Preparation method of adsorption-type base materials

An adsorption type, base material technology, applied in chemical instruments and methods, tobacco, other chemical processes, etc., can solve the problems of insufficient flavoring, complex industrialization, and inability to fill volatile flavors into cigarettes. Sensory comfort, reduced throughput, enhanced adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

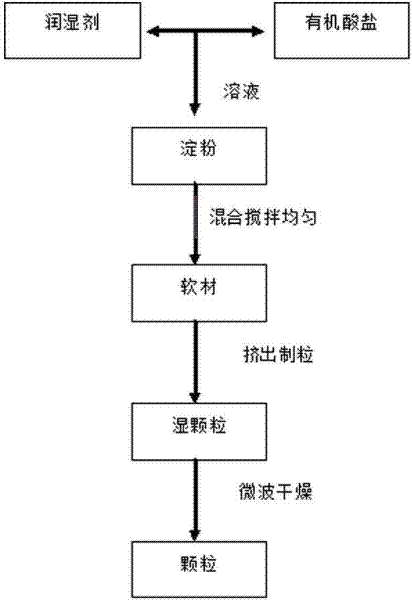

[0043] The preparation method of adsorption type base material of the present invention, its method is:

[0044] a. Mix potassium malate, potassium citrate, sodium malate, sodium citrate, and potassium sorbate in a ratio of 1:1:1:1:1 evenly.

[0045] b. Mix the organic acid salt mixed in a with purified water at a ratio of 2:10, and fully dissolve to prepare a wetting and bonding solution.

[0046] c Spray the wetting and bonding solution prepared in b evenly on the porous starch in a ratio of 1:1, and mix evenly while spraying.

[0047]d. Make the soft material made in c into granules of a certain shape and size by extrusion granulation.

[0048] e. Put the granules made in d into a microwave plate according to the quantity of 800 grams per portion, bake in the microwave oven, take it out after baking for 5 minutes, disperse, then continue to put it in the plate, then bake it for 8 minutes, take it out Scatter, continue to be loaded into the pan, then bake, 8 minutes, conti...

Embodiment 2

[0054] The preparation method of adsorption type base material of the present invention, its method is:

[0055] a. Mix potassium malate, potassium citrate, sodium malate, sodium citrate, and potassium sorbate in a ratio of 1:1:2:1:1;

[0056] b. Mix the organic acid salt mixed in a with purified water in a ratio of 3:11, and fully dissolve to prepare a wetting and bonding solution;

[0057] c. Spray the wetting and bonding solution prepared in b evenly on the porous starch according to the ratio of 2:1, and mix evenly while spraying;

[0058] d. The soft material made in c is made into granules of a certain shape and size by extrusion granulation;

[0059] e. Put the granules made in d into a microwave plate according to the quantity of 800 grams per portion, bake in the microwave oven, take it out after baking for 5 minutes, disperse, then continue to put it in the plate, then bake it for 8 minutes, take it out Scatter, continue to be loaded into the pan, then bake, 10 min...

Embodiment 3

[0065] The preparation method of adsorption type base material of the present invention, its method is:

[0066] a. Mix potassium malate, potassium citrate, sodium malate, sodium citrate, and potassium sorbate in a ratio of 1:1:4:1:1;

[0067] b. mix the organic acid salt mixed in a with purified water in a ratio of 4:12, and dissolve fully to prepare a wetting and bonding solution;

[0068] c. Spray the wetting and bonding solution made in b evenly on the porous starch according to the ratio of 3:2, and mix evenly while spraying;

[0069] d. The soft material made in c is made into granules of a certain shape and size by extrusion granulation;

[0070] e. Put the granules made in d into a microwave plate according to the quantity of 800 grams per portion, put it in the microwave oven and bake it for 5 minutes, take it out, disperse it, then continue to put it in the plate, then bake it for 10 minutes, take it out Scatter, continue to be loaded into the pan, then bake, 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com