth stop from an unsecured position to a secured position. Once in the secured position, a locking member is moved within the depth stop to secure the depth stop in place. In use, the blade is advanced through the workpiece until the depth stop contacts the proximal surface of the workpiece.

Owner:GREENLEE TEXTRON

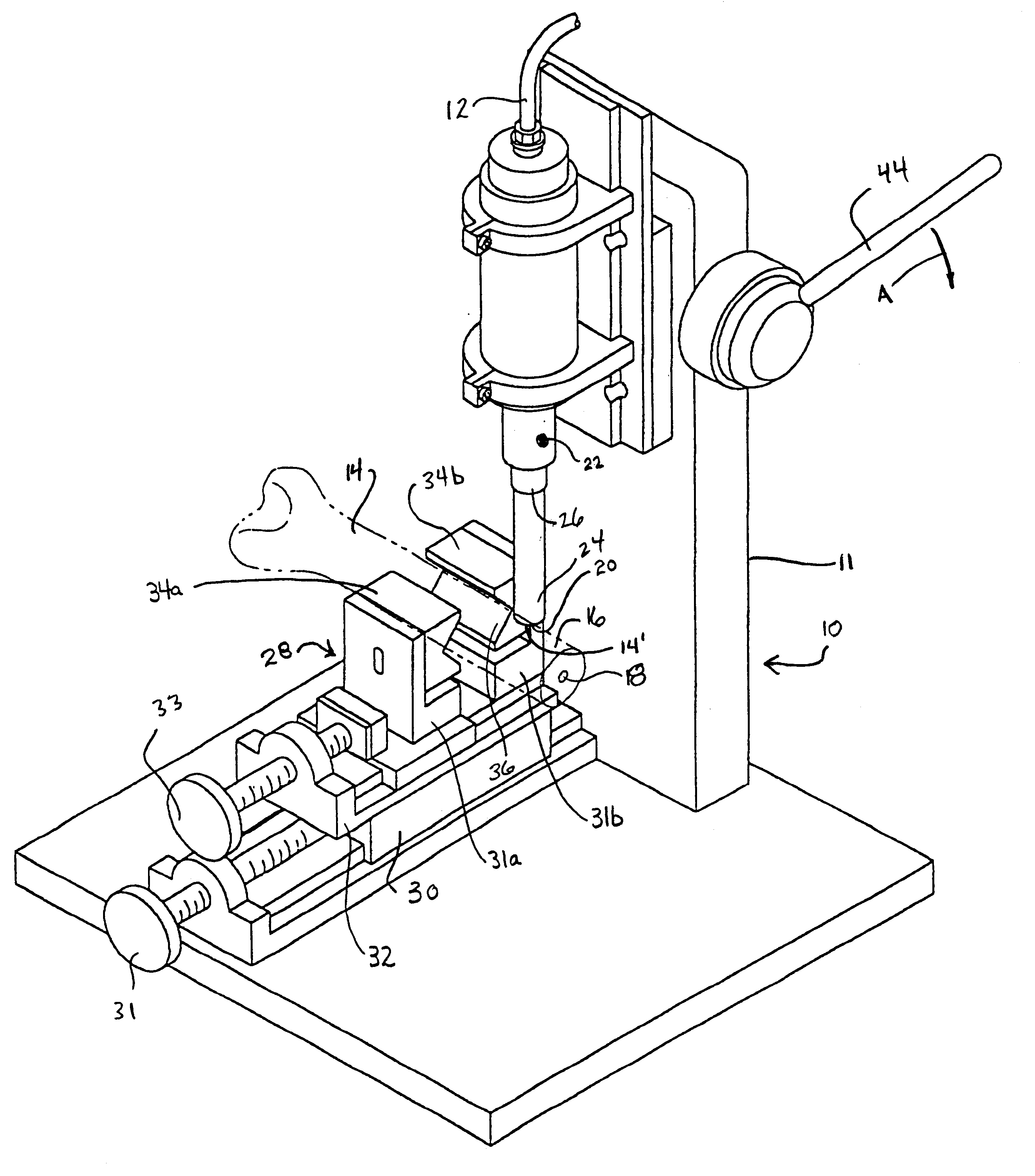

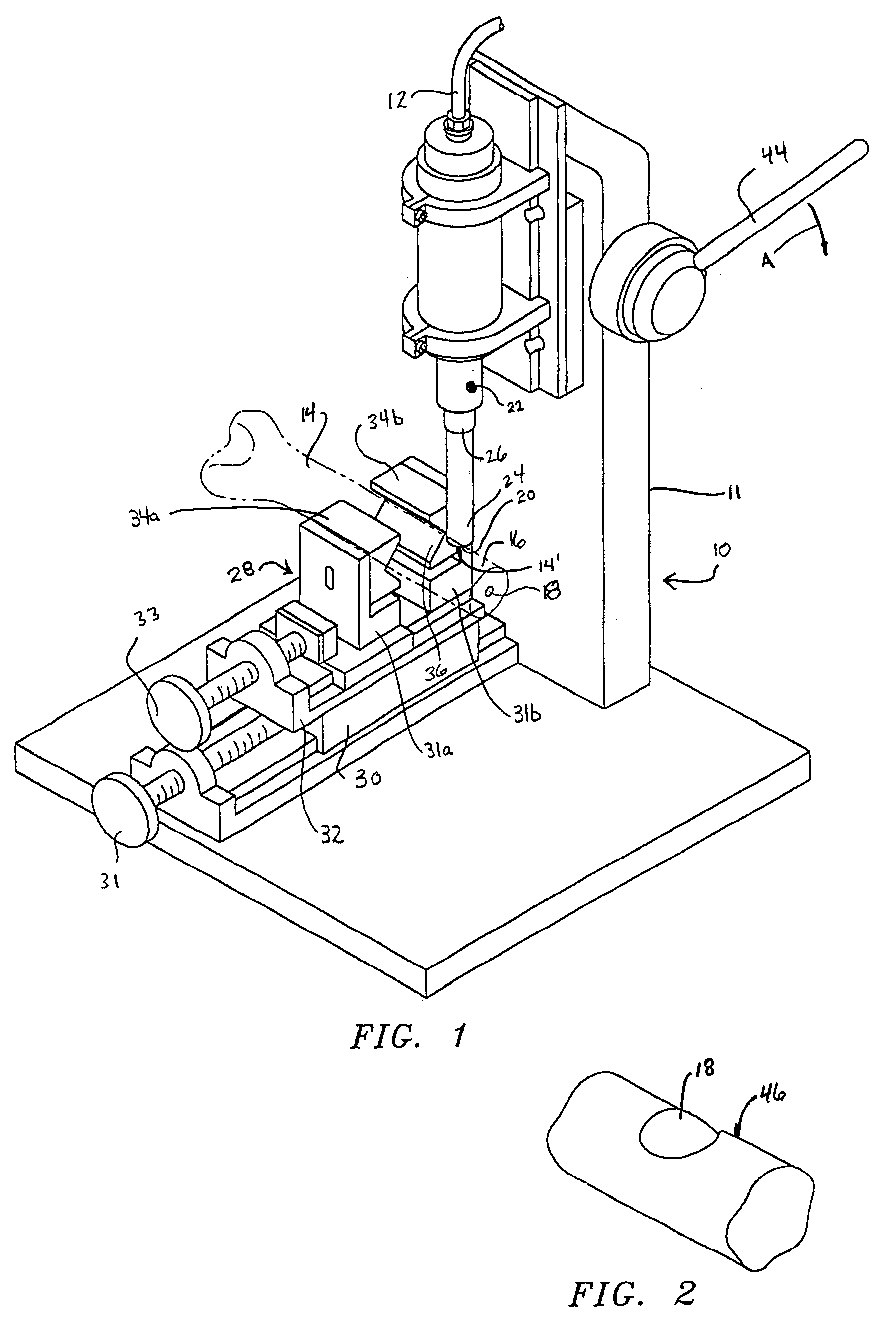

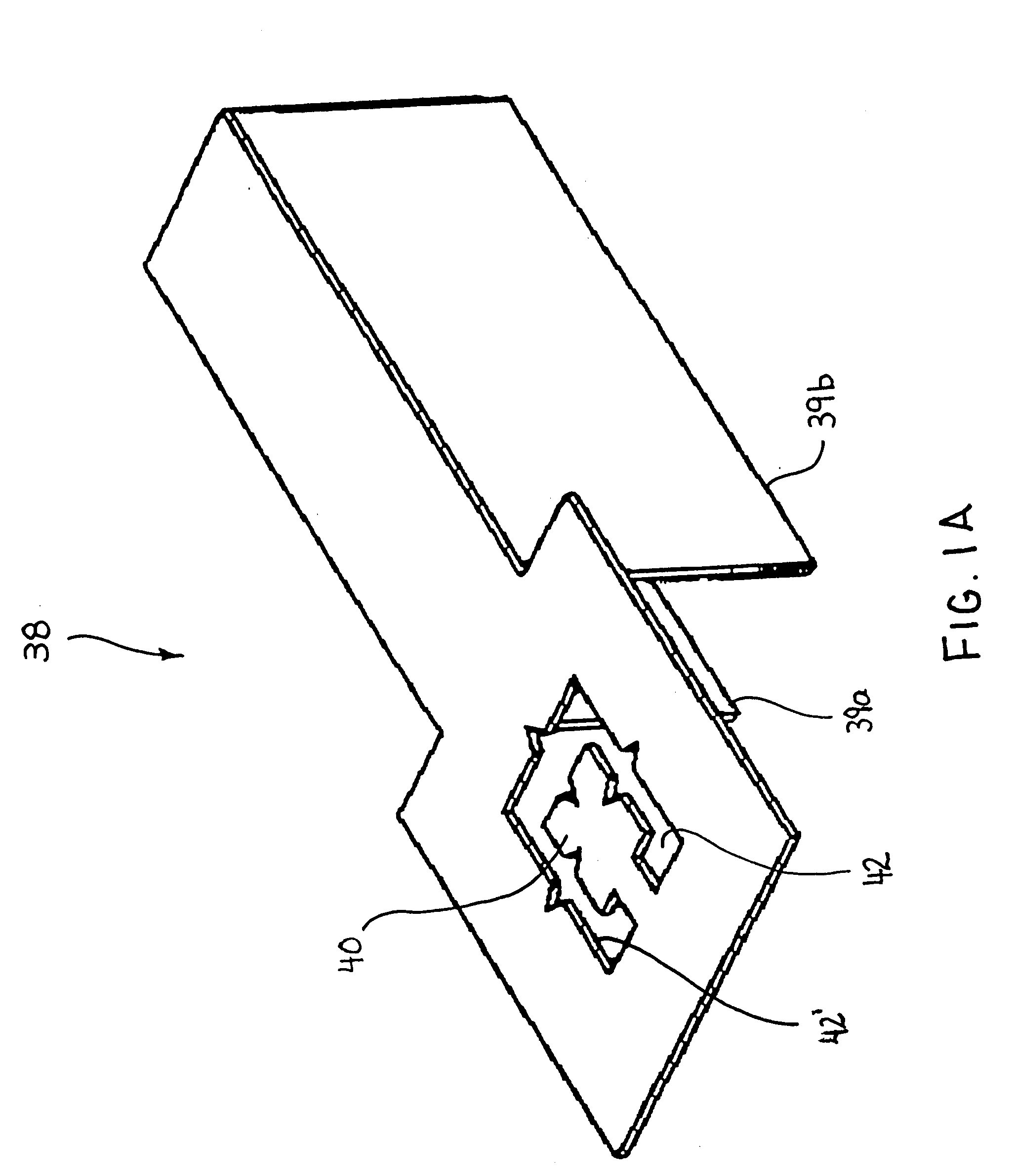

Methods for manufacturing skeletal implants

Instrumentation for manufacturing a bone dowel from human or animal cadaveric bone and instrumentation for evaluating the suitability of the bone and / or dowel for implant use after each step of the manufacturing process is provided. Such instrumentation for manufacturing a bone dowel includes a blanking or coring apparatus, a milling apparatus, a threading apparatus and a tapping apparatus. A gauge is provided to inspect and determine the suitability of the bone dowel at each step of the manufacturing process. By inspecting the dowel being manufactured after each step of the manufacturing process, time and effort which is needlessly wasted during completion of the manufacturing of dowels which are unsuitable for implant use (due to unsuitable bone and / or inaccurate machining of bone) can be avoided. Instrumentation for more accurately positioning bone and the partially manufactured dowel into the instrumentation for machining the dowel is also provided. Such instrumentation includes a gauge for positioning a piece of bone in relation to the apparatus, and mounting blocks for securing the partially manufactured dowel in relation to the milling apparatus.

Owner:OSTEOTECH INC

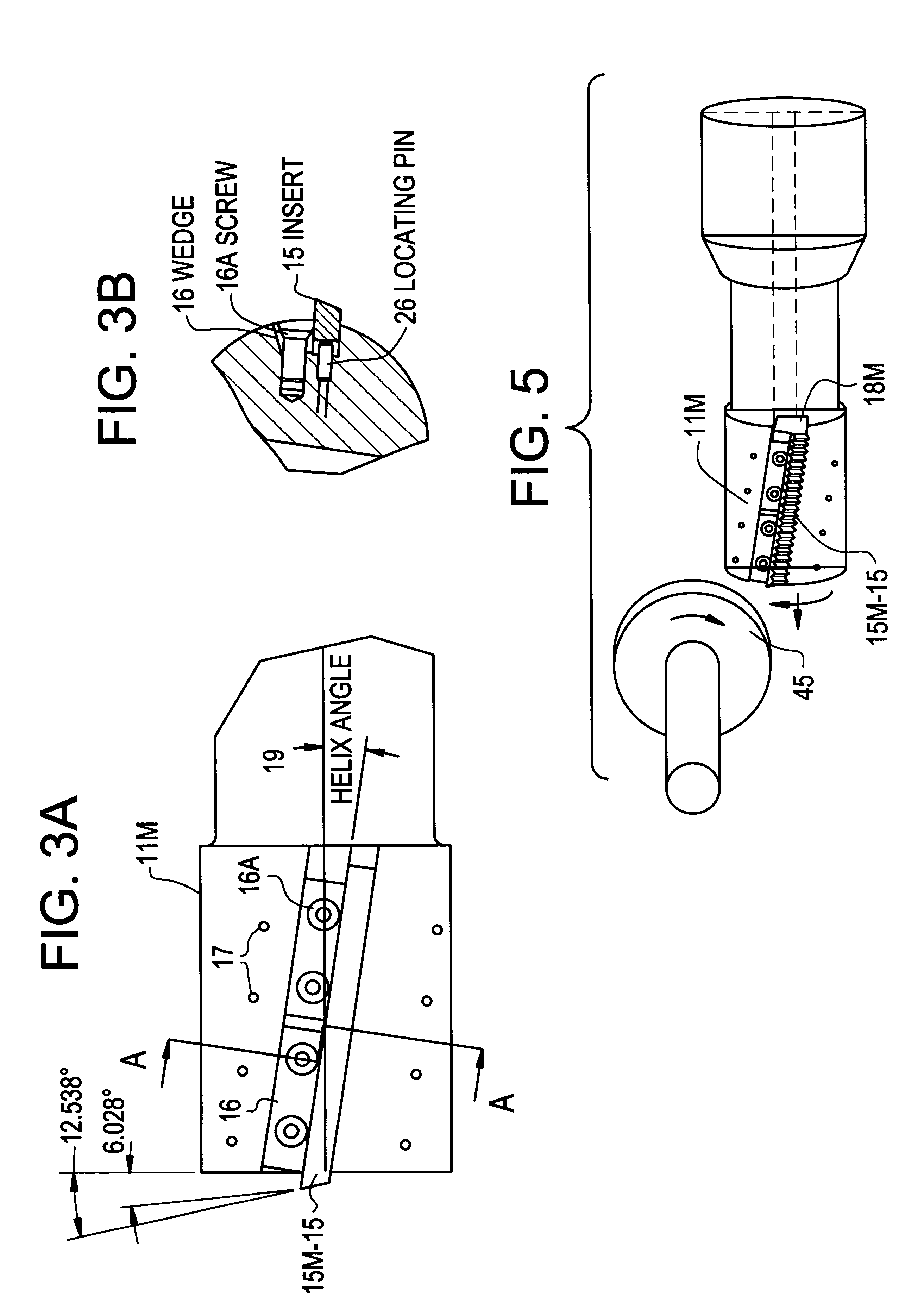

Tool with straight inserts for providing helical cutting action

A milling tool having replaceable straight elongated inserts that provide a helical cutting action. The tool has grooves formed at an angle with the longitudinal axis of the tool, the grooves have flat surfaces. Wedge means secure the respective inserts in respective grooves of the tool. The wedge means each have a plurality of apertures on the surface bearing against the insert, and coolant fluid under pressure is provided through said apertures to exit adjacent the cutting edge of said insert and against the work surface.

Owner:FRECSKA LASZLO +1

T00l for rotary cutting machining

ActiveUS20090311060A1Promote formationEasy to manufactureThread cutting toolsWood turning toolsCouplingEngineering

A tool for rotary cutting machining includes a tool body and a replaceable cutting head detachably attachable to the tool body. At its front end, the tool body is provide with two coupling legs projecting in an axial direction. The respective coupling leg is provided with a stop surface for transferring torque from the tool body to the cutting head, which stop surface is designed for abutment against a corresponding stop surface of the cutting head. The respective coupling leg is provided with a shoulder protruding from the stop surface of the coupling leg. The cutting head is provided with two shoulders facing the front end of the cutting head and arranged on opposite sides of the center axis of the cutting head, which shoulders border on a respective one of said stop surfaces of the cutting head and are arranged to extend in under a respective one of said shoulders of the coupling legs of the tool body when the cutting head is attached to the tool body, so as to thereby present the cutting head from being displaced in axial direction away from the tool body. The invention also relates to a tool body and a cutting head included in such a tool.

Owner:SECO TOOLS AB

Tool, tool body and cutting head

ActiveUS20100021253A1High standardComplicate to achieveThread cutting toolsTool workpiece connectionCouplingMachining

A tool for rotary cutting machining includes a tool body and a replaceable cutting head detachably attachable to the tool body. The cutting head has a coupling portion which is receivable in a space between two axially projecting coupling legs of the tool body. Cylindrical internal gripping surfaces are arranged in said space and designed for engagement with corresponding cylindrical external gripping surfaces of the cutting head. The gripping surfaces of the cutting head and the gripping surfaces of the tool body are dimensioned so as to prevent, by engagement with each other, the cutting head from being displaced in axial direction away from the tool body when the cutting head is attached to the tool body. A tool body and a cutting head included in such a tool are also disclosed.

Owner:SECO TOOLS AB

Multi-Piece Drill Head and Drill Including the Same

One non-limiting aspect of the present disclosure is directed to a multi-piece spade drill head for a spade drill, wherein the spade drill includes an elongate body portion and a cutting portion removably secured to an end of the body portion. The multi-piece spade drill head includes at least two insert pieces, each piece including a cutting edge. The at least two insert pieces are configured to be removably secured to the body portion of the spade drill adjacent one another and with the cutting edges of the insert pieces aligned to together form a cutting edge on an end of the spade drill.

Owner:KENNAMETAL INC

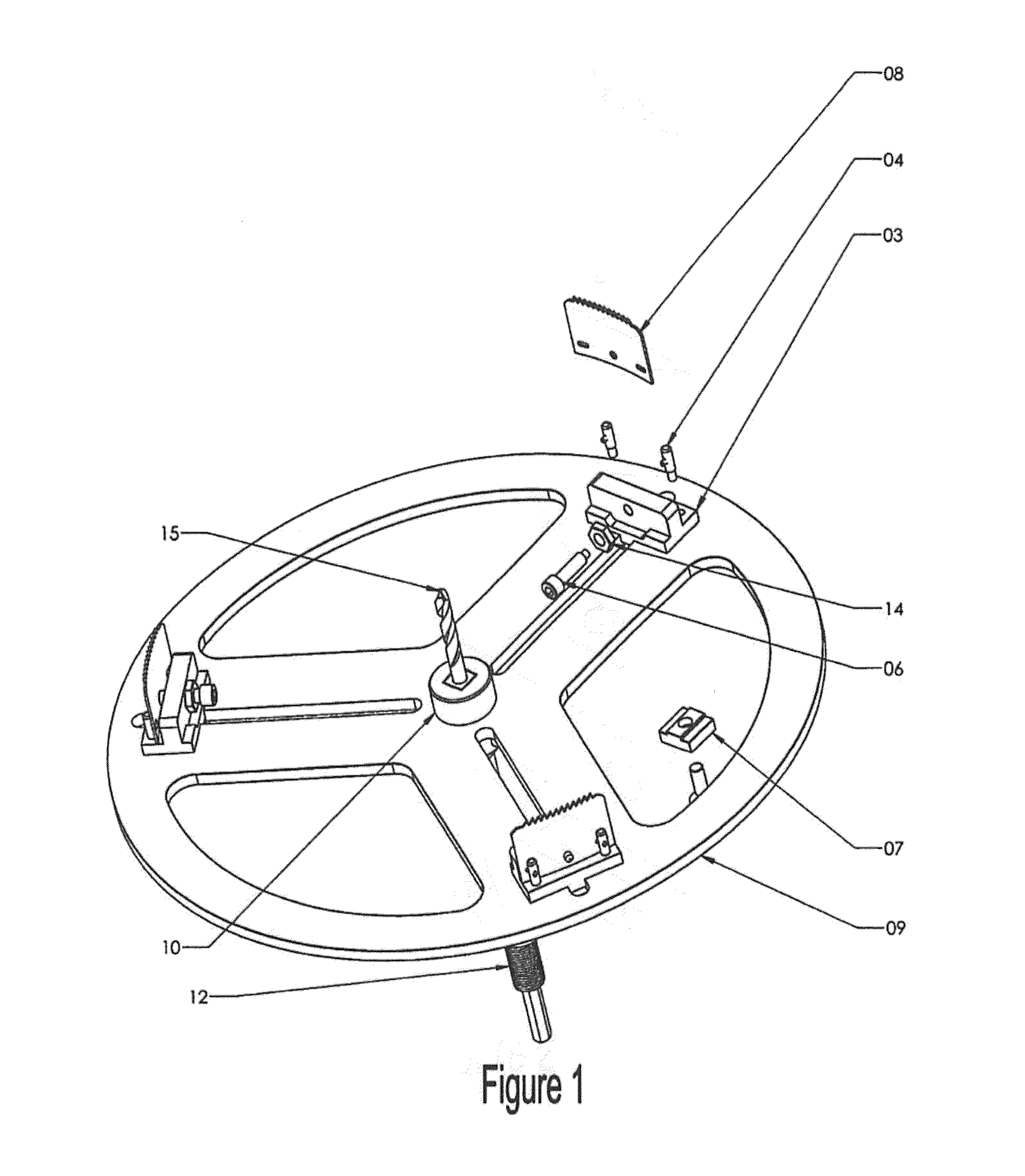

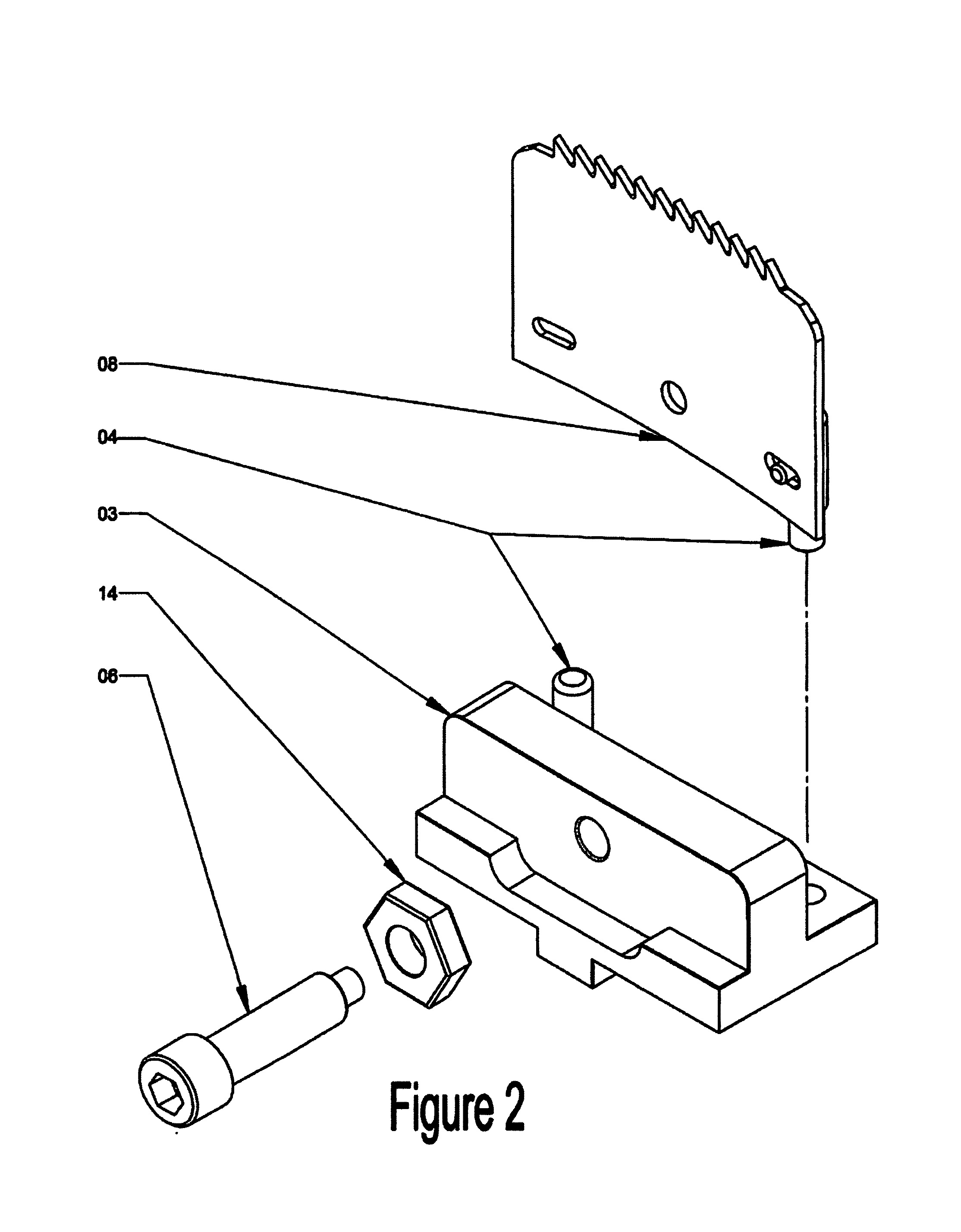

Adjustable hole cutters

ActiveUS8840344B2Quick removalFast replacementThread cutting toolsDrilling/boring measurement devicesEngineeringKnife blades

An adjustable hole cutter for cutting a hole with a predetermined diameter in sheet or panel material includes a blade holder that moves along a track or slot to alter a diameter of the cut hole; a blade arc adjuster coupled to the blade holder; and one or more replaceable blade segments coupled to the blade holder.

Owner:STENMAN BRUCE WINTER

Drilling tool

A drilling tool includes a tool main body having a cutting edge at its forward end, a groove provided in the outer peripheral surface provided at the forward end of the tool main body, a cartridge accommodated in the groove and capable of elastic deformation in a radial direction of the tool main body, and a burr removing tip in the form of a substantially triangular flat plate detachably mounted to the cartridge and capable of protruding from and retracting into the outer peripheral surface of the tool main body. The cartridge is equipped with two holding walls which are in face contact with the two side surfaces of the three side surfaces corresponding to the three sides of the triangle formed by the burr removing tip. The two side surfaces of the burr removing tip are in face contact with the two holding walls, and the remaining one side surface is mounted to the cartridge in an open state.

Owner:MITSUBISHI MATERIALS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com