Patents

Literature

117results about How to "Reduce debris" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

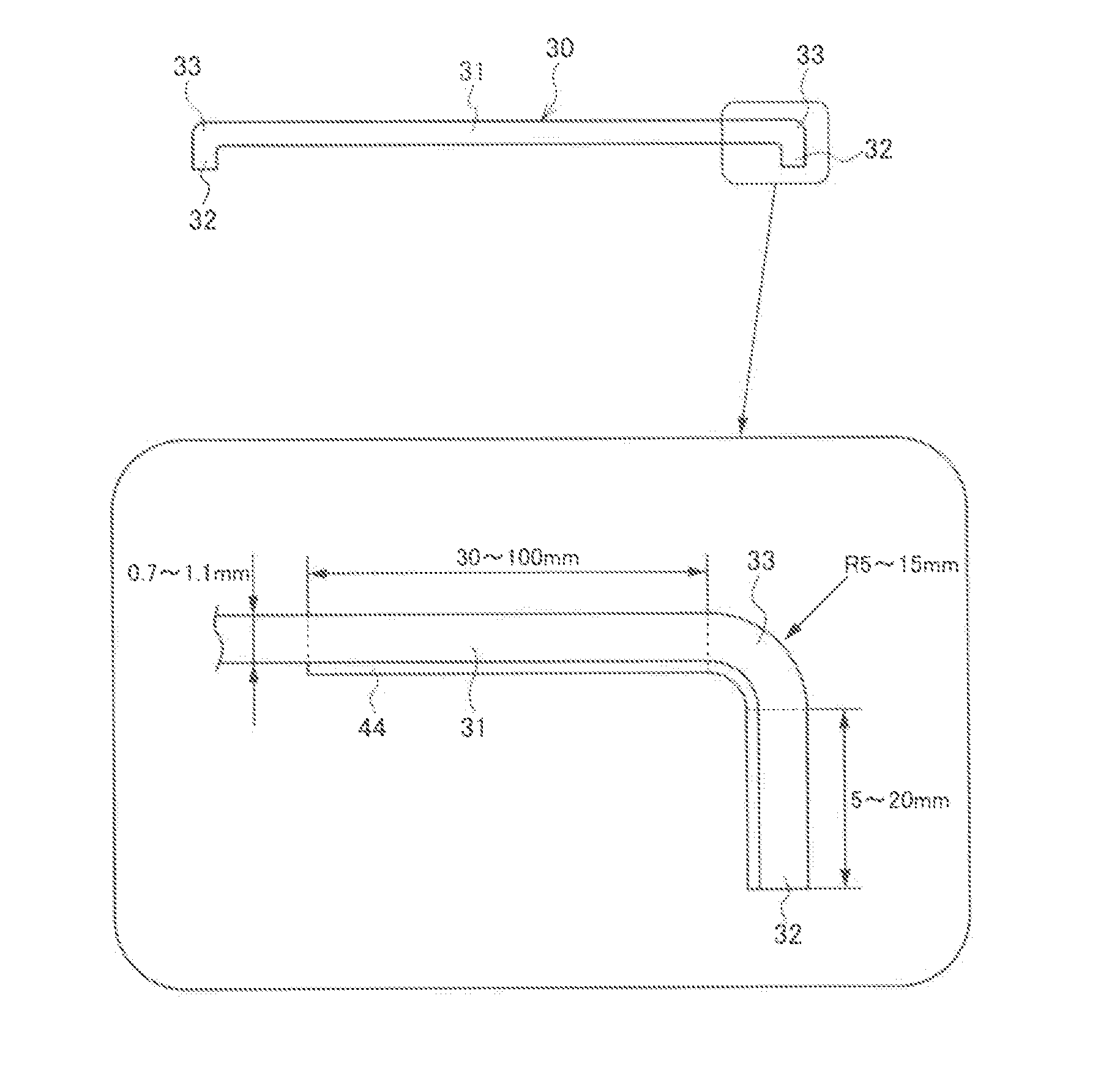

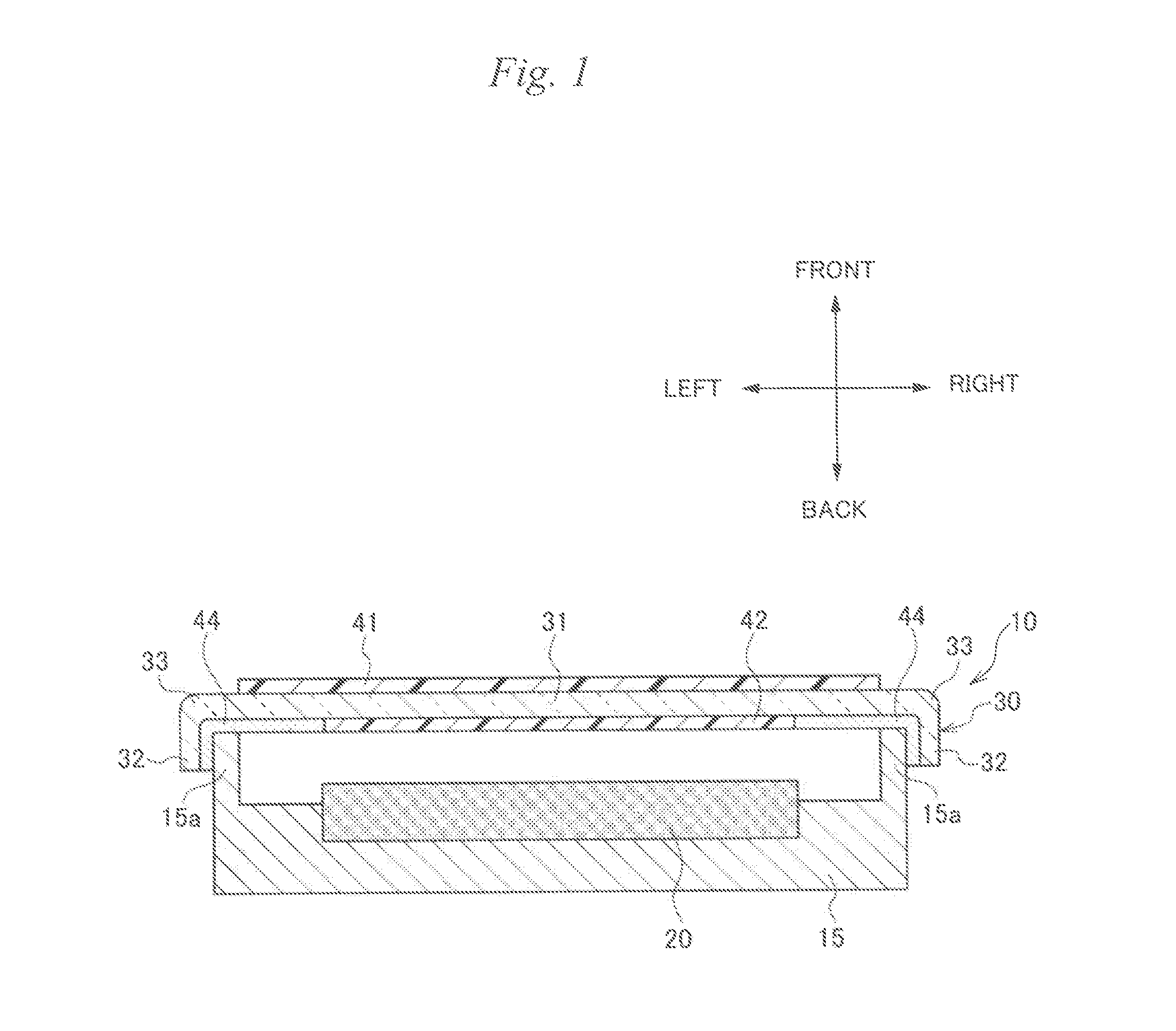

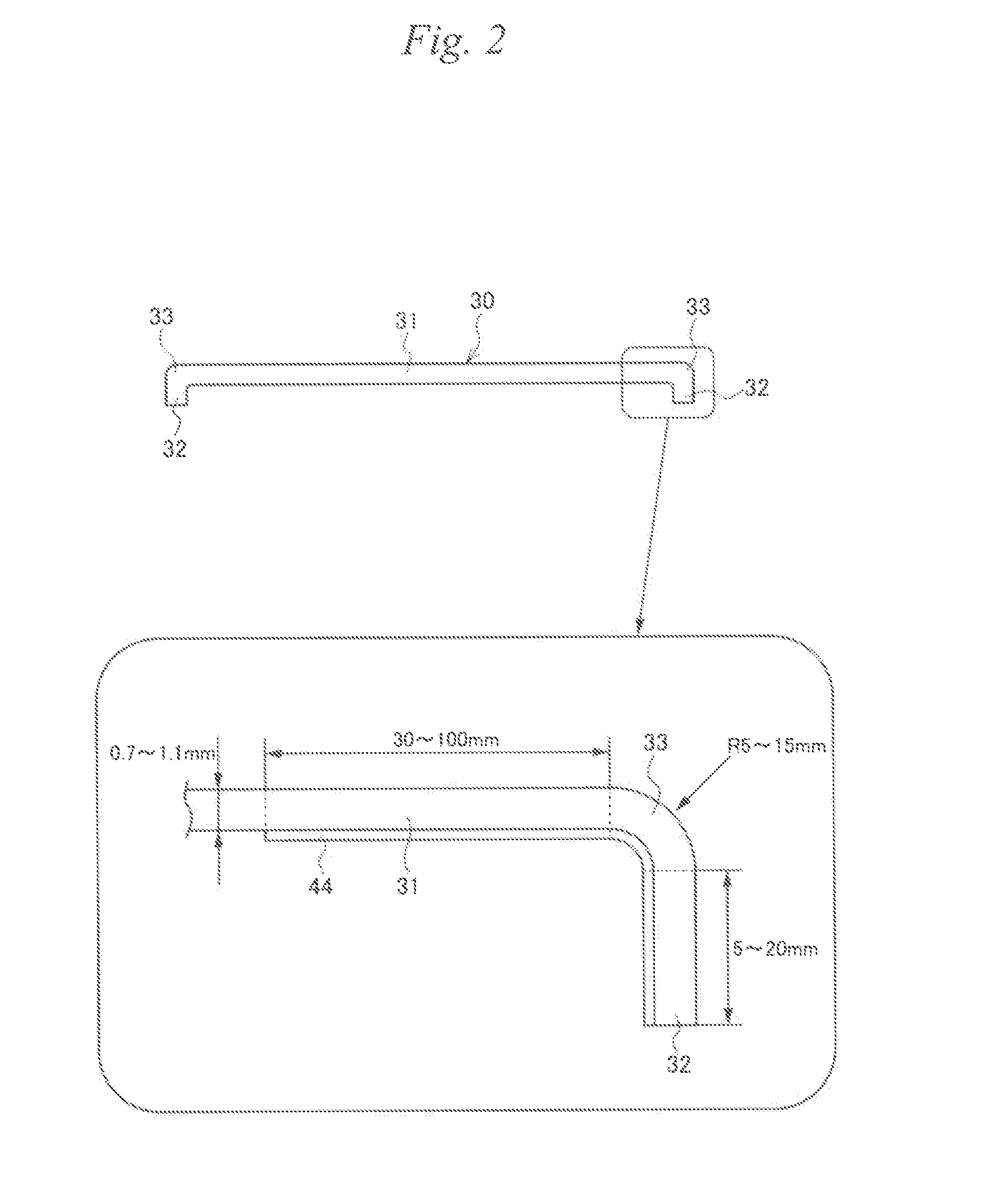

Cover glass for flat panel displays and method for producing the same

InactiveUS20120114901A1Good designSimplify treatmentElectrical equipmentGlass/slag layered productsEngineeringCover glass

The present invention provides a cover glass for flat panel displays, which can simplify an edge treatment and is excellent in design, and a method for producing the same. The method includes: a local heating step S3 of locally heating regions 1b to be the bent portions 33 of the cover glass 30 in the sheet glass 1; and a bending step S4 of forming the skirt portions 32 by bending the sheet glass 1 at the regions 1b to be the bent portions 33, during or after the local heating step.

Owner:ASAHI GLASS CO LTD

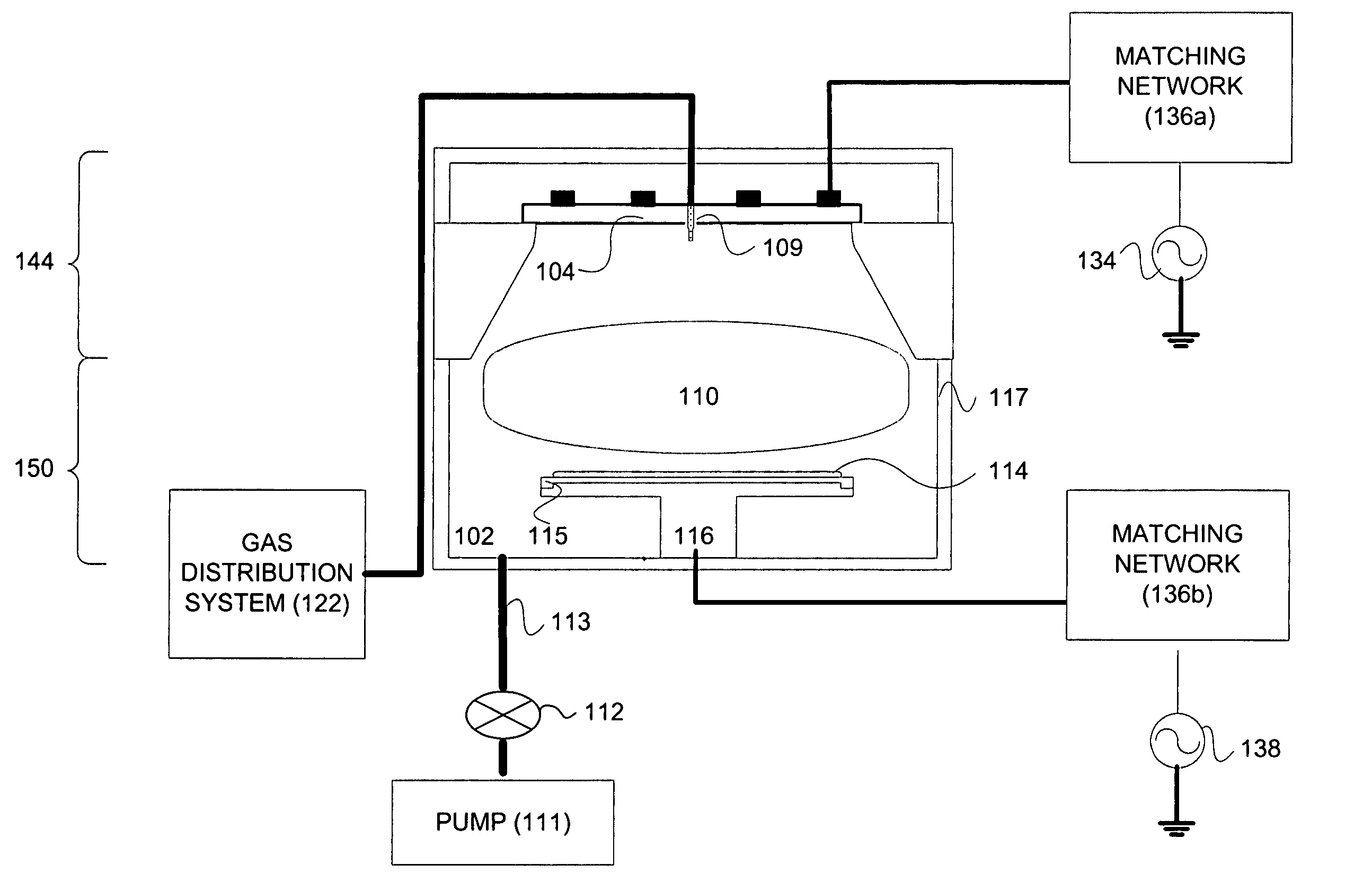

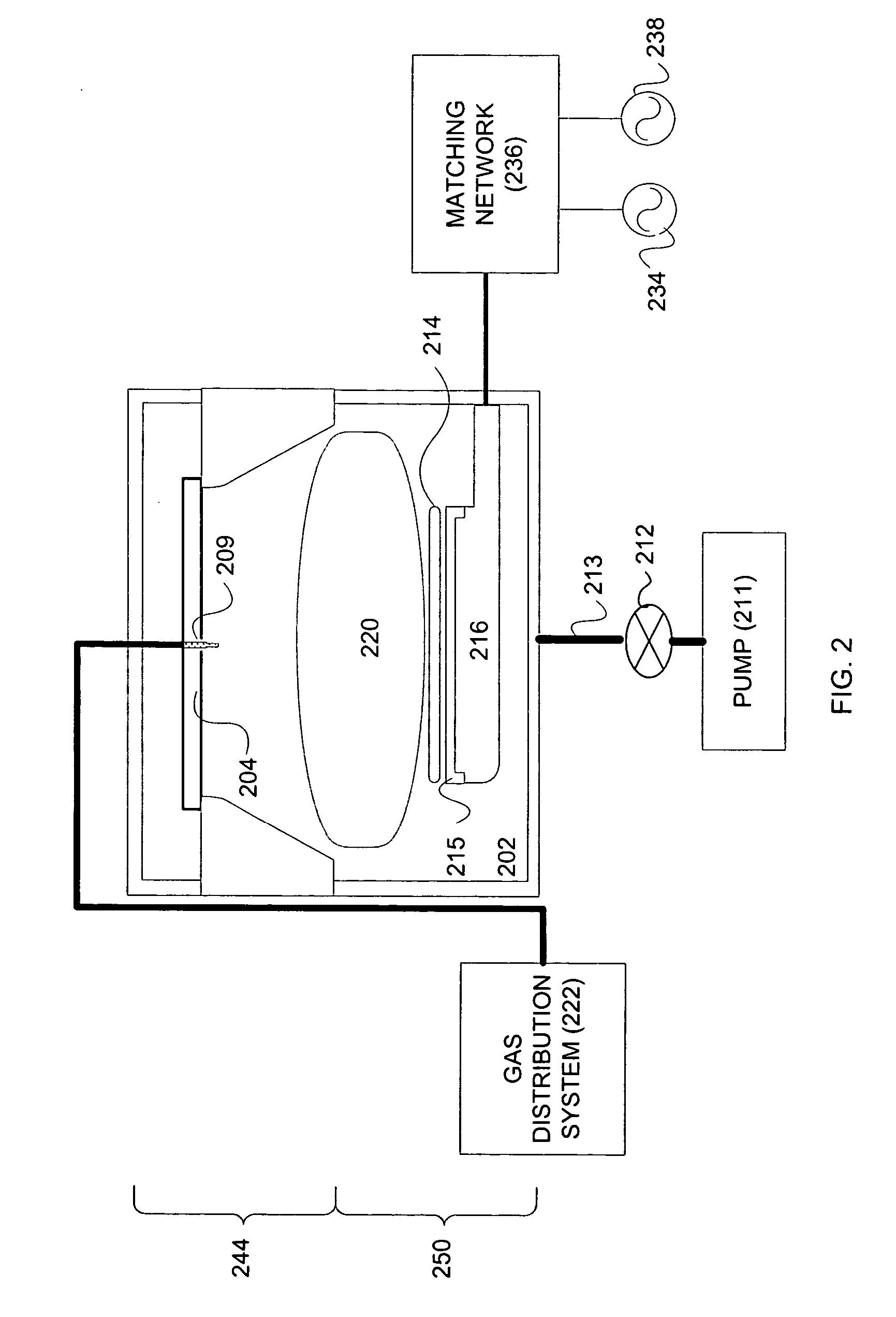

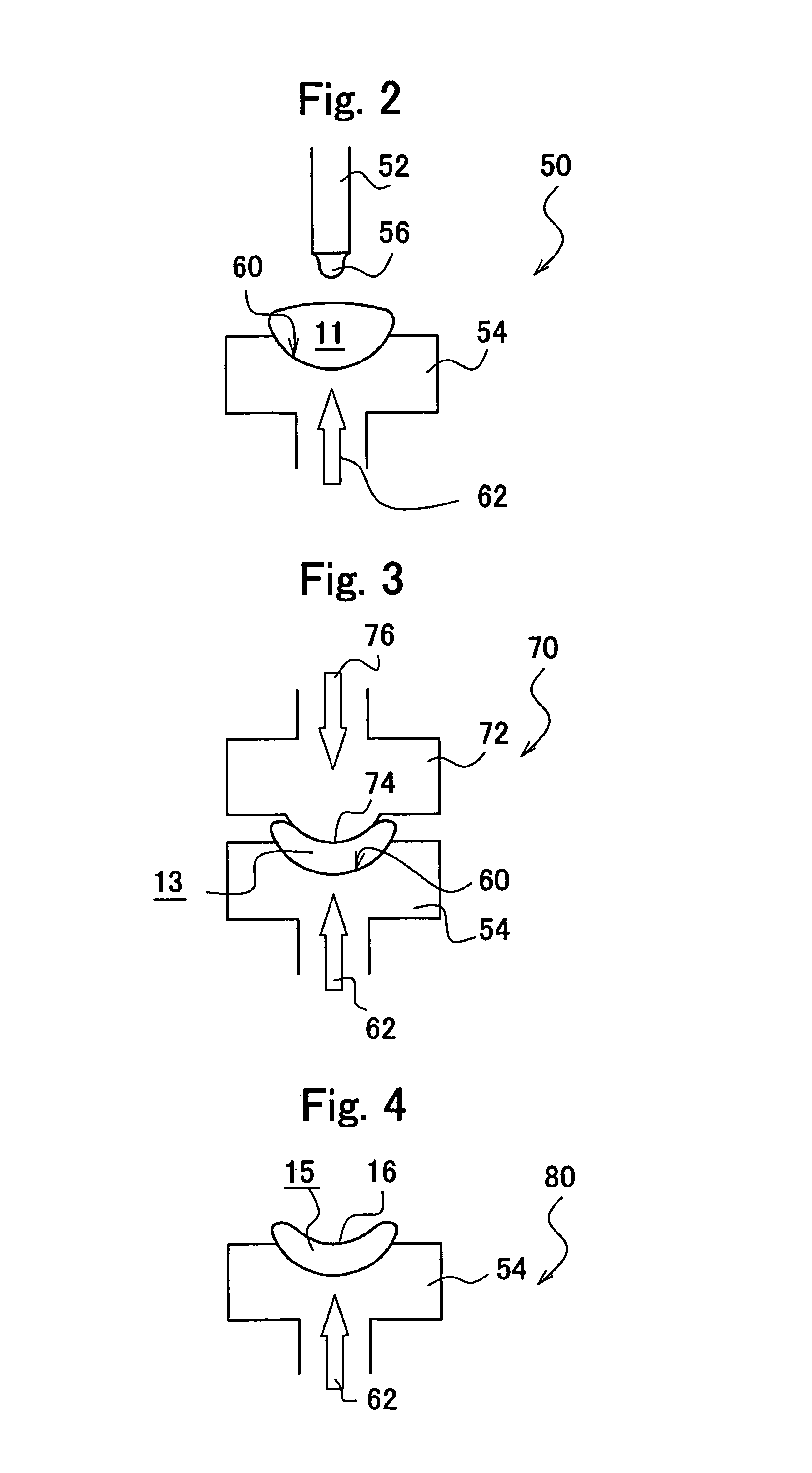

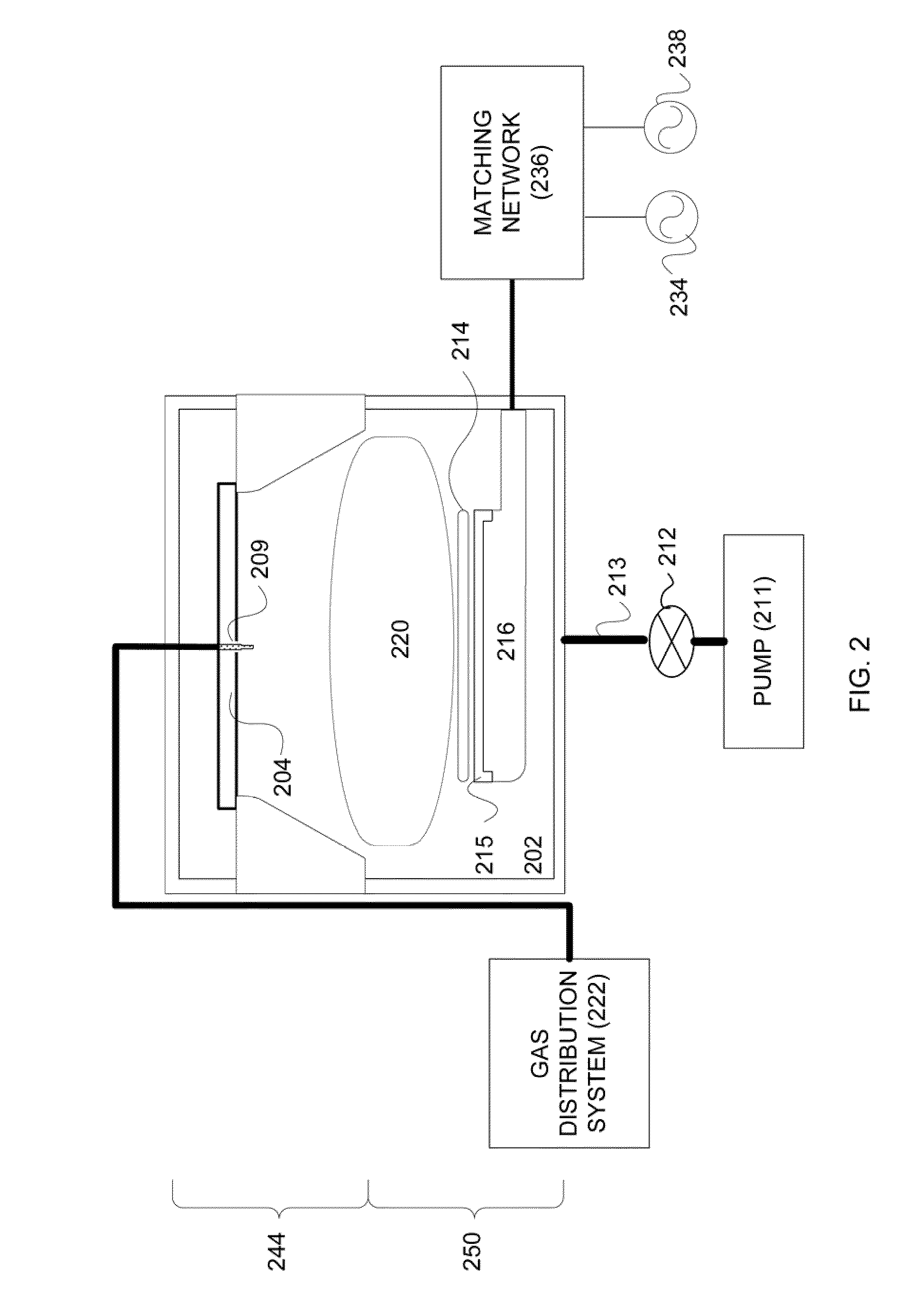

Apparatus for servicing a plasma processing system with a robot

InactiveUS20060218680A1Reduce debrisEliminate errorsElectric discharge tubesHollow article cleaningEmbedded systemPlasma processing

A robot apparatus for executing a set of service procedures on a plasma processing system including a docking port is disclosed. The apparatus includes a platform and a docking probe coupled to the platform, wherein the docking probe is configured to dock with the docking port. The apparatus also includes a robot arm coupled to the platform, and further configured to substantially perform the set of service procedures, and a tool coupled to the robot arm. The apparatus further includes a computer coupled to the platform, wherein the computer is further configured to execute the set of service procedures, and wherein when the docking probe is docked to the docking port, the set of service procedures is performed by the tool.

Owner:LAM RES CORP

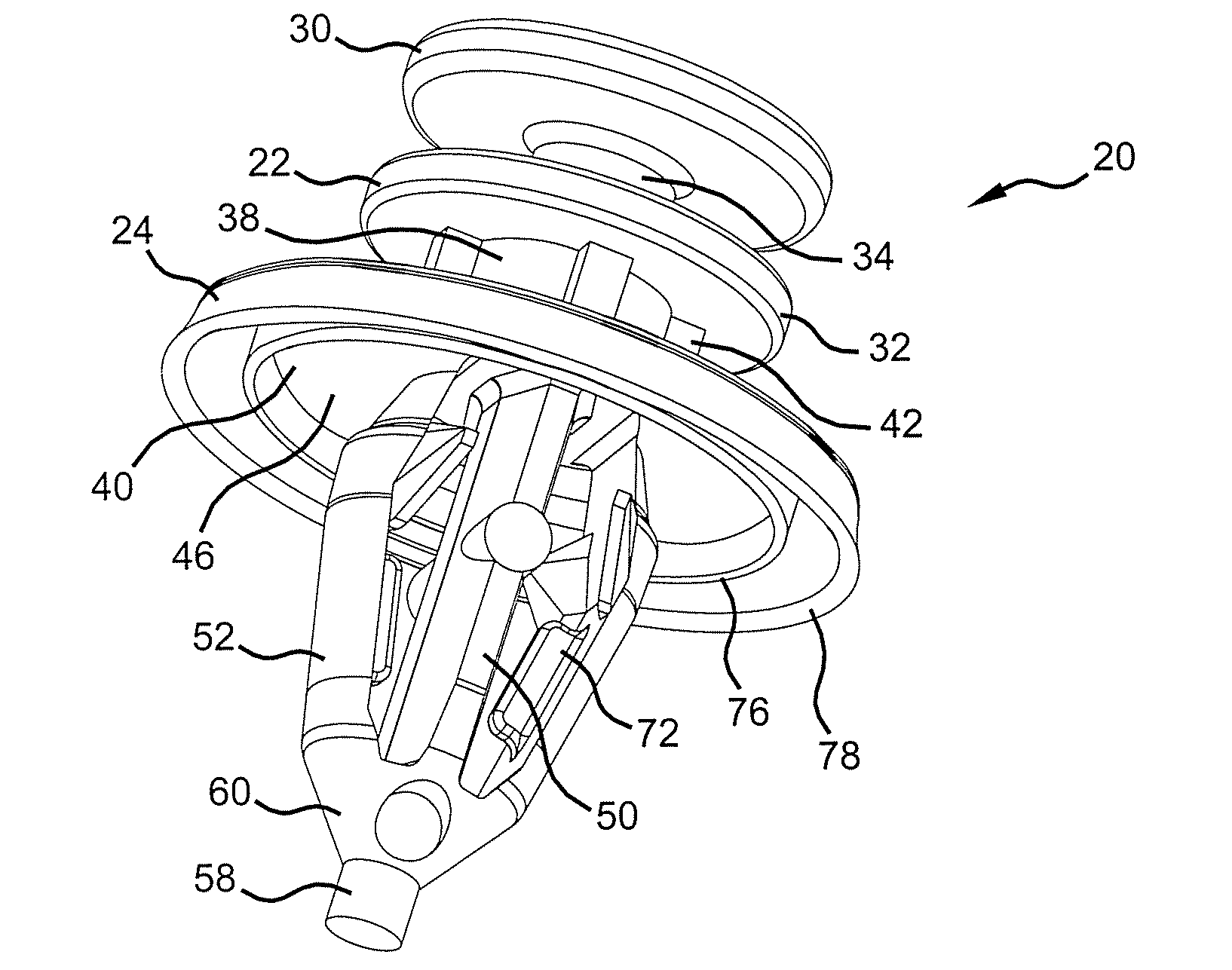

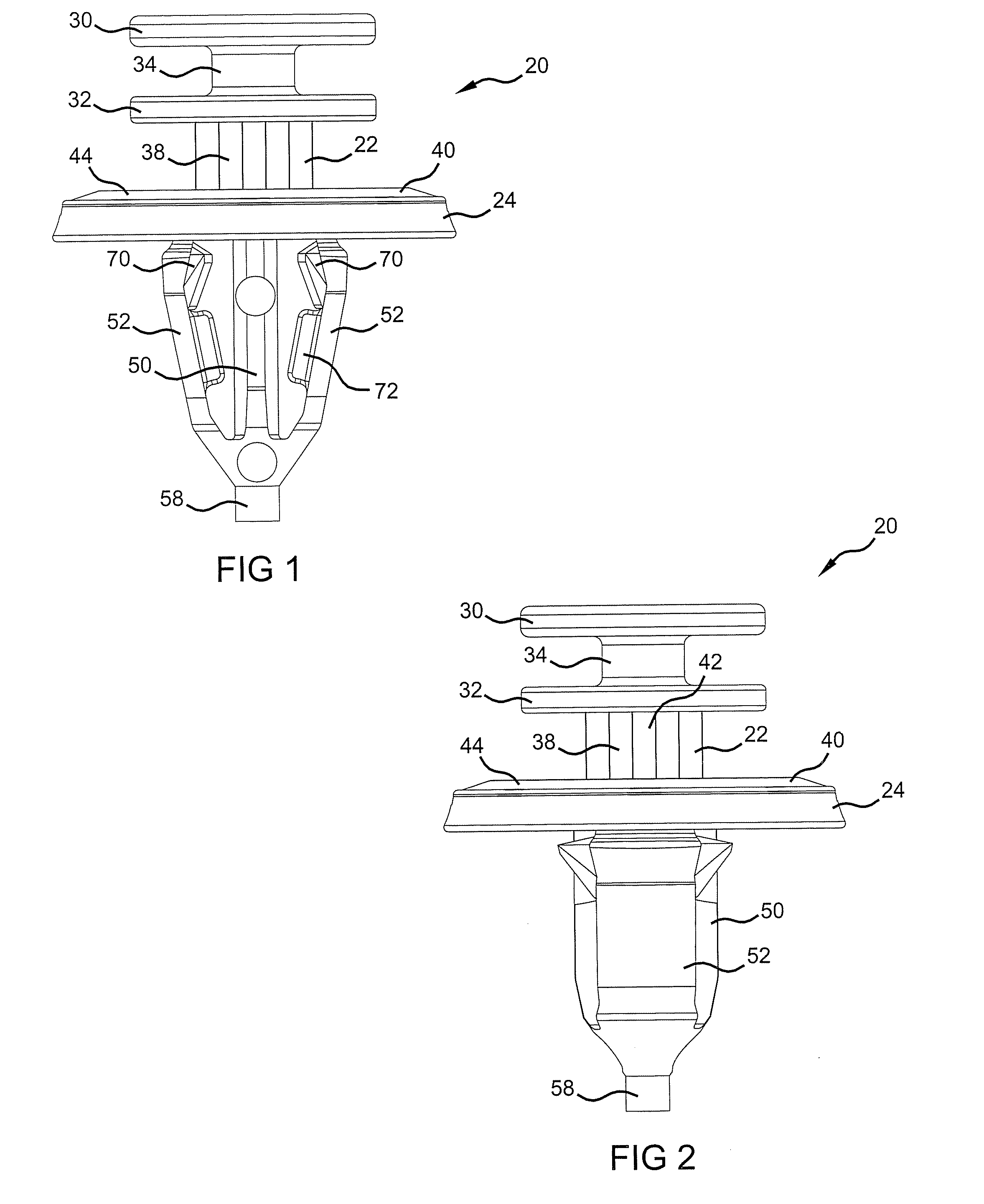

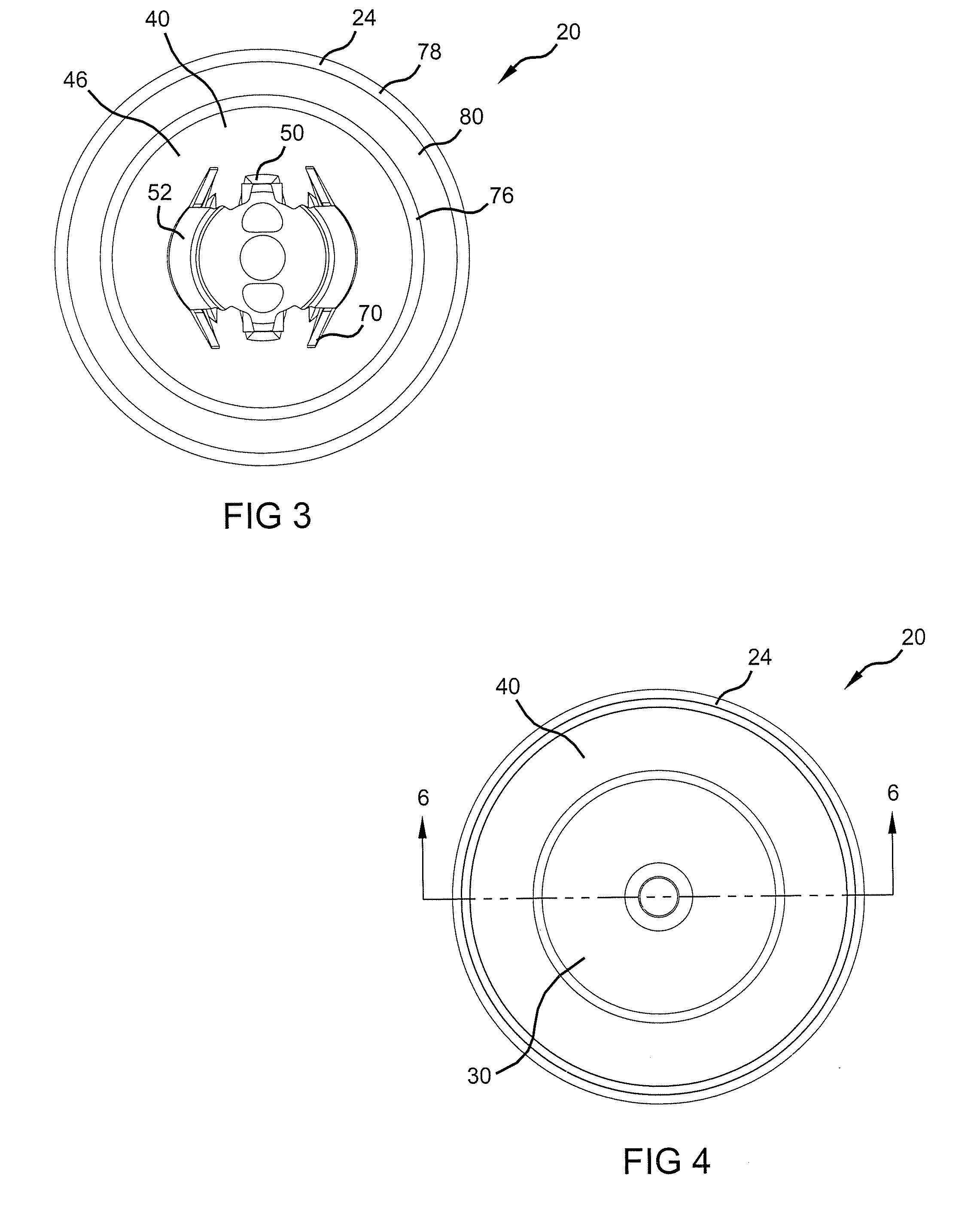

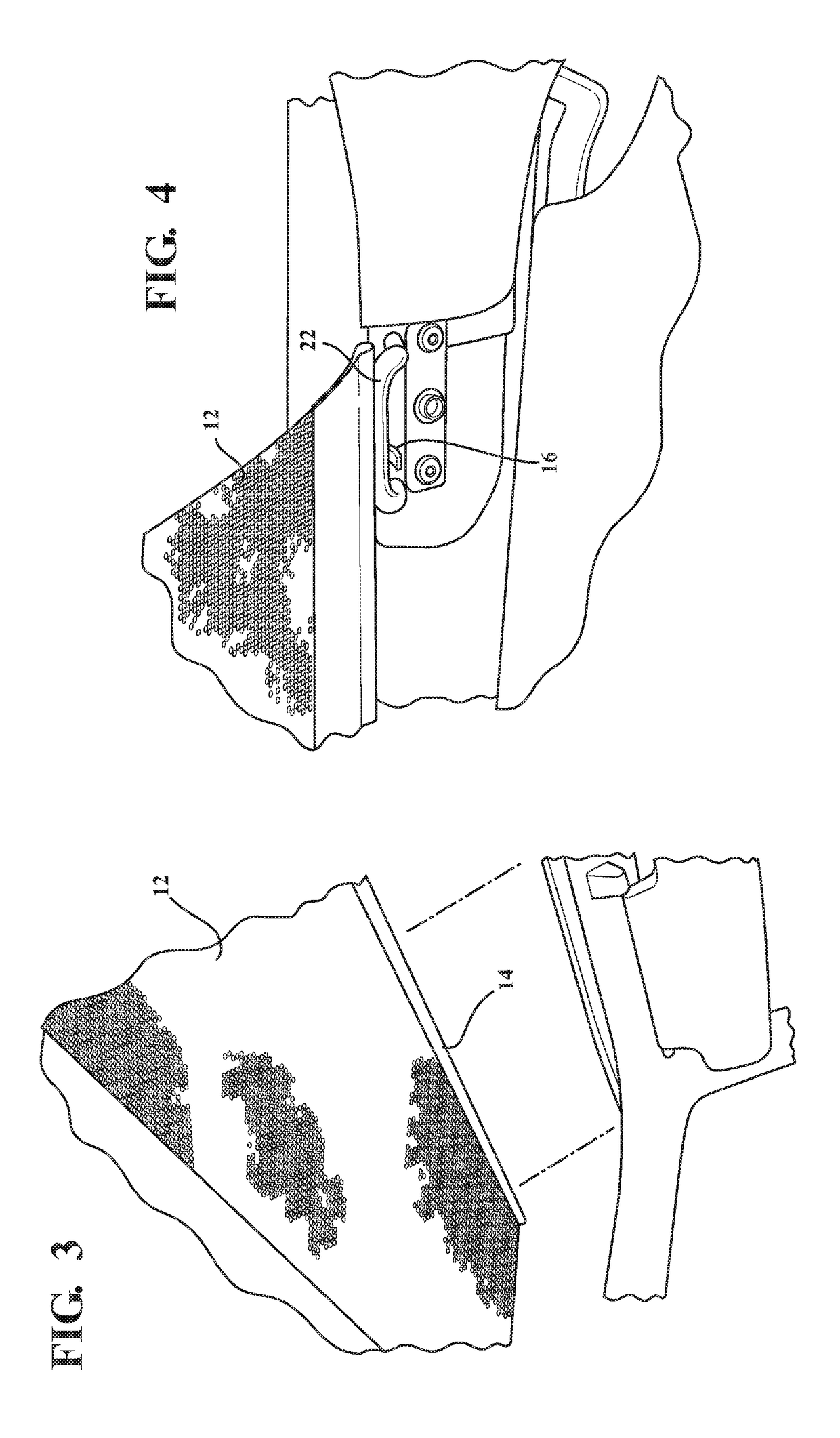

Fastener Clip with Seal

InactiveUS20080052878A1Reduce liquidReduce debrisSnap fastenersDeformable pinsVarying thicknessFastener

A single-piece fastener includes a relatively hard clip and a relatively soft seal. The seal can be overmolded onto the clip. A thermal bond is formed between the seal and the clip to inhibit removal of the seal from the clip. The flexible nature of the umbrella of the clip and the seal can accommodate sealing openings in panels of varying thicknesses.

Owner:NEWFREY

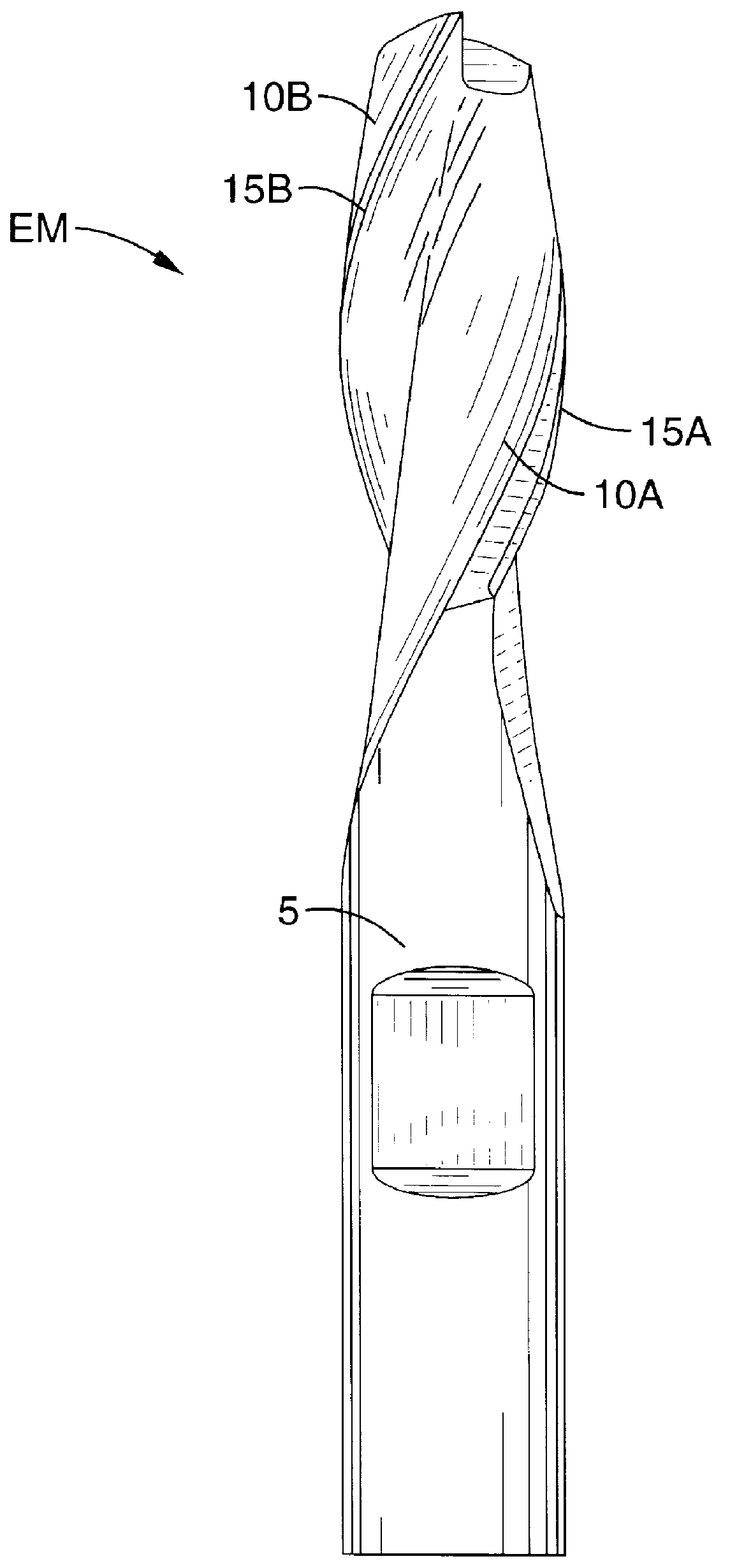

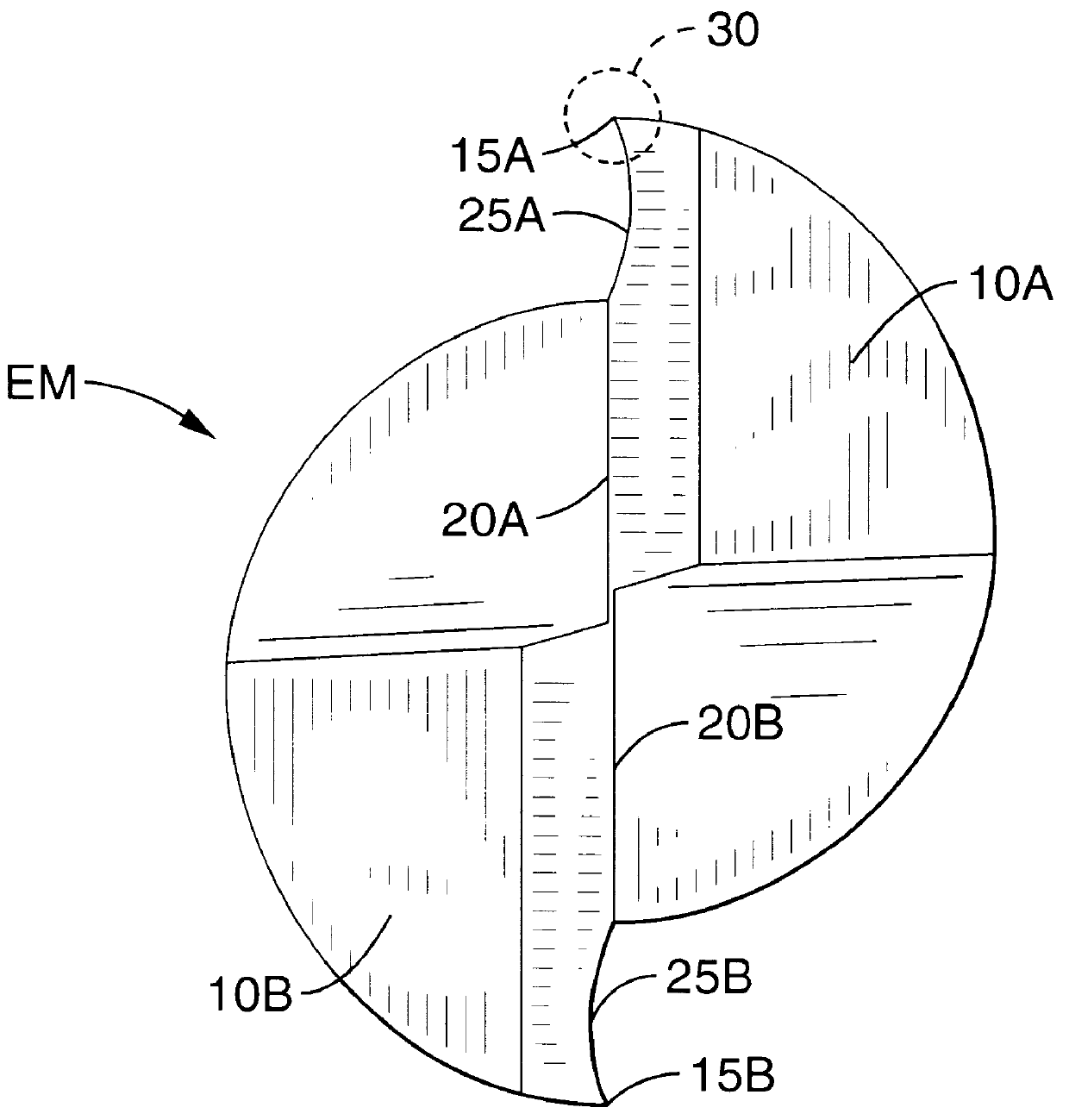

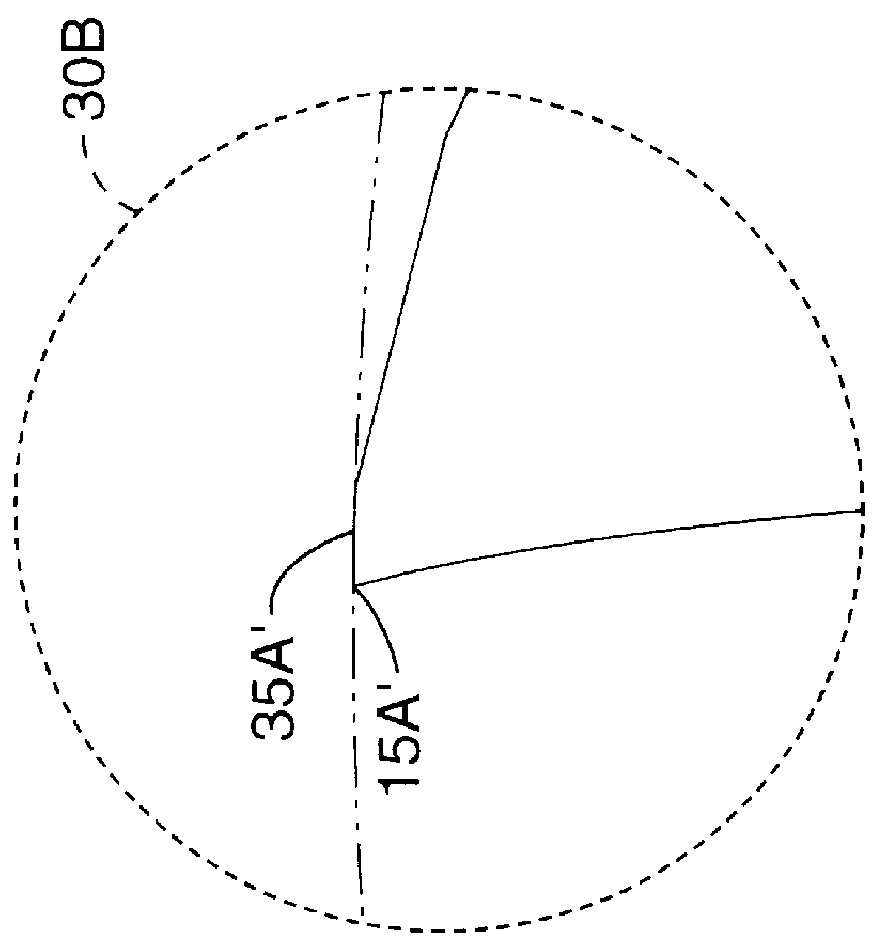

Method for preparing a cutting edge on an end mill

InactiveUS6105467AEasy to prepareReduce debrisMetal-working drilling toolsMilling cuttersMilling cutterEnd mill

A method of increasing the length of time a tool maintains sharp cutting edges utilizes the steps of manufacturing the tool with the cutting edges ground sharp and then partially dulling, to a lighter or heavier extent, those previously ground sharp cutting edges. Often the partial dulling is accomplished by means of applying a brush wheel to the selected cutting edges.

Owner:ROBBJACK CORP

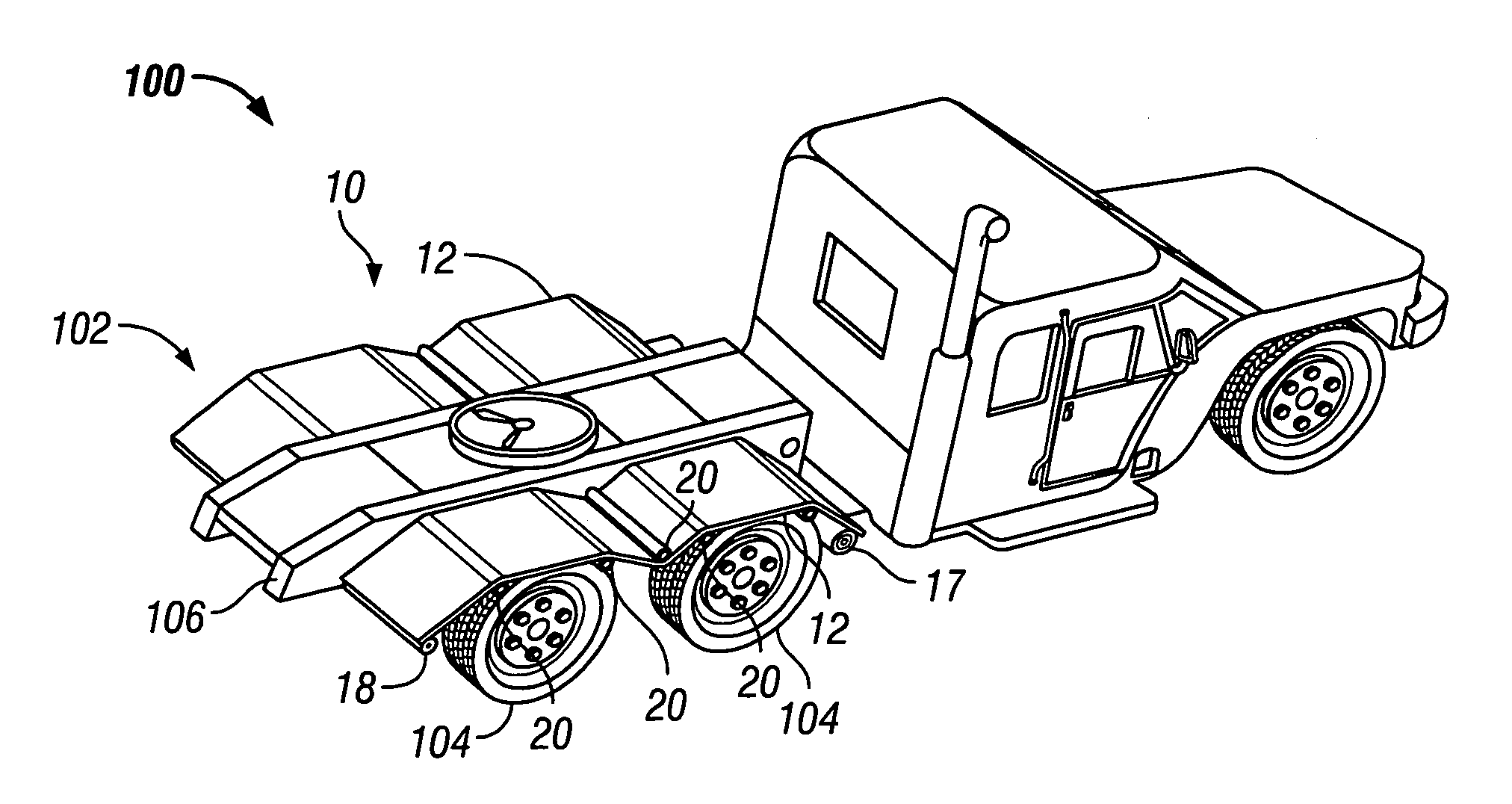

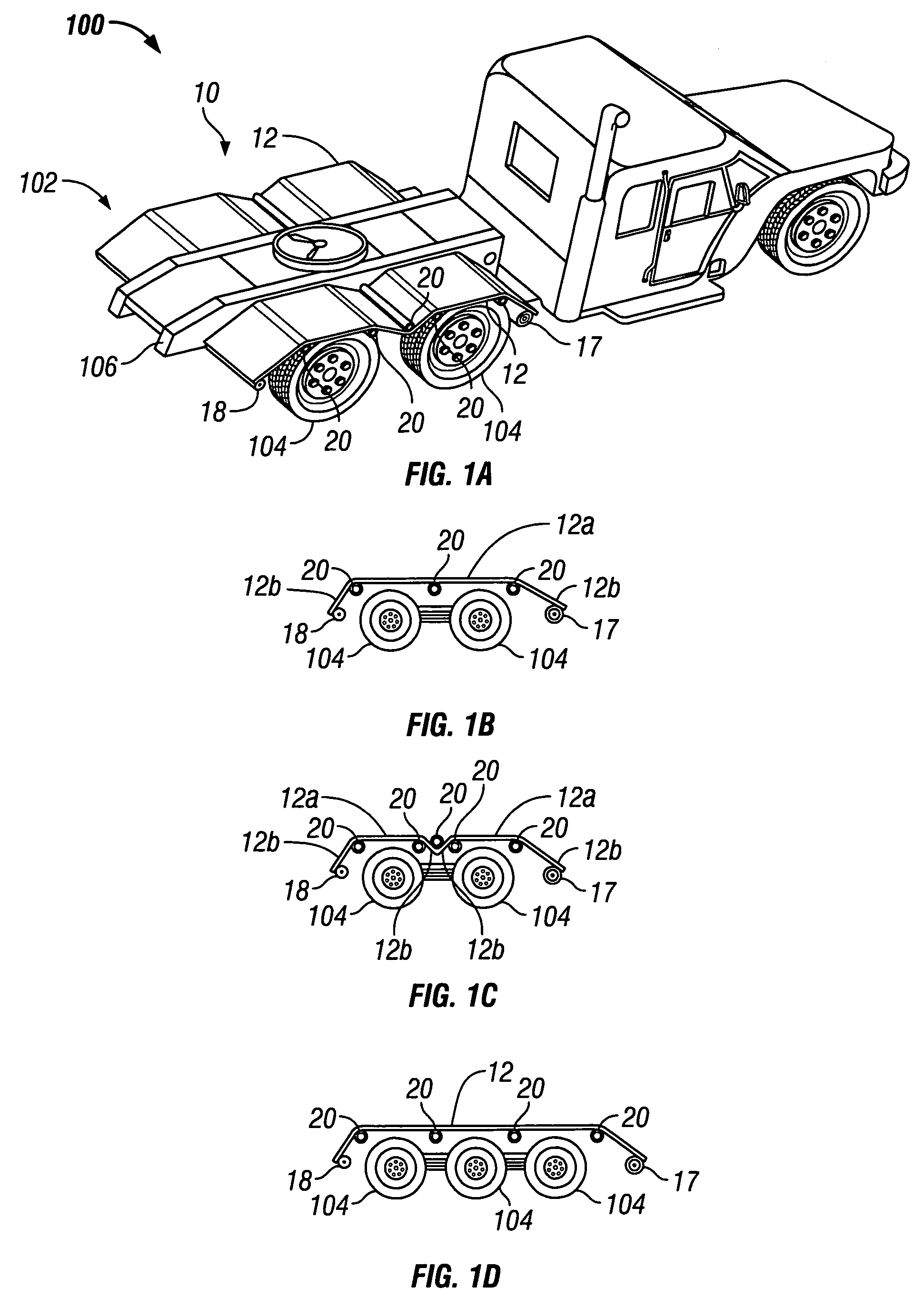

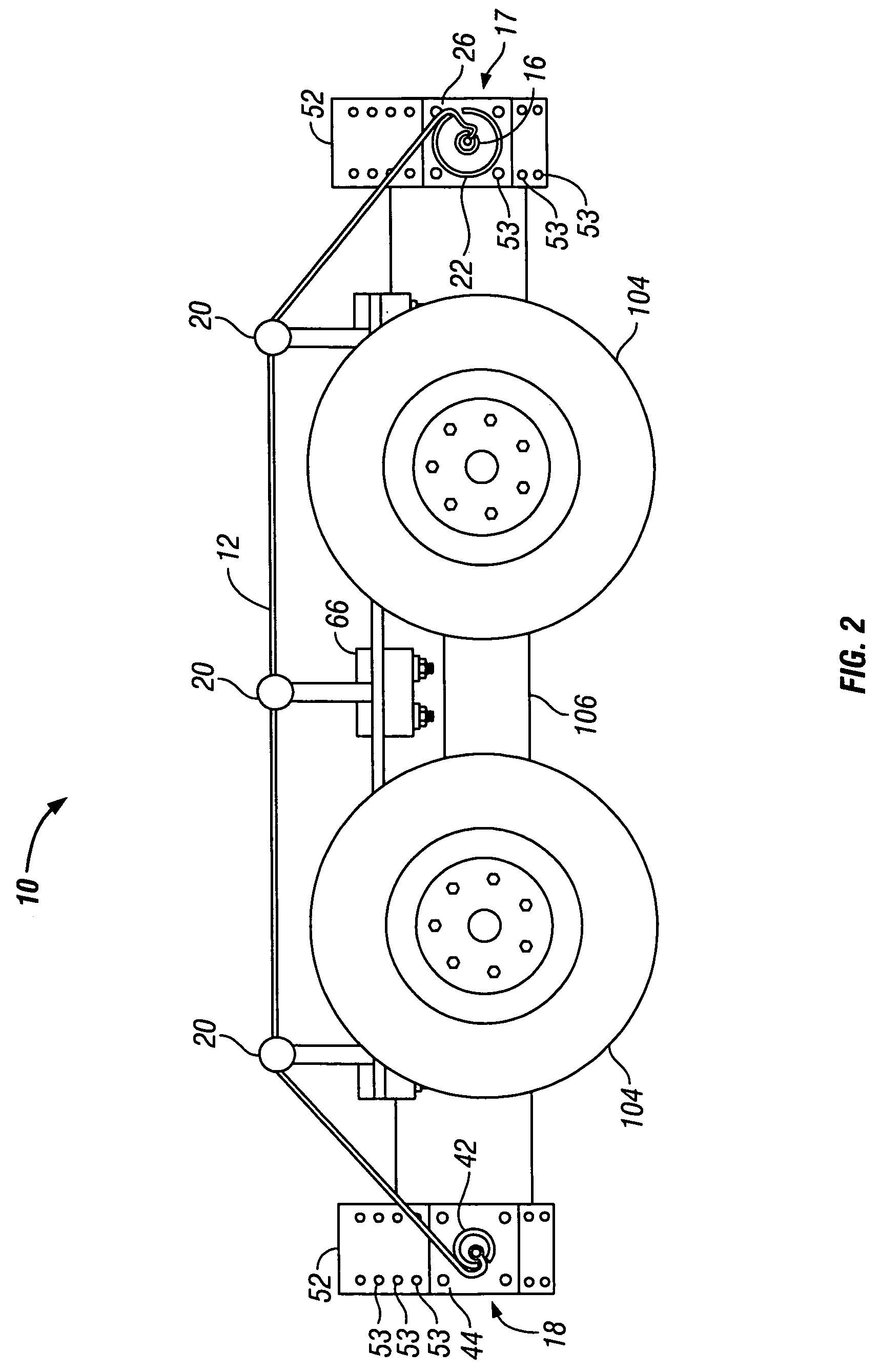

Retractable wheel and track covers

InactiveUS7185920B2Quantity minimizationReduce inconvenienceSuperstructure subunitsSupplementary fittingsCovering systemEngineering

The invention provides a retractable cover apparatus, which when extended to cover the wheel or track area of a variety of vehicles minimizes the amount of spray and debris flying from the tires or tracks of the vehicle. The cover system is mounted to the frame of a vehicle without requiring extensive modifications to the frame, and includes, for each side of the vehicle, an elongated flexible cover having first and second ends and a width sufficient to extend laterally outwardly beyond an outer extent of the wheels or tracks of the vehicle. The cover system also include at least first and second cover housings, one of the housings adapted to contain the cover in a rolled retracted condition and the other housing being adapted to anchor a free end of the cover in an extended condition thereof. At least one support bar is removably mounted to the frame of the vehicle over which the cover is supported. When the cover is required, it is pulled from the one cover housing, over the support bars and is anchored in place at the other cover housing.

Owner:HERCULES SLR

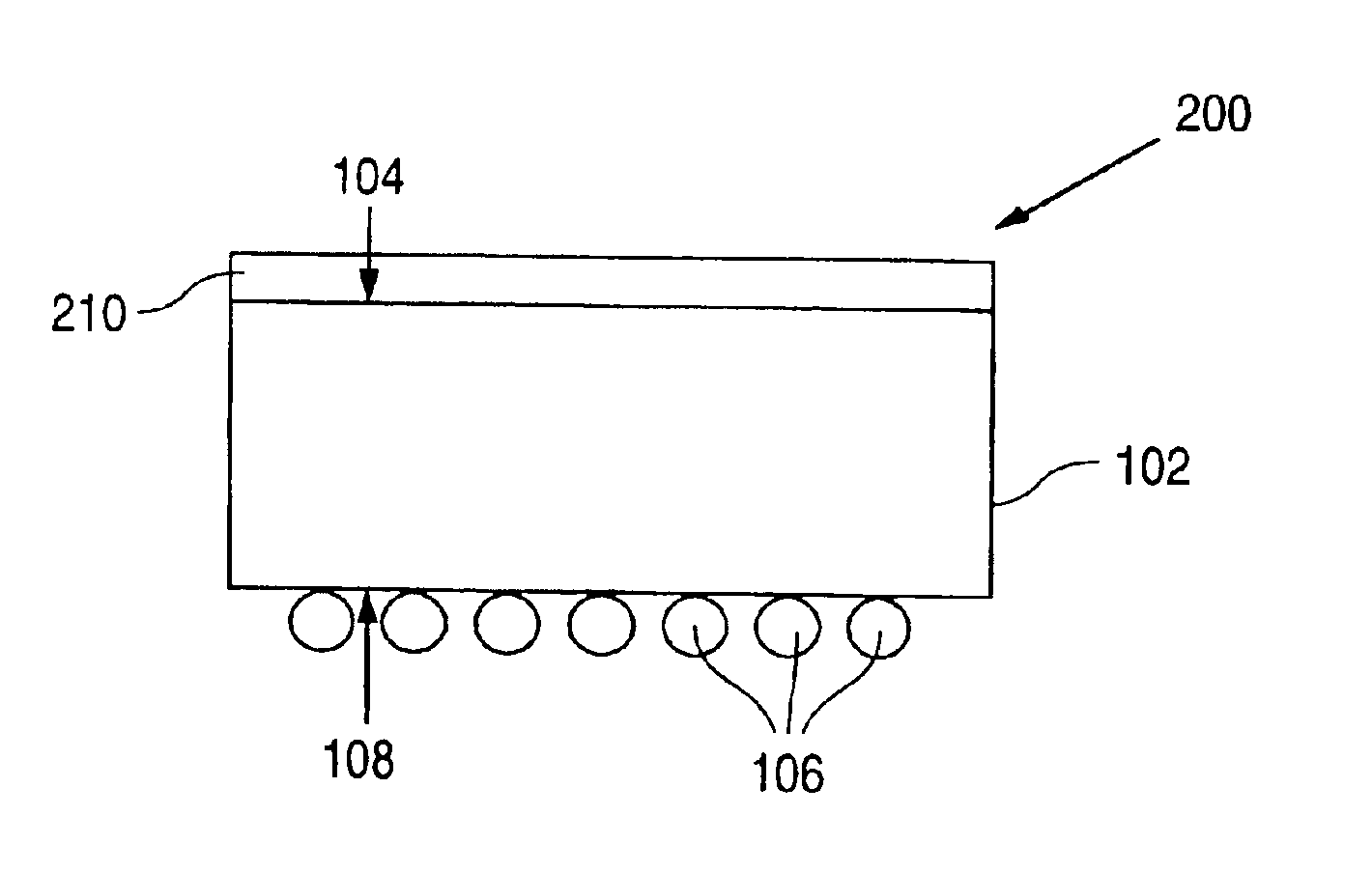

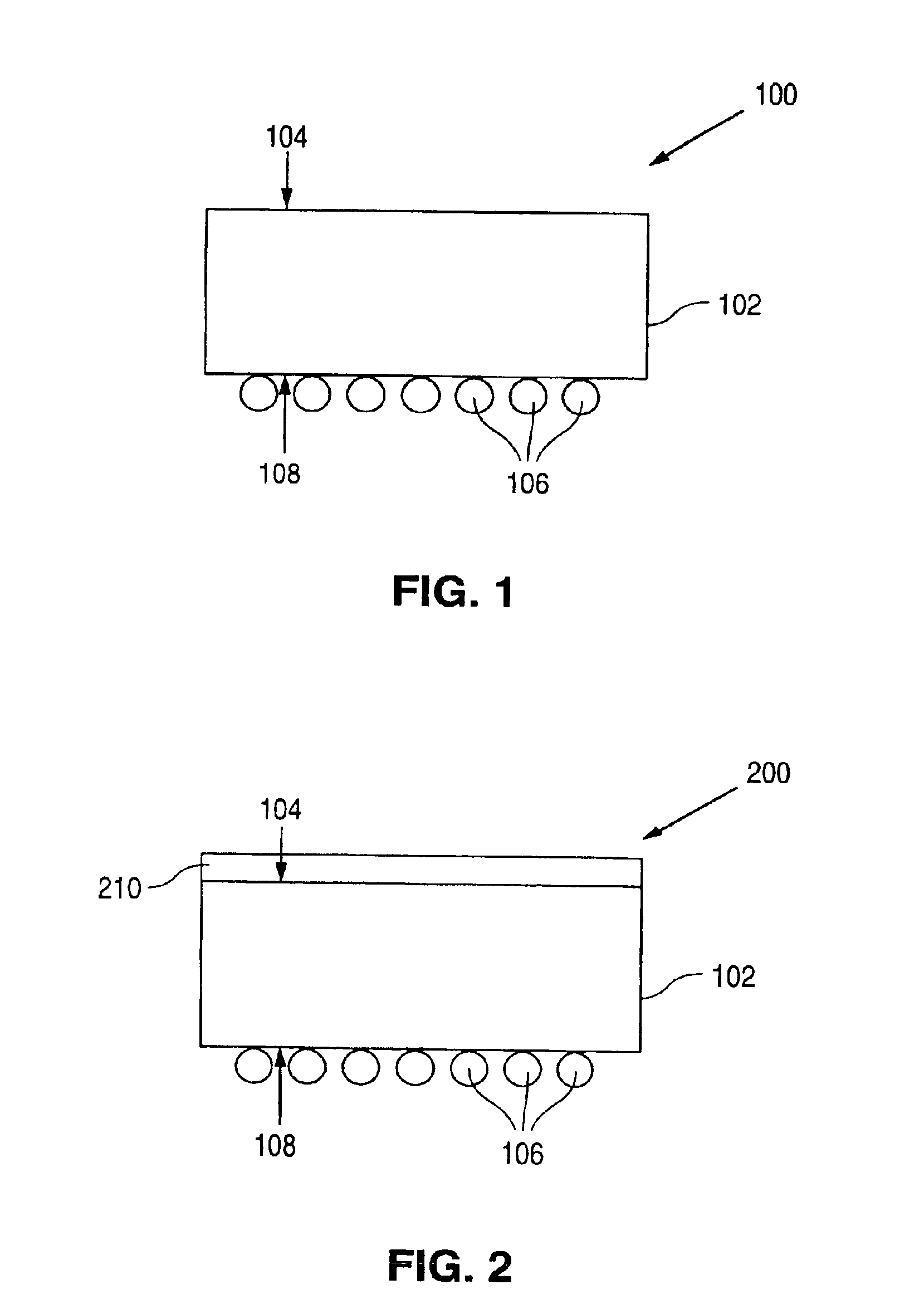

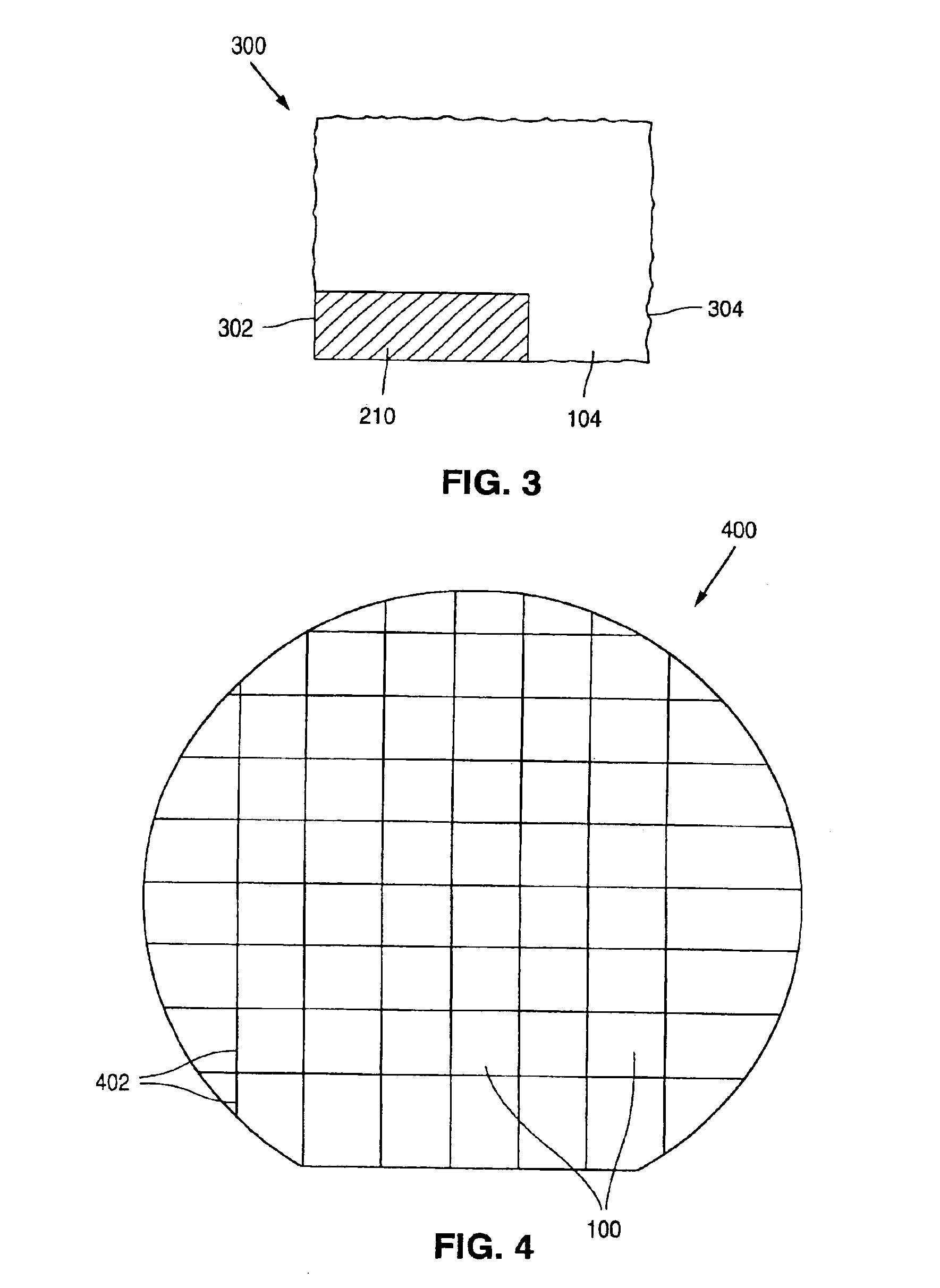

Semiconductor wafer having a bottom surface protective coating

InactiveUSRE38789E1Reduce debrisSemiconductor/solid-state device detailsSolid-state devicesScreen printingEngineering

Disclosed is a packaged integrated circuit device. The device includes a die having a plurality of electrical contacts on a first surface of the die and a protective film adhered directly to a back surface of the die, the protective film being thick enough to allow laser marking of the protective film without the laser penetrating to the die. In one preferred embodiment, the protective film of the device is a thick film formed by screen printing. In a preferred embodiment, the protective film has a thickness of between about 1.5 and 5 mils. Also, disclosed is a method of fabricating a semiconductor wafer having a wafer substrate with a top surface and a bottom surface and a plurality of dies. In this embodiment, the method includes providing a plurality of dies on the top surface of the wafer substrate, applying a thick film over the bottom surface of the wafer substrate, adhering the thick film to a mounting tape that is not ultraviolet curable, and dicing the wafer to separate the dies. The thick film reduces chipping along edges of the separated dies.

Owner:NAT SEMICON CORP

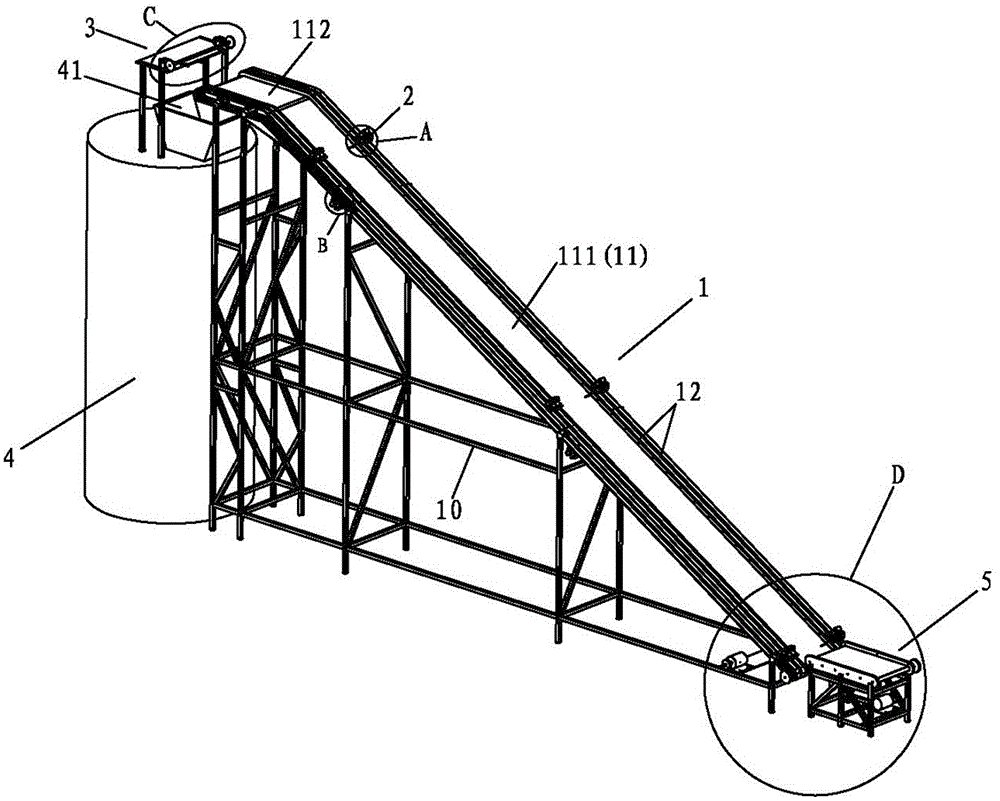

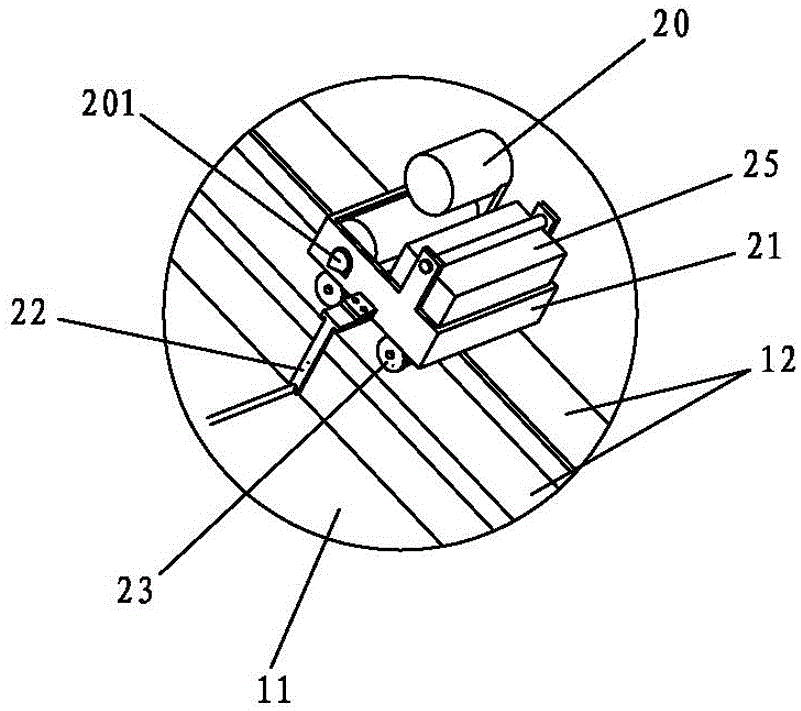

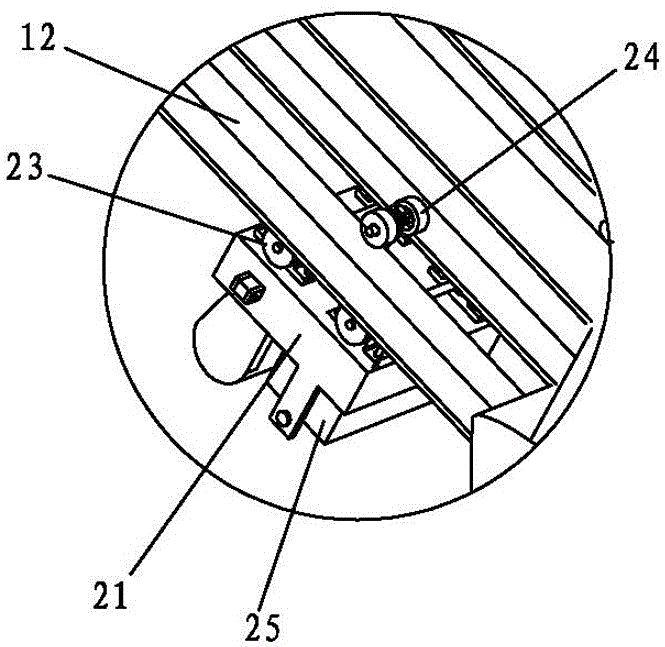

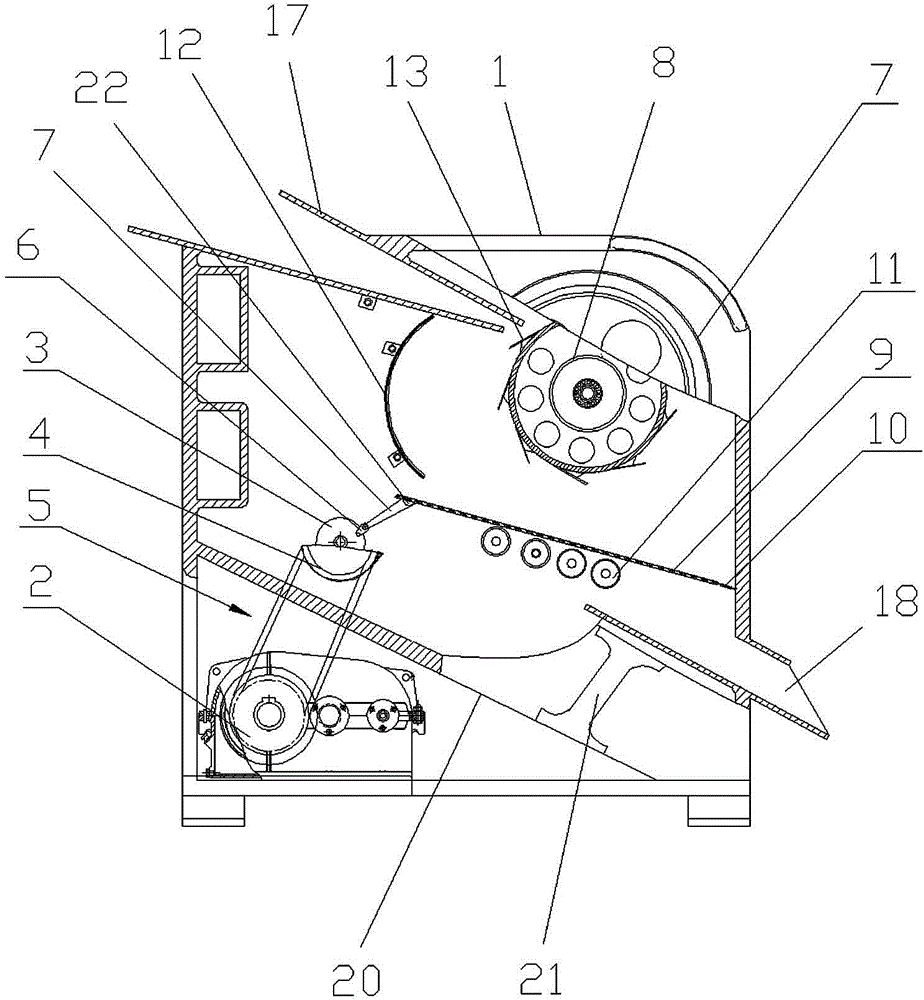

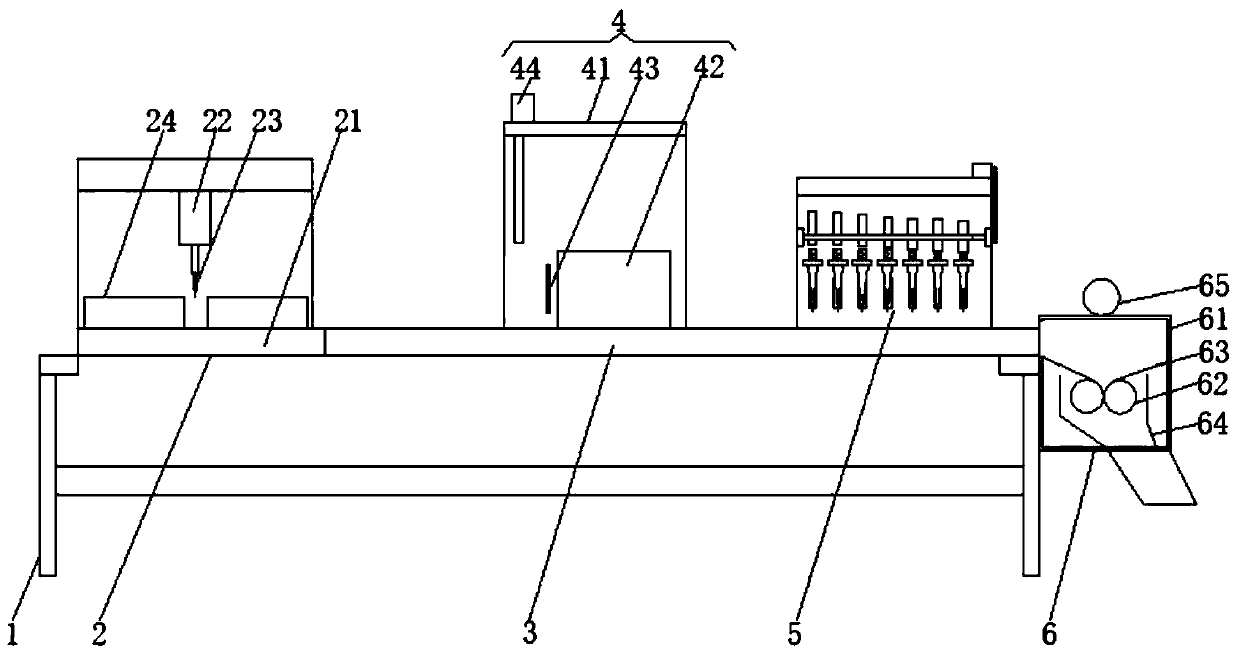

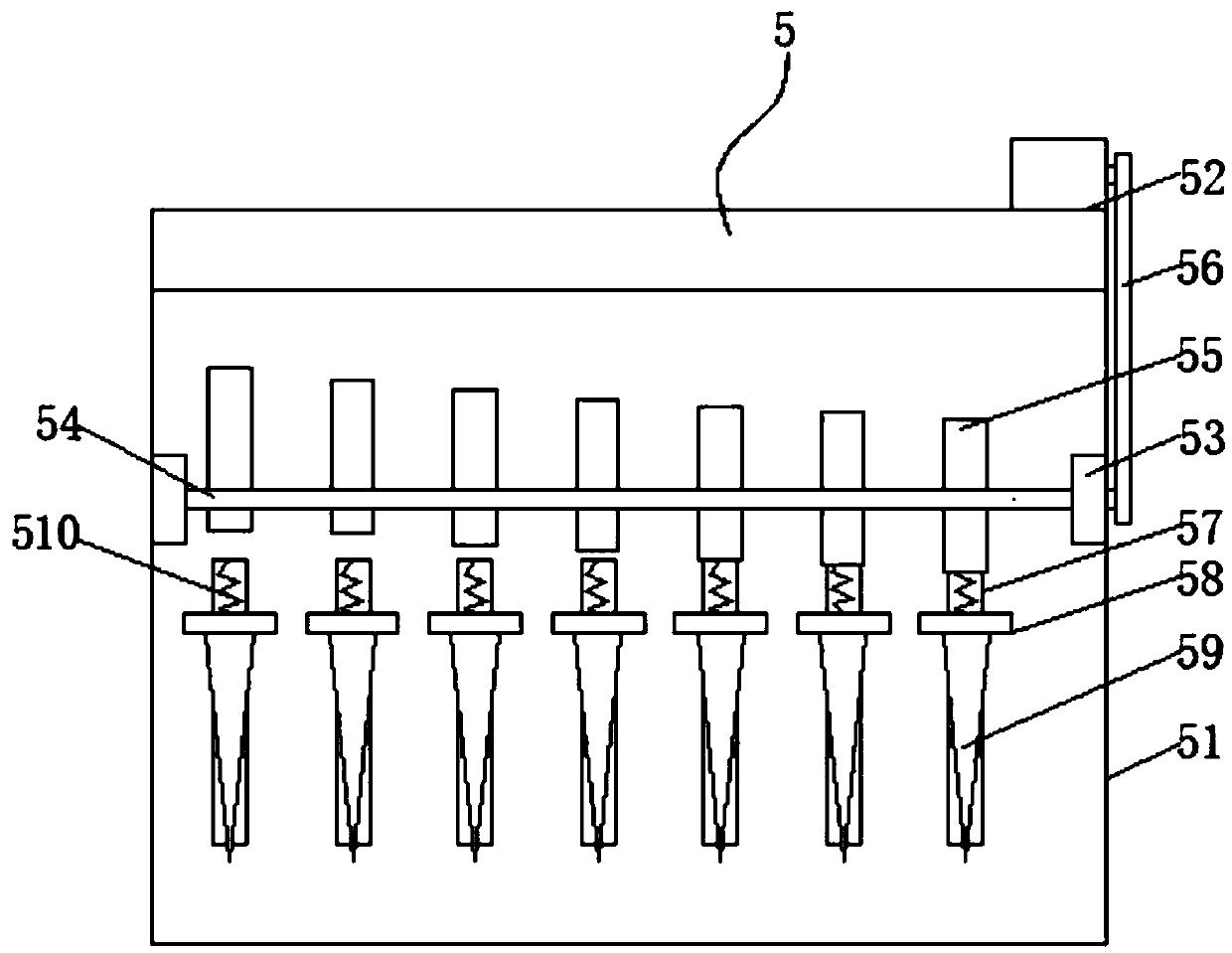

Intelligent full-automatic unpacking machine

ActiveCN105035440AScientific and reasonable structure designEasy to operateBags openingMechanical engineeringEngineering

The invention discloses an intelligent full-automatic unpacking machine which comprises an upward conveying device, an empty bag recycling device, an unpacking device and a material collecting device. The upward conveying device is provided with an upward conveying belt. The empty bag recycling device is arranged beside the upward conveying belt and moves along with the upward conveying belt, and the empty bag recycling device is provided with a barbed electric push rod. The unpacking device is arranged behind the tail end of the upward conveying belt and provided with a knife. The material collecting device is arranged below the unpacking device, and a feeding opening of the material collecting device is correspondingly located under the tail end of the upward conveying belt. The intelligent full-automatic unpacking machine is scientific and reasonable in structural design and easy to operate; gravity is ingeniously utilized, the knife is intelligently controlled in a full-automatic manner, blanking is accurate by combining the conveying belt and the action of gravity, and the machine can be suitable for being applied to different unpacking environments; the unpacking effect is good, the bag opening breaking speed is high, and few chippings exist; and compared with previous unpacking machines, the contamination of the chippings of material bags to materials is reduced to a large degree.

Owner:XIAMEN UNIV OF TECH

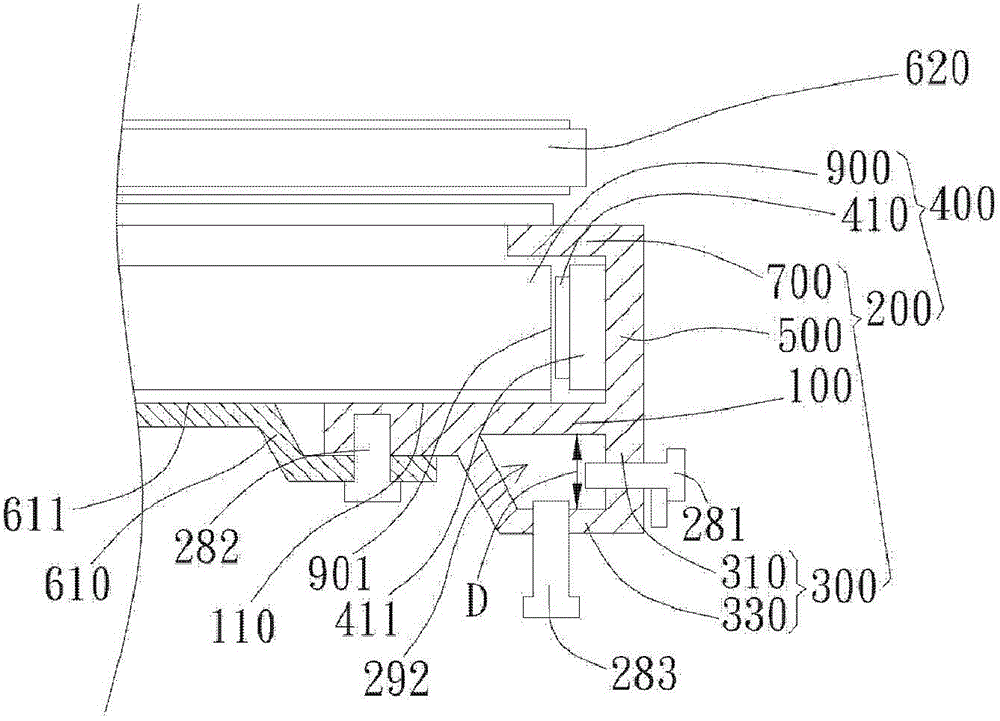

Supporting member for supporting light guide plate, and backlight module, display module, and display device made from the supporting member

InactiveCN102721011AReduce debrisGood light source fixed effectLighting support devicesLight fasteningsLight guideComputer module

The invention provides a supporting member for supporting a light guide plate, and a backlight module, a display module, and a display device made from the supporting member. The supporting member includes a support plate and a fixing part. The support plate is provided with a support surface to support the light guide plate, and the fixing part is formed by extending one side of the light guide plate along the direction opposite to the facing direction of the support surface. The fixing part is provided with a wall body and a bending part, and an interval is left between the bending part and the support plate. The backlight module, in conjunction use with a back board, includes the supporting member equipped with a light source installing part, a light source arranged at the light source installing part, and a light guide plate arranged on the support surface and provided with the in-light side end face facing the light source.

Owner:AU OPTRONICS CORP

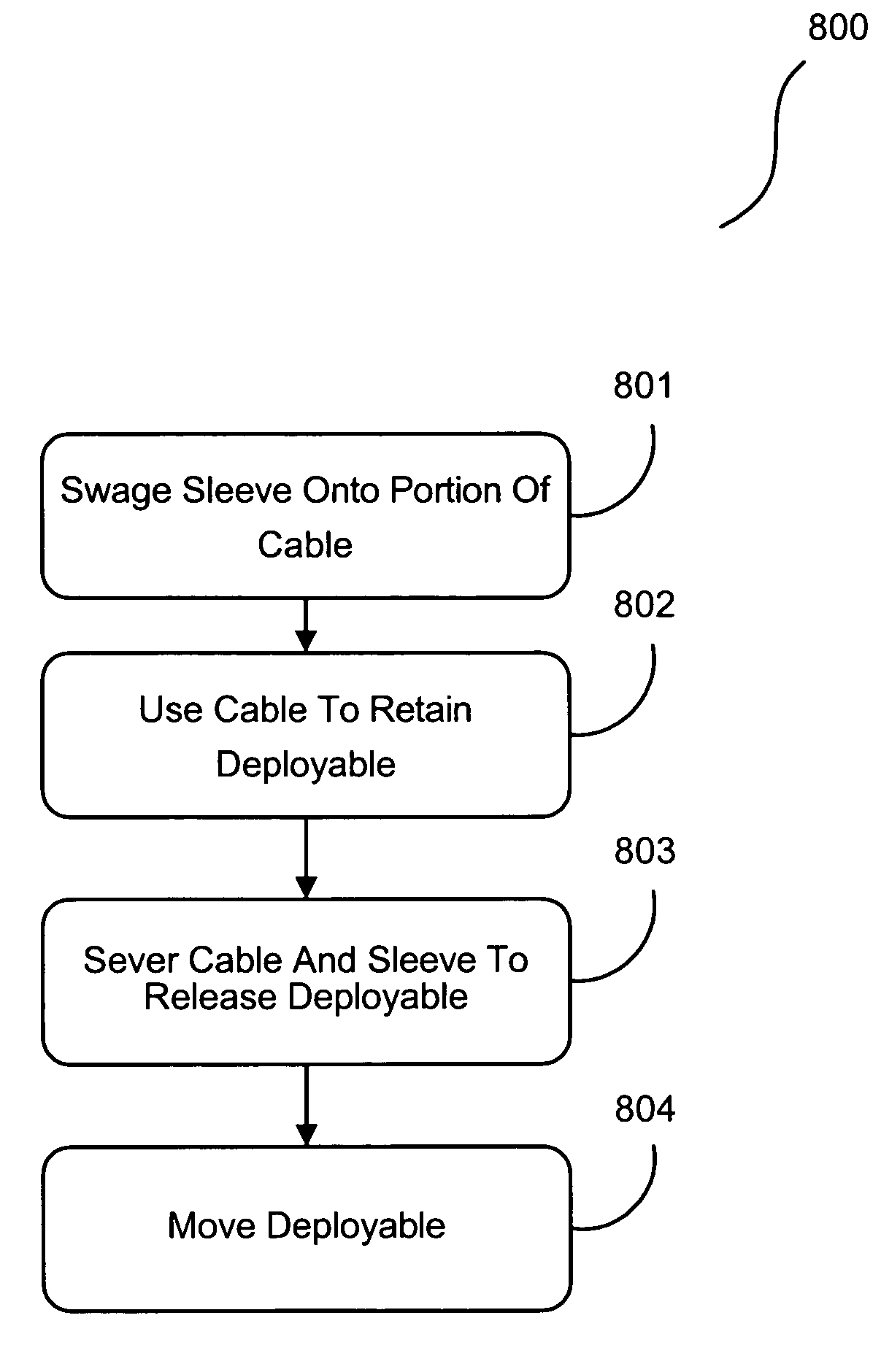

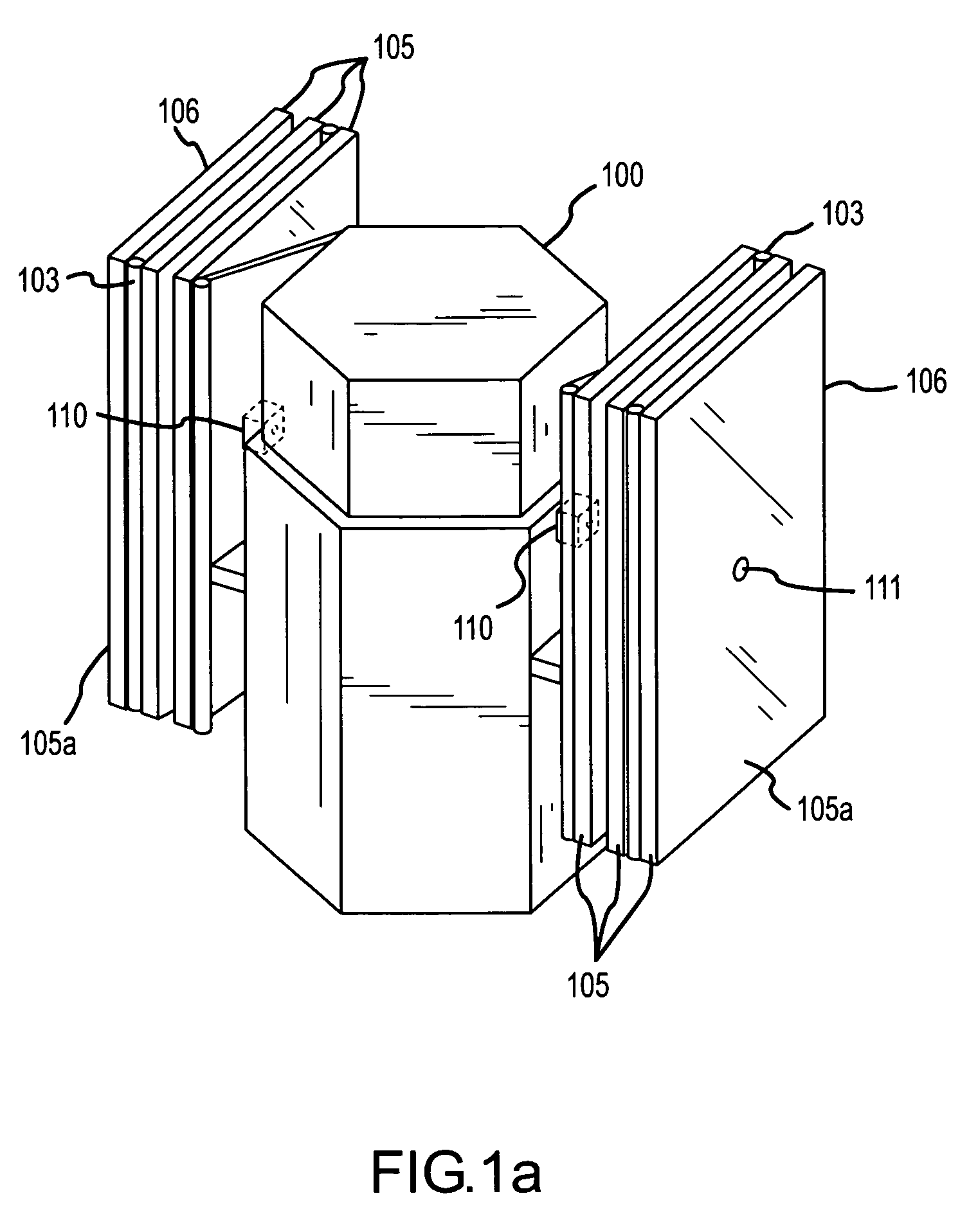

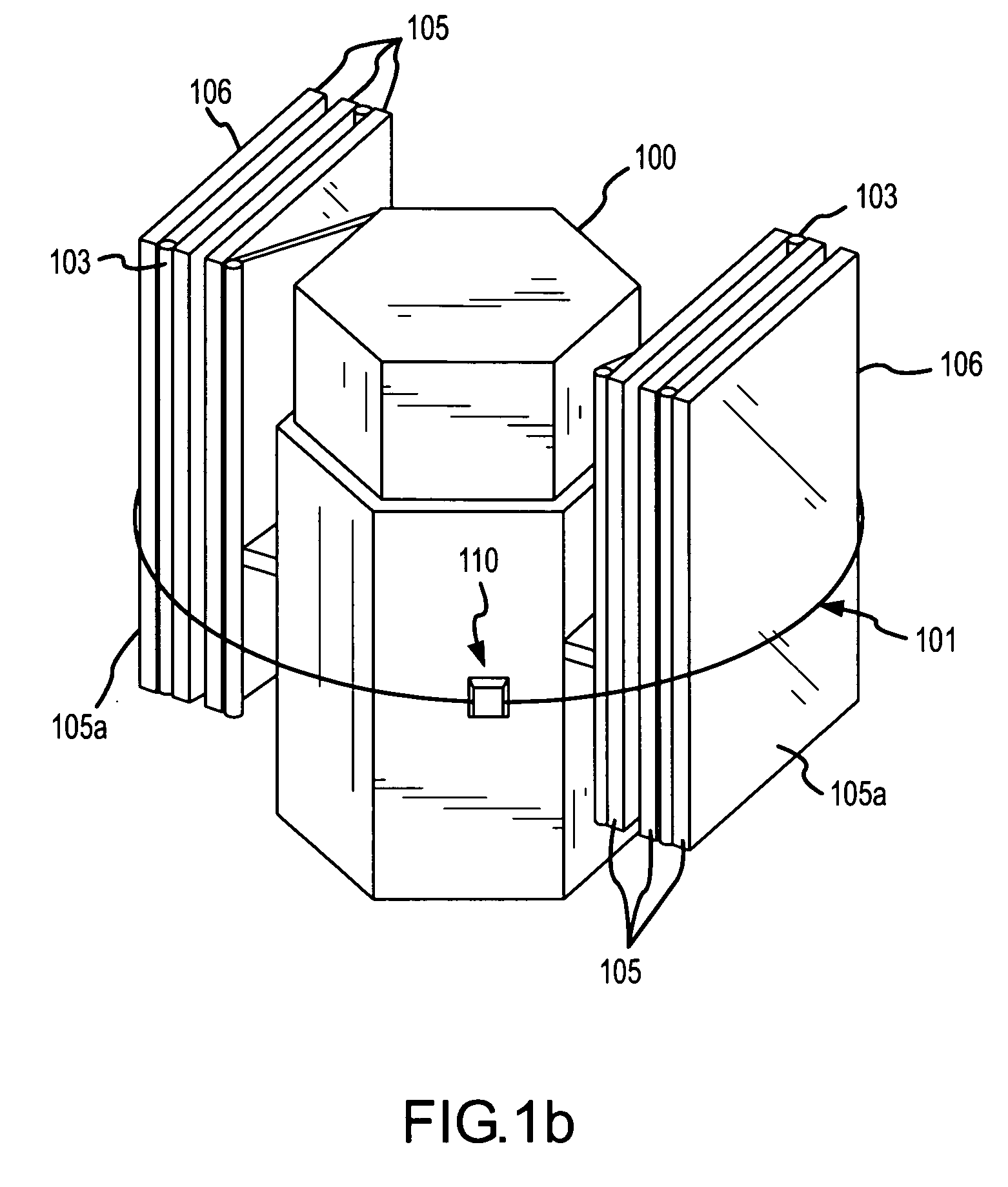

Swaged cable deployment in space

ActiveUS7278612B1Eliminate such splayingMaintain integrityCosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringElectric cables

A cable restraint / deployment mechanism is disclosed for deploying an object in space from a spacecraft. To deploy the object, the cable restraint / deployment mechanism cuts a cable attached to the spacecraft and the object. For example, a spacecraft may include a solar panel array that is restrained by the spacecraft in a stowed form through the use of a wire rope cable. The cable may be affixed at one end to a deployable object. The other end of the cable is affixed to the spacecraft through a cutting mechanism, such as a pyrotechnically actuated cutting device. The cutting mechanism cuts the cable at a swaged sleeve of the cable. The swaged sleeve of the cable substantially prevents splaying of the cable and cutting debris.

Owner:LOCKHEED MARTIN CORP

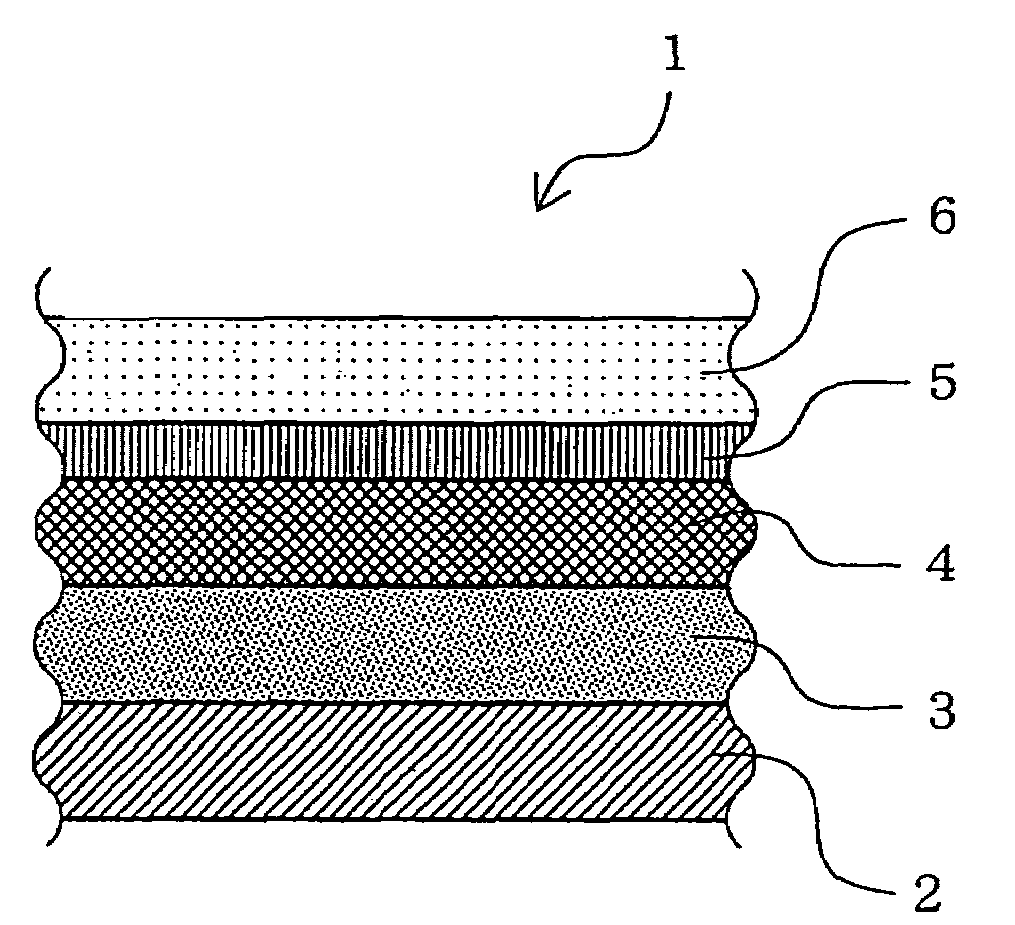

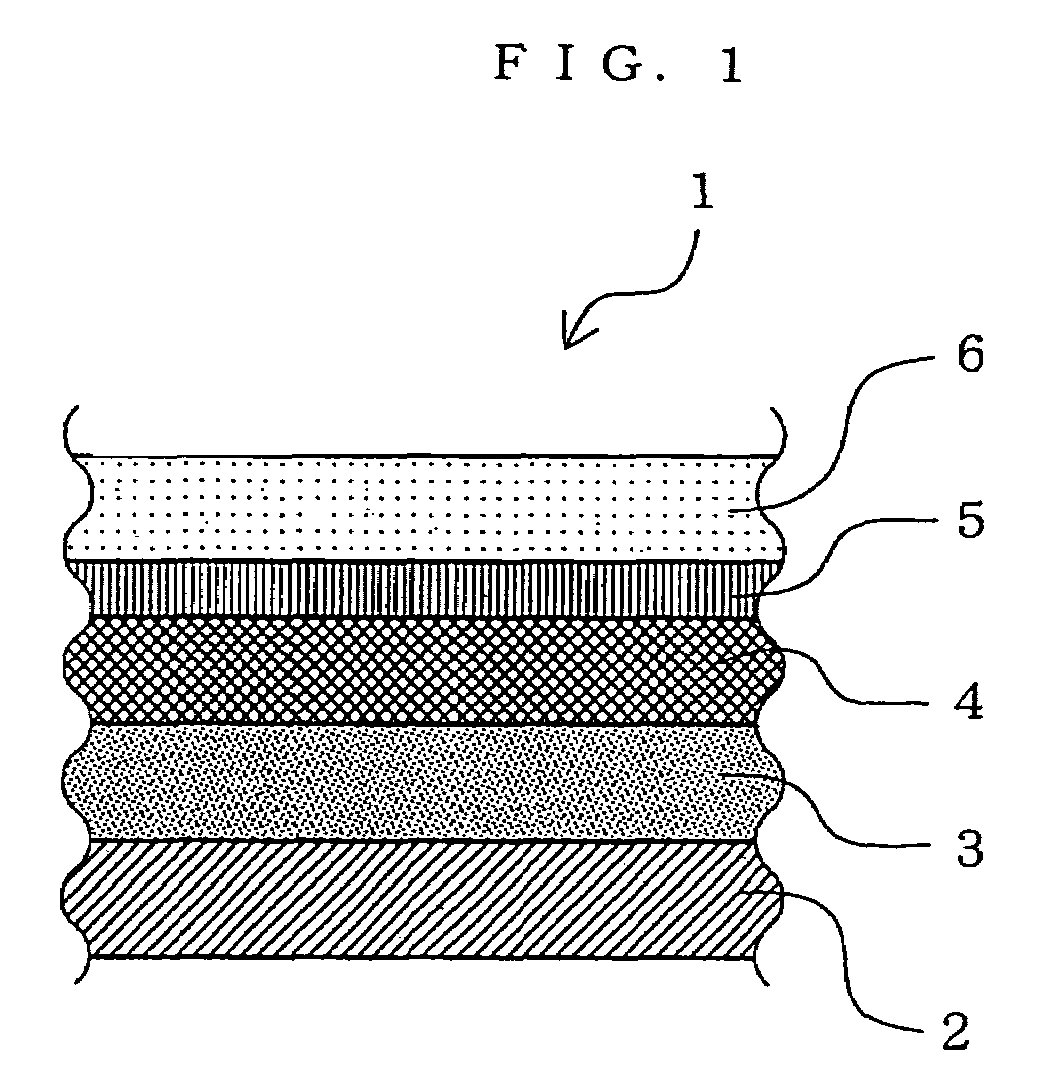

Heat-peelable pressure-sensitive adhesive sheet and method for processing adherend using the heat-peelable pressure-sensitive adhesive sheet

InactiveUS7635516B2Reduce debrisHigh elastic modulusFixed capacitor dielectricLaminating printed circuit boardsShear modulusFoaming agent

Disclosed is a heat-peelable pressure-sensitive adhesive sheet that can prevent the deformation of a pressure-sensitive adhesive layer caused by pressurization, further reduce chipping in grinding and cutting processes, be easily peeled off from a processed article after processing, and can be easily applied to an adhered at ordinary temperature. The heat-peelable pressure-sensitive adhesive sheet includes a substrate, and a heat-expandable pressure-sensitive adhesive layer arranged on or above at least one side of the substrate, the heat-expandable pressure-sensitive adhesive layer containing a foaming agent and having a shear modulus (23° C.) in an unfoamed state of 7×106 Pa or more. The adhesive sheet further includes a pressure-sensitive adhesive layer being arranged on or above heat-expandable pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer has a shear modulus (23° C.) of less than 7×106 Pa and a thickness of 0.01 to 10 μm.

Owner:NITTO DENKO CORP

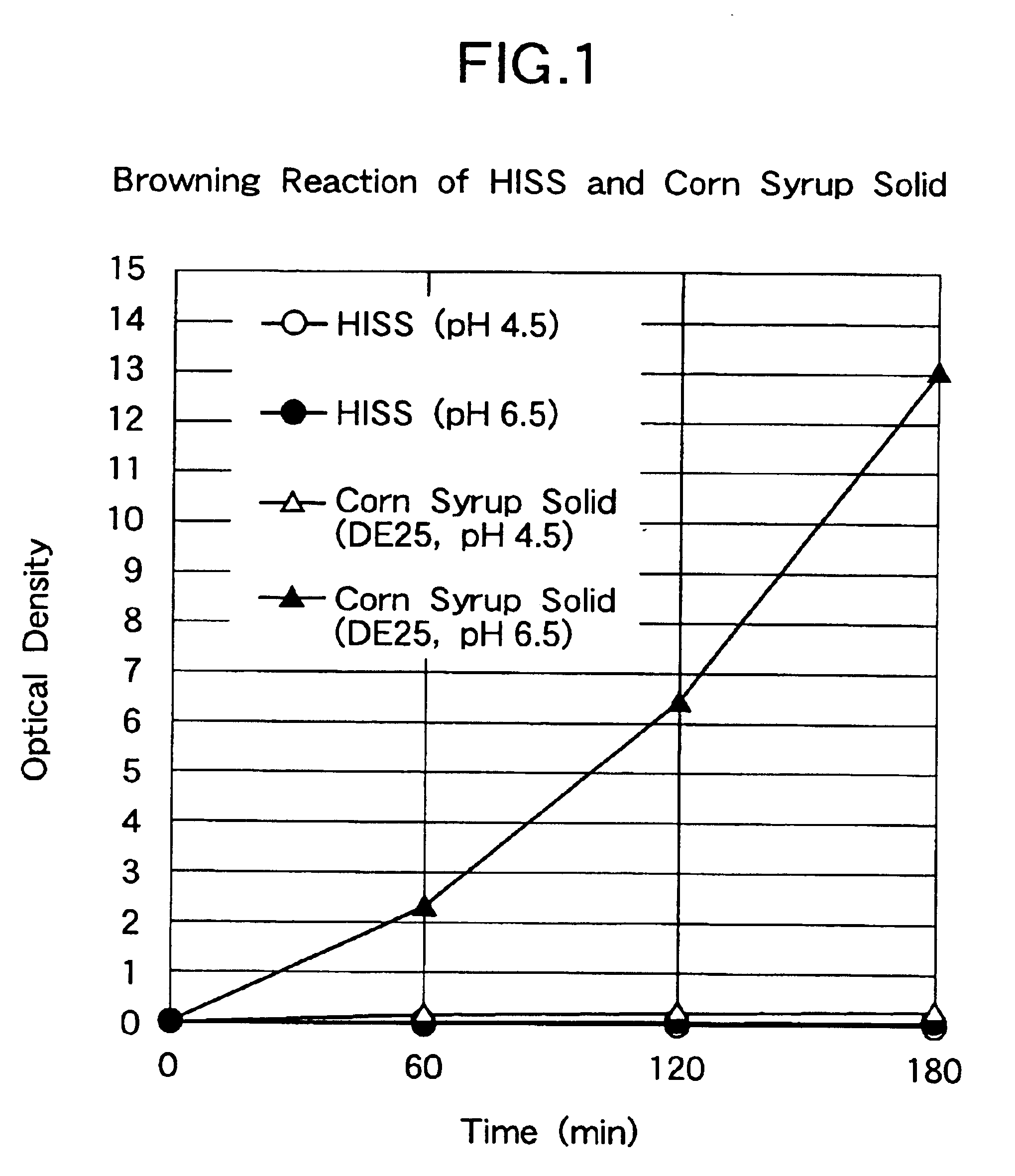

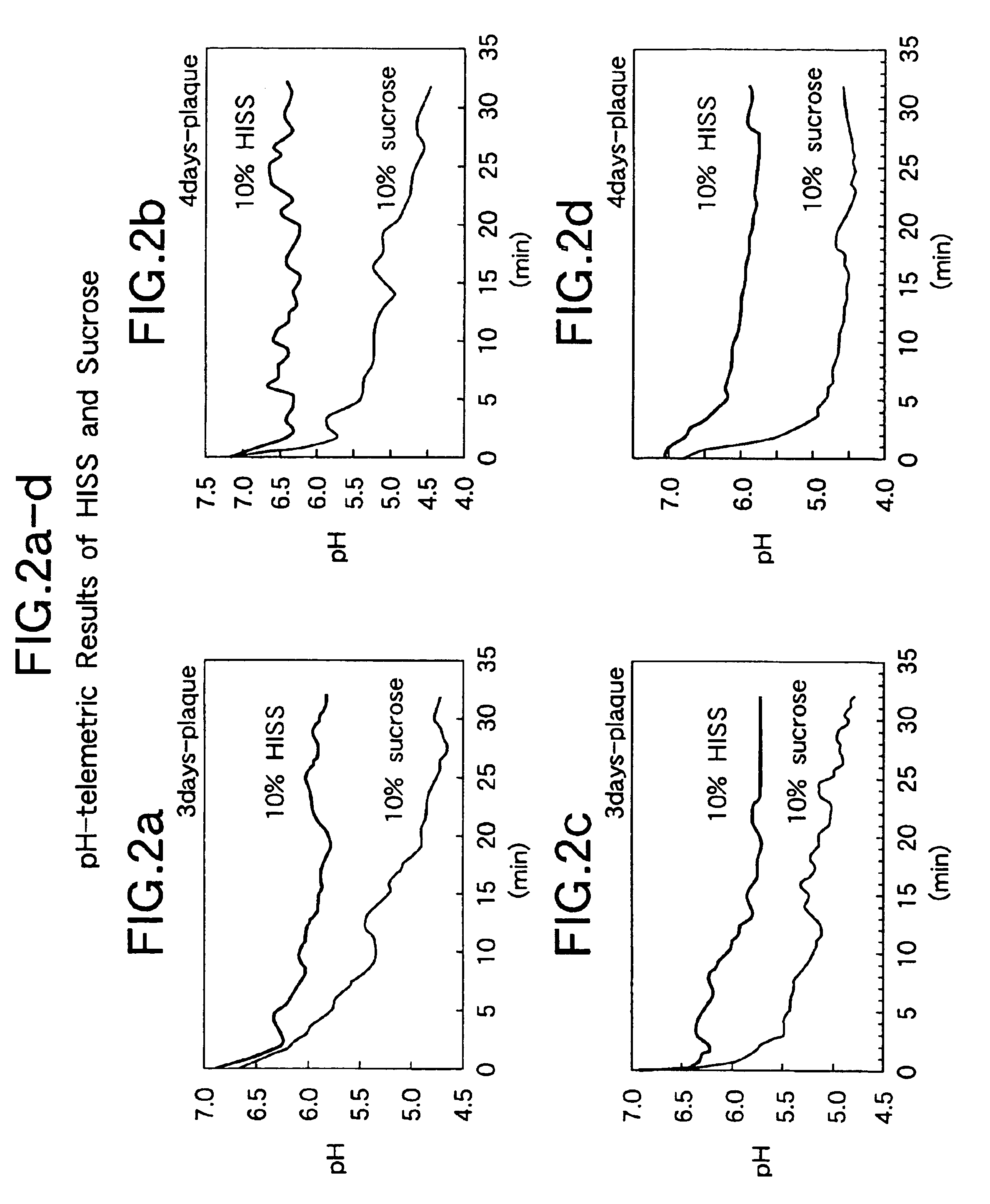

Coated chewing gum products containing hydrogenated indigestible starch syrup as a binding agent

InactiveUS6866876B2Increase stiffnessReduce debrisContainers for annular articlesConfectioneryChewing gumStarch

An object of the present invention is to provide a coated product with increased stiffness to reduce the chipping after manufacturing and several days of storage, and before wrapping. A coated product such as chewing gum, medicines and medicinal tablets, wherein the product is coated with a coating composition comprising hydrogenated indigestible starch syrup as a binding agent.

Owner:WM WRIGLEY JR CO +1

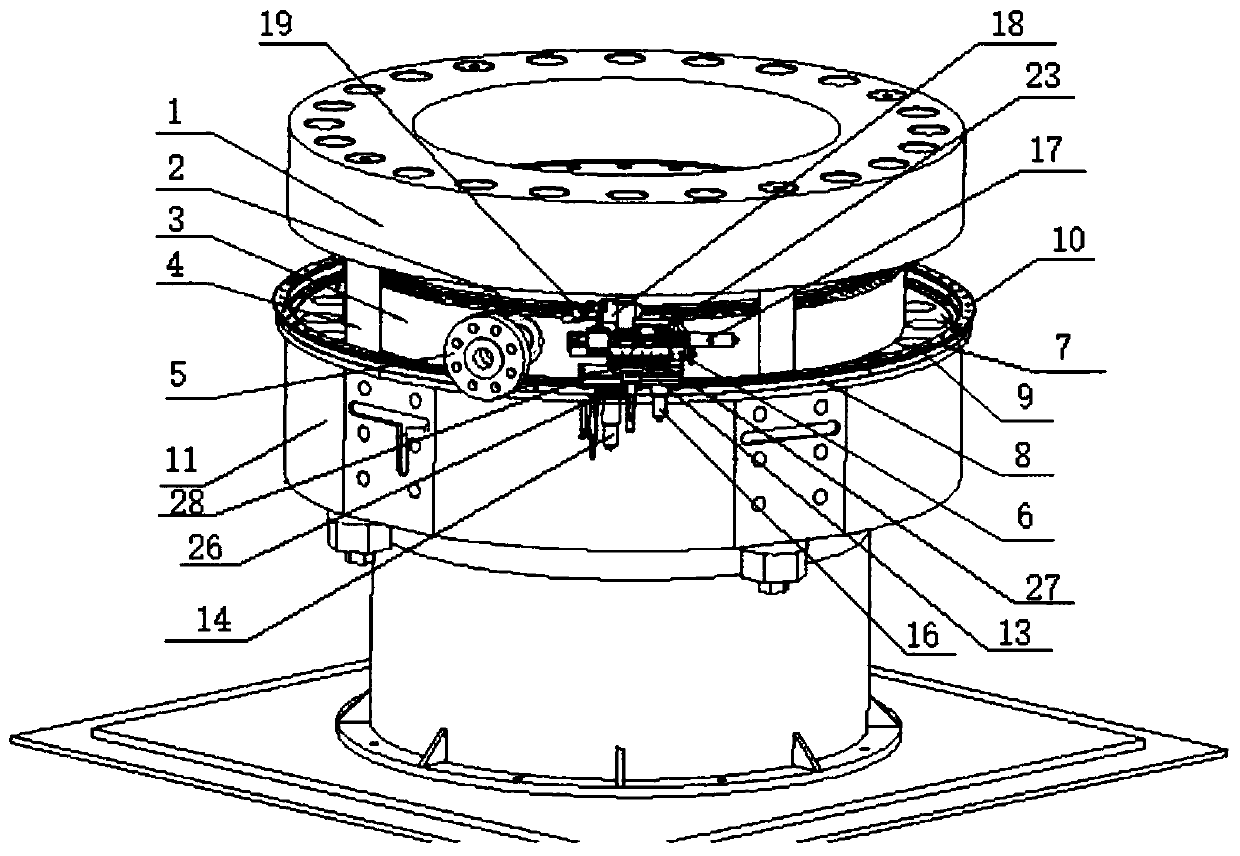

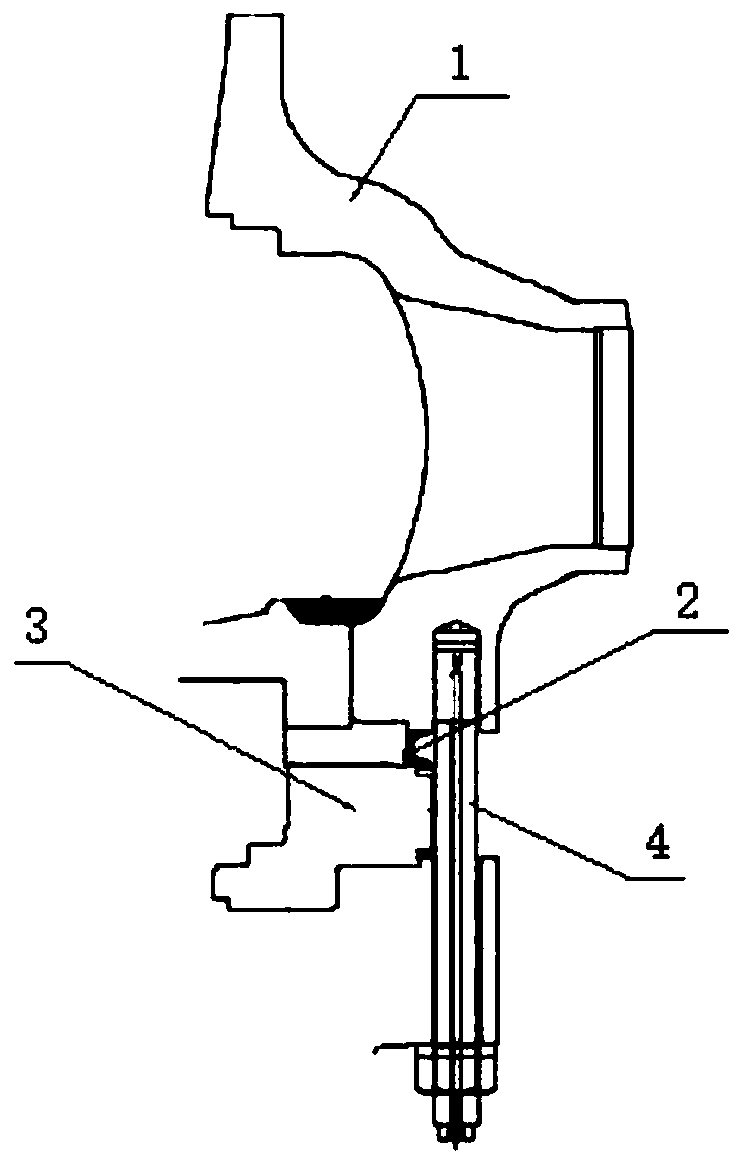

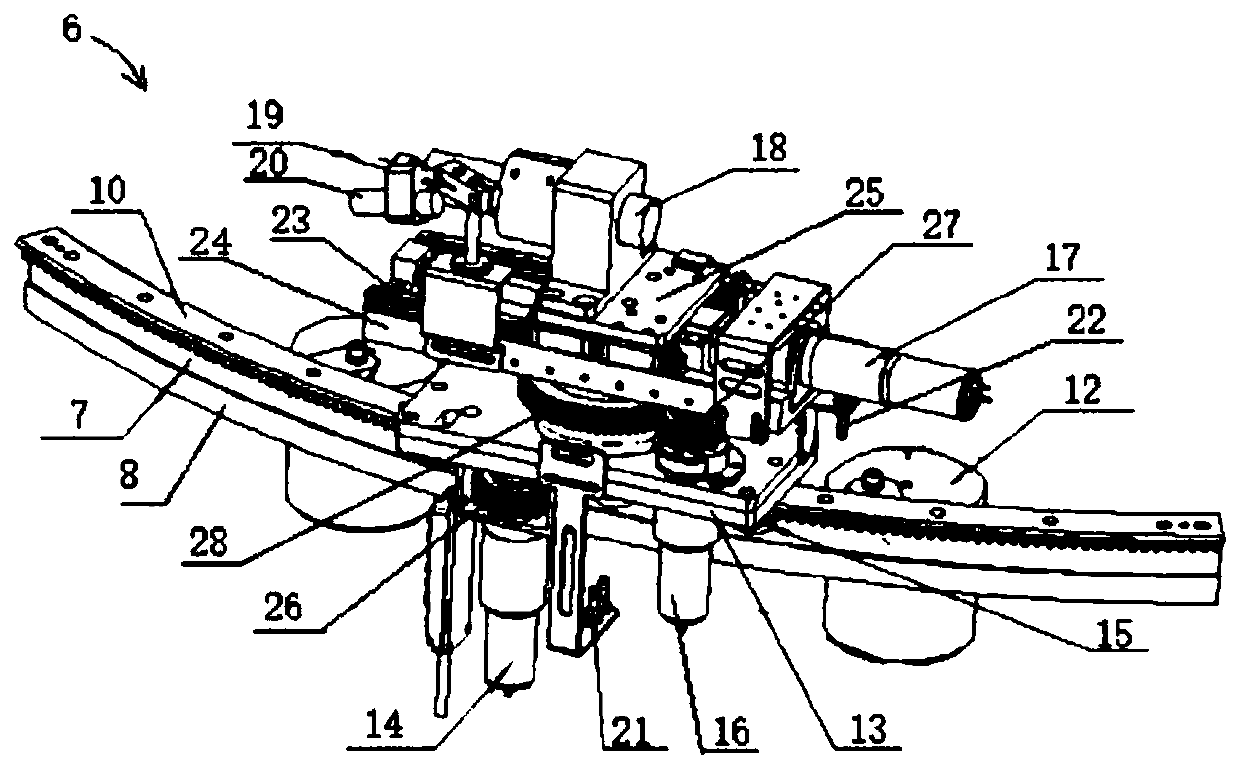

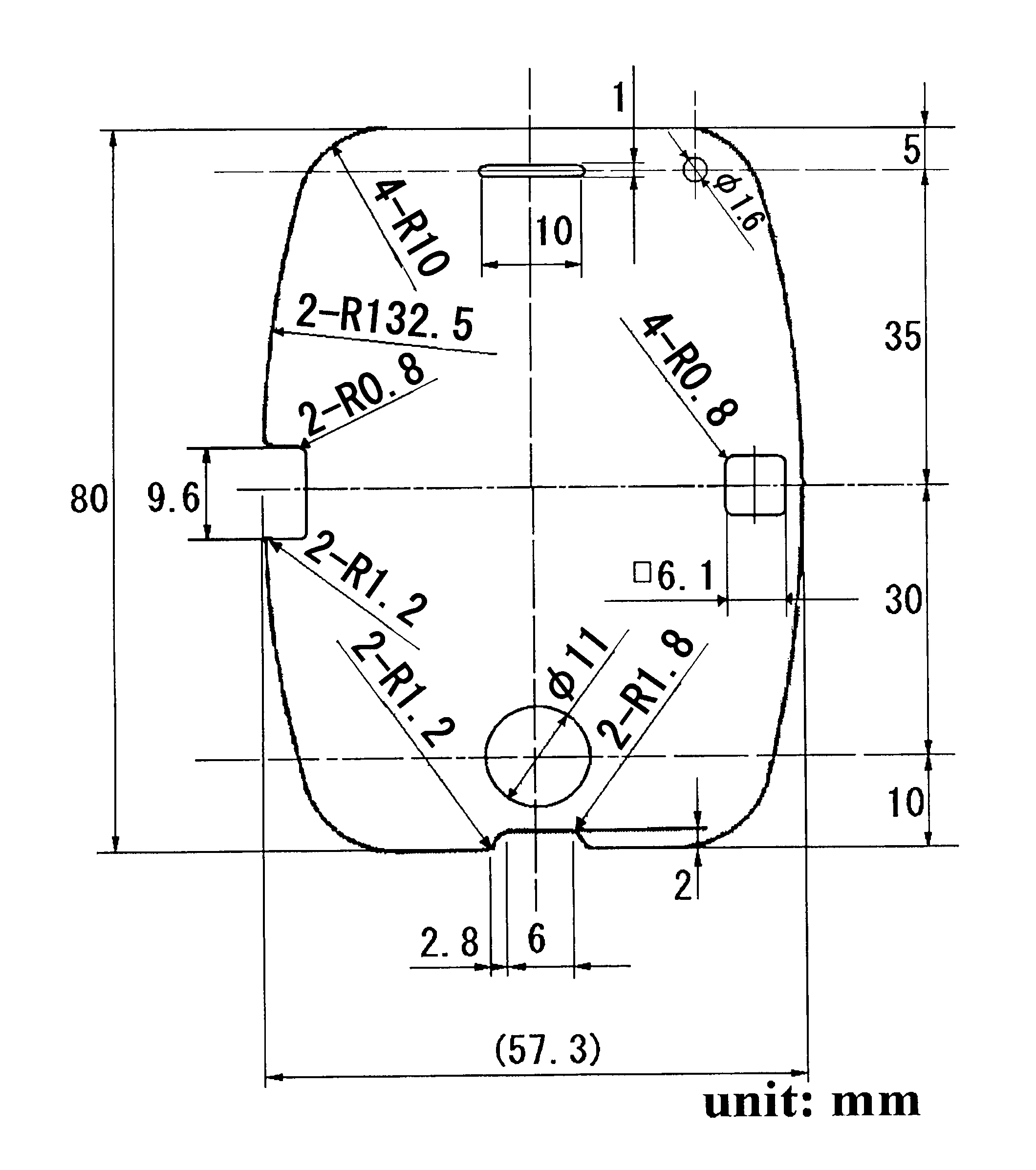

Sealing ring cutting device and cutting method thereof

ActiveCN110587030ARealize automatic cuttingSmall doseMeasurement/indication equipmentsManufacturing technologyEngineering

The invention discloses a sealing ring cutting device and a cutting method thereof, and relates to the technical field of equipment manufacturing. The sealing ring cutting device comprises an annularrail mounted on the outer side of a sealing ring, a cutting machine mounted on the annular rail, and a first motor connected with the cutting machine to drive the cutting machine to move along the annular rail. According to the sealing ring cutting device, the rail and the cutting machine are arranged on the outer side of the sealing ring, automatic cutting on the sealing ring is achieved, and theproblem that an operator receives a lot of irradiation dose in an existing sealing ring cutting process is solved.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Method for making coated chewing gum products with a coating including an aldehyde flavor and a dipeptide sweetener

InactiveUS7115288B2Reduce debrisImproved pellet crunchContainers for annular articlesConfectioneryPolymer scienceDipeptide

A method of making coated chewing gum products comprises the steps of providing chewing gum cores; providing a first coating syrup comprising a bulk sweetener; providing an aldehyde flavor; providing a second coating syrup separate from the first coating syrup and comprising a dipeptide sweetener; and applying the first and second coating syrups to the cores and drying the syrups to produce a coating on the cores. Calcium carbonate or another antacid may be incorporated in the coating by being mixed into the first coating syrup or applied as a dry charge.

Owner:WM WRIGLEY JR CO

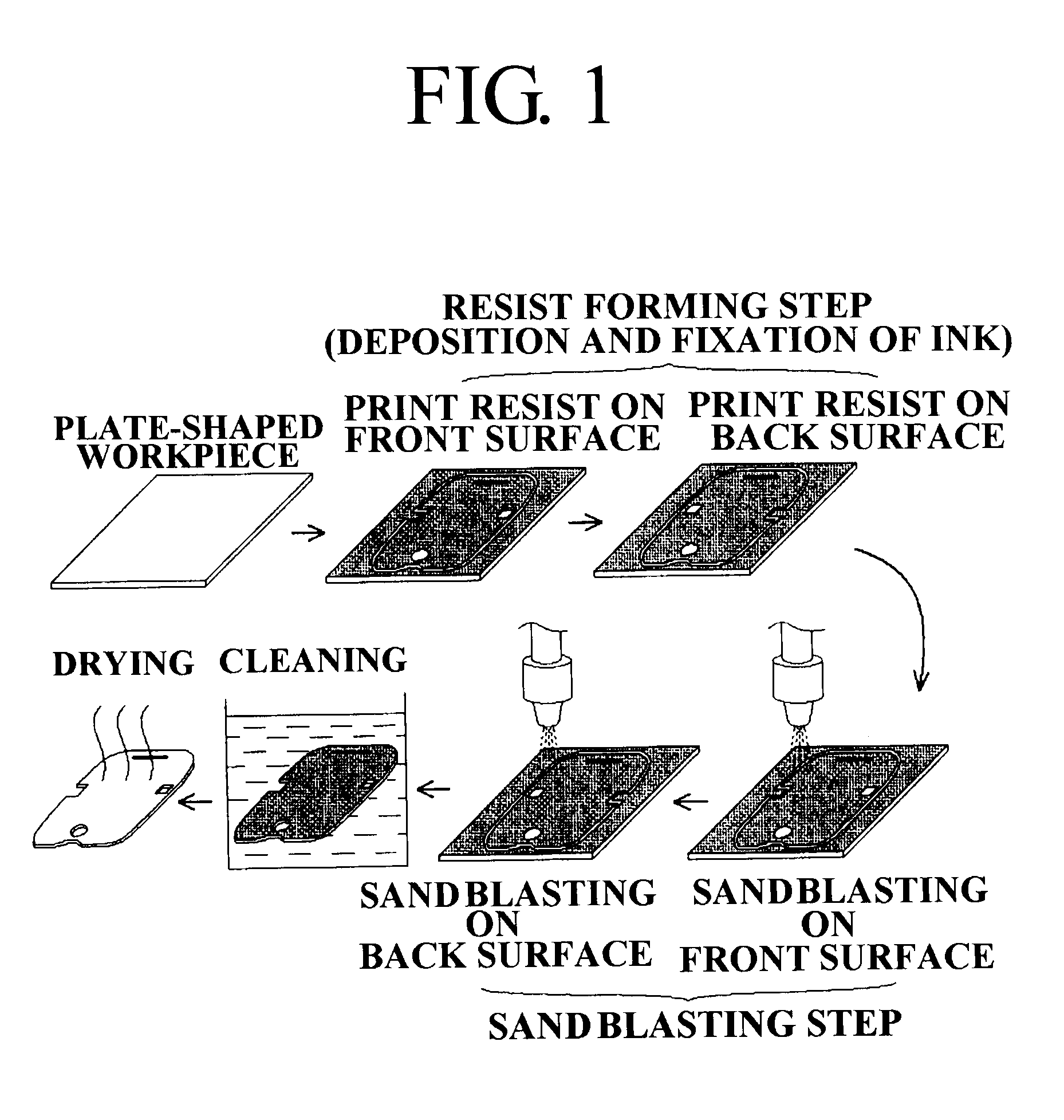

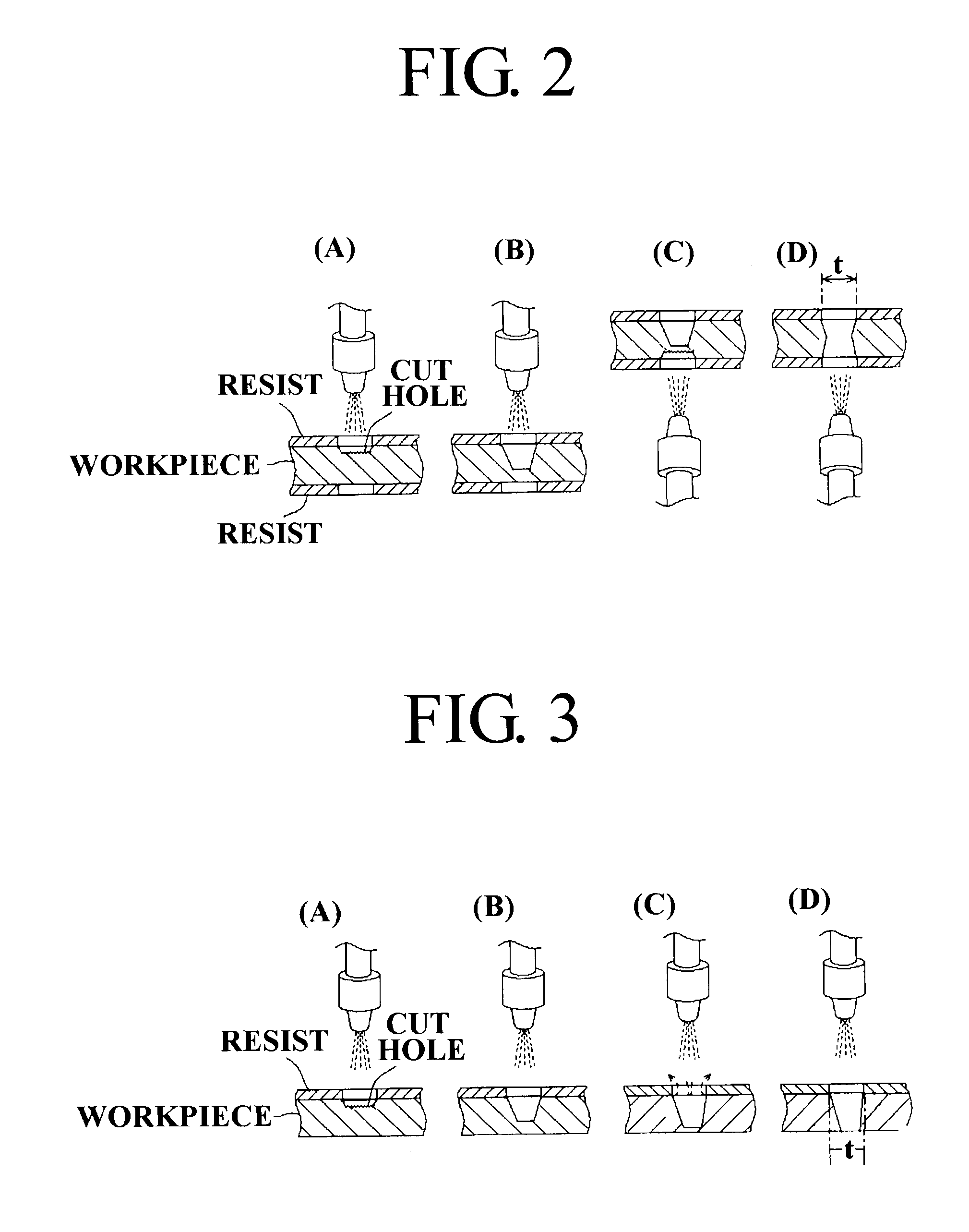

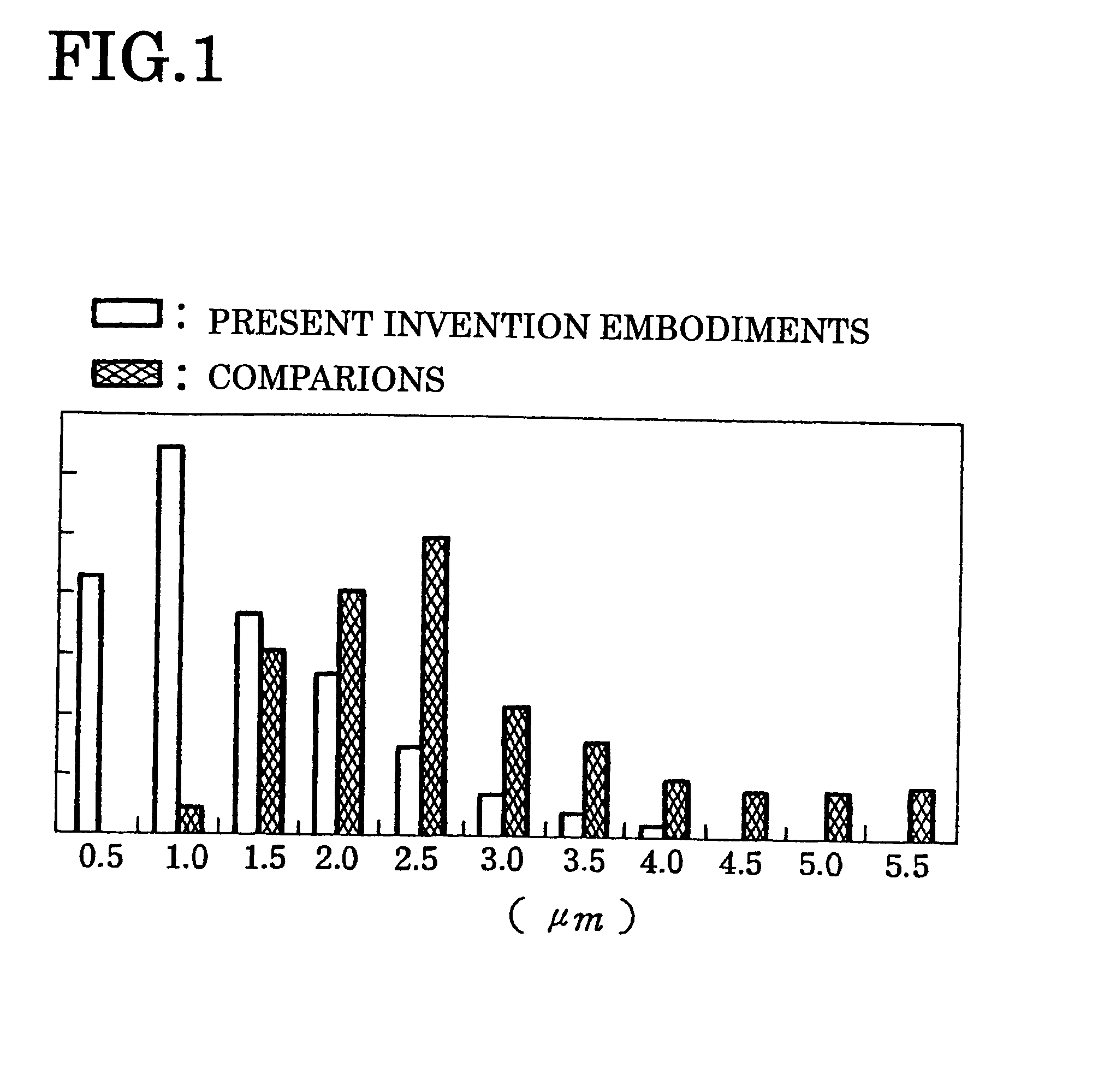

Cutting method by sandblasting

A cutting method by sandblasting in which cutting through of a workpiece and / or formation of a through-hole in the workpiece are / is performed by forming a resist on a plate-shaped workpiece and projecting abrasive against the workpiece to cut a portion of the workpiece where no resist is formed, comprises the steps of: forming the resist in a predetermined pattern on a front surface and a back surface of the workpiece symmetrically between the front and back by inkjet printing, and projecting the abrasive against each of the front and back surfaces of the workpiece to make a cut from the front surface side communicate with a cut from a back side at an approximately intermediate position of a thickness of the workpiece.

Owner:FUJI MFG CO LTD

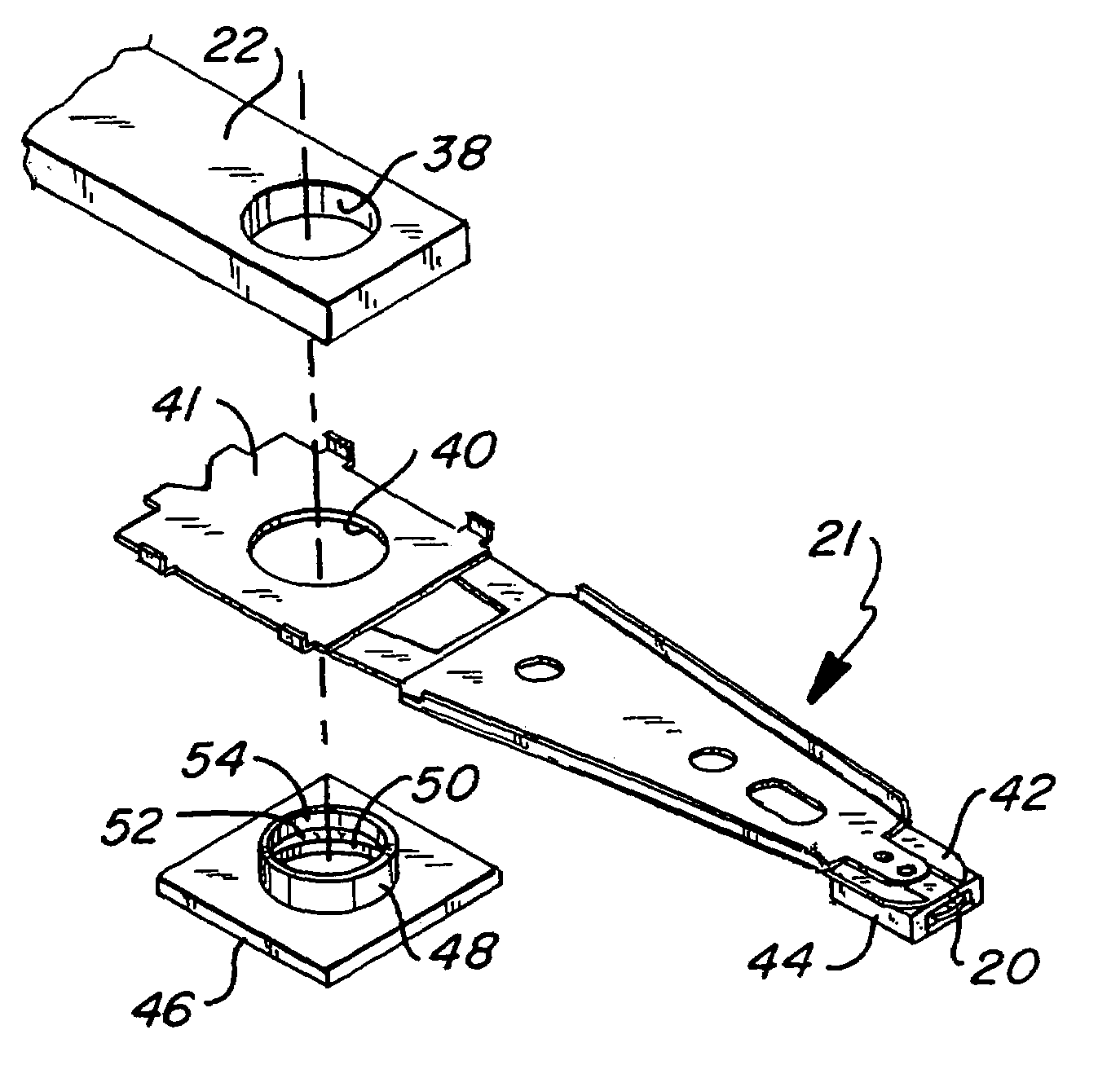

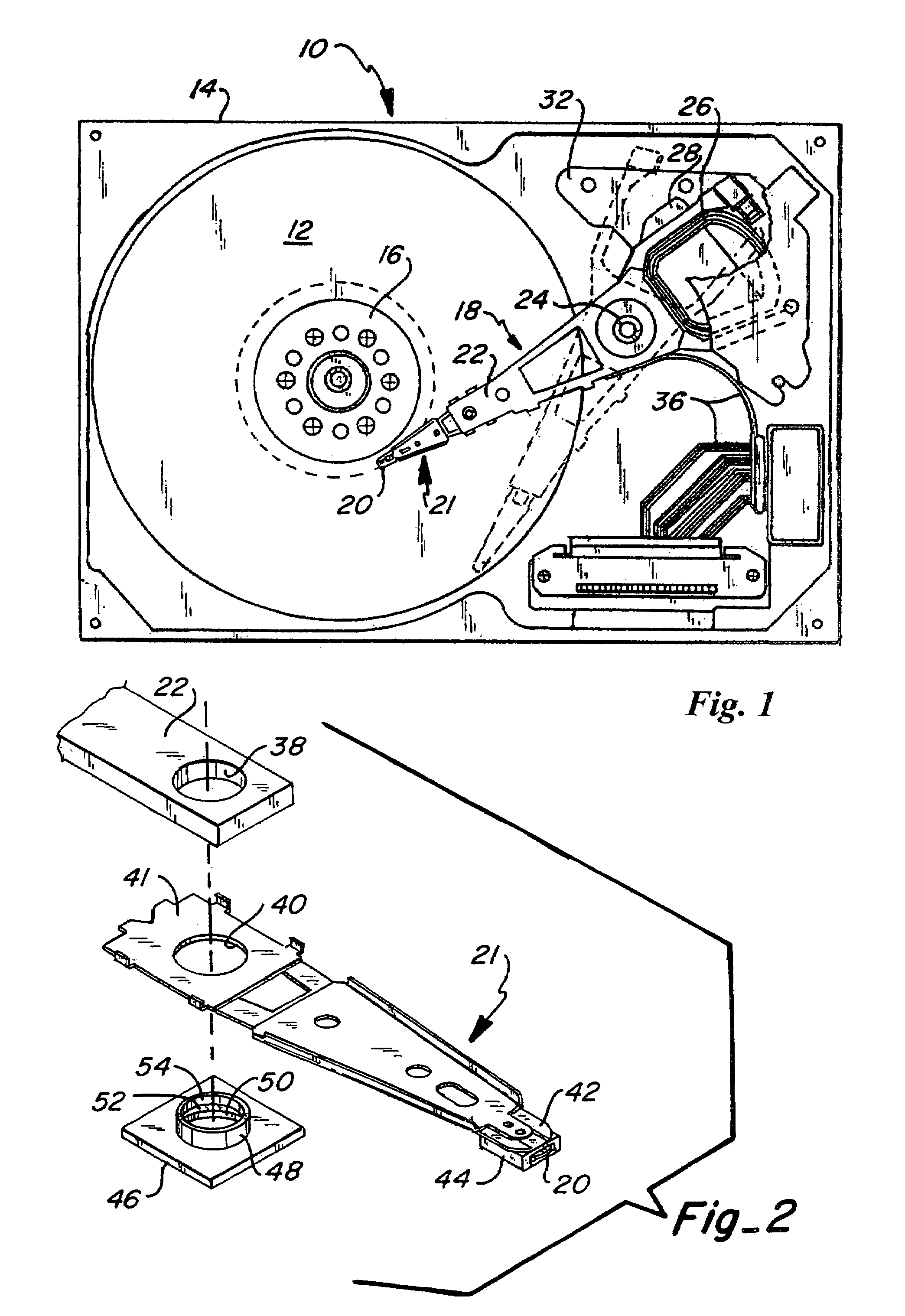

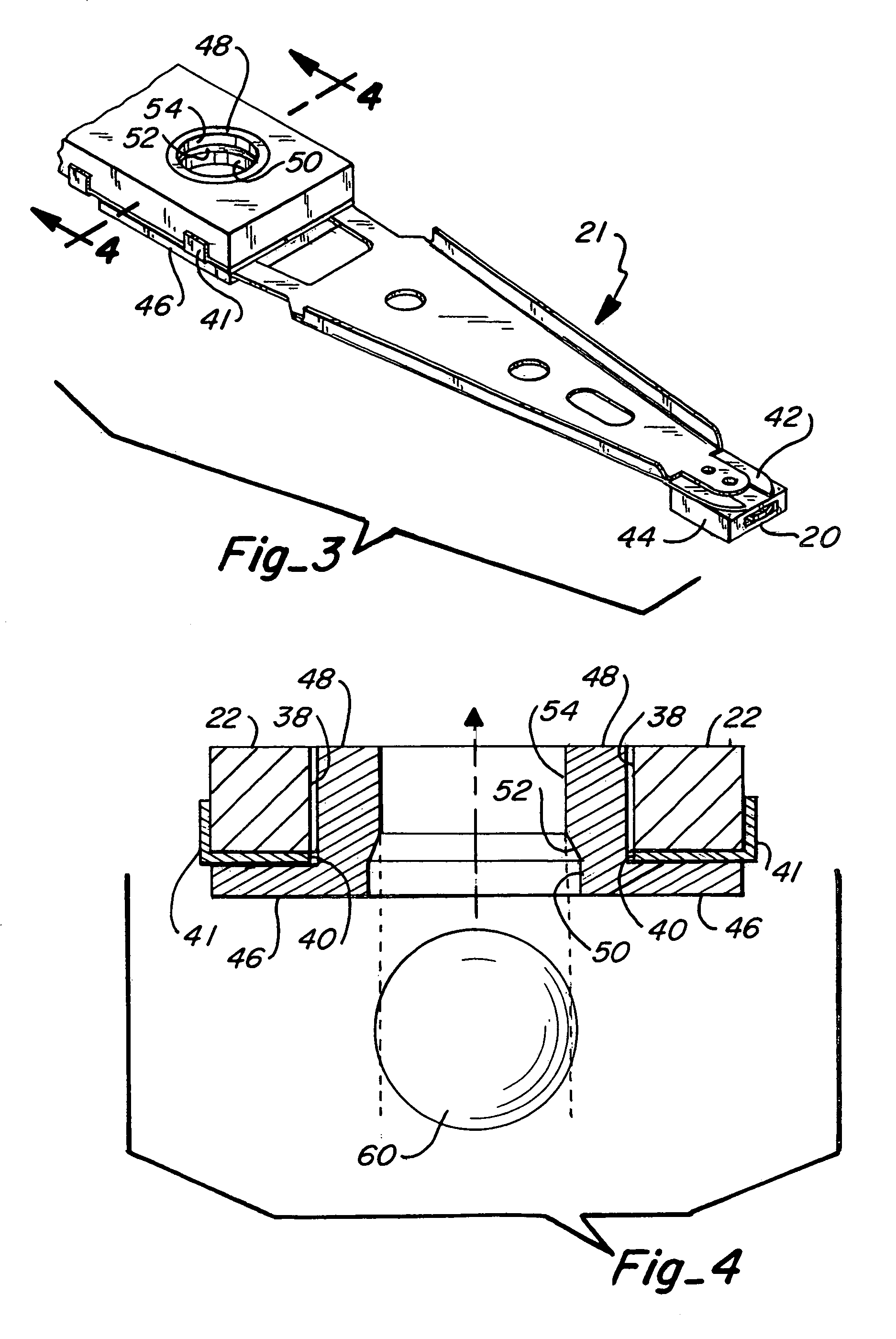

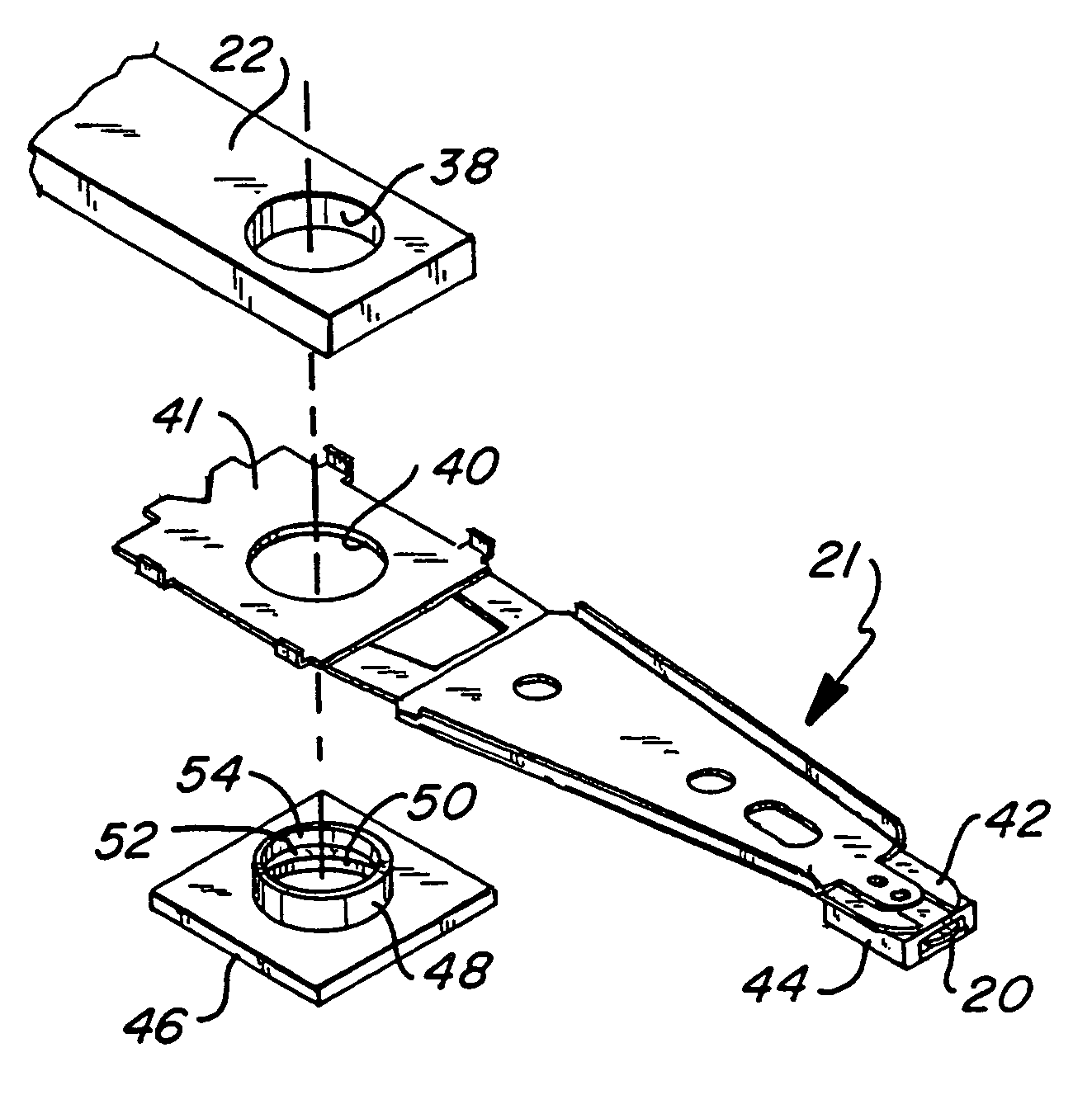

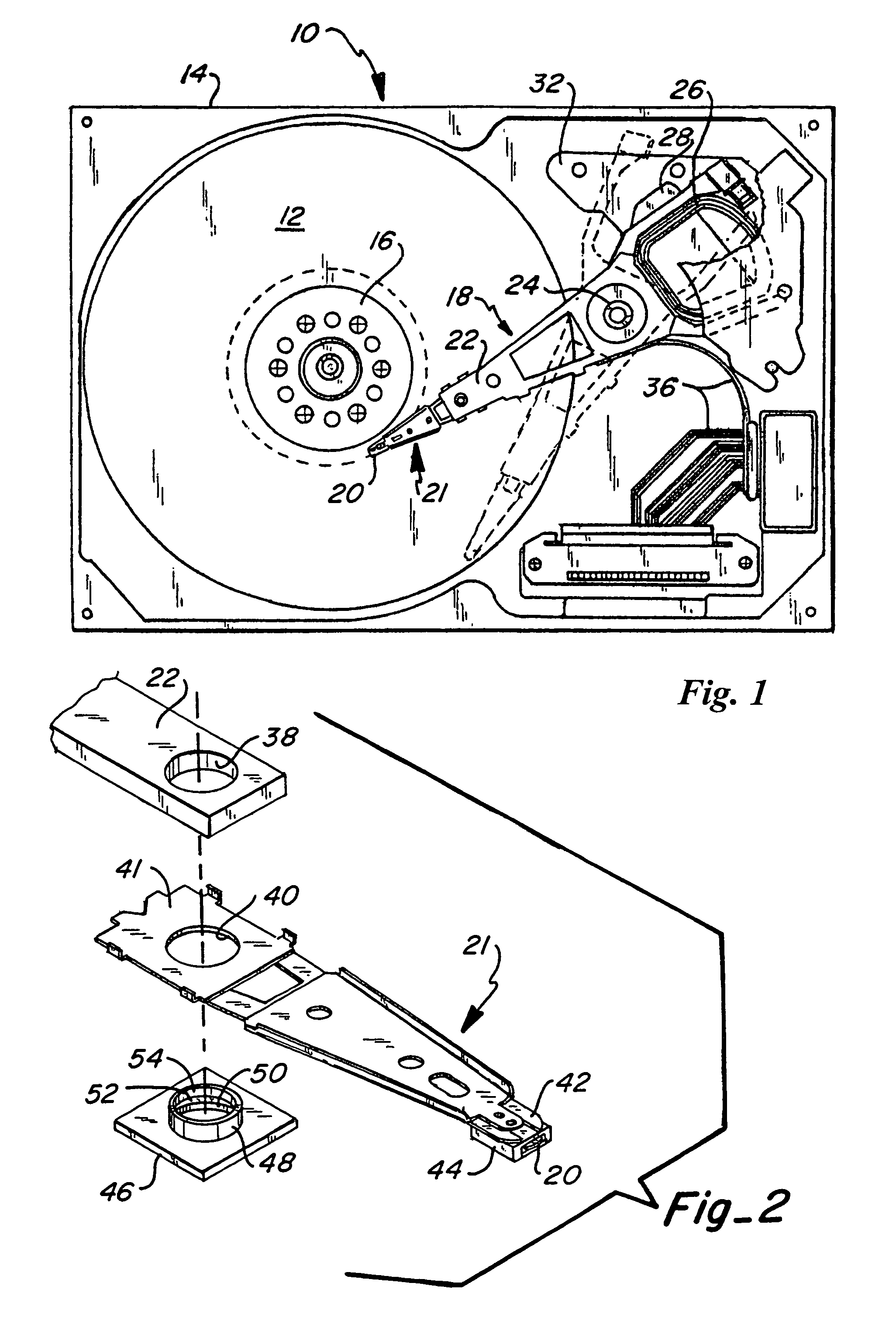

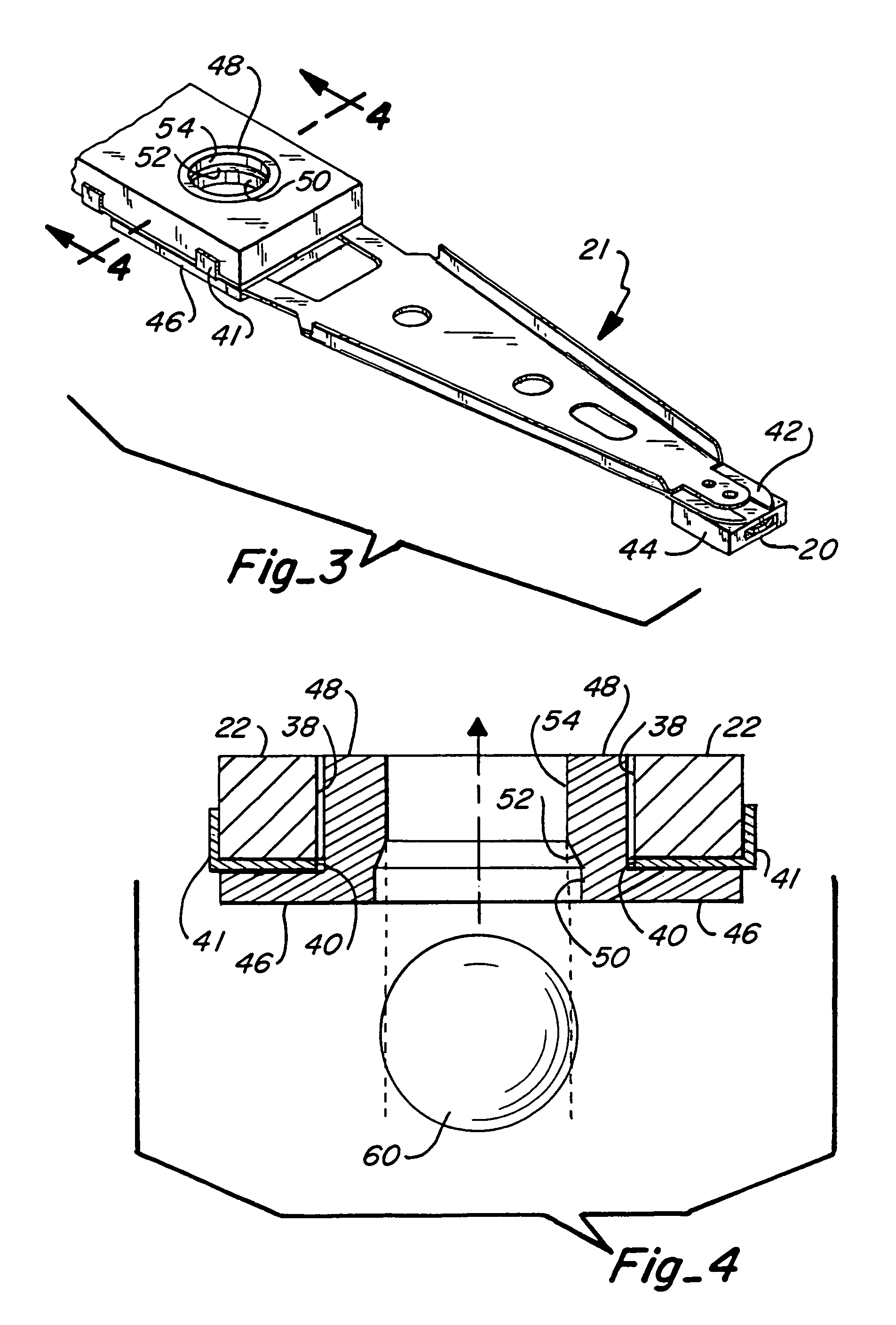

Method of assembling an actuator assembly of a disk drive and of reducing torque out retention values in subsequent de-swaging

InactiveUS7024754B1Reduced retention torqueGood deformation propertiesElectrical transducersManual lubricationGramSwaging

A method is provided for assembling an actuator assembly of a disk drive. The method includes providing an actuator arm, providing a suspension arm, fixing a swage plate to the suspension arm, the swage plate including a swage boss extending therefrom, depositing a film lubricant upon at least an outer surface of the swage boss, and attaching the suspension arm to the actuator arm by swaging. A method is also provided for reducing torque out retention values between the actuator arm and the suspension arm when the actuator arm and suspension arm must be separated in a subsequent de-swaging process. This method includes providing an outer surface of the swage boss, and applying a lubricant film coating to the outer surface of the swage boss. A preferred thin film lubricant may be applied by emersion and draining, localized spraying, or various deposition processes. Application of the lubricant has also shown to improve gram load uniformity and to reduce adverse distortion to the actuator assembly which otherwise occurs during swaging.

Owner:MAXTOR

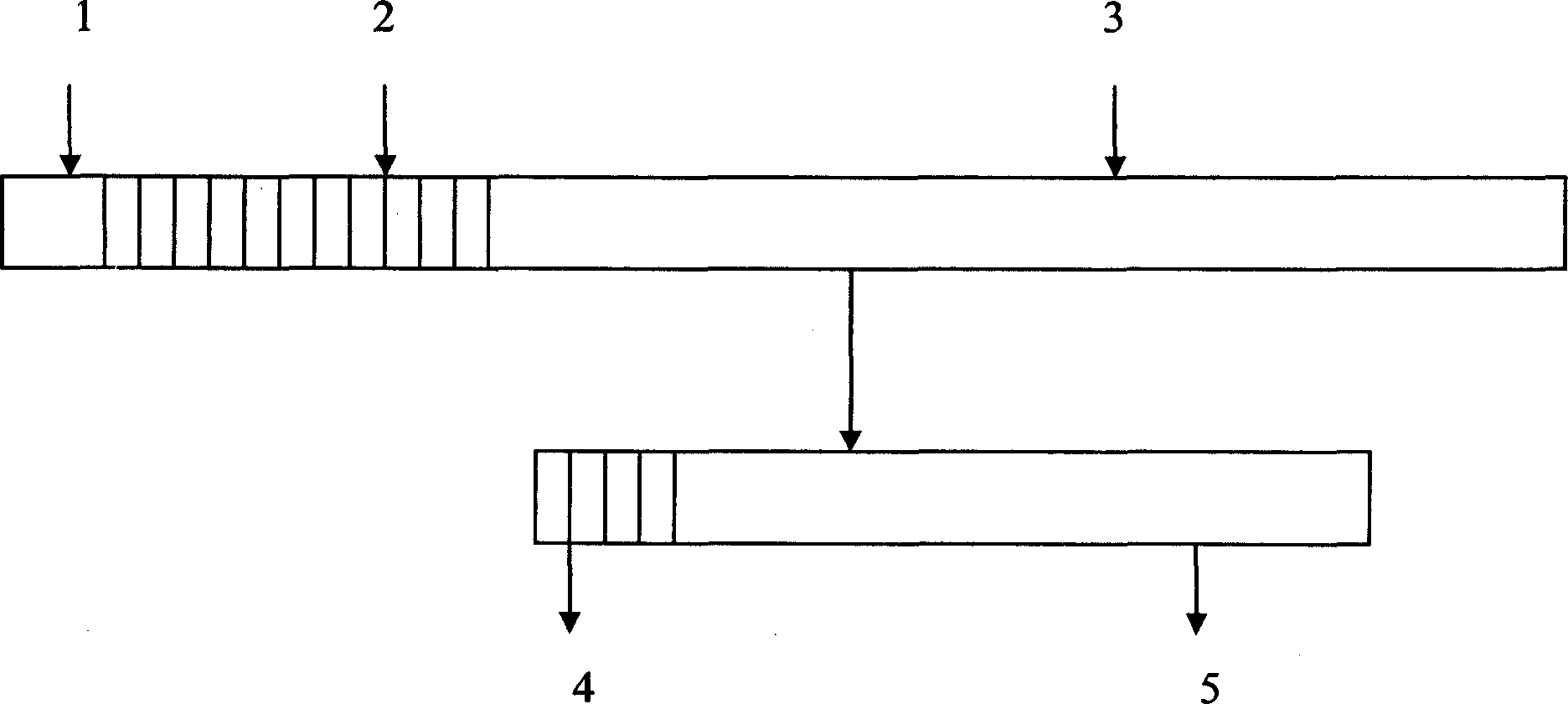

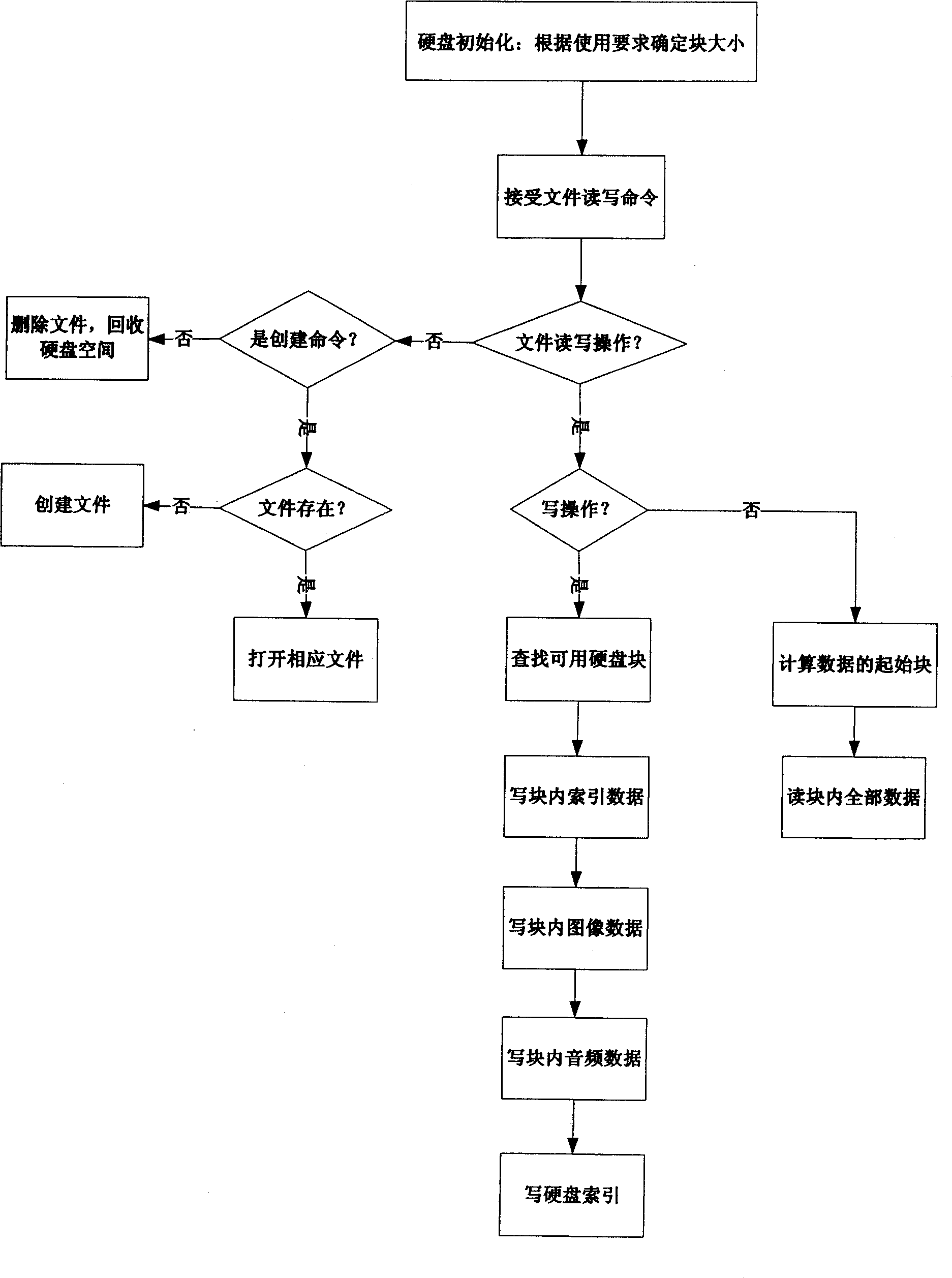

Method for establishing medium file system

InactiveCN1702633AIncrease the number of channelsImprove read performanceMemory adressing/allocation/relocationSpecial data processing applicationsFile systemFile storage

This invention relates to a method for building media file system, which belongs to the computer storing technique field of multimedia files. The existing file system can't satisfy the request for real time under the read-write operation, especially under the environment that has multi flows. The property of media file storing system is also affected strongly by using standard file format; such file format sometimes doesn't support the flow transmission, and it produces the hard disk shiver easily. Wherein the media file system which relates to this invention brings forward the picture group as the basic unit of disk read-write through integrating those correlative multi media files information into the media file system, which avoids the limitation in traditional file system.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

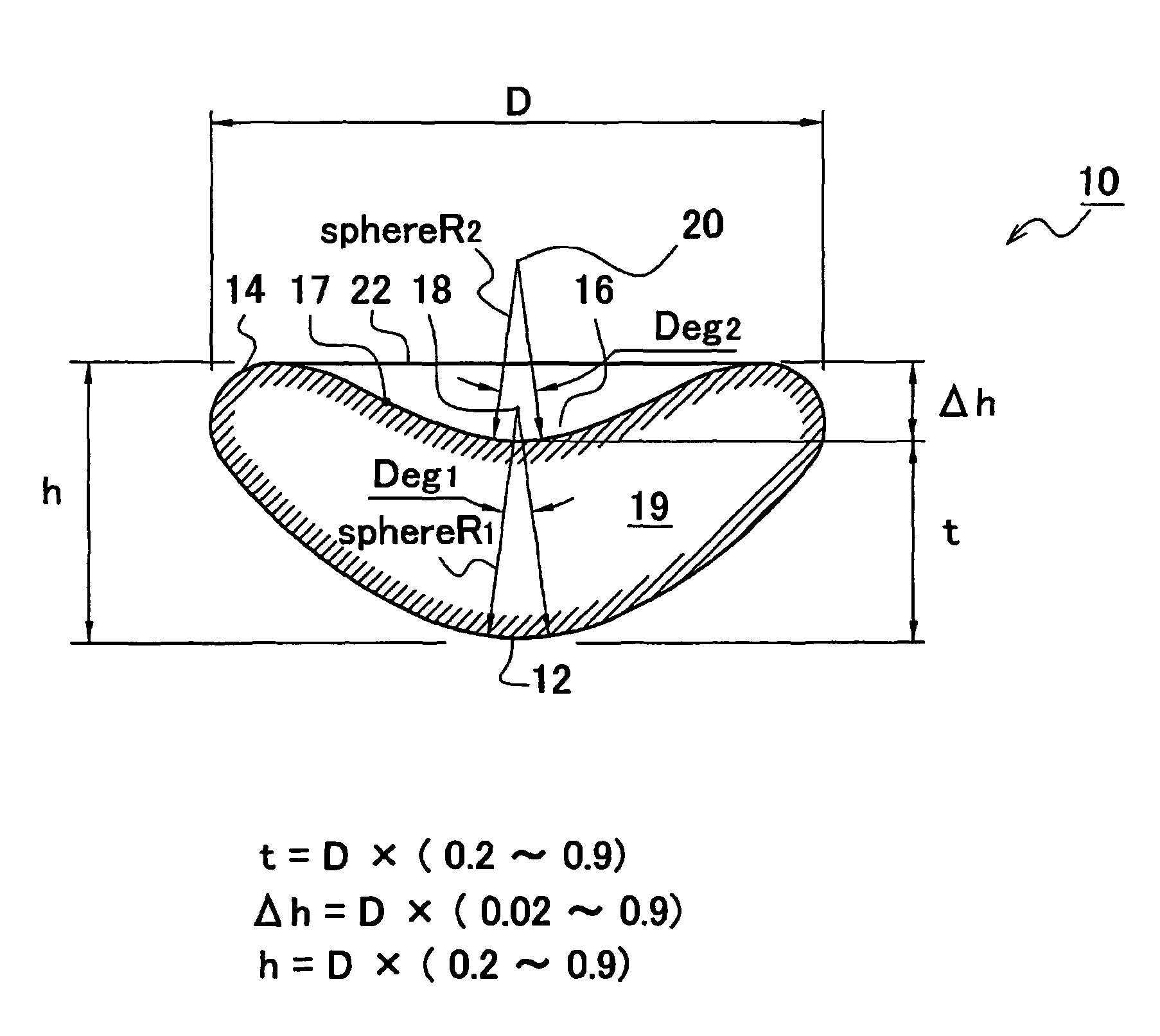

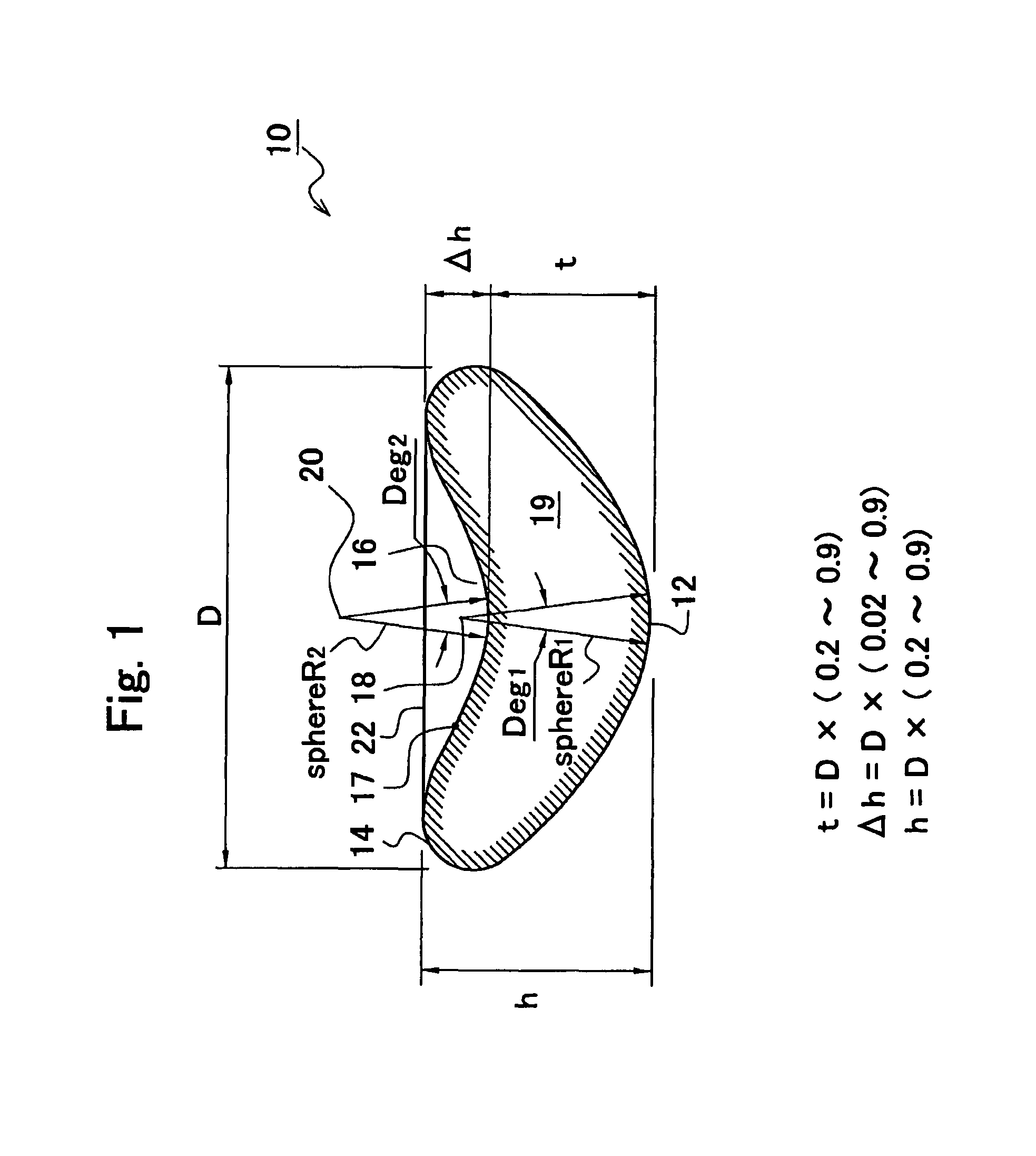

Preform for optical element and optical element

InactiveUS8003186B2Extended service lifeReduce generationSpectales/gogglesLayered productsConvex sideEngineering

Owner:OHARA

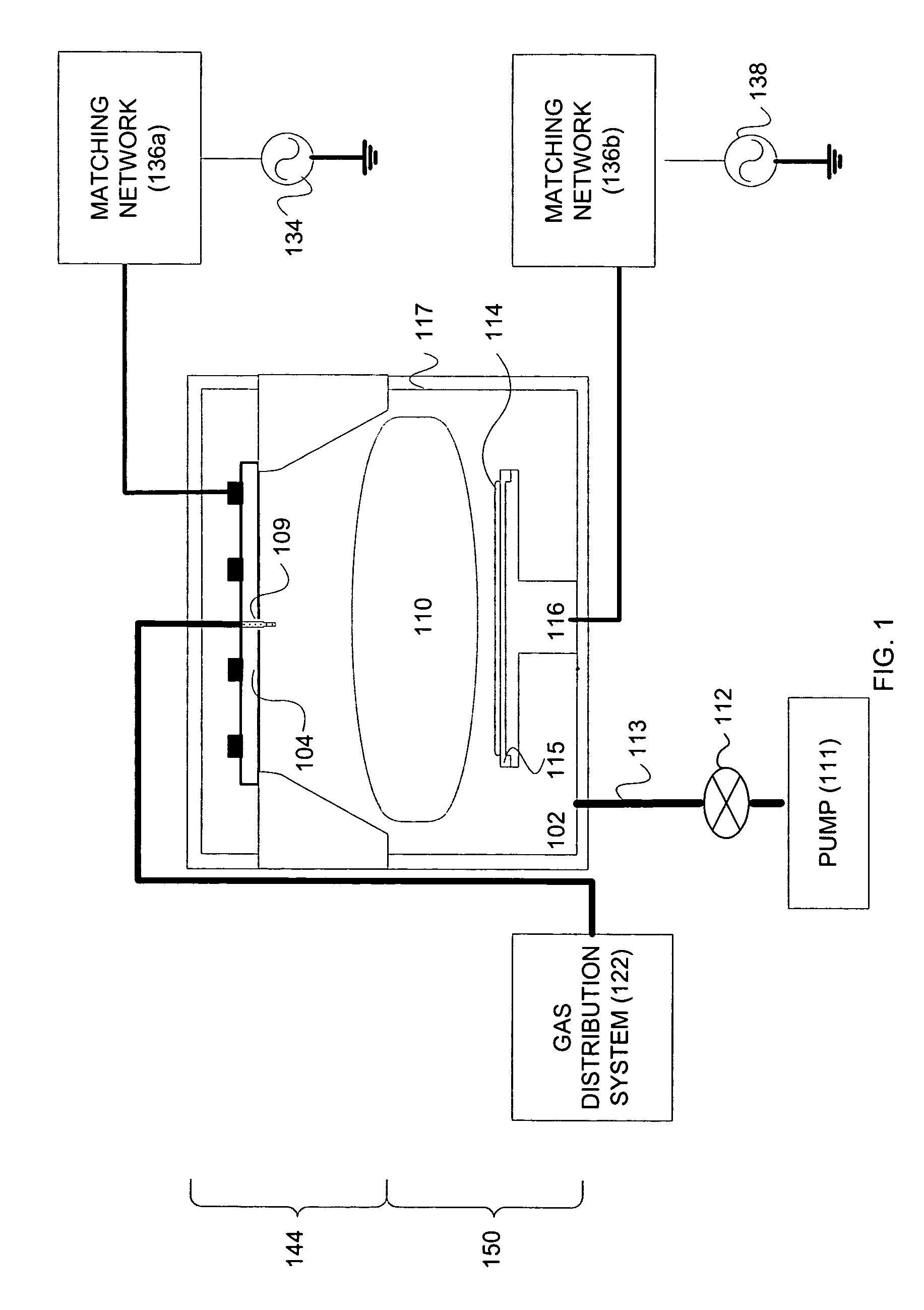

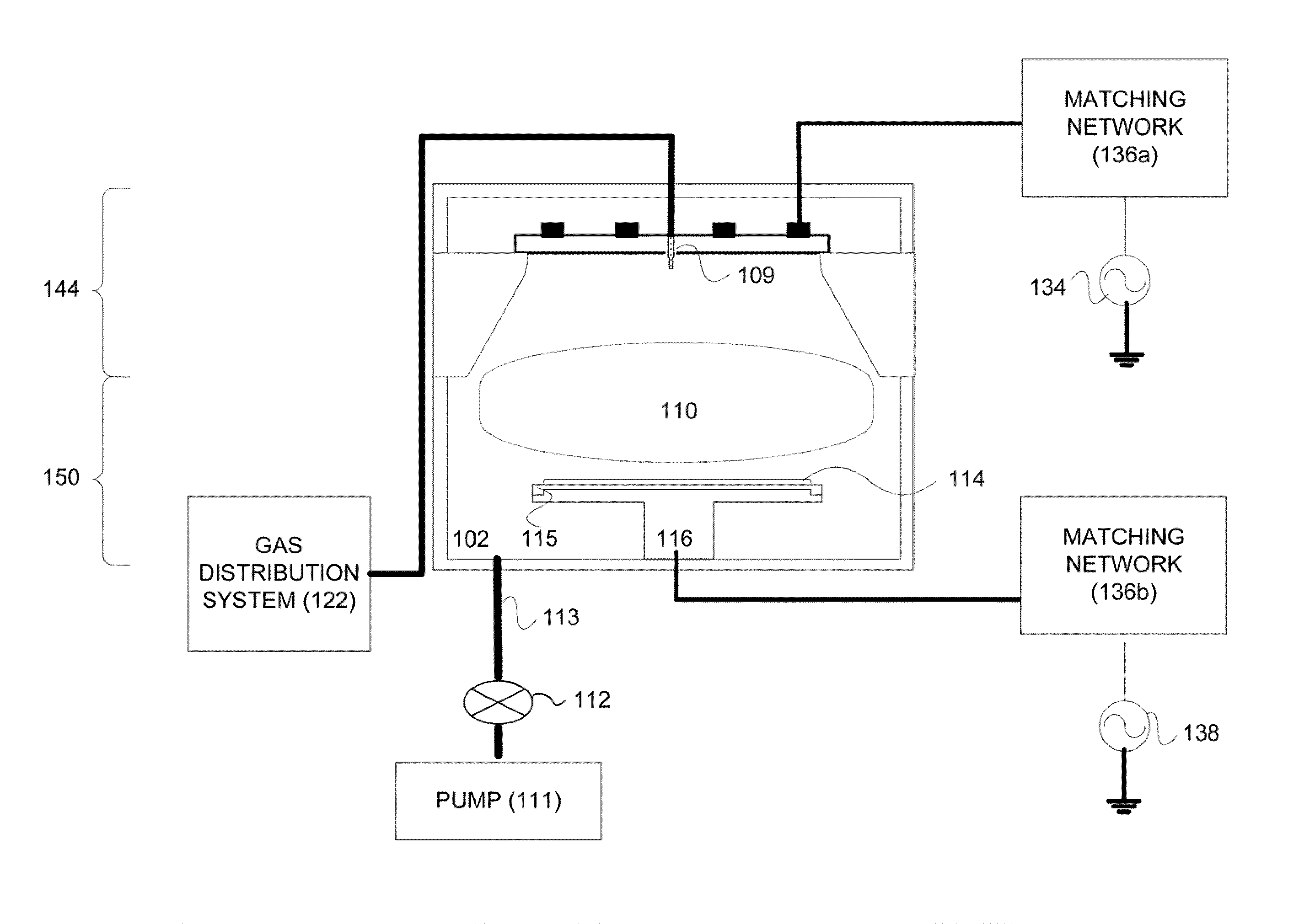

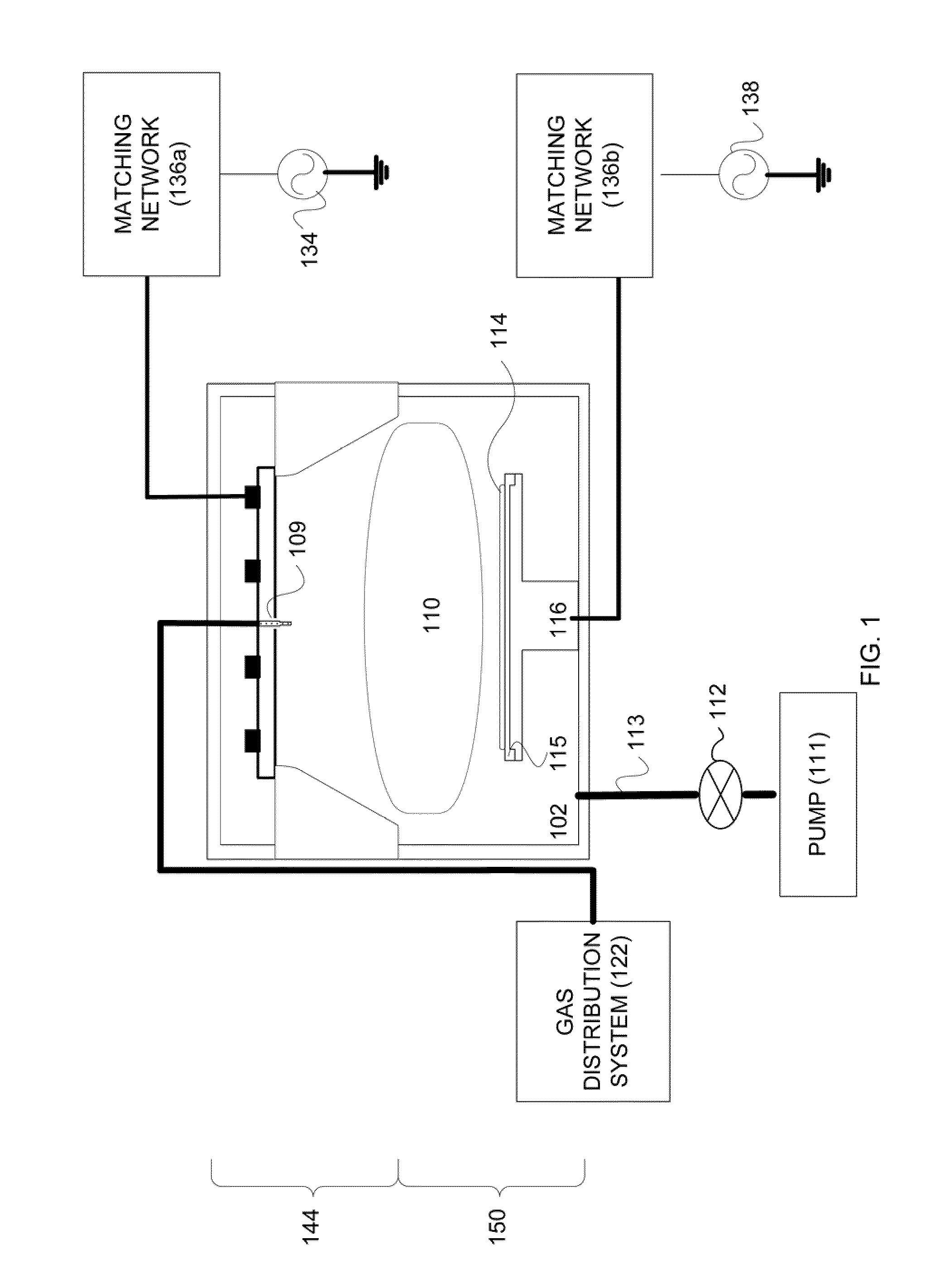

Servicing a plasma processing system with a robot

ActiveUS20100024186A1Reduce debrisEliminate errorsElectric discharge tubesHollow article cleaningMechanical engineeringPlasma processing

A method for servicing a plasma processing system. The plasma processing system may include a plasma chamber. The plasma chamber may include a top piece and a bottom piece, wherein the top piece may be disposed above the bottom piece. The method may include using a robot device to control a lift mechanism to lift the top piece from the bottom piece. The method may also include extending a first member of the robot device into the top piece to perform a first set of tasks according to a first set of service procedures. The method may also include extending a second member of the robot device into the bottom piece to perform a second set of tasks according to a second set of service procedures.

Owner:LAM RES CORP

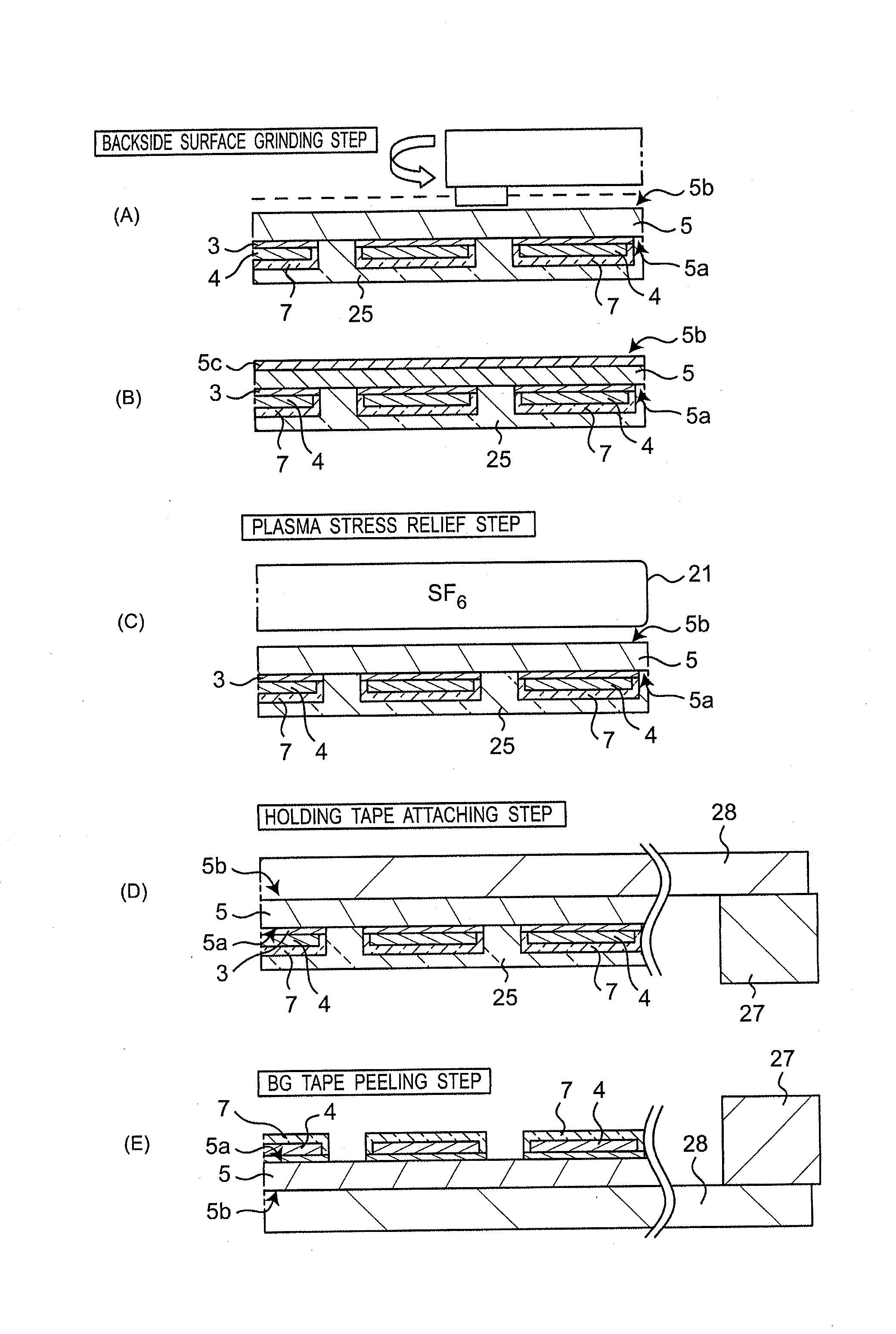

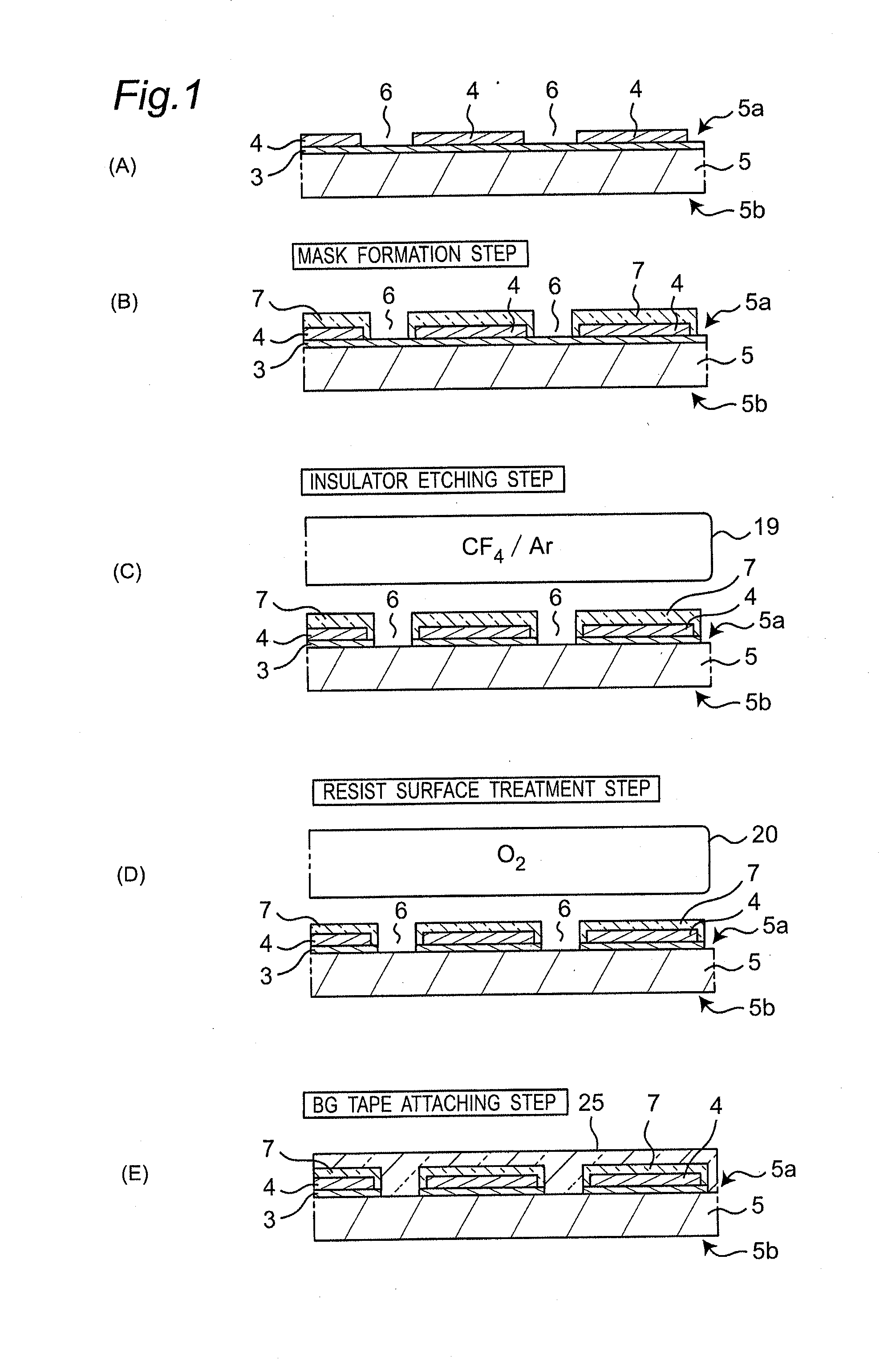

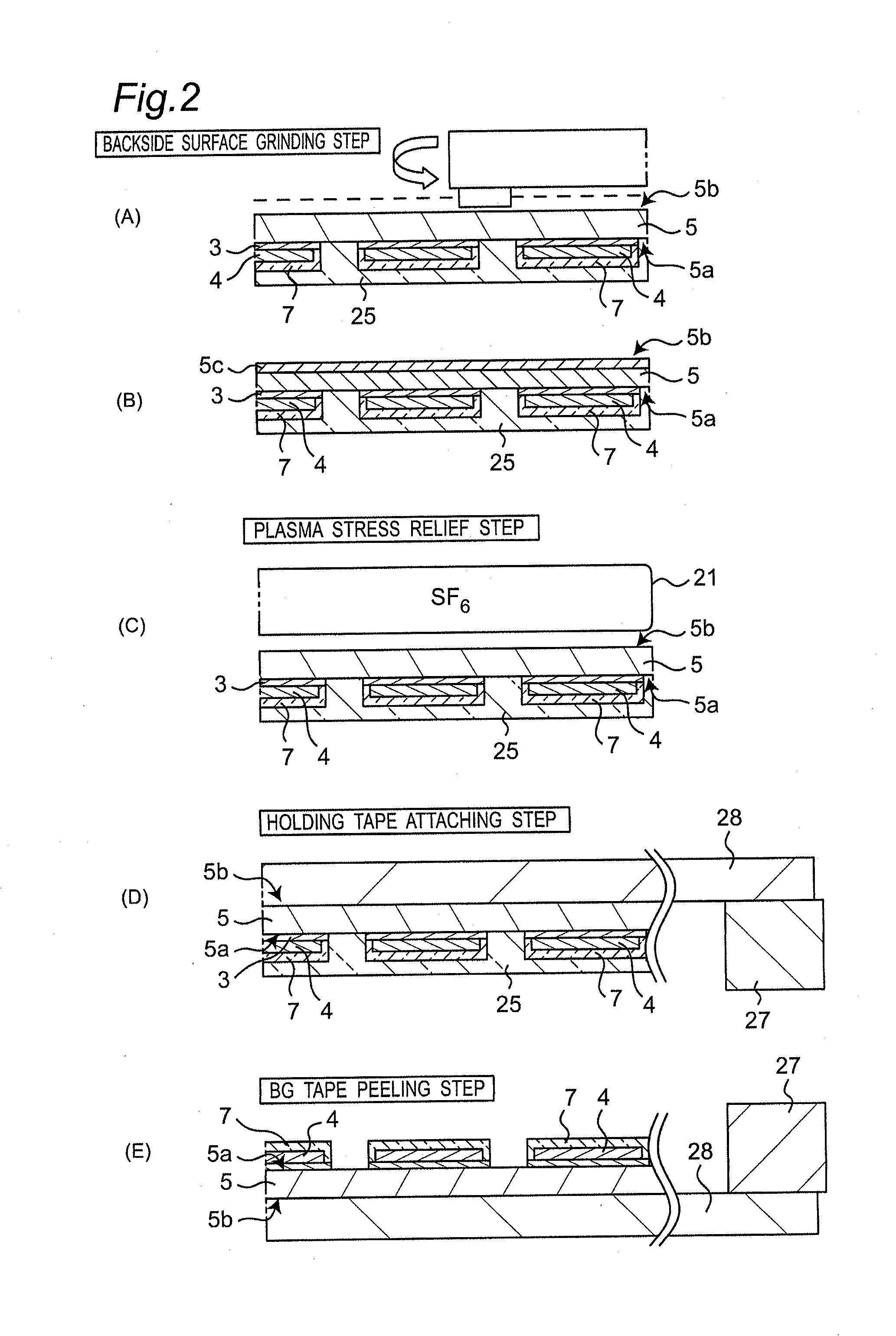

Method of manufacturing semiconductor chips

ActiveUS20140295644A1Easy to handleReduce debrisElectric discharge tubesSolid-state devicesSemiconductor chipEngineering

Provided is a method of manufacturing semiconductor chips superior in chip yield, reduction in chipping, and handling ability. An insulating film in a dividing region is removed by plasma etching to a front surface. Then, roughness on a resist mask formed on the front surface is removed by plasma treatment before a BG tape is attached. After a semiconductor wafer is thinned by grinding of a backside surface thereof, the BG tape is peeled. The semiconductor wafer is divided into individual semiconductor chips by plasma etching from the front surface thereof.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

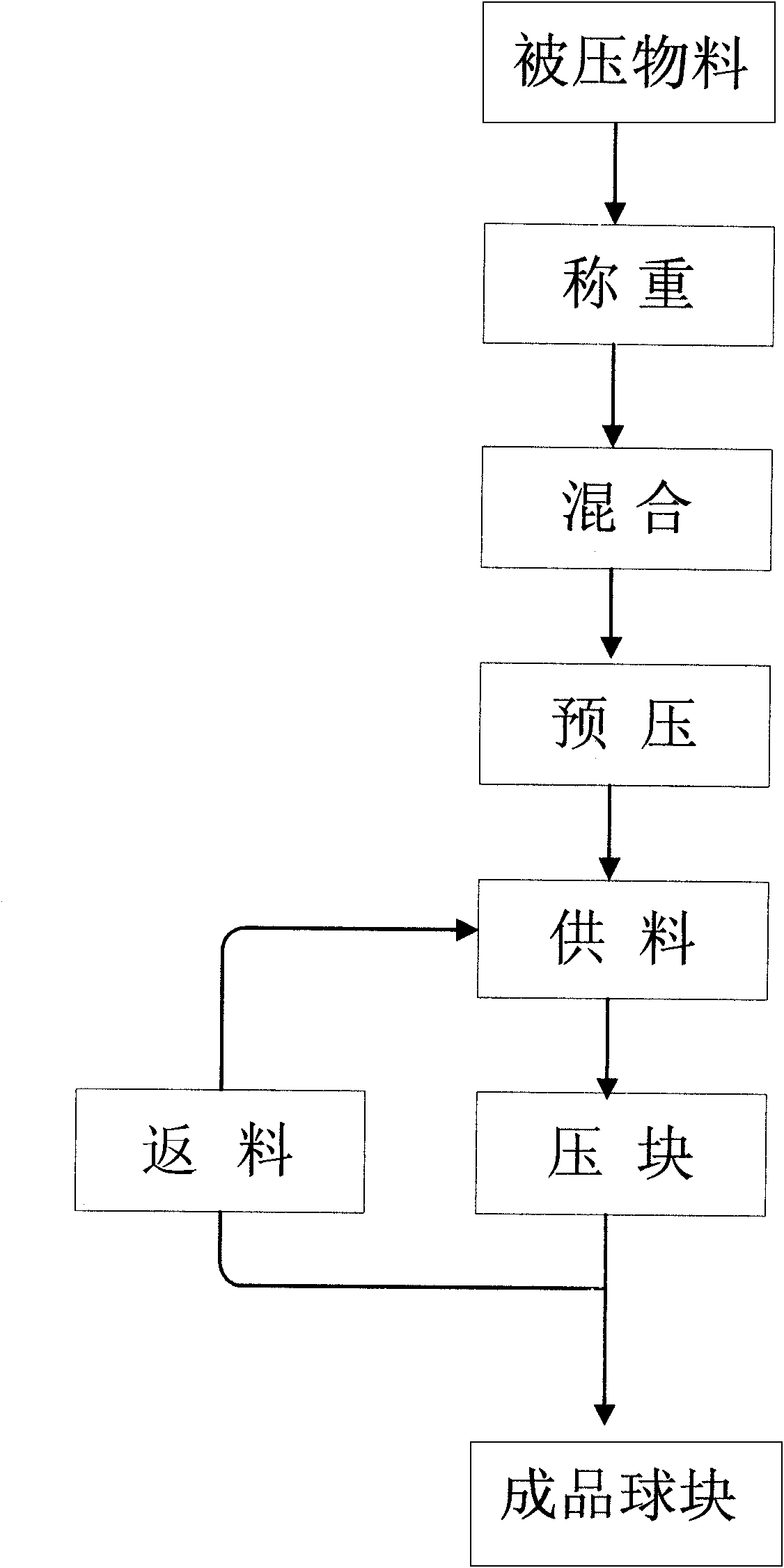

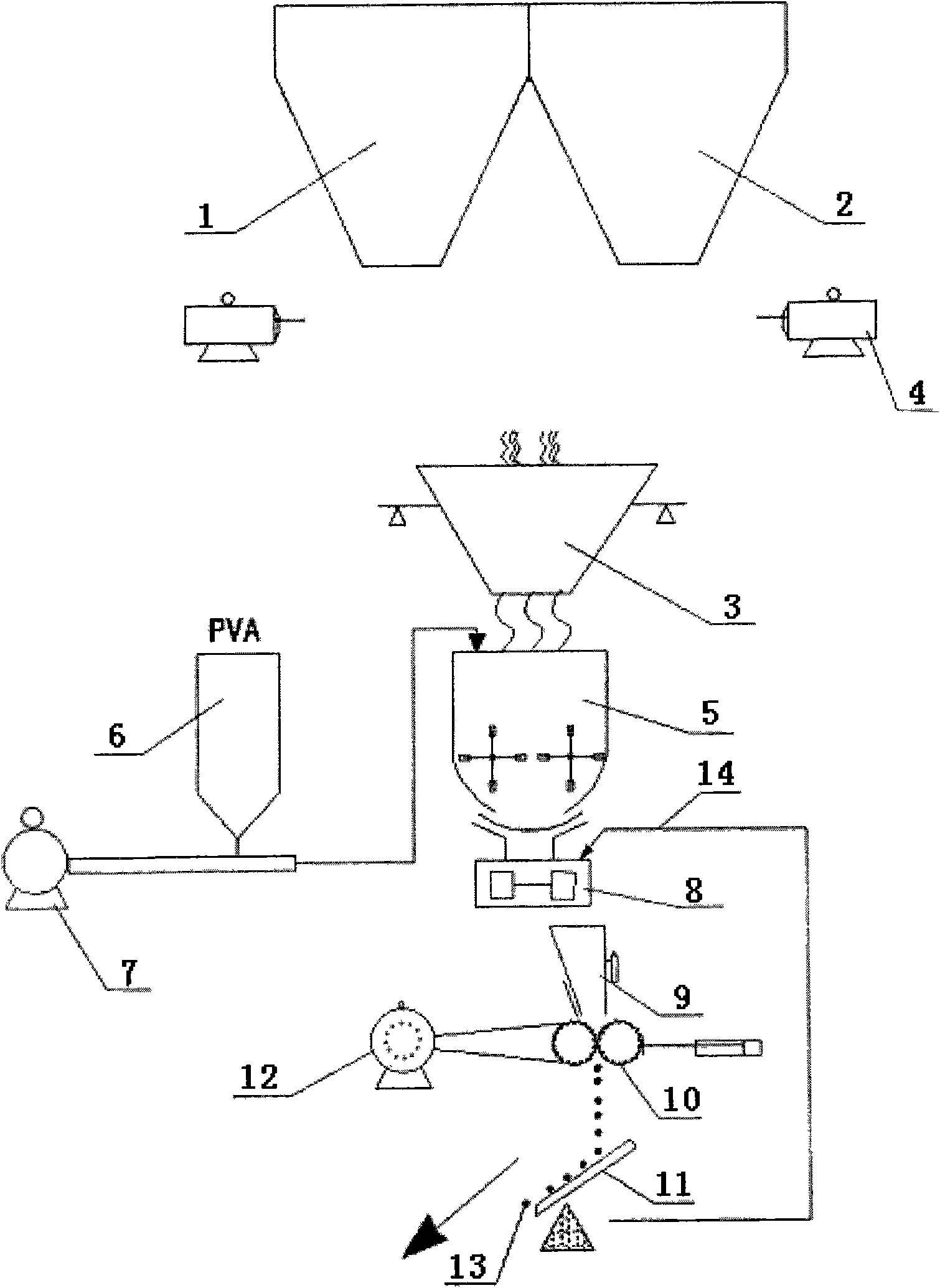

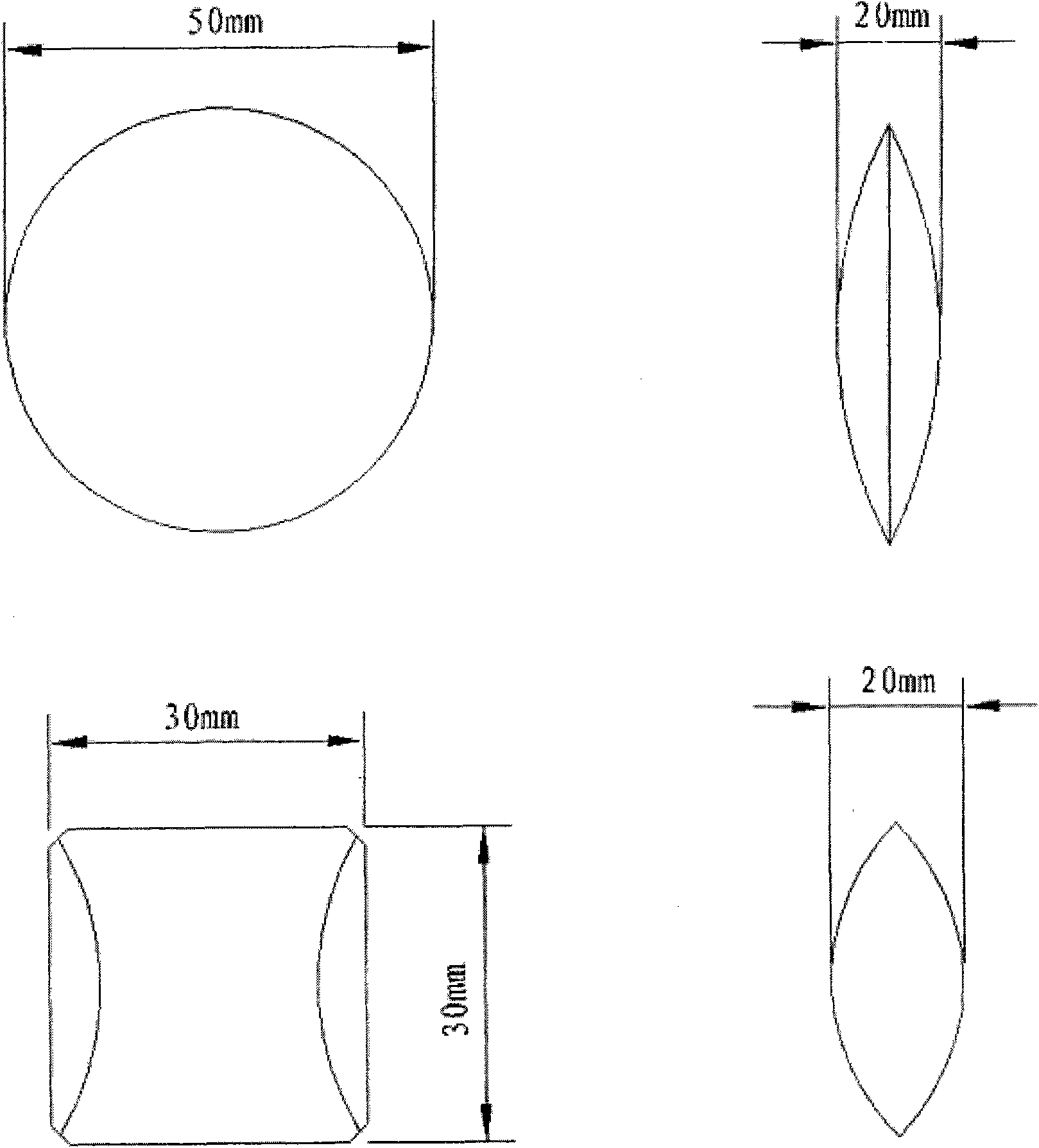

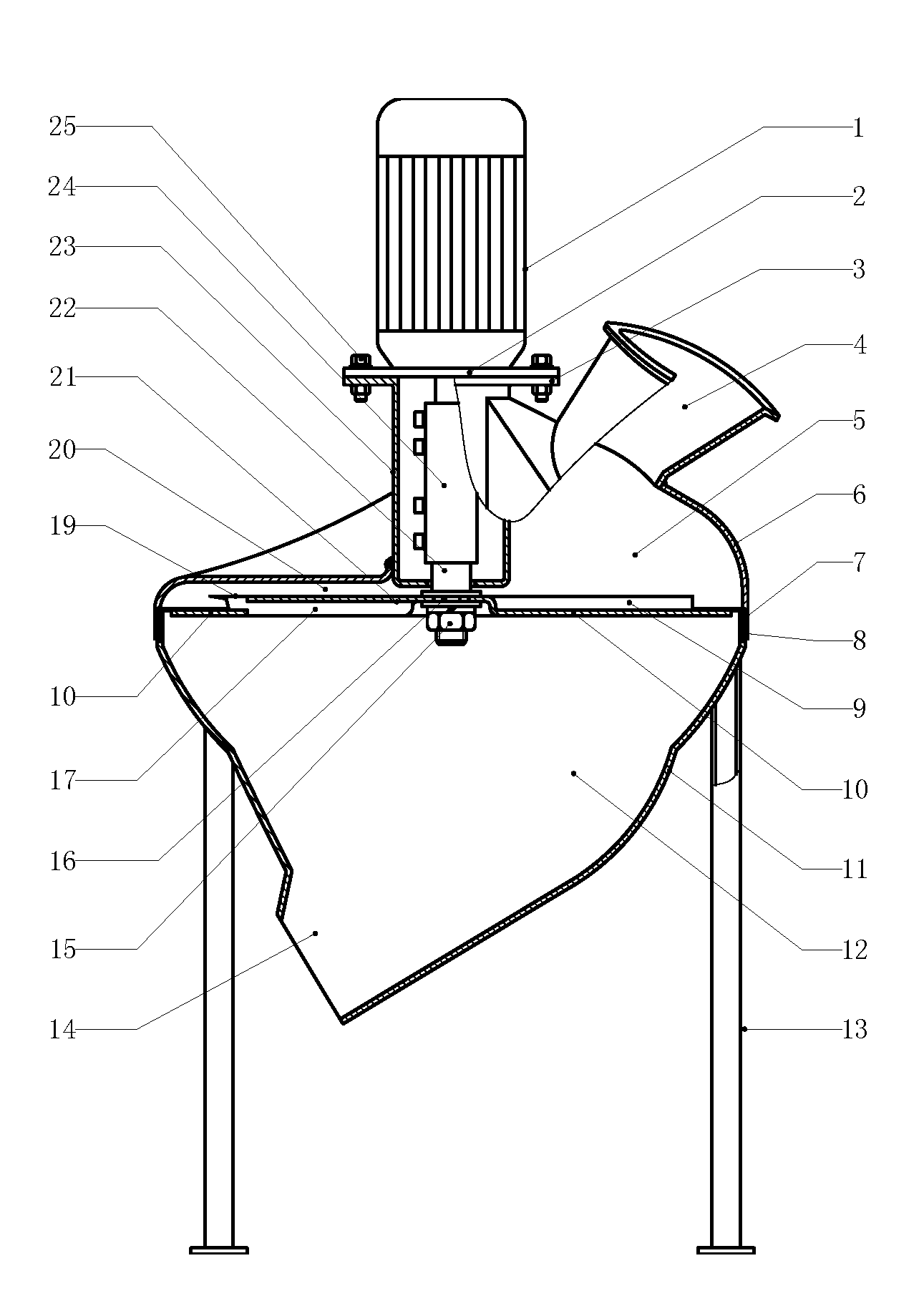

Method for manufacturing high strength green ball block by coal-based direct reduction and device therefor

The invention relates to a method for manufacturing green ball blocks by coal-based direct reduction and a device therefor, which is suitable to be used for a raw material ball pressing section by the coal-based direct reduction in the steel and iron metallurgical industry. The method adopts accurate weight batching, high mixing evenness degree, proper mixture prepressing, suitable feeding, suitable returning charge adding, suitable pressure to a roller, and suitable briquette size, acquires the suitable molding time by frequency control in the required yield, obviously improves the strength of the green ball blocks, reduces the generation of powder materials, improves the material yield and the productivity of a reducing furnace, reduces the flue gas dust removal load of the reducing furnace and the like, and has obvious economic benefits and industrialized popularization value .

Owner:SICHUAN LOMON MINING & METALLURGY

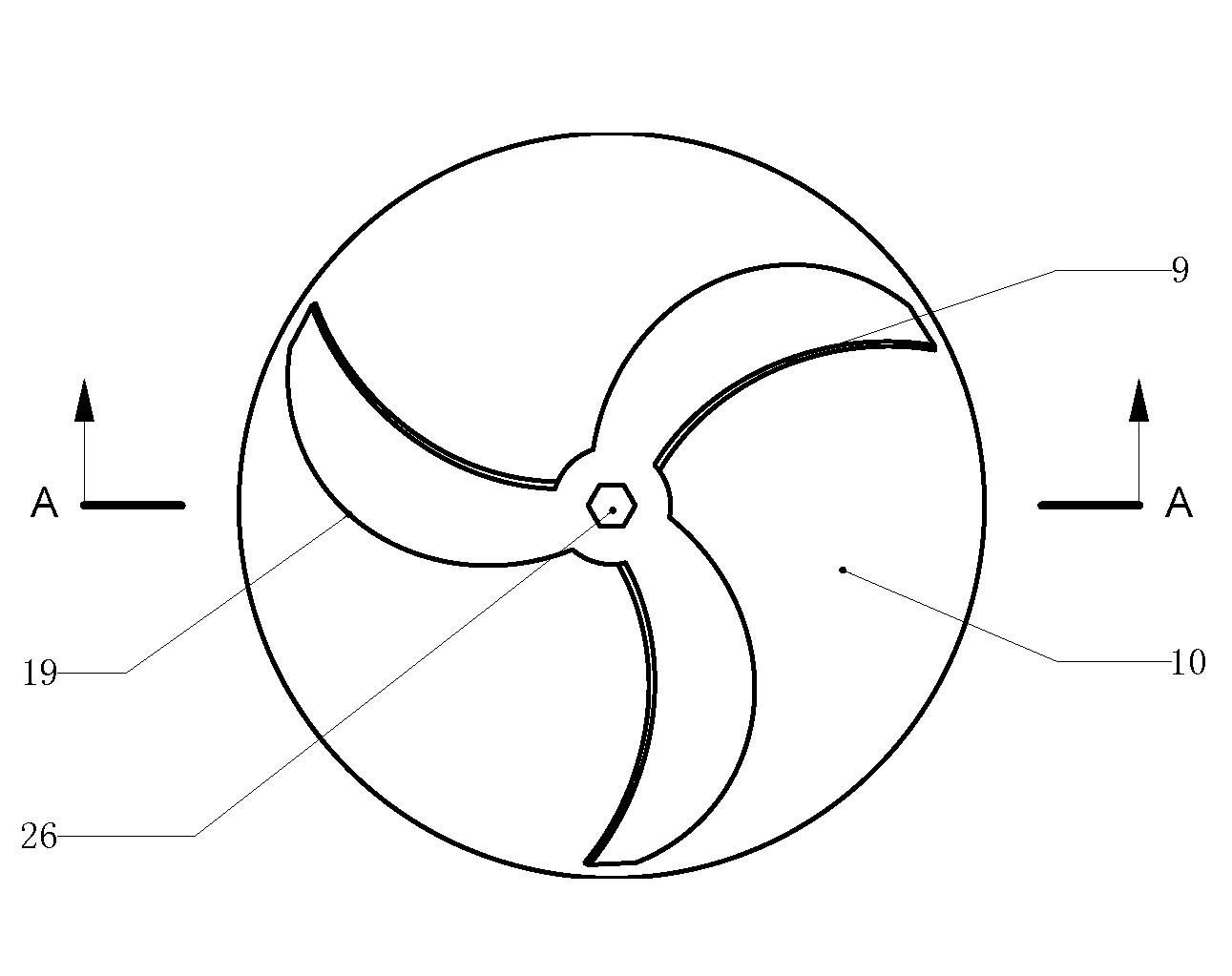

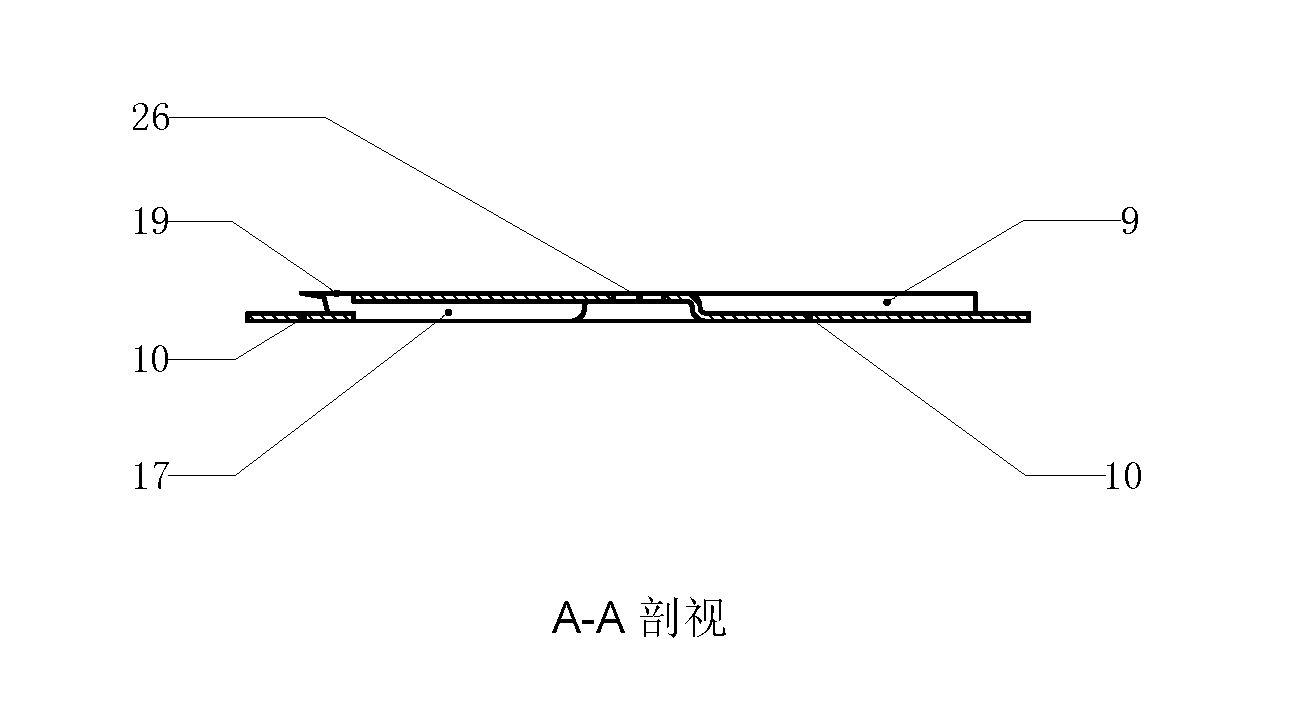

Volute fruit and vegetable slicing machine

InactiveCN103072150ACompact structureSave materialMetal working apparatusCouplingAgricultural engineering

The invention discloses a volute fruit and vegetable slicing machine, and relates to a fruit and vegetable slicing machine. The volute fruit and vegetable slicing machine mainly comprises a motor, a transitional connecting piece, a coupling, a three-edge blade, a blade rotating shaft, an upper volute, a lower volute and a bracket, wherein the three-edge blade has a disc structure; three arc-shaped knives and a carrier are arranged on the disc structure; the upper volute is a hemispherical shell; a circular hole is formed in the center of the hemispherical shell of the upper volute; the transitional connecting piece is connected to the circular hole in the center of the hemispherical shell of the upper volute in an insertion mode; the lower volute is a revolving shell which gradually shrinks downwards; the revolving shell of the lower volute is connected with the bracket; a mounting flange of the motor is connected to a mounting flange of the transitional connecting piece; a rotating shaft of the motor is connected with the rear end of the blade rotating shaft through the coupling; the three-edge blade is arranged on the blade rotating shaft; and the upper volute is connected to the lower volute. The invention provides the fruit and vegetable slicing machine which has the advantages of compact structure, convenience in dismantling and washing, high efficiency and safety in operation; and machined fruit and vegetable slices have flat and smooth surfaces, uniform thickness and fewer pulps.

Owner:于静

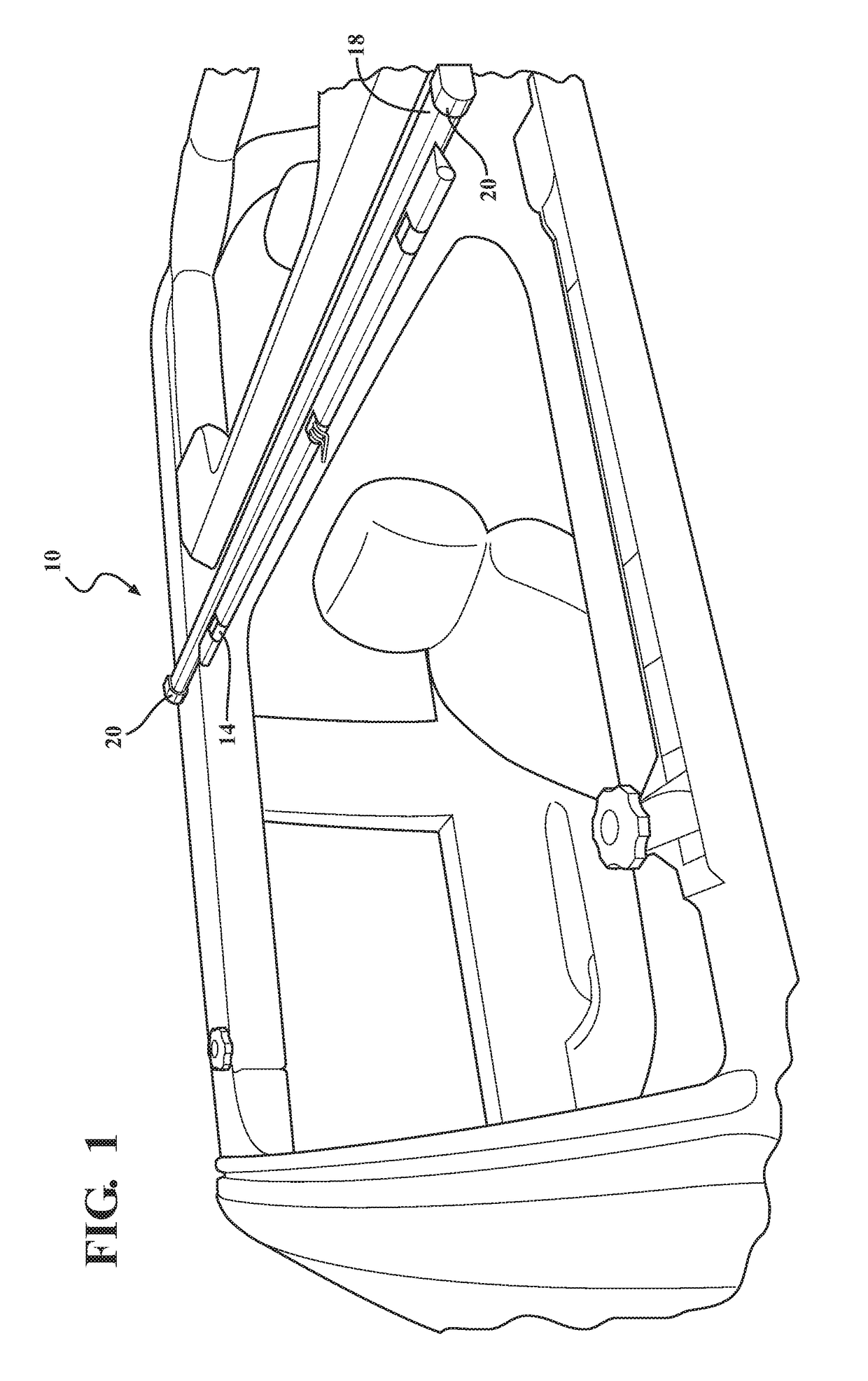

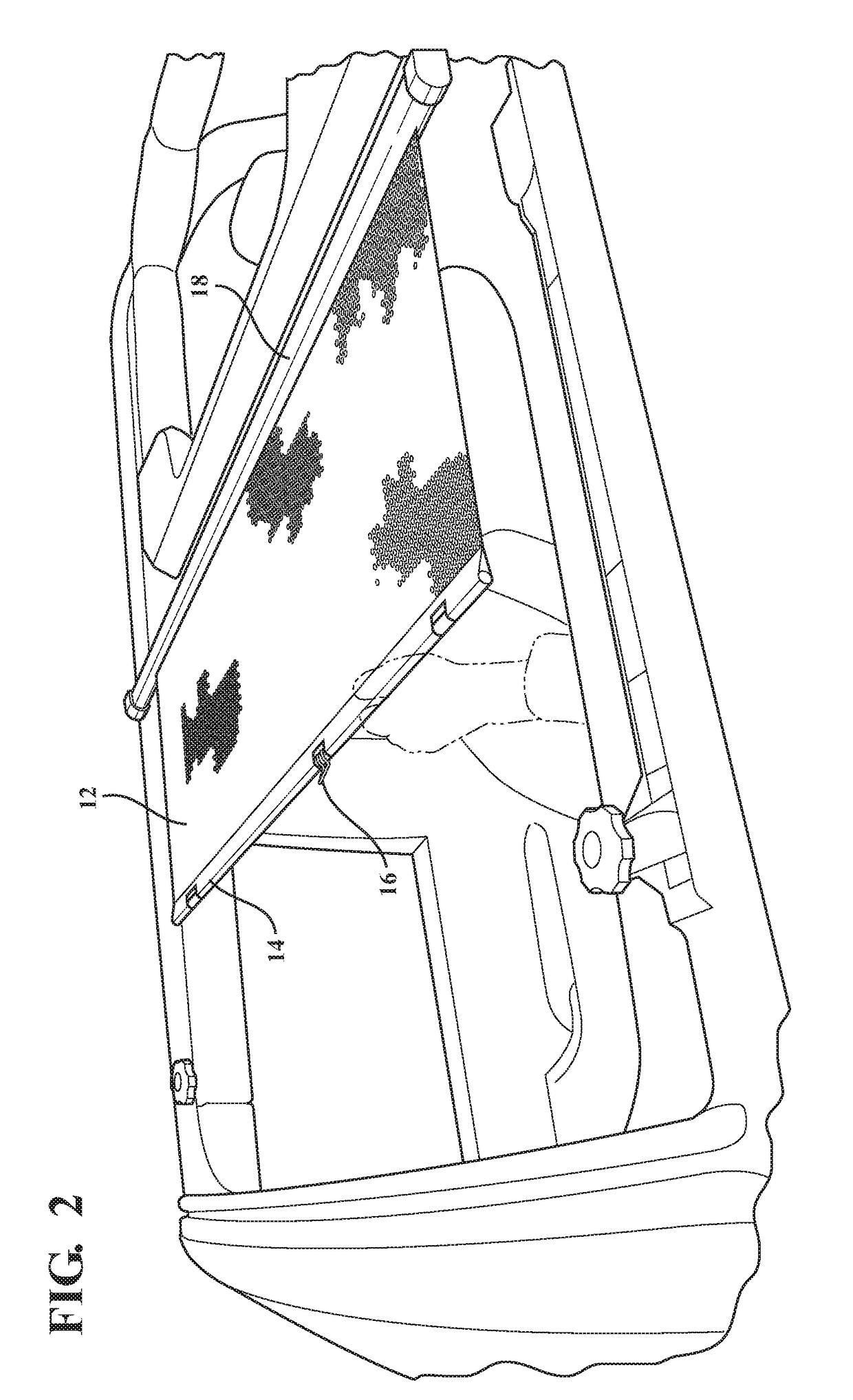

Retractable overhead shade

ActiveUS20190054806A1Maximum vehicle packaging efficiencyReduce wind noiseWindowsWindscreensEngineeringHardtop

A retractable overhead assembly for a vehicle having a retractable cover (912) under tension and an integrated stiffening rod that includes attachment features (916) to selectively connect to a windshield area. The retractable system is self contained within an extrusion keeping the overall package size small and the installation / removal simple. The retractable cover creates a sun shade over the vehicle front cockpit and / or rear passenger area when deployed, and is retractable to a stowed position. The retractable overhead assembly is installable under any hard or soft top assembly configuration, and does not impede use or operation of the hard top or soft top assembly.

Owner:BESTOP

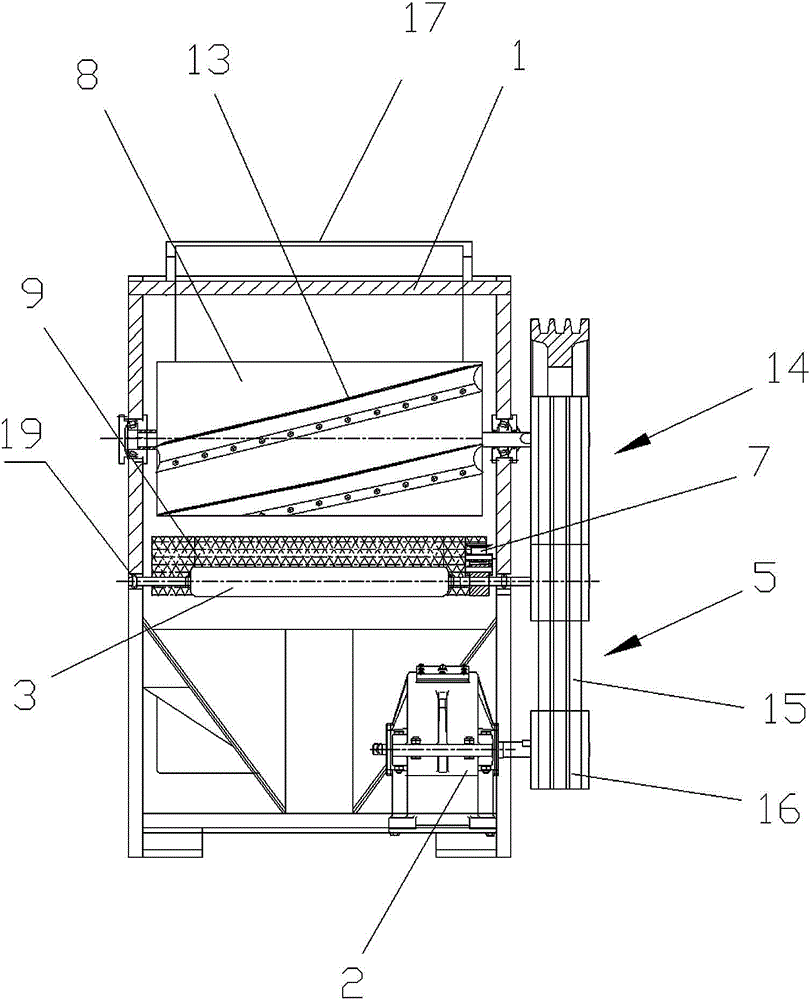

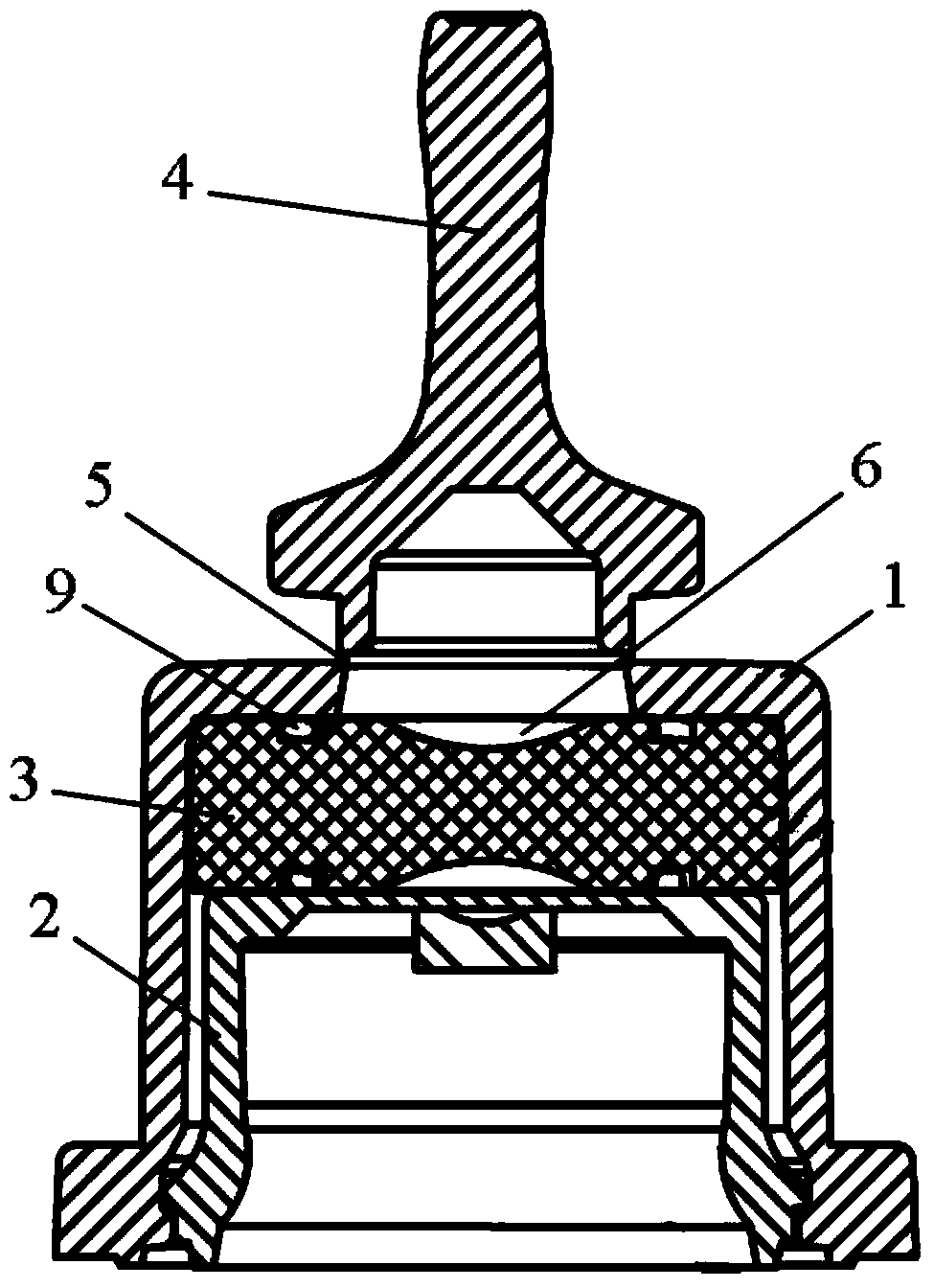

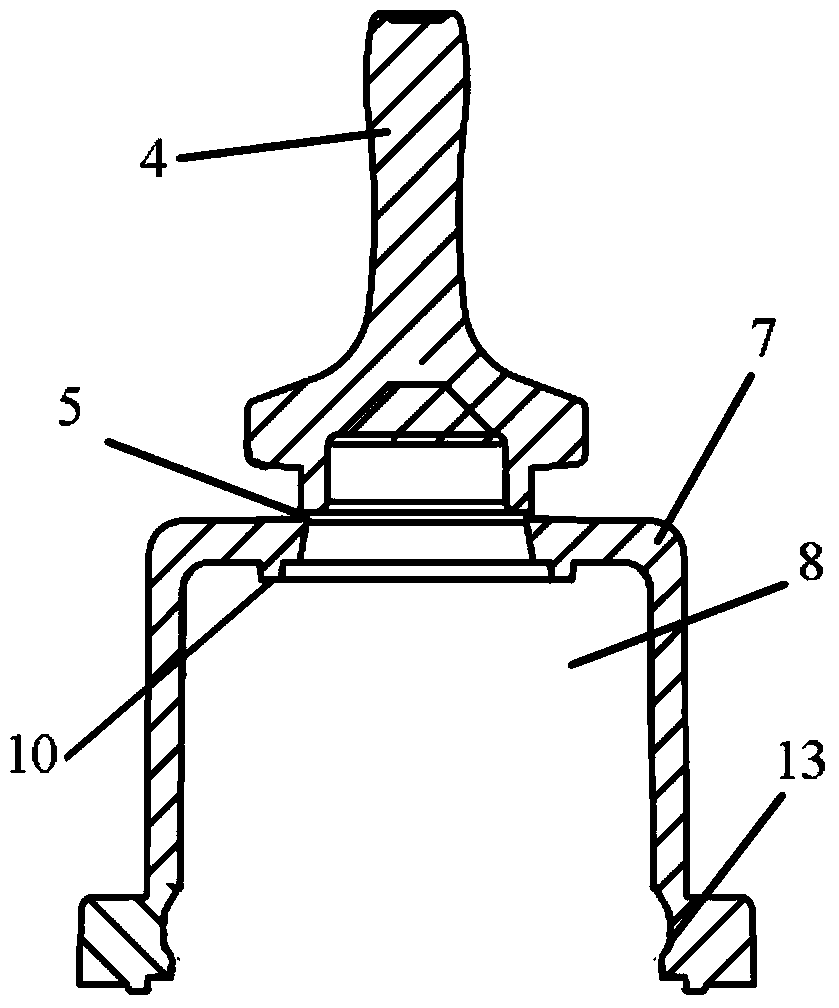

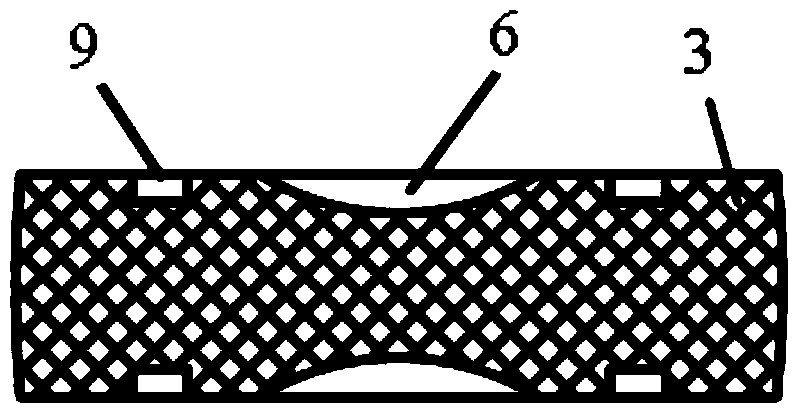

Mechanical slicing machine

InactiveCN105171813AIncrease spiral movementReduce churnMetal working apparatusElectric machineMechanical engineering

The invention relates to a mechanical slicing machine. The mechanical slicing machine is characterized by comprising a machine shell (1) with a motor (2) and a rotating shaft (3); a rotary disc (4) is connected to the rotating shaft (3) in a sleeved manner, the motor (2) is connected with the rotating shaft (3) through a first transmission device (5), the rotary disc (4) is connected with a screen plate (9) through a swing rod (6) and a crank (7), and the screen plate (9) is connected to the machine shell (1) through a tension spring (10). A slicer roller (8) is arranged in the machine shell (1), slicers (13) are evenly distributed on the periphery of the slicer roller (8), and the slicer roller (8) is connected with the rotating shaft (3) through a second transmission device (14); and a feeding pipe (17) is arranged above one side of the machine shell (1), and a discharging pipe (18) is arranged below the other side of the machine shell (1). The mechanical slicing machine has the beneficial effects that materials are cut in a beveling manner, spiral motion of the slicers in the horizontal direction is increased, force is saved during cutting, chippings generated by material cutting are fewer, liquid losses are fewer, slicing sheets are higher in uniformity and evenness, the homogeneity of sheet thickness is good, and raw materials are thoroughly sliced

Owner:安徽数驰机电设备制造有限公司

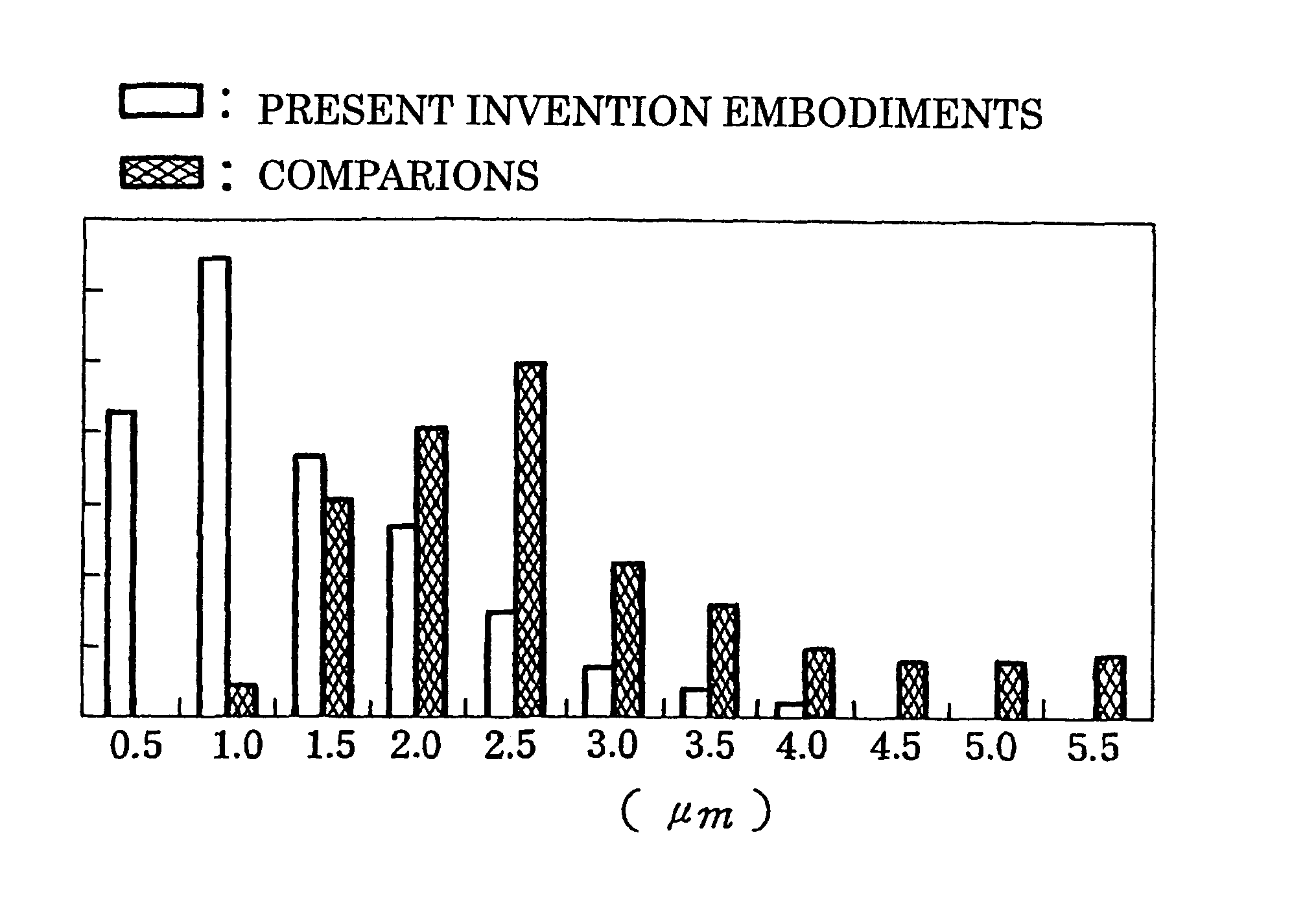

Manufacturing method for semiconductor gas-phase epitaxial wafer

InactiveUS6211088B1Improve flatnessLow processing deformationSemiconductor/solid-state device manufacturingProcess integrationWafering

The present invention has as an object, the provision of a manufacturing method for a semiconductor gas-phase epitaxial wafer which achieves the extremely high wafer flatness demanded in line with making wafers larger in size and heightening device process integration levels, and which forms either a backside CVD film or a thermal oxide film required as a gas-phase epitaxial wafer, and solves problems related thereto. More particularly, it achieves the high flatness and low processing deformation required by a large-diameter wafer, and makes it possible to enhance yield in the device process. In a manufacturing method for a semiconductor gas-phase epitaxial wafer, which enables a thin, disc-shaped wafer to be sliced from a single-crystal ingot, a required surface to be finished to a mirror surface, and an epitaxial layer to be formed on the main surface, that introducing into the above-mentioned manufacturing method a two-sided polishing process for polishing both the front and back surfaces of a wafer; a process for forming either a CVD film or a thermal oxide film on the backside of a wafer; and a one-sided mirror-finish polishing process for polishing the main surface of a wafer enables the realization of the extremely high wafer flatness demanded by a large-diameter wafer, while preventing autodoping.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Single-folding-handle type infusion assembling cover and preparation method thereof

ActiveCN103417374AHigh strengthImprove securityPharmaceutical containersMedical packagingSingle foldAgricultural engineering

Disclosed are a single-folding-handle type infusion assembling cover and a preparation method thereof. The assembling cover comprises an outer cover, an inner cover and a rubber plug. The outer cover is composed of a cover body, a folding handle and a rubber plug chamber. The size of the rubber plug chamber is the same as the size of the rubber plug, and the rubber plug is placed in the rubber plug chamber. A folding line is arranged at the joint of the folding handle and the cover body, holes are formed in the upper portion of the cover body of the outer cover below the folding handle, and the inner cover is placed inside the outer cover and is tightly attached to the lower portion of the rubber plug. Further, pits are formed in the upper surface of the rubber plug, the holes correspond to the pits, and the size of the diameter of each hole is the same as the size of the diameter of each pit. The preparation method of the single-folding-handle type infusion assembling cover includes the steps that raw materials and additives are made to form a uniform mixture, bracing bars are squeezed out, water cooling is conducted, granule cutting and drying are carried out to obtain an inner cover material and an outer cover material, and injection molding is further directly achieved according to the shape of the inner cover and the shape of the outer cover. The assembling cover is convenient to use, needle inserting is convenient during transfusion, chippings are reduced, the preparation technology of the assembling cover is simple and convenient, and the prepared assembling cover is free of deformation, non-discoloring, high in strength and high in safety in the sterilization treating process at the temperature of 121 DEG C.

Owner:苏州创扬新材料科技股份有限公司

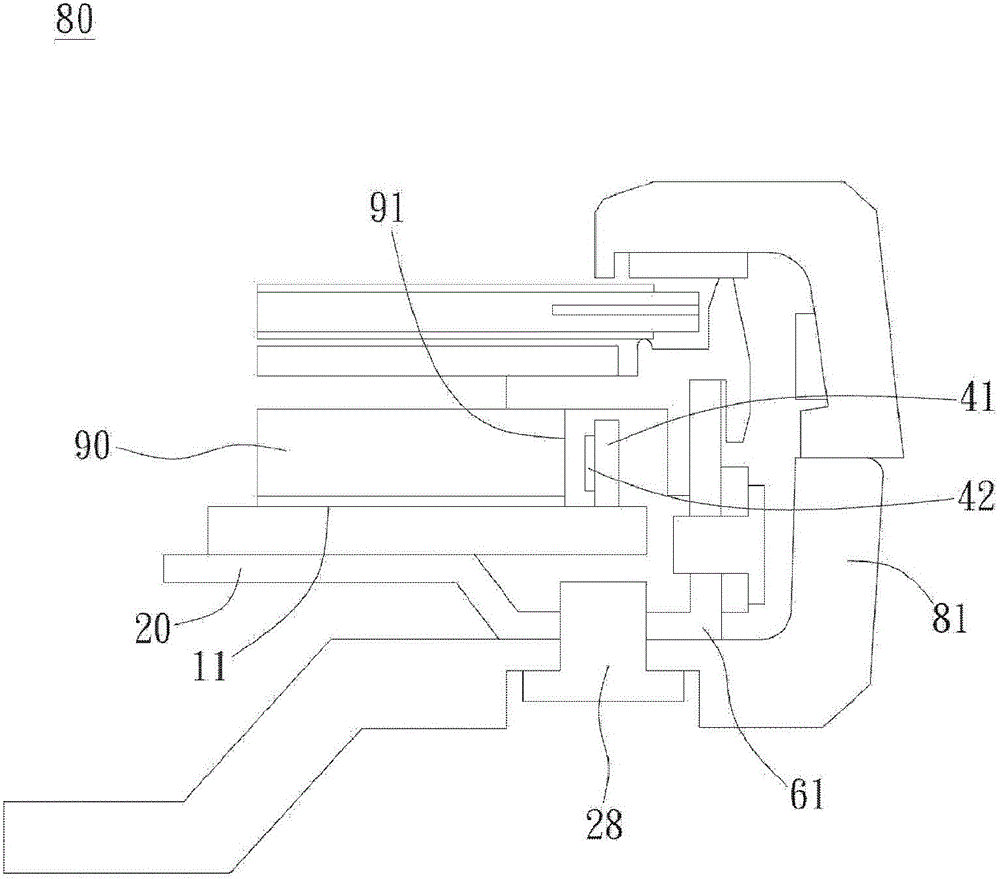

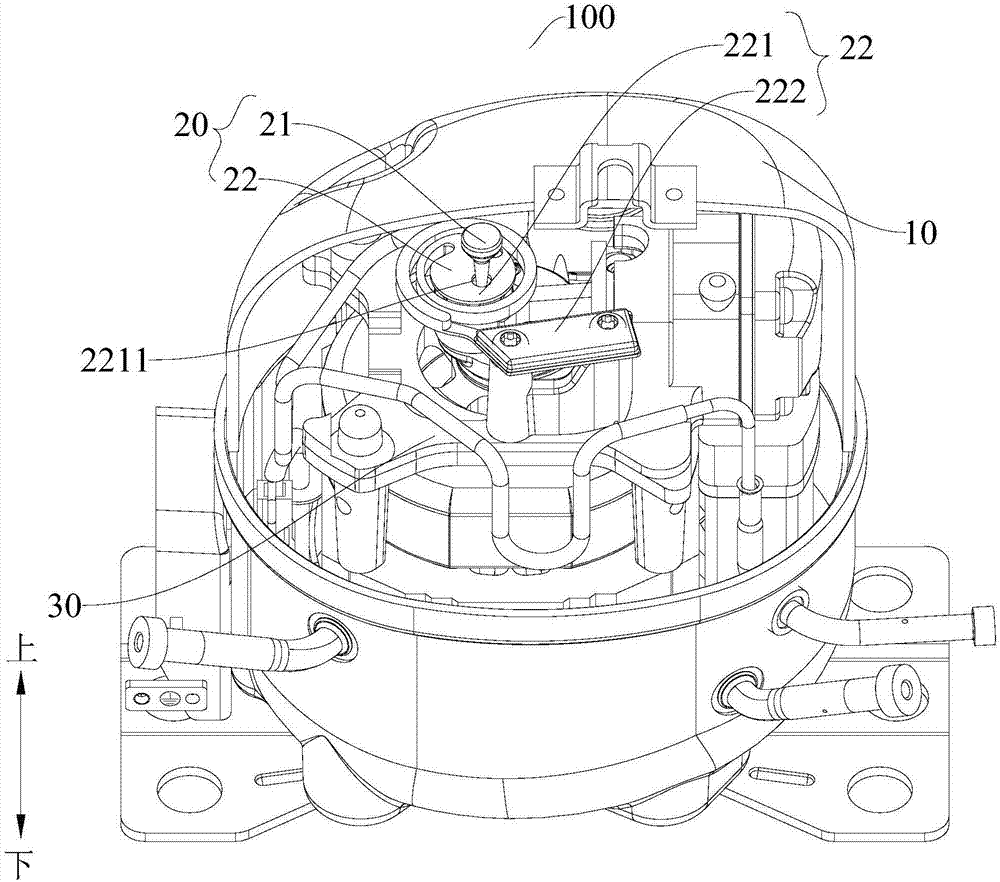

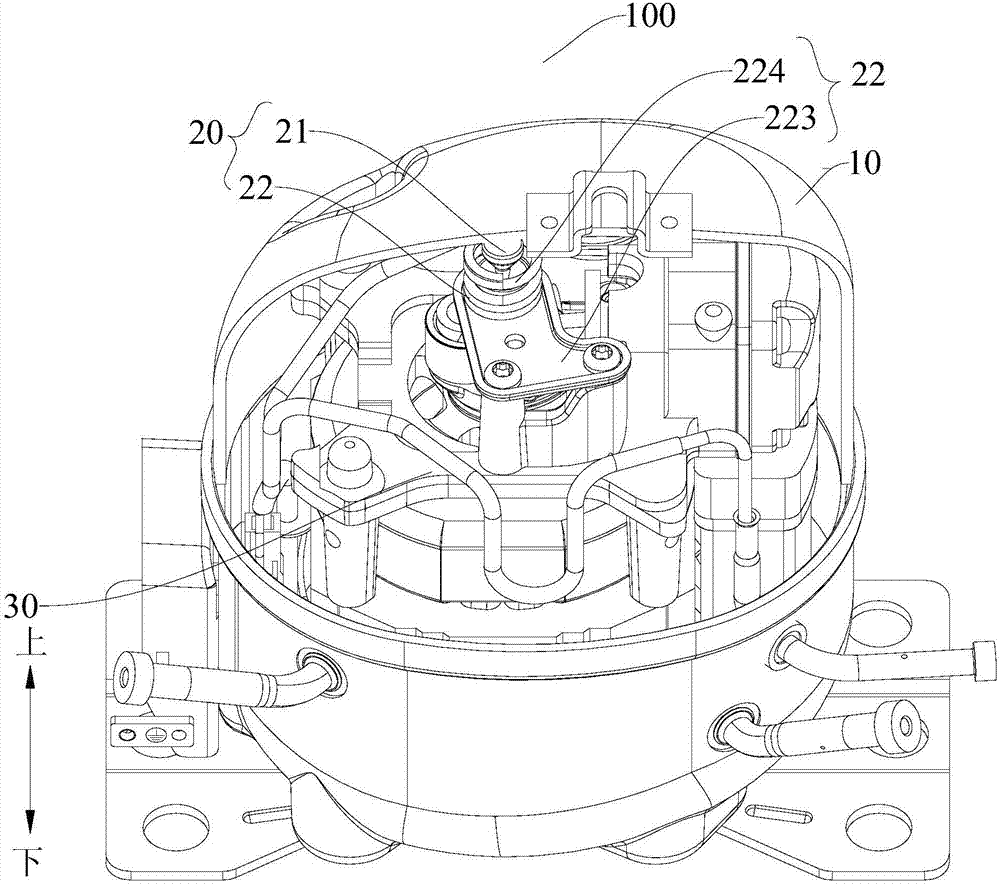

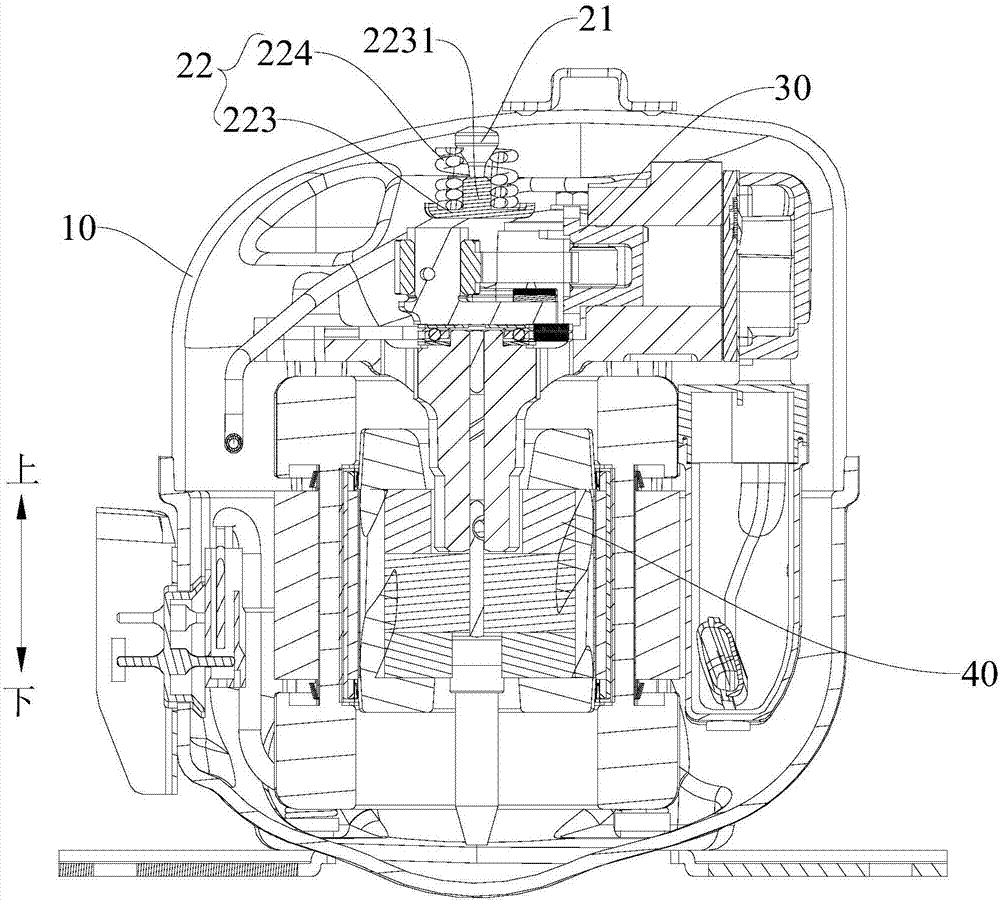

Compressor

ActiveCN107084112AReduce the probability of collisionReduce running noisePositive displacement pump componentsPositive-displacement liquid enginesEngineeringMechanical engineering

The invention discloses a compressor which comprises a shell, a motor part, a compressing mechanism part and a limiting assembly. The motor part is arranged in the shell. The compressing mechanism part is arranged in the shell and connected with the motor part. The compressing mechanism part comprises a crankcase arranged above the motor part. One end of the limiting assembly is connected with the inner top wall of the shell, and the other end of the limiting assembly is connected with the crankcase so as to limit the movement of the crankcase. According to the compressor provided by the embodiment of the invention, the limiting assembly is arranged in the compressor, and one end of the limiting assembly is connected with the inner top wall of the shell, and the other end of the limiting assembly is connected with the crankcase, and accordingly, the movement of the crankcase relative to the shell is limited under the limiting effect of the limiting assembly; and therefore, the probability of collision between the crankcase and the shell is effectively lowered, operating noise is reduced, and the operating reliability of the compressor is improved.

Owner:ANHUI MEIZHI COMPRESSOR

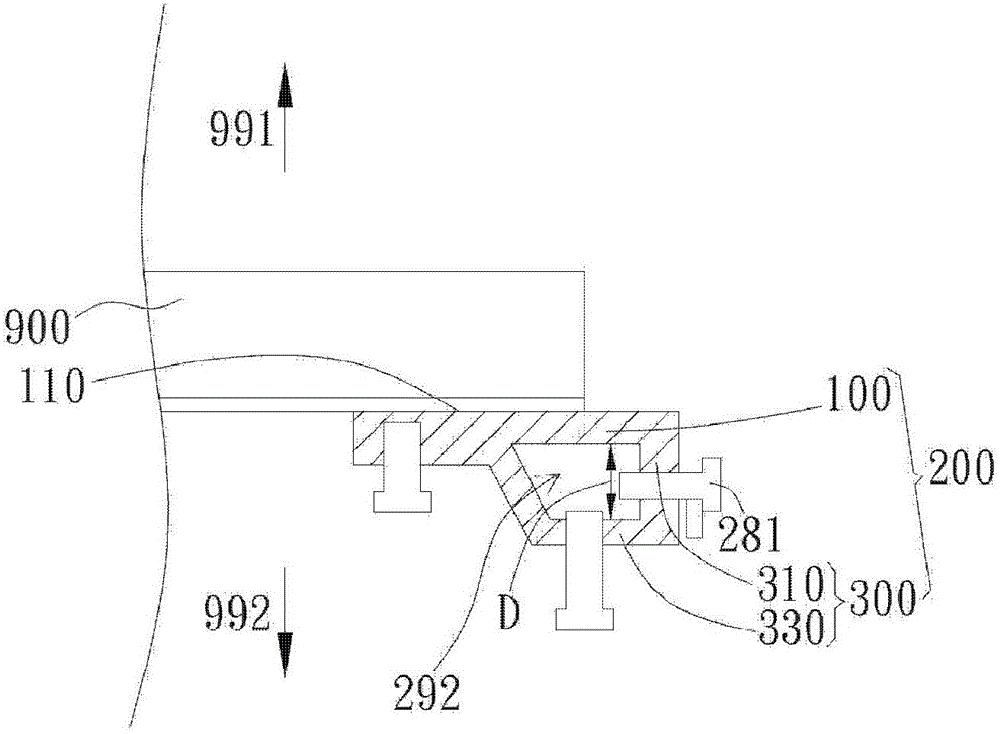

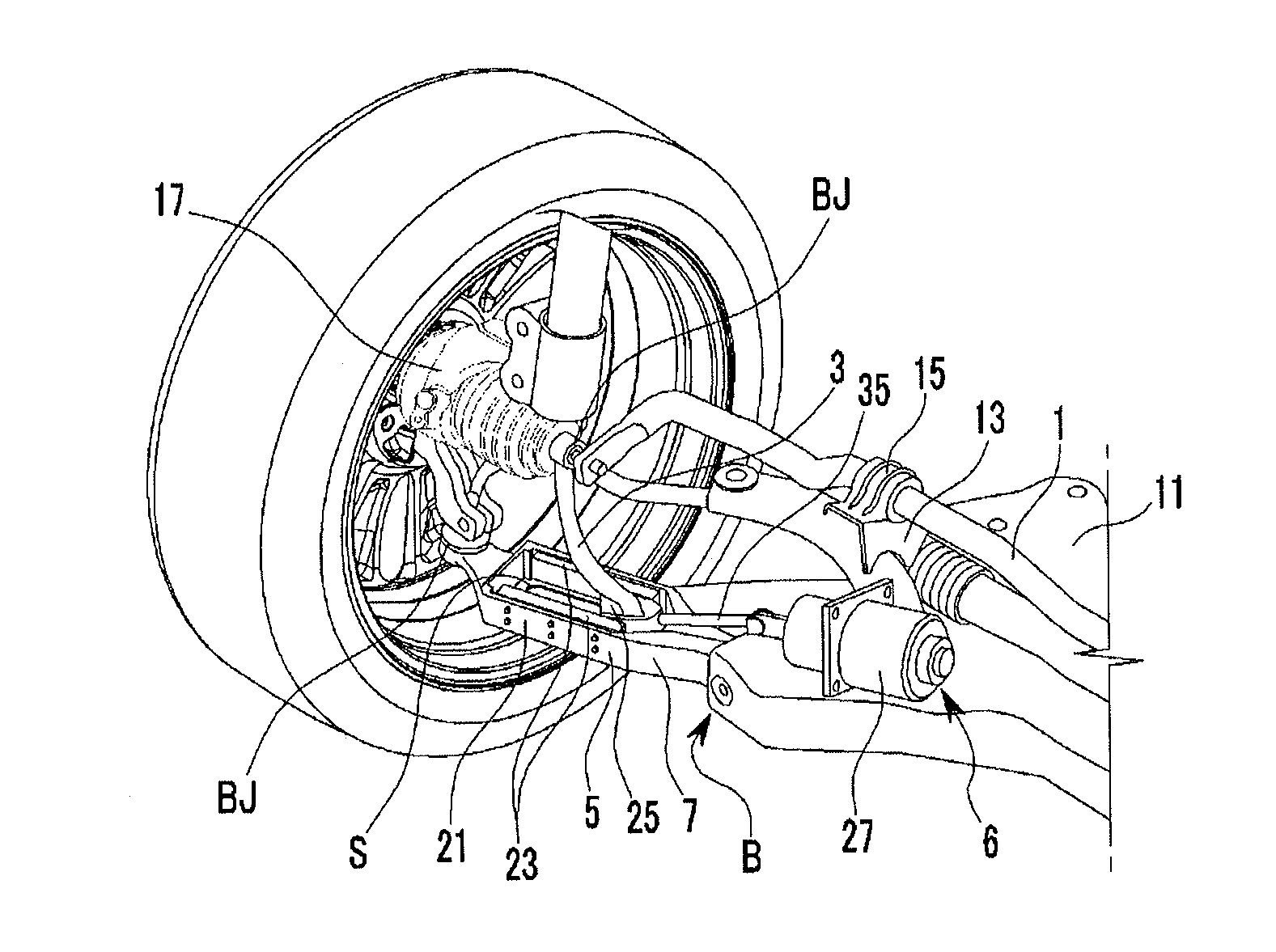

Active roll control system

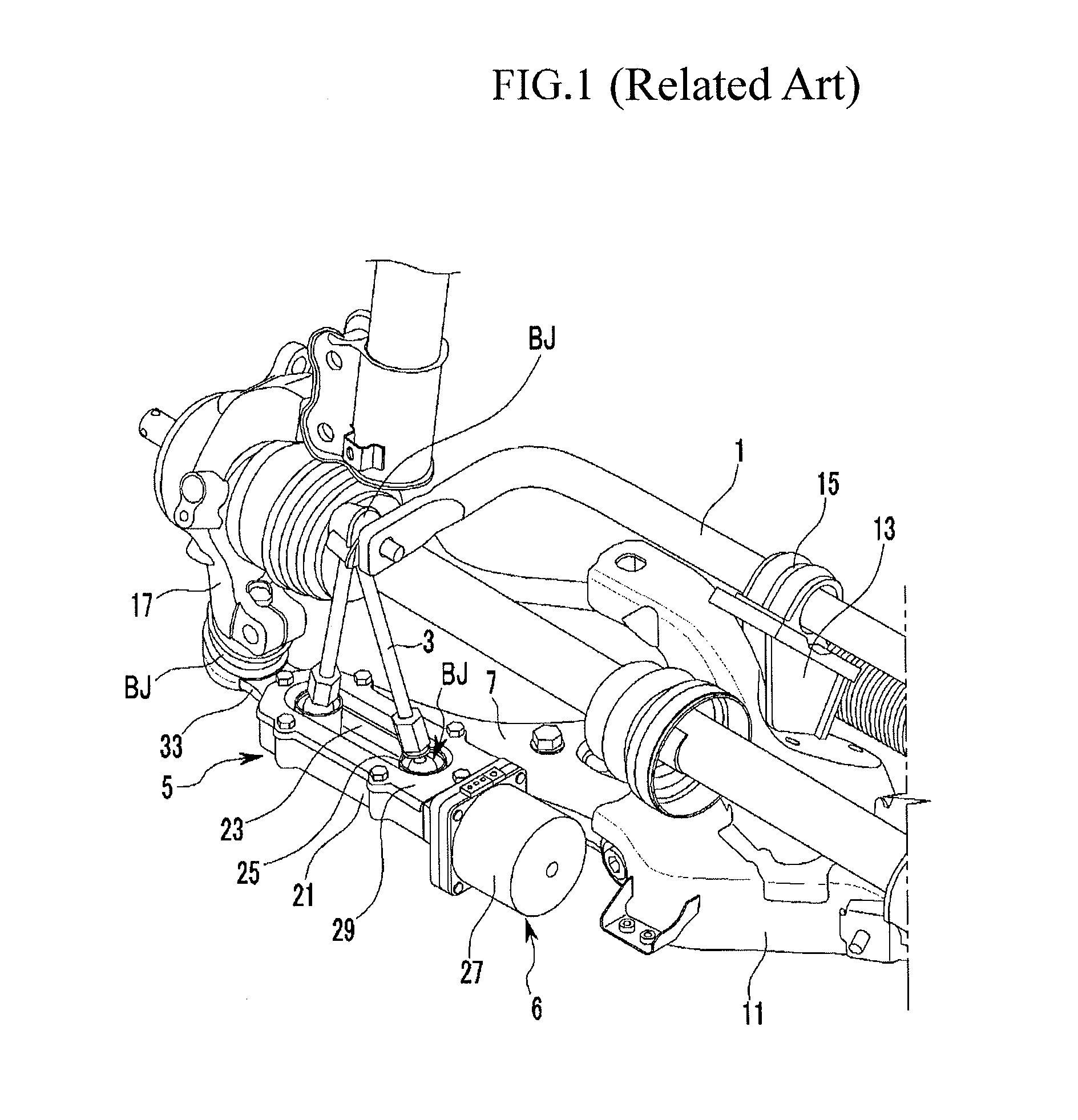

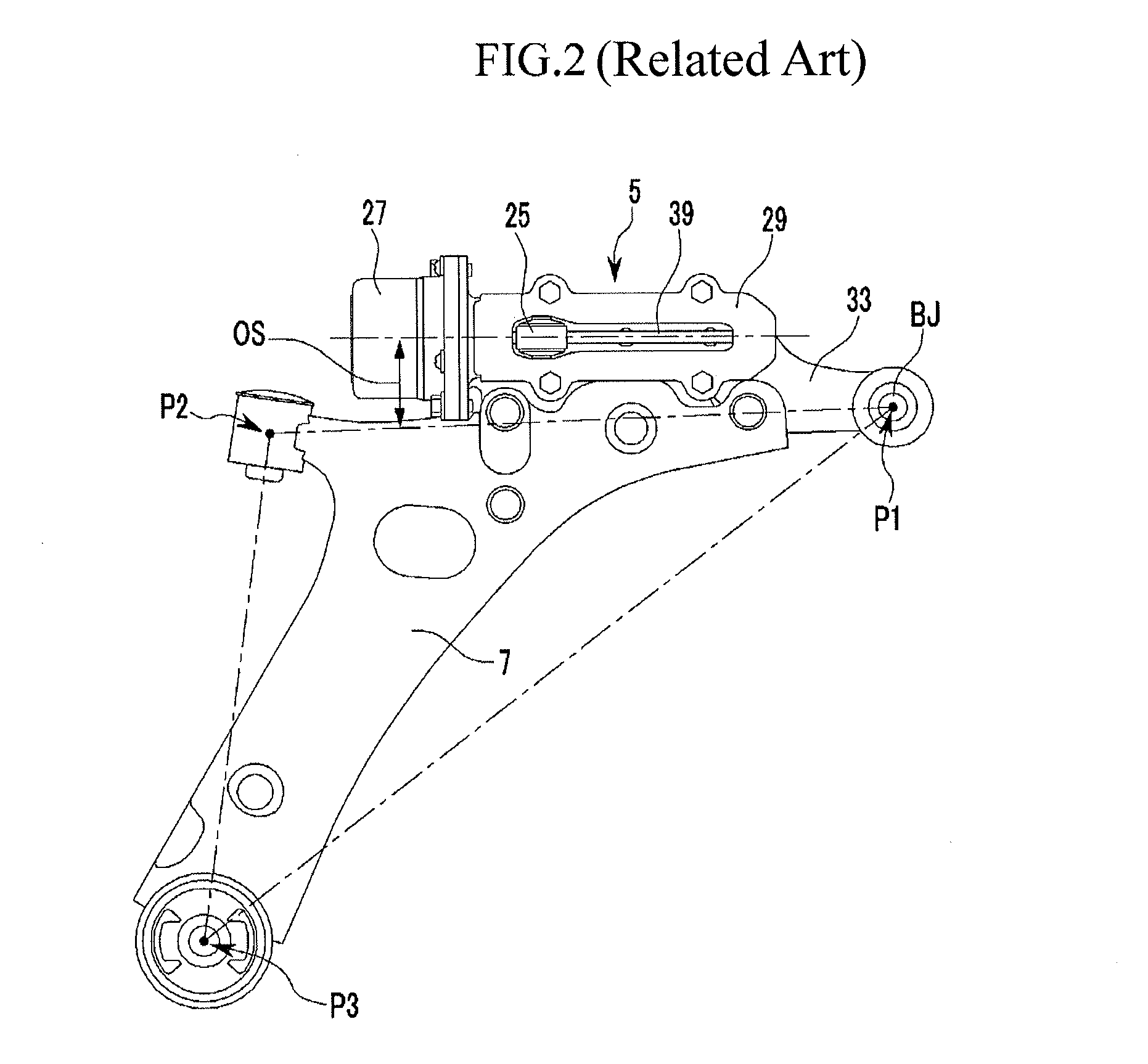

ActiveUS20130147136A1Minimize impactMinimize complianceInterconnection systemsResilient suspensionsControl systemEngineering

An active roll control system may include a sliding unit which includes a housing disposed on a suspension, a slide rail disposed within the housing along vehicle width direction, and a connector movably disposed on the slide rail, wherein the connector may be pivotally connected with a lower end of the stabilizer link, the connector guided along the vehicle width direction according to vehicle driving condition, and a driving unit connected with the connector so as to drive the connector, wherein the connector may be movable at inward of an imaginary line connecting the first connecting point connected with the knuckle and the second connecting point connected with the outward portion of the sub frame.

Owner:HYUNDAI MOTOR CO LTD

Method of reducing torque out retention values in de-swaging of actuator of disk drive

InactiveUS7624495B1Promote resultsReduce debrisElectrical transducersManual lubricationGramDeposition process

A lubricant is applied to swage contact surfaces in a disk drive of the type including a suspension arm connected to an actuator arm by a swaging process. A preferred thin film lubricant may be applied to the contact surfaces by immersion and draining, immersion and raising the part out of the solution, localized spraying, or various deposition processes. Application of the lubricant reduces chipping during de-swaging, particularly with nickel plated metal components. Application of the lubricant has also shown to improve gram load uniformity, reduce adverse distortion to the actuator assembly and reduces torque out retention values. Improved gram load uniformity enhances overall disk drive functioning, reduced distortion preserves intended attitude and flatness of the actions for assembly and reduced torque out retention values improves reworkability of the disk drive.

Owner:SEAGATE TECH LLC

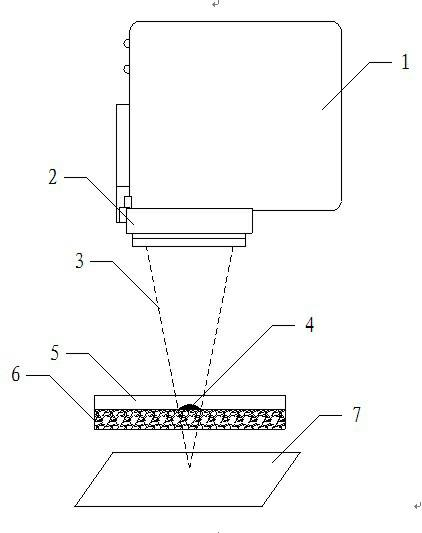

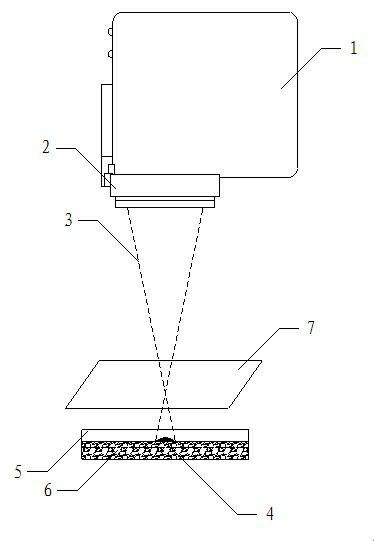

New method for welding plastics by metal laser welding machine

The invention discloses a new method for welding plastics by a metal laser welding machine, which comprises the following steps of: a) controlling a special board card by adopting a computer to output a near infrared ray laser with a certain frequency and wavelength of between 800 and 1,064 nanometers; and b) clamping two plastic components to be welded, allowing the near infrared ray laser to transmit a first component in a mode of deviating from a focal point, absorbing the transmitted near infrared ray laser by a second component, converting the absorbed near infrared ray laser into heat energy, and melting a contact surface of the two components to form a welding area. By the method, precise, firm and sealing welding can be formed, resin degradation is less, generated fragments are fewer, surfaces of products are connected closely on the periphery of a welding line, high-speed welding can be realized only by low frequency, and the efficiency of the method is three times that of general plastic welding.

Owner:东莞市创普光电技术有限公司

Straw charging and processing method and system

InactiveCN109609337AAvoid Legacy SituationsReduce debrisBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringTransformation efficiency

The invention relates to the technical field of a straw charging and processing method and system, and discloses a straw charging and processing method and system. The system comprises an equipment main frame, wherein a segment cutting device and a conveying device are respectively and fixedly connected to the left side and the right side of the top of the equipment main frame, and opposite sidesof the segment cutting device and the conveying device are fixedly connected; a briqueting device and a cutting-up device are respectively and fixedly connected to the left side and the right side ofthe top of the conveying device; and a rolling device is fixedly connected to the right side of the equipment main frame. According to the straw charging and processing method and system disclosed bythe invention, the problems that when conventional straw is fermented, the technological process of preliminary treatment is simple, so that the conversion rate of methane is low, and the purity of the methane is low, are solved. The cutting-up device is used, 8 semicircle wheels are driven by a motor, 8 cutting-up knives can perform cutting-up operation at different times when the straw is conveyed, extruded briquetd straw can be further crushed, and the size of straw granules can be reduced, so that the transformation efficiency of the straw treated in a fermenting room can be improved.

Owner:安徽天马环保装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com