Speed reducer for conveyor

A technology for reducers and conveyors, applied in conveyors, mechanical equipment, transportation and packaging, etc., can solve the problems of high sealing requirements of reducers, poor heat dissipation conditions of reducers, failure of monitoring and communication equipment, etc., to meet the requirements of mechanical noise The effect of controlling requirements, increasing aesthetic feeling, and being easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

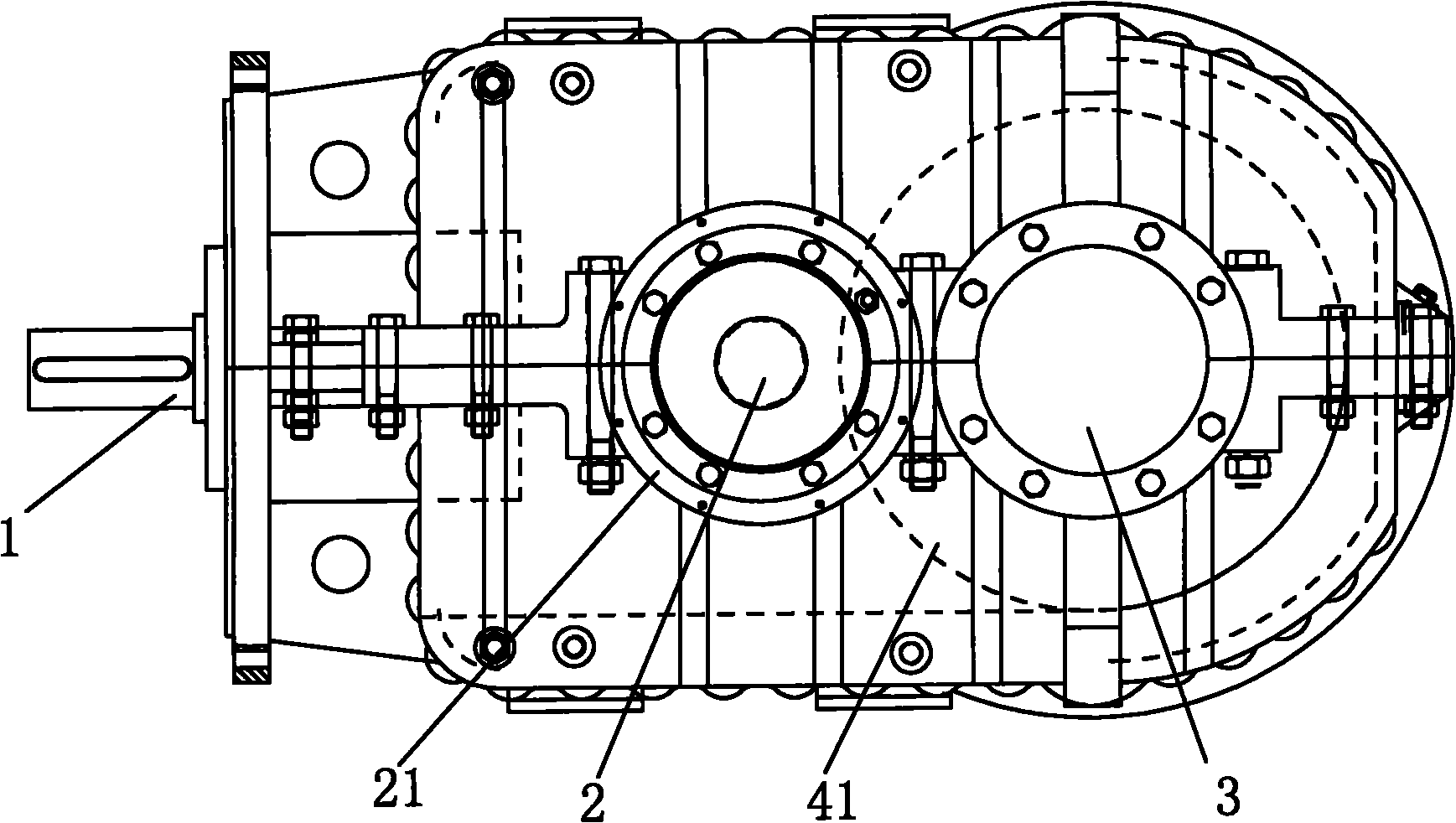

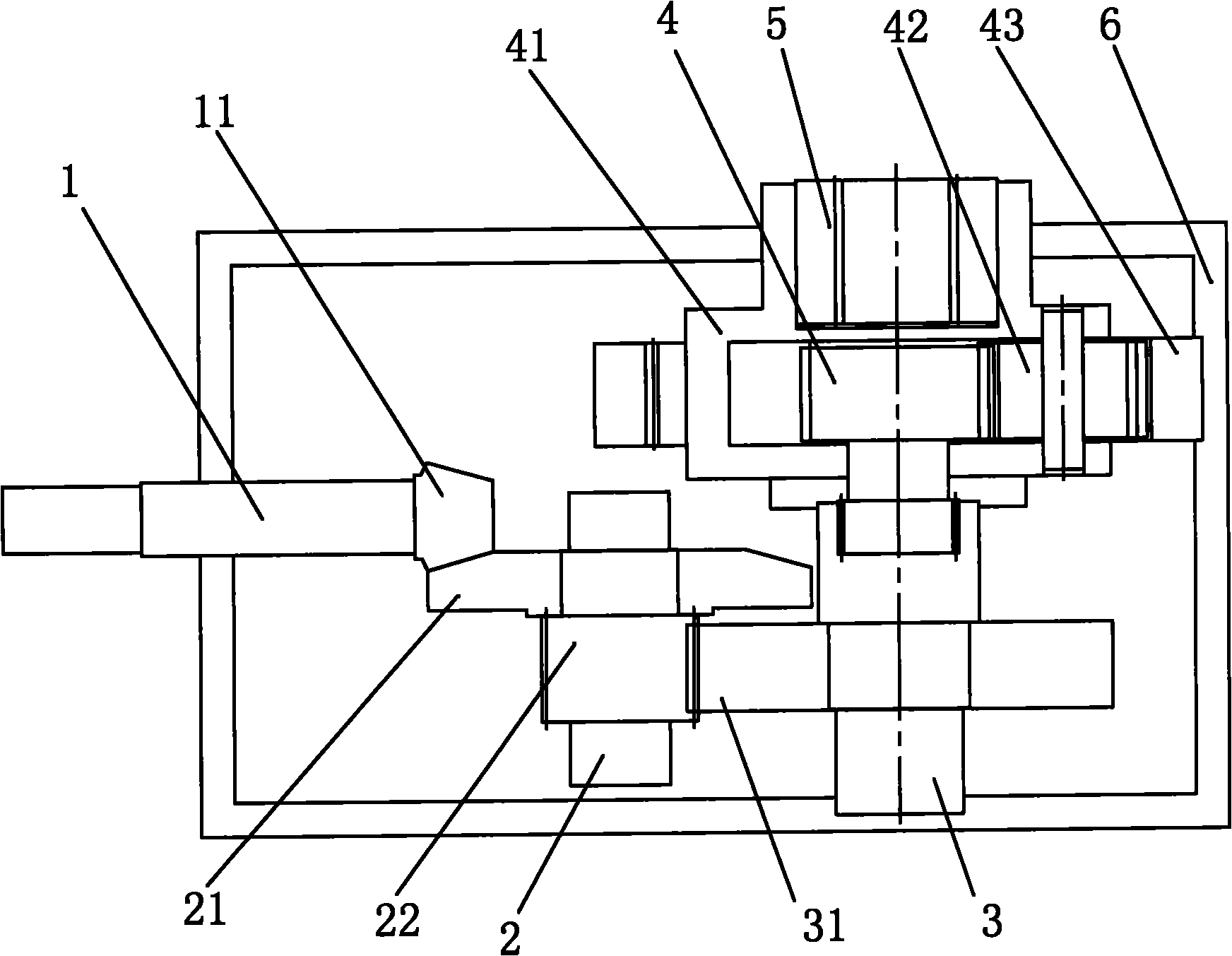

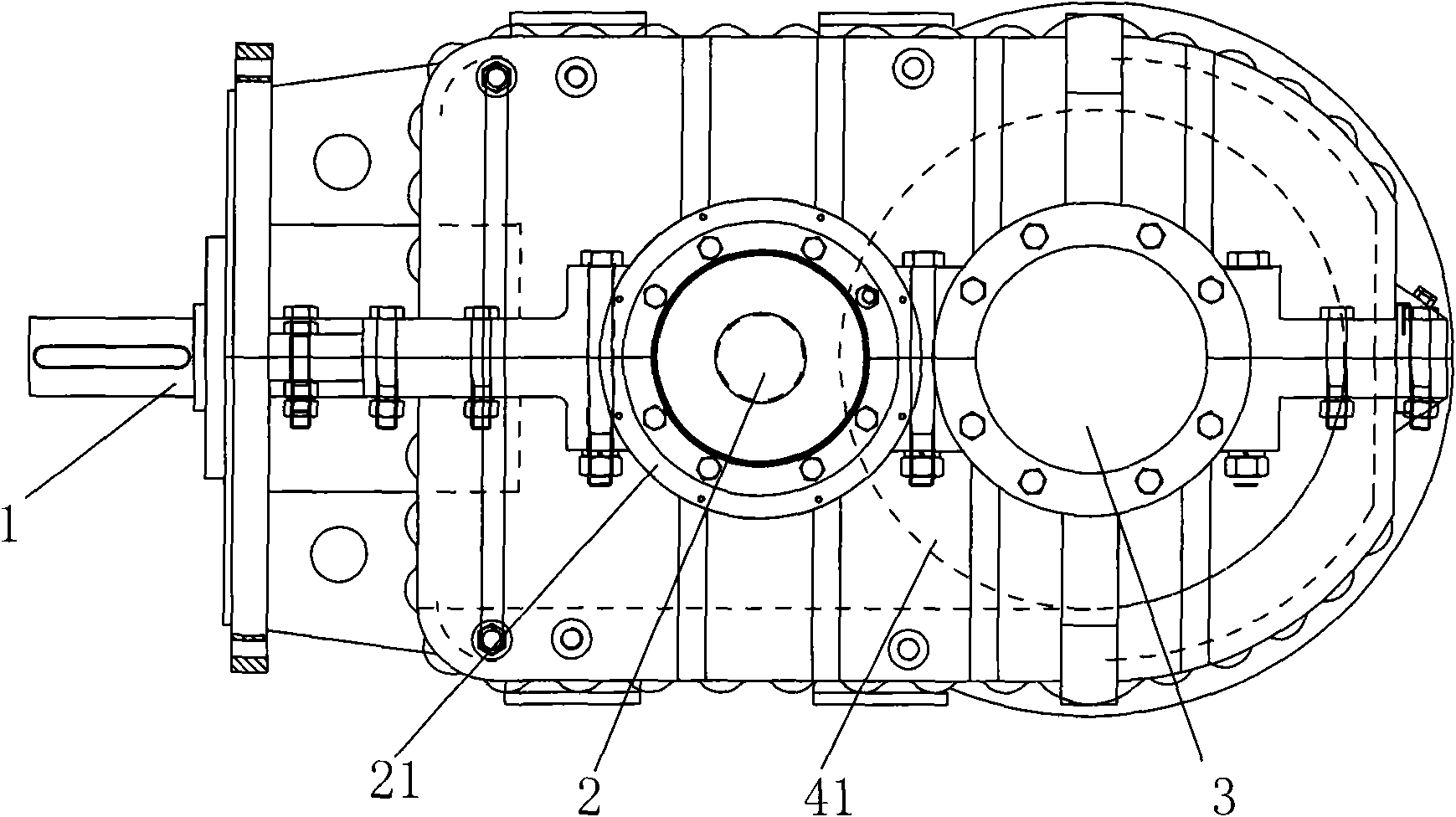

[0016] See figure 1 , figure 2 , the present invention has body 6, transmission mechanism, cooling system and sealing element, transmission mechanism comprises input bevel gear shaft 1, intermediate gear shaft 2, output internal gear shaft 3 and planetary gear train, input bevel gear shaft 1 has bevel tooth end 11 , the intermediate gear shaft 2 has a bevel gear 21 and a cylindrical gear 22, the output internal gear shaft 3 has a cylindrical gear 31, the bevel gear end 11 of the input bevel gear shaft meshes with the bevel gear 21 of the intermediate gear shaft, and the output internal gear shaft 3 The cylindrical gear 31 meshes with the cylindrical gear 22 of the intermediate gear shaft, and both the cylindrical gear and the cylindrical gear are helically meshed; the planetary gear system includes the sun gear 4, the planetary carrier 41, the planetary gear 42 and the ring gear 43 fixed on the body , the output inner gear shaft 3 is circumferentially positioned with the sun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com