Multifunctional essence slow-release carrier and preparation method thereof

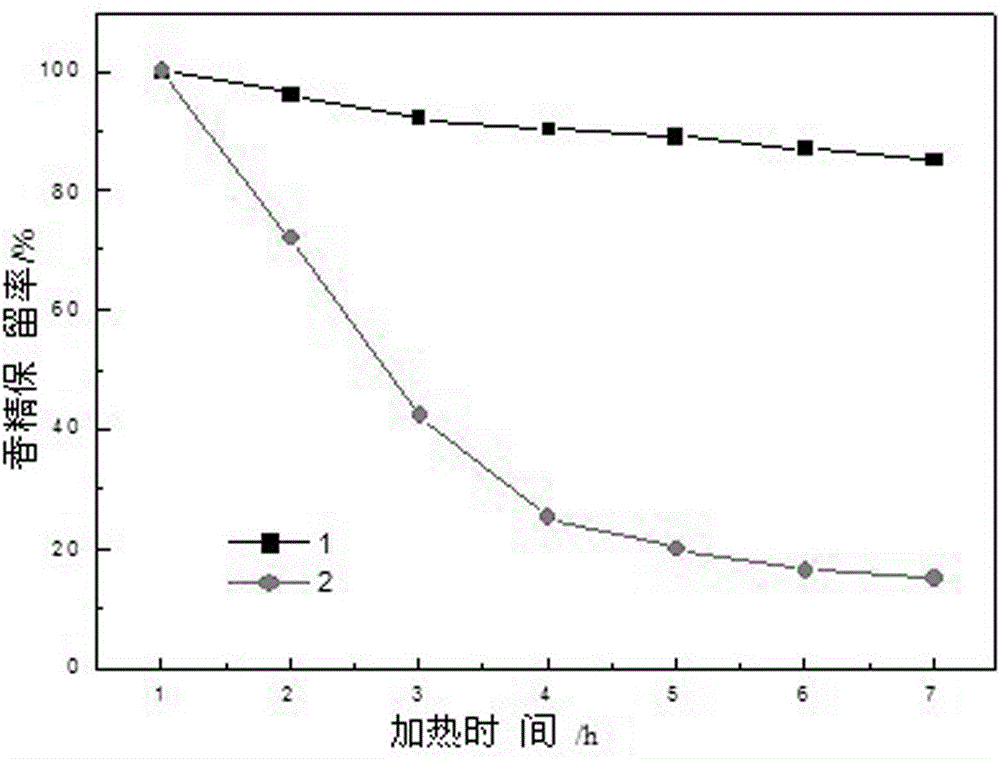

A technology of flavors and fragrances and slow-release carrier, applied in the field of flavors and fragrances, can solve the problems of expensive equipment, increase production costs, etc., and achieve the effects of simple equipment, not easy to dust, and adjustable color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Weigh 20g sweet orange essence, add 1.3g lecithin, 14.8g Tween-20, 9.2g sucrose fatty acid ester successively under stirring condition, slowly add 7.0g propylene glycol, 15.72g glycerin after stirring evenly, stir rapidly, To form a transparent and stable emulsified system for one embedding. The emulsification system was fully mixed with 60g of porous starch, and second embedding and adsorption were carried out, and then 36.64g of microcrystalline cellulose, 36.64g of lactose, 0.04g of vitamin C, and 0.02g of aspartame were added to the system, and the materials were fully Stir to combine well. Extrusion and spheronization are used to extrude and granulate the material. The screen aperture used in the screw extruder is 0.6mm, and the spheronization rate of the spheronizer is 300r / min. Dissolve 10g of gum arabic and 0.4g of sunset yellow pigment 60 in 90g of water to prepare a coating liquid, place the rounded and dried essence carrier particles in a coating pan, and sp...

Embodiment 2

[0079] Weigh 14.7g of natural mint essence, add 0.98g lecithin, 11.62g Tween-20, 7.22g sucrose fatty acid ester in turn under stirring condition, slowly add 32.2g glycerol, 3.28g water after stirring well, and stir rapidly , so that a transparent and stable emulsification system is formed for one embedding. The emulsification system was fully mixed with 60g of porous activated carbon for secondary embedding and adsorption, and then 28g of microcrystalline cellulose, 42g of lactose, and 10g of green tea extract were added to the system, and the materials were fully stirred and mixed evenly. The material is granulated by a rotary granulator, the sieve diameter used is 1.0mm, and the spheronization rate of the spheronizer is 350r / min. Dissolve 10g of hydroxypropyl methylcellulose, 0.08g of lemon yellow pigment, and 0.01g of brilliant blue pigment in 190g of 50% ethanol solution to prepare a coating liquid, and place the rounded and dried essence carrier particles in the coating p...

Embodiment 3

[0081] Weigh 7.0g lavender essential oil, add 8.4g polyoxyethylene hydrogenated castor oil, 1.4g Tween-80 successively under stirring condition, after stirring evenly, slowly add 14.24g propylene glycol, 28.46g glycerin, 10.5g water, stir rapidly , to form a transparent and stable emulsification system. The emulsification system was fully mixed with 65g of porous silicon dioxide, then 35g of microcrystalline cellulose and 35g of lactose were added, the materials were fully stirred and mixed evenly, and the materials were extruded and granulated by extrusion spheronization. The aperture of the sieve is 0.4mm, and the spheronization speed of the spheronizer is 200r / min. Dissolve 8g of hydroxypropyl methylcellulose in 192g of 50% ethanol solution as a coating solution, place the rounded and dried essence carrier particles in a coating pan, and spray the coating solution evenly on the carrier particles to obtain Lavender slow-release granules are used for fragrance of daily chemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com