Low temperature type lithium ion battery electrolyte with high temperature property and lithium ion battery

A lithium-ion battery, high-temperature performance technology, applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of poor cycle performance and high-temperature performance, limit the application range of lithium-ion batteries, etc., achieve good low-temperature rate performance, The effect of widening the liquid state range and excellent low-temperature discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

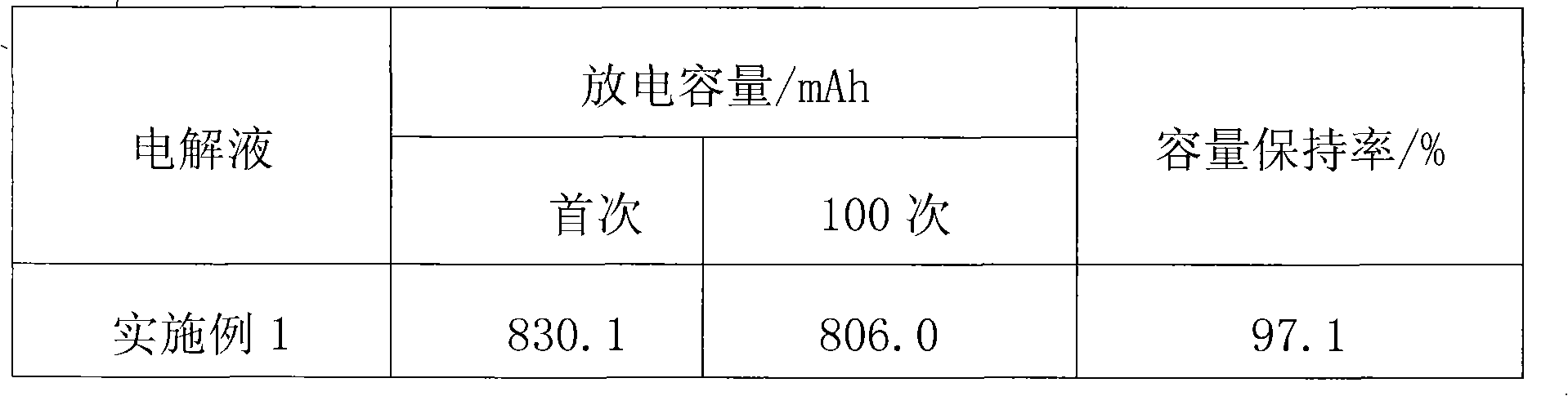

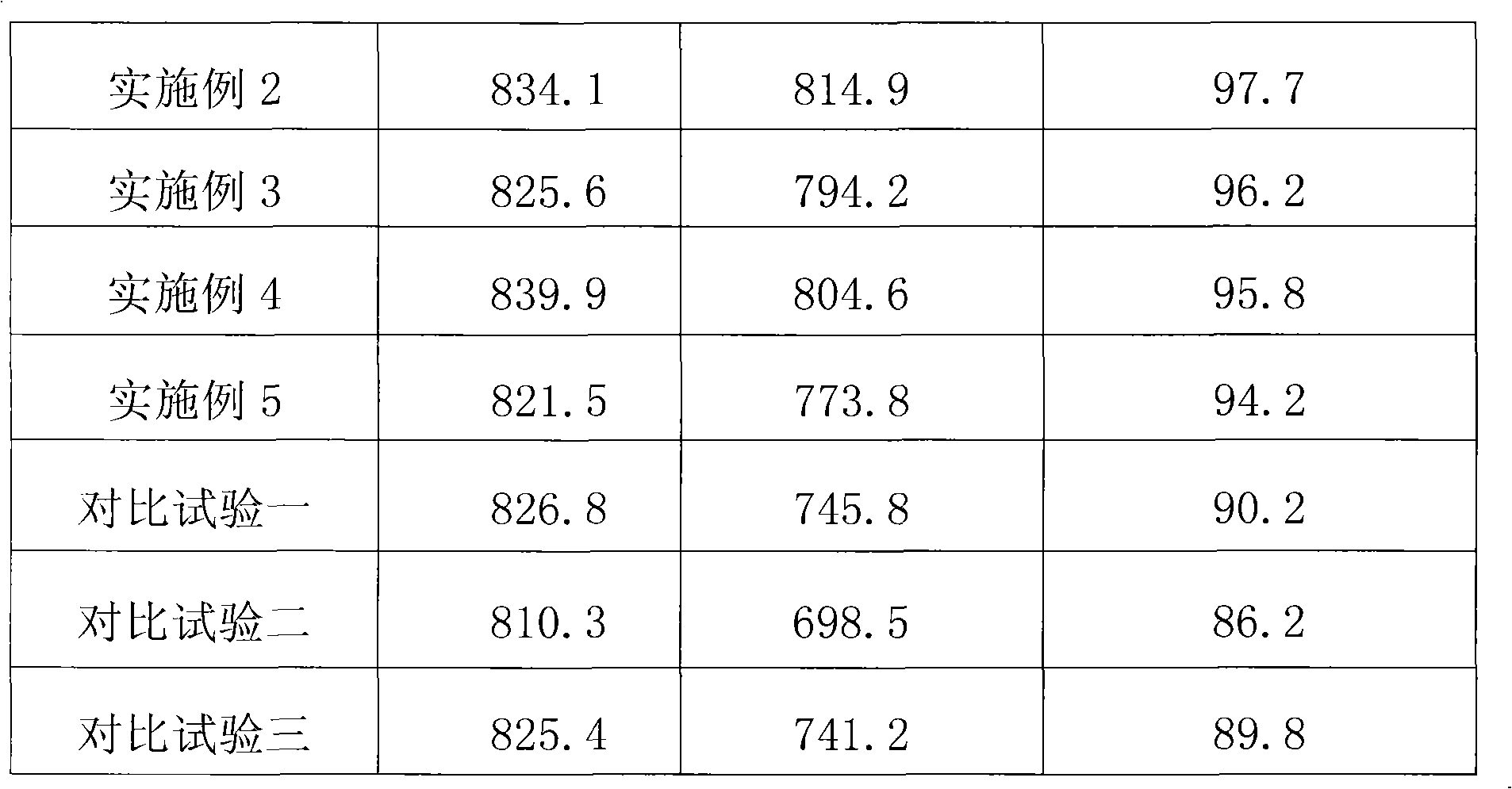

Embodiment 1

[0027] In this example, when preparing the electrolyte: first in a glove box with a humidity of less than 1%, mix the solvents ethylene carbonate, methyl formate and methyl ethyl carbonate in a ratio of 1:1:3 by volume Make a non-aqueous organic solvent, then add the corresponding quality of LiBF to the made non-aqueous organic solvent 4 The mixed lithium salt formed by uniform mixing with LiBOB is prepared into a mixed lithium salt solution with a volume of 30ml and a concentration of 1mol / L after uniform mixing, wherein LiBF in the mixed lithium salt 4 The molar ratio with LiBOB is 8: 2; Simultaneously, in described mixed lithium salt solution, add vinylene carbonate (VC) earlier and the mass percent between added VC and the non-aqueous organic solvent that is made into is 2%, Then add heptamethyldisilazane and the mass percentage between the added heptamethyldisilazane and the non-aqueous organic solvent is 1.0%, after the electrolyte salt (i.e. the mixed lithium salt) is f...

Embodiment 2

[0033] In this embodiment, the difference from Example 1 is: when preparing the electrolyte: in a glove box with a humidity of less than 1%, ethylene carbonate, ethyl acetate and methyl ethyl carbonate are mixed in a volume ratio of 1:2 : The ratio of 6 is mixed evenly to make a non-aqueous organic solvent, and then in the non-aqueous organic solvent made, add the corresponding quality of LiBF 4 The mixed lithium salt formed by uniform mixing with LiBOB is prepared into a mixed lithium salt solution with a volume of 30ml and a concentration of 1mol / L after uniform mixing, wherein LiBF in the mixed lithium salt 4 The molar ratio of LiBOB and LiBOB is 9: 1; Simultaneously, in described mixed lithium salt solution, add 1,3-propane sultone (PS) earlier and the mass between the added PS and the non-aqueous organic solvent that is made into The percentage is 2%, then add heptamethyldisilazane and the mass percentage between the added heptamethyldisilazane and the prepared non-aqueou...

Embodiment 3

[0036] In this embodiment, the difference from Example 1 is: when preparing the electrolyte: in a glove box with a humidity of less than 1%, ethylene carbonate, methyl butyrate and methyl ethyl carbonate are mixed in a volume ratio of 1: The ratio of 2:5 was mixed evenly to make a non-aqueous organic solvent, and then the corresponding mass of LiBF was added to the prepared non-aqueous organic solvent 4 The mixed lithium salt formed by uniform mixing with LiBOB is prepared into a mixed lithium salt solution with a volume of 30ml and a concentration of 1mol / L after uniform mixing, wherein LiBF in the mixed lithium salt 4 The molar ratio of LiBOB and LiBOB is 9: 1; Simultaneously, in described mixed lithium salt solution, add gamma-butyrolactone (GBL) earlier and the mass percentage between the added GBL and the non-aqueous organic solvent that is made into is 3% , then add heptamethyldisilazane and the mass percentage between the added heptamethyldisilazane and the prepared non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com