Blank multivesicular liposome as well as preparation method and device thereof

A multivesicular liposome and blank technology, which is applied in the fields of botanical equipment and methods, chemical instruments and methods, animal repellents, etc., can solve the problem of loose multivesicular liposome structure, uneven vesicle size, Poor vesicle stability and other problems, to achieve the effect of improving drug release time, good vesicle stability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

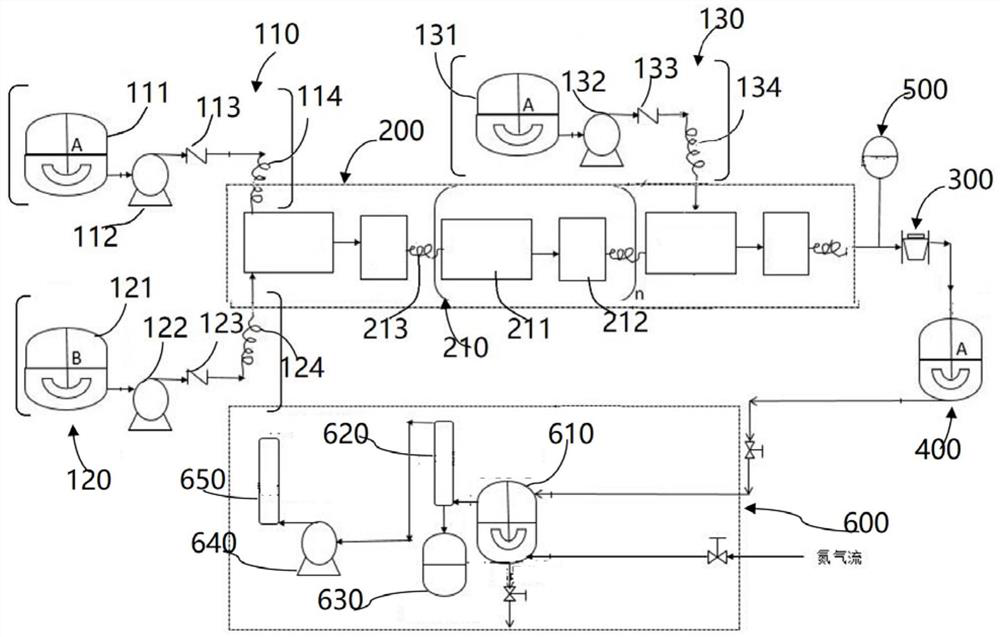

[0076]The preparation device of the multivesicular liposome in this embodiment is asfigure 1Shown. Among them, the treatment kettle A 111 and the treatment kettle B121 are 2L reaction kettles, and the treatment kettle C 131 is a 15L conventional small-scale reaction kettle; the number n of the micro-reaction group 210 is 5; among them, the thermostatic tube (A 114, B 124, C 134) has a length of 0.3m and a diameter of 3mm; the delay tube 213 has a diameter of 3mm and a length of 1m; the microchannel cross-sectional equivalent diameter of the microchannel reactor 211 is 0.5mm, and the microchannel length is 1m; The mixer 212 has a plurality of microchannels, the cross-sectional equivalent diameter of the microchannels is 0.3mm, and the length of the microchannels is 0.5m.

[0077]In this embodiment, the specific steps of the preparation method of multivesicular liposomes are as follows:

[0078]1) Preparation of oil phase fluid A: pre-add 80g of soybean phospholipid, 40g of cholesterol, 10g...

Embodiment 2

[0085]The preparation device of the multivesicular liposome in this embodiment is asfigure 1Shown. Among them, the treatment tank A 111 and the treatment tank B121 are 2L reactors, and the treatment tank C 131 is a 15L conventional small test reactor; the number n of the micro-reaction group 210 is 6; among them, the thermostatic tube (A 114, B 124, C 134) has a length of 0.2m and a diameter of 4mm; the diameter of the delay tube 213 is 2mm and a length of 6m; the microchannel cross-sectional equivalent diameter of the microchannel reactor 211 is 3mm, and the microchannel length is 2m; The device 212 has a plurality of microchannels, the cross-sectional equivalent diameter of the microchannels is 4mm, and the length of the microchannels is 0.8m.

[0086]In this embodiment, the specific steps of the preparation method of multivesicular liposomes are as follows:

[0087]1) Preparation of oil phase fluid A: In advance, 40g egg yolk phospholipids, 10g cholesterol, 5g tricaprylin, 1g Tween 80,...

Embodiment 3

[0094]The preparation device of the multivesicular liposome in this embodiment is asfigure 1Shown. Among them, the treatment kettle A 111 and the treatment kettle B121 are 2L reaction kettles, and the treatment kettle C 131 is a 15L conventional small-scale reaction kettle; the number n of the micro-reaction group 210 is 3; among them, the thermostatic tube (A 114, B 124, C 134) has a length of 0.11m and a diameter of 4mm; the delay tube 213 has a diameter of 4mm and a length of 0.7m; the microchannel cross-sectional equivalent diameter of the microchannel reactor 211 is 9mm, and the microchannel length is 1.9m; The micromixer 212 has a plurality of microchannels, the cross-sectional equivalent diameter of the microchannels is 8mm, and the length of the microchannels is 7m.

[0095]In this embodiment, the specific steps of the preparation method of multivesicular liposomes are as follows:

[0096]1) Preparation of oil phase fluid A: In advance, add 50 g of soybean phospholipid, 20 g of ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com