Microcapsule containing sialic acid and DHA and preparation method thereof

A technology of sialic acid and microcapsules, which is applied in the field of microcapsules containing sialic acid and DHA and its preparation, can solve problems such as unsuitable for human health, prone to oxidation, and loss of physiological functions of DHA, so as to improve storage stability and enhance anti-inflammatory effects. Oxidation, effect of promoting brain development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

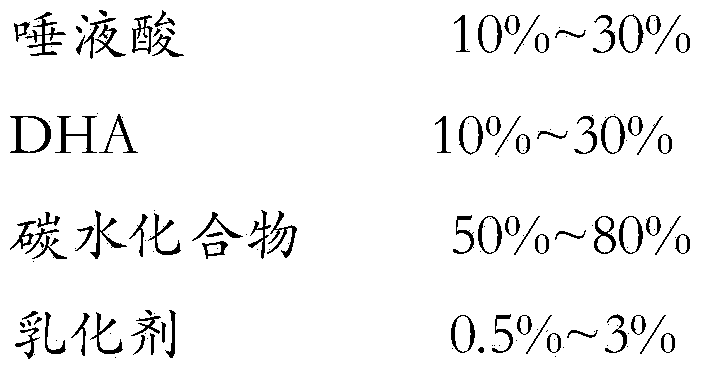

Method used

Image

Examples

Embodiment 1

[0031] Add 500g of sialic acid into 10kg of water to dissolve, then add 100g of sucrose ester to dissolve. 500g of DHA was added and dispersed by high-speed shearing to obtain an emulsion. Add 3kg of β-cyclodextrin into the emulsion, dissolve it with magnetic stirring, homogenize for the second time under 35MPa, and spray dry. The inlet temperature is 150°C and the outlet temperature is 90°C. The average particle size of the prepared microcapsules was 332.41nm, the microencapsulation efficiency was 88.64%, and the retention rates of sialic acid and DHA were 99.12% and 75.52%, respectively, after being stored at 45°C for 30 days.

[0032] Among them, the sialic acid used can be extracted from bird's nest by the following process:

[0033] (1) Soak 3kg bird's nest in 45kg deionized water at room temperature for 6 hours, and remove impurities such as bird hair during the soaking process;

[0034] (2) Get the soaked bird's nest, add 30 kg of deionized water with a quality of 10...

Embodiment 2

[0041] Add 2kg of sialic acid to 100kg of water to dissolve, then add 1kg of whey protein isolate to dissolve. Add 8kg of DHA, and disperse with high-speed shearing to obtain an emulsion. Add 30kg of β-cyclodextrin into the emulsion, stir and dissolve with magnetic force, homogenize for the second time at 40MPa, freeze-dry at -50°C and 15Pa. The average particle size of the prepared microcapsules was 295.78nm, the microencapsulation efficiency was 89.53%, and the retention rates of sialic acid and DHA were 98.15% and 77.92%, respectively, after being stored at 45°C for 30 days.

[0042] Among them, the sialic acid used can be extracted from bird's nest by the following process:

[0043] (1) Soak 5kg bird's nest in 100kg deionized water at room temperature for 8 hours, and remove impurities such as bird hair during the soaking process;

[0044](2) Get the soaked bird's nest, add 75kg of deionized water with a quality of 15 times the dry weight of the bird's nest, and crush th...

Embodiment 3

[0051] Add 1kg of sialic acid to 50kg of water to dissolve, then add 500g of whey protein isolate to dissolve. Add 4kg of DHA, and disperse with high-speed shearing to obtain an emulsion. Add 15kg of porous starch into the emulsion, stir and dissolve with magnetic force, homogenize for the second time under 45MPa, and spray dry. The inlet temperature is 150°C and the outlet temperature is 90°C. The average particle size of the prepared microcapsules was 358.94nm, the microencapsulation efficiency was 91.78%, and the retention rates of sialic acid and DHA were 99.58% and 81.34%, respectively, after being stored at 45°C for 30 days.

[0052] Among them, the sialic acid used can be extracted from bird's nest by the following process:

[0053] (1) Soak 1 kg of swallow cake in deionized water at room temperature for 12 hours, and remove impurities such as swallow hair during the soaking process;

[0054] (2) Take the soaked swallow cake, add 25 kg of deionized water with a quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com