Patents

Literature

237 results about "Micromixer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mechanics, a micromixer is a device based on mechanical microparts used to mix fluids. This device represents a key technology to fields such as chemical industry, pharmaceutical industry, analytical chemistry, biochemical analysis, and high-throughput synthesis, since it makes use of the miniaturization of the fluids associated in the mixing to reduce quantities involved in the chemical and/or biochemical processes.

Micromixer

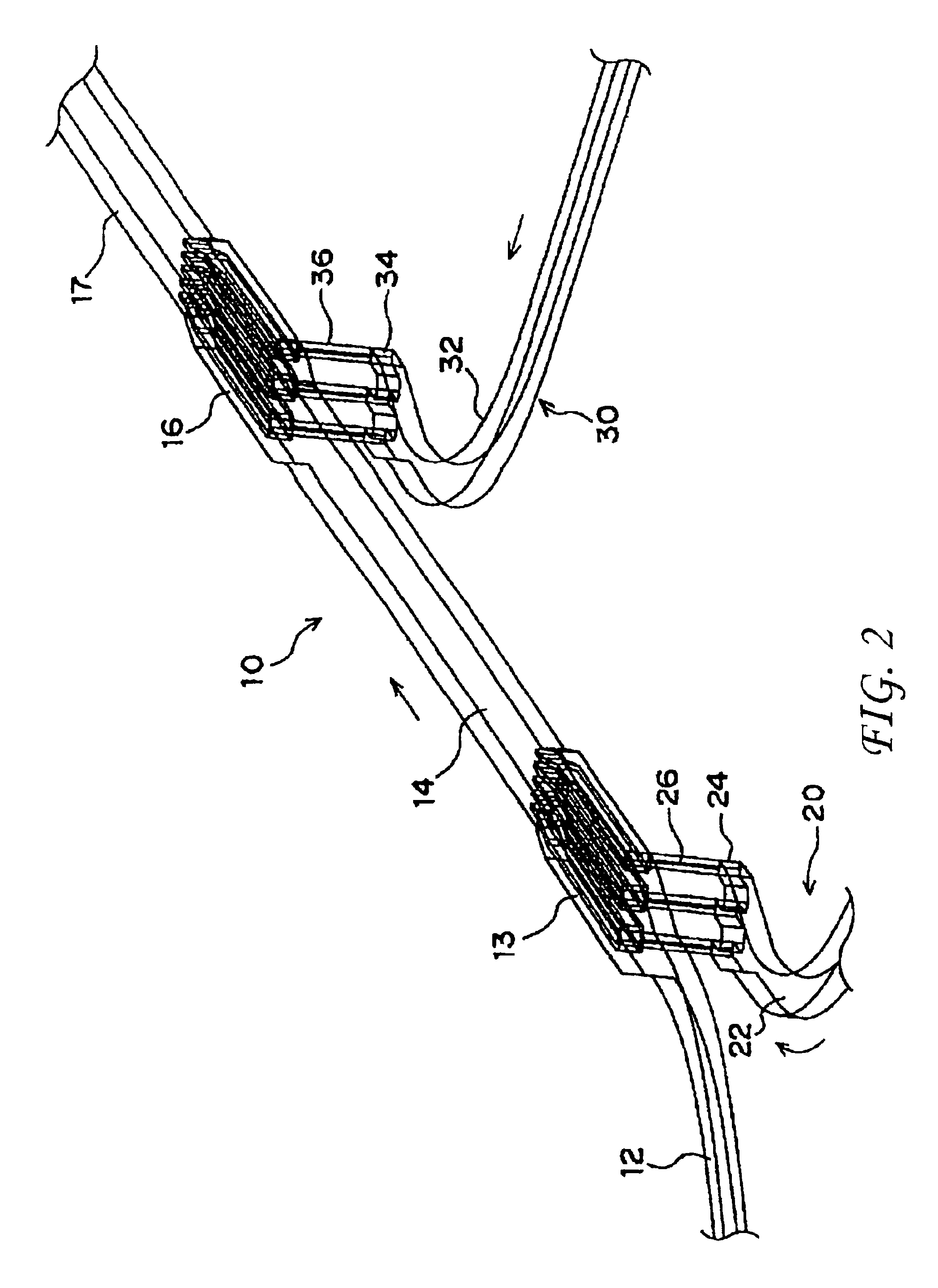

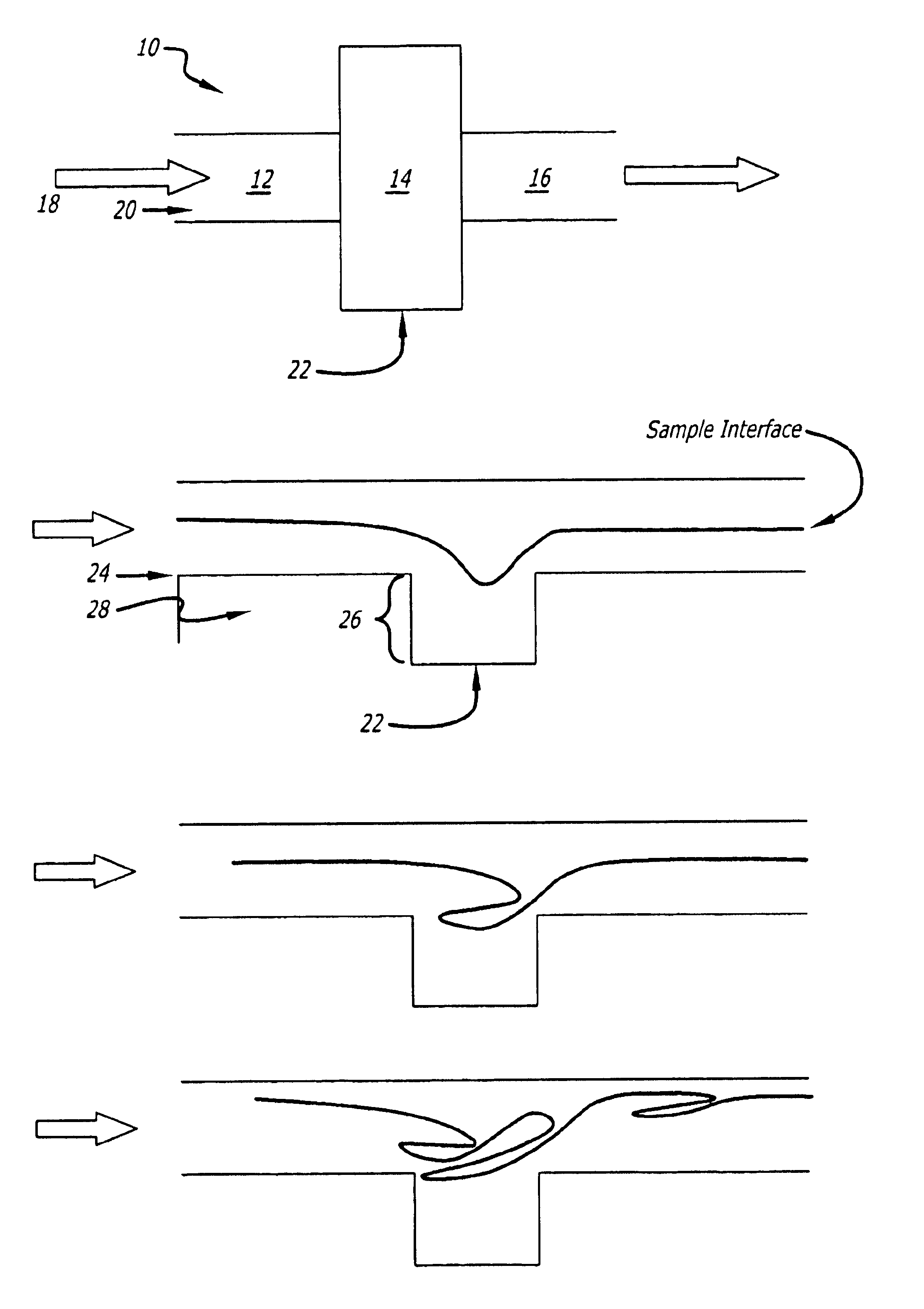

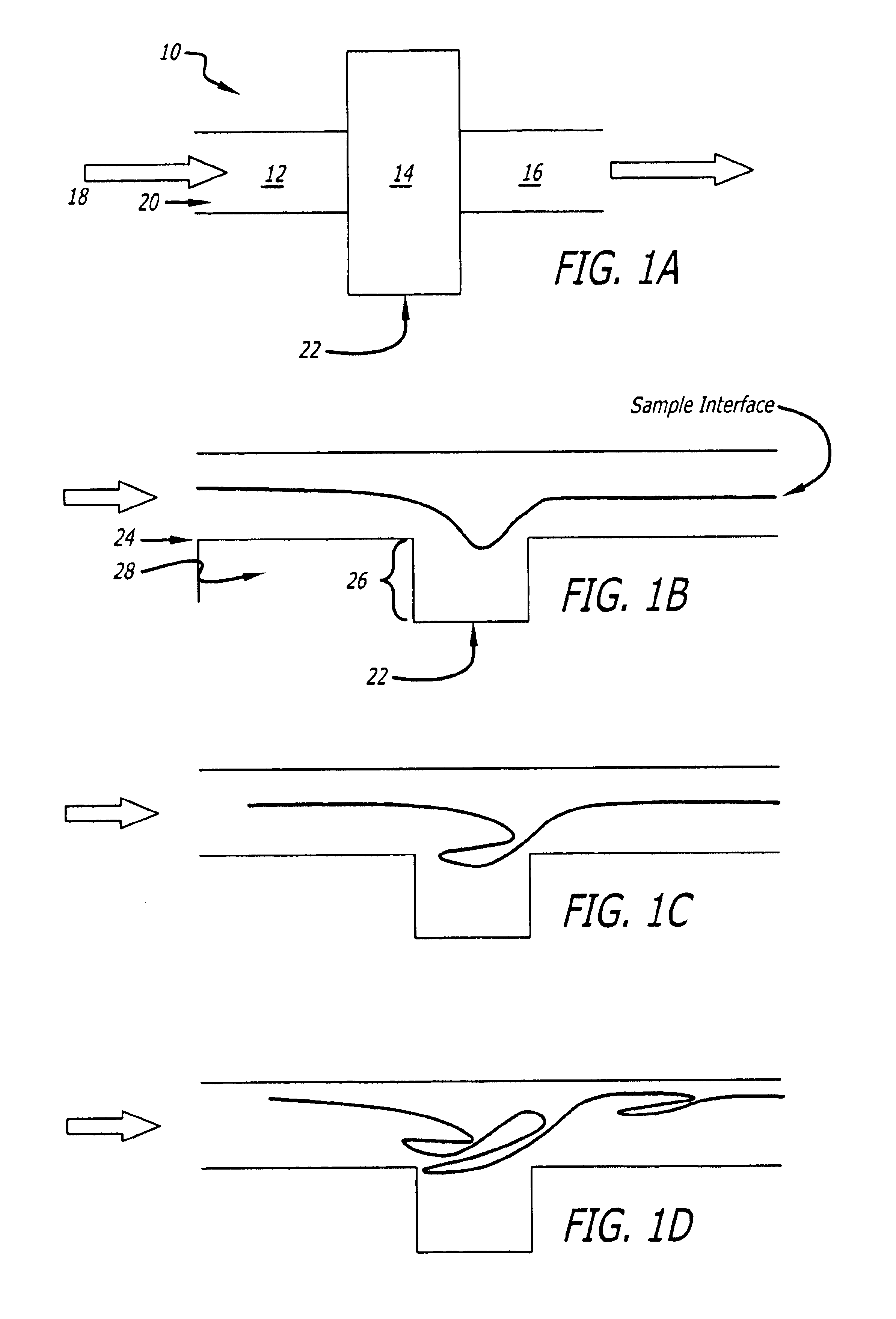

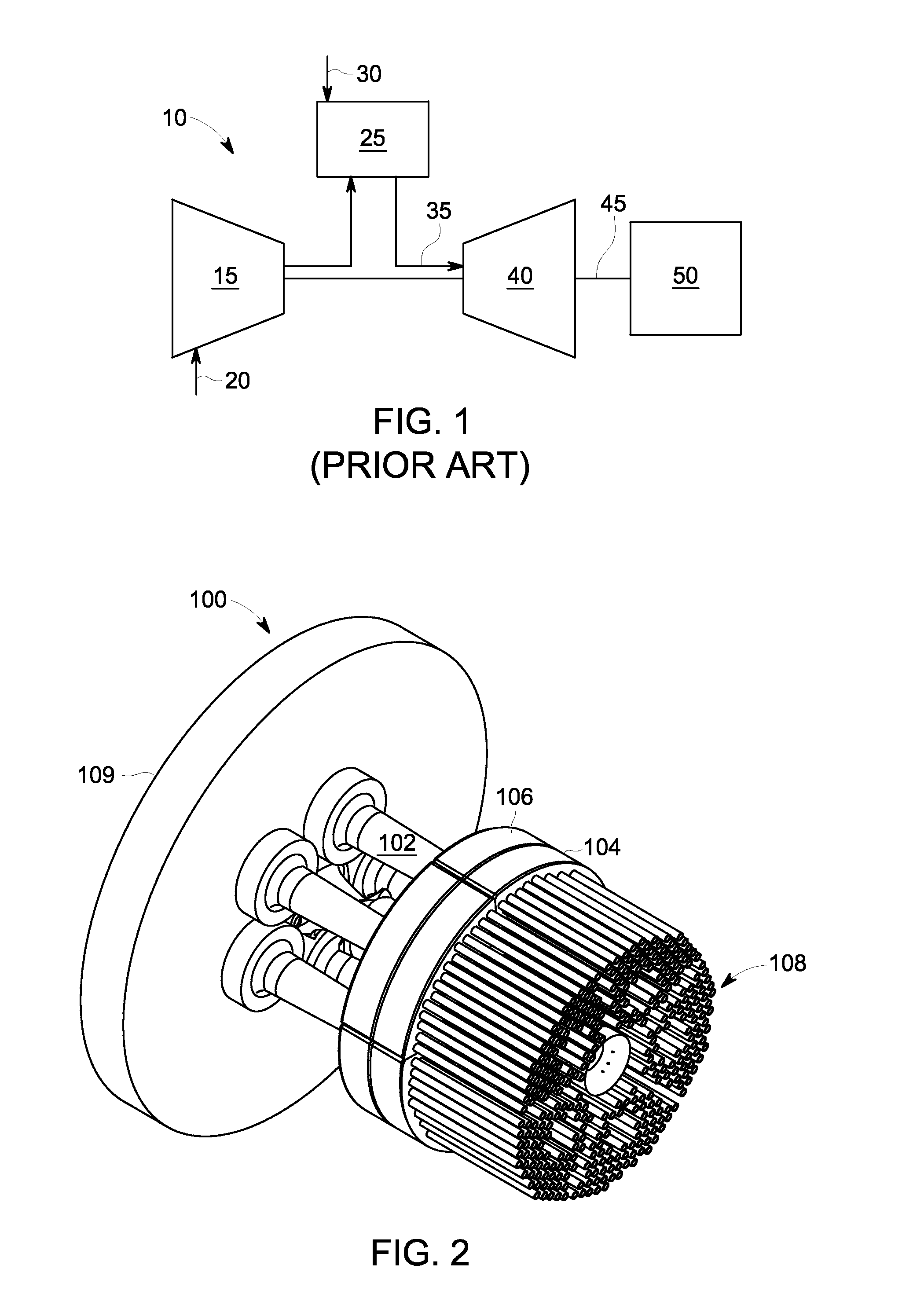

InactiveUS20050252840A1Efficient mixingEnhanced mixing processIon-exchange process apparatusFlow mixersComputer scienceDynamic range

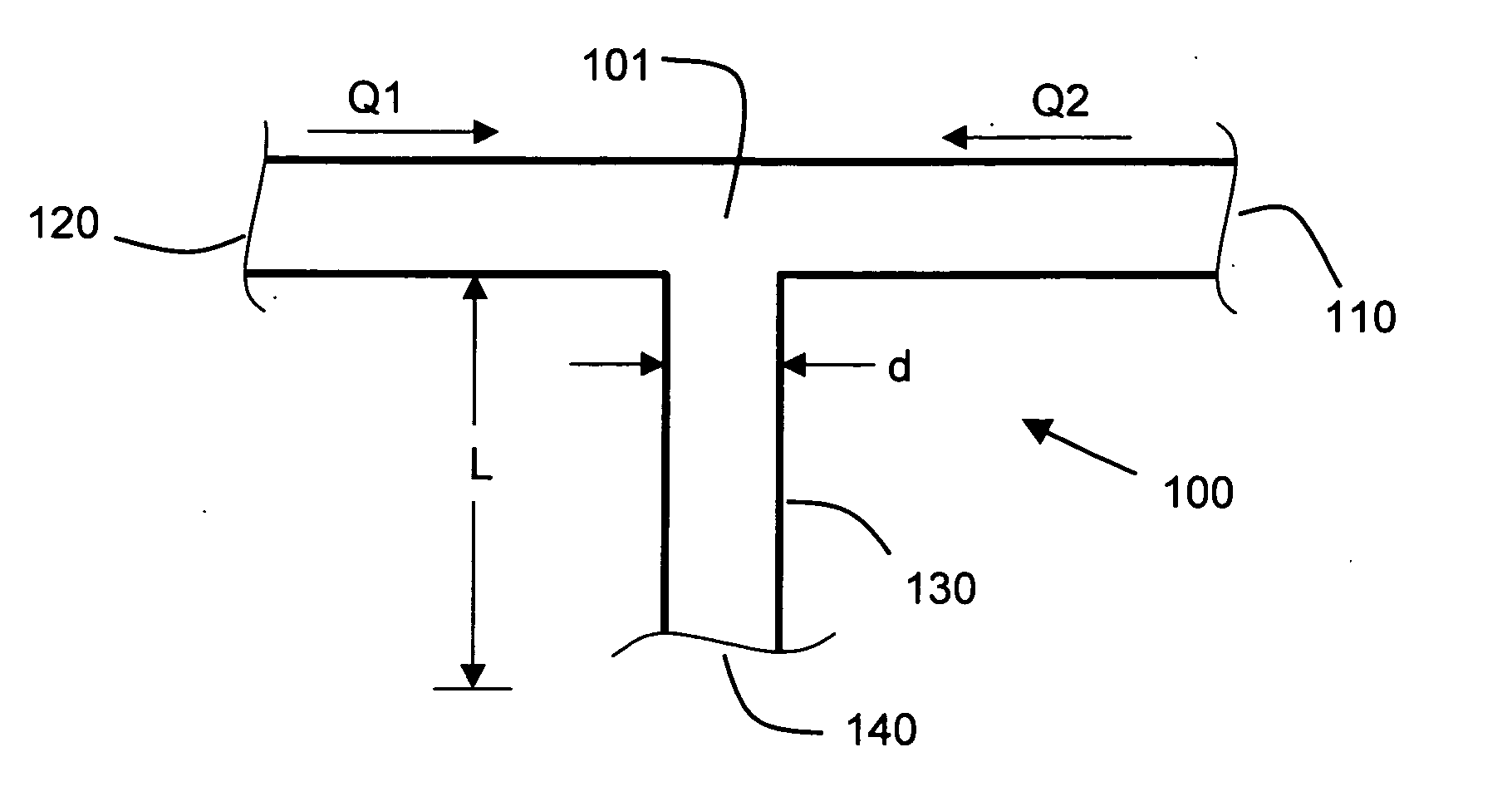

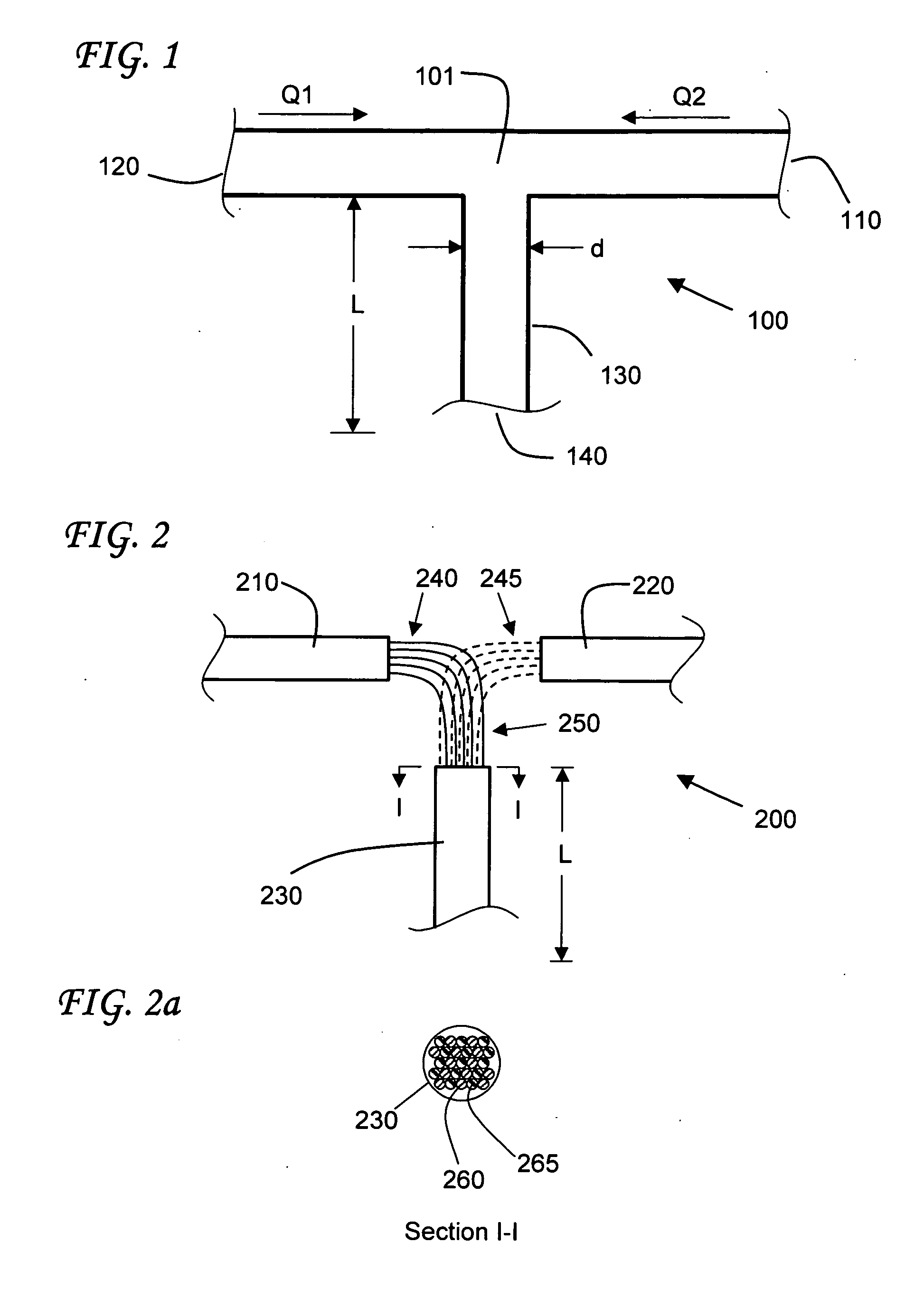

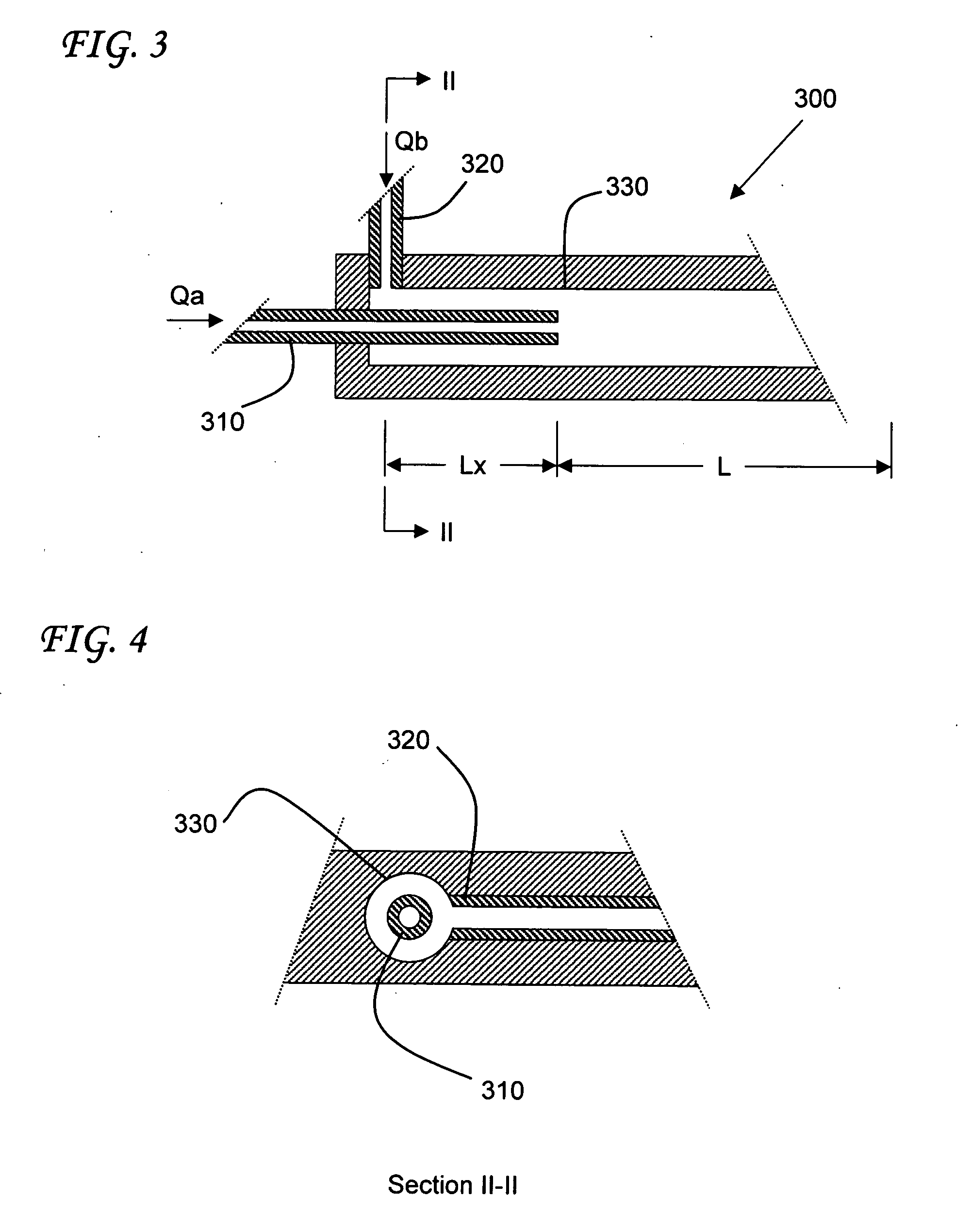

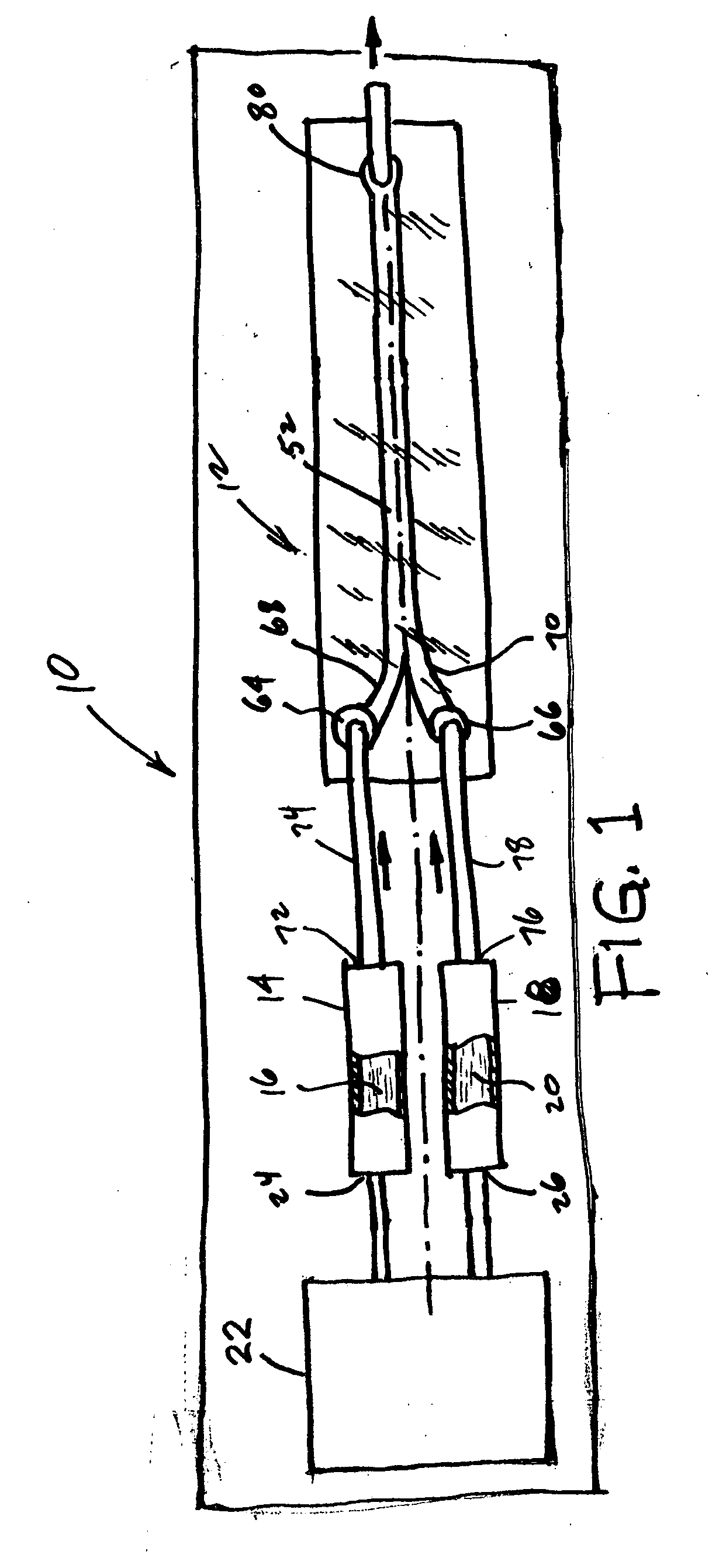

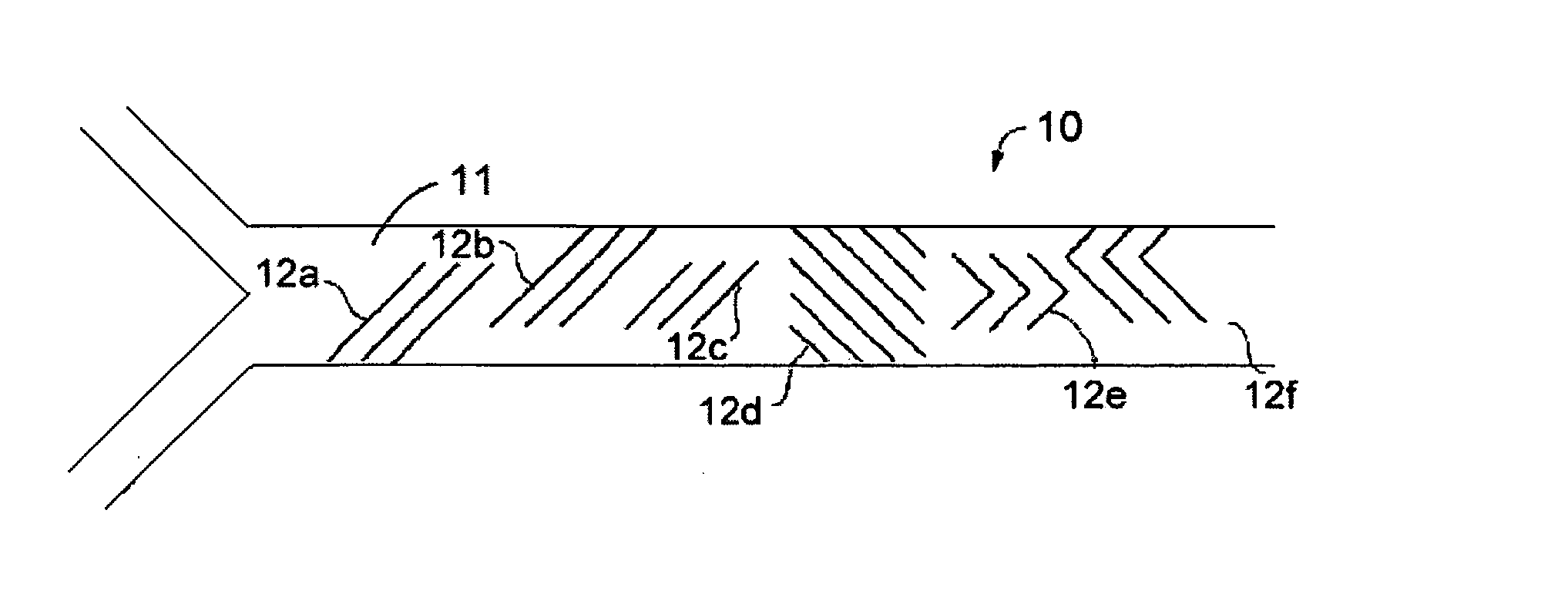

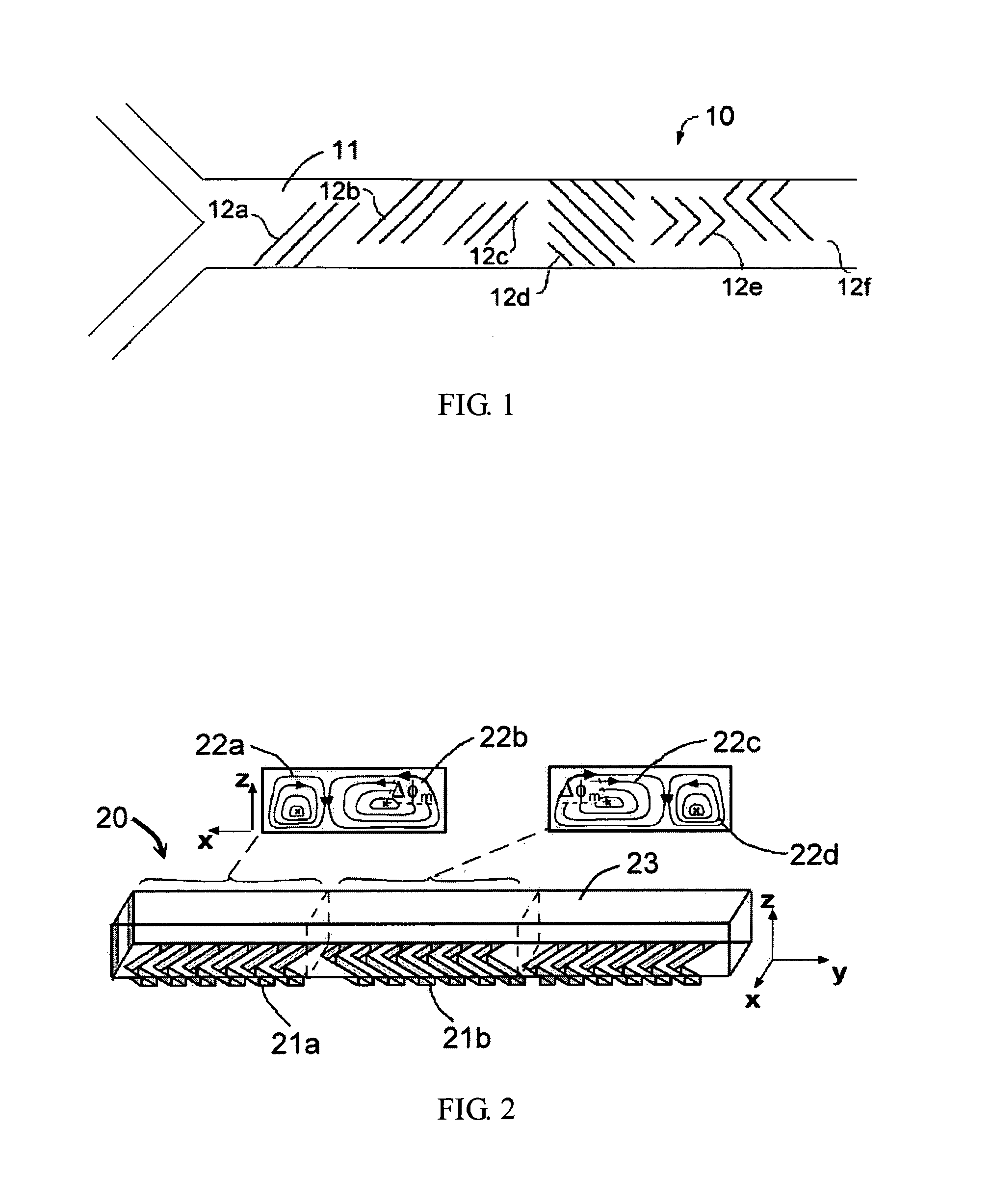

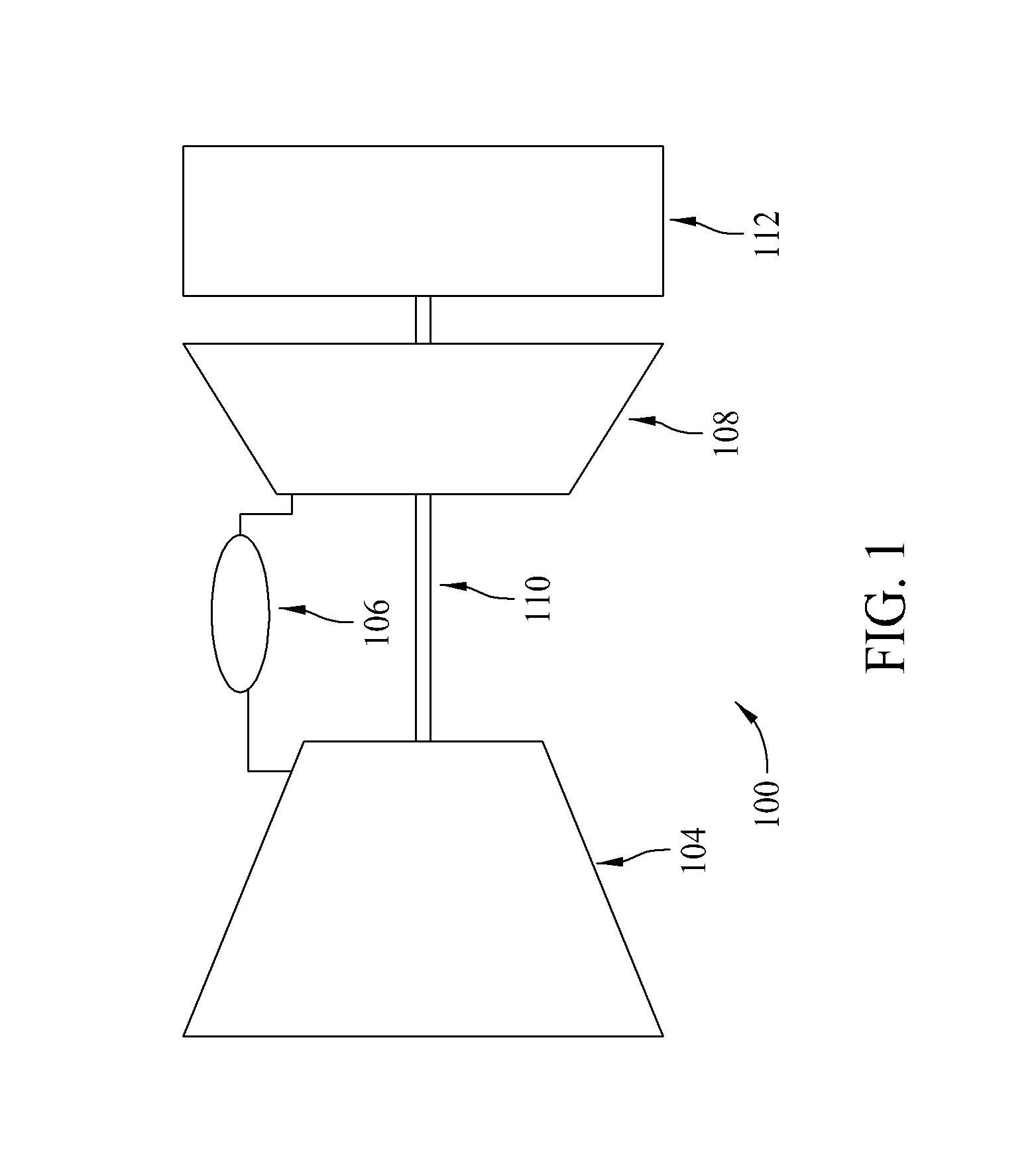

Methods and apparatus for mixing fluids are provided. The devices and methods operate without moving parts, and generate well-mixed fluids over a broad dynamic range of flow rates. Preferred embodiments include junction-type mixers, bundled mixers, and co-axial mixers. The devices and methods are optimized to produce rapid, accurate gradients to improve associated system throughput and reproducibility.

Owner:EKSIGENT TECH

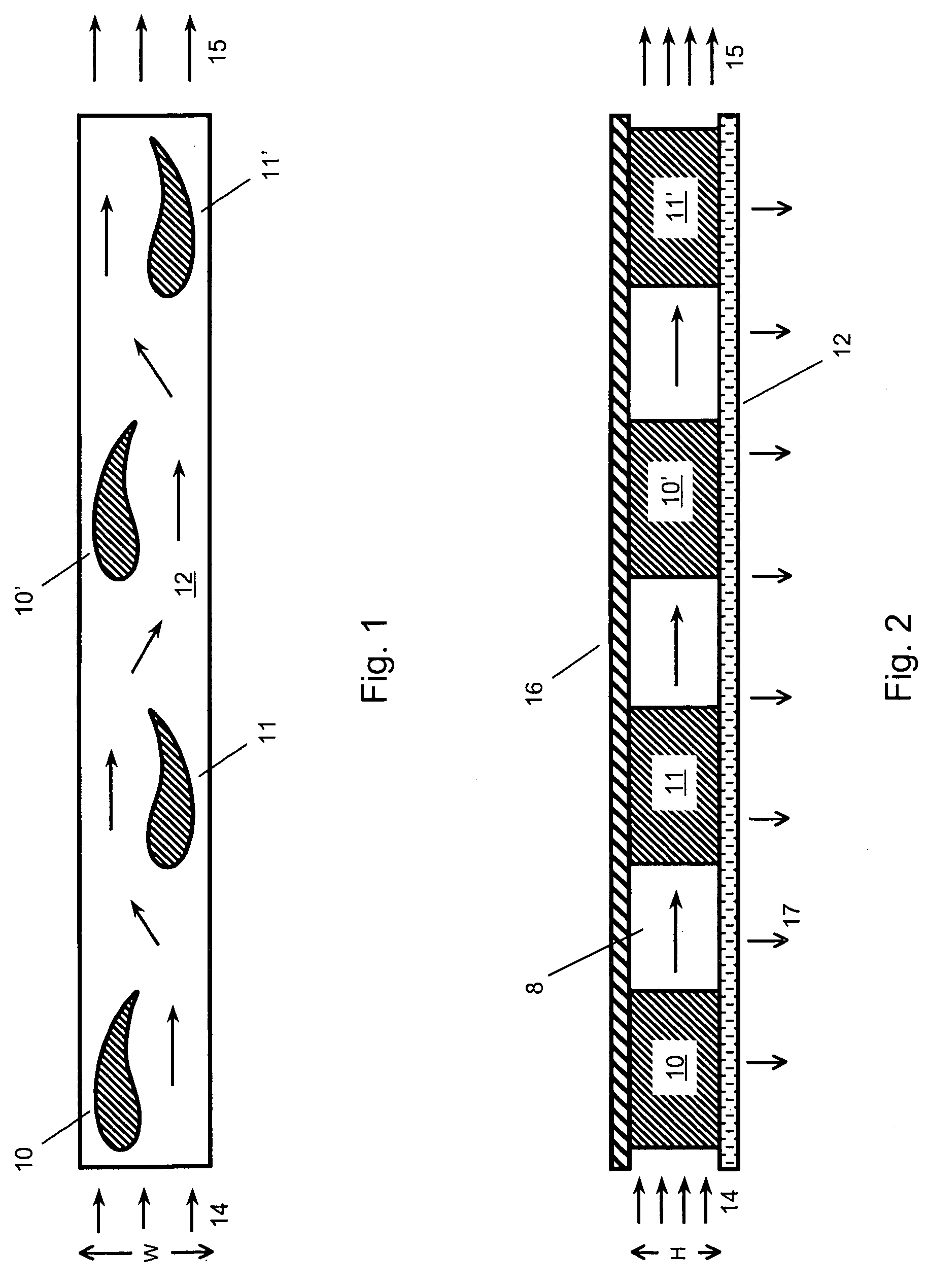

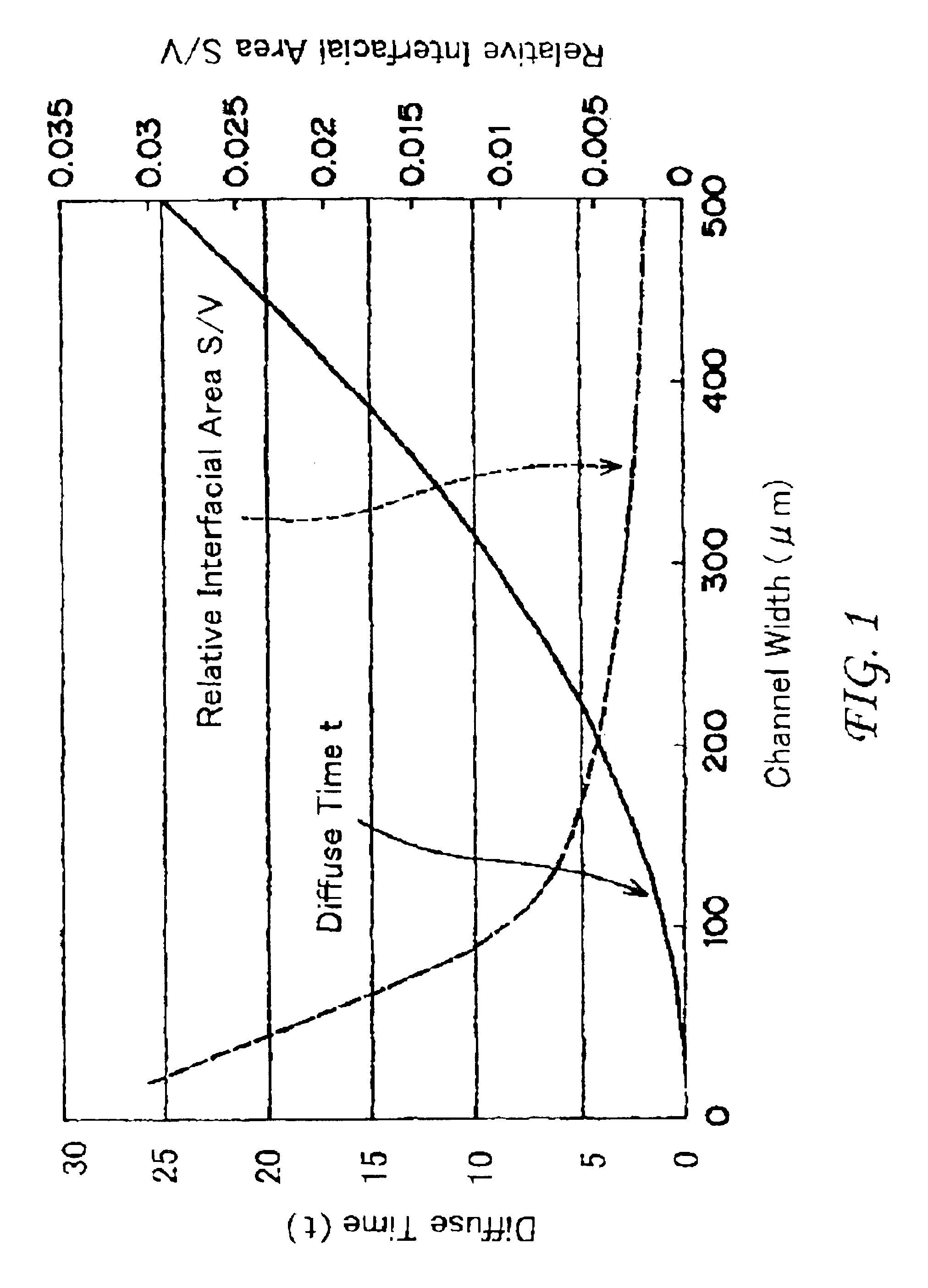

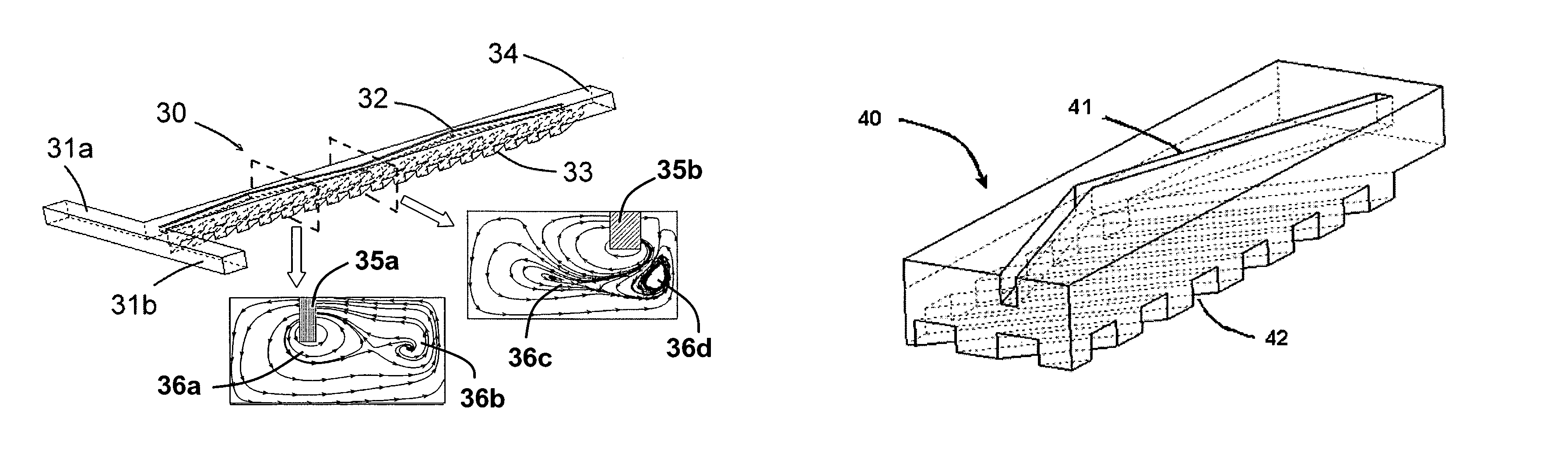

Fluidic mixing structure, method for fabricating same, and mixing method

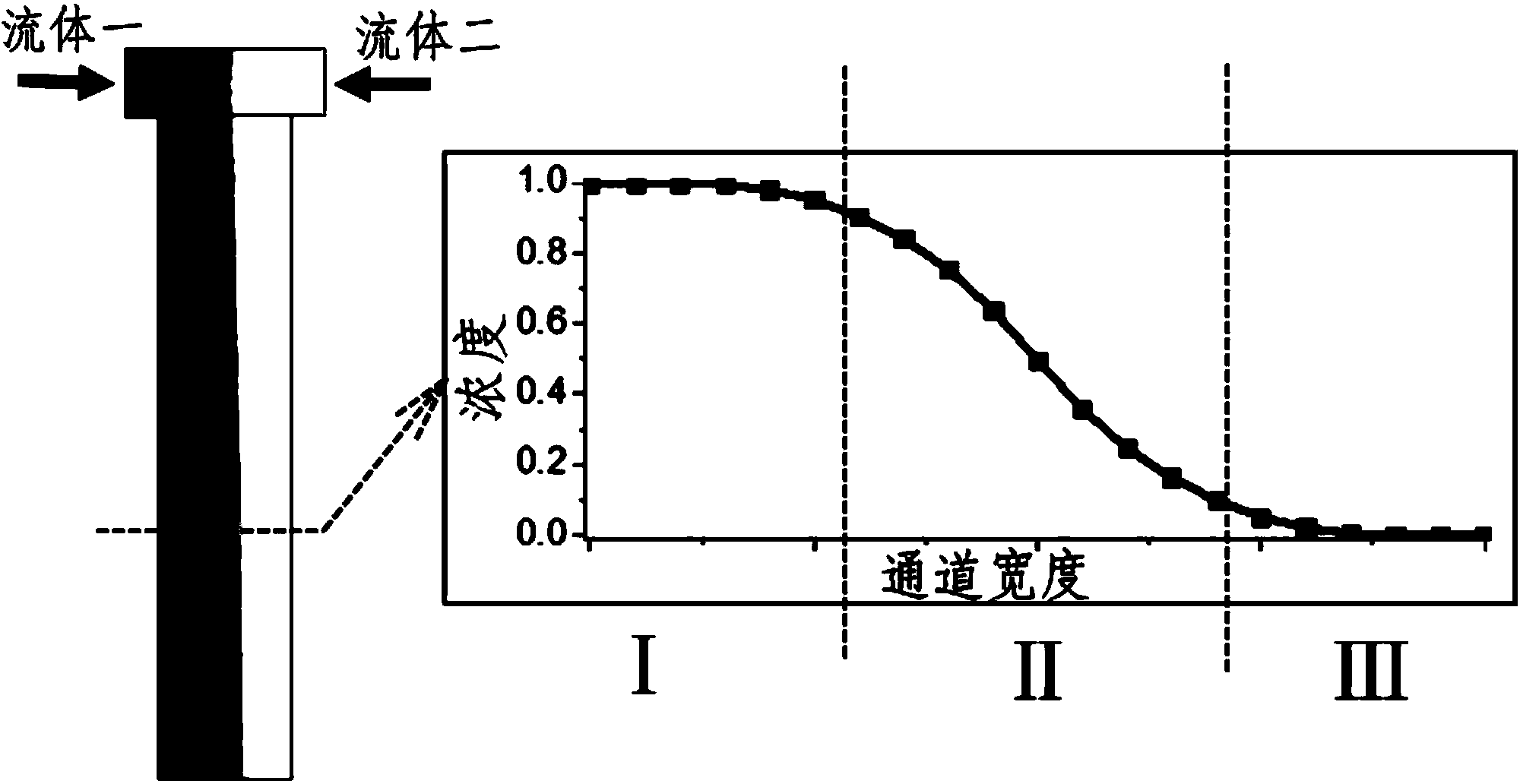

InactiveUS20070047388A1Semi-permeable membranesFixed microstructural devicesSurface patternInstability

A fluidic micromixer comprises a plurality of fluid inlets in communication with a mixing chamber, the plurality of fluid inlets being adapted to introduce into the chamber a corresponding plurality of distinct fluid streams. The mixing chamber comprises at least one surface patterned to define hydrophobic and hydrophilic regions spaced apart along a principal direction of fluid flow within the chamber from the fluid inlets to a fluid outlet, the regions being adapted to induce fluid flow in a direction transverse to the principal direction of fluid flow to mix the fluid streams. At least one of the hydrophobic regions may comprise microstructures patterned on the at least one surface. Also disclosed are a method for fabricating the micromixer, a method of mixing a plurality of fluid streams by vortex mixing or instability mixing, and a system comprising the micromixer, fluid reservoirs and a pump for generating flow of fluids from the reservoirs to the micromixer.

Owner:TELEDYNE LICENSING

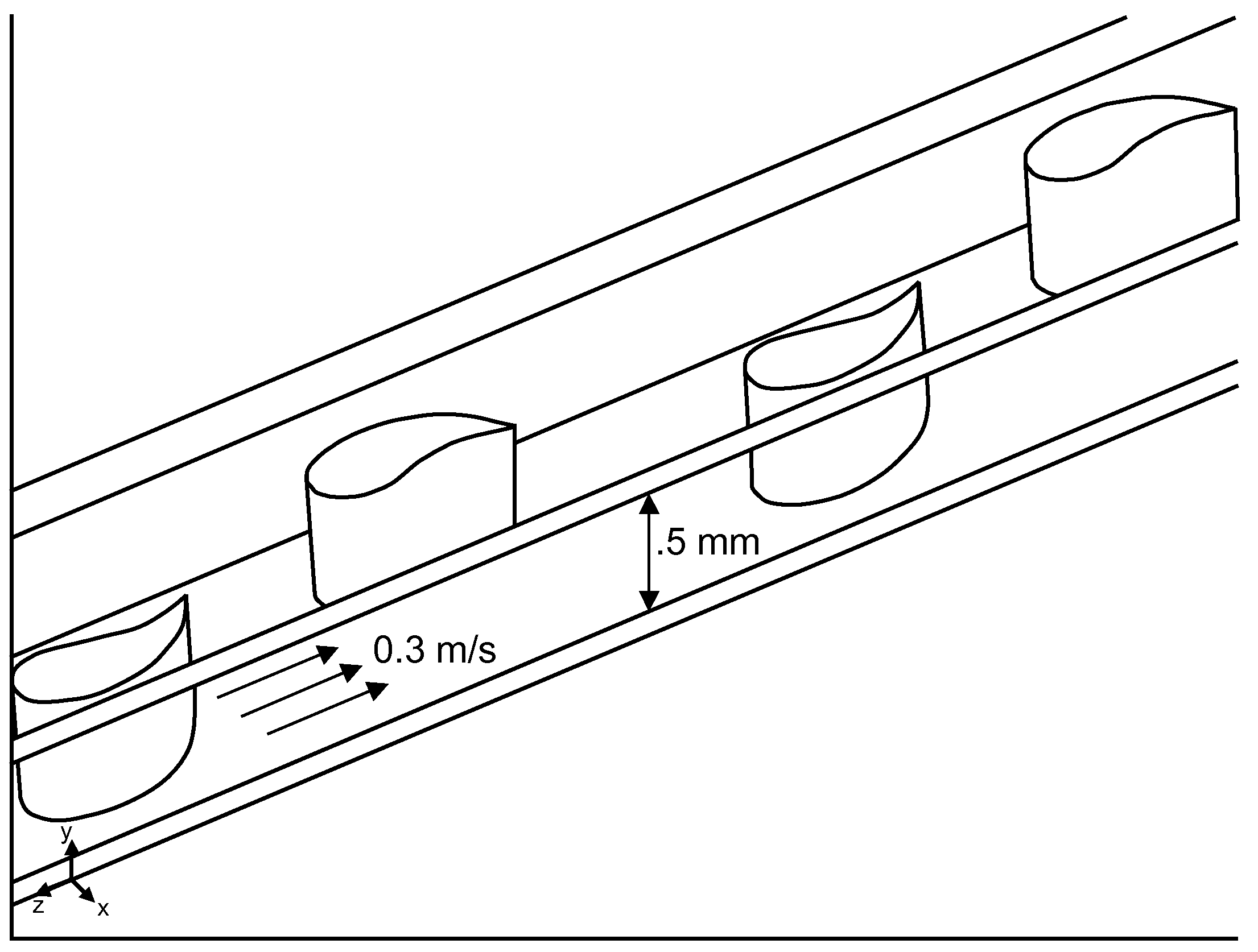

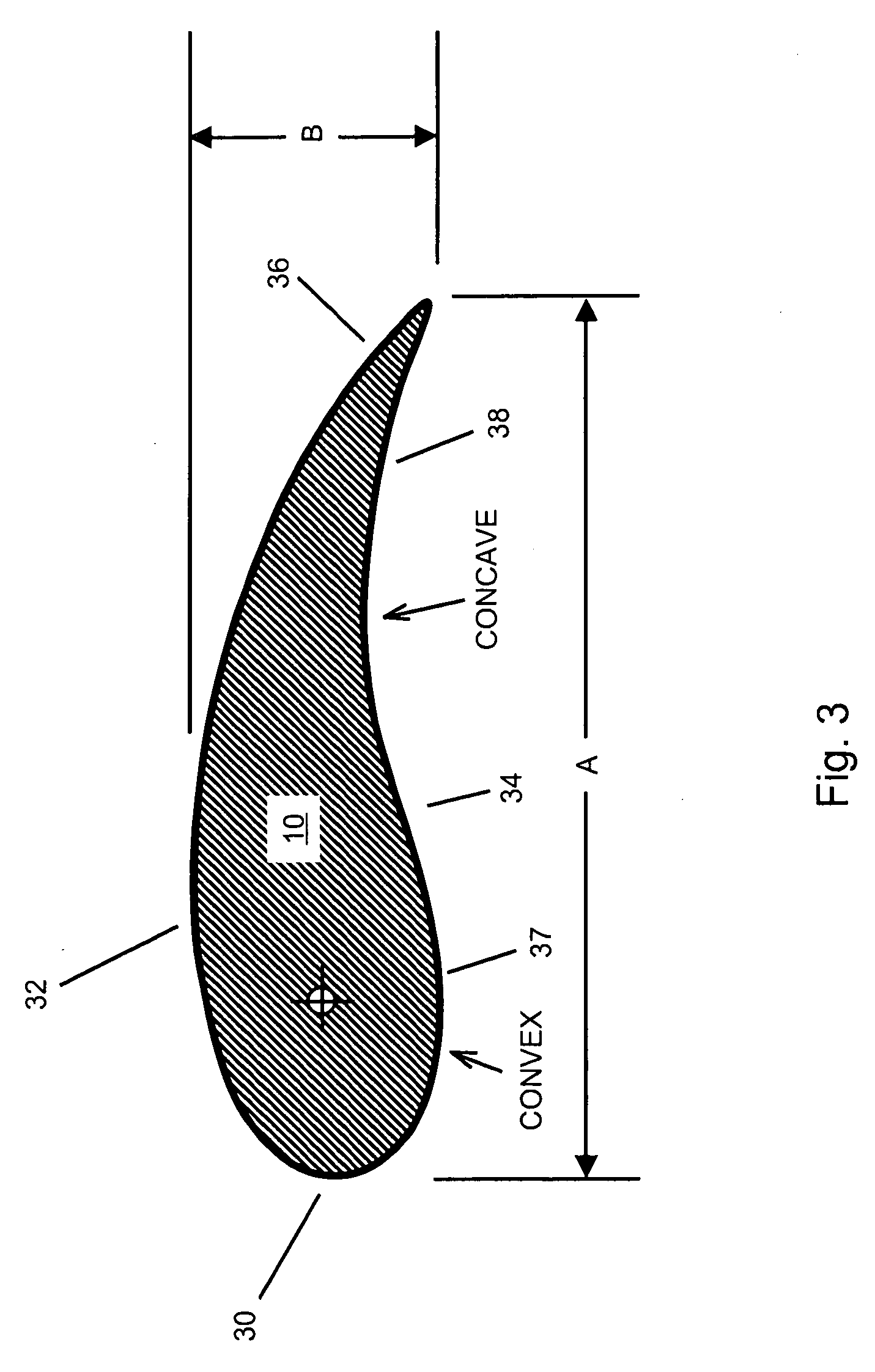

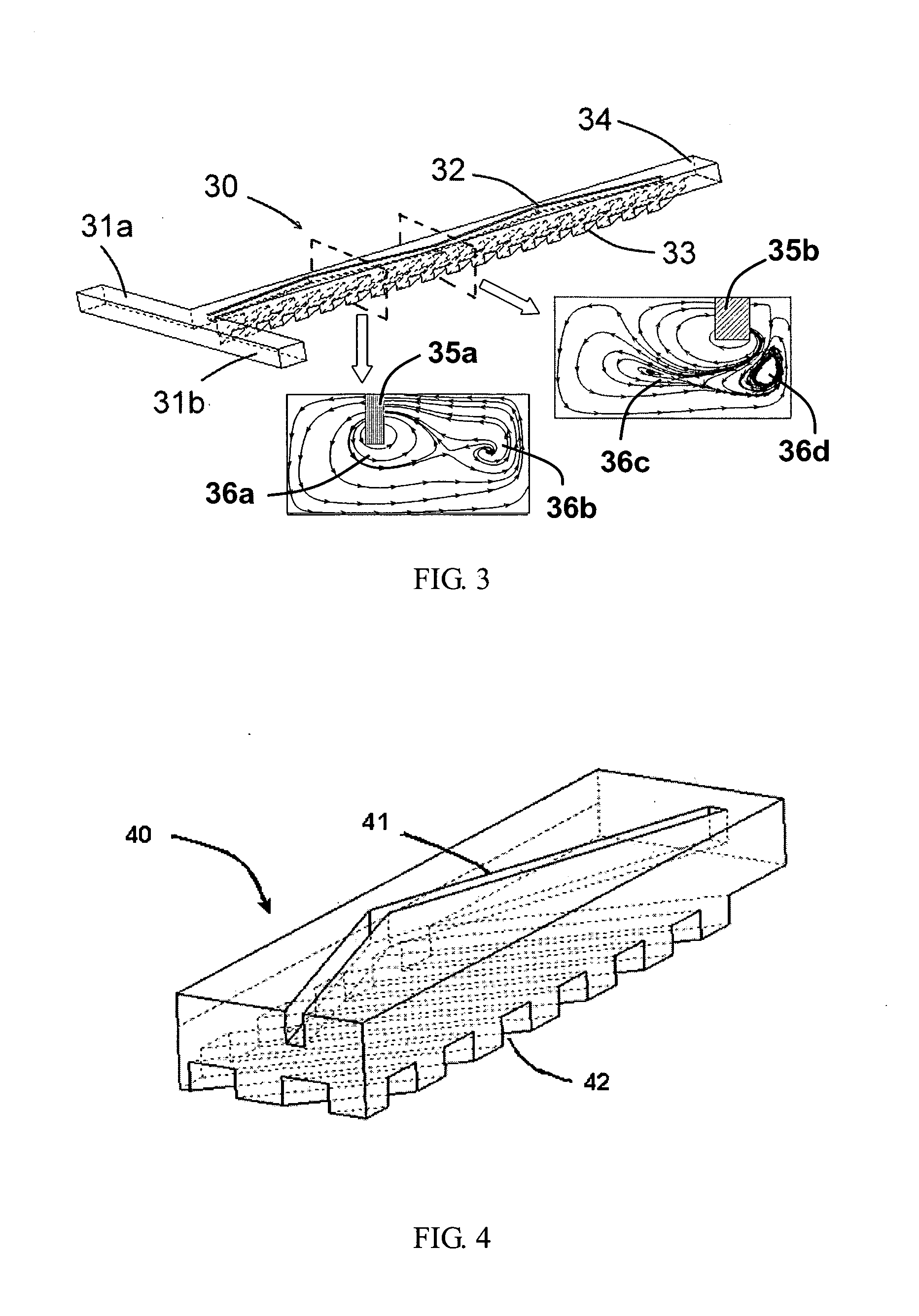

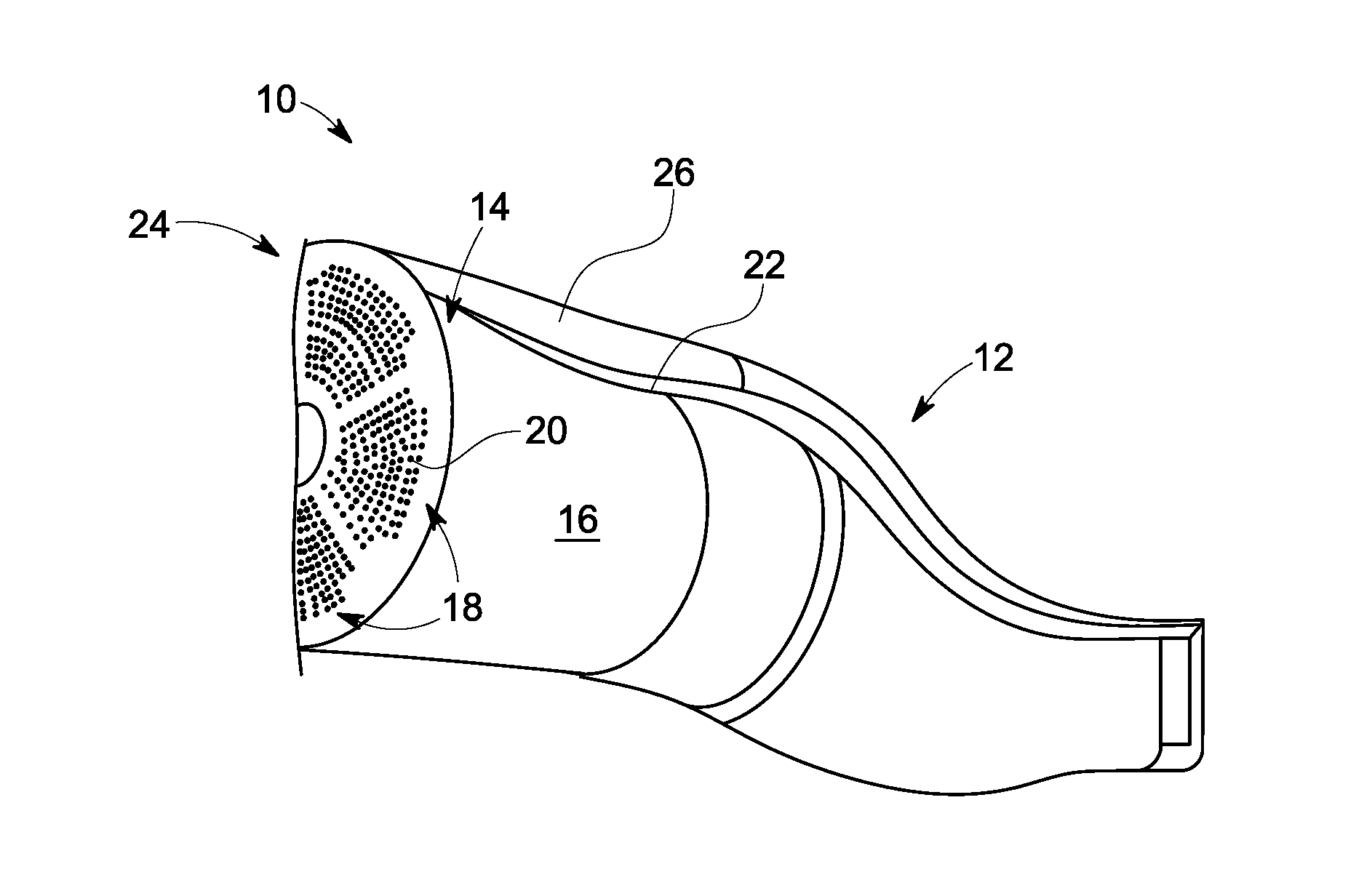

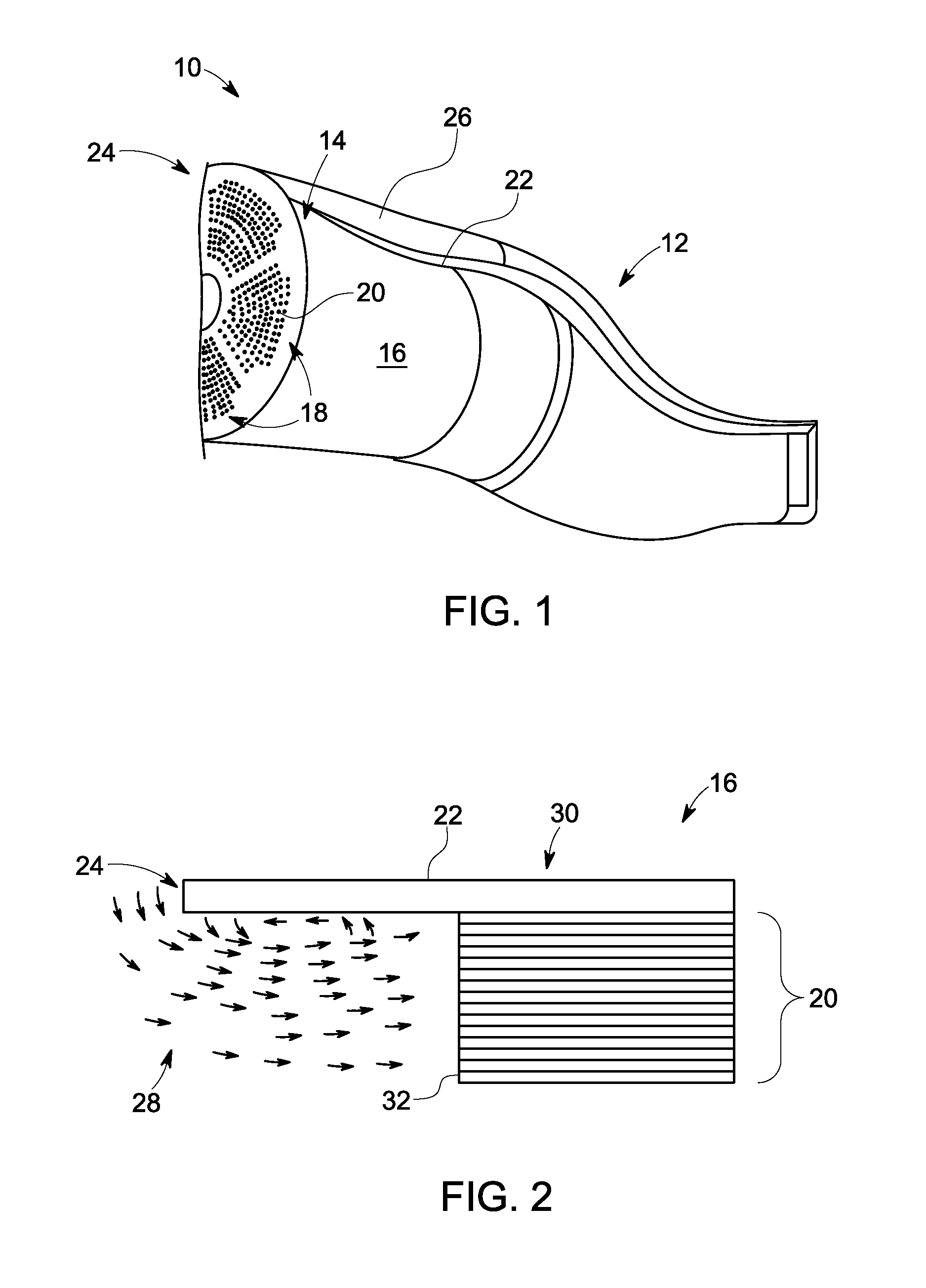

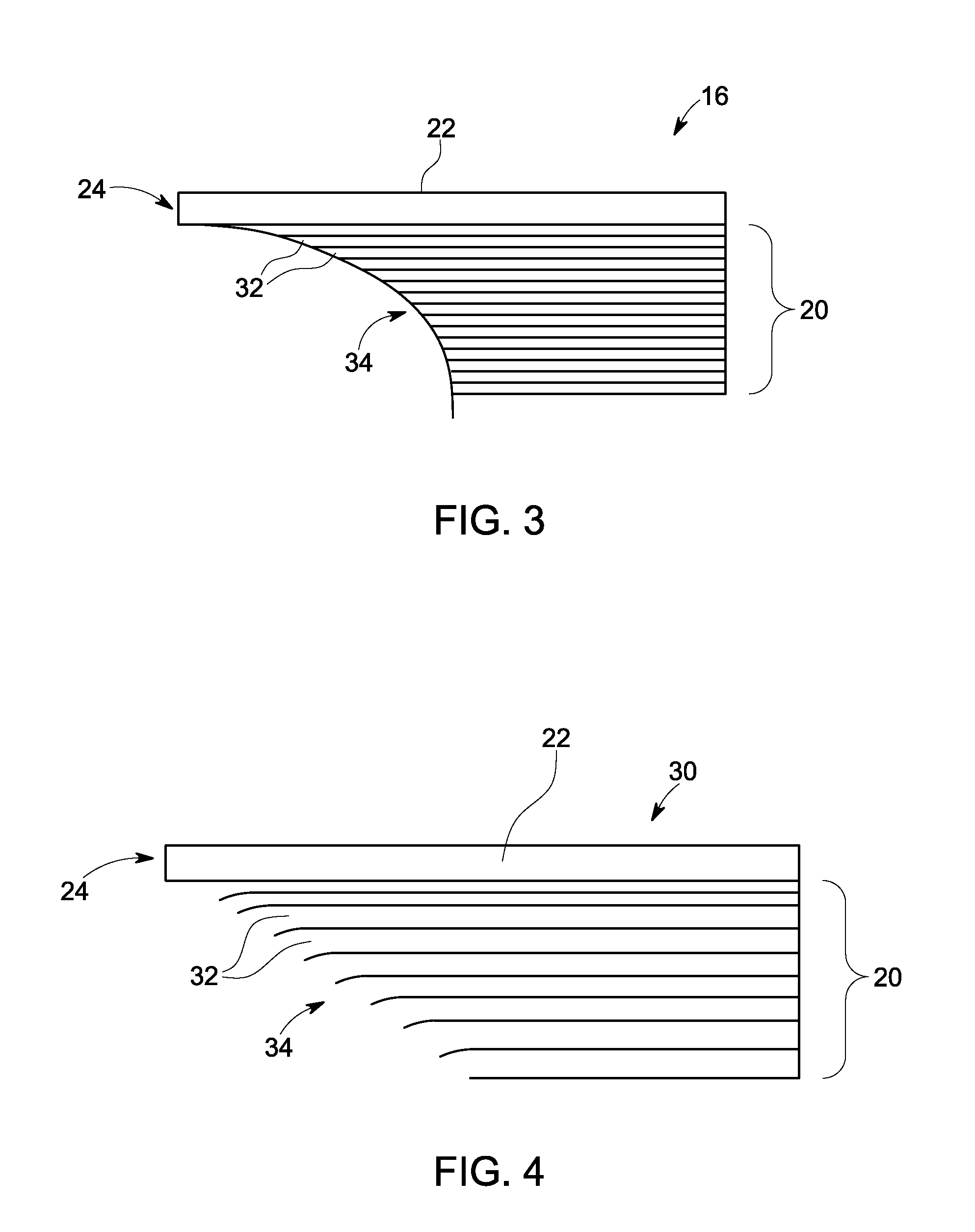

Airfoil-Shaped Micro-Mixers for Reducing Fouling on Membrane Surfaces

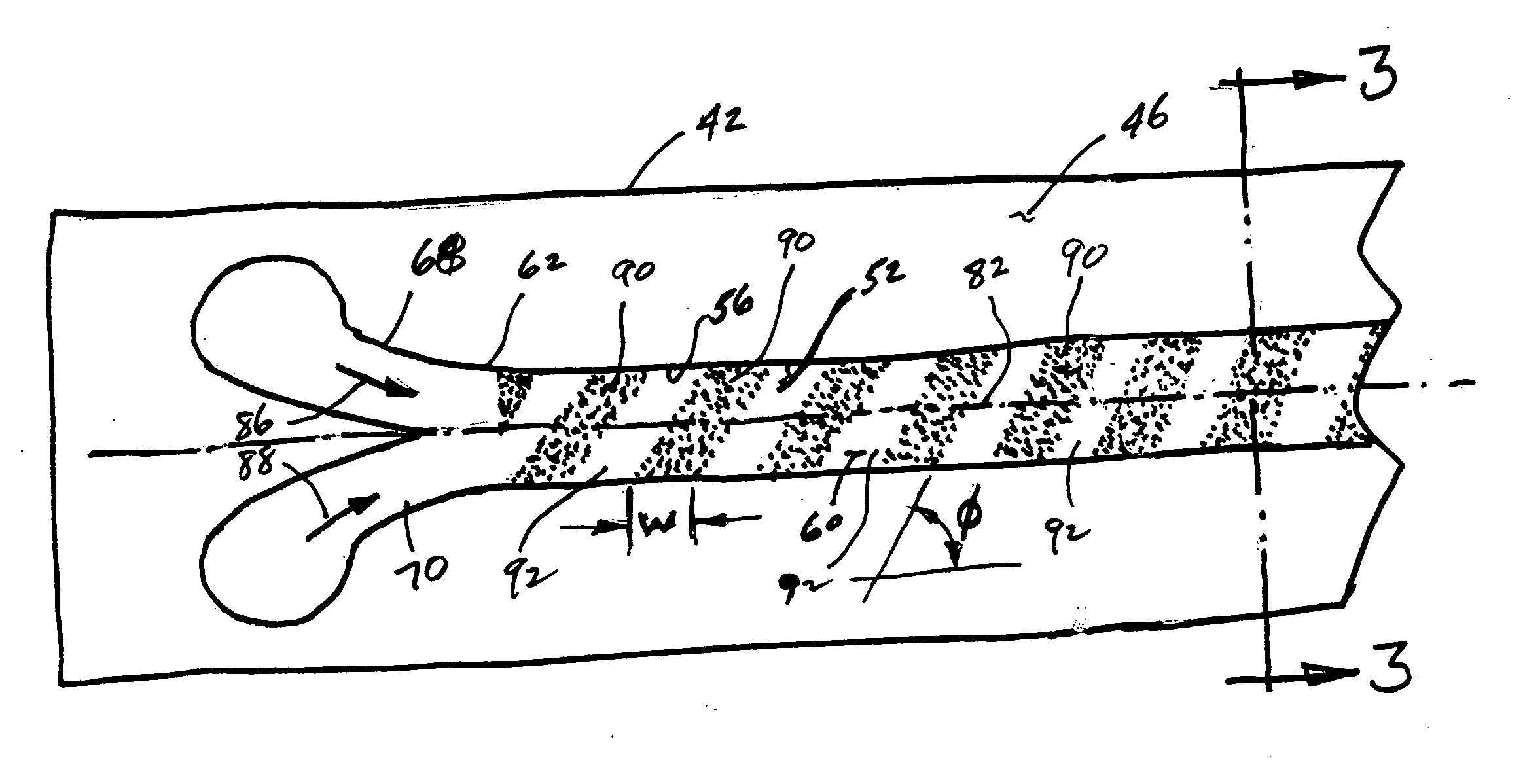

ActiveUS20100118642A1Enhance fluid mixingMinimized pressure dropSemi-permeable membranesMembranesFiltrationMembrane channel

An array of airfoil-shaped micro-mixers that enhances fluid mixing within permeable membrane channels, such as used in reverse-osmosis filtration units, while minimizing additional pressure drop. The enhanced mixing reduces fouling of the membrane surfaces. The airfoil-shaped micro-mixer can also be coated with or comprised of biofouling-resistant (biocidal / germicidal) ingredients.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Micromixer apparatus and methods of using same

Owner:AGENCY FOR SCI TECH & RES +1

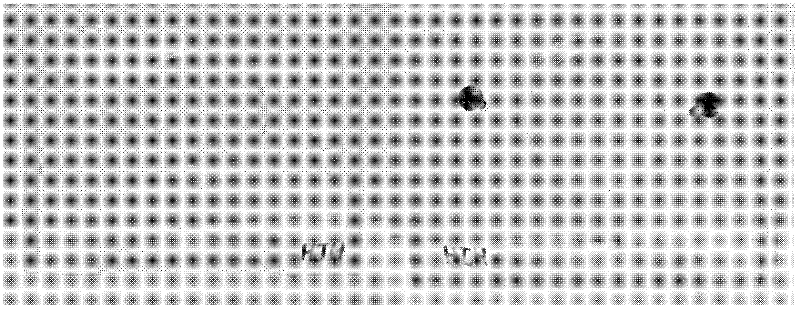

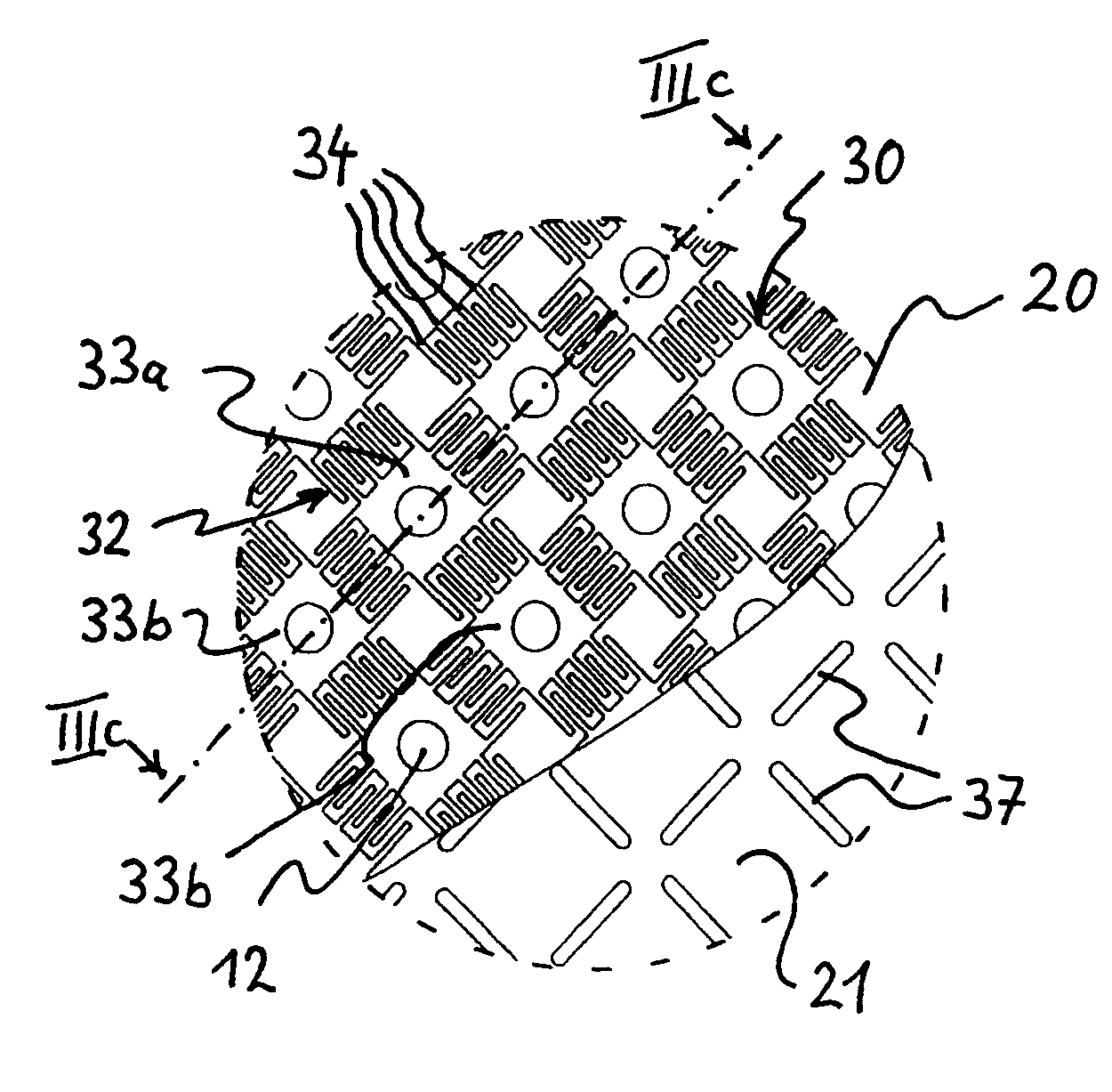

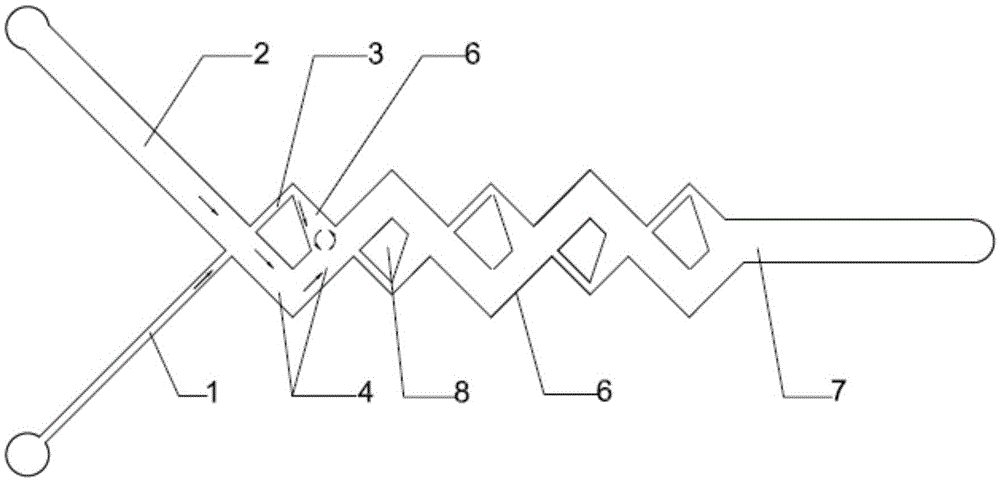

Micromixer with overlapping-crisscross entrance

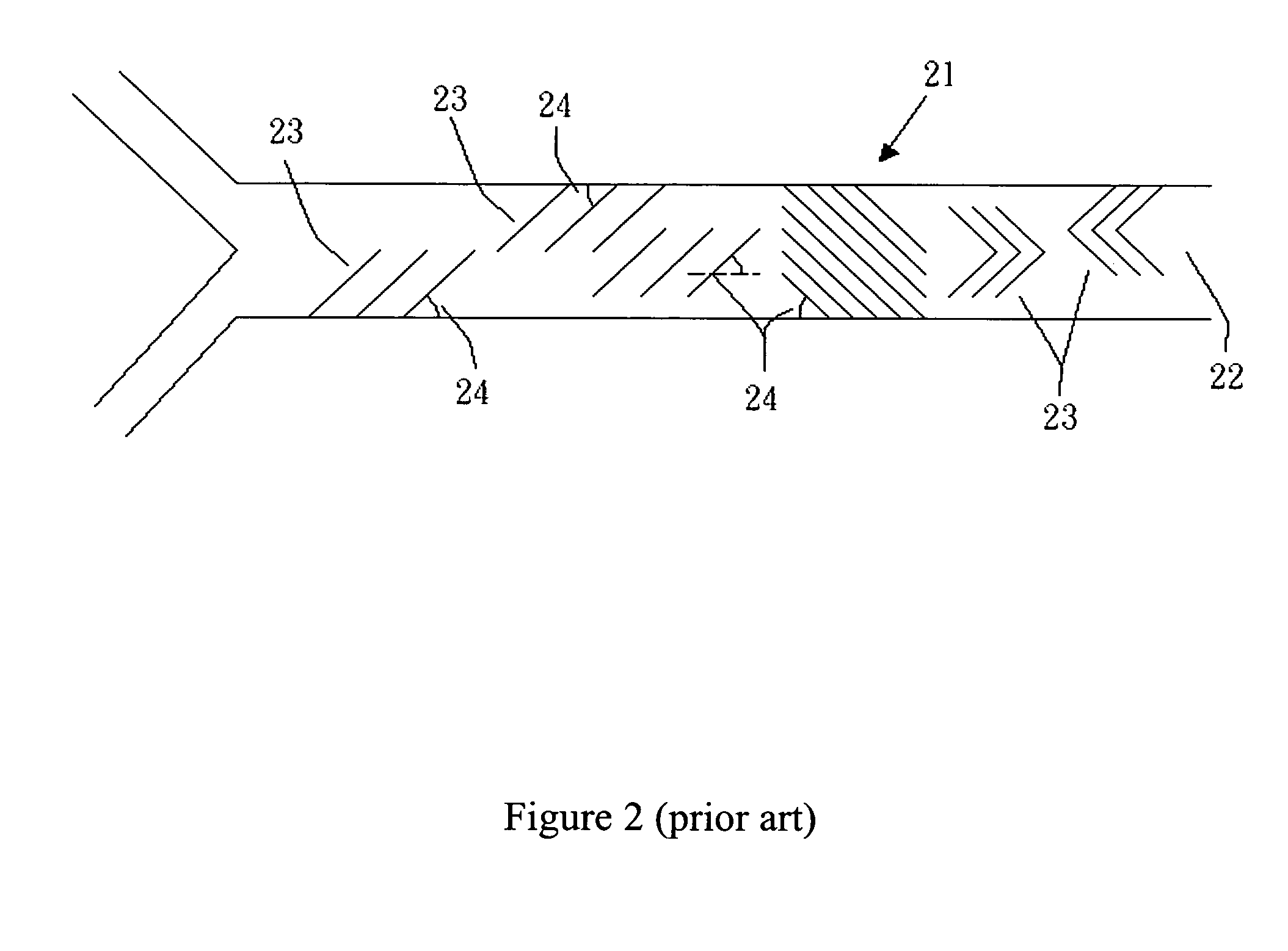

InactiveUS20050232076A1Improve the mixing effectSemi-permeable membranesFlow mixersCapillary electrophoresisShortest distance

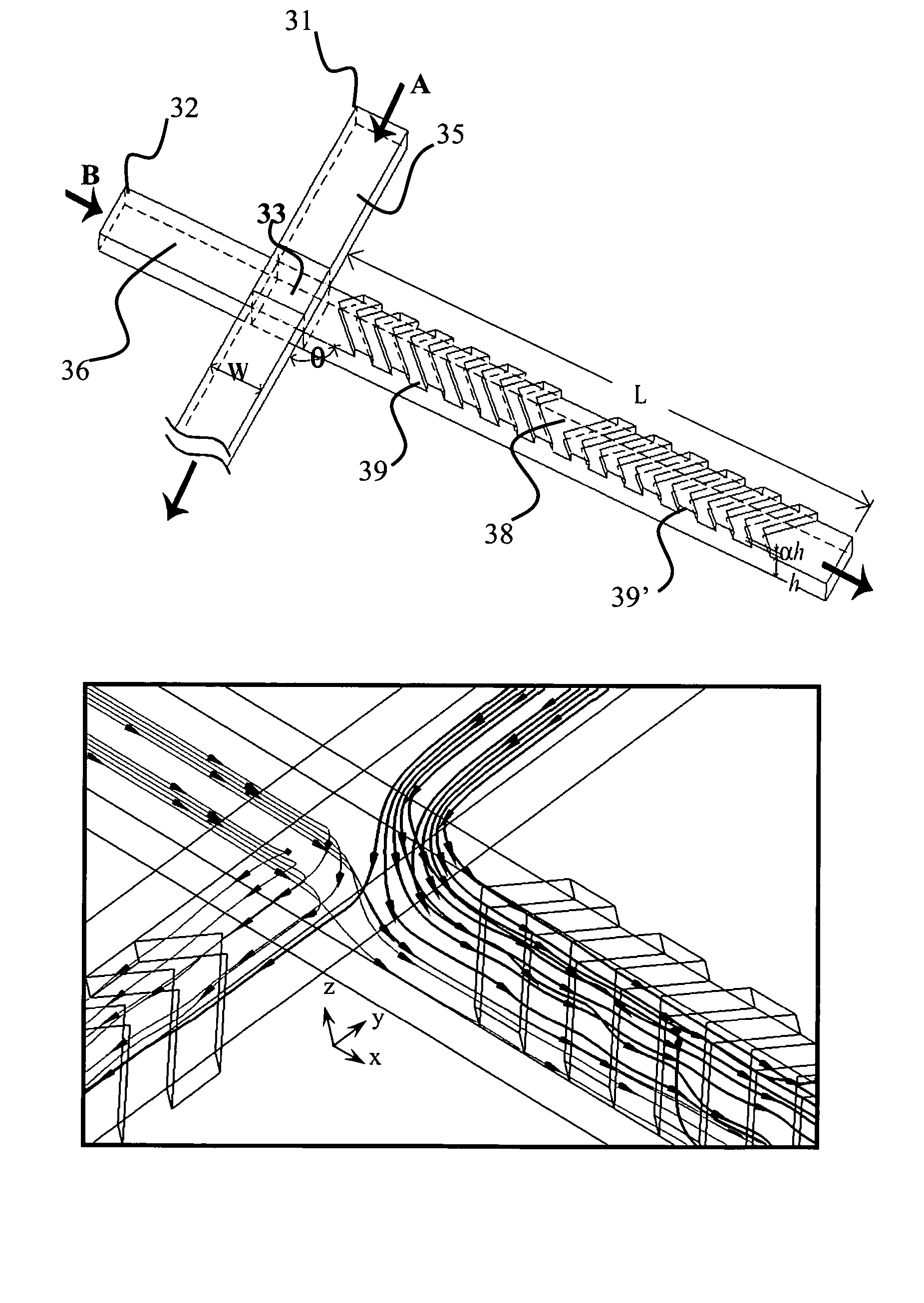

The micromixer with overlapping-crisscross entrance incorporated with the grooved microchannel, is used effectively for mixing two or more fluid streams. The X-shape overlapping-crisscross inlet ports wherein two microfluidic channels contact over a small area, allow the fluid streams flow through and create the tumbling inside the micromixer. Then merging with some patterned grooves on the walls also induces swirling motion. As a result, the folding and stretching effects of the flow are augmented to amplify the fluid mixing of two or more streams of the inlet fluids within a relative short distance in the micromixer. All of the flow streams are actuated with either pressure driven by a syringe pump or capillary electrophoresis. The present invention is applicable for micro total analysis systems and drug delivery systems.

Owner:YANG JING TANG

Accurate and rapid micromixer for integrated microfluidic devices

Owner:RGT UNIV OF CALIFORNIA

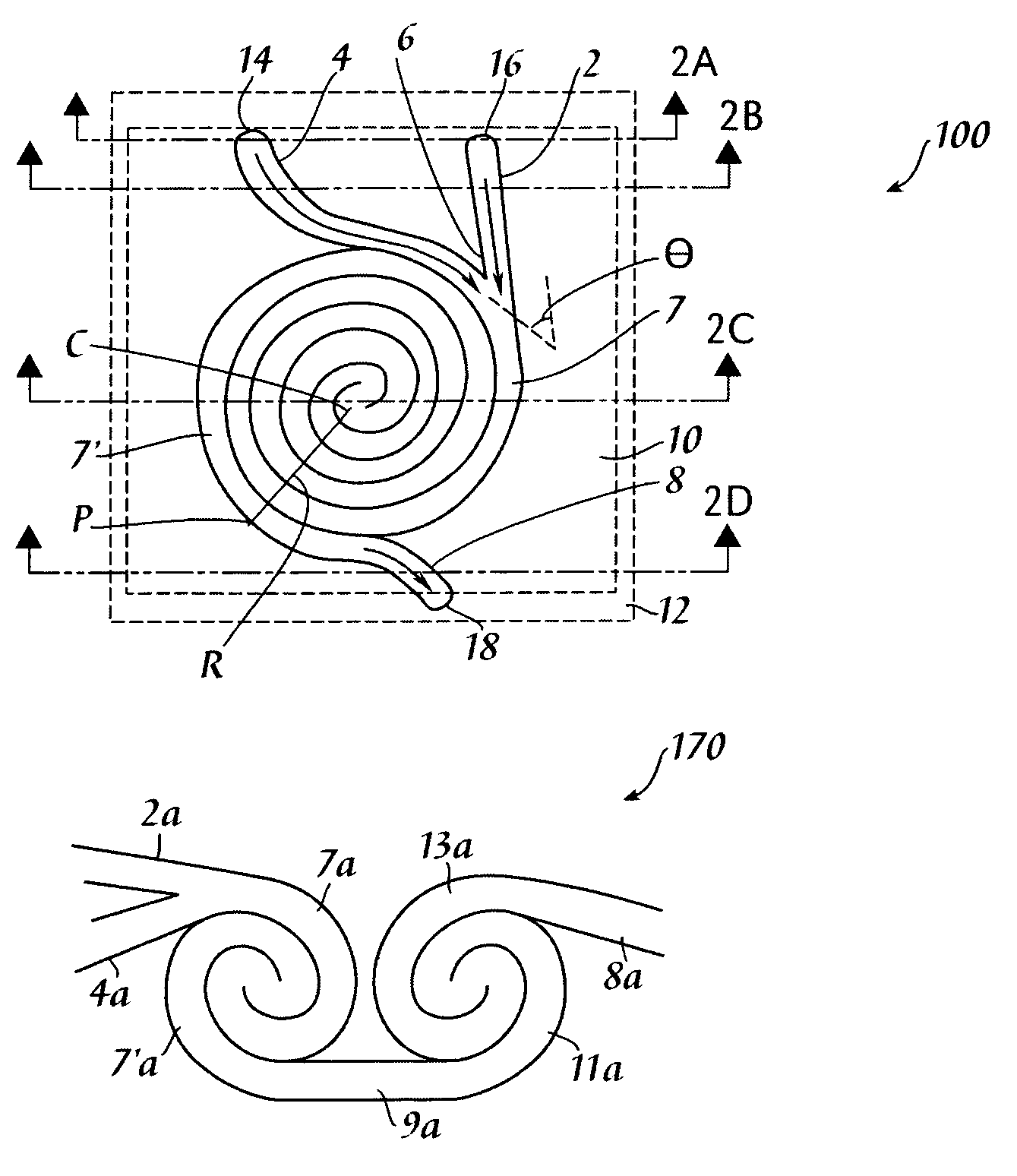

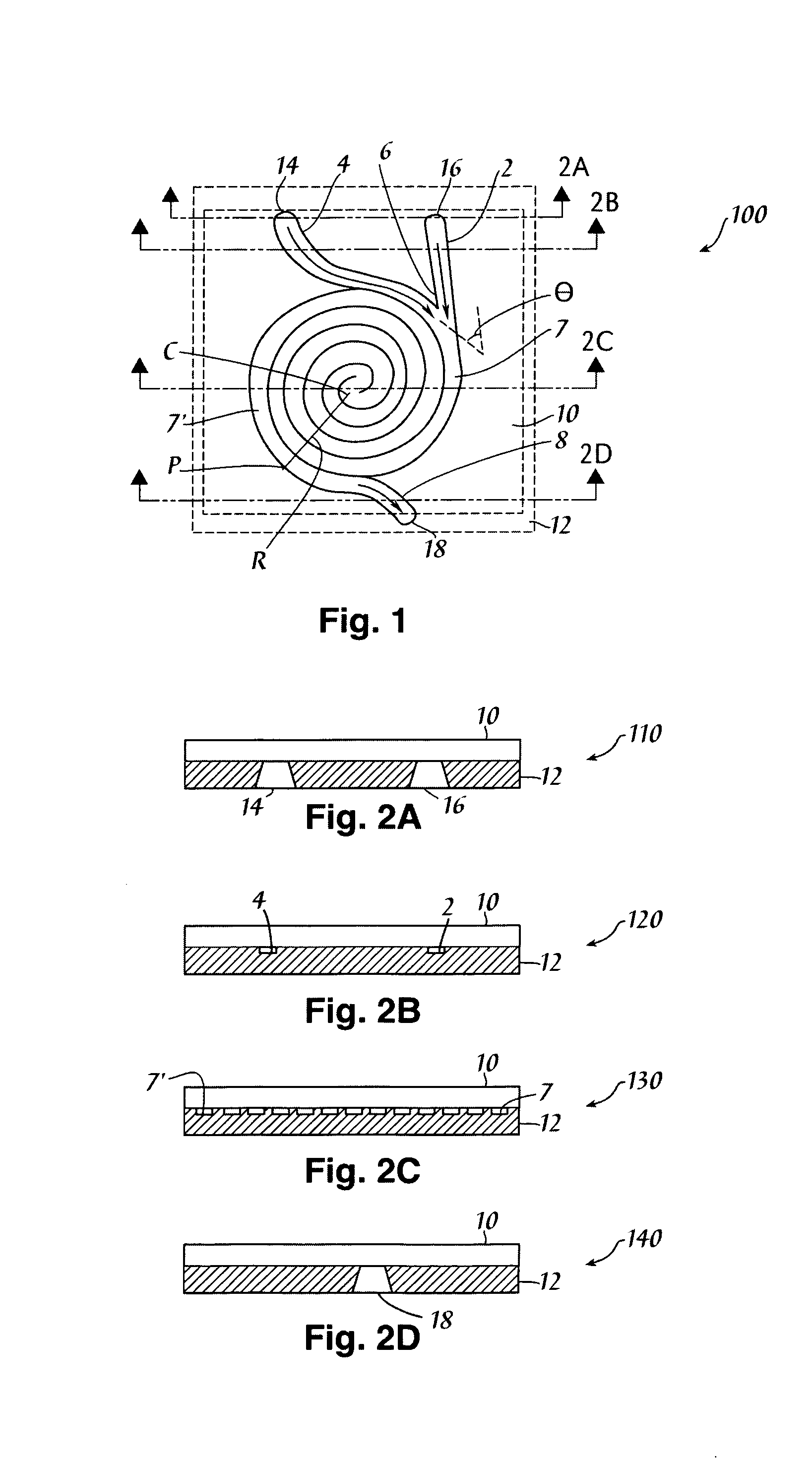

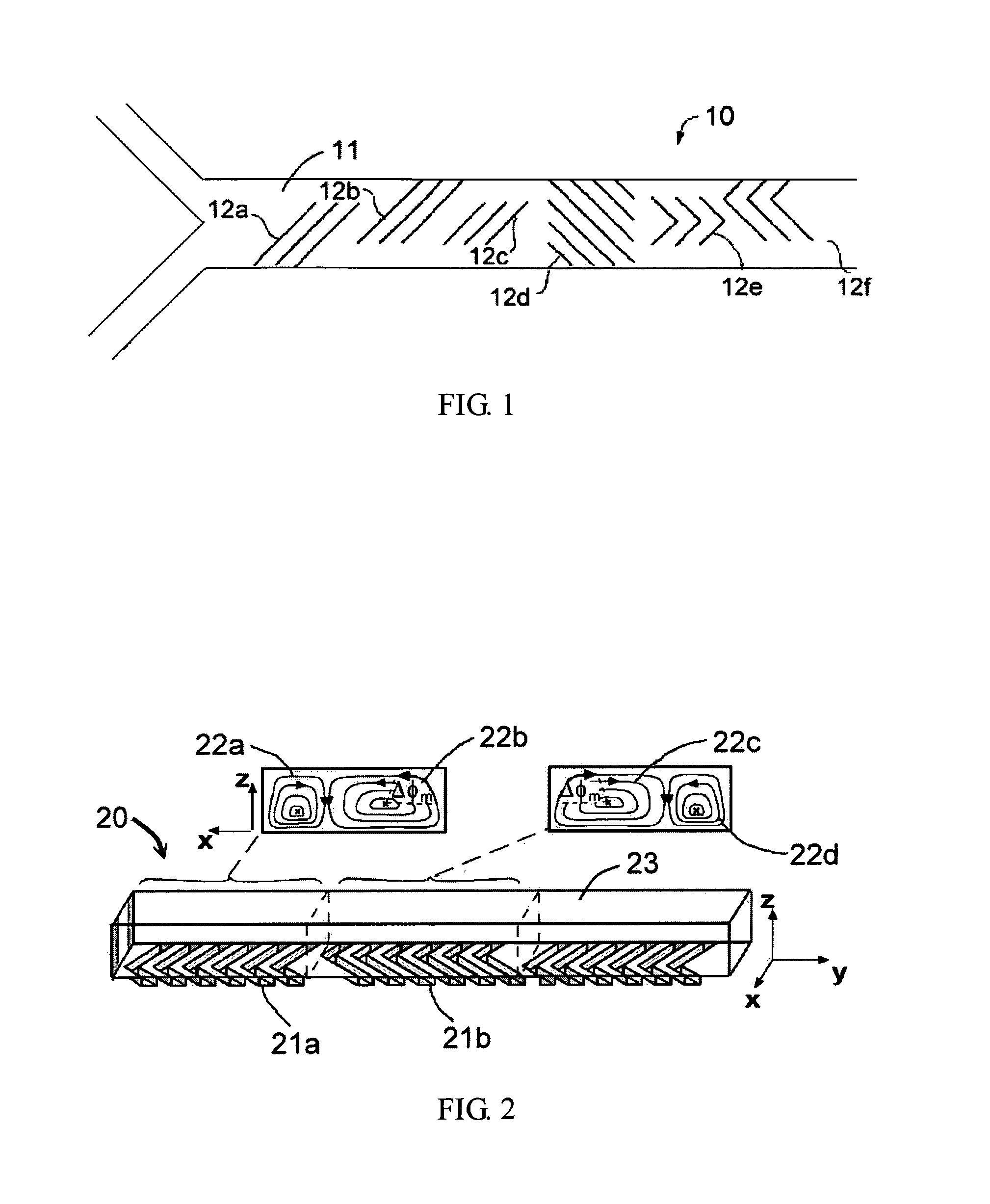

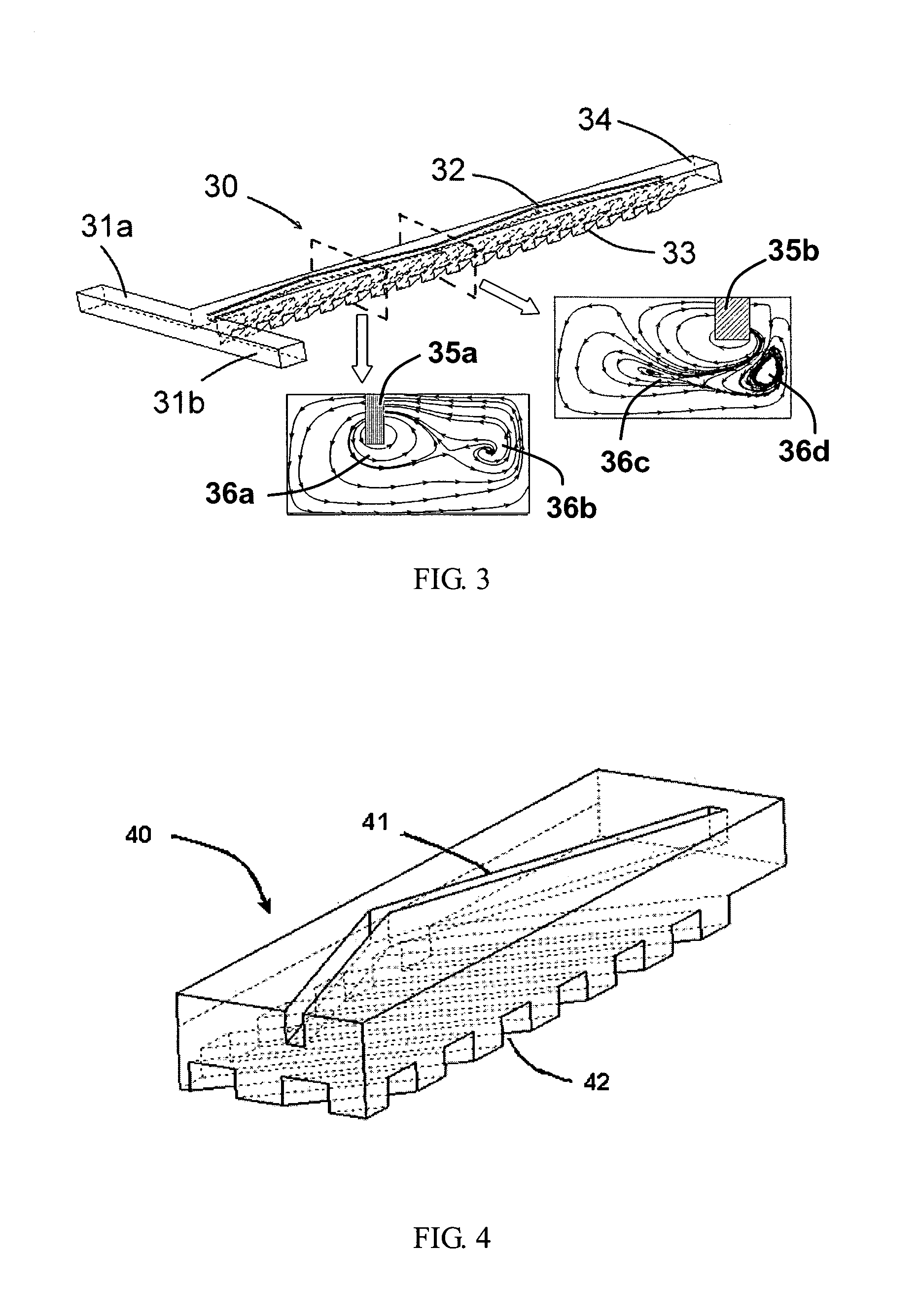

Twin-vortex micromixer for enforced mass exchange

InactiveUS20070263485A1Well mixedImprove mixing efficiencySemi-permeable membranesOther chemical processesShortest distanceLab-on-a-chip

The present invention discloses a vortex-modulation based micromixer for enforced mass exchange. The micromixer of the present invention comprises a mixing chamber with grooves on one wall thereof and a special-shape barrier on another wall. As different fluids are injected into the mixing chamber respectively from two inlets of the micromixer, the grooves and barriers of the micromixer of the present invention create the constructive interferences to form the active-like agitation of the fluid. For every groove, the flux passed by can be increased via its high pressure gradient. Understandably, the mixing efficiency of the fluids can be greatly improved within a very short distance. At last, the outlet of the micromixer is located in the downstream of the mixing chamber and further is able to connect with other elements. The present invention is entirely a passive micromixer and no additional energy is required. The present invention can apply to a continuous chemical analysis, particularly to a lab-on-a-chip or a micro total analysis system.

Owner:NATIONAL TSING HUA UNIVERSITY

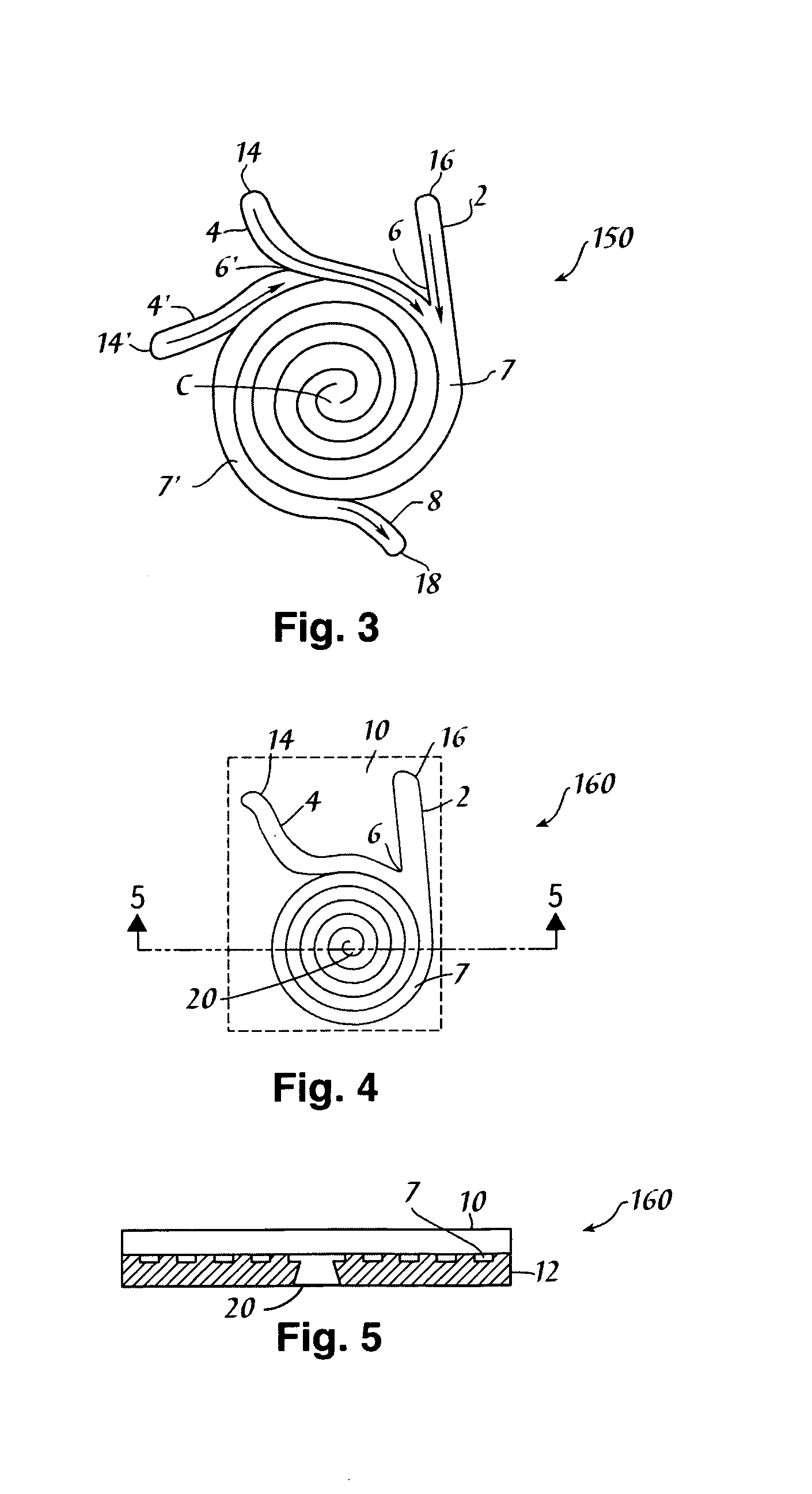

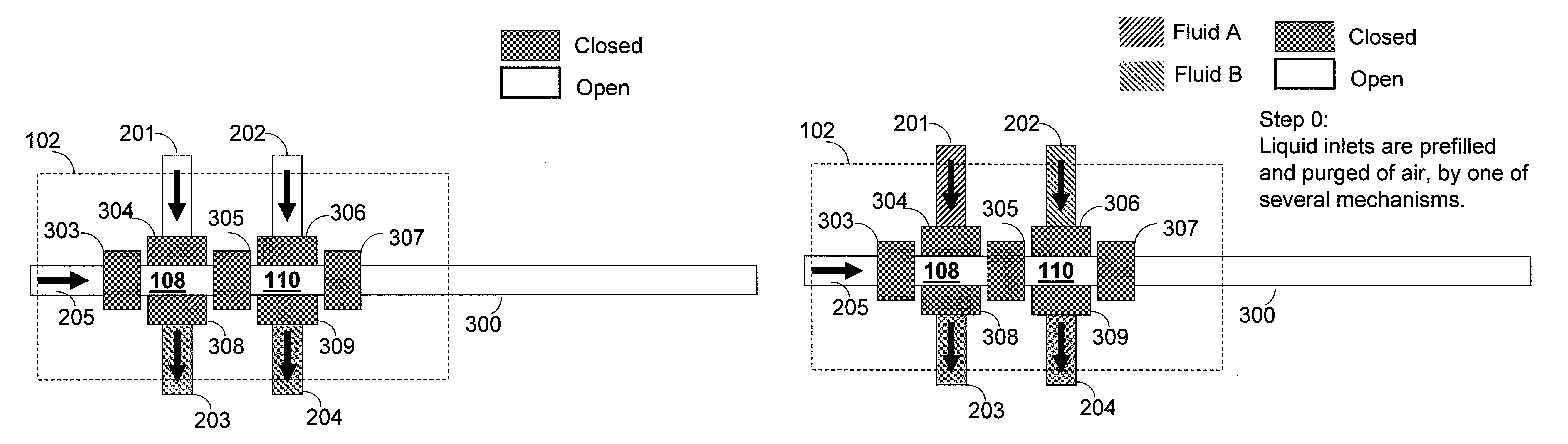

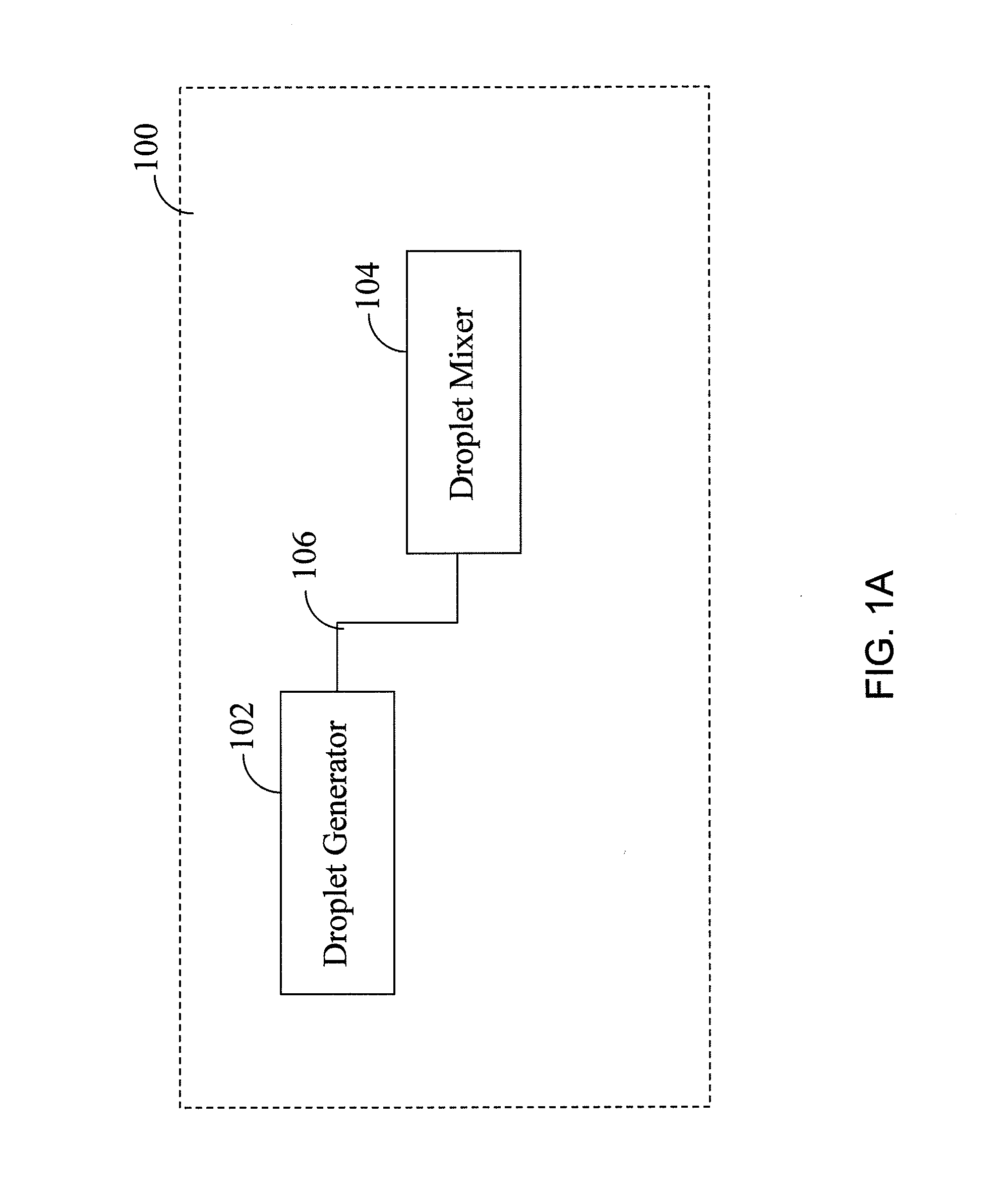

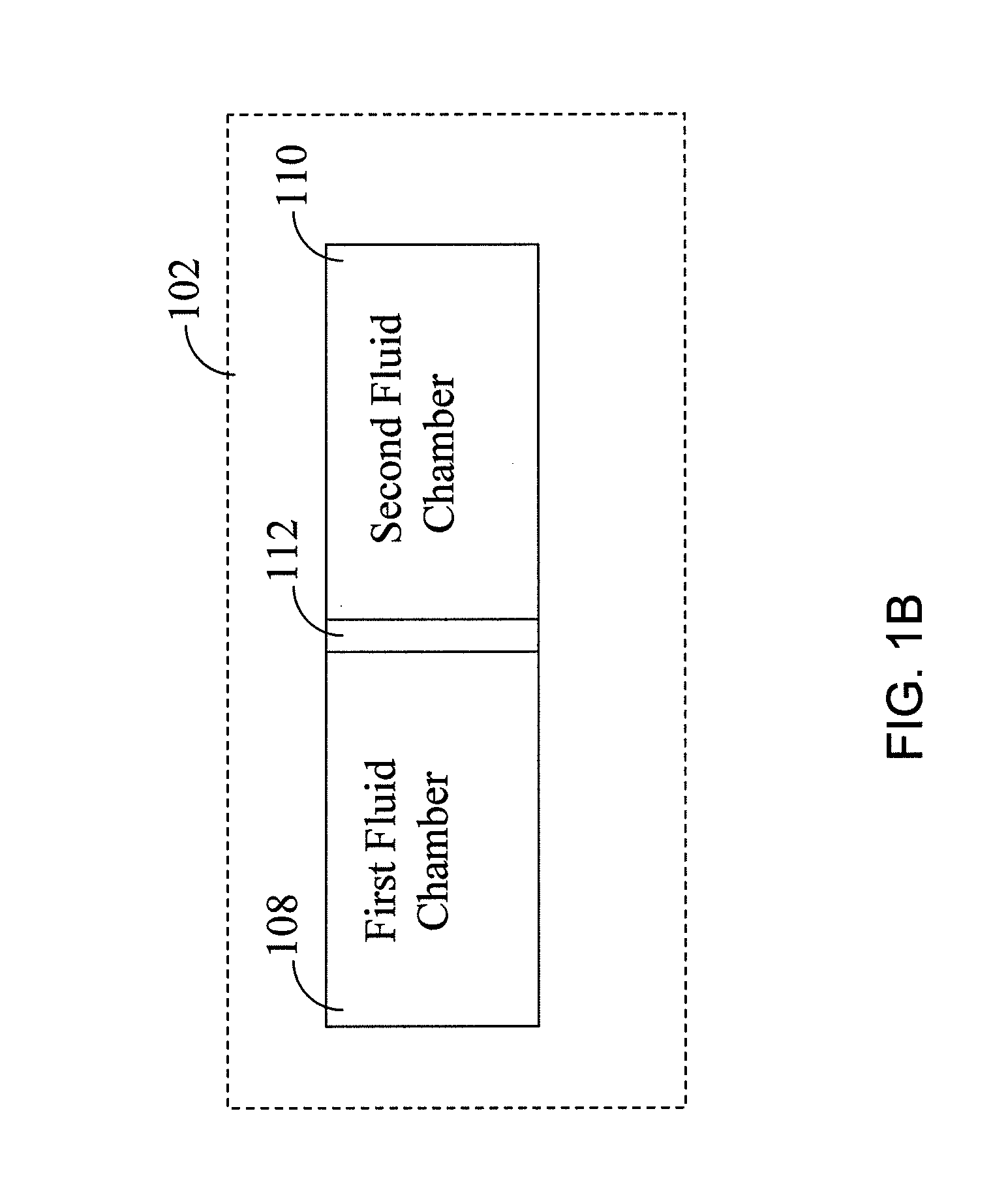

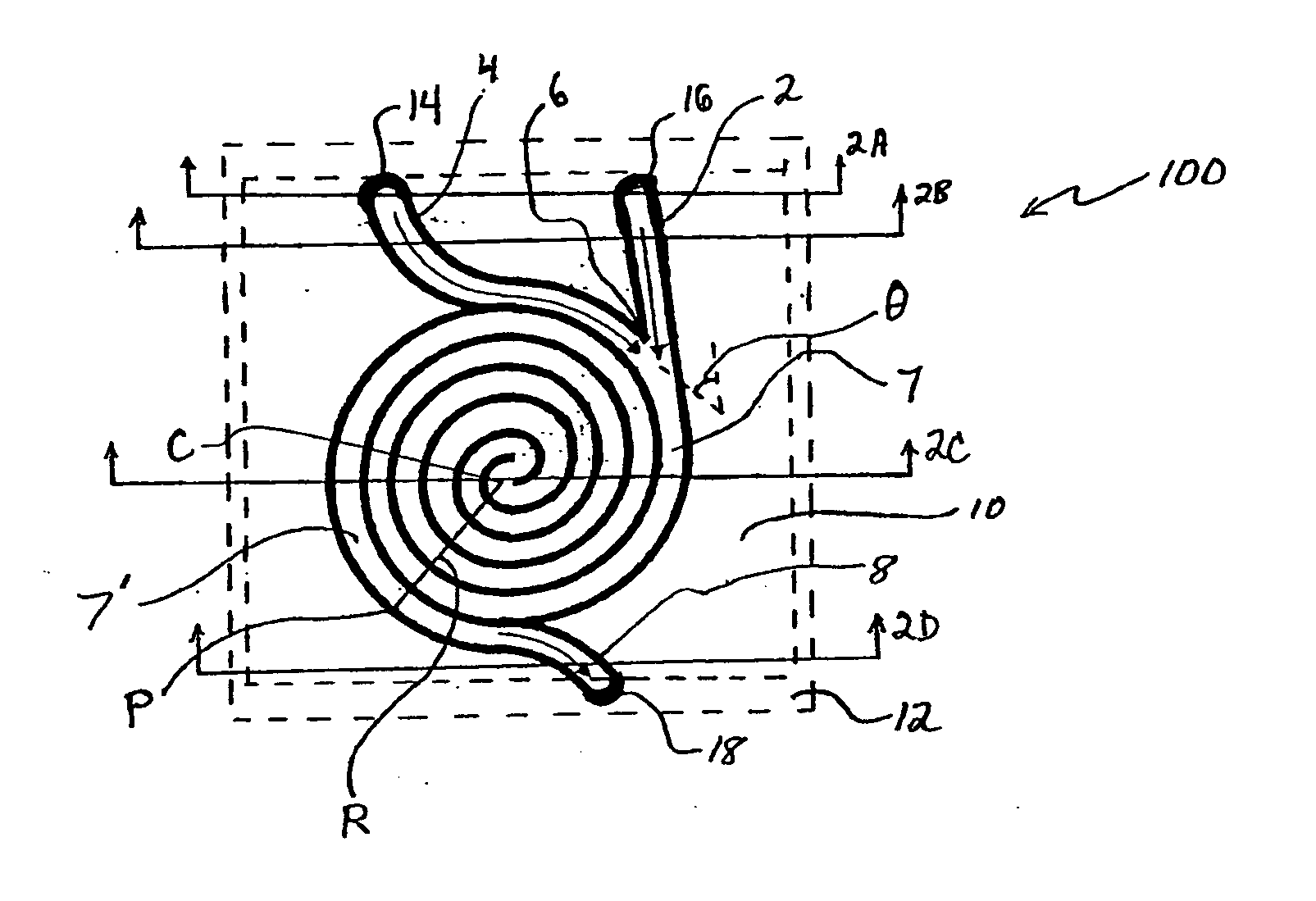

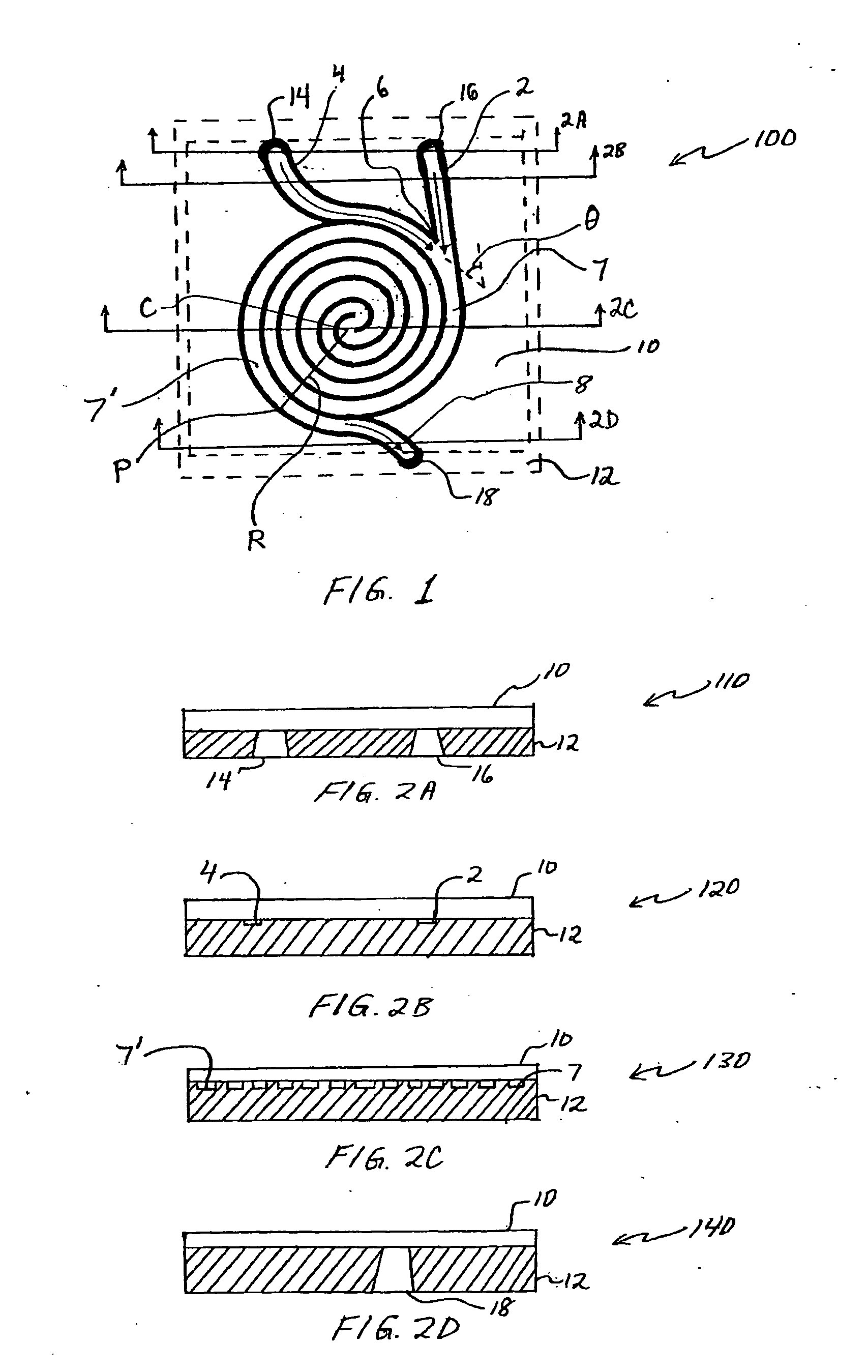

Micromixer apparatus and methods of using same

Microfluidics mixing apparatus and methods of using same are disclosed for mixing fluids using increasing centrifugal force as the fluids being mixed traverse a mixing channel. One inventive apparatus comprises a generally planar substrate having a top major surface and a bottom major surface generally parallel to the top major surface, and a cover plate over the top major surface. The substrate has at least one inlet port that routes fluid to the top major surface, and at least one outlet port for mixed fluid. The substrate comprises a mixing channel having a depth measured from the top surface and a width, the mixing channel adapted to route fluids to be mixed therein in laminar flow and in a substantially spiral flow pattern that is parallel to the top surface. Apparatus of the invention can mix fluids flowing serially, or two or more fluids entering the device from different feed channels.

Owner:AGENCY FOR SCI TECH & RES

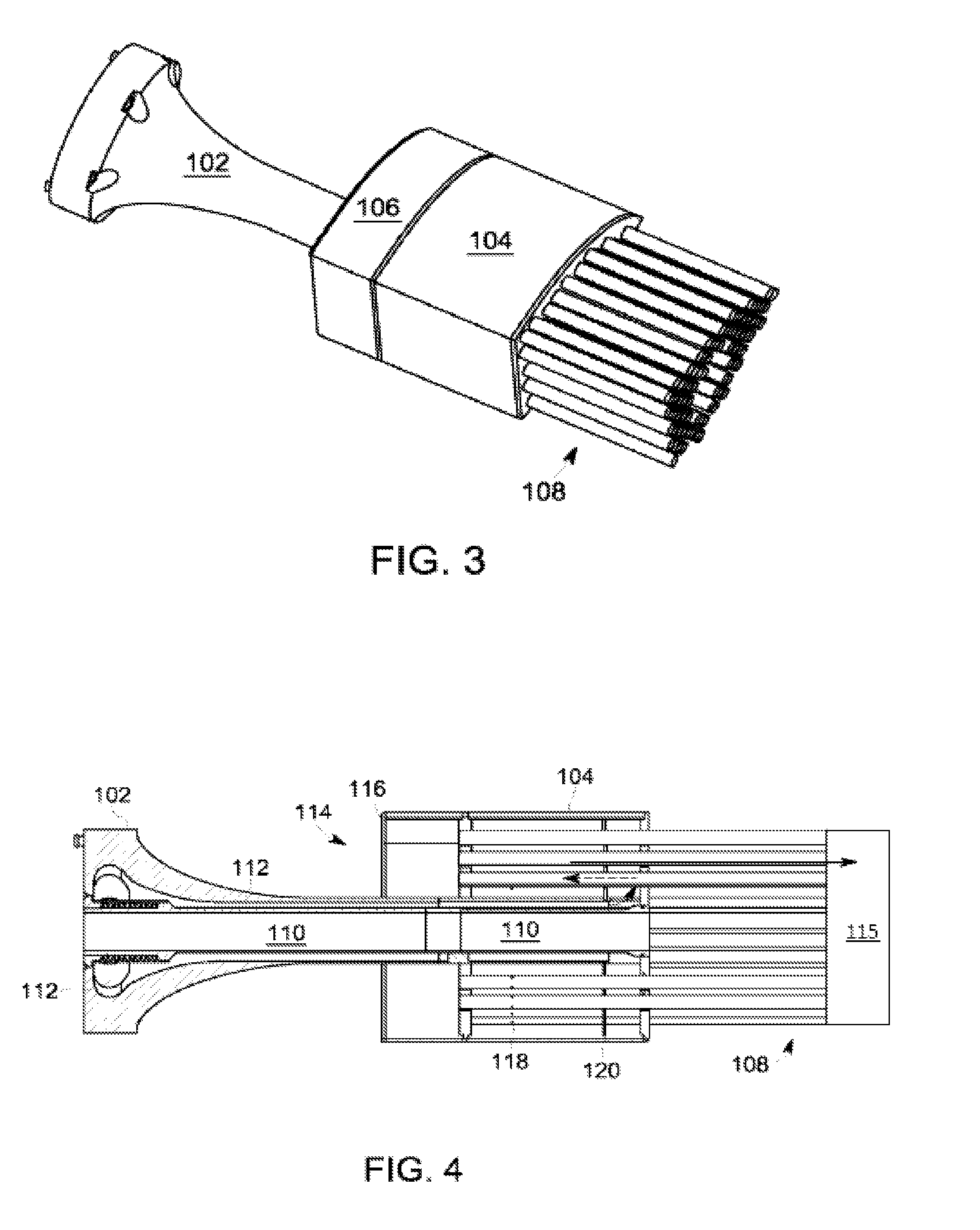

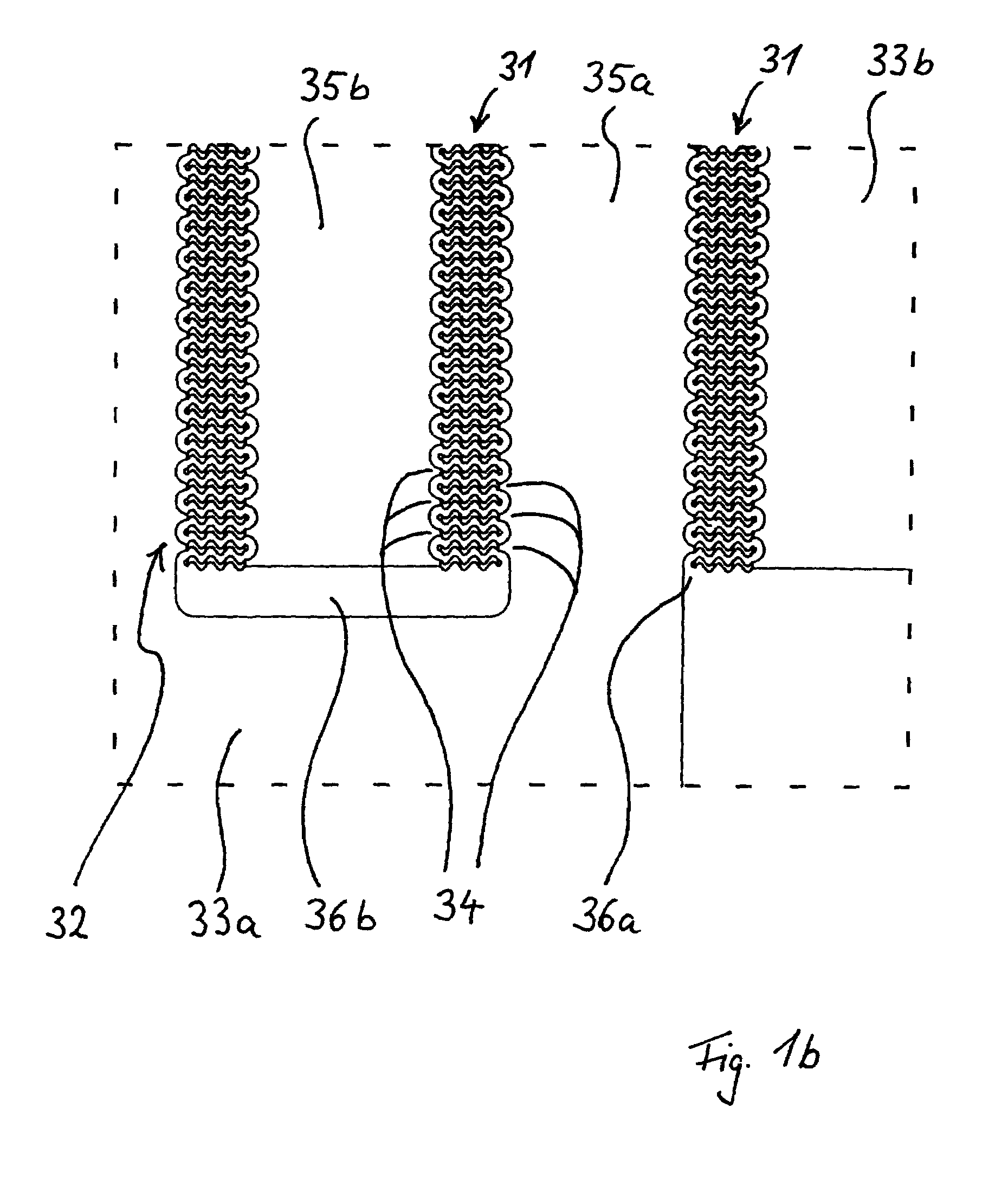

Micro-mixer

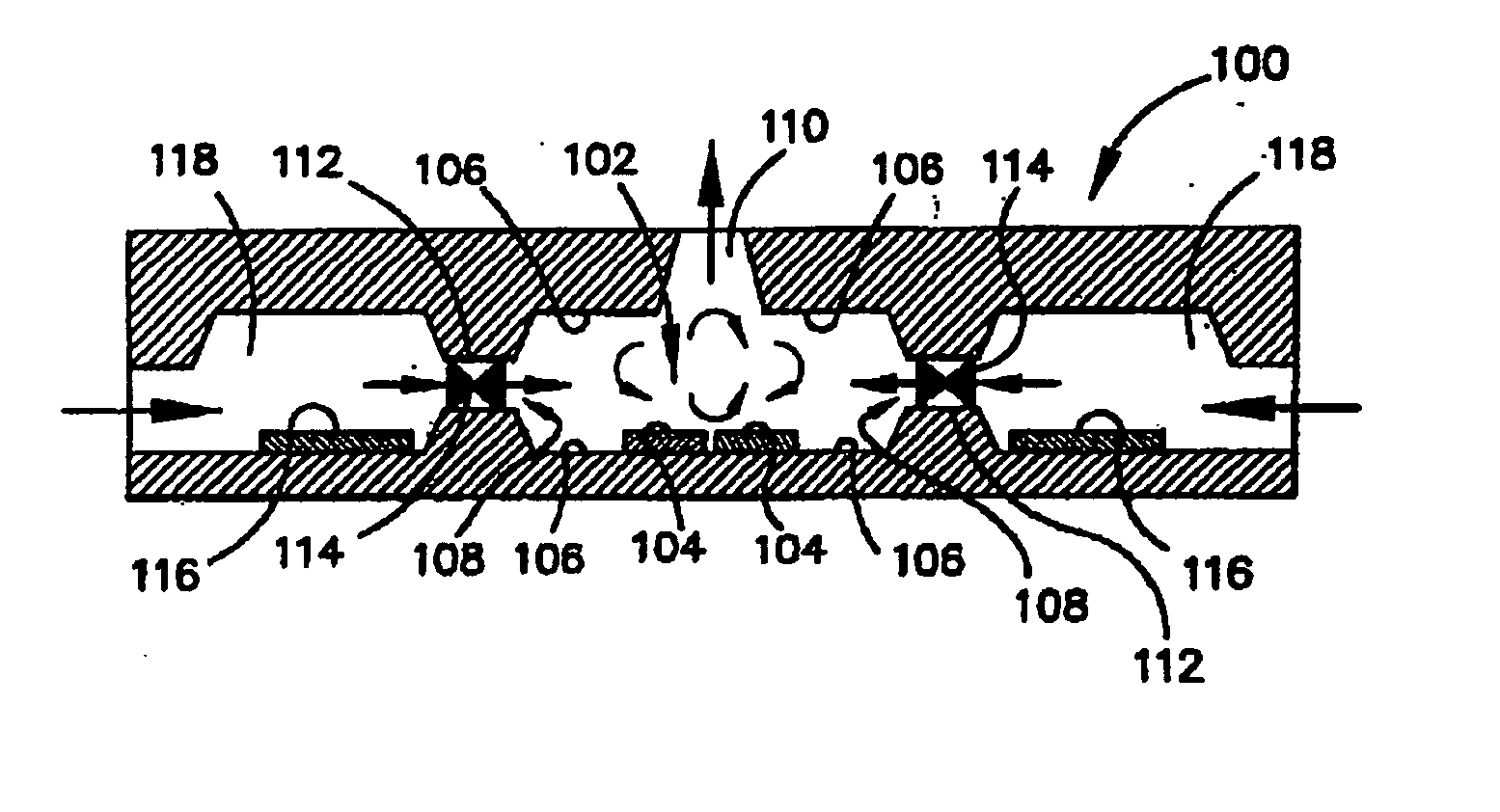

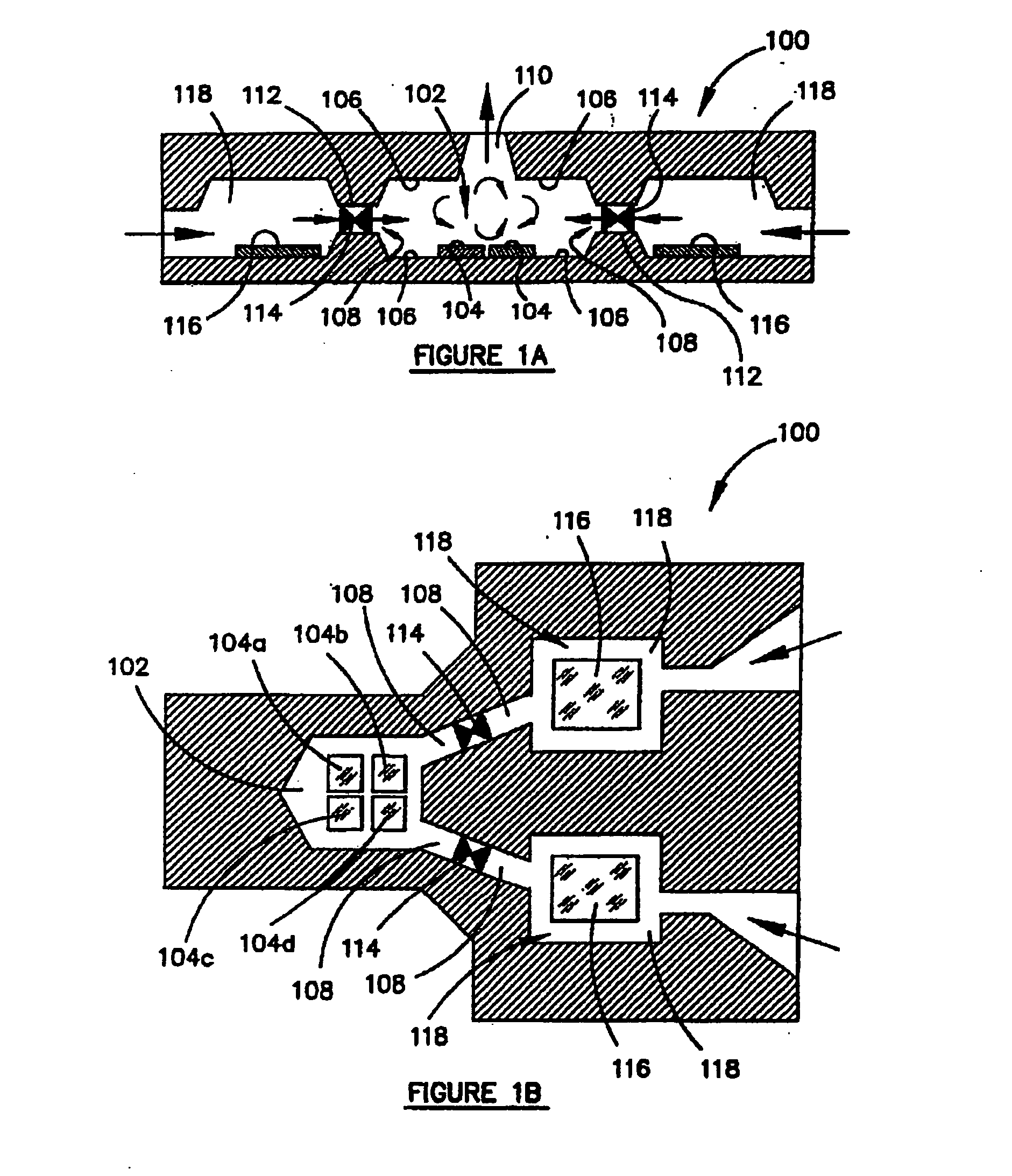

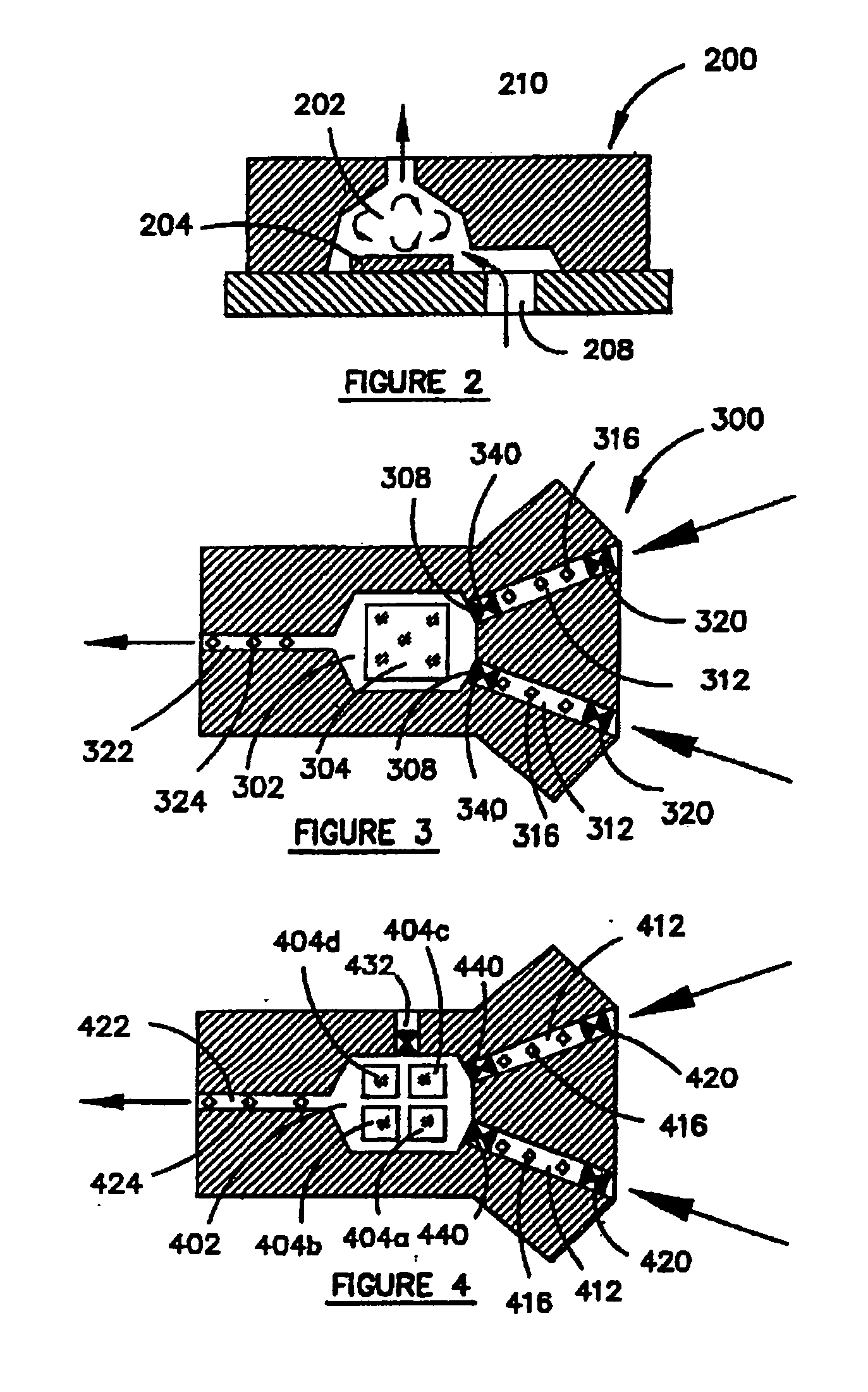

InactiveUS20060028908A1Turbulence be causeValve arrangementsTransportation and packagingEngineeringElectrical impulse

A micro-mixer 100 having a body in which there is disposed a micro-mixing chamber for mixing liquid. Micro-channels 108 extend from an external surface of the body of the micro-mixer 100 to the micro-mixing chamber 102 and define passageways for supplying liquid into the micro-mixing chamber 102. The micro-mixer 100 also has an electrical circuit that includes an electrical pulse generator that is connected to two or more spaced electrical heating elements 104 located in the mixing chamber 102 that receive electrical pulses from the pulse generator. In use, electrical pulses received by the heating elements 104 cause the heating elements to heat liquid in the mixing chamber in regions locally of each of the heating elements and thereby generating a vapour bubble which will, in turn, cause turbulence and mixing of liquid within the micro-mixing chamber.

Owner:HEWLETT PACKARD DEV CO LP

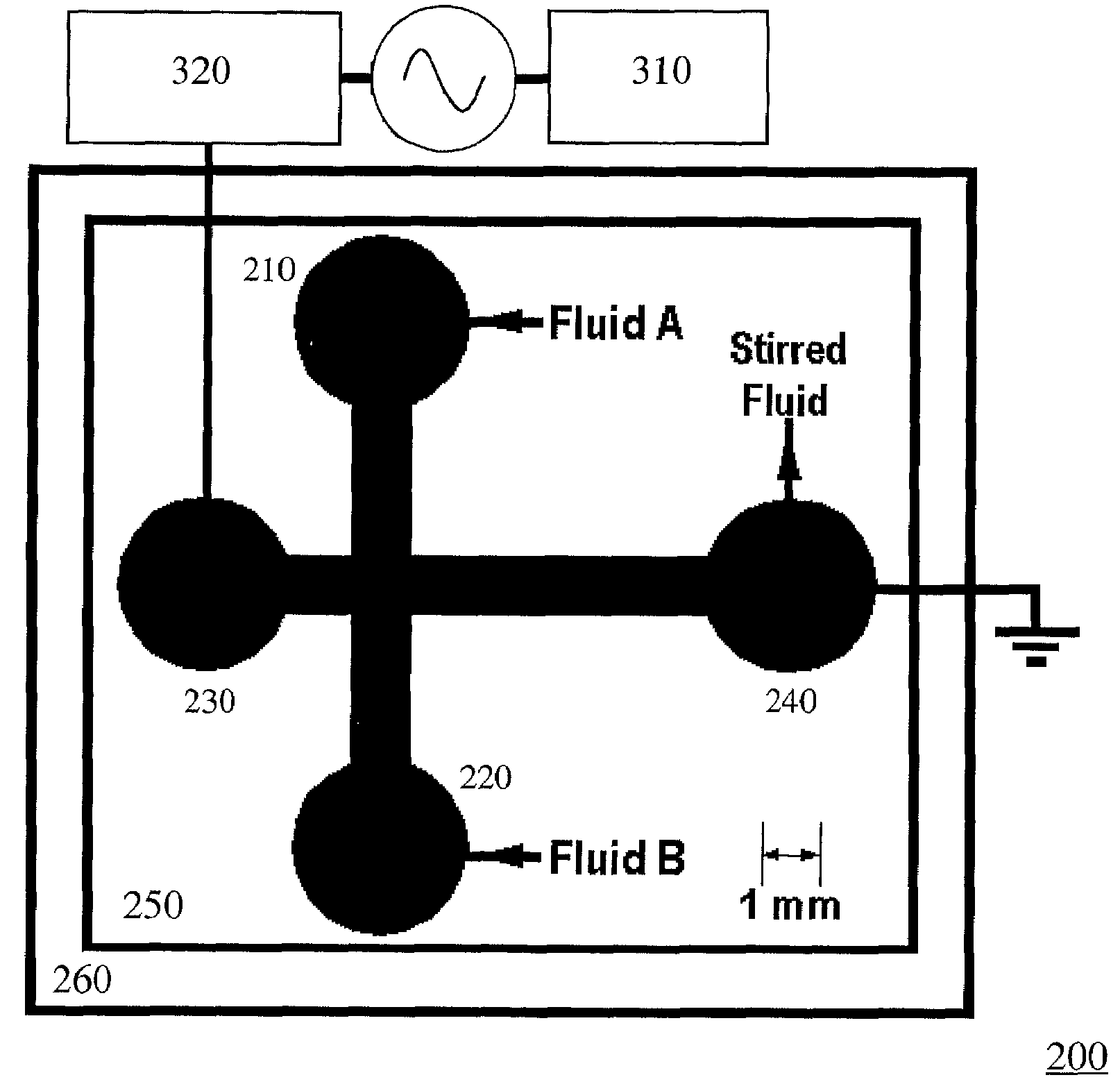

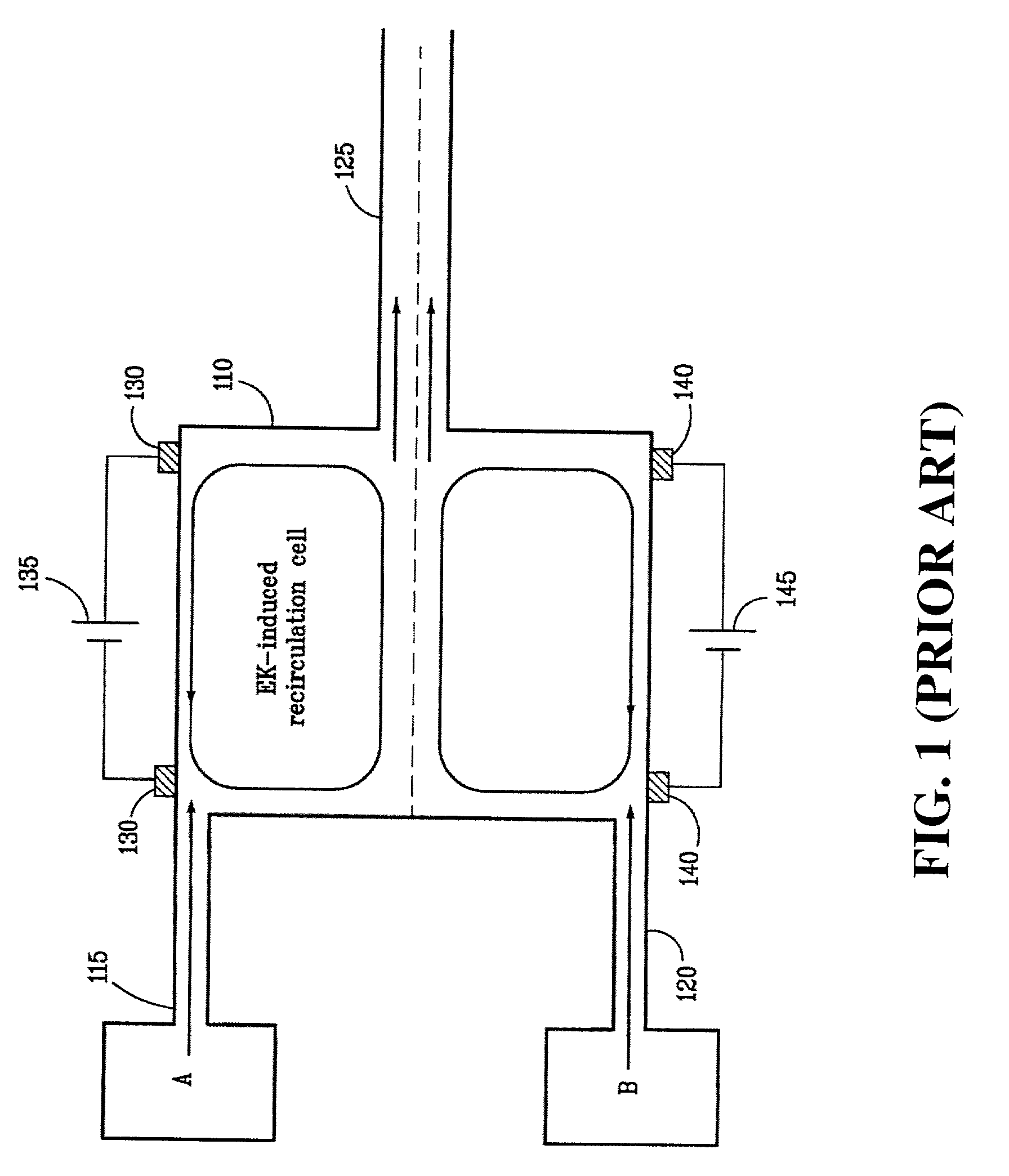

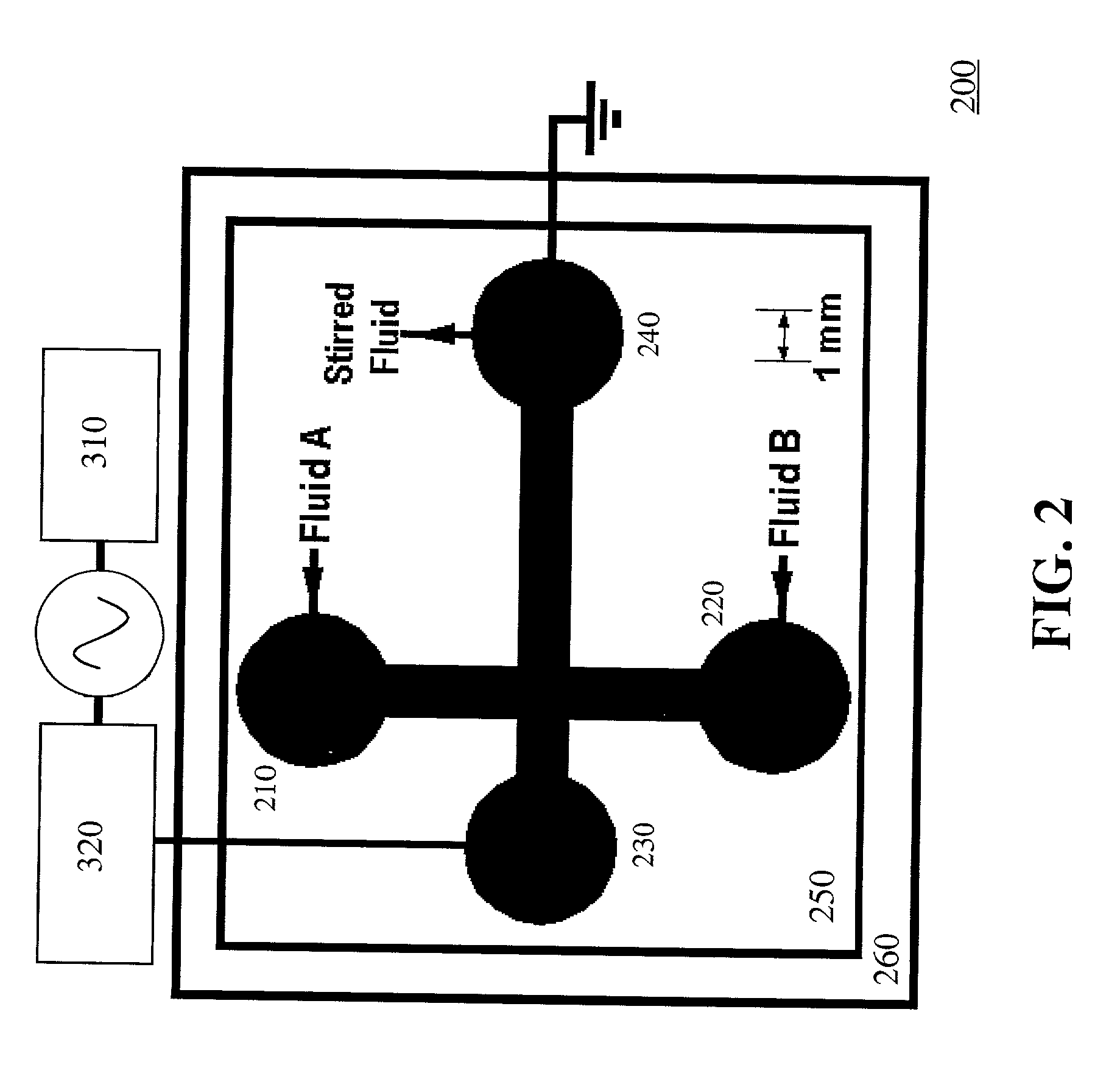

Electrokinetic instability micromixer

InactiveUS7070681B2Stir quicklyQuick mixElectrostatic separatorsSludge treatmentMicrofabricationInstability

A novel electrokinetic instability (EKI) micromixer and method takes advantage of the EKI to effect active rapid stirring of confluent microstreams of biomolecules without moving parts or complex microfabrication processes. The EKI is induced using an alternating current (A / C) electric field. Within seconds, the randomly fluctuating, three-dimensional velocity field created by the EKI rapidly and effectively stirs an initially heterogeneous solution and generates a homogeneous solution that is useful in a variety of biochemical and bioanalytical systems. Microfabricated on a glass substrate, the inventive EKI micromixer can be easily and advantageously integrated in molecular diagnostics apparatuses and systems, such as a chip-based “Lab-on-a-Chip” microfluidic device.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

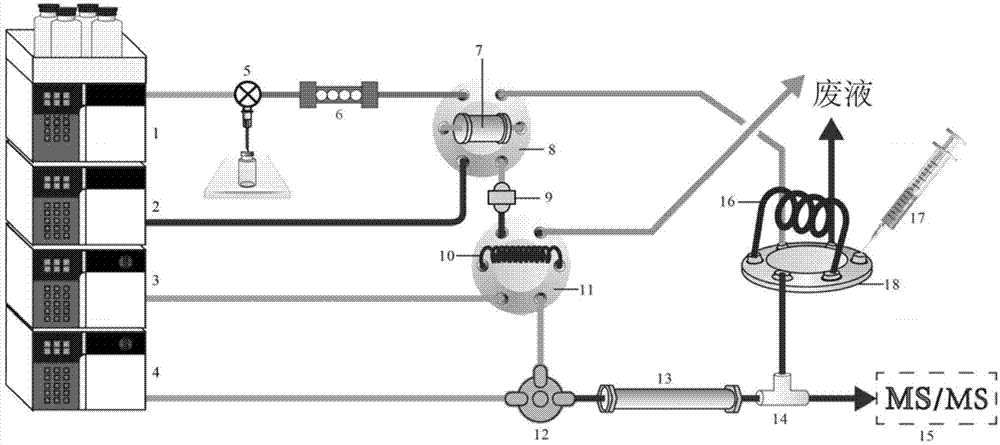

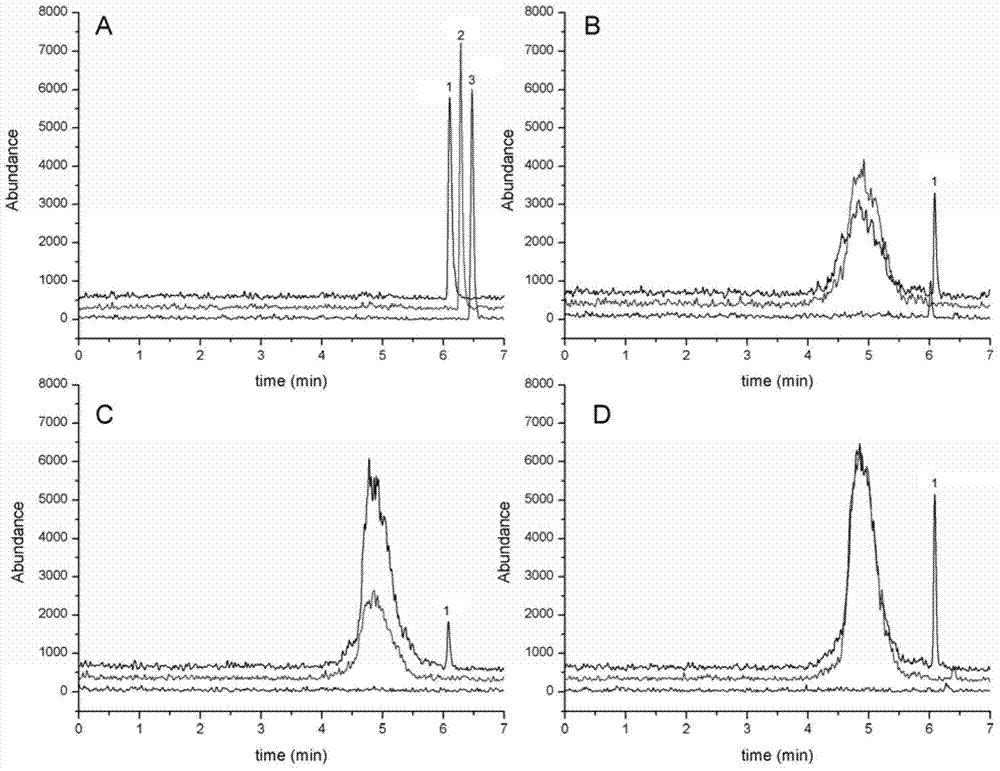

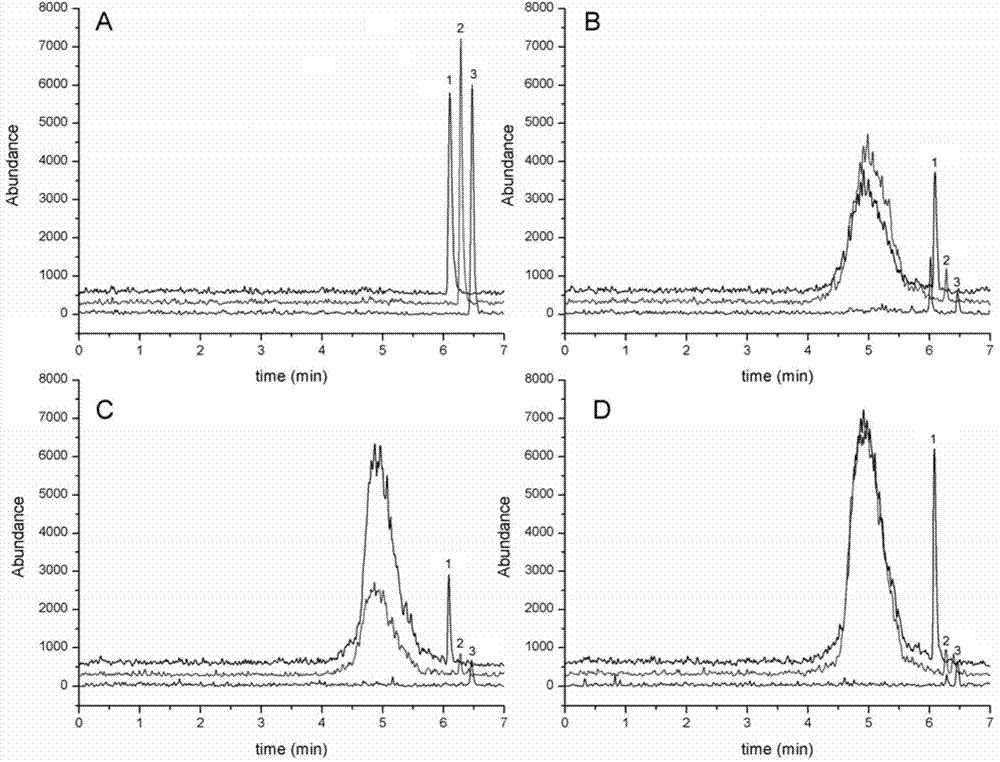

On-line analysis system for automatic pretreatment by adopting ultra high performance liquid chromatography/mass spectrum

The invention discloses an on-line analysis system for automatic pretreatment by adopting an ultra-high performance liquid chromatography / mass spectrum. The on-line analysis system has an automatic pretreatment mode and a post-column compensation mode, and comprises four chromatography pumps, two high-pressure switch valves, an automatic sample injector, an on-line diluter, an extraction column, an on-line filter, two sample rings, a miniature mixer, a chromatographic column, a tee joint, a mass spectrometry detector and the like. On-line dilution, extraction, desorption, separation, detection and post-column compensation analysis can be carried out on a target analyte in a liquid sample by combination of an on-line dilution / extraction / desorption device, a stigma focusing device, a post-column compensation device and an ultra high performance liquid chromatography / mass spectrum device, the overall analysis process is automatically controlled, and is high in accuracy and precision, and the on-line analysis system can be effectively applied to the analysis detection on trace organic compounds in a complicated liquid sample or a liquid extracting solution.

Owner:SHIMADZU (CHINA) CO LTD

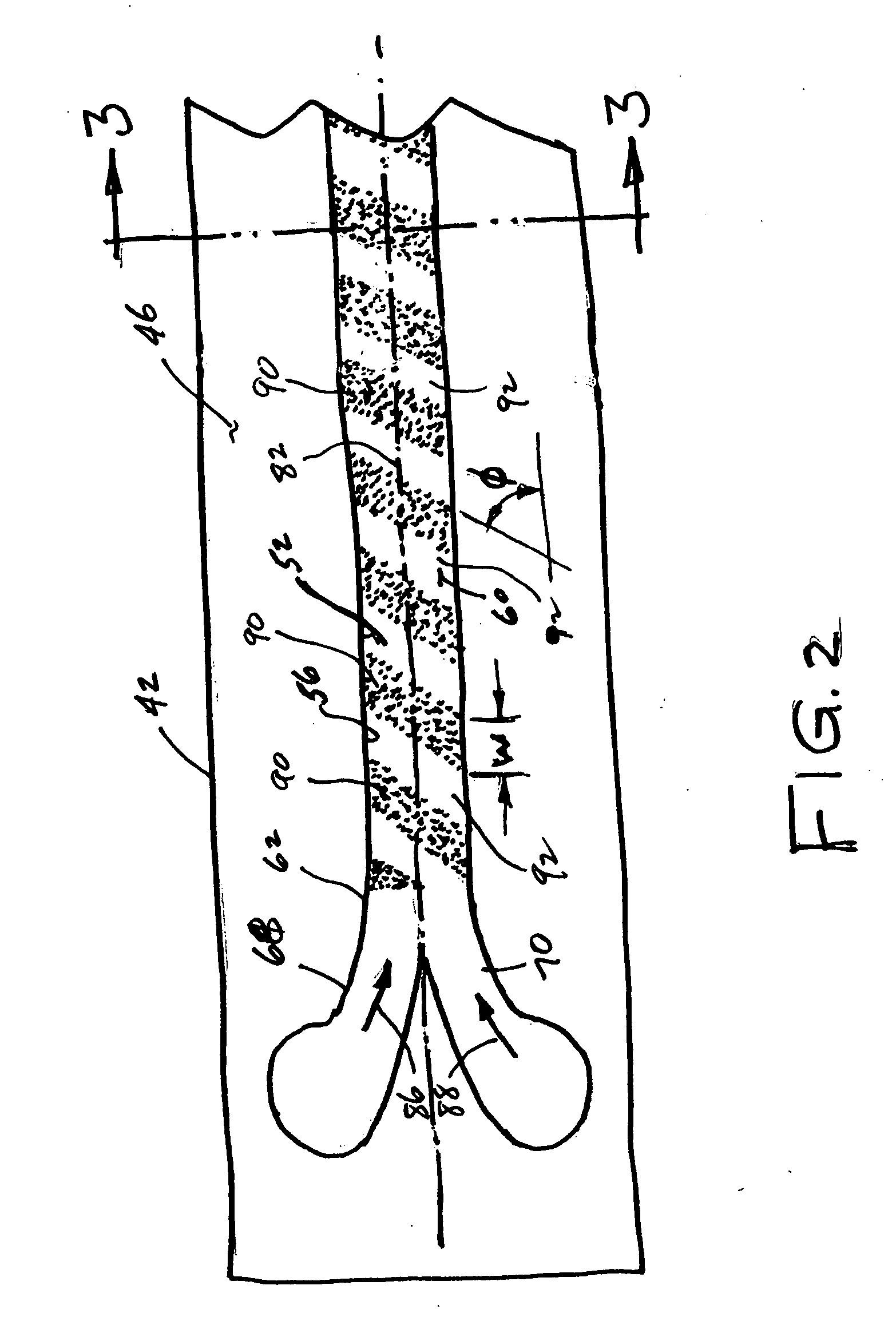

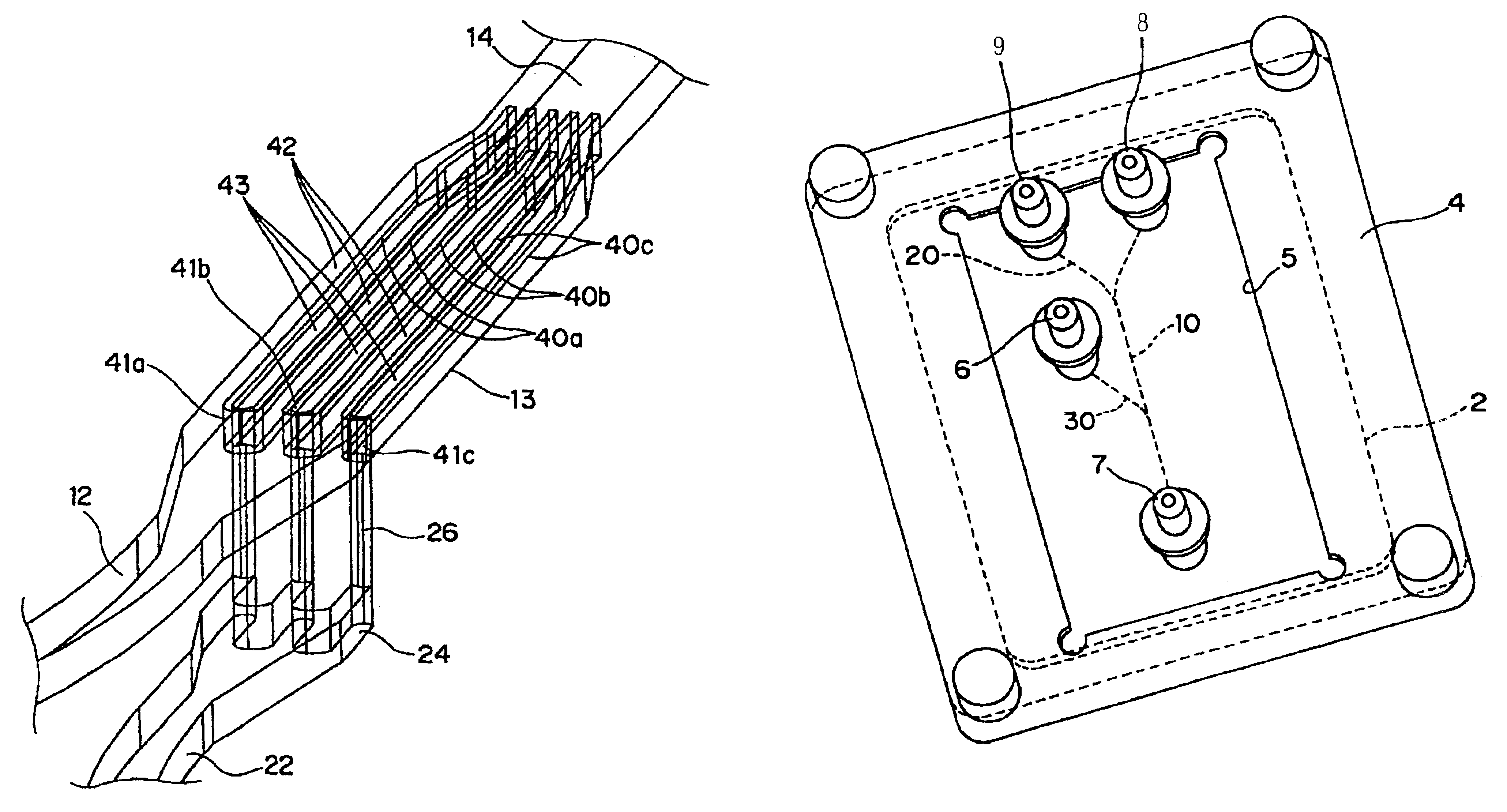

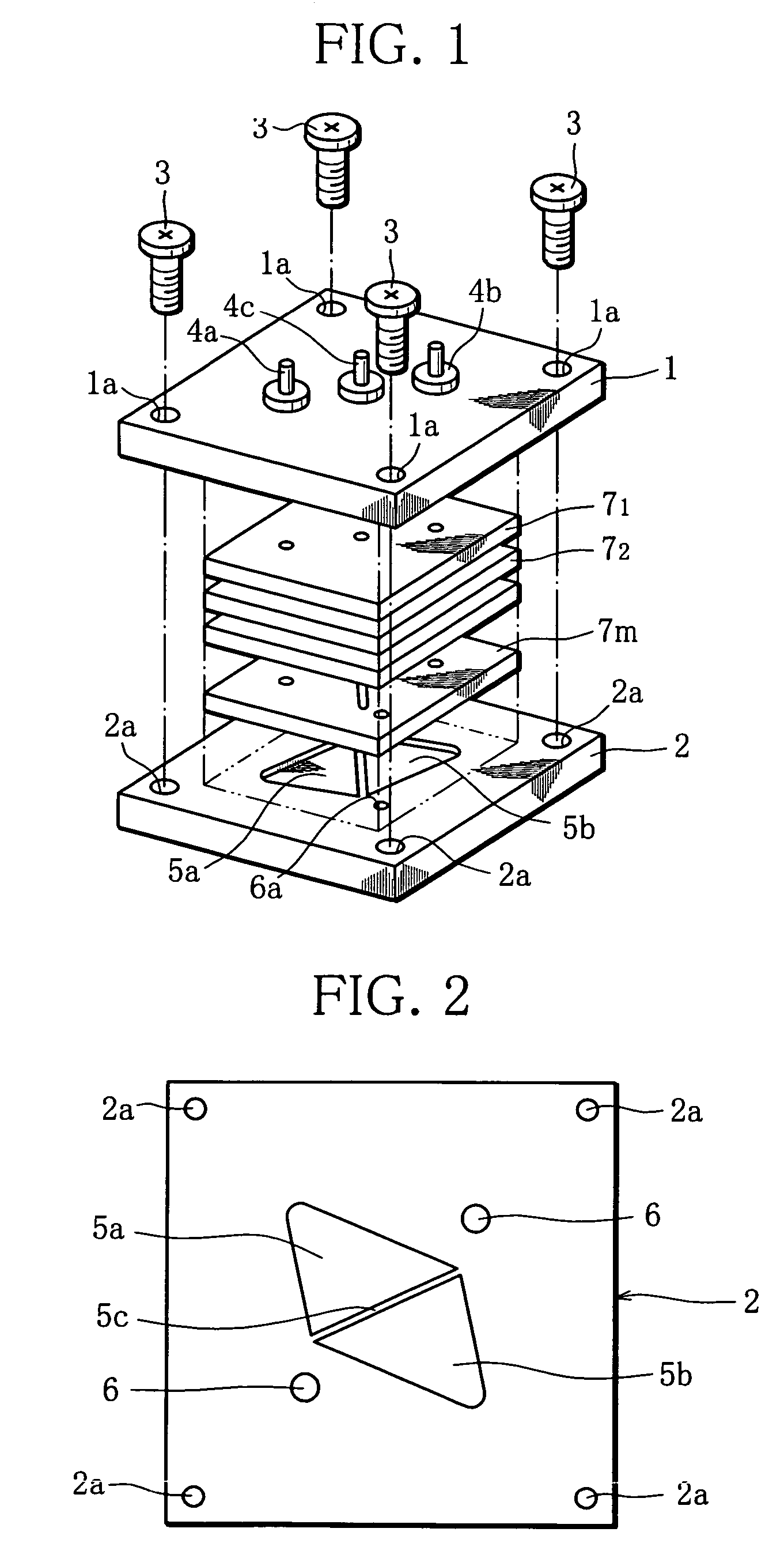

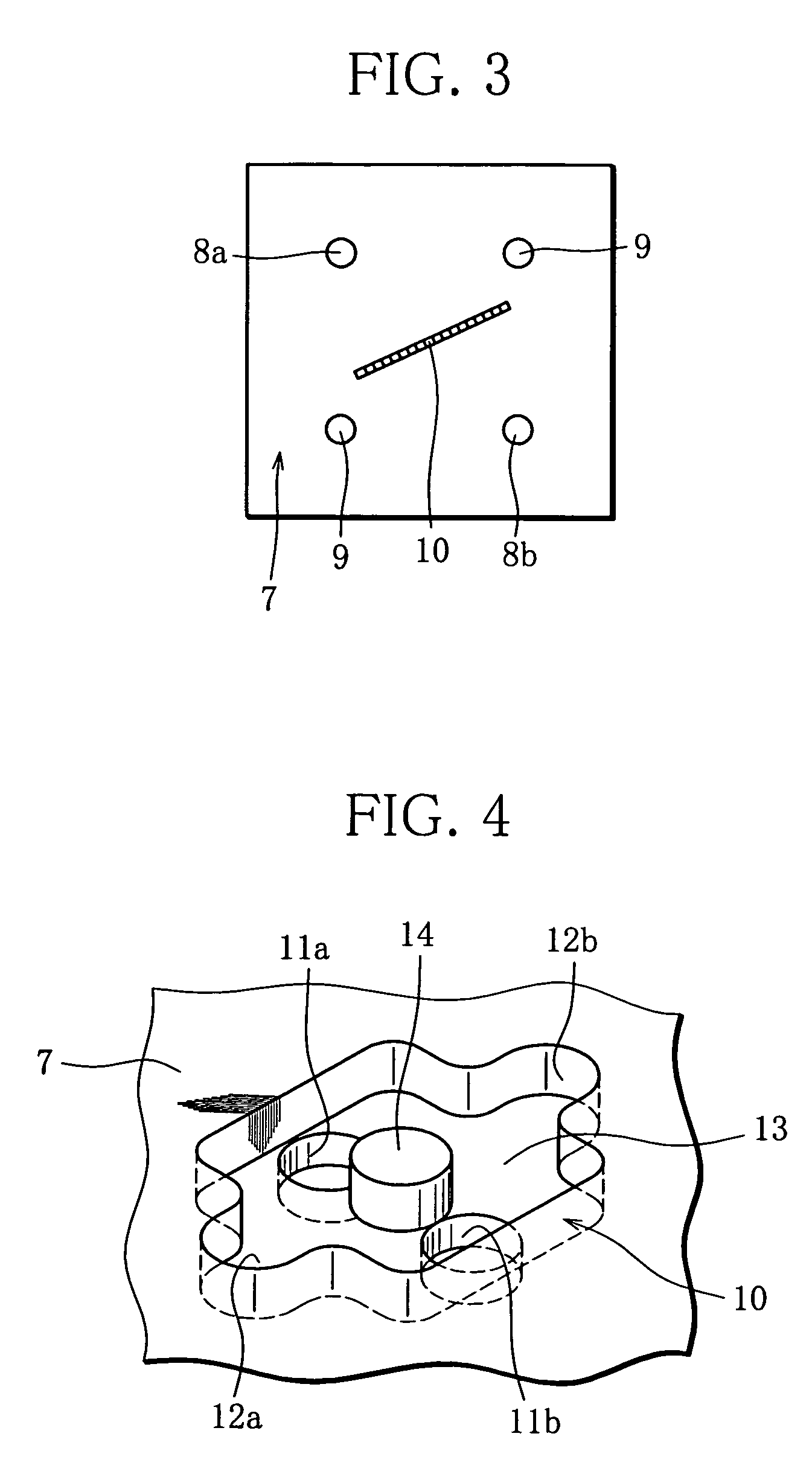

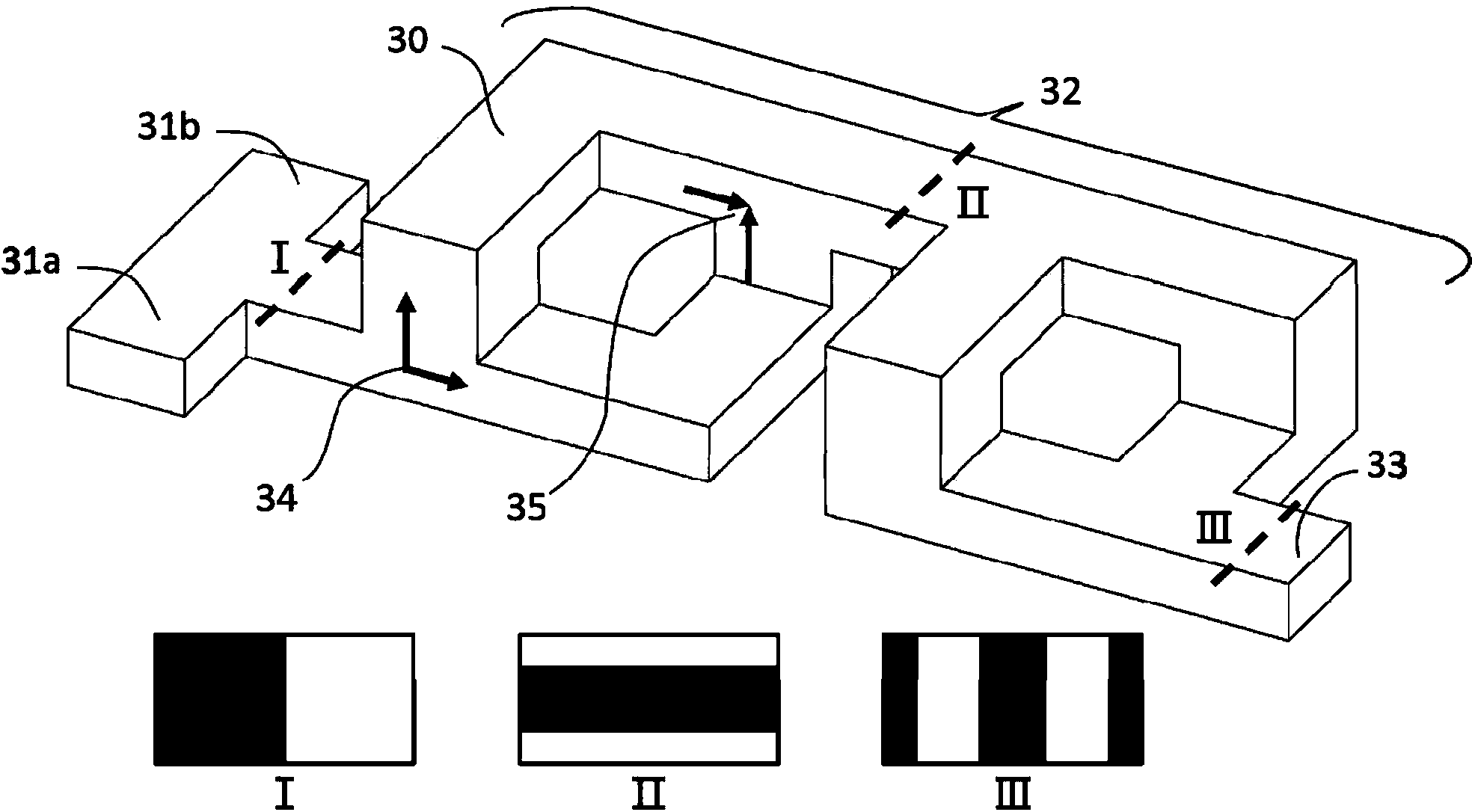

Mixing method, mixing structure, micromixer and microchip having the mixing structure

Disclosed herewith is a microchip having a micromixer therein. The mixromixer employs a mixing or extracting structure having (1) a first flow pass provided at a first level of the microchip; (2) a second flow pass provided at a second level of the microchip, which is different from the first level; (3) a third flow pass having a plurality of sub flow passes separately layered at the first level and each having a first end and second end thereof, each sub flow pass being connected to one of the first and second flow passes at the first end thereof; and (4) a fourth flow pass, provided at the first level, connected to the second ends of the sub flow passes so that, at least connecting portions between the fourth flow pass and the sub flow passes of the third flow pass, an extending direction of the fourth flow pass is substantially identical to those of the sub flow passes. By allowing the first liquid to flow from the first flow pass to the fourth flow pass through the third flow pass while the second liquid to flow from the second flow pass to the fourth flow pass through the third flow pass, the first and second liquids are mixed at the fourth flow pass.

Owner:MINOLTA CO LTD

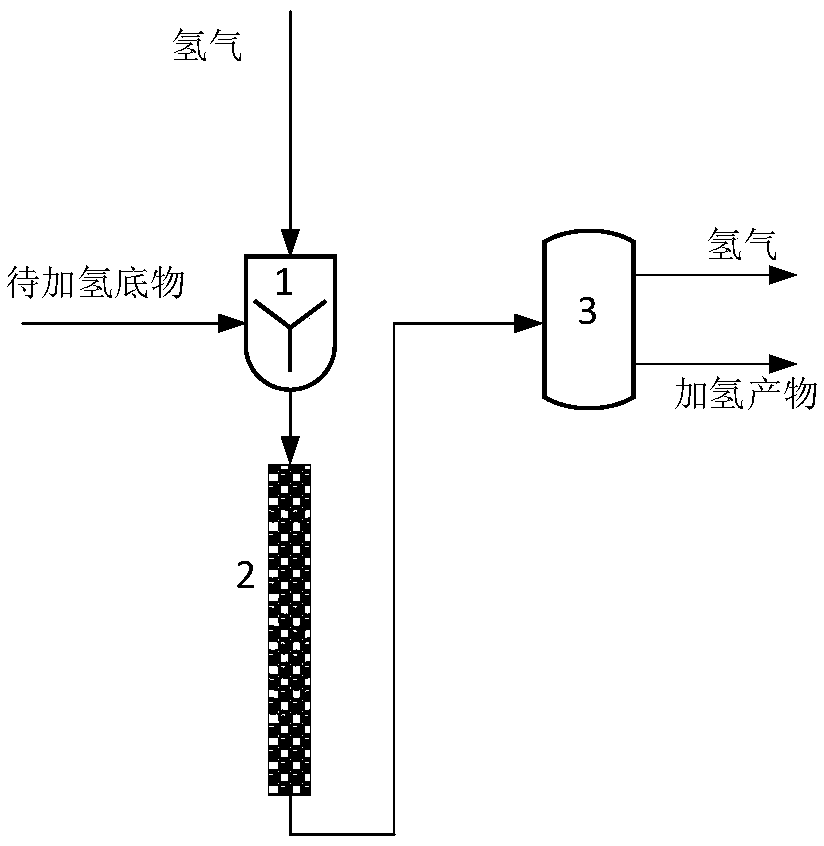

Hydrogenation reaction device in micropacked bed and method for hydrogenation reaction by using same

ActiveCN109225073AIncrease contact areaImprove mass transfer efficiencyChemical/physical processesPetrochemicalChemical reaction engineering

The invention discloses a hydrogenation reaction device in a micropacked bed and a method for a hydrogenation reaction by using the same in the technical field of chemical reaction engineering. The method comprises the steps: firstly, dispersing hydrogen into a solution containing a to-be-hydrogenated substrate by a micromixer to obtain a gas-liquid mixed fluid containing micro-scale bubbles; andthen, finishing a hydrogenation process on the gas-liquid mixed fluid by a micropacked bed filled with a hydrogenation catalyst. By using the method, the high mixing efficiency and excellent mass transfer and heat transfer performances of a microreactor are utilized, the gas-liquid and liquid-solid mass transfer in a hydrogenation reaction process is enhanced, the heat transfer capacity of the reactor is remarkably improved, and the size of a hydrogenation reactor can also be remarkably reduced; the hydrogenation reaction device has the advantages of high hydrogenation efficiency, safety, controllability and simplicity in amplification and can be widely applied to the technical fields such as petroleum and petrochemicals, fine chemical engineering, medicines, environments and foods.

Owner:TSINGHUA UNIV

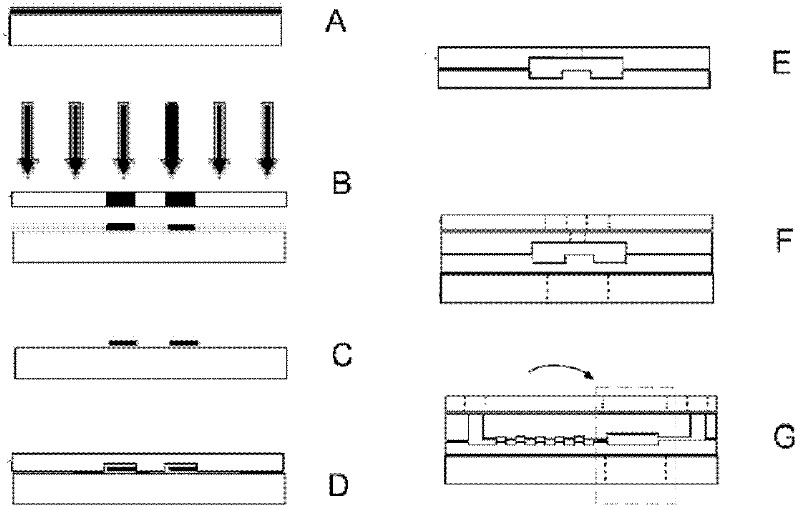

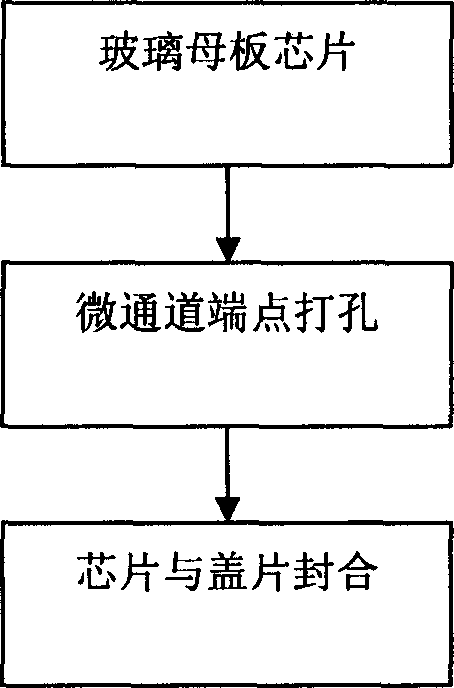

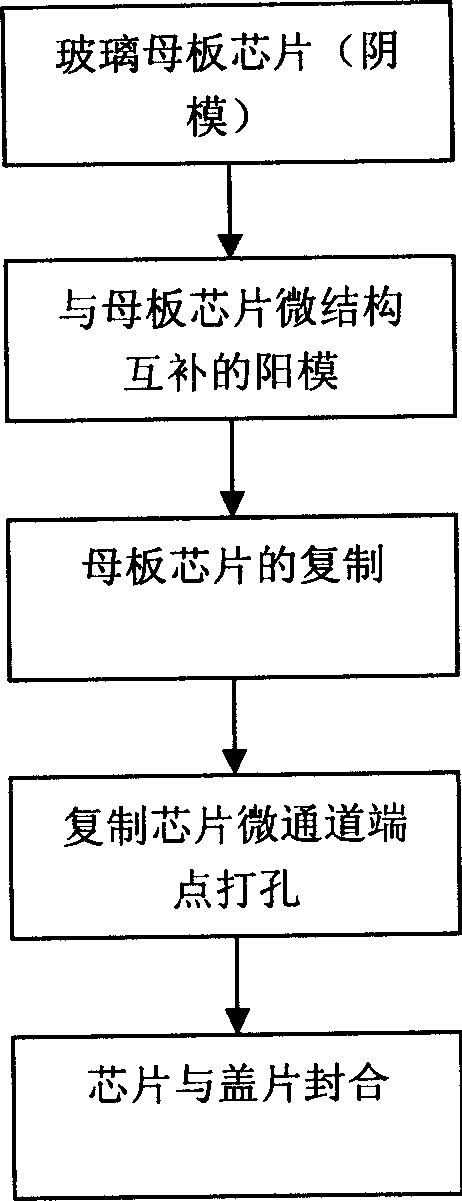

Method for manufacturing three-dimensional micromixer microfluidic chip

InactiveCN102240534AEasy to operateLow costLaboratory glasswaresColor/spectral properties measurementsUltraviolet lightsDimethyl siloxane

The invention discloses a method for manufacturing a three-dimensional micromixer microfluidic chip, which comprises the following steps: (1) making a mask by the microchannel graph of the three-dimensional micromixer microfluidic chip by laser photocomposition; (2) coating negative photoresist on a glass slide, laying the mask on the negative photoresist, exposing the glass slide covered with the negative photoresist and mask in an ultraviolet light source and developing to obtain a negative photoresist film; (3) casting mixed pulp of polydimethylsiloxane main agent and a curing agent on the negative photoresist film, curing, removing the negative photoresist film and thus obtaining a polydimethylsiloxane chip A; (4) making a polydimethylsiloxane chip B by the steps (1), (2) and (3); and (5) tightly laminating and bonding the polydimethylsiloxane chip A and the polydimethylsiloxane chip B to obtain the three-dimensional micromixer microfluidic chip. The method is simple in operation, low in cost, short in manufacturing period and high in repeatability and is very suitable for processing microstructures which are scores of micrometers long.

Owner:INST OF CHEM CHINESE ACAD OF SCI

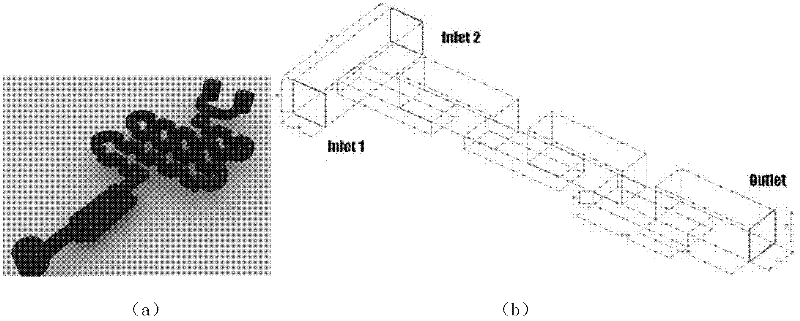

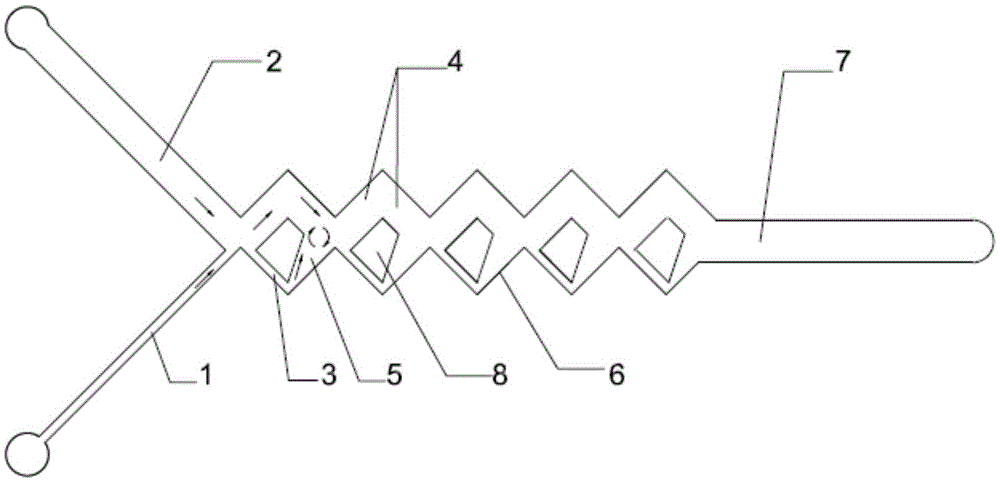

Device of fast synthetizing CdSe quantum dots and method thereof

InactiveCN101565175AImplementation is flexibleReliable implementationNanostructure manufactureLuminescent compositionsFluorescenceQuantum dot

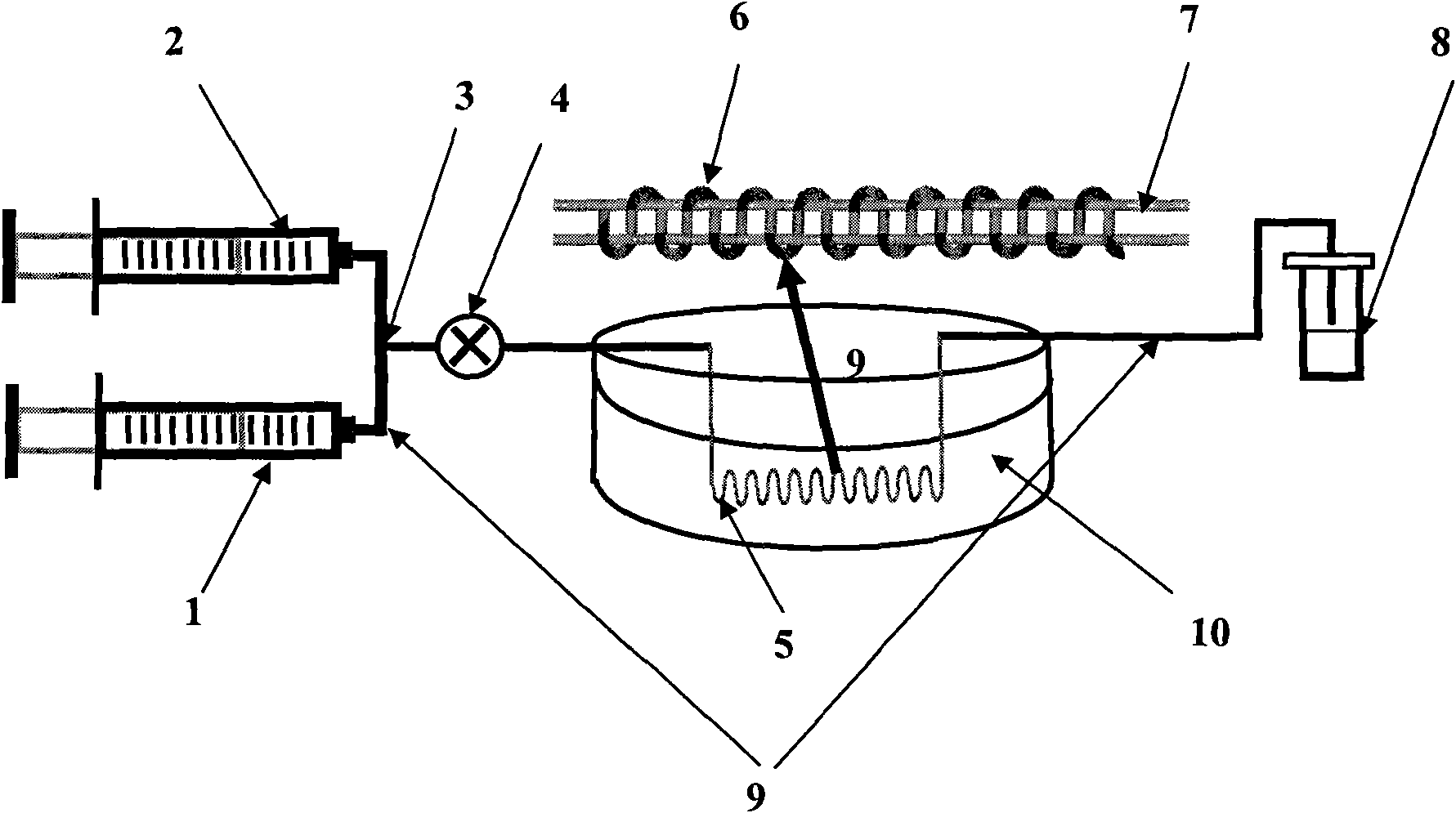

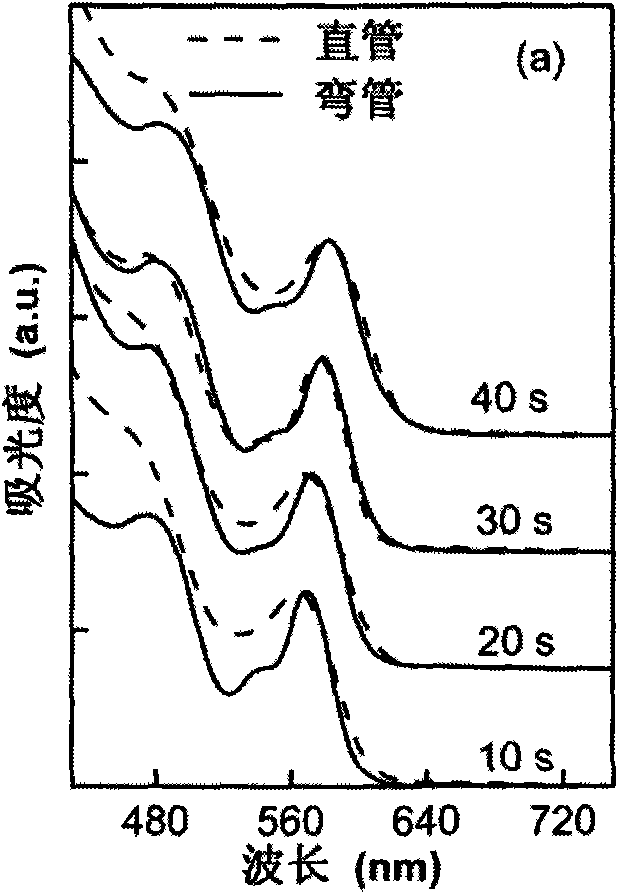

The invention relates to a device of fast synthetizing CdSe quantum dots and a method thereof. The device is connected with a Y-shaped tee 3 through Cd and Se precursor injectors, a polyfluortetraethylene connecting pipe 9 is sequentially connected with the Y-shaped tee 3, a convection micromixer 4, a bending micro-channel 5 and a liquid trap 8; particularly, the bending micro-channel is formed by alternatively winding a capillary tube along an external template, thereby obtaining a reaction channel with geometrical turning and causing nonsymmetry of fluid flow field. The device strengthens the mixing of fluid by utilizing the consecutive transition of the geometrical turning along axial direction and radial direction, thereby improving the uniformity of detention time and concentration distribution. The device and method of the invention lead the prepared quantum dots to be uniform in size; simultaneously, based on same temperature and detention time, by the variation of the relative sample injection ratio of Cd / Se precursor, the fast synthetizing of CdSe nanocrystalline in wide particle size range can be realized, and high quality CdSe nanocrystalline with adjustable fluorescence spectrum can be synthetized continuously.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for producing passive micro-mixer and micro-reactor in micro-flow control chip

InactiveCN1811421AFacilitates flow mixingAchieve replicationSemiconductor/solid-state device manufacturingBiological testingMicroreactorGlass chip

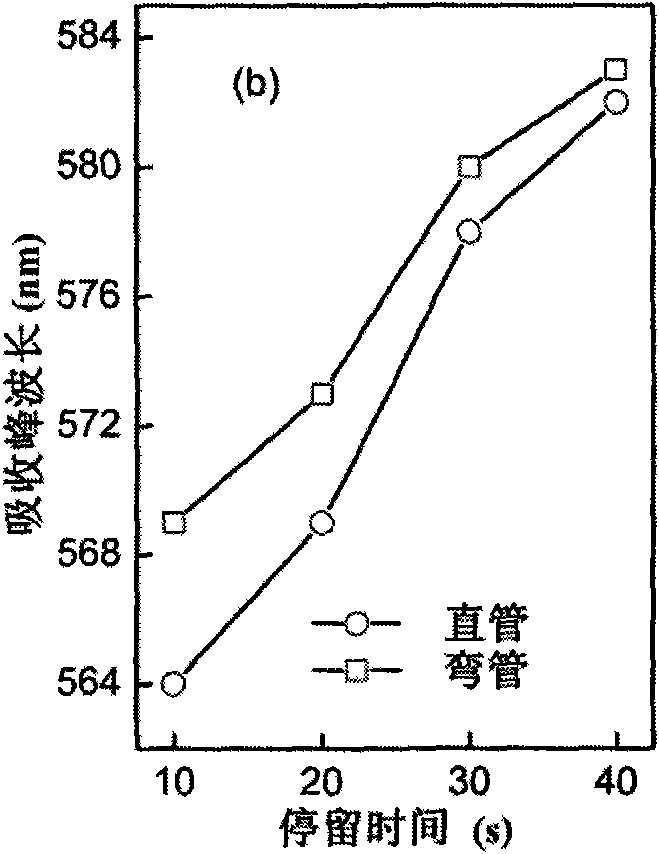

The present invention relates to a method for making passive micromixer and microreactor in microfluidic chip. Said method includes the following steps: firstly, making glass mother die chip whose bottom surface and side surface have submicrostructure, utilizing glass mother plate chip to prepare all-glass chip or all-glass mixed chip whose three faces or all-channel have submicrostructure, or utilizing the process of pouring polymer to obtain the male die complementary with glass mother plate microstructure, utilizing said male die to make secondary pouring and duplication so as to obtain the chip of polymer base material with glass, mother plate structure, then further making packaging combination to obtain all-polymer mixed chip or composite chip.

Owner:NORTHEASTERN UNIV

Micro chaotic mixer

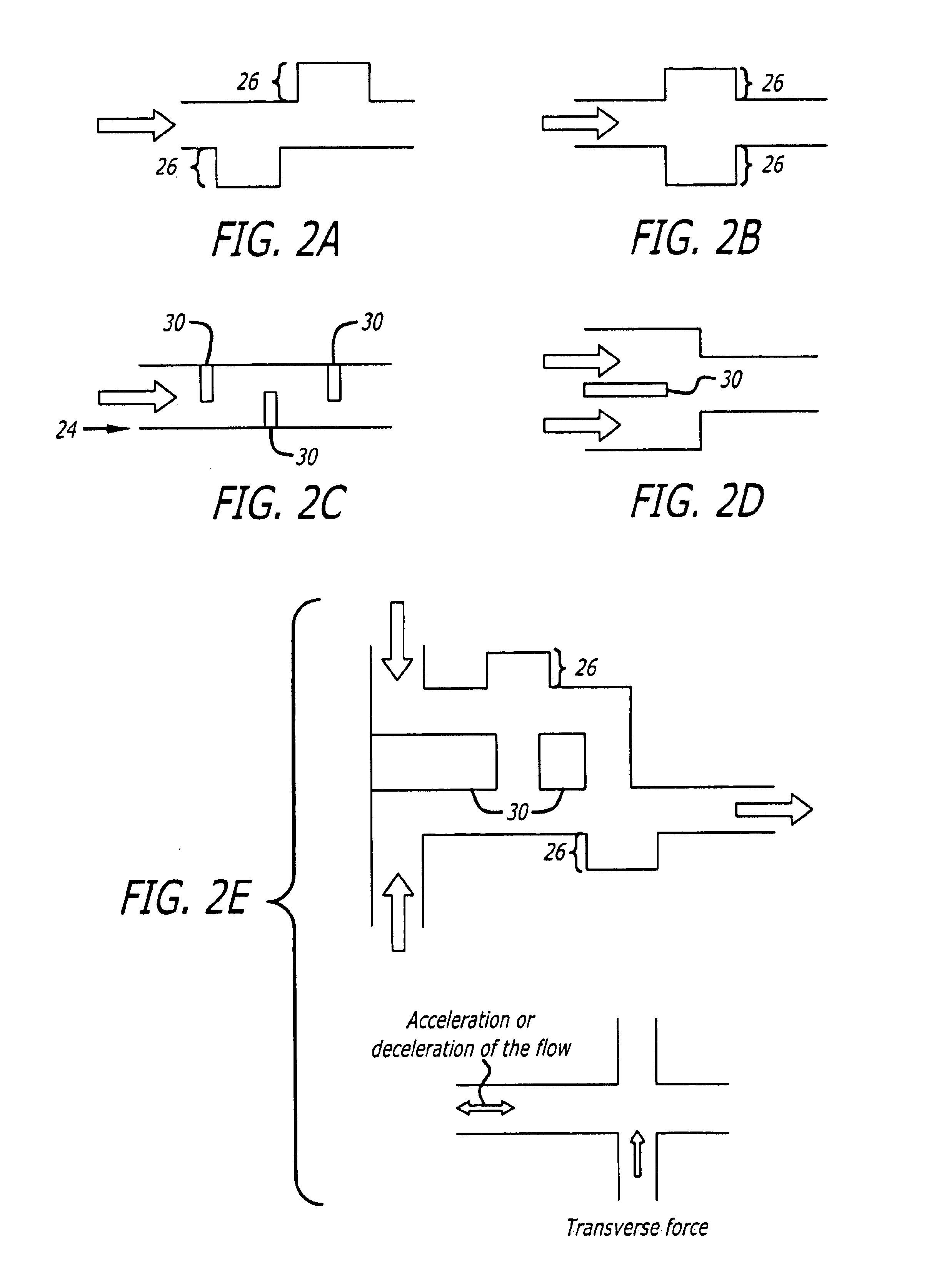

InactiveUS6902313B2Simple structureEasily integrated into any microdeviceElectrolysis componentsShaking/oscillating/vibrating mixersTransverse forceChaotic

A micro mixer for use in a microdevice which utilizes time-varying force fields to induce bulk fluid and / or sample component motion leading to homogenization of sample components. Time-varying force fields employed includes at least one of a physical displacement field, electrical field, pressure field or magnetic field to generate transverse forces which induce the mixing of samples within the micro mixer.

Owner:UNIVERSTIY OF CALIFORNIA

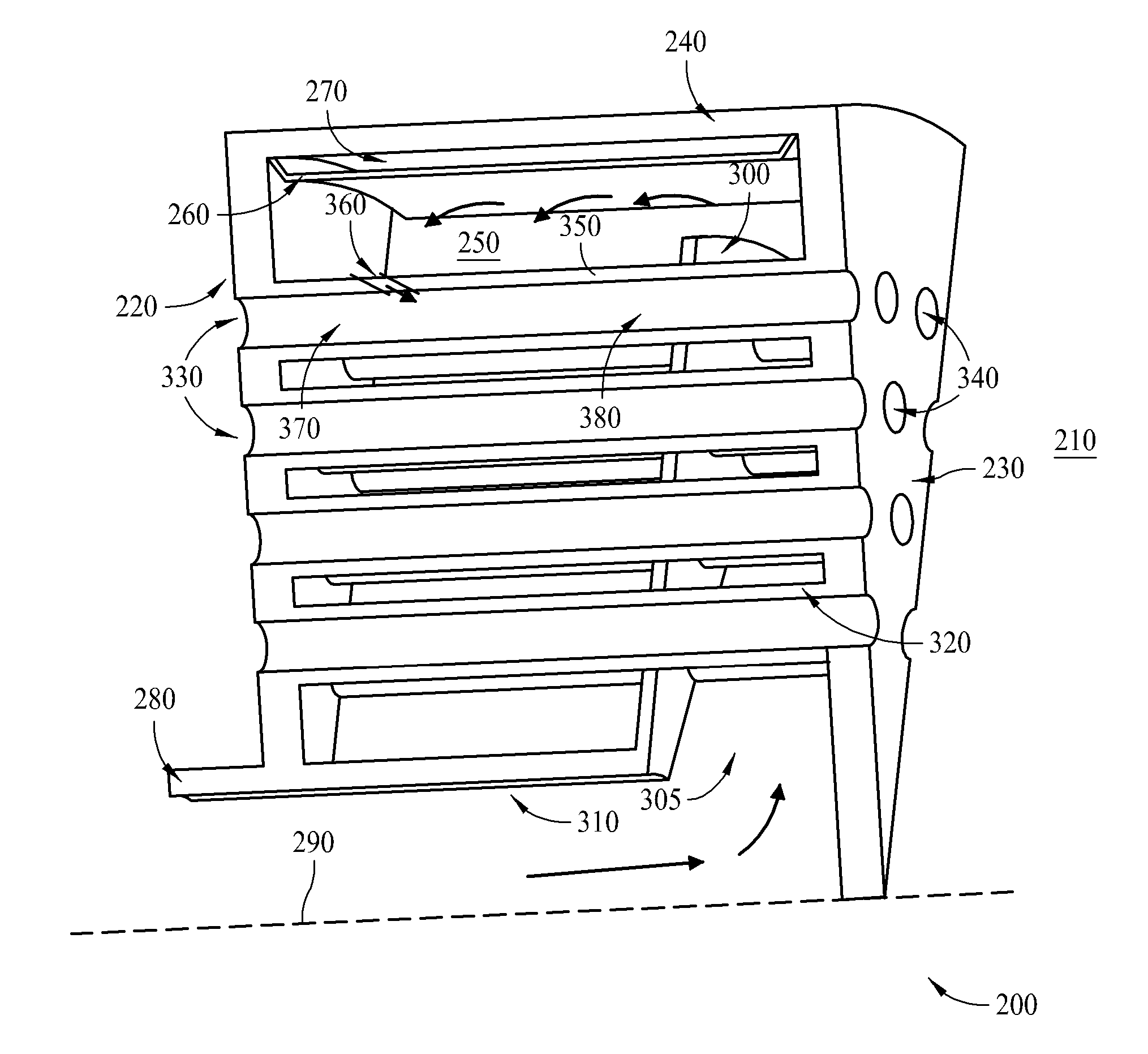

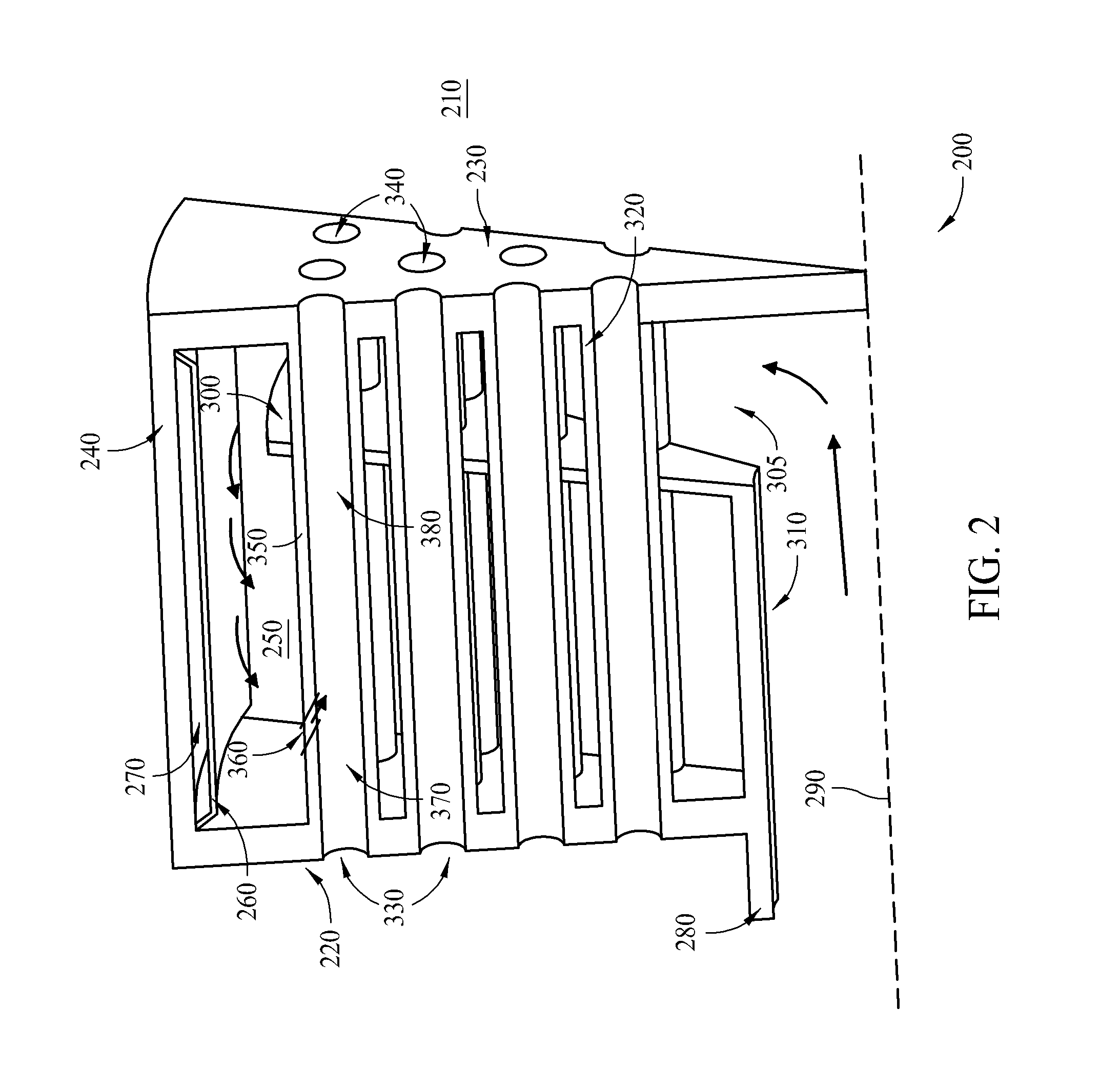

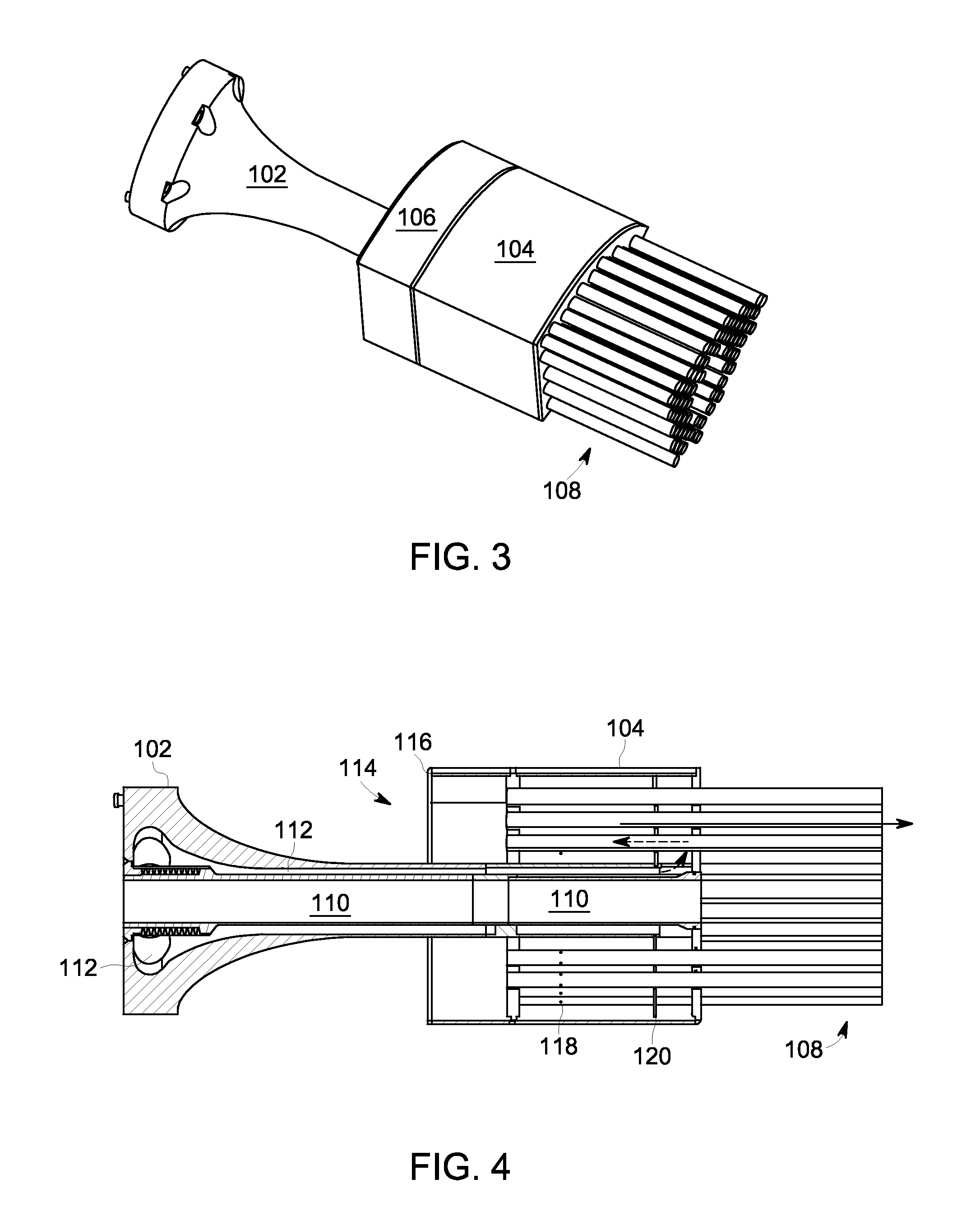

Micromixer heat shield

InactiveUS20130042625A1Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorSpray nozzle

A combustor includes a combustor wall defining a combustion zone and a fuel nozzle. The fuel nozzle includes a forward face, an aft face downstream from the forward face and adjacent to the combustion zone, a plurality of mixing tubes extending between the forward face and the aft face, an outer sleeve positioned radially outward of the plurality of mixing tubes, a heat shield positioned radially inward of the outer sleeve, and a baffle plate between the forward face and the aft face. At least one of the plurality of mixing tubes includes a sidewall that includes an injection opening defined therethrough. The baffle plate is oriented to channel fuel between the plurality of mixing tubes and between the baffle plate and the aft face prior to the fuel being channeled through the injection opening.

Owner:GENERAL ELECTRIC CO

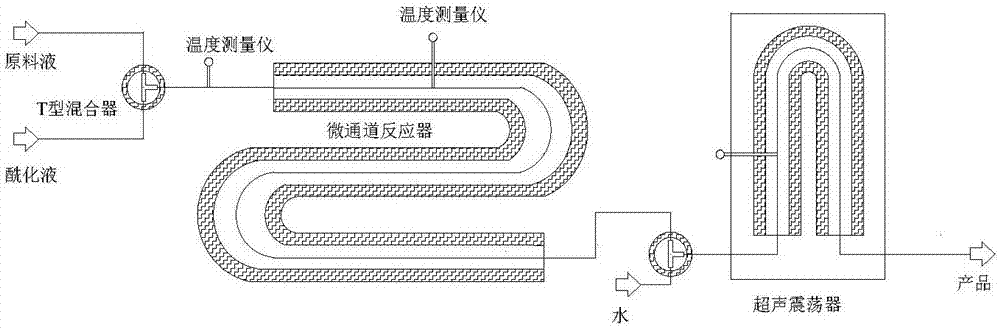

Method for synthesizing acyl naphthalene by using micro-channel reactor

InactiveCN107879909AImprove airtightnessImprove securityCarbonyl compound preparation by condensationCarbonyl compound separation/purificationWater bathsIce water

The invention discloses a method for synthesizing acyl naphthalene by using a micro-channel reactor. The method comprises the following steps: (1) preparing acylation liquid, namely adding nitrobenzene and anhydrous aluminum chloride into a reactor in a low-temperature tank, finally adding acyl chloride, and controlling the temperature in the reactor to be 0-3 DEG C; (2) preparing a feed solution,namely adding nitrobenzene and 2-methyl naphthalene into a reactor provided with a stirrer; (3) reacting, namely injecting the feed solution and the acylation liquid into a micro mixer to be mixed, and feeding into the micro-channel reactor to be reacted; (4) washing, namely enabling the product discharged from the micro-channel reactor to enter the micro mixer again so as to be washed, enablingthe mixture into the micro-channel reactor, controlling the reactor temperature to 40-50 DEG C, and performing ultrasonic oscillation outside the reactor; (5) performing reduced pressure distillation,namely separating the products obtained in the step (4), and performing vacuum decompression to 500-1000Pa so as to obtain a crude product 2-methyl-6-acyl naphthalene; and (6) recrystallizing, namelyadding the crude product obtained in the step (5) into a solvent of 50-60 DEG C, stirring and dissolving, naturally cooling and crystallizing, continuously cooling and crystallizing in an ice-water bath, and finally filtering to obtain the purified product 2-methyl-6-acyl naphthalene.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

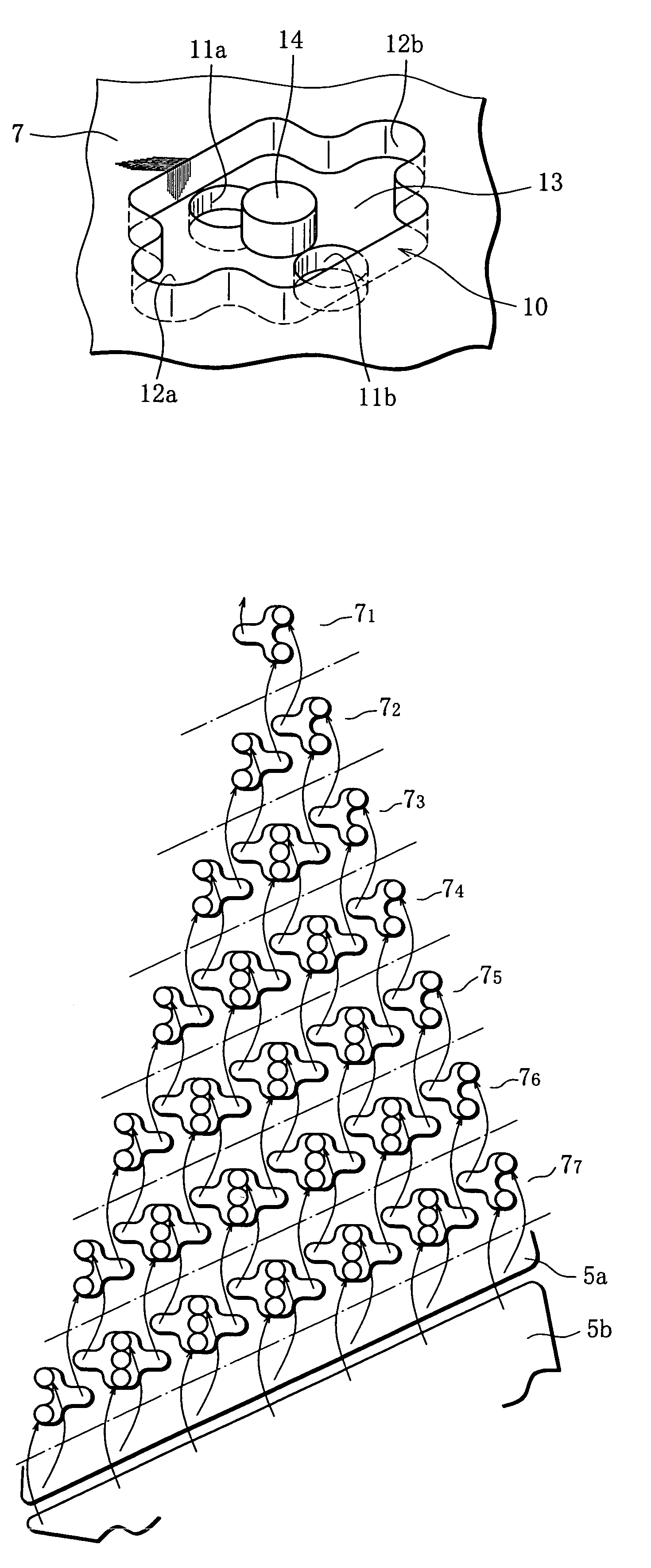

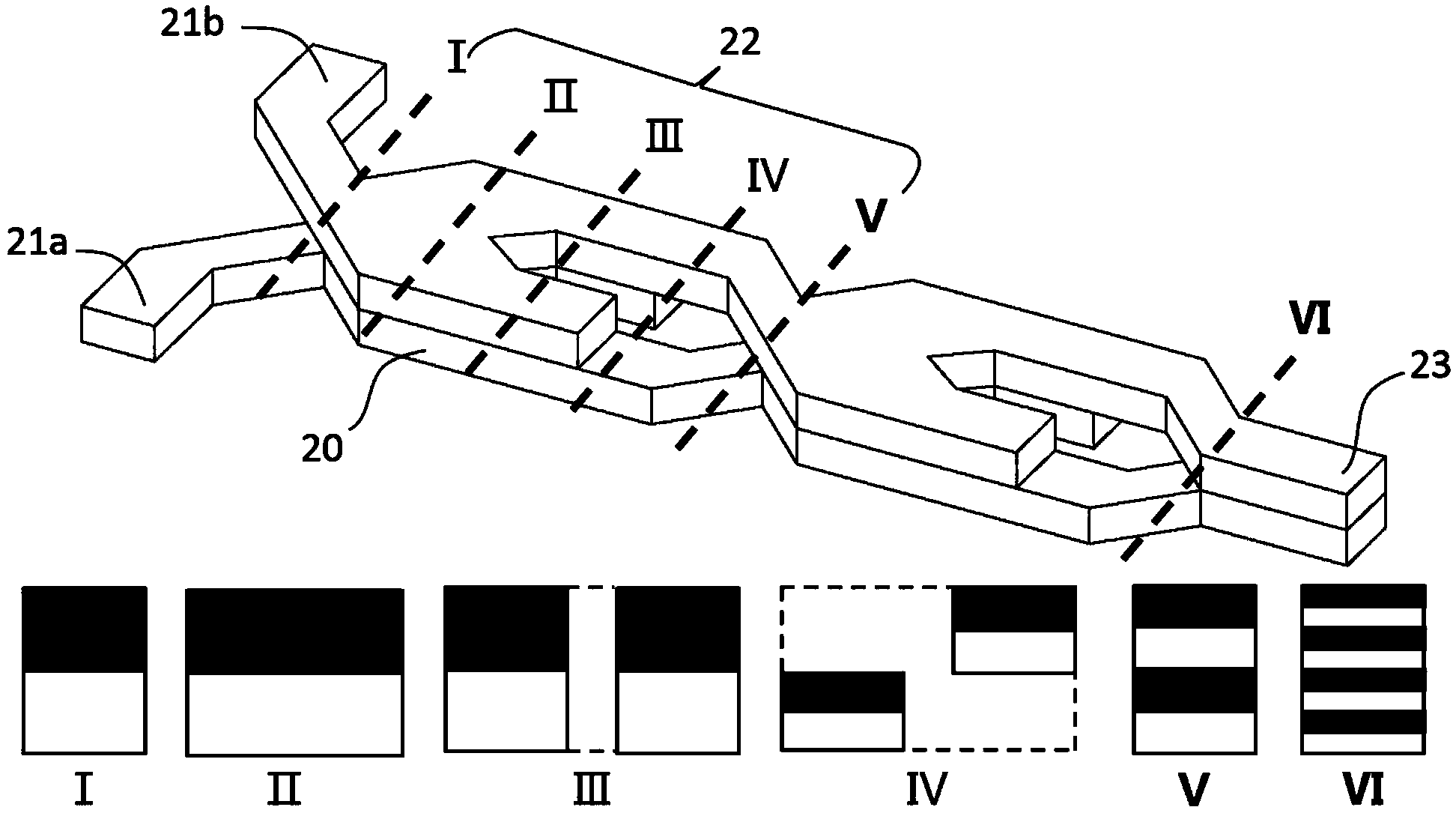

Twin-vortex micromixer for enforced mass exchange

InactiveUS7794136B2Well mixedImprove mixing efficiencyOther chemical processesFlow mixersShortest distanceLab-on-a-chip

The present invention discloses a vortex-modulation based micromixer for enforced mass exchange. The micromixer of the present invention comprises a mixing chamber with grooves on one wall thereof and a special-shape barrier on another wall. As different fluids are injected into the mixing chamber respectively from two inlets of the micromixer, the grooves and barriers of the micromixer of the present invention create the constructive interferences to form the active-like agitation of the fluid. For every groove, the flux passed by can be increased via its high pressure gradient. Understandably, the mixing efficiency of the fluids can be greatly improved within a very short distance. At last, the outlet of the micromixer is located in the downstream of the mixing chamber and further is able to connect with other elements. The present invention is entirely a passive micromixer and no additional energy is required. The present invention can apply to a continuous chemical analysis, particularly to a lab-on-a-chip or a micro total analysis system.

Owner:NATIONAL TSING HUA UNIVERSITY

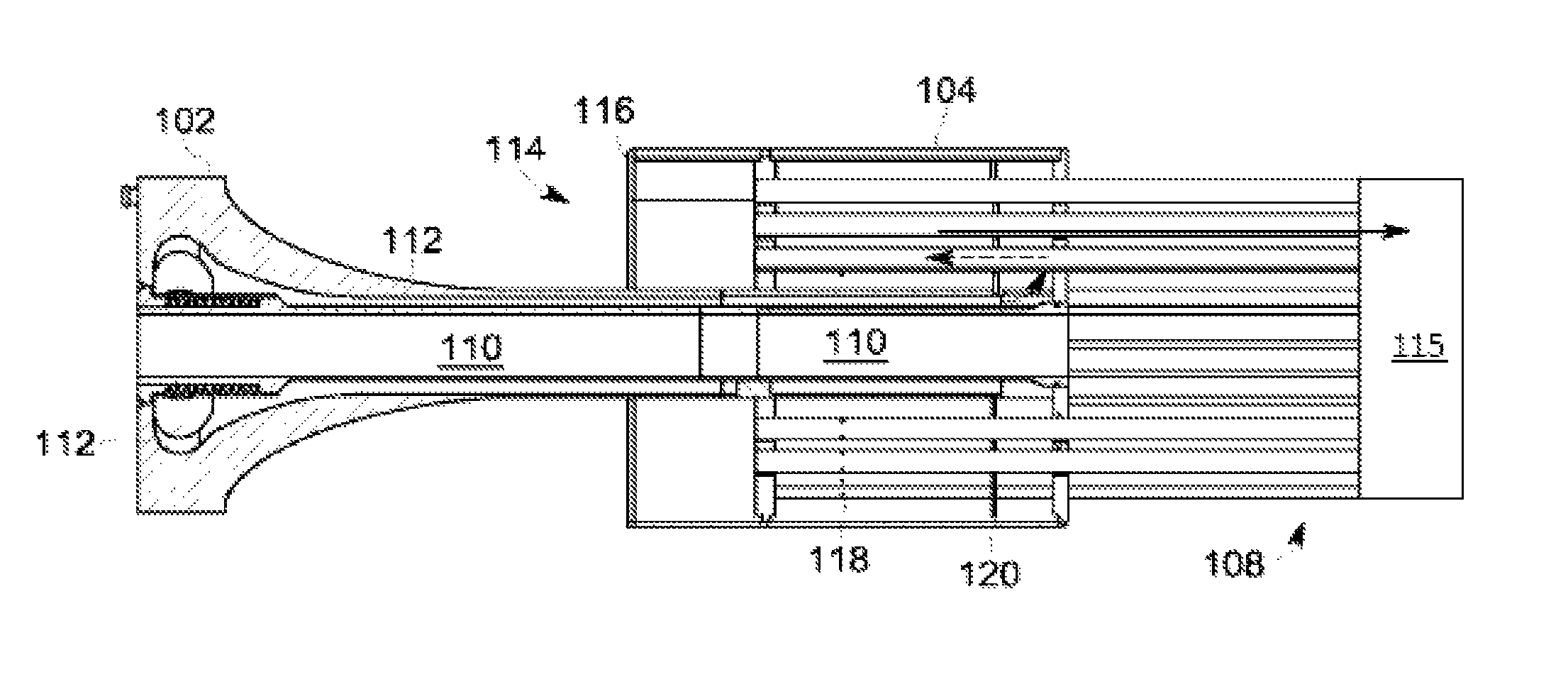

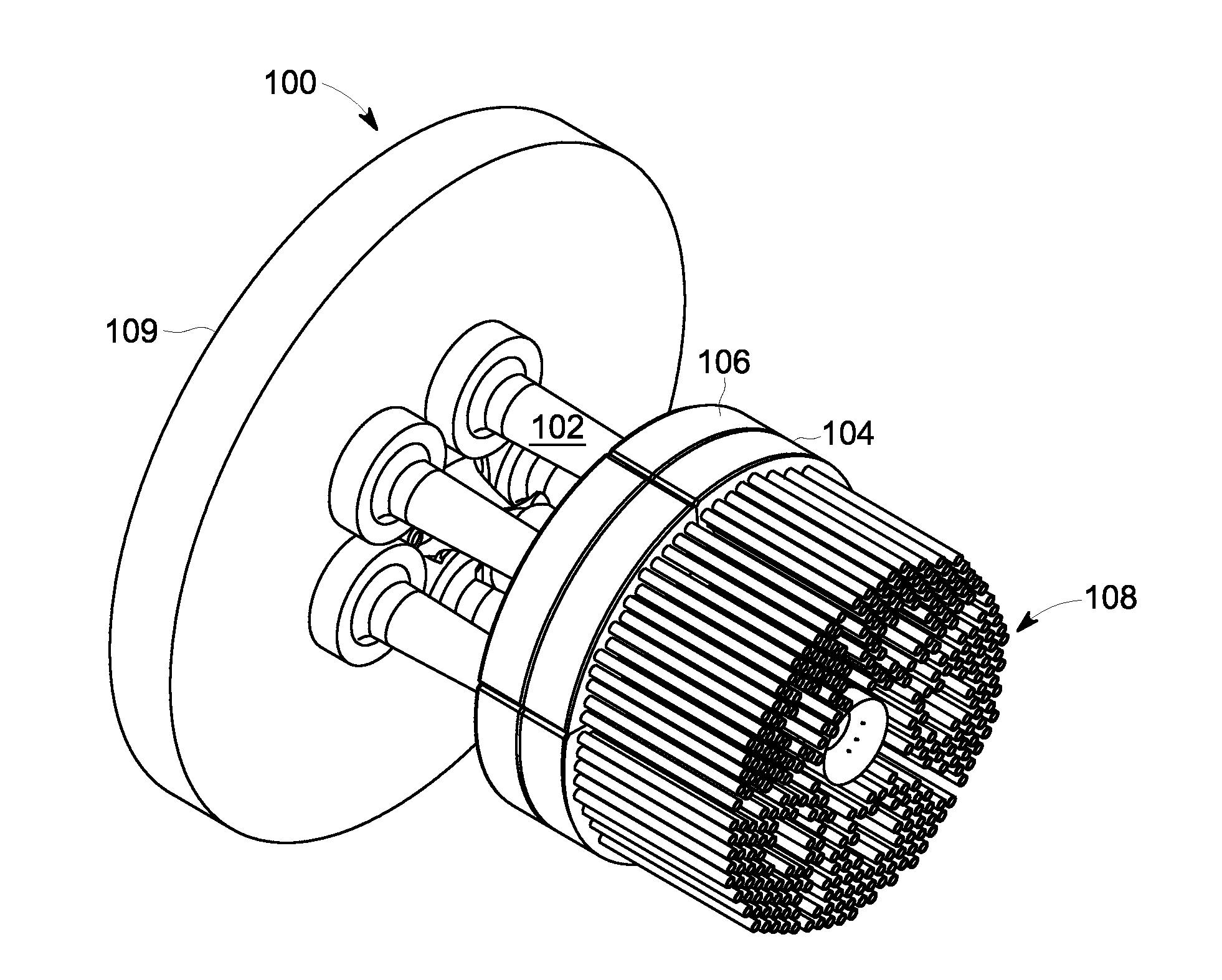

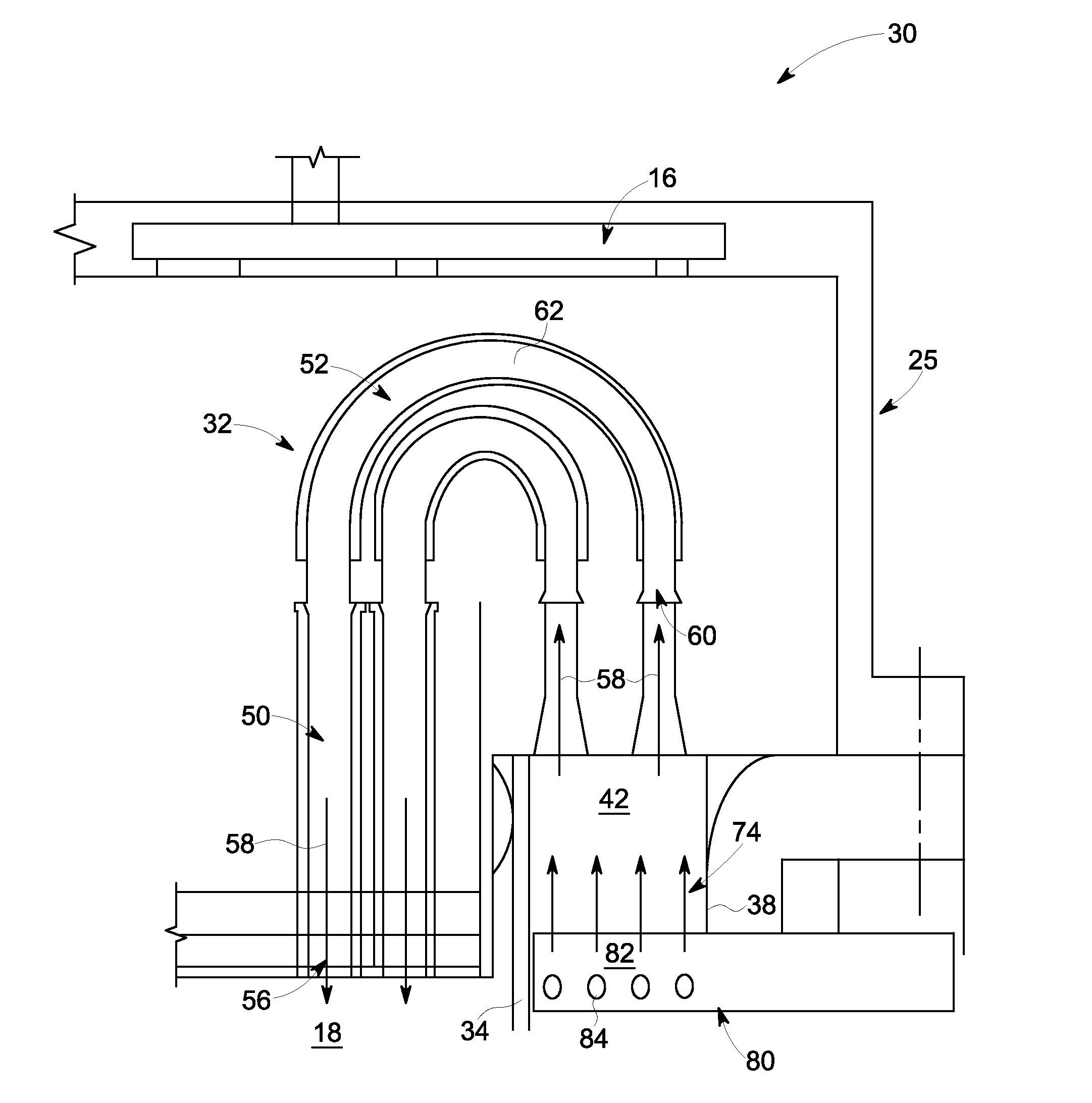

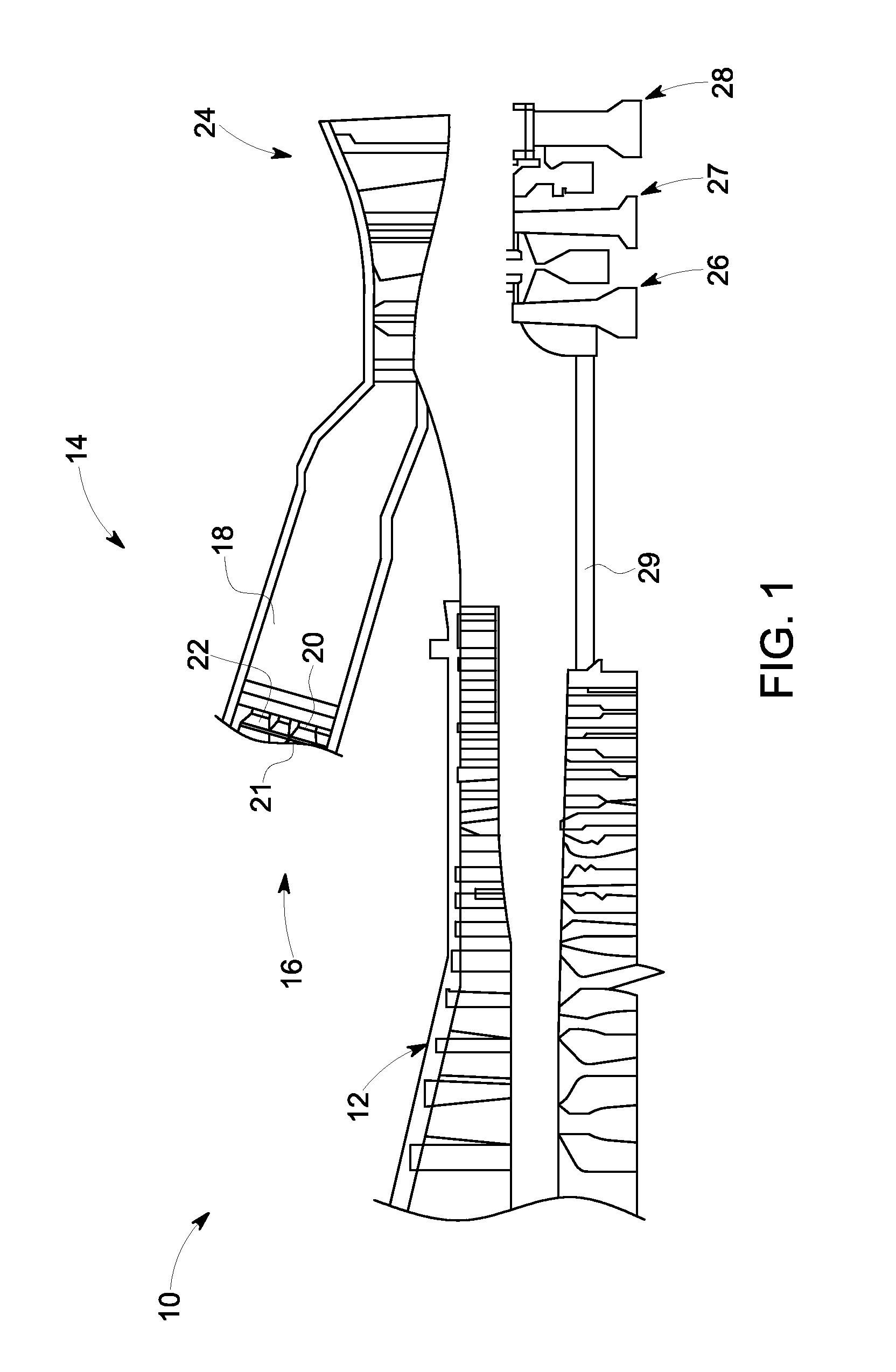

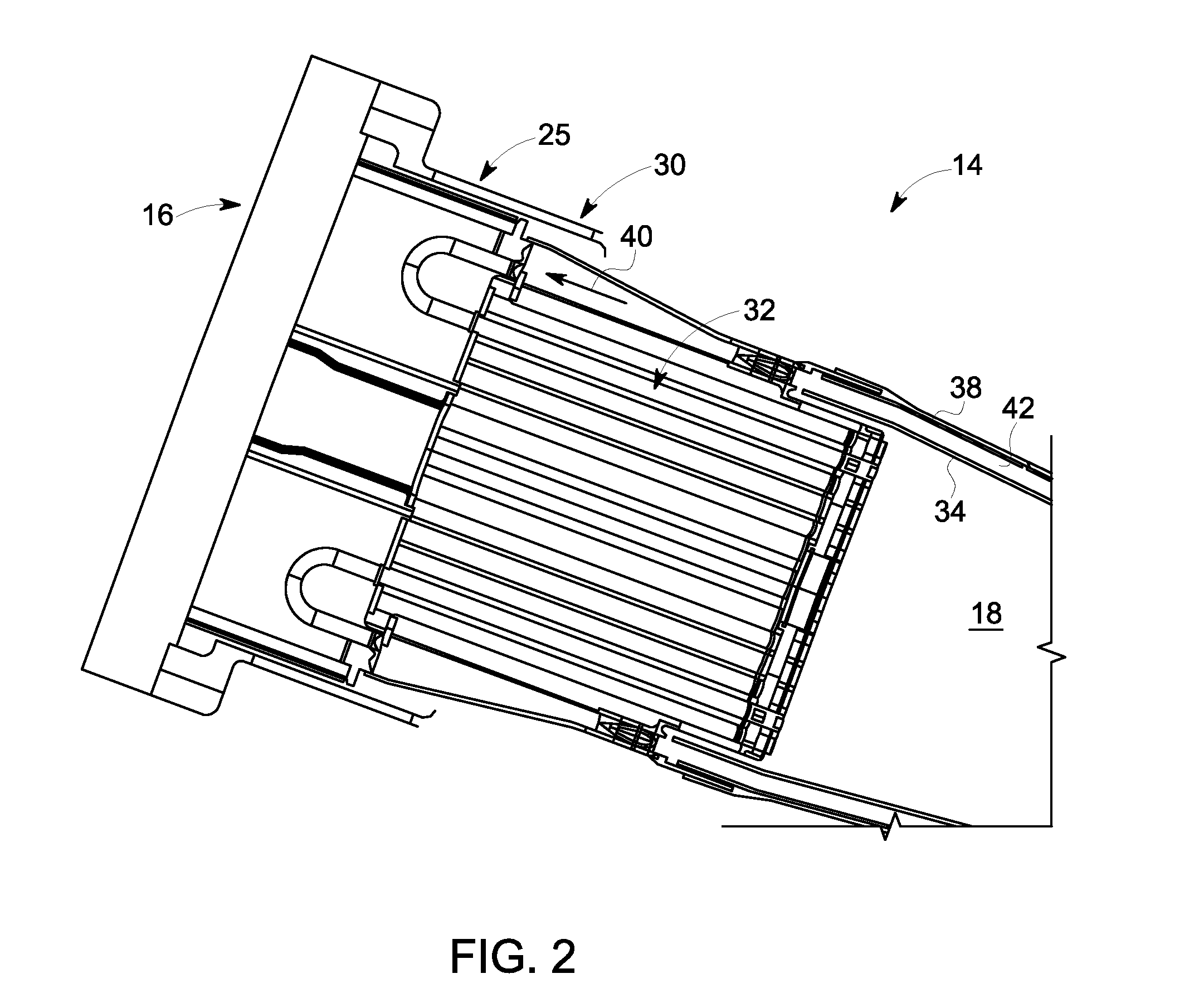

Micromixer of turbine system

A micromixer of a turbine system is provided and the micromixer includes a plurality of pipes each having an inlet and an outlet for receiving flow and dispersing the flow to a combustor. Also provided is a non-uniform inlet arrangement defined by the inlets of the plurality of pipes, wherein at least one of the inlets extends to an axial location distinct from at least one other inlet.

Owner:GENERAL ELECTRIC CO

Micromixer combustion head end assembly

Embodiments of the present application can provide systems and methods for a micromixer combustion head end assembly. The micromixer may include one or more base nozzle structures. The base nozzle structures may include coaxial tubes. The coaxial tubes may include an inner tube and an outer tube. The micromixer may also include one or more segmented mixing tube bundles at least partially supported by a respective base nozzle structure. Moreover, the micromixer may include an end cap assembly disposed about the one or more segmented mixing tube bundles.

Owner:GENERAL ELECTRIC CO

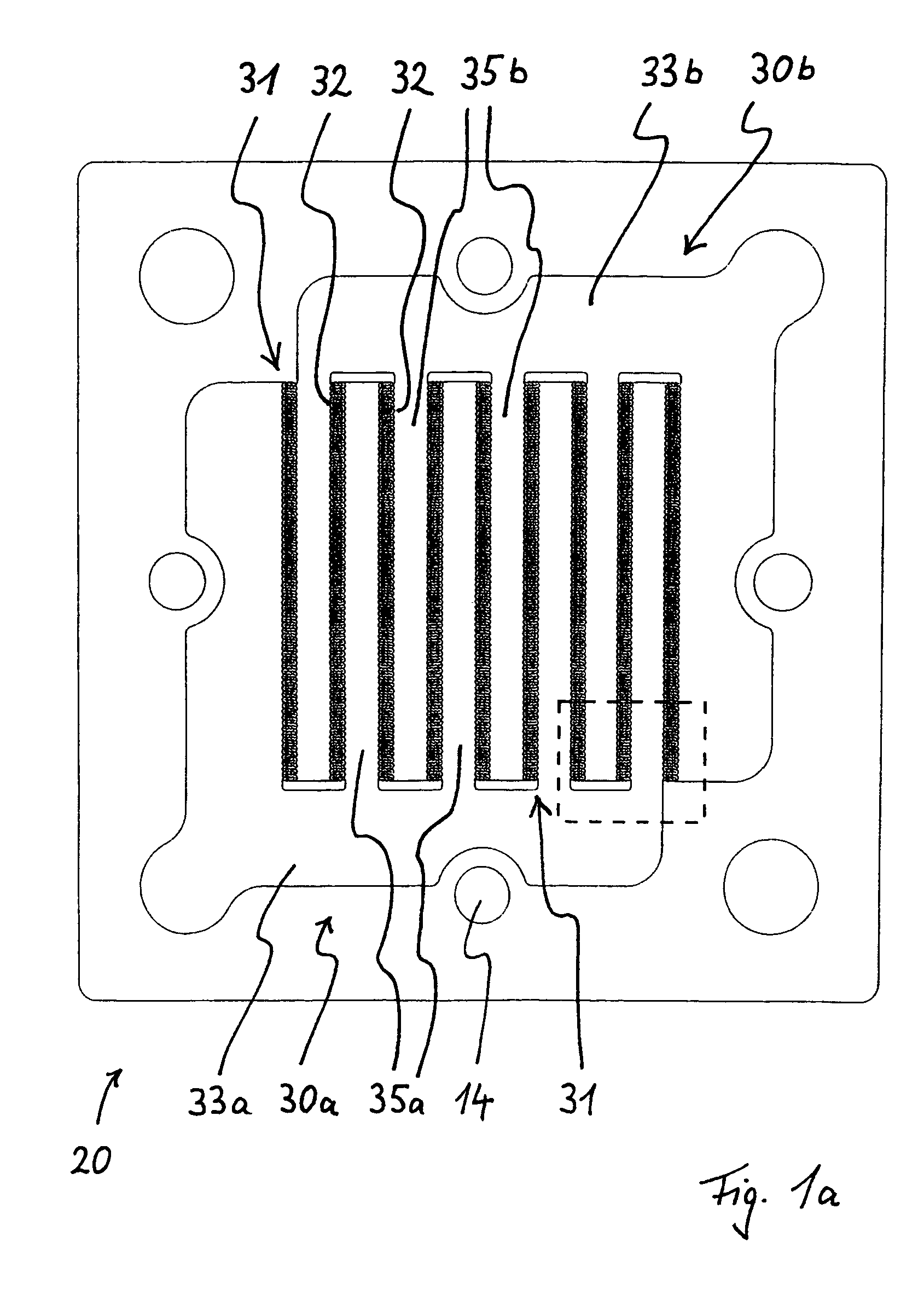

Micromixer

InactiveUS7066641B2Improve the mixing effectEasy to produceFlow mixersFixed microstructural devicesEngineeringMICRO MIXER

Owner:YAMATAKE HONEYWELL CO LTD

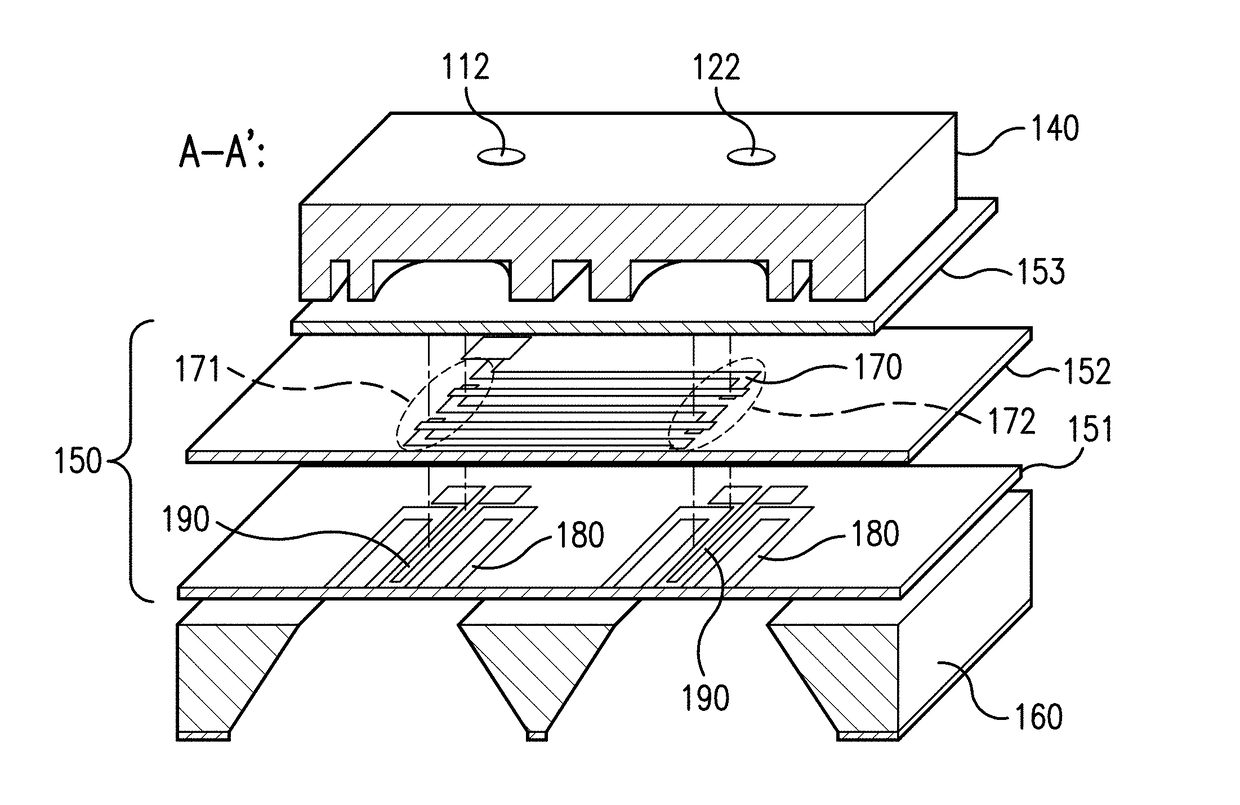

Mems-based calorimeter, fabrication, and use thereof

A MEMS-based calorimeter includes a reference channel, a sample channel, and a thermopile configured to measure a temperature differential between the reference channel and a sample channel. The reference channel and the sample channel each include a passive mixer such as a splitting-and-recombination micromixer. The passive mixer can be formed by a first set of channels in a first layer and a second set of channels in a second layer. Methods for fabricating the MEMS-based calorimeter and methods of using the calorimeter to measure thermodynamic properties of chemical reactions are also provided.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

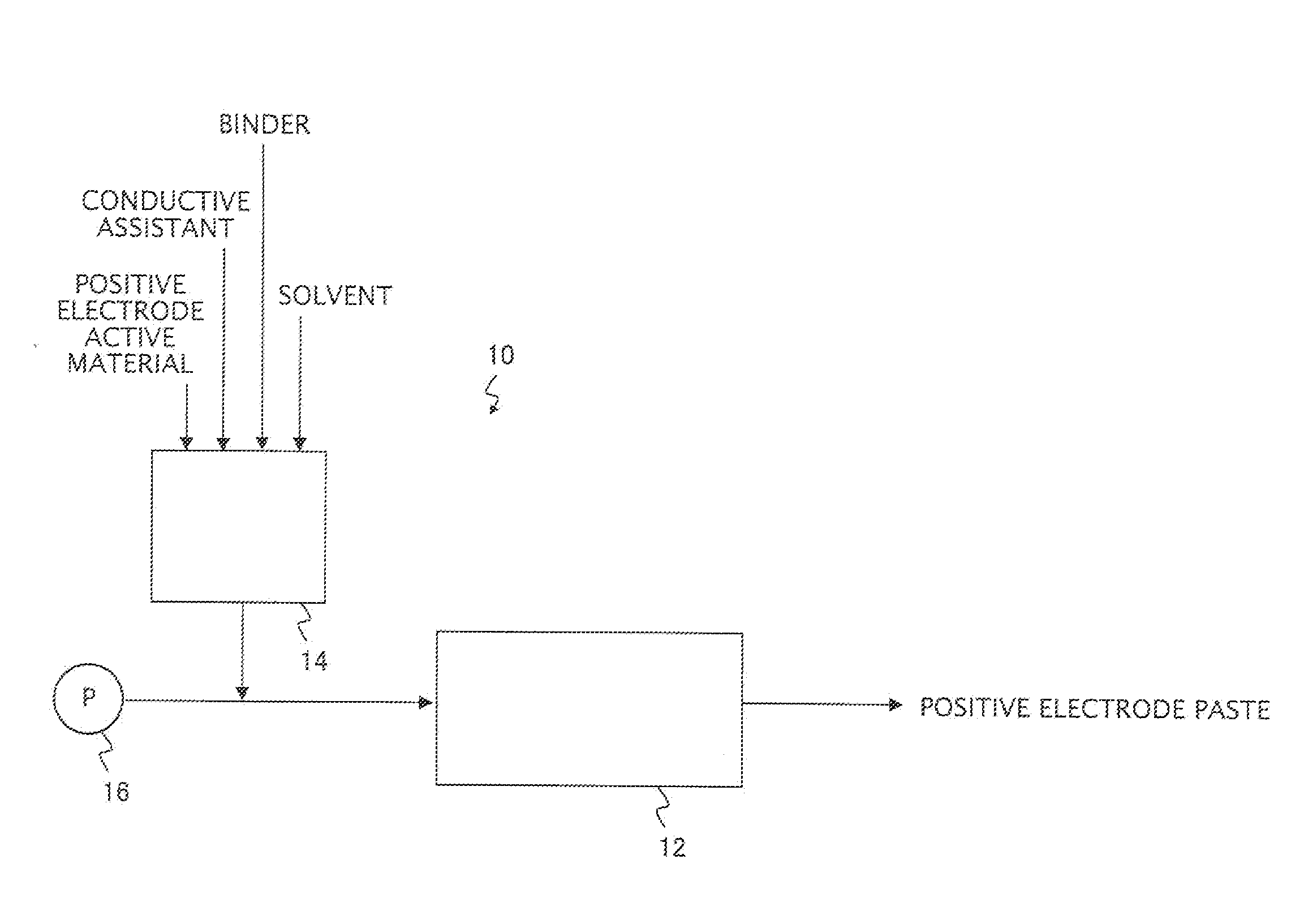

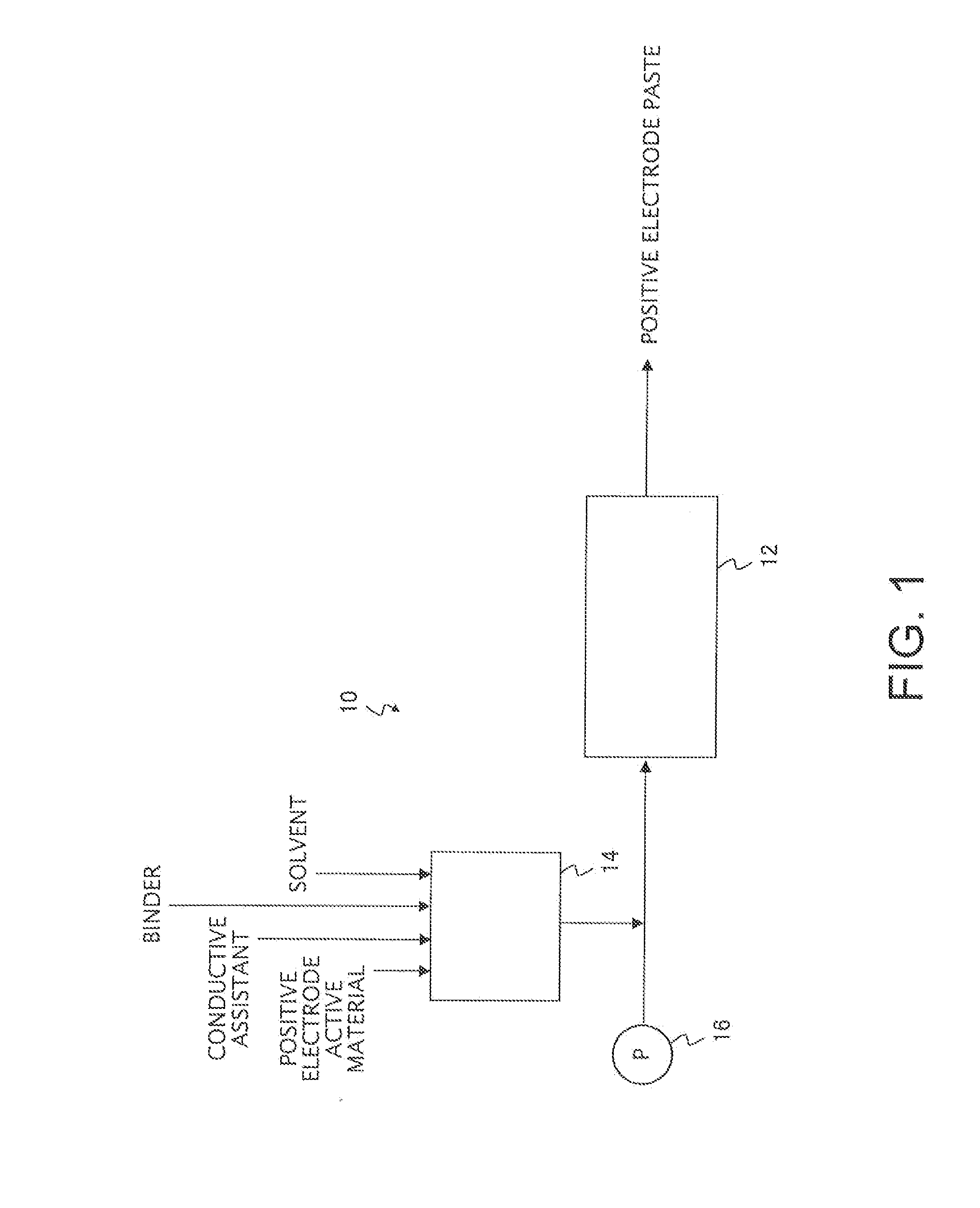

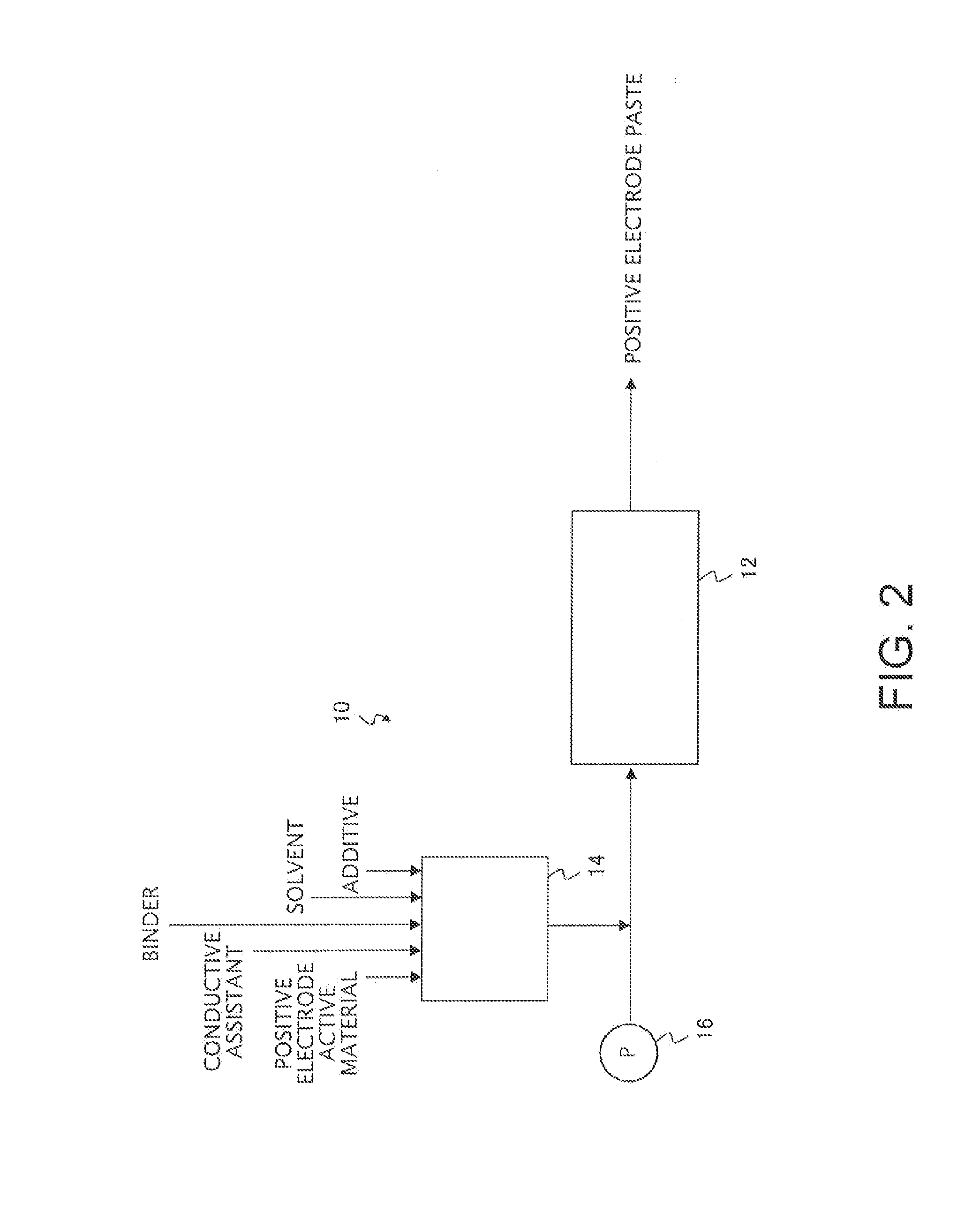

Electrode paste production method

ActiveUS20160099461A1Efficient use ofLow-viscosity electrodeRotary stirring mixersSecondary cellsSolid fractionSolvent

Provided is an electrode paste production method that can produce a low-viscosity electrode paste which can be readily applied even if the solid content concentration is high, for example in excess of 65% by mass. The electrode paste production method, in which the paste contains an active material and a solvent, includes a micromixing treatment step in which a mixture of a solid fraction containing an active material blended at a high solid content concentration and a solvent is kneaded using a micromixer.

Owner:TOYOTA JIDOSHA KK

Micromixer

InactiveUS6982064B1Increase the number ofReduce percentageFluid heatersNetwork traffic/resource managementEmulsionEngineering

Known static micromixers that work according to the principle of multilamination allow for a rapid mixing by diffusion. The invention provides a means for substantially increasing the throughput of known micromixers. To this end, the inventive micromixer for mixing two or more reactants comprises microstructures that define mixer cells. Each of said mixer cells is provided with a feeding chamber which adjoins at least two groups of digital channels. Said channels intermesh with the digital channels of the groups adjoining the feeding channels in a comb-like manner, thereby producing mixing zones]. Outlet ports are located above said mixing zones, said outlet ports extending perpendicularly to the digital channels and discharging the product. The inventive micromixer is especially useful for the large-scale production of mixtures, dispersions and emulsions.

Owner:IMM INST FUR MIKROTECHNIK GMBH

Micromixer Combustion Head End Assembly

Embodiments of the present application can provide systems and methods for a micromixer combustion head end assembly. The micromixer may include one or more base nozzle structures. The base nozzle structures may include coaxial tubes. The coaxial tubes may include an inner tube and an outer tube. The micromixer may also include one or more segmented mixing tube bundles at least partially supported by a respective base nozzle structure. Moreover, the micromixer may include an end cap assembly disposed about the one or more segmented mixing tube bundles.

Owner:GENERAL ELECTRIC CO

Micromixer assembly for a turbine system and method of distributing an air-fuel mixture to a combustor chamber

Owner:GENERAL ELECTRIC CO

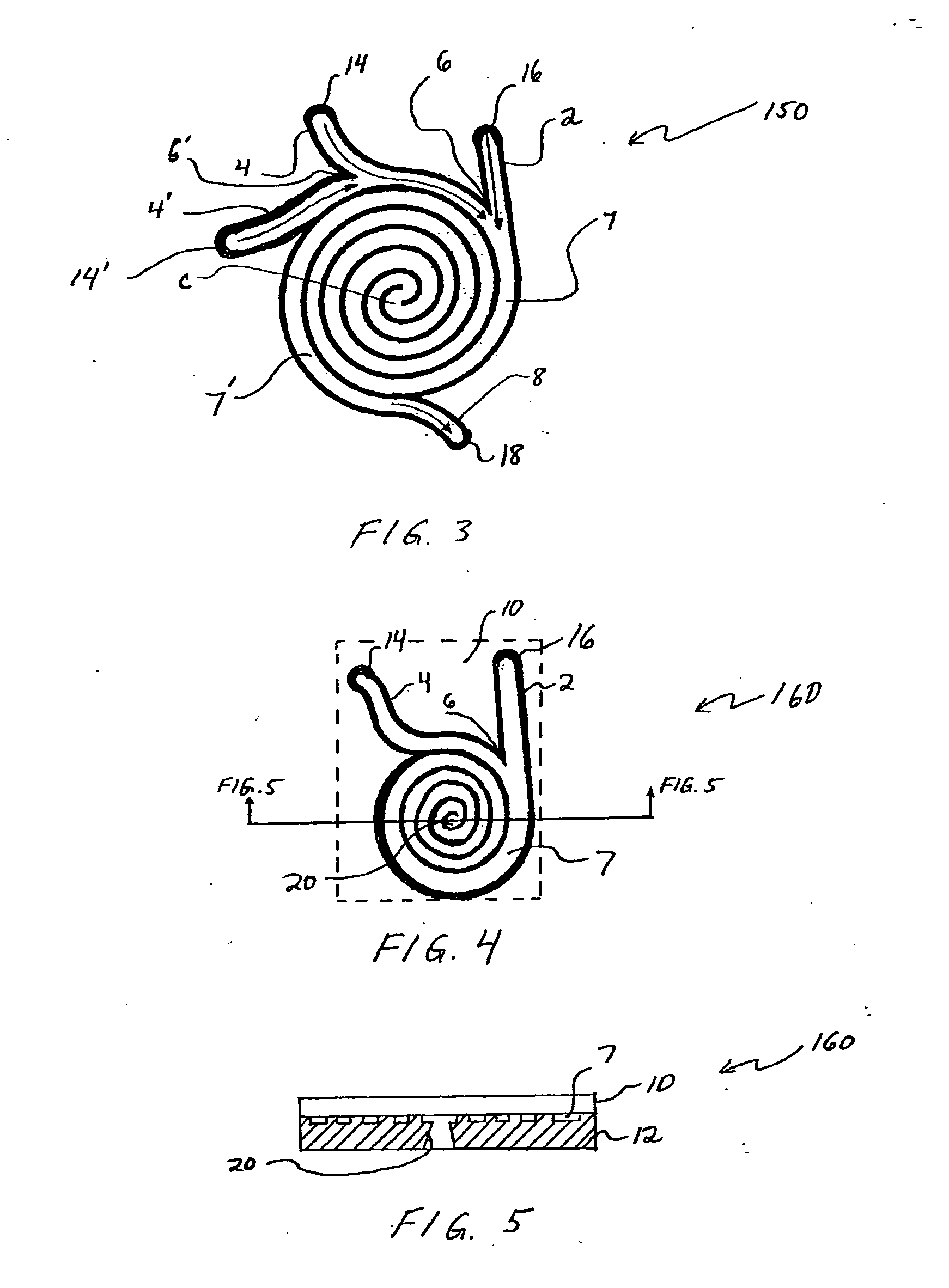

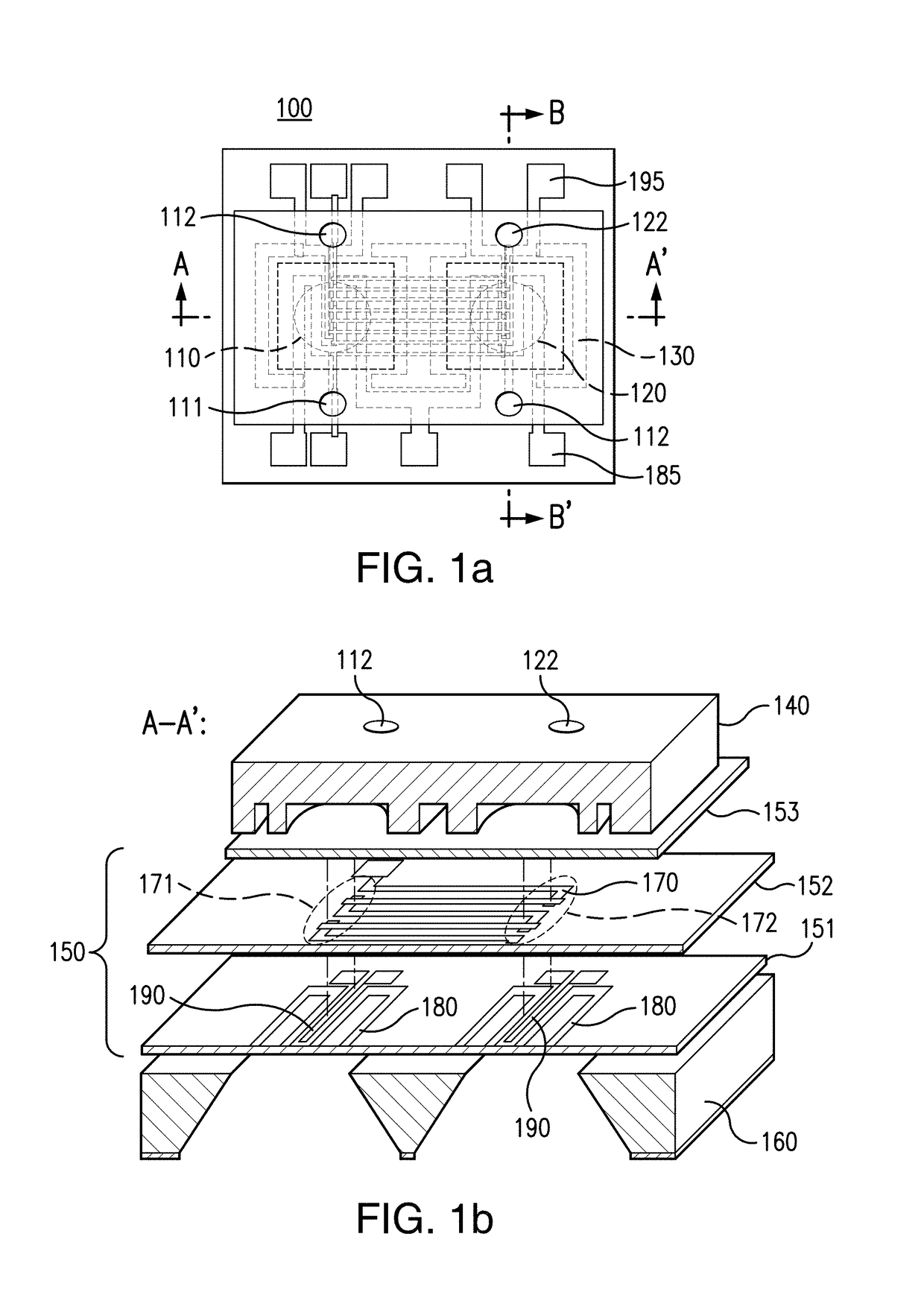

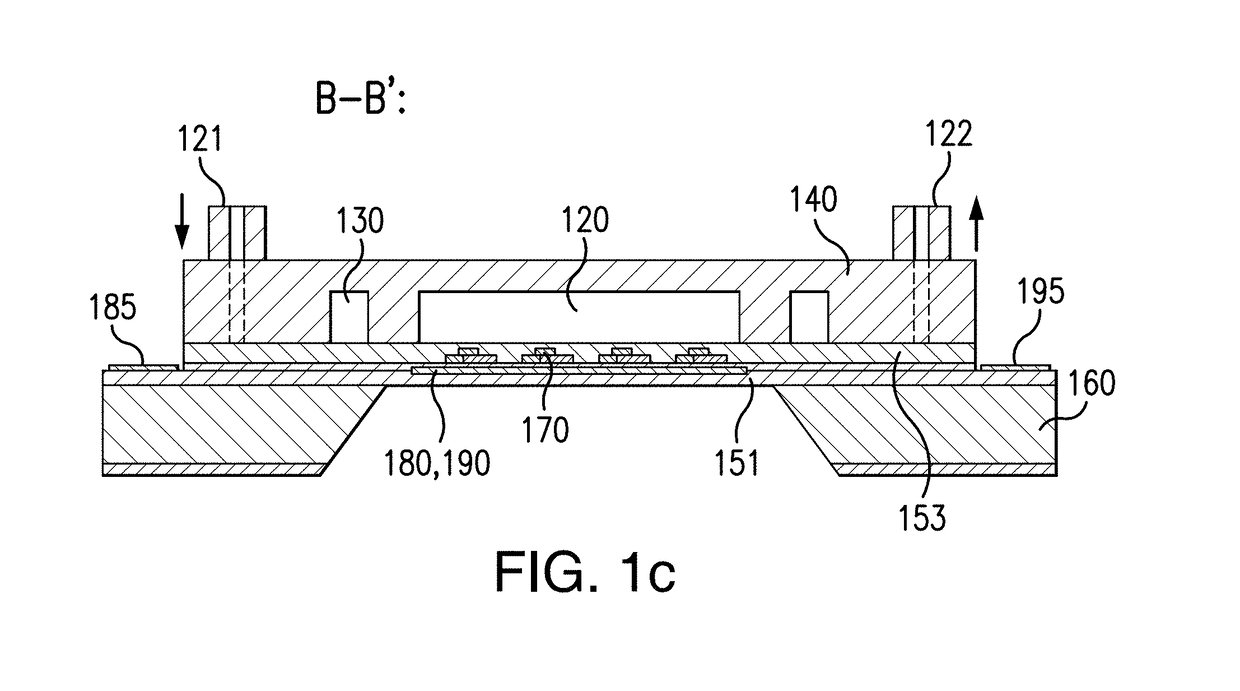

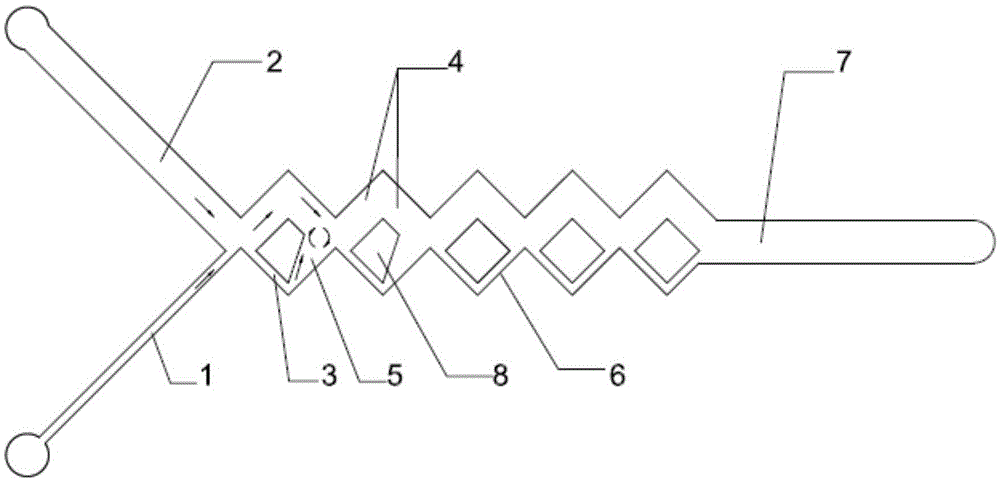

Split and recombined passive micromixer with bridge-type structure

ActiveCN104138728AIncrease contact areaWell mixedMixersLaboratory glasswaresSquare waveformBridge type

The invention discloses a split and recombined passive micromixer with a bridge-type structure, belonging to the technical field of micro-fluidic chips. The micromixer mainly comprises a plurality of mixing units 43 which are located between an inlet and an outlet, wherein each mixing unit 43 is composed of a square-wave-shaped channel 44 located in a lower-layer plane and a bridge-type structural channel 45 located outside the plane; each bridge-type structural channel 45 comprises two interlayer through holes 45a and an upper-layer inclined channel 45b. The split and recombined passive micromixer has the beneficial effects: due to the existence of the interlayer through holes 45a and the bridge-type structural channel 45, a fluid is split into branch fluids and then the branch fluids are remixed in a mixing region 47 when the fluid reaches a split region 46 of each mixing unit 43, and vertical and horizontal interfaces are simultaneously generated in the process to form a T-shaped fluid interface, so that the contact area between two kinds of fluids is greatly increased; the fluid flows in a bent three-dimensional channel, and secondary flow disturbance can also be generated at each corner, so that the chaotic advection effect is enhanced, and furthermore, the mixing effect is enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Planar passive micromixer

ActiveCN105664773ASave spaceSimple structureTransportation and packagingMixersEngineeringMixing effect

The invention discloses a planar passive micromixer.The planar passive micromixer comprises an inlet passage, an outlet passage and at least one mixing unit between the inlet passage and the outlet passage.Each mixing unit comprises a first flow distribution passage, a second flow distribution passage and a flow mixing cavity, wherein the first flow distribution passage and the second flow distribution passage are used for liquid flow distribution, the flow mixing cavity is used for mixing liquid flowing from the first flow distribution passage and the second flow distribution passage and communicated with the first flow distribution passage and the second flow distribution passage of the adjacent mixing unit or communicated with the outlet passage.According to Coada effects, the micromixer structurally leads a medium to form chaotic convection in a convection cavity, and mixing effects are remarkably improved.

Owner:SUZHOU WENHAO MICROFLUIDIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com