Patents

Literature

61results about How to "Rounded edges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for the semiconductor pipe core assembly crystal surface

InactiveCN101017773AEliminate tip dischargeImprove electrical performanceSemiconductor/solid-state device manufacturingIonHeavy metals

The related process method for grain surface in semiconductor die assembly comprises: inserting the target assembly into the cleaning tank, pouring corrosive agent into tank to remove the organic sewage on objective surface in 1-10min; inclining the tank to pour out the agent and fast clean the objective with deionized water; in turn, pouring the first cleaning agent into the tank to remove the metal ion and organic and form oxidation layer in 1-5min, then pouring out the agent and cleaning fast with deionized water; pouring the second cleaning agent in tank to remove heavy metal ion and organic in 1-5min, then pouring out the agent and cleaning fast with deionized water; finally, using ultrasonic wave to clean and dry the objective. This invention is low cost and benefit to improve semidiode performance.

Owner:江苏佳讯电子有限公司 +2

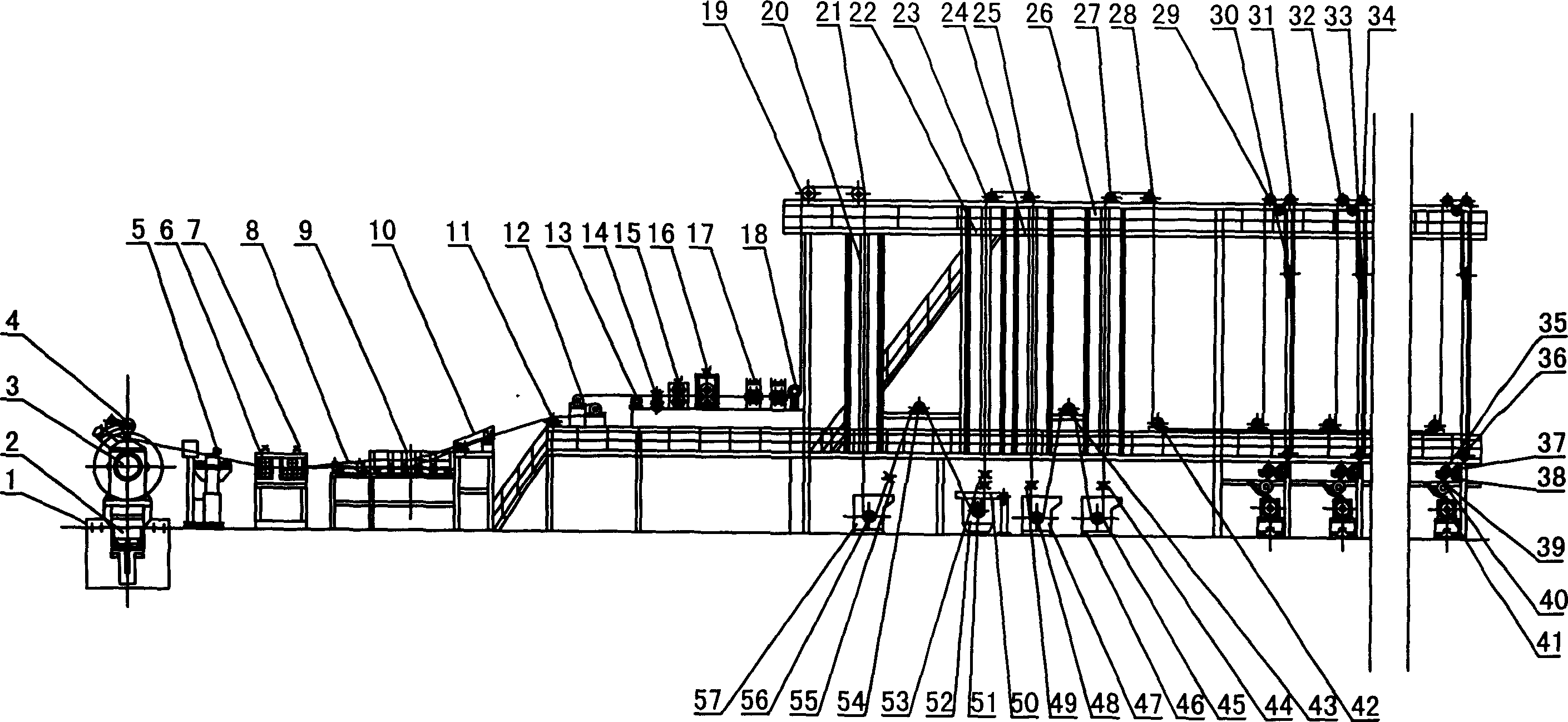

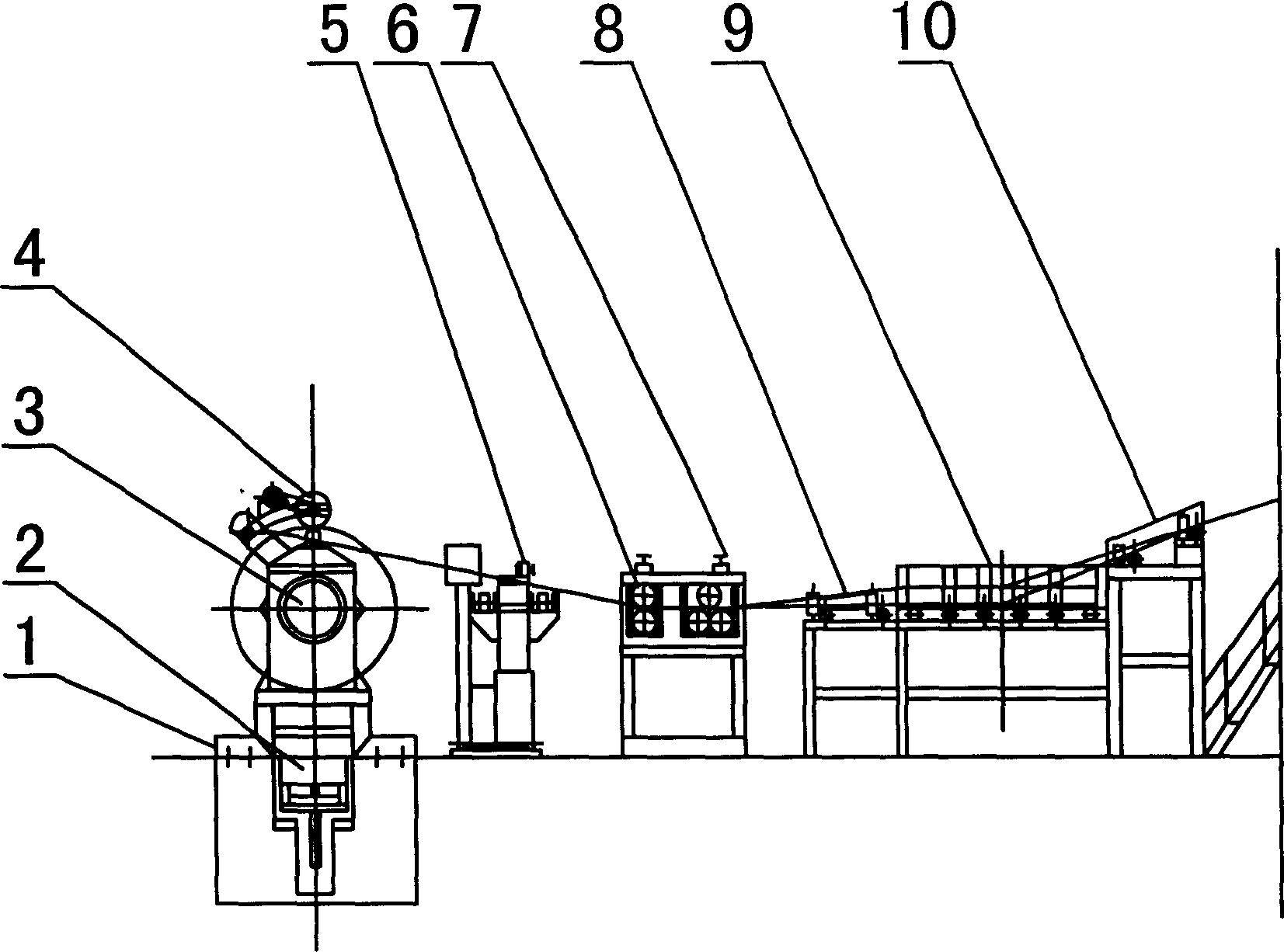

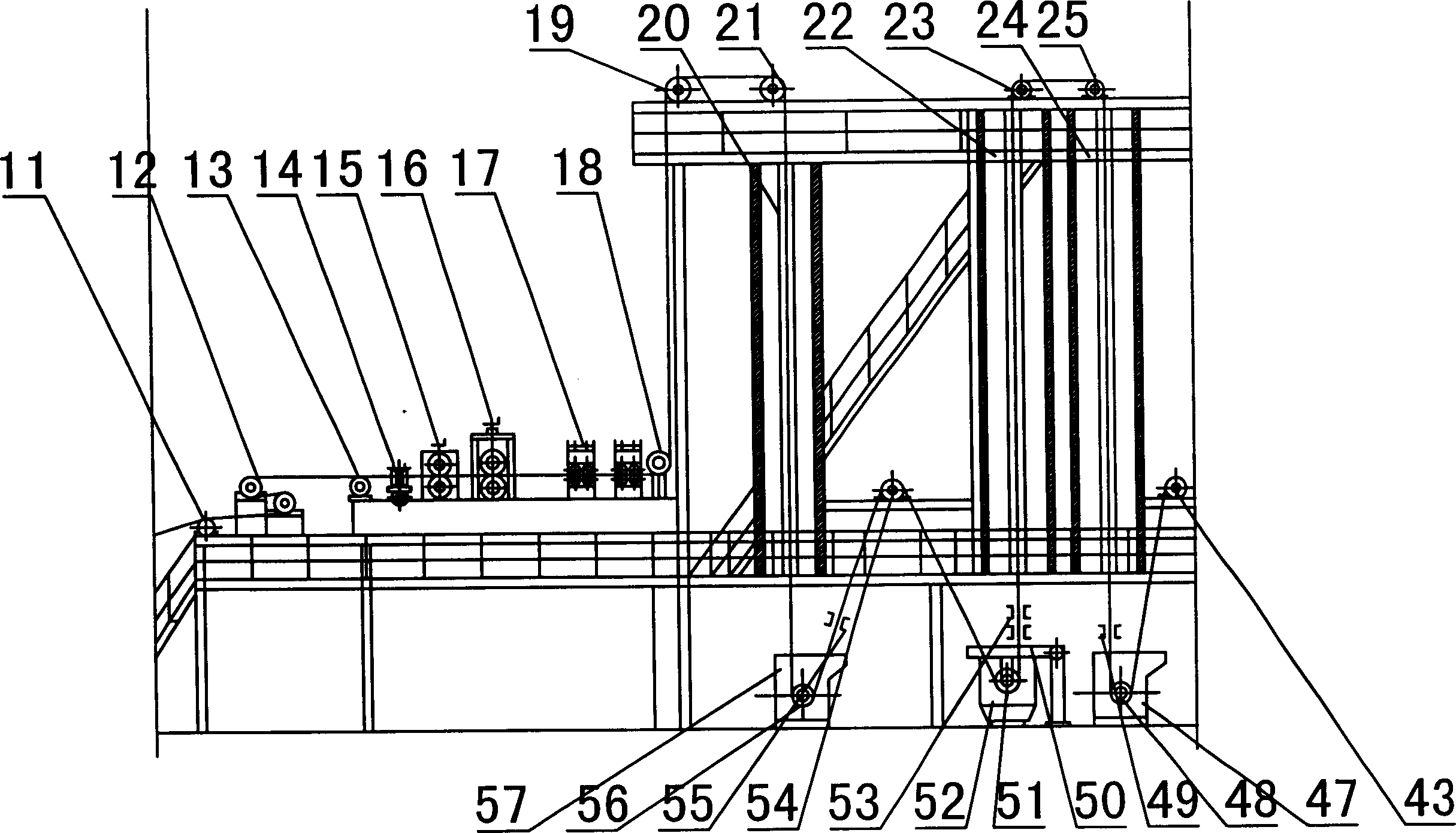

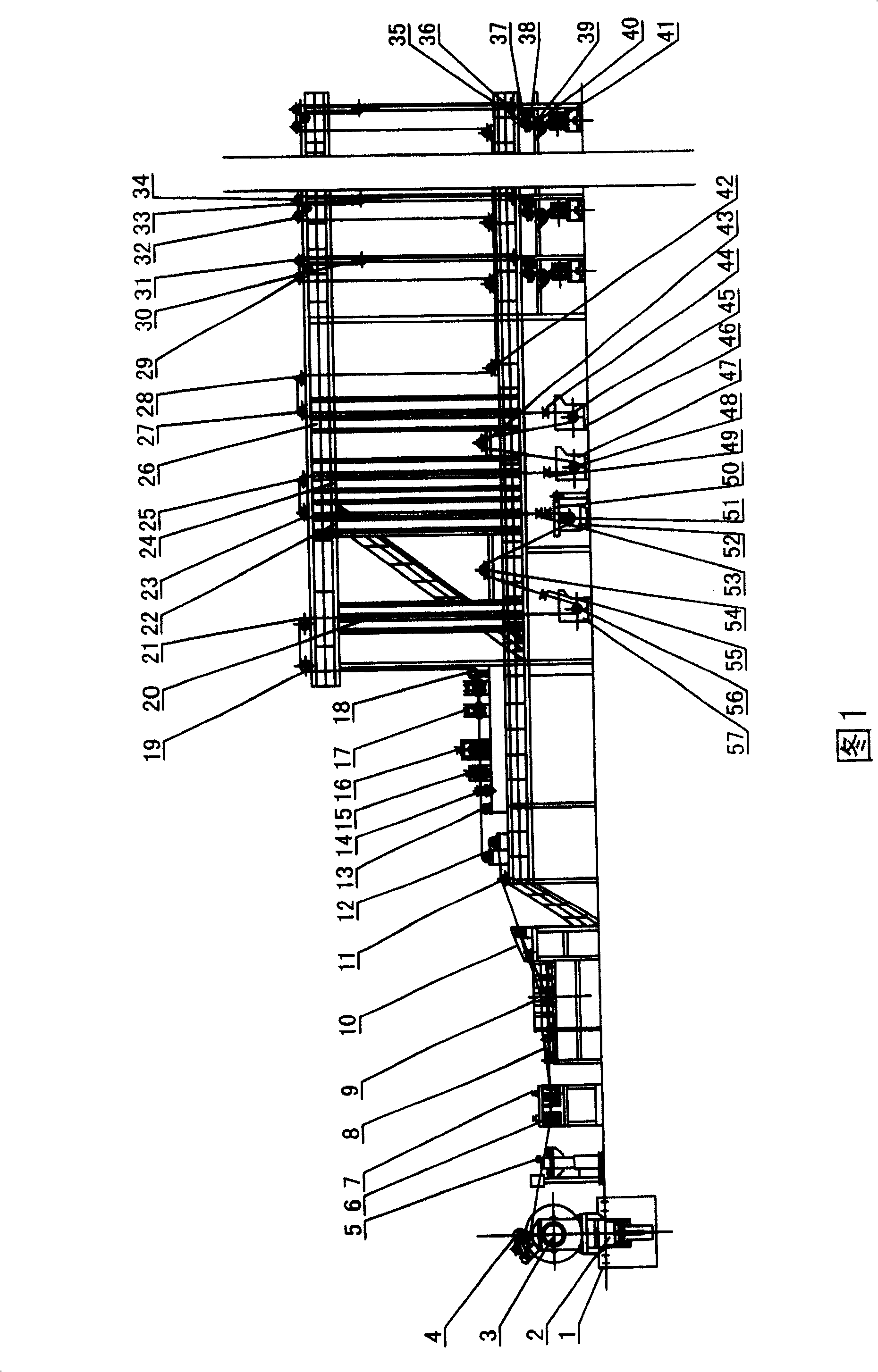

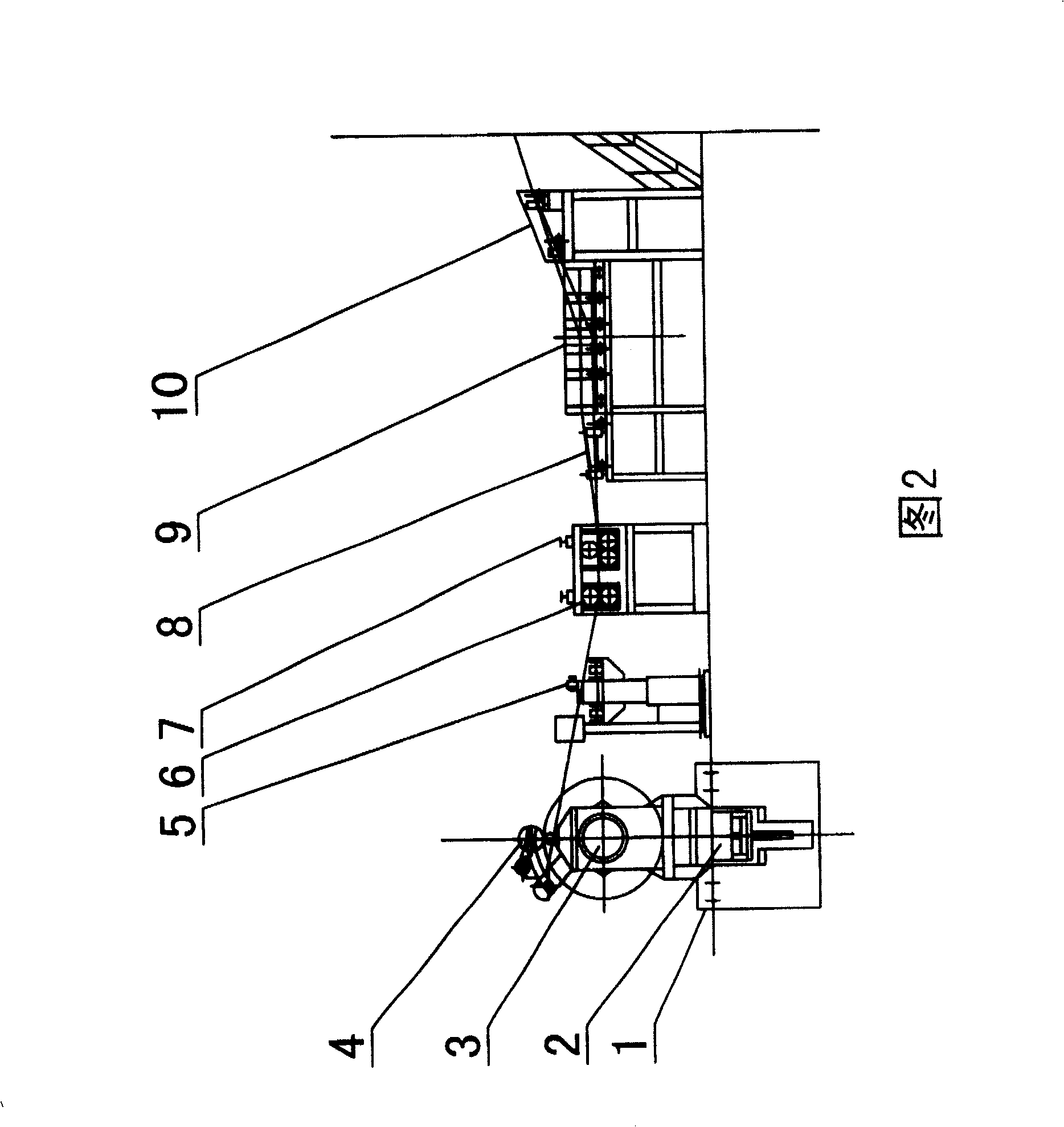

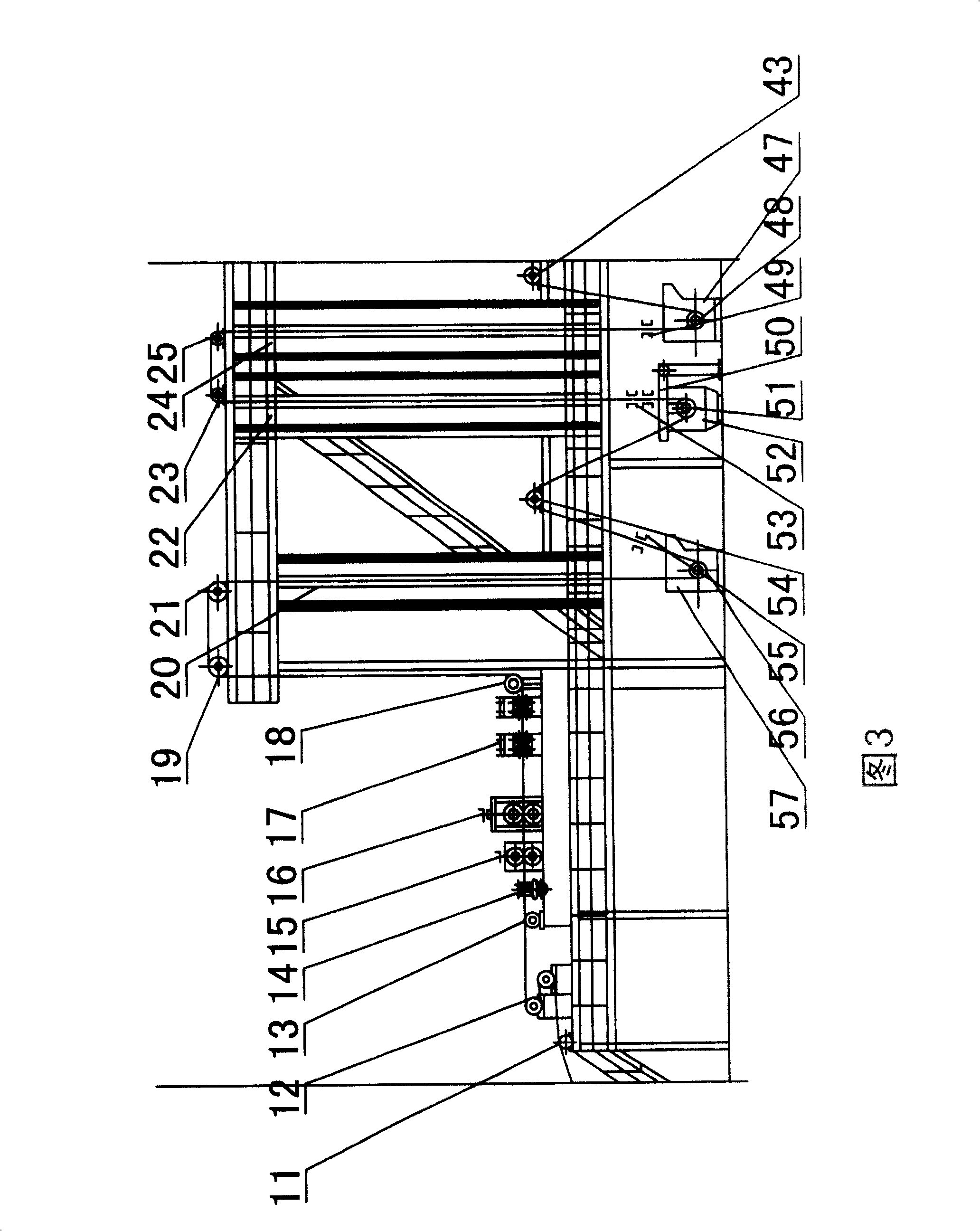

Automatic production line for producing high-strength color coated package steel strip by utilizing non-tempering process

ActiveCN1807003ALess investmentUndiminished strengthLiquid surface applicatorsFurnace typesProduction lineWax

The invention relates the automatic production line producing high-strength colored paint package steel band with non tempering technology, comprising pull-type recoiler, bonding machine, feeding planisher, storage bin, tension speed control S roll units, slitting shears, flat edge trimmer, heating furnace, the first and second cooling trough, coating groove, coating drying furnace, wax or oil groove, drying powder, differential tension speed control S roll units, separate gravity loop units, roll-up units, shipping package units and automatic control system. The roll-up machine comprises adjusting wheel, pressing wheel, nylon wheel, and air-actuated cut, correcting wheel, material received reel and dummy car. The production line makes the whole industrial process on the one production line, and the metallurgical structure of steel band comprises pearlyte and ferrolites. Compared with high-strength package steel band production line at home and abroad, the said production line reduces the cost of manufacture by 40% and equipment investment by 90%.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

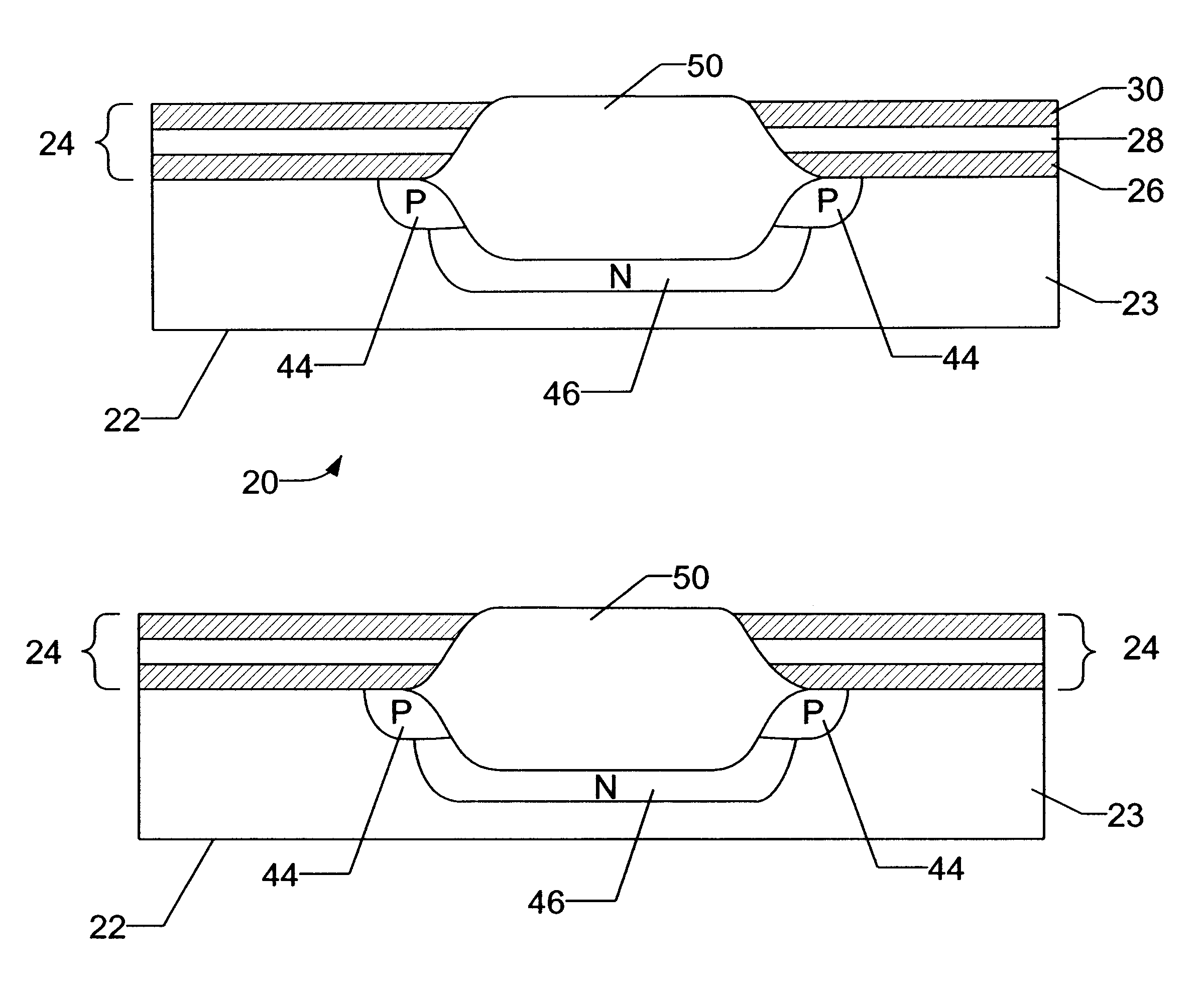

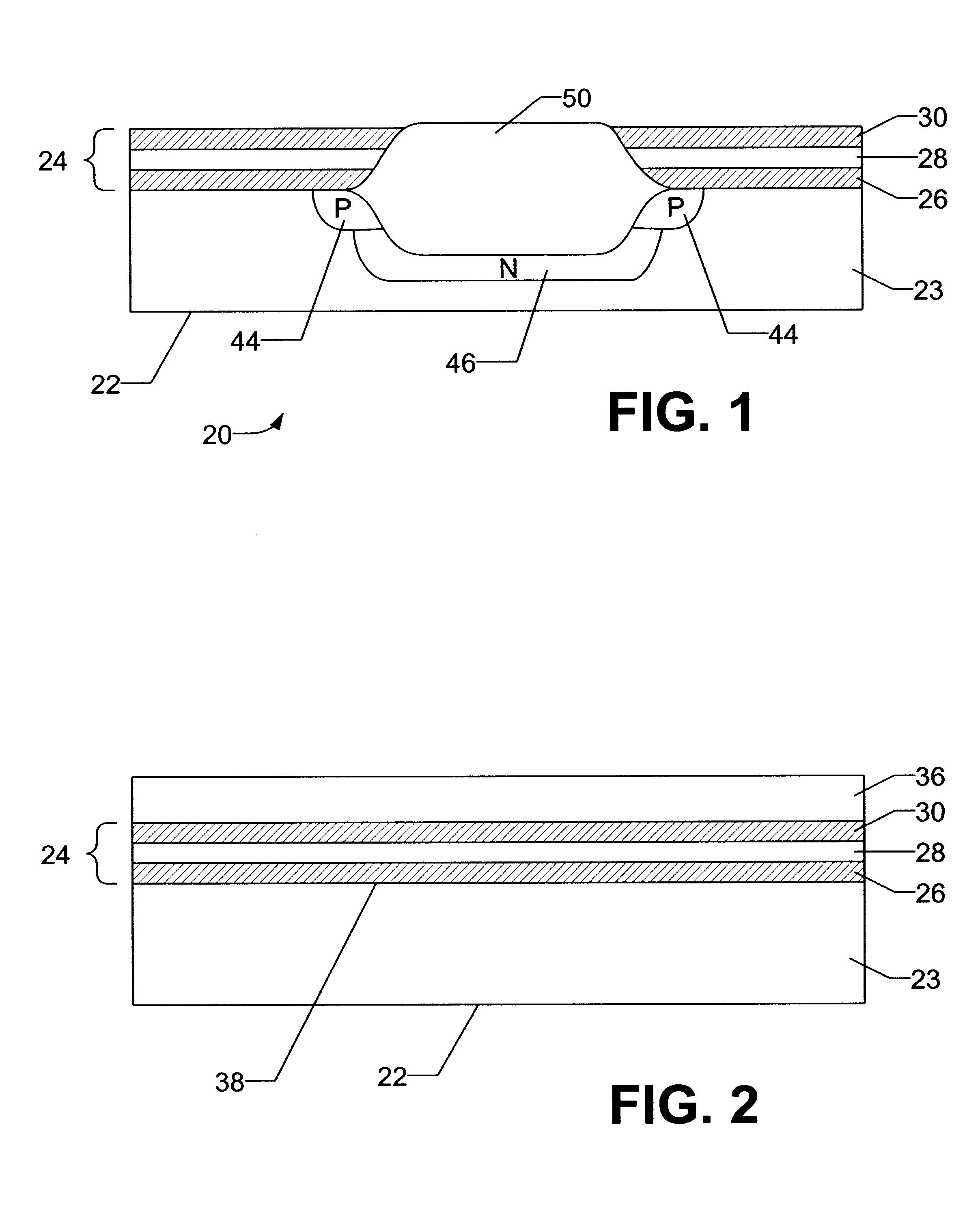

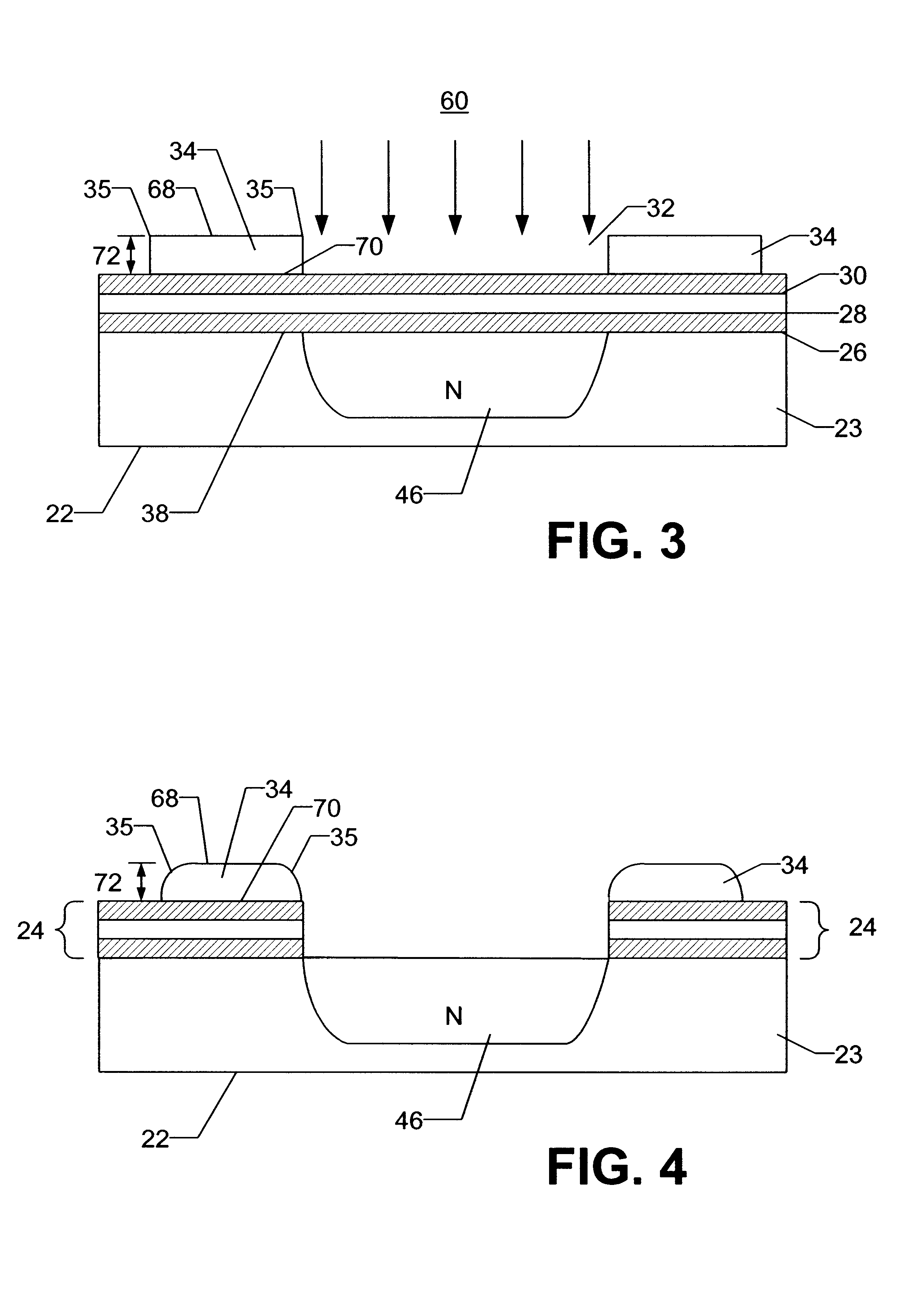

Use of an etch to reduce the thickness and around the edges of a resist mask during the creation of a memory cell

InactiveUS6362052B1Easy to controlReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingResistDopant

A process for fabricating a memory cell, the process includes forming an ONO layer overlying a semiconductor substrate, depositing a resist mask overlying the ONO layer, patterning the resist mask, implanting the semiconductor substrate with an n-type dopant, wherein the resist mask is used as an ion implant mask, and etching the resist mask upon implanting the semiconductor substrate with an n-type dopant. In one preferred embodiment, the etching of the resist mask includes performing a blanket anisotropic etch to reduce the thickness of the resist mask and round the edges of the resist mask. Preferably, the blanket anisotropic etch is performed using an etch including an element selected from the group consisting of nitrogen, hydrogen, chlorine, and helium.

Owner:SPEARHEAD IP LLC

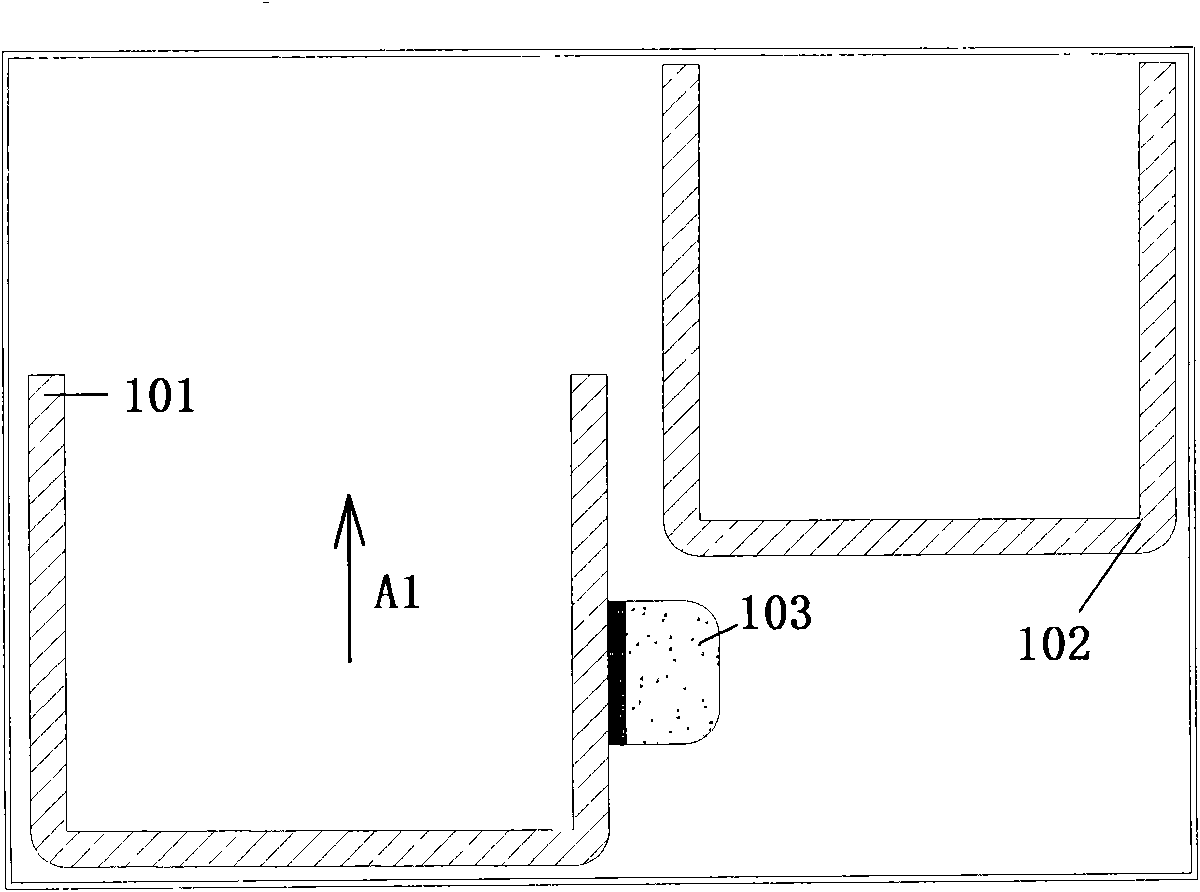

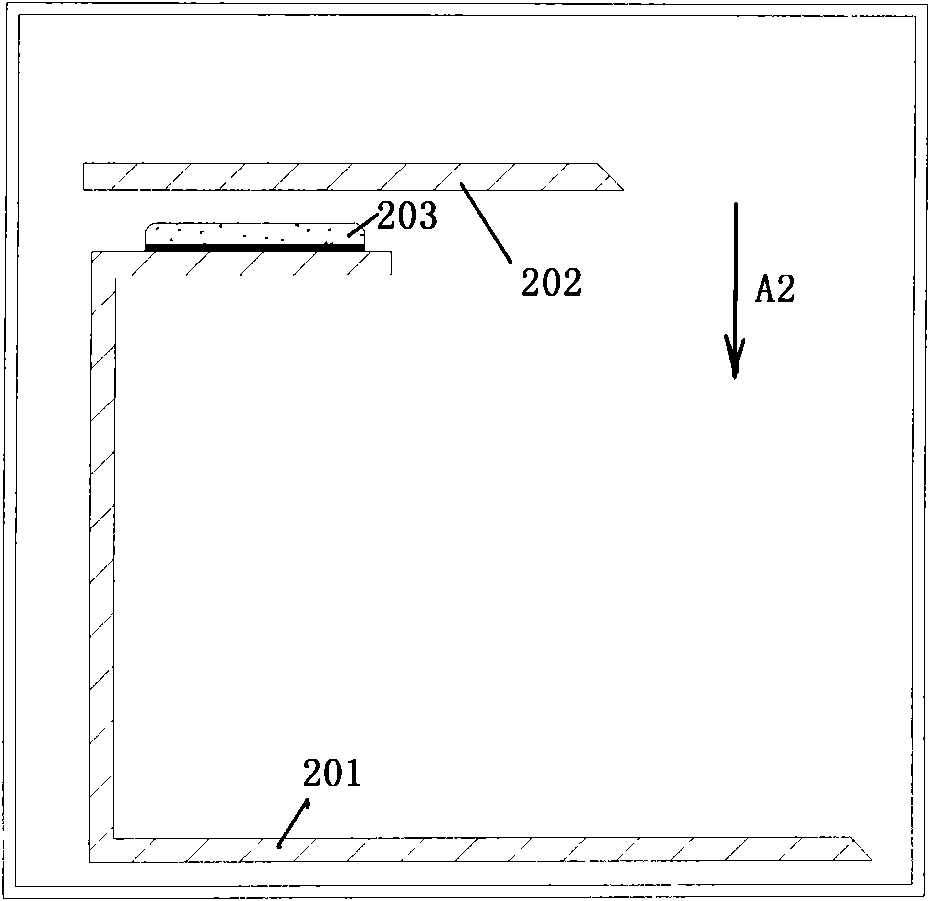

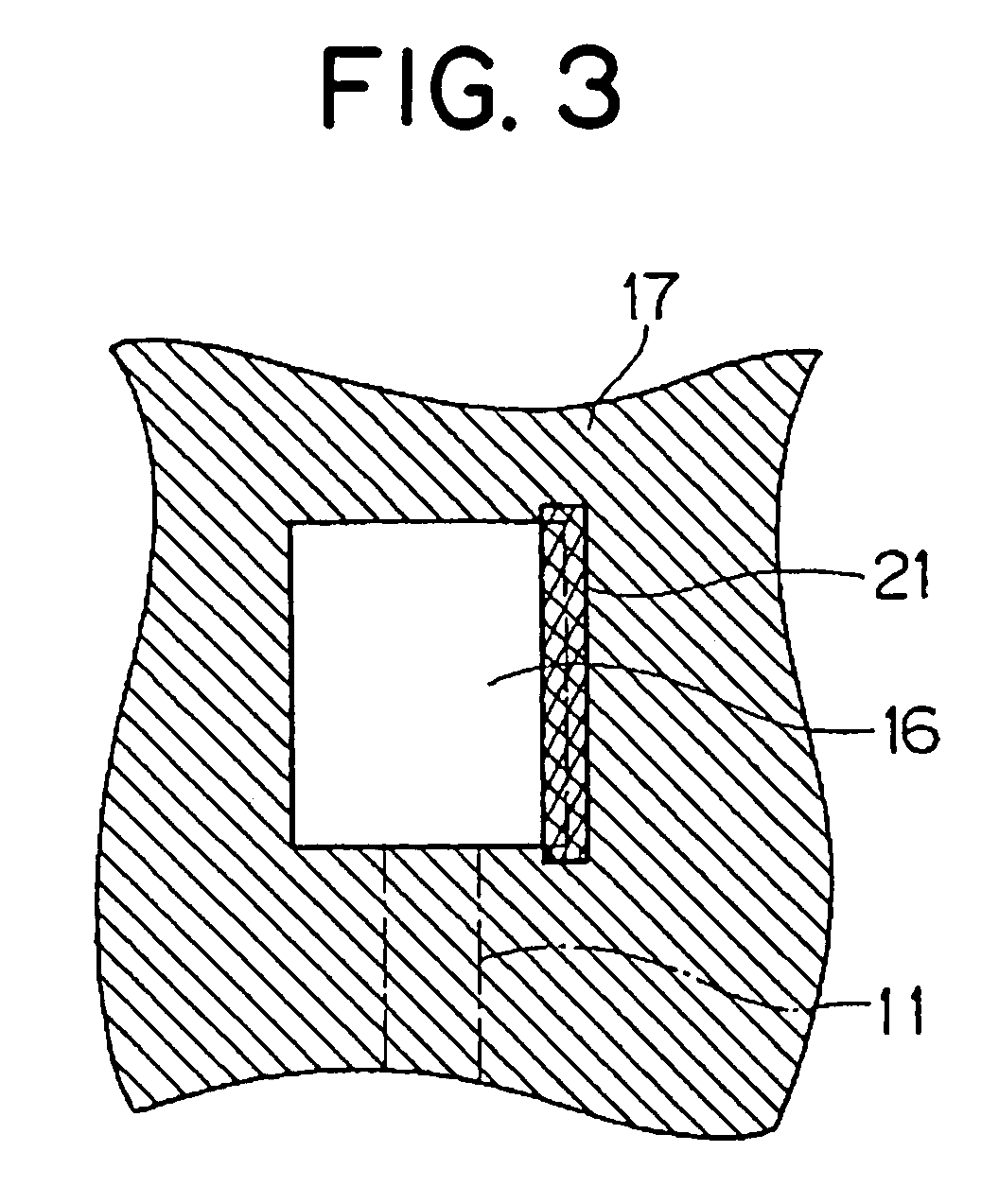

Structure for electromagnetic shielding between panels and manufacturing method thereof

ActiveCN101600330AQuality improvementLow costMagnetic/electric field screeningCasings/cabinets/drawers detailsElectromagnetic shieldingEngineering

The invention discloses a structure for electromagnetic shielding between panels, which comprises a first panel, a second panel and an electromagnetic shielding piece arranged between the first panel and the second panel, wherein the first panel and the second panel are oppositely arranged; the first panel is provided with a groove, and the electromagnetic shielding piece is accommodated in the groove. In addition, the invention provides a method for forming the electromagnetic shielding structure between the panels, which comprises the following steps: arranging the opposite first panel and second panel; arranging the groove on one side of the first panel opposite to the second panel; and arranging the electromagnetic shielding piece in the groove. The structure and the method for the electromagnetic shielding between the panels reduce the production cost and enhance the panel connection strength of the electromagnetic shielding structure, thus a device utilizing the electromagnetic shielding structure can be more attractive and safer to operators.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

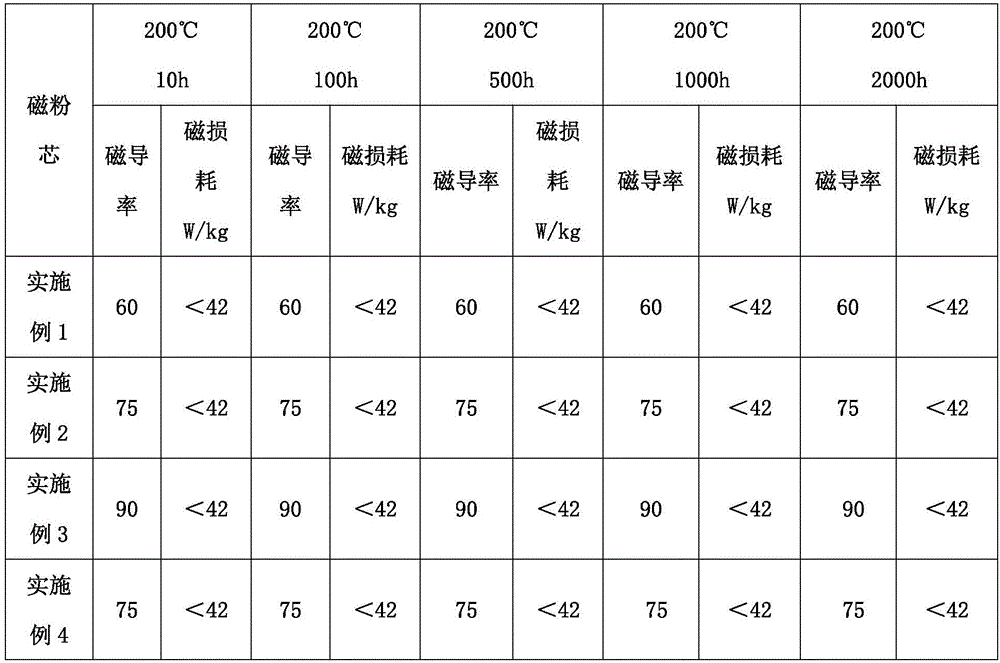

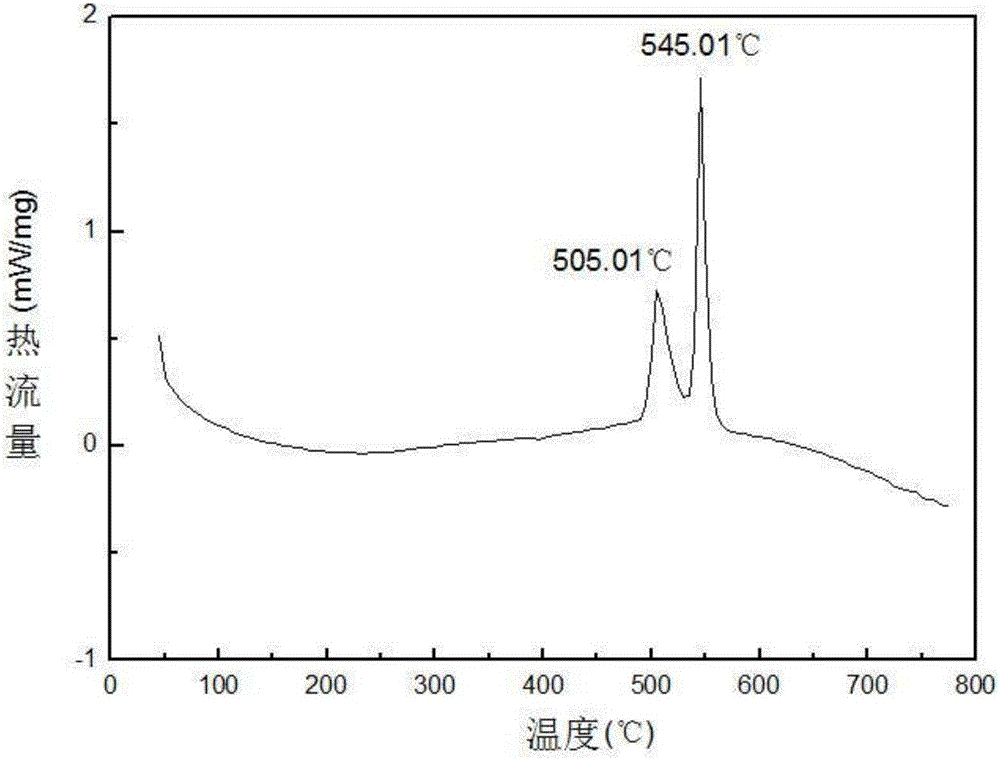

Amorphous soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN106205935AGood calenderabilityExcellent magnetic propertiesTransportation and packagingMetal-working apparatusMagnetic powderPrecursor polymer

The invention belongs to the field of a metal-based soft magnetic composite material. A preparation method comprises the following steps of preparing amorphous alloy powder from an amorphous alloy thin strip; screening and compounding the amorphous alloy powder to obtain a first product; performing passivation and coupling processing on the first product to obtain a second product; mixing and stirring the second product and a ceramic precursor polymer solution to obtain composite amorphous powder; and performing formation, thermal processing and insulation layer coating on the composite amorphous powder to obtain amorphous soft magnetic composite magnetic powder. By adopting a ceramic precursor polymer as an insulation binding agent, the step of adding insulation agent powder is omitted, the problems of unstable magnetic conductivity and poor thermal stability during traditional preparation of the magnetic powder core by crashing the amorphous thin strip are solved, the production cost is reduced, and the amorphous soft magnetic composite magnetic powder can be applied to a certain electronic device with application requirements for high frequency and low loss.

Owner:张听

Edge finishing method of capacitive touch screen

ActiveCN102063233ARounded edgesSleek shapeInput/output processes for data processingCapacitanceEngineering

The invention relates to an edge finishing method of a capacitive touch screen, comprising the steps of: respectively forming an inner protection layer and an outer protection layer at the inner and outer sides of an outer faceplate; grinding off the inner protection layer and the outer protection layer in the area of edges of the inner and outer sides of the outer faceplate by utilizing a grinding tool to form an uncovering area of the outer faceplate; and etching off partial outer faceplate material in the uncovering area by utilizing glass etching liquid to ensure that the edge of the outer faceplate is in a smooth shape through controlling etching quantity. In the invention, by means of the processing method, the edge of the outer faceplate of the capacitive touch screen has a smoother shape and the processing yield can be enhanced; the processing method is suitable for the processing of some thinner outer faceplates; moreover, the inner protection layer and the outer protection layer in the method can respectively serve as an anti-reflection optical layer and an anti-fingerprint coating to be reserved in an end product, thereby saving relevant processing steps.

Owner:SHANTOU GOWORLD DISPLAY

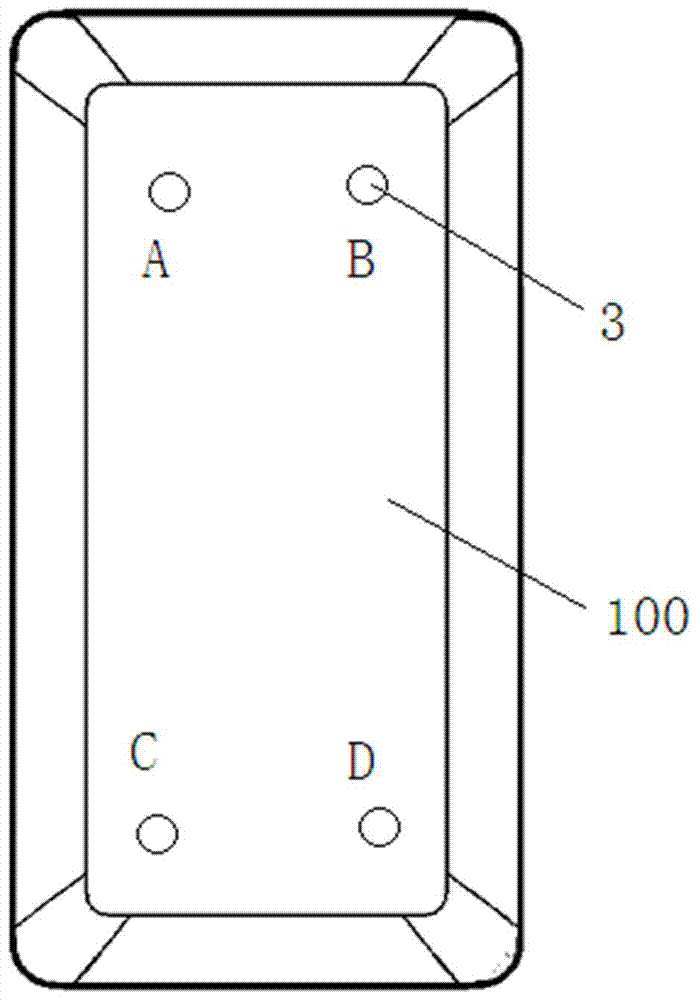

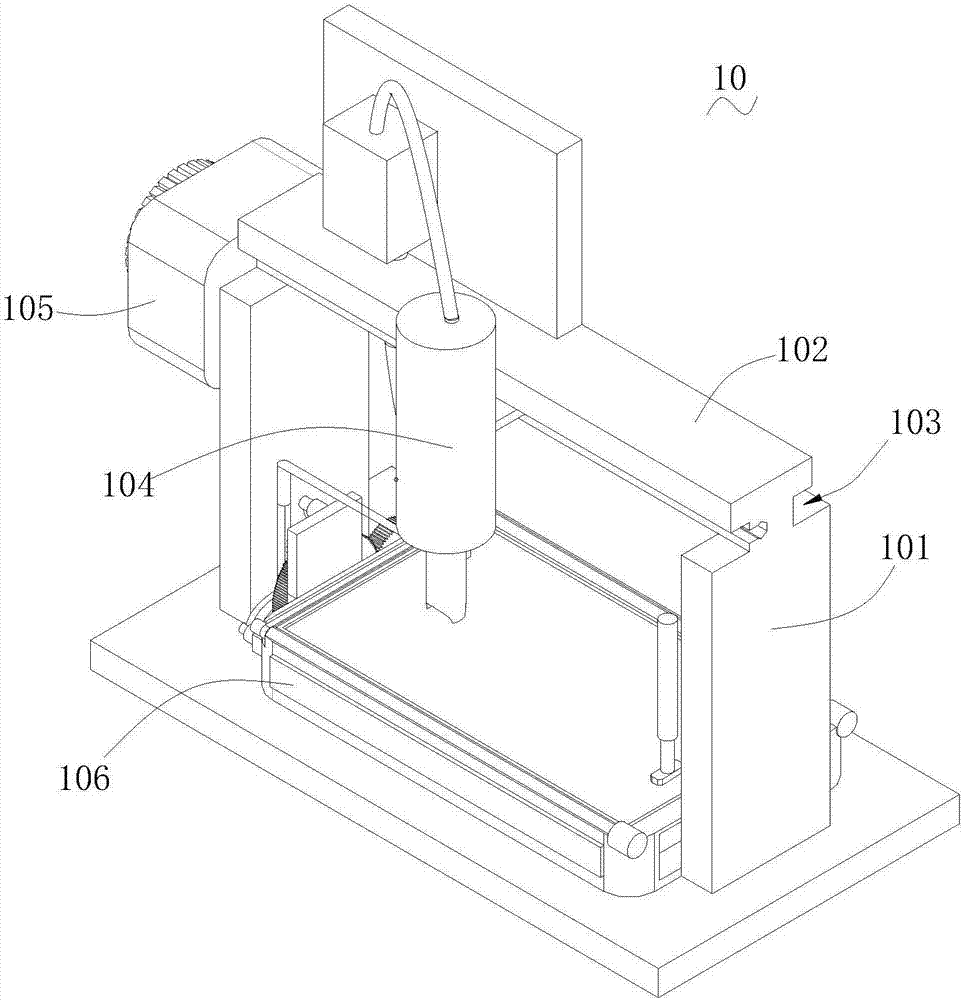

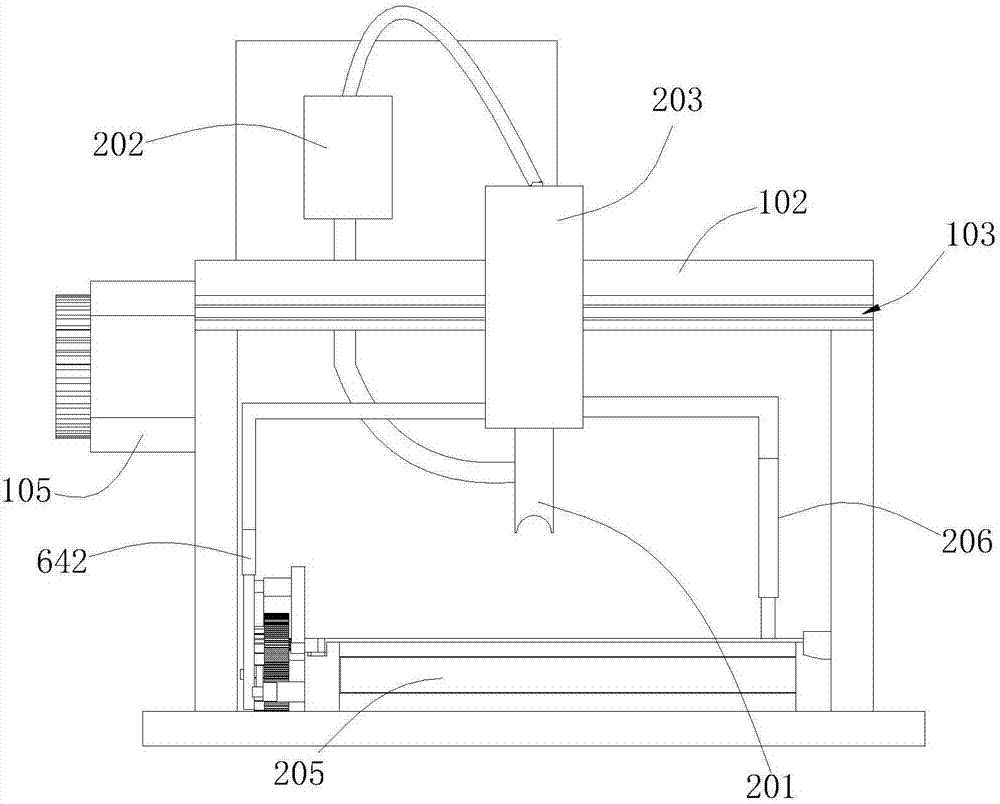

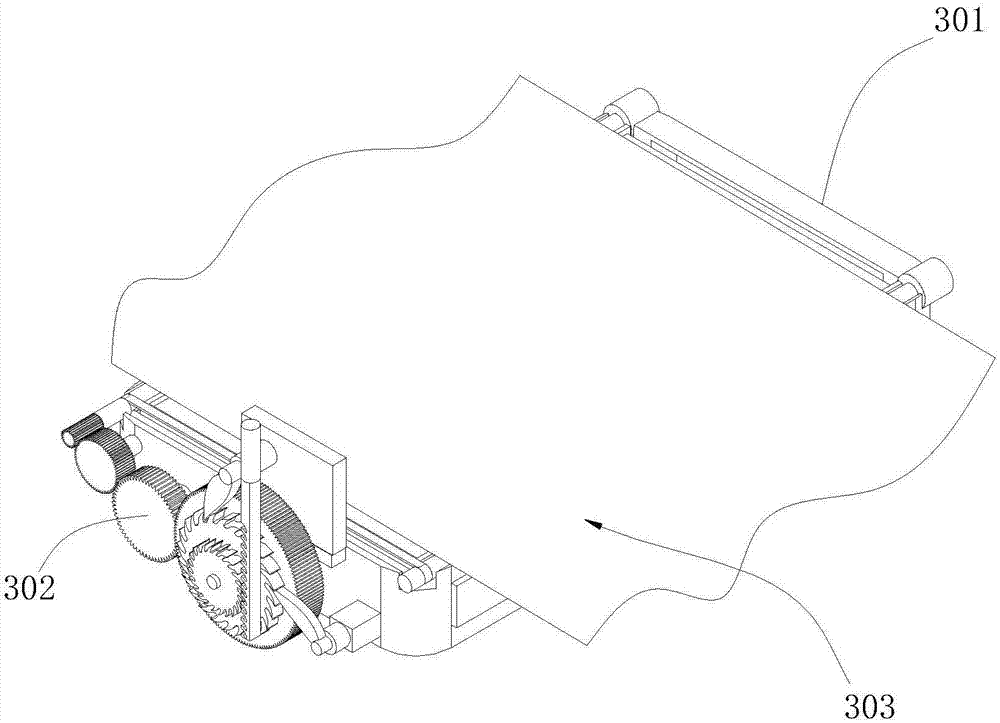

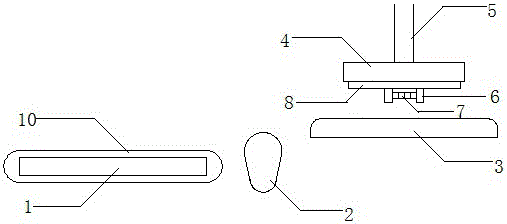

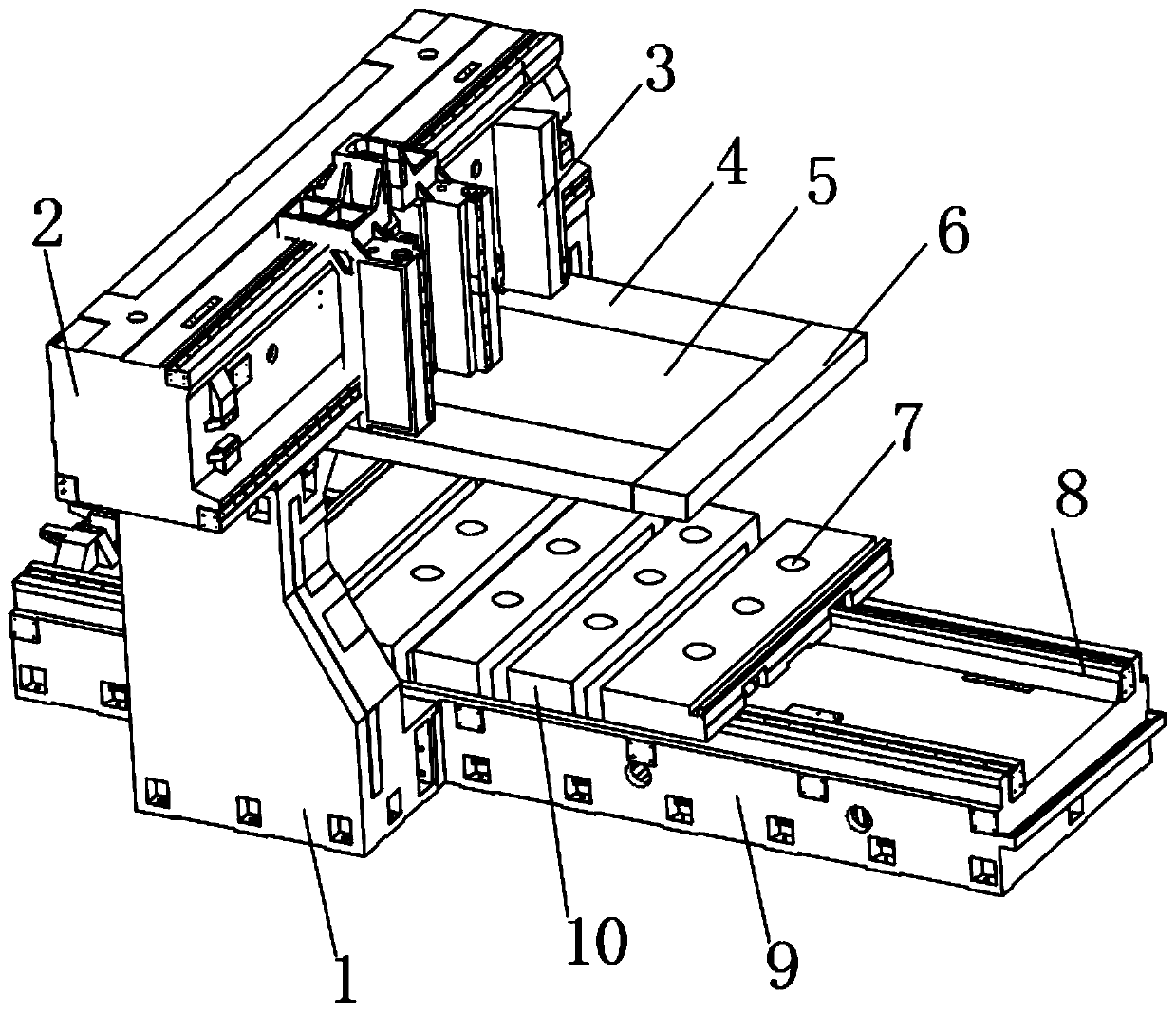

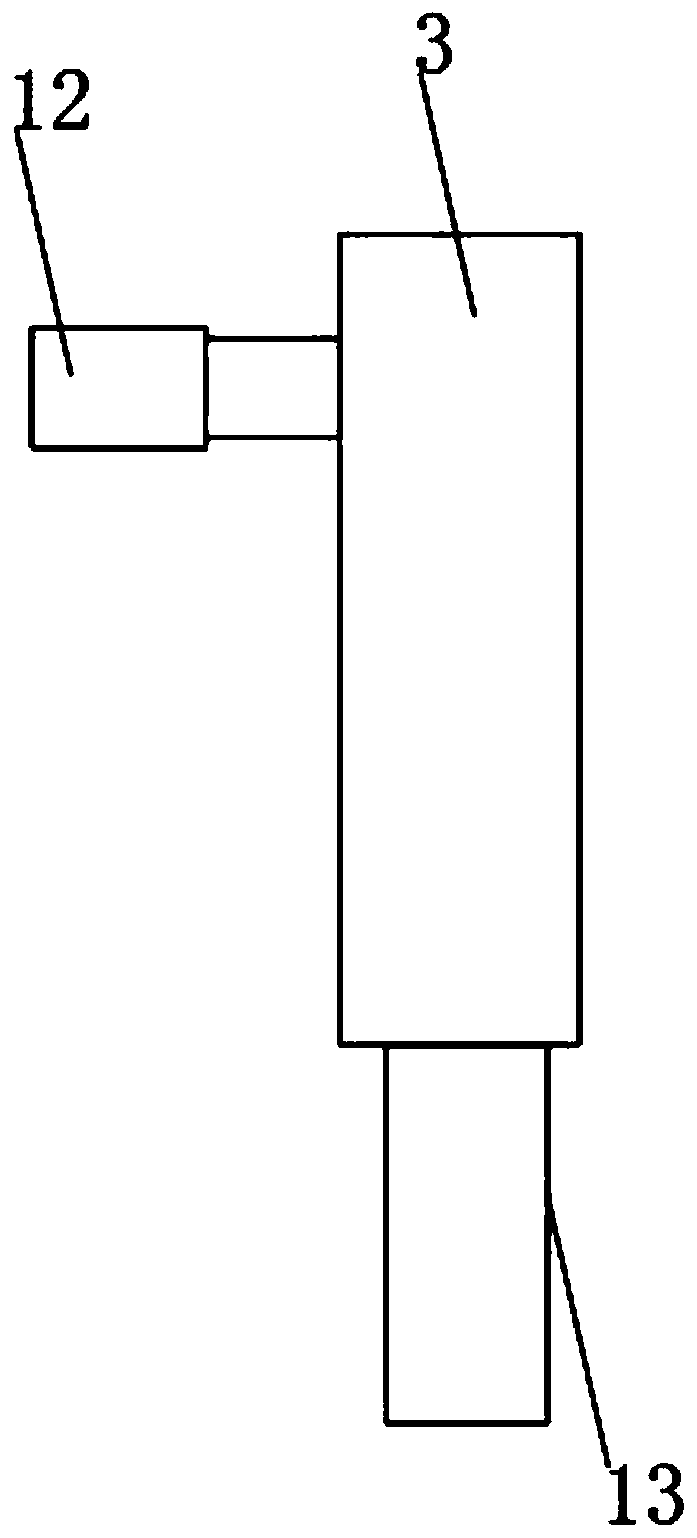

Mobile phone 3D glass positioning and processing system and method

InactiveCN107132813ASmooth edgesRounded edgesComputer controlSimulator controlNumerical controlMachine control

The invention relates to the technical field of mobile phone manufacturing and processing, and discloses a mobile phone 3D glass positioning processing system, including a CNC machine tool head, a probe and a CNC machine tool control unit. The mobile phone 3D glass is fixed on the processing table, and the probe is installed on the CNC machine tool. On the head, determine at least three thickness measurement positions on the surface of the 3D glass of the mobile phone. The control unit of the CNC machine tool controls the probe to probe at the thickness measurement position to obtain the average thickness of the 3D glass surface of the mobile phone and determine the processing amount. On the side of the 3D glass of the mobile phone Determine at least two positions in the edge direction, the control unit of the CNC machine tool controls the probe to detect the position in the direction of the edge, obtains the boundary line of the 3D glass of the mobile phone and determines the processing path, and the control unit of the CNC machine tool performs decrement machining according to the processing amount and the processing path . The invention also discloses a processing method using the above system. The invention makes the edge of the 3D glass smoother and rounder, and increases the precision and strength of the product.

Owner:浙江宇鑫光学科技有限公司

High-voltage tantalum powder and preparation method thereof

ActiveCN104209511AGood particle shapeImproved Leakage Current PerformanceElectrolytic capacitorsCapacitorParticle-size distribution

The invention belongs to the field of preparation of capacitor-level high-voltage tantalum powder and particularly relates to high-voltage tantalum powder and a preparation method thereof. The tantalum powder provided by the invention is spherical or ball-like tantalum powder, is round in corner angle, uniform in particle size distribution, relatively small in leakage current and high in breakdown voltage, and can be applied under a relatively high voltage.

Owner:NINGXIA ORIENT TANTALUM IND +1

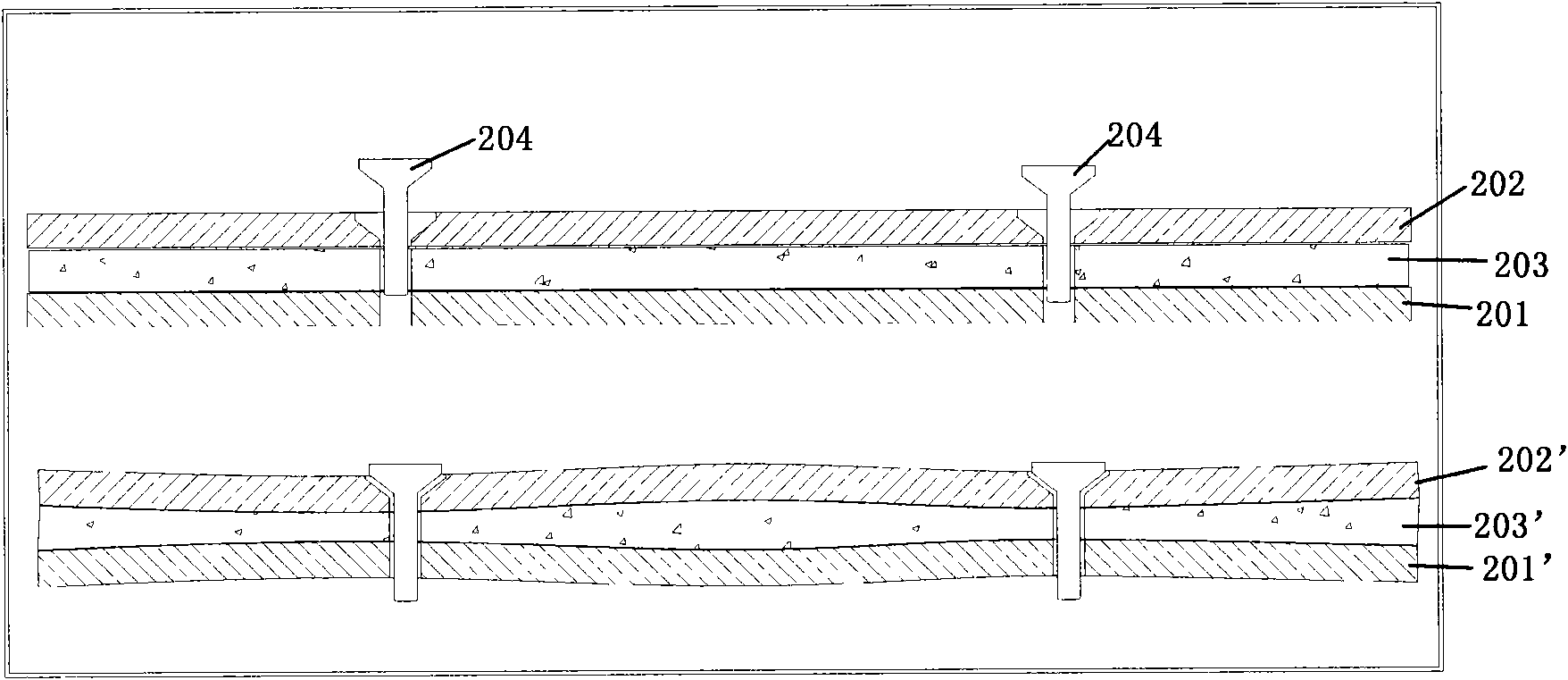

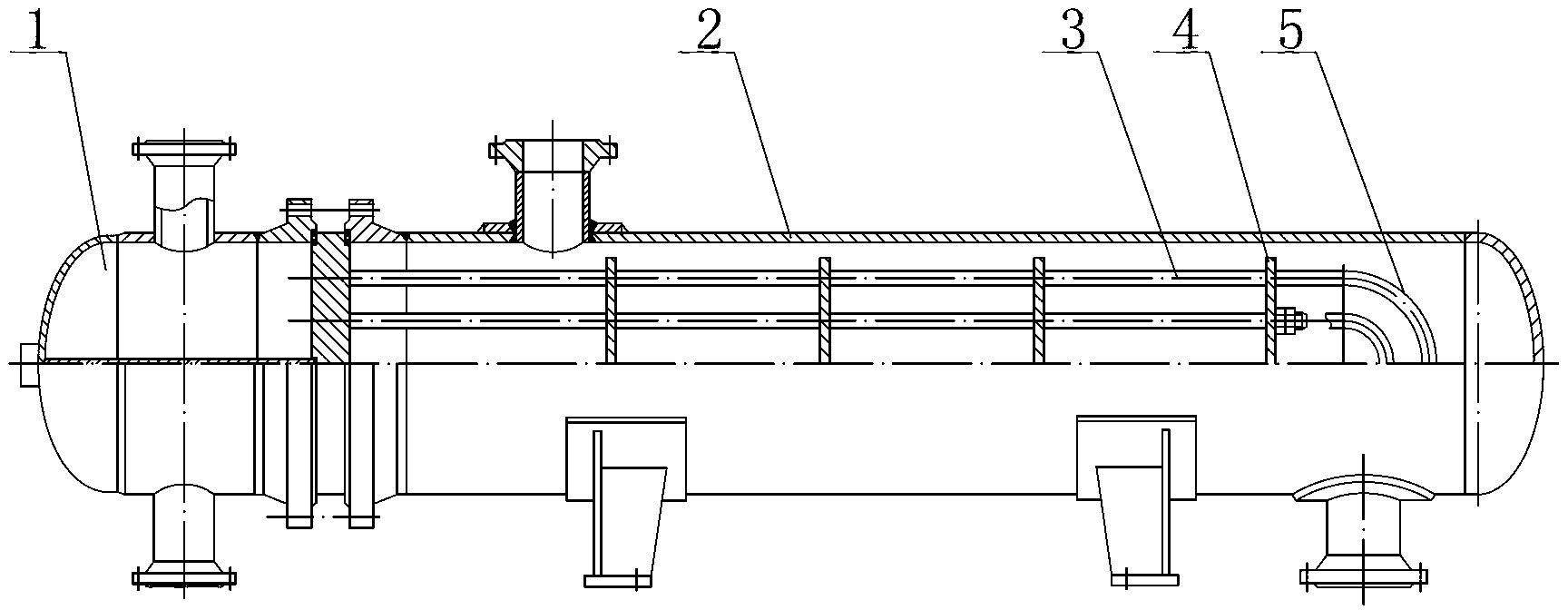

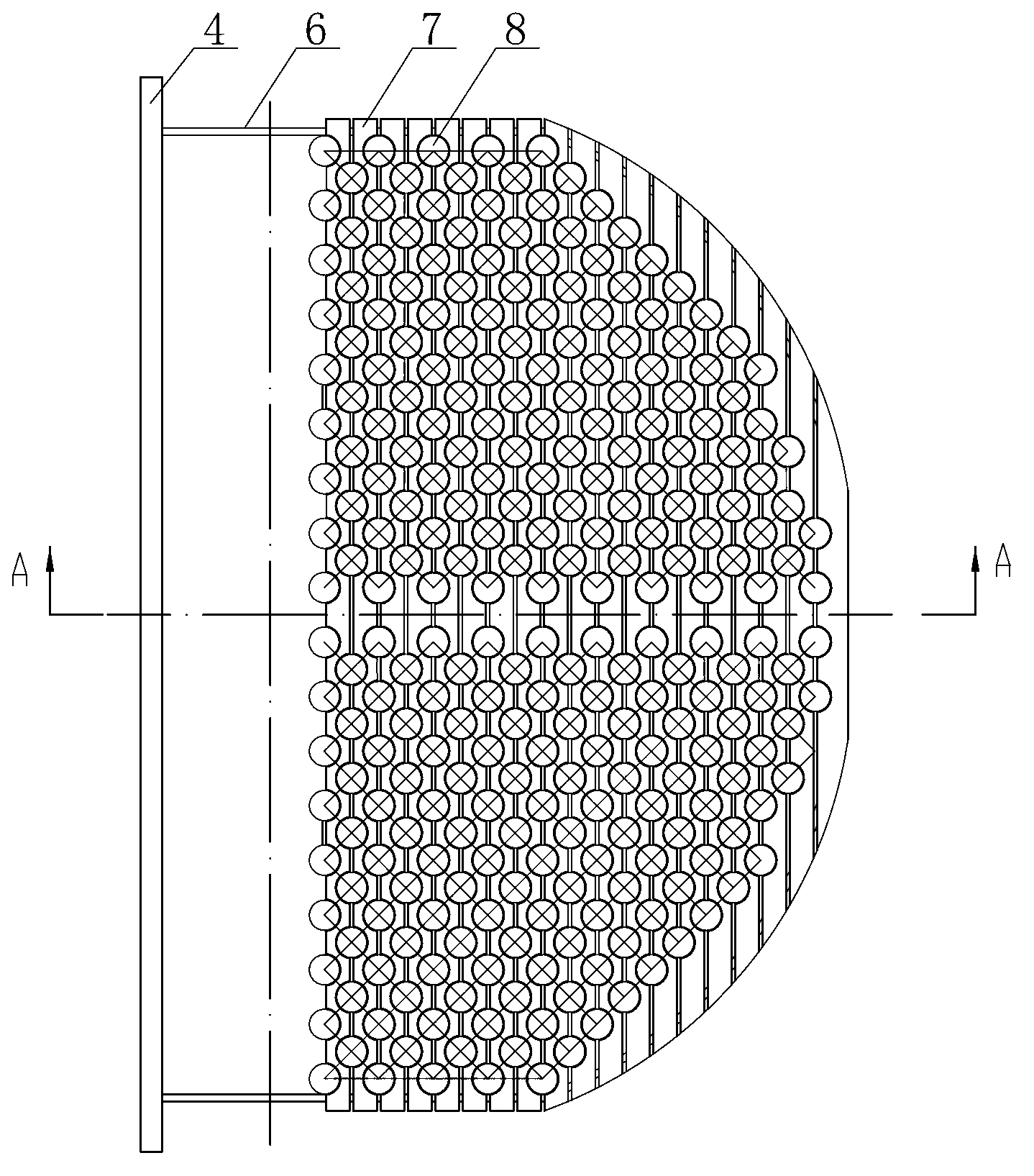

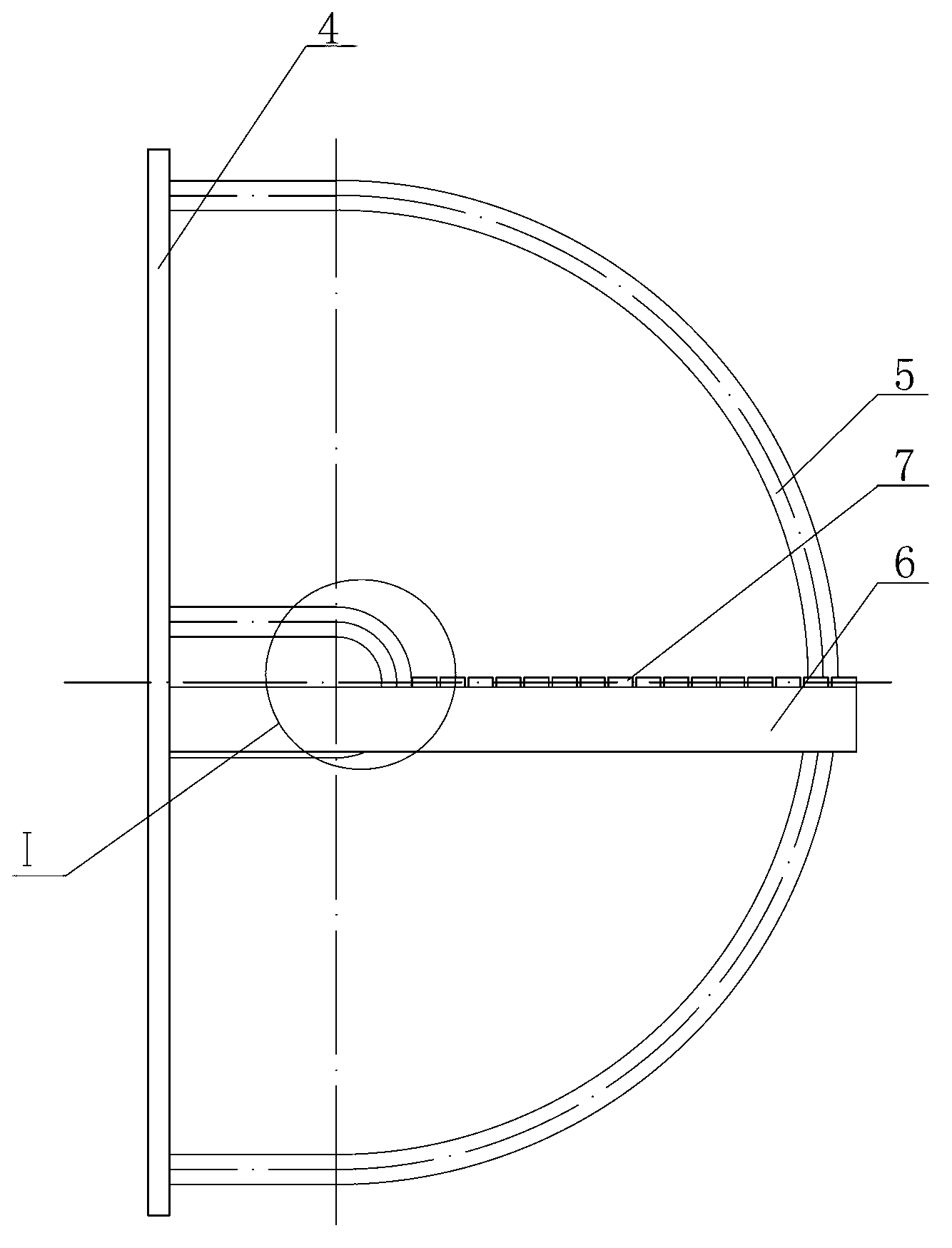

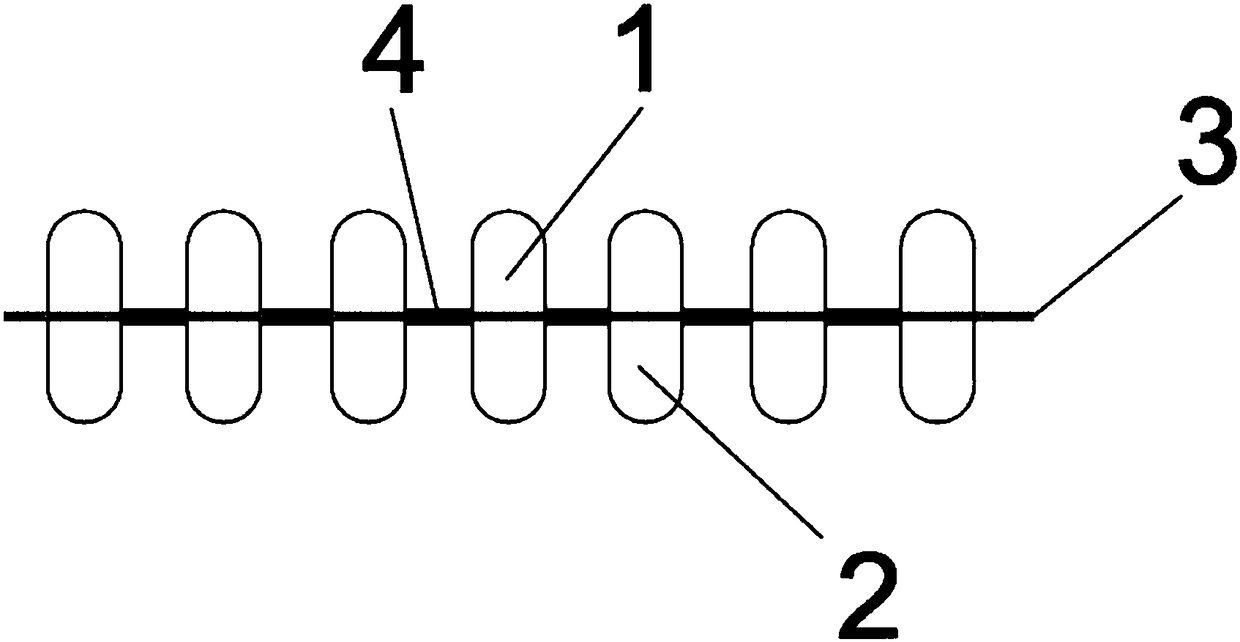

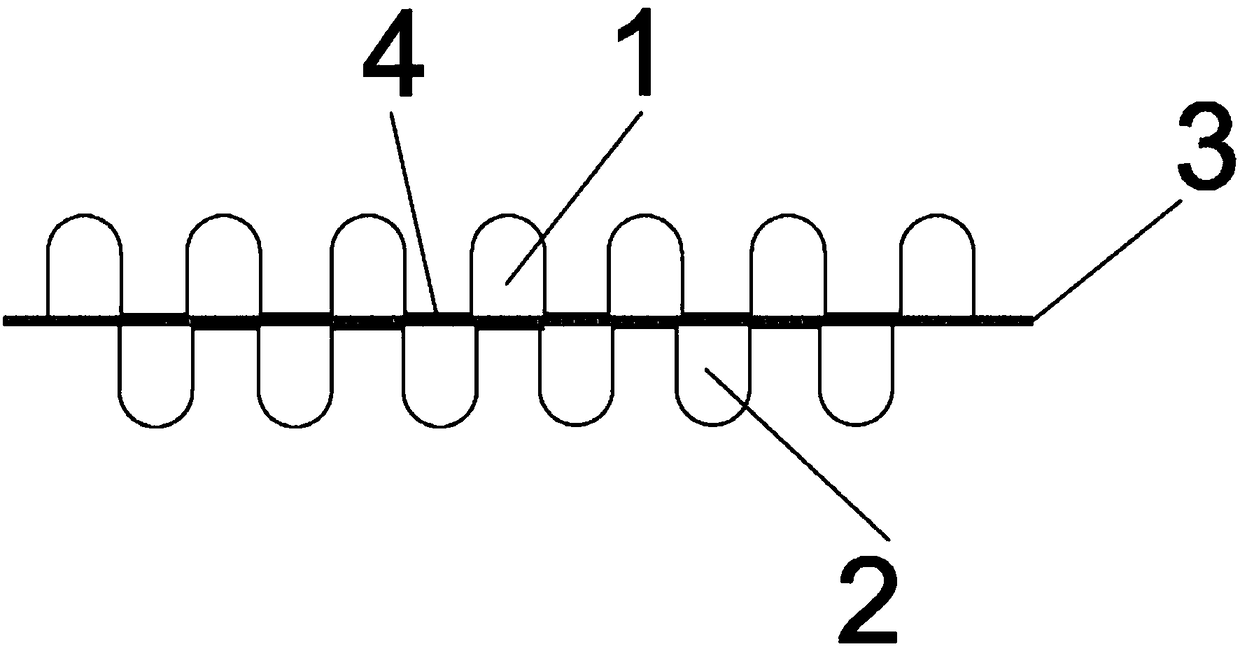

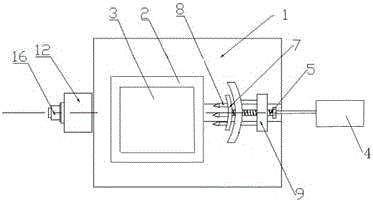

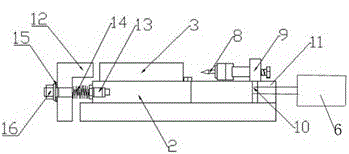

Shakeproof process and shakeproof device for bent tube sections of U-shaped tube heat exchanger tube bundle

InactiveCN103317315AExtended service lifeEasy to fixHeat exchanger casingsShell and tube heat exchangerEngineering

The invention belongs to the field of shell and tube heat exchangers and particularly relates to a shakeproof process for bent tube sections of a U-shaped tube heat exchanger tube bundle. The process comprises the steps of first processing a shakeproof plate according to a tube arrangement mode of heat exchange tubes of the U-shaped tube heat exchanger tube bundle, drilling rows of mutually parallel tube holes on the shakeproof plate, cutting the shakeproof plate into a plurality of mutually parallel strip-shaped plates, enabling holes in the strip-shaped plates to be semicircular holes, enabling a connecting plate to be welded to a supporting plate positioned at the tail of the U-shaped tube heat exchanger tube bundle, finally assembly the U-shaped tube heat exchanger tube bundle, simultaneously installing the strip-shaped plates at the tails of the bent tube sections of the tube bundle to fill gaps among the heat exchange tubes, and installing the strip-shaped plates from inside to outside; when installation of one strip-shaped plate is finished, enabling the strip-shaped plate to be welded to the connecting plate, and fixing every strip-shaped plate through the connecting plate. Shake prevention is achieved, and service life of a U-shaped heat exchanger is prolonged. The invention simultaneously provides a shakeproof device adopted in the shakeproof process. The shakeproof device is simple and reasonable in structure, easy to process and manufacture and good in fixity.

Owner:SHANDONG MEILING CHEM EQUIP

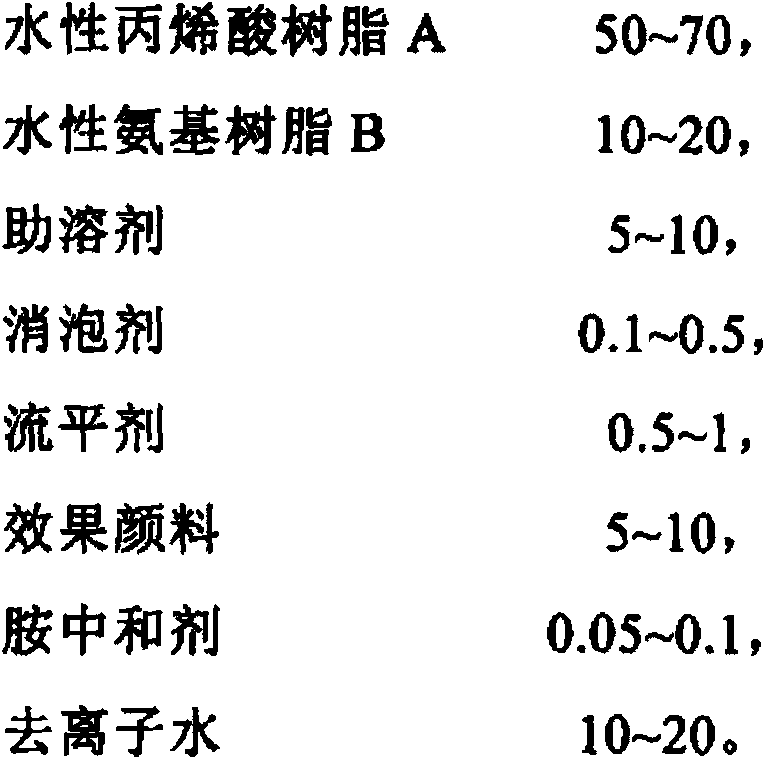

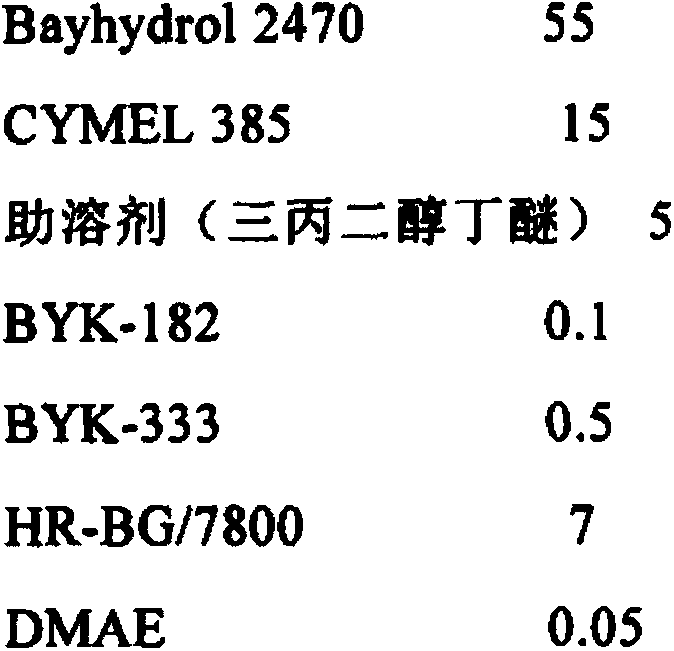

Water based paint with mirror surface effect and preparation method thereof

The invention relates to water based paint with a mirror surface effect and a preparation method thereof. The water based paint is composed of the following components in parts by weight: 50-70 parts of water-based acrylic resin A, 10-20 parts of water-based amino resin B, 5-10 parts of cosolvent, 0.1-0.5 part of defoaming agent, 0.5-1 part of leveling agent, 5-10 parts of effect pigment, 0.05-0.1 part of amine neutralizer and 10-20 parts of deionized water. The preparation method comprises the following steps: sequentially adding the water-based acrylic resin A, the water-based amino resin B, 50% of deionized water, the defoaming agent and the cosolvent into a container, and stirring uniformly to obtain a mixture A; uniformly mixing and stirring the residual deionized water, the leveling agent and the effect pigment to obtain a component B; adding the component B into the component A while stirring, uniformly stirring and finally regulating the pH to 7.0-7.5 by use of the amine neutralizer. Compared with the prior art, the water based paint provided by the invention has the advantages of low VOC emission, environmental friendliness, excellent adhesive force, high hardness and scratch resistance, and the like.

Owner:DONGLAI COATING TECH SHANGHAI

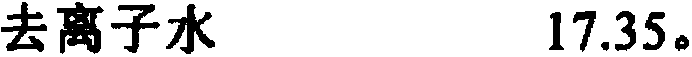

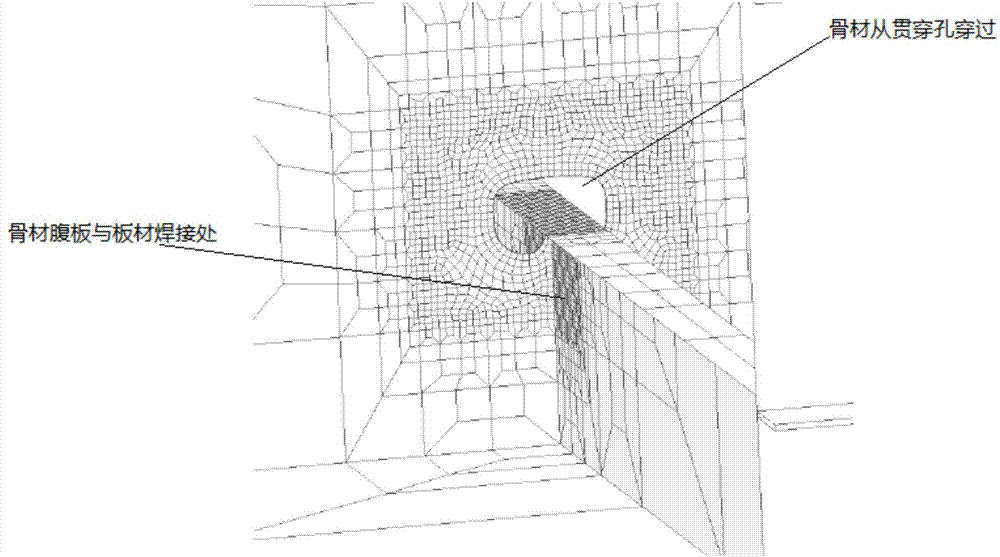

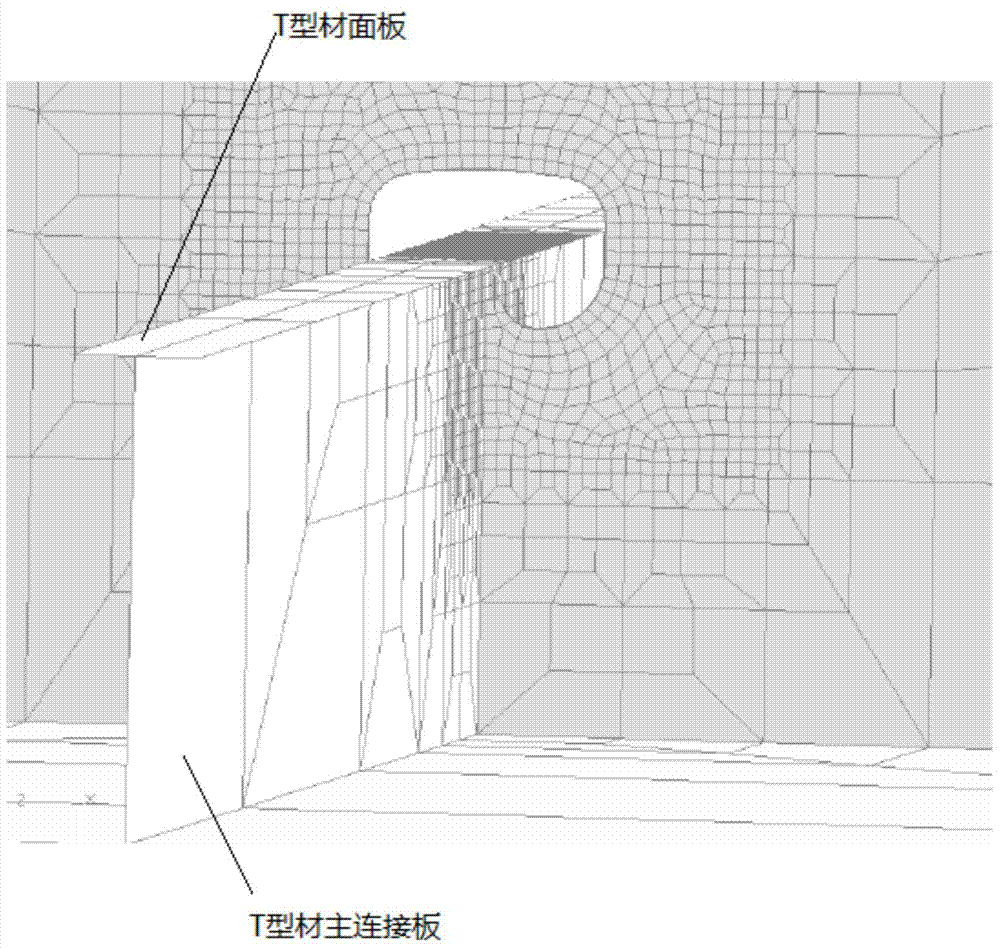

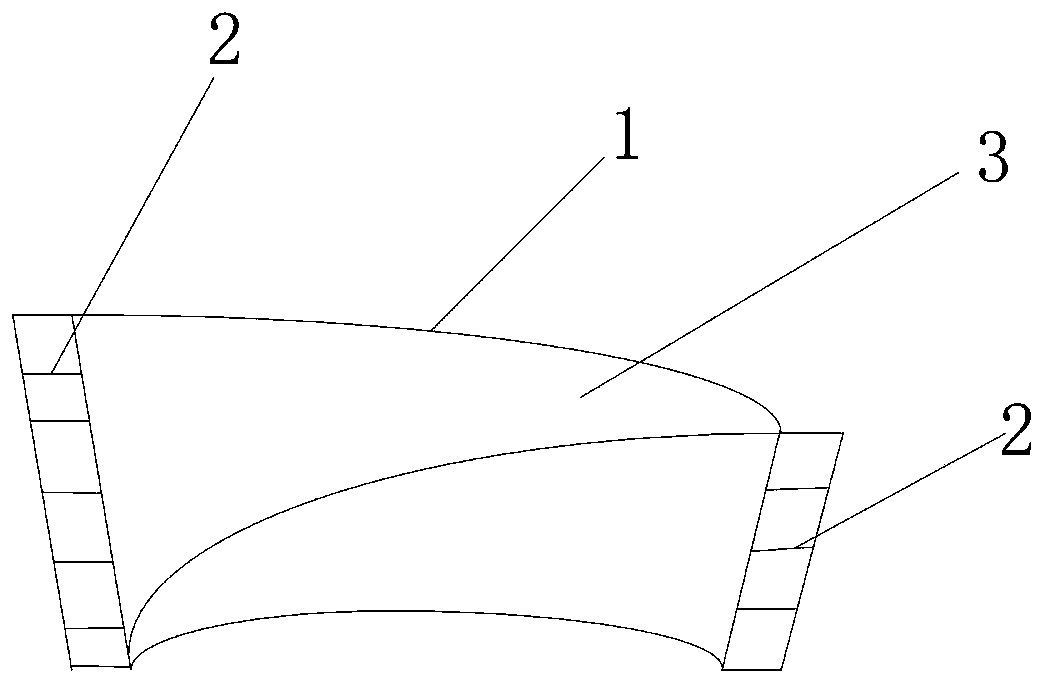

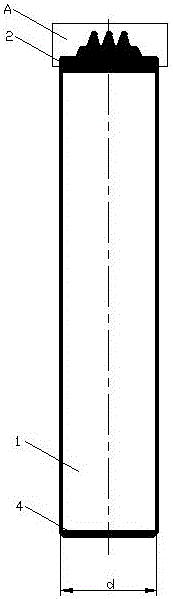

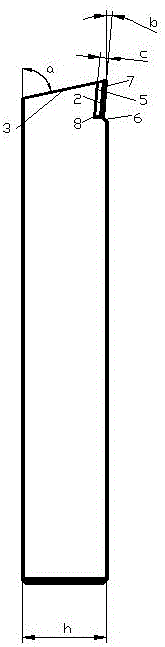

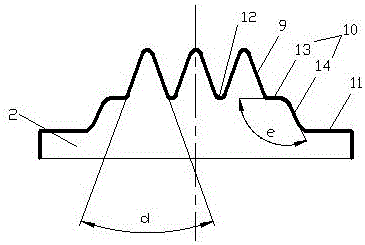

Ship T-shaped bar through hole linear structure

InactiveCN104850714ARounded edgesHigh strengthSpecial data processing applicationsMarine engineeringFree edge

The invention relates to a ship T-shaped bar through hole linear structure. The ship T-shaped bar through hole linear structure is characterized in that a T-shaped bar through hole is provided with a left-right-symmetry structure; the line type of one single side sequentially includes an elliptical arc, a first arc, a second arc and a straight line which are sequentially connected; the long radius b of the elliptical arc is close to the inner side of the T-shaped bar through hole, and the short radius c of the elliptical arc is close to outer side of the T-shaped bar through hole; the whole T-shaped bar through hole is of an apple shape with the head facing downwardly. The ship T-shaped bar through hole linear structure has the advantages the hole is full and round, the through hole is welded with at least one edge of a T-shaped bar, part of the stress on the free edge of the through hole is transmitted through weld joints from the T-shaped bar, the other part of the stress on the free edge of the through hole is caused by plate deformation, stress testing and analysis prove that by the form of the elliptical arcs, the first arcs, the second arcs and the straight lines, fatigue limit brought by the stress of a plate is long, the theoretical service life of the plate is long, and high design safety is achieved.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

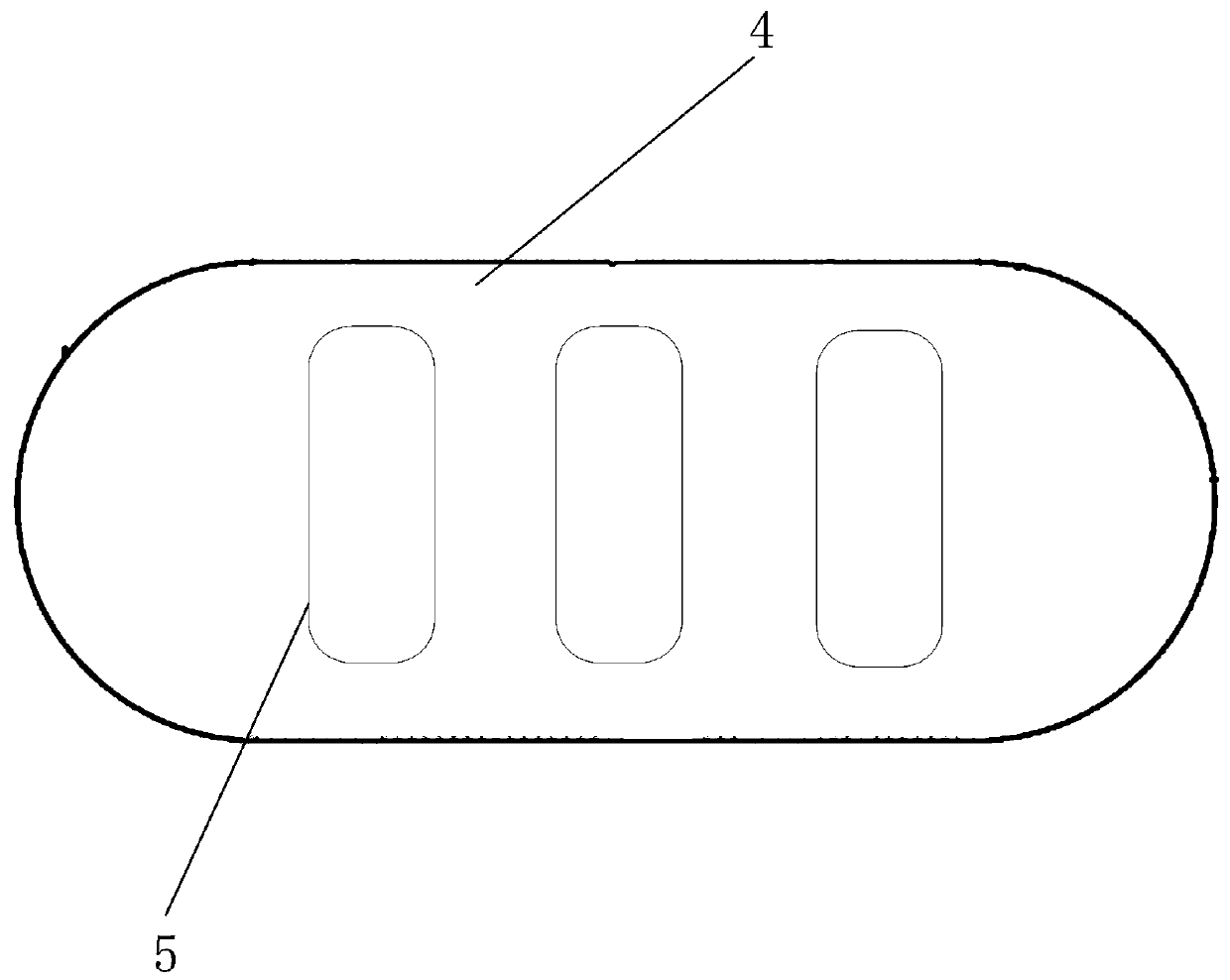

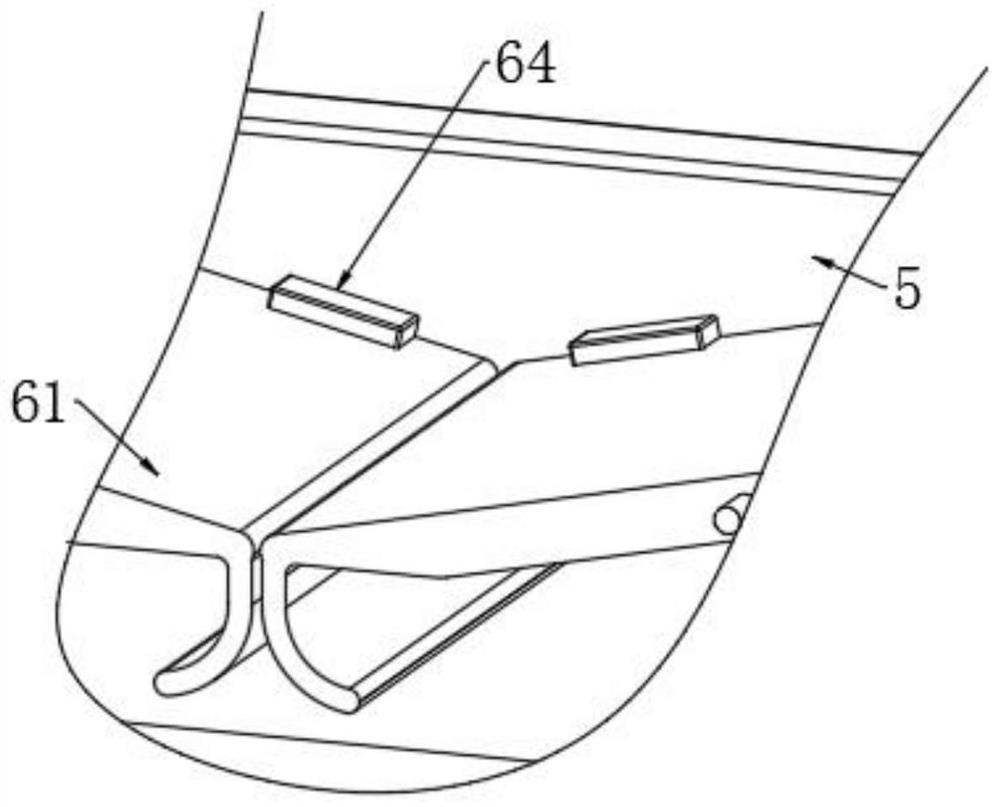

Inflation-free type double-side air bag and preparation method thereof

PendingCN108313519APlay a protective effectReduce impactDomestic articlesContainers to prevent mechanical damageAbsorbed energyEngineering

The invention belongs to the technical field of air bags, and specifically relates to an inflation-free type double-side air bag and a preparation method thereof. The inflation-free type double-side air bag comprises a plurality of upper air bags which are arranged in an array form and are interconnected to form a planar body, a plurality of air bags which are arranged in an array form and are interconnected to form a planar body, and an elastic material layer which is arranged between each upper air bag and the corresponding lower air bag; the upper surfaces of the elastic material layers areconnected to the upper air bags, and the lower surfaces of the elastic material layers are connected to the lower air bags; soft edge connecting parts are arranged between adjacent upper air bags andadjacent lower air bags; in case of being pierced, the air bag still remain the protection effect; in addition, when the inflation-free type double-side air bag is subjected to outside pressure, theelastic material layers are capable of buffering and absorbing energy, thus the deformation degree of the air bag can be reduced, and as a result, the impact force on an air bag body or a product canbe reduced. The preparation method comprises the steps of (1) molding single edge; and (2) sealing an opening, and forming. The preparation method is simple in processes, easy to operate, and high inproduction efficiency.

Owner:DONGGUAN ZHONGDING PLASTIC PROD CO LTD

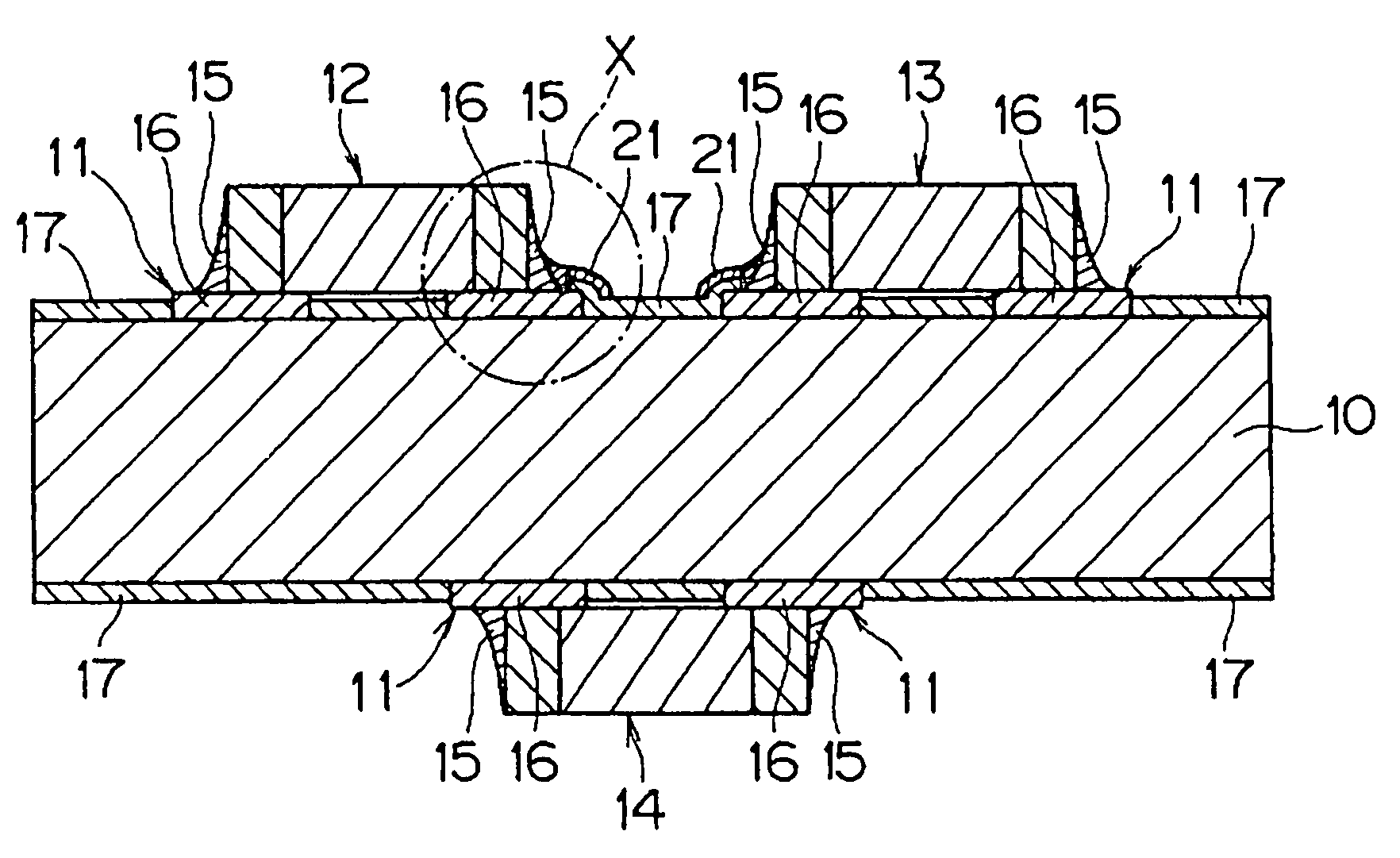

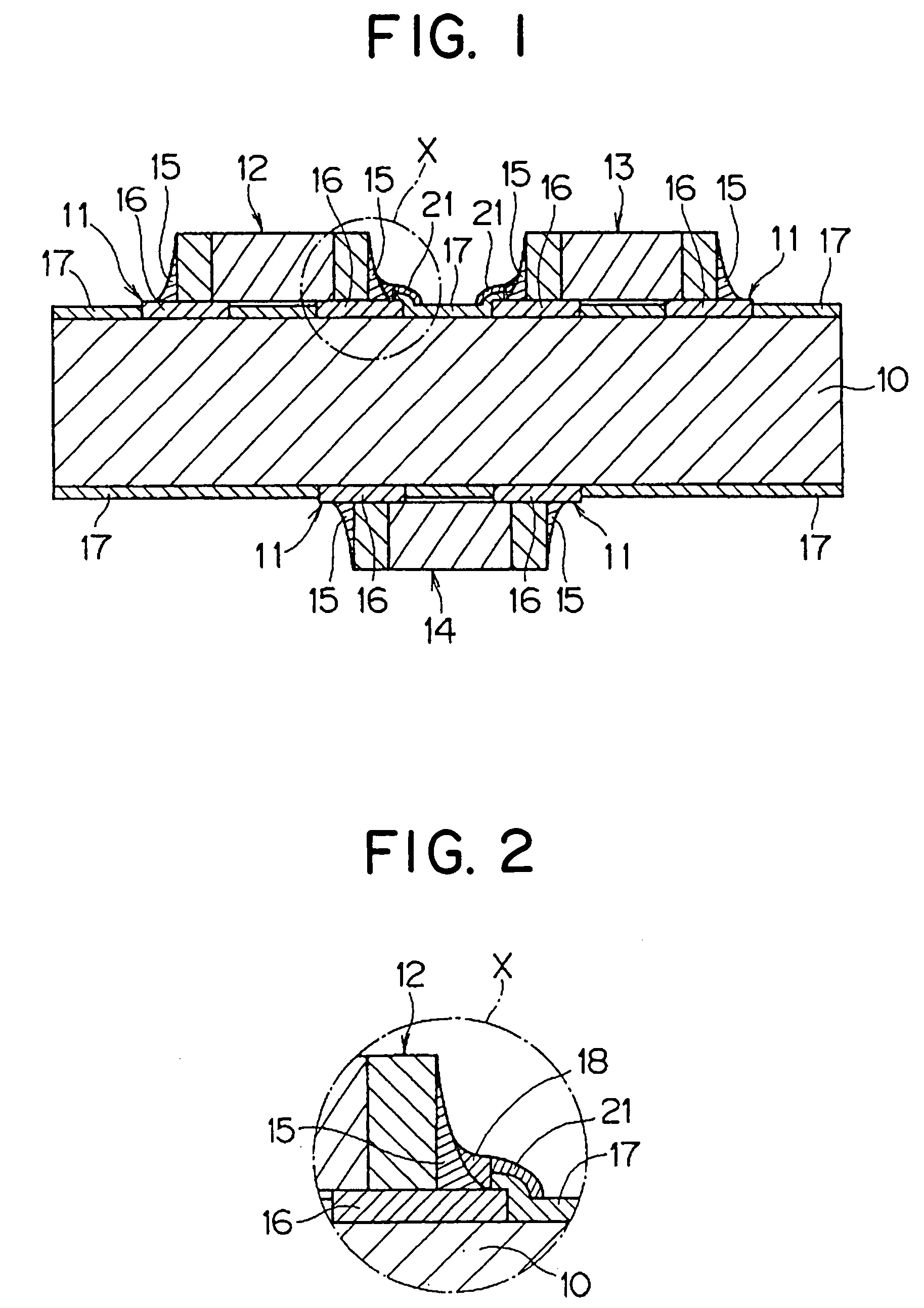

Printed wiring board and process for manufacturing the same

InactiveUS7586754B2Low costSmall constructionPrinted circuit assemblingSecond resist patternElectrical and Electronics engineeringEngineering

The printed wiring board includes: a conductive wiring which is formed on a surface of a board and has a plurality of solder lands, to which components to be mounted are electrically connected by solder; and first and second electrically insulating layers formed on the conductive wiring, wherein the first insulating layer is formed on the conductive wiring in such a manner that the first insulating layer covers a portion of a peripheral part of one solder land and a central part of the one solder land is exposed, the portion of the peripheral part being situated on the side of another solder land, wherein the second insulating layer is piled up on the first insulating layer which covers the portion of the peripheral part of the one solder land.

Owner:YAZAKI CORP

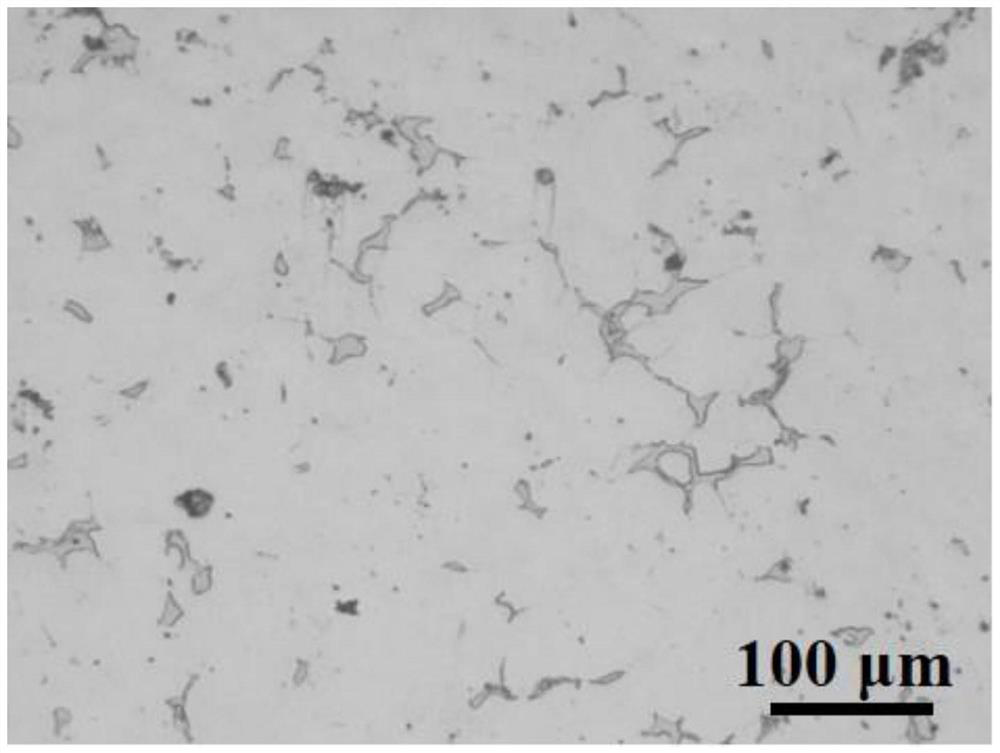

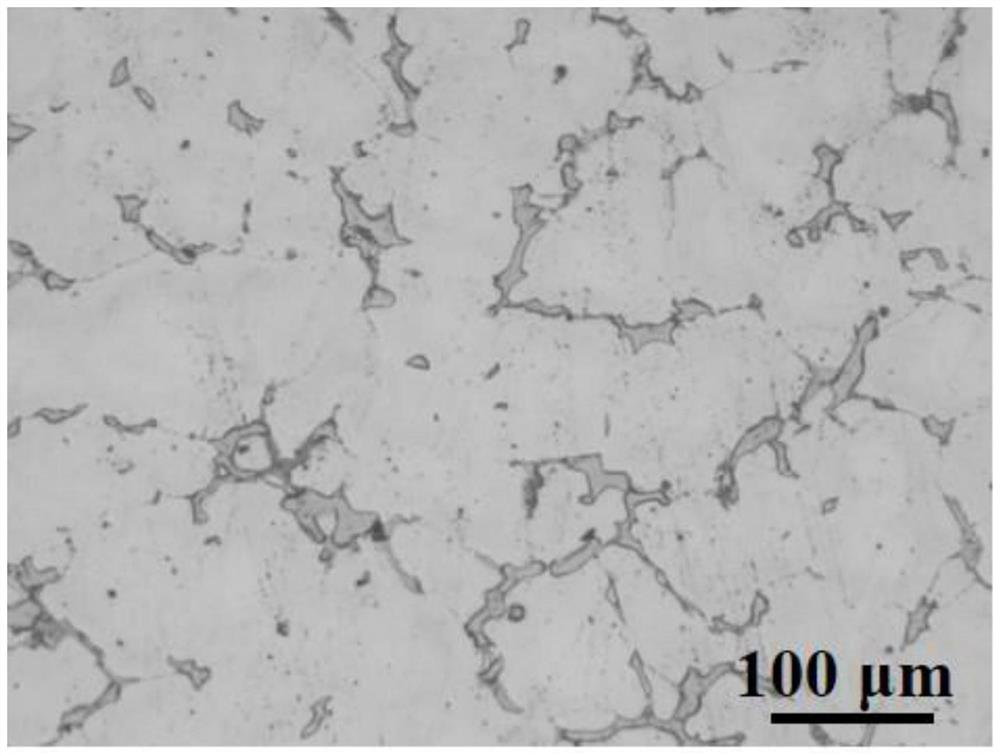

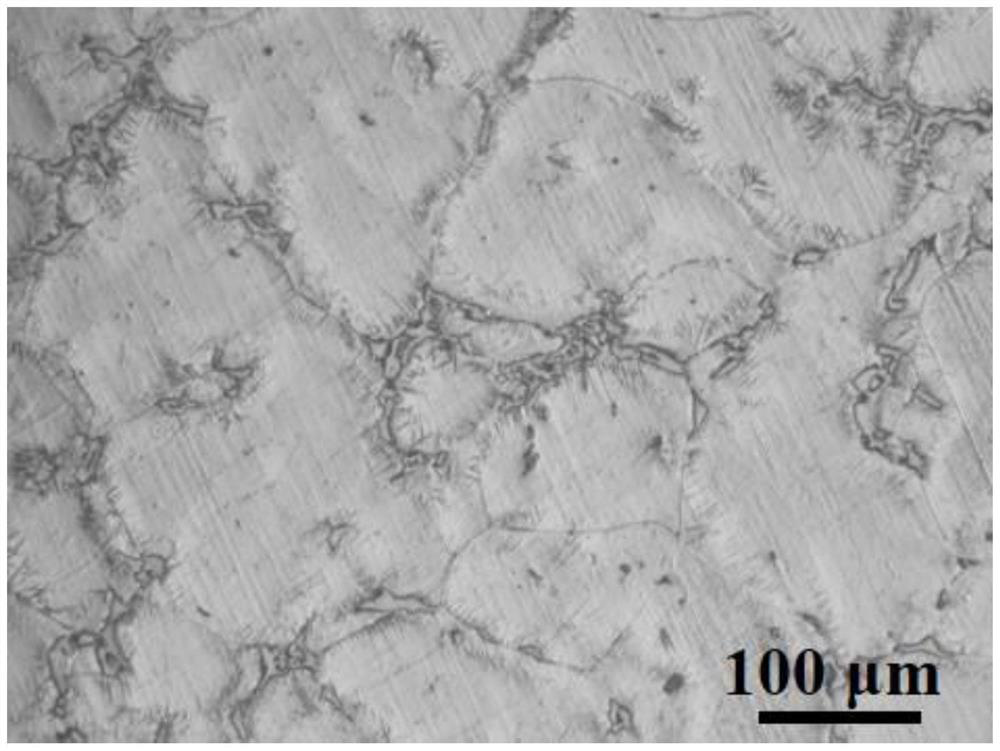

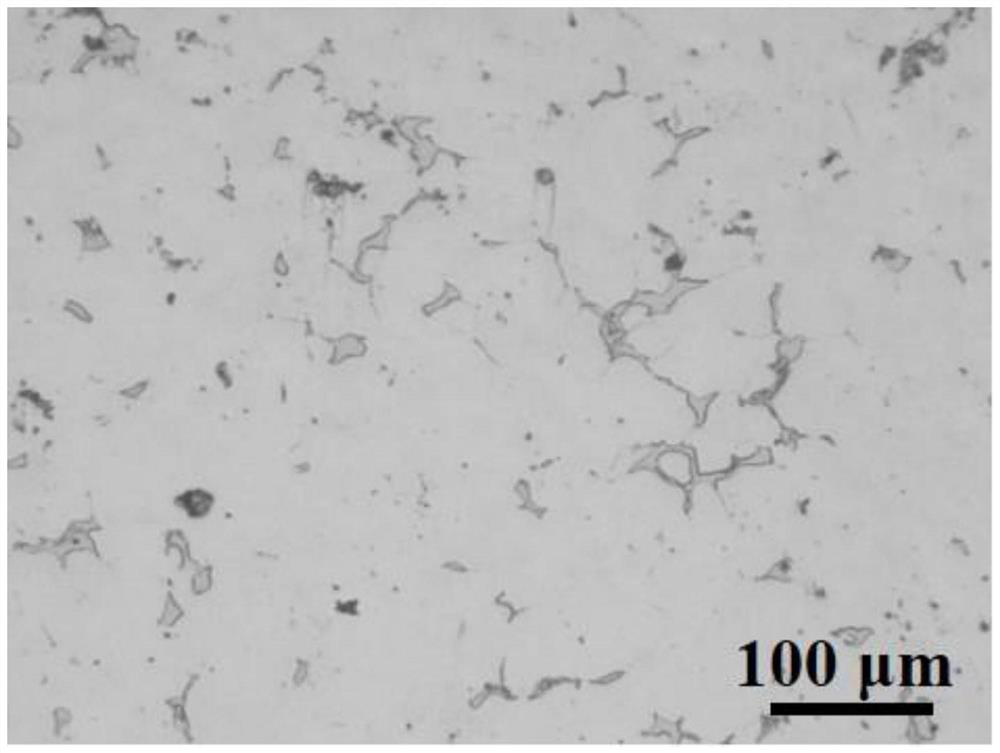

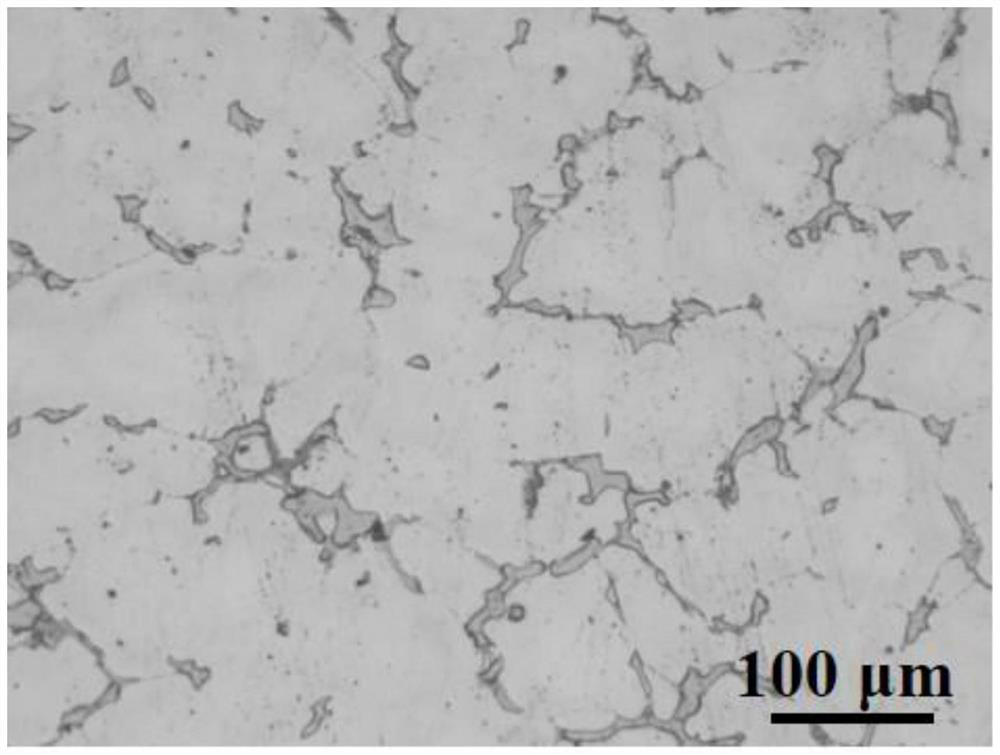

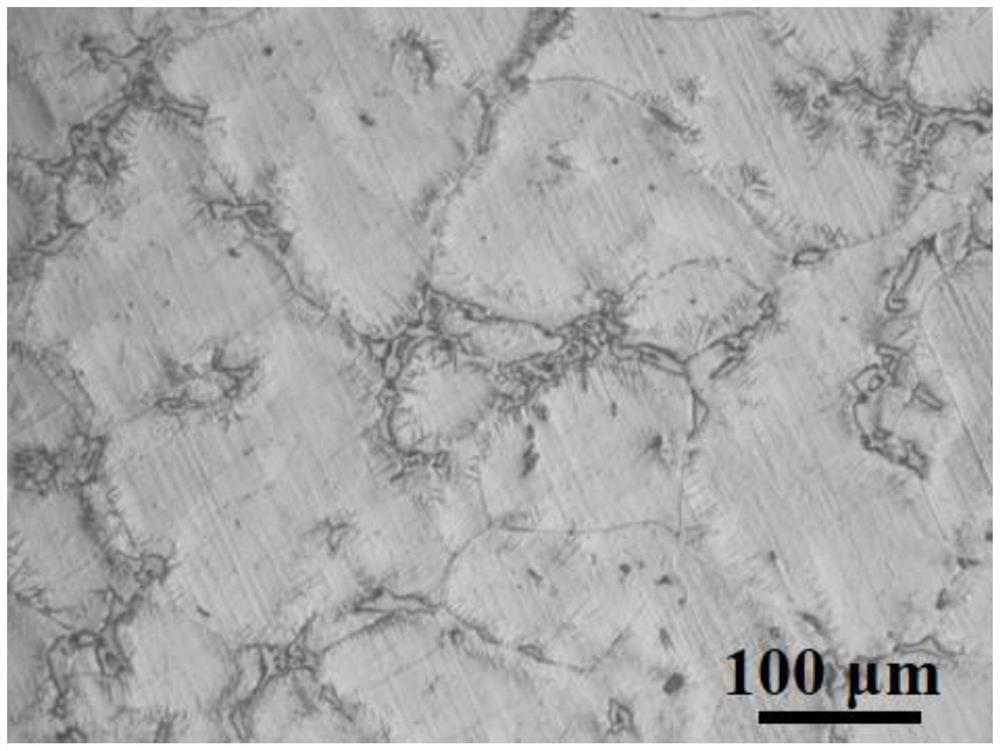

Multi-element microalloyed high-strength heat-resistant rare earth magnesium alloy and preparation method thereof

The invention provides a rare earth magnesium alloy. The rare earth magnesium alloy is a modified Mg-Gd-Y-Zr series rare earth magnesium alloy. The as-cast metallographic structure of the rare earth magnesium alloy is provided with an Mg5Gd phase with a round edge; and or the extruded metallographic structure of the rare earth magnesium alloy has a small granular precipitated phase, and the radial size of the granules is 10-150 nm. The microstructure morphology of the alloy is improved through a multi-element microalloying method, the microstructure morphology of the alloy material is improved by adding trace Ag and Sc in a specific proportion, the age hardening and grain refinement effects are improved, and then excellent room-temperature and high-temperature mechanical properties are obtained. On the premise that the total amount of rare earth is not increased, the strength performance index is high, good plasticity is reserved, engineering application is easy to achieve, and the requirements of the current fields of aerospace, missile military industry, rail transit and the like for the mechanical property of a light structural material under the room-temperature and high-temperature environment can be met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

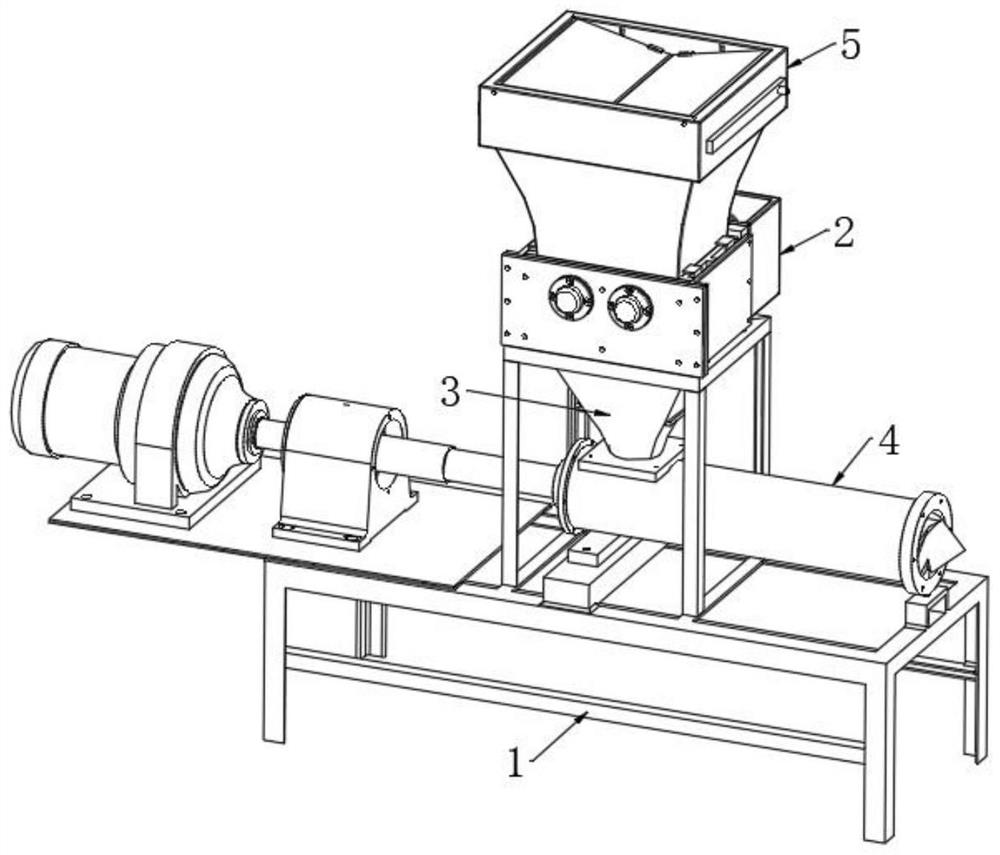

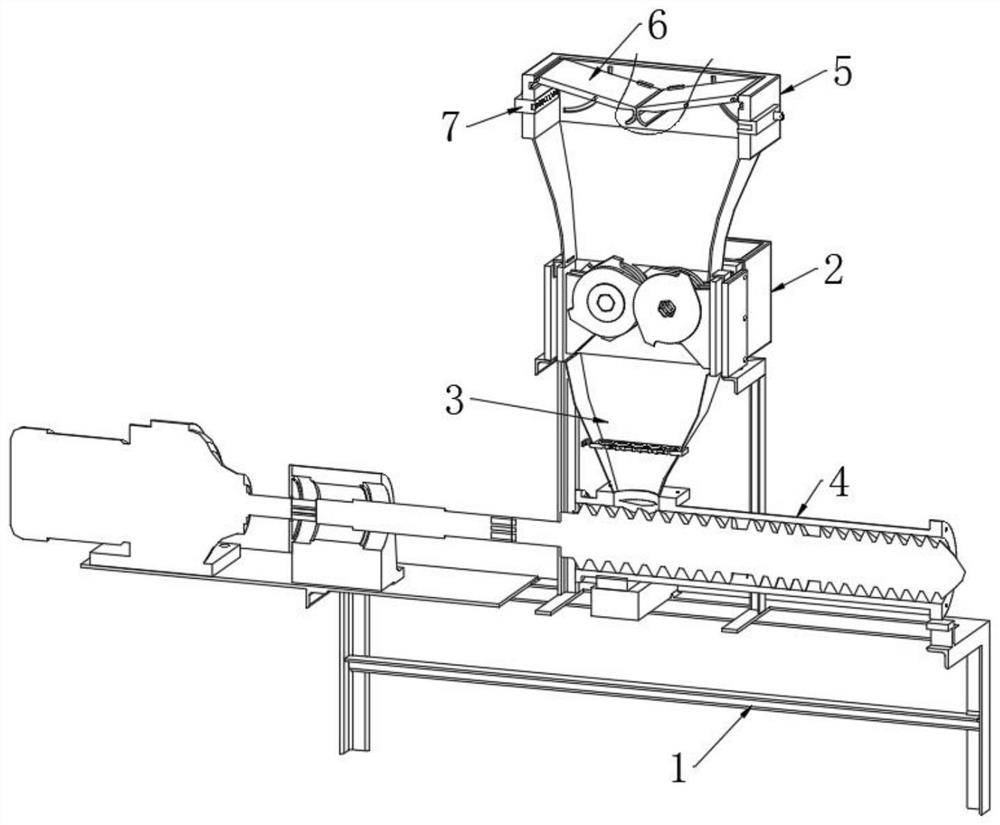

Uniform material distributing perforating machine

ActiveCN107471310APrevent movementHole punching is effective and fastMetal working apparatusEngineeringDrill bit

The invention provides a uniform material distributing perforating machine which comprises two force bearing rods. The upper ends of the two force bearing rods is connected to a force bearing plate, and a slide rail and a perforating device are arranged on the force bearing plate; a driving device is also arranged on the force bearing rod; a feeding mechanism is arranged in the bottom of the perforating device which comprises a drill, a pressurizing device and a lifting air cylinder; the drill is connected to the lifting air cylinder, and a pressure pipeline is connected between the pressurizing device and the drill; the pressurizing device is connected to the drill; the feeding mechanism comprises a material paving device and a material pressing device, and the material paving device and the material pressing device are connected to the perforating device; the material paving device comprises a material paving part and a feeding device, the material paving part is arranged in a position corresponding to the bottom of the perforating device, and the feeding device is arranged on one side of the material paving part; the material pressing device comprises a telescopic rod and a pressure block, the telescopic rod is connected to the pressure block, and the tail end of the telescopic rod is connected to the lifting air cylinder. The uniform material distributing perforating machine can prevent a to-be-processed material from moving, holes perforated by the drill are more delicate, and the edges of the holes are smoother.

Owner:安徽宜民服饰股份有限公司

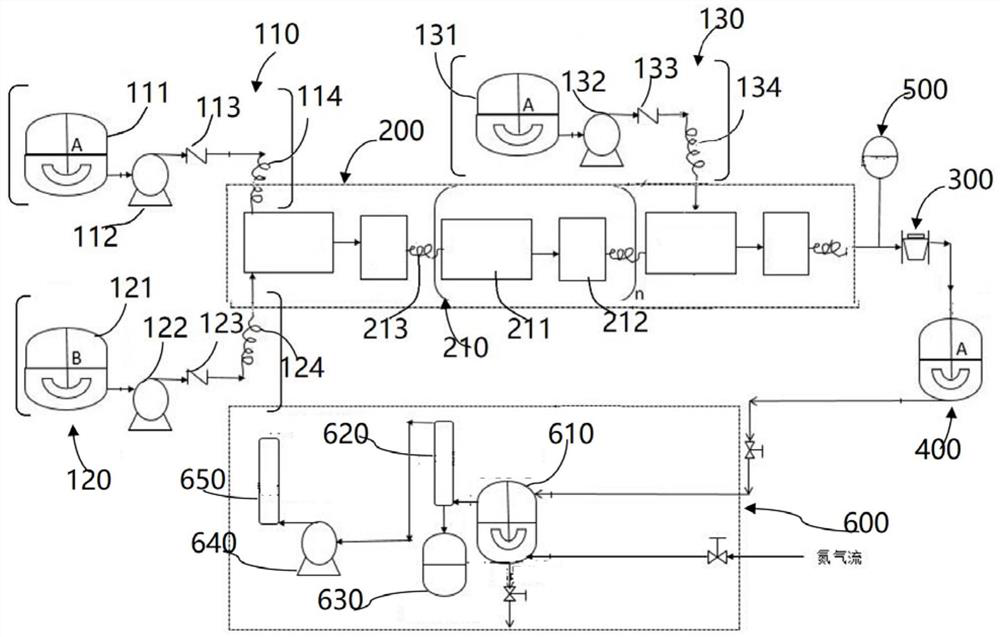

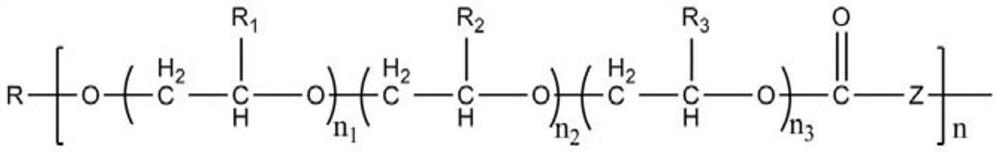

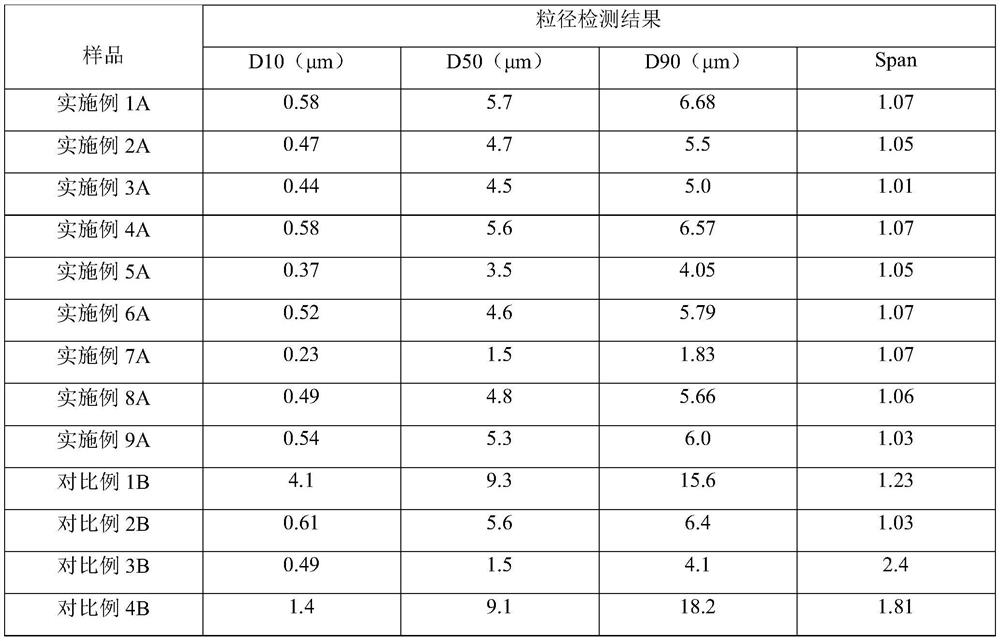

Blank multivesicular liposome as well as preparation method and device thereof

InactiveCN112120022ACompact structureSmall particle sizeBiocideChemical/physical/physico-chemical microreactorsPESTICIDE ADJUVANTSMultivesicular liposomes

The invention discloses a blank multivesicular liposome and a preparation method and device thereof, and belongs to the field of pesticide adjuvants. The preparation raw materials of the polycystic lipidosome provided by the invention comprise phospholipid substances, sterol substances, neutral lipidosome, fatty acid ester substances and vitamins; the polycystic lipidosome containing vesicles withhigh electronegativity and steric hindrance can be obtained; coagulation of the multivesicular liposome can be effectively inhibited, the drug release time is prolonged, and the drug effect is improved. The invention provides a blank multivesicular liposome preparation method and device. According to the blank multivesicular liposome preparation method and device, a continuous flow micro-channelreactor is used for replacing traditional high-speed shearing equipment; by means of the device, the vesicle stability and particle size uniformity of the multivesicular liposome can be obviously improved, the vesicle size is reduced, the environment-friendly multivesicular liposome can wrap pesticide active matters and is applied to the field of pesticides.

Owner:YANGZHOU SPED CHEM

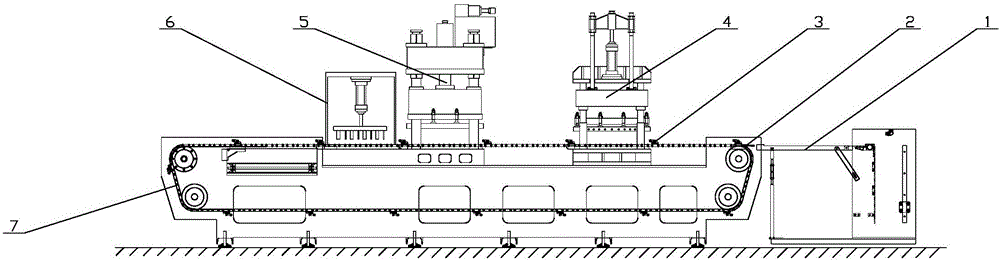

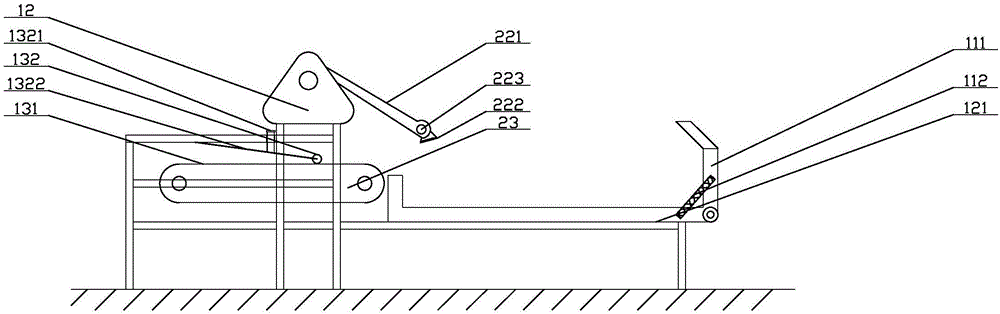

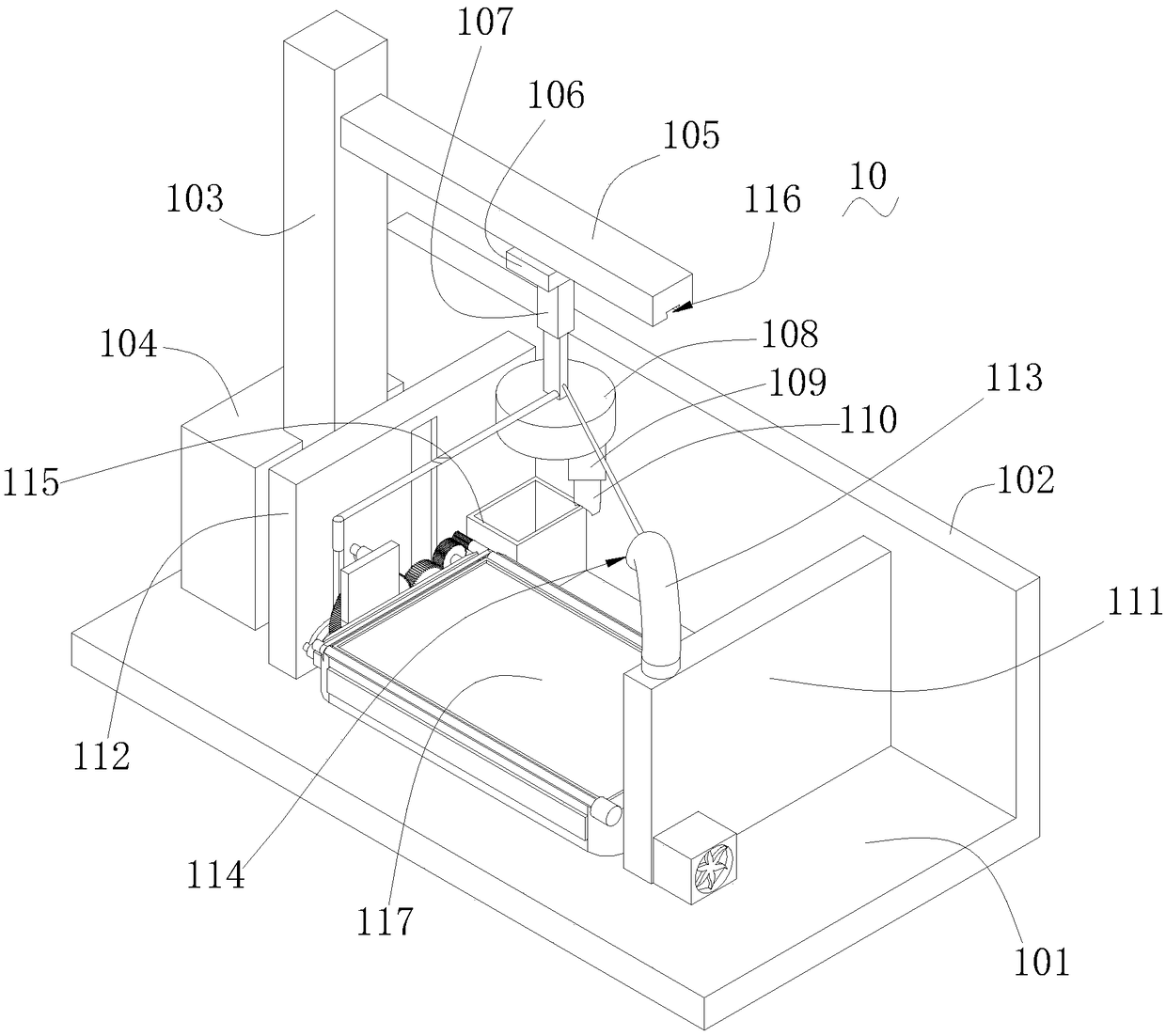

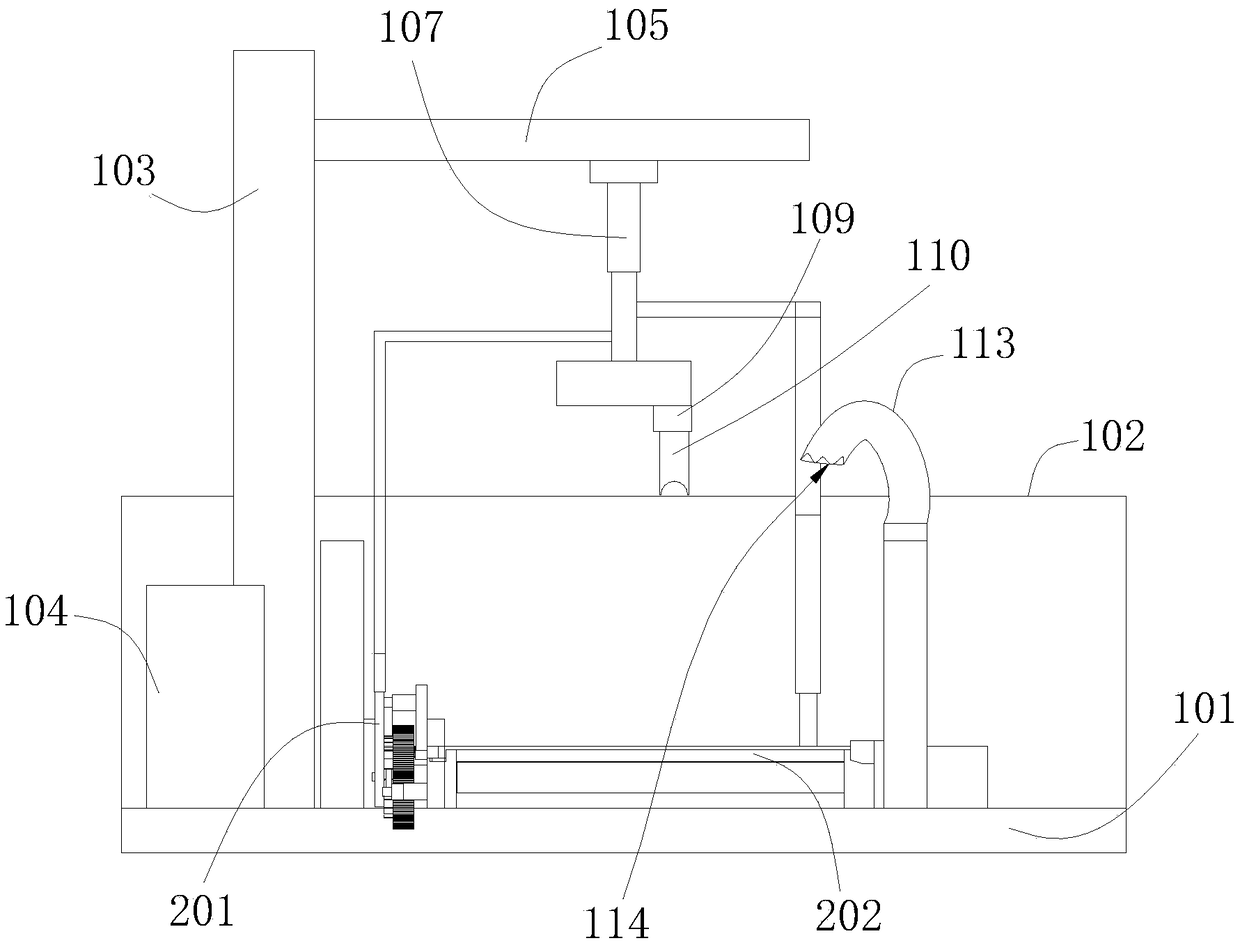

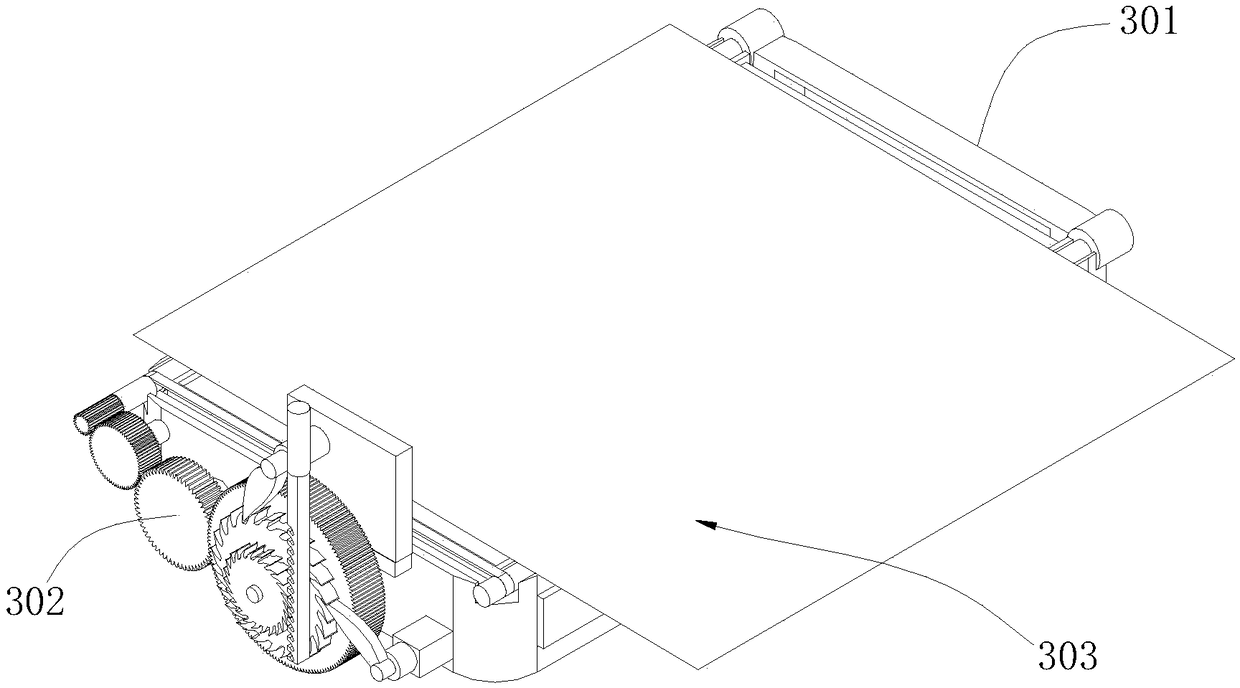

Full-automatic soft-line sectional die-cutting machine and operating method thereof

InactiveCN106739137ASave human effortReduce labor intensityPaper-makingBox making operationsMechanical engineeringEngineering

The invention relates to a packing box processing device, in particular to a full-automatic soft-line sectional die-cutting machine and an operating method thereof. The full-automatic soft-line sectional die-cutting machine is simple in structure and is characterized in that two procedures of indentation and slitter edge removal of a plastic sheet are finished during one-time clamping to realize high-precision processing and high processing efficiency. The full-automatic soft-line sectional die-cutting machine comprises a rack and a controller, wherein a closed-cycle chain conveyor is arranged on the rack, a plurality of clamping and conveying mechanisms are uniformly distributed in the conveying direction of the chain conveyor, and a support wheel part at the head ends of the rack and the chain conveyor is a feeding end; and adjustment holes are formed in the two ends of stiffeners, adjustable bolts are arranged in the adjustment holes, and a stop block is arranged on the rear side of each adjustment hole. The full-automatic soft-line sectional die-cutting machine has the advantages that dents and cut edges are integrally formed, the borders of the cut edges are smooth, the dents are equal in depth, the processing efficiency is high and the structure is simple.

Owner:YANGZHOU SU PACK NEW MATERIAL TECH CO LTD

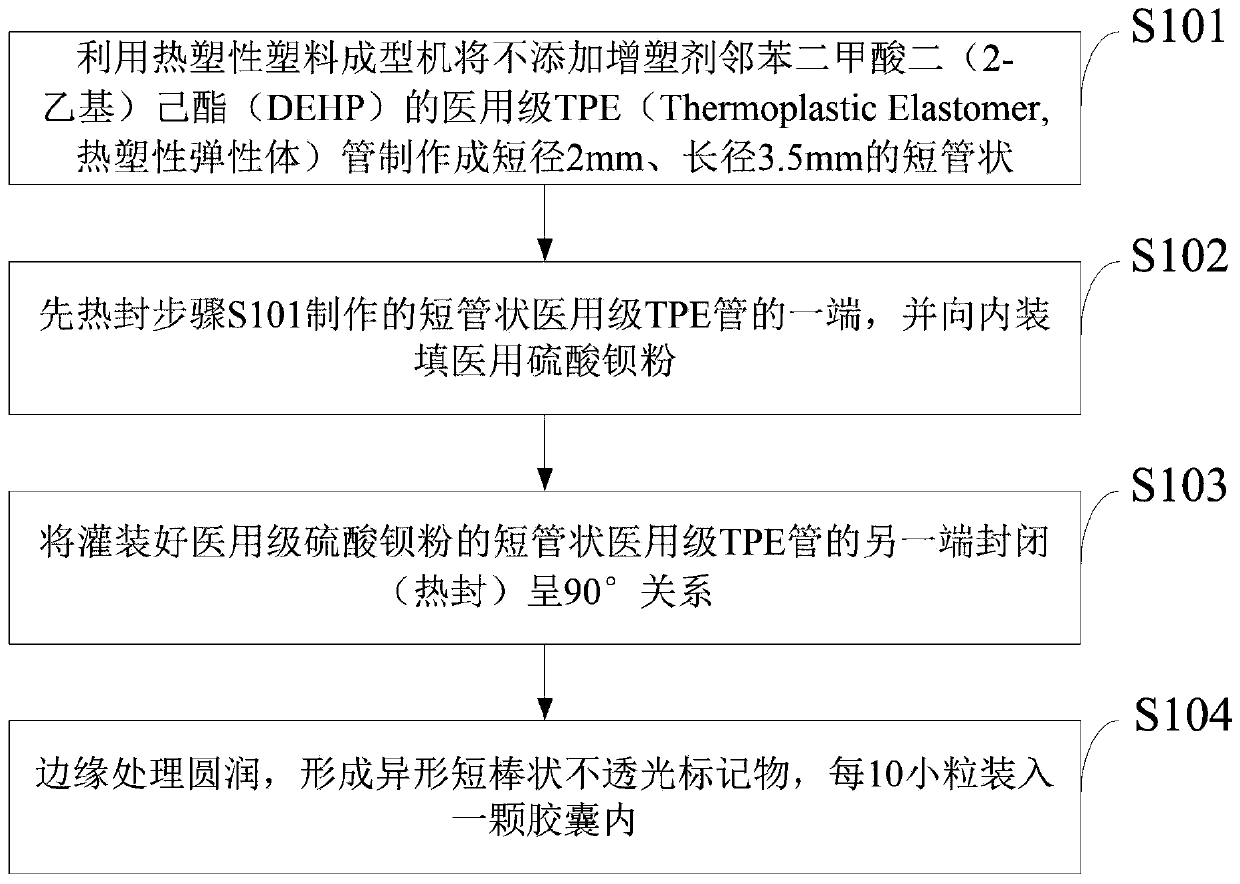

Barium colon transit test marker and preparation thereof

InactiveCN110064060AStable physical and chemical propertiesEasy to carry and swallowX-ray constrast preparationsOpaque markerLongest Diameter

The invention belongs to the technical field of in-vivo test preparations, and discloses a barium colon transit test marker and a preparation thereof. The method includes the steps that a medical-grade TPE tube without plasticizer dihexylphthalate is made into a short tube with the short diameter of 2 mm and the long diameter of 3.5 mm; after the short tube is filled with medical barium sulfate powder, the two ends are heat-sealed at an angle of 90 degrees; finally, the edges are trimmed to be smooth, and a special-shaped short-rod-like opaque marker is formed. Every ten grains are put into one capsule for a patient to swallow for examination; after the capsule is dissolved in the stomach, the short-rod-like marker participates in subsequent cavity digestive system transit together with food; observation is performed once every 24 hours in a colon transit test, reexamination radiography is performed 2-3 times according to the condition, and finally whether the patient suffers from intestinal canal motility disorder or not is judged. The barium colon transit test marker is convenient to make, safe and convenient, the marker quantity can be recorded more accurately, statistic analysis is performed, and an accurate diagnosis is made according to a radiopaque marker method.

Owner:焦俊

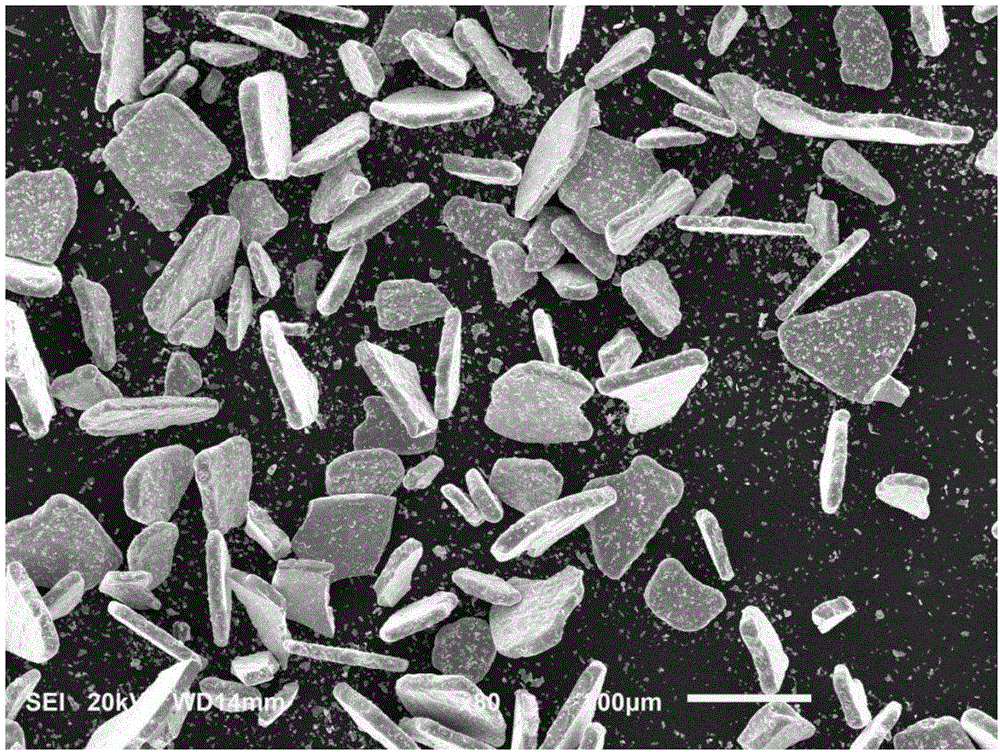

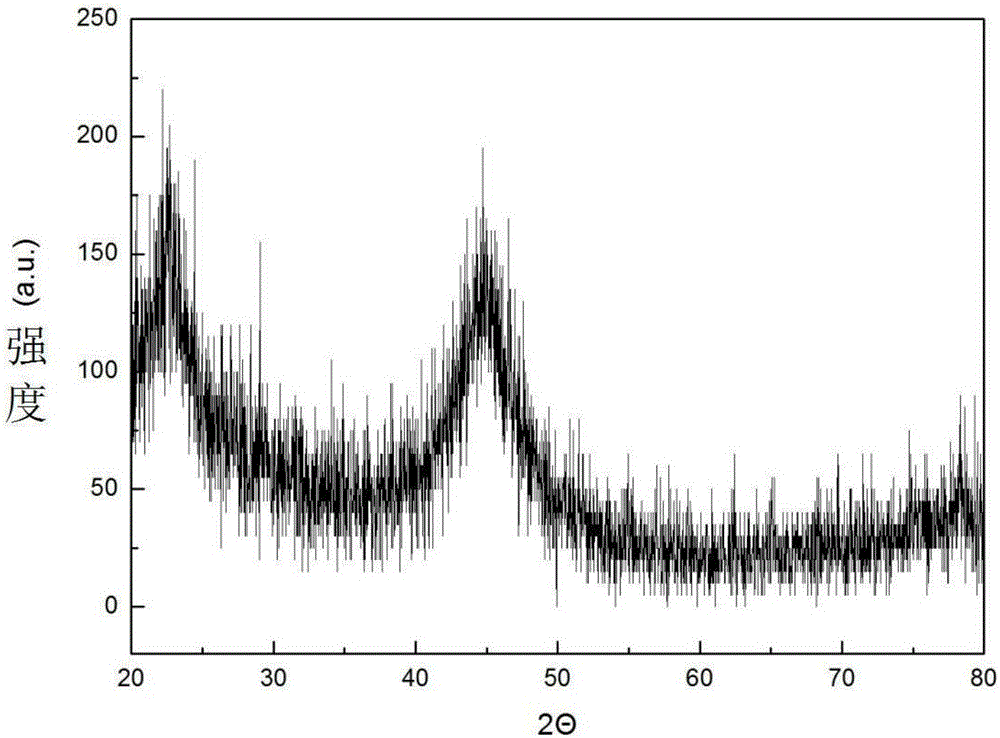

Amorphous alloy powder and preparation method thereof

ActiveCN106158221ALarge particle sizeSmooth edgesInorganic material magnetismAcute angleWaste product

The invention belongs to the field of metal matrix soft magnetic compound materials. The preparation method comprises the following steps: carrying out breaking processing on an amorphous alloy ribbon to obtain fragments; under inert atmosphere, carrying out heat treatment on the fragments, and continuously stirring the fragments in a heat treatment process; and carrying out grinding processing on the fragments subjected to the heat treatment to obtain amorphous alloy powder. The preparation method has the advantages of being high in production efficiency, low in rejection rate and low in production cost and can realize large-scale industrialized application. The prepared amorphous alloy powder has the advantages of smooth edge, no acute angles and even particle length and width, can be largely used in electronic devices which have high-frequency low-loss application requirements, and especially can be largely used for air gap type soft magnetic powder core raw materials.

Owner:张听

Hydraulic straightening machine

InactiveCN106334729AEffective alignmentSimple structureMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention provides a hydraulic straightening machine. The hydraulic straightening machine comprises a feeding plate, a feeding cam, a straightening plate, a clamping plate, a lifting hydraulic cylinder, clamping blocks and a straightening telescopic rod, wherein the feeding plate and the straightening plate are arranged at an interval, and the height of the feeding plate is lower than that of the straightening plate; the feeding cam is arranged between the feeding plate and the straightening plate; the clamping plate is arranged at the upper part of the straightening plate through the lifting hydraulic cylinder, and the bottom of the clamping plate is provided with a guide rail; the guide rail is arranged in the length direction of the straightening plate and is kept parallel with the straightening plate; the number of the clamping blocks is two, and the clamping blocks are matched on the guide rail in a sliding manner; and the two clamping blocks are connected through the straightening telescopic rod. The hydraulic straightening machine is simpler in structure, low in production and manufacturing cost and suitable for popularization and can effectively straighten shaft class products.

Owner:YANCHENG SHENGAO HEAT TREATMENT CO LTD

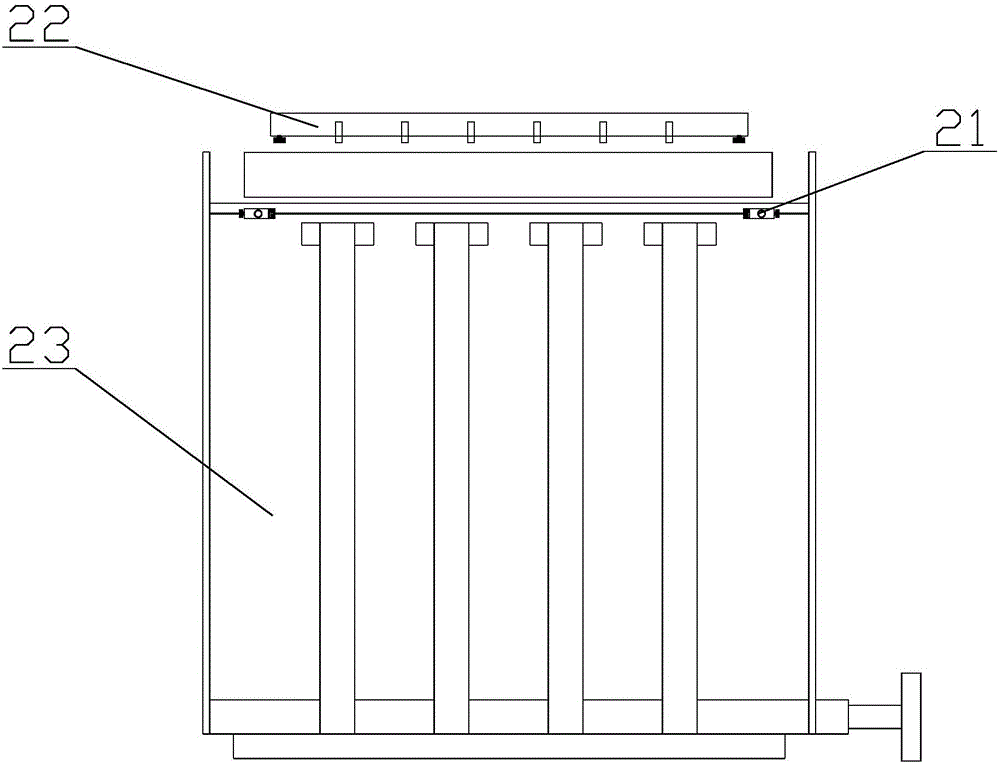

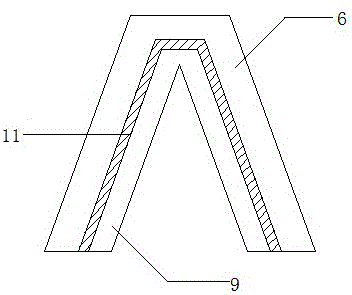

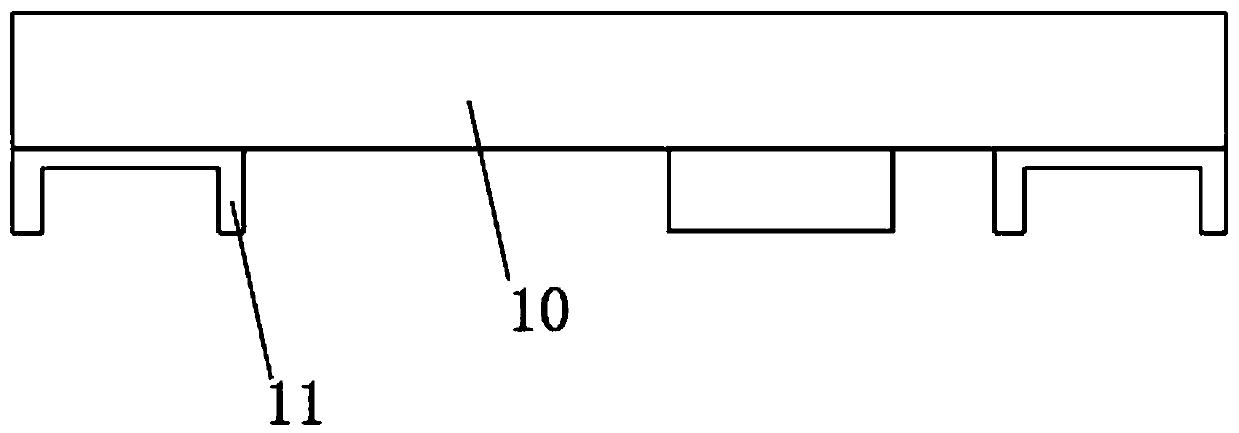

AGM partition plate forming device and application method thereof

ActiveCN111055324AUniform supportEven by forceEdge grinding machinesRotary pressesScreen printingMotor drive

The invention discloses an AGM partition plate forming device. The AGM partition plate forming device comprises a bearing mechanism and a cutting mechanism. The cutting mechanism is mounted on one side of a transverse plate. The two ends of the bottom of the transverse plate are both connected with vertical plates. A base is horizontally mounted between the two vertical plates. The cutting mechanism comprises an end plate. Side plates are horizontally connected to the two ends of the side, close to the transverse plate, of the end plate. A silk-screen printing plate is horizontally arranged between the two side plates. The tops of the side plates and the top of the silk-screen printing plate are all connected with telescopic columns. The tops of the telescopic columns are mounted at the bottom ends of the interiors of oil cylinders in a telescopic mode. First hydraulic columns are horizontally connected between the tops of the oil cylinders and the transverse plate. A fourth hydrauliccolumn can drive grinding rolls to move towards a partition plate until the outer edge of the partition plate is clamped between the grinding rolls at the upper and lower ends. A motor drives the grinding rolls to rotate, and the grinding rolls can conduct grinding on the cut edge of the partition plate, so that the edge of the partition plate is more smooth and is not likely to hurt the hands ofworkers during follow-up mounting and carrying. The using performance of the AGM partition plate forming device is better in the using process.

Owner:安徽宝鸿新材料科技有限公司

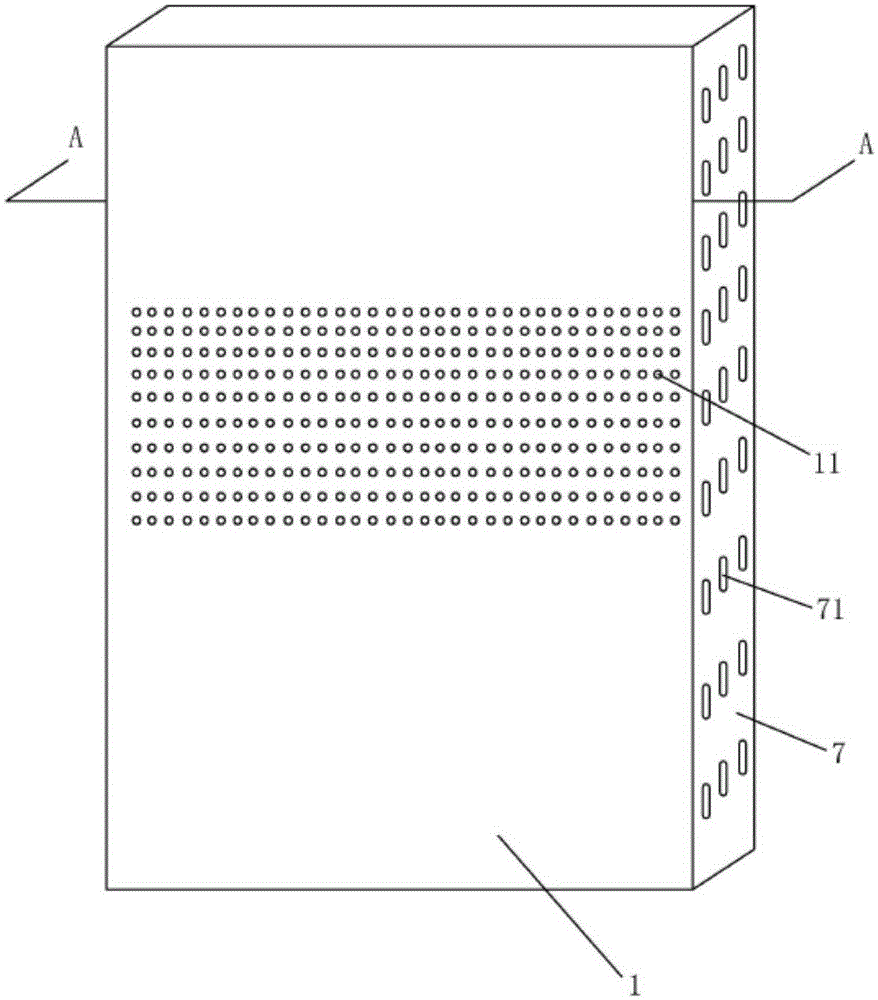

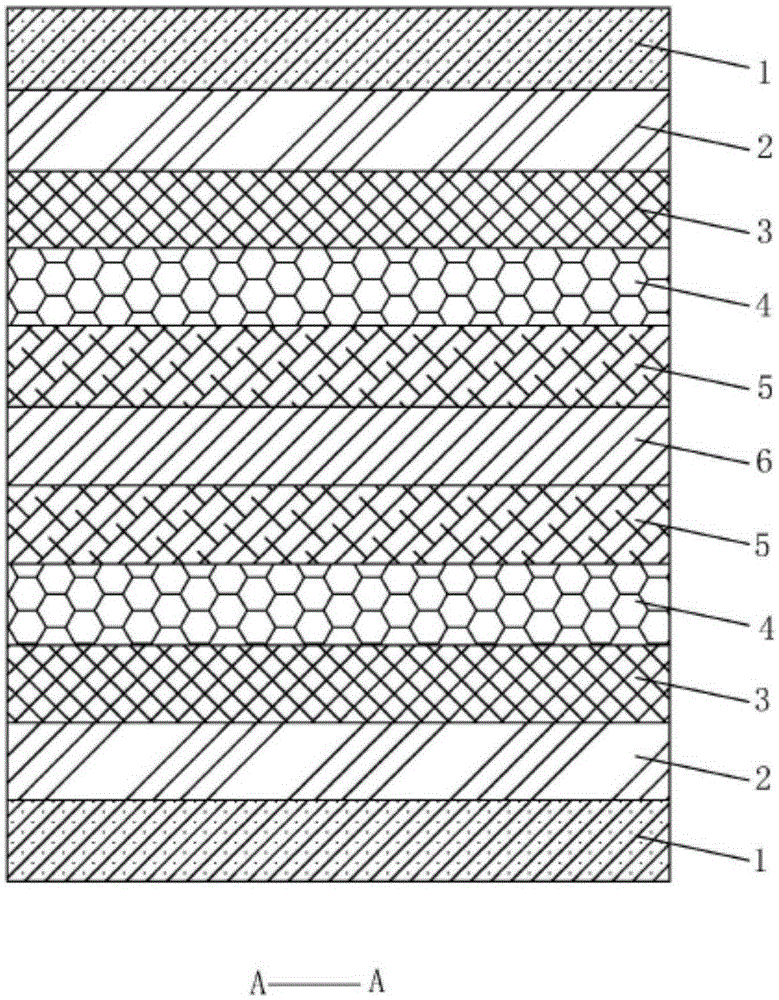

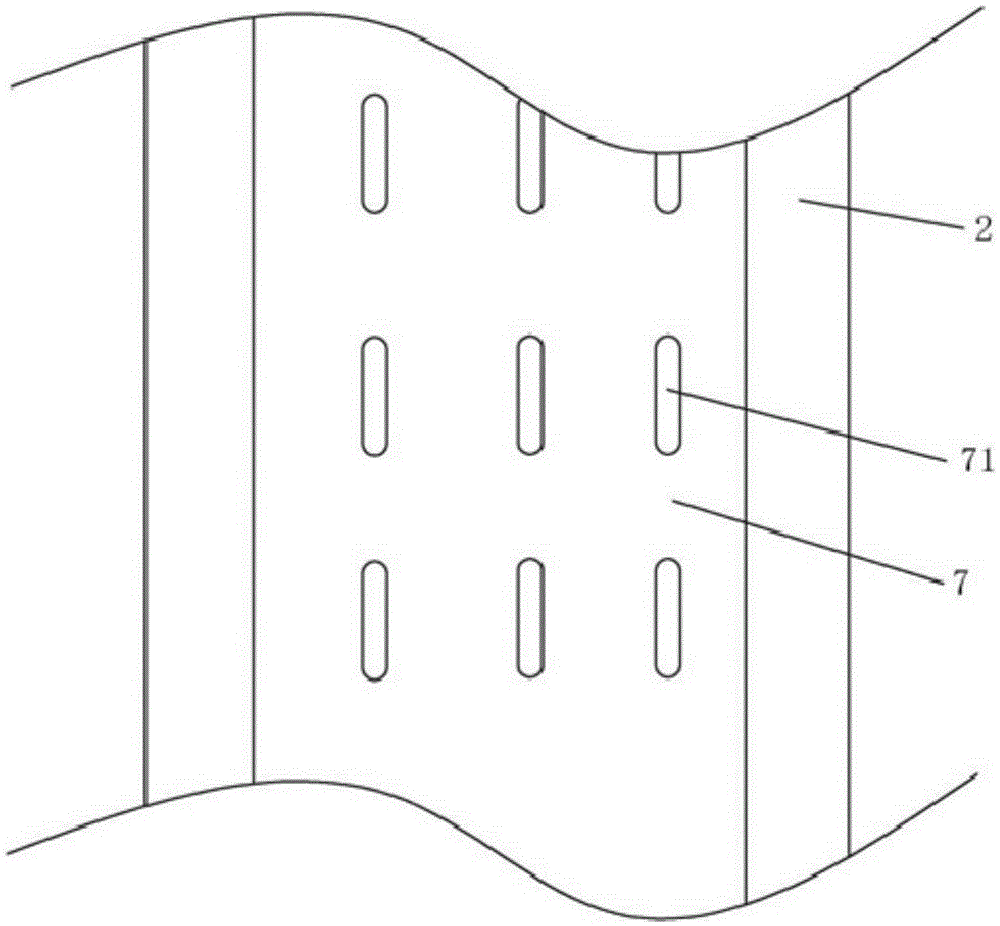

Color steel plate

InactiveCN105421653AImprove sound absorptionReduce heat lossSound proofingFire proofingSteel platesSheet steel

The invention discloses a color steel plate. According to the technical scheme, the color steel plate comprises two steel plates and strip steel for connecting the edges of the two steel plates. A fireproof rock wool core plate is arranged between the two steel plates, anti-radiation films are arranged on the two sides of the fireproof rock wool core plate, cellular plates are arranged on the outer sides of the anti-radiation films, anti-static films are arranged on the outer surfaces of the steel plates, sound absorption holes are formed in the steel plates and the anti-static films, and non-woven fabric is arranged between the cellular plates and the steel plates. Compared with an existing color steel plate, the color steel plate has the functions of good fireproofness, anti-radiation performance, sound insulation and anti-static performance, and the problem that the existing color steel plate cannot be applied to special plants is solved.

Owner:NANTONG ZHIGAO HEAVY IND TECH CO LTD

Silumin alloy melt alterant and silumin alloy preparation method using alterant

A silumin alloy melt alterant is characterized by comprising the following components in percentage by weight: 8-12% of Na2SO4, 8-12% of NaCl, 16-24% of K2ZrF6, and 48-72% of Na3PO4. The invention further discloses a silumin alloy melt preparation method. Compared with the prior art, the silumin alloy melt alterant has the advantages that the alterant provided by the invention has a better alteration function, so that an alloy structure is remarkably improved, the result obtained through structure observation and analysis shows that the alloy structure is thin and tiny, the size of primary silicon is 5-25 micrometers, and the primary silicon is round and smooth in edges and has no cuspidal edge or sharp corner.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

Garbage harmless treatment equipment for urban construction

ActiveCN114433604AShorten speedAvoid smashed situationsConstruction waste recoveryLighting and heating apparatusBrickIron removal

The invention belongs to the technical field of garbage treatment, and particularly relates to harmless garbage treatment equipment for urban construction, which comprises a rack, and a crushing assembly for crushing bricks and stones and a slow discharging assembly for slowly discharging crushed bricks and stones are mounted at the top of the rack; the same iron removal assembly capable of adsorbing steel and iron scraps is connected between the crushing assembly and the slow discharging assembly, a feeding hopper used for feeding is installed at the top of the crushing assembly, and two symmetrically-distributed buffering protection assemblies for slowing down the falling speed of bricks and stones and preventing crushed bricks and stones from splashing are rotationally installed in the feeding hopper; air curtains for preventing dust from escaping are symmetrically installed on the inner walls of the two sides of the feeding hopper, and air blown out by the air curtains forms an eddy current capable of gathering dust below the buffering protection assembly. The dust-proof and protection device has good dust-proof and protection effects, and metal resources in garbage can be recycled.

Owner:孙永伟

Processing method for the semiconductor pipe core assembly crystal surface

InactiveCN100428406CImprove stabilityImprove qualitySemiconductor/solid-state device manufacturingEnvironmental engineeringCleansing Agents

The related process method for grain surface in semiconductor die assembly comprises: inserting the target assembly into the cleaning tank, pouring corrosive agent into tank to remove the organic sewage on objective surface in 1-10min; inclining the tank to pour out the agent and fast clean the objective with deionized water; in turn, pouring the first cleaning agent into the tank to remove the metal ion and organic and form oxidation layer in 1-5min, then pouring out the agent and cleaning fast with deionized water; pouring the second cleaning agent in tank to remove heavy metal ion and organic in 1-5min, then pouring out the agent and cleaning fast with deionized water; finally, using ultrasonic wave to clean and dry the objective. This invention is low cost and benefit to improve semidiode performance.

Owner:江苏佳讯电子有限公司 +2

Automatic production line for producing high-strength color coated package steel strip by utilizing non-tempering process

ActiveCN100431776CLess investmentUndiminished strengthLiquid surface applicatorsFurnace typesProduction lineWax

Owner:ANSHAN FALAN STEEL STRIP CO LTD

Punching equipment for automotive lampshade

The invention discloses automatic punching equipment for an automotive lampshade. The automatic punching equipment comprises a upper mold base, a lower mold base and a pressing device. A square base is arranged on the lower mold base. A square lampshade sucker is arranged on the base. The slidable upper mold base is arranged on one side of the lampshade sucker. A knockout rod penetrates the middle of the upper mold base. The end, close to the lampshade sucker, of the knockout rod is connected with a female mold. Odd numbers or even numbers of pairs of tapered punching needles for punching the lampshade are arranged on the female mold. The other end of the knockout rod is connected with an air pump with a control switch. The pressing device is opposite to an upper mold plate. The pressing device comprises a pressing plate. A pressing bolt and a pressing nut are arranged on the side face of the pressing plate. The pressing bolt penetrates the rod portion of the pressing plate and is connected with the base. An elastic element is arranged in the middle of the pressing bolt. A gasket is arranged on the portion, connected with the pressing plate, of the pressing nut. The automatic punching equipment has the beneficial effects of being precise in punching, high in punching precision, free of burrs, high in production efficiency, automatic, capable of saving time and labor, low in production cost and the like.

Owner:WUXI JINGSHENGZHOU TECH

PCD (Poly Crystal Diamond) molding cutter for machining belt pulley

InactiveCN106270703AImprove processing efficiencyImprove wear resistanceMilling cuttersWorkpiecesTransition edgePulley

The invention relates to a PCD (Poly Crystal Diamond) molding cutter for machining a belt pulley. The PCD molding cutter comprises a cutter handle and a PCD cutter bit, wherein a tangent plane is arranged at the top of the cutter handle; a groove is formed in the top of the side wall of the cutter handle; a chamfer edge is arranged between the bottom of the groove and the side wall of the cutter handle; the PCD cutter bit is provided with a front cutter face and a rear cutter face; the front cutter face is arranged obliquely relative to the side wall of the cutter handle; the rear cutter face is arranged obliquely relative to the front cutter face; the PCD cutter bit comprises a plurality of milling teeth, a transition edge and a side edge; a milling groove is formed between the adjacent milling teeth; and the section of the transition edge comprises a horizontal plane and an inclined plane. The PCD molding cutter provided by the invention can be used for machining a plurality of grooves at the same time, is rapid in molding and resists abrasion, so that the machining efficiency and the machining quality are improved.

Owner:江苏中晟钻石工具有限公司

A kind of multi-element microalloyed high-strength heat-resistant rare earth magnesium alloy and preparation method thereof

The invention provides a rare earth magnesium alloy, which is a modified Mg-Gd-Y-Zr rare earth magnesium alloy; the as-cast metallographic structure of the rare earth magnesium alloy has rounded edges Mg 5 Gd phase; or, the metallographic structure of the rare earth magnesium alloy in the extruded state has small particle-like precipitates; the radial size of the small particles is 10-150 nm. The invention improves the microstructure and morphology of the alloy through the method of multi-element microalloying, improves the microstructure and morphology of the alloy material by adding a specific proportion of trace Ag and Sc, and improves the effect of age hardening and grain refinement, thereby obtaining excellent room temperature and temperature. High temperature mechanical properties. On the premise of not increasing the total amount of rare earths, the present invention has high strength and performance indexes, retains good plasticity, is easy to realize engineering application, and can meet the requirements for lightweight structural materials in the current aerospace, missile military, rail transit and other fields. Requirements for mechanical properties at room temperature and high temperature.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A cleanable cloth hole puncher

The invention provides a cleanable clothing material puncher which comprises a base, a baffle, a column, a control box, a fixing plate, a sliding block, a telescopic rod, a turntable, a motor, a drill bit, a first clamp support, a second clamp support, a first sliding groove, a press plate, a supporting rod, an electric fan, a dust collecting box, a garment material, a foam plate, a second sliding groove and a third sliding groove. A feeding mechanism comprises a material laying device and a material pressing device. The material laying device comprises a material laying part and a feeding device, wherein the material laying part is arranged at the bottom of a punching device. The first clamp support is provided with a supporting rod, the supporting rod is provided with the electric fan, and the second clamp support is provided with the dust collecting box. The cleanable clothing material puncher utilizes the electric fan to blow dust produced on ends or fabrics due to punching into the dust collecting box, a press block is in abutting connection wit a material to be processed when a lifting air cylinder moves down, accordingly the material to be processed is pressed on a punching foam block and is prevented from moving, accordingly holes formed by the drill bit are more exquisite, and the edges of the holes are smoother.

Owner:桐乡市绅凡服饰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com