Intraocular gas injector

a gas injector and gas technology, applied in the field of intraocular gas injectors, can solve the problems of increasing increasing the risk of errors, and achieving the effect of reducing the likelihood of errors, reducing the time necessary to fill the syringe, and simplifying the procedur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

of Pressurized Chamber

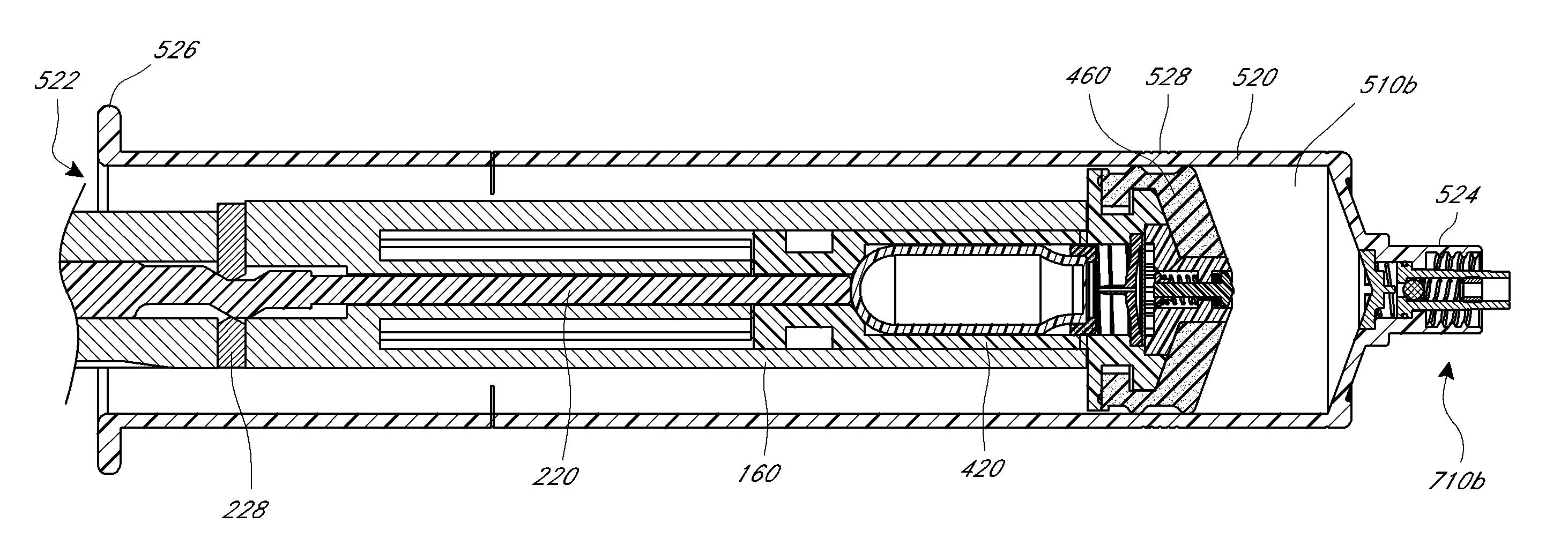

[0145]With reference to FIG. 24, an embodiment of a pressurized chamber is shown along with components of an activation system. As illustrated, the pressurized chamber can have a two-part housing with a first housing member 1020 and a second housing member 1022 which are translatable with respect to each other. As shown in the illustrated embodiment, the two members 1020, 1022 can have a generally cylindrical shape such that some or all portions of the two members 1020, 1022 can be received within a channel 868 of the plunger body 860. In some embodiments, the two members 1020, 1022 can be detached from one another to allow free translation of the two members 1020, 1022. In other embodiments, the two-part housing can be attached while still allowing translation of the members 1020, 1022 with respect to each other. Such attachment can be used to increase the stability of the two members 1020, 1022.

[0146]As shown in the illustrated embodiment and similar to other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total volume | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com