Patents

Literature

499 results about "Porous starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing porous starch and its application

InactiveCN1546529AHigh adsorption rateRaw materials are readily availableGlucose-Fructose SyrupPotato starch

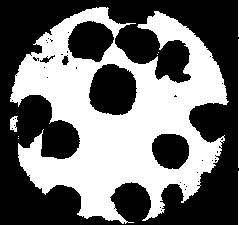

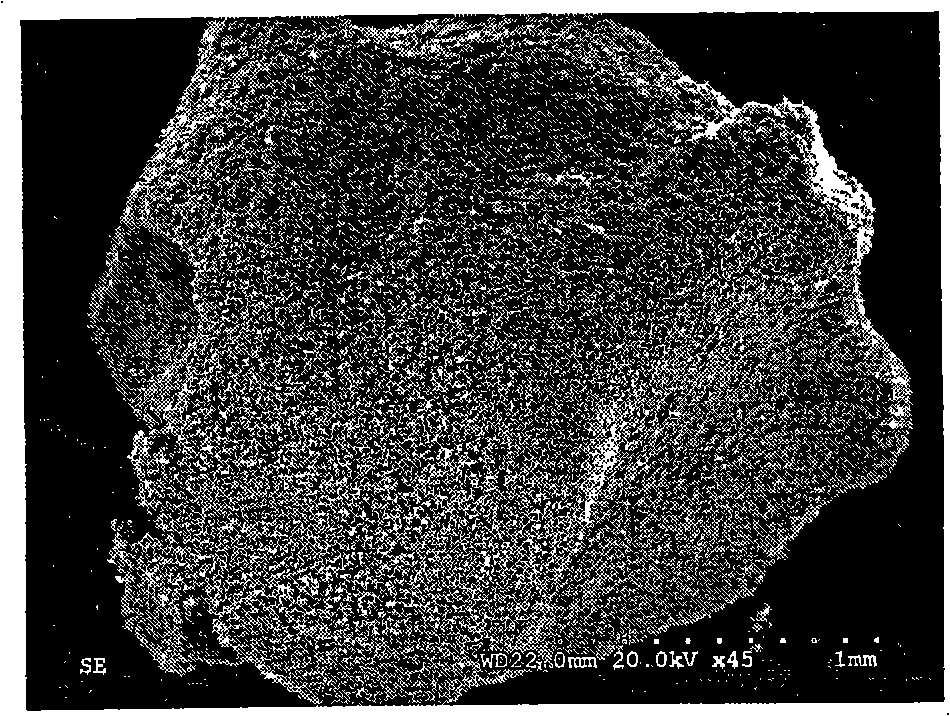

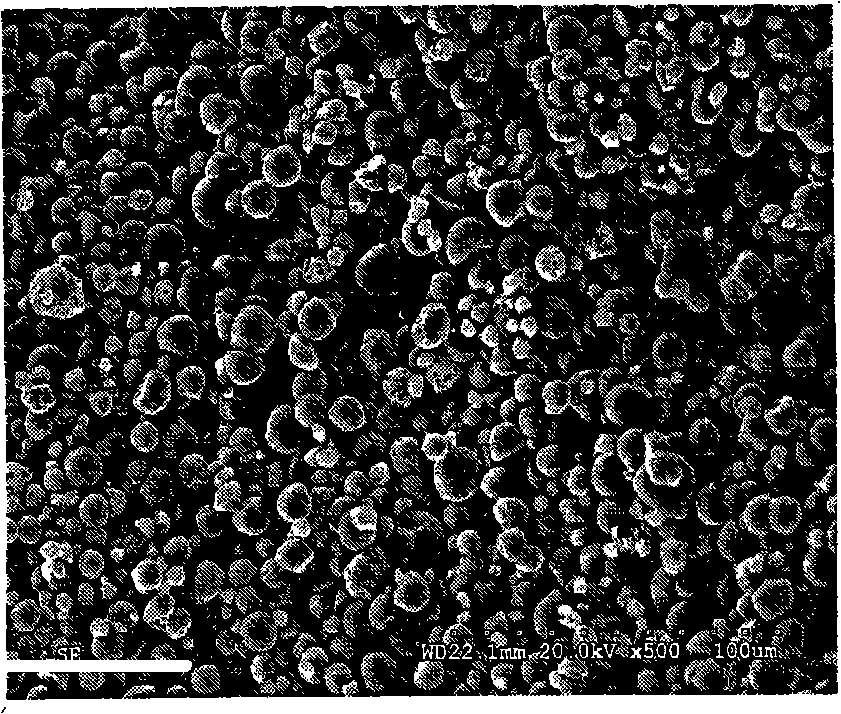

The invention discloses a method for producing porous starch and its application by using starch, maize starch, tapioca starch, sweet potato starch and potato starch as raw material, and charging complex enzyme of saccharified enzymes and alpha-amylase possessing raw starch hydrolysis vitality under the temperature lower than gelatinization temperature, agitating continuously, reacting for a finite period of time at constant temperature, and obtaining porous starch product through centrifuging, scrubbing and drying.

Owner:JIANGNAN UNIV

A method of using spray drying for preparing probiotics micro-capsules

The present invention relates to a method of using spray drying for preparing probiotics micro-capsules, belonging to the technical field of micro-organisms. According to the method, a probiotic suspension or probiotics adsorbed in porous starch is used as a core material, gum arabic and maltodextrin are used as a wall material, and the probiotics micro-capsules are prepared through a spray drying process. The method comprises the steps of: arabic gum and maltodextrin at a ratio of 1:7 to 1:10 as the wall material, at a concentration of 15 to 20% dissolved in deionized water, mixing uniformly with the probiotic suspension or the probiotics adsorbed in porous starch at room temperature; and spray drying under conditions of a inlet air temperature being 130-150DEG C and a feeding rate being 12.50-15.50mL / min, wherein skim milk powder is adopted as a heat-resistant protective agent in an amount of 1 to 3%, and embedding rate of the probiotics is above 85% by using the method of the invention. The method has the advantages of being fast in drying rate, short in time, low in material temperature, good in product dispersion and solubility, simple in production process, stable in effect, long in shelf life of products, and suitable for continuous production.

Owner:GUANGZHOU GLAM BIOTECH

Method for preparing porous starch through enzyme method in high temperature

A process for preparing the porous starch by high-temp enzyme method includes such steps as proportionally mixing starch with water, regulating pH=1.5-12.5, adding the cross-linking agent with multiple function groups, stirring while reacting to obtain cross-linked starch, regulating pH=6-7, dewatering, washing, drying to obtain powdered cross-linked starch, regulating concentration of emulsion, adding amylase, enzymolyzing, regulating pH=6-7, filtering, washing, centrifugal dewatering, pulverizing filtered cake, and drying to obtain porous starch.

Owner:SOUTH CHINA UNIV OF TECH

Complex microbial agent for producing soybean paste in Pixian County and preparation method thereof

InactiveCN101897429AKeep the featuresShorten the production cycleFood preparationMicrobial agentTrehalose

The invention discloses a complex microbial agent for producing soybean paste in Pixian County, which mainly comprises coculture of saccharomyces cerevisiae, candida utilis, lactobacillus plantarum and salt tolerant tetrads, and skim milk powder, glycerin, maltodextrin, trehalose and L-sodium glutamate, or mainly comprises coculture of saccharomyces cerevisiae, candida utilis, lactobacillus plantarum and salt tolerant tetrads, and porous starch, maltodextrin and polyvinyl pyrrolidone. A method for preparing the complex microbial agent for producing soybean paste in Pixian County comprises the following technological steps of: (1) activating and propagating strains; (2) inoculating; (3) co-culturing; and (4) adding a protective agent and drying. By using the complex microbial agent in the preparation of cooked soybean paste, the complex microbial agent maintains the characteristics of traditional soybean paste in Pixian County. Meanwhile, compared with the traditional technology, the complex microbial agent has the advantages of shortening the production period by 1 / 3, improving the amino nitrogen content by 3 to 8 times, improving the volatile aroma content by 2 to 4 times, and ensuring the aflatoxin B1 of 0 to 0.5ppm only.

Owner:XIHUA UNIV

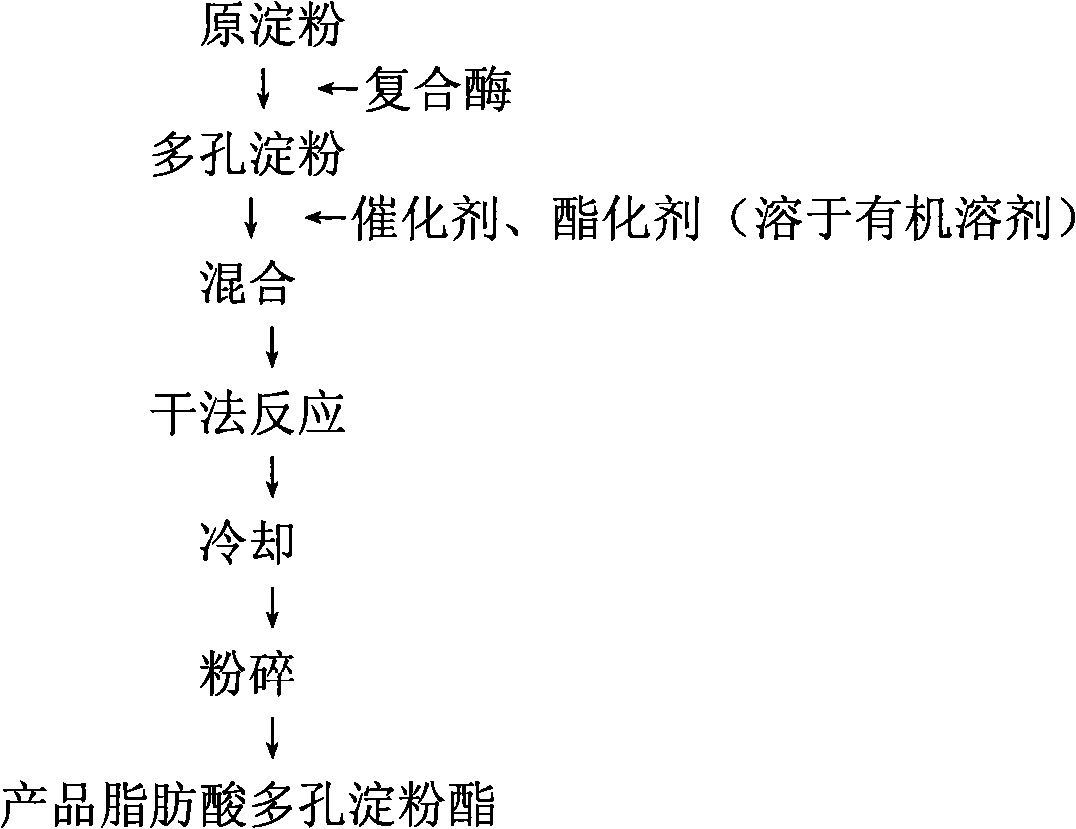

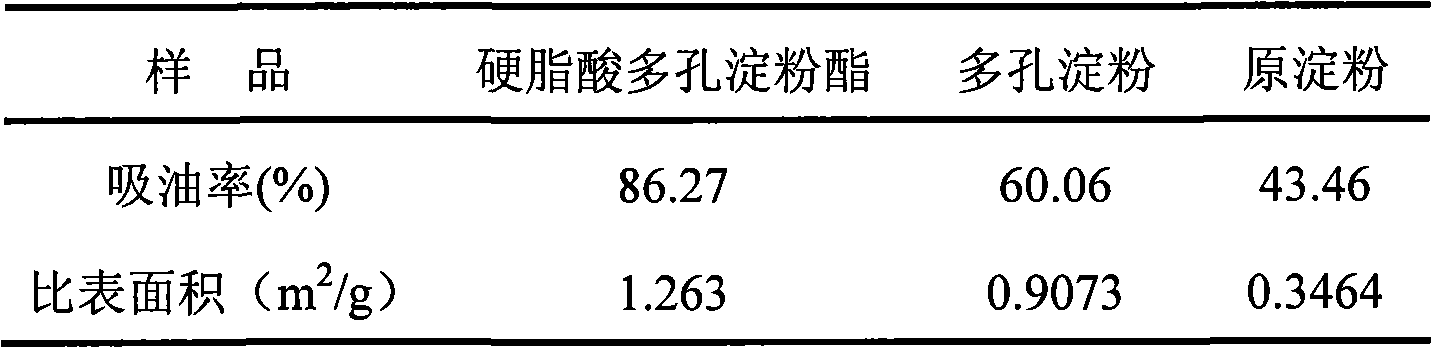

Method for preparing fatty acid stephanoporate starch ester and application thereof

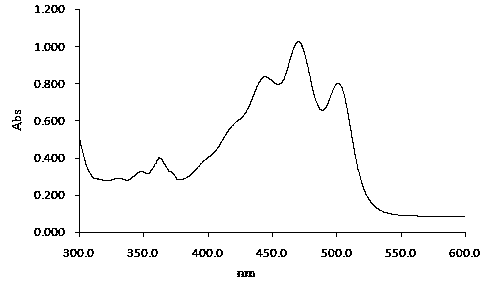

InactiveCN101319053AReduce pollutionImprove adsorption capacityOther chemical processesPorous starchService efficiency

The invention relates to a method for preparing fatty acid porous starch ester and an application of the fatty acid porous starch ester, belonging to the modified starch technical field. The method performs enzymolysis on native starch at first to prepare porous starch, and then performs acidolysis and esterification for composition of modified starch, so as to prepare fatty acid porous starch ester products with low degree of substitution. The products have strong adsorptivity which is greatly improved compared with porous starch prepared by single acidolysis and starch ester prepared by single esterification, and can be applied in various fields of foodstuff, for example, the products can be used as a microcapsule material and used as an absorbent for absorbing various functional substances such as pennyroyal, edible essence, pigment, olive oil, probiotics and so on. By adoption of the fatty acid porous starch ester for absorbing a target substance, the function of slow release can be reached and the service efficiency can be improved. The method has the advantages that: the method takes the porous starch as a raw material and performs secondary esterification modification on the porous starch with strong adsorptivity; the whole reaction process is simple to operate and easy to implement and has small environmental pollution; and the products prepared have superior performance.

Owner:JIANGNAN UNIV

Modified starch particle, preparation and application thereof

InactiveCN101314646AHigh specific surface areaImprove adsorption capacityTobacco smoke filtersSodium hydroxideCigarette filter

The invention discloses modified starch granules, the preparation method and the application thereof. The preparation method comprises the following steps: stirring starch and acetic buffer solution uniformly, adding saccharifying enzyme for enzymolysis reaction, adding sodium hydroxide solution to stop the reaction, centrifugally separating to obtain paste-shape porous starch, microwave drying, pulverizing and sieving to obtain the desired modified starch granule. The modified starch granule is superior to active carbon in adsorption performance, and can be added into the filter core of a cigarette filter to prepare a binary or ternary filter, which can effectively reduce the delivery amount of tar and carbon monoxide in the smoke, improve the cigarette sense quality, effectively improve the cigarette sense comfort and improve the centralization degree of the cigarette smoke. The modified starch granule has good application prospects.

Owner:YUNNAN RES INST OF TOBACCO SCI

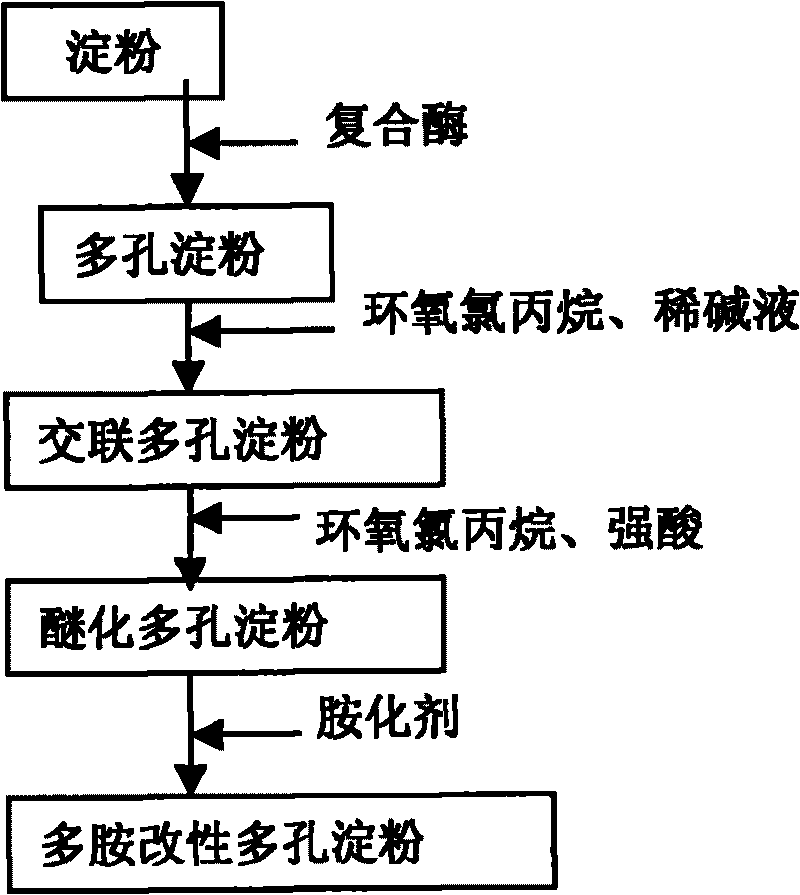

Method for preparing modified polyamine porous starch

InactiveCN101759808AImprove adsorption capacityHigh removal rateWater contaminantsWater/sewage treatment by sorptionCross-linkAbsorption capacity

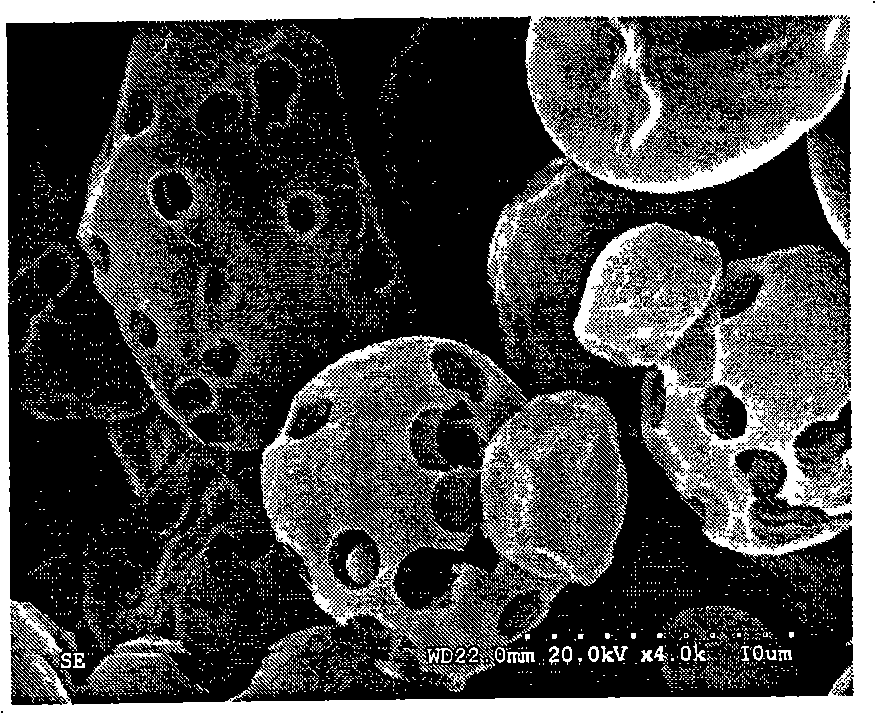

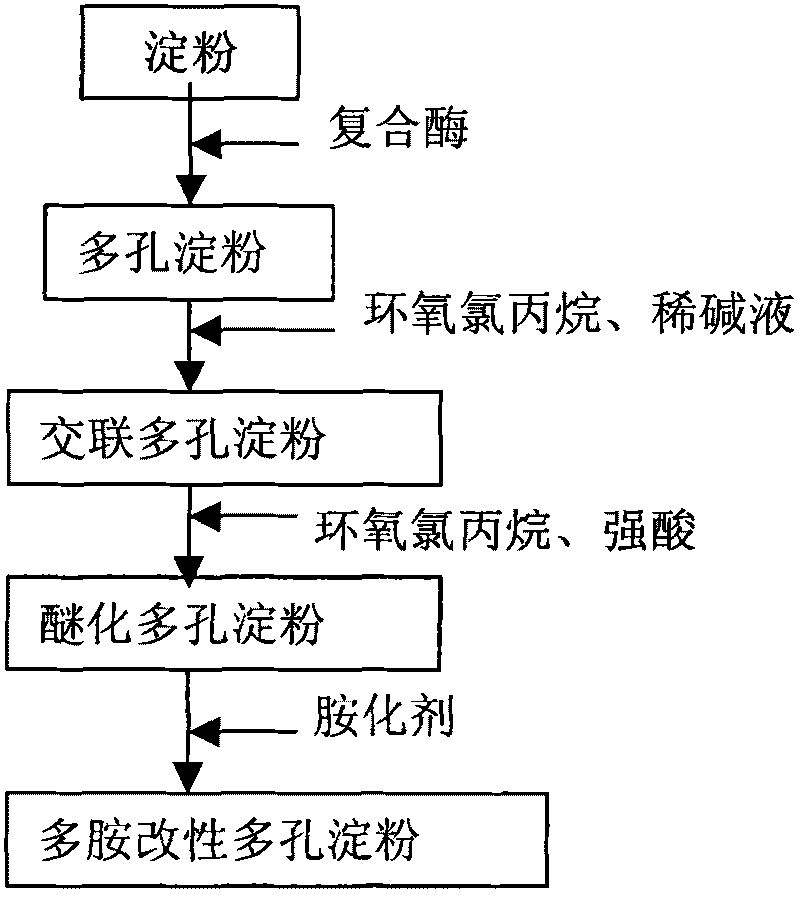

The invention relates to a method for preparing modified polyamine porous starch obtained through the following steps: preparing starch as the raw material and compound enzymes into porous starch; cross-linking the porous starch; modifying the porous starch through etherification; and grafting different polyamine molecules. The modified polyamine porous starch is capable of absorbing AG25 and AR18 in wastewater by the hollow structure and grafted functional groups thereof, particularly, the removal rate of both AG25 and AR18 in the wastewater is higher than 98% according to the tests; the modified polyamine porous starch can be taken out and dipped in a sodium sulfate solution with the molar concentration thereof being 0.05mol / L to 1mol / L for desorption when the absorption effect is reduced, particularly, the desorption rate of AG25 and AR18 is higher than 90%; and the absorption effect of the modified polyamine porous starch is not reduced after being subjected to desorption and analysis for multiple times. Compared with the common porous starch, the product of the invention increases the absorption capacity by more than two times and ensures the high selectivity. Therefore, the method of the invention is of significant economic and social benefits and is applicable to the absorption treatment of heavy-metal ions and wastewater containing various dyes in the industries, such as printing and dyeing, textile and cosmetics.

Owner:TONGJI UNIV +1

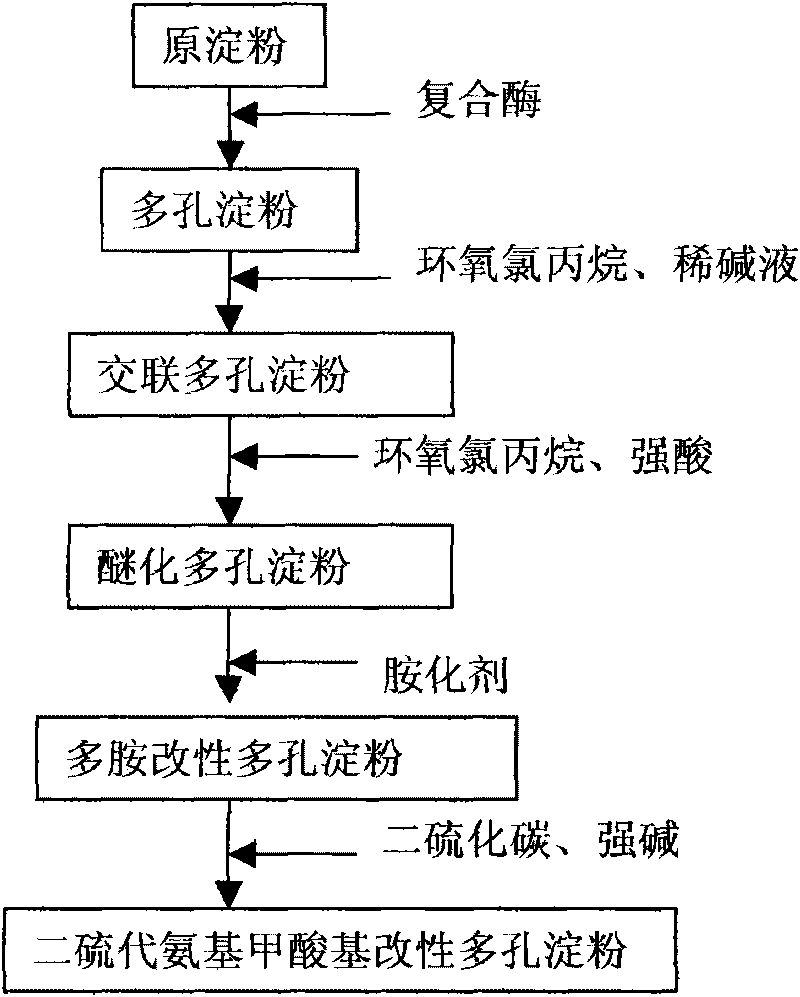

Method for preparing dithiocarbamate-based modified porous starch

InactiveCN101759809AImprove adsorption capacityHigh removal rateWater contaminantsWater/sewage treatment by sorptionDesorptionAlpha-amylase

The invention relates to a method for preparing dithiocarbamate-based modified porous starch. The method comprises the steps that: using starch as the raw material; carrying out enzymolysis on the starch for 1 to 26 hours under the condition that the pH is between 4 and 6 and the temperature is between 30 and 60 DEG C by a complex enzyme consisting of a saccharifying enzyme and an alpha-amylase; drying the obtained product to prepare porous starch; and after carrying out crosslinking, etherification and aminating modification on the porous starch, grafting the product with carbon disulfide under the alkaling conndition to obtain the dithiocarbamate-based modified porous starch. Compared with the conventional porous starch, the dithiocarbamate-based modified porous starch of the invention has strong absorption characteristic and high adsorptive selectivity. When the adsorption effect is reduced, the dithiocarbamate-based modified porous starch is taken out and immersed in 2mol.L-1 of HNO3 solution to carry out desorption, the desorption ratio is over 90 percent, and the absorption effect is not reduced by repeated desorption. The invention has commendable economic and social benefits, and can be used for treatment of heavy metal ions in waste water in galvanization, battery and mining industries and the like.

Owner:TONGJI UNIV +1

Colorful modified starch particle, preparation and application thereof

InactiveCN101314645AHigh specific surface areaImprove adsorption capacityTobacco smoke filtersCigarette filterSodium hydroxide

The invention discloses a color modified starch granule, the preparation method and the application thereof. The method comprises the following steps: stirring starch and acetic buffer solution uniformly, adding saccharifying enzyme for enzymolysis reaction, adding sodium hydroxide solution to stop the reaction, centrifugally separating to obtain paste-shape porous starch, colorizing, microwave drying, pulverizing and sieving to obtain the desired color modified starch granule. The color modified starch granule is superior to active carbon in adsorption performance, and can be added into the filter core of a cigarette filter to prepare a binary or ternary filter, which can effectively reduce the delivery amount of tar and carbon monoxide in the smoke, improve the cigarette sense quality, effectively improve the cigarette sense comfort and improve the centralization degree of the cigarette smoke. The color modified starch granule has good application prospects.

Owner:YUNNAN RES INST OF TOBACCO SCI

Lycopene microcapsule prepared by adopting a double-coating method and preparation method thereof

InactiveCN103948565AImprove functionalityAvoid lostHydrocarbon active ingredientsAntinoxious agentsLycoperseneIsomerization

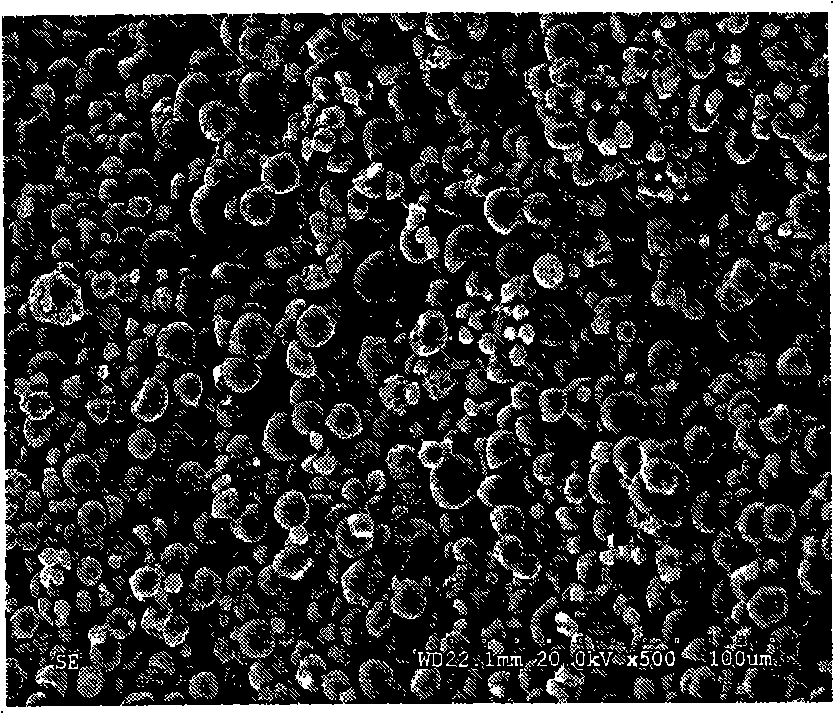

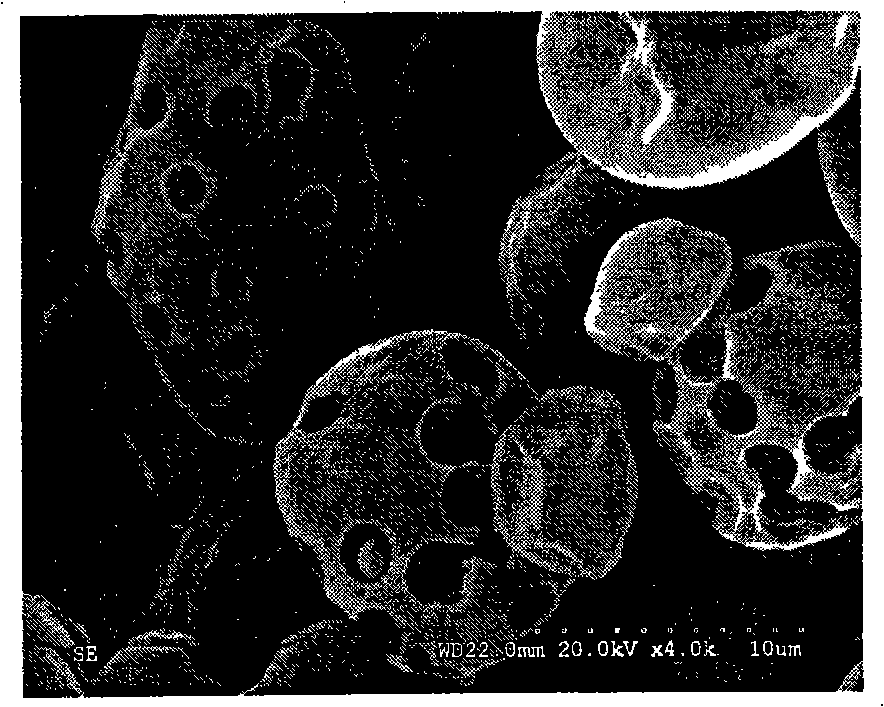

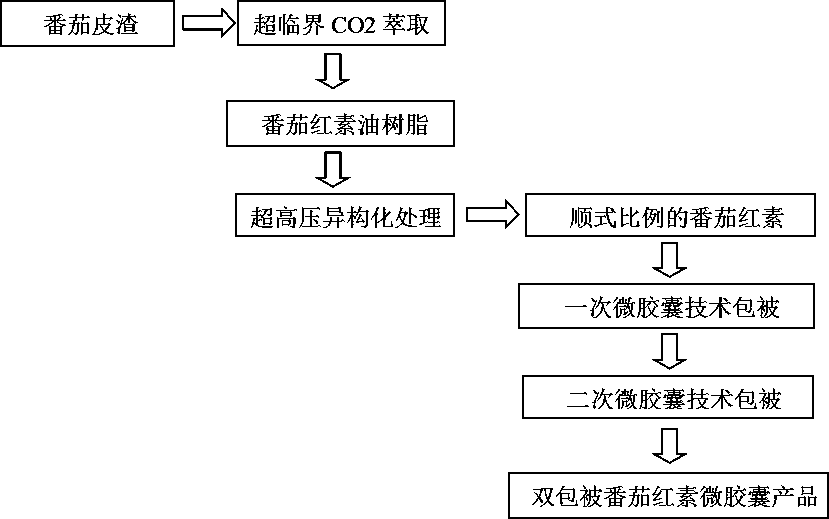

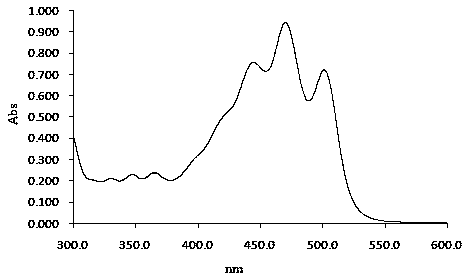

The invention discloses a lycopene microcapsule prepared by adopting a double-coating method and a preparation method thereof. An appropriate mixed wall material is adopted, an optimal emulsification condition and a drying technological parameter are researched, a supercritical fluid extraction technology and a superhigh-pressure isomerization treatment technology are combined, a double-coating method is adopted for preparing the lycopene microcapsule, a process for preparing the double-coated lycopene microcapsule adopts porous starch with the usage amount of 0.16% and beta-cyclodextrin with the usage amount of 0.16%, adsorption temperature is 50 DEG C, and adsorption time is 30 minutes; lycopene is closed in a capsule and isolated with the external environment, so that stability to light and oxygen is improved, serviceable range is expanded, the technical bottleneck existing in application of lycopene at present is effectively overcome, ratio of cis-isomer in the prepared lycopene microcapsule is 45-50%, and bioavailability is high; embedding rate can be 97.75%, lycopene carrying capacity is 40.70mg / g, and the lycopene microcapsule has strong practicability and high application value.

Owner:XINJIANG UNIVERSITY +1

Pest control agent, method for manufacture of pest control agent, and method for pest control

Disclosed are a pest control agent, a method for preparing a pest control agent, and a method for controlling a pest. Generally, the pest control agent is formed by providing a porous starch and an active control agent absorbed within the porous starch, and compressing the porous starch in the presence of heat to form discrete plural particles. Preferably, one or more binders are employed, as are one or more secondary absorbents / fillers. In highly preferred embodiments of the invention, the pest control agent is prepared via pelletizing in a commercial pellet mill. The particles so prepared should be sufficiently durable to withstand bulk transport, such as by rail car or bag shipment. The particles should, however, release the control agent quickly upon contact with water, such that, for instance, the control agent may be released when the pest control agent is introduced to standing water. It is contemplated that the control agent is preferably a mosquito control agent.

Owner:GRAIN PROCESSING CORP

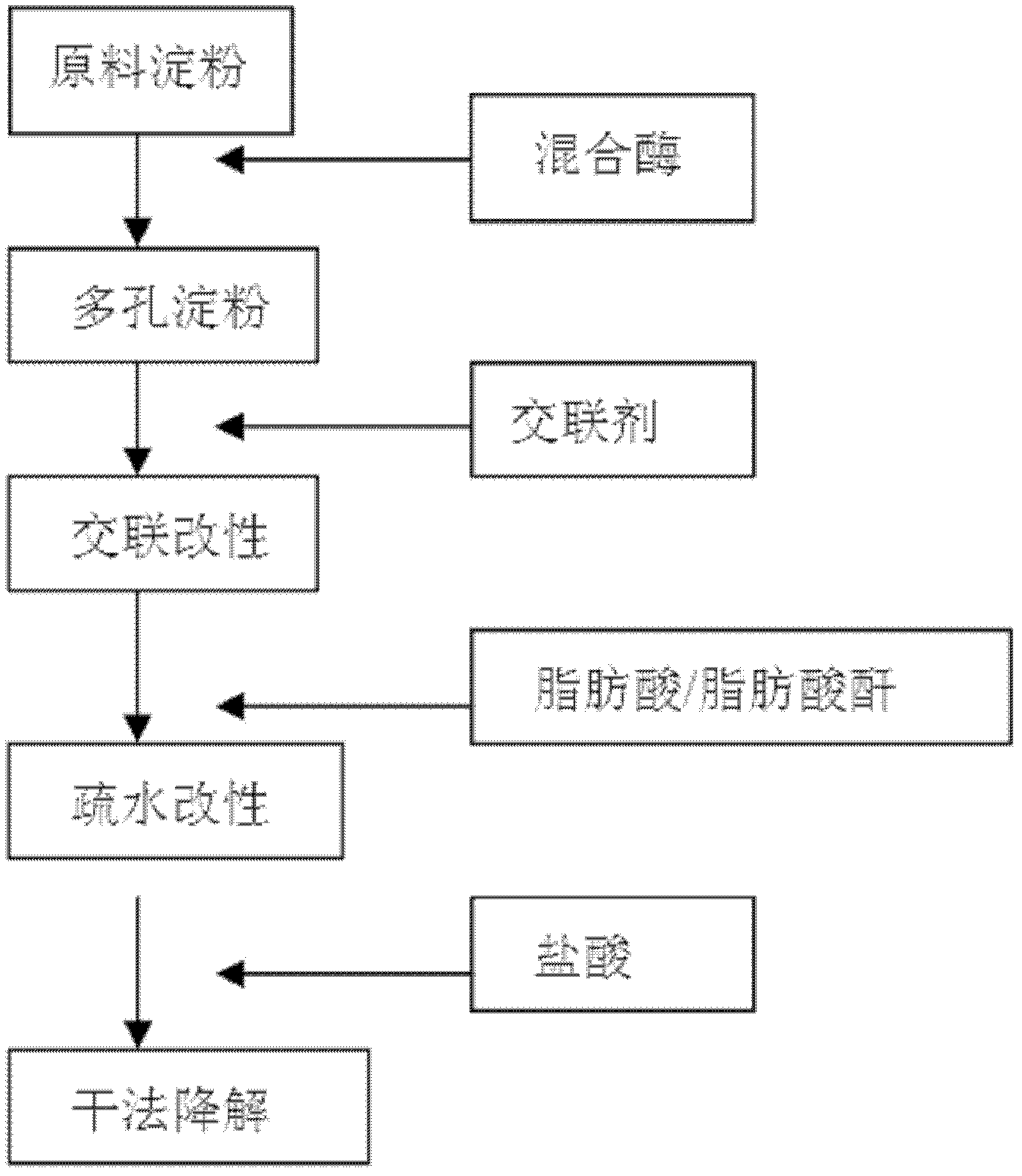

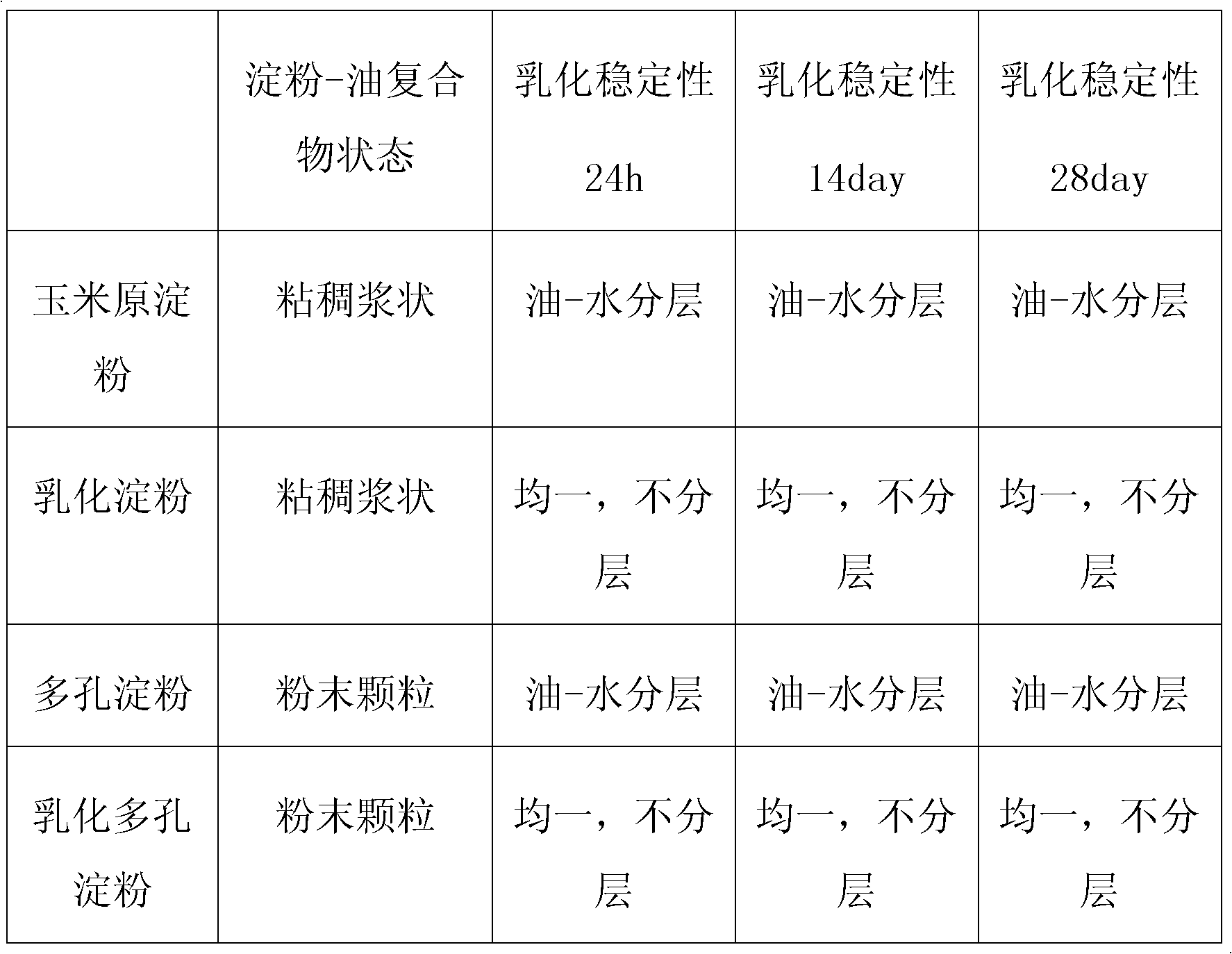

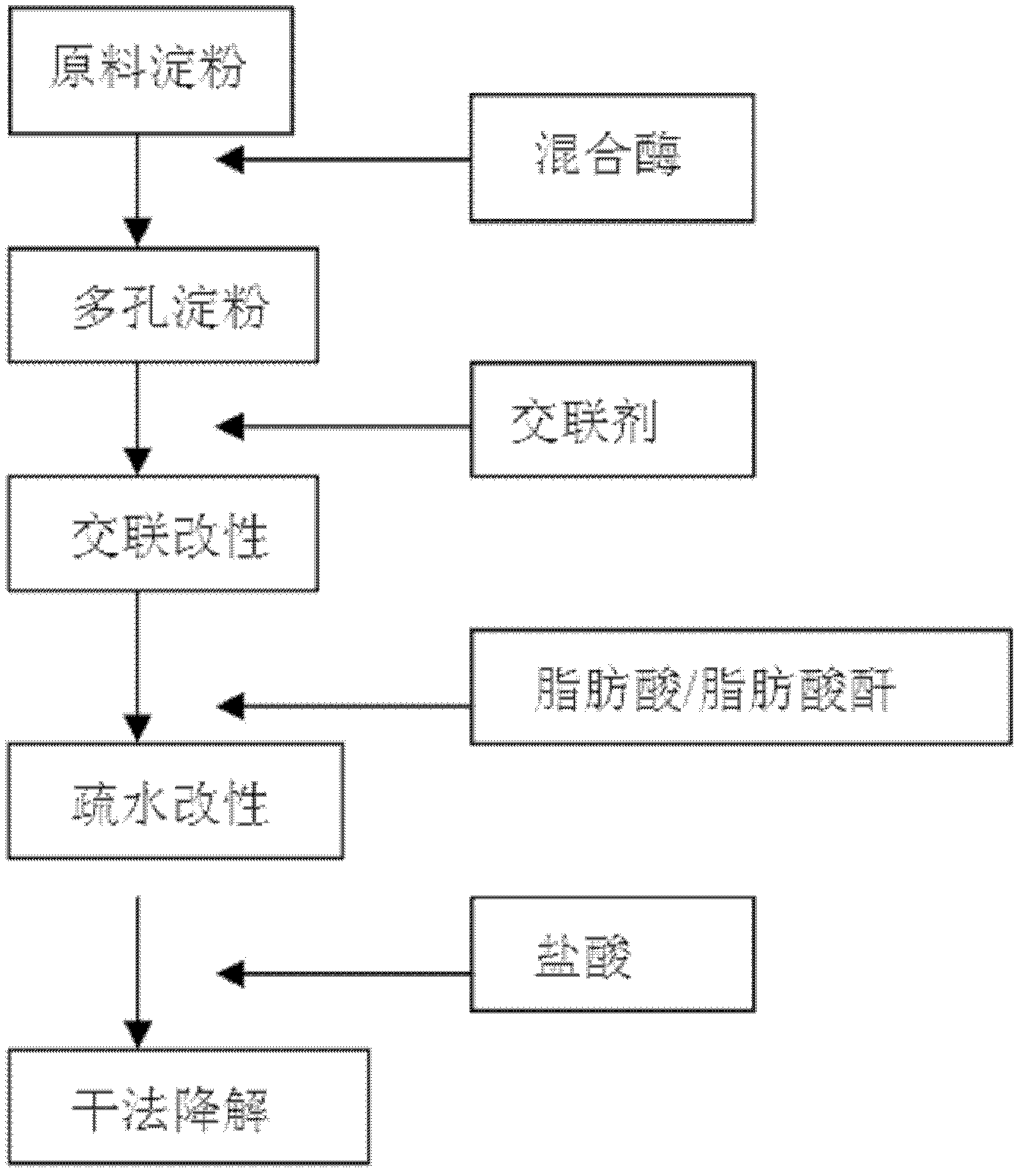

A kind of preparation method of porous starch with emulsification

InactiveCN102276851AGood emulsificationSimple production processOther chemical processesFermentationAmylaseSolubility

The invention discloses a method for preparing porous starch with emulsibility. The method comprises the following steps of: degrading starch serving as a raw material in presence of amylase, modifying by crosslinking, modifying hydrophobic groups, degrading by acid, and thus, synthesizing composite modified starch with absorptive embedding performance and emulsibility. In the method, after beingsubjected to modification of crosslinking and esterification, the starch is washed and filtered to remove residues and is dried at normal temperature, crushed and sieved, moisture is regulated, and the pH value is regulated by an acid to react at high temperature, the starch is in the integral granular state and has the porous property, and after being degraded to a certain extent, the starch hascold water solubility.

Owner:苏州高峰淀粉科技有限公司

Production method of alpha-linolenic acid microcapsule

InactiveCN101336905AEasy to useStable in natureOrganic active ingredientsMetabolism disorderAlpha-Linolenic acidAlcohol

A production method of an ALPHA-linolenic acid microcapsule comprises the steps of: mixing cold pressed linseed oil and corn protein porous starch used as a carrier, coating with alcohol-dissolved corn protein liquid, and producing ALPHA-linolenic acid microcapsule with a rotary embedding method. The used corn protein porous starch and alcohol-dissolved corn protein are both natural food raw materials with good safety and stable properties, which can effectively powder liquid oil and fat, so as to prevent the oil and fat contacting with air and delay the oxidative deterioration of the unsaturated fatty acids in the linseed oil, and can block the unpleasant odor sent out from the linseed oil. The inventive production method is simple; and the obtained ALPHA-linolenic acid microcapsule can be conveniently stored and transported, and can be widely used in foods or nutritional health products.

Owner:SHANXI ZHONGDA TECH

Folium isatidis cellulose fiber having antiviral, antibacterial and skin-care functions and preparation method thereof

InactiveCN105603556AEasy to takeGood textile processabilityArtificial filaments from viscoseWet spinning methodsSodium CaseinateEngineering

The invention discloses a folium isatidis cellulose fiber having antiviral, antibacterial and skin-care functions and a preparation method thereof. The folium isatidis cellulose fiber contains, by weight, 2.0-8.0 parts of folium isatidis extract, 2.0-8.0 parts of sodium caseinate, 2-30 parts of porous starch and 2-50 parts of protein. The preparation method includes the following steps that 1, preparation of folium isatidis extract-sodium caseinate compound microcapsules, 2 preparation of a blended spinning stock solution and 3 spinning and post-processing. Compared with conventional viscose fibers, the influenza A virus inactivation rate of the fiber is 82.0% or above, the herpes virus inactivation rate is 84.0% or above, a bacteriostatic activity value is greater than or equal to 2.0, a bactericidal activity value is greater than or equal to 0.2, a variety of amino acids and trace elements are contained in the fiber, the fiber has good skin-care and health-care functions, the physical index of the product can meet the requirements of GB / T14463-2008 viscose staple fiber first-grade products, and the fiber has good wearability and textile processing performance.

Owner:单大伟

Active microorganism coated slow release composite fertilizer

InactiveCN104098390AImprove the phenomenon of single fixationAvoid churnFertilizer mixturesPolyvinyl alcoholMonopotassium phosphate

The invention relates to the field of composite fertilizers, in particular to an active microorganism coated slow release composite fertilizer, which is prepared from the following raw materials by weight part: 10-15 of 1250-2000 mesh diatomite, 10-12 of triple superphosphate, 15-18 of potassium dihydrogen phosphate, 20-22 of urea, 18-20 of ammonium carbonate, 10-12 of boric magnesium fertilizer, 14-15 of plant fallen leaves, 7-8 of soy bean residue, 0.02-0.03 of a JT strain, 1-2 of ammonium molybdate, 5-6 of Oenanthe javanica, 1-2 of freshwater shrimp shell powder, 10-12 of crop straw, 8-10 of peanut meal, 1-3 of radix isatidis, 6-8 of fermented chicken manure, 10-12 of porous starch, 1-3 of sodium trimetaphosphate, 4-6 of acrylic acid, 6-8 of polyvinyl alcohol, 0.1-0.2 of ammonium persulfate, 3-5 of cherry stone powder, 2-4 of orange peel, 15-18 of fermented alga liquid, and 4-5 of an additive. The composite fertilizer provided by the invention has wide material sources and comprehensive and rich nutrients, and in terms of the production technology, diatomite and an active slow release coating agent are utilized to form dual coating on nutrients, so that the fertility can be more lasting, and the soil vitality can be improved, plant diseases and insect pests can be reduced, and the efficacy of enhancing crop yield and quality can be achieved.

Owner:HEFEI CHANGRUN AGRI TECH

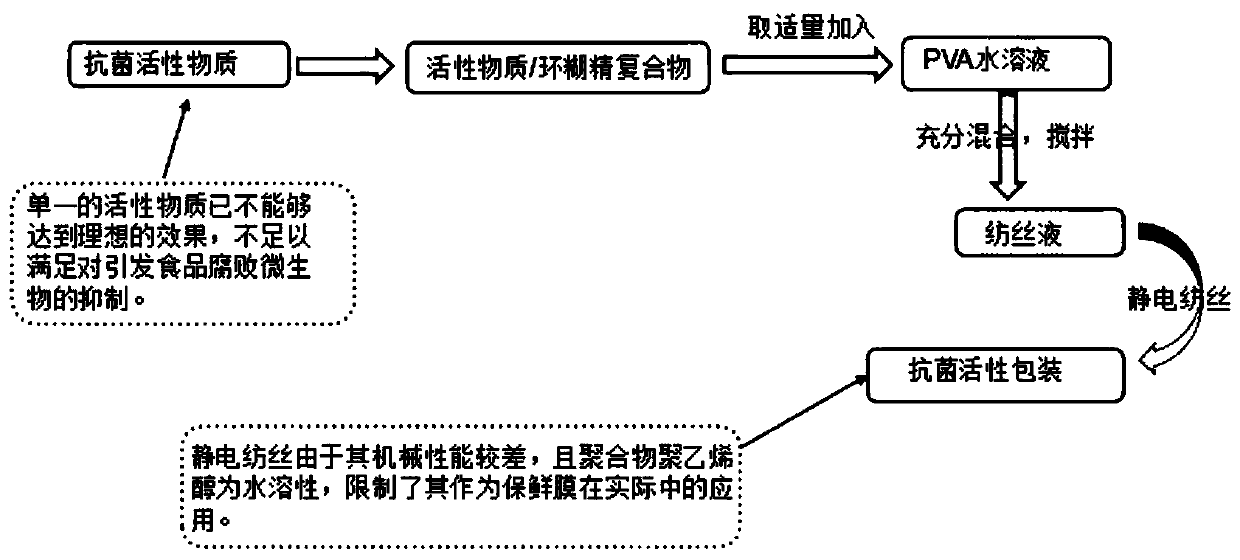

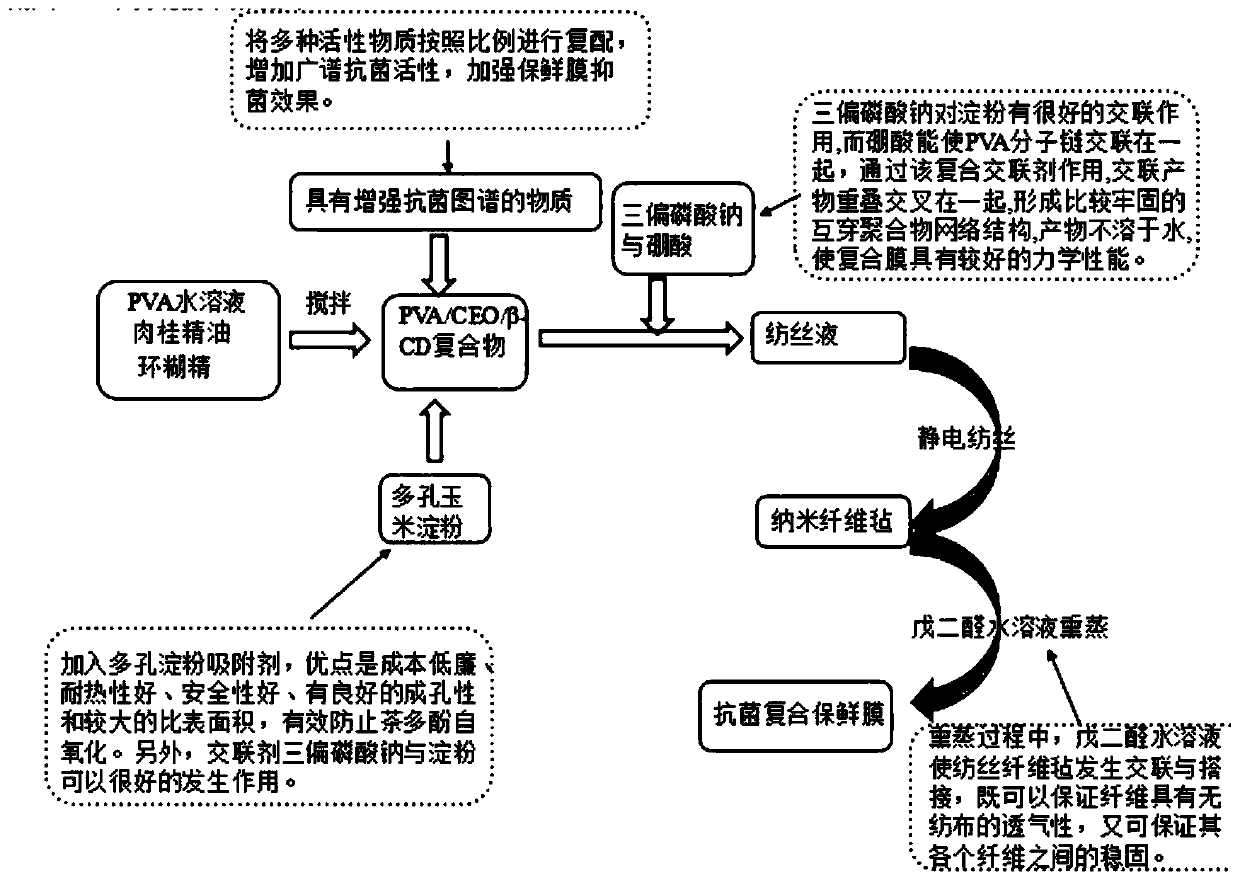

Preparation method of enhanced bacteriostatic and breathable composite fiber electrostatic spinning membrane

InactiveCN109881369AImprove the preservation effectExtended shelf lifeFibre typesMonocomponent synthetic polymer artificial filamentFiberCyclodextrin

The invention provides a preparation method of an enhanced bacteriostatic and breathable composite fiber electrostatic spinning membrane. The preparation method includes the following steps that 6-8 parts of polyvinyl alcohol are weighed and dissolved in 100 parts of 60-80 DEG C deionized water, and a PVA water solution is prepared; (2), 4 parts of active bacteriostatic substances are added into the PVC water solution, the active bacteriostatic substances are formed by mixing cinnamon essential oil, allicin, tea polyphenol and thyme essential oil according to the mass ratio of (2-4):(1-3):(0.5-2.5):(0.4-2.4), then 0.5-1.5 parts of cyclodextrin and 1-3 parts of corn porous starch are added, after the materials are fully mixed and stirred for 5-8 hours, 5-10 parts of sodium trimetaphosphateand boric acid complex are added for crosslinking, the sodium trimetaphosphate and boric acid complex is formed by compounding sodium trimetaphosphate and boric acid at the mass ratio of 4:5 until thesolution is uniform, and a spinning solution is obtained; (3), the spinning solution is arranged on an electrostatic spinning machine for spinning, and a spinning membrane is obtained; (4), the spinning membrane is subjected to glutaraldehyde fumigation crosslinking, and after the spinning membrane is dried in the air, the composite fiber electrostatic spinning membrane is obtained.

Owner:ZHEJIANG UNIV OF TECH

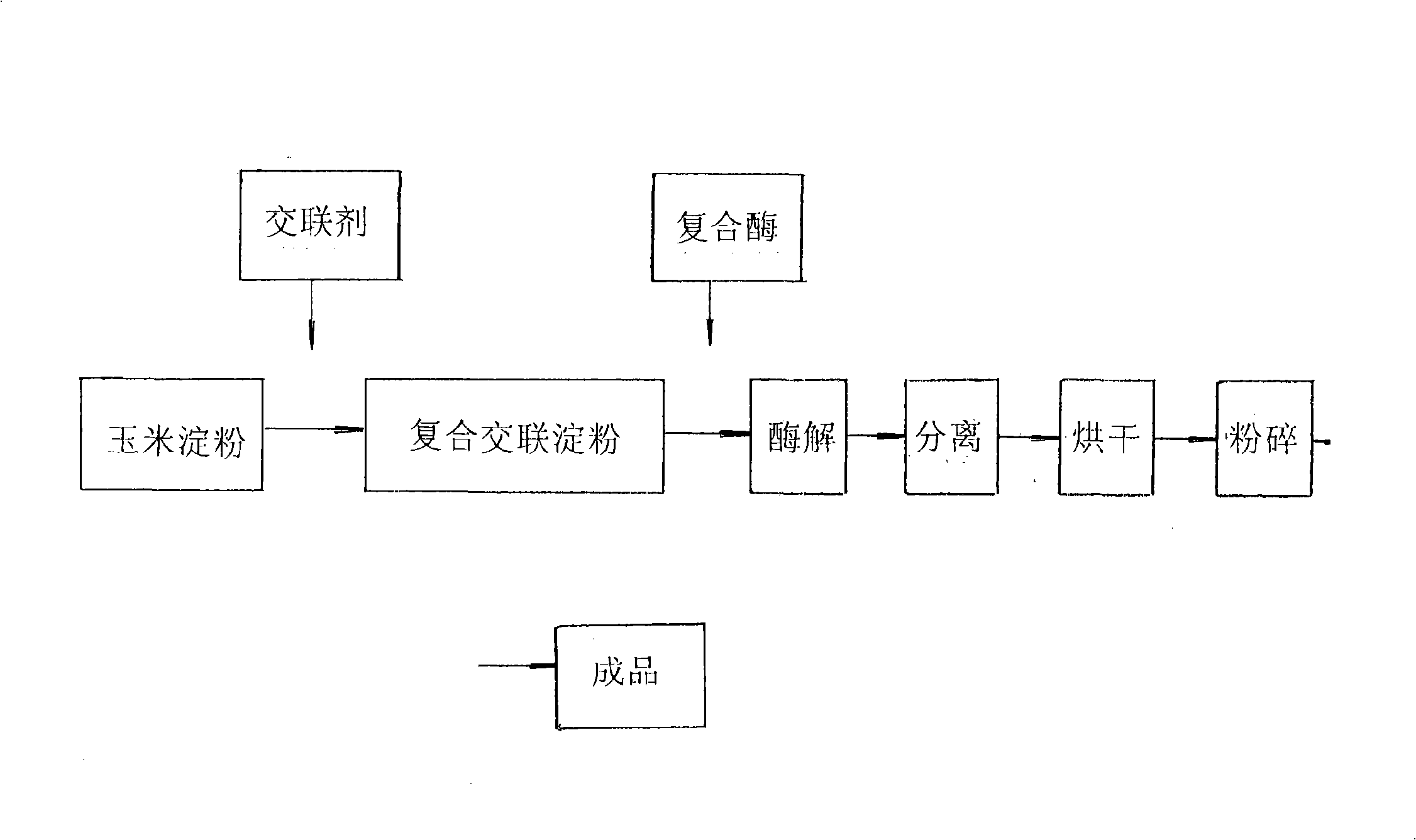

Method for preparing modified corn porous starch by composite cross linkage

InactiveCN101289684AImprove structural stabilityImprove water absorptionFermentationCross-linkFlavoring essences

The invention aims to provide a new method for taking corn starch as raw material and obtaining corn multi-orifice starch through enzymolysis after compound cross linking modification, that is to say a preparing method for compound cross linking modification corn multi-orifice starch. The invention adopts the preparation process of a one-step continuous method; the compound enzyme with the proportion of alpha-amylase to maltogenic amyiase being one to eight serves as an enzymolysis agent to improve the structural stability, the water and oil absorption performance of the multi-orifice starch through compound modification; compared with the multi-orifice starch, the water absorption performance and the oil absorption performance of the compound cross linking multi-orifice starch are respectively improved by 25 percent and 66 percent. The invention relates to a plurality of application fields such as flavoring essence, pigment, probiotics, pesticide, fertilizer, agricultural chemicals, medicine, cosmetics, printing ink and paper pulp. The multi-orifice starch which is used to absorb a great variety of objects before direct use has the functions of releasing the objects slowly and protecting the objects.

Owner:HARBIN UNIV OF COMMERCE

Composite microcapsule additive containing phase change material and sarcandra glabra extract and application of composite microcapsule additive

InactiveCN105316784AGuaranteed stabilityGood temperature regulationArtificial filaments from viscoseCelluloseDistilled water

The invention belongs to the technical field of functional cellulosic fibers and relates to a composite microcapsule additive containing a phase change material and sarcandra glabra extract. A preparation method comprises the following steps: adding the phase change material, an emulsifying agent, an initiator and distilled water into a heating device, and stirring to form a stable emulsifying solution; slowly dripping methyl methacrylate into the emulsifying solution, and carrying out a polymerization reaction after a pre-polymerization reaction; standing and washing with ethanol and filtering to obtain a solid matter; drying the solid matter to obtain a phase change material microcapsule; mixing the phase change material microcapsule with a sarcandra glabra extract solution, wherein the phase change material microcapsule sufficiently adsorbs the sarcandra glabra extract; drying the mixture to obtain the phase change material microcapsule adsorbing the sarcandra glabra extract on the surface; and adding the phase change material microcapsule into a porous starch ethanol solution to carry out adsorption; adding beta-cyclodextrin and emulsifying at a high speed to obtain composite microcapsule additive containing the phase change material and the sarcandra glabra extract from inside to outside. Sarcandra glabra viscose prepared by using the additive has good temprature adjusting and antibacterial functions.

Owner:山传雷

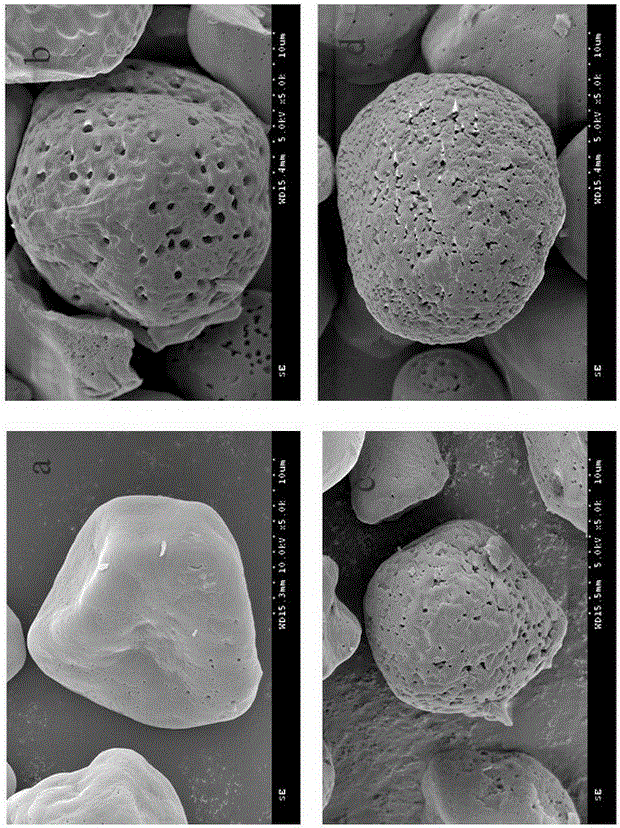

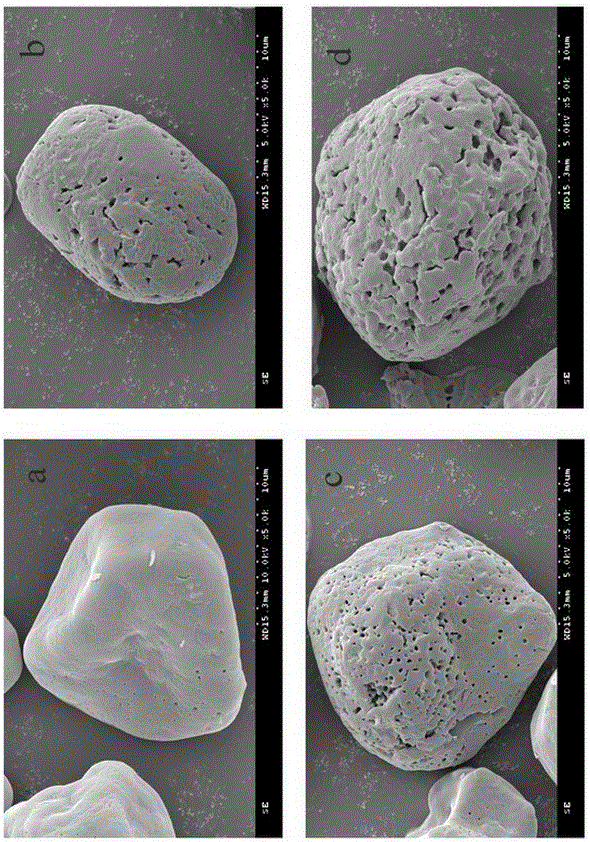

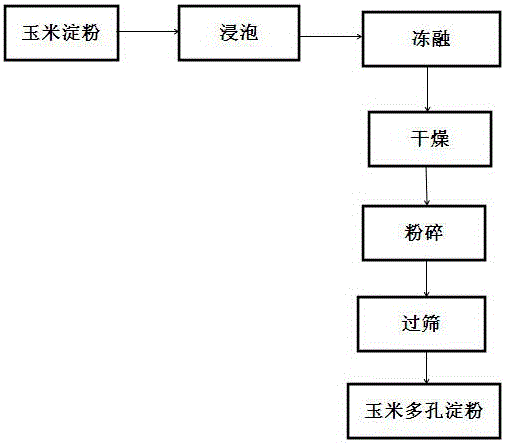

Method for producing corn porous starch by using low temperature freeze-thawing technology

A method for producing corn porous starch by using a low temperature freeze-thawing technology comprises the following steps: 1, immersing corn starch; 2, freeze-thawing: freezing the immersed corn starch at -10 ~ -196 DEG C for 0.5-12 h, unfreezing the frozen corn starch at 20-50 DEG C for 3-8 h, and repeatedly carrying out freezing and unfreezing treatment 1-50 times. The method has the advantages of simplicity in operation, high production efficiency, clean production technology, no pollution to environment, realization of large-scale continuous production, and low production cost due to adoption of reagents and materials having common specifications; and the corn porous starch produced in the invention has the advantages of high freeze-thawing stability, strong reaction activity, good adsorptivity and good embedding property.

Owner:QIQIHAR UNIVERSITY

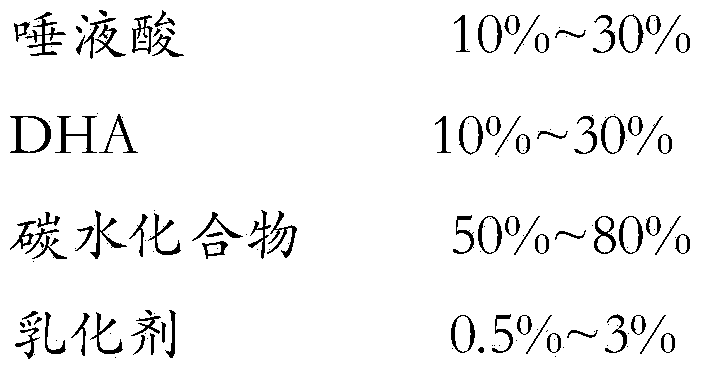

Microcapsule containing sialic acid and DHA and preparation method thereof

InactiveCN104041827AImprove antioxidant capacityGood storage stabilityFood shapingFood preparationMonoglycerideSucrose

The invention discloses a microcapsule containing sialic acid and DHA and a preparation method thereof. The microcapsule containing sialic acid and DHA comprises following components in percentage by mass: 10%-30% of sialic acid, 10%-30% of DHA, 50%-80% of a carbohydrate and 0.5%-3% of an emulsifying agent, wherein the carbohydrate is one or a mixture of more of following components at any ratio: maltodextrin, beta-cyclodextrin and porous starch; the emulsifying agent is one or a mixture of more of following components at any ratio: sucrose ester, monoglyceride, whey protein isolate, sodium caseinate and soybean protein isolate. The invention provides the stable microcapsule which contains sialic acid and DHA nutritional factors and can be widely applied to various food systems.

Owner:南京极燕食品有限公司

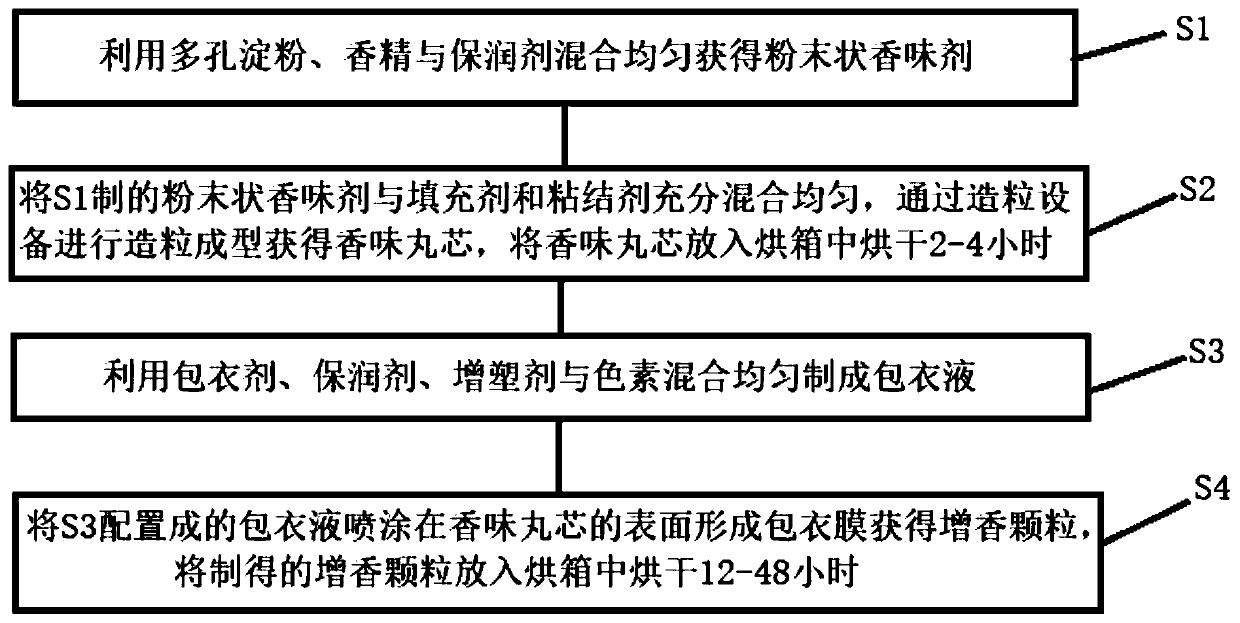

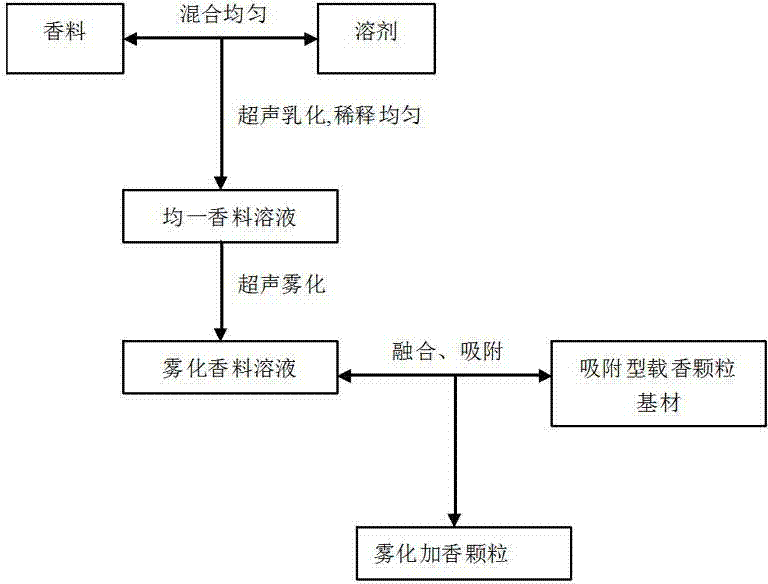

Preparation method of aroma enhancement particle for cigarette filter tip and cigarette filter tip

InactiveCN110384251ASmell has no effectImprove comfortTobacco smoke filtersFiller ExcipientCigarette filter

The invention belongs to the technical field of cigarette auxiliary materials and provides a preparation method of an aroma enhancement particle for a cigarette filter tip and a cigarette filter tip for solving the problem that the existing cigarettes are insufficient in smoke fragrance and non-obvious in characteristics. The preparation method comprises the following steps: S1, uniformly mixing porous starch, essence and humectant to obtain a powdery flavoring agent; S2, thoroughly and uniformly mixing the powdery flavoring agent prepared in the step S1 with a filling agent and a binding agent, performing granulating and forming through granulation equipment to obtain a fragrant pellet core, and putting the fragrant pellet core into a drying oven to be dried for 2-4 hours; S3, uniformly mixing a coating agent, the humectant, a plasticizer and a pigment to prepare a coating liquid; and S4, spraying the coating liquid prepared in the step S3 on the surface of the fragrant pellet core toform a coating film so as to obtain an aroma enhancement particle, and putting the prepared aroma increasing particle into a drying oven for drying for 12-48 hours. The prepared aroma enhancement particle can improve the comfort of cigarette smoking, and the harm of nicotine and carbon monoxide to smokers can be reduced.

Owner:江苏万腾新材料科技有限公司

Solid fat powder for suckling pigs and preparation method for solid fat powder

The invention discloses solid fat powder for suckling pigs and a preparation method for the solid fat powder. The solid fat powder is characterized by comprising the following components: oleic acid, linoleic acid, linolenic acid, palmitic acid, beta vegetable oil, stearic acid, vitamin E, esterified porous starch, ultrafine silicon dioxide and lactic acid monoglyceride, wherein the components are mixed in a proportion. The preparation method comprises the following steps of: sequentially performing mixed emulsification, powerful mixing and spray granulation. The solid fat powder for the suckling pigs which is prepared by the method can meet the requirements on the oleic acid, the linoleic acid, the linolenic acid, the palmitic acid and the beta vegetable oil at a suckling pig stage; and the fat composition of the solid fat powder stimulates fat components of milk, fatty acid is completely emulsified, and the beta vegetable oil can be completely absorbed, so the requirements of intestinal tracts of the suckling pigs on energy can be improved, and the disadvantages that intestinal villi are atrophic and the suckling pigs are diarrheic and dead due to inadequate intestinal energy caused by low feed intake when the suckling pigs are weaned are overcome.

Owner:SHANGHAI XINNONG FEED

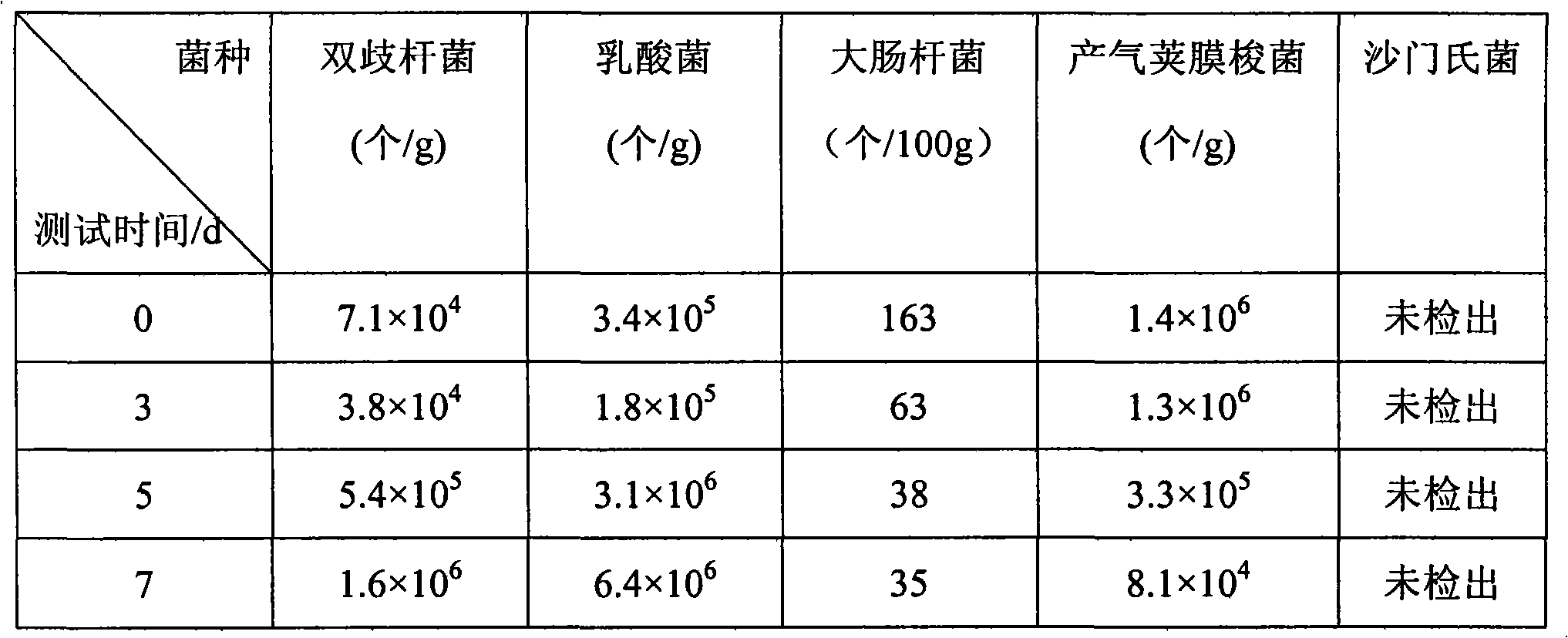

Compound probiotic microcapsules that can improve the intestinal microecology of small dogs

InactiveCN102283334AImproving the gut microbiome of small dogsAnimal feeding stuffFreeze-dryingPorous starch

The invention discloses a composite probiotic microcapsule capable of improving the intestinal microecology of a small dog. The preparation method comprises the following steps: A1, preparing a composite bacterial preparation; A2, preparing a composite probiotic bacteria liquid; A3, mixing 2-5% The porous starch was mixed with the composite probiotic liquid, the pH value was adjusted to 6.0, and the temperature was controlled at 25-35°C for 30 minutes of shaking. After being fully adsorbed, add the following outer layer embedding materials in sequence according to the weight percentage: 1-3% sodium alginate, 1-5% gelatin, 1-5% dextrin, stir evenly, drop calcium chloride solution to solidify, freeze drying to obtain composite probiotic microcapsules. The invention uses porous starch as the core material, absorbs the composite probiotic bacteria liquid, and then uses sodium alginate, dextrin and gelatin as the wall materials, and processes to obtain the composite probiotic bacteria microcapsules.

Owner:XIHUA UNIV

Sewage treatment composite gel material for microbe embedding, and preparation method thereof

ActiveCN105523643AImprove water swellabilityGuaranteed normal growthWater contaminantsWater/sewage treatment by sorptionCross-linkCarrageenan

The invention relates to a sewage treatment composite gel material for microbe embedding, and a preparation method thereof. The sewage treatment composite gel material for microbe embedding comprises, by weight, 60-80 parts of carrageenan, 5-15 parts of polyacrylamide, 5-8 parts of porous starch, 4-8 parts of microbes, 0.1-0.3 parts of a growth factor, 1-4 parts of inorganic powder, 1-3 parts of a cross-linking agent and 0.5-0.8 parts of a potassium salt. The composite gel material is prepared by adopting carrageenan and the polyacrylamide composite gel as an embedding agent, the porous starch as an adsorbent and a carrier and the inorganic powder as an additive, is used for embedding microbes, is applied to sewage treatment, can effectively adsorb and remove heavy metal ions and degrade organic matters, and has the advantages of simple preparation process, low cost and market application prospect.

Owner:河南格恩阳光环境科技有限公司

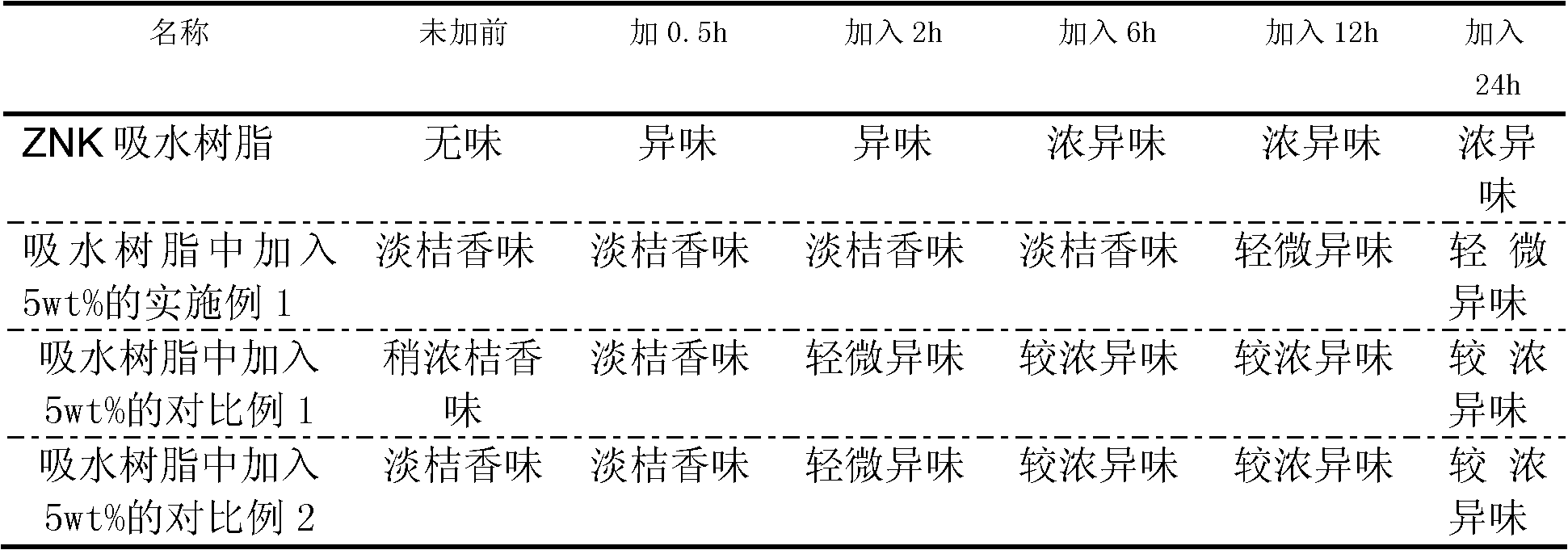

Water-soluble fragrance microcapsule having slow release characteristics and preparation method thereof

InactiveCN102513045AEasy to storeLong-lasting odor maskingEssential-oils/perfumesMicroballoon preparationPolyethylene glycolPorous starch

The invention provides a water-soluble fragrance microcapsule having slow release characteristics and a preparation method thereof. A capsule core of the microcapsule is porous starch having adsorbed oil-soluble essential oil, and a capsule wall is water-soluble polyethylene glycol. The microcapsule does not release fragrance when the microcapsule does not contact with aqueous liquid like body fluid and has good storage performance; when the microcapsule contacts with aqueous liquid, the water-soluble capsule wall at the exterior of the microcapsule is dissolved in the aqueous liquid, so capsule core substances having fragrance permeate micropores in the porous starch at an internal layer and are slowly released, thereby achieving the goals of lasting shielding of stink and removal of a peculiar smell. In the preparation process of the microcapsule, loss of the fragrant substances is small, the preparation method is simple and is suitable for industrial production, and an absorbent resin is endowed with special deodorizing capability when the absorbent resin is combined with the microcapsule.

Owner:SHANDONG HAOYUE NEW MATERIALS CO LTD +1

Microencapsulated multistage release biogenic preservative for raw materials of pickled solanaceous vegetables

InactiveCN102487995AGuaranteed qualityGood fresh-keeping effectFruit and vegetables preservationFlavorPreservative

The invention discloses microencapsulated multistage release biogenic preservative for raw materials of pickled solanaceous vegetables, which is made by steps: firstly, preparing beta-cyclodextrin-essential oil microcapsules; secondly, preparing chitosan essential oil-microcapsules; thirdly, preparing porous starch-essential oil quick release microcapsules; and fourthly, mixing the microcapsules prepared from the second step to the third step according to a weight ratio of 2:4:5 to 6:3:1, and bagging the microcapsules into small packing bags or placing on coated composite paper to obtain the multistage release biogenic preservative. The microencapsulated multistage release biogenic preservative for raw materials of pickled solanaceous vegetables is convenient in application, efficient, pollution-free and effective in preservation and has no effect on flavor of pickles, mature stages of the pickled solanaceous vegetables are uniform, fermenting effect of the pickled solanaceous vegetables is fine, contamination by sundry fungi brought by the raw materials in fermentation is avoided, loss is reduced, and the quality of pickles is high and stable.

Owner:XIHUA UNIV +1

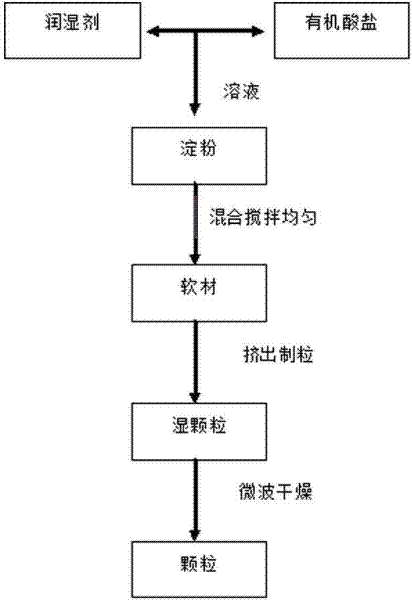

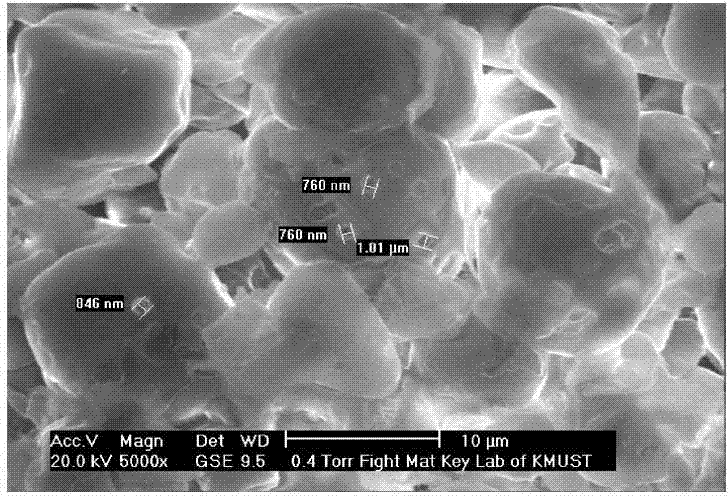

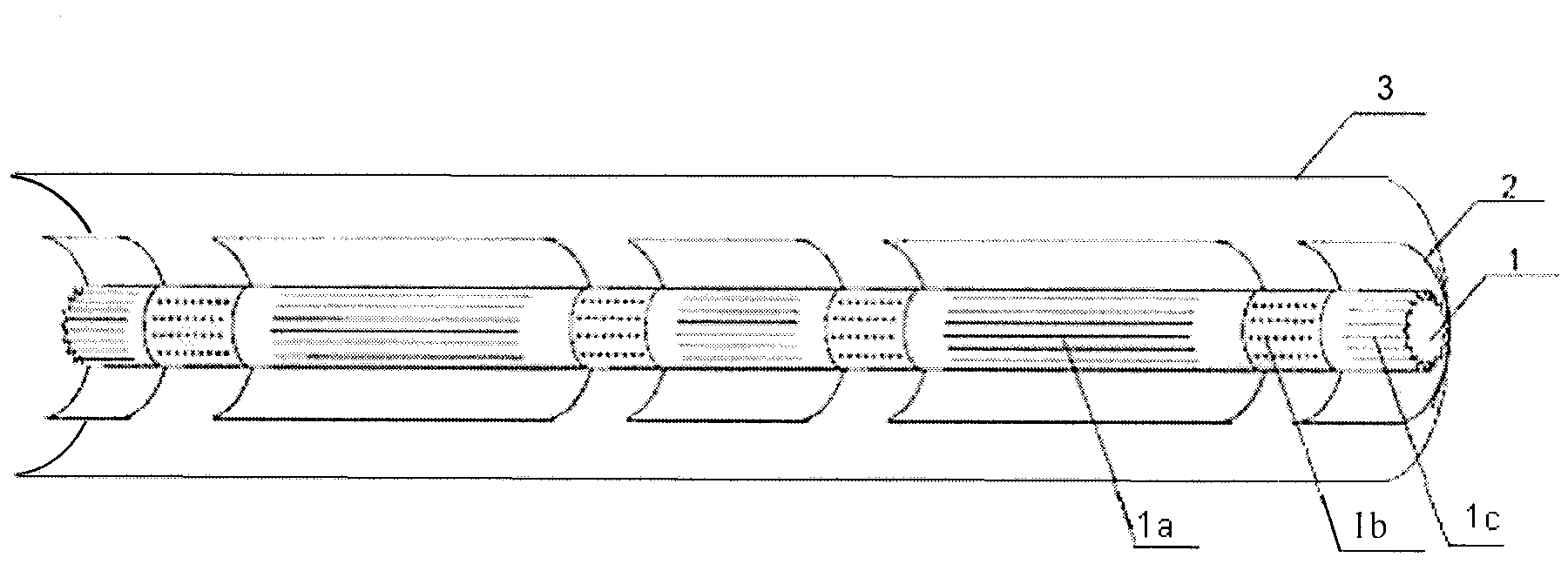

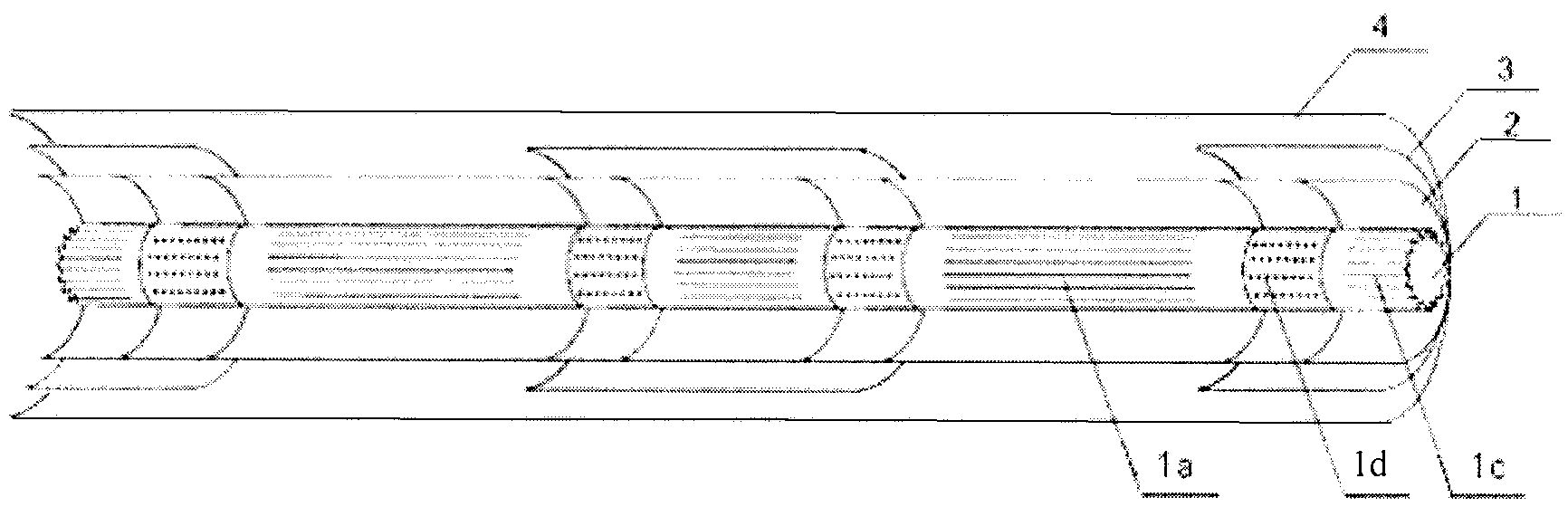

Preparation method of adsorption-type base materials

InactiveCN102551203AThe preparation method is simple and easyImprove cigarette smoking qualityOther chemical processesTobacco smoke filtersOrganic acidMicrowave oven

The invention discloses a preparation method of adsorption-type base materials, belongs to the technical field of cigarette materials, in particular relates to a granule, and further relates to preparation method and application of the granule. The preparation method comprises the following steps: (a), thoroughly mixing an organic acid salt of the granule with a wetting agent, adding porous starch, and thoroughly mixing to make a soft material with the water content of 20% to 50%; (b), processing the soft material obtained in the step (a) by extrusion granulation to make granules with a particle size of 15 to 80 meshes; (c), loading the granules obtained in the step (b) to a microwave dish at an amount of 800 g to 1200 g per dish, placing in a microwave oven and oven-drying for at least one time to obtain dry granules; and (d), sieving to obtain the final products of adsorption-type base materials. Perfumes are uniformly adsorbed due to the adsorbing property of the base materials and then sieved to obtain the adsorption-type perfume-loading granules. The granules are added to cigarette filter sticks, so as to achieve the effect of adsorbing cigarette harmful substances, improve the smoking quality of cigarettes and enhance the characteristics and features of cigarettes.

Owner:ZHENGBANG BIOTECH CO LTD YUNNAN

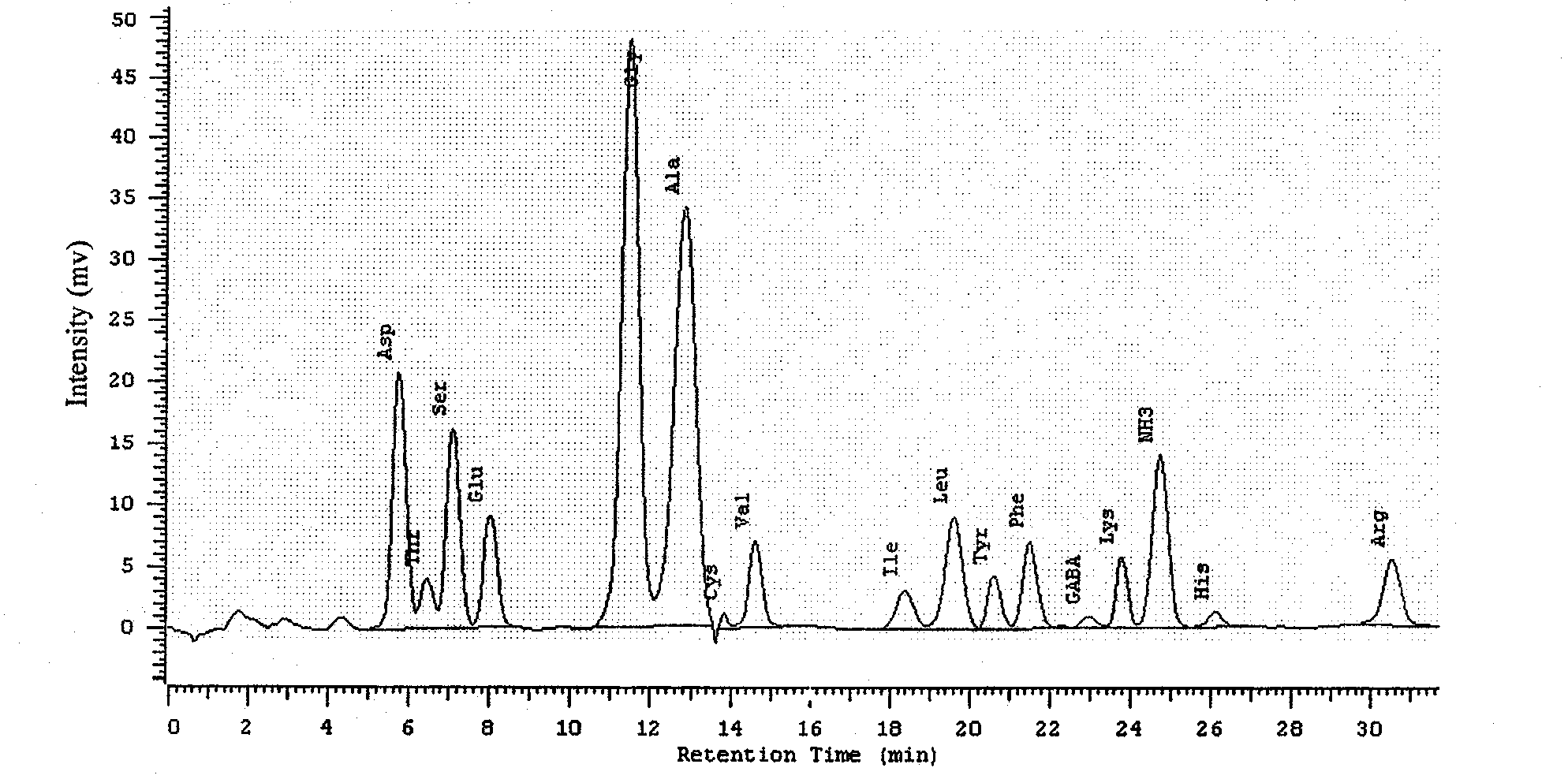

Method for preparing pearl-powder composite porous starch crystalline particles and application of pearl-powder composite porous starch crystalline particles to cigarette filtering tip

The invention discloses a method for preparing pearl-powder composite porous starch crystalline particles and the application of the pearl-powder composite porous starch crystalline particles to the cigarette filtering tip. The method comprises the following steps: mixing pearl powder and porous corn starch uniformly according to a certain proportion, moistening by deionized water, granulating, shaping by microwave, drying by microwave, and sieving to obtain the pearl-powder composite porous starch crystalline particles with high strength. The pearl-powder composite porous starch crystalline particles can be added into the cigarette filtering stick to prepare the ternary composite cigarette filtering stick, can reduce the content of benzo [a] pyrene, phenol, tar and other harmful components in the smoke and can increase the content of amino acids and other nutritional components in the smoke. The sensory cigarette smoking evaluation shows that the pearl-powder composite porous starch crystalline particles can be added to the cigarette filtering stick to reduce the smoke irritation and improve the cigarette smoking quality.

Owner:CHINA TOBACCO GUANGXI IND

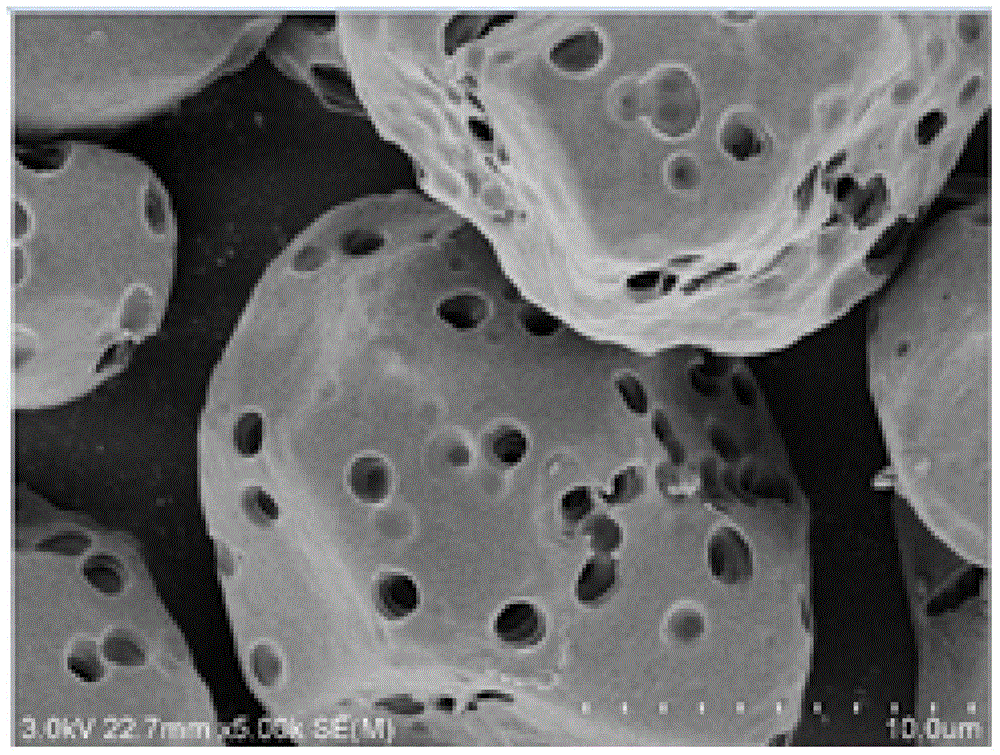

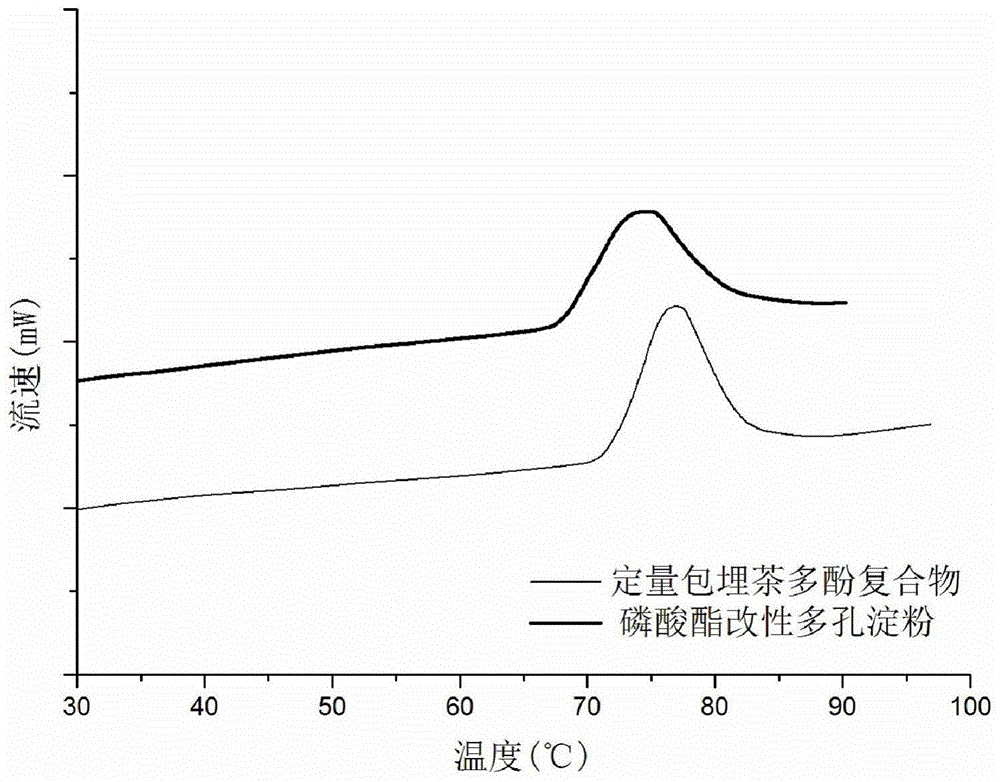

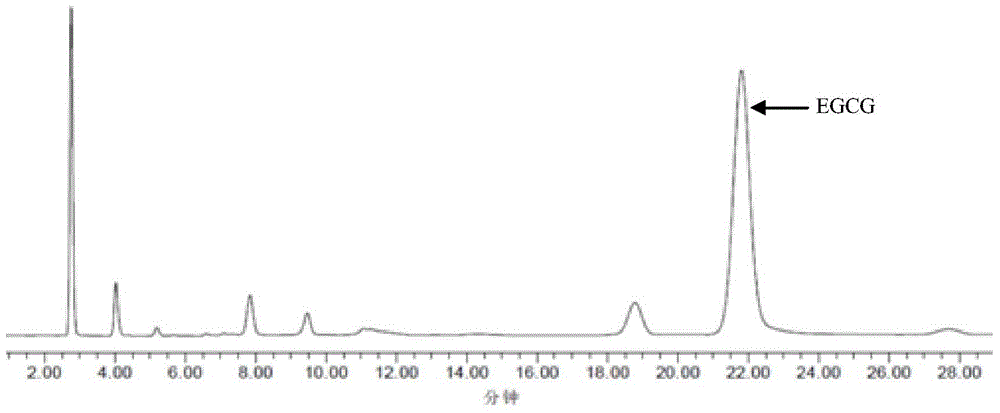

Phosphate-modified porous starch quantitative embedding tea polyphenol compound and preparation method and application thereof

InactiveCN105105335AReduce free radicalsExplain protection abilityTobacco smoke filtersPhosphatePorous starch

The invention discloses a phosphate-modified porous starch quantitative embedding tea polyphenol compound and a preparation method and application thereof. The phosphate-modified porous starch quantitative embedding tea polyphenol compound is a compound which is obtained in the way that porous starch absorption embedding tea polyphenol is modified by phosphate and then freezing and drying are carried out. The phosphate-modified porous starch quantitative embedding tea polyphenol can serve as a cigarette filter tip addition agent, and the dosage is 10 mg per cigarette. Through a manufactured binary combination filter tip, the solid-phase free radical and the gaseous-phase free radical in cigarette main stream smoke are lowered by 12.2% and 33.4% respectively, and after cigarettes are stored for one month at a normal temperature, the solid-phase free radical and the gaseous-phase free radical are lowered by 13.1% and 31.7% respectively.

Owner:ANHUI AGRICULTURAL UNIVERSITY

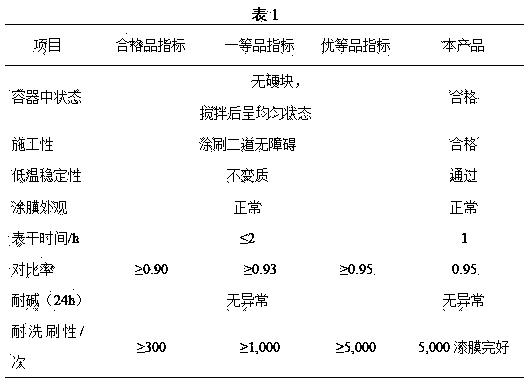

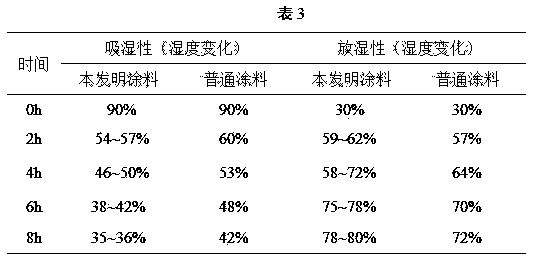

Biomass internal wall paint and preparation method thereof

ActiveCN104109444AGood film formingGood scrub resistanceStarch coatingsHazardous substanceSoftened water

The invention discloses a biomass internal wall paint and a preparation method thereof, and aims to solve the problems of high harmful substance content and especially high formaldehyde content in the existing internal wall paint. The preparation method comprises the following steps: taking softened water, dodecenyl starch aluminum succinate, dispersing agent, wetting agent, titanium white, calcined kaolin, highly-crosslinked porous starch, ground calcium carbonate and light calcium carbonate, adding into a dispersion machine, dispersing at the high speed of 1500 r / min for 20-40 minutes, lowering the speed to 500 r / min, sequentially adding the composite modified starch emulsion, propanediol and defoaming agent, and uniformly dispersing to obtain the composite modified starch-base biomass paint. The obtained biomass internal wall paint has the advantages of delicate paint film, scrub resistance, low VOC (volatile organic compound) content and no formaldehyde, has favorable humidity regulation function, and is green and environment-friendly.

Owner:GANSU GLDARK NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com