Patents

Literature

104results about How to "Increase thermal power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

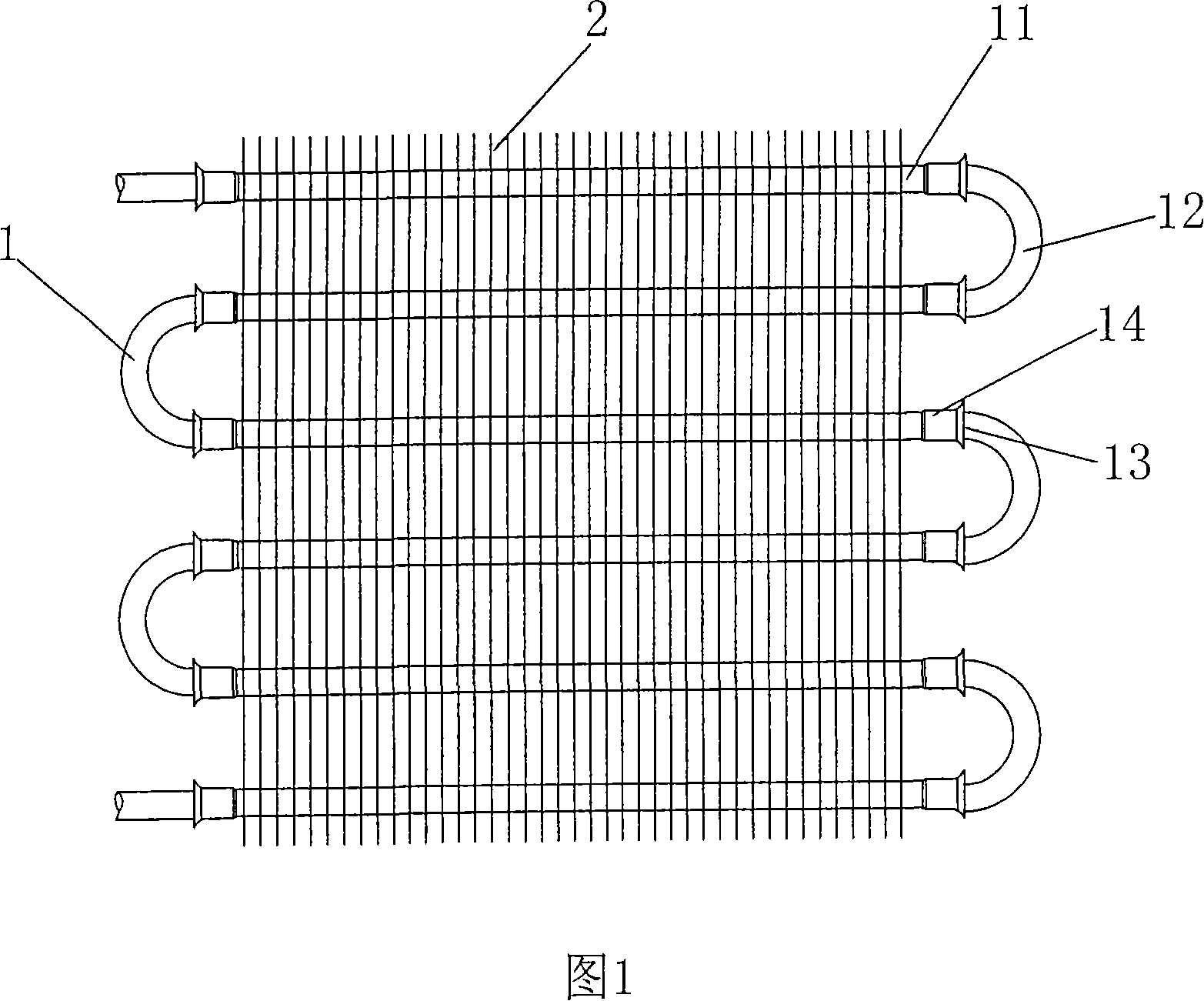

Fin type non-corrosive steel alloy foil tube heat-exchanger and its manufacture method

ActiveCN101149237AHigh strengthIncrease thermal powerSoldering apparatusTubular elementsEvaporatorHeating power

This invention is a fin type stainless steel alloy foil pipe heat transferring machine and its production method. The heat transferring machine is composed of densely distributed radiating alloy material or non-ferrous metal fin and stainless steel alloy foil coil. The thickness of the pipe wall is 0.1mm-0.3mm. The production method includes: material prepare, bended pipe or straight pipe end making, fin fixation on the straight pipe and welding. This invention has reasonable structure and easy technique. The chlorine anion resistant capability of the said coil is higher than 100ppm and increases more than 50% times than that of the copper materials. The strength increases one time. The ductility is nearly the same as that of the copper materials. The heat power is higher than that of the existing fin type copper pipe heat transferring machine. Its heat superconductivity is suitable for various kinds of condensers and evaporators. This invention can be used on various kinds of air conditioners and refrigerating equipments.

Owner:SHENZHEN ARTWAY PIPING CORP

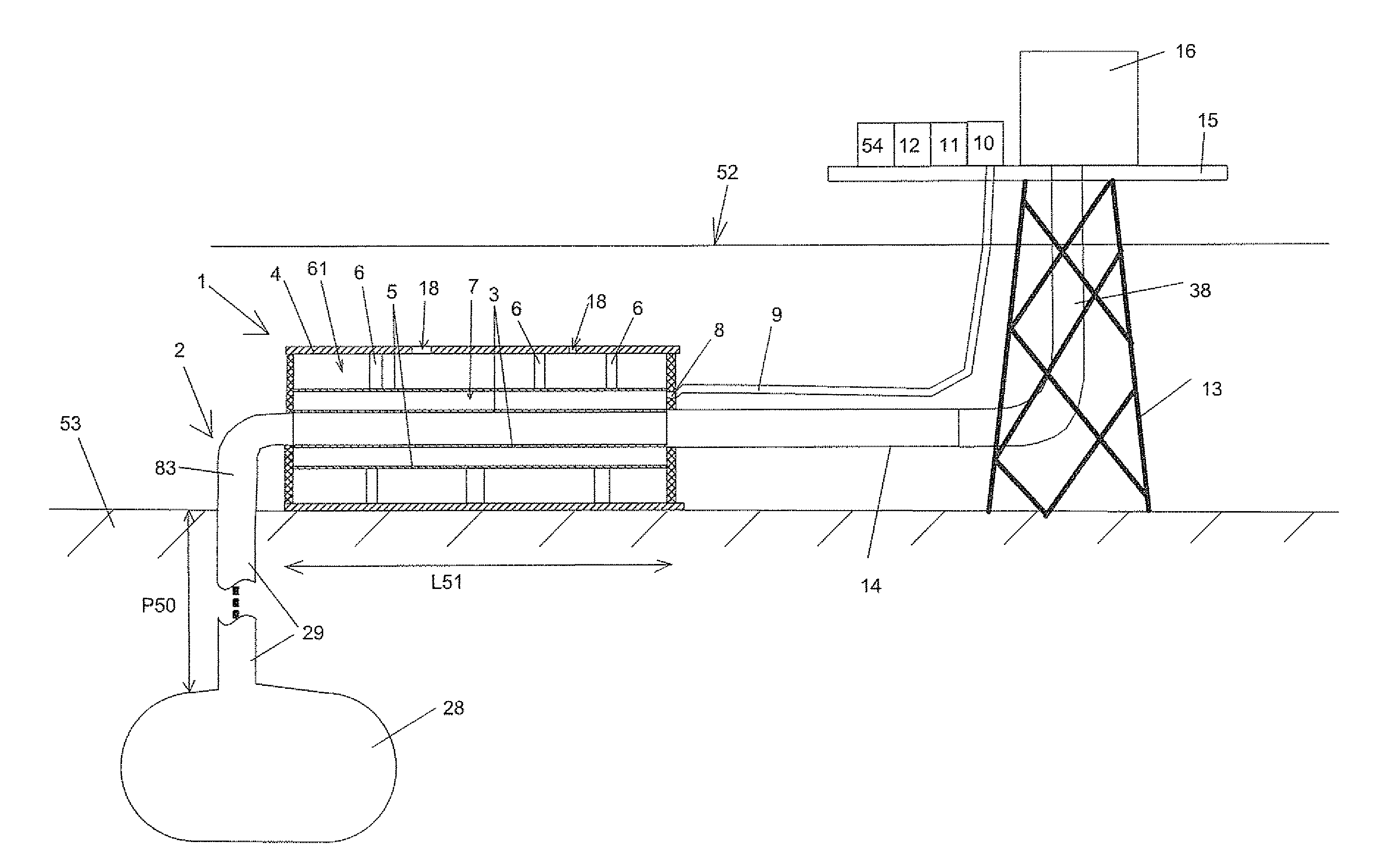

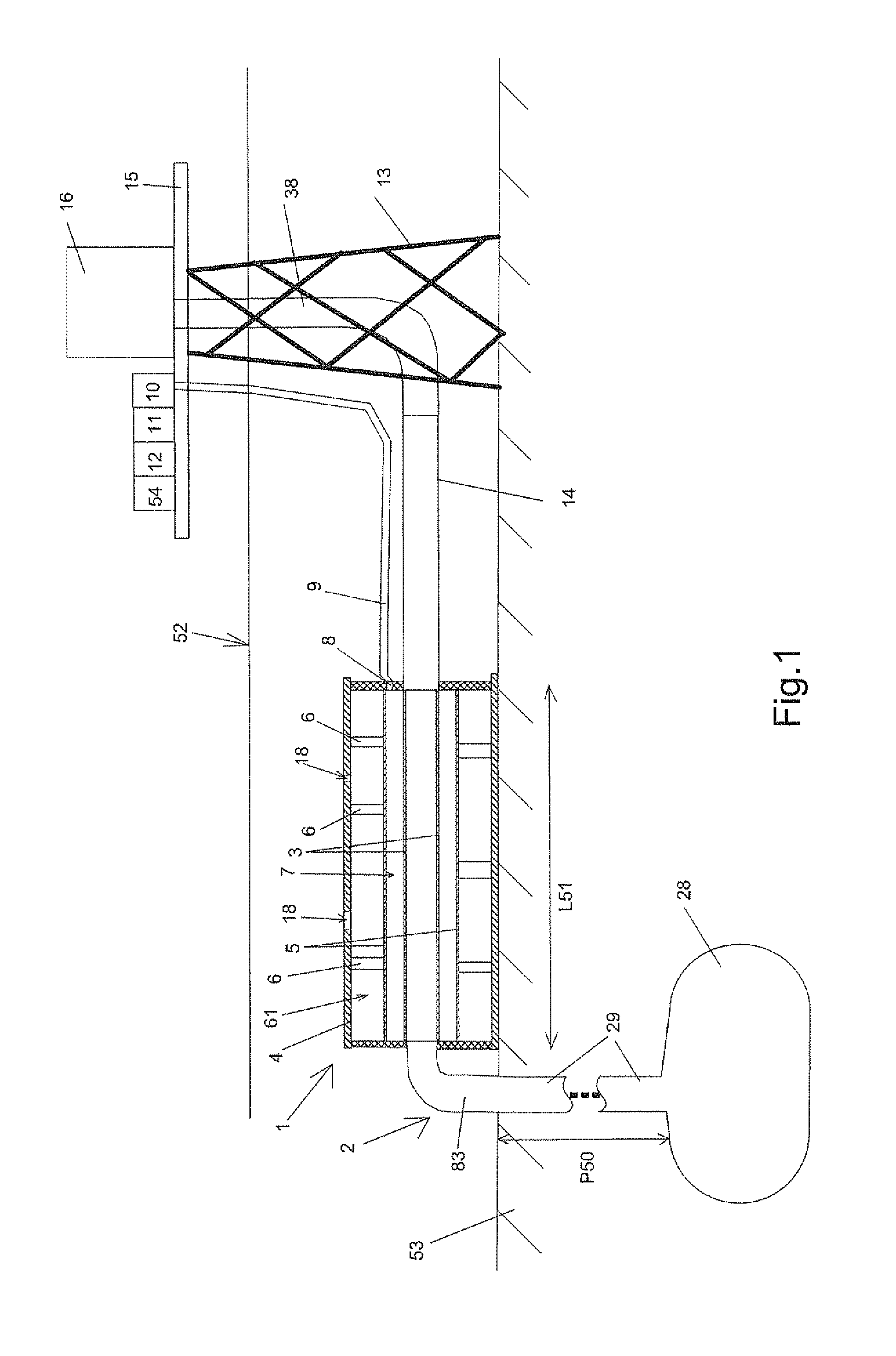

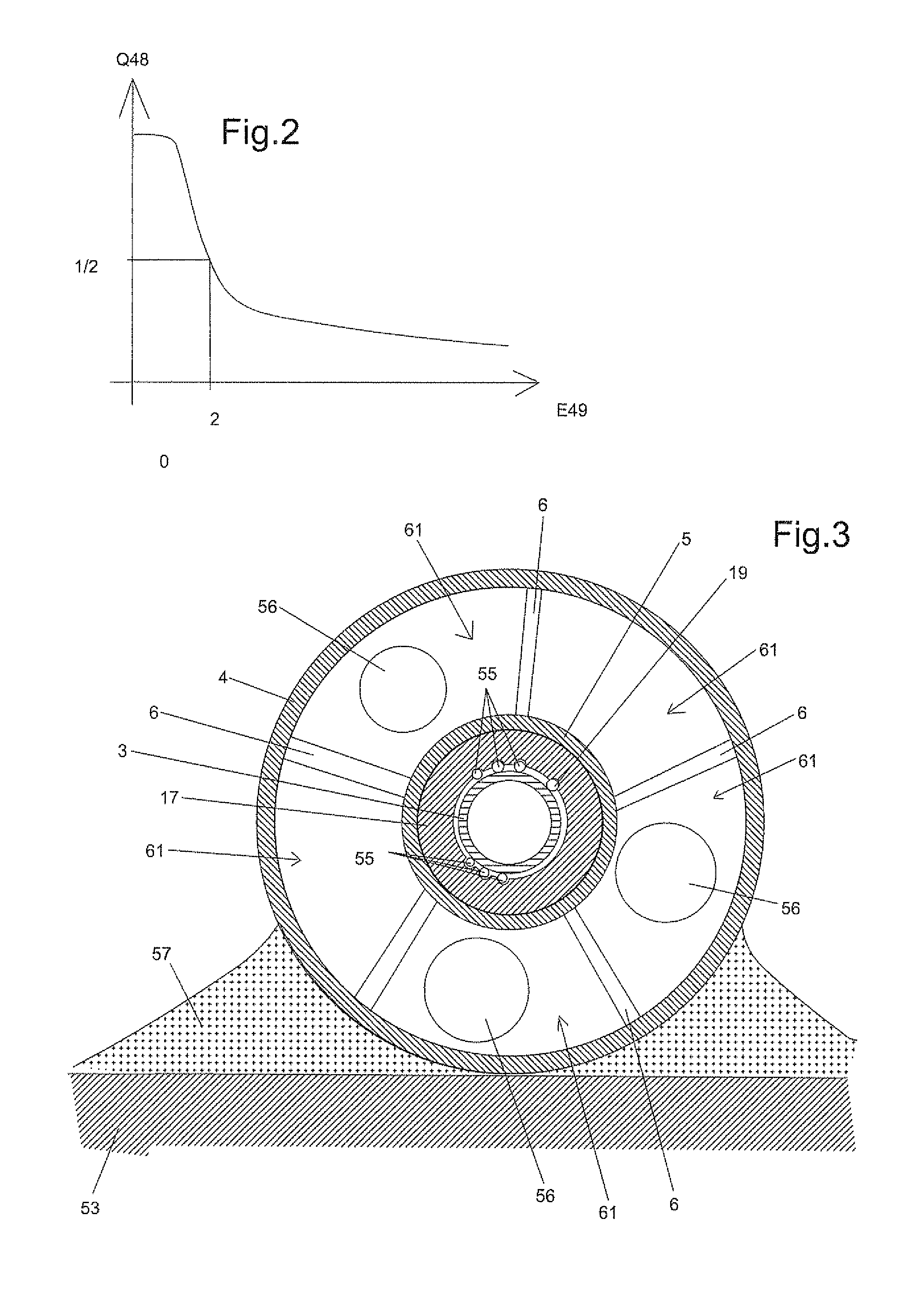

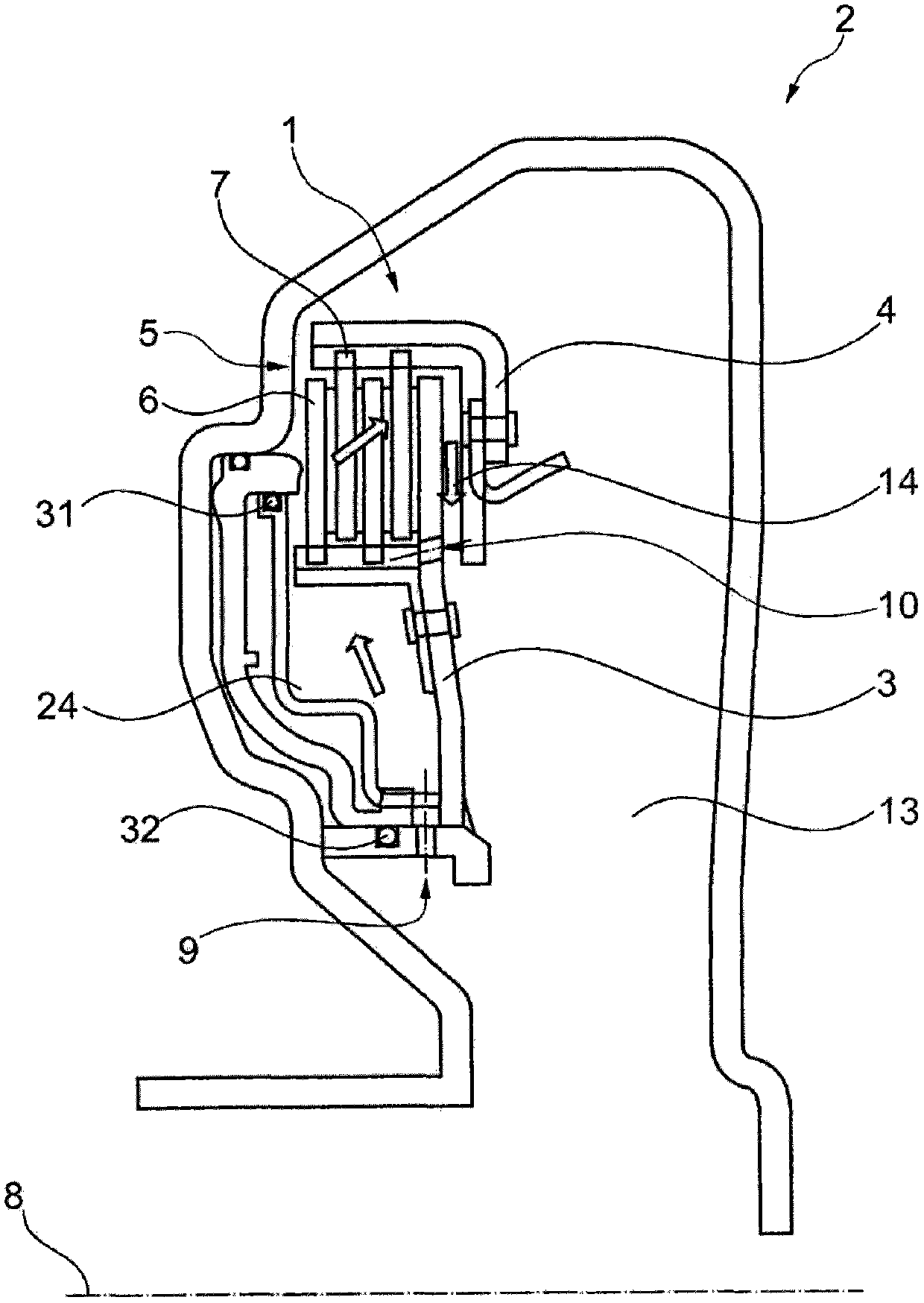

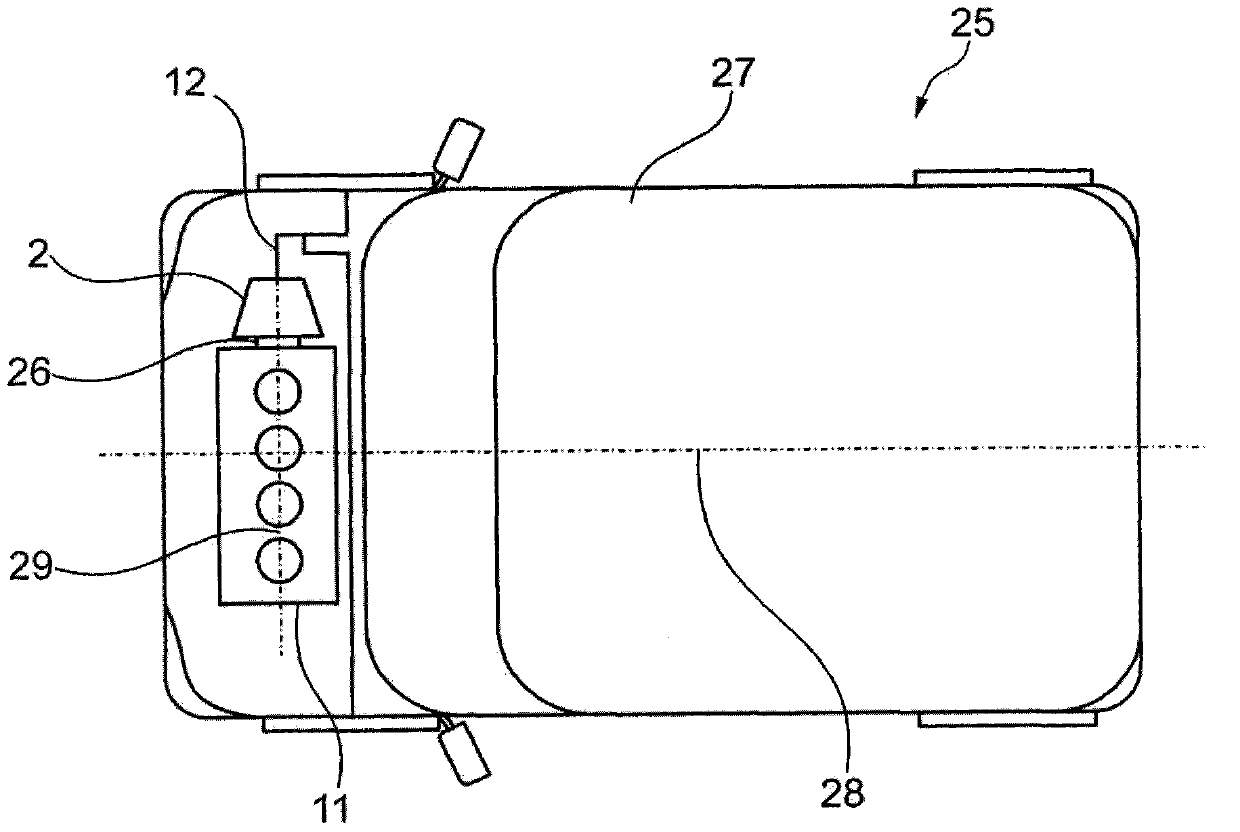

Underwater hydrocarbon transport and temperature control device

ActiveUS20120298216A1Increase thermal powerSimple and robust devicePipe supportsValve members for heating/coolingTemperature controlLiquid medium

The invention relates to a hydrocarbon transport device intended to be immersed and arranged at an extraction wellhead, comprising a first pipe through which a first fluid leaving the extraction well flows, the first pipe being arranged in an external protective casing, a piloting system to pilot the temperature in the first pipe controlling an activation element of a regulating system for regulating a heat exchange between the first pipe and the liquid medium filling the immersed external casing, the regulating system comprising at least a second pipe arranged around the first pipe and delimiting an annular space enclosing at least one regulating fluid, this regulating fluid being injected into or expelled from the annular space by the activation element of the regulating system.

Owner:ITP

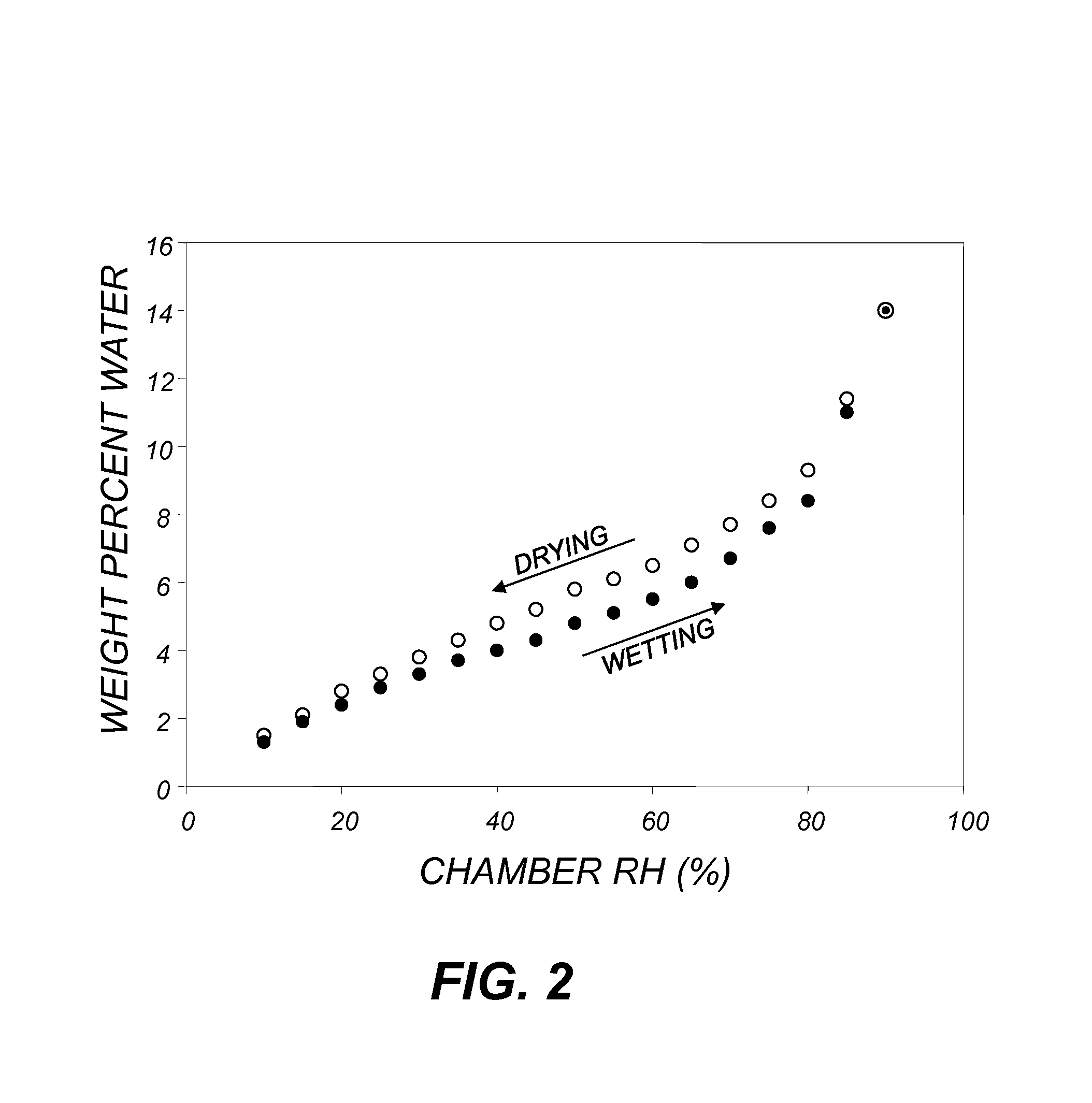

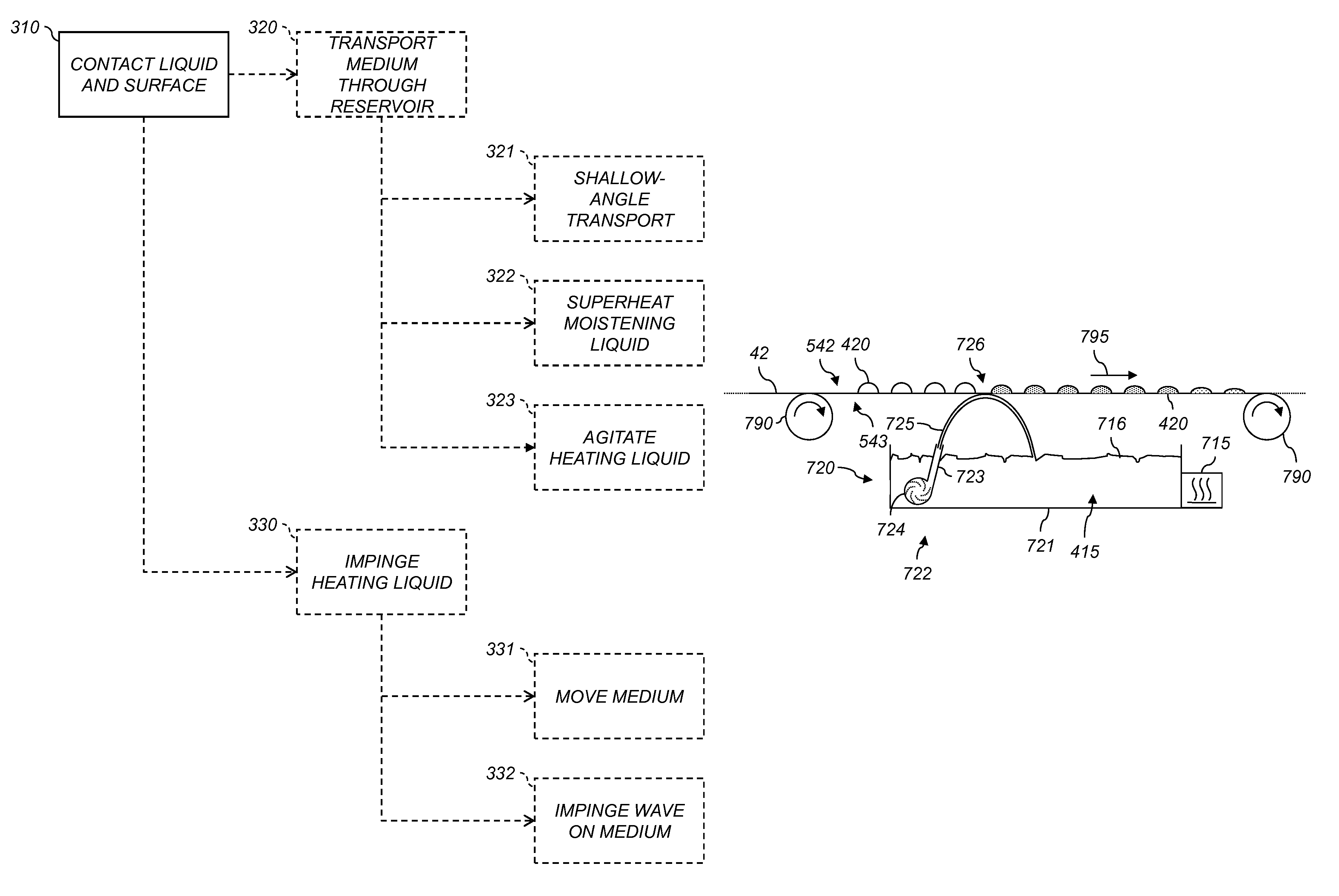

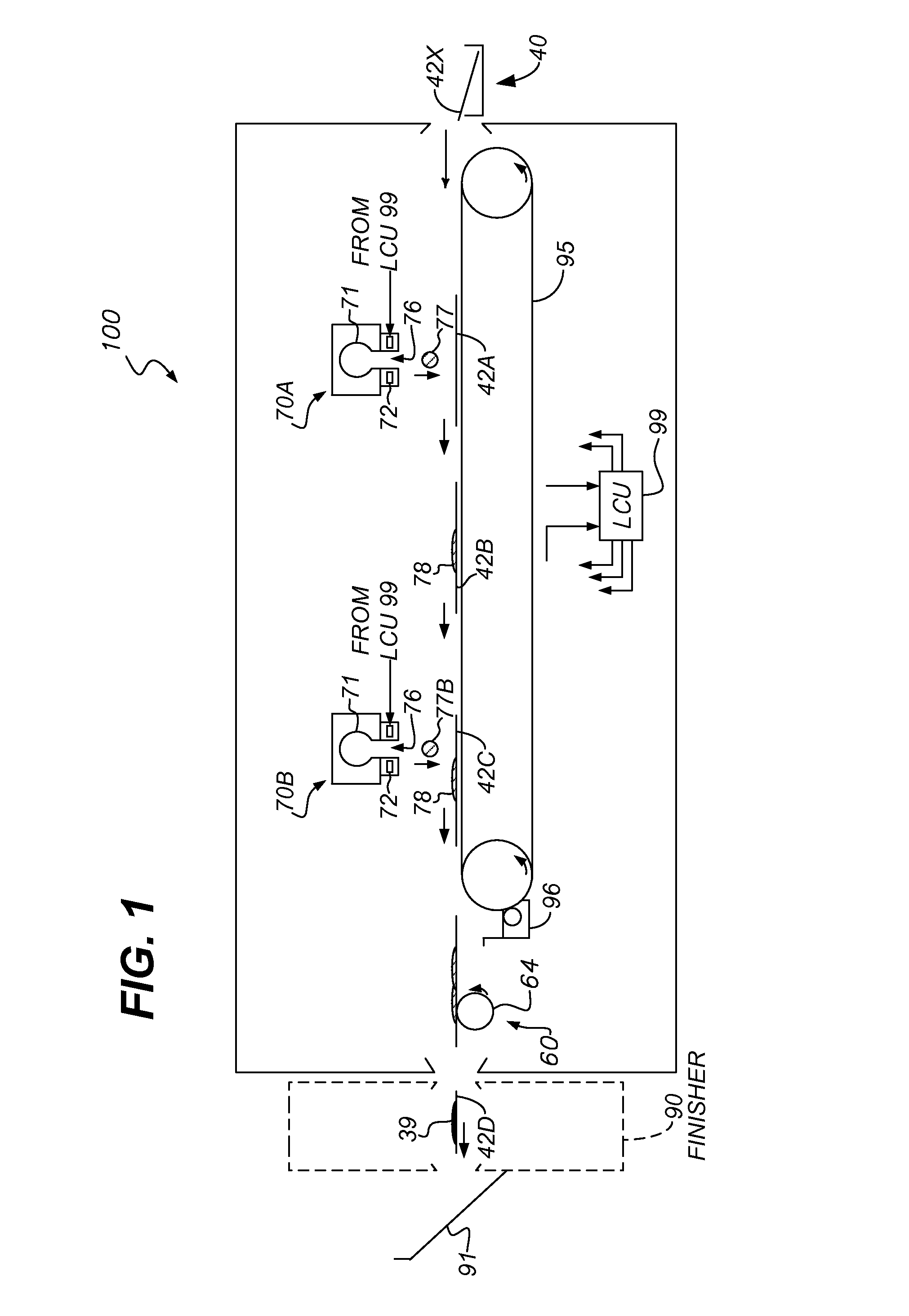

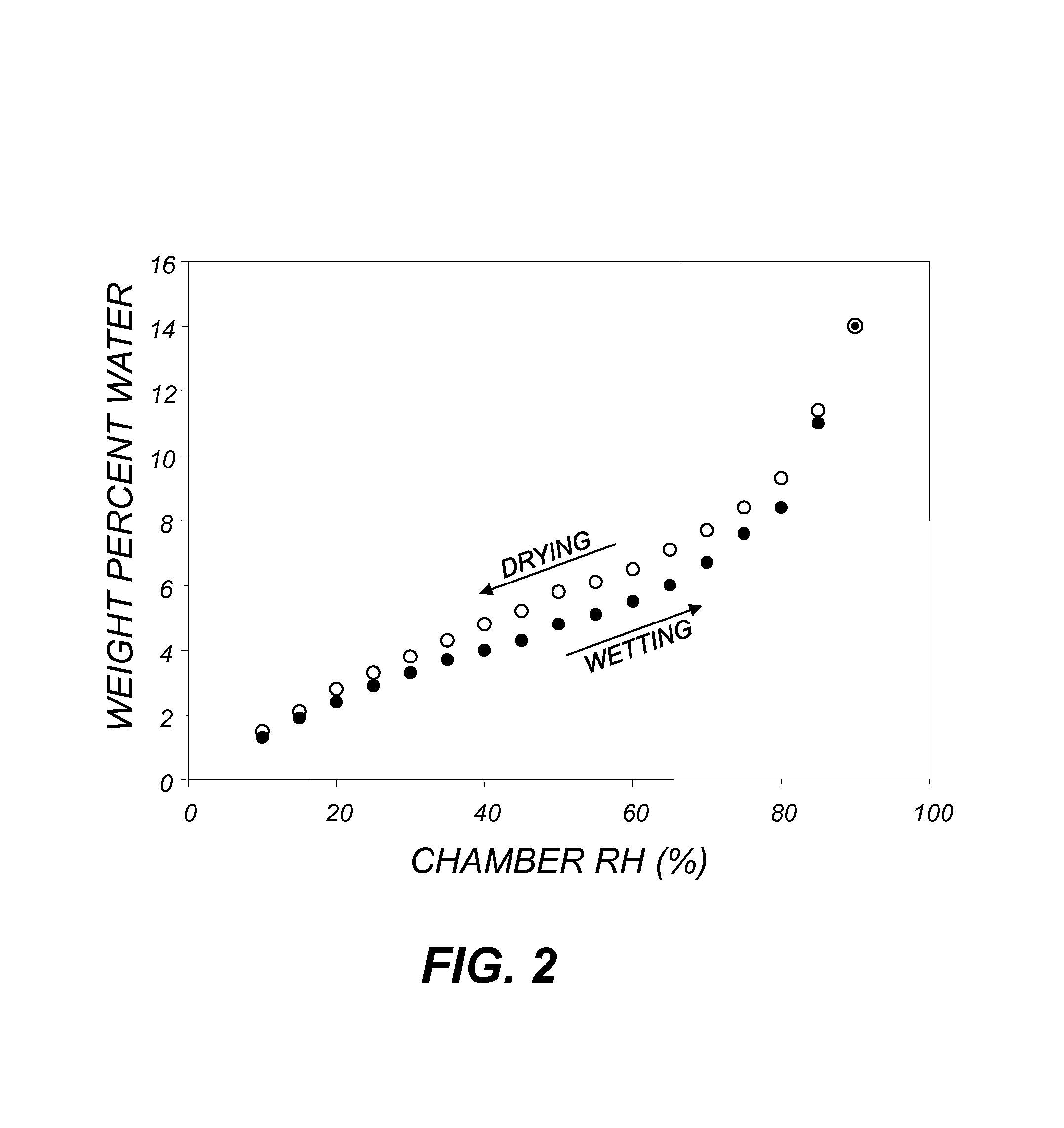

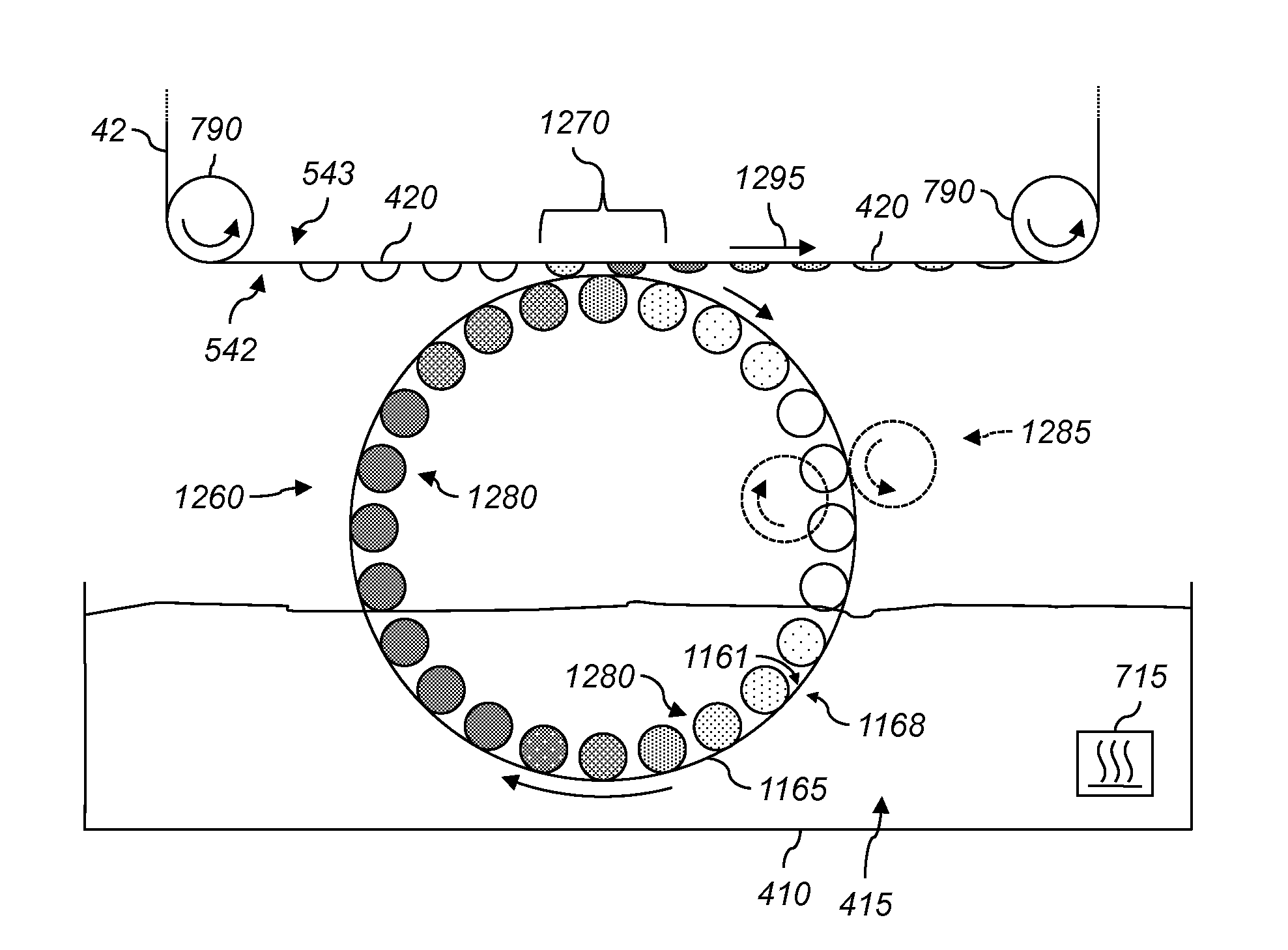

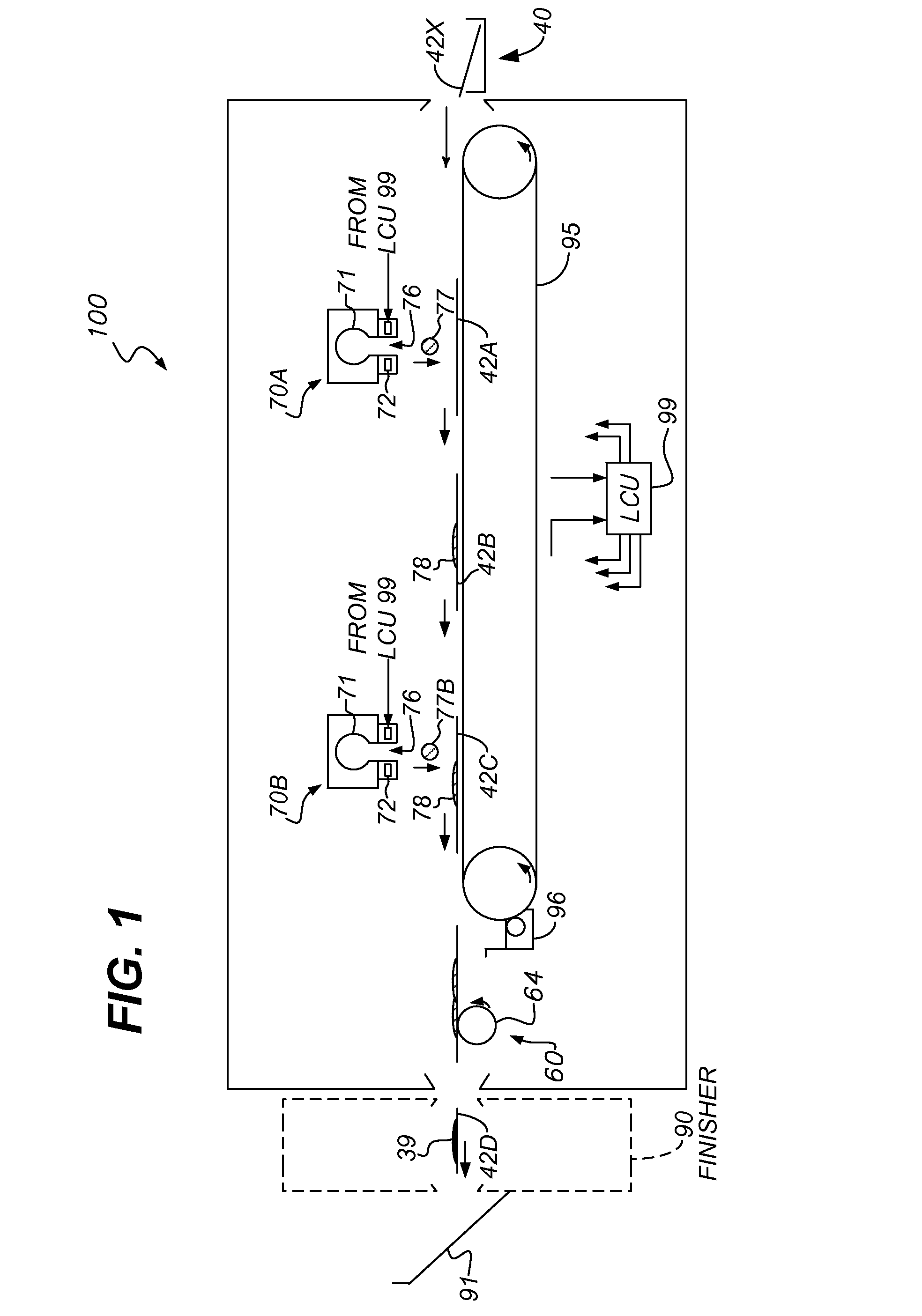

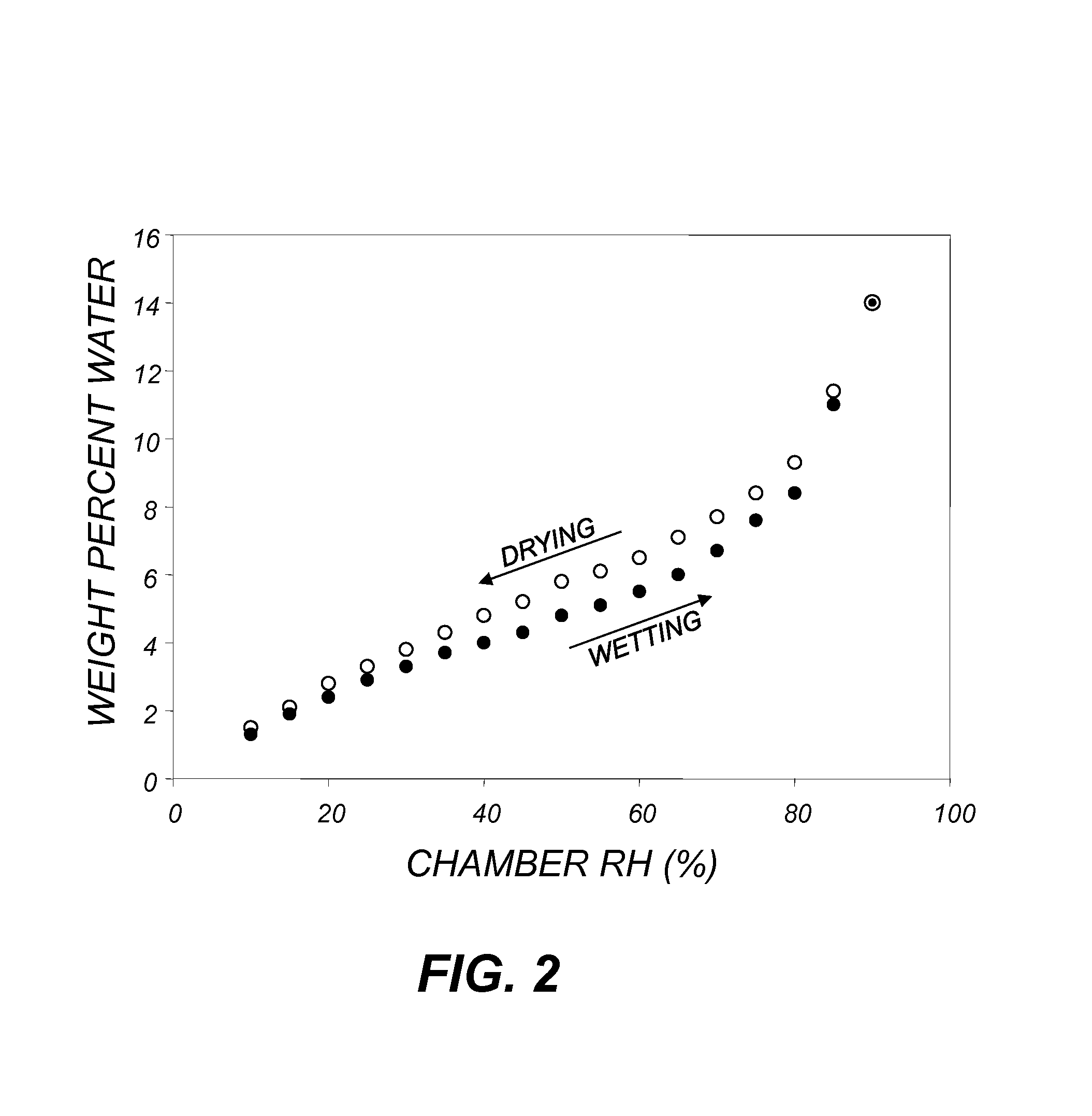

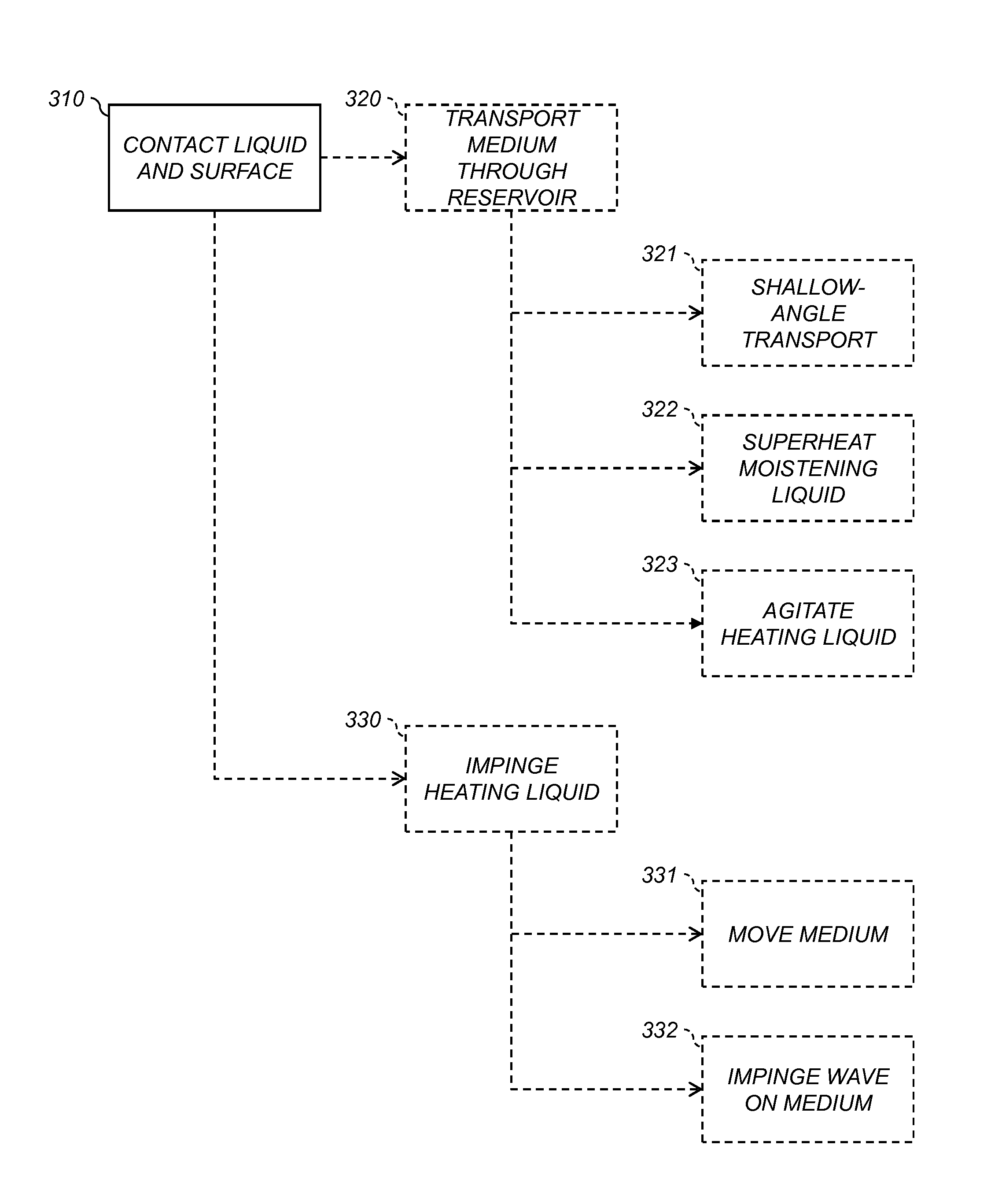

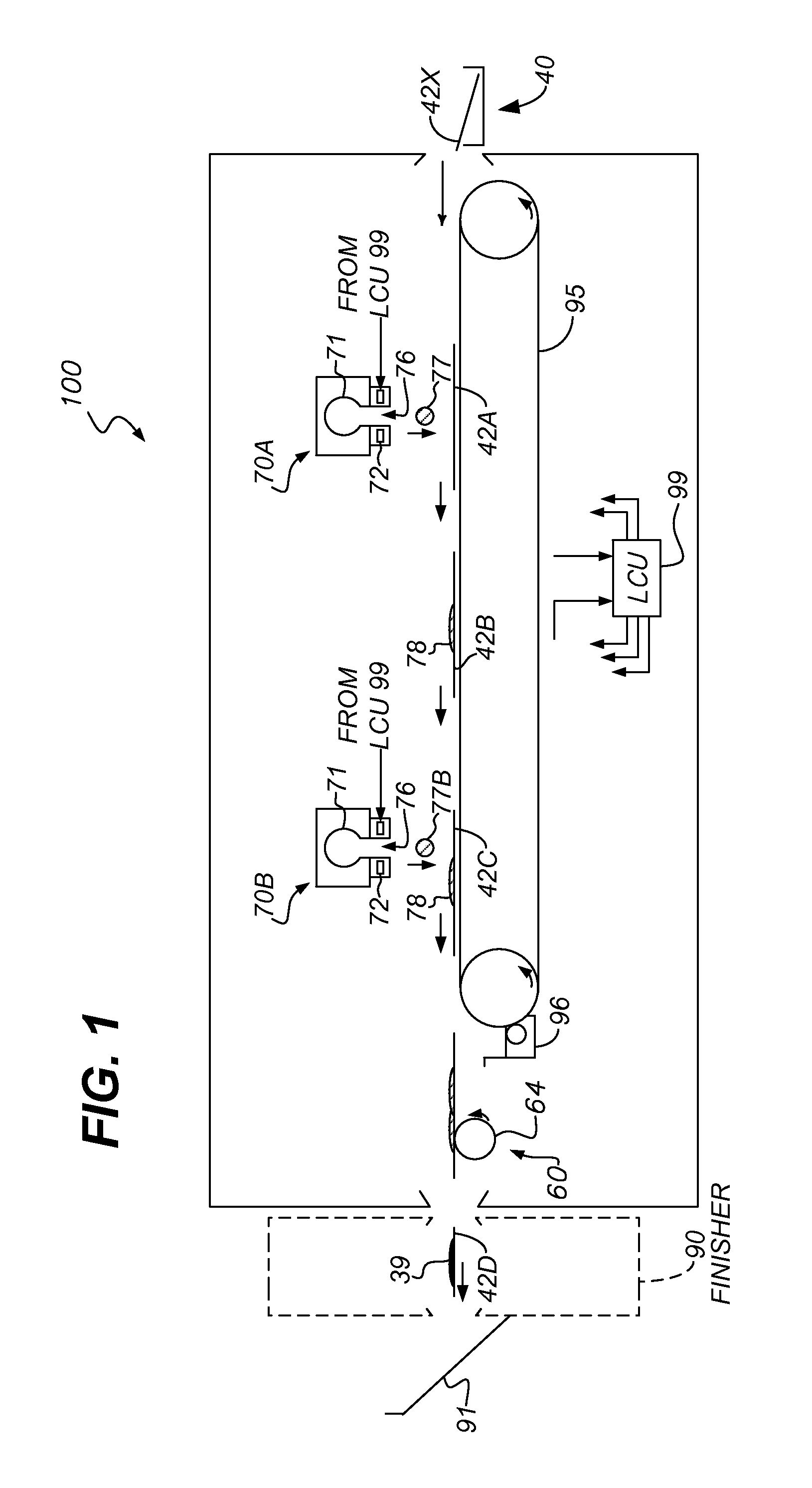

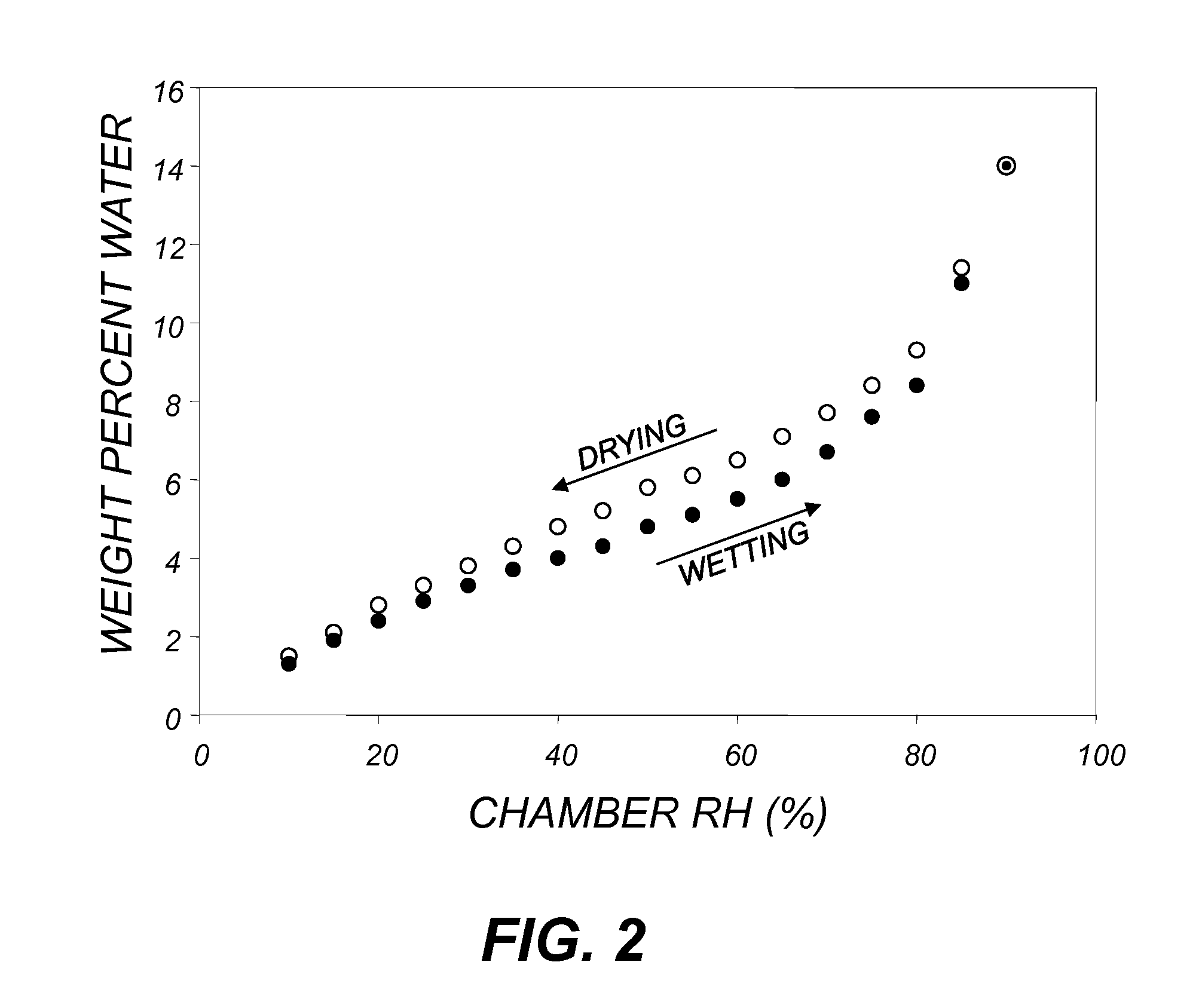

Barrier dryer transporting medium through heating liquid

InactiveUS8826558B2Efficient removalReduce probabilityLiquid surface applicatorsDrying solid materials with heatTransport systemBoiling point

A media drying system removes a moistening liquid from a moistened medium having first and second surfaces. A liquid reservoir contains a heating liquid heated above a moistening-liquid boiling point. A rotatable liquid-blocking member has a liquid-blocking layer with an inner surface and an outer surface. A media-transport system transports the medium entrained around the liquid-blocking member so that the first surface of the moistened medium is brought into contact with the outer surface of the liquid-blocking layer. An entrained portion of the moistened medium passes through the liquid reservoir and is submerged in the warmed heating liquid. The heating liquid contacts the inner surface of the liquid-blocking layer so that heat is transferred through the liquid-blocking layer from the warmed heating liquid to the moistening liquid, or heat is transferred from the warmed heating liquid to the second surface of the moistened medium.

Owner:EASTMAN KODAK CO

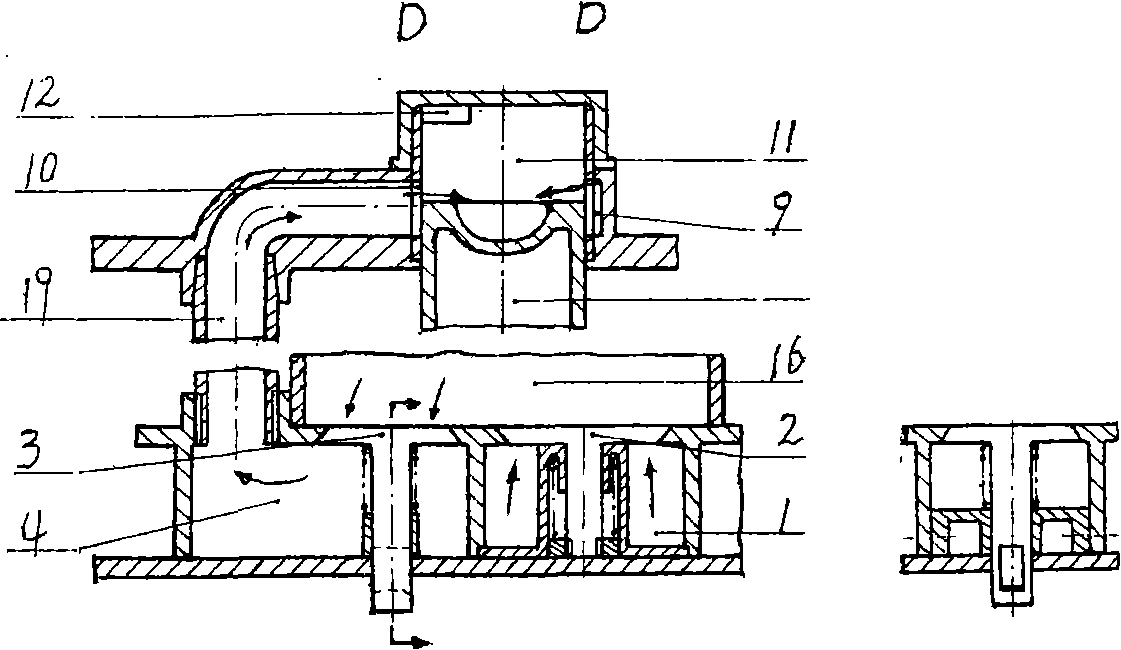

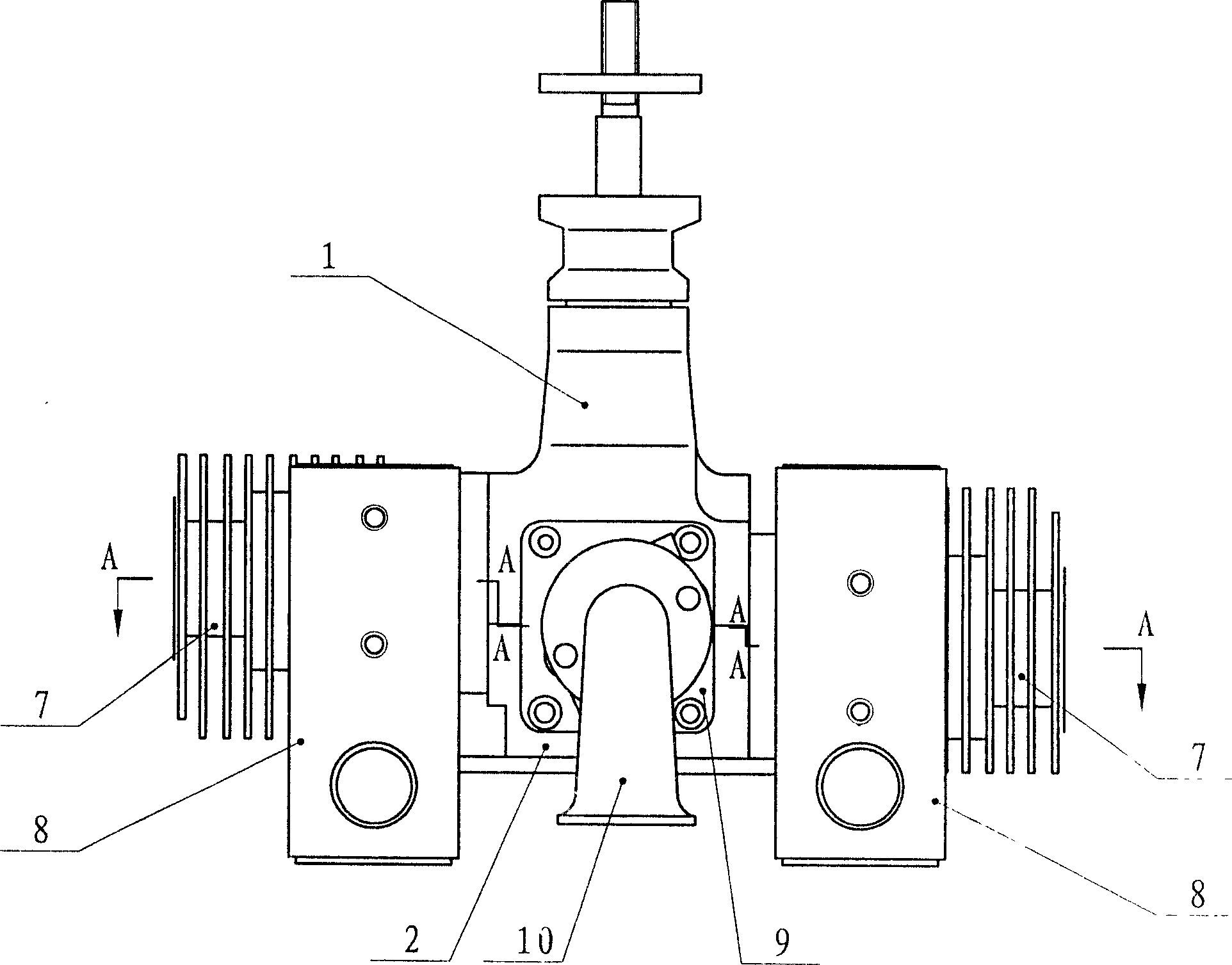

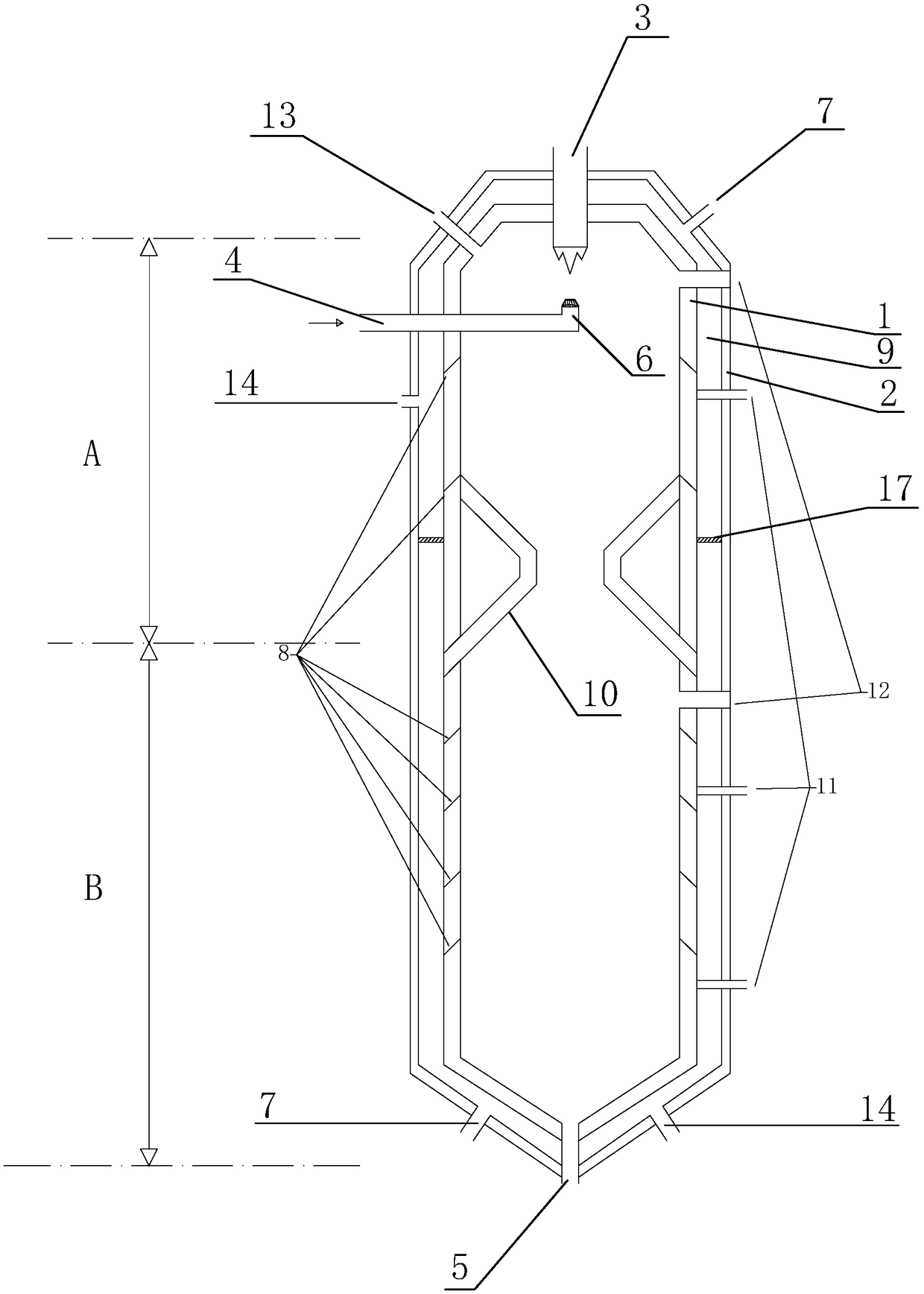

Piston reciprocating internal-combustion engine working substance flow system and its device

InactiveCN101289956AHigh thermal efficiencyEasy to achieve coolingNon-fuel substance addition to fuelInternal combustion piston enginesAir compressionControl set

The invention discloses a working substance flowing system of a piston reciprocating internal combustion engine and regulation and control setting thereof. An upper end of a frame moving up and down along the rotation of a power shaft is connected with an engine cylinder piston [7]; the lower end of the frame is made into a pressure cylinder piston [5]; an air inlet pipe[14], an air inlet check valve[2] and an air compression check valve[3] are arranged on a bottom cover plate of the pressure cylinder; air sucked from the air inlet pipe[14] by the pressure cylinder is sprayed by water mist for intercooling in compression; compressed air is stored in an air storage channel, tangentially supplied to an air inlet[10] of an engine cylinder sleeve; a rod head of the air compression check valve[3] is connected with the compressed air regulating and controlling device. An exhaust port [12] of the engine cylinder is arranged in the rear side of the cylinder top; a pressurized air bypass channel tightly pressed on the lower side of a flashboard-type exhaust valve [21] and an air suction check valve [22] of the upper side of a vent-pipe inlet cool an exhaust system and exhaust air and have the effects of both decontamination and preventing an exhaust gas turbine from surging. The supercharging mechanism has compact structure, indirect transmission, stable pressurization and cooling function; the working substance flowing system is provided with the regulating and controlling device with optimized performance and is convenient to the actualization of a small and medium sized engine.

Owner:肖光宇

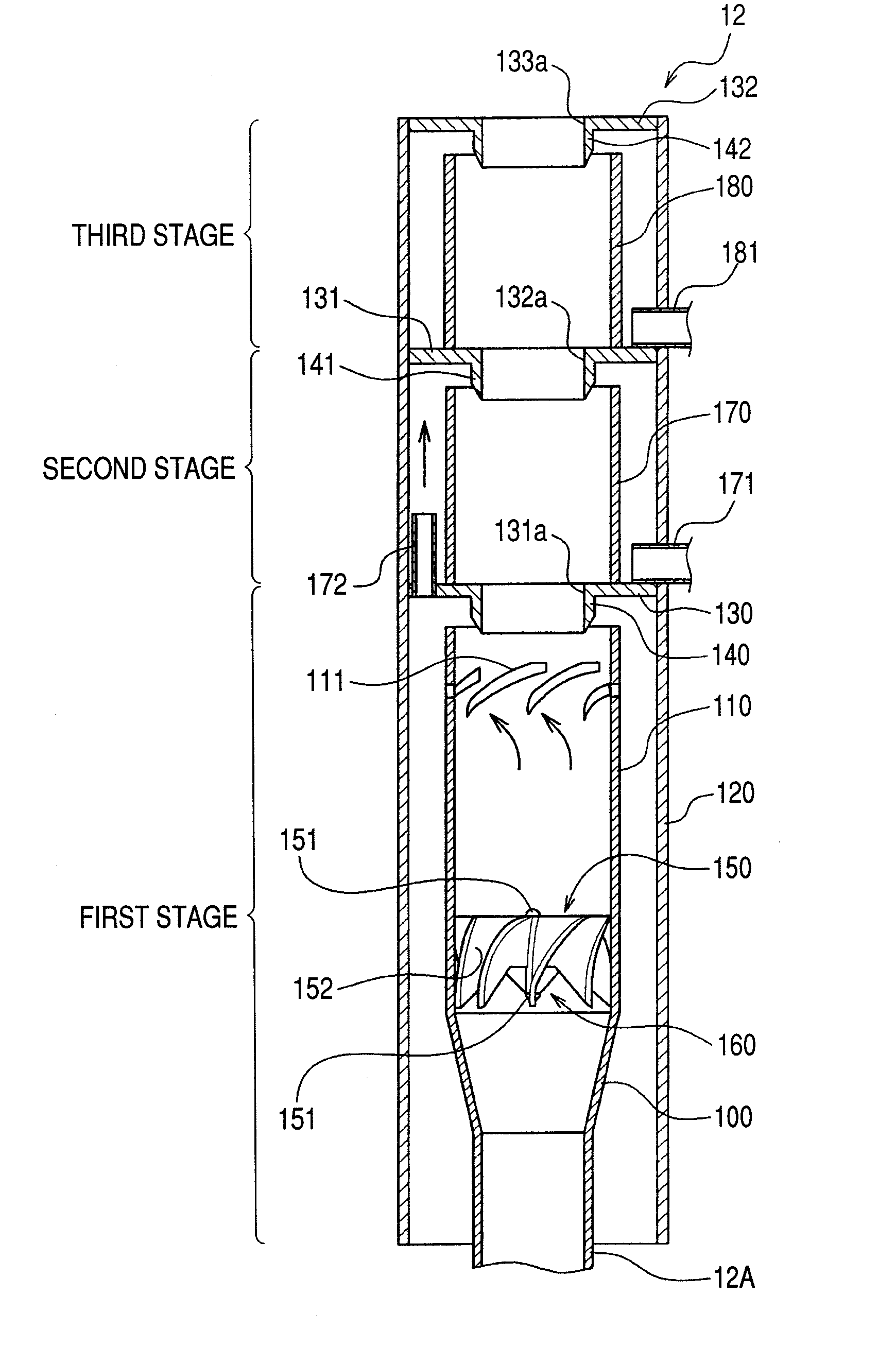

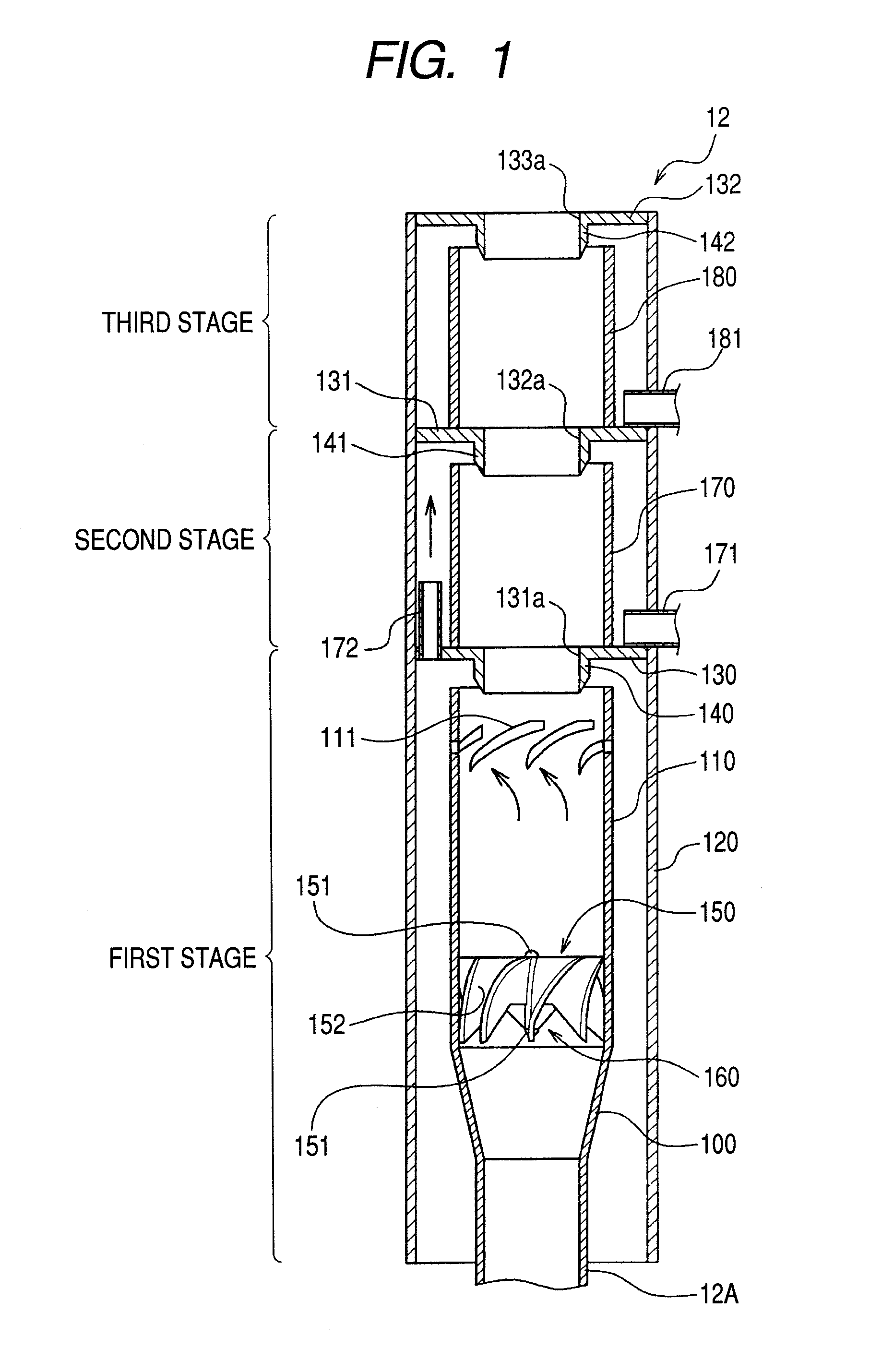

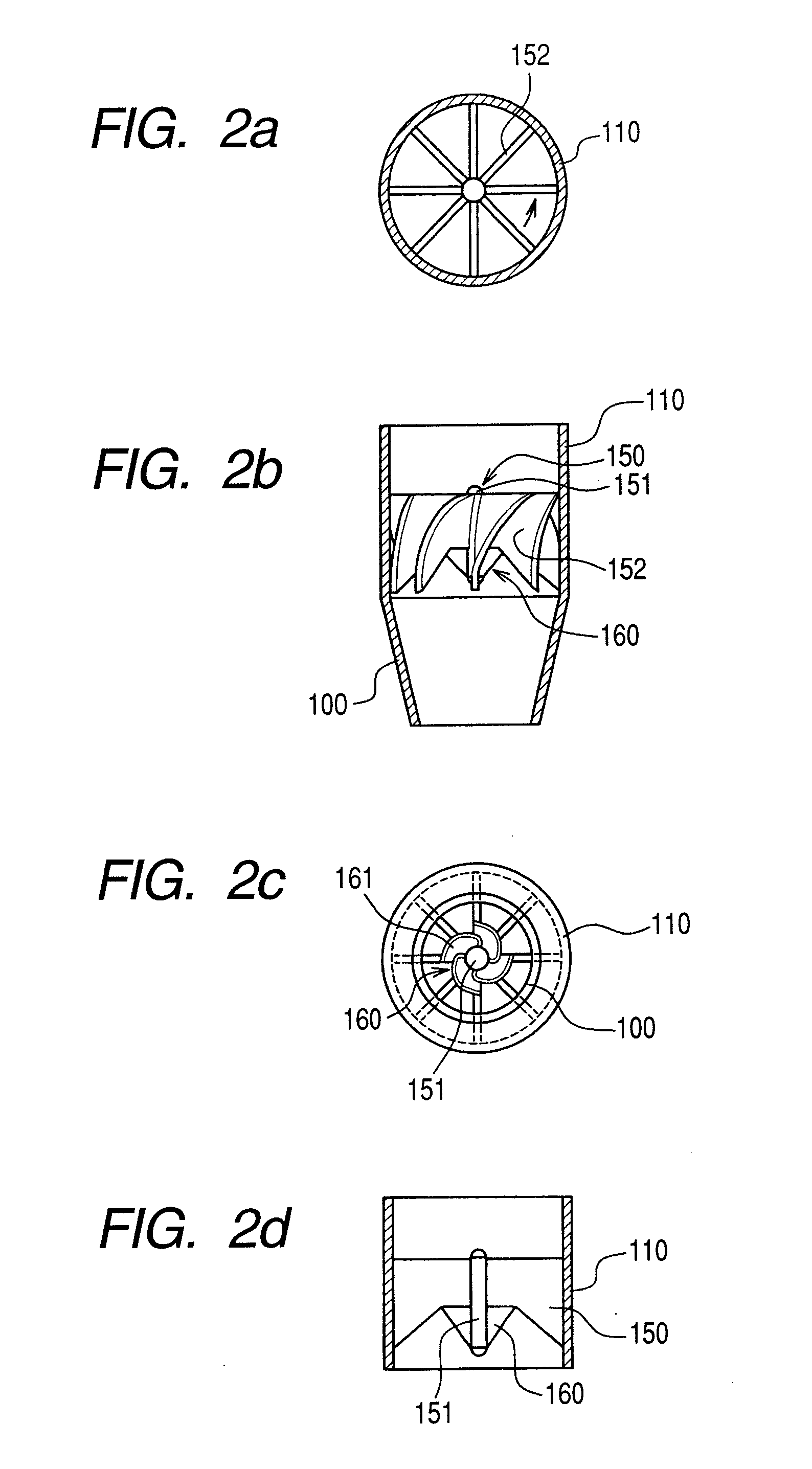

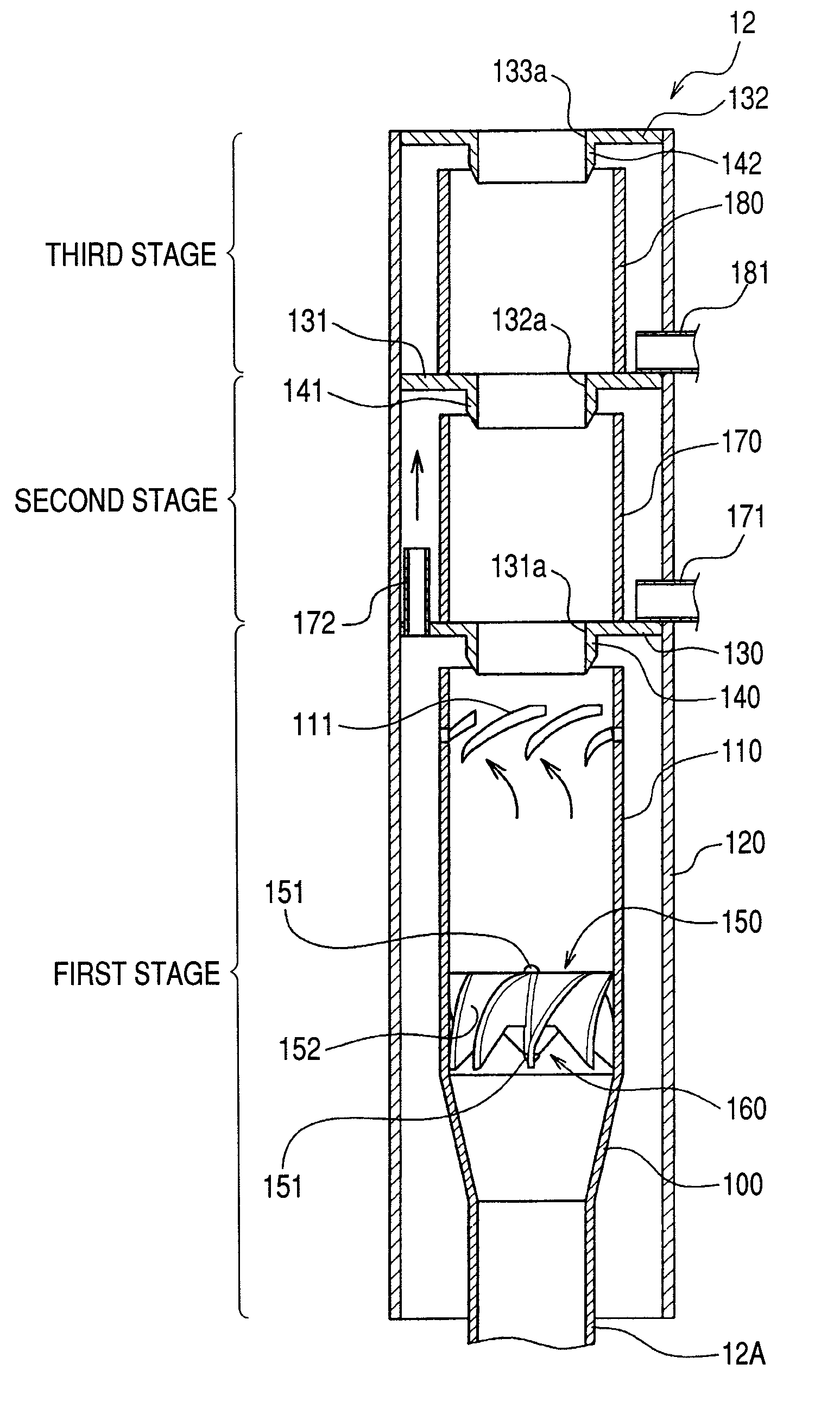

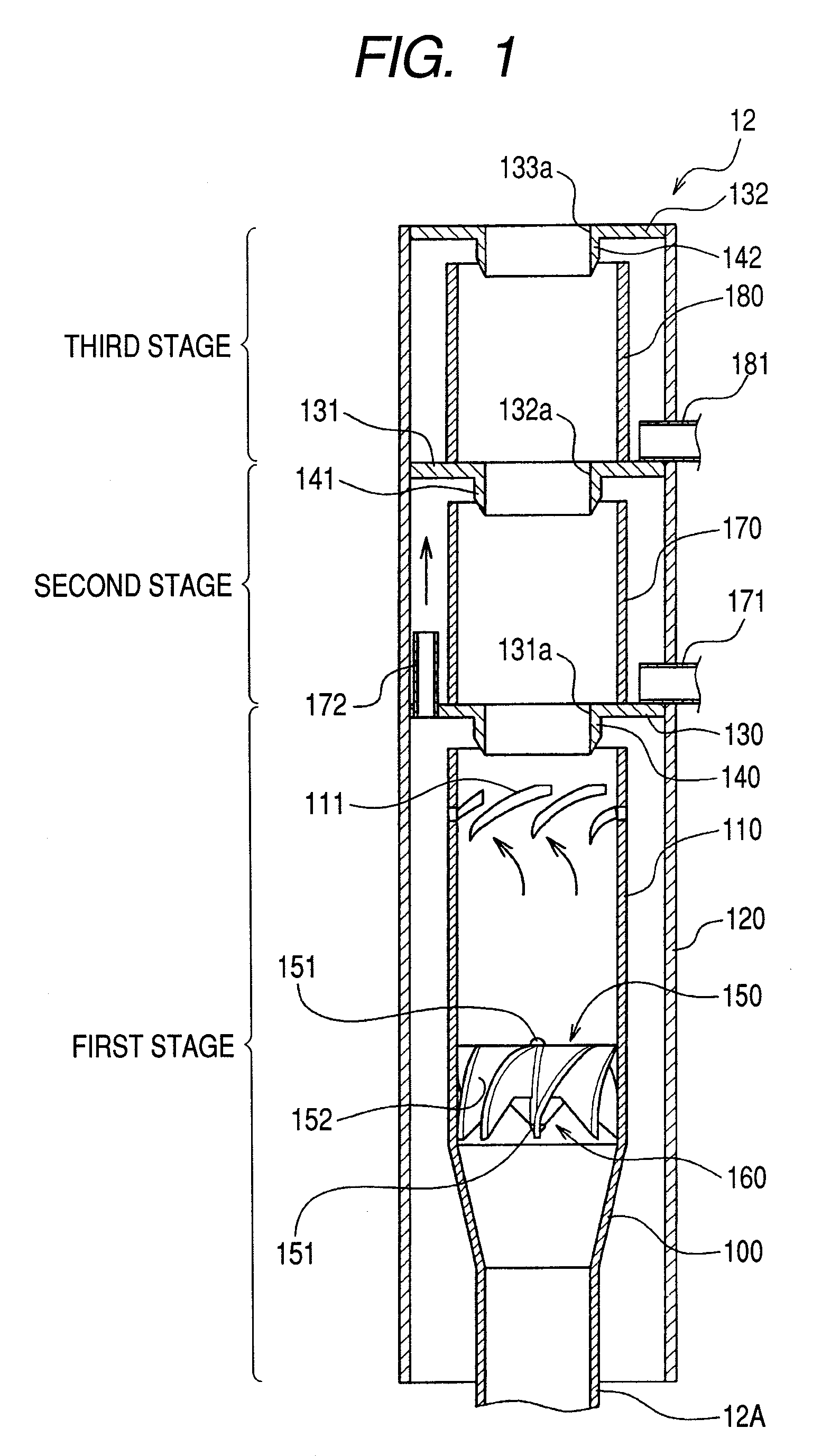

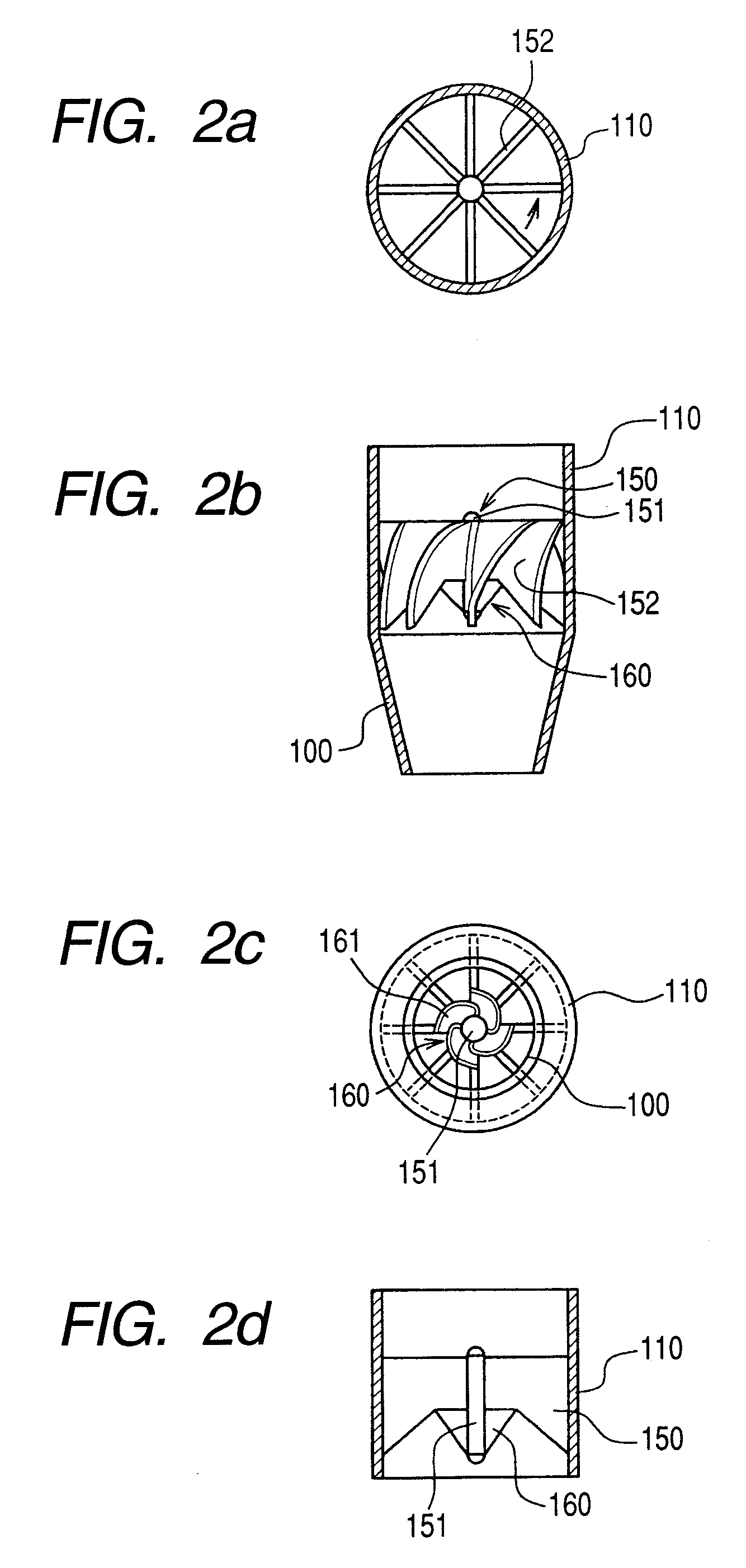

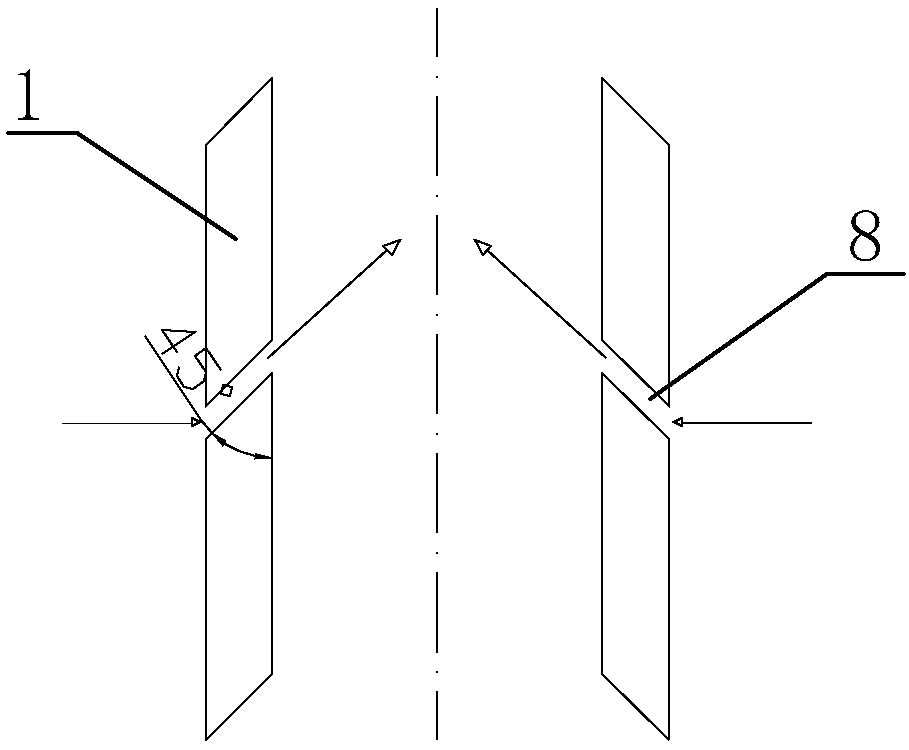

Steam separator, boiling water reactor and swirler assembly

ActiveUS20070201604A1Easy to separateSmall pressure lossNuclear energy generationDispersed particle separationEngineeringCentrifugal force

A steam separator comprises an outer main swirler and an inner auxiliary swirler which is smaller than the main swirler. The swirlers are provided so as to be concentric on the inner wall at the lower side of the first stage inner cylinder. In the steam separator, when the gas-liquid two-phase flow which flows in the vicinity of the axial center of the first stage inner cylinder passes the auxiliary swirler, it is separated into steam and water by the centrifugal force. The separated water (droplets) is introduced into the main swirler. When the separated water (droplets) passes the main swirler, it is separated at the inner wall side of the first stage inner cylinder by the centrifugal force.Pressure loss in a steam separator is reduced and steam separation capability is increased without increasing the moisture from the steam separator.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

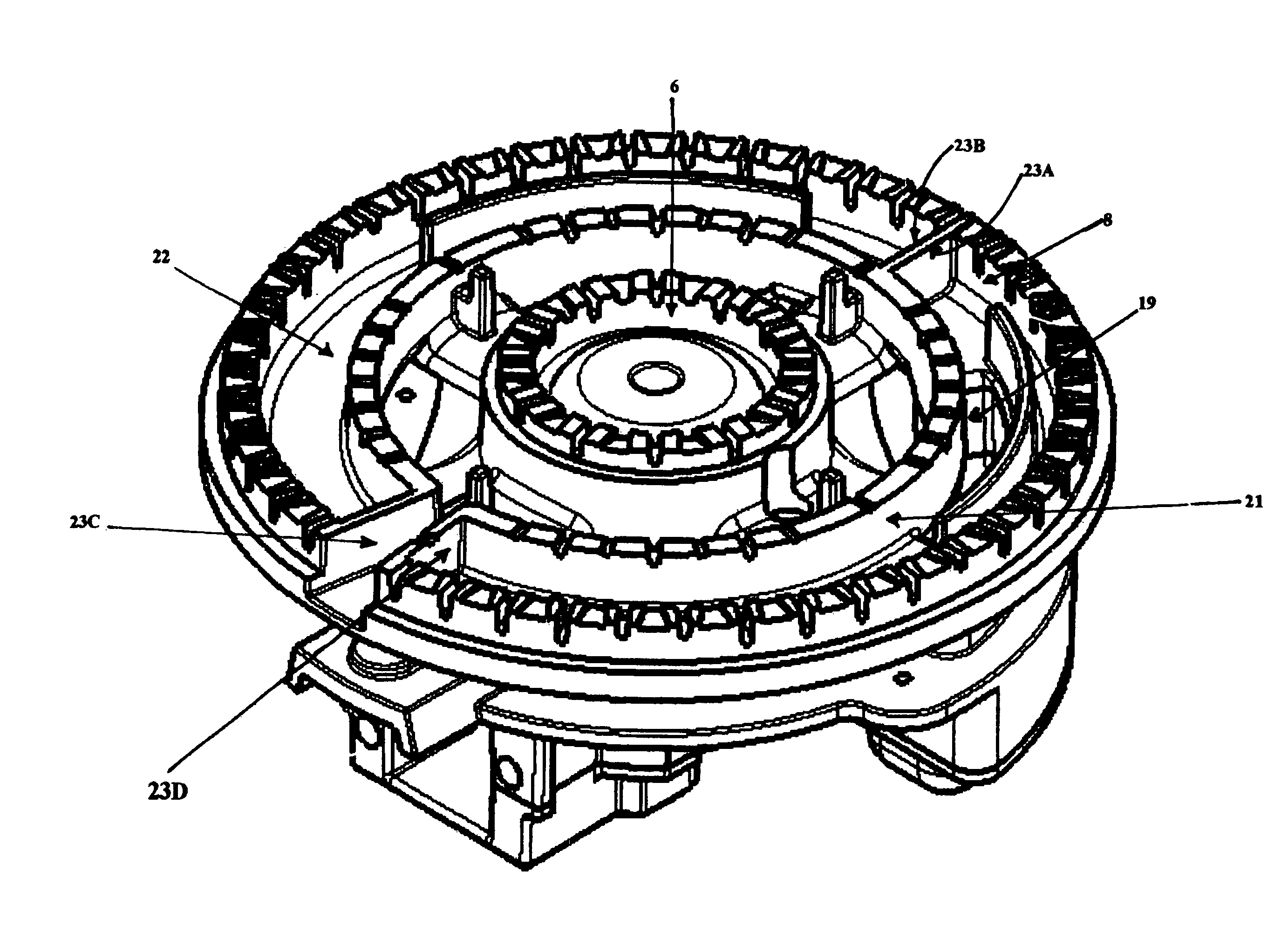

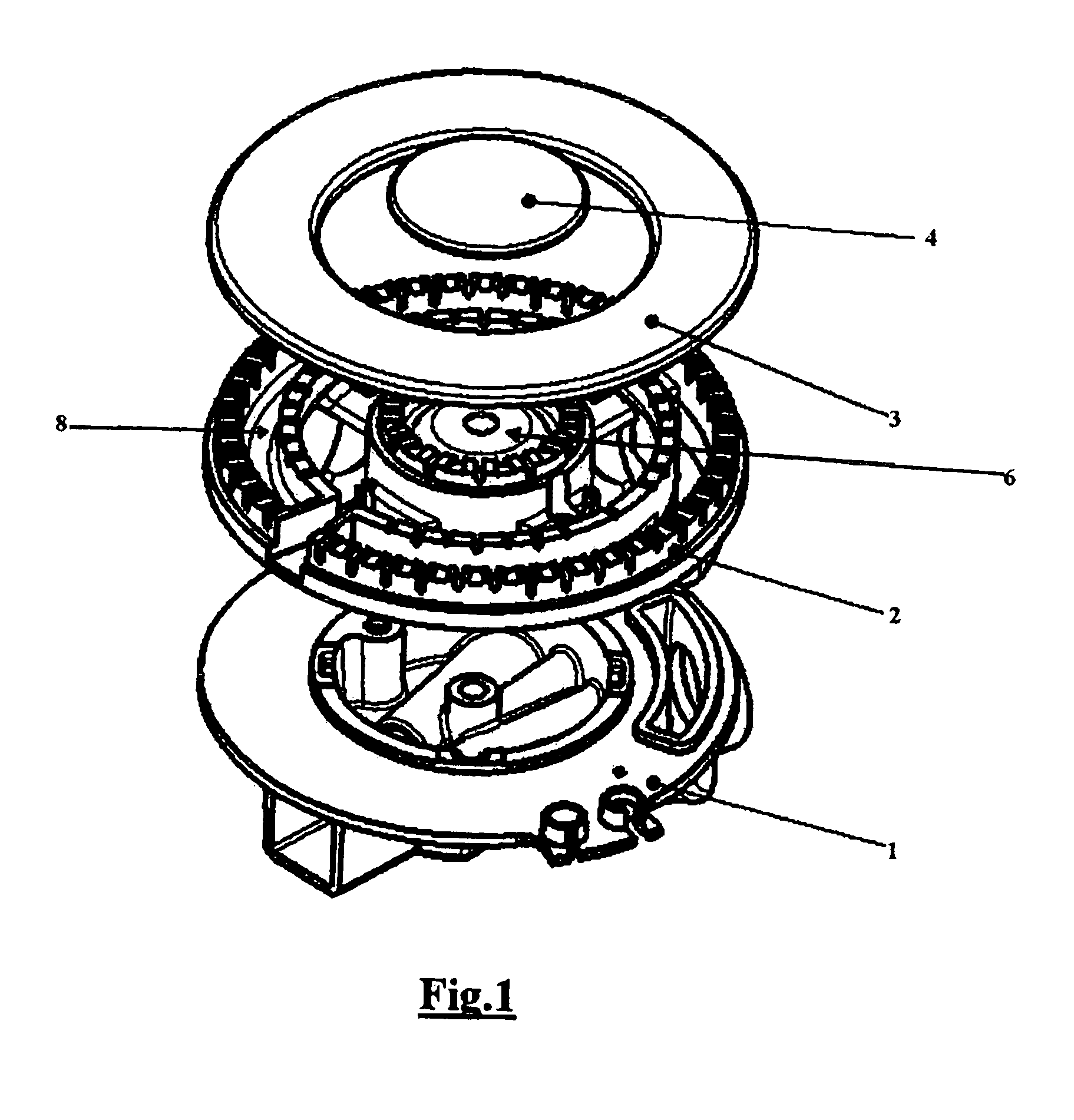

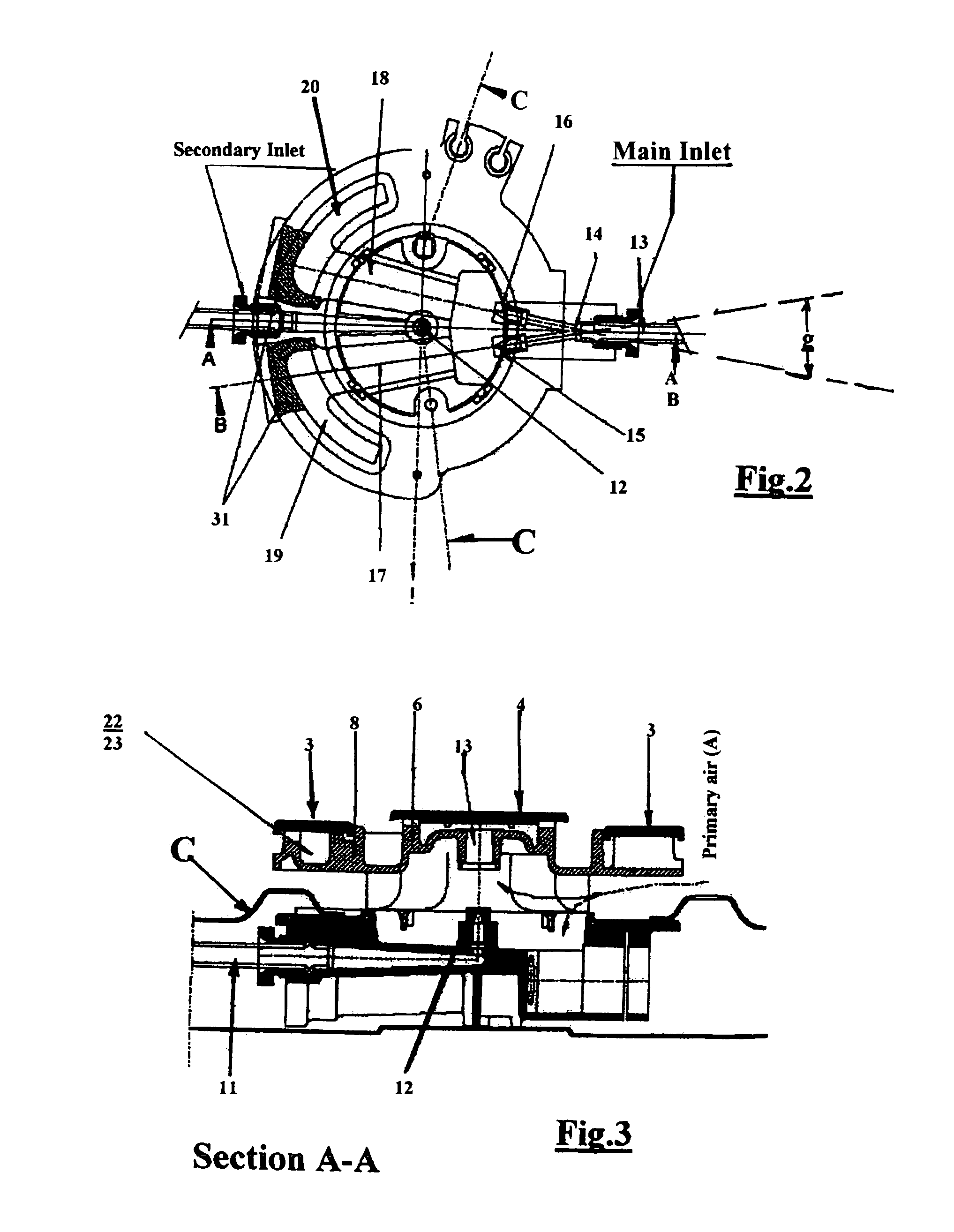

Gas burner

ActiveUS8221116B2Increase thermal powerDomestic stoves or rangesElectric spark ignitersGas syringeEngineering

Gas burner provided with a plurality of concentric flame crowns, and comprising a first central burner to supply a peripheral flame ring, a second annular burner surrounding the central burner at a defined distance and able of supplying at least a respective peripheral ring, a burner body apt to be mounted on the surface of a cooking hob, a first gas inlet in communication with the body, a first vertical gas injector, the central burner being provided with a first chamber for the diffusion of the air / gas mixture, a second gas inlet in communication with the body, wherein the second annular burner is provided with two separate chambers for the diffusion of the mixture, wherein the second gas inlet is in communication with the two separate chambers through suitable injection and conveying means, which comprise two distinct injectors in communication with the second gas inlet, and two respective horizontal Venturi pipes each of which being able of supplying with the air / gas mixture a respective of the two diffusion chambers; these are physically separate and not in communication to each other. The two horizontal and separate injectors are placed on the same end position of the second gas inlet.

Owner:ELECTROLUX HOME PROD CORP NV

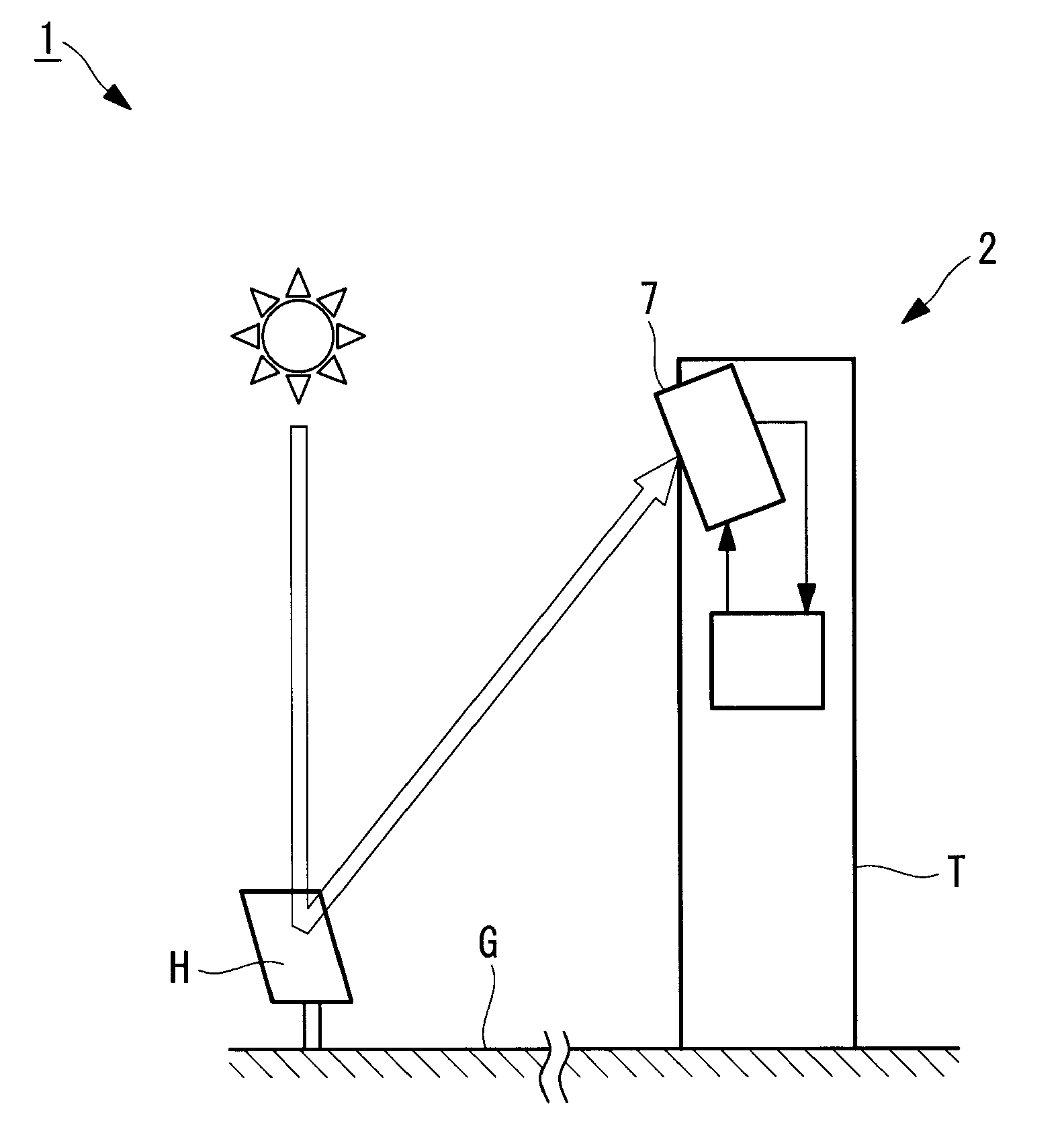

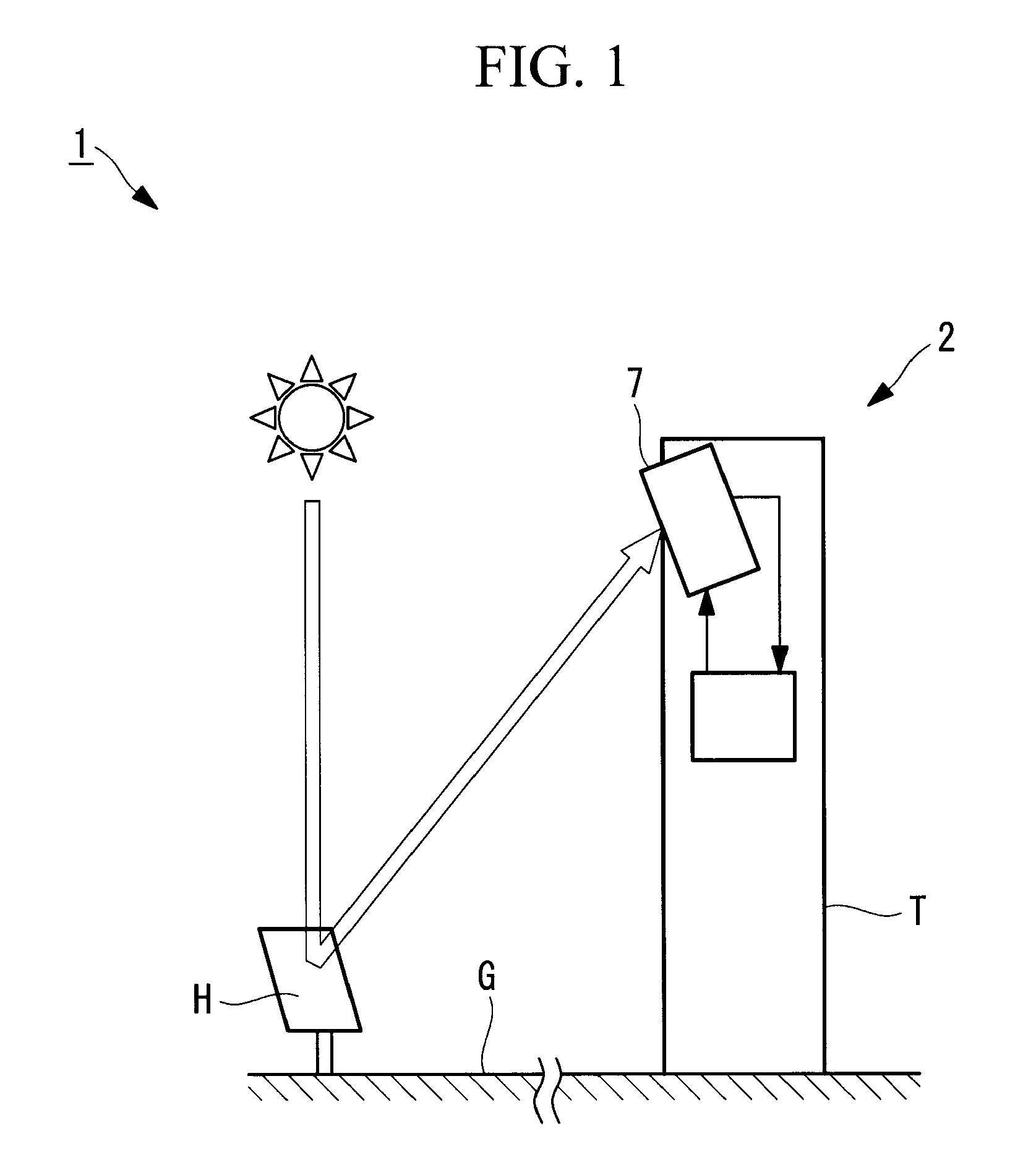

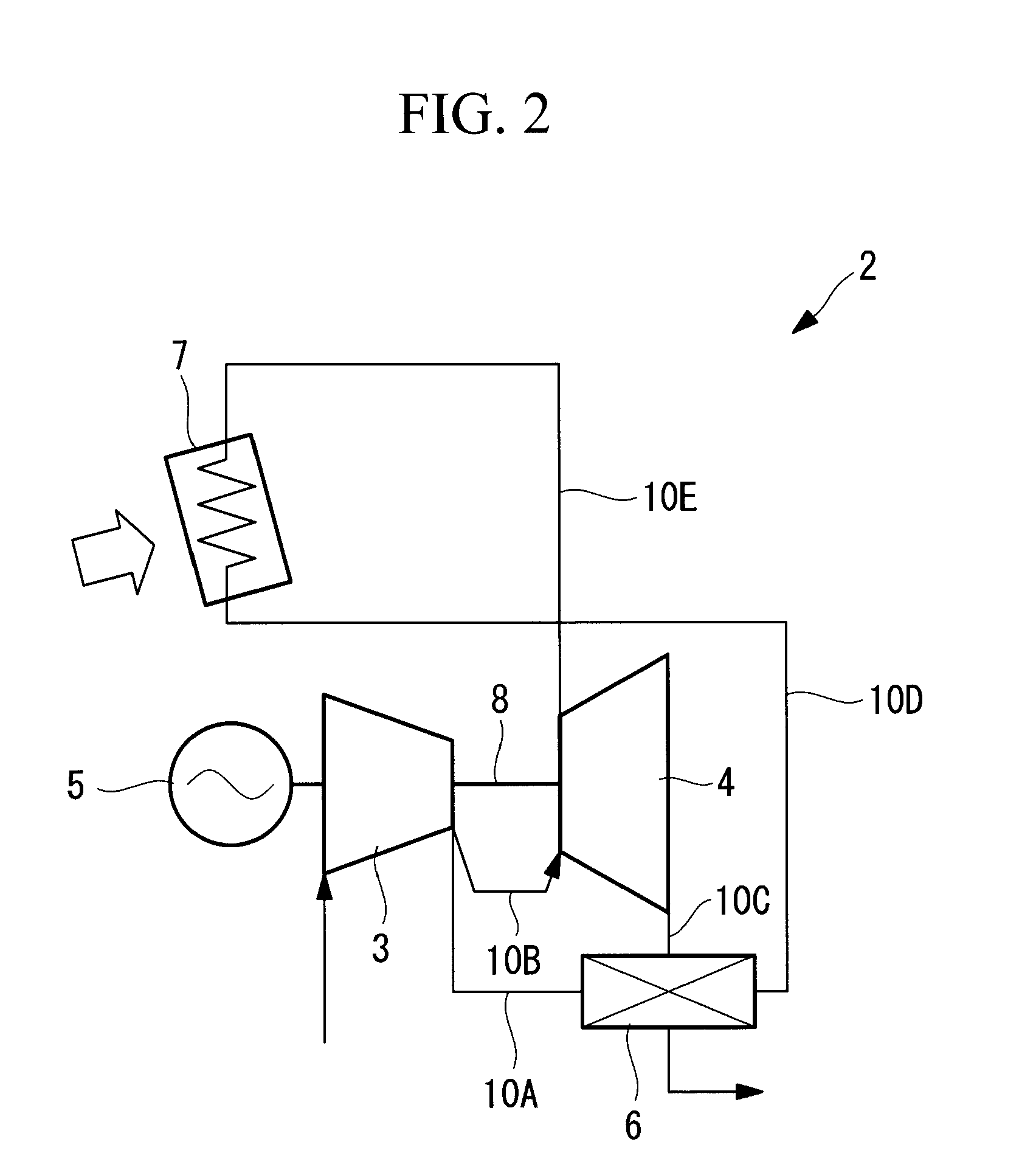

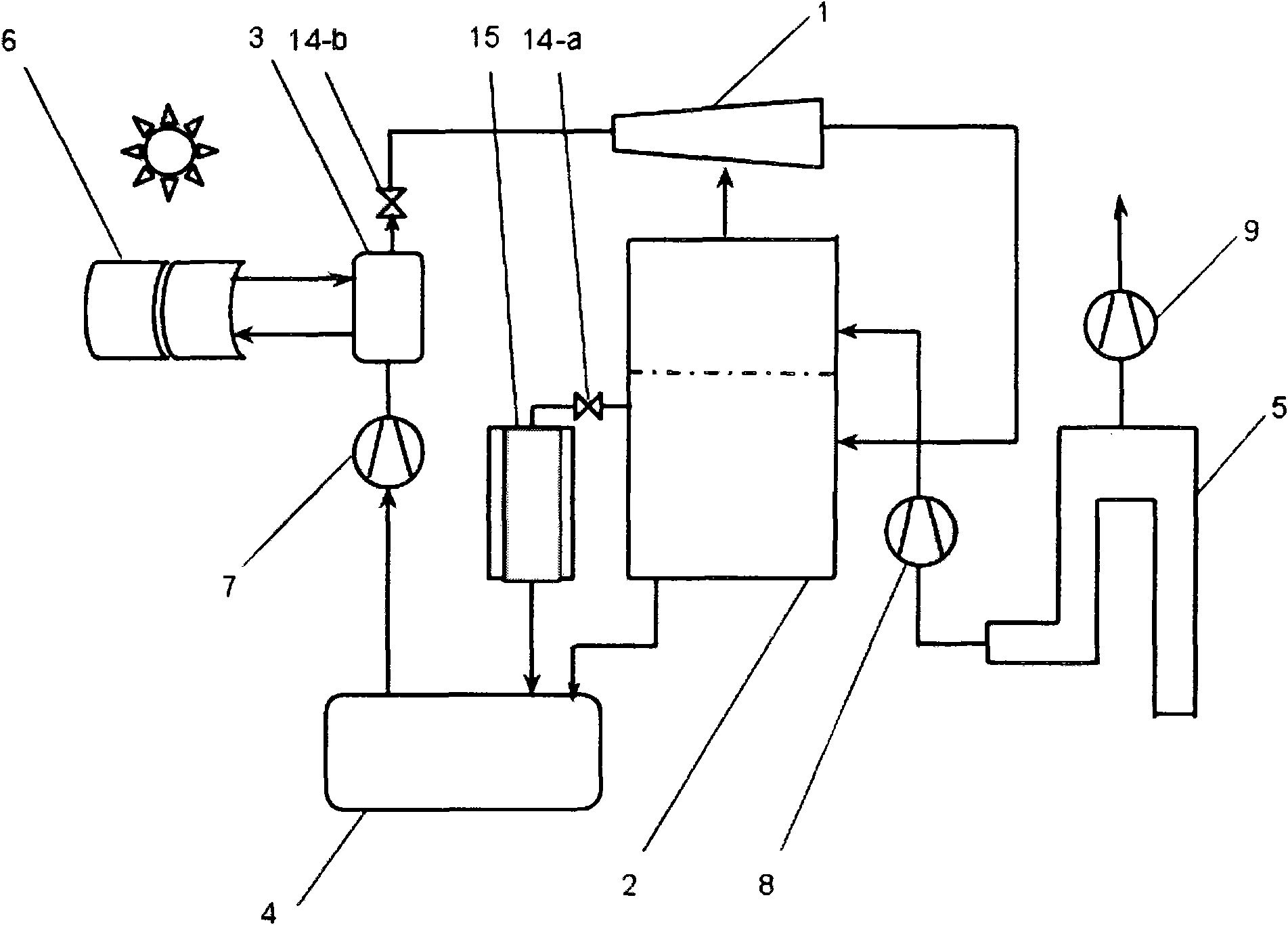

Solar thermal receiver and solar thermal power generation facility

InactiveUS20100223925A1Improve power generation efficiencyLow production costSolar heating energyAuxillary drivesHeat resistanceAbsorbed energy

A solar thermal receiver capable of improving the power generation efficiency in solar thermal power generation, reducing the production cost, and enhancing the thermal shock resistance and a solar thermal power generation facility using the solar thermal receiver are provided. The solar thermal receiver that receives solar radiation to heat fluid includes a heat-receiving section that is made of metal and that constitutes a flow path in which at least the fluid flows; and a coating layer that is disposed on at least a surface of an area of the heat-receiving section irradiated with the sunlight, that absorbs energy of the sunlight, and that has heat resistance.

Owner:MITSUBISHI HEAVY IND LTD

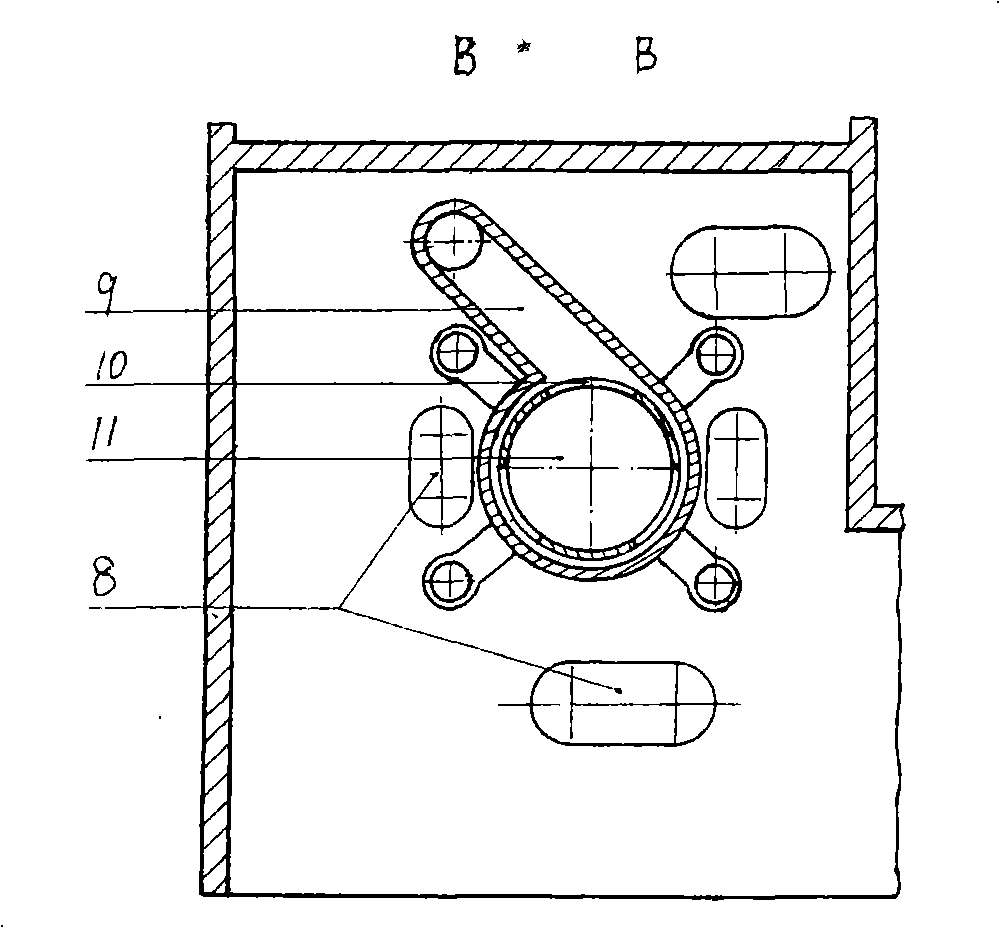

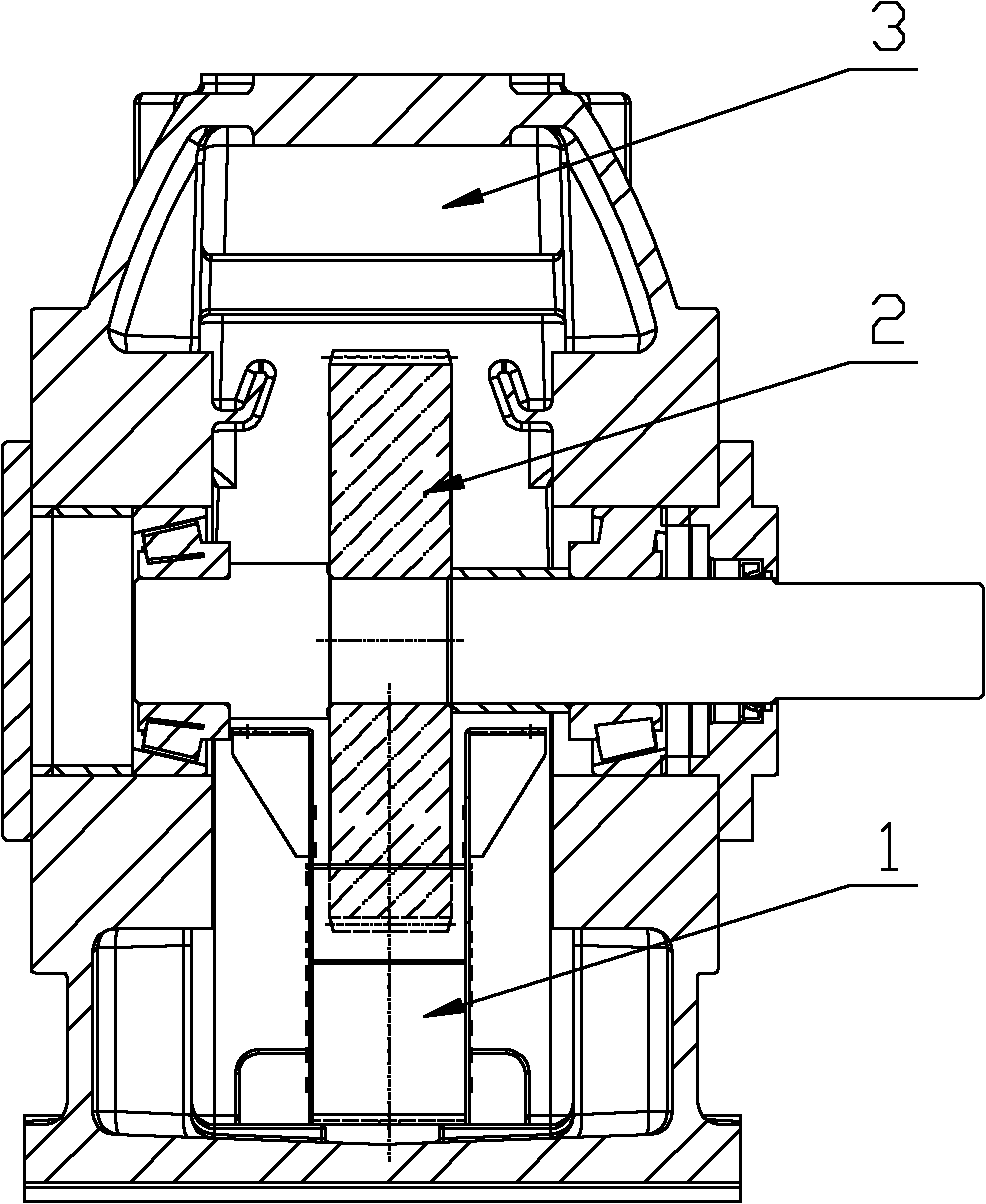

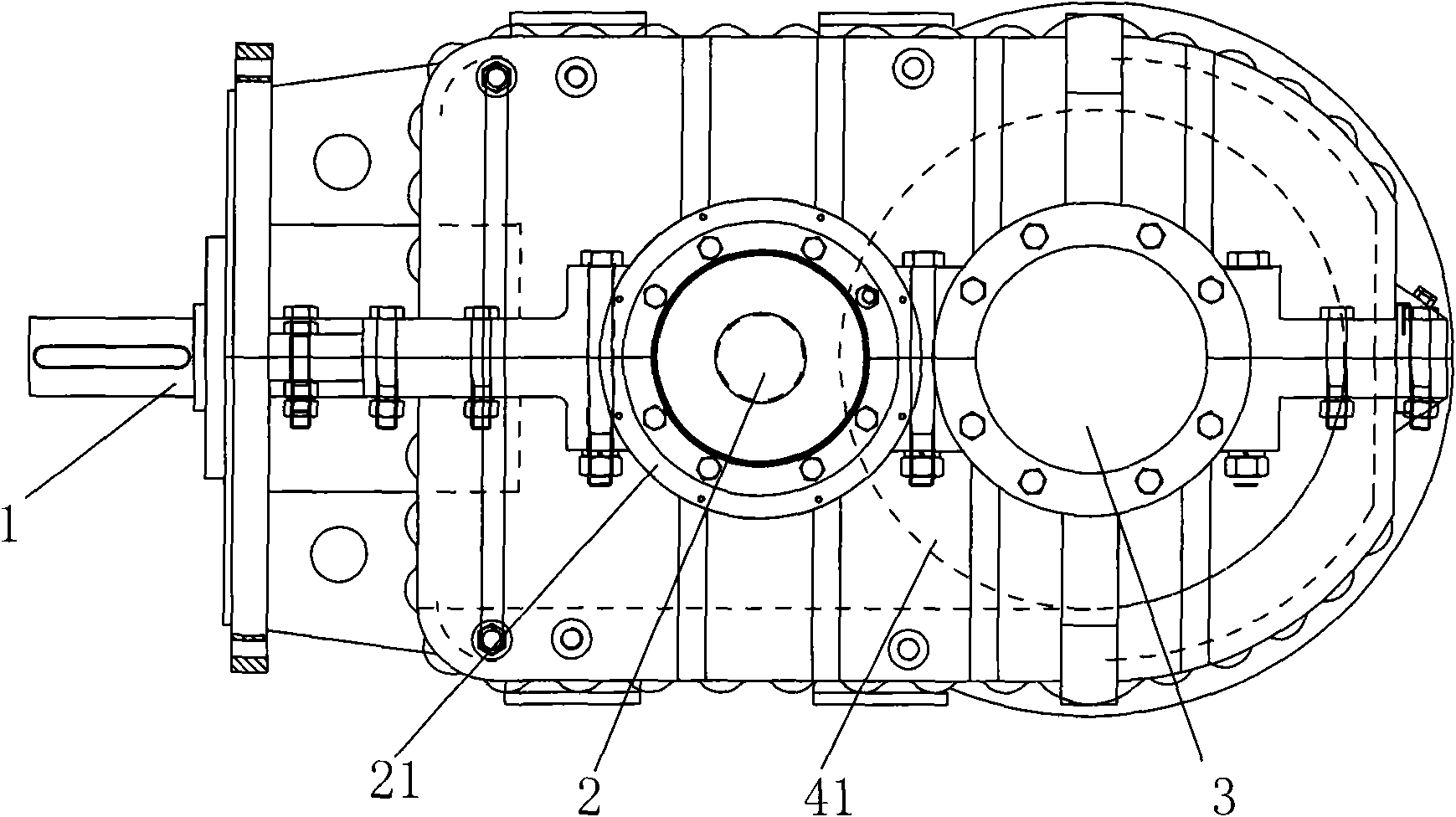

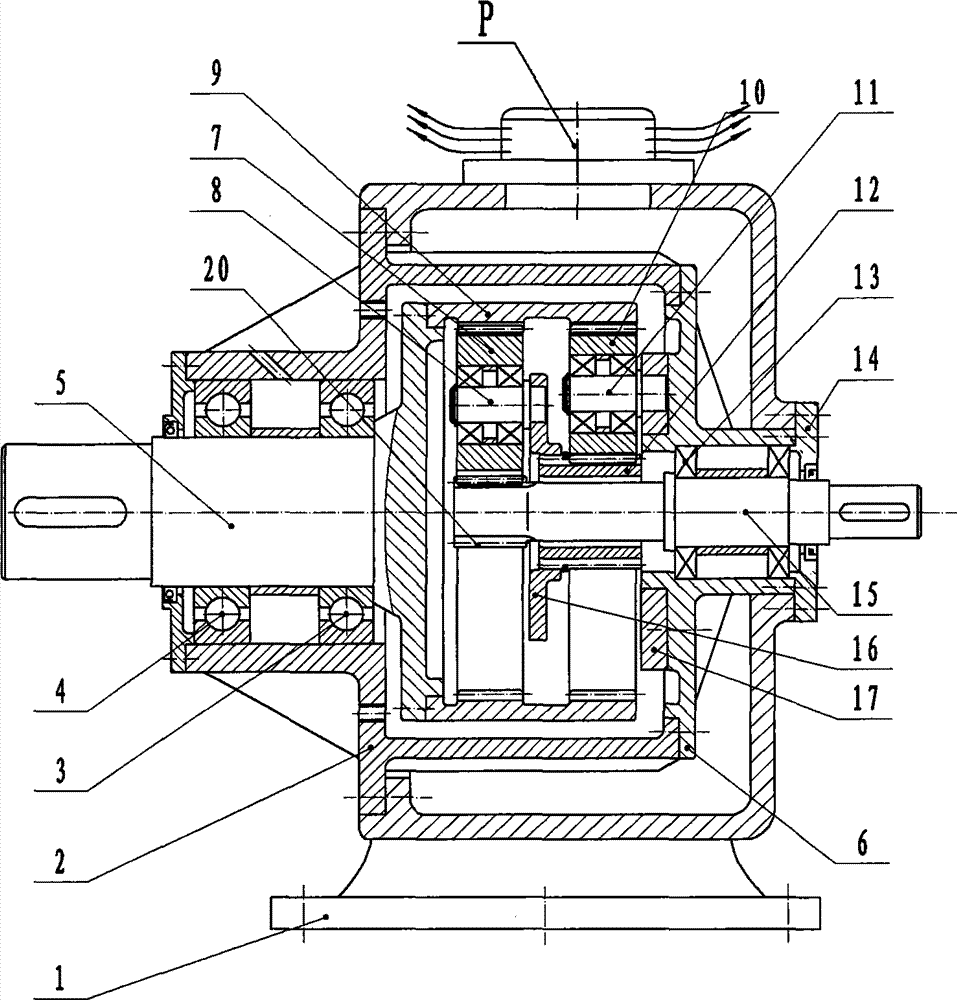

Speed reducer and oil blocking cover thereof

InactiveCN102734446AIncrease thermal powerReduce the temperatureGear lubrication/coolingInlet channelReducer

The invention relates to the mechanical field, and in particular relates to a speed reducer. The speed reducer comprises an oil blocking cover fixed inside a box body of the speed reducer, wherein the oil blocking cover surrounds the lower portion of a gear, a gap is arranged between the oil blocking cover and the gear, and the oil blocking cover is provided with an oil inlet channel. When the speed reducer is in a work state, the gear can bring lubricating oil in the oil blocking cover to a region of engagement to conduct lubrication in a rotating process, friction heat in the region of engagement of the gear is brought to an oil pool so that temperature of the region of engagement of the gear is lowered, and the lubricating oil on the outside of the oil blocking cover can flow in the oil blocking cover continuously through the oil inlet channel so as to supplement the lubricating oil in the oil blocking cover. Simultaneously, the gear stirs the lubricating oil inside the oil blocking cover in the rotating process; namely, corresponding work is done on the lubricating oil inside the oil blocking cover. Due to the fact that the lubricating oil inside the oil blocking cover is less; namely, the lubricating oil stirred by the gear is less, so that the work done by the gear on the lubricating oil is less, temperature rise of the lubricating oil is less, and thermal power of the speed reducer is improved.

Owner:WORLD TRANSMISSION TECH TIANJIN SHARE LTD

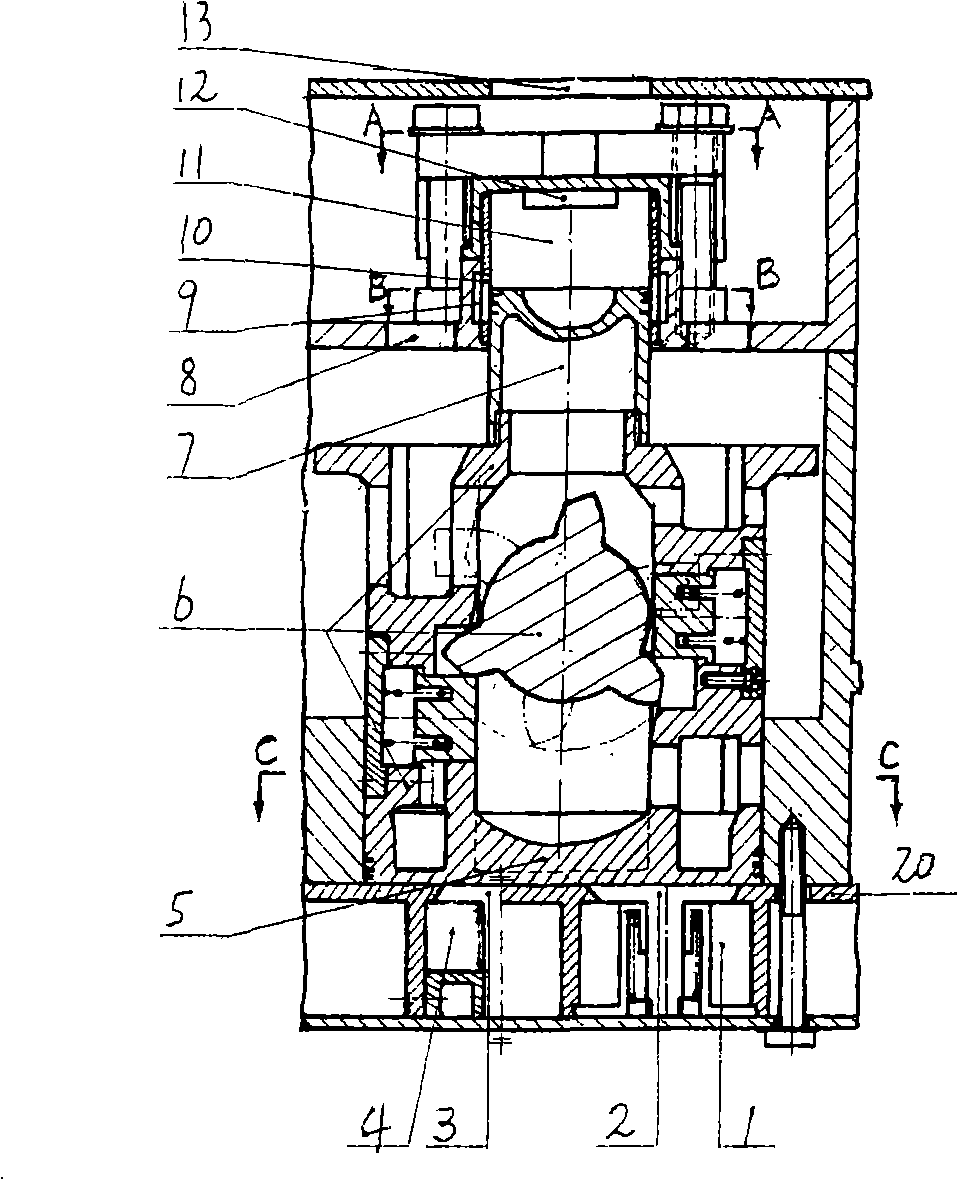

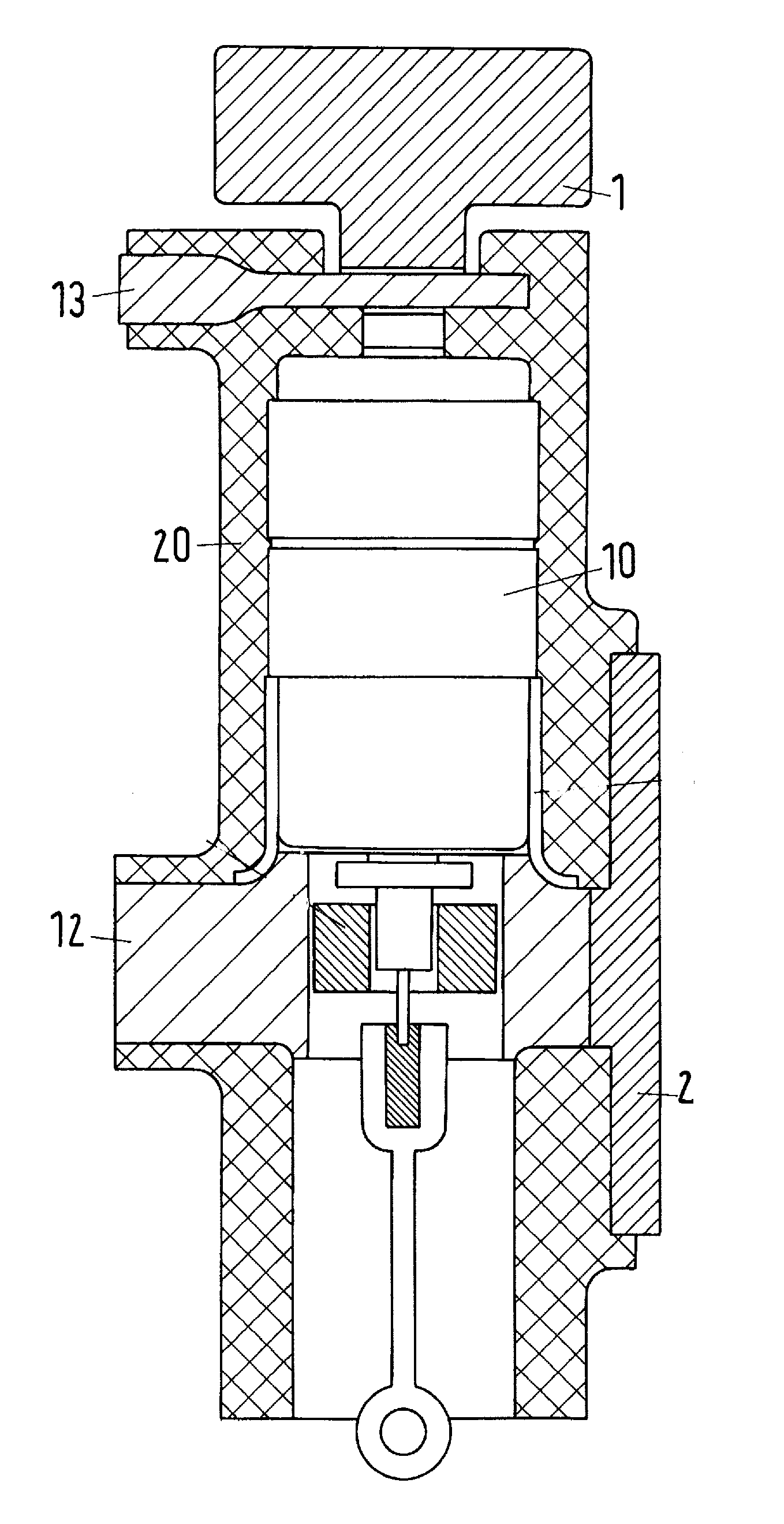

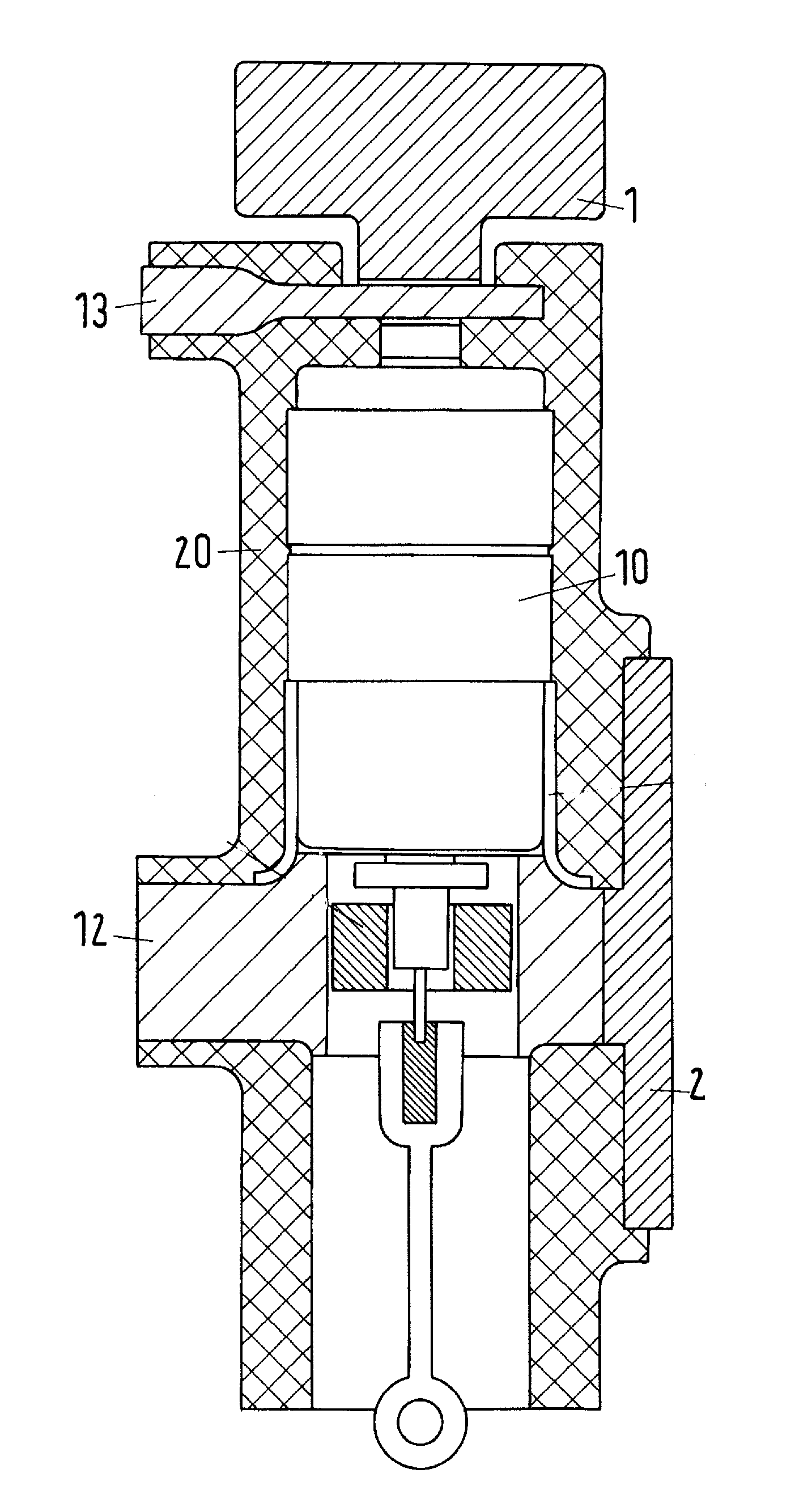

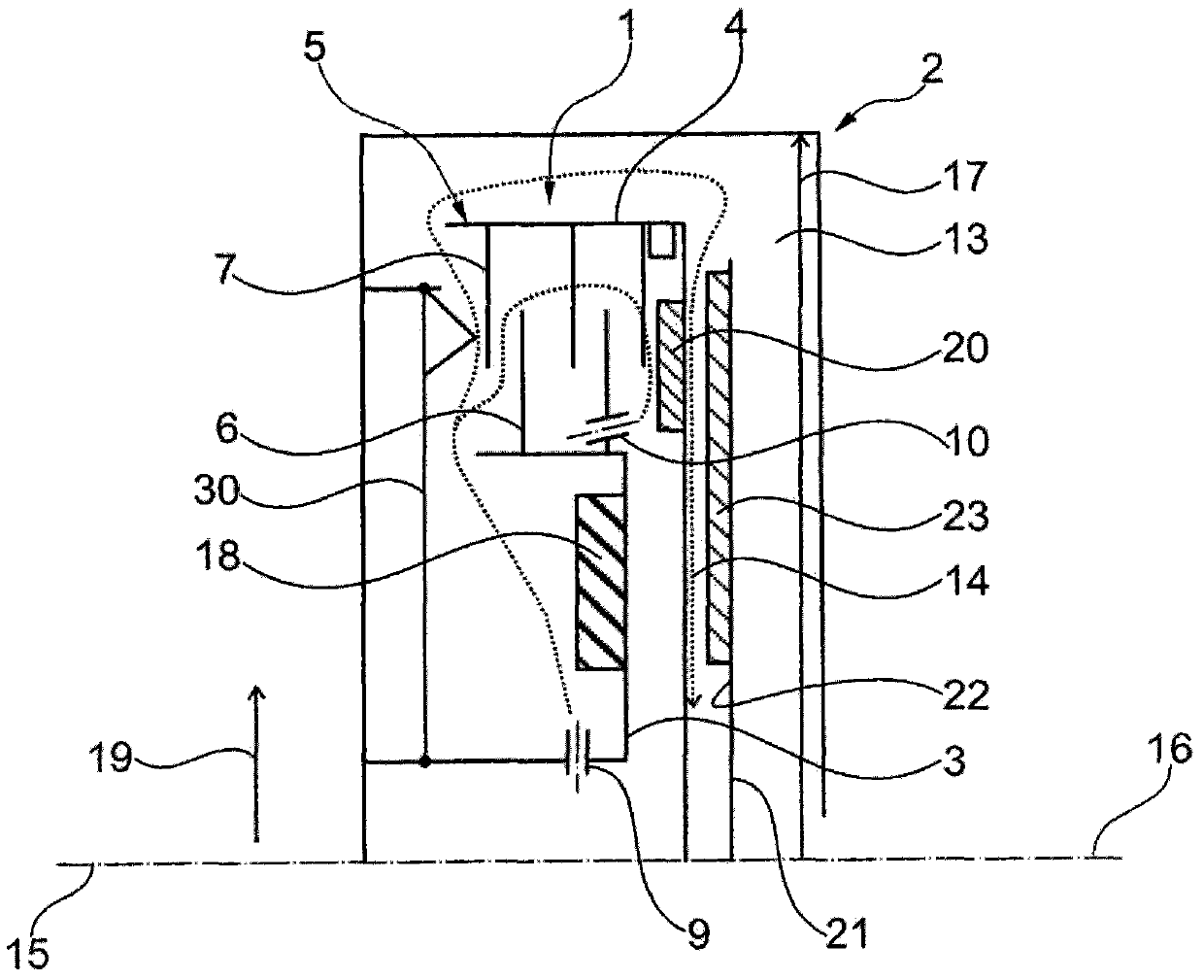

Pole part of a medium-voltage or high-voltage switch gear assembly, and method for its production

InactiveUS20110120976A1Increase heat transfer areaIncrease thermal powerContact mechanismsHigh-tension/heavy-dress switchesHeat transmissionSwitchgear

A pole part of a switchgear assembly having a vacuum interrupter chamber is provided. To ensure that heat is dissipated to the exterior for convection, a thermally conductive heat transmission element in the form of a cylindrical casing is provided between the vacuum interrupter chamber, a contact holder and an encapsulation casing. An inner surface of the heat transmission element rests on the vacuum interrupter chamber and the contact holder, and an outer surface of the heat transmission element rests on an inner surface of the encapsulation casing inner surface. The heat transmission element can be produced from a thermally conductive plastic using an injection-molding or molding-compound production process. The heat transmission element can be connected to the pole part through openings. The heat transmission element can be arranged before the encapsulation of with an encapsulation compound, and be cast in the encapsulation casing.

Owner:ABB TECH AG

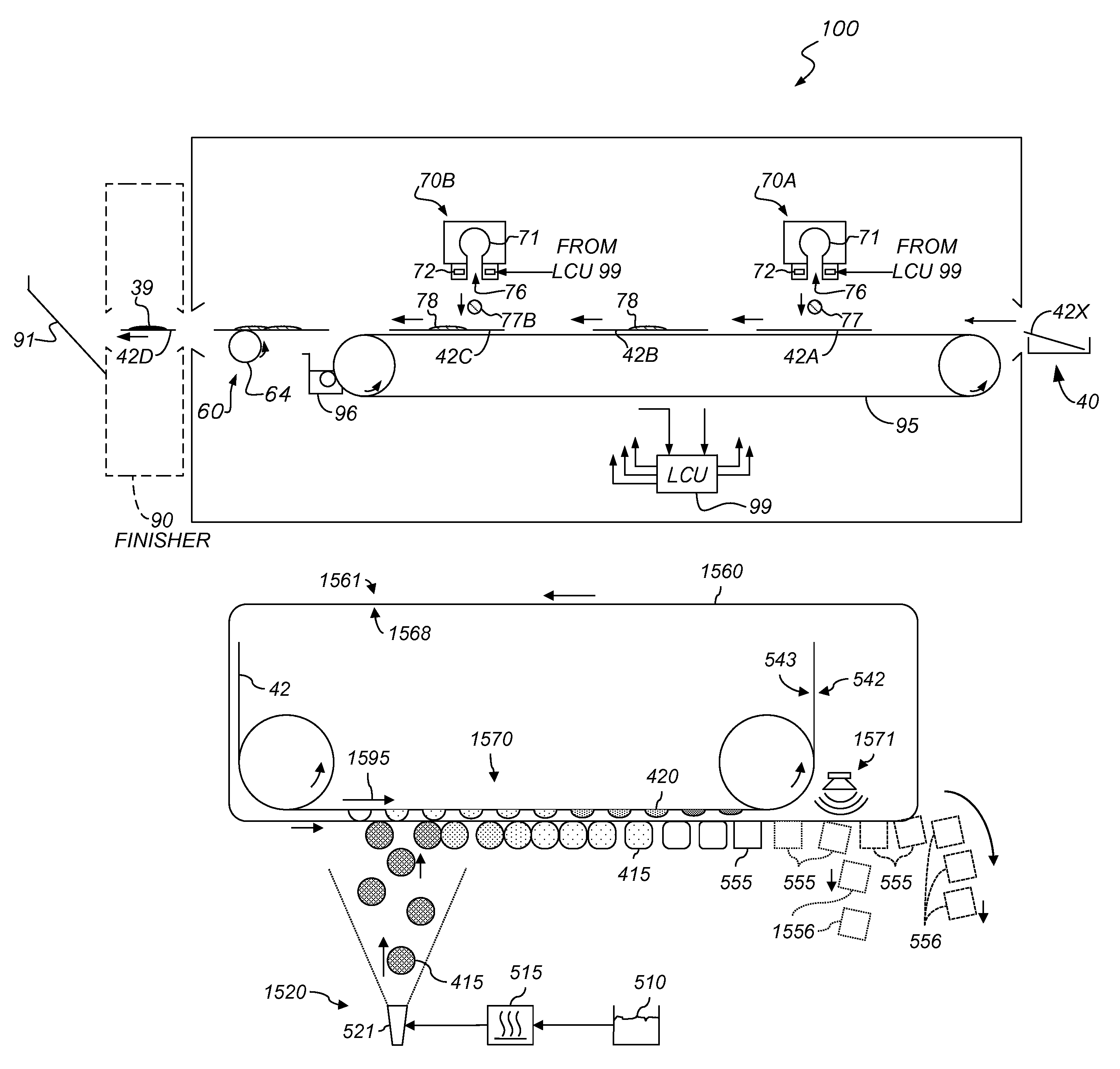

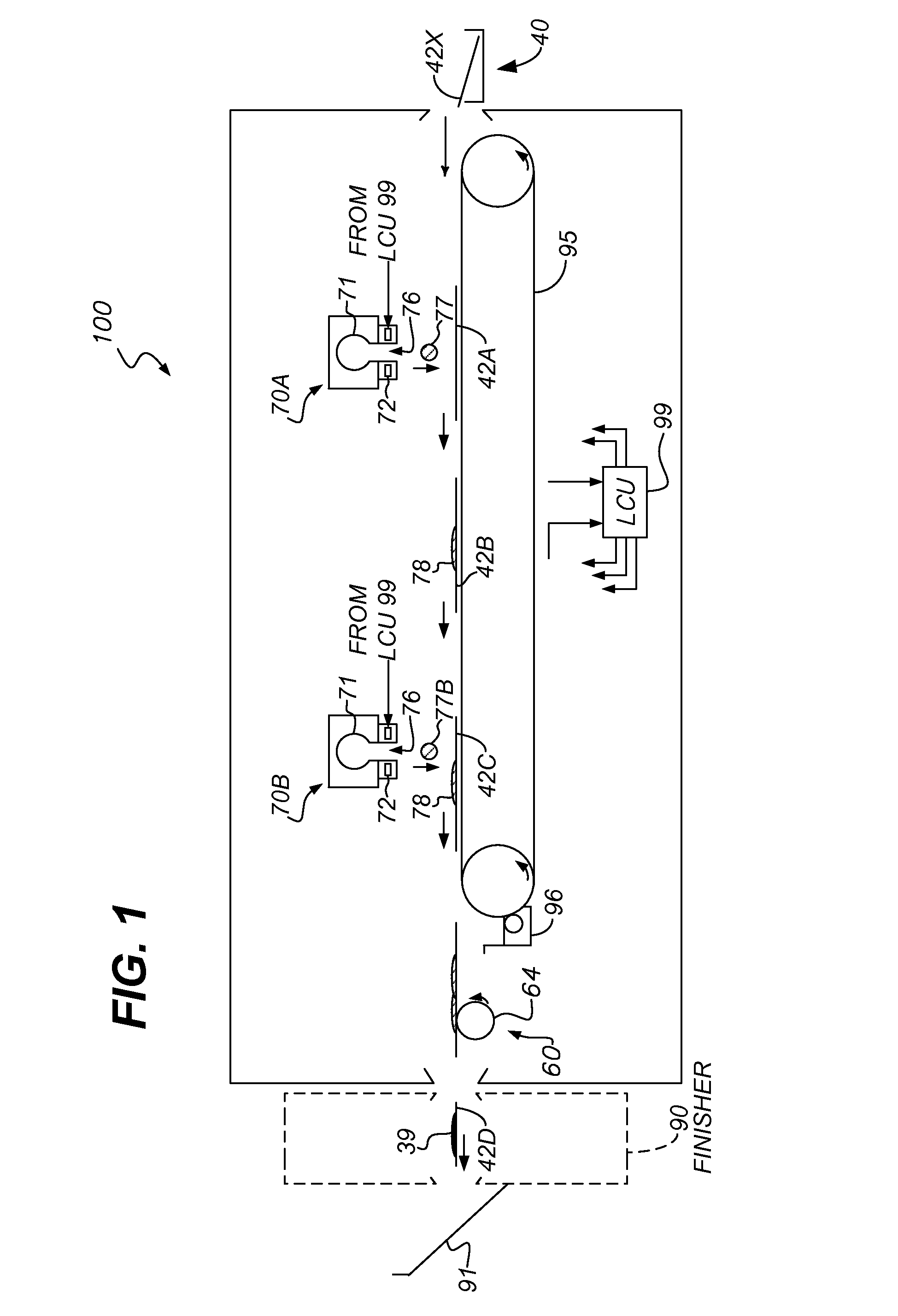

Removing moistening liquid using heating-liquid barrier

InactiveUS8756825B2Efficient removalReduce probabilityLiquid surface applicatorsDrying solid materials with heatBoiling pointChemistry

Owner:EASTMAN KODAK CO

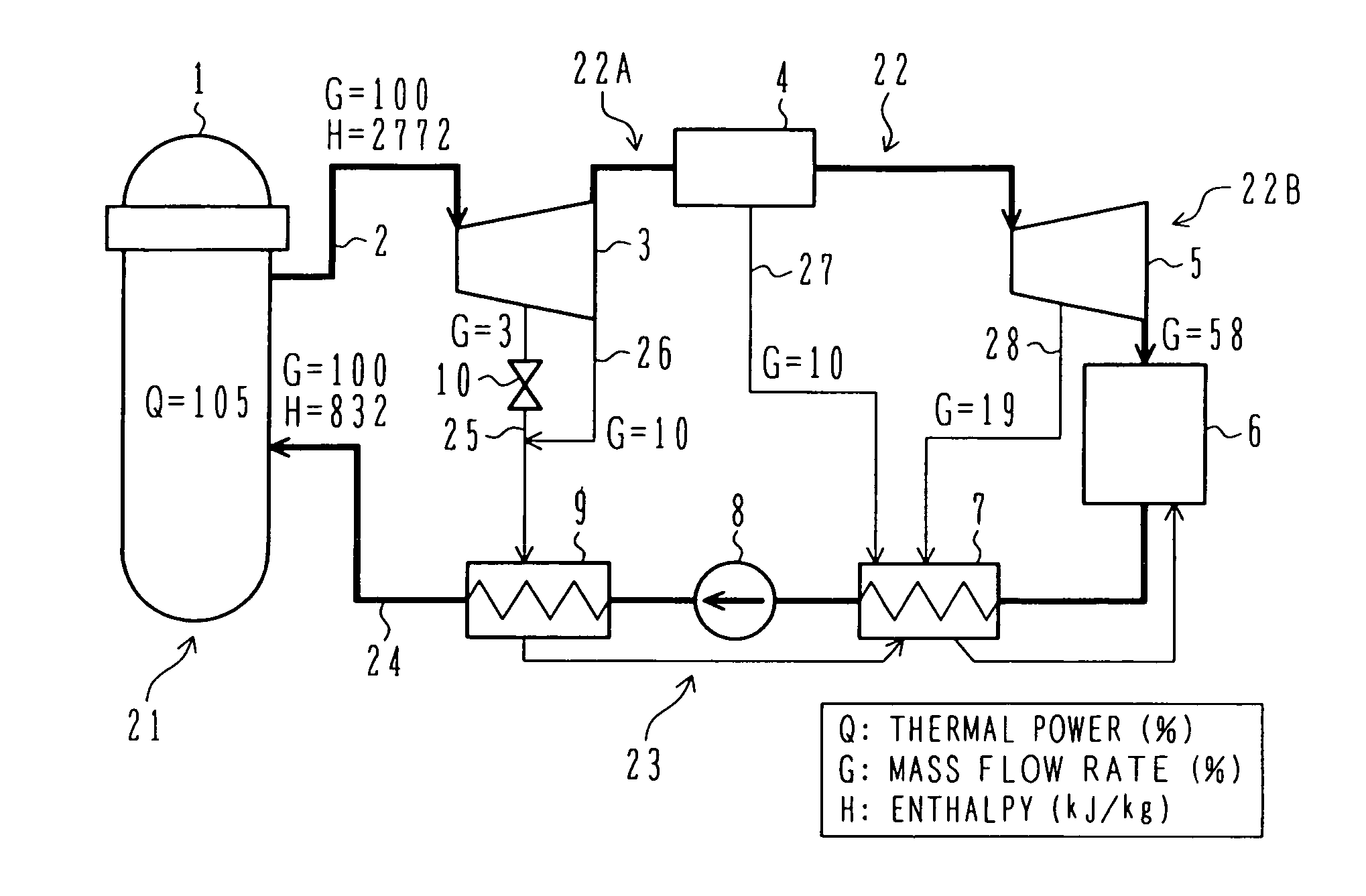

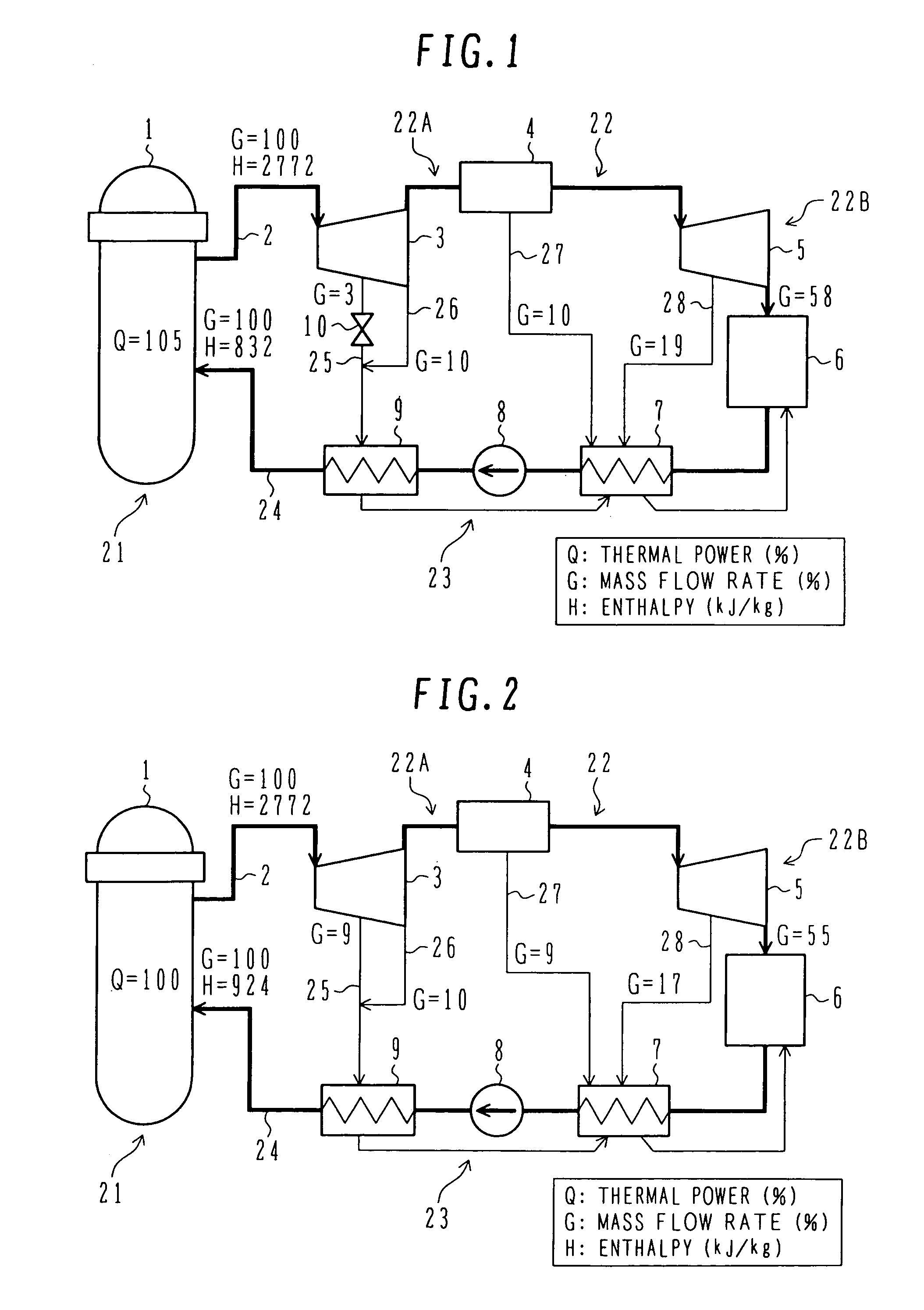

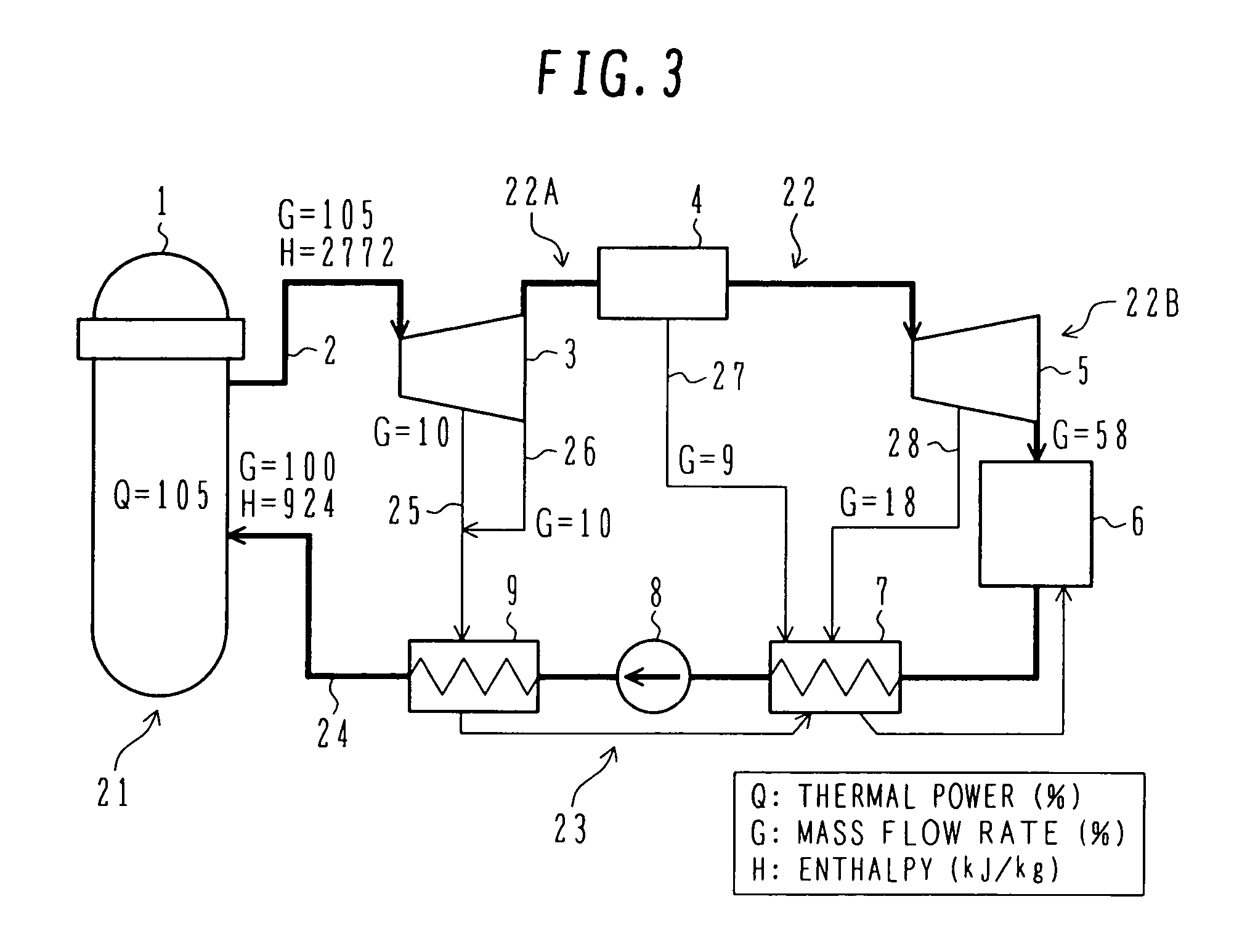

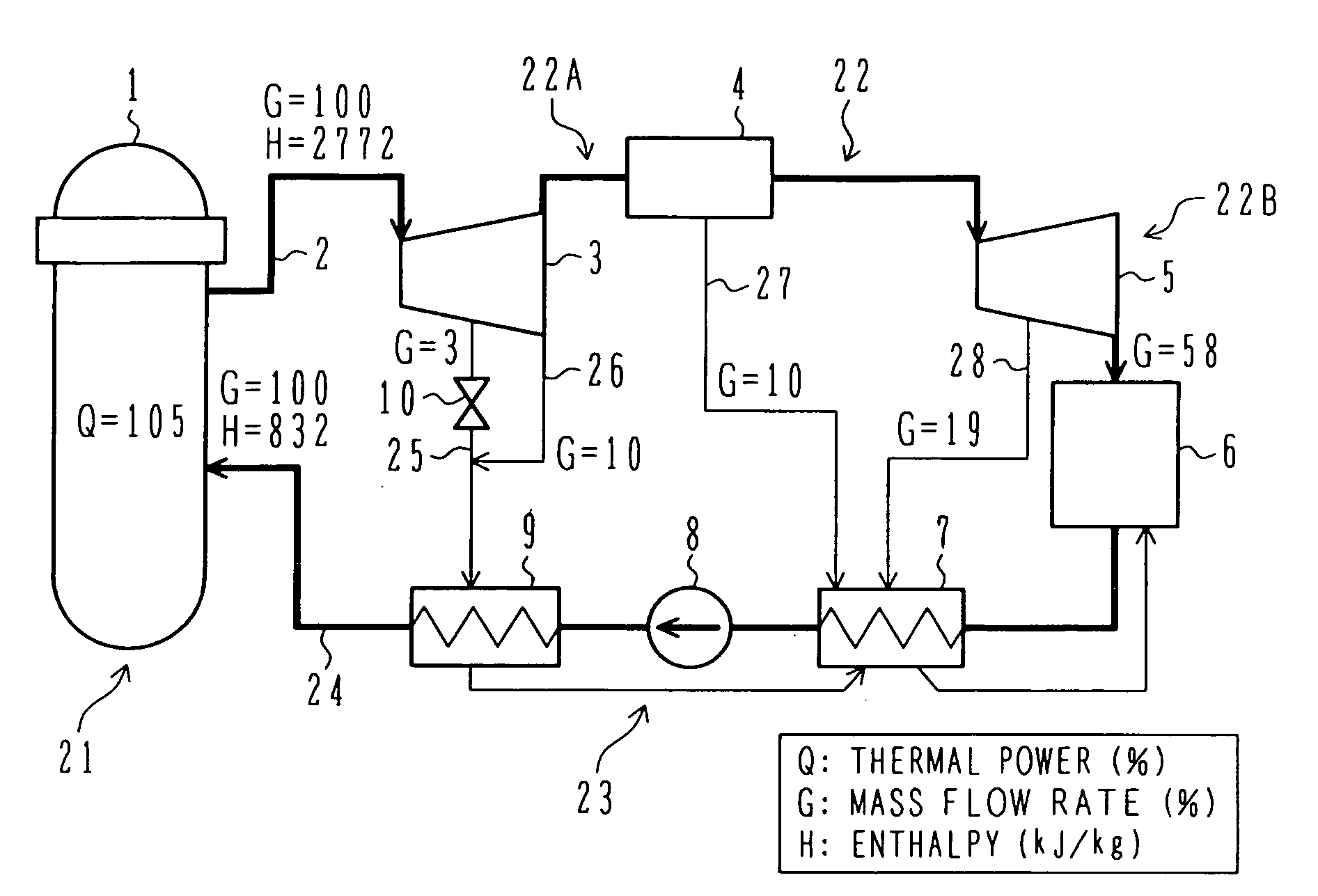

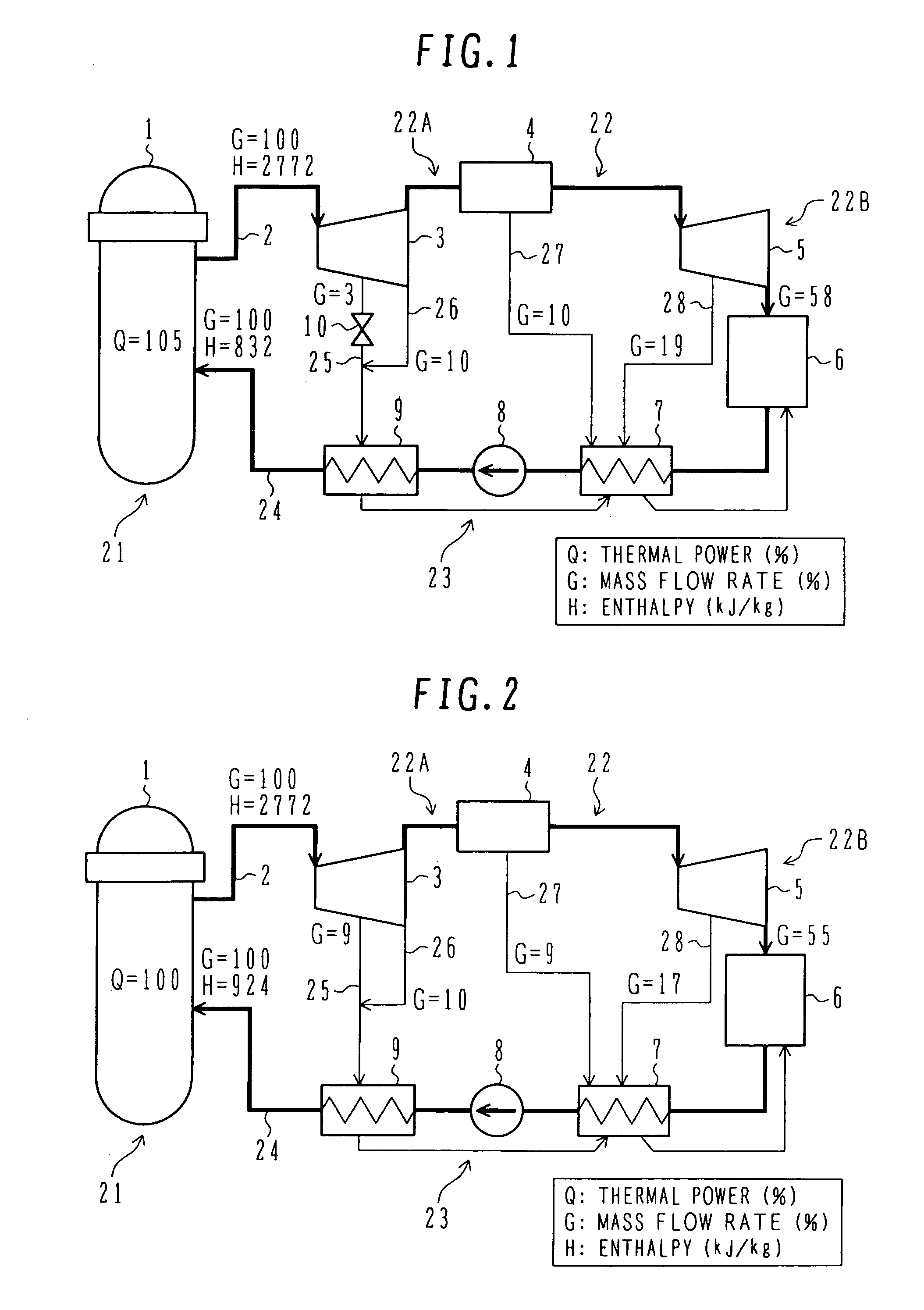

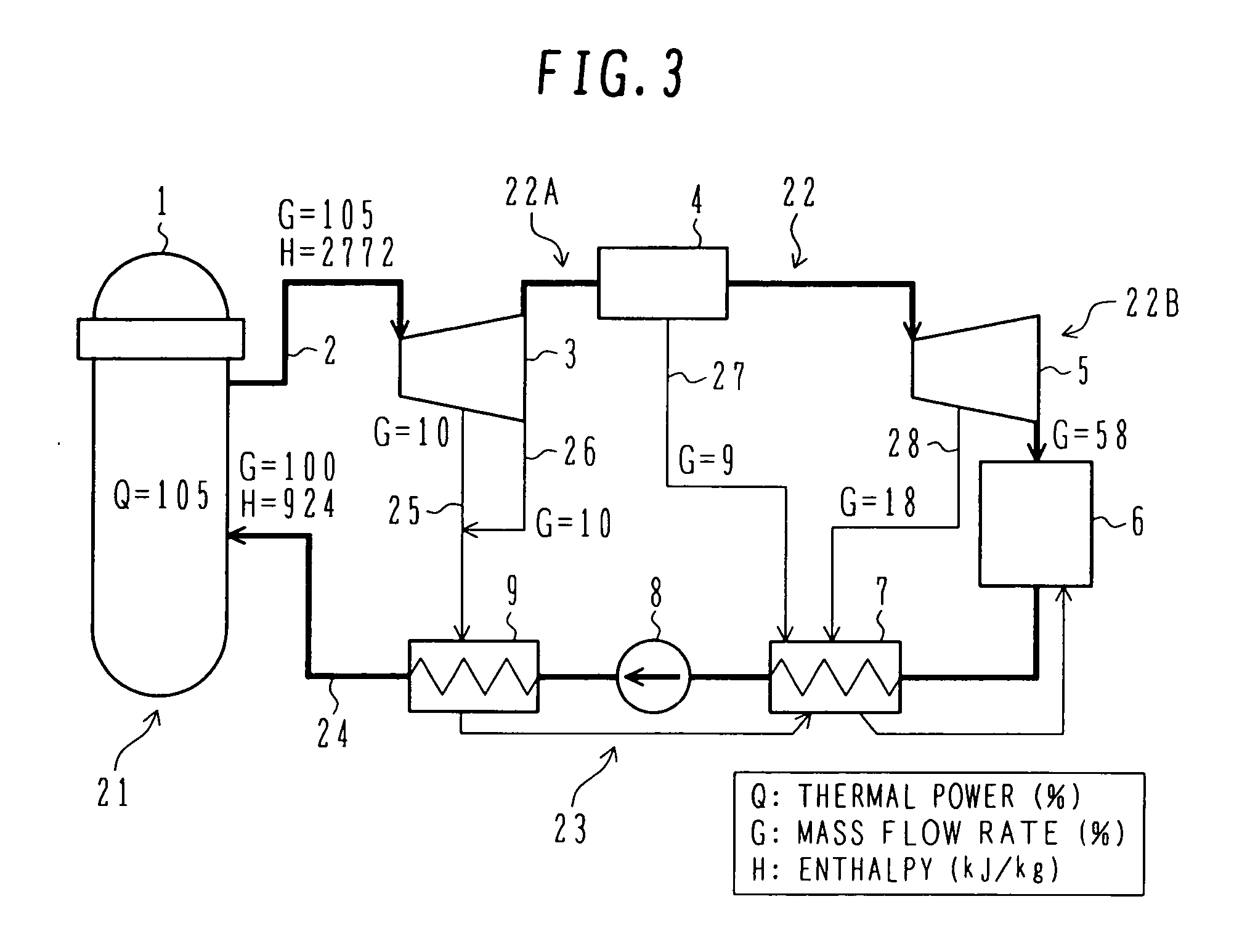

Operation method of nuclear power plant

ActiveUS7614233B2Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear reactorNuclear power

In a nuclear power plant, thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle by at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam, is reduced in the second operation cycle from that in the first operation cycle such that the temperature of feedwater discharged from the feedwater heater is lowered by 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Operation method of nuclear power plant

ActiveUS20070000250A1Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear powerHigh pressure

A nuclear power plant and an operation method of the nuclear power plant, which can uprate plant power without greatly modifying the construction of plant equipment, while keeping a core's pressure loss characteristic, a safety margin, and a design margin in the transient state substantially the same as those before the power uprate. Thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam is reduced in the second operation cycle from that in the first operation cycle such that temperature of feedwater discharged from the feedwater heater lowers in the range of 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Method for smelting crude lead in oxygen-enriched side-blowing smelting furnace

InactiveCN102776383AEmission reductionSimplify the melting processProcess efficiency improvementLead smeltingPhysical chemistry

The invention relates to a method for smelting crude lead in an oxygen-enriched side-blowing smelting furnace, belonging to the technical field of lead smelting. The method comprises the process steps of: 1) crude lead material preparation: proportioning lead-containing materials, quartz stones and limestone flux according to silicate degree being 0.9-1.3 percent, evenly mixing and crushing the lead-containing materials and the flux to grain size being less than or equal to 40mm; 2) crude lead smelting preparation: melting partial crude lead materials to a depth of 300-400mm in the oxygen-enriched side-blowing smelting furnace; and 3) crude lead smelting: continuously feeding the crude lead materials into a hearth and then controlling smelting air-coal ratio, temperature and high-pressure oxygen-enriched air supply, wherein molten lead sinks down and automatically flows into a furnace bed for heat preservation and storage through a siphon port, the molten lead automatically flows into a casting mold to form ingots when the depth of the stored molten lead reaches an overflow port, and the accumulated floating lean slag is discharged and is introduced into the crude lead material preparation process. The method for smelting crude lead in the oxygen-enriched side-blowing smelting furnace has the advantages that the investment is small, the smelting efficiency is high, the energy consumption is low, the arrangement is facilitated, the treatment capacity is high, the method is suitable for mass production, the materials are not required to be granulated, bricked, dried and stored, and the quantity of flue dust is small.

Owner:杨龙安

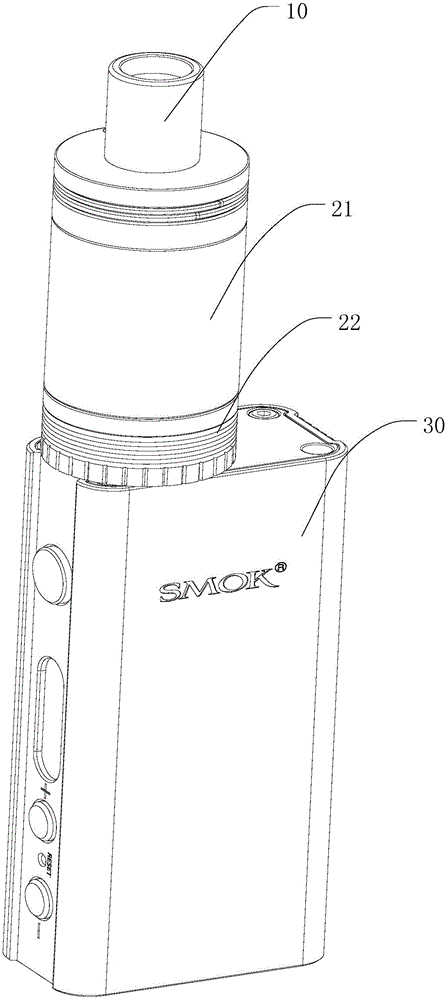

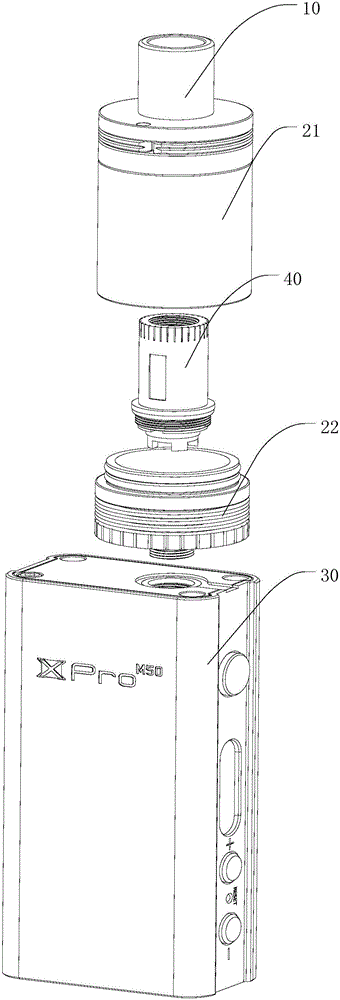

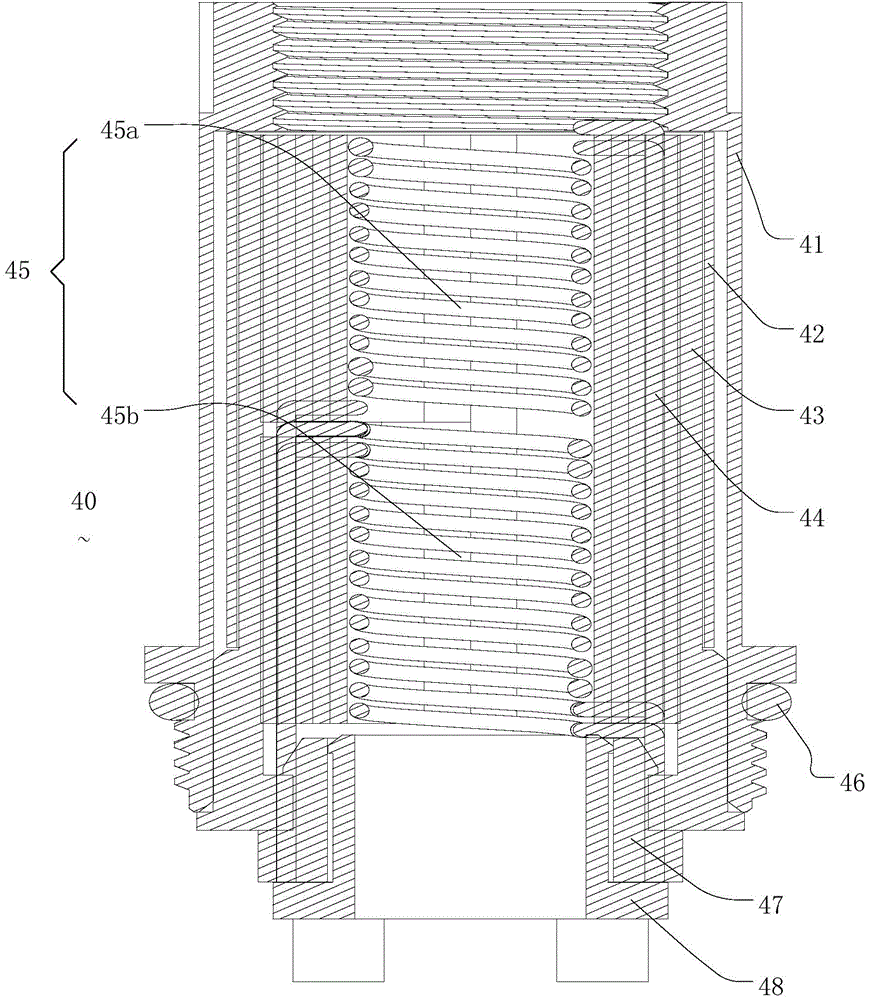

Atomizer and electronic cigarette

The invention discloses an atomizer, which is mounted in an electric cigarette and comprises a heating assembly, wherein the heating assembly comprises a first heating member and and second heating member parallel to the first heating member; a first heating wire is twisted to form the first heating member; a second heating wire is twisted to form the second heating member; and the first heating member and the second heating member are set on a same shaft. According to the invention, the heating assembly is divided into the first heating wire and the second heating wire; the first heating wire is parallel to the second heating wire; the thermal power of the heating assembly is greatly improved, that the effect that the atomizer is used to atomize oil smoke is better; and the smoke amount is more.

Owner:SHENZHEN IVPS TECH

Steam separator, boiling water reactor and swirler assembly

ActiveUS7835483B2Easy to separateSmall pressure lossNuclear energy generationDispersed particle separationEngineeringCentrifugal force

A steam separator comprises an outer main swirler and an inner auxiliary swirler which is smaller than the main swirler. The swirlers are provided so as to be concentric on the inner wall at the lower side of the first stage inner cylinder. In the steam separator, when the gas-liquid two-phase flow which flows in the vicinity of the axial center of the first stage inner cylinder passes the auxiliary swirler, it is separated into steam and water by the centrifugal force. The separated water (droplets) is introduced into the main swirler. When the separated water (droplets) passes the main swirler, it is separated at the inner wall side of the first stage inner cylinder by the centrifugal force.Pressure loss in a steam separator is reduced and steam separation capability is increased without increasing the moisture from the steam separator.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Preparation method of silicon nitride powder

The invention relates to the field of silicon nitride preparation and discloses a preparation method of silicon nitride powder. The preparation method comprises the steps: 1) equipment preheating, 2)material heating: putting a mixture of silicon powder and ammonia, and nitrogen in a coil of a microwave plasma preheater for mixing and preheating to 700-750 DEG C, putting the materials in a heatingarea of an inner cavity of a suspension reactor for heating continuously, and supplying an upward nitrogen vortex flow into the heating area to drive the materials to rotate, 3) reaction: dropping the materials to a reaction area, supplying the upward nitrogen vortex flow into the reaction area to drive the materials to rotate for reaction to generate silicon nitride during dropping, 4) heat insulation and cooling: allowing silicon nitride and unreacted nitrogen to enter a heat insulation cooler, cooling the materials through water cooling, then through water cooling and air cooling, and finally through water cooling, and 5) gas-powder separation. The silicon nitride powder prepared according to the method is high in purity, small in particle size and high in yield and is produced quickly, and an alpha phase content is high.

Owner:ZHEJIANG YUYAO NEW MATERIAL CO LTD

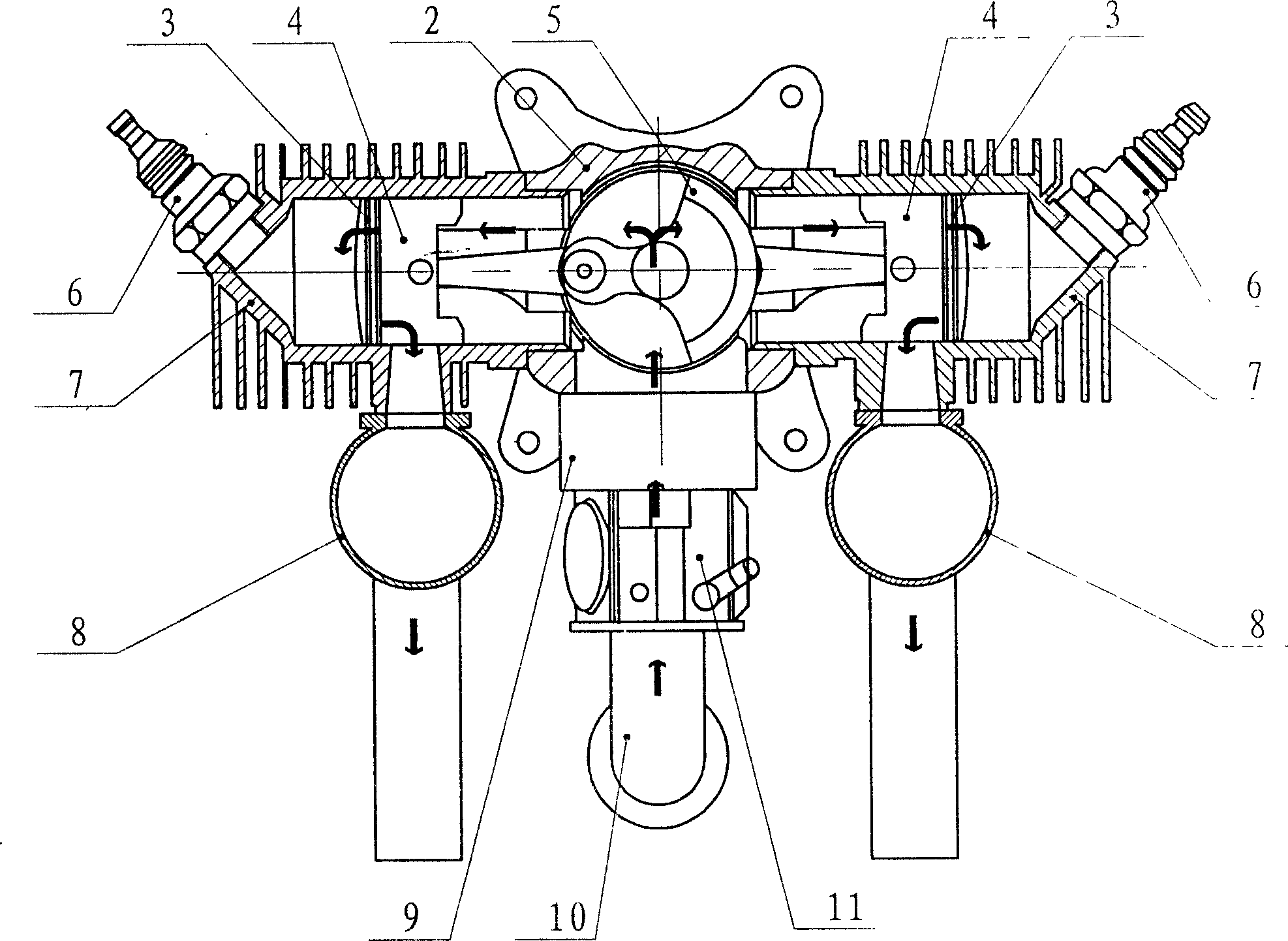

Gasoline engine with two horizontally and oppositely arranged cylinders

The gasoline engine with two horizontally and oppositely set cylinders includes upper and lower engine bodies, cylinders, spark plug, piston assembly, piston ring, crankshaft link assembly, leaf valve assembly and carburetor. The crankshaft link assembly is set inside the crankshaft box comprising the upper and the lower engine bodies, the right and the left cylinders are set horizontally on two sides of the crankshaft box and are provided with separated exhaust pipes, the piston assembly is connected to the crankshaft link assembly and set inside the right and the left cylinders, and the carburetor is fixed on the crankshaft box via the leaf valve and has fixed gas intake seat. With the said structure, the gasoline engine of cylinder diameter of 33 mm has displacement of 48 cc, maximum power up to 3.1 kw in 8500 rpm rotation speed and rotation speed stability within 1 %.

Owner:应宁宁

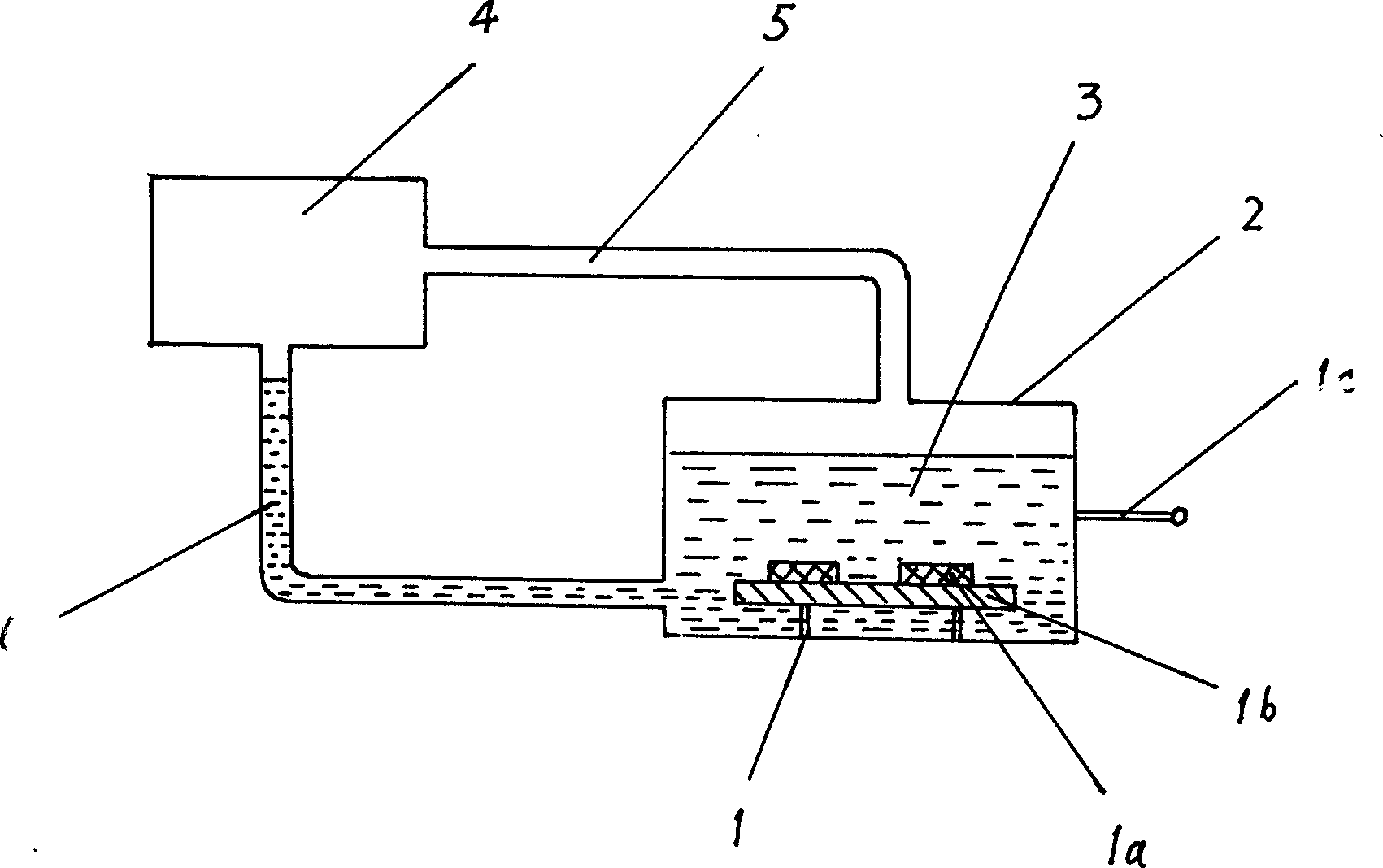

Active evaporating radiation tech of power semiconductor device or modular

InactiveCN1601733AImprove cooling efficiencyImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceElectrical conductor

In the invention, body case of power semiconductor device or module is fabricated to a hollow sealed shell body. Condenser is installed above the shell body. The said sealed shell body and condenser are connected to each other through pipe. Shell body of semiconductor device or module is as case of evaporator so as to form fully enclosed cooling circulation system. The disclosed cooling circulation system possesses very high cooling and heat radiation efficiency. Heat conductivity of the said system is more than 350 times of heat conductivity of good conductor (such as solid copper) with same geometrical size. Power semiconductor devices and modules with different power are available. The invention is suitable for cooling device with large power or devices in large installation density.

Owner:原泽

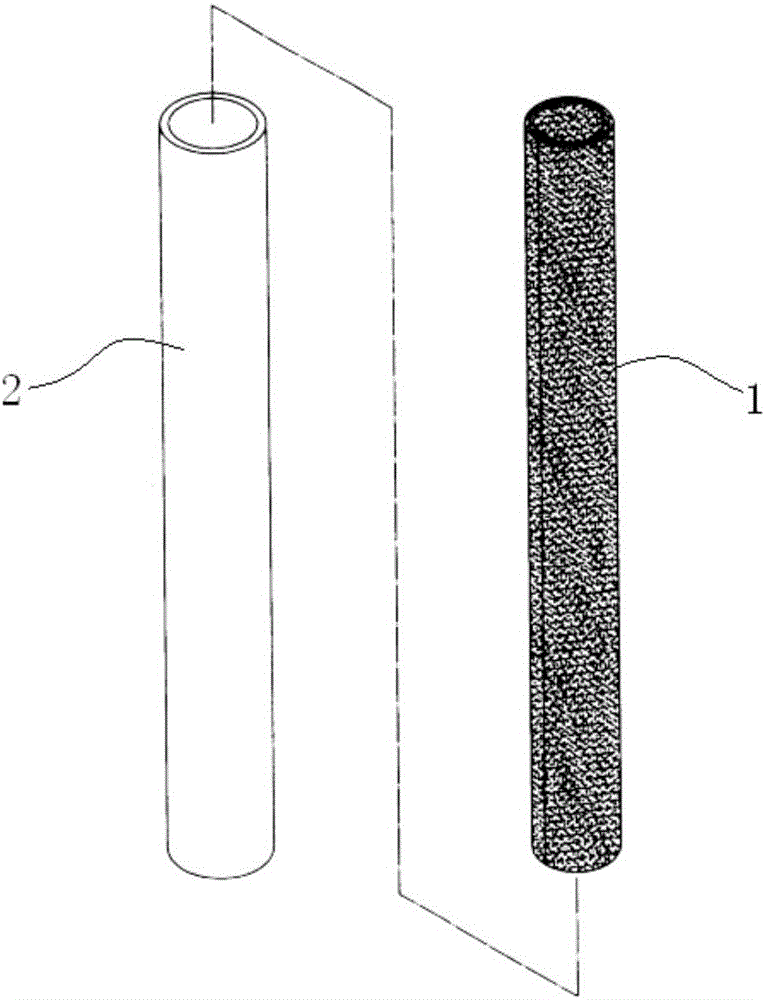

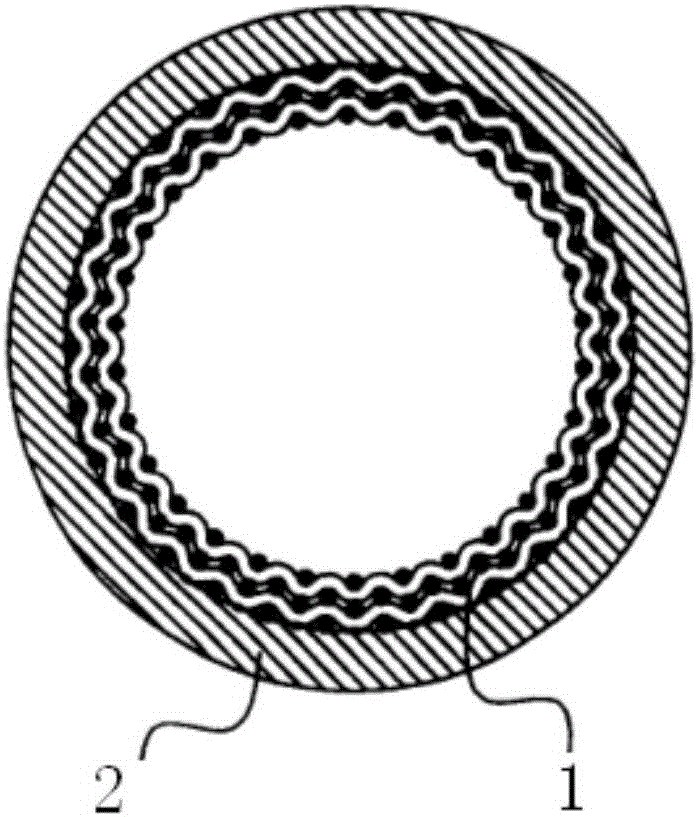

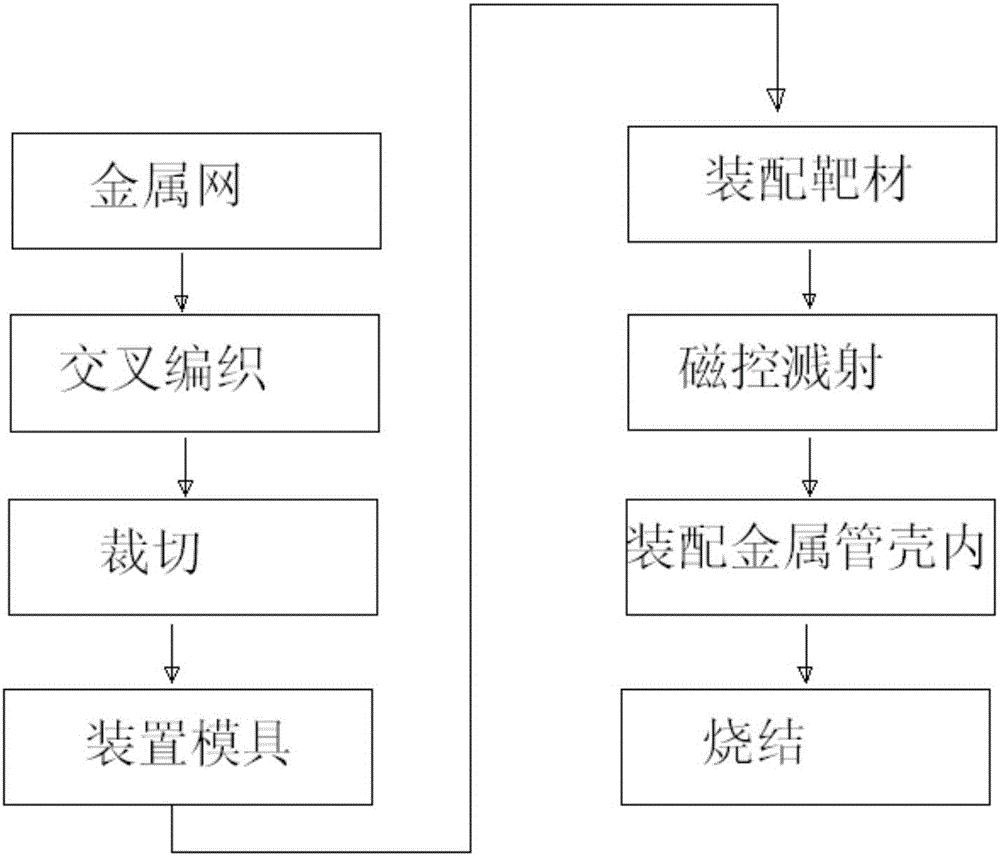

Heat pipe core, heat pipe and sputtering process of heat pipe

InactiveCN106705723ARefined selection specificationsFast response timeIndirect heat exchangersTubular elementsSputteringTemperature difference

The invention discloses a heat pipe core, a heat pipe and a sputtering process of the heat pipe. The pipe core structure of a traditional heat pipe is improved. A layer of graphene material is arranged on the surface of a metal net attached to the inner wall of a metal pipe shell through sputtering. Due to the ultrahigh heat conductivity of graphene assisting traditional design, the response time in the heat pipe during phase change is promoted greatly, the efficiency of heat conduction is promoted, phase change switching time is shortened, thus the temperature difference of the cold end and the hot end of the heat pipe is reduced, and the heat conduction power is promoted. In addition, detailed quantitative processing is conducted on both the wire diameter and number of the metal net, and thus model selection specification of the heat pipe is detailed.

Owner:SUZHOU KANRONICS ELECTRONICS TECH CO LTD

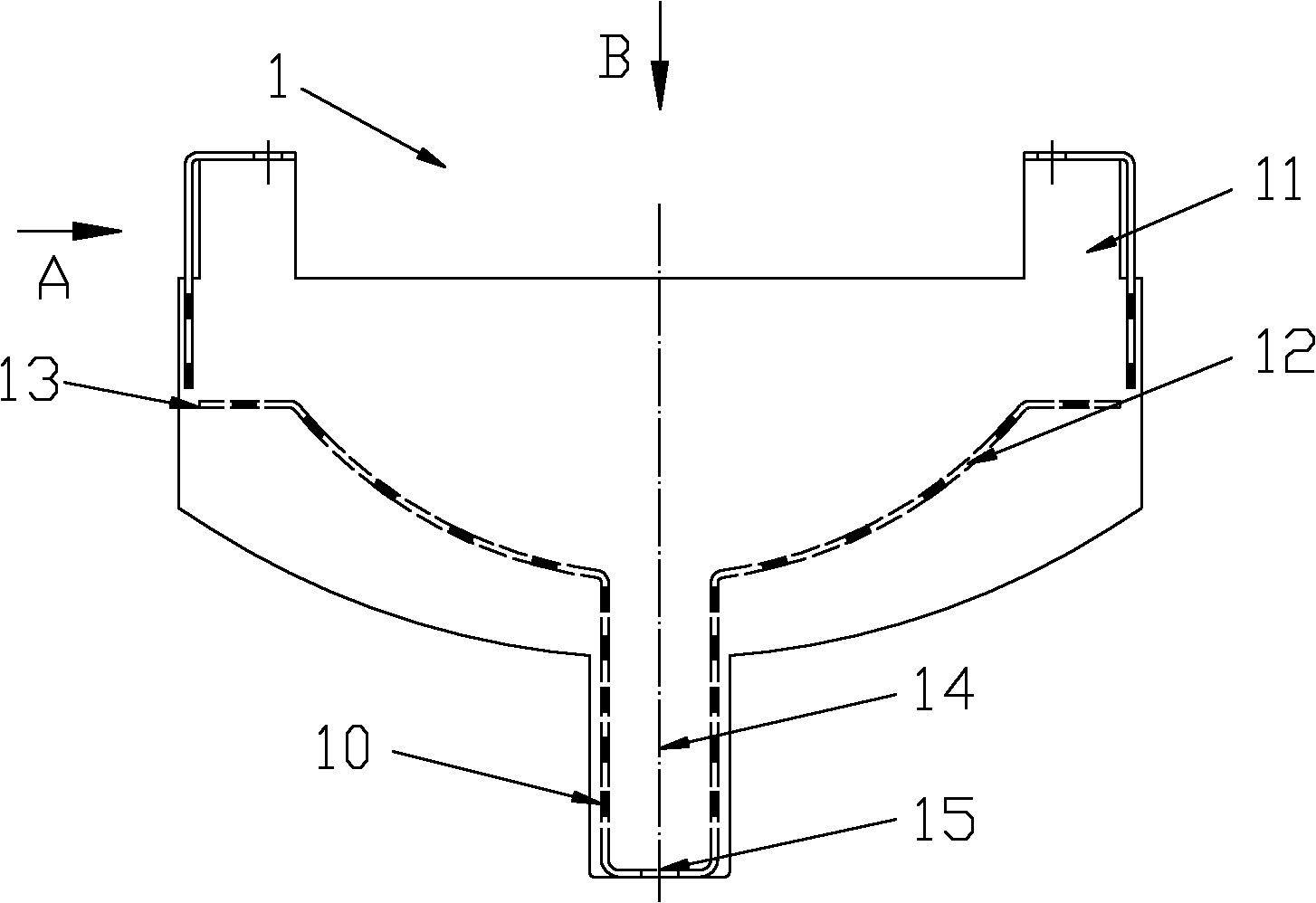

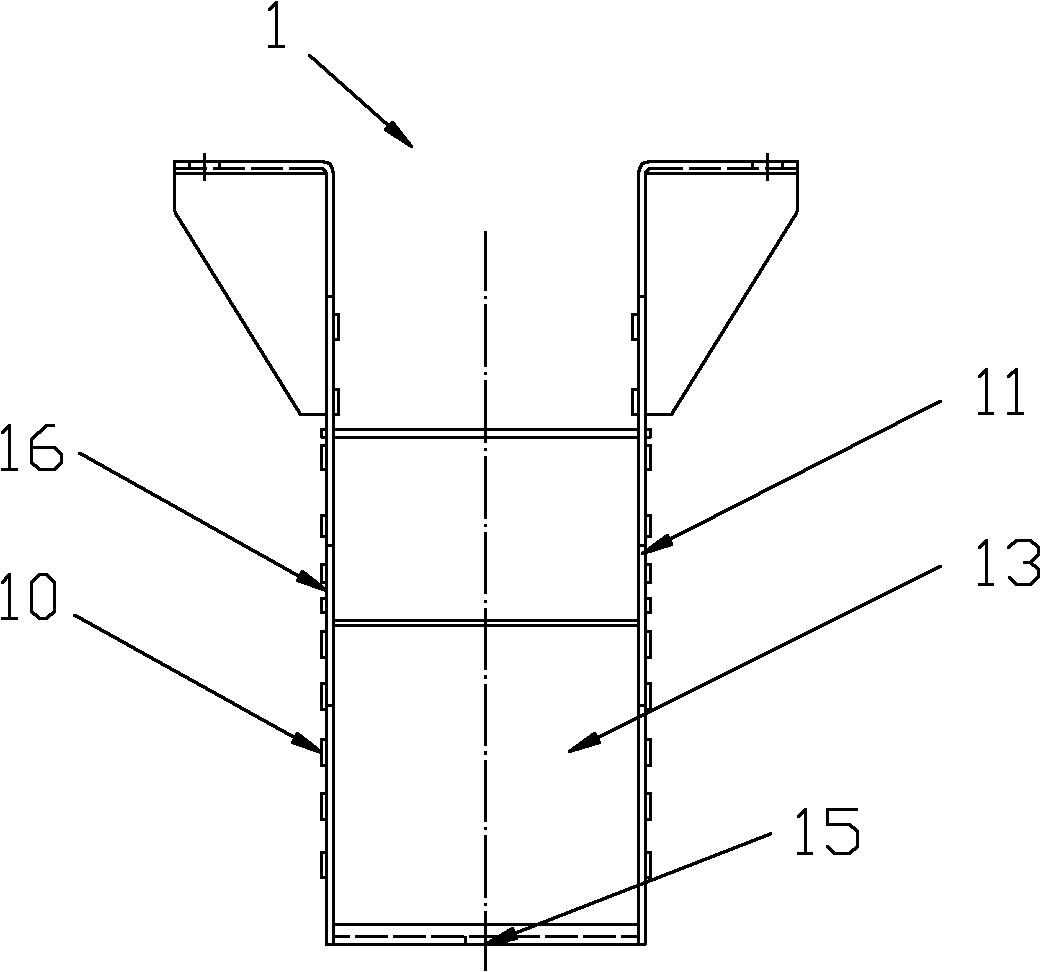

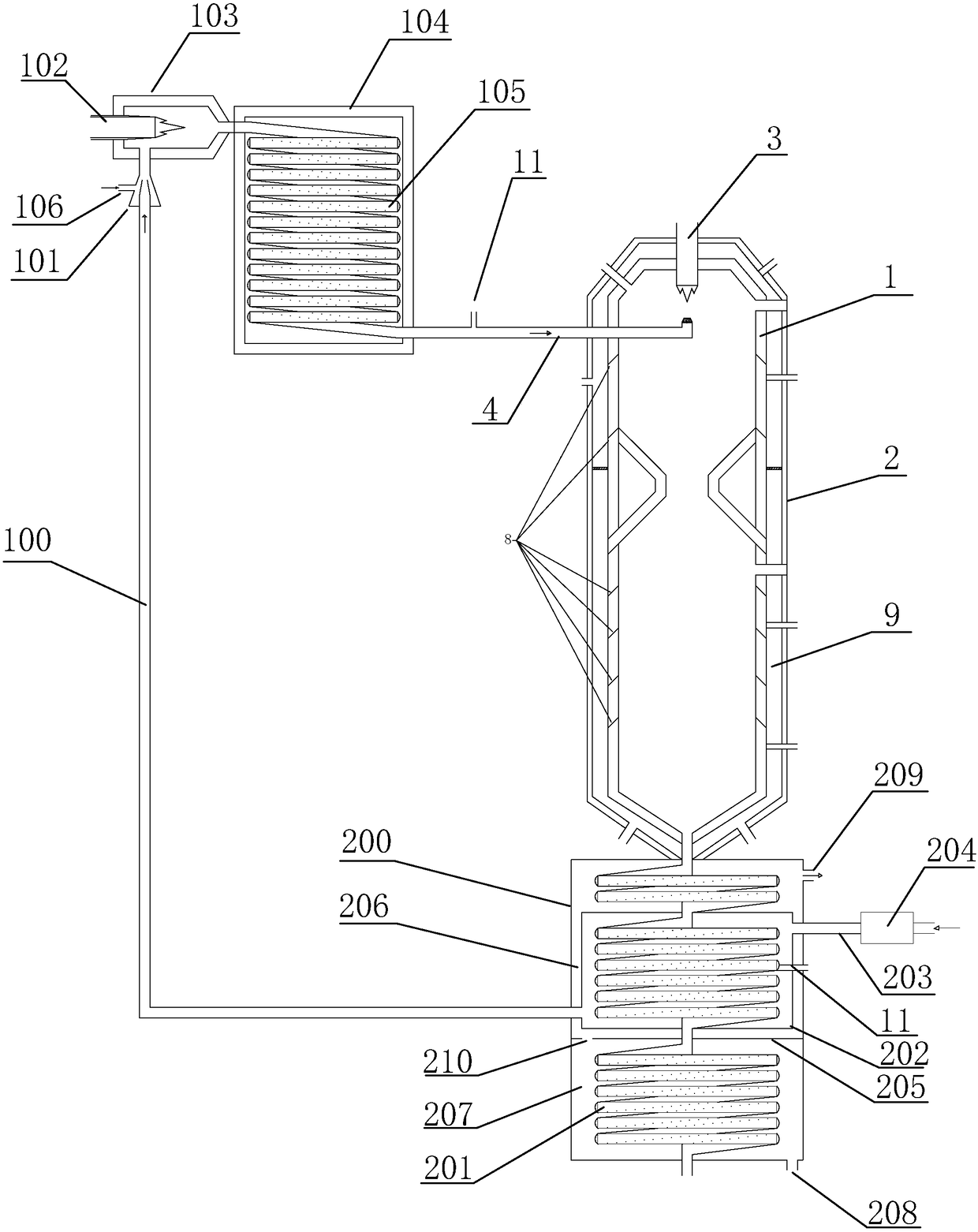

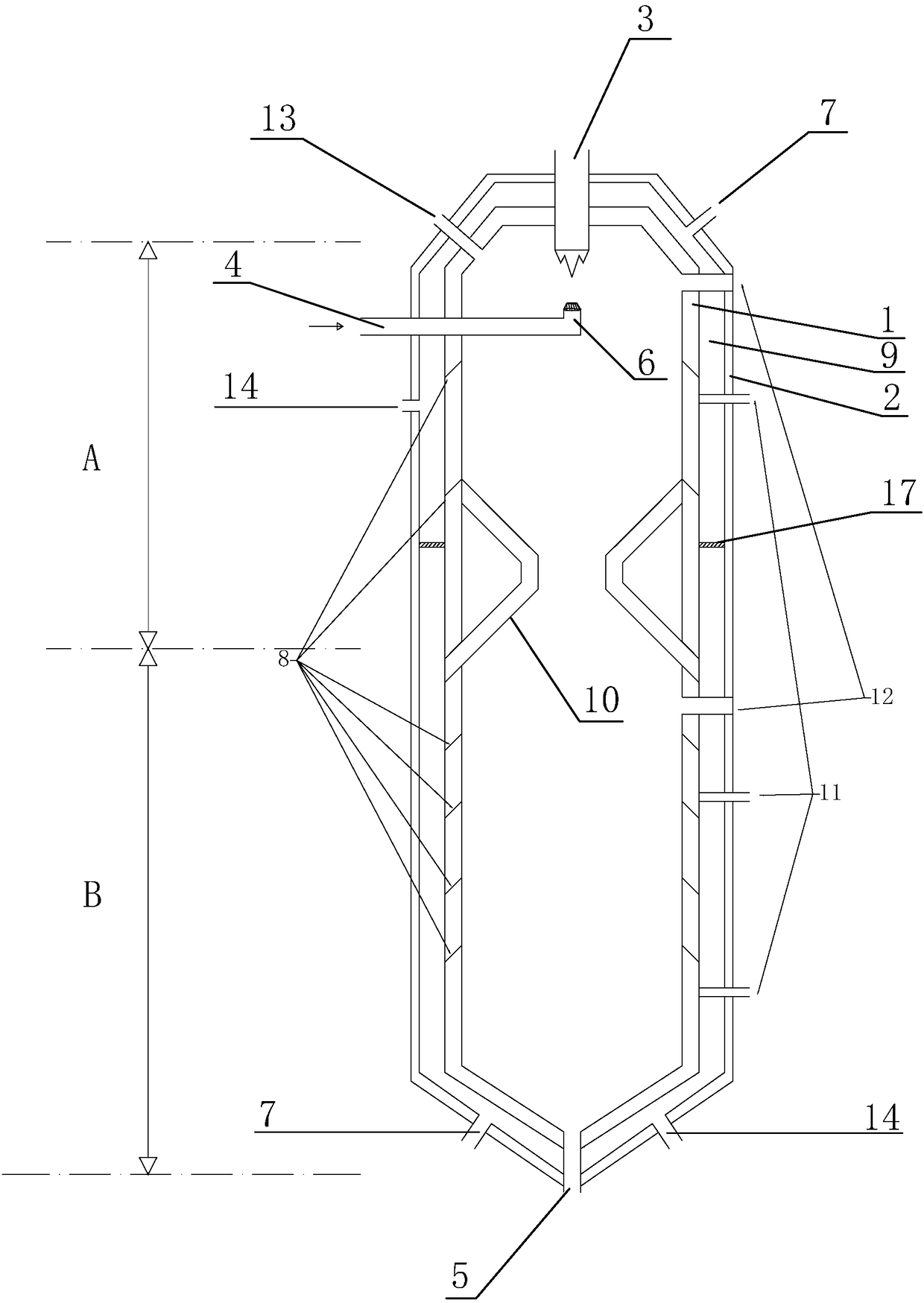

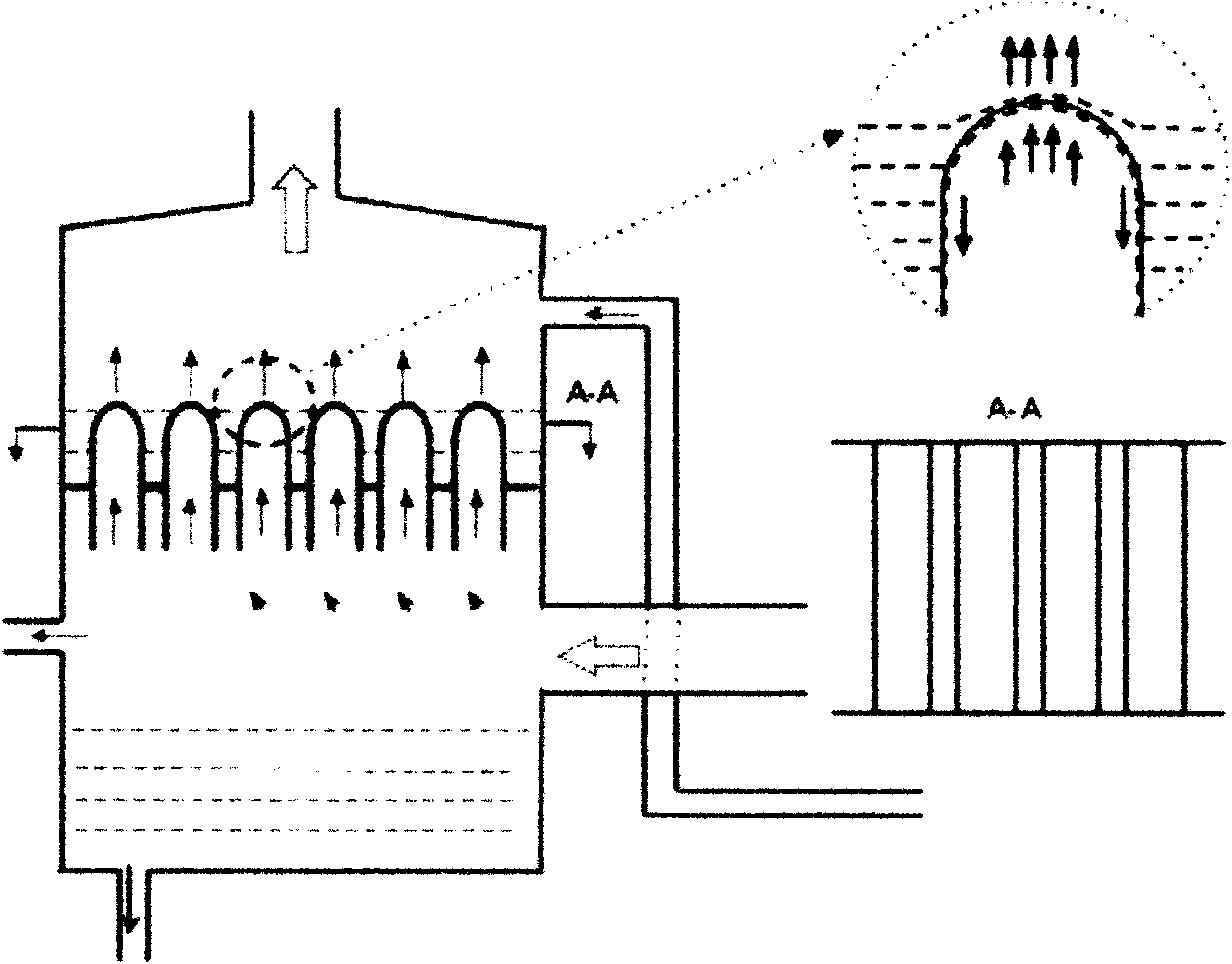

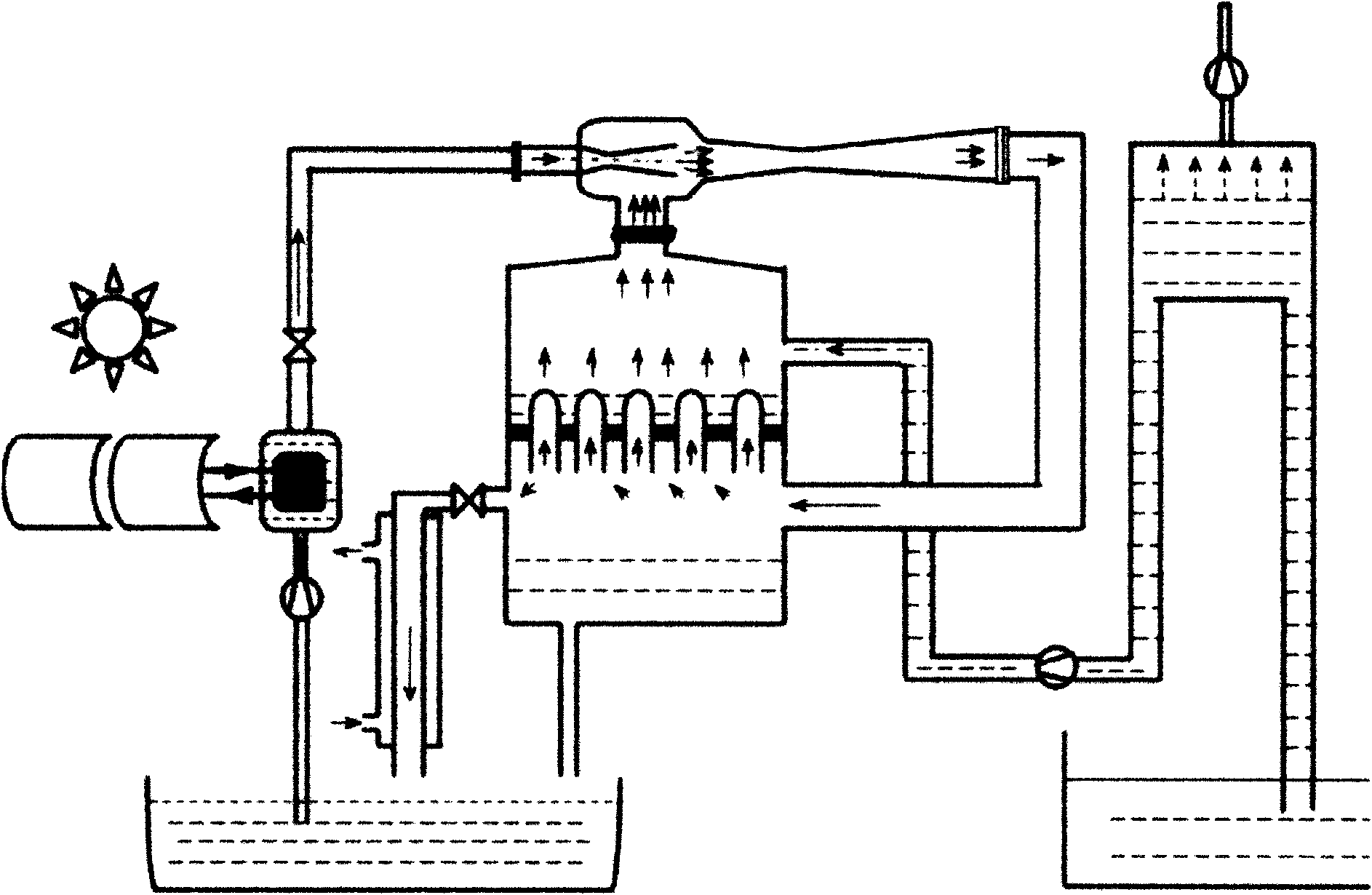

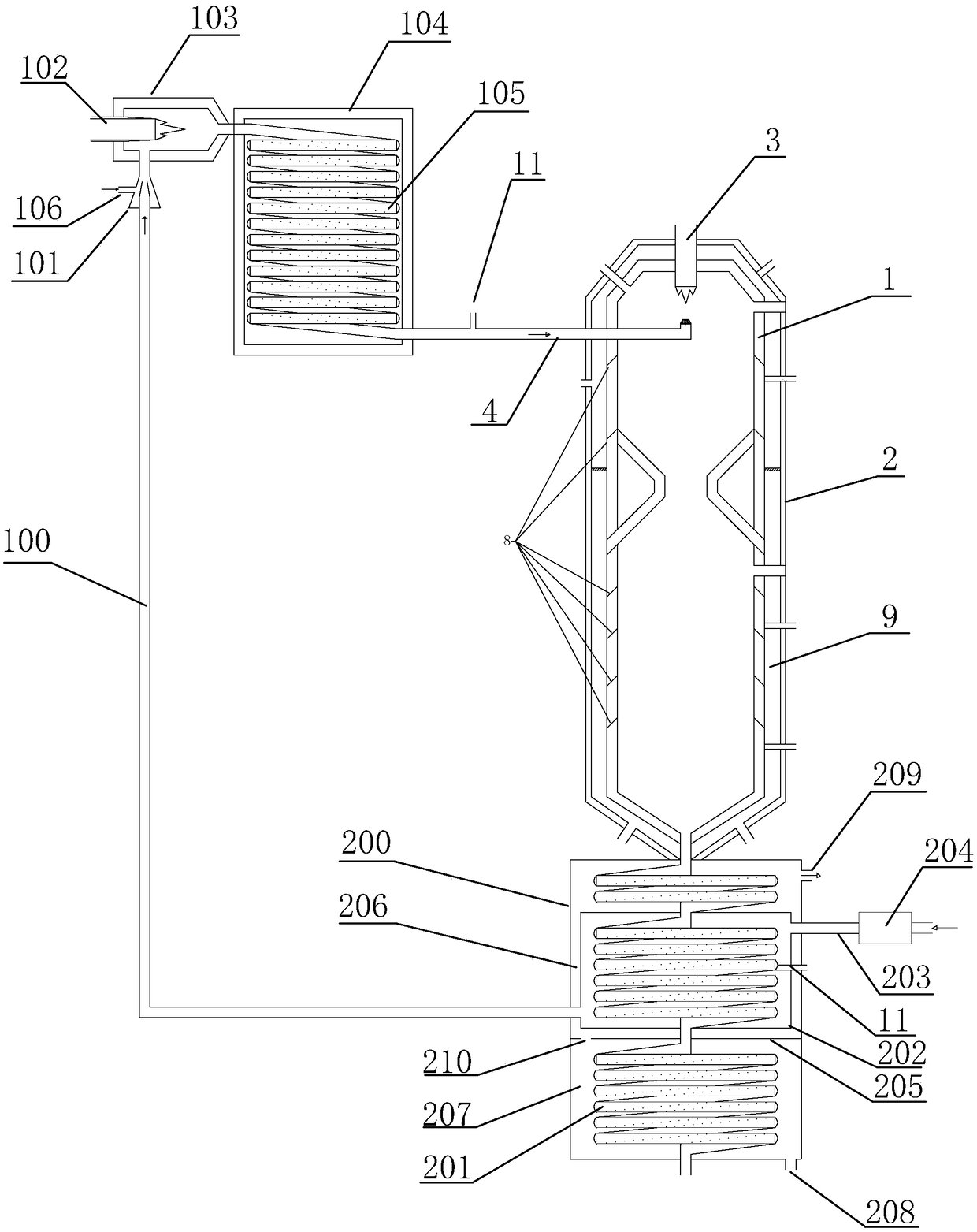

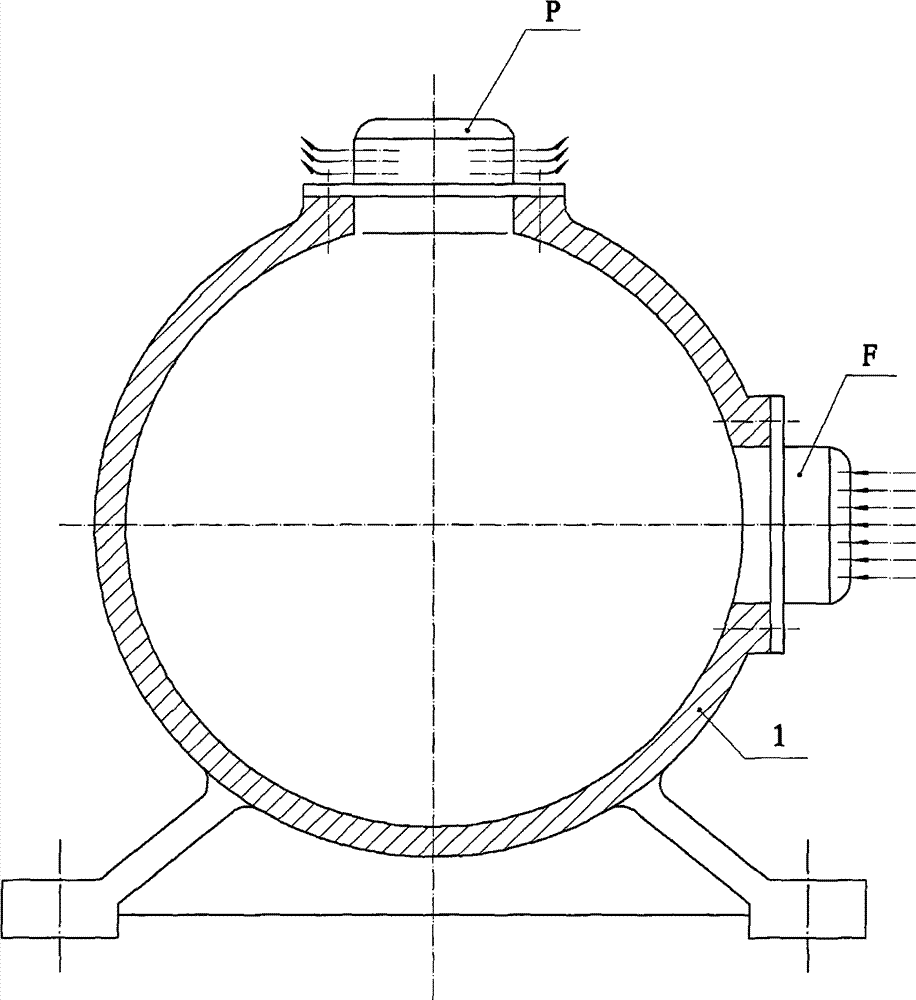

Low-pressure solar seawater desalination device using ejector

InactiveCN102134110AReduce thermal resistanceIncrease thermal powerGeneral water supply conservationSeawater treatmentInjectorSeawater

A Low-pressure solar seawater desalination device using an ejector belongs to the technical fields of solar energy utilization and seawater desalination. In the device, solar energy is used as an auxiliary heat source; the self gravity of seawater is used to counteract the atmospheric pressure; the suction effect of the ejector is used to generate a negative pressure lower than the saturation pressure of seawater; the ejector is used to generate a temperature difference between seawater and condensed water steam; the condensation heat of water steam is recycled; the thin-wall arched structure where the heat exchanging wall ascends slowly in a thin-wall heat exchanging device is used to increase the heat conduction power and the heat exchange area; therefore the evaporation and the condensation are performed at a low temperature difference, and the COP of the ejector is greatly improved. The desalination process has low energy consumption and high fresh water yield, and the seawater desalination cost is reduced.

Owner:徐同德

Friction component used for wet-type friction clutch

InactiveCN103629266ATurnover rate is smallExtended service lifeFluid actuated clutchesFriction clutchesEngineeringCooling efficiency

The invention relates to a friction component used for a wet-type friction clutch comprising an internal friction sheet carrier; an external friction sheet carrier; a friction sheet chamber used for accommodating the friction sheets to transmit the torque in a locked manner; a central shaft, around which rotates the friction sheet carrier. The internal friction sheet carrier is provided with a first through opening and a second through opening. The first through opening is extended from the central shaft to the friction sheet chamber, and the second through opening is extended from the outer side of friction sheet chamber to the friction sheet chamber. By using the wet-type friction clutch or the friction component can be used to utilize the cooling efficiency of the cooling liquid, reduce the required structural space and the production costs.

Owner:SCHAEFFLER TECH AG & CO KG

Confinement of caesium and/or rubidium in apatitic ceramics

InactiveUS6489531B1Confirmed durabilityConfirmed stabilityShieldingRadioactive decontaminationRubidiumApatite

The invention relates to the containment of caesium and / or rubidium, in particular 135Cs and 137Cs in an apatitic matrix of formula:in which:M represents Cs and / or Rb,Ln represents at least one trivalent cation,X represents at least one anion chosen from among 2F-, S2-, 2Cl-, 2Br-, 2I-, 2OH- and O2-, andt, x, y, and u are such that:0<t.2.52.x.81.y.70.u.6x+y+t=10and the total number of positive charges provided by the cations M, Ca and Ln are equal to (20+u).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

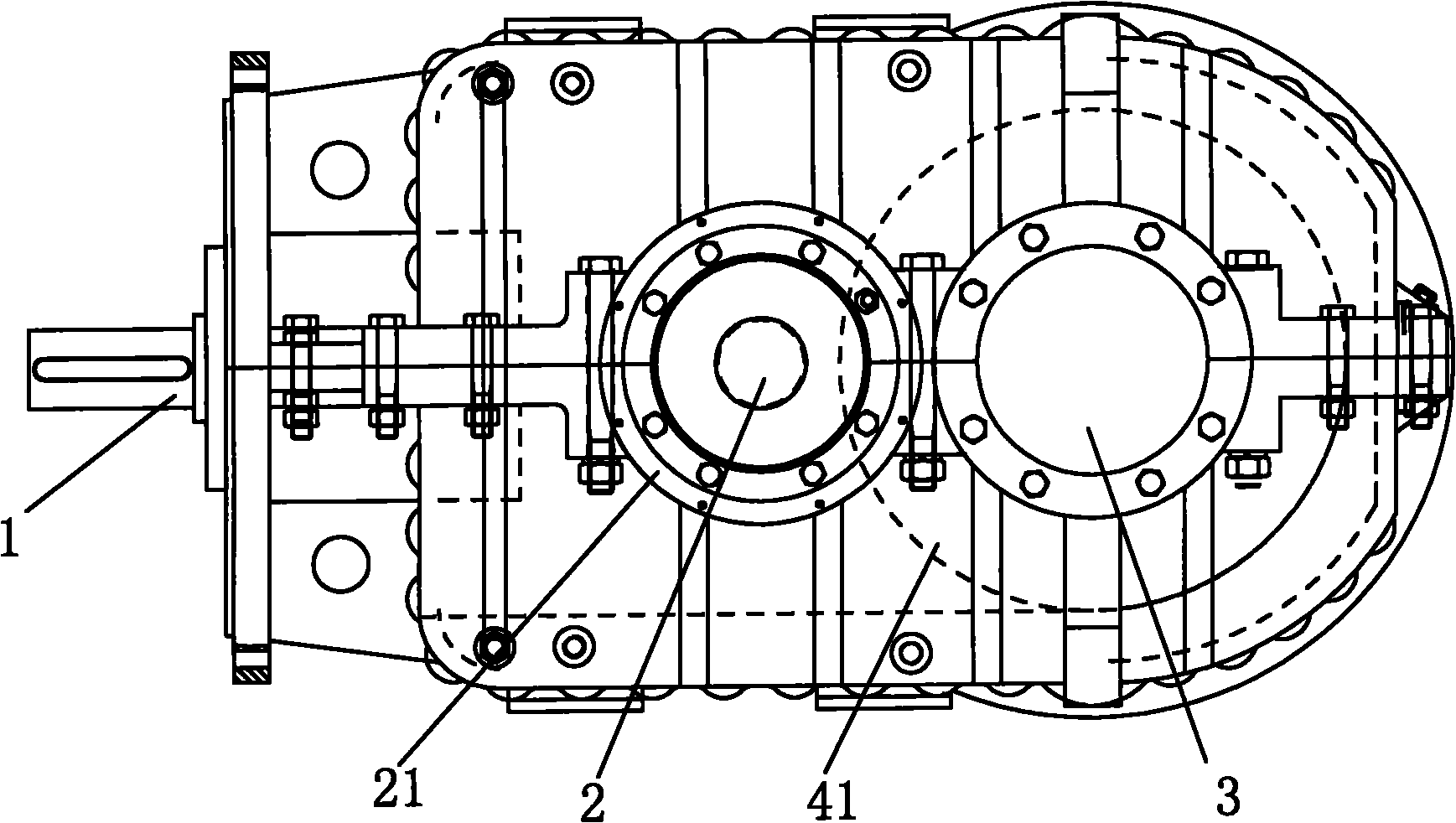

Speed reducer for conveyor

InactiveCN101804900ANice appearanceSatisfy the requirement of using the maximum excess coalConveyorsToothed gearingsReduction driveReducer

The invention relates to a main drive device on a scraper conveyor for mines, in particular to a speed reducer for a conveyor, and aims to provide the speed reducer for the conveyor with the advantages of novel structure, small volume, large bearing capacity, and excellent performance. The speed reducer for the conveyor comprises a body, a drive mechanism, a cooling system and a sealing element. The drive mechanism comprises an input bevel gear shaft, an intermediate gear shaft, an output inner gear shaft, and a planetary gear train. The input bevel gear shaft is provided with a bevel gear end; the intermediate gear shaft is provided with a bevel gear and a cylindrical gear which are meshed with the bevel gear end; the output inner gear shaft is provided with a cylindrical wheel meshed with the cylindrical gear; the planetary gear train comprises a sun gear, a planet carrier, a planet gear and an annular gear which is fixed on the body; the output inner gear shaft is connected with the periphery of the sun gear in a positioning mode through crowned teeth; the sun gear and the annular gear are arranged coaxially; the planet gear is positioned between the sun gear and the annular gear and meshed with the sun gear and the annular gear respectively; and the planet carrier and the output inner gear are arranged coaxially.

Owner:CHANGZHOU SPEED REDUCER GENERAL FACTORY

Three-valve hot-air engine

InactiveCN103089486AImprove thermal efficiencyIncrease thermal powerHot gas positive displacement engine plantsExhaust valveCombustion chamber

The invention discloses a three-valve hot-air engine, and the three-valve hot-air engine includes an air cylinder piston mechanism and a combustion chamber. An air cylinder of the air cylinder piston mechanism is provided with an air inlet. An air inlet valve is arranged at the position of the air inlet. The air cylinder of the air cylinder piston mechanism is provided with a reciprocating flow mouth which is provided with a reciprocating flow control valve. The reciprocating flow mouth is communicated with a timing pulse air mechanism through a reciprocating communicating channel. A heat regenerator is arranged on the reciprocating communicating channel. An exhaust air outlet is formed on the air cylinder of the cylinder piston mechanism, and an exhaust valve is arranged at the position of the exhaust air outlet. The combustion chamber is arranged inside the air cylinder piston mechanism. Due to the facts that the combustion motor is combined with the thermomotor, and the air exhausted from combustion motor is regarded as a circular working medium of a thermomotor, the further utility of the waste heat in the exhaust of the engine has the advantages of effectively improving thermal efficiency of the engine, and being simple in structure, strong in practicability, and broad in application prospect.

Owner:ZEROQ SCI & TECH

Barrier dryer with porous liquid-carrying material

InactiveUS8684514B1Efficient removalIncrease thermal powerOther printing apparatusTransport systemBoiling point

A media drying system removes a moistening liquid from a moistened medium. A liquid reservoir containing a heating liquid heated above a moistening-liquid boiling point. A rotatable liquid-blocking member has a liquid-blocking layer with an inner surface and an outer surface. A media-transport system transports the moistened medium so it contacts or is entrained around the liquid-blocking member in a path zone so that the moistened medium is brought into contact with the outer surface of the liquid-blocking layer. A porous material absorbs heating liquid from the liquid reservoir and brings the absorbed heating liquid into contact with the inner surface of the liquid-blocking layer for at least a portion of the path zone. Heat is transferred through the liquid-blocking layer from the absorbed warmed heating liquid to the moistening liquid, vaporizing the moistening liquid and removing it from the moistened medium.

Owner:EASTMAN KODAK CO

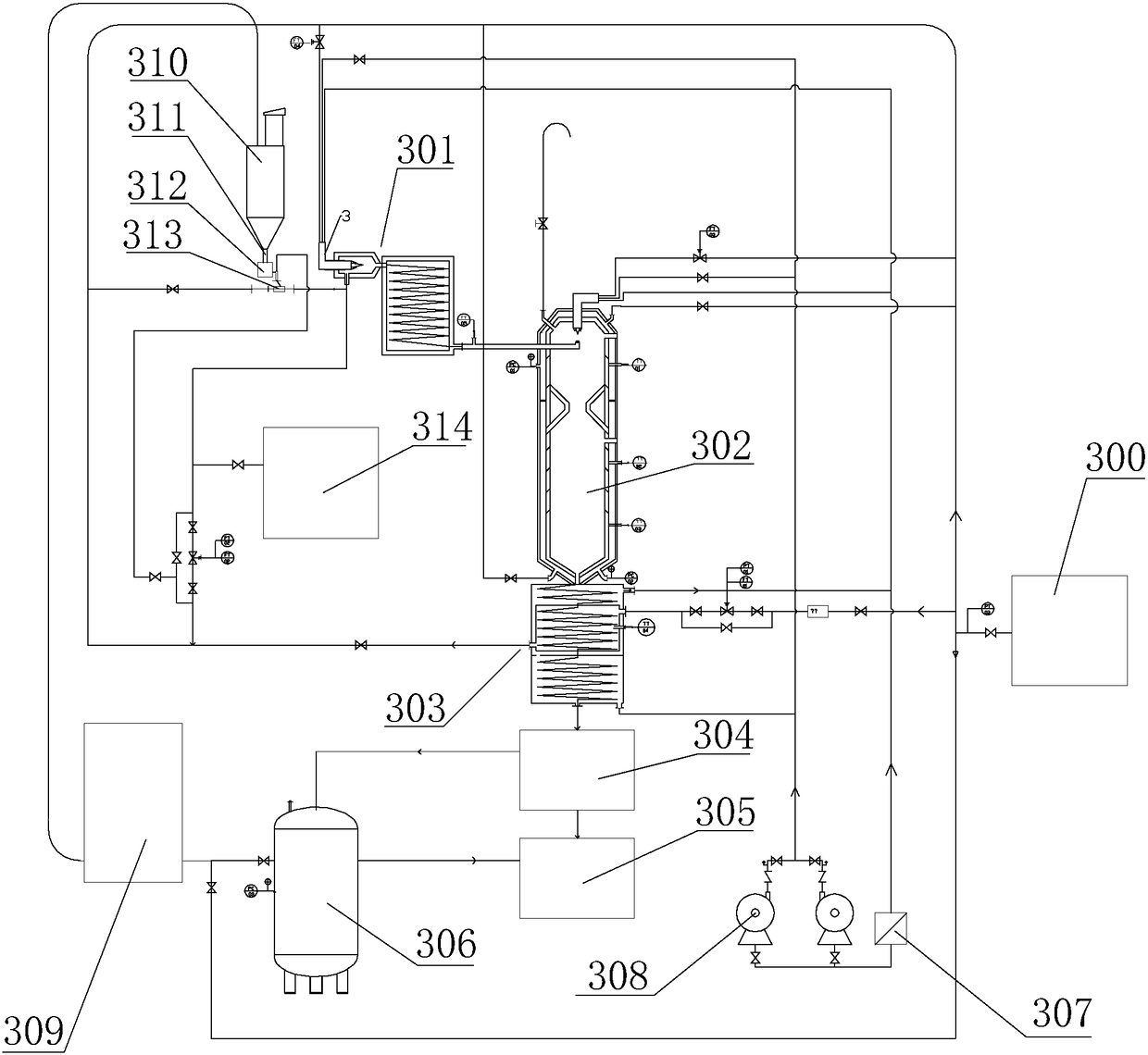

Reaction system for synthesizing silicon nitride powder

ActiveCN108622864AIncrease thermal powerReduce the temperatureProductsNitrogen compoundsSpray nozzleSilicon nitride

The invention relates to the field of silicon nitride preparation, and discloses a reaction system for synthesizing silicon nitride powder. The reaction system comprises a microwave plasma preheater,a suspension reactor and a heat insulation cooler, wherein the suspension reactor comprises a furnace tube, a furnace case, a heating torch and a spray pipe; an inner cavity of the furnace pipe is divided into a heating region and a reaction region; the upper end of the furnace pipe is fixedly provided with the heating torch; the lower end of the furnace pipe is provided with a discharging opening; the furnace case is sleeved outside the furnace pipe; heat insulation cotton is arranged between the furnace pipe and the furnace case; the spray pipe penetrates through the furnace case and the furnace pipe to enter the heating region of the inner cavity of the furnace pipe; in addition, a spray nozzle is arranged at the tail end of the spray pipe; a nitrogen gas inlet is formed in the furnacecase; a circle of air inlet seam is arranged at the same height on the inner wall of the furnace pipe; the air inlet seam is provided with an opening in the vertical direction and is in an inclined upward direction towards the inner cavity of the furnace pipe; the air inlet seam is provided with an opening in the horizontal plane, is approximately or completely tangent with the curve surface of the inner wall of the furnace pipe; in addition, the facing directions of all openings are identical. The silicon nitride powder prepared by the reaction system has the advantages of high purity, fine particle diameter, high alpha phase content, high yield and fast production.

Owner:ZHEJIANG YUYAO NEW MATERIAL CO LTD

Barrier dryer with porous liquid-carrying material

InactiveUS20140104354A1Efficient removalReduce probabilityOther printing apparatusTransport systemBoiling point

A media drying system removes a moistening liquid from a moistened medium. A liquid reservoir containing a heating liquid heated above a moistening-liquid boiling point. A rotatable liquid-blocking member has a liquid-blocking layer with an inner surface and an outer surface. A media-transport system transports the moistened medium so it contacts or is entrained around the liquid-blocking member in a path zone so that the moistened medium is brought into contact with the outer surface of the liquid-blocking layer. A porous material absorbs heating liquid from the liquid reservoir and brings the absorbed heating liquid into contact with the inner surface of the liquid-blocking layer for at least a portion of the path zone. Heat is transferred through the liquid-blocking layer from the absorbed warmed heating liquid to the moistening liquid, vaporizing the moistening liquid and removing it from the moistened medium.

Owner:EASTMAN KODAK CO

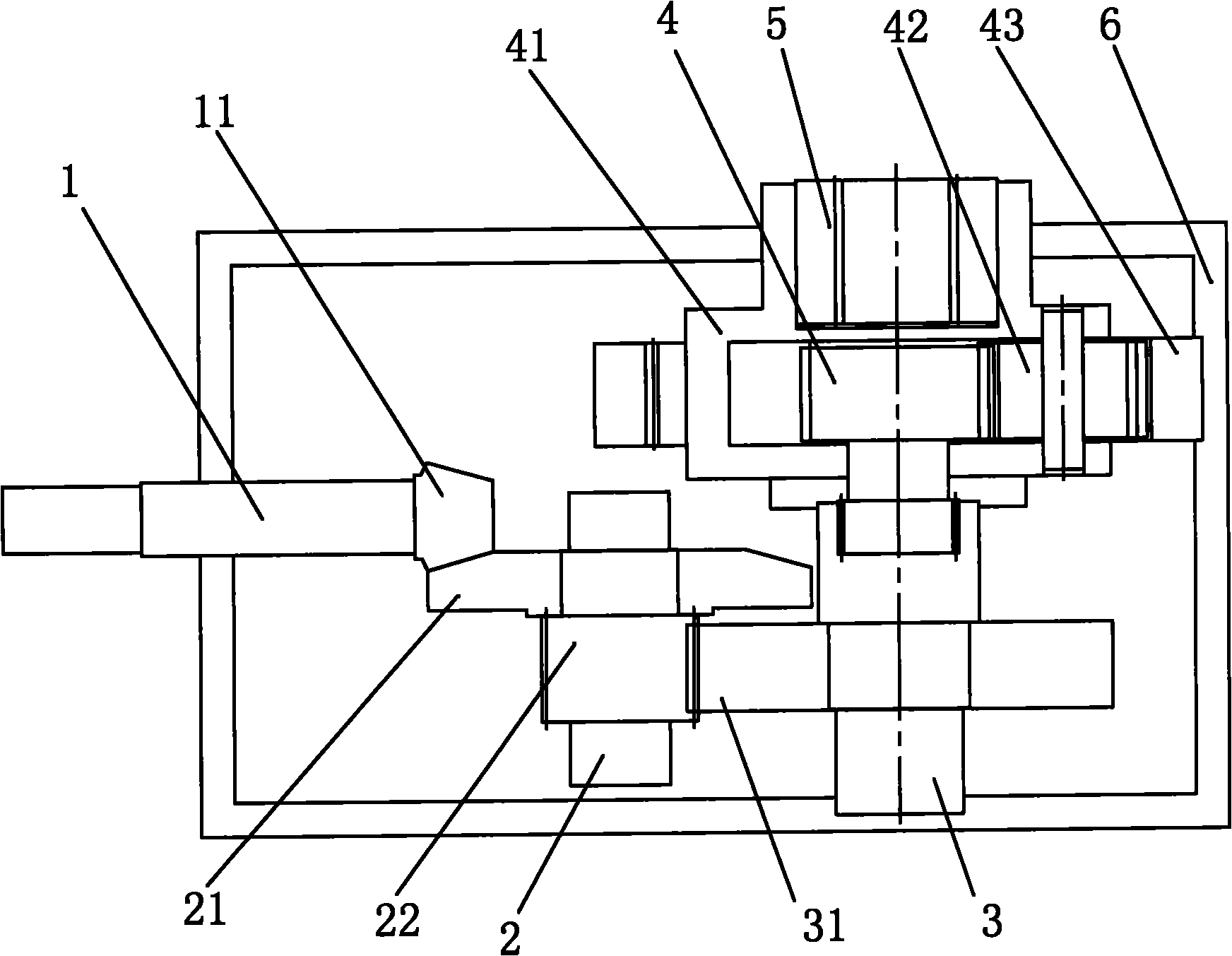

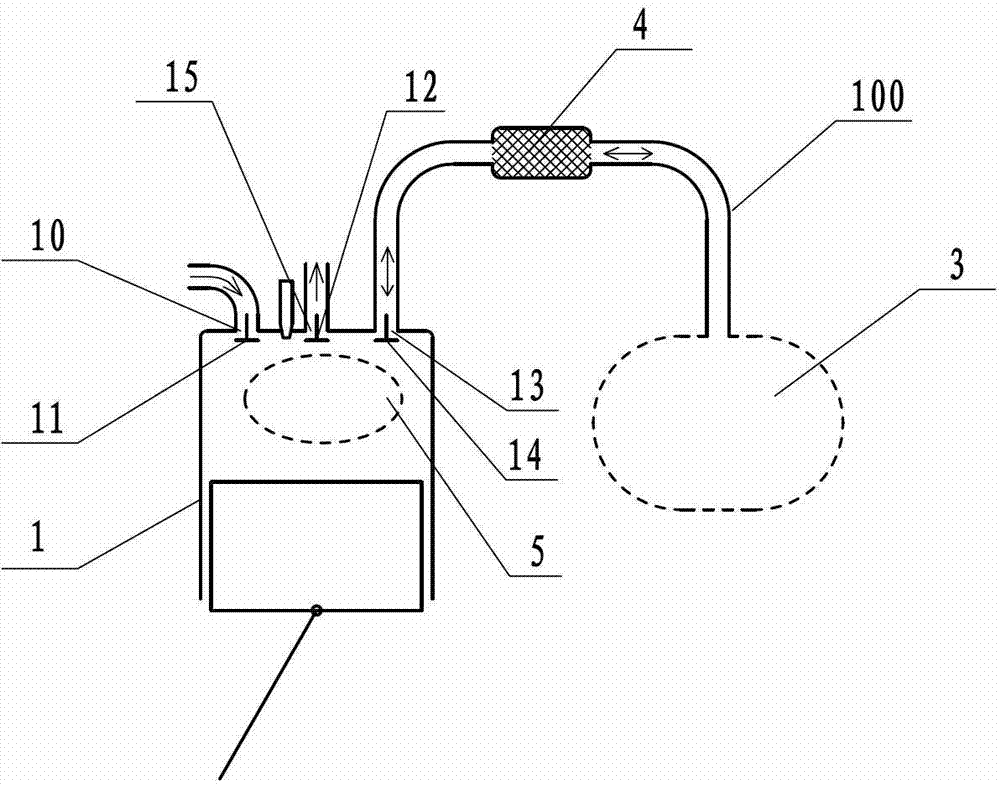

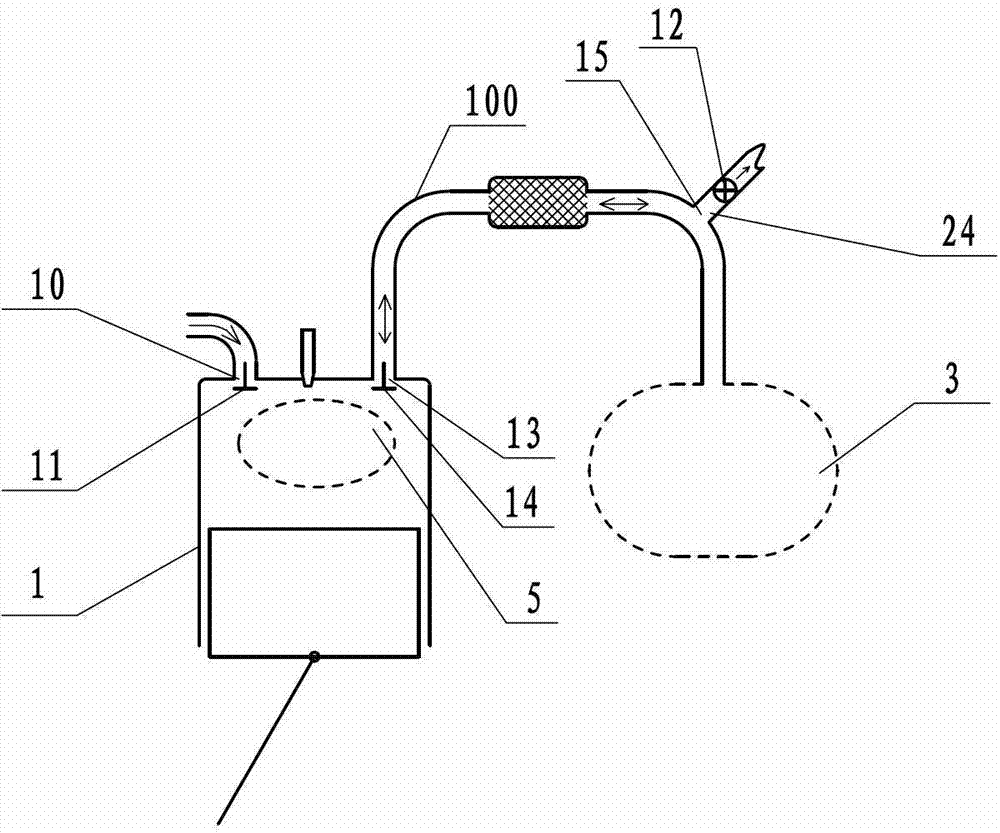

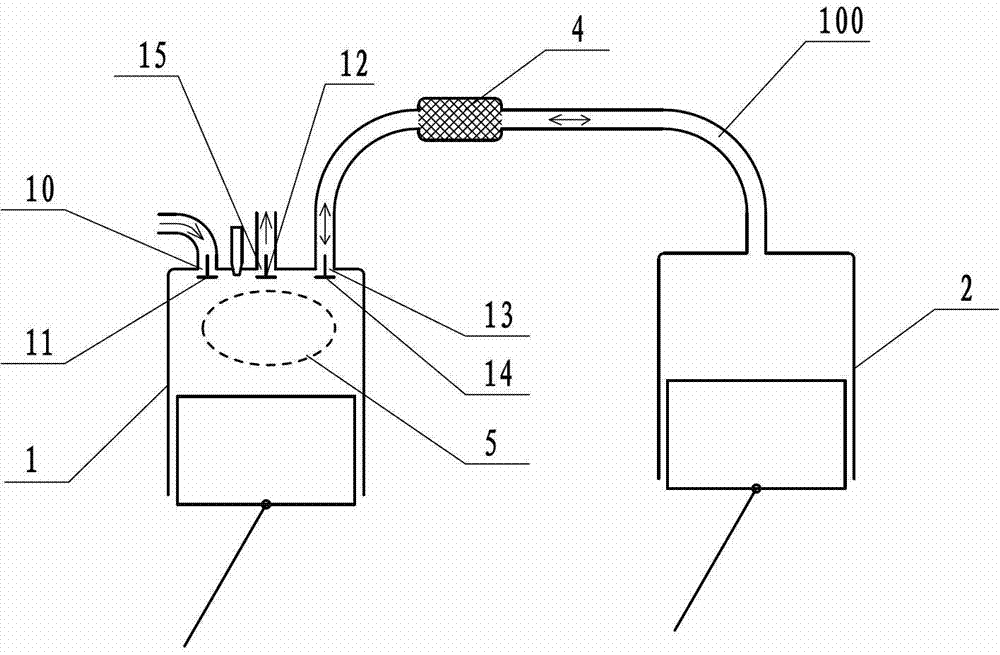

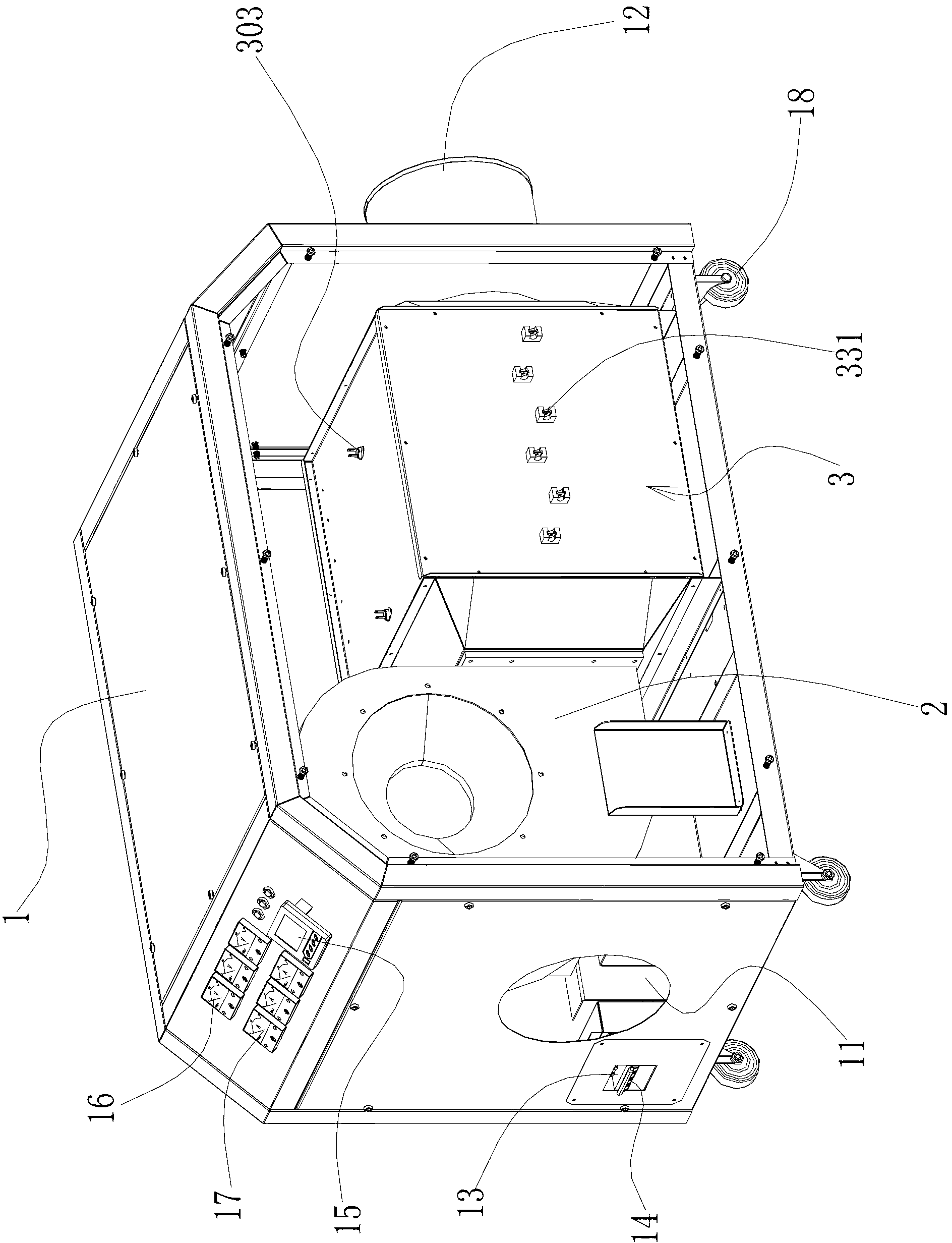

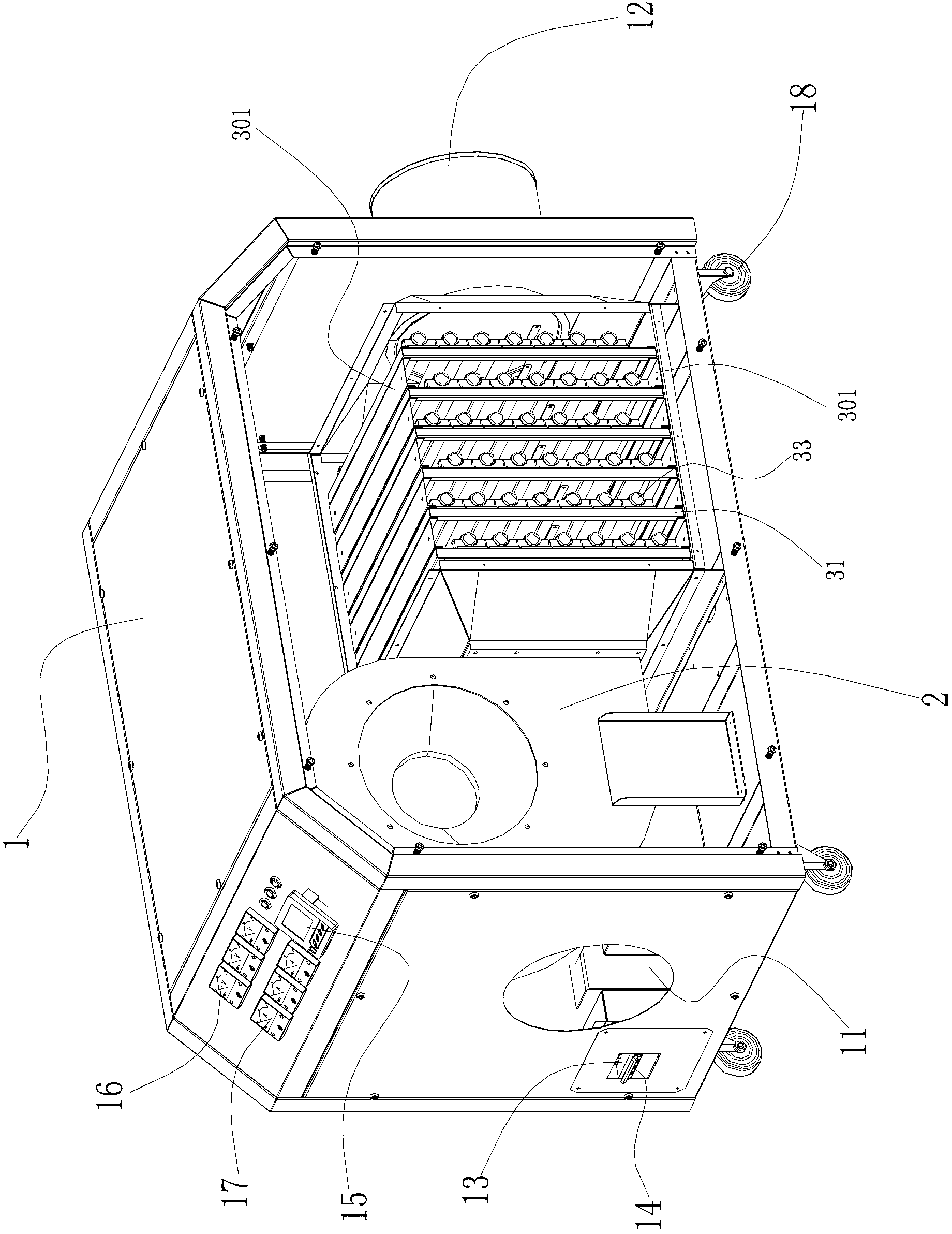

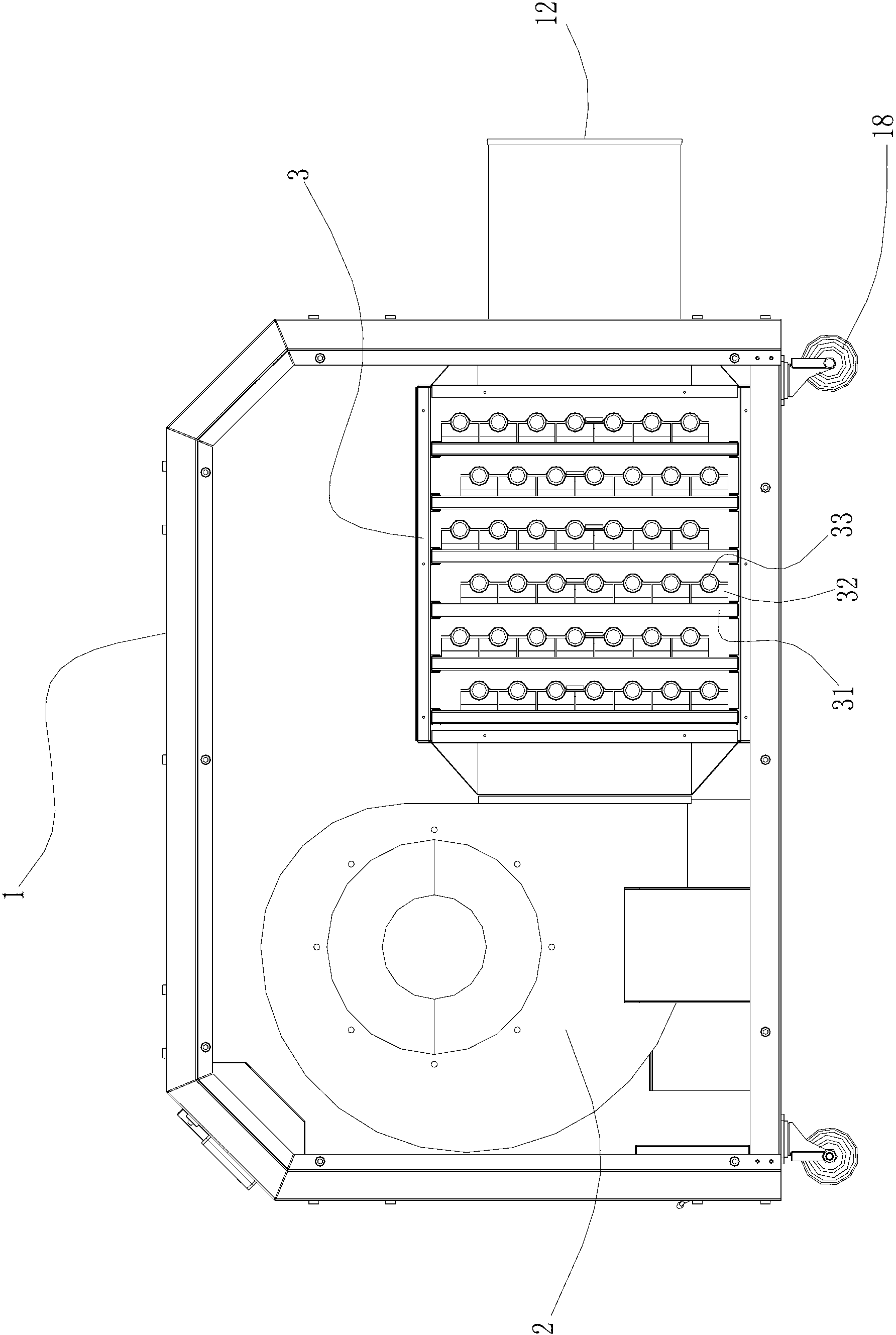

Box body interlayer air cooling high thermal power differential planetary reduction box

InactiveCN104728349ALarge cooling capacityIncrease thermal powerGearboxesGear lubrication/coolingReducerThin walled cylinder

The invention relates to an improvement on a differential planetary reducer. A box body interlayer air cooling high thermal power differential planetary reduction box comprises a box body, an input shaft, a transmission mechanism and an output shaft, wherein the input shaft, the transmission mechanism and the output shaft are arranged in the box body and are in successive transmission. The box body interlayer air cooling high thermal power differential planetary reduction box is characterized in that a connecting part of an inner cylinder and a circular end cover is arranged in the box body, a flange of the inner cylinder is connected with the output end face of the box body, an outer circle of the input end of the circular end cover is in close fit with an inner hole of the input end of the box body, the input end face of the circular end cover and the input end of the box body are in seal connection through the same annular pad, the inner wall of the box body and the outer wall of the connecting part of the inner cylinder and the circular end cover form an interlayer, a draught fan is arranged on the lateral part of the box body, an exhaust window is arranged on the top of the box body, the input shaft is supported in the circular end cover through a bearing, the output shaft is supported in the inner cylinder through a bearing, and the transmission mechanism comprises a differential assembly and a standard planet assembly, and each assembly comprises a sun wheel, a planet wheel, a planet carrier and an inner tooth ring. The box body interlayer air cooling high thermal power differential planetary reduction box has the technical advantages that heat in the interlayer is exhausted from the exhaust window and meanwhile transferred to the uniform thin-walled cylinder of the box body to be dissipated to the outside of the box body, the heat dissipation area extends all over the box body, the structure is simple, and manufacturing cost is low.

Owner:吴小杰

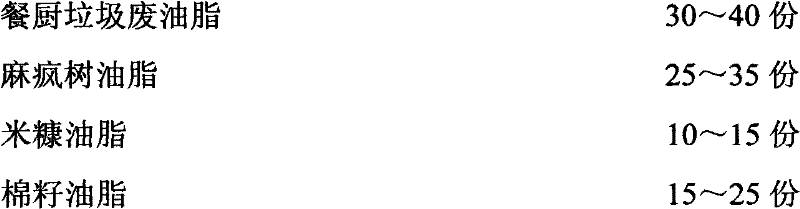

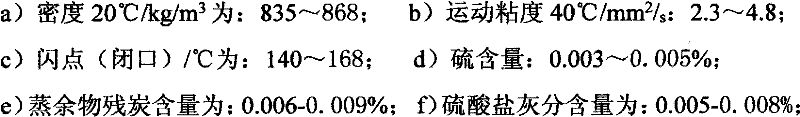

Biological regeneration diesel oil produced by use of food waste grease and manufacturing method thereof

InactiveCN102226115AIncrease oxygen contentBurn completelyFatty acid esterificationBiofuelsOil and greaseResource utilization

The invention relates to biological regeneration diesel oil produced by the use of food waste grease and a manufacturing method thereof. The manufacturing method is characterized by taking food waste grease, Jatropha curcas grease, rice bran grease, cottonseed grease, Chinese honey locust grease, camphor grease, methanol, tween T-80, span S-80, petroleum ether, acetone and sodium hydroxide as raw materials; uniformly mixing by the use of a paddle agitator and preheating while controlling the temperature within the range of 30 DEG C to 60 DEG C; adding the raw materials into a reaction vessel by a proportioning device to remove impurities, decolour, esterify and separate, separating by a centrifuge, filtering and purifying to produce the biological regeneration diesel oil product from food waste grease. The product provided by the invention has renewable performance so as to solve the problem of the food waste processing difficulty and realize the resource recycling and utilization of food wastes, and meets the relative rules of the state council 2010 thirty sixth document on the resource utilization and harmless treatments of food wastes.

Owner:广州中滔绿由环保科技有限公司

Energy-saving type silicon crystal film ceramic electric heating warm air furnace

InactiveCN103162409ASimple structureStable thermal powerAir heatersHeating element shapesEngineeringCeramic

An energy-saving type silicon crystal film ceramic electric heating warm air furnace comprises an outer shell, a fan unit and a heating unit, wherein the fan unit and the heating unit are arranged in the outer shell. An air returning opening and an air feeding opening are formed in the outer shell. The fan unit is provided with an air inlet and an air outlet. The air inlet of the fan unit is communicated with the air returning opening of the outer shell. The heating unit is arranged between the air outlet of the fan unit and the air feeding opening of the outer shell. The energy-saving type silicon crystal film ceramic electric heating warm air furnace is characterized in that the heating unit comprises at least one heating module; the heating module comprises a support, a supporting seat arranged on the support and a silicon crystal film ceramic heating body arranged on the supporting seat; and heat energy generated by the silicon crystal film ceramic heating body is sent outside through air on the air outlet of the fan unit and is sent to areas needing to be heated through the air feeding opening of the outer shell.

Owner:中山市露玛暖通热设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com