Patents

Literature

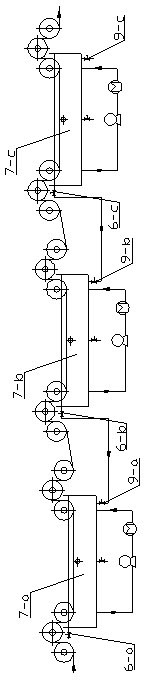

336results about How to "Increase spinning speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

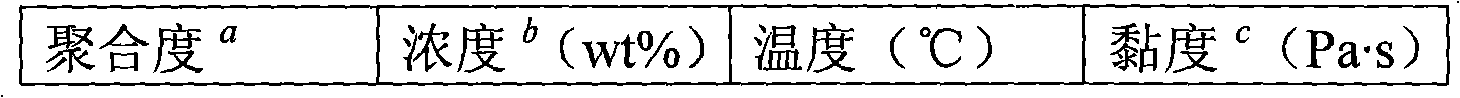

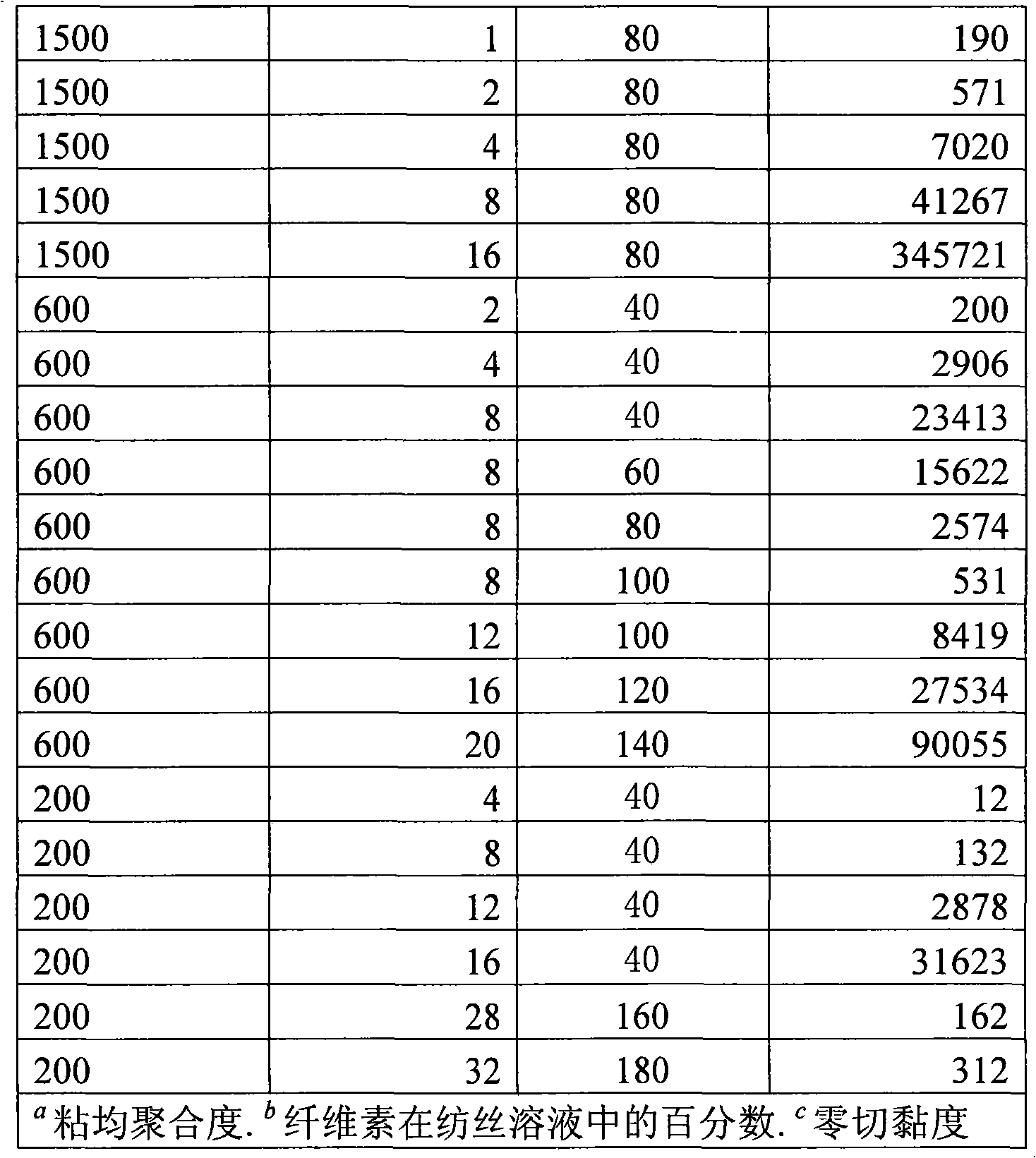

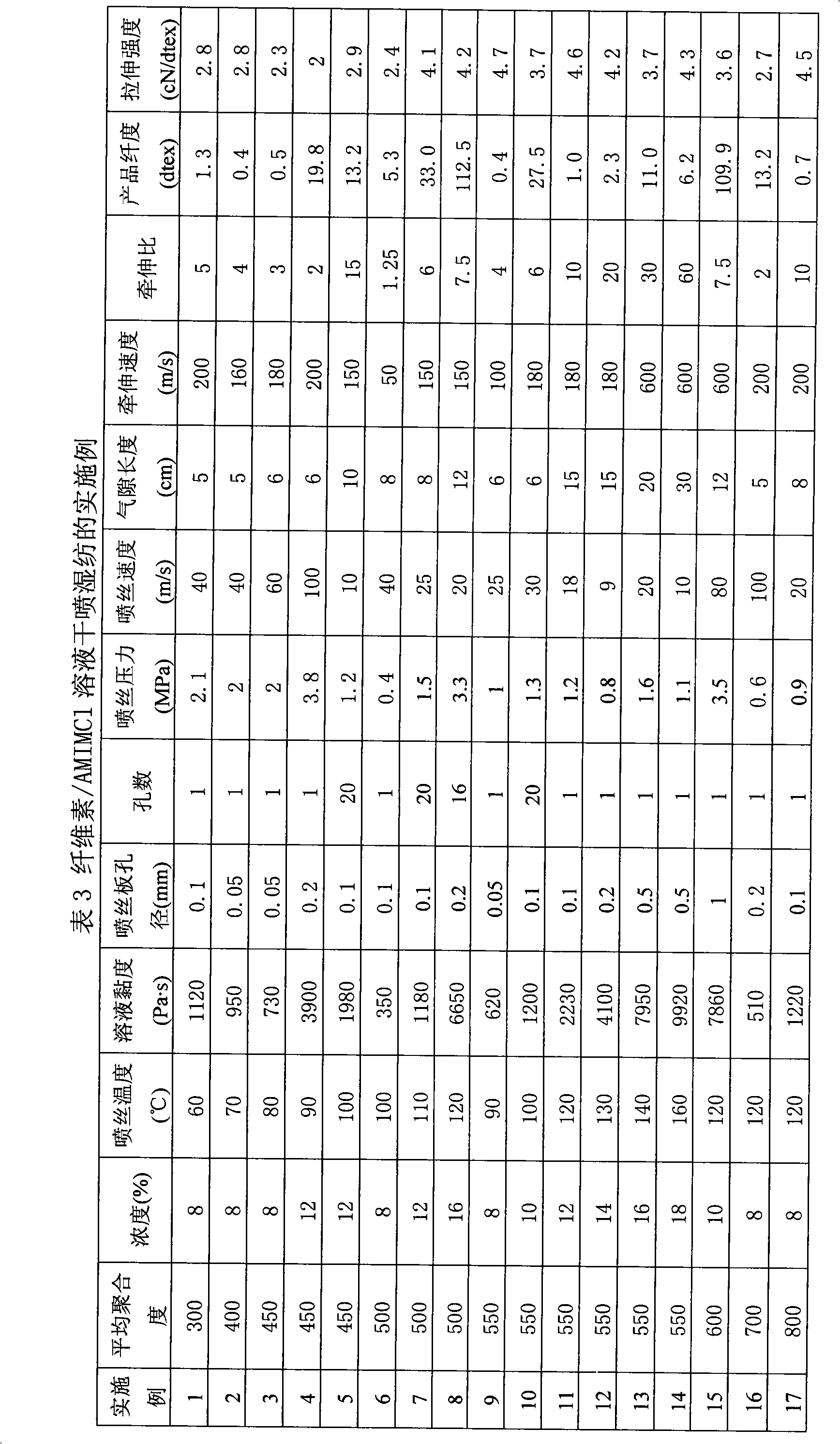

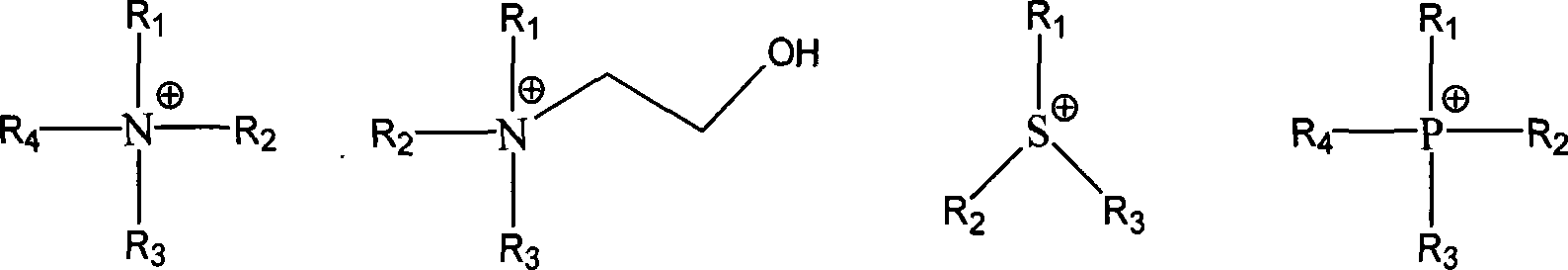

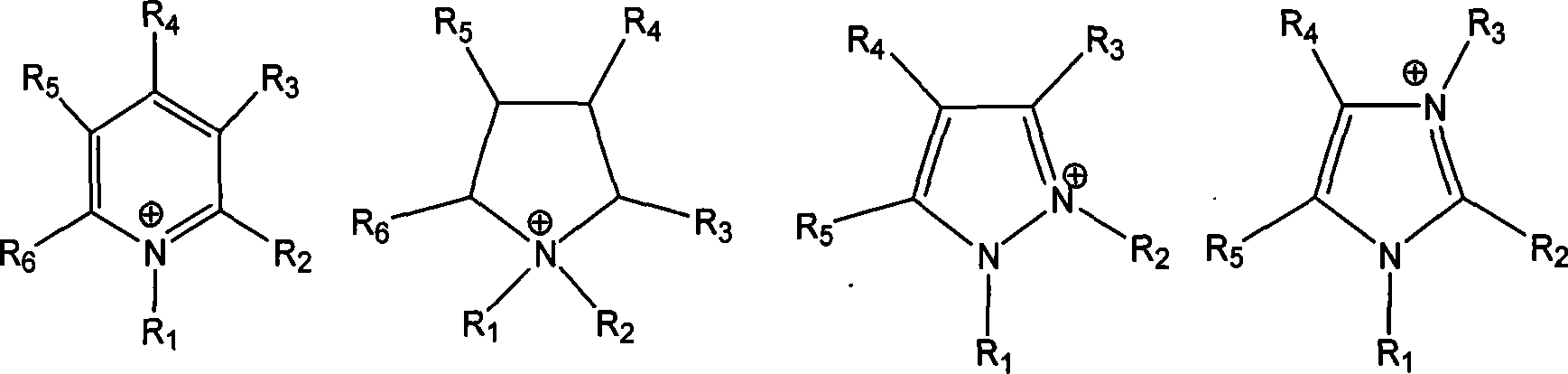

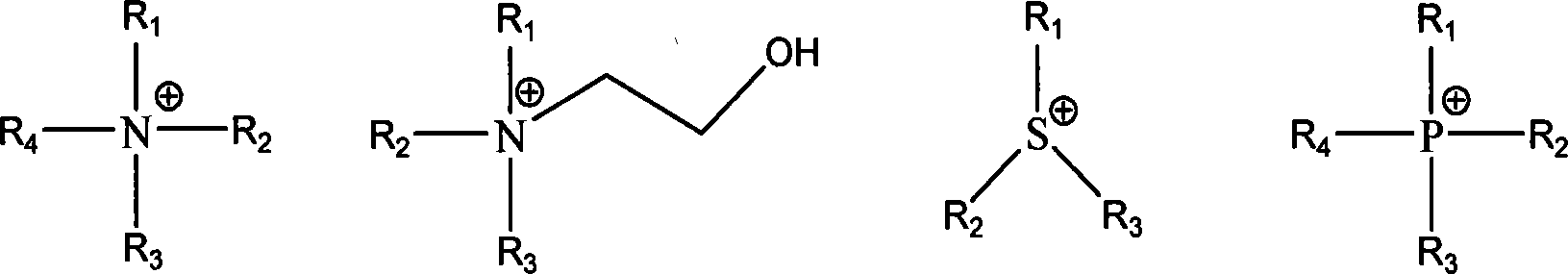

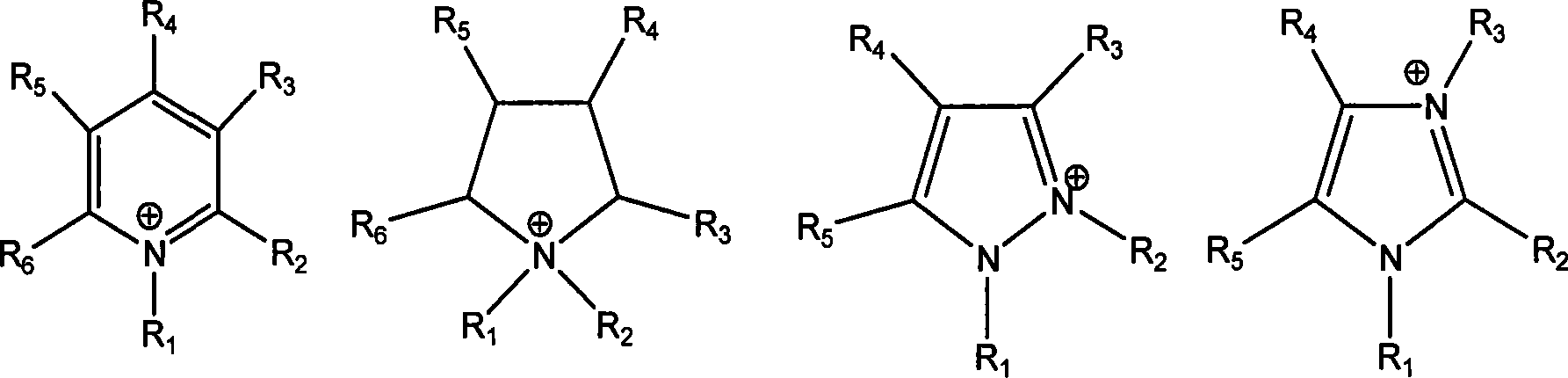

Method for continuously preparing regenerated cellulose fibre

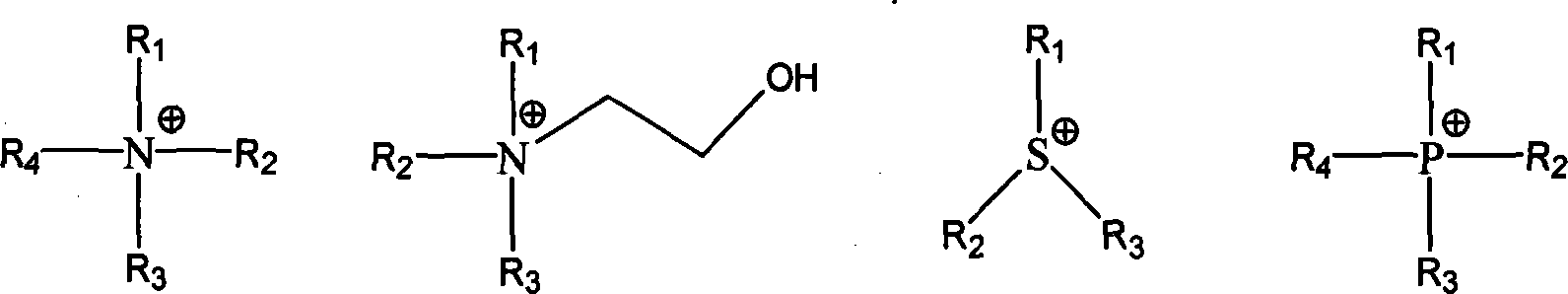

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

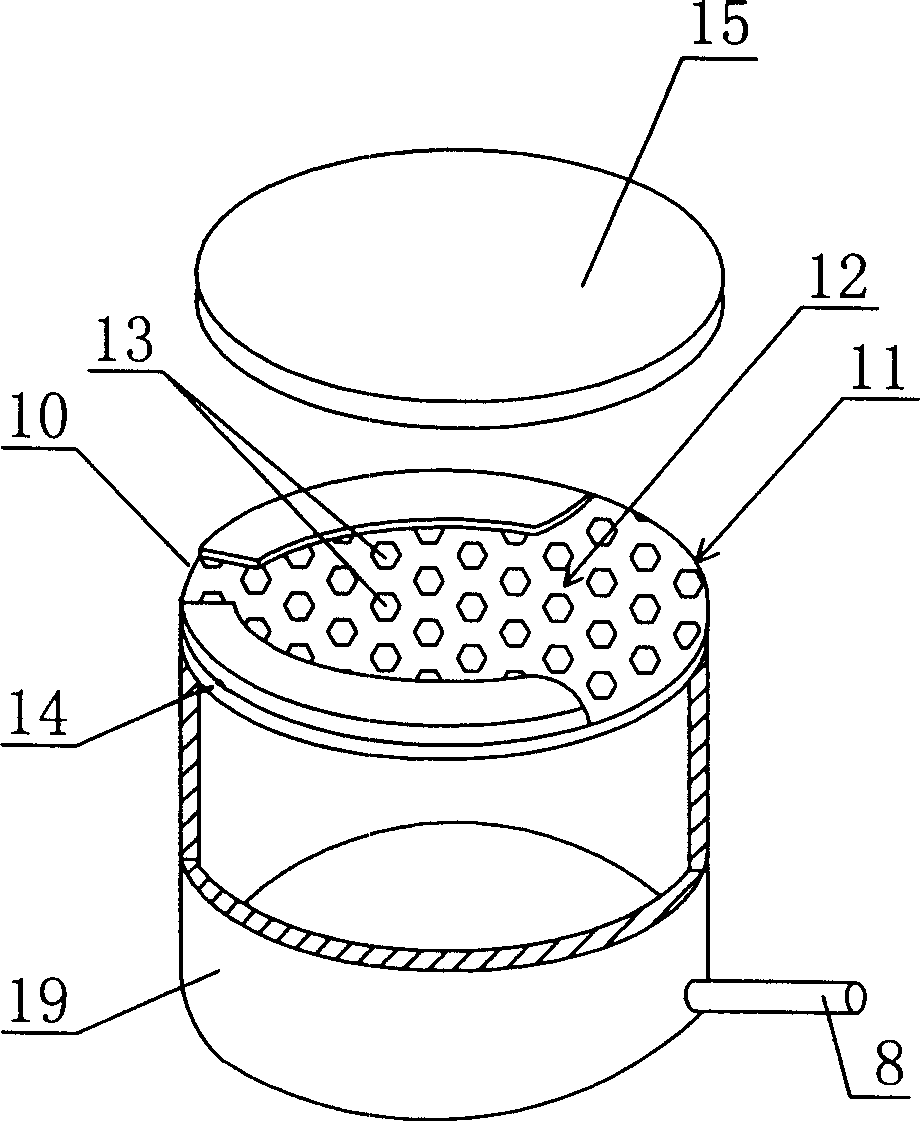

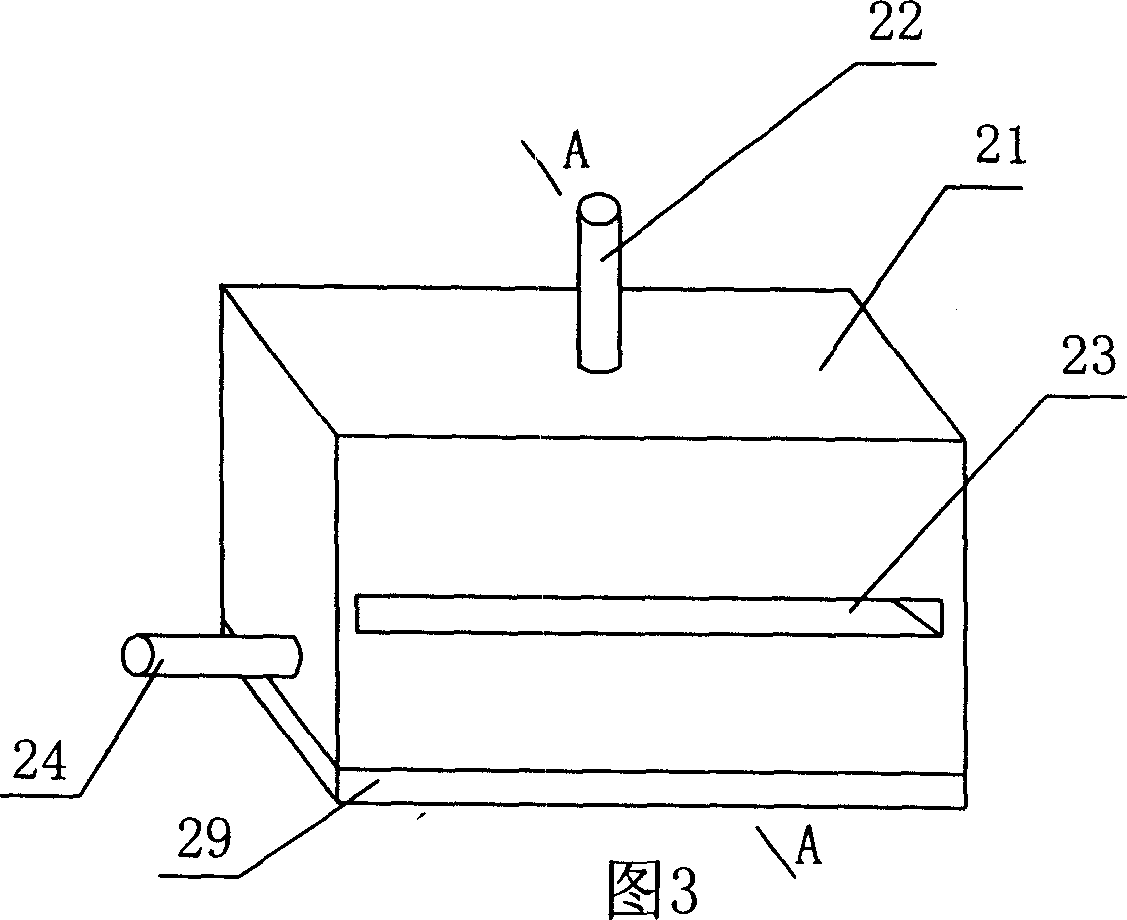

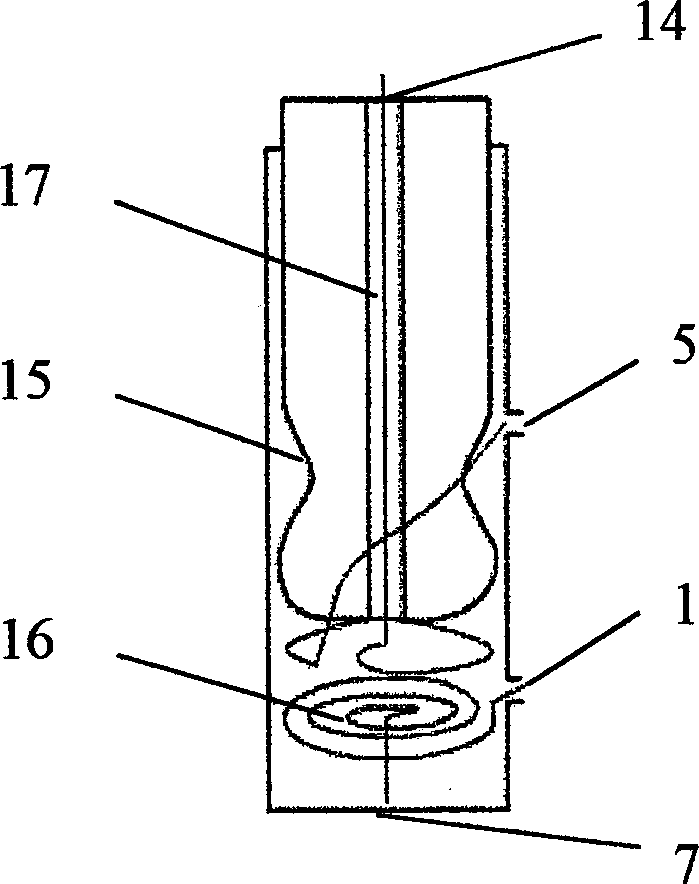

Continuous tow dispersing device

InactiveCN1811025AAvoid damageEvenly distributedFilament handlingFibre rougheningEngineeringMechanical engineering

The continuous tow dispersing device includes unwinding roller, winding roller and tightening roller, as well as air separator and carding unit set successively between the unwinding roller and the winding roller. The air separator has a hollow barrel, and a tow separating cavity in the upper port of the hollow barrel with a tow separating plate with ventilating holes in the bottom and a closing cover plate in the top. The carding unit has a box; inside the box, there are horizontal upper plate with at least two parallel air slots, lower plate with air holes and carding groove between the upper plate and the lower plate; and on the box, there is mechanical vibrator. The device has simple structure, no need of outer power, tow dispersing action completed with air pressure, good tow dispersing effect, low tow damage and other advantages.

Owner:HUNAN UNIV

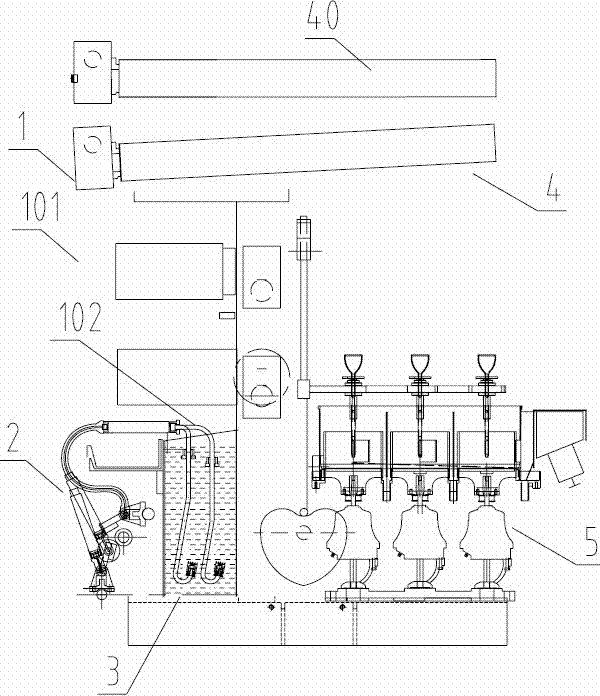

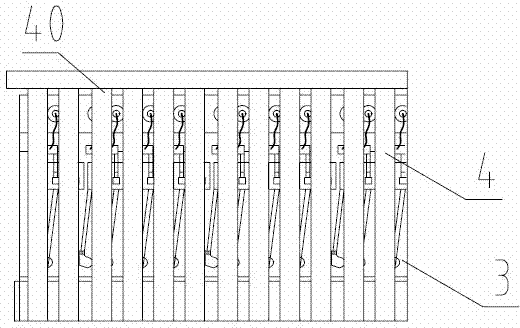

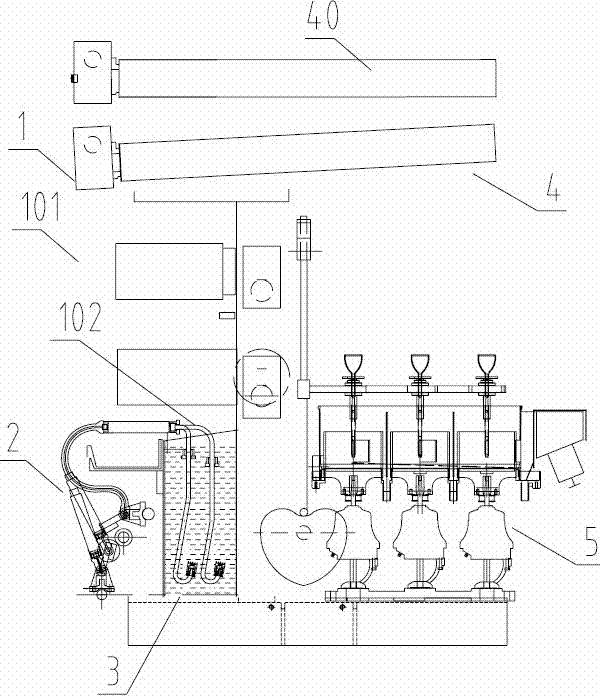

Spinning technology applied to semi-continuous high-speed spinning machine with spinning roller arranged horizontally

InactiveCN103290496ASmooth rotationNo shakingArtificial filaments from viscoseWet spinning methodsYarnSpinning

The invention relates to a spinning technology applied to a semi-continuous high-speed spinning machine with a spinning roller arranged horizontally. The spinning technology comprises glue measurement and supply, pre-spinning filtering, yarn strip forming, spinning and winding. The spinning technology aims at the specific semi-continuous high-speed spinning machine with the spinning roller arranged horizontally, under the mutual action of all processes and control of technological parameters, the spinning speed is ensured to be improved, independent walking of single yarn strips can be achieved, operations are simplified, the problems of doubling, burrs, breakage and the like are solved, the yarn strips are fully reacted and good in uniformity, the product quality is guaranteed, meanwhile, operations of workers are facilitated, and equipment maintenance is easy, overhaul costs are low, so that product costs are greatly reduced while the production efficiency is effectively improved.

Owner:YIBIN HIEST FIBER +2

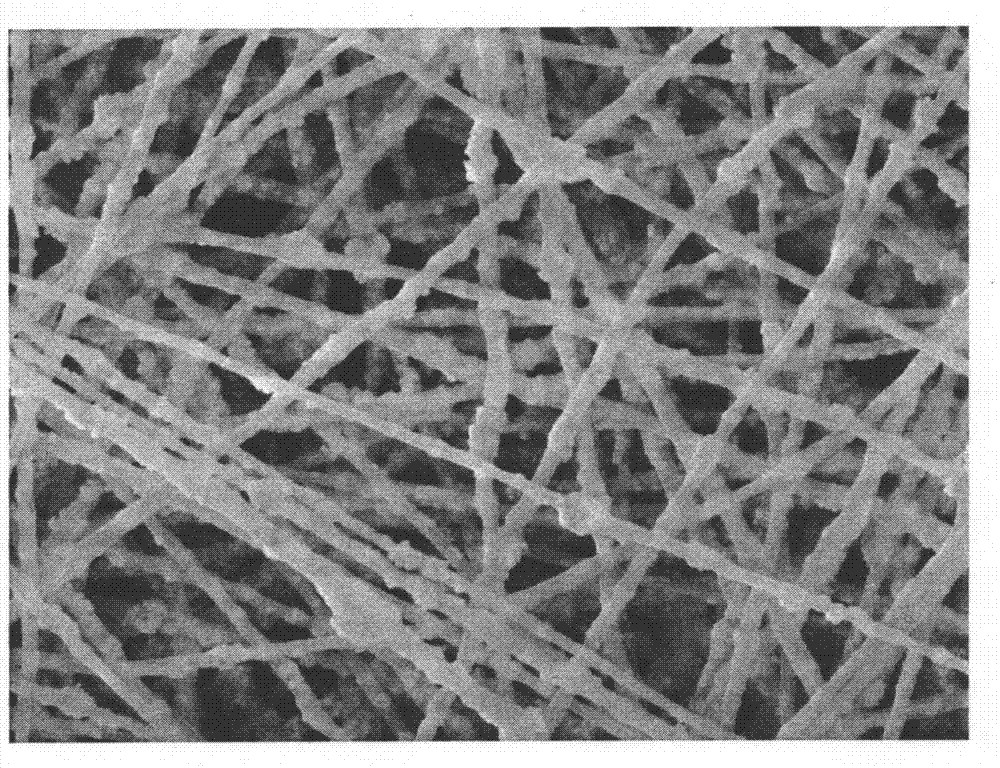

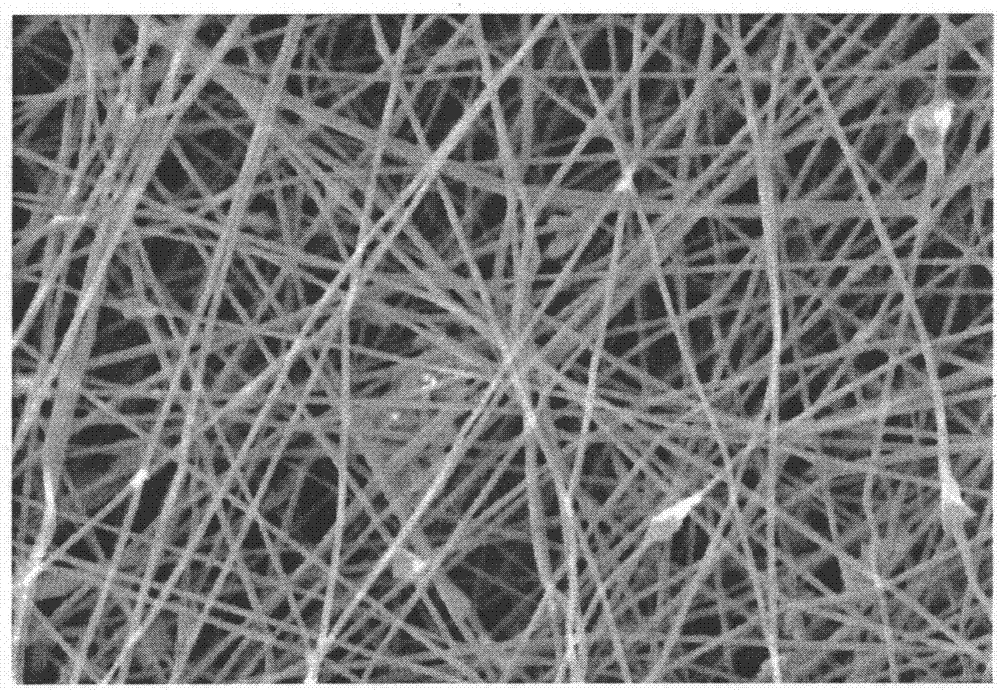

Composite nano fiber filtration material with photocatalysis/anti-bacterial functions and preparation method of filtration material

ActiveCN107497182AIncrease spinning speedSolve problems such as easy blockageDispersed particle separationElectro-spinningFiberSpinning

The invention relates to a composite nano fiber filtration material with photocatalysis / anti-bacterial functions and a preparation method of the filtration material. The filtration material comprises a supporting layer and a nano fiber filtration layer which adheres to the surface of the supporting layer, the nano fiber layer is uniformly filled with an photocatalyst and an antibacterial agent, and the preparation method comprises the following steps: 1, preparing a spinning liquid: dispersing a certain amount of the photocatalyst and the antibacterial agent into a solution uniformly to form a dispersion liquid, performing ultrasonic treatment, and adding a high polymer to form a stable and uniform electrostatic spinning solution; 2, performing electrostatic spinning: setting up electrostatic spinning parameters, and performing stretching on the spinning polymer solution at solid metal wire tips for wire production by utilizing an assembled needle head; and 3, performing slight dissolving treatment on the surface of the composite nano fiber filtration material by adopting solvent vapour recovery at a certain releasing speed to obtain the final composite nano fiber filtration material with the photocatalysis / the anti-bacterial functions. The composite nano fiber filtration material effectively solves a problem that the liquid outlet end of a current needle head / spray nozzle used for the electrostatic spinning is easy to block, can be directly used for decomposition of organic pollutants, inactivation of microorganism pathogenes and the like under visible light, and has excellent filtration performance at the same time.

Owner:DONGHUA UNIV

Method for preparing protein modified cellulose fibre

InactiveCN101113535AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsYarnCellulose fiber

The invention relates to a preparation method of a protein modified cellulose fiber, comprising the steps that: (1) a protein and a cellulose are dissolved in ion solution to prepare homogeneous mixing spinning solution; (2) the spinning solution is deaerated, filtered, measured, and extruded out through spinning jet to form spinning rills, and the spinning rills pass through a wet air layer and enter into a solidification bath to be solidified and molded; (3) the yarn is extended, cleaned by water, dried and heat molded, and formed into fiber to prepare the protein modified cellulose fiber. The method has the advantages of environmental protective, low cost, fast spinning speed and high production efficiency, and the prepared fiber has the advantages of comfort and health care, etc.

Owner:DONGHUA UNIV

Polyethylene fiber and a non-woven fabric using the same

InactiveUS6303220B1Superior crimp retainabilityImprove radiation resistanceFilament/thread formingWoven fabricsPolymer scienceYoung's modulus

A polyethylene fiber having a high apparent Young's modulus, high breaking tensile strength and low breaking elongation. The fiber also exhibits residual percentage crimp suitable enough for carding, so that the cardability, which has been conventionally difficult to improve, can be remarkably increased. Further, the fiber can be formed into a non-woven fabric having a soft touch feeling such that the fabric is suitable for medical use as well as hygienic use. In addition, the polyethylene fiber of this invention can be mixed with other fibers such as cellulose fiber to obtain a high absorbent fiber network material.

Owner:JNC CORP

Multilayer electret nano-fiber filtering material and preparation method thereof

ActiveCN107441827AIncrease spinning speedSolve problems such as easy blockageSynthetic fibresElectro-spinningFiberSpinning

The invention relates to a multilayer electret nanofiber filtering material and a preparation method thereof. The invention adopted the technical scheme is as follows: through an electric-field stepped increasing / reducing technology, utilizing a combined needle head for electrostatic spinning to realize deposition of spinning polymer solution on a receiving substrate to obtain nanofiber, carrying out slight dissolving treatment on the surface of a nanofiber layer by a certain release rate by adopting a recovery solvent steam, wherein the nanofiber layer is uniformly filled with electret materials and the diameter of the nanofiber layer is distributed in a stepped-increasing or stepped-reducing manner along the direction vertical to the breadth. According to the multilayer electret nano-fiber filtering material, the electret charge stability is extremely high, the surface electrostatic potential is 250-7000V, simultaneously the filtering performance is excellent, the filtering efficiency for 0.03-10 microns particulates is more than 99.997%, the resistance pressure drop is less than or equal to 39Pa, the service life is long, and the development and application prospect in the aspect of filtering materials for air purifiers, window gauzes, masks and filtering papers and the like are wide.

Owner:DONGHUA UNIV

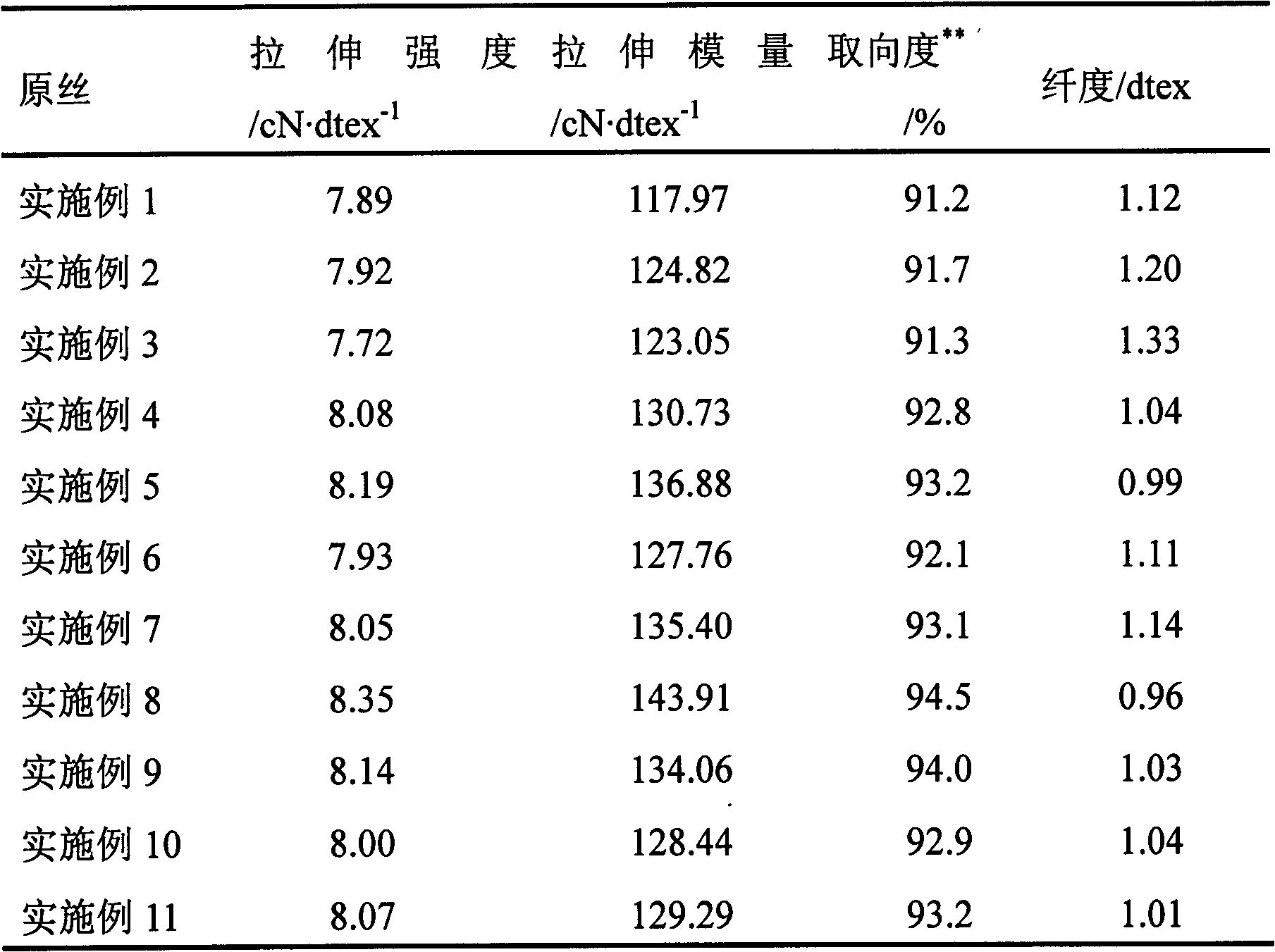

A kind of preparation method of high-performance polyacrylonitrile-based carbon fiber precursor

InactiveCN102277645AGood orientationIncrease spinning speedArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFinenessHigh intensity

The invention relates to a preparation method of a high-performance polyacrylonitrile-based carbon fiber precursor. The method provided by the invention comprises the following steps of: (1) dissolving less high-performance polyacrylonitrile resin into a diluted polyacrylonitrile solution; (2) dissolving certain amount of polyacrylonitrile with conventional molecular weight into the diluted polyacrylonitrile solution with super-high molecular weight to obtain a polyacrylonitrile spinning solution; (3) obtaining a polyacrylonitrile carbon fiber precursor through utilizing a dry-wet spinning method; and (4) washing the primary precursor by water, stretching, carrying out a second-grade stretching by hot water, drying and densifying, and stretching by saturated steam to obtain the high-performance polyacrylonitrile-based carbon fiber precursor. Compared with the prior art, the method provided by the invention can prepare the good-quality polyacrylonitrile-based carbon fiber precursor with high strength, high modulus, high orientation degree and small fineness.

Owner:SHANGHAI JIAO TONG UNIV

Process of making poly (trimethylene dicarboxylate) fibers

InactiveUS6923925B2Raise the draw ratioGood orientationLayered productsDrafting machinesPolymer scienceSpinning

A process for preparing poly(trimethylene dicarboxylate) multifilament yarns and monofilaments. One process for preparing poly(trimethylene dicarboxylate) multifilament yarns includes (a) providing a polymer blend including poly(trimethylene dicarboxylate) and about 0.1 to about 10 weight % styrene polymer, by weight of the polymer in the polymer blend, (b) spinning the polymer blend to form poly(trimethylene dicarboxylate) multiconstituent filaments containing dispersed styrene polymer, and (c) processing the multiconstituent filaments into poly(trimethylene dicarboxylate) multifilament yarn including poly(trimethylene dicarboxylate) multiconstituent filaments containing styrene polymer dispersed throughout the filaments. Another process includes spinning at a speed of at least 3,000 m / m and processing a blend including poly(trimethylene dicarboxylate) to form partially oriented poly(trimethylene dicarboxylate) multifilament yarn. A poly(trimethylene terephthalate) yarn including poly(trimethylene terephthalate) multiconstituent filament containing styrene polymer dispersed throughout the multiconstituent filament. The invention is also directed to uses of the filament yarns and monofilament.

Owner:DUPONT IND BIOSCIENCES USA LLC

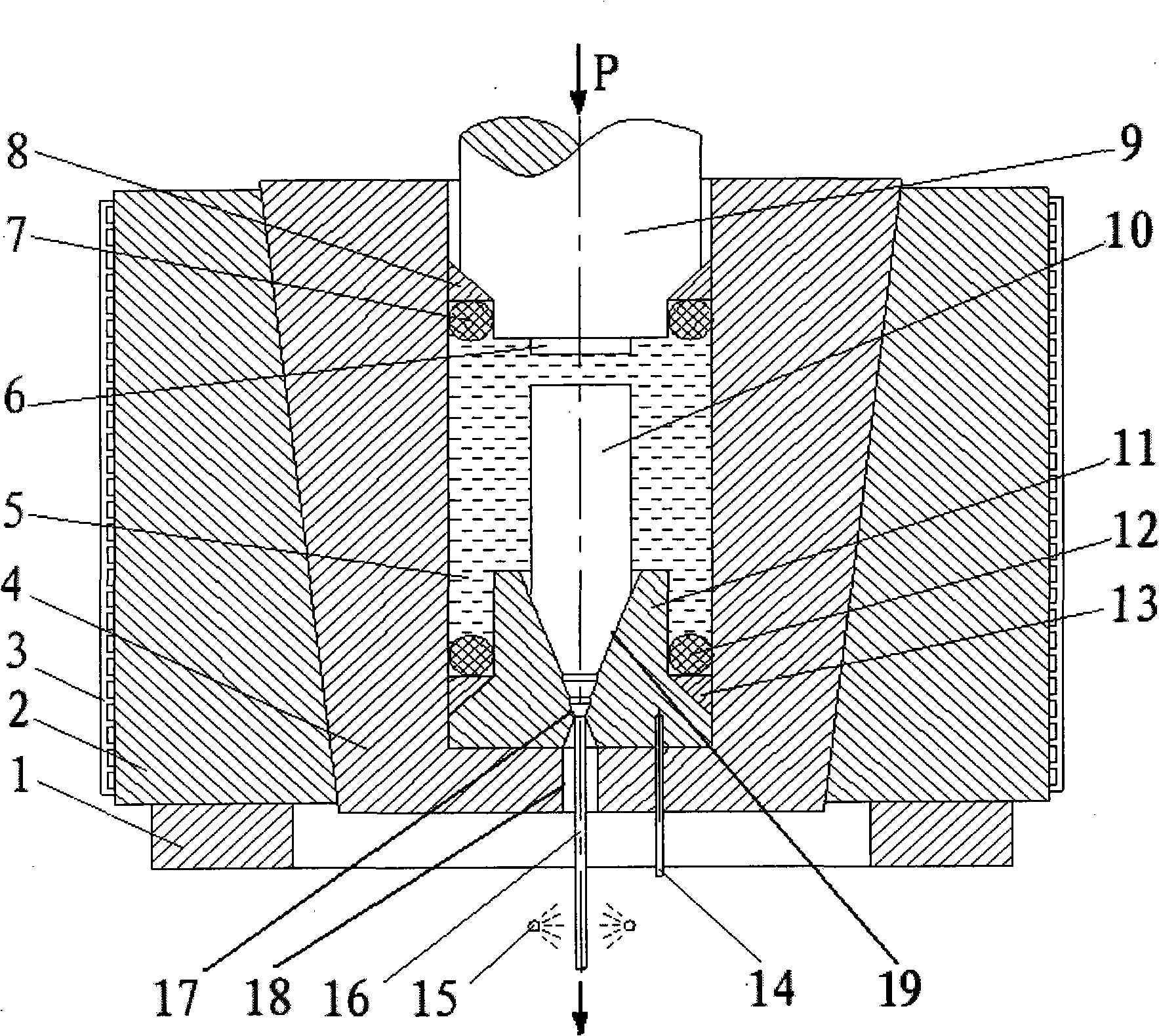

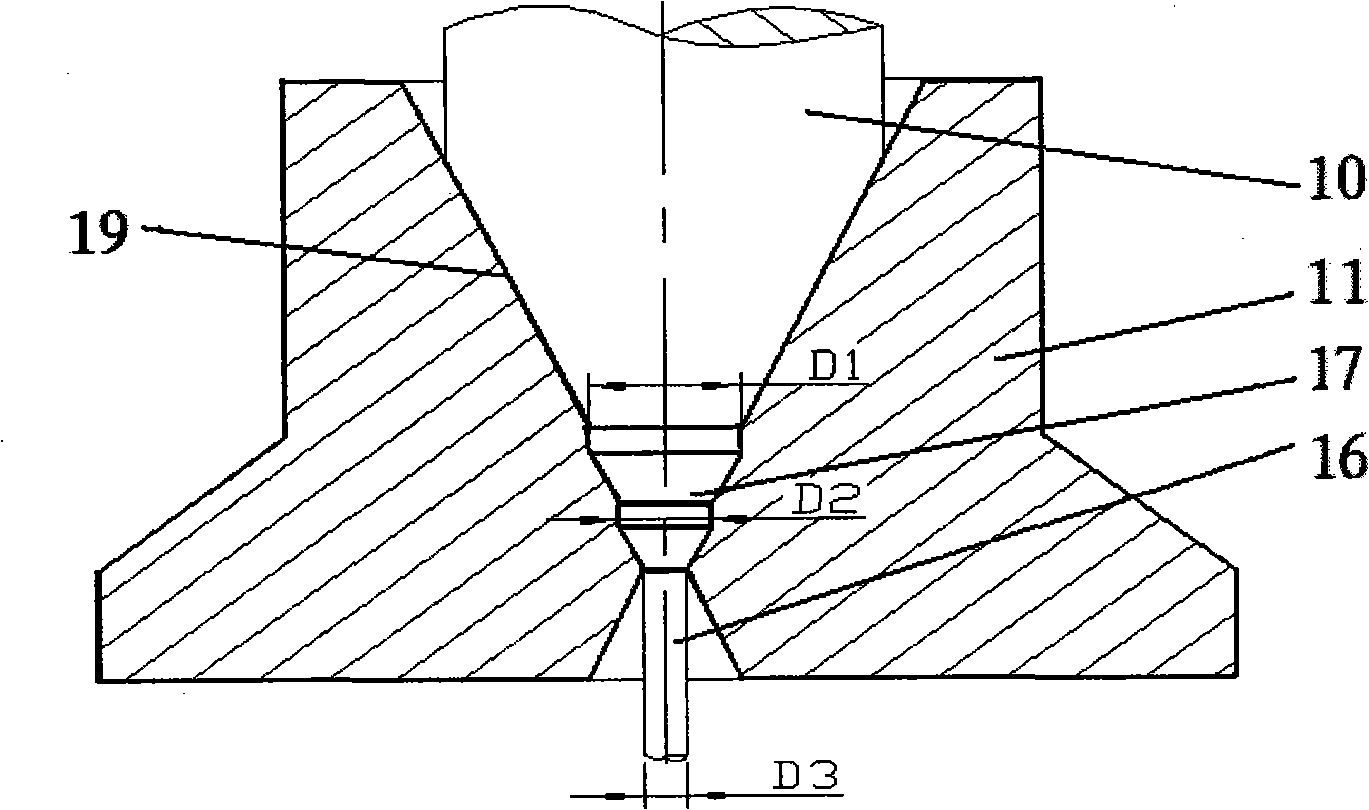

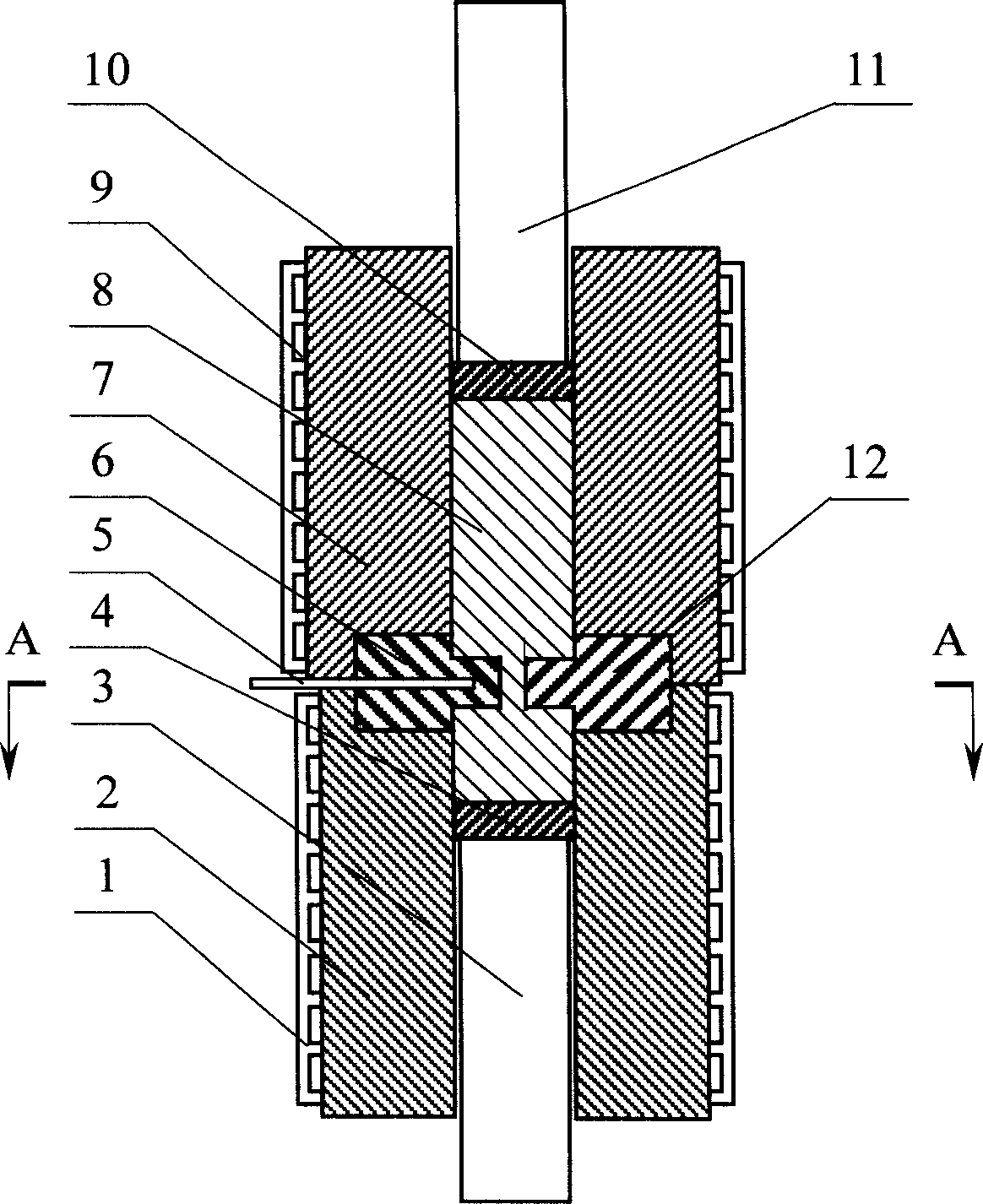

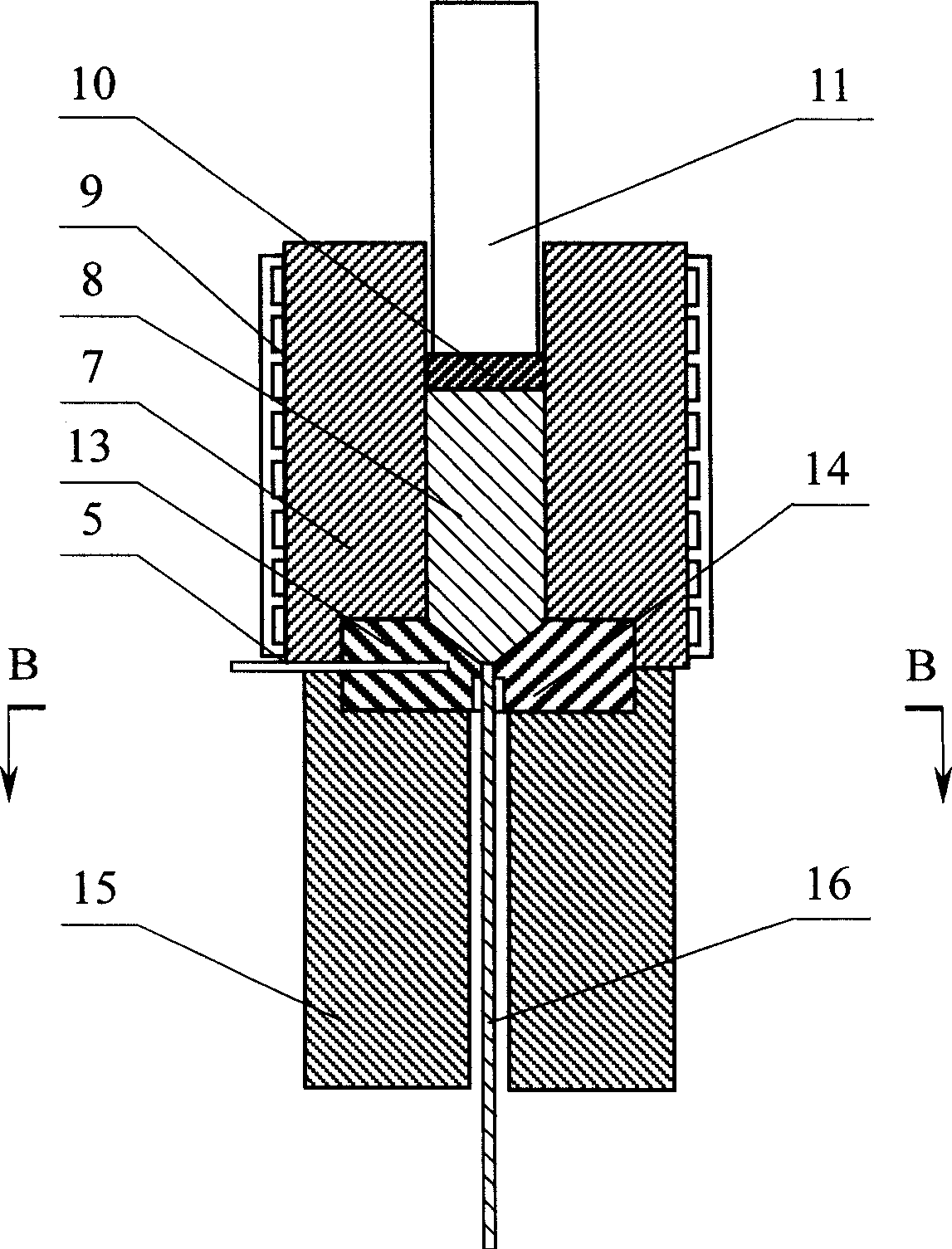

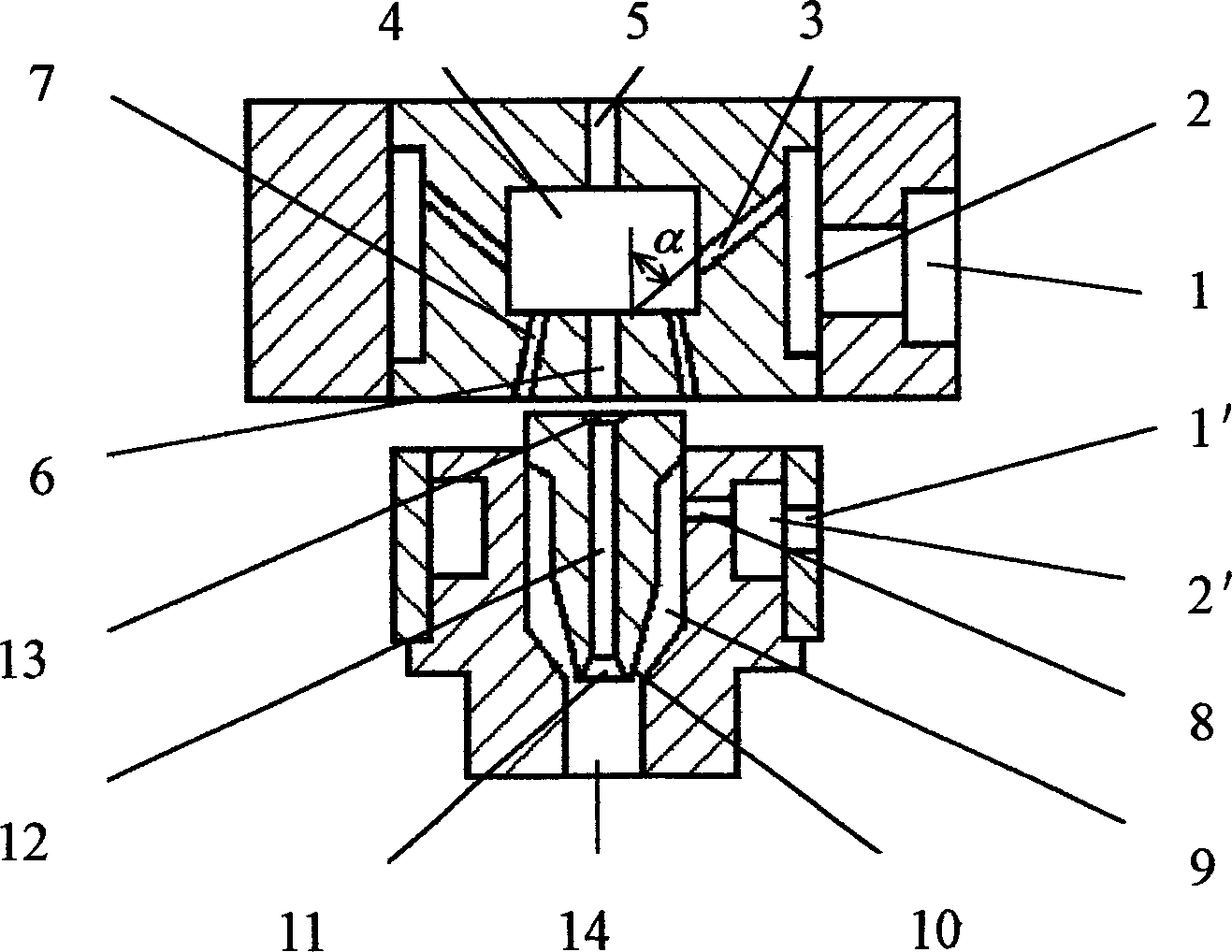

Wire hydrostatic extrusion device and method for extruding superfine grain wire using the device

InactiveCN101279331AGuaranteed qualityWill not oxidizeExtrusion diesExtrusion control devicesWire rodEngineering

The invention discloses a linear material static liquid extruding device which comprises an external extruding cylinder; an internal extruding cylinder is sheathed in the external extruding cylinder; the empty cavity of the internal extruding cylinder is filled with a hydraulic medium; the upper end of the empty cavity of the internal extruding cylinder is connected with an extruding rod; a sealing device is arranged between the extruding rod and the internal extruding cylinder. The lower end surface of the empty cavity of the internal extruding cylinder is provided with a discharge channel along the axes direction; the inner side of the lower end surface of the empty cavity of the internal extruding cylinder is provided with an extruding mould; the sealing device is arranged between the extruding mould and the internal extruding cylinder; the extruding mould is provided with an leading-in hole and an extruding hole along the axes direction; the leading-in hole, the extruding hole and the discharge channel are arranged on the same axes and are permeable. The invention also discloses a method for preparing super-thining crystal grain linear materials by the extruding device; the whole device has the advantages of compact structure, simple technique and easy operation, which is suitable for static liquid extruding to prepare aluminum alloy linear materials with thin diameters and is applied to continuously extruding other light alloys or brittle alloy linear materials that are hard to be extruded.

Owner:XIAN UNIV OF TECH

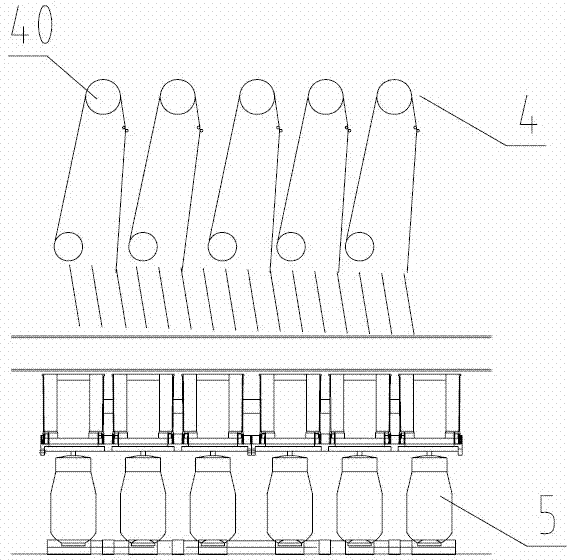

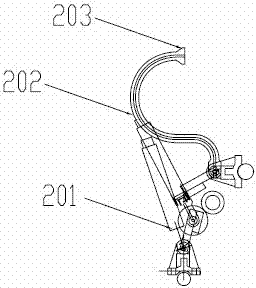

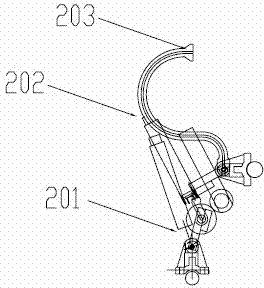

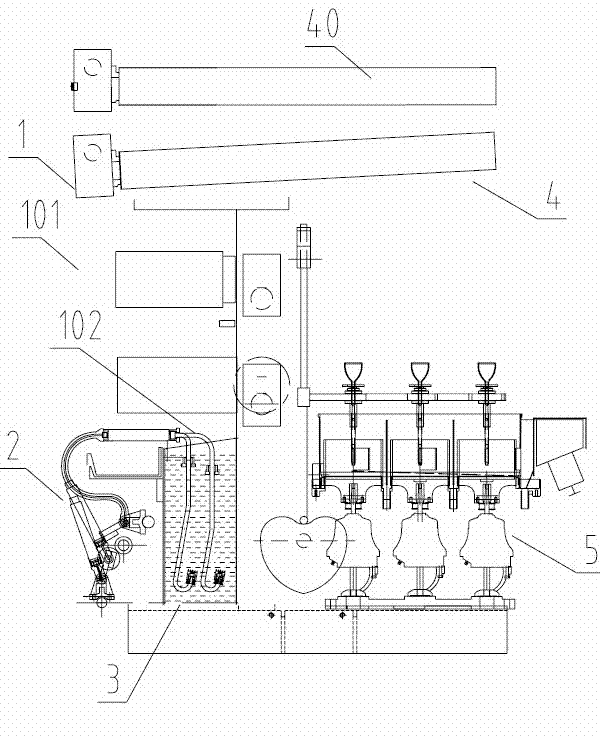

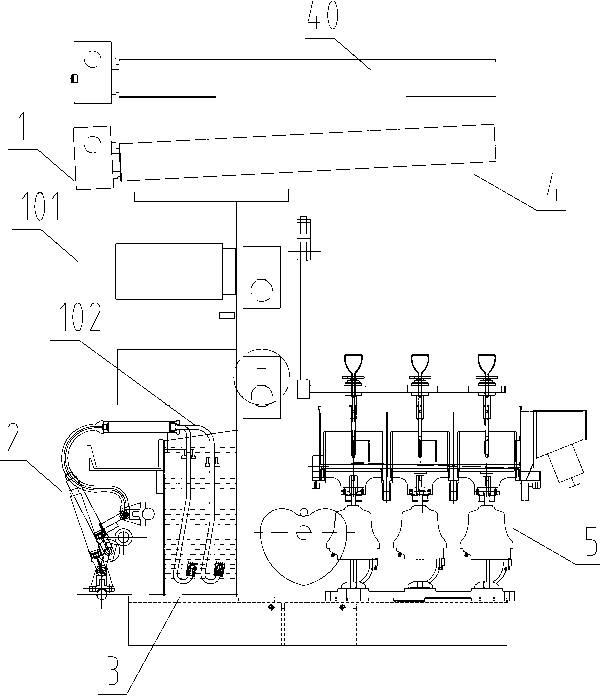

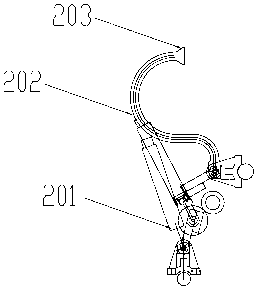

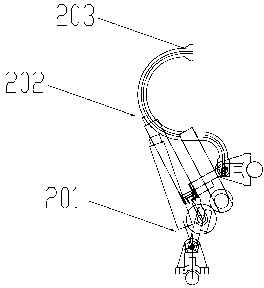

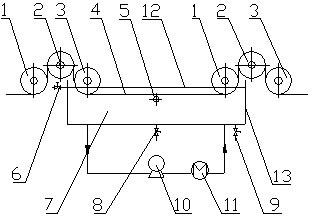

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

Continuously extruding method of magnesium alloy silk material

A continuous extruding method for preparing the Mg-alloy wire includes such steps as treating the surface of Mg alloy, loading it in the moulding cavity formed by big and small extruding cylinders, the first half of female die and the second half of female die, repeated extruding at 300-350 deg.C for fining its crystal grains and increasing its plasticity, loading it in a continuous extruder of wire material, and repeated extruding at 300-350 deg.C.

Owner:XIAN UNIV OF TECH

Method for producing full drafting silk of fine denier chinlon 66

ActiveCN101634053ASave spaceBest spinning processSpinnerette packsSpinning head liquid feederEngineeringMetering pump

The invention discloses a method for producing full drafting wires of fine denier chinlon 66, comprising the following steps: (1) adding chinlon 66 slices by a drying tower for drying for 20 to 40 hours; (2) transmitting the dried chinlon 66 slices into a screw extruder with the function of electrical heating for forming a silk spinning melting body; (3) quantitatively pressing the obtained silk spinning melting body into a silk spinning component by a metering pump; spraying by a silk spraying plate in a silk spinning box body for forming silk, wherein the hole diameter of the silk spraying plate is from 0.20 to 0.28 mm and the ratio of the length to the diameter is (2 to 4):1; (4) cooling the obtained silk bundle by side blowing wind with more than 70% of humidity; passing through a pre-communicating nozzle after oiling by an oil mouth; spraying out compressed air by the pre-communicating nozzle; treating the silk bundle, wherein the pressure of the compressed air is from 0.5 to 1.2 bar; (5) drafting and shaping the obtained silk bundle by a first group of silk guiding rollers and a second group of silk guiding rollers ,wherein the speed ratio of the second group of silk guiding rollers to the first group of silk guiding rollers is (1.2 to 2.5):1; and (6) bringing the obtained silk bundle to a high-speed rolling machine by a third silk guiding roller for rolling.

Owner:烟台华润锦纶有限公司

Magnesium alloy wire continuous extruding method

The continuous extrusion method of magnesium alloy wire is characterized by that the extrusion shaft is divided into heat extrusion shaft and cold extrusion shaft, and said continuous extrusion method includes the following steps: successively placing the compression die, magnesium alloy ingot covered with graphite flake and heat extrusion shaft into extruding cylinder, compacting, placing the extruding cylinder into electric furnace together with supporting pad, heating to 500-550 deg.C, heat-insulating for 30 min., at the same time of insulating heat preheating base to 200-300 deg.C, preheating heat-insulating cylinder to 400-450 deg.C, then taking out extruding cylinder together with supporting pad and placing them on the base, covering with heat-insulating cylinder, placing the cold extrusion shaft on the heat extrusion shaft, extruding on extruder.

Owner:DALIAN UNIV OF TECH

Method of preparing protein modified polyacrylonitrile fibre

InactiveCN101109115AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsIonic liquidHigh productivity

The invention relates to a preparing method for a protein modified polyacrylonitrile fiber, which comprises the following procedures: (1) some protein and polyacrylonitrile are solved in some ion liquid to prepare some equal-phase mixed crude liquid for spinning; (2) the spinning liquid is de-bubbled, filtered, dosed, then extruded by a spinning jet to form a fine spinning flow, which passes a wet air layer and enters into a condensing bath to condense and form; (3) fiber is spun after pre-tensioning, tensioning, water washing, drying and thermal forming, so protein modified polyacrylonitrile fiber is prepared. The method is environmental friendly, easy to recycle, of low production cost and high productivity; the clothing from the product made by the method is highly comfortable and healthy, and is of high fiber property.

Owner:DONGHUA UNIV

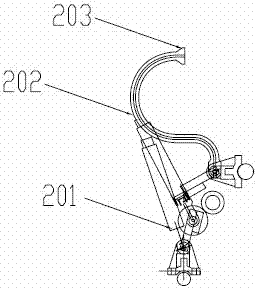

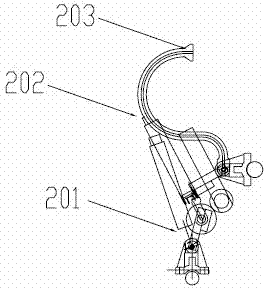

Complex twisting device for air-jet eddy-current spinning

InactiveCN1388278ANo suction phenomenonImprove production rateContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The complex twisting device for air-jet eddyc-current spining to twist fiber strand consists of the upper twisting unit and the lowr twisting unit. Positive pressure air flow is utilized to produce eddy-current field and pipe flow and the fiber is fed to the eddy-current field via the conveying pipe. Fiber strand rotates with the high-speed rotating air flow while the pipe flow protects and guides the twisted fiber strand to leave from the eddy-current field. During the process, fiber strand is twisted to produce twisted yarn in high speed. The present invention makes it possible to produce high-quality yarn at low cost and high speed.

Owner:DONGHUA UNIV

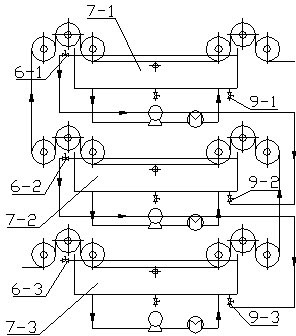

Spinning process of bamboo-like flat filaments produced by semi-continuous high-speed spinning machine

ActiveCN103290495AEasy maintenanceLow cost of spinningArtificial thread manufacturing machinesArtificial filaments from viscoseFrequency changerPolymer science

The invention relates to a spinning process of bamboo-like flat filaments produced by a semi-continuous high-speed spinning machine and belongs to the technical field of spinning of semi-continuous spinning machines. The spinning process comprises glue supply, filament strip forming, spinning and winding. The spinning process is characterized in that the glue supply is achieved through a glue supply device which comprises a metering pump, a glue supply tube and a filter; the metering pump is connected with a frequency converter which is used for controlling the amount of the glue supply of the metering pump; the frequency converter controls the metering pump to perform intermittent glue supply; the spinning is achieved through a spinning device which comprises at least one spinning roller which is horizontally arranged relative to an operating surface of a spinning surface; and filament strips surround the spinning roller to achieve drafting, solidification and deacidification in the spinning processes under the rotation of the spinning roller. The spinning process of the bamboo-like flat filaments produced by the semi-continuous high-speed spinning machine has the advantages of solving the problems that the filament strips of the semi-continuous spinning machines are inadequate in response, so that the spinning speed cannot be improved and the production efficiency and product quality cannot be integrated, enabling the arrangement direction of the spinning roller to be changed to enable the spinning speed of the spinning machine to be improved and enabling the high quality bamboo-like flat filaments to be spun out.

Owner:YIBIN HIEST FIBER +2

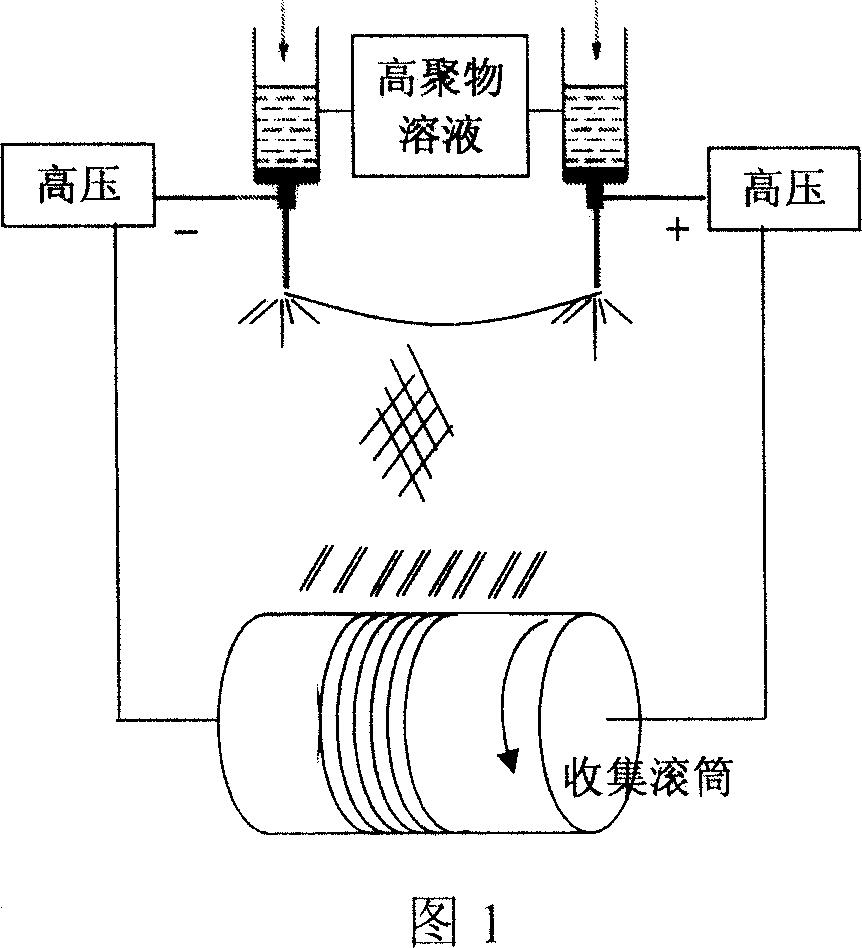

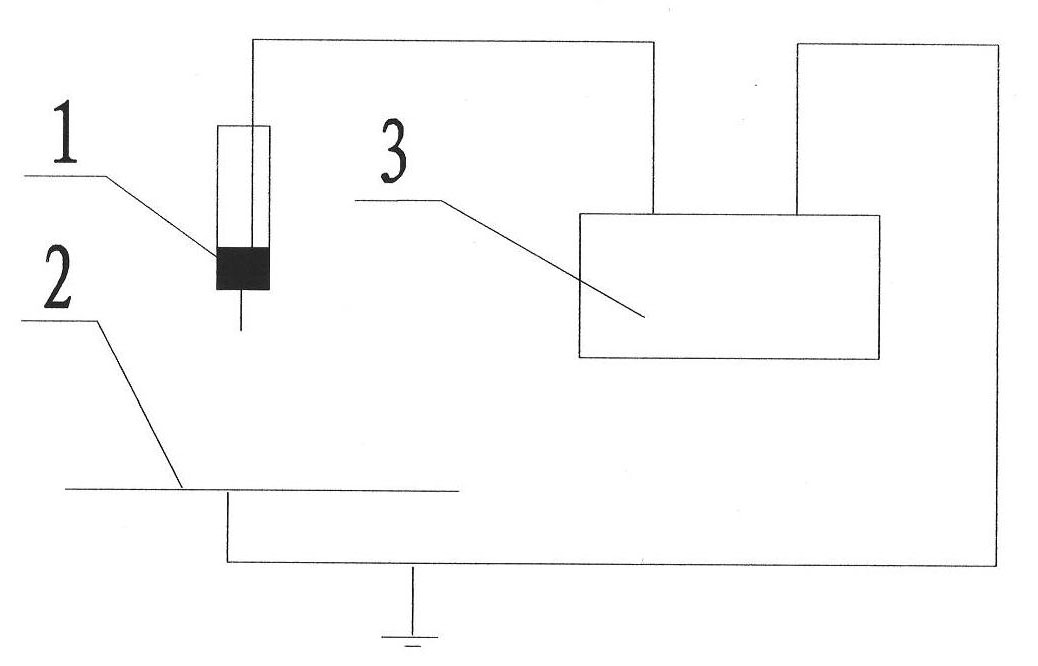

Complex type electrostatic spinning method with positive and negative electrodes in same electric field, and application

InactiveCN101003917AIncrease spinning speedOvercome the defects of single productsFilament/thread formingArtificial filaments from cellulose derivativesComplex typeElectrospinning

Owner:CIVIL AVIATION UNIV OF CHINA

Preparation method of polyurethane raw liquid for high-speed spinning

ActiveCN103710786AIncrease productivityIncrease concentrationMonocomponent synthetic polymer artificial filamentPolyesterFiber

The invention relates to a preparation method of polyurethane raw liquid for high-speed spinning. The preparation method comprises the following steps: (1) adding a solvent and mixed polyester to a pre-polymerization tank; (2) accurately adding mixed diisocyanate according to a predetermined NCO / OH ratio so as to carry out prepolymefization reaction; (3) after ending prepolymefization reaction, transferring a prepolymer to a chain extension tank, adding a cleaning solvent, uniformly stirring, and cooling a refrigerant to about 0-20 DEG C; (4) slowly adding chain extension amine and a chain terminating agent solution, and reacting so as to form a polyurethane urea solution in the end; (5) transferring the obtained polyurethane urea solution to a storage tank, and adding multiple functional auxiliary materials and additives; and (6) fully and uniformly stirring, carrying out vacuum defoamation, and preparing polyurethane fibers by using polymerization raw liquid through dry spinning. The polyurethane raw liquid for high-speed spinning can be used for the spinning of fibers at the spinning speed of above 1000m / min. The new technology can be used for improving the spinning efficiency and reducing energy consumption and labor cost.

Owner:ZHEJIANG HUAFENG SPANDEX

Spinning technology of semi continuous high speed spinning machine

InactiveCN103305935AThe transmission mechanism is simpleEasy to maintainArtificial thread manufacturing machinesWet spinning methodsPhysicsSpinning

The invention relates to a spinning technology of a semi continuous high speed spinning machine, belongs to the technical field of semi continuous spinning machine spinning, and comprises the steps of glue supplying, filament forming, spinning and winding, wherein the spinning is accomplished by a spinning device which comprises one or more spinning rollers arranged on an operating surface corresponding to the spinning surface, the filament winds around the spinning roller, the drafting, solidification and deacidification of the spinning step are accomplished under the rotation of the spinning roller. According to the spinning technology provided by the invention, the problems that the spinning speed can not be accelerated and dual attention to the working efficiency and the product quality cannot be given, caused by the insufficiency reaction of the semi continuous high speed spinning machine filament, are solved, the changing of the spinning roller distribution direction enables the spinning machine to accelerate spinning speed and reserve the structure of other parts of the conventional device, the filament to walk farther, and the reaction of the filament and the acid bath to be more efficient, both the working efficiency and the product quality are considered.

Owner:YIBIN HIEST FIBER +2

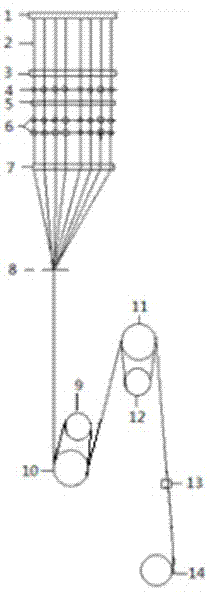

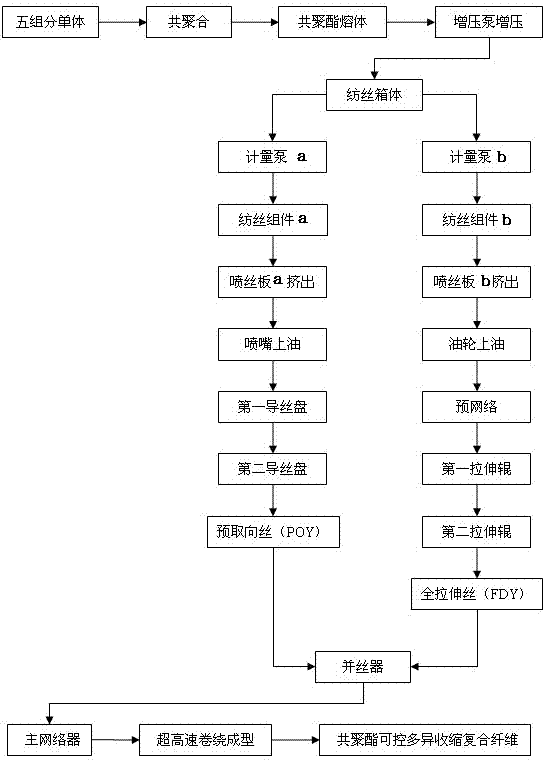

Controllable multiple-differential-shrinkage composition fiber made from copolyester melt through ultra-fast direct spinning, and preparation method of composition fiber

InactiveCN103484967AIncrease spinning speedIncrease added valueArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnFiber

The invention relates to a controllable multiple-differential-shrinkage composition fiber made from a copolyester melt through ultra-fast direct spinning, and a preparation method of the composition fiber. The copolyester melt, which is made from five components including terephthalic acid, ethylene glycol, poly ethylene glycol, diethylene glycol and pentaerythritol, is pressurized by a booster pump and transported through a melt pipeline into a spinning box body, and is then divided by two measuring pumps into two branches, which enter a spinning component and a spinneret respectively and finally be extruded. After cooling and curing, two yarns are formed, wherein one yarn is subject to oiling by an oil wheel, pre-entwining, stretching and thermoforming to obtain an FDY yarn, and the other yarn is subject to oiling by an oil nozzle, and is guided to two spinning discs to obtain a POY yarn; the two yarns are simultaneously input into a doubling device and a main entwining device for combination, and are formed through the ultra-fast rolling, so as to obtain the composition fiber. The composition fiber has the characteristics of relatively good micro three-dimensional morphological structure, moisture absorption property, moisture preservation property, air permeability and antistatic property, easiness in dyeing, uniform dyeing, high coloration uniformity and the like; the composition fiber is high in processing speed, high in yield, low in consumption, low in manufacturing cost, high in value added, high in product functions, good in quality, and obvious in advantage of performance price ratio.

Owner:SUZHOU UNIV

Device for producing polyamide 6POY/FDY composite fiber according to high-speed spinning and confounding one-step method

InactiveCN104032397AGood melt uniformityShort production processNew-spun product collectionSpinning head liquid feederPolyamideYarn

The invention discloses a device for producing polyamide 6POY / FDY composite fiber according to a high-speed spinning and confounding one-step method. A cooling device of the device is a gradually-cooling device which is arranged below a spinneret plate. A cross air blow cooling device is arranged below a heater of the gradually-cooling device, the effect of lowering the cooling speed of melt thin flow can be achieved by enabling melt extruded out of the spinneret plate to pass through the cooling device, and yarn bundle cooling is uniform and consistent. An oil spraying device is arranged below the cross air blow cooling device. A stretching heat setting device and a yarn guiding and winding device are arranged in parallel. The stretching heat setting device is used for preparing polyamide 6POY fully-drawn yarn. The yarn guiding and winding device is used for preparing polyamide 6FDY fully-drawn yarn. A winding device is used for compositing 6POY with FDY at the speed ranging from 4000m / min to 5000m / min. The device has the advantages of being short in production process, simple in procedure, low in device production cost, low in energy consumption, high in efficacy, diversified in product structure and good in quality.

Owner:SUZHOU UNIV

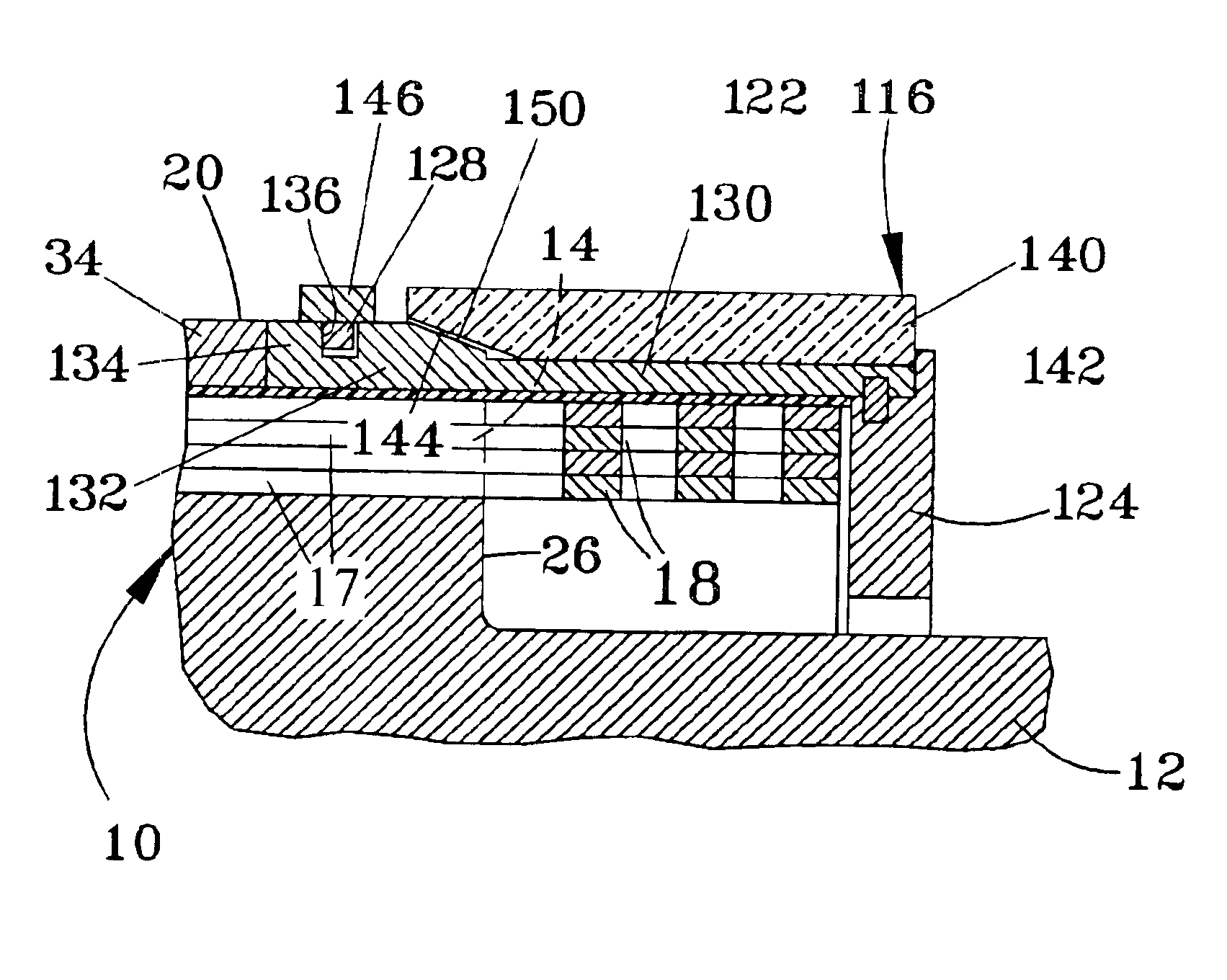

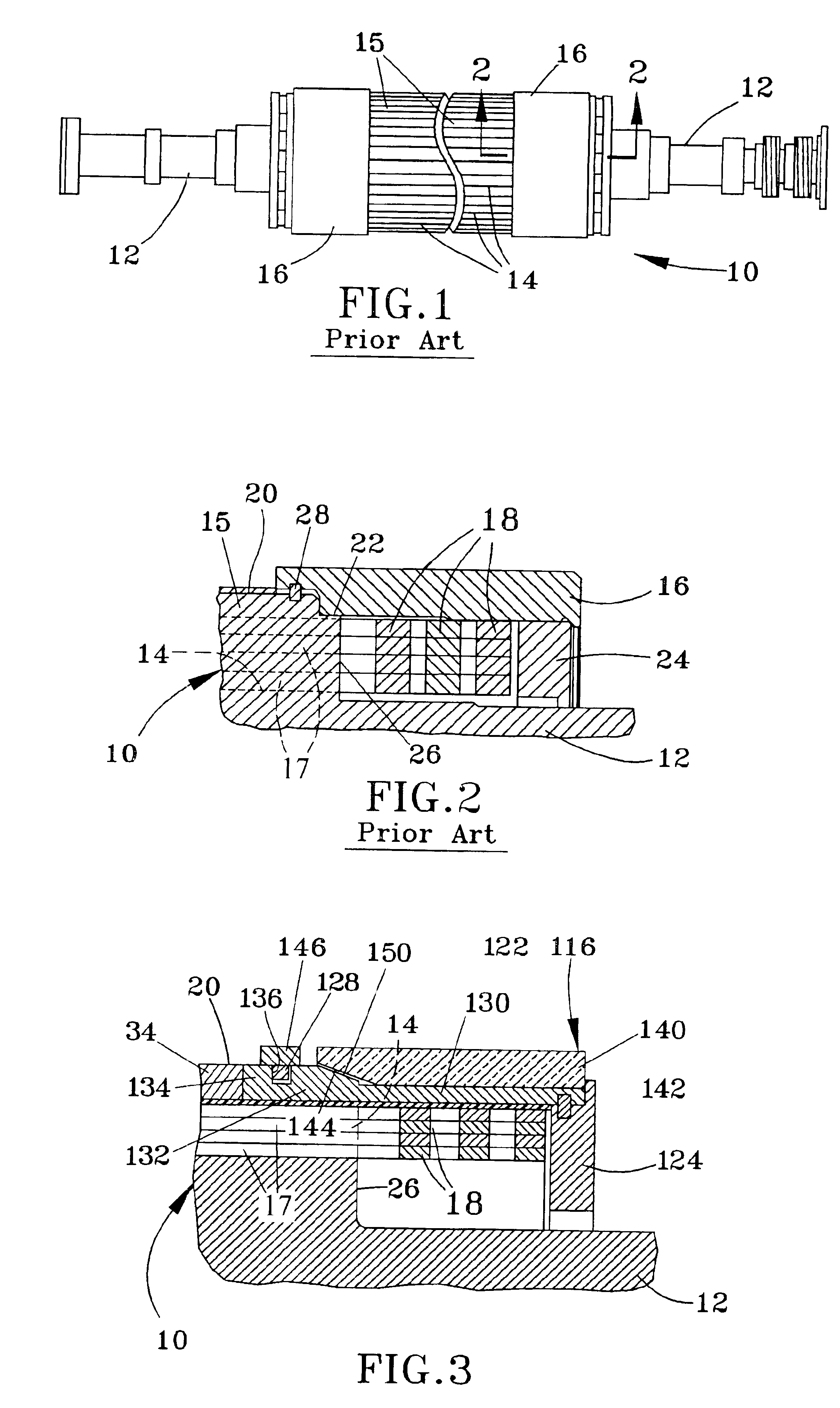

Retaining system for a rotor of a dynamoelectric machine

A retaining system for field winding end turns of a rotor, such as for a dynamoelectric machine. The rotor has an outer peripheral surface, radial end surfaces, axially-extending slots in the peripheral surface, and field windings in the slots. The field windings axially project from the end surfaces of the rotor and are connected outside of the slots by field winding end turns. The end turns are surrounded by the retaining system, which includes a shield member surrounding the end turns and a retainer member surrounding to the shield member. The shield member has flanges received in the slots along with the field windings. Fastening features engage the flanges to inhibit axial movement of the retaining system.

Owner:GENERAL ELECTRIC CO

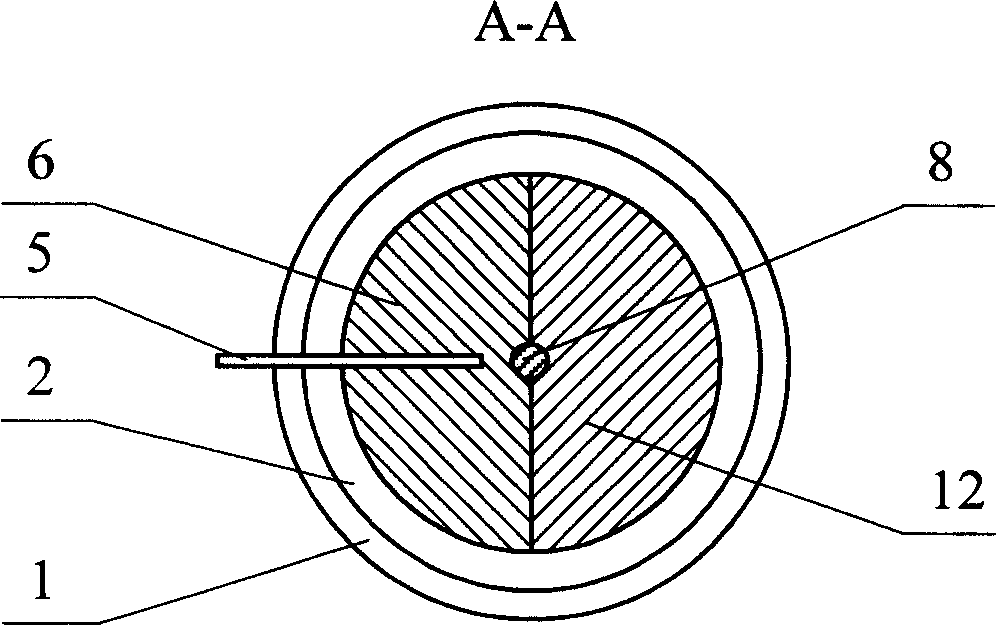

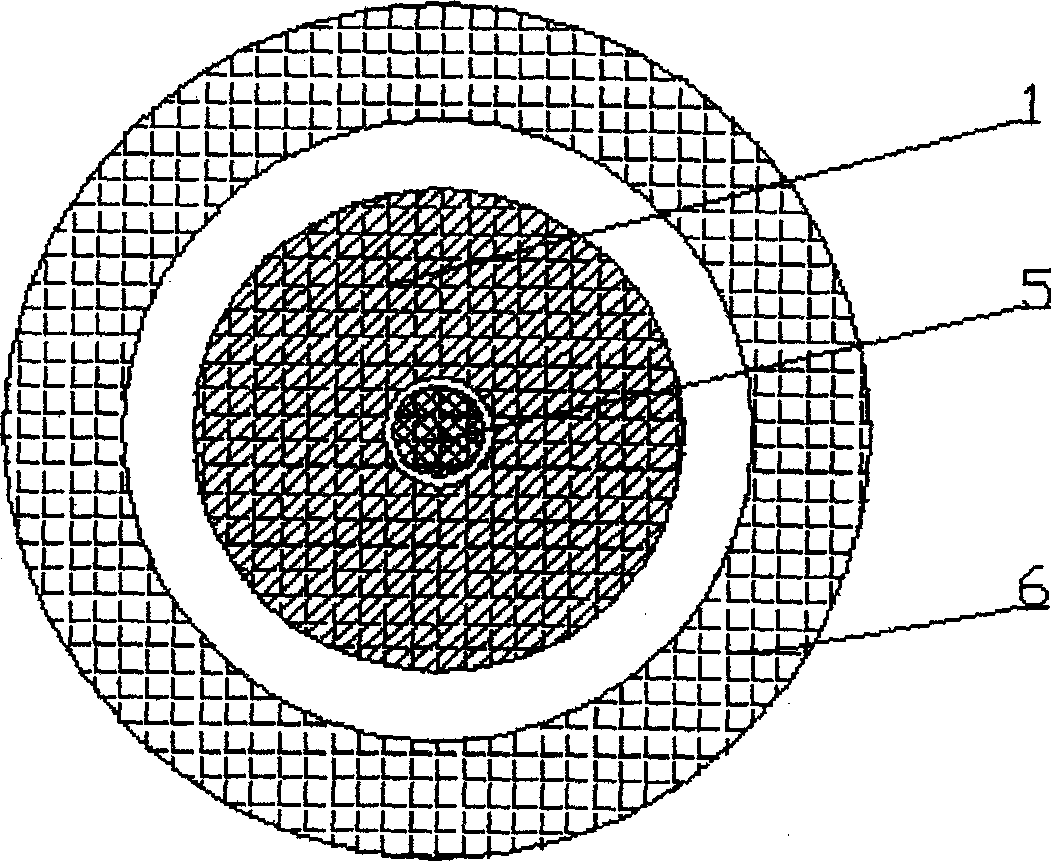

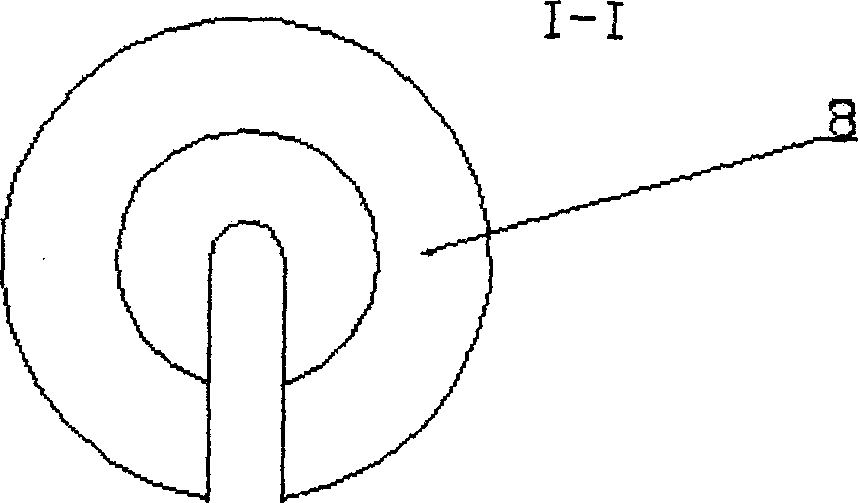

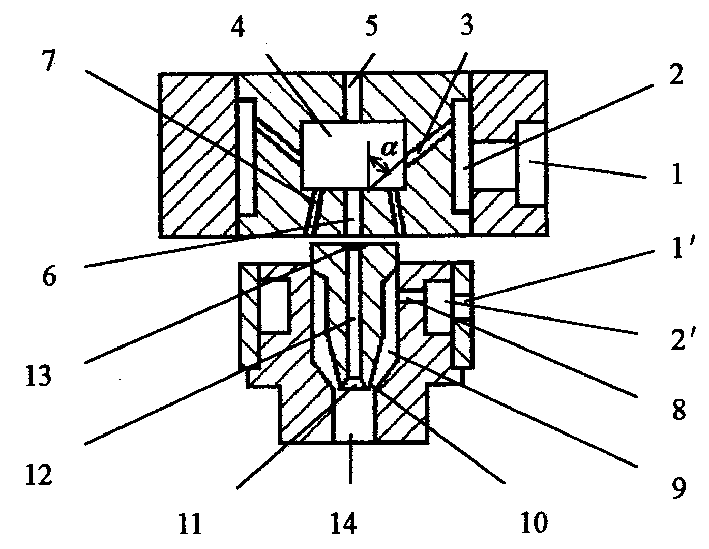

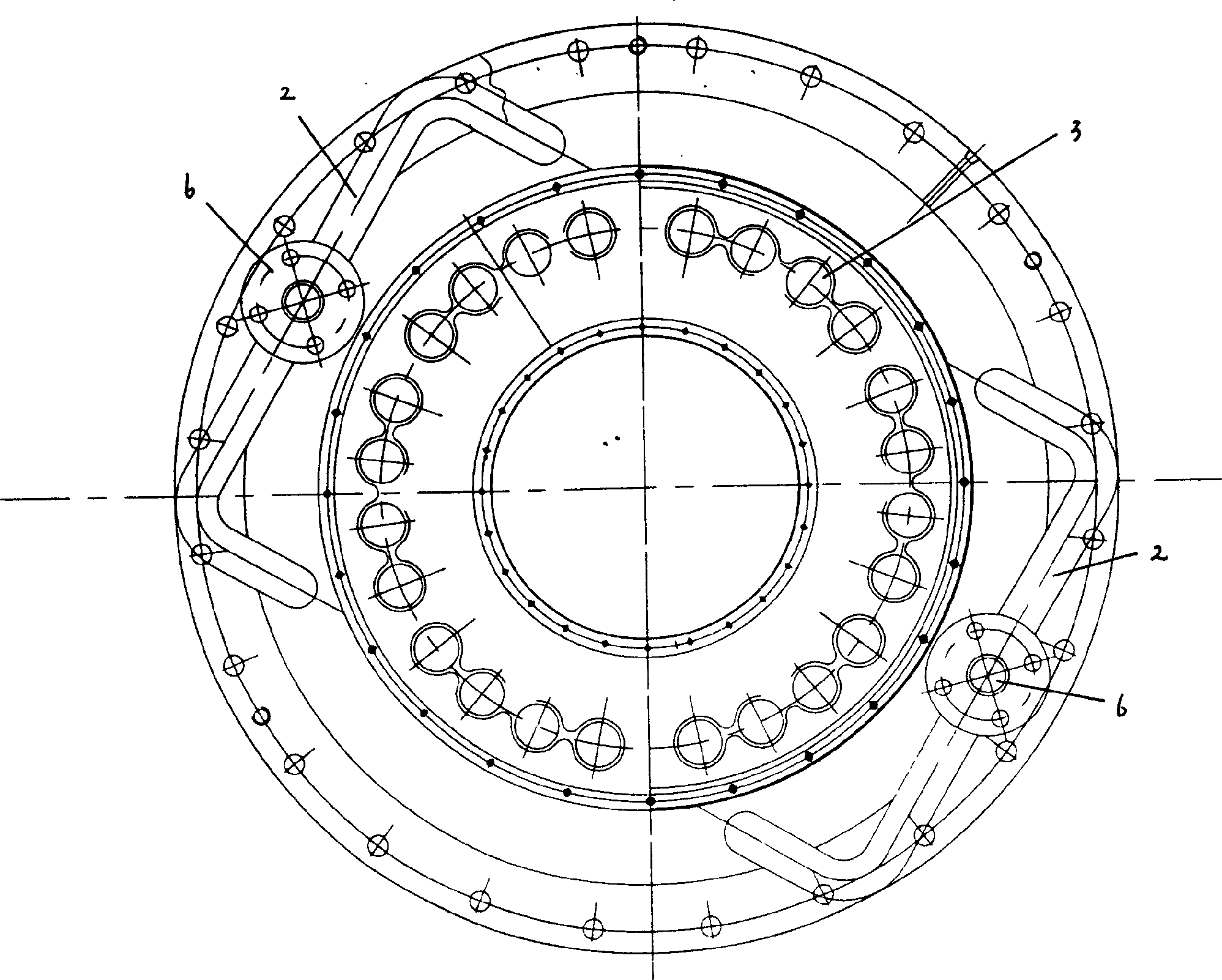

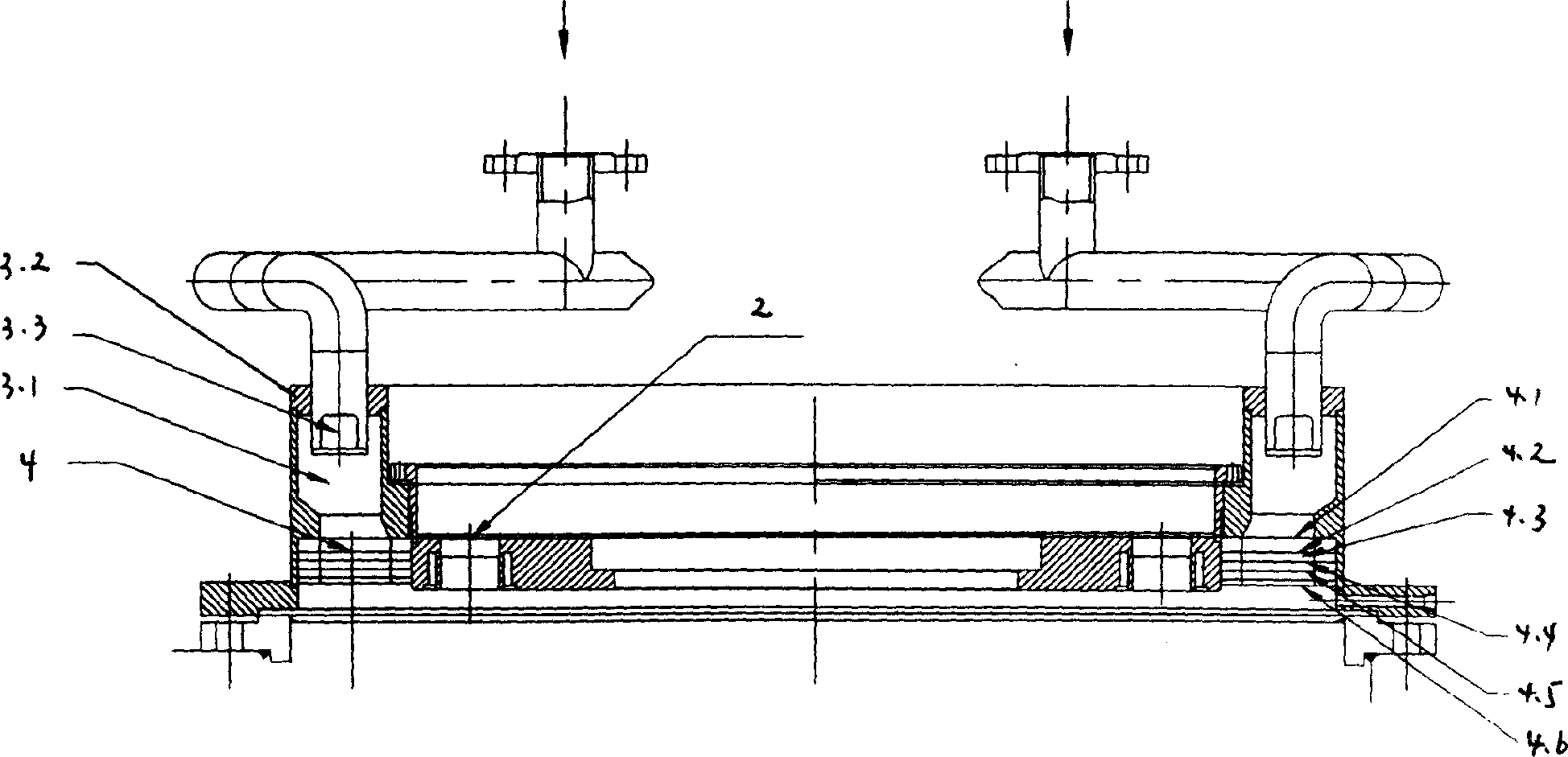

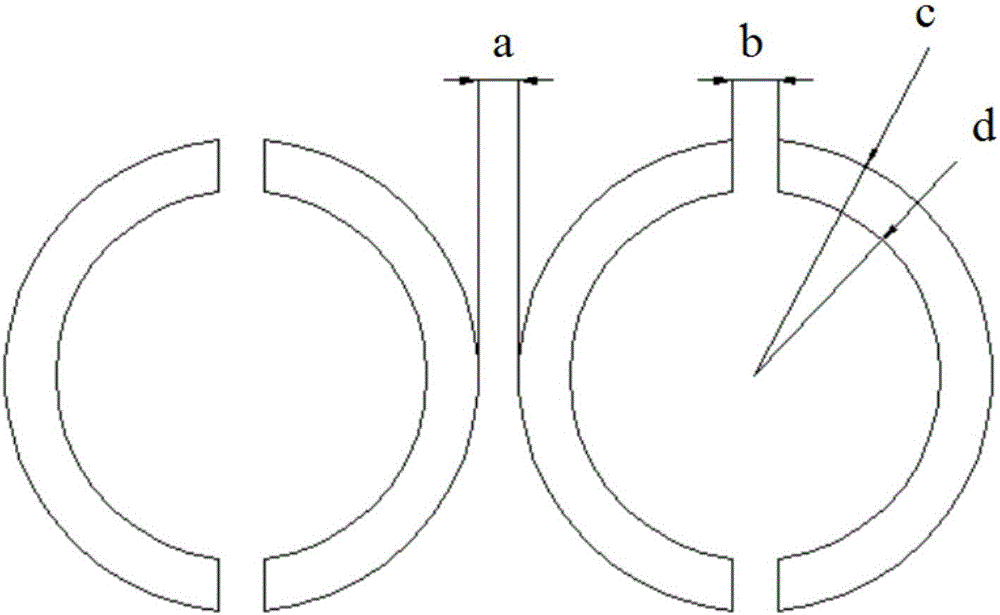

Circular corridor for spinning of urethane elastic fiber

ActiveCN1727529AAvoid interferenceAvoid intertwiningMonocomponent polyurethanes artificial filamentFilament/thread formingCylindrical channelFiber

A circular channel for spinning polyurethane fibers is composed of cylindrical channel, spinneret plate module, annular air blower, annular air inlet flow-regulator, annular air-returning flow-regulator, hot airflow inlet and hot airflow outlet. Its advantages are high airflow stability, distribution uniformity and spinning quality.

Owner:JIANGYIN L V CHEM FIBER PROCESS TECH

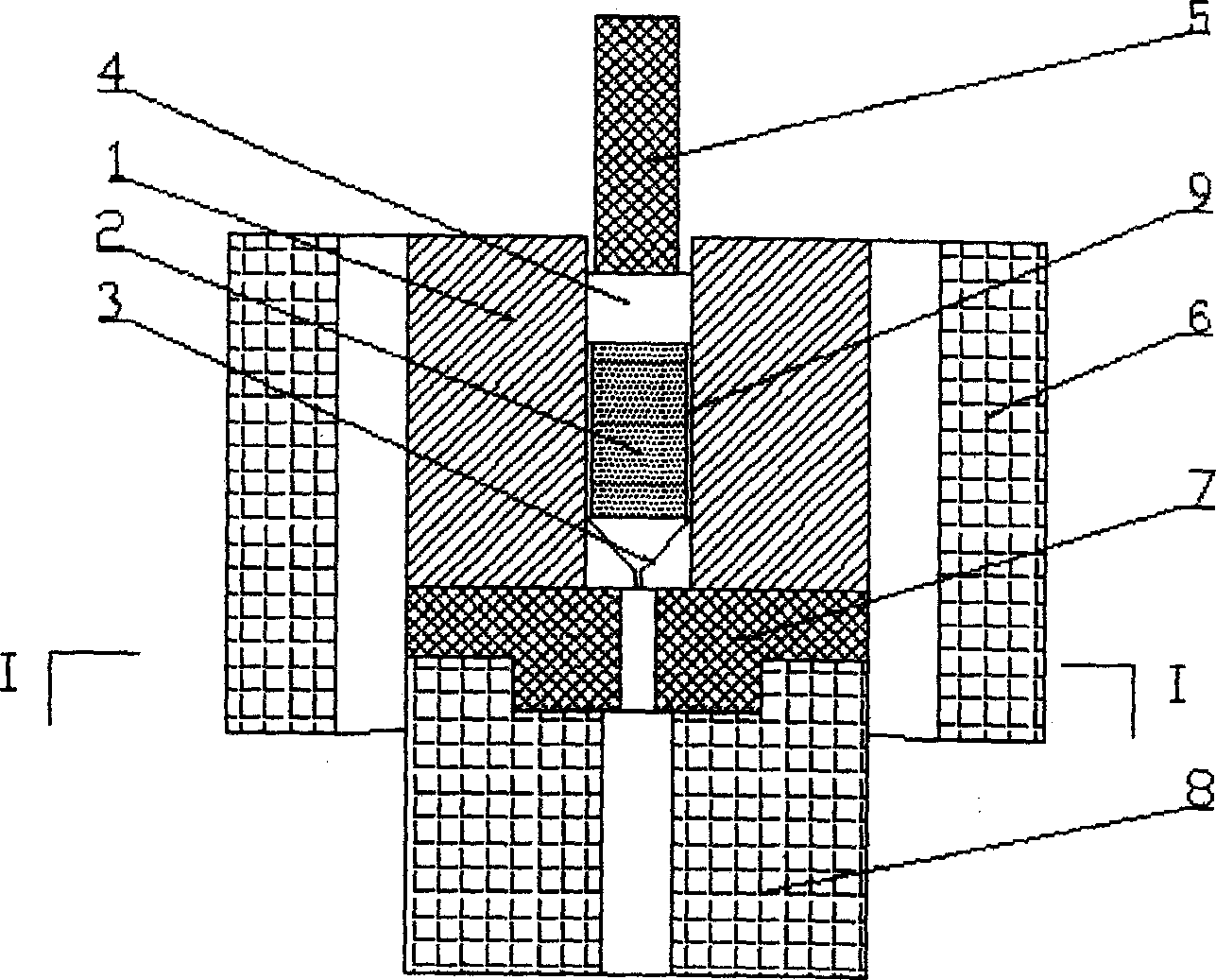

Polyacrylonitrile as-formed fiber rinsing bath and application

ActiveCN102677200AConserve waterFree to adjust the quantityArtificial filament washing/dryingOutfallPulp and paper industry

The invention provides a polyacrylonitrile as-formed fiber rinsing bath. The rinsing bath is characterized in that a shell (13) of the rinsing bath is a U-shaped bath; a circulating pump (10) and a heat exchanger (11) are connected with the bottom of the shell (13); an outfall (8) and a water inlet (9) are arranged at the bottom of the shell (13); a temperature measurement hole (5) is arranged on the side of the shell (13); drawing rollers are installed on the shell (13) and comprise silk entering drawing rollers (1), intermediate drawing rollers (2) and silk exiting drawing rollers (3), which are in the same size; a water outlet (6) is arranged on the shell (13) and is on the same level with a rinsing bath liquid level (12); and the water outlet and the water inlet (9) are arranged at the two ends of the shell (13). The rinsing bath has the advantages of uniform water temperature distribution, simultaneous suitability for big and small tows, high rinsing efficiency and good effect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of tin oxide fiber precursor and tin oxide crystal fibers

ActiveCN103556303AUniform diameterGood whitenessInorganic material artificial filamentsTin oxidesElectrospinningPhotocatalysis

The invention relates to a preparation method of a tin oxide fiber precursor and tin oxide crystal fibers. The preparation method comprises the following steps: carrying out a replacement reaction on halides of tin and potassium (sodium) acetate to synthesize the tin oxide fiber precursor which takes acetic acid as a ligand; concentrating a precursor solution to obtain a spinning solution and carrying out centrifugal silk spinning to obtain tin oxide precursor fibers; and carrying out procedures of special atmosphere pre-treatment, high-temperature heat treatment and the like on the precursor fibers to obtain the tin oxide crystal fibers. According to the preparation method, the long-diameter ratio of the tin oxide crystal fibers is greater than 1000, the tensile strength of the fibers is 0.8GPa-1.1GPa, the whiteness of the fibers is good and the color and luster of the fibers are soft. The preparation method is simple in preparation process, moderate in condition and stable in quality of fibers in batches; spinning sol does not go bad after being placed for a long time. The tin oxide crystal fibers can be applied to the fields of photocatalysis, air sensitivity, humidity sensitivity and the like. The tin oxide fiber precursor can also be used for preparing oxide thin films, nano powder and nano wires or preparing tin-containing functional materials including nano tin oxide fibers and the like by an electrostatic spinning method.

Owner:SHANDONG UNIV

Artificial hair made from animal protein and process for producing same

InactiveCN1699646AHigh tide rateSpeed up the flowMonocomponent protein artificial filamentWigsCross-linkHair streams

The present invention discloses a kind of artificial hair made of animal protein and its method of production, which essentially consists of blended protein of cross-linking agent and chemical modification, wherein the blended protein of chemical modification is made by taking keratin and albumen protein as the protein materials with its production steps comprising compound of spinning silk original liquid, wet spinning, solidification, de-dissolvent, drawing and chemical cross-linking. The invention has overcome the defects like hard skin and scanty and hollow core existing in the original products of the same and the hair of its product is soft, non-inflammable, and good to the touch with high wet returning rate, gentle luster, long lifespan and low cost.

Owner:POLY WELL NANTONG IND

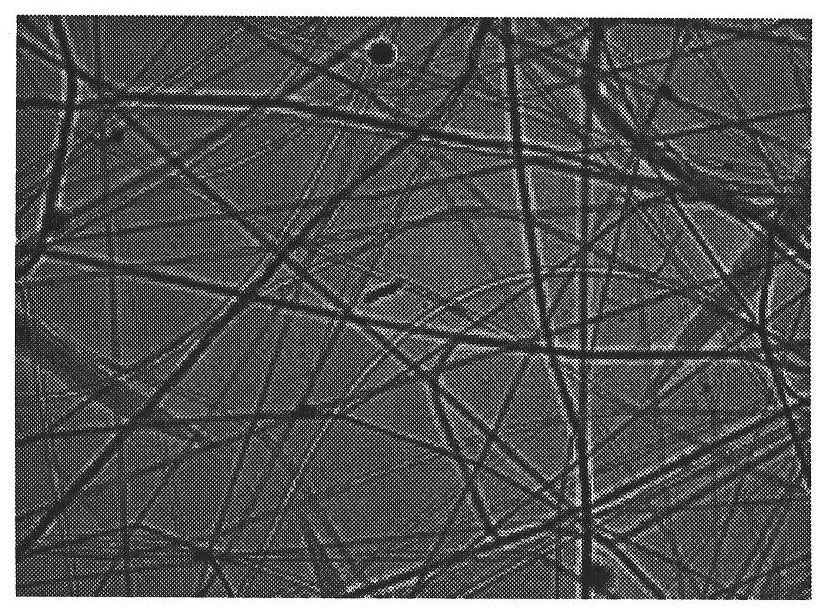

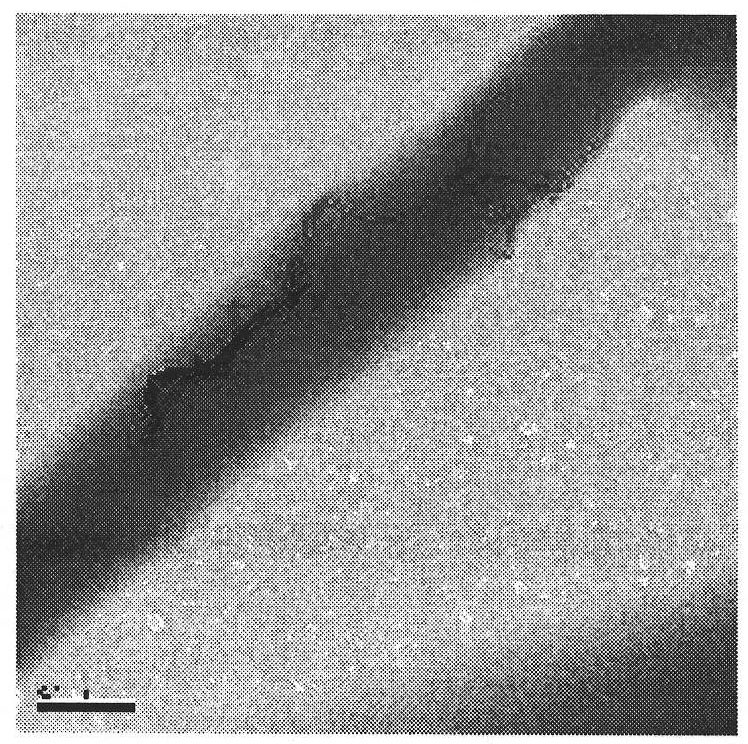

Biocompatible nano-conductive fiber and preparation method thereof

InactiveCN101805938AReasonable formReasonable morphology is better, the distribution of carbon nanotubes in the fiberElectroconductive/antistatic filament manufactureFilament/thread formingCarbon nanotubeBiocompatibility Testing

The invention discloses a biocompatible nano-conductive fiber and a preparation method thereof. The biocompatible nano-conductive fiber comprises the following three components in part by mass: 100 parts of polylactic acid, 5 to 10 parts of carbon nano tubes and 1 part of sodium dodecyl sulfate. The three components are prepared into spinning solution by utilizing compound solvents, i.e. chloroform and dimethyl sulfoxide, and an electrostatic spinning device is used to spray to prepare the biocompatible nano-conductive fiber, wherein the fiber diameter is between 200 and 500nm; the carbon nano tubes are coated uniformly with the polylactic acid and are orderly arrayed in the fiber; the surfaces of the carbon nano tubes are subjected to hydroxylation; the mass percentage of hydroxy is 3.06 weight percent; the diameter of the carbon nano tubes is between 10 and 20nm; the length of the carbon nano tubes is 30mum; the purity of the carbon nano tubes is over 95 weight percent; and the specific surface area of the carbon nano tubes is over 200m<2> / g. The invention has advanced and simple process and reasonable formula. The prepared nano-conductive fiber has good biocompatibility and has wide application prospect.

Owner:YANGZHOU UNIV

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

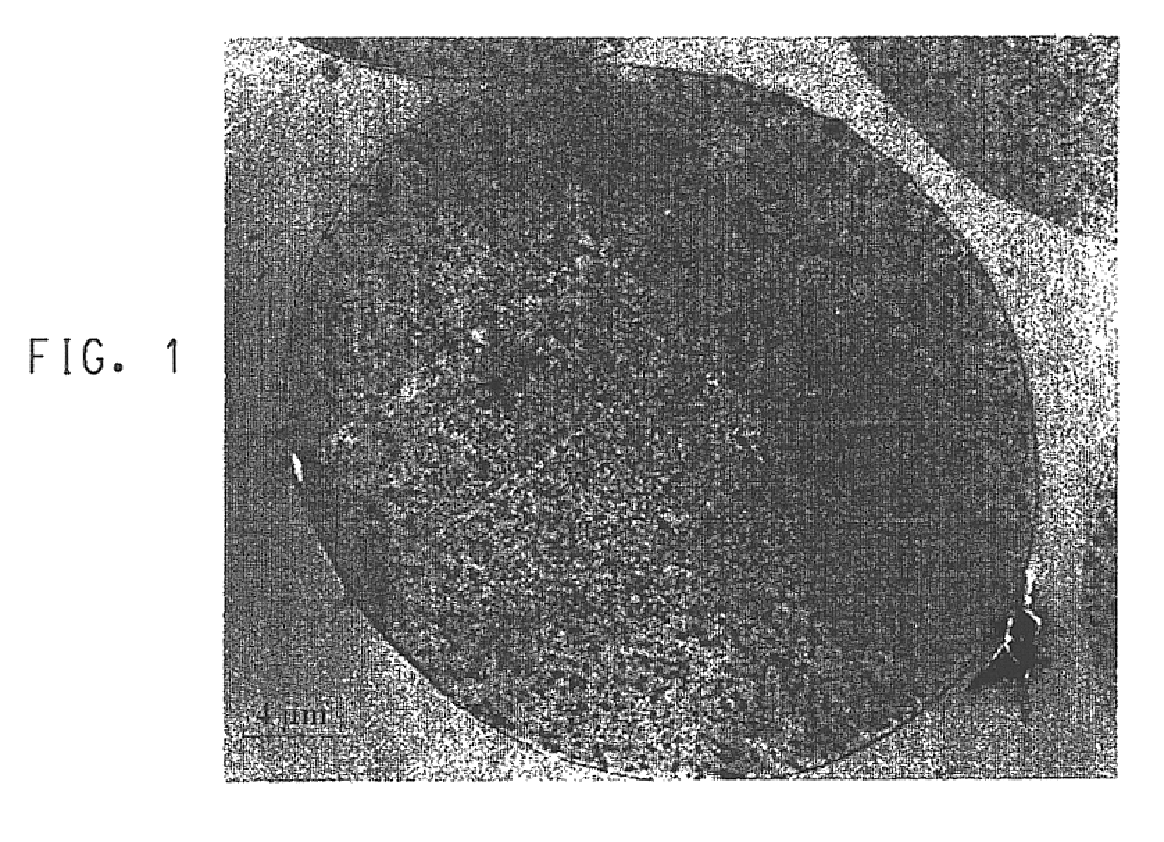

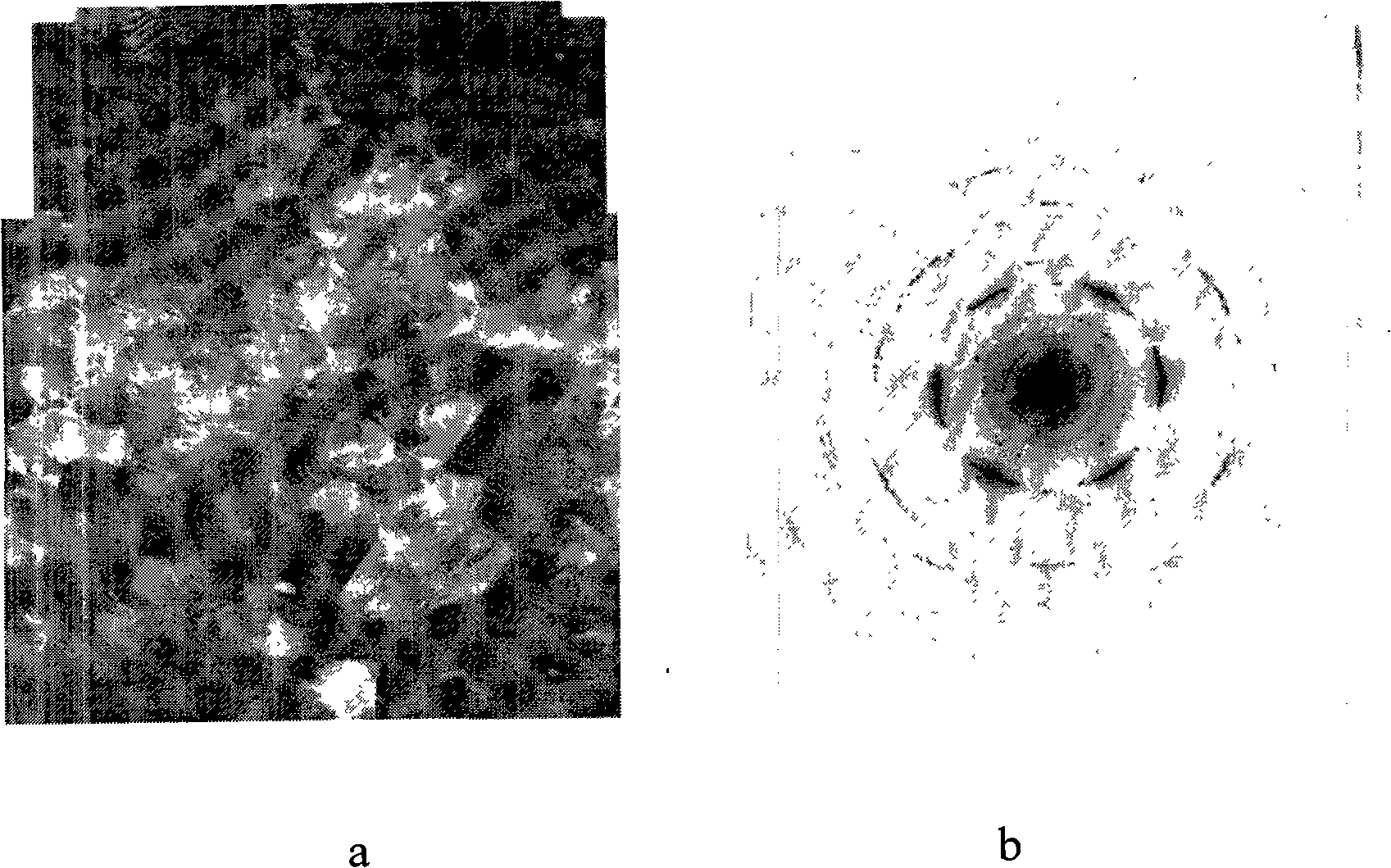

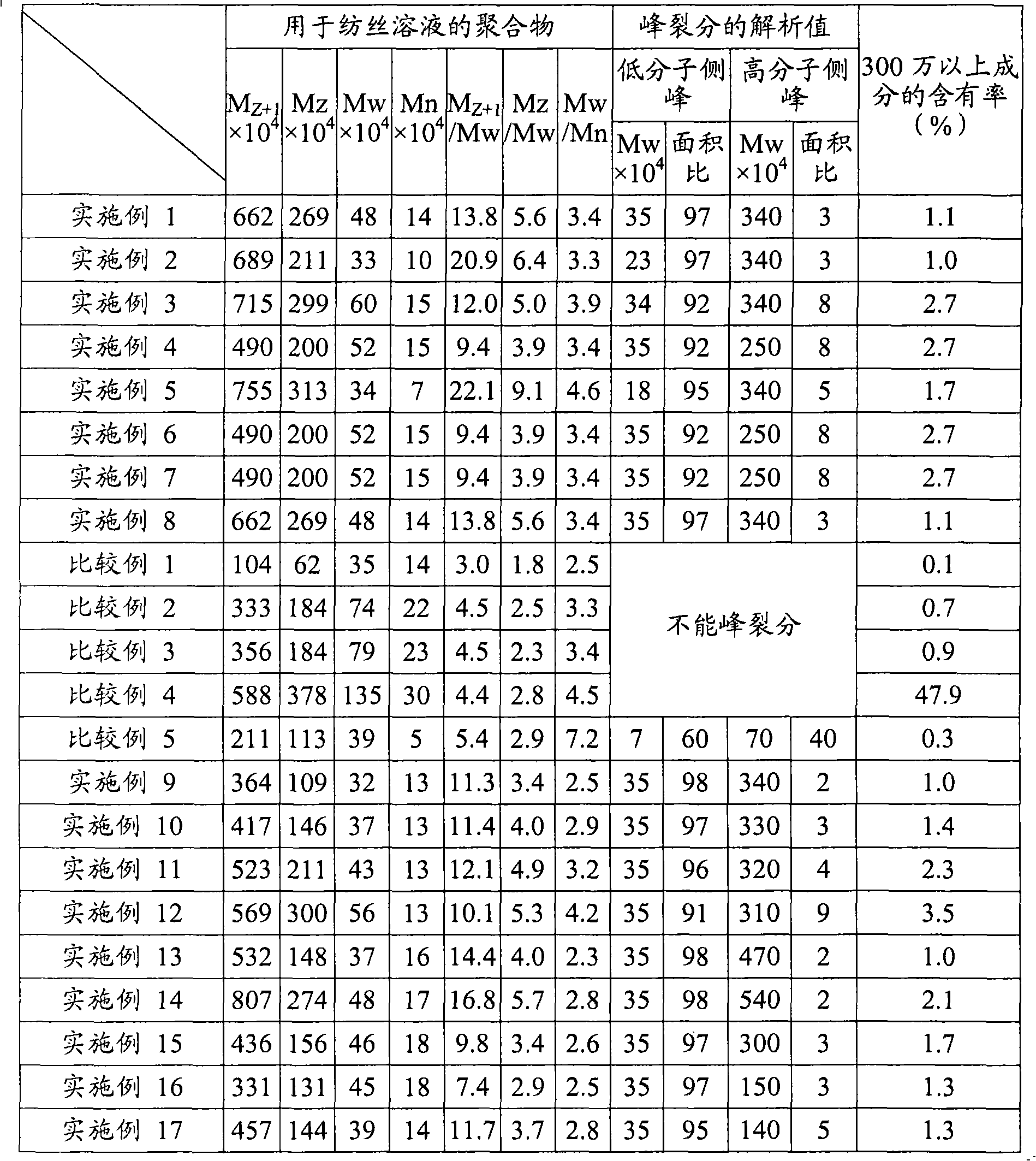

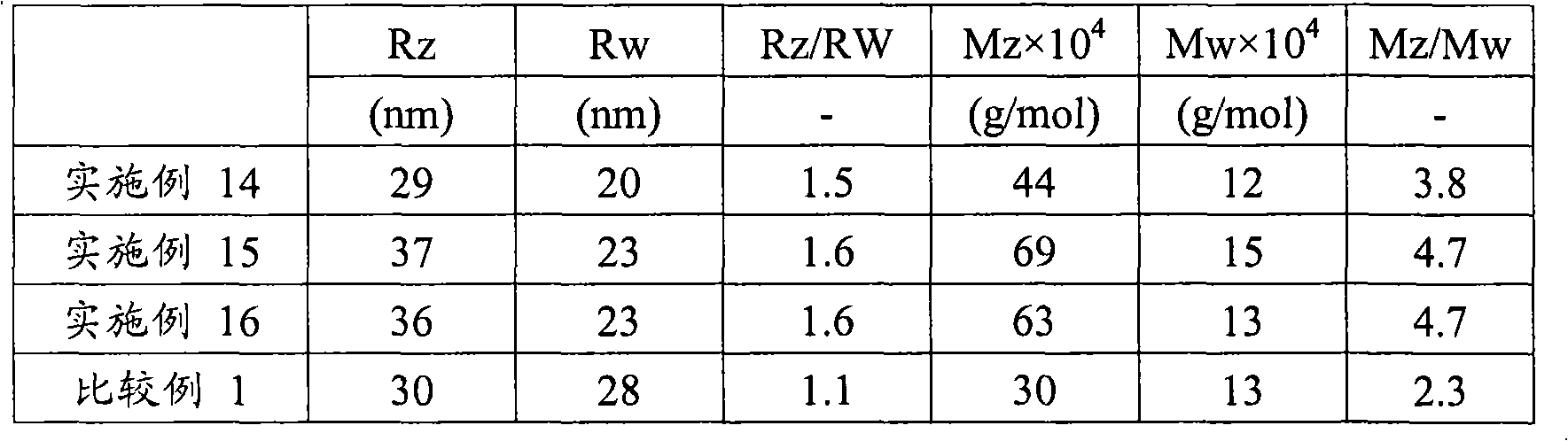

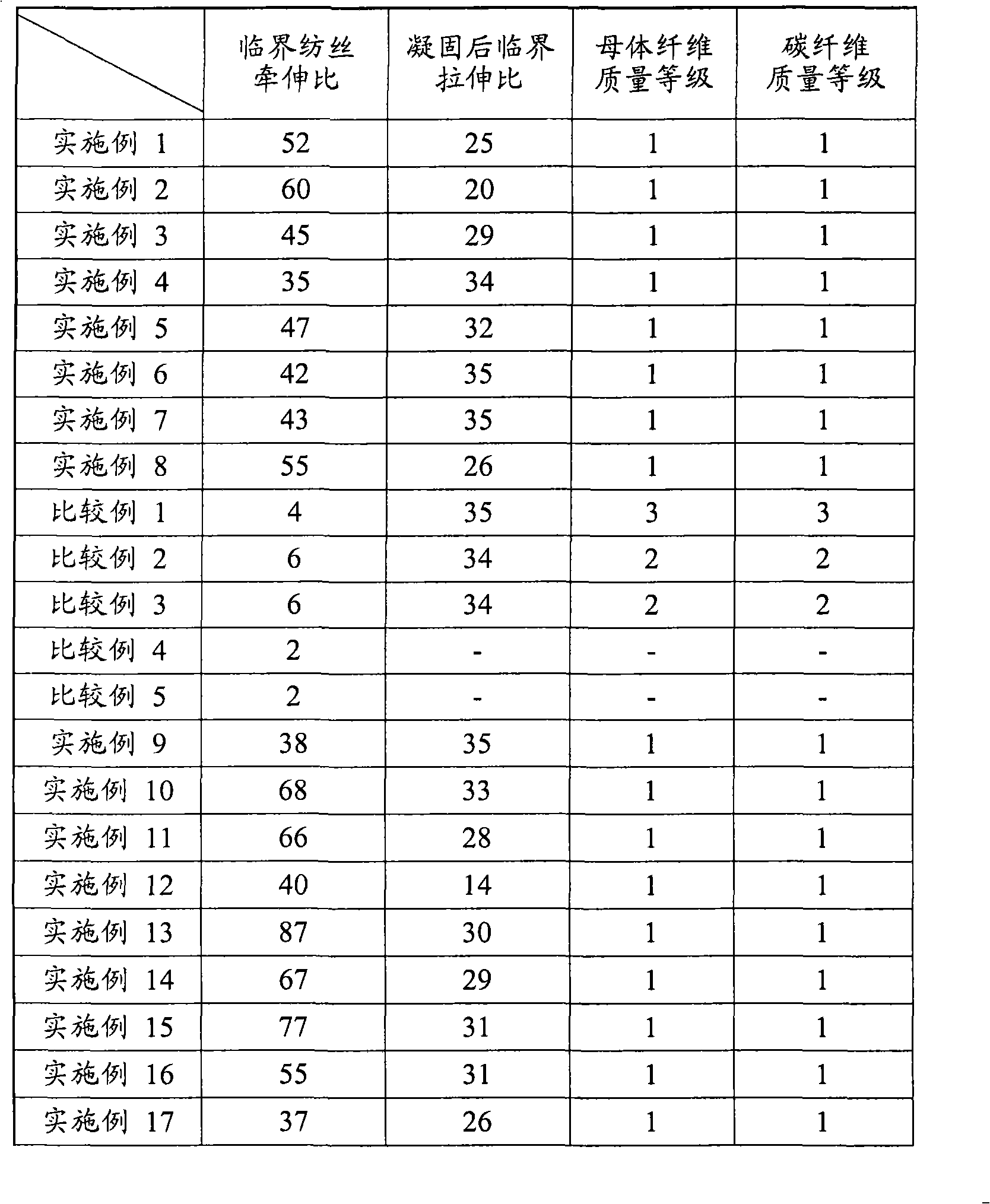

Polyacrylonitrile polymer, process for production of the polymer, process for production of precursor fiber for carbon fiber, carbon fiber, and process for production of the carbon fiber

InactiveCN101553511AIncrease spinning draft ratioQuality improvementMonocomponent synthetic polymer artificial filamentThin material handlingPolymer scienceCarbon fibers

The invention relates to a polyacrylonitrile-based polymer, containing a polymer of which main component is acrylonitrile, which satisfies at least one kind requirement selected from the following [a] to [d]. [a] Z-average molecular weight (Mz) determined by gel-permeation chromatograph is 800,000 to 6,000,000 and degree of polydispersity (Mz / Mw) (Mw denotes weight average molecular weight) is 3.0 to 10.0. [b] Z+1-average molecular weight (Mz+1) determined by GPC method is 3,000,000 to 10,000,000 and degree of polydispersity (Mz+1 / Mw) is 6.0 to 25.0. [c] Mzm determined by gel-permeation chromatograph[space]multi-angle laserlight scattering photometry is 400,000 to 1,000,000 and degree of polydispersity (Mzm / Mwm) is 3.0 to 10.0. [d] Z-average radius of gyration (Rz) determined by gel-permeation chromatograph[space]multi-angle laserlight scattering photometry is 25 to 45 nm and its ratio to weight average radius of gyration (Rz / Rw) is 1.3 to 2.5.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com