Air purification material and preparation method and application thereof

A technology of air purification materials and fiber materials, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of weak catalyst loading and powder falling, and achieve good contact, low cost, and low wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Use cordierite ceramic sheets as the carrier of manganese oxide, add 10g / L KMnO4 solution and 15g / L (NH4)2C2O4 solution into the container and stir well, the ratio of the two is 4:1. The pH of the solution was adjusted to 7.3 with sodium hydroxide, a ceramic sheet made of cordierite was added, and then placed in constant temperature water at 90° C. for 10 h. After the reaction, the honeycomb ceramic sheet loaded with manganese oxide was taken out and washed with deionized water until clarified. Put the cleaned ceramic sheet into an oven at 105° C. for 12 hours and heat and dry it to obtain a formaldehyde purification material.

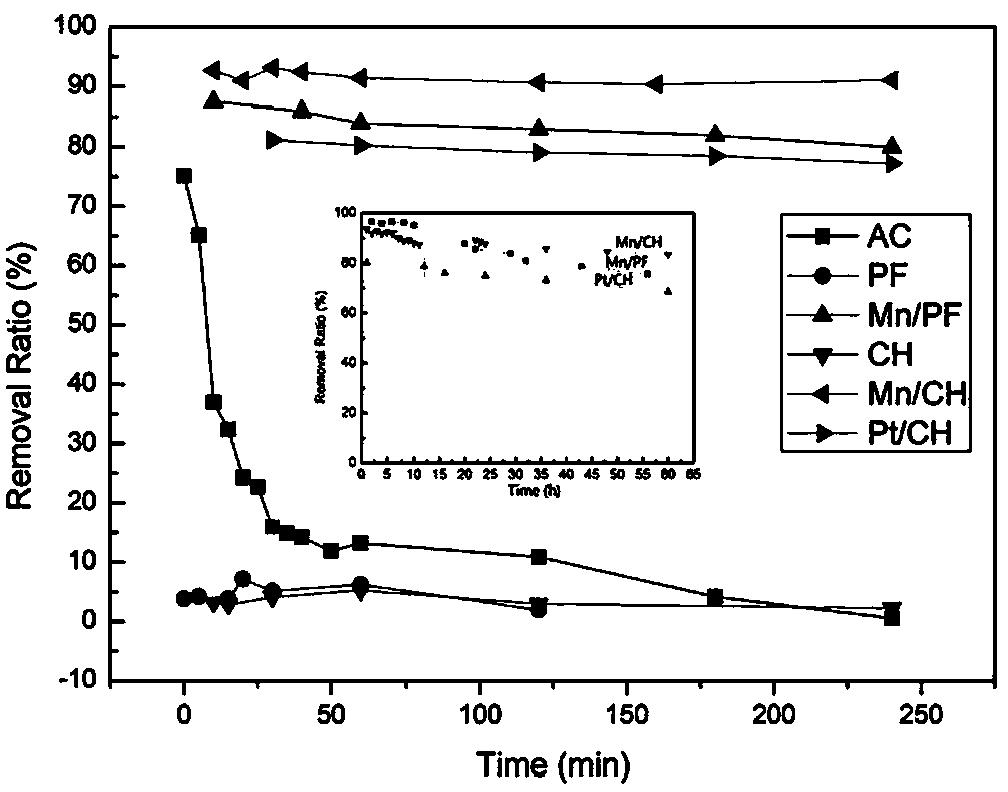

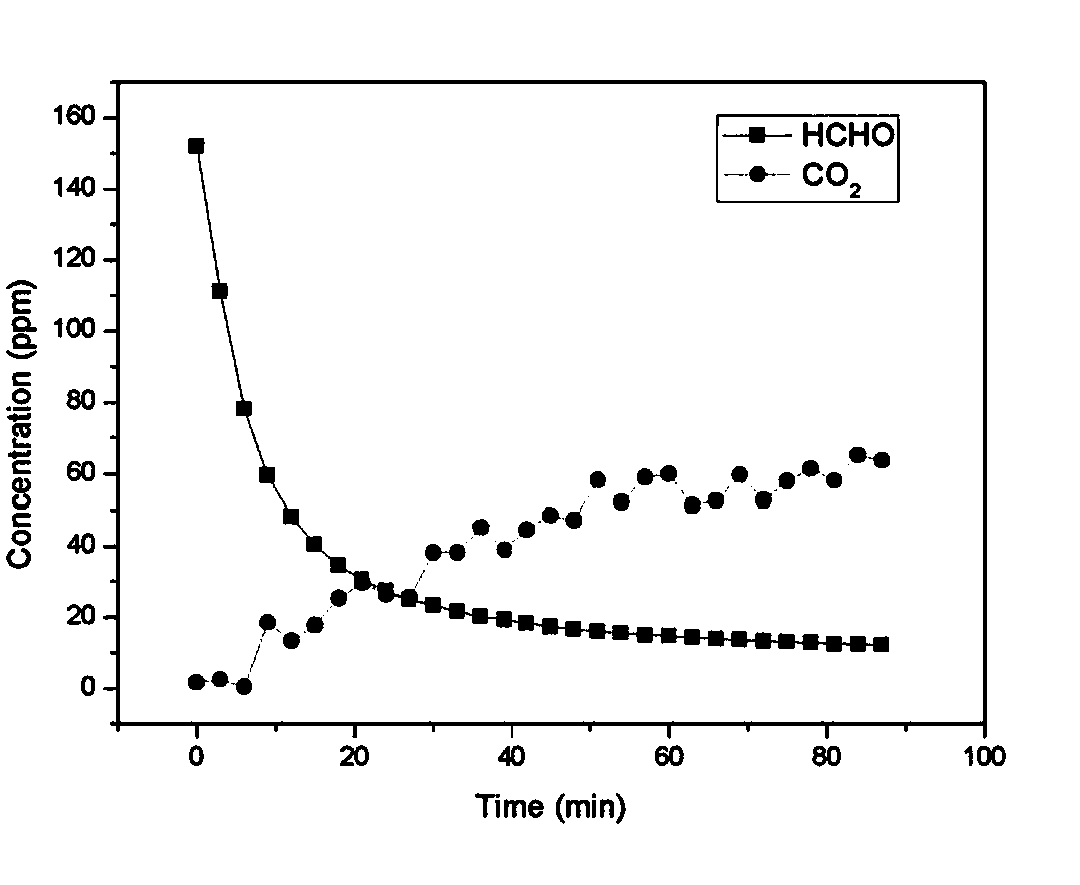

[0034] figure 1 In a and b are photos before and after loading manganese oxide on the ceramic sheet of the present invention. The color of the ceramic sheet before loading is white, but after loading it is dark, indicating that a large amount of manganese oxide has been loaded on the ceramic sheet. Depend on figure 1 It can be seen that there...

Embodiment 2

[0036] A ceramic sheet made of alumina is used as a carrier of manganese oxide, and 4g / L NaMnO4 solution and 4g / L Na2C2O4 solution are added to the container and stirred evenly, and the ratio of the two is 5:1. The pH of the solution was adjusted to 6 with hydrochloric acid, a ceramic sheet made of alumina was added, and then placed in constant temperature water at 80° C. for 10 h. After the reaction is finished, the honeycomb ceramic sheet loaded with manganese oxide is taken out and washed with deionized water for more than 3 times. The cleaned ceramic sheet was dried in a silica gel drier at room temperature for 12 hours to obtain a formaldehyde purification material.

Embodiment 3

[0038]A ceramic sheet made of mullite is used as a carrier of manganese oxide. Add 4g / L KMnO4 solution and 4g / L K2C2O4 solution into the container and stir well, the ratio of the two is 0.5:1. The pH of the solution was adjusted to 9.3 with sodium hydroxide, a mullite ceramic sheet was added, and then placed in constant temperature water at 60° C. for 24 hours. After the reaction, the honeycomb ceramic sheet loaded with manganese oxide was taken out and washed with deionized water until clarified. The cleaned ceramic sheet was dried in a silica gel desiccator at room temperature for 12 hours, then calcined in a muffle furnace at 500° C. for 2 hours, and then taken out for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com