Automatic production line for producing high-strength color coated package steel strip by utilizing non-tempering process

An automated production line and high-strength technology, applied in the direction of surface coating liquid devices, coatings, manufacturing tools, etc., can solve the problems of not disclosing the composition of production equipment, etc., to facilitate packaging operations, increase product added value, reduce The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

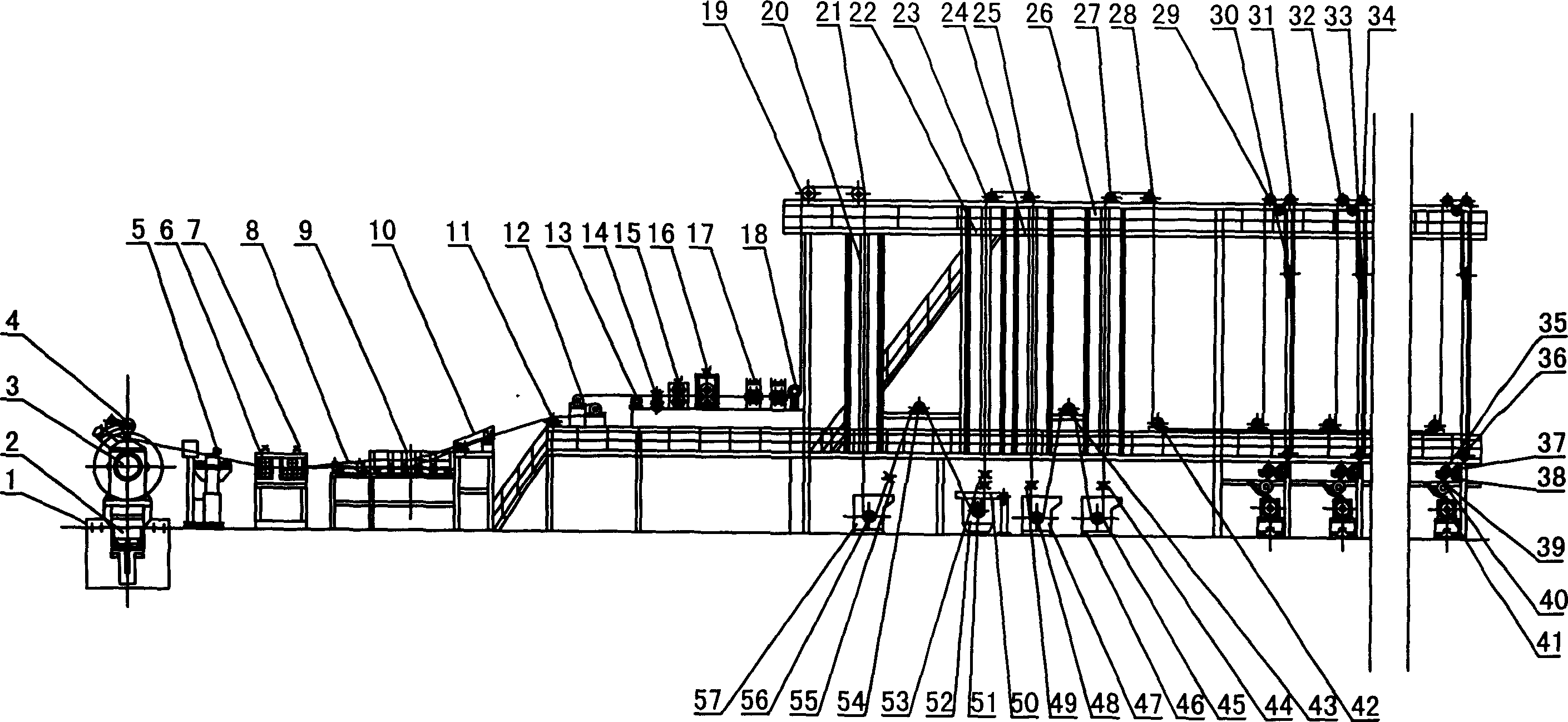

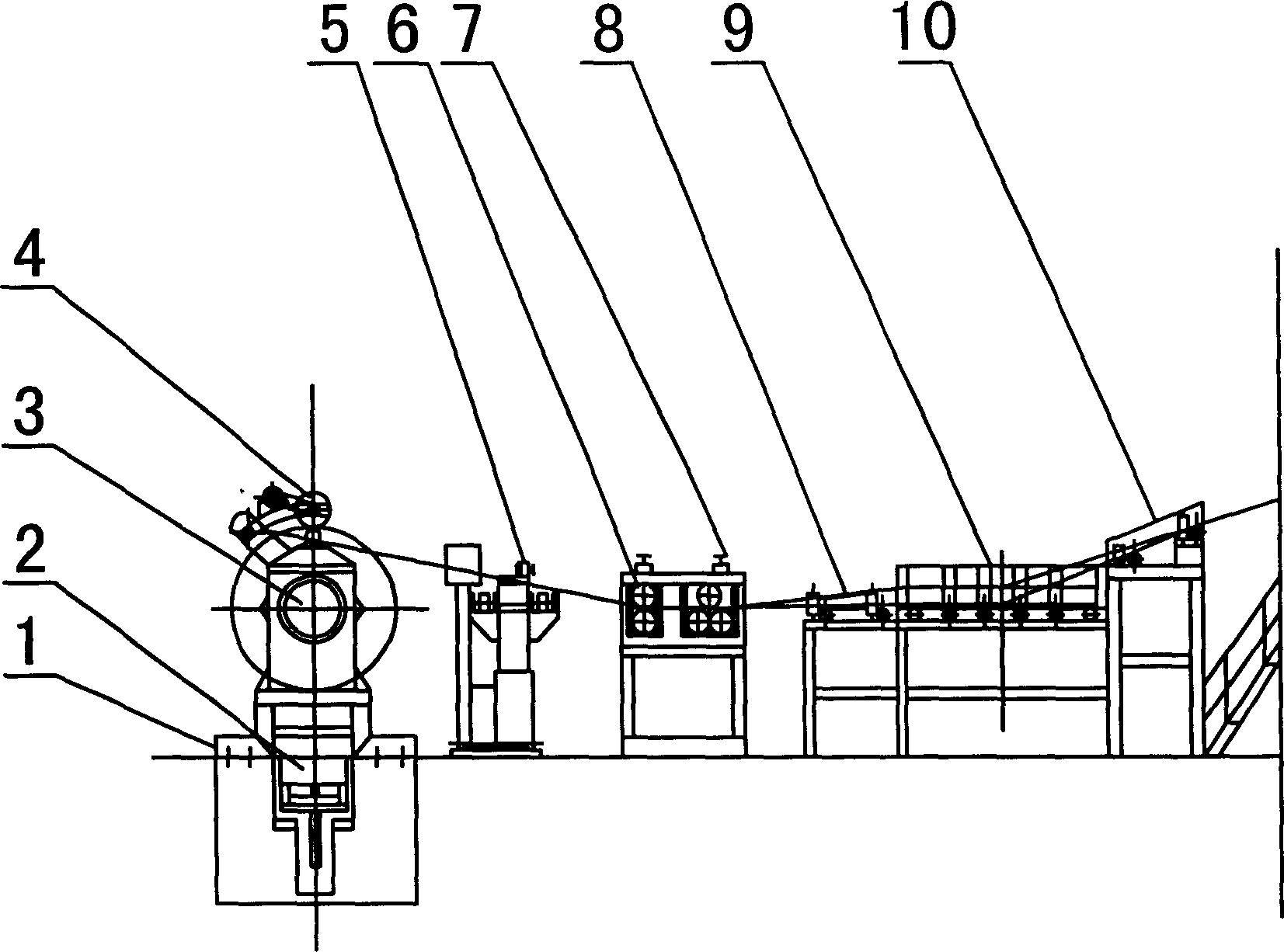

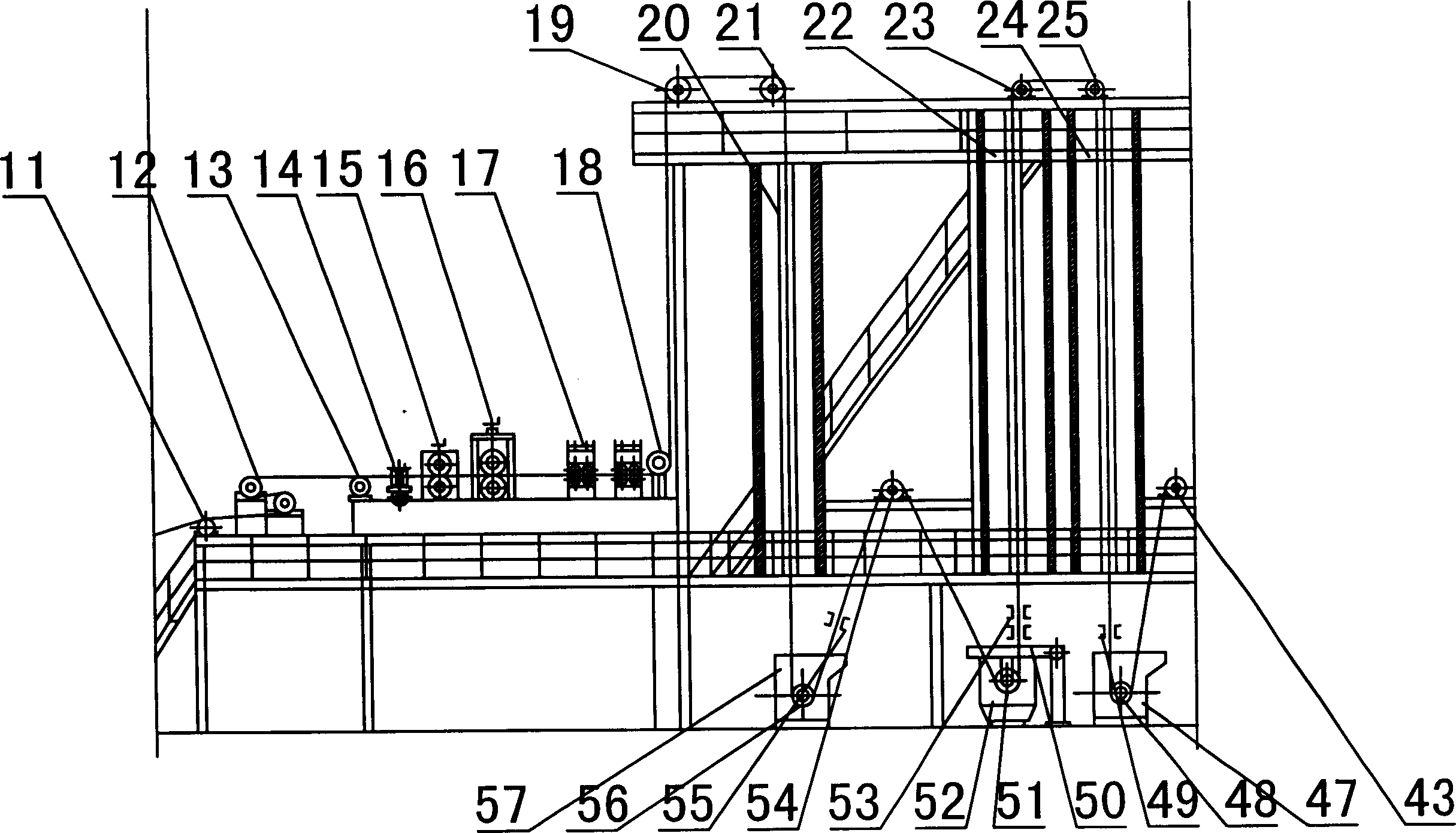

[0032] Such as figure 1 As shown, the production line of the present invention includes unwinding equipment, slitting unit, coating equipment, independent gravity looper unit, and finished product winding and packaging equipment, and is characterized in that the production line includes the following equipment arranged successively: tension unwinding unit, Strip welding machine 5, feeding roller 6, skin pass machine 7, storage bin 9, tension speed control S roller unit, longitudinal shearing unit, trimming machine 17, heating furnace 20, first cooling tank 57, coating tank 52. Paint drying furnace 22, 24, second cooling tank 47, wax or oil tank 46, drying tower 26, differential tension speed control S roller unit, independent gravity looper unit, winding unit, packaging and transportation unit, PLC It is connected with the control devices...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com