Patents

Literature

530 results about "Line filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A line filter is the kind of electronic filter that is placed between an electronic equipment and a line external to it, to attenuate conducted radio frequencies -- RFI, also known as electromagnetic interference (EMI) -- between the line and the equipment.

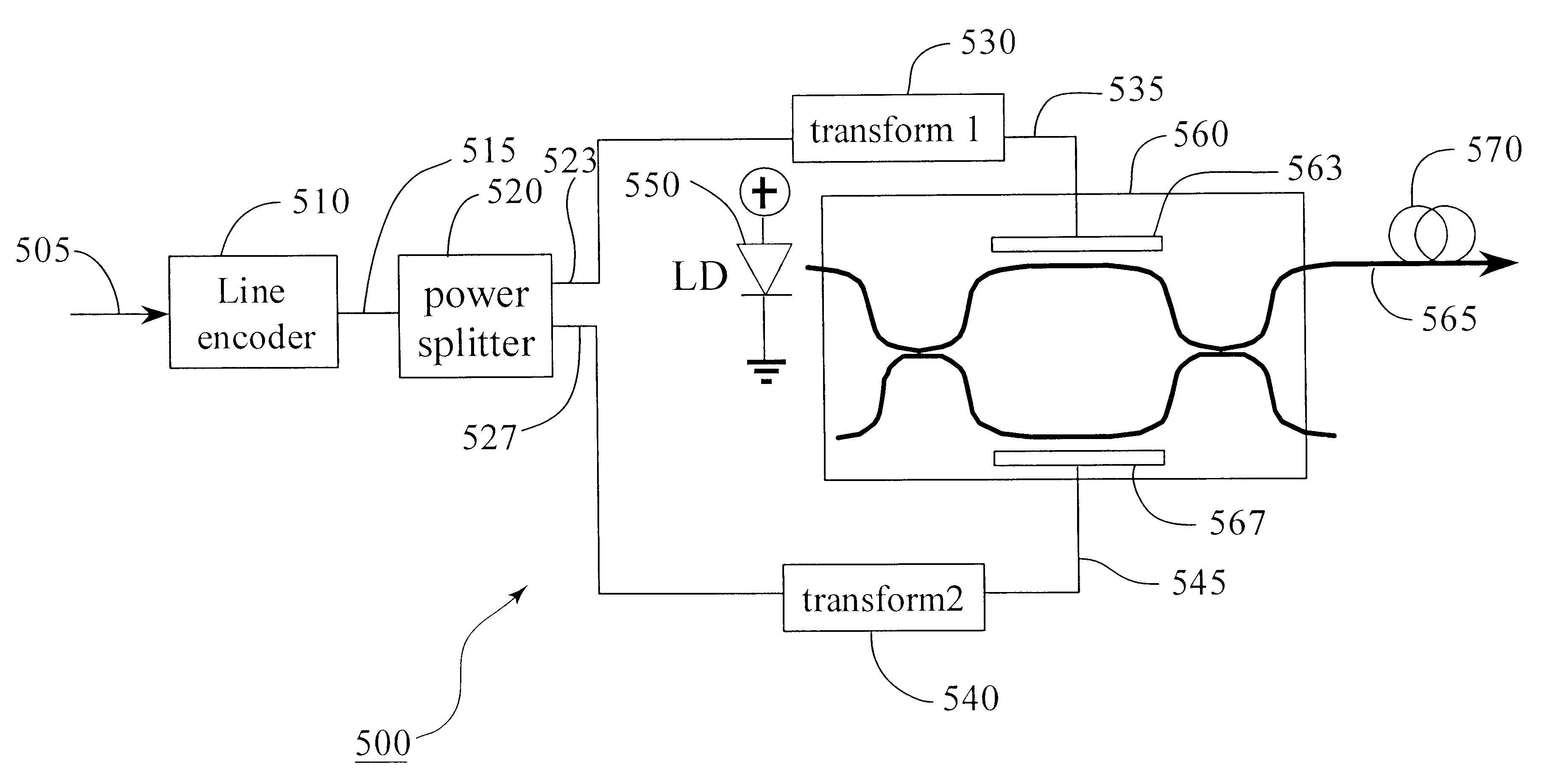

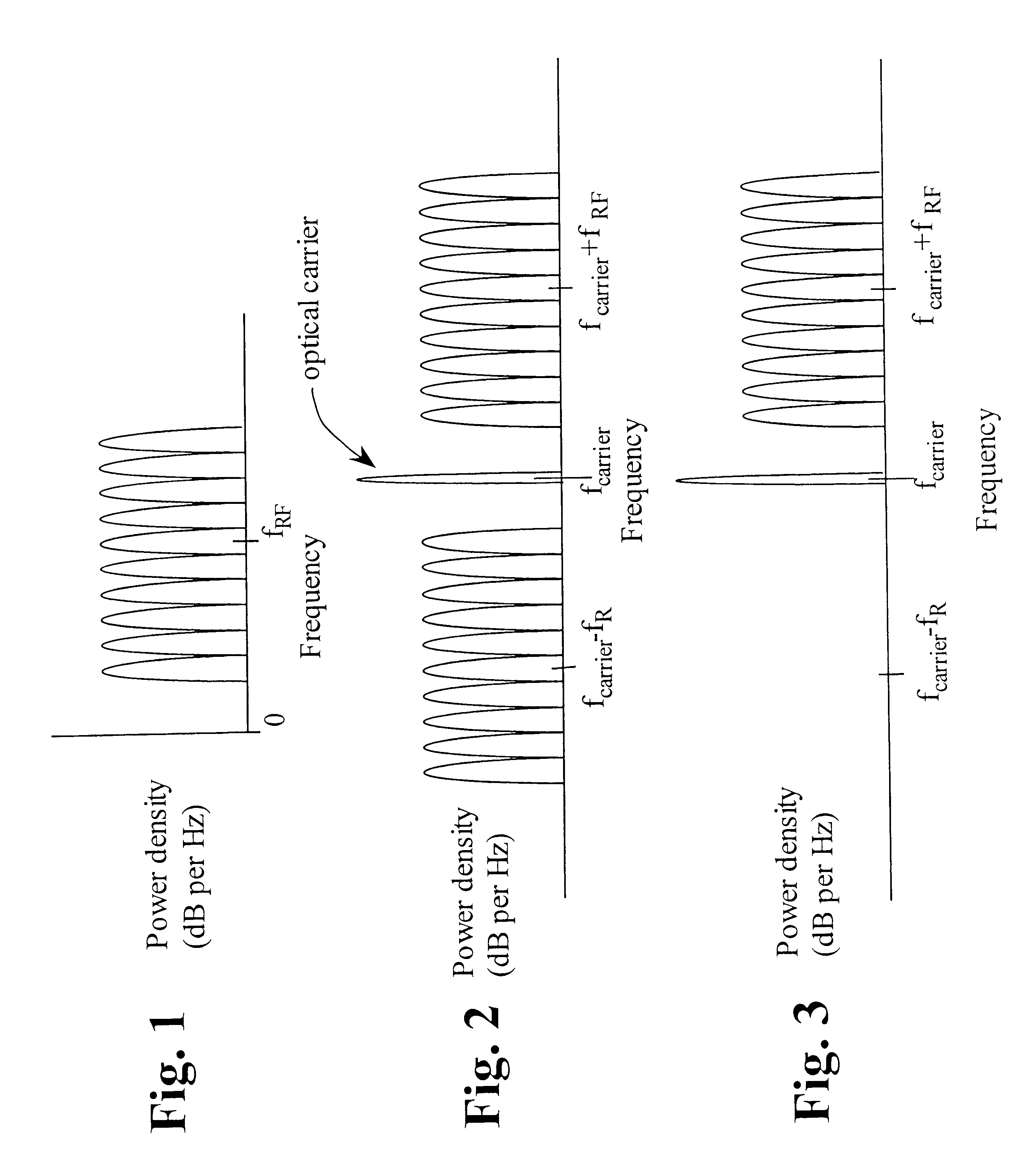

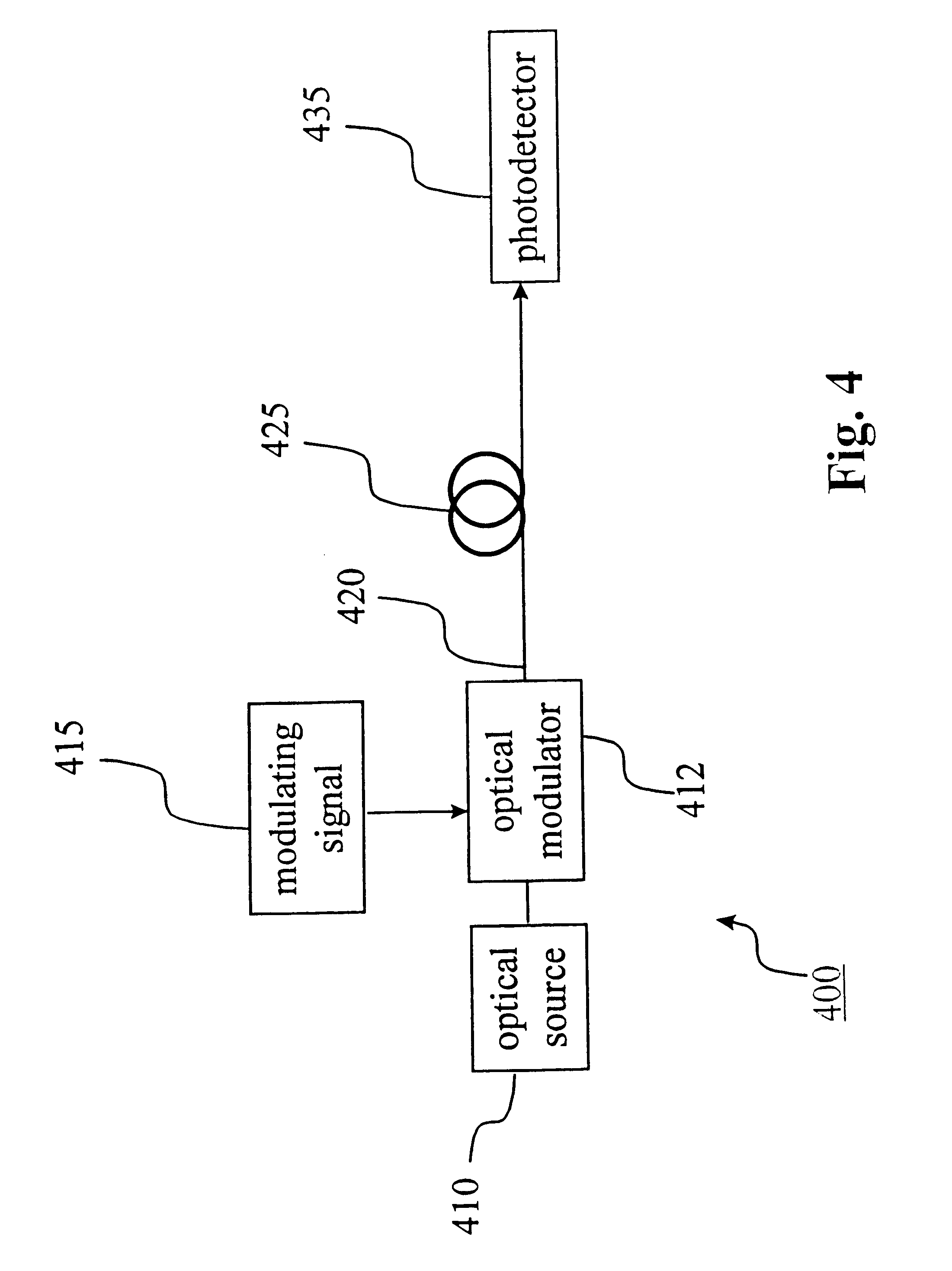

Method and system for single-sideband optical signal generation and transmission

InactiveUS6661976B1Modulation with suppressed carrierAmplitude-modulated carrier systemsTransport systemFrequency spectrum

A method and system for generating and transmitting optical signals with only one sideband. Single-sideband optical signal transmission reduces the signal impairment effects associated with dispersion. Such transmission also increases the spectral efficiency of optical transmission systems. Single-sideband modulation also makes possible electrical compensation for optical link dispersion during transmission. Single-sideband modulation is generated using the modulating data signal and its Hilbert transform, which is approximated by a tapped-delay time filter. Line coding is used to remove the low-frequency content in the modulating data signal, avoiding the inefficiencies of tapped-delay-line filter approximated Hilbert transformers at low frequencies. Line coding can also help optical single side band signal generation and transmission using a simple optical filter instead of Hilbert transformers.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

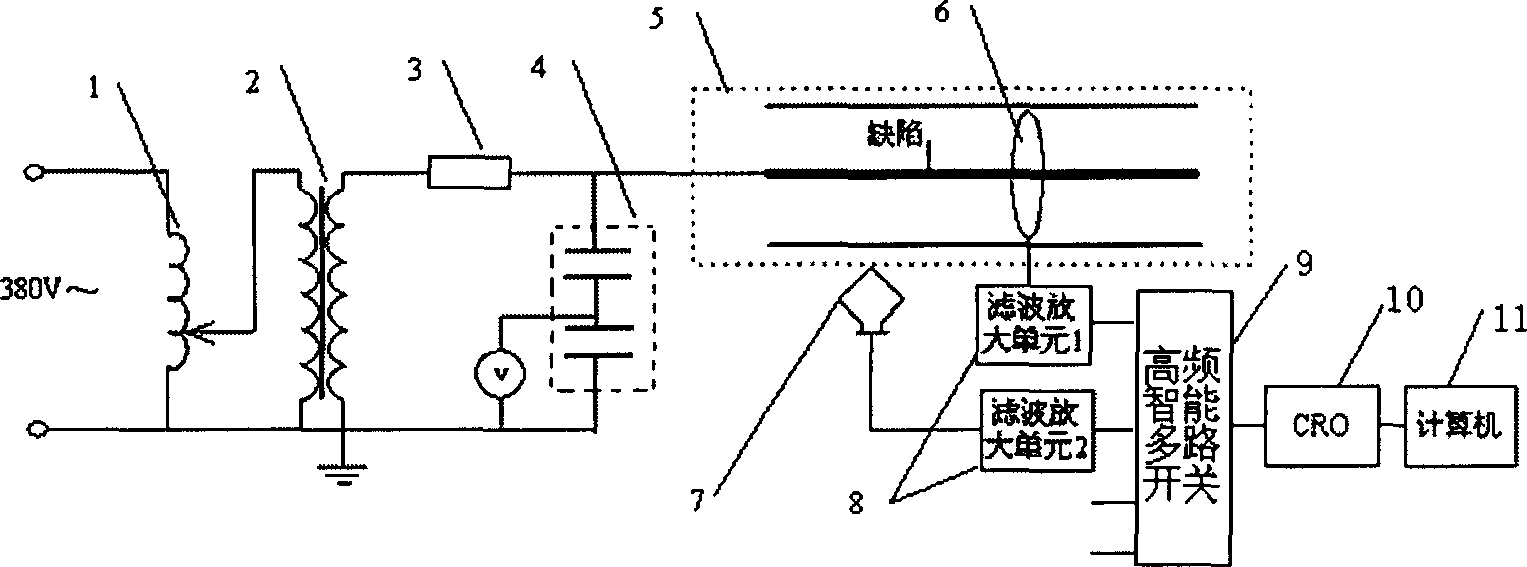

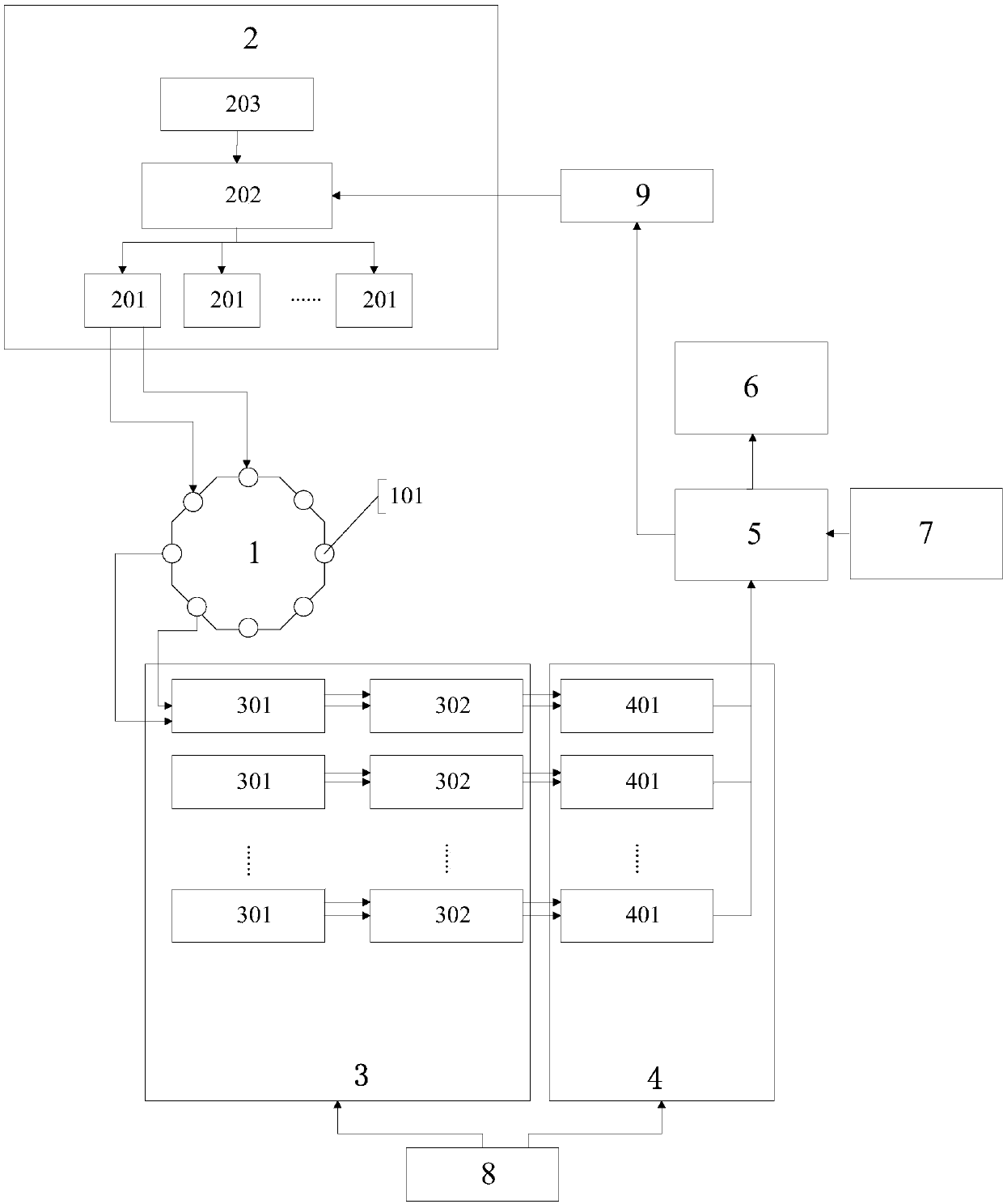

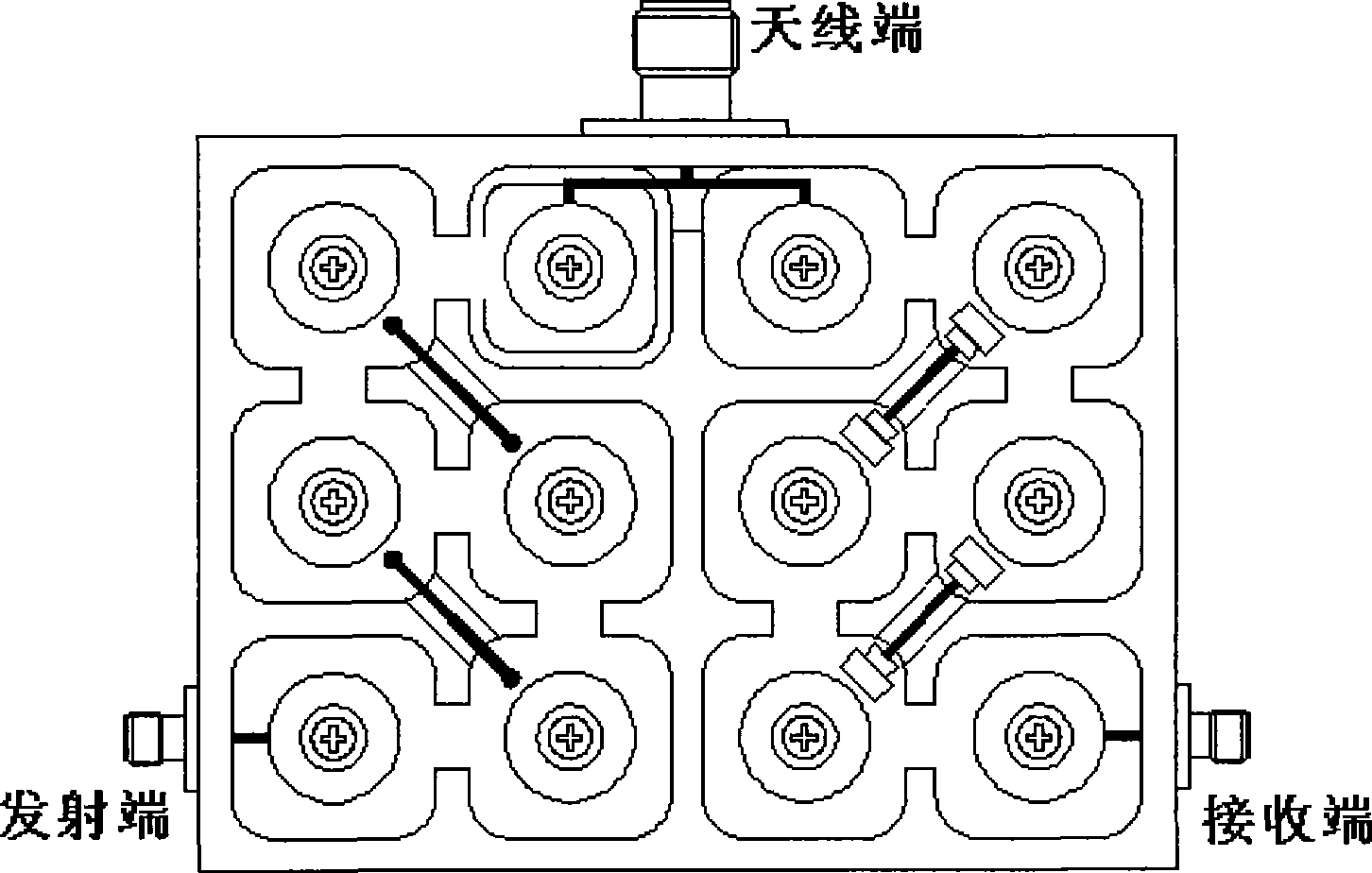

Gasinsulation combined electric device local discharge analog experimental apparatus and experimental method

The simulating experiment equipment for local discharge in gas insulated combined electric appliance consists of inducing pressure regulator, no-corona experiment transformer, no-local discharge protecting resistor, standard capacity voltage divider, GIS simulating experimental device, internal UHF antenna sensor and external UHF antenna sensor, microstrip line filtering amplifier, intelligent UHF multiplexer, wide band high speed ultrahigh capacirty digital storage oscilloscope and microcomputer. The simulating experiment equipment and method for local discharge in gas insulated combined electric appliance may be used for simulating various defaults inside GIS to obtain PD experiment data reflecting various kinds of insulation defaults and distinguish the PD modes of the insulation defaults in GIS, so that the present invention may be used widely in relevant theoretical analysis and application research.

Owner:CHONGQING UNIV

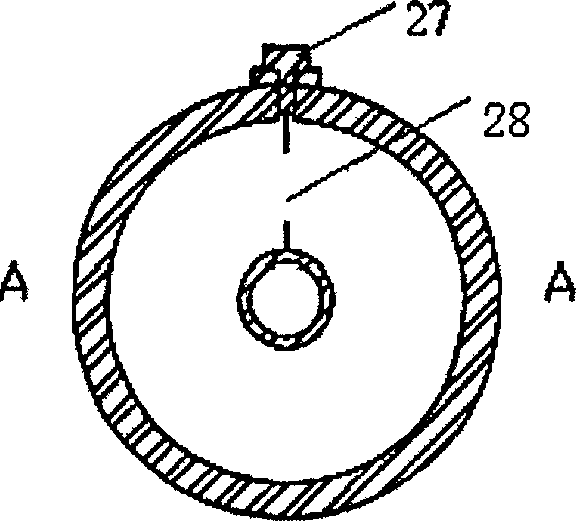

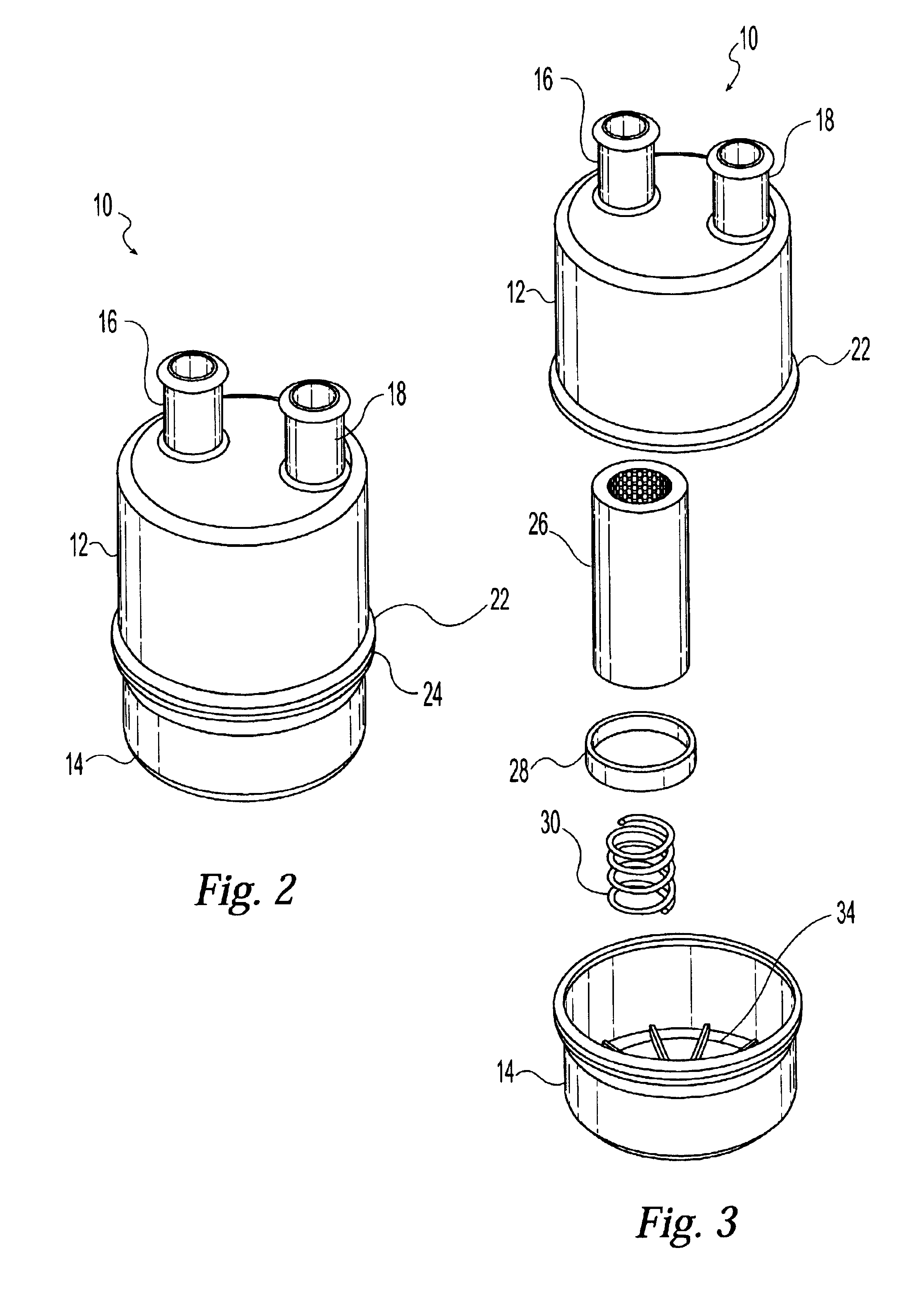

Filter assembly for exhaust gases

InactiveUS6883321B2Non-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesInternal combustion engine

An in-line filter assembly for filtering engine exhaust gases utilized by turbocharged internal combustion engine systems. The filter assembly includes an external housing having a lower housing section and an upper housing section. The upper housing section further includes an air inlet port and an air outlet port. A filter unit for decontaminating the exhaust stream is positioned below the air inlet port. An interior chamber is in communication with the outlet port and surrounds the filter unit. A spring positioned directly beneath the filter unit stabilizes the filter unit within the chamber and urges the filter unit upward into sealing engagement with the inlet port. The lower housing section also includes a sump for collecting contaminants captured by the filter unit.

Owner:BENDIX COMML VEHICLE SYST LLC

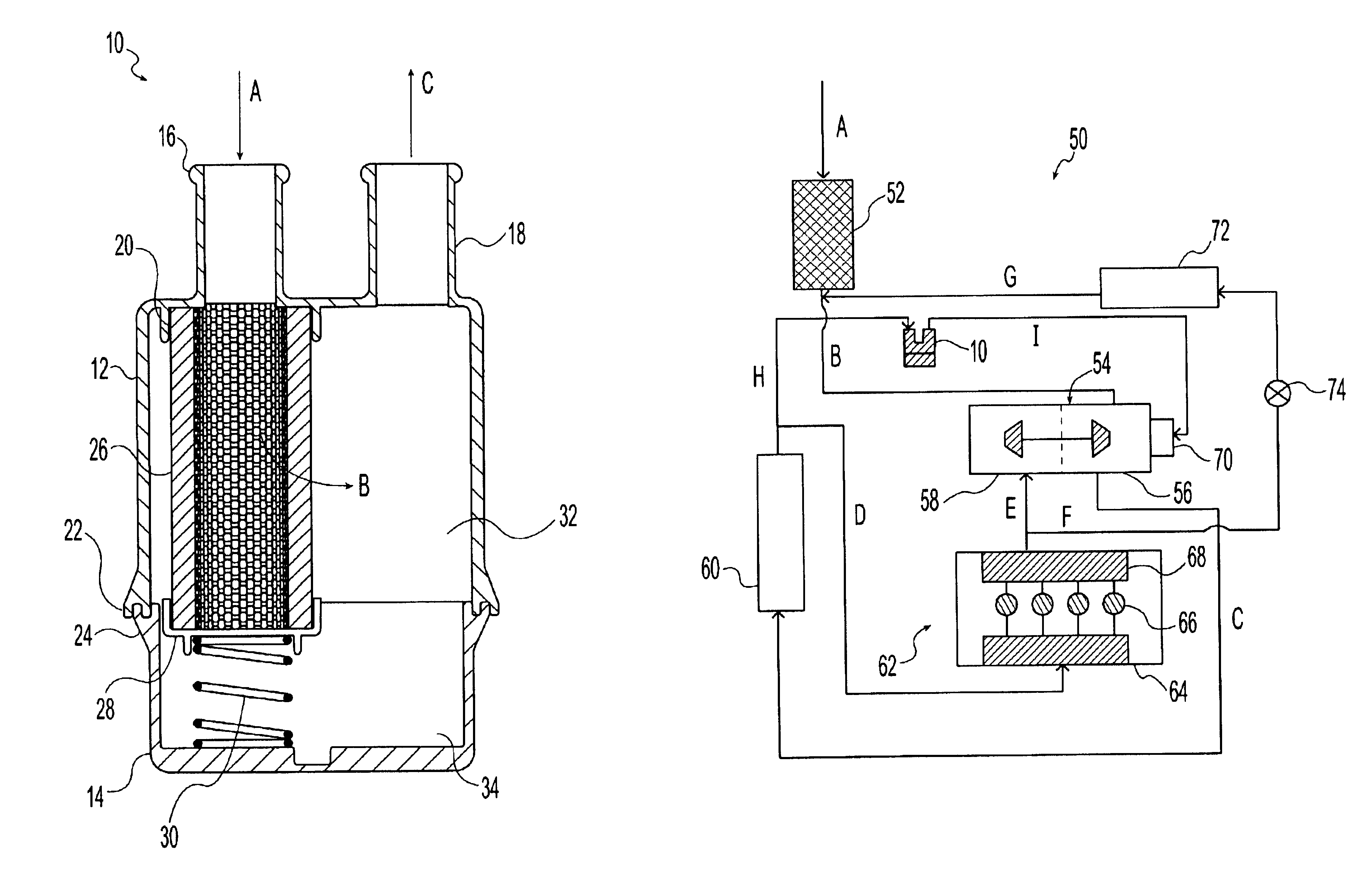

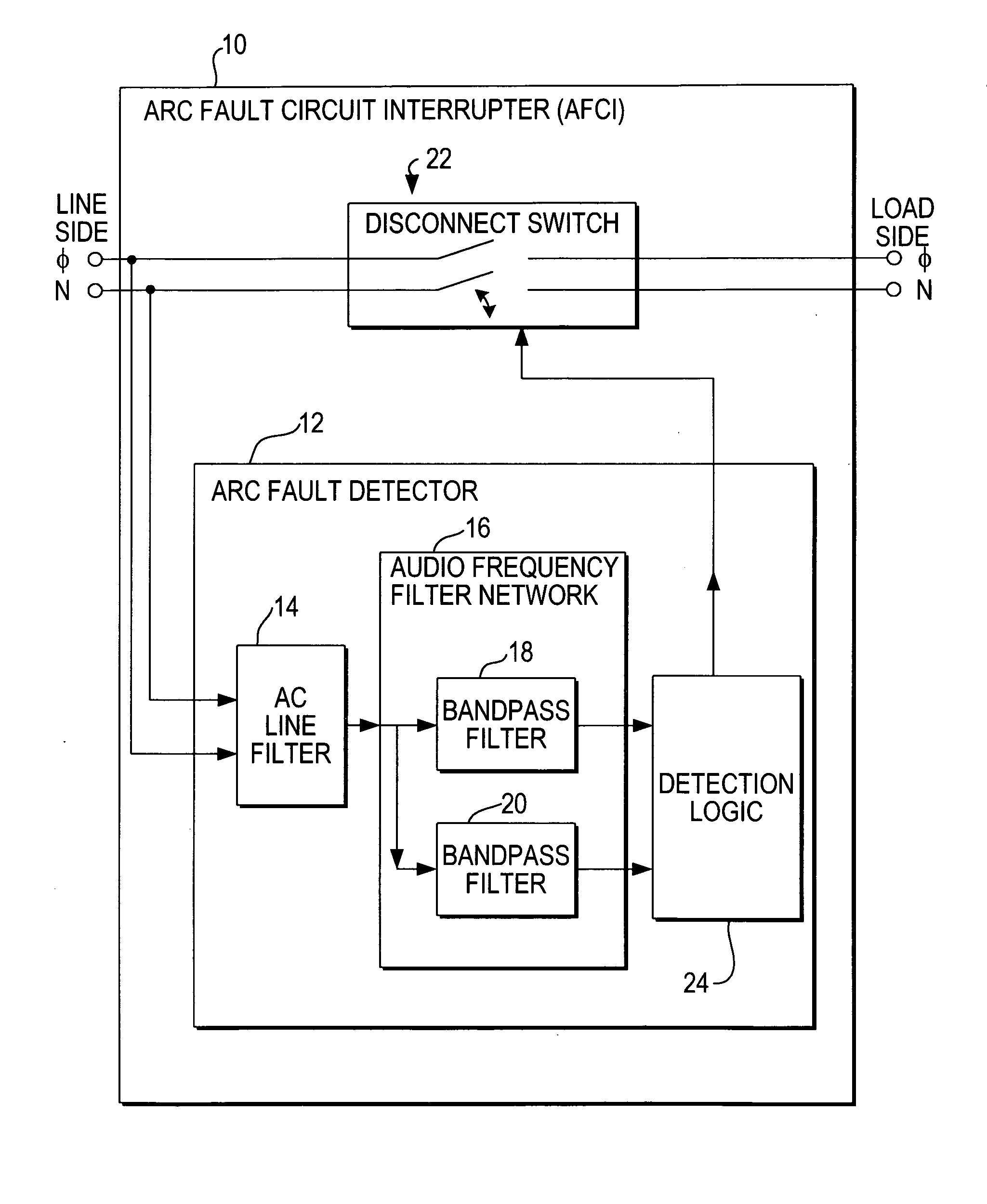

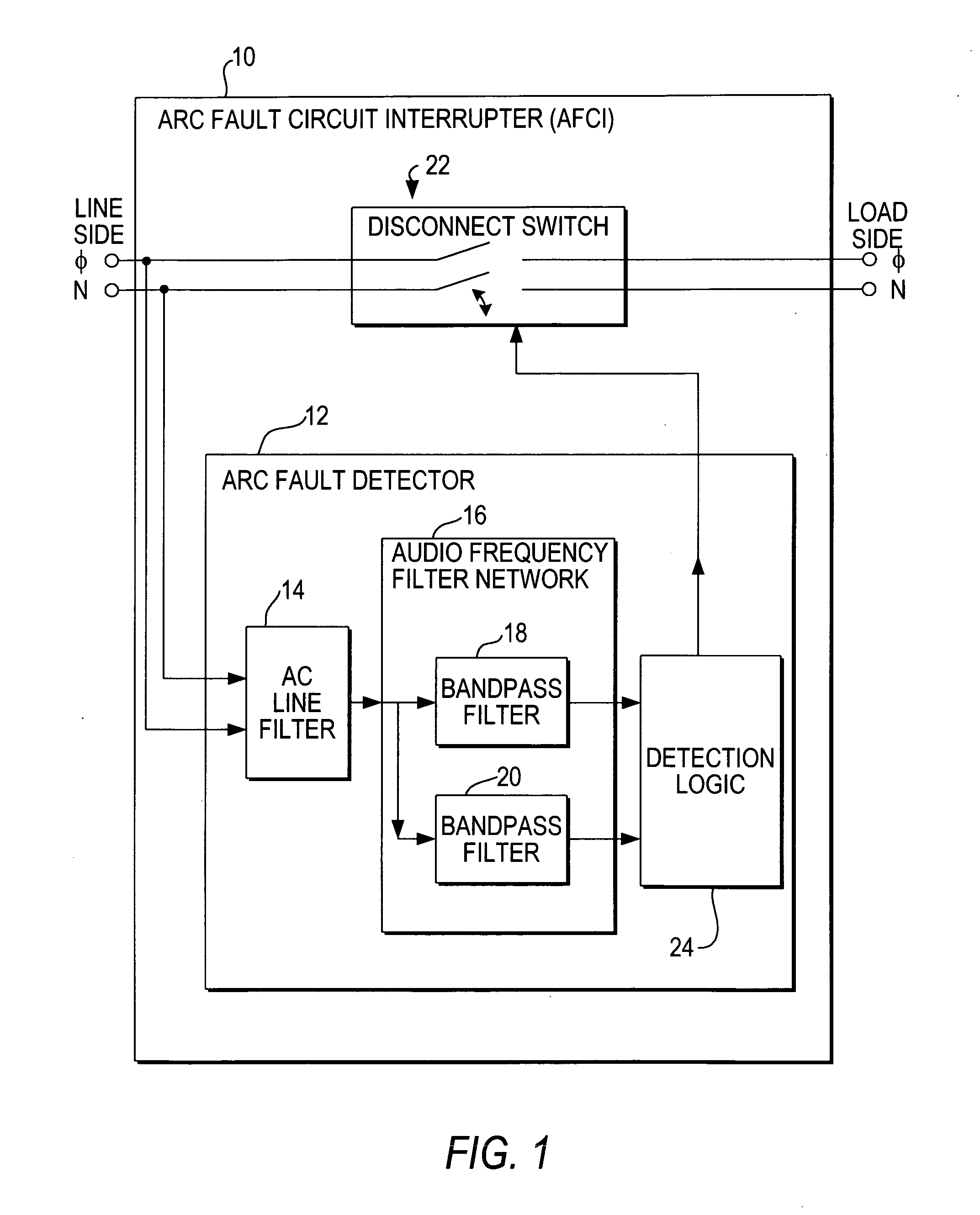

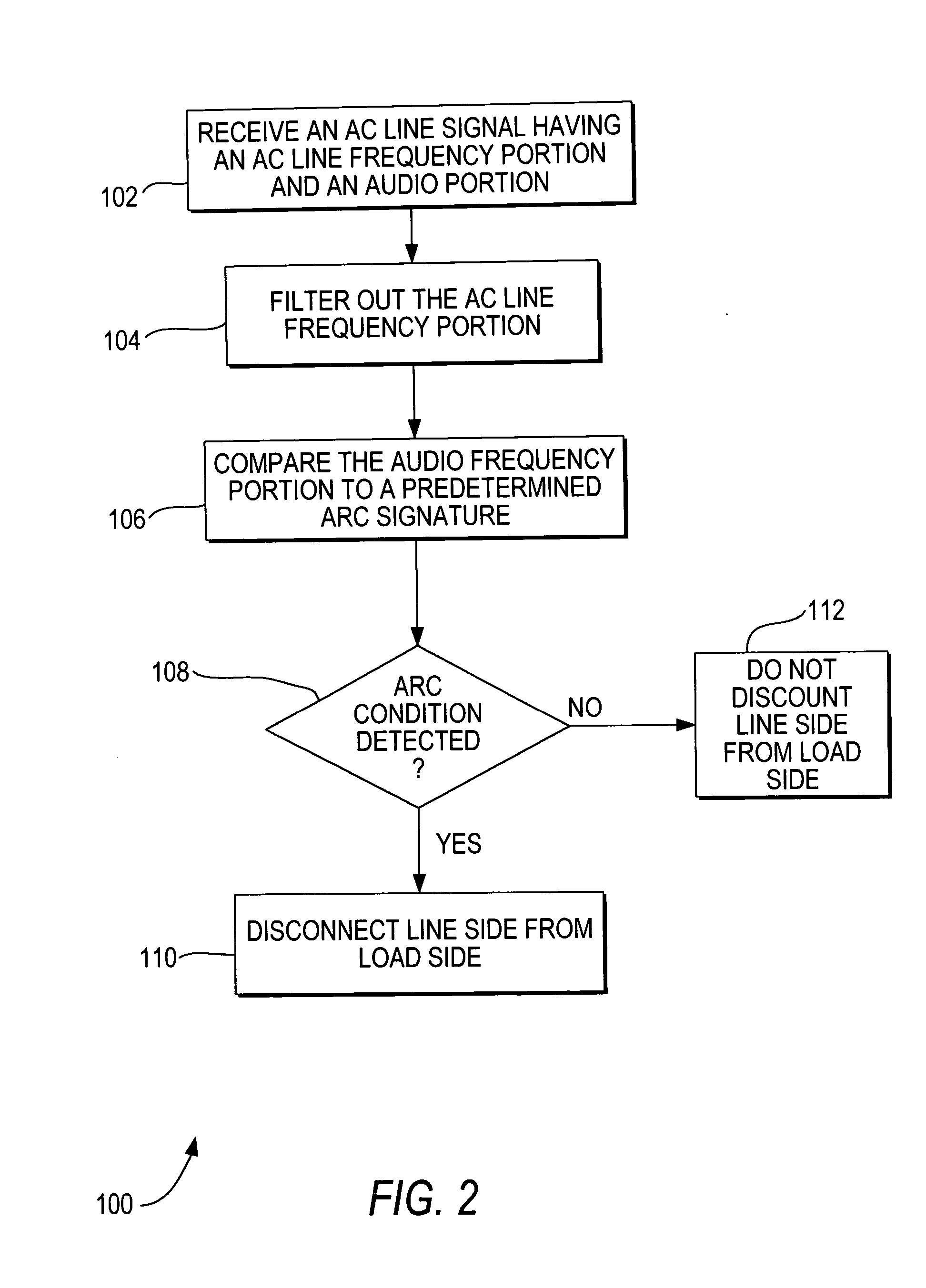

Arc fault detection

InactiveUS20060171085A1Emergency protective arrangement detailsEmergency protective arrangements for automatic disconnectionFrequency spectrumElectromagnetic spectrum

An arc fault detector configured to process audio frequencies associated with an arc fault condition to detect the occurrence of an arc fault condition. In one embodiment, the arc fault detector includes an alternating current (AC) line filter for receiving an AC line signal having a line frequency portion and an audio frequency portion in the electromagnetic spectrum associated with at least one arc condition. The AC line filter removes the line frequency portion and passes the audio frequency portion to an audio frequency filter which processes the audio frequency portion for an arc fault signature to detect for the occurrence of an arc fault condition.

Owner:LEVITON MFG

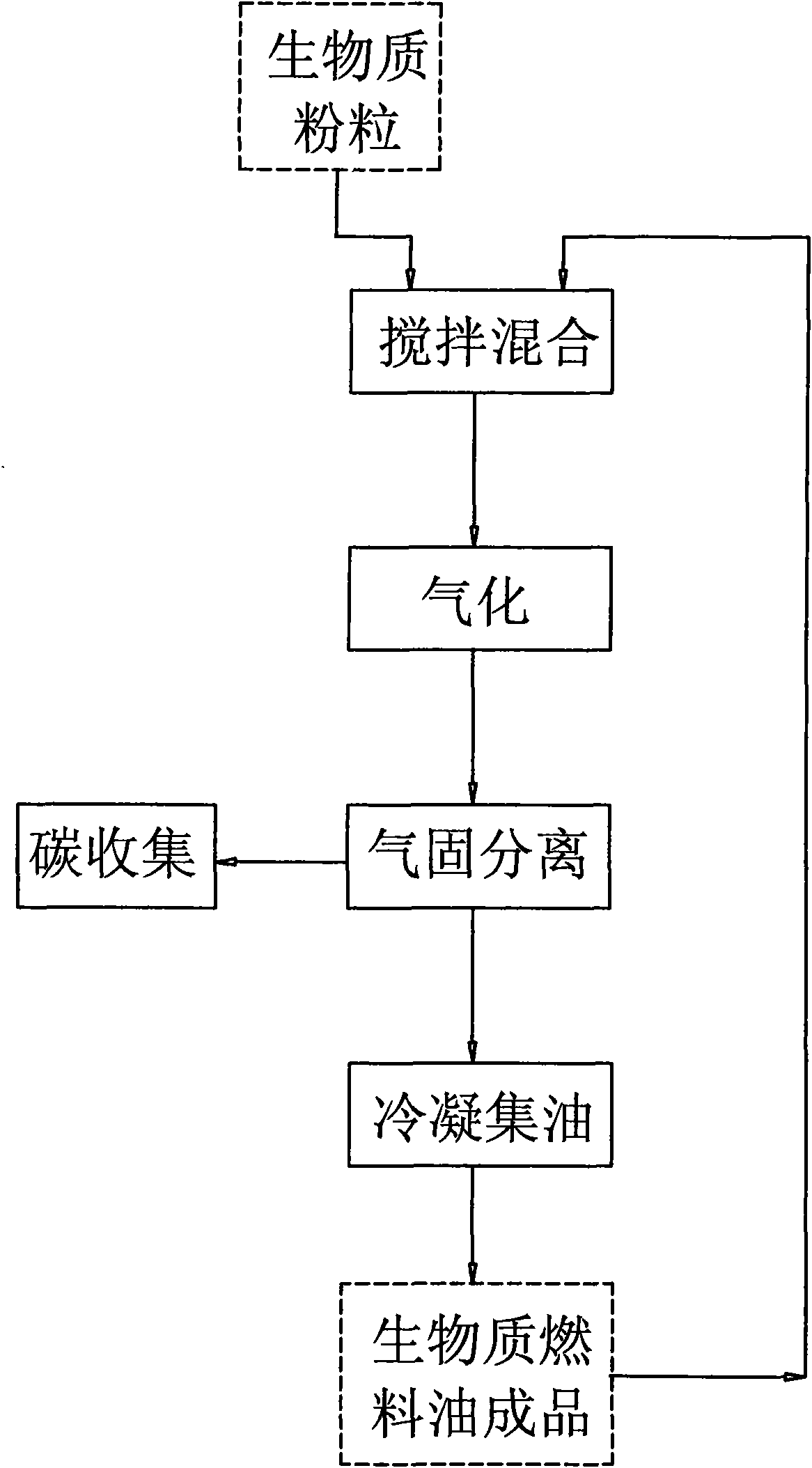

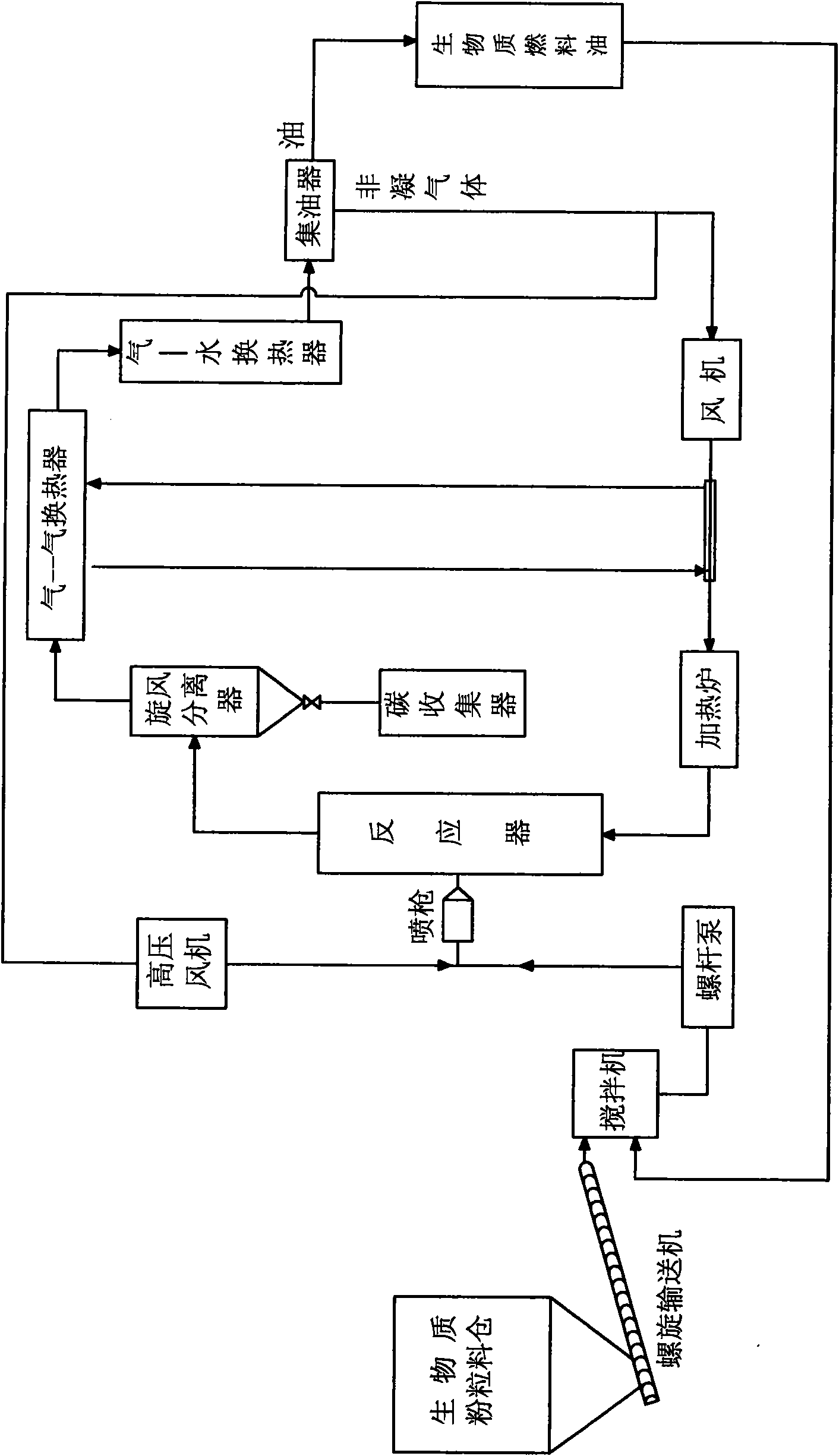

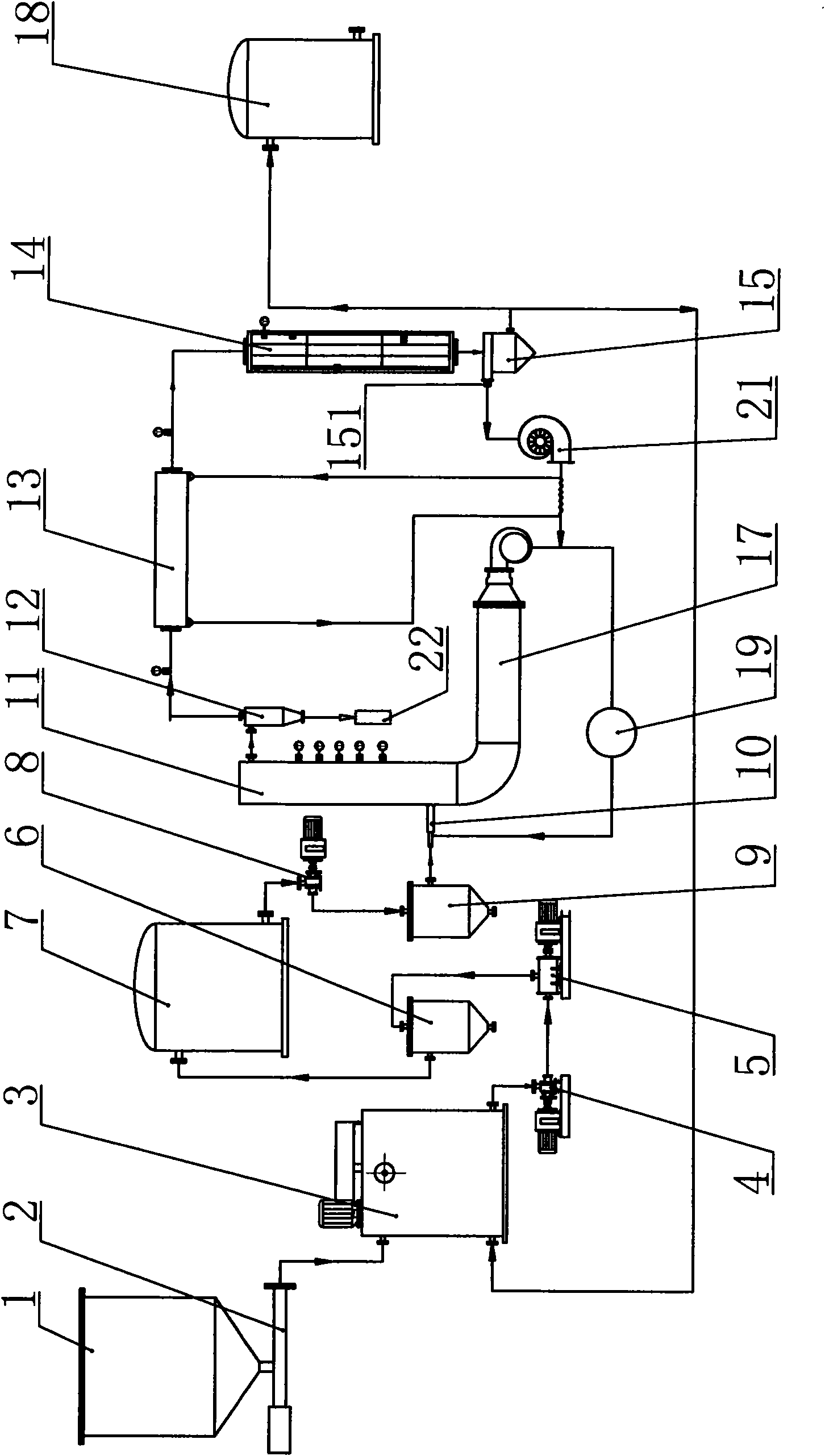

Biomass slurry atomization thermal cracking process and device

InactiveCN101550347AImprove atomization effectWell mixedLiquid hydrocarbon mixture productionProcess engineeringSlurry

The invention relates to a biomass slurry atomization thermal cracking process which comprises the following steps of stirring, mixing, gasifying, gas-solid separating, condensing and oil gathering. Adevice of the invention comprises a screw pump, an on-line grinder, a I-stage on-line filter, a slurry biomass storage tank, a slurry supply pump, a II-stage one-line filter, an atomization spray gun, a thermal cracking reactor, a cyclone separating device, a gas-gas thermal exchanger, a steam-water thermal exchanger and an oil gathering device which are sequentially connected with the output endof a stirring machine through pipes. Biomass comprises crop straws, other plant straws, branches and wooden meals. Because of adopting the slurry atomization reactor, the invention has the advantagesthat the slurry biomass atomization effect is good, the temperature field is stable, the slurry atomization realizes the uniform mixing of gas and material for ensuring the fully thermal cracking, the thermal cracking effect and the utilization ratio of the material are improved, the structure of the device is compact, the investment cost is low, the process adopts the continuous circulating operation, the production efficiency is high and the oil yield is large.

Owner:江苏东工环保科技股份有限公司

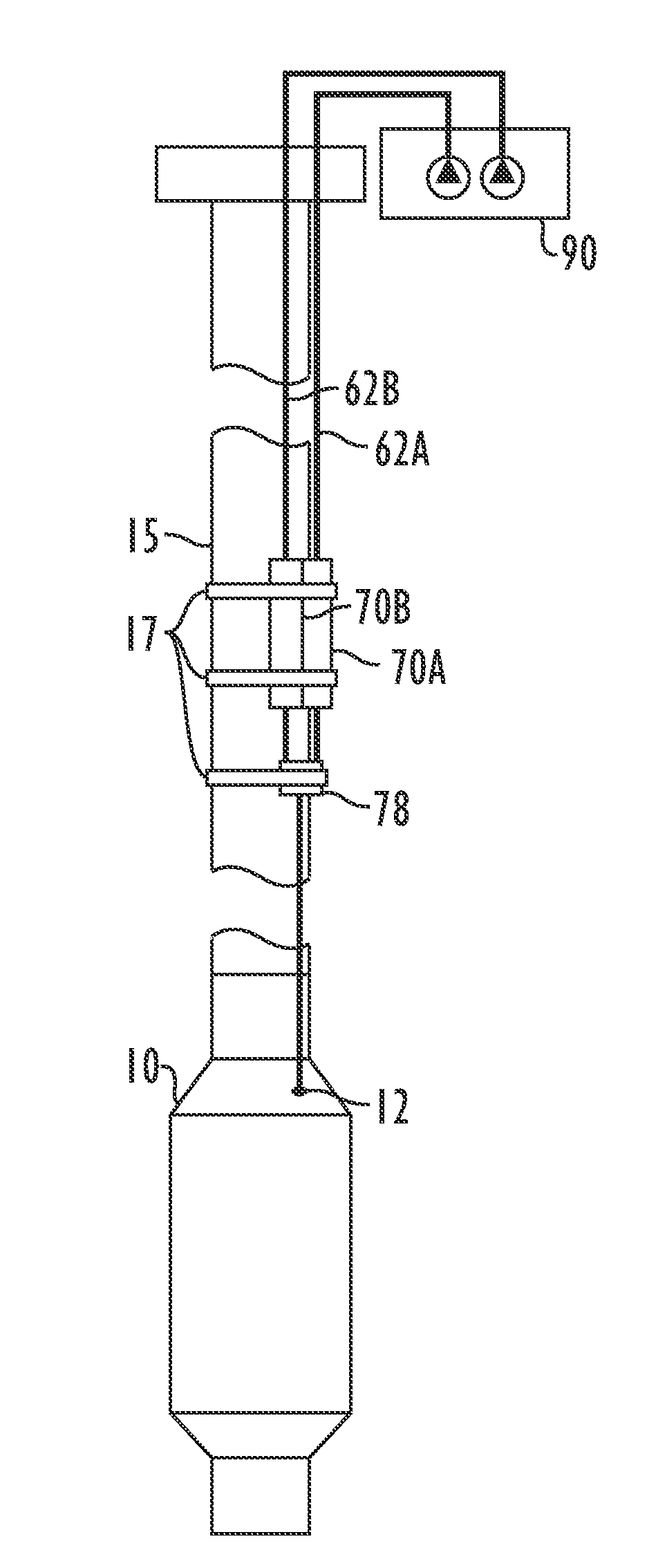

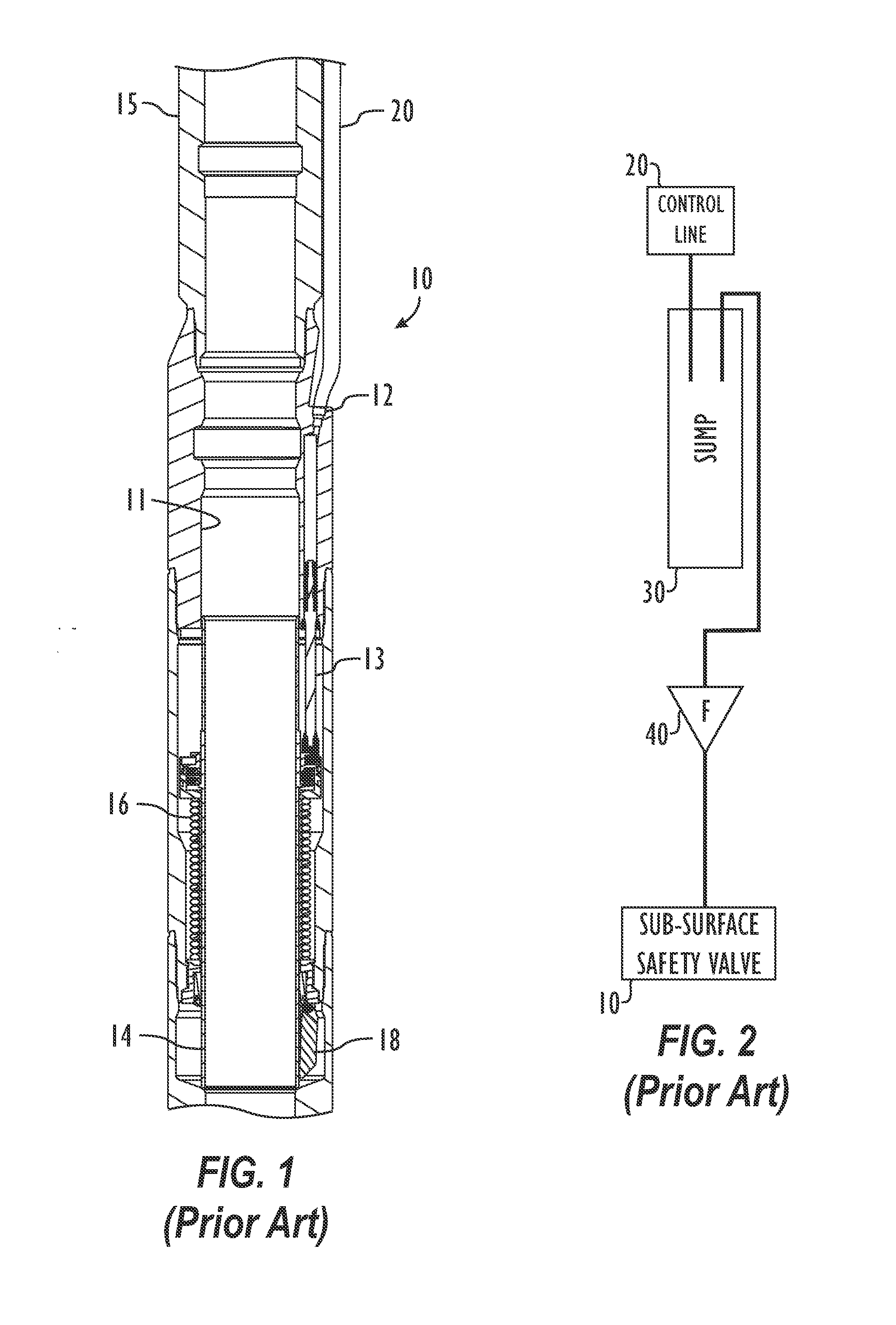

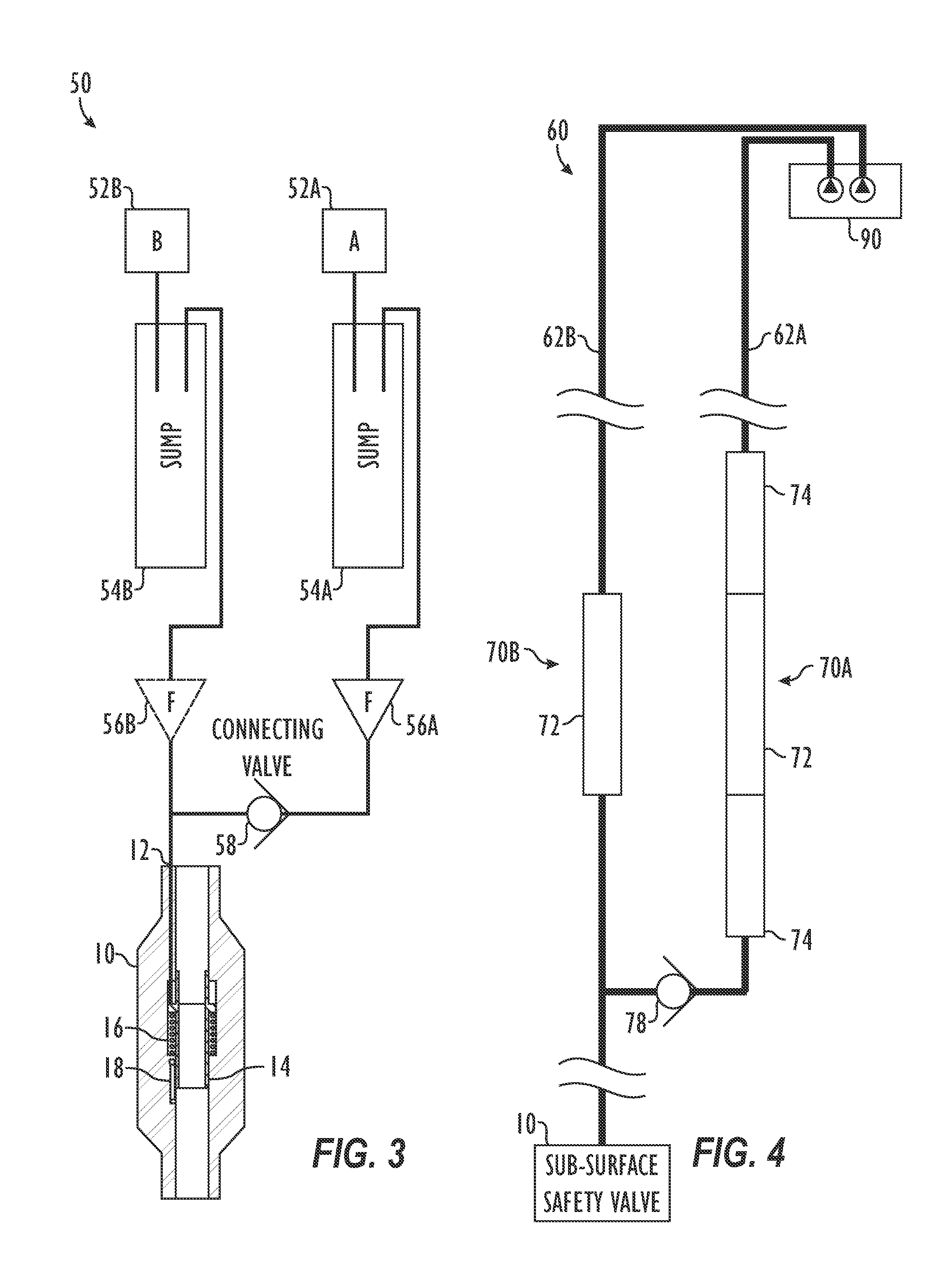

Dual Control Line System and Method for Operating Surface Controlled Sub-Surface Safety Valve in a Well

ActiveUS20090050333A1Reduce debrisReduce contaminationFluid removalWell/borehole valve arrangementsLine tubingControl system

A control system for a surface controlled sub-surface safety valve has first and second control lines. The first control line communicates control fluid to the sub-surface safety valve and preferably has a sump and in-line filters. Hydraulic pressure applied to the safety valve with this first control line can open the safety valve. The second control line also communicates control fluid to the sub-surface safety valve and preferably has a sump. A connecting valve is connected between the first and second control lines. The connecting valve allows control fluid to communicate from the first control line to the safety valve but prevents fluid communication from the second control line to the first control line. To open the valve, the second control line is exhausted to a reservoir. The dual control lines provide redundant control of the safety valve and can also be cycled to remove debris from the system.

Owner:WEATHERFORD TECH HLDG LLC

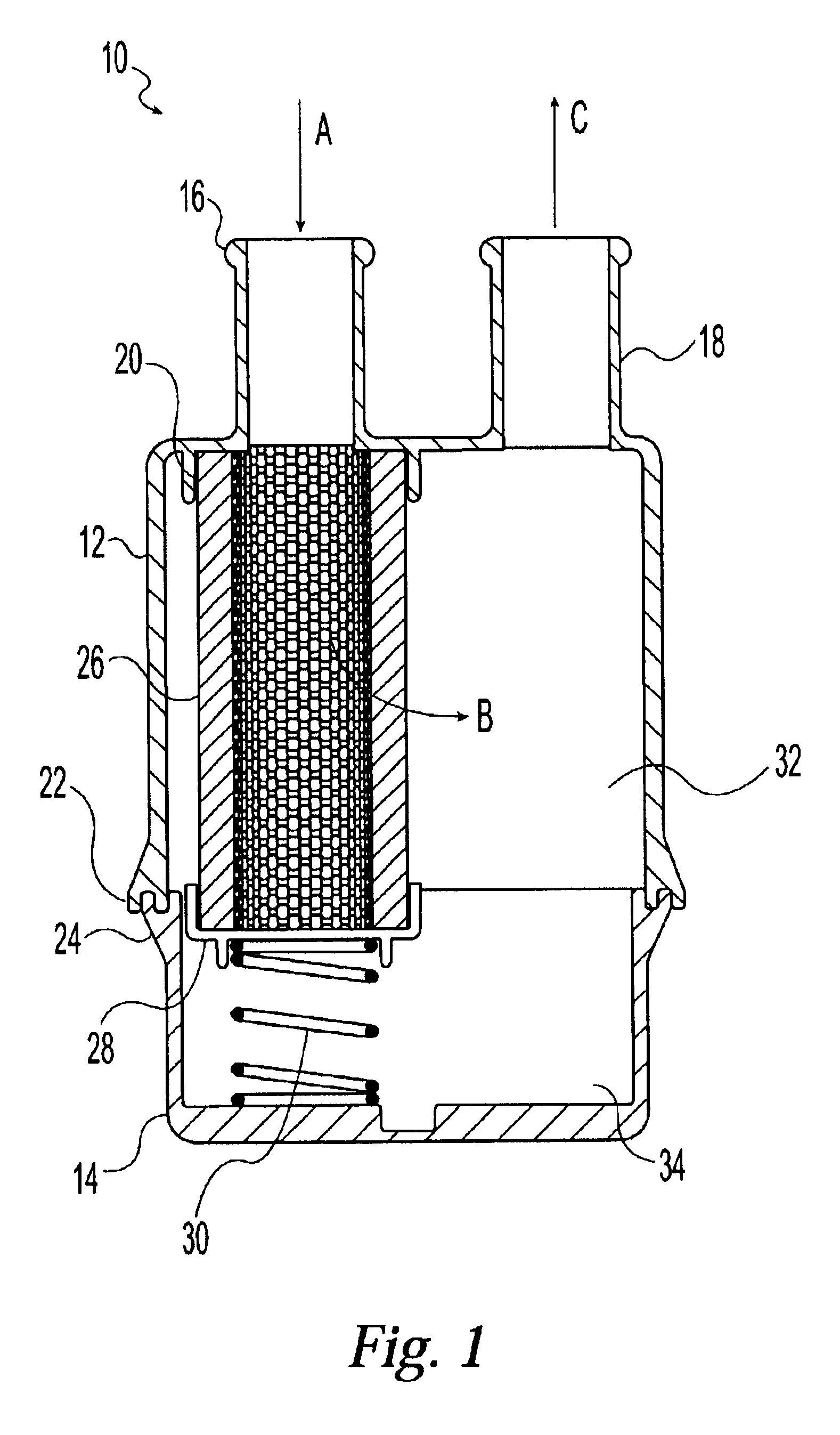

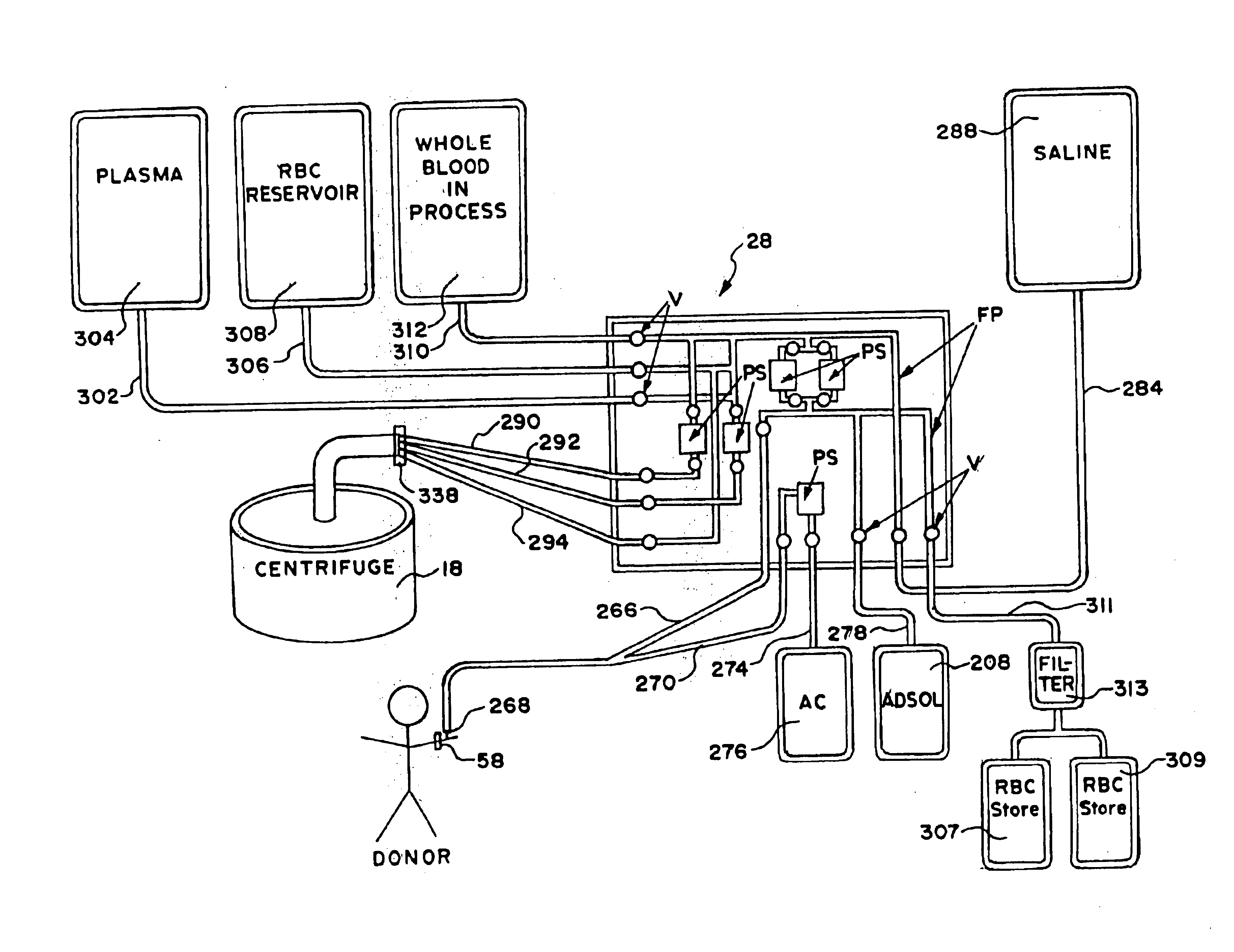

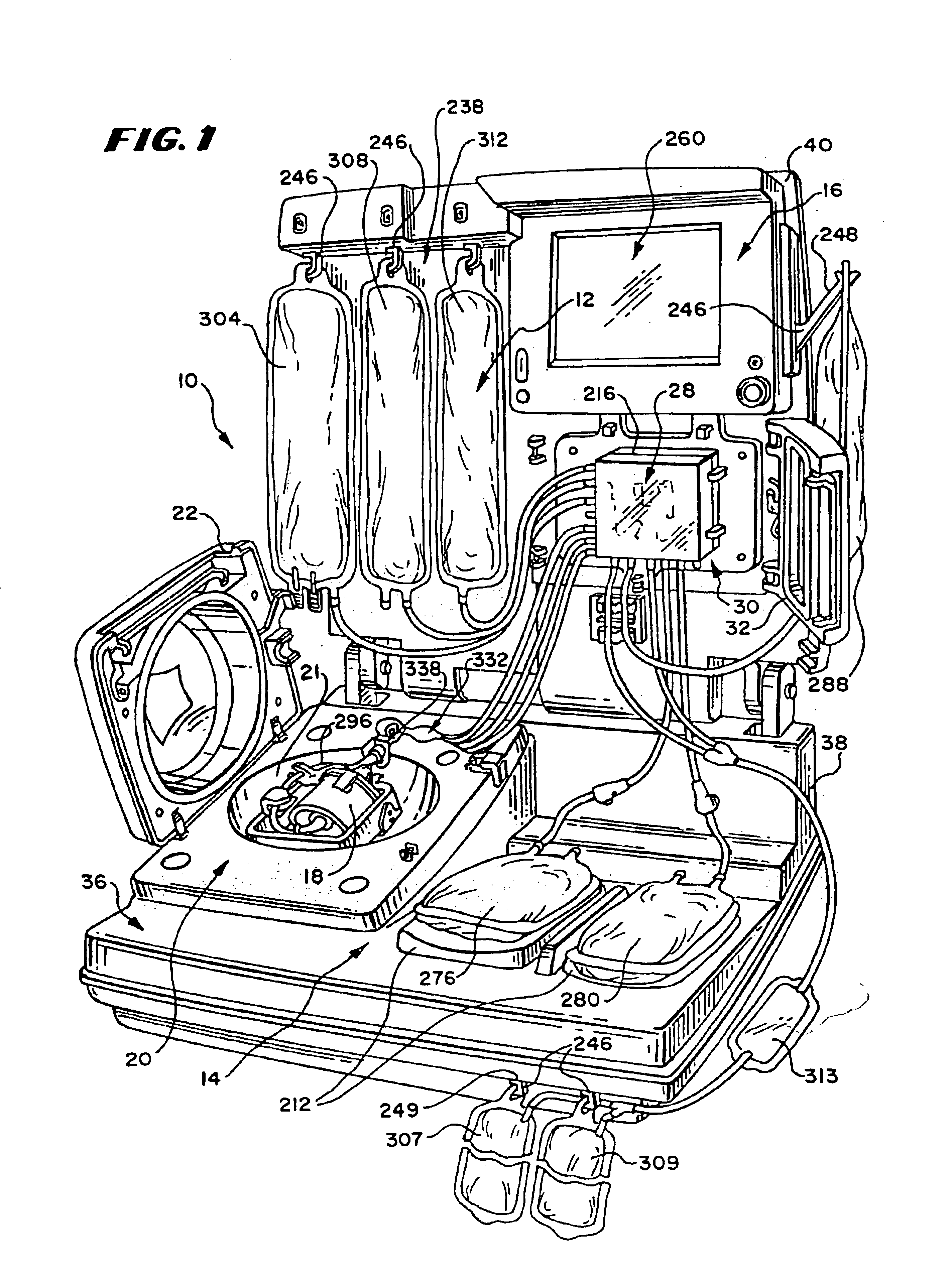

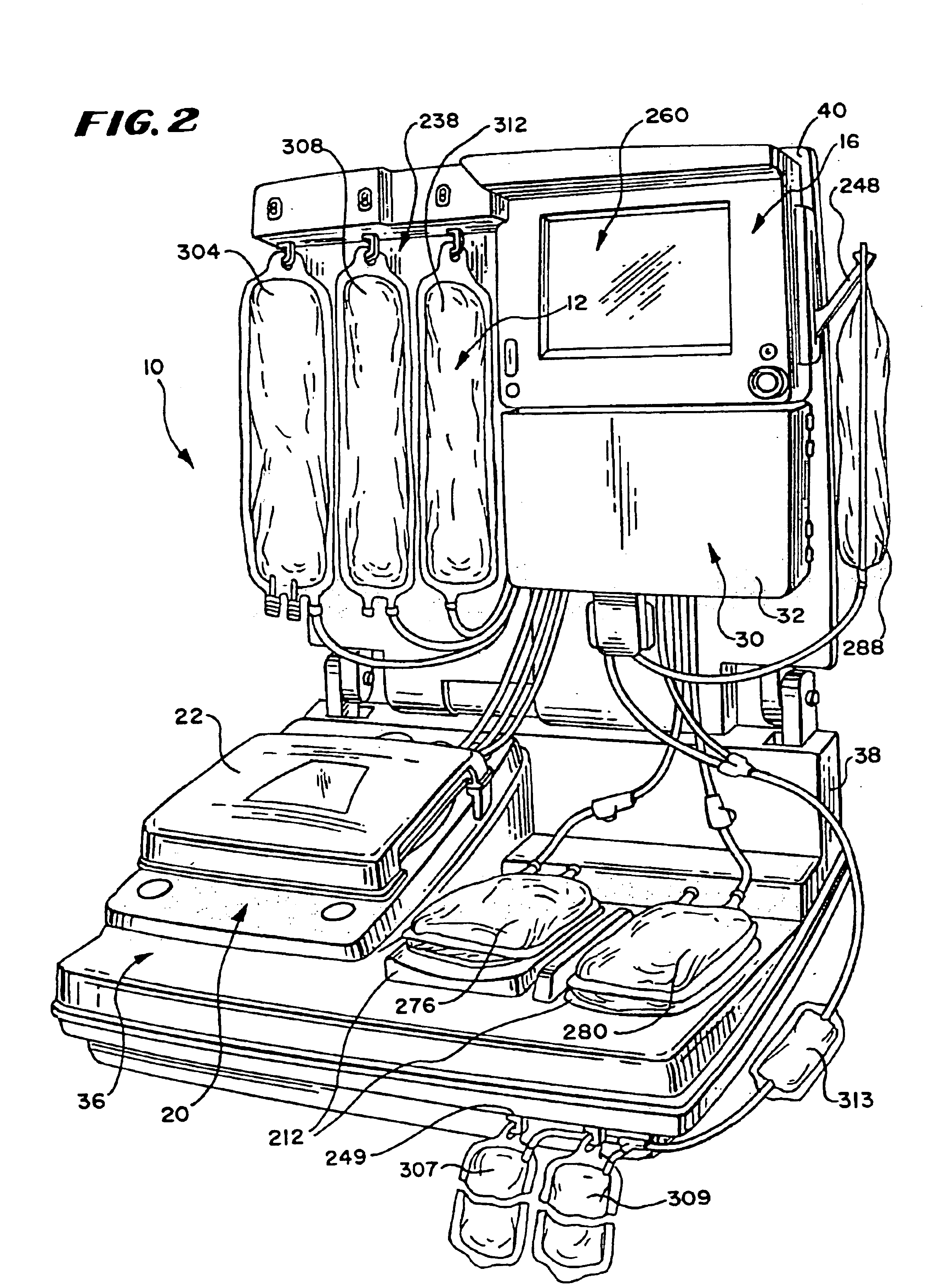

Blood processing systems and methods that alternate flow of blood component and additive solution through an in-line leukofilter

InactiveUS6875191B2Straightforward and accurate control functionOther blood circulation devicesHaemofiltrationBlood componentMedicine

Blood processing systems and methods convey blood cells from a blood cell source into a blood component collection flow channel that includes a blood cell storage container and an in-line filter to remove leukocytes from blood cells before entering the blood cell storage container. The systems and methods also convey additive solution from an additive solution source into the blood component collection flow channel. The systems and methods alternate the conveyance of blood cells through the filter with the conveyance of additive solution through the filter.

Owner:FENWAL

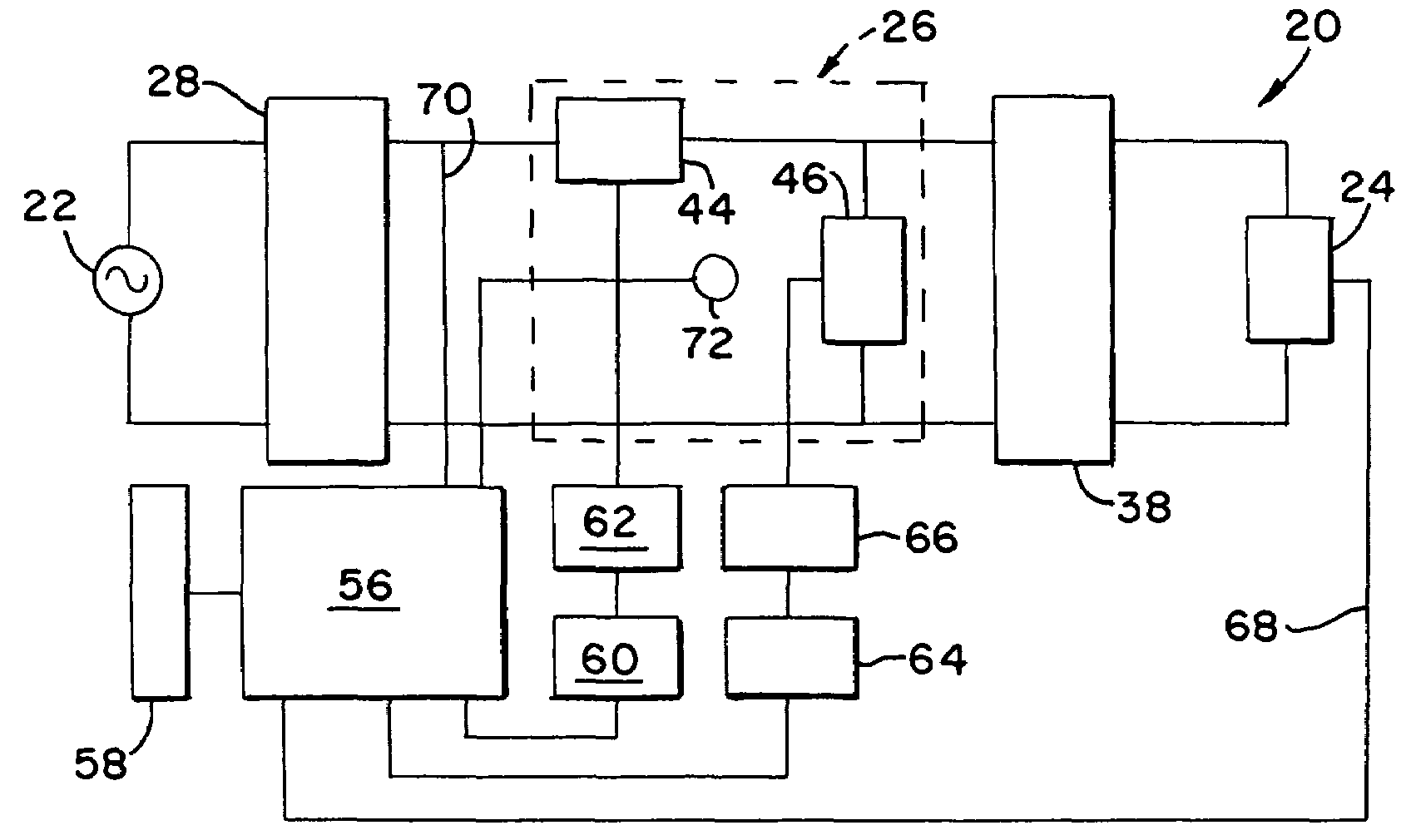

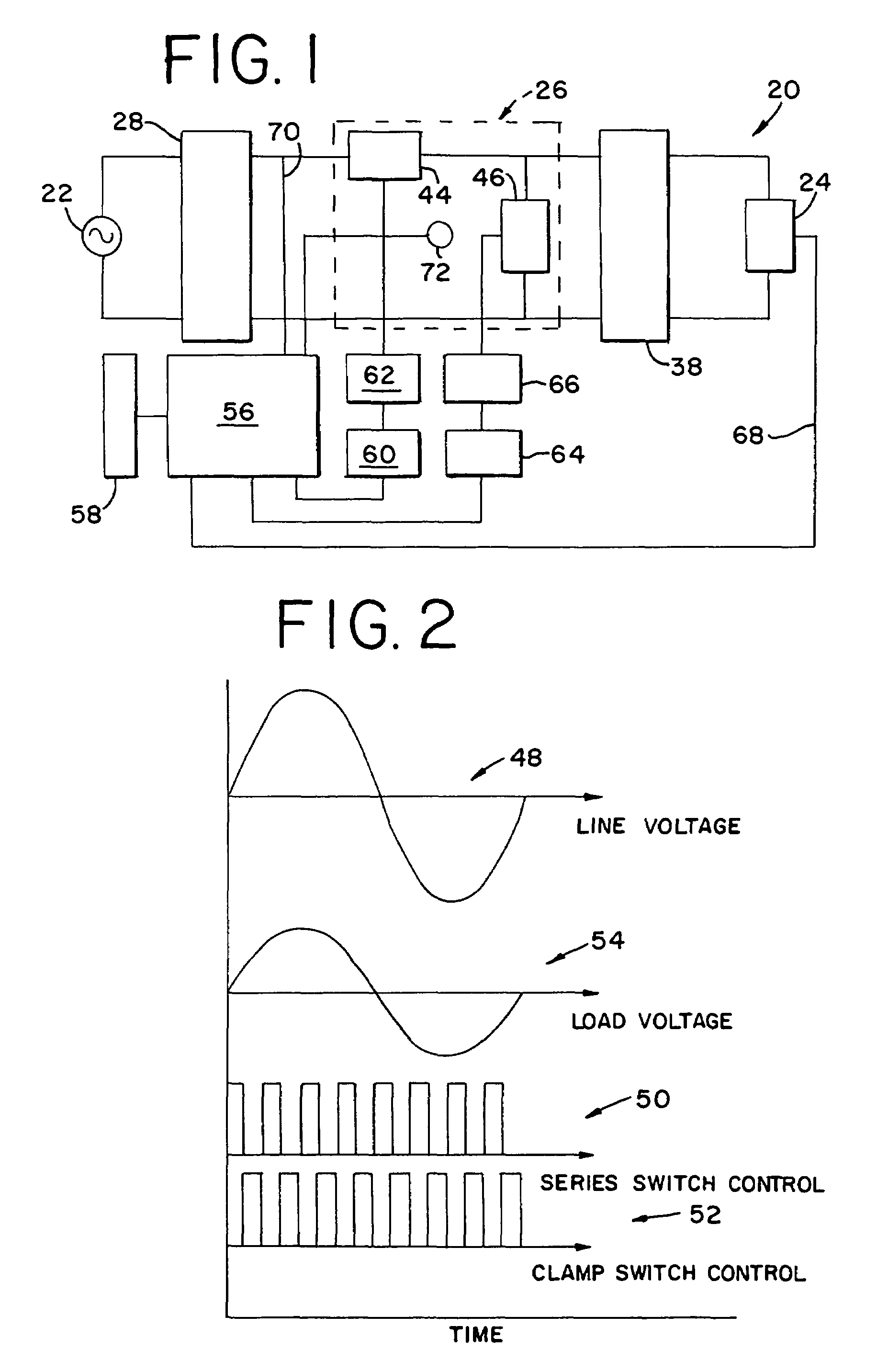

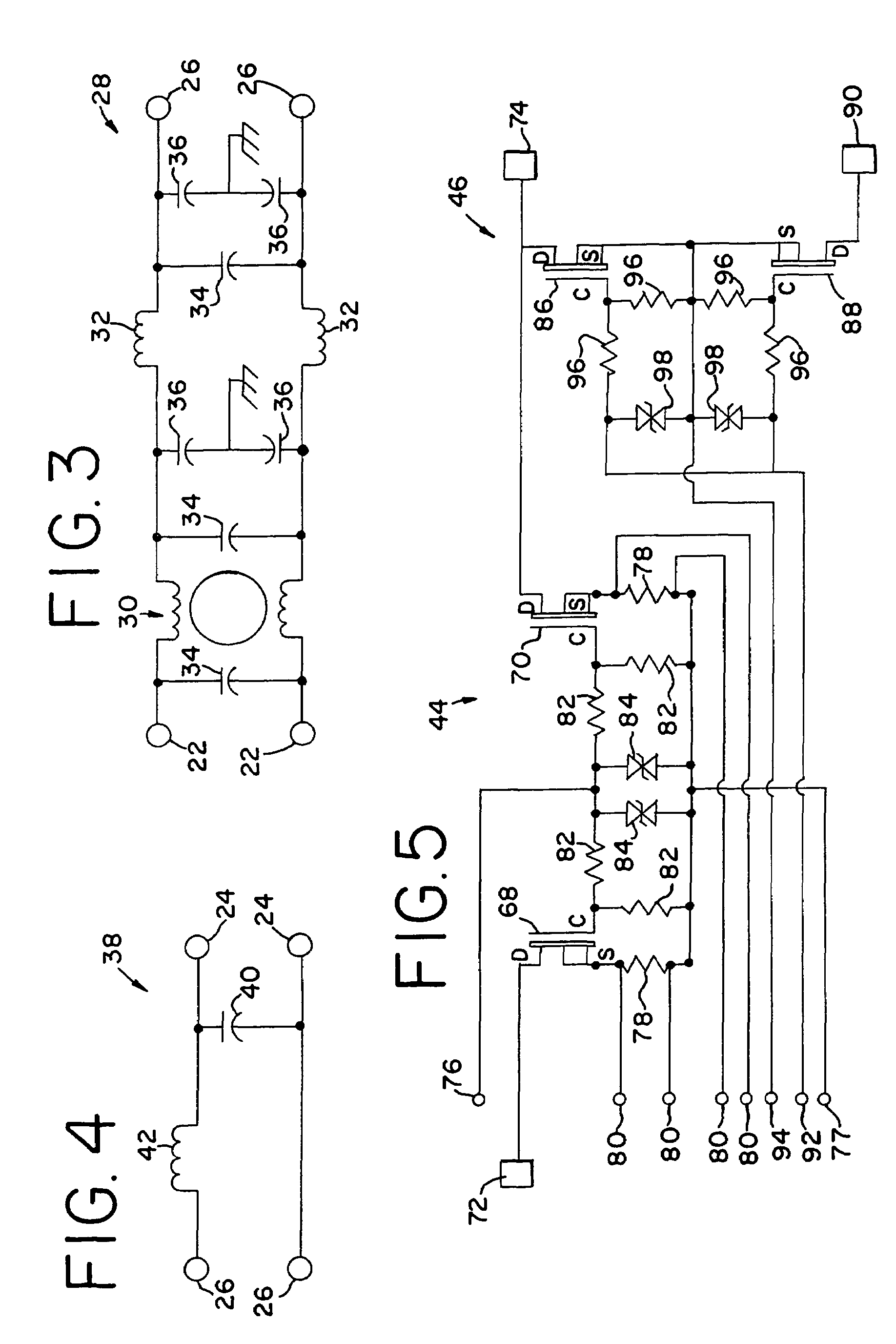

Sinewave dimmer control method

InactiveUS7019469B1Efficient couplingMaximizes efficient power transferElectric light circuit arrangementAc-ac conversionMOSFETControl signal

An input line filter separates an ac sinusoidal power source from a power switching stage having a series switching section and a clamp switching section. Both the series switching section and a clamp switching section include complementary pairs of high power and high speed MOSFETs. The series switching section is connected in series between the input line filter and the inductor of an output load filter between the power switching stage and a load. The clamp switching section is connected to shunt the inductor and load. Synchronous operation is achieved by alternately operating the series and clamp switching sections to conductive conditions at a high pulse width modulation frequency. The duty cycle is selected to provide a sinusoidal output waveform with a desired amplitude. A microprocessor based programmable controller provides control signals for alternate conduction of the series and clamp switching sections. A dead time interval stored in memory in the controller separates the control signals for reliable and efficient operation. The dead time interval may be constant, or may be varied in accordance with load power variations.

Owner:ELECTRONIC THEATRE CONTROLS

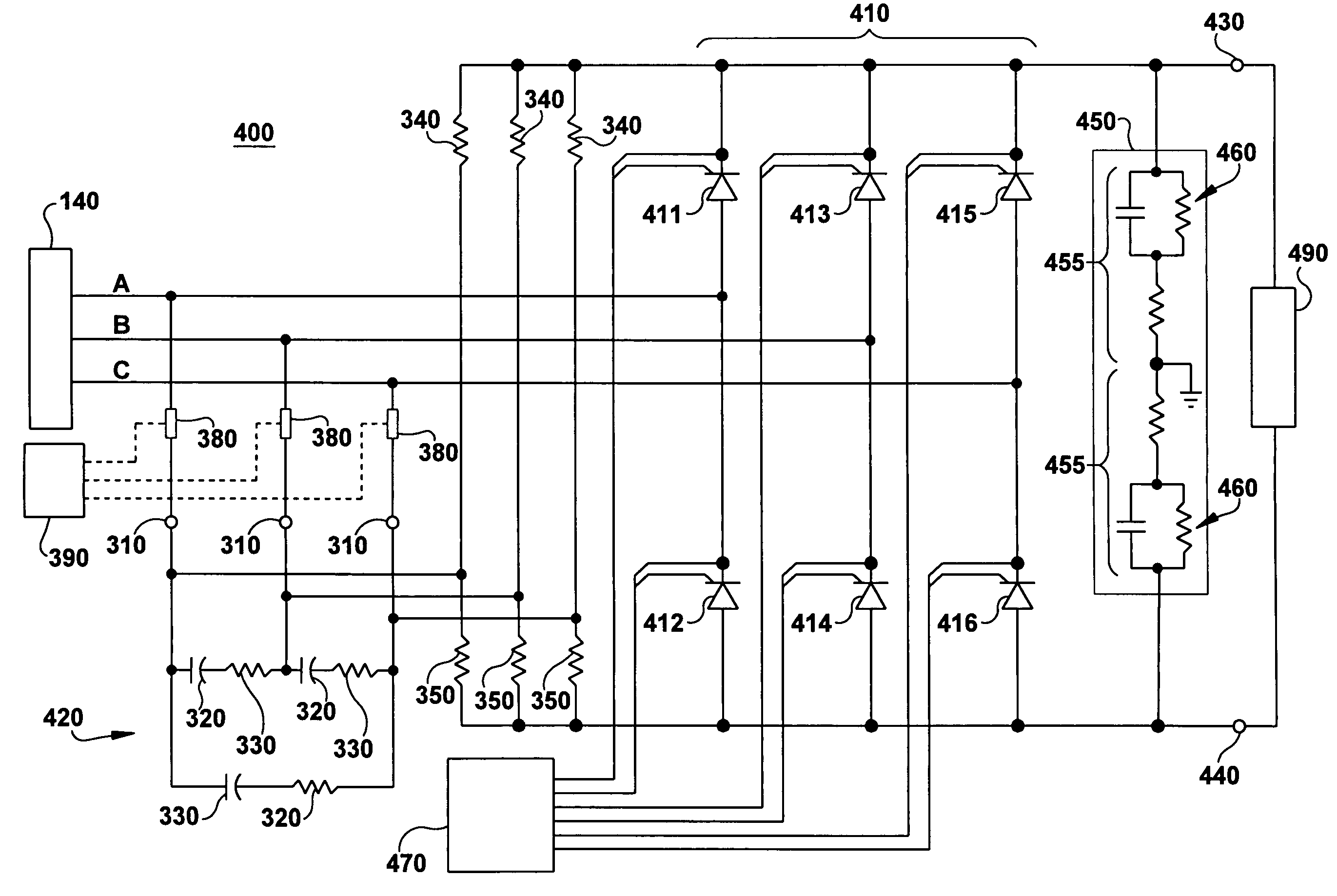

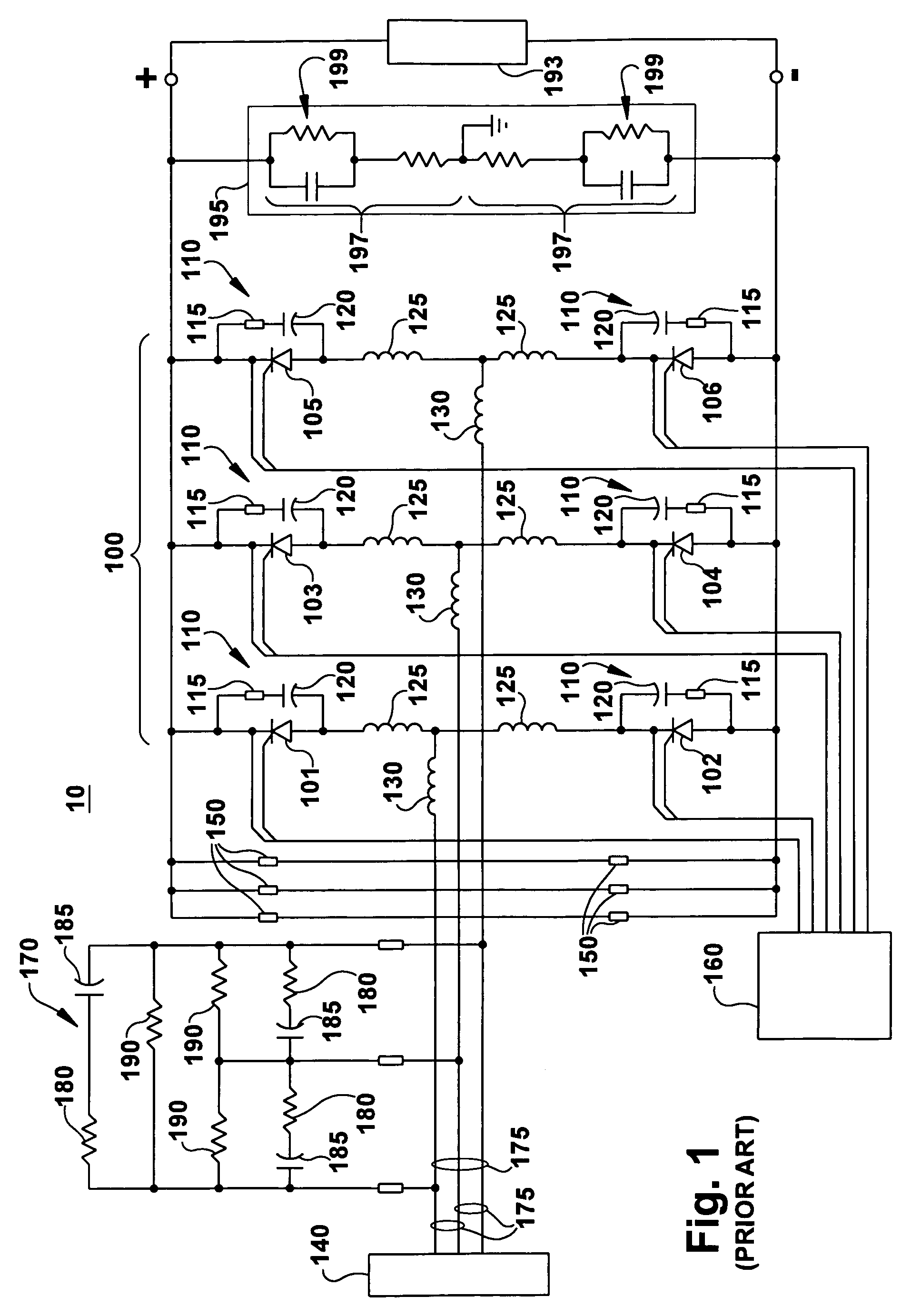

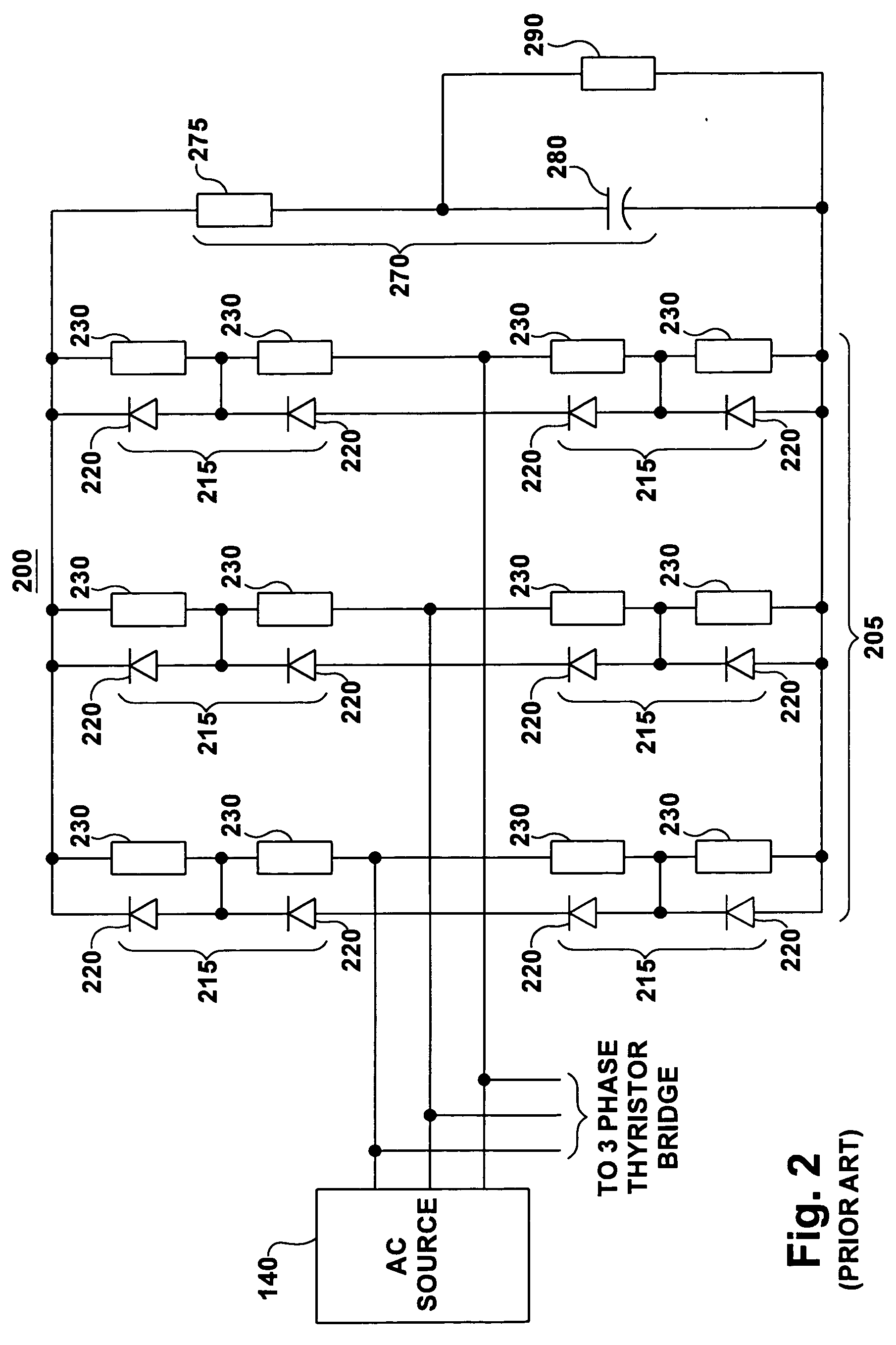

Thyristor power converter filter for excitation applications

ActiveUS20080074910A1ThyristorEmergency protective circuit arrangementsCapacitanceElectrical resistance and conductance

An exciter system for the field of a synchronous generator excitation is provided. The exciter system includes an AC power source; a three-phase thyristor bridge having six legs, the three-phase bridge being connectable with the AC power source, and being adapted to provide a variable DC voltage output; a thyristor in each of the six legs of the three-phase bridge, wherein the thyristors provide a path for a device current; and a three-phase AC line filter series, including series resistive and capacitive elements across each phase of the AC power source and a plurality of bleed resistors, wherein at least one bleed resistor is connected to each AC input connection of the filter.

Owner:GENERAL ELECTRIC CO

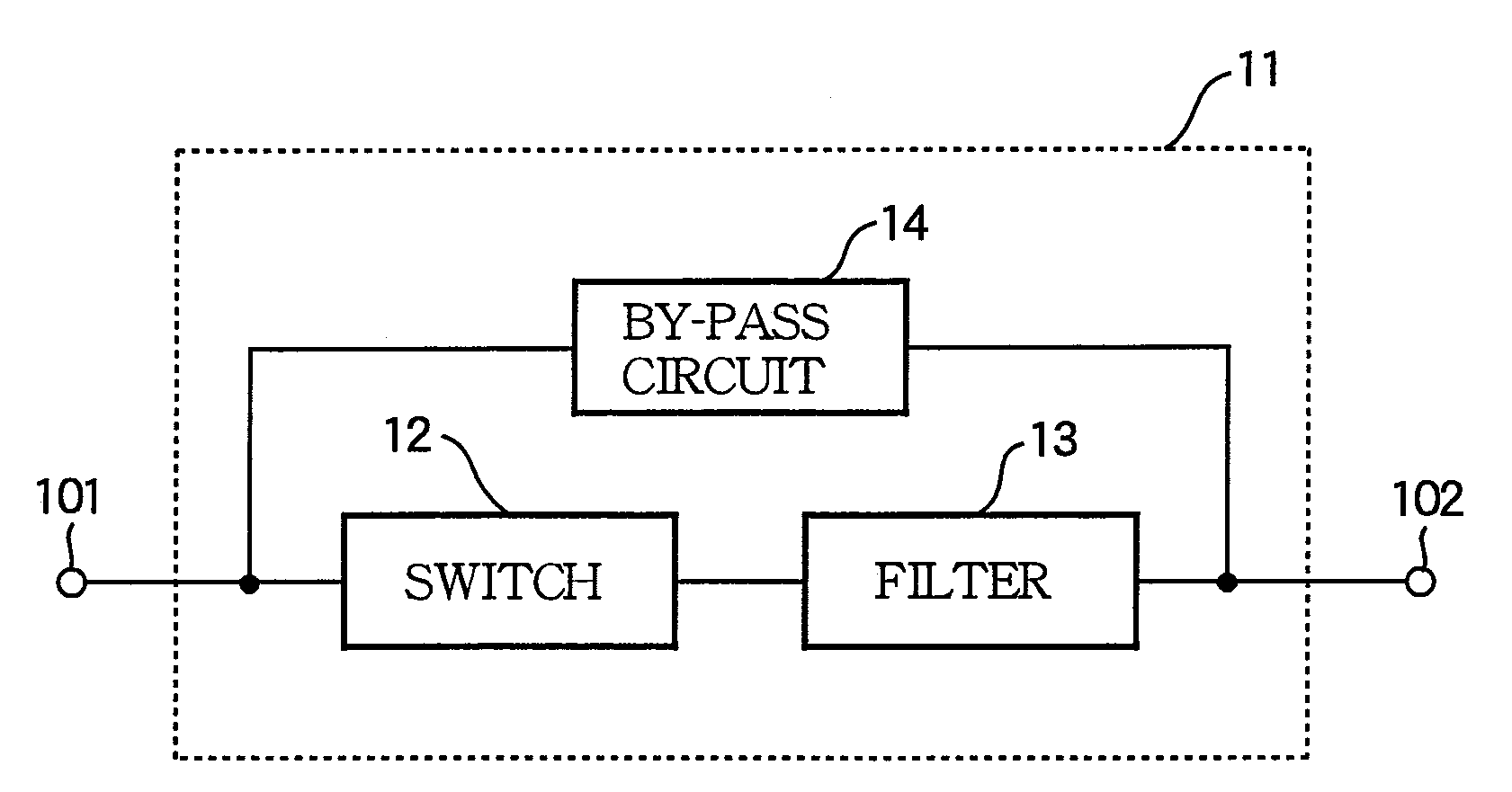

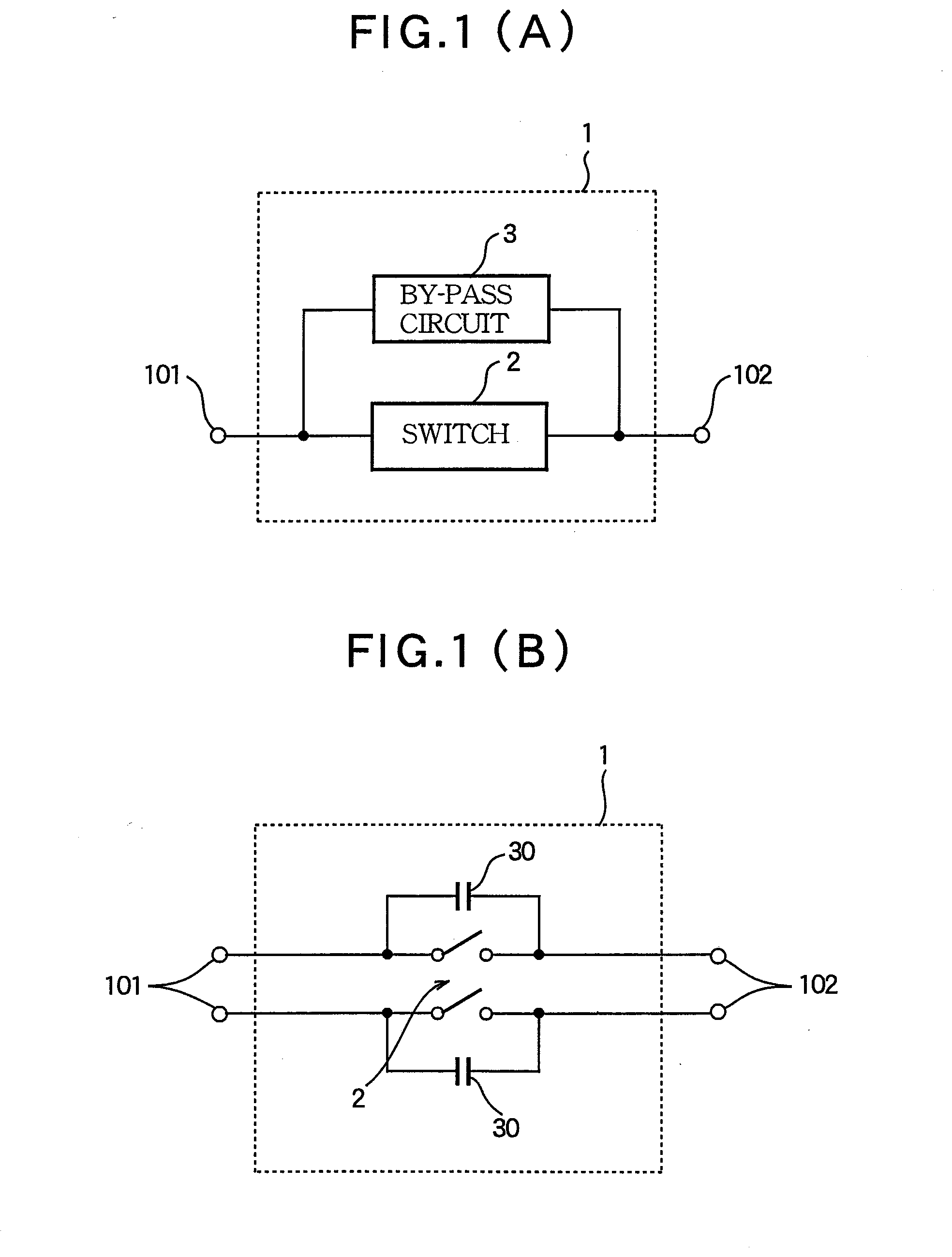

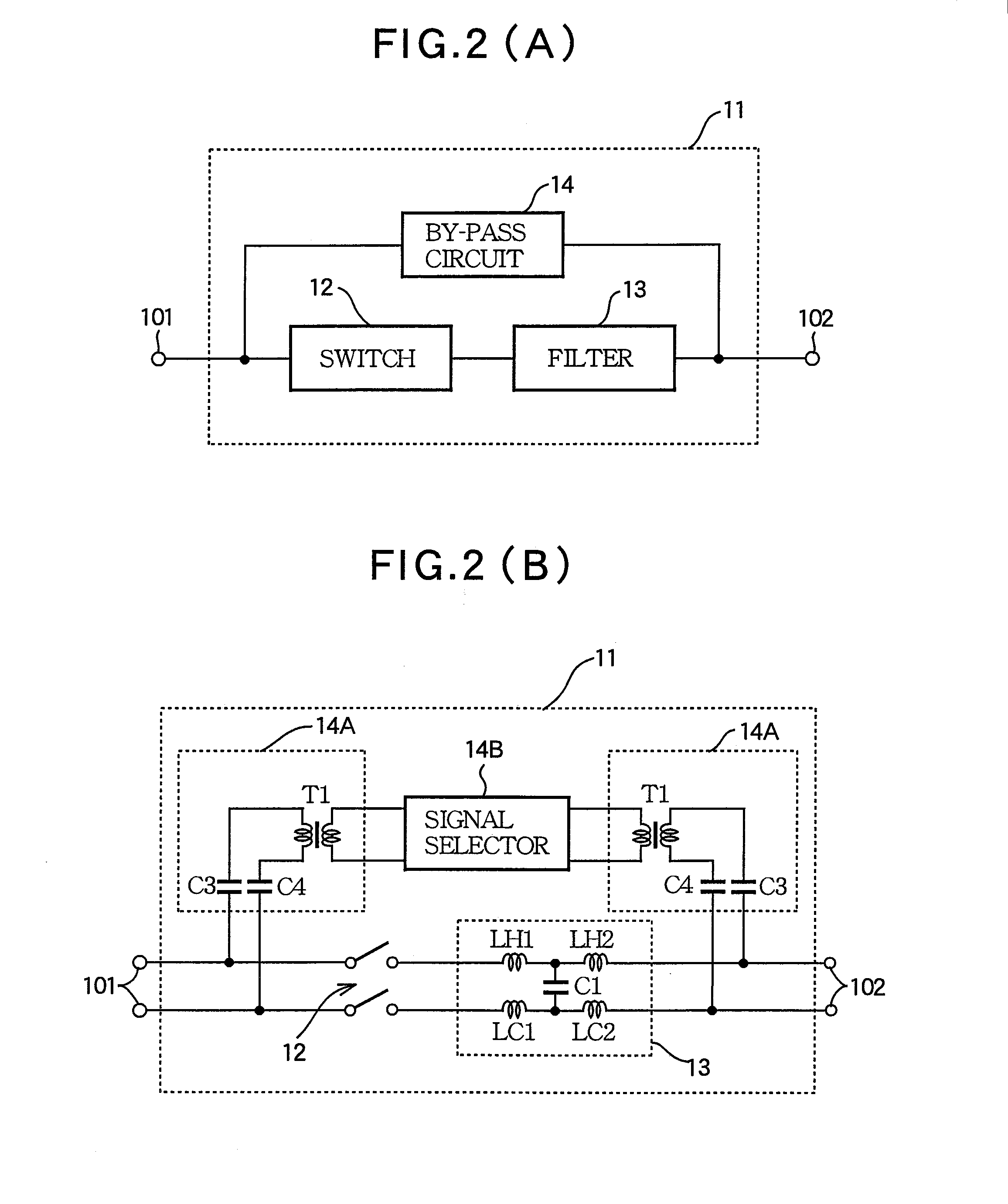

Transmission Line Structure for Power Line Communication and Power Line Switch Used Therein

InactiveUS20080224536A1Process stabilitySystems using filtering and bypassingDc network circuit arrangementsLow-pass filterBand-pass filter

A power line switch apparatus is provided for use in a power line communication system that transmits a signal through a power line that feeds a power supply current. In the power line switch apparatus, a switch section is inserted in the power line to make or break connection of the power line. A power line filter is connected in series to the switch section and inserted in the power line, the power line filter being used to pass the power supply current and to cut off the signal of the power line communication system. A by-pass circuit is connected in parallel with the series connection of the switch section and the power line filter, the by-pass circuit including a by-pass filter for cutting off the power supply current and passing the signal of the power line communication system.

Owner:YAMAHA CORP

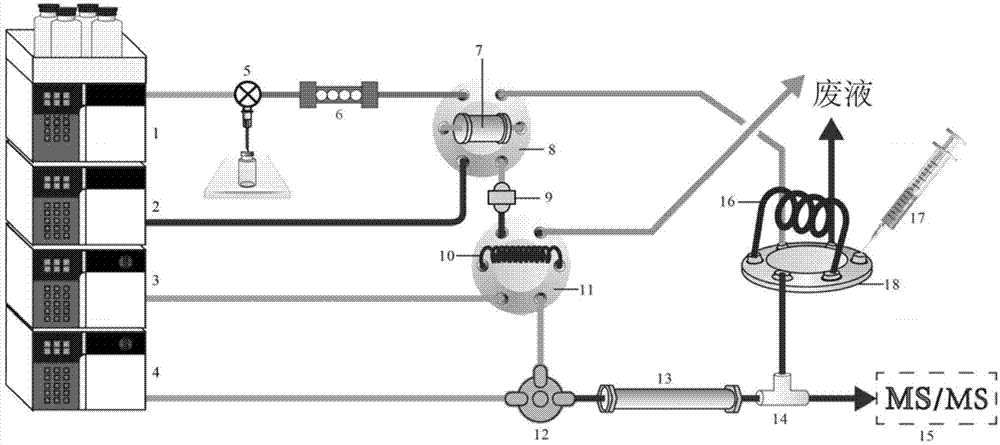

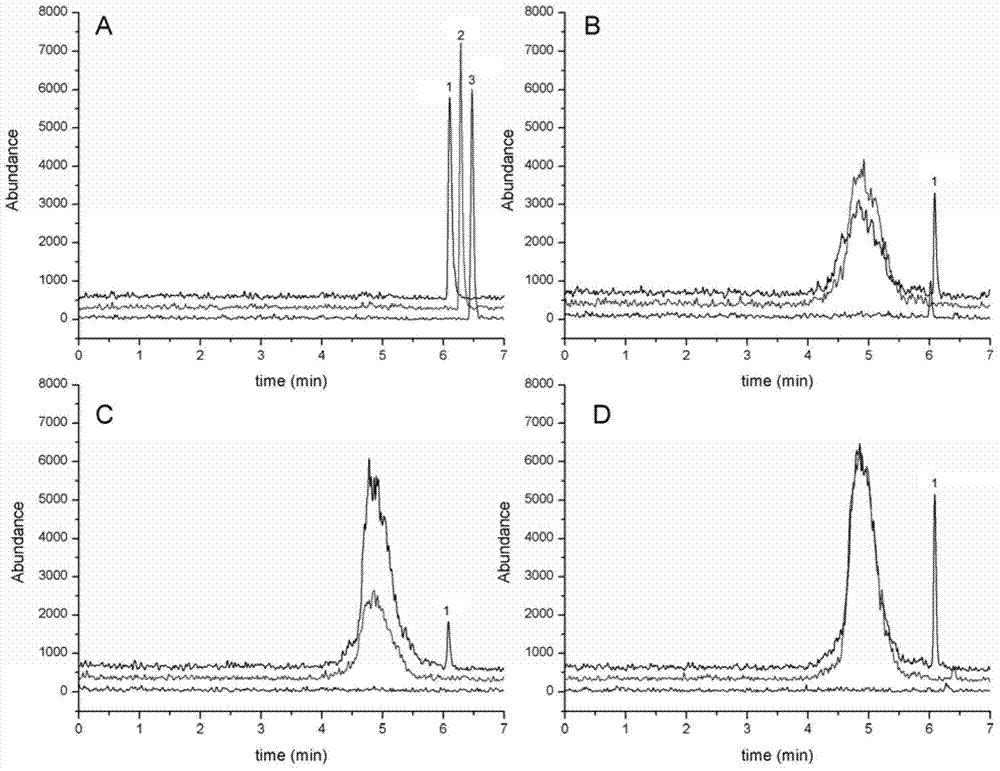

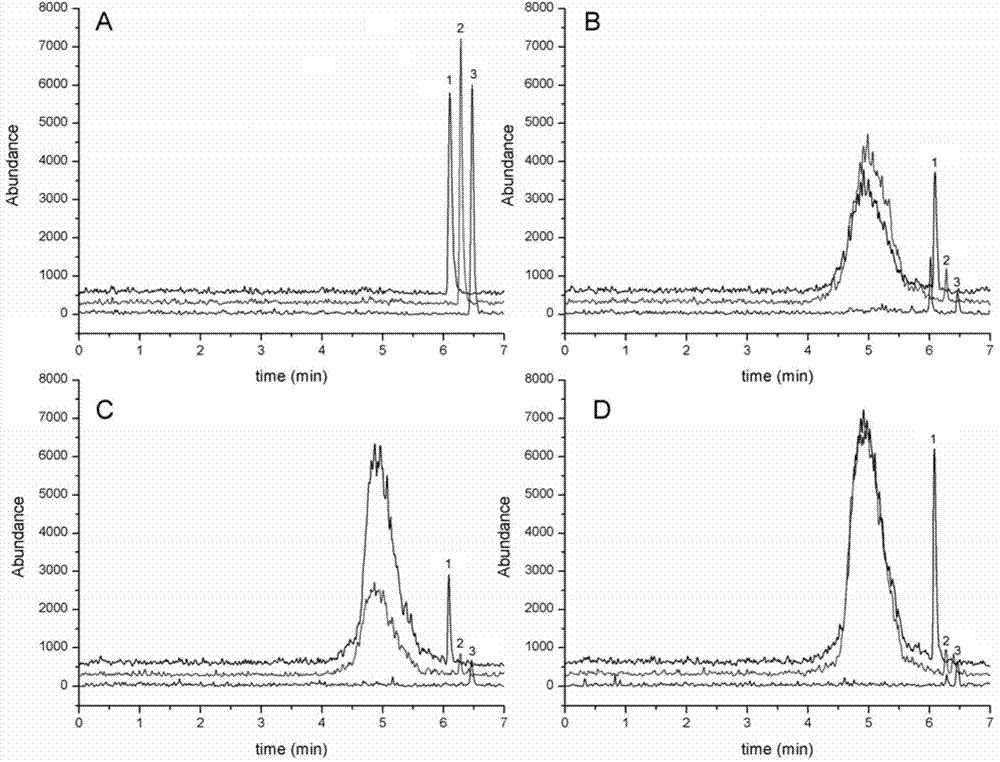

On-line analysis system for automatic pretreatment by adopting ultra high performance liquid chromatography/mass spectrum

The invention discloses an on-line analysis system for automatic pretreatment by adopting an ultra-high performance liquid chromatography / mass spectrum. The on-line analysis system has an automatic pretreatment mode and a post-column compensation mode, and comprises four chromatography pumps, two high-pressure switch valves, an automatic sample injector, an on-line diluter, an extraction column, an on-line filter, two sample rings, a miniature mixer, a chromatographic column, a tee joint, a mass spectrometry detector and the like. On-line dilution, extraction, desorption, separation, detection and post-column compensation analysis can be carried out on a target analyte in a liquid sample by combination of an on-line dilution / extraction / desorption device, a stigma focusing device, a post-column compensation device and an ultra high performance liquid chromatography / mass spectrum device, the overall analysis process is automatically controlled, and is high in accuracy and precision, and the on-line analysis system can be effectively applied to the analysis detection on trace organic compounds in a complicated liquid sample or a liquid extracting solution.

Owner:SHIMADZU (CHINA) CO LTD

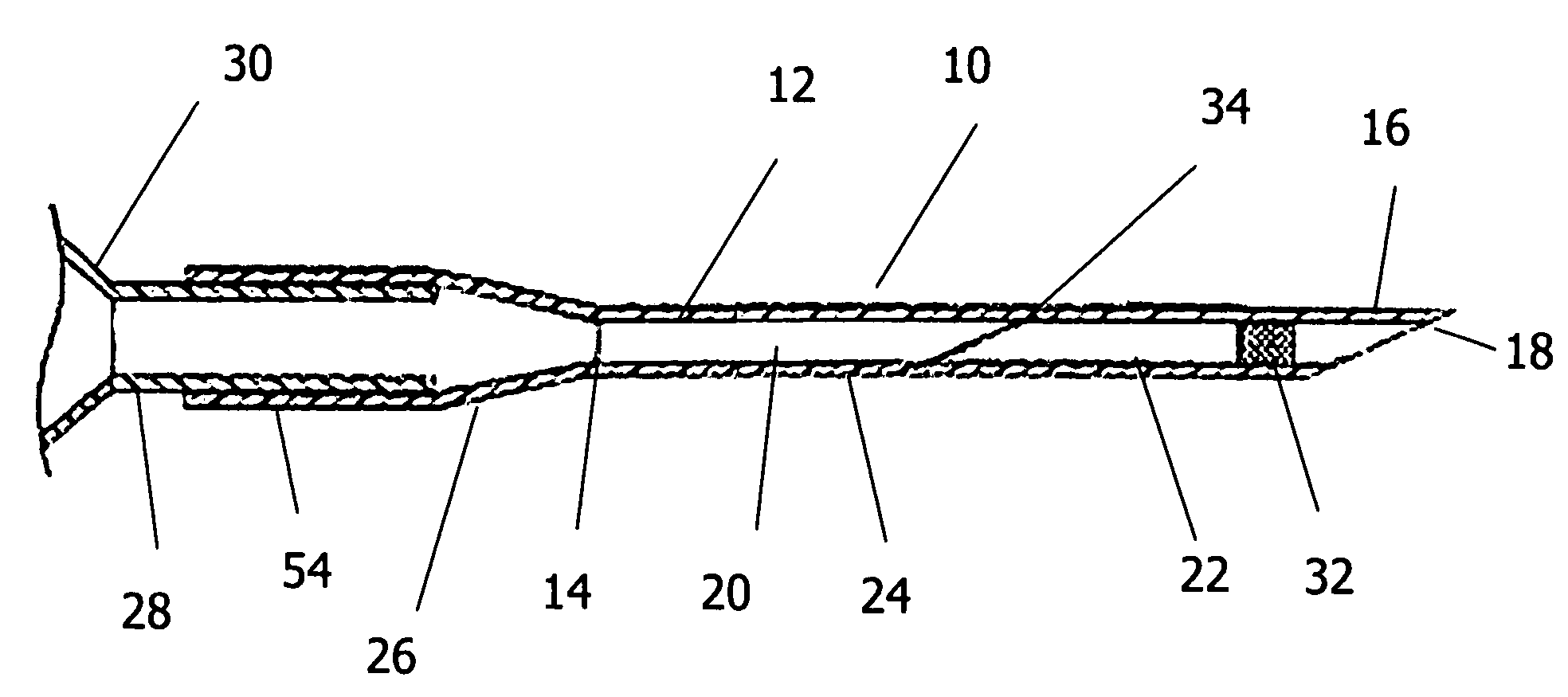

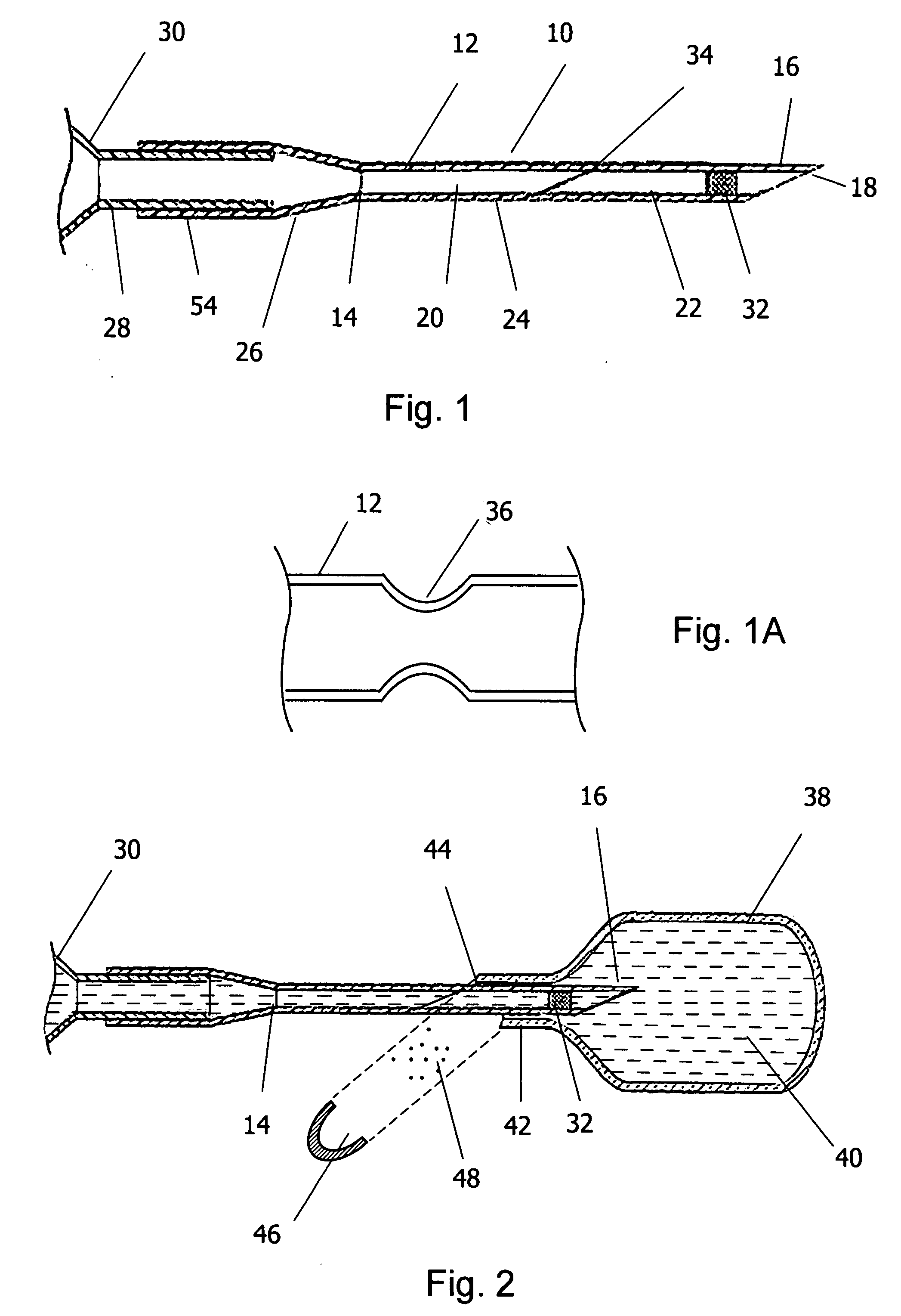

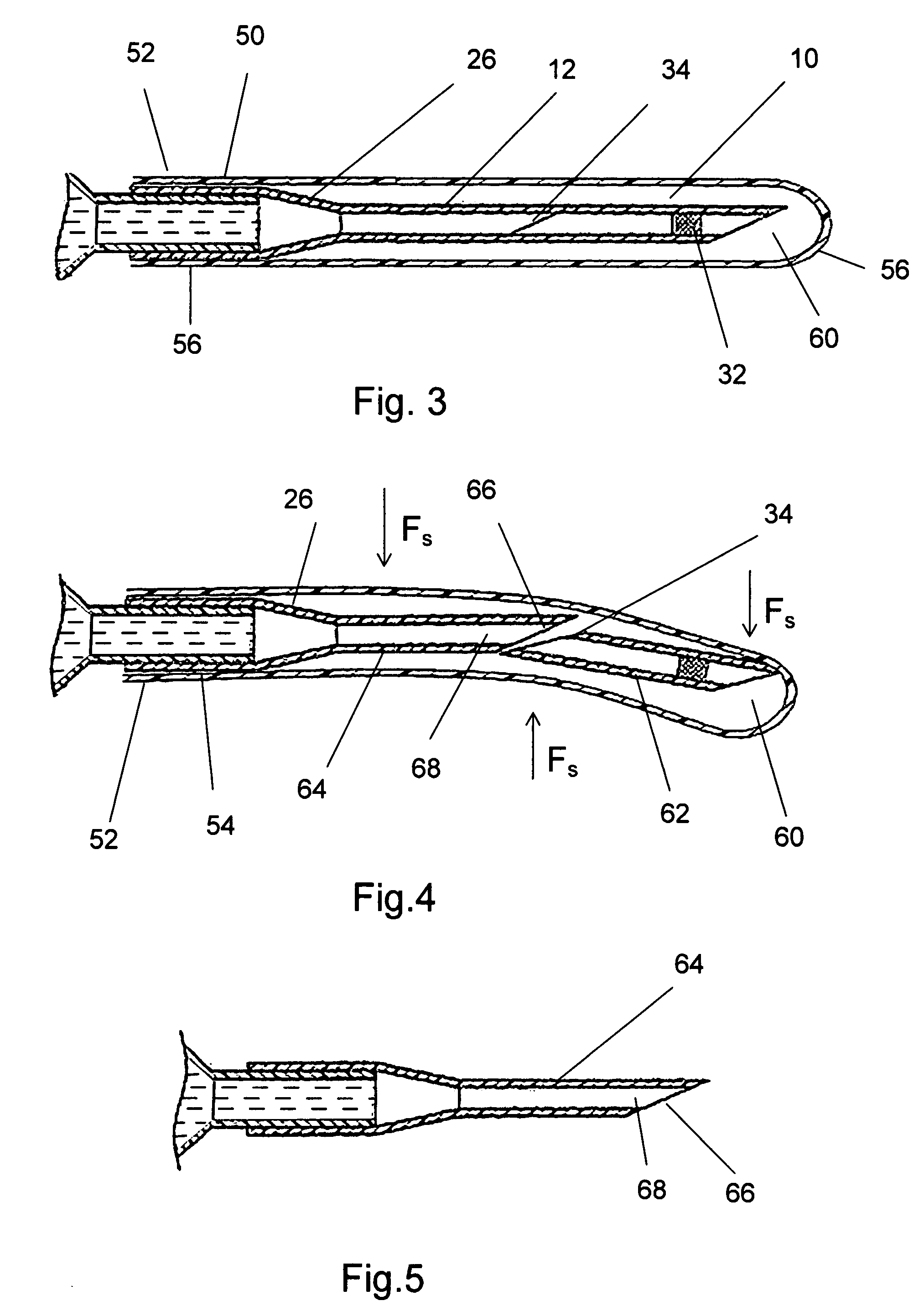

Filter needle

A single in-line filter hollow needle has an outer wall, a proximal end, a distal end with a pointed tip and a central opening between the ends for communicating fluids therethrough. The proximal end is secured to a luer lock for removable connection to a syringe. A filter is located in the central opening proximate to the tip. The outer wall of the needle has a frangible deformation proximate to the filter and remote from the end of the needle whereby the needle may be broken to expose a fresh point after fluid is aspirated through the needle to the syringe is filtered.

Owner:CARRTECH

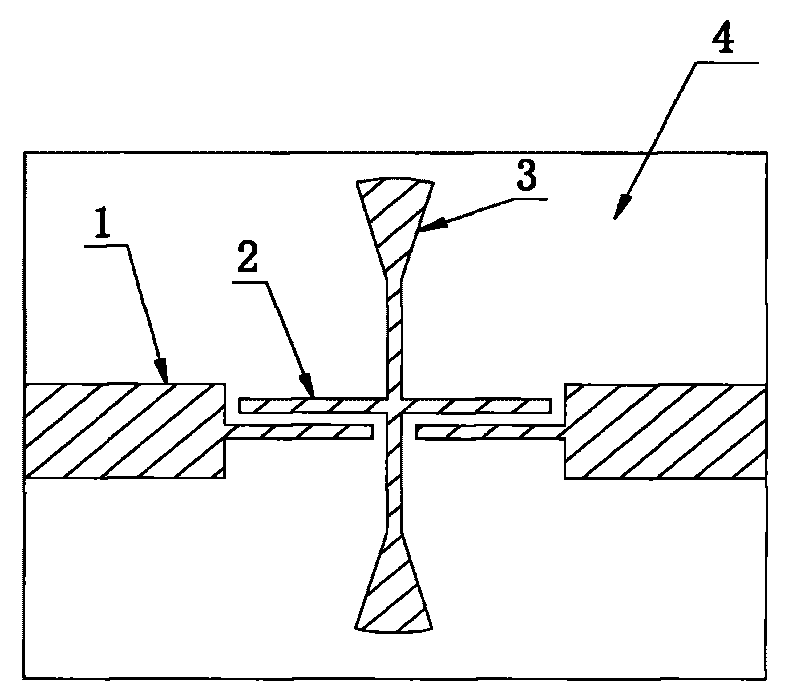

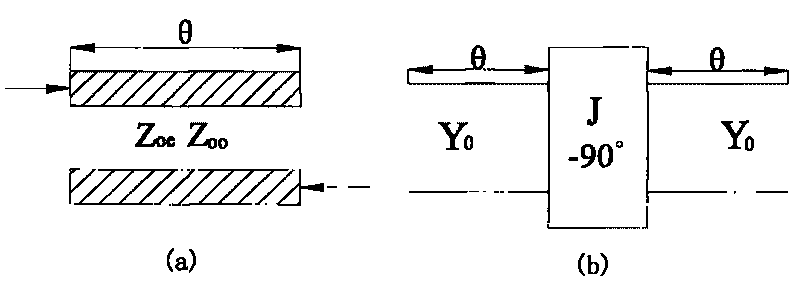

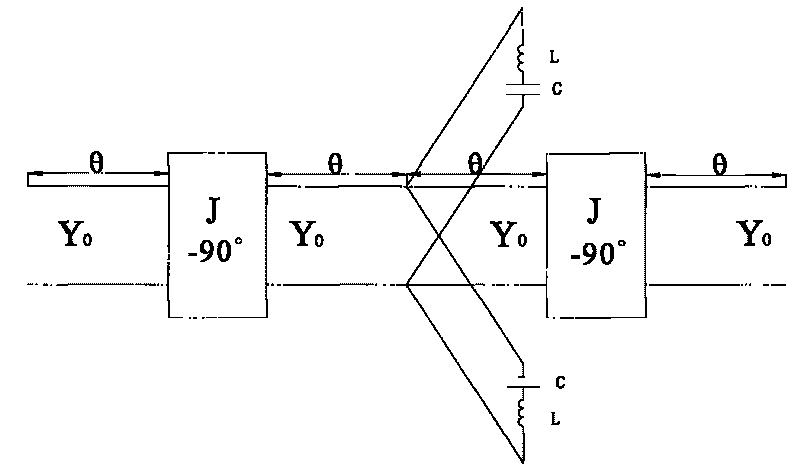

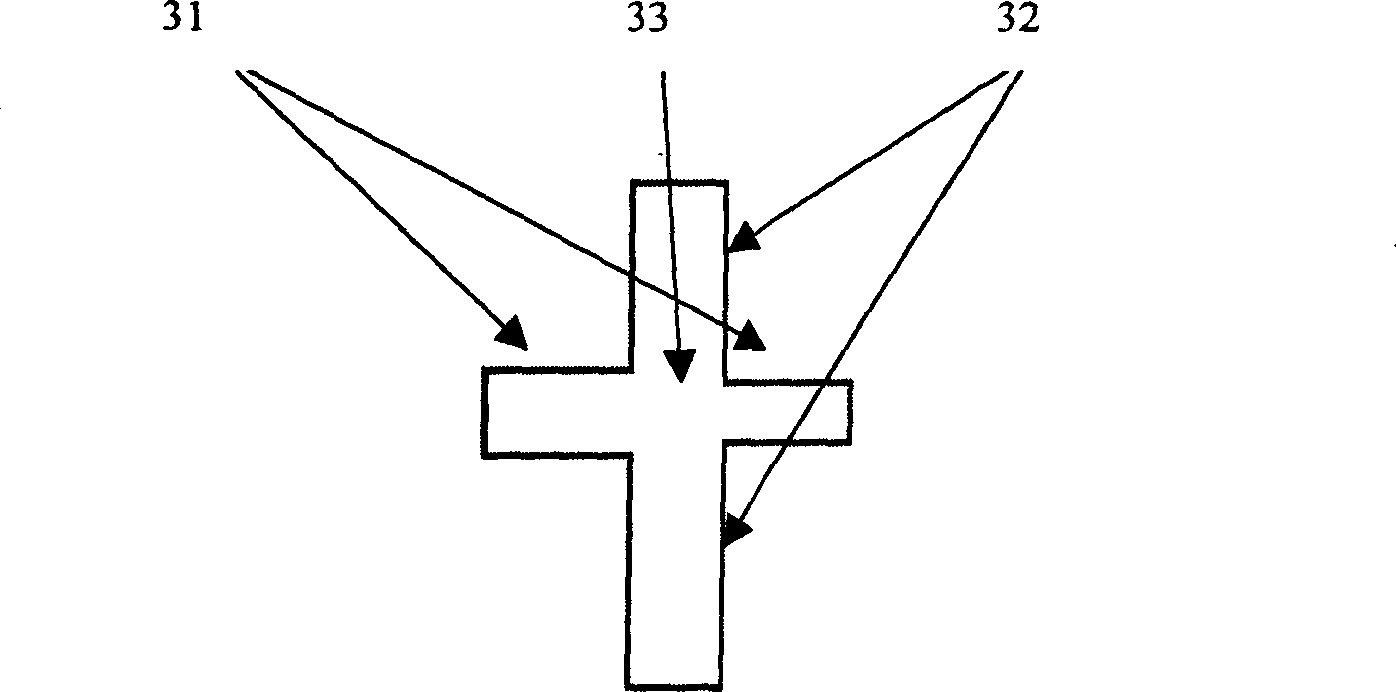

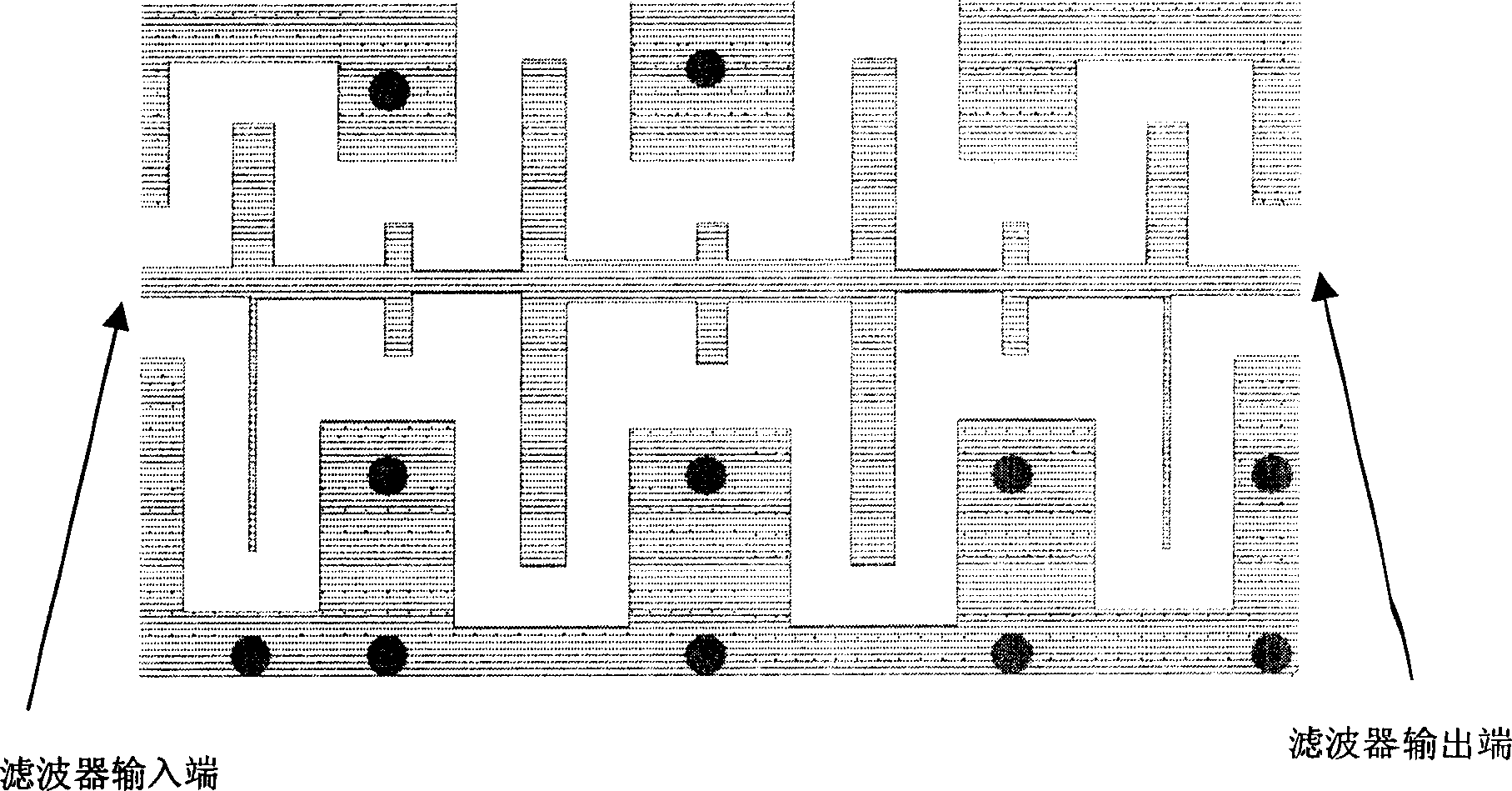

Microstrip bandpass filter with sector open-circuit structure

InactiveCN101694899AHigh rectangularityWell formedWaveguide type devicesUltrasound attenuationSubmillimeter wave

The invention relates to a microstrip bandpass filter with a sector open-circuit structure, belonging to the technical field of microwave / millimeter wave devices and relating to a microwave / millimeter wave integrated circuit. Based on a traditional parallel coupling microstrip line filter, the microstrip bandpass filter with the sector open-circuit structure adds two sections of sector open-circuit shunts; either sector open-circuited shunt is a one-fourth wavelength terminal open-circuit line with a sector-structure end terminal; and the start terminals of the two sections of sector open-circuit shunts are perpendicularly connected with a center point of an auxiliary microstrip line. The invention has the advantages of simple form, compact structure and high beyond-strip attenuation, not only can be used in a microwave / millimeter wave integrated circuit, but also can be used in a submillimeter wave band with higher frequency. Meanwhile, an input microstrip line and an output microstrip line of the microstrip bandpass filter with the sector open-circuit structure are on the same straight line, thereby facilitating the application in practical projects.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

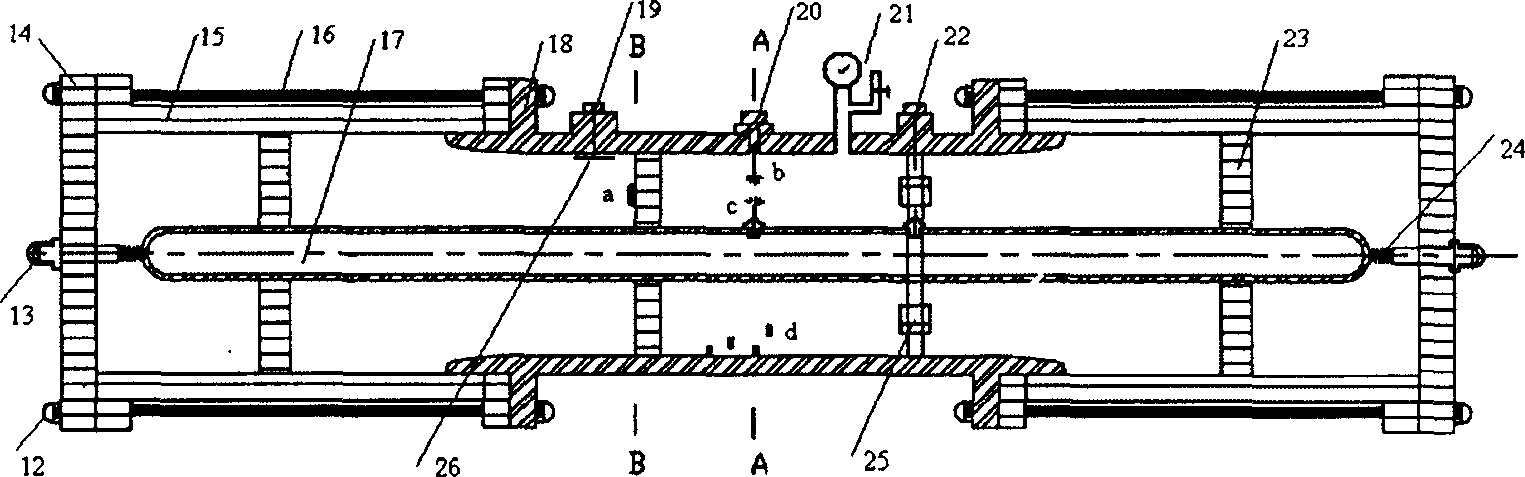

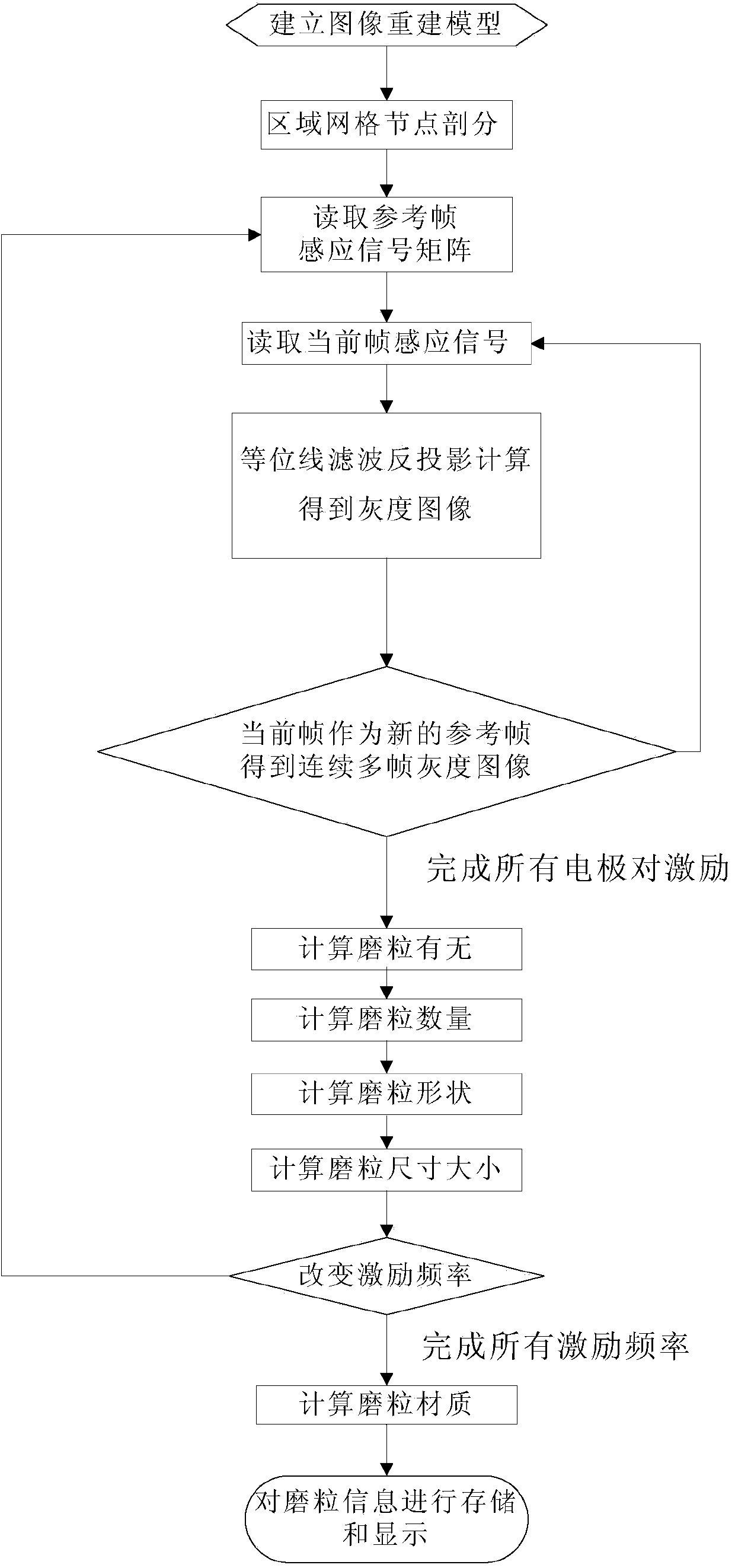

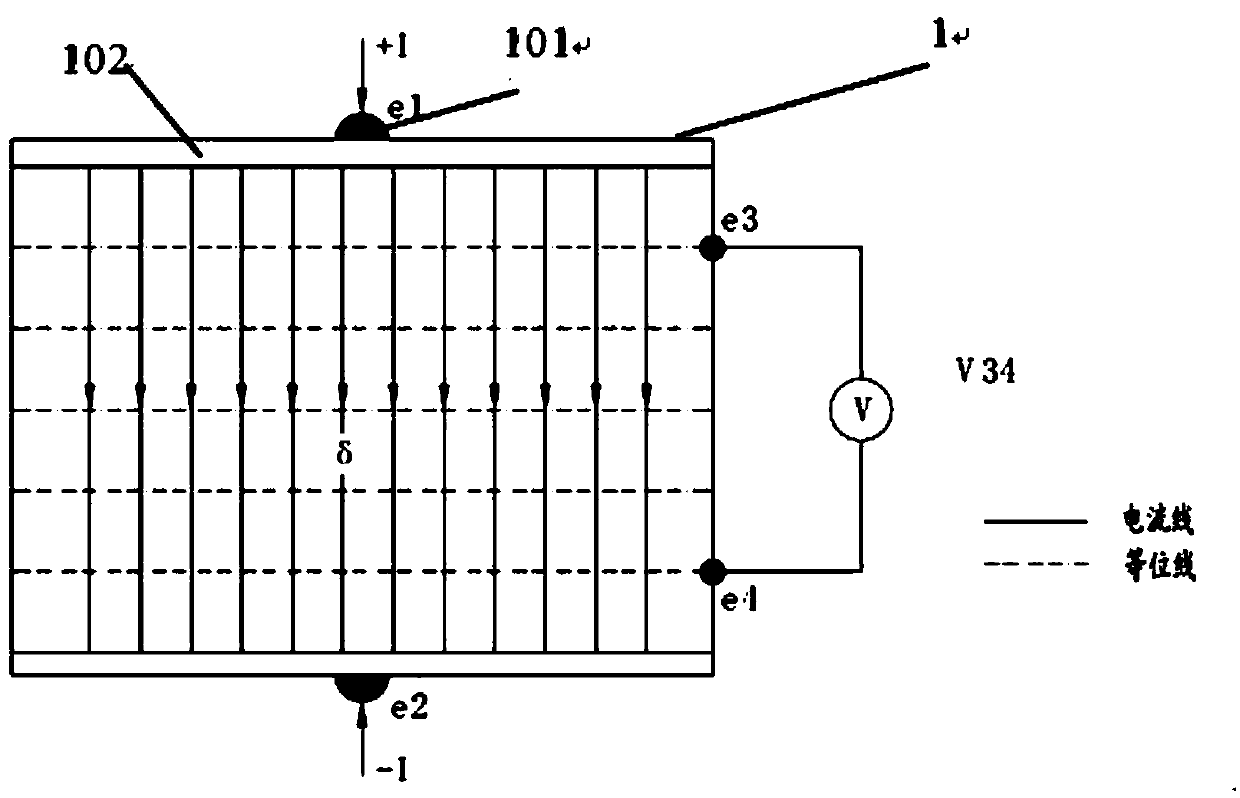

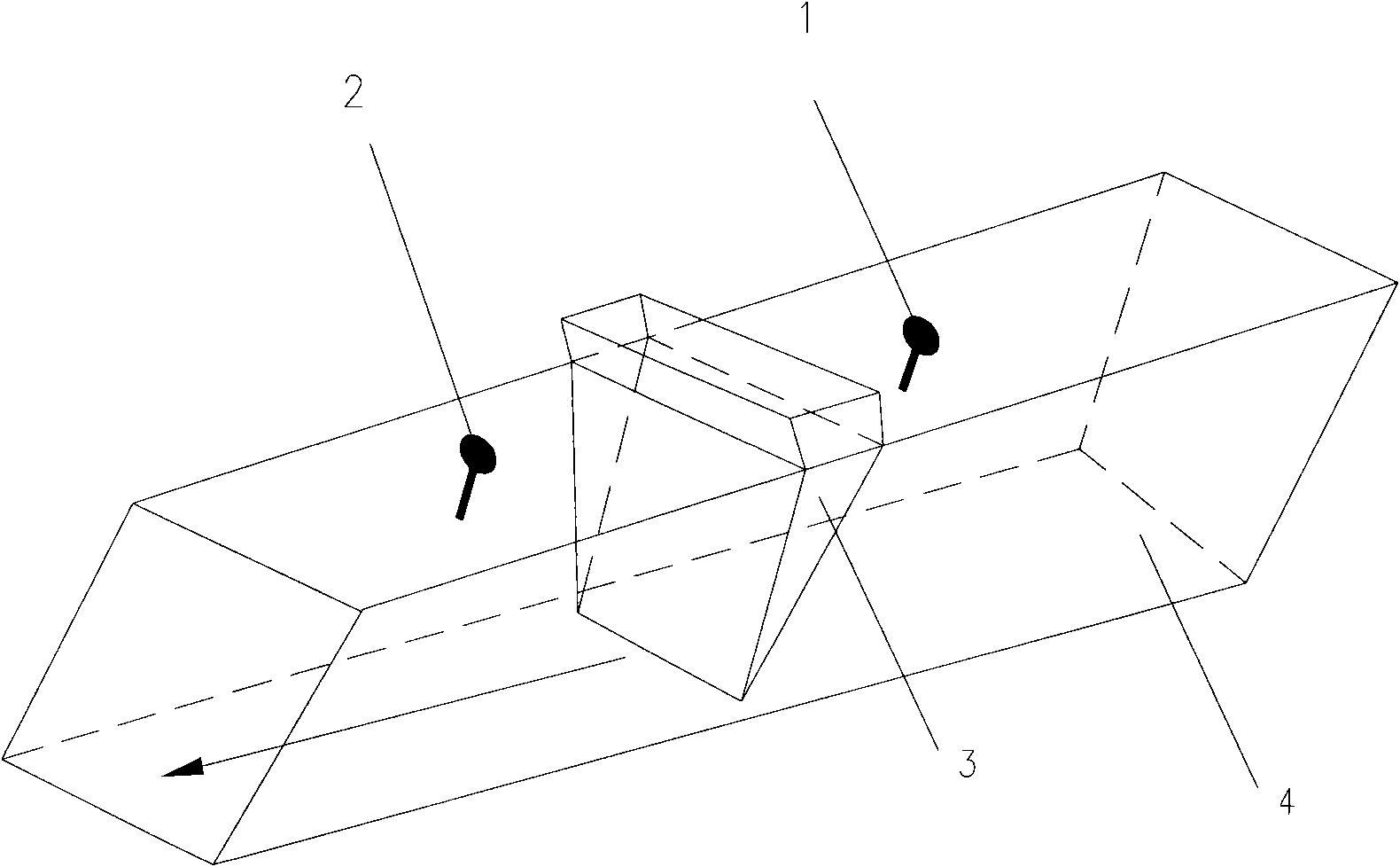

Online oil liquid abrasive particle monitoring device and measuring method

InactiveCN103926276AAvoid the impact of detection accuracyMeet online real-time detection needsMaterial resistanceWave measureMultiple frame

The invention discloses an online oil liquid abrasive particle monitoring device and measuring method. The online oil liquid abrasive particle monitoring device comprises an online multi-electrode chromatography imaging abrasive particle sensor, a photoelectric isolation module, an exciting part circuit, a measuring part circuit, power sources, a signal filtering circuit, an AD (Analog / Digital) conversion circuit and a signal path, wherein the power sources are used by the exciting part circuit and the measuring part circuit, respectively, and the signal path adopts fully differential signal transmission. The measuring method comprises the following steps: pre-processing a software phase wave measuring signal; rebuilding an image model according to a finite element rule; reading a frame induction signal; calculating equipotential line filtering reverse projection to generate a gray image; generating a continuous multi-frame image; calculating the count, sizes and shapes of abrasive practices; generating a multi-frequency gray image and calculating the textures of the abrasive practices; and storing and displaying abrasive particle information which represents the abrasive particle information in oil liquid and the abrasion state of a device. According to the online oil liquid abrasive particle monitoring device and the measuring method, both metallic and non-metallic particles can be measured and the count, sizes, shapes and varieties of the abrasive particles can be quantitatively measured.

Owner:TIANJIN UNIV

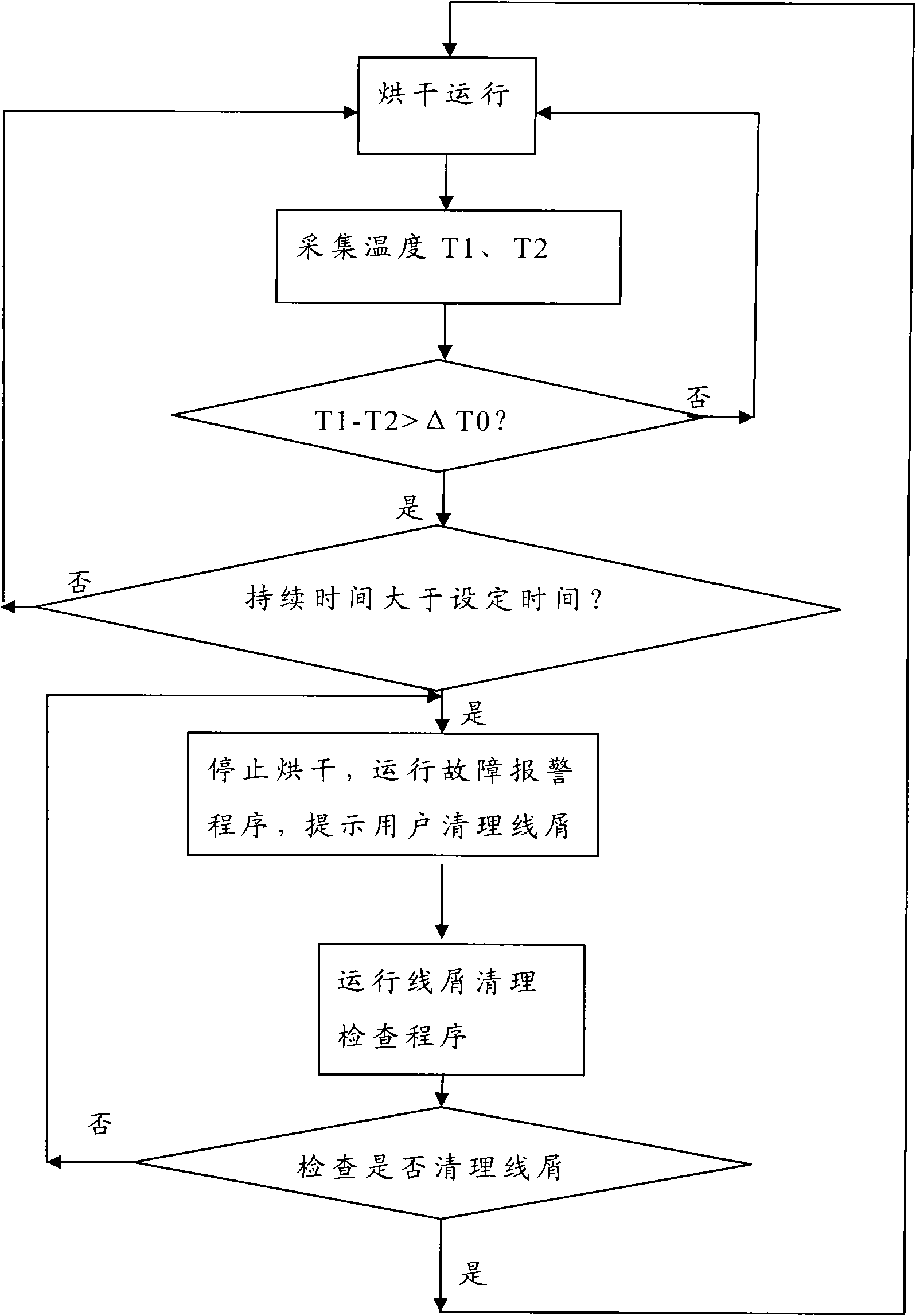

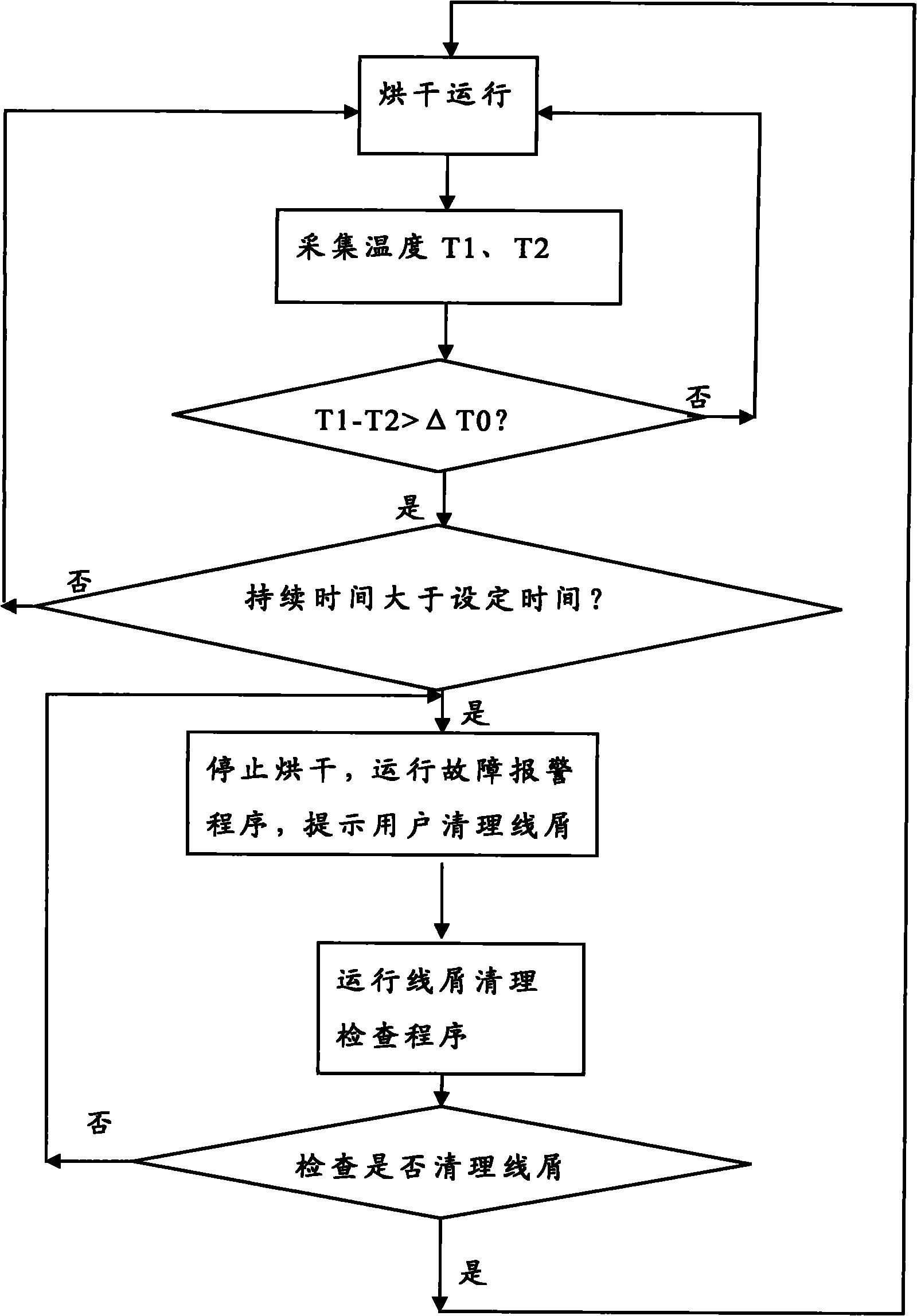

Method for intelligently prompting trash line clearup for clothes dryer and clothes dryer

ActiveCN101929060AImprove securityImprove drying efficiencyTextiles and paperLaundry driersTemperature differenceLine filter

The invention relates to a method for intelligently prompting trash line clearup for a clothes dryer, which comprises the following steps that: drying operation is carried out; temperature sensors acquire temperatures T1 and T2 at an air inlet end and an air outlet end of a trash line filter; and a computer program controller calculates the temperature difference, if the temperature difference Delta T is greater than the set value Delta T0, the computer program controller is timed for operation, and if the duration is longer than the set time t0, an alarm program is operated, and the computer program controller transmits a signal to a prompting device for alarm to make a user timely clear up trash lines. The clothes dryer which uses the method is provided with a temperature sensor I and a temperature sensor II at two ends of the trash line filter; the temperature sensors transmit signals to the computer program controller; and the computer program controller calculates the temperature difference and transmits a command to the prompting device. Due to the adoption of the technical scheme, the method is more humanized to clear up the trash lines, improves the product safety, improves the drying efficiency and saves the energy.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

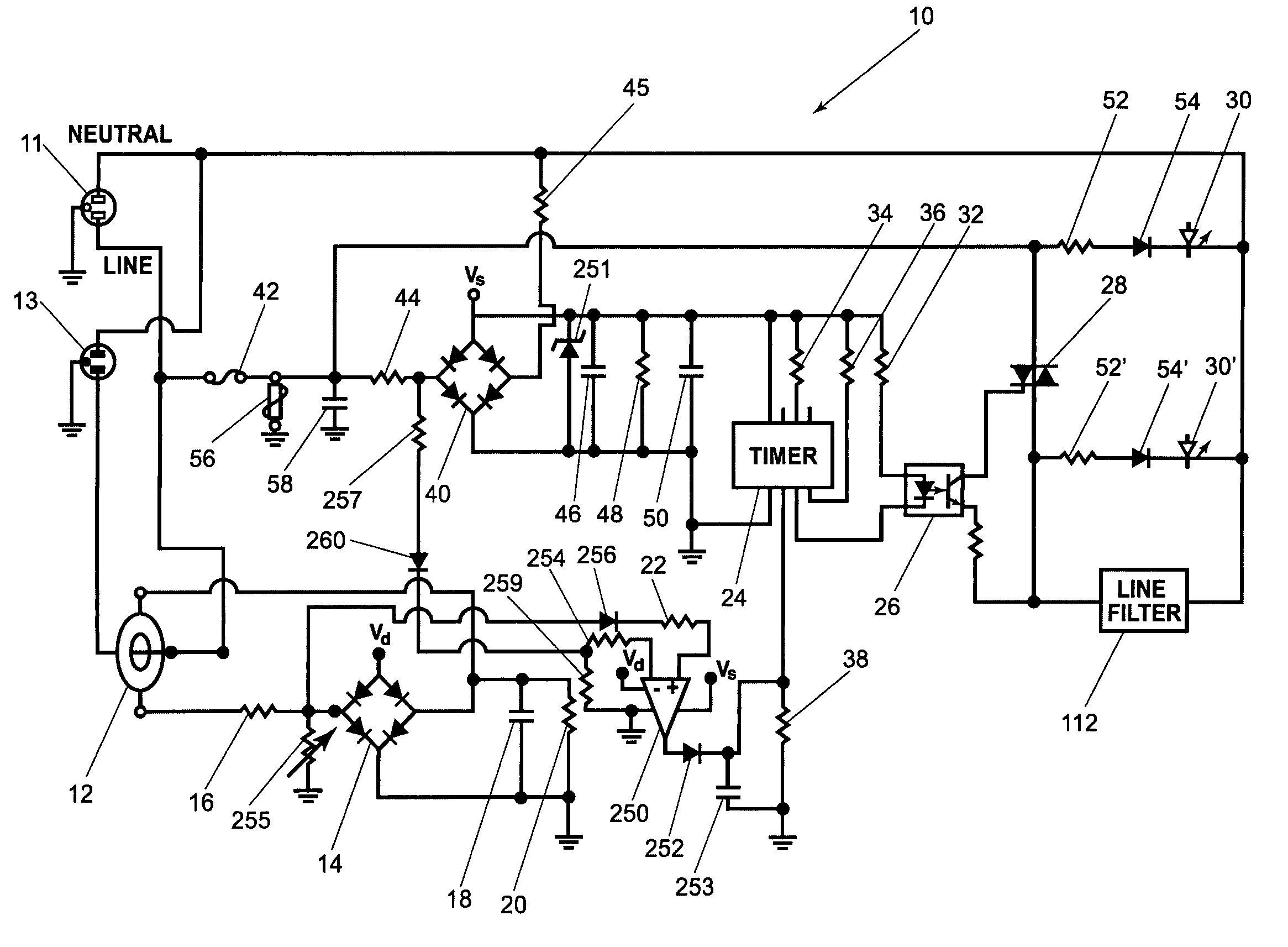

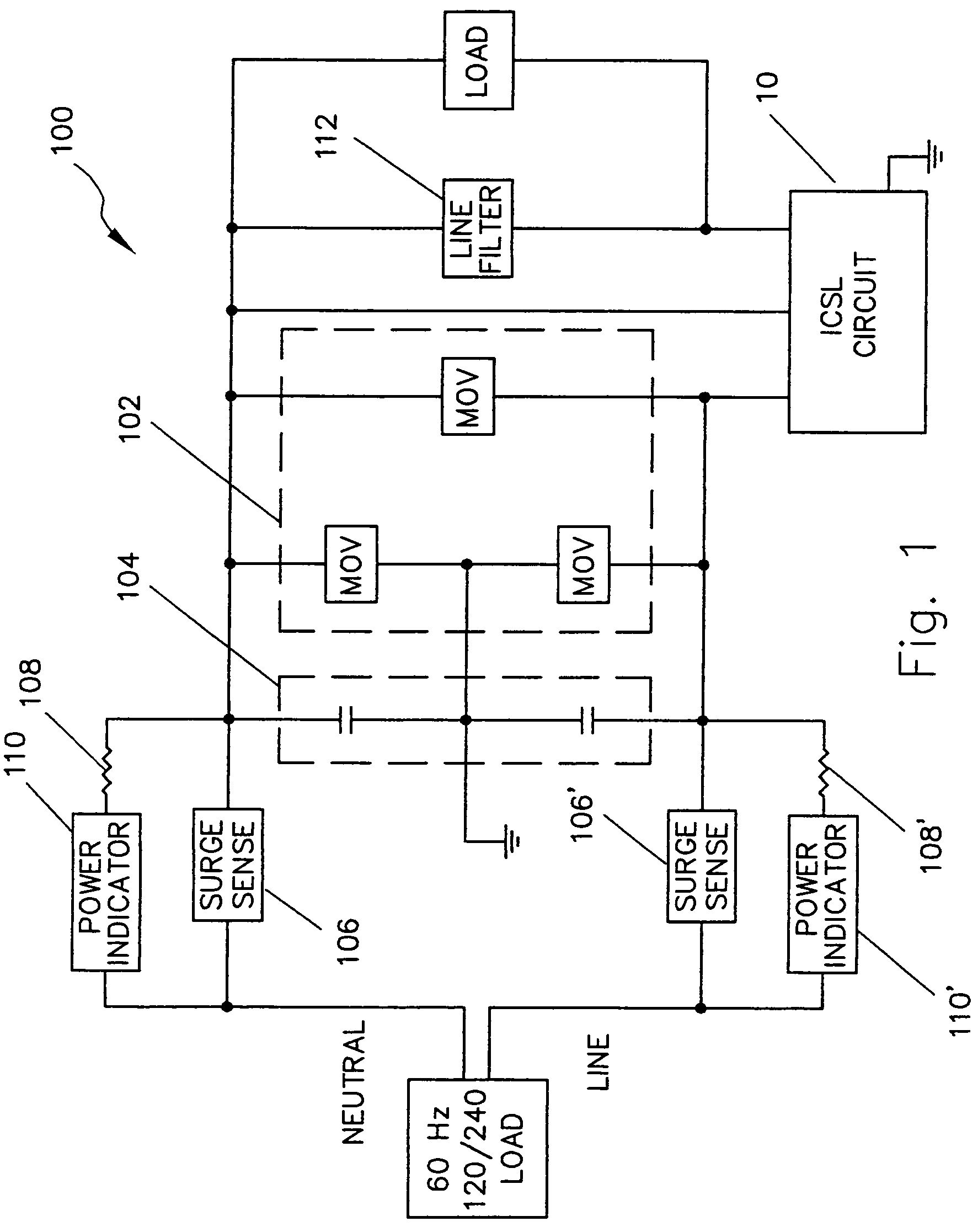

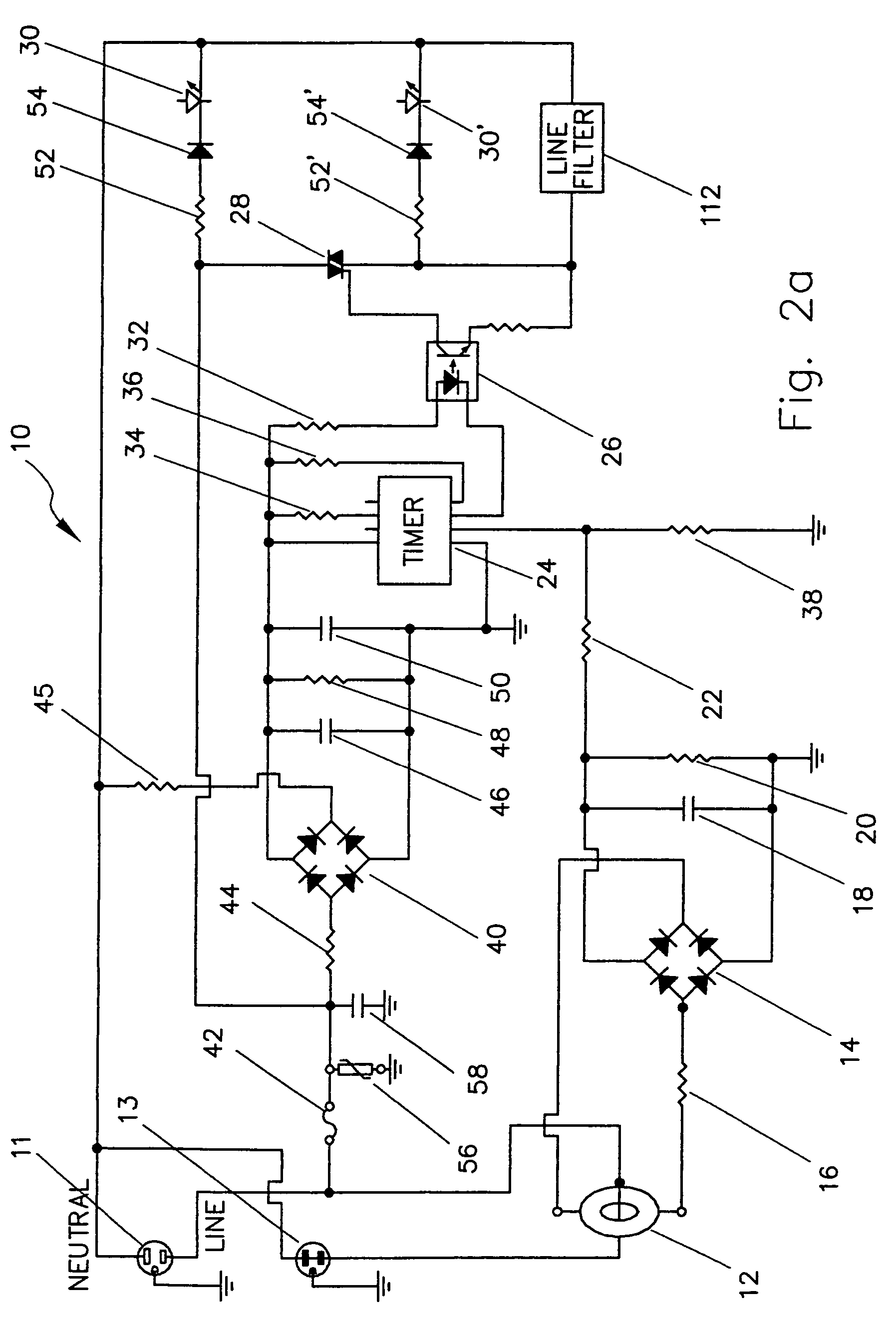

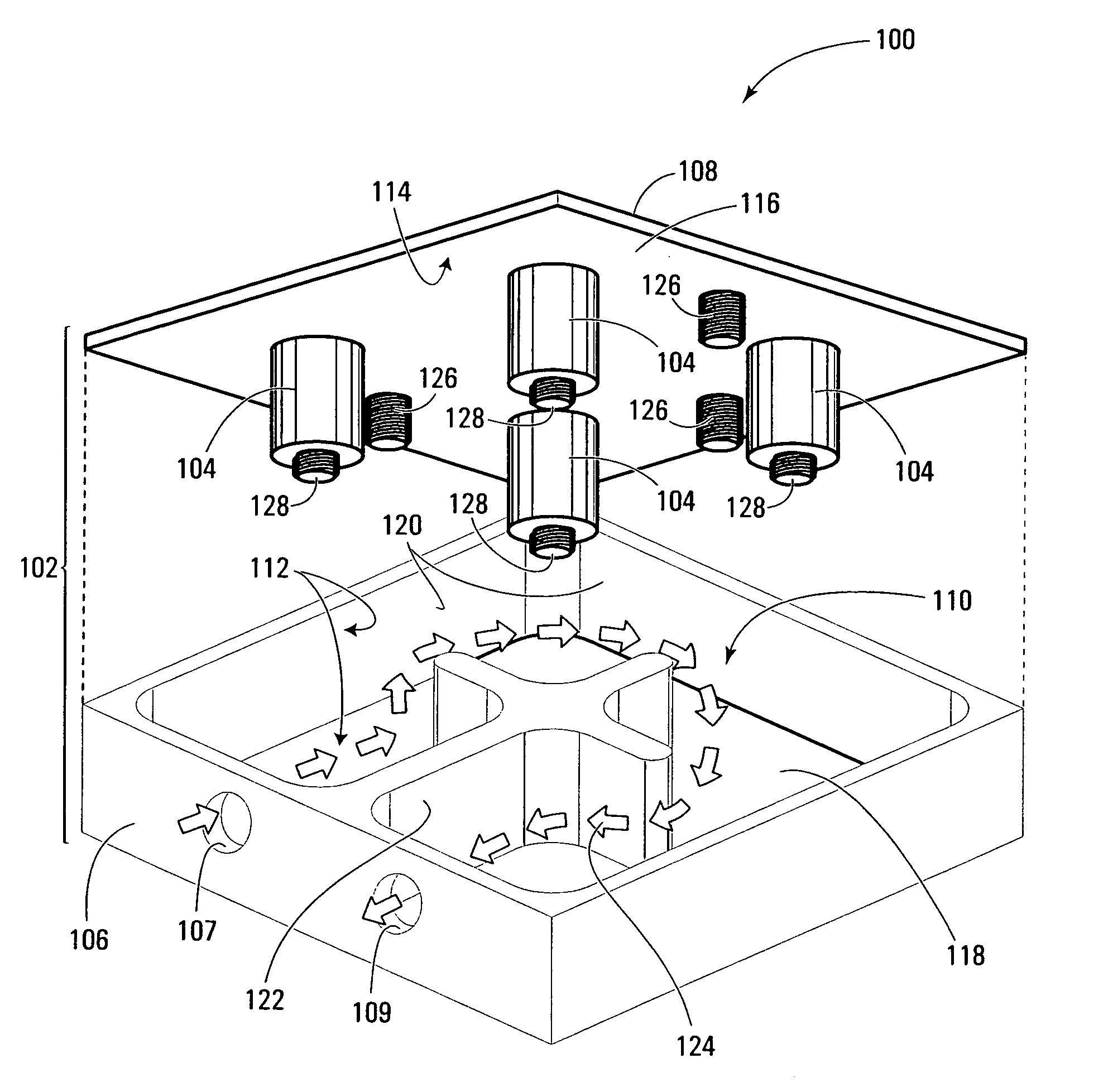

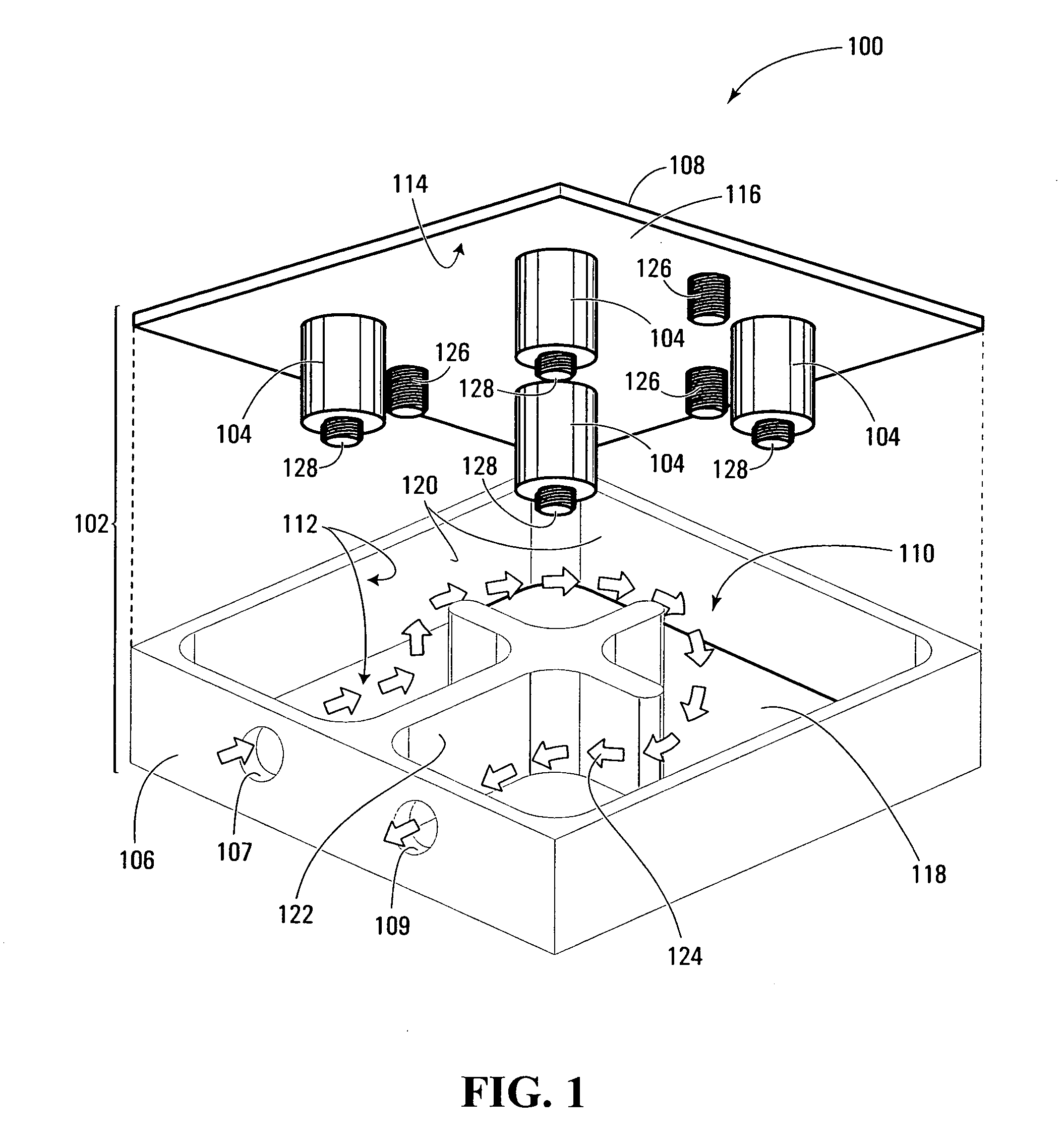

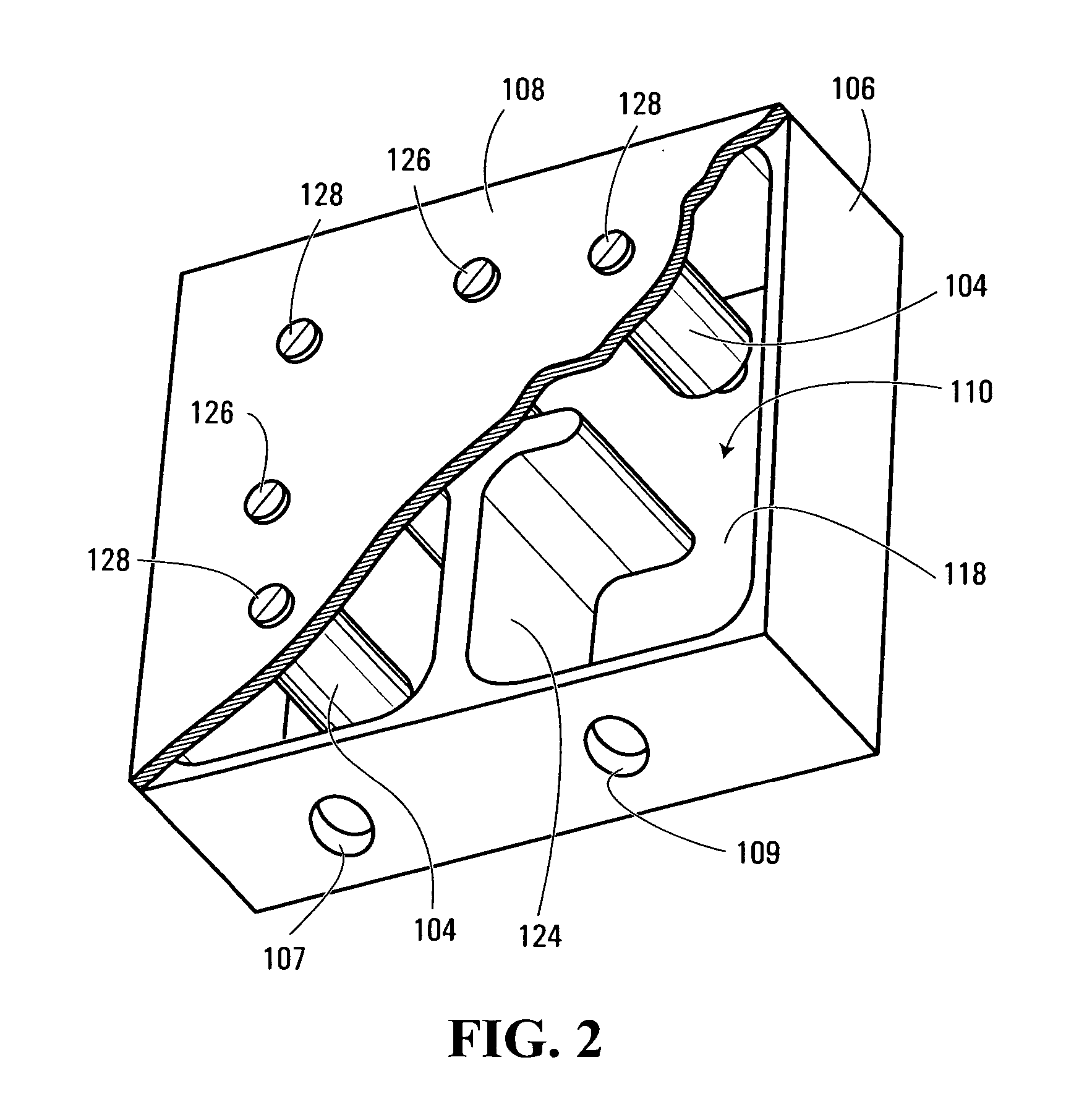

Automated AC line filter and surge suppression apparatus and method

InactiveUS7940506B2Extended service lifeReduce power consumptionEmergency protective arrangement detailsOvervoltage protection resistorsCapacitanceCurrent sensor

An automated AC line filter and surge suppression apparatus 100 having an inductive current sense loop (ICSL) circuit 10 for sensing inductive current at a load and controlling the application of AC line filter 112 to an AC power line to the load. Current sensor 12 in series with the input line senses inductive load current. A first bridge rectifier 14 rectifies the sensed load current to a proportionate DC voltage, which triggers a switch 24. The output of switch 24 is fed into an opto-isolator 26, which in turn controls second switch 28. Switch 28 connects or disconnects AC line filter 112 from the system according to a predetermined sensed inductive current at the load. MOVs 102 and capacitive elements 104 provide continuous surge suppression protection to the load.

Owner:DOLLAR ENERGY GROUP

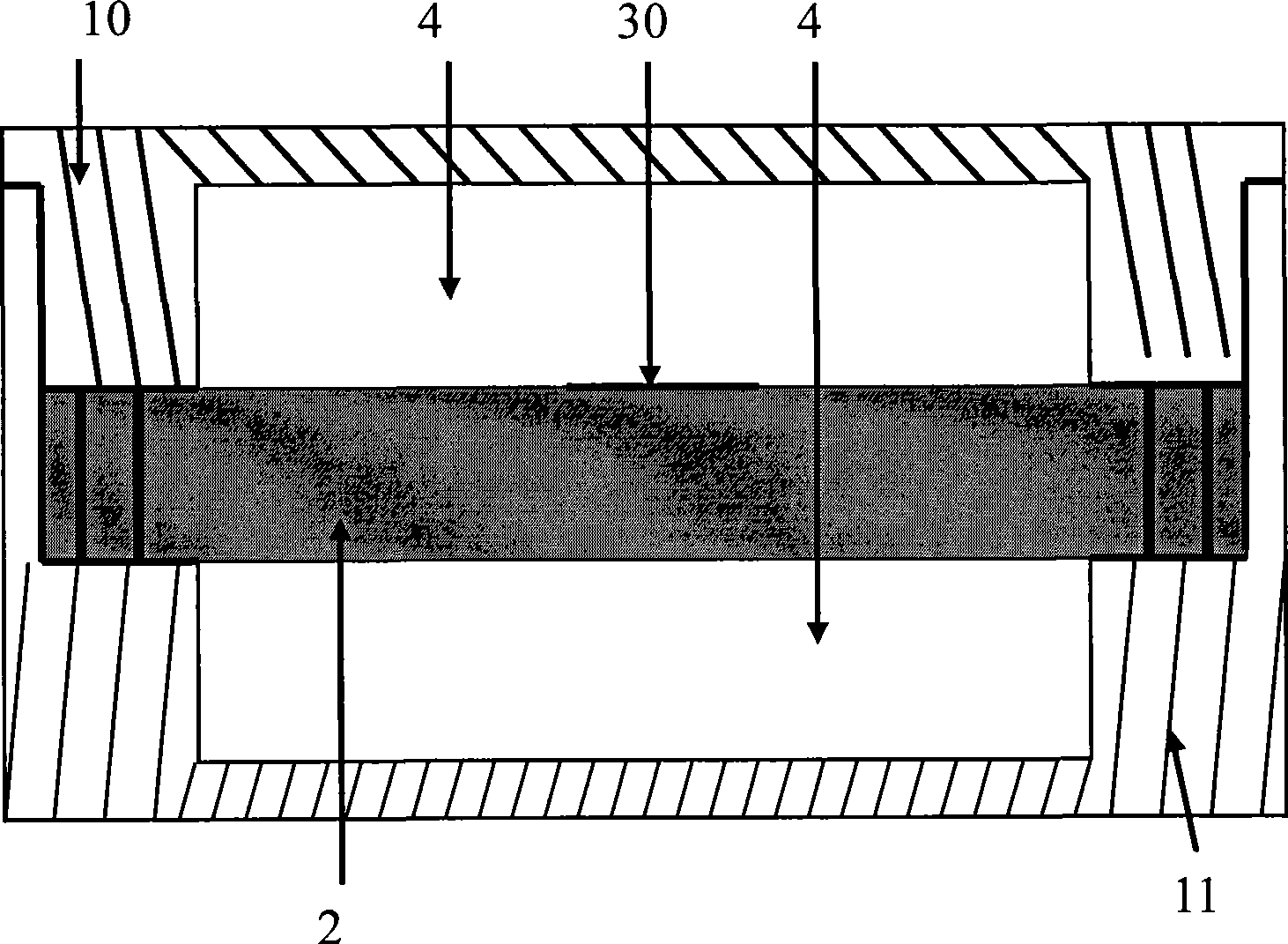

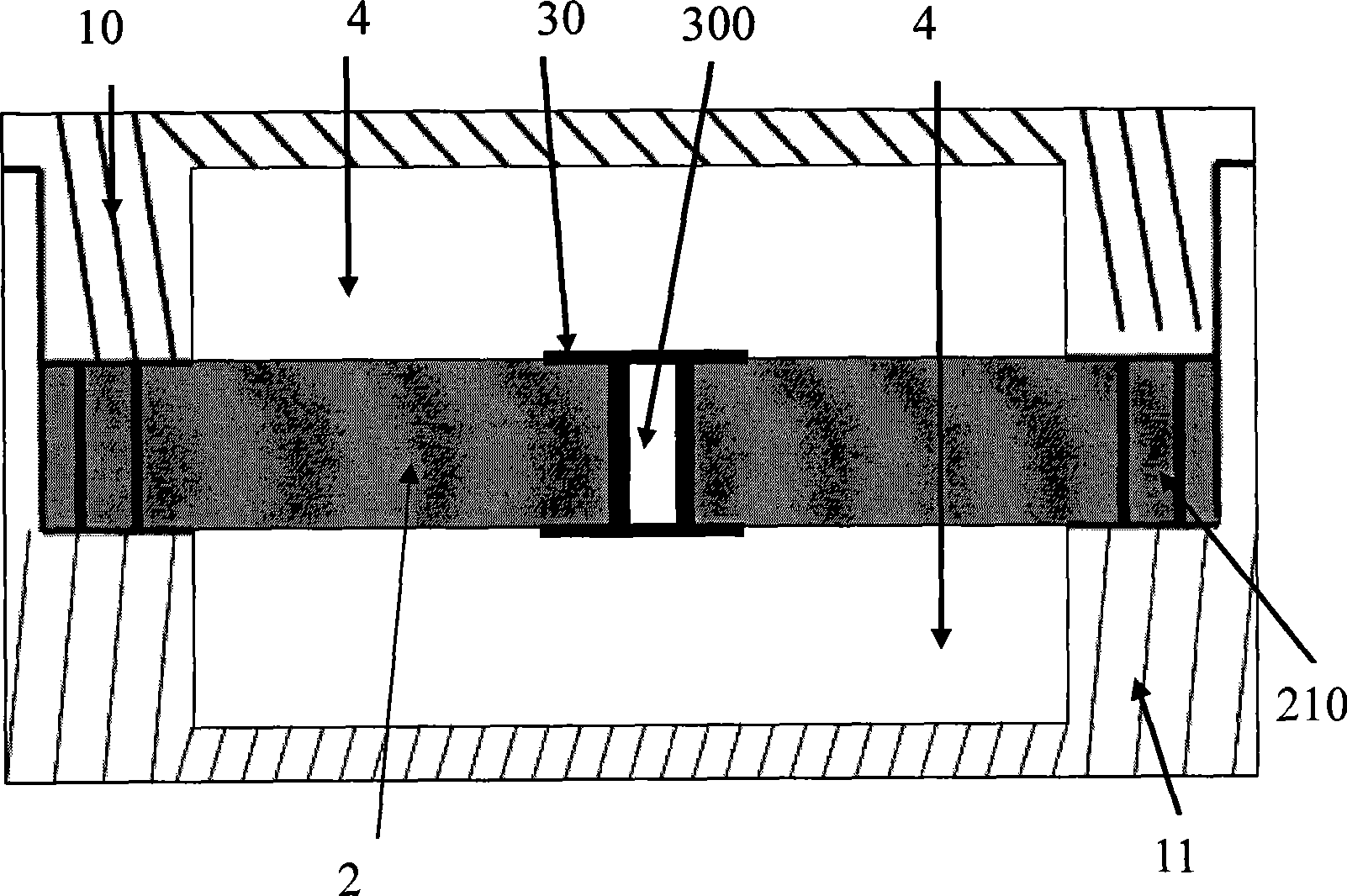

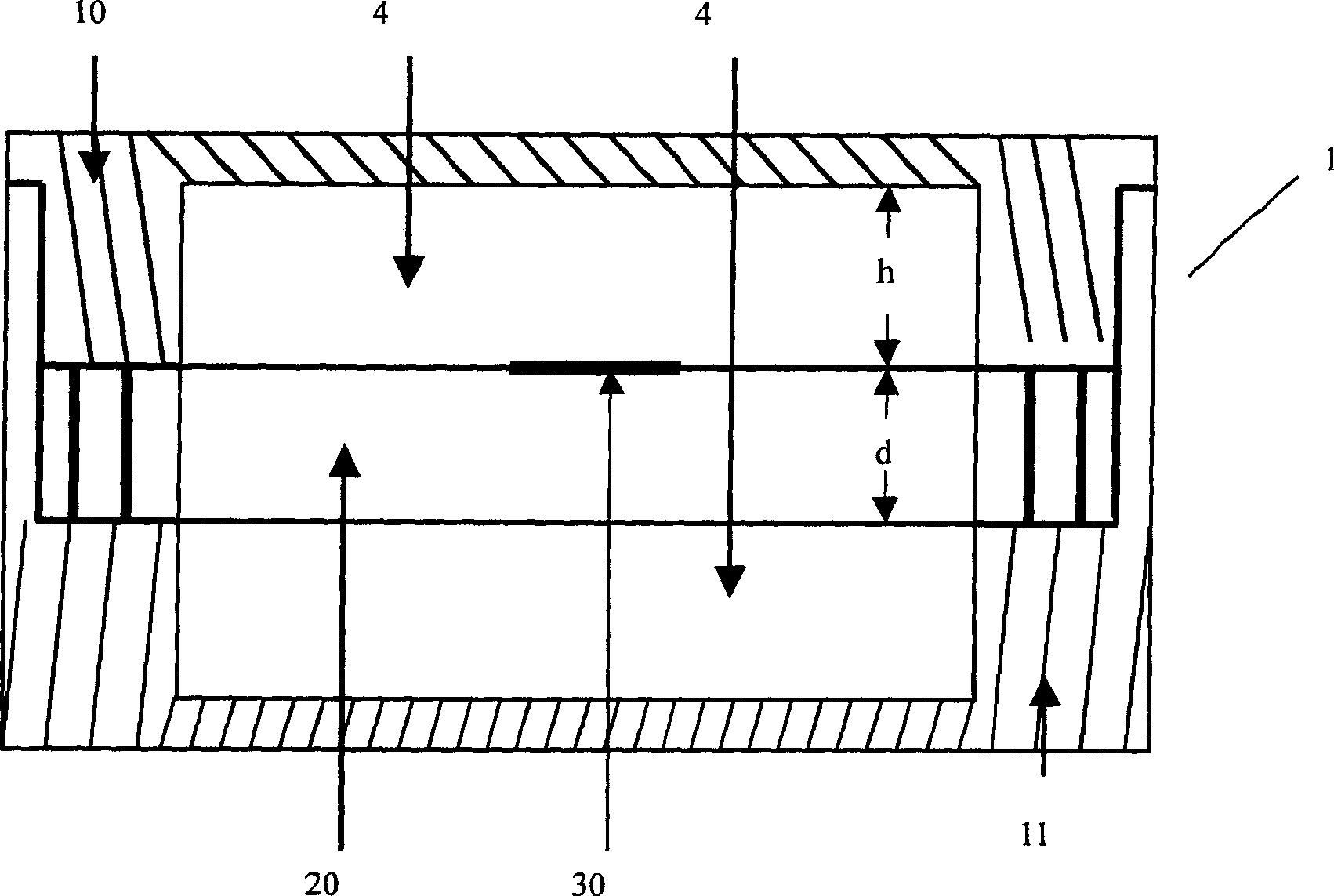

Microstrip linear filter, duplexer and radio-frequency device

InactiveCN101420056ASmall dielectric lossWaveguide type devicesAgricultural engineeringLinear filter

The invention discloses a microstrip line filter, which comprises a chamber which is provided with a PCB plate; the top and bottom inner wall of the PCB plate and the chamber are provided with a certain air height; the two sides of the PCB plate are both provided with corresponding cross cascaded transmission line and the cross cascaded transmission line arranged on one side of the PCB plate is connected with the transmission line on the other side through a hole. The invention also discloses a corresponding duplexer and a radio-frequency device. The embodiment of the invention has the advantages of simple producing processing, high quality rate, low transmission loss, low cost, etc.

Owner:HUAWEI TECH CO LTD

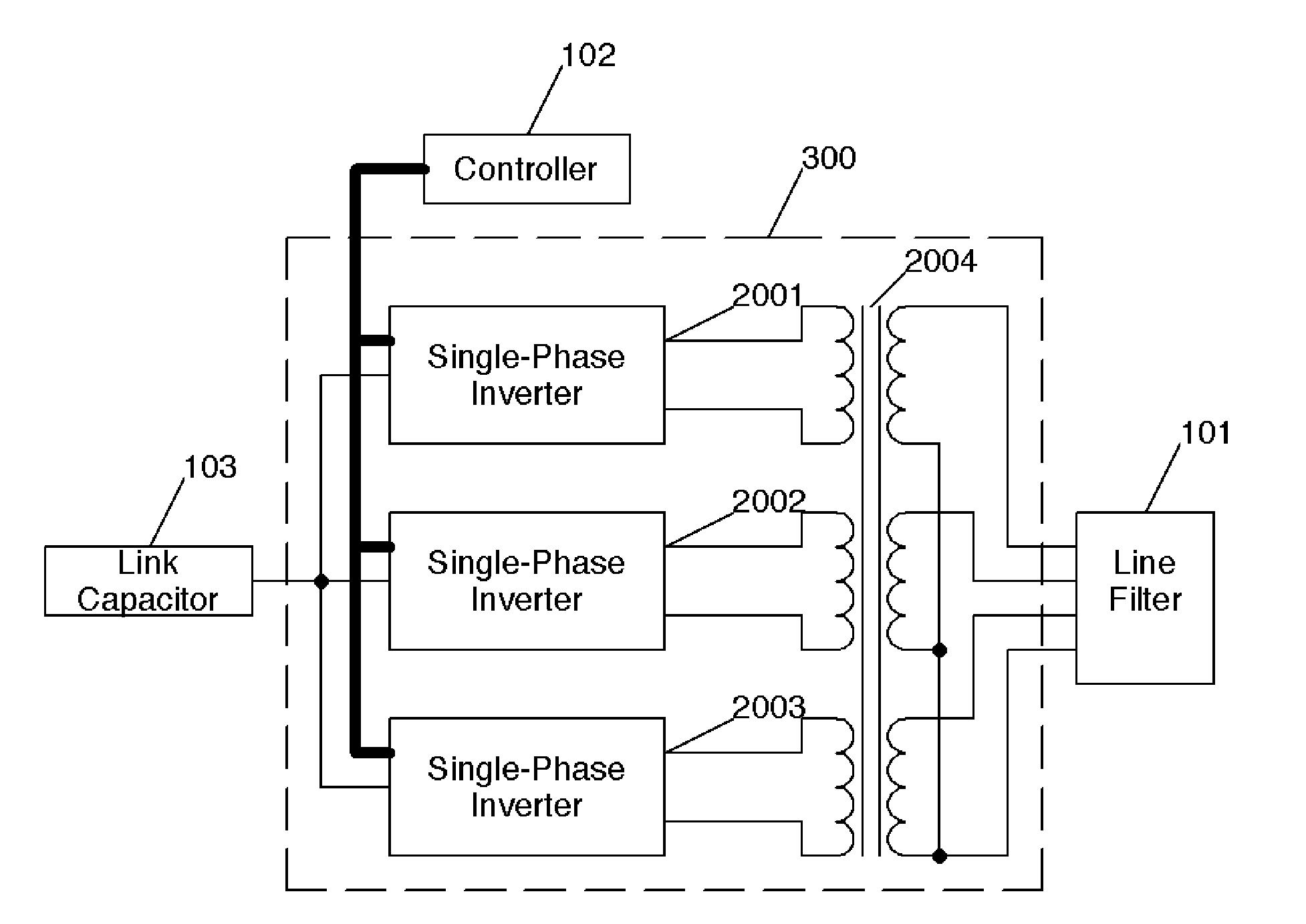

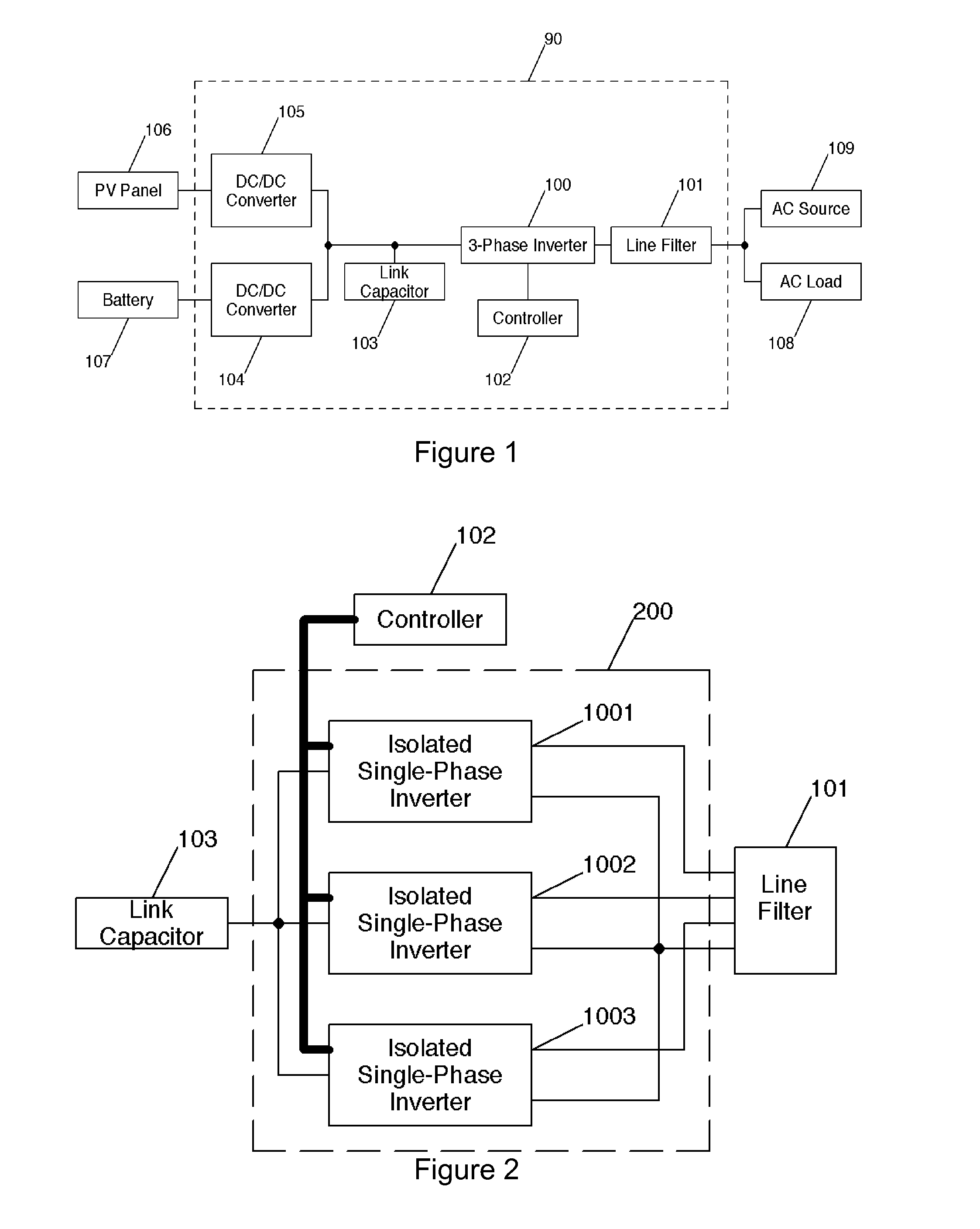

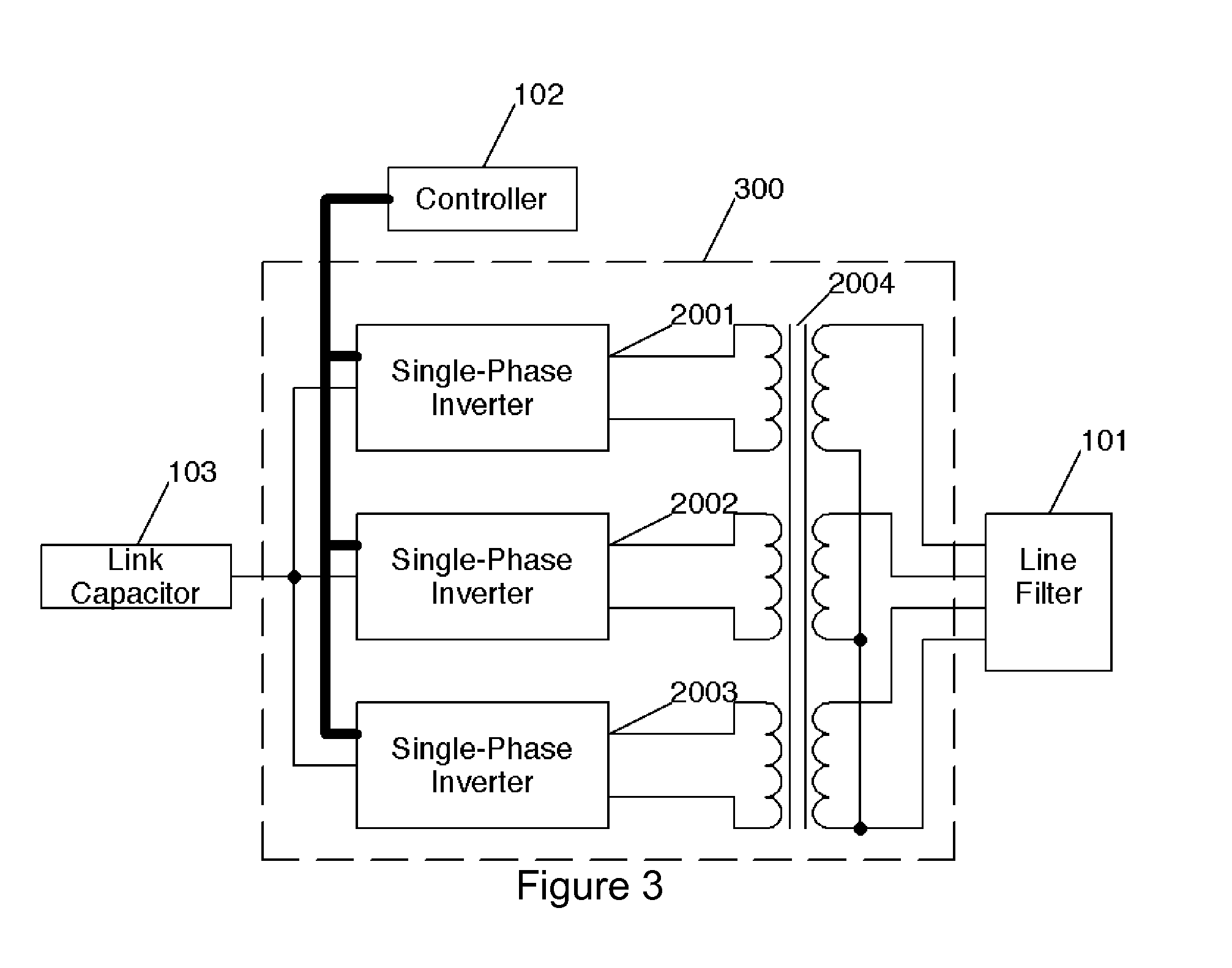

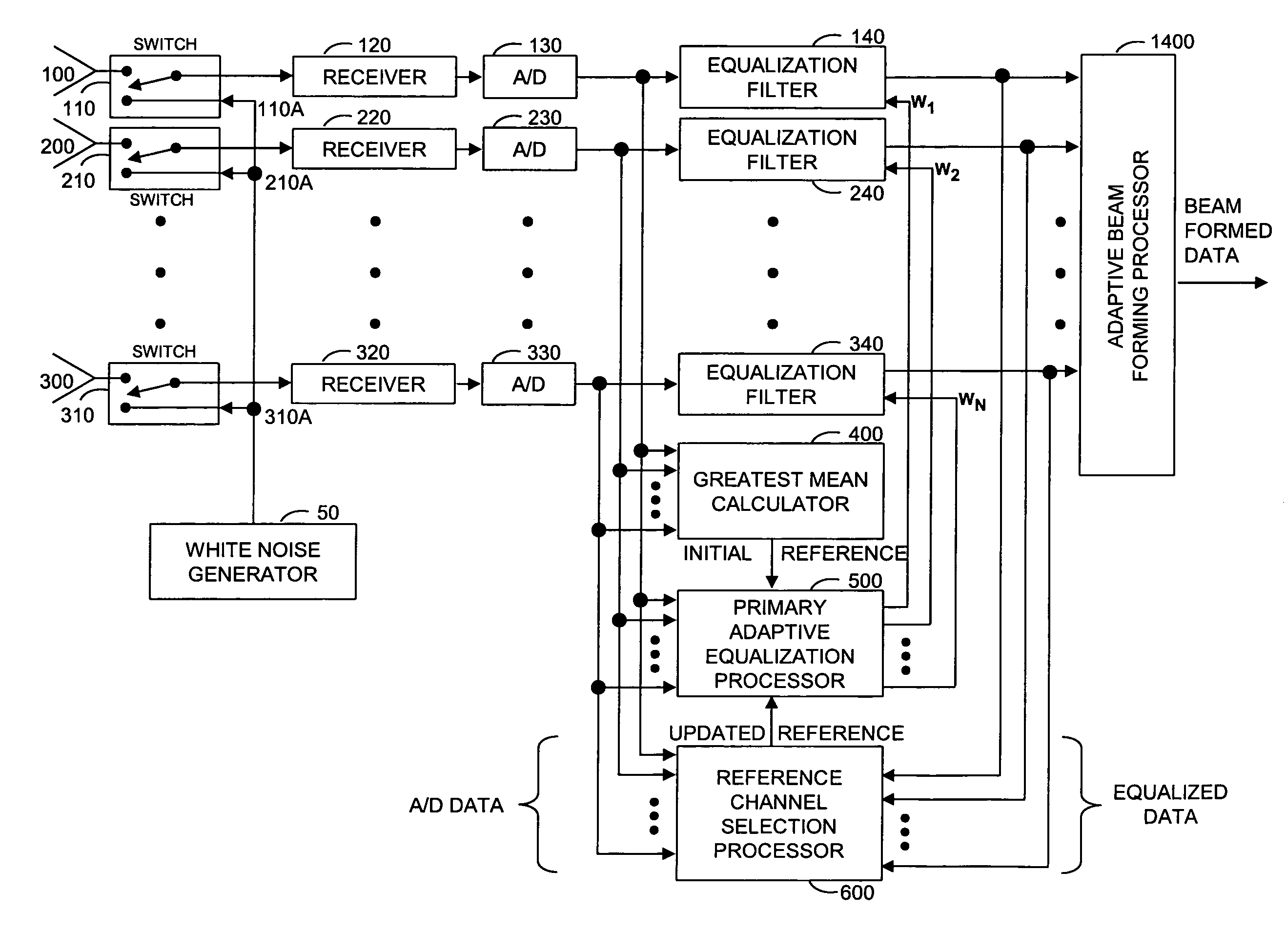

Poly-phase inverter with independent phase control

ActiveUS20150103574A1Batteries circuit arrangementsEfficient power electronics conversionPhase differenceEngineering

A converter system and inverter system are disclosed with individual real and reactive power control for each phase of a poly-phase system. The converter system includes a controller, bidirectional single-phase inverters with AC sides coupled to an AC line filter and DC sides connected in parallel to a link capacitor coupled to DC / DC converters. Each inverter handles a separate AC phase. The controller controls the inverters and DC / DC converters so the current amplitude of each AC phase is independent, and the phase difference of each AC phase is independent. The inverters can be galvanically isolated between the DC and AC sides. The inverters can be non-isolated inverters having line and neutral connectors coupled to an isolated transformer winding, and the output windings of the transformer can be wired in a Wye configuration. The inverters can have local controllers.

Owner:IPS SYST INC

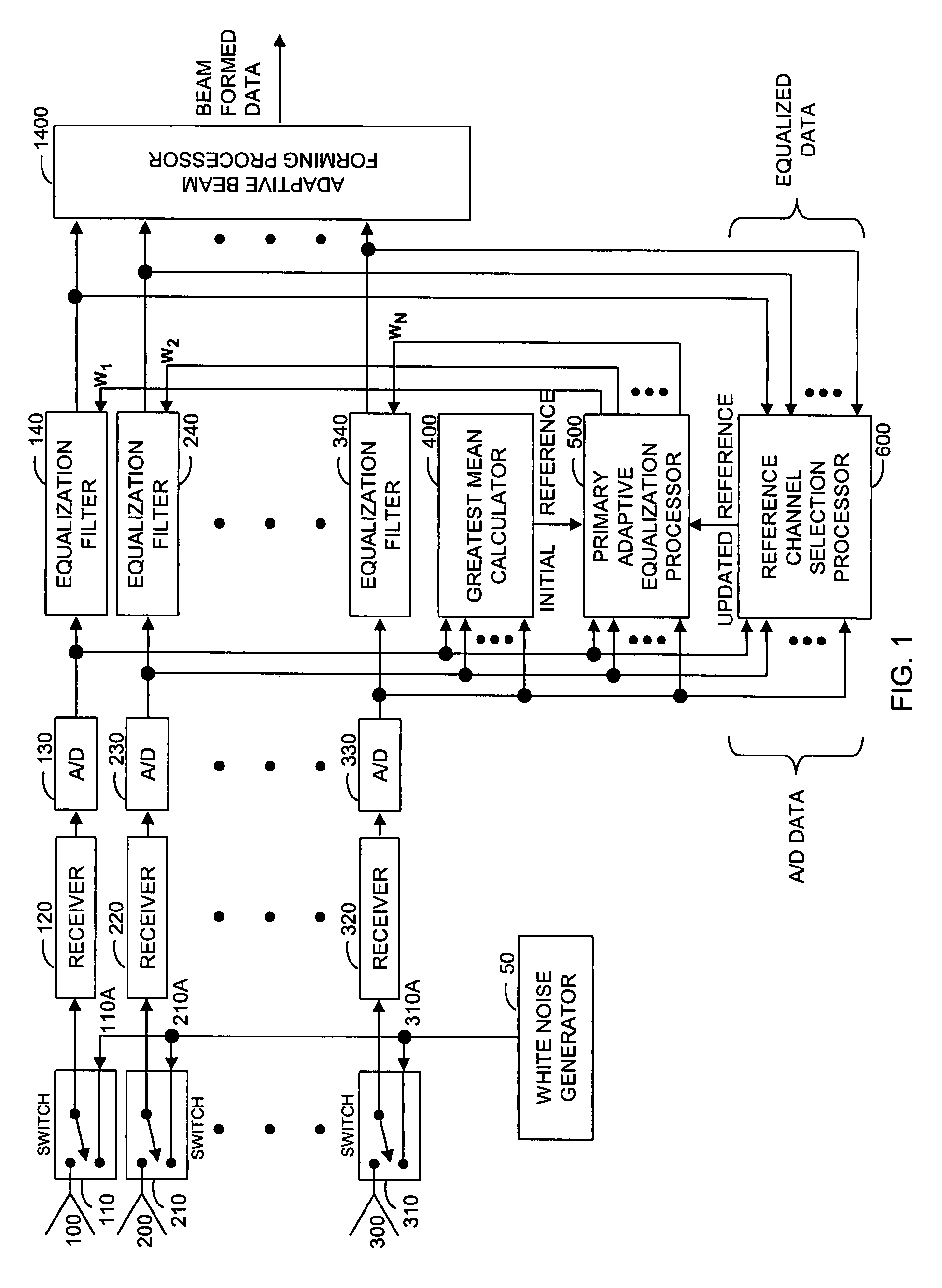

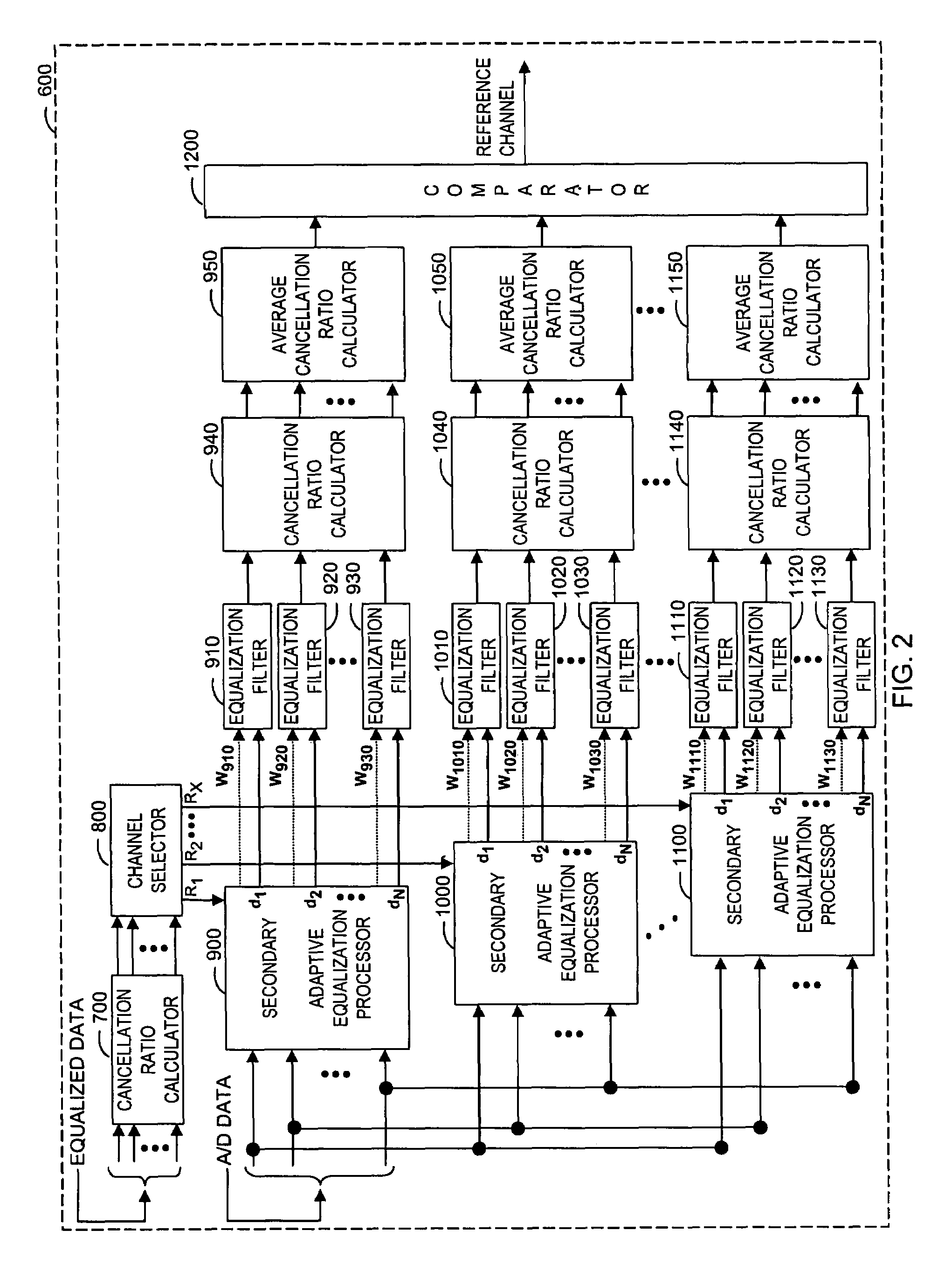

Apparatus and method for multi-channel equalization

InactiveUS7330507B2Improving channel equalizationQuick selectionMultiple-port networksSpatial transmit diversityCommunications systemEngineering

A communication system with a multi-channel array antenna utilizes a receiver matching process that adapts the pass band frequency response of each channel to a selected reference channel. This process is implemented digitally by inserting a tapped delay line filter in each channel, selecting one of the channels as a reference, and adapting the others to match the reference in both phase and amplitude. The process is performed for each system calibration cycle, which occurs just before receive data is captured and processed. The improvements include an apparatus and an algorithm that select a reference channel in the adaptive process during each system calibration cycle, producing optimal, or near optimal, channel matching.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Suspended mictrostrip filter and duplexer and method for designing and debugging filter

InactiveCN1838476AHigh precisionImprove manufacturing yieldDiversity/multi-antenna systemsRadio relay systemsEngineeringLine filter

This invention discloses a suspending strip line filter and duplexer and filter's design and adjusting method. The filter includes a cavity formed by metal hull, the inner of the cavity has a PCB double-faced board which fixed at the side wall of the metal hull, between the up and down inner wall there has a certain air height; one side of PCB double-faced board etches cross nodel line transmission line with destined type. The frequency deviation index of the filter and duplexer is decided by the PCB double-faced board etches cross nodel line transmission line graph's processing precision, so it is easy to control and it has high disposal quality.

Owner:HUAWEI TECH CO LTD

Comb-line filter

A comb-line filter and method of manufacturing the comb-line filter. The comb-line filter comprising a housing and at least one resonator. The housing comprises a first portion and a second portion, wherein the first portion is made of a dielectric material and the second portion is made of a conductive material. The first portion and the second portion are adapted for being attached together so as to define an interior chamber for conducting signals. The at least one resonator is attached to the second portion, and is adapted for extending within the interior chamber when the first portion and the second portion are attached. Comb-line filters in accordance with the present invention provide relatively low-cost and light-weight composite material comb-line filters.

Owner:MITEC TELECOM

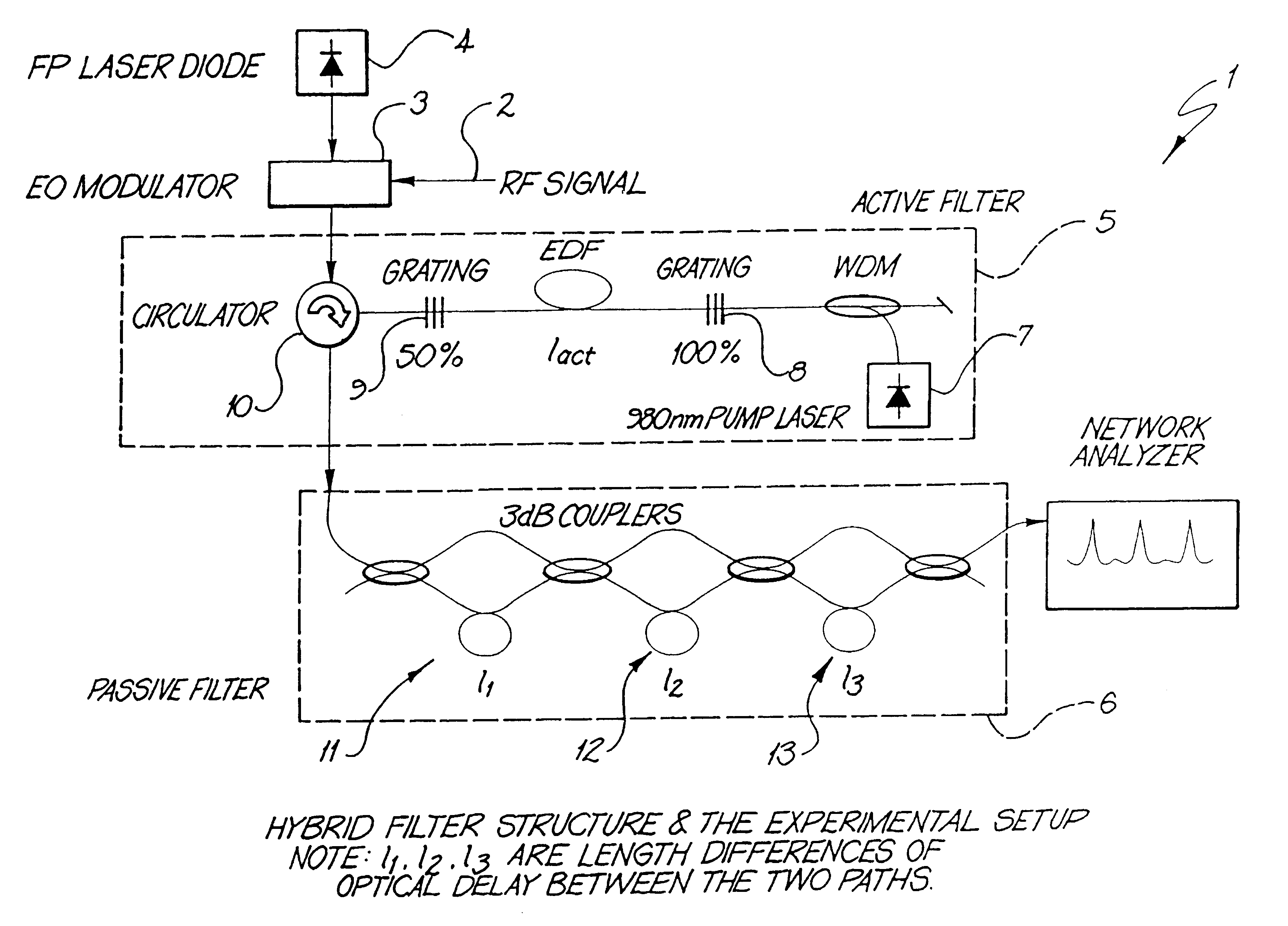

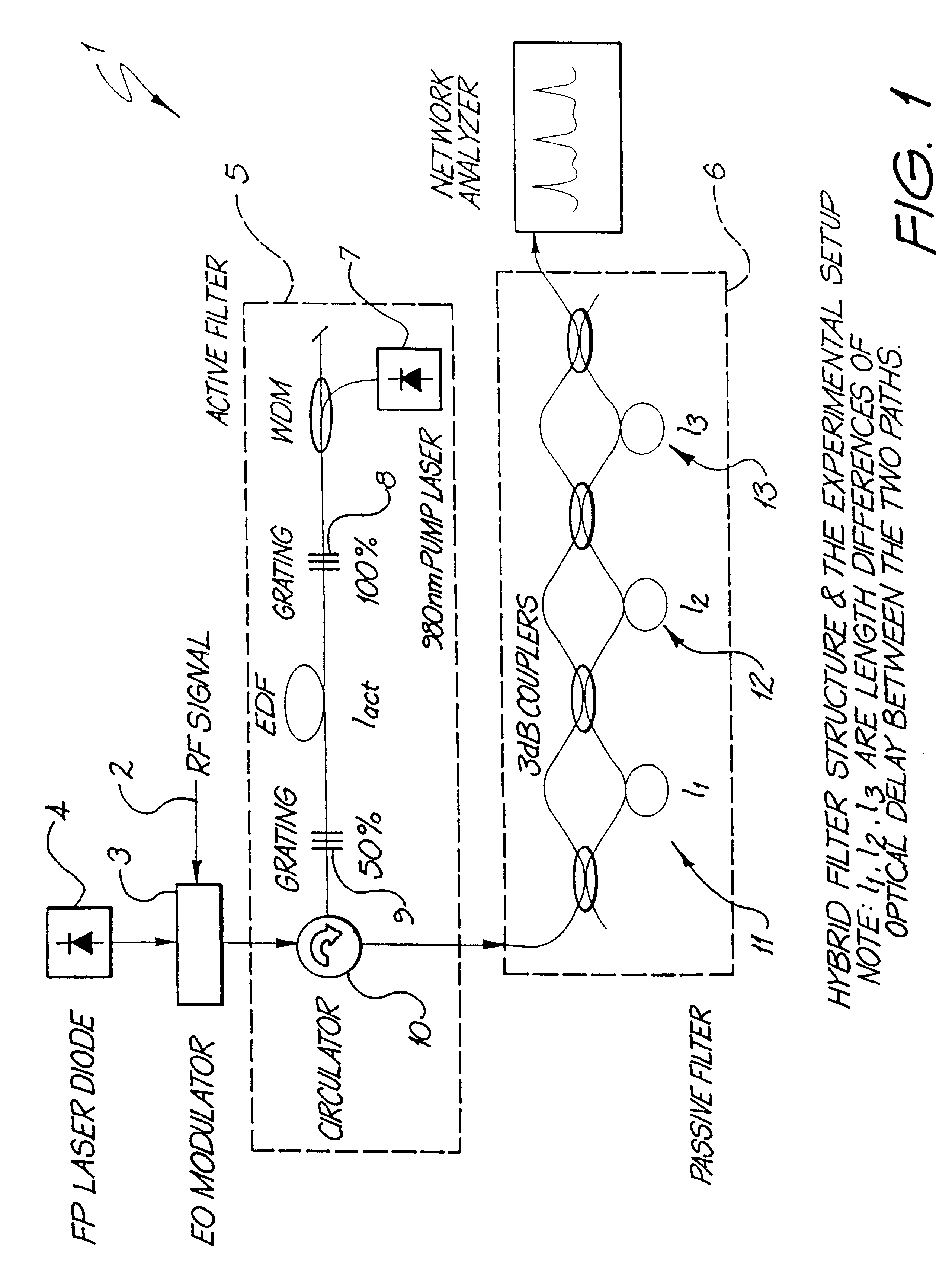

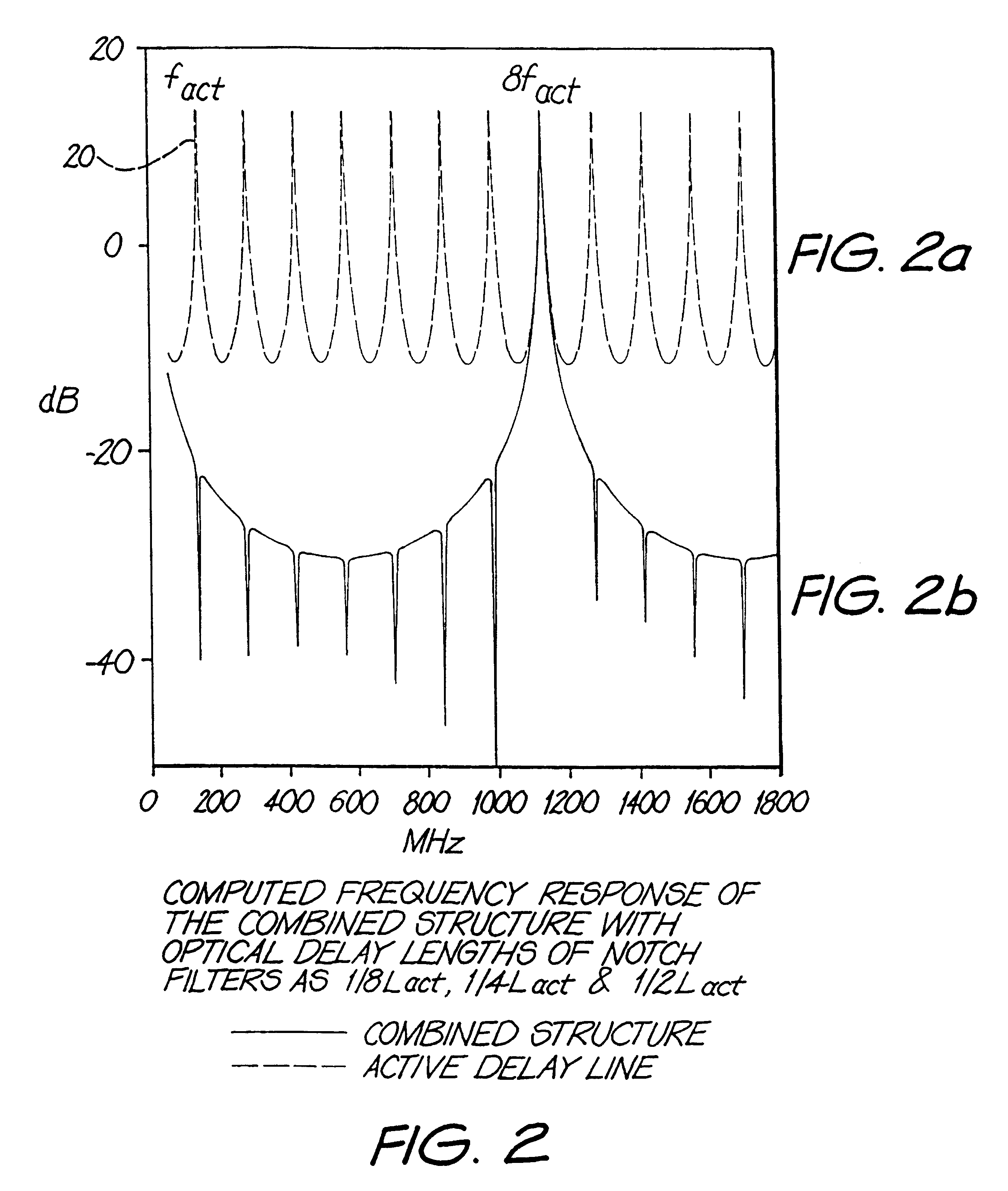

High Q optical microwave processor using hybrid delay-line filters

A hybrid active-passive signal bandpass filter comprising an active filter arranged in use to operate at a fundamental frequency which is a sub-multiple of a desired filter frequency of the bandpass filter, and a passive filter arranged in use to eliminate any pass bands in the frequency response of the active filter other than at the desired filter frequency for providing the pass band signal of the bandpass filter.

Owner:THE UNIV OF SYDNEY

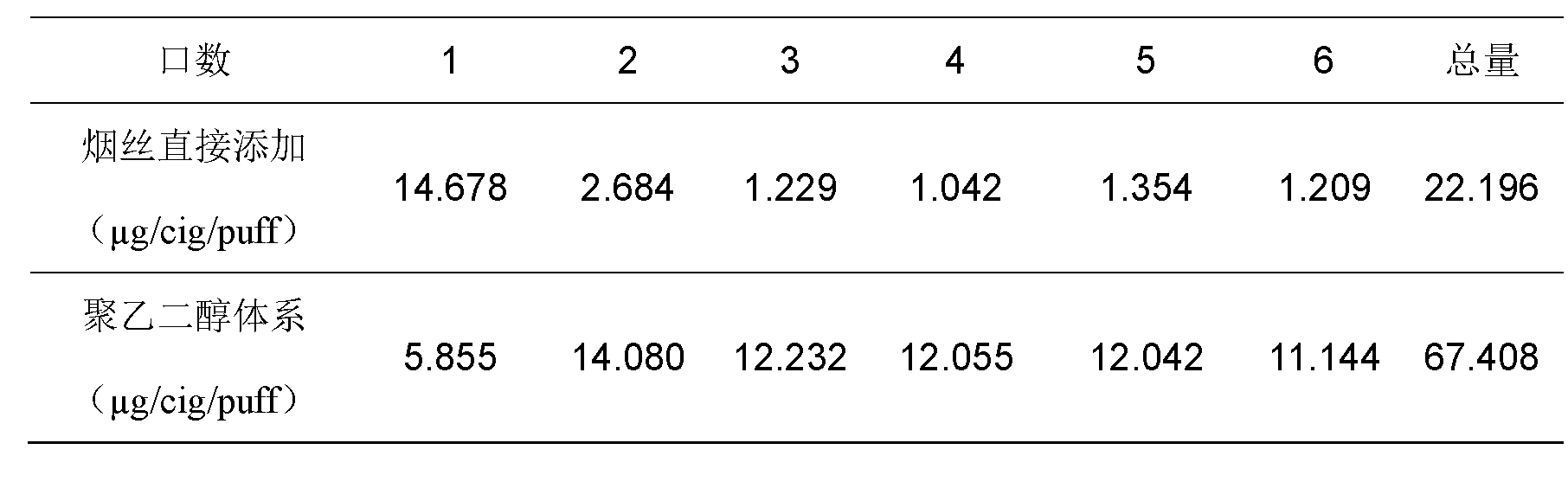

Linear polyethylene glycol fragrance slow-release cigarette filter rod and production method thereof

InactiveCN103271442AReduce the amount of adsorptionEvenly dispersedTobacco preparationTobacco smoke filtersBenzeneFlavor

The invention discloses a linear polyethylene glycol fragrance slow-release cigarette filter rod and a production method thereof. A polyethylene glycol flavored line is arranged in the linear polyethylene glycol fragrance slow-release cigarette filter rod along the axis direction of the linear polyethylene glycol fragrance slow-release cigarette filter rod and phenylethyl alcohol flavor components are embedded in the linear polyethylene glycol fragrance slow-release cigarette filter rod with the polyethylene glycol flavored line as a carrier. The production method includes the following steps that polyethylene glycol is heated to 60 to 80 DEG C to be completely melted; the phenylethyl alcohol flavor components with the proportion of 5 weight percentage are added and uniformly stirred; liquid polyethylene glycol containing phenylethyl alcohol passes through a pore with a 0.5 mm pore diameter to form into trickles; the trickles directly flow on the surface of filter tows with the proportion of 40 mg per branch after opening of the filter tows; and the liquid polyethylene glycol can be cooled and solidified in a filter to form into the flavored line after the liquid polyethylene glycol passes through an opium pipe and the filter is solidification formed. According to the linear polyethylene glycol fragrance slow-release cigarette filter rod and the production method thereof, the problems that the release of the flavor components of favored line filters is non-uniform, the adsorbed quantity of the flavor components is small, the fragrance depositing time is short, the transfer efficiency is low and the like can be greatly solved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

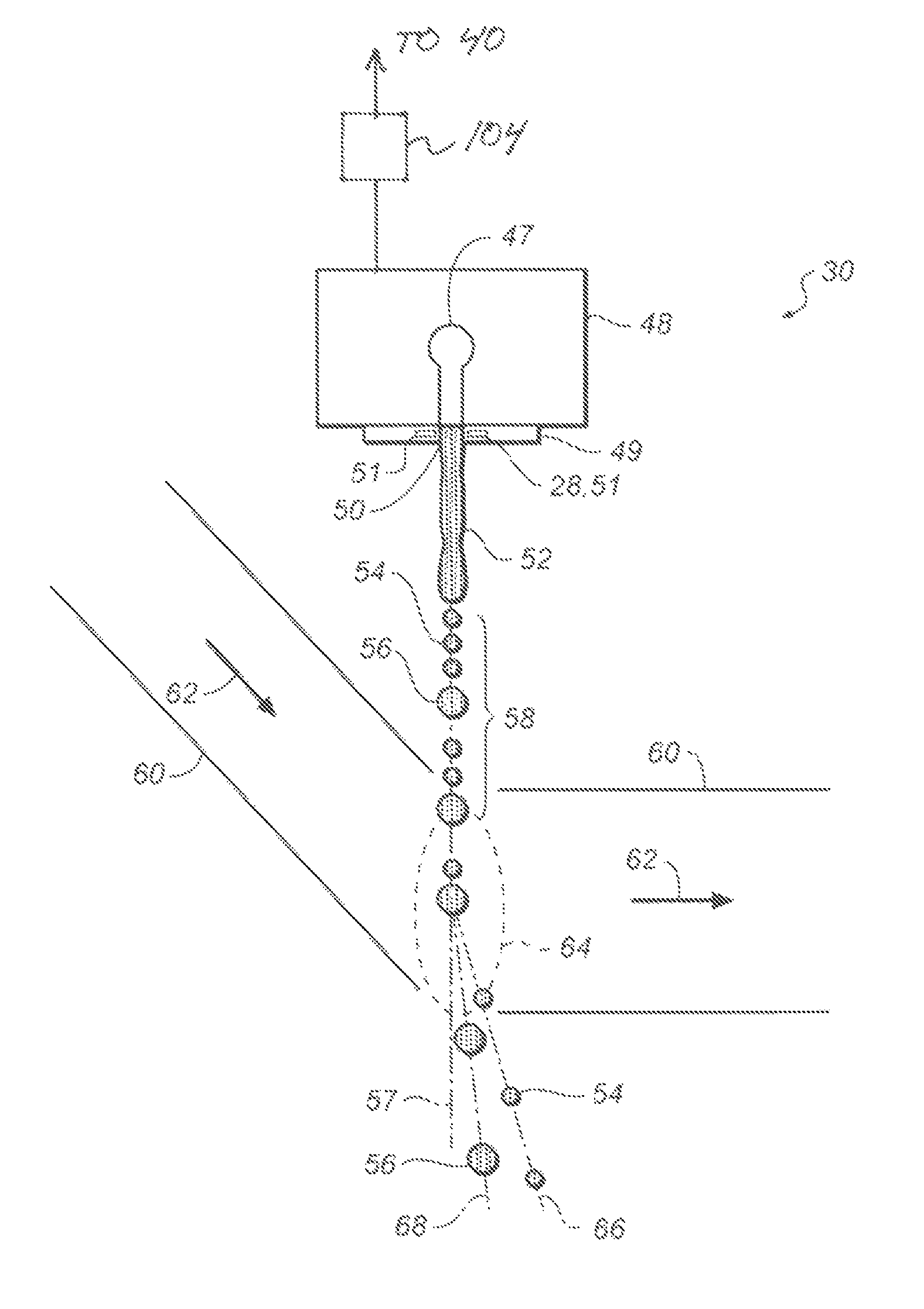

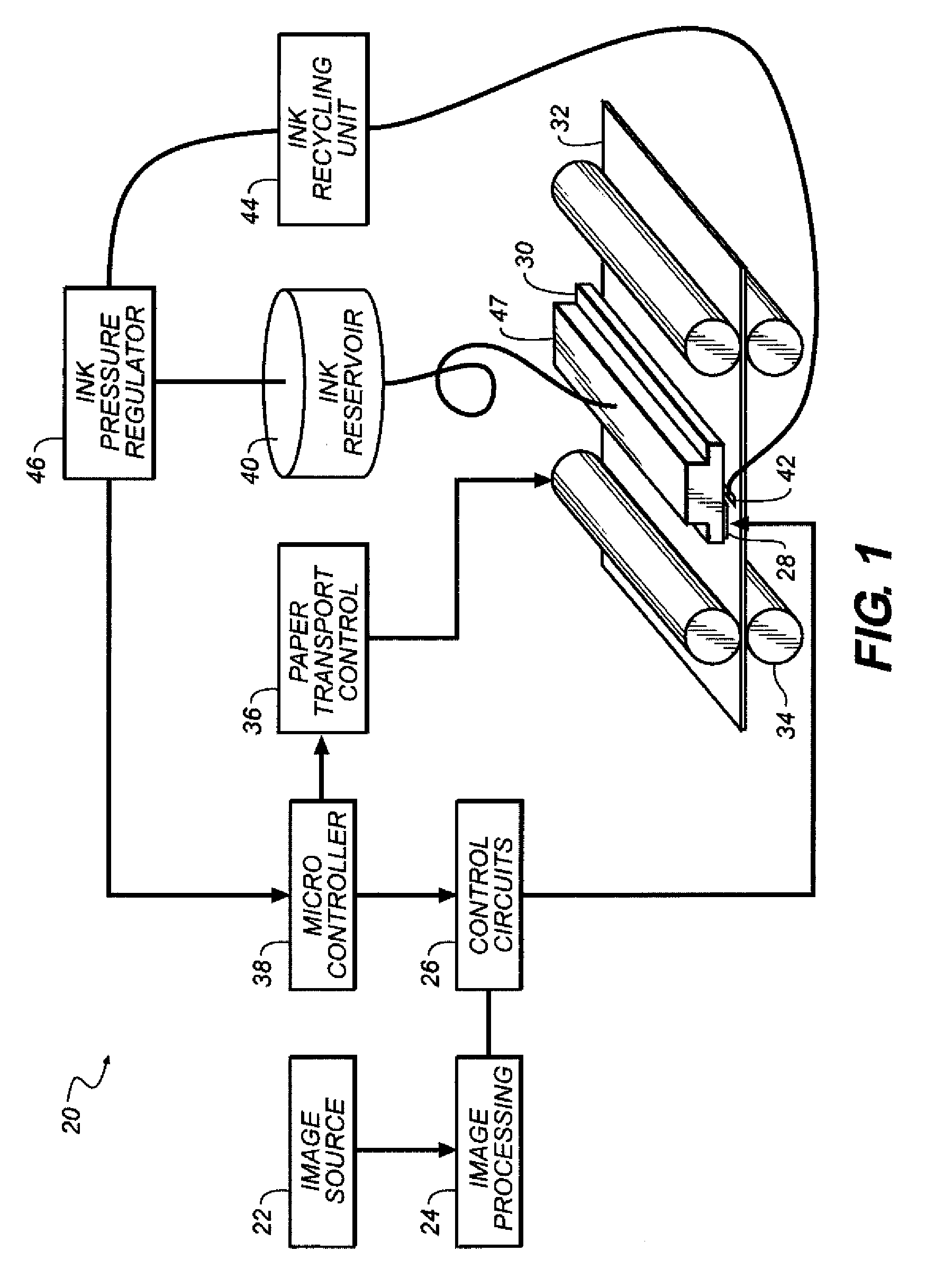

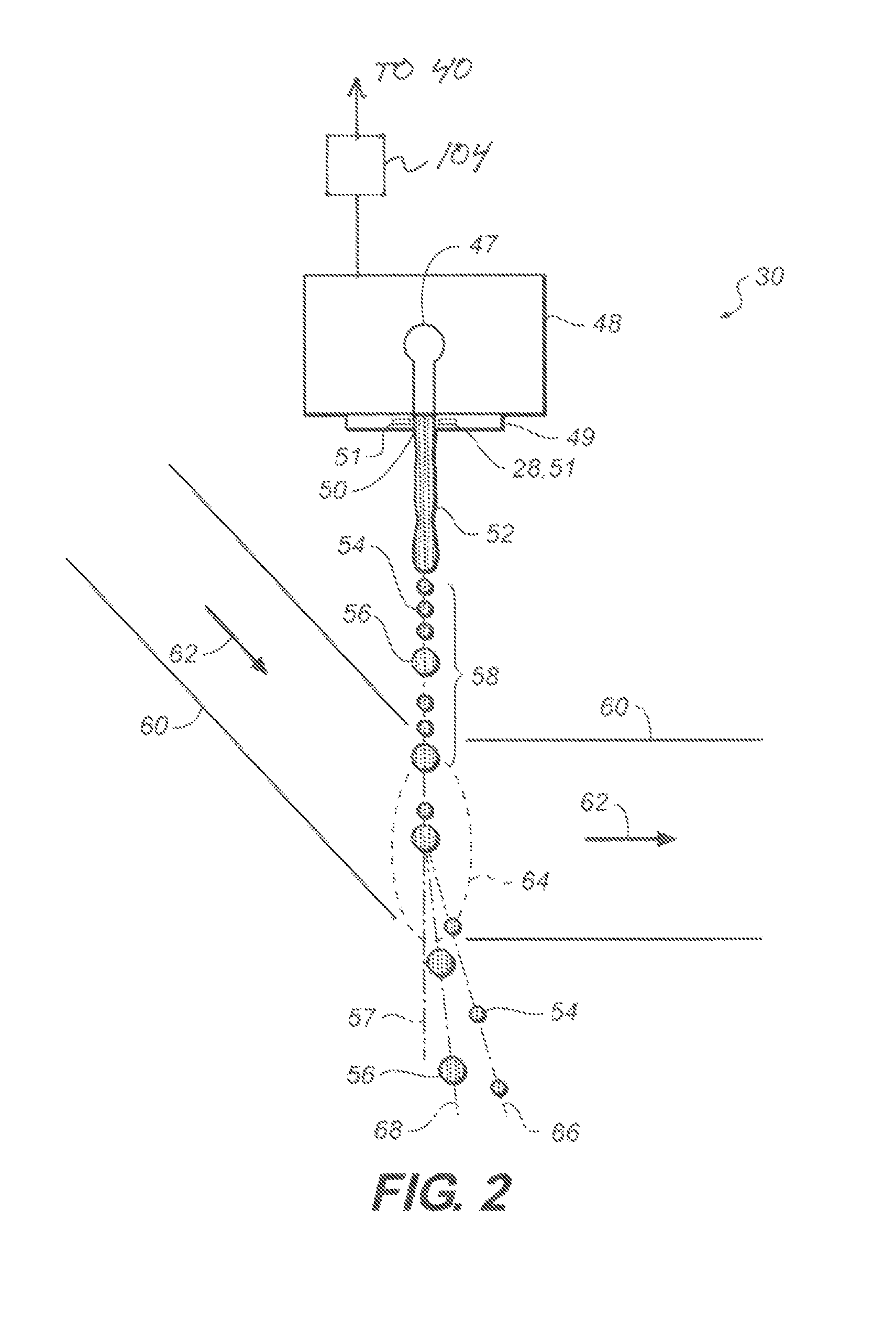

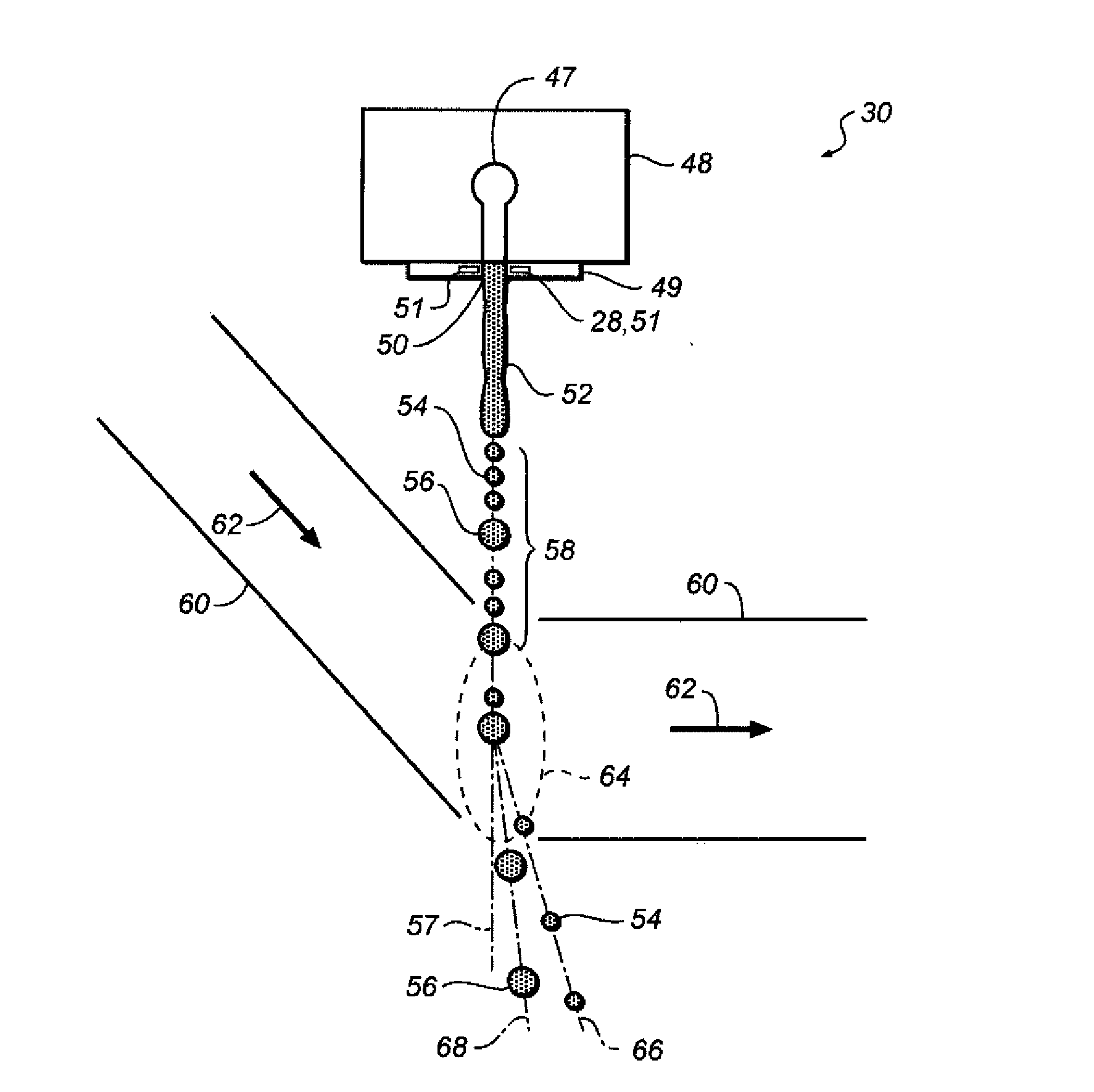

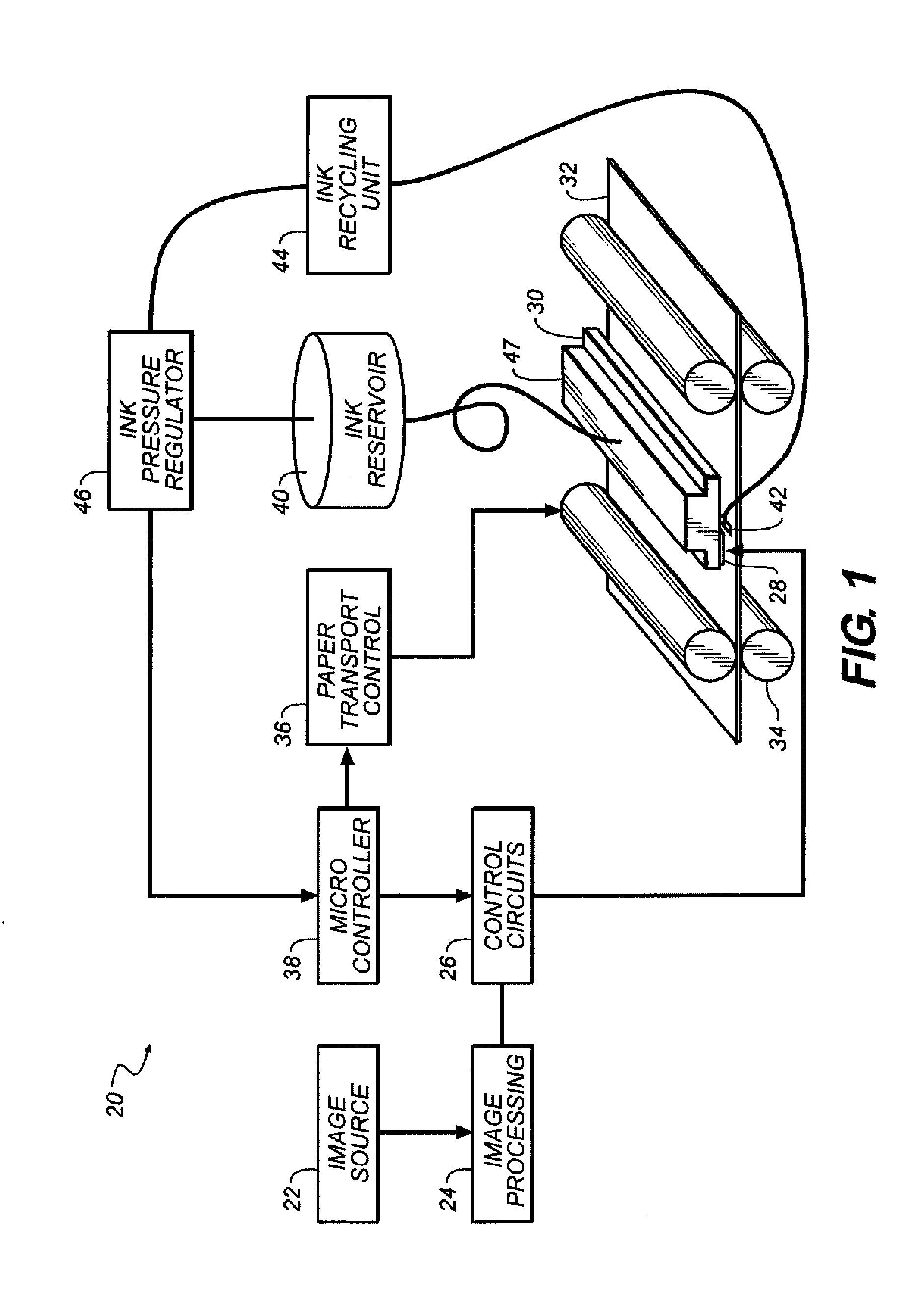

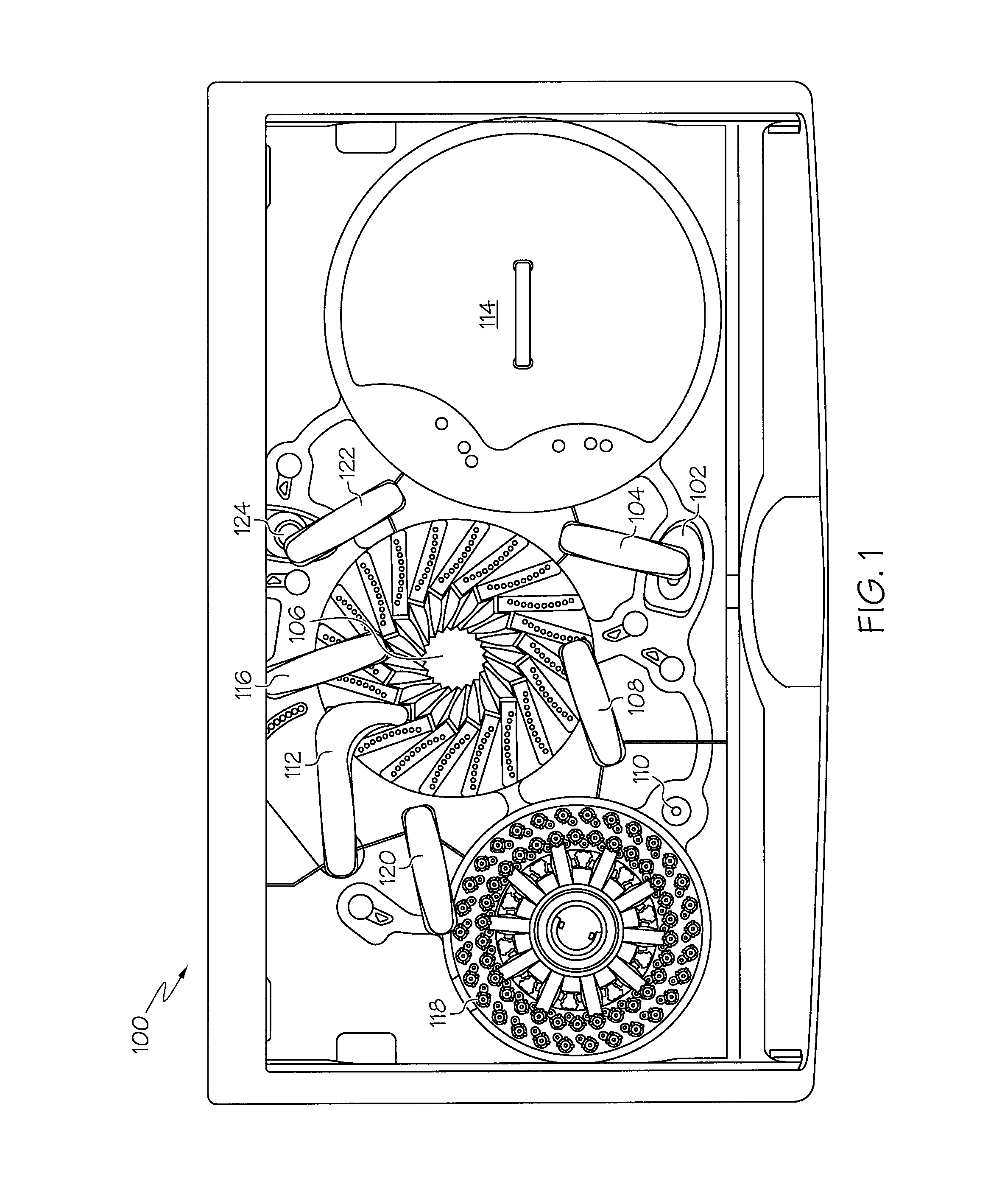

Continuous inkjet printing method

A method of printing an image with a continuous inkjet printer system employing bimodal drop size generation with pigmented inkjet ink compositions comprising a polymer additive, wherein the liquid ink is an aqueous inkjet ink comprises dispersed pigment colorant particles having a mean particle size of less than 150 nanometers and at least about 0.1 wt % of polymer additive distinct from any polymer dispersant used to disperse the pigment particles, and recirculating liquid ink supplied to the nozzle if the printer system from a liquid ink source is in-line filtered with a filter selected to be effective at retaining particles having particle sizes equal to and greater than 0.6 micrometers from the liquid ink and to pass the dispersed pigment particles. The invention enables high quality drop control in a continuous inkjet printing system.

Owner:EASTMAN KODAK CO

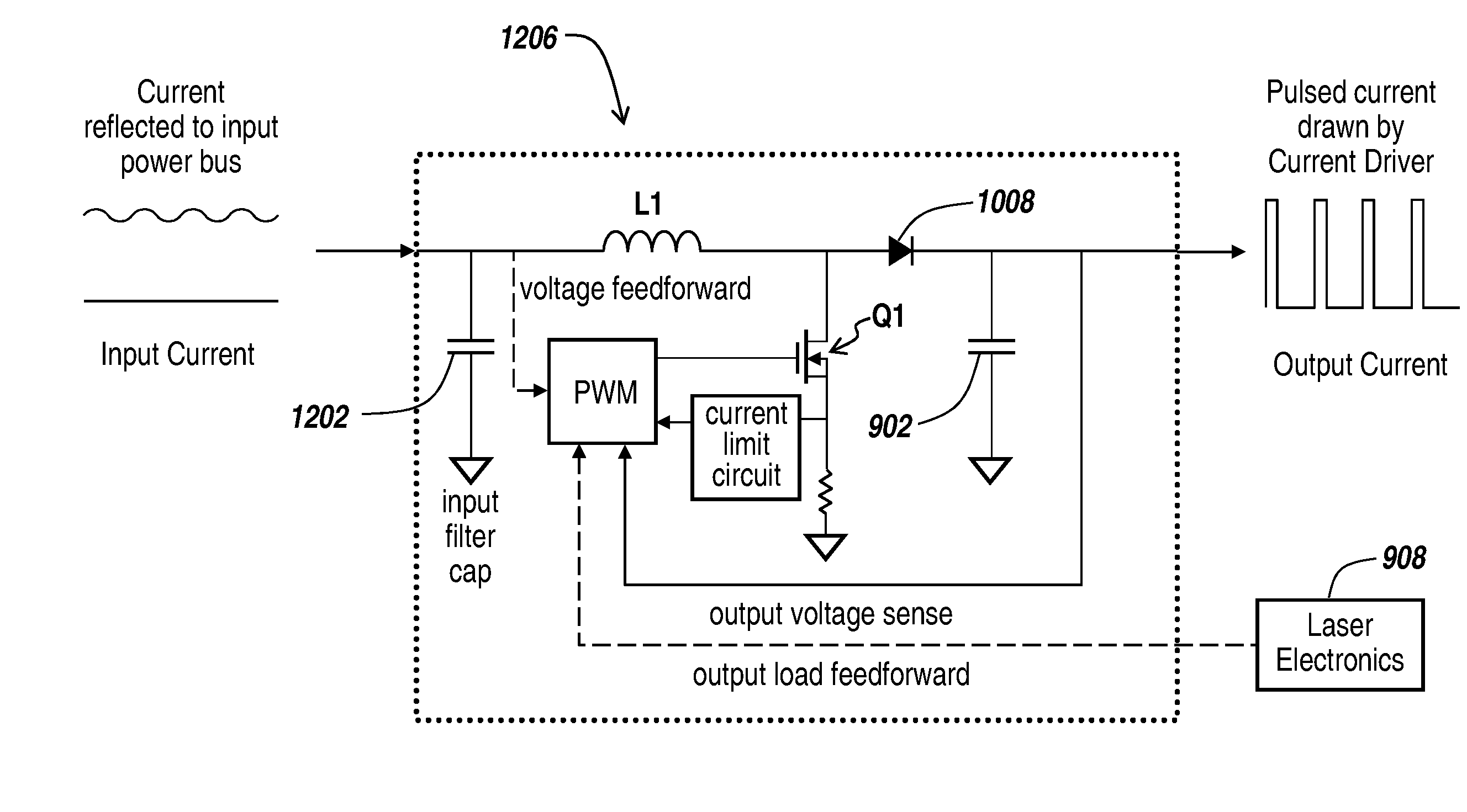

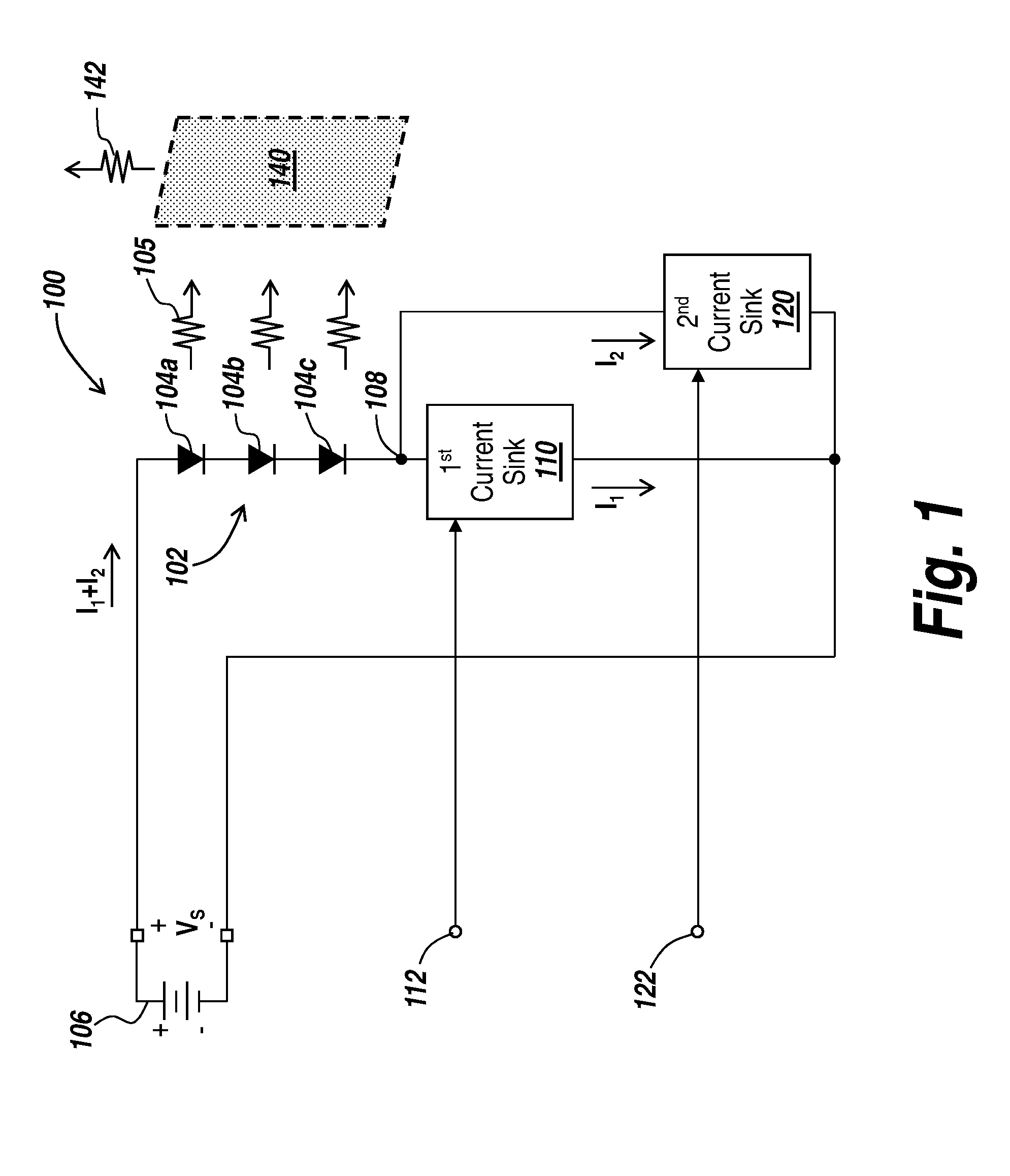

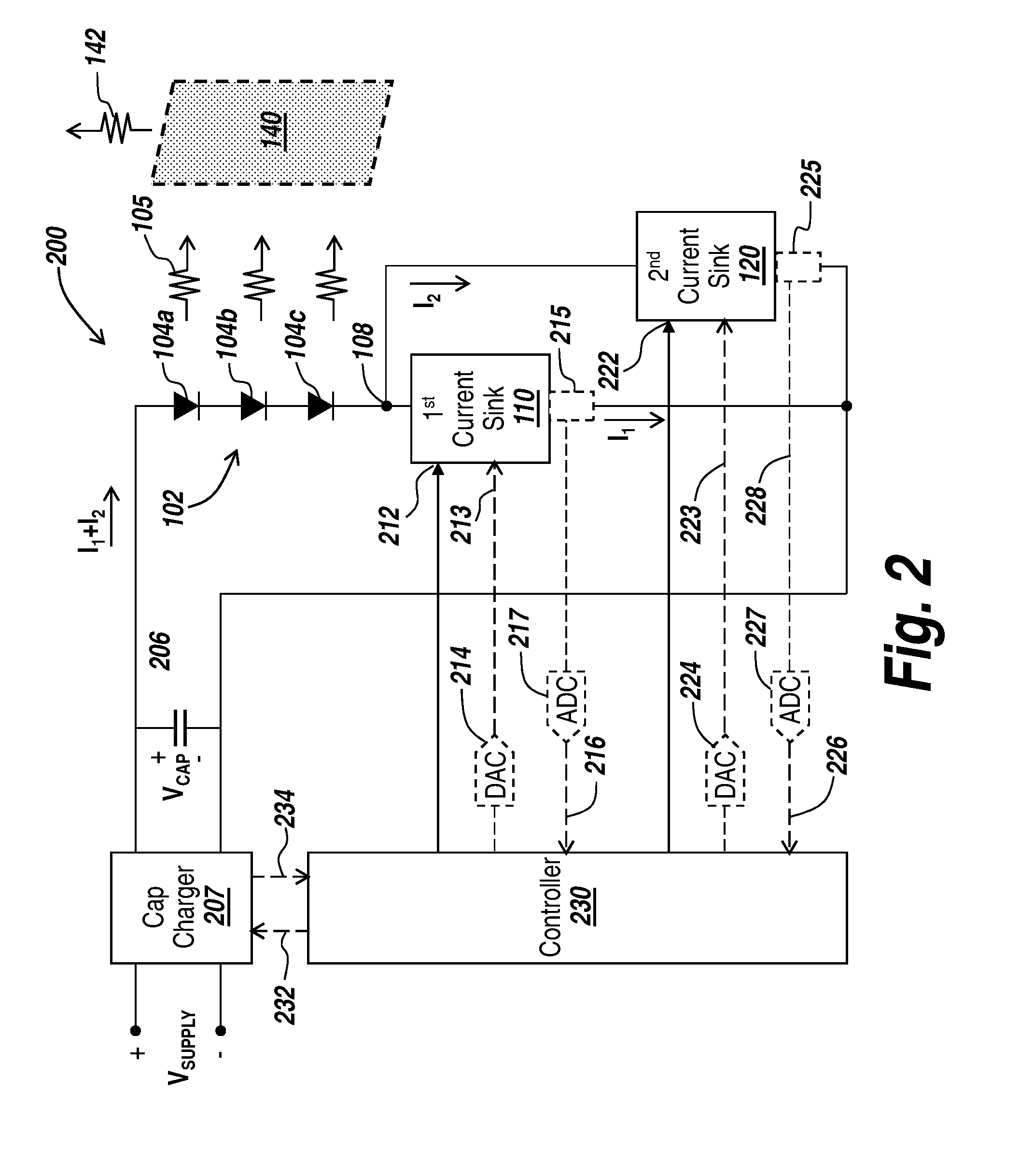

Diode driver for battery operated laser systems

A diode driver system includes an input power source and an active line filter receiving input power from the input power source and providing a filter output power form. A current driver receives an input power form and generates a driving output signal for driving at least one diode. A capacitive energy storage device is coupled between the active line filter and the current driver, the capacitive energy storage device receiving the filter output power form from the active line filter and providing the input power form to the current driver.

Owner:RAYTHEON CO

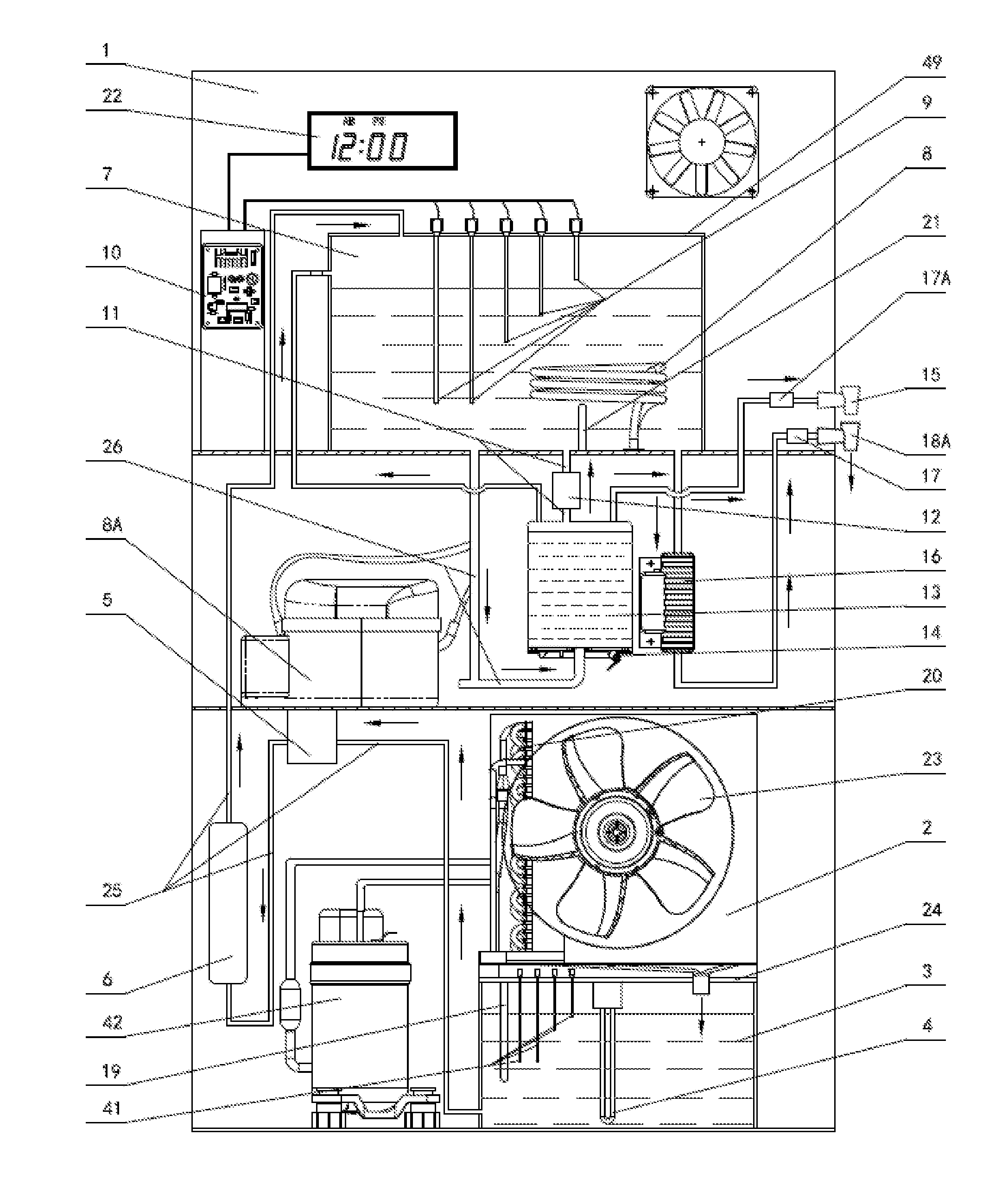

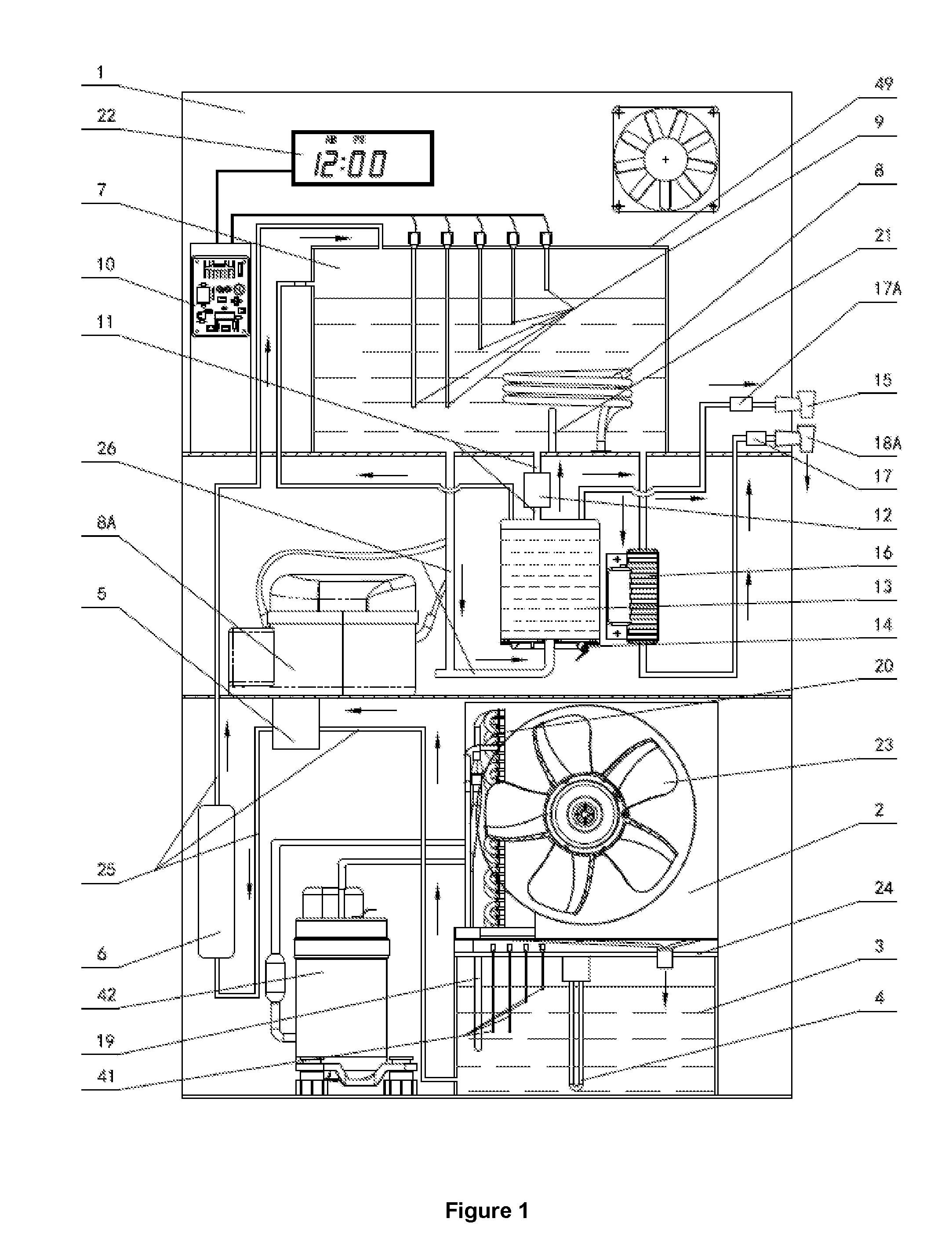

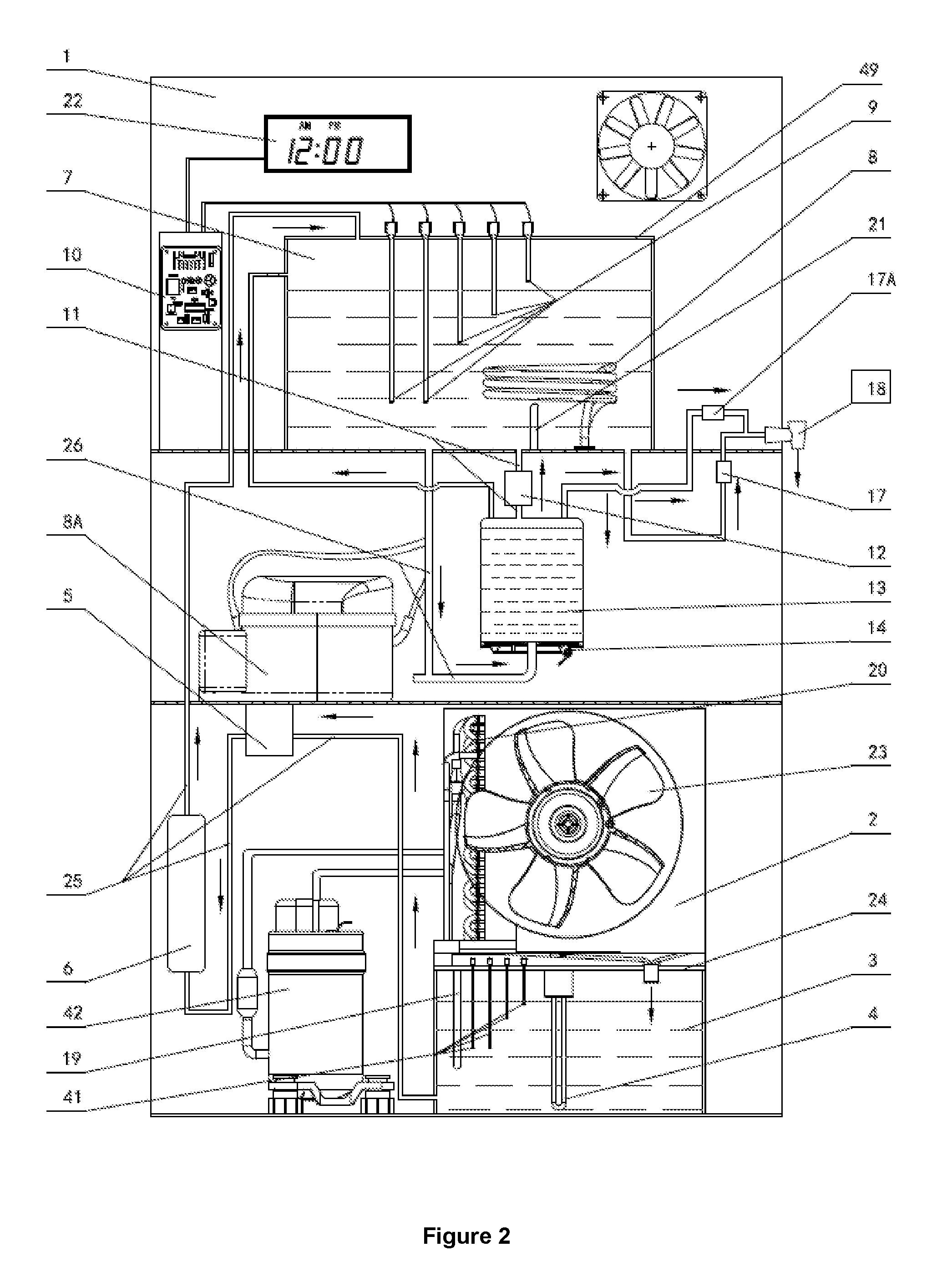

Devices and methods for collecting, sanitizing, and dispensing condensed forms of atmospheric water

InactiveUS20160244951A1General water supply conservationSpecific water treatment objectivesLine filterWaste management

Devices and methods for condensing, cooling, heating, sanitizing, and dispensing drinkable water that is collected from atmospheric water vapor are disclosed. The devices generally include a dehumidifier that is configured to harvest and condense atmospheric water vapor within the device; and a collection tank that is configured to receive and collect condensed atmospheric water vapor within the dehumidifier. The devices further include a first means for heating water within the collection tank to a temperature that is effective to kill bacteria; and a first tube that fluidly connects the collection tank with a cold water tank. The first tube includes one or more in-line filters through which water must travel to reach the cold water tank. The devices further include a second means for heating water within the cold water tank to a temperature that is effective to kill bacteria, and a second tube that fluidly connects the cold water tank with a hot water tank.

Owner:YUI GEORGE

Continuous inkjet printing method

InactiveUS20130278689A1Excellent printing durabilityEasy to controlInksPrintingMicrometerLine filter

A method of printing an image with a continuous inkjet printer system employing bimodal drop size generation with pigmented inkjet ink compositions comprising a polymer additive, wherein the liquid ink is an aqueous inkjet ink comprises dispersed pigment colorant particles having a mean particle size of less than 150 nanometers and at least about 0.1 wt % of polymer additive distinct from any polymer dispersant used to disperse the pigment particles, and recirculating liquid ink supplied to the nozzle if the printer system from a liquid ink source is in-line filtered with a filter selected to be effective at retaining particles having particle sizes equal to and greater than 0.6 micrometers from the liquid ink and to pass the dispersed pigment particles. The invention enables high quality drop control in a continuous inkjet printing system.

Owner:EASTMAN KODAK CO

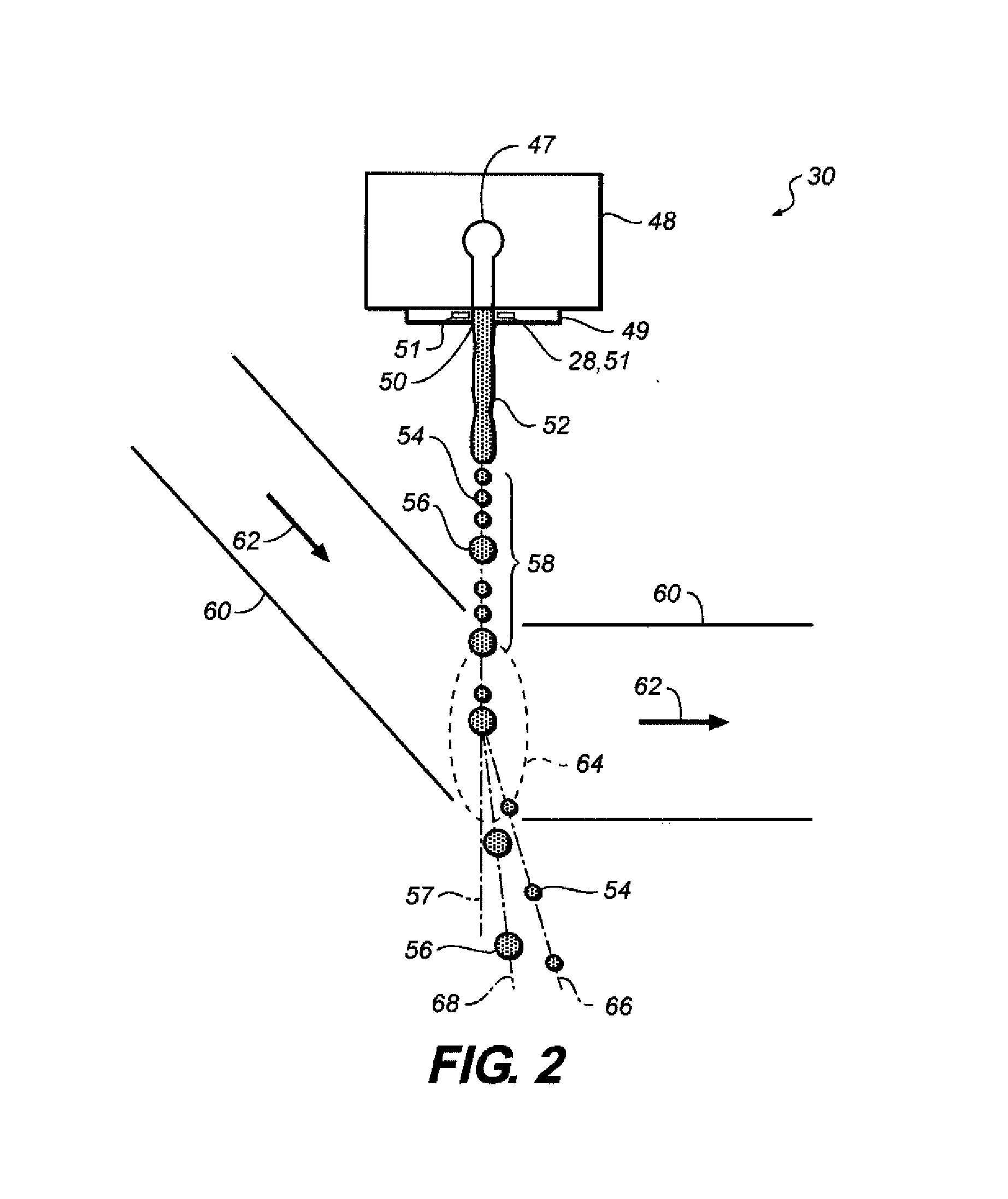

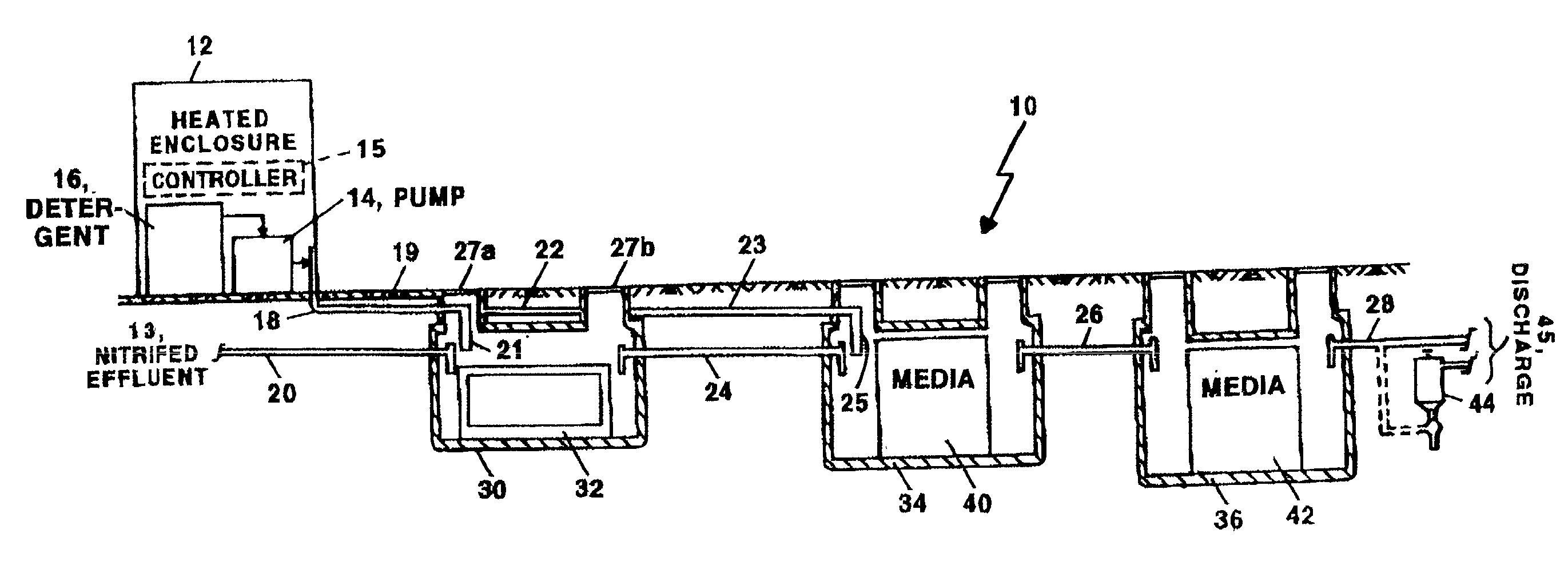

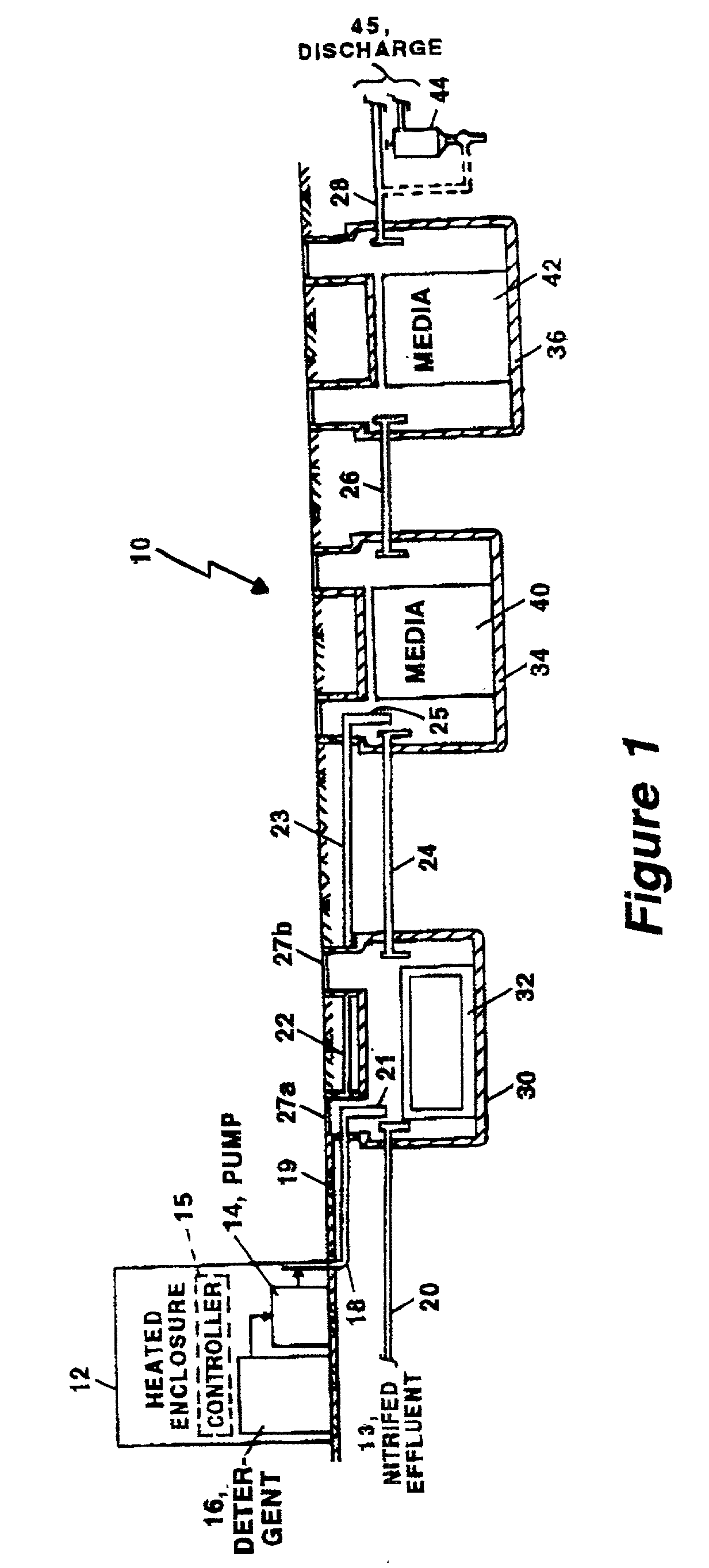

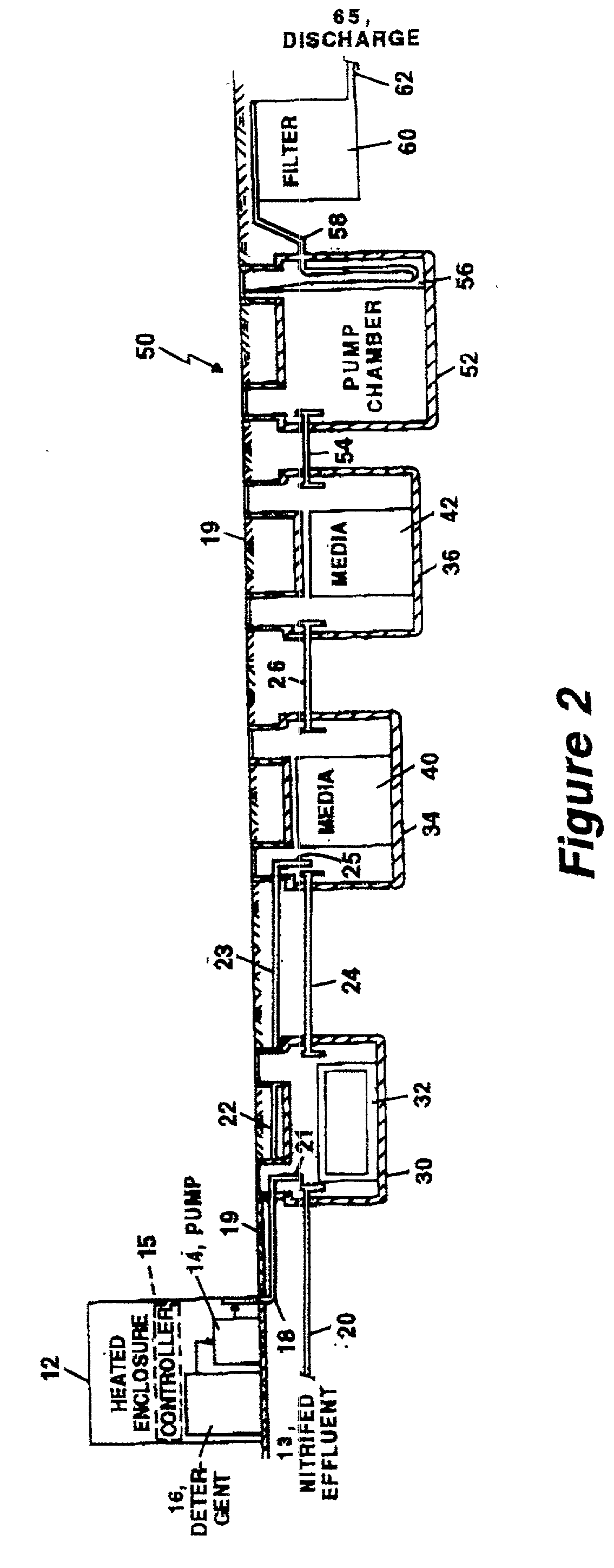

Denitrification system for nitrified wastewater or nitrified water

InactiveUS20020170857A1Economic securityAccelerate denitrificationOther chemical processesWater treatment compoundsPump chamberSand filter

A denitrification system for denitrified wastewater or nitrified water treatment using a detergent or detergent-like compound comprising available carbon. The system comprises a plurality of interconnected tanks including a mixing tank which feeds detention tanks which in combination provide a detention time period for the effluent. A controller determines the amount of detergent dispensed into the mixing tank in accordance with the measured volume of effluent to be treated. The mixing tank comprises a heater for maintaining the nitrified effluent temperature above 50 degrees F. An optional line filter can be added to the output of the system for further reducing organic nitrogen concentration. An alternate embodiment comprises passing the final denitrified effluent through a pump chamber for pumping of the effluent to a sand filter capable of reducing bacterial populations.

Owner:MCGRATH MICHAEL B +1

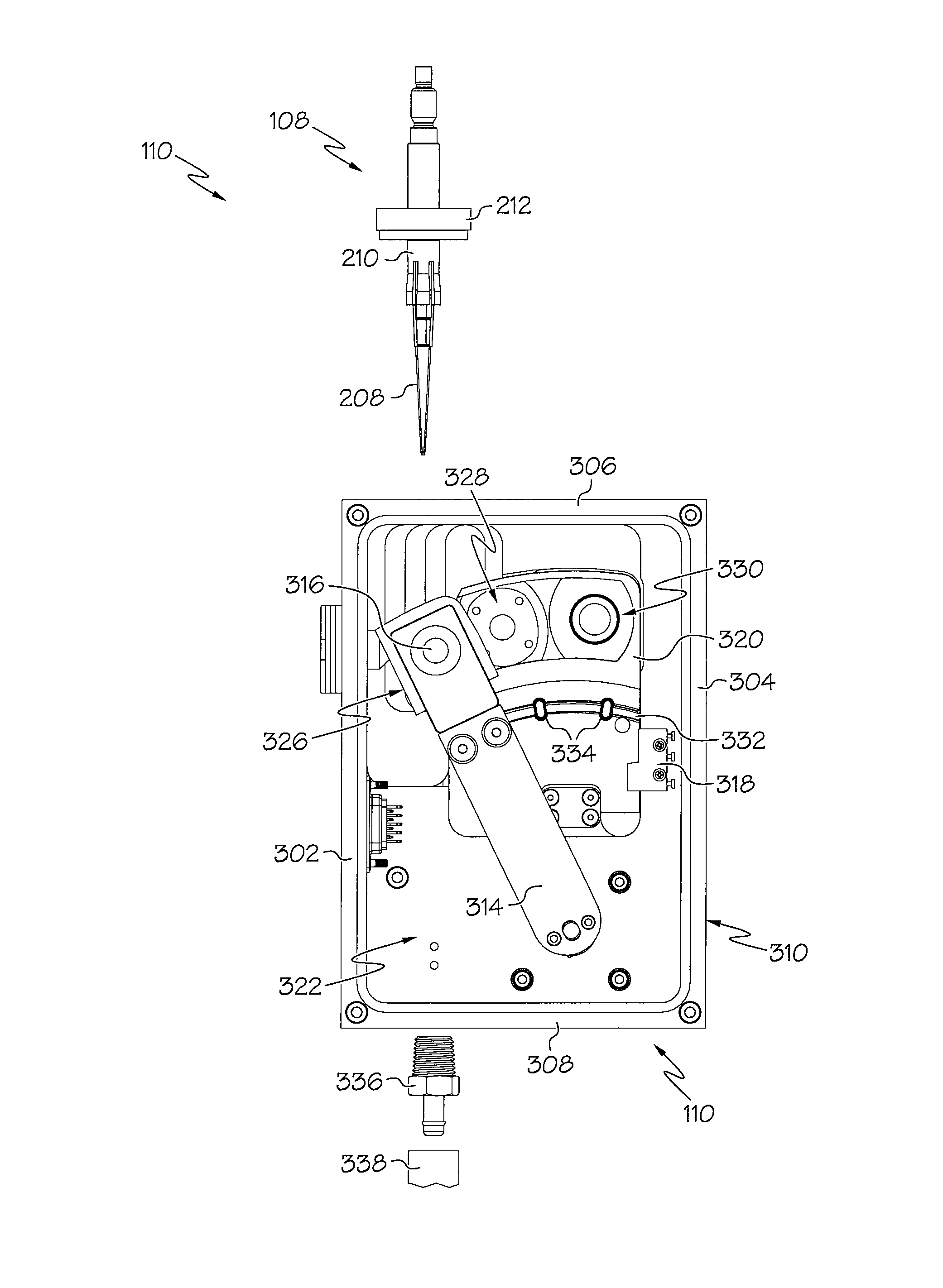

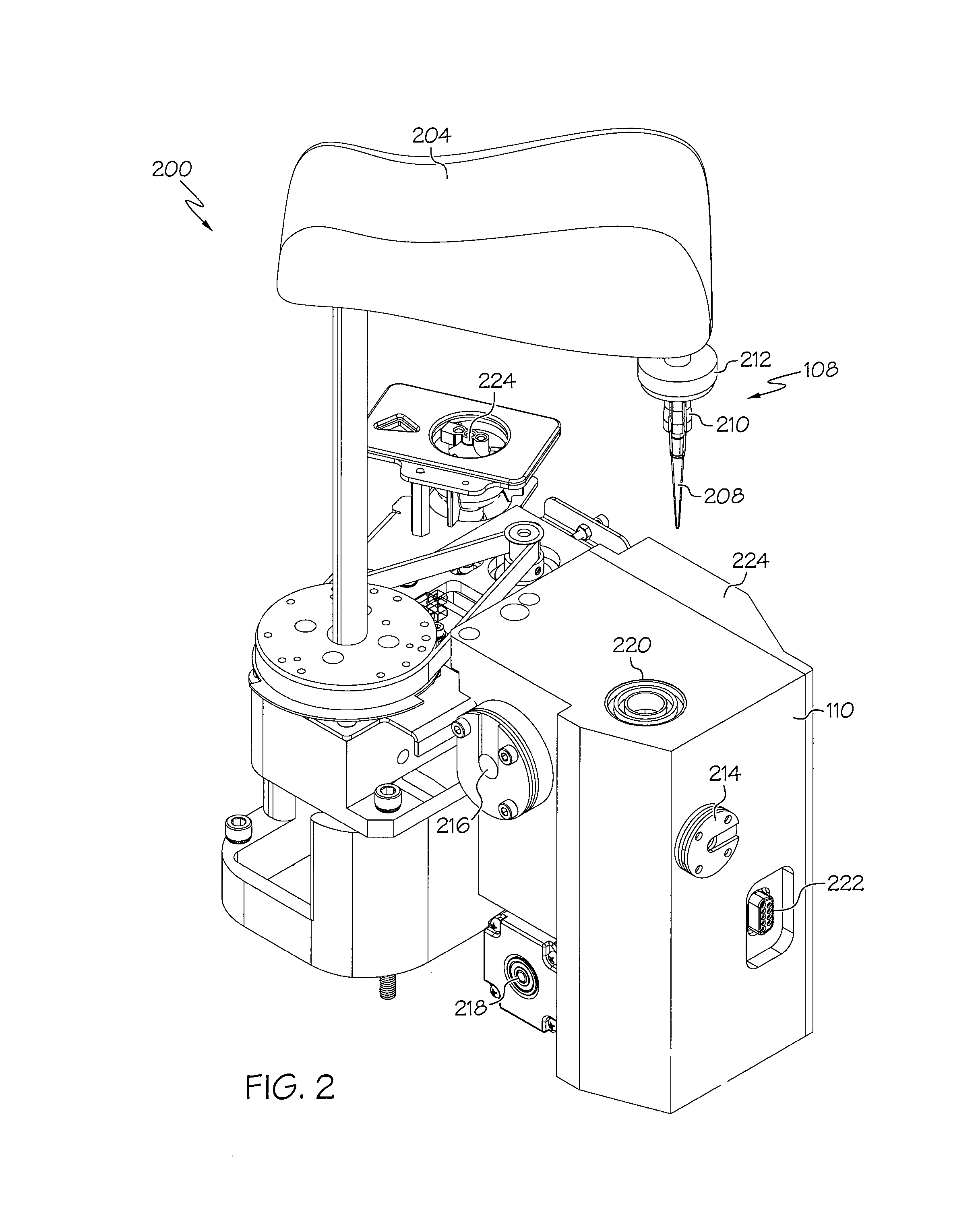

Device and associated methods for performing luminescence and fluorescence measurements of a sample

ActiveUS9075055B2Crosstalk from the fluorescence light source can be minimizedMinimize crosstalkChemiluminescene/bioluminescenceDisease diagnosisFluorescencePipette

An apparatus for measuring the luminescence and the fluorescence of a sample, comprising: a light tight optics box capable of receiving a pipette tip containing a sample; an optical sensor located within the optics box and capable of being disposed in both a luminescence reading position and a fluorescence reading position; an excitation light fiber optic bundle and a sample transmission fiber optic bundle; an excitation light assembly that projects excitation light onto a first terminus end of the excitation light fiber optic bundle; and an in-line filter located along the sample transmission fiber optic bundle.

Owner:HYCOR BIOMEDICAL LLC

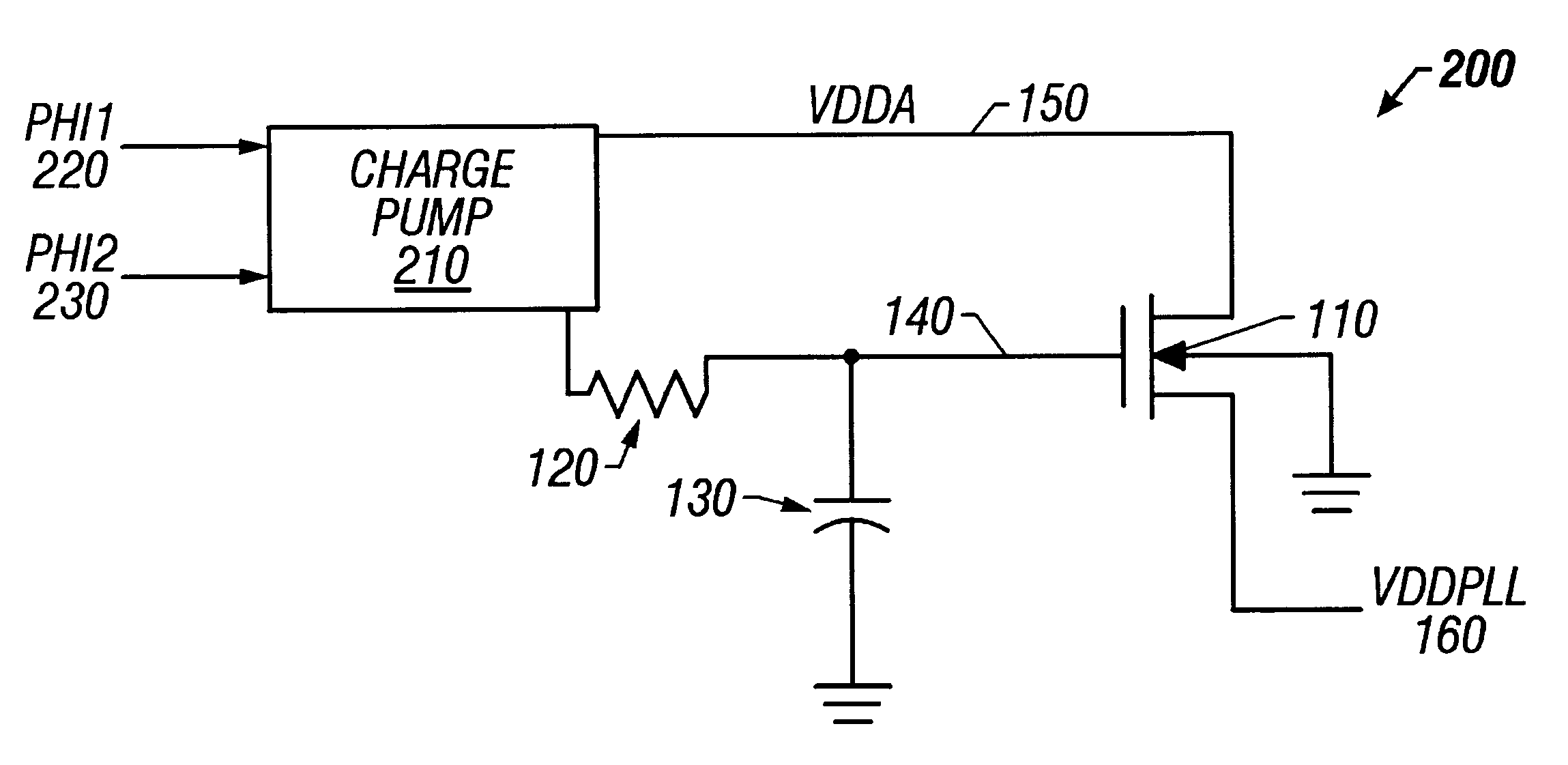

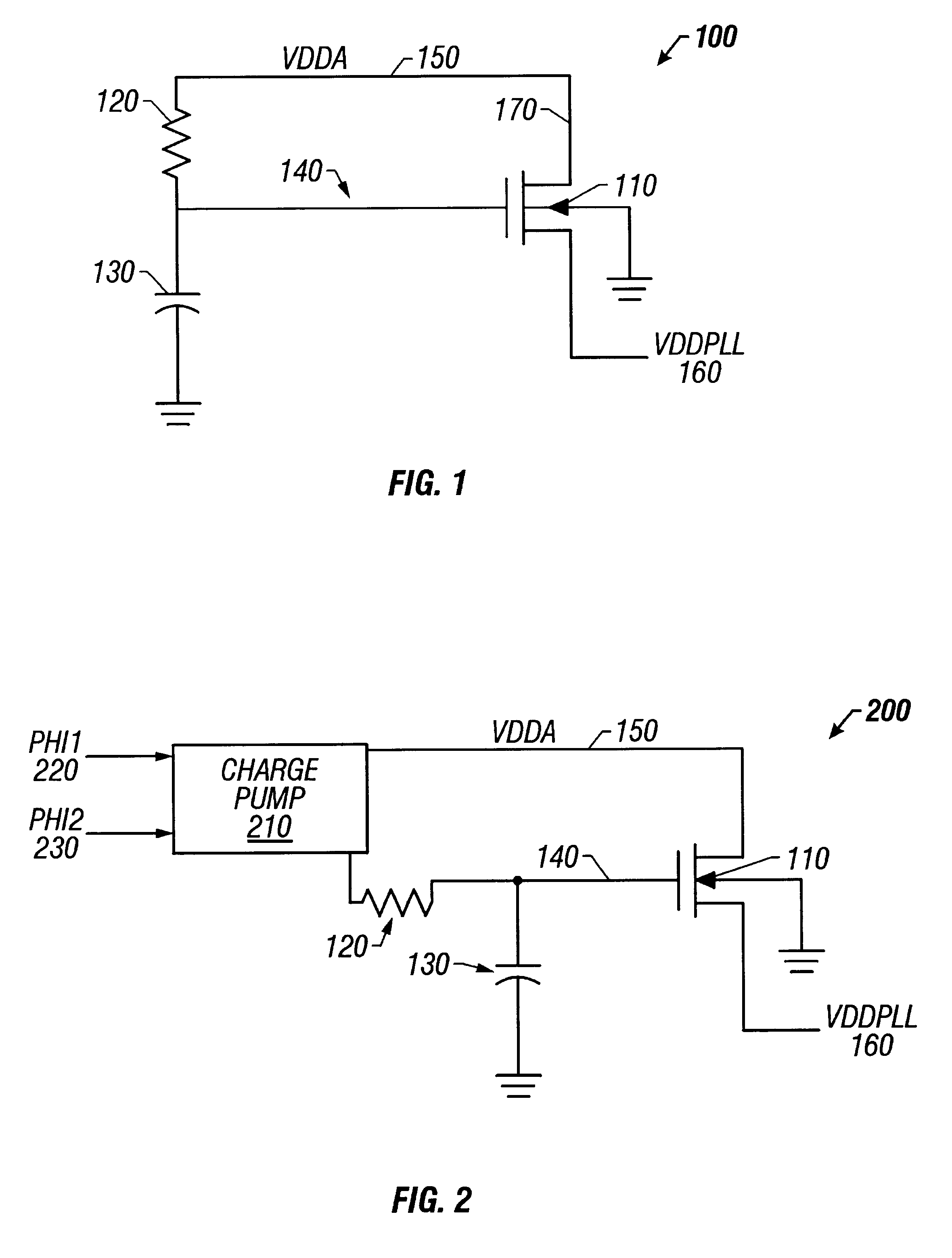

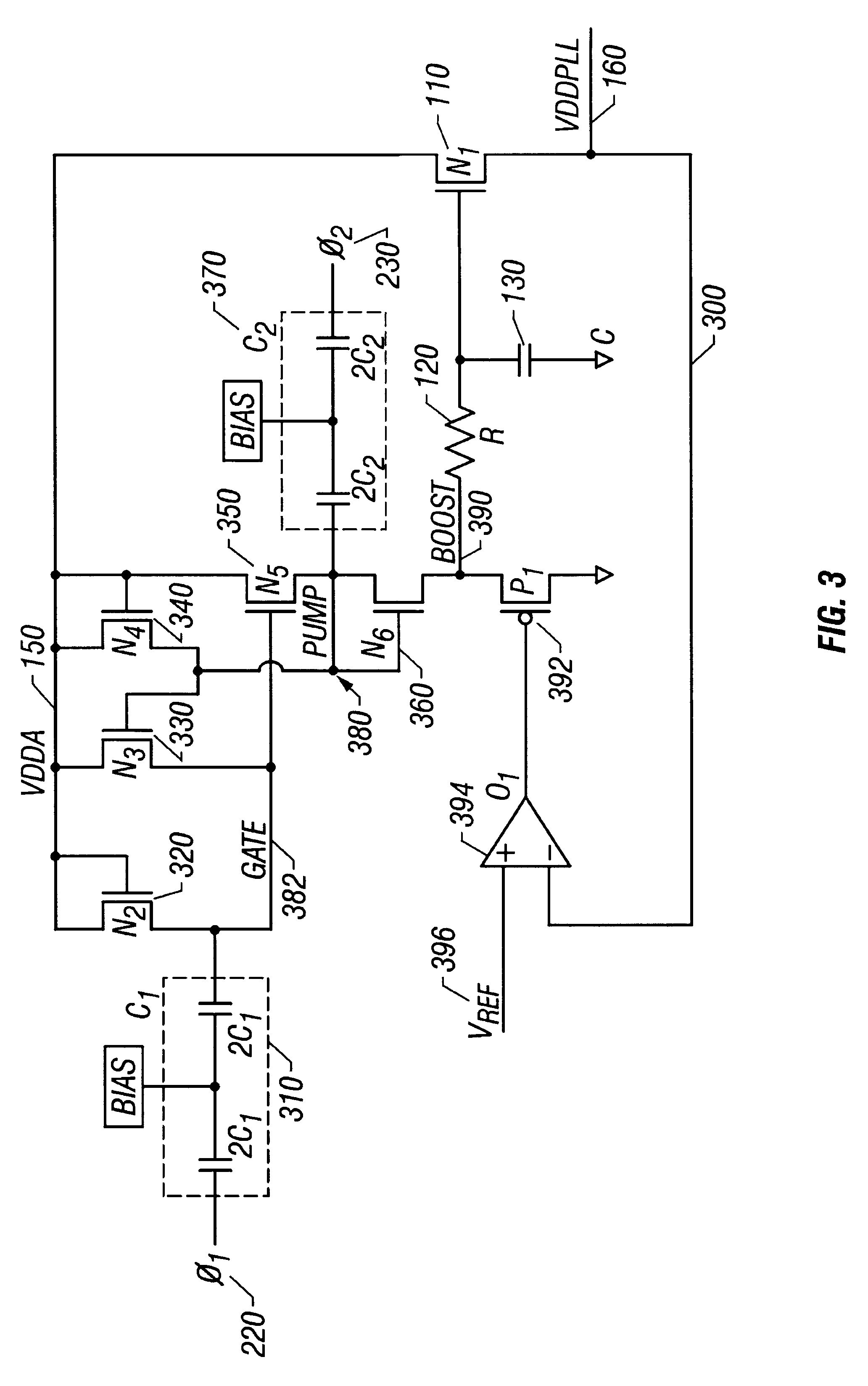

PLL power supply filter (with pump) having a wide voltage range and immunity to oxide overstress

A power supply filter capable of functioning with low power supply voltages includes a resistor-capacitor circuit coupled to a power supply line and a transistor for providing power to a target circuit, such as a phase-locked loop circuit, coupled between the resistor-capacitor circuit and the power supply line. The resistor-capacitor circuit is coupled to a charge pump controller to keep the transistor in a saturation state. The charge pump controller receives at least one clock signal that is coupled to at least one capacitive circuit. The at least one capacitive circuit includes at least two capacitors in series with a biased middle node located between the at least two capacitors in order to provide immunity to time dependent dielectric breakdown, the middle node coupled to approximately half the power supply line. A method of filtering noise from a power supply includes providing an N-channel source follower circuit coupled between the power supply and a target circuit, the N-channel source follower circuit including a resistor-capacitor circuit and a transistor with a threshold voltage. The method also includes maintaining the transistor in a saturation state through placing a charge pump in the N-channel source follower circuit, the charge pump receiving a first clock signal and a second clock signal, and allowing the voltage provided to a target circuit to exceed the voltage of the power line minus the threshold voltage while maintaining the transistor in a saturation state.

Owner:ADVANCED MICRO DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com