Patents

Literature

362 results about "Reaction site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An injection site reaction is inflammation in or damage to the tissue surrounding where a drug was injected. There are two types of injection site reactions: a local allergic reaction called a flare reaction, and a more severe reaction characterized by damage to the tissue due to extravasation.

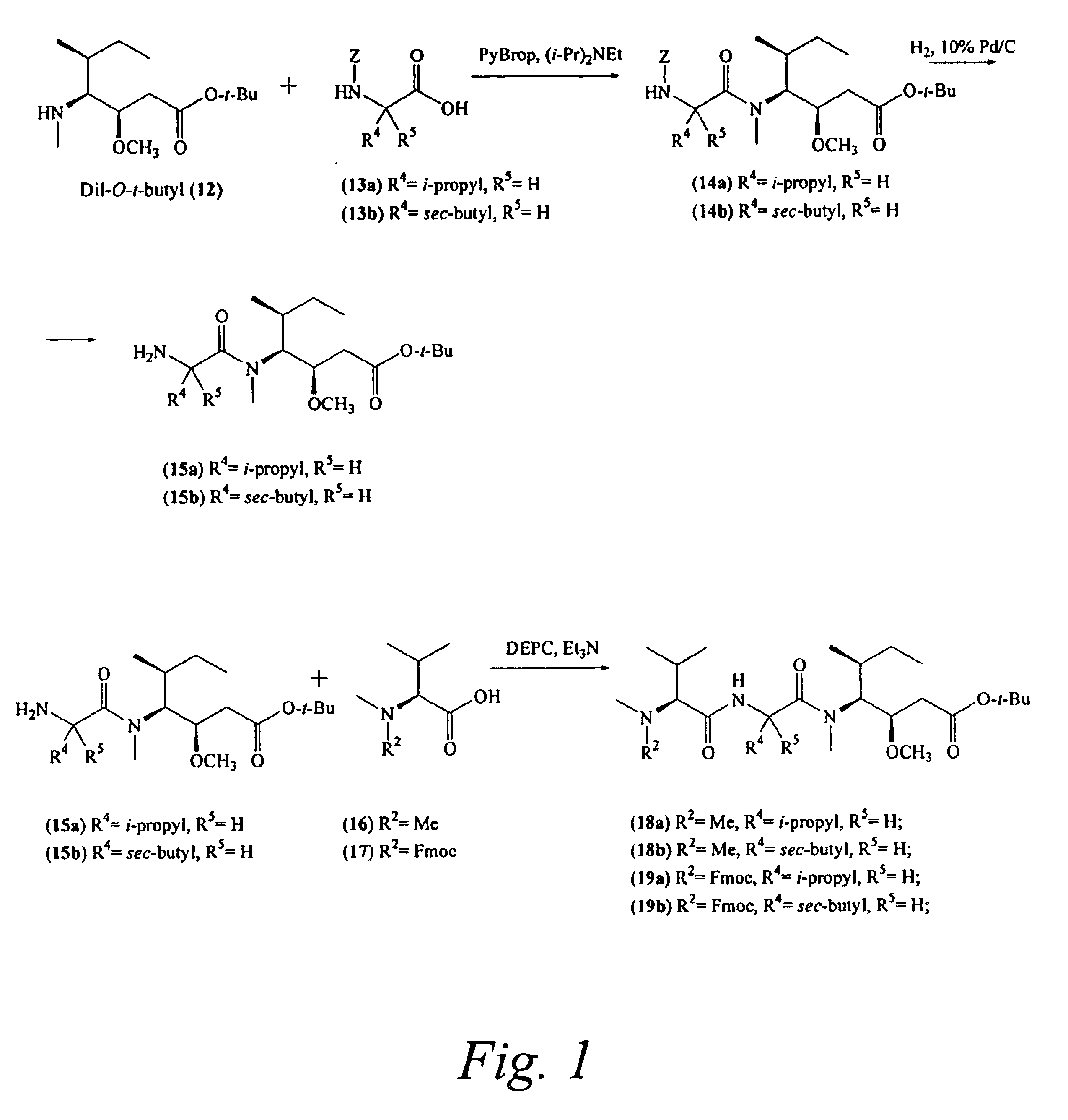

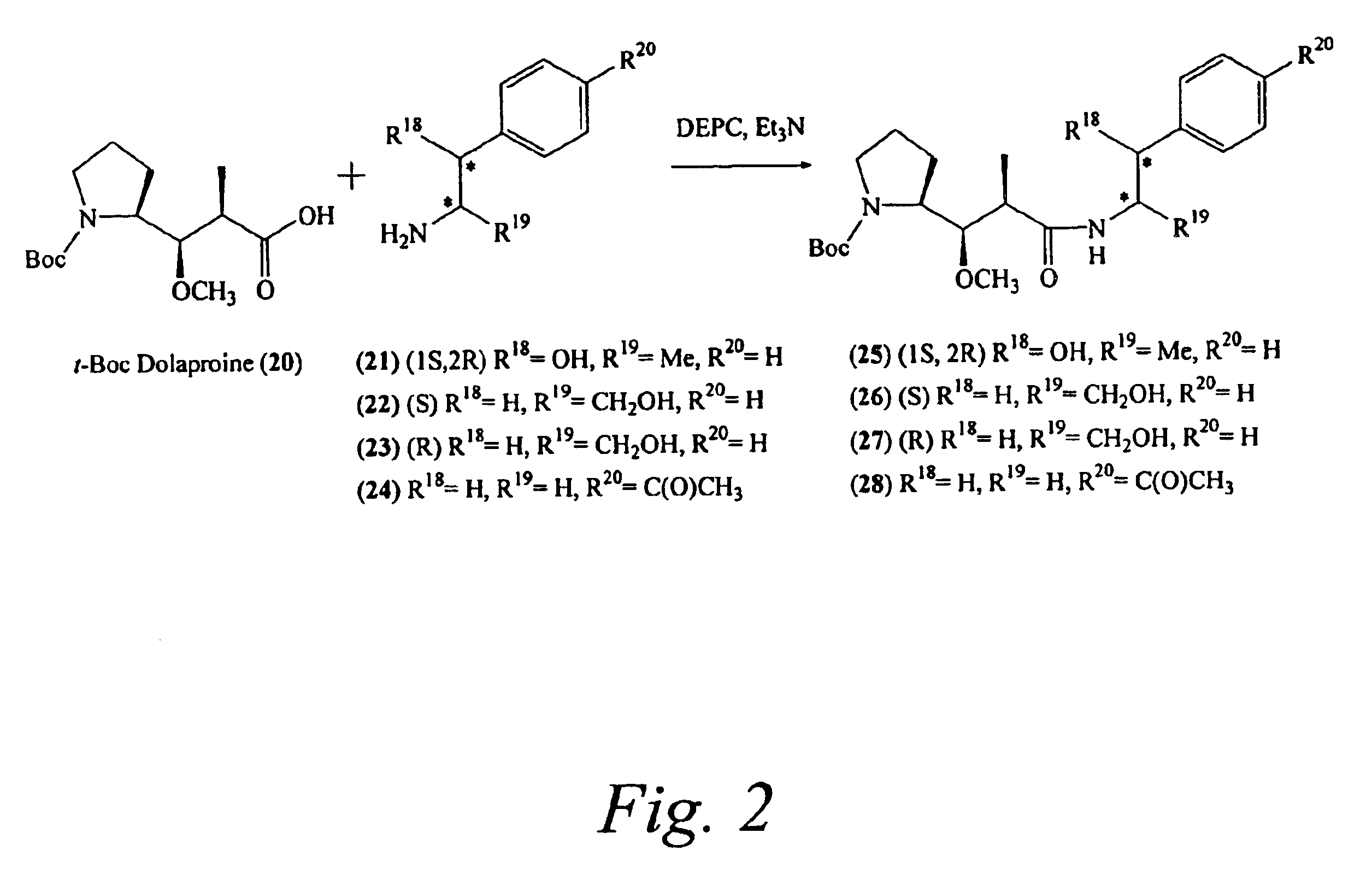

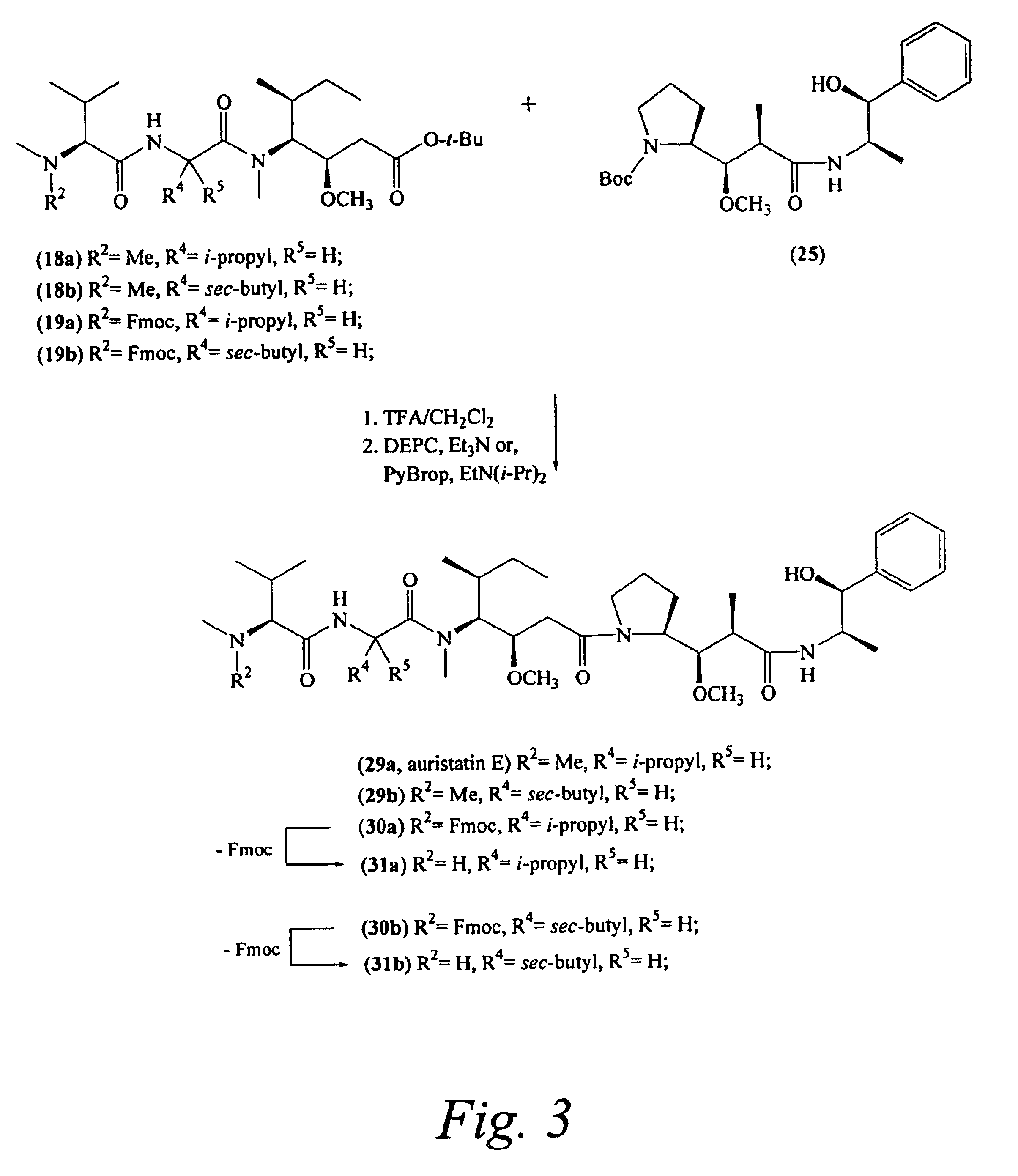

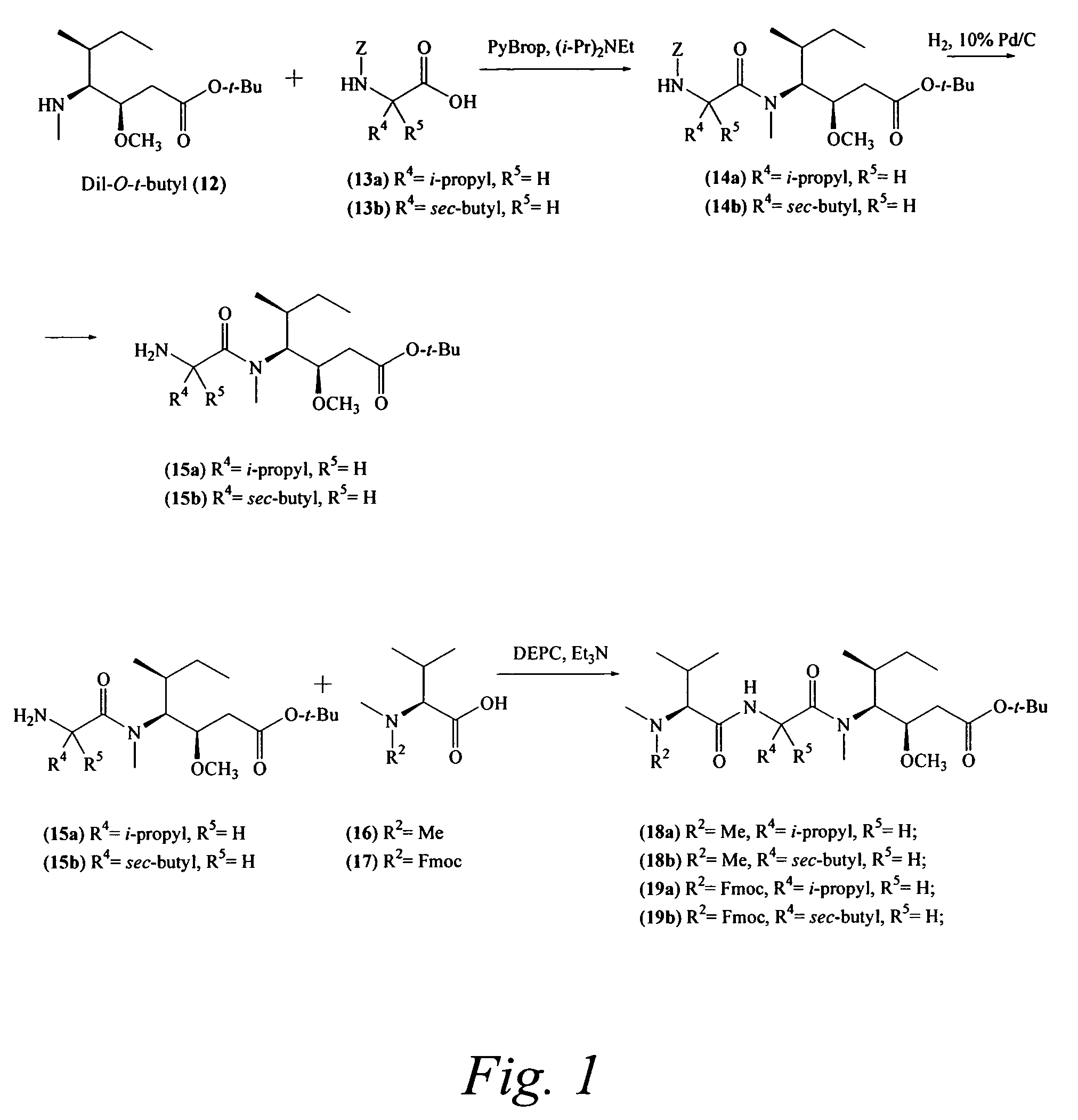

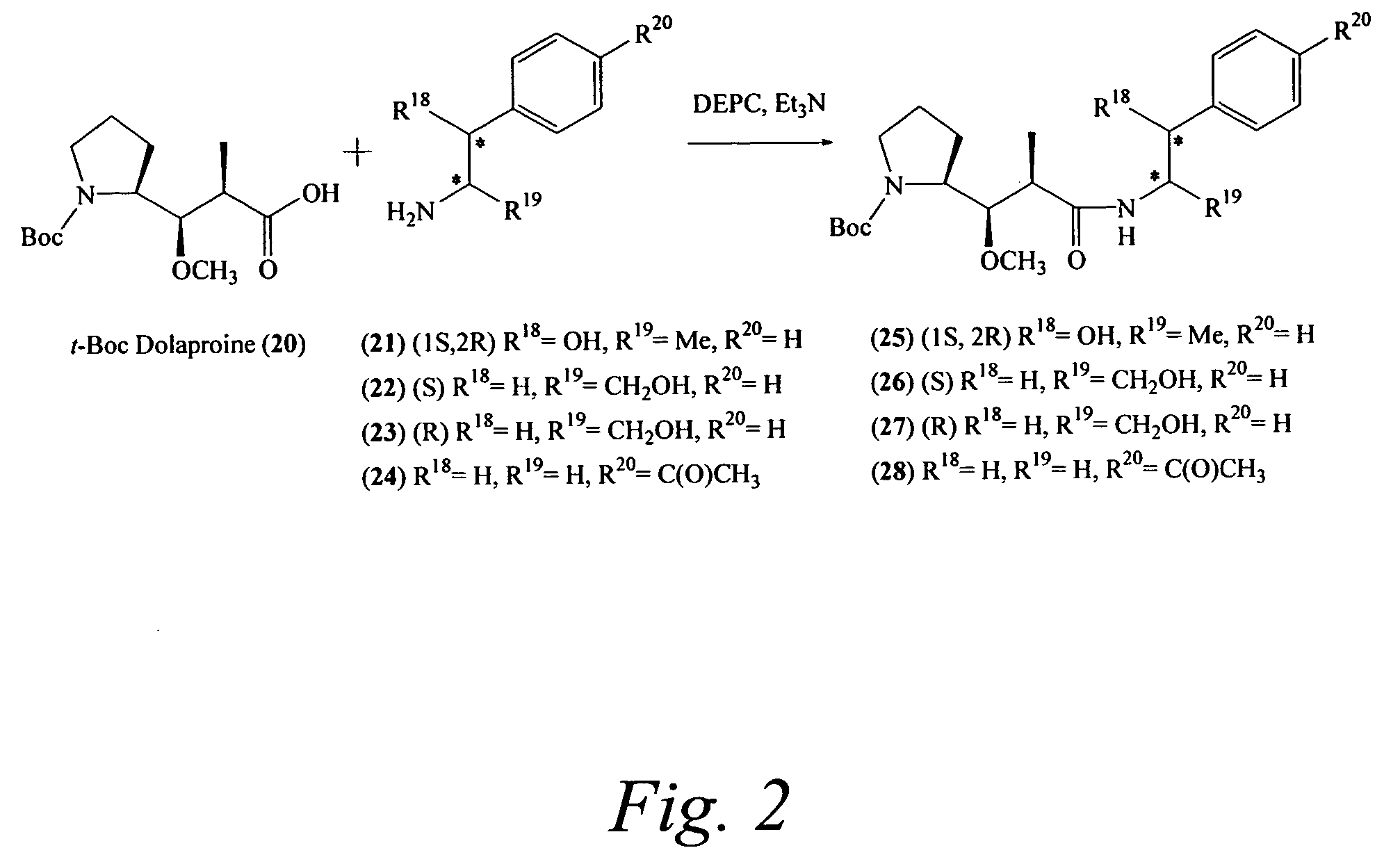

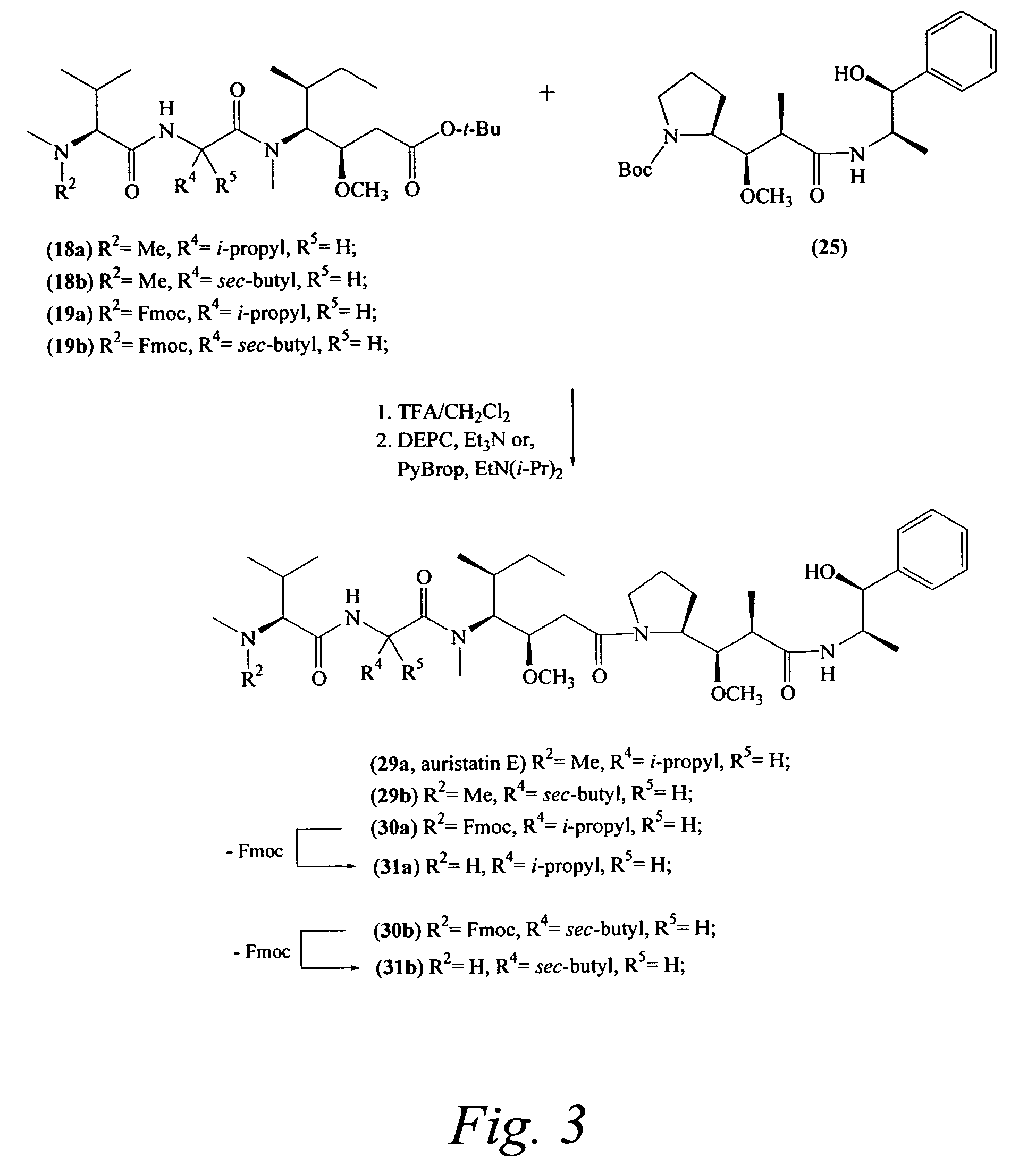

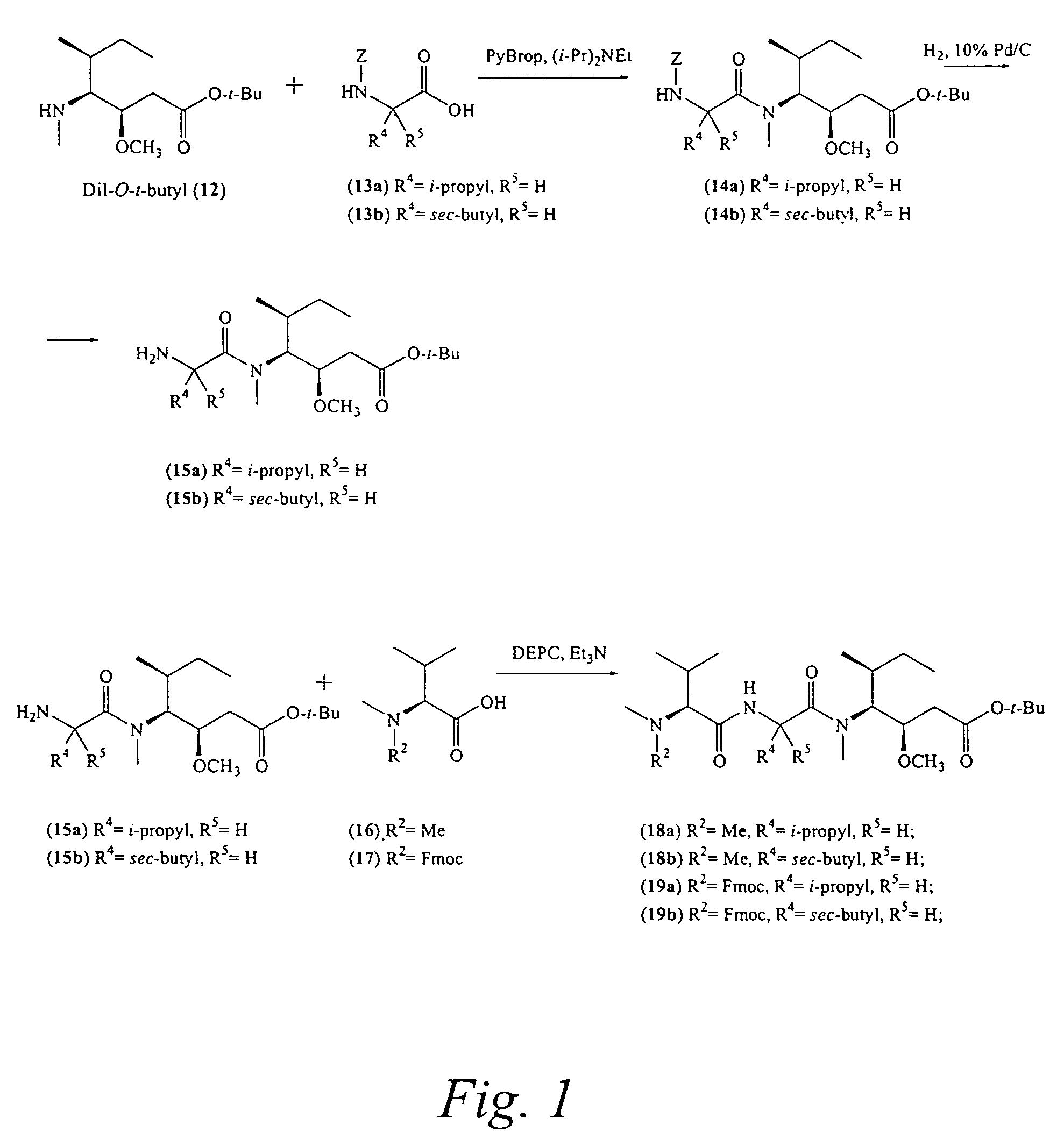

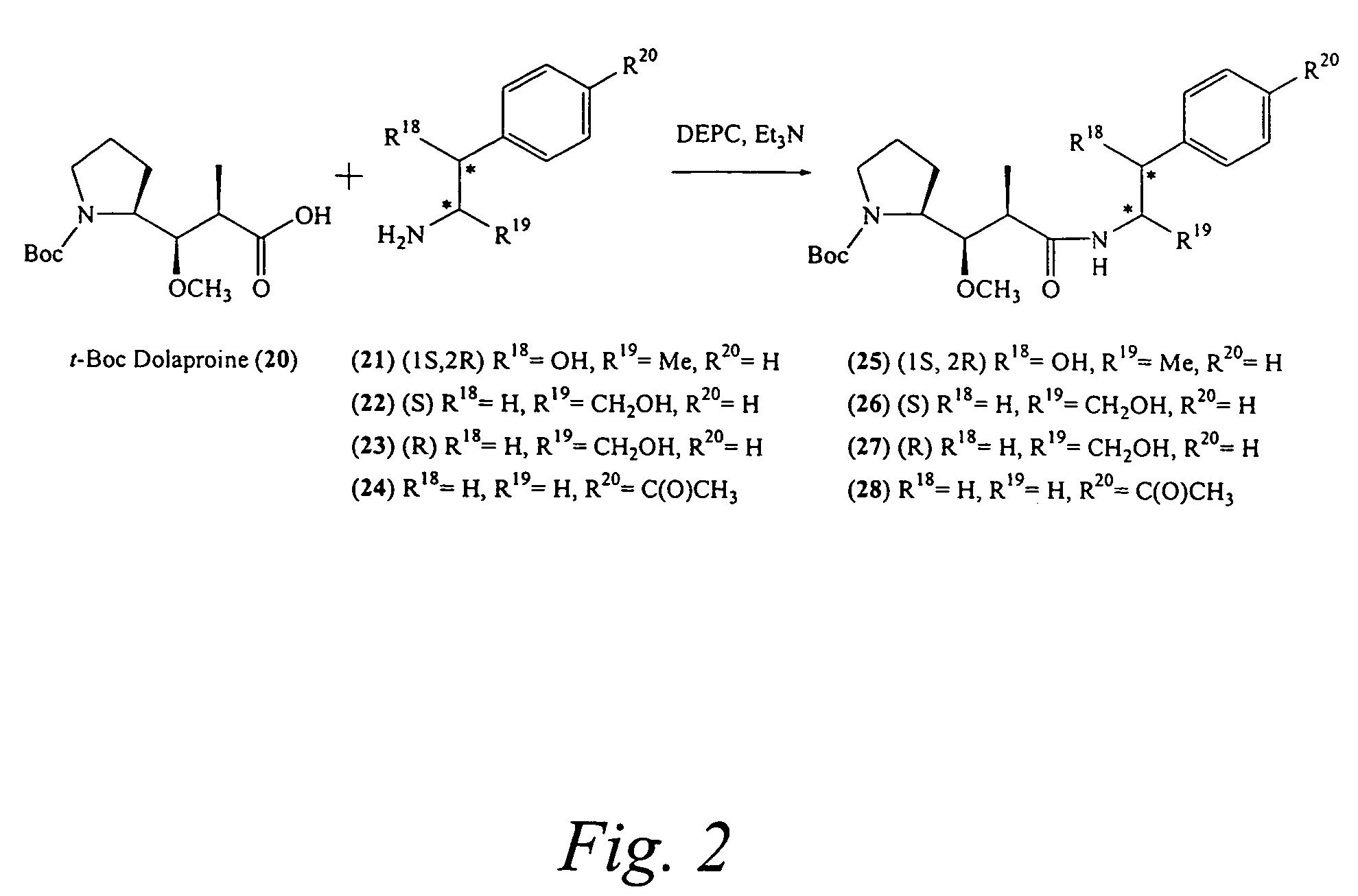

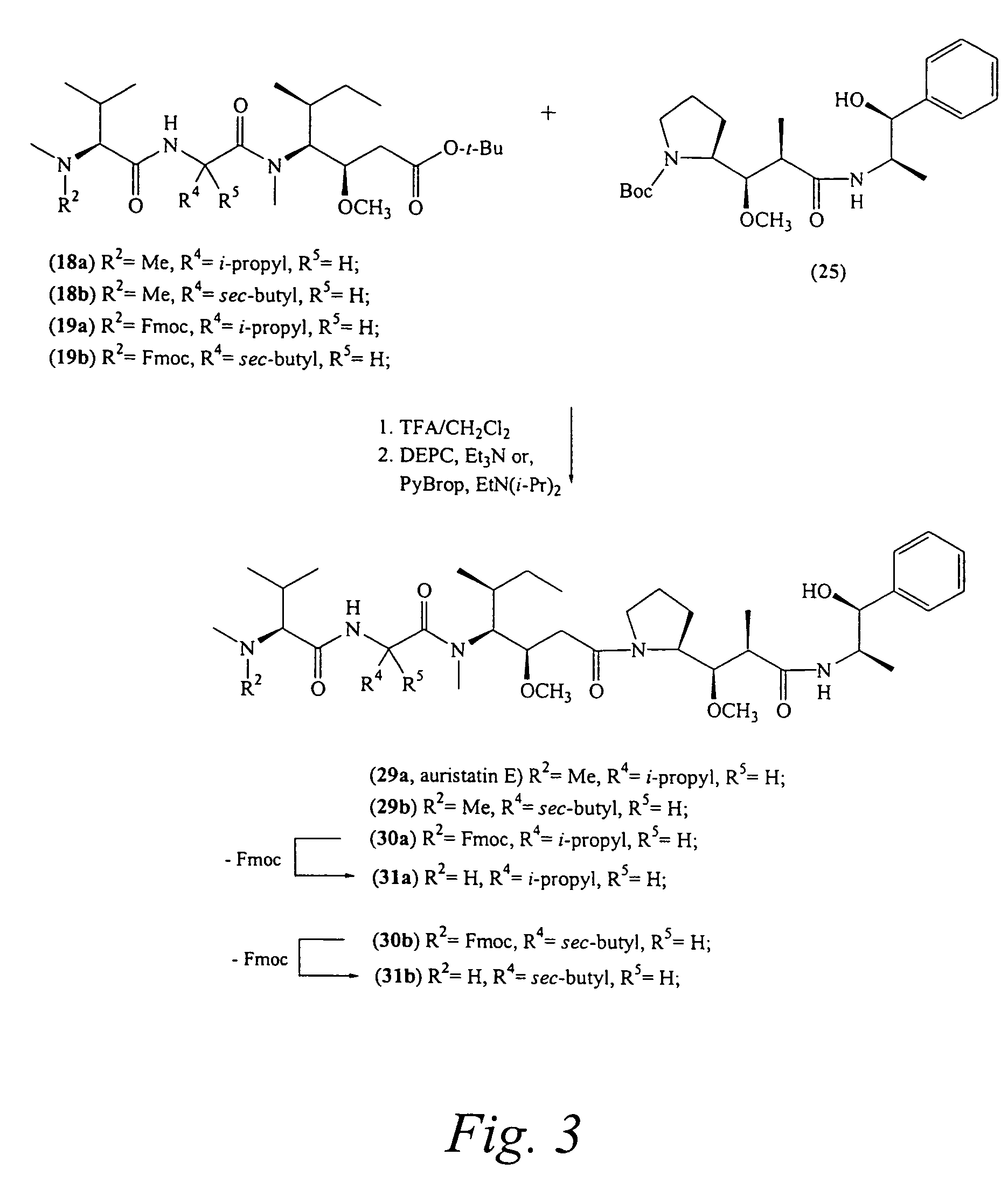

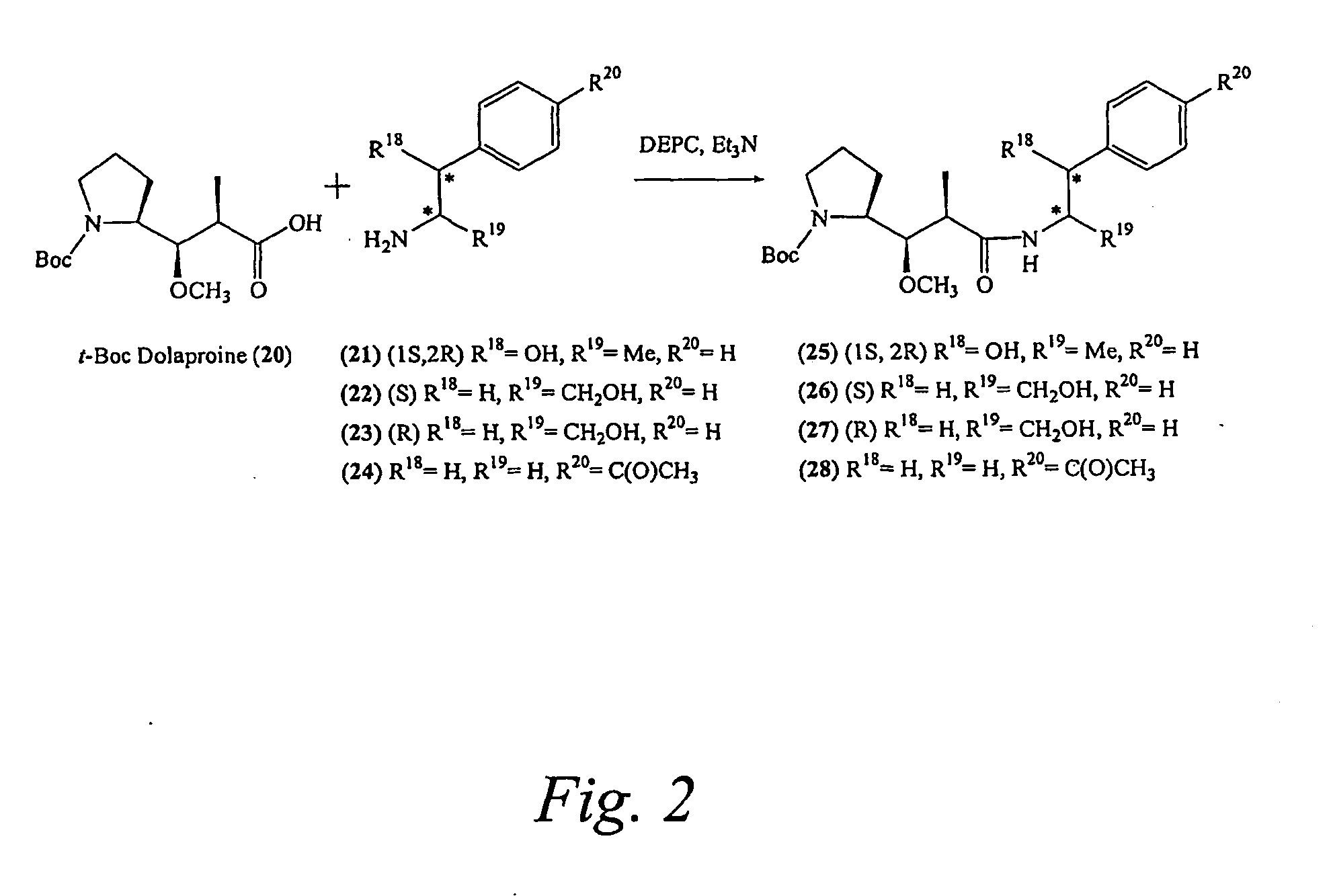

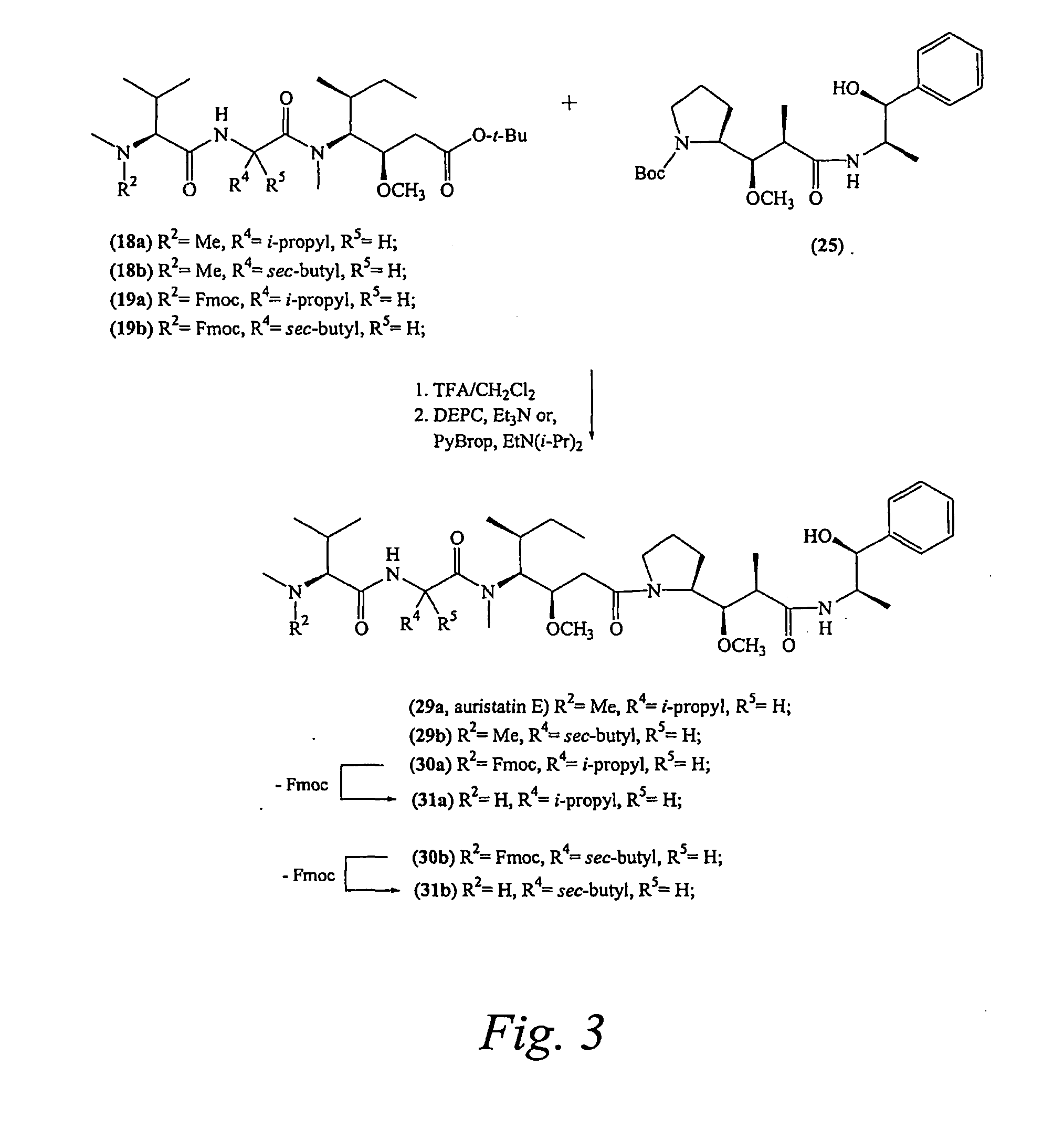

Pentapeptide compounds and uses related thereto

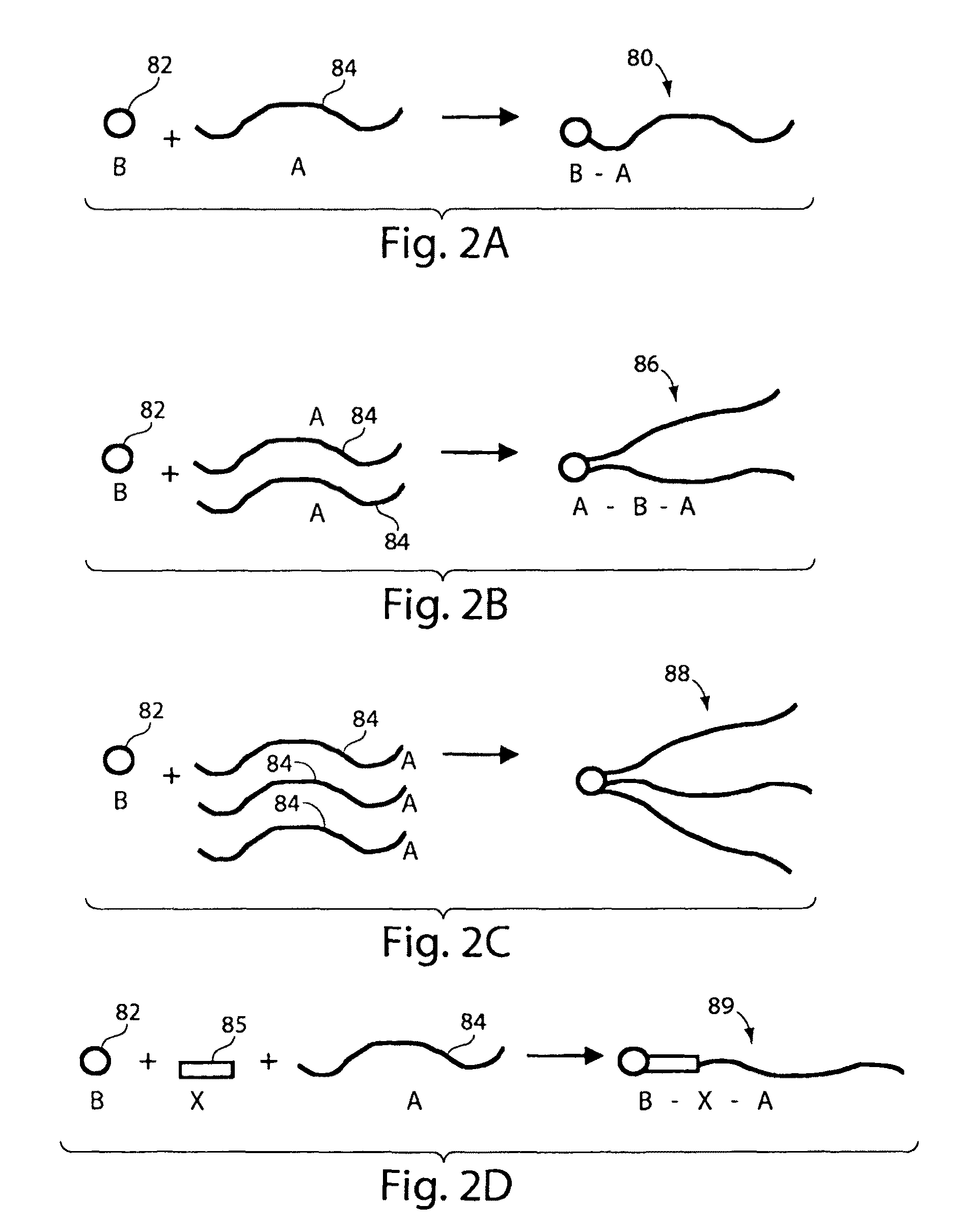

Pentapeptide compounds are disclosed. The compounds have biological activity, e.g., cytotoxicity. Prodrugs having targeting groups and pentapeptide moieities, as well as precursors thereof are also disclosed. For example, precursors having a reactive linker that can serve as a reaction site for joining to a targeting agent, e.g., an antibody, as disclosed.

Owner:SEAGEN INC

Method and apparatus for determining copy number variation using digital PCR

ActiveUS20090239308A1Easy to useBioreactor/fermenter combinationsBiological substance pretreatmentsConfidence intervalStatistical Confidence

Owner:STANDARD BIOTOOLS INC

Pentapeptide compounds and uses related thereto

Pentapeptide compounds are disclosed. The compounds have biological activity, e.g., cytotoxicity. Prodrugs having targeting groups and pentapeptide moieities, as well as precursors thereof are also disclosed. For example, precursors having a reactive linker that can serve as a reaction site for joining to a targeting agent, e.g., an antibody, as disclosed.

Owner:SEAGEN INC

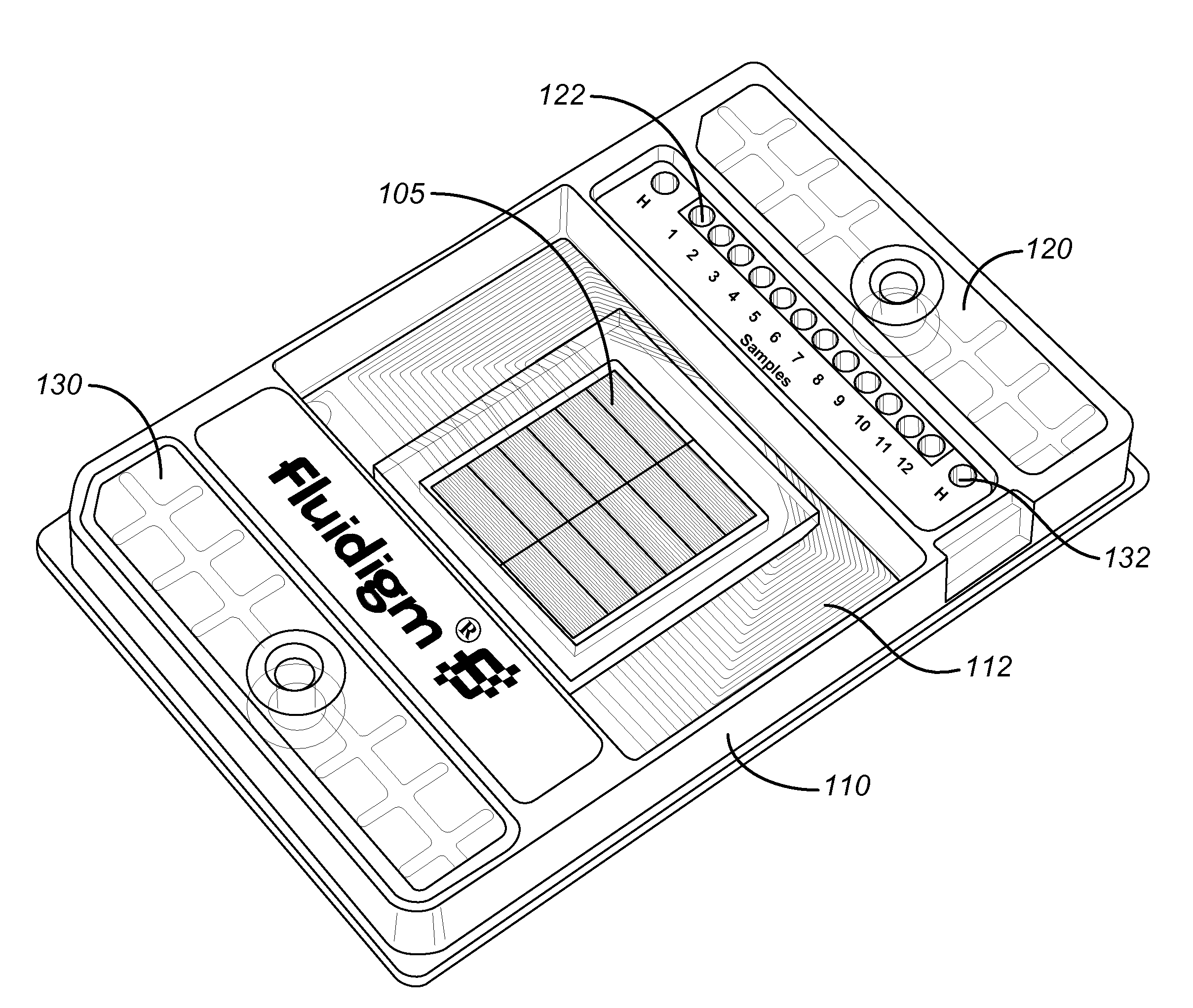

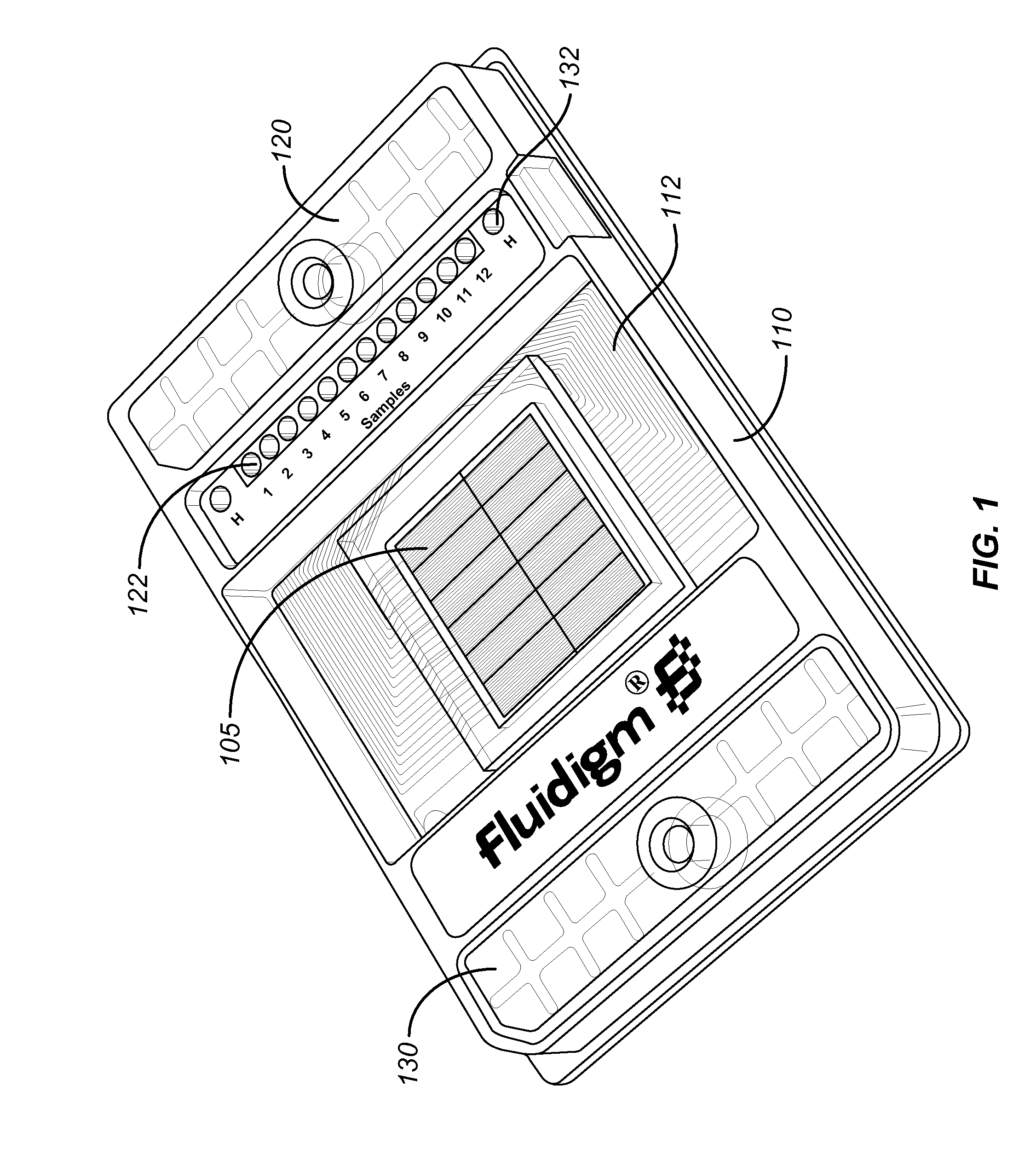

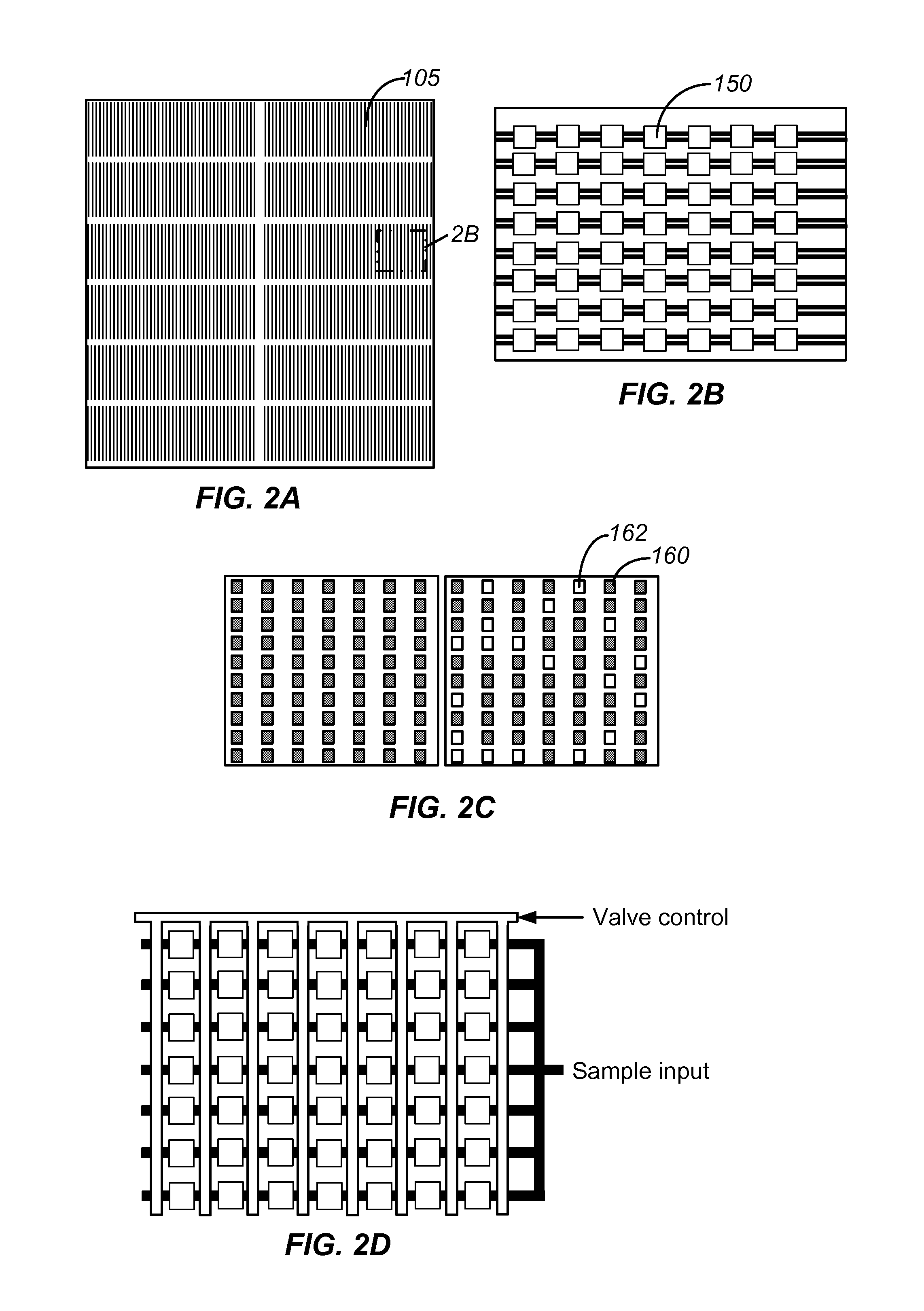

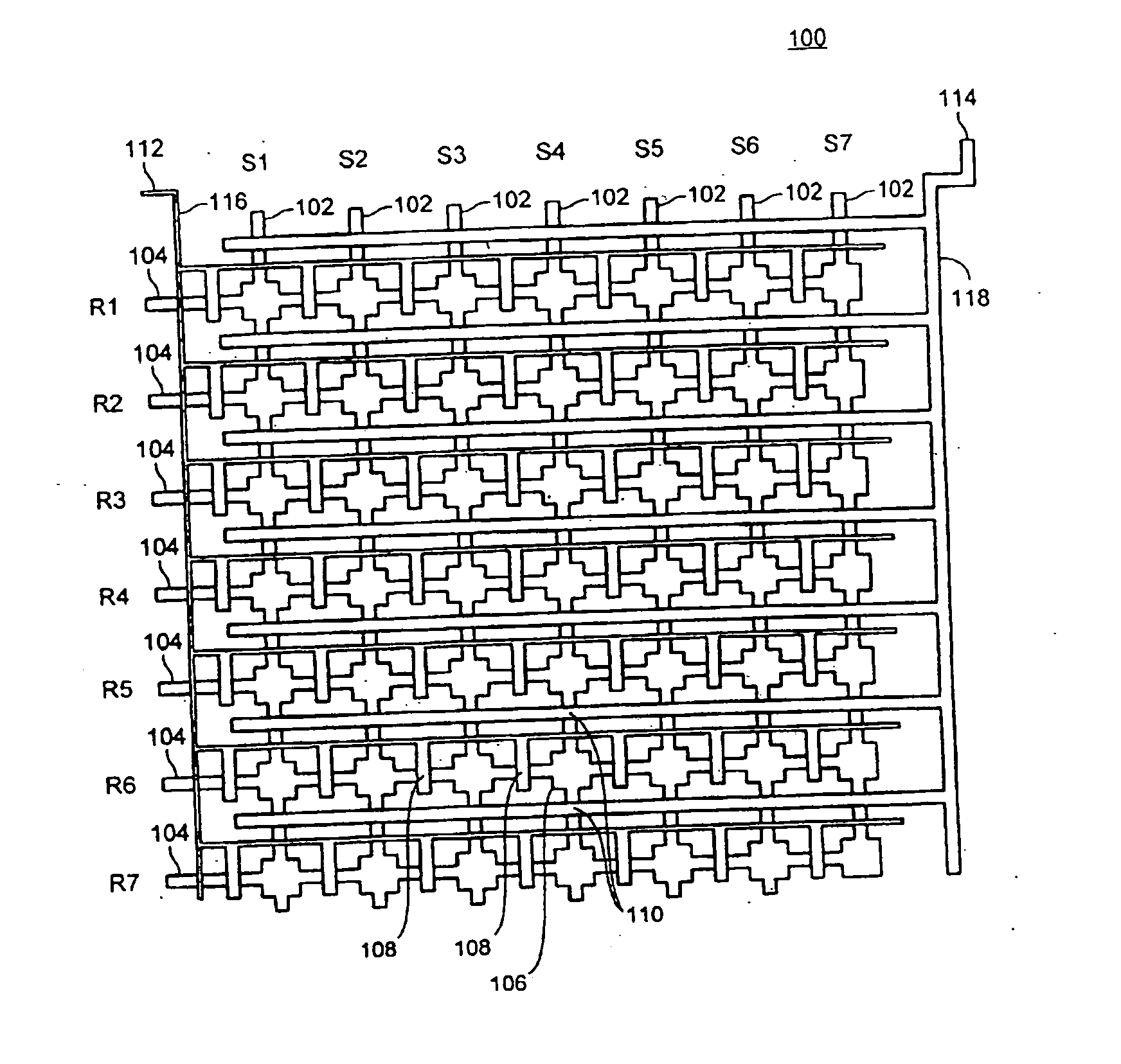

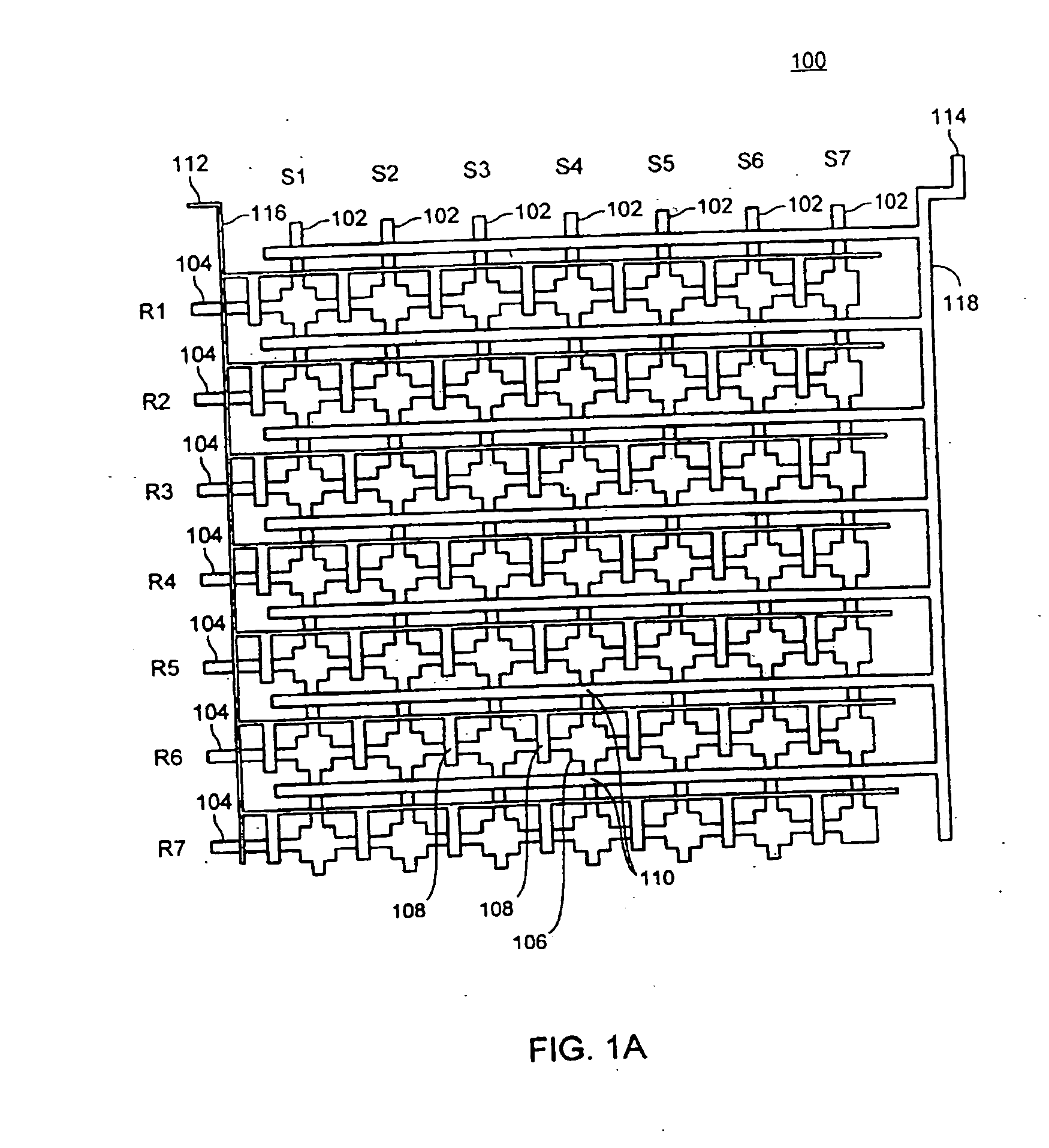

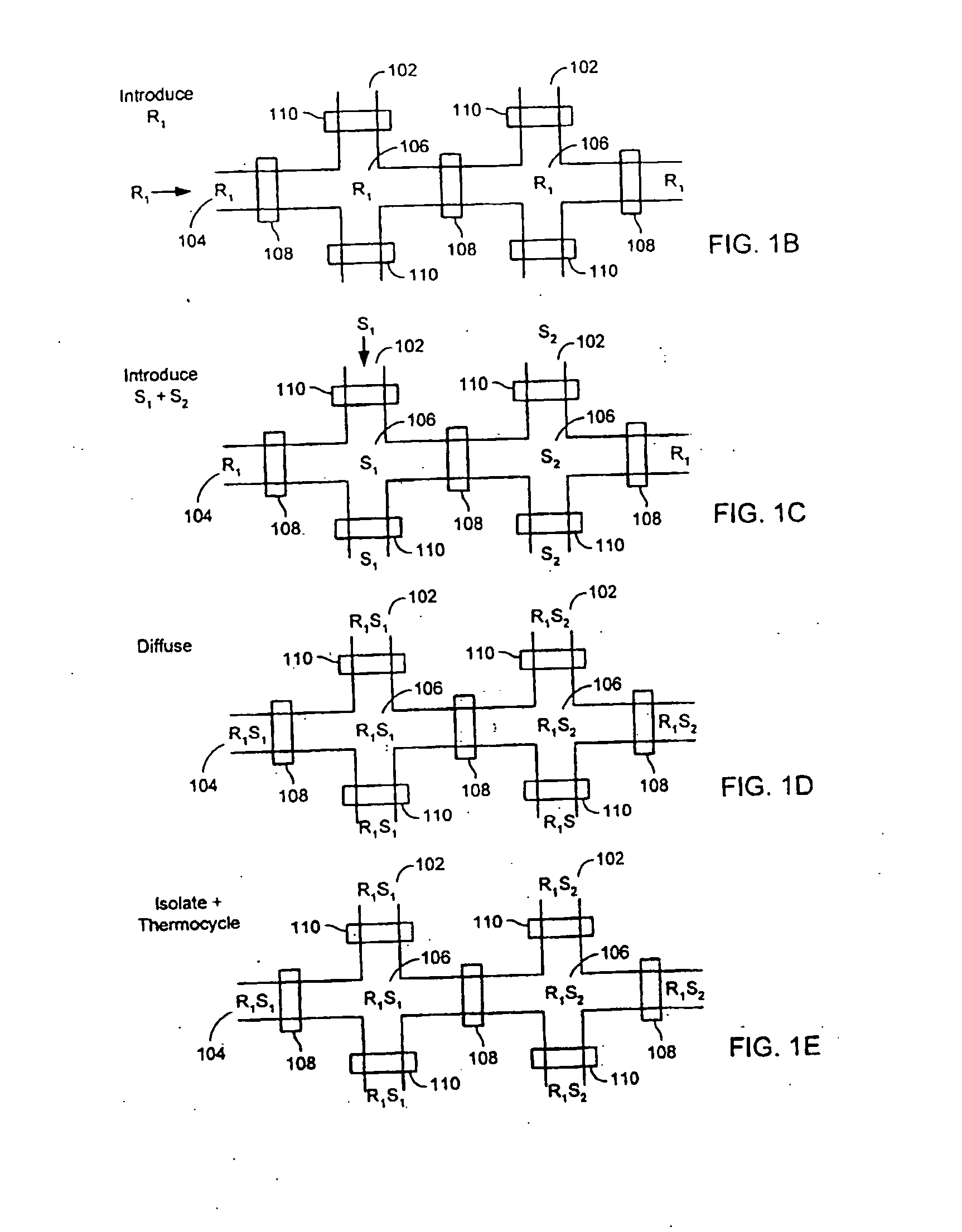

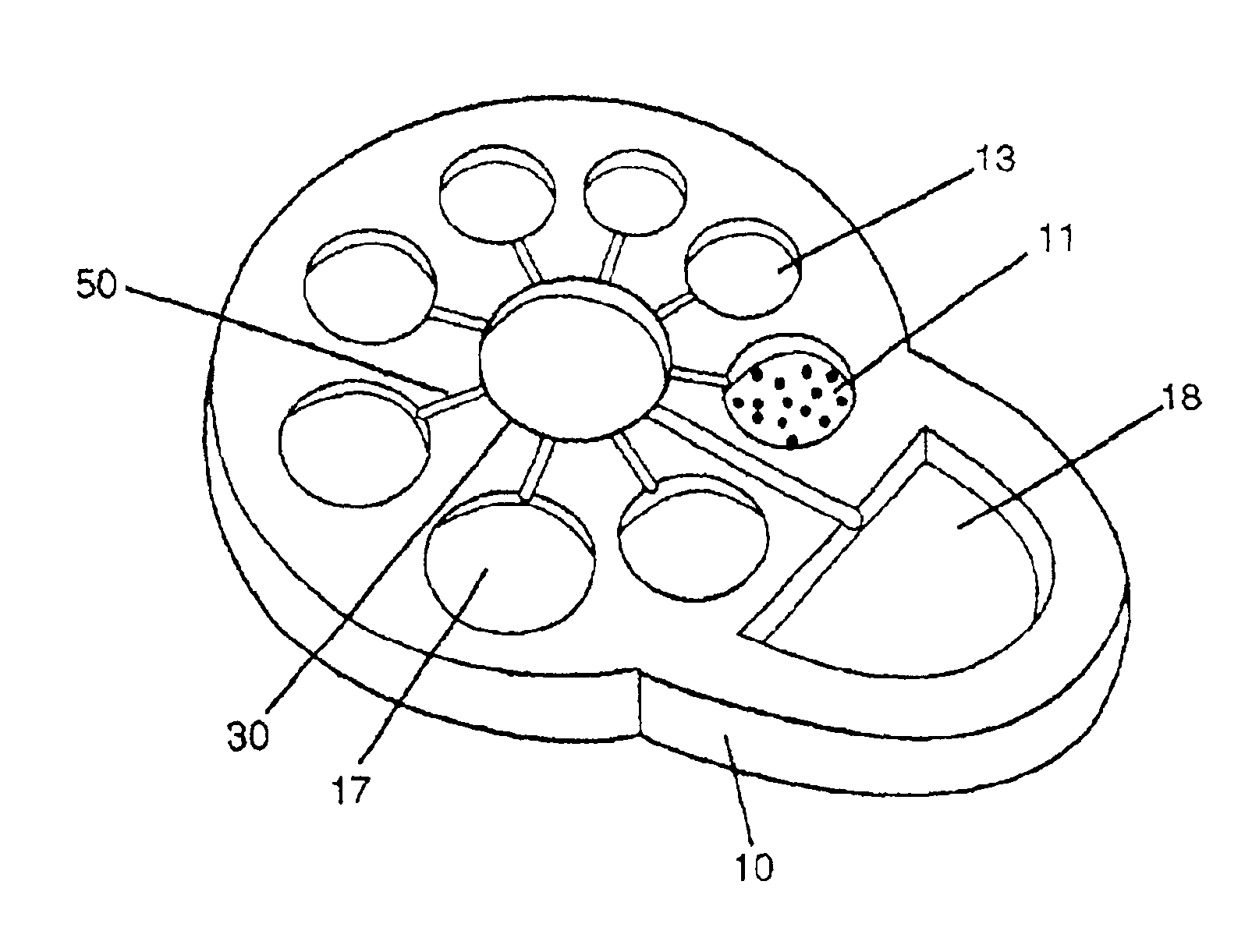

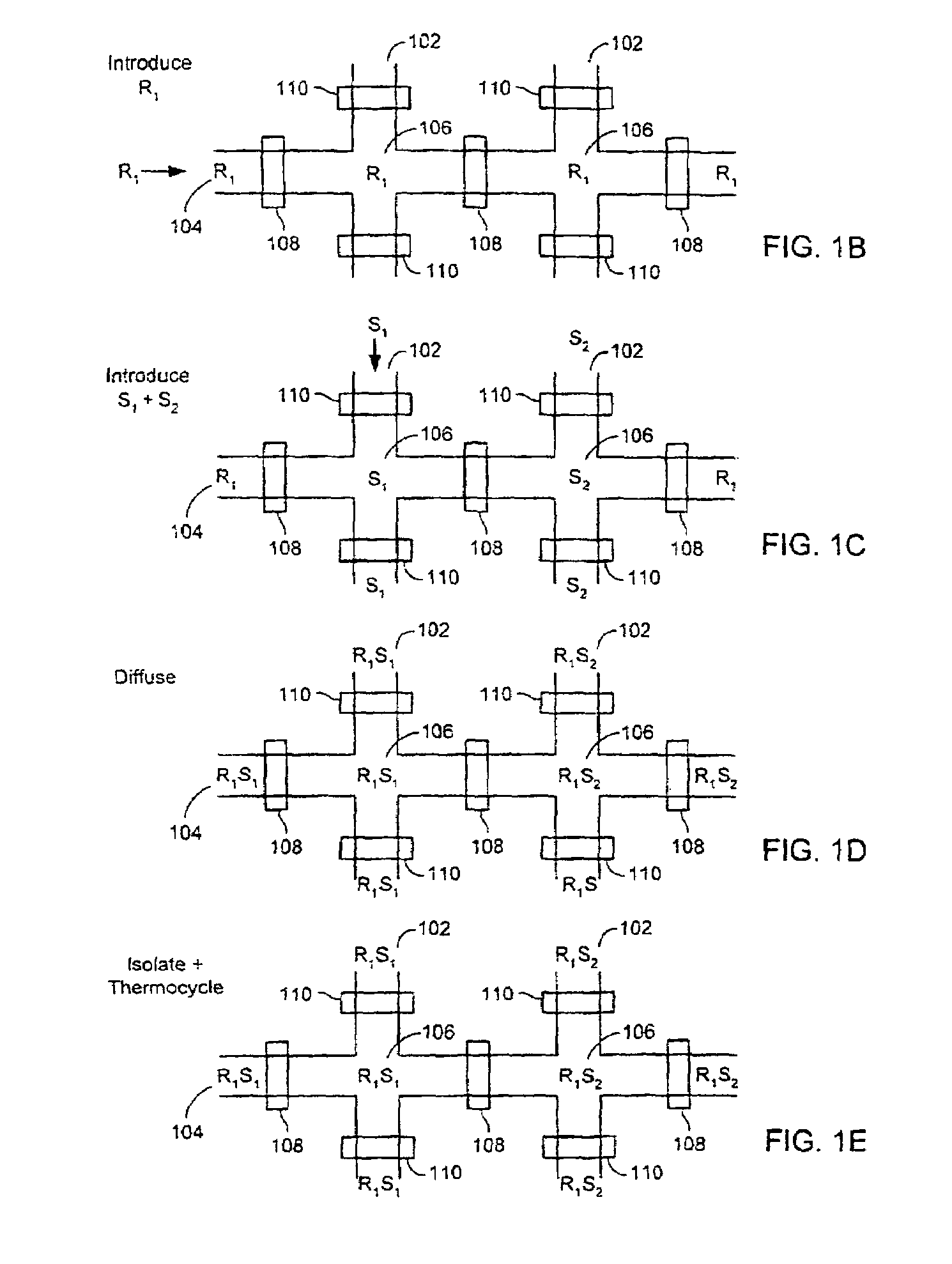

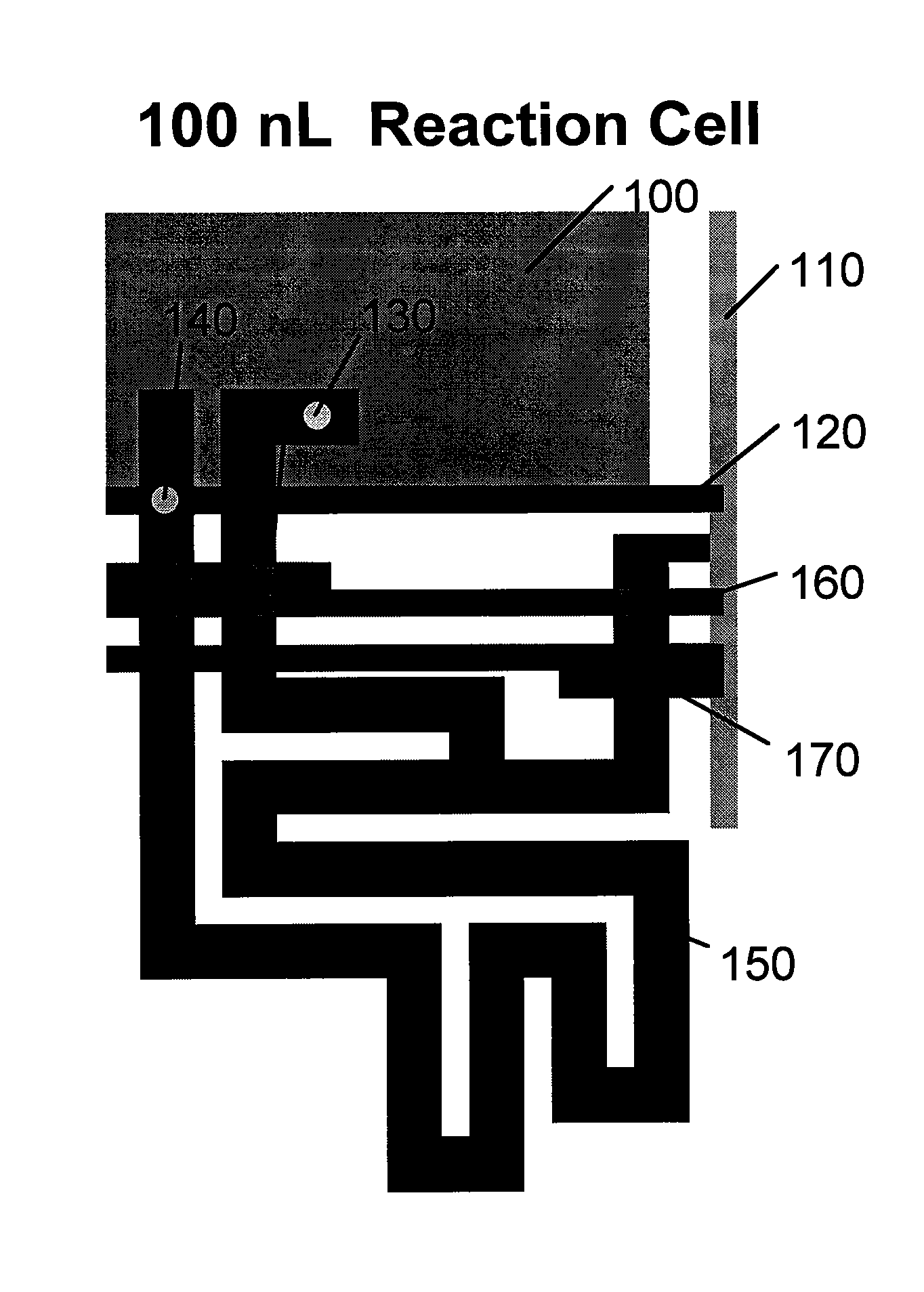

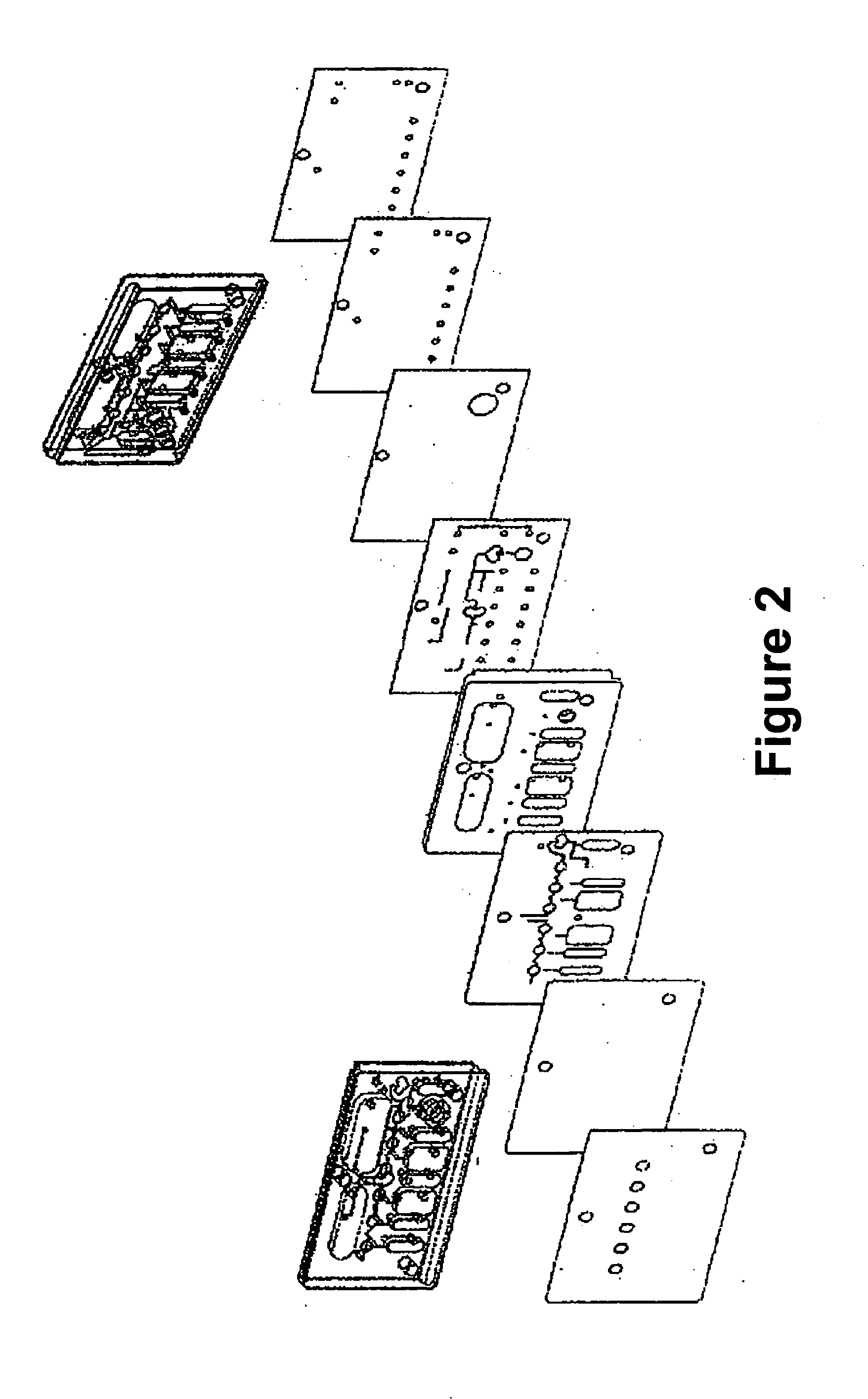

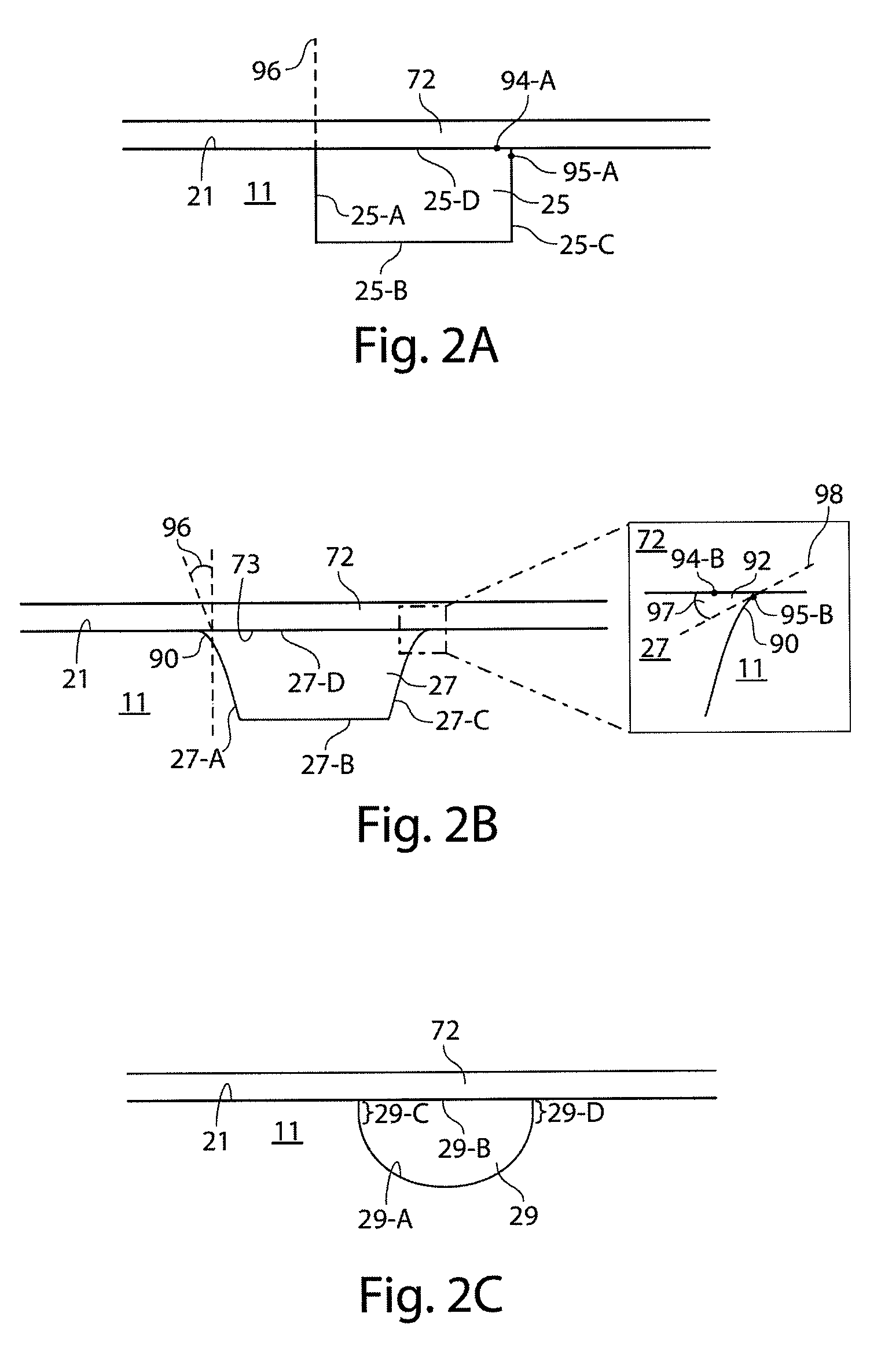

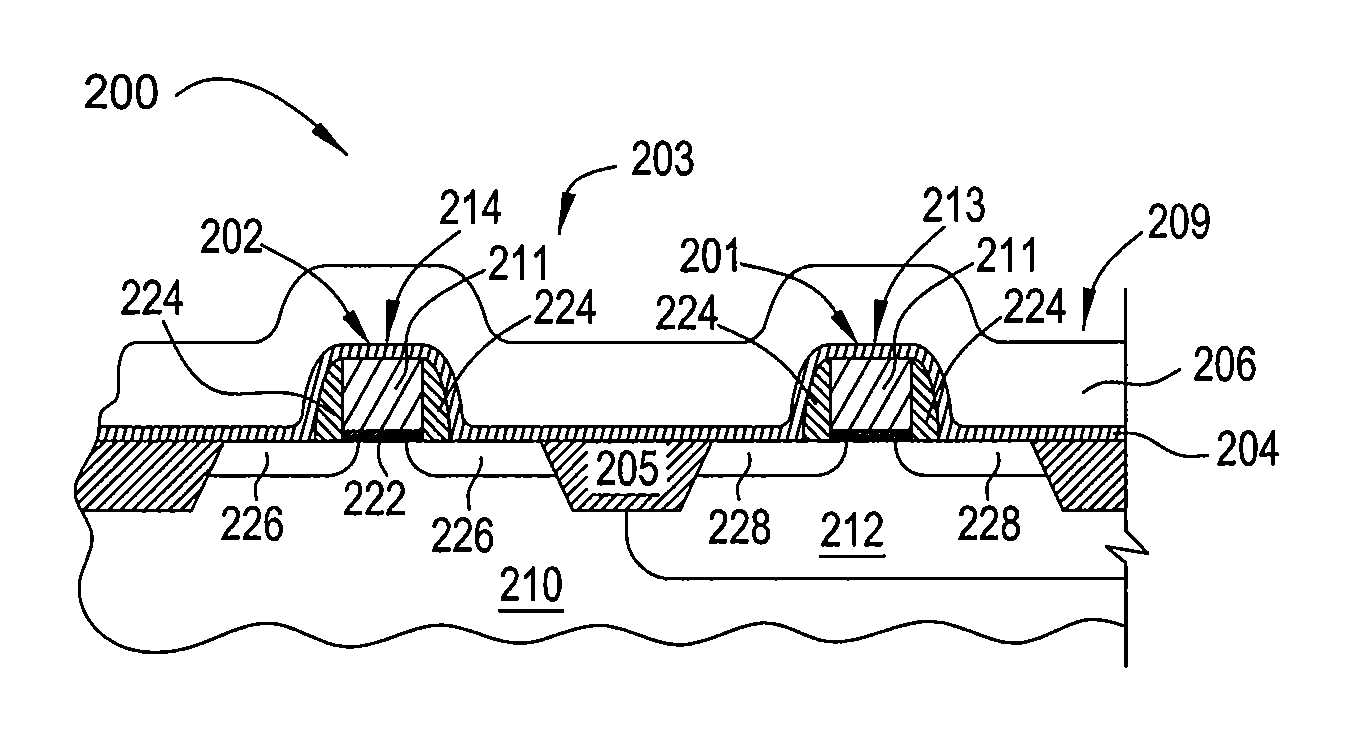

Microfluidic device and methods of using same

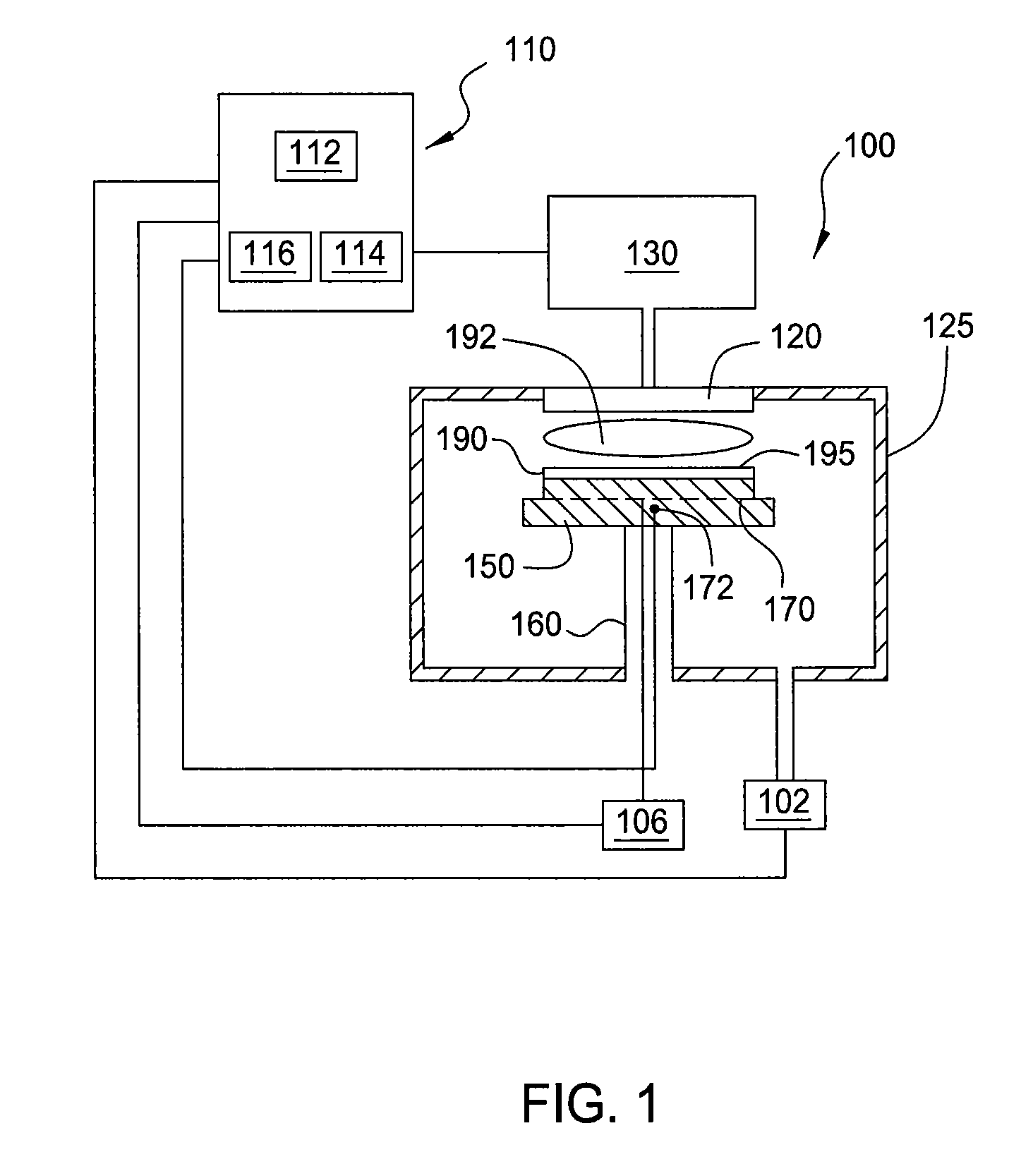

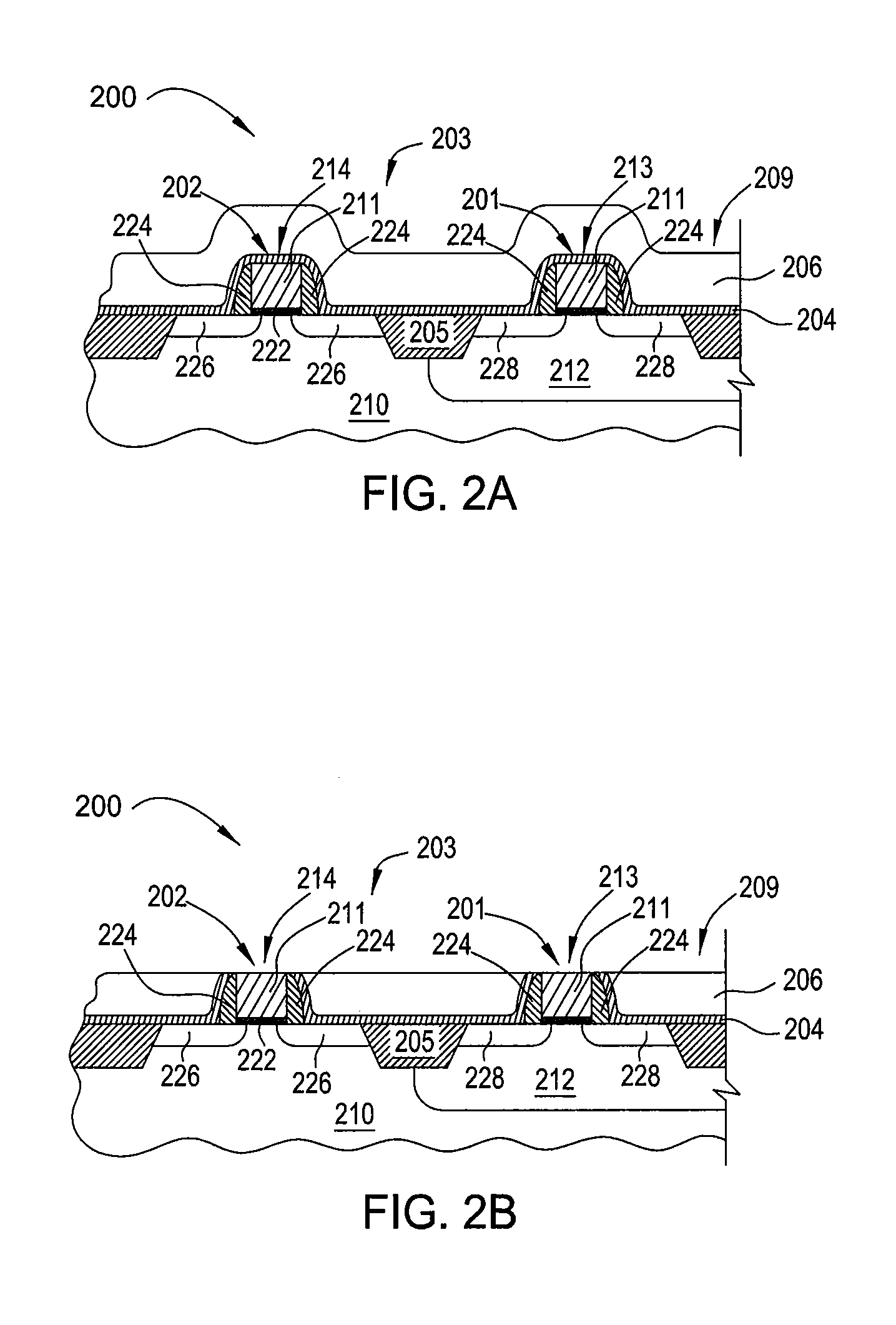

ActiveUS20050019792A1Prevent evaporationBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlGenotyping

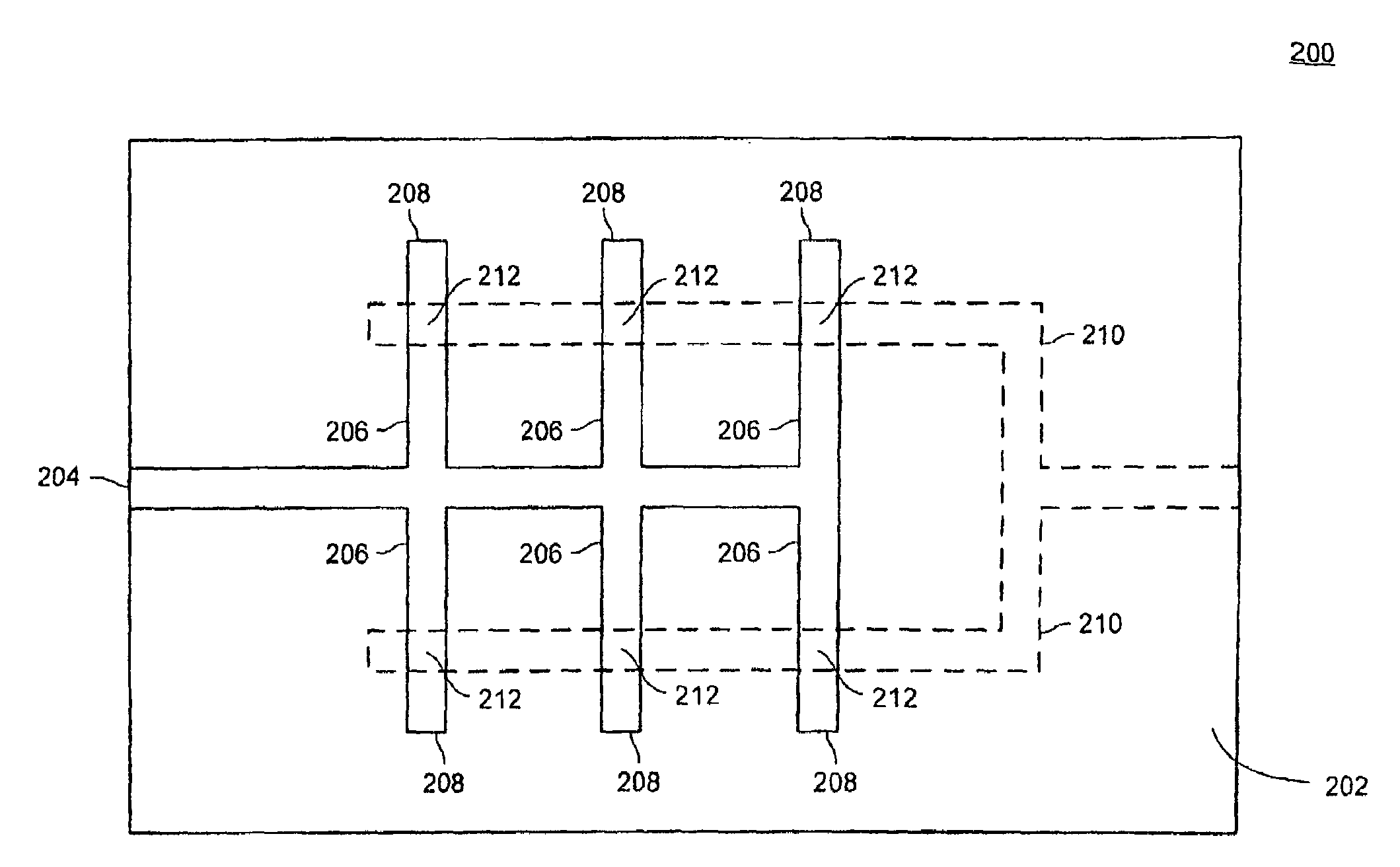

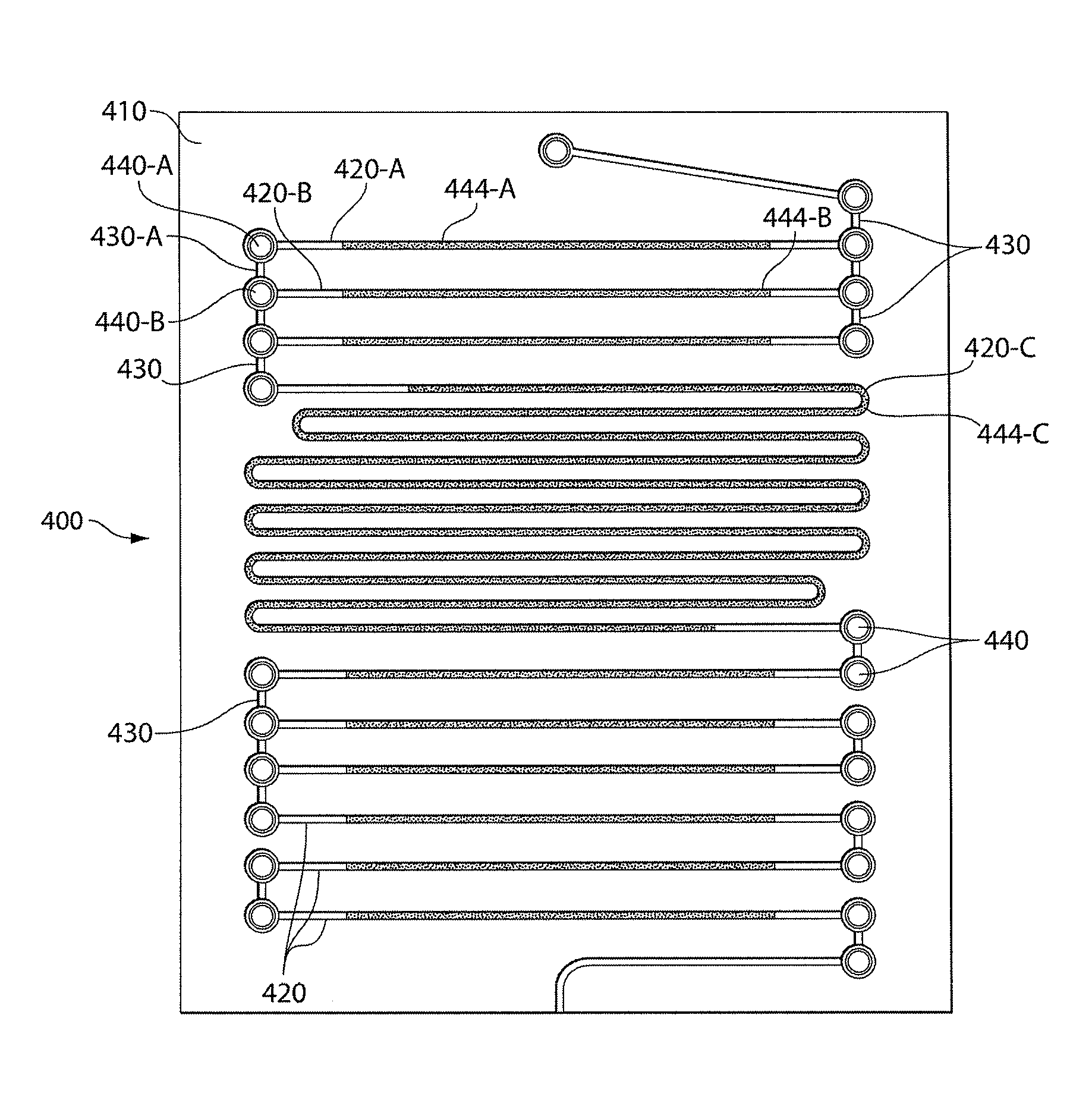

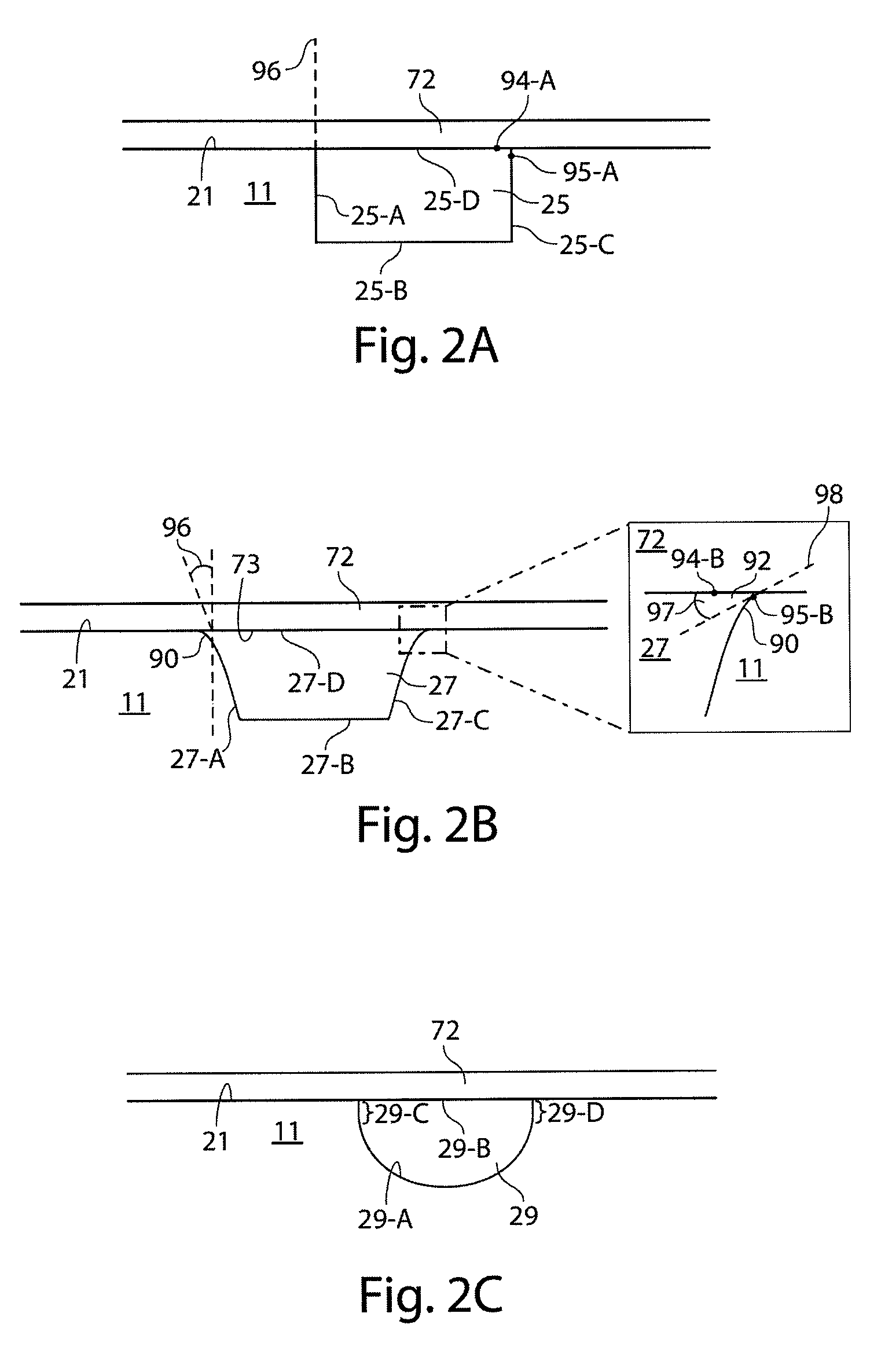

A variety of elastomeric-based microfluidic devices and methods for using and manufacturing such devices are provided. Certain of the devices have arrays of reaction sites to facilitate high throughput analyses. Some devices also include reaction sites located at the end of blind channels at which reagents have been previously deposited during manufacture. The reagents become suspended once sample is introduced into the reaction site. The devices can be utilized with a variety of heating devices and thus can be used in a variety of analyses requiring temperature control, including thermocycling applications such as nucleic acid amplification reactions, genotyping and gene expression analyses.

Owner:STANDARD BIOTOOLS INC

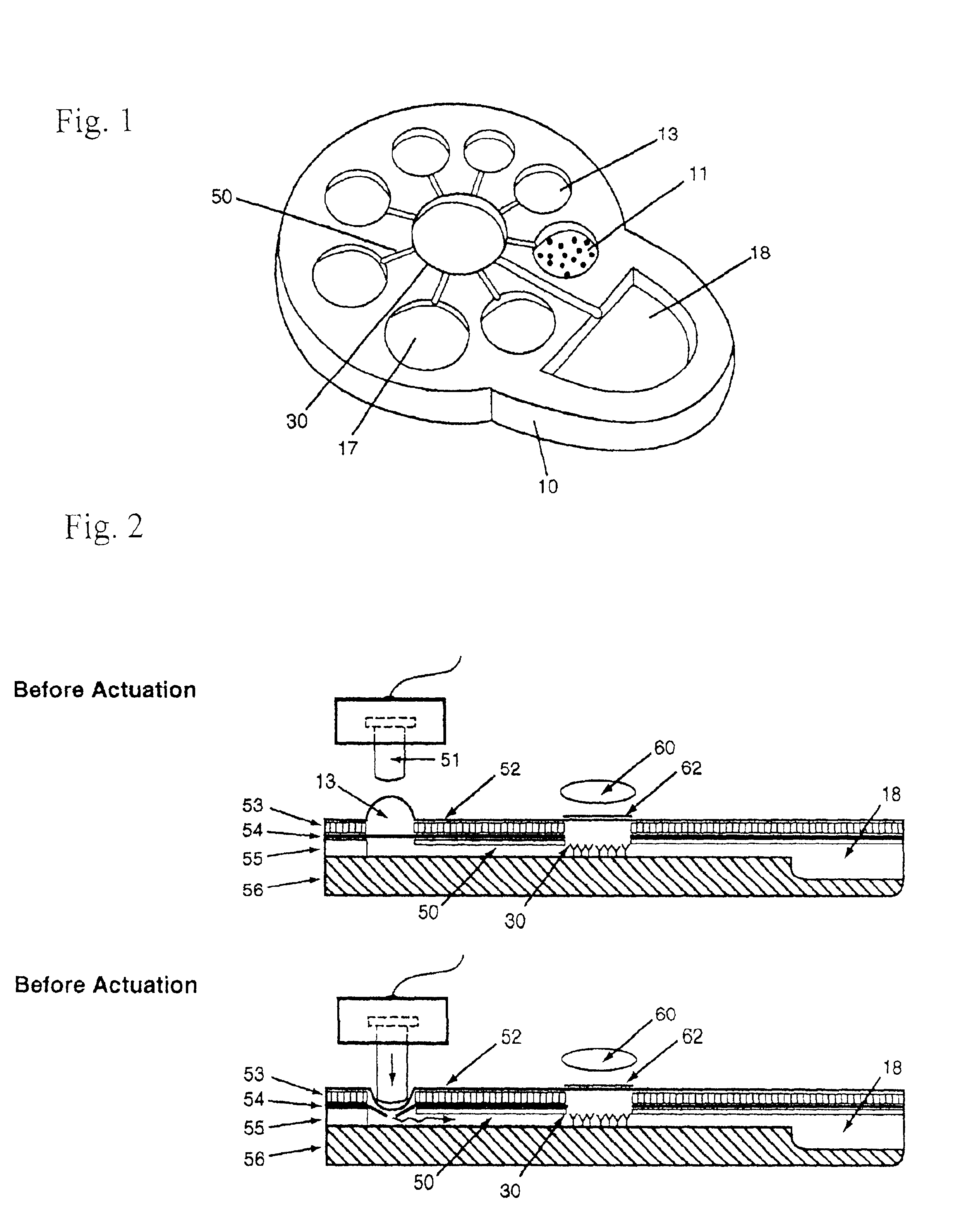

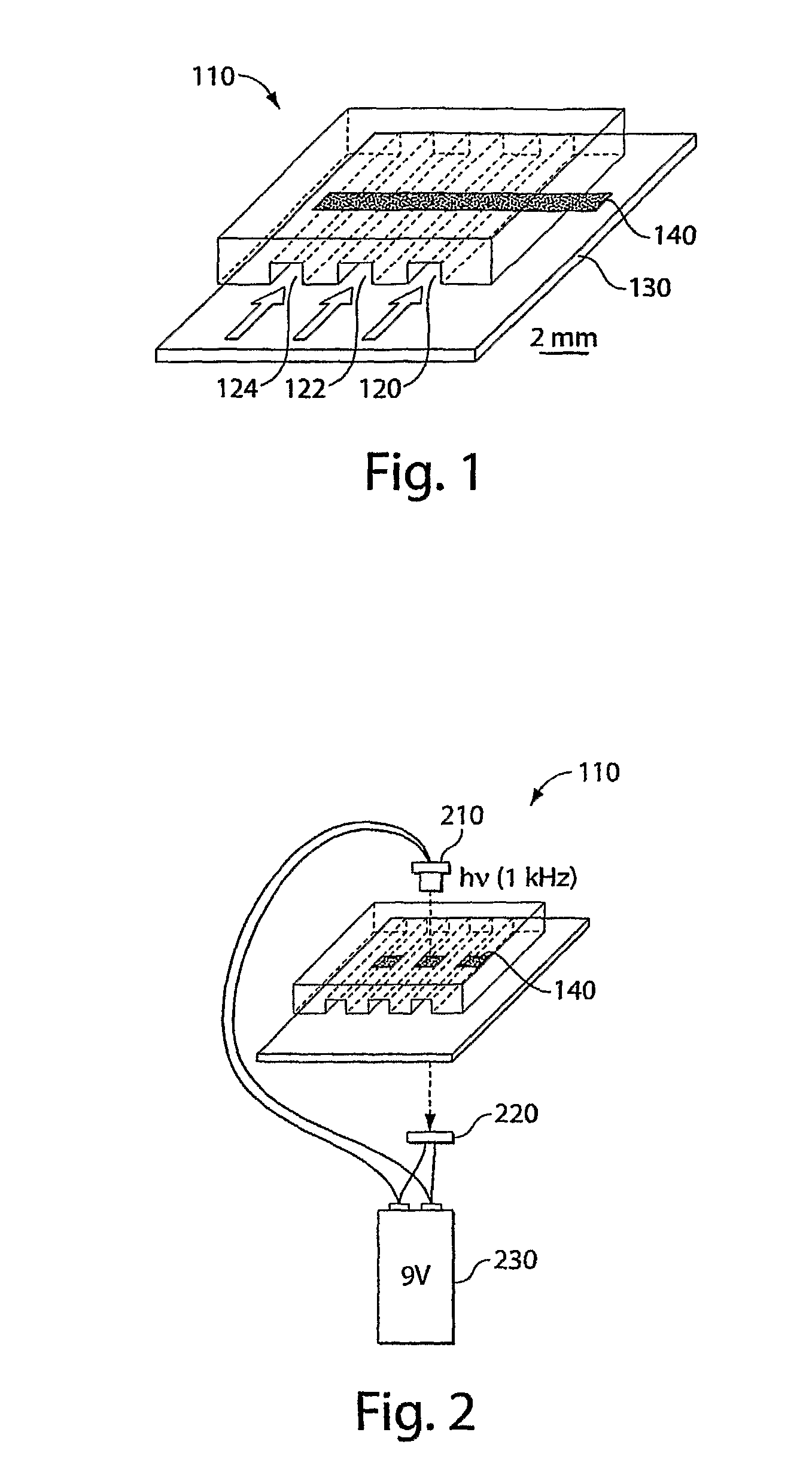

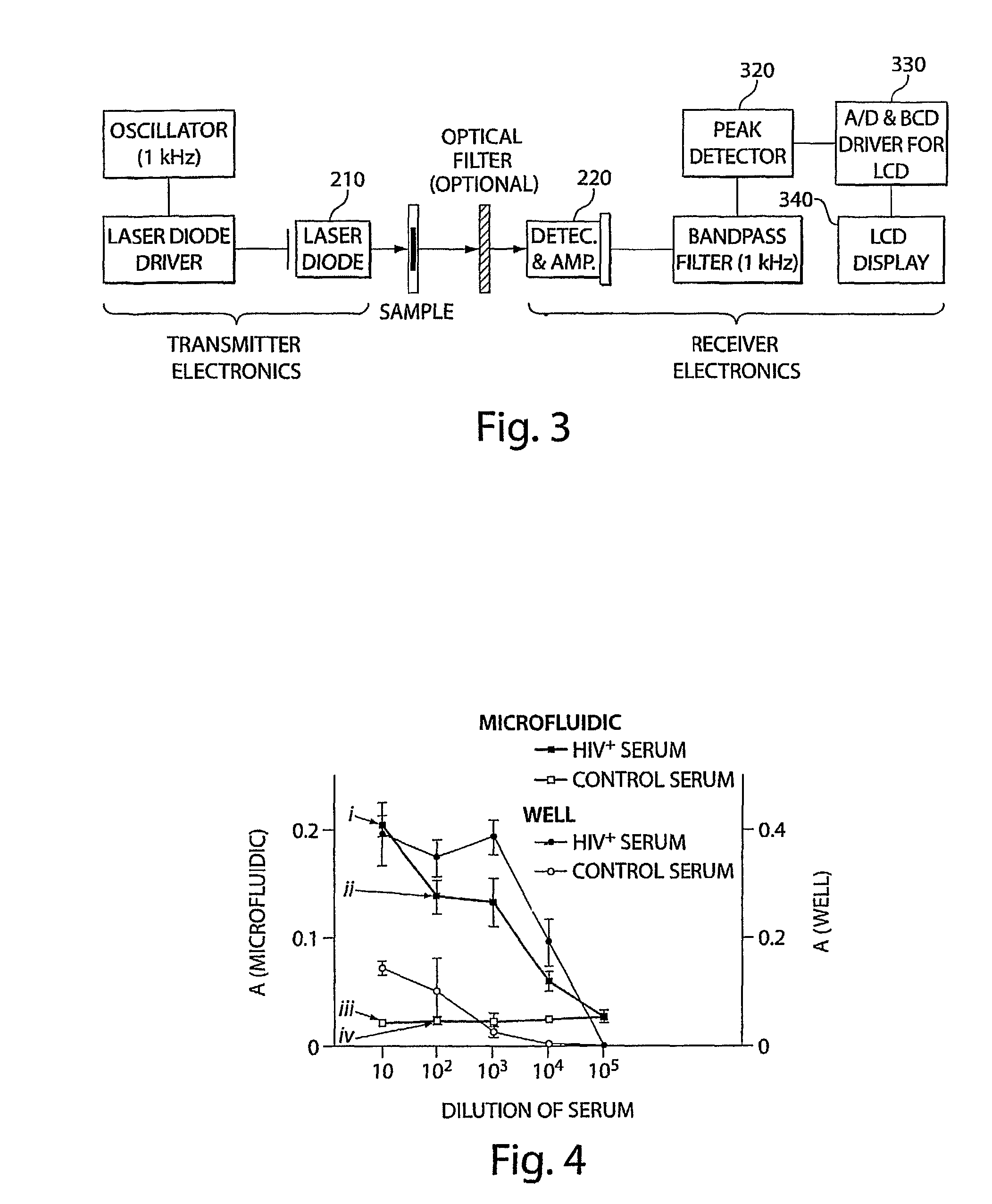

Chemiluminescence-based microfluidic biochip

InactiveUS6949377B2Accurate and reproducible resultSimple and rapid and POCT applicationBioreactor/fermenter combinationsBiological substance pretreatmentsPositive pressureBiochip

The disclosure describes how to use luminescence detection mechanism, move microfluid, and control multiple-step biochemical reactions in closed confined microfluidic biochip platform. More particularly, a self-contained disposable biochip with patterned microchannels and compartments having storage means for storing a plurality of samples, reagents, and luminescent substrates. At least one external microactuator in the biochip system produces positive pressure and automates multiple-step reactions in microfluidic platforms for clinical chemistry, cell biology, immunoassay and nucleic acid analysis. The method comprises the steps of transferring sequentially at least one of samples, reagents, and then luminescent substrate from compartments through microchannels to reaction sites. The luminescent substrates react with probes to form a probe complex resulting into luminescence, which is detected by an optical detector.

Owner:HO WINSTON Z

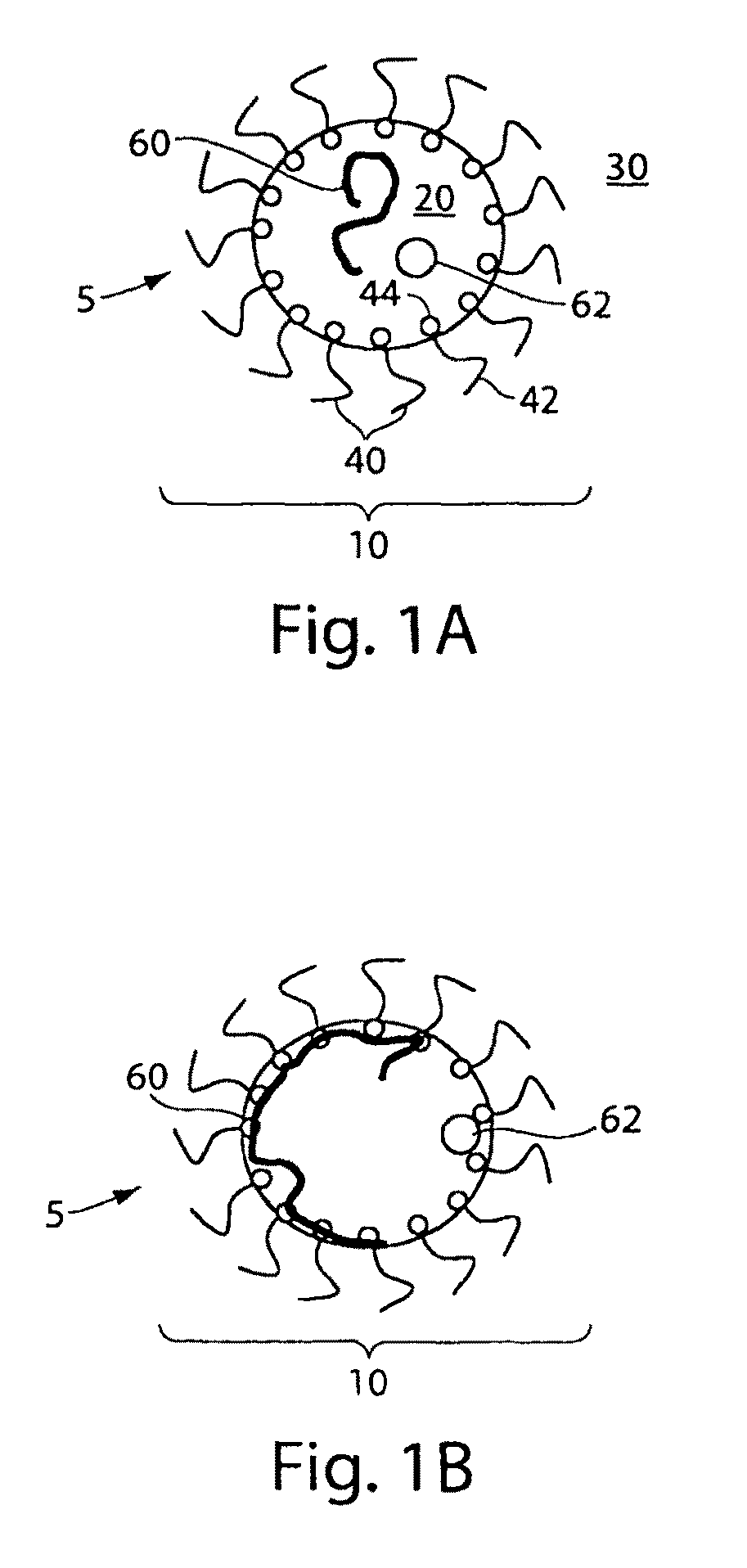

Fluorocarbon emulsion stabilizing surfactants

Surfactants (e.g., fluorosurfactants) for stabilizing aqueous or hydrocarbon droplets in a fluorophilic continuous phase are presented. In some embodiments, fluorosurfactants include a fluorophilic tail soluble in a fluorophilic (e.g., fluorocarbon) continuous phase, and a headgroup soluble in either an aqueous phase or a lipophilic (e.g., hydrocarbon) phase. The combination of a fluorophilic tail and a headgroup may be chosen so as to create a surfactant with a suitable geometry for forming stabilized reverse emulsion droplets having a disperse aqueous or lipophilic phase in a continuous, fluorophilic phase. In some embodiments, the headgroup is preferably non-ionic and can prevent or limit the adsorption of molecules at the interface between the surfactant and the discontinuous phase. This configuration can allow the droplet to serve, for example, as a reaction site for certain chemical and / or biological reactions. In another embodiment, aqueous droplets are stabilized in a fluorocarbon phase at least in part by the electrostatic attraction of two oppositely charged or polar components, one of which is at least partially soluble in the dispersed phase, the other at least partially soluble in the continuous phase. One component may provide collodial stability of the emulsion, and the other may prevent the adsorption of biomolecules at the interface between a component and the discontinous phase. Advantageously, surfactants and surfactant combinations of the invention may provide sufficient stabilization against coalescence of droplets, without interfering with processes that can be carried out inside the droplets.

Owner:BIO RAD LAB INC +2

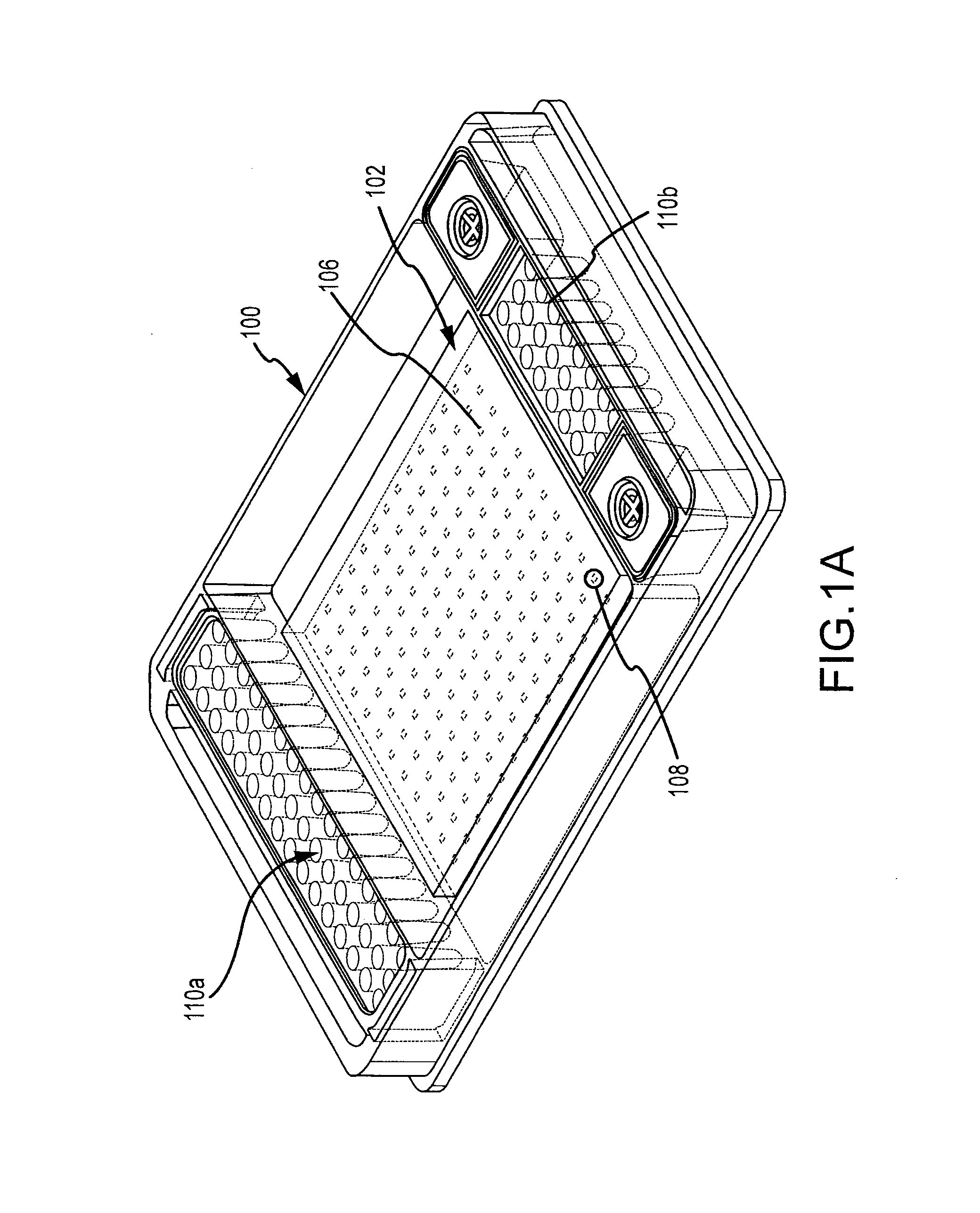

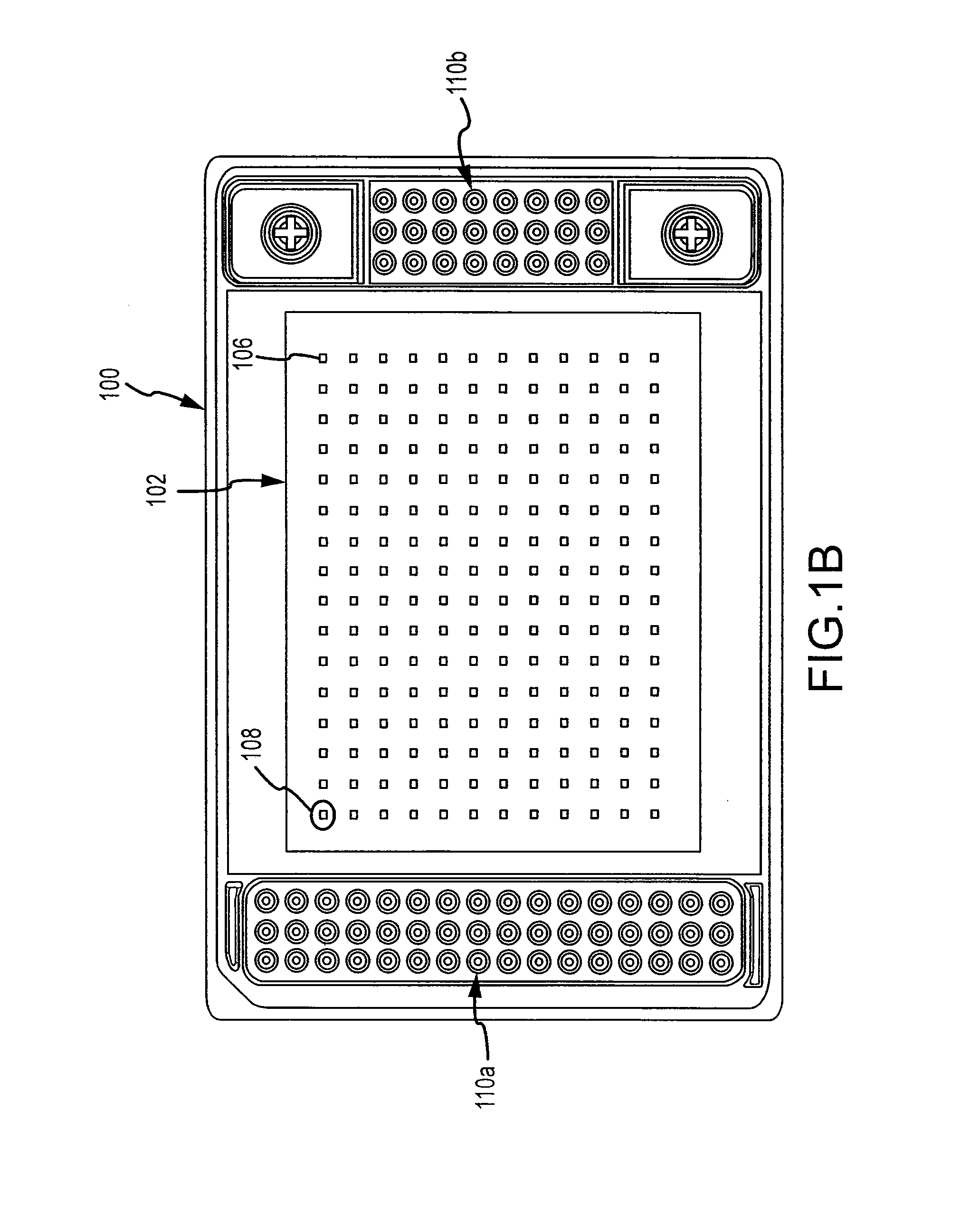

Microfluidic devices and methods of using same

ActiveUS7666361B2Prevent evaporationHeating or cooling apparatusMicrobiological testing/measurementTemperature controlElastomer

A variety of elastomeric-based microfluidic devices and methods for using and manufacturing such devices are provided. Certain of the devices have arrays of reaction sites to facilitate high throughput analyses. Some devices also include reaction sites located at the end of blind channels at which reagents have been previously deposited during manufacture. The reagents become suspended once sample is introduced into the reaction site. The devices can be utilized with a variety of heating devices and thus can be used in a variety of analyses requiring temperature control, including thermocycling applications such as nucleic acid amplification reactions, genotyping and gene expression analyses.

Owner:STANDARD BIOTOOLS INC

Microfluidic reaction apparatus for high throughput screening

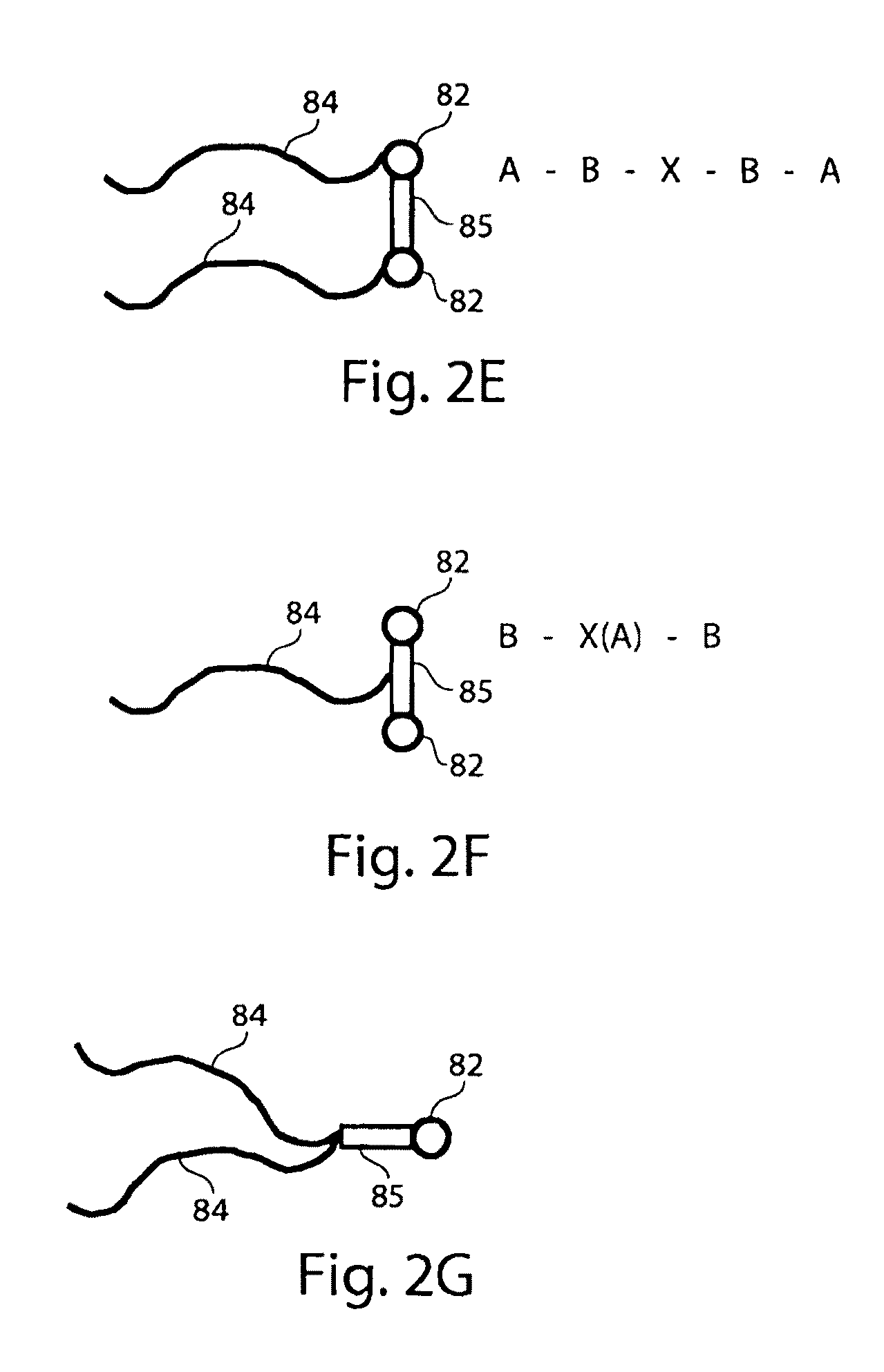

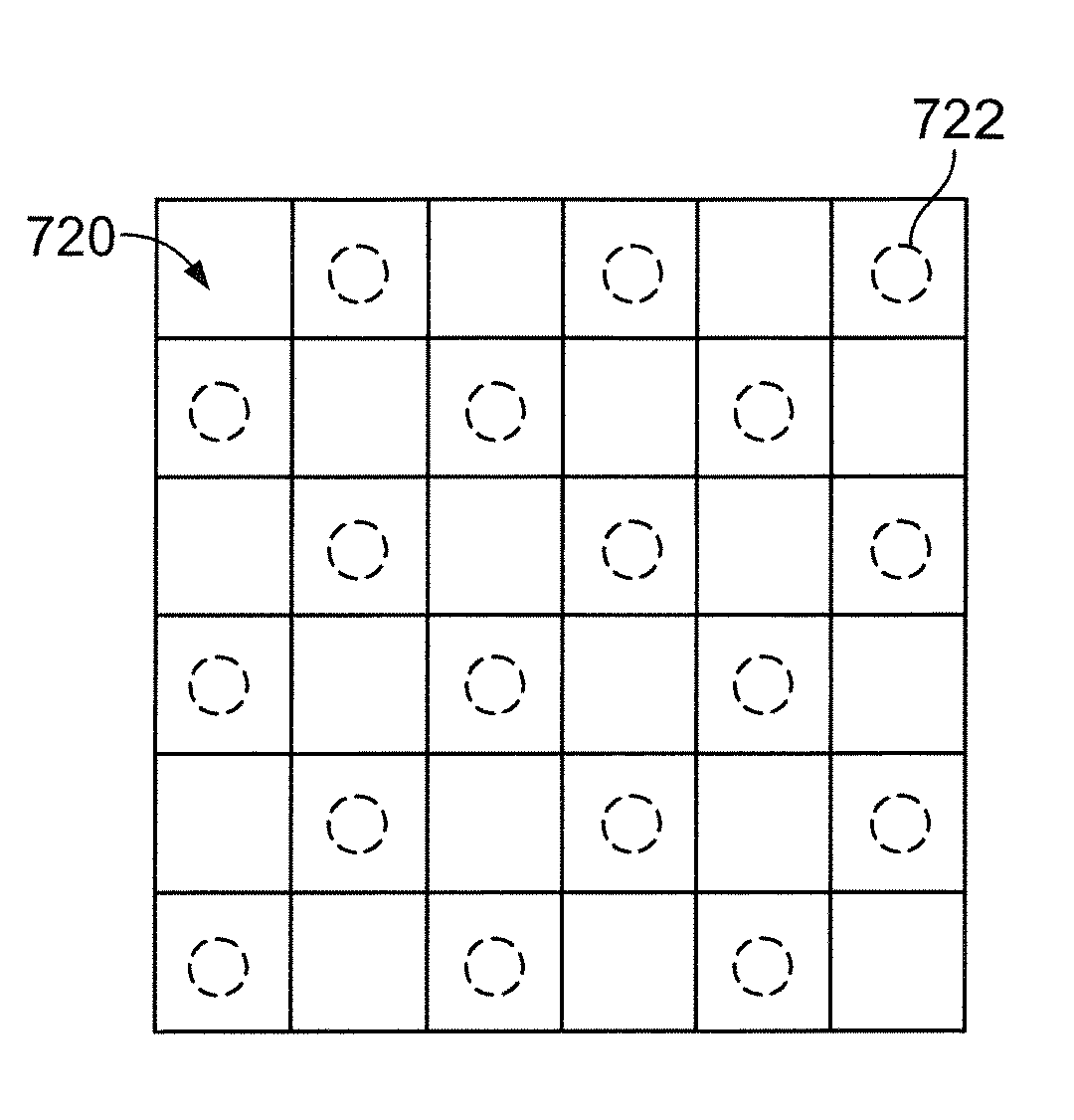

An SBS-formatted microfluidic device where the geometry of the plate defines an array of interrogation areas, and where each interrogation area encompasses at least one reaction site.

Owner:FLUIDIGM CORP

Fluidic medical devices and uses thereof

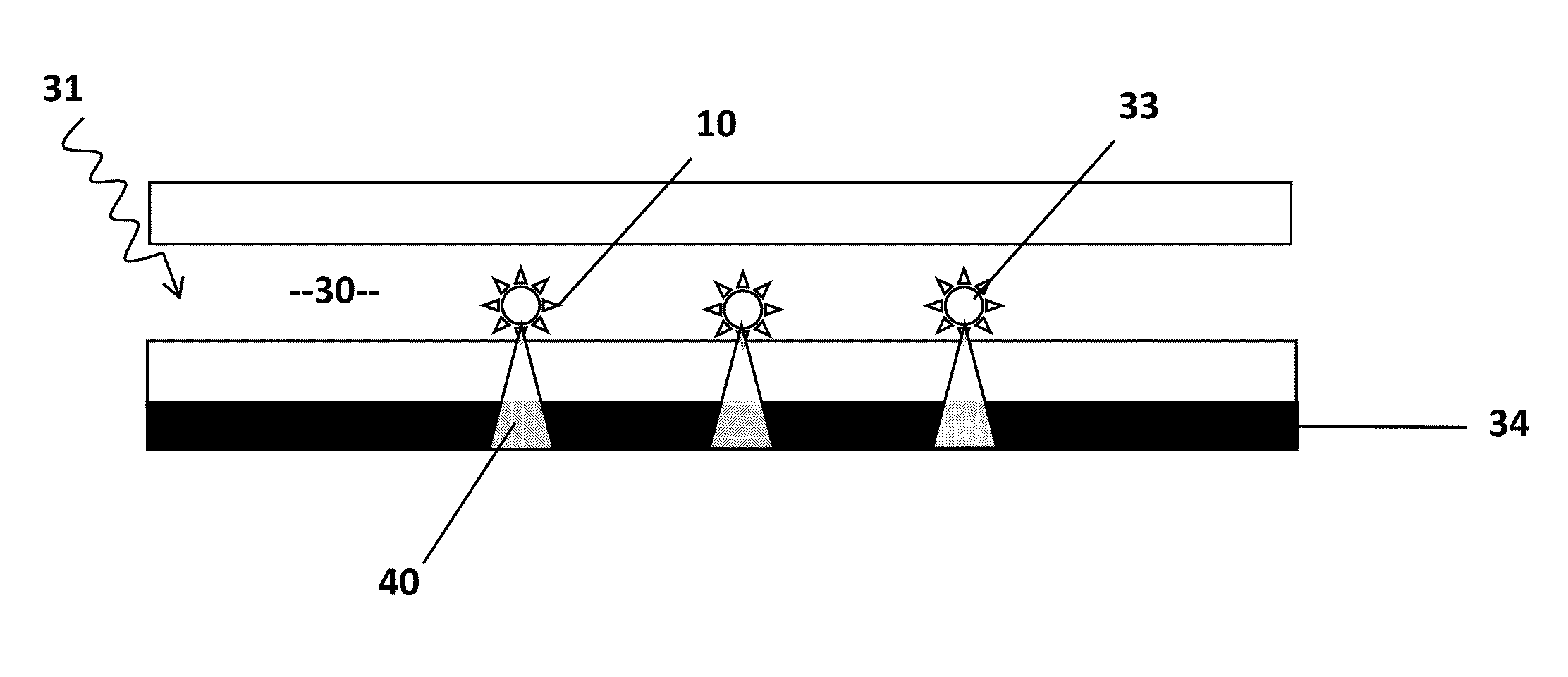

InactiveUS20060264779A1Reduce Optical InterferenceSatisfies needCompound screeningApoptosis detectionMedical deviceOptical barrier

Owner:GOLDEN DIAGNOSTICS TOP CORP +2

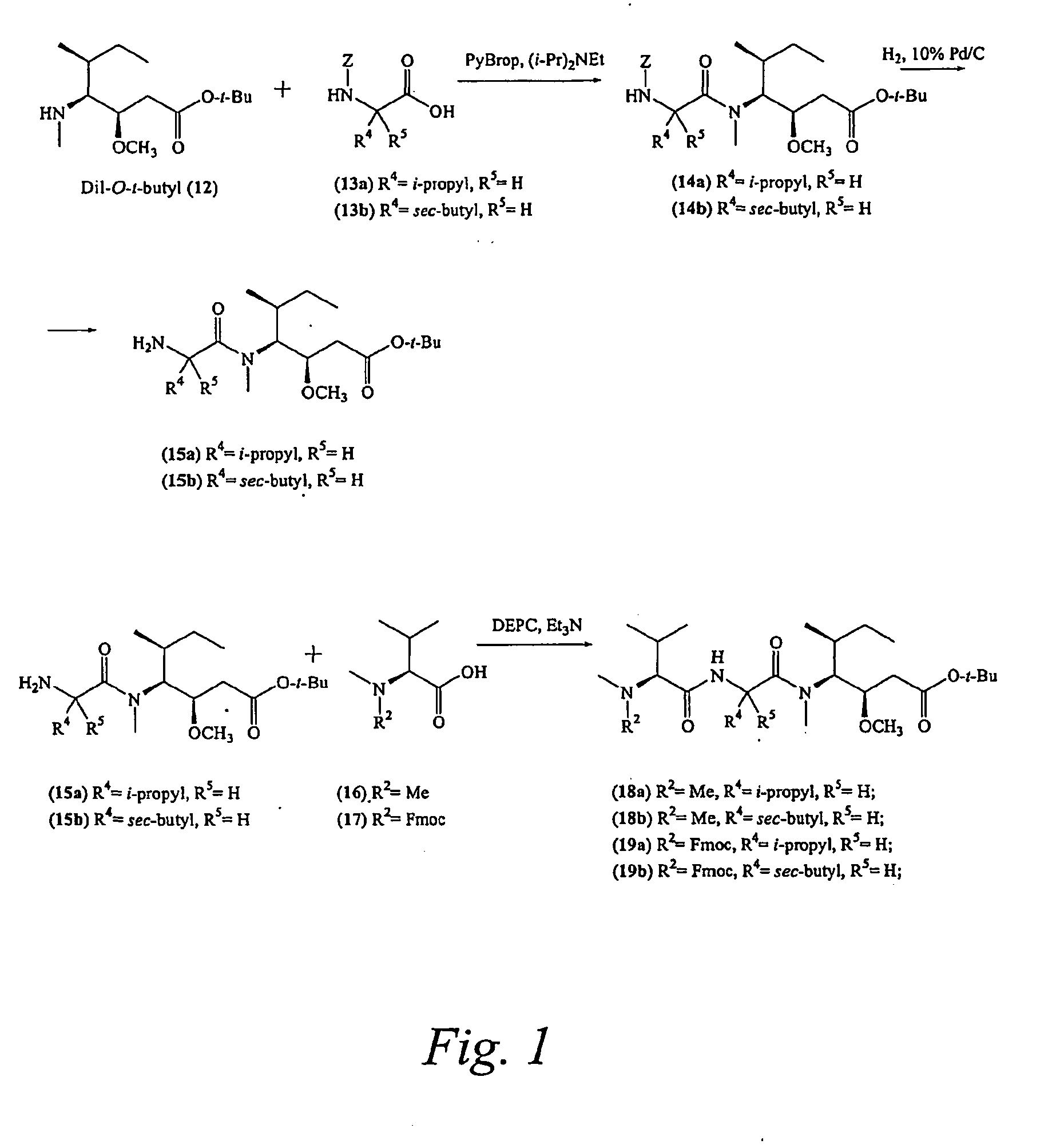

Pentapeptide compounds and uses related thereto

InactiveUS7256257B2Organic active ingredientsPeptide/protein ingredientsCytotoxicityCombinatorial chemistry

Pentapeptide compounds are disclosed. The compounds have biological activity, e.g., cytotoxicity. Prodrugs having targeting groups and pentapeptide moieities, as well as precursors thereof are also disclosed. For example, precursors having a reactive linker that can serve as a reaction site for joining to a targeting agent, e.g., an antibody, as disclosed.

Owner:SEAGEN INC

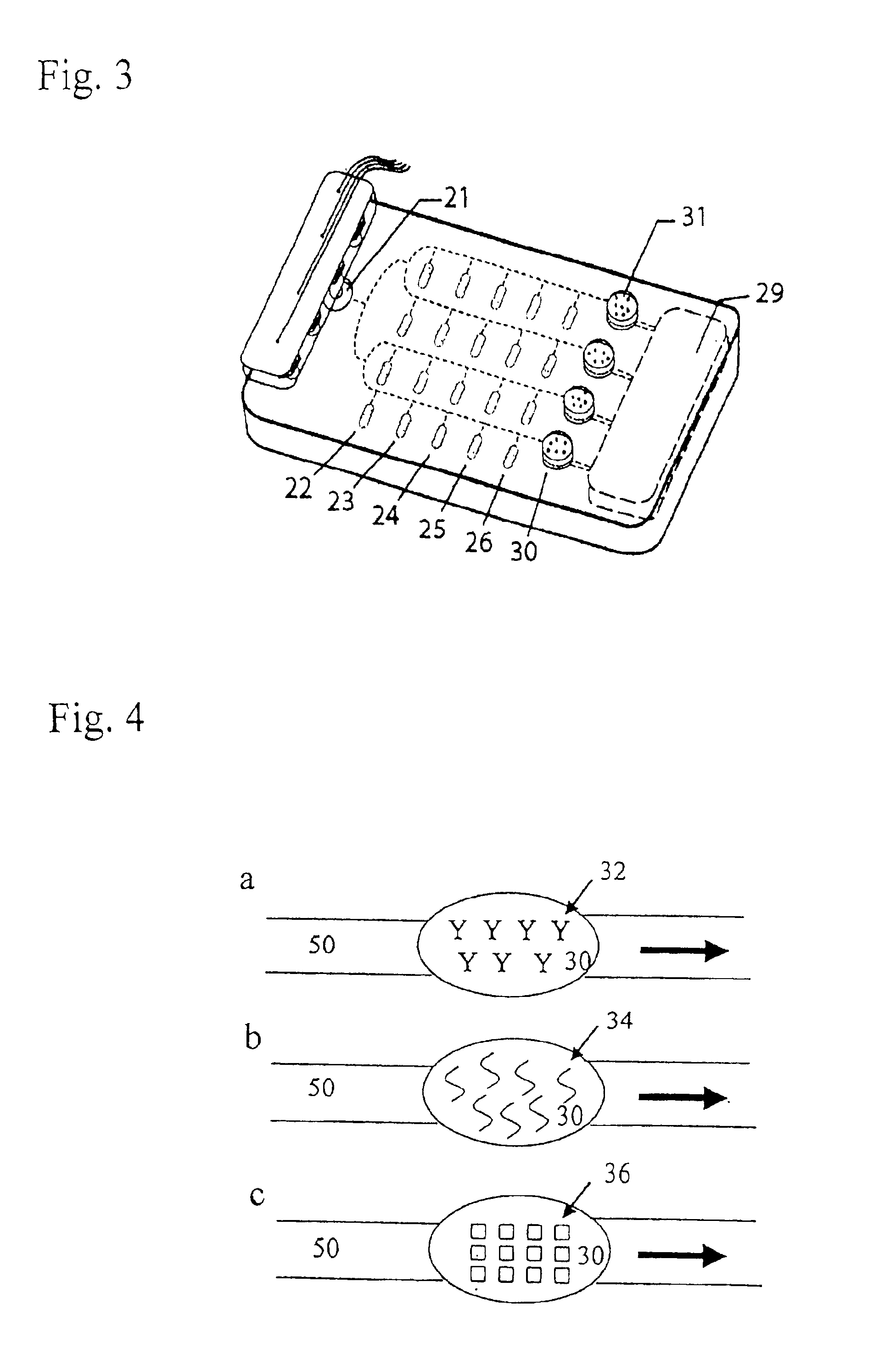

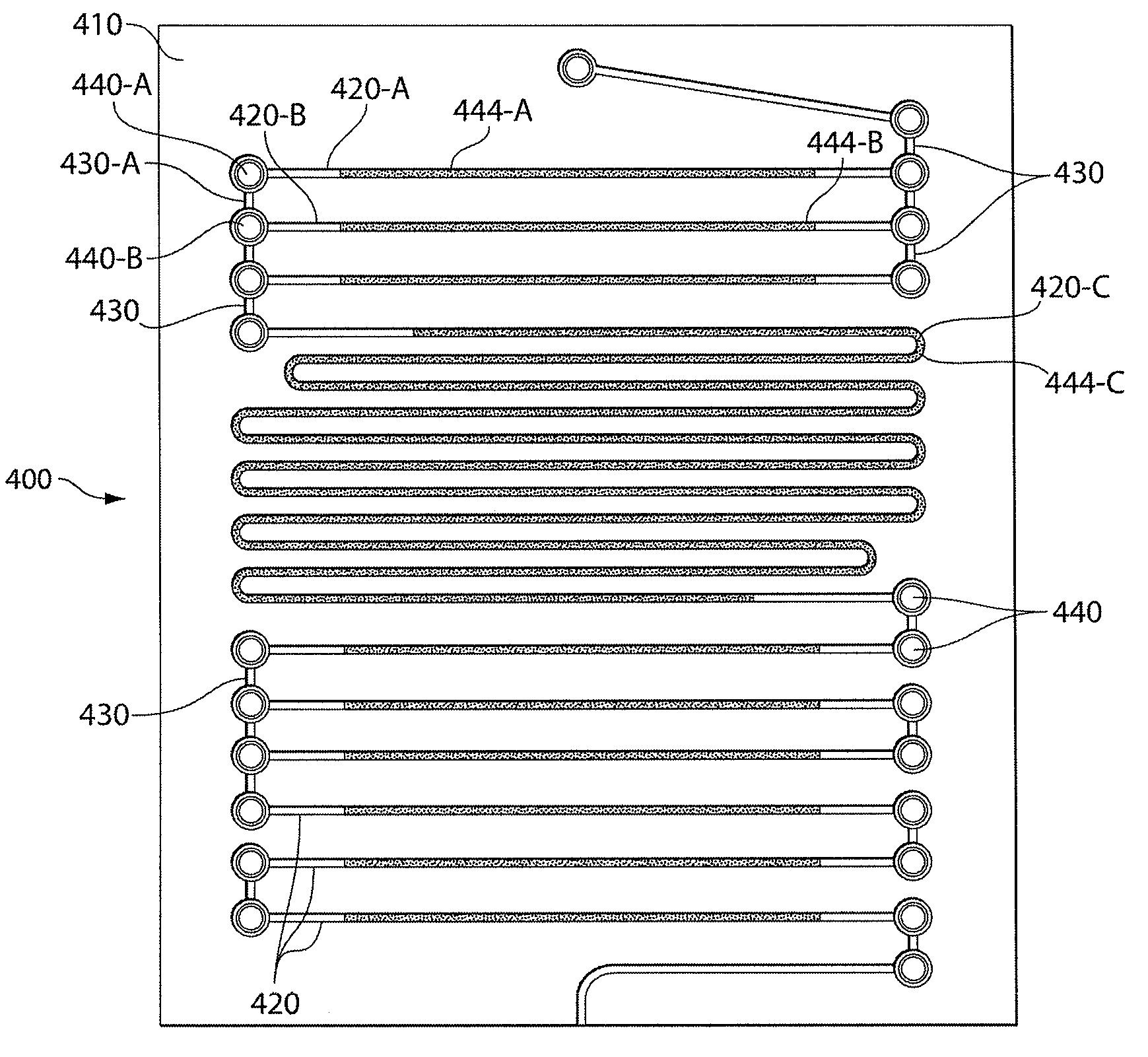

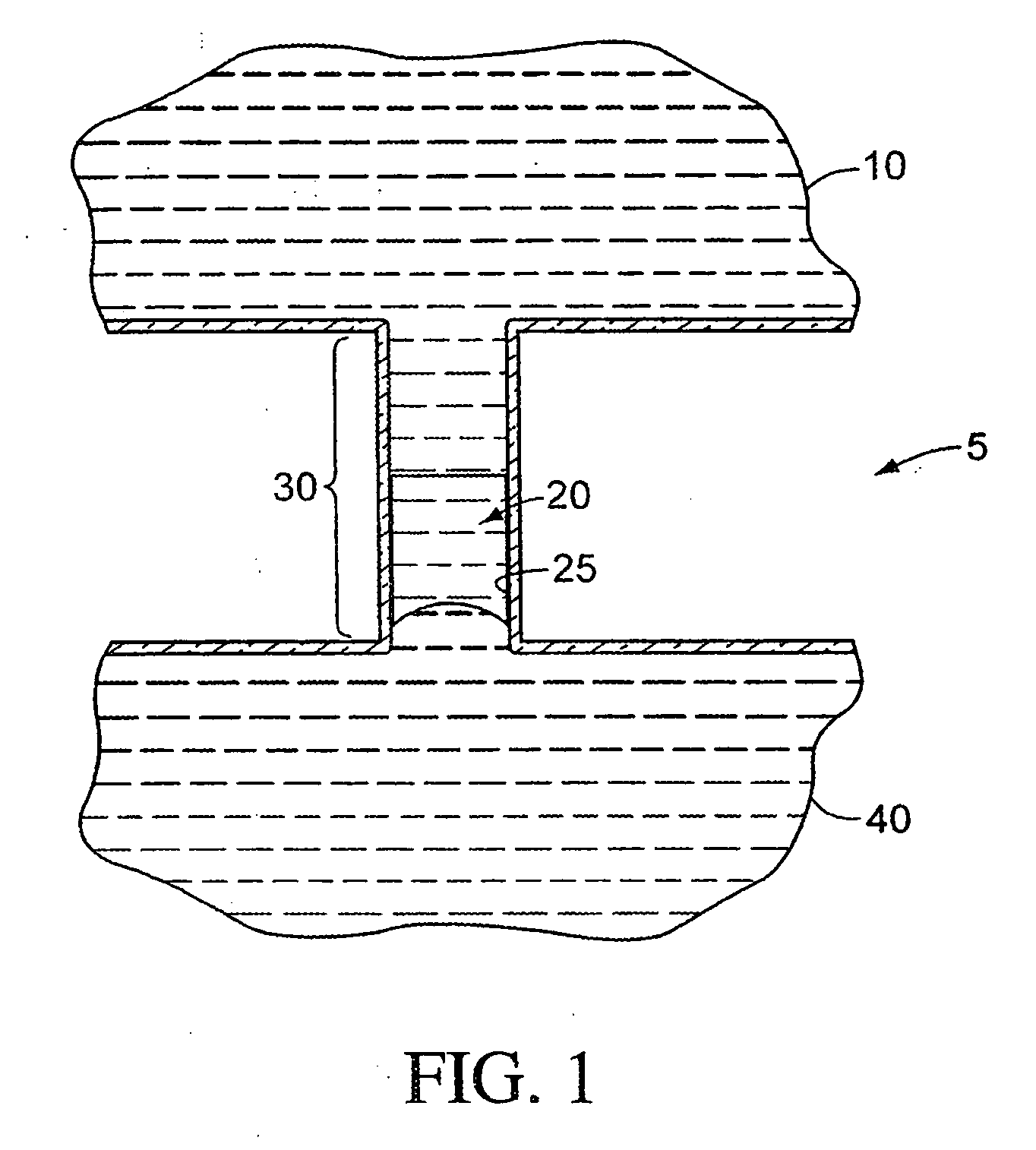

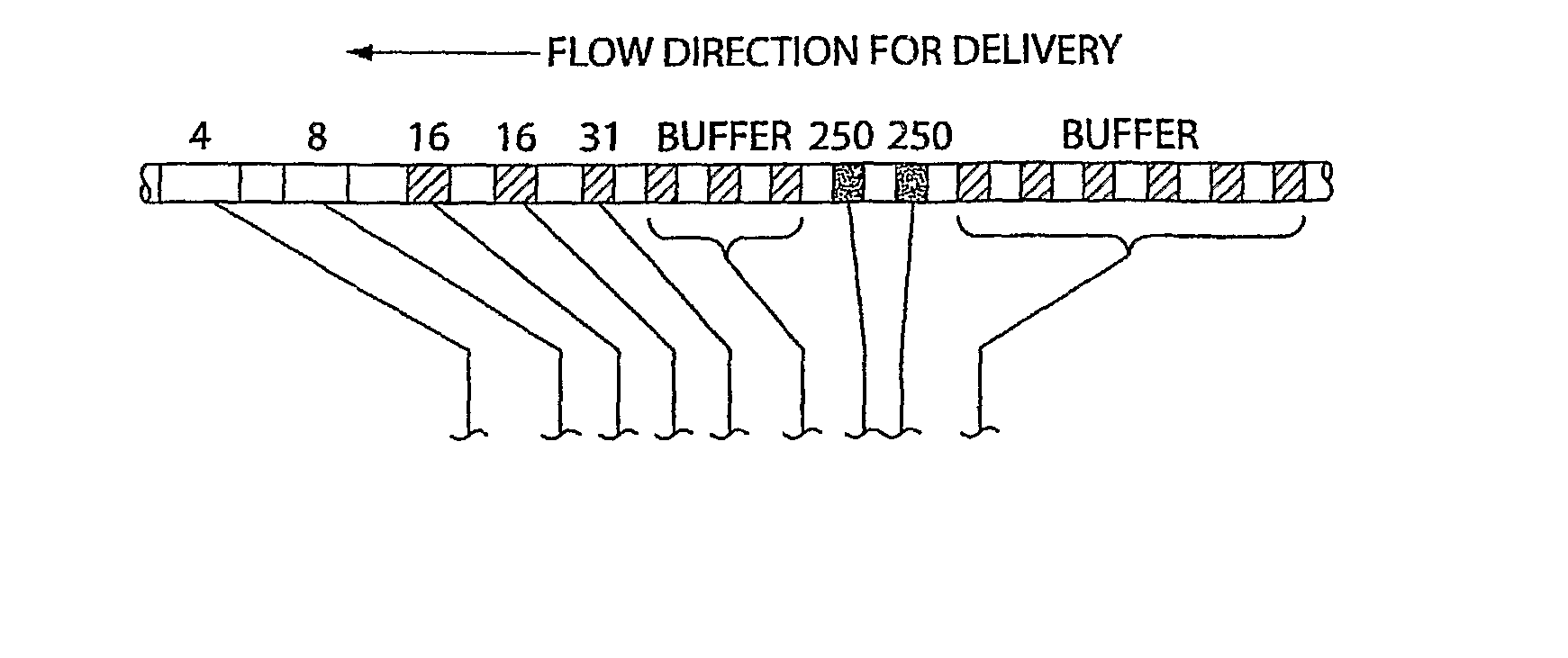

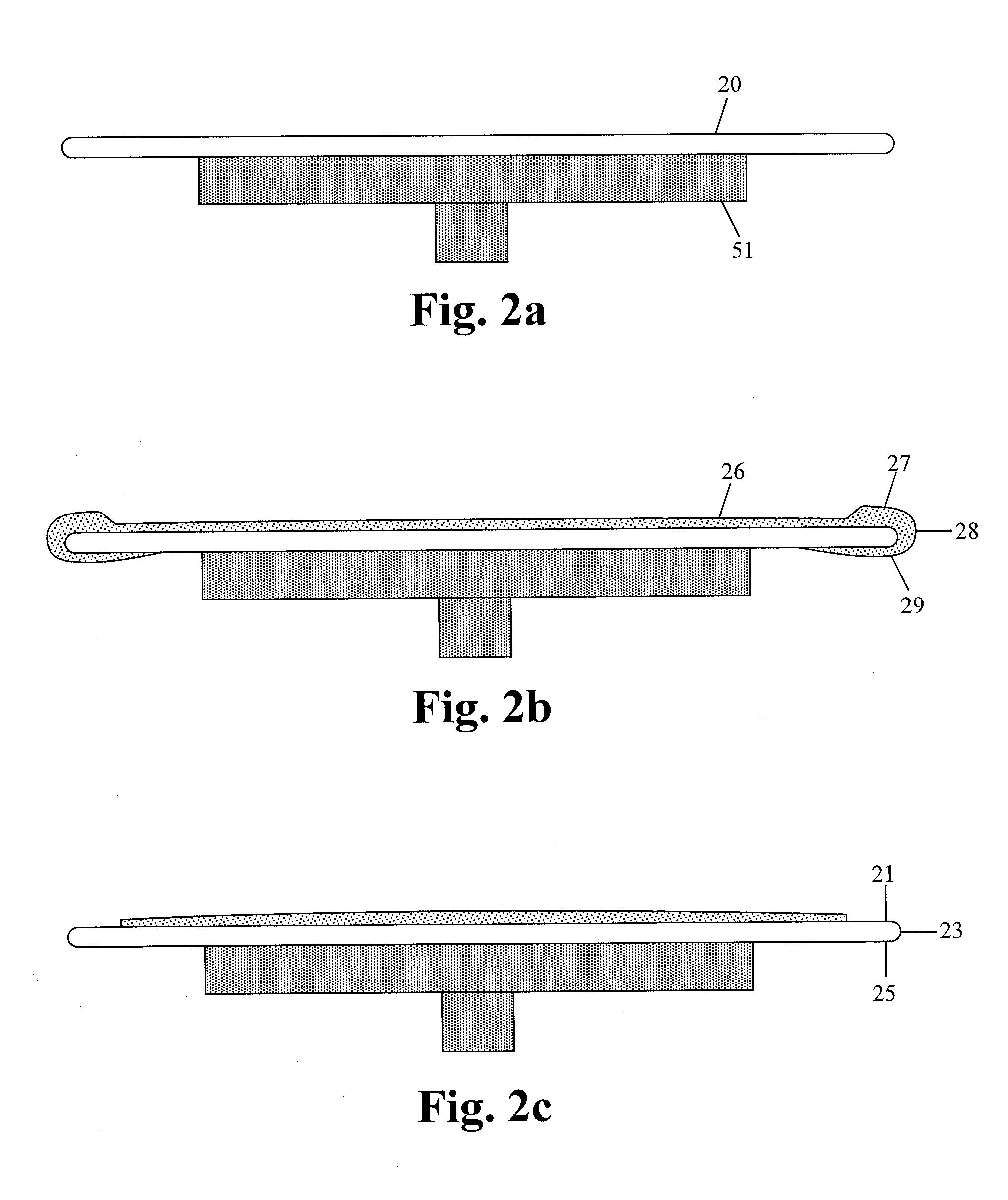

Reagent storage in microfluidic systems and related articles and methods

ActiveUS20100158756A1Prevent evaporation and contaminationComponent separationLaboratory glasswaresReagentReaction site

Fluidic devices and methods including those that provide storage and / or facilitate fluid handling of reagents are provided. Fluidic devices described herein may include channel segments positioned on two sides of an article, optionally connected by an intervening channel passing through the article. The channel segments may be used to store reagents in the device prior to first use by an end user. The stored reagents may include fluid plugs positioned in linear order so that during use, as fluids flow to a reaction site, they are delivered in a predetermined sequence. The specific geometries of the channel segments and the positions of the channel segments within the fluidic devices described herein may allow fluid reagents to be stored for extended periods of time without mixing, even during routine handling of the devices such as during shipping of the devices, and when the devices are subjected to physical shock or vibration.

Owner:OPKO DIAGNOSTICS

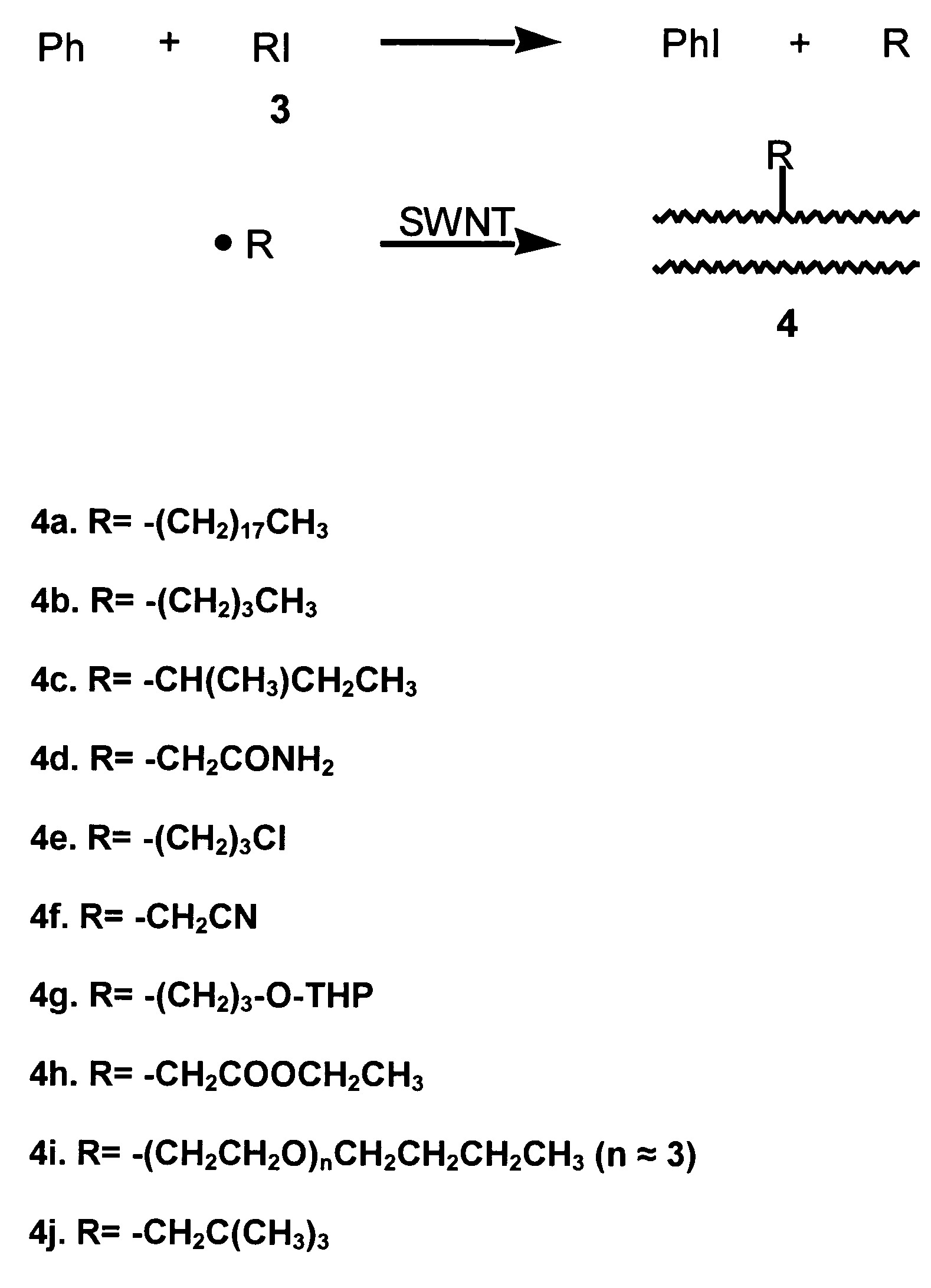

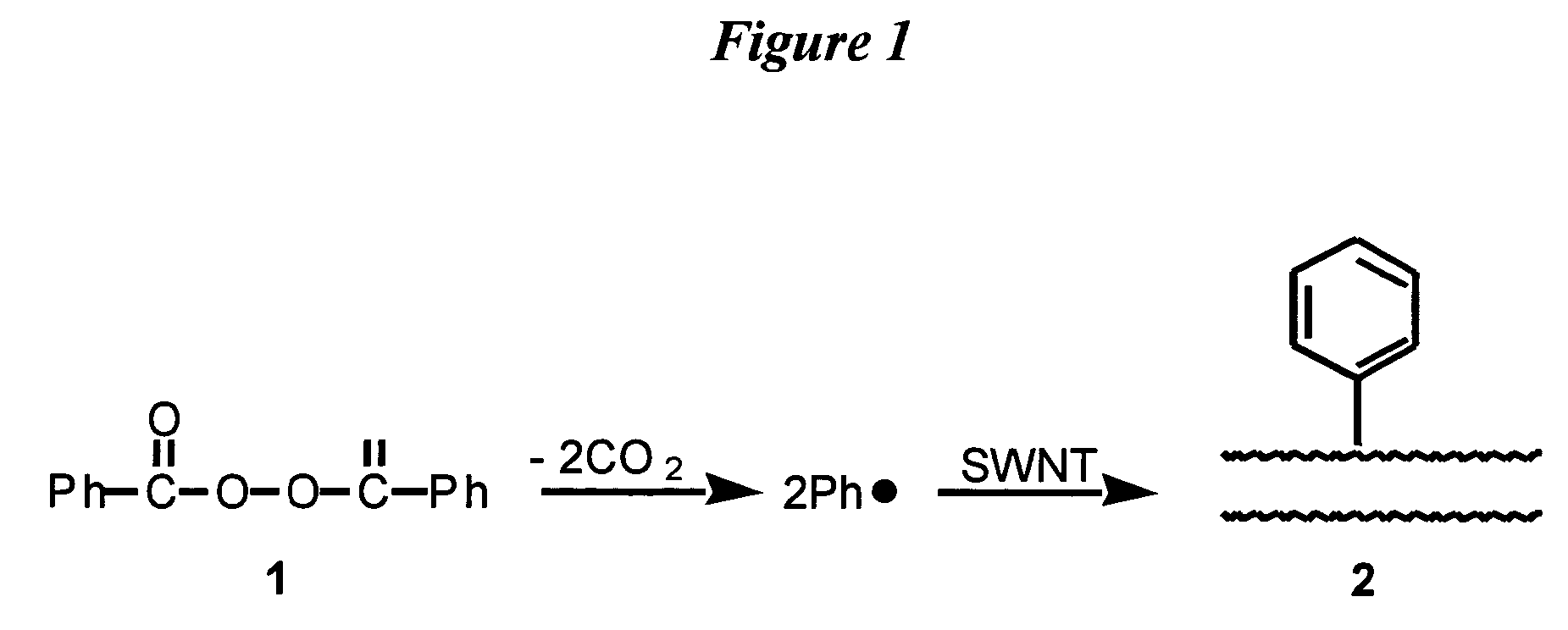

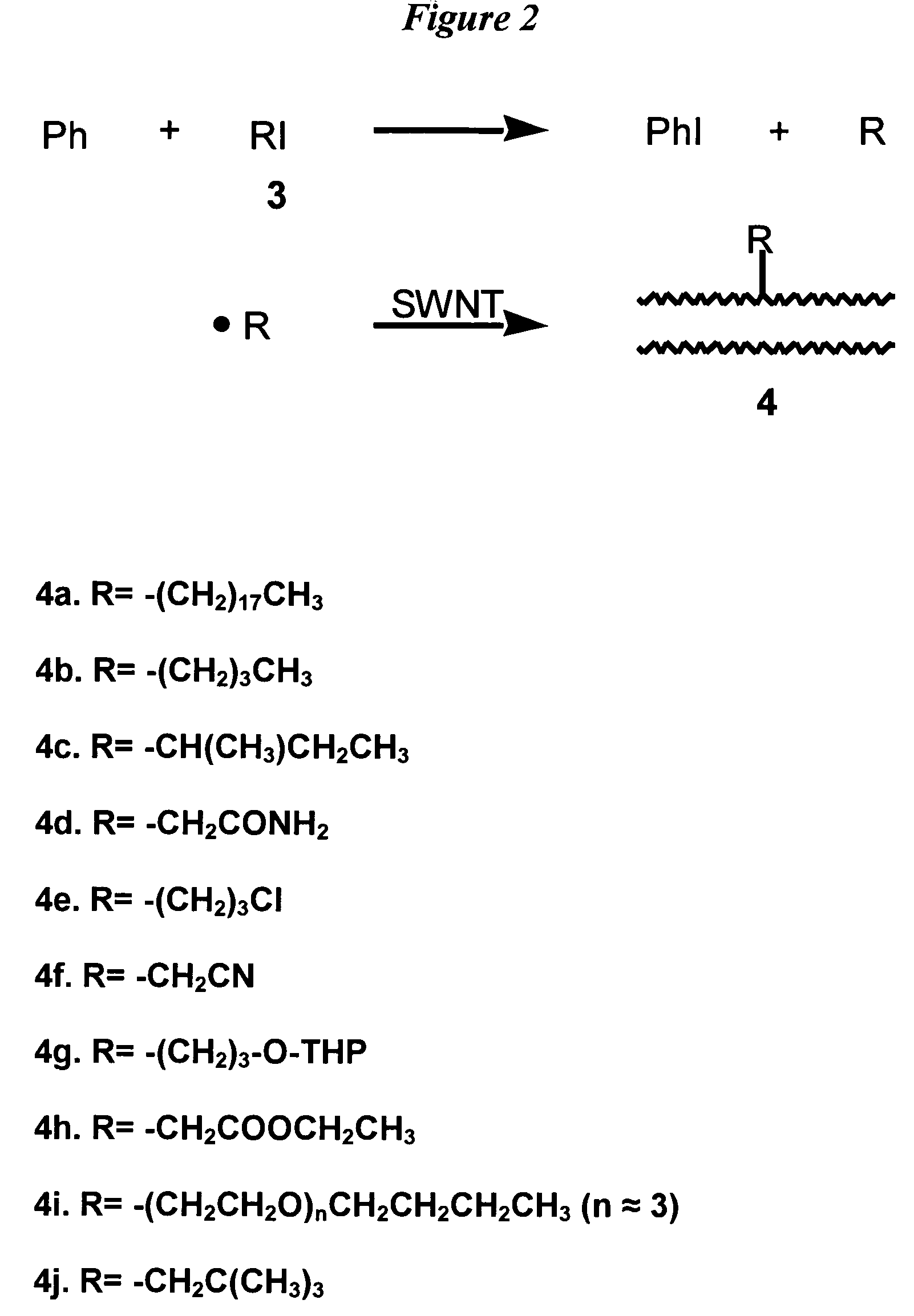

Method for functionalizing carbon nanotubes utilizing peroxides

ActiveUS7125533B2Good dispersionSimple materialMaterial nanotechnologyPigmenting treatmentCarbon centered radicalsAcyl group

A method for functionalizing the wall of single-wall or multi-wall carbon nanotubes involves the use of acyl peroxides to generate carbon-centered free radicals. The method allows for the chemical attachment of a variety of functional groups to the wall or end cap of carbon nanotubes through covalent carbon bonds without destroying the wall or endcap structure of the nanotube. Carbon-centered radicals generated from acyl peroxides can have terminal functional groups that provide sites for further reaction with other compounds. Organic groups with terminal carboxylic acid functionality can be converted to an acyl chloride and further reacted with an amine to form an amide or with a diamine to form an amide with terminal amine. The reactive functional groups attached to the nanotubes provide improved solvent dispersibility and provide reaction sites for monomers for incorporation in polymer structures. The nanotubes can also be functionalized by generating free radicals from organic sulfoxides.

Owner:RICE UNIV

Reagent storage in microfluidic systems and related articles and methods

ActiveUS8591829B2Prevent evaporation and contaminationComponent separationLaboratory glasswaresEngineeringReagent

Fluidic devices and methods including those that provide storage and / or facilitate fluid handling of reagents are provided. Fluidic devices described herein may include channel segments positioned on two sides of an article, optionally connected by an intervening channel passing through the article. The channel segments may be used to store reagents in the device prior to first use by an end user. The stored reagents may include fluid plugs positioned in linear order so that during use, as fluids flow to a reaction site, they are delivered in a predetermined sequence. The specific geometries of the channel segments and the positions of the channel segments within the fluidic devices described herein may allow fluid reagents to be stored for extended periods of time without mixing, even during routine handling of the devices such as during shipping of the devices, and when the devices are subjected to physical shock or vibration.

Owner:OPKO DIAGNOSTICS

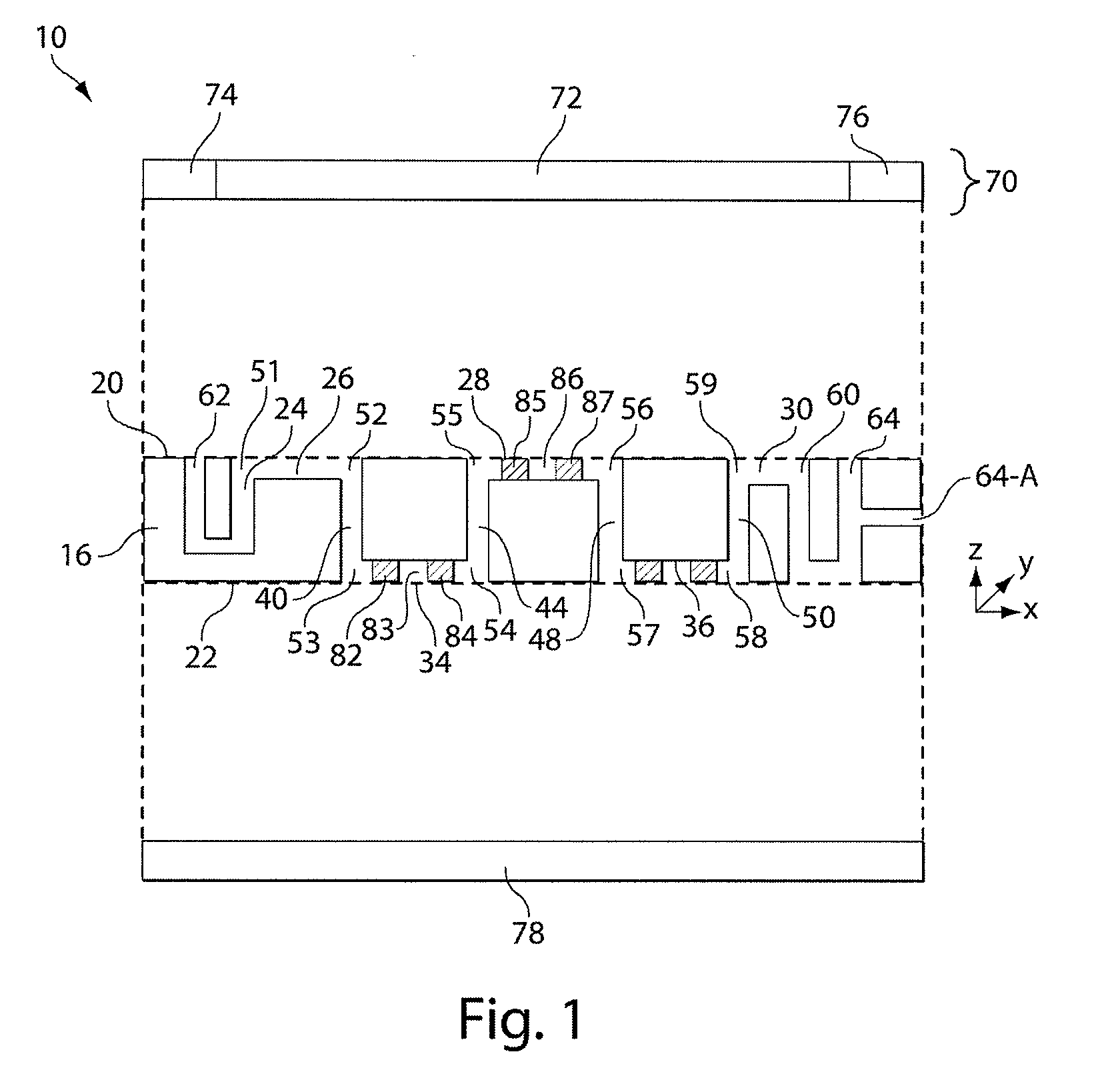

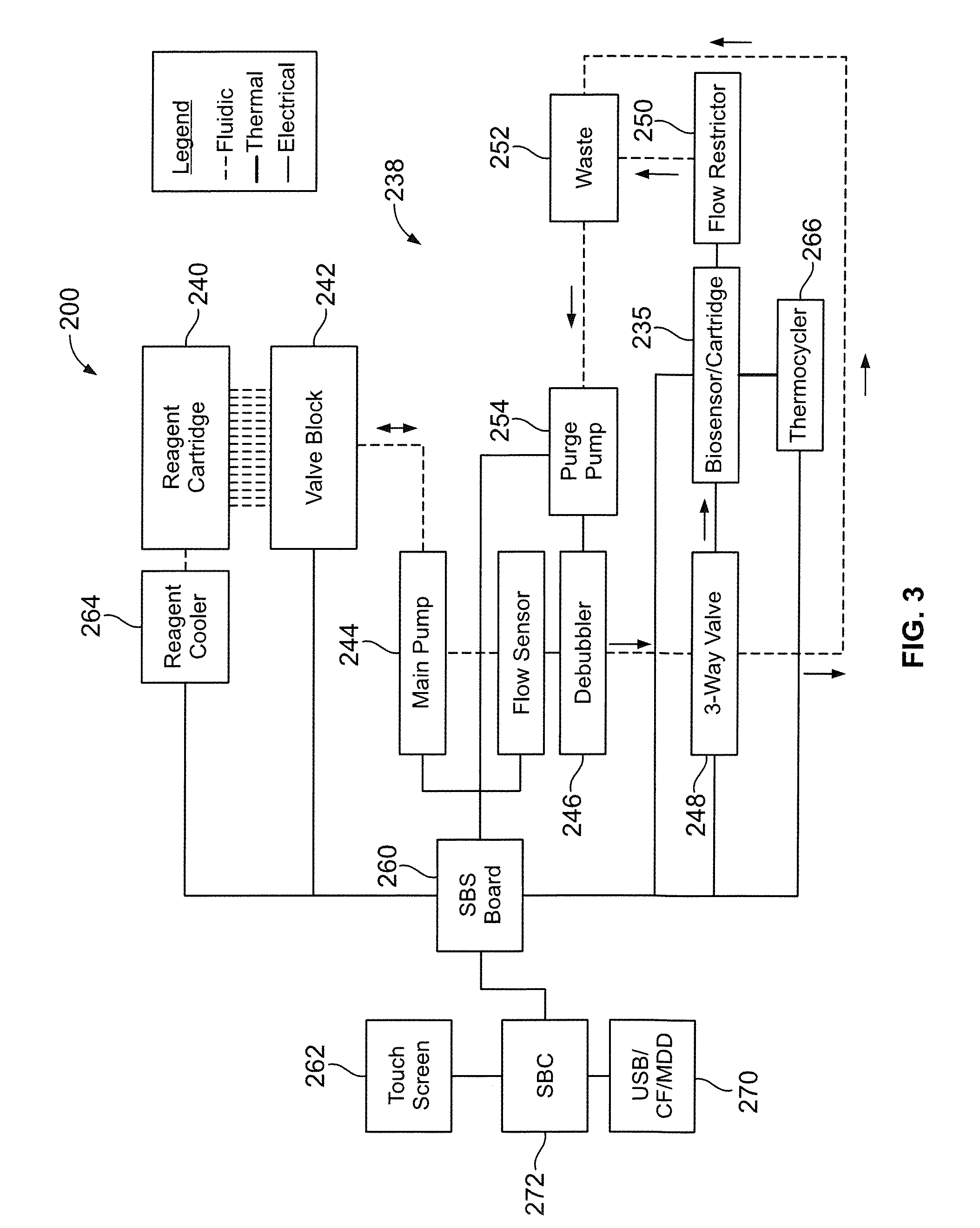

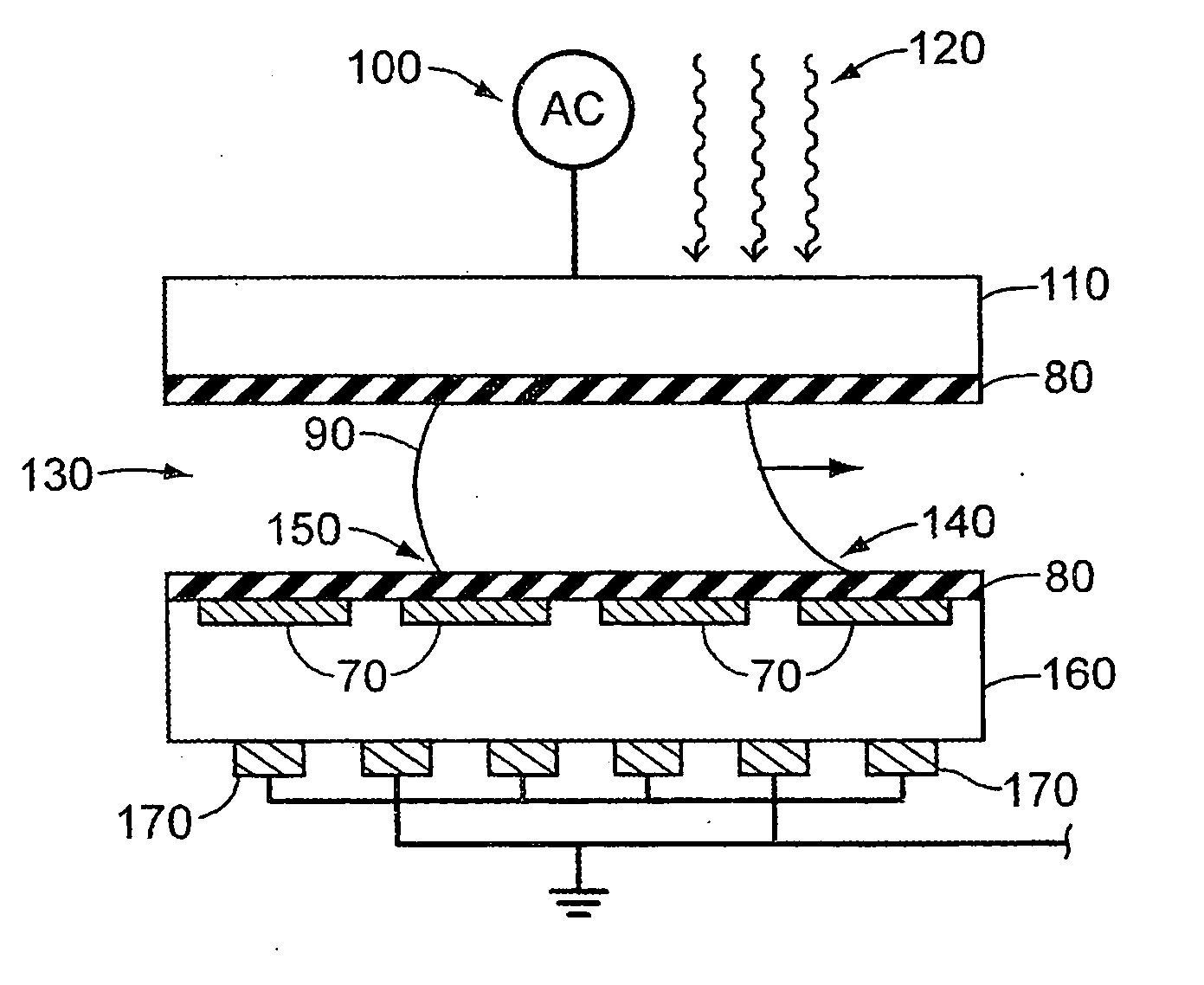

Biosensors for biological or chemical analysis and systems and methods for same

ActiveUS20150079596A1Bioreactor/fermenter combinationsBiological substance pretreatmentsLight signalBiosensor

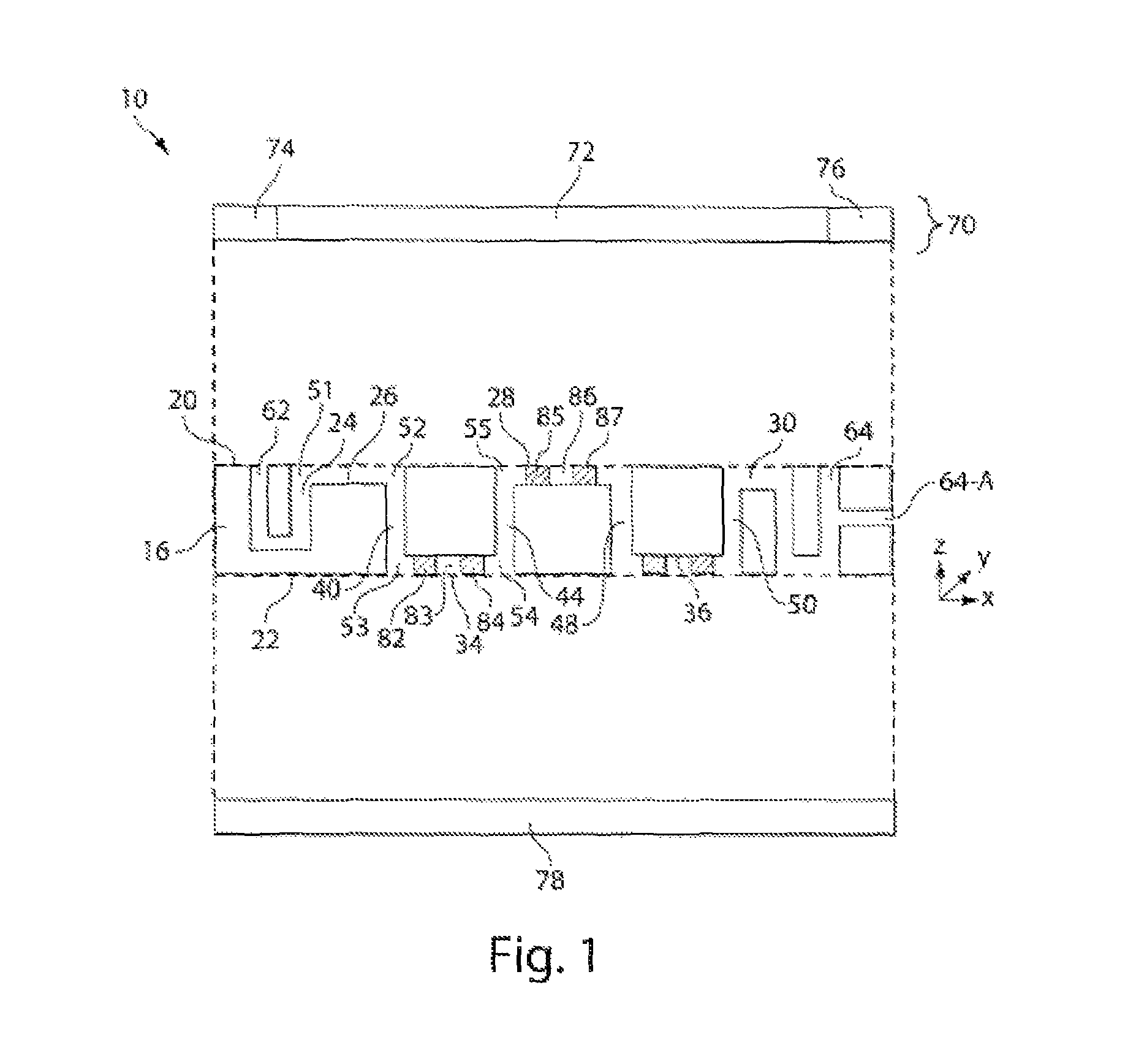

A biosensor is provided including a detection device and a flow cell mounted to the detection device. The detection device has a detector surface with a plurality of reaction sites. The detection device also includes a filter layer that is configured to at least one of (a) filter unwanted excitation light signals; (b) direct emission signals from a designated reaction site toward one or more associated light detectors that are configured to detect the emission signals from the designated reaction site; or (c) block or prevent detection of crosstalk emission signals from adjacent reaction sites.

Owner:ILLUMINA INC

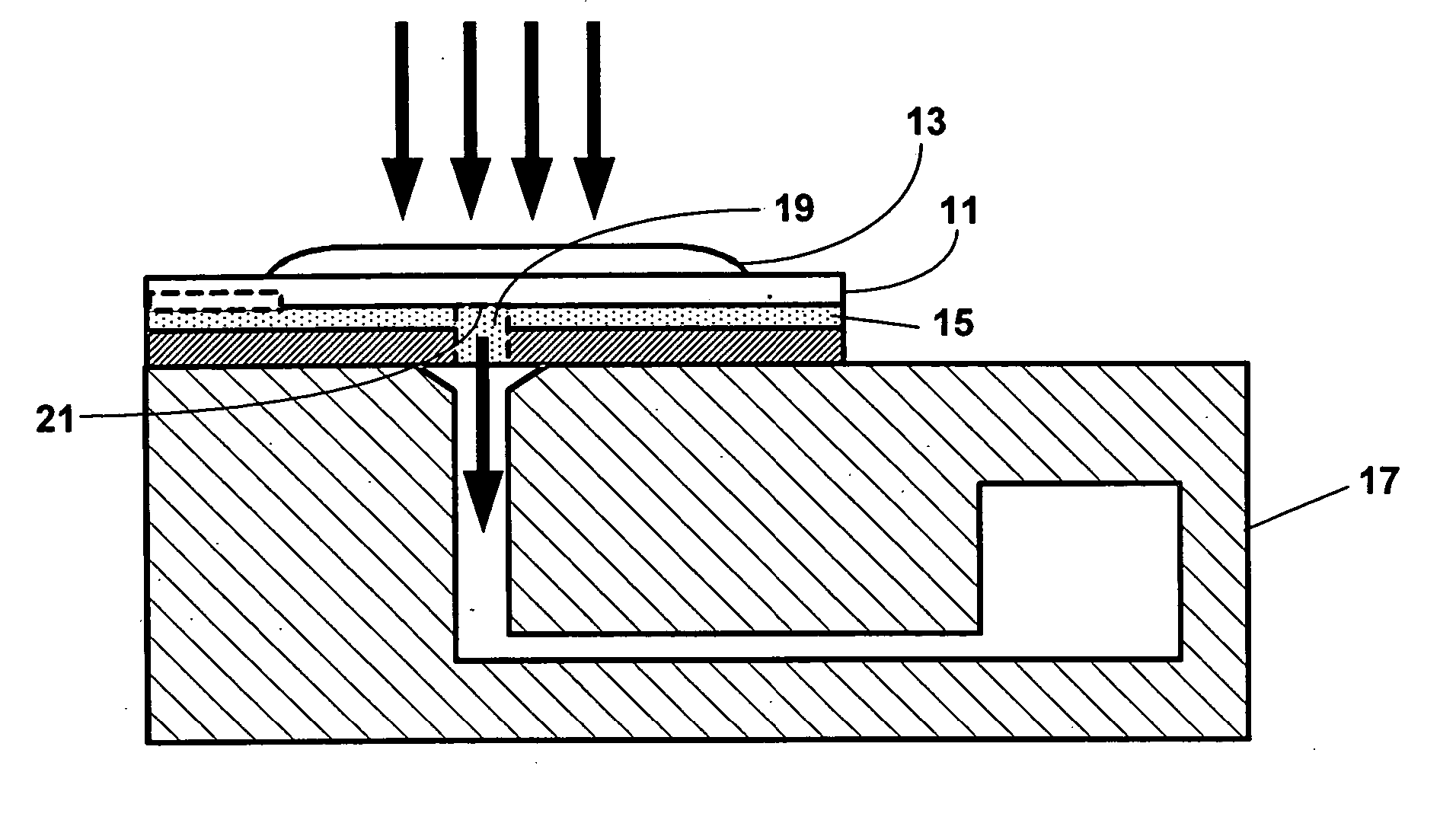

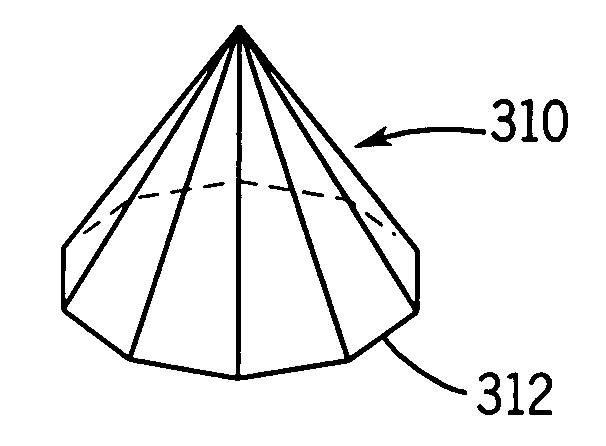

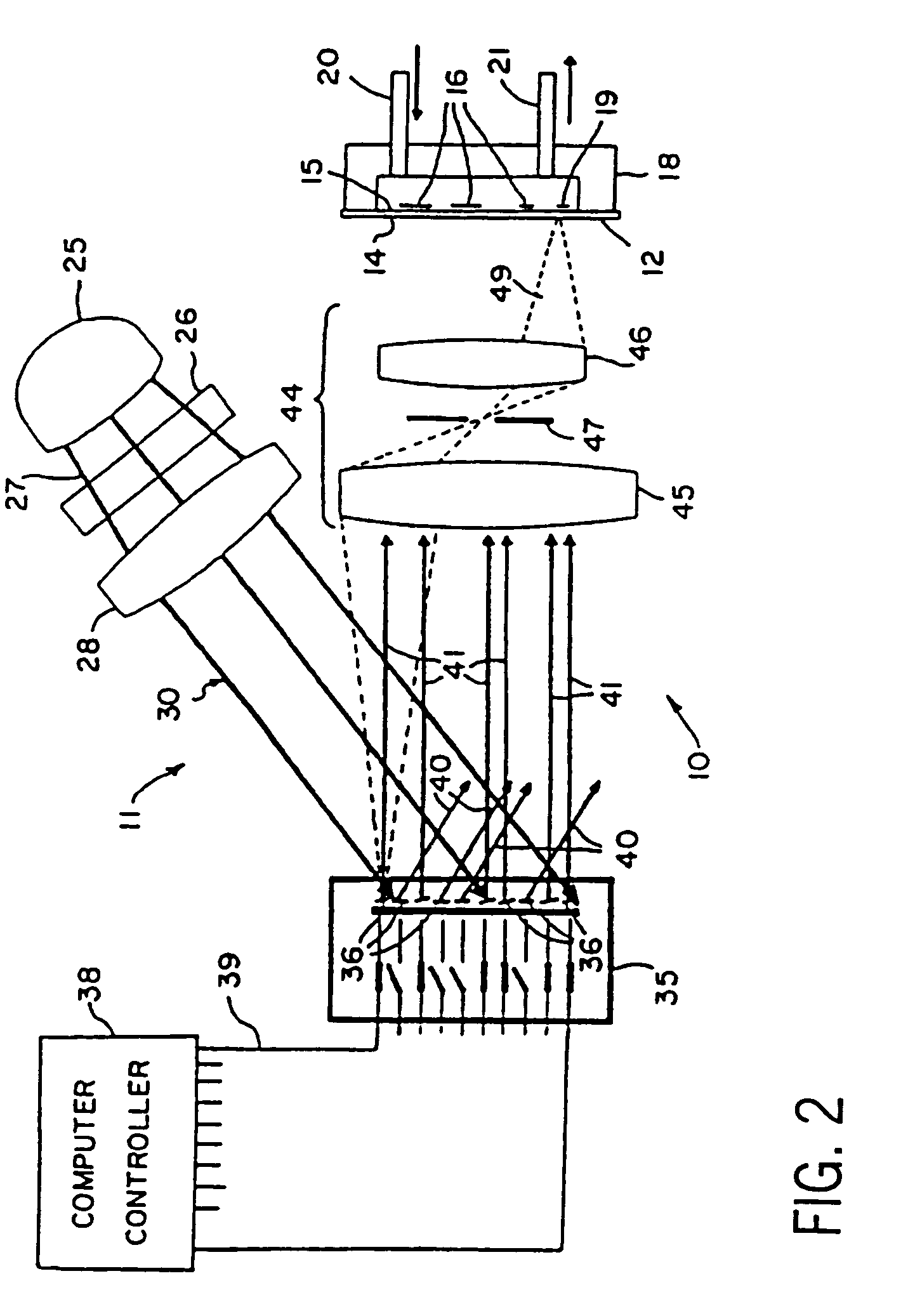

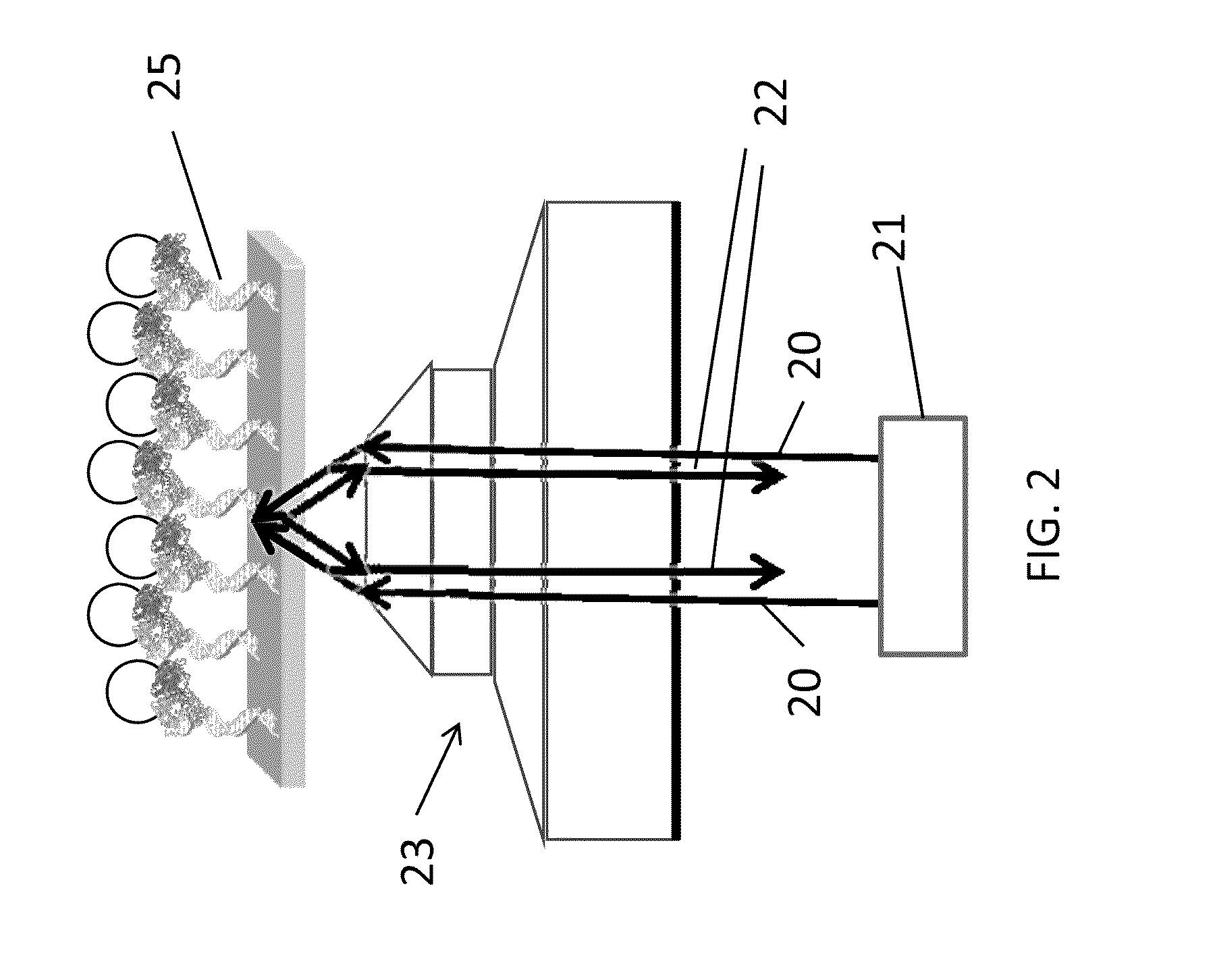

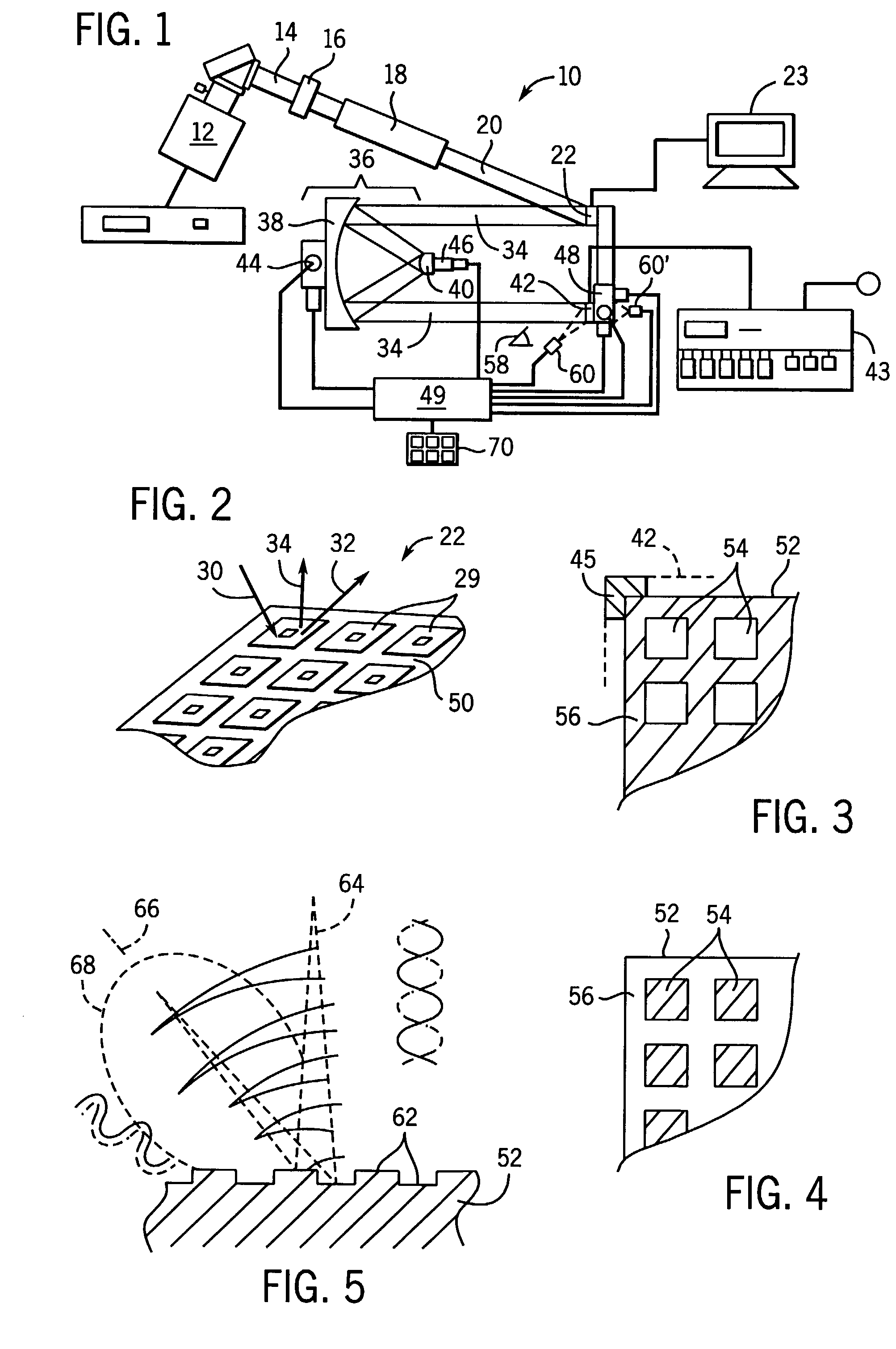

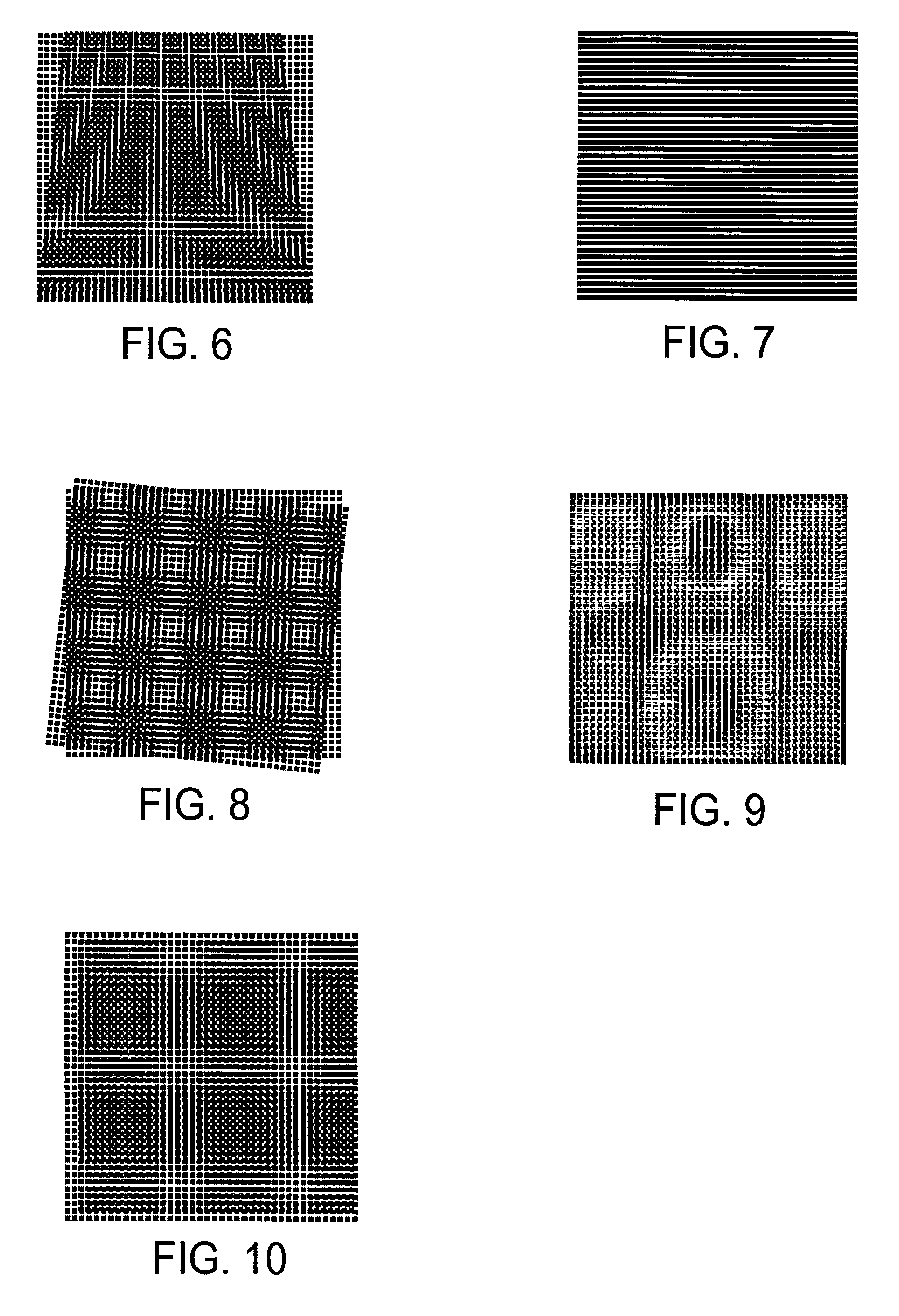

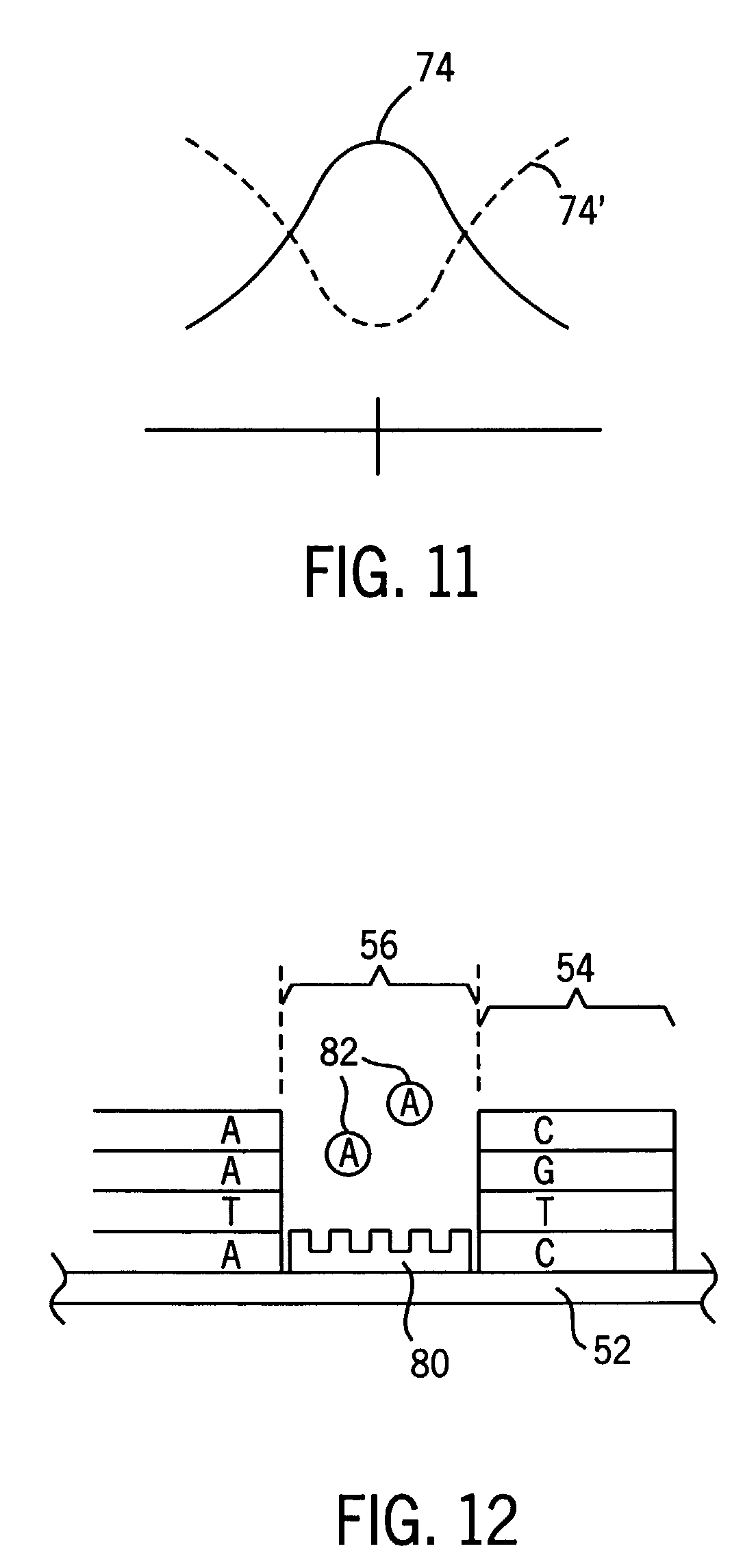

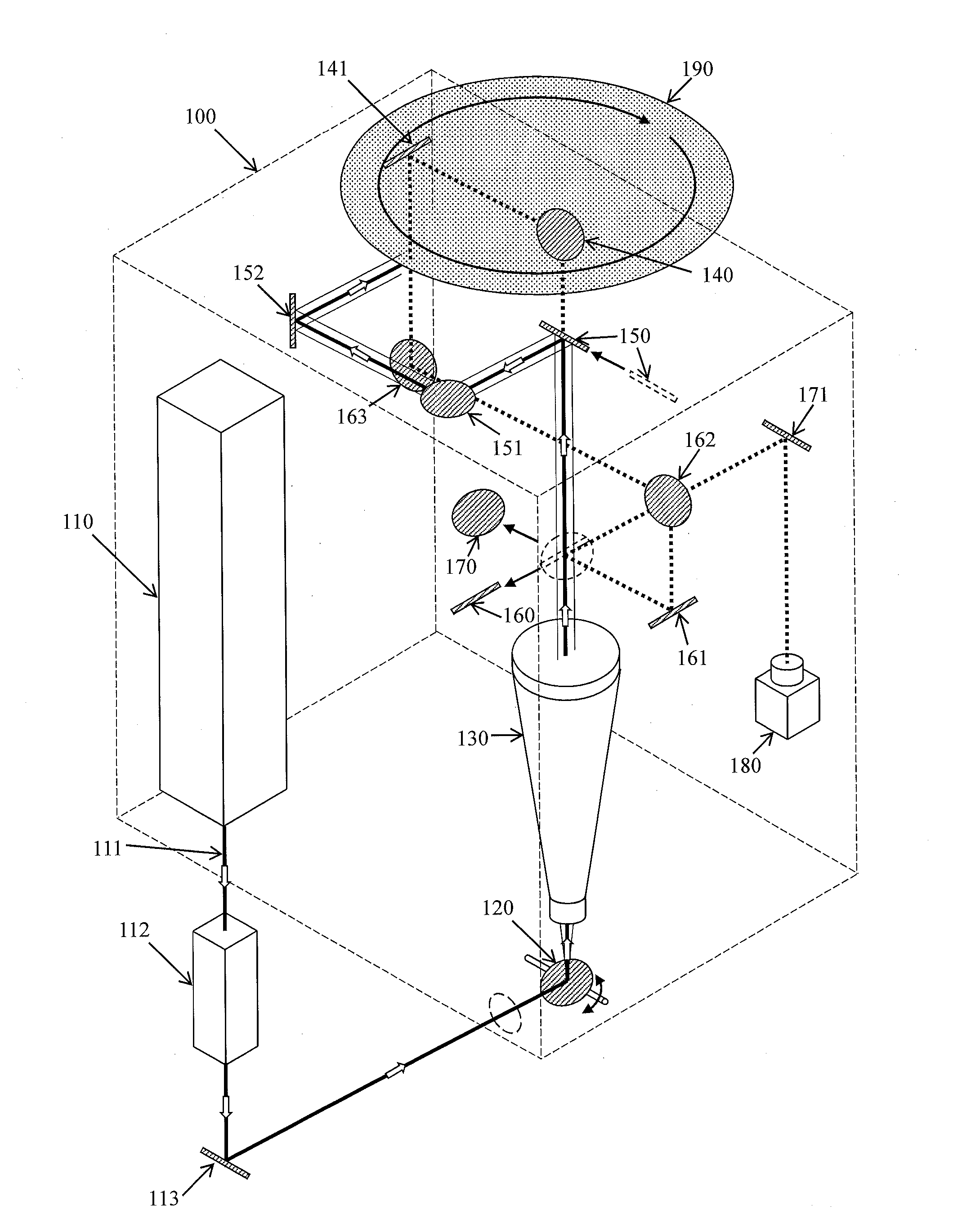

Apparatus for constructing DNA probes having a prismatic and kaleidoscopic light homogenizer

InactiveUS7037659B2Improve evenlyImprove uniformityBioreactor/fermenter combinationsMaterial nanotechnologyLight beamPrism

The present invention provides an apparatus for constructing arrays of DNA sequences using the image of a micromirror array projected on a reaction site using a highly uniform beam of light produced by a homogenizer formed of a prismatic refractive element followed by a kaleidoscopic element.

Owner:NIMBLEGEN SYST

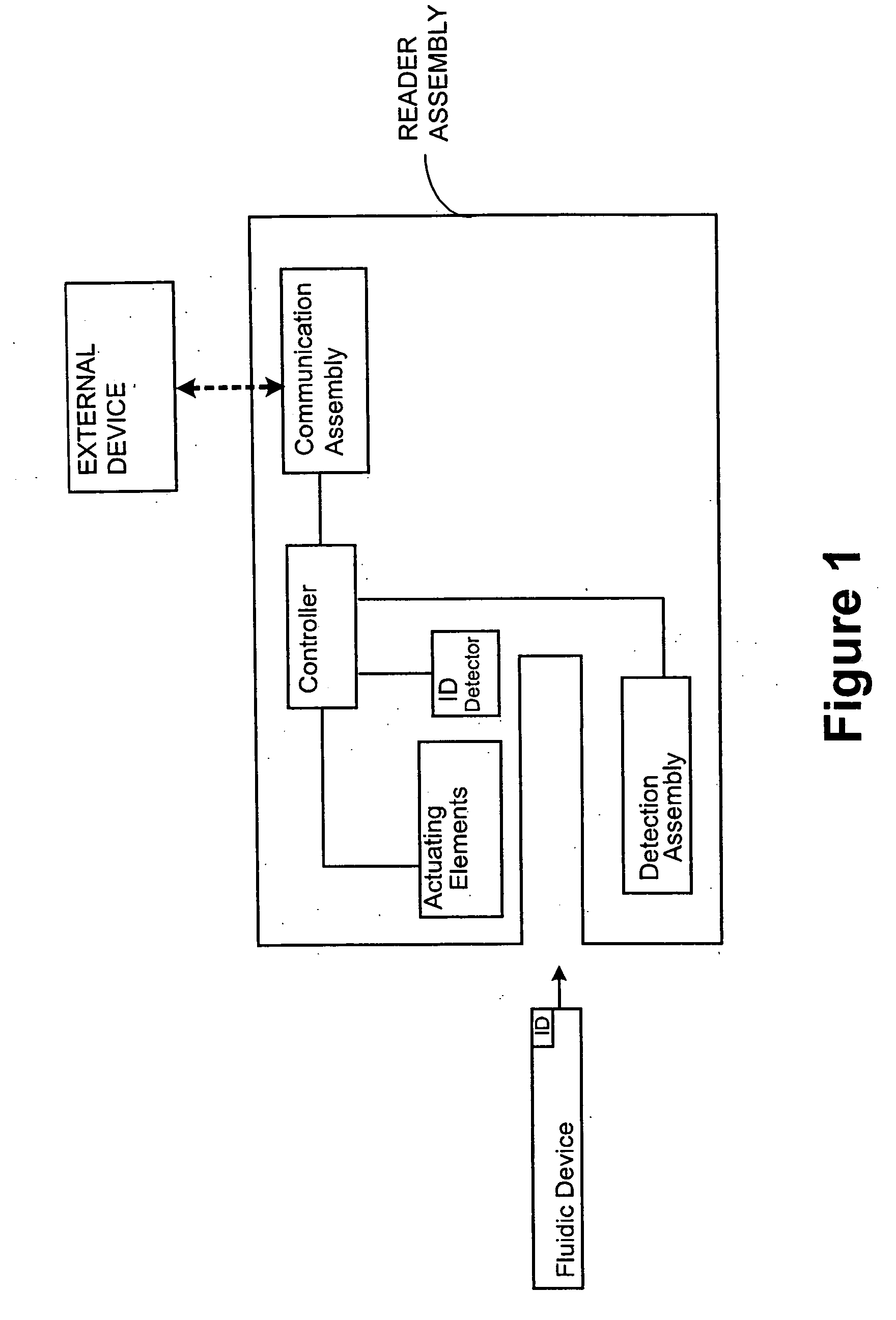

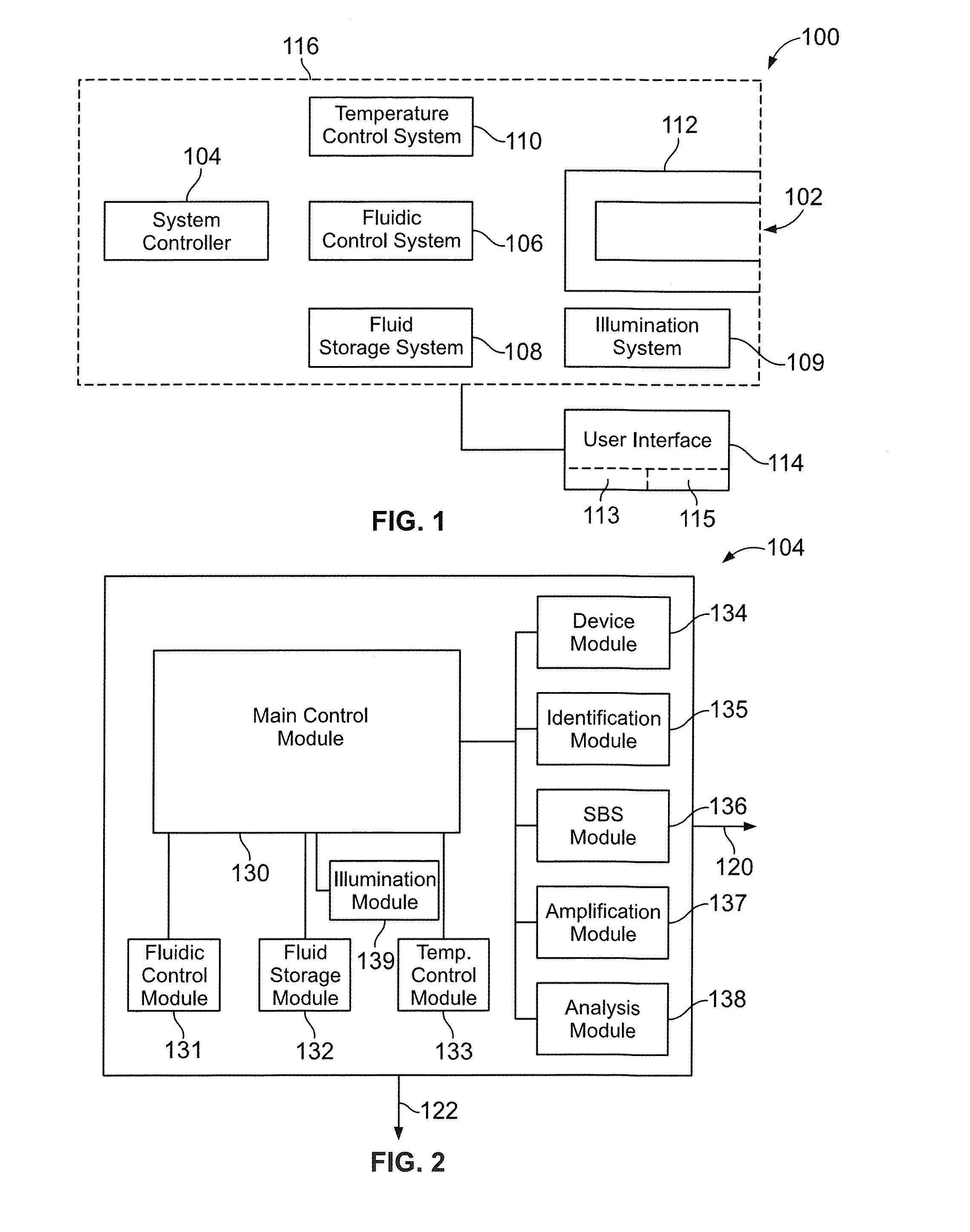

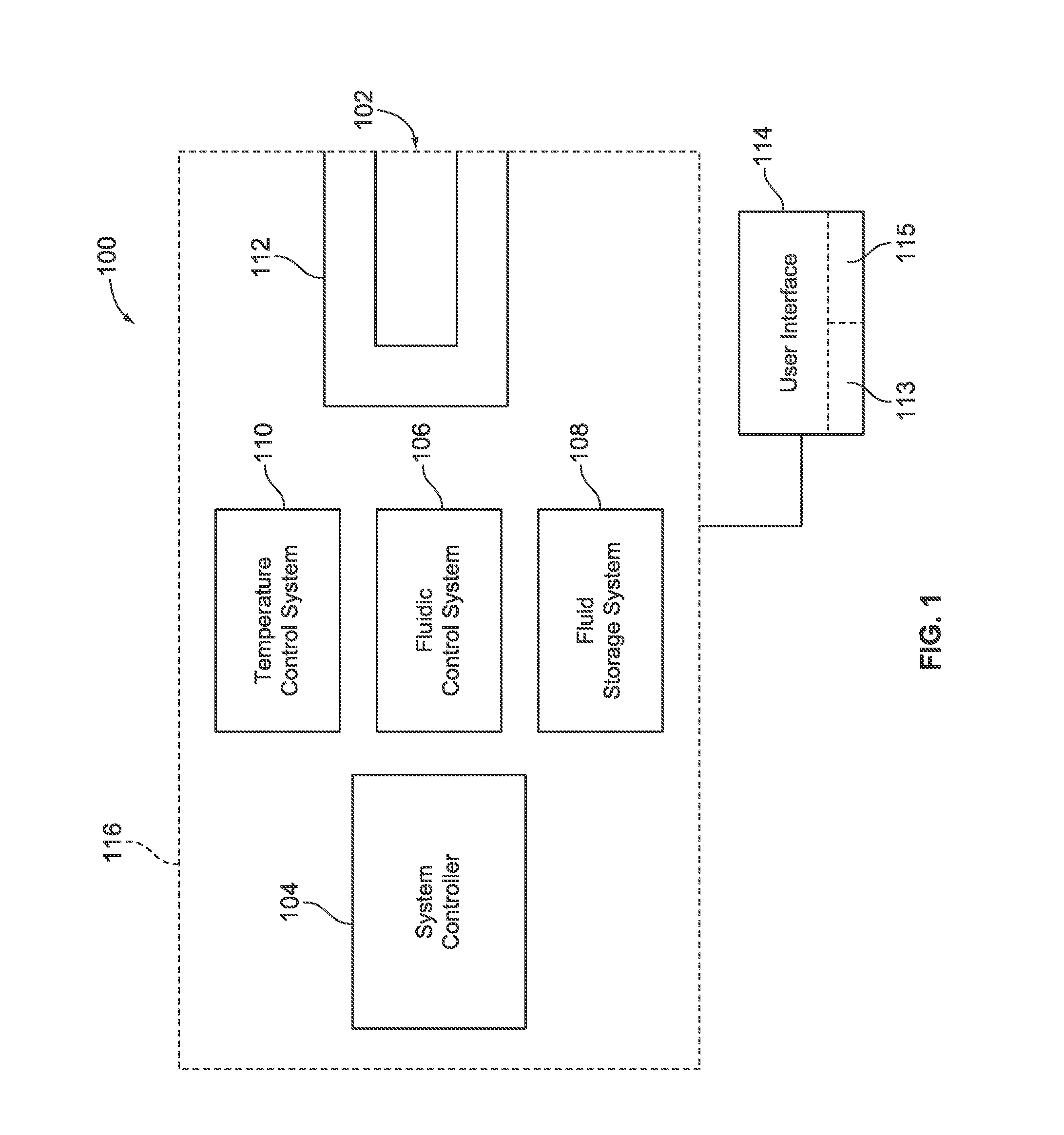

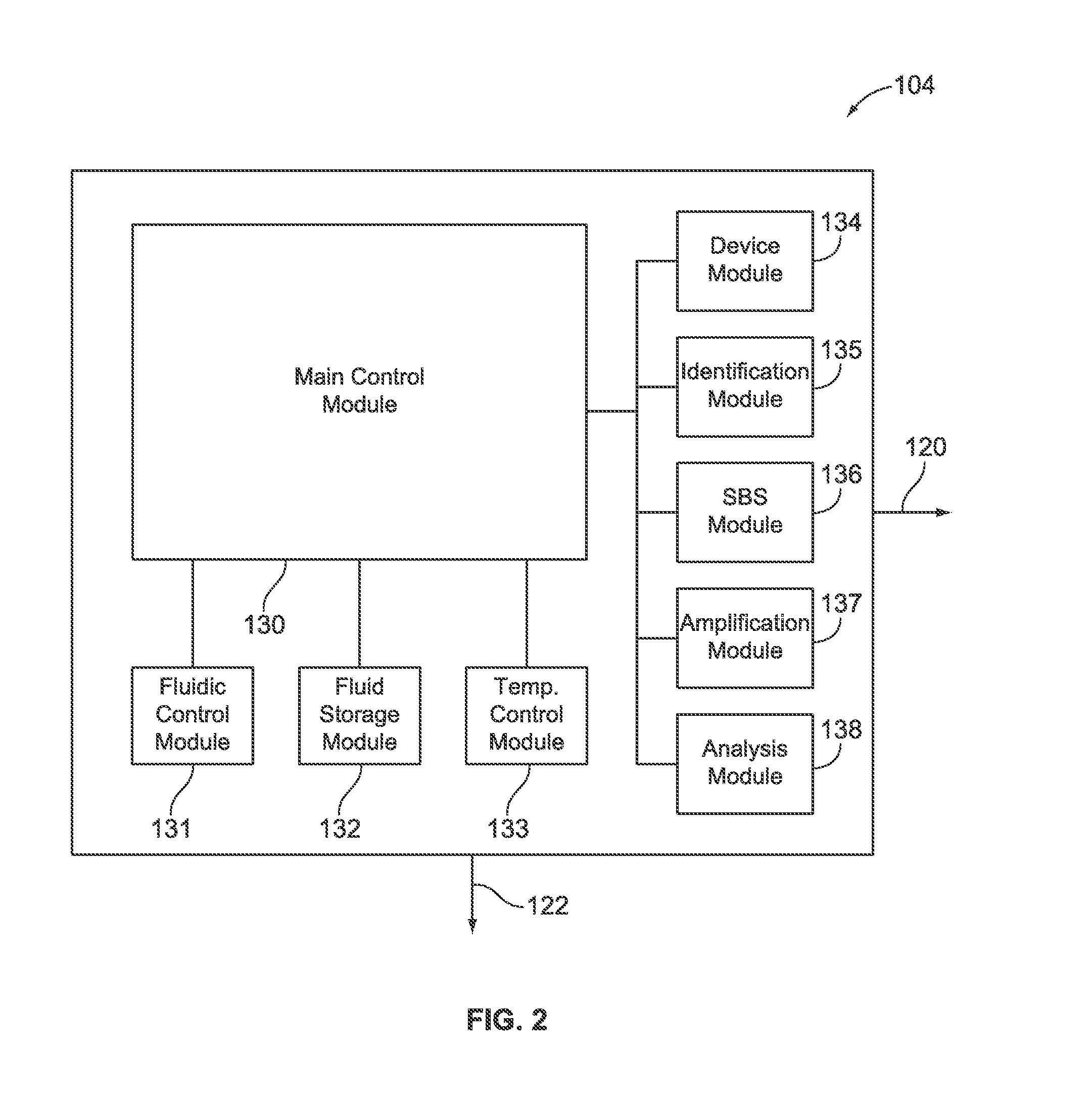

Microdevices and biosensor cartridges for biological or chemical analysis and systems and methods for the same

ActiveUS20130210682A1Low costEasy to controlHeating or cooling apparatusMicrobiological testing/measurementFlow cellMicro devices

Owner:ILLUMINA INC

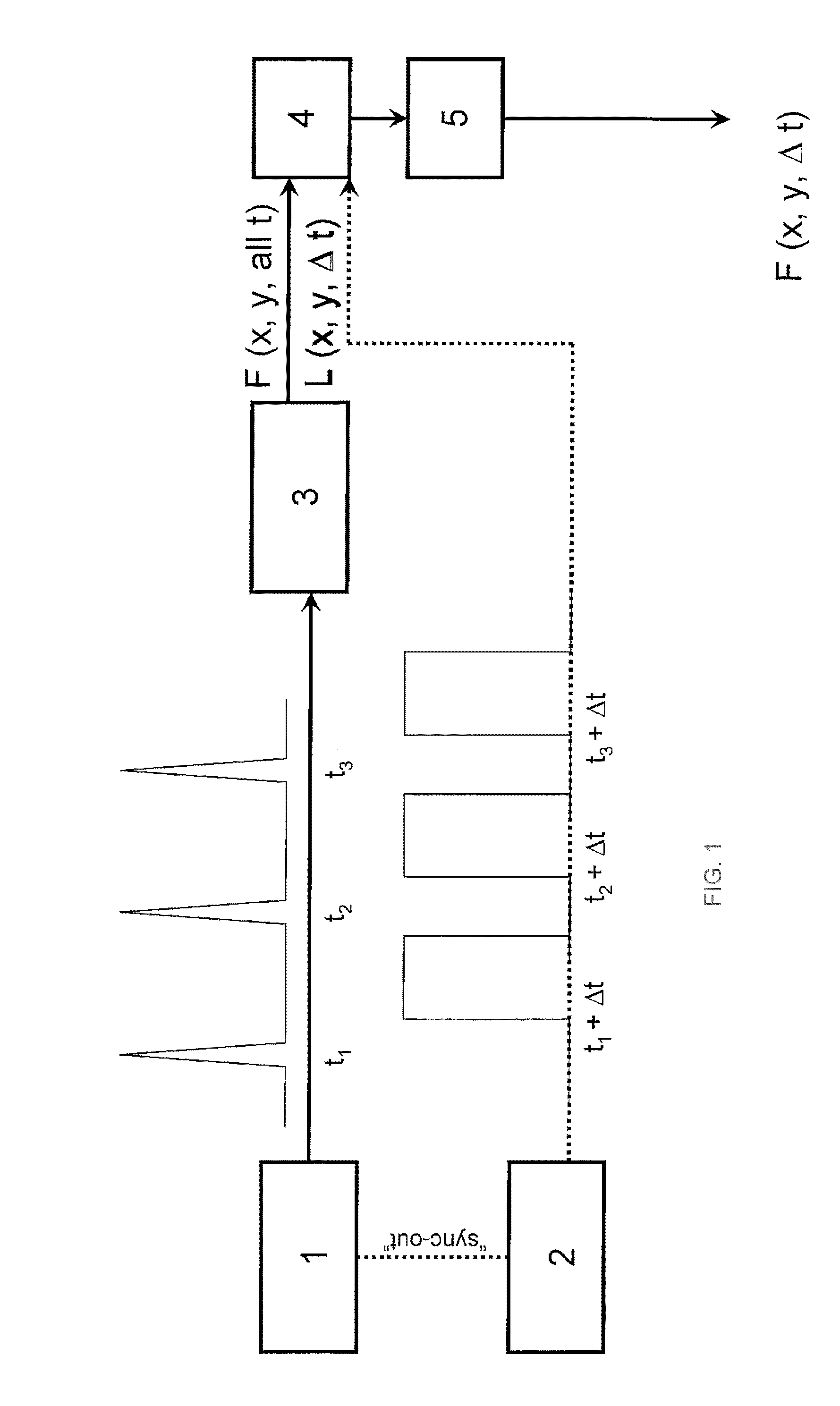

Single molecule detection and sequencing using fluorescence lifetime imaging

InactiveUS20110236983A1Avoid detectionMicrobiological testing/measurementAnalysis by electrical excitationEnergy transferNucleic acid detection

A nucleic acid detection system and method are provided, in which excitation energy is transmitted from a pulsed excitation source to a reaction site including a fluorescence resonance energy transfer (FRET)-based dye system to generate a fluorescent signal at the reaction site, the fluorescent signal is detected by a detector from the reaction site, and detection of the fluorescent signal is respectively blocked and permitted at the detector by a detector gate this is timed based on an emission start time of the transmitted excitation energy.

Owner:LIFE TECH CORP

Low temperature plasma enhanced chemical vapor deposition of conformal silicon carbon nitride and silicon nitride films

ActiveUS20130183835A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseCarbon nitride

Methods and apparatus for forming conformal silicon nitride films at low temperatures on a substrate are provided. The methods of forming a silicon nitride layer include performing a deposition cycle including flowing a processing gas mixture into a processing chamber having a substrate therein, wherein the processing gas mixture comprises precursor gas molecules having labile silicon to nitrogen, silicon to carbon, or nitrogen to carbon bonds, activating the precursor gas at a temperature between about 20° C. to about 480° C. by preferentially breaking labile bonds to provide one or more reaction sites along a precursor gas molecule, forming a precursor material layer on the substrate, wherein the activated precursor gas molecules bond with a surface on the substrate at the one or more reaction sites, and performing a plasma treatment process on the precursor material layer to form a conformal silicon nitride layer.

Owner:APPLIED MATERIALS INC

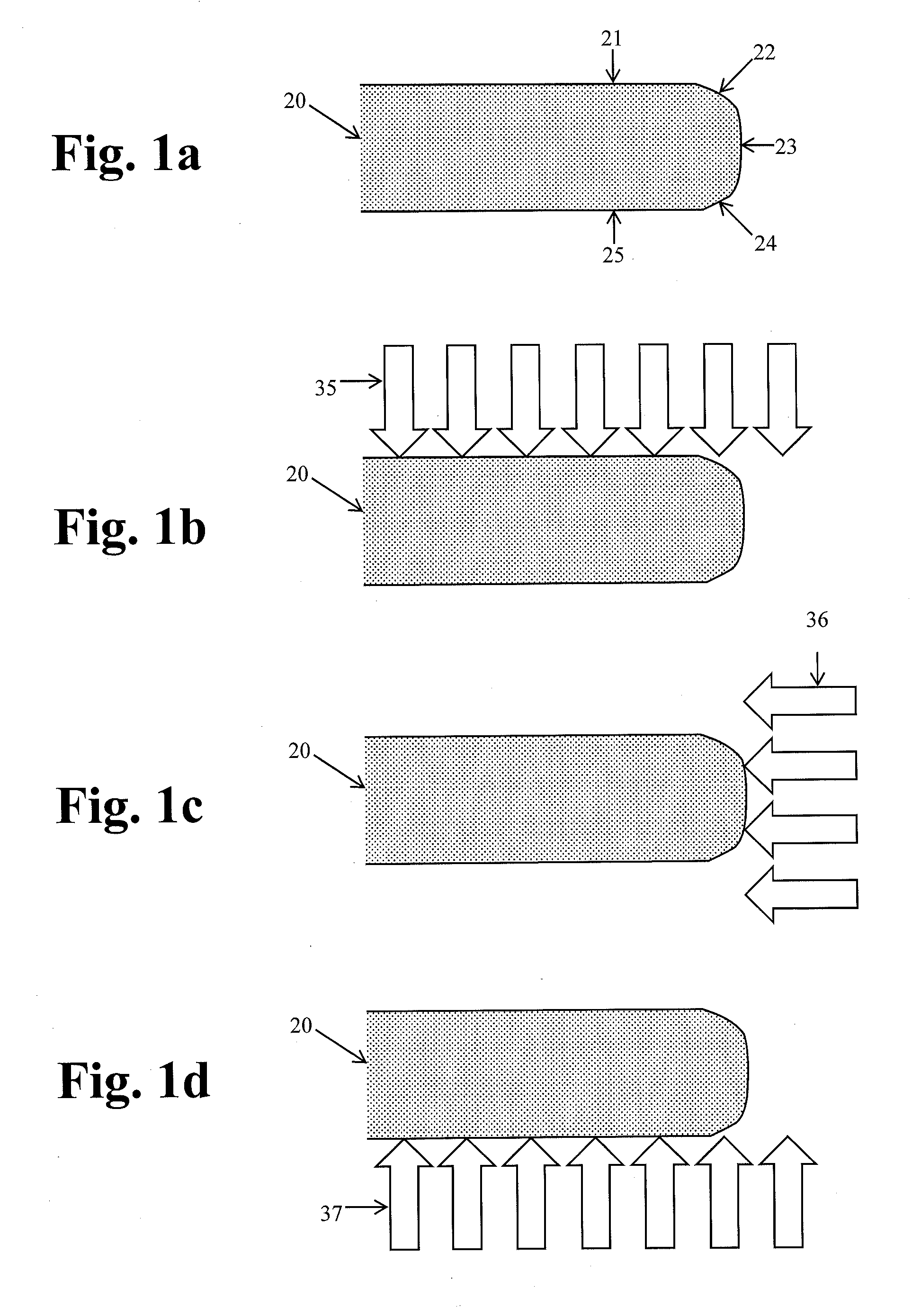

Fluid processing device comprising surface tension controlled valve

InactiveUS20060165565A1Reduce resistanceMaterial nanotechnologySequential/parallel process reactionsOligomerControl valves

A fluid processing device adapted to produce different oligomers in a plurality of respective reaction sites and methods of using the same are provided. The fluid processing device can comprise a first manifold for delivering reactants to the plurality of reaction sites, and a second manifold for removing waste from, and optionally delivering wash fluid to, the plurality of reaction sites. Surface tension controlled valves can be disposed in fluid communication with the first manifold, the second manifold, or both, and can selectively allow reactants and / or fluids into the reaction sites. A method of making oligonucleotides is also provided.

Owner:APPL BIOSYSTEMS INC

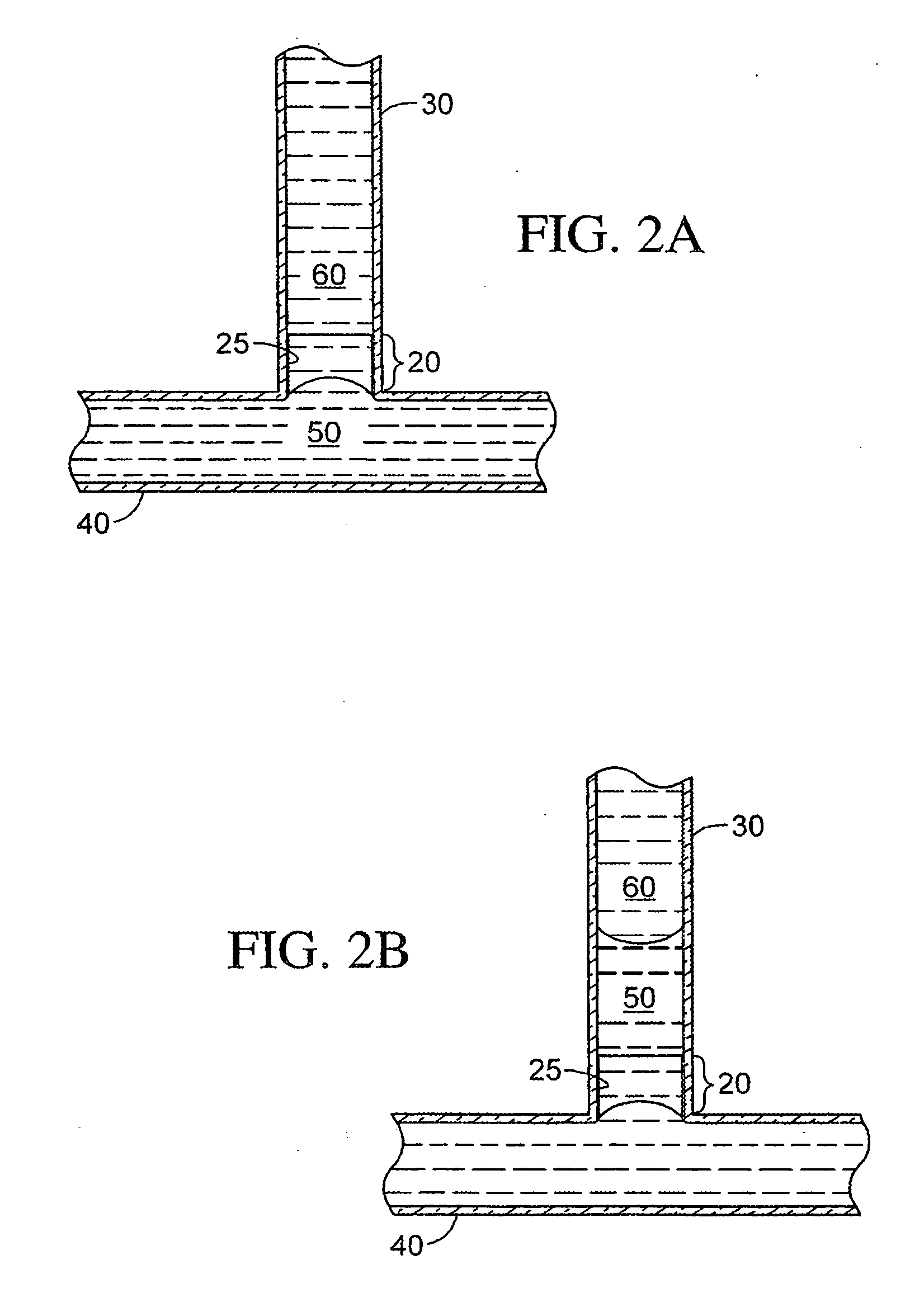

Fluid delivery system and method

ActiveUS8030057B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBiochemistryDelivery system

Method and device for storing and / or delivering fluids, wherein at least a first and a second fluid, such as chemical or biochemical reagents or rinse solutions, are maintained separately from each other in a common vessel and transferred in series from the vessel to a reaction site to carry out a predetermined chemical or biochemical reaction. Separation may be achieved by interposing a third fluid, e.g., a gaseous fluid plug, between the first and second fluids.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

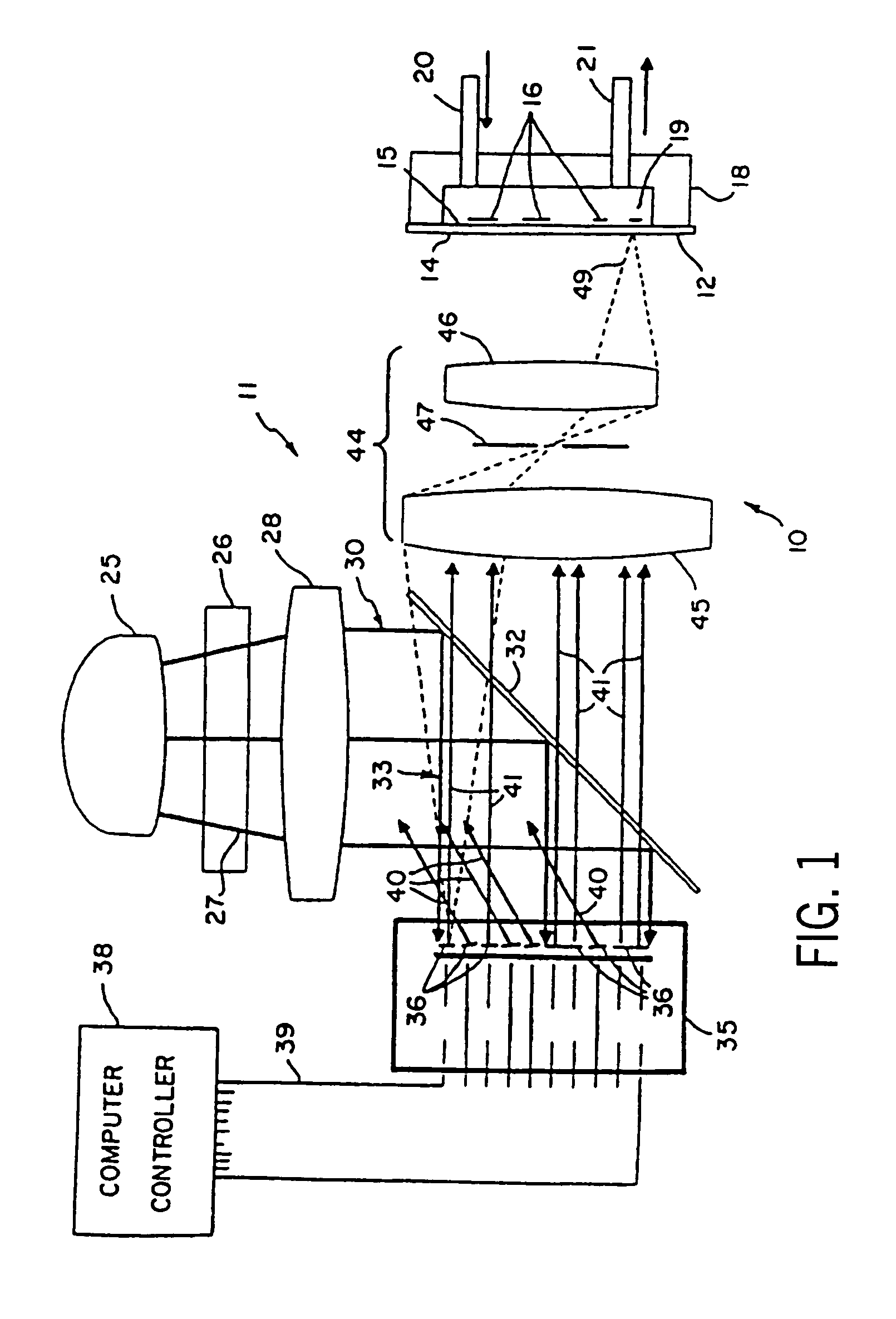

Prepatterned substrate for optical synthesis of DNA probes

InactiveUS7157229B2Great reaction spatial definitionSimple and preciseMaterial nanotechnologyBioreactor/fermenter combinationsPatterned substrateOptical alignment

An optical alignment system for a device for synthesizing DNA polymers provides for a patterned substrate for simple alignment of the system. The substrate may also be used for synthesis allowing precise alignment of the synthesis substrate during each synthesis operation. The patterning of the substrate may be used to promote separation of reaction sites.

Owner:ROCHE NIMBLEGEN

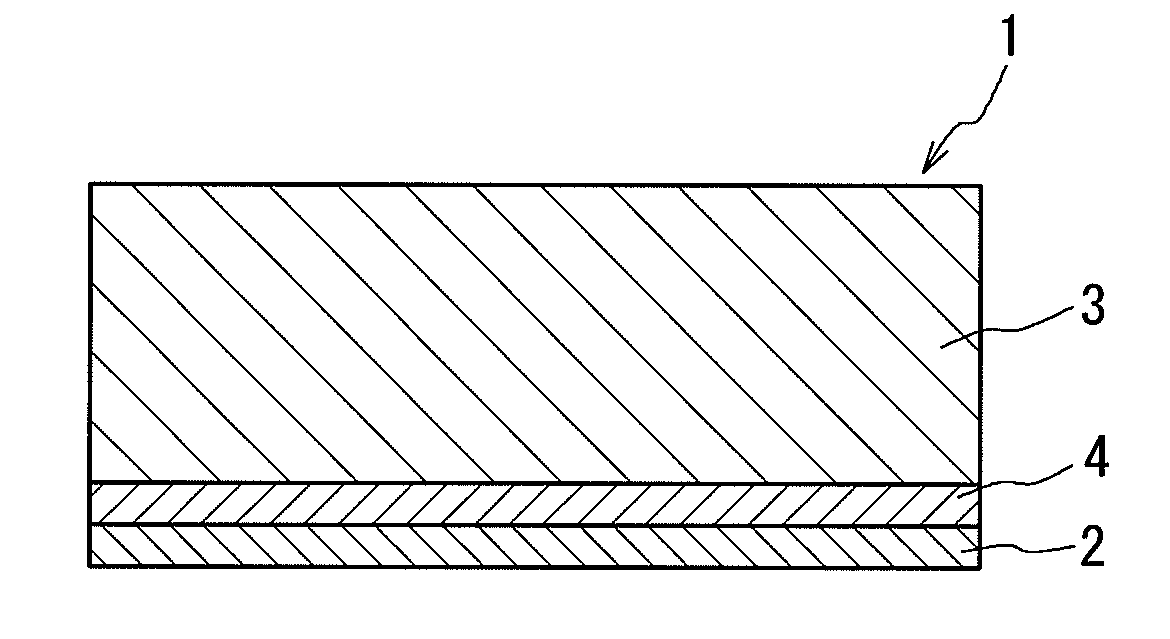

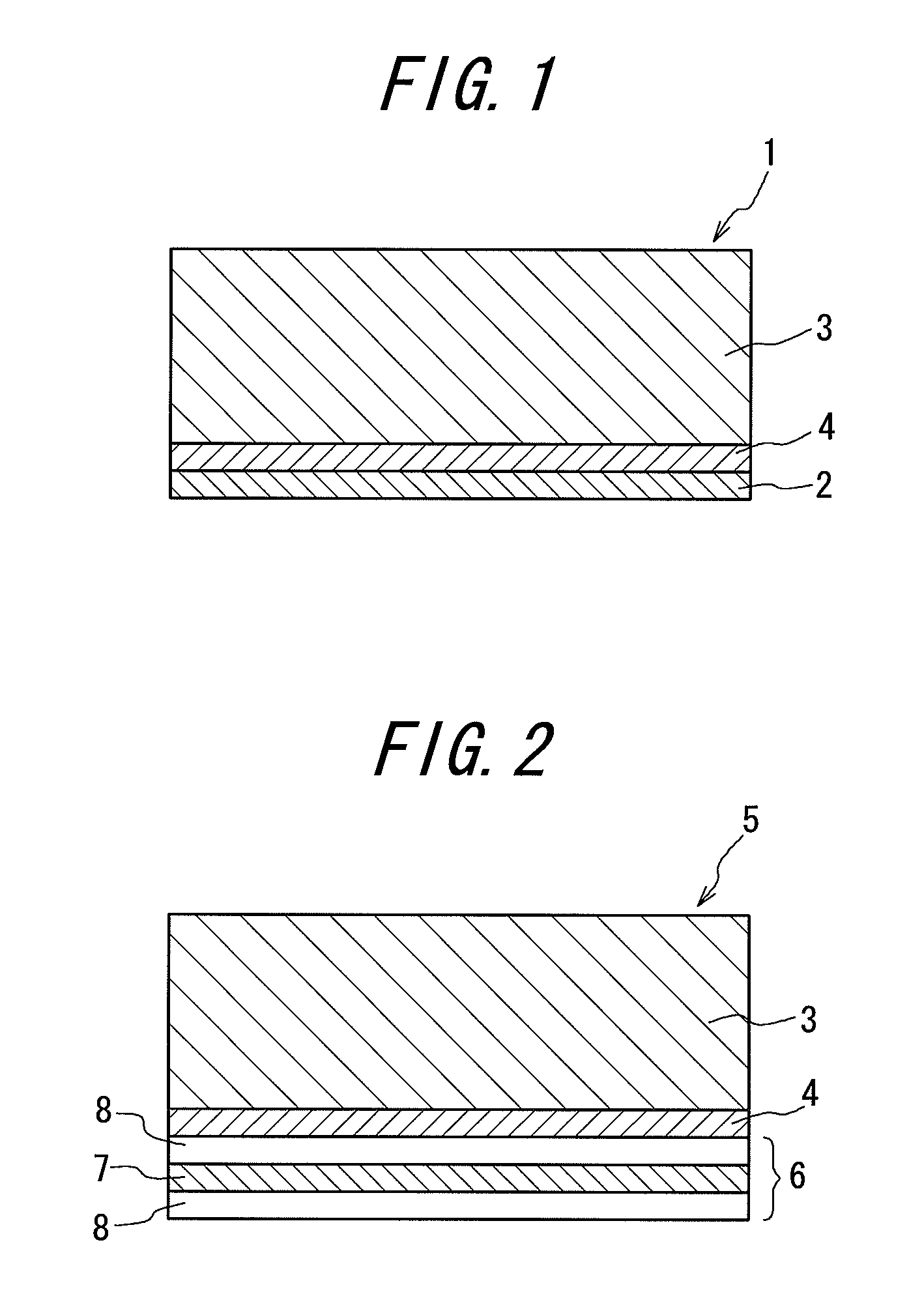

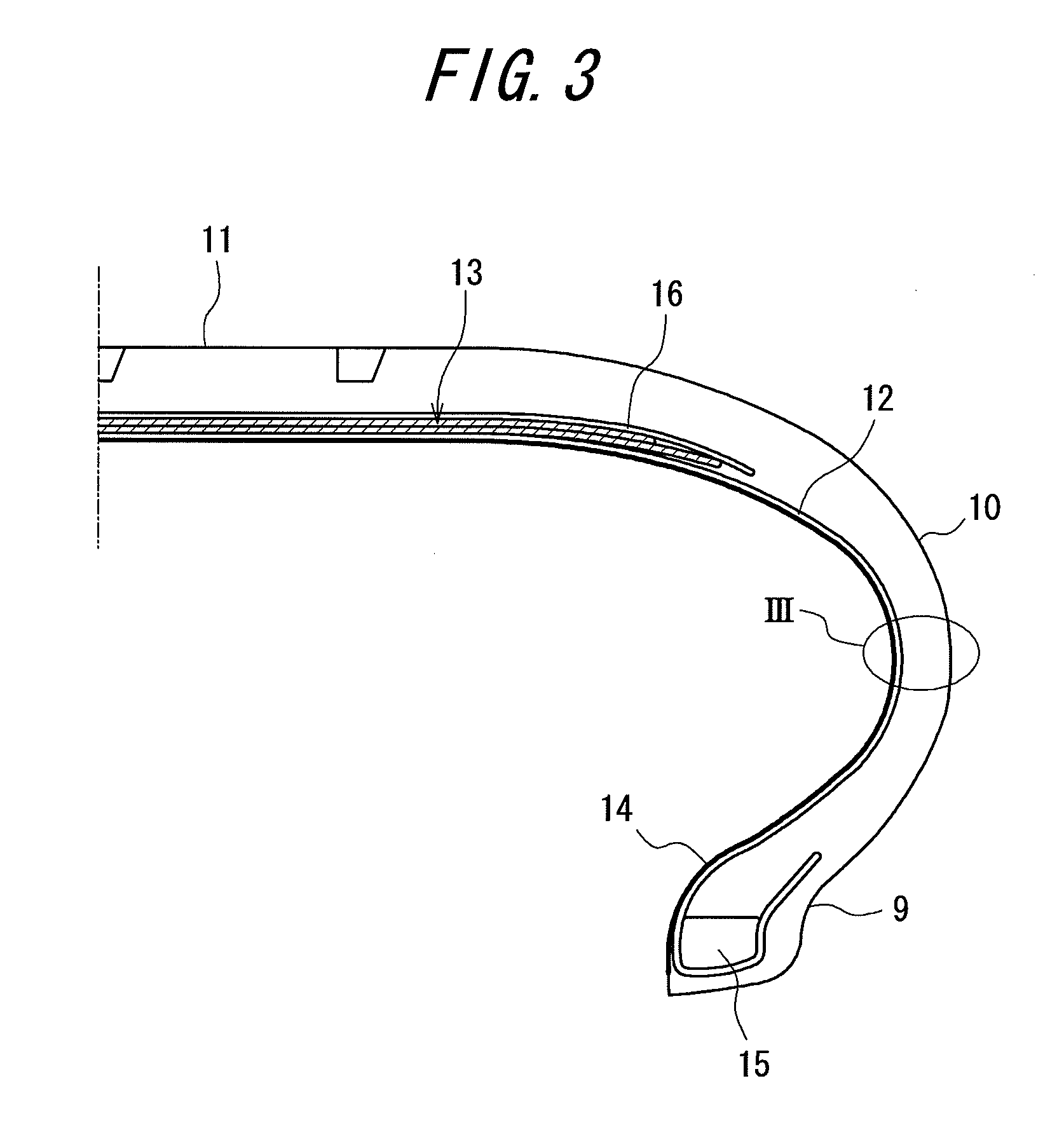

Laminated body and method of producing the same as well as innerliner for pneumatic tire and pneumatic tire

InactiveUS20090308517A1Improve machinabilityImprove anti-stripping performanceCoatingsWheelsElastomerYoung's modulus

The invention provides a laminated body (1) having a good workability during the production and an excellent peeling resistance, which is formed by joining a resin film layer (D) (2) comprising at least a layer composed of a resin composition (C) in which a soft resin (B) having a Young's modulus at 23° C. lower than that of a thermoplastic resin (A) is dispersed in a matrix made from the thermoplastic resin (A) and a rubbery elastomer layer (E) (3) through an adhesive layer (F) (4), wherein an adhesive composition (I) formed by compounding not less than 0.1 part by mass of at least one of a maleimide derivative (H) having not less than two reaction sites in a molecule thereof and poly-p-dinitrosobenzene based on 100 parts by mass of a rubber component (G) is applied to the adhesive layer (F) (4).

Owner:KURARAY CO LTD +1

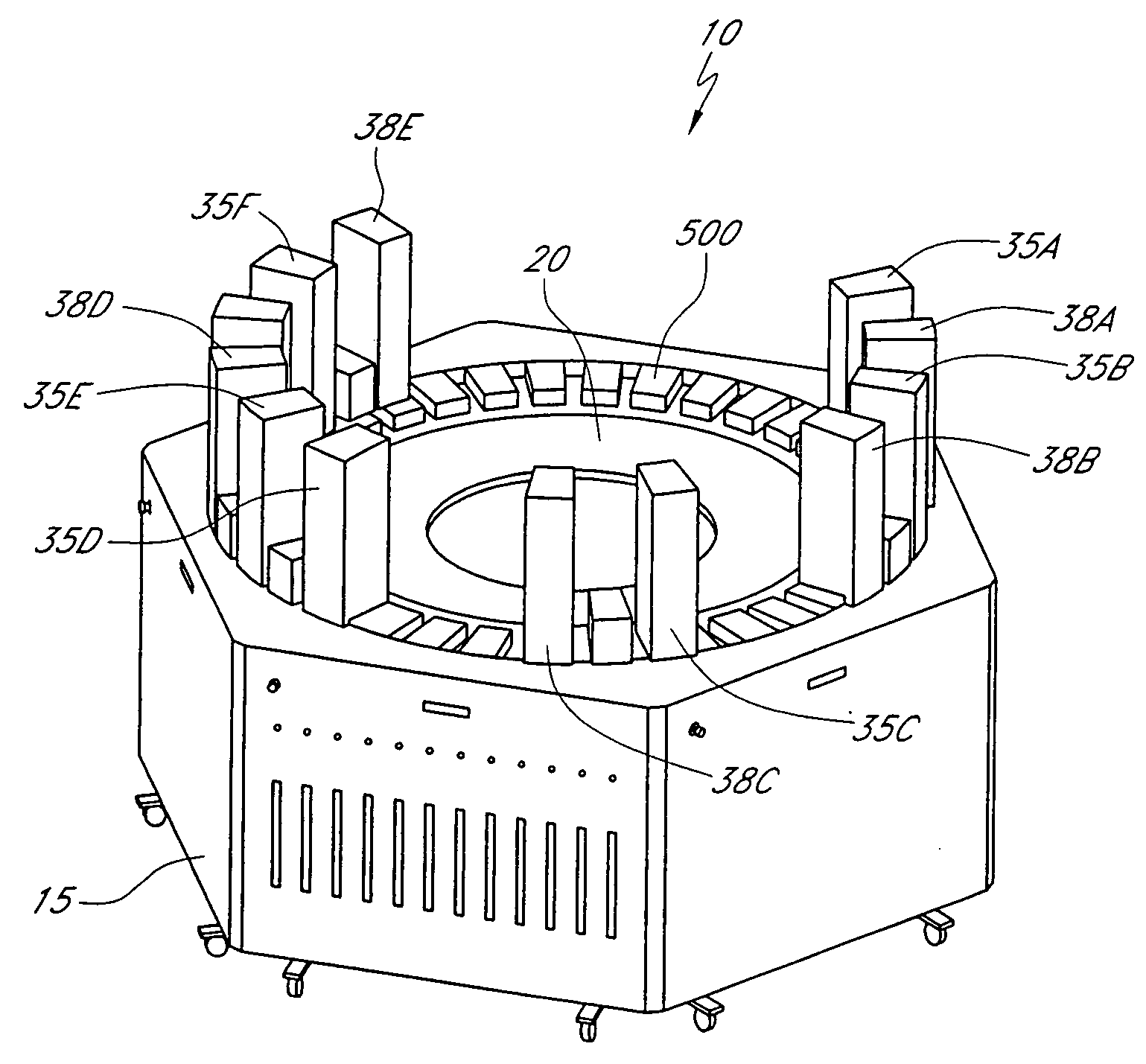

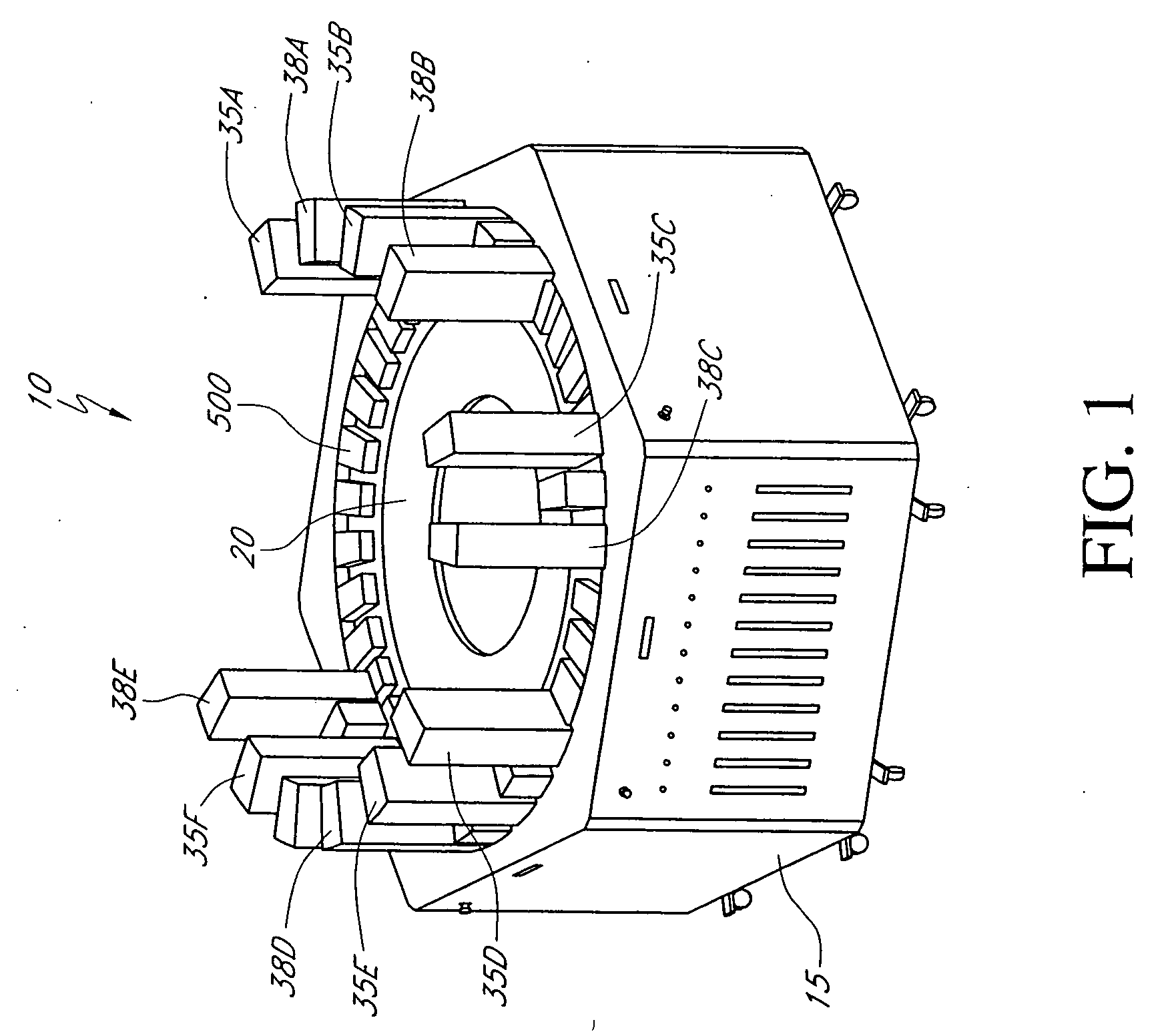

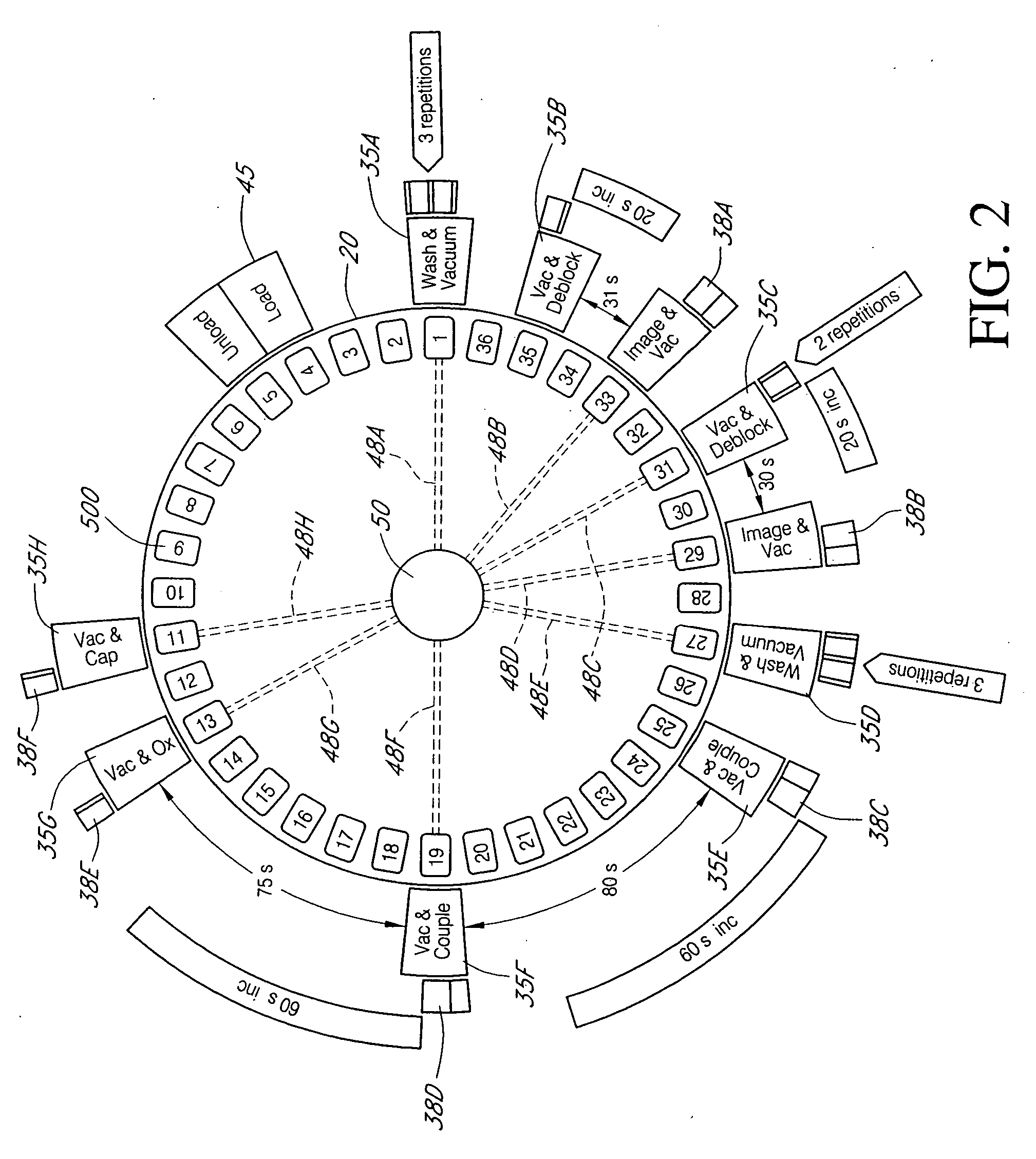

Continuous polymer synthesizer

ActiveUS20070110638A1Reduces instantaneous demandReduce electricity costsMaterial nanotechnologySequential/parallel process reactionsComputational chemistryReaction step

Described is a system and method for synthesizing polymeric molecules such as oligonucleotides and polypeptides. The system is capable of continuously synthesizing molecules by providing an array of reaction sites and an array of stations for carrying out synthetic manipulations. The reaction sites in the former array can be placed in a fixed order and at fixed intervals relative to each other. Similarly, the stations can be placed in a fixed order and at fixed intervals relative to each other. The two arrays can be moved relative to each other such that the stations carry out desired steps of a reaction scheme at each reaction site. The relative locations of the stations and the schedule for the relative movement can correlate with the order and duration of reaction steps in the reaction scheme such that once a reaction site has completed a cycle of interacting with the full array of stations then the reaction scheme is complete.

Owner:ILLUMINA INC

Method and apparatus for processing substrate edges

InactiveUS20110168672A1Process environmental protectionEliminate needDecorative surface effectsPhotomechanical apparatusGas syringeSolvent

A method and apparatus for processing substrate edges is disclosed that overcomes the limitations of conventional edge processing methods and systems used in semiconductor manufacturing. The edge processing method and apparatus of this invention includes a laser and optical system to direct a beam of radiation onto a rotating substrate supported by a chuck, in atmosphere. The optical system accurately and precisely directs the beam to remove or transform organic or inorganic films, film stacks, residues, or particles from the top edge, top bevel, apex, bottom bevel, and bottom edge of the substrate. An optional gas injector system directs gas onto the substrate edge to aid in the reaction. Process by-products are removed via an exhaust tube enveloping the reaction site. This invention permits precise control of an edge exclusion zone, resulting in an increase in the number of usable die on a wafer. Wafer edge processing with this invention replaces existing solvent and / or abrasive methods and thus will improve die yield.

Owner:UVTECH SYST

Method of manufacturing thermoplastic resin, crosslinked resin, and crosslinked resin composite material

InactiveUS20060211834A1Efficient productionAdhesive processes with surface pretreatmentSynthetic resin layered productsPolymer scienceBulk polymerization

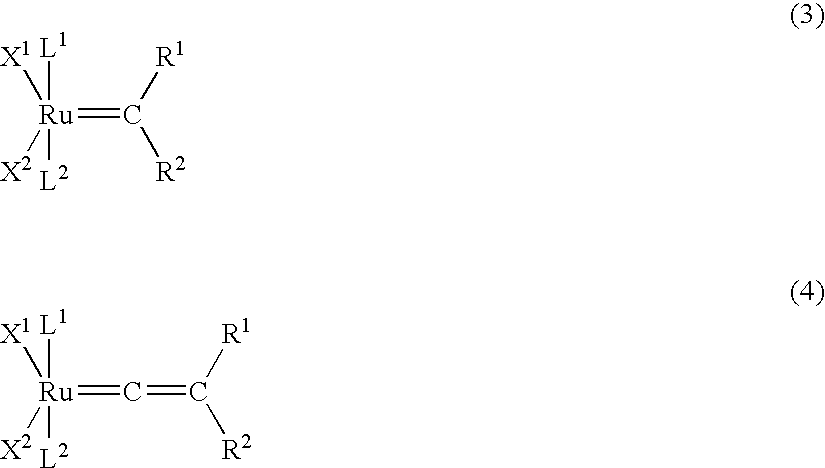

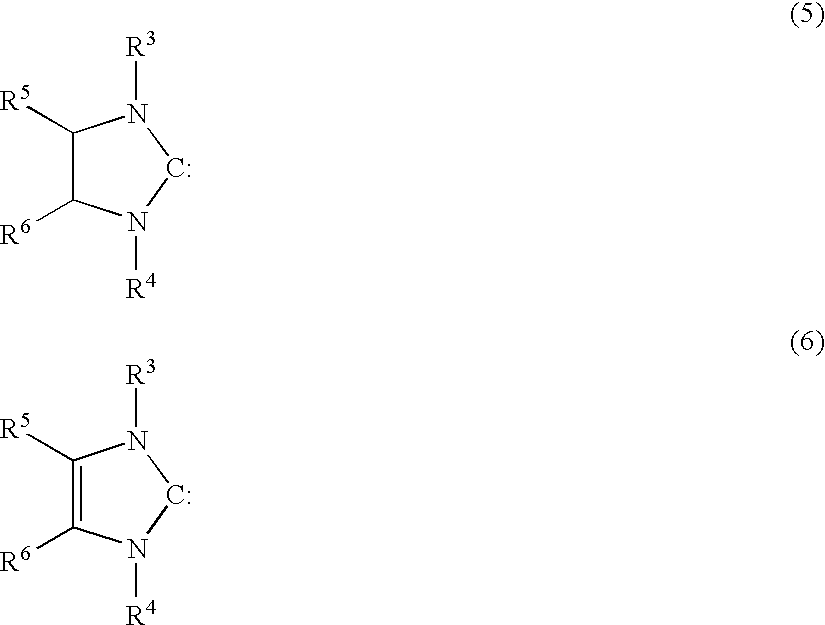

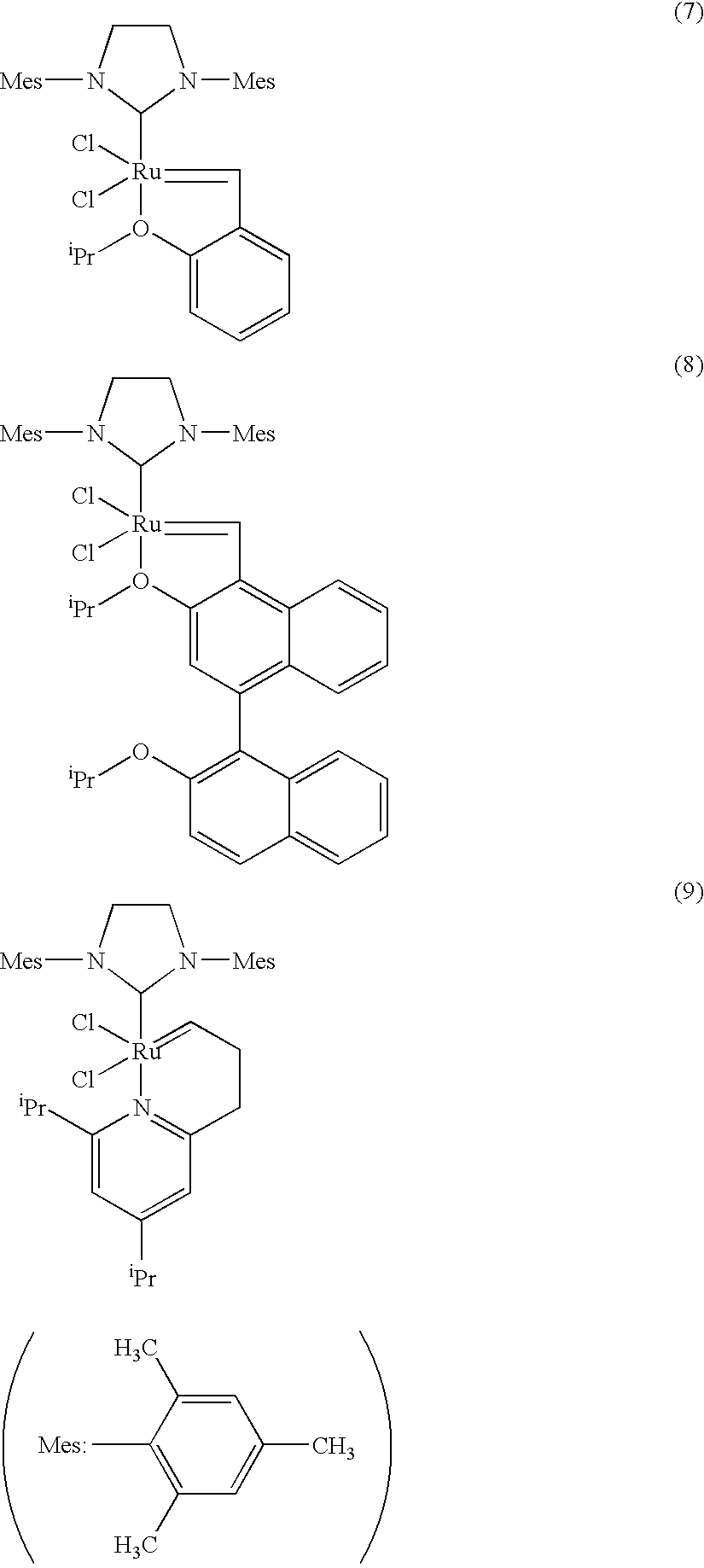

The invention relates to a process for the production of post-crosslinkable thermoplastic resins by bulk-polymerizing a polymerizable composition (A) comprising (I) a monomer fluid containing a cyclic olefin (α) having two or more metathetical ring-opening reaction sites in the molecule in an amount 10 wt % or above based on the total amount of the monomers or a monomer fluid containing a norbornene monomer and a crosslinking agent, (II) a metathetical polymerization catalyst, and (III) a chain transfer agent; thermoplastic resins obtained by this process; and a process for producing crosslinked resins or crosslinked resin composite materials which comprises laminating such a thermoplastic resin with a substrate at need and then crosslinking the thermoplastic resin. According to the invention, thermoplastic resins which are free from odor due to residual monomers and excellent in storage stability can be efficiently obtained by a simple process of bulk-polymerizing the composition (A). The process is not only easy and simple but also applicable to continuous production, thus being industrially advantageous. The crosslinked resins and crosslinked resin composite materials obtained according to the invention are excellent in electrical insulation properties, mechanical strengths, heat resistance, dielectric characteristics and so on, thus being useful as electrical materials or the like.

Owner:ZEON CORP

Pentapeptide compounds and uses related thereto

Pentapeptide compounds are disclosed. The compounds have biological activity, e.g., cytotoxicity. Prodrugs having targeting groups and pentapeptide moieties, as well as precursors thereof are also disclosed. For example, precursors having a reactive linker that can serve as a reaction site for joining to a targeting agent, e.g., an antibody, as disclosed.

Owner:SEATTLE GENETICS INC

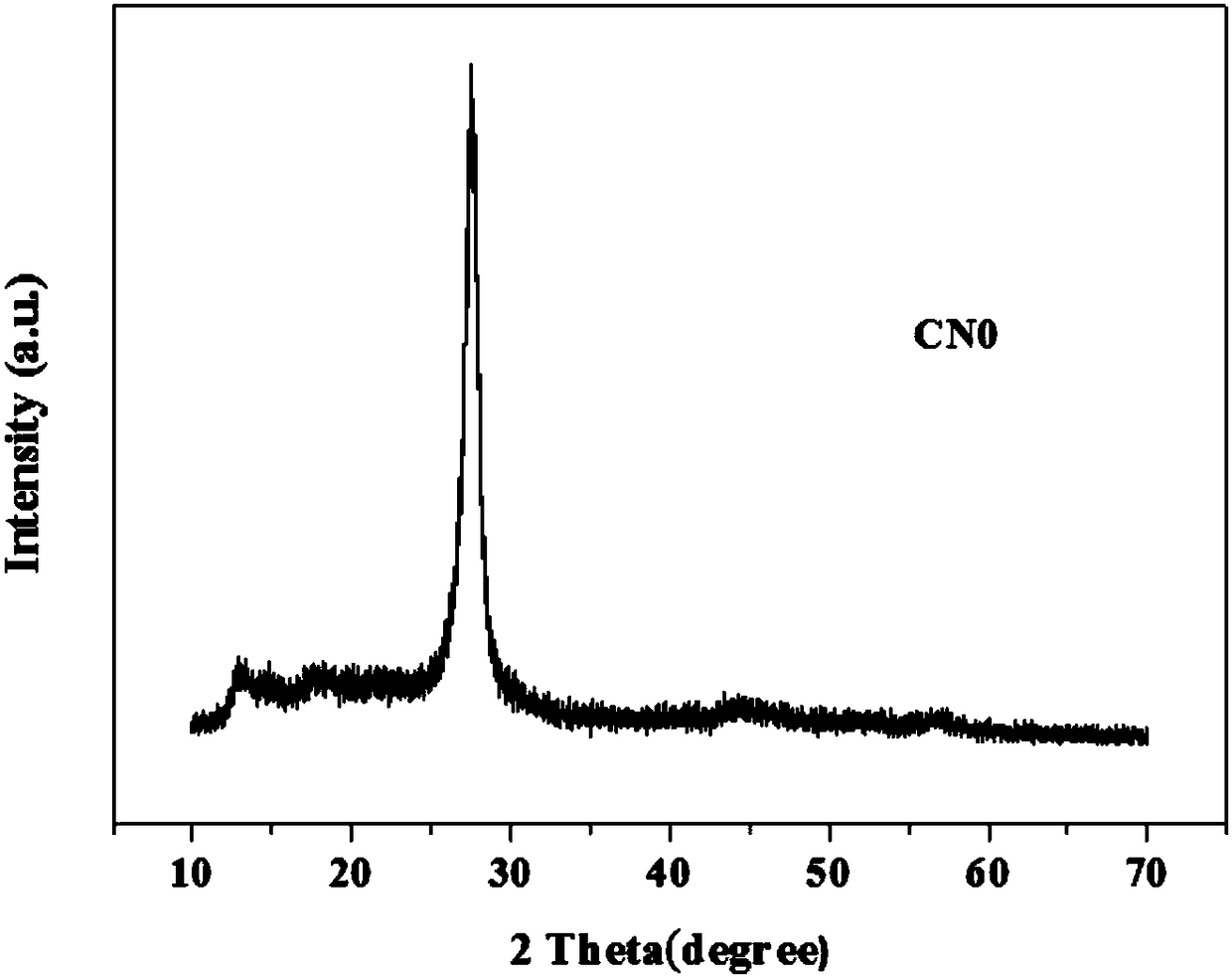

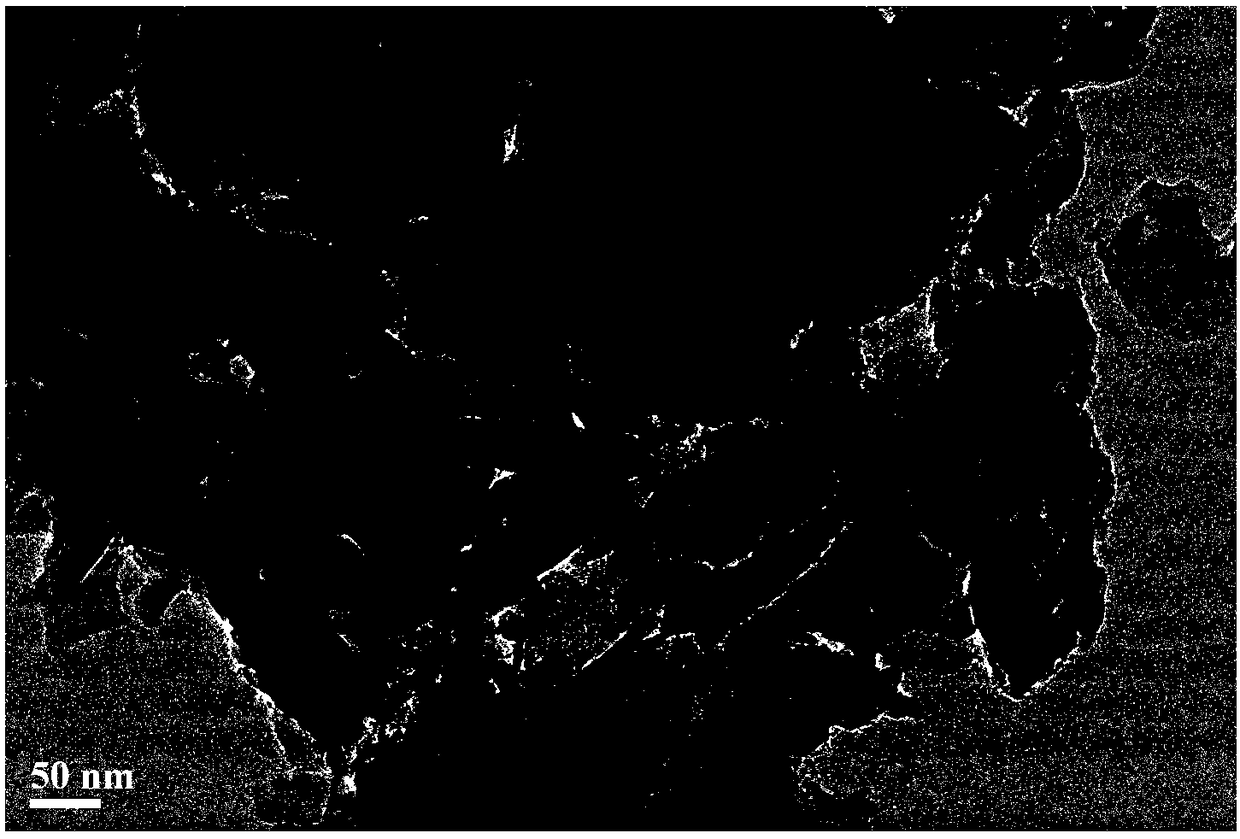

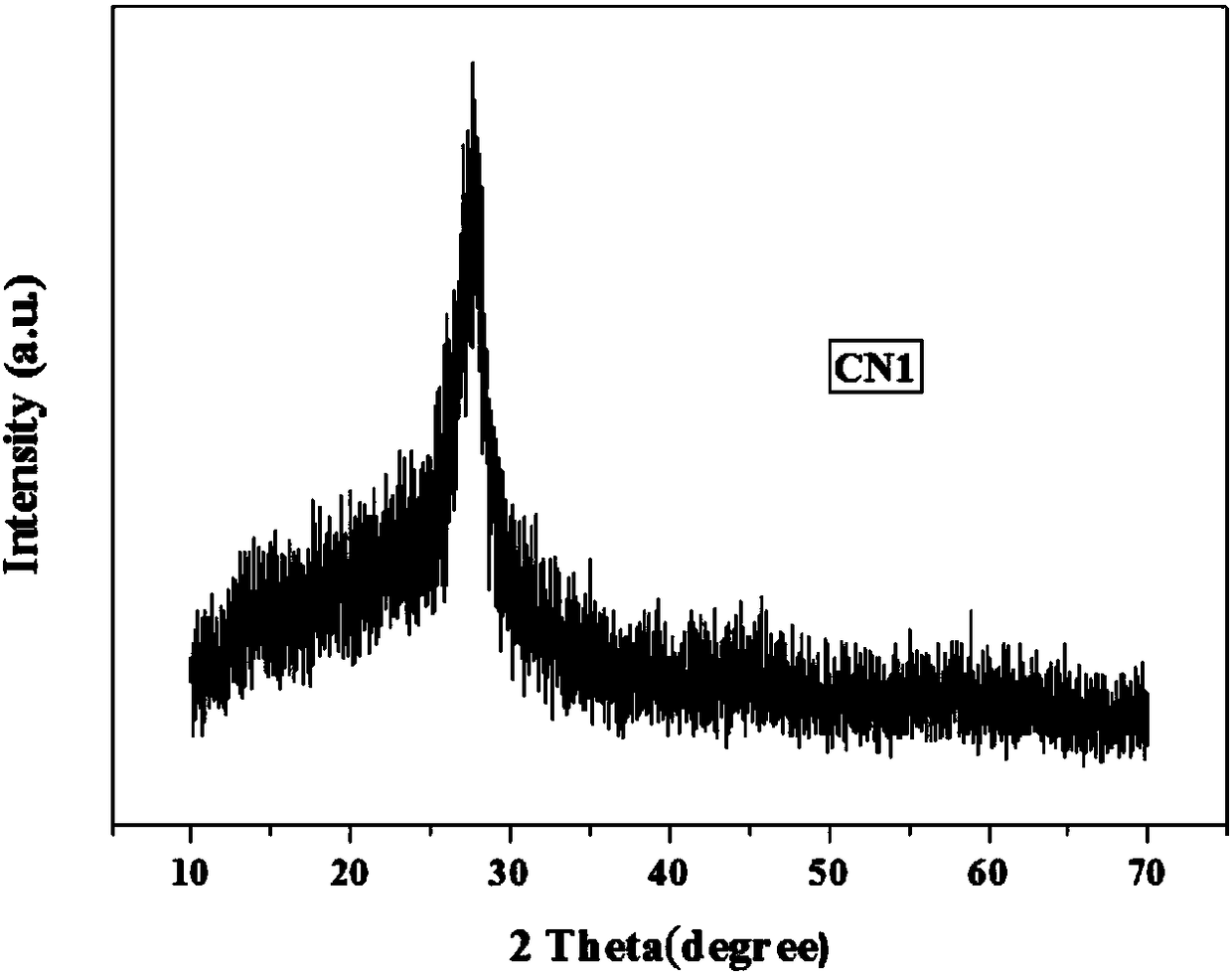

Nitrogen-defect graphite-phase carbon nitride nanosheet photocatalyst, method for preparing same and application

ActiveCN108380237AEasy to separateEfficient separationPhysical/chemical process catalystsDispersed particle separationThioureaCalcination

The invention discloses a nitrogen-defect graphite-phase carbon nitride nanosheet photocatalyst, a method for preparing the same and application. The method includes 1), placing nitrogen-rich organicmatters such as melamine, dicyandiamide and thiourea urea into crucibles, keeping carrying out high-temperature calcination treatment on the nitrogen-rich organic matters at the temperatures ranging from 220-420 DEG C for 0.5-10 h, and carrying out cooling to obtain precursors; 2), grinding the precursors, and calcining the precursors in inert gas environments to obtain a product which is the nitrogen-defect graphite-phase carbon nitride nanosheet photocatalyst. The nitrogen-defect graphite-phase carbon nitride nanosheet photocatalyst, the method and the application have the advantages that large quantities of catalytic reaction sites can be provided by nitrogen-defect graphite-phase carbon nitride nanometer materials prepared by the aid of the method, photo-induced electrons can be trapped by nitrogen defects, photo-induced electron-hole separation can be effectively carried out, the composition rate can be reduced, and the photocatalytic activity can be improved; organic pollutants can be effectively degraded by the nitrogen-defect graphite-phase carbon nitride nanosheet photocatalyst in visible light irradiation.

Owner:LIAONING UNIVERSITY

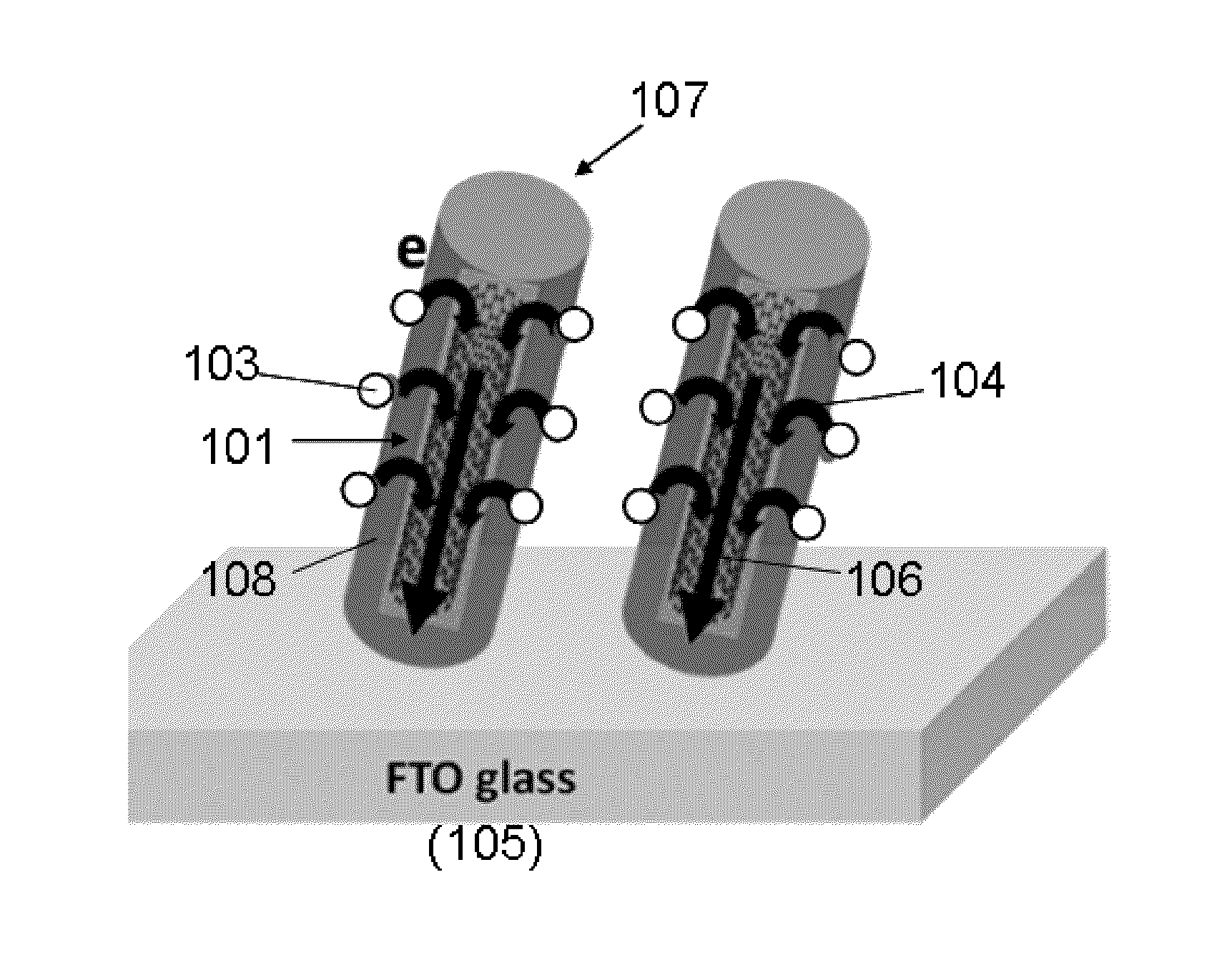

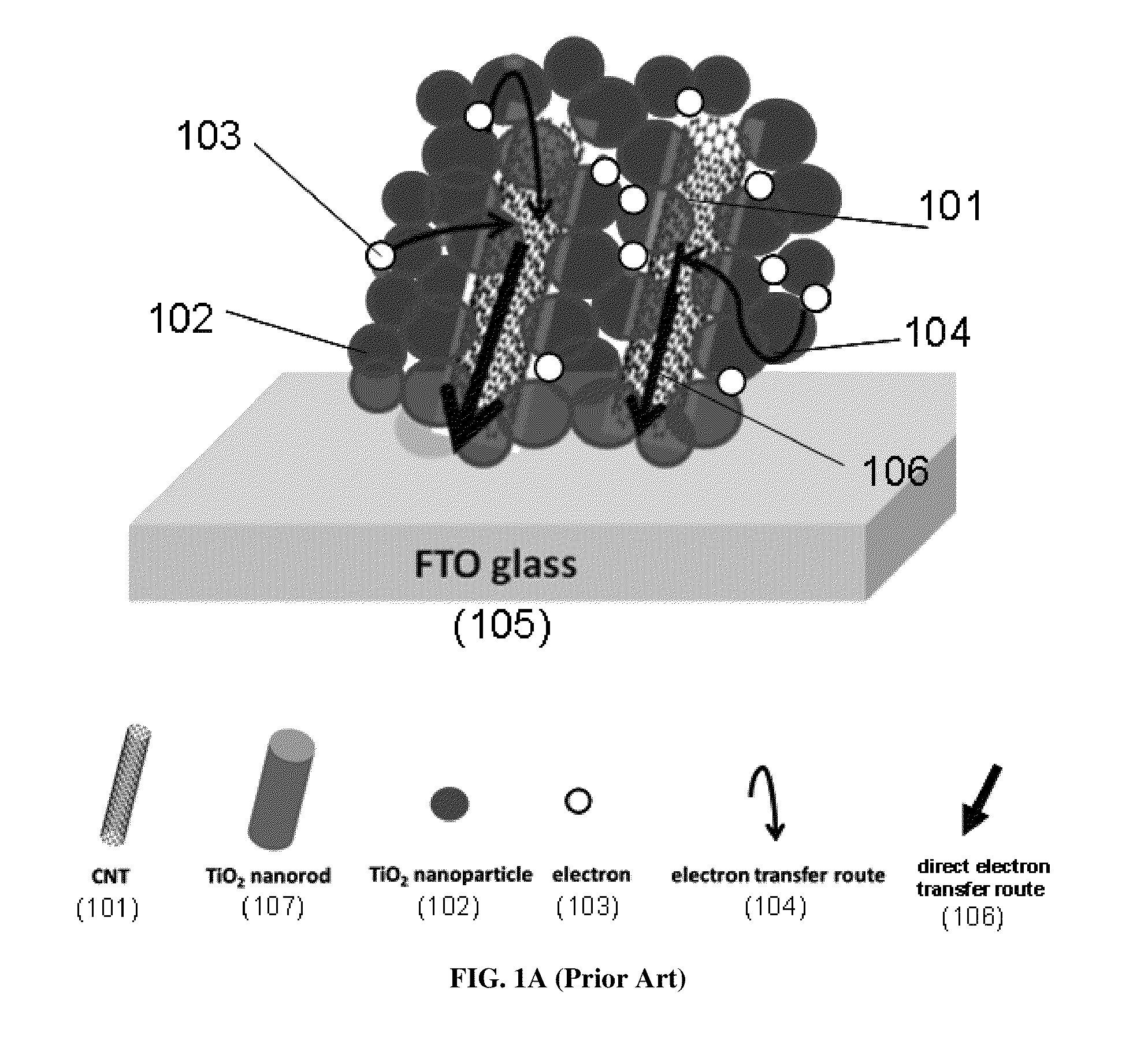

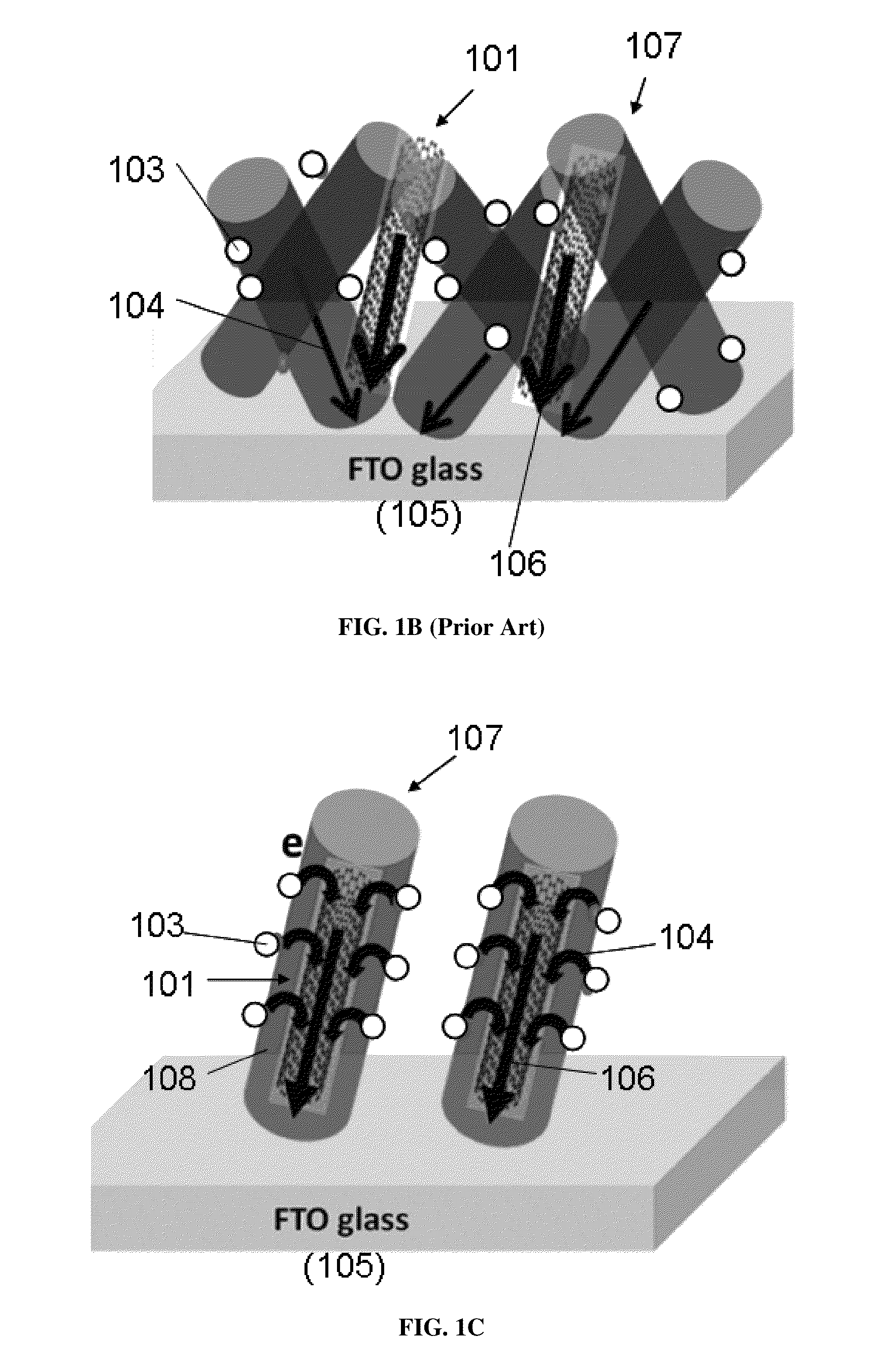

Highly Conductive Nano-structures incorporated in Semiconductor Nanocomposites

ActiveUS20140158986A1Enhanced charge transferReduce lossesMaterial nanotechnologyCell electrodesPhotocatalytic reactionSolar cell

The presently claimed invention provides a highly conductive composite used for electric charge transport, and a method for fabricating said composite. The composite comprises a plurality of one-dimensional semiconductor nanocomposites and highly conductive nanostructures, and the highly conductive nanostructures are incorporated into each of the one-dimensional semiconductor nanocomposite. The composite is able to provide fast electric charge transport, and reduce the rate of electron-hole recombination, ultimately increasing the power conversion efficiency for use in solar cell; provide fast electrons transport, storage of electrons and large surface area for adsorption and reaction sites of active molecular species taking part in photocatalytic reaction; enhance the sensitivity of a surface for biological and chemical sensing purposes for use in biological and chemical sensors; and lower the impedance and increase the charge storage capacity of a lithium-ion battery.

Owner:THE HONG KONG POLYTECHNIC UNIV

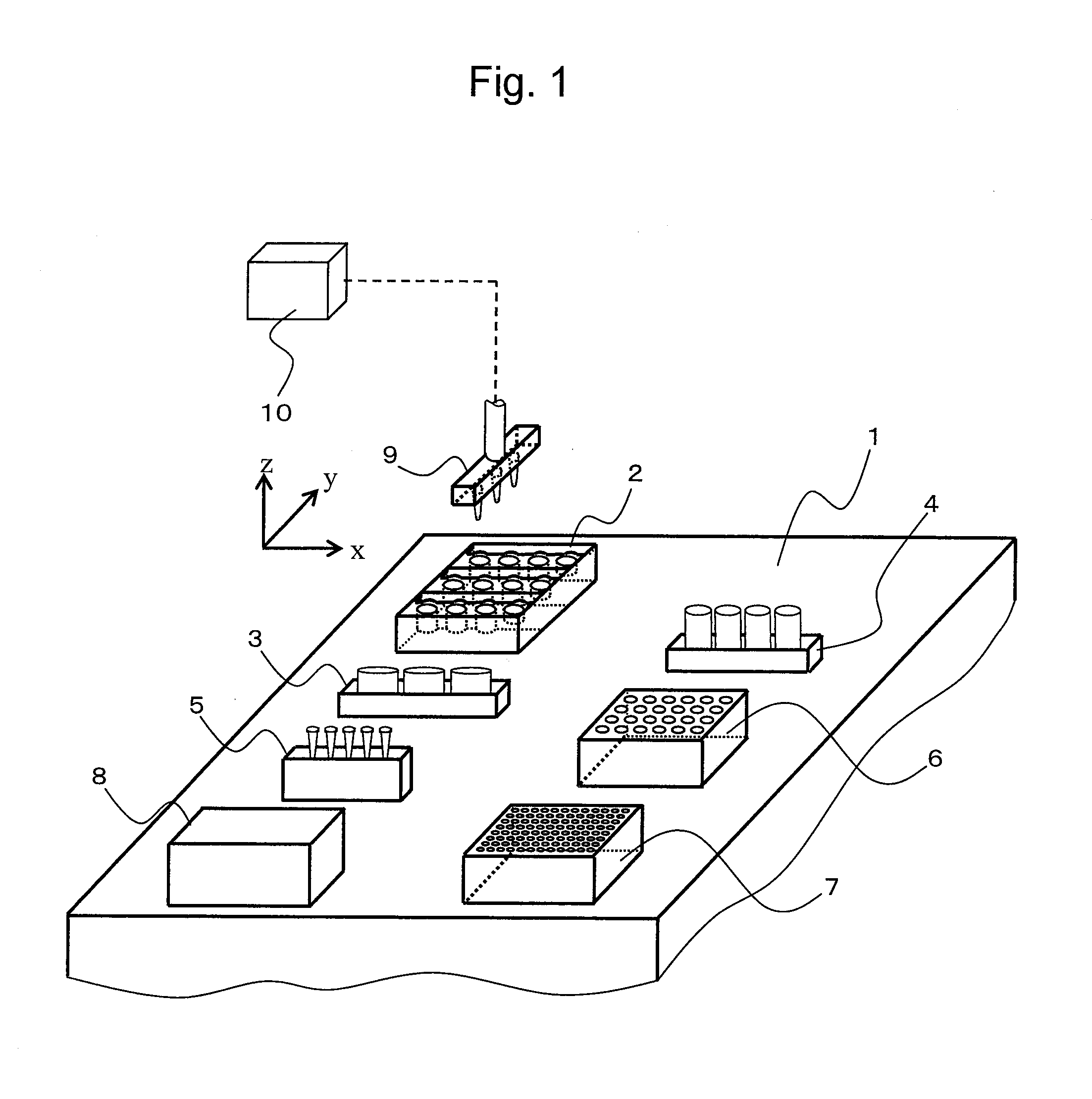

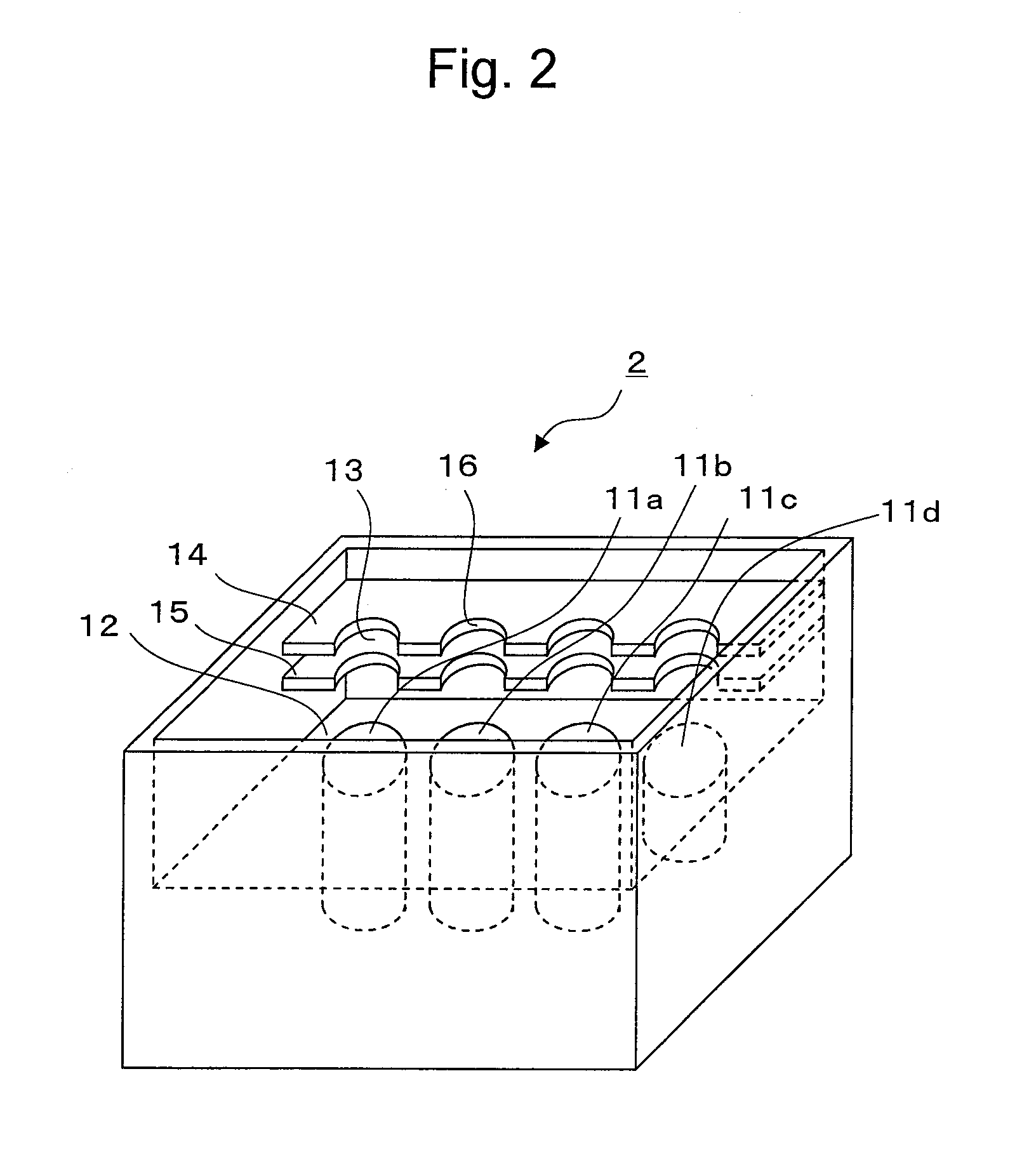

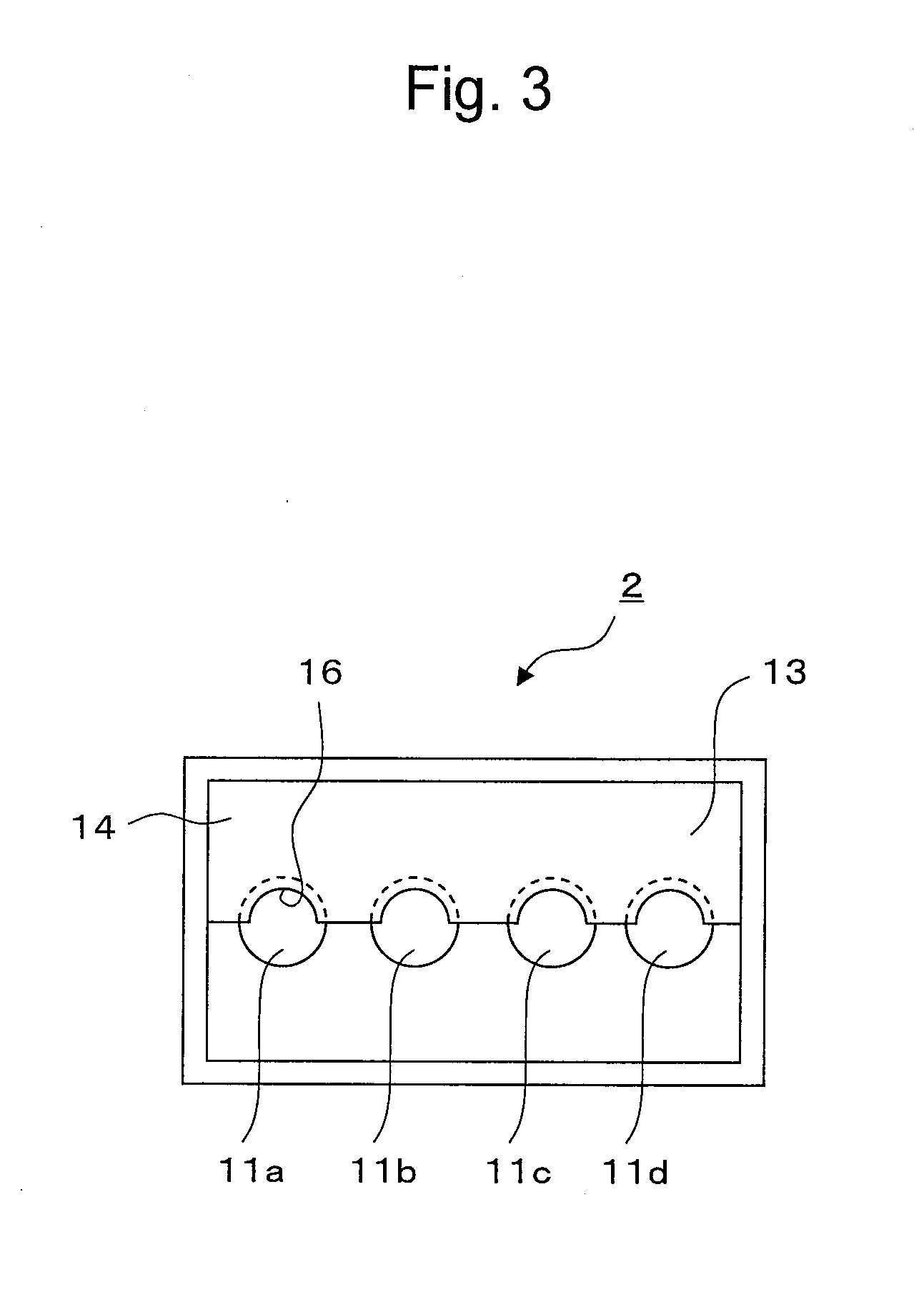

Sample Processing Device, Sample Processing Method, and Reaction Container Used in These Device and Method

ActiveUS20120309104A1Effective recoveryElectrostatic separationPreparing sample for investigationMagnetic beadEngineering

This invention concerns a sample processing device capable of efficiently recovering biological molecules, such as nucleic acids or proteins. The sample processing device is capable of placing a reaction container having a plurality of reaction sites, and it comprises a nozzle mechanism with a nozzle capable of attaching and removing a dispenser tip for dispensing a solution into the reaction sites of the reaction container and a magnetic tip for generating a magnetic field that allows magnetic beads to migrate to a space among the plurality of reaction sites in the reaction container, and a drive control unit controlling the nozzle mechanism.

Owner:HITACHI HIGH-TECH CORP

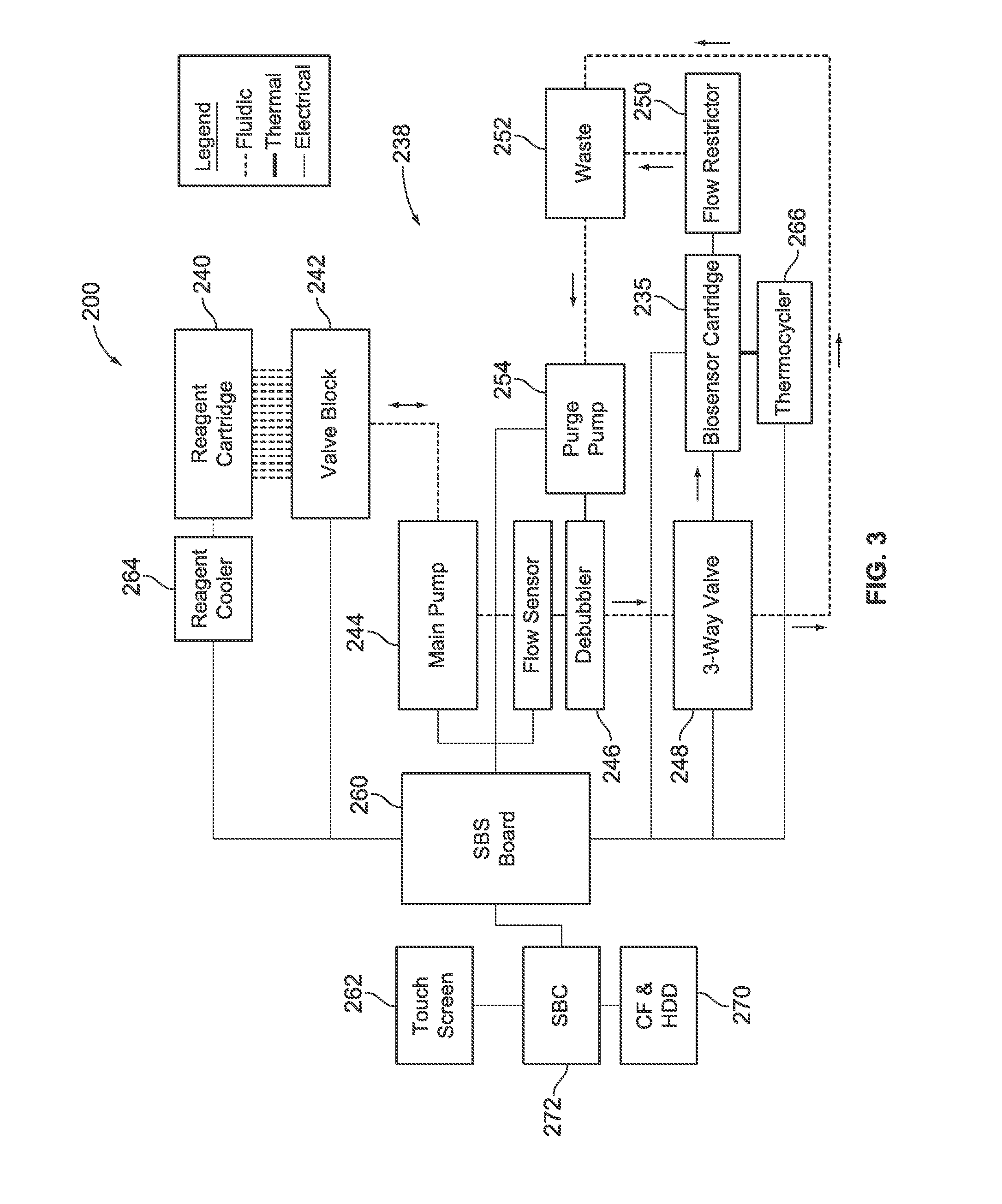

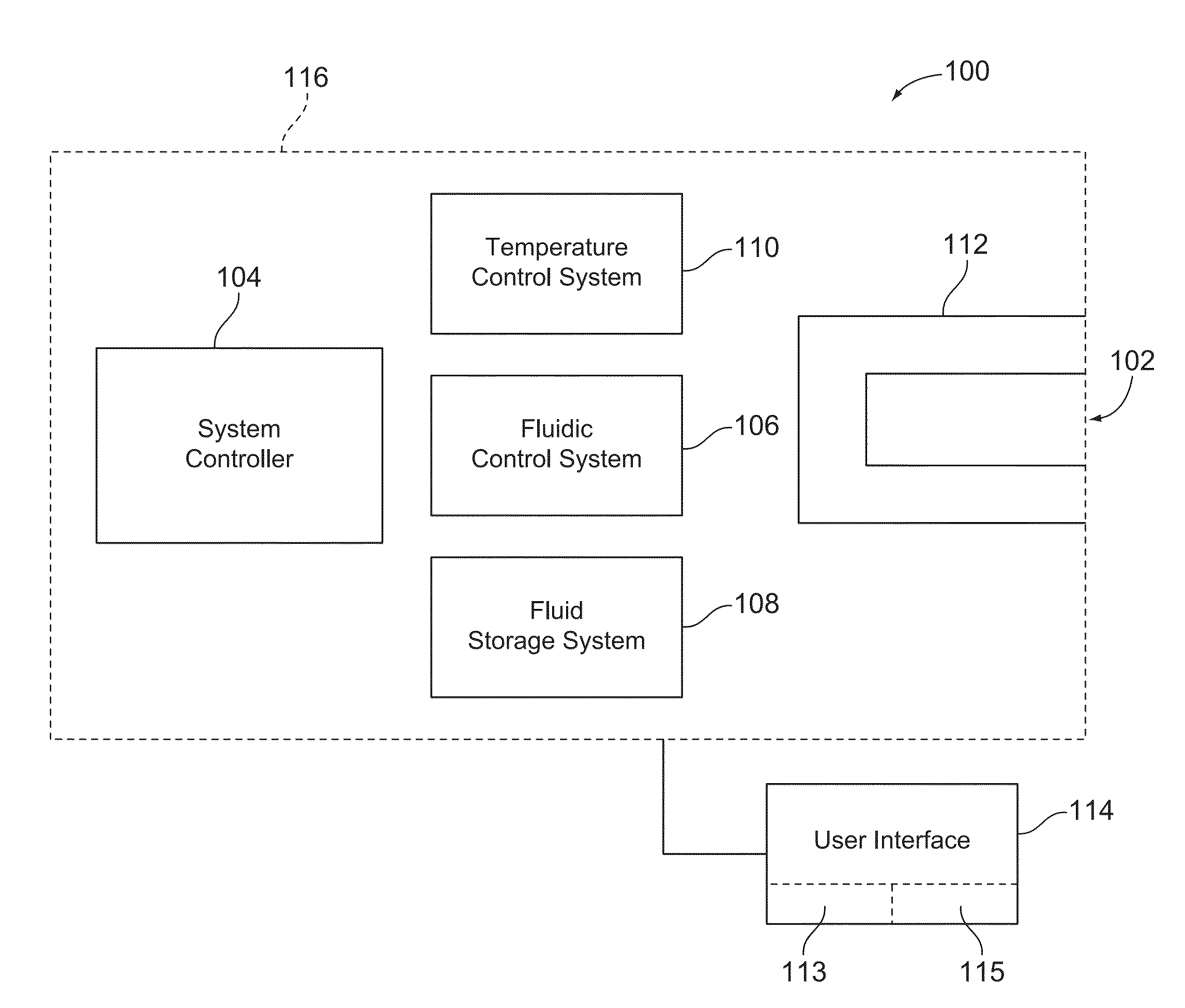

Microdevices and biosensor cartridges for biological or chemical analysis and systems and methods for the same

ActiveUS20150266022A1Heating or cooling apparatusMicrobiological testing/measurementFlow cellEngineering

A flow cell including inlet and outlet ports in fluid communication with each other through a flow channel that extends therebetween. The flow channel includes a diffuser region and a field region that is located downstream from the diffuser region. The field region of the flow channel directs fluid along reaction sites where desired reactions occur. The fluid flows through the diffuser region in a first flow direction and through the field region in a second flow direction. The first and second flow directions being substantially perpendicular.

Owner:ILLUMINA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com