Patents

Literature

3071results about How to "Quick removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

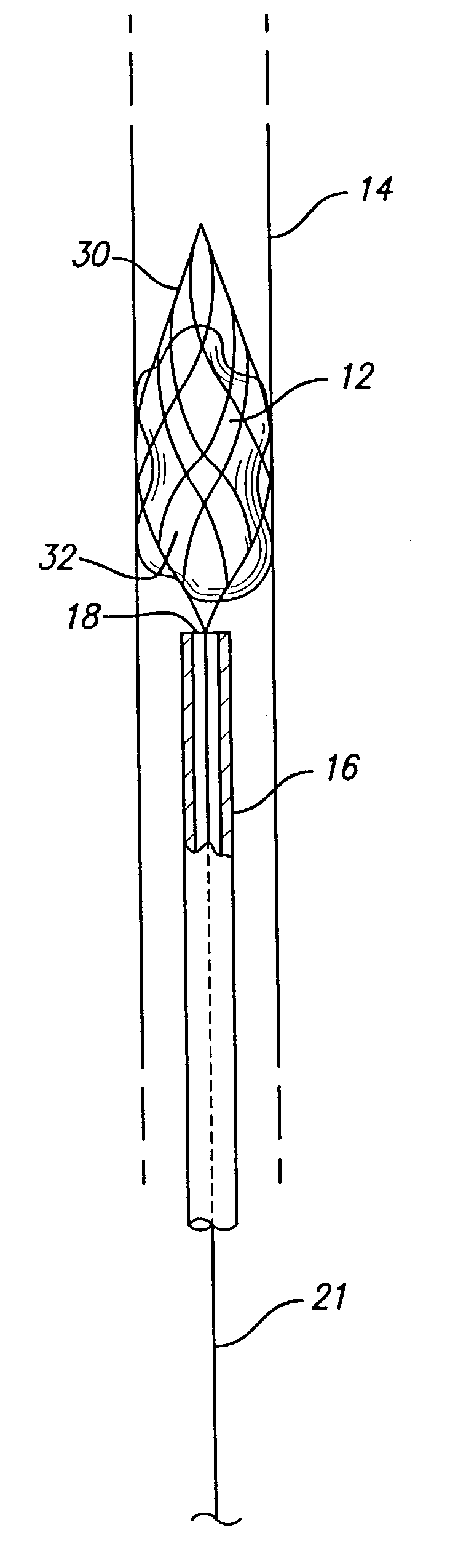

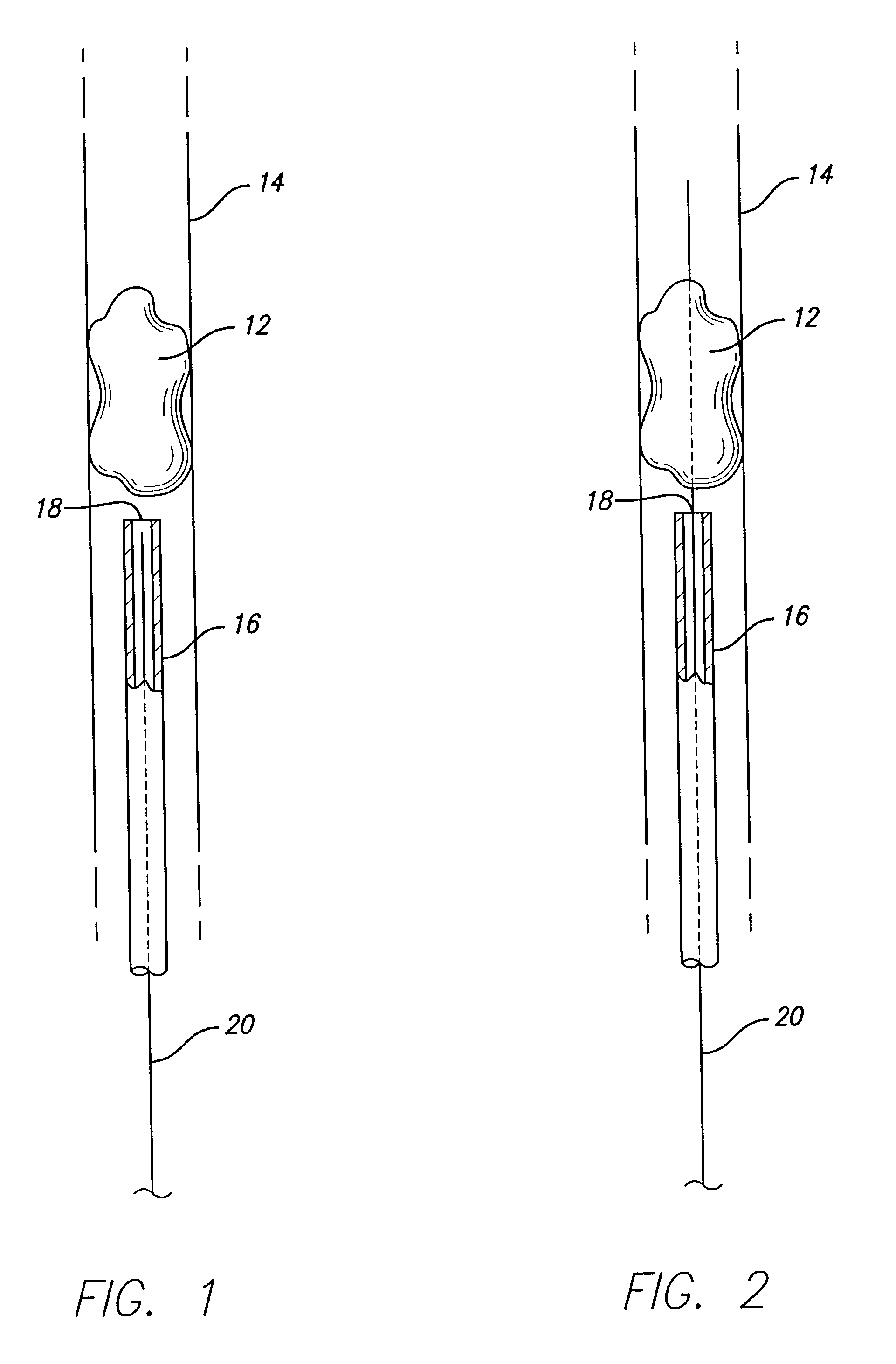

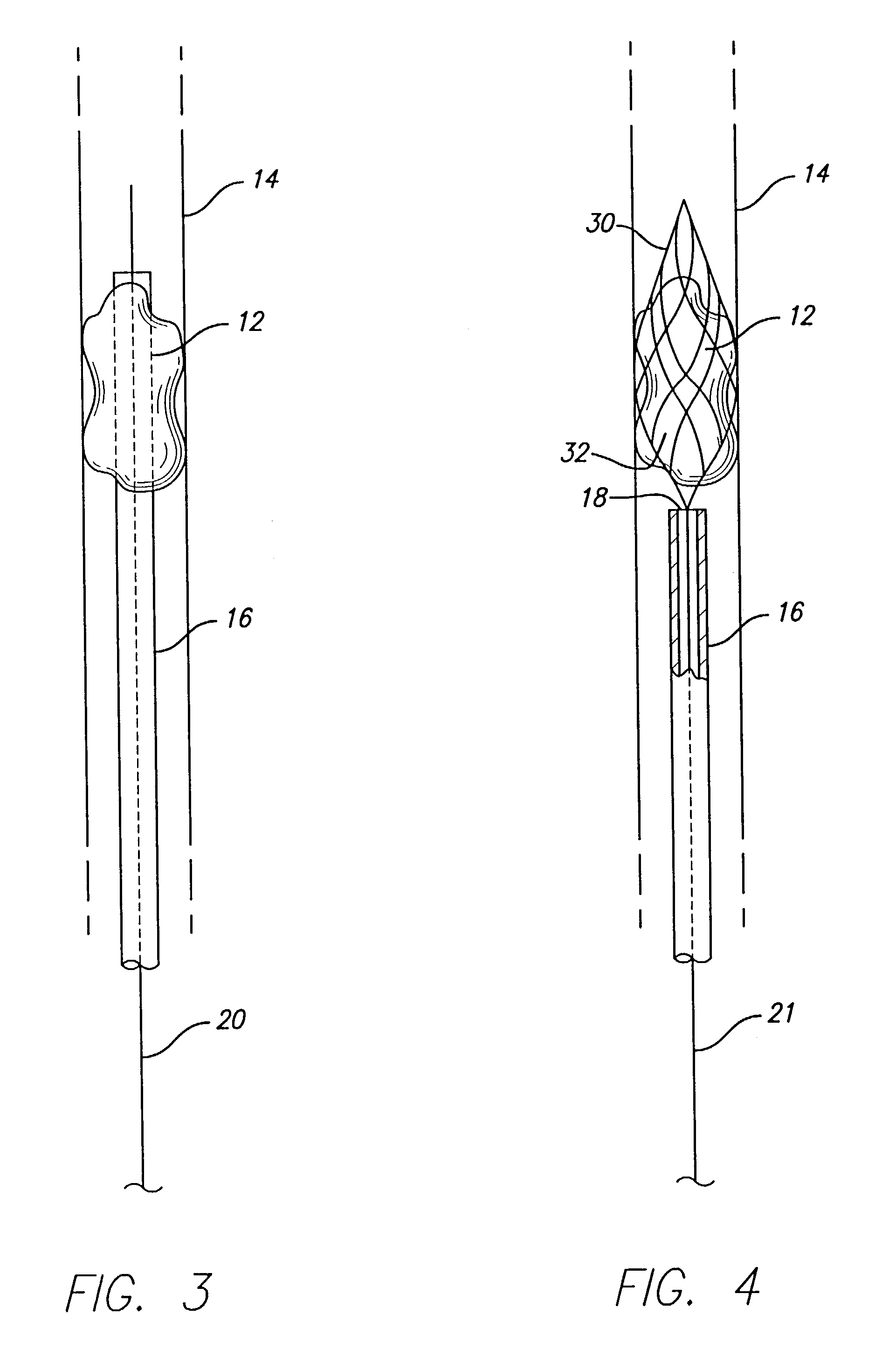

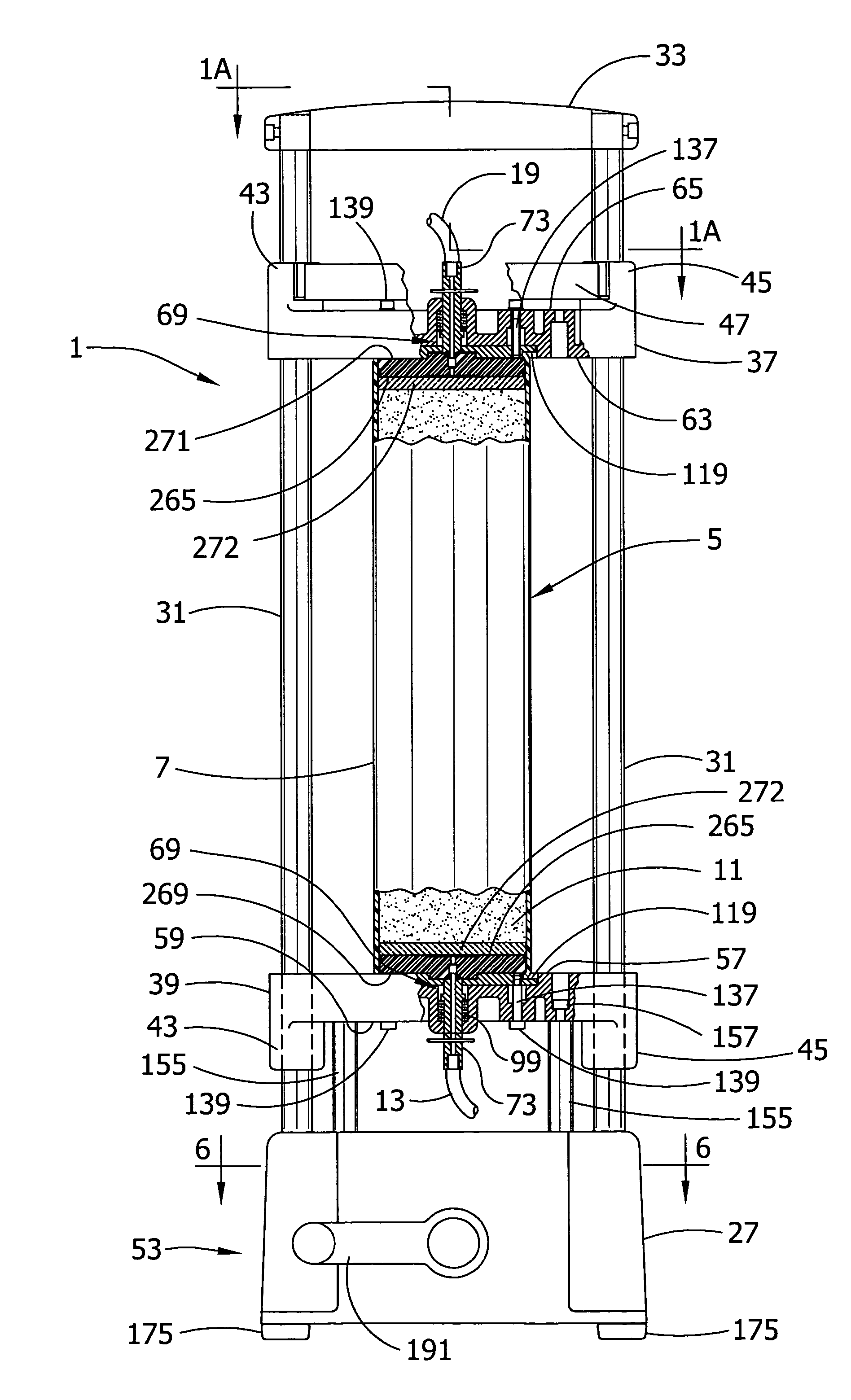

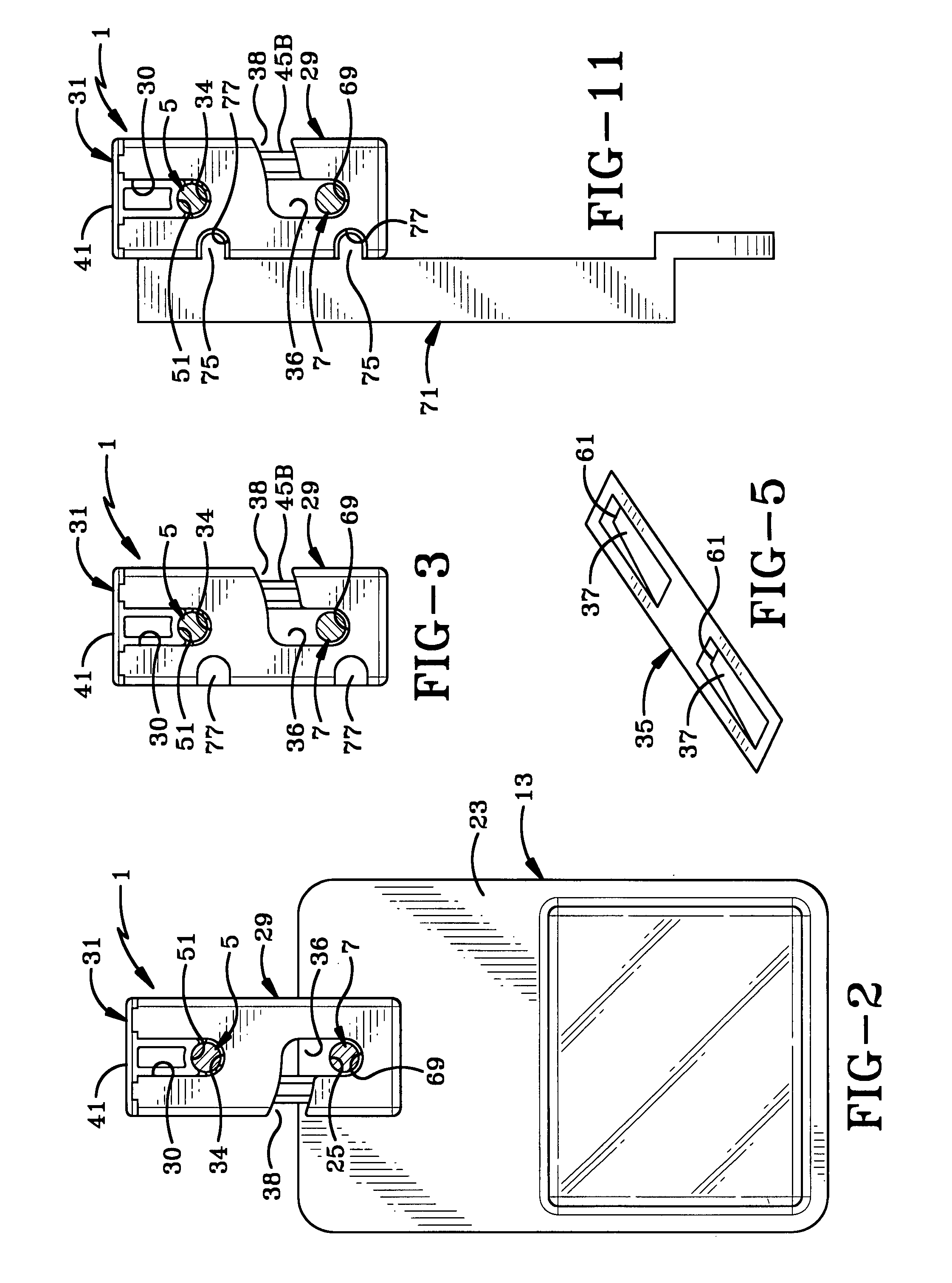

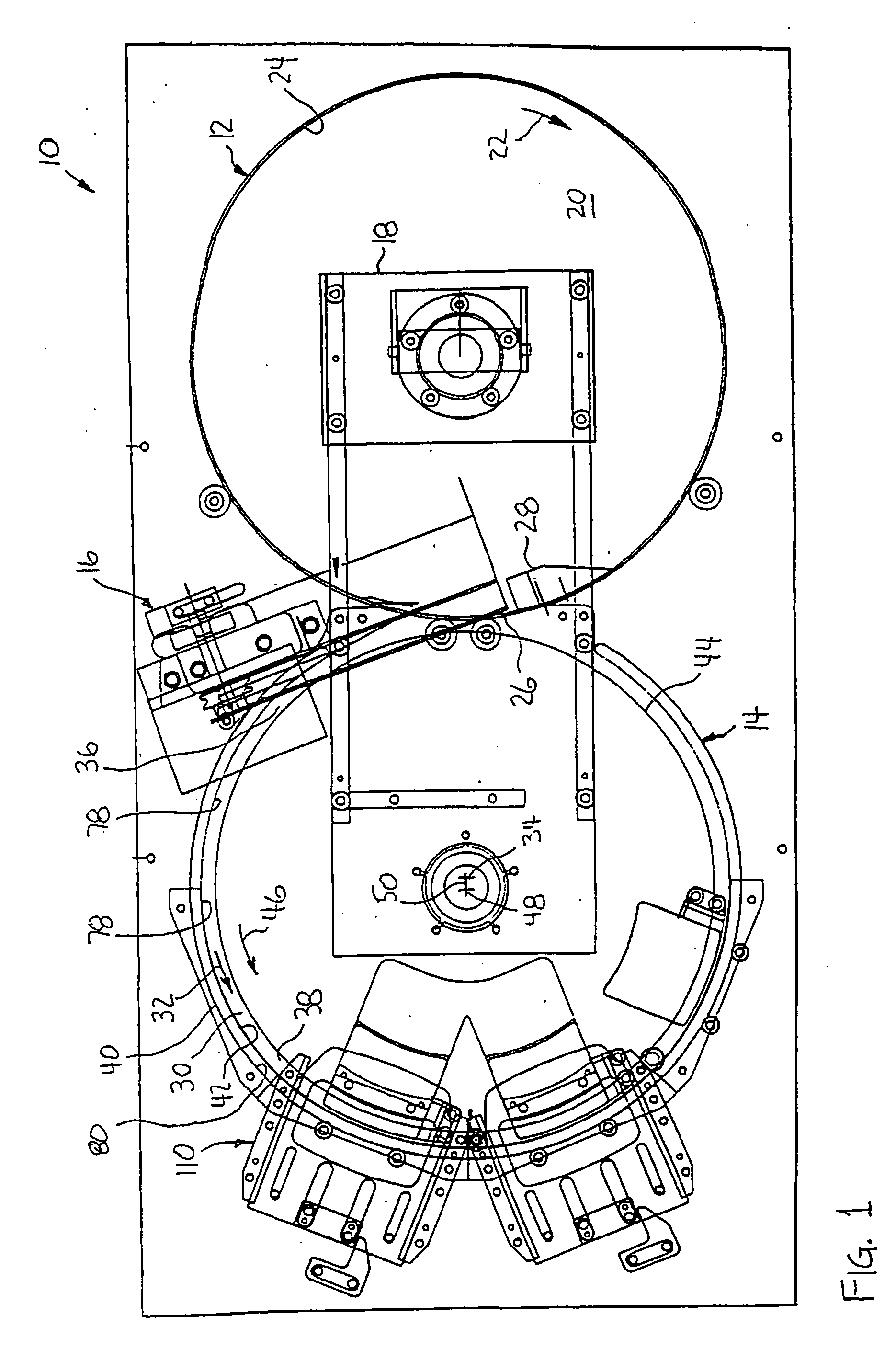

Device for removal of thrombus through physiological adhesion

InactiveUS7004954B1Raise the level of performanceRestoring native blood flowBalloon catheterSurgeryMedicineThrombus

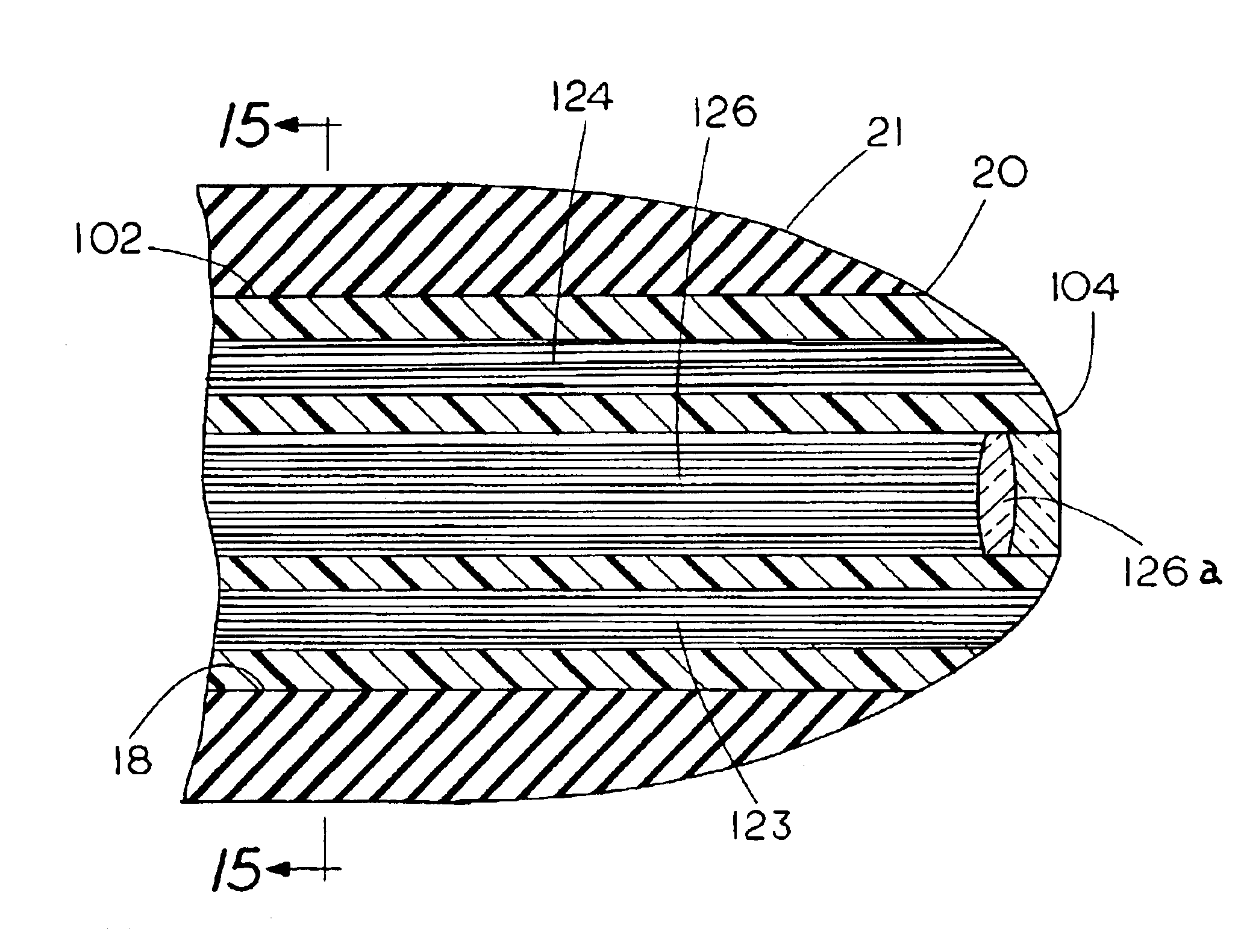

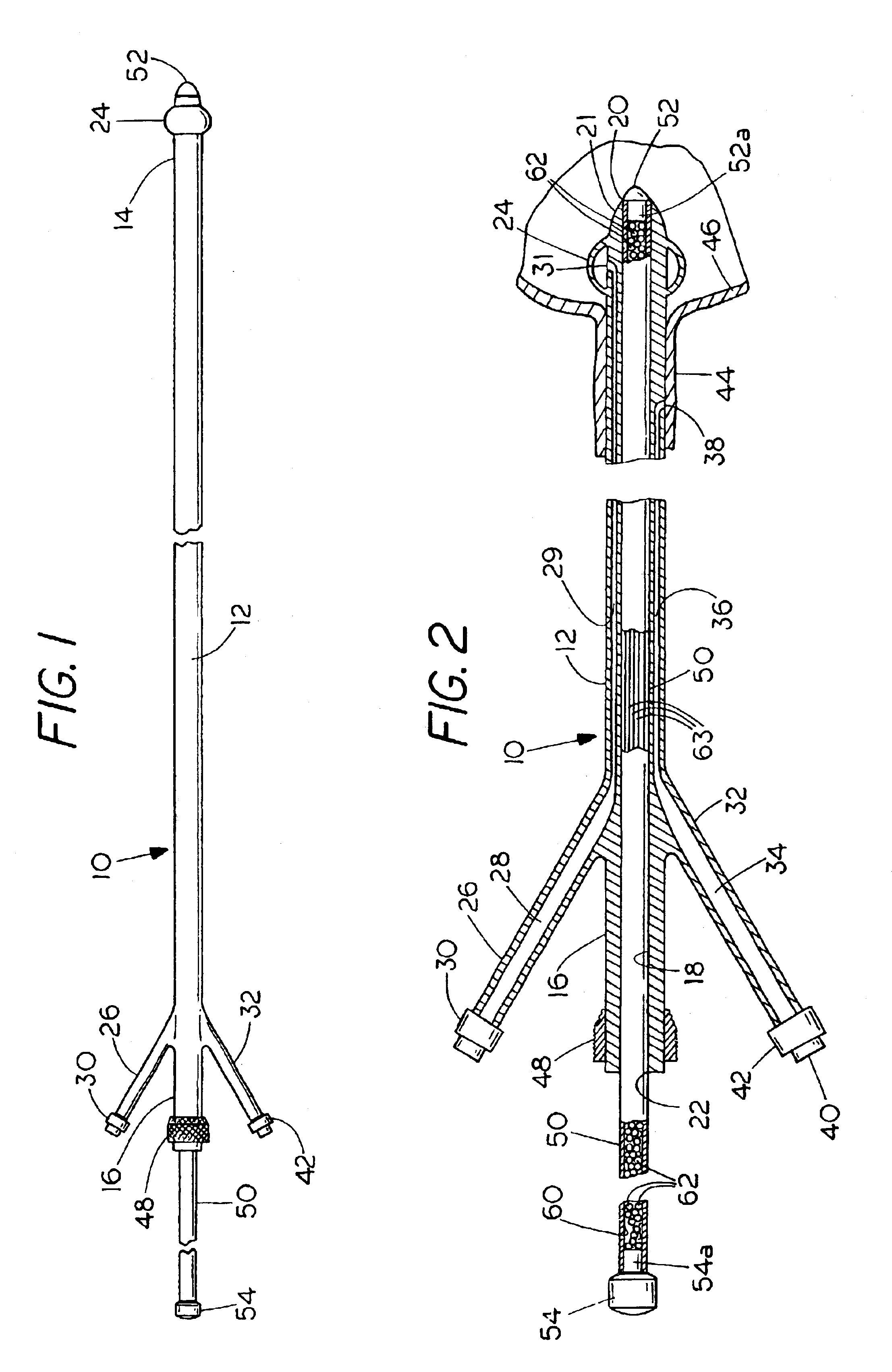

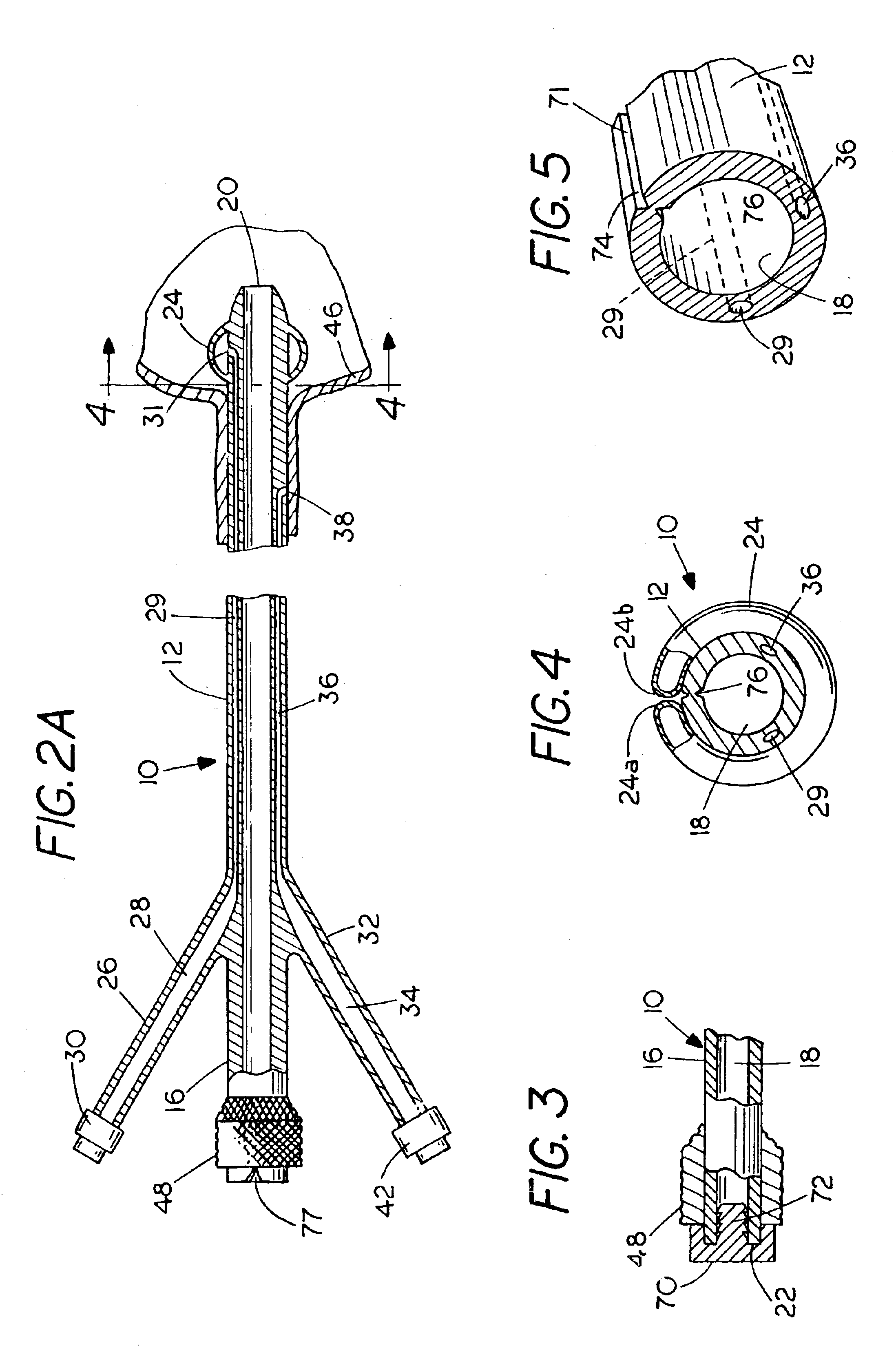

A device that is useful for removing obstructions from vessels. Various embodiments and methods of use are contemplated for the effective removal of obstructions. The disclosed devices utilize a thrombogenic material to promote the formation of fibrin bonds, thus enhancing adhesion. It is further contemplated that the disclosed devices may be used in all vasculature including the cerebral vasculature and the neurovasculature.

Owner:ENDOVASCULAR TECH

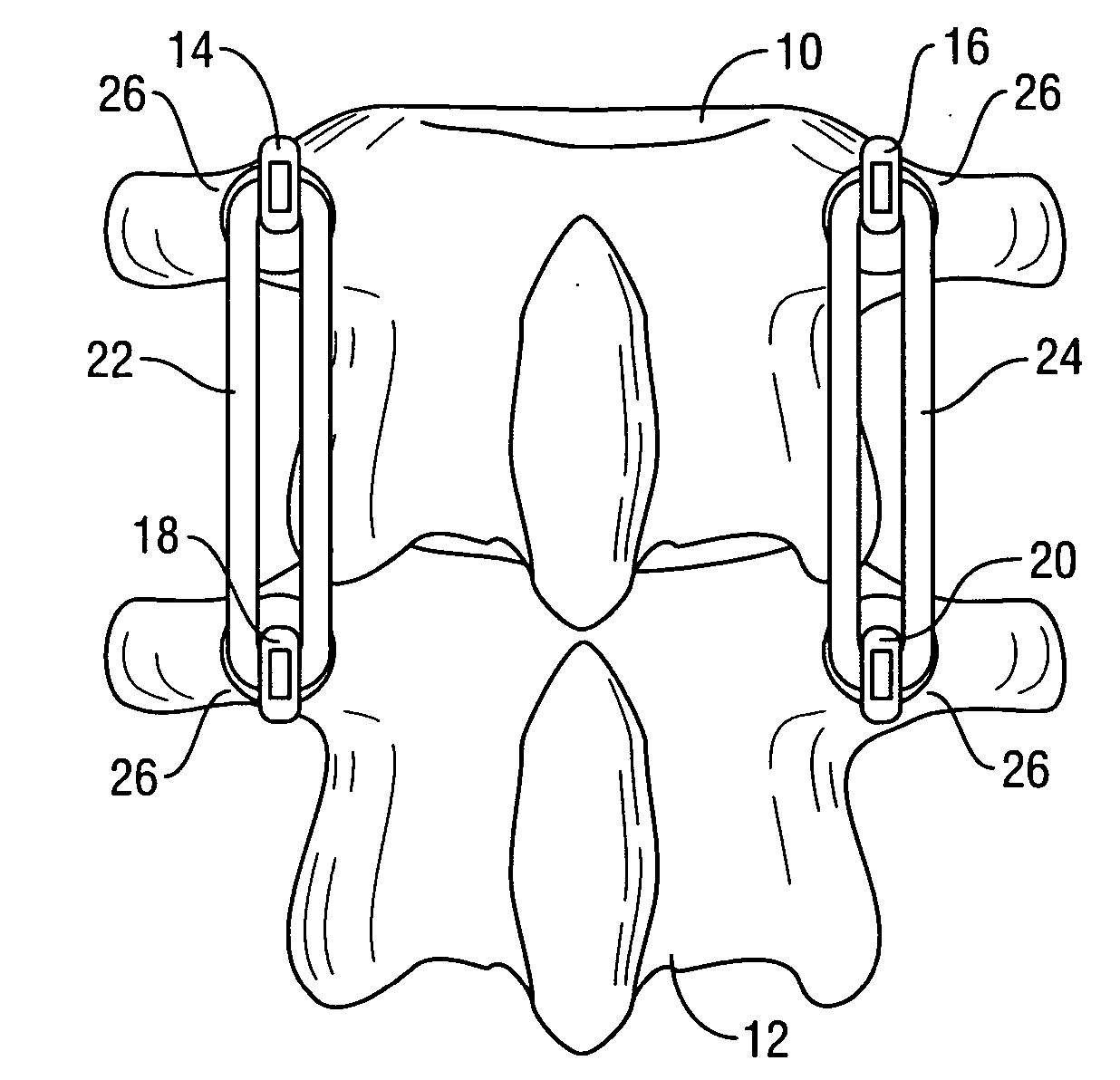

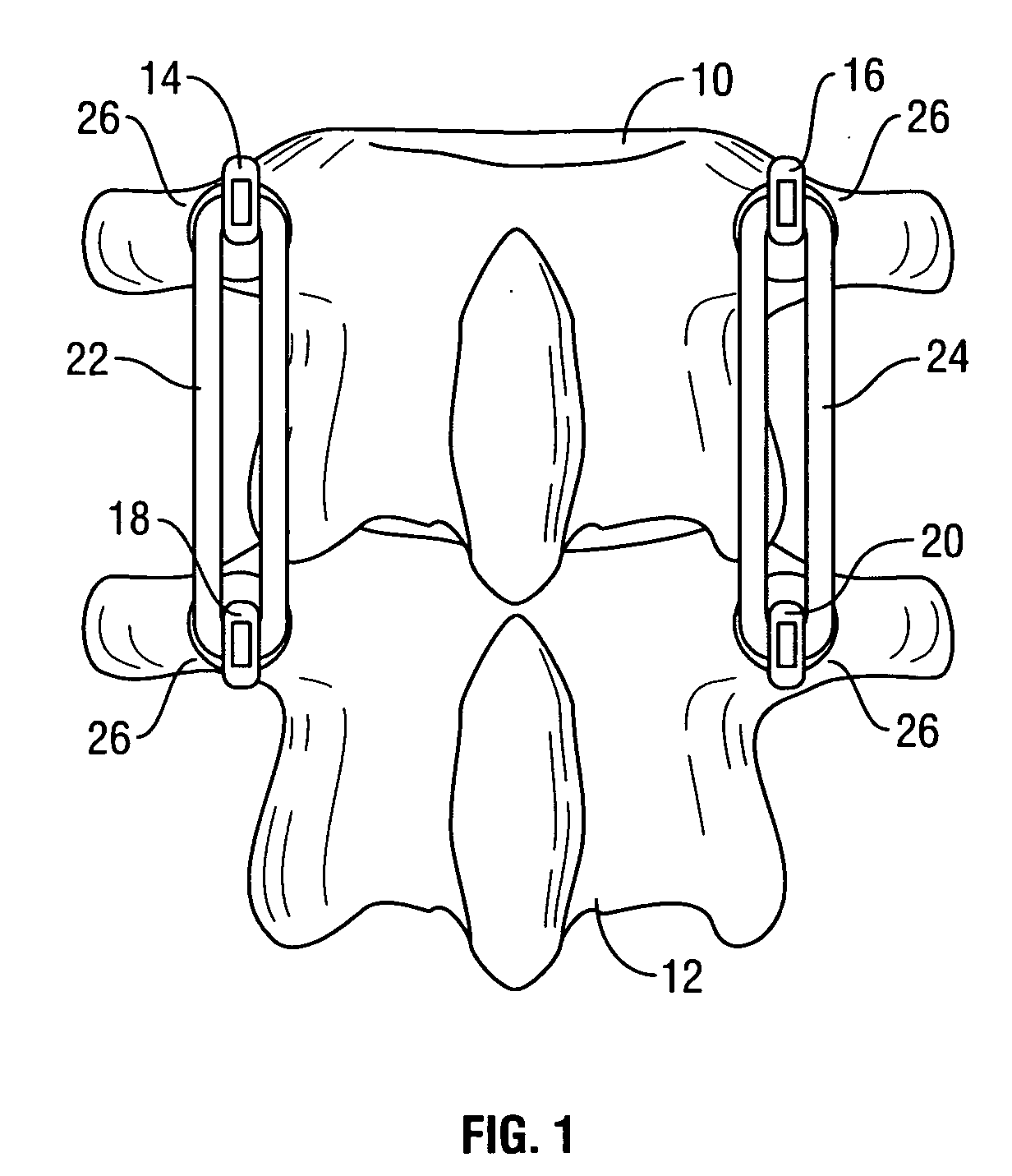

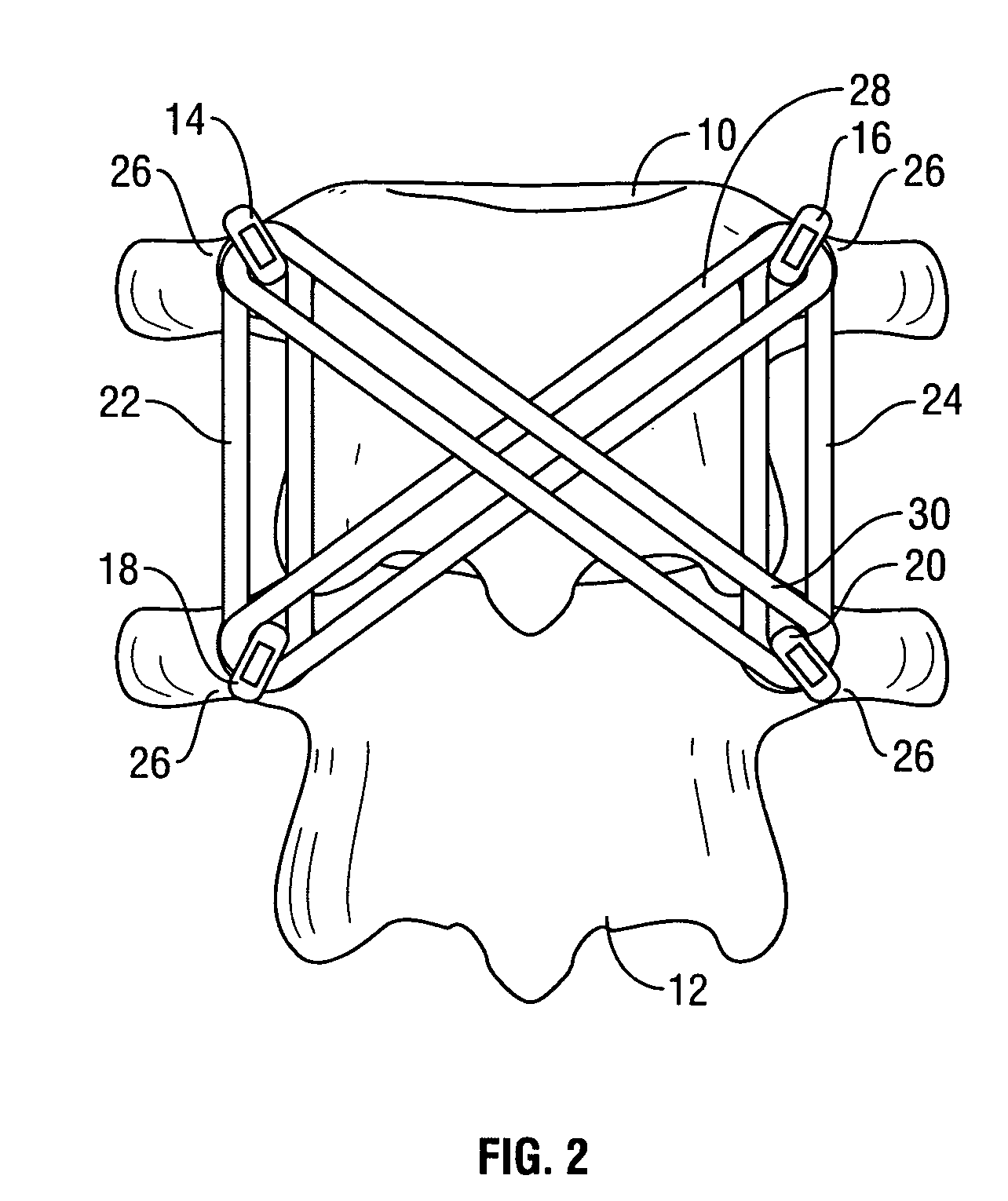

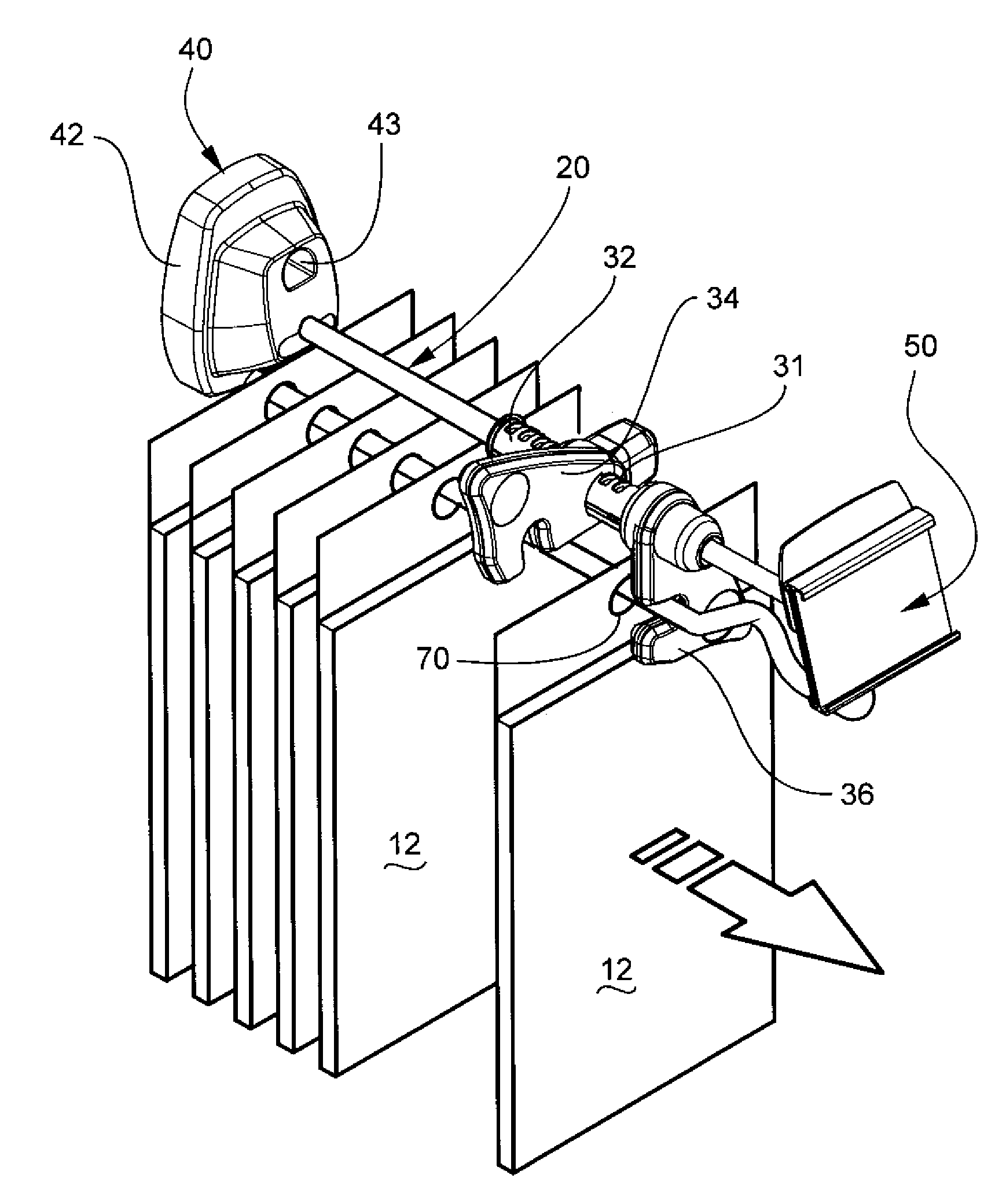

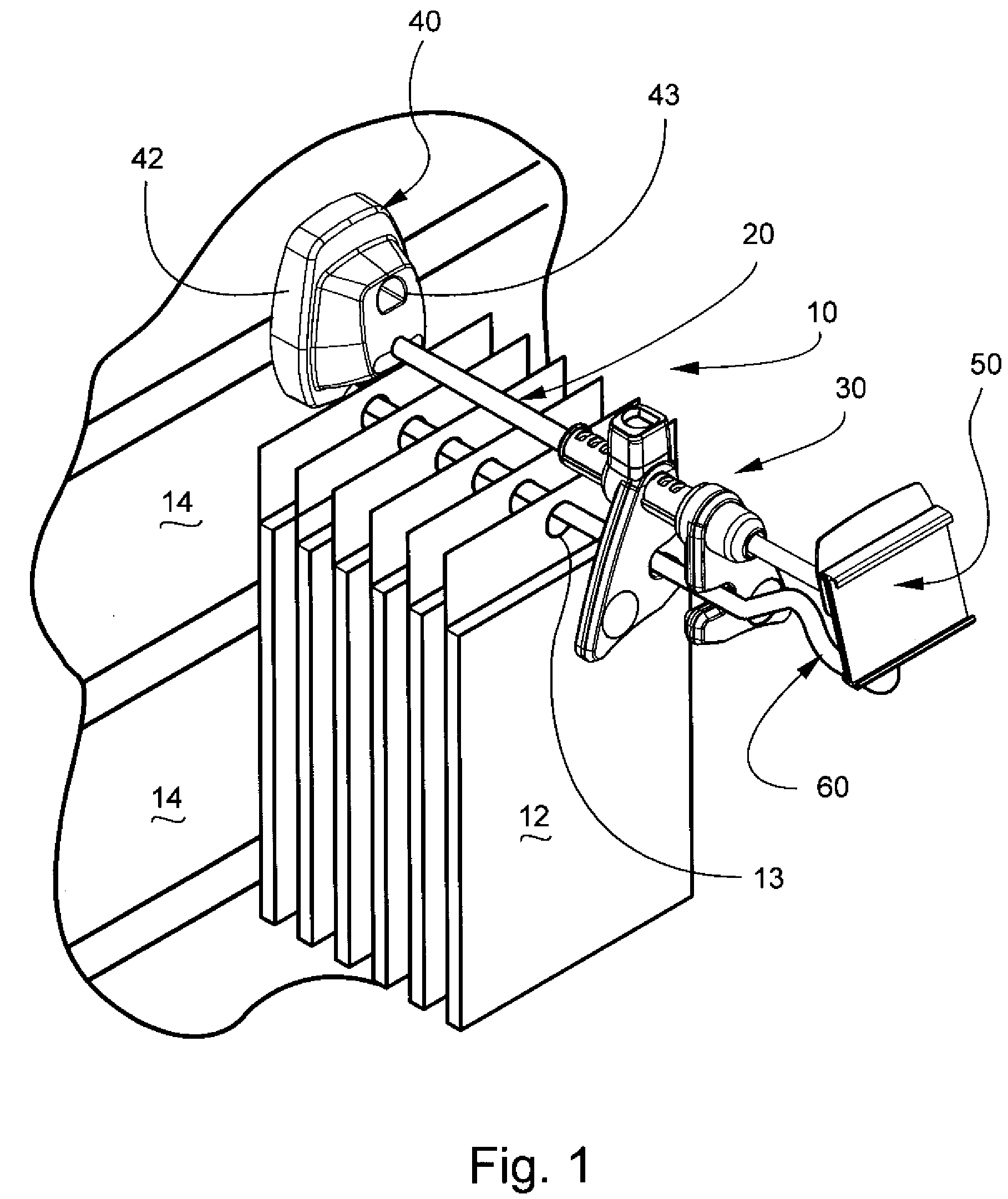

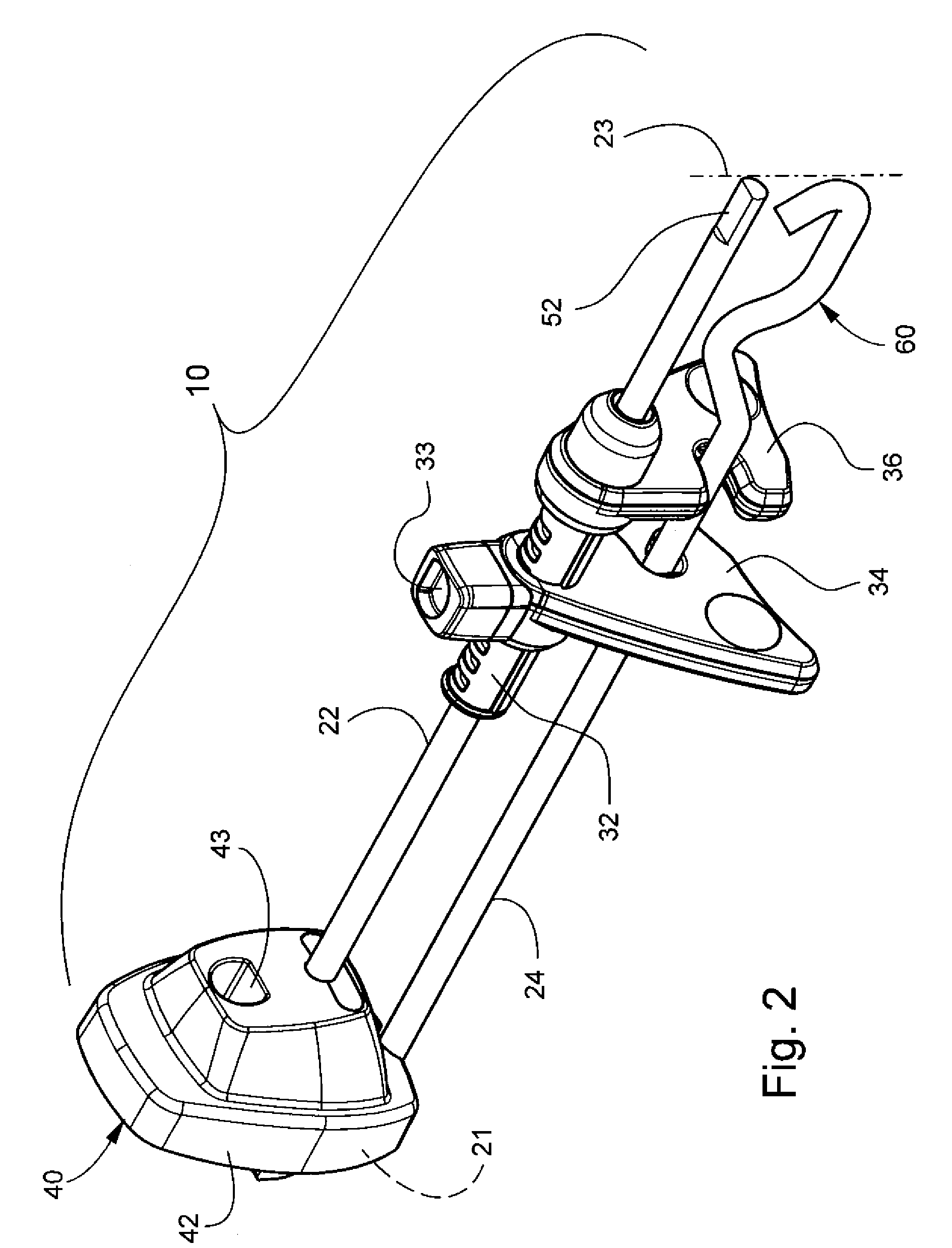

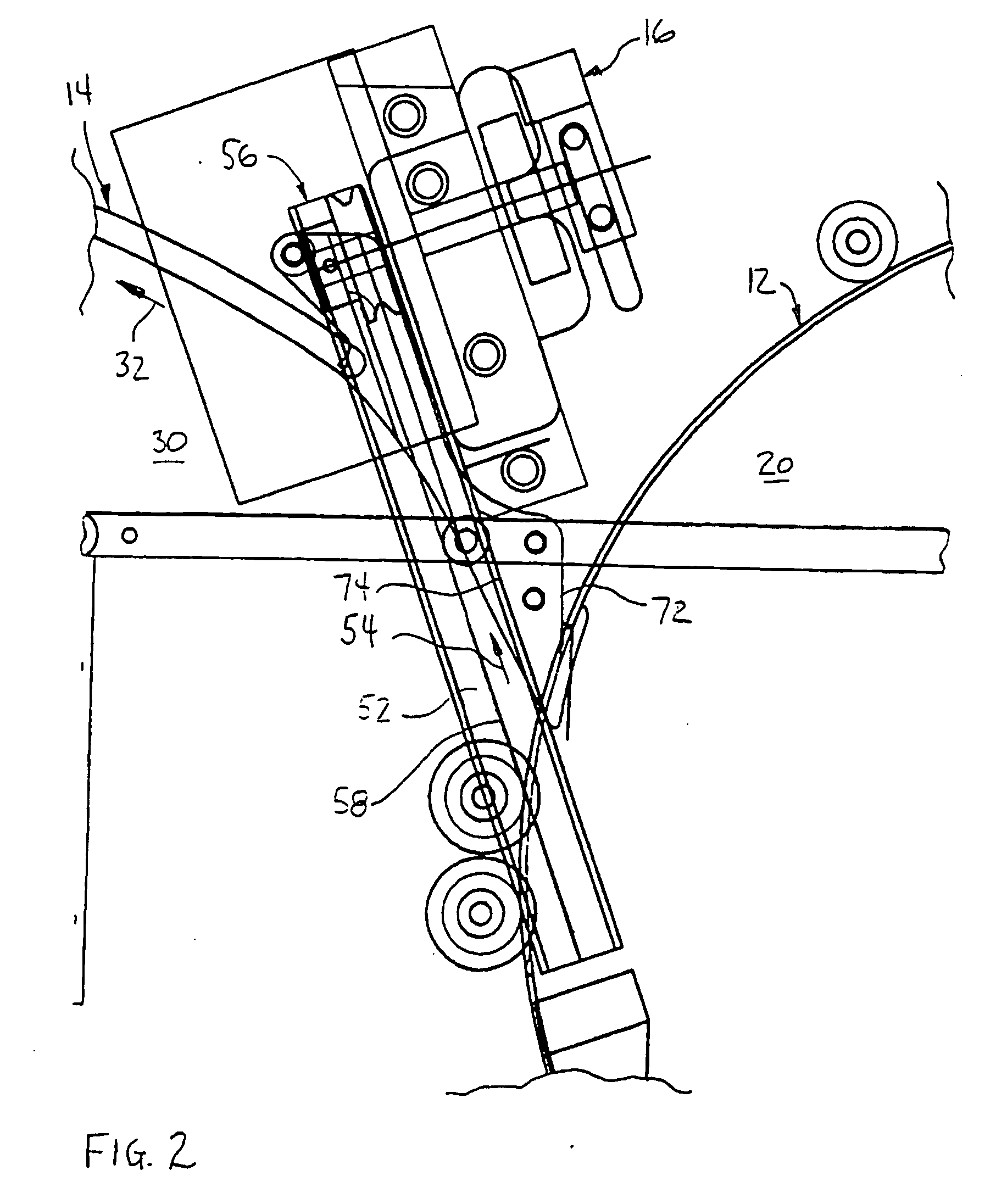

Spinal stabilization system to flexibly connect vertebrae

InactiveUS20050267470A1Preventing excessive motionPrecise alignmentInternal osteosythesisJoint implantsSpinal columnDeformity

A surgically implanted spinal stabilization system uses posterior anchor hooks attached to vertebrae to retain elastic bands to retain flexibility and mobility while maintaining alignment and preventing excessive motion and deformity. The elastic bands may parallel the longitudinal axis of the spine, or, for enhanced promotion of alignment, they may also arranged in a diagonally crossing configuration. Multi-level fixation can be achieved using the spinal stabilization system with longer elastic bands. A method of applying the spinal stabilization system using an elastic band application tool facilitates simple, rapid application of the system to a patient.

Owner:MCBRIDE DUNCAN Q

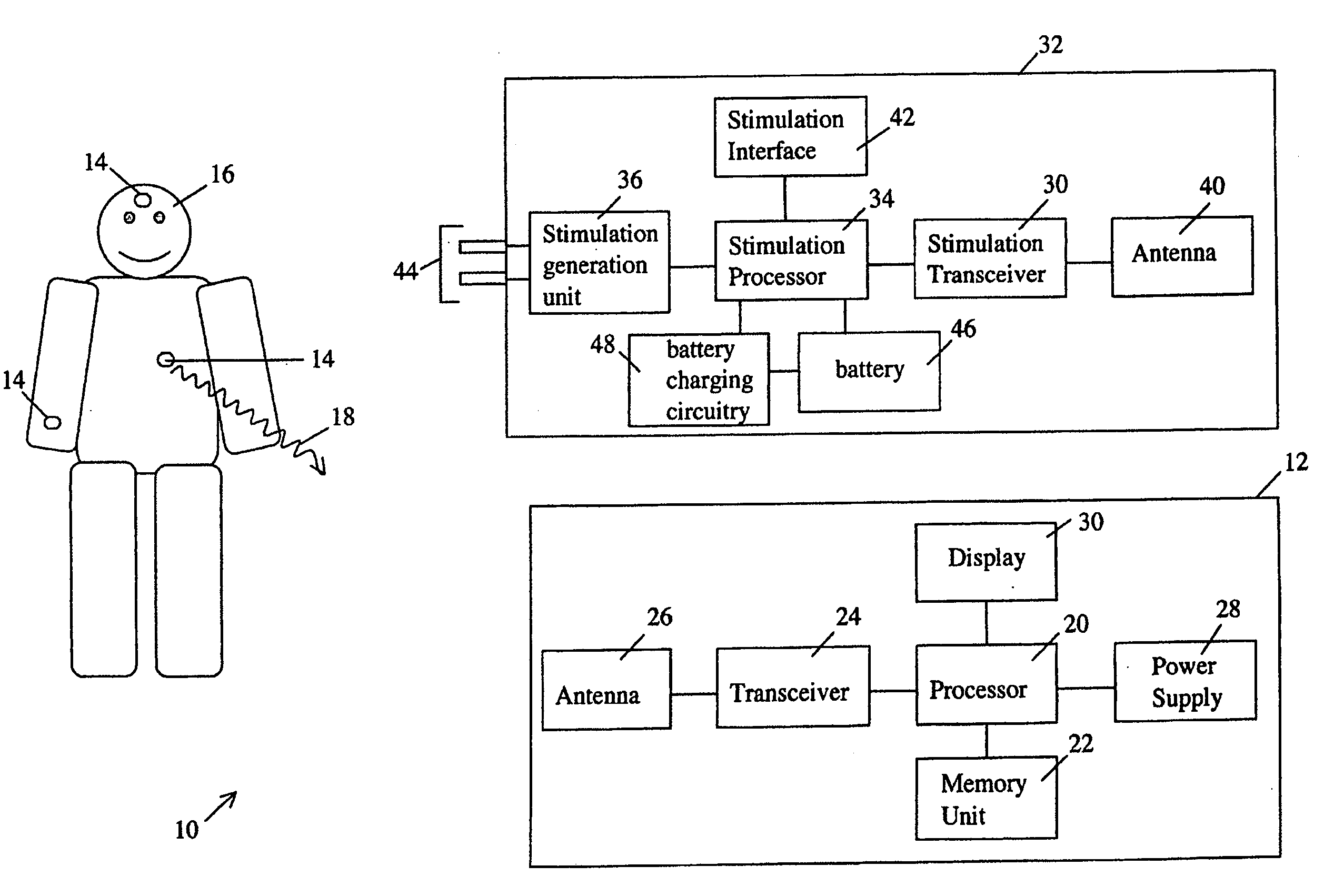

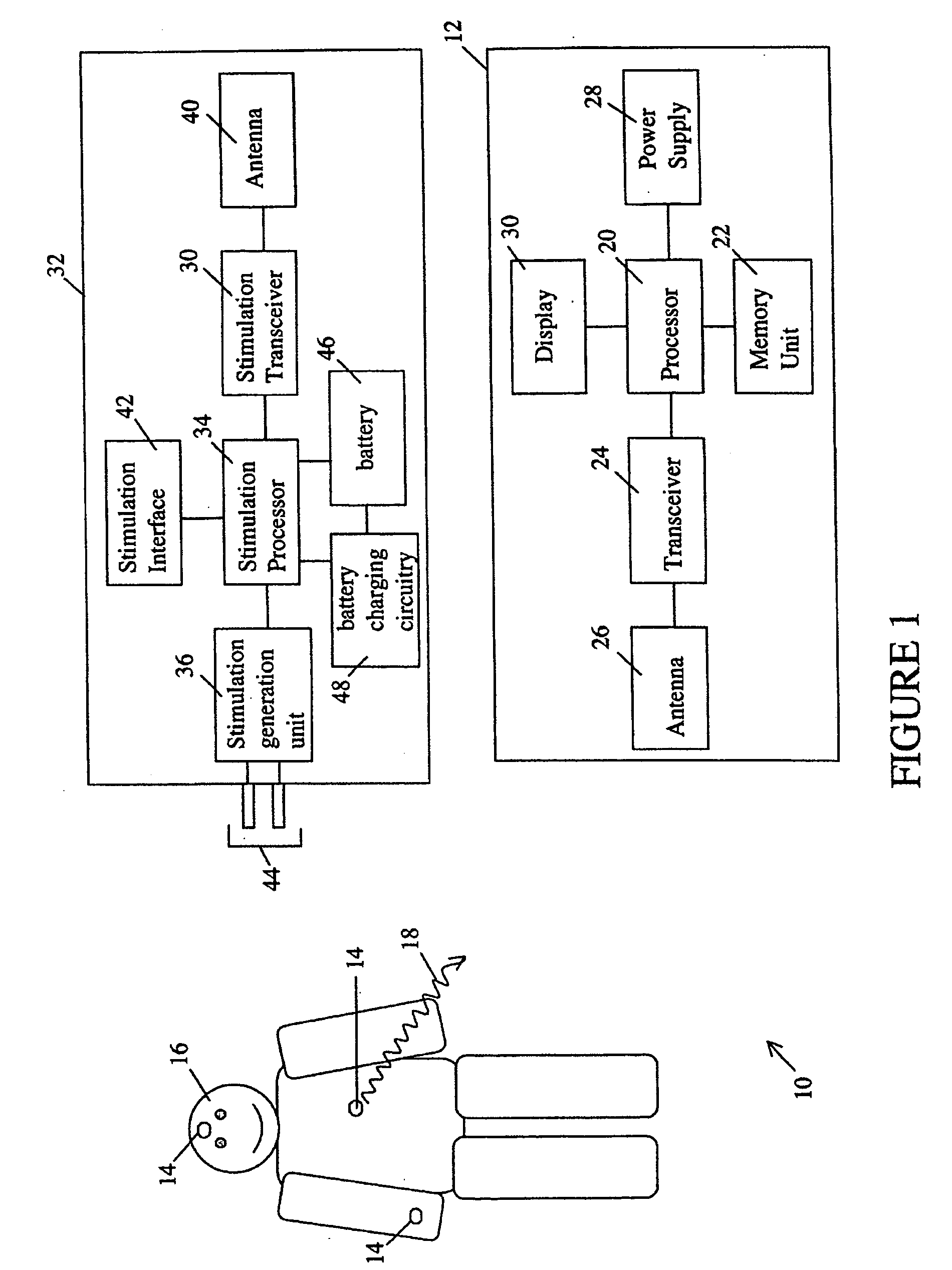

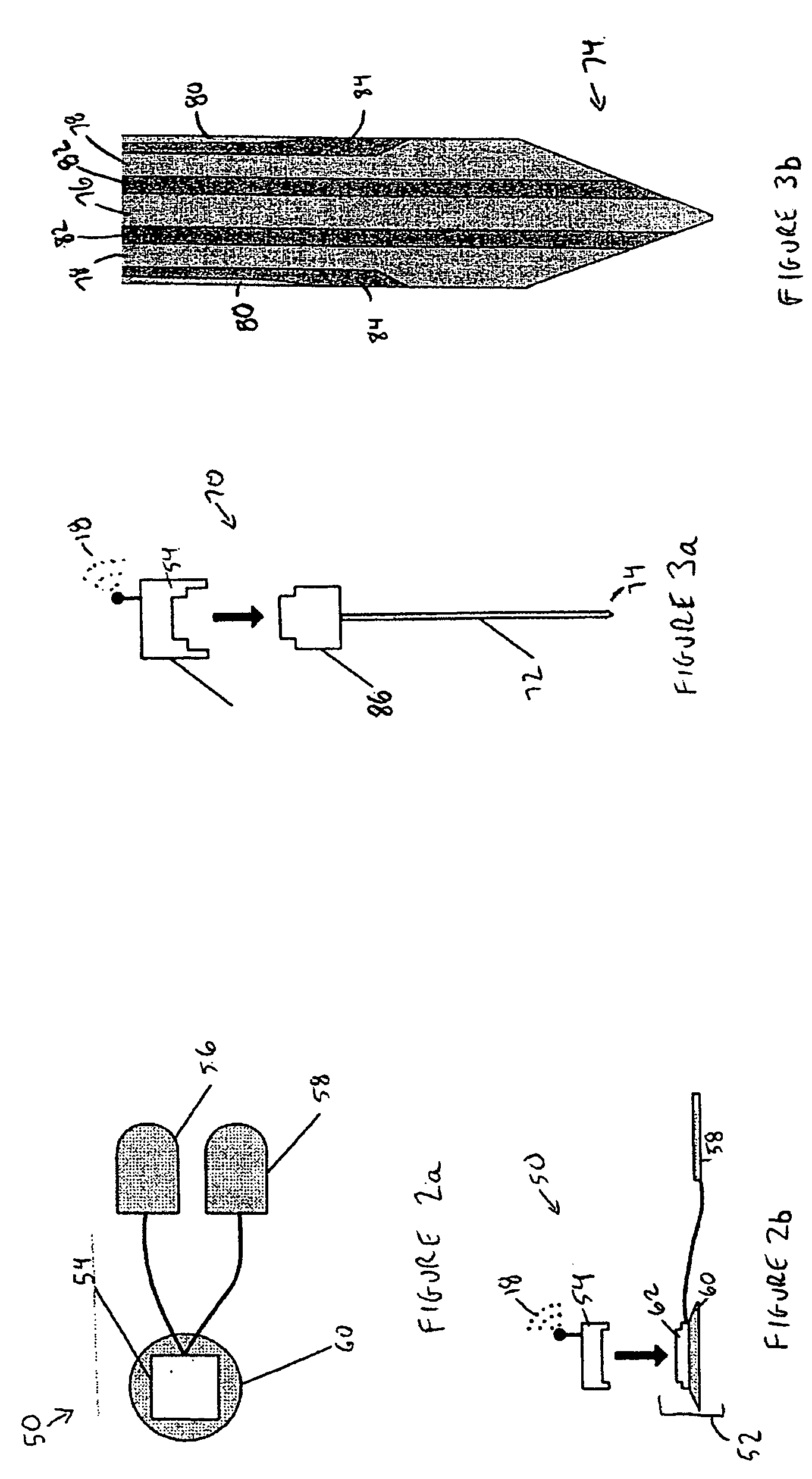

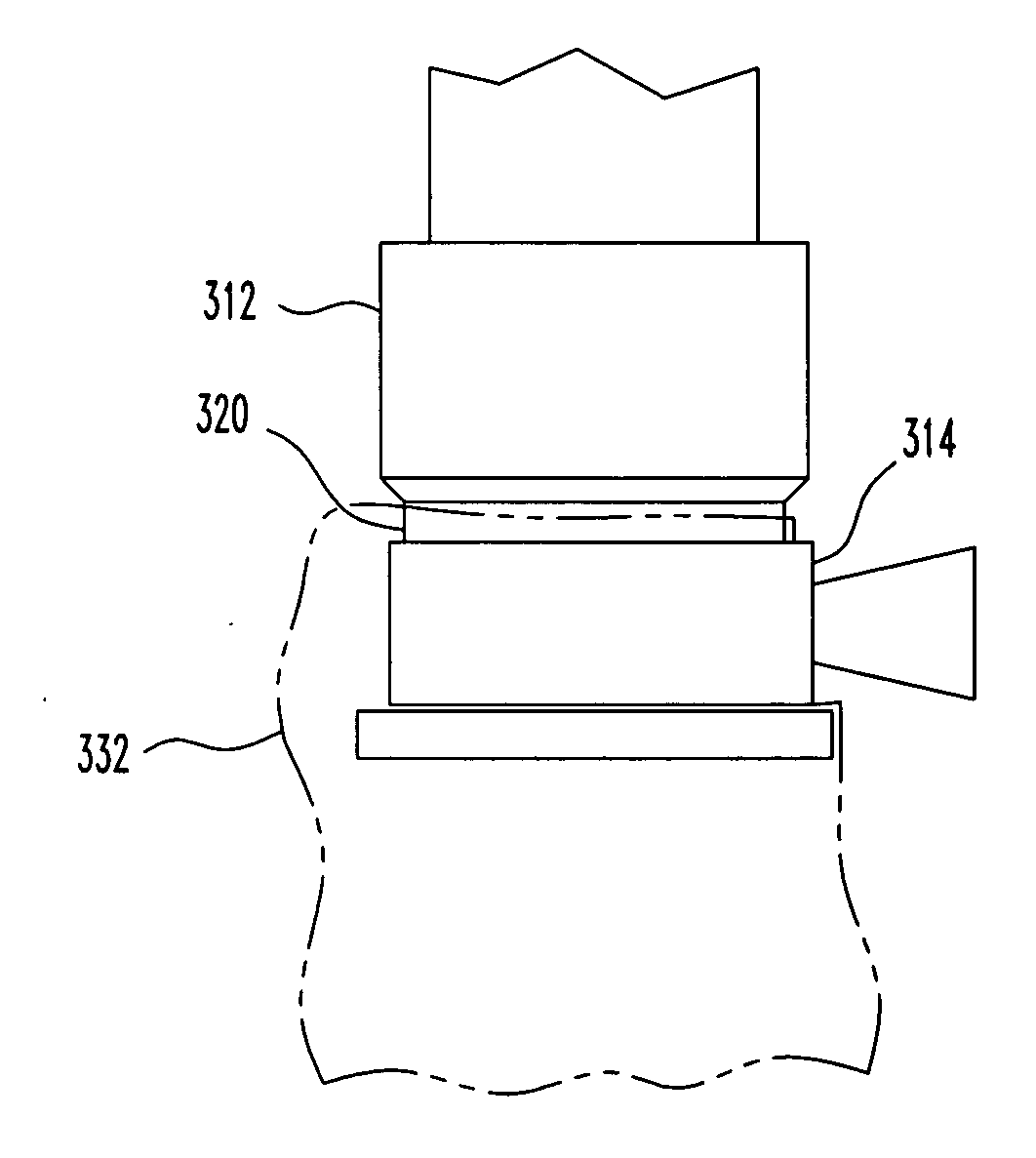

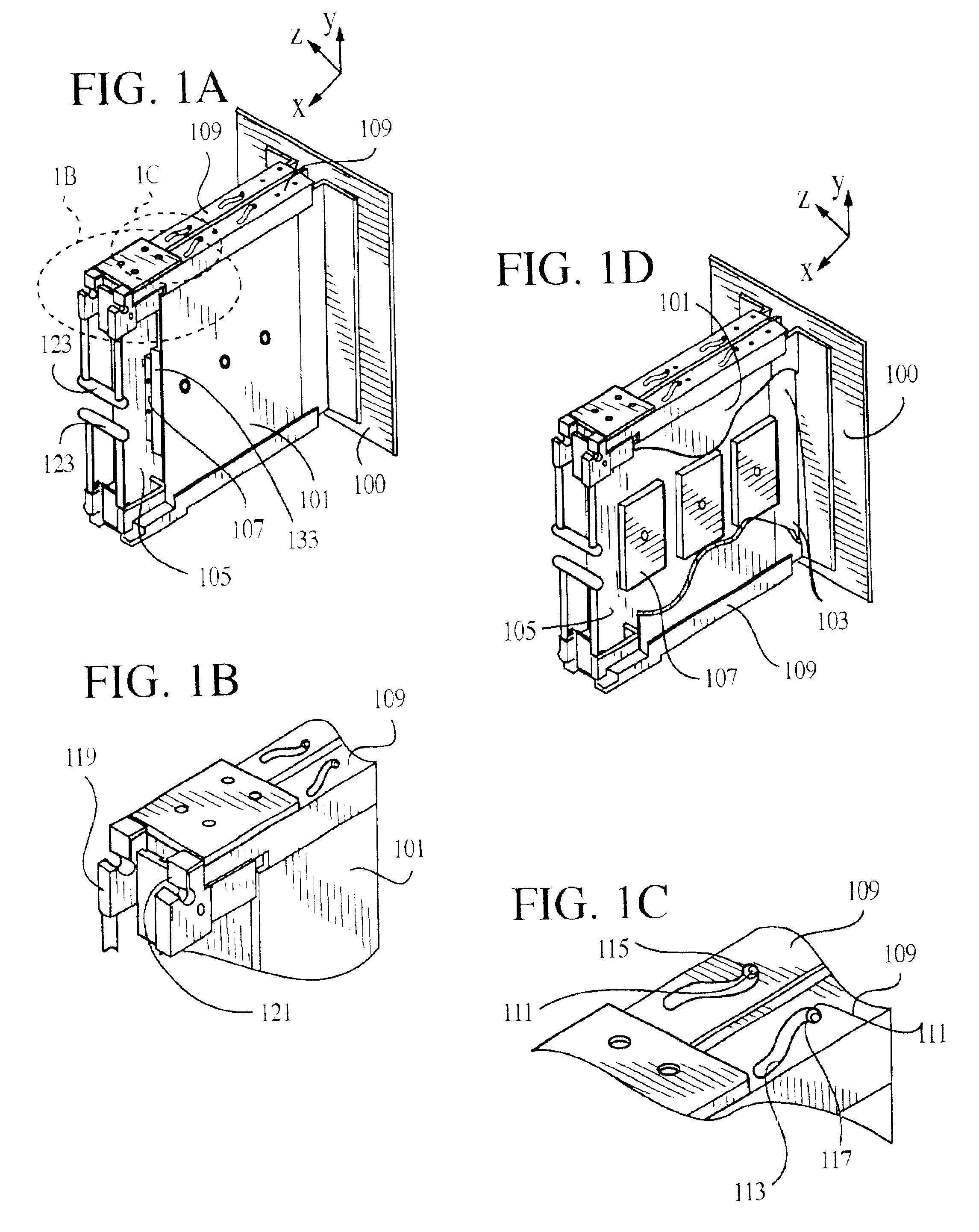

Wireless physiological monitoring system

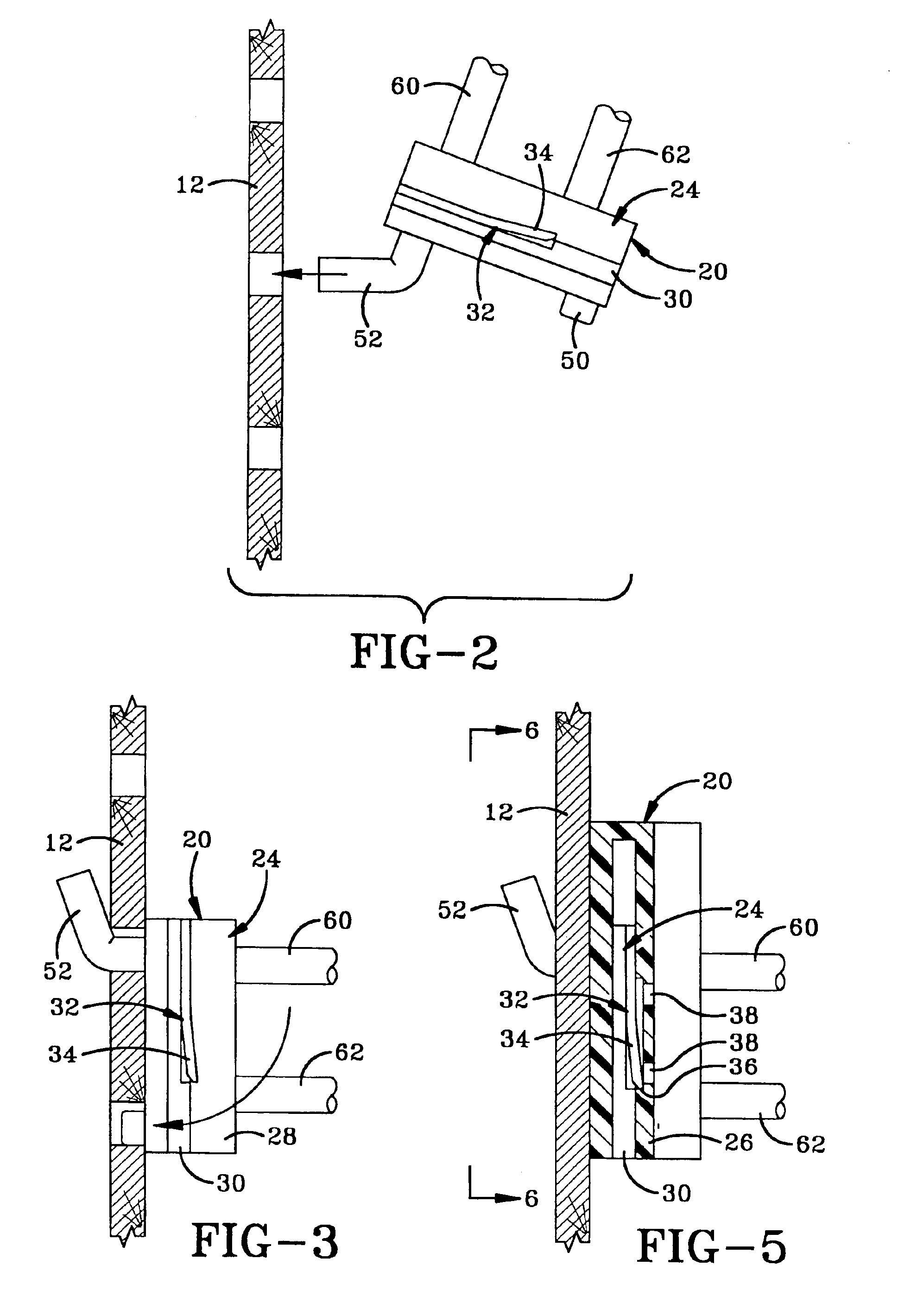

InactiveUS20050261559A1Quick applicationQuick removalSensorsSkin piercing electrodesLine sensorElectrical conductor

Embodiments of the invention relate to a wireless physiological monitoring system. The system includes at least one wireless sensor and a monitoring device which are linked to one another of a wireless fashion for measuring physiological signals of a patient. The at least one wireless sensor is located on the patient and may comprise a wireless surface electrode assembly or a wireless needle assembly. The system may also comprise a wireless stimulator syncronized with the wireless sensor for performing certain diagnostic tests, such as nerve conduction velocity tests, for example. The wireless sensor preferably includes active, reference and common conductors. The common conductor can be used to measure the common mode voltage of the patient in the vicinity of the testing, and this voltage can then be subtracted from the measured active and reference voltages.

Owner:EXCEL TECH

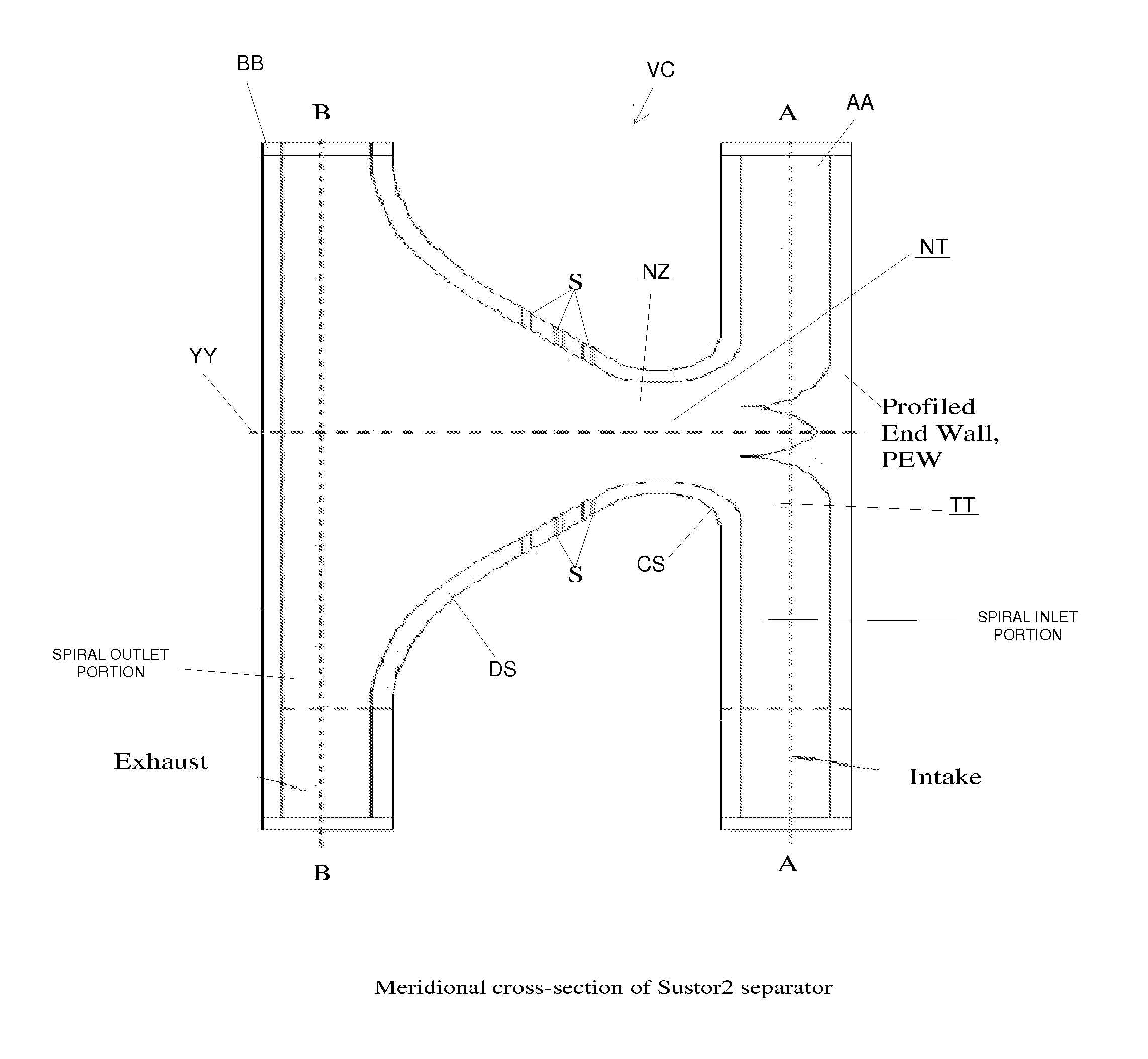

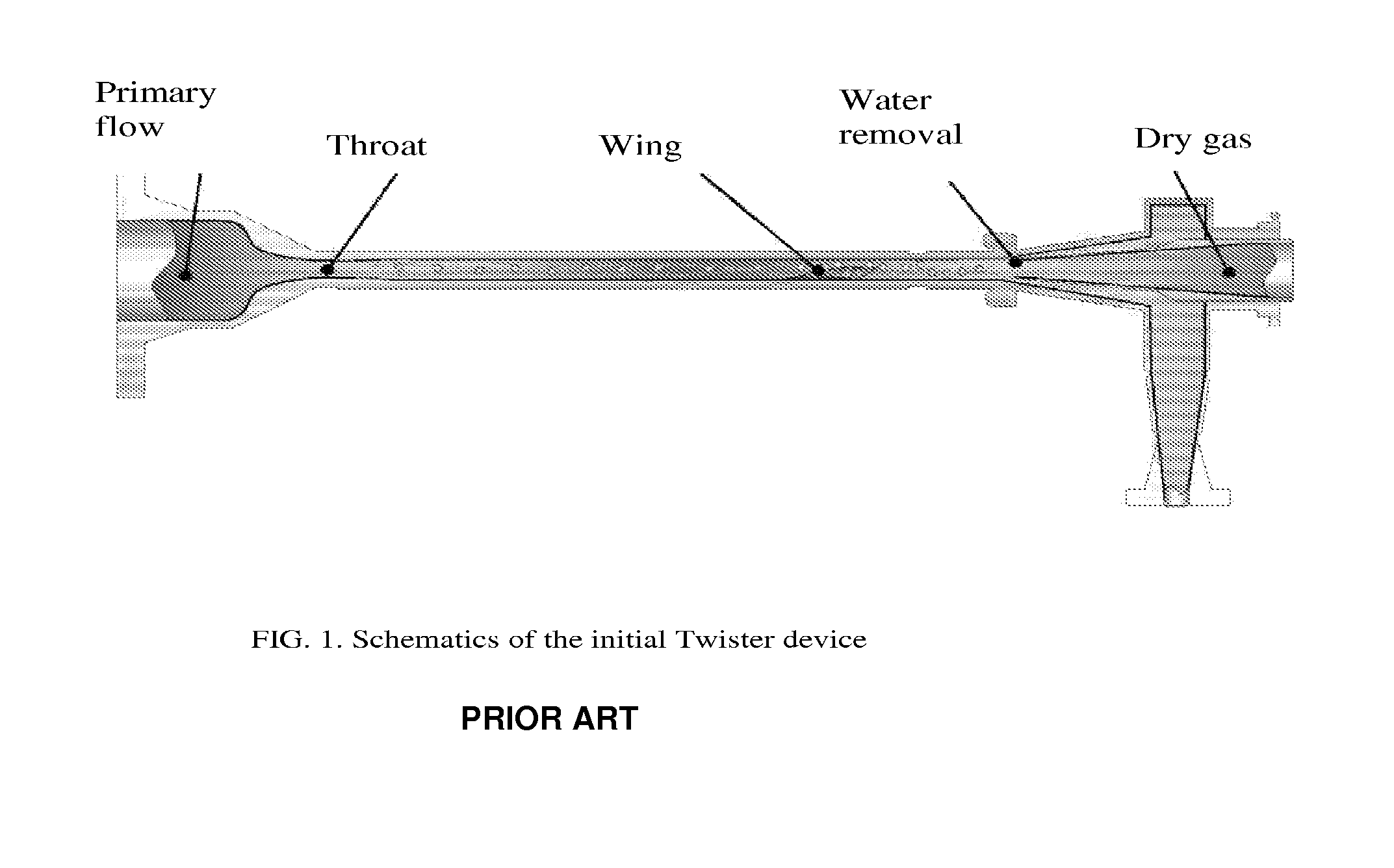

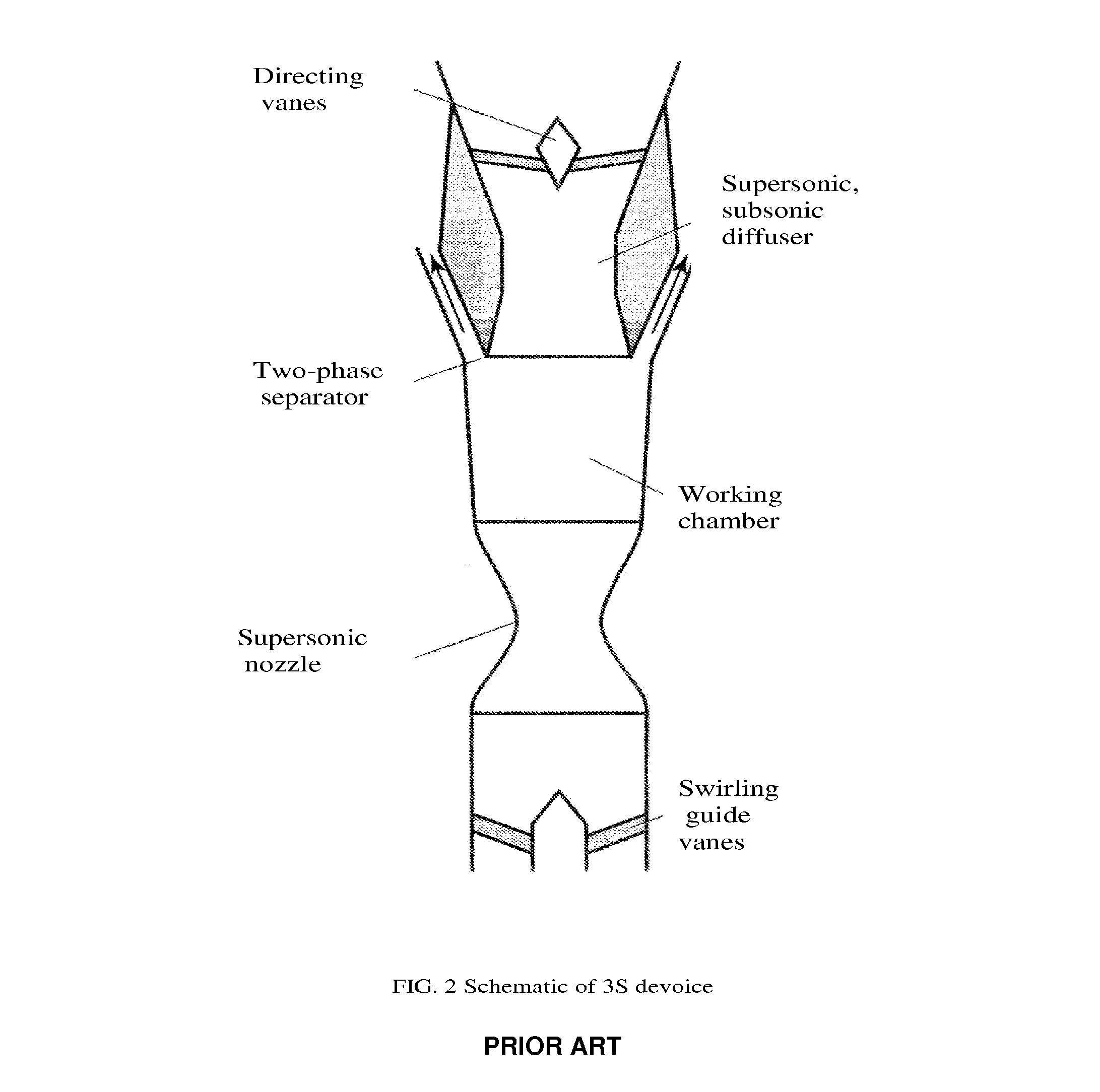

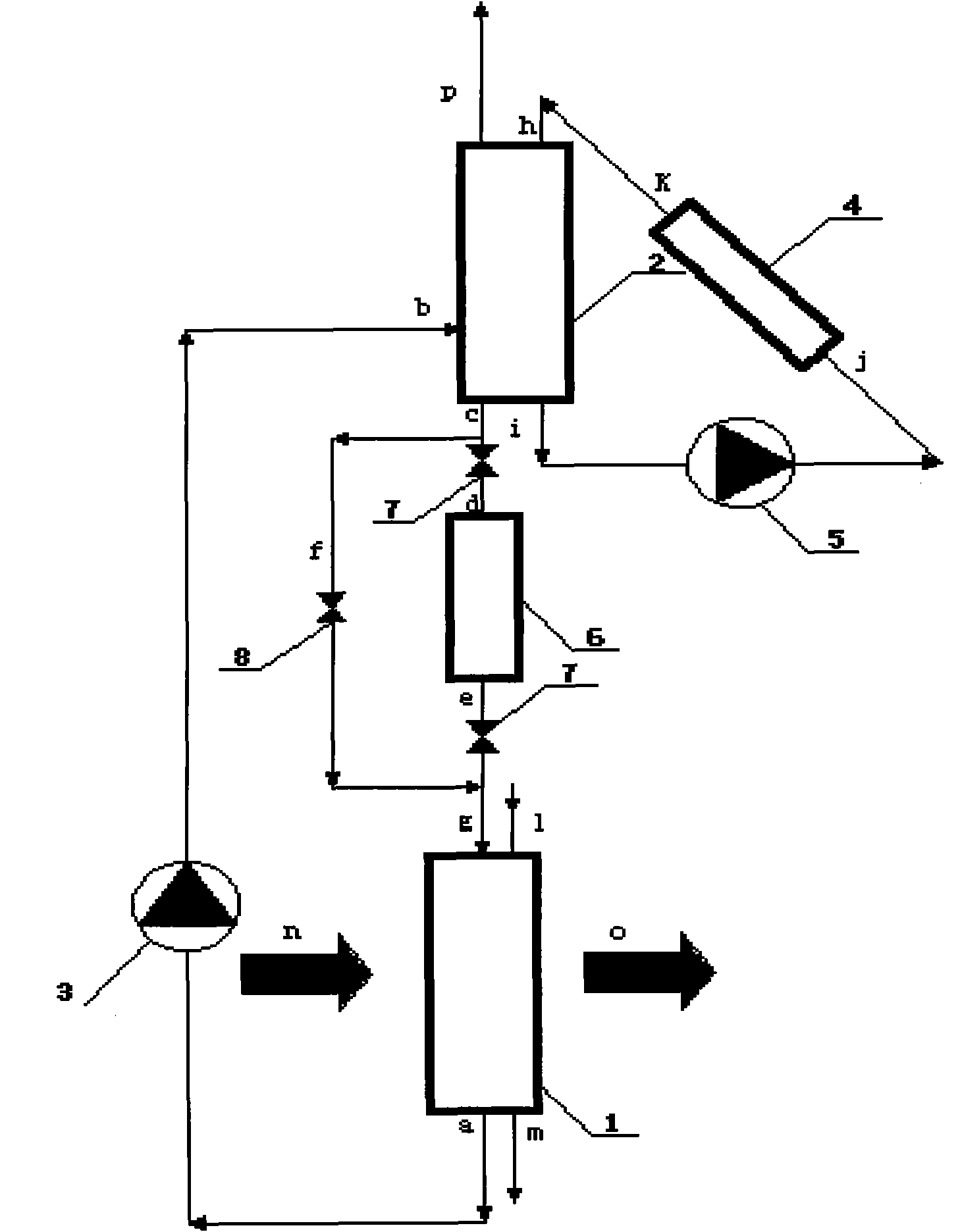

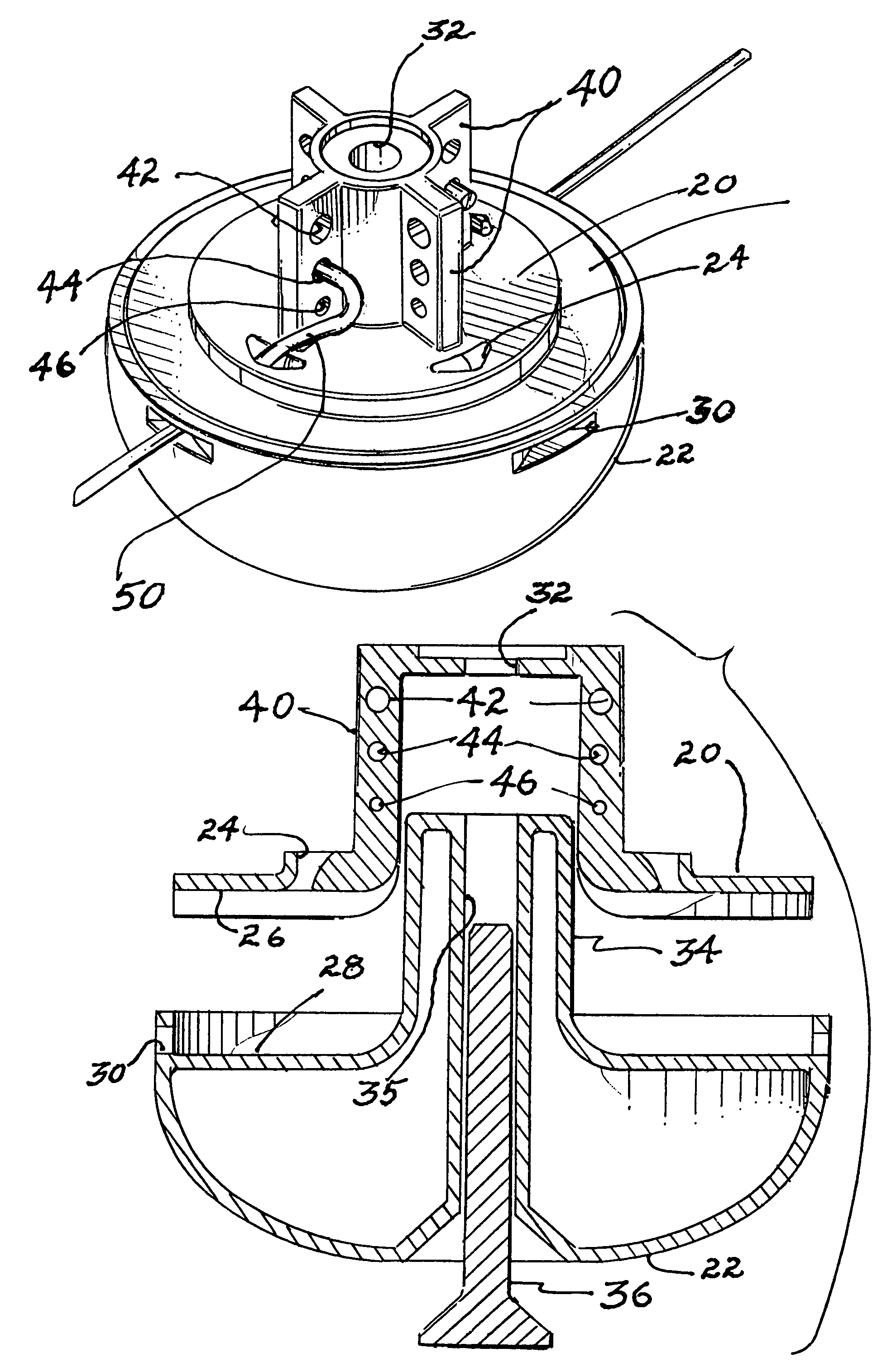

Supersonic swirling separator 2 (Sustor2)

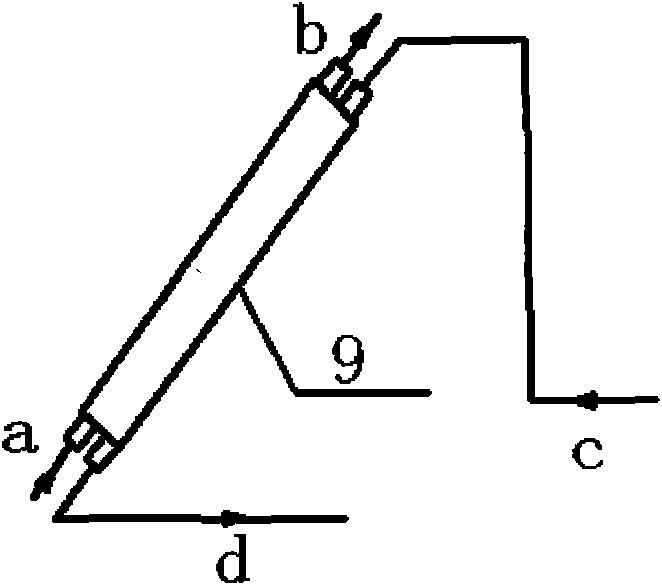

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

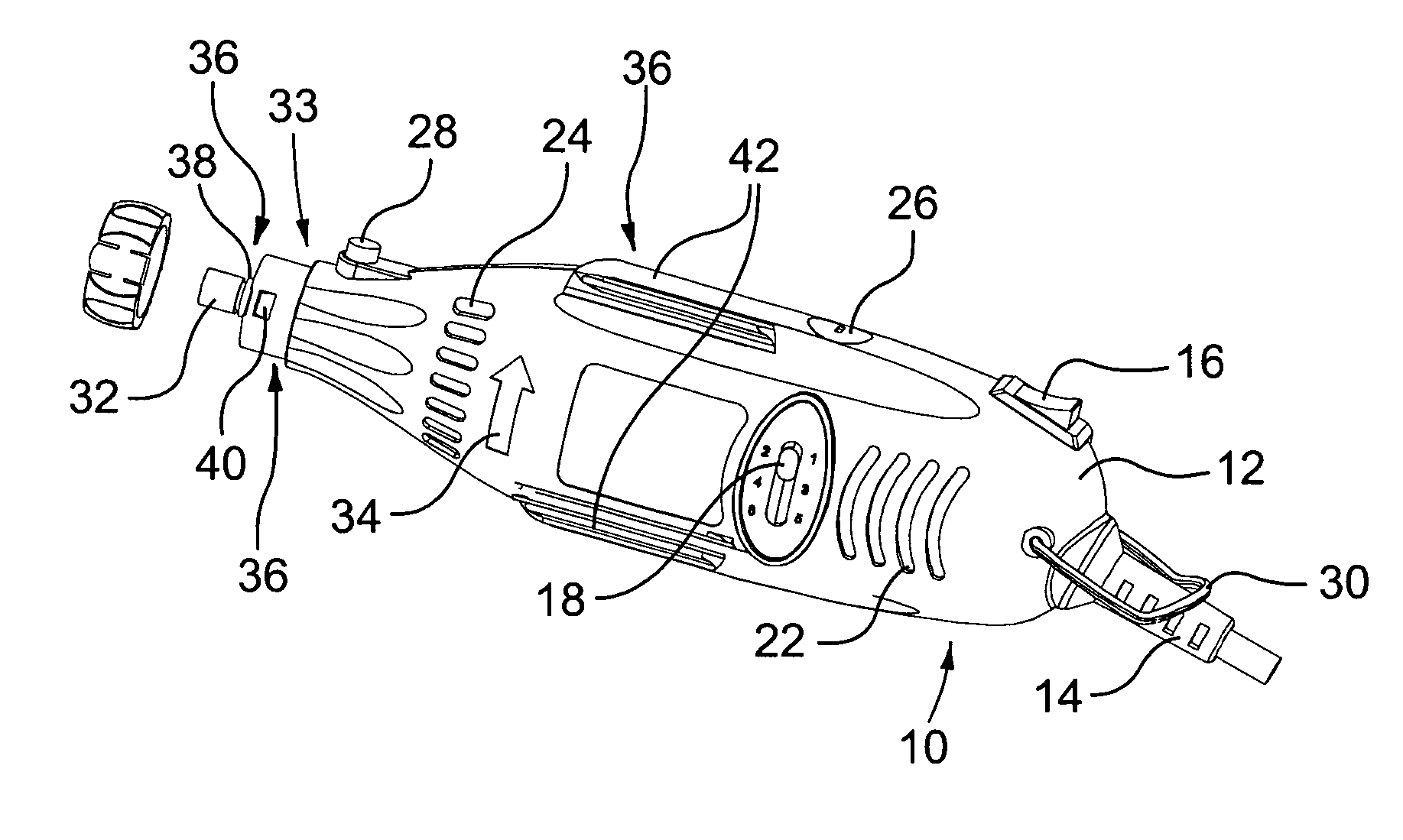

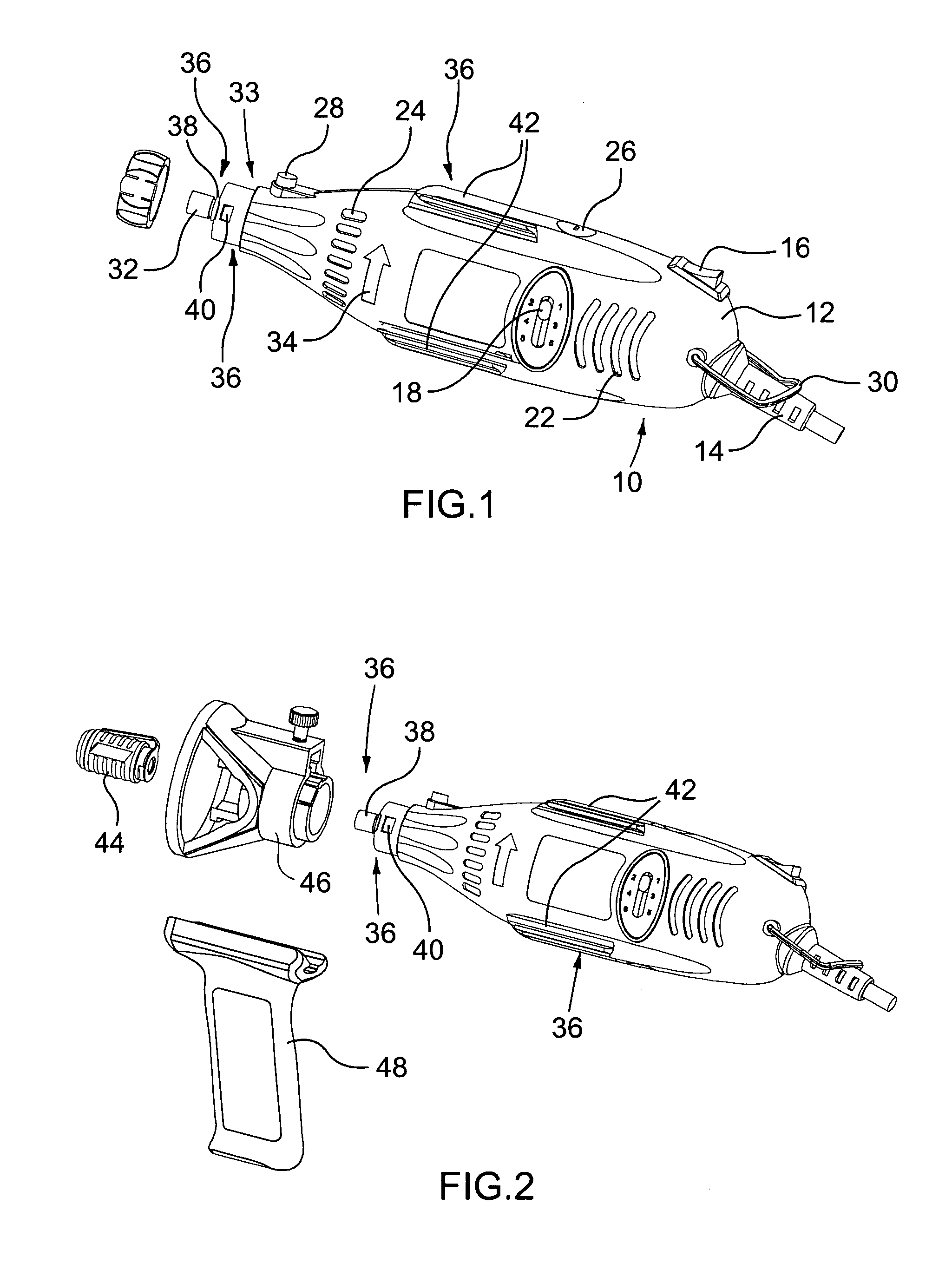

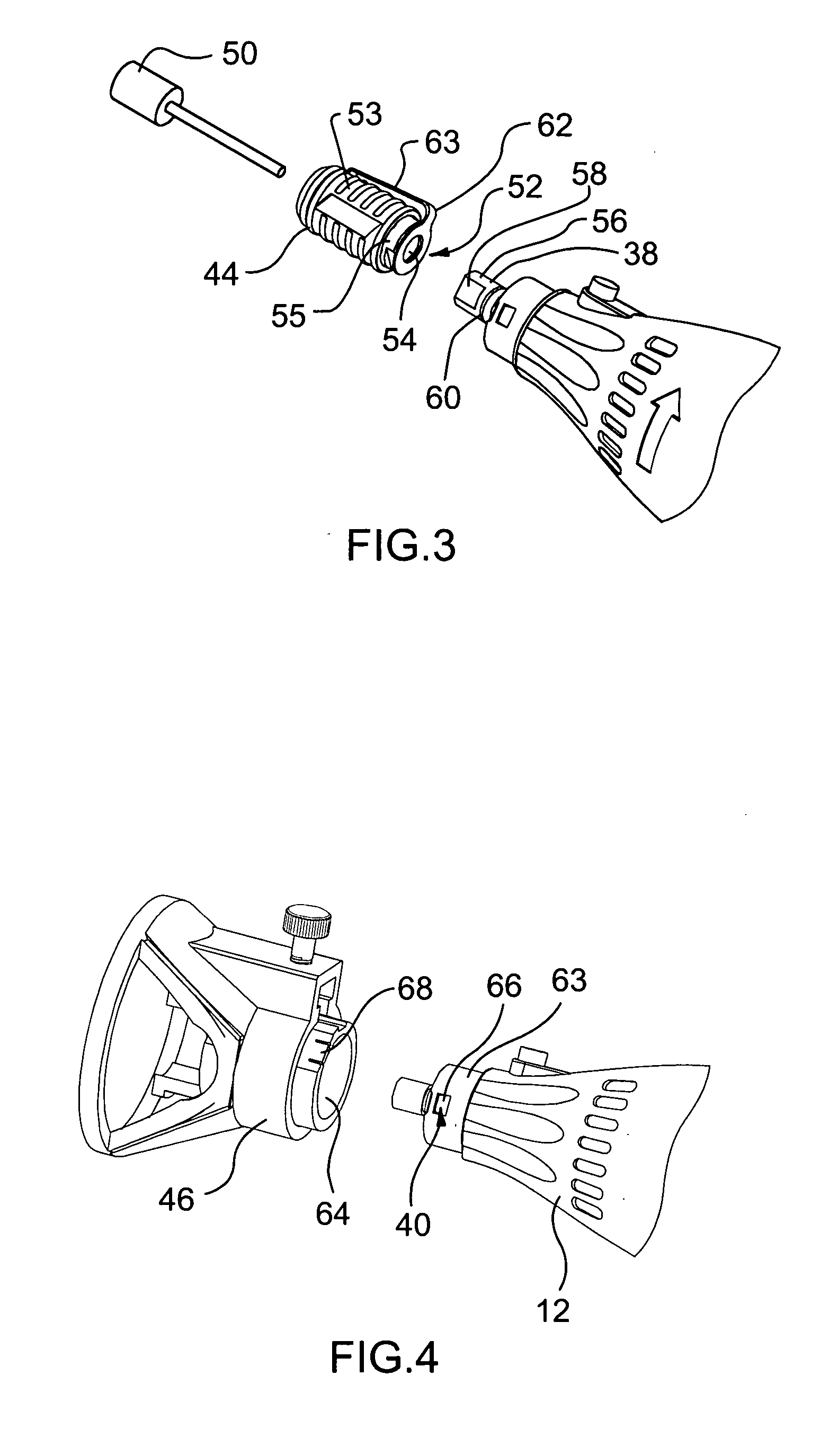

Rotary tool with quick connect means and attachments thereto

InactiveUS20050200087A1Function increaseReduce the amount requiredSleeve/socket jointsPortable power-driven toolsHand heldEngineering

The present invention is directed at a handheld power tool comprising means for receiving a tool accessory; means for rotating said tool accessory; and at least one quick connect means for use with power tool attachments.

Owner:TEAM FAIR HLDG

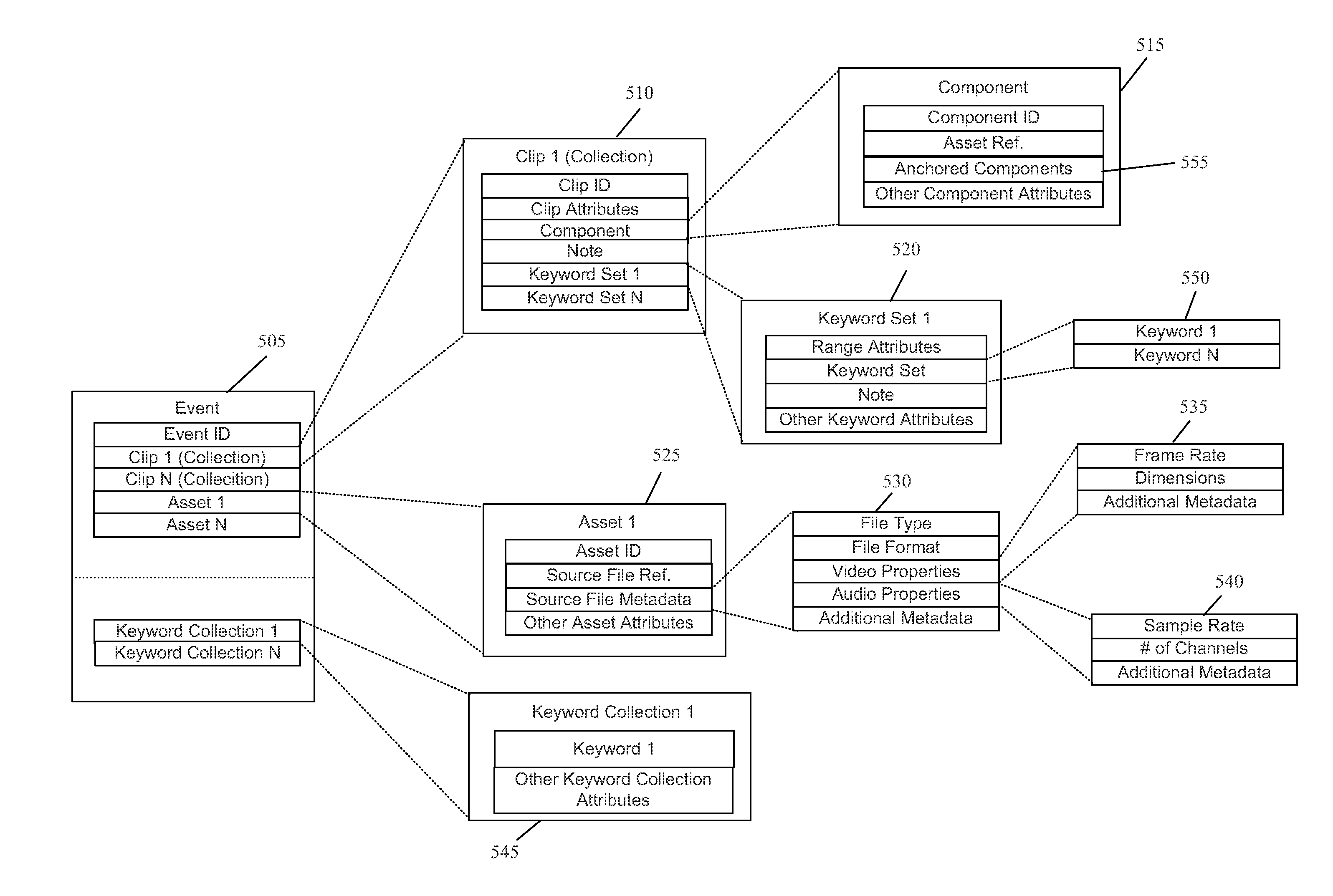

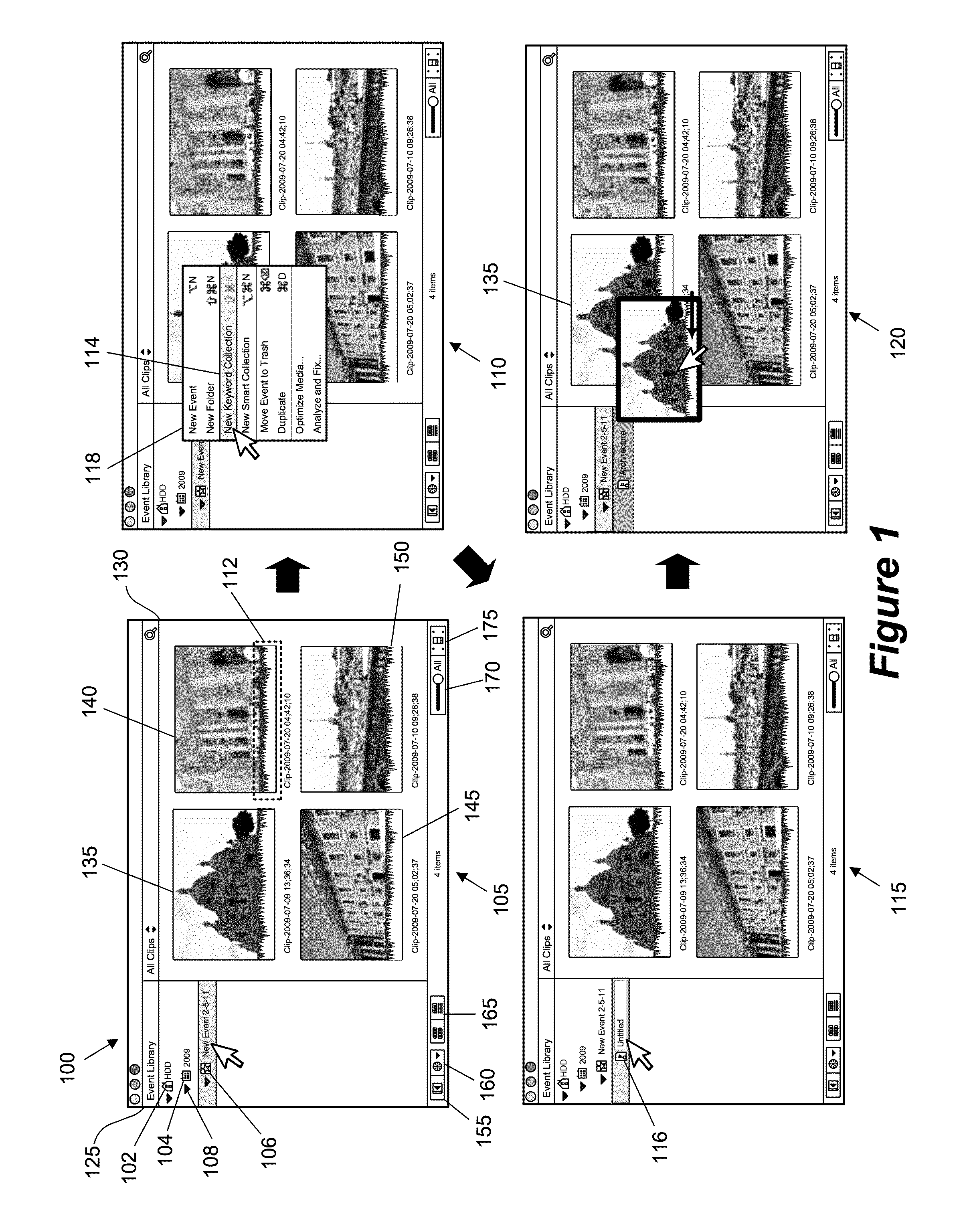

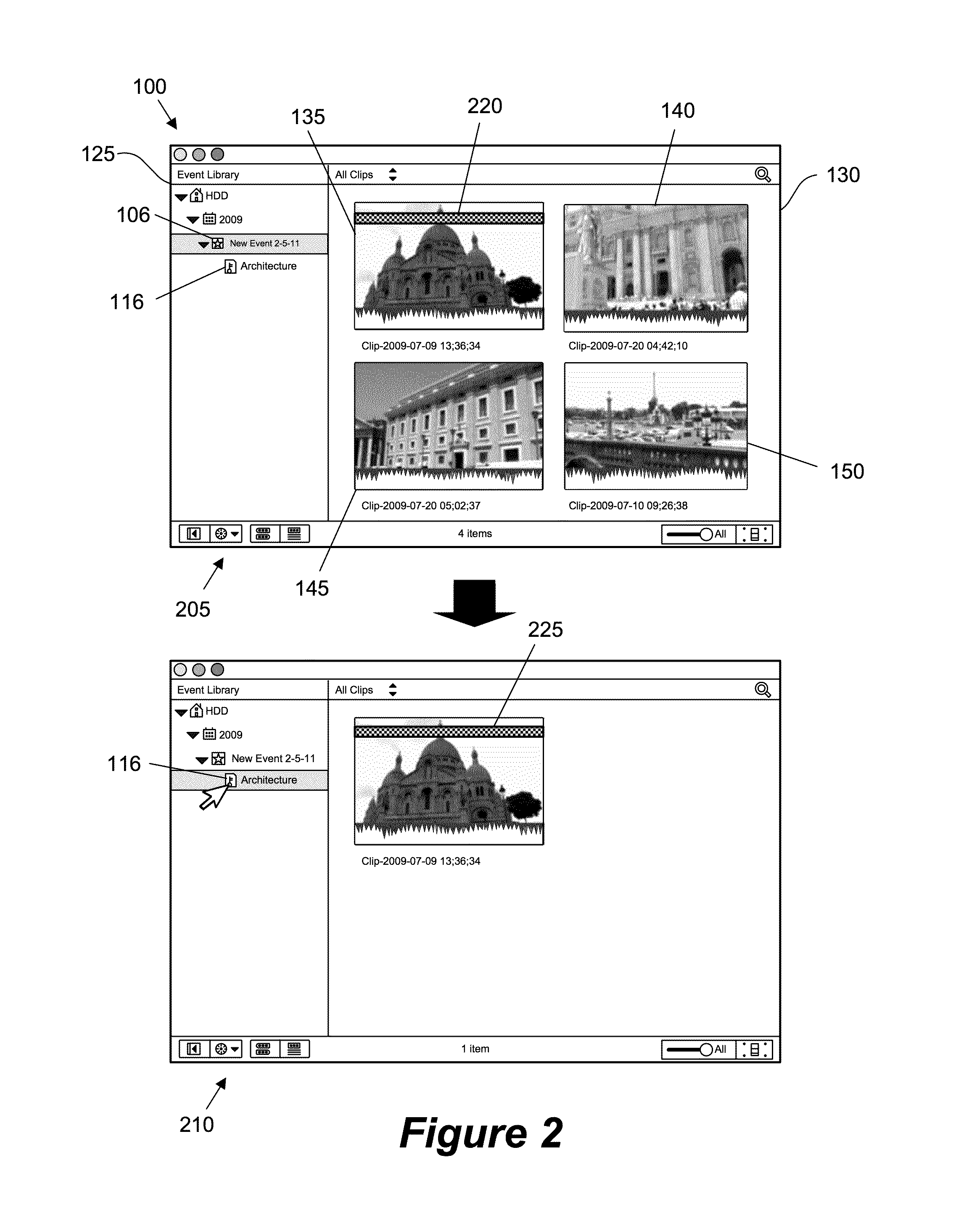

Timeline search and index

ActiveUS20120210220A1Easy to removeQuick associationTelevision system detailsDigital data information retrievalInformation retrievalWorld Wide Web

Some embodiments provide a timeline search tool for searching and navigating a timeline. The timeline search tool includes a search field that allows a user to search for clips. In some embodiments, each clip in the list of clips is selectable such that a selection of the clip causes the timeline to navigate to the position of the clip in the timeline. In some embodiments, the timeline search tool allows a user to search for clips based on keywords or markers.

Owner:APPLE INC

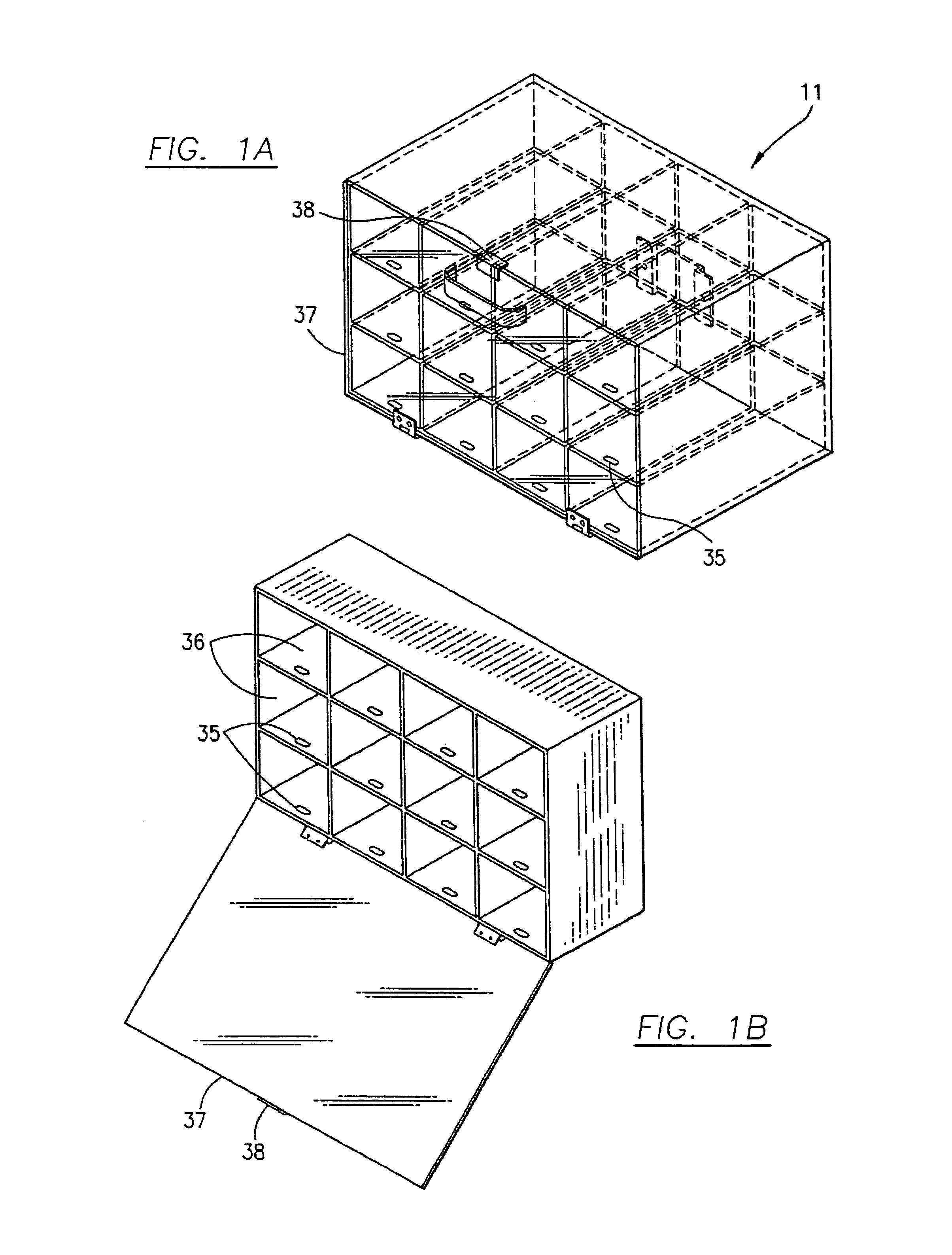

Portable dispensing device for refreshments and sundries

ActiveUS7418311B1Increase salesReadily availableLighting and heating apparatusCoin-freed apparatus detailsPaymentEngineering

A portable dispensing system comprising a vending machine including an upper snack-holding portion, an intermediate beverage-holding portion, a lower refrigeration portion, contained within a housing that fits within the basket of a golf cart. The snack-holding portion and the beverage-holding portion occupy a common cabinet being separated by an insulating wall, allowing a refrigeration mechanism within the refrigeration portion to refrigerate the beverage-holding portion without refrigerating the snack-holding portion. The cabinet is disposed above the basket within the golf cart, and may be provided with a pair of belts for fastening the dispensing system to the golf cart. Within the snack-holding portion, snacks are held in a plurality of snack-holding bins, with similar snacks being stored in a single bin, separated from one another by sliding platforms. When a sliding platform is pulled away, the snack product resting atop the sliding platform is released to fall downward into a lowest position within the bin, to be retrieved by the user through a door. Within the beverage-holding portion, cans are stored in a plurality of columns to be retrieved through doors. An inventory management system is disclosed for controlling and monitoring the dispensing of refreshments and sundries. The inventory management system including a systems for electronically accepting payment, a system for monitoring inventory levels, and a system for wirelessly communicating with a remote terminal.

Owner:GOLF CONCESSIONS

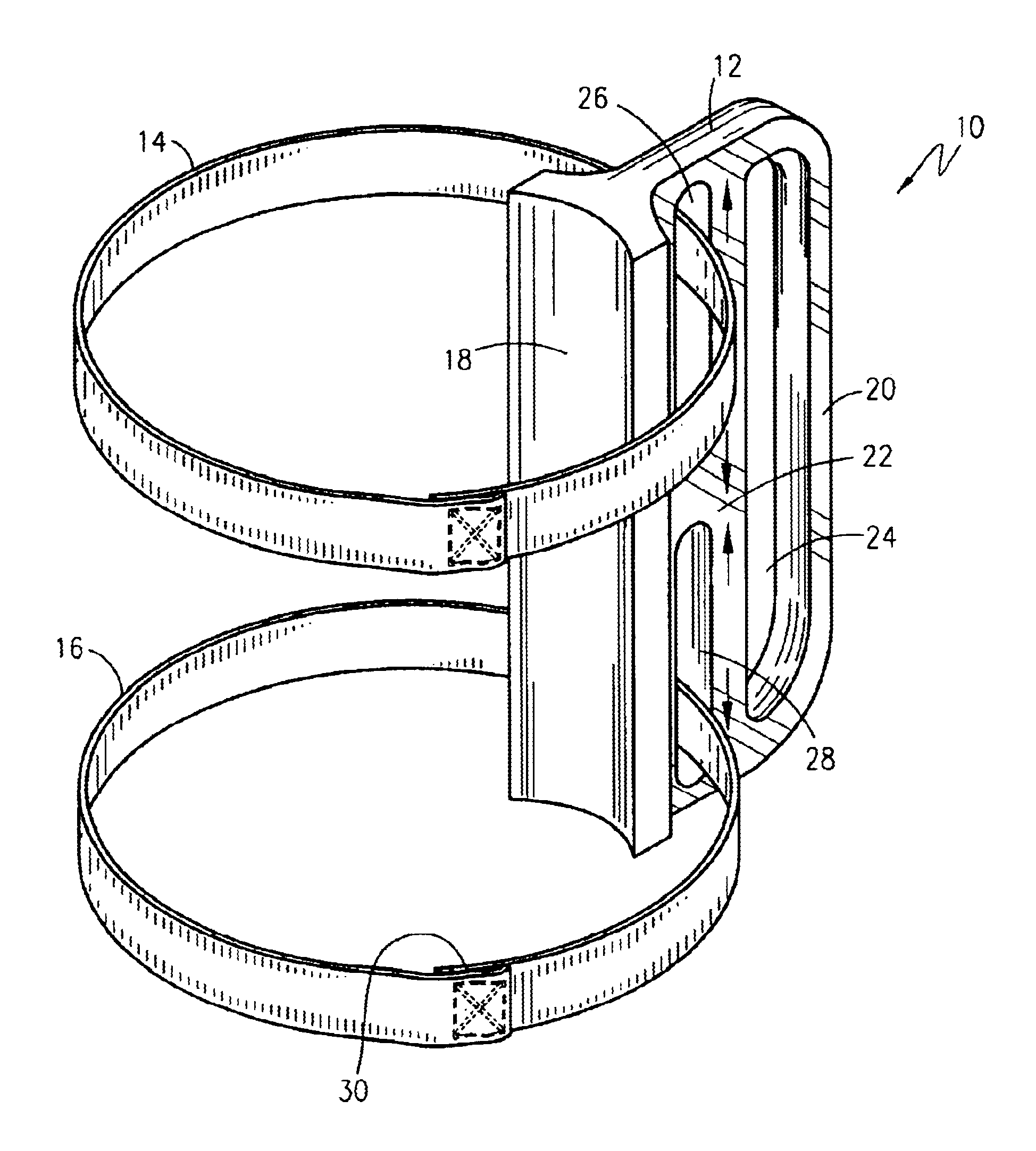

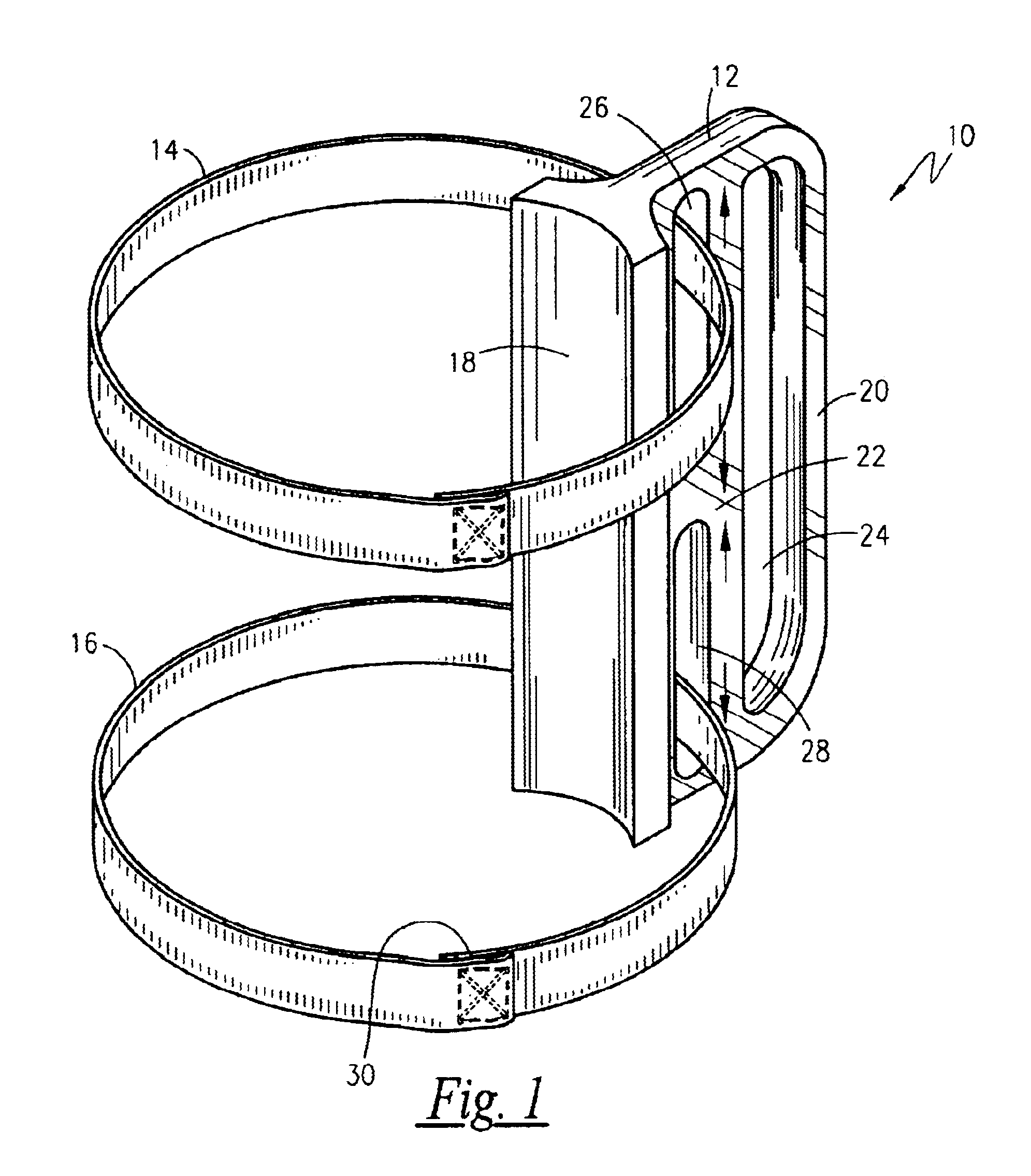

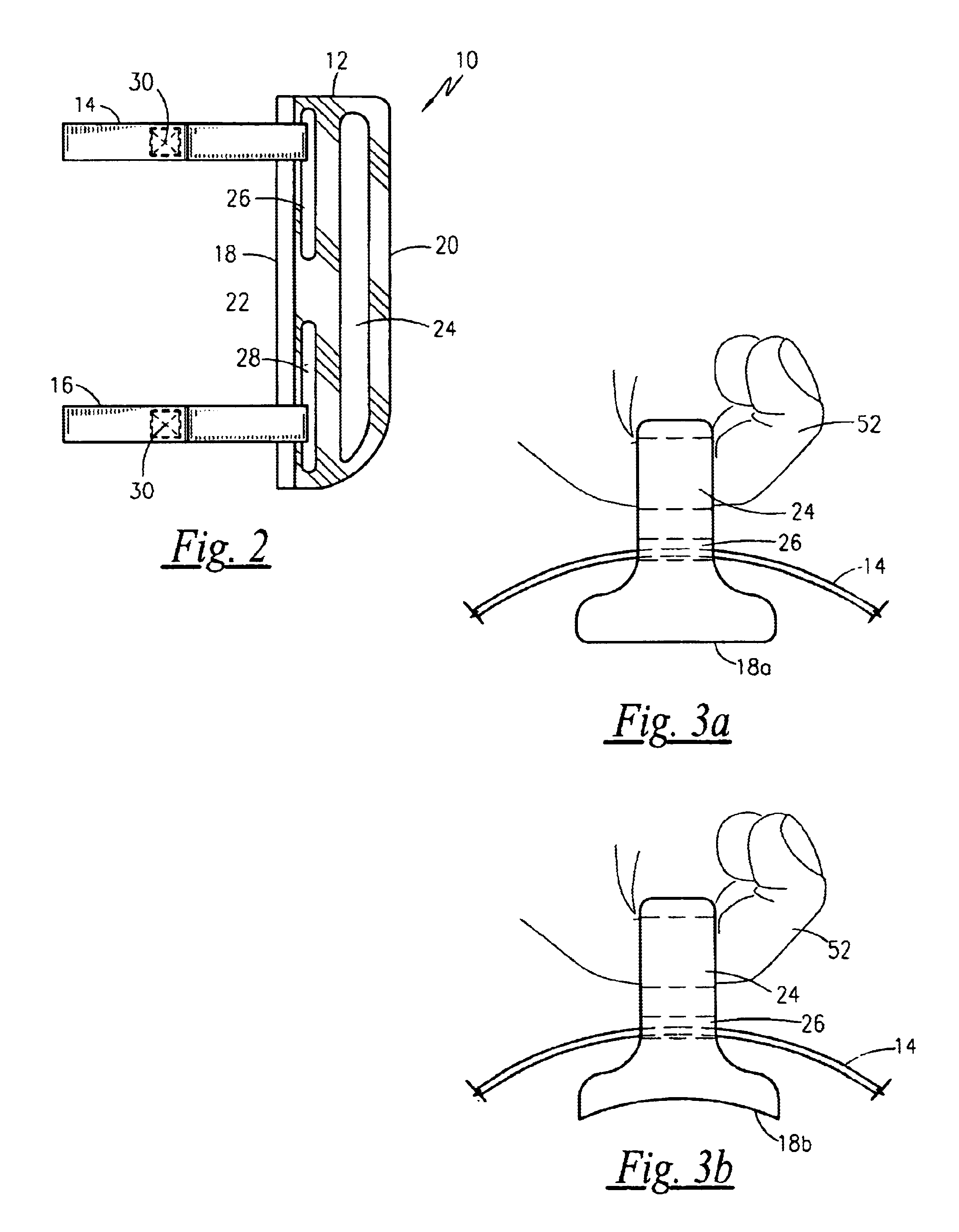

Adjustable pouring handle

An adjustable pouring handle is a linearly elongated body having a pair of adjustable container straps that are detachably affixed to the body. The body includes a grasping aperture, a first aperture and a second aperture. The grasping aperture allows a user to firmly and comfortably grasp the handle body so as to permit the pouring or movement of the affixed beverage container. The first and second apertures each receive an adjustable container strap. The adjustable container straps are placed about the outer circumference of the beverage container and detained by a securing mechanism. The securing mechanism may be one of a variety of securing devices, including hook and loop material, snap fasteners, button snaps, buttons or buckles.

Owner:POSEY ALBERT E +1

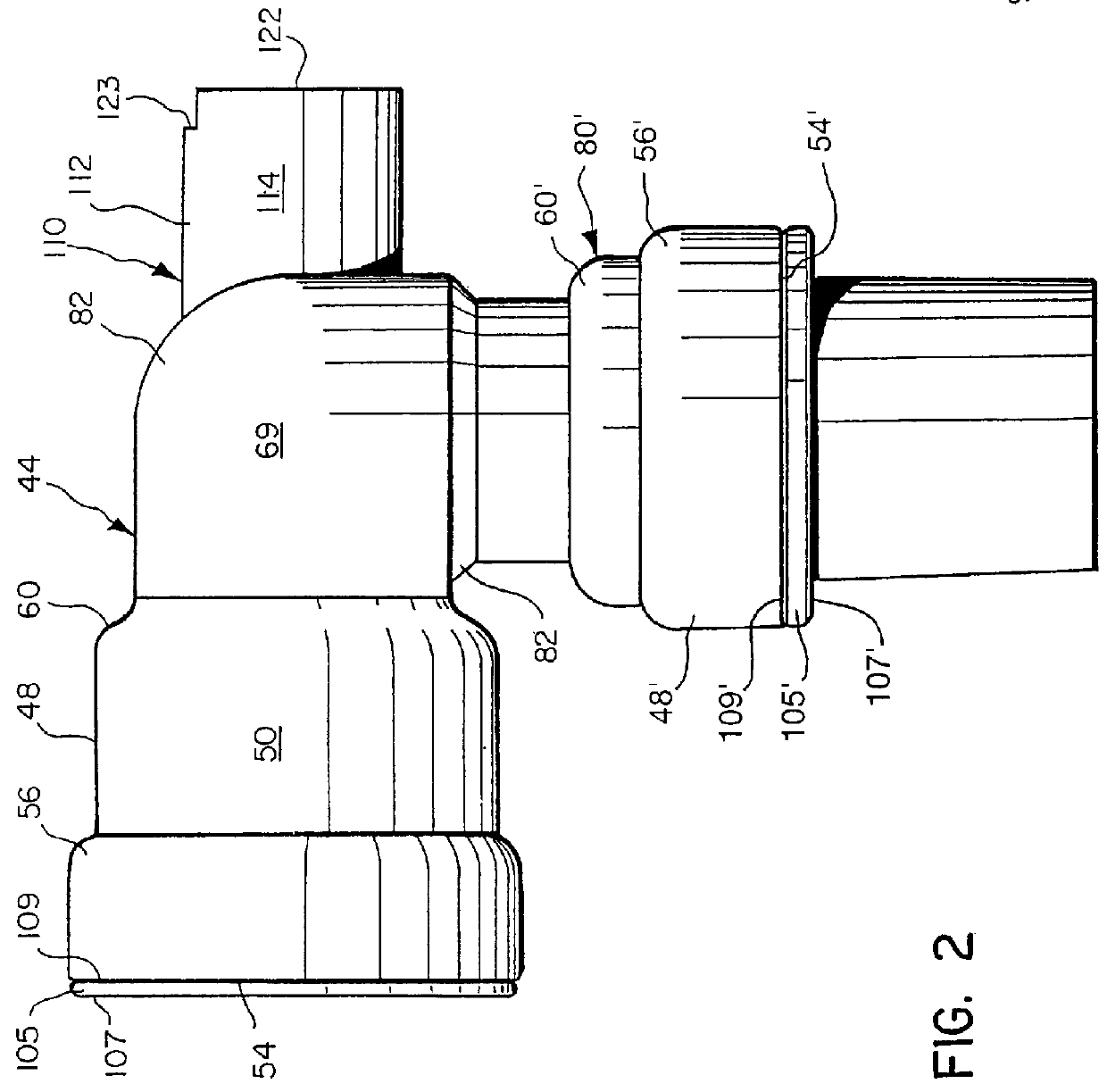

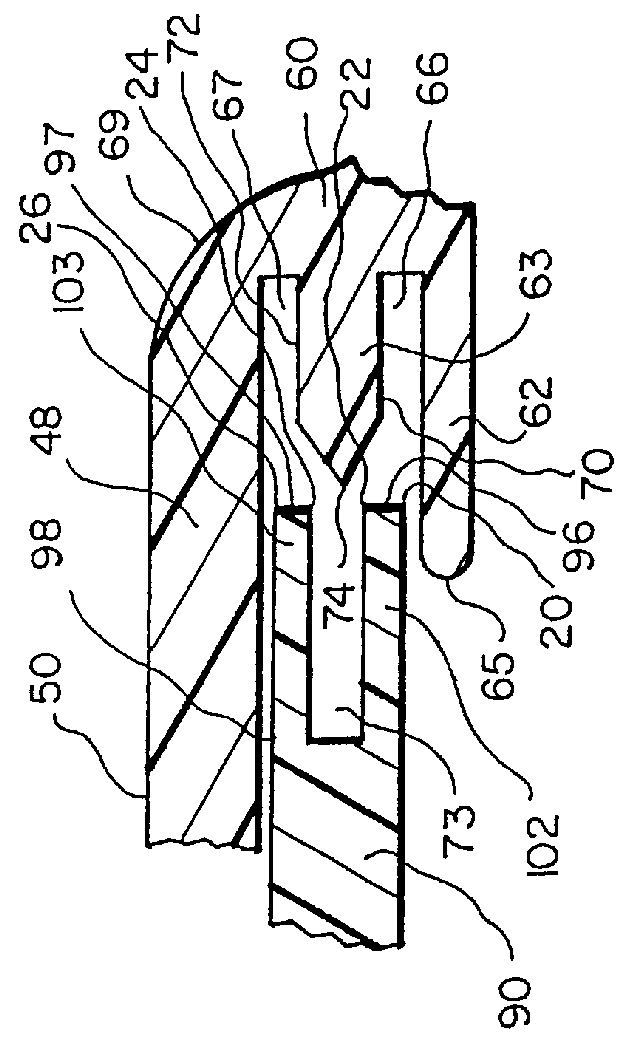

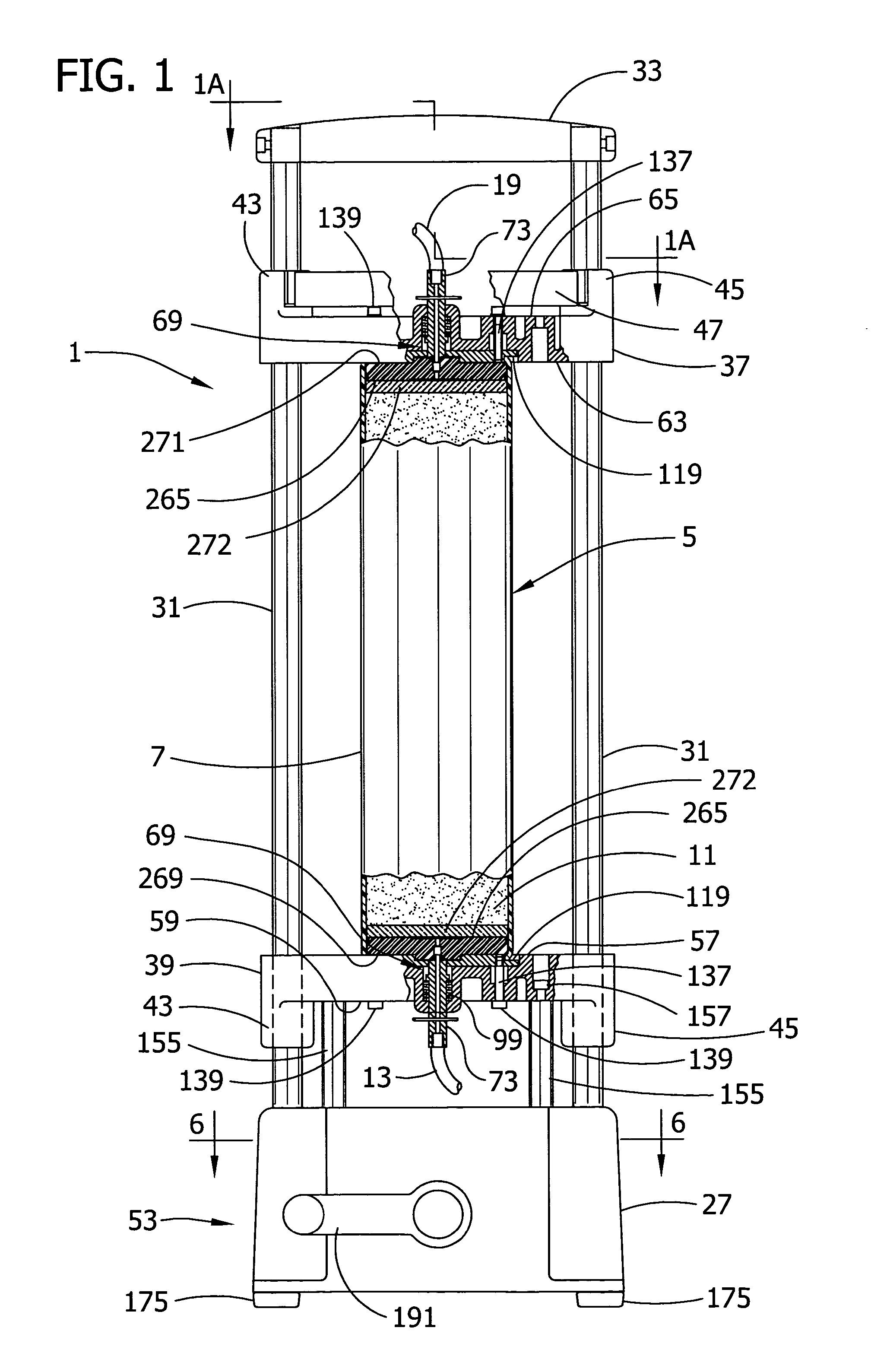

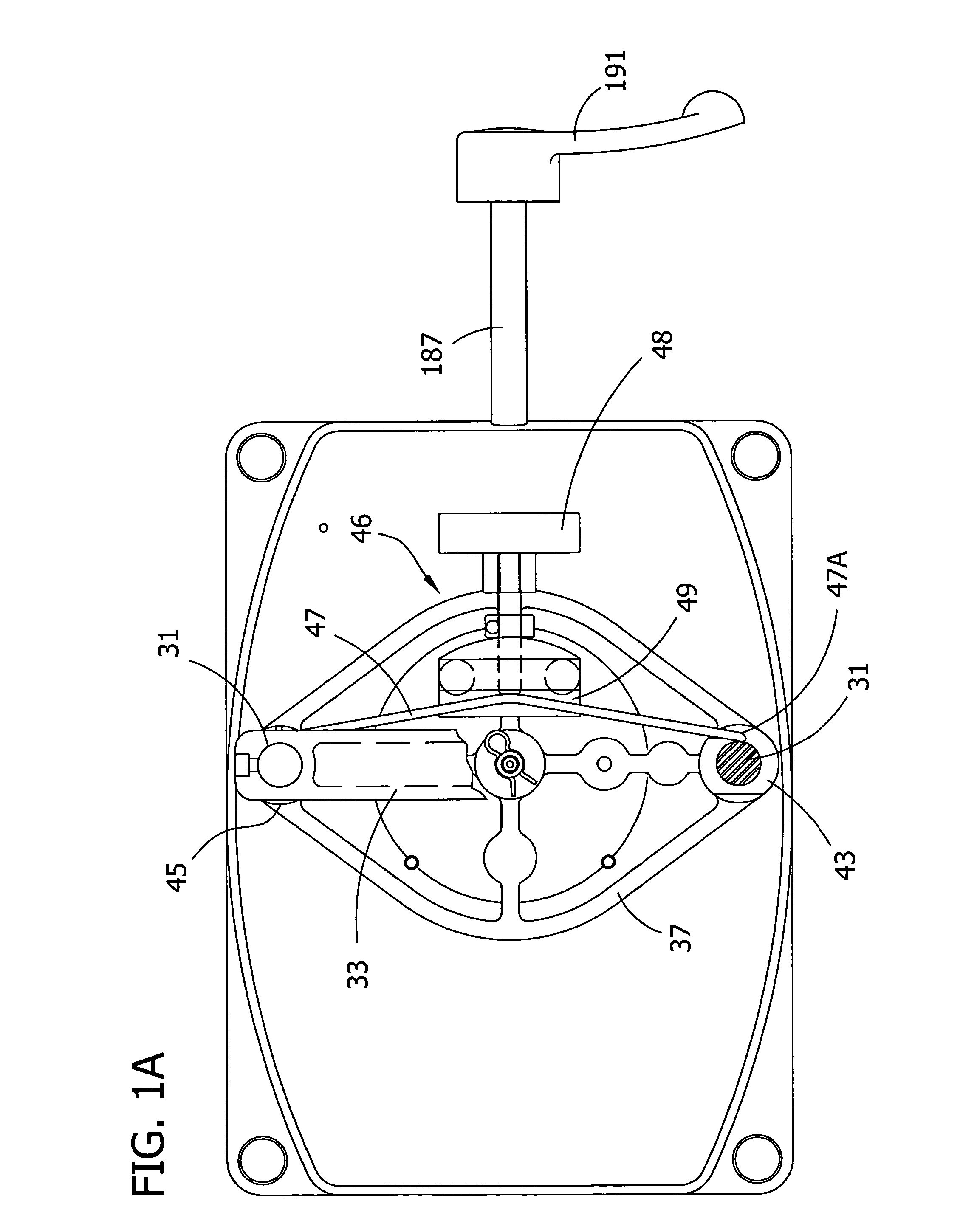

Medical aspirating/ventilating closed system improvements and methods

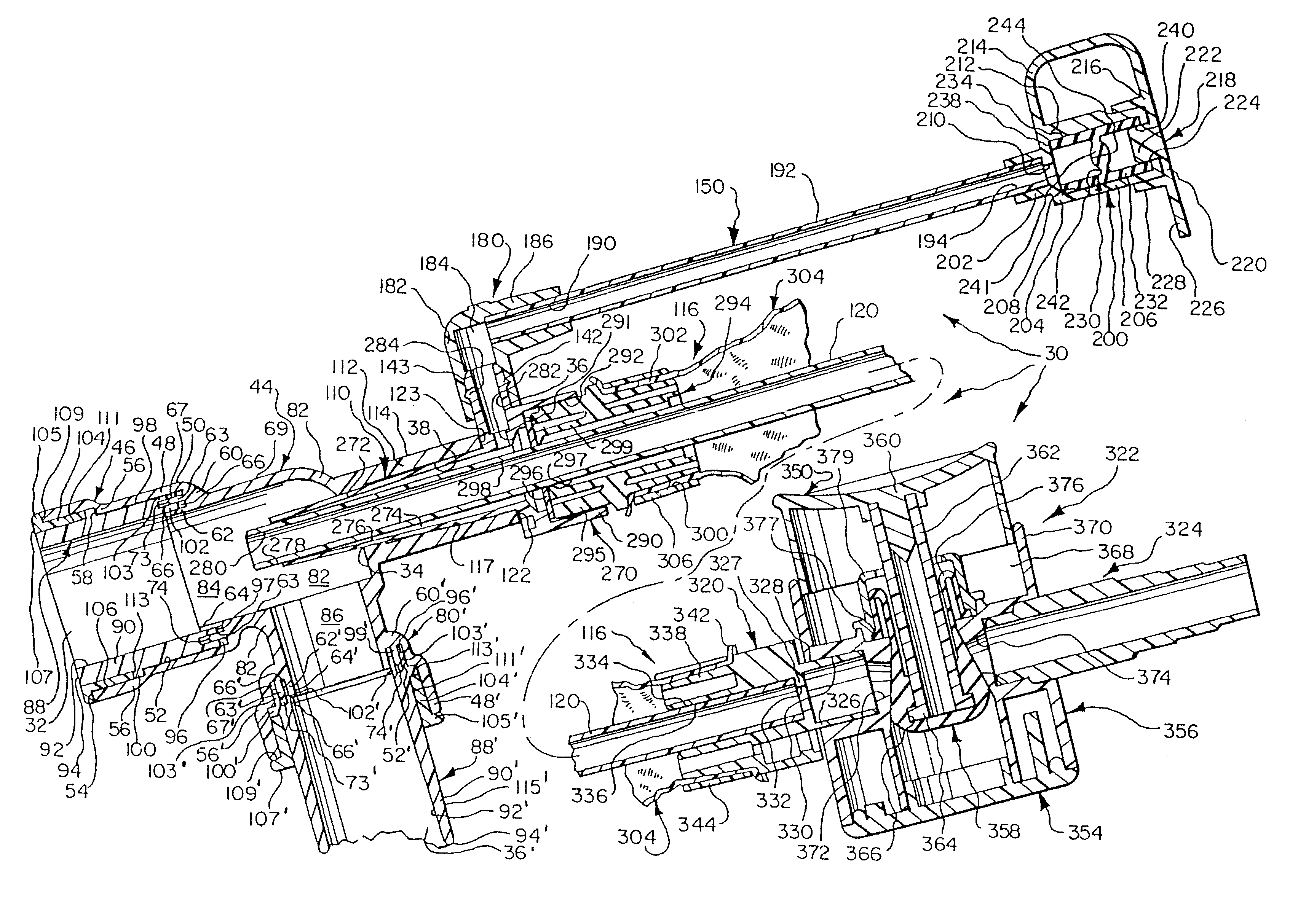

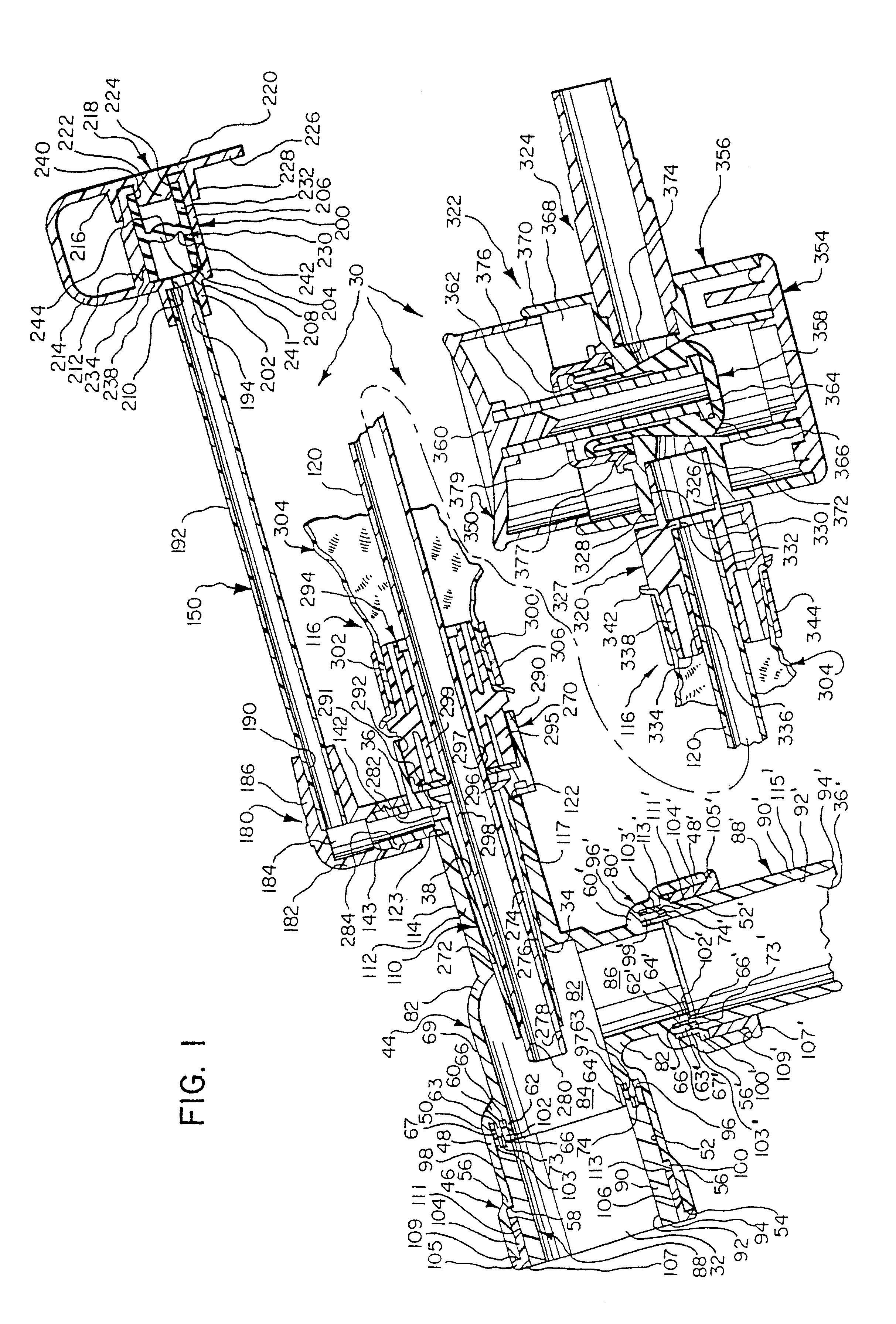

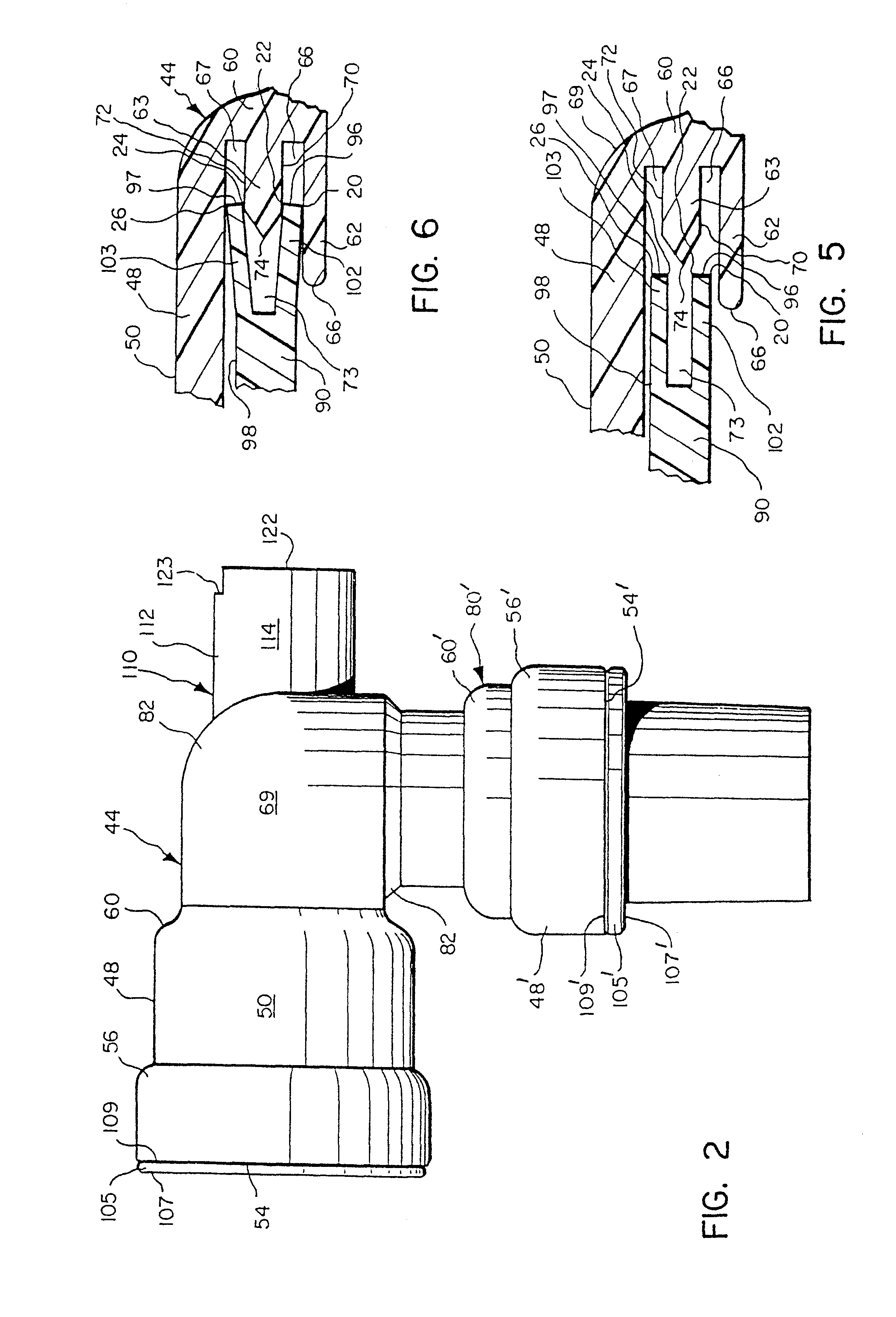

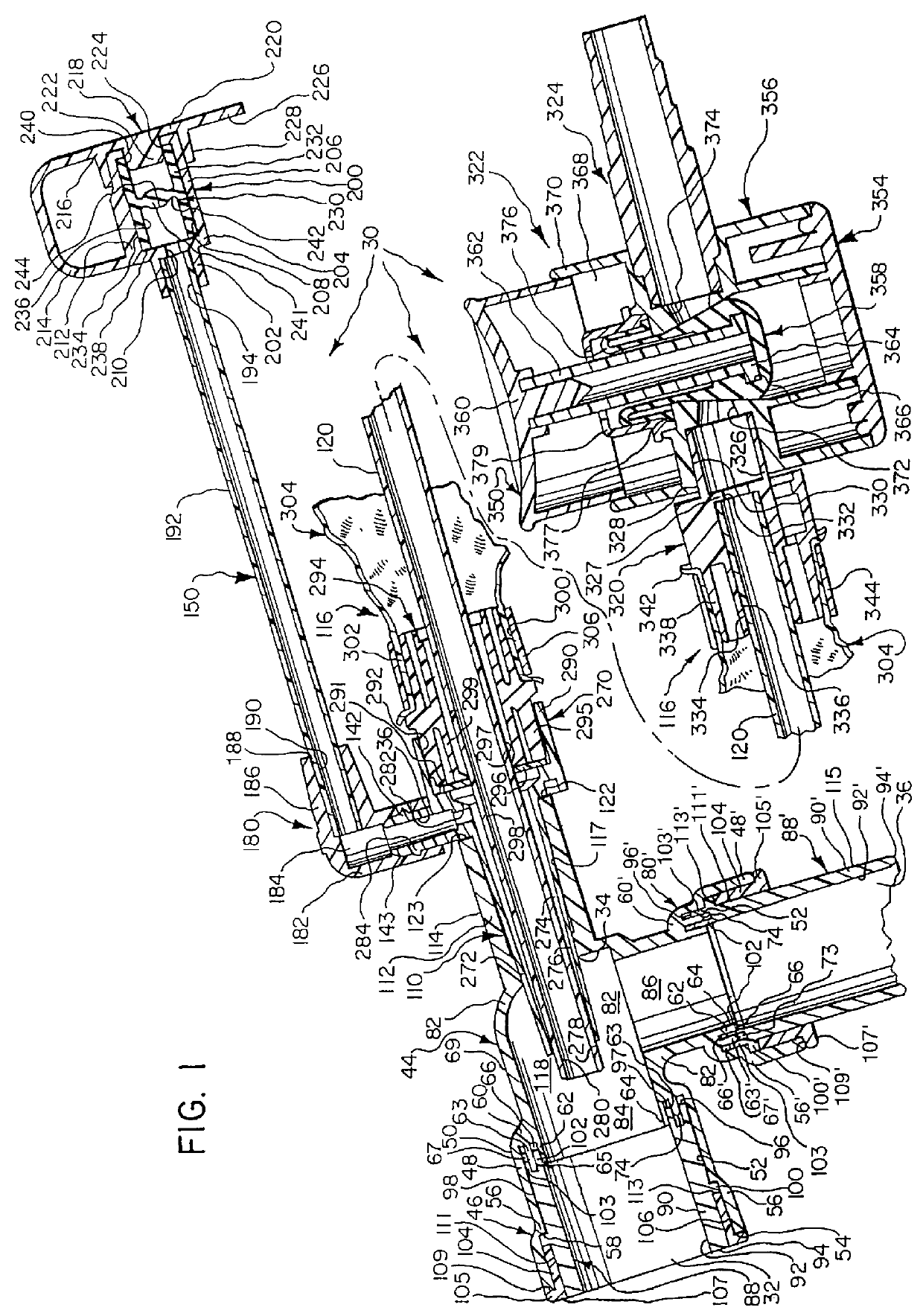

Apparatus and methods are disclosed by which a closed ventilating system accommodates multiple access to the respiratory system of an intubated medical patient without compromising the closed character of the system. Access to the respiratory system through one or more access sites of the closed system apparatus is provided at proximal adapter ports to ventilate the lungs of the patient with gas or gases, to aspirate secretions from the lungs, to oxygenate the lungs to eliminate or reduce residual co2 therefrom, to visually inspect selected parts of the respiratory system, to sample sputum and gases, to sense parameters such as flow rates, pressure, and temperature, to flush with washing solution, and / or to administer medication, gases, and / or lavage. A distal swivel fitting provides multiple sealing sites by which entry of atmosphere is prevented.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Medical aspirating/ventilating closed system improvements and methods

InactiveUS6012451AEasy to limitCost effectiveTracheal tubesRespiratory apparatusEmergency medicineOxygen

Apparatus and methods are disclosed by which a closed ventilating system accommodates multiple access to the respiratory system of an intubated medical patient without compromising the closed character of the system. Access to the respiratory system through one or more access sites of the closed system apparatus is provided at proximal adapter ports to ventilate the lungs of the patient with gas or gases, to aspirate secretions from the lungs, to oxygenate the lungs to eliminate or reduce residual co.sub.2 therefrom, to visually inspect selected parts of the respiratory system, to sample sputum and gases, to sense parameters such as flow rates, pressure, and temperature, to flush with washing solution, and / or to administer medication, gases, and / or lavage. A distal swivel fitting provides multiple sealing sites by which entry of atmosphere is prevented.

Owner:KIMBERLY-CLARK WORLDWIDE INC

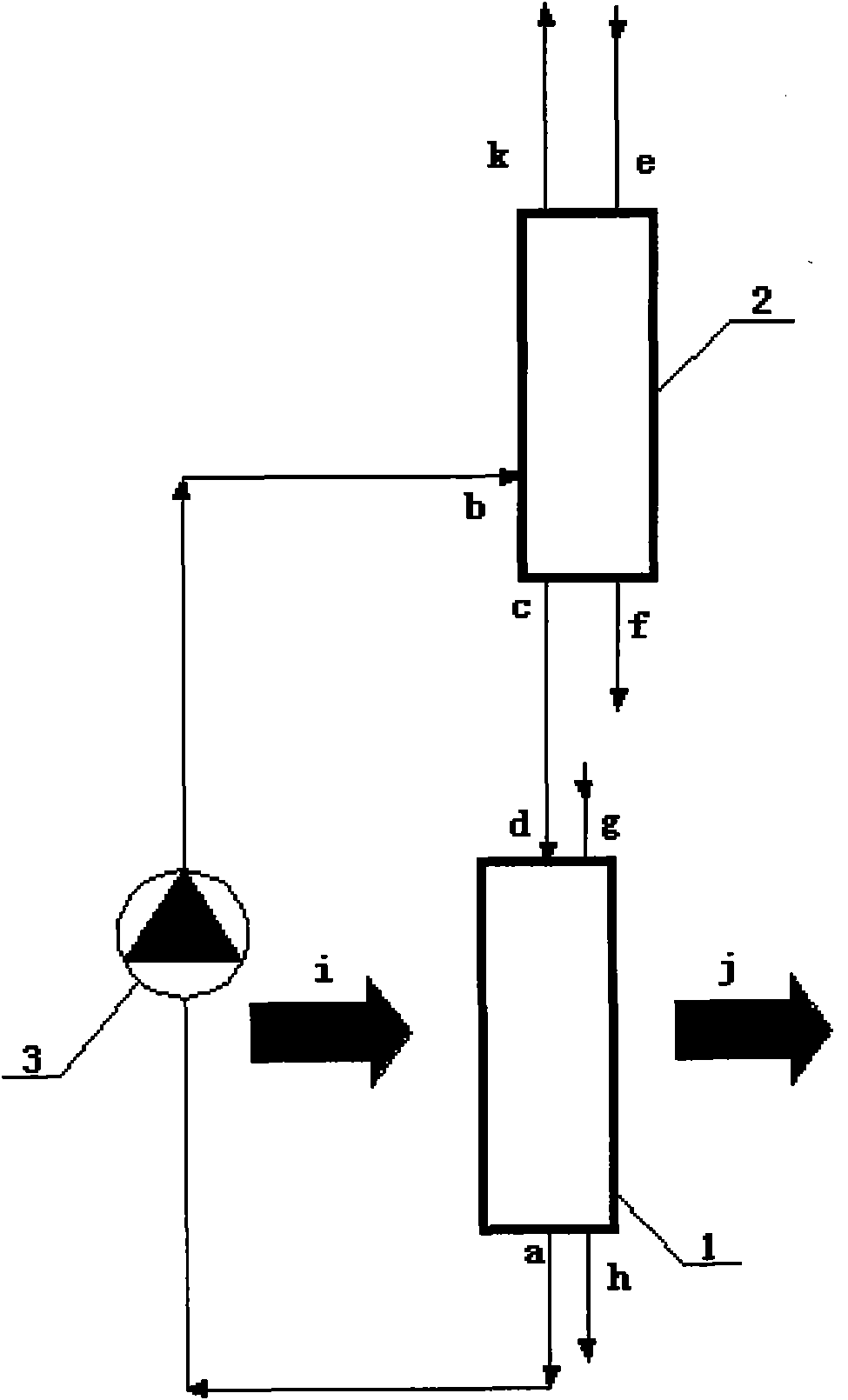

Dehumidizer for air dehumidification, air dehumidification method and device

InactiveCN102335545AEfficient removalQuick removalLighting and heating apparatusDispersed particle separationLithium chlorideWater vapor

The invention discloses a dehumidizer for air dehumidification. The dehumidizer provided by the invention is an ionic liquid solution formed by dissolving an ionic liquid in water, wherein the ionic liquid is formed by organic positive ions and inorganic negative ions, and the melting point of the ionic liquid is close to or is lower than room temperature. In addition, the invention further discloses a method and a device for air dehumidification by the adoption of the above dehumidizer. In comparison with traditional salting liquids (lithium bromide, lithium chloride and calcium chloride aqueous solutions and the like), the dehumidizer provided by the invention has the following advantages: 1) the applied ionic liquid solution is in the liquid state at normal temperature, is intermiscible with water, and will not be crystallized during operation, so as to guarantee the reliable operation of a system; 2) the applied ionic liquid solution has similar or lower water vapor pressure than a traditional dehumidifying salting liquid so as to raise the dehumidifying efficiency; 3) the applied ionic liquid solution will not corrode metal equipment such as steel equipment such that the equipment has low cost and long service life; 4) the dehumidizer has nonvolatility so as to reduce the environmental pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method and apparatus for facilitating urological procedures

A flexible direct vision fiberoptical viewing cable is placed within a urinary catheter with its tip located at a distal end of the catheter such that the surfaces of the distal end of both the viewing cable and the catheter are aligned so as to fit together in such a way as to form a composite smoothly curved surface to facilitate negotiating obstructions. The cable is maintained in this position within the catheter with the surfaces that comprise the tip of the instrument, maintained in alignment. The urethra is then viewed therethrough during all or part of the insertion procedure for observing and identifying obstructions that may be present and thereafter the fiberoptic cable is withdrawn while allowing the catheter to remain in place within the urethra.Another form of instrument includes a working sheath and an obturator. A method is also described for facilitating endoscopic examination and surgical procedures through the sheath.

Owner:PERCUVISION

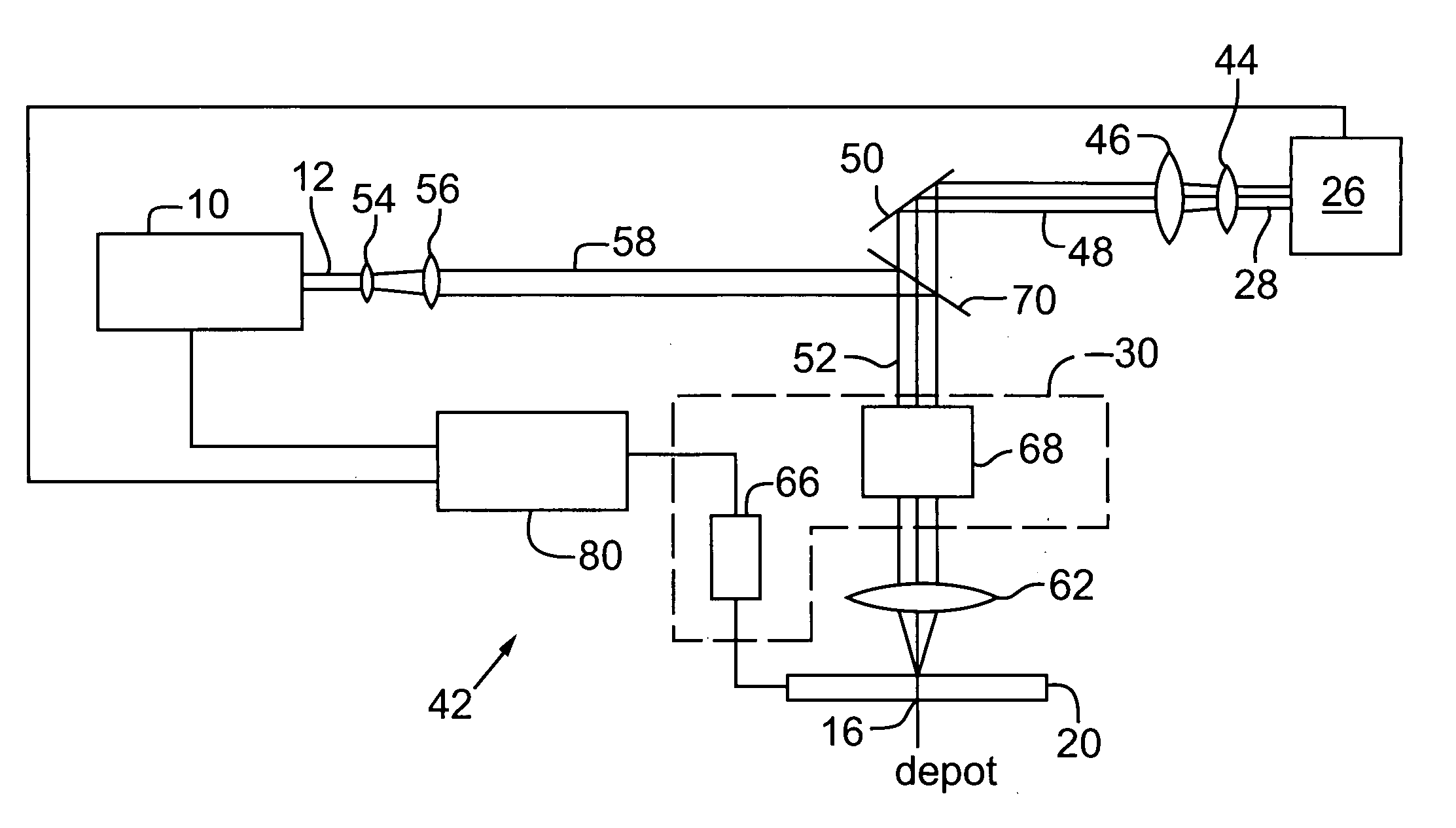

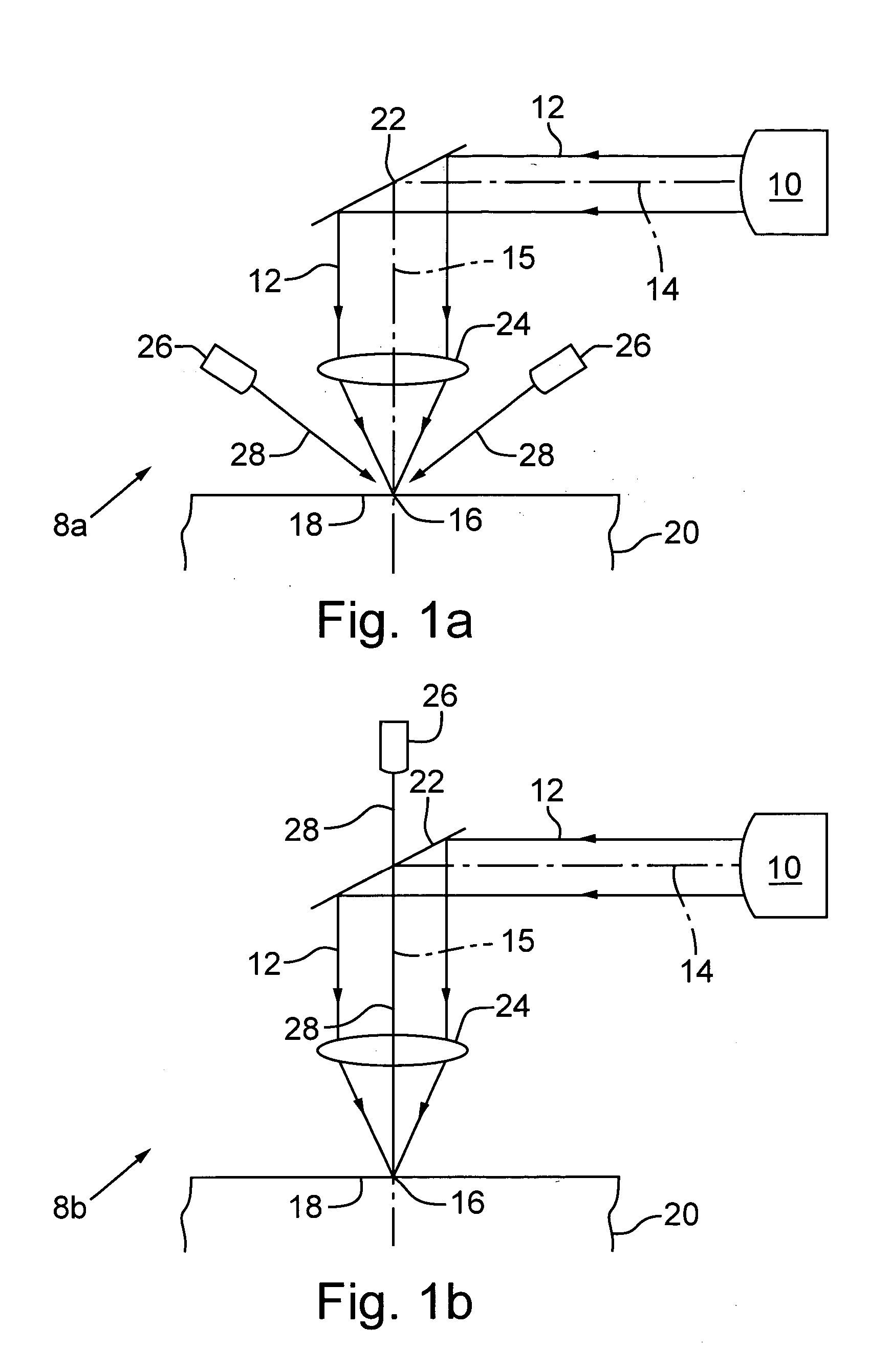

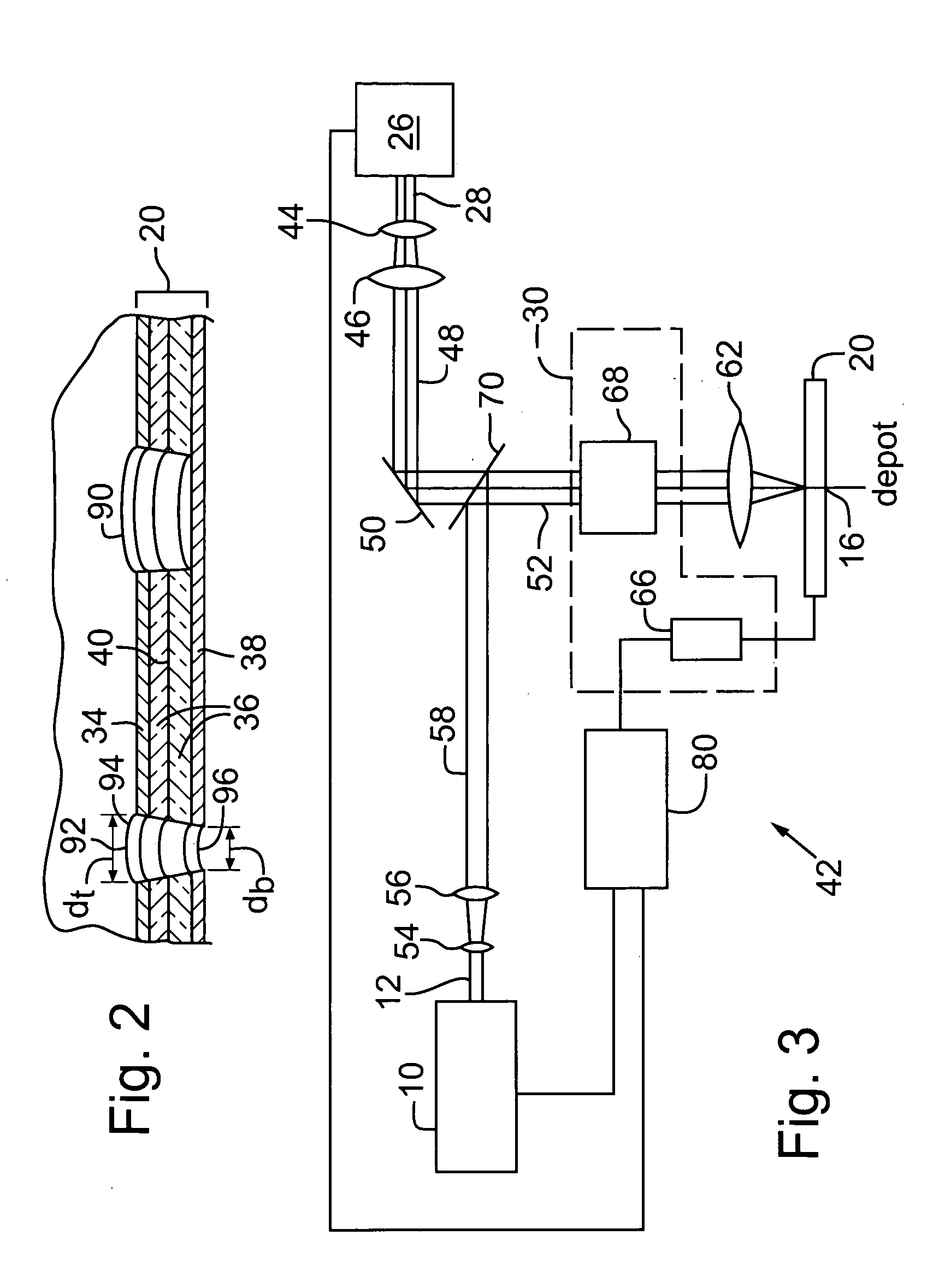

Laser processing of a locally heated target material

InactiveUS20050087522A1Improve efficiencyIncrease speedPrinted circuit manufactureWelding/soldering/cutting articlesThermal energyLaser processing

A method and laser system effect rapid removal of material from a workpiece by applying heating energy in the form of a light beam to a target location on the workpiece to elevate its temperature while maintaining its dimensional stability. When the target portion of the workpiece is heated, a laser beam is directed for incidence on the heated target location. The laser beam preferably has a processing laser output that is appropriate to effect removal of the target material from the workpiece. The combined incidence of the processing laser output and the heating energy on the target location enables the processing laser output to remove a portion of the target material at a material removal rate that is higher than the material removal rate achievable when the target material is not heated.

Owner:ELECTRO SCI IND INC

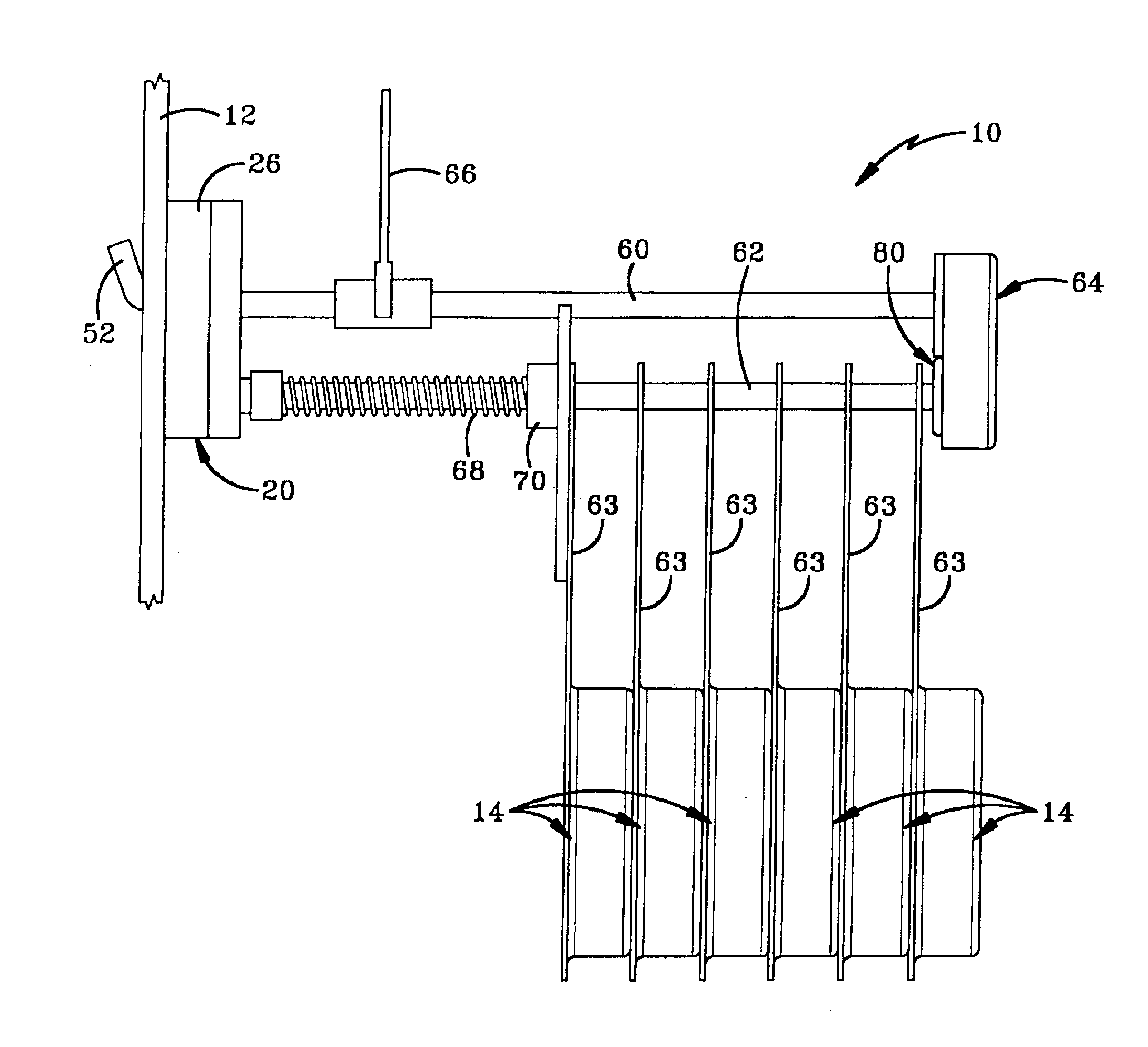

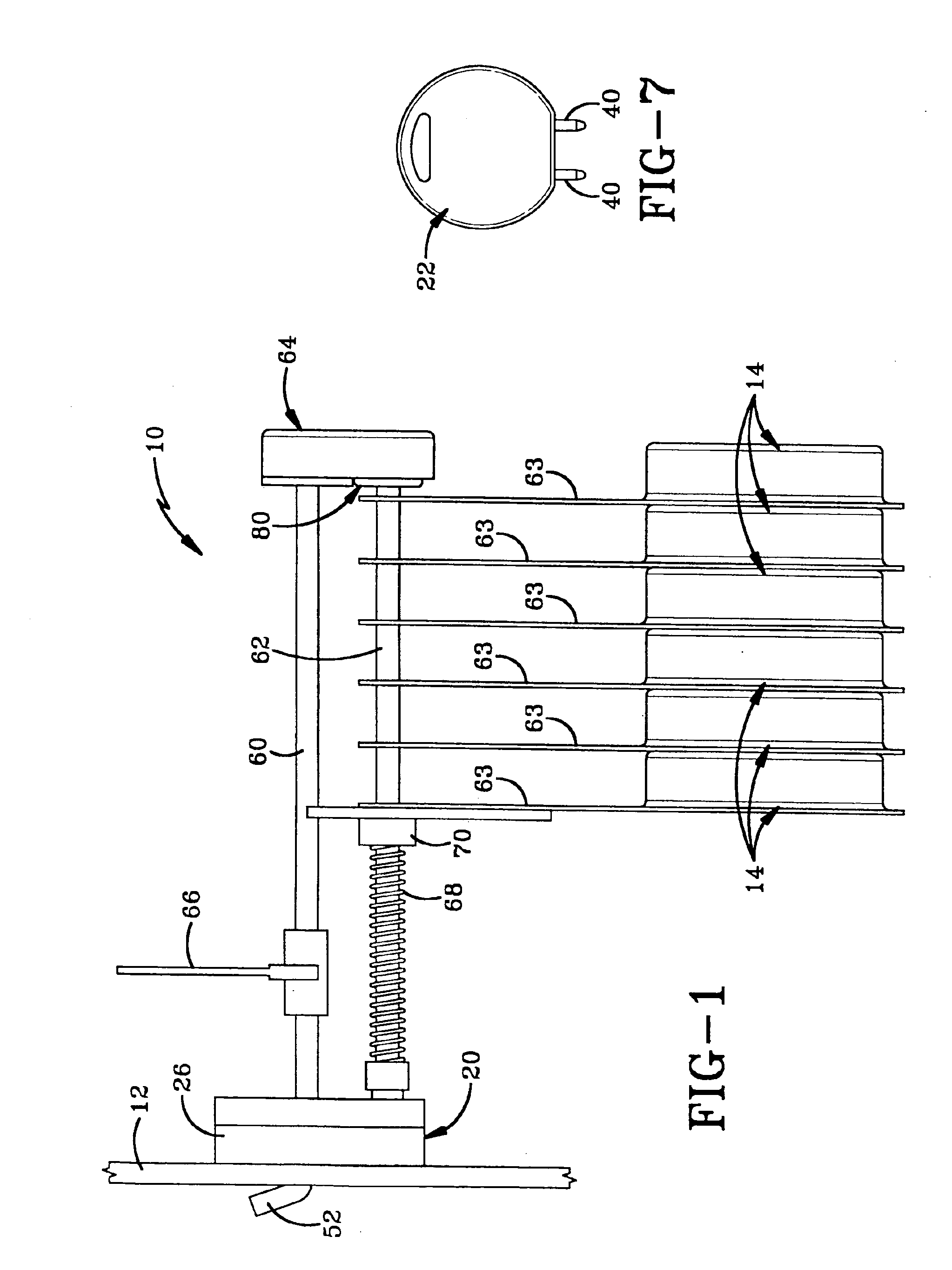

Merchandise display hook having interlocking time delay arms

A display hook for supporting items of merchandise includes a rod assembly and a pair of mechanically interlocked time delay arms medially disposed on the rod assembly. The time delay arms are sequentially movable to permit a potential purchaser to manipulate an item beyond the time delay arms for removal from the display hook. The time delay arms include a guide tube slidingly disposed on the rod assembly, a first arm rotatably mounted on the guide tube and a second arm spaced outwardly from the first arm and fixedly mounted on the guide tube. The first arm is spaced-apart from the second arm sufficiently to permit at least one of the items to be disposed between the arms. The first arm has a circumferentially extending groove and the guide tube has a key that cooperates with the groove to permit limited rotation between the guide tube and the first arm.

Owner:INVUE SECURITY PROD INC

Security device for preventing rapid removal of merchandise

Owner:INVUE SECURITY PROD INC

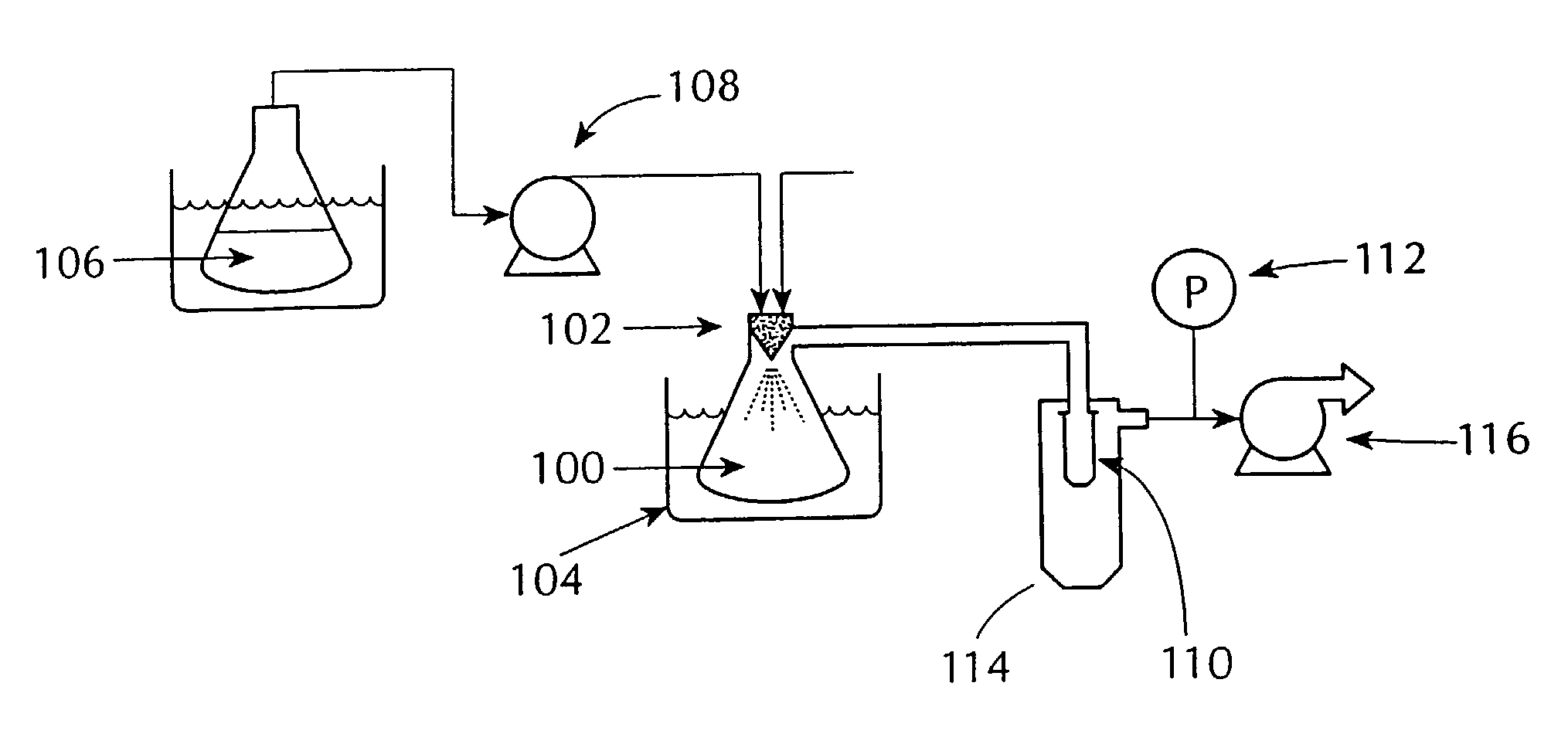

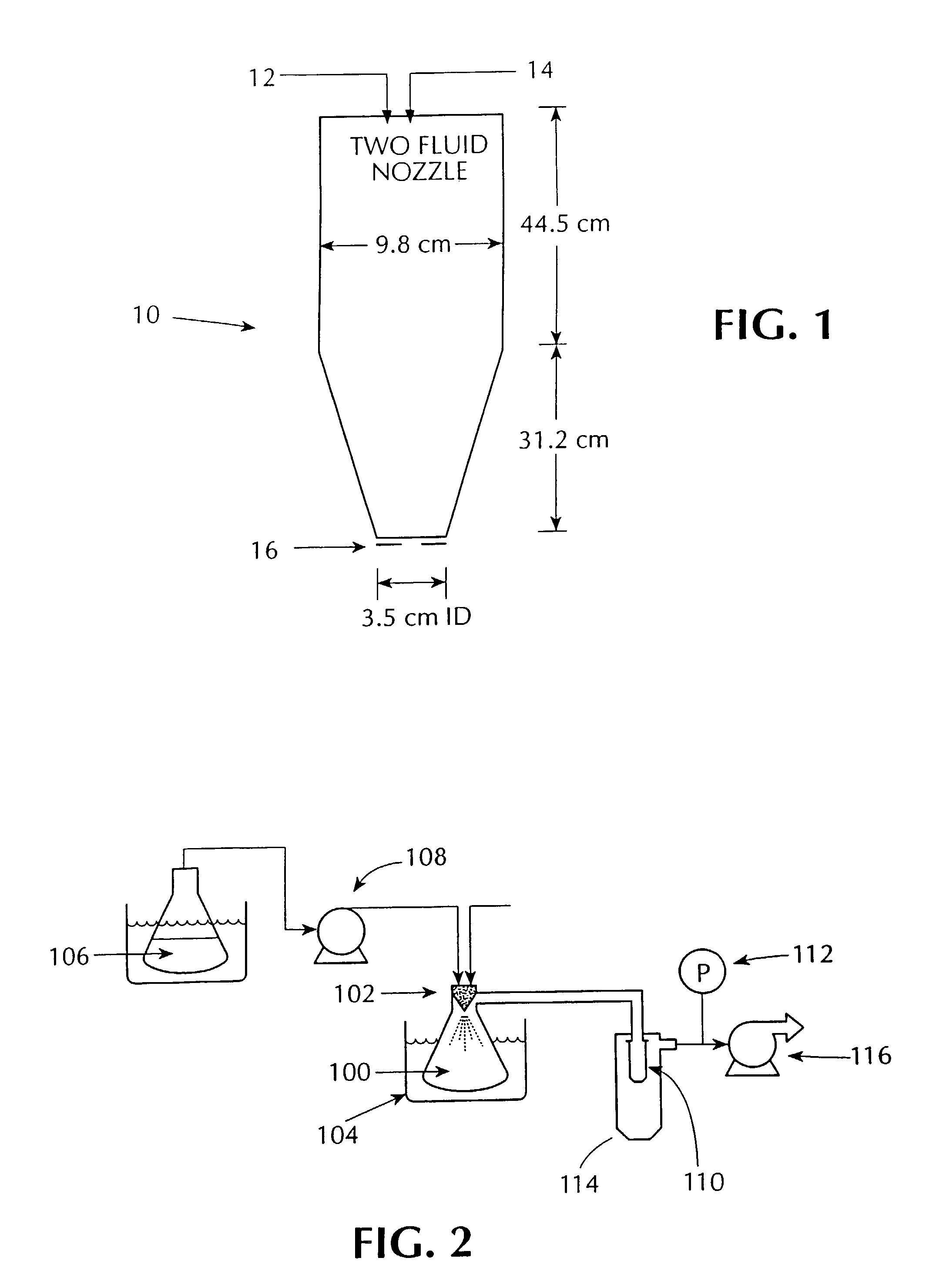

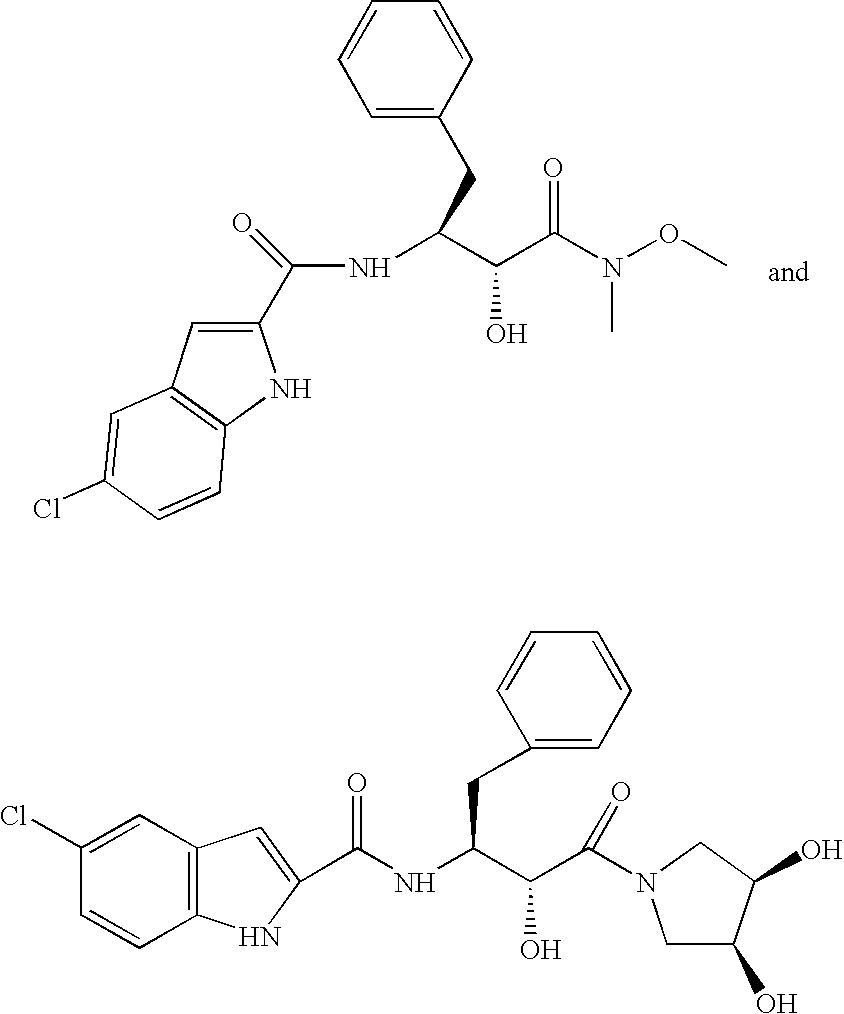

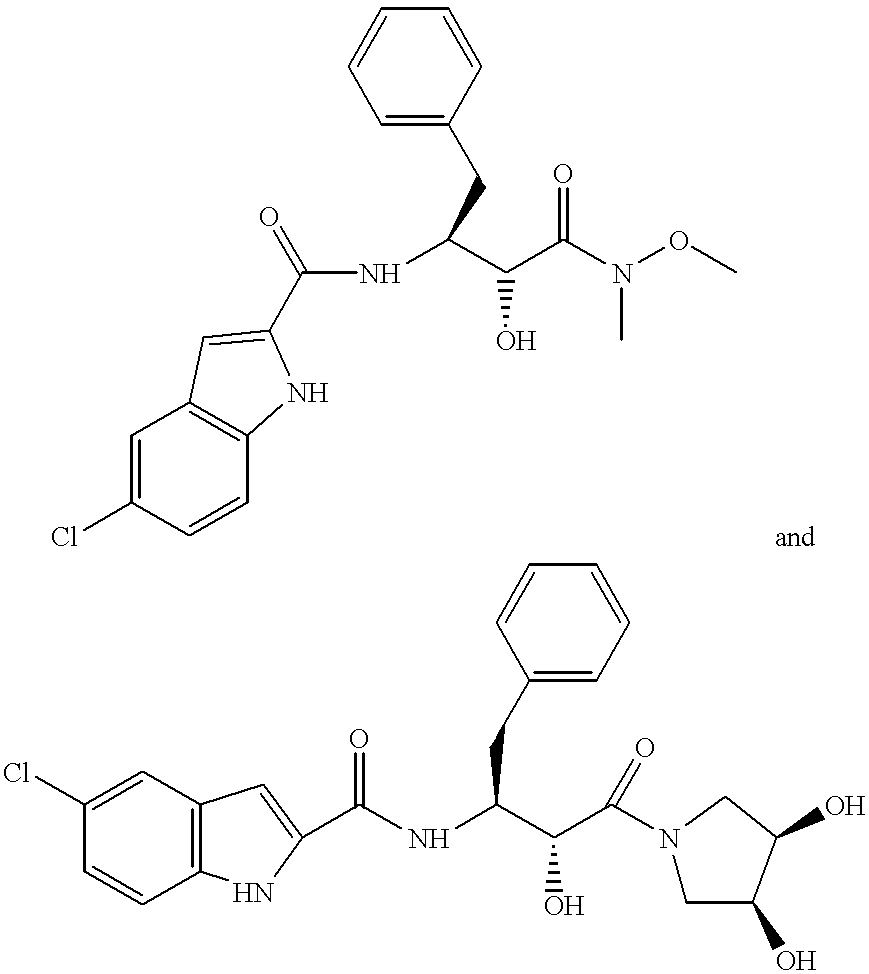

Solid pharmaceutical dispersions with enhanced bioavailability

InactiveUS8257741B2Improve solubilityEffective dispersionPowder deliveryBiocideAcetic acidHydroxypropylmethylcellulose acetate succinate

Spray dried solid dispersions comprising a sparingly soluble drug and hydroxypropylmethylcellulose acetate succinate (HPMCAS) provide increased aqueous solubility and / or biavailability in a use environment.

Owner:BEND RES

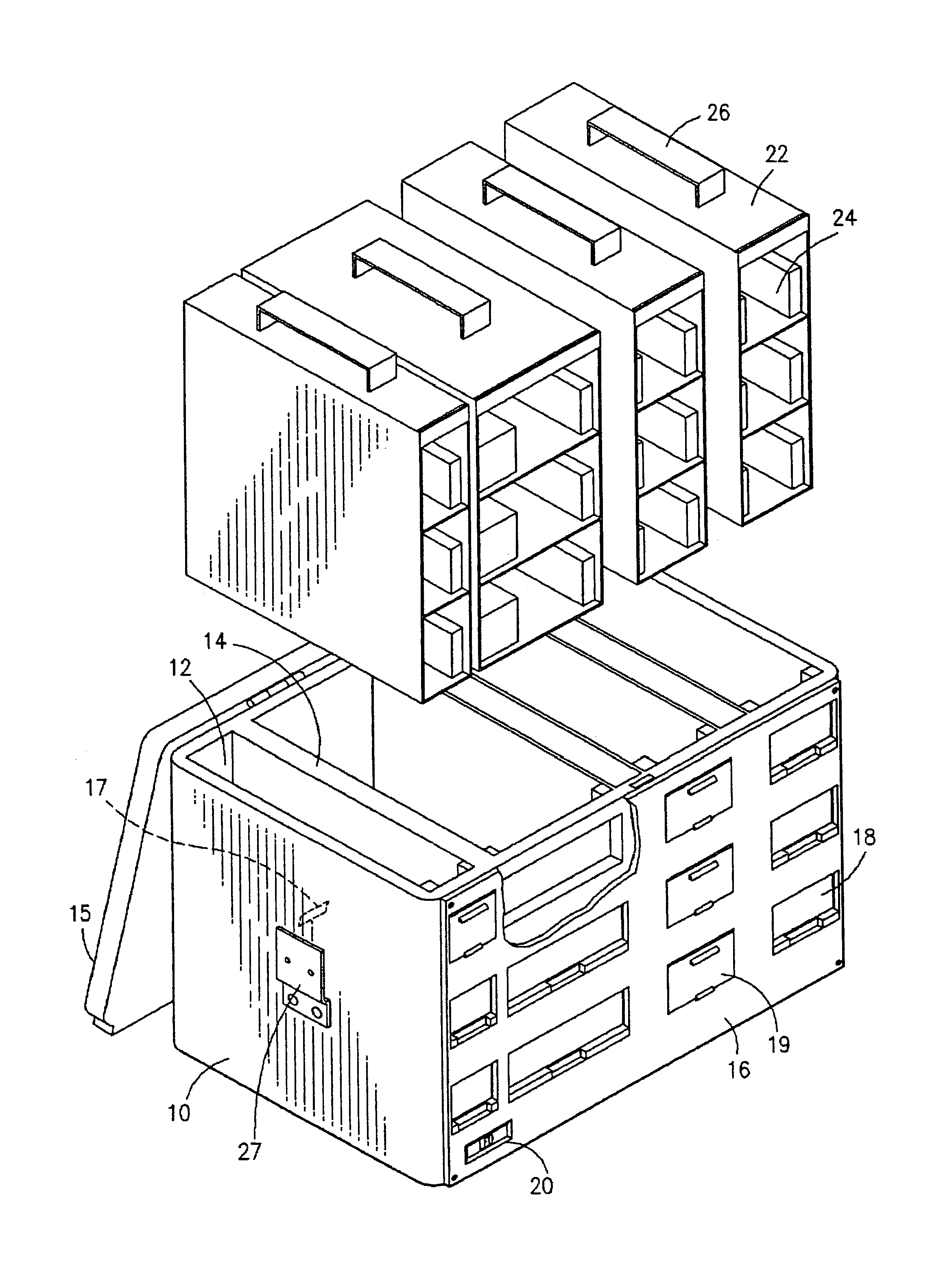

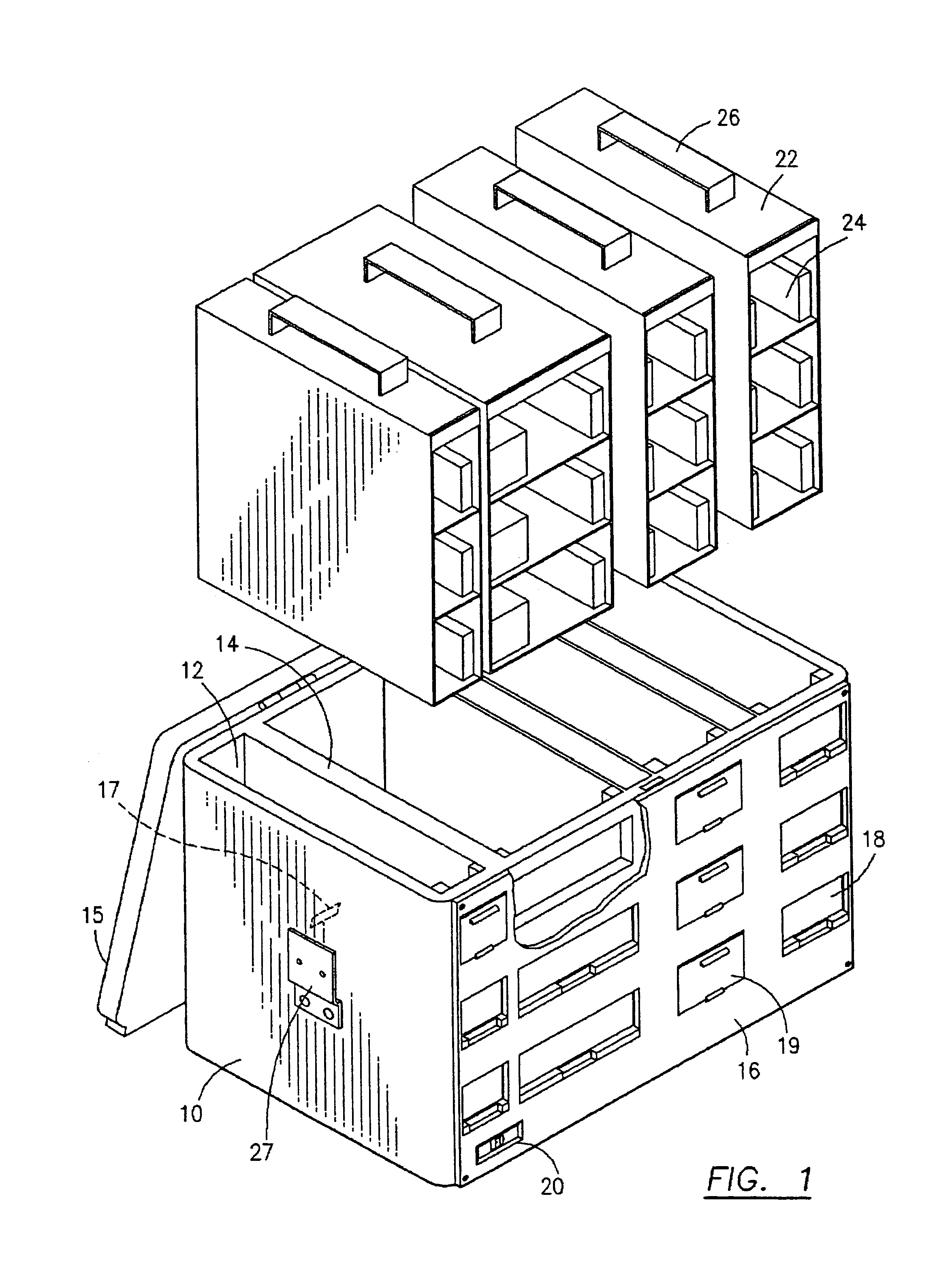

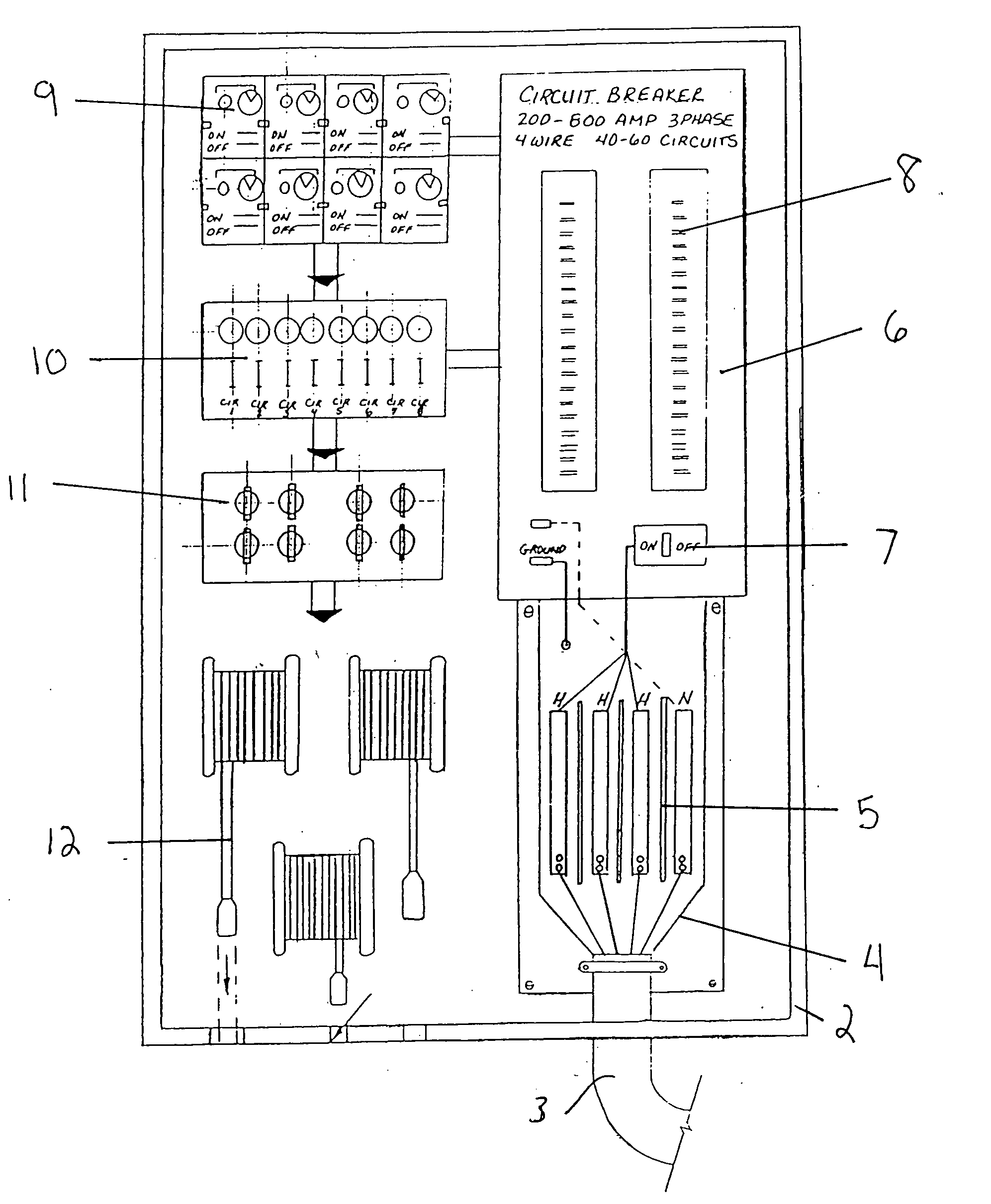

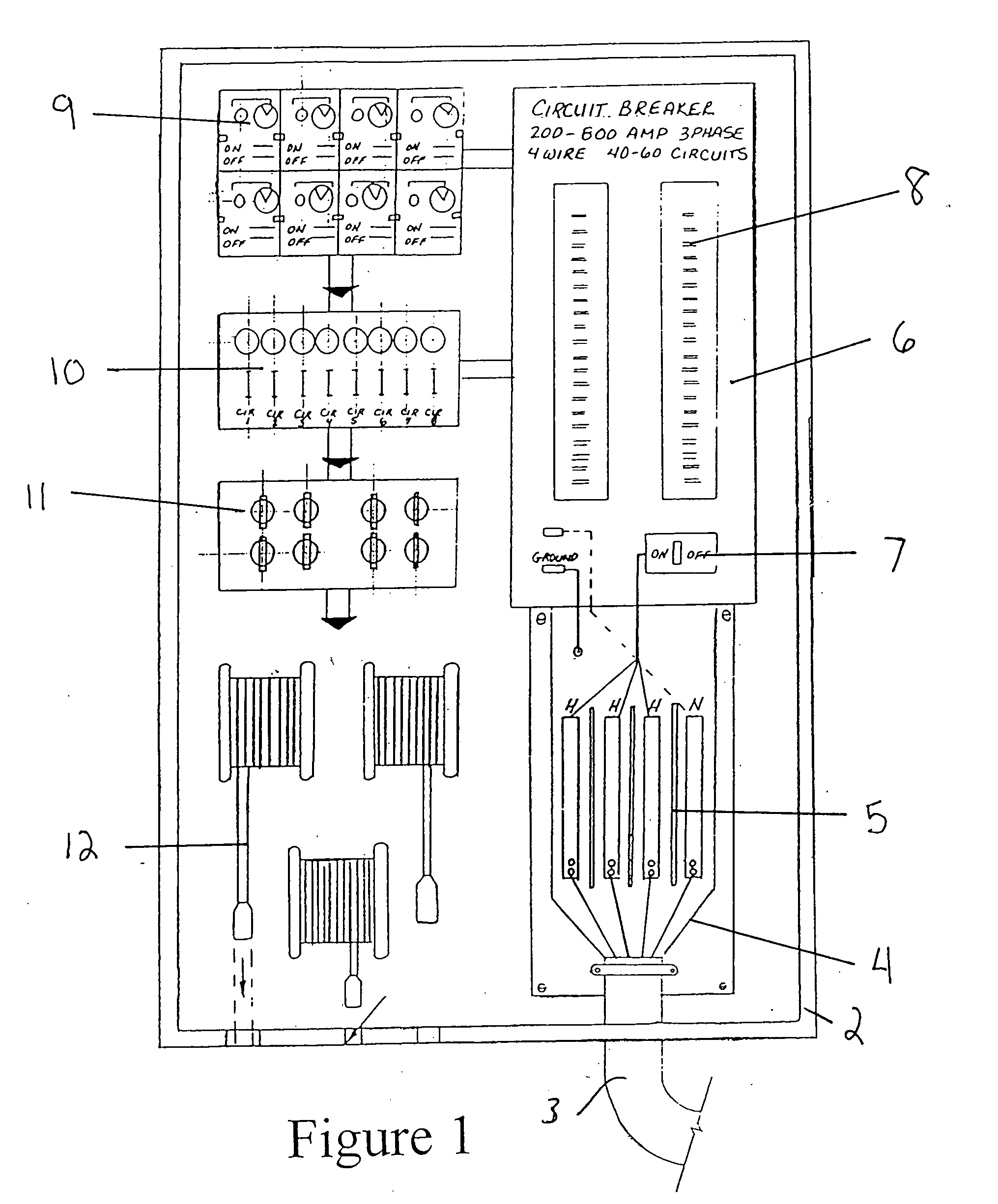

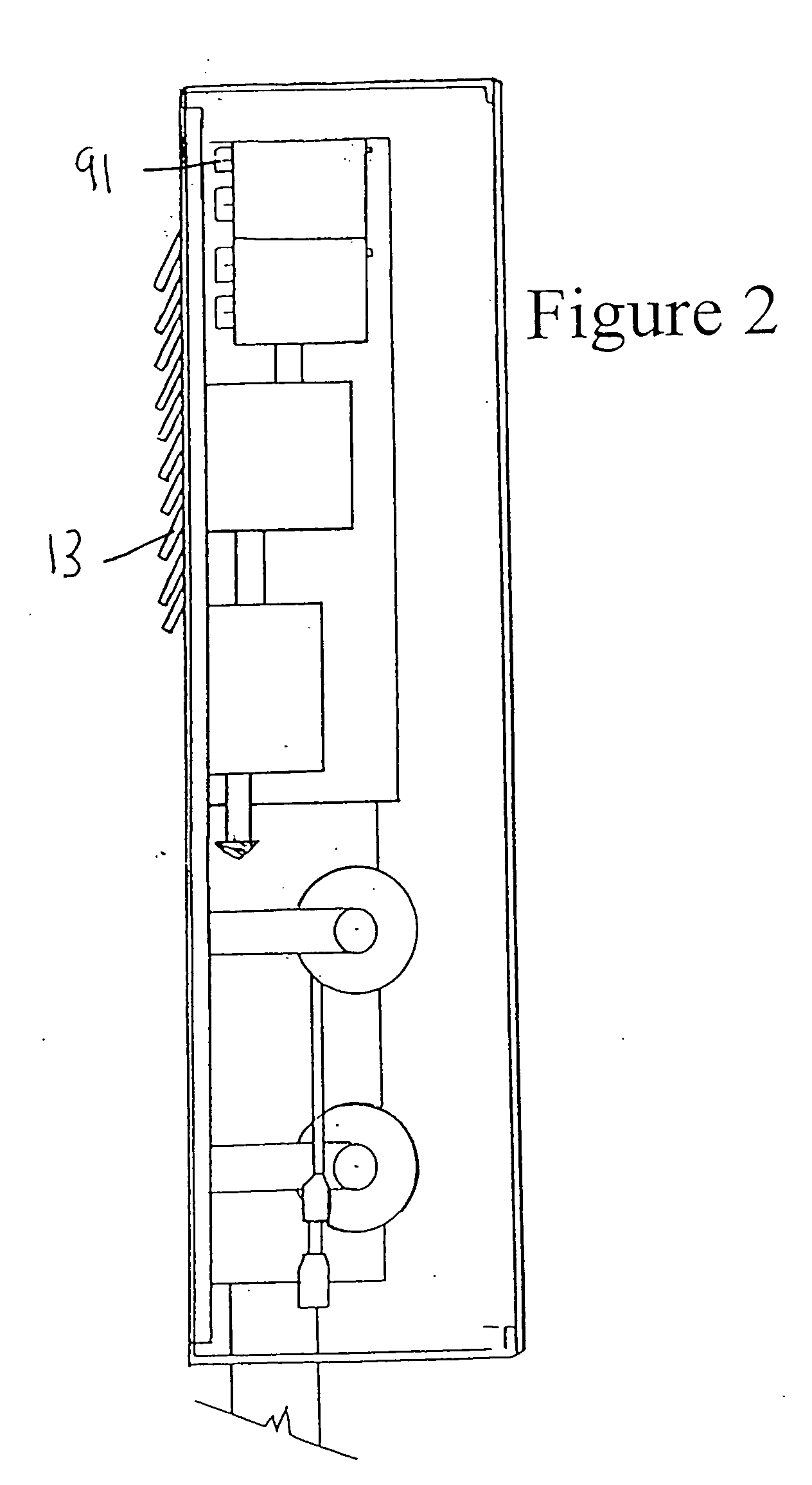

Integrated, self-contained power distribution system

InactiveUS20070230094A1Facilitates repeatableEasy to useSubstation/switching arrangement casingsLow voltageDistribution power system

A portable, temporary power distribution system is contained in a fully integrated, reusable container, and is particularly useful in temporary applications, especially as an alternative power distribution system. The portable system provides comprehensive functionality for all aspects of a power system, and any adjuncts thereto. The portable power distribution system is fully integrated, and can include, for example, low voltage capability, emergency lighting control, communication, power allocation control and circuit protection, as well as any other protective or control feature that is used in a permanent power distribution system for virtually any installation.

Owner:CARLSON CURT S

High throughput flash purification stand and cartridge

InactiveUS20050011835A1Increase the lengthReliable fluid connectionIon-exchange process apparatusComponent separationEngineeringChromatography column

A chromatography stand for supporting a chromatographic column in use for chromatographic analysis has a first and a second platen adapted to receive and hold the chromatographic column therebetween. The first and second platens are mounted on a frame in generally opposed relation for relative movement toward and away from each other. At least one of the first and second platens is constructed for plug-in connection to the chromatographic column such that the column is positively located relative to the platens and placed in fluid connection through said at least one platen. In one embodiment, the cartridges can be stacked between the platens. The cartridges can be quickly and efficiently pre-loaded with sample.

Owner:SIGMA ALDRICH CO LLC

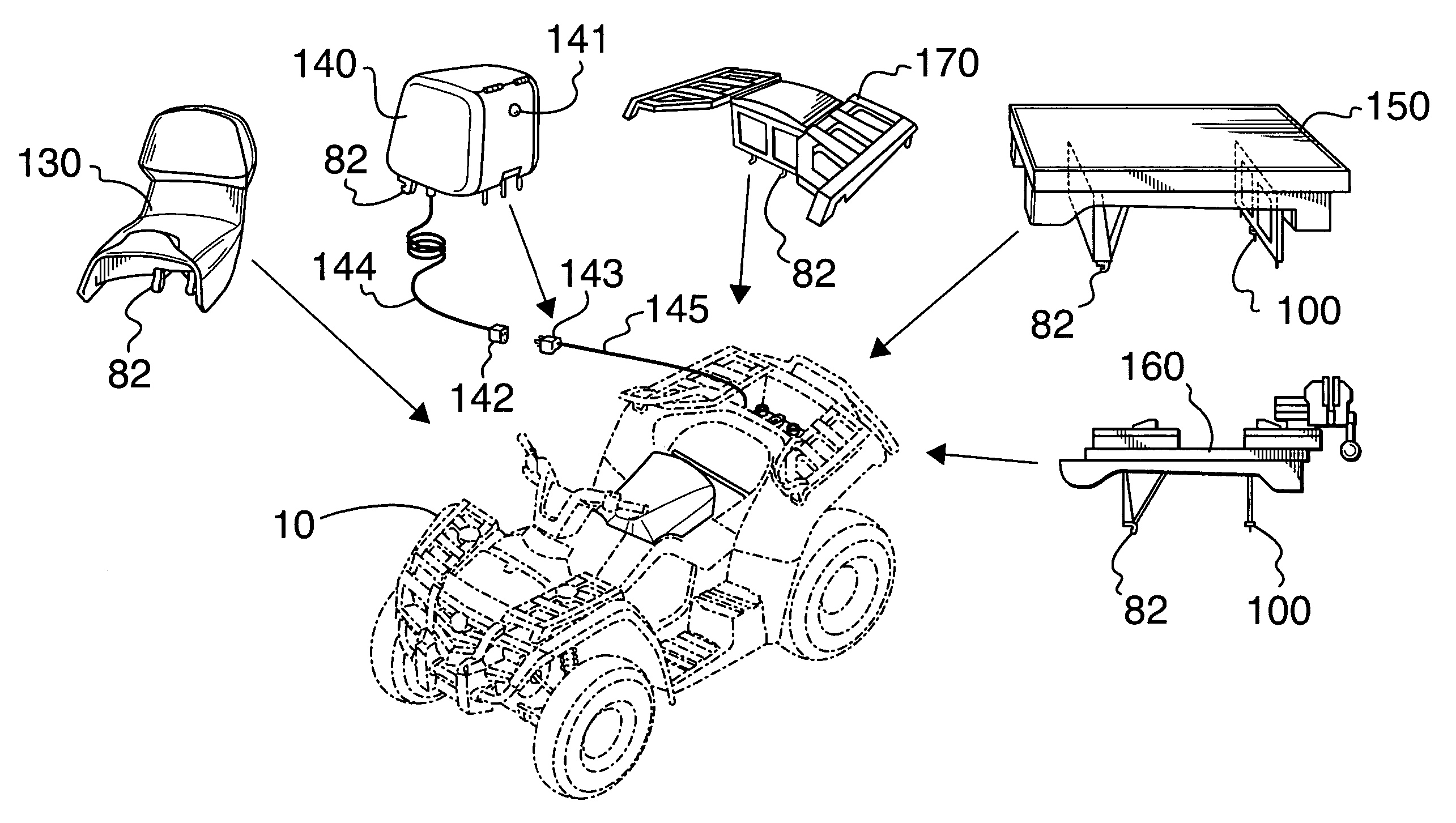

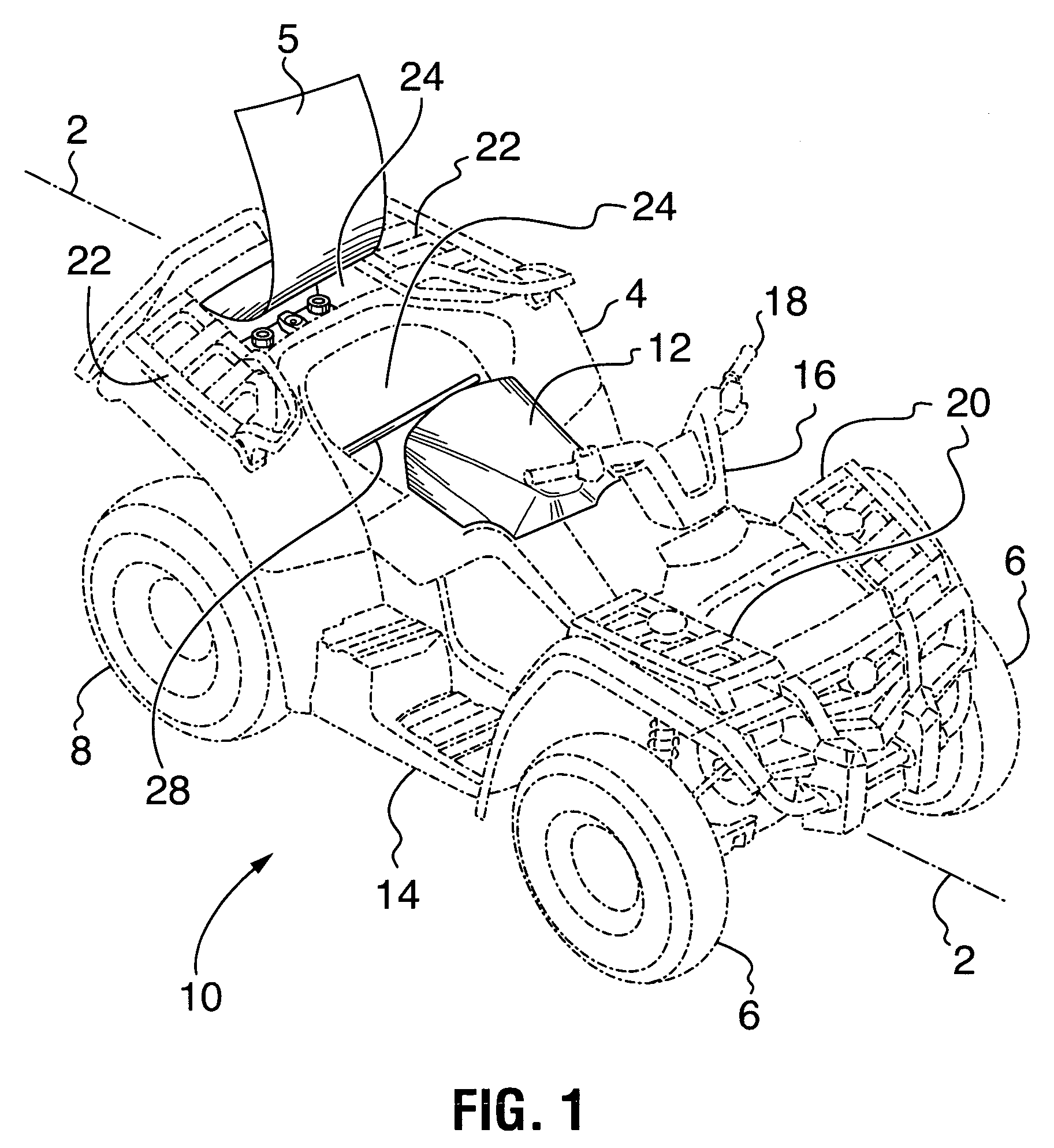

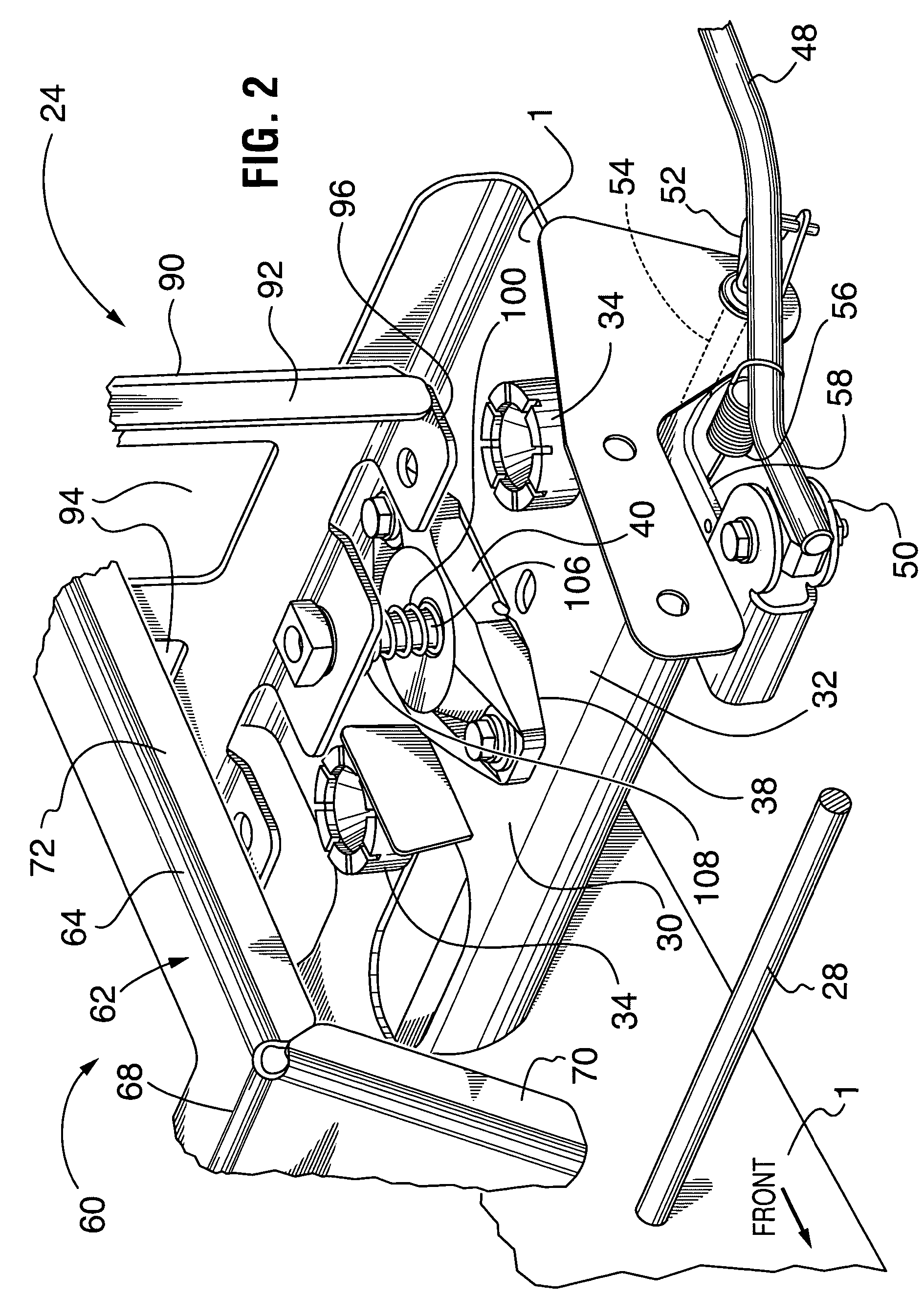

Modular components for an all-terrain vehicle

InactiveUS7377570B2Easy to replaceEasy interchangeCyclesSuperstructure subunitsModularityElectrical connection

An all-terrain vehicle (ATV) with an elongated wheelbase has a rear-mounted receptacle for receiving one of a plurality of interchangeable modular components, such as a passenger seat, a cargo container, a cargo rack, a flatbed or a workbench. The modular component has an electrical connection and a mechanical connector on an underside thereof which has hooks and posts for engaging, respectively, a transverse rod and sockets. A latching mechanism locks the modular component to the rear of the vehicle. Accordingly, the modular component is selectively releasable to easily and quickly interchange one modular component with another.

Owner:BOMBARDIER RECREATIONAL PROD INC

Lock mechanism for display rod

InactiveUS7392673B2Quick removalSimple and compactClothing locksLocks for portable objectsLocking mechanismEngineering

Owner:INVUE SECURITY PROD INC

Solid pharmaceutical dispersions with enhanced bioavailability

InactiveUS8263128B2Improve bioavailabilityPreventing and retarding ratePowder deliveryBiocideAcetic acidHydroxypropylmethylcellulose acetate succinate

Spray dried solid dispersions comprising a sparingly soluble drug and hydroxypropylmethylcellulose acetate succinate (HPMCAS) provide increased aqueous solubility and / or biavailability in a use environment.

Owner:BEND RES

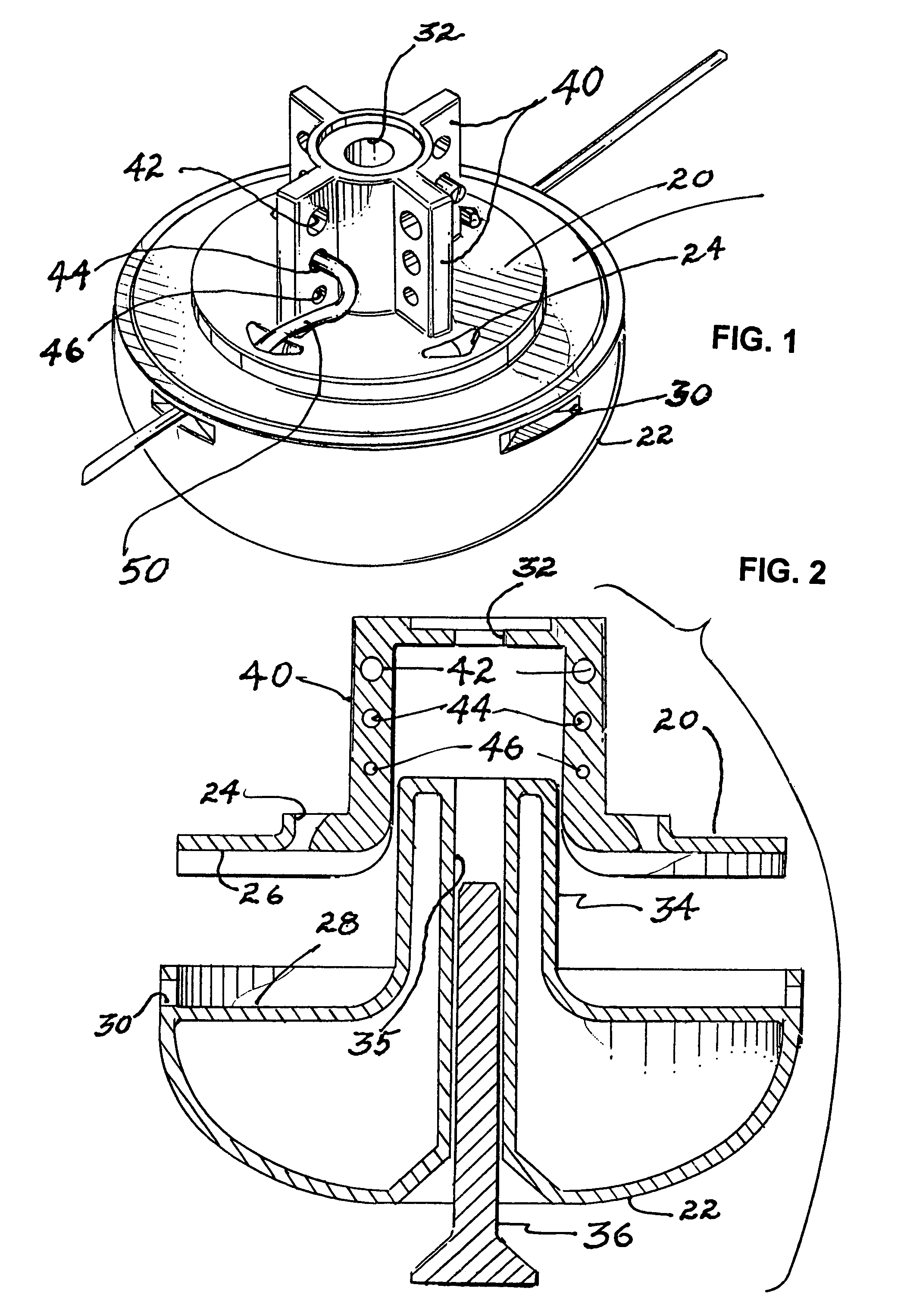

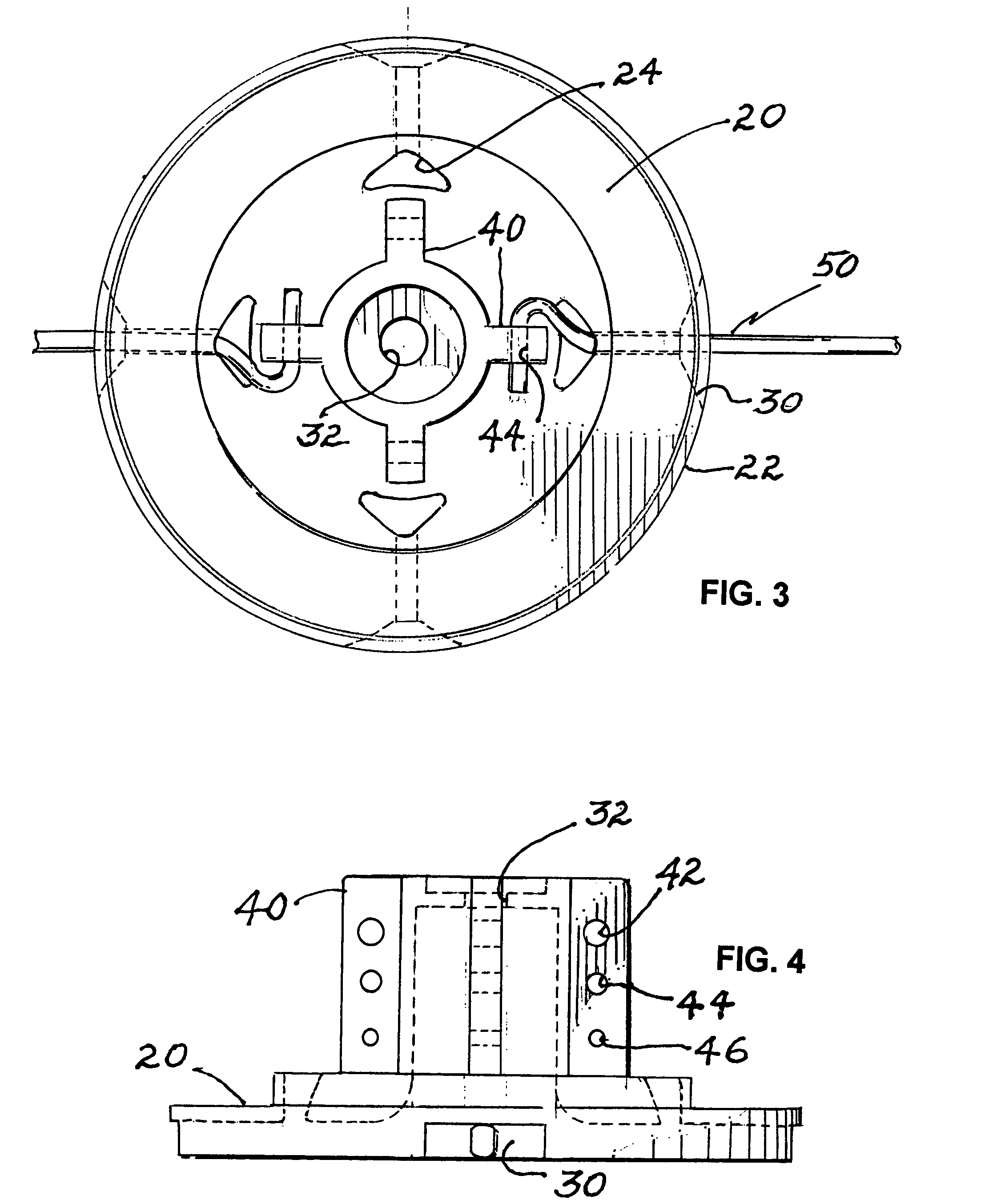

Top loading fixed line trimmer head

InactiveUS7000324B2Simple to install and replaceEasy loadingMowersMetal working apparatusLine segmentFlange

A fixed line top-loading trimmer head for string trimmer machines, uses line segments of a predetermined length. The head has a central hub designed for attachment to the drive shaft of a string trimmer machine. A circular flange is attached to, and extends outwardly from, the central hub. This circular flange has one or more trimmer line exit openings on the circumference. The hub, located above the upper surface of the circular flange, is provided with either line termination apertures in the form of holes or channels which are angularly offset from the exit openings in the circular flange; or it is provided with an offset guide channel through which a trimmer line is passed between the exit openings. A line guide channel is located in the flange between the line exit openings and the line termination apertures, or the offset channel on the hub, for guiding line between the exit openings and the offset channel or termination apertures.

Owner:DESERT EXTRUSION CORP

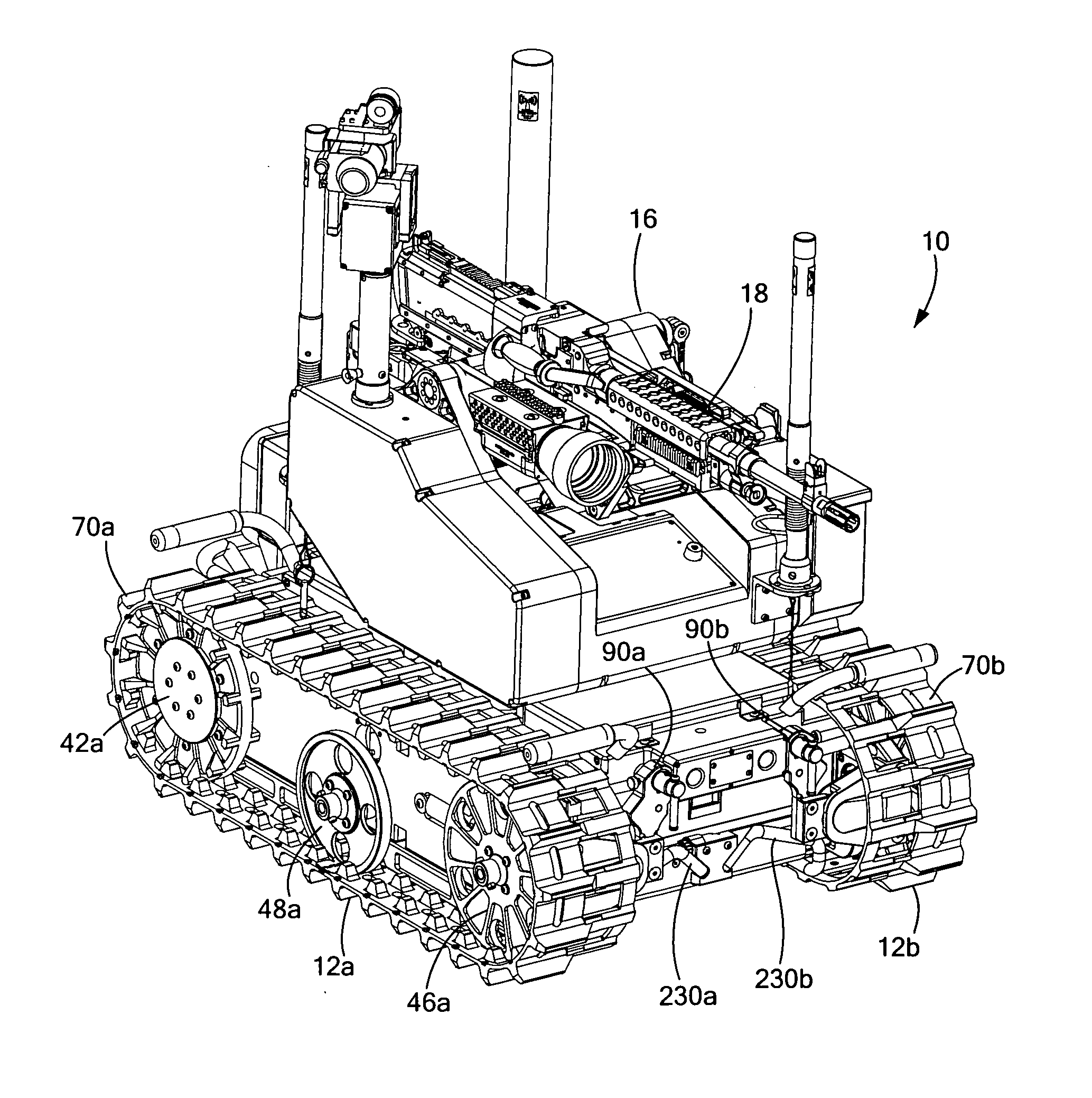

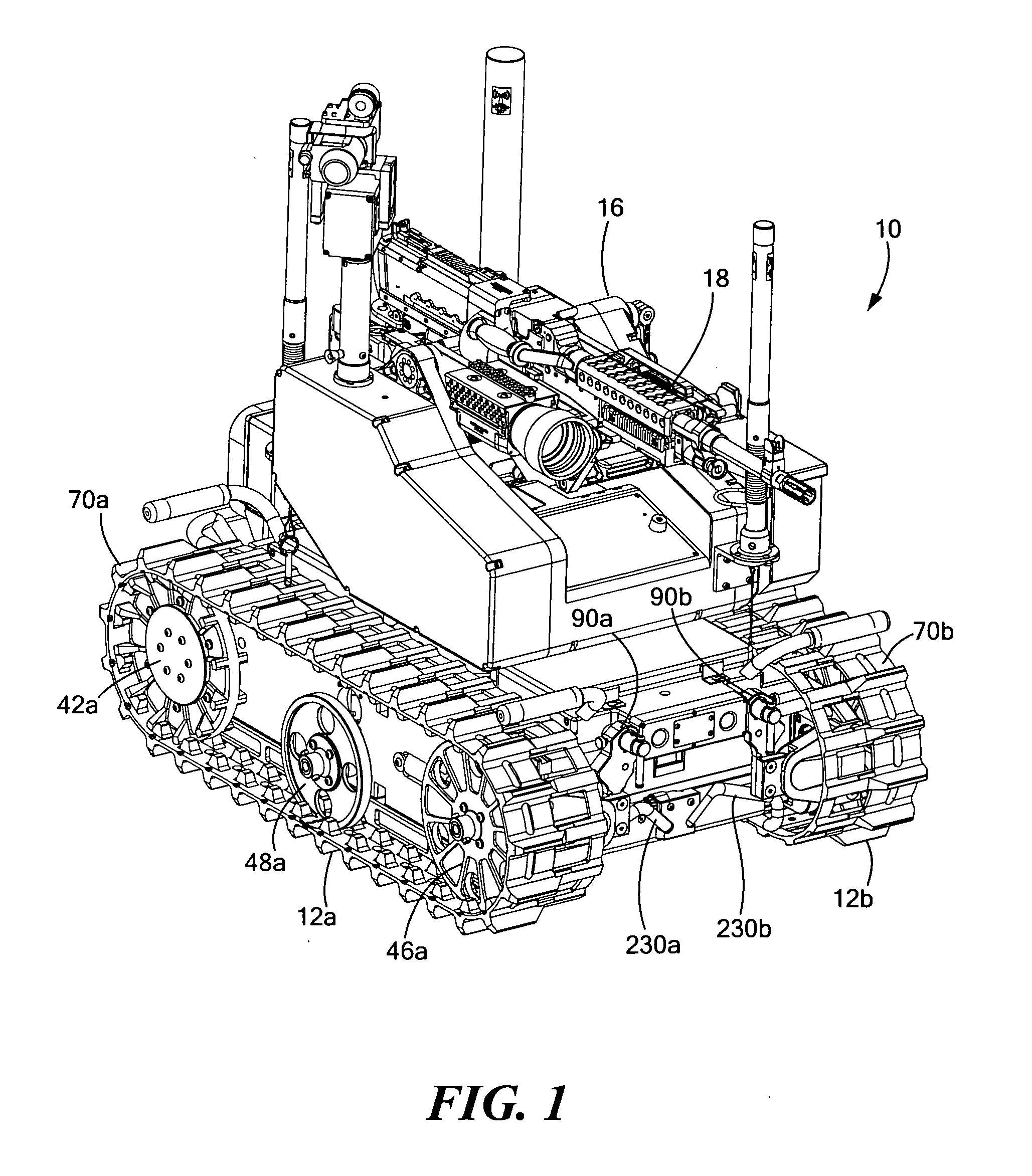

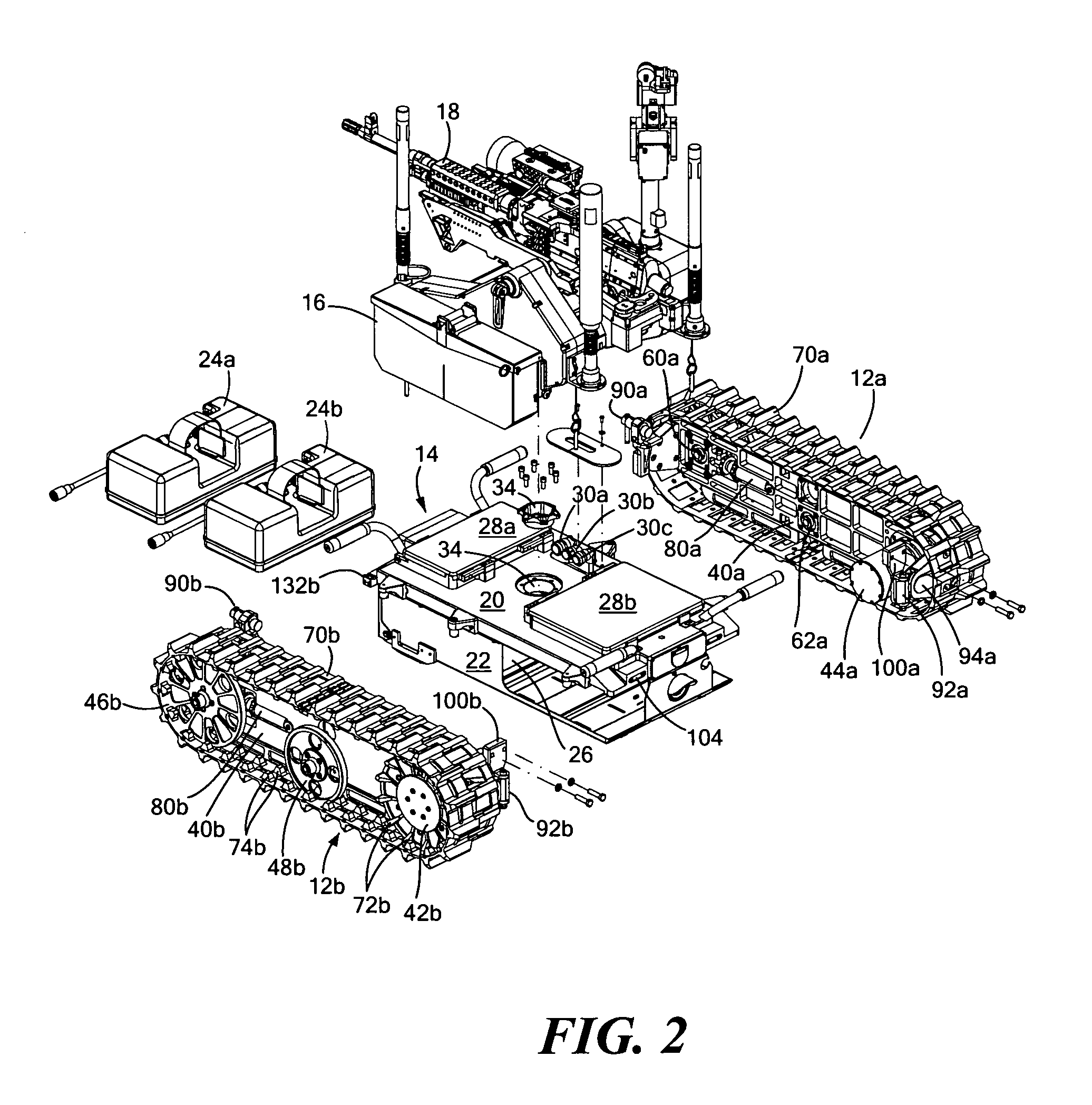

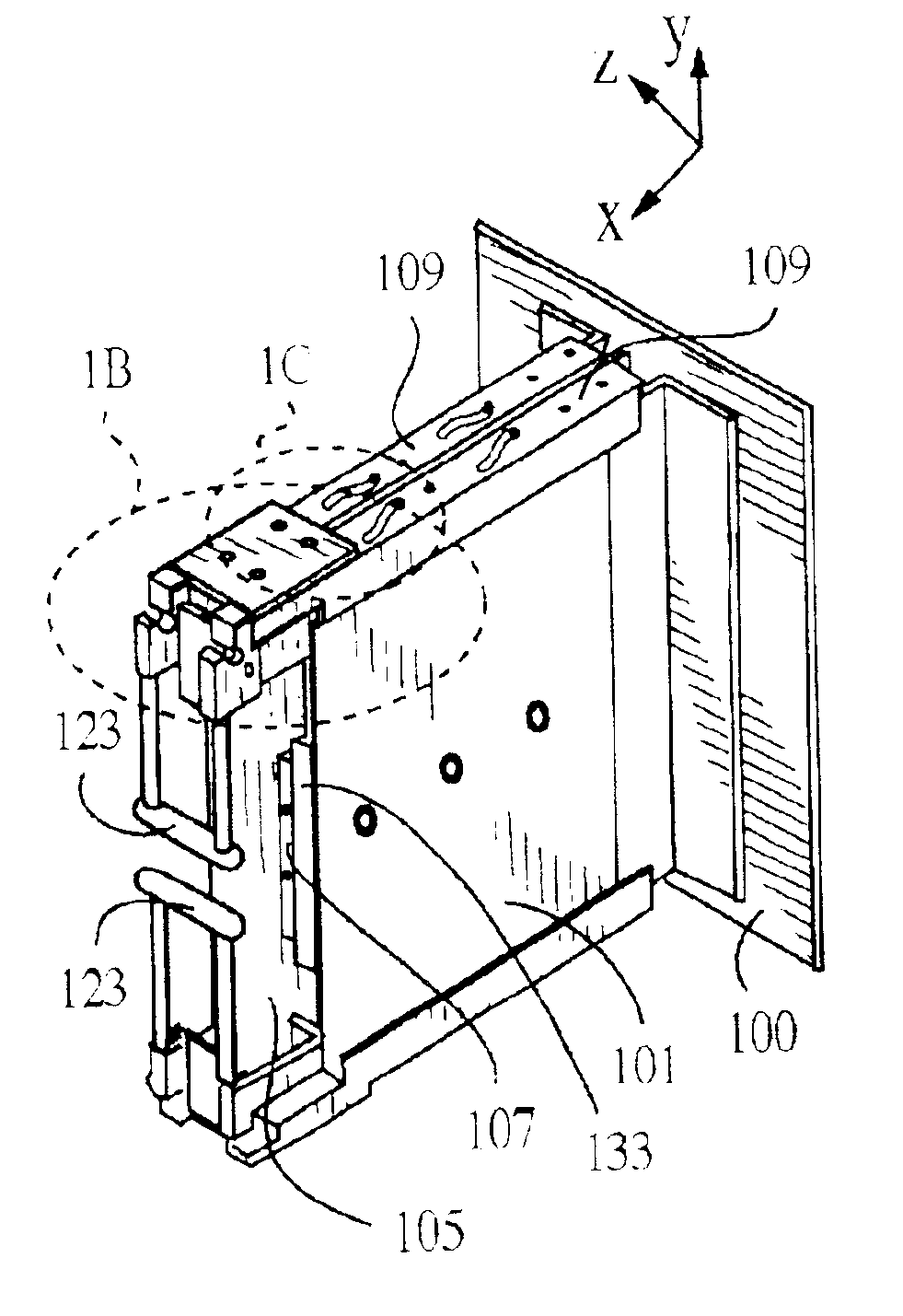

Modular mobile robot

ActiveUS20110005847A1Easy to decoupleSelf containedProgramme controlDefence devicesEngineeringMobile robot

A modular mobile robot with a chassis including a power source housed therein. Right and left hand track modules are each removeably coupled to the robot chassis. Each track module includes a side plate, at least one drive wheel rotatable with respect to the side plate, a motor for driving the drive wheel, at least one idler rotatable with respect to the side plate, and a track extending around the drive wheel, the side plate, and the idler. A turret assembly with its own turret drive subsystem is removeably coupled to the robot chassis via a quick release mechanism.

Owner:FOSTER-MILLER

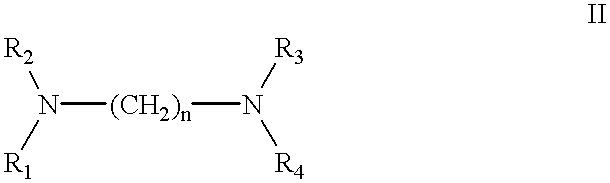

Thickened hard surface cleaner

InactiveUS6268324B1Efficient use ofHigh viscosityInorganic/elemental detergent compounding agentsCationic surface-active compoundsHard-surface cleanerWater rinsing

A low viscosity aqueous cleaning composition provides increasing viscosity upon dilution which provides a high viscosity diluted cleaning composition having solvents compatible with the rod micelle thickener and the cleaning system that clings for an extended period of time in a thickened form containing cleaning system ingredients that can penetrate and remove hard baked-on soils on vertical surfaces in cleaning units. The composition contains active cleaning ingredients (acid, alkaline and enzyme) that, in combination with thickening systems, provide the useful properties. The thickened materials can be applied on cold or hot surfaces and can successfully penetrate, soften and remove baked-on food soil on a variety of surfaces including oven walls, doors and grills, baking dishes, utensils, etc. The material is applied in the form of a thick diluted liquid spray or hot foam directly to the hardened soil, is permitted to penetrate the soil, resulting softened soils are then easily removed by hot or cold water rinse or by mechanical action such as scrubbing, scraping or wiping.

Owner:ECOLAB USA INC

High speed coin processing machine

A coin processing machine for sorting or verifying coins discharges coins through one or more coin tubes and includes a disk mounted on a drive shaft by a nut threaded on the shaft. Each coin tube includes a coin bag support with a non-flexible bracket that presses the bag against the support. A high-friction washer is located between the nut and disk to resist loosening of the nut during machine operation.

Owner:STRING GREGORY F

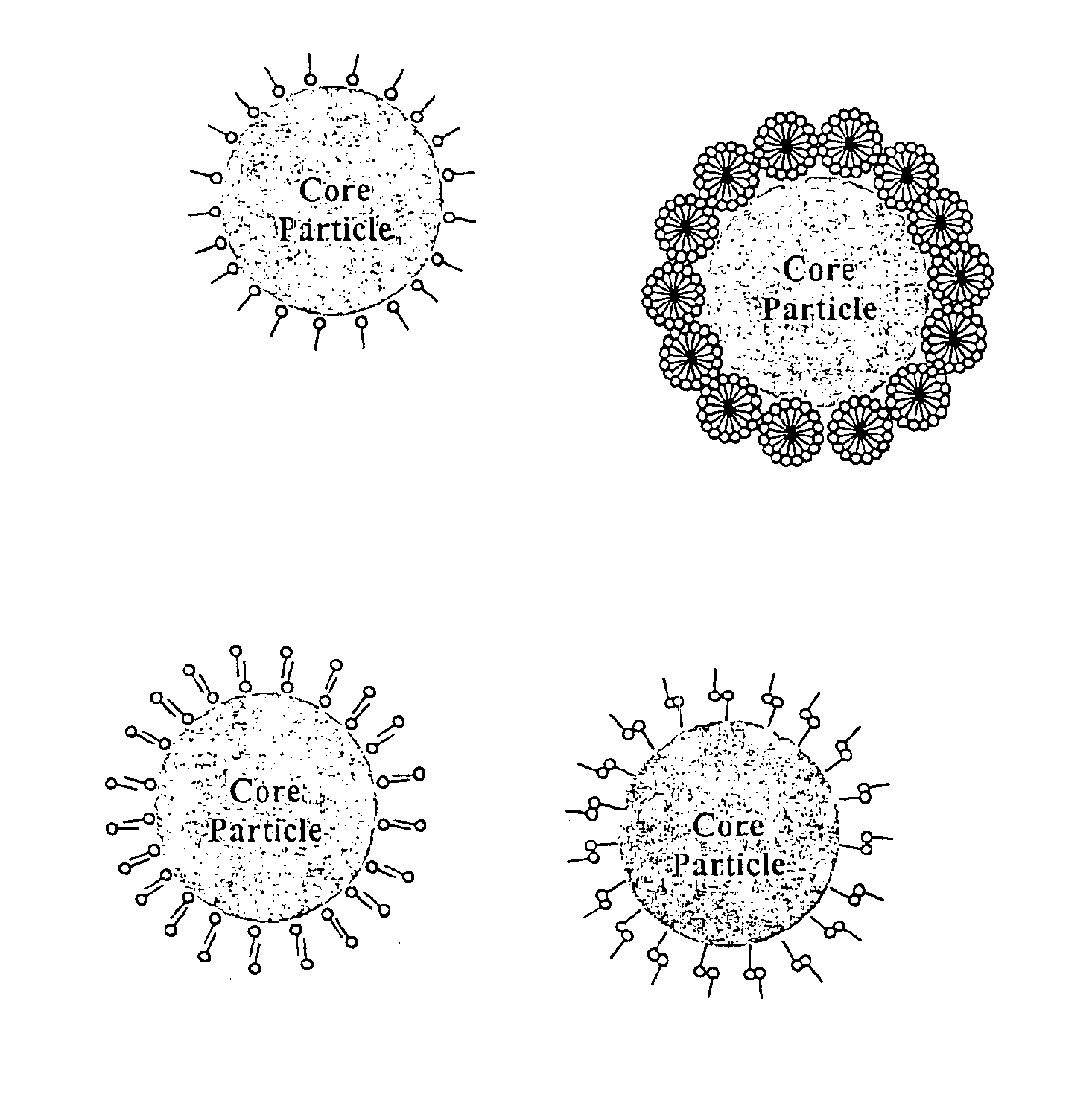

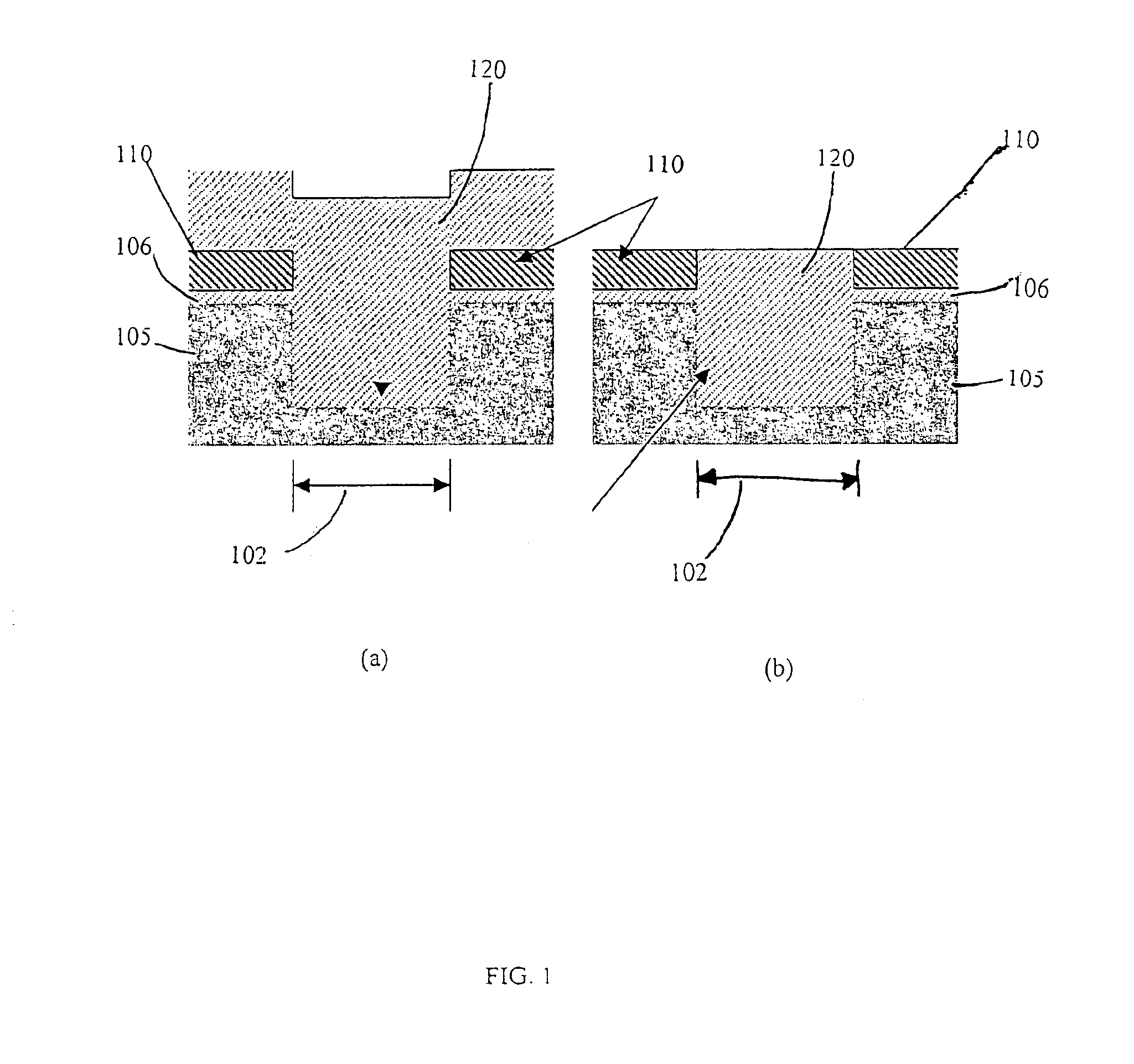

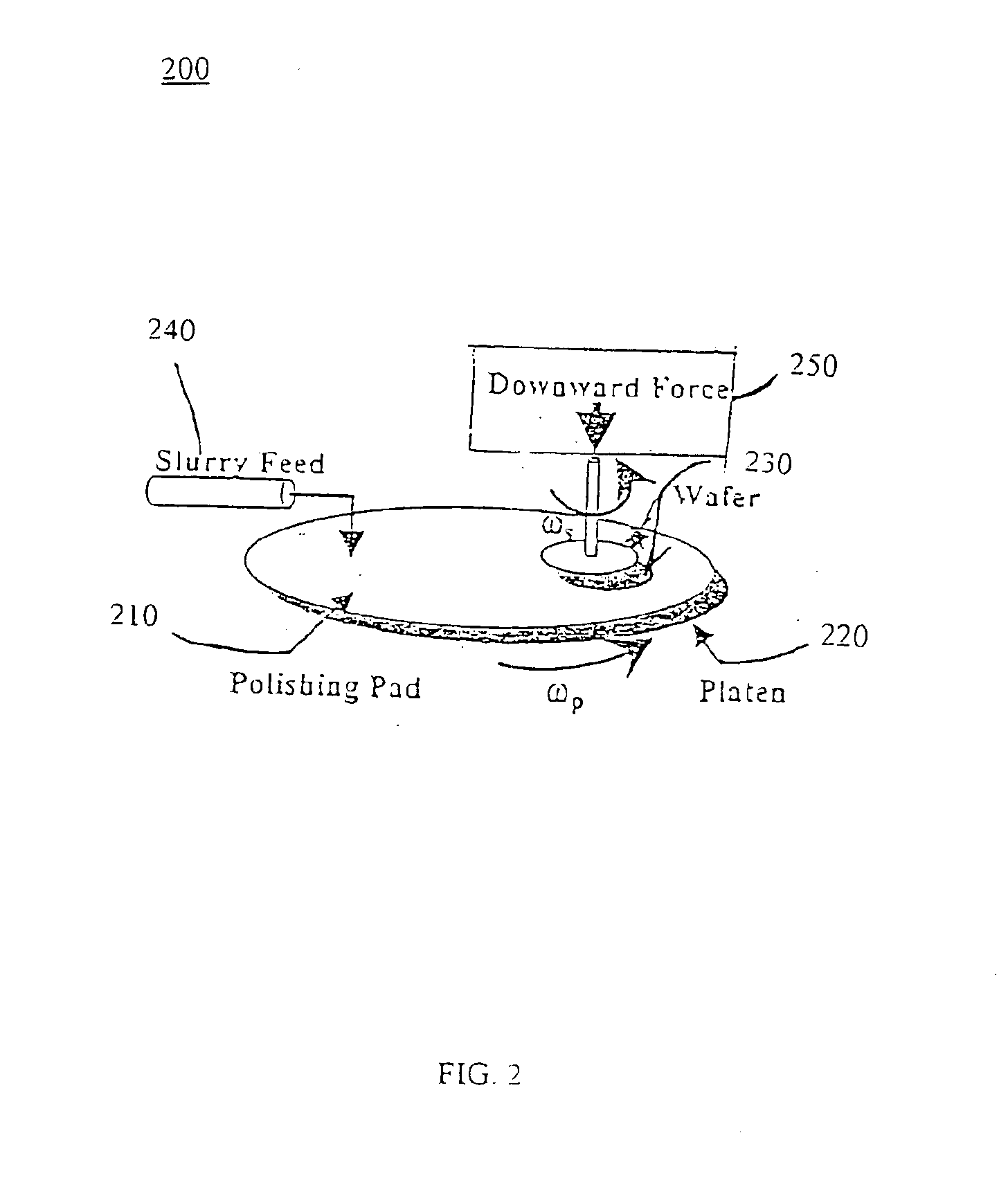

High selectivity and high planarity dielectric polishing

InactiveUS6866793B2Efficiently planarizedImprove planarization efficiencyPolycrystalline material growthFrom normal temperature solutionsSlurryDielectric structure

A slurry includes a plurality of particles and at least one selective adsorption additive. The particles are preferably composite particles including a core surrounded by a shell provided by the selective adsorption additive. The slurry can be used to polish a structure including silicon dioxide or a low K dielectric film and a silicon nitride containing film, such as to form a shallow trench isolation (STI) structure or a metal-dielectric structure. The silicon nitride containing film surface substantially adsorbs the selective adsorption additive, whereas the silicon dioxide or low K dielectric film shows non-substantial adsorption characteristics to the adsorption additive. In another embodiment of the invention, silicon dioxide or low K dielectric film shows non-substantial adsorption of the selective adsorption additive at a pressure above a predetermined first pressure, and substantial adsorption of the selective adsorption additive for pressures below a predetermined second pressure, where the first pressure is greater than the second pressure.

Owner:UNIV OF FLORIDA

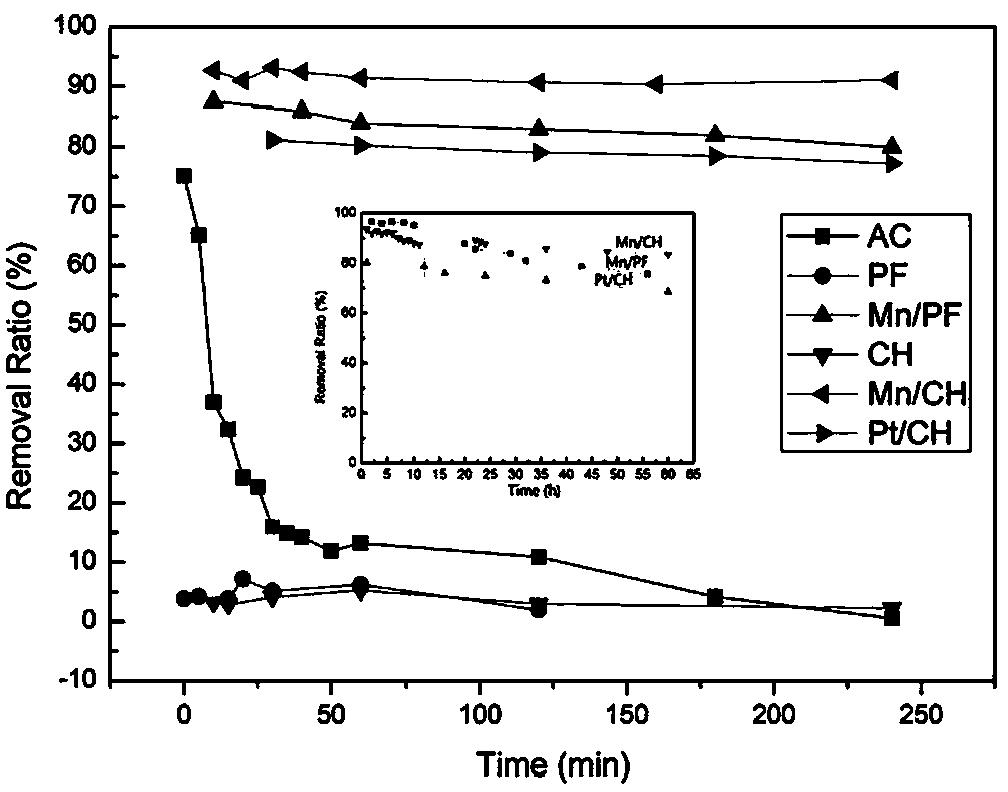

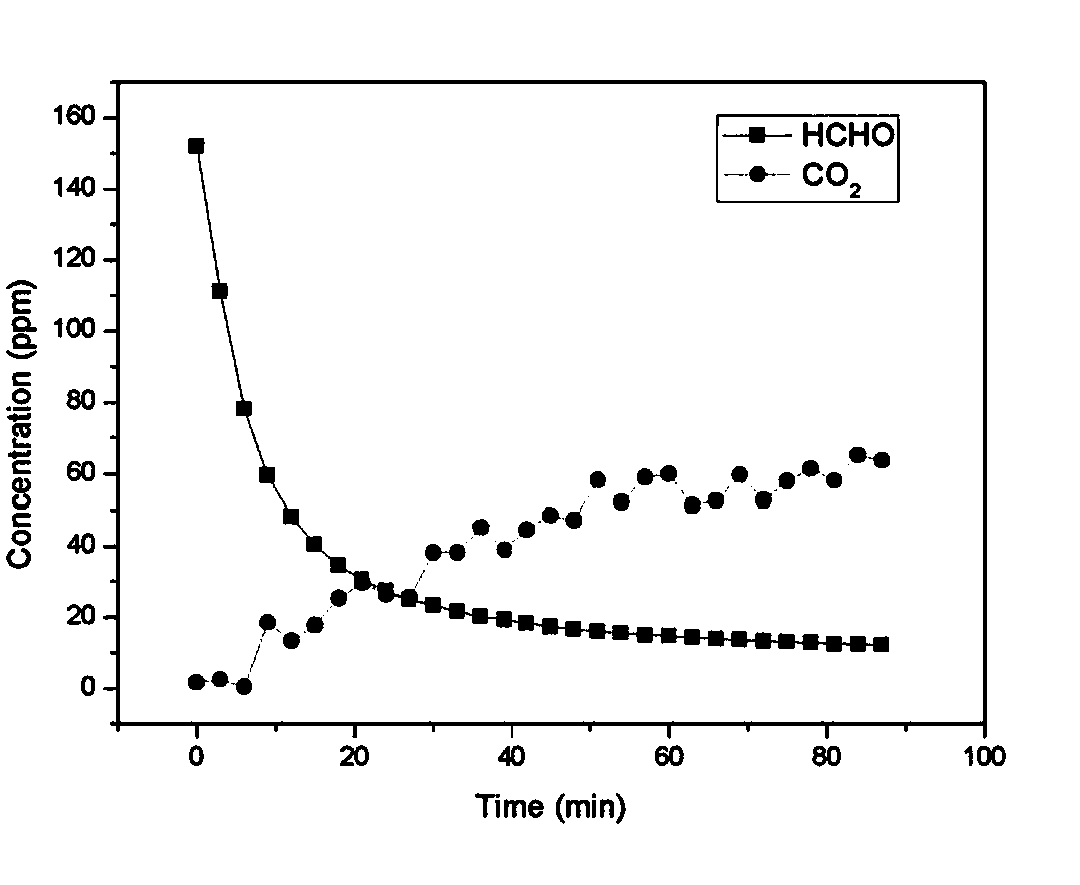

Air purification material and preparation method and application thereof

ActiveCN104190251AEfficient decompositionQuick removalDispersed particle separationFiberParticulates

The invention relates to an air purification material and a preparation method and application thereof, belonging to the technical field of chemical catalytic decomposition, in particular belonging to the technical field of decomposition of formaldehyde pollutants in environment air. The air purification material comprises a base material and manganese oxide, wherein the manganese oxide is supported on the base material, the base material is honeycomb ceramics or a fiber material with a particle filtering function, and the manganese oxide is birnessite manganese oxide prepared from permanganate and oxalate. The air purification material can effectively decompose formaldehyde pollutants in indoor air and can rapidly and constantly remove the formaldehyde pollutants in indoor air at room temperature. The air purification material can be regenerated through heating, so that the service life of the material is prolonged and the practical application is facilitated.

Owner:TSINGHUA UNIV

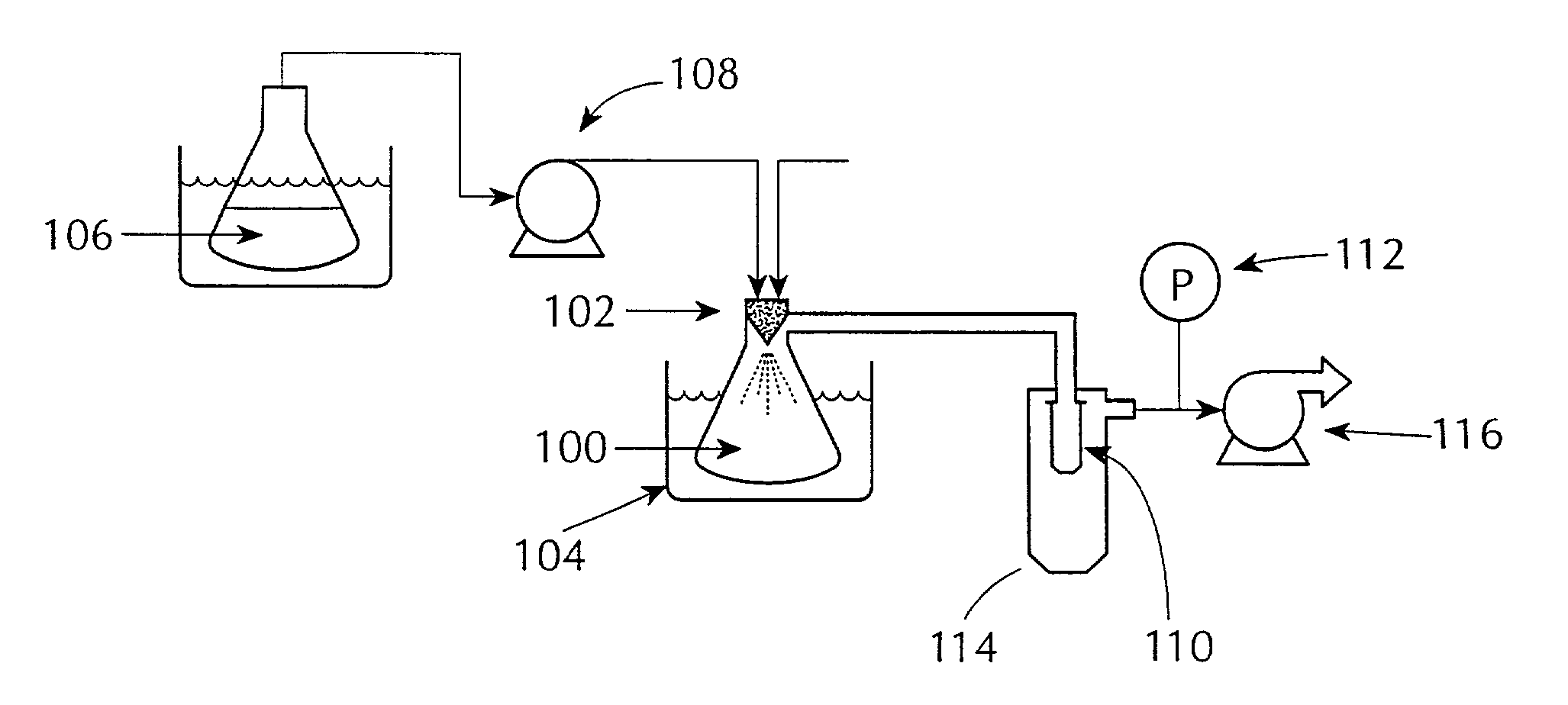

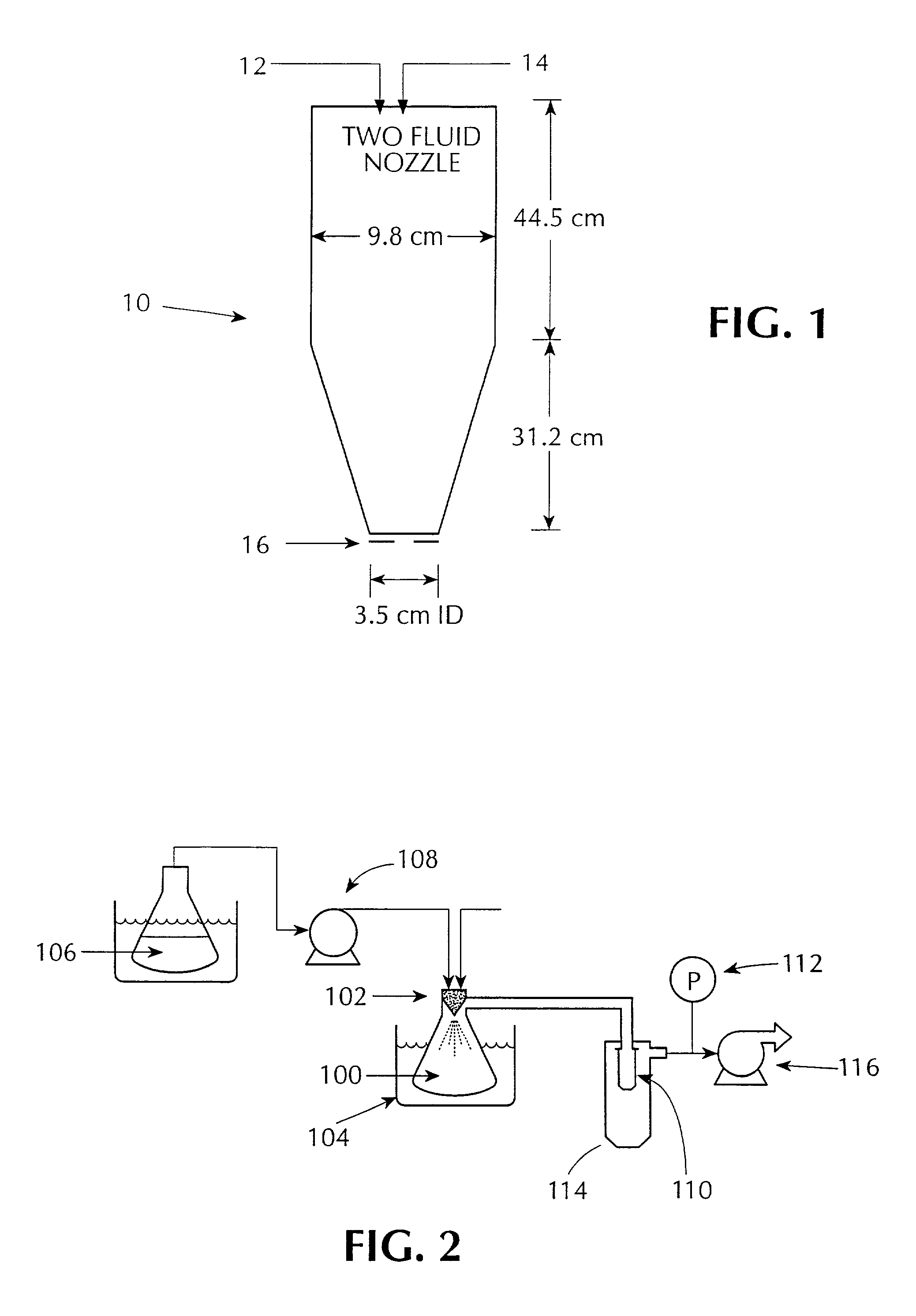

Thermal connector for cooling electronics

InactiveUS6882533B2Balance of powerProvide supportSemiconductor/solid-state device detailsSolid-state devicesSprayerModularity

A modular semiconductor chip cooling system having a readily openable enclosure defining a chamber configured to hold a printed circuit board carrying components to be cooled. The enclosure can include a reservoir, a condenser and a pump. Sprayers within the chamber are adjustably mounted on one or more brackets to allow each sprayer to be set for the individual height of its respective component. The enclosure can be readily removed from a computer system through a quick release connection. The computer system can include a condenser and pump to operate all its modular cooling systems, removing the condensing function from the individual modules.

Owner:HEWLETT PACKARD DEV CO LP

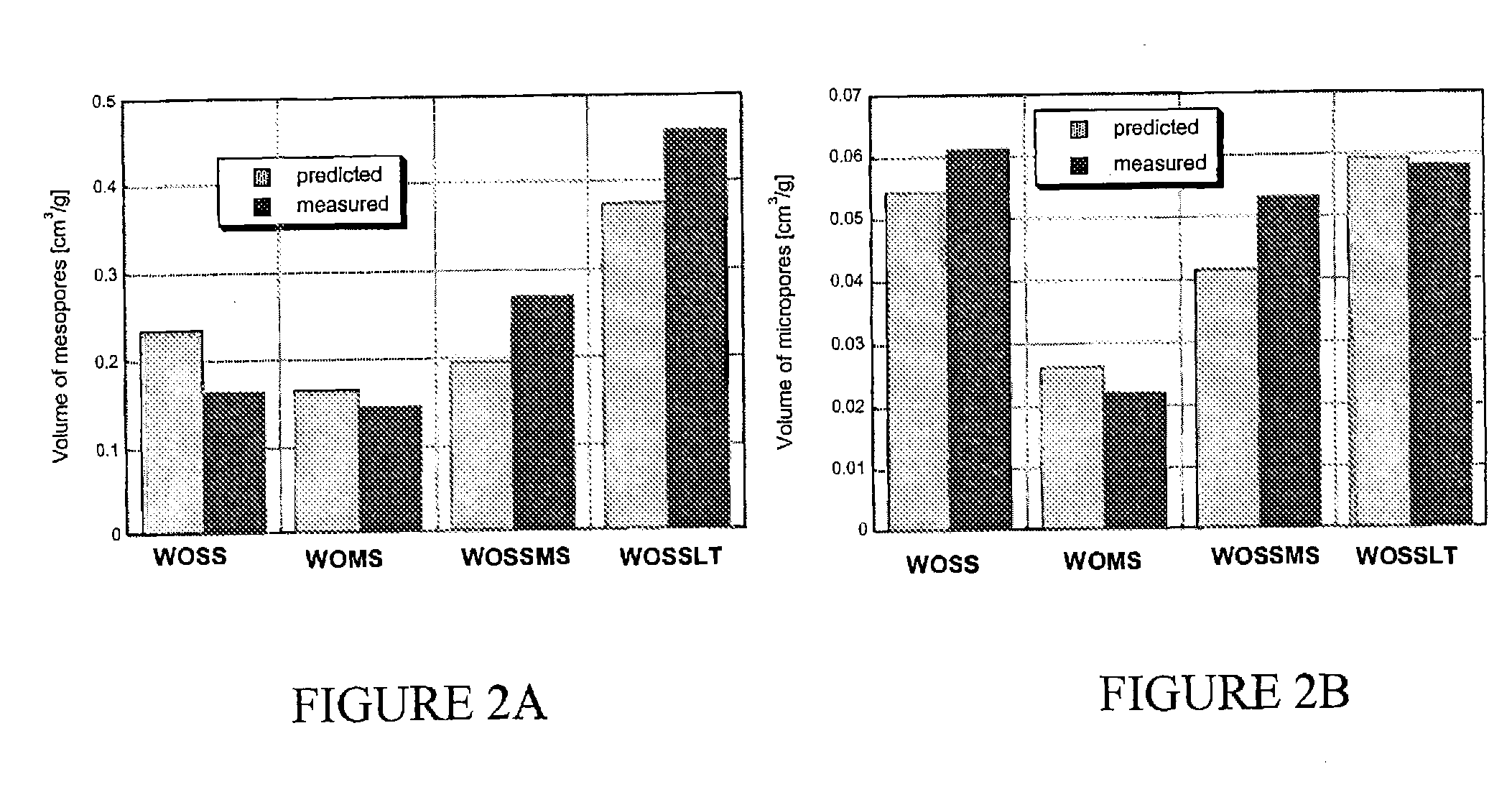

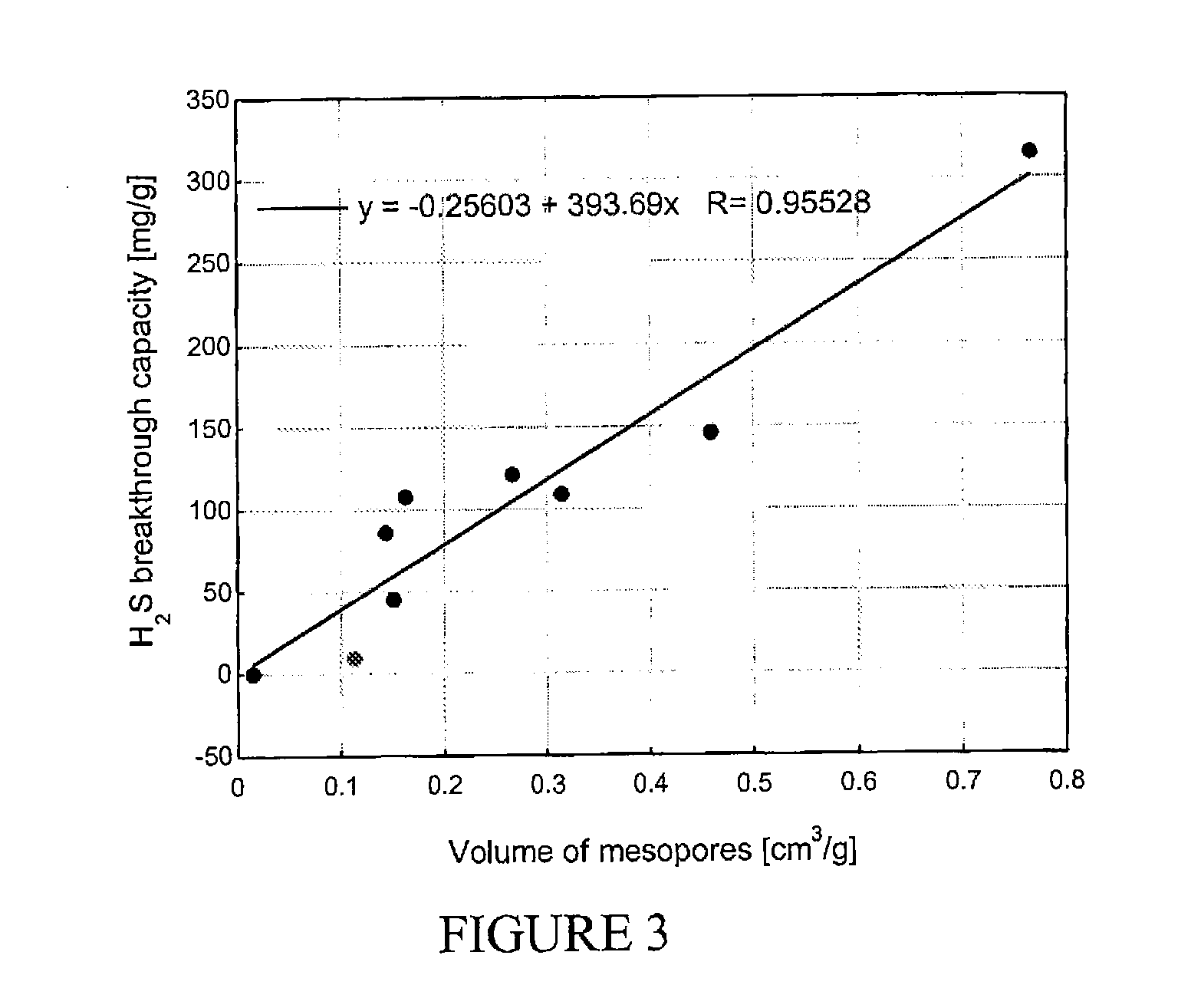

Catalytic adsorbents obtained from municipal sludges, industrial sludges, compost and tobacco waste and process for their production

InactiveUS20070113736A1Large capacityQuick removalGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsSorbentSludge compost

Industrial waste derived adsorbents were obtained by pyrolysis of sewage sludge, metal sludge, waste oil sludge and tobacco waste in some combination. The materials were used as media to remove hydrogen sulfide at room temperature in the presence of moisture. The initial and exhausted adsorbents after the breakthrough tests were characterized using sorption of nitrogen, thermal analysis, XRD, ICP, and surface pH measurements. Mixing tobacco and sludges result in a strong synergy enhancing the catalytic properties of adsorbents. During pyrolysis new mineral phases are formed as a result of solid state reaction between the components of the sludges. High temperature of pyrolysis is beneficial for the adsorbents due to the enhanced activation of carbonaceous phase and chemical stabilization of inorganic phase. Samples obtained at low temperature are sensitive to water, which deactivates their catalytic centers.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

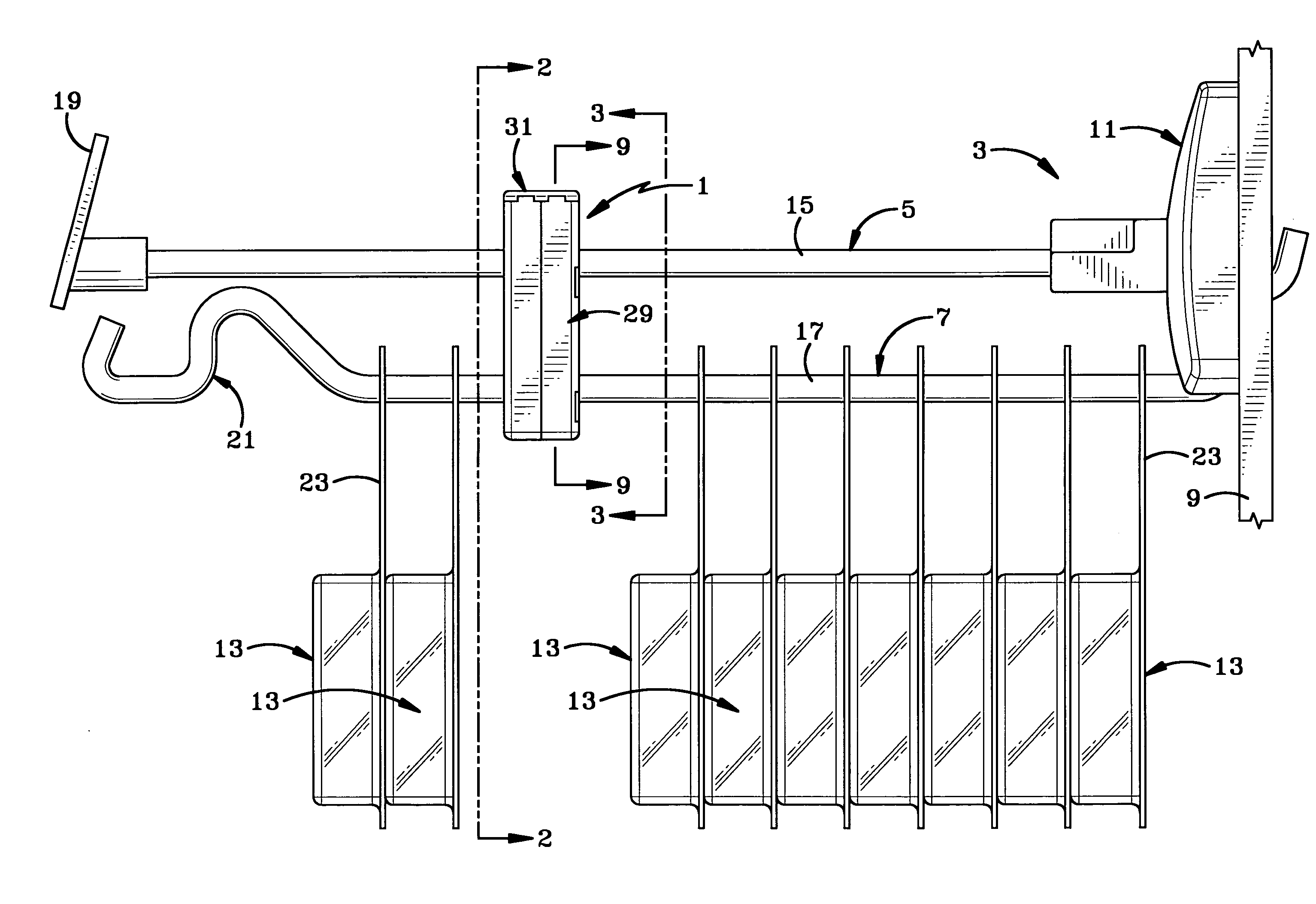

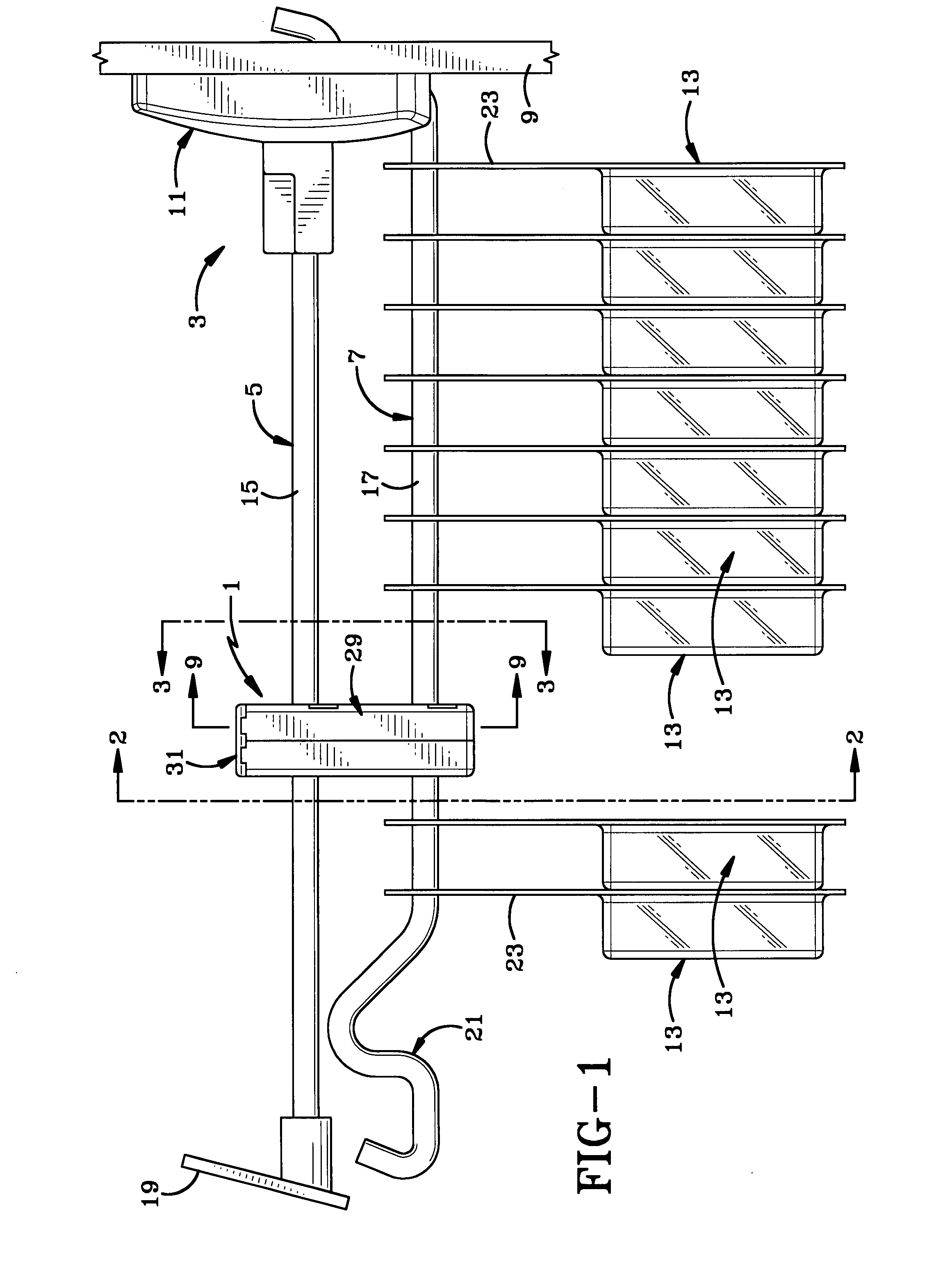

Cold metal plate strip cold continuous rolling production line and production method

InactiveCN102172835AImprove the effect of energy saving and emission reductionIncrease flexibilityWork treatment devicesOther manufacturing equipments/toolsProduction lineEngineering

The invention relates to a cold metal plate strip cold continuous rolling production line, which comprises at least uncoiling machine (1), a plate strip head and tail cutting machine (2), welding equipment (17), a stretching and straightening device (4), at least one jet flow descaling unit (5), tension rolls (11), a trimming device (15), randomly selected cold continuous rolling machine set (9), flying shears (7), a coiling machine (8), and a movable sleeve device, wherein the stretching and straightening device (4) comprises at least two tension roll groups (11) and a bending roll group (12); the tension roll groups (11) are arranged in front and at back of the jet flow descaling unit (5) respectively; and the movable sleeve device is only welded between the welding equipment and the stretching and straightening device (4). When the continuous type metal plate strip cold continuous rolling production line and a high-pressure jet flow descaling mode are improved, the productivity of the cold continuous rolling line is improved obviously, the environmental-protection control index of the cold rolling process segment is obviously improved, and the floor area and maintenance cost of the production line are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com