Continuously extruding method of magnesium alloy silk material

An extrusion method and magnesium alloy technology, which is applied in the continuous extrusion of magnesium alloy wire and the extrusion of metal materials, can solve the problems of easy oxidation of hot extrusion blanks, unfavorable mold life, and high extrusion costs, and achieve high quality Excellent, low extrusion cost, fast wire output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

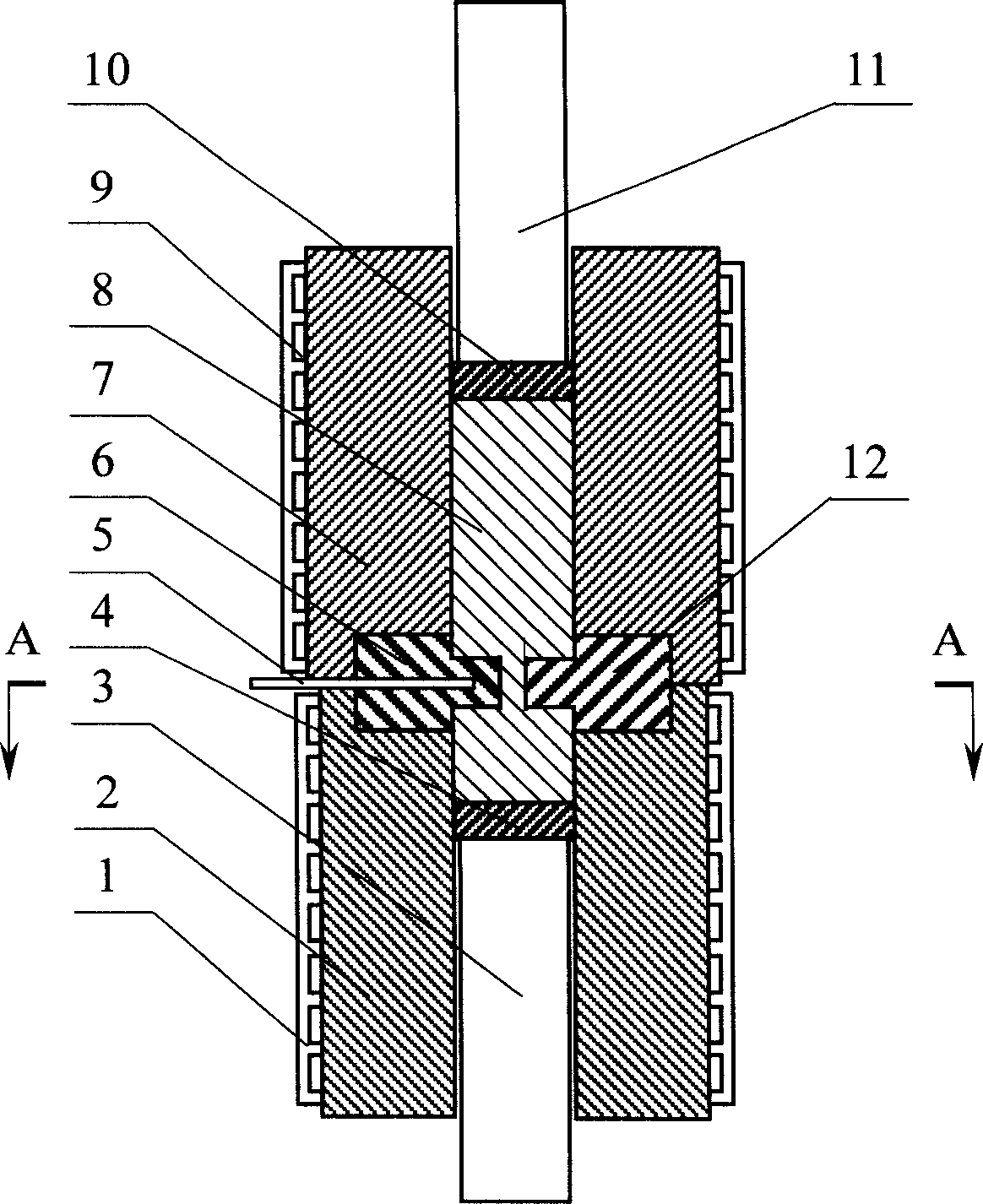

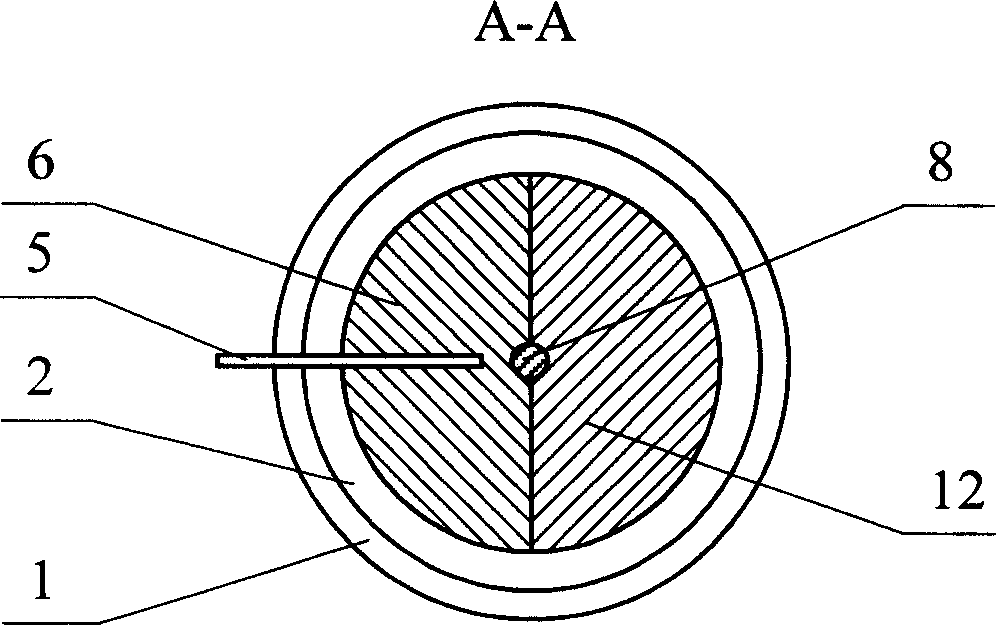

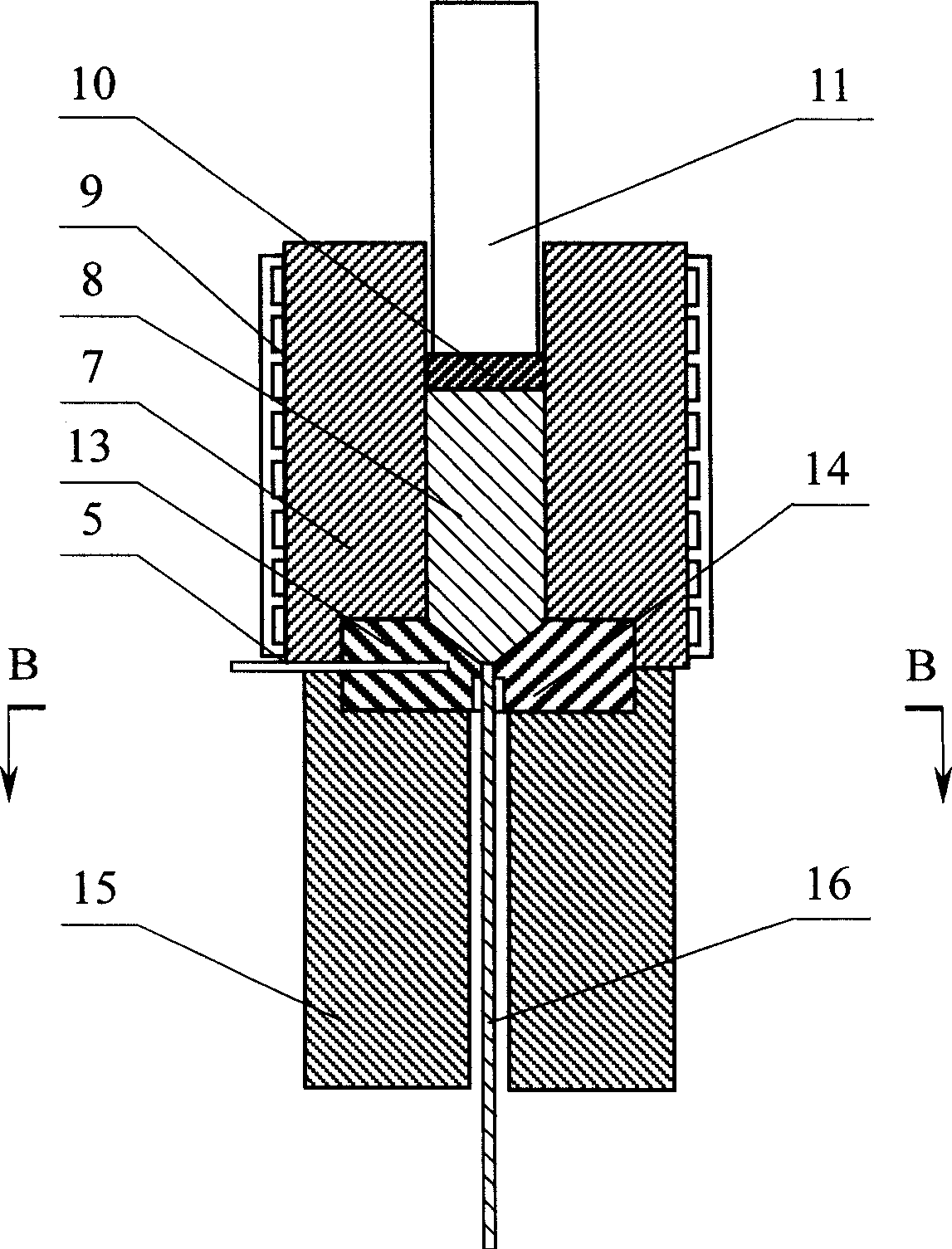

[0031] After the reciprocating extrusion of AZ91D magnesium alloy, it is continuously extruded into ф5mm magnesium alloy wire.

[0032] Material preparation Remelt and cast the industrial state AZ91D magnesium alloy ingot into a cylindrical ingot with a diameter 1mm to 2mm larger than the diameter of the inner hole of the extrusion cylinder, and then process the ingot into a diameter larger than that of the extrusion cylinder For a cylindrical ingot with a hole diameter of 0.2 mm, remove the processing oil and coat the side wall and upper surface with MoS 2 grease;

[0033] First, put the reciprocating extrusion device on the press, use the press to press the first half die 6 and the second half die 12 into the large extrusion barrel 7, and then press into the small extrusion barrel 2 for mold closing , the above-mentioned treated extruded AZ91D magnesium alloy ingot 8 is packed into the mold cavity surrounded by the large extrusion barrel 7, the small extrusion barrel 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com