Patents

Literature

309results about How to "Complete specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously preparing regenerated cellulose fibre

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

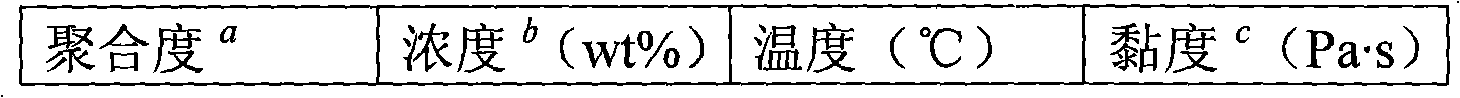

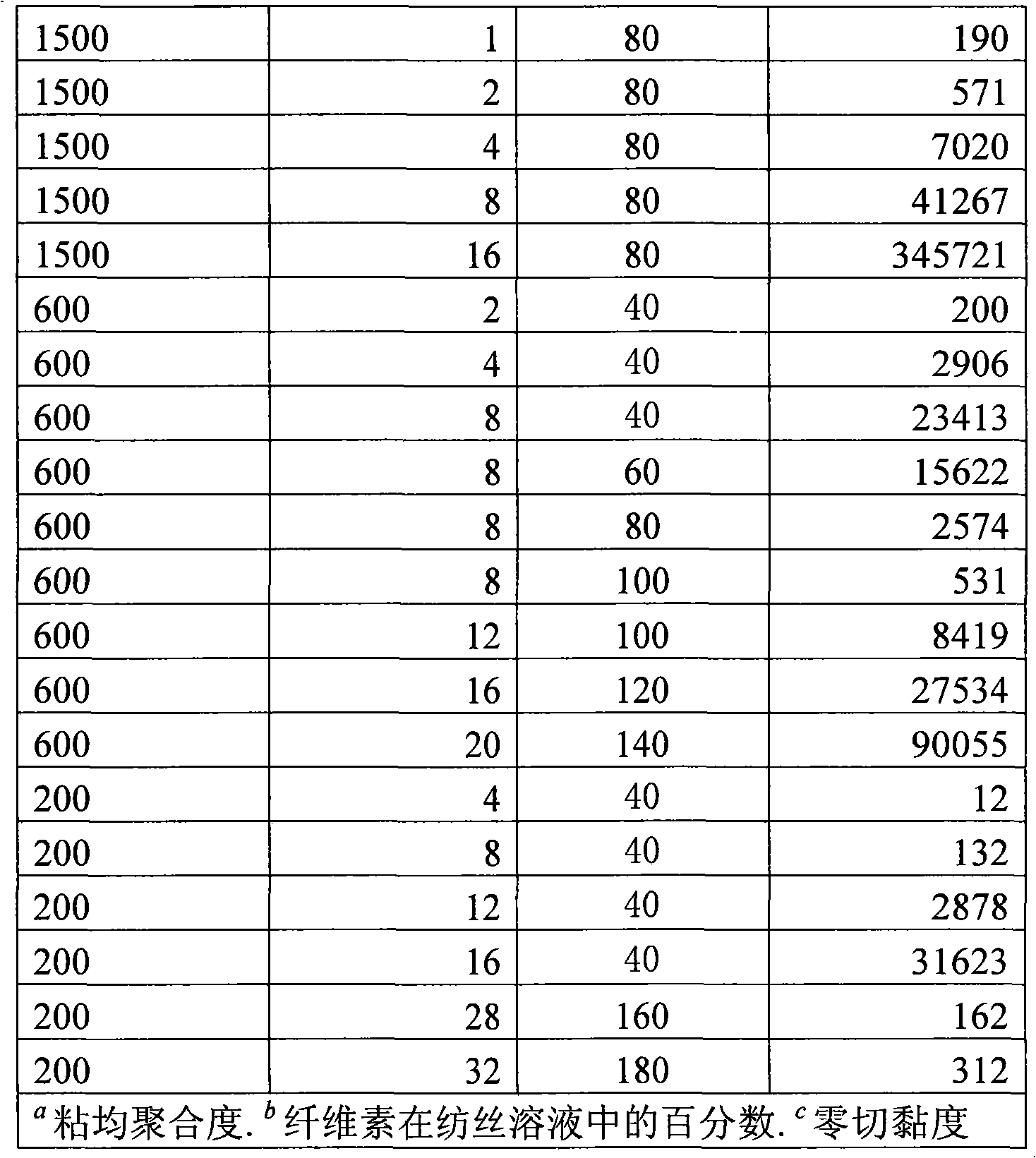

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

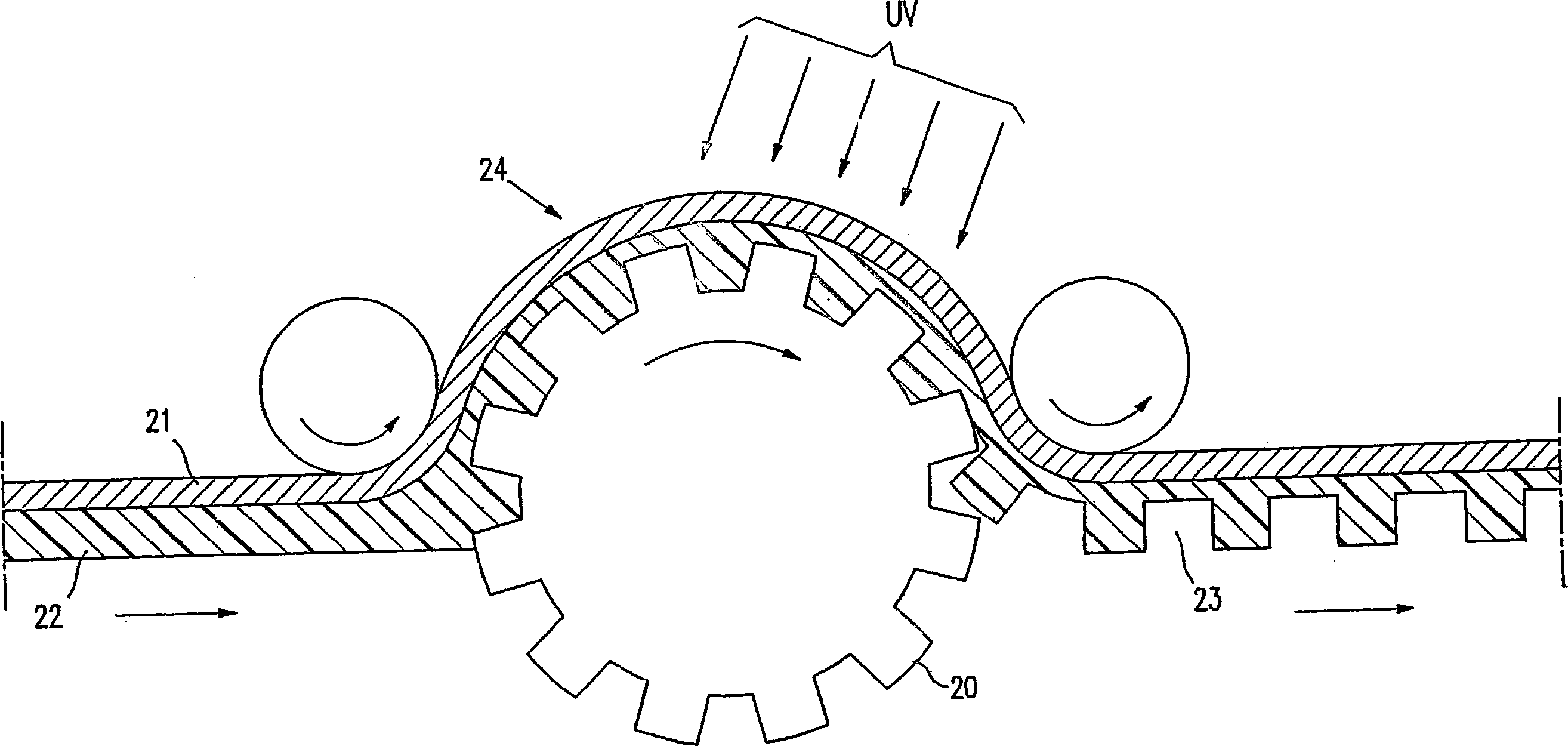

Polishing film and method for making same

ActiveCN101225281AUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventRoller Coating Method

The invention discloses a polishing film and the preparation method, which adopts the ultrafine micro mist as the grinding material and prepares in flow-casting coating method, namely the powdered or granular resin is dissolved into the organic solvent and then added in functional additive to make the resin adhesive, then the abrasive of surface-modified ultrafine micro mist is added into the resin adhesive and the spread coating liquid can be obtained after fully mixing, finally the paint is painted on the surface of soft base in flow-casting coating method and the polishing film can be obtained after drying and curing. The preparation method of the polishing film has the advantages of small equipment investment, simple operation, high productivity and automation level, steady craft, even film performance and low manufacturing cost. The polishing film can adjust the craft parameters of the flow-casting craft conveniently according to the different quality requirement and standards of the products, and can achieve production in multi-specification and small lot production and overcomes the problems that the rapid transformation of the product specification is difficult due to the limit of the equipment structure in roller coating method.

Owner:HENAN UNION ABRASIVES

A high-performance cooper-coated aluminum rectangle section compound conductive bus bar and its making technology

ActiveCN101241778AMeet the requirements of multiple specificationsGreat widthSingle bars/rods/wires/strips conductorsMeasuring devicesCopperAluminum composites

The present invention provides a high-performance copper-clad aluminum cross section composite conductive bus-bar and the preparing technique thereof, and the invention relates to a rectangle-cross section bimetal composite material and the preparation thereof. The copper-clad aluminum rectangular cross section composite conductive bus-bar is compounded by the core-part aluminum and the coating layer copper. The area proportion of the coating copper layer is 15to 50 The technique comprises the following procedures: Adopting horizontal continuous casting for directly compounding and forming the copper-clad aluminum composite blank. Commonly flat-roller rolling and finish drawing-pulling the copper-clad aluminum blank according to requirement or rolling with the flat roller provided with a vertical roller, the range of the rolling speed is 3-50m / min, and the single-pass relative reduction is between 15and 40 The speed range of finish drawing-pulling is 1-20m / min and the single-pass cross section scalage is 10%. When the multiple-pass relative reduction is up to 70%, the low-temperature intermediate annealing is executed to the copper-clad aluminum composite conductive bus-bar. The annealing temperature is between 250 and 450 DEG C and the annealing time is between 0.5 and 3h. The annealed composite conductive bus-bar is executed with hole-form rolling or drawing. The invention not only can produce the high-performance copper-clad aluminum cross section composite conductive bus-bar, but also has the advantages of short process flow and high efficiency of the producing method.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing niobium-contained HRB400 grade reinforcing steel

InactiveCN101007316AGuaranteed welding effectGuaranteed mechanical propertiesTemperature control deviceMetal rolling arrangementsChemical compositionNiobium

A method of produce containing niobium HRB400 reinforcement which process flow includes: electric furnace smelting, refining, billet casting, casting blank solidification and cooling, putting it into heating-furnace, hot-rolling, air cooling, sizing and hoping. The characteristics are: control the chemical composition range of molten steel (weight%): Ceq <= 0.45%, C: 0.18 ~ 0.24%, Si: 0.40 ~ 0.65%, Mn: 1.00~ 1.50%, Nb: 0.03 ~ 0.045% , S: <= 0.045%, P: <= 0.045%, V: 0 ~ 0.035%; little billet casting tandem rolling art parameters: casting blank continuous casting aligning temperature >=950DEG C, casting blank heating temperature is 1100 ~ 1250 degree C, soakage temperatures is 1150 ~ 1230 degree C, cut temperature is 1050~1100 DEG C, free air-cooling mode. The method can be used to produce Nb microalloy and Nb,V composite microalloying HRB400 reinforcement which Ceq(carbon equivalent) <=0.45wt.%, and has high intensity, seismic behavior and weldability in the electric furnace- continuous casting-tandem rolling process.

Owner:广州工业投资控股集团有限公司

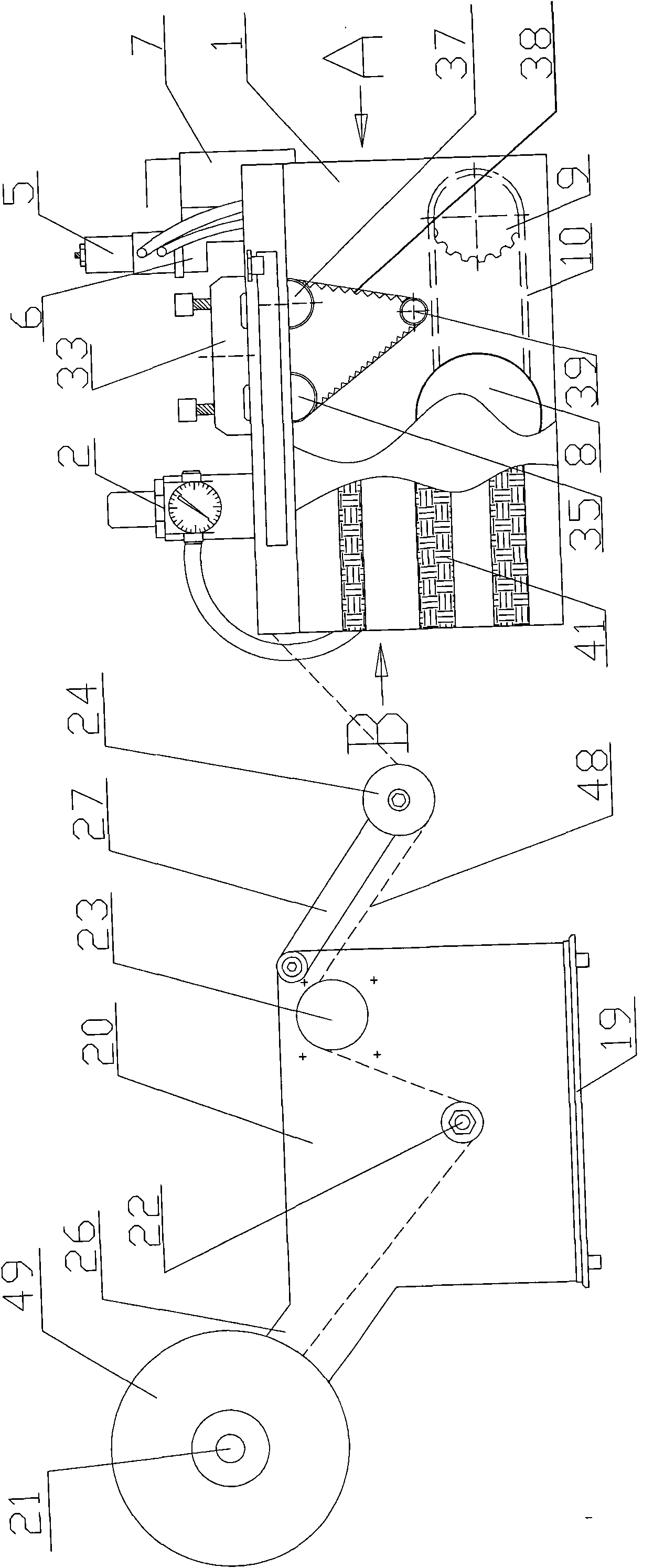

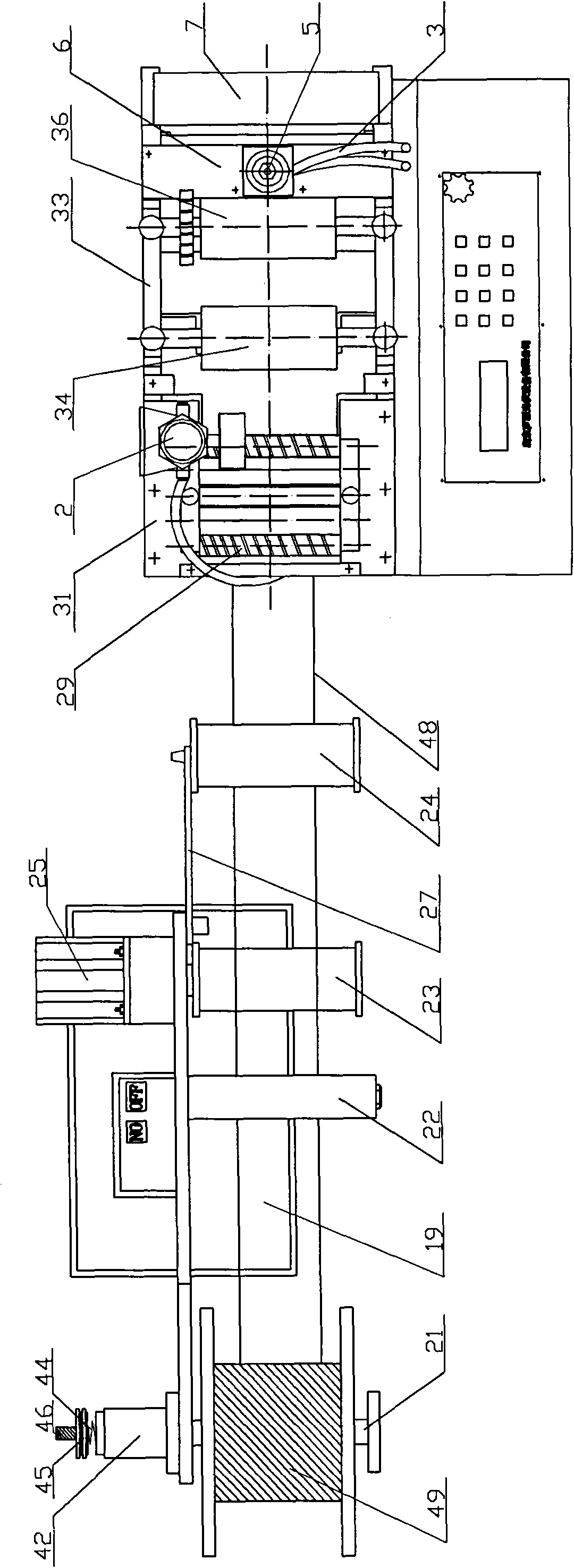

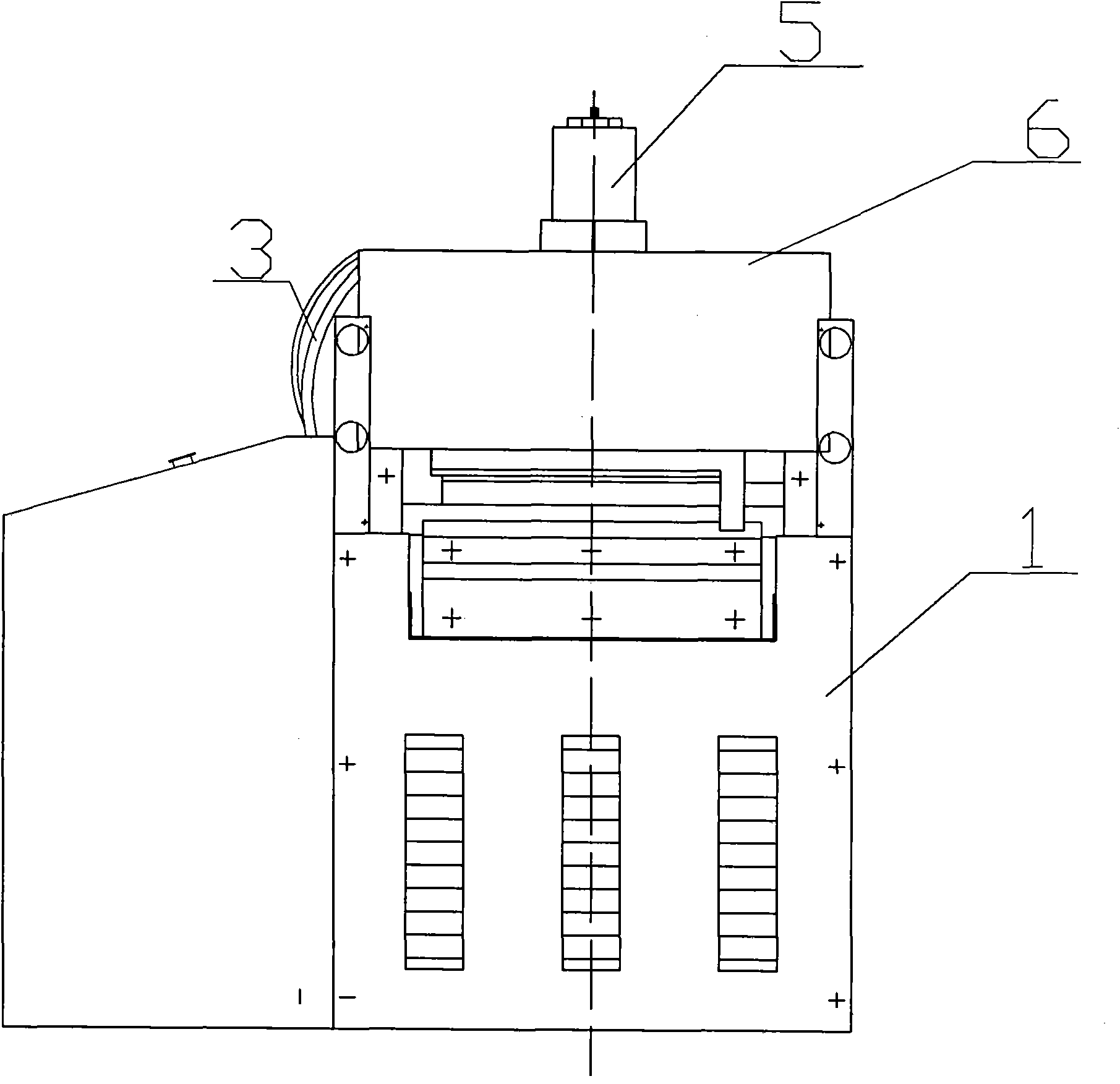

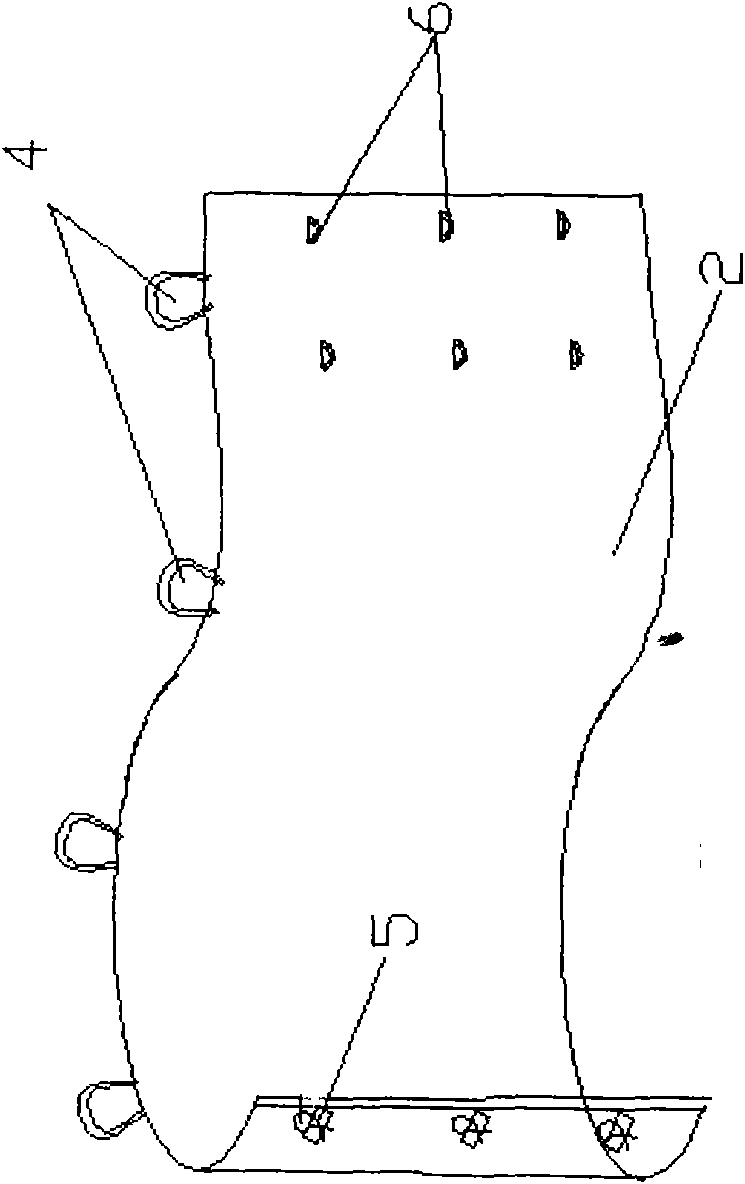

Full-automatic welding strip cutting bender

InactiveCN101837392AControl the feeding speedControl cutting speedMetal working apparatusElectric machineryPulp and paper industry

The invention relates to a full-automatic welding strip cutting bender, which is characterized by comprising an emptying mechanism, a levelling mechanism, a bending mechanism, a cutting mechanism and a box body, wherein one end of the oil-water separator of the bending mechanism is connected with a gas resource, and the other end of the oil-water separator is connected with a cylinder by a pipeline; the cylinder is fixed on a cylinder frame; the cylinder shaft of the cylinder is connected with a bending path frame; the cylinder frame is fixed on a fixed mount on the discharge end of the box body; the lower cutter of the cutting mechanism is fixed on the lower end of the fixed mount; the upper cutter is fixed on an upper cutter frame capable of moving up and down; a motor is connected with one of two eccentric sprockets with same eccentricity, and the eccentric sprockets are fixed on an eccentric shaft by a chain; two eccentric sprockets are fixedly connected with two ends on the bottom of the upper cutter frame via a link block; a small eccentric wheel with a photosenser is fixed in the middle of the eccentric shaft between two eccentric sprockets; and a photo-groove is arranged near the position below the small eccentric wheel. The invention improves production efficiency, lowers labour cost and improves product quality.

Owner:启东市罗源光伏设备有限公司

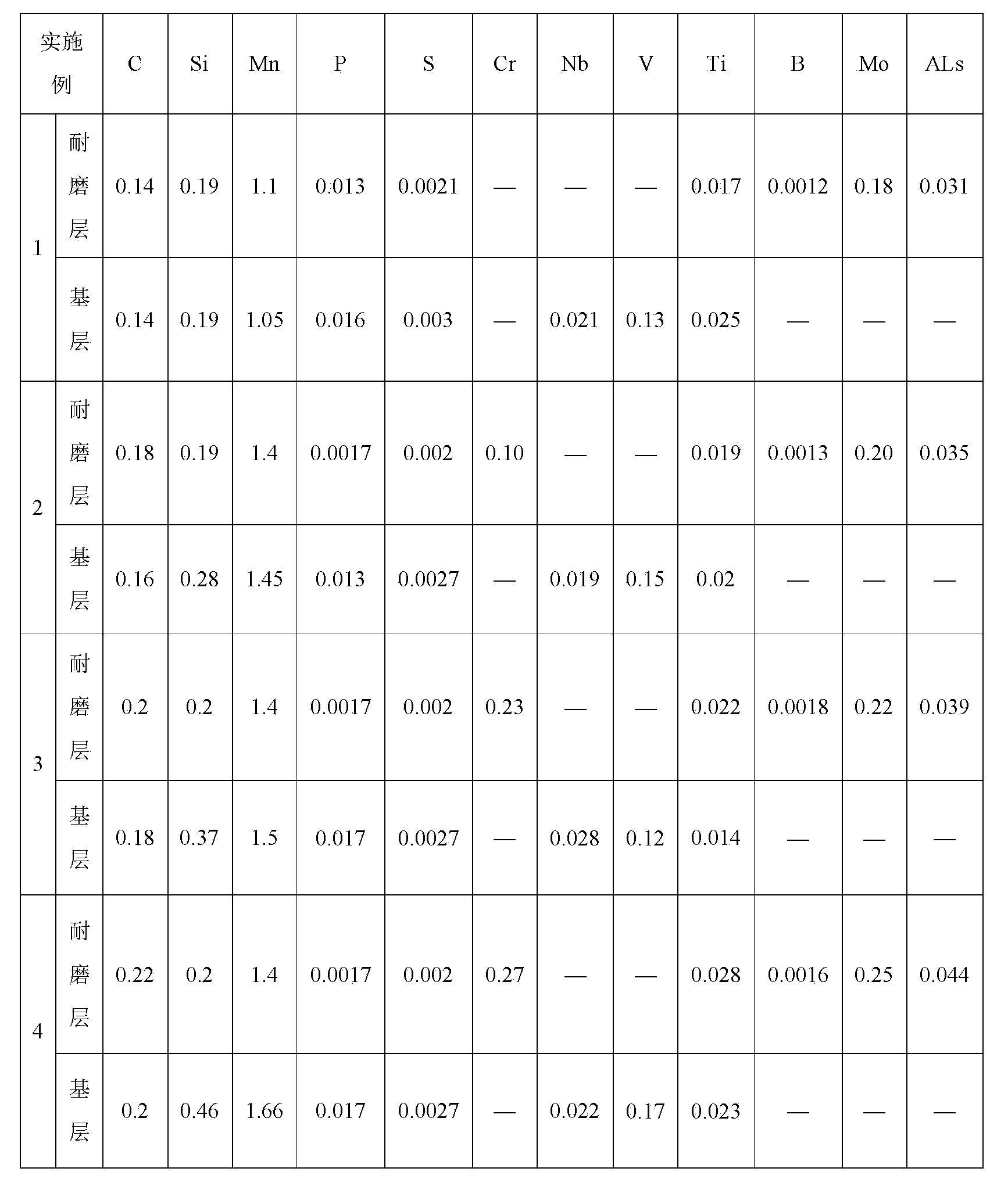

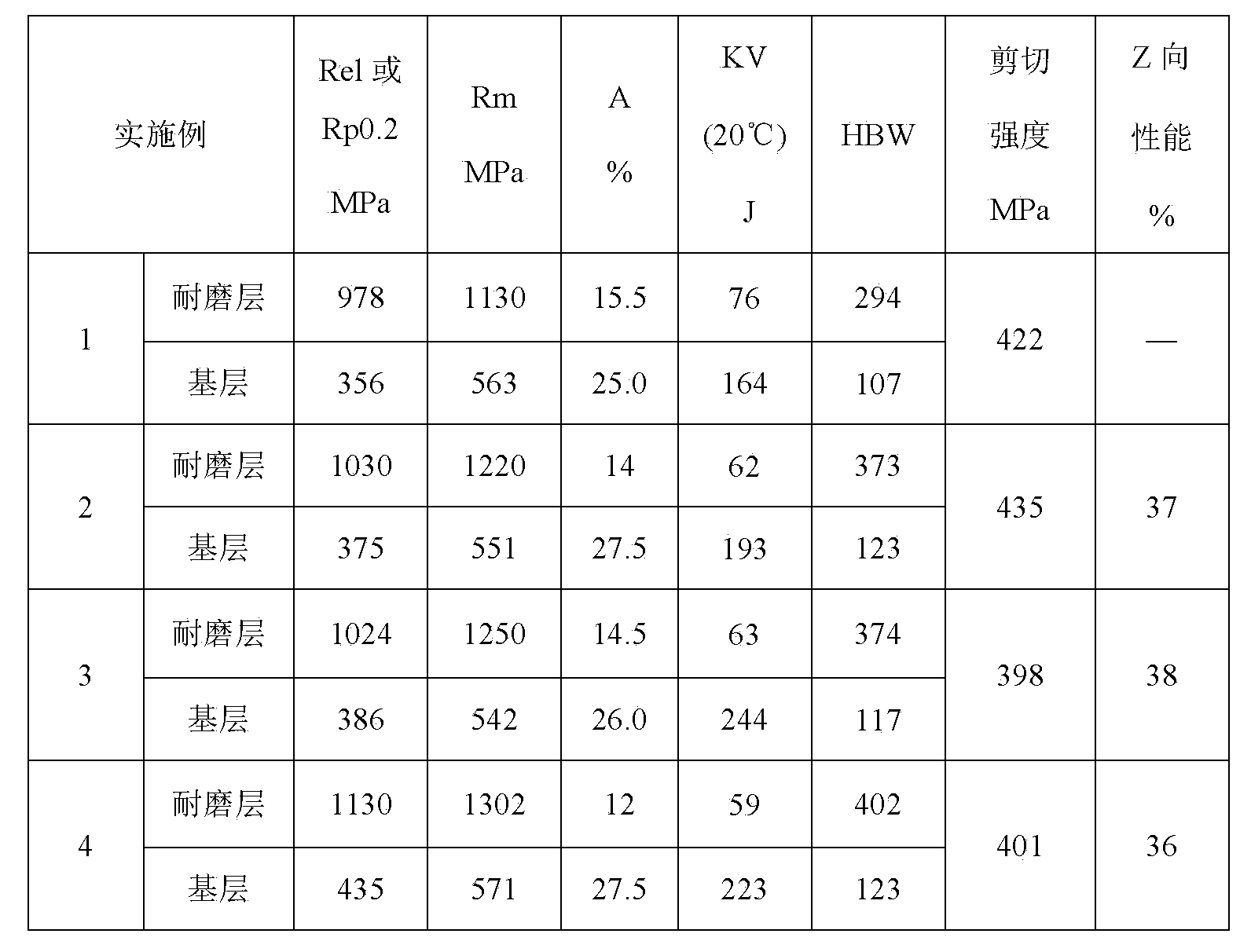

Composite wear-resistant steel plate with good ductility and toughness, and manufacturing method thereof

The invention provides a composite wear-resistant steel plate with good ductility and toughness, and a manufacturing method thereof. The upper wear-resistant layer of the steel is composed of the following chemical components in percentage by weight: 0.13% to 0.22% of C, 0.15% to 0.50% of Si, 1.0% to 1.50% of Mn, not more than 0.005% of S, not more than 0.02% of P, 0.0% to 0.50% of Cr, 0.18% to 0.25% of Mo, 0.015% to 0.03% of Ti, 0.0010% to 0.0020% of B, 0.03% to 0.05% of Als, and the balance being Fe and inevitable impurities; and the lower basic layer comprises the following chemical components in percentage by weight: 0.13% to 0.20% of C, 0.15% to 0.50% of Si, 0.8% to 1.70% of Mn, not more than 0.005% of S, not more than 0.02% of P, 0% to 0.050% of Nb, 0% to 0.2% of V, 0% to 0.03% of Ti, and the balance being Fe and inevitable impurities. The manufacturing method comprises following steps: welding the upper continuous casting slab and the lower continuous casting slab together, then rolling, wherein the rolling temperature is not lower than 1000 DEG C, and the reduction rate of the first three rolling processes is 10% to 25%; thermally leveling the integrated slab after the rolling process, piling up, slowly cooling down, simultaneously carrying out a offline thermal treatment on the wear-resistant layer and the basic layer after the cooling process, wherein the wear-resistant layer is on the top and the basic layer is on the bottom; carrying out a quenching treatment on the wear-resistant layer, and carrying out an air-cooling and normalizing treatment on the basic layer. The steel plate has the advantages of low alloy content, long service life, uniform performance, good ductility and toughness, and completeness in specifications. Moreover, the steel can be produced through automatic production lines, and thus the production efficiency is improved.

Owner:ANGANG STEEL CO LTD

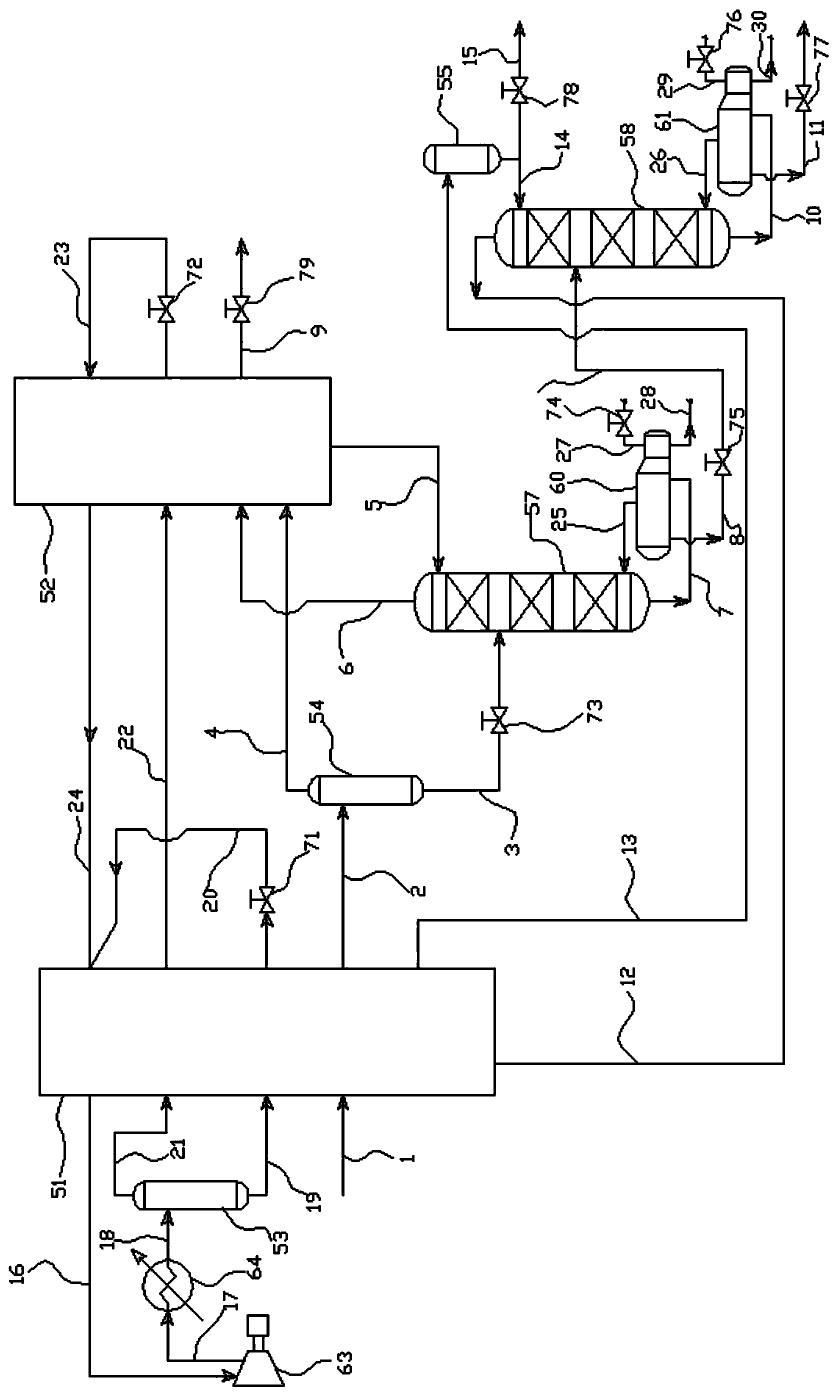

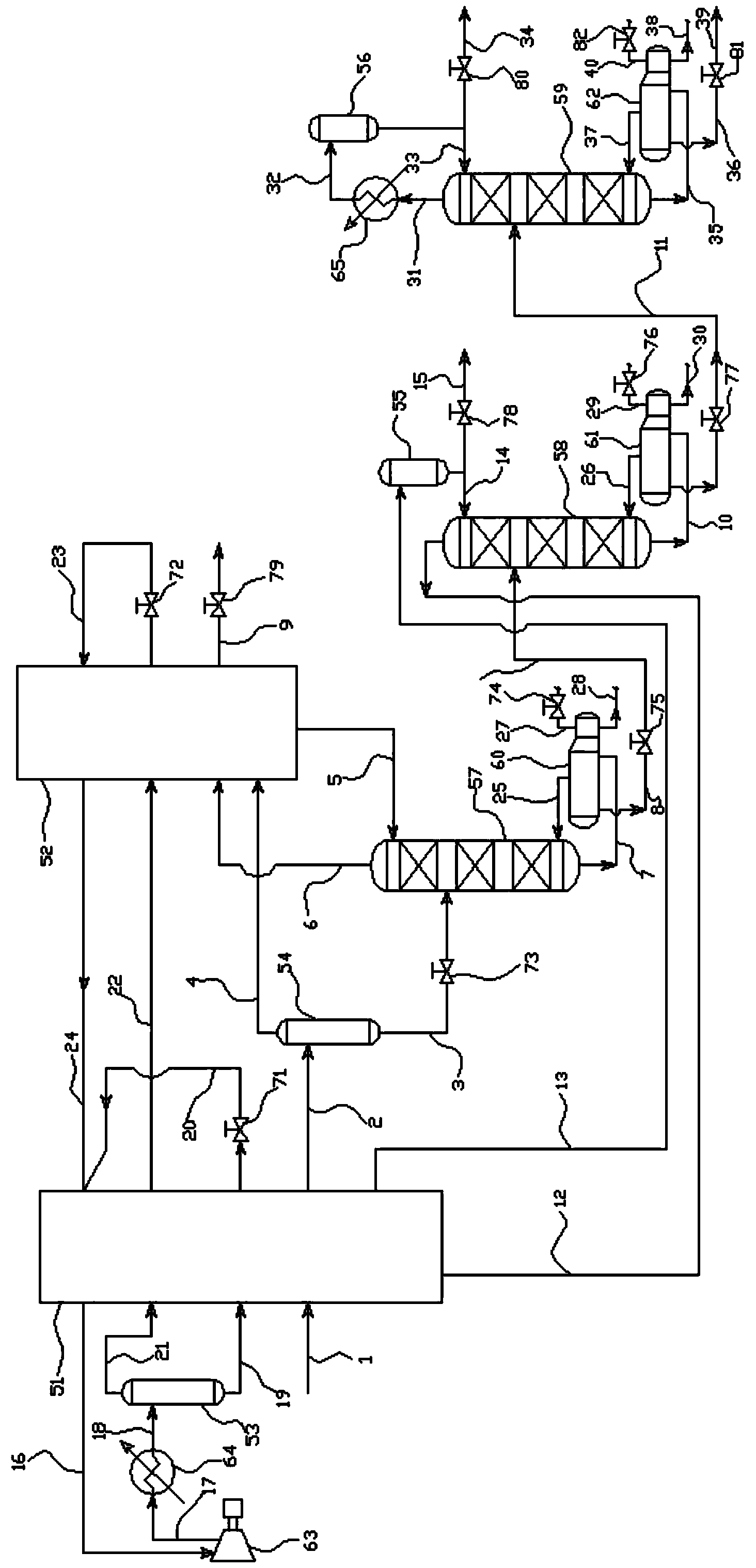

Natural gas liquefying method and device with light hydrocarbon recovery function

InactiveCN103453730AAdjust qualityHigh puritySolidificationLiquefactionPhysical chemistryRefrigerant

Owner:HANGZHOU FORTUNE CRYOGENIC EQUIP CO LTD

Technique for producing purple common perilla rosemary acid

InactiveCN1796362AComplete specificationsSimple production processOrganic compound preparationCarboxylic acid esters preparationFood additiveFiltration

This invention relates to a production technique of perilla-derived rosmarinic acid which is accessible for large-scale industrial production. Perilla leaves serving as raw materials are dipped in acidic water and the mixture undergoes filtration with the extracted liquid adsorbed and desorbed in macroporous adsorption resin; the desorbed liquid is vacuum distilled to obtain romarinic acid with a purity of 10%; the 10%-purity rosmarinic acid product is extracted with petroleum ether and the organic phase is vacuum distilled to obtain rosmarinic acid with a purity of 50%; the 50%-purity rosmarinic acid product is gradient eluted with ethanol solutions of different concentrations in adsorption resin and the 95% eluent is vacuum-condensed and crystallized to produce a rosmarinic acid product with a purity of 95%. This invention has the advantages of simple production technique, easy operation, low cost, variable product types, security and reliability and therefore it is applicable in producing food additives, medical intermediates and cosmetics.

Owner:QINGDAO UNIV

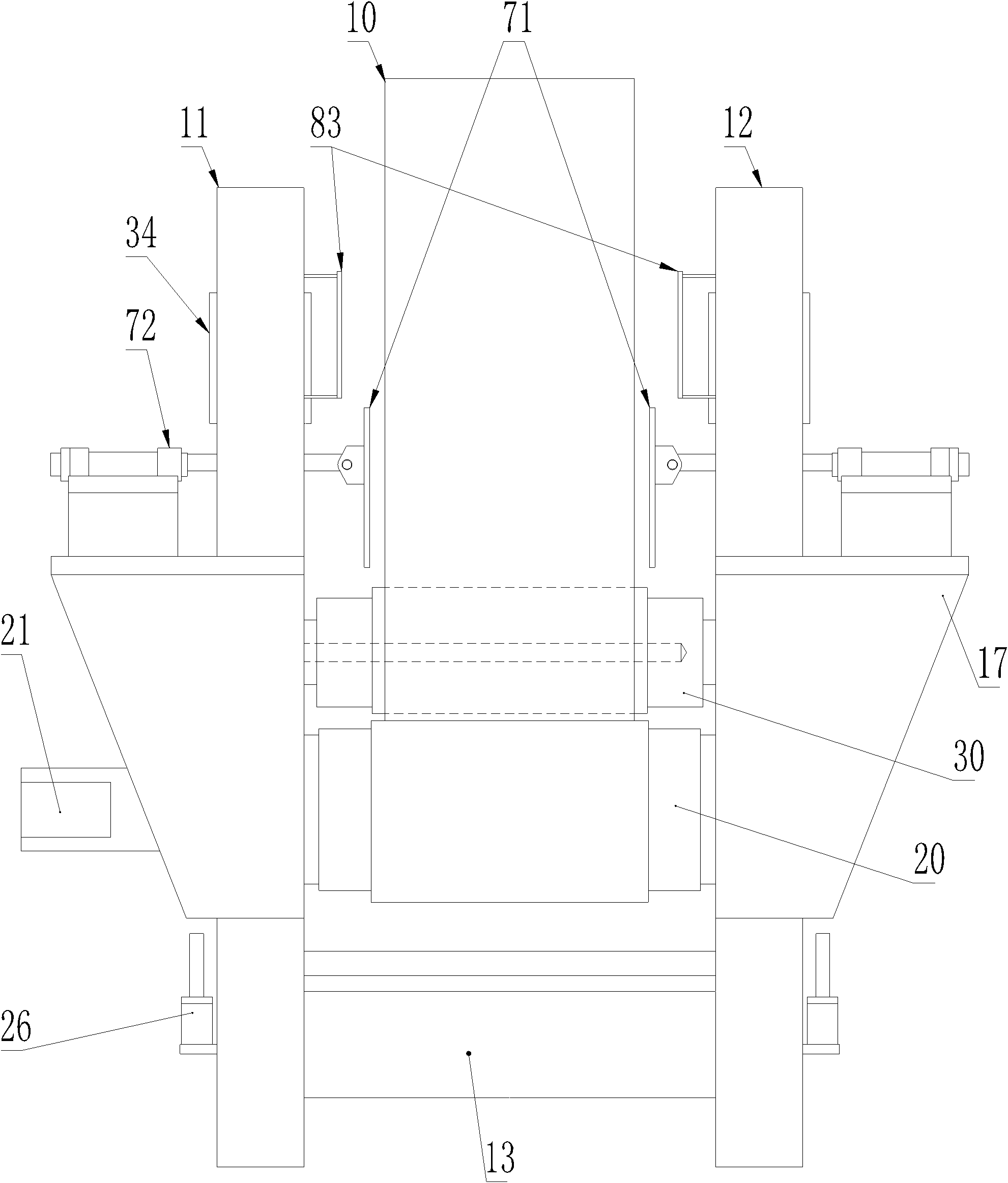

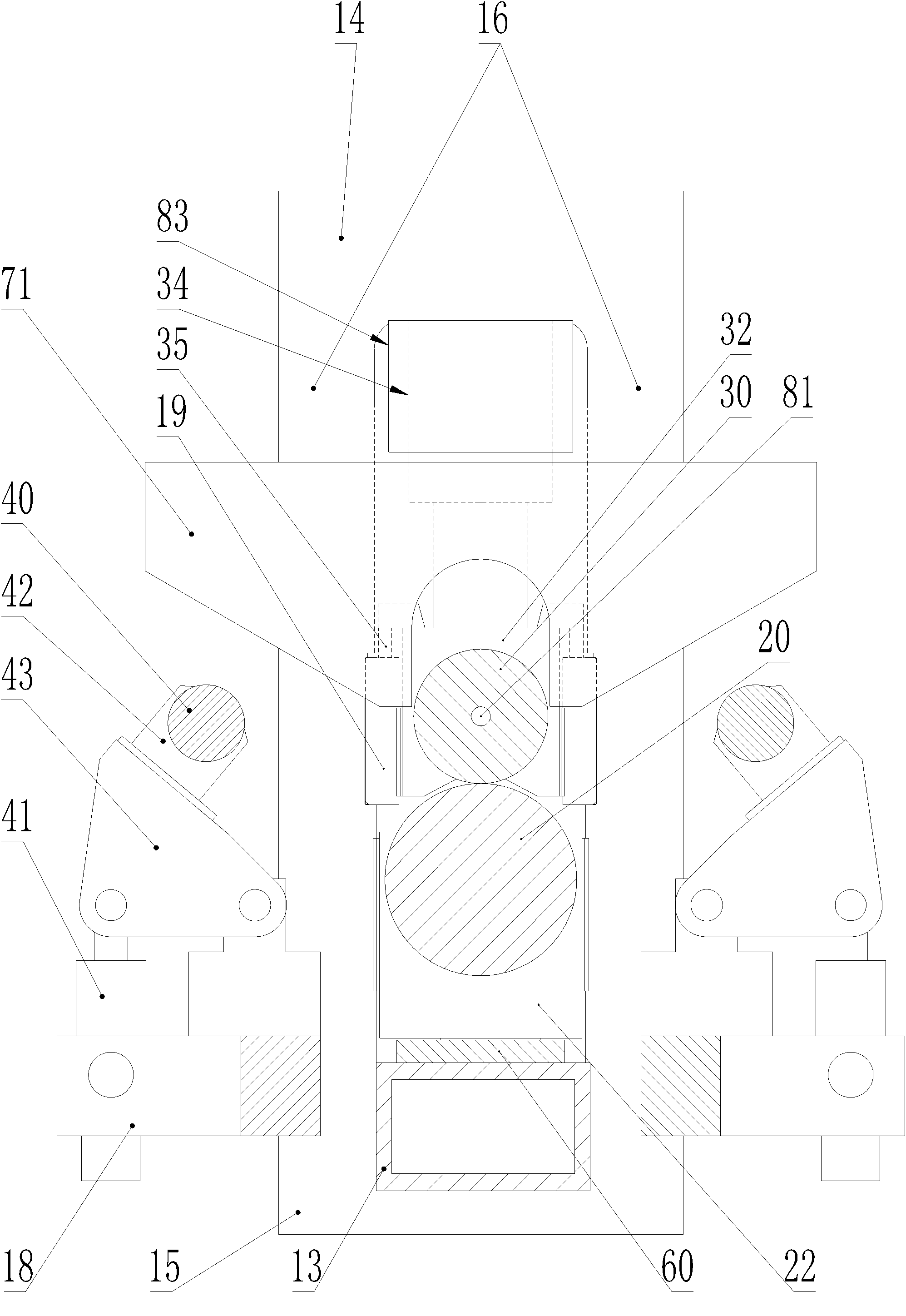

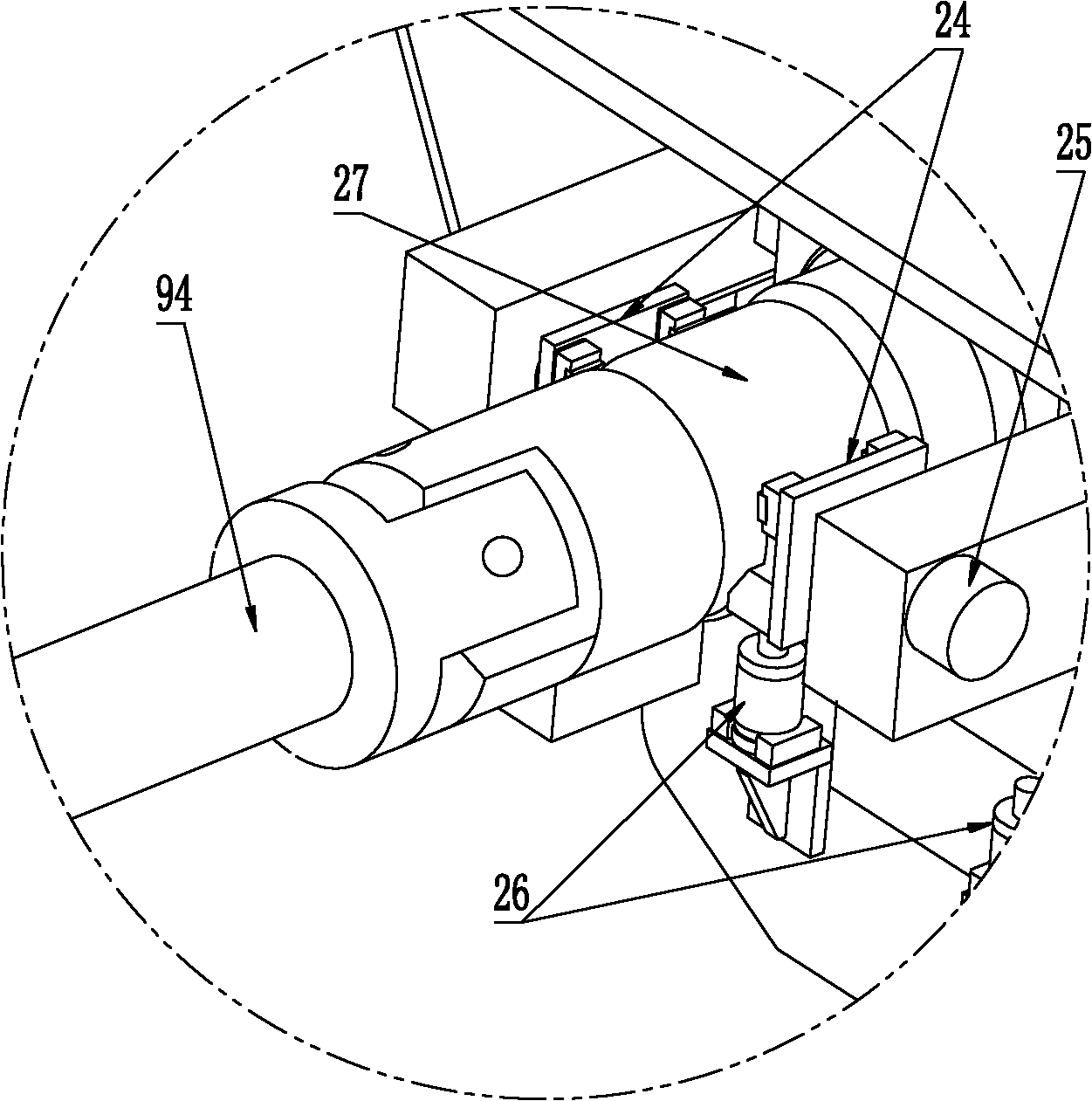

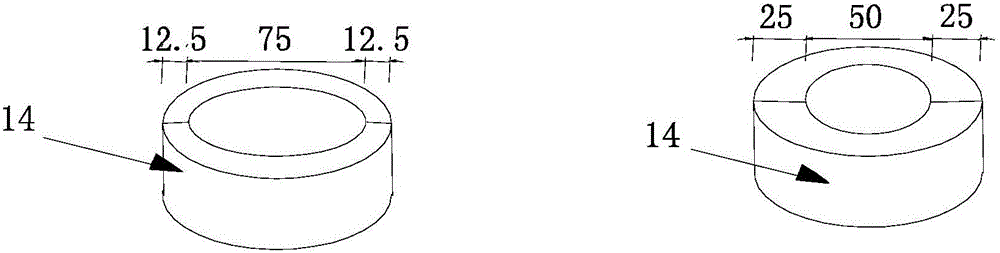

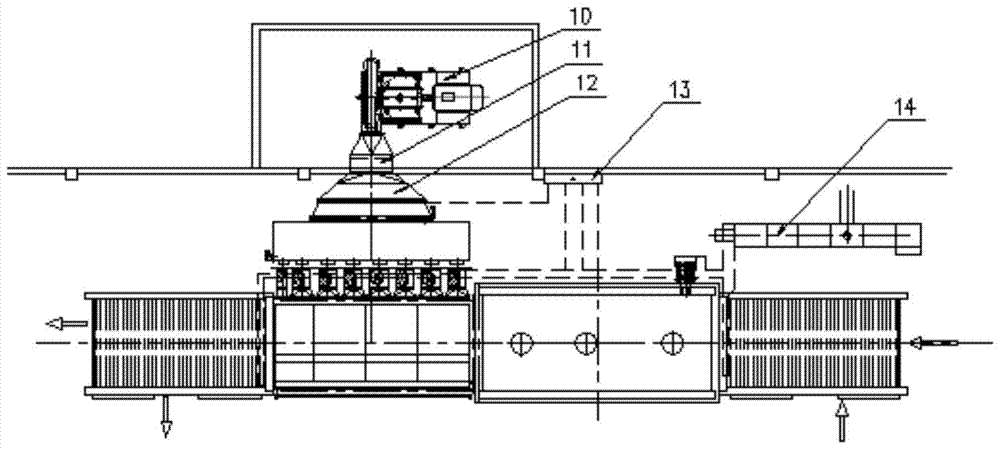

Overlarge type ring rolling machine

ActiveCN101823111AImprove rigidityGood rolling forceMetal rollingReciprocating motionProcessing cost

The invention relates to the field of metal pressure moulding and provides an overlarge type ring rolling machine which has large rolling force, good rigidity, high processing precision, high processing efficiency and low processing cost and can be suitable for the manufacturing requirement on a large cylindrical section. A stand of the overlarge type ring rolling machine comprises a drive side stand and an operating side stand which are longitudinally and oppositely arranged, both ends of each roll are supported, and axes are horizontally arranged; a drive roll is arranged at the lower part of the stand, and a core roll is positioned on the drive roll; at least one of double axial directions of the core roll is set to be a drawing direction of the core roll, one end of the core roll points to the other end along the drawing direction, the starting point end is a suspending end, and the terminal point end is a drawing end; a drawing unit comprises the core roll and a drawing end core roll bearing seat thereof or the core roll and core roll bearing seats at both ends of the core roll; the overlarge type ring rolling machine is provided with a roll drawing mechanism for doing reciprocating motion along the drawing direction of the core roll; and the roll drawing mechanism is provided with a detachable type fixing structure of the drawing unit. The invention is suitable for producing a large cylindrical section with large axial size, weight and wall thickness in the fields of large nuclear power, petrochemical container, aerospace, and the like.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

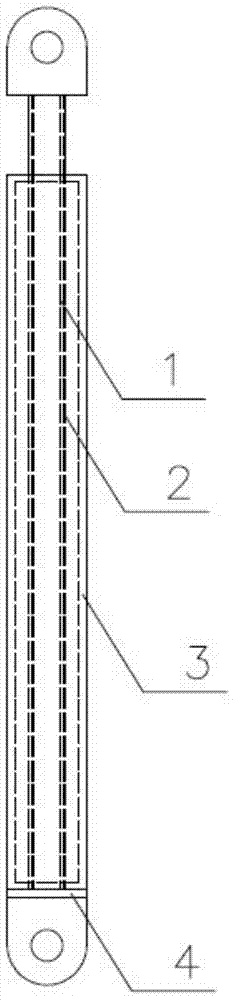

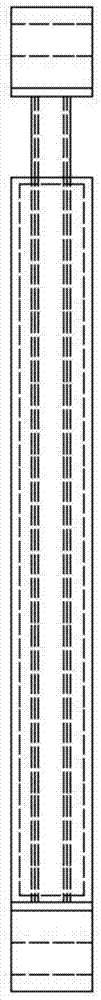

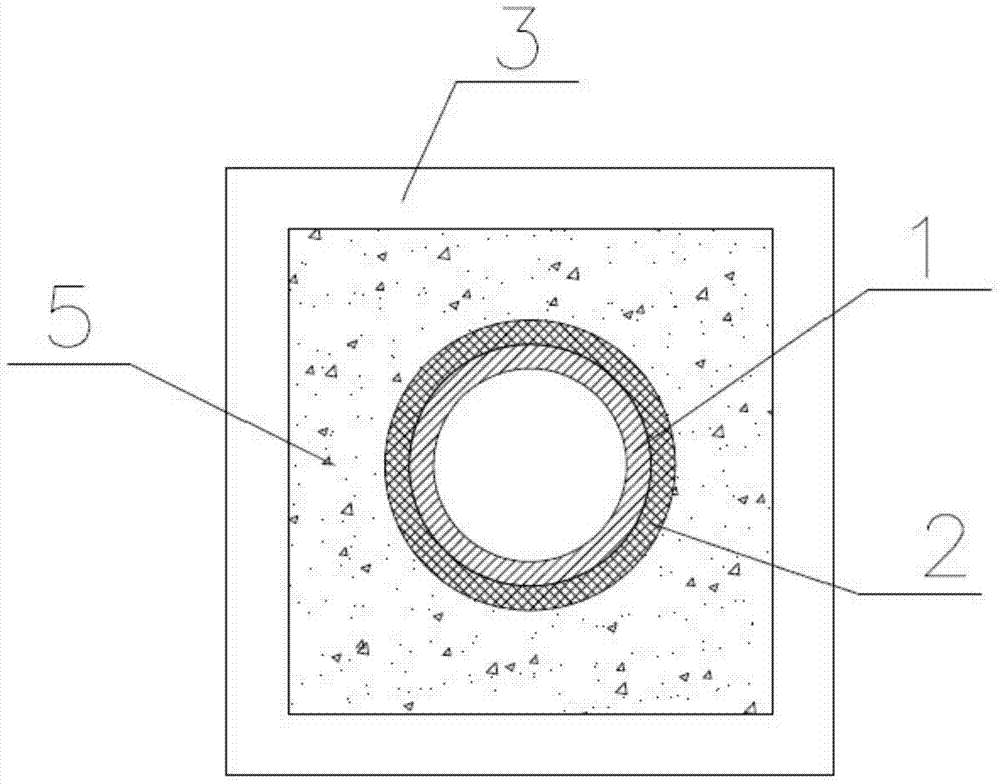

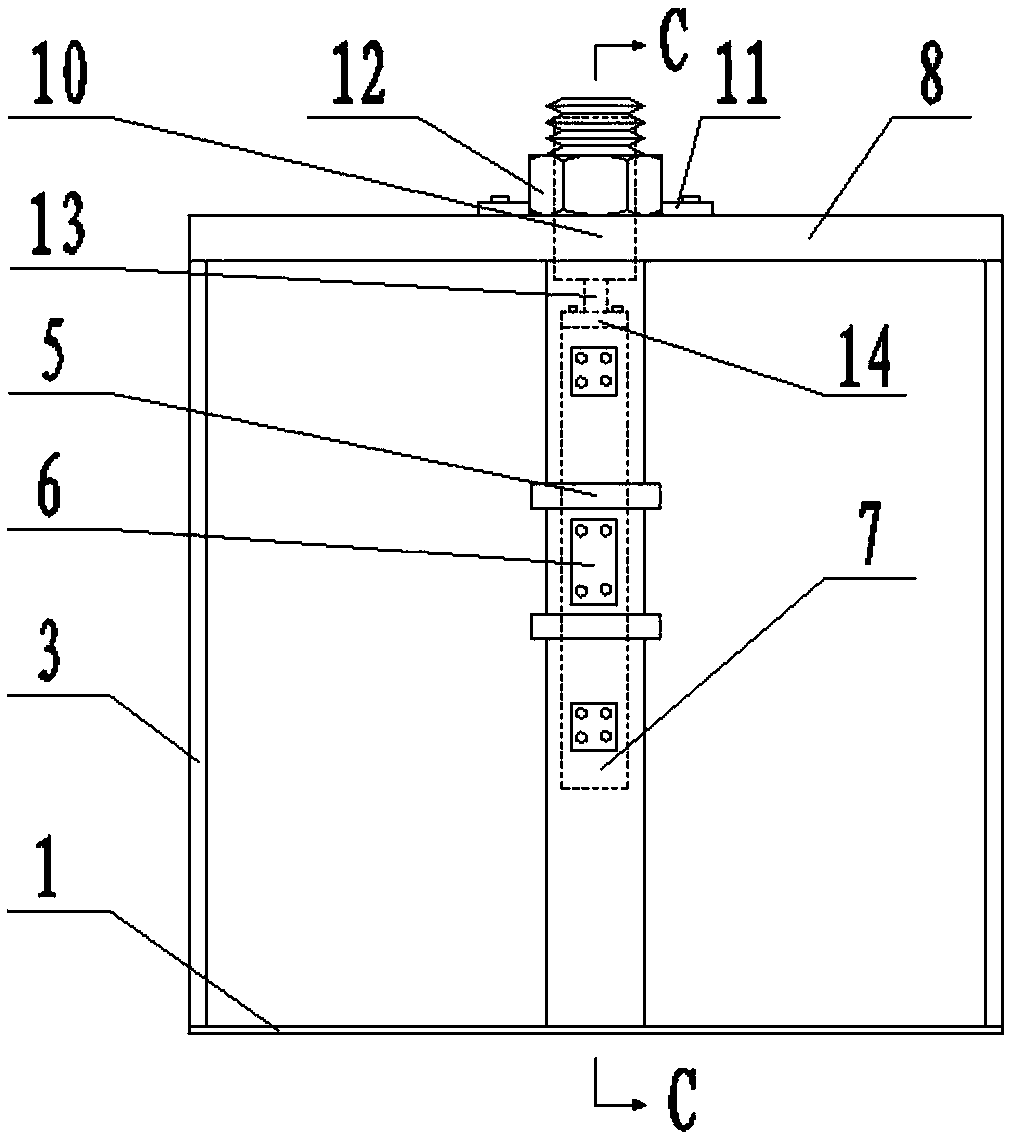

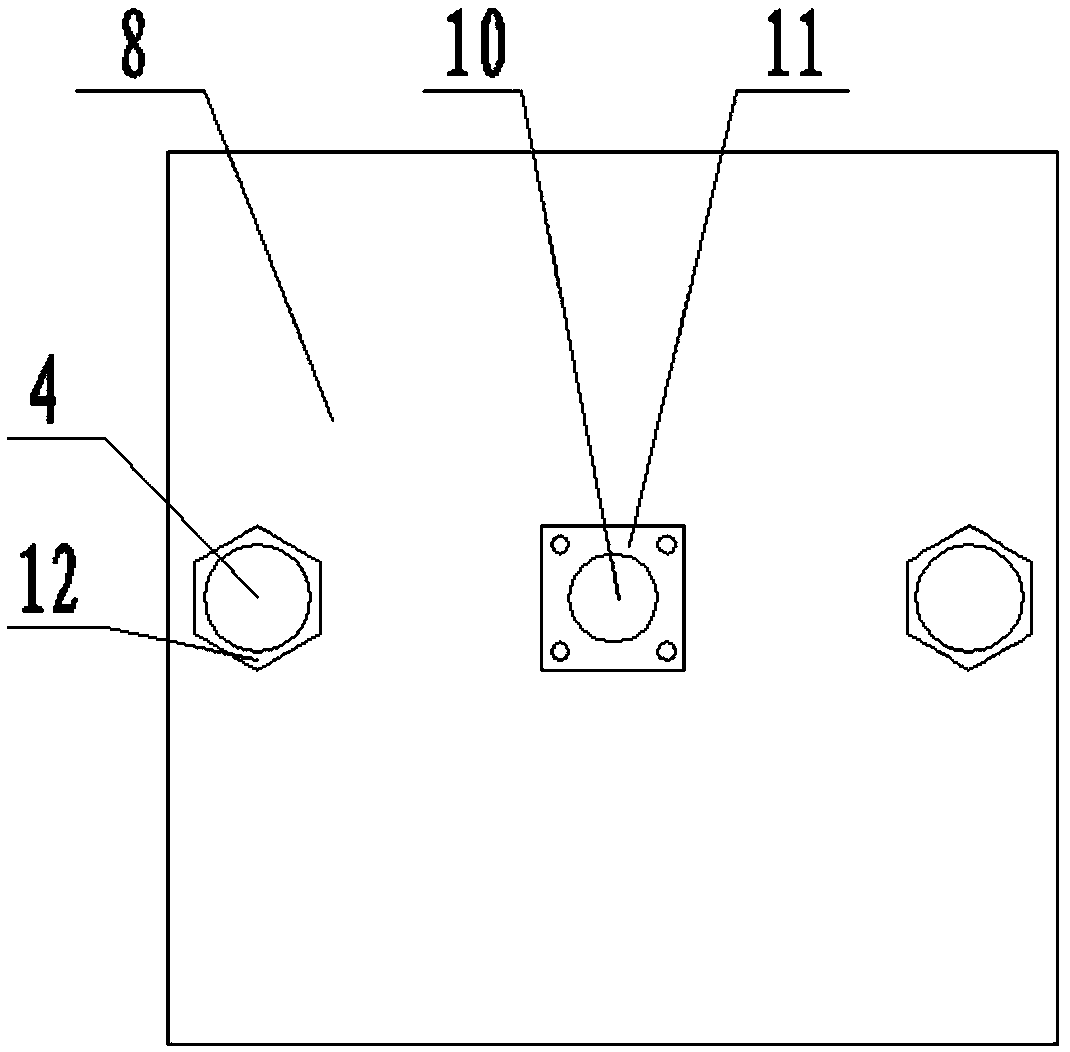

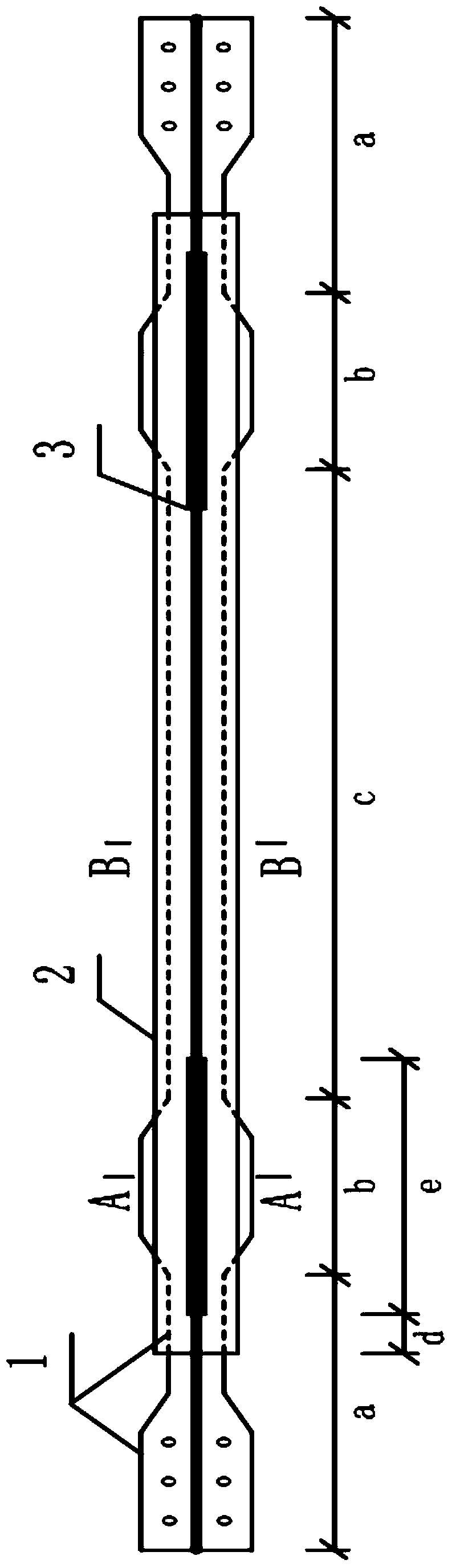

Double-casing energy-dissipation inner-core buckling restrained brace member with double yield points

InactiveCN103924702AImprove hysteresis characteristicsReduce internal forceShock proofingBuckling-restrained braceElastic plastic

A double-casing energy-dissipation inner-core buckling restrained brace member with double yield points comprises a low yield-point steel plate of a casing-shape energy-dissipation inner core plate, a high yield-point steel plate of the casing-shape energy-dissipation inner core plate, an external constraint steel plate, an end connecting plate and cement mortar. The problem that according to an existing buckling restrained brace, energy dissipation can be yielded by relying on single material only, the energy dissipation effect cannot be guaranteed during ultra-expected great earthquakes or huge earthquakes are aimed to be solved, and the novel energy dissipation core made by overlapping the low yield-point steel plate and high yield-point steel plate of the energy-dissipation inner core plate is provided. The mechanical characteristic of the low yield point is prone to yielding, and the fine hysteretic characteristic is provided with during shaping, a large amount of energy is absorbed in the process of elastic-plastic hysteretic deformation, the internal force of the rest part of the structure is significantly reduced, and the structure is protected accordingly; the yield point of high-yield-point steel is higher than that of low-yield-point steel, and elasticity can be retained when the low-yield-point steel is yielded.

Owner:BEIJING UNIV OF TECH

Construction method for mucky soft soil roadbase tubular pile

InactiveCN104894937ASolve widening and transformationComplete specificationsRoadwaysBulkheads/pilesPile capPre stress

The invention discloses a construction method for a mucky soft soil roadbase tubular pile. The construction method comprises the steps of preparatory work, construction for a roadbase soleplate, construction for a prestressed pipe pile, construction for a pile cap, construction for a cushion layer and the like. The construction method for the mucky soft soil roadbase tubular pile provides new thinking for governing differential settlement of a roadbase and solving bump at a bridge-head, freeway widening, etc. The problems of unmanageable construction quality of soft foundation at the bridge head in the soft foundation treatment and uneven settlement after being opening to traffic are solved.

Owner:成军

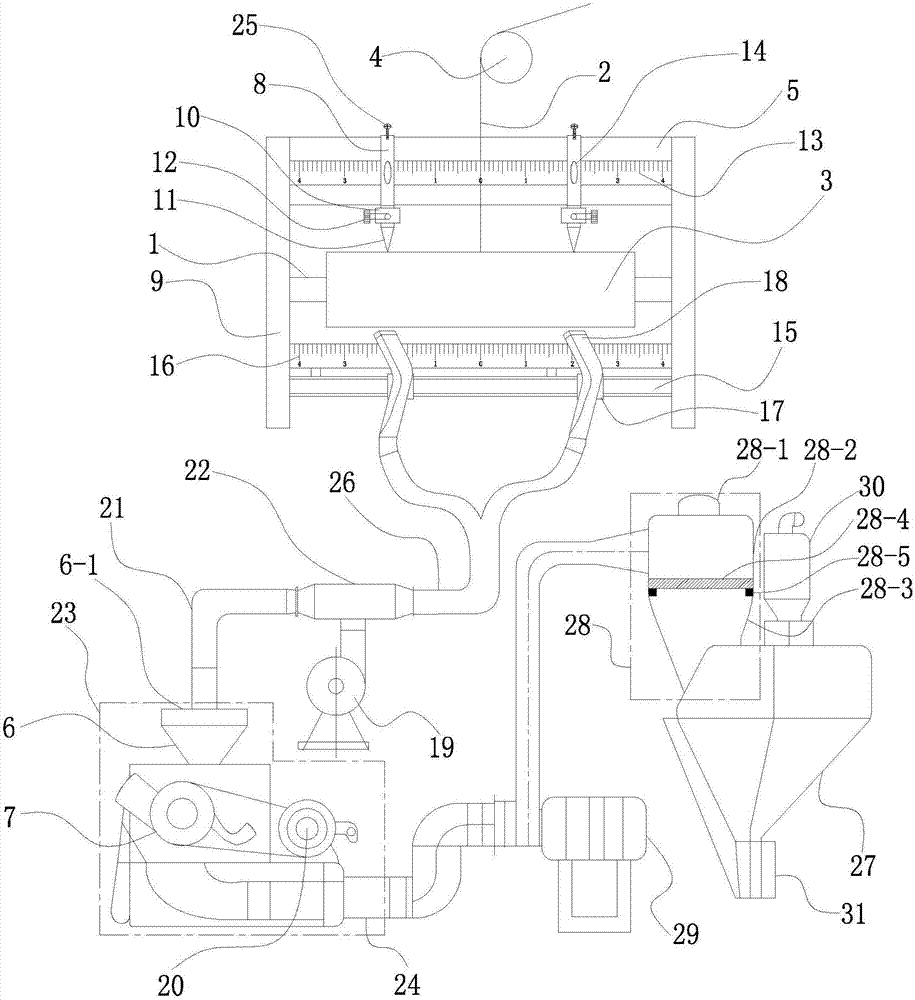

Thin film edge material recycling device

InactiveCN106956298AComplete specificationsVarious sizesPlastic recyclingMetal working apparatusEngineeringCrusher

The invention relates to a thin film edge material recycling device which comprises an edge material collecting device, a rack and a cutting device arranged on the rack. A reeling shaft is rotationally connected to the rack, and a material receiving roller is connected to the reeling shaft in a sleeving manner; the cutting device and the edge material collecting device are located at the upper end and the lower end of the material receiving roller and correspond to the material receiving roller in position; the thin film edge material recycling device further comprises an edge material crusher device, a cyclone separator and a recovery device which are sequentially connected in the edge material flowing direction; a cutter knife capable of being adjusted left and right is arranged on a fixed transverse rod and can be adjusted up and down on a stretchable rod, so that the specification and size of cut thin films are diversified, and the working efficiency is improved; meanwhile, the receiving efficiency of thin film waste edge materials can be improved, it can be guaranteed that the thin film waste edge materials cannot be secondarily polluted in the recovering process, the production cost is effectively reduced, and the finished product rate is improved.

Owner:浙江凯阳新材料股份有限公司

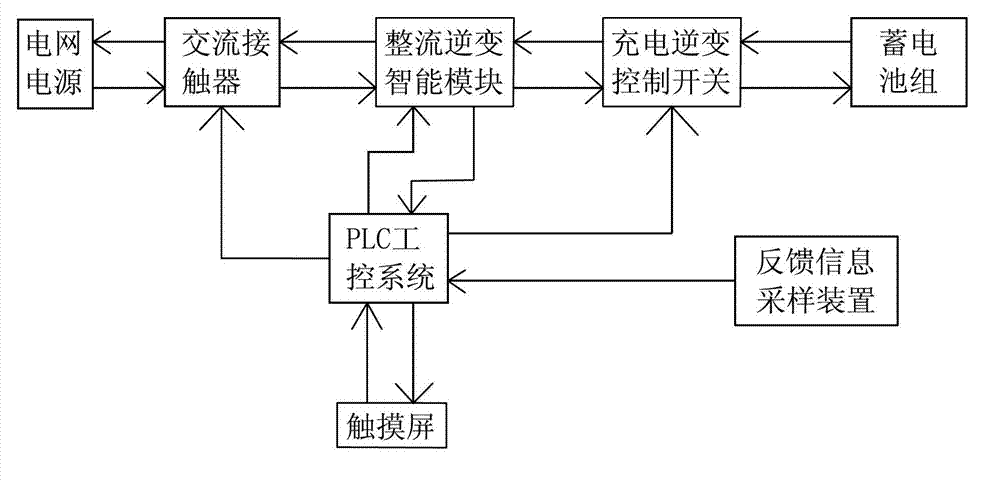

Intelligent charging pile for electric vehicle storage battery

InactiveCN102969777ACompact structureImprove reliabilityBatteries circuit arrangementsElectric powerLithium iron phosphateNickel cadmium

The invention discloses an intelligent charging pile of an electric vehicle storage battery, which belongs to the field of an intelligent charging and discharging device of a storage battery. The intelligent charging pile comprises a PLC (programmable logic controller) industrial control system inside a shell, wherein the electric vehicle storage battery is arranged outside the shell. The intelligent charging pile is characterized in that a wiring terminal, an intelligent rectifying and inverting module and the electric vehicle storage battery are orderly connected with one another through a lead; the control end of the intelligent rectifying and inverting module is connected with the PLC industrial control system; an alternating current contactor contact is arranged on an inlet lead; a charging inverting control switch is arranged on the lead between the intelligent rectifying and inverting module and the storage battery; the control ends of an alternating current contactor and the charging inverting control switch are connected to the PLC industrial control system; a touch screen is arranged at the data end of the PLC industrial control system; and a wiring terminal, the touch screen and a storage battery interface are arranged on the shell. The intelligent charging pile is suitable for various storage batteries, for example, a lead-acid storage battery, a maintenance-free storage battery, a nickel-cadmium accumulator and a lithium iron phosphate battery, can protect the electric vehicle storage battery, can be used for charging quickly and fully, and is high in safety performance, long in service life and simple to operate.

Owner:淄博京科电气研究所

Method for dyeing yarns of superfine-denier lyocell and long stapled cotton to obtain high-count fabrics

ActiveCN104928824ASoft drapeImprove appearance and textureDyeing processWoven fabricsEngineeringLyocell

The invention provides a method for dyeing yarns of superfine-denier lyocell and long stapled cotton to obtain high-count fabrics. The method includes steps of carrying out a spinning technological process (1); carrying out a weaving technological process (2). The spinning technological process (1) includes (1.1), manufacturing combed cotton silver from long stapled cotton warps; (1.2), manufacturing lyocell pre-drawn silver from the superfine-denier lyocell; (1.3), mixing the lyocell pre-drawn silver and the combed cotton silver with each other to obtain lyocell and cotton blended yarns. The weaving technological process (2) includes (2.1), weaving the lyocell and cotton blended yarns to obtain warp yarns; (2.2), weaving the lyocell and cotton blended yarns to obtain weft yarns; (2.3) weaving the warp yarns manufactured in the step (2.1) and the weft yarns manufactured in the step (2.2) to obtain grey cloth, examining and repairing the grey cloth, mercerizing the grey cloth, carrying out silk-like finishing on the grey cloth, pre-shrinking and setting the grey cloth to obtain finished products and checking and warehousing the finished products. The method has the advantages of capability of manufacturing fabrics for business shirts, diversified product weaves and specifications, stable product quality, high durability, good elasticity, difficulty in wrinkling and convenience in caring and washing.

Owner:ANHUI HUAMAO TEXTILE

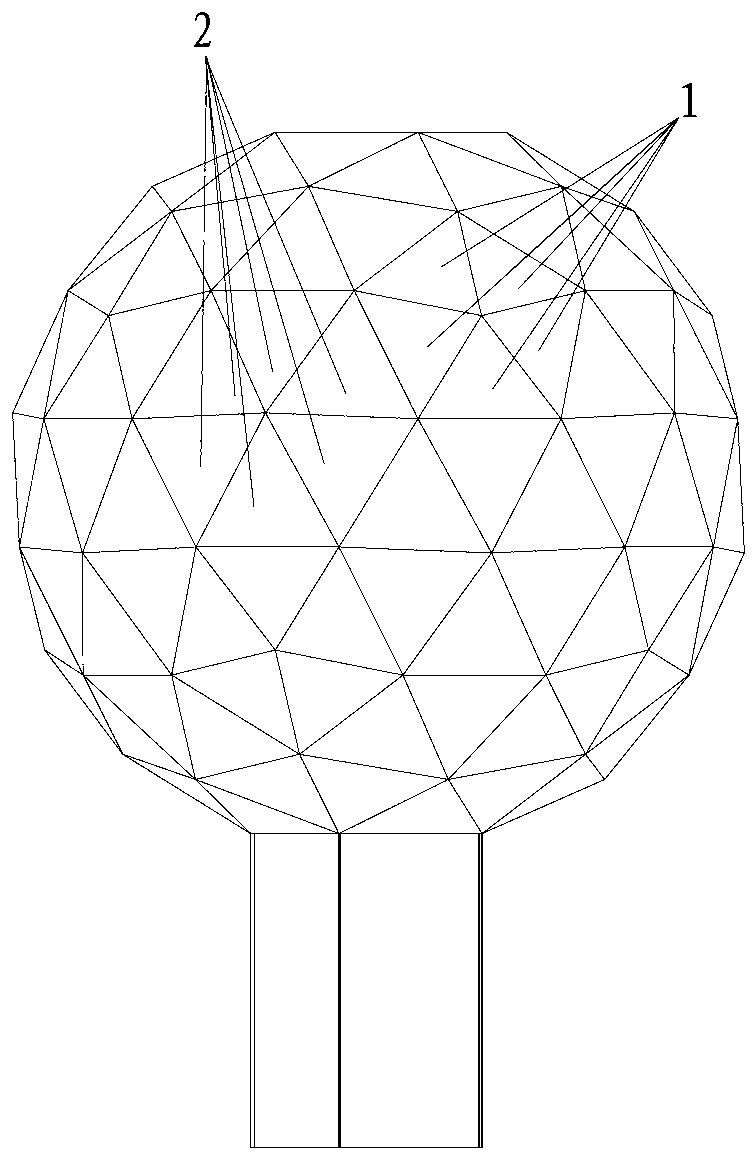

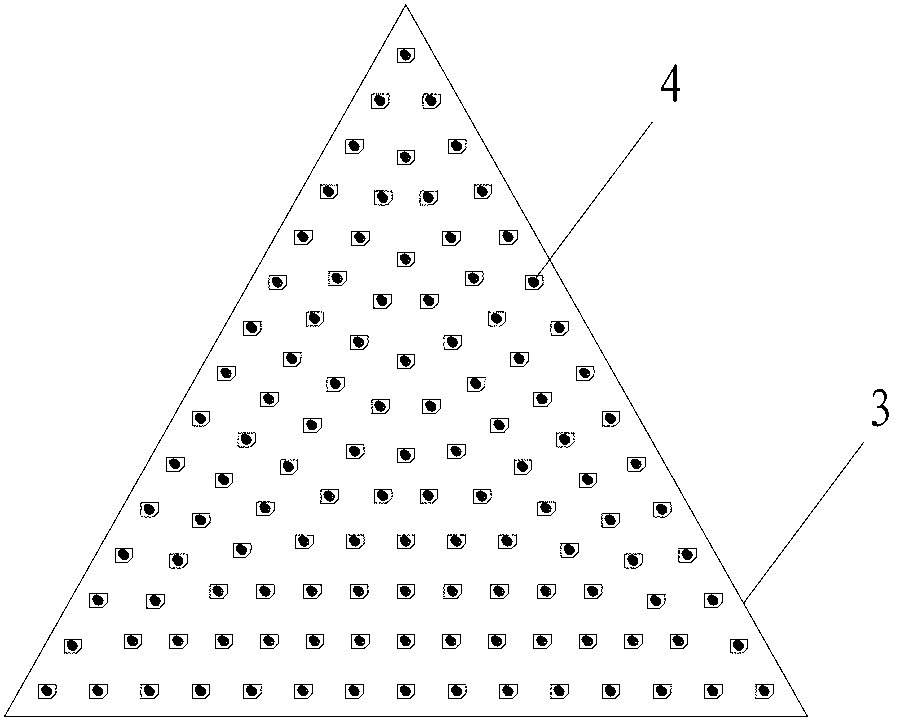

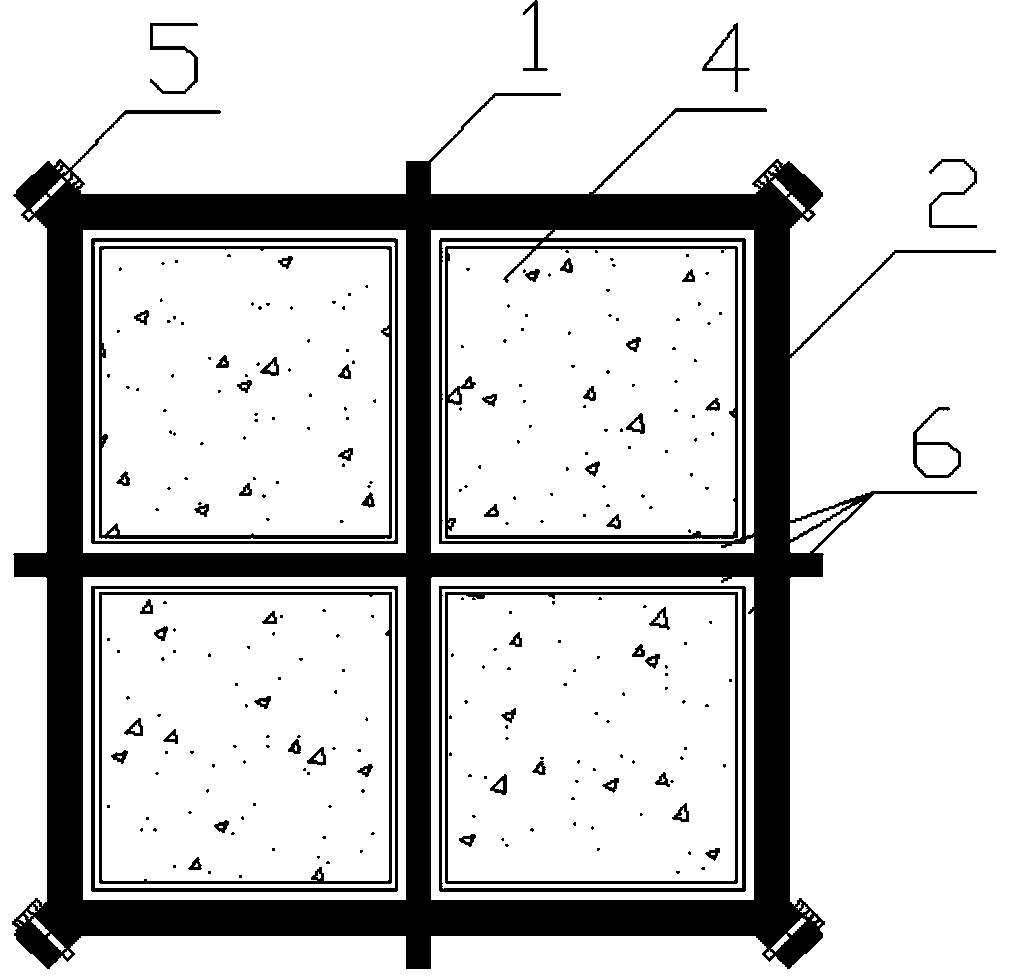

Spherical display screen and manufacturing method thereof

InactiveCN103310709AComplete specificationsSimple structureIdentification meansSpherical shapedDistortion

The invention discloses a spherical display screen and a manufacturing method thereof. The method comprises the following steps: according to the Euler's formula in space, obtaining 12 pentagons and 20 hexagons which can form a 32-face body inscribed in a spherical surface; then causing one points on the spherical surfaces corresponding to the pentagons and the hexagons to be connected with the end points of corresponding pentagons and hexagons to form pentagonal pyramids and hexagonal pyramids; according to the side faces of the pentagonal pyramids and the hexagonal pyramids, manufacturing pentagonal display modules and hexagonal display modules; finally assembling 12 pentagonal display modules and 20 hexagonal display modules into a spherical screen similar with a sphere. Therefore, when the display modules are designed, at most 32 display modules are designed, the product-design period is greatly shortened, and a lot of design labor resources are reduced. In the spherical display screen manufactured with the method, glowing pixel points can be uniformly arranged on each triangular side face of the pentagonal display modules and the hexagonal display modules. The spherical display screen has the advantages of simple structure, good pictures of displayed images and small distortion.

Owner:UNILUMIN GRP

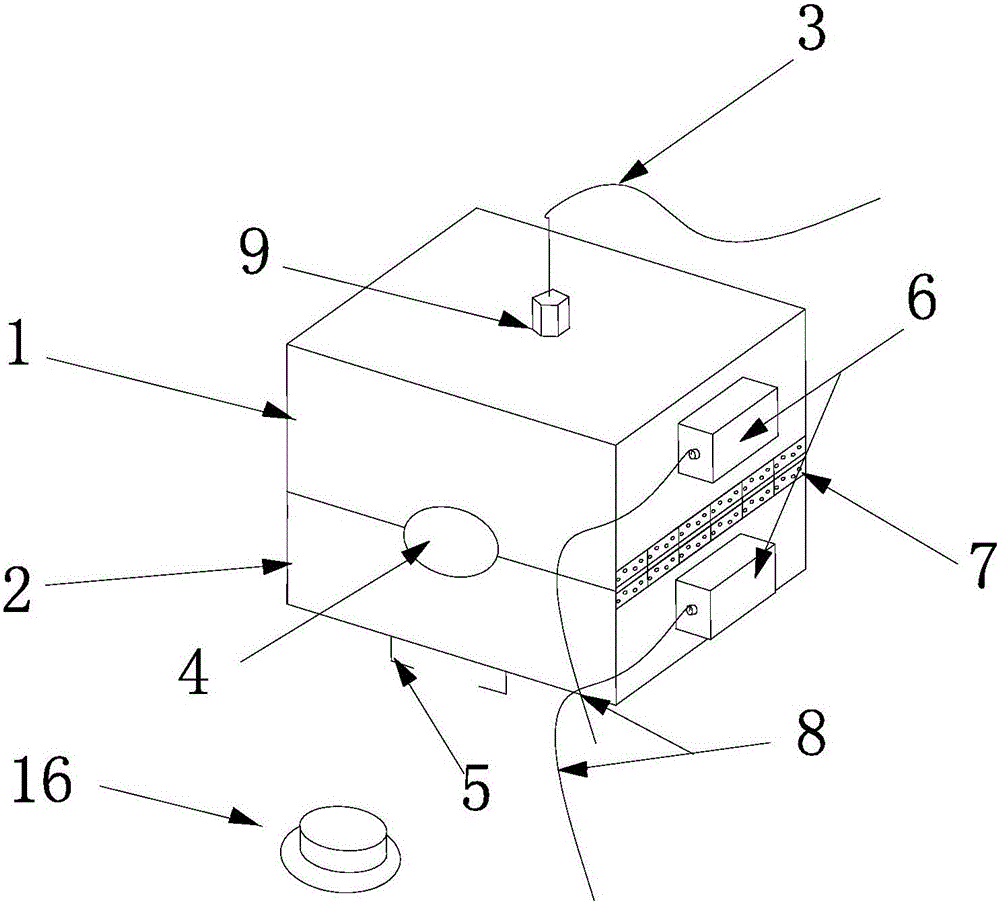

Quick heating device for high-temperature SHPB dynamic impact experiment

InactiveCN105699169AAdjustable temperaturePrecise control of heating temperaturePreparing sample for investigationTemperature controlEngineering

The invention discloses a quick heating device for a high-temperature SHPB dynamic impact experiment. The device comprises an upper box, a lower box, a temperature sensor, a heating channel, a guide rail, an electric-thermal conversion device, a hinge, a wire, a temperature measurement hole, a heating tile, heat insulation cotton, a wall, a handle, a ring, a fastener and a heat insulation plate, wherein the temperature sensor is connected with a temperature control device to regulate the temperature inside the heating device in real time, temperature is displayed through the temperature control device, and precise control of heating temperature is achieved; by arranging the heat insulation plate, dissipation of temperature does not occur easily, temperature inside a test piece and temperature outside the test piece can be made consistent, and the situation that the temperature of the test piece is uneven is avoided. The device not only can heat test pieces independently but also can quickly installing and heating test pieces, heating and impacting can be conducted at the same position, test pieces can be positioned accurately, the structure is simple and compact, operation is easy, working efficiency is high, capital input is low, and the device is economical and convenient to popularize.

Owner:ANHUI UNIV OF SCI & TECH

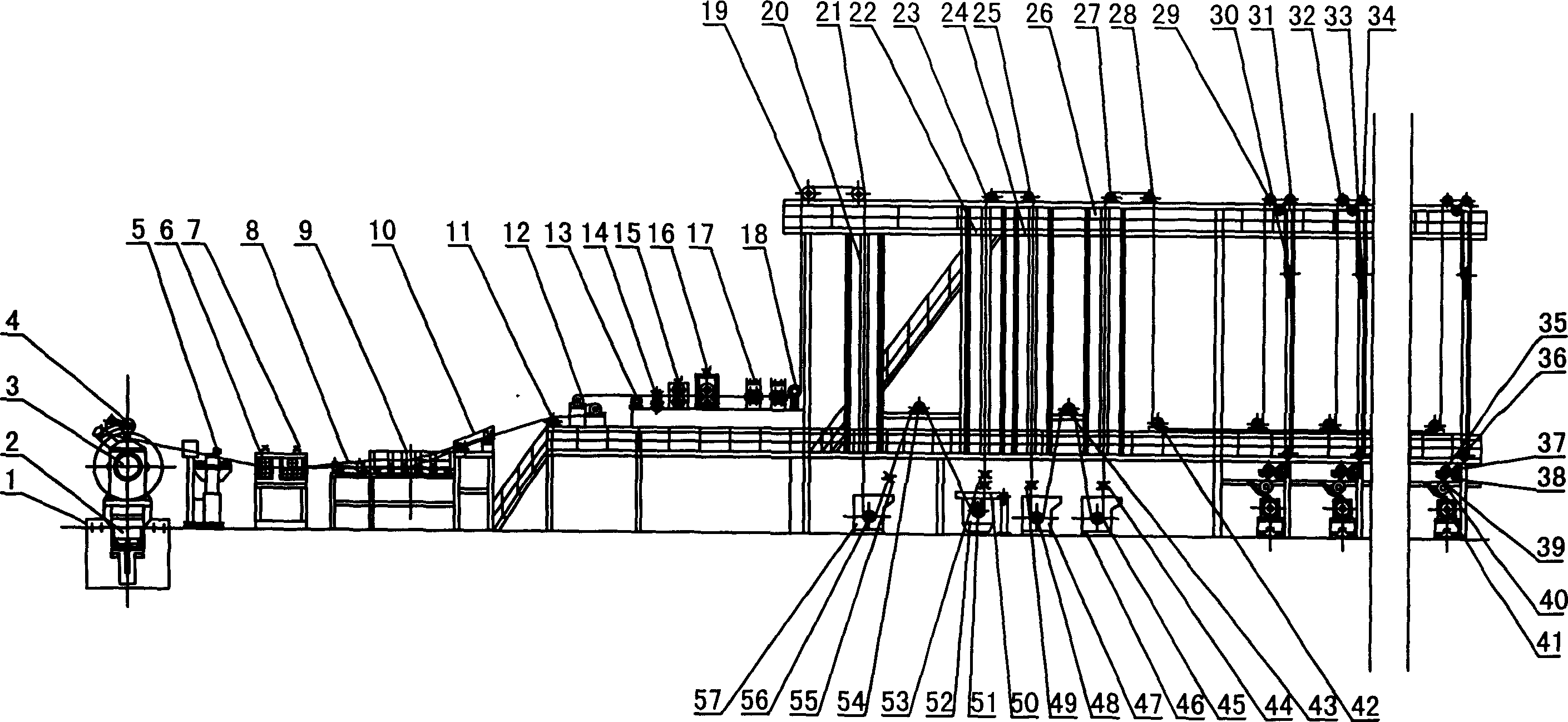

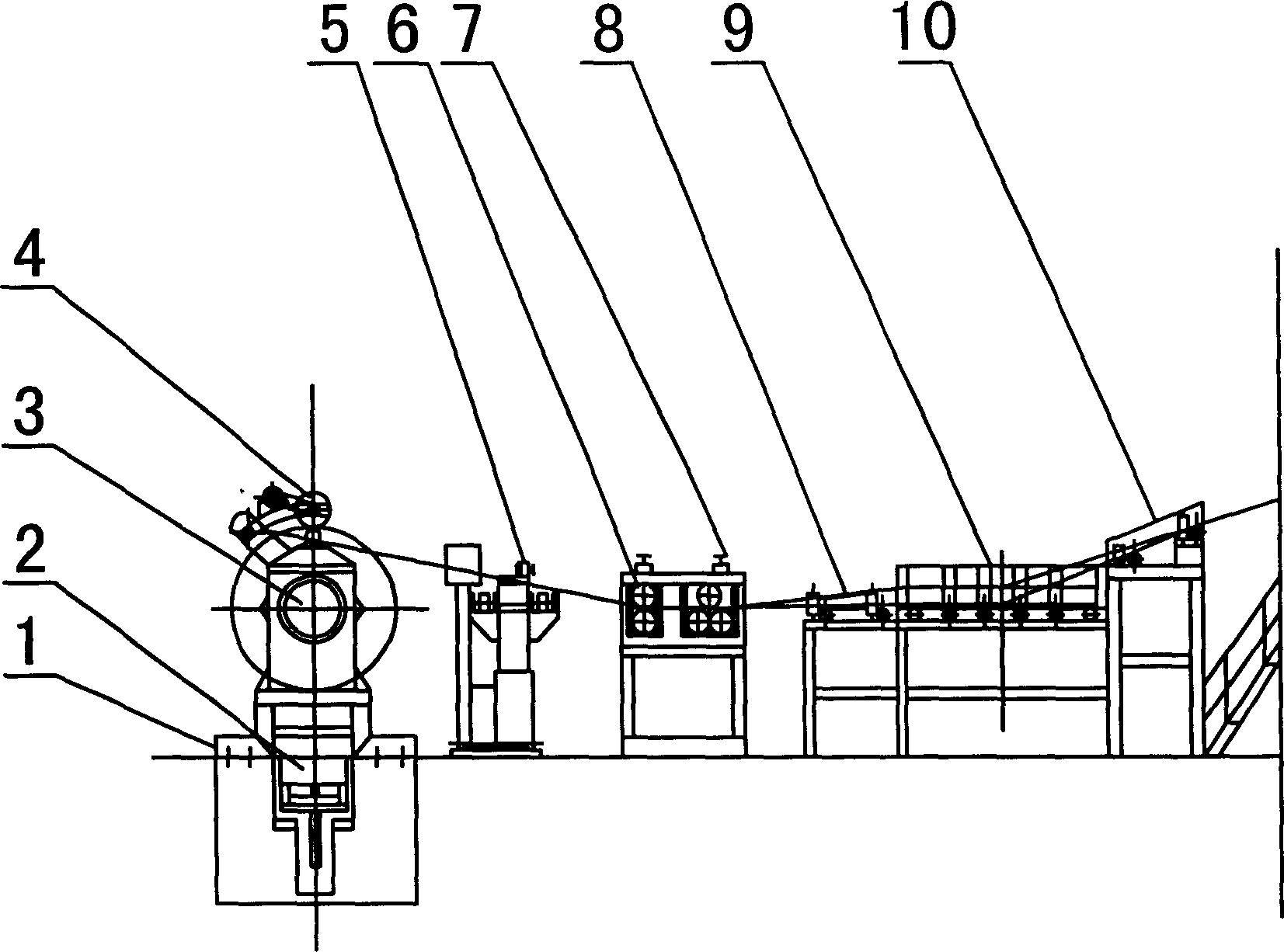

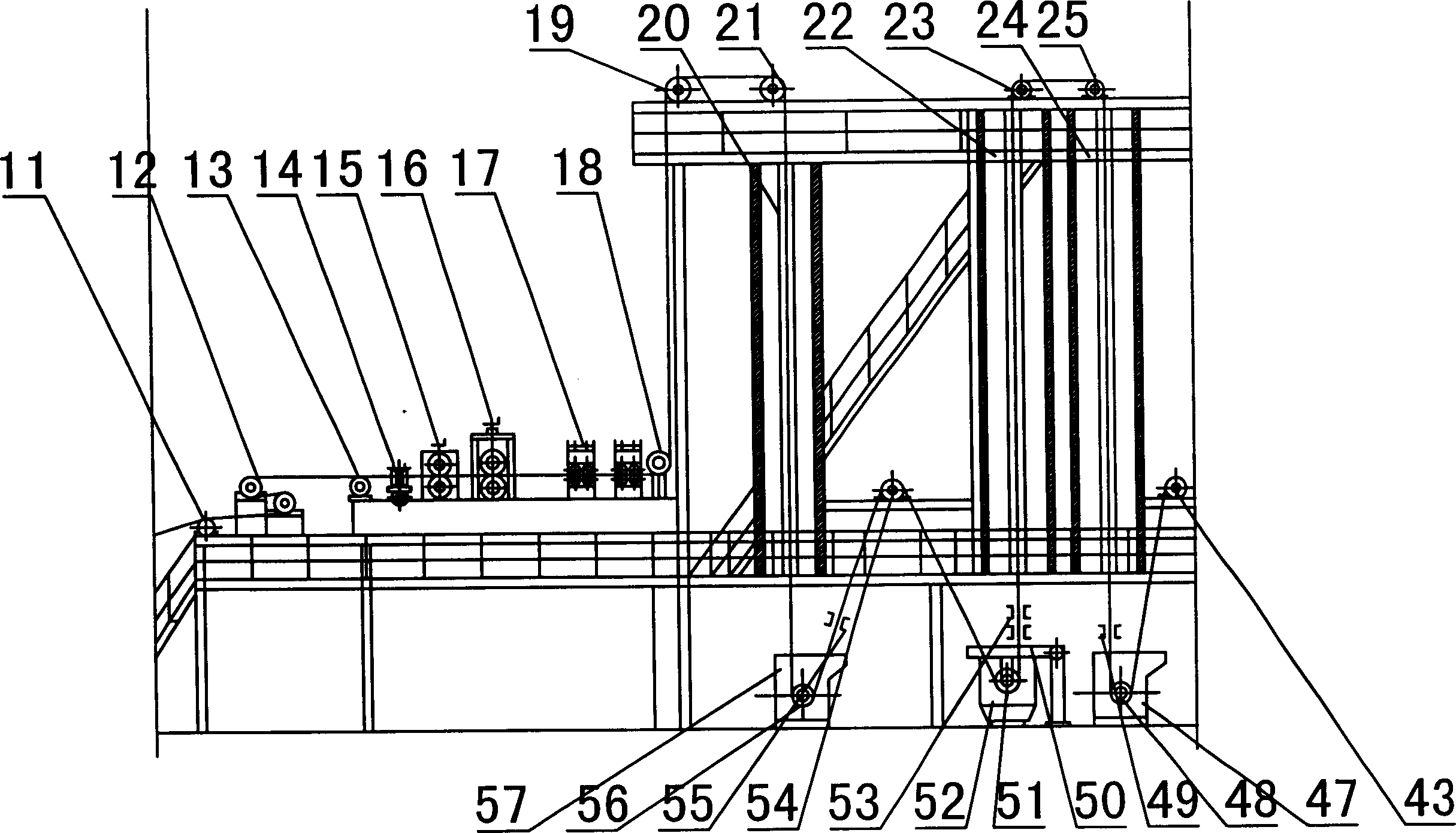

Automatic production line for producing high-strength color coated package steel strip by utilizing non-tempering process

ActiveCN1807003ALess investmentUndiminished strengthLiquid surface applicatorsFurnace typesProduction lineWax

The invention relates the automatic production line producing high-strength colored paint package steel band with non tempering technology, comprising pull-type recoiler, bonding machine, feeding planisher, storage bin, tension speed control S roll units, slitting shears, flat edge trimmer, heating furnace, the first and second cooling trough, coating groove, coating drying furnace, wax or oil groove, drying powder, differential tension speed control S roll units, separate gravity loop units, roll-up units, shipping package units and automatic control system. The roll-up machine comprises adjusting wheel, pressing wheel, nylon wheel, and air-actuated cut, correcting wheel, material received reel and dummy car. The production line makes the whole industrial process on the one production line, and the metallurgical structure of steel band comprises pearlyte and ferrolites. Compared with high-strength package steel band production line at home and abroad, the said production line reduces the cost of manufacture by 40% and equipment investment by 90%.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

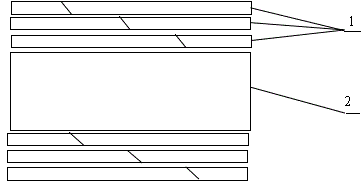

Continuous forming composite structure material and manufacturing method thereof

ActiveCN104084997AIncrease productivityLess investmentOther plywood/veneer working apparatusWood veneer joiningWood veneerSurface layer

The invention discloses a continuous forming composite structure material and a manufacturing method of the continuous forming composite structure material. According to the structure, an upper surface layer material and a lower surface layer material respectively comprise 2-4 layers of longitudinal veneer, or the upper surface layer material and the lower surface layer material respectively comprise 1-4 layers longitudinal veneer and 1-2 layers of transverse veneer; a core layer is a batten obtained after the edges of a shaving board or converted timber or plywood are sawn. The continuous forming composite structure material has the advantages that battens of shaving boards produced in a large scale, the converted timber, the plywood left after being processed and all kinds of coniferous wood and broad-leaved wood veneer can be made into composite structure materials with continuous length through a single fixed high-frequency press; the continuous forming composite structure material has the advantages that investment is low, efficiency is high, the number of product specifications is large, and the requirements for bottom beams, bottom plates and other structure materials of automobiles, trains, containers and ships are met.

Owner:贵州新锦竹木制品有限公司

Method and device for transplanting nursery stock

InactiveCN101632342AMeet the needs of transplantation and hydrationAvoid damageClimate change adaptationAfforestationEngineeringGrowing season

The invention provides a method and a device for transplanting nursery stock, wherein the method comprises the following steps: 1. properly selecting a tray and a surrounded plate according to a soil column of a nursery stock, wherein the tray is made into a dustpan shape with an opening at one side, lifting lugs are arranged at the upper part of the tray and correspond to lifting lugs arranged on the surrounded plate which is buttoned on the tray, hanging lugs are evenly distributed at one end of the interface part of the surrounded plate and correspond to adjusting hanging lugs at the other end thereof so as to regulate the size of the surround plate; 2. respectively fixing hanging lugs at two sides of the surrounded plate, lifting lugs on the tray and the lifting lugs on the surround plate together by iron wires and then lifting simultaneously; 3. filling soil after the soil column is wrapped by the surrounded plate; 4. timely replenishing water when the nursery stock is in growing seasons or transported for a long distance; 5. stably putting the nursery stock into a dug cave firstly after the nursery stock reaches a planting site (cave), taking a support plate out from the bottom, filling soil to reach 1 / 3-1 / 2 height of the soil column, pulling the surrounded plate out, filling soil, treading and watering to finish nursery stock planting. The method and the device are suitable for transplanting arbors, shrubs and perennial herb nursery stock with 1.0-10.0cm of chest diameter and achieve the afforested survival rate to be more than 95 percent.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

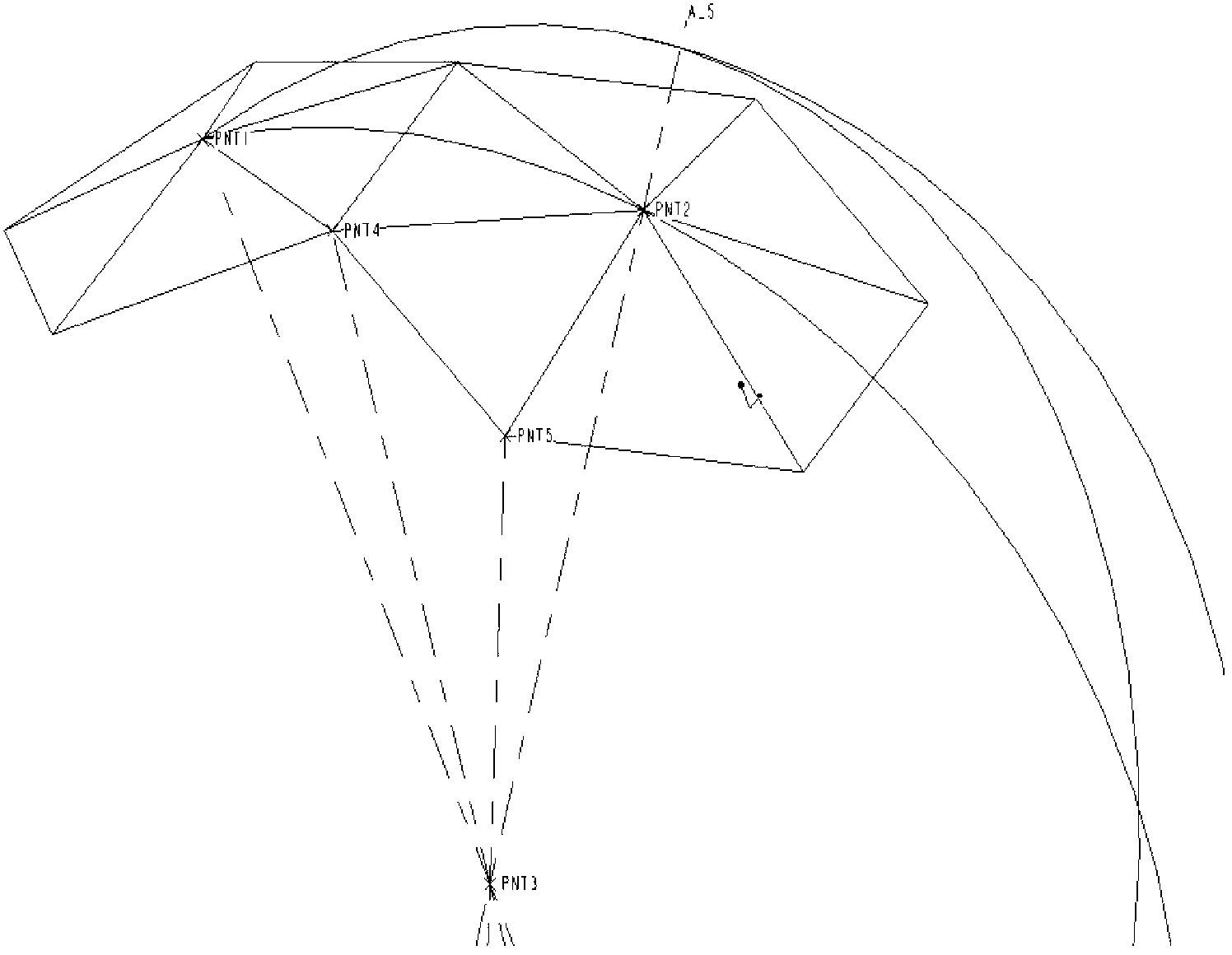

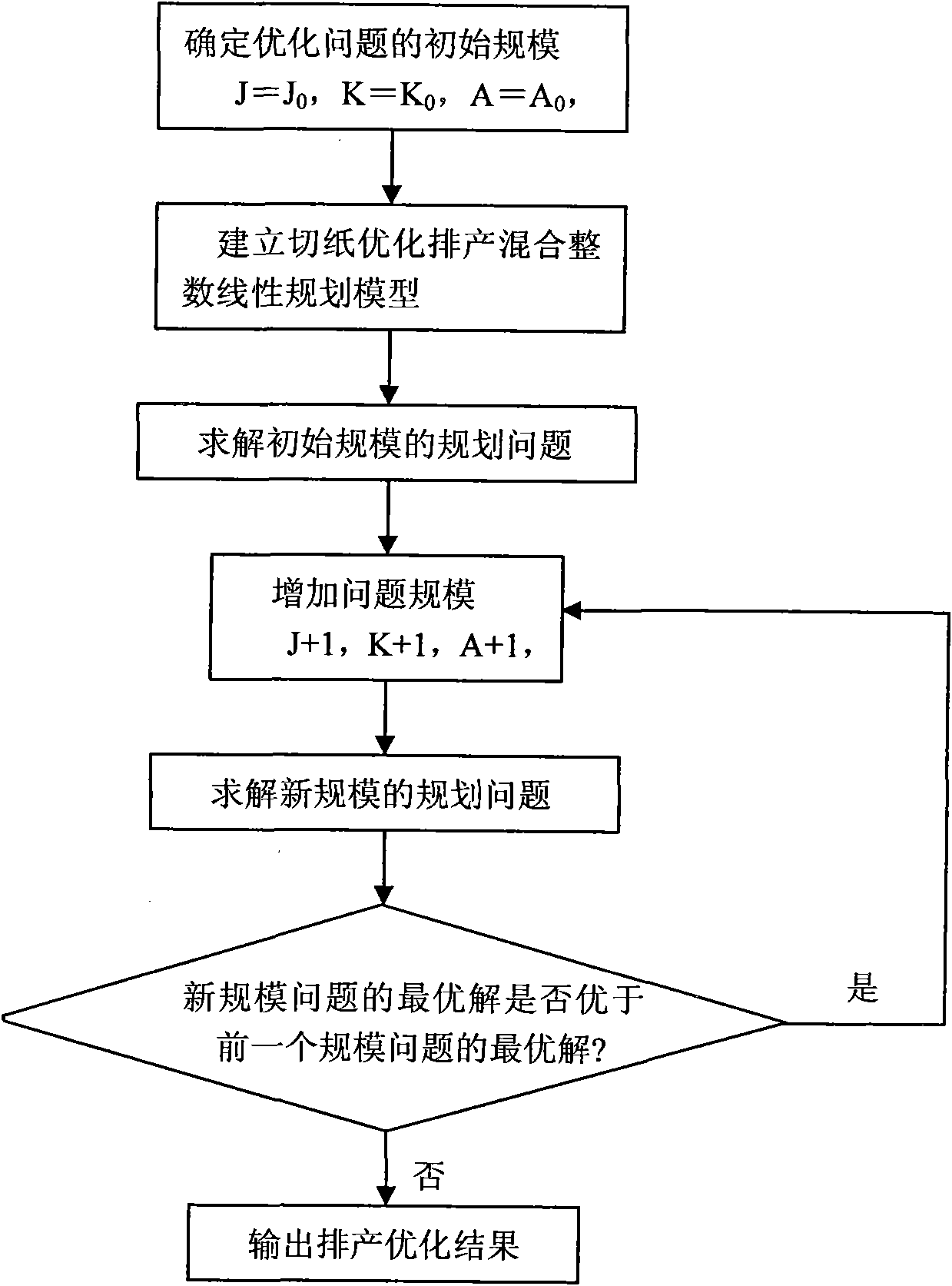

Method of rolled paper cutting and integrated stock optimization in paper factory

InactiveCN101587573AOptimal production planImprove solution efficiencyLogisticsRolling paperPulp and paper industry

This invention provides a method of rolled paper cutting and integrated stock optimization in paper factory, comprising the following steps: step one, determining an initial size of a problem about rolled paper cutting and integrated stock optimization; step two, establishing a mixed integer linear programming model for rolled paper cutting and integrated stock optimization; step three, solving a problem about mixed integer linear programming for rolled paper cutting and integrated stock optimization that is combined by two steps above to obtain an optimum target value and scheduling project; step four, adding one level to the size of the optimization problem to compose an optimization problem in new size; step five, solving the optimization problem in new size to obtain a new optimum target value and scheduling project possibly; step six, if the target value obtained in step five is superior to the target value obtained in step three, repeating steps four and five, otherwise, outputting the scheduling project obtained in step five. This invention can obtain the optimum rolled paper scheduling project without excessively adding the problem size.

Owner:SOUTH CHINA UNIV OF TECH

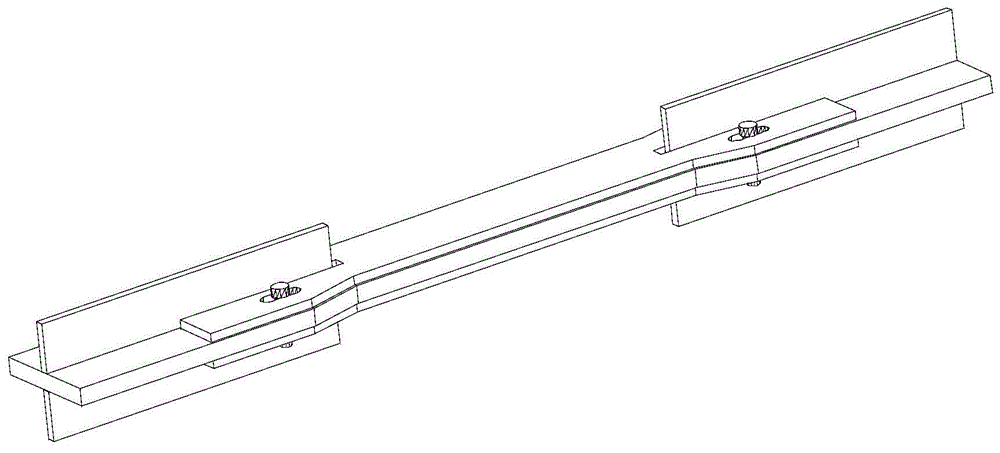

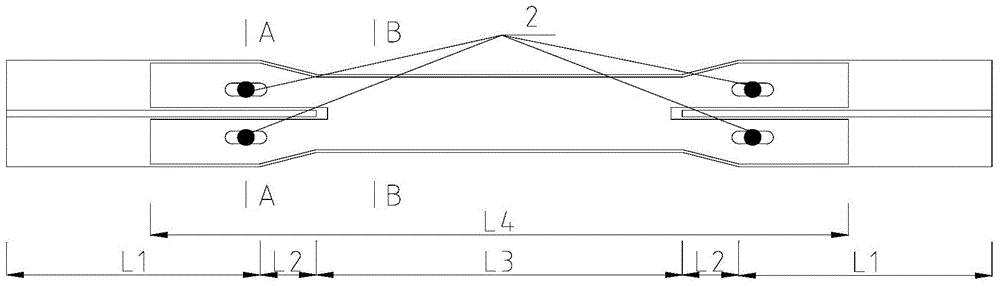

Anti-buckling limit support member for reinforcing post-yield stiffness

The invention discloses an anti-buckling limit support member for reinforcing a post-yield stiffness, which belongs to the technical field of building construction. The anti-buckling limit support member comprises a two-order yield steel core and an outer constraint steel tube, wherein the two-order yield steel core comprises a first-level yield steel core and a vertically-covering steel plate; the first-level yield steel sequentially comprises a connection section L1, transition sections L2 and a yield working section L3 from the both ends to the middle, the connection section L1 and the transition sections L2 are cross sections, the yield working section L3 is an inline section, and the yield working section L3 is located between the two transition sections L2; bolts are arranged on connection sections at the both sides of the first-level yield steel core; the lengths of the first-level yield steel core and the vertically-covering steel plate are L4, the steel plate is connected to the upper surface and the lower surface of the first-level yield steel core by the bolts at the both ends, grooves are opened in thee both ends of the steel plate, the cross sections of the first-level yield steel core stretch into the grooves, and the two-order yield steel core is located in the outer constraint steel tube. The anti-buckling limit support member disclosed by the invention is convenient to take materials, definite in force transfer, and capable of being widely applied to energy dissipation and seismic mitigation, and limit control for buildings.

Owner:BEIJING UNIV OF TECH

Fluorine-removing lanthanum-supported fiber adsorbent and synthesis method thereof

InactiveCN102814169AEasy to shapeHigh strengthOther chemical processesWater contaminantsSorbentSynthesis methods

The invention discloses a fluorine-removing lanthanum-supported fiber adsorbent and a synthesis method thereof, belonging to the field of polymer materials. The fiber adsorbent comprises an active component and a matrix fiber, wherein the matrix fiber is an amidoxime fiber prepared through polyamine crosslinking reaction and amidoxime modification reaction of an acrylic fiber; and the active component is element lanthanum supported on the matrix fiber through in-situ reaction. The fiber adsorbent can be used for adsorbing and removing fluorine pollutants in water. Compared with the conventional fluorine-removing adsorbents, the novel fiber adsorbent disclosed by the invention has the characteristics that the adsorption speed is high, the adsorption capacity is as high as 34mg / g, the range of applicable pH value is as wide as 4-8 and the fiber adsorbent can be applied in various forms such as fiber bundles, non-woven fabrics and fabrics and can further meet the requirement of actual water treatment. The synthesis method has the advantages of available raw materials, simple process, mild reaction conditions and the like.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

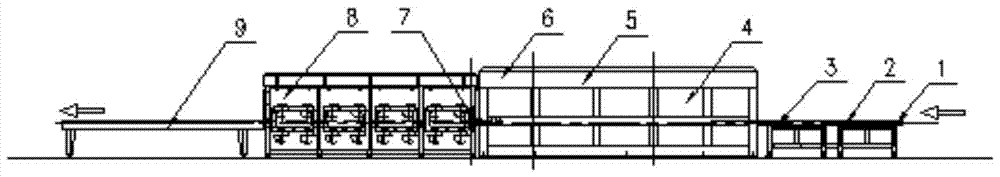

Isothermal-isobaric multipurpose thermal tempering equipment for ultra-thin glass

ActiveCN106865964AVersatileComplete specificationsGlass reforming apparatusGlass tempering apparatusElectrical controlEngineering

The invention discloses isothermal-isobaric multipurpose thermal tempering equipment for ultra-thin glass. The equipment comprises an upper piece platform, a heating furnace, a tempering section, a lower piece platform, a draught fan, a draught fan pipeline system and an electrical control system, wherein the draught fan is connected with the tempering section through the draught fan pipeline system and is used for continuously and uniformly supplying wind to the tempering section, a glass preheating region, a glass softening region and a glass stabilizing region are respectively arranged in the heating furnace, and the tempering section is divided into a glass shaping region and a glass tempering region. The isothermal-isobaric multipurpose thermal tempering equipment is provided with the glass preheating region and the glass stabilizing region, so that the adequate and uniform heating of glass is guaranteed; by utilizing an upper-lower duel roller bed, the glass deformation in the heating process can be furthest reduce; and furthermore, the upper-lower duel roller bed type glass shaping region is arranged at the tempering section, so that the softened glass can be shaped before being tempered, and the flatness of the softened glass reaches the standard requirement of tempered glass. The isothermal-isobaric multipurpose thermal tempering equipment has multiple purposes of flattening and bending and can be used for producing flat and bent tempered glass of various specifications and shapes.

Owner:侯维绪

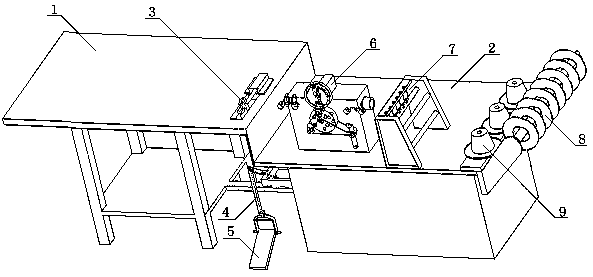

Workbench special for cutting wires

The invention relates to a workbench special for cutting wires. The workbench special for cutting wires is characterized in that an operation table and an equipment table which is connected with one end of the operation table are included, the part, close to the equipment table, on the surface of the operation table is provided with a guide wire cutter, and a guide wire length measuring device, a guide wire guiding device and a guide wire fixing device are sequentially arranged on the equipment table from the end, close to the operating table, of the equipment table to the other end of the equipment table. The workbench is the special equipment for cutting secondary guide wires needed when high and low voltage switch equipment is machined, and under the conditions that the cut guide wires are in large batch, and specifications are various, the advantages of being high in working efficiency and accurate in cut length specification are achieved. Meanwhile, the structure is simple, and operation is convenient.

Owner:DALIAN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +2

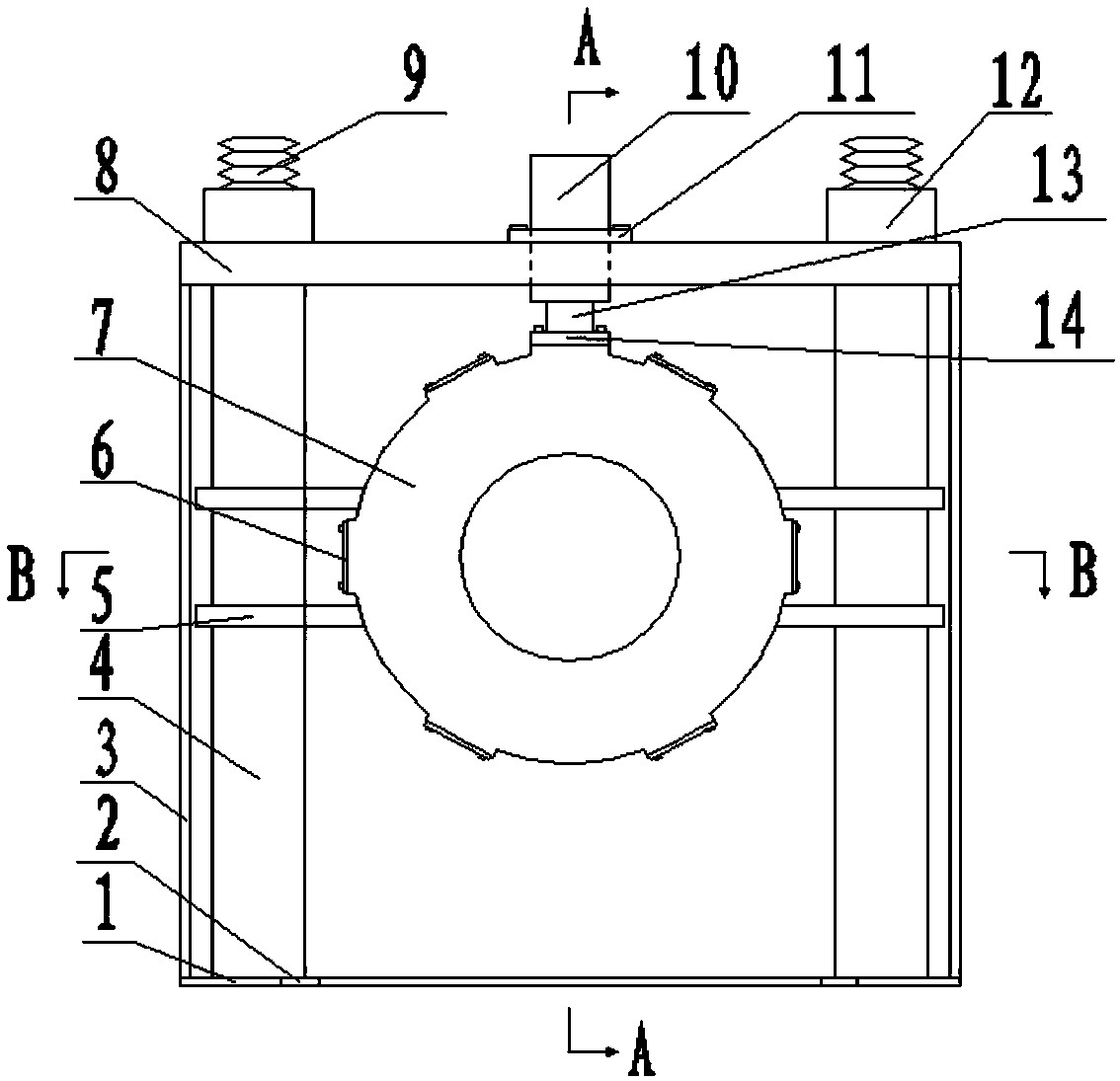

Round steel surface imaging regulating device and method

ActiveCN108627518ARealize detectionRealize real-time high-precision adjustmentOptically investigating flaws/contaminationComputer moduleEngineering

The invention belongs to the technical field of imaging regulation, and particularly discloses a round steel surface imaging regulating device. The round steel surface imaging regulating device comprises a support module, a regulation module and an imaging module, wherein the support module comprises a bottom plate, a top plate and support plates; wherein the top plate is arranged above the bottomplate; the support plates are connected with the bottom plate and the top plate; upright posts are also arranged between the bottom plate and the top plate; the regulation module comprises an ascending and descending oil cylinder; the ascending and descending oil cylinder are fixed on the top plate; a first displacement sensor is arranged at the inside; a positioning lug boss is arranged under apiston rod of the ascending and descending oil cylinder; the imaging module comprises an installing frame and a plurality of imaging units; the installing frame is arranged under the positioning lug boss and is arranged on a guide plate; the axial line is parallel to the horizontal plane; the guide plate is sleeved on the upright posts; a plurality of guide grooves in annular distribution are formed in a cylinder; the plurality of imaging units are sequentially inserted into the corresponding guide grooves and face a round steel to be tested inside the hollow cylinder. The real-time high-precision regulation of the height of a plurality of cameras and the distance away from the round steel surface can be realized; the advantages of simple structure, operation convenience and the like are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

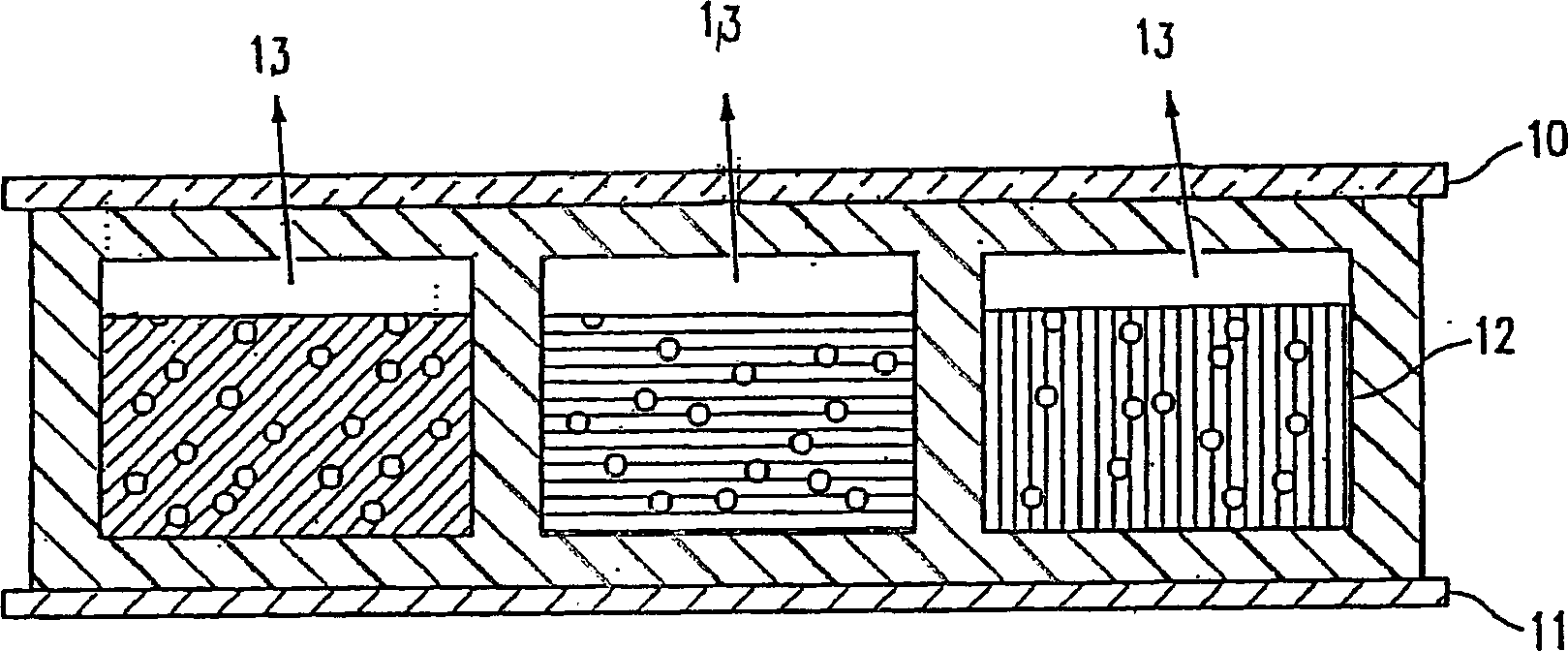

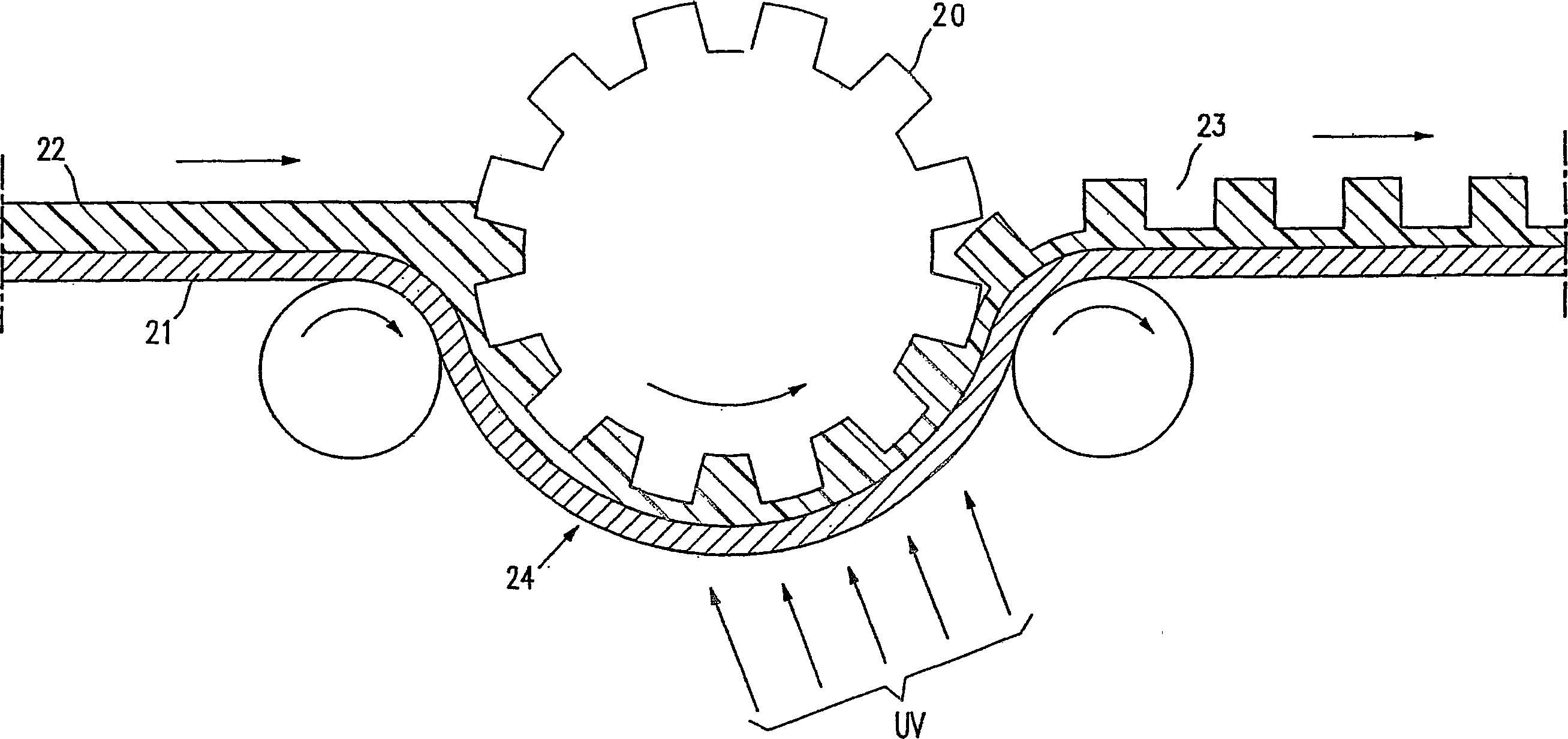

Electrophoretic display and process for its manufacture

ActiveCN1774659AEfficient manufacturingCost effectiveStatic indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisDisplay device

Owner:SIPIX IMAGING INC

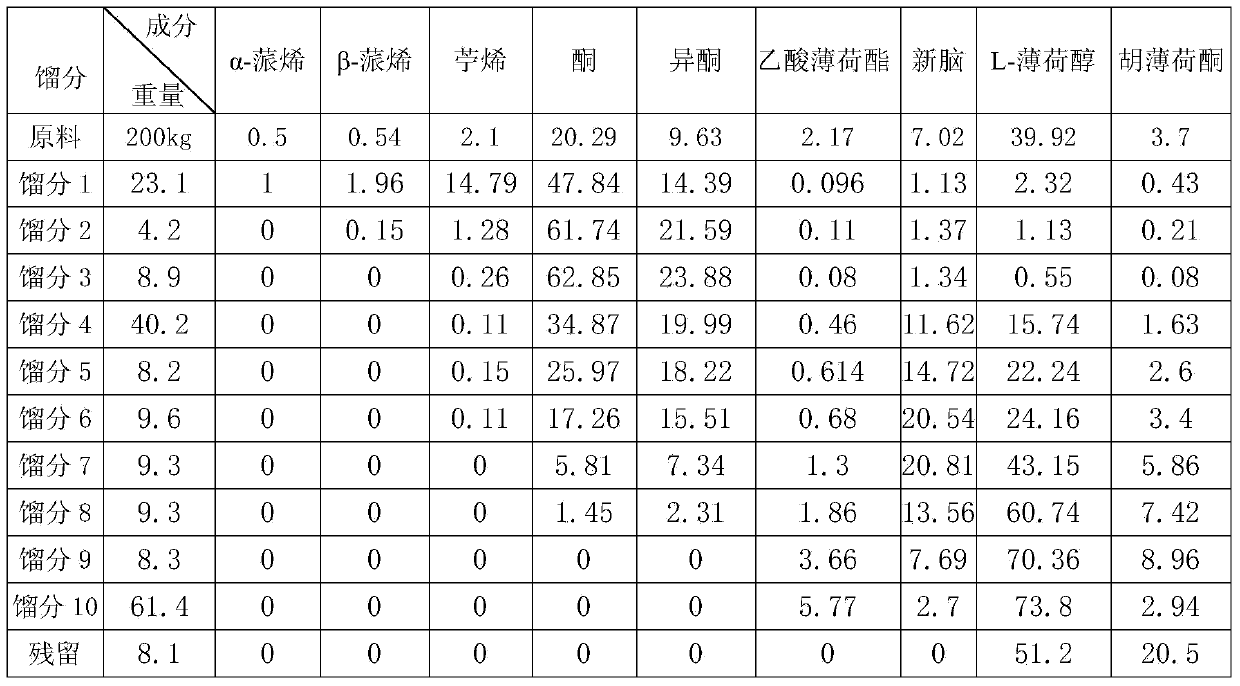

Method for preparing terpeneless dementholized peppermint oil through azeotropic distillation

ActiveCN104178347AReduced vacuum requirementsPure aromaFatty-oils/fats refiningEssential-oils/perfumesFlavorPeppermints

The invention discloses a method for preparing terpeneless dementholized peppermint oil through azeotropic distillation. The method comprises the following concrete steps of pumping dementholized peppermint oil into a rectifying tower filled with a packed rectifying column under negative pressure, then, adding an entrainer, then, reflowing, and fractionally collecting fractions; and separating the entrainer under normal pressure to obtain fractions, and selecting the fractions to be blended according to the content of the fractions to obtain the terpeneless dementholized peppermint oil. By using the method disclosed by the invention, the defects that the traditional rectifying method is high in energy consumption, the requirement for vacuum degree of a system is high, a distilled substrate is easily carbonized at high temperature, the loss of raw materials is relatively high, and the distilled substance has burnt flavor can be effectively avoided; on one hand, the dementholized peppermint oil prepared by using the method has low requirements for the system, and the prepared finished product has no burnt flavor and is pure in fragrance, and on the other hand, the terpeneless dementholized peppermint oil can be prepared by blending, so that the specification of the product is enriched, and different requirements are met; in addition, the method is simple and convenient to operate and suitable for large-scale production and application in industry.

Owner:ANHUI FENGLE PERFUME

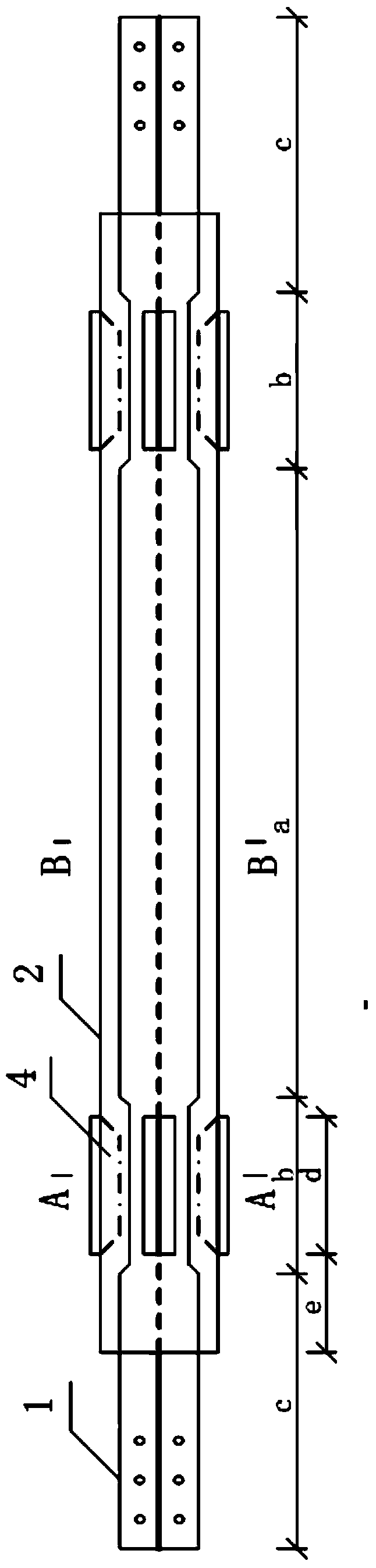

Rectangular steel tube variable-cross-section steel core anti-buckling limiting energy dissipation supporting member assembled with bolt shaped like Chinese character 'tian'

InactiveCN103711216ALimited lateral movementReach the limit effectShock proofingChinese charactersMaterials science

The invention relates to a rectangular steel tube variable-cross-section steel core anti-buckling limiting energy dissipation supporting member assembled with a bolt shaped like a Chinese character 'tian', and belongs to the technical field of anti-buckling supporting. The anti-buckling limiting energy dissipation supporting member comprises a cross-shaped steel core and an outer limiting body, the cross-shaped steel core is located in the outer limiting body, and four spaces defined by the steel core and the outer limiting body are respectively filled with a light-gauge steel section concrete filled steel tube. The anti-buckling limiting energy dissipation supporting member is characterized in that the partial cross section of the steel core becomes large, a limiting groove (3) is formed in the position, corresponding to a partial cross section largened section c, of the outer limiting body, the groove length of the limiting groove (3) is slightly larger than the section length of the corresponding partial cross section largened section, and the portion, located on a partial cross section largened section b, of the cross-shaped steel core outwards extends out of the outer limiting body through a corresponding limiting groove. After the steel core is deformed and buckled, an outer limiting steel tube and the axial stiffness of the buckled steel core are used for limiting the whole displacement of the structure to achieve the limiting target.

Owner:BEIJING UNIV OF TECH

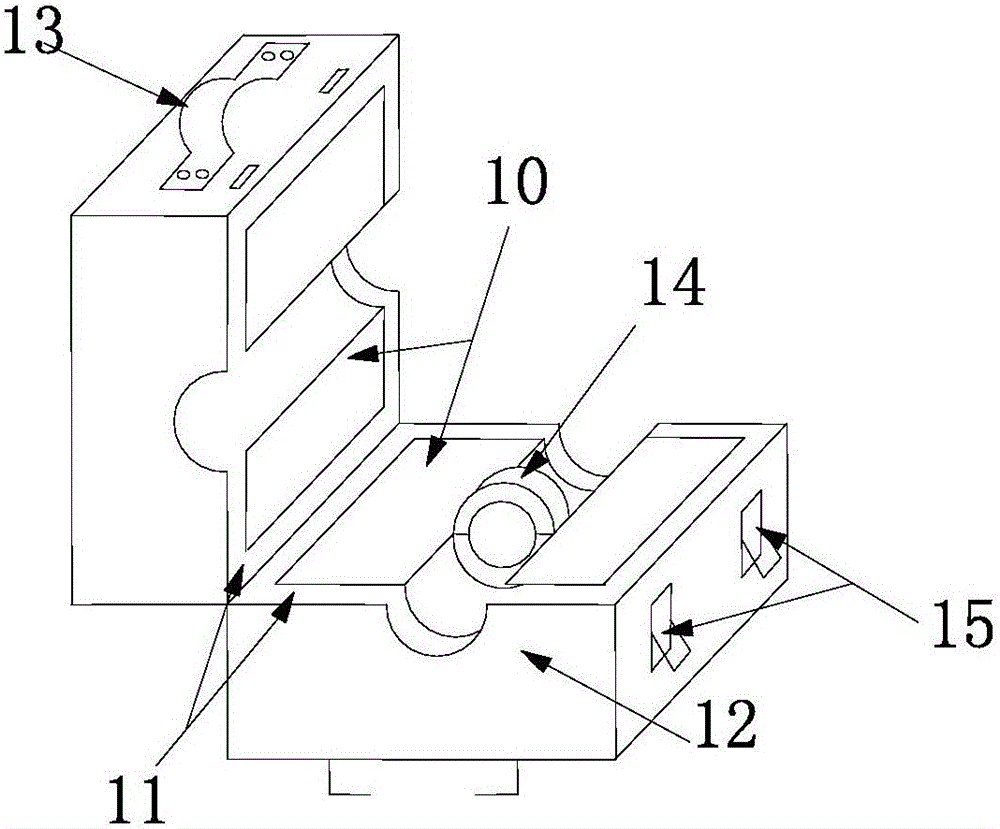

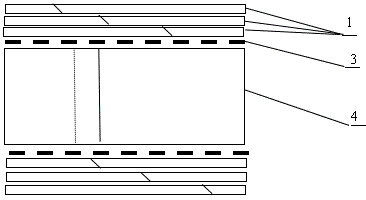

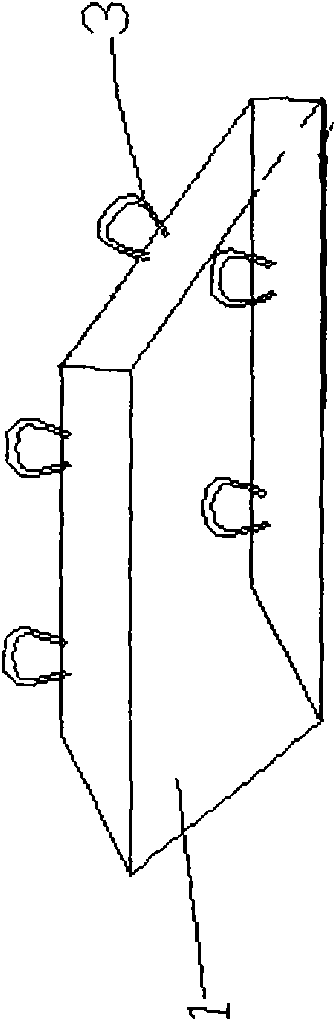

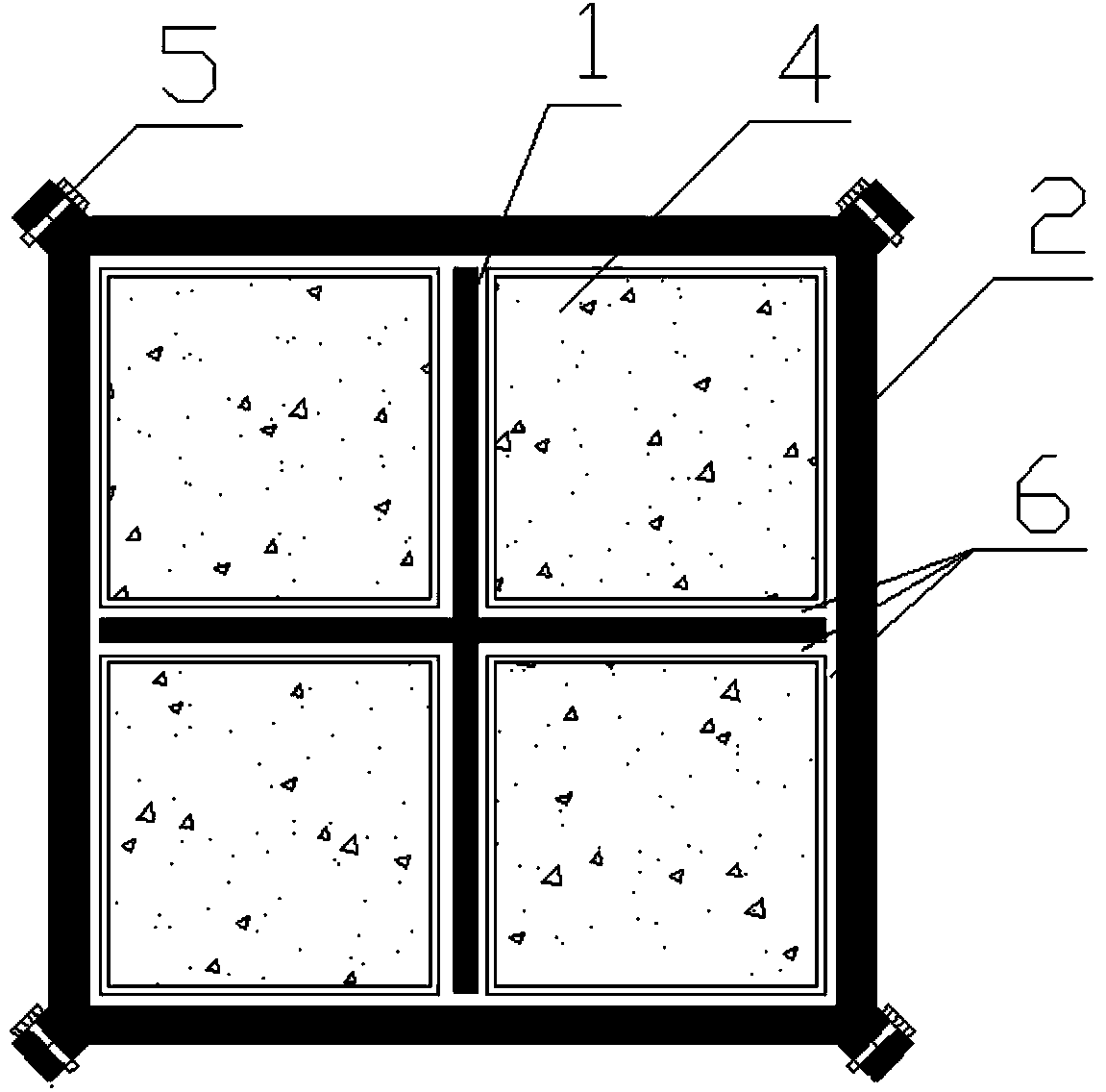

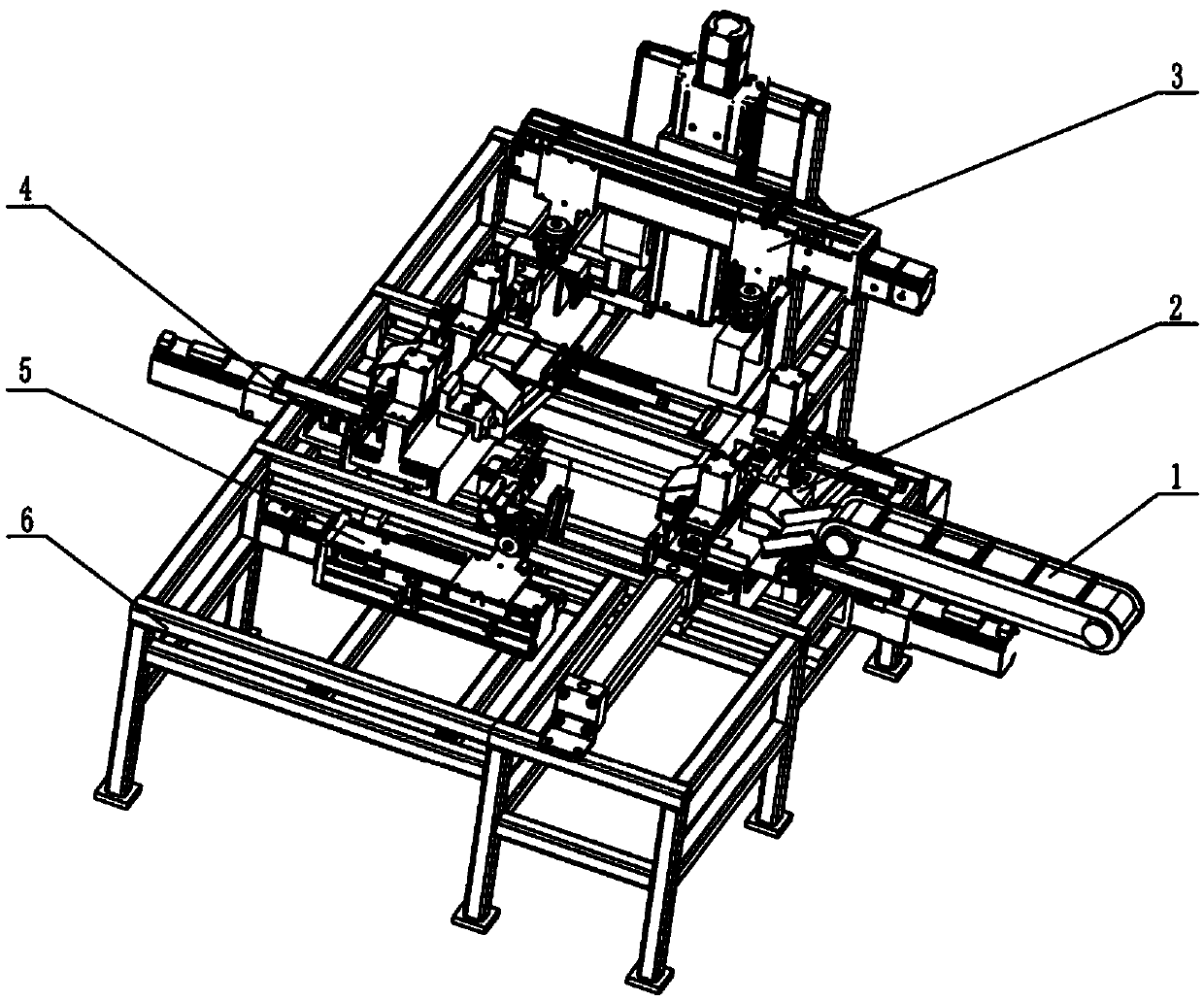

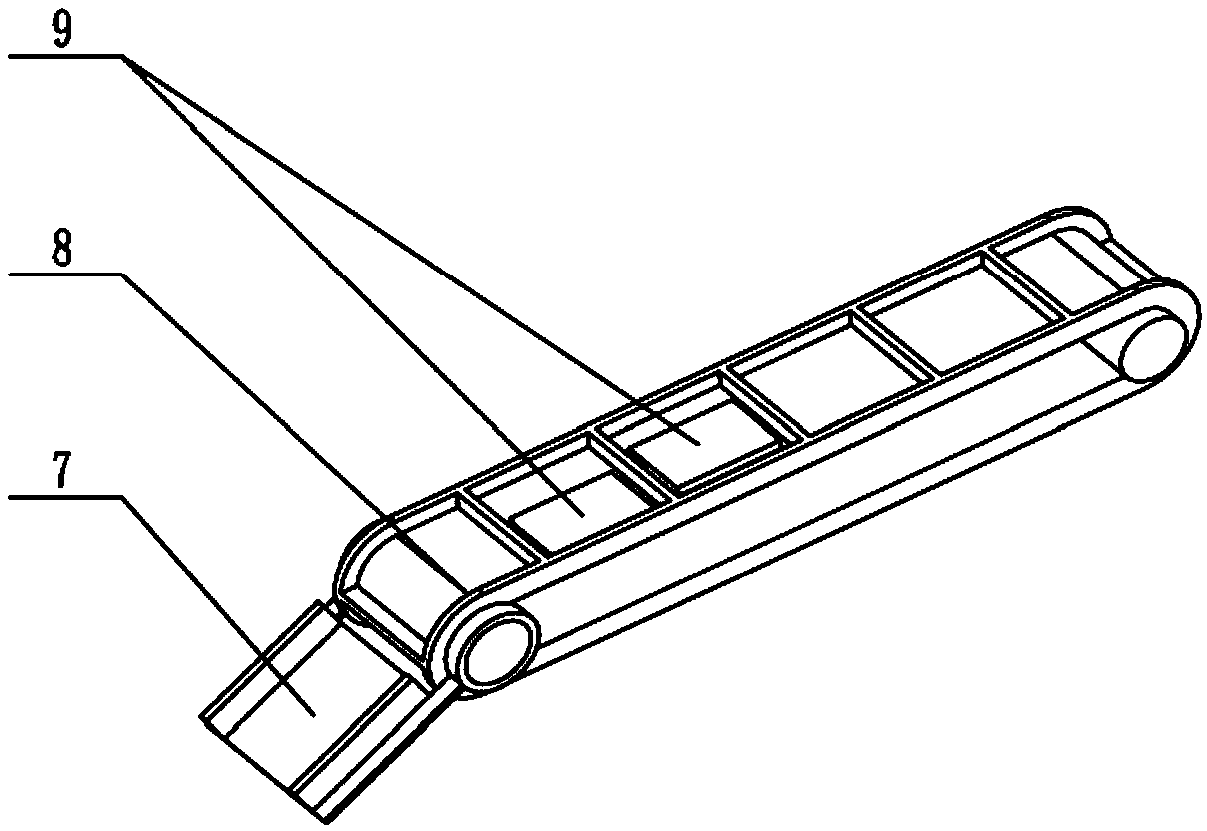

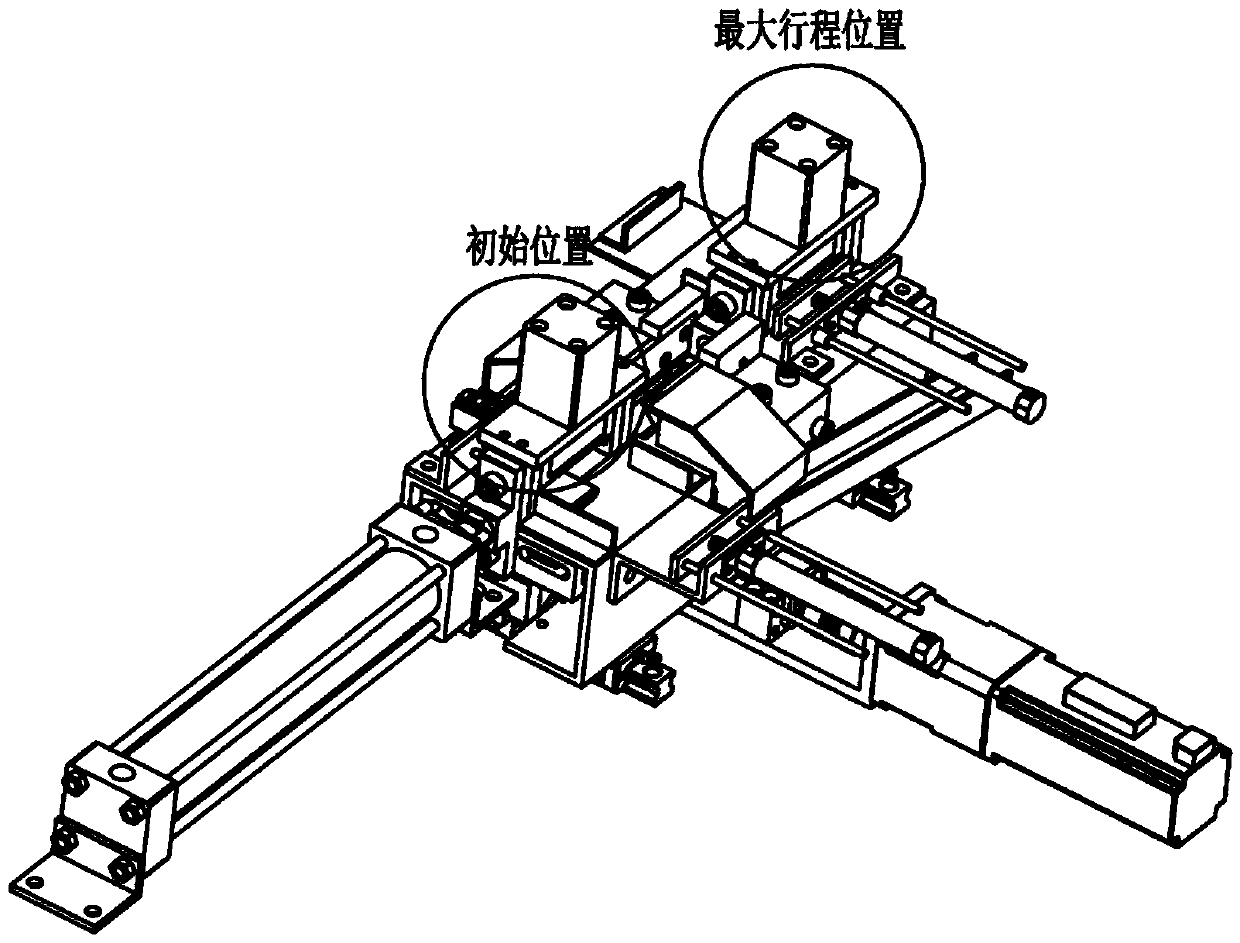

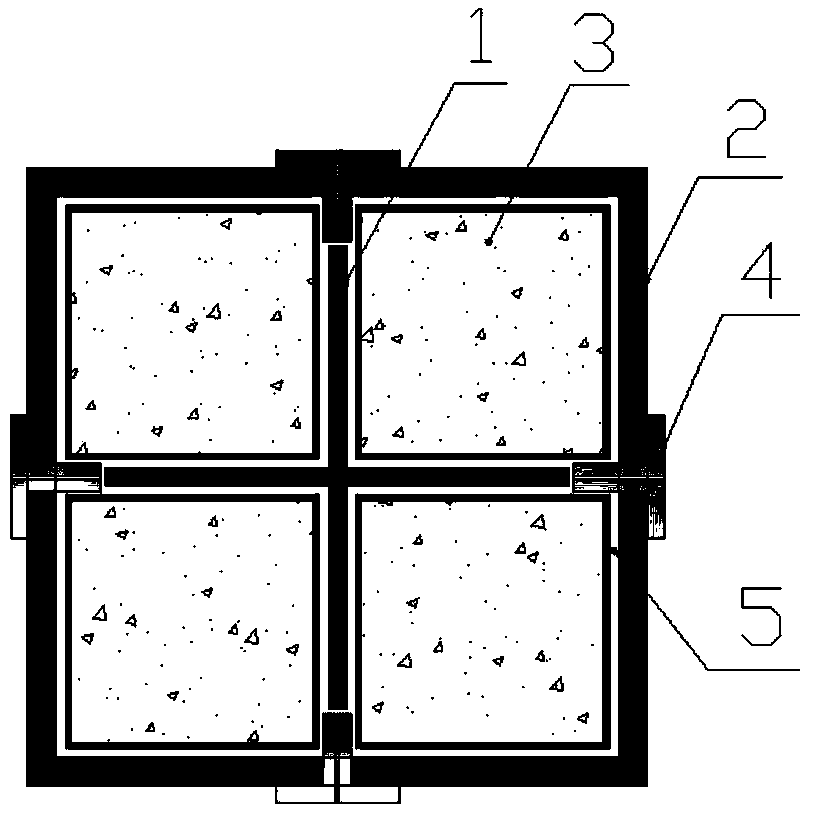

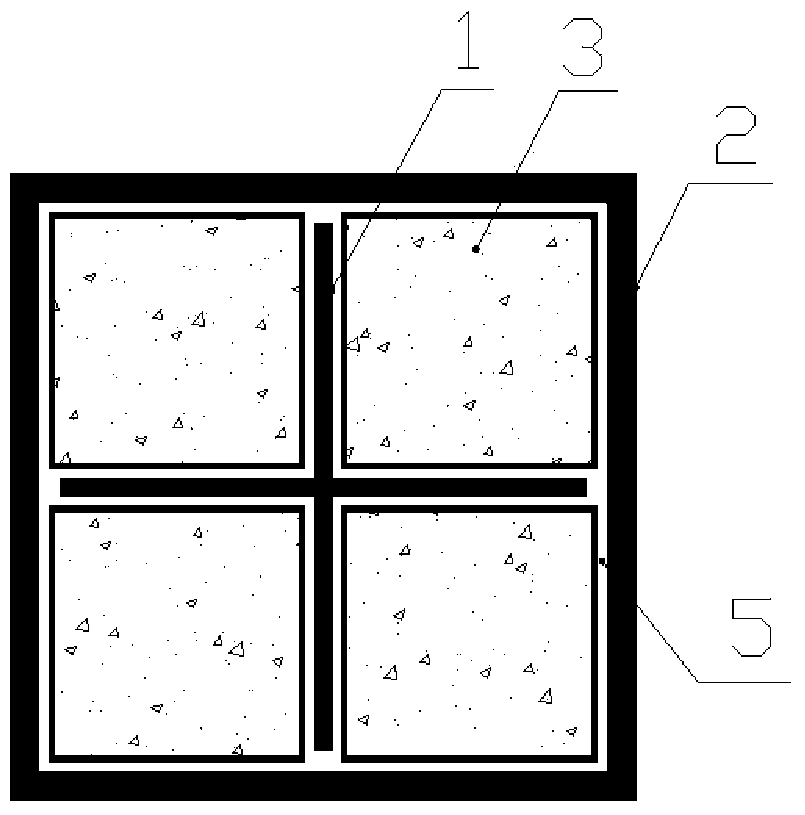

Device and method for disassembling square lithium ion batteries of multiple specifications

ActiveCN109672003AHigh degree of automationNo human intervention requiredSolid waste disposalTransportation and packagingControl systemAssembly line

The invention discloses a device and a method for disassembling square lithium ion batteries of multiple specifications. The device comprises a control system and an assembly line type disassembling system. The assembly line type disassembling system comprises an intermittent feeding device (1), a first automatic edge cutting device (2), a station conversion device (3), a second automatic edge cutting device (4) and a separating and core taking device (5). The control system controls all parts of the disassembling system to conduct the assembly line type operation. The intermittent feeding device conveys waste lithium ion batteries to the first automatic edge cutting device to complete the edge cutting operation on the two symmetrical sides of the batteries. The station switching device rotates the cut batteries by 90 degrees and conveys the cut batteries to the second automatic edge cutting device to complete the edge cutting operation on the other two sides of the batteries. The separating and core taking device separates and collects upper and lower meter shells and battery cells. The lithium ion battery disassembling device is high in automation degree and high in adaptability.The discharging and safety problems in the lithium ion battery disassembling process are effectively guaranteed in a knife-cutting disassembling mode. The separation of a battery cell and a battery shell is achieved to the maximum extent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Bending-prevention limiting energy-dissipation supporting component with steel pipe with baffles inside and cross-shaped inward contracting type variable-section steel core

InactiveCN103711219ATake full advantage of axial stiffnessImprove performanceShock proofingSteel tubeEngineering

The invention discloses a bending-prevention limiting energy-dissipation supporting component with a steel pipe with baffles inside and a cross-shaped inward contracting type variable-section steel core, and belongs to the technical field of bending-prevention limiting energy-dissipation supporting components. The cross-shaped steel core sequentially includes a non-variable-section section a, section-decreasing sections b and a connecting section c from the two ends to the middle, wherein the non-variable-section section a is located between the two section-decreasing sections b, the section-decreasing sections b are near the two ends of the external limiting steel pipe respectively, limiting grooves correspond to the section-decreasing sections b of the cross-shaped steel core, a T-shaped-section baffle is welded to each limiting groove, a wing edge plate of each T-shaped-section baffle is welded to the outer surface of the outer limiting steel pipe, a web plate is vertically inserted into each limiting groove, an interval is reserved between each web plate with and each section-decreasing section b of the cross-shaped steel core, the two ends of each section-decreasing section b of the cross-shaped steel core contracts inwards at the rope angle of 60 degrees, the end of the web plate of each T-shaped-section baffle also contracts inwards at the rope angle of 60 degrees and is parallel with the ends of the section-decreasing sections b of the steel core. The bending-prevention limiting energy-dissipation supporting component with the steel pipe with the baffles inside and the cross-shaped inward contracting type variable-section inner core can be widely applied to energy dissipation, seismic mitigation and limiting control of a building.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com