Patents

Literature

5519results about "Mixers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

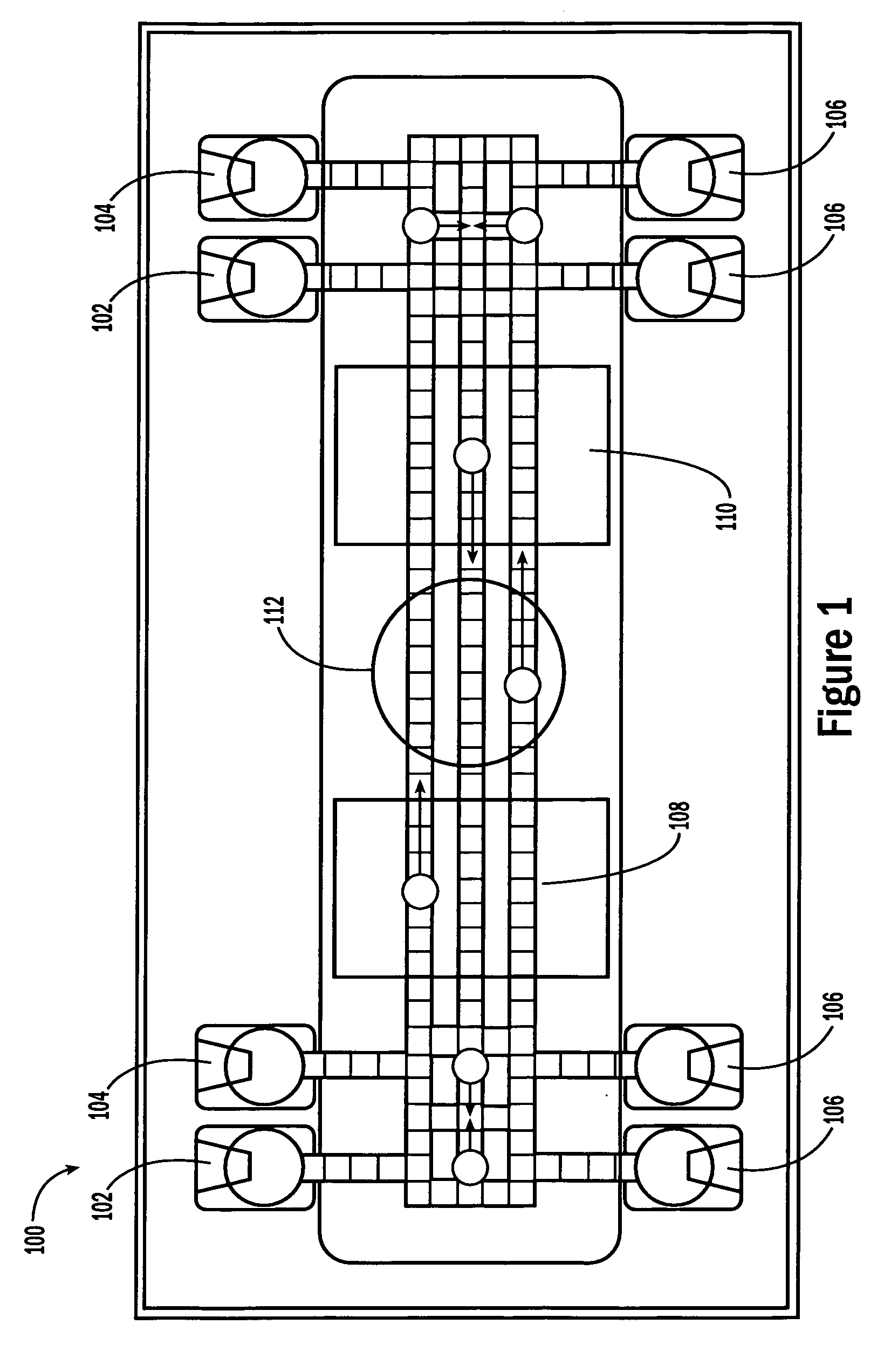

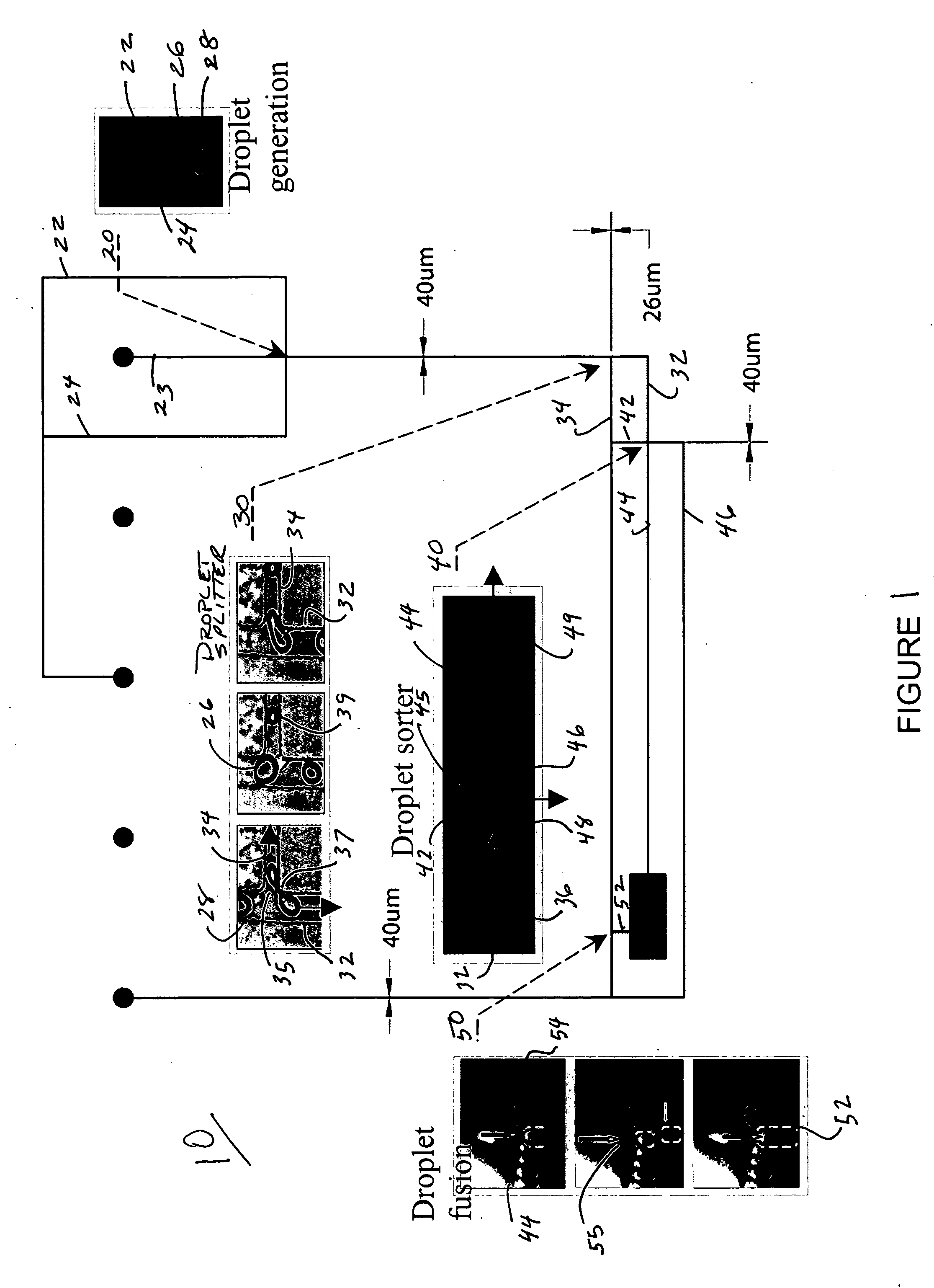

Microfluidic devices

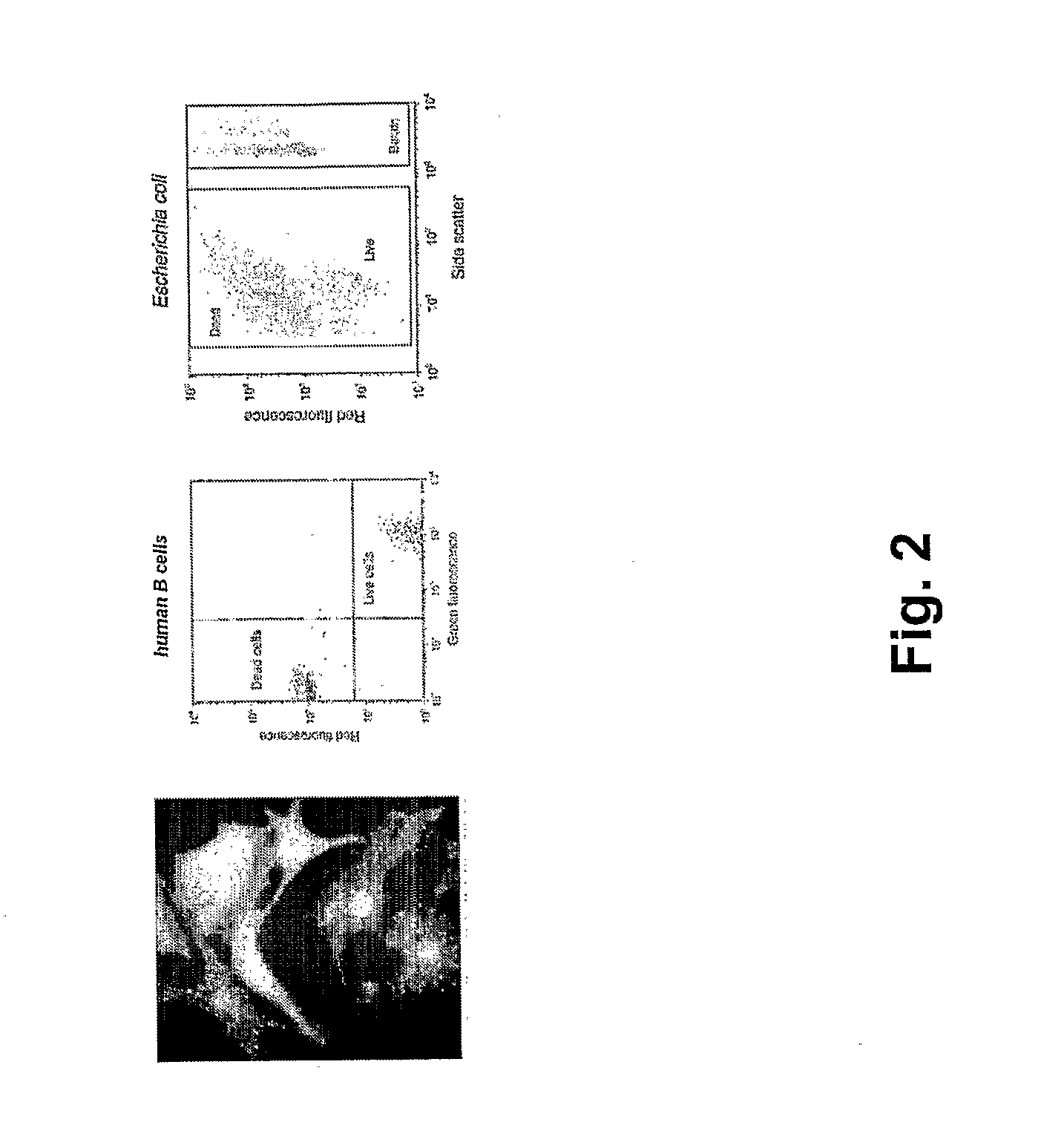

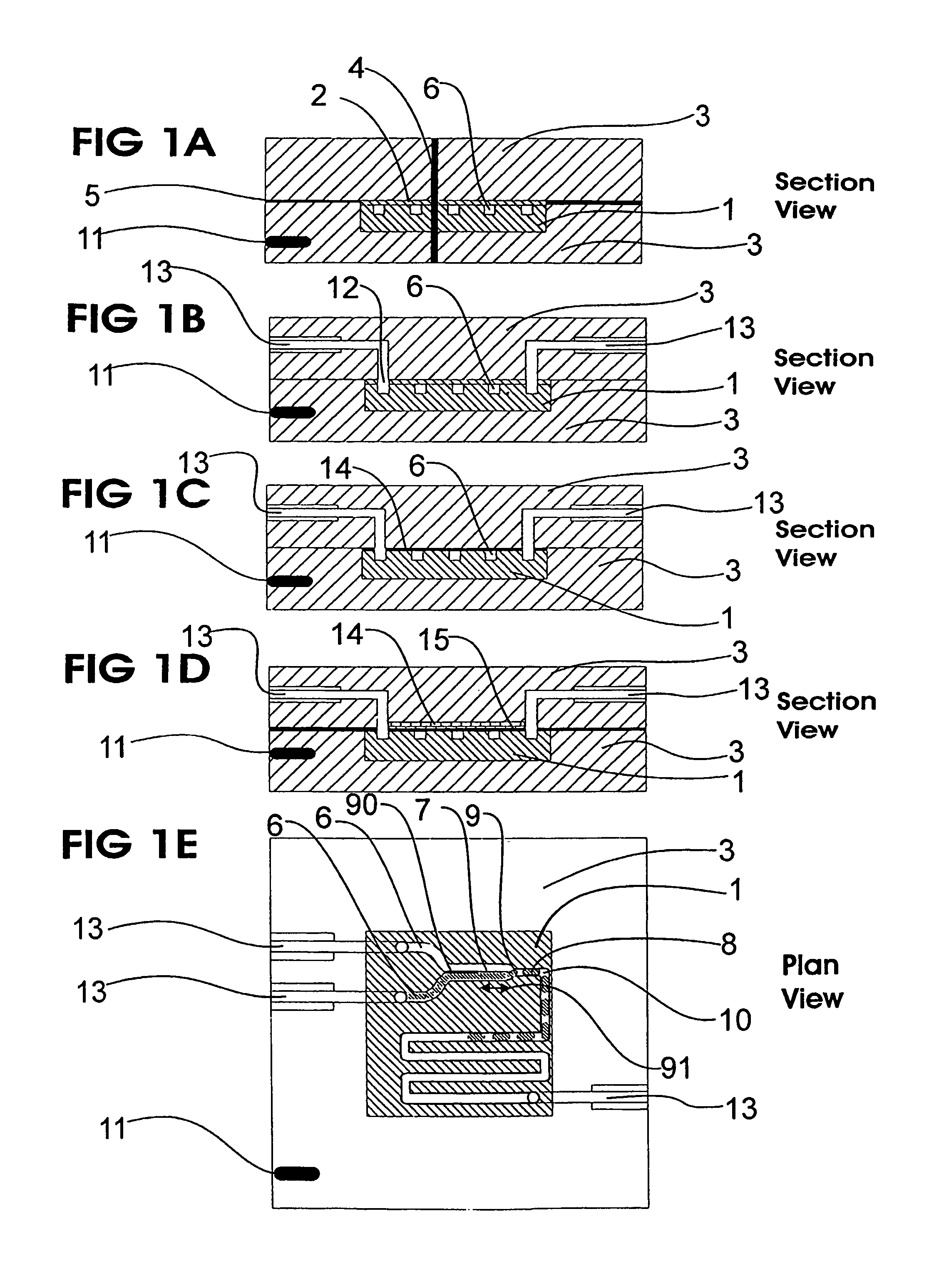

InactiveUS20080003142A1Quickly and effectively and inexpensivelyDielectrophoresisHeating or cooling apparatusEngineering

Owner:BIO RAD LAB INC

Microfluidic Devices and Methods of Use in The Formation and Control of Nanoreactors

InactiveUS20100137163A1Material nanotechnologyCompound screeningHigh-Throughput Screening AssaysEmulsion

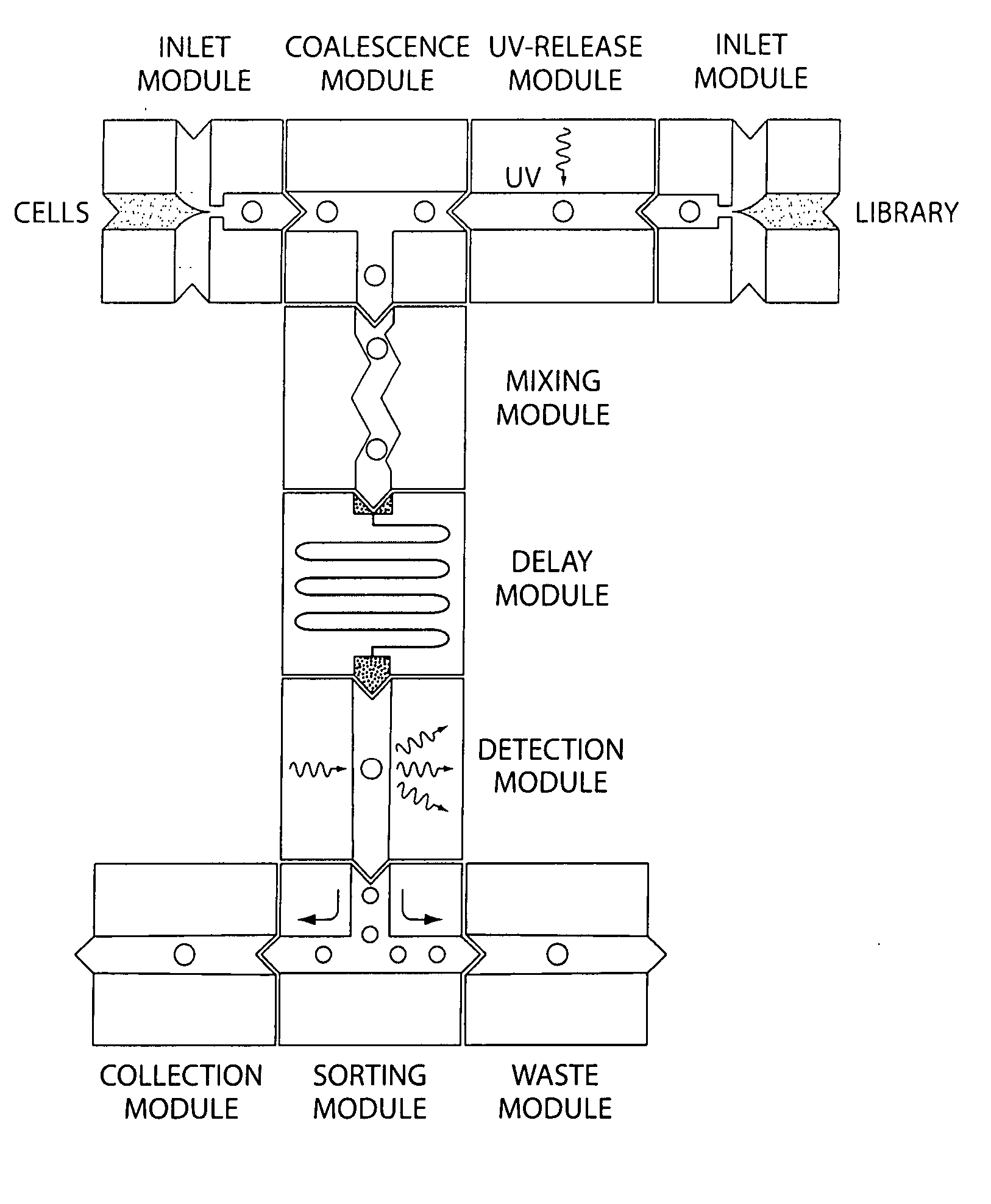

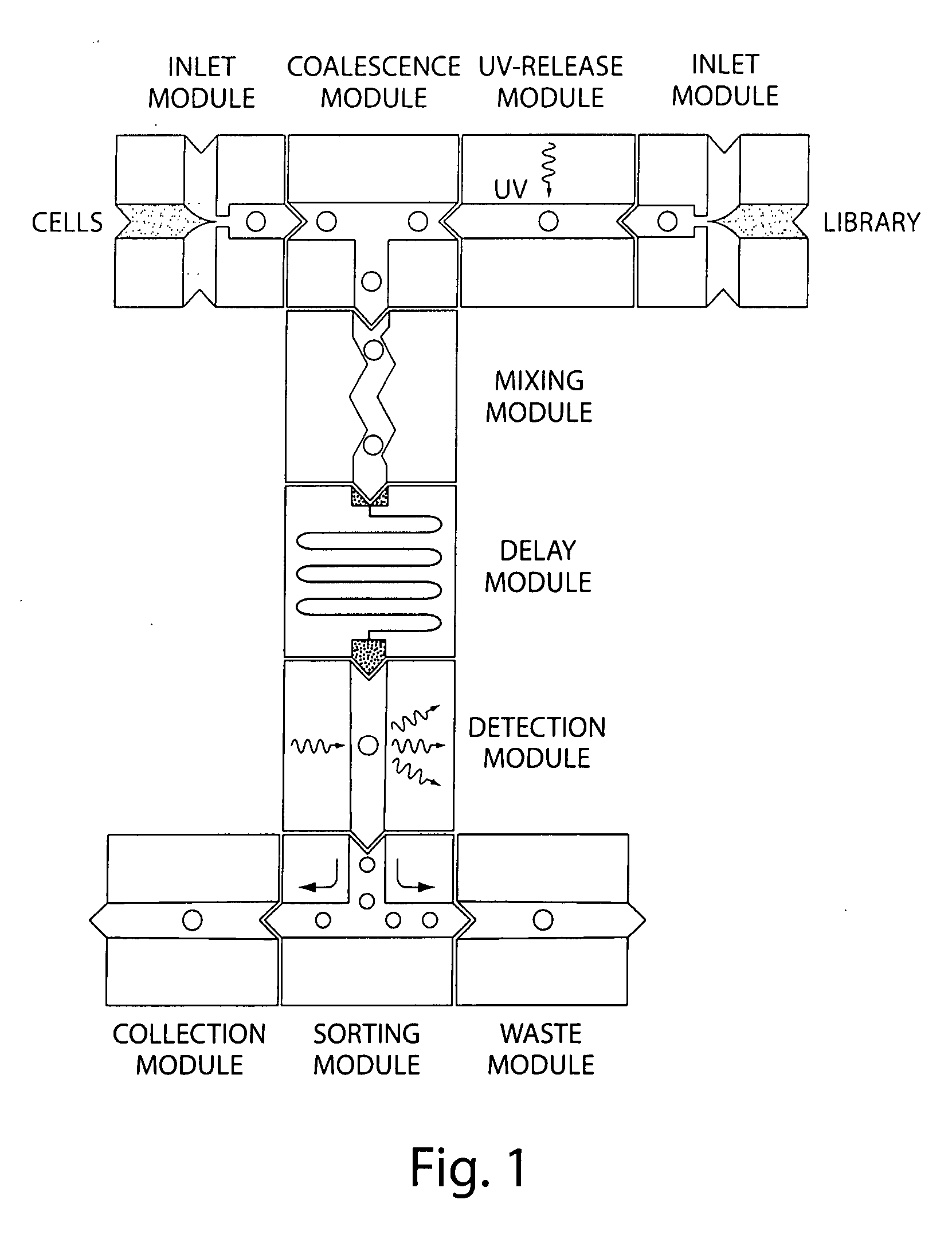

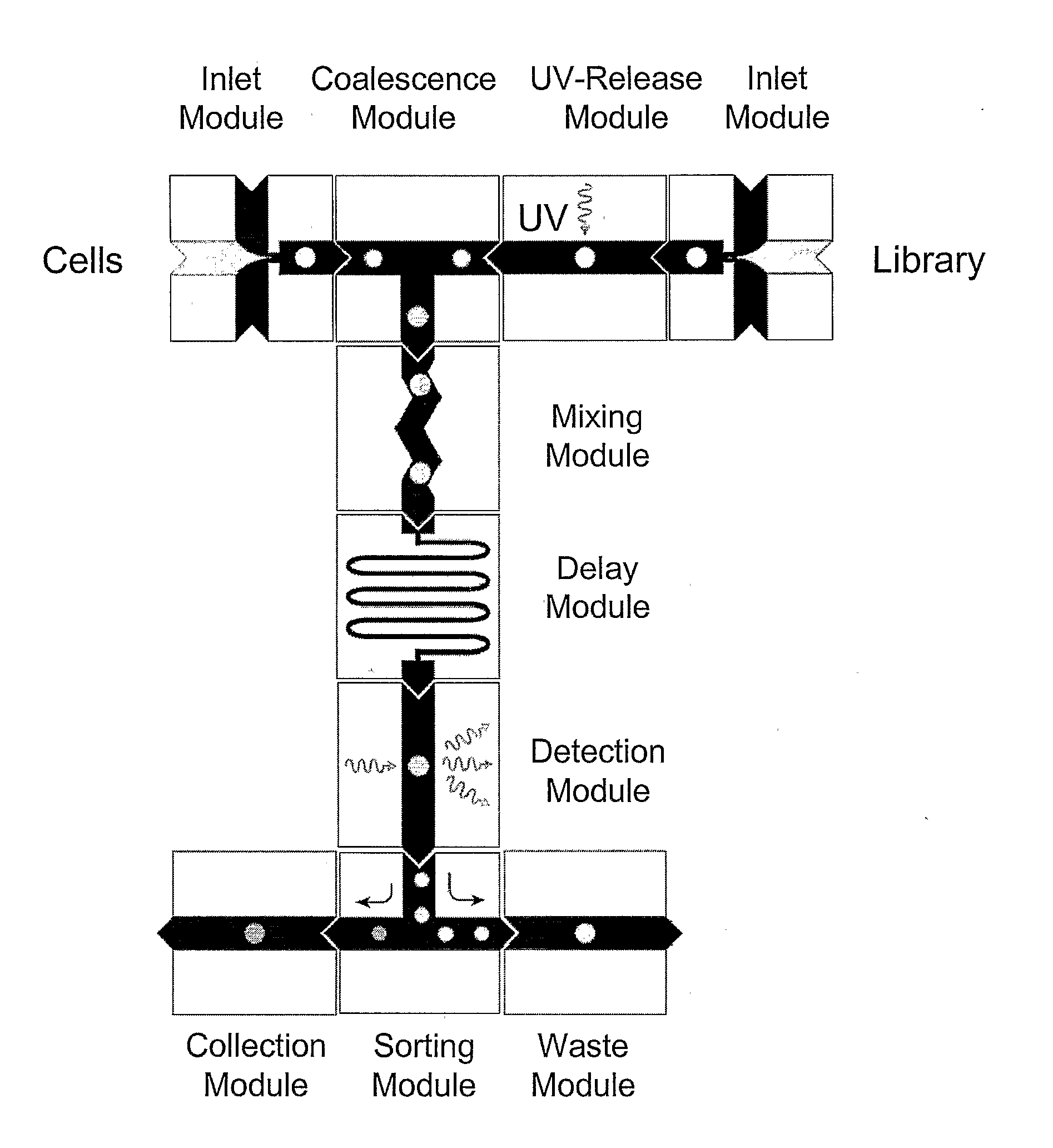

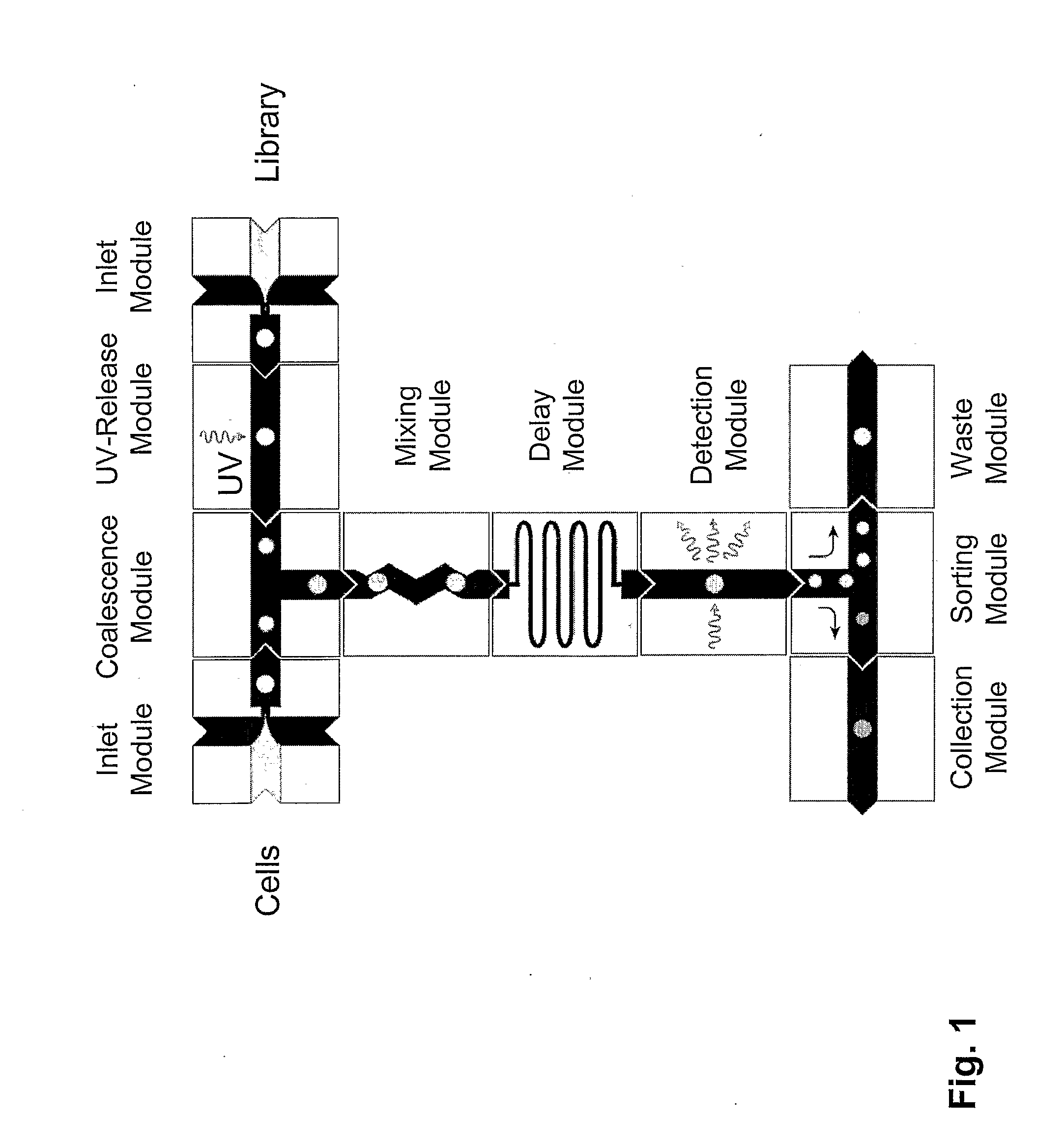

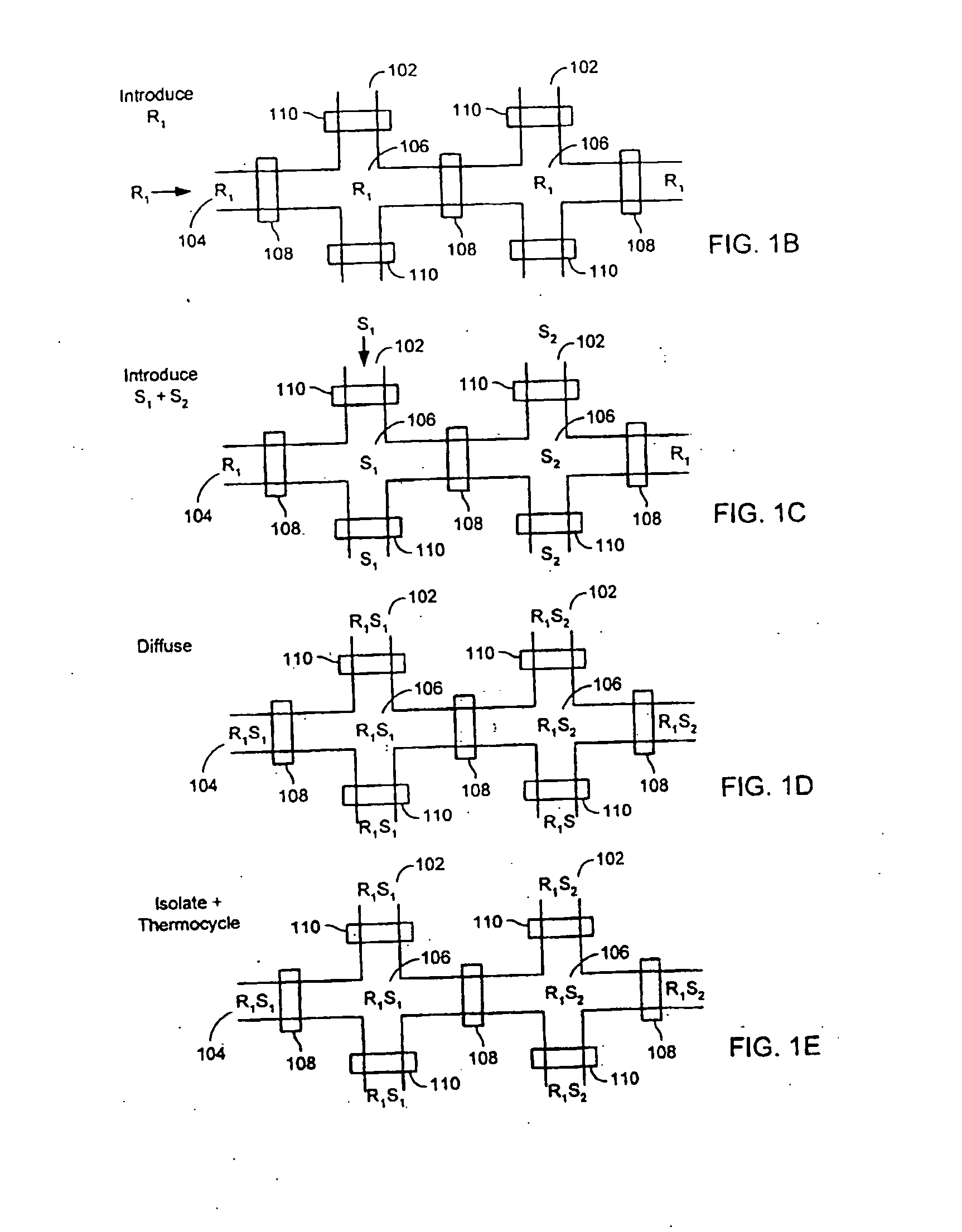

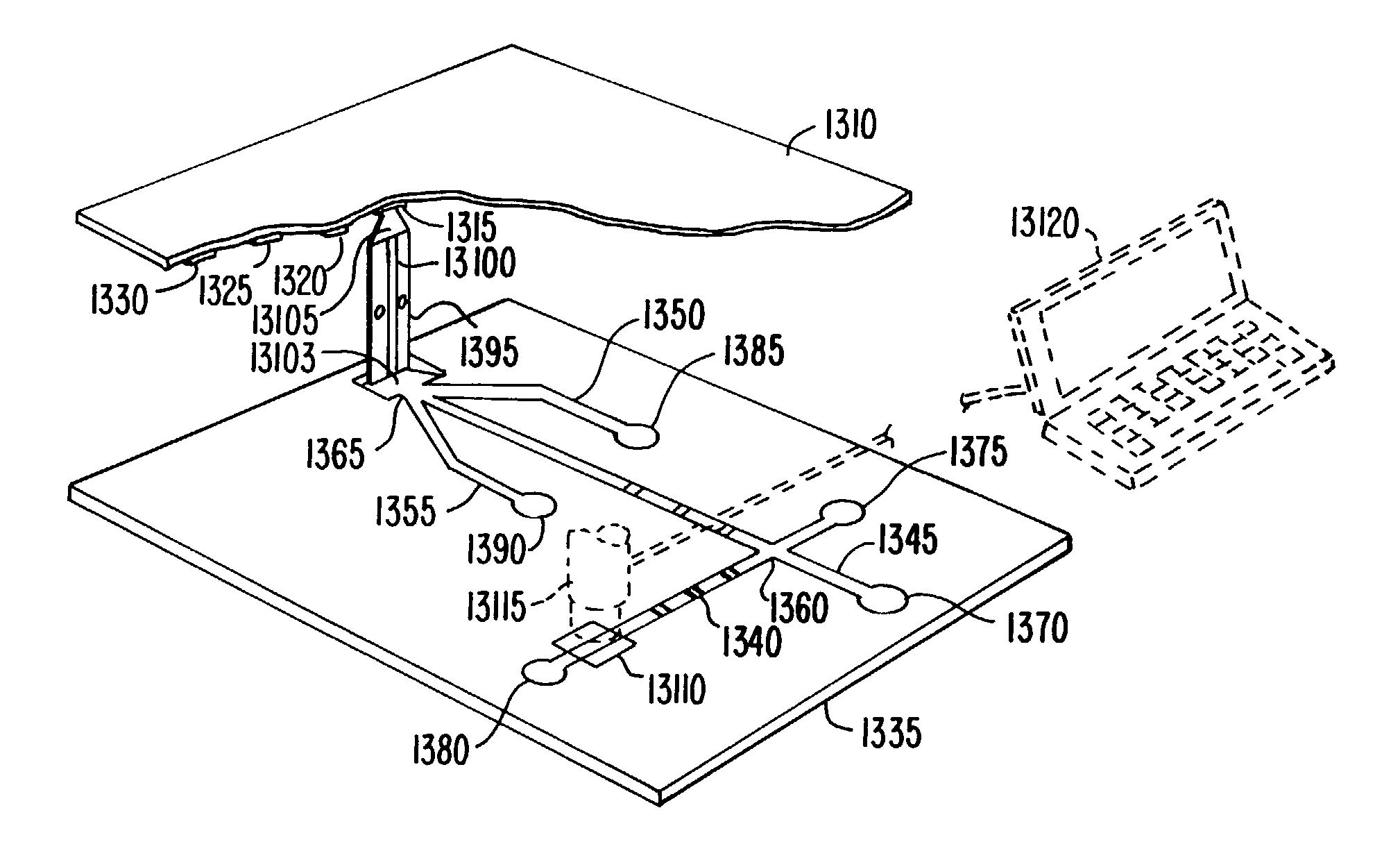

The present invention provides novel microfluidic devices and methods that are useful for performing high-throughput screening assays and combinatorial chemistry. Such methods can include labeling a library of compounds by emulsifying aqueous solutions of the compounds and aqueous solutions of unique liquid labels on a microfluidic device, which includes a plurality of electrically addressable, channel bearing fluidic modules integrally arranged on a microfabricated substrate such that a continuous channel is provided for flow of immiscible fluids, whereby each compound is labeled with a unique liquid label, pooling the labeled emulsions, coalescing the labeled emulsions with emulsions containing a specific cell or enzyme, thereby forming a nanoreactor, screening the nanoreactors for a desirable reaction between the contents of the nanoreactor, and decoding the liquid label, thereby identifying a single compound from a library of compounds.

Owner:BIO RAD LAB INC

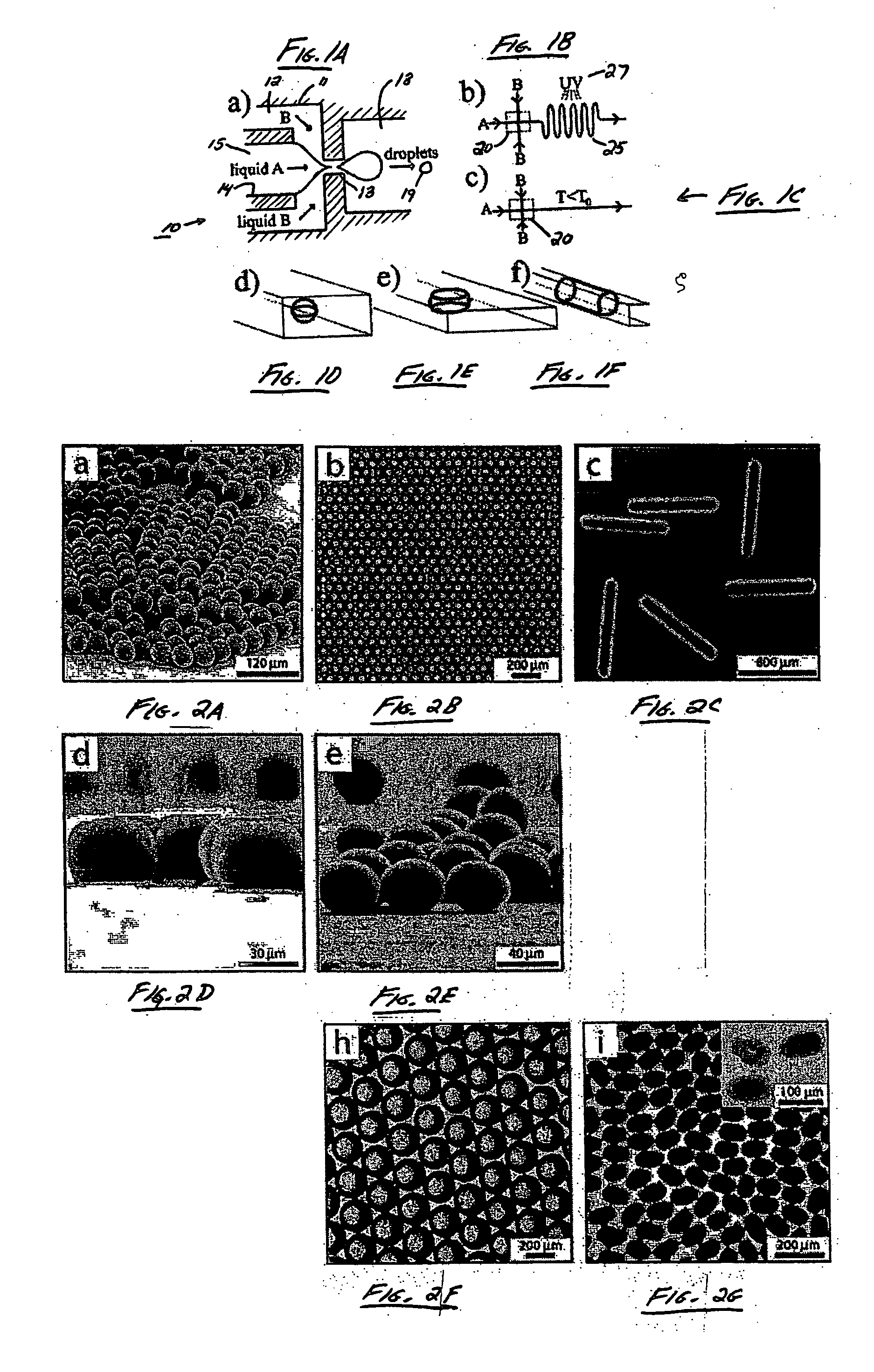

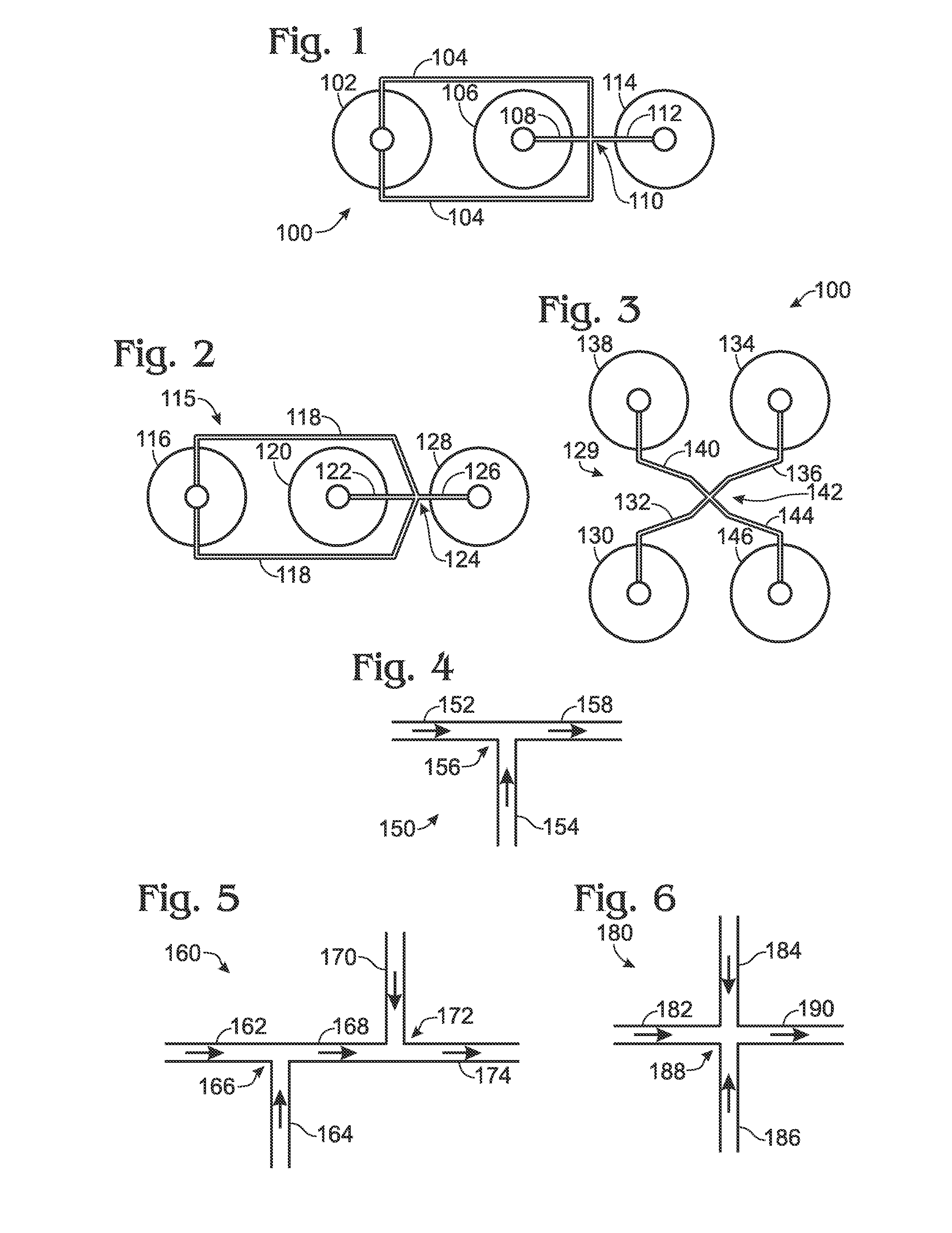

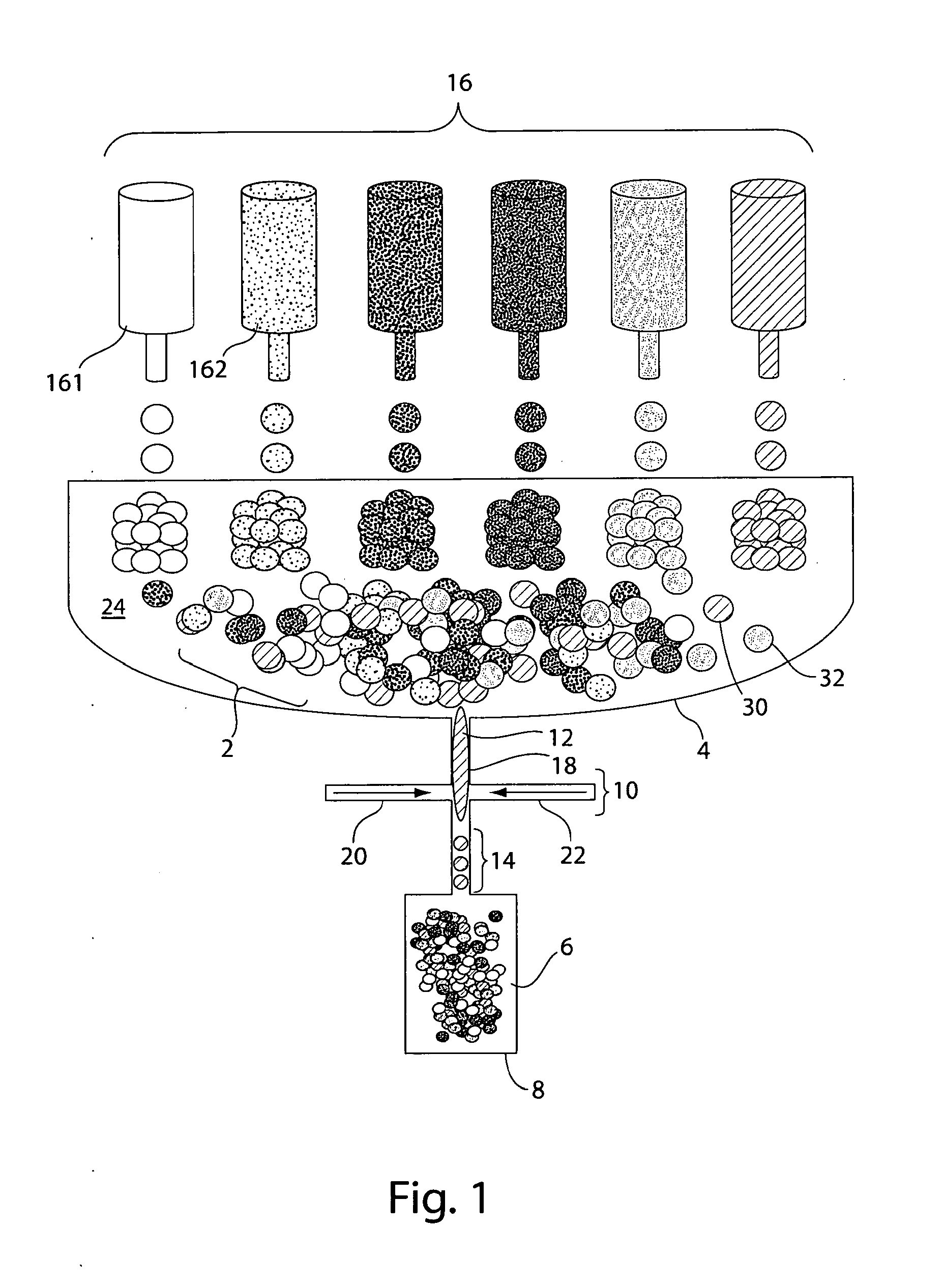

Systems and methods of forming particles

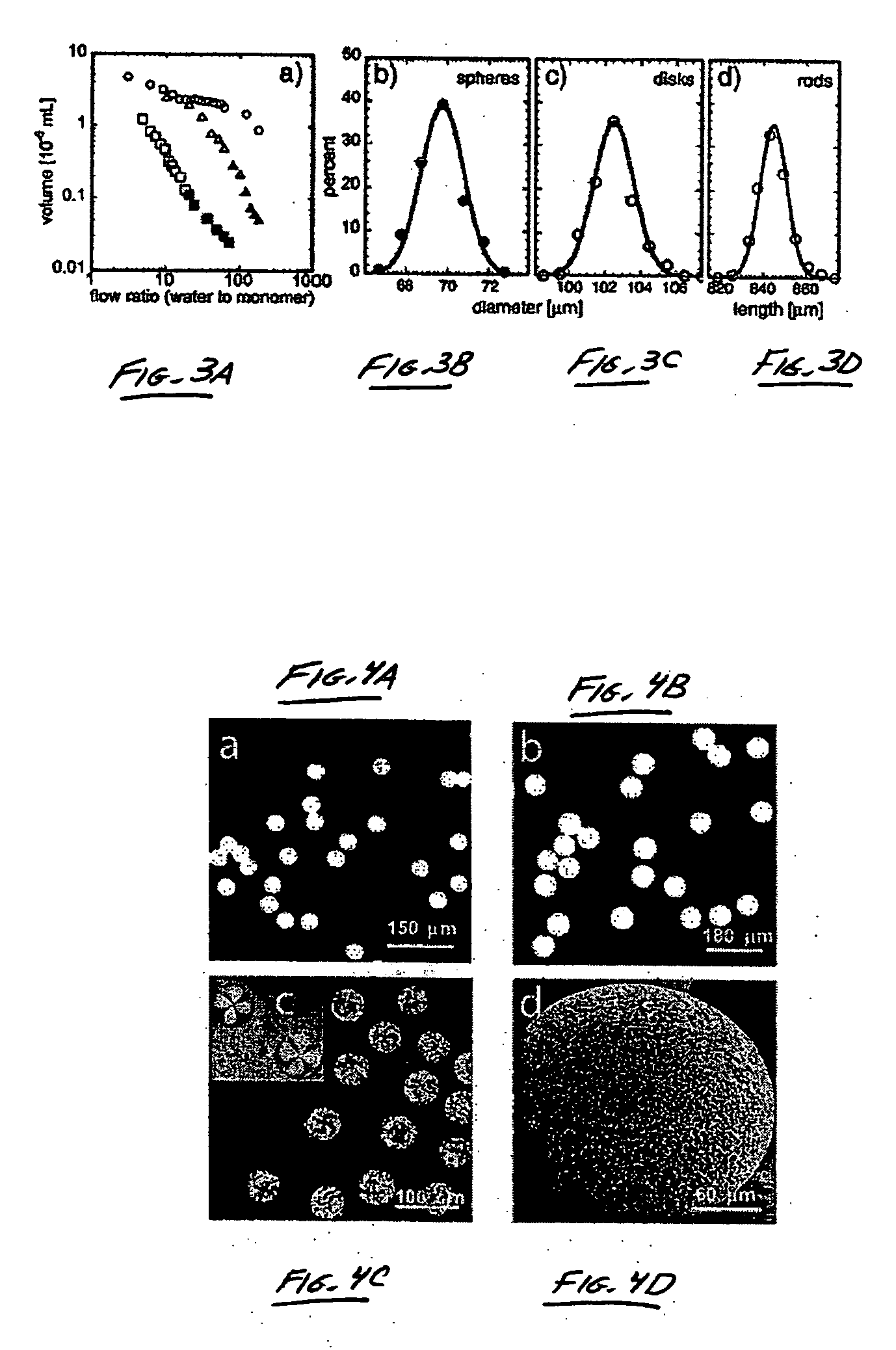

InactiveUS20070054119A1Synthetic resin layered productsChemical/physical/physico-chemical microreactorsChemical reactionMicrometer

The present invention generally relates to systems and methods of forming particles and, in certain aspects, to systems and methods of forming particles that are substantially monodisperse. Microfluidic systems and techniques for forming such particles are provided, for instance, particles may be formed using gellation, solidification, and / or chemical reactions such as cross-linking, polymerization, and / or interfacial polymerization reactions. In one aspect, the present invention is directed to a plurality of particles having an average dimension of less than about 500 micrometers and a distribution of dimensions such that no more than about 5% of the particles have a dimension greater than about 10% of the average dimension, which can be made via microfluidic systems. In one set of embodiments, at least some of the particles may comprise a metal, and in certain embodiments, at least some of the particles may comprise a magnetizable material. In another set of embodiments, at least some of the particles may be porous. In some embodiments, the invention includes non-spherical particles. Non-spherical particles may be formed, for example, by urging a fluidic droplet into a channel having a smallest dimension that is smaller than the diameter of a perfect mathematical sphere having a volume of the droplet, and solidifying the droplet, and / or by exposing at least a portion of a plurality of particles to an agent able to remove at least a portion of the particles.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

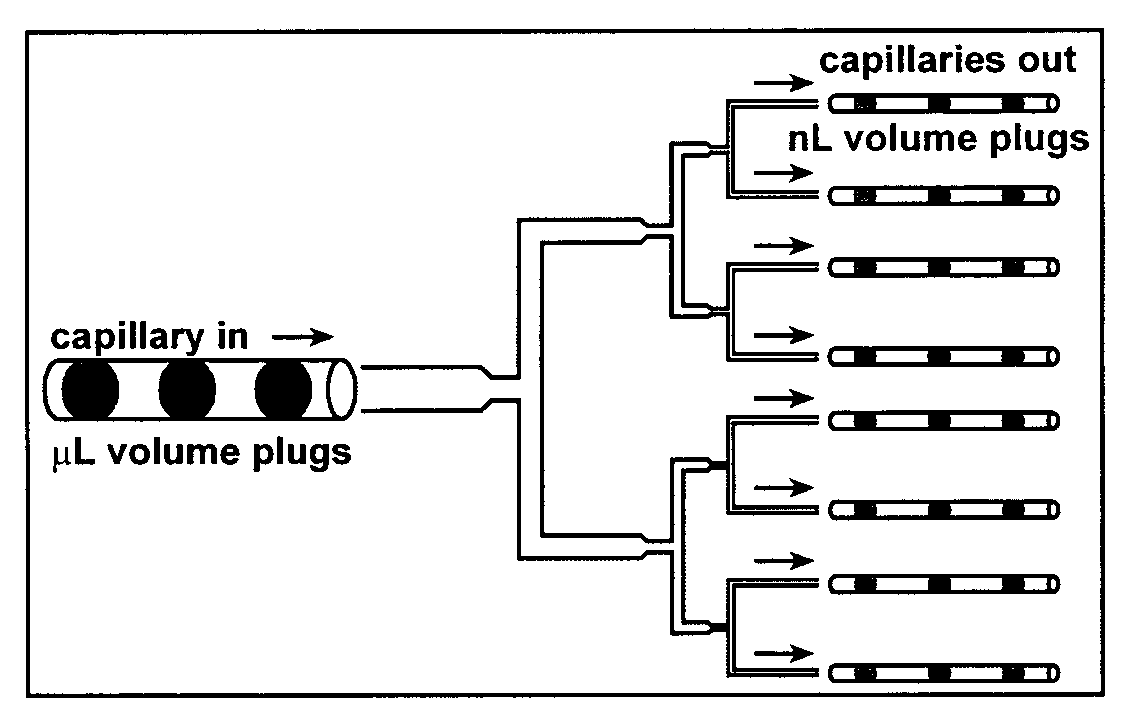

Microfluidic system

ActiveUS20060094119A1Rapid and economical reactionIncrease rangePolycrystalline material growthAnalysis using chemical indicatorsFemtoliterEngineering

Owner:CHICAGO UNIV OF

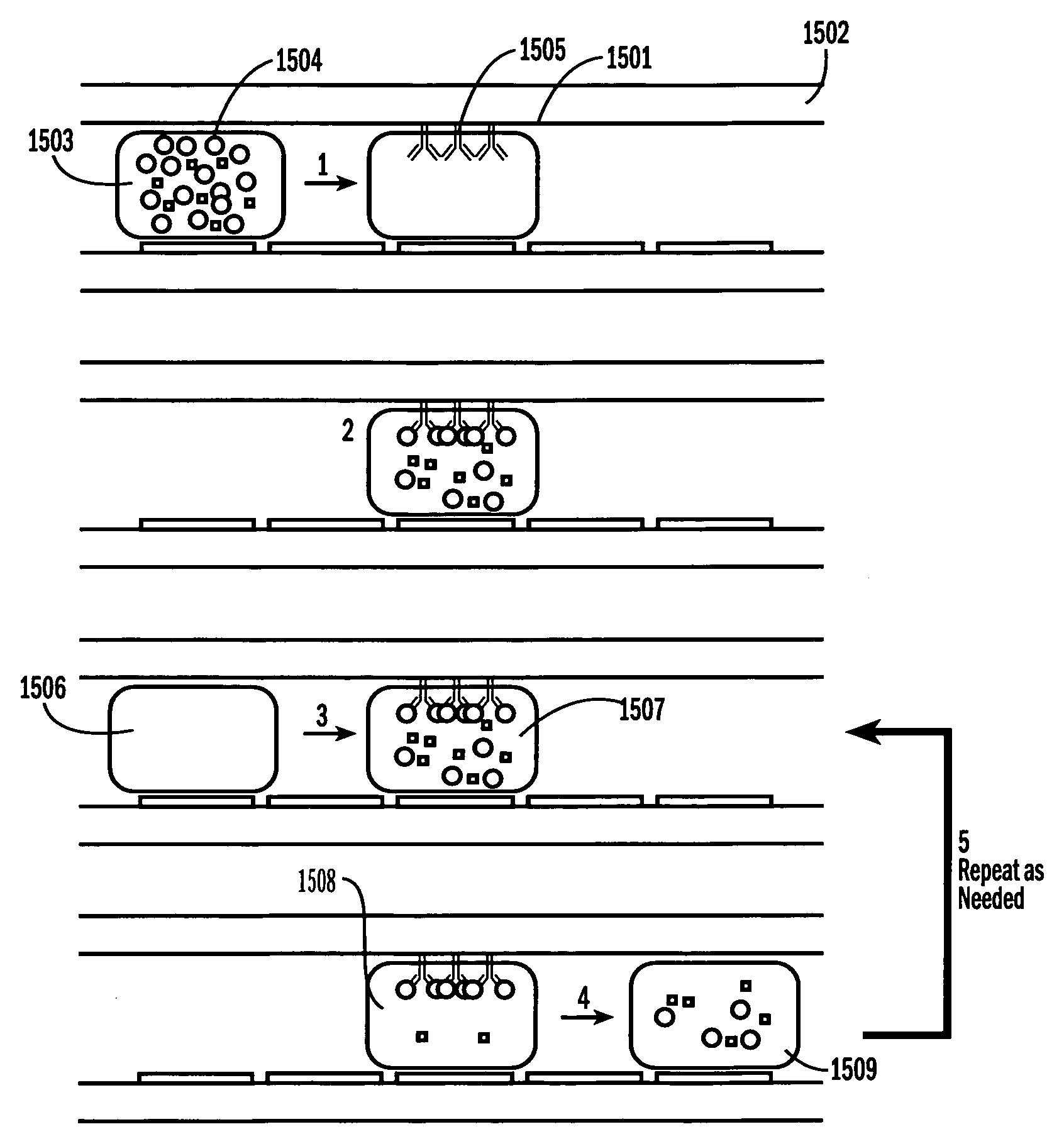

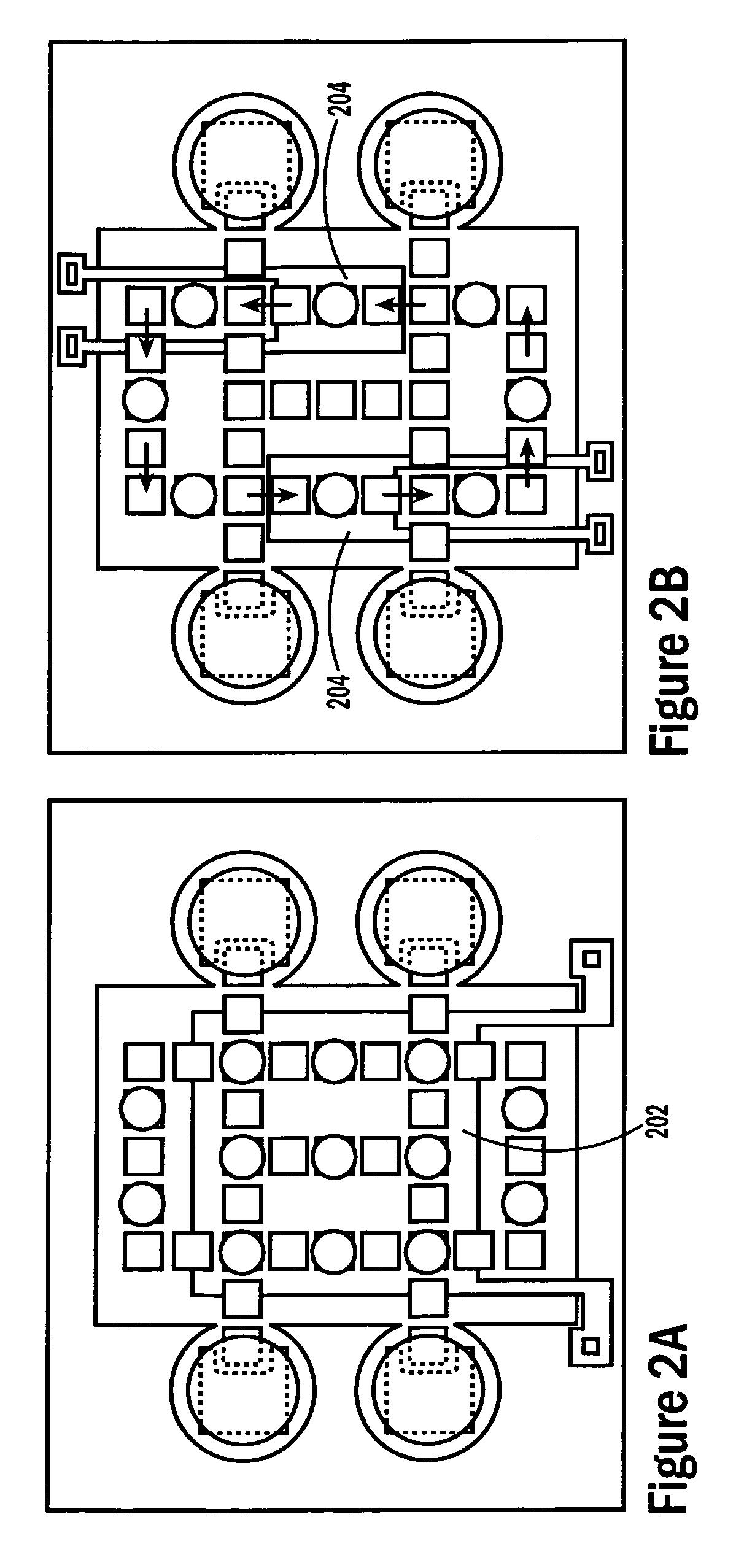

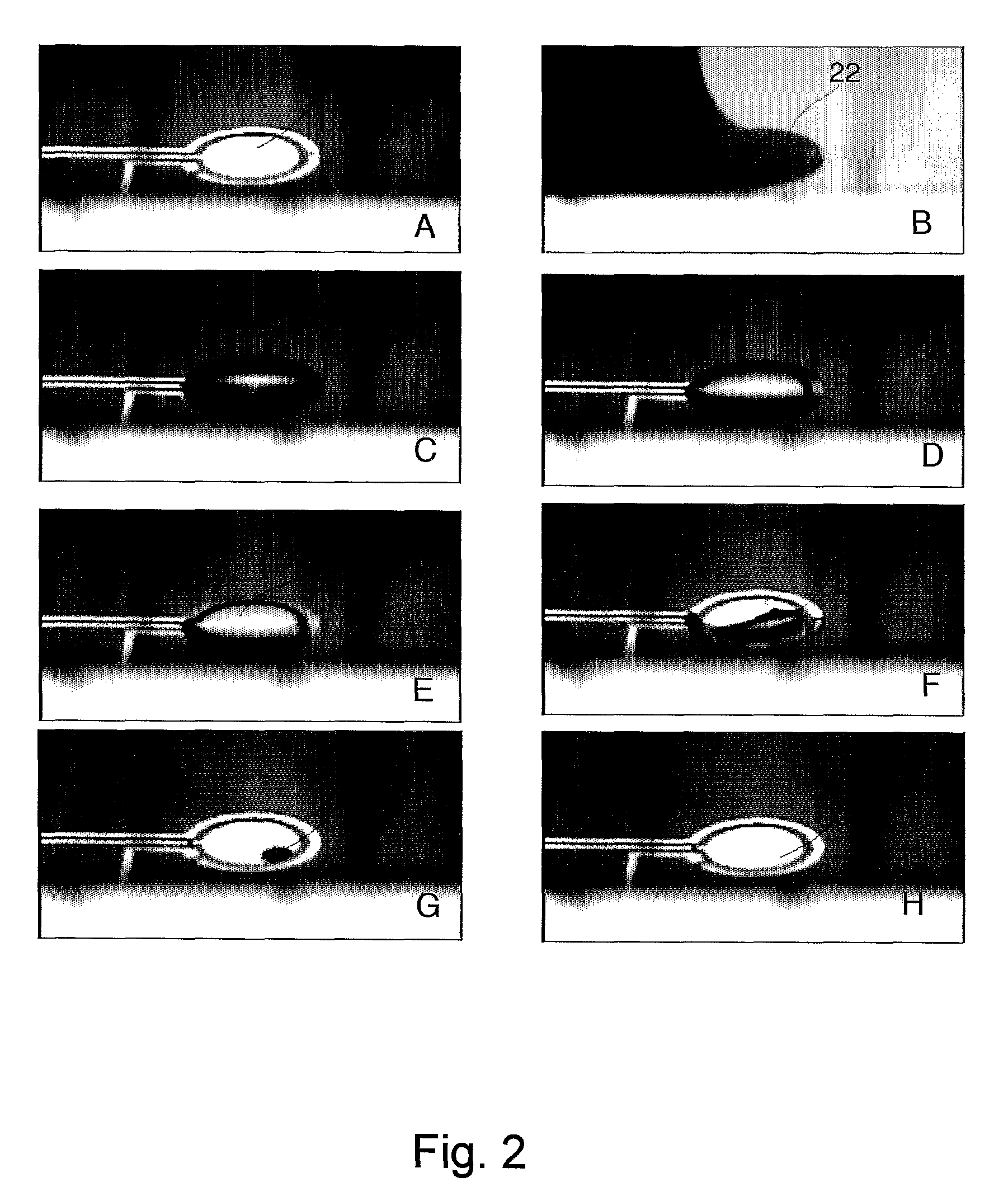

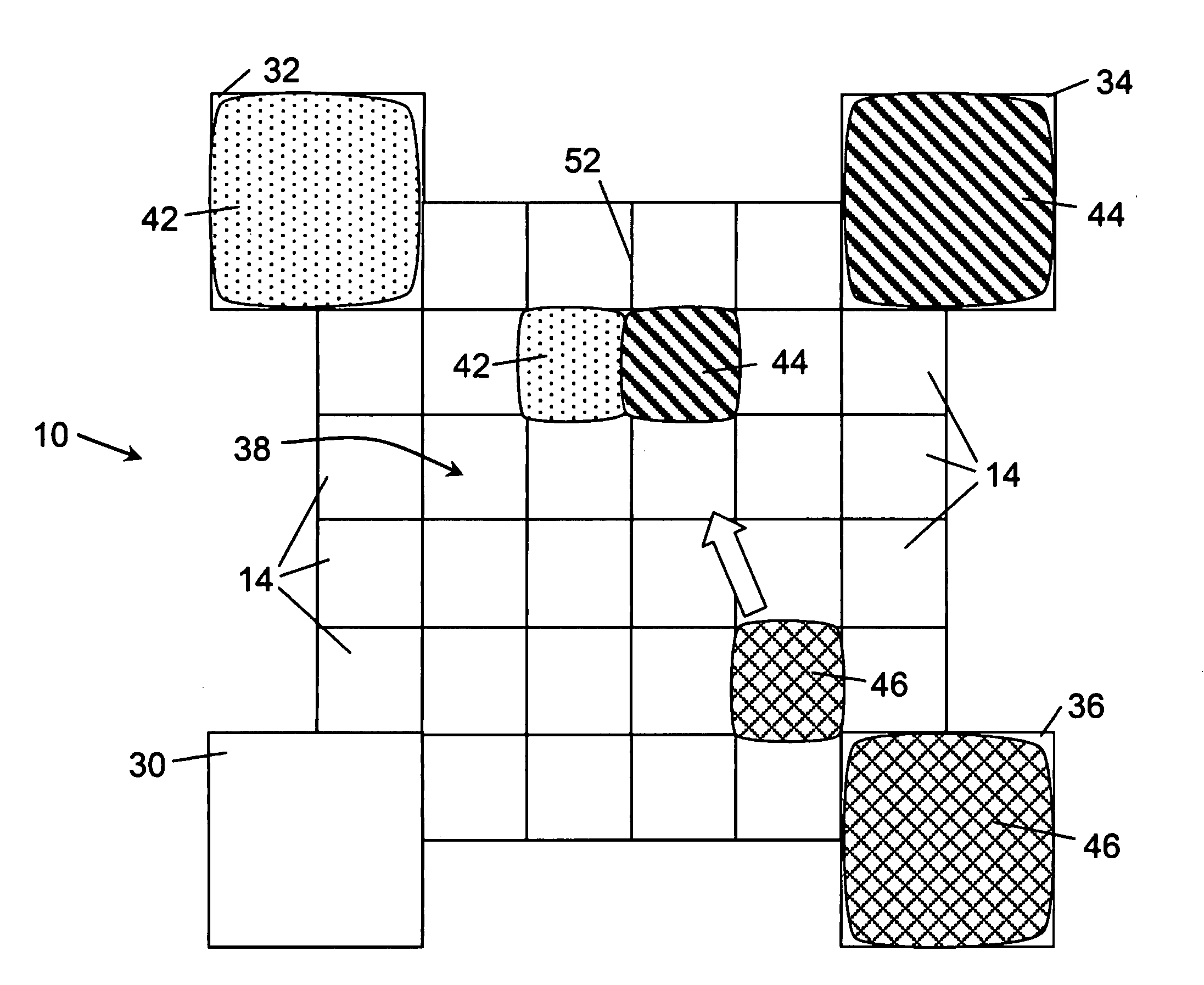

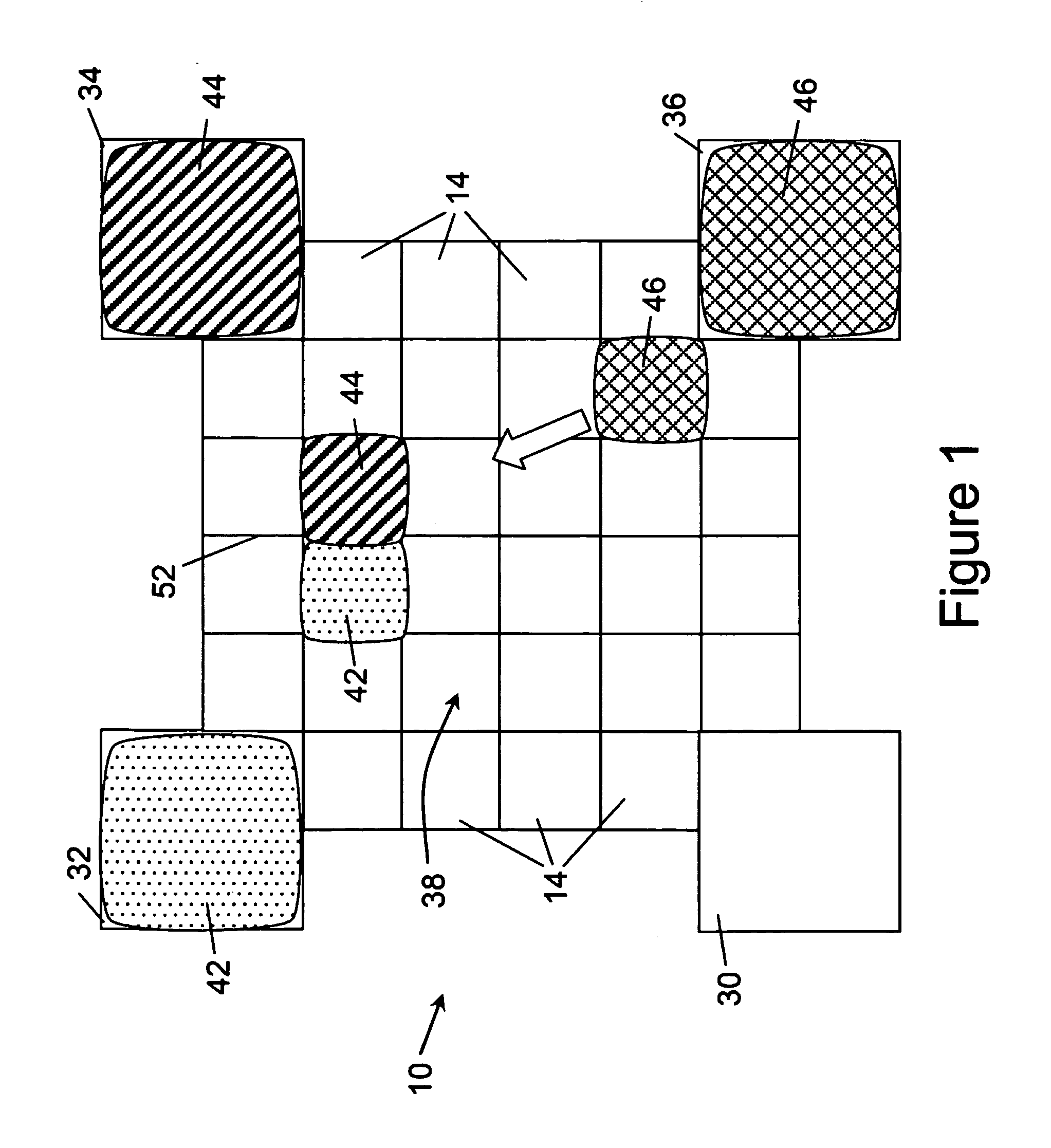

Droplet-based surface modification and washing

ActiveUS20070243634A1Reduces and eliminates build-upImprove efficiencyHeating or cooling apparatusTransportation and packagingSurface modificationAmount of substance

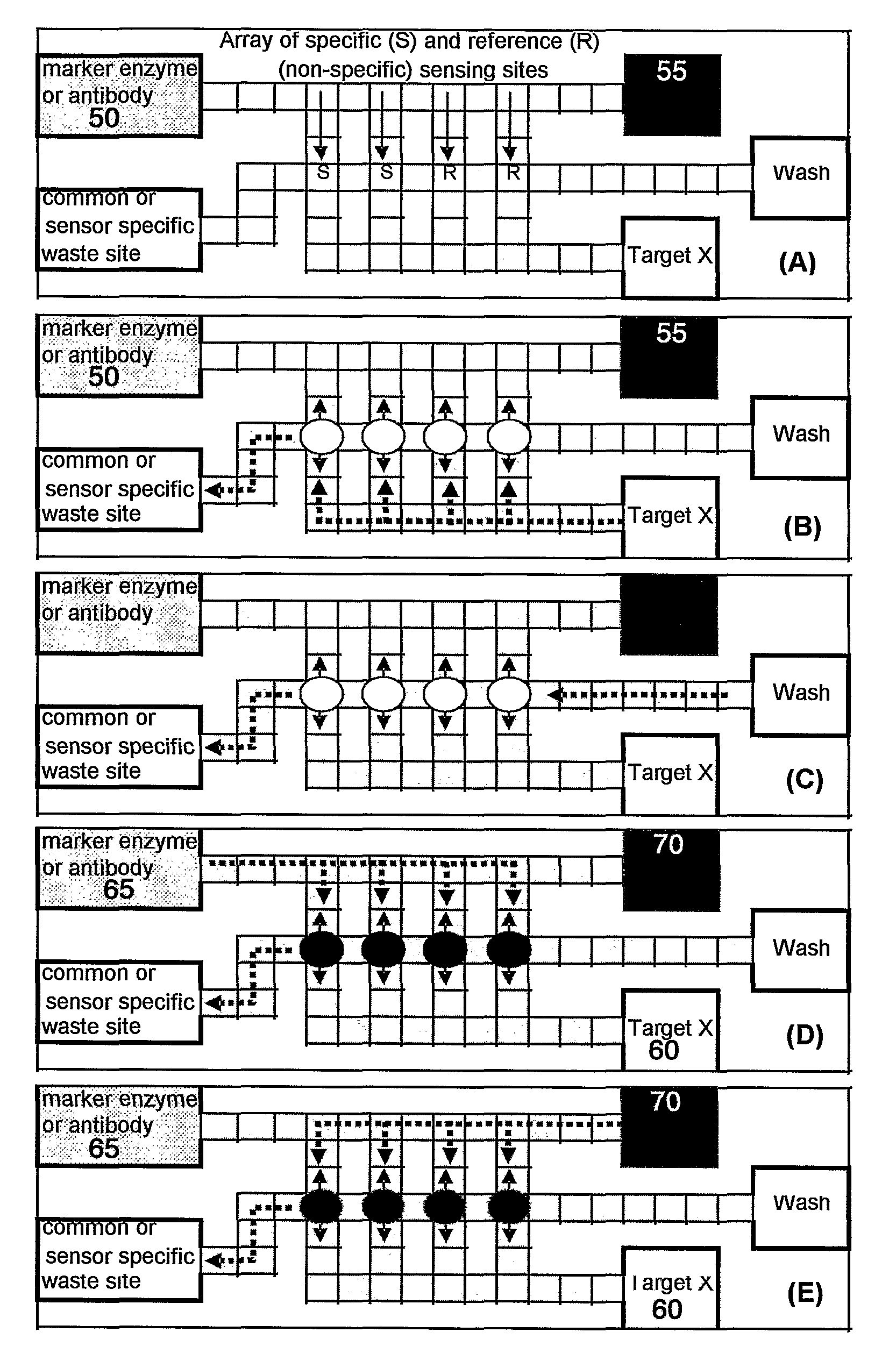

The present invention relates to droplet-based surface modification and washing. According to one embodiment, a method of providing a droplet in contact with a surface with a reduced concentration of a substance is provided, wherein the method includes: (a) providing a droplet microactuator comprising a surface in contact with a droplet comprising a starting concentration and starting quantity of the substance and having a starting volume; (b) conducting one or more droplet operations to merge a wash droplet with the droplet provided in step (a) to yield a combined droplet; and (c) conducting one or more droplet operations to divide the combined droplet to yield a set of droplets comprising: (i) a droplet in contact with the surface having a decreased concentration of the substance relative to the starting concentration; and (ii) a droplet which is separated from the surface.

Owner:ADVANCED LIQUID LOGIC +1

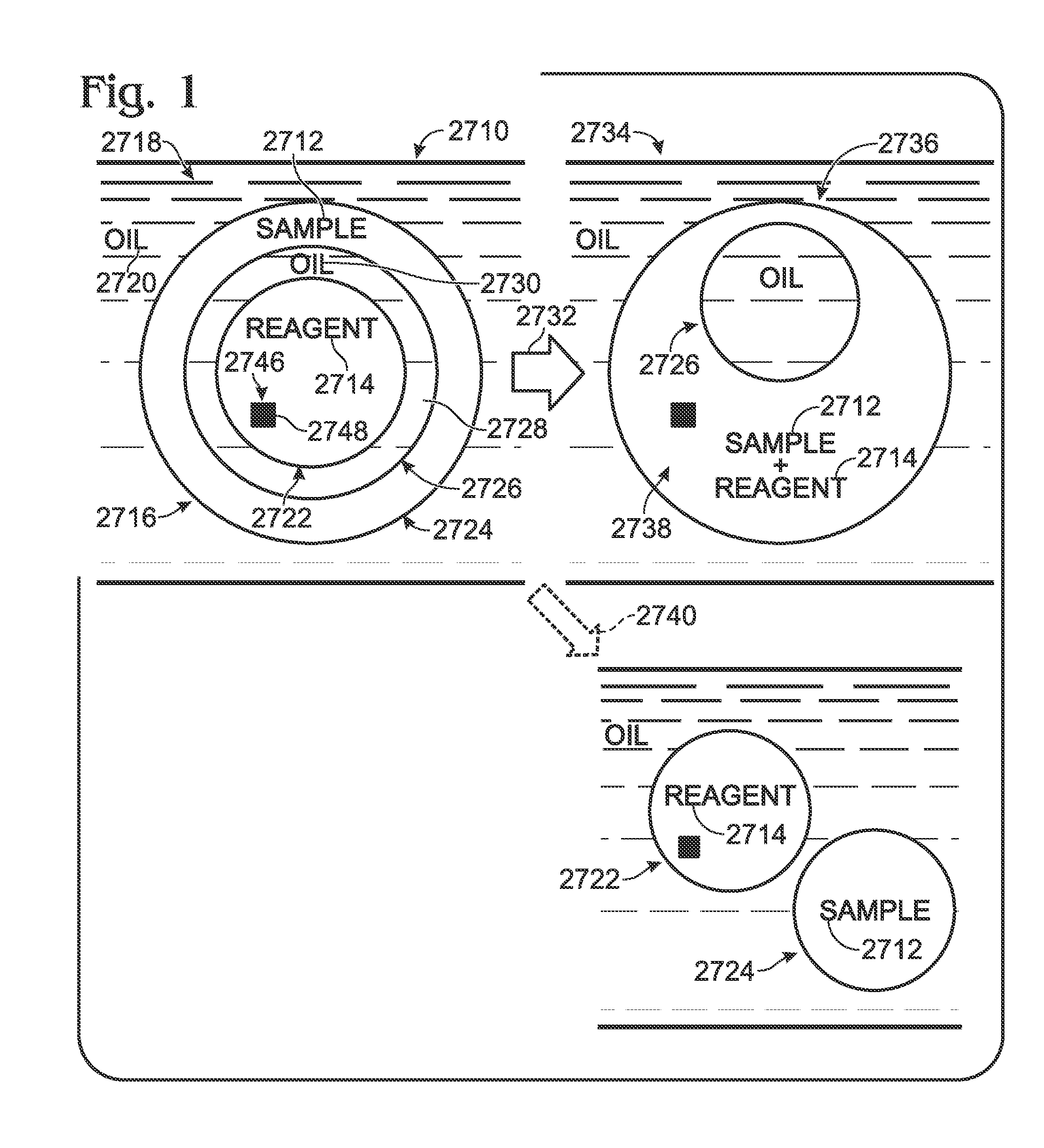

System for mixing fluids by coalescence of multiple emulsions

ActiveUS20110053798A1High-confidence resultLower the volumeSequential/parallel process reactionsHeating or cooling apparatusEmulsionChemistry

System, including methods, apparatus, compositions, and kits, for the mixing of small volumes of fluid by coalescence of multiple emulsions.

Owner:BIO RAD LAB INC

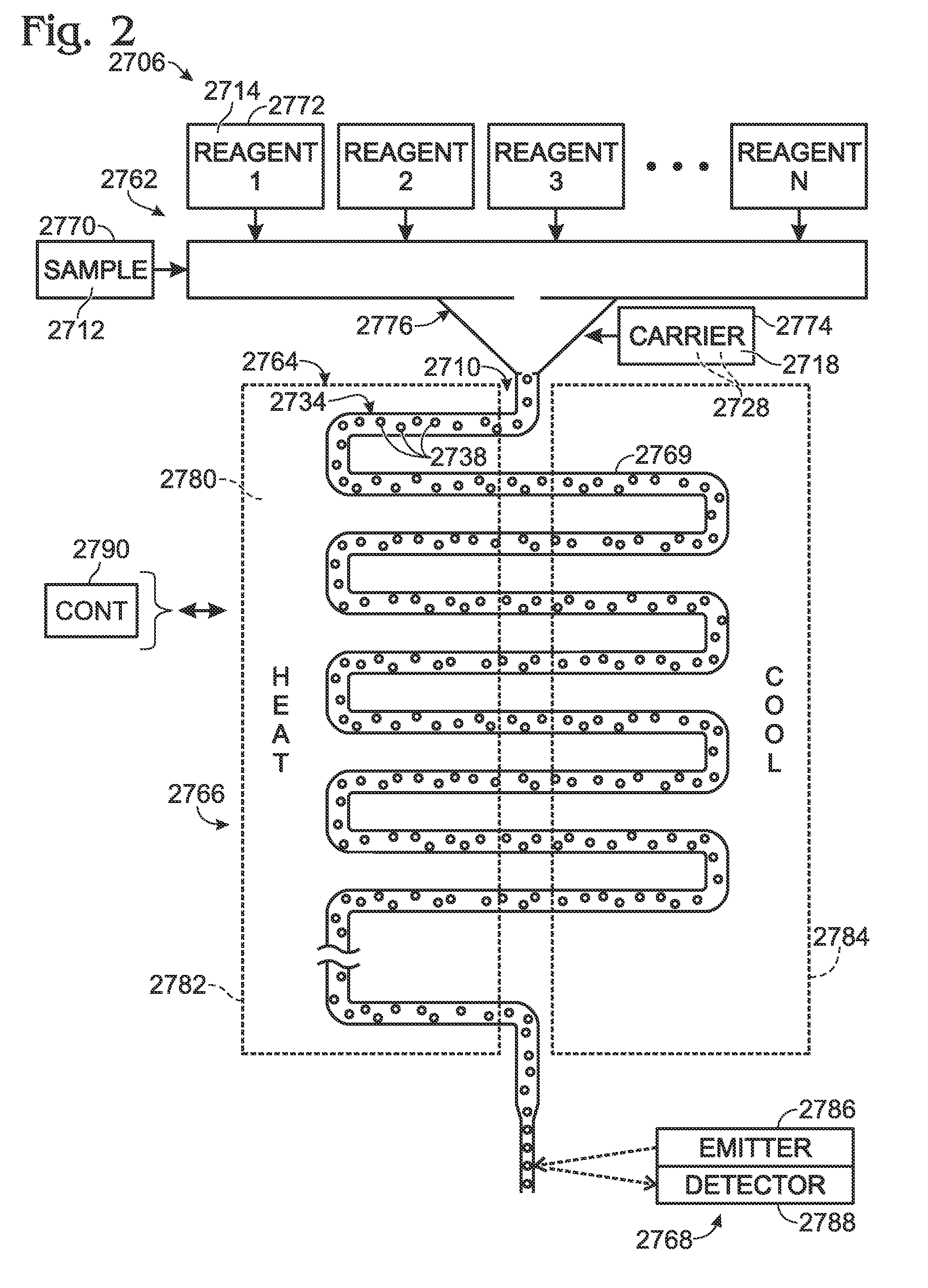

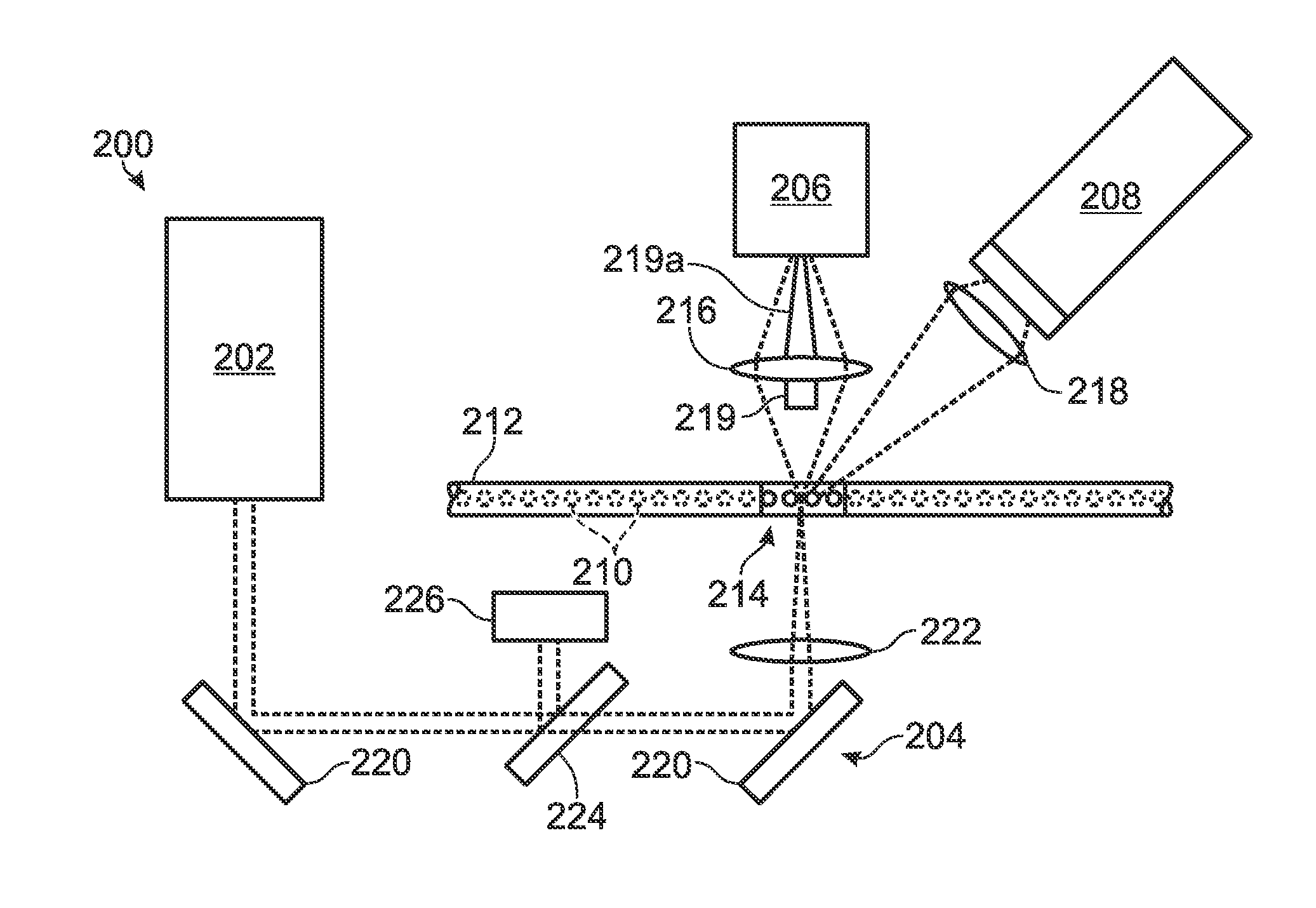

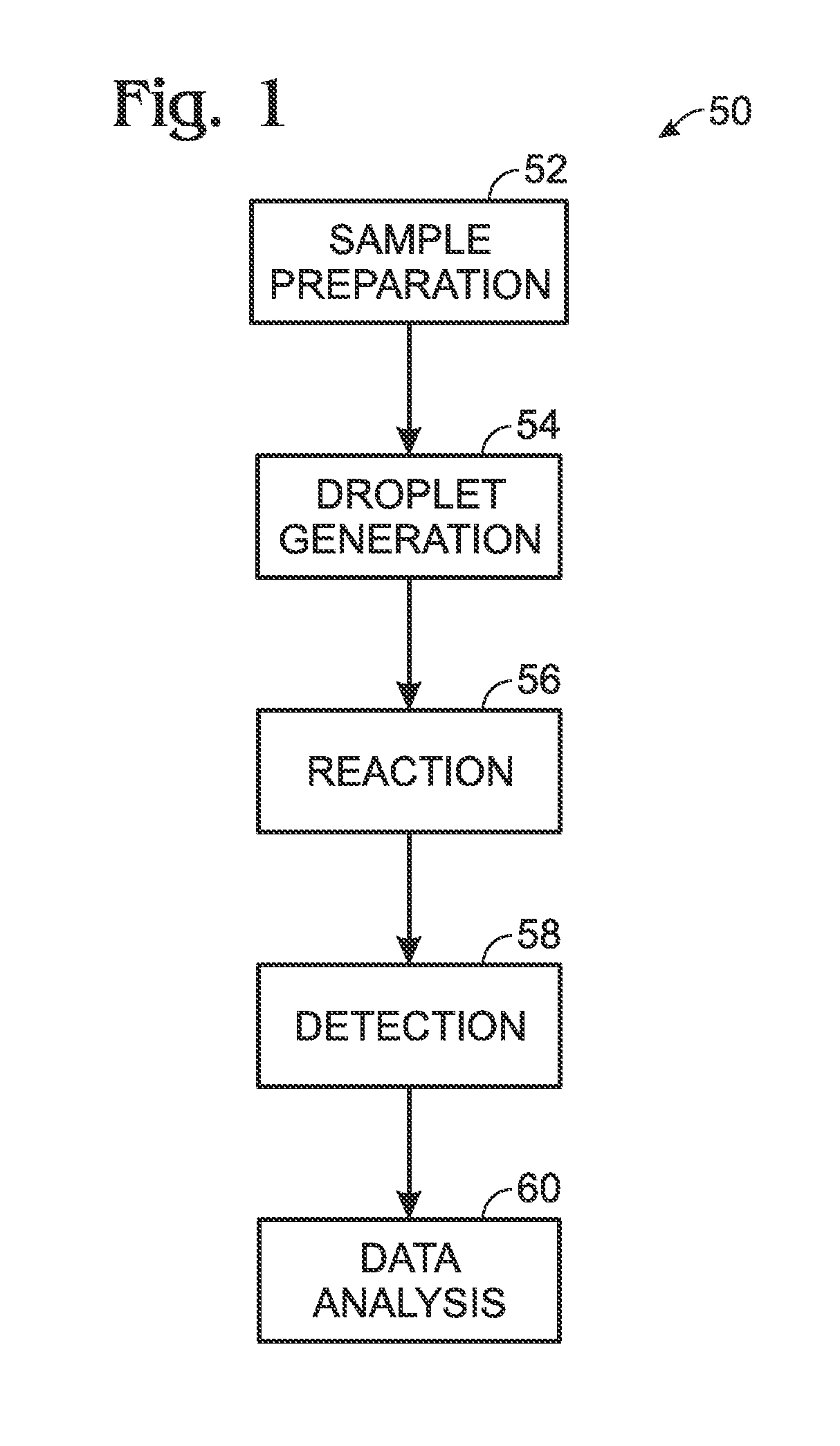

Droplet generation for droplet-based assays

ActiveUS20120190032A1High-confidence resultLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsAssayEmulsion

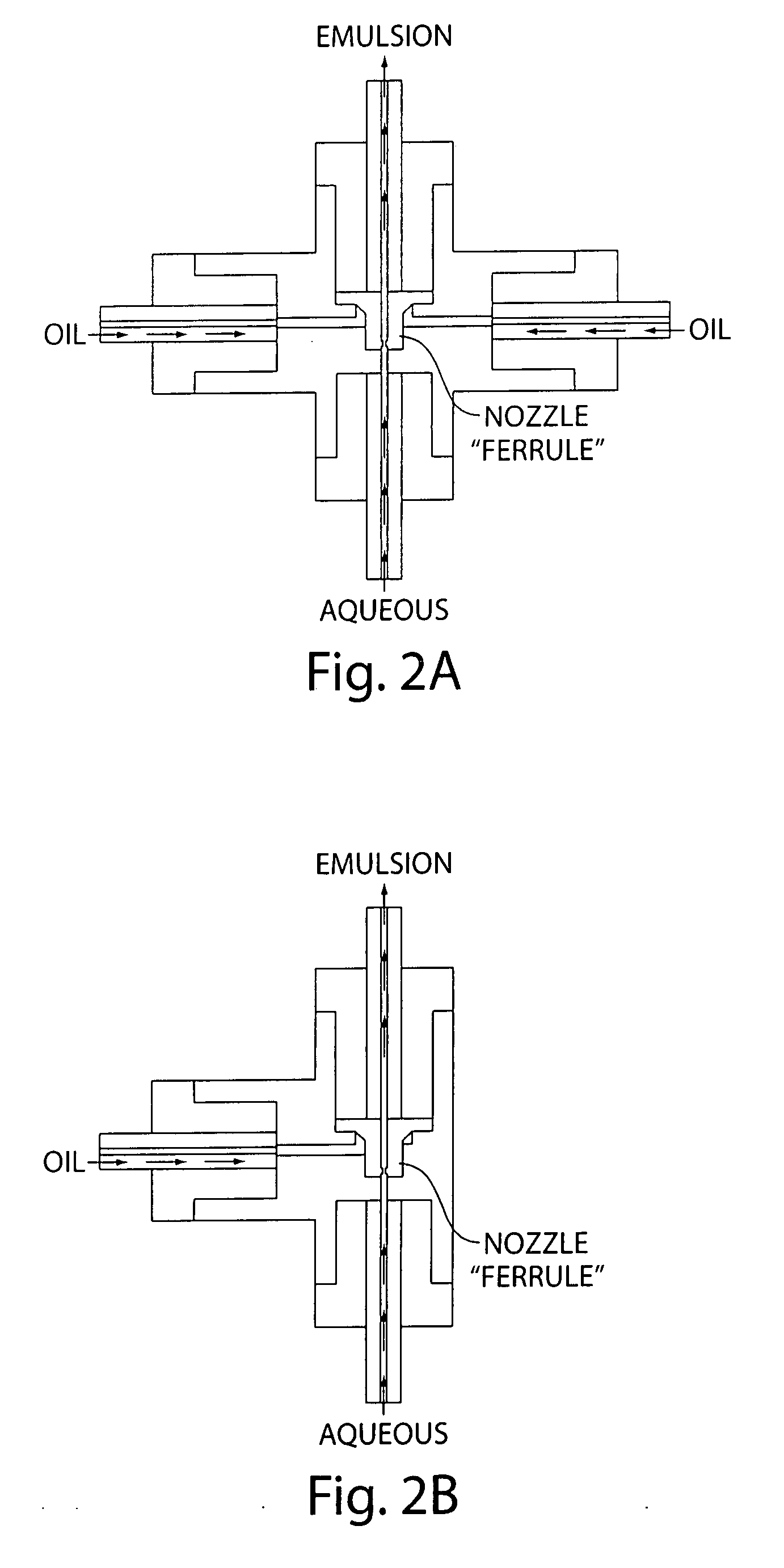

A system, including method and apparatus, for generating droplets suitable for droplet-based assays. The disclosed systems may include either one-piece or multi-piece droplet generation components configured to form sample-containing droplets by merging aqueous, sample-containing fluid with a background emulsion fluid such as oil, to form an emulsion of sample-containing droplets suspended in the background fluid. In some cases, the disclosed systems may include channels or other suitable mechanisms configured to transport the sample-containing droplets to an outlet region, so that subsequent assay steps may be performed.

Owner:BIO RAD LAB INC

Droplet-based surface modification and washing

ActiveUS7439014B2Reduces and eliminates build-upImprove efficiencyHeating or cooling apparatusTransportation and packagingSurface modificationSurface modified

The present invention relates to droplet-based surface modification and washing. According to one embodiment, a method of providing a droplet in contact with a surface with a reduced concentration of a substance is provided, wherein the method includes: (a) providing a droplet microactuator comprising a surface in contact with a droplet comprising a starting concentration and starting quantity of the substance and having a starting volume; (b) conducting one or more droplet operations to merge a wash droplet with the droplet provided in step (a) to yield a combined droplet; and (c) conducting one or more droplet operations to divide the combined droplet to yield a set of droplets comprising: (i) a droplet in contact with the surface having a decreased concentration of the substance relative to the starting concentration; and (ii) a droplet which is separated from the surface.

Owner:ADVANCED LIQUID LOGIC +1

Liquid transfer device

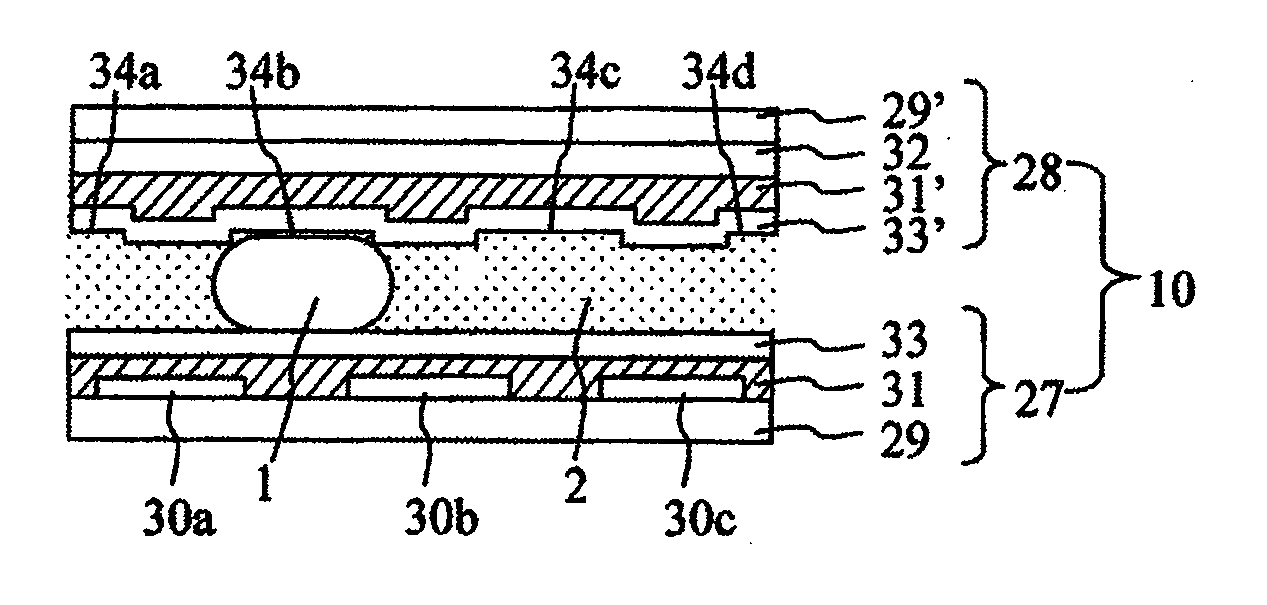

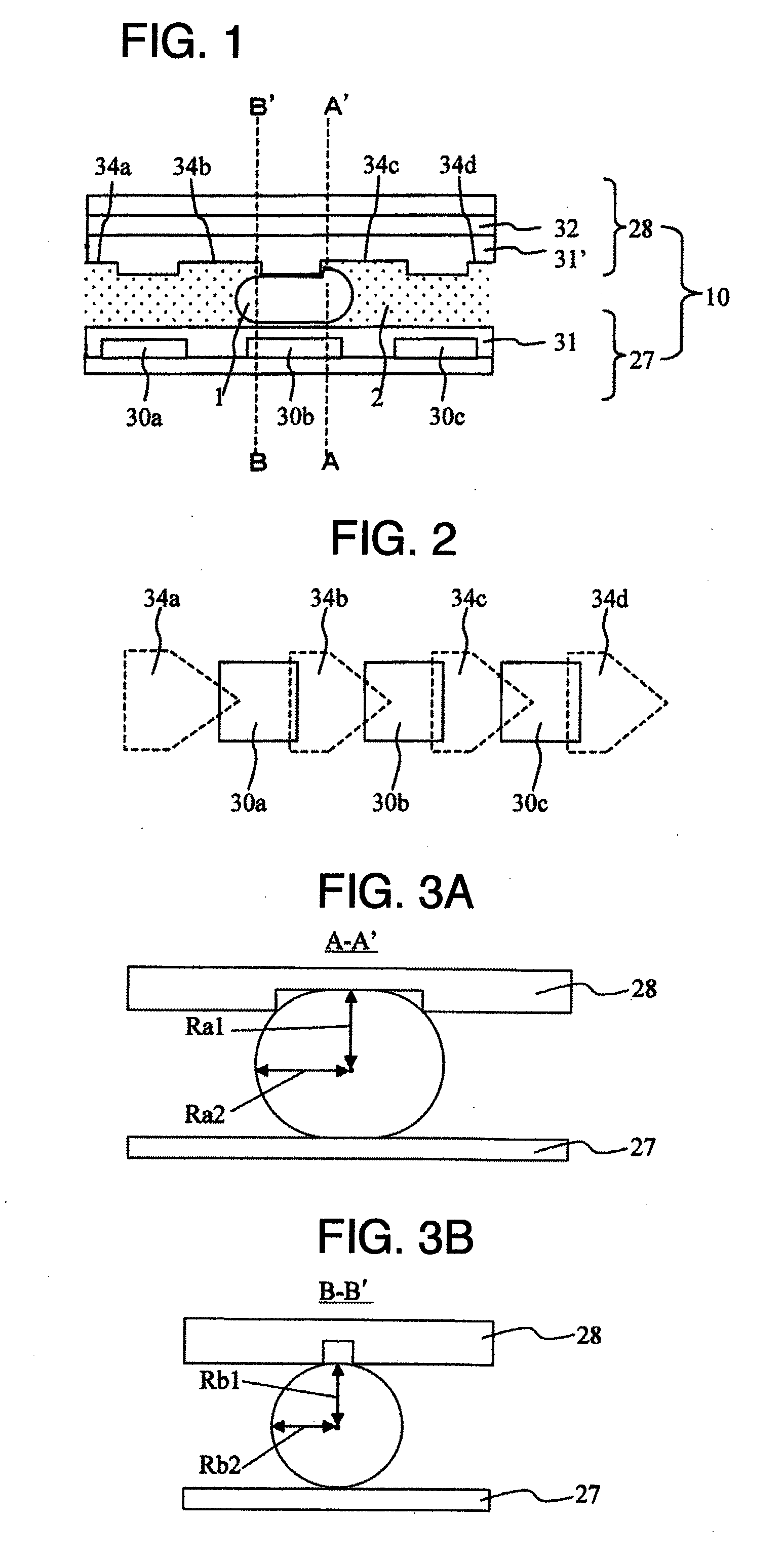

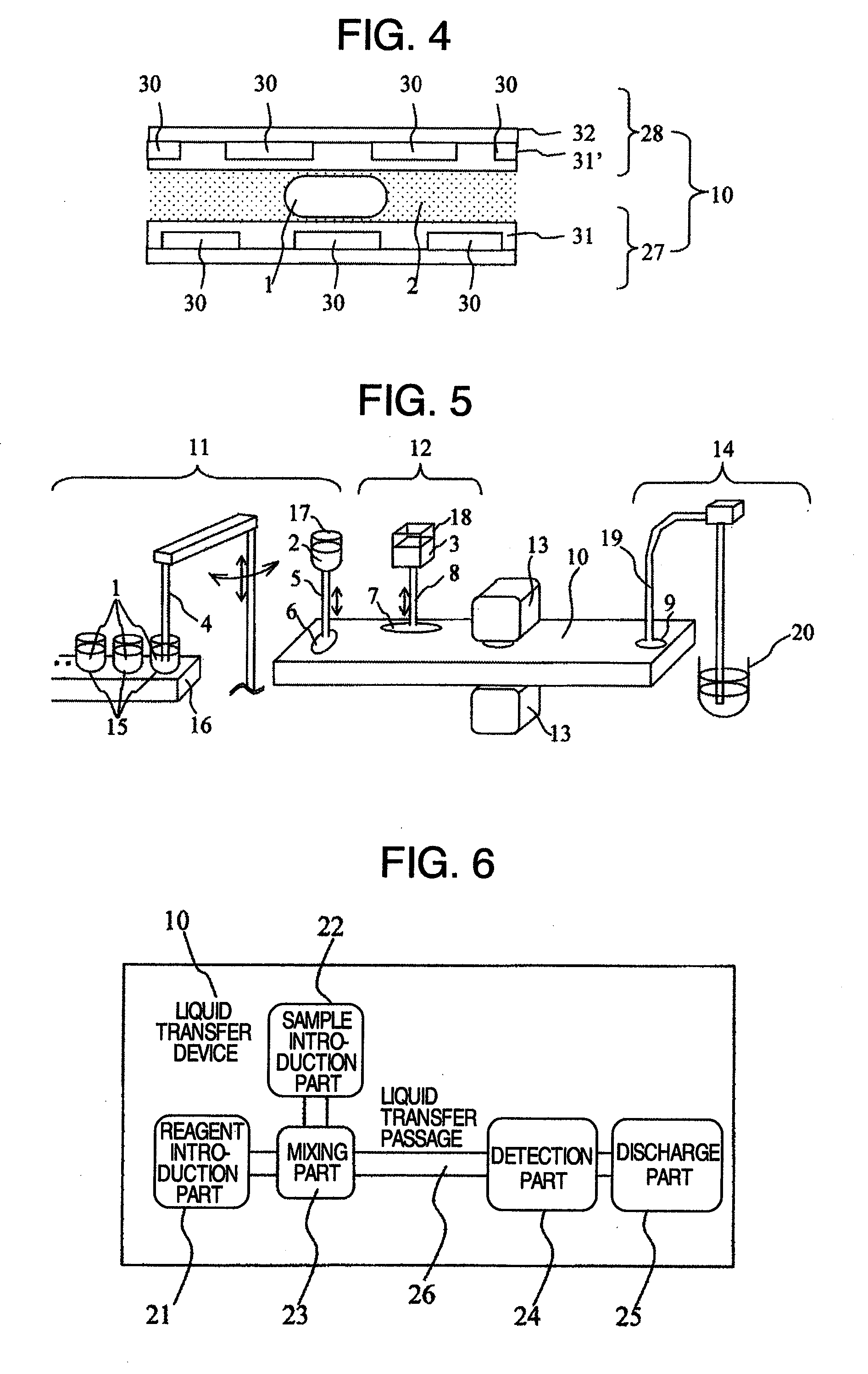

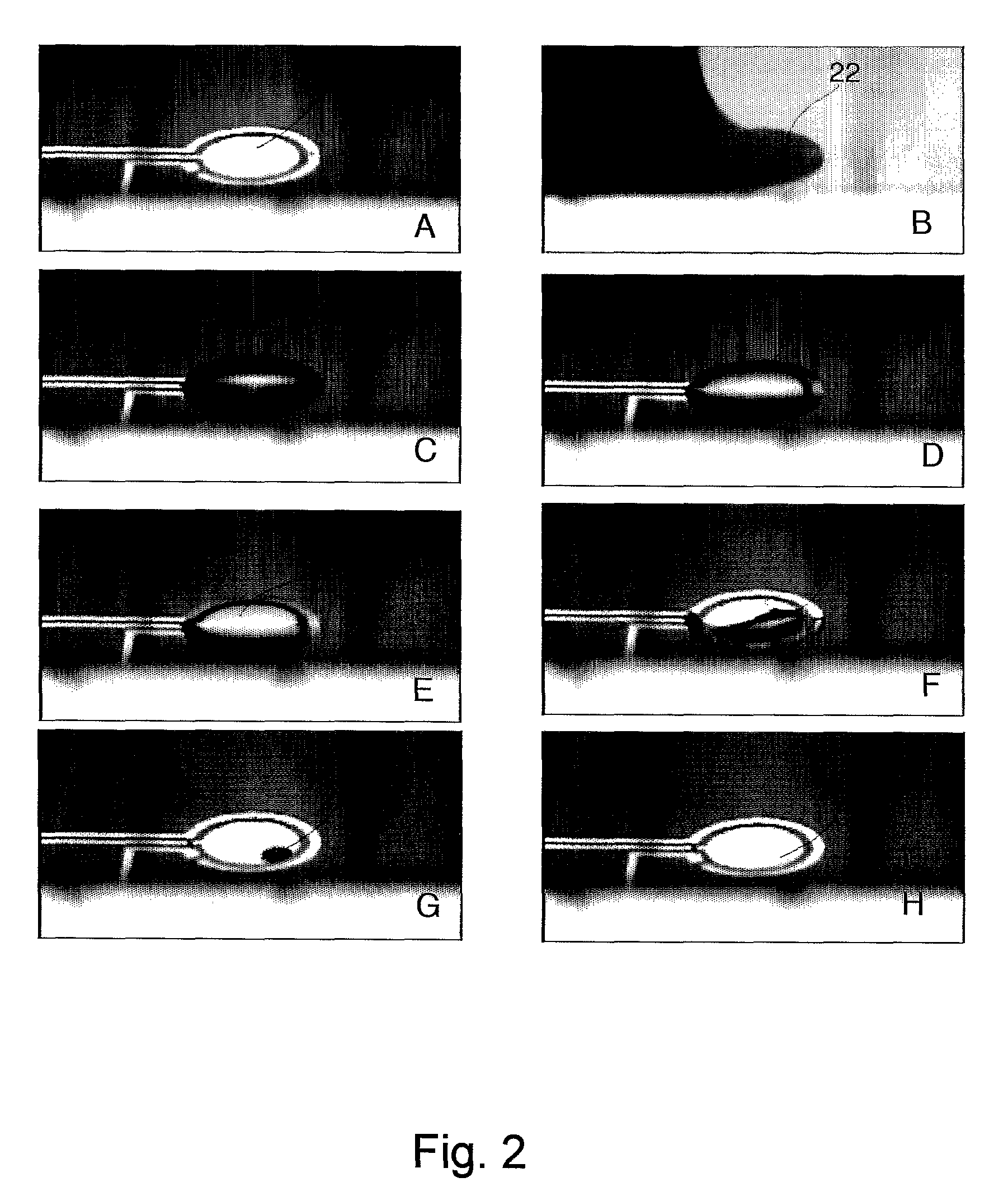

InactiveUS20090321262A1Reduce in quantityEasy to controlSludge treatmentTransportation and packagingSpherical shapedEngineering

Provided is a liquid transfer device which controls electrically liquid position. The surface of the liquid transfer device is provided with unevenness in order to solve a problem of having a large number of electrodes for controlling voltage. The number of electrodes for controlling voltage can be halved by utilization of restoring force of liquid to a spherical shape by surface tension, in addition to electrical force.

Owner:HITACHI HIGH-TECH CORP

Filler fluids for droplet operations

ActiveUS20070242105A1Reduces and eliminates build-upImprove efficiencyElectrostatic separatorsFixed microstructural devicesEngineeringLiquid drop

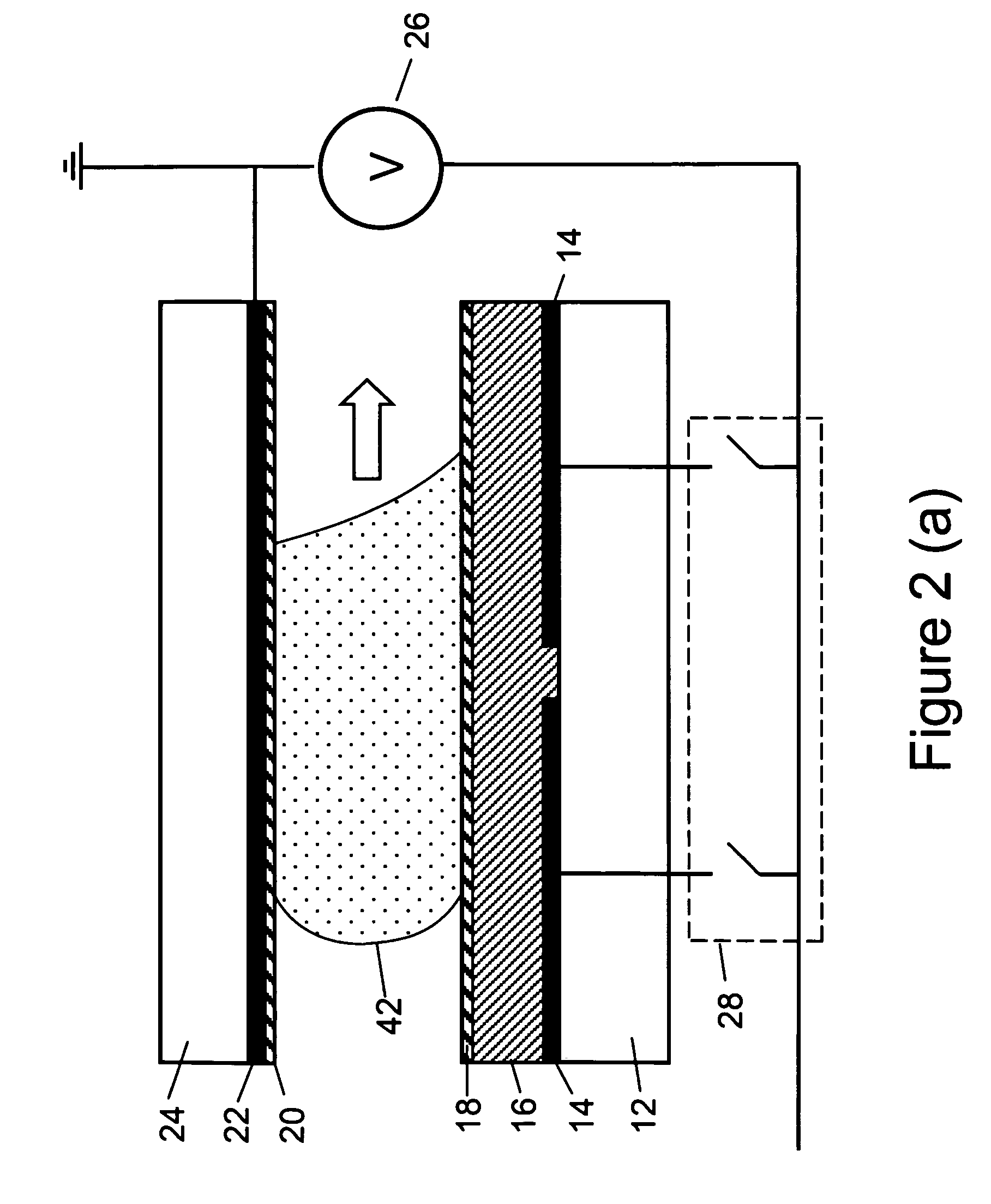

The present invention relates to filler fluids for droplet operations. According to one embodiment of this aspect, a droplet microactuator is provided and includes: (a) a first substrate comprising electrodes configured for conducting droplet operations on a surface of the substrate; (b) a second substrate spaced from the surface of the substrate by a distance sufficient to define an interior volume between the first substrate and second substrate, wherein the distance is sufficient to contain a droplet disposed in the space on the first substrate; and (c) a droplet arranged in the interior volume and arranged with respect to the electrodes in a manner which permits droplet operations to be effected on the droplet using the electrodes.

Owner:DUKE UNIV +1

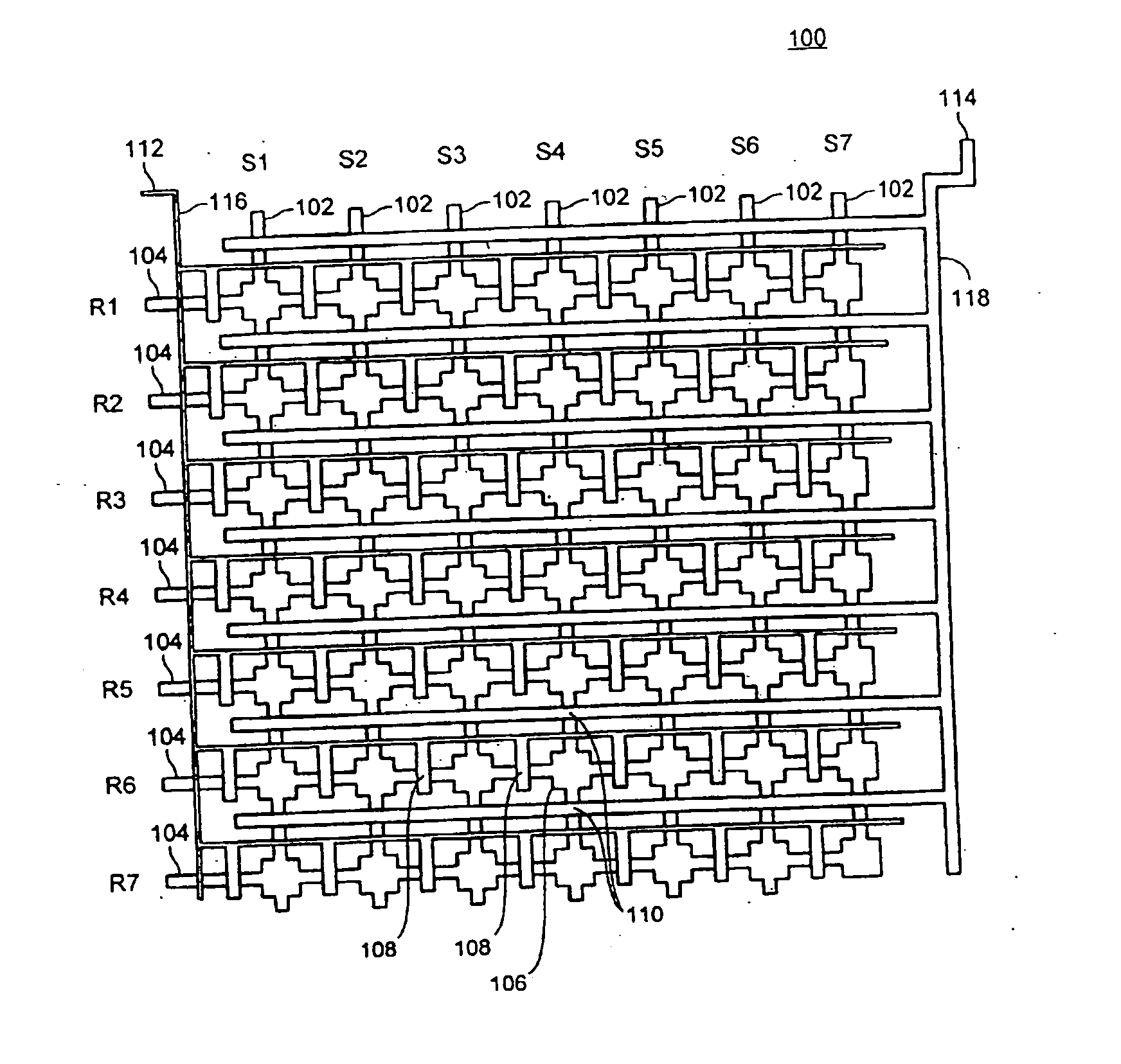

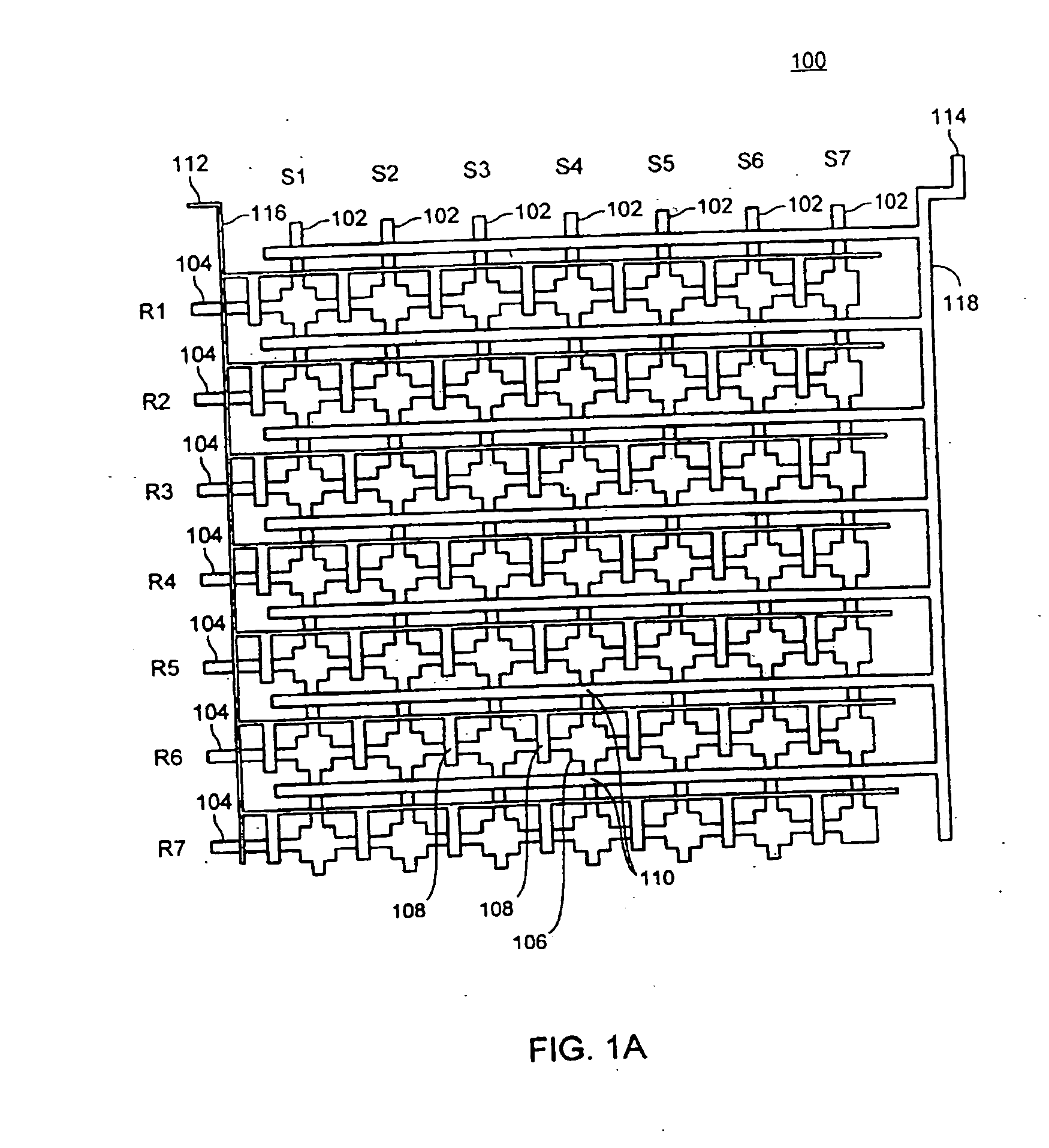

Microfluidic device and methods of using same

ActiveUS20050019792A1Prevent evaporationBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlGenotyping

A variety of elastomeric-based microfluidic devices and methods for using and manufacturing such devices are provided. Certain of the devices have arrays of reaction sites to facilitate high throughput analyses. Some devices also include reaction sites located at the end of blind channels at which reagents have been previously deposited during manufacture. The reagents become suspended once sample is introduced into the reaction site. The devices can be utilized with a variety of heating devices and thus can be used in a variety of analyses requiring temperature control, including thermocycling applications such as nucleic acid amplification reactions, genotyping and gene expression analyses.

Owner:STANDARD BIOTOOLS INC

Microfluidic sequencing systems

InactiveUS7238323B2Minimize contaminationIncrease speedBioreactor/fermenter combinationsBiological substance pretreatmentsGenomic screeningSoftware

Owner:CAPLIPER LIFE SCI INC

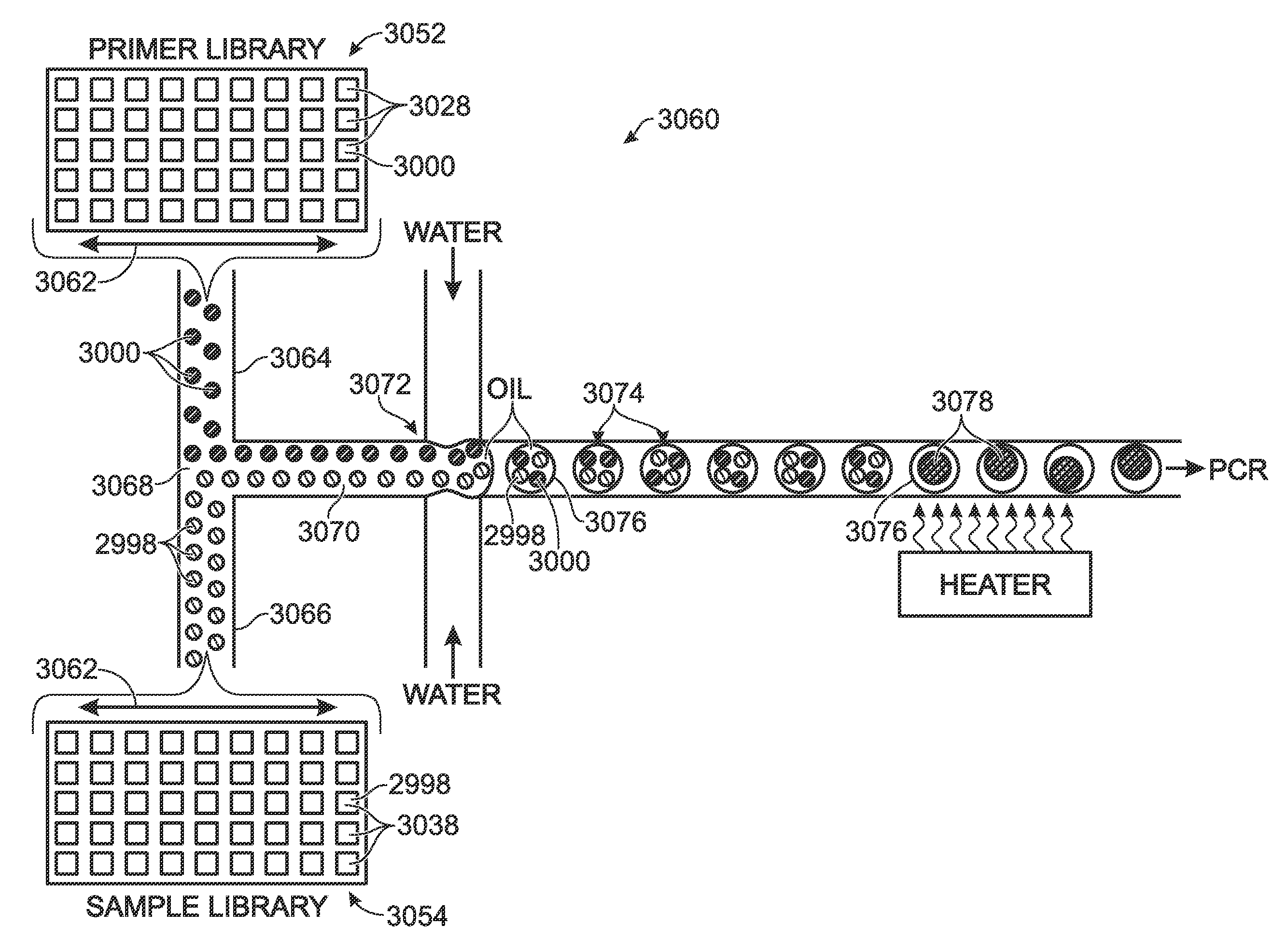

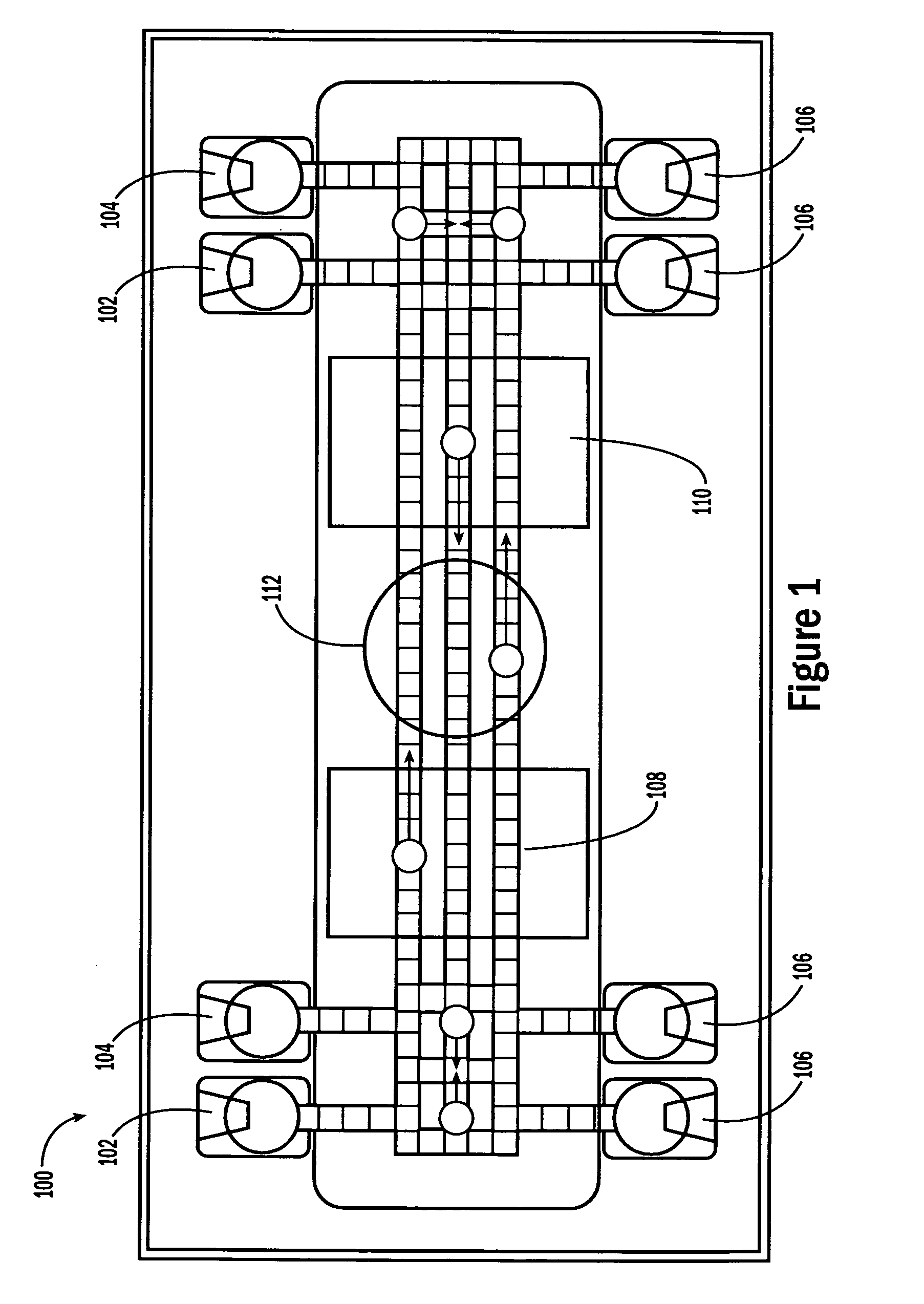

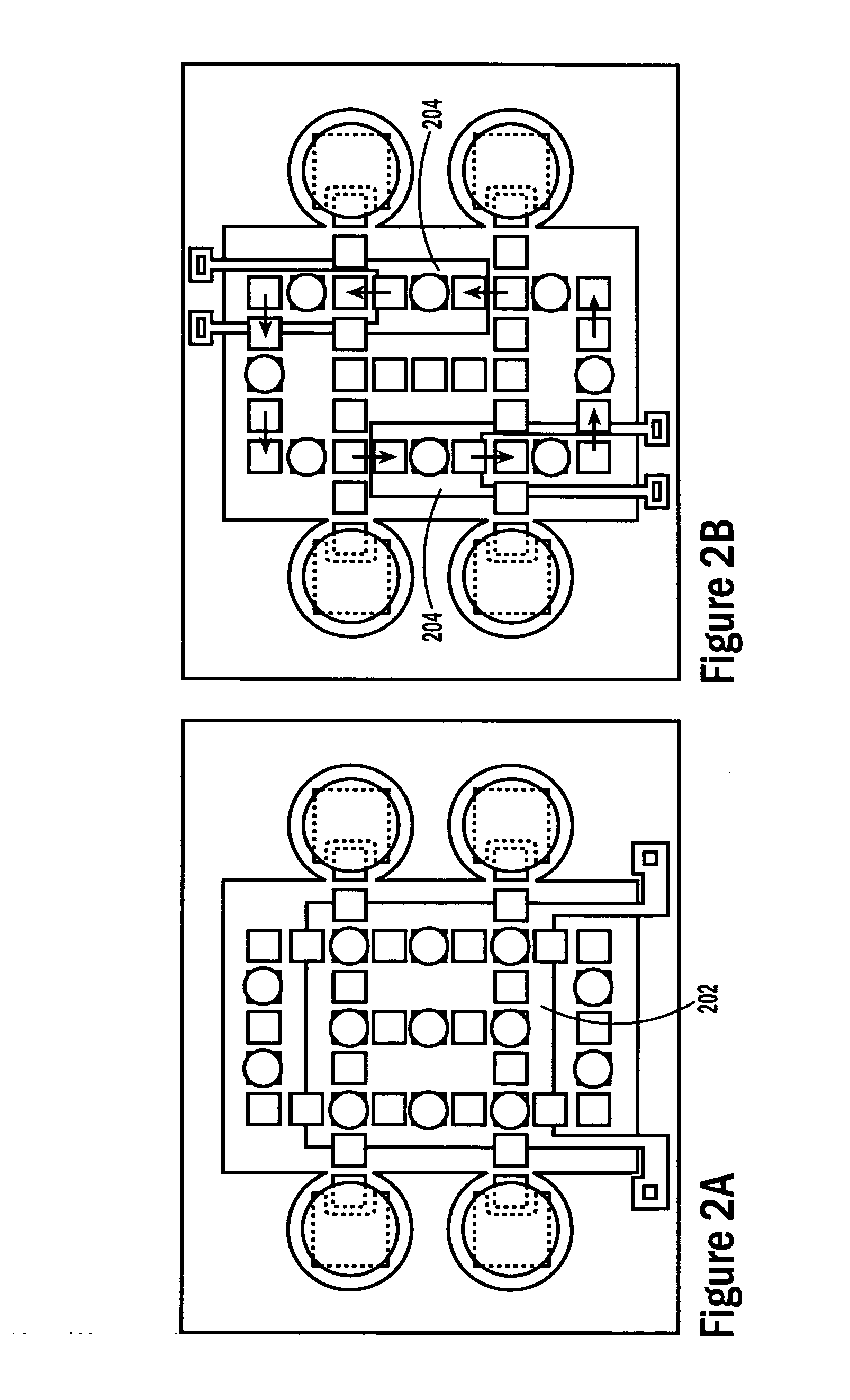

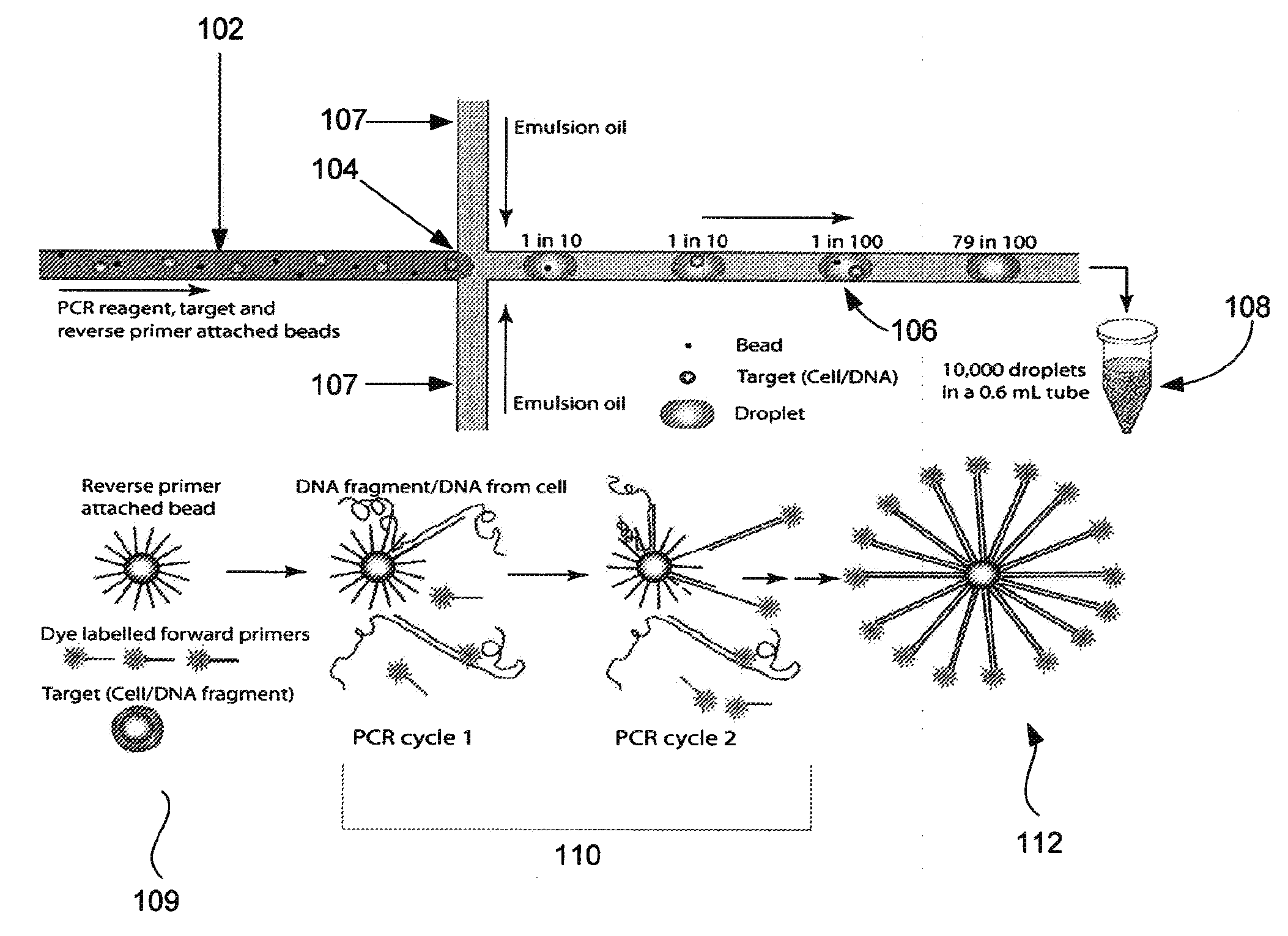

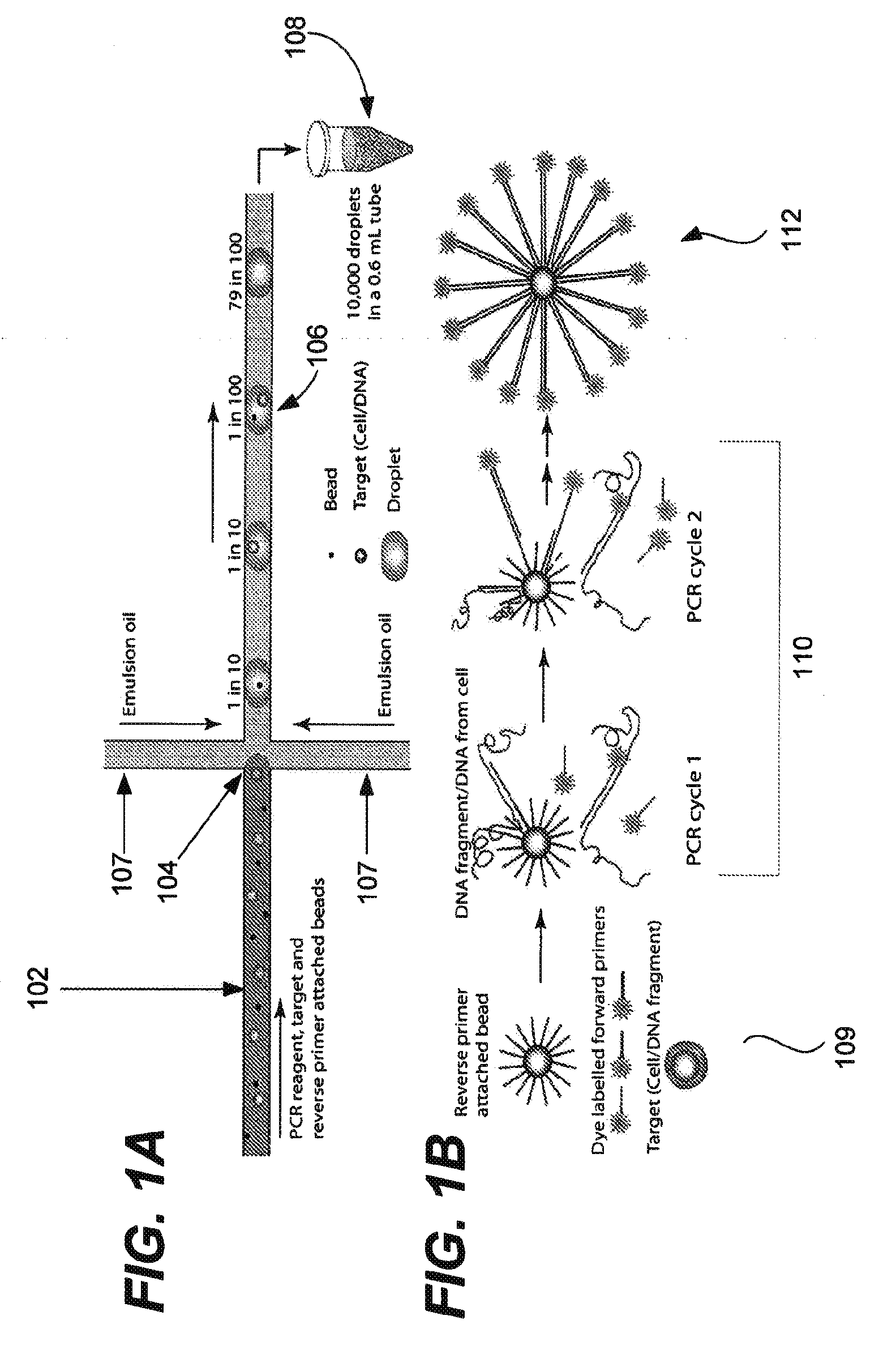

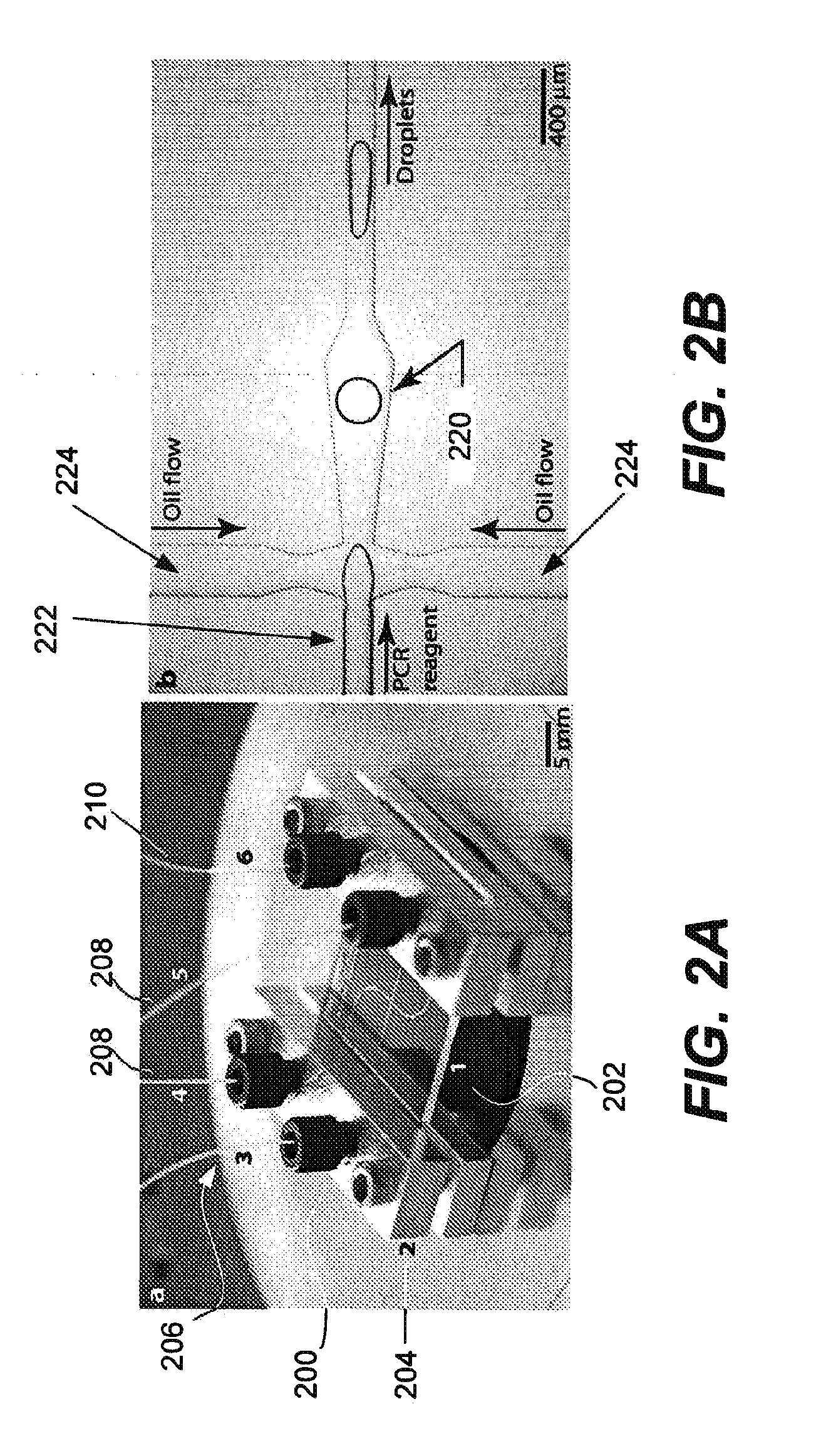

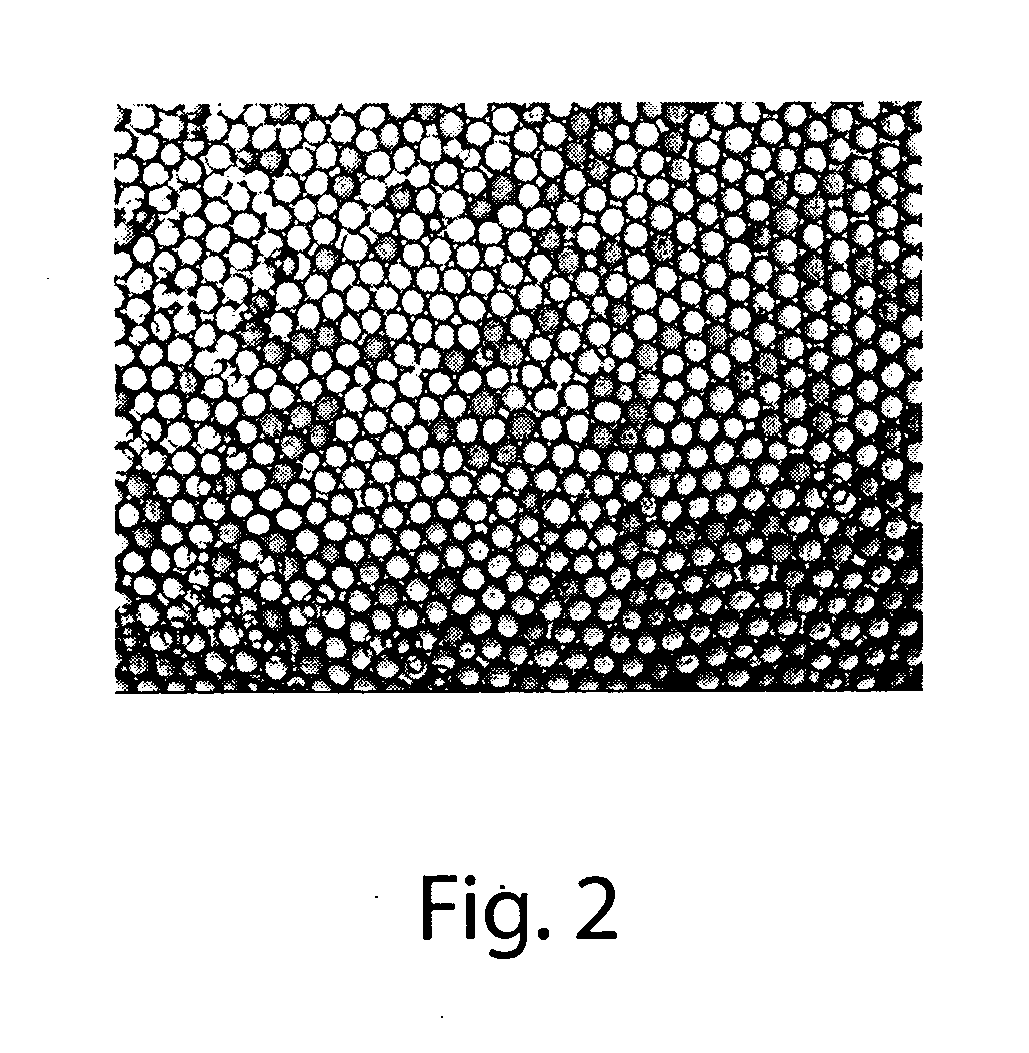

Microfabricated droplet generator for single molecule/cell genetic analysis in engineered monodispersed emulsions

ActiveUS20100285975A1Efficient routingEfficient single-molecule amplificationTransportation and packagingLibrary screeningEmulsionMicroparticle

Provided are microfluidic designs and methods for rapid generation of monodisperse nanoliter volume droplets of reagent / target (e.g., molecule or cell) mix in emulsion oil. The designs and methods enable high-throughput encapsulation of a single target (e.g., DNA / RNA molecules or cells) in controlled size droplets of reagent mix. According to various embodiments, a microfabricated, 3-valve pump is used to precisely meter the volume of reagent / target mix in each droplet and also to effectively route microparticles such as beads and cells into the device, which are encapsulated within droplets at the intersection of the reagent channel and an oil channel. The pulsatile flow profile of the microfabricated pumps provides active control over droplet generation, thereby enabling droplet formation with oils that are compatible with biological reactions but are otherwise difficult to form emulsions with.

Owner:RGT UNIV OF CALIFORNIA

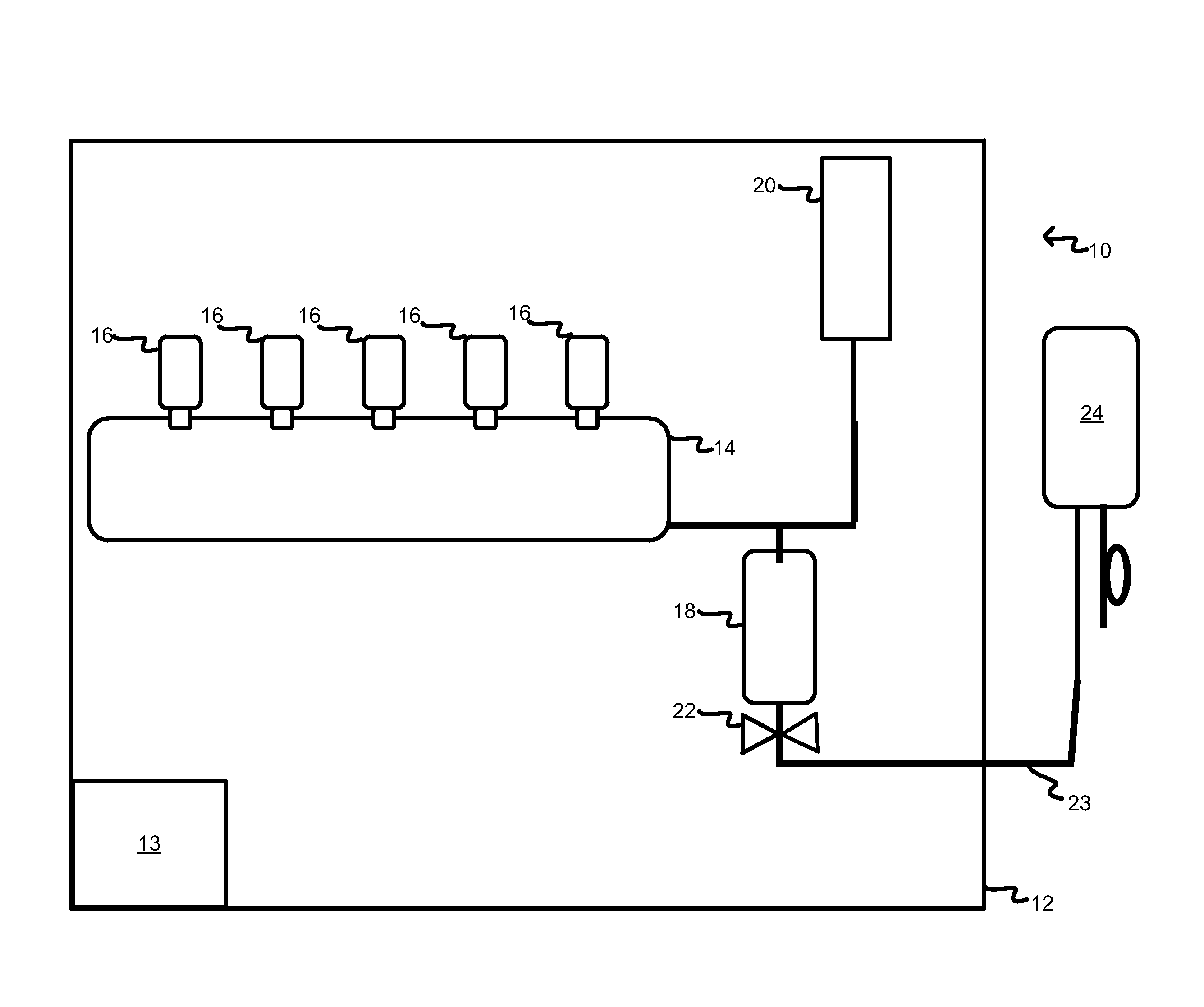

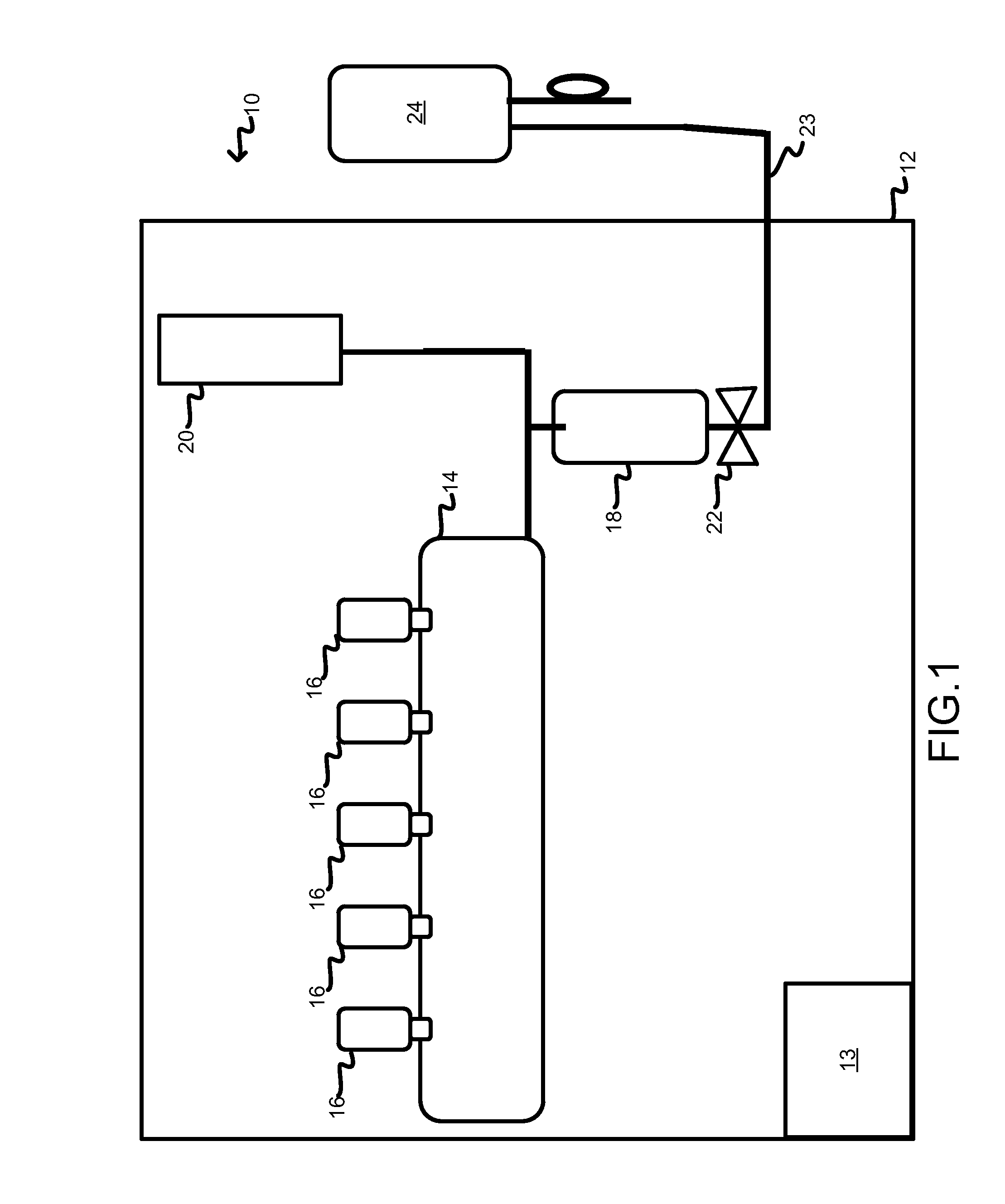

Compounder Apparatus

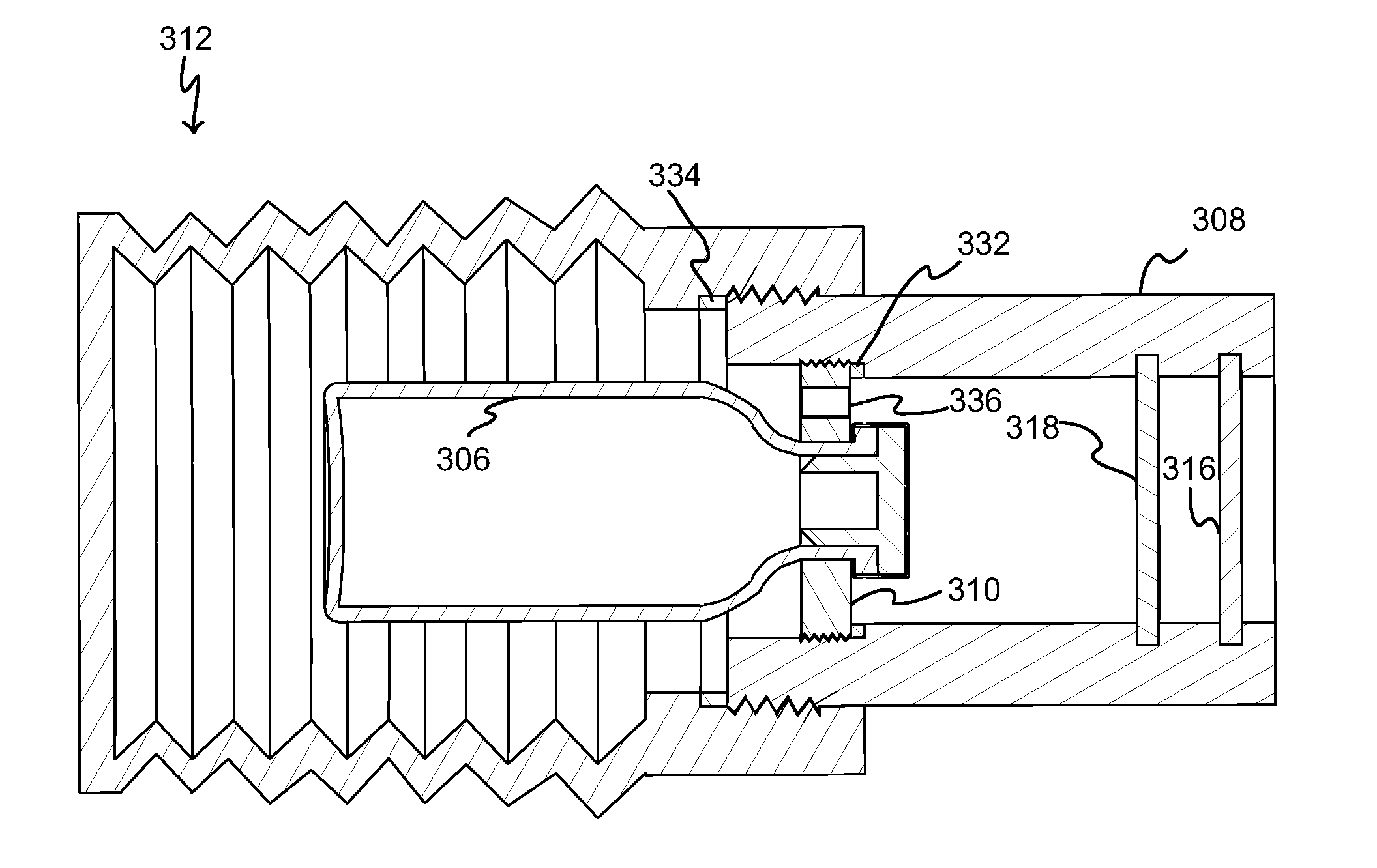

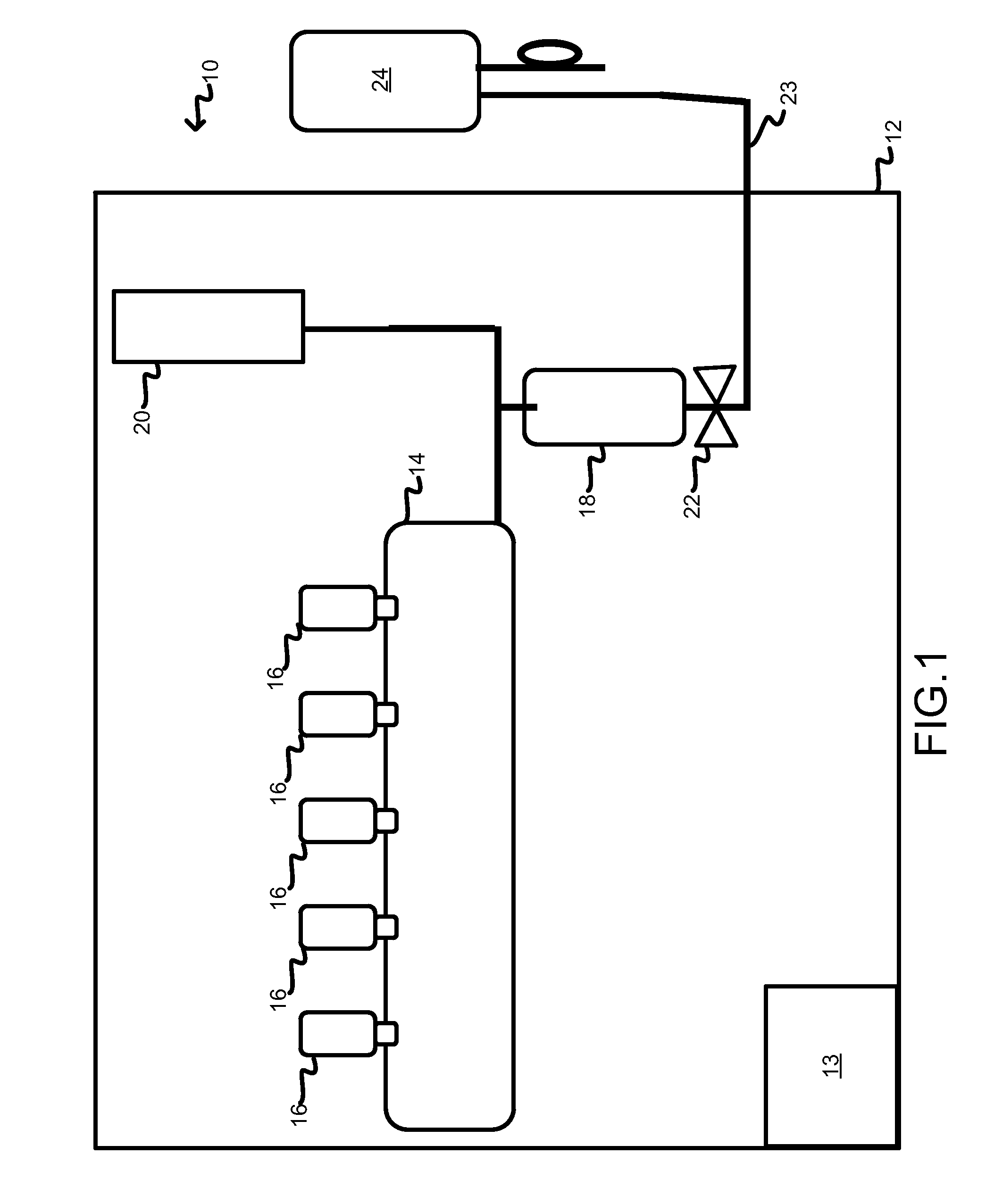

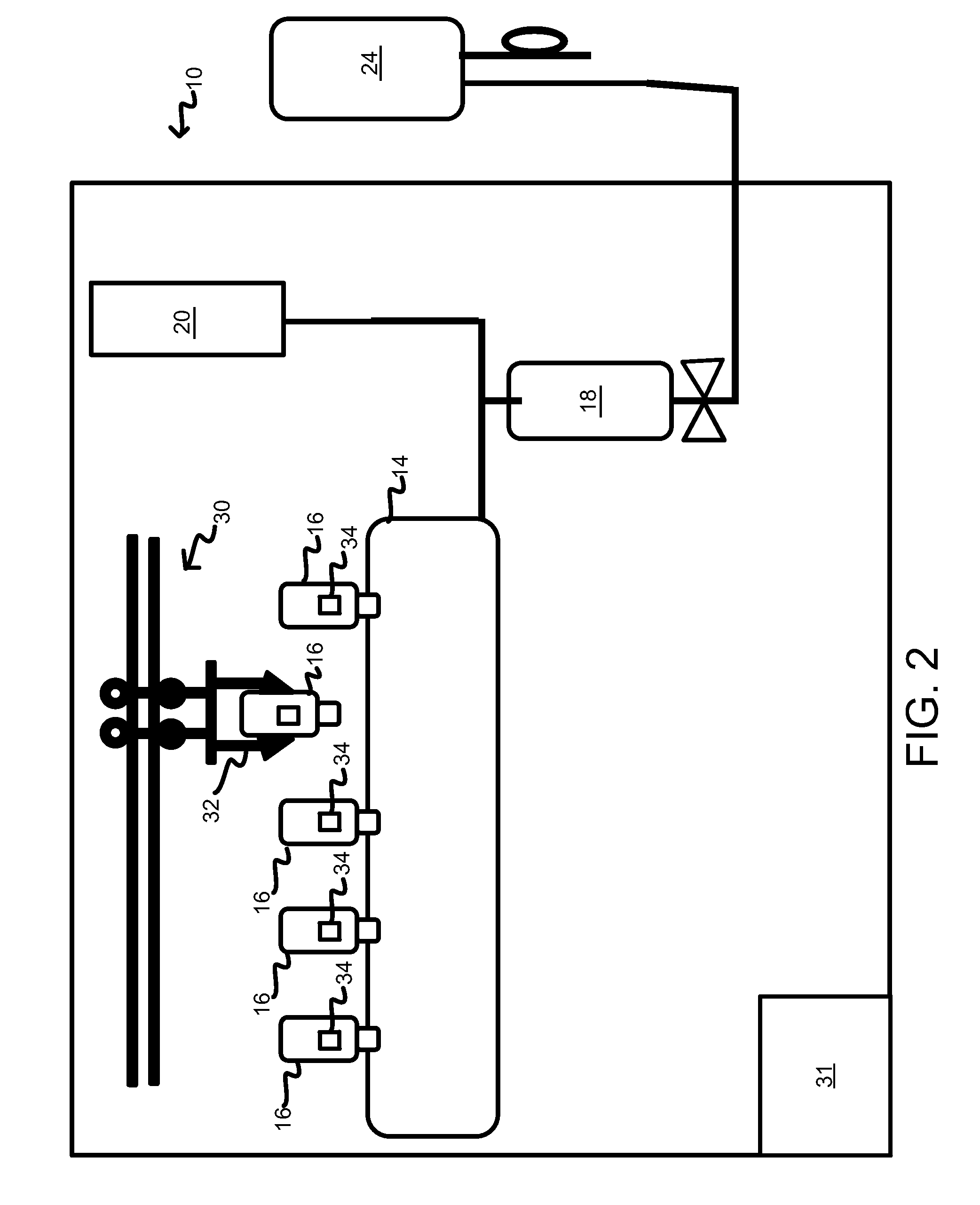

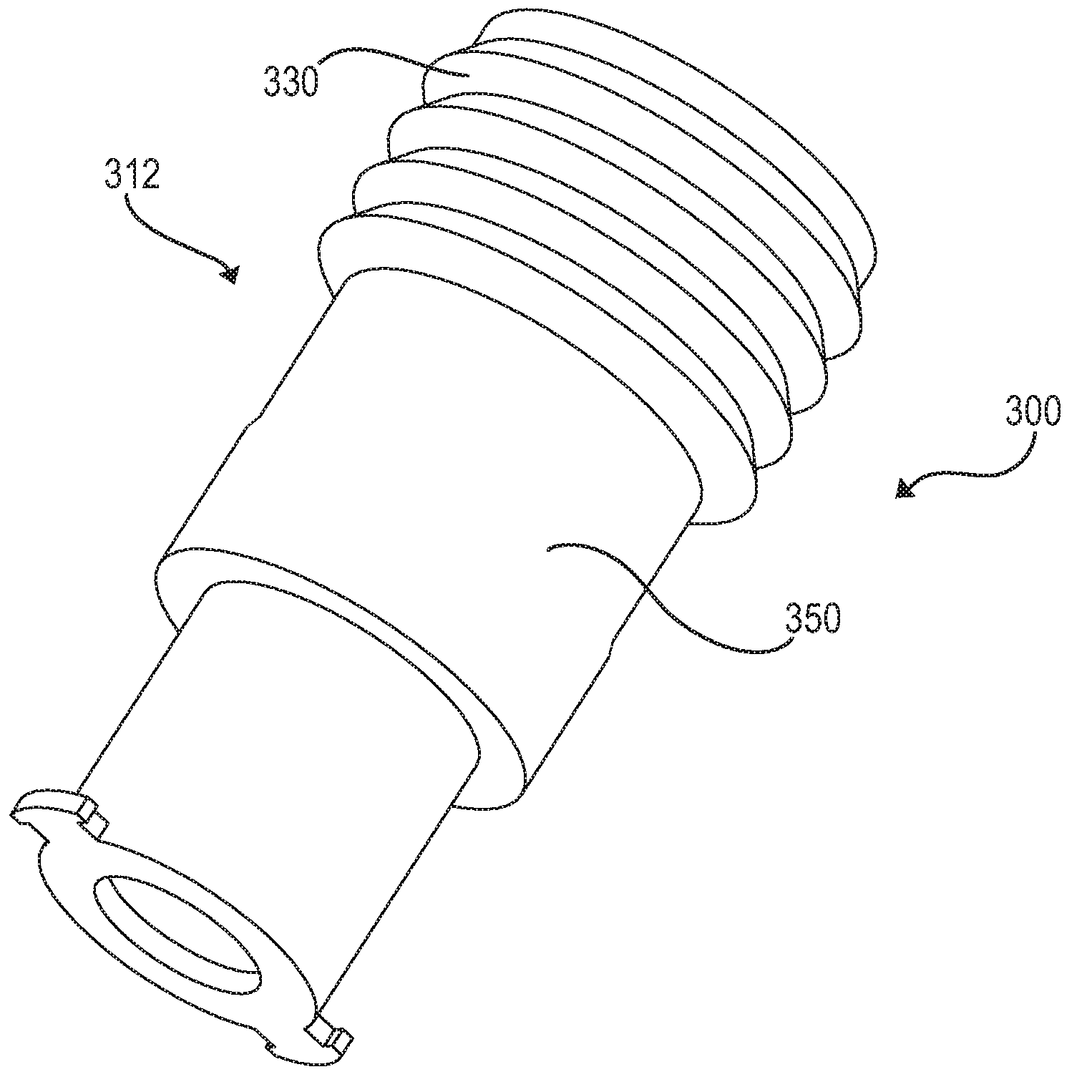

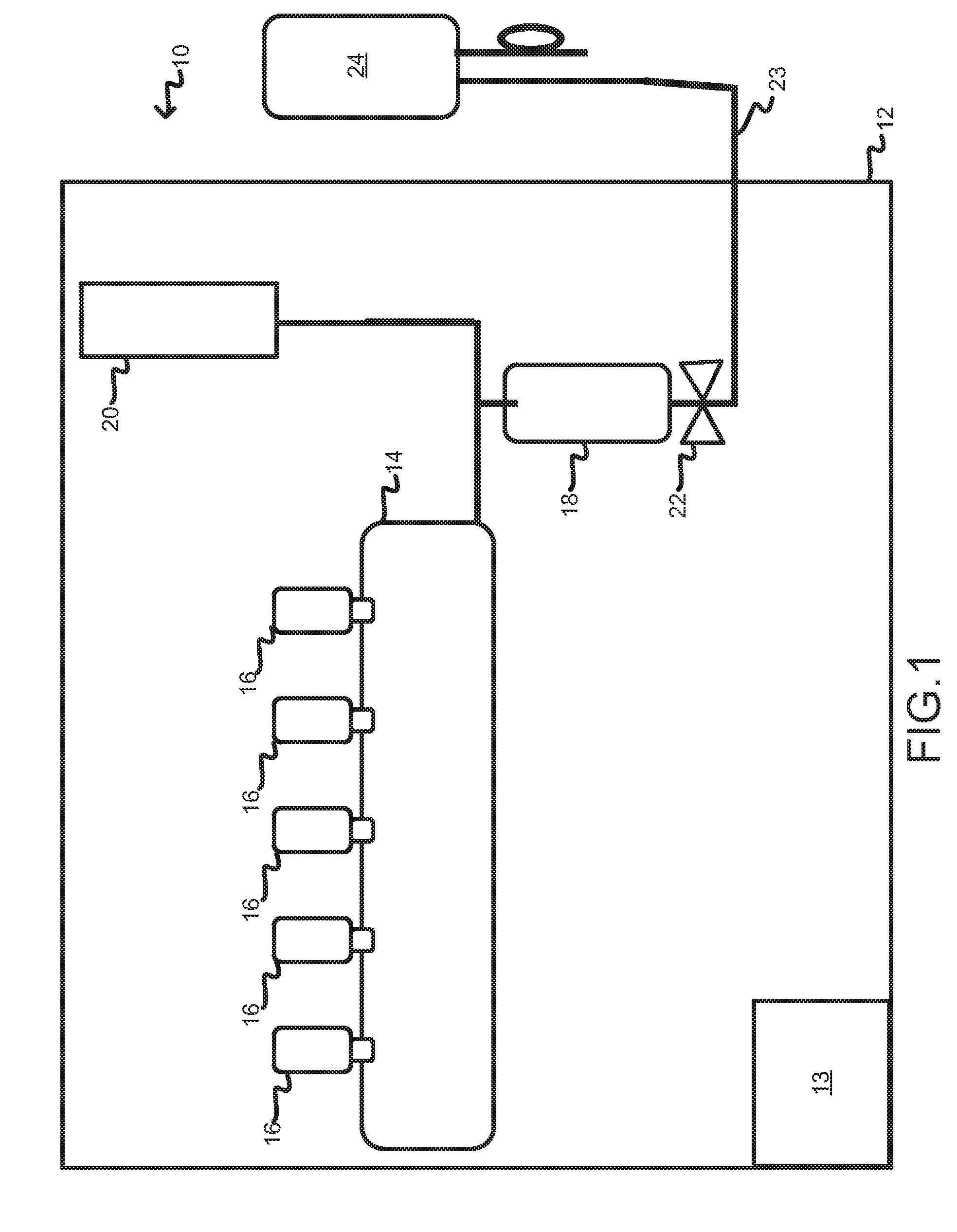

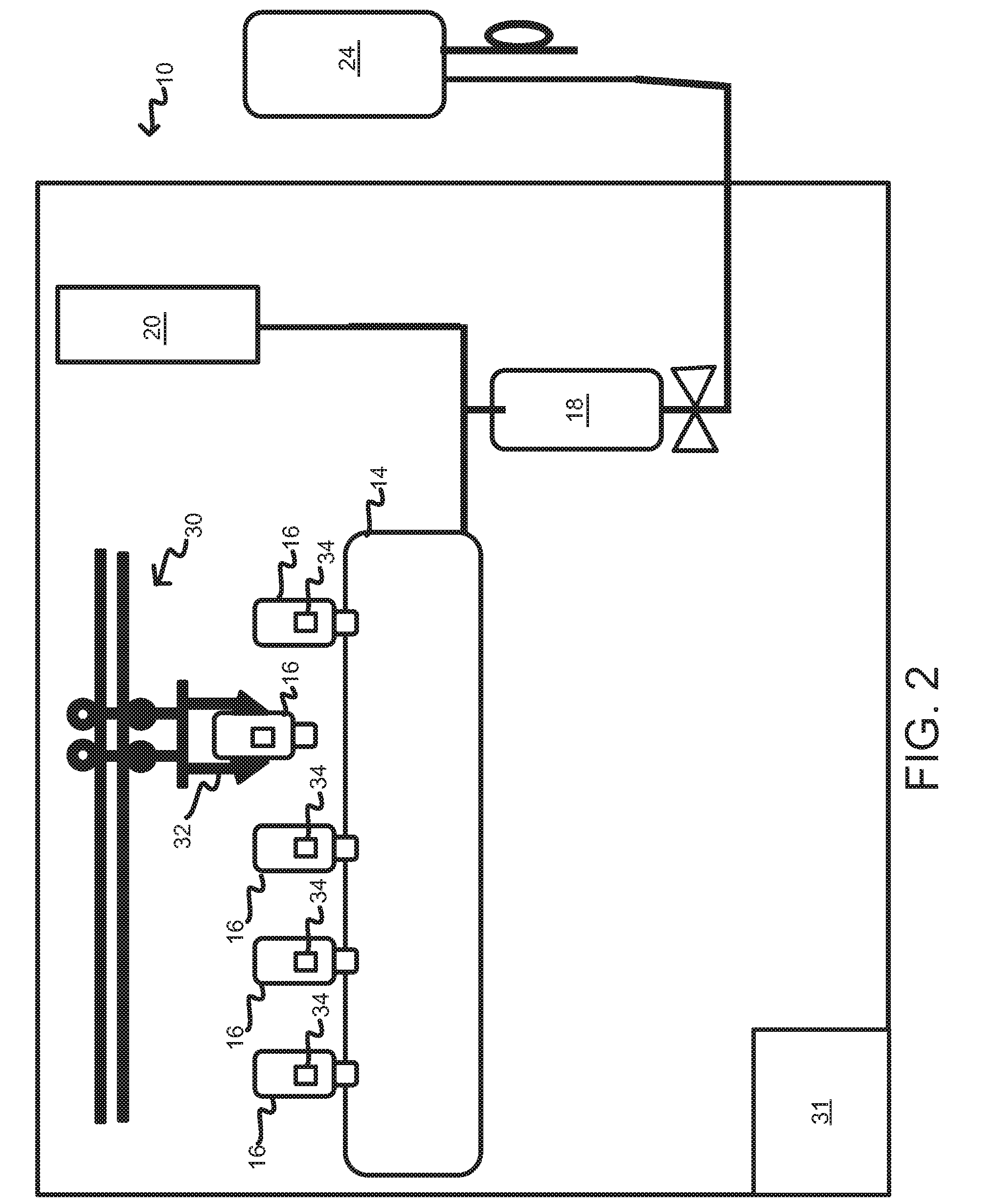

A containment assembly for enclosing a medication vial may comprise a first housing portion or interface portion having a proximal end and a distal end. The interface portion may include a housing wall which defines a channel spanning from the proximal end to the distal end. The channel may be open at the proximal and distal end. The containment assembly may further comprise at least one pierceable septum disposed at least at one of: on the proximal end of the channel and within the channel forming a barrier between the proximal end of the channel and distal end of the channel of the interface portion. The containment assembly may further comprise a variable-volume housing portion having a variable volume chamber. The variable-volume portion chamber of the variable-volume housing portion may be in fluid communication with the distal end of the channel.

Owner:DEKA PROD LLP

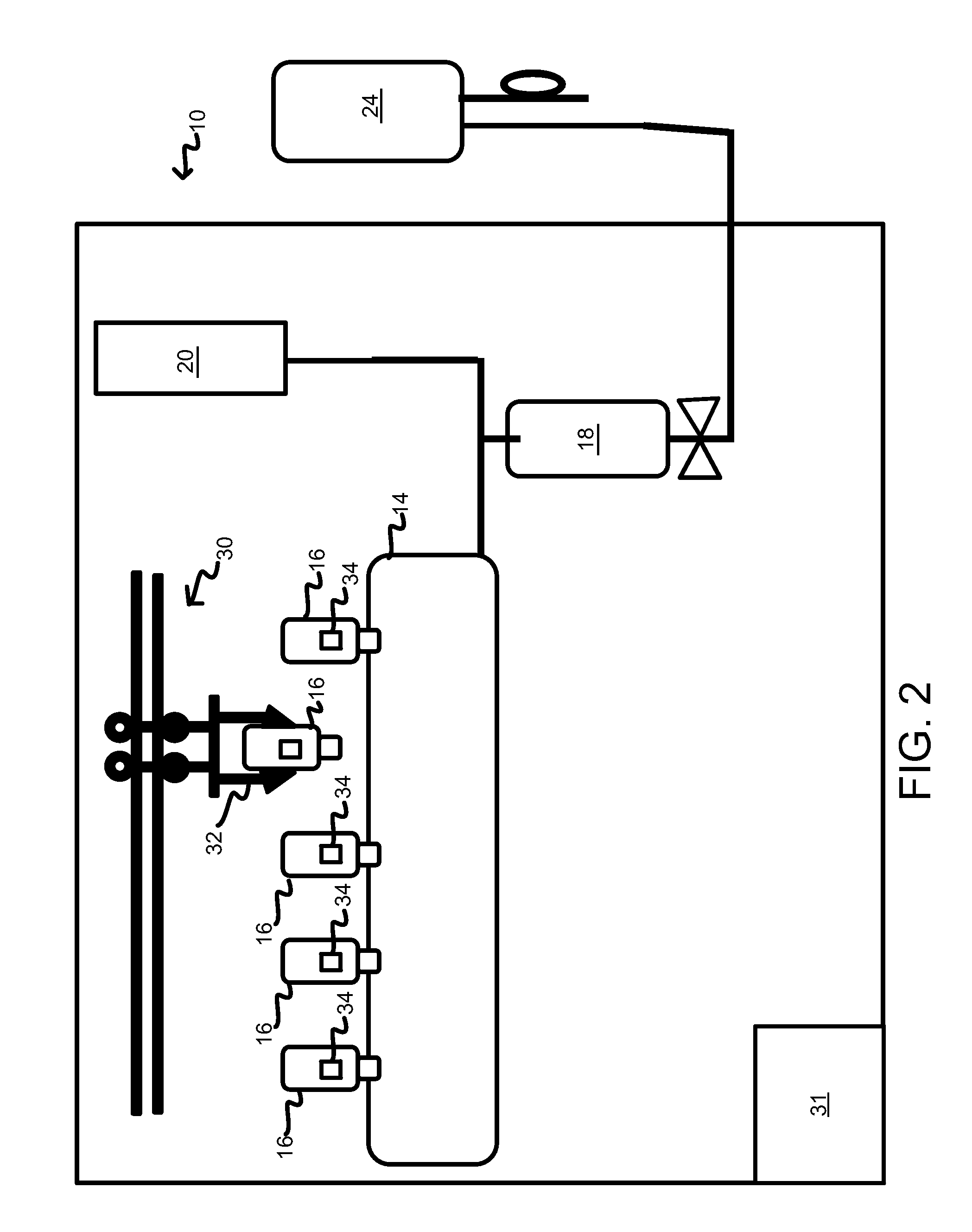

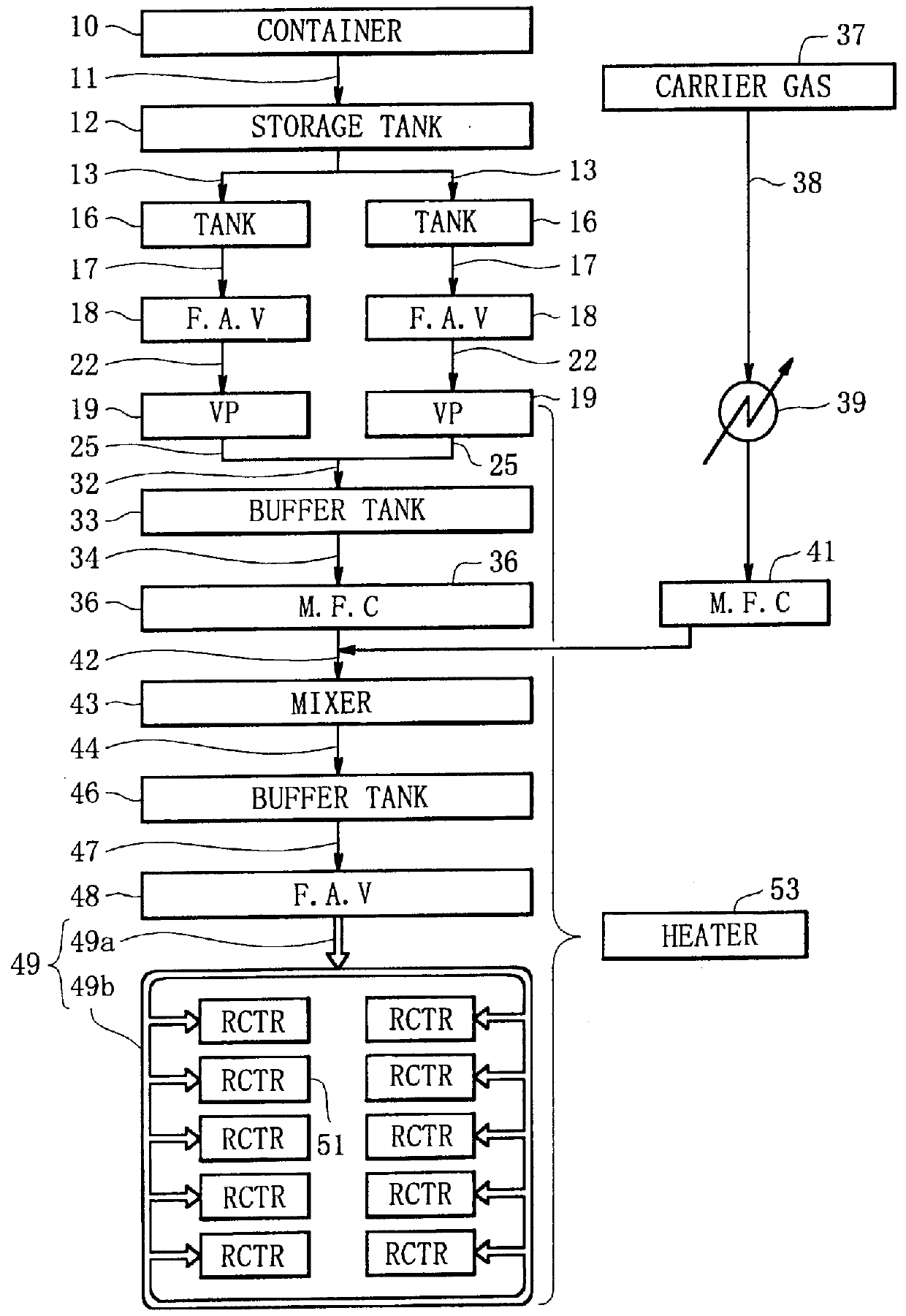

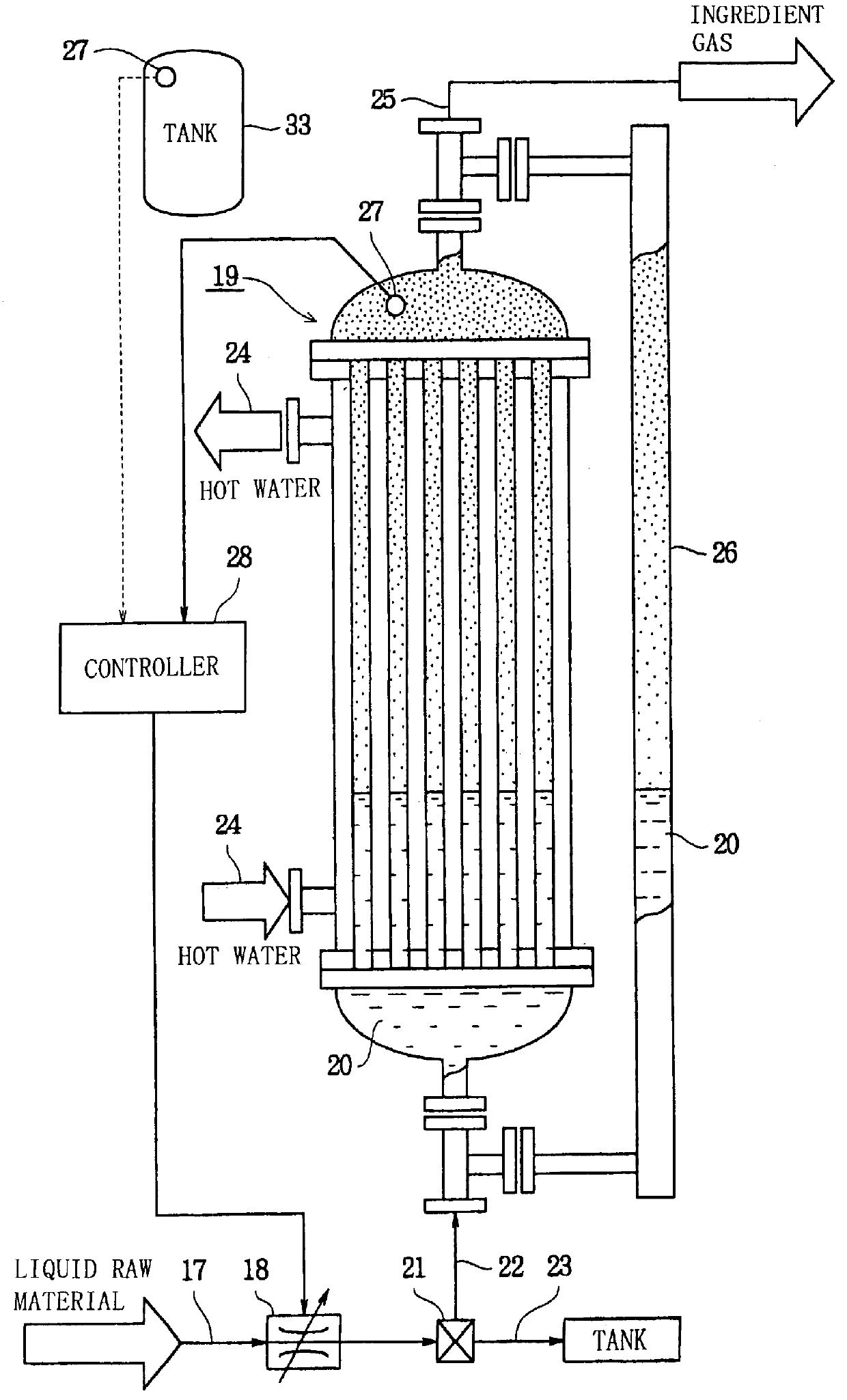

Method and apparatus for feeding a gas for epitaxial growth

InactiveUS6039809APolycrystalline material growthTransportation and packagingBoiling pointProduct gas

A liquid raw material is heated to its boiling point or higher at a vaporizer to mix the vaporized ingredient gas and a carrier gas at a mixer at predetermined concentrations. The flow of the mixed gas is adjusted while the mixed gas is heated to over its condensing point and the temperature thereof is kept. Subsequently, the mixed gas is fed to a reactor for epitaxial growth while the mixed gas is heated to over its condensing point and the temperature thereof is kept. When the temperature of a heating medium is kept constant at the vaporizer to vaporize the liquid raw material and the feeding amount of the liquid into the vaporizer is adjusted by the pressure of the gas inside the vaporizer, the liquid surface level can be controlled to be constant.

Owner:MITSUBISHI MATERIALS CORP

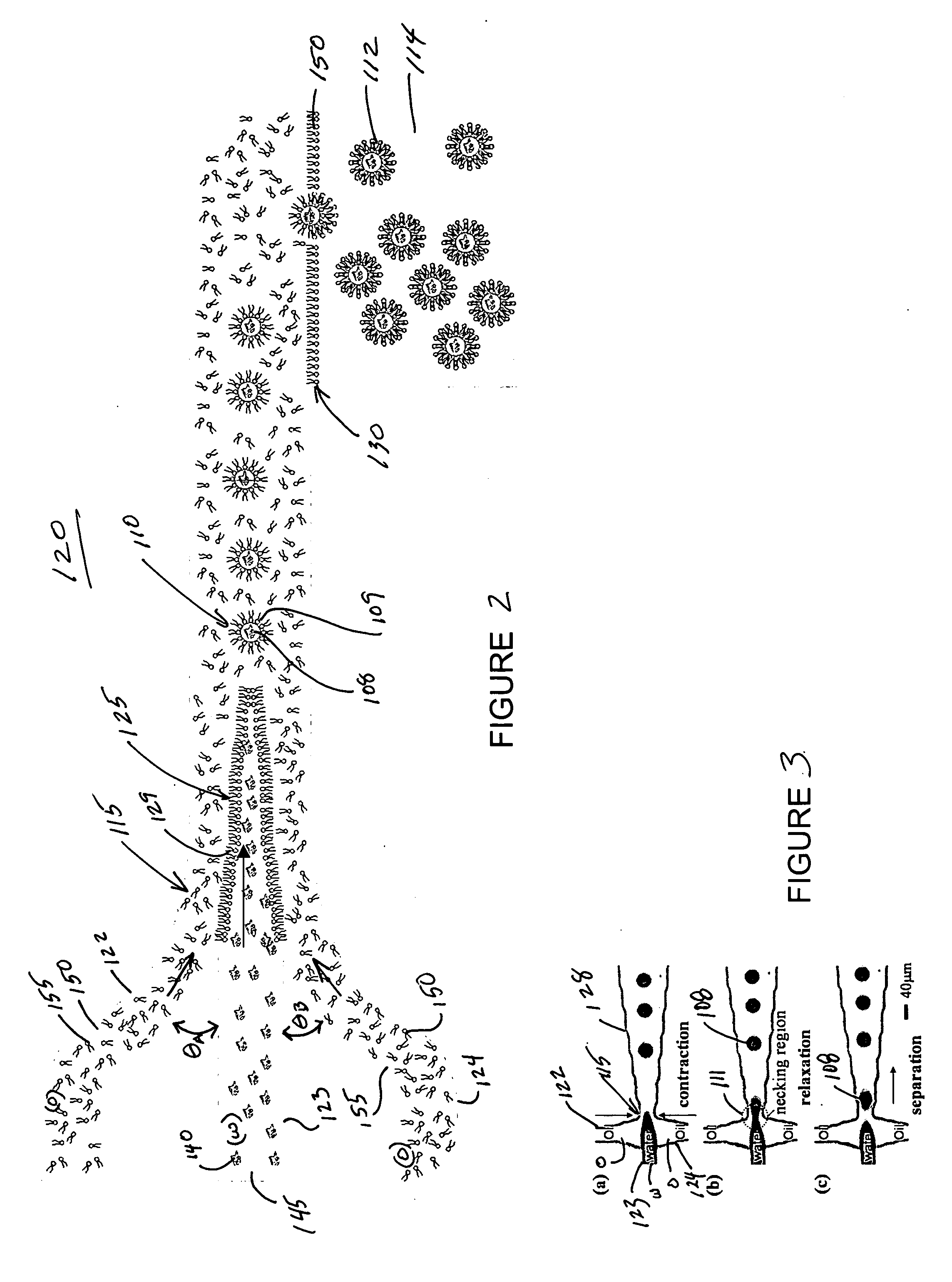

Microfluidic devices for controlled viscous shearing and formation of amphiphilic vesicles

ActiveUS20050032240A1Facilitates programmable control of sizeIncrease shear forceMixing methodsTransportation and packagingViscous shearEngineering

Systems and methods that control the size and composition of emulsified droplets, multi-lamellar and asymmetric vesicles, encapsulation of reagents, membrane proteins, and sorting of vesicles / droplets. More particularly, microfluidic devices for controlled viscous shearing of oil-water emulsions of micro- and nano-scale droplets, the subsequent formation of amphiphilic vesicles such as liposomes, polymer vesicles, micelles, and the like, the post-assembly and post-processing of the droplets including splitting, fusing, sorting and the like, polymer emulsions, and the integration of amphiphilic vesicle production-line on a single microfluidic chip. Preferably, the microfluidic device enables oil-water co-flows with tunable viscous shear forces higher than the immiscible interfacial tension forces that generate favorable conditions for droplet formation.

Owner:RGT UNIV OF CALIFORNIA

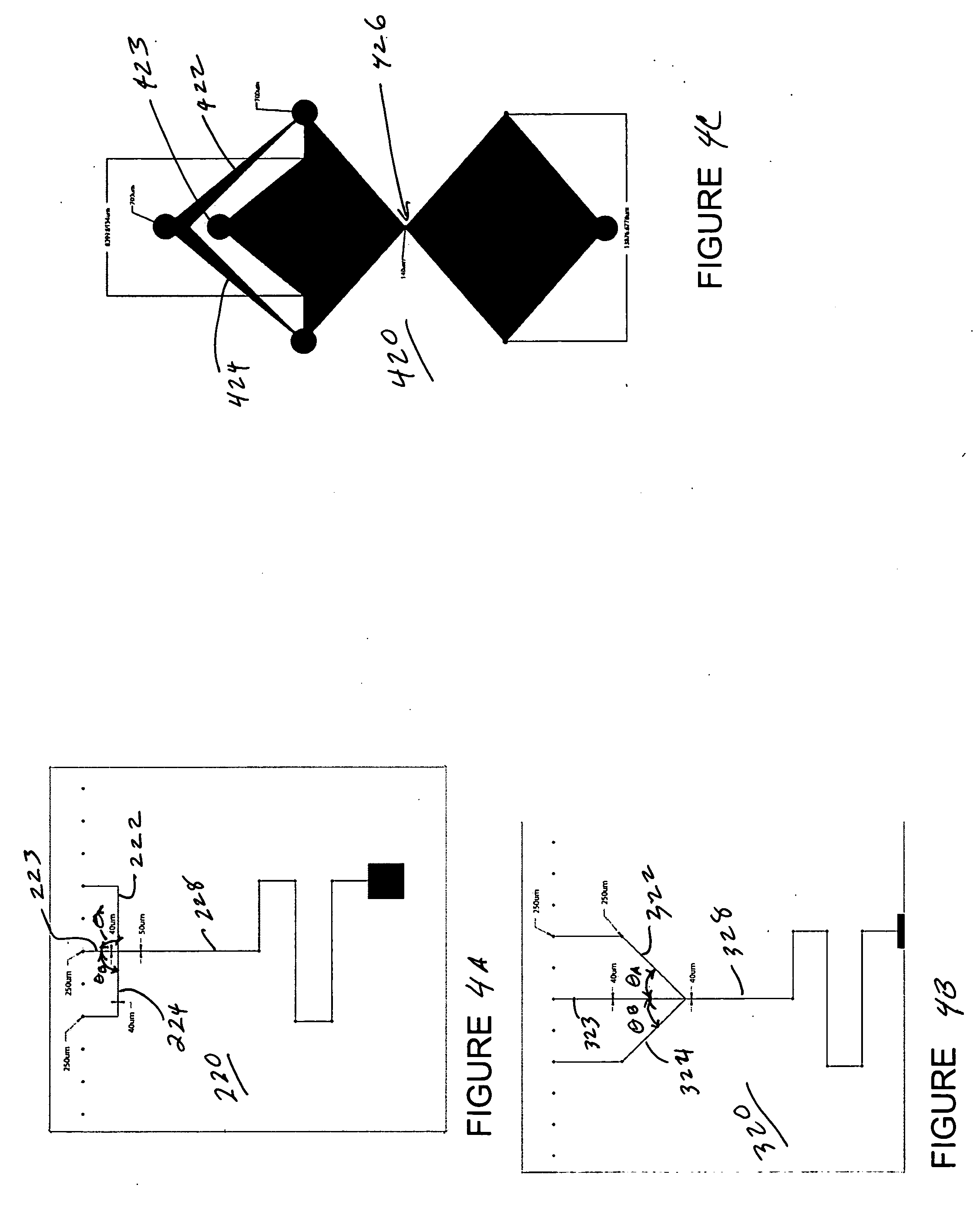

Droplet creation techniques

The present invention is generally related to systems and methods for producing droplets. The droplets may contain varying species, e.g., for use as a library. In some cases, at least one droplet is used to create a plurality of droplets, using techniques such as flow-focusing techniques. In one set of embodiments, a plurality of droplets, containing varying species, can be divided to form a collection of droplets containing the various species therein. A collection of droplets, according to certain embodiments, may contain various subpopulations of droplets that all contain the same species therein. Such a collection of droplets may be used as a library in some cases, or may be used for other purposes.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

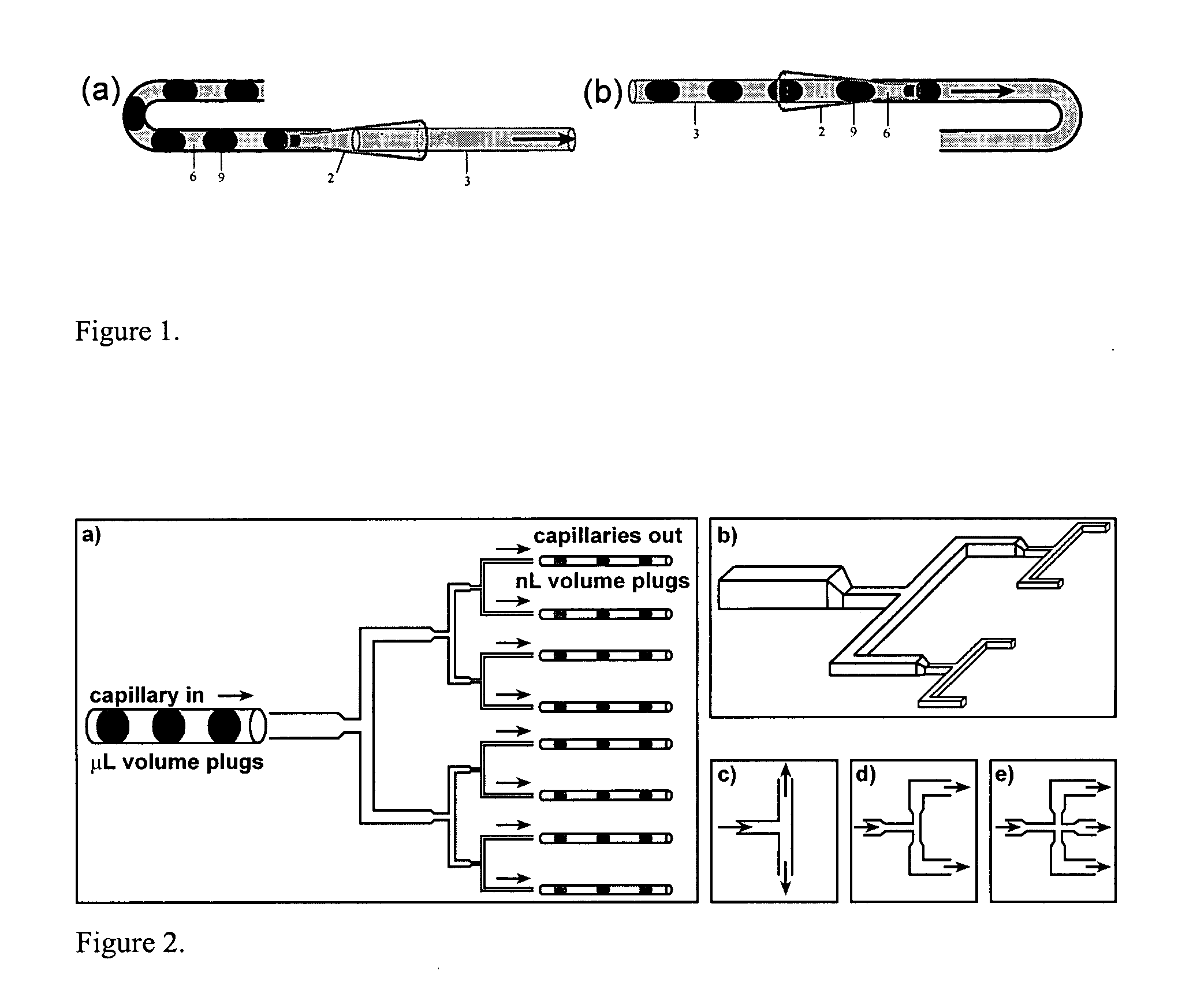

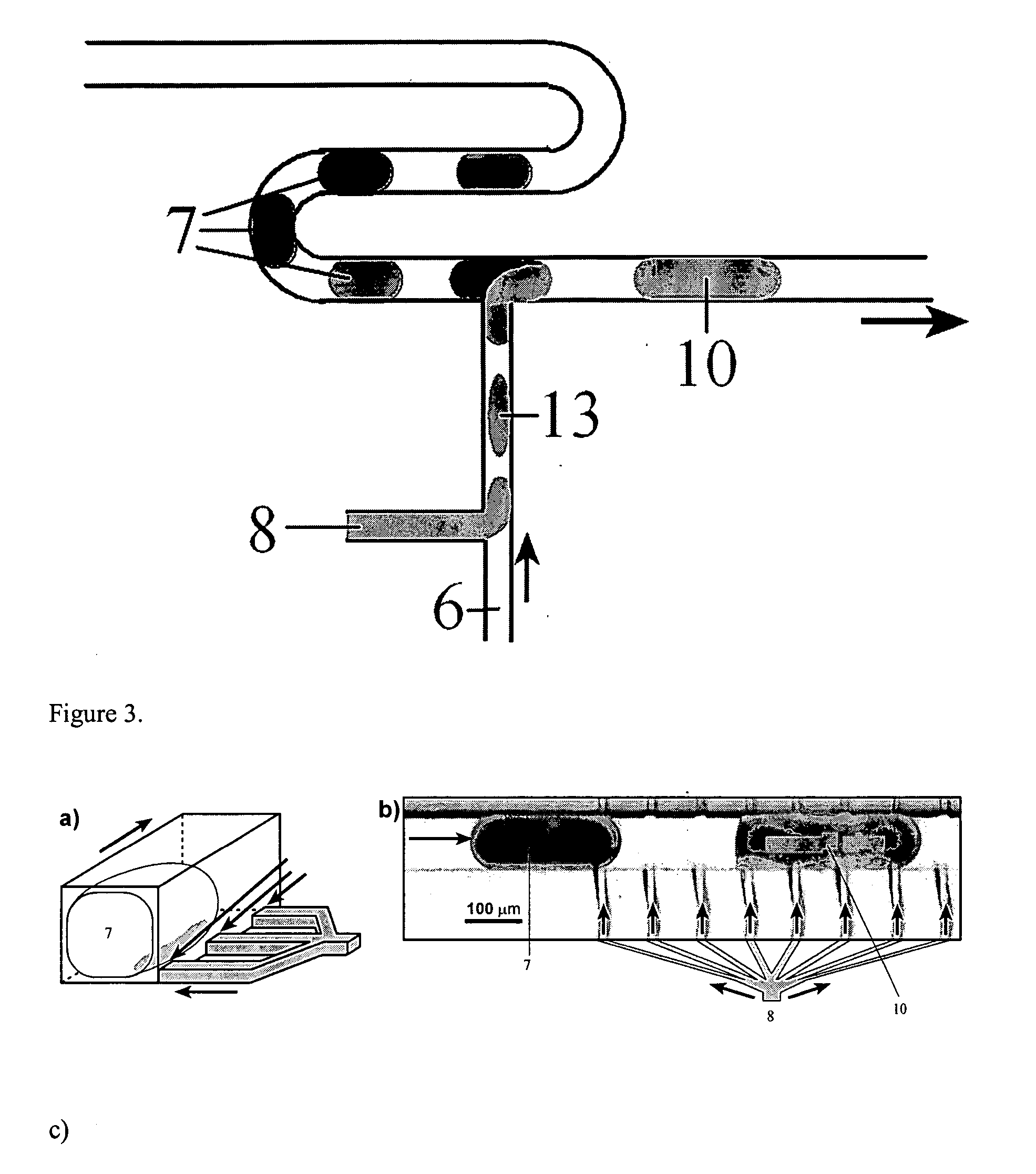

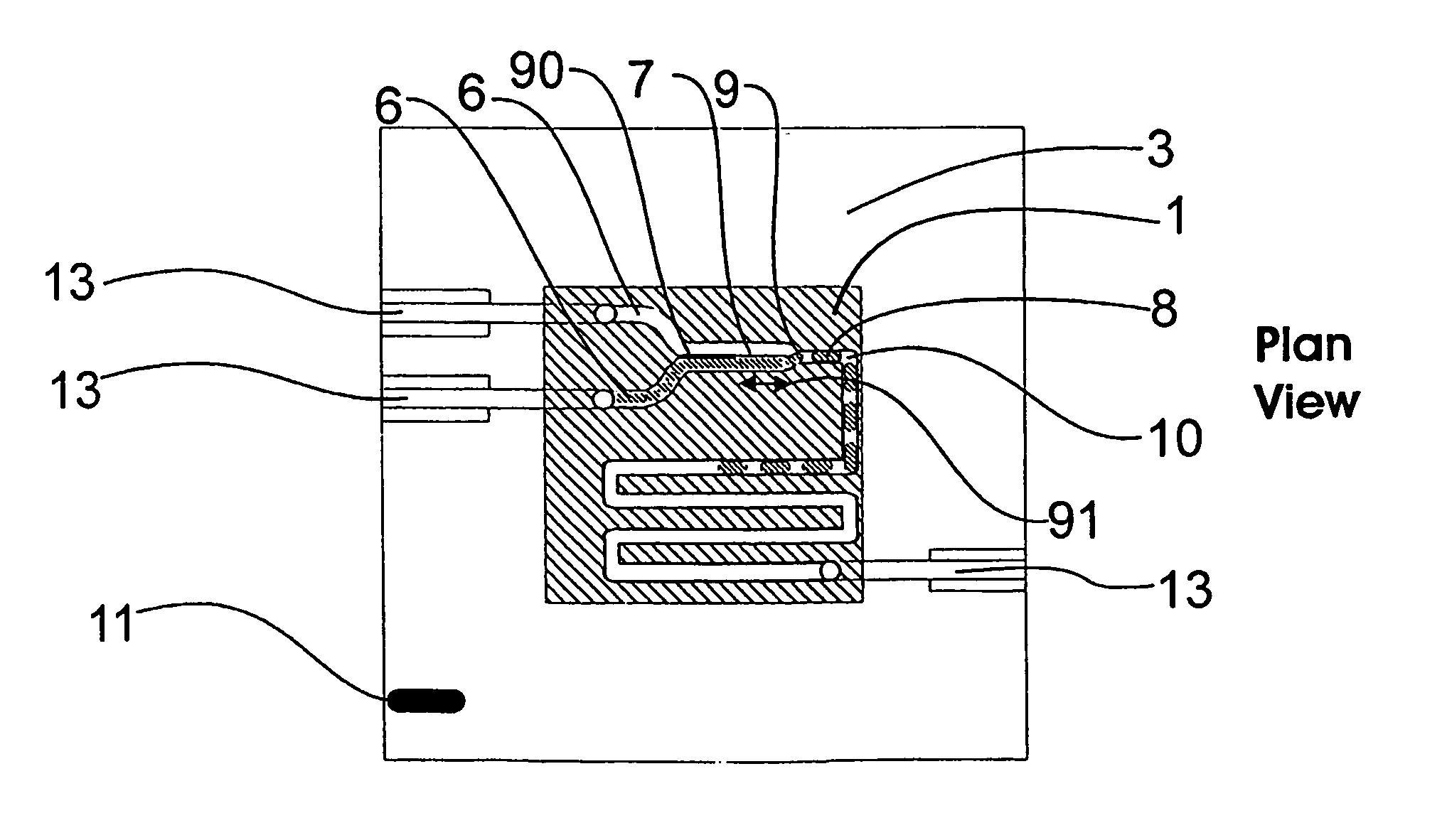

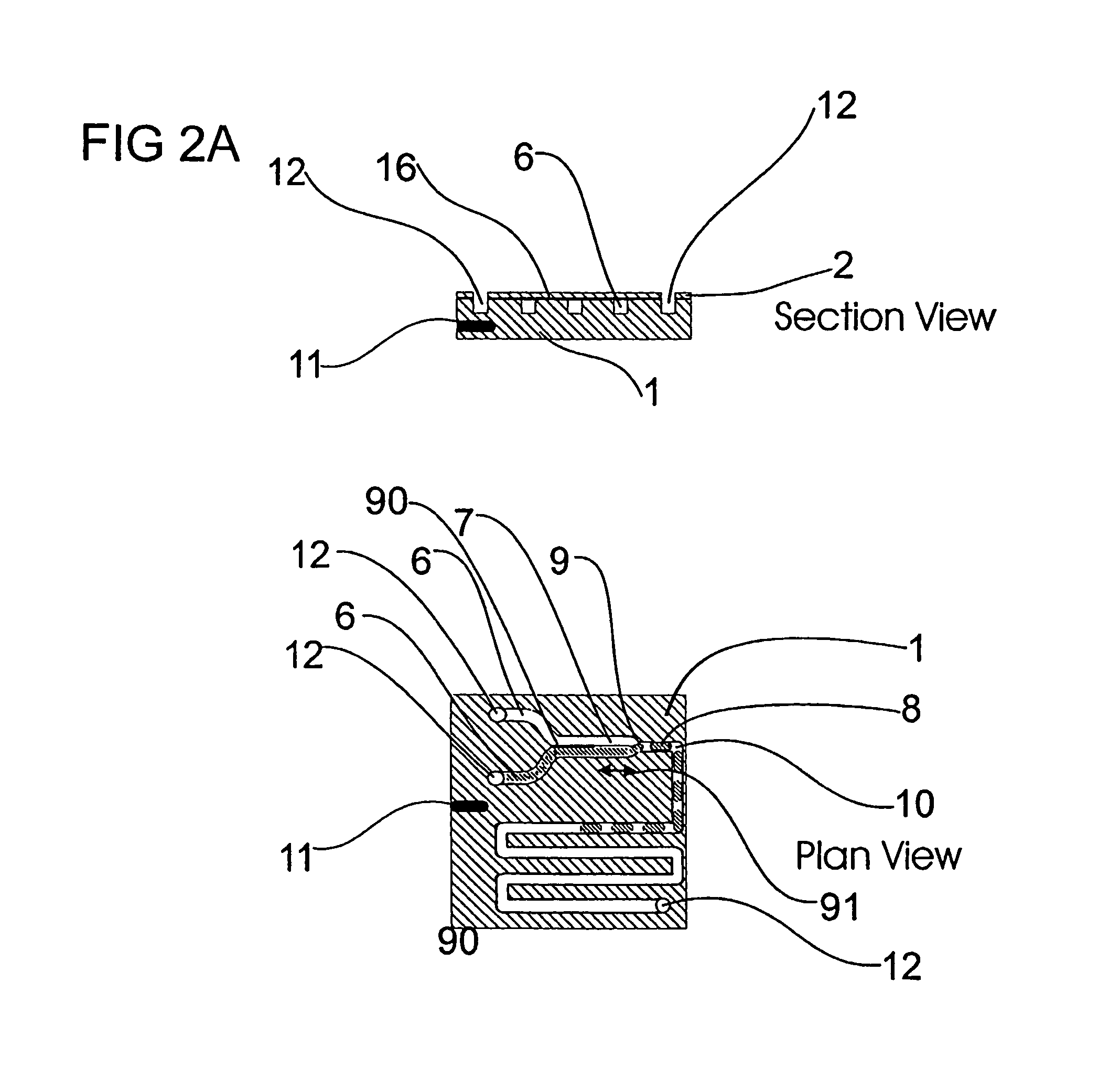

Microfluidic device and methods for construction and application

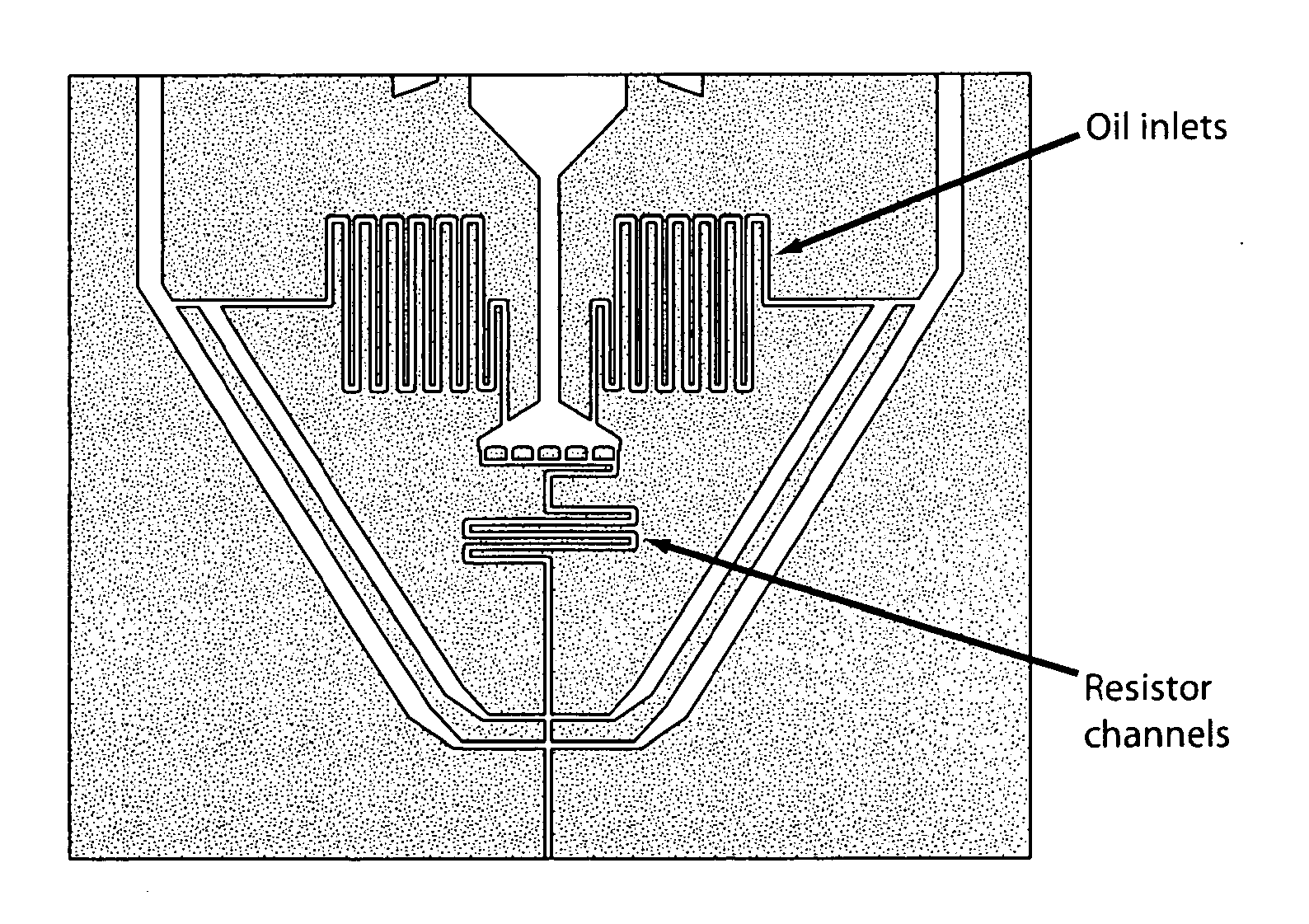

InactiveUS20060108012A1Considerable precisionEasy to controlMaterial nanotechnologyCircuit elementsEngineeringTwo fluid

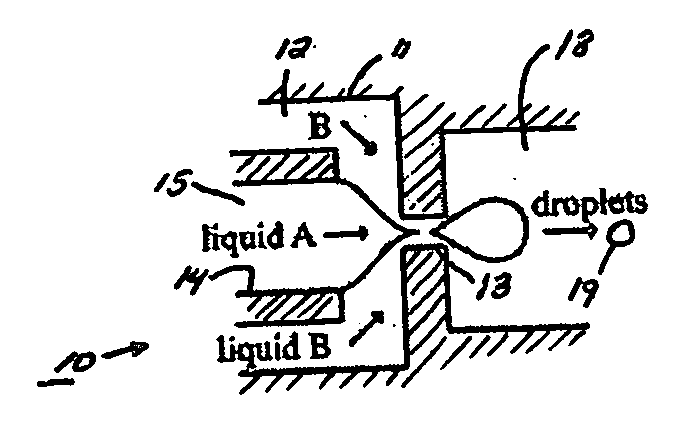

A microfluidic device comprises first and second inlet passages (13) for respective immiscible fluids, these inlet passages merging into a third passage (8) along which the two fluids flow under parallel laminar flow conditions, the third passage being formed with a constriction or other discontinuity (9) causing the two fluids to form into a flow of alternate segments.

Owner:Q CHIP

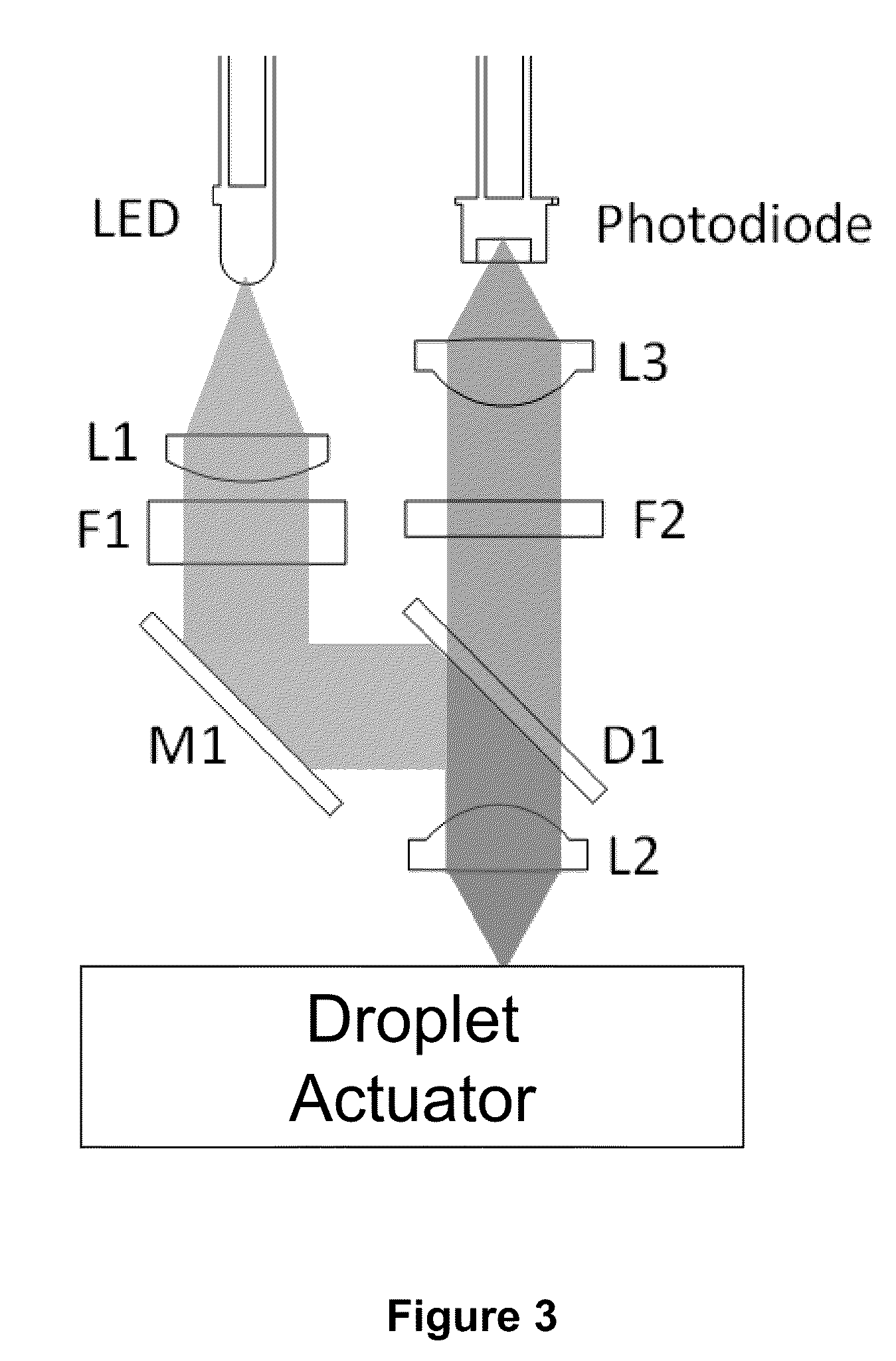

System for detection of spaced droplets

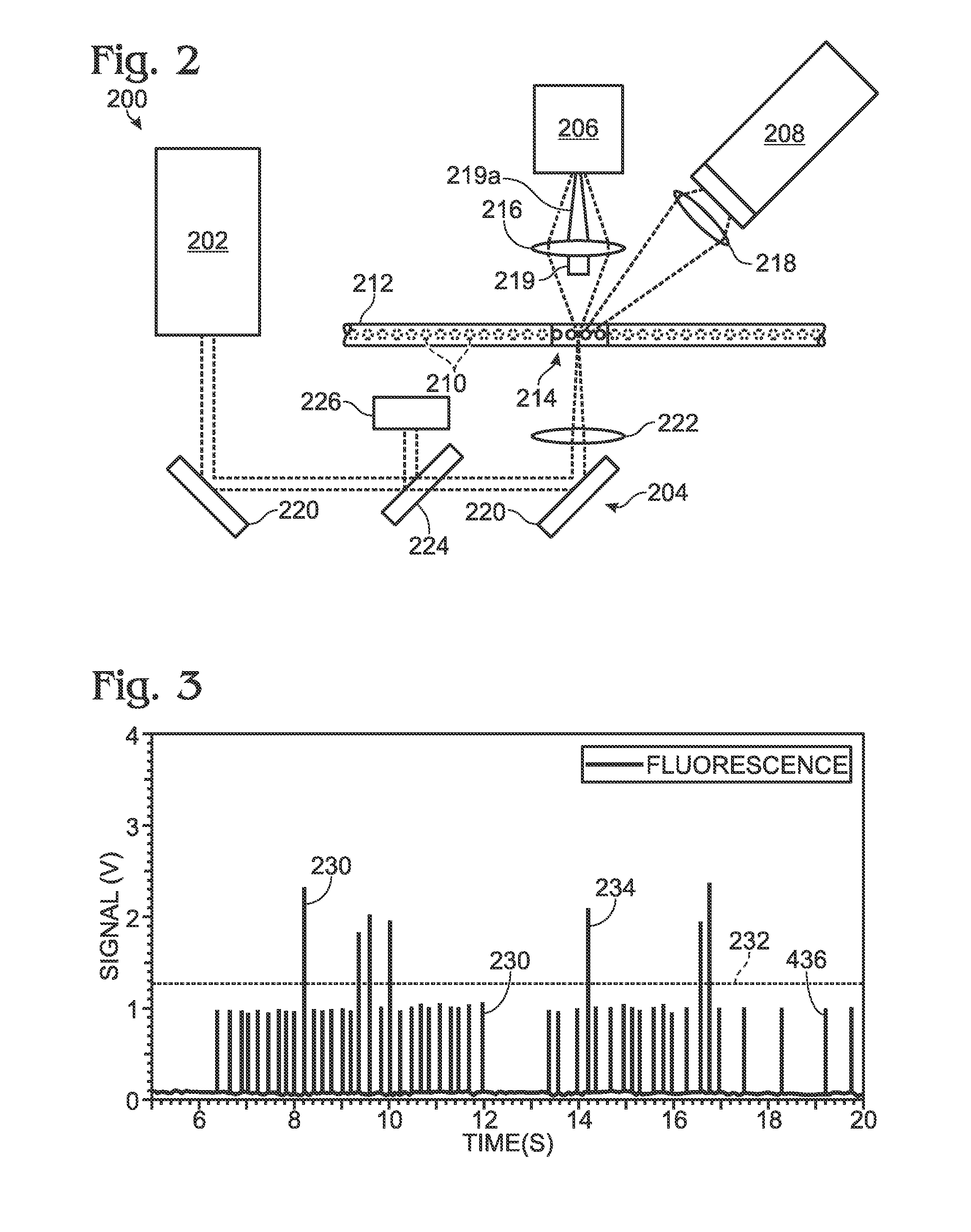

ActiveUS20110311978A1High-confidence resultLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsComputational physics

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Surface assisted fluid loading and droplet dispensing

InactiveUS8685344B2Easy to useFacilitates of propertyElectrostatic separatorsSludge treatmentMicro actuatorFluid loading

The present invention relates to surface assisted fluid loading and droplet dispensing on a droplet micro actuator. A droplet actuator is provided and includes one or more electrodes configured for conducting one or more droplet operations on a droplet operations surface of the substrate. The droplet actuator further includes a wettable surface defining a path from a fluid reservoir into a locus which is sufficiently near to one or more of the electrodes that activation of the one or more electrodes results in a droplet operation. Methods and systems are also provided.

Owner:ADVANCED LIQUID LOGIC

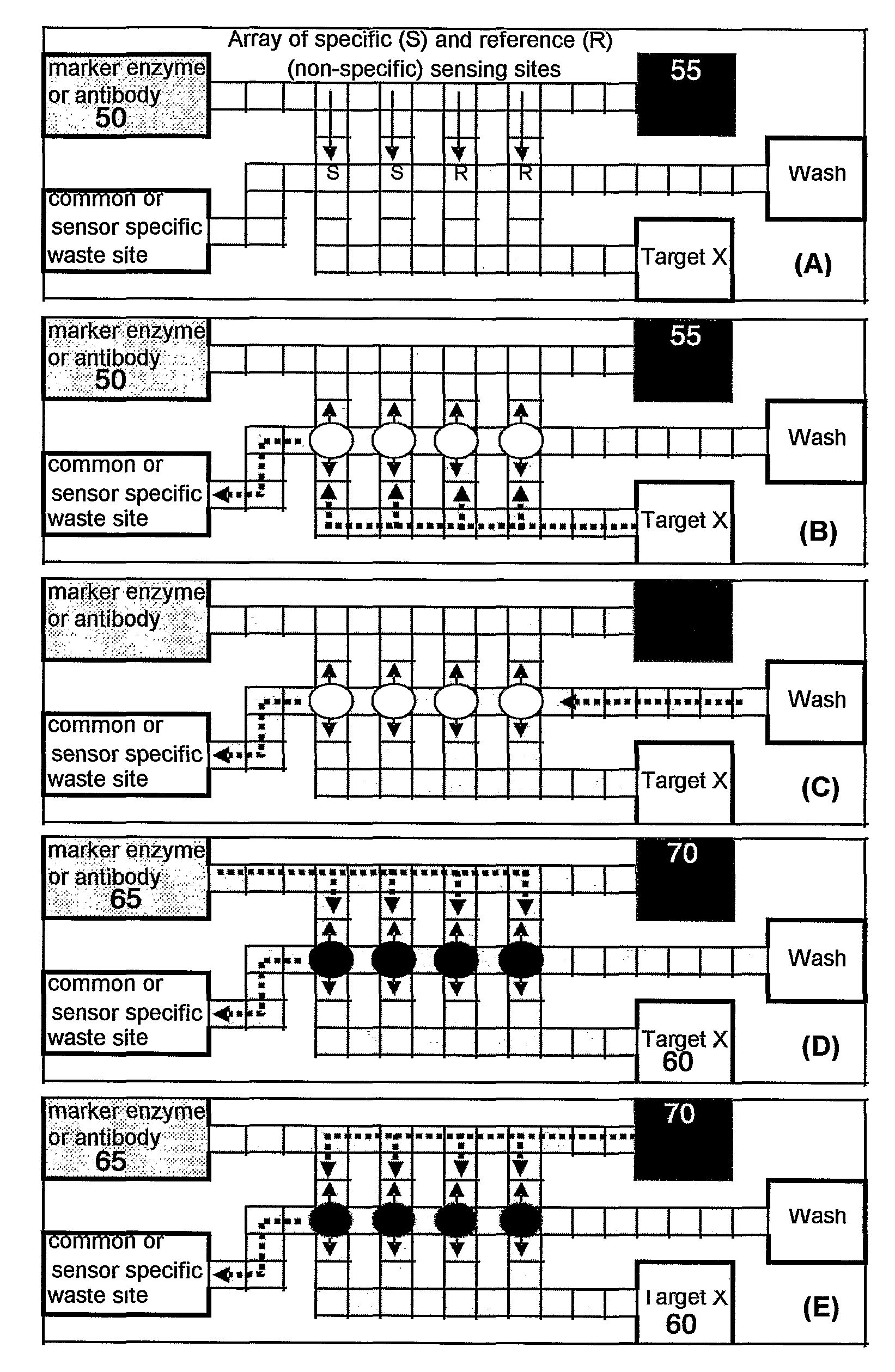

Biosensor Detection By Means Of Droplet Driving, Agitation, and Evaporation

InactiveUS20090042319A1More dataLow costSamplingTransportation and packagingSignal-to-noise ratio (imaging)Analyte

Methods of improving microfluidic assays are disclosed. Assays can be improved (better signal to noise ratio) by using sessile drop evaporation as an analyte concentration step (enhanced signal) and repeated passes of wash droplets as a means to reduce non-specific binding (noise reduction). In addition multiple massively parallel analyses improve the statistical precision of the analyses.

Owner:ADVANCED LIQUID LOGIC

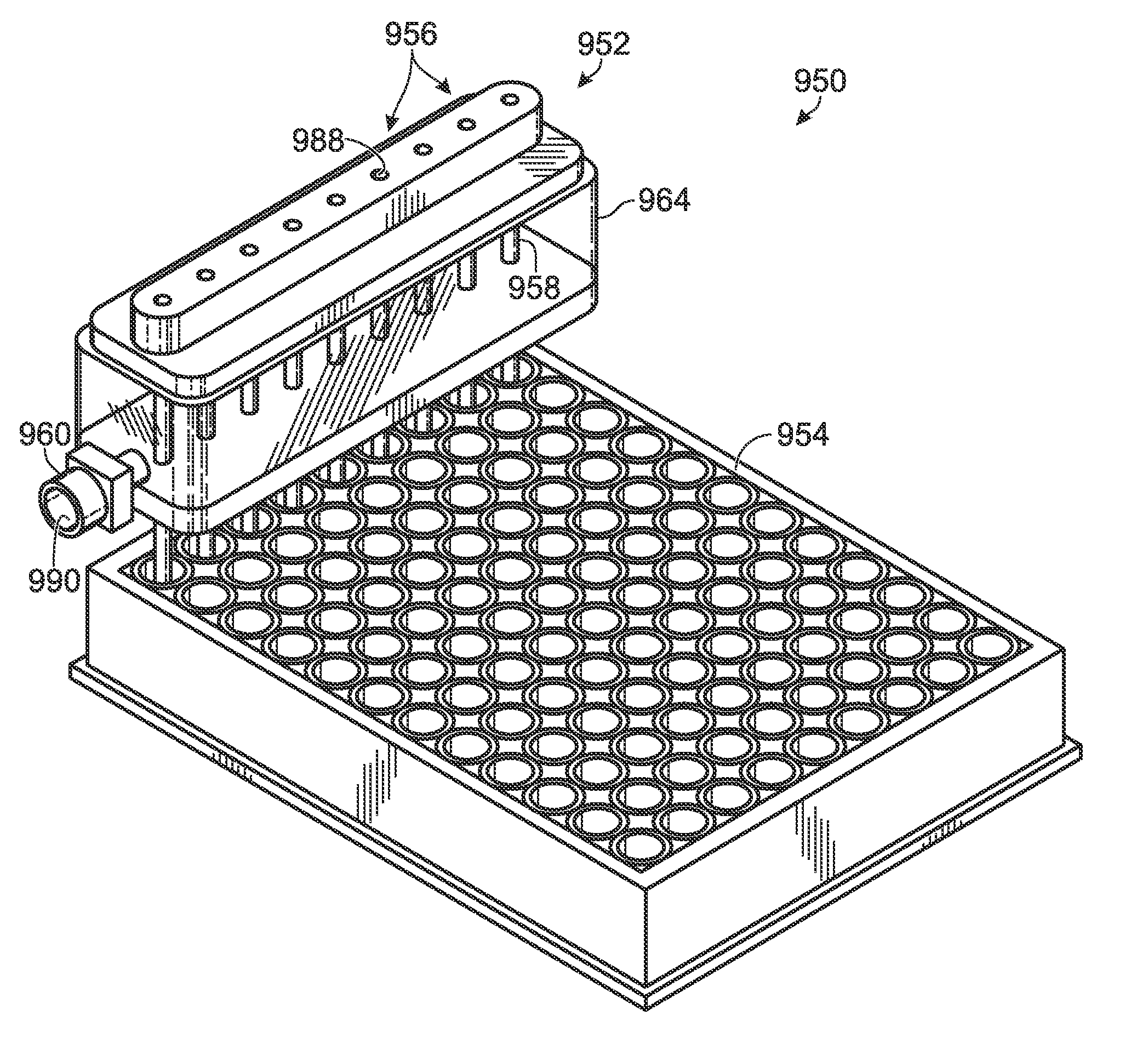

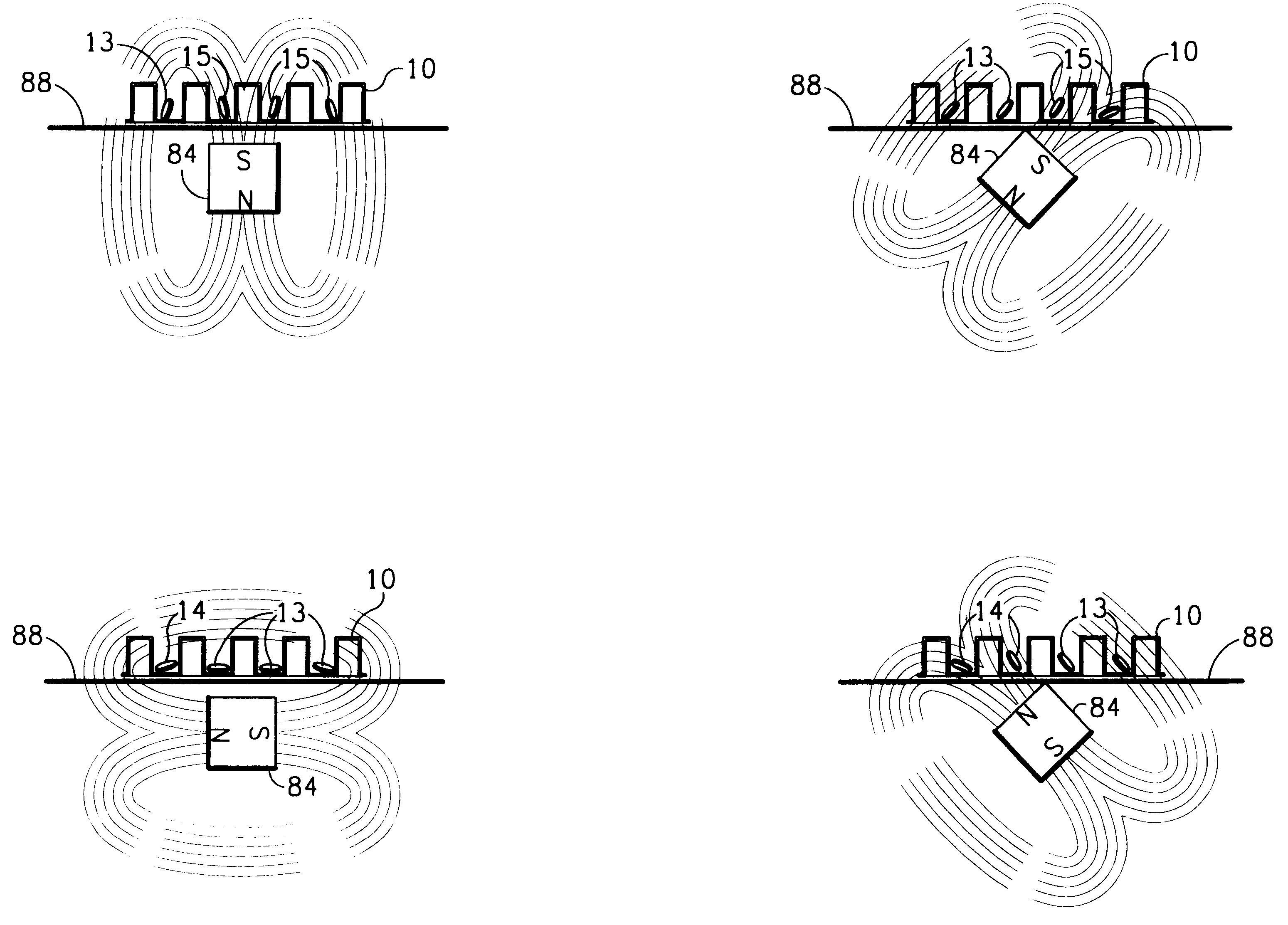

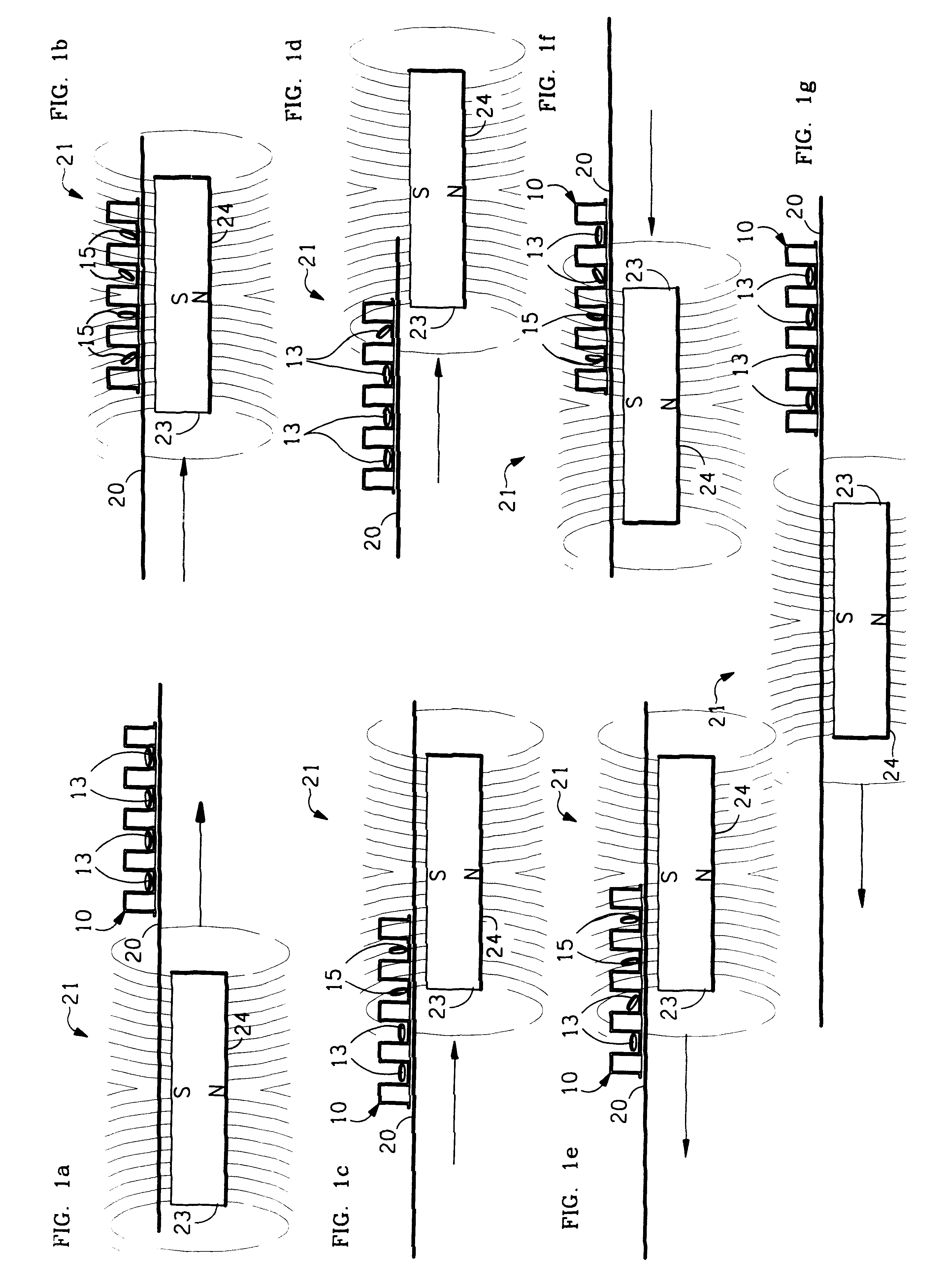

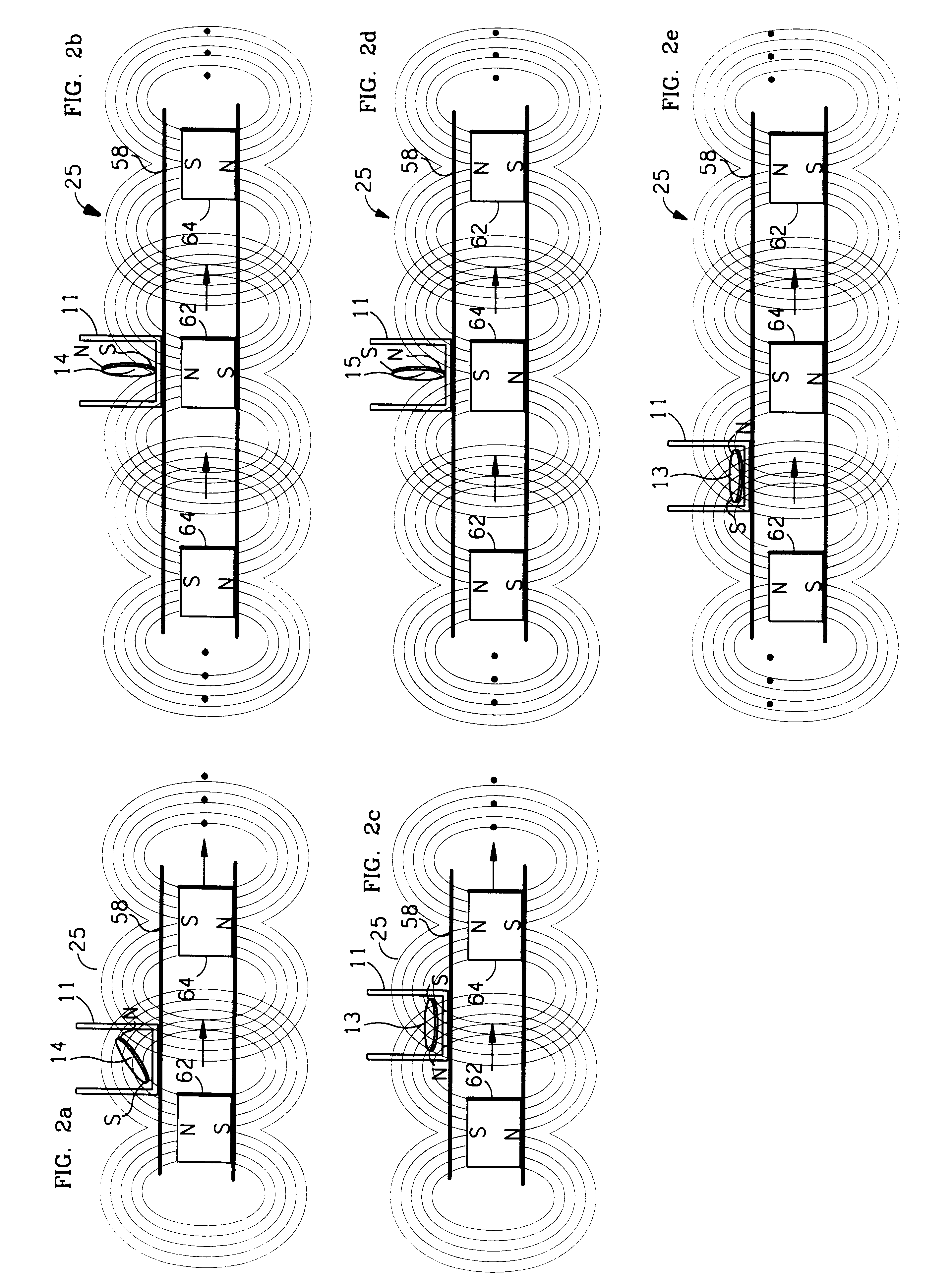

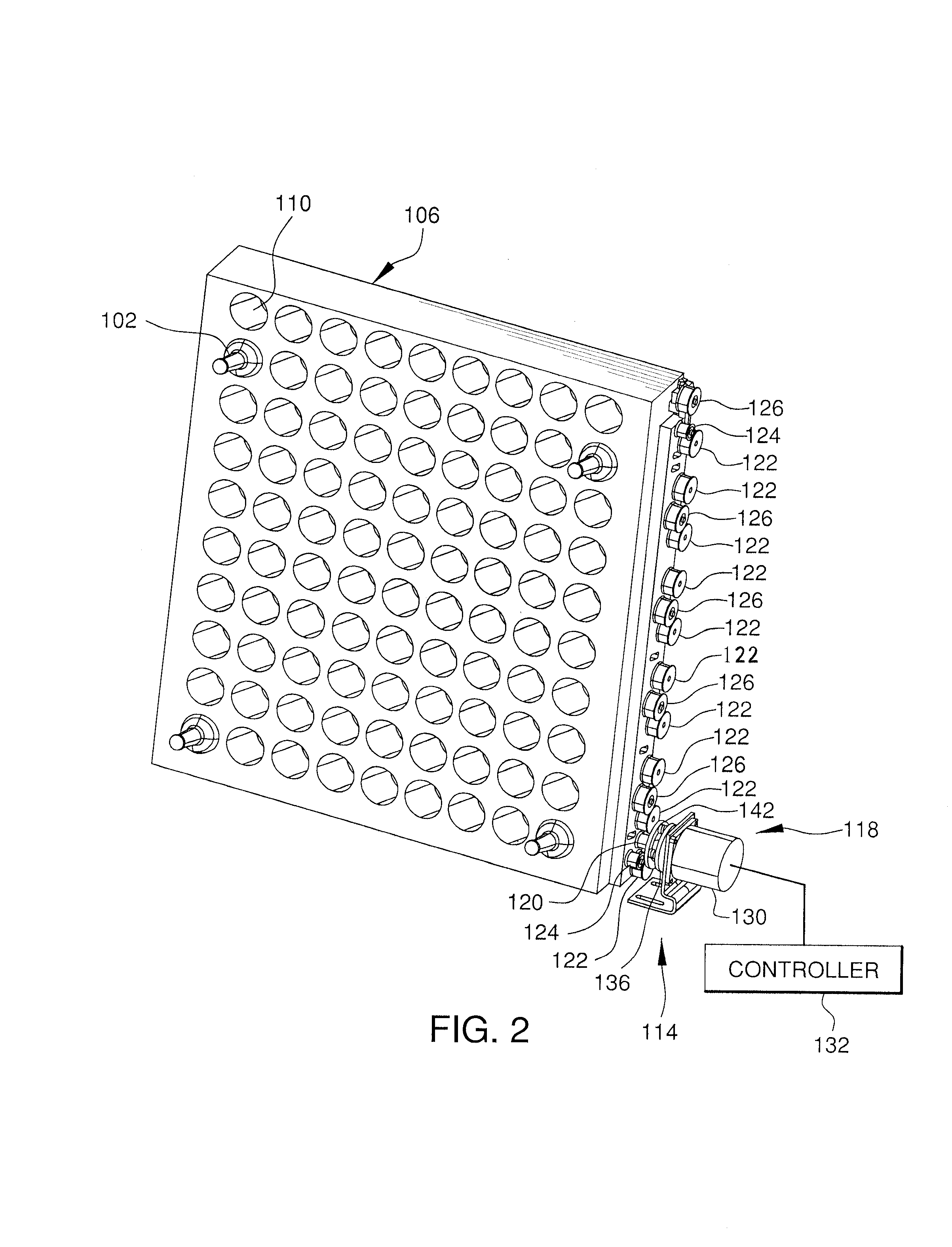

Magnetic tumble stirring method, devices and machines for mixing in vessels

InactiveUS6176609B1Corrosion resistanceGreat magnetic couplingBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic tension forceMicrowell Plate

The invention provides a simple method, device and several machines for simultaneously stirring thousands of vessels or wells of microplates in a robust manner and with economy. This method uses the simple principle of magnetic stirrers aligning themselves to a vertical driving magnetic field placed beneath them and moving laterally or by moving the vessels over a stationary magnetic field or by spinning the drive magnets, or by using a modulating / reversing electromagnetic field to produce the moving effect. Each vessel contains a magnetic disc, bar, dowel or other shape (stirrers) which in it's magnetic attraction to the vertical driving magnetic field will cause it to move and align it's magnetic field as the opposite poles of the drive magnet and the stirrer attract each other. The attraction of the stirrers to the vertical driving magnetic field causes the stirrers to stand on end and tumble as the stir devices try to align to the opposite moving magnetic pole. The stirrers tumble because the walls of the vessels or friction with the vessel bottom prevents their lateral movement.

Owner:V & P SCI

Droplet-based cell culture and cell assays using digital microfluidics

ActiveUS20090203063A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAssay3D cell culture

We introduce a new method for implementing cell-based assays and long-term cell culture. The method is based on digital microfluidics (DMF) which is used to actuate nanoliter droplets of reagents and cells on a planar array of electrodes. DMF method is sutable for assaying and culturing both cells in suspension and cells grown on surface (adherent cells). This method is advantageous for cell culture and assays due to the automated manipulation of multiple reagents in addition to reduced reagent use and analysis time. No adverse effects of actuation by DMF were observed in assays for cell viability, proliferation, and biochemistry. These results suggest that DMF has great potential as a simple yet versatile analytical tool for implementing cell-based assays and cell culture on the microscale.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

Method of improving sensor detection of target molcules in a sample within a fluidic system

InactiveUS7919330B2More dataLow costSamplingTransportation and packagingAnalyteSignal-to-noise ratio (imaging)

Owner:ADVANCED LIQUID LOGIC

Compounder apparatus

A containment assembly for enclosing a medication vial may comprise a first housing portion or interface portion having a proximal end and a distal end. The interface portion may include a housing wall which defines a channel spanning from the proximal end to the distal end. The channel may be open at the proximal and distal end. The containment assembly may further comprise at least one pierceable septum disposed at least at one of: on the proximal end of the channel and within the channel forming a barrier between the proximal end of the channel and distal end of the channel of the interface portion. The containment assembly may further comprise a variable-volume housing portion having a variable volume chamber. The variable-volume portion chamber of the variable-volume housing portion may be in fluid communication with the distal end of the channel.

Owner:DEKA PROD LLP

Compounder Apparatus

A containment assembly for enclosing a medication container may comprise a first housing portion or interface portion having a proximal end and a distal end. The interface portion may include a housing wall which defines a channel spanning from the proximal end to the distal end. The channel may be open at the proximal and distal end. The containment assembly may further comprise at least one pierceable septum disposed at least at one of: on the proximal end of the channel and within the channel forming a barrier between the proximal end of the channel and distal end of the channel of the interface portion. The containment assembly may further comprise a variable-volume housing portion having a variable volume chamber. The variable-volume portion chamber of the variable-volume housing portion may be in fluid communication with the distal end of the channel.

Owner:DEKA PROD LLP

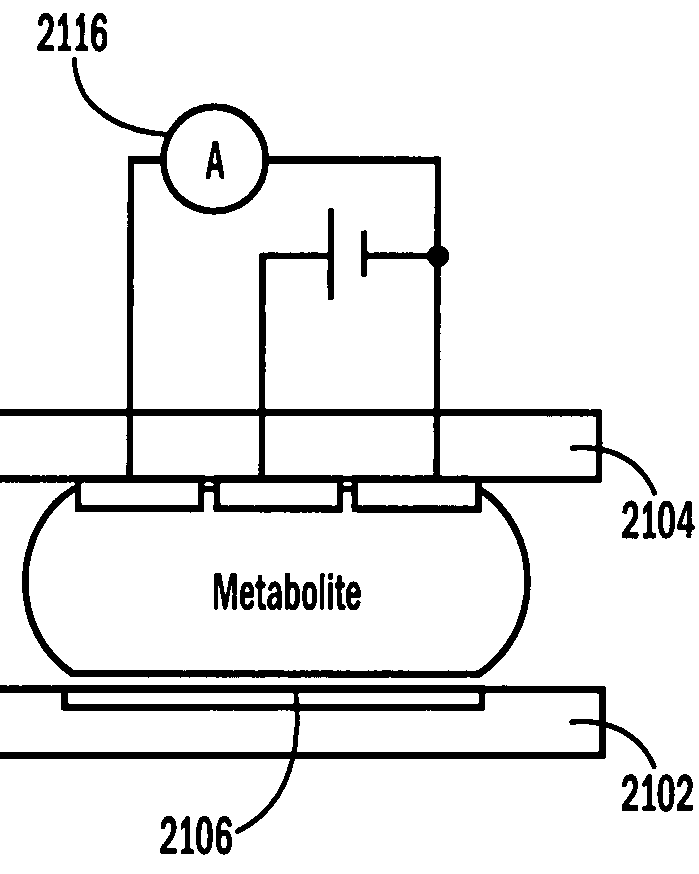

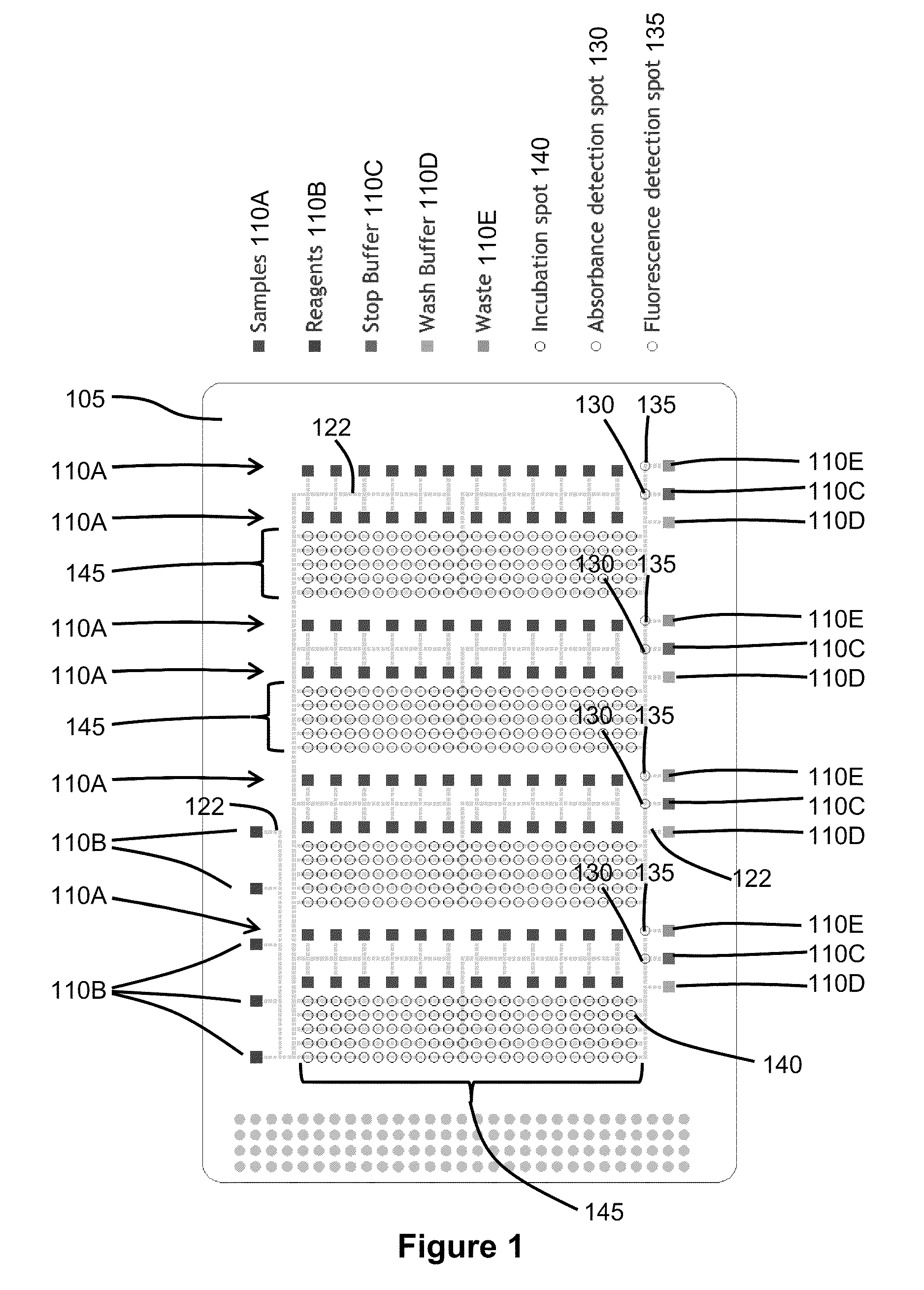

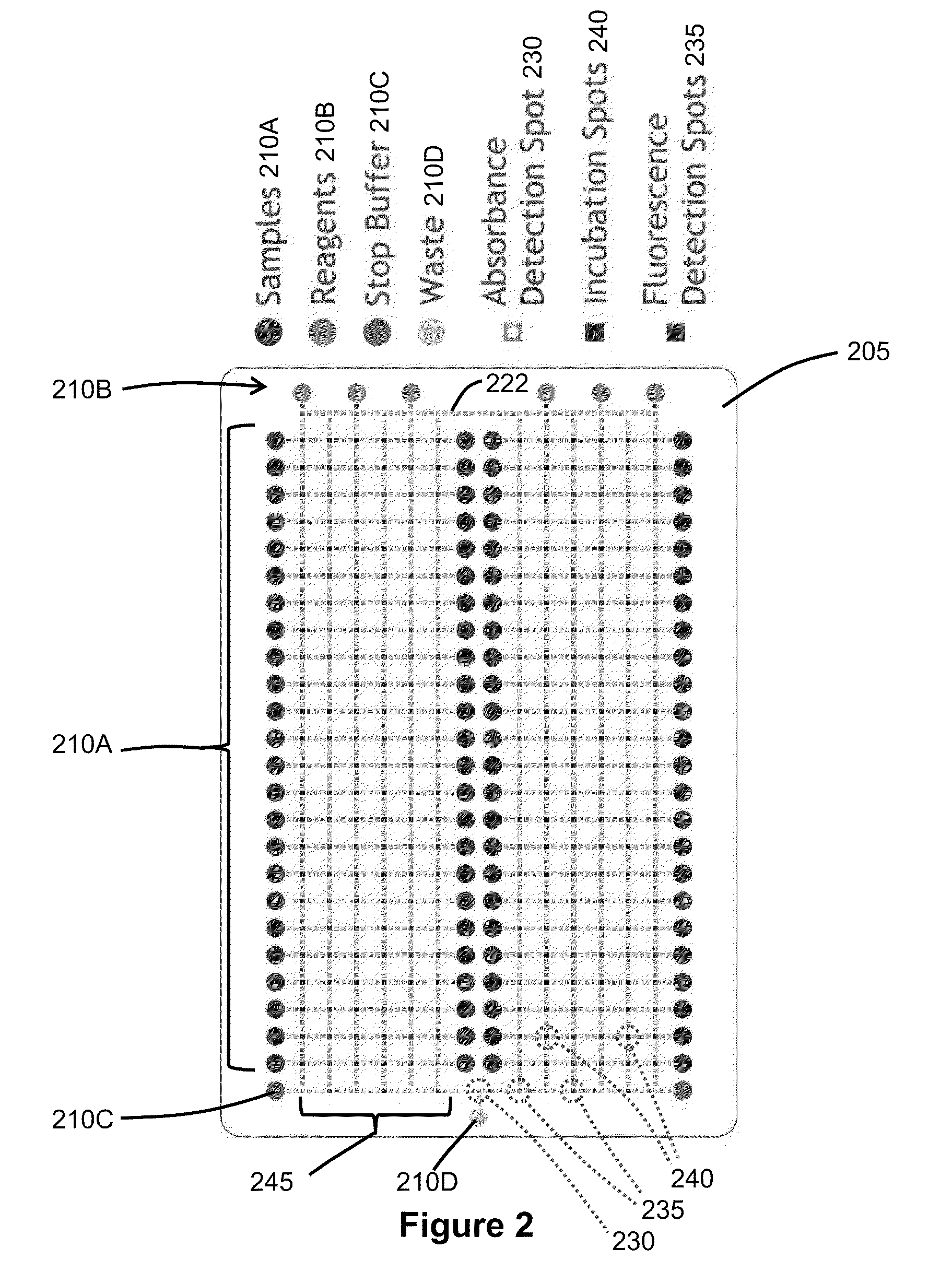

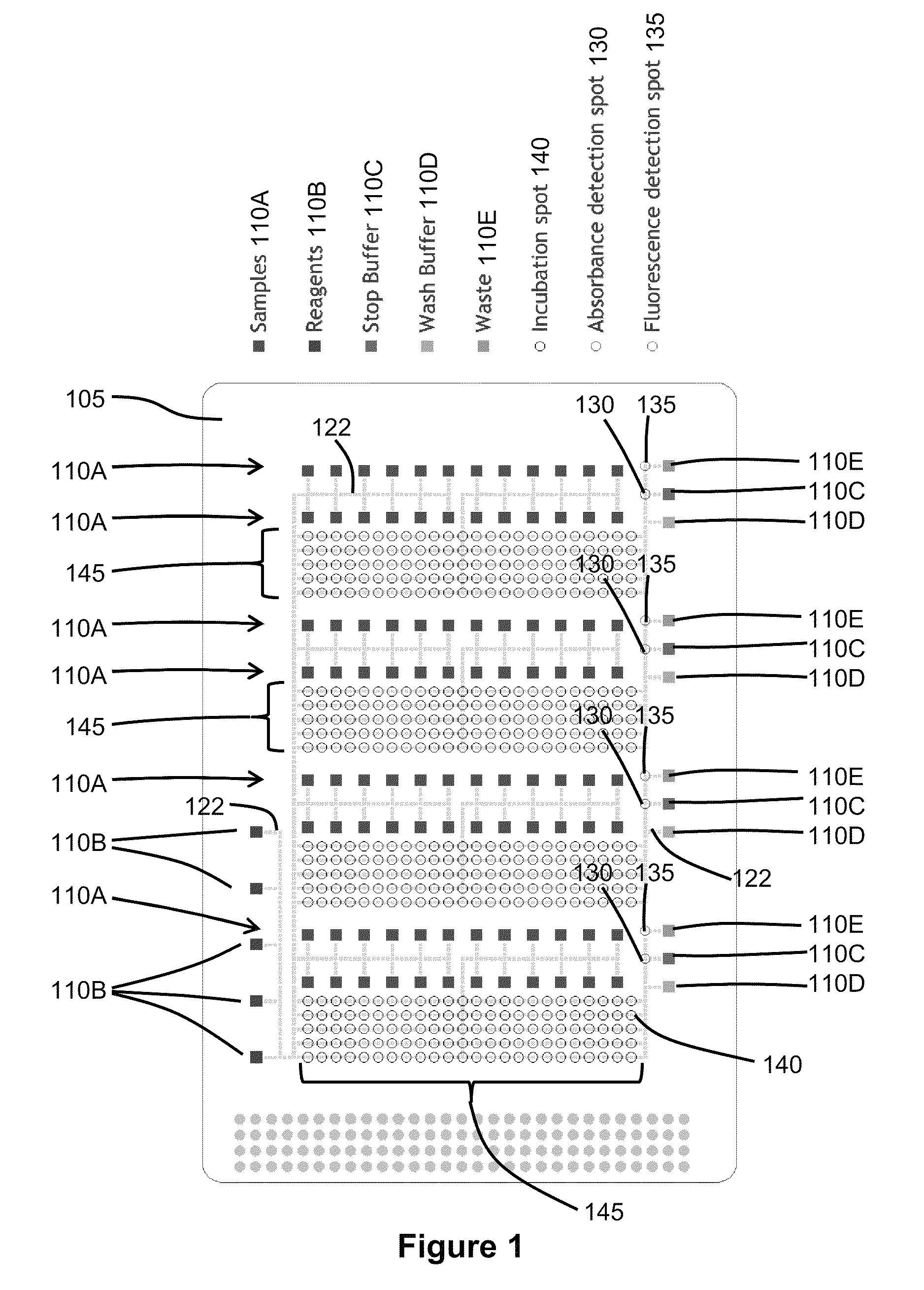

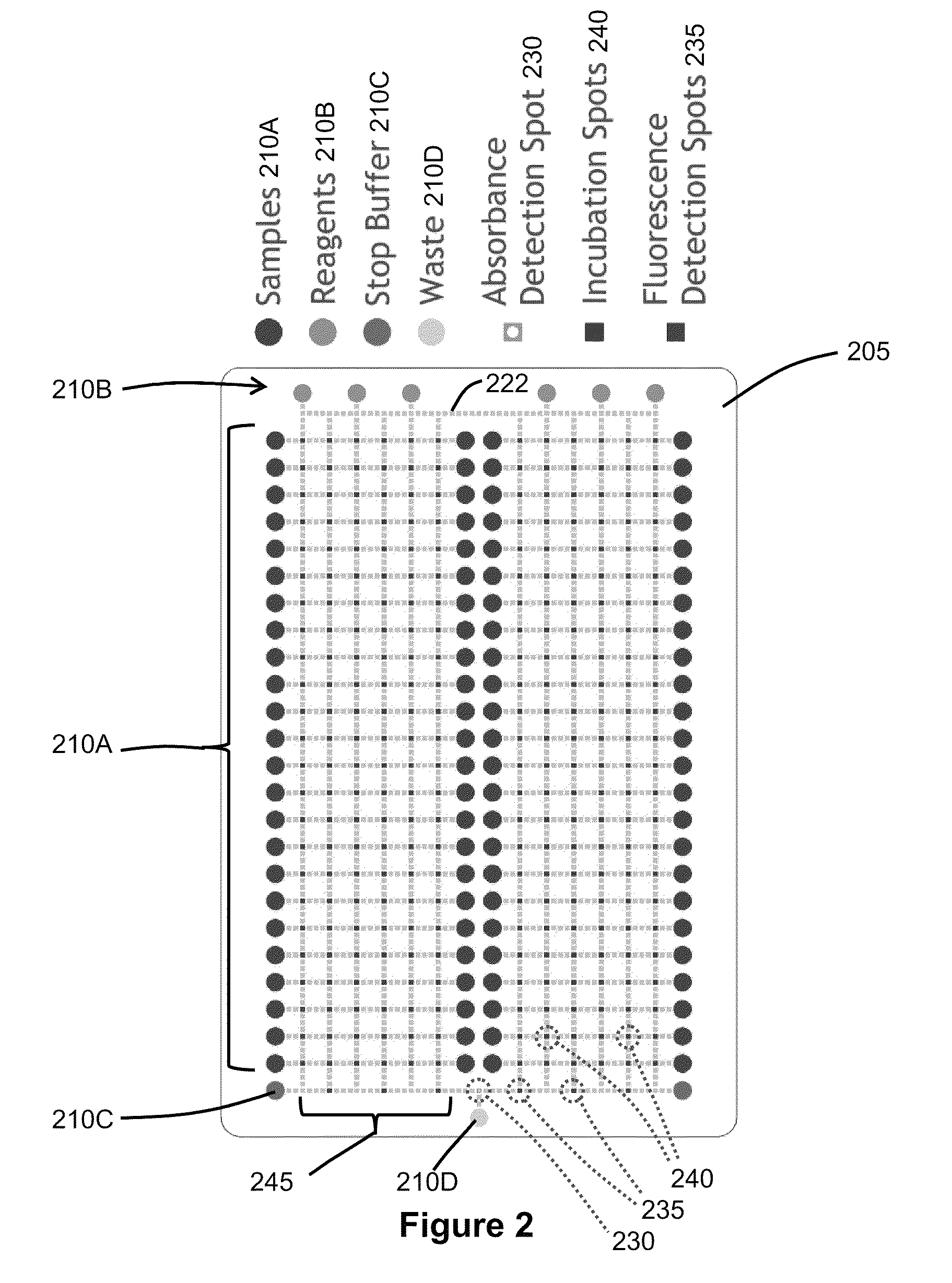

Enzyme Assays for a Droplet Actuator

ActiveUS20100041086A1Easy to useFacilitates of propertyTransportation and packagingMicrobiological testing/measurementEnzyme assayActuator

The invention relates to a microfluidic platform and methods of using the platform for conducting enzyme assays using a droplet actuator. The enzyme assays of the invention are useful for, among other things, identifying and / or characterizing disorders resulting from conditions in which enzymes are defective or are produced in inappropriate amounts. Enzyme assays of the invention may, for example, be used to detect altered activity of a particular enzyme in a sample, which may serve as an indicator of a particular disease. Altered activity may, for example, be caused by conditions which result in the increased or reduced production of a certain enzyme or its substrate and / or conditions which result in defective enzymes and / or substrates exhibiting increased or decreased effectiveness relative to corresponding normal enzymes and / or substrates.

Owner:ADVANCED LIQUID LOGIC

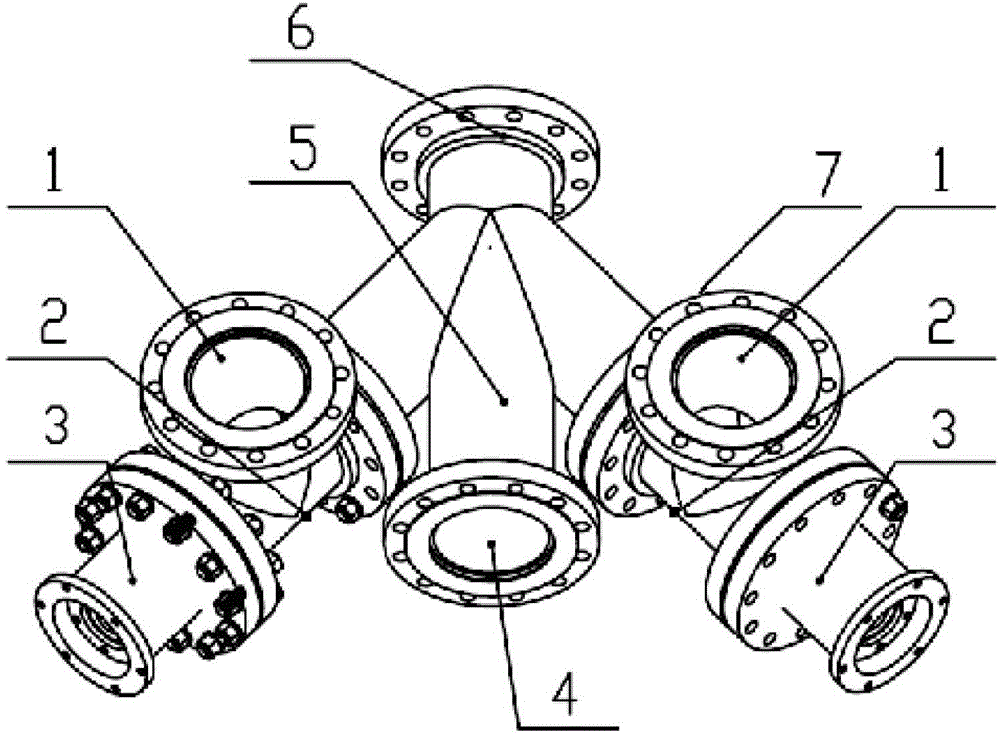

Solid-liquid mixing device

The invention provides a solid-liquid mixing device which is used for mixing a fracturing fluid. The solid-liquid mixing device contains a low-temperature and pressure resistant enclosed mixing container, a solid introducing port which is arranged on the mixing container and used for introducing solid particles of the fracturing fluid into an inner chamber of the mixing container, a liquid introducing port which is disposed on the mixing container and used for introducing a base solution of the fracturing fluid into the inner chamber, and a solid-liquid outlet which is arranged on the mixing container and used for exporting the fracturing fluid out of the inner chamber. According to the solid-liquid mixing device provided by the invention, by the adoption of the low-temperature and pressure resistant enclosed mixing container, the solid-liquid mixing device can meet mixing requirements for low temperature under pressure; and as the mixing container is respectively provided with the solid introducing port, the liquid introducing port and the solid-liquid outlet, the process of putting the solid particles and the base solution into the mixing container and the process of exporting the fracturing fluid out of the mixing container will not interfere with each other, and mixing of the fracturing fluid can be continuously carried out.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

Enzyme assays for a droplet actuator

ActiveUS8202686B2Easy to useFacilitates of propertyMicrobiological testing/measurementTransportation and packagingEnzyme assayActuator

The invention relates to a microfluidic platform and methods of using the platform for conducting enzyme assays using a droplet actuator. The enzyme assays of the invention are useful for, among other things, identifying and / or characterizing disorders resulting from conditions in which enzymes are defective or are produced in inappropriate amounts. Enzyme assays of the invention may, for example, be used to detect altered activity of a particular enzyme in a sample, which may serve as an indicator of a particular disease. Altered activity may, for example, be caused by conditions which result in the increased or reduced production of a certain enzyme or its substrate and / or conditions which result in defective enzymes and / or substrates exhibiting increased or decreased effectiveness relative to corresponding normal enzymes and / or substrates.

Owner:ADVANCED LIQUID LOGIC

System for stirring growth medium

InactiveUS7211430B2Enhanced growthImprove resultBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringRare-earth magnet

An improved system and method for stirring suspended solids in a liquid media to enhance sample growth and improve sample detection results. The system and method employs a sample vessel holder which adapted to receive at least one sample vessel which contains the solids and liquid media and a stirrer, such as a ferrous metal filled stirrer, and maintain the sample vessel in a position such that the longitudinal axis of the sample vessel extends at an angle substantially less than 90 degrees with respect to the horizontal, such as within the range of about 15 degrees to about 25 degrees with respect to the horizontal. The system and method further employs a magnet driver, adapted to move a magnet, such as a rare earth magnet, proximate to an outer surface of the sample vessel to permit the magnet to impose a magnetic influence on the stirrer to move the stirrer in the sample vessel. Specifically, the magnet driver is adapted to move and, specifically, rotate the magnet such that the magnetic influence moves the stirrer along a side wall of the sample vessel. The magnet driver is further adapted to move the magnet away from said outer surface of the sample vessel to allow gravity to move the stirrer toward the bottom of the sample vessel. This technique therefore provides a more gentle and controlled stirring of the suspended solution.

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com