Energy-saving type silicon crystal film ceramic electric heating warm air furnace

An air heater, energy-saving technology, applied in the direction of air heater, fluid heater, heating element shape, etc., can solve the problem of inflexible control of coal (gas) furnace, inability to market promotion, unstable operation of equipment, etc. problem, to achieve the effect of simple structure, reasonable setting and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

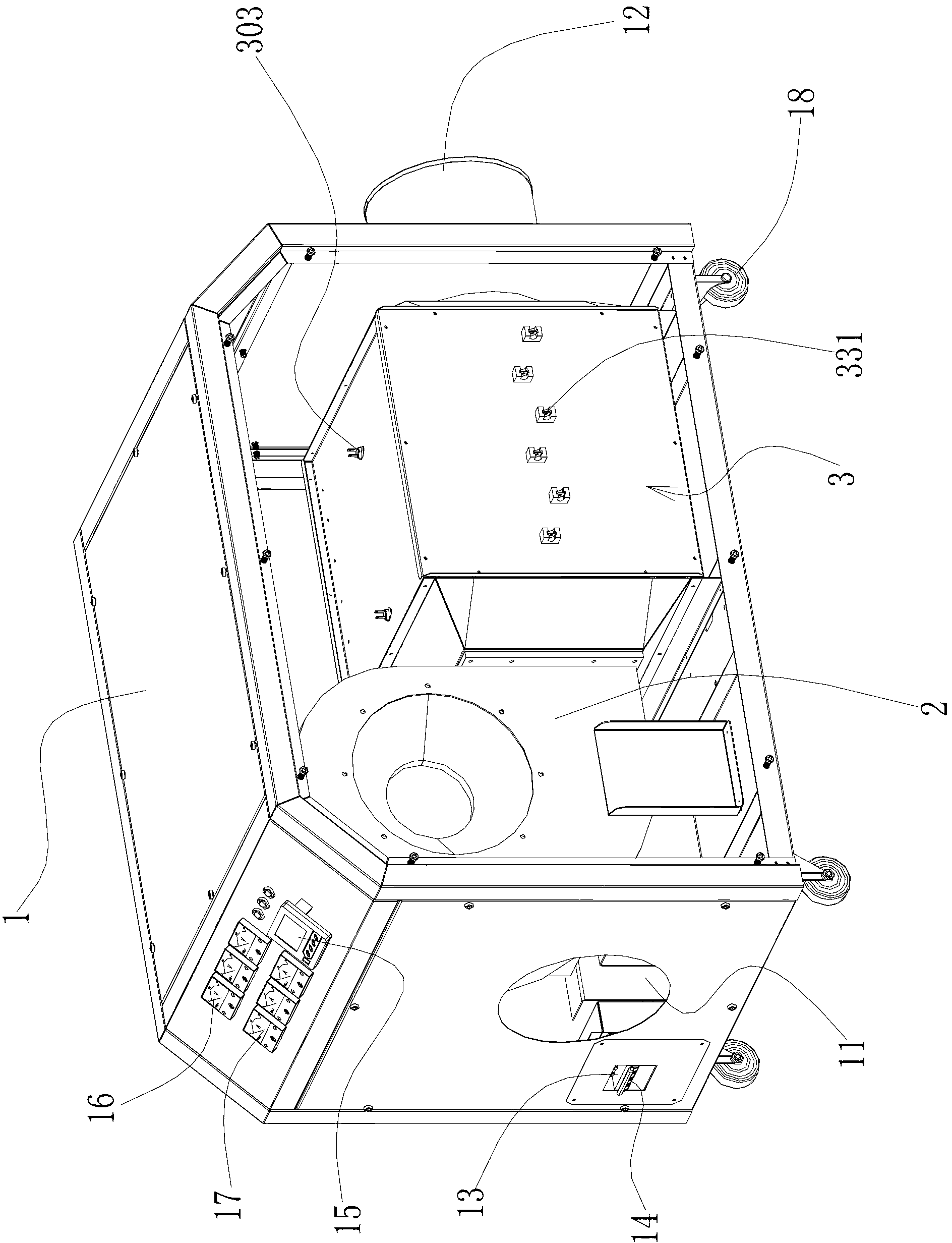

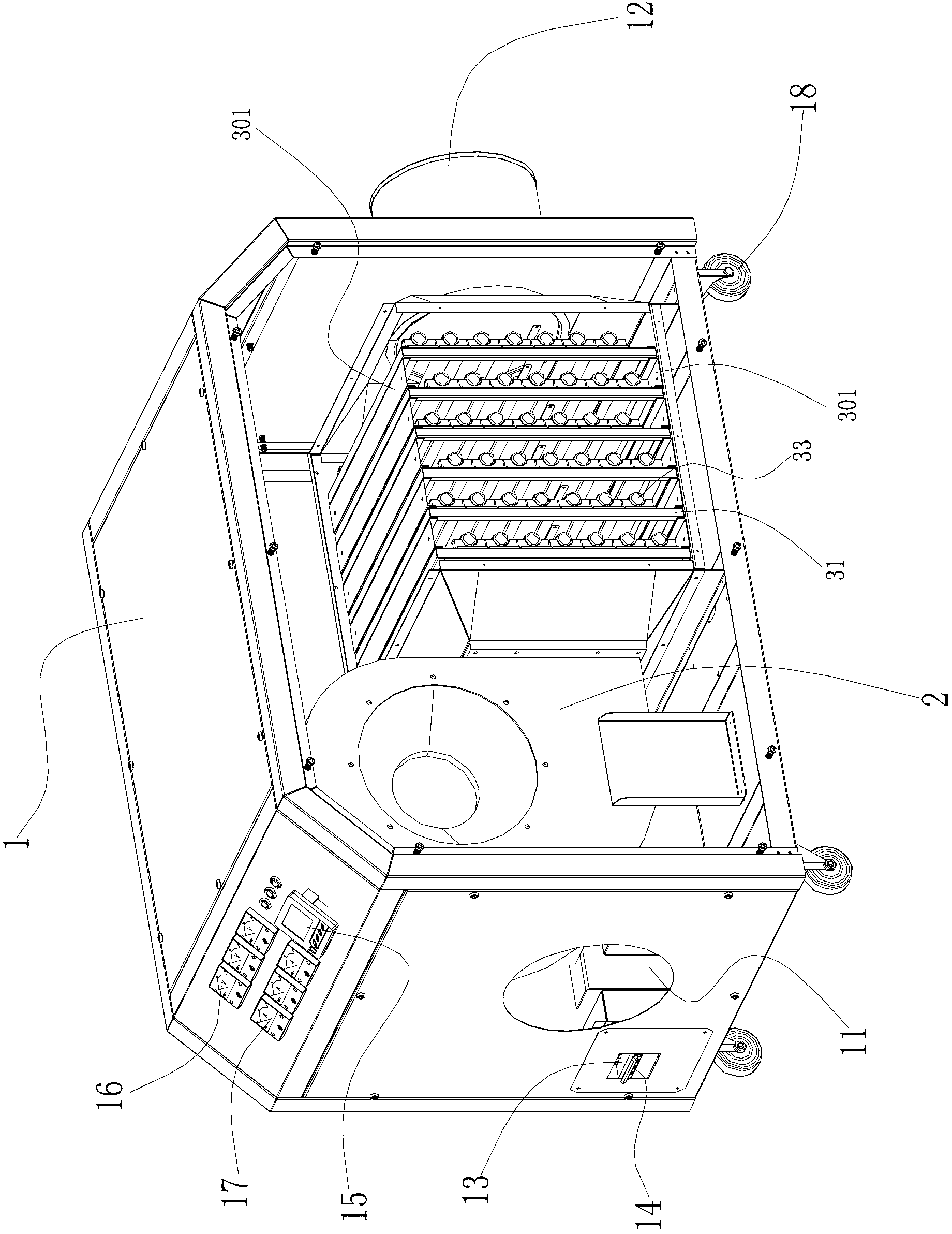

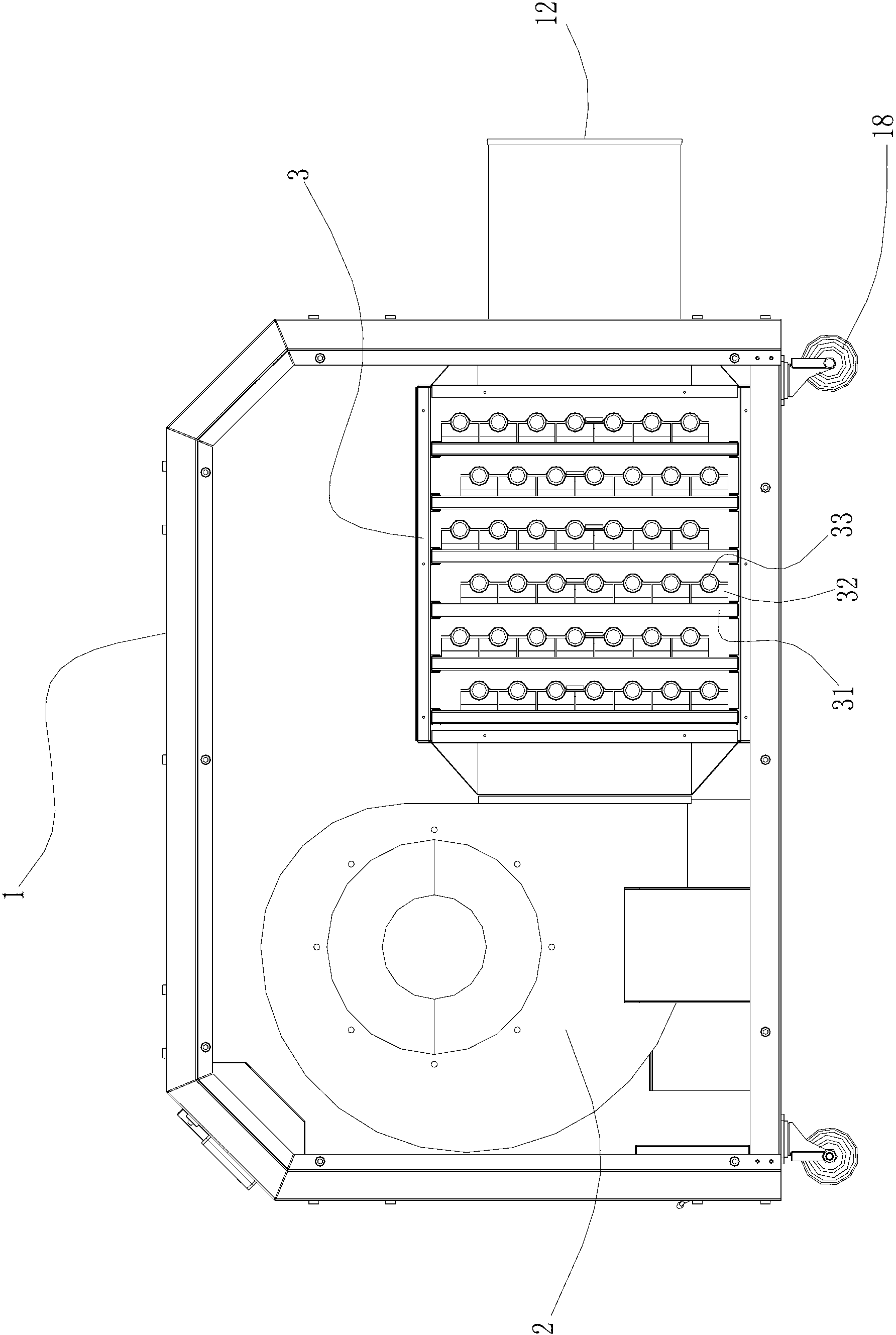

[0029] Such as Figure 1 to Figure 7 As shown, an energy-saving silicon crystal film ceramic electric heating stove includes a casing 1, a fan unit 2 and a heating unit 3 arranged in the casing, and the casing 1 is provided with an air return port 11 and an air supply port 12. The fan unit 2 is a blower with an air inlet and an air outlet. The air inlet of the fan unit 2 communicates with the air return port 11 of the casing. The heating unit 3 is arranged between the air outlet of the fan unit 2 and the air supply port 12 of the casing. The unit 3 includes at least one heating module, and the heating module includes a support 31, a support seat 32 arranged on the support, and a number of silicon crystal film ceramic heating elements 33 arranged on the support seat, and the silicon crystal film ceramic heating element 33 The generated heat energy is transported outward by the wind at the air outlet of the fan unit and sent to the area to be heated through the air outlet 12 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com