Patents

Literature

127 results about "Gas syringe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas syringe is a piece of laboratory glassware used to insert or withdraw a volume of a gas from a closed system, or to measure the volume of gas evolved from a chemical reaction. A gas syringe can also be used to measure and dispense liquids, especially where these liquids need to be kept free from air.

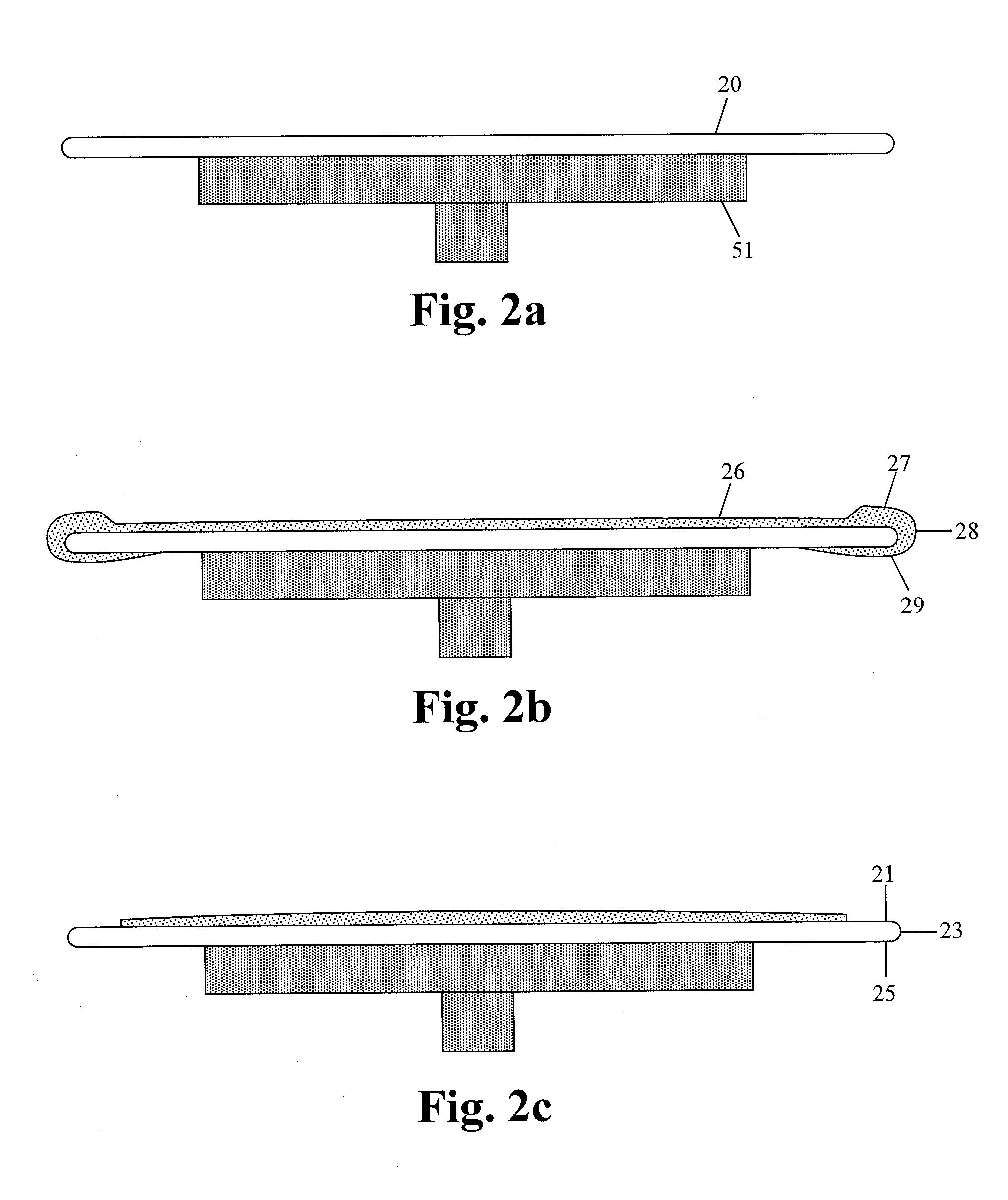

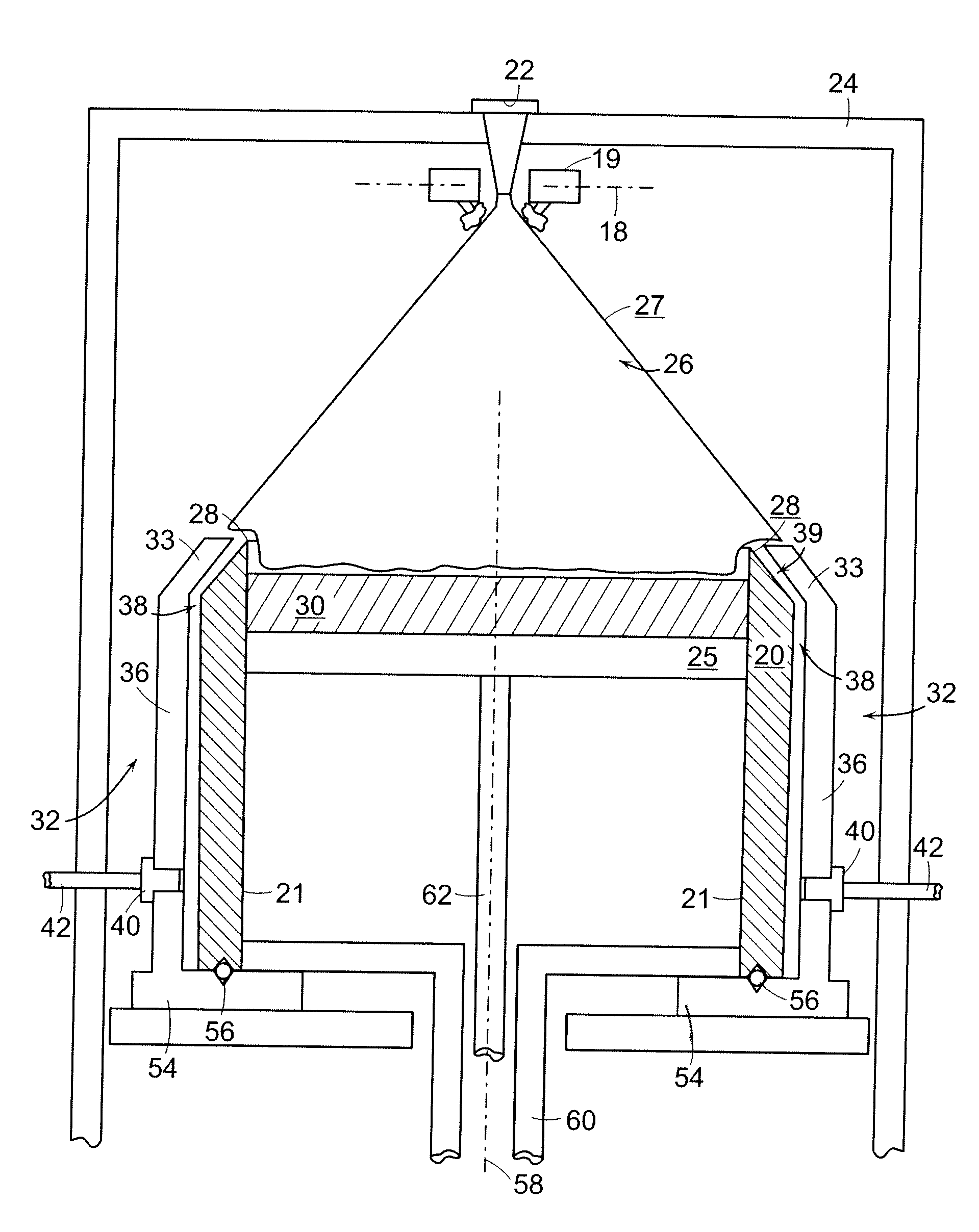

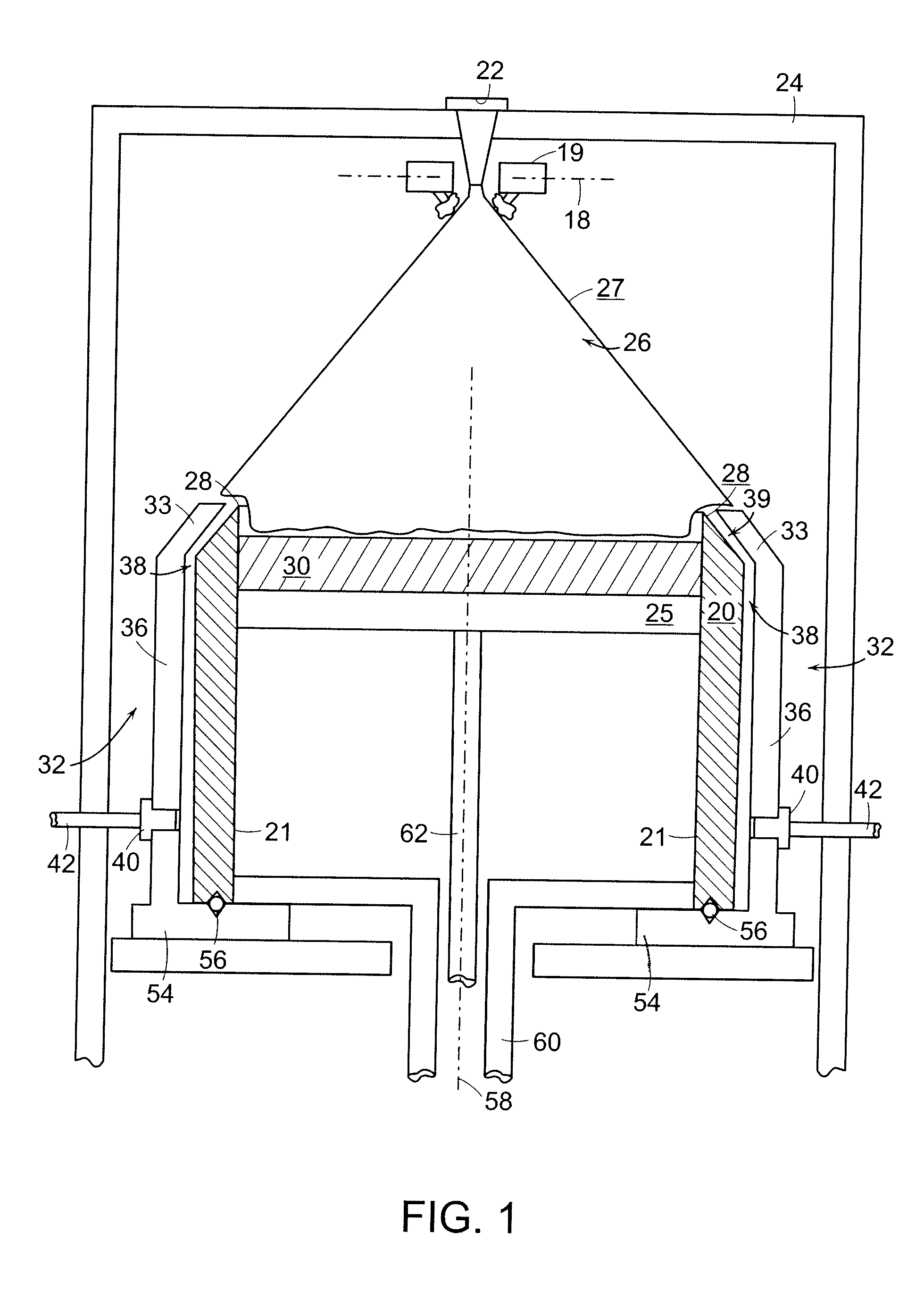

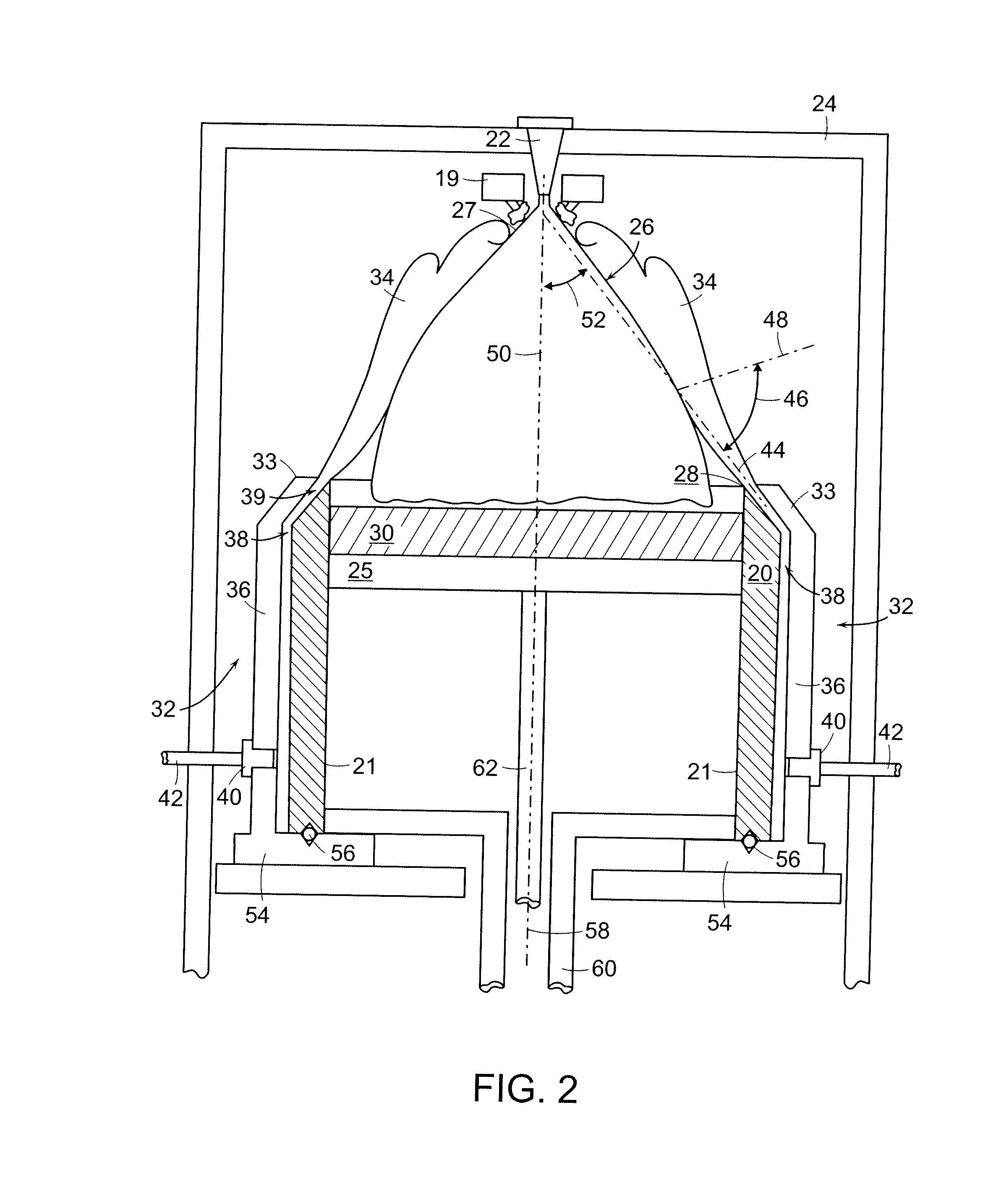

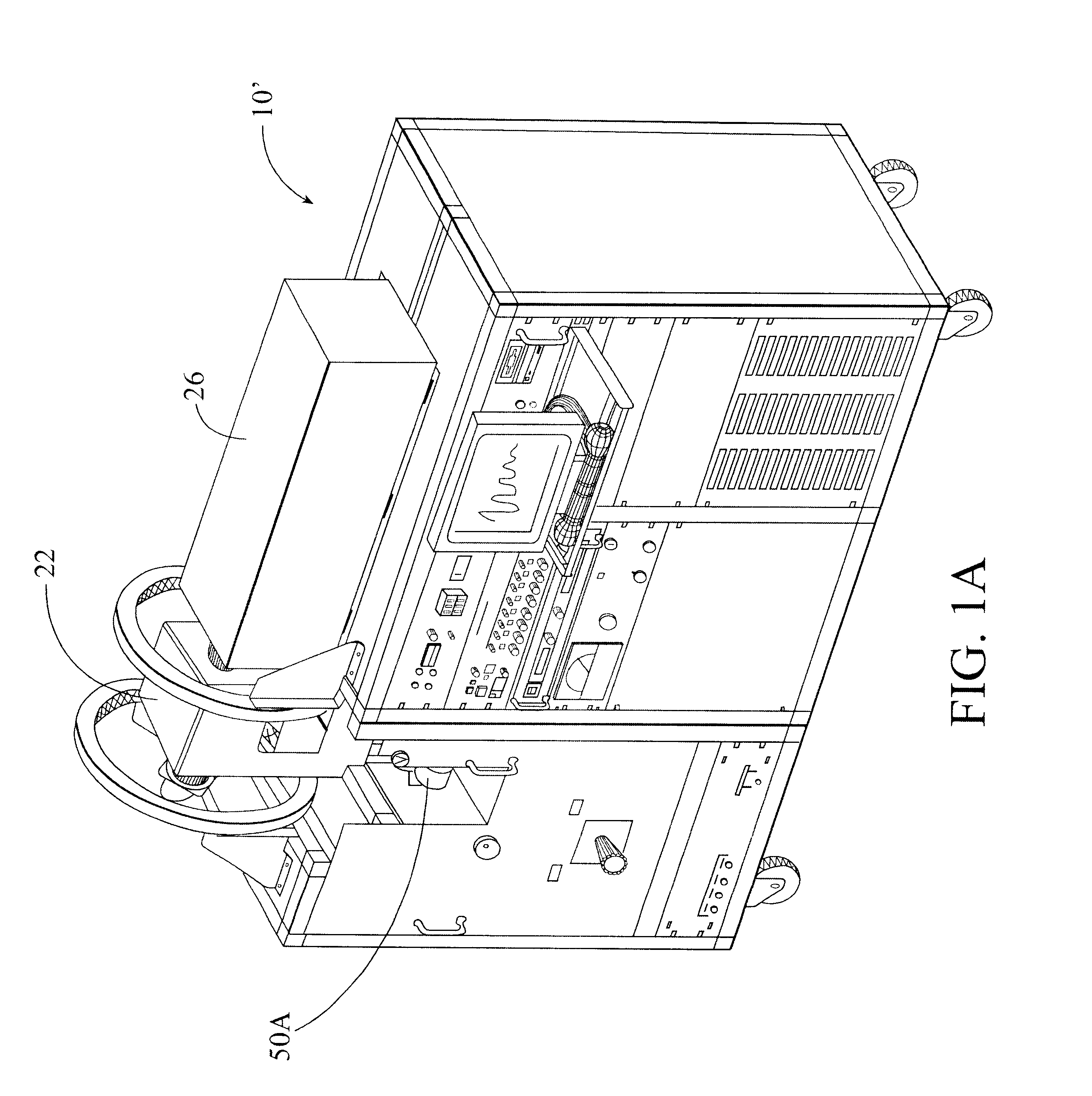

Deposition systems having interchangeable gas injectors and related methods

InactiveUS20150292088A1After-treatment apparatusPolycrystalline material growthGas syringeEngineering

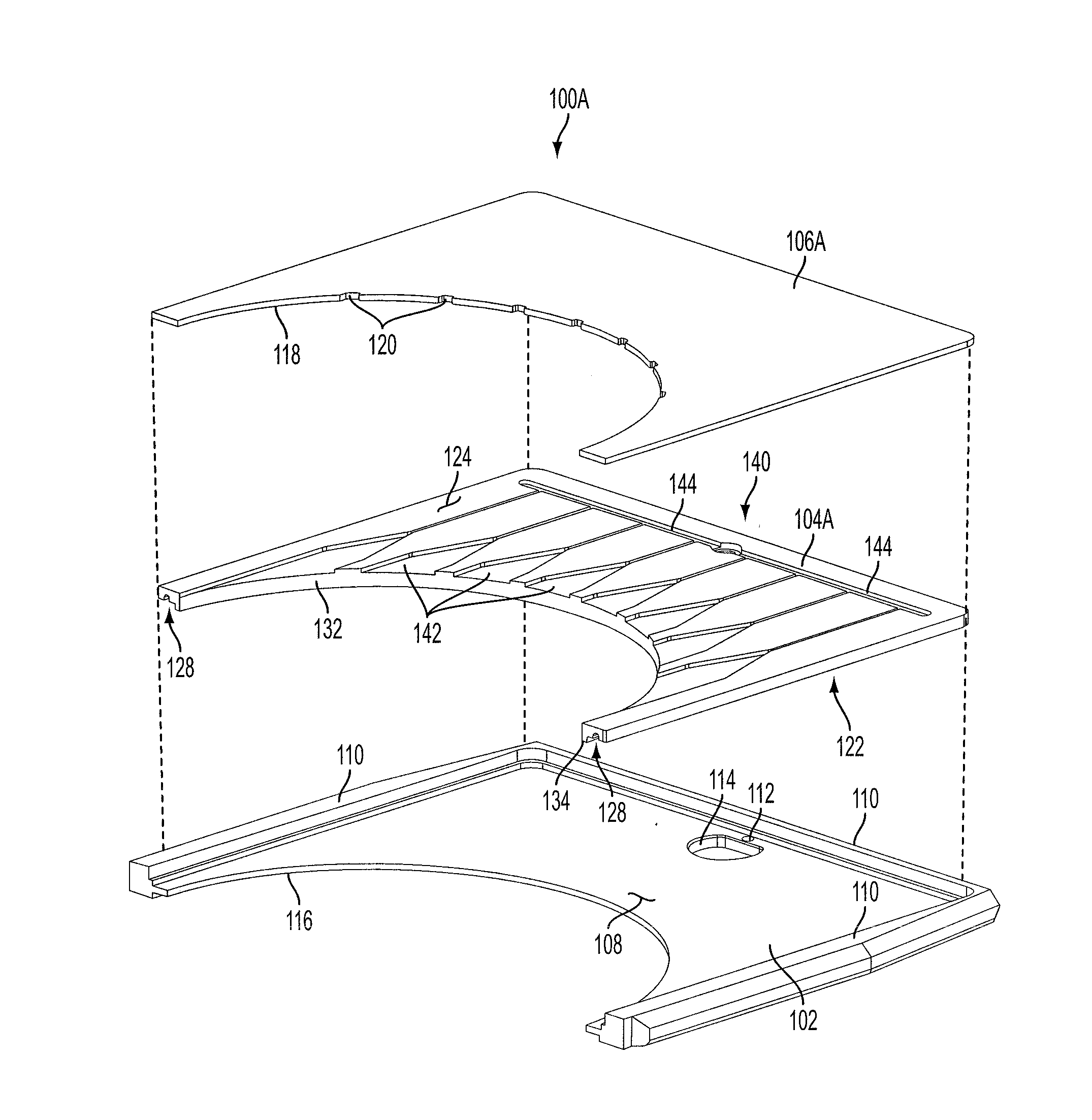

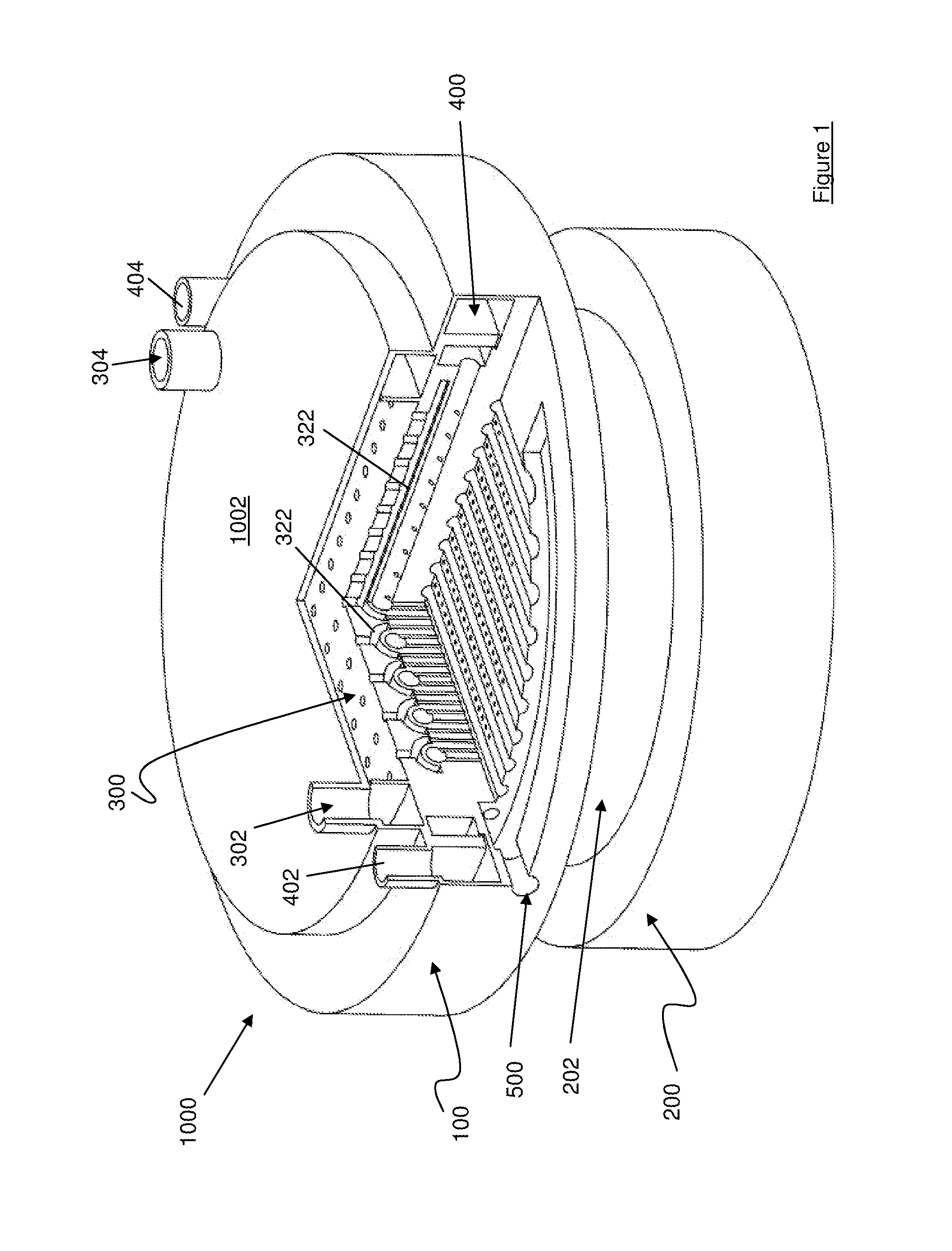

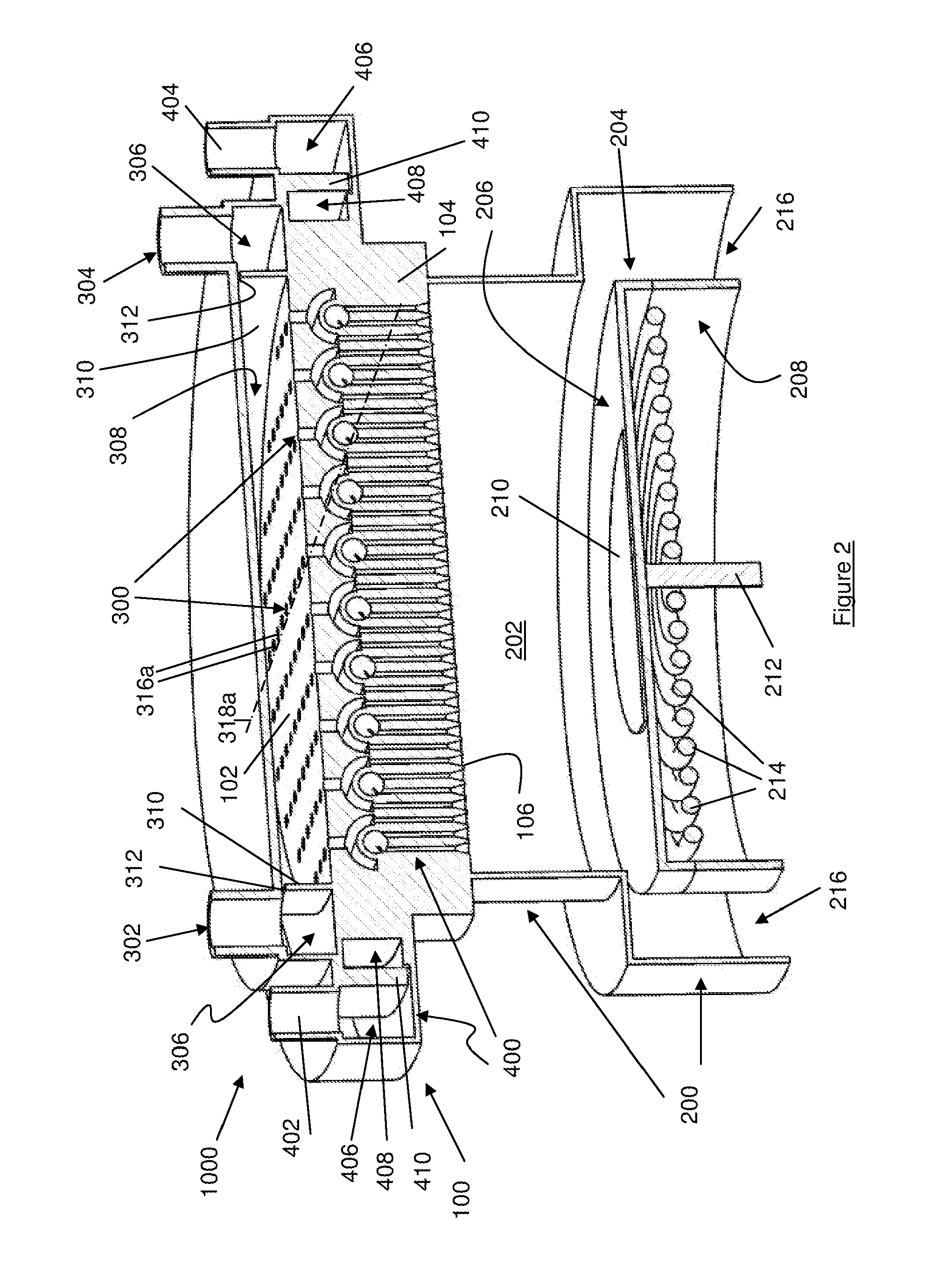

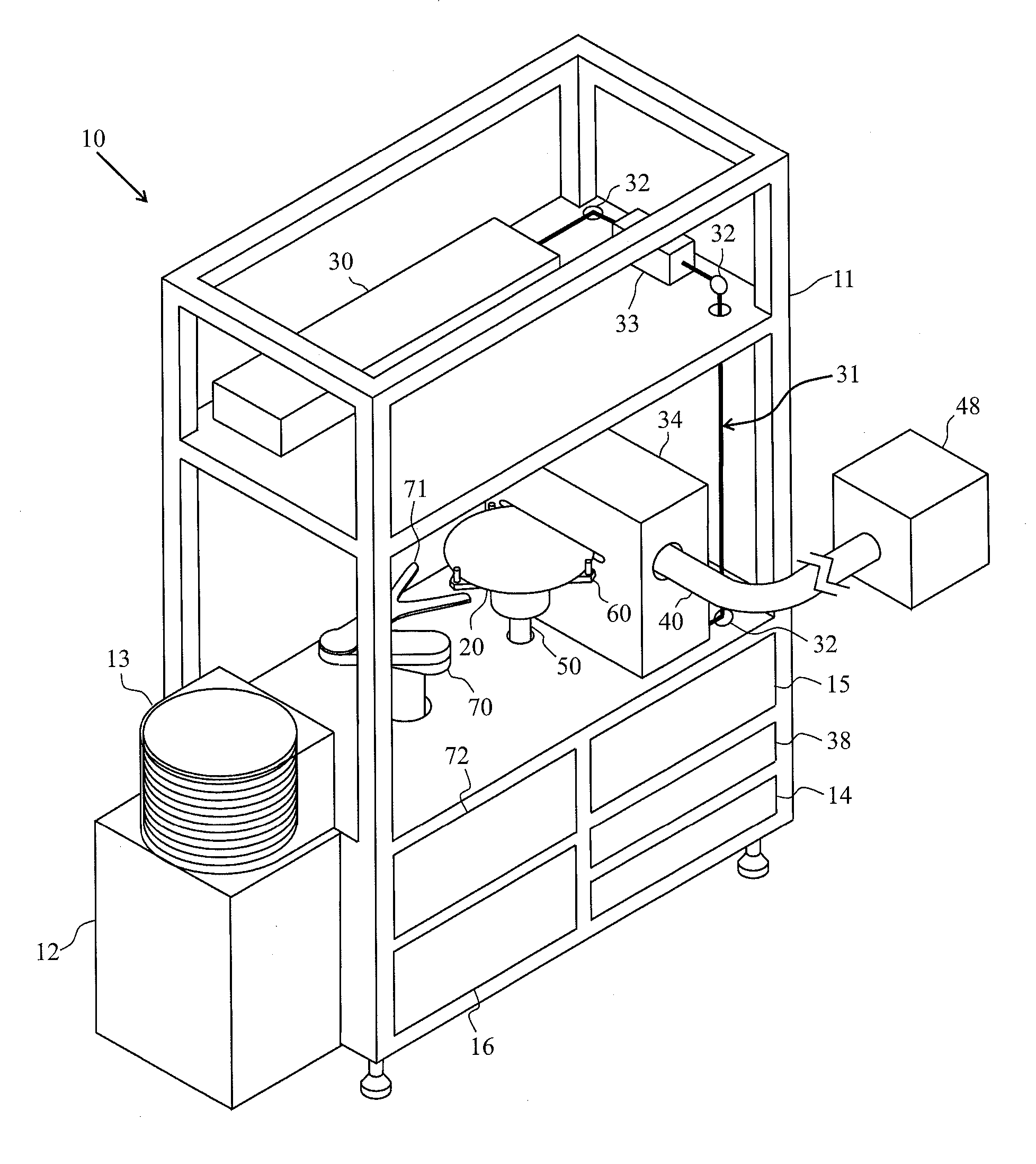

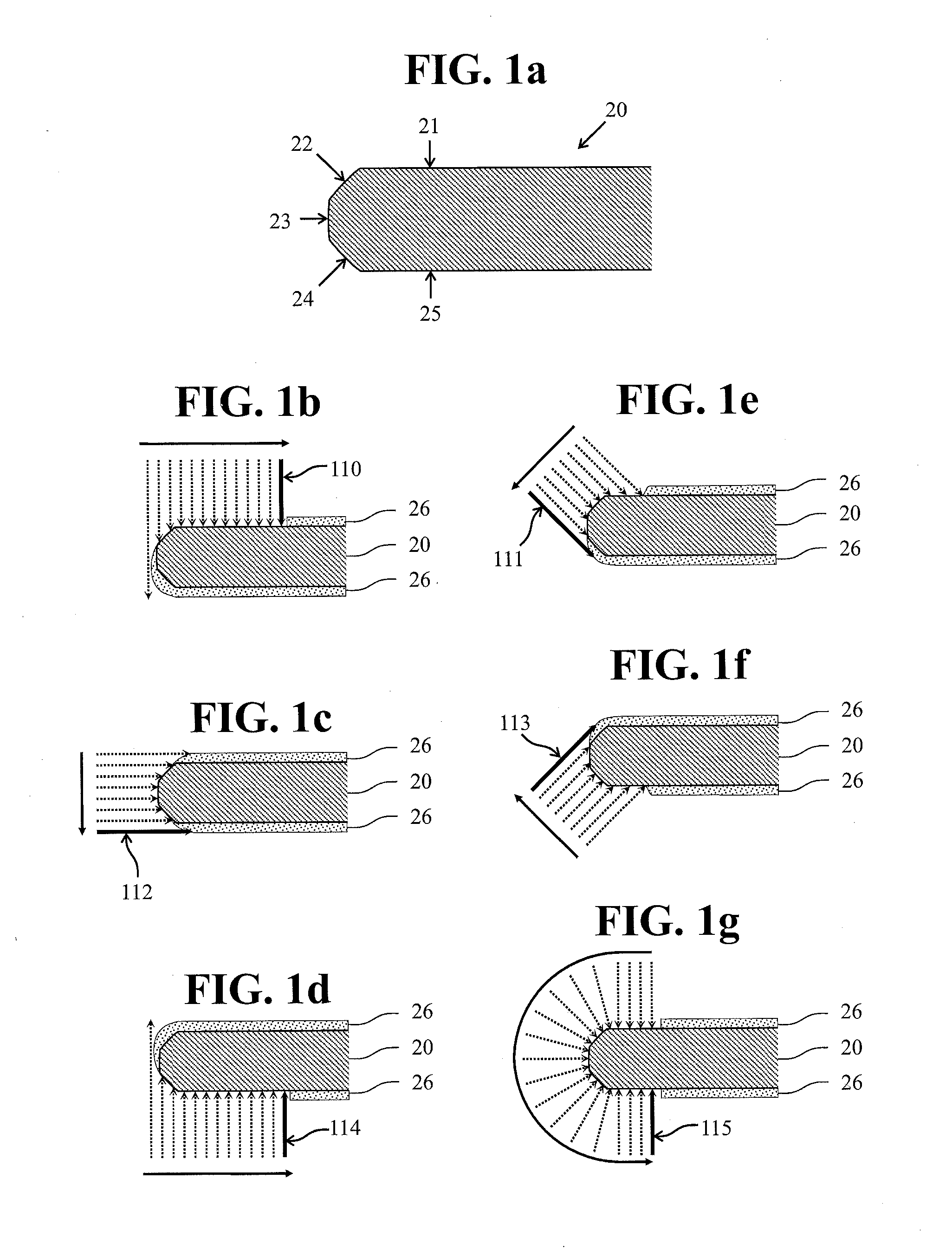

A deposition system includes two or more gas injectors that may be interchangeably used in a chamber of the deposition system. Each of the gas injectors may be configured to generate a sheet of flowing gas over a substrate support structure. The sheets may have differing widths, such that the gas injectors may be used with substrates having different diameters, which may enable use of the system with different substrates while maintaining efficient use of precursor gas. A method of forming such a deposition system includes forming and configuring such gas injectors to be interchangeably used at a common location within the deposition chamber. A method of using such a deposition system includes using two or more such gas injectors to deposit material on substrates having different sizes.

Owner:SOITEC SA

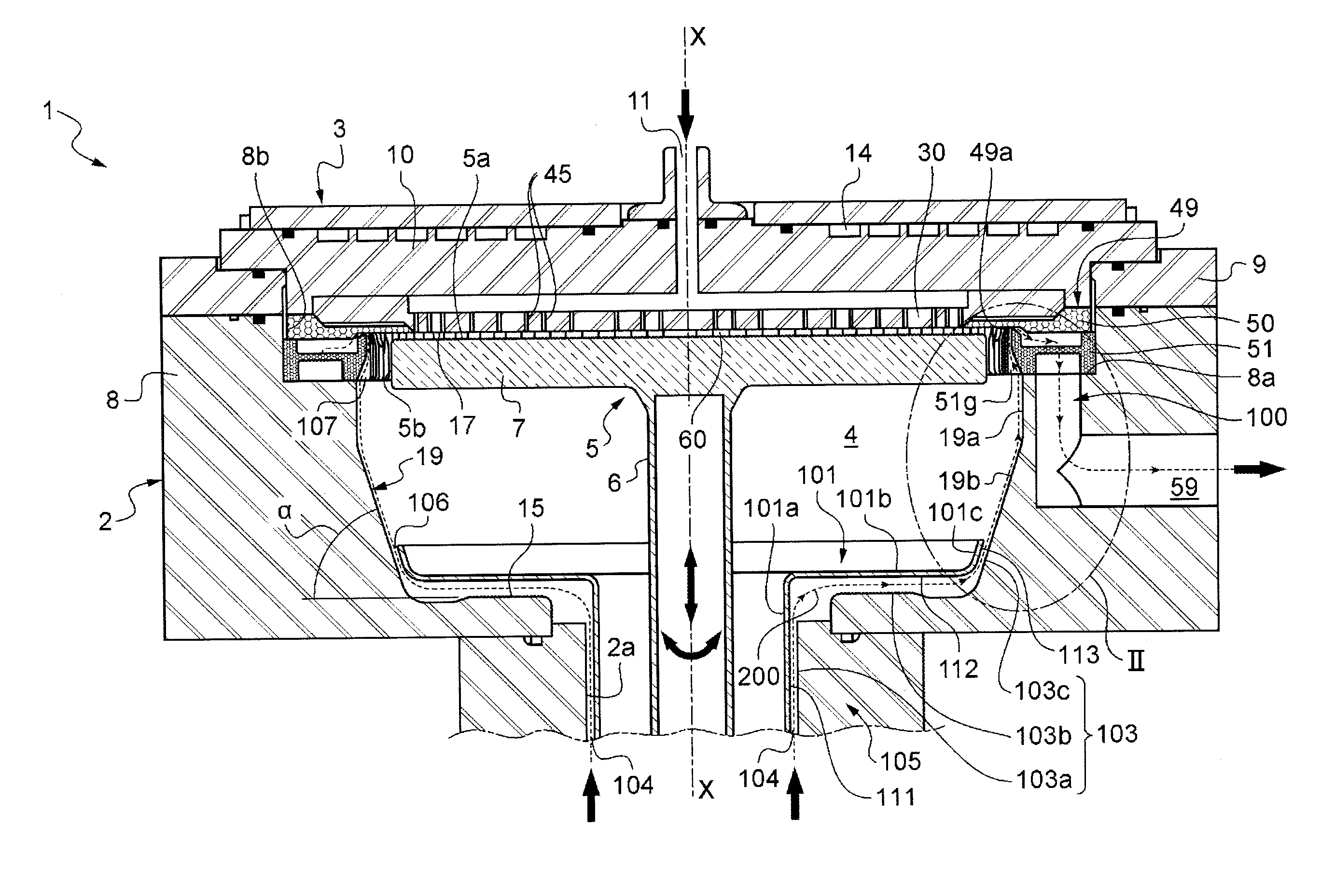

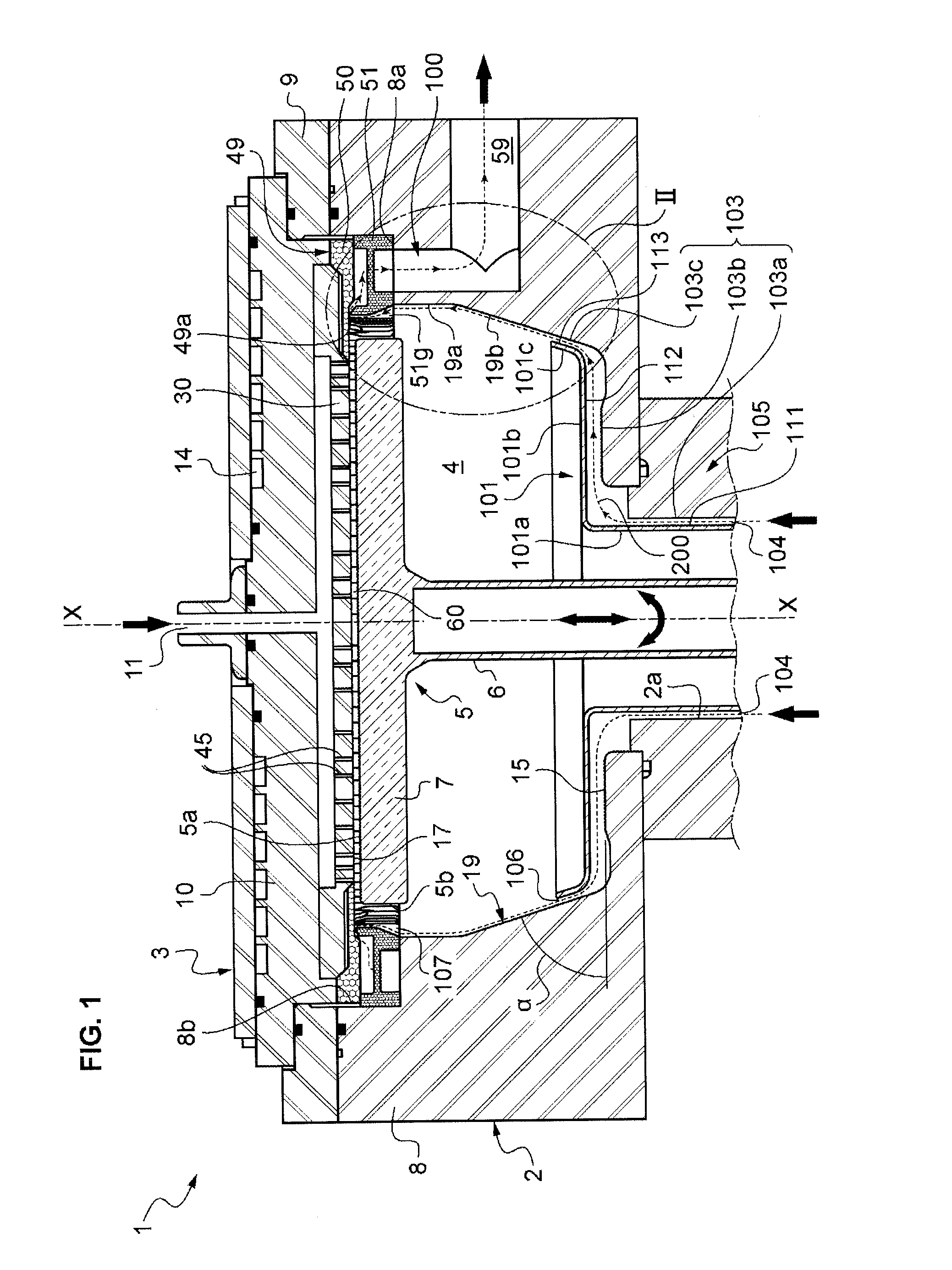

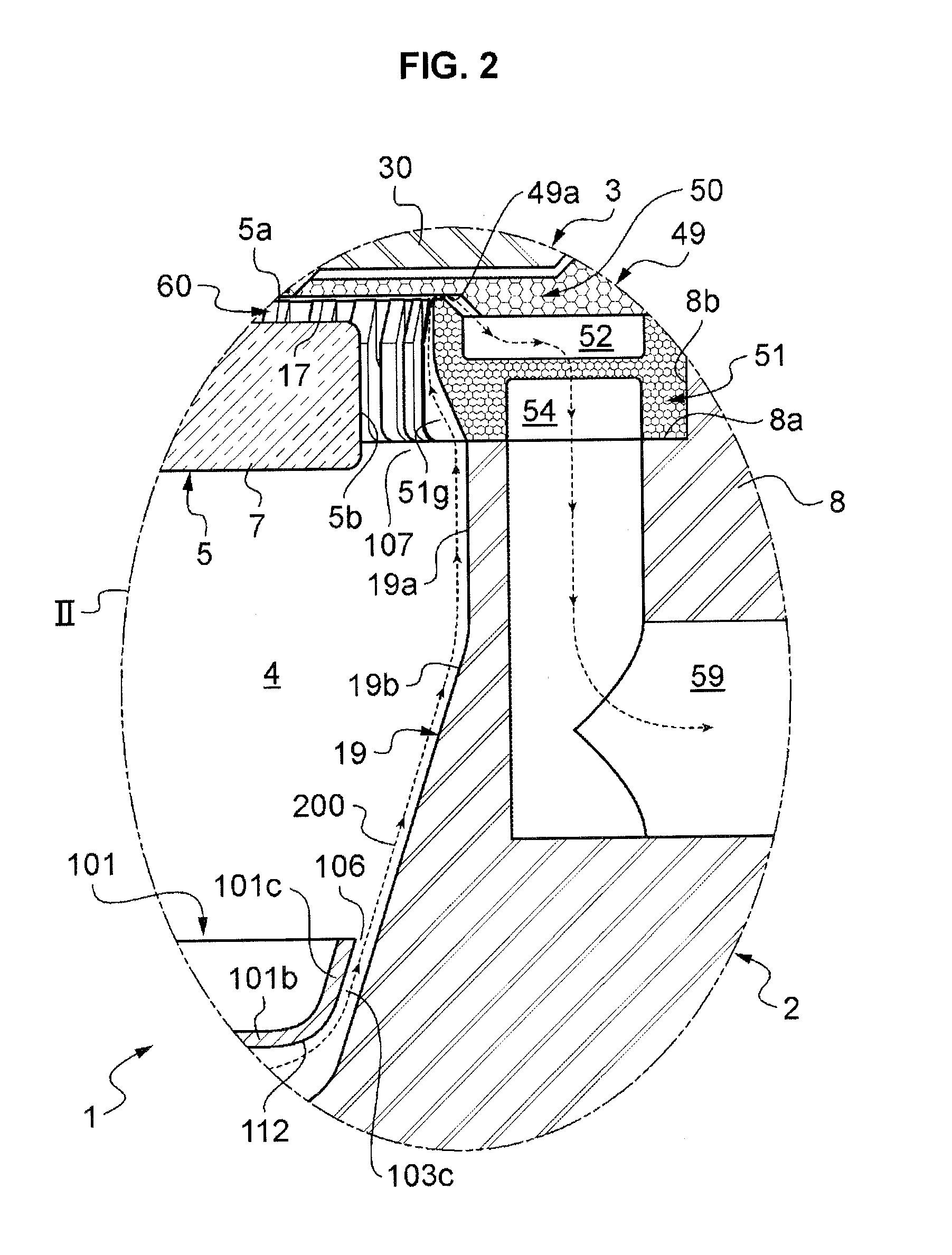

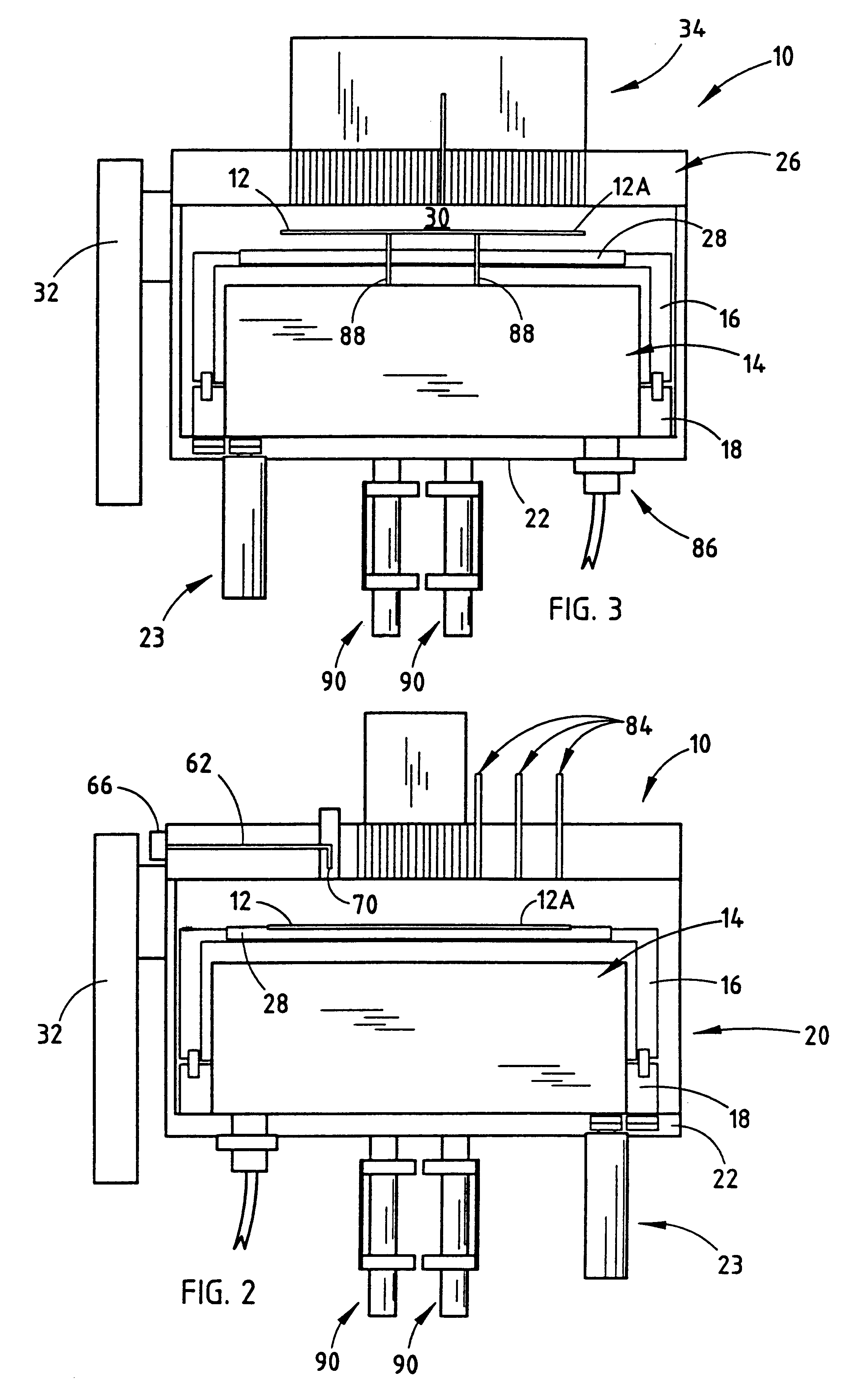

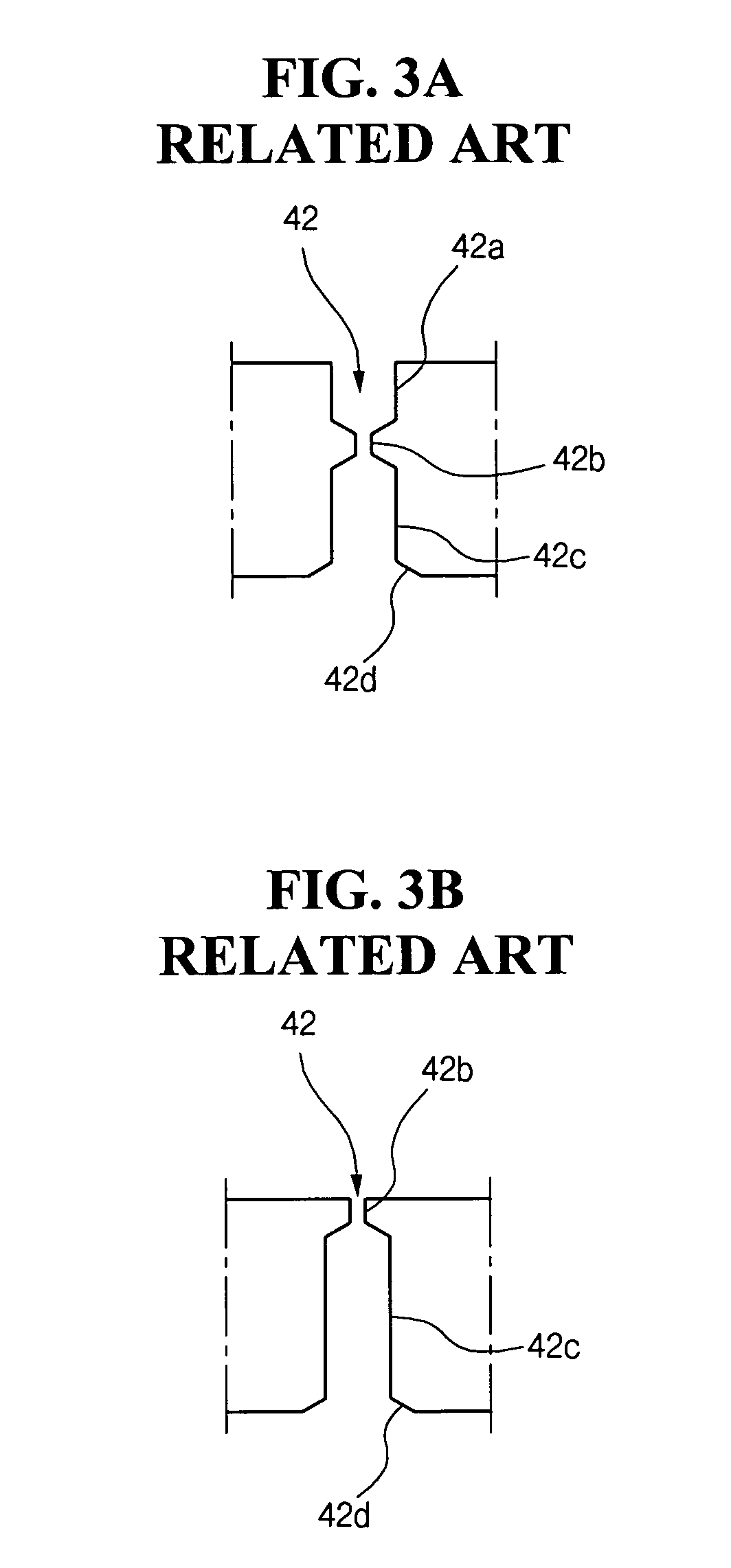

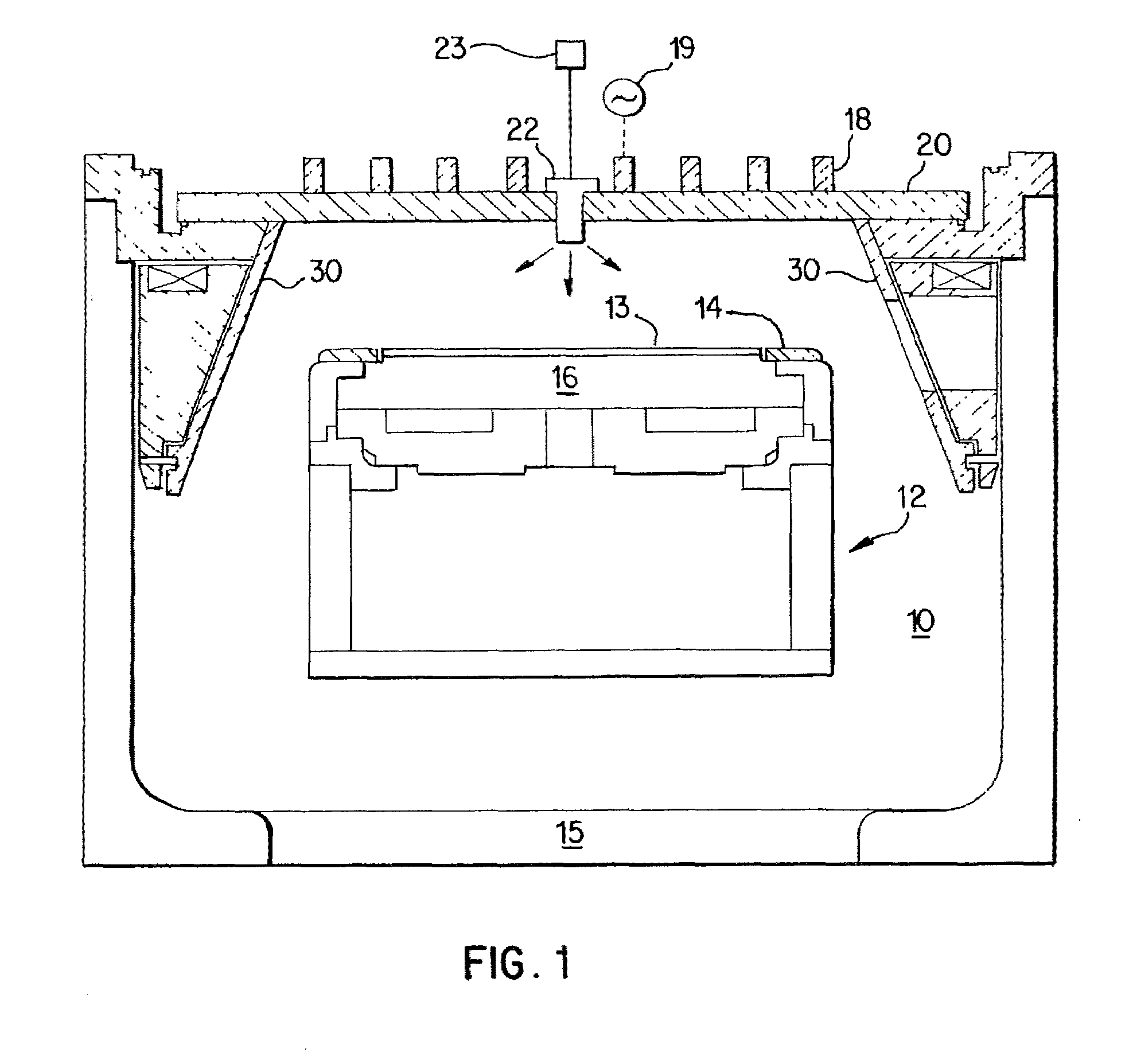

Chemical vapor deposition device

A reactor device for chemical vapor deposition includes a reaction chamber having a side wall and a substrate stand having a peripheral surface and a main surface facing a reactive gas injector, the injector and said surface defining a work space therebetween. The substrate stand is arranged in the reaction chamber such as to form an annular passage between the peripheral surface of the substrate stand and the side wall of the reaction chamber. A system for discharging gases is in fluid connection with the reaction chamber. A purge gas injector includes an injection channel leading into the reaction chamber through an annular opening. A laminar flow of purge gas is injected through the annular opening and flows in said annular passage to an opening.

Owner:KOBUS SAS

Reactor and method of processing a semiconductor substrate

InactiveUSRE37546E1Accurately determineEliminate needThermometer detailsRadiation pyrometryGas syringeEngineering

Owner:KOKUSAI SEMICON EQUIP CORP

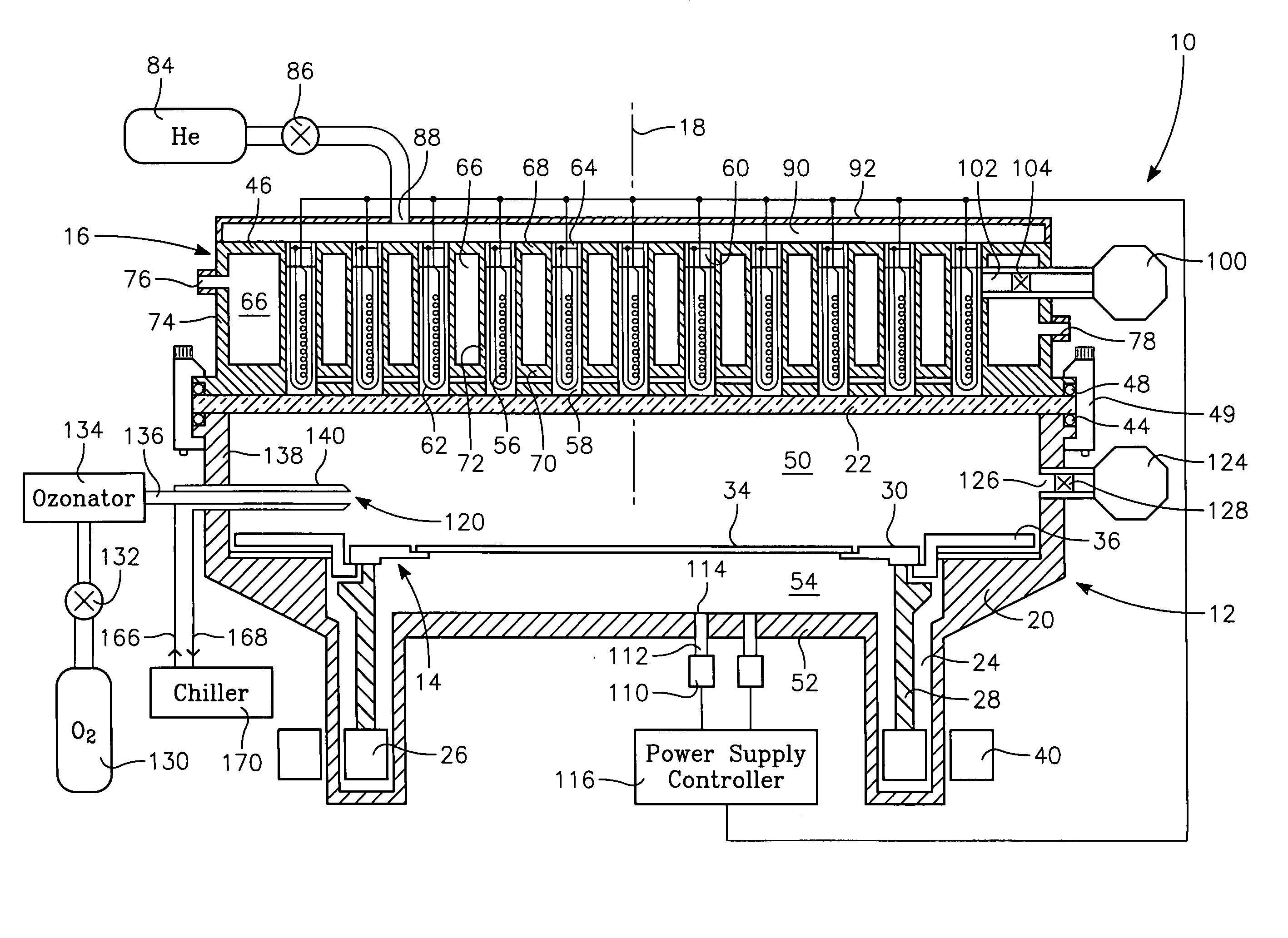

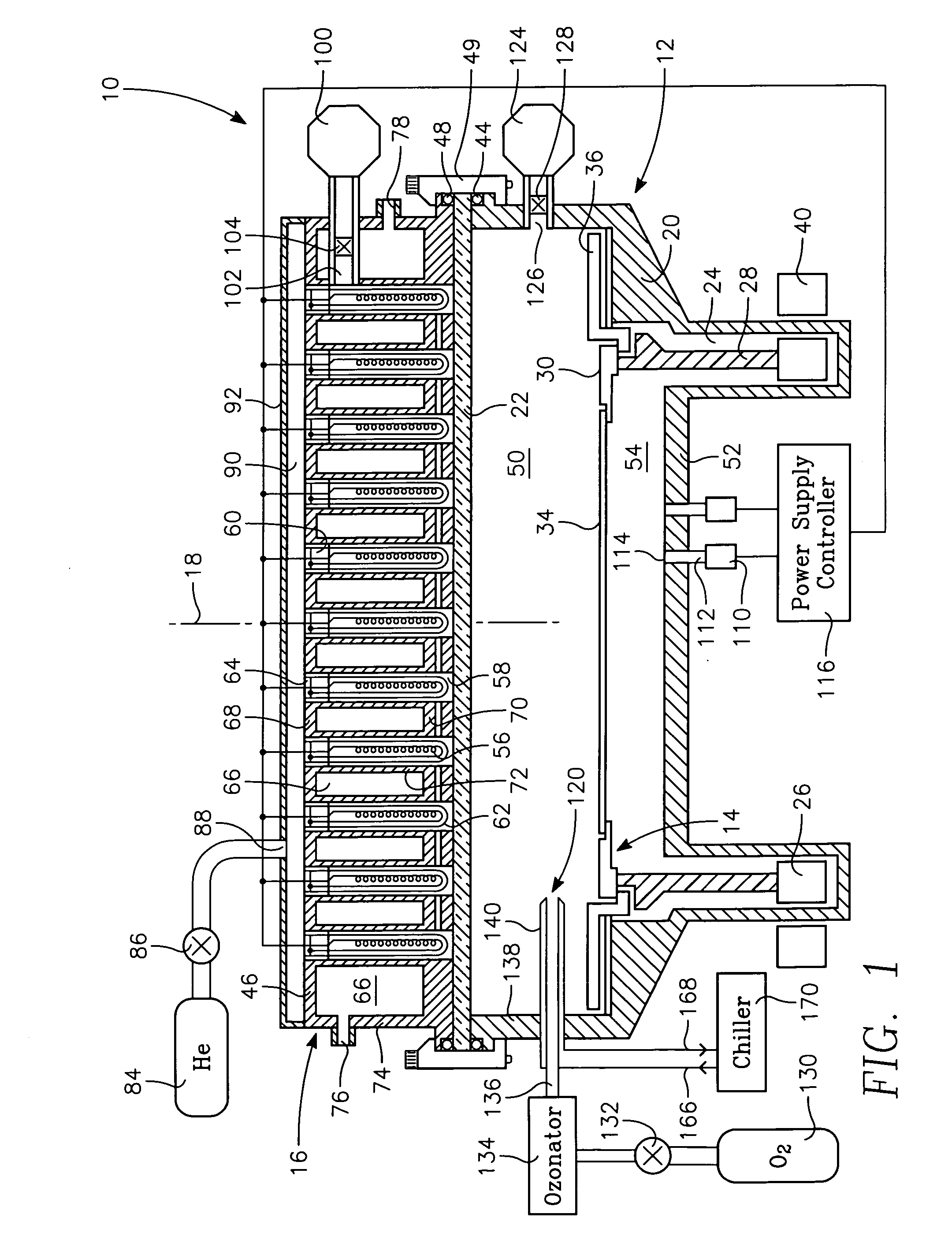

Thermal oxidation of silicon using ozone

A method and apparatus for oxidizing materials used in semiconductor integrated circuits, for example, for oxidizing silicon to form a dielectric gate. An ozonator is capable of producing a stream of least 70% ozone. The ozone passes into an RTP chamber through a water-cooled injector projecting into the chamber. Other gases such as hydrogen to increase oxidation rate, diluent gas such as nitrogen or O2, enter the chamber through another inlet. The chamber is maintained at a low pressure below 20 Torr and the substrate is advantageously maintained at a temperature less than 800° C. Alternatively, the oxidation may be performed in an LPCVD chamber including a pedestal heater and a showerhead gas injector in opposition to the pedestal.

Owner:APPLIED MATERIALS INC

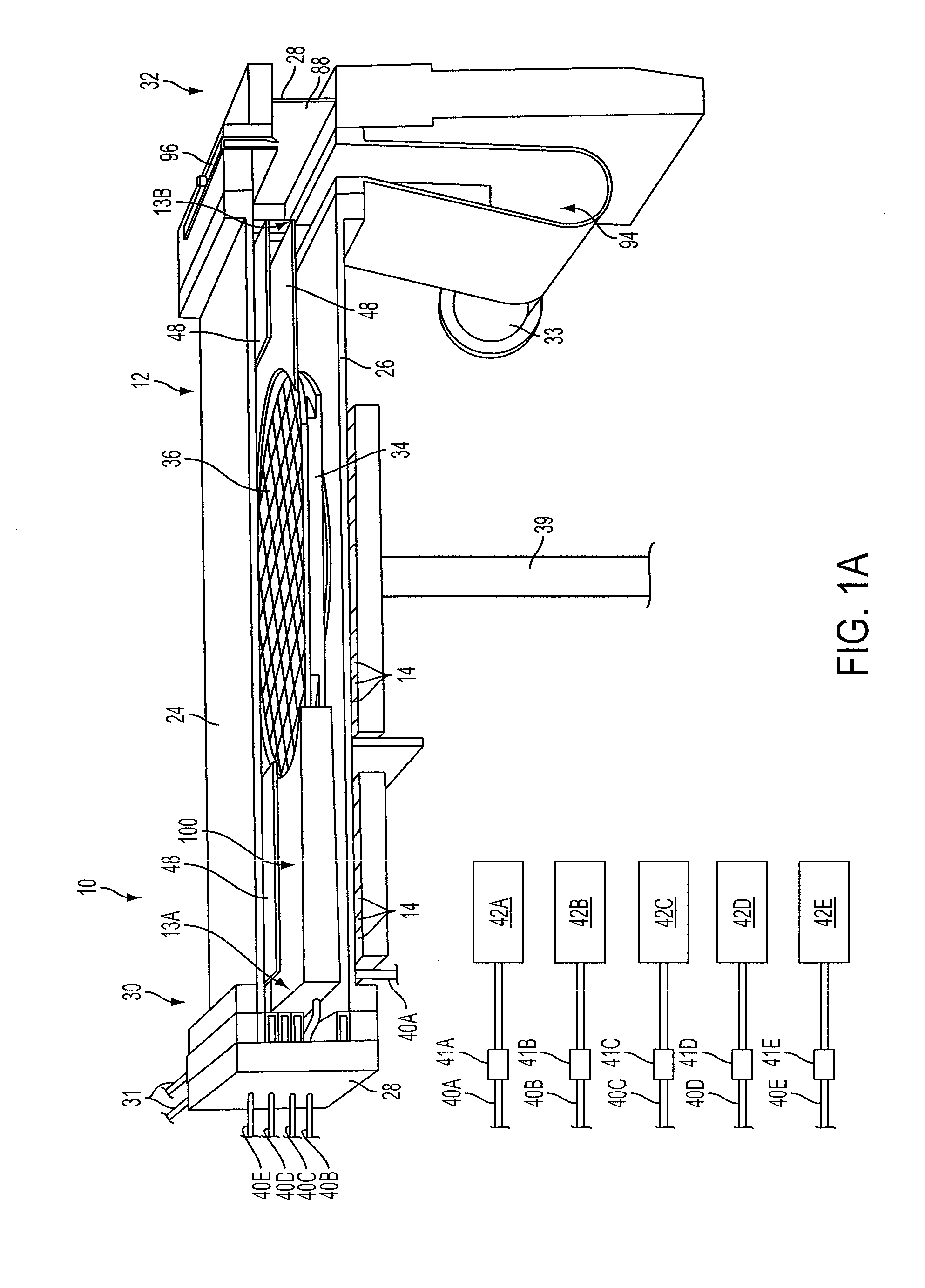

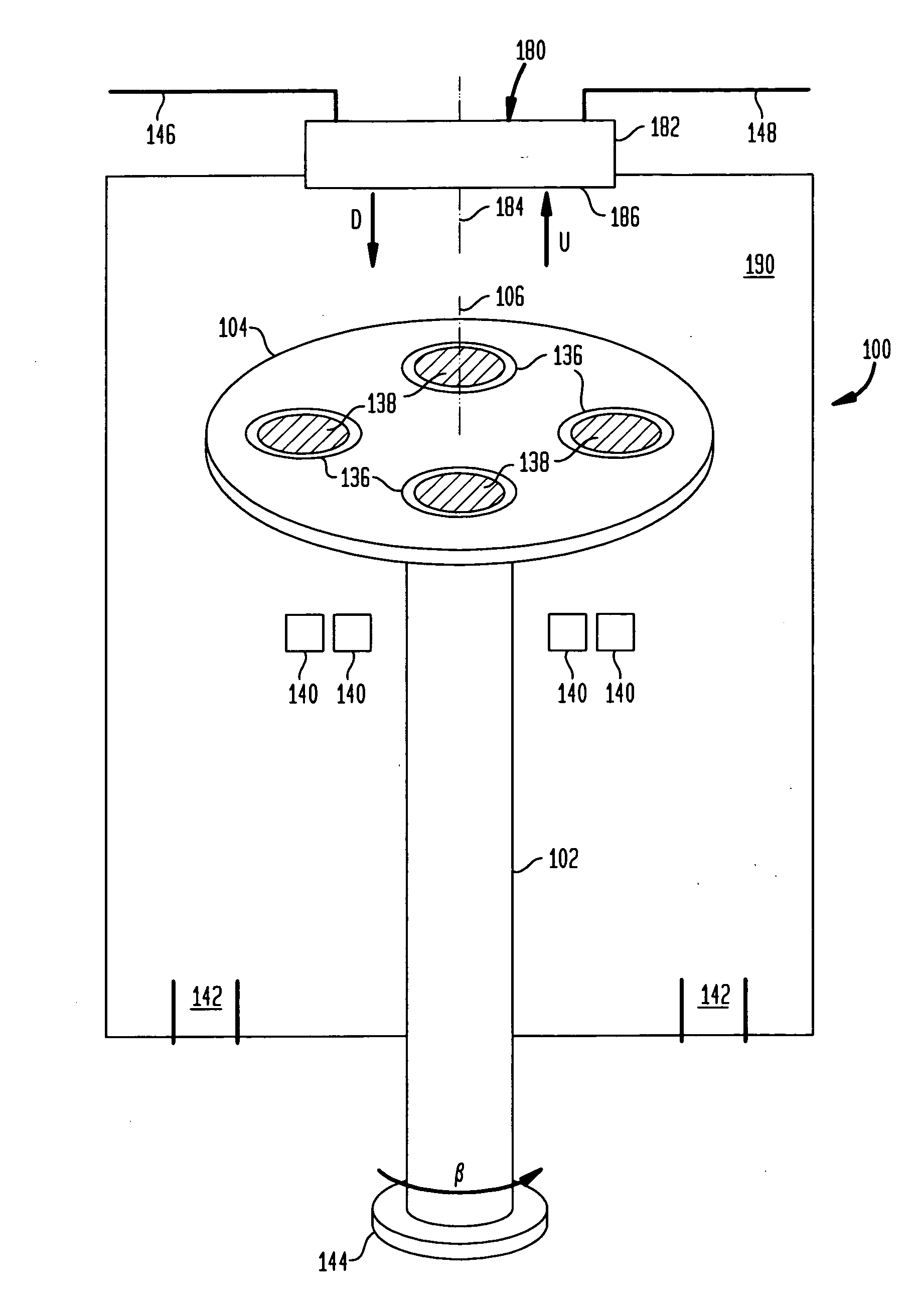

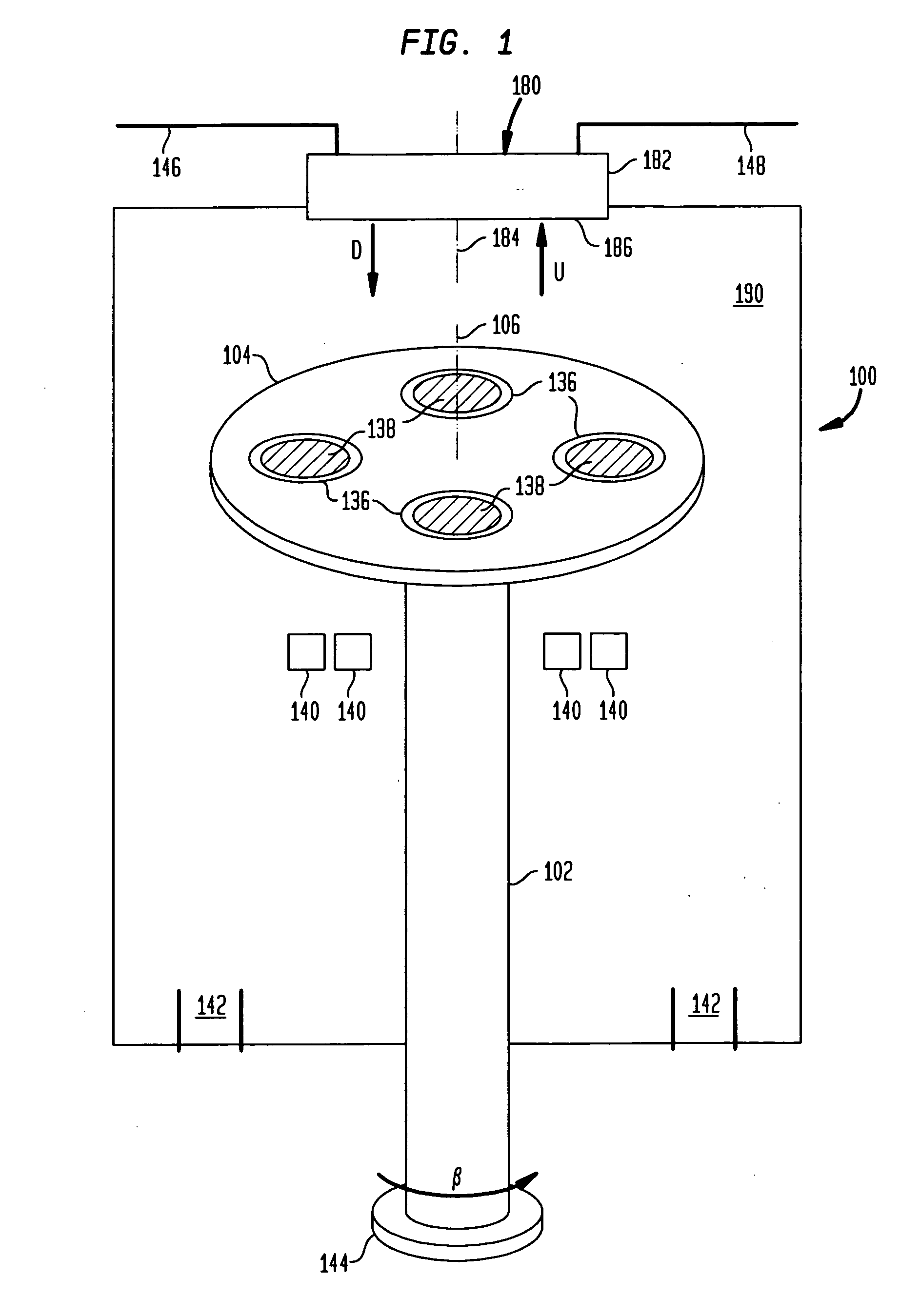

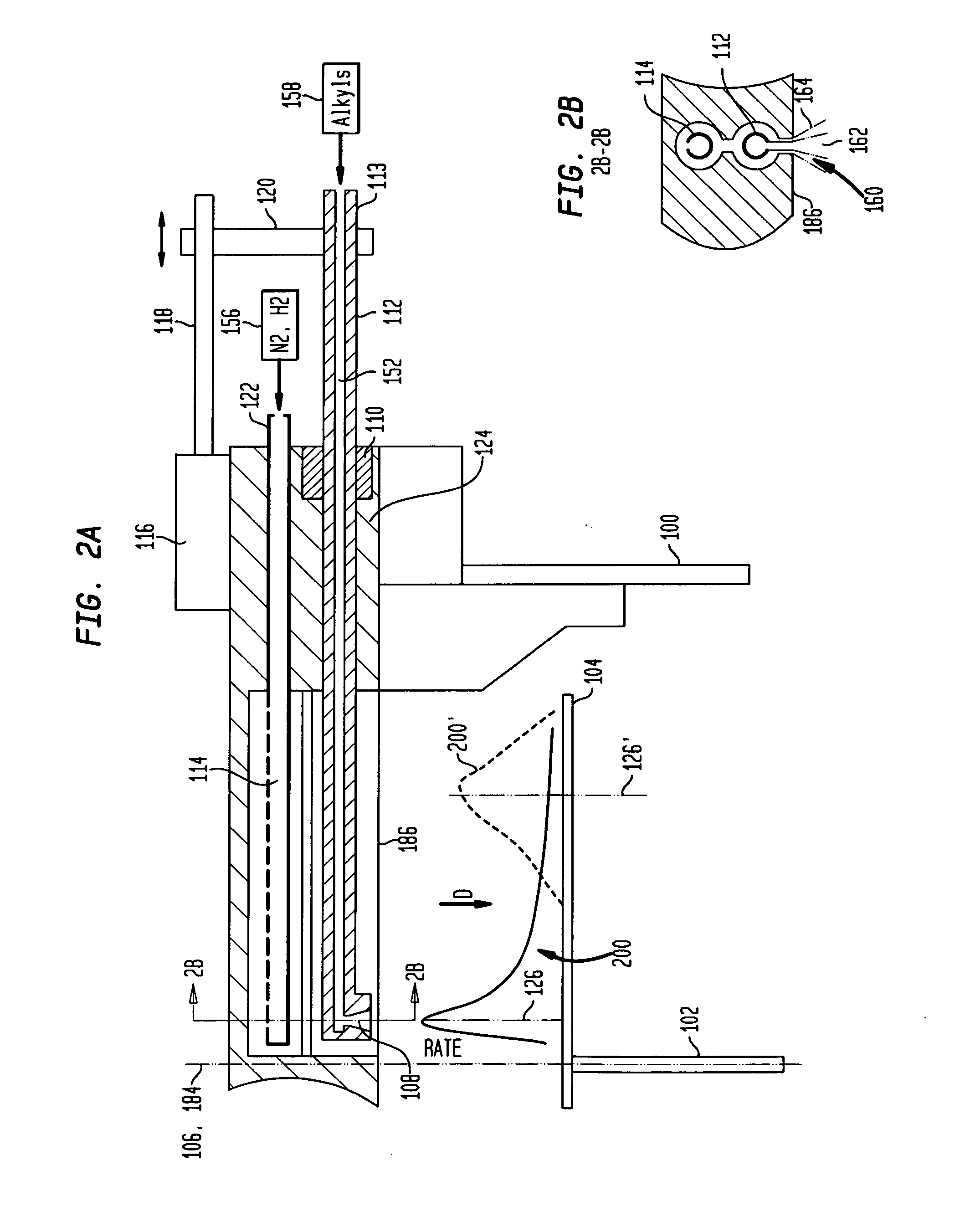

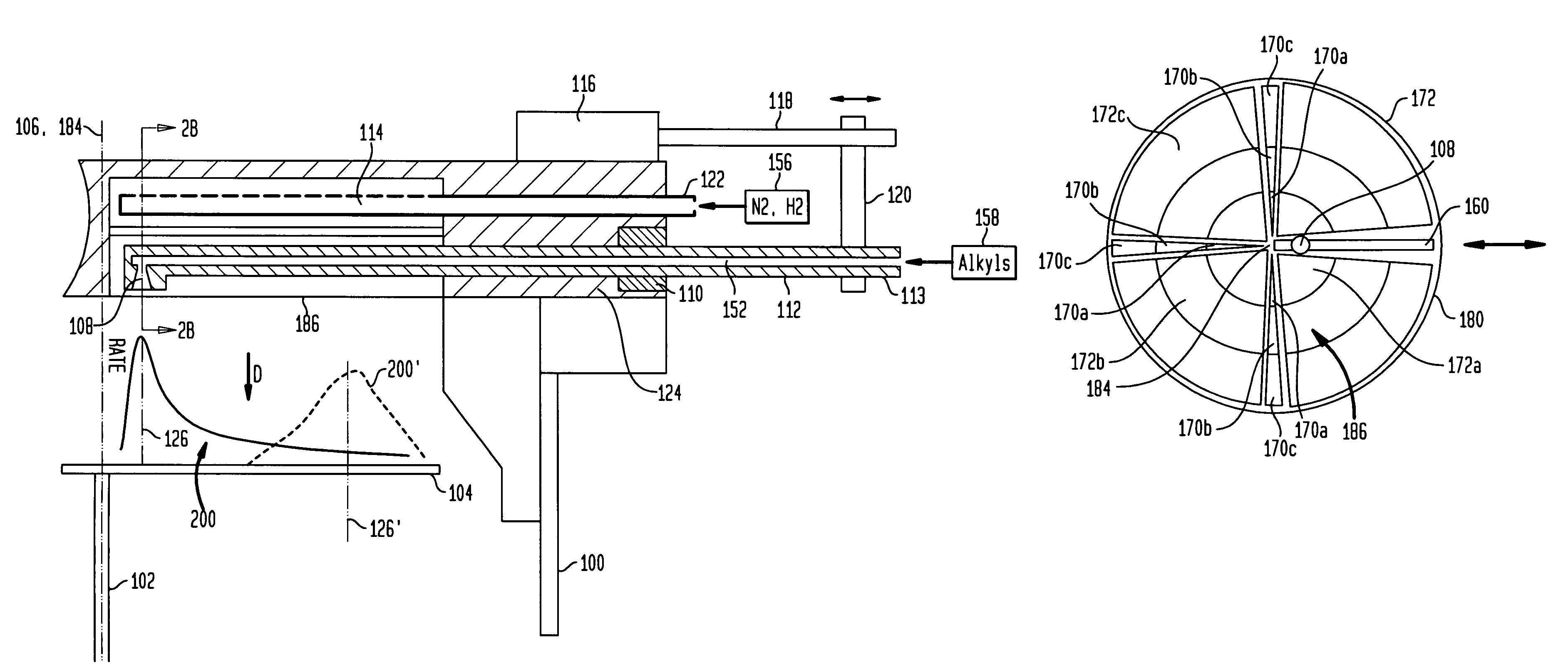

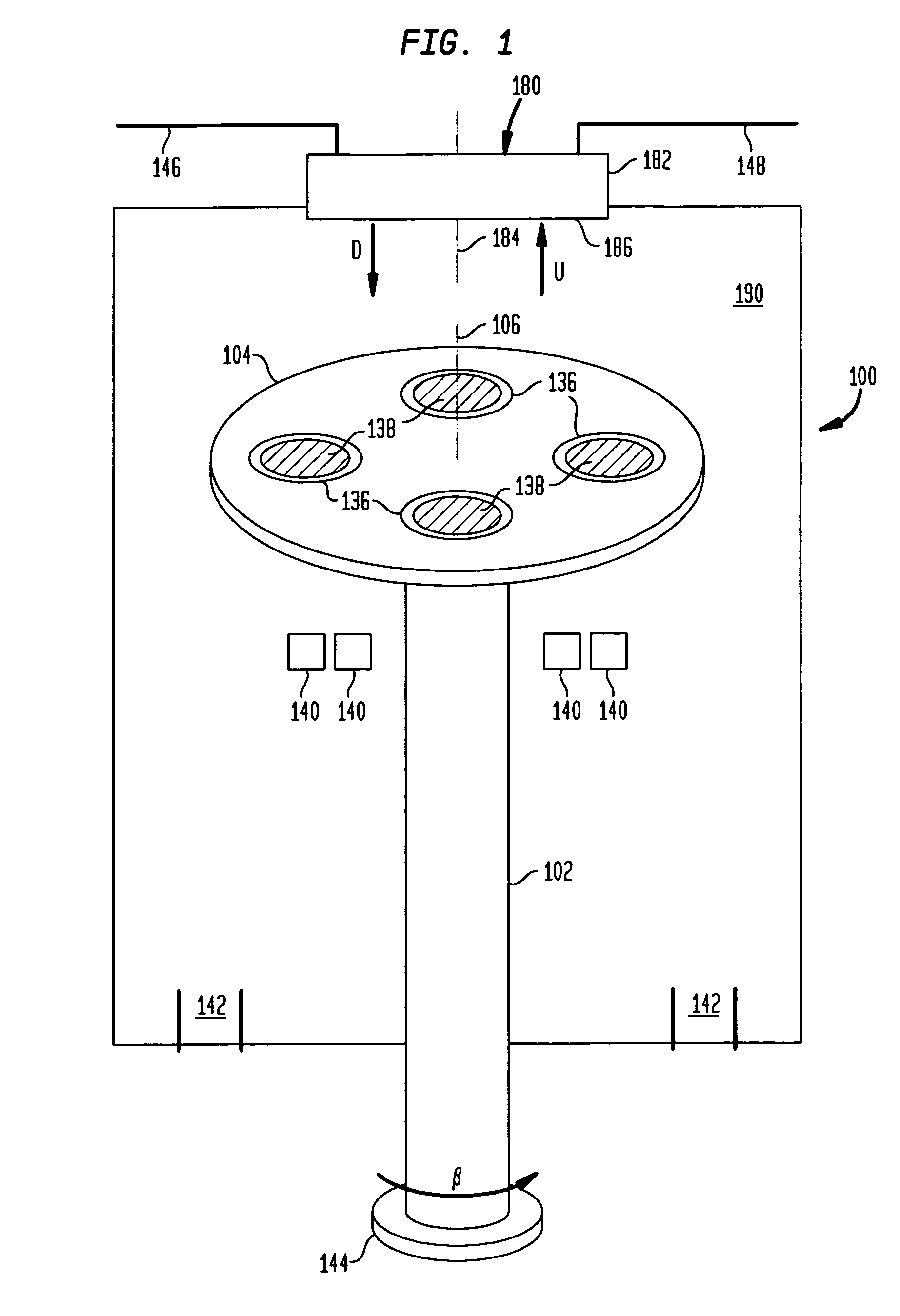

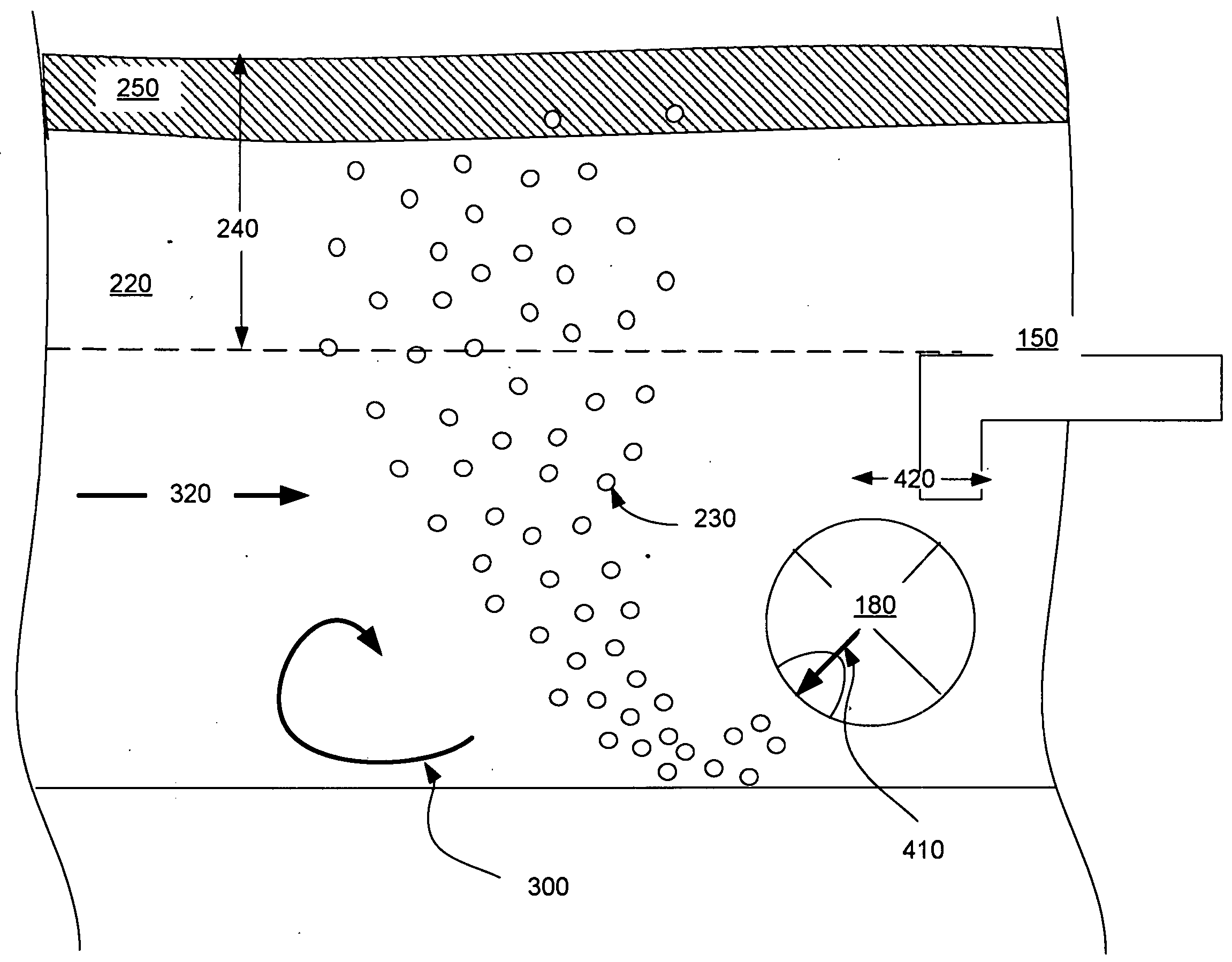

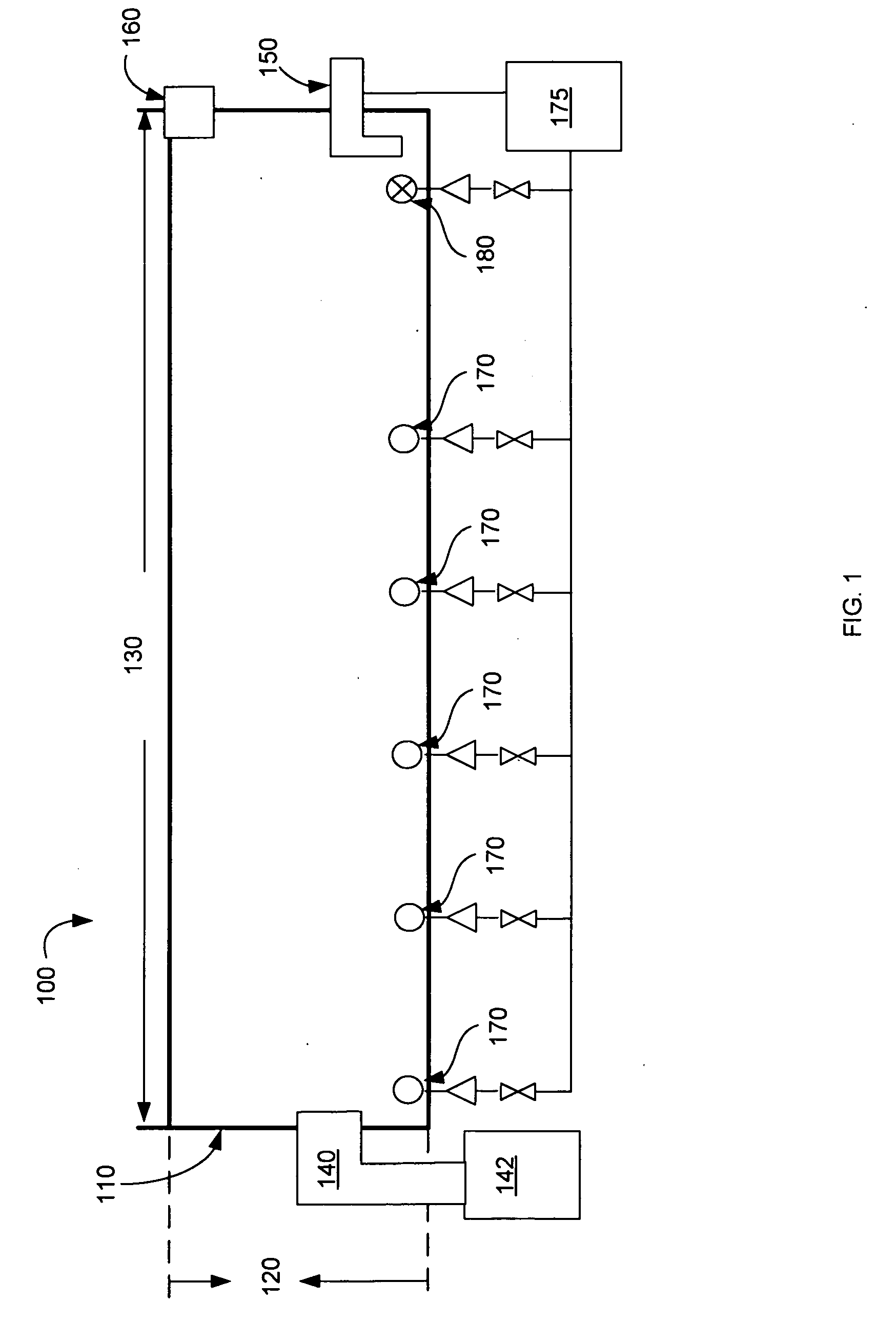

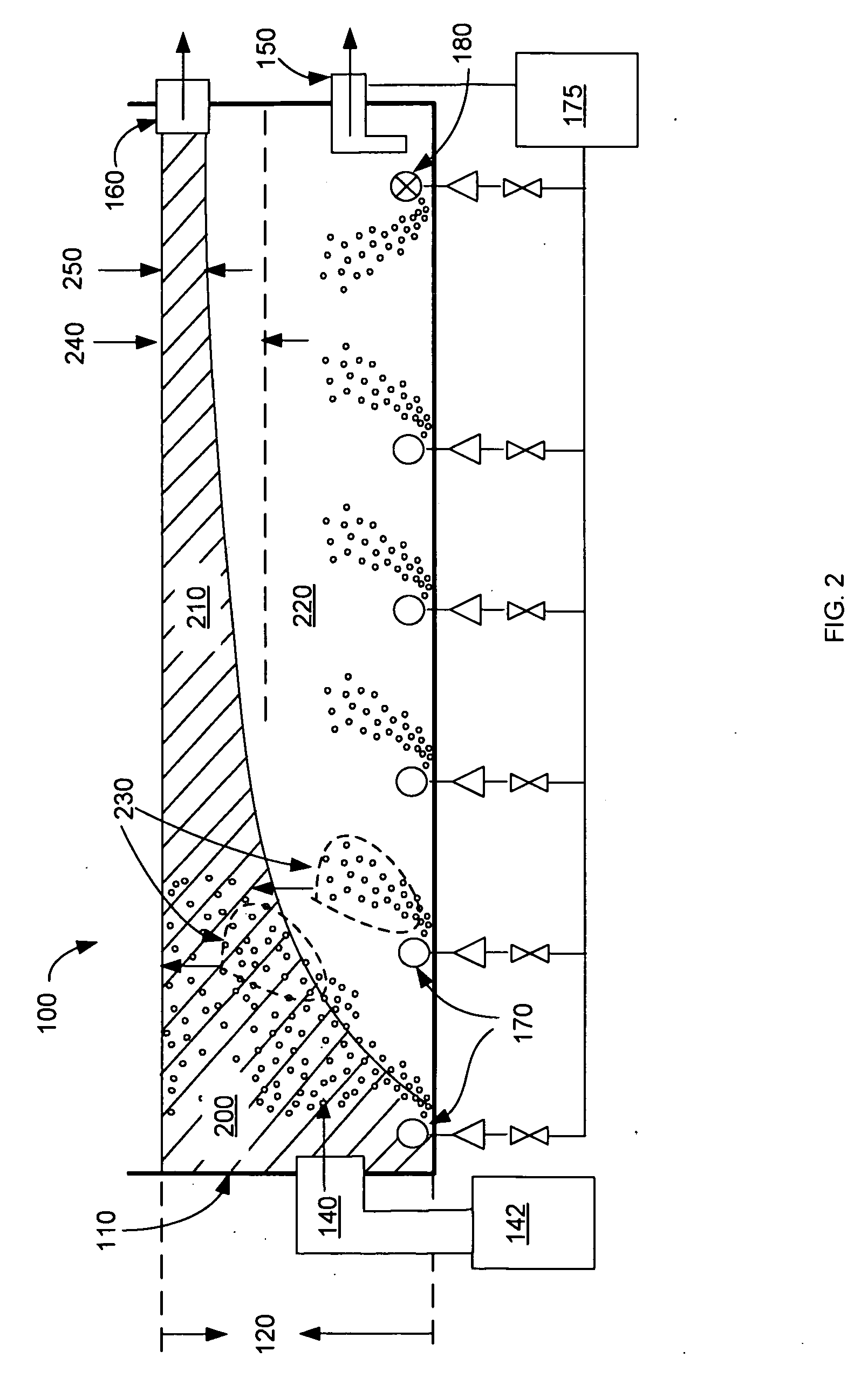

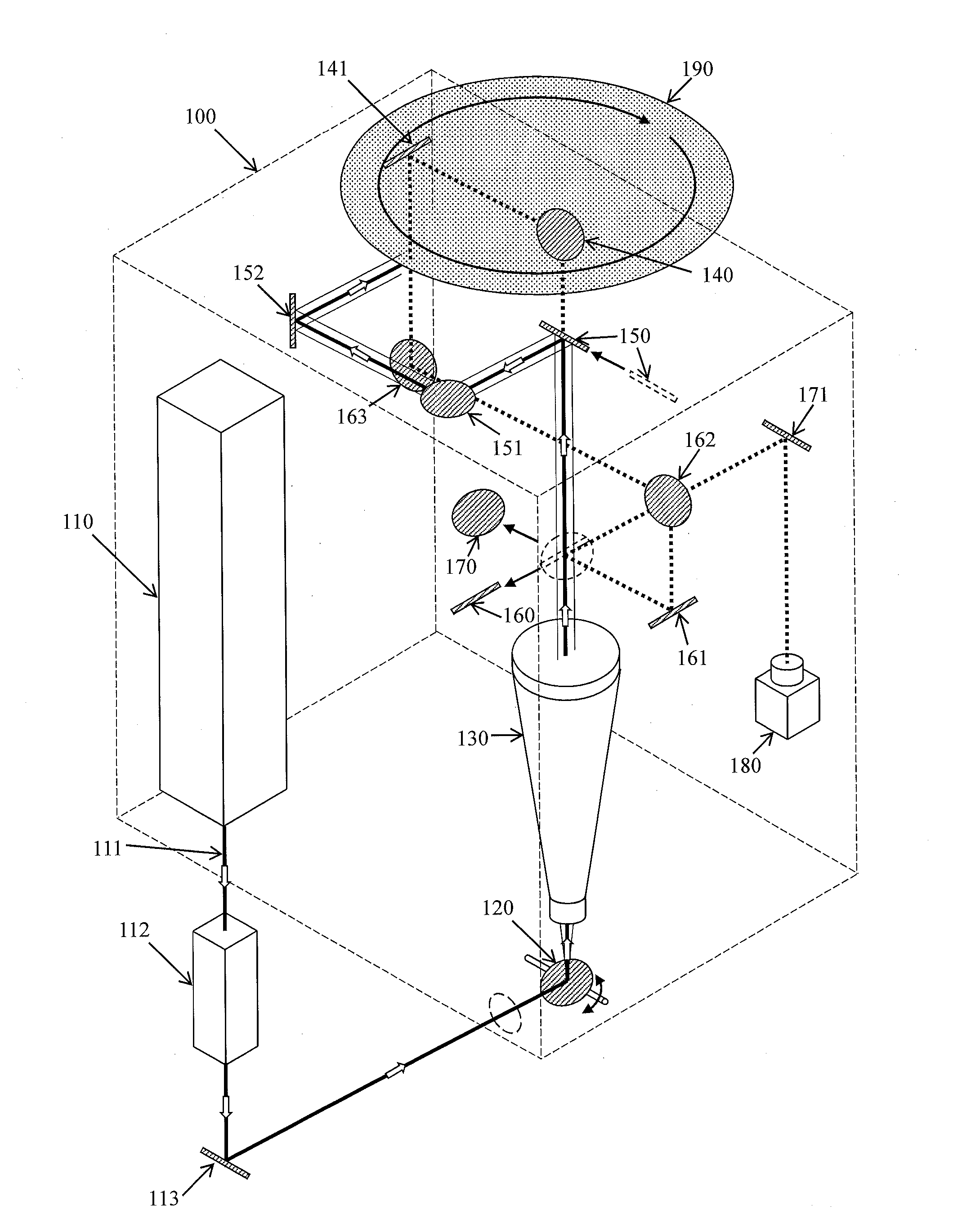

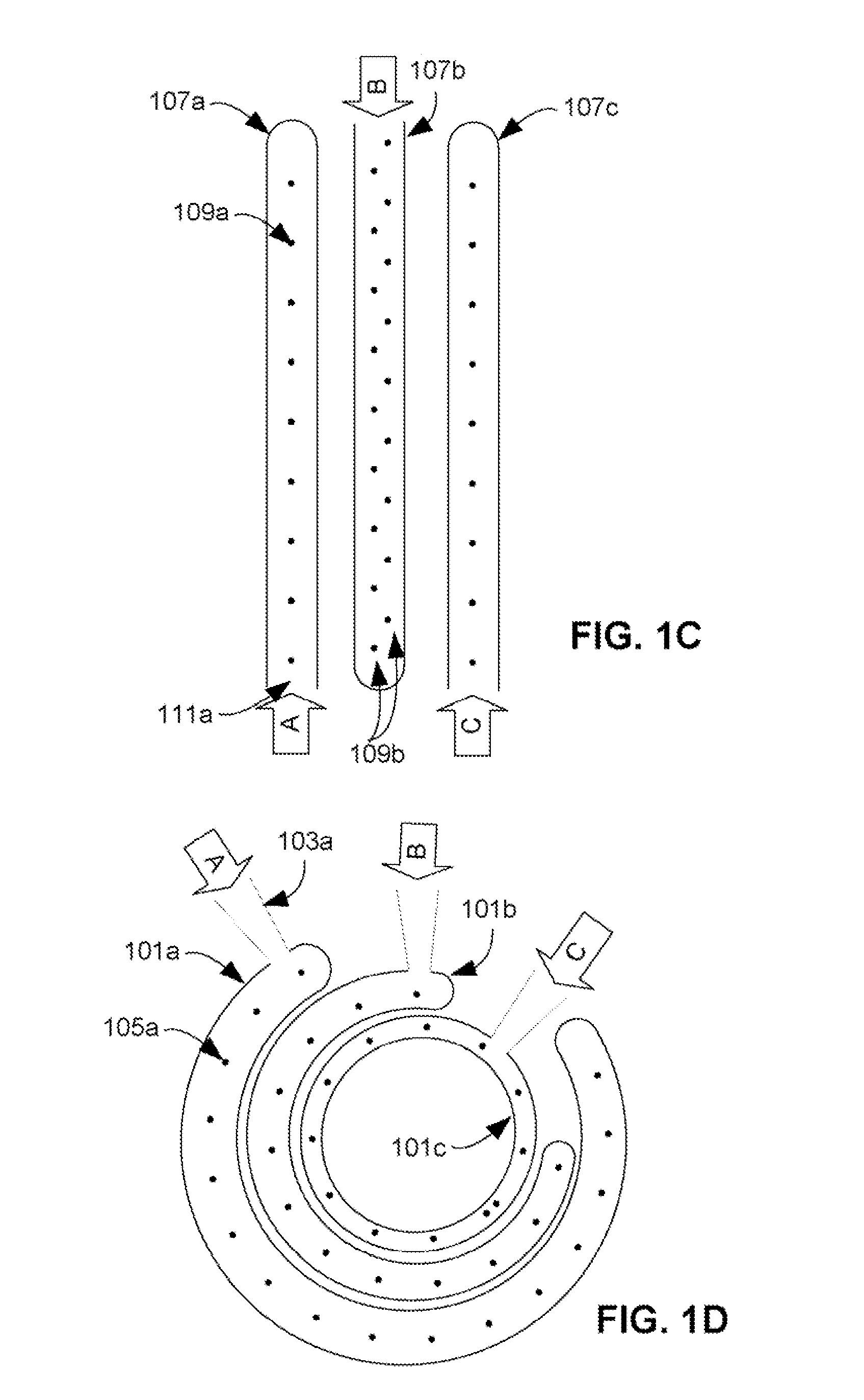

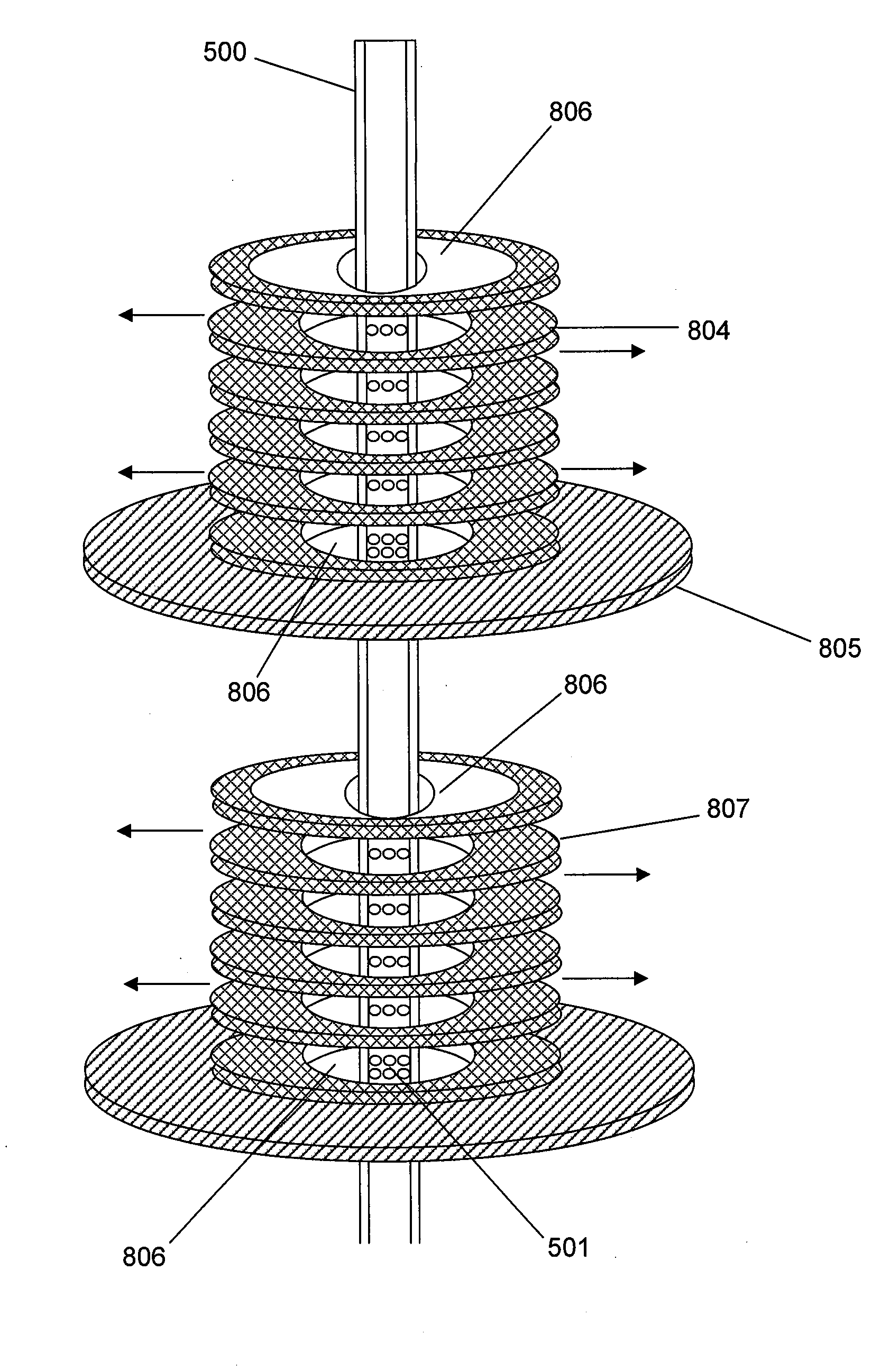

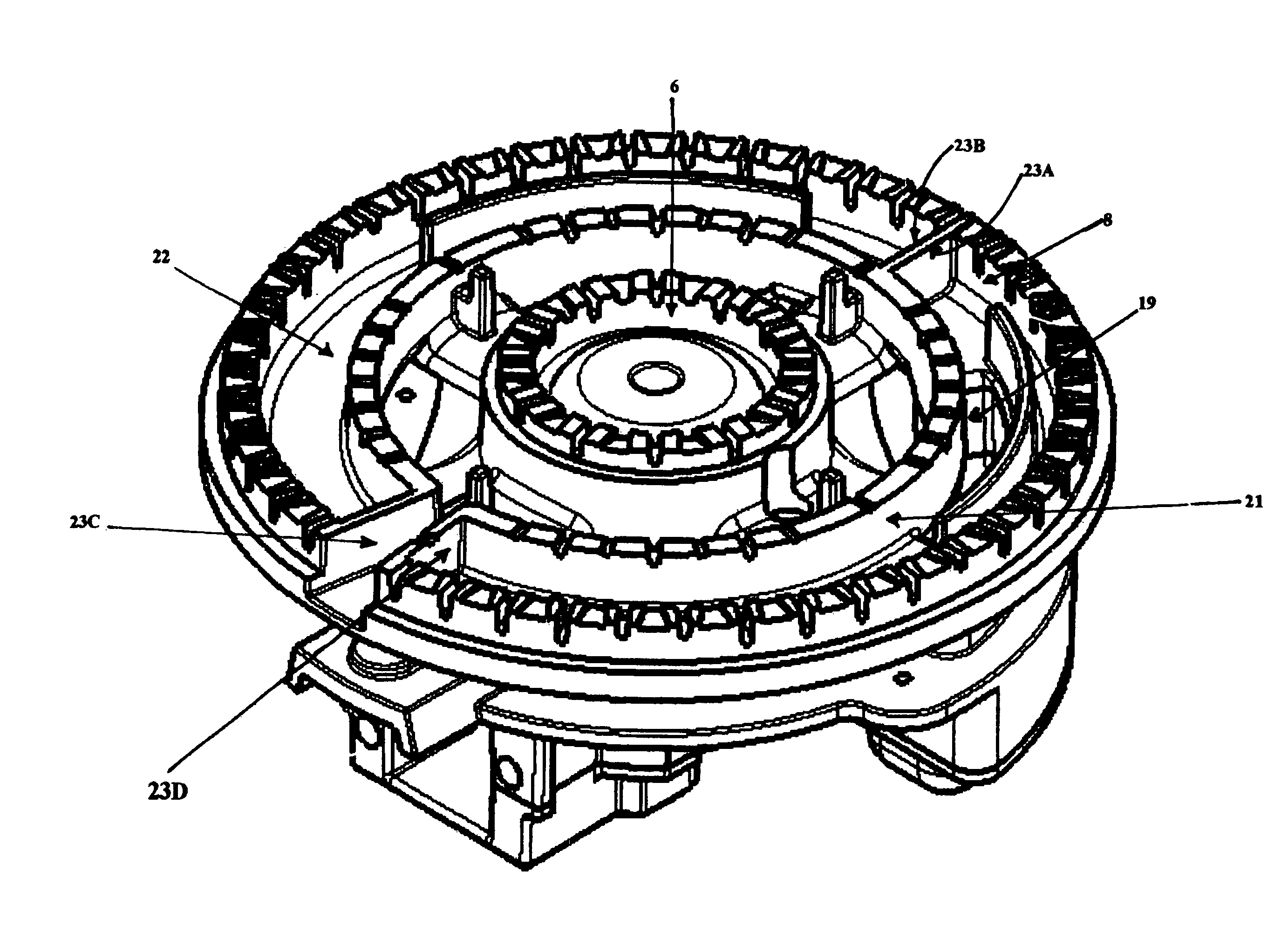

Movable injectors in rotating disc gas reactors

A system and method for uniform deposition of material layers on wafers in a rotating disk chemical vapor deposition reaction system is provided, wherein one or more substrates are rotated on a carrier about an axis while maintaining surfaces of the one or more substrates substantially perpendicular to the axis of rotation and facing in an upstream direction along the axis of rotation. During rotating a first gas is discharged in the downstream direction towards the one or more substrates from a first set of gas inlets. A second gas is discharged in the downstream direction towards the one or more substrates from at least one movable gas injector, and the at least one movable gas inlet is moved with a component of motion in a radial direction towards or away from the axis of rotation.

Owner:VEECO INSTR

Movable injectors in rotating disc gas reactors

InactiveUS8092599B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas syringeEngineering

Owner:VEECO INSTR

Gas injector and apparatus including the same

ActiveUS20060219362A1Reduce manufacturing costShorten the production cycleElectric discharge tubesSemiconductor/solid-state device manufacturingGas syringePetroleum engineering

Owner:JUSUNG ENG

Clarification of Suspensions

A clarification system may comprise a channel having an inlet and an outlet, a length, bottom, and a height sufficient to contain a liquid having a depth. The clarification system may include one or more gas injectors disposed within the channel, configured to inject gas bubbles into a suspension flowing in the channel. In some embodiments, at least one gas injector injects gas bubbles having average or median size that does not exceed 100 microns in diameter. Some gas injectors inject bubbles having mean size below 50 microns. Some gas injectors inject gas via the precipitation of gas bubbles from a supersaturated liquid including a dissolved gas. Certain embodiments may be configured to form a quiet zone, typically near the top of the flowing suspension, in which turbulence may be minimized or substantially eliminated. Certain systems include a plurality of gas injectors disposed at different lengths along the channel.

Owner:AURORA ALGAE

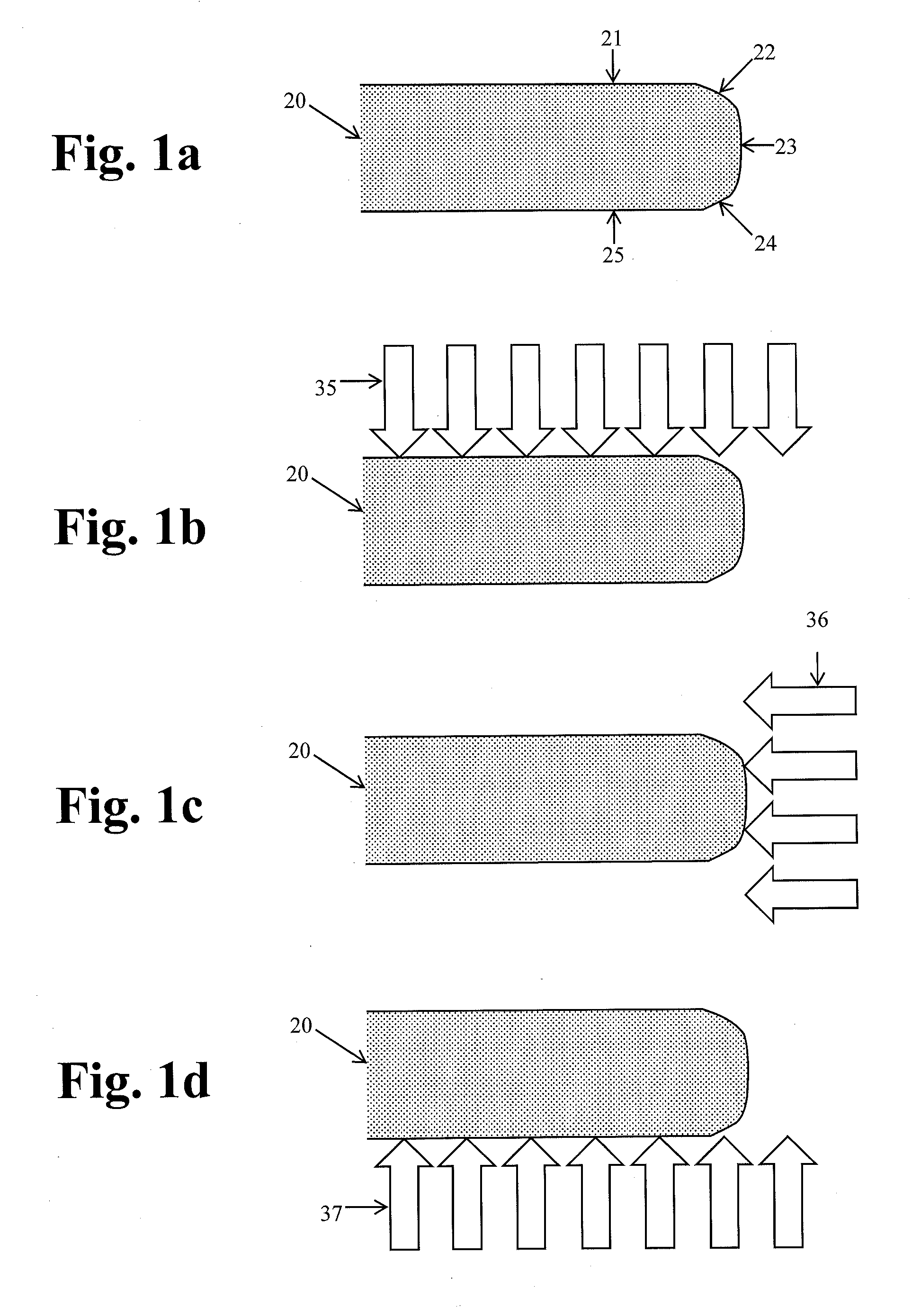

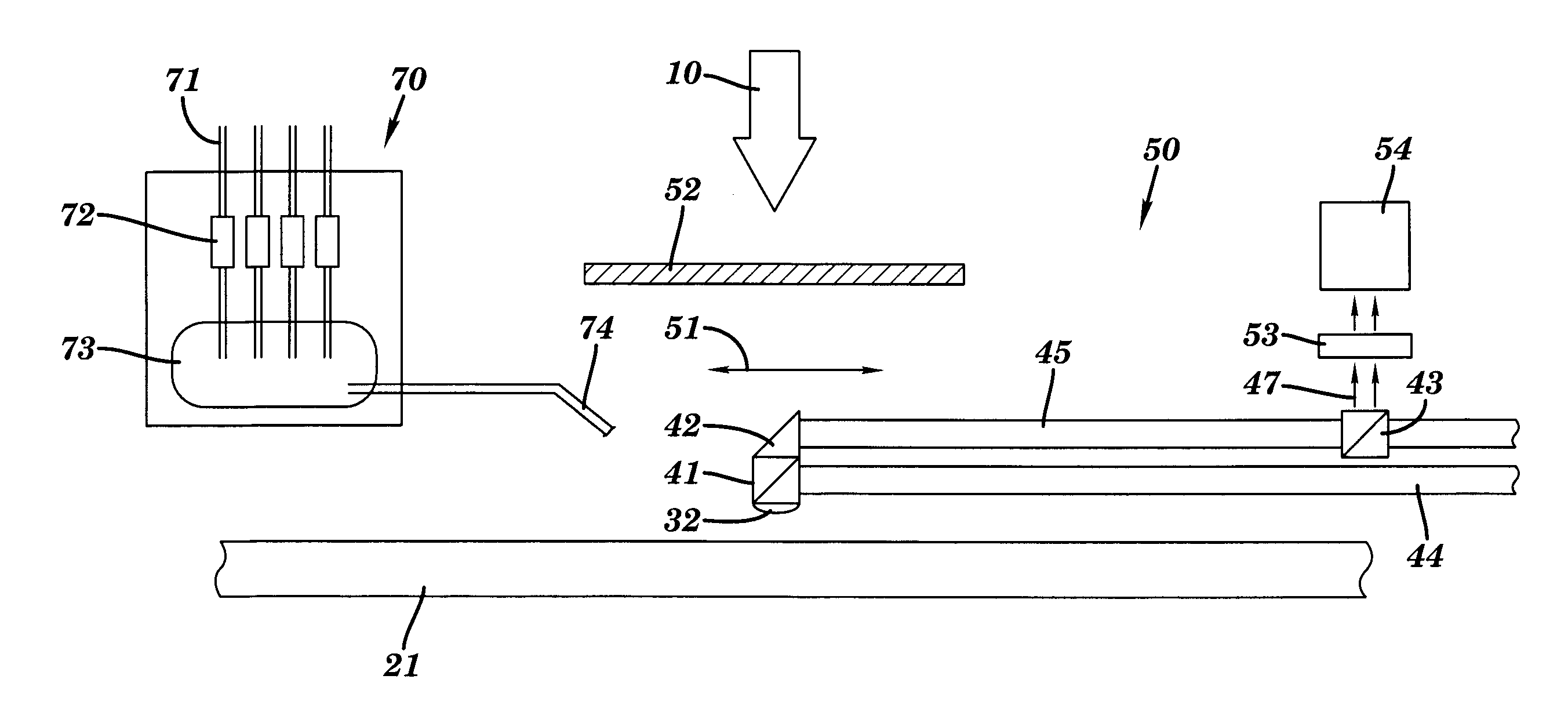

Method and apparatus for processing substrate edges

InactiveUS20110168672A1Process environmental protectionEliminate needDecorative surface effectsPhotomechanical apparatusGas syringeSolvent

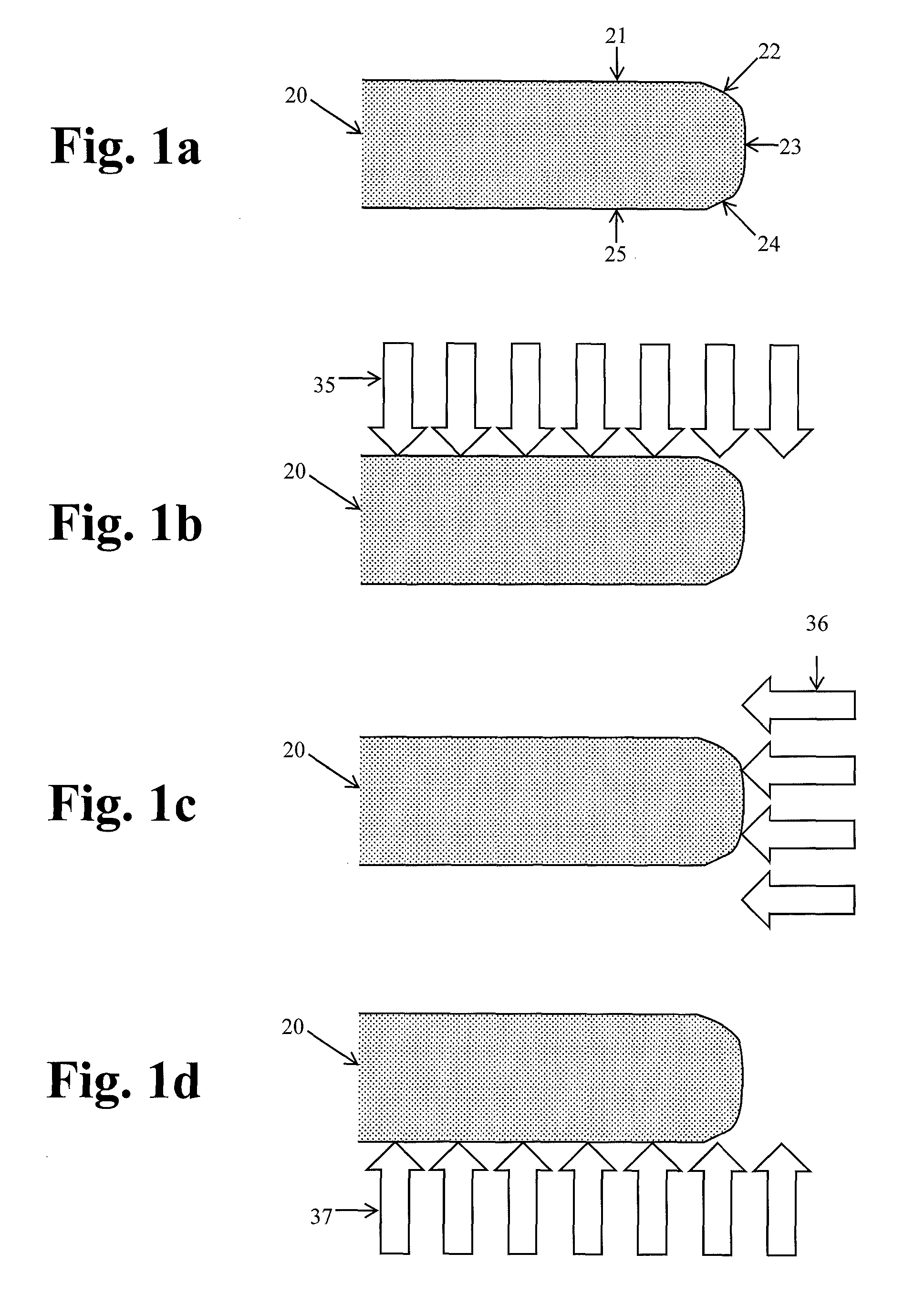

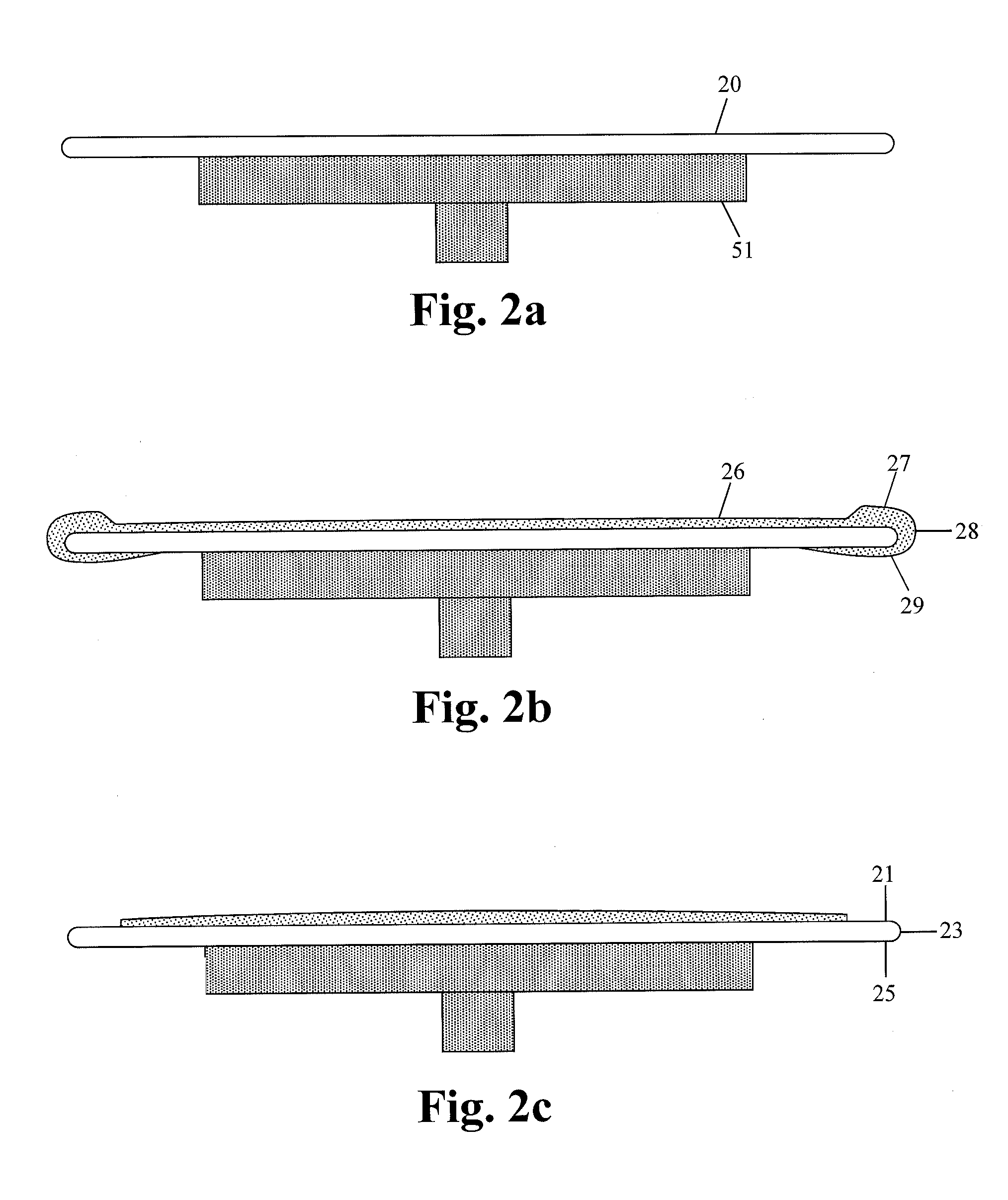

A method and apparatus for processing substrate edges is disclosed that overcomes the limitations of conventional edge processing methods and systems used in semiconductor manufacturing. The edge processing method and apparatus of this invention includes a laser and optical system to direct a beam of radiation onto a rotating substrate supported by a chuck, in atmosphere. The optical system accurately and precisely directs the beam to remove or transform organic or inorganic films, film stacks, residues, or particles from the top edge, top bevel, apex, bottom bevel, and bottom edge of the substrate. An optional gas injector system directs gas onto the substrate edge to aid in the reaction. Process by-products are removed via an exhaust tube enveloping the reaction site. This invention permits precise control of an edge exclusion zone, resulting in an increase in the number of usable die on a wafer. Wafer edge processing with this invention replaces existing solvent and / or abrasive methods and thus will improve die yield.

Owner:UVTECH SYST

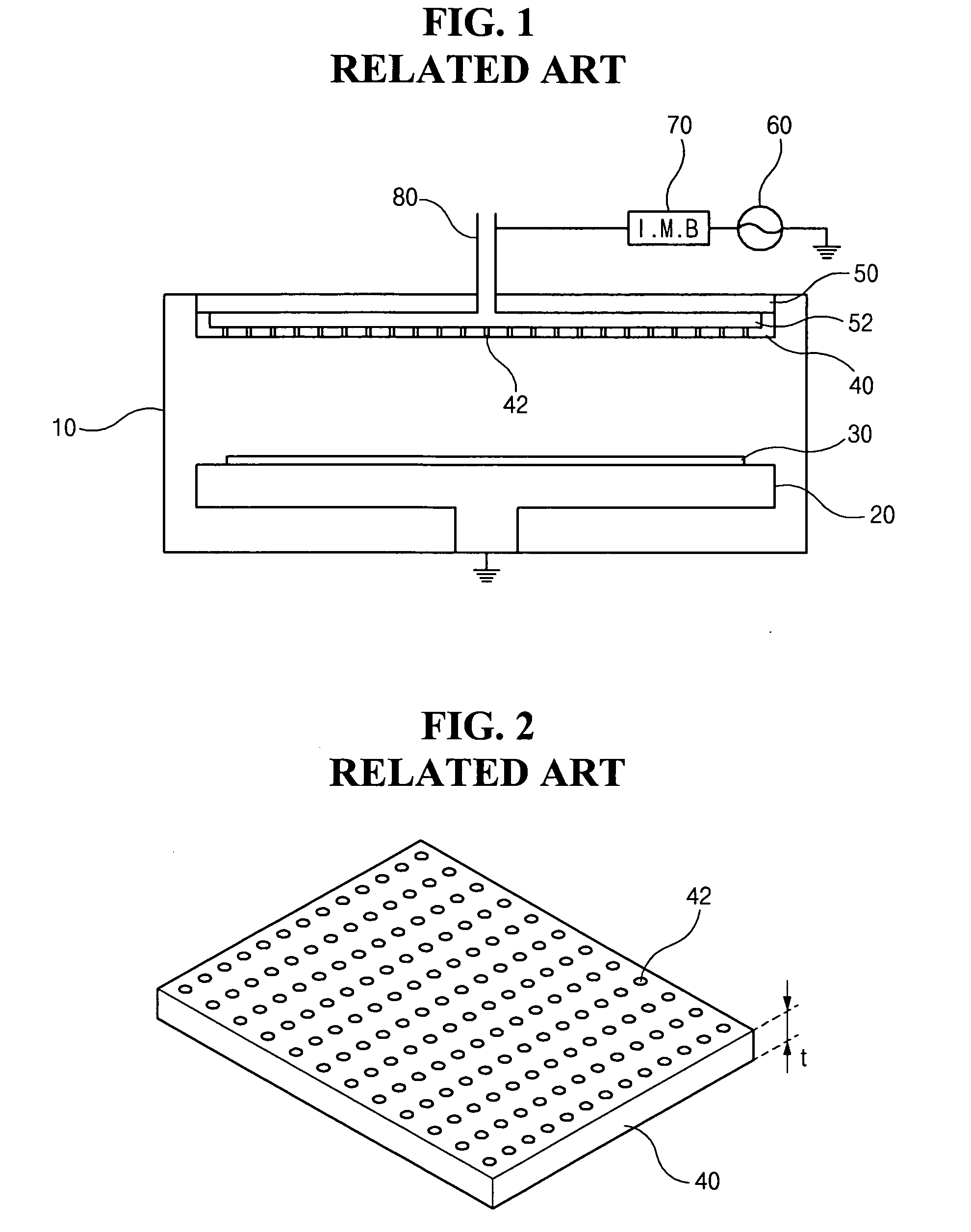

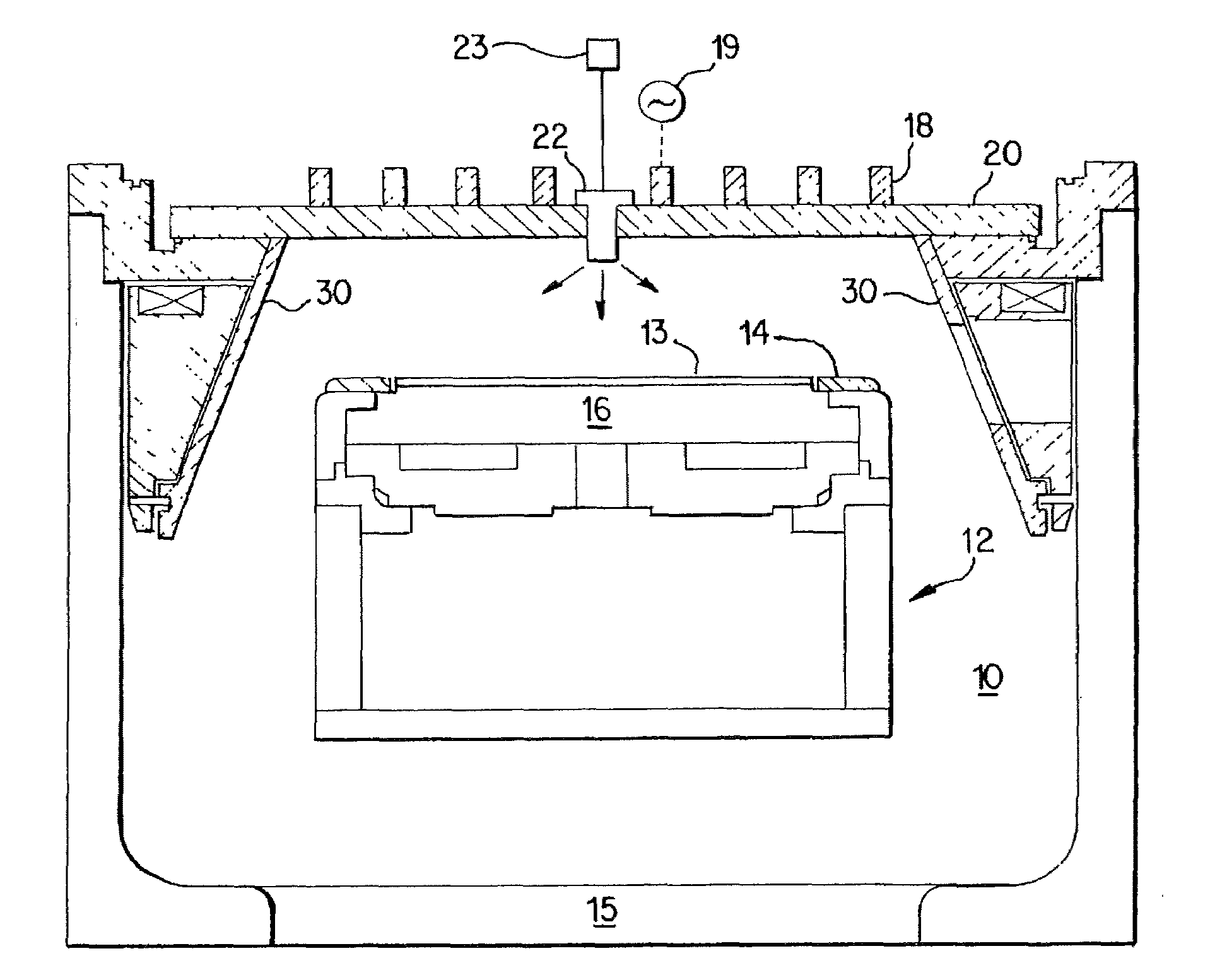

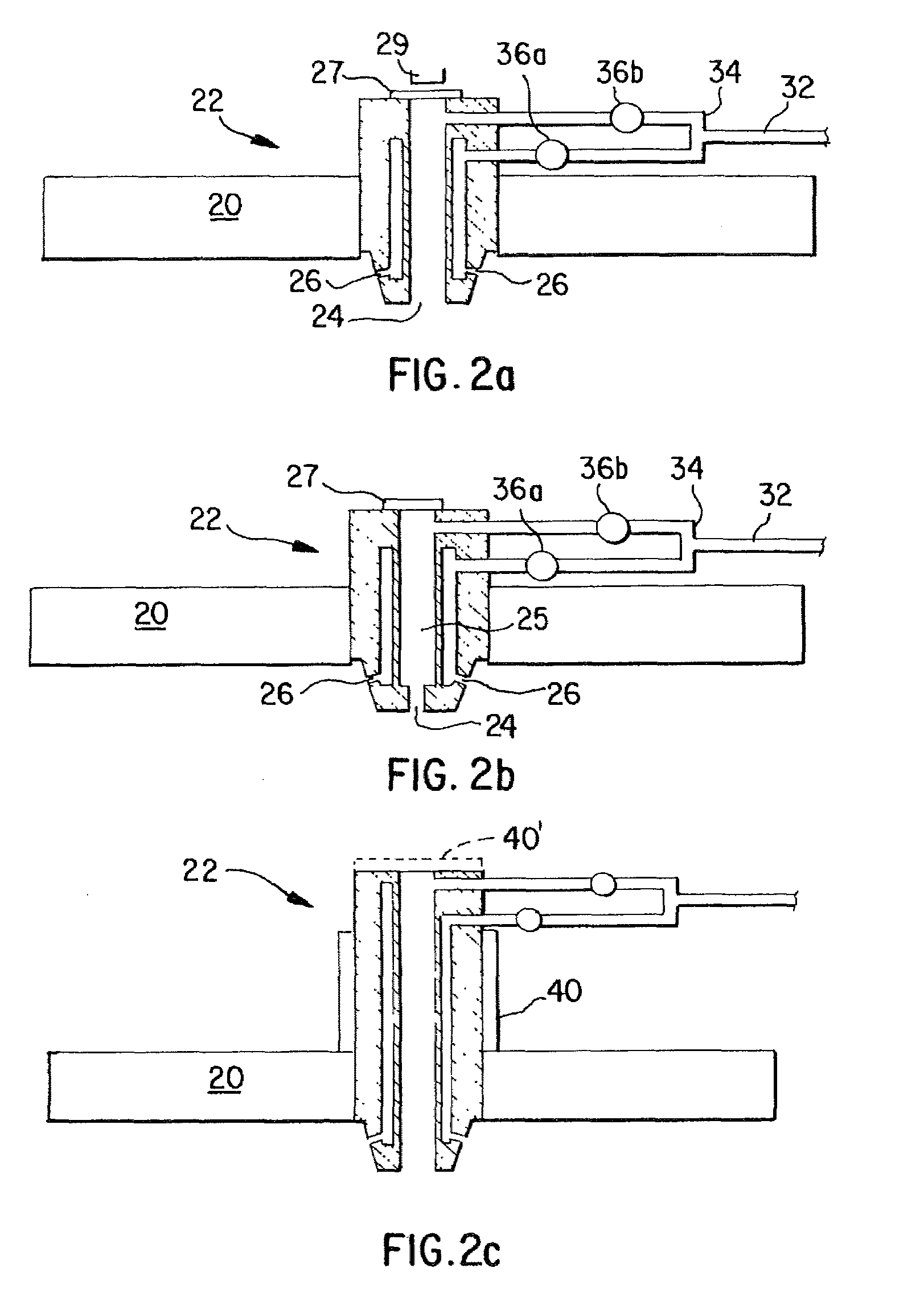

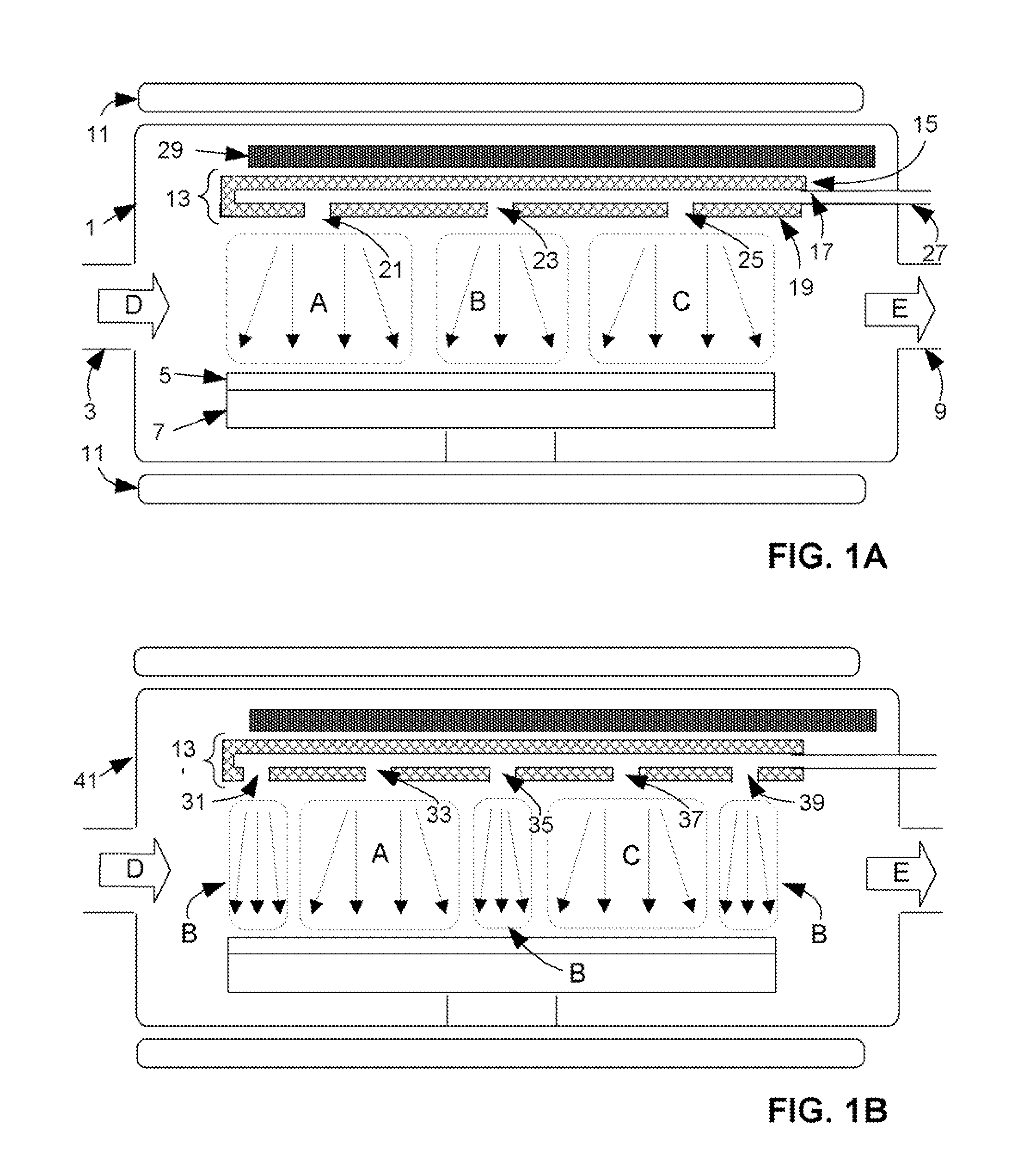

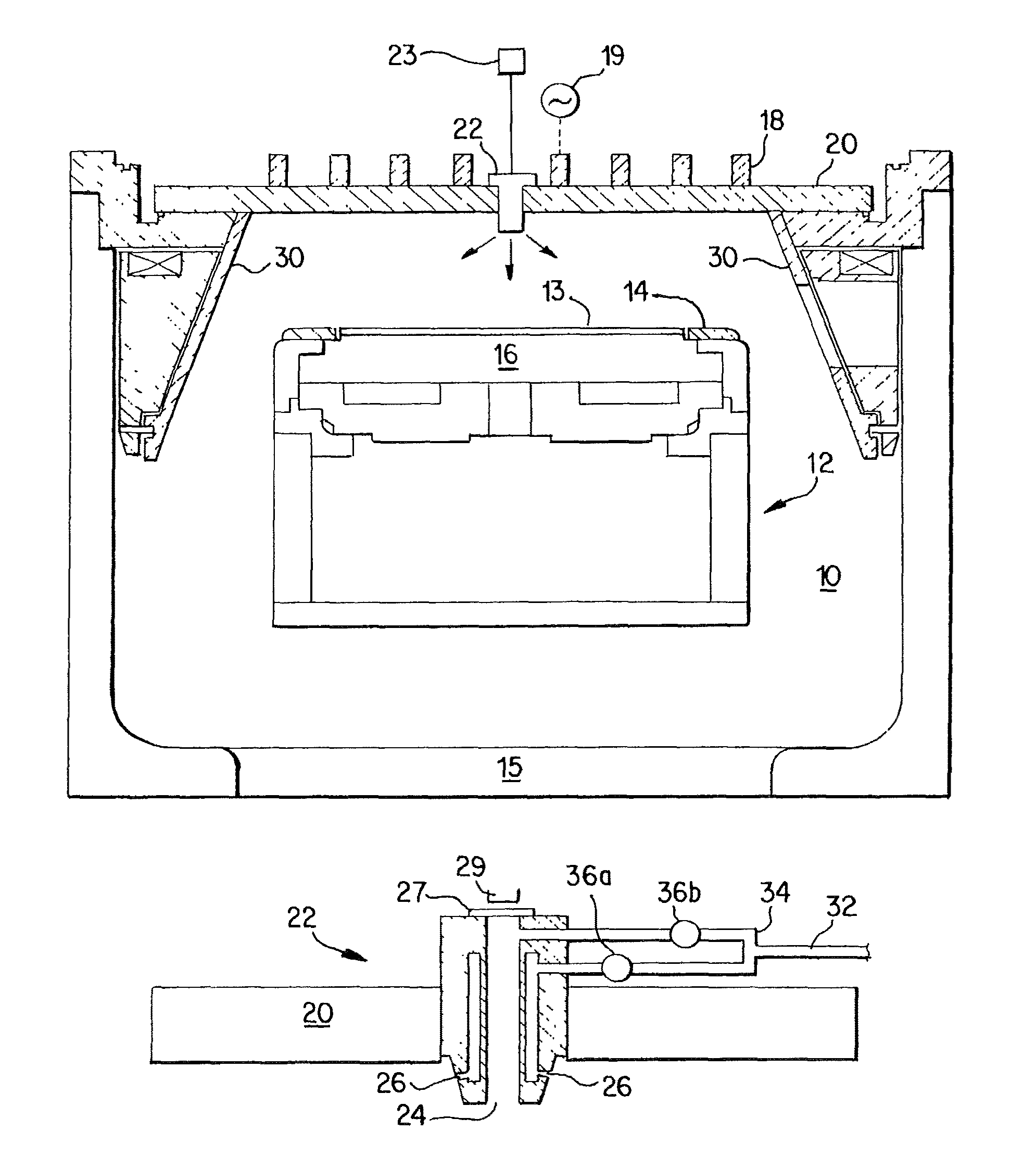

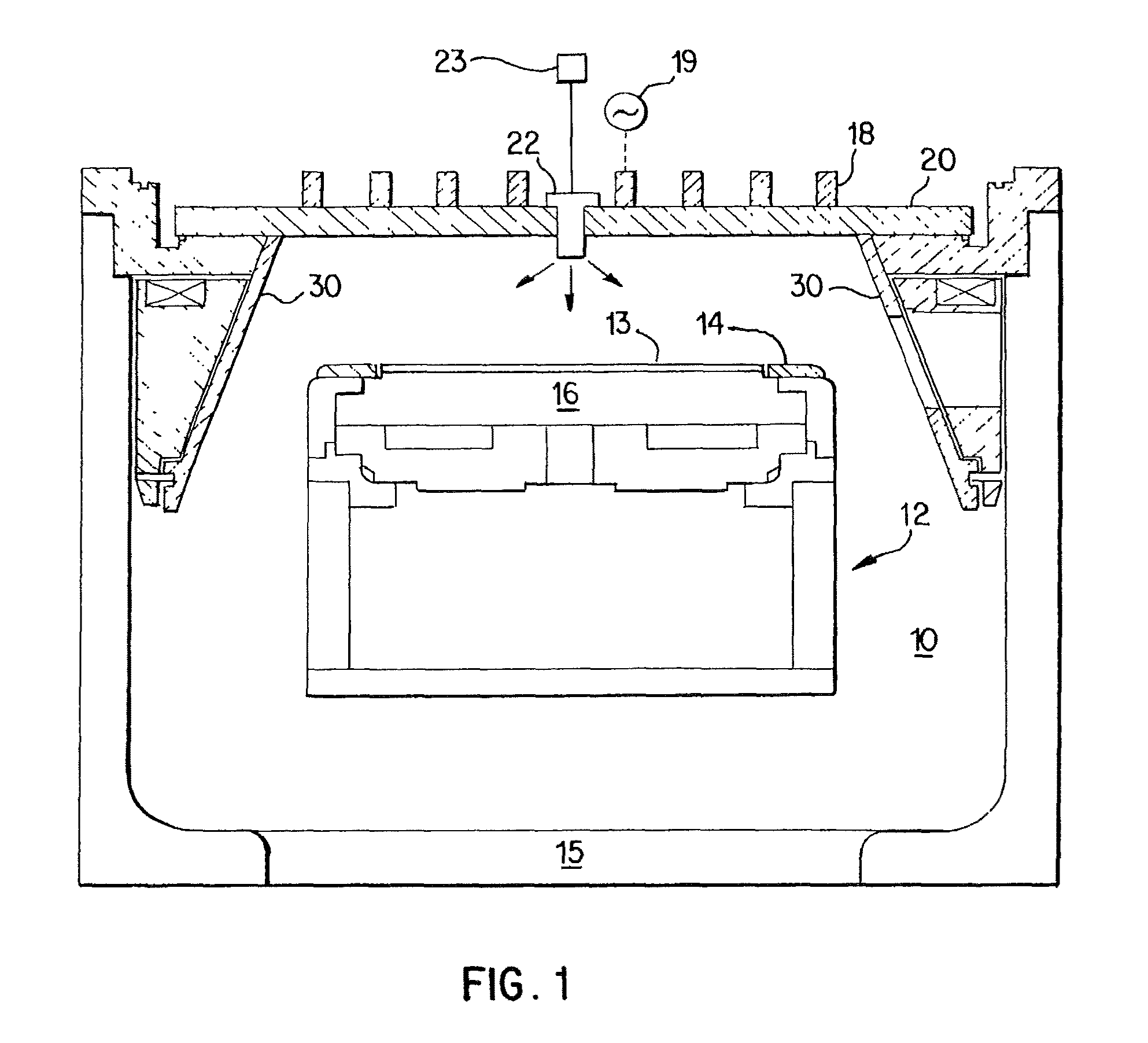

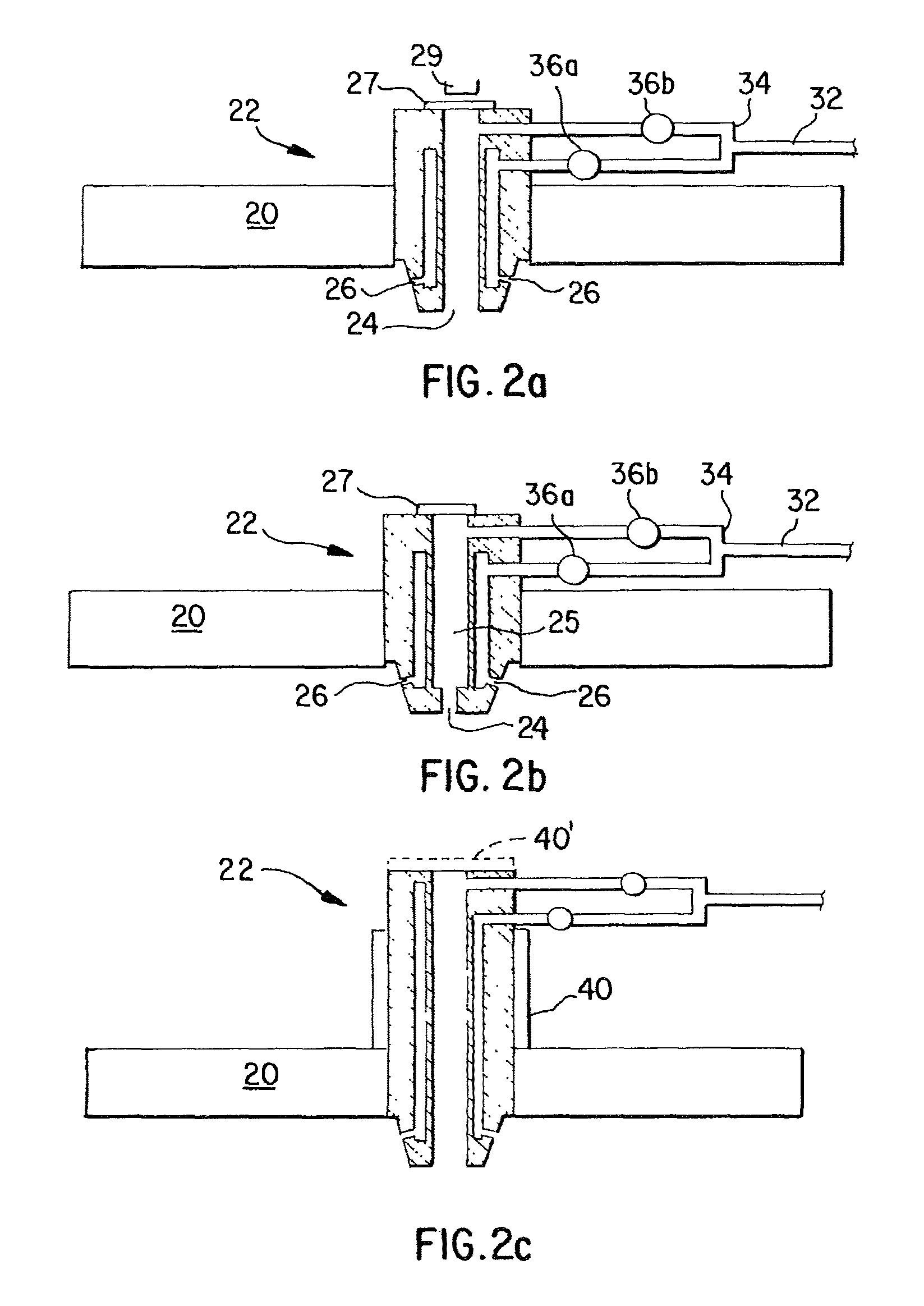

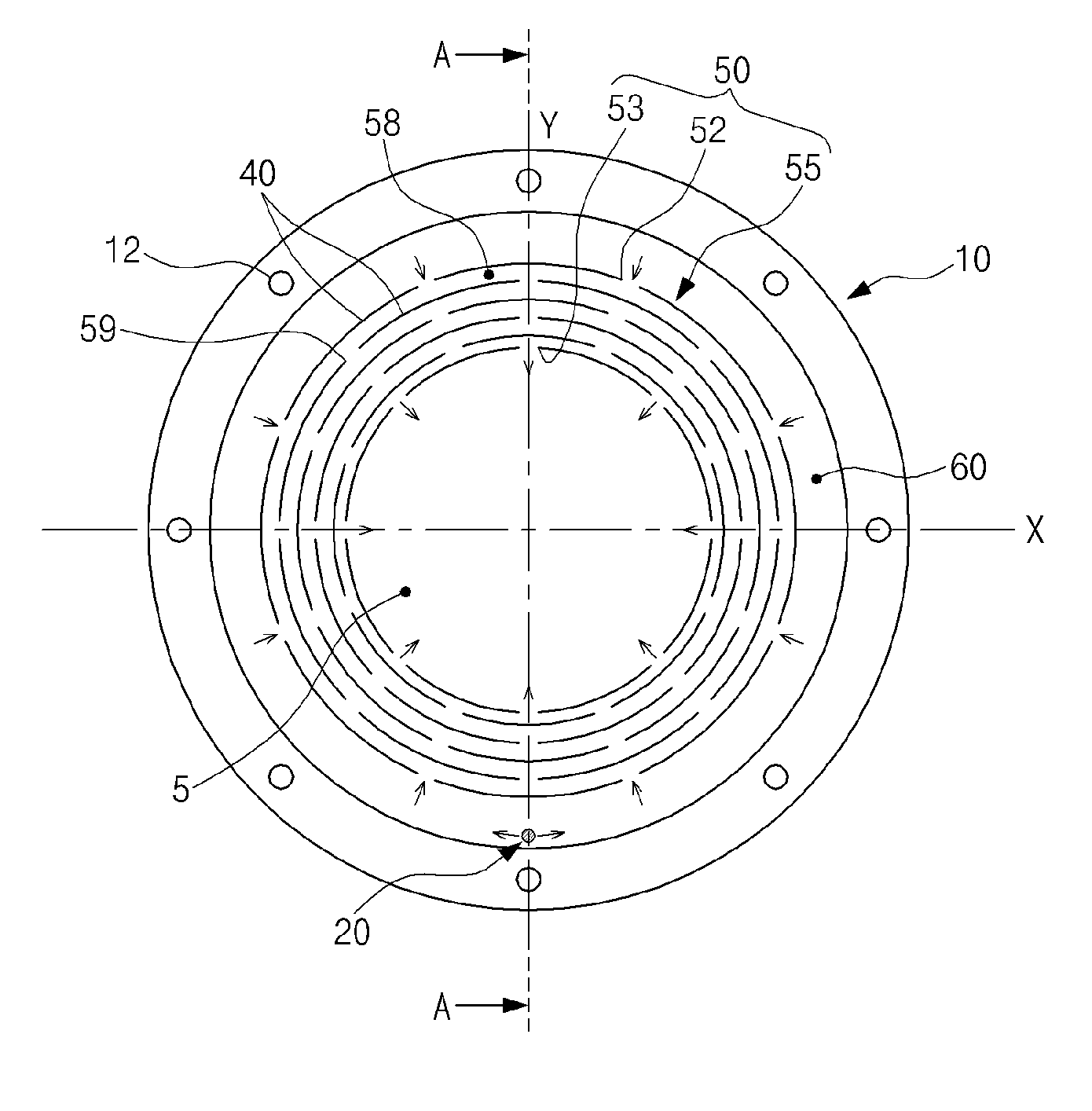

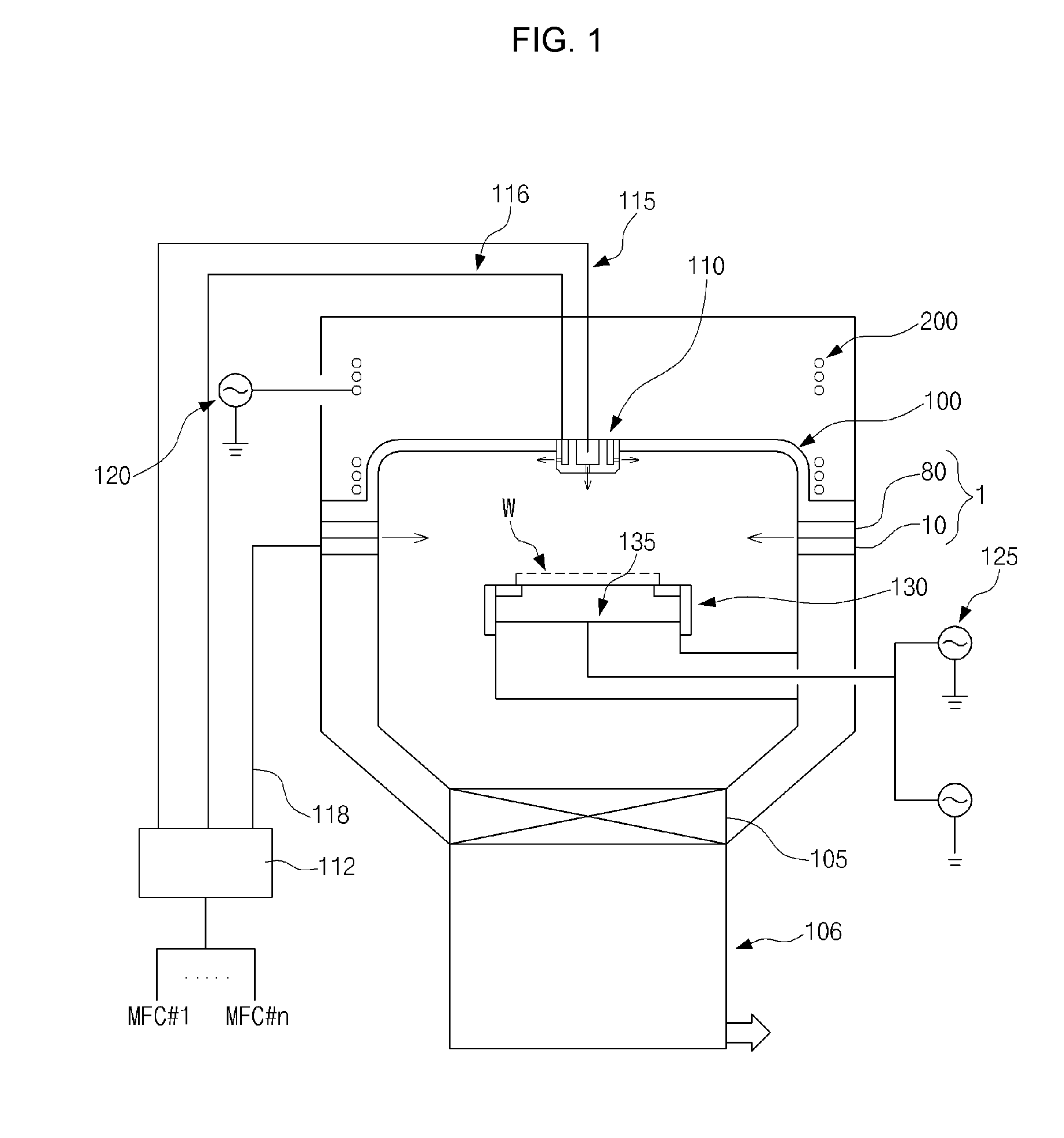

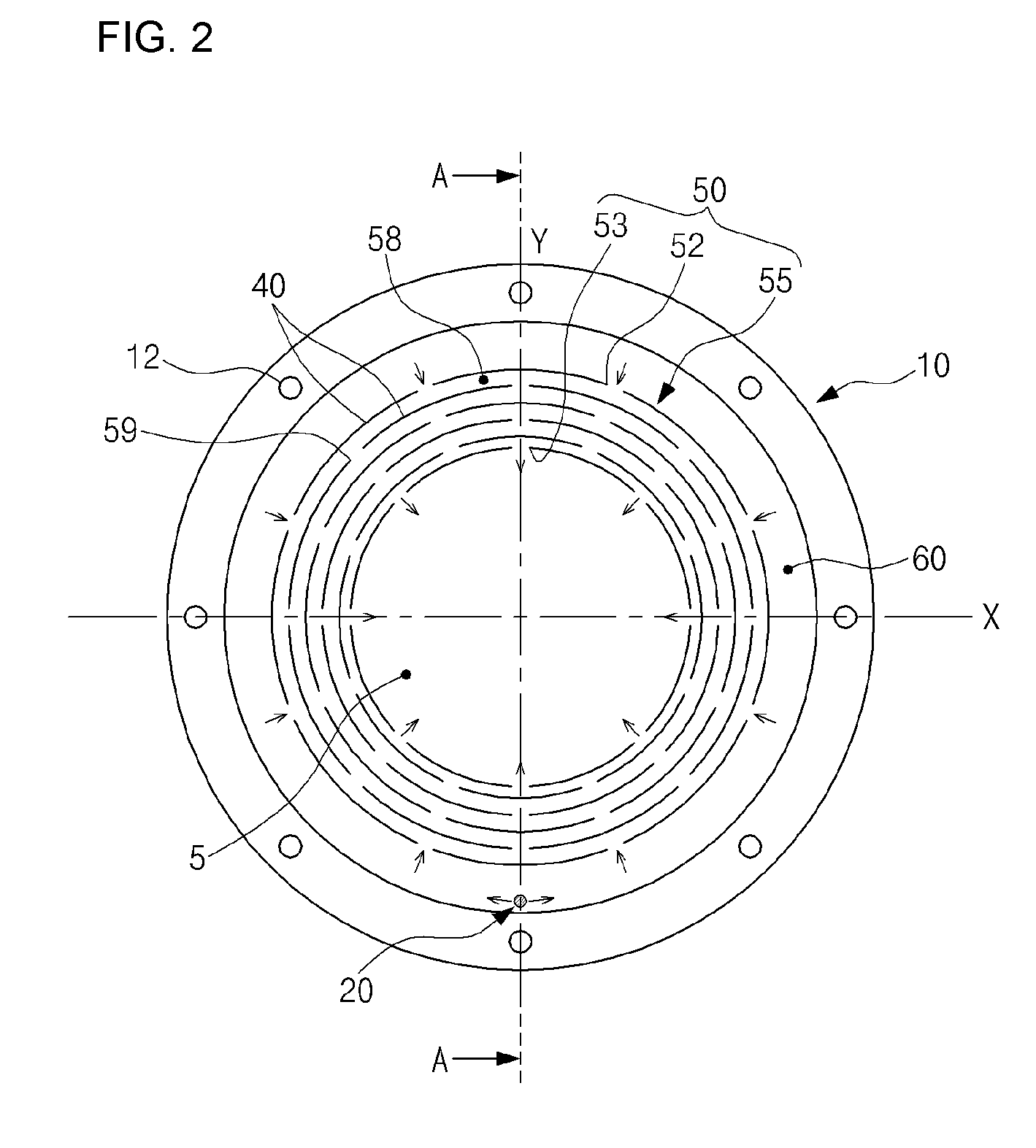

Tunable multi-zone gas injection system

ActiveUS20100041238A1Improve uniformityElectric discharge tubesDecorative surface effectsDielectricElectricity

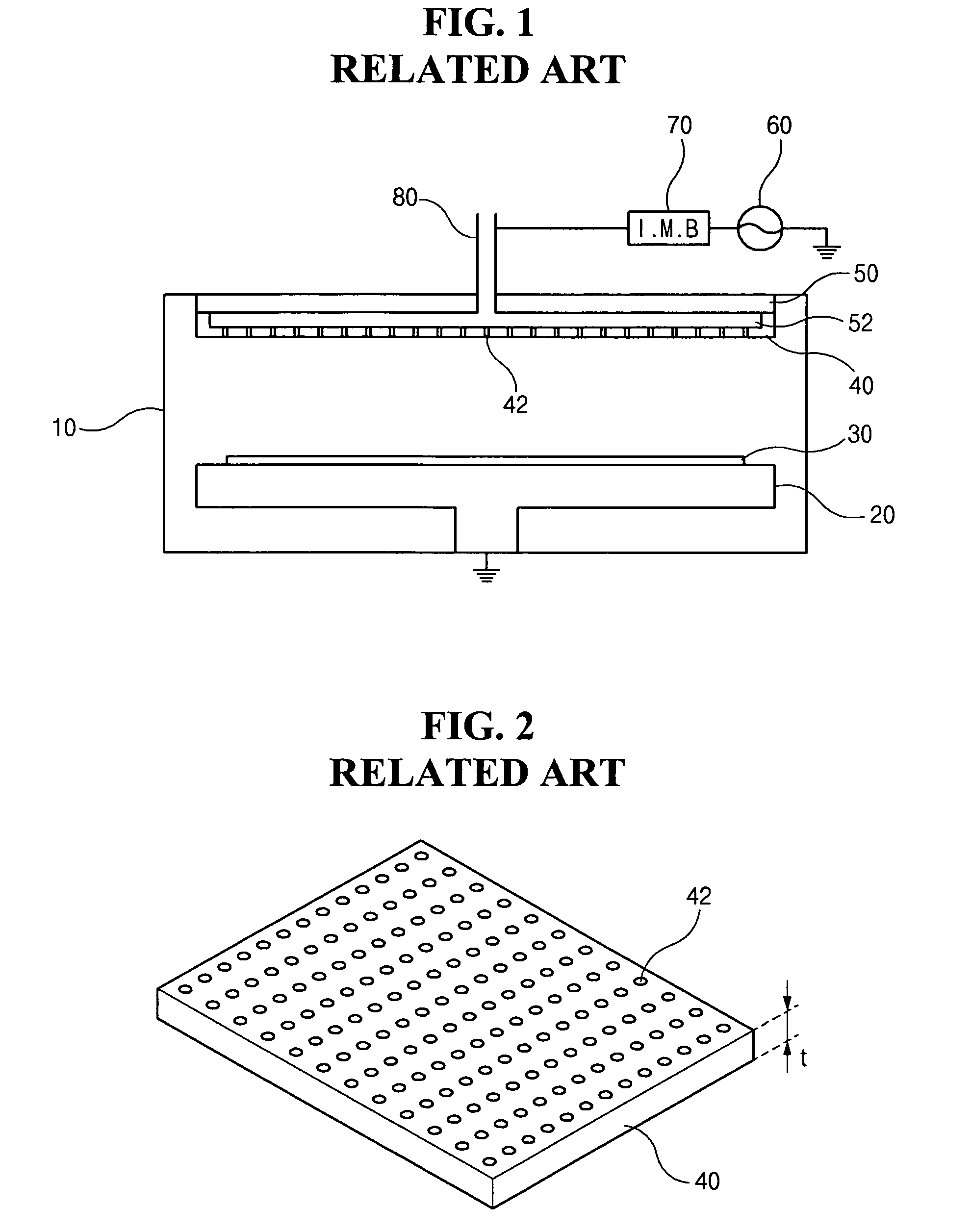

A tunable multi-zone injection system for a plasma processing system for plasma processing of substrates such as semiconductor wafers. The system includes a plasma processing chamber, a substrate support for supporting a substrate within the processing chamber, a dielectric member having an interior surface facing the substrate support, the dielectric member forming a wall of the processing chamber, a gas injector fixed to part of or removably mounted in an opening in the dielectric window, the gas injector including a plurality of gas outlets supplying process gas at adjustable flow rates to multiple zones of the chamber, and an RF energy source such as a planar or non-planar spiral coil which inductively couples RF energy through the dielectric member and into the chamber to energize the process gas into a plasma state. The injector can include an on-axis outlet supplying process gas at a first flow rate to a central zone and off-axis outlets supplying the same process gas at a second flow rate to an annular zone surrounding the central zone. The arrangement permits modification of gas delivery to meet the needs of a particular processing regime by allowing independent adjustment of the gas flow to multiple zones in the chamber. In addition, compared to consumable showerhead arrangements, a removably mounted gas injector can be replaced more easily and economically.

Owner:LAM RES CORP

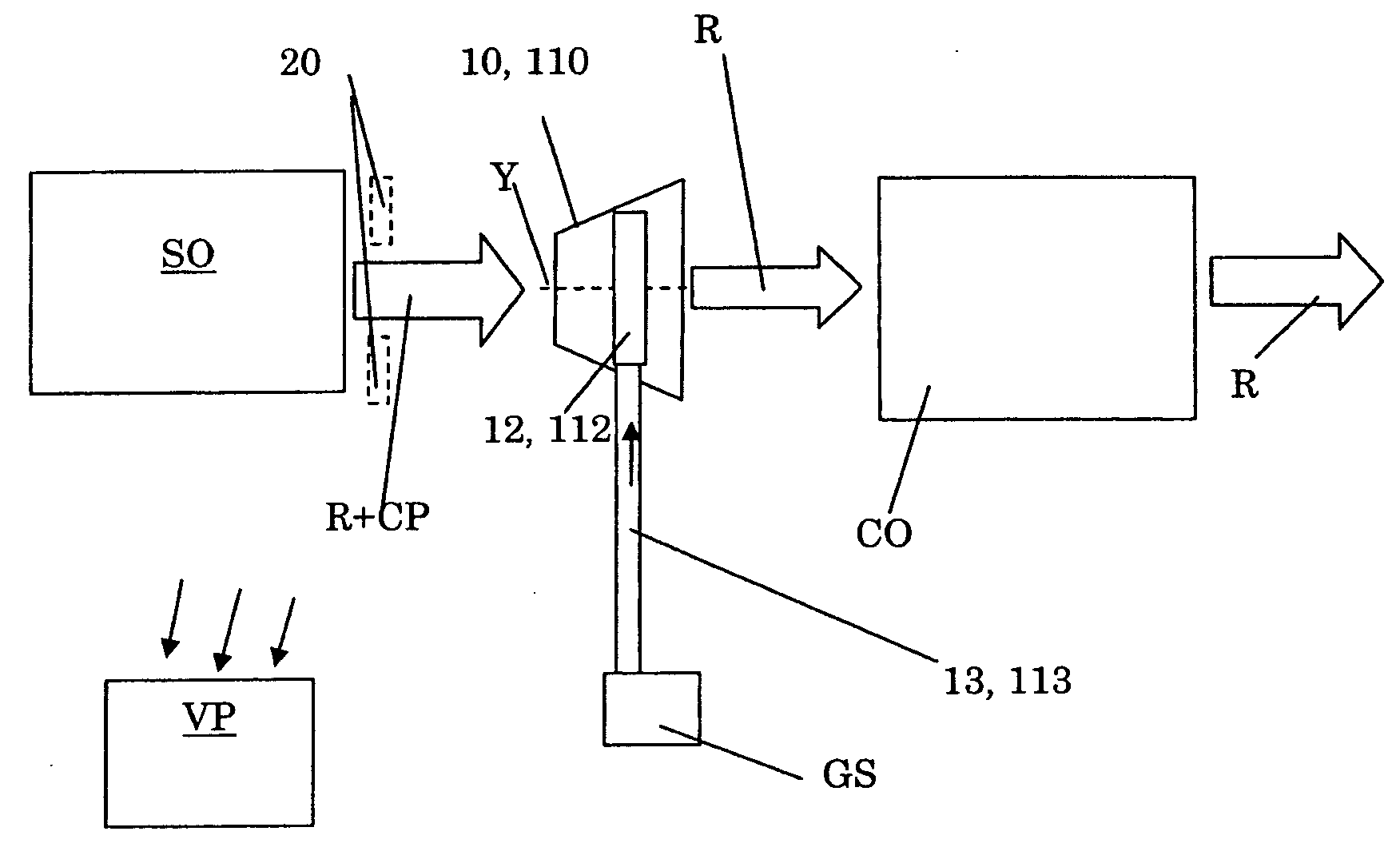

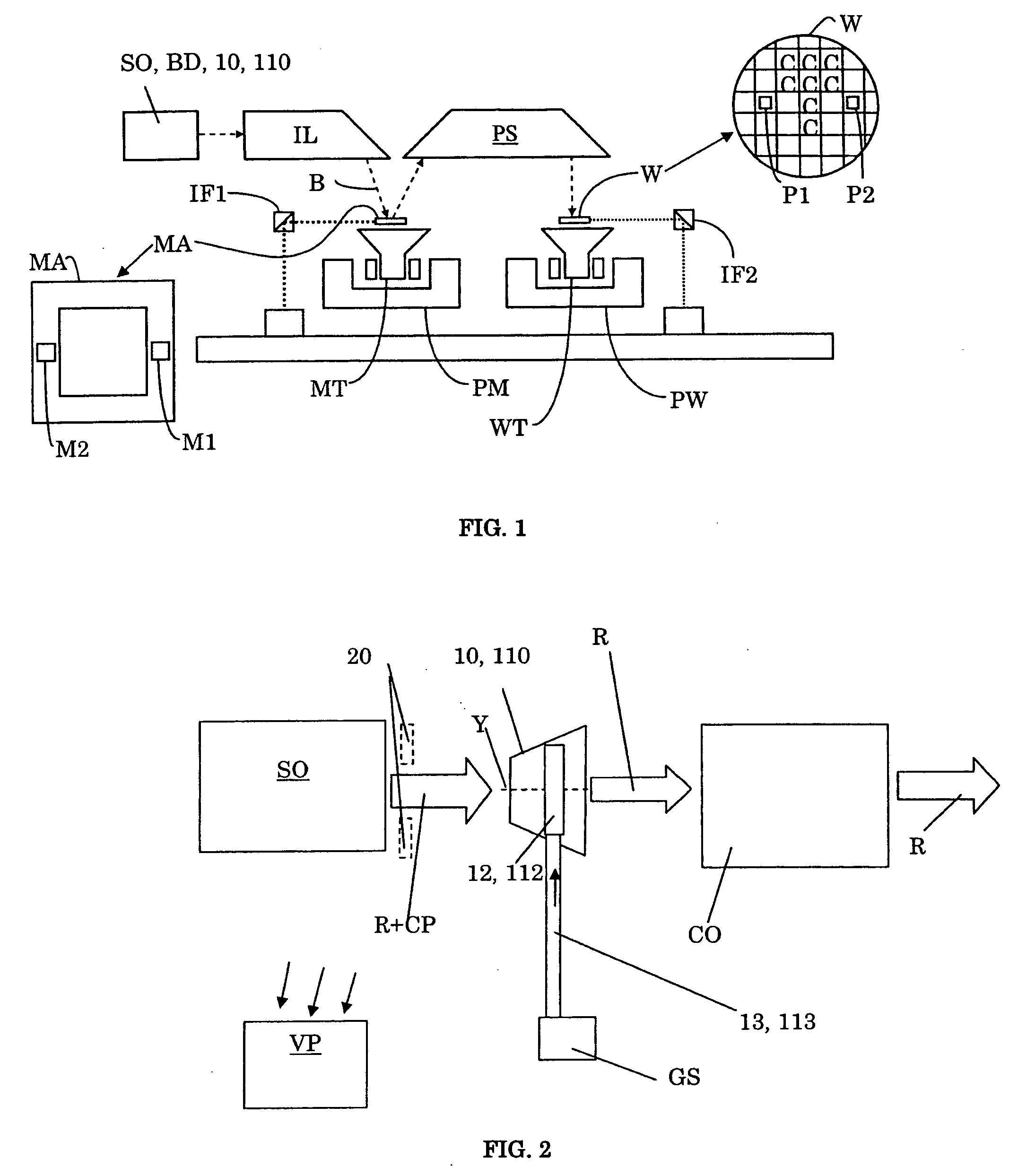

Lithographic apparatus, contaminant trap, and device manufacturing method

InactiveUS20070018118A1Increase trappingImprove mitigating debrisNanoinformaticsPhotometryOptical axisGas syringe

A lithographic apparatus includes a radiation system including a radiation source for the production of a radiation beam, and a contaminant trap arranged in a path of the radiation beam. The contaminant trap includes a plurality of foils or plates defining channels that are arranged substantially parallel to the direction of propagation of said radiation beam. The foils or plates can be oriented substantially radially with respect to an optical axis of the radiation beam. The contaminant trap can be provided with a gas injector which is configured to inject gas at least at two different positions directly into at least one of the channels of the contaminant trap.

Owner:ASML NETHERLANDS BV

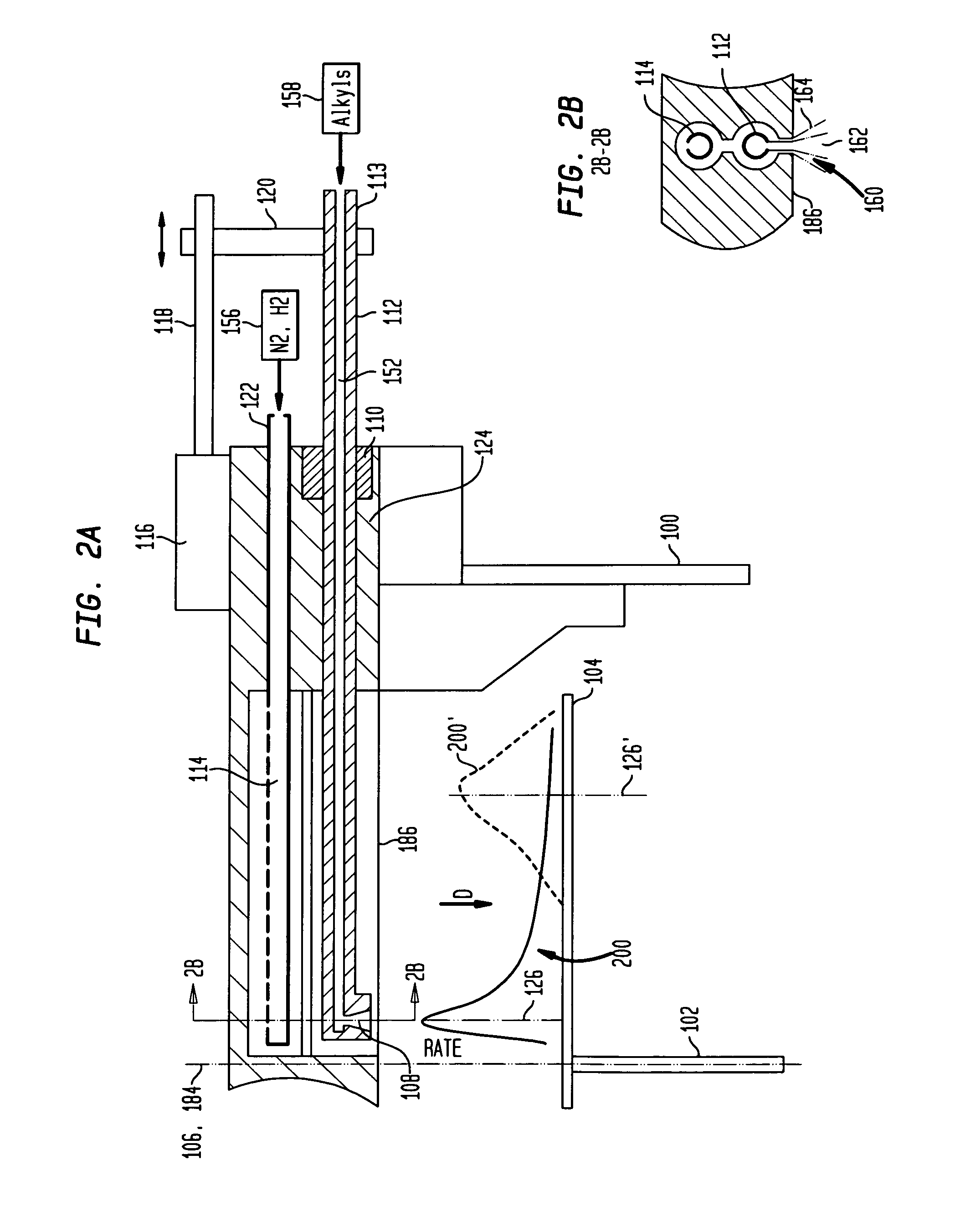

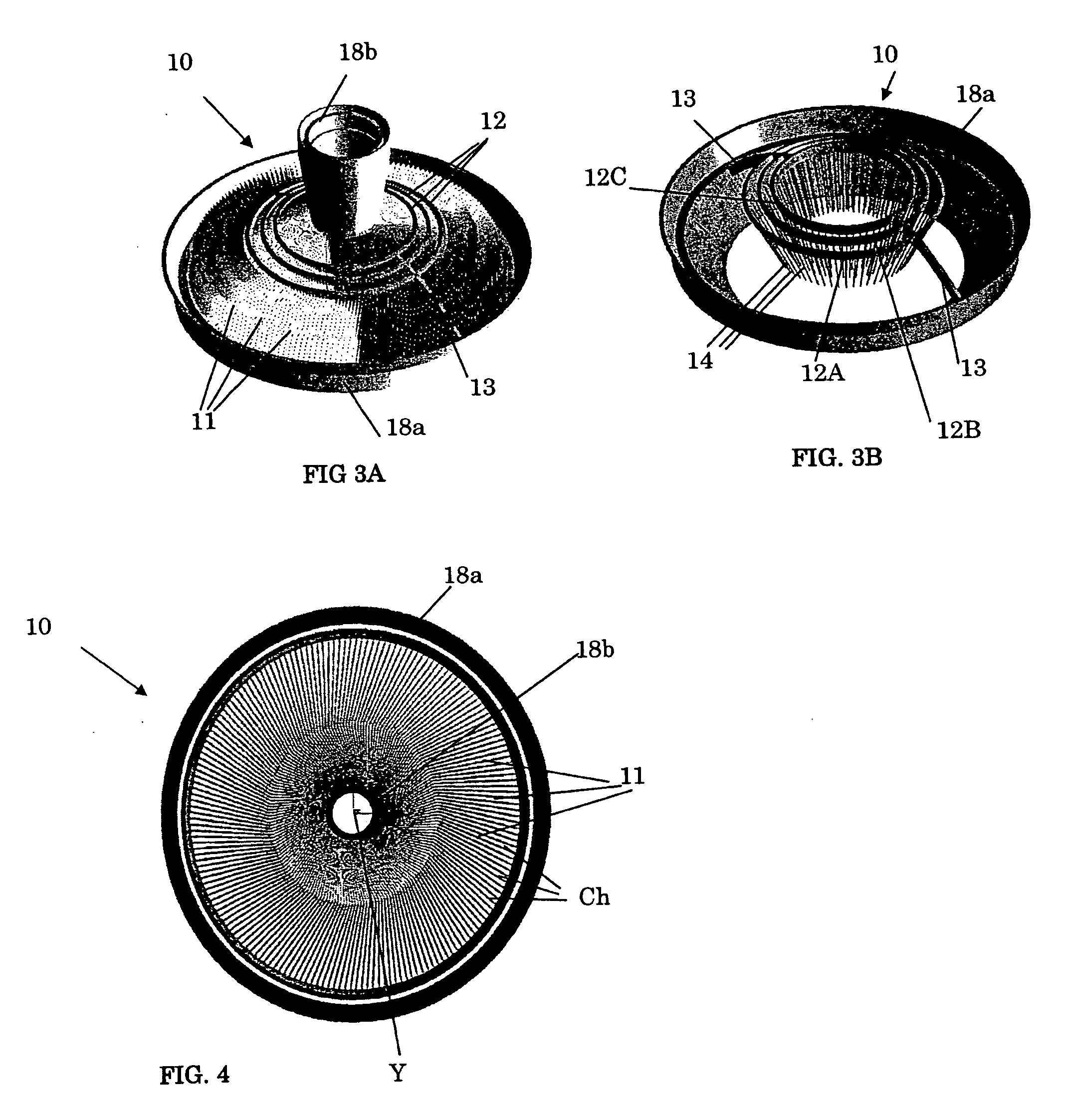

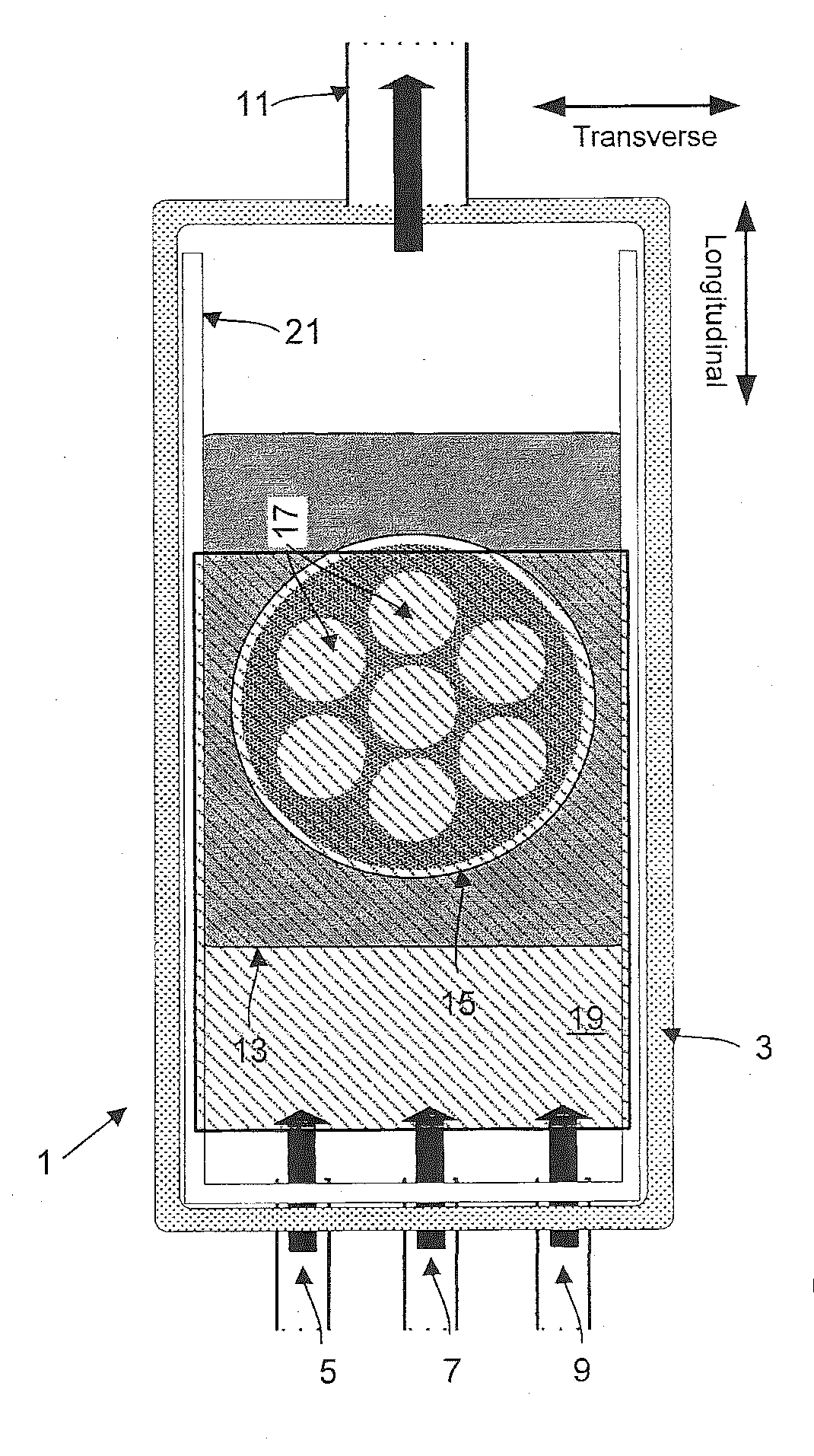

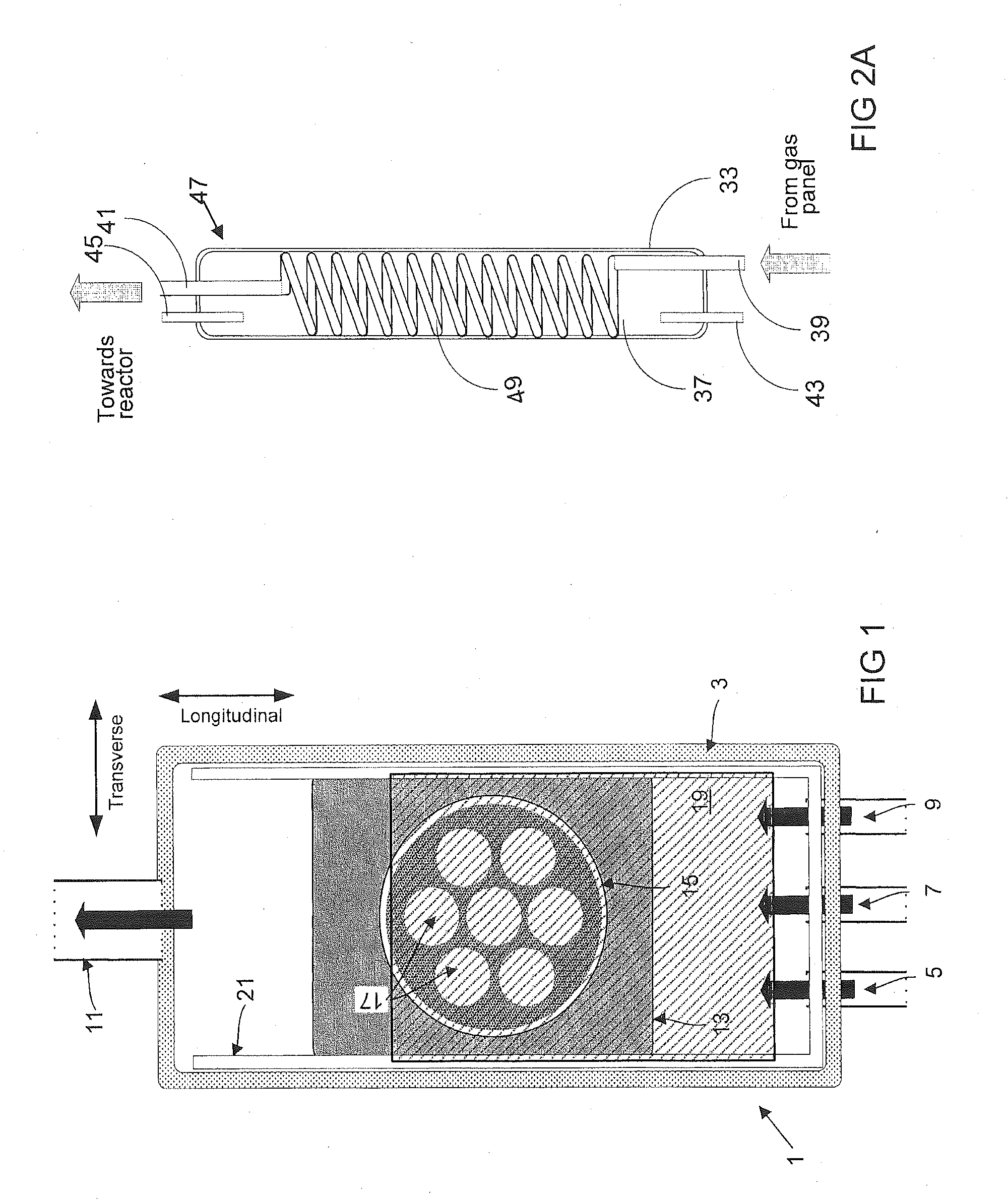

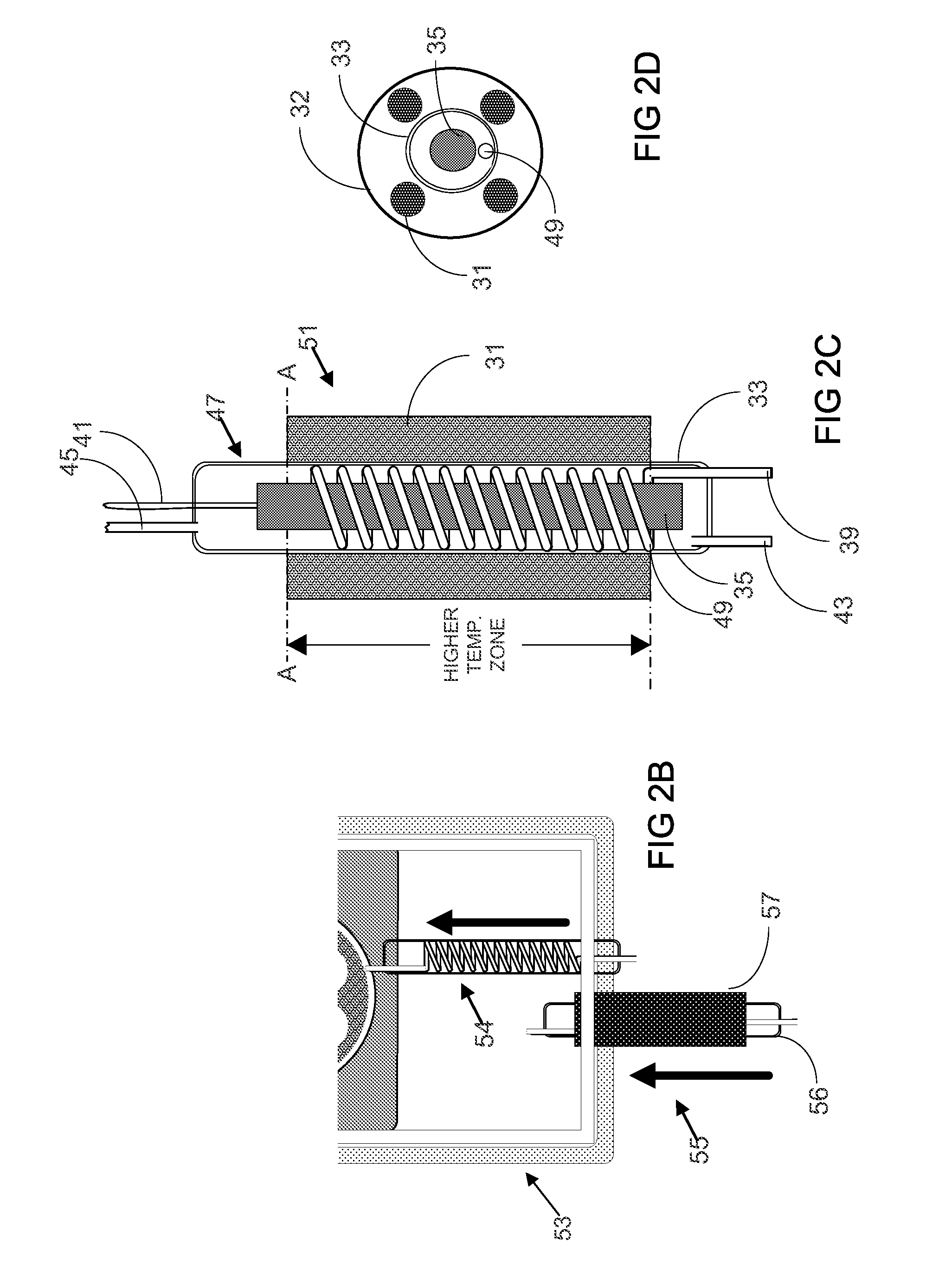

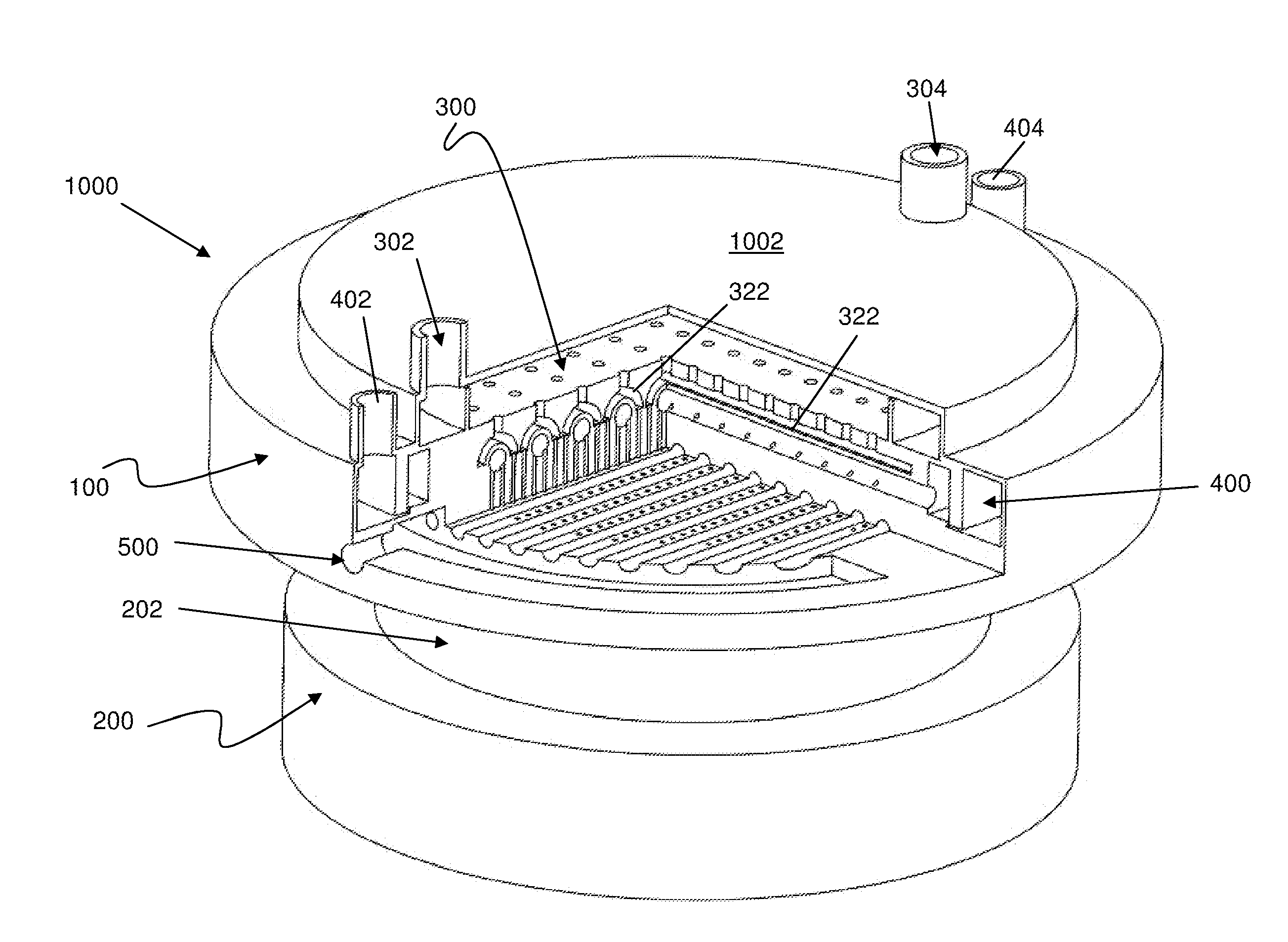

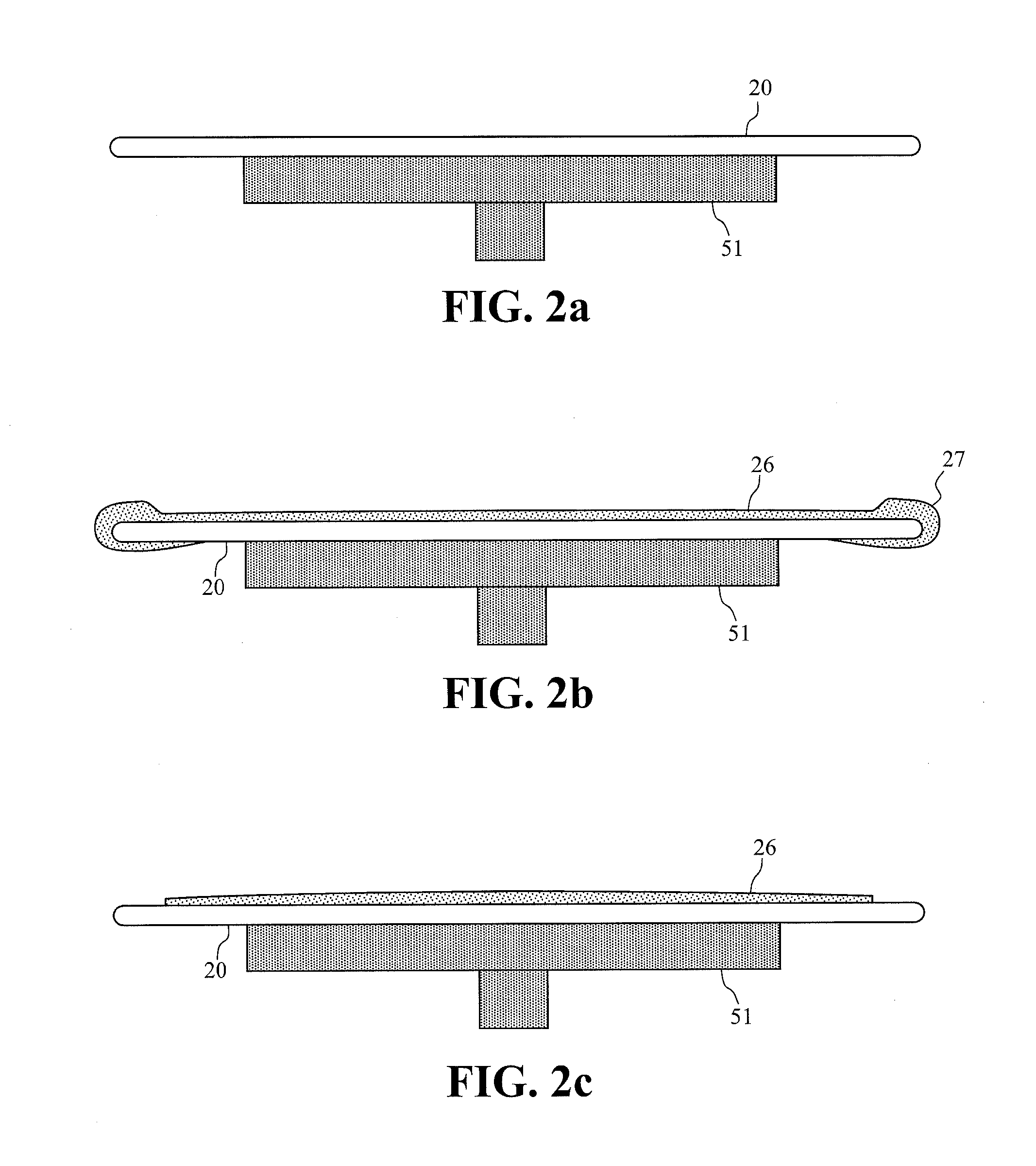

Apparatus for delivering precursor gases to an epitaxial growth substrate

InactiveUS20100258053A1Precise deliveryIncrease volumePipe supportsServomotor componentsGas syringeProduct gas

This invention provides gas injector apparatus that extends into a growth chamber in order to provide more accurate delivery of thermalized precursor gases. The improved injector can distribute heated precursor gases into a growth chamber in flows that spatially separated from each other up until they impinge of a growth substrate and that have volumes adequate for high volume manufacture. Importantly, the improved injector is sized and configured so that it can fit into existing commercial growth chamber without hindering the operation of mechanical and robot substrate handling equipment used with such chambers. This invention is useful for the high volume growth of numerous elemental and compound semiconductors, and particularly useful for the high volume growth of Group III-V compounds and GaN.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

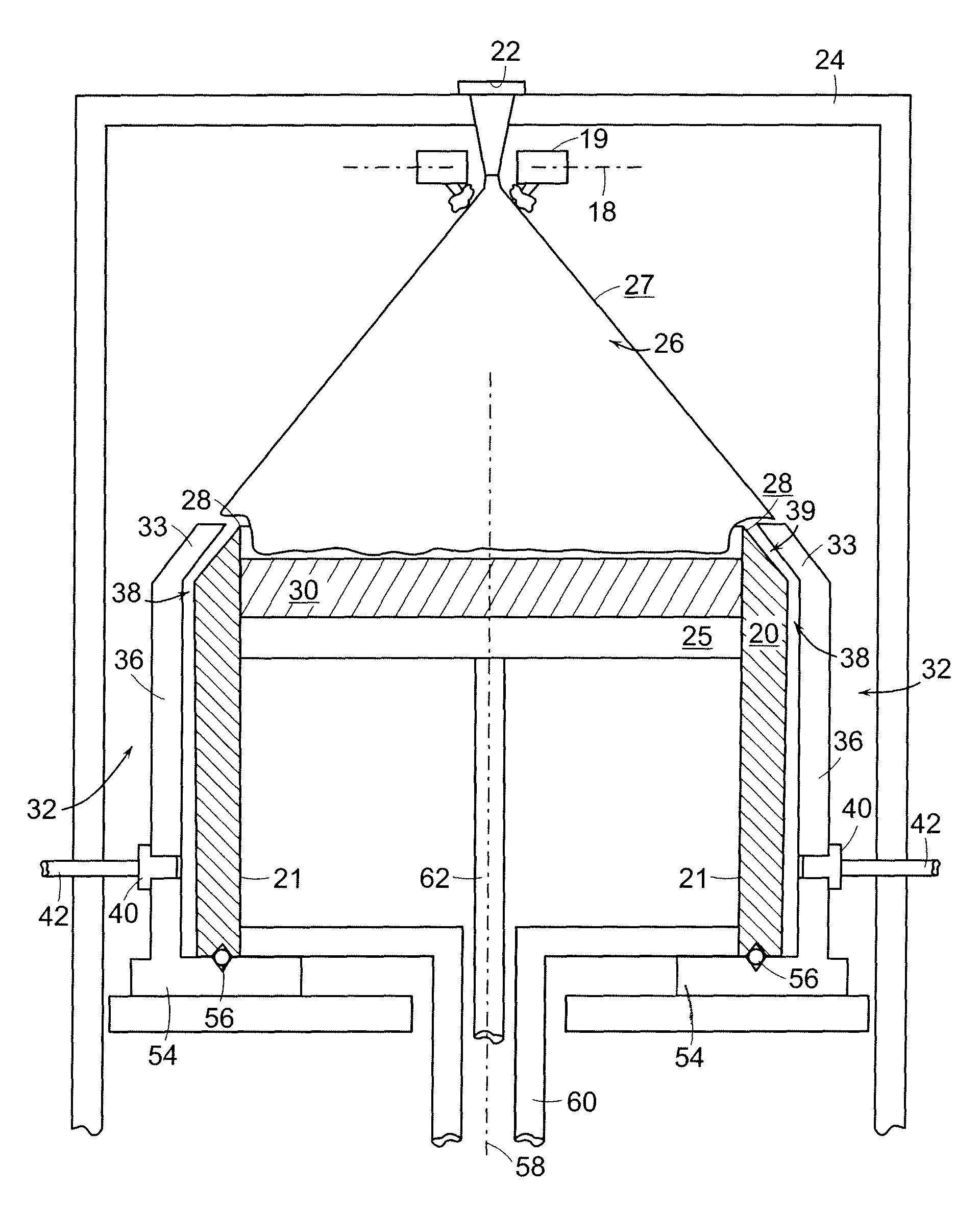

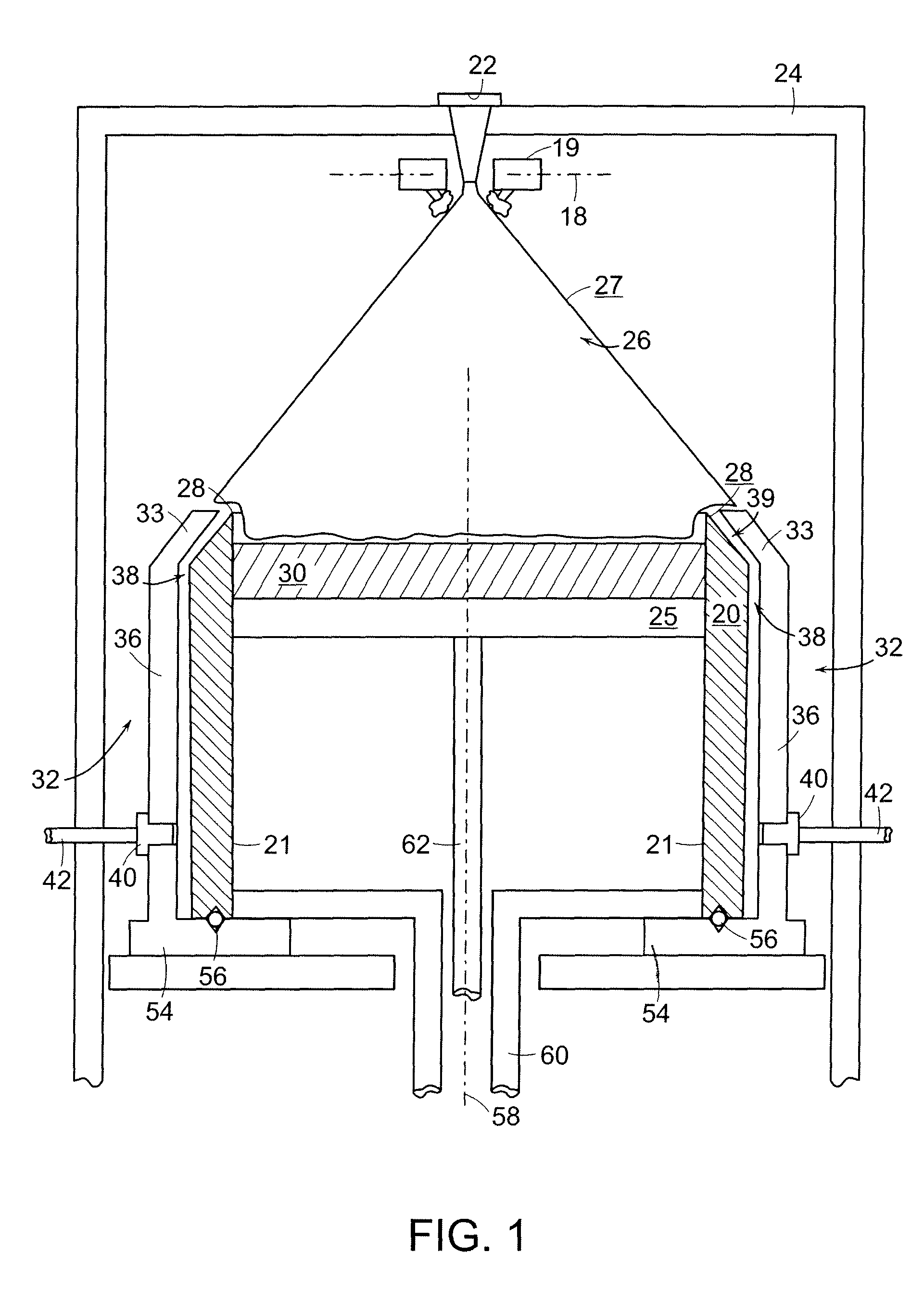

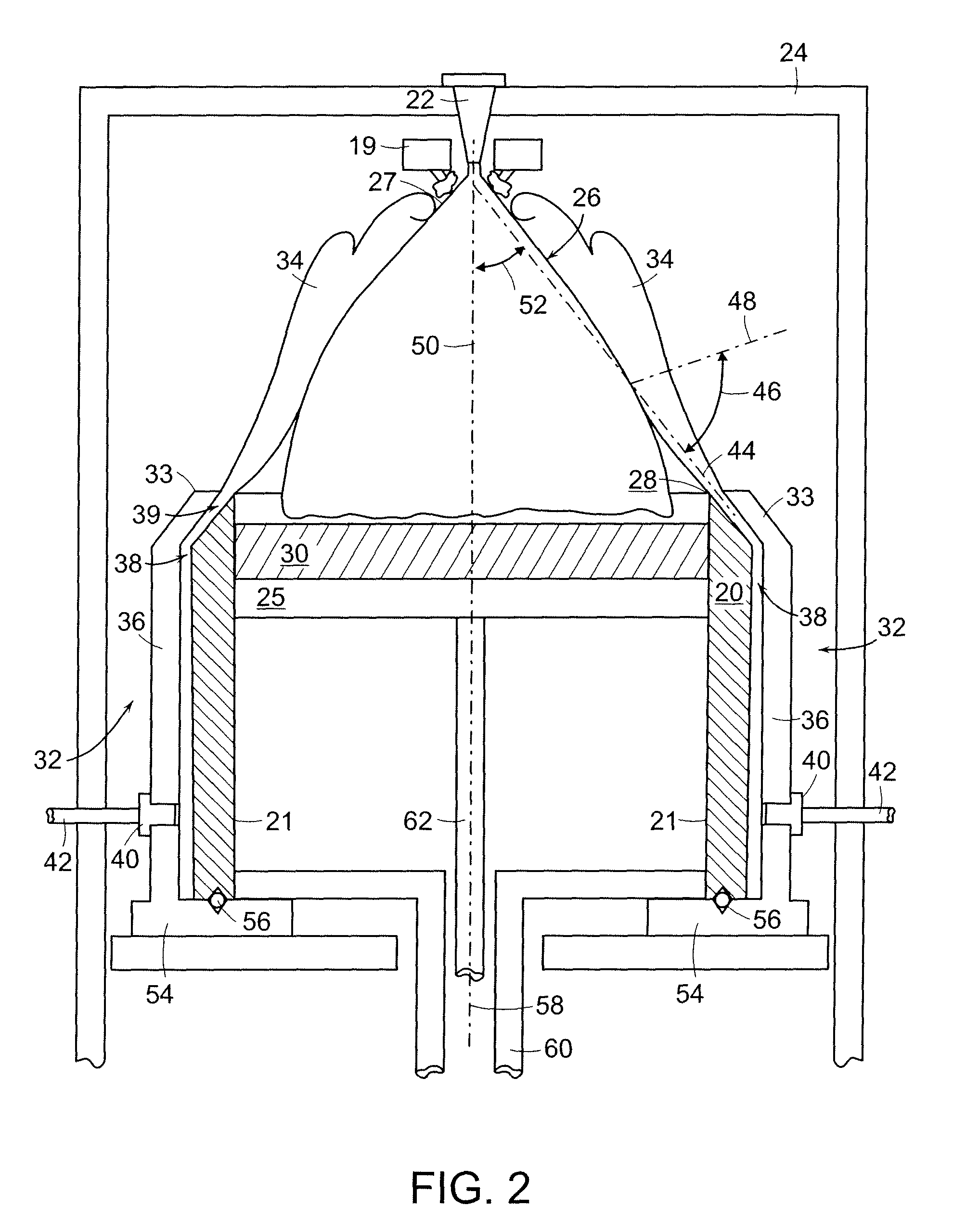

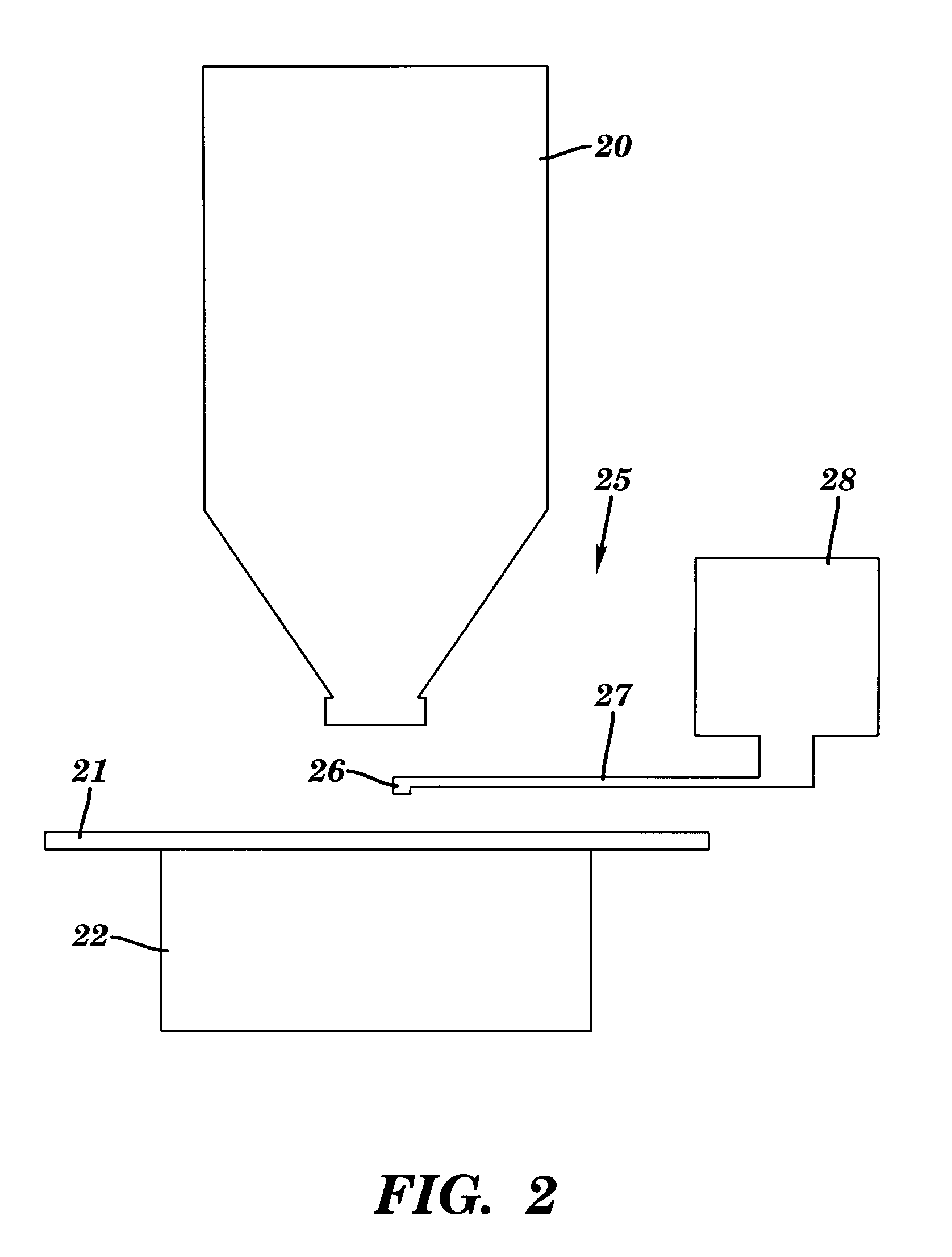

Casting Apparatus and Method

ActiveUS20090139682A1Reduce the amount requiredPrevent, oversprayMolten spray coatingMetallic materialsGas syringe

A nucleated casting apparatus including an atomizing nozzle configured to produce a droplet spray of a metallic material, a mold configured to receive the droplet spray and form a preform therein, and a gas injector which can limit, and possibly prevent, overspray from accumulating on the mold. The gas injector can be configured to produce a gas flow which can impinge on the droplet spray to redirect at least a portion of the droplet spray away from a side wall of the mold. In various embodiments, the droplet spray may be directed by the atomizing nozzle in a generally downward direction and the gas flow may be directed in a generally upward direction such that the gas flow circumscribes the perimeter of the mold.

Owner:ATI PROPERTIES

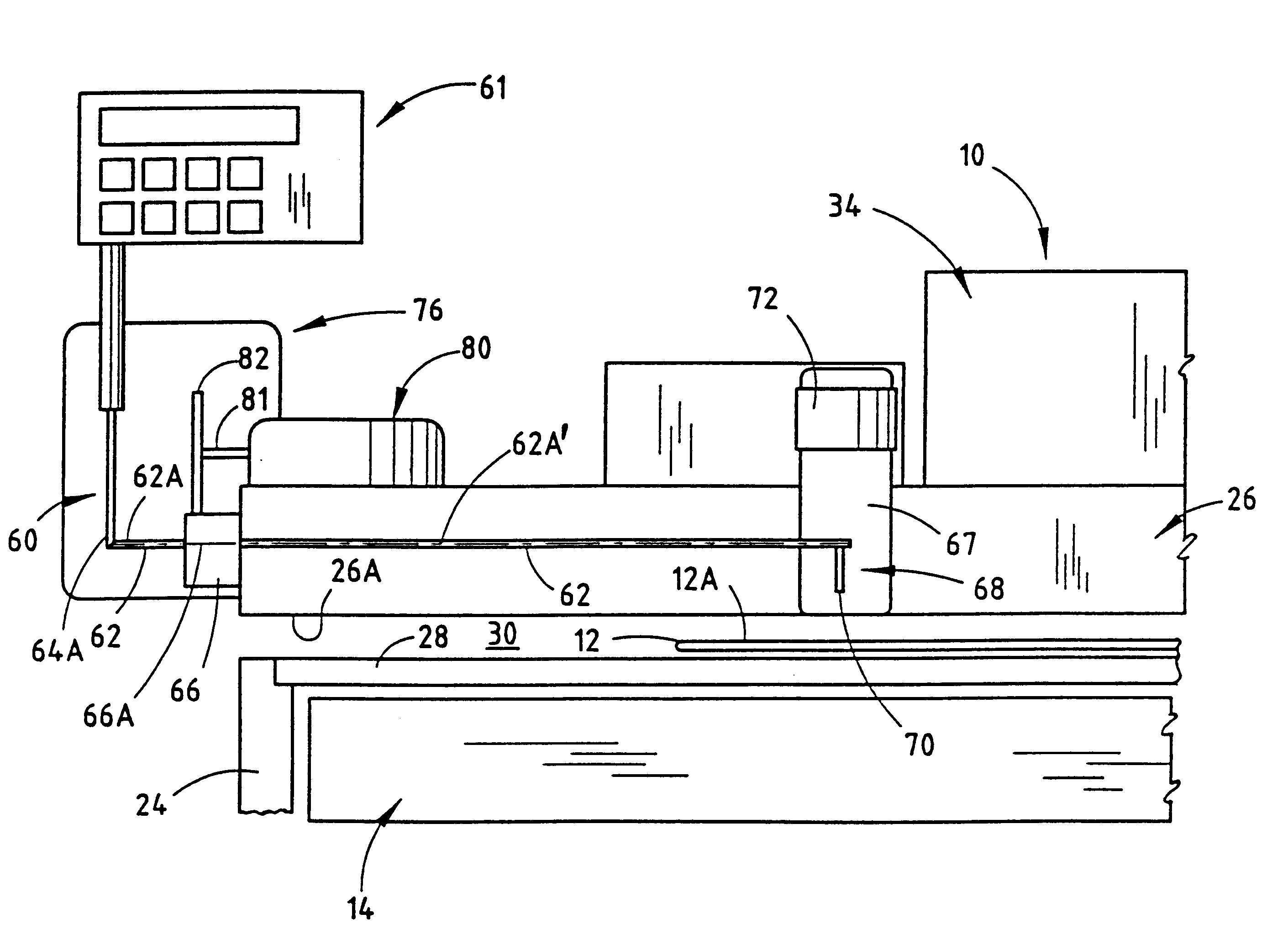

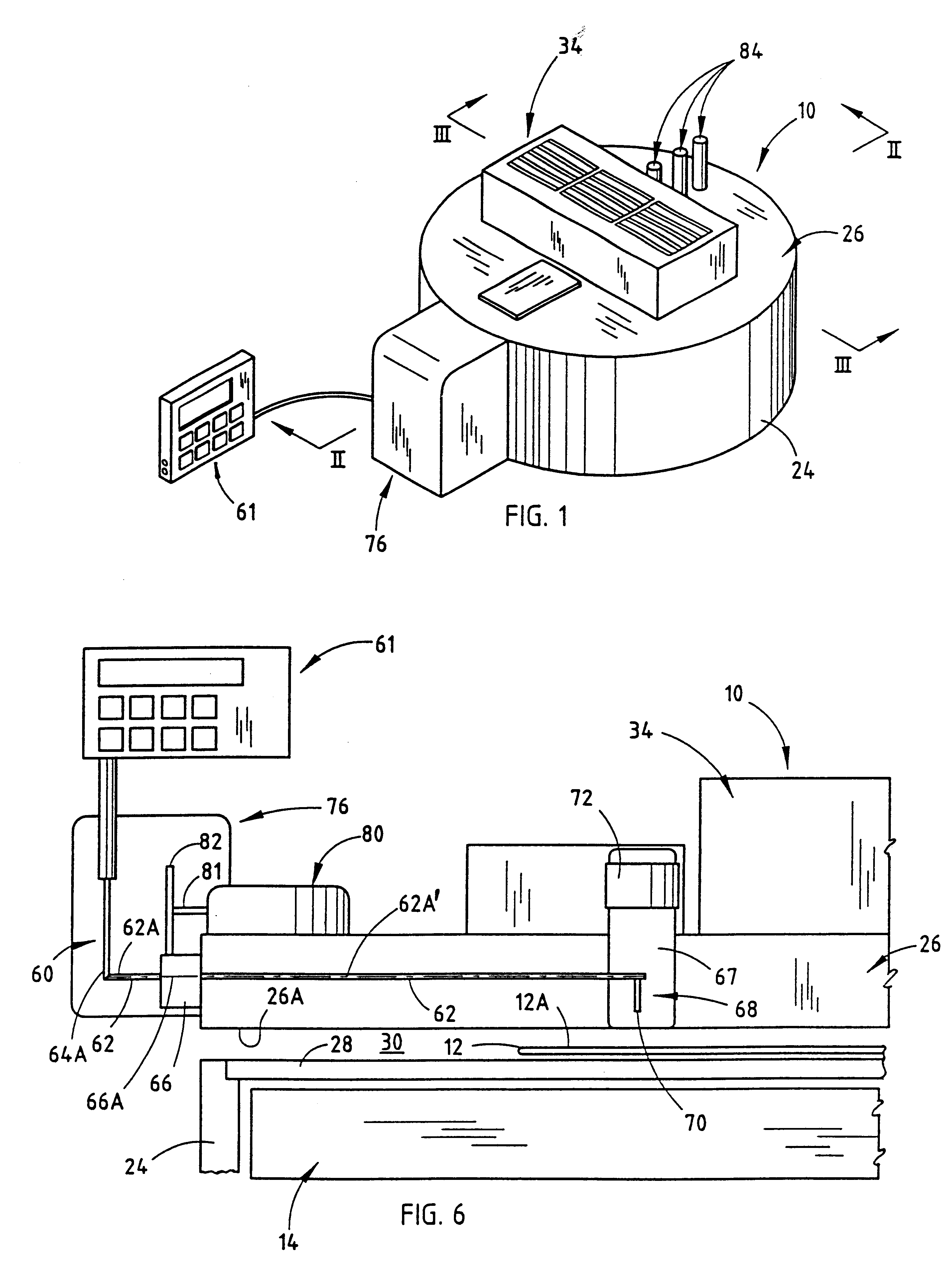

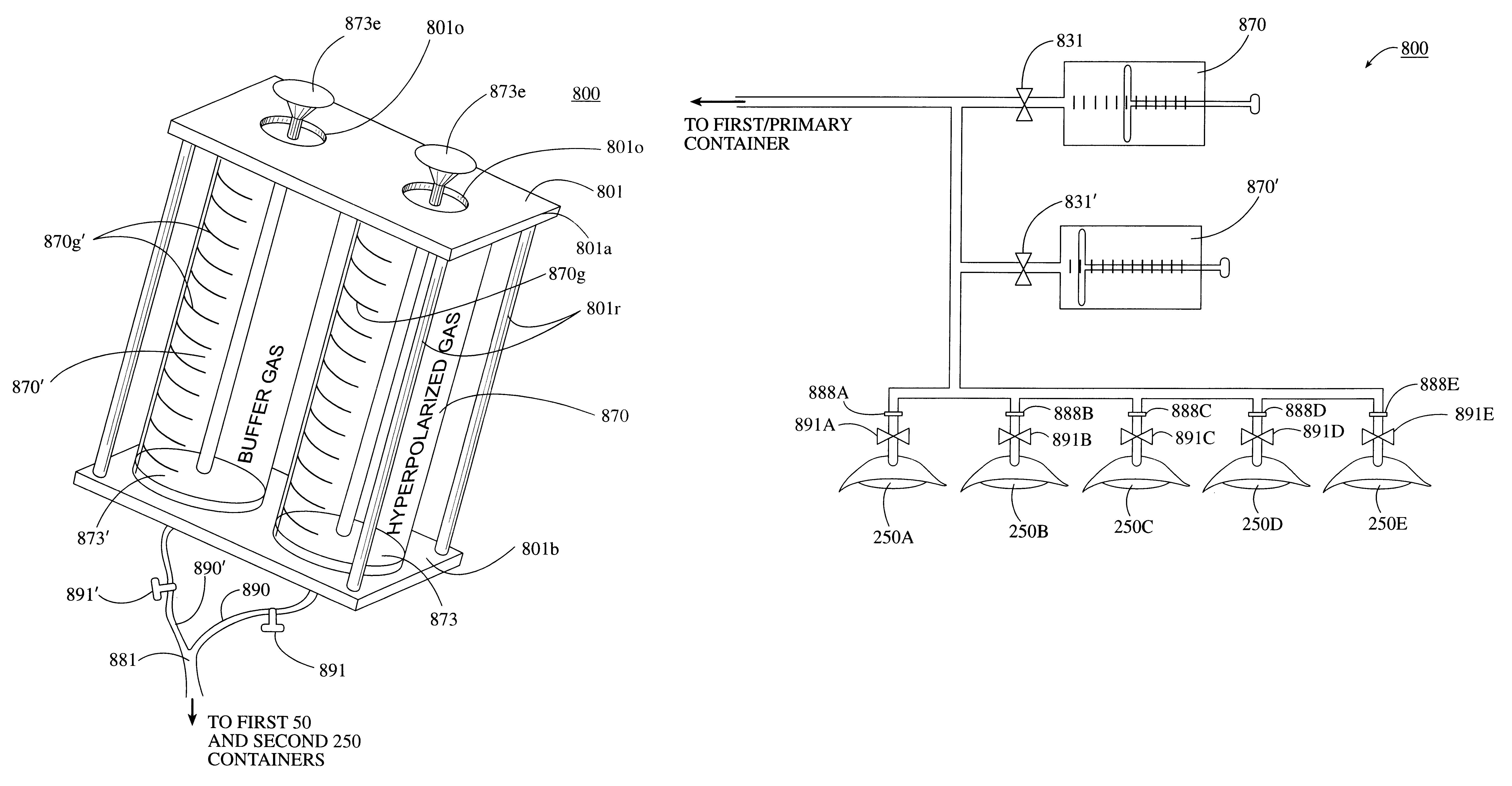

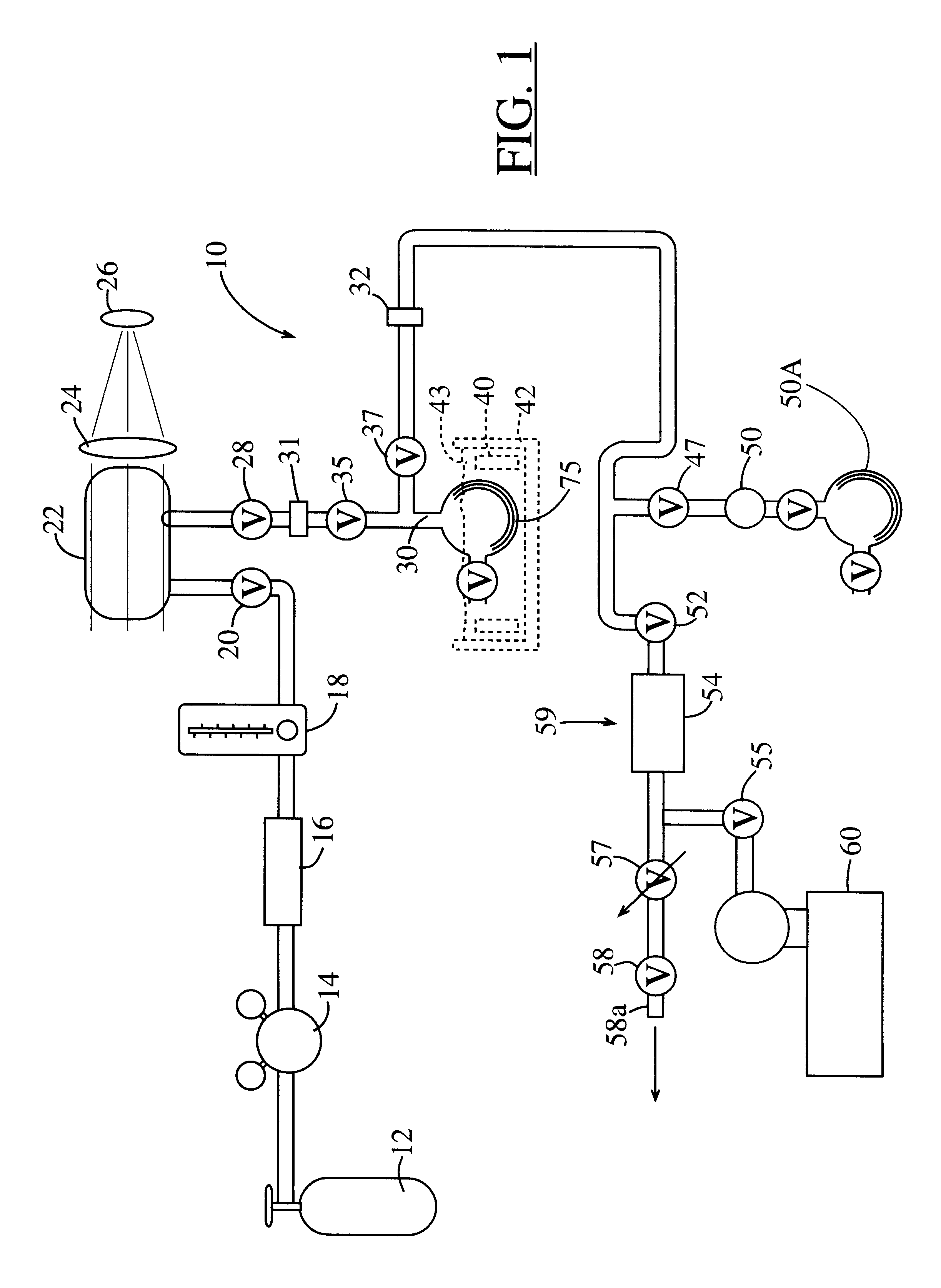

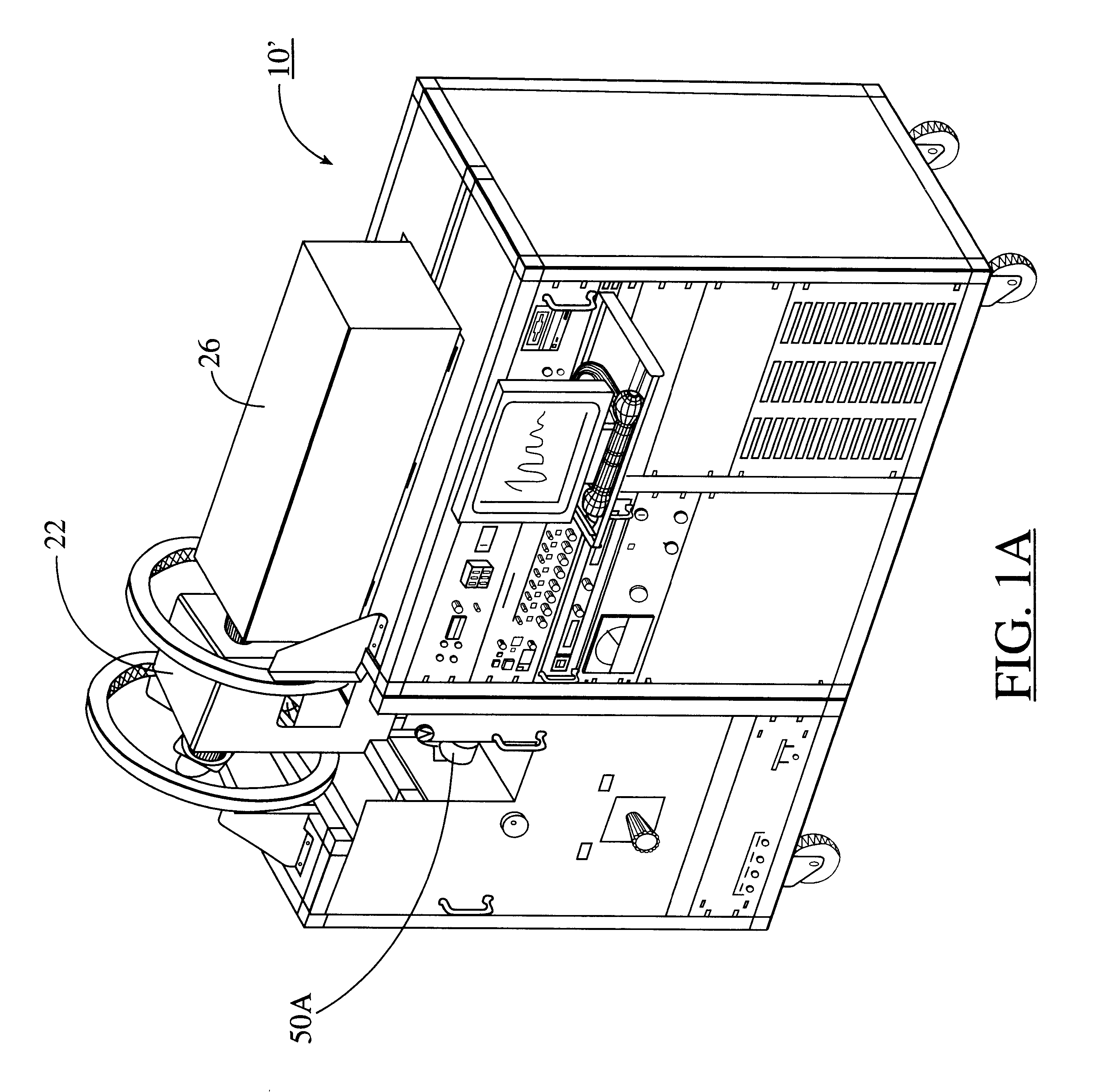

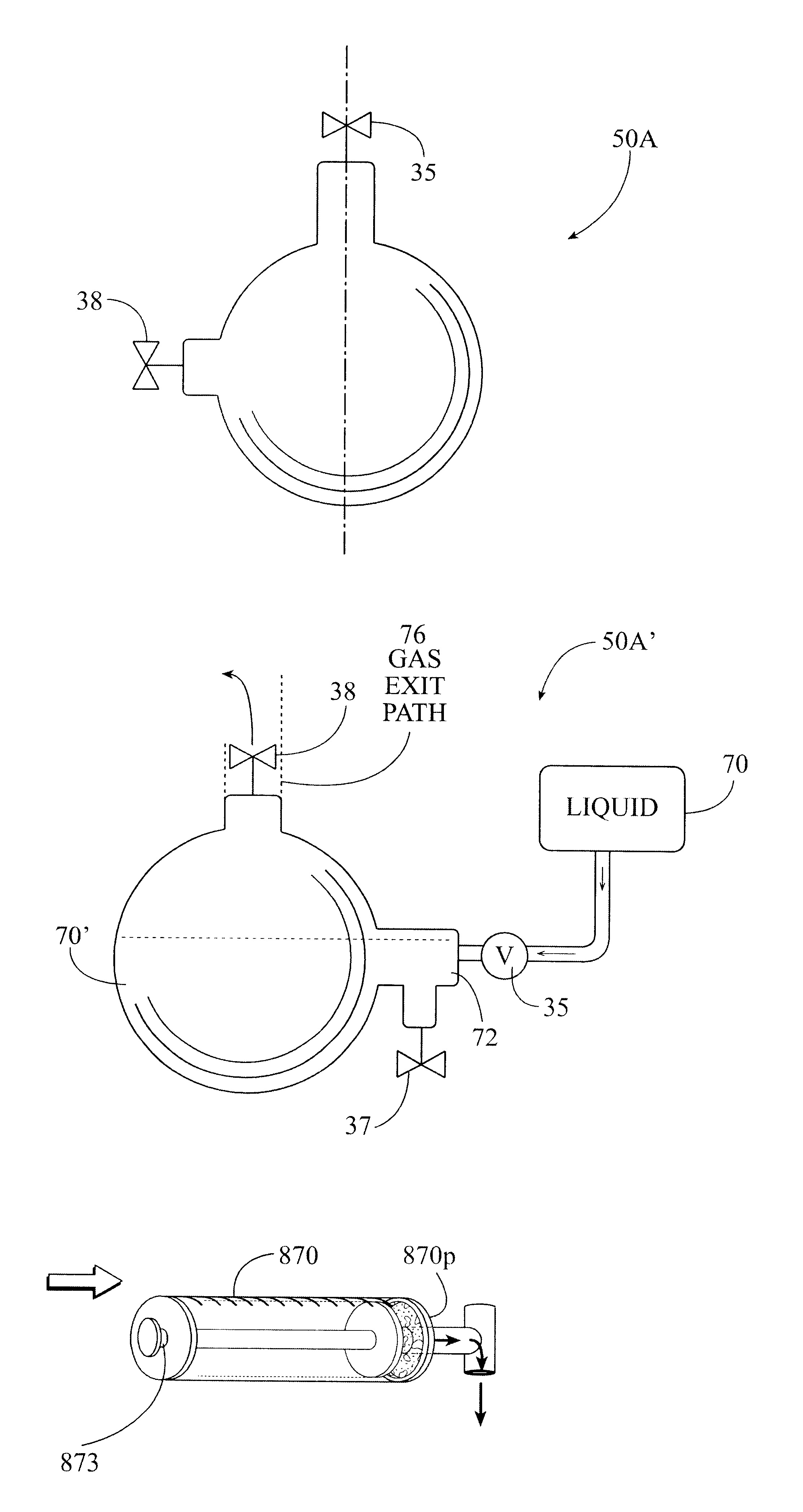

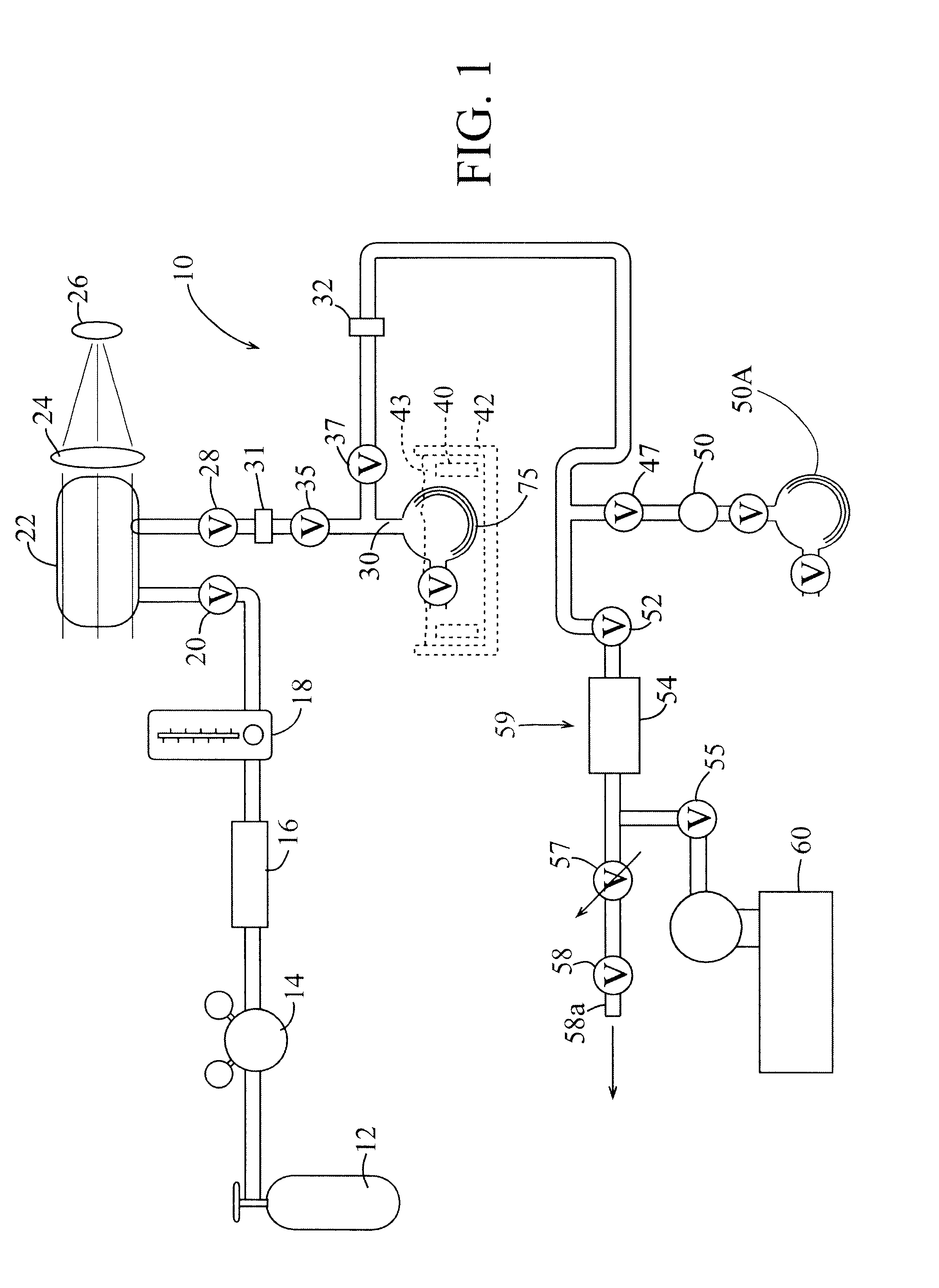

Meted hyperpolarized noble gas dispensing methods and associated devices

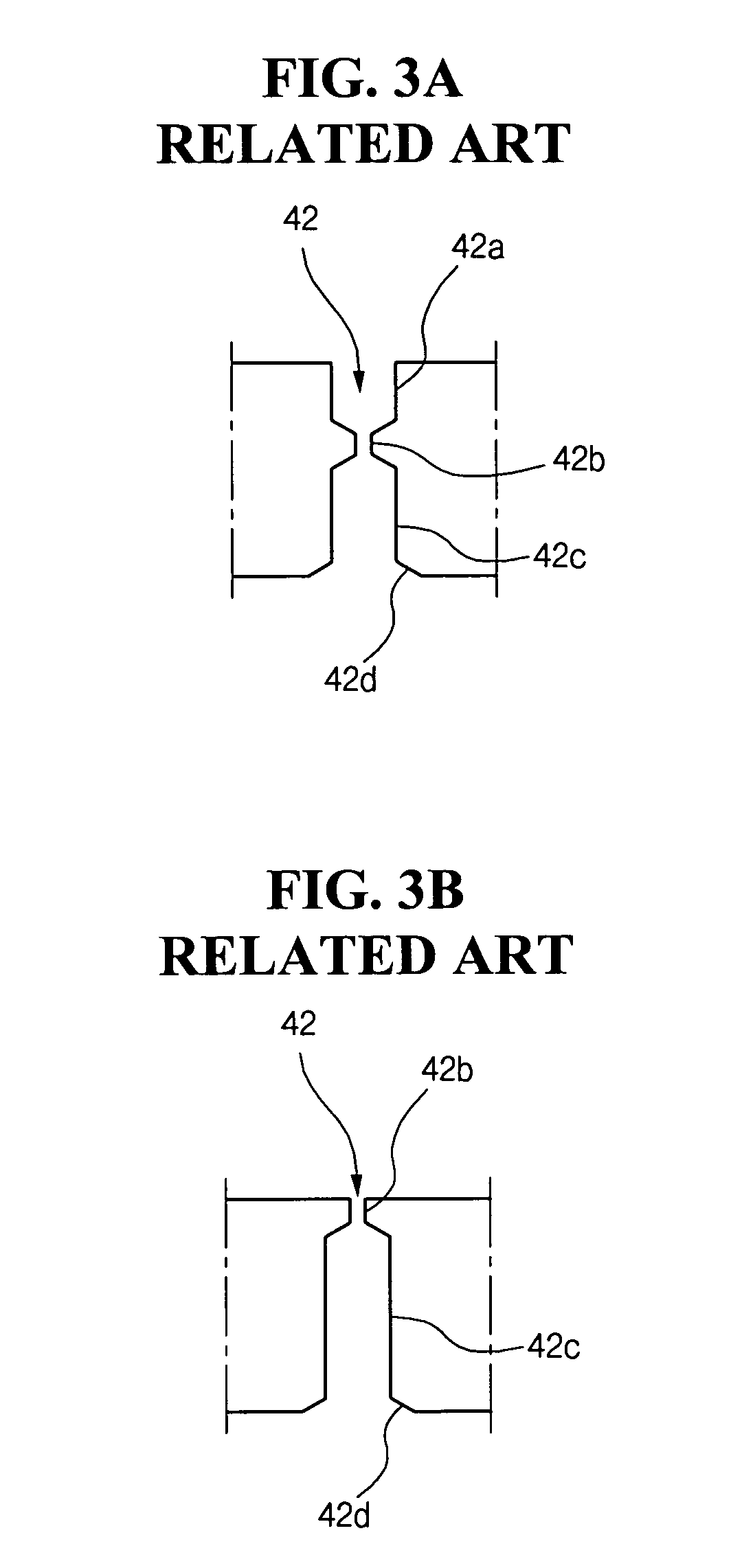

InactiveUS6286319B1Minimize impactReduce decreaseDispersion deliveryContainer filling methodsNoble gasControl manner

Methods of extracting and removing hyperpolarized gas from a container include introducing an extraction fluid into the container to force the hyperpolarized gas out of an exit port. The hyperpolarized gas is forced out of the container separate and apart from the extraction fluid. Alternatively, if the fluid is a gas, a portion of the gas is mixed with the hyperpolarized gas to form a sterile mixed fluid product suitable for introduction to a patient. An additional method includes engaging a gas transfer source such as a syringe to a transport container and pulling a quantity of the hyperpolarized gas out of the container in a controlled manner. Alternatively, one or more gas syringes can be employed to mete out predictable quantities of hyperpolarized gas or gas mixtures including quantities of buffer gases. Another method includes introducing a quantity of liquid into a container and covering at least one predetermined internal surface or component with the liquid to mask the surfaces and keep the hyperpolarized gas away from the predetermined internal surface, thereby inhibiting any depolarizing affect from same. Examples of surfaces or components suitable for masking include valves, seals, and the like. Yet another extraction method includes expanding a resilient member inside the container to force the hyperpolarized gas to exit therefrom. Containers include a resilient member positioned in fluid communication with the hyperpolarized gas in the container. An additional container includes inlet and outlet ports in fluid communication with the chamber and positioned on opposing sides or end portions of the container. Another container includes a port configured to receive a portion of a syringe therein. An additional aspect of the disclosure relates to calibration methods and apparatus for identifying the hyperpolarization status of the gas.

Owner:POLAREAN

Meted hyperpolarized noble gas dispensing methods and associated devices

InactiveUS6523356B2Reduce decreaseExtend your lifeDispersion deliveryContainer filling methodsNoble gasGas syringe

Methods of dispensing meted quantities of hyperpolarized gas to form a hyperpolarized gas mixture include pre-filling a gas syringe with a quantity of non-polarized gas, then introducing the hyperpolarized gas therein while the non-polarized gas is held therein, and expelling both the hyperpolarized gas and non-polarized gas from the syringe. Methods of inhibiting the presence of oxygen in gas flow paths and extraction systems are also described.

Owner:POLAREAN

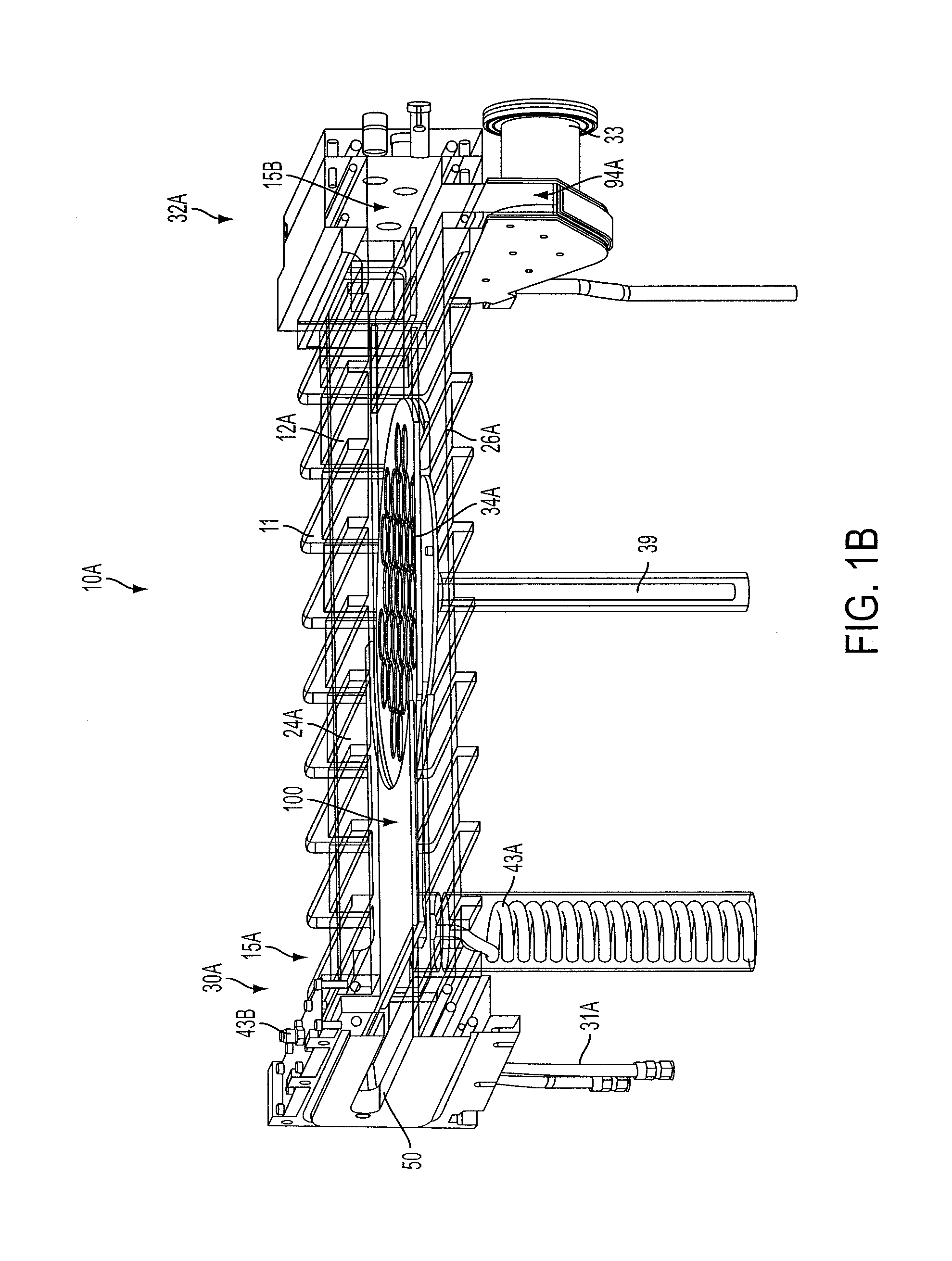

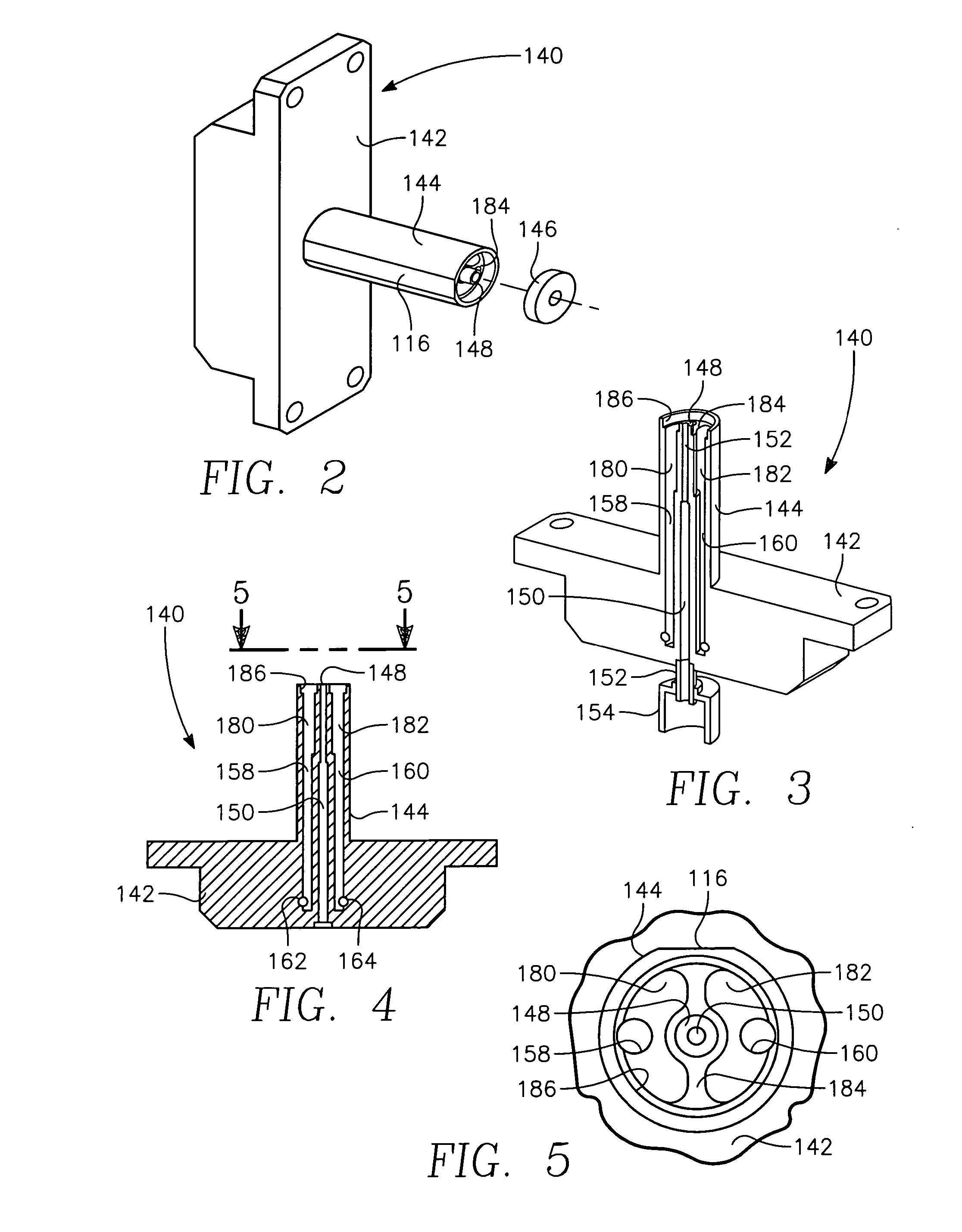

Gas injectors for CVD systems with the same

InactiveUS20110277681A1Improving precursor thermalizationWell mixedPolycrystalline material growthValve members for heating/coolingHigh volume manufacturingGas syringe

The present invention provides improved gas injectors for use with chemical vapour deposition (CVD) systems that thermalize gases prior to injection into a CVD chamber. The provided injectors are configured to increase gas flow times through heated zones and include gas-conducting conduits that lengthen gas residency times in the heated zones. The provided injectors also have outlet ports sized, shaped, and arranged to inject gases in selected flow patterns. The invention also provides CVD systems using the provided thermalizing gas injectors. The present invention has particular application to high volume manufacturing of GaN substrates.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

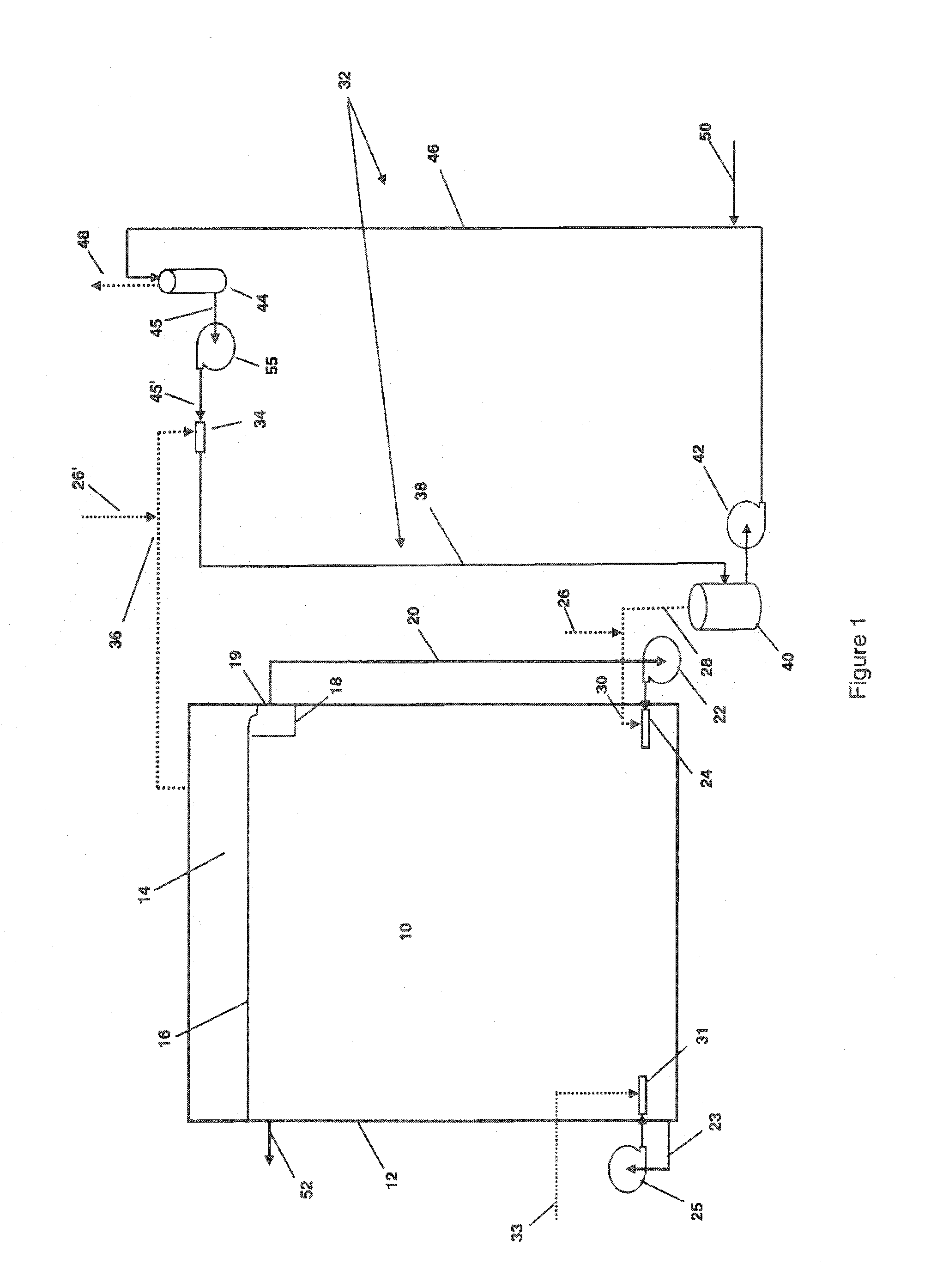

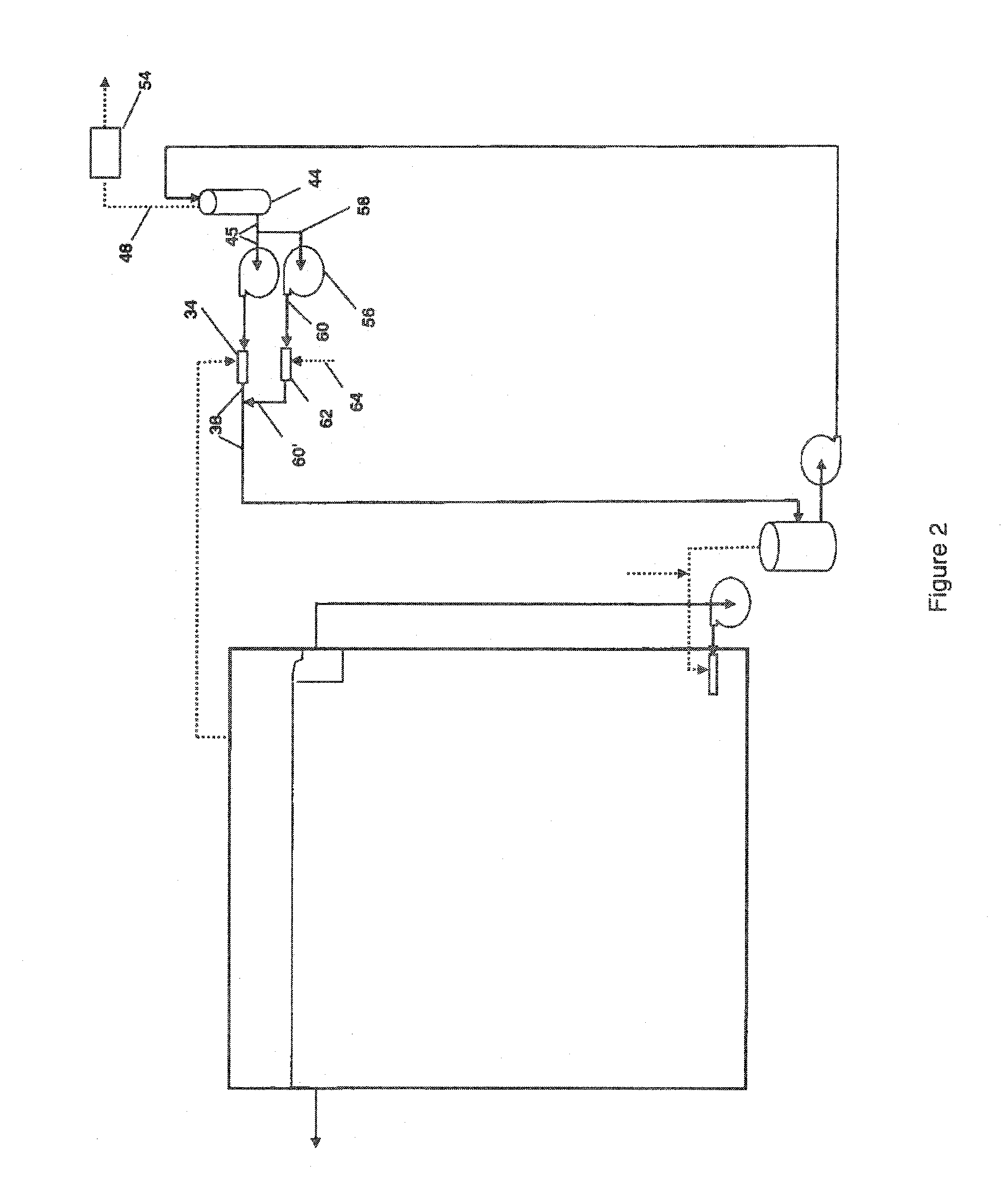

Process for Converting a CO and CO2 Feed Gas Stream to Liquid Products by Fermentation

ActiveUS20120003706A1Lower requirementIncrease pressureBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productStream flow

A process converts a gas input stream comprising CO, CO2, and H2 by contact with fermentation liquid into a liquid product that controls the concentration of CO and CO2 in the fermentation vessel. The process charges the feed gas stream and a recycle gas stream to the fermentation vessel and an off-gas stream collects above the fermentation liquid. The off-gas stream flows to a gas injector that uses a recycle liquid as the motive fluid to mix the off-gas with the recycle liquid into a gas-liquid dispersion. Contact of the recycle liquid with the off-gas absorbs CO2 to provide the recycle stream. A gas separation vessel separates the remainder of the off-gas into the recycle gas. Mixing the recycle gas with the gas input stream dilutes the concentration of CO to lower the CO concentration in the fermentation vessel. Separated recycle liquid flows to a CO2 stripper for removal of CO2.

Owner:SYNATA BIO INC

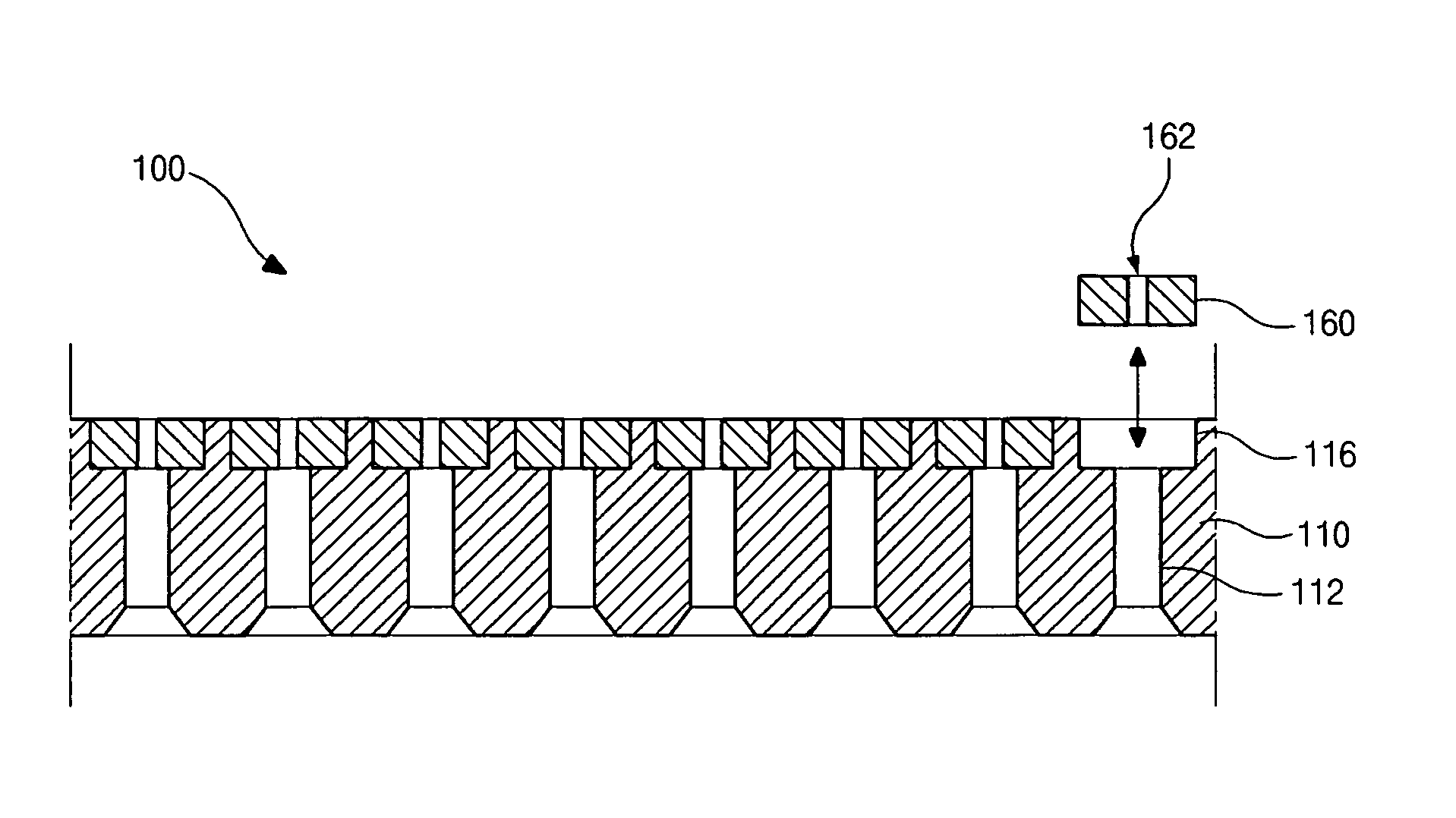

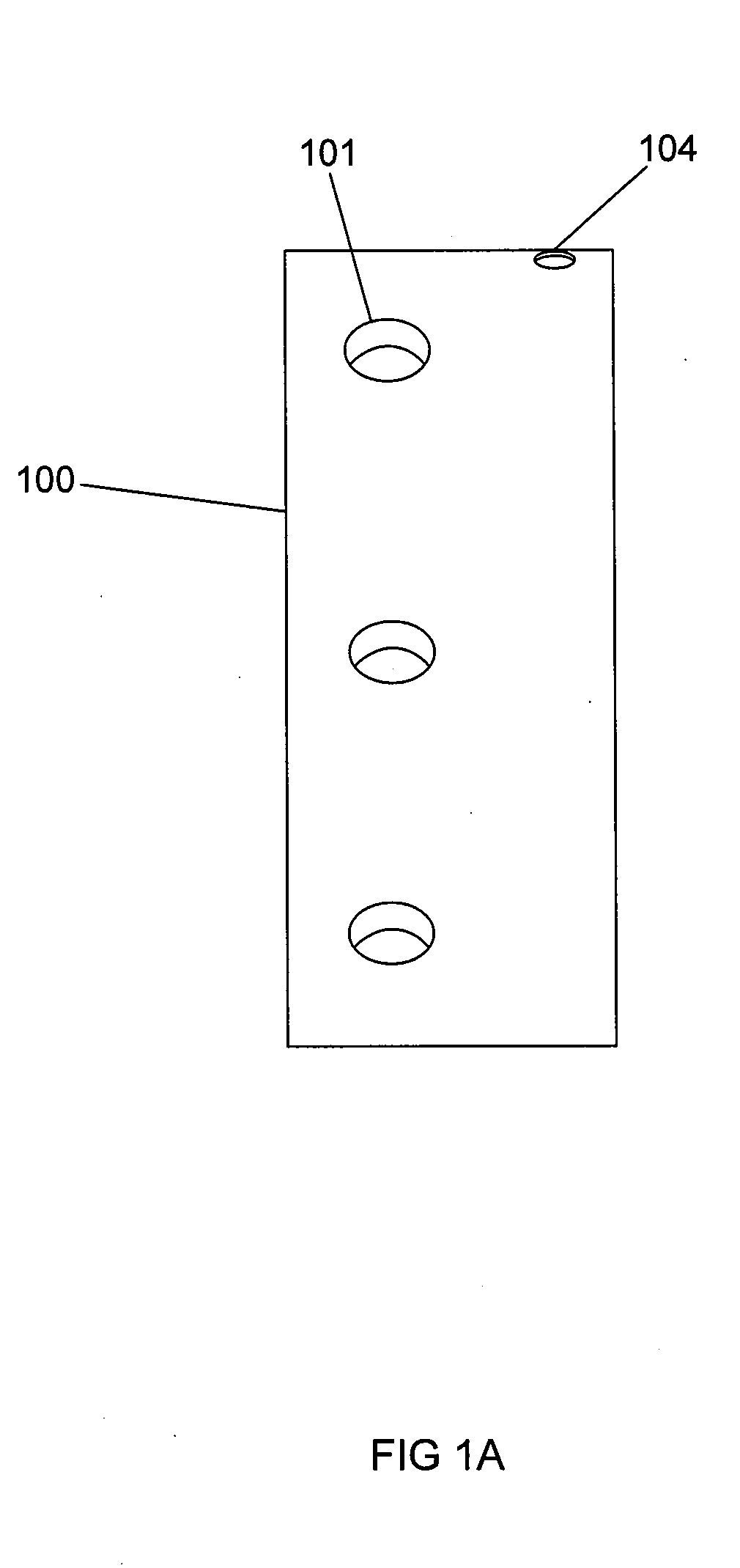

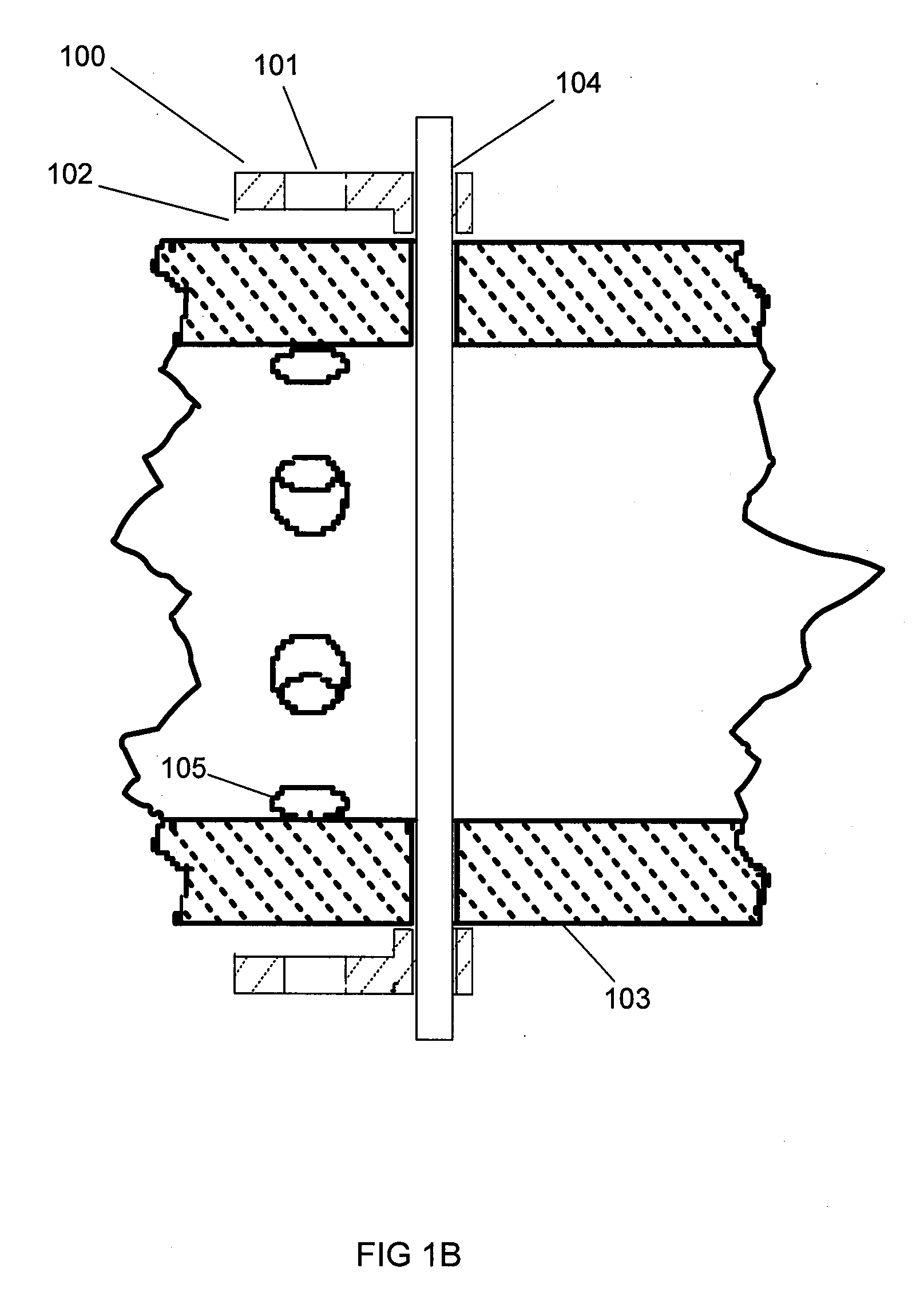

Chemical vapour deposition injector

InactiveUS20140284404A1Uniform flow rateEasy to manufactureLiquid spraying apparatusChemical vapor deposition coatingCompound (substance)Gas syringe

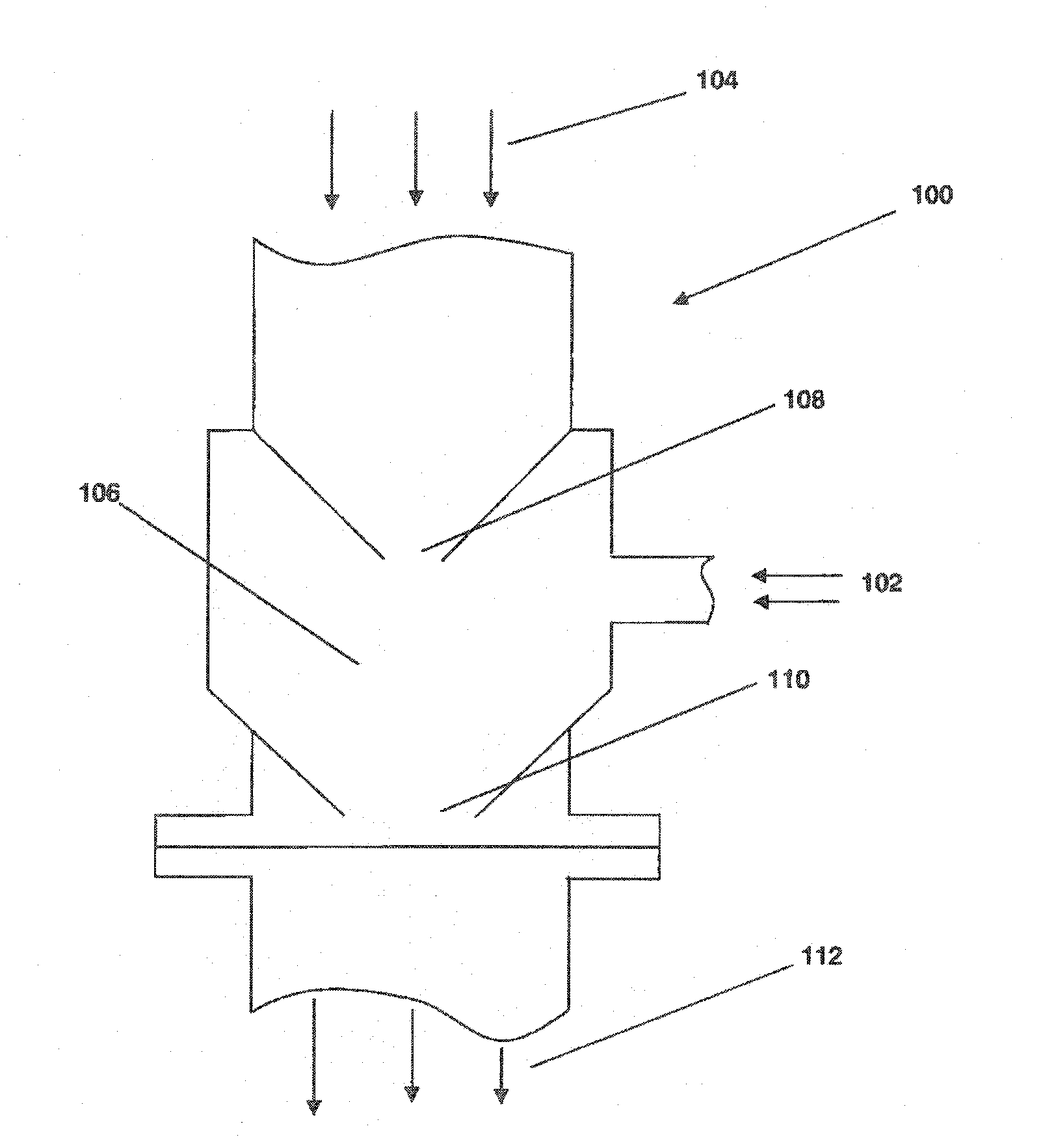

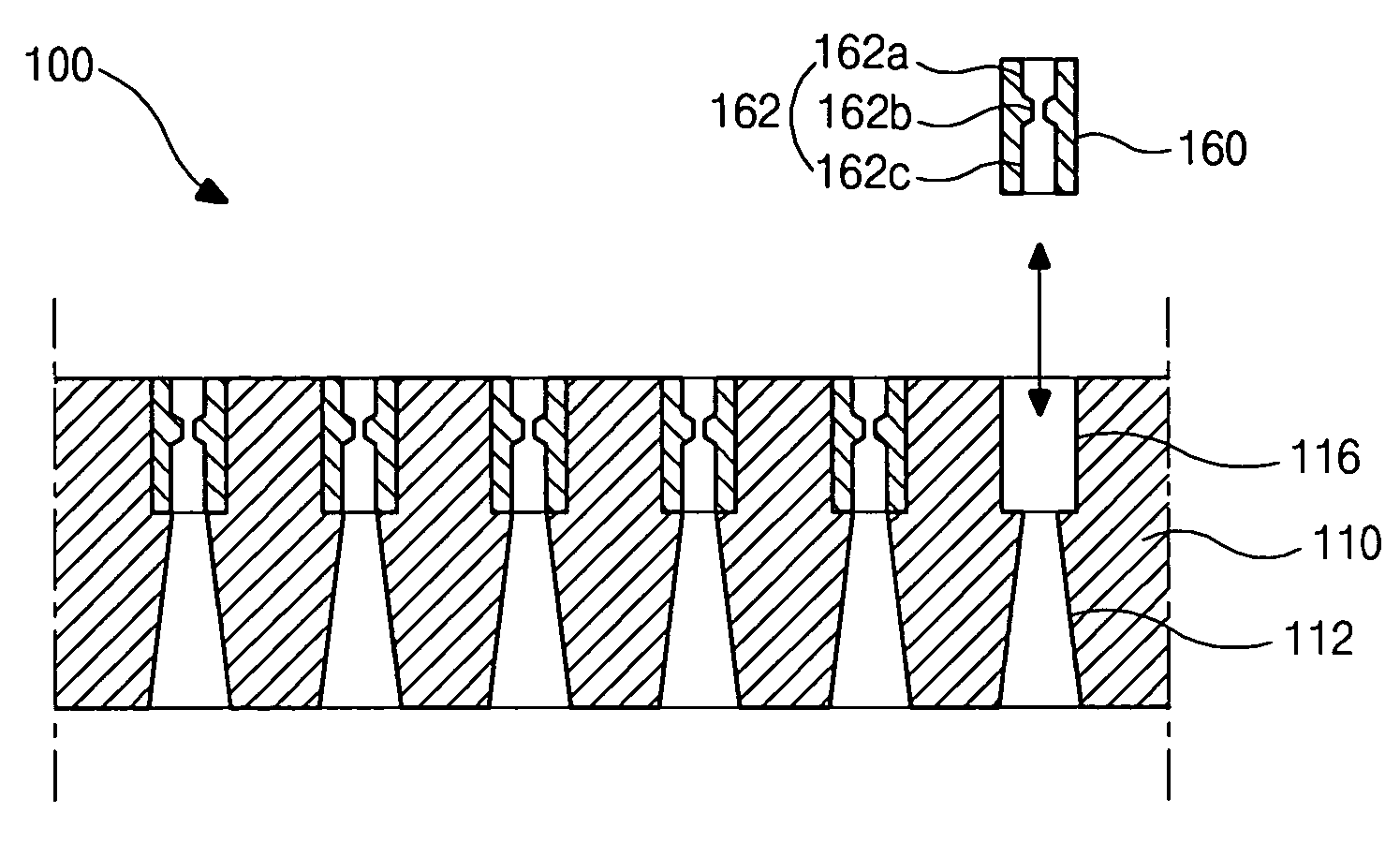

Disclosed is a chemical vapour deposition injector 100, comprising a gas injector body 104 having a plurality of holes for directing a first gas from a first gas plenum into respective first gas channels of the gas injector body, each first gas channel extending in a first direction and arranged to branch into separate flow paths; a plurality of discrete first conduits, each first conduit being arranged to connect to a respective one of the discrete flow paths for carrying the first gas to a reaction chamber; a second gas channel for directing a second gas from a second gas plenum into the gas injector body, the second gas channel having a longitudinal axis which extends in a second direction transverse to the first direction; and a plurality of discrete second conduits coupled to the second gas channel and arranged to carry the second gas from the second gas channel to the reactor chamber; wherein at least some of the discrete second conduits are arranged between the discrete first conduits.

Owner:ASM TECH SINGAPORE PTE LTD

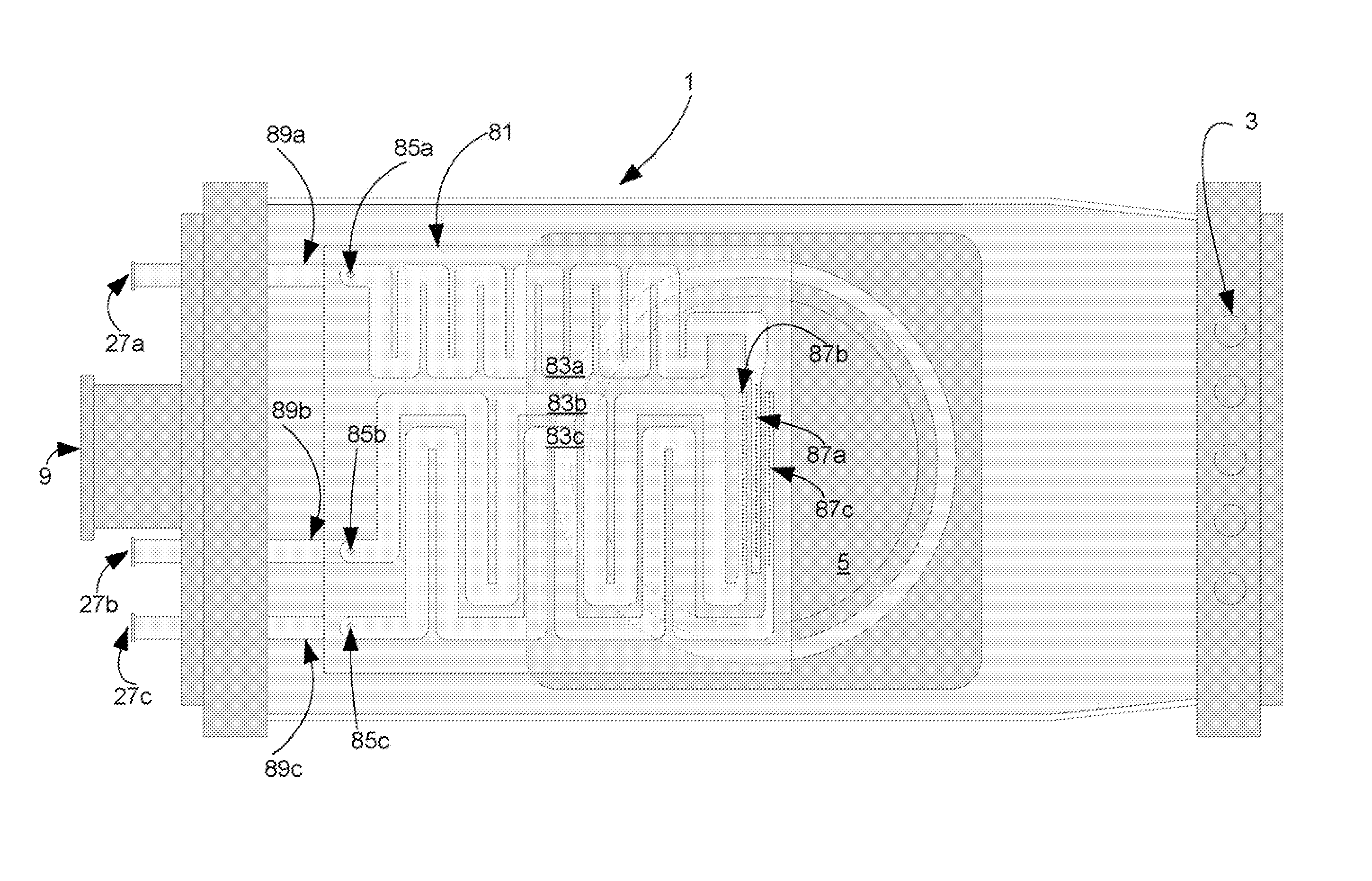

Methods and apparatus for controlled chemical vapor deposition

ActiveUS20100221427A1Improves distribution and directional controlChemical vapor deposition coatingMetal working apparatusGas phaseGas syringe

A gas injector system is provided that allows for improved distribution and directional control of the vapor material in a CVD or CVI process. Gas injector systems may be used without experiencing significant clogging of gas injector tube apertures over multiple CVD procedures. Further, a gas injector system include a dual aperture release system and / or allow vapor material to flow both substantially horizontally and substantially vertically.

Owner:THE BF GOODRICH CO

Tunable multi-zone gas injection system

ActiveUS9051647B2Improve uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricElectricity

A tunable multi-zone injection system for a plasma processing system for plasma processing of substrates such as semiconductor wafers. The system includes a plasma processing chamber, a substrate support for supporting a substrate within the processing chamber, a dielectric member having an interior surface facing the substrate support, the dielectric member forming a wall of the processing chamber, a gas injector fixed to part of or removably mounted in an opening in the dielectric window, the gas injector including a plurality of gas outlets supplying process gas at adjustable flow rates to multiple zones of the chamber, and an RF energy source such as a planar or non-planar spiral coil which inductively couples RF energy through the dielectric member and into the chamber to energize the process gas into a plasma state. The injector can include an on-axis outlet supplying process gas at a first flow rate to a central zone and off-axis outlets supplying the same process gas at a second flow rate to an annular zone surrounding the central zone. The arrangement permits modification of gas delivery to meet the needs of a particular processing regime by allowing independent adjustment of the gas flow to multiple zones in the chamber. In addition, compared to consumable showerhead arrangements, a removably mounted gas injector can be replaced more easily and economically.

Owner:LAM RES CORP

Method and apparatus for processing substrate edges

ActiveUS20110139757A1Not harm environmentEliminate needWelding/cutting auxillary devicesAuxillary welding devicesSingle processGas syringe

A method and apparatus for processing substrate edges is disclosed that overcomes the limitations of conventional edge processing methods and systems used in semiconductor manufacturing. The edge processing method and apparatus of this invention includes a laser and optical system to direct a beam of radiation onto a rotating substrate supported by a chuck. The optical system accurately and precisely directs the beam to remove or transform organic or inorganic films, film stacks, residues, or particles, in atmosphere, from the top edge, top bevel, apex, bottom bevel, and bottom edge of the substrate in a single process step. An optional gas injector system directs gas onto the substrate edge to aid in the reaction. Reaction by-products are removed by means of an exhaust tube enveloping the reaction site. This invention permits precise control of an edge exclusion width, resulting in an increase in the number of usable die on a wafer. Wafer edge processing with this invention replaces existing methods that use large volumes of purified water and hazardous chemicals including solvents, acids, alkalis, and proprietary strippers.

Owner:UVTECH SYST

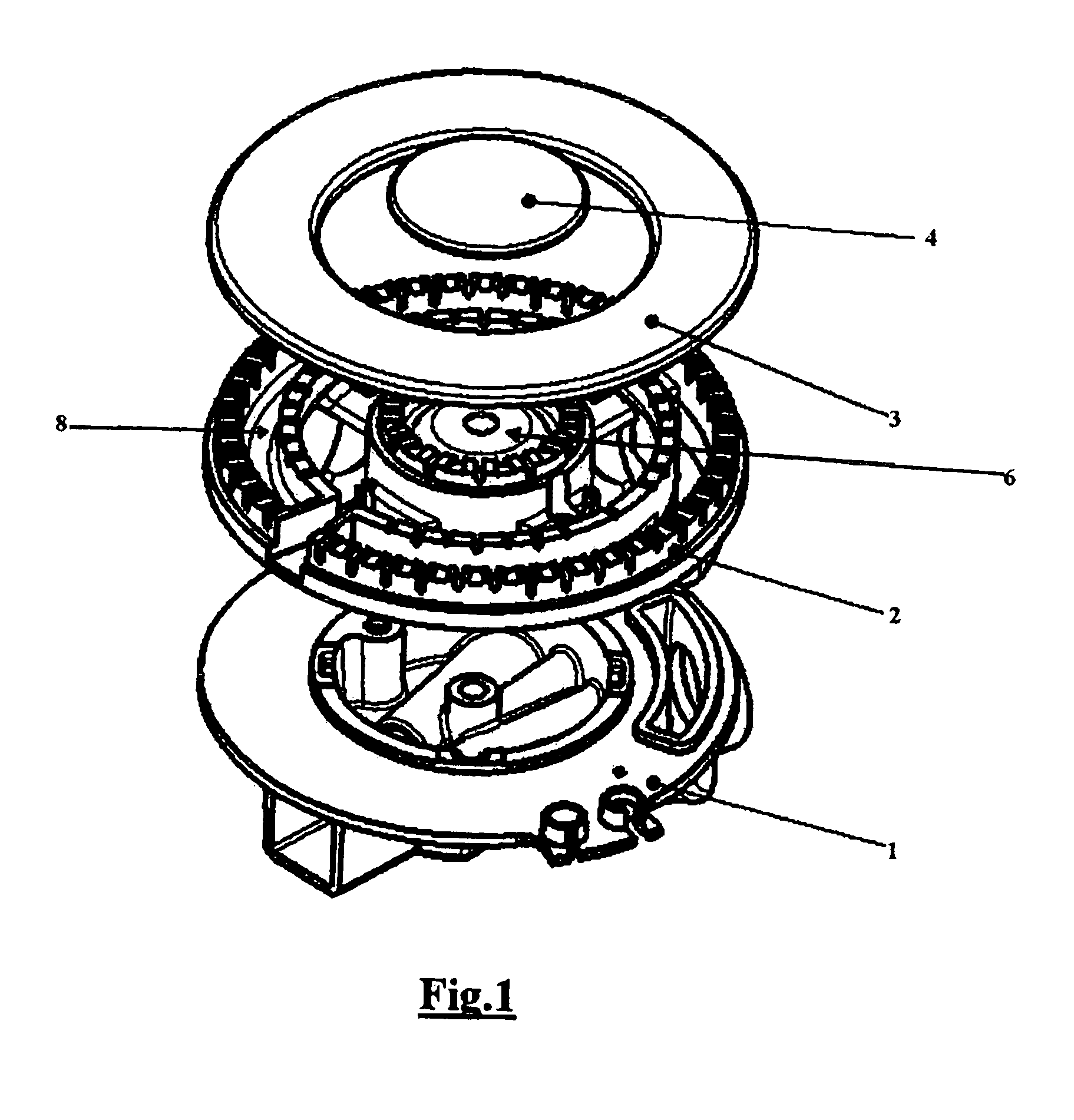

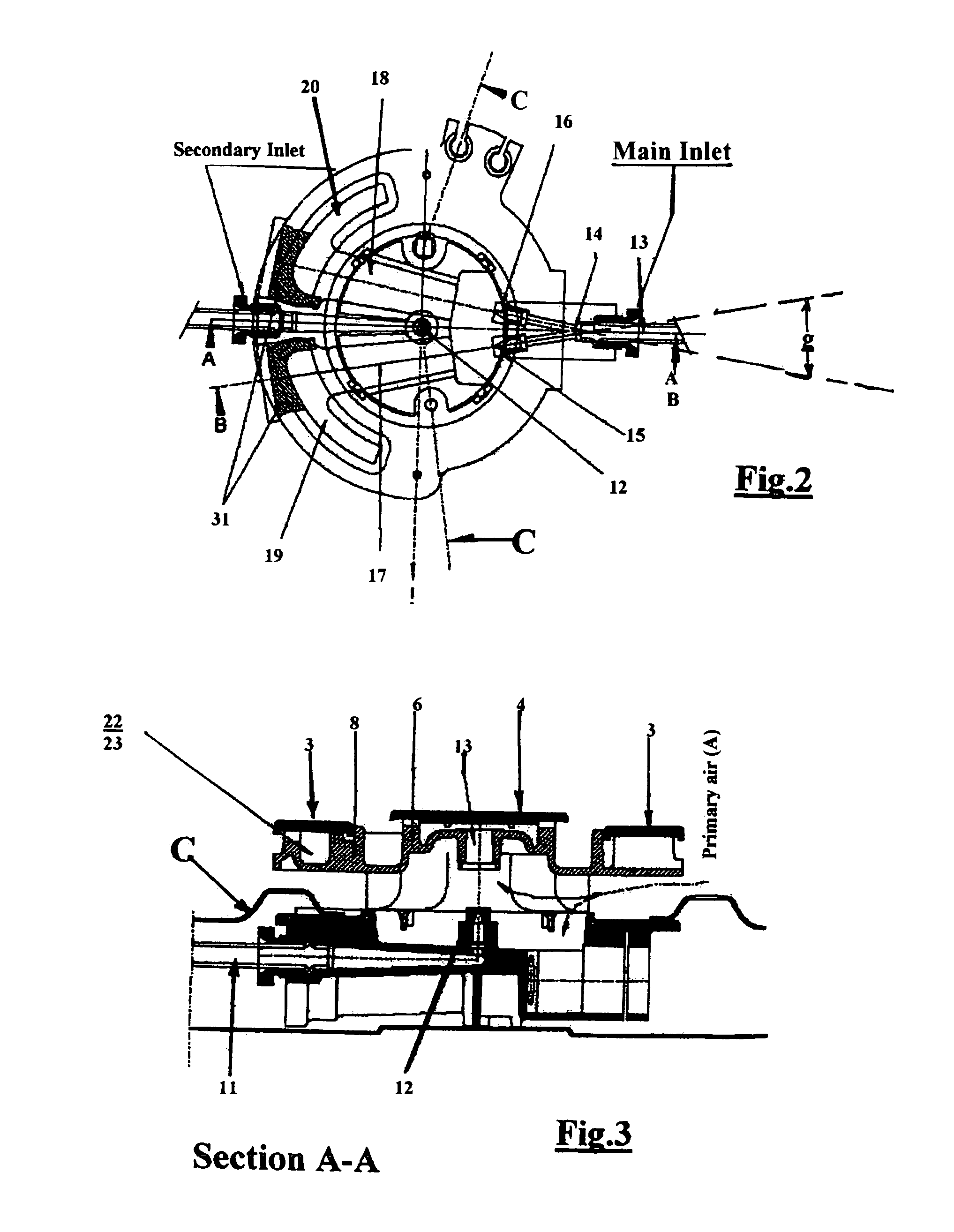

Gas burner

ActiveUS8221116B2Increase thermal powerDomestic stoves or rangesElectric spark ignitersGas syringeEngineering

Gas burner provided with a plurality of concentric flame crowns, and comprising a first central burner to supply a peripheral flame ring, a second annular burner surrounding the central burner at a defined distance and able of supplying at least a respective peripheral ring, a burner body apt to be mounted on the surface of a cooking hob, a first gas inlet in communication with the body, a first vertical gas injector, the central burner being provided with a first chamber for the diffusion of the air / gas mixture, a second gas inlet in communication with the body, wherein the second annular burner is provided with two separate chambers for the diffusion of the mixture, wherein the second gas inlet is in communication with the two separate chambers through suitable injection and conveying means, which comprise two distinct injectors in communication with the second gas inlet, and two respective horizontal Venturi pipes each of which being able of supplying with the air / gas mixture a respective of the two diffusion chambers; these are physically separate and not in communication to each other. The two horizontal and separate injectors are placed on the same end position of the second gas inlet.

Owner:ELECTROLUX HOME PROD CORP NV

Casting apparatus and method

ActiveUS7798199B2Reduce the amount requiredPrevent, oversprayMolten spray coatingGas syringeMetallic materials

A nucleated casting apparatus including an atomizing nozzle configured to produce a droplet spray of a metallic material, a mold configured to receive the droplet spray and form a preform therein, and a gas injector which can limit, and possibly prevent, overspray from accumulating on the mold. The gas injector can be configured to produce a gas flow which can impinge on the droplet spray to redirect at least a portion of the droplet spray away from a side wall of the mold. In various embodiments, the droplet spray may be directed by the atomizing nozzle in a generally downward direction and the gas flow may be directed in a generally upward direction such that the gas flow circumscribes the perimeter of the mold.

Owner:ATI PROPERTIES

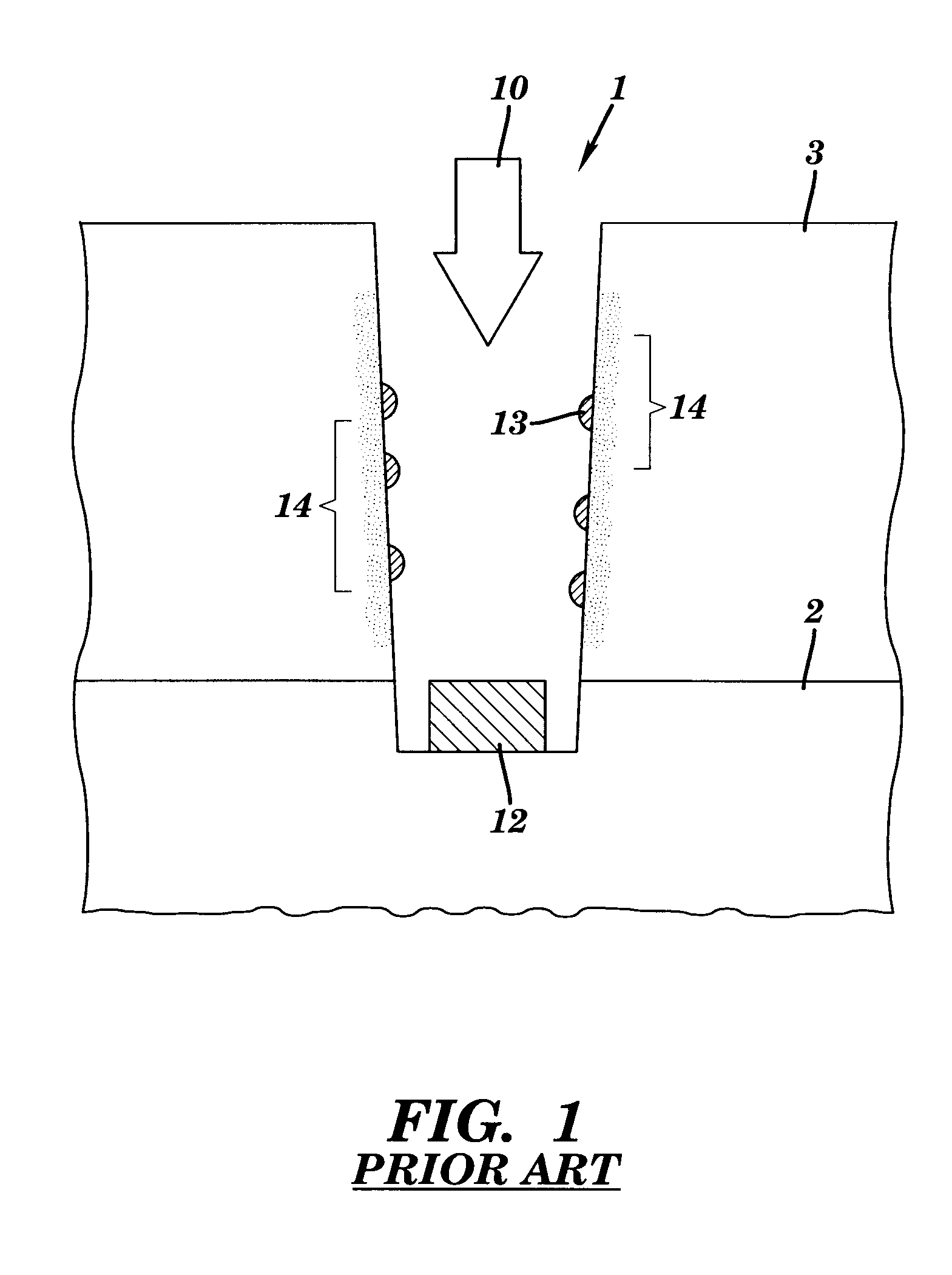

Side gas injector for plasma reaction chamber

ActiveUS20110079356A1Avoid differencesAvoid non-uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingGas syringeEngineering

A side gas injector for a plasma reaction chamber is provided. The side gas injector includes a circular distribution plate and a cover plate. The circular distribution plate includes an injection hole for injecting a reaction gas and a distribution channel part for distributing the reaction gas such that the reaction gas introduced from the injection hole can be radially simultaneously jetted in a plurality of positions along an inner circumference surface of the distribution plate. The cover plate is coupled to a top of the distribution plate and seals a top of the distribution channel part.

Owner:DMS CO LTD

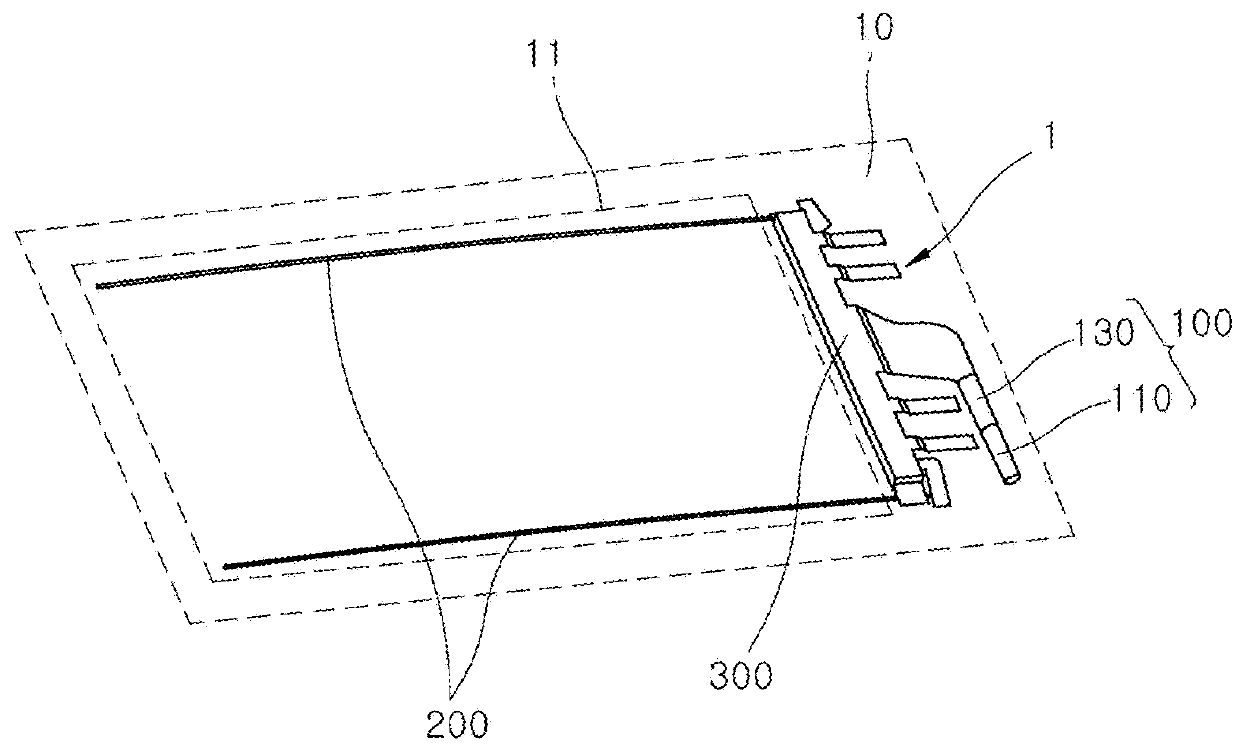

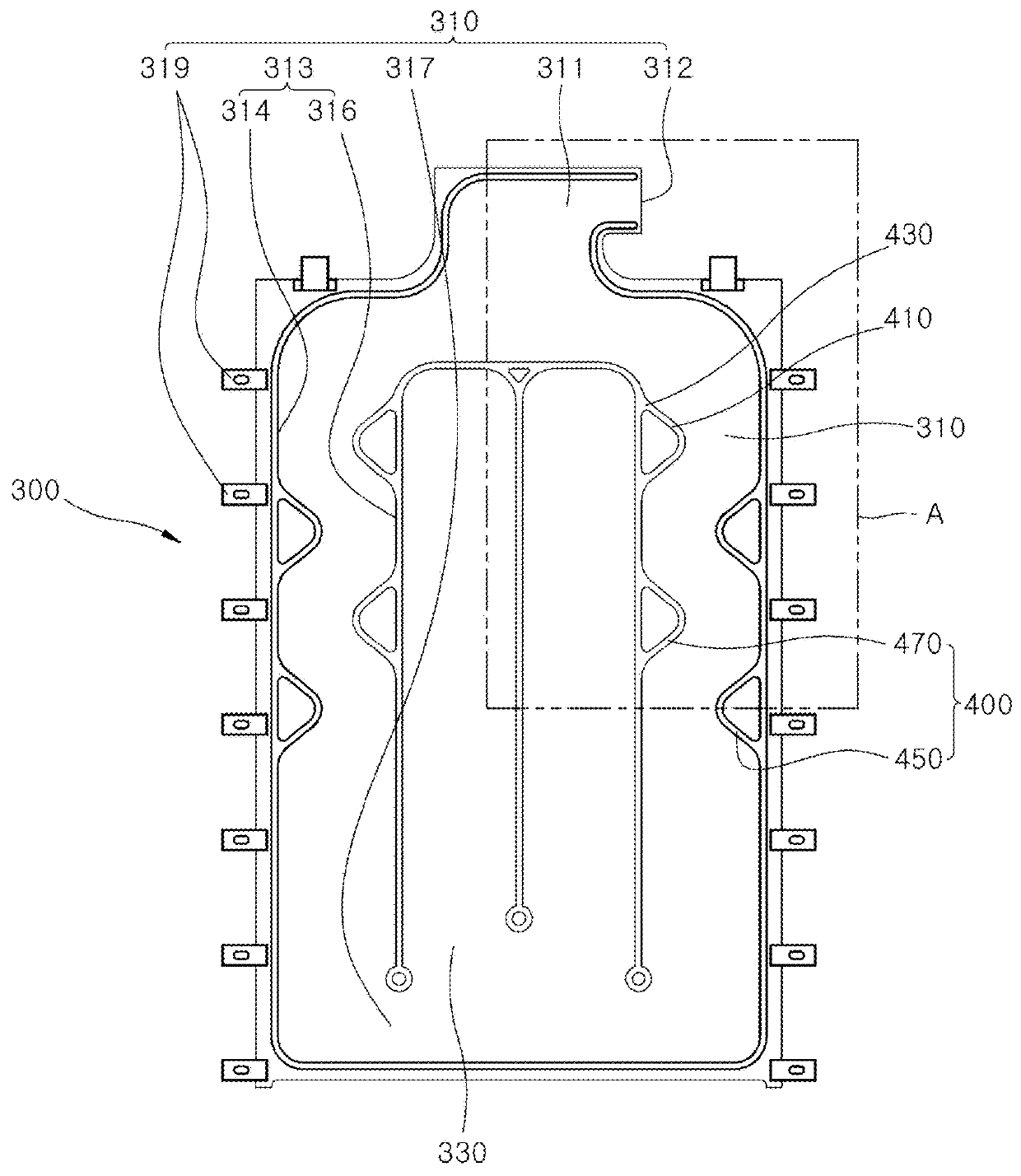

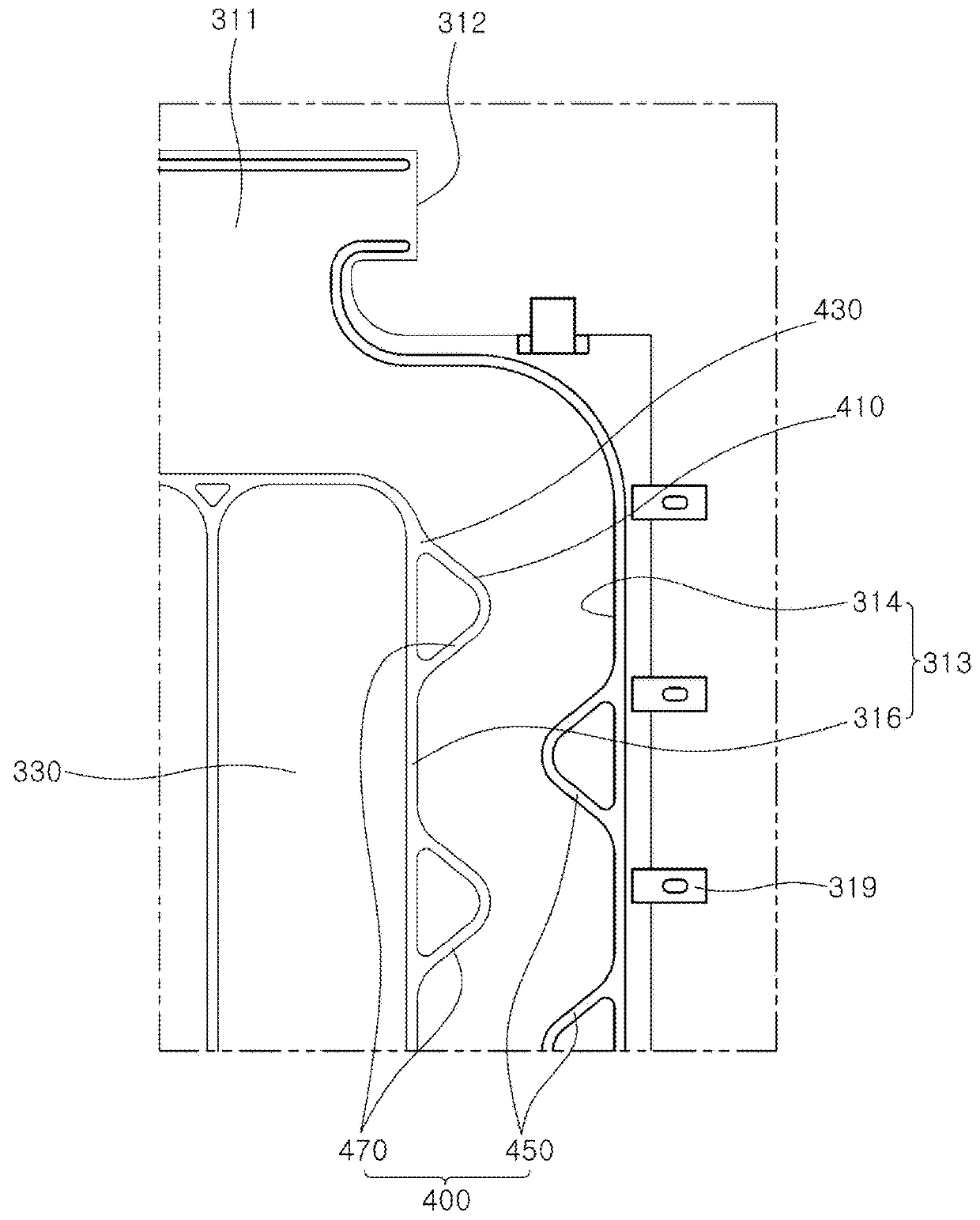

Roof airbag apparatus

ActiveUS20180162313A1Avoid injuryAvoid separationPedestrian/occupant safety arrangementGas syringeEngineering

A roof airbag apparatus may include: a gas injector configured to inject gas; a tether guide disposed along the longitudinal direction of a roof; a chamber part connected to the tether guide, and deployed by gas received from the gas injector; and a chamber moving part installed in the chamber part, and moving the chamber part while being pressed by the gas transferred to the chamber part.

Owner:HYUNDAI MOBIS CO LTD

Method and apparatus for processing substrate edges

InactiveUS8658937B2Eliminate needEfficient removalDecorative surface effectsPhotomechanical apparatusGas syringeSolvent

Owner:UVTECH SYST

Gas injector and apparatus including the same

ActiveUS7846292B2Reduce manufacturing costShorten the production cycleElectric discharge tubesSemiconductor/solid-state device manufacturingGas syringePetroleum engineering

Owner:JUSUNG ENG

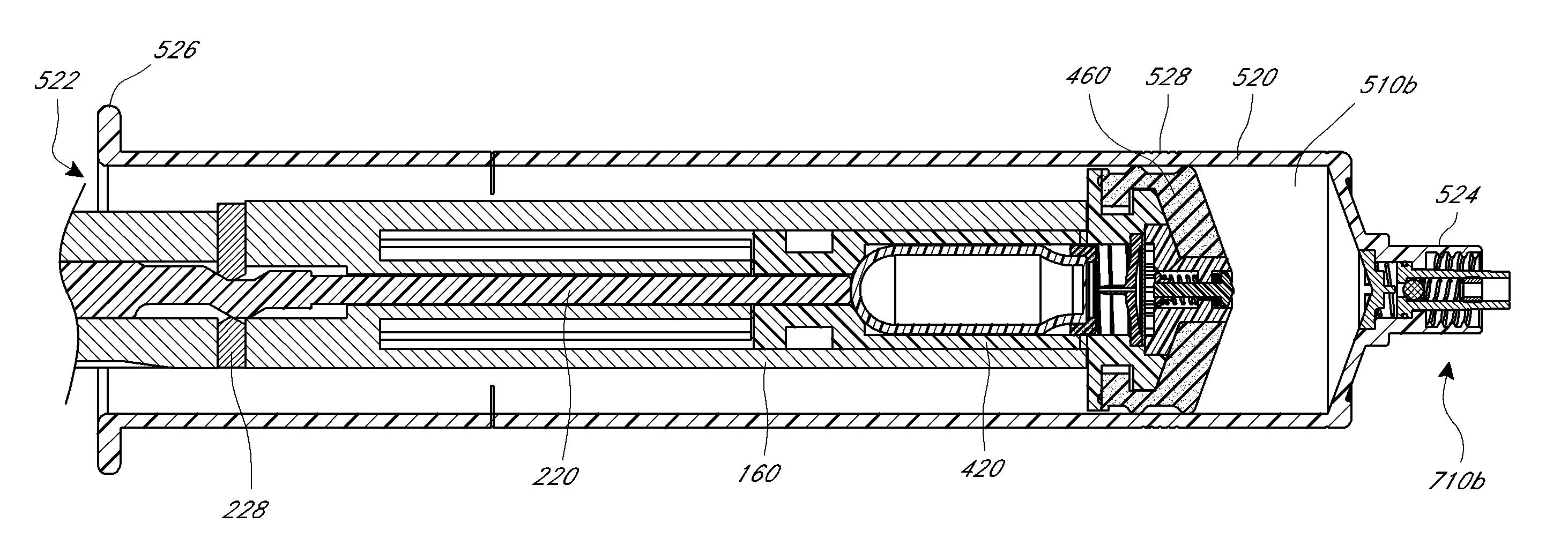

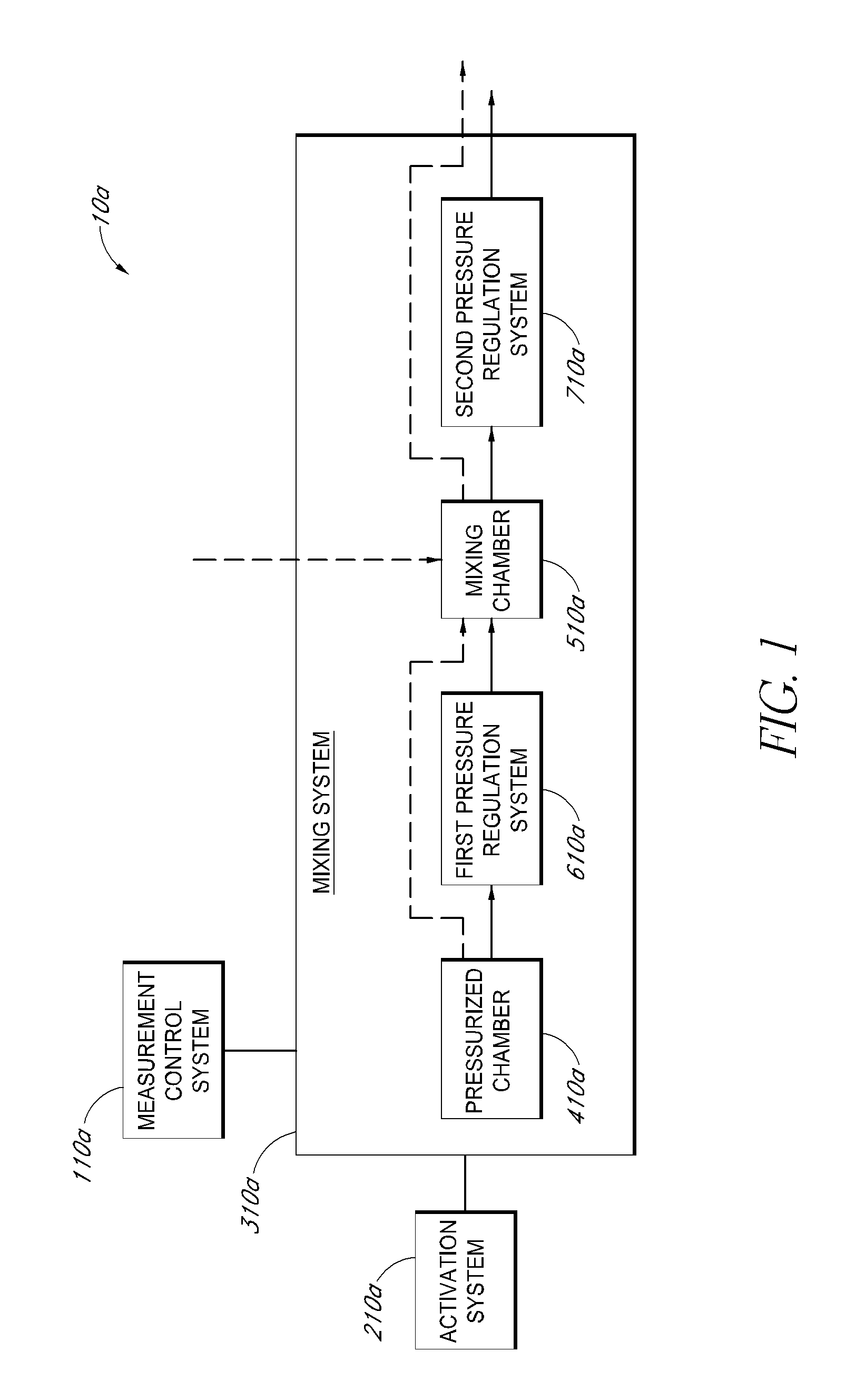

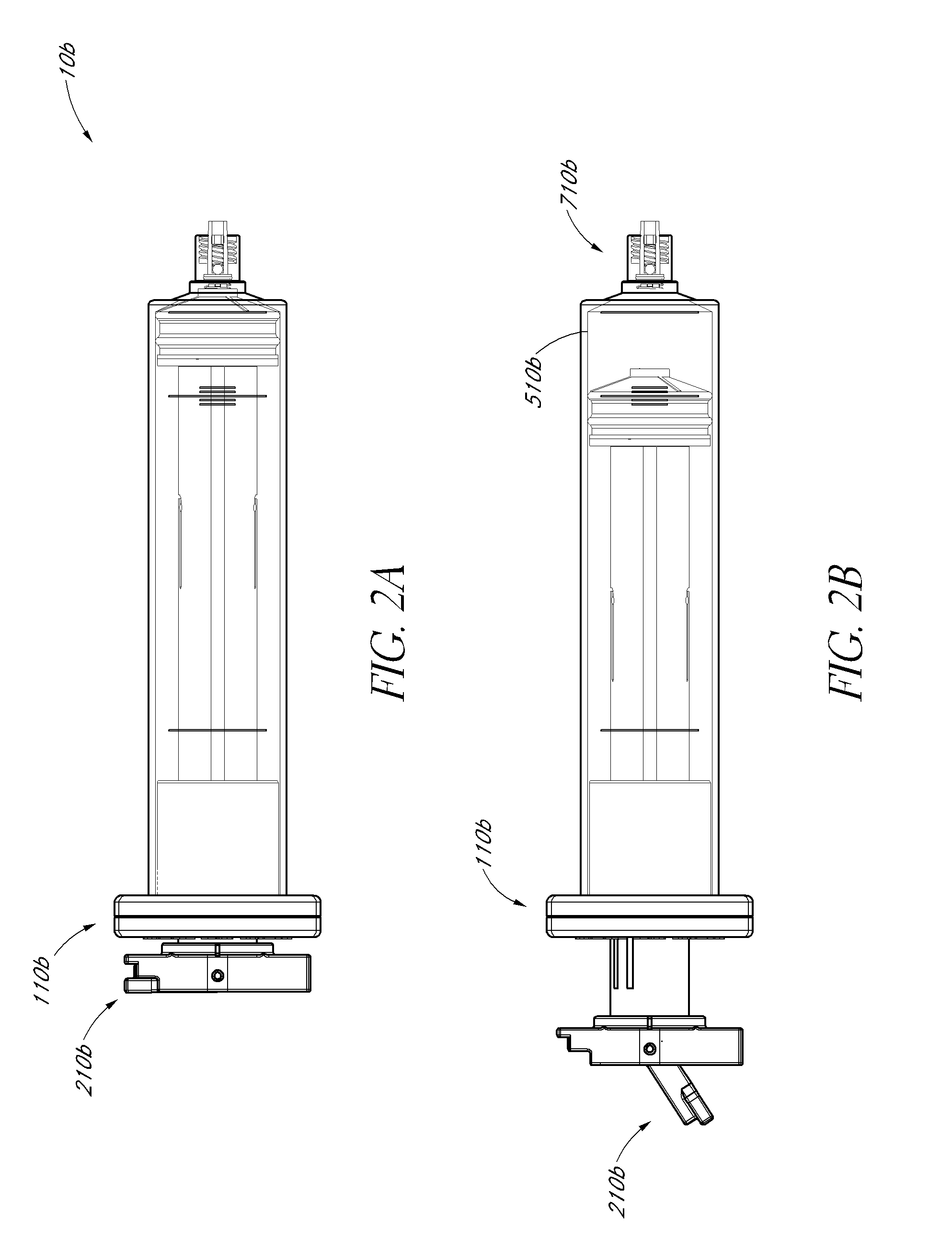

Intraocular gas injector

ActiveUS8986242B2Extension of timeReduce the possibilityEye surgeryInfusion syringesControl systemGas syringe

A gas mixture apparatus includes a measurement control system, an activation system, a pressurized chamber with one or more gases, and a mixing chamber. The apparatus can also include additional pressure regulation control systems. The gas mixture apparatus can be used to introduce and automatically perform the steps to achieve a desired concentration of the one or more gases contained in the pressurized chamber. The gas mixture apparatus can include the pressurized chamber within the apparatus itself such that no external devices are necessary for introducing the one or more gases into the mixing chamber.

Owner:ALCON INC

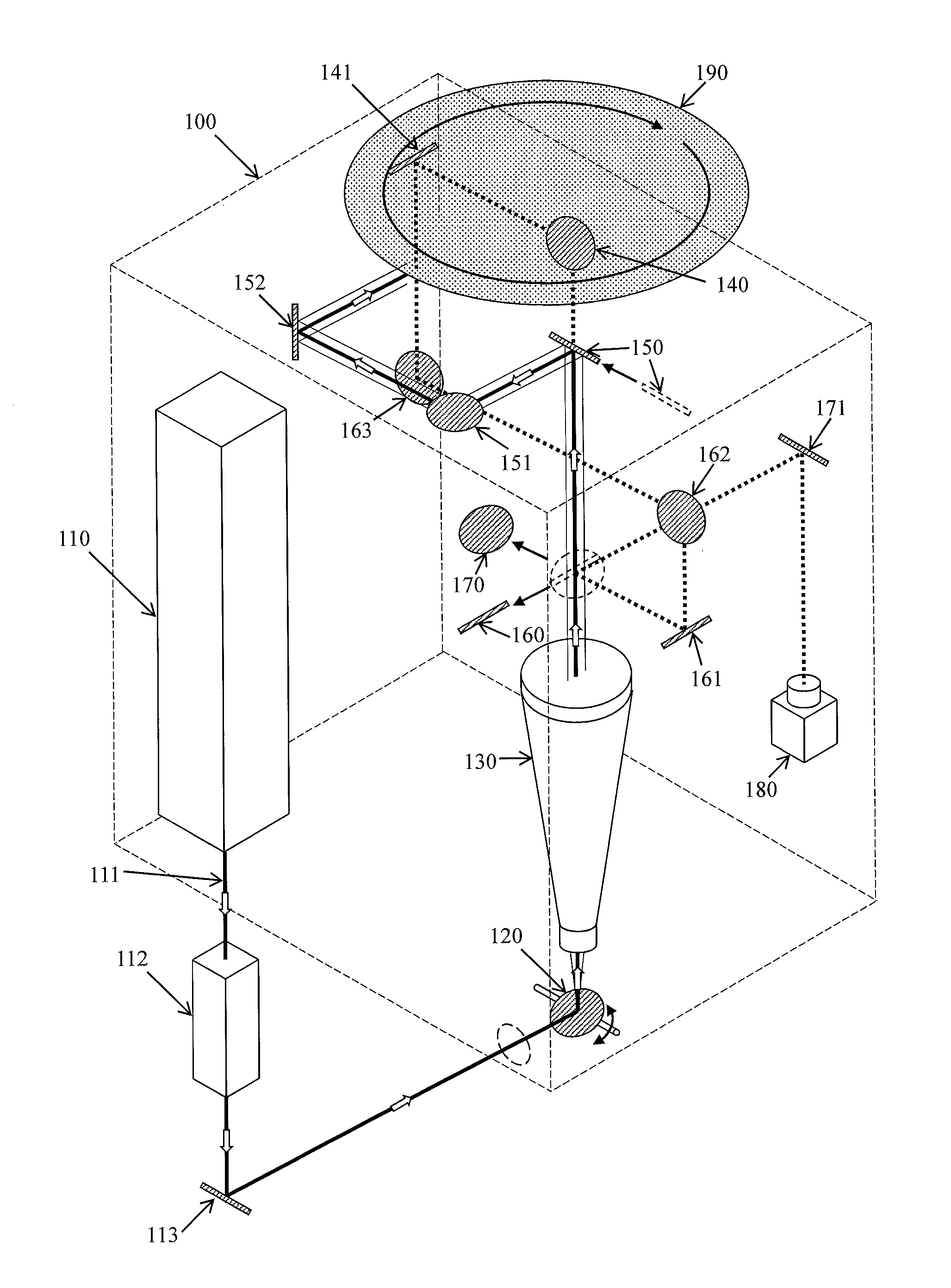

High-resolution optical channel for non-destructive navigation and processing of integrated circuits

InactiveUS7351966B1Convenient to accommodateEasy to installMaterial analysis using wave/particle radiationElectric discharge tubesImage transferGas syringe

An optical-fiber based light channel system is included in an ion / electron beam tool for imaging and / or processing integrated circuits. The optical channel system includes an image collection portion, an optical fiber image transmission portion and a detector portion. The image collection portion includes micro-optical components and has submillimeter dimensions, so that it is easily accommodated within the working distance of the ion / electron beam tool. The entire system is sufficiently compact and lightweight so that it may easily be mounted on a translation stage inside the sample chamber, which permits the optical channel to be mechanically extended and retracted to avoid blocking the primary ion or electron beam. The system may be mounted to a translation stage or to a gas injector assembly, which may itself be mounted to a flange plate on the chamber wall with feed-through ports for electrical and optical signals.

Owner:GLOBALFOUNDRIES INC

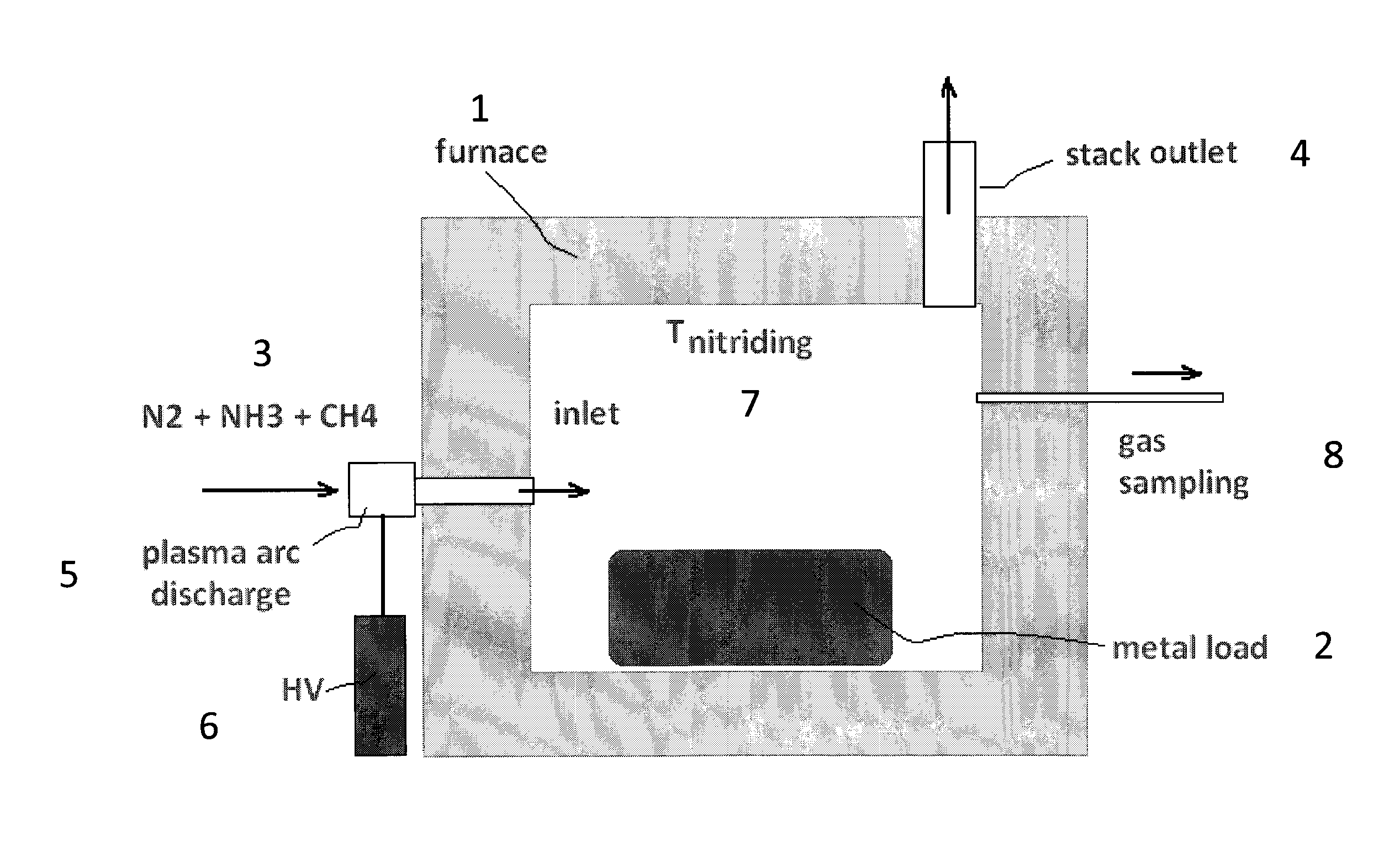

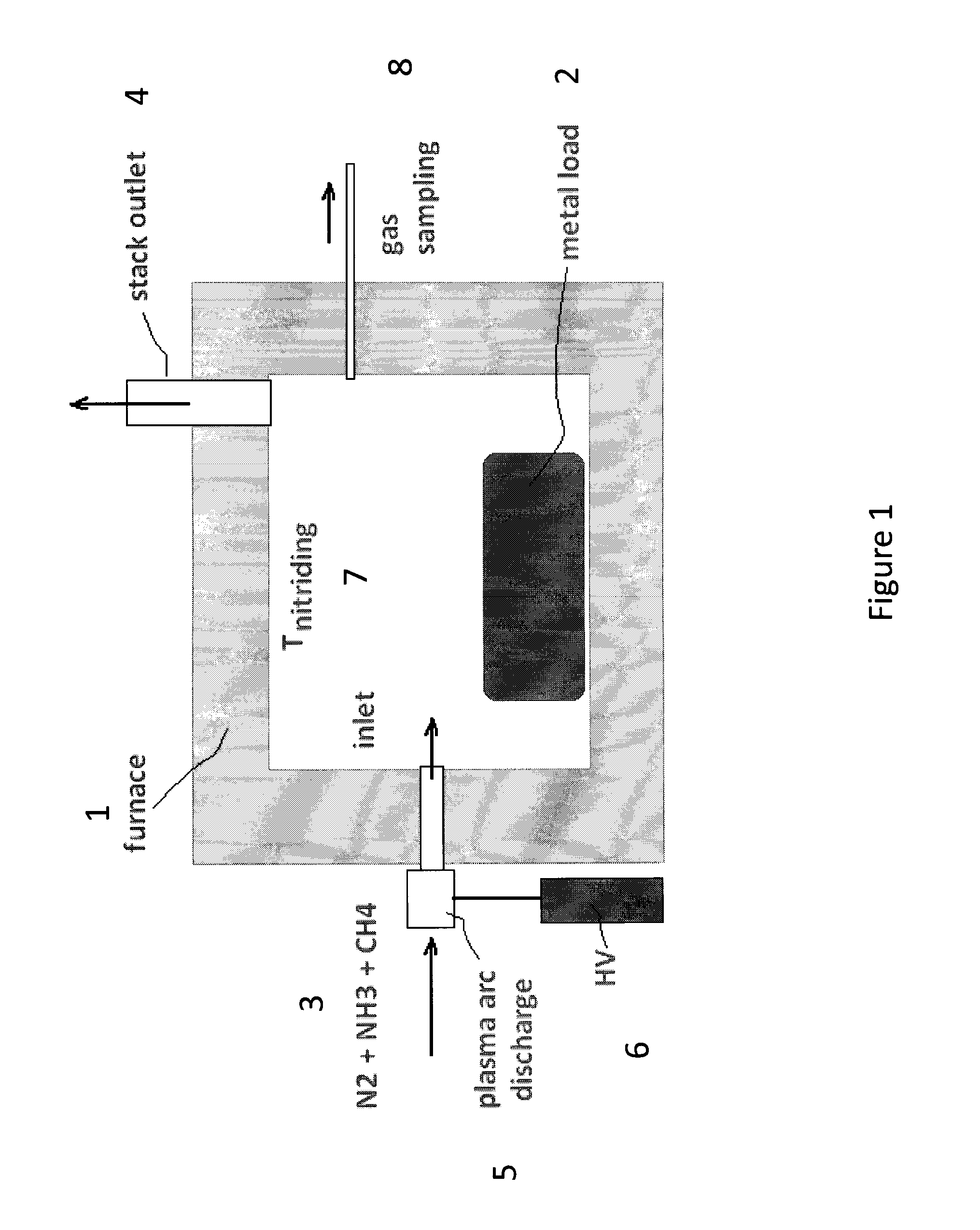

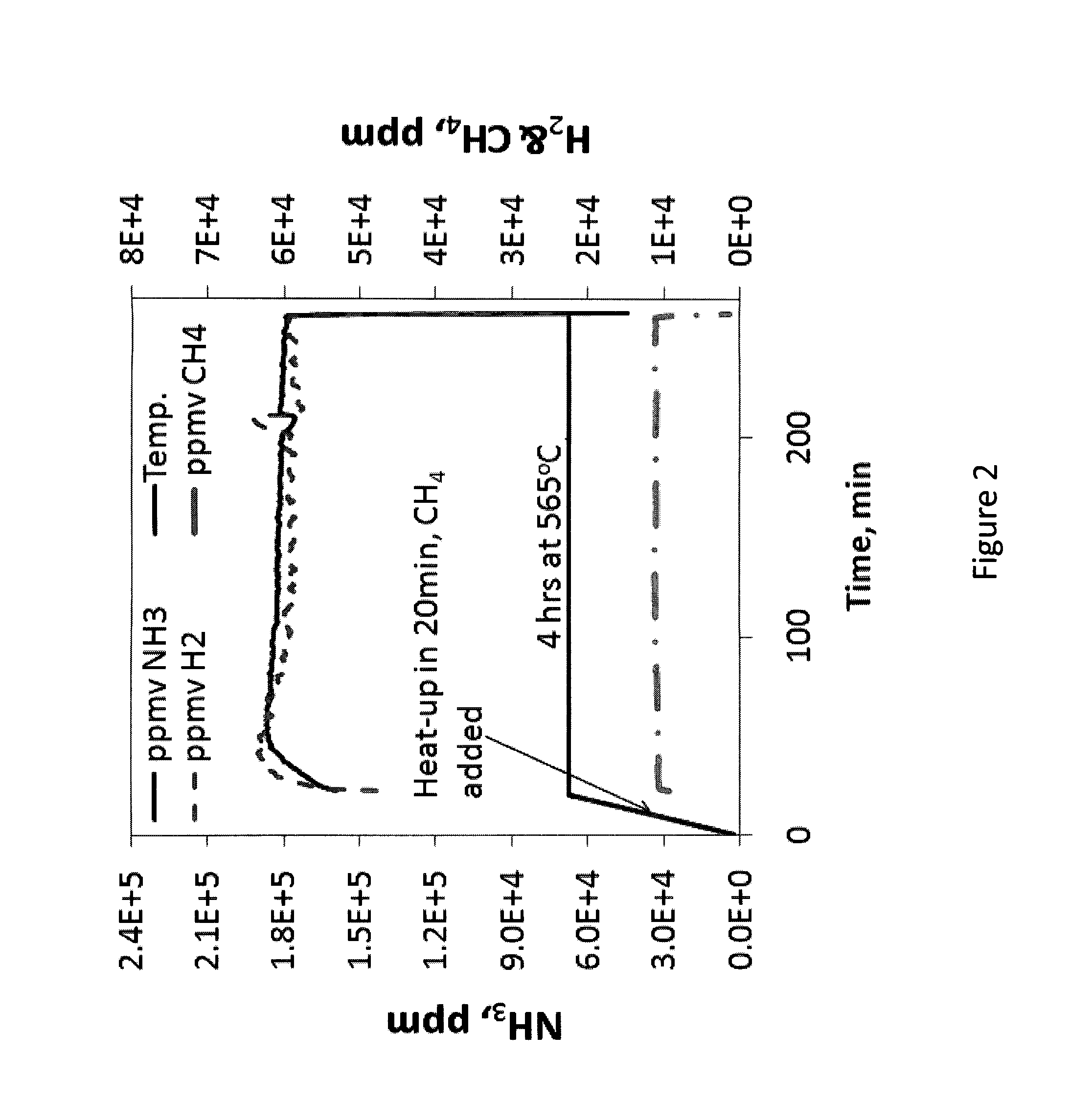

Method and Apparatus for Nitriding Metal Articles

InactiveUS20120118435A1Solid state diffusion coatingChemical vapor deposition coatingGas syringeOxygen

A method and apparatus for nitriding of highly-alloyed metal article is disclosed herein. In one embodiment, the method and apparatus uses at least one nitrogen source gas such as nitrogen and / or ammonia in an oxygen-free nitriding gas atmosphere, with small additions of one or more hydrocarbons. In this or other embodiments, the method and apparatus described herein is applicable to metal articles comprising iron, nickel and cobalt based alloys and which tend to form passive oxide films on at least a portion of their surface, heated to and nitrided at a certain temperature without prior surface preparation. The apparatus includes an external gas injector comprising 50-60 Hz AC, high voltage / low-current arc discharge electrodes, activating the nitriding atmosphere stream on its way from source to nitriding furnace.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com