Patents

Literature

52results about How to "Good deformation properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

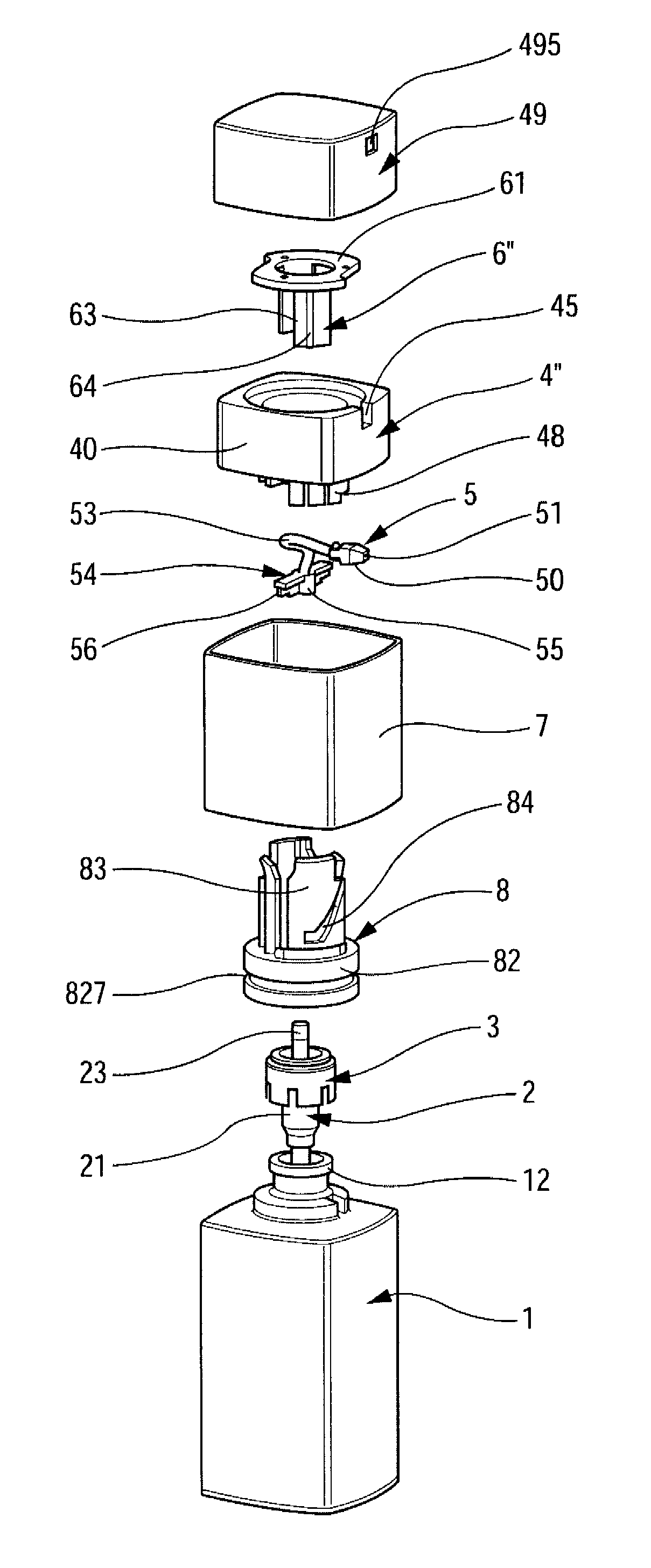

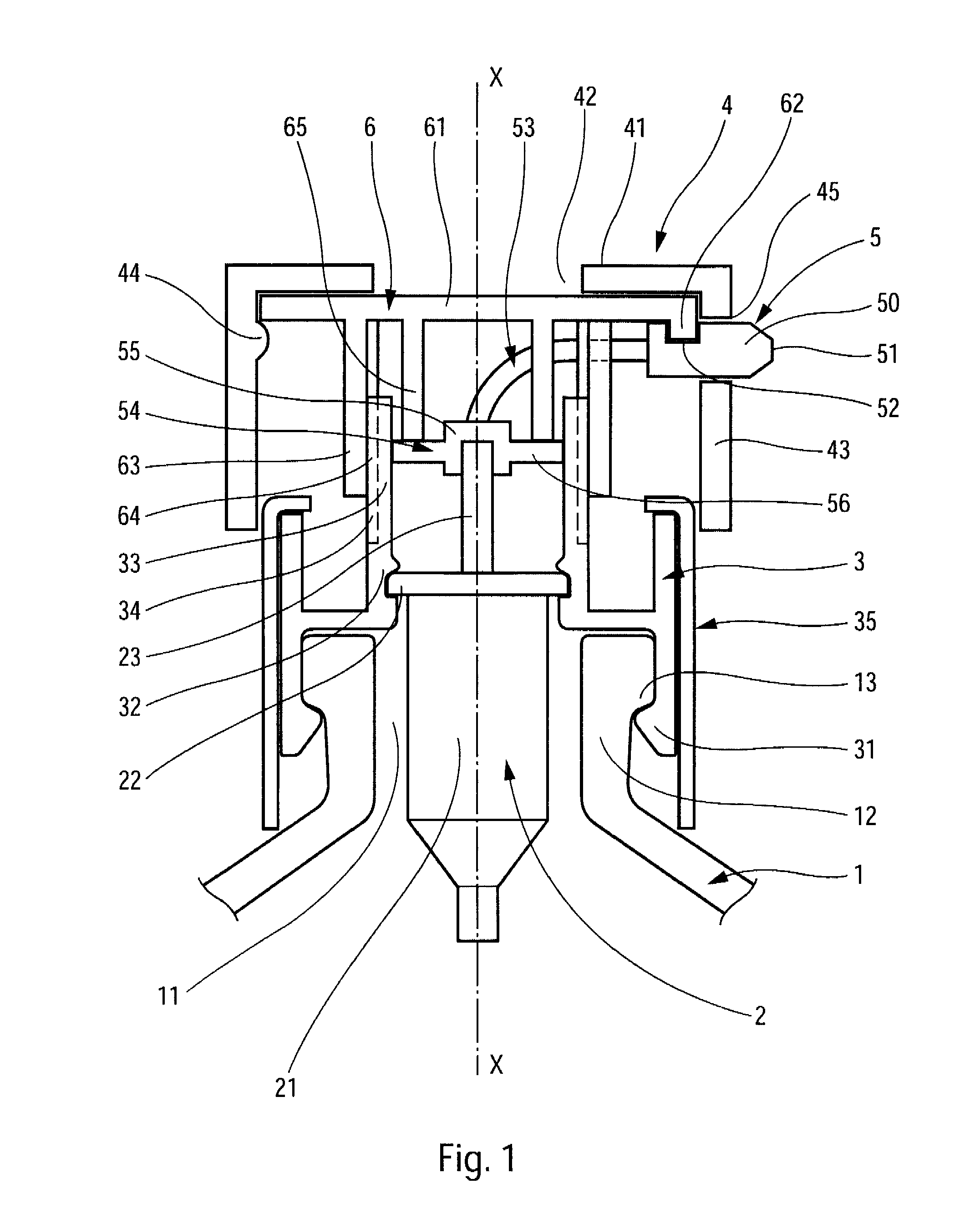

Fluid dispenser

InactiveUS20080116232A1Good deformation propertiesClosuresLiquid flow controllersAxial displacementEngineering

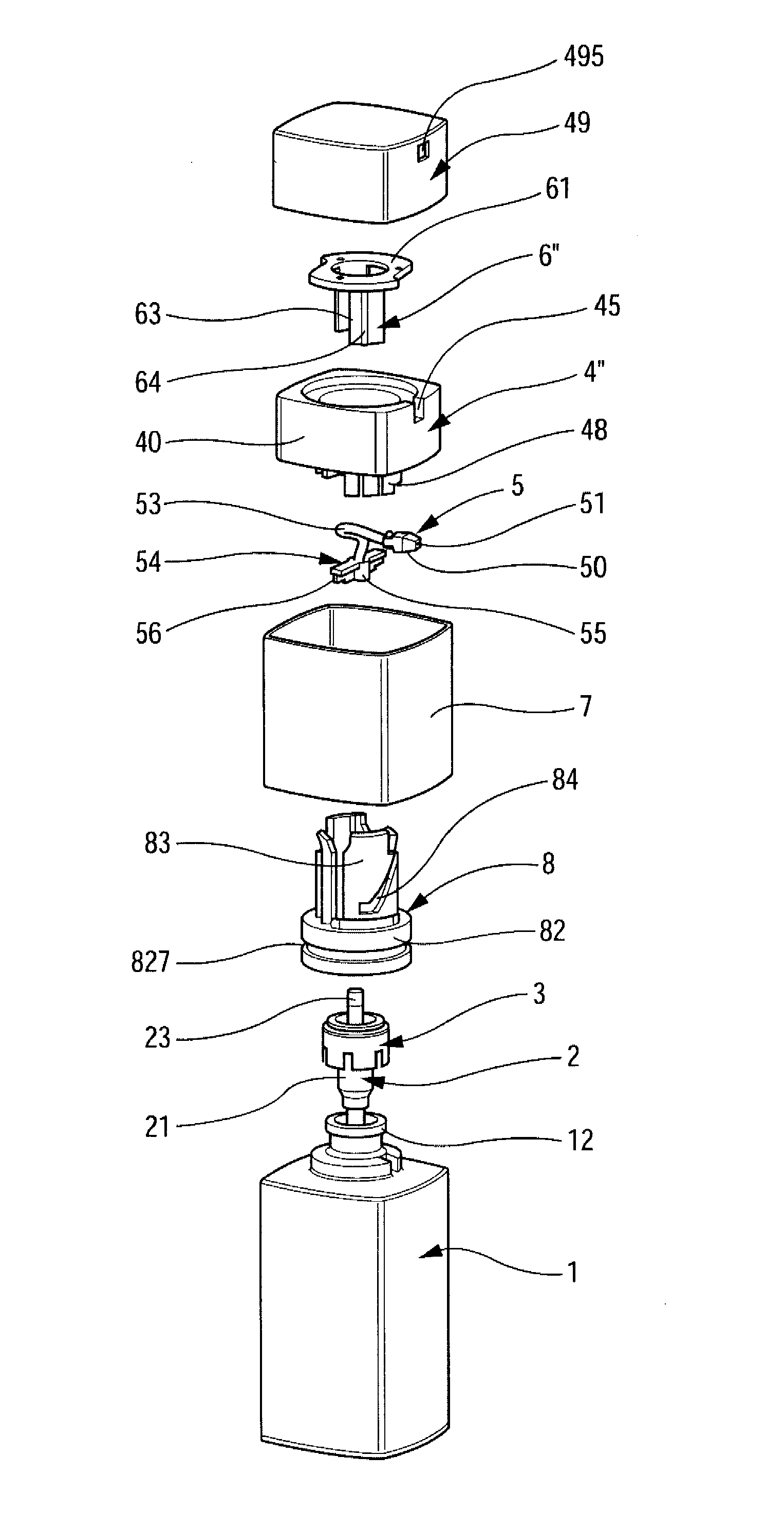

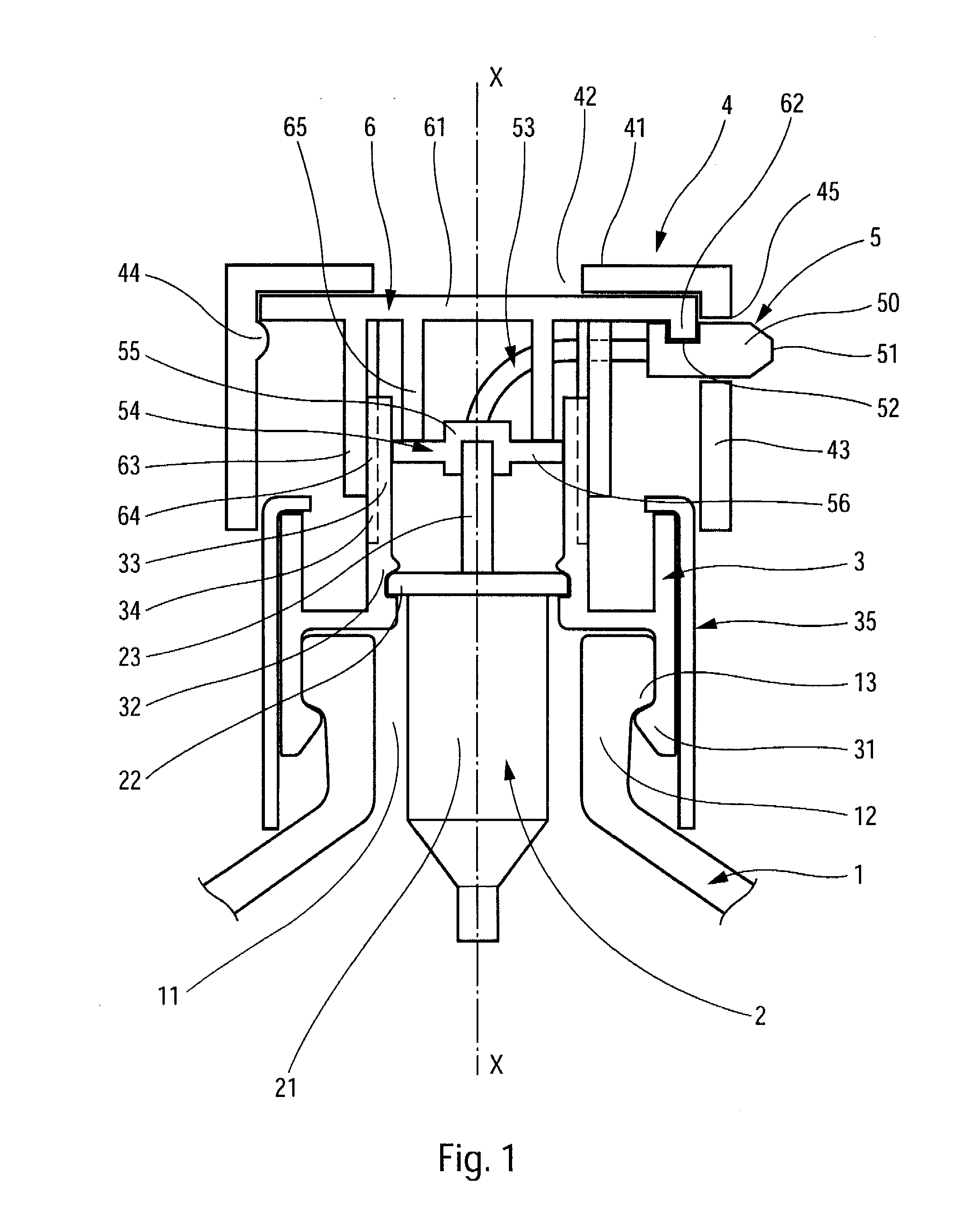

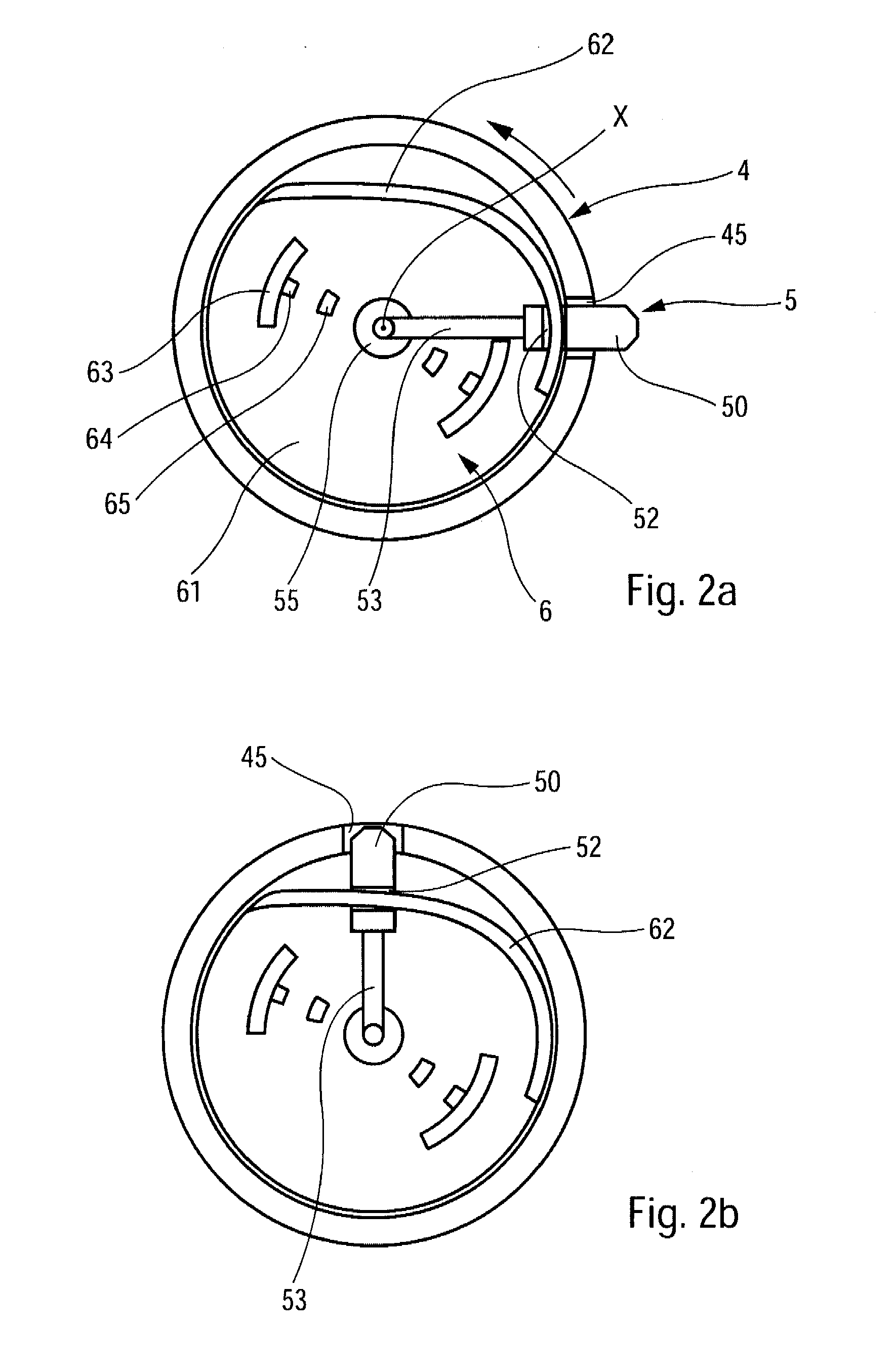

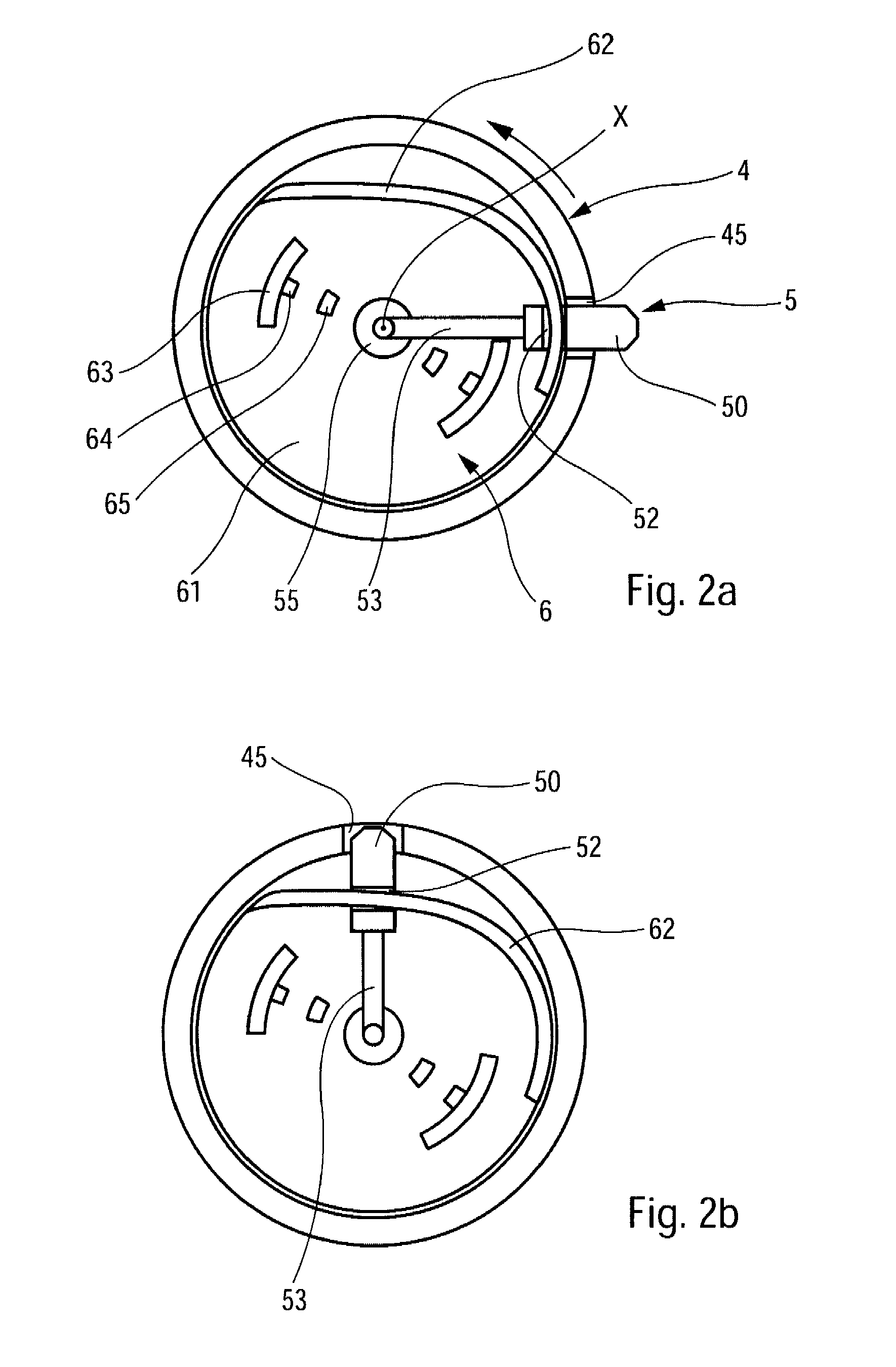

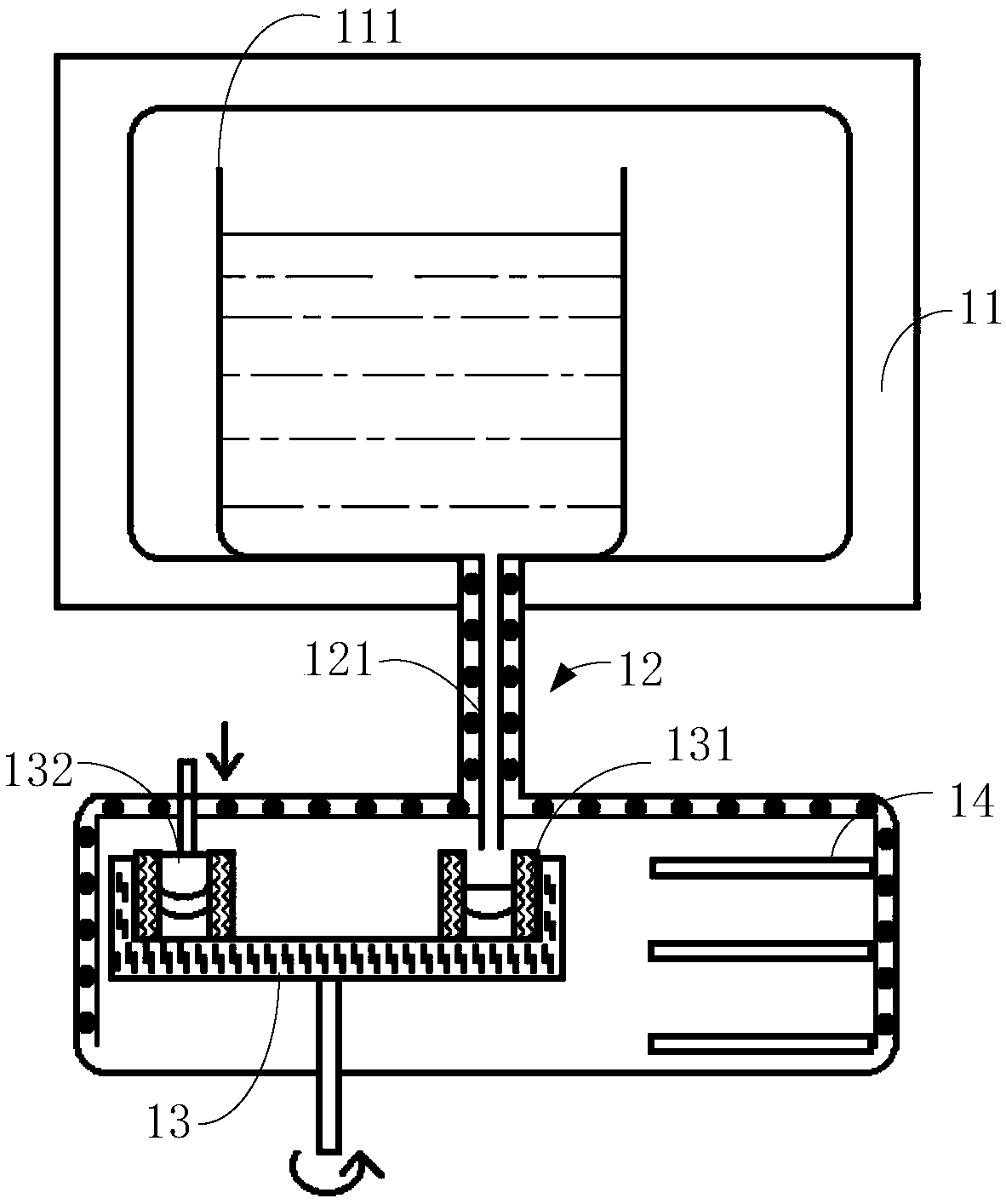

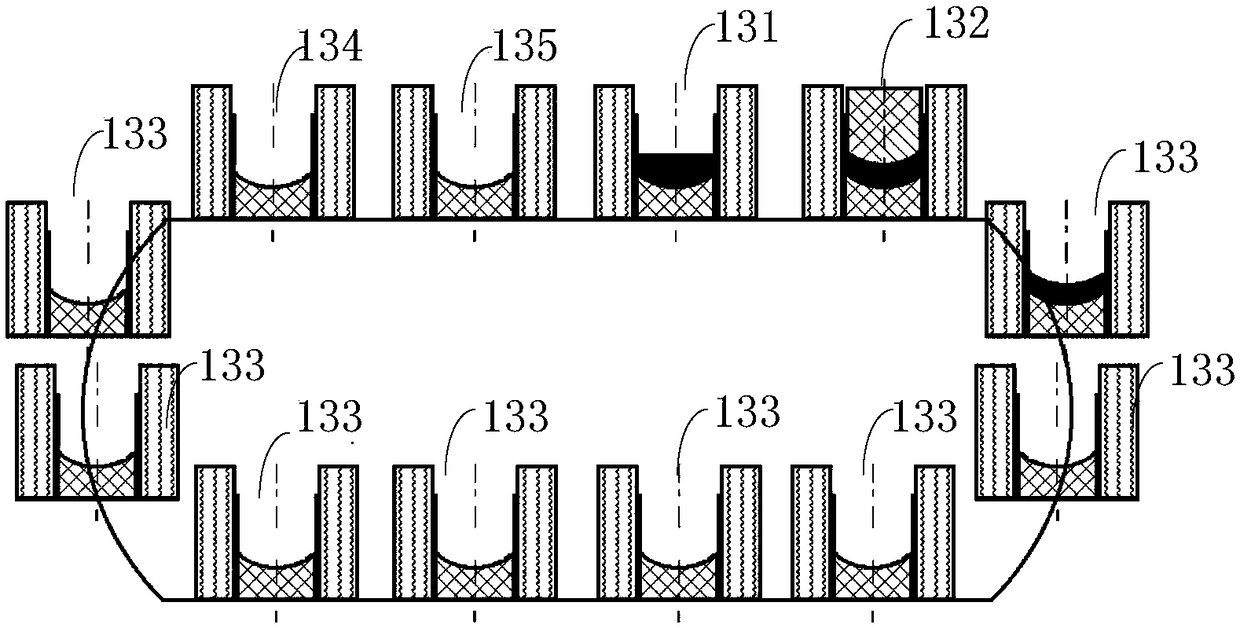

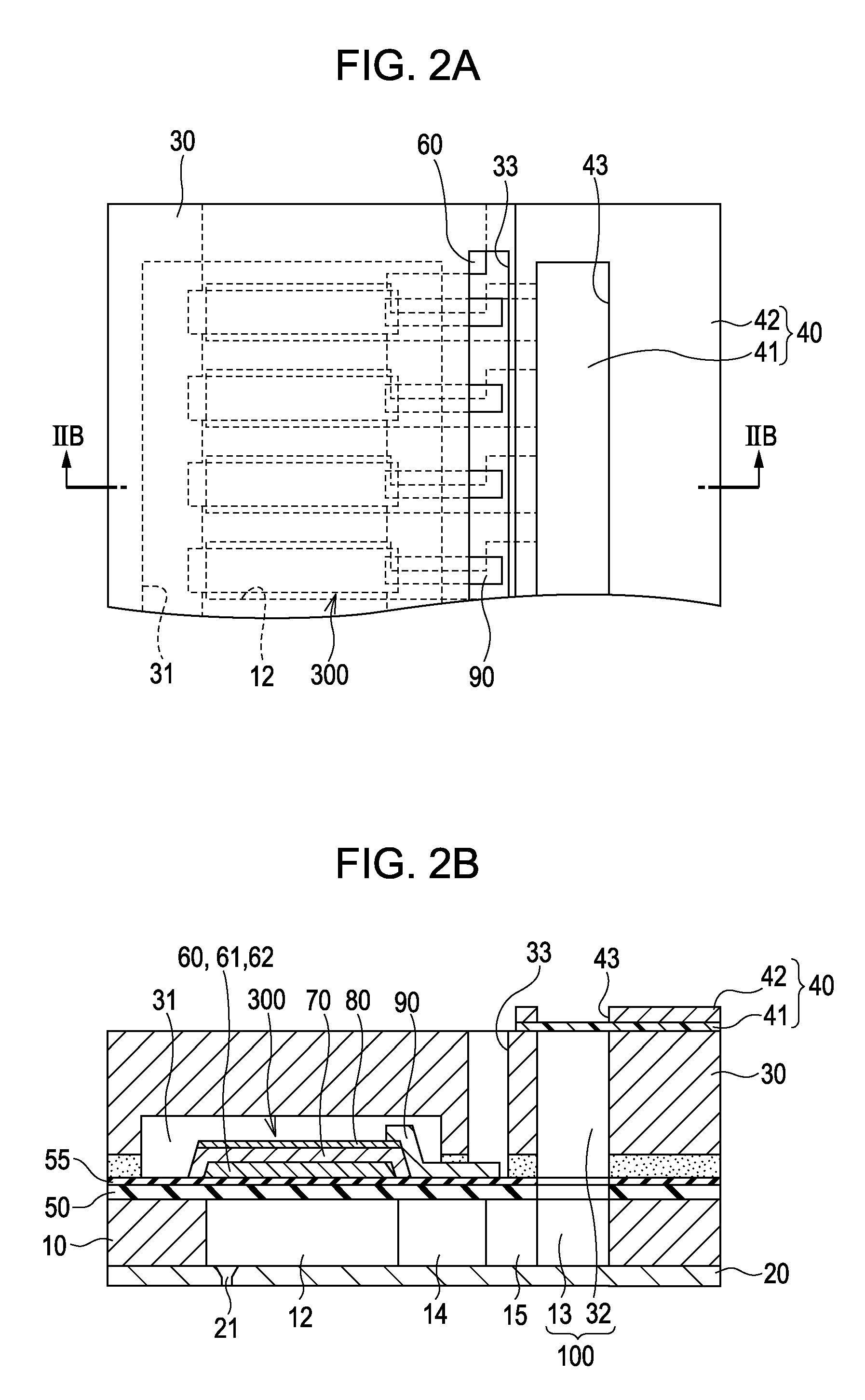

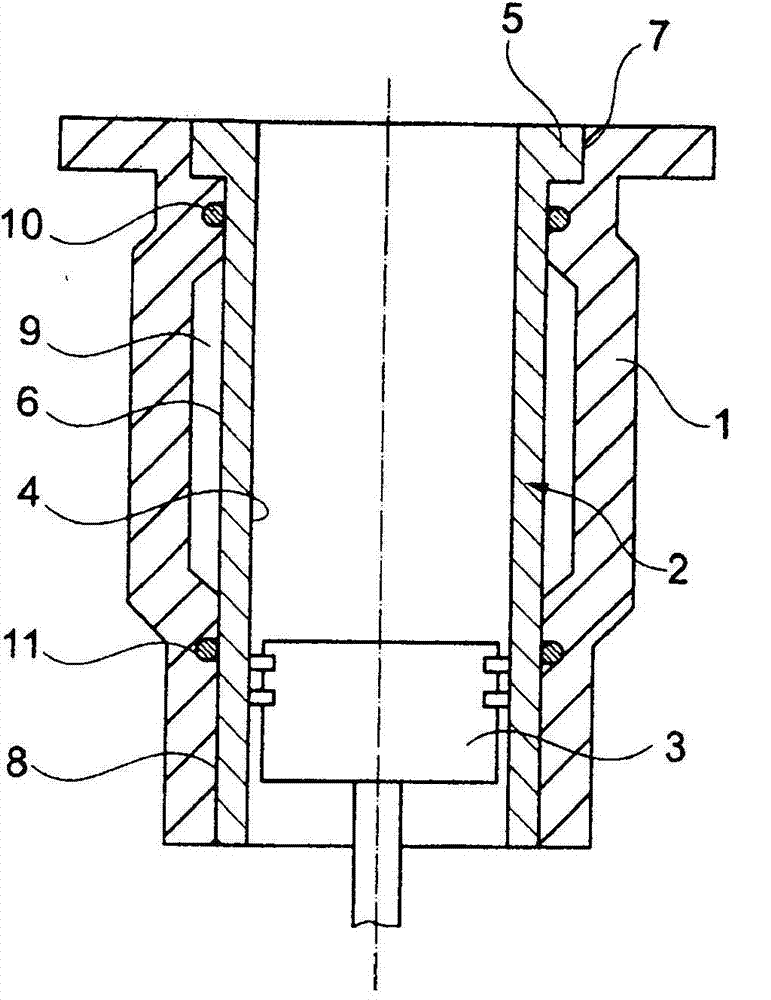

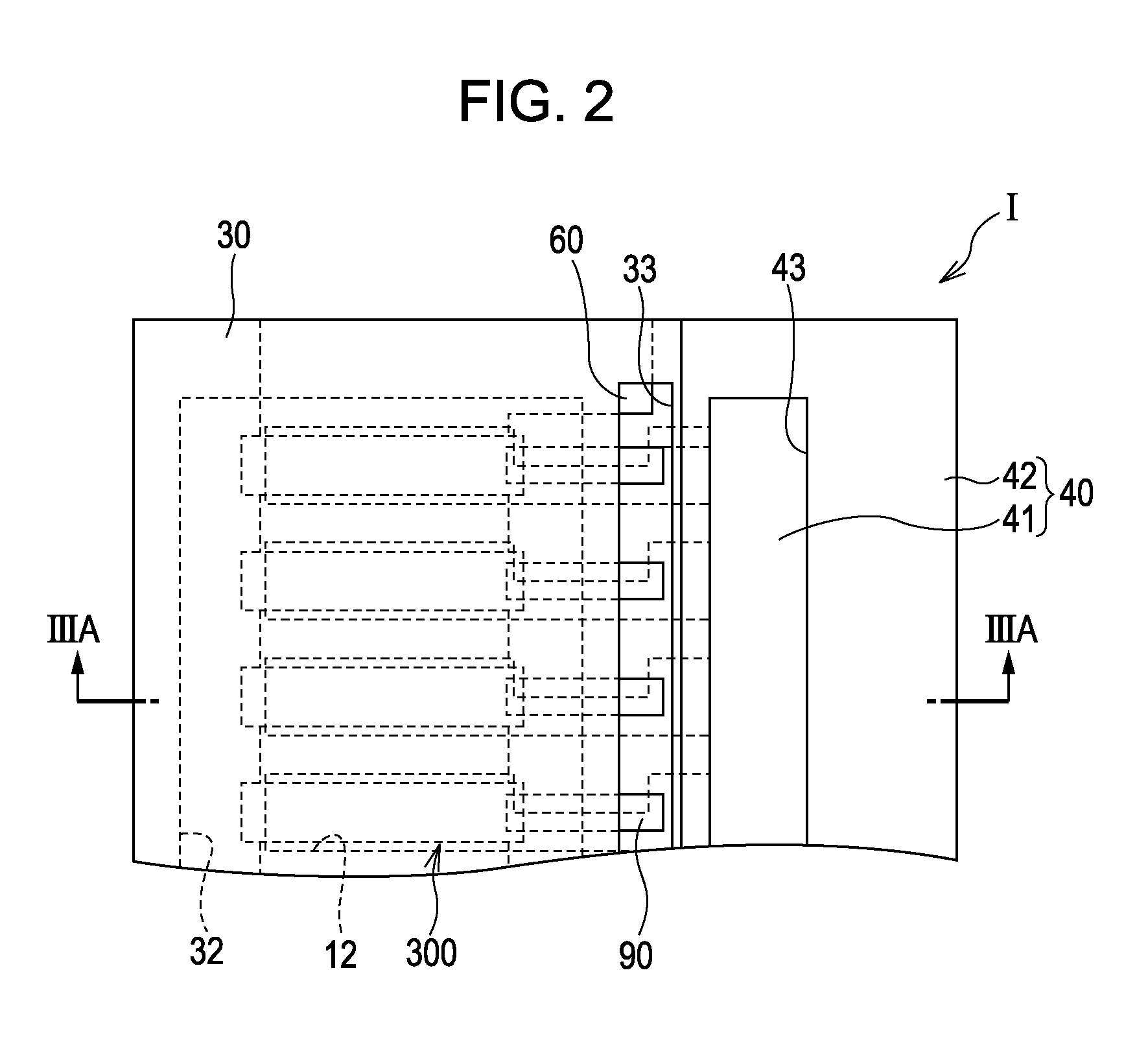

A fluid dispenser comprising:a fluid reservoir (1) provided with an opening (11);a fluid dispenser member (2), such as a pump or a valve, said member comprising a body (21) and an actuator rod (23) that is displaceable down and up along an axis X;a fastener ring (3) for fastening the dispenser member on the opening of the reservoir;a pusher (4; 4′; 4″) that is axially displaceable down and up so as to displace the actuator rod (23); anda dispenser endpiece (50) defining a dispenser orifice (51);displacement means (6, 4; 6′, 7; 6″, 7, 4″) that are suitable for displacing the endpiece (50) both in turning about the axis X and in radial translation, the radial distance between the endpiece and the axis X varying as the endpiece turns about said axis X, such that the endpiece is displaceable between an extended position remote from the axis X and a retracted position close to the axis X, the displacement means comprising a rotary actuator member (4; 7) that turns about the axis X, the endpiece (50) being constrained to turn with said actuator member, and a cam path (62) that is prevented from turning relative to the reservoir (1), the radial distance between the path (62) and the axis X varying along the path, the endpiece (50) being engaged with the cam path in such a manner that it follows the cam path while it is being turned by the actuator member (4; 7),the fluid dispenser being characterized in that the cam path (62) is formed by a cam element (6″) that is mounted on a ferrule (8) that is mounted in stationary manner relative to the reservoir (1), the cam element (6″) being prevented from turning relative to the ferrule (8), but being capable of being displaced axially, the pusher (4″) being in engagement with the ferrule (8) via a second threaded cam path (84), the pusher (4″) being turned by the actuator member (7), the pusher (4″) being displaced axially relative to the ferrule (8) and to the actuator member (7) by following the second threaded cam path (84) while said pusher is being turned by the actuator member, such that turning the actuator member simultaneously causes the rotary axial displacement of the pusher and the rotary radial displacement of the endpiece.

Owner:APTAR FRANCE SAS

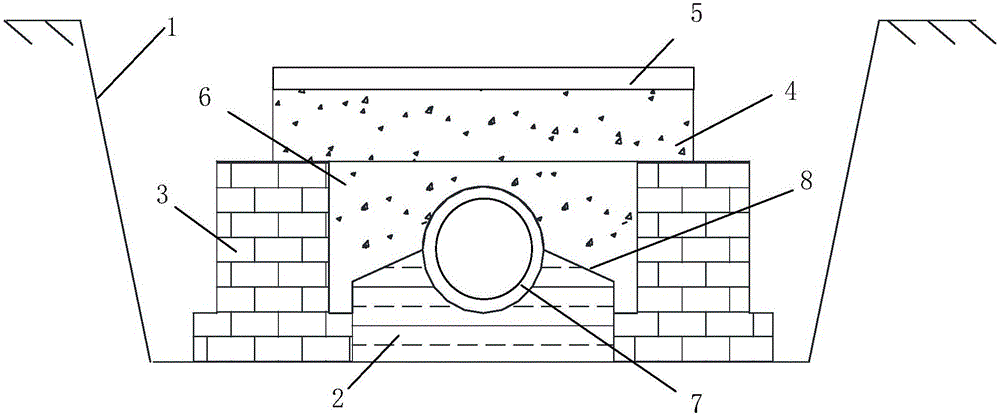

Full-section pre-reinforcing construction method for tunnel free-machining anchor bar

InactiveCN101487393AGood deformation propertiesConstruction method safetyUnderground chambersTunnel liningGlass fiberFiber

The invention discloses a tunnel easy-cutting anchor-rod full-section pre-consolidation construction method, comprising the following steps: firstly, survey design before construction is carried out, pre-consolidation is carried out to a face core body to be excavated by adopting an easy-cutting anchor rod according to the sampling analysis and classification of rock-soil, meanwhile, a measuring instrument is installed to monitor the change thereof, and then full-section excavation is carried out. The construction method takes the problem of how to deal with the 'core body to be excavated' in front of the face as the key for controlling the integral stability of the tunnel, an easy-cutting glass fiber anchor rod which is pre-consolidated along tunnel vertical full-section is used for improving the equivalent stiffness of the 'core body to be excavated' and controlling the deformation of the 'core body to be excavated' so as to cause arching effect around the tunnel to function naturally, thus guaranteeing the full-section, safe and quick excavation and drivage of the tunnel. The construction method is safe and reliable, can realize tunnel full-section mechanized and modernized construction, and has good production efficiency, continuous and stable construction progress, and controllable project cost.

Owner:中铁西南科学研究院有限公司

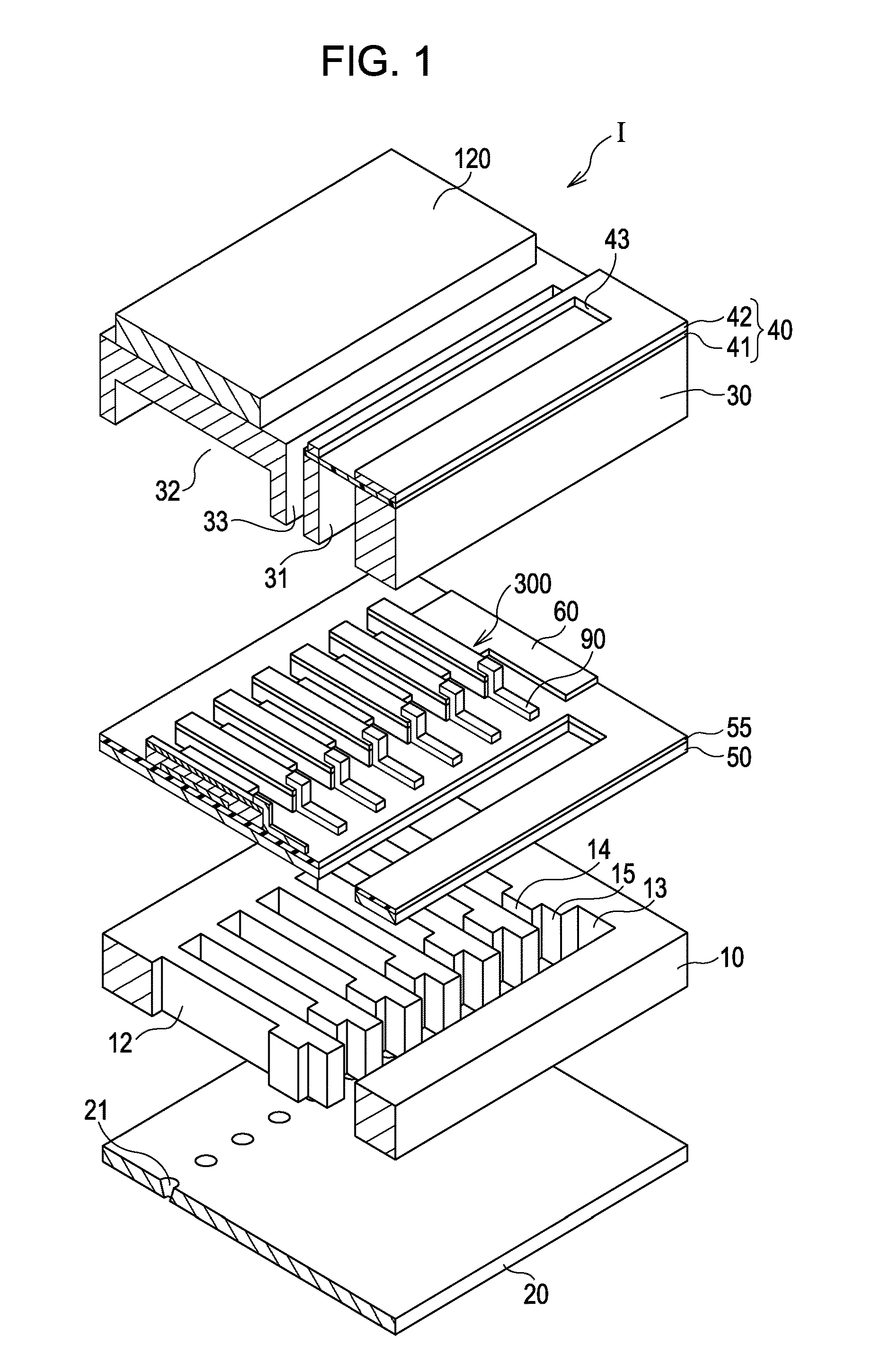

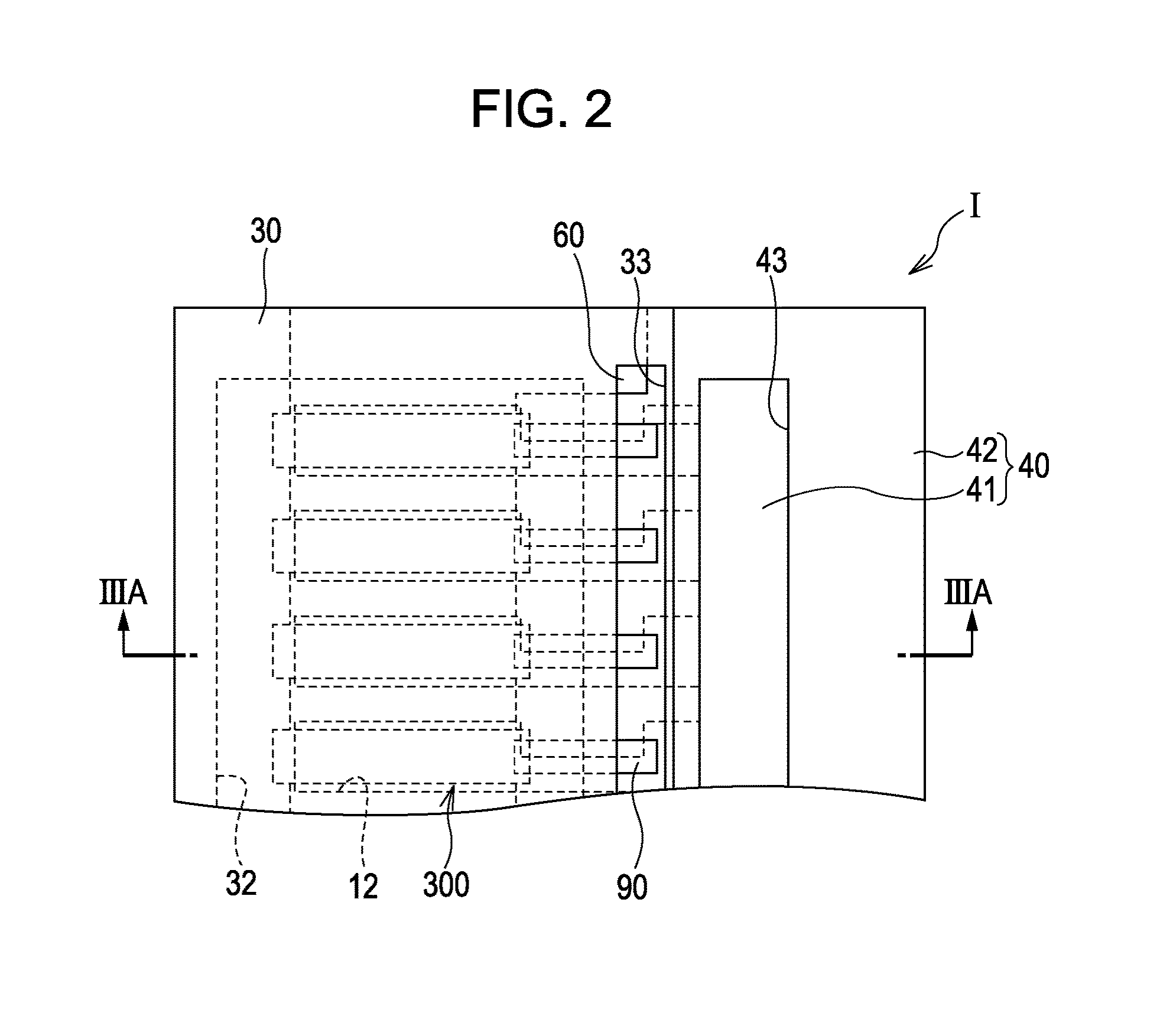

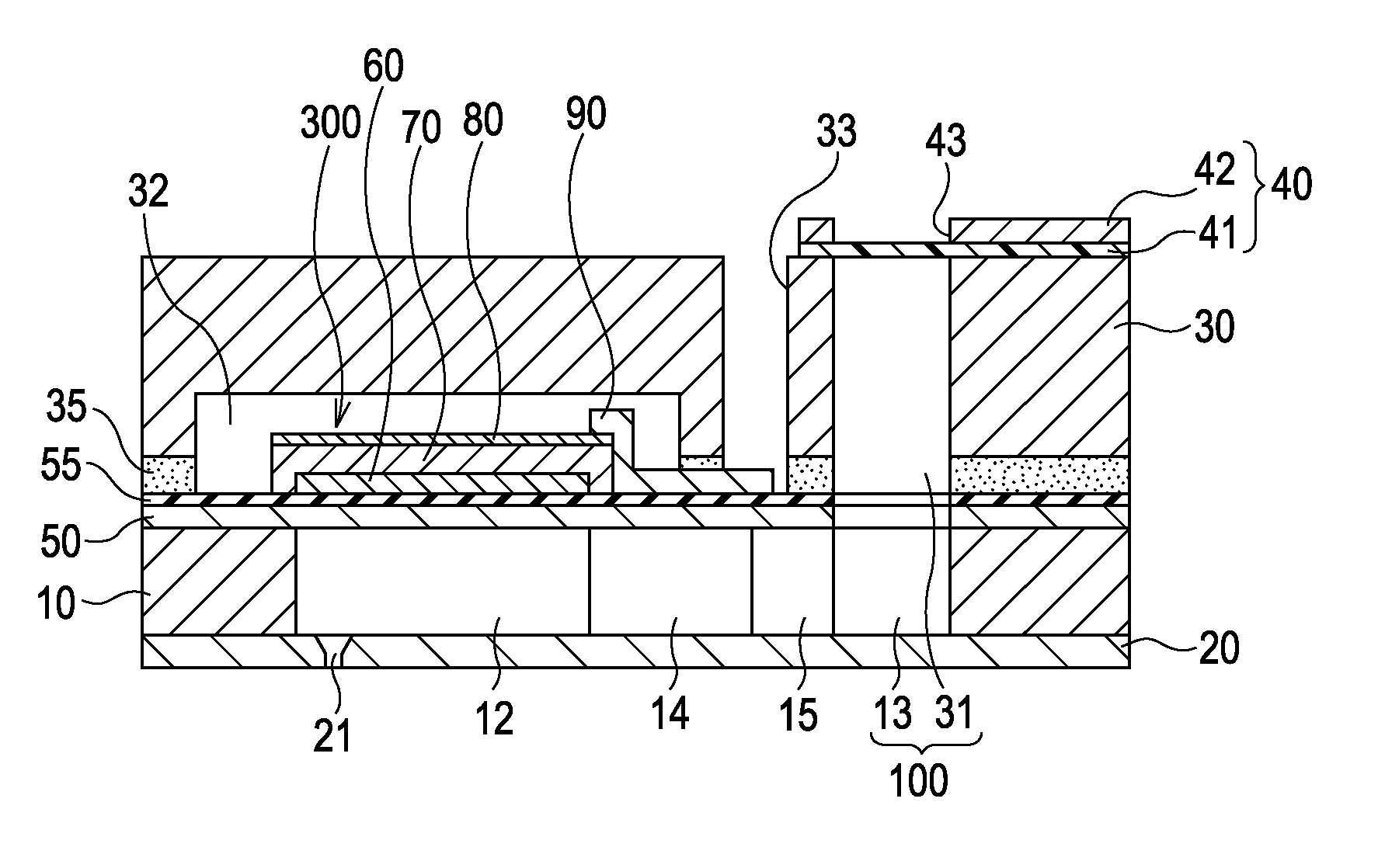

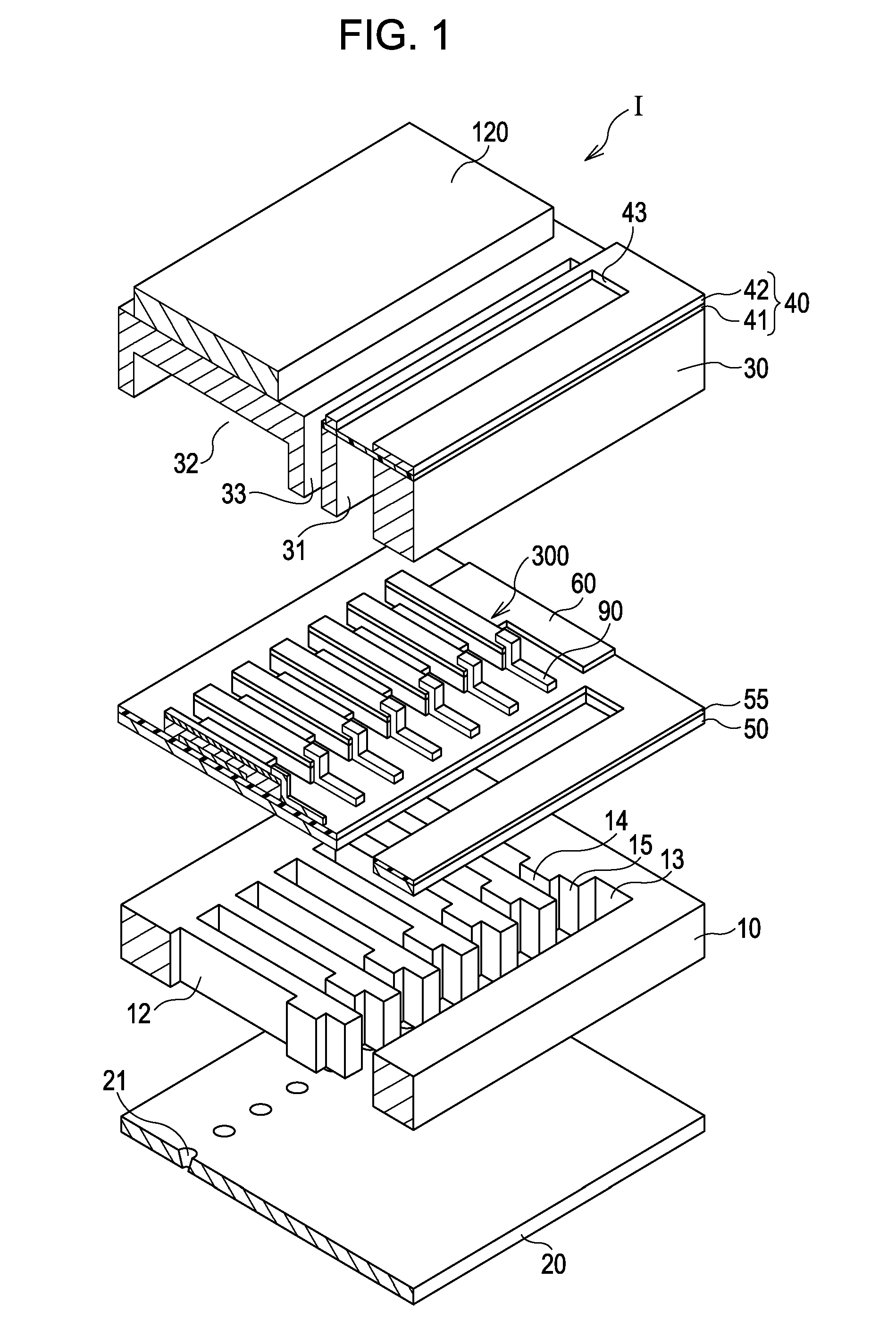

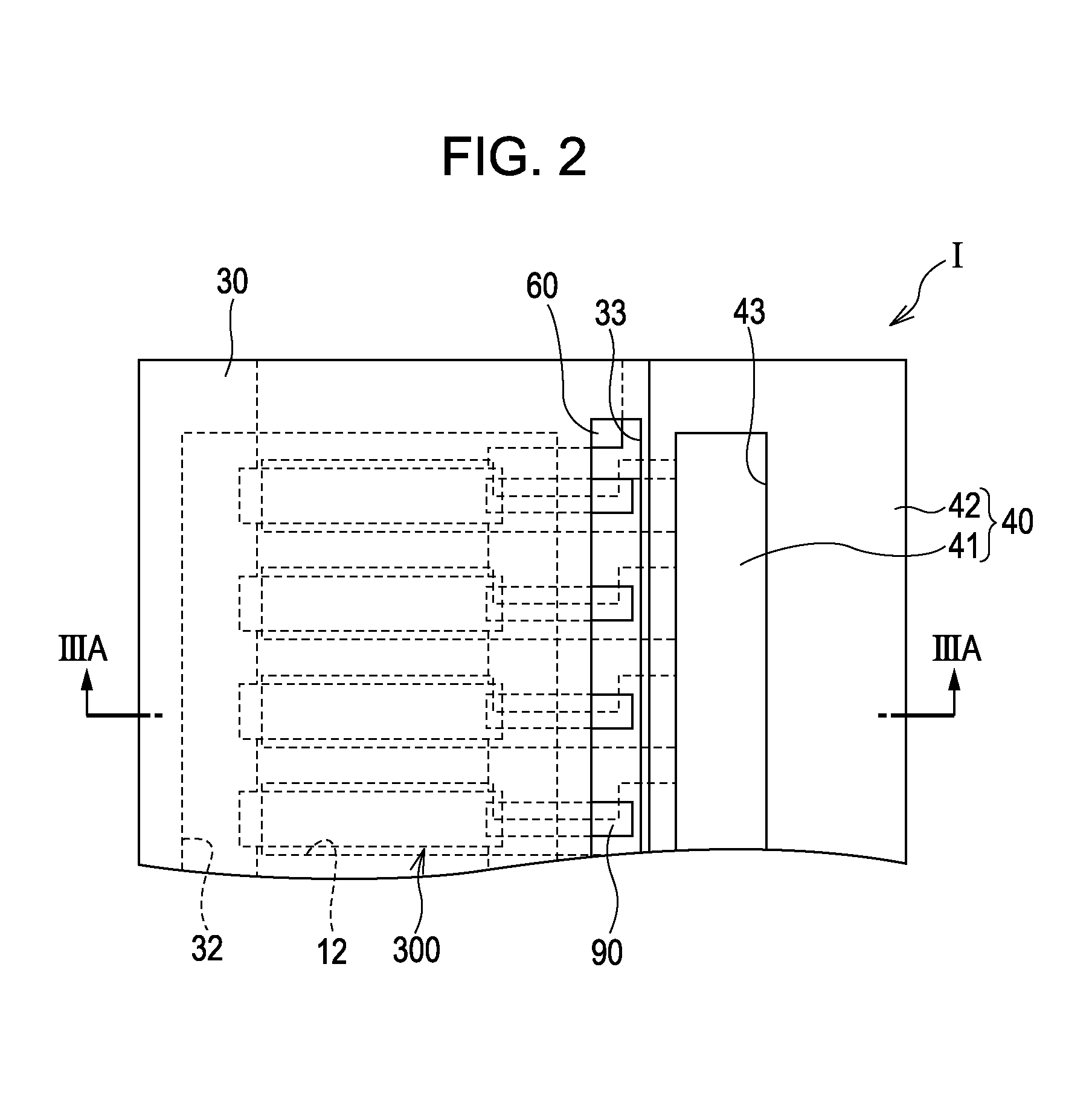

Liquid-ejecting head, liquid-ejecting apparatus, piezoelectric element, and method for manufacturing liquid-ejecting head

InactiveUS20110164098A1Easy to manufactureWell formedPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusLiquid jetManganese

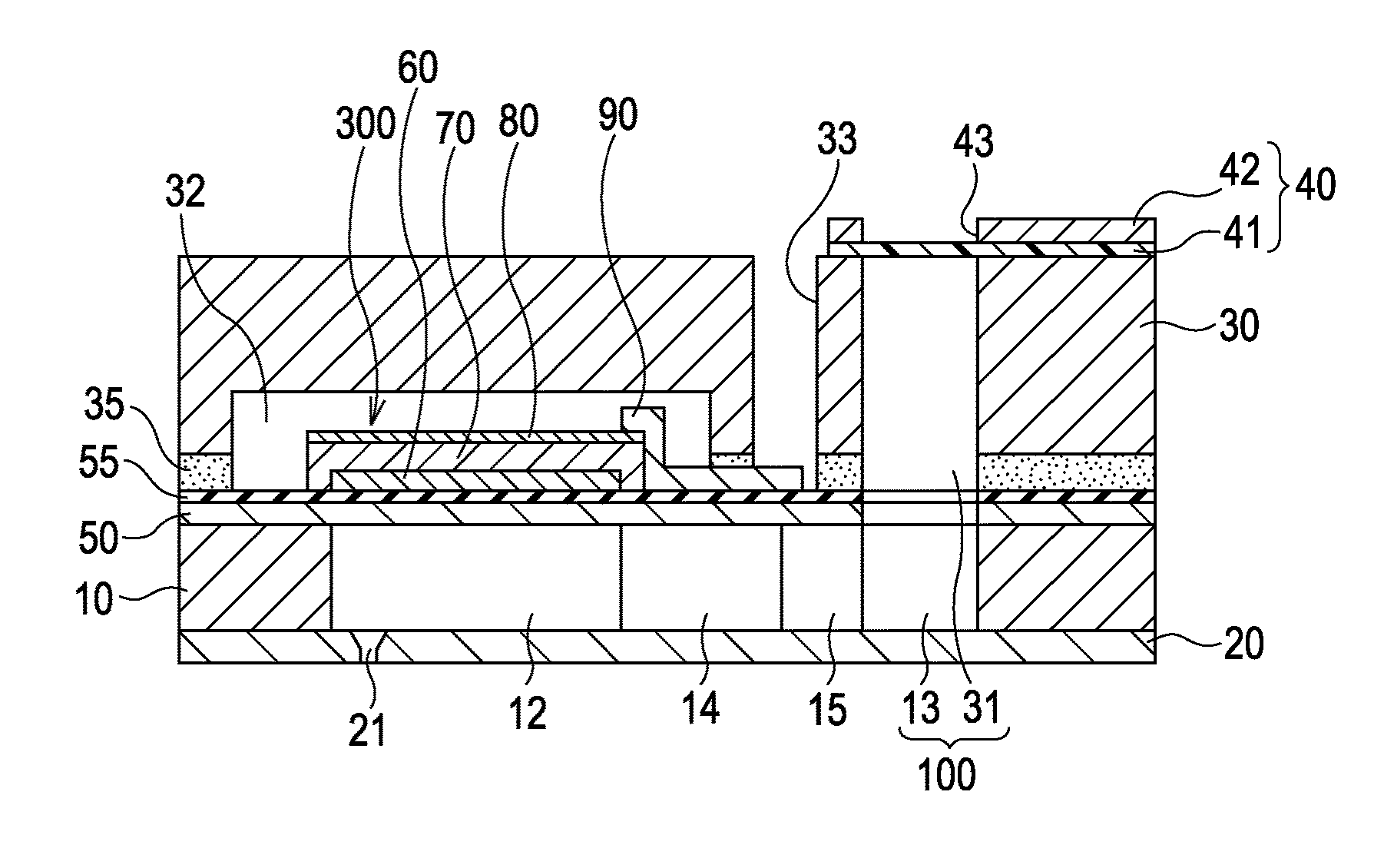

A piezoelectric element comprising a first electrode, a piezoelectric layer containing bismuth lanthanum iron and manganese formed above the first electrode, and a second electrode formed above the piezoelectric layer. The piezoelectric layer contains crystals preferentially oriented in a (111) plane.

Owner:SEIKO EPSON CORP

Fluid dispenser

A fluid dispenser having: a fluid reservoir, a fluid dispenser member having actuator rod (23) that is displaceable down and up along an axis X, a pusher (4; 4; 4″) that displaces the actuator rod (23), a dispenser endpiece (50) defining a dispenser orifice (51), and a displacement mechanism (6, 4; 6′, 7; 6″, 7, 4″) that displaces the endpiece (50) both in turning about the axis X and in radial translation, the radial distance between the endpiece and the axis X varying as the endpiece turns about the axis X, such that the endpiece is displaceable between an extended position remote from the axis X and a retracted position close to the axis X.

Owner:APTAR FRANCE SAS

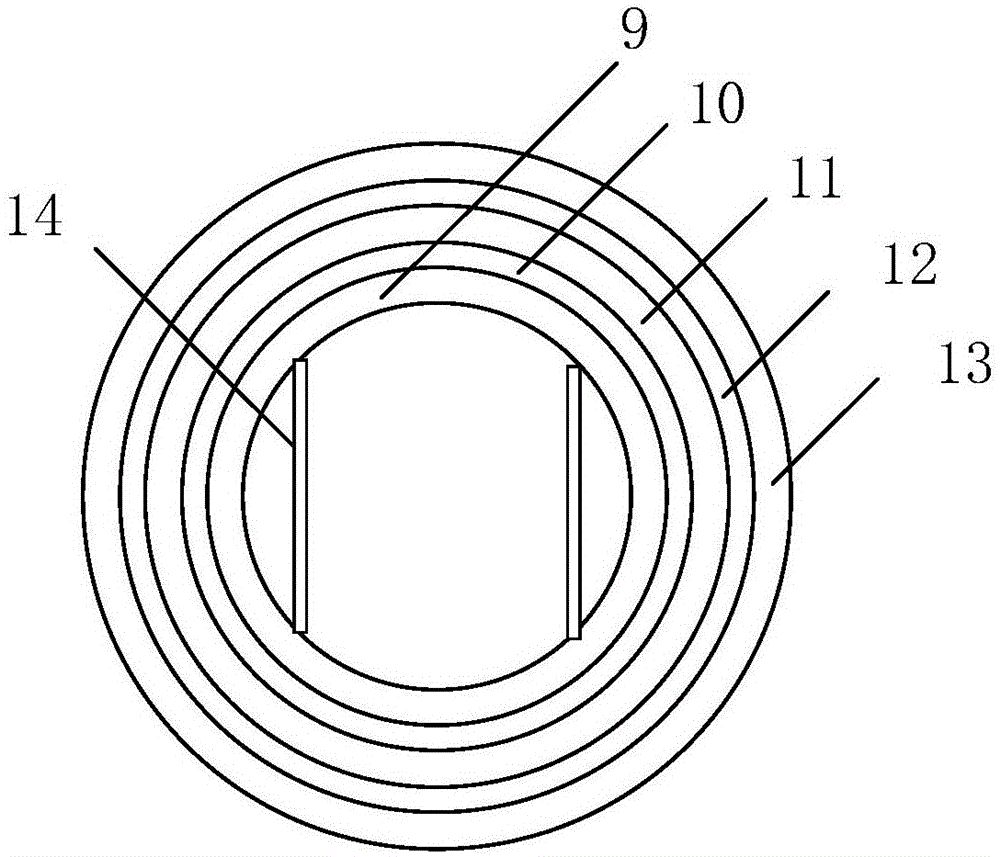

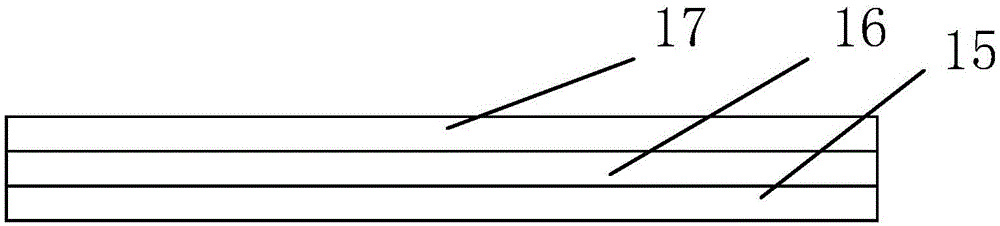

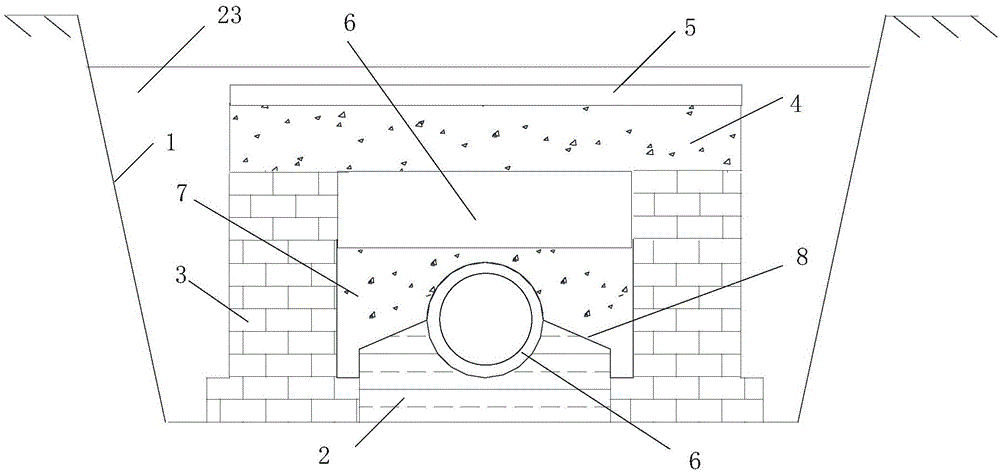

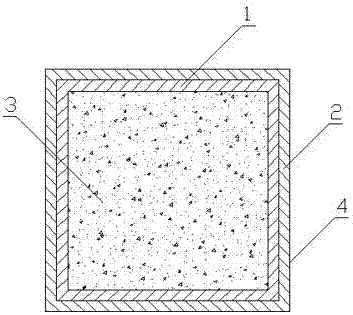

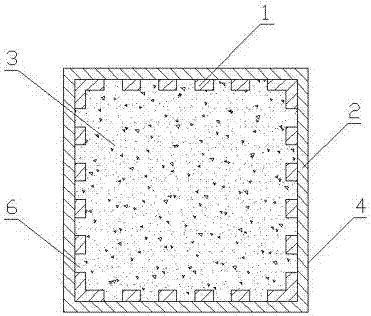

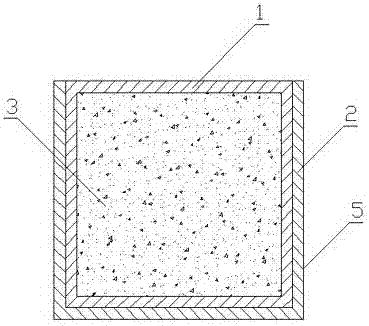

Non-pressed pipeline reinforcing structure for road surface and construction method for non-pressed pipeline reinforcing structure

InactiveCN105155376ANot affectedPrevent penetration corrosionPipe laying and repairRoadwaysArchitectural engineeringStructural engineering

The invention relates to a non-pressed pipeline reinforcing structure for a road surface and a construction method for the non-pressed pipeline reinforcing structure. The non-pressed pipeline reinforcing structure comprises a road surface embedded groove, wherein a base layer is arranged in the road surface embedded groove. The non-pressed pipeline reinforcing structure is characterized in that symmetrically-distributed blocking assemblies are arranged on the two sides of the base layer and the top ends of the blocking assemblies are connected with a cover board; meanwhile, a separation assembly is arranged on the cover board, and a sealed protective space is formed among the blocking assemblies and the cover board and filled with a filling layer; a pipeline reinforcing assembly is arranged on the base layer; each blocking assembly comprises a bottom base material layer provided with a lateral reinforcing wall; and guide slopes are distributed at the two ends of the upper portion of the base layer and the pipeline reinforcing assembly is located at the joint of the guide slopes. Therefore, water can be prevented from flowing in transversely, external transverse force can be effectively borne, and an inner pipeline is protected against impact; the pipeline can be better prevented from being corroded by seeping underground water; and more importantly, the deformation characteristic is better while firmness is good, and the structure cannot crack easily.

Owner:苏州同尚工程设计咨询有限公司

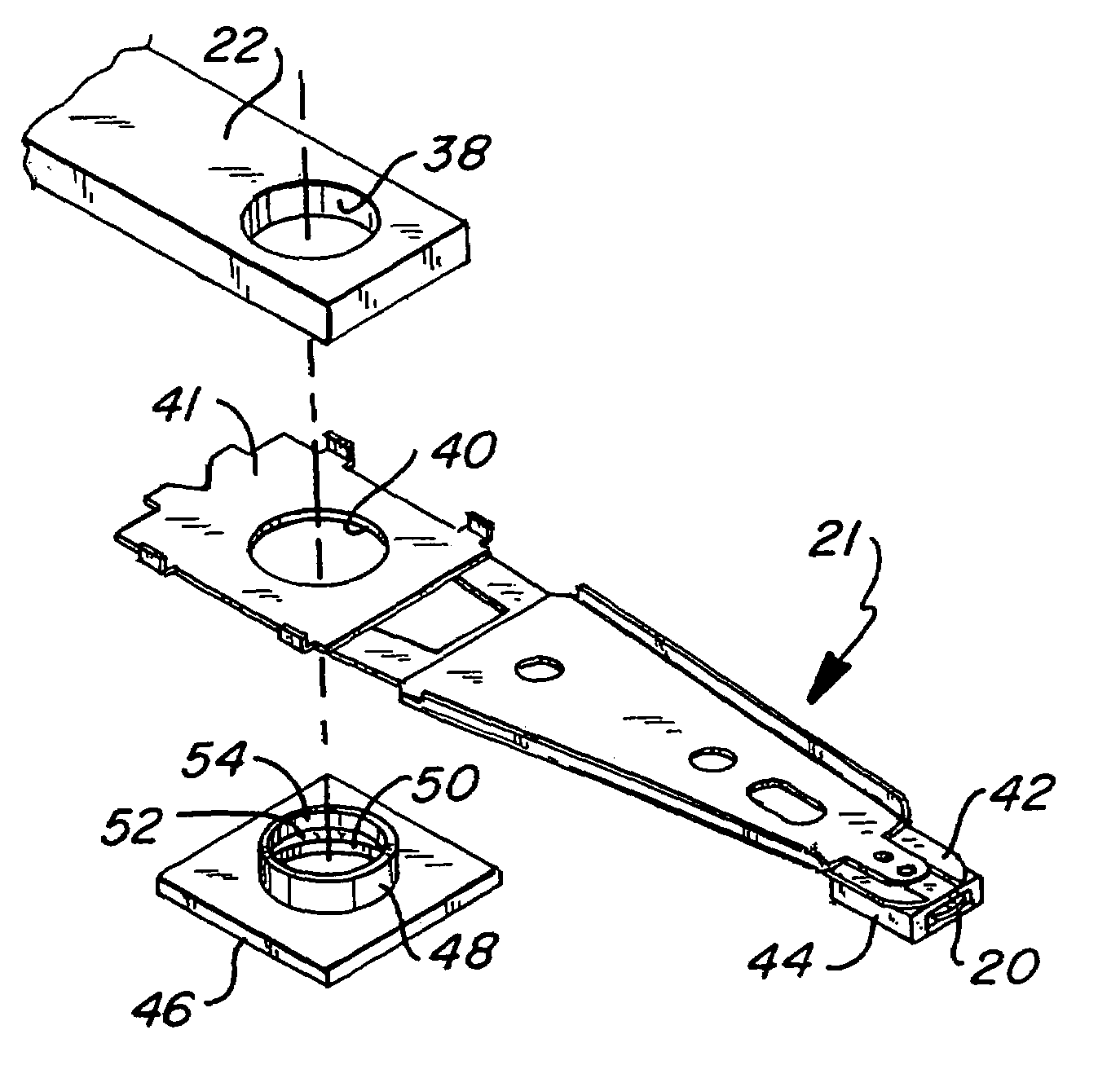

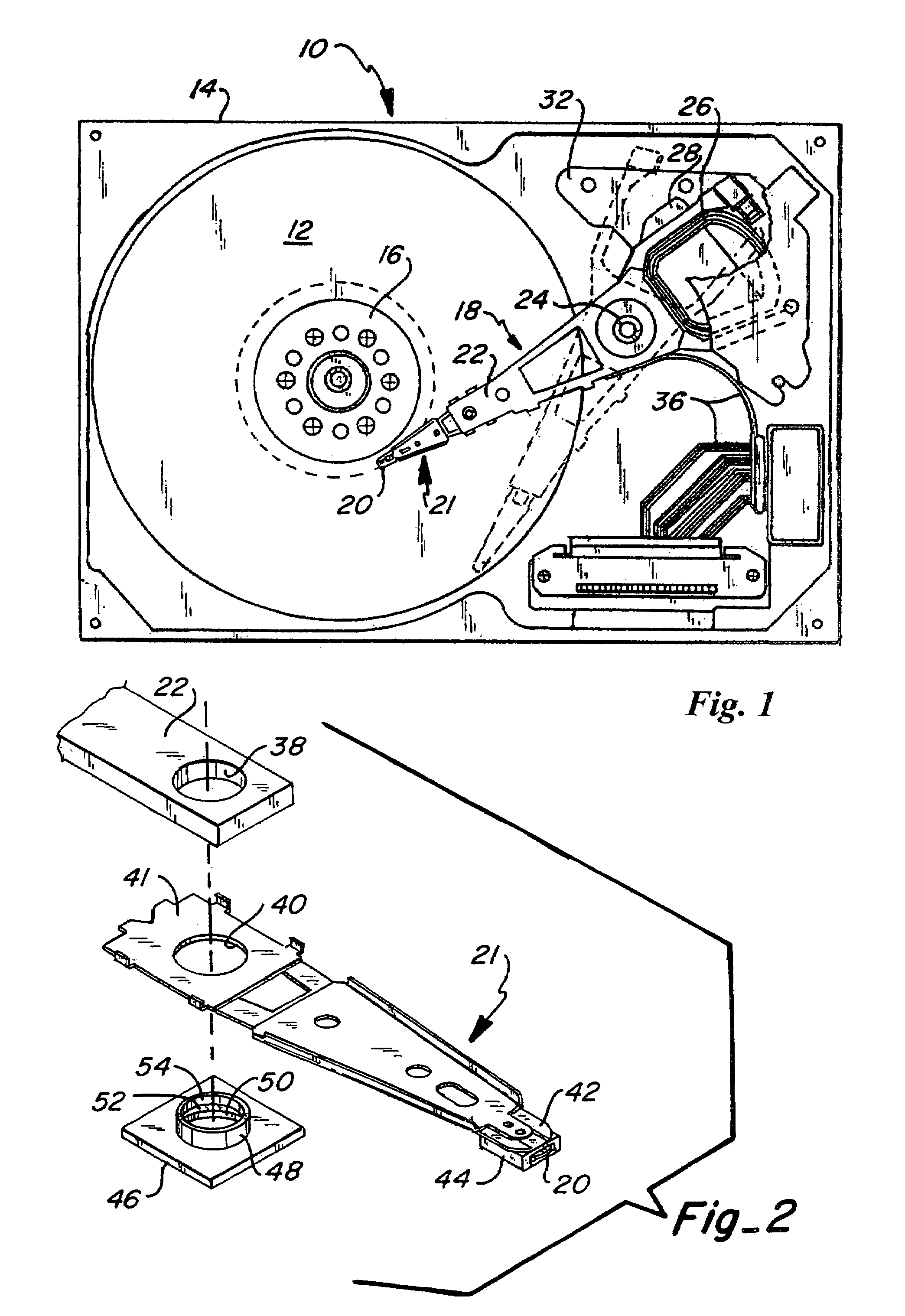

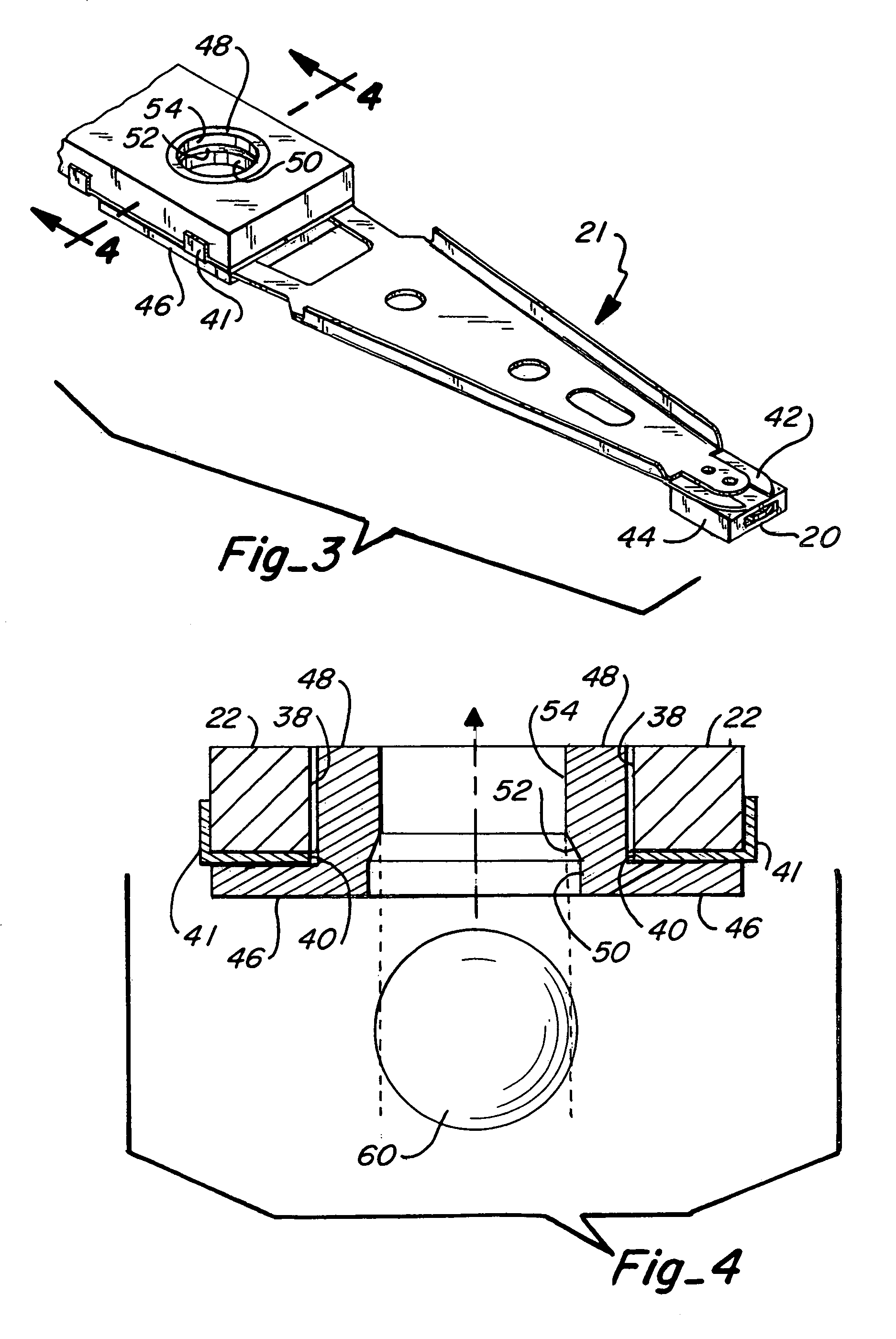

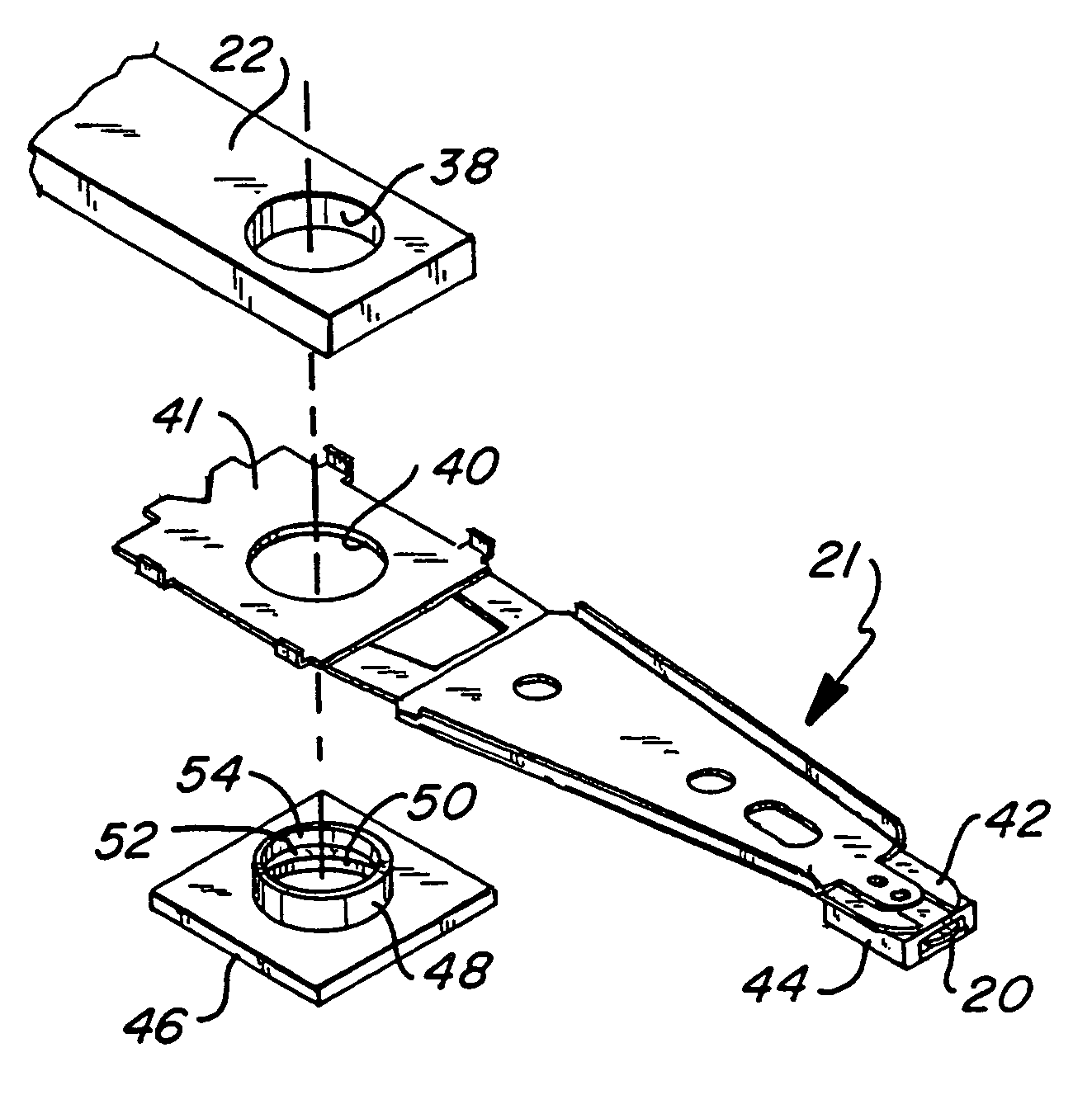

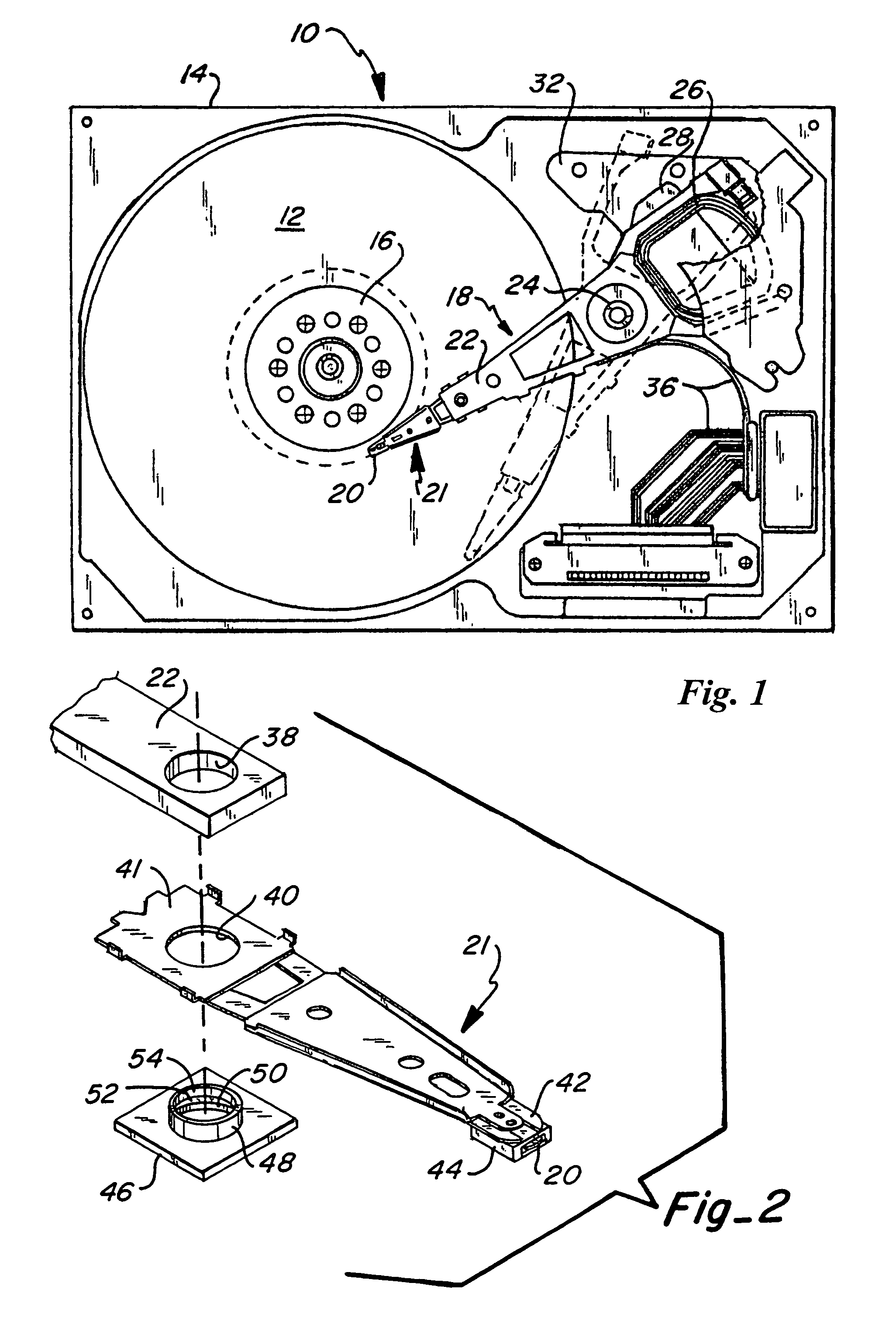

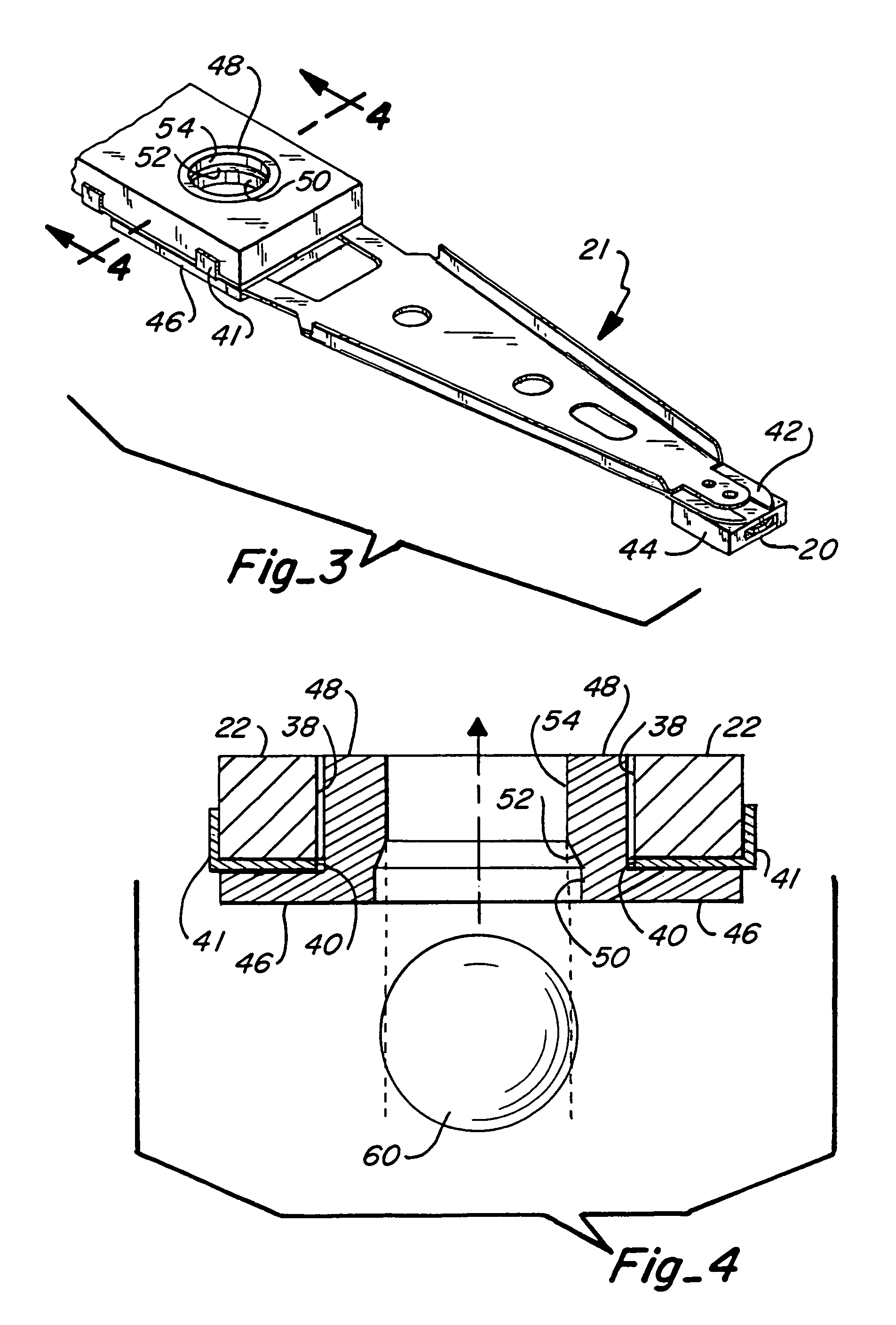

Method of assembling an actuator assembly of a disk drive and of reducing torque out retention values in subsequent de-swaging

InactiveUS7024754B1Reduced retention torqueGood deformation propertiesElectrical transducersManual lubricationGramSwaging

A method is provided for assembling an actuator assembly of a disk drive. The method includes providing an actuator arm, providing a suspension arm, fixing a swage plate to the suspension arm, the swage plate including a swage boss extending therefrom, depositing a film lubricant upon at least an outer surface of the swage boss, and attaching the suspension arm to the actuator arm by swaging. A method is also provided for reducing torque out retention values between the actuator arm and the suspension arm when the actuator arm and suspension arm must be separated in a subsequent de-swaging process. This method includes providing an outer surface of the swage boss, and applying a lubricant film coating to the outer surface of the swage boss. A preferred thin film lubricant may be applied by emersion and draining, localized spraying, or various deposition processes. Application of the lubricant has also shown to improve gram load uniformity and to reduce adverse distortion to the actuator assembly which otherwise occurs during swaging.

Owner:MAXTOR

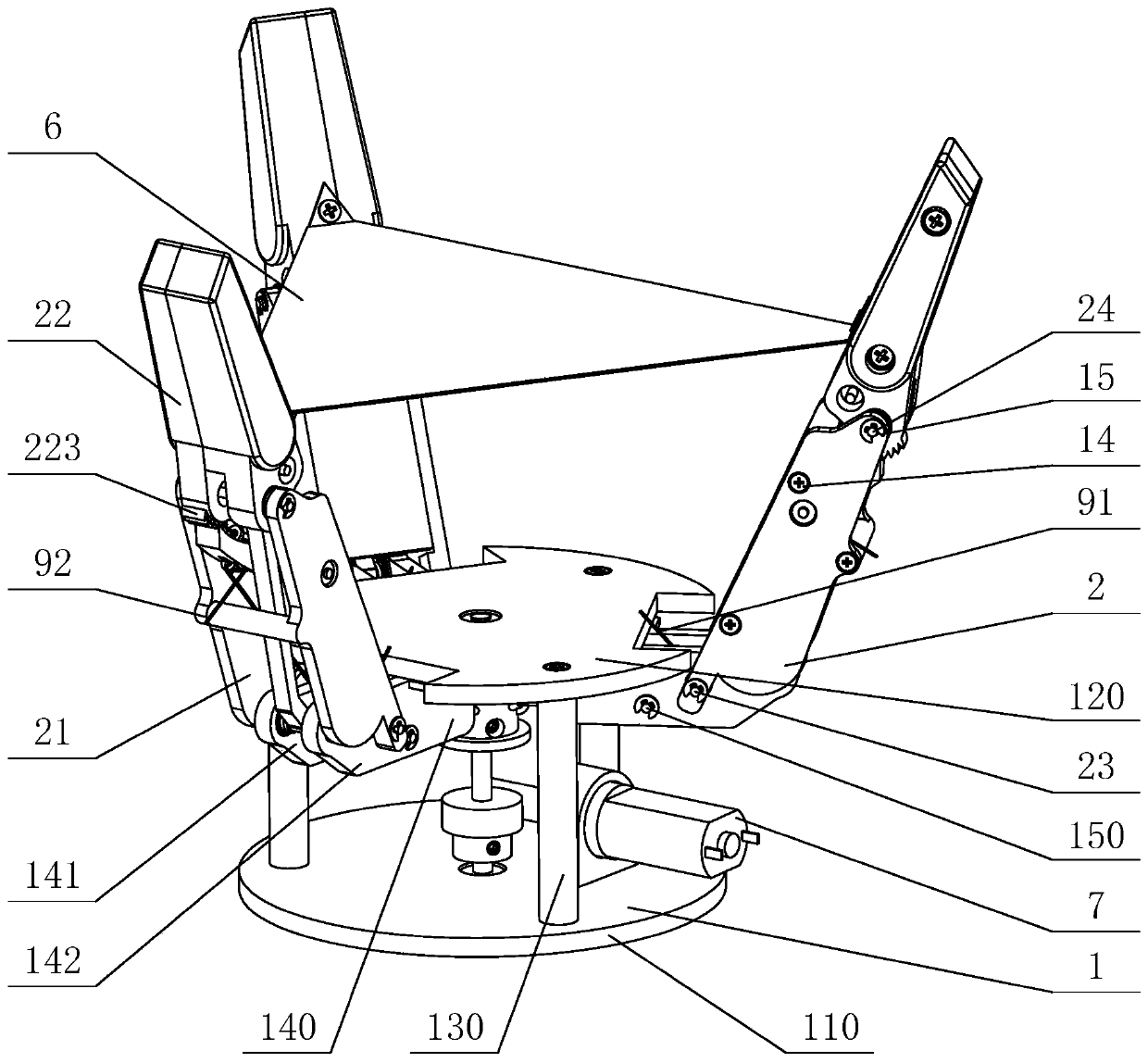

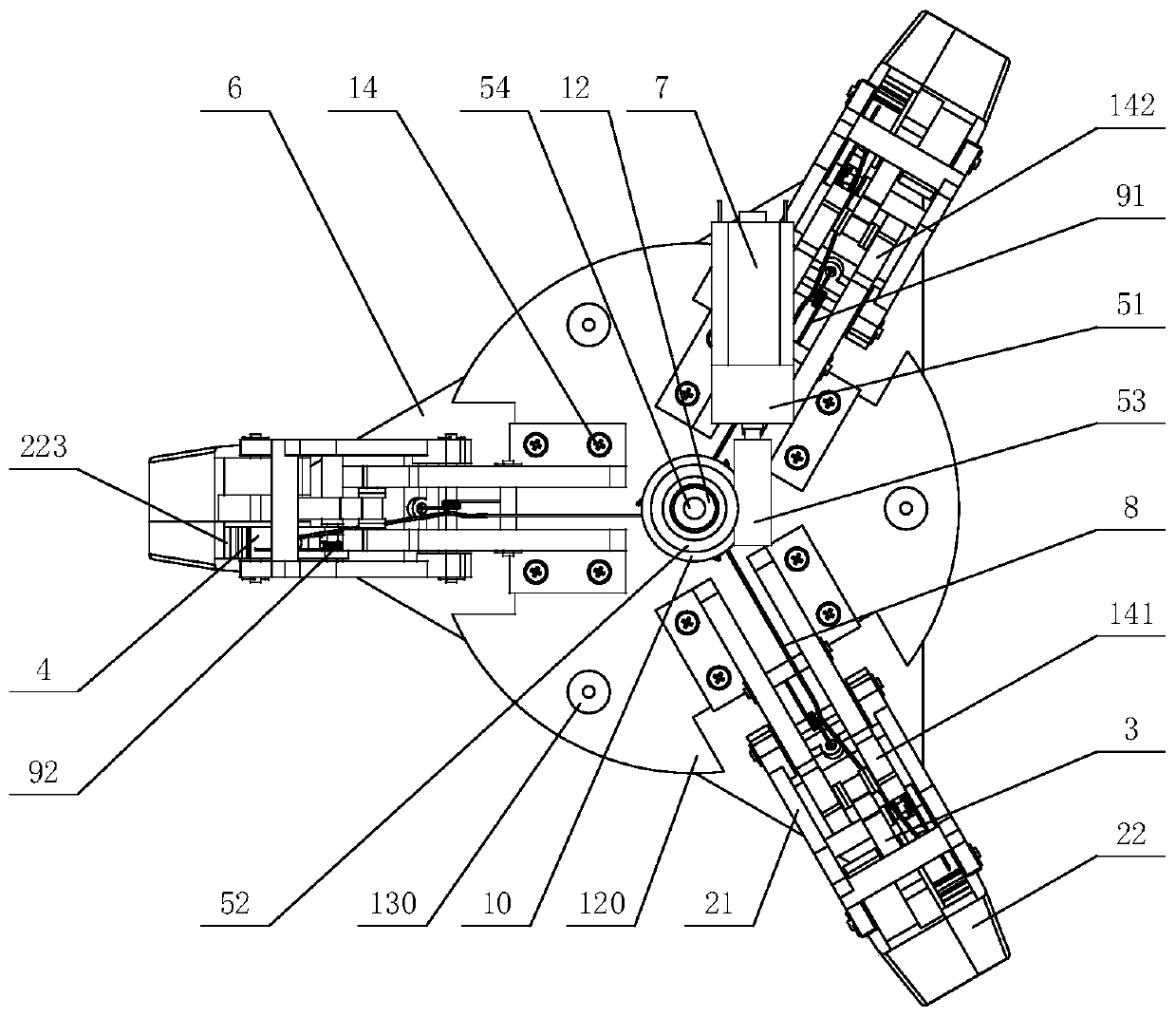

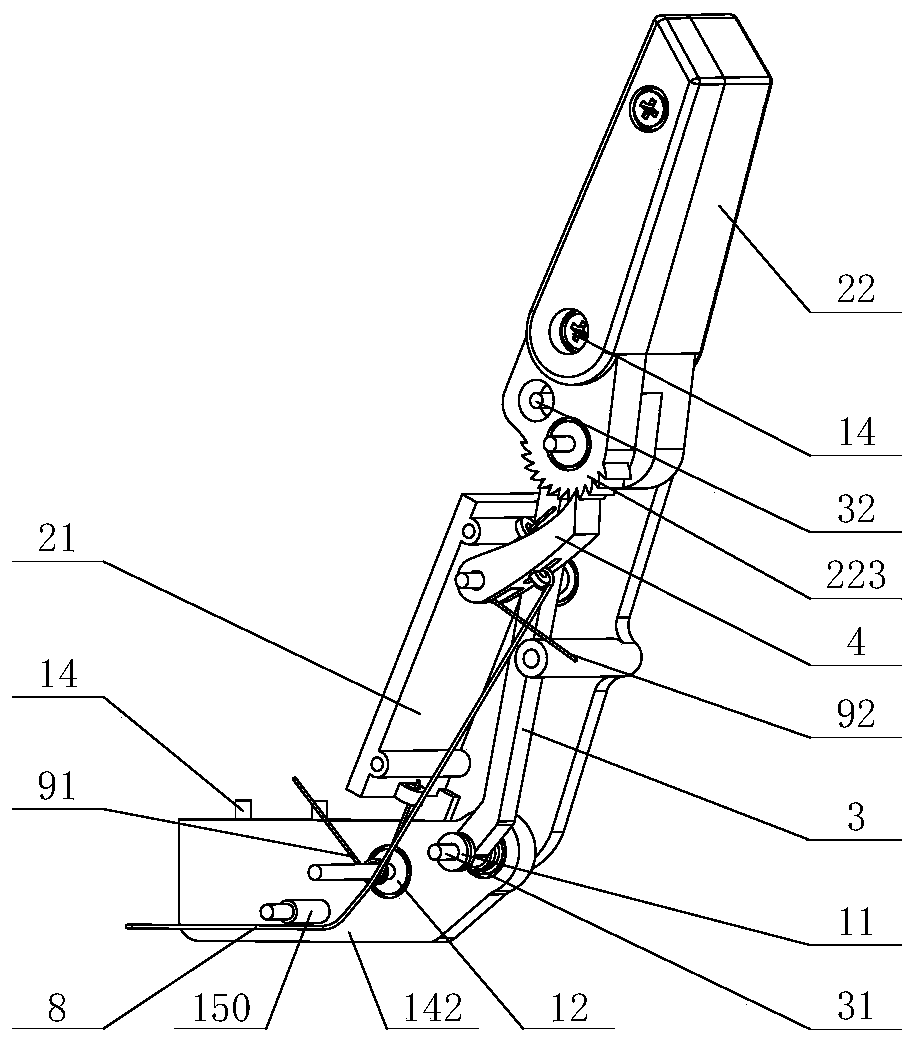

Flexible palm type self-adaptive and rapid grabbing robot hand device

The invention provides a flexible palm type self-adaptive and rapid grabbing robot hand device, and belongs to the technical field of robot hands. The device comprises a base, three fingers, three connecting rods, three ratchet wheels, three pawls, a flexible cloth, a driving device, a spring, a wire rope and a wire coiling device. According to the device, a grabbed object moves relative to the robot hand, and the flexible cloth is capable of driving the fingers to close to achieve the purpose of wrapping and grabbing; the ratchet wheels and the pawls are provided, so that the device is capable of self-locking, and the object can be fixed after being grabbed so as to be prevented from separating; when the object is to be released, the wire rope is driven through the driving device to pullthe pawls and release the ratchet wheels, and thus the fingers can be released under the effect of the spring; the purpose of self-adapting the shape of the object can be achieved based on the deformation property of the flexible cloth; the device is simple in structure, and small in energy consumption; the device can quickly act and grab the object once being in contact with the object; a complexsensing and control system is saved; and the manufacturing and maintaining cost is low.

Owner:TSINGHUA UNIV

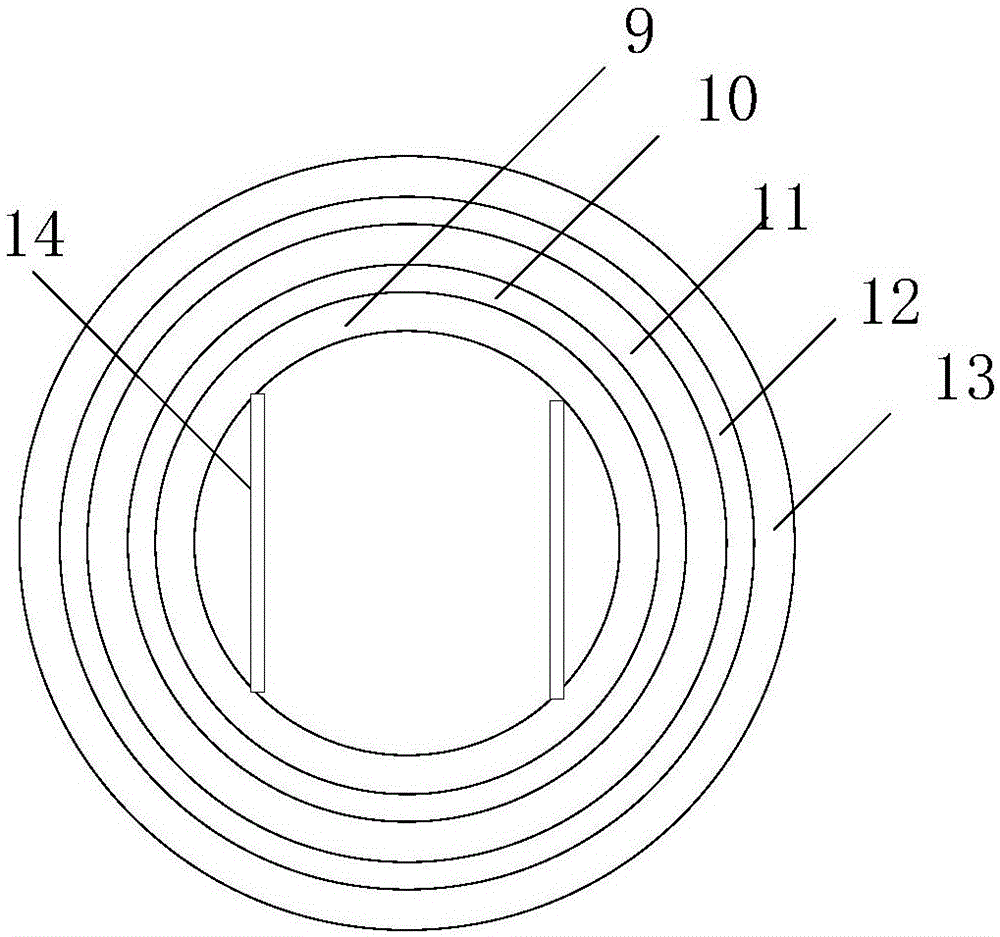

Pre-buried pipeline suitable for pavement shallow layers

ActiveCN105113354ANot affectedPrevent penetration corrosionTemporary pavingsPaving detailsRoad surfaceMechanical engineering

The invention relates to a pre-buried pipeline suitable for pavement shallow layers. The pre-buried pipeline comprises a pavement pre-buried groove, wherein a foundation layer is arranged in the pavement pre-buried groove. The pre-buried pipeline is characterized in that a pipeline strengthening assembly is arranged on the foundation layer; supporting channels are distributed in the pipeline strengthening assembly; auxiliary supporting rods are arranged in each of the supporting channels; besides, partition assemblies are distributed at the periphery of each of the supporting channels; a filling layer is arranged between the partition assemblies and the periphery of each of the supporting channels; a back-filling layer is distributed in the pavement pre-buried groove, and a blocking layer is distributed on the back-filling layer. Therefore, the laying requirement of multiple pipelines is met, and besides, the pre-buried pipeline can effectively bear external stress, so that an internal pipeline can be protected from being stricken, and underground water can be prevented from permeating into the pipeline and eroding the pipeline; in addition, the pipeline can bear downward longitudinal stress from the ground, so that the longitudinal extrusion for a subsequent pipeline is avoided.

Owner:苏州同尚工程设计咨询有限公司

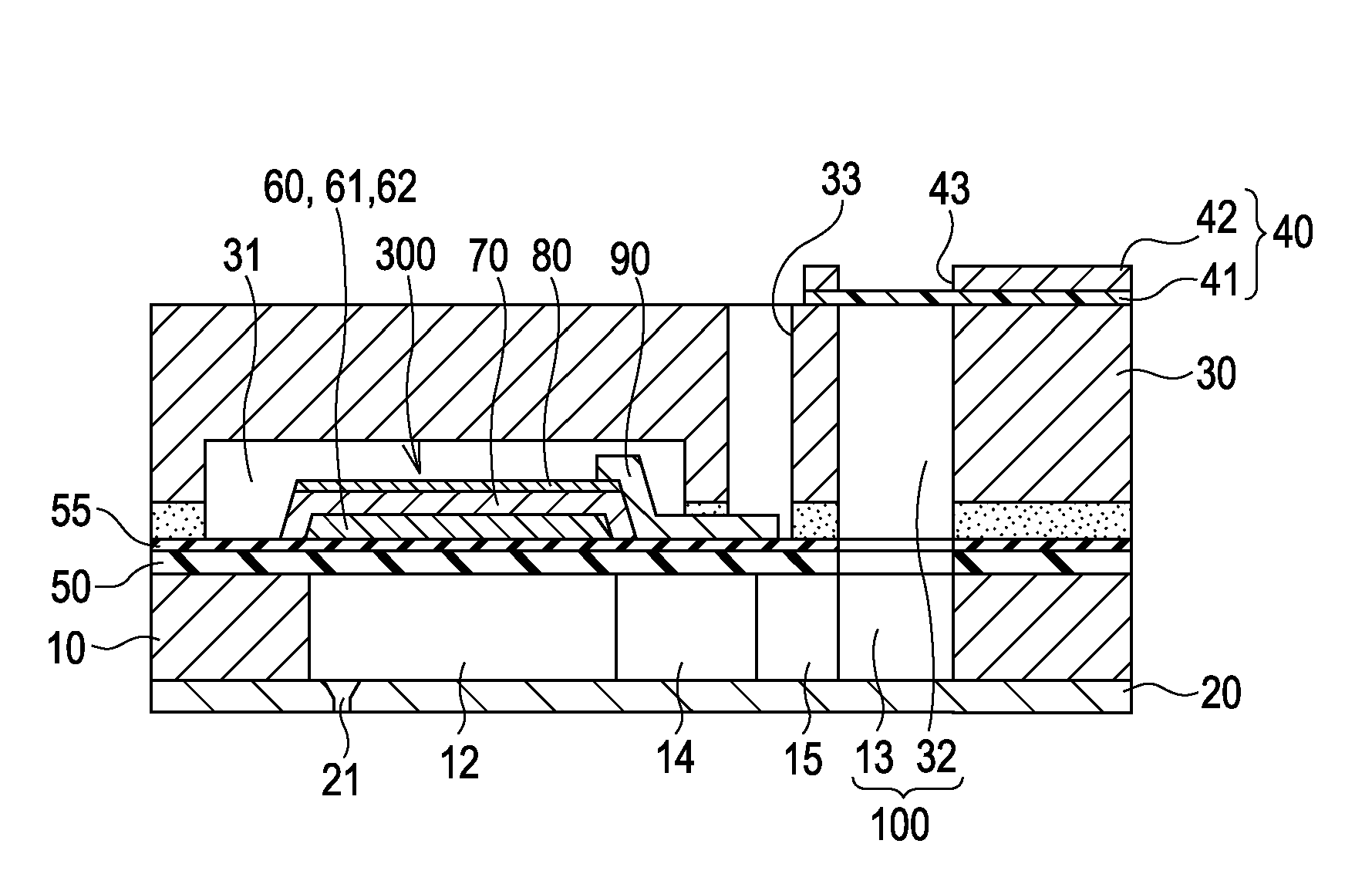

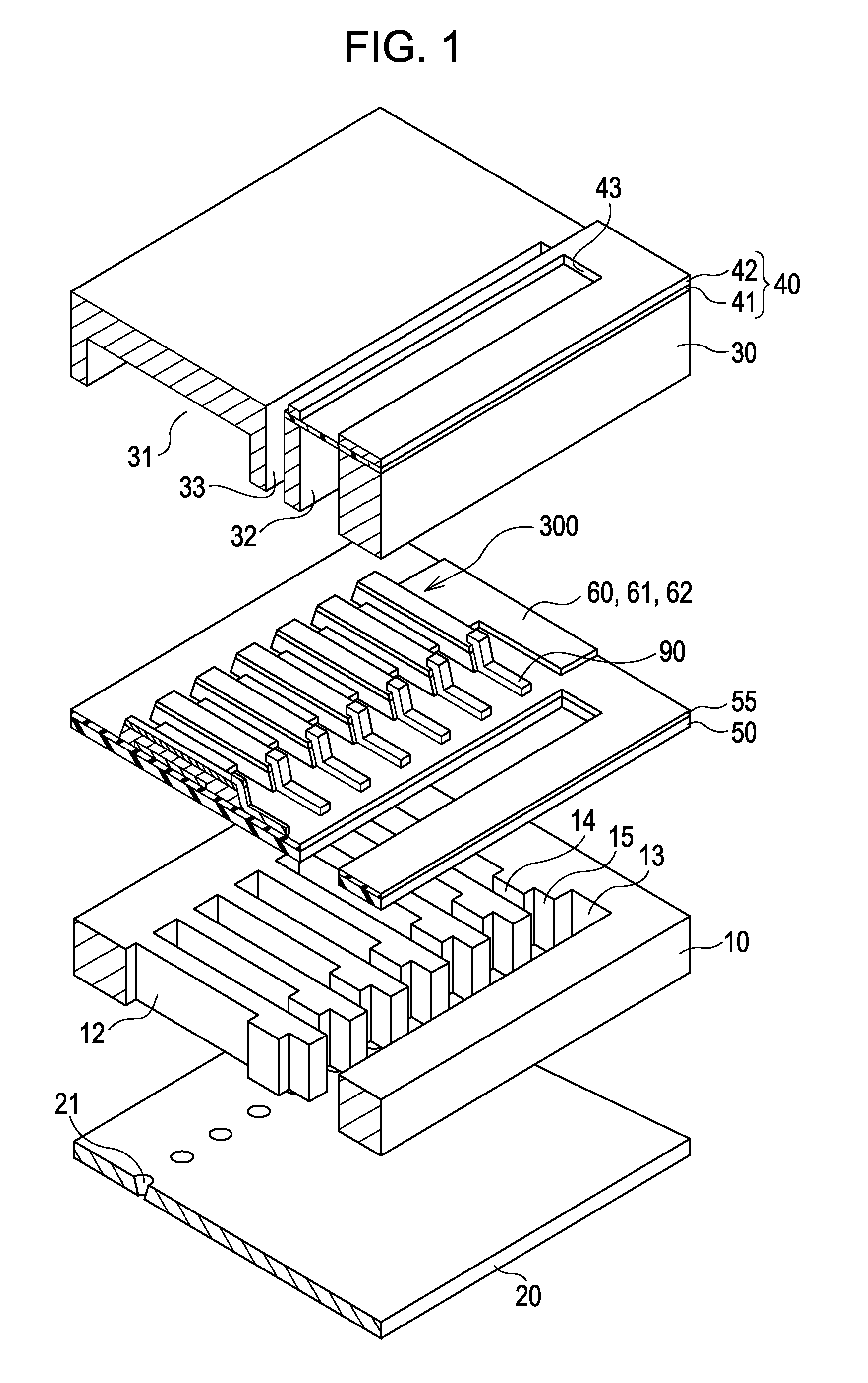

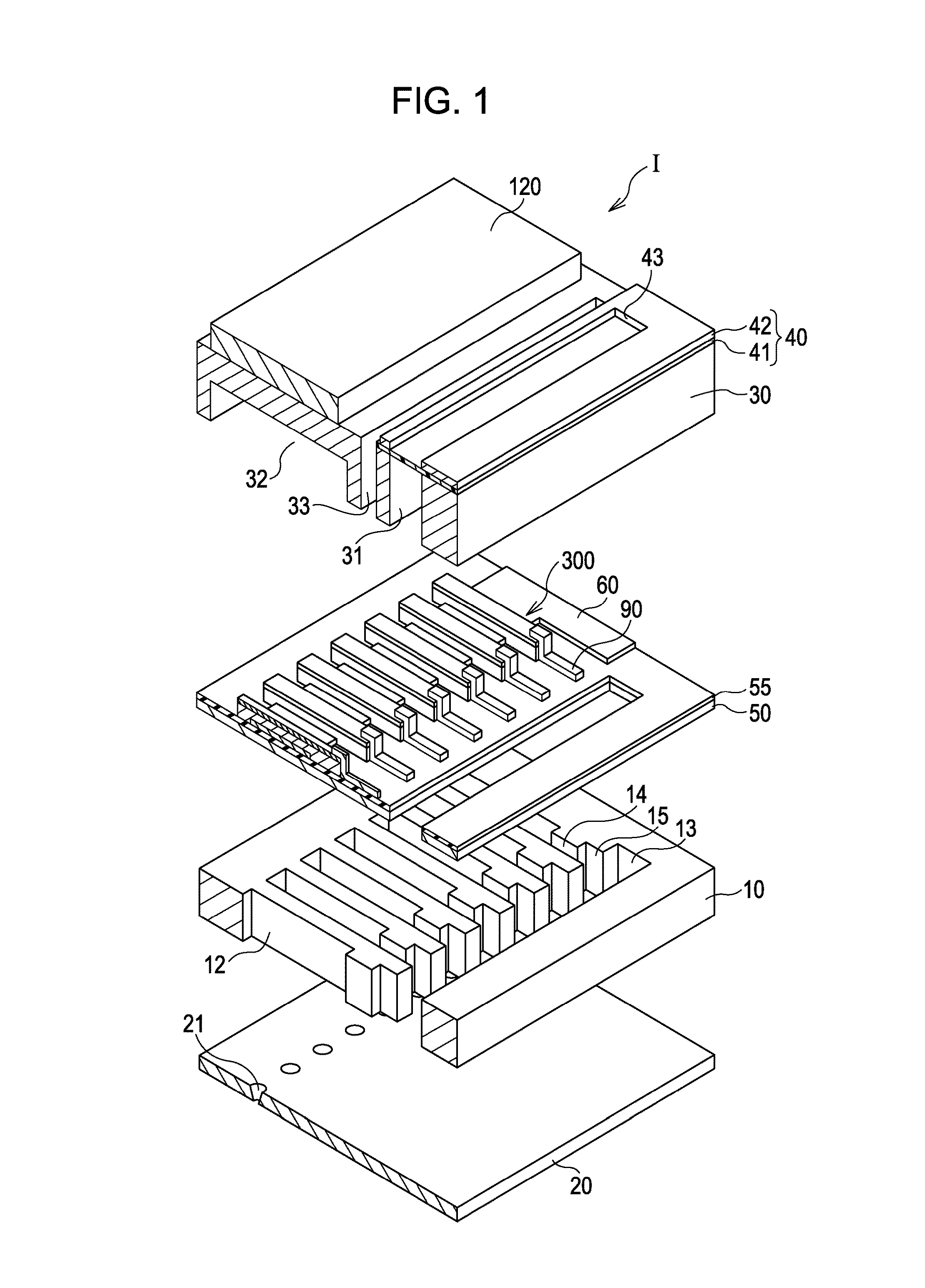

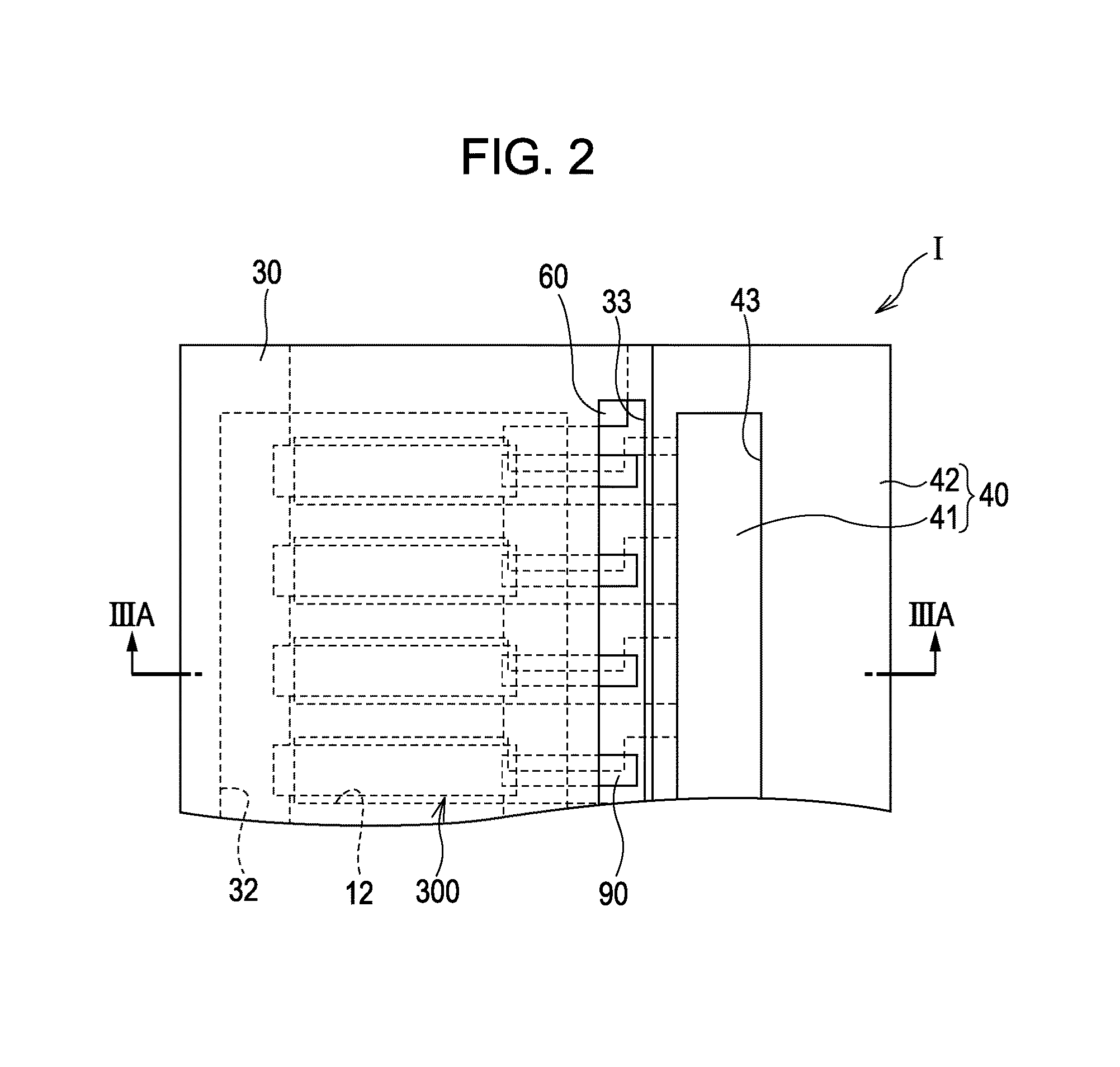

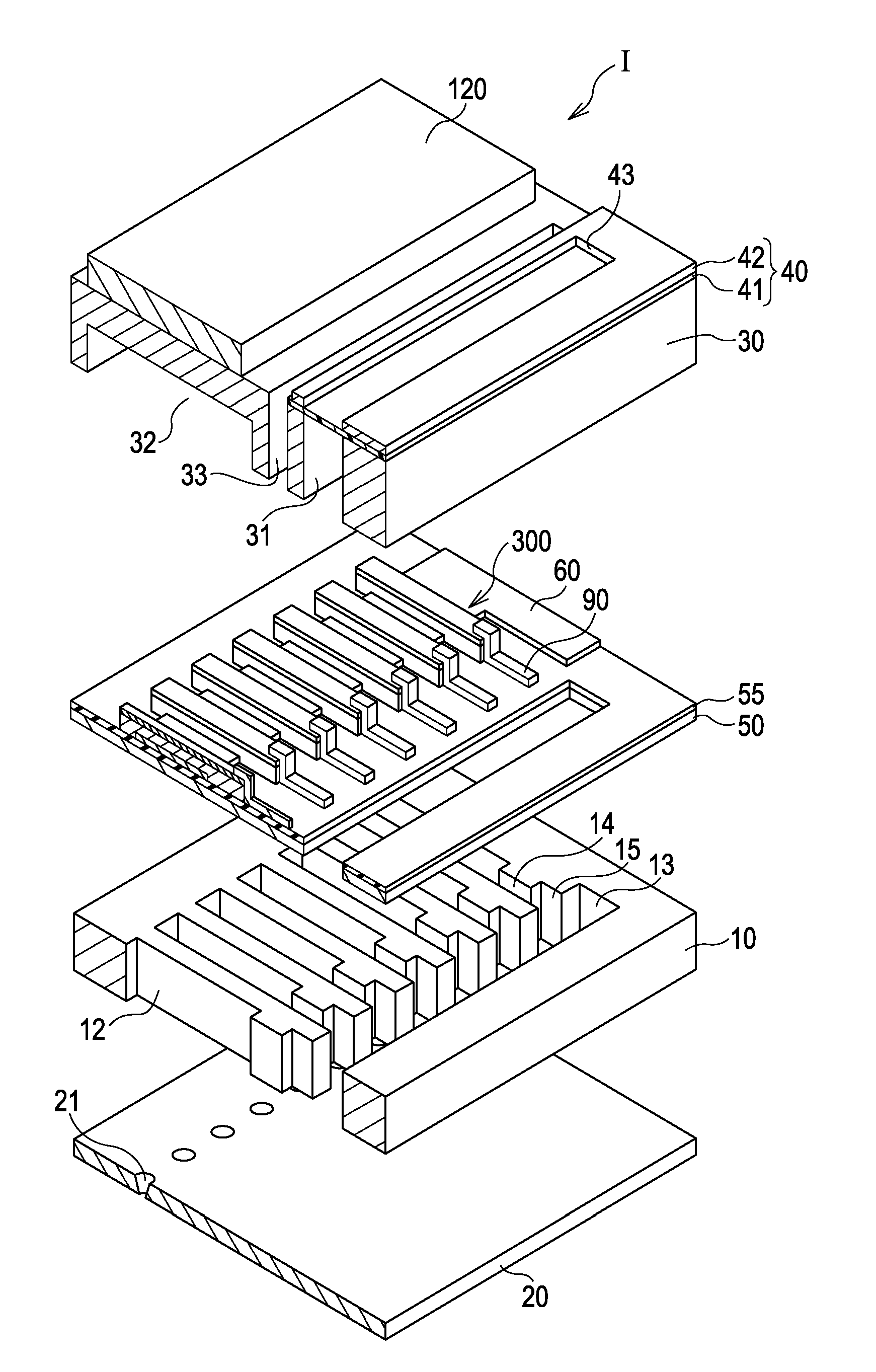

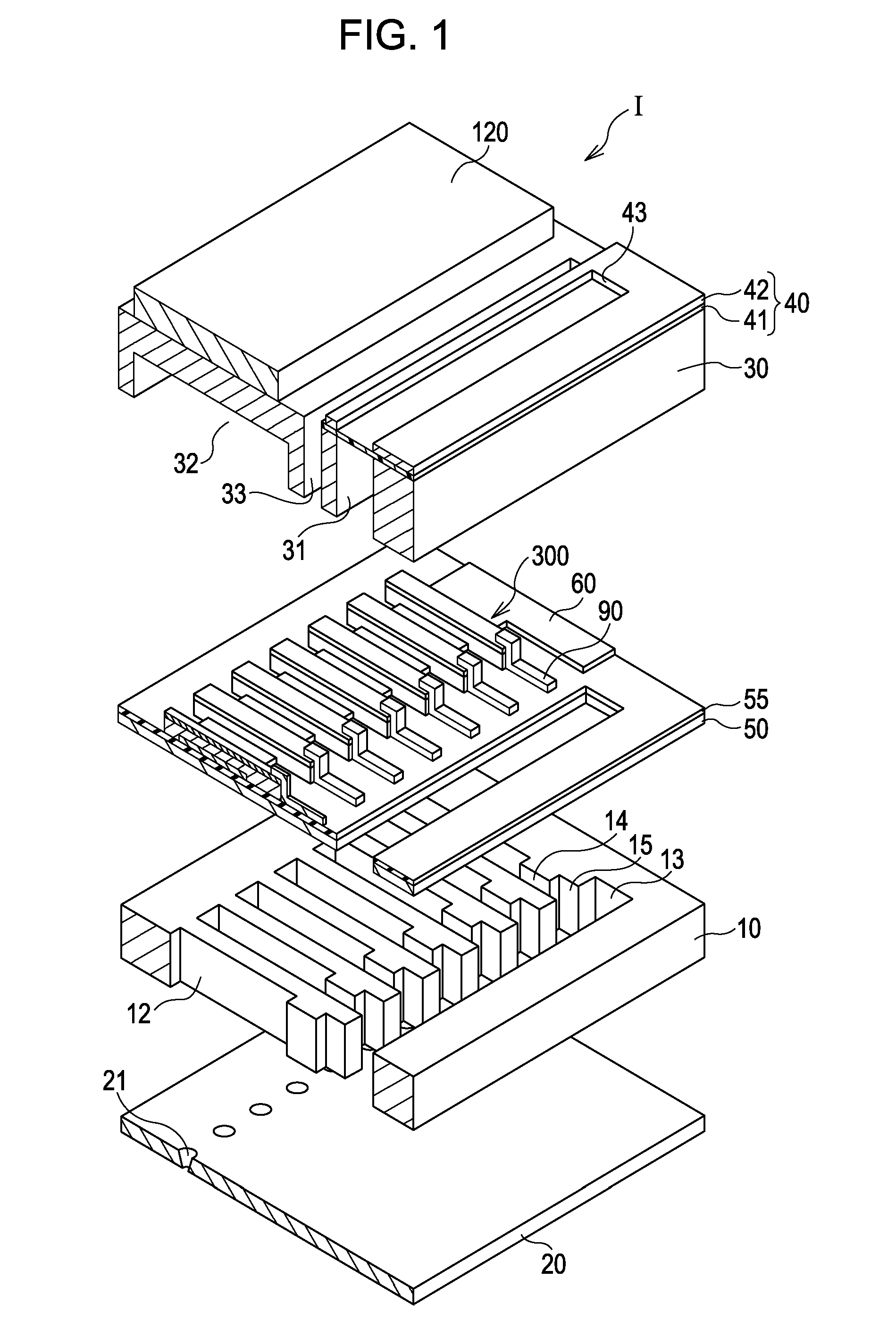

Liquid-ejecting head, liquid-ejecting apparatus, and actuator

ActiveUS20100253750A1Reduce variationHigh crystallinityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionInternal pressureEngineering

A liquid-ejecting head includes a flow-passage-forming substrate that includes a pressure-generating chamber, the pressure-generating chamber being in communication with a nozzle through which droplets are ejected, and a piezoelectric element disposed on the flow-passage-forming substrate, the piezoelectric element altering the internal pressure of the pressure-generating chamber. The piezoelectric element includes a piezoelectric layer containing titanium (Ti) and zirconium (Zr), a first electrode, and a second electrode. The first electrode and the second electrode are disposed on the opposite sides of the piezoelectric layer,. The component ratio Ti / (Zr+Ti) of the piezoelectric layer is 0.40 or more but less than 0.50. At least a portion of the piezoelectric layer formed on the first electrode contains tetragonal crystals formed by phase transition under stress caused by an underlying layer.

Owner:SEIKO EPSON CORP

Liquid-ejecting head, liquid-ejecting apparatus, and piezoelectric element

InactiveUS20110164096A1Improve reliabilityImprove featuresPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusManganeseX-ray

A piezoelectric element comprising a first electrode, a piezoelectric layer which includes bismuth, lanthanum iron, and manganese and which formed above the first electrode and a second electrode formed above the piezoelectric layer. The integrated intensity of a diffraction peak observed at 20°<2θ<25° is 90% or more of the sum of the integrated intensities of diffraction peaks observed at 20°<2θ<50° in an X-ray powder diffraction pattern of the piezoelectric layer measured at φ=Φ=0°.

Owner:SEIKO EPSON CORP

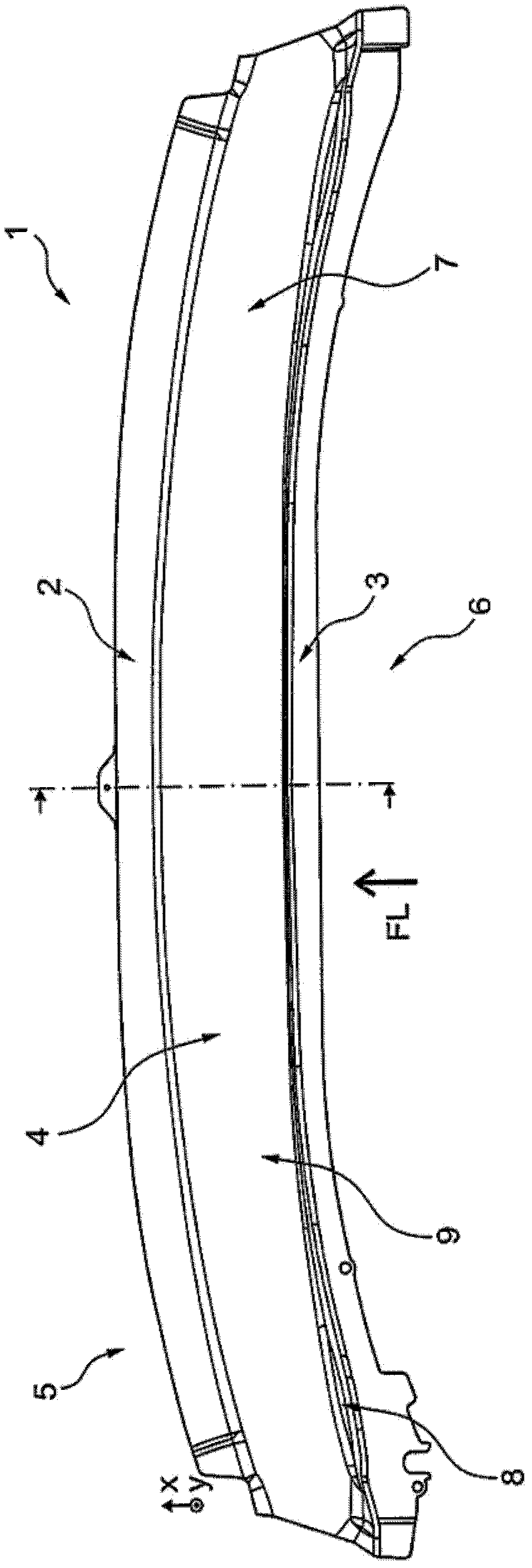

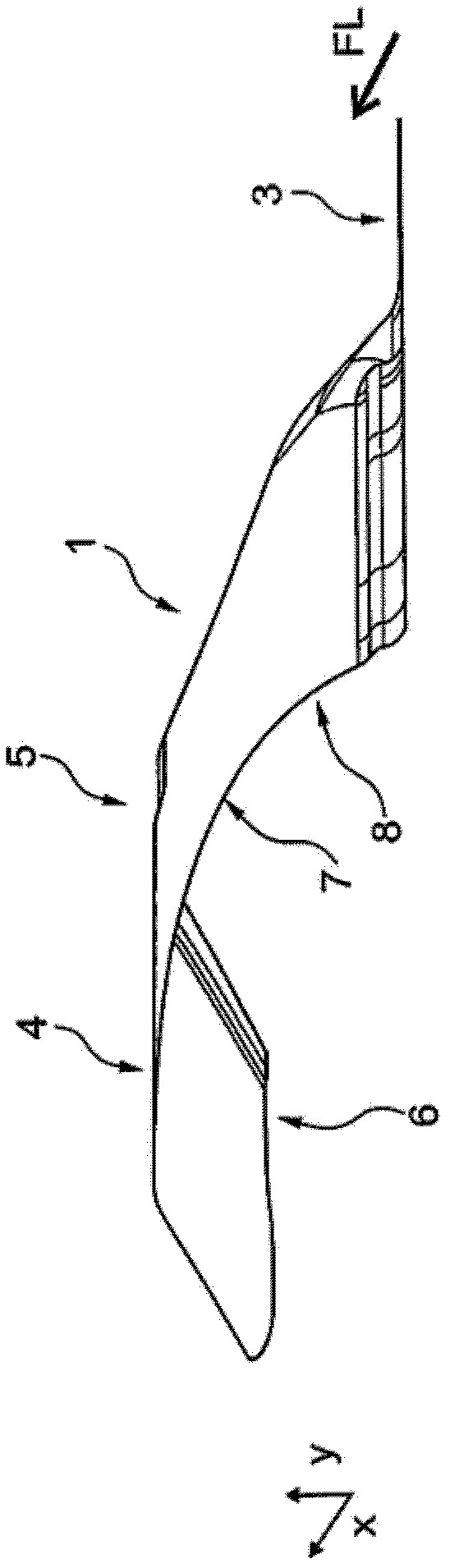

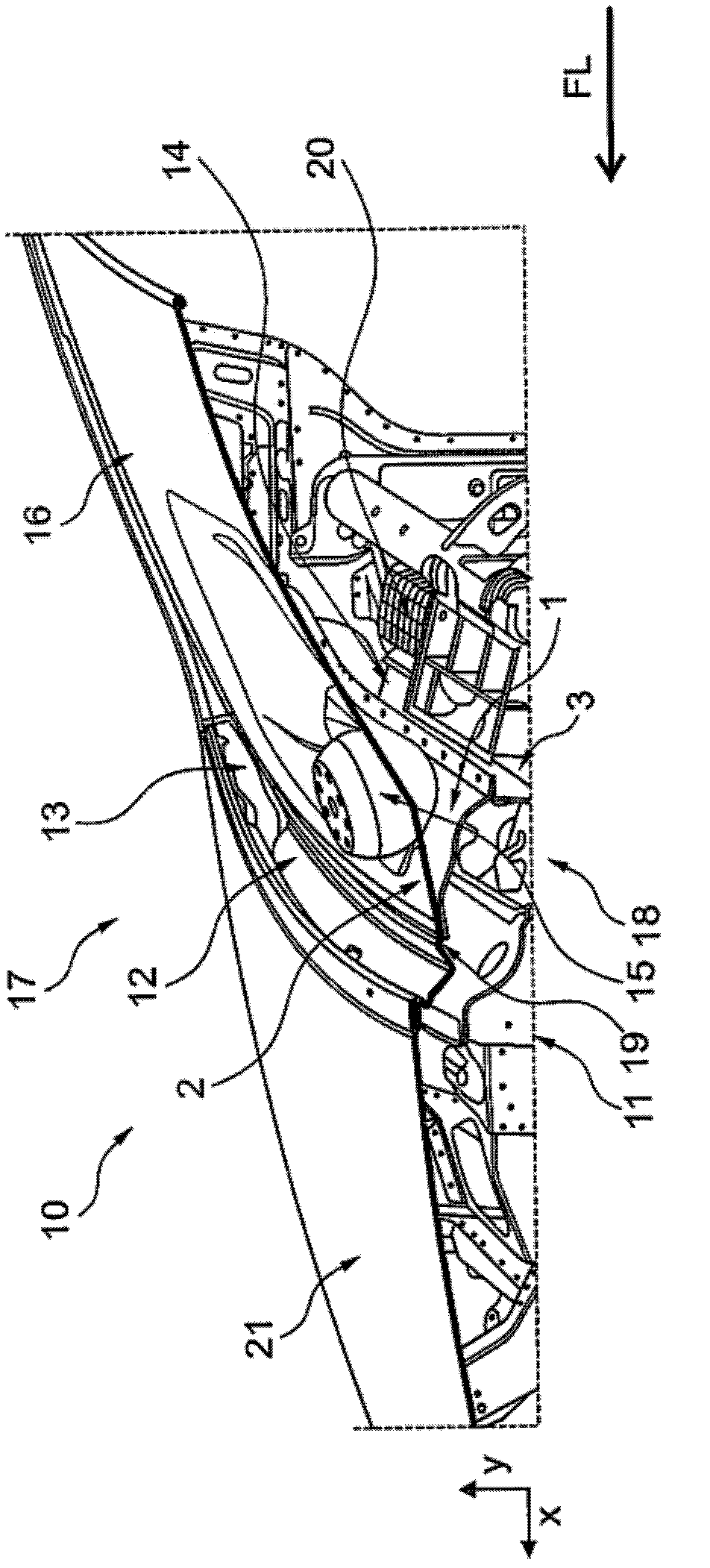

Body structure for a car with a windshield with front glass cross member

The invention relates to a body structure for a motor vehicle with a windshield, the body structure having a windshield cross member (1) supporting the windshield (16), wherein the windshield cross member (1 ) comprises a first edge section (2) and a second edge section (3) in the form of a cantilever and an intermediate section (4) with a U-shaped cross-section between them, wherein the first edge section (2 ) form a support section (13) for the windshield, the second edge section (3) is arranged longitudinally behind the first edge section (2) along the vehicle (10) and is fixed on the on a fixed part of the body structure (14), and the middle section (4) is designed such that it has a cross-section arched in the direction of the bonnet (21) of the motor vehicle (10) and can be positioned above the and / or deform when a forward force is applied.

Owner:GM GLOBAL TECH OPERATIONS LLC

Forming method for amorphous alloy component

ActiveCN105710334APoor surface finishHigh surface finishMelt-holding vesselsMolten metal conveying equipmentsSurface finishCondensation process

The invention discloses a forming method for an amorphous alloy component, and belongs to the technical field of amorphous alloy. According to the method, in the temperature interval of the condensation process of amorphous alloy melt, namely the temperature range from liquidus (T1) to glass transition (Tg), low-pressure precise formation is carried out on the amorphous alloy. The technology makes full use of the characteristics that the smooth free surface formed after the alloy melt is condensed, the deformation feature is good and the condensation shrink factor is low, and the obtained amorphous alloy component is high in size accuracy, good in surface smoothness, internally compact and free of shrinking holes or shrinkage porosity and other defects. The process of the technical method is short, production efficiency is high, cost is reduced, and product quality is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

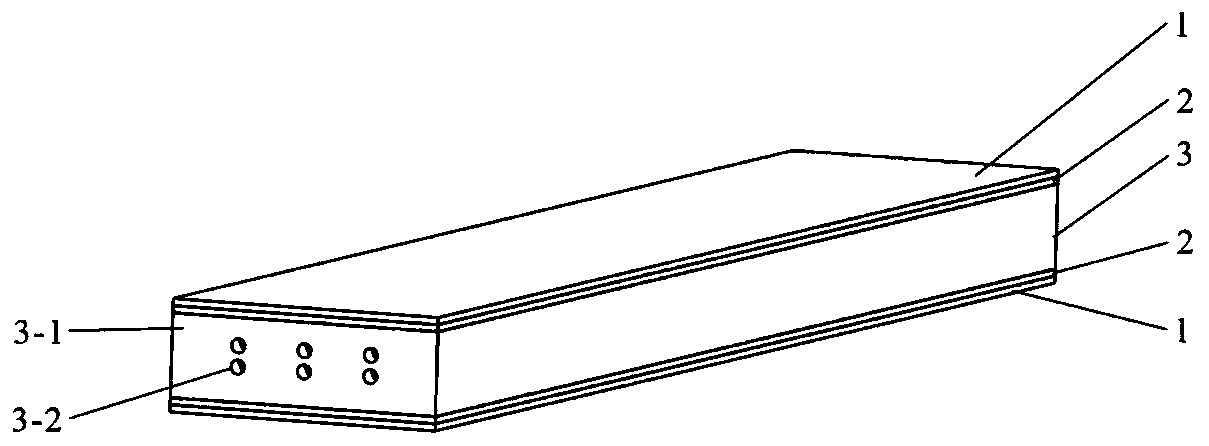

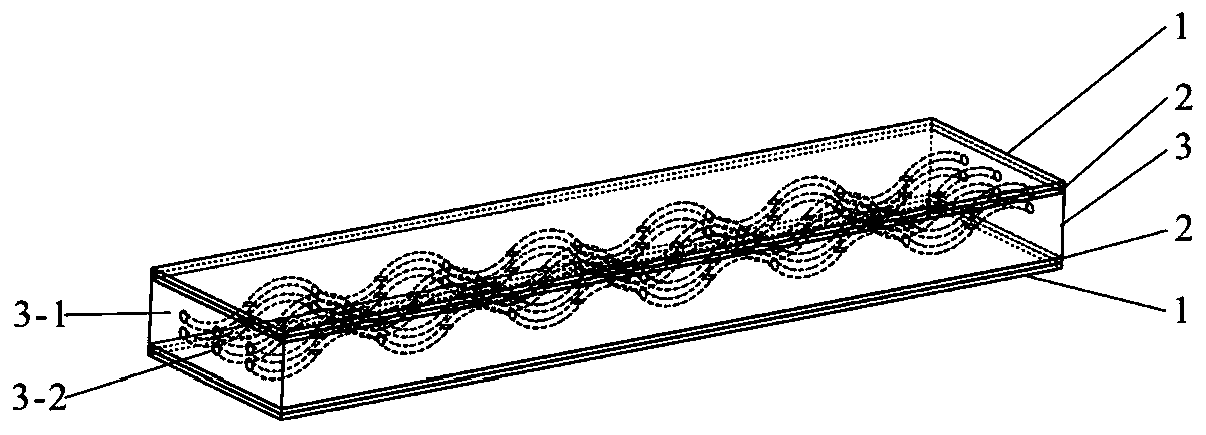

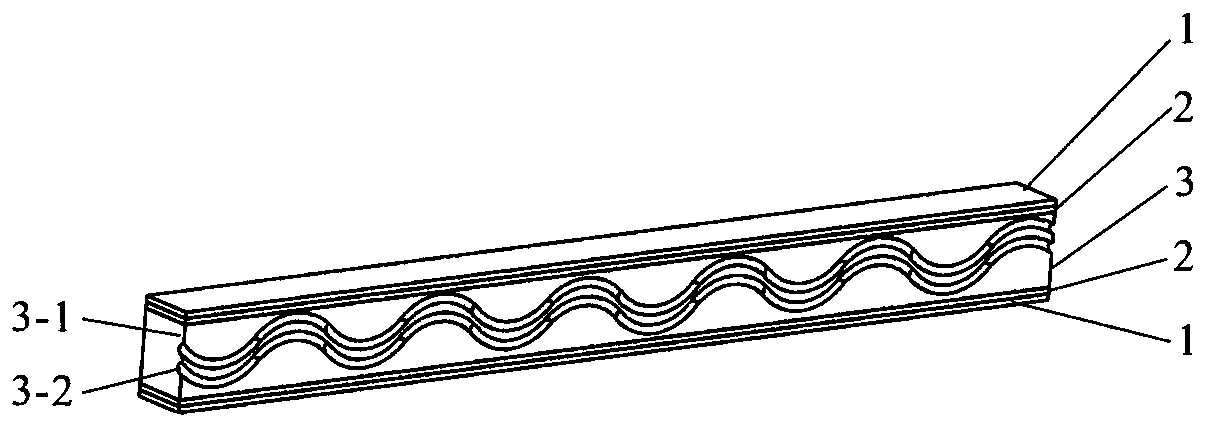

Capacitive flexible tensile sensor based on S-shaped micro-channel liquid metal composite dielectric layer

InactiveCN111504522AImprove anti-interferenceHigh elongationForce measurementStrain sensorMechanical engineering

The invention discloses a capacitive flexible tensile sensor based on an S-shaped micro-pore channel liquid metal composite dielectric layer, and belongs to the field of flexible tensile strain sensors. The S-shaped micro-pore channel liquid metal composite dielectric layer is formed by arranging an S-shaped micro-pore channel cavity in a rectangular flexible substrate and injecting liquid metal into the S-shaped micro-pore channel cavity, and a flexible electrode and a flexible packaging layer are sequentially arranged on the upper surface and the lower surface of the S-shaped micro-pore channel liquid metal composite dielectric layer. The S-shaped micro-channel liquid metal composite dielectric layer uses a silicone rubber substrate as an elastic substrate, uses liquid metal as a liquid-phase filler to fill the S-shaped micro-channels, and the cavities are distributed in the elastic substrate in an S shape. According to the capacitive flexible stretching sensor, a bionic structure similar to plant rhizomes is adopted, the capacitive flexible tensile sensor has the characteristics of good ductility, high sensitivity and low delay, and a feasible scheme is provided for designing the high-sensitivity capacitive flexible tensile strain sensor meeting the requirements of the application fields of human body posture monitoring, human-computer interaction, human physiological signalmonitoring and the like.

Owner:JILIN NORMAL UNIV

Method of reducing torque out retention values in de-swaging of actuator of disk drive

InactiveUS7624495B1Promote resultsReduce debrisElectrical transducersManual lubricationGramDeposition process

A lubricant is applied to swage contact surfaces in a disk drive of the type including a suspension arm connected to an actuator arm by a swaging process. A preferred thin film lubricant may be applied to the contact surfaces by immersion and draining, immersion and raising the part out of the solution, localized spraying, or various deposition processes. Application of the lubricant reduces chipping during de-swaging, particularly with nickel plated metal components. Application of the lubricant has also shown to improve gram load uniformity, reduce adverse distortion to the actuator assembly and reduces torque out retention values. Improved gram load uniformity enhances overall disk drive functioning, reduced distortion preserves intended attitude and flatness of the actions for assembly and reduced torque out retention values improves reworkability of the disk drive.

Owner:SEAGATE TECH LLC

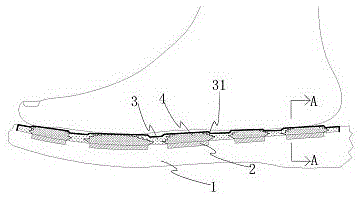

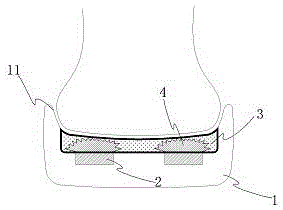

Magnet therapy massage shoe sole and shoe with same

The invention relates to a shoe sole, and provides a magnet therapy massage shoe sole and a shoe with the same. The magnet therapy massage shoe sole is simple in structure, can effectively conduct magnet therapy on acupuncture points of a foot sole and can also have effects on damping and buffering the foot sole. The magnet therapy massage shoe sole comprises an outsole. The outsole is provided with a magnet and further provided with a magnetic fluid layer covering the magnet. The magnetic fluid layer is filled with magnetic fluid.

Owner:FUJIAN DENGTAI TECH CO LTD

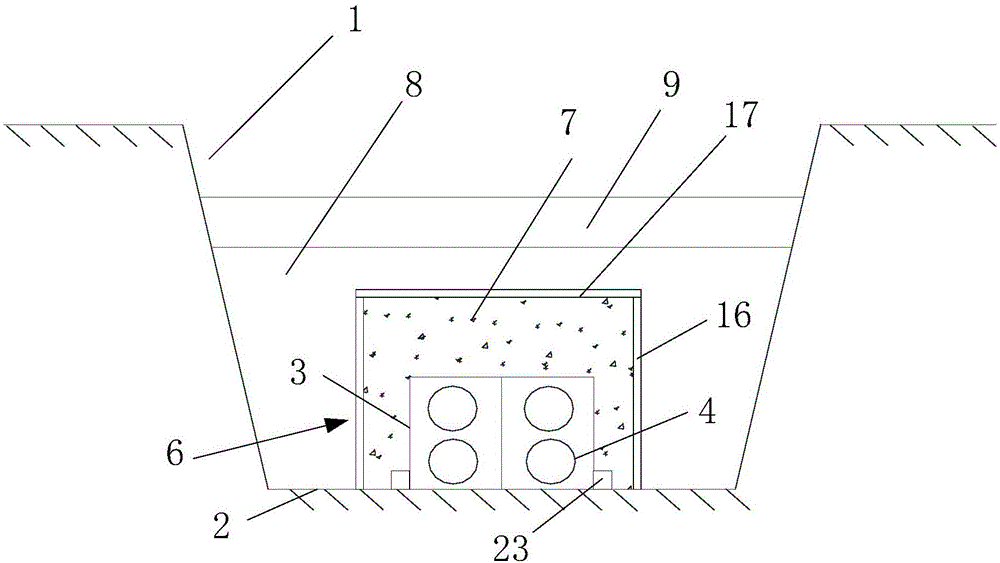

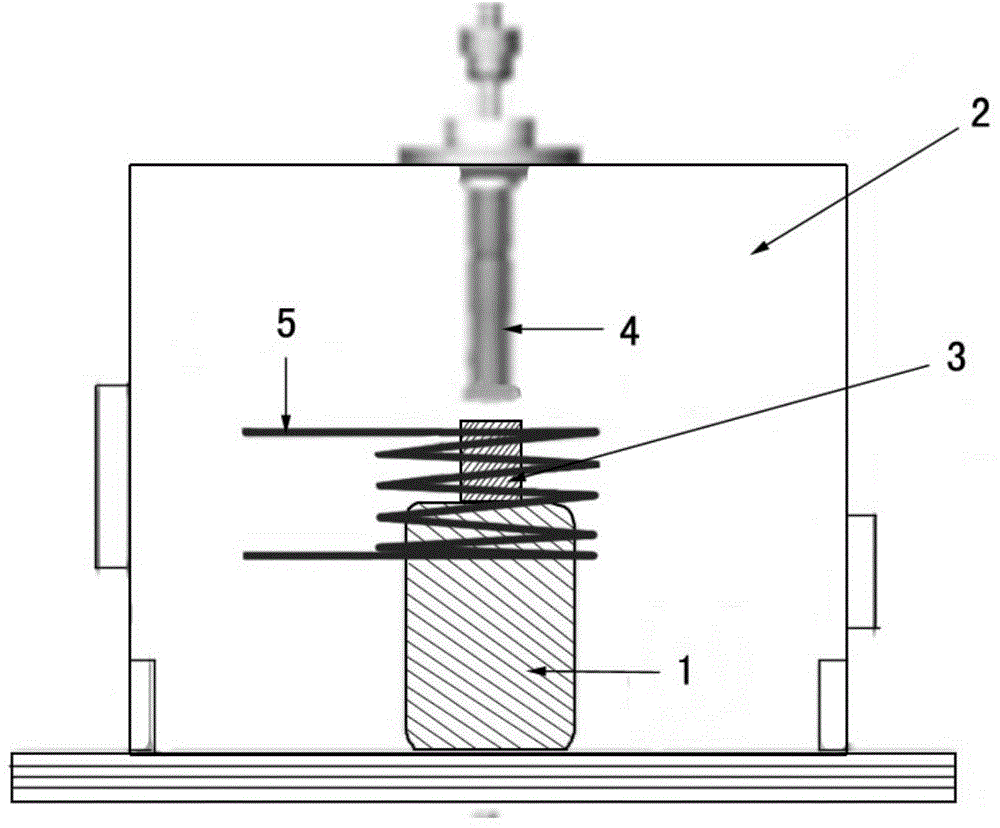

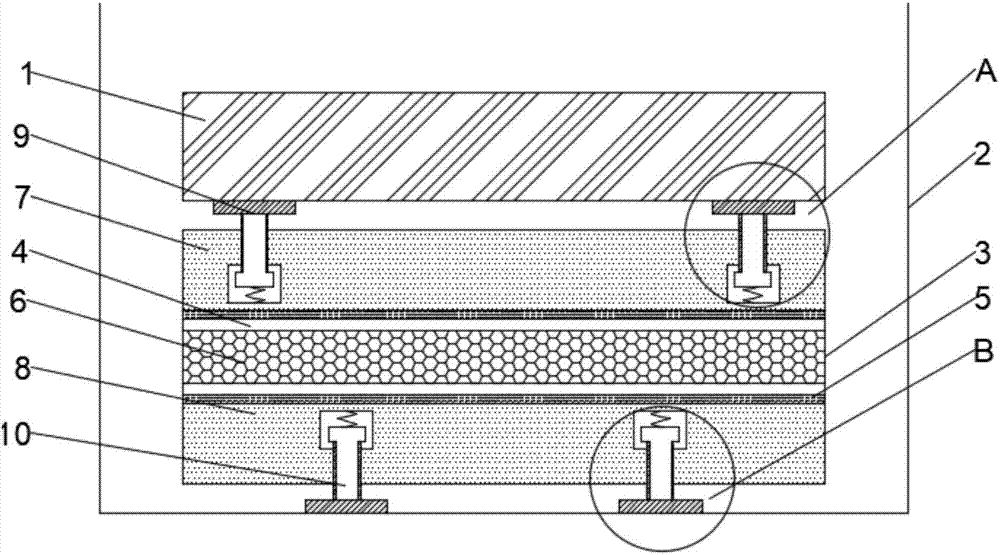

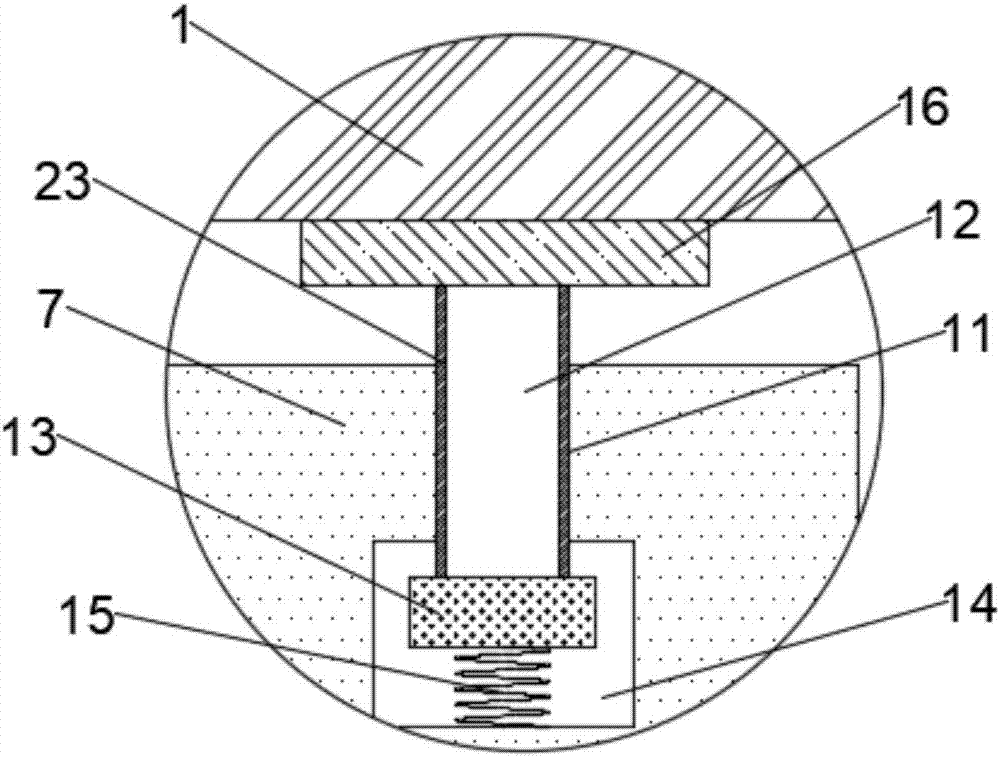

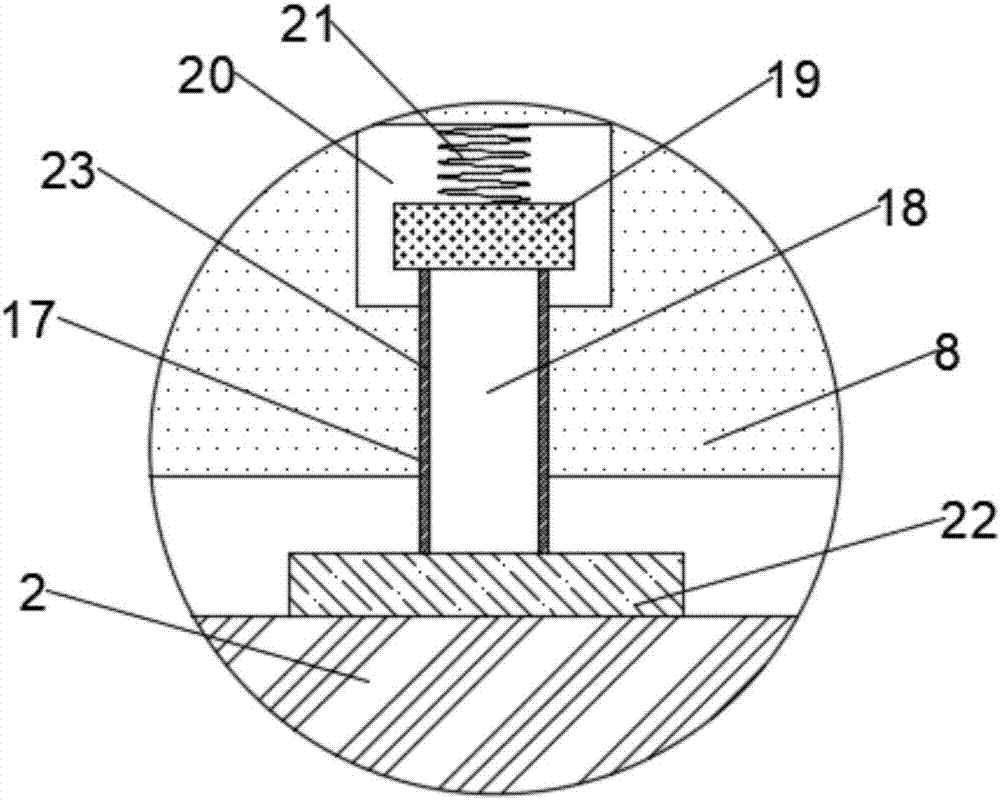

Vibration isolation and sound insulation device of air conditioner compressor

InactiveCN107388417AGood deformation propertiesReduce vibrationLighting and heating apparatusAir conditioning systemsInsulation layerEngineering

The invention discloses a vibration isolation and sound insulation device of an air conditioner compressor. The vibration isolation and sound insulation device comprises a compressor body, the body is installed in a machine case of an outdoor unit, a base is arranged in the machine case, the upper surface and the lower surface of the base are each provided with a panel, and sound insulation layers are arranged on the upper surface of the panel located at the upper end and the lower surface of the panel located at the lower end; an interlayer is arranged between the two panels and is of a regular hexagonal honeycomb structure, the upper end and the lower end of the base are provided with a body plate and a machine case plate, a body damping device is arranged at the upper end of the body plate, and a machine case damping device is arranged at the lower end of the machine case plate; the body damping device comprises four body installing holes formed in the four corners of the upper end face of a main machine plate, body lifting columns are arranged in the body installing holes, body containing cavities are arranged in the body installing holes, body damping springs are arranged between the body lifting columns and the body containing cavities, and a body installing base is arranged on the upper end faces of the body lifting columns; and the body is fixed to the body installing base through screws, and the very good sound insulation and vibration isolation capacity is achieved.

Owner:安徽诺鑫自动化设备有限公司

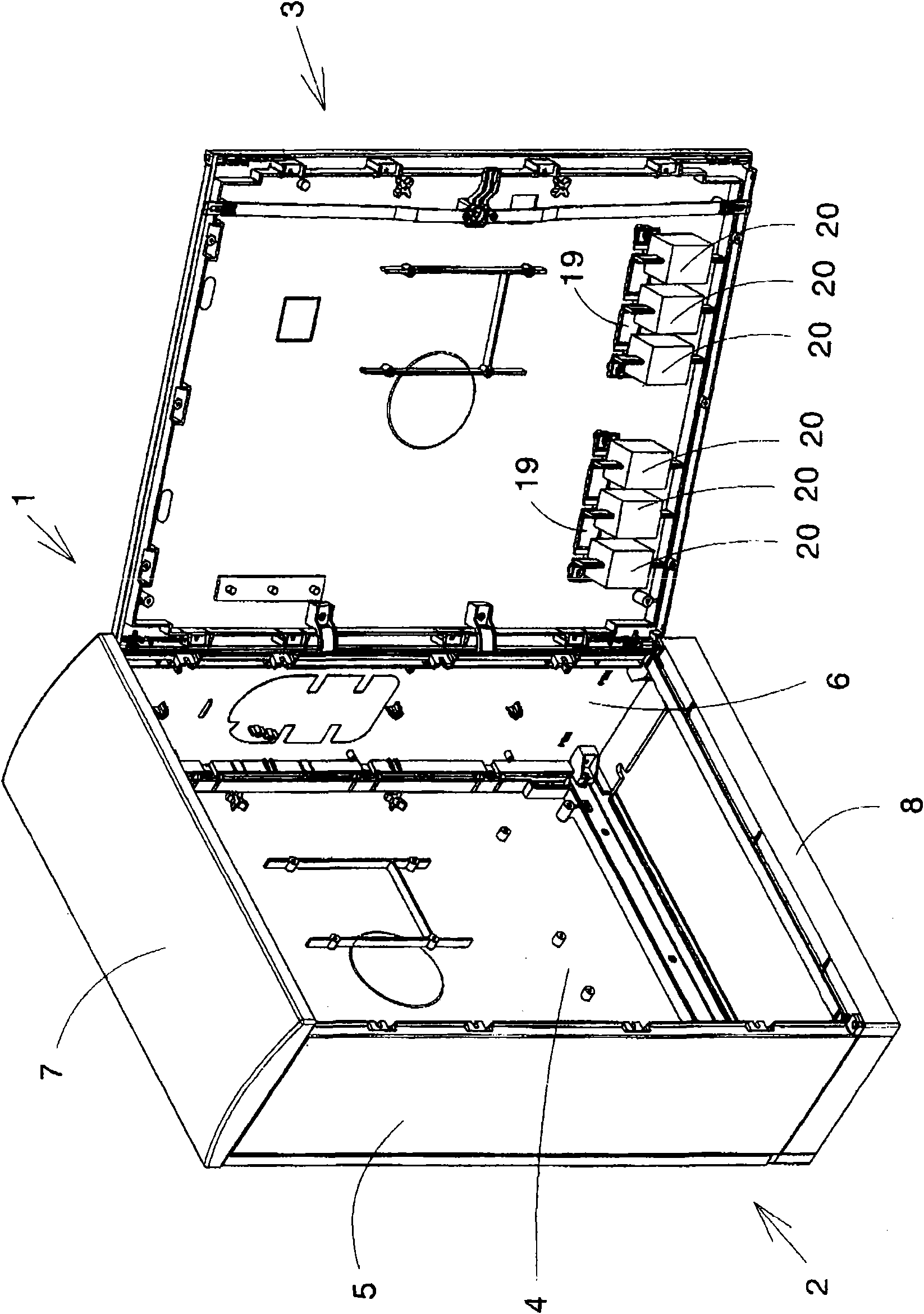

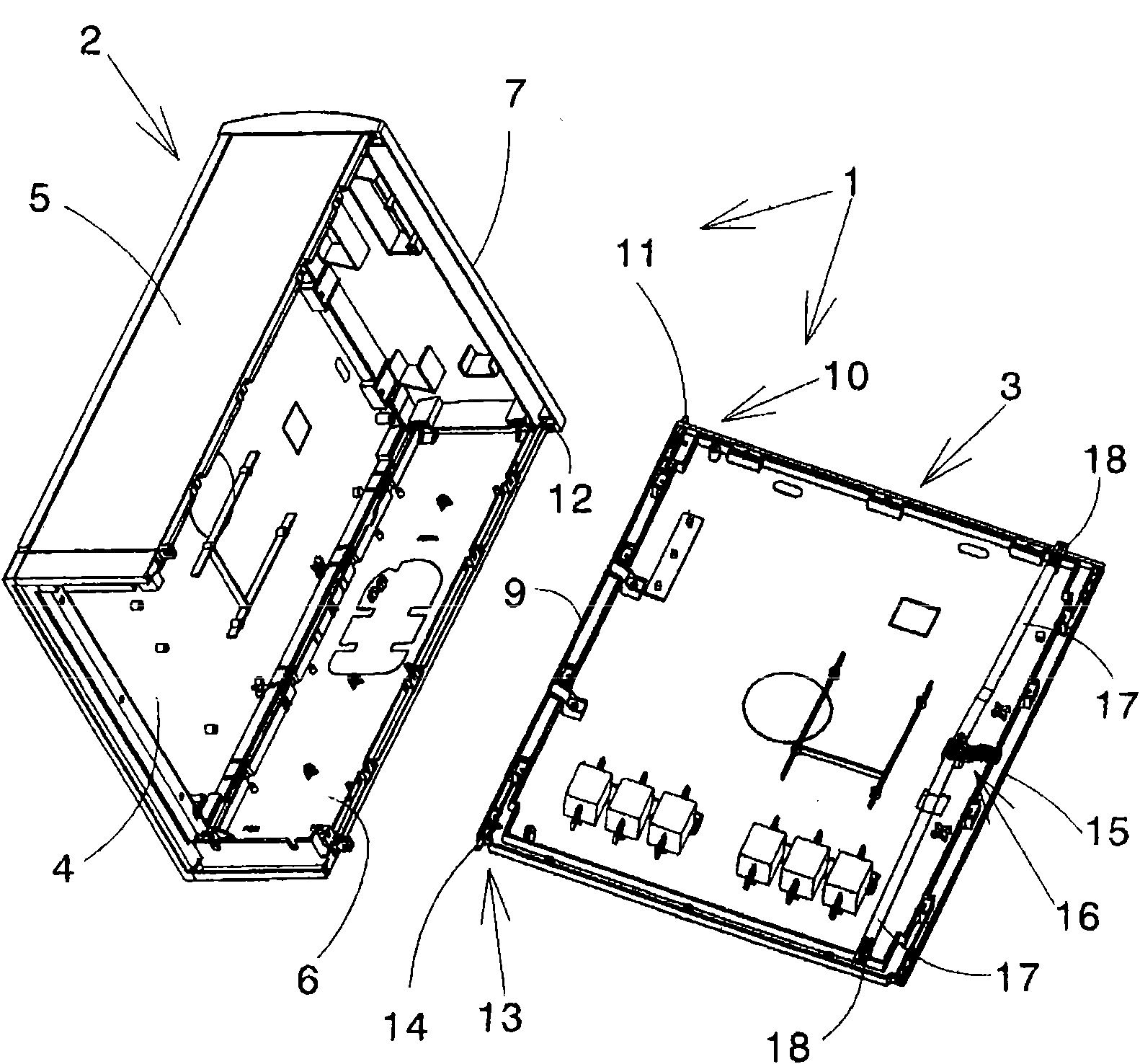

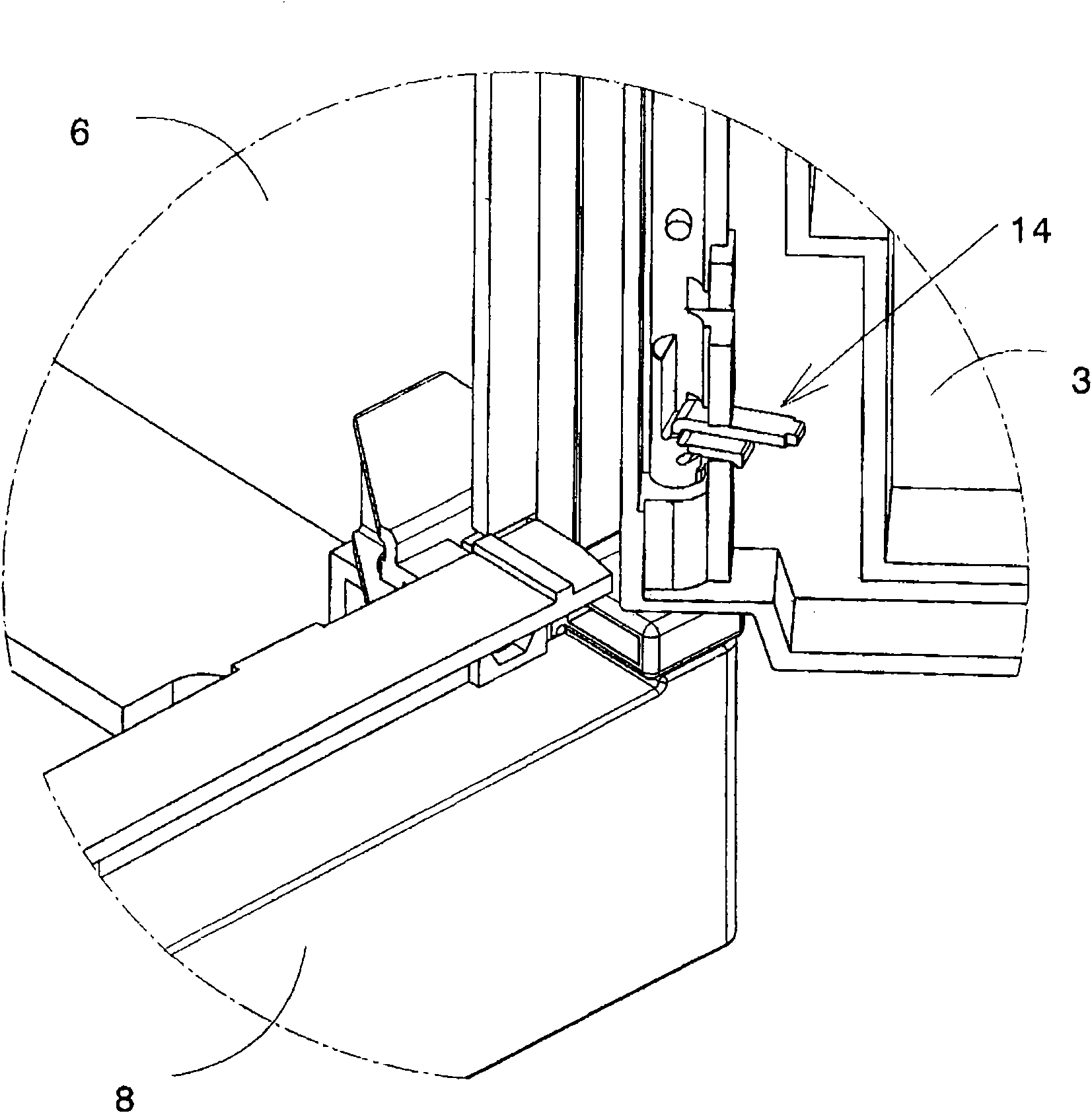

Cable distribution box with a housing and a door supported in the housing

InactiveCN101783487APrevent overloadGood deformation propertiesSubstation/switching arrangement detailsElectrical and Electronics engineeringHinge angle

The invention relates to a cable distribution box with a housing and a door supported in the housing and capable of locking with the housing, wherein the housing has a lateral wall and a bottom piece. According to the invention, in such a cable distribution box, the door has a hinge pin in the lower supporting part region of the door, and the hinge component is connected to the lateral wall, wherein the hinge component has a hole perforating the hinge component for supporting the hinge pin, and the bottom piece has a gap for supporting the hinge pin in the lower support of the hinge component. Such a cable distribution box has advantage of simple structure, stable design in the lower support region of the door, and not complicated mounting.

Owner:JEAN MULLER ELEKTROTECHN FAB

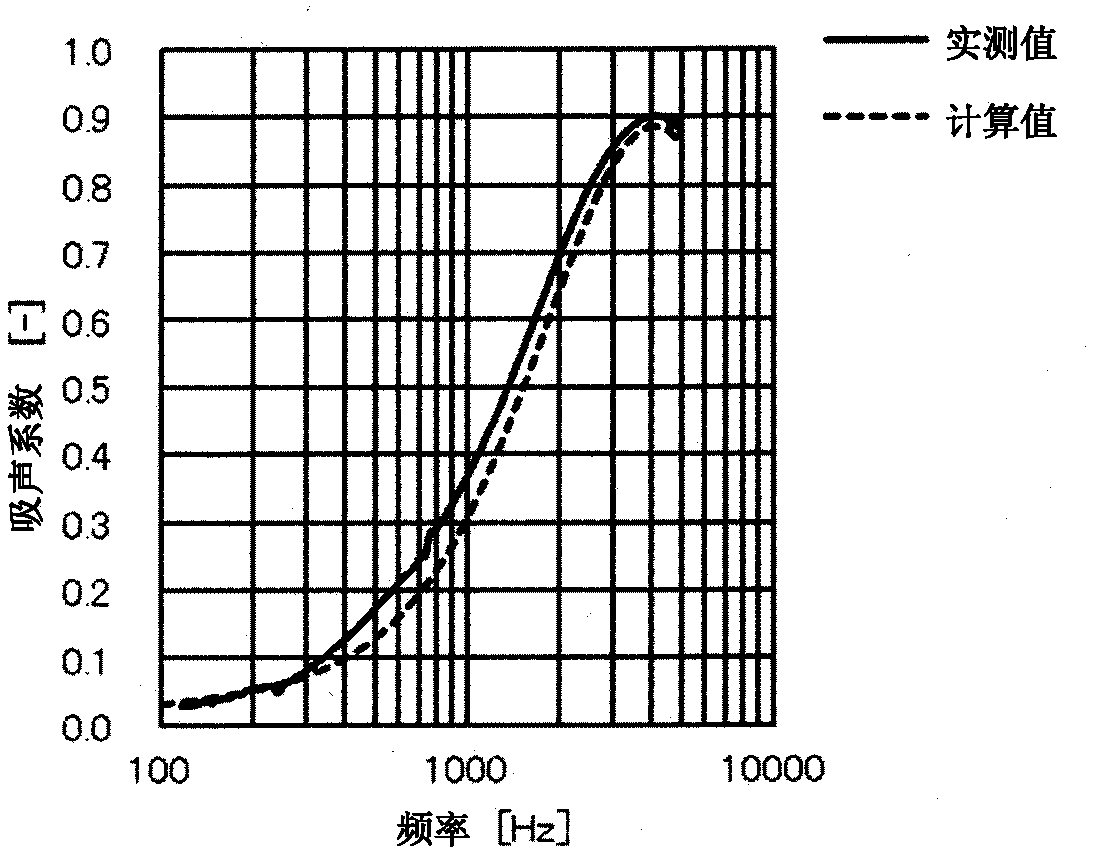

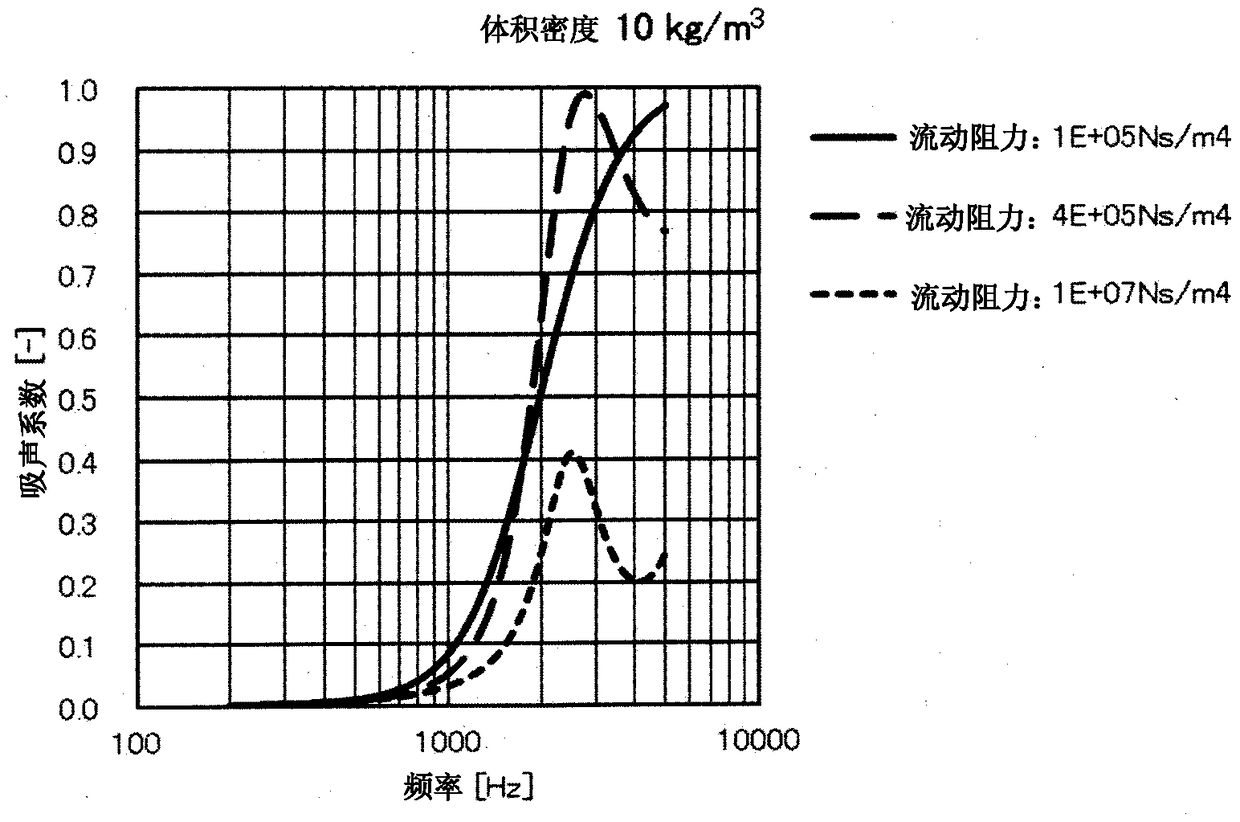

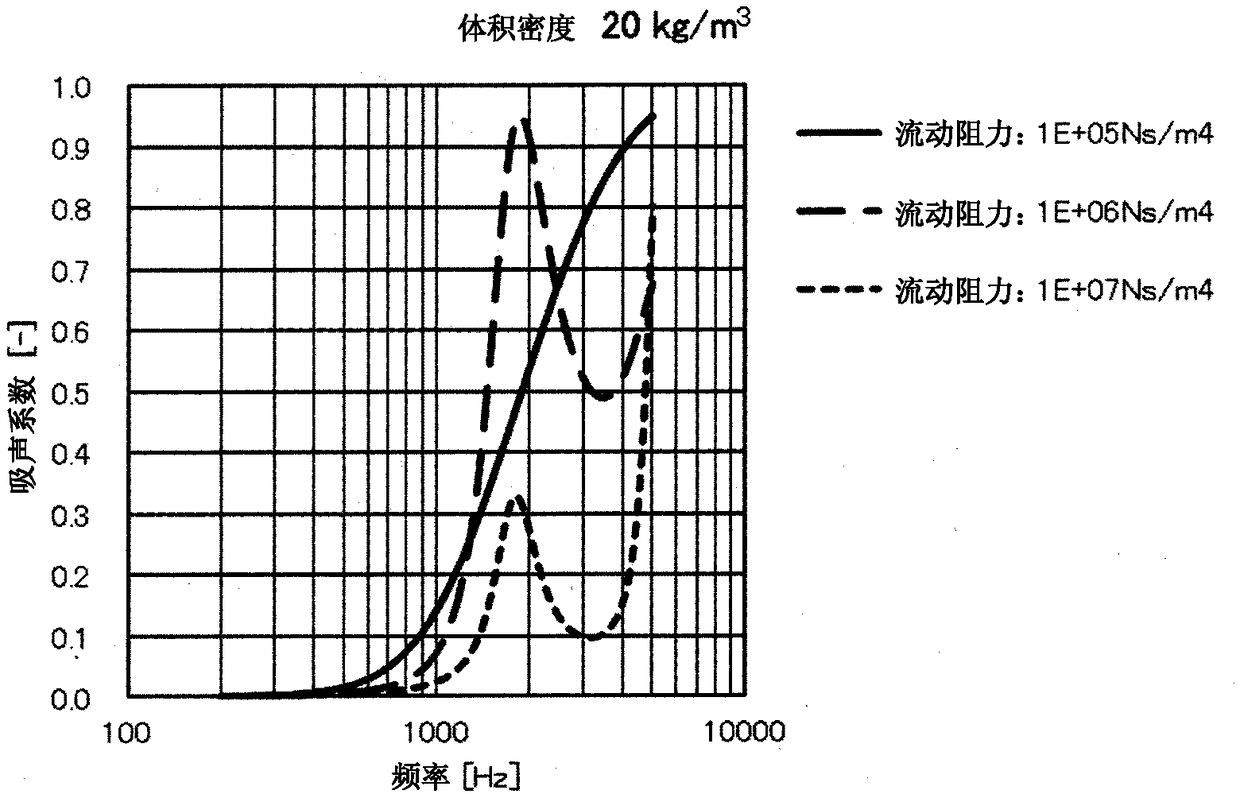

Soundproofing material

A soundproofing material comprises a porous body with a cell structure including inorganic fibers other than asbestos, the soundproofing material having an average cell diameter of more than 300 [Mu]mand not more than 1000 [Mu]m, a bulk density of 0.007 to 0.024 g / cm3, and a flow resistance of 170,000 to 2,000,000 Ns / m4.

Owner:NICHIAS CORP

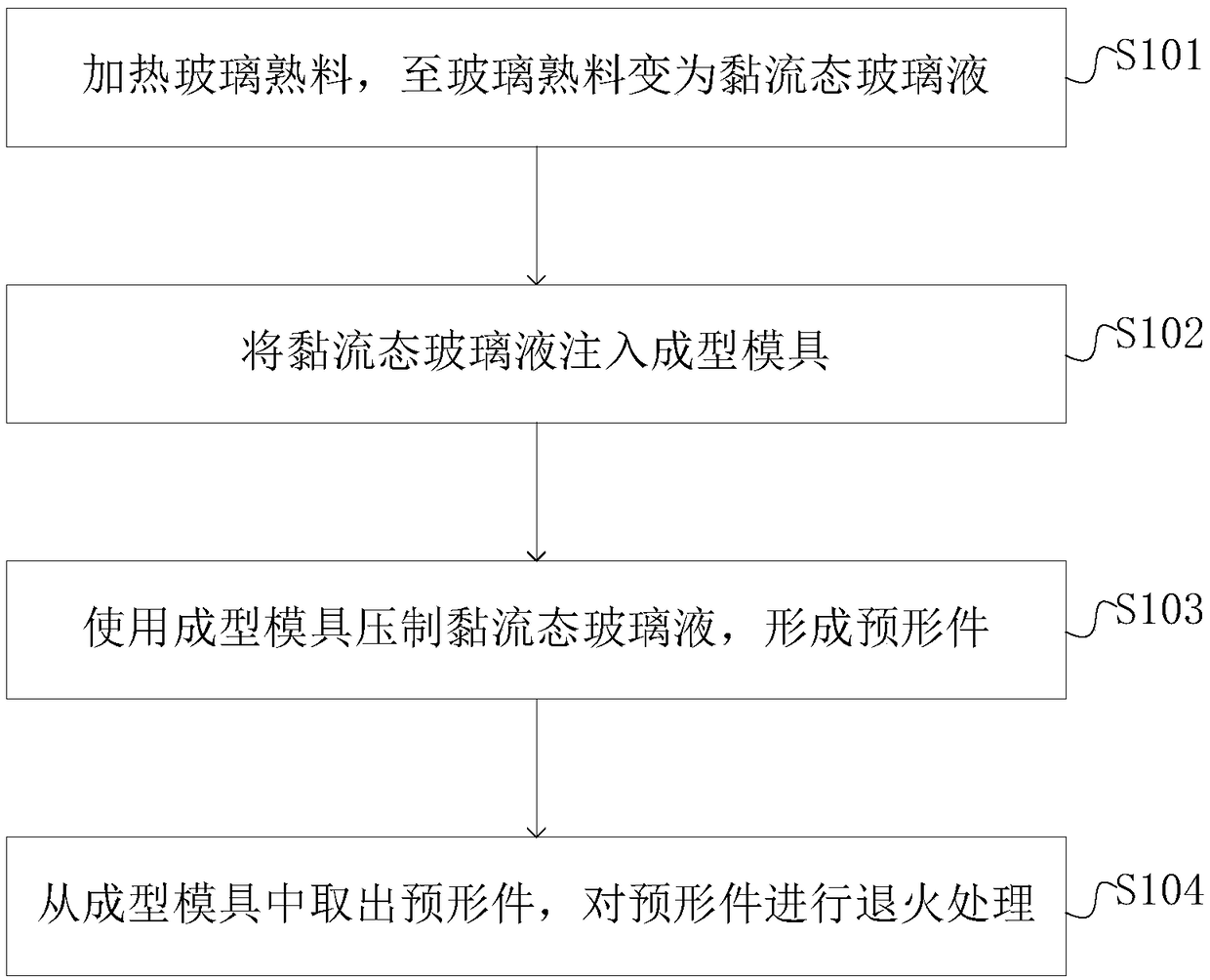

Machining method of glass preform

InactiveCN109095755AGood deformation propertiesGood deformabilityGlass pressing apparatusMolten glassViscous flow

The invention provides a machining method of a glass preform. The machining method of the glass preform comprises the following steps of heating a glass clinker till the glass clinker is changed intoviscous flow state molten glass; injecting the viscous flow state molten glass into a forming mould; using the forming mould to press the viscous flow state molten glass and cooling the pressed viscous flow state molten glass to a temperature below a softening point temperature so as to form a preform; taking out the preform from the forming mould; and annealing the preform. The machining method of the glass preform, provided by the invention, has the advantages that the glass clinker is heated to form the viscous flow state molten glass and then injected into the forming mould to be pressurized to form the preform; as the temperature of the glass clinker while the glass clinker is injected into the forming mold is higher than the softening point temperature, the glass clinker still possesses very good deformation performance while being injected into the forming mould; in the forming mould pressurizing process, the viscous flow state molten glass is changed into the shape of the preform with the mould pressure without a cracking problem caused when the internal temperature of the viscous flow state molten glass does not reach the softening point; and under a situation that the viscous flow state molten glass is enough, a problem of incomplete mould filling cannot be caused.

Owner:CHINA BUILDING MATERIALS ACAD

Liquid-ejecting head, liquid-ejecting apparatus, and actuator

ActiveUS8277031B2Good deformation propertiesReduce variationPiezoelectric/electrostrictive device material selectionPrintingInternal pressureTitanium

A liquid-ejecting head includes a flow-passage-forming substrate that includes a pressure-generating chamber, the pressure-generating chamber being in communication with a nozzle through which droplets are ejected, and a piezoelectric element disposed on the flow-passage-forming substrate, the piezoelectric element altering the internal pressure of the pressure-generating chamber. The piezoelectric element includes a piezoelectric layer containing titanium (Ti) and zirconium (Zr), a first electrode, and a second electrode. The first electrode and the second electrode are disposed on the opposite sides of the piezoelectric layer,. The component ratio Ti / (Zr+Ti) of the piezoelectric layer is 0.40 or more but less than 0.50. At least a portion of the piezoelectric layer formed on the first electrode contains tetragonal crystals formed by phase transition under stress caused by an underlying layer.

Owner:SEIKO EPSON CORP

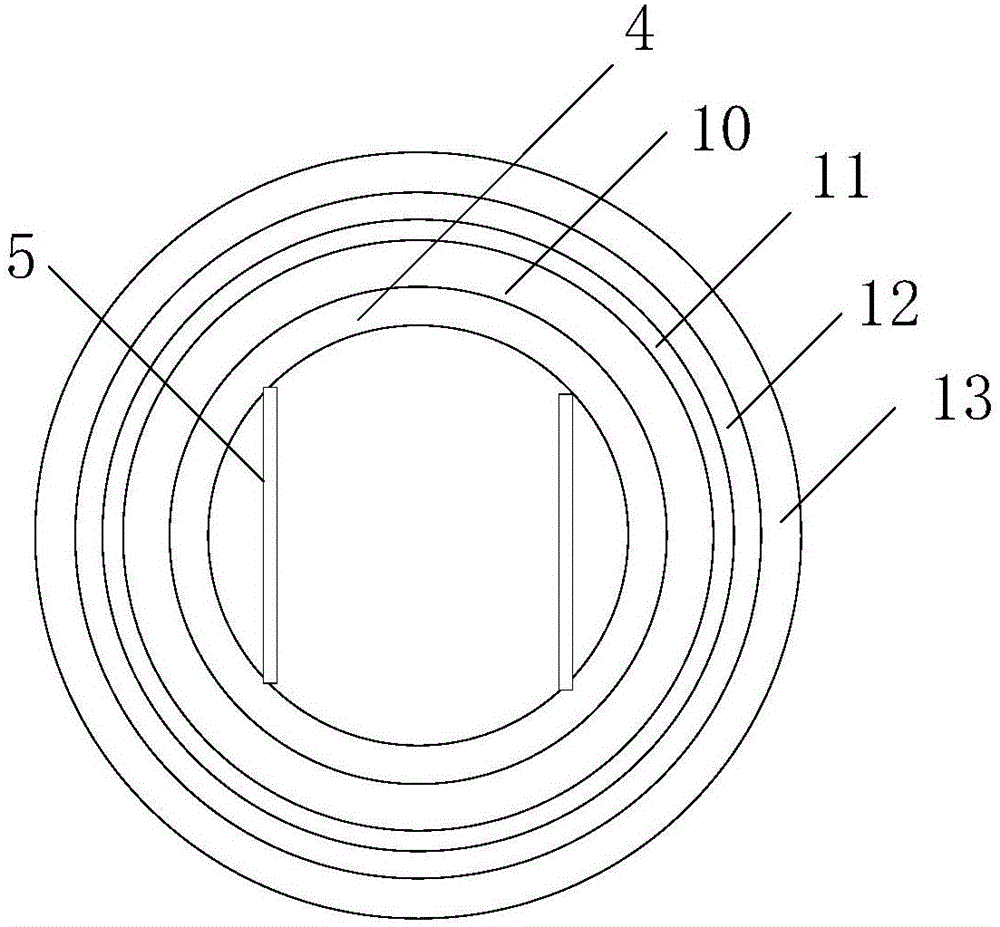

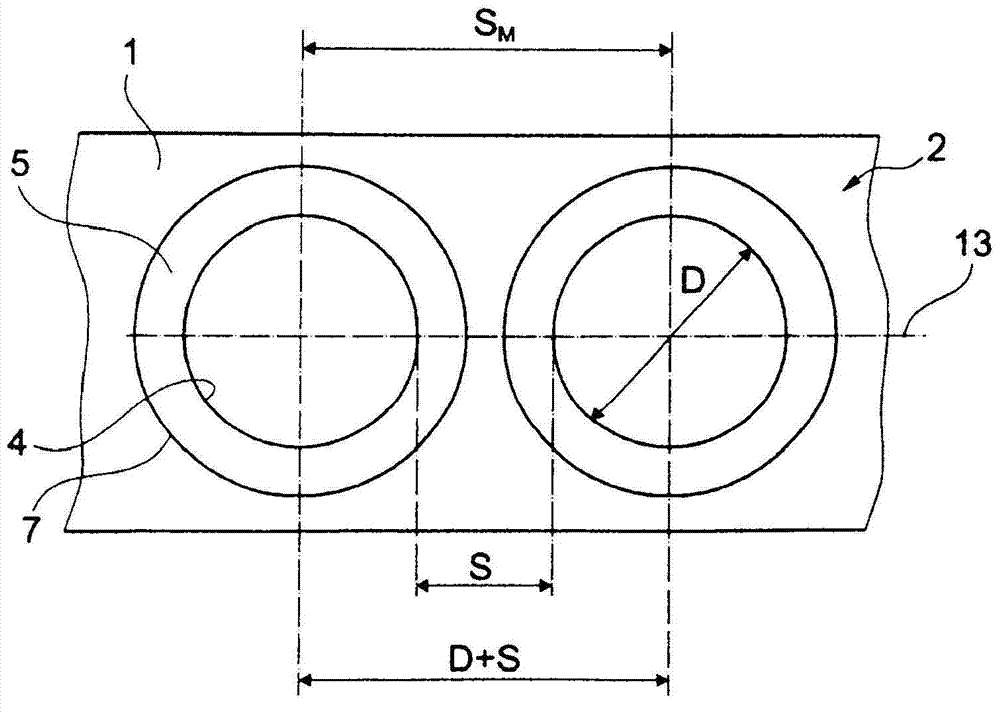

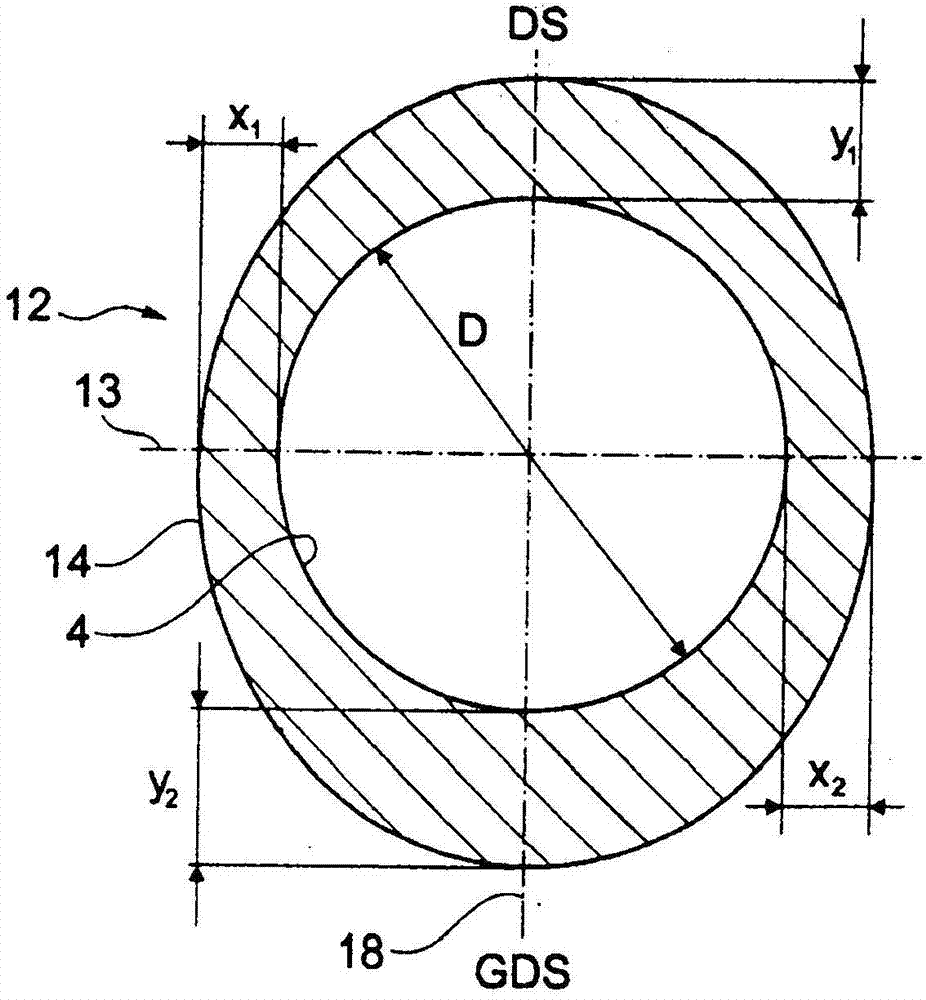

Functionally optimized design of a cylinder liner

ActiveCN103946606AOptimized structural spaceDurable and Reliable ProtectionCylinder headsCylindersPistonEngineering

The invention relates to a cylinder liner (2) of a cylinder of an internal combustion engine, in which cylinder liner an oscillating piston (3) is guided on a running surface (4), wherein the cylinder liner (2) is fixed vertically by means of a collar (5) between a cylinder housing (1) and a cylinder head. The wet cylinder liner (2) comprises an outer side (6) which deviates from a circular shape and / or a rotationally asymmetrical outer contour of the collar (5). The cylinder liner (2) is fitted in a positionally oriented manner in a corresponding receptacle of the cylinder housing (1).

Owner:KOLBENSCHMIDT AG

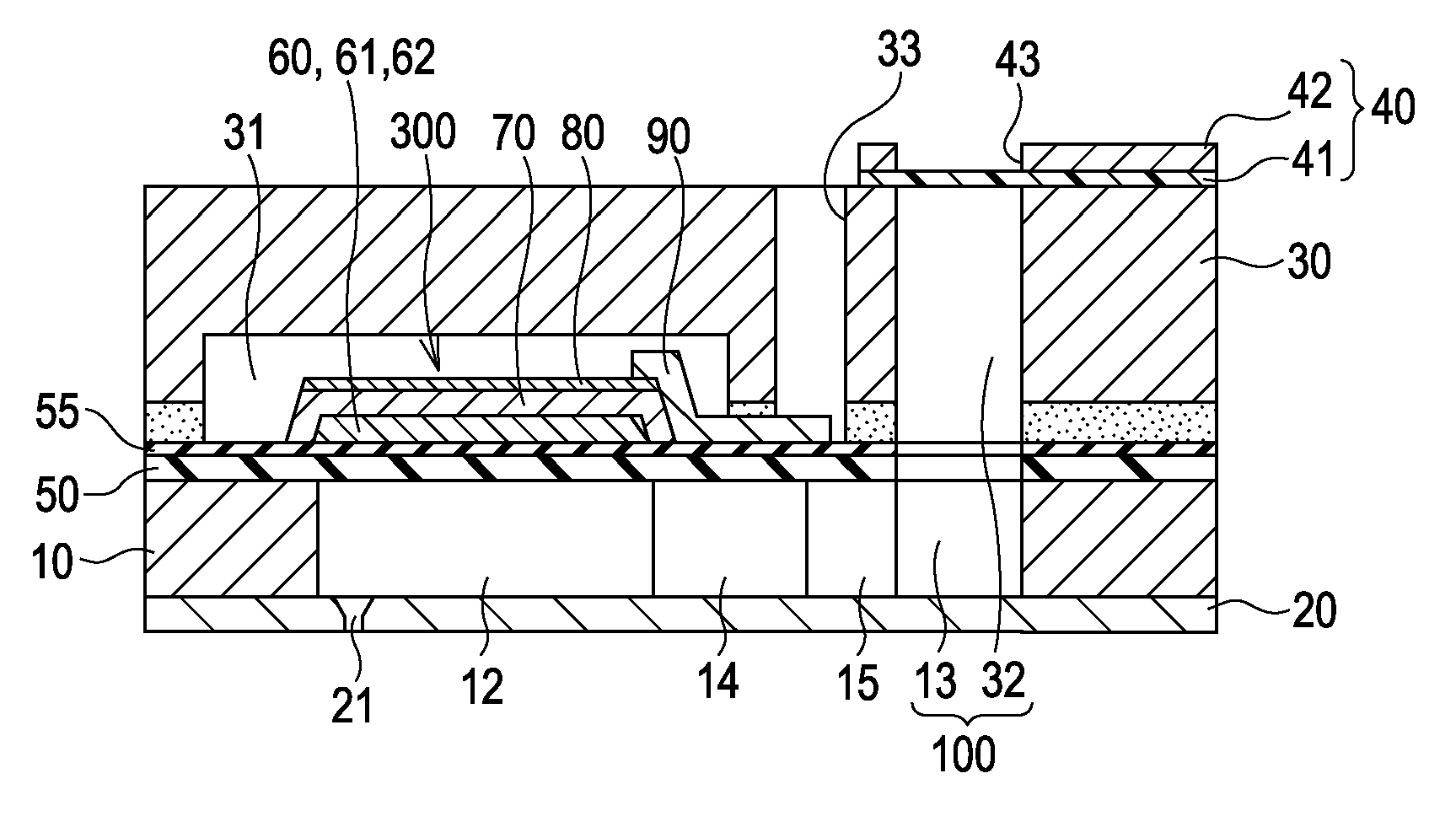

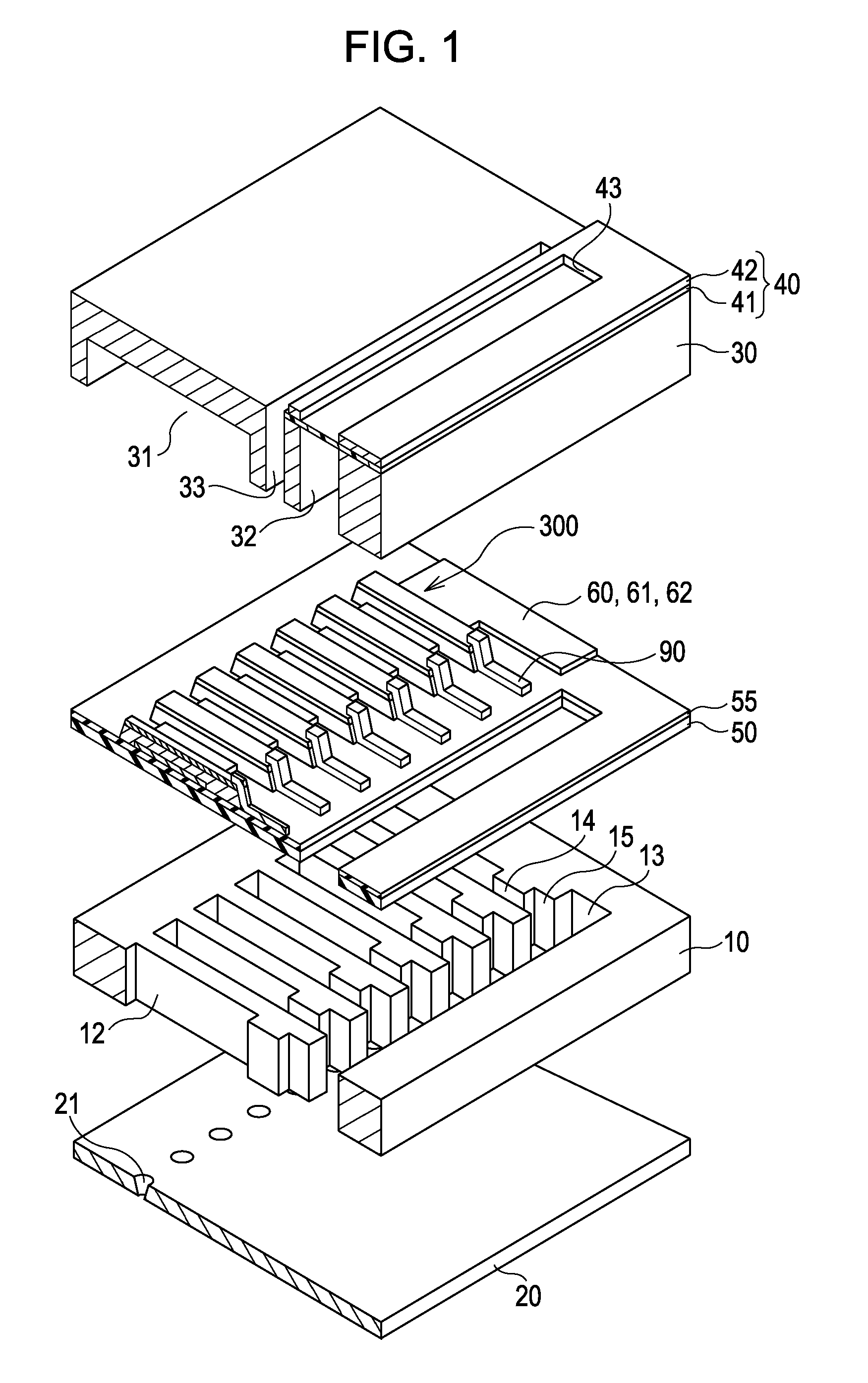

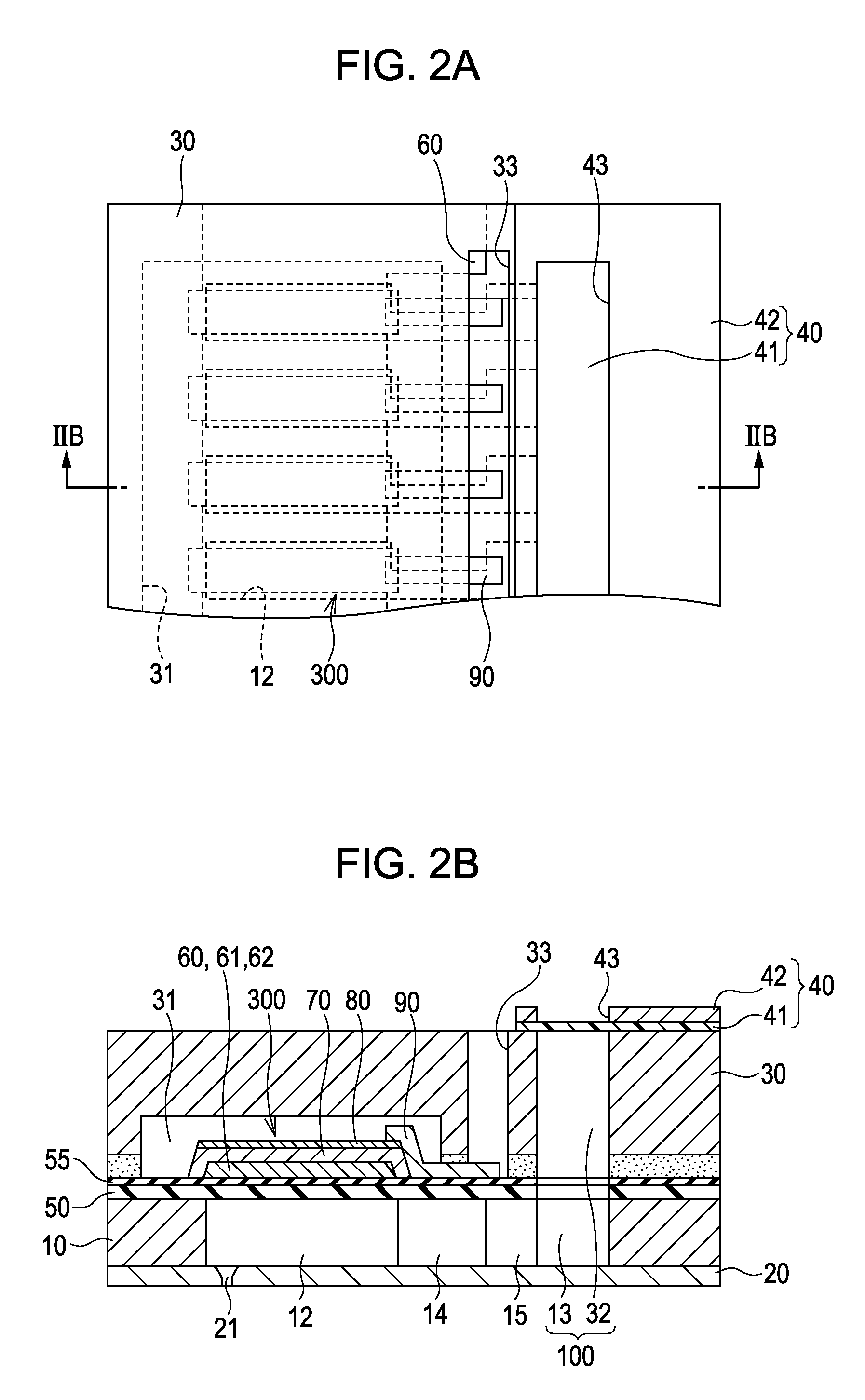

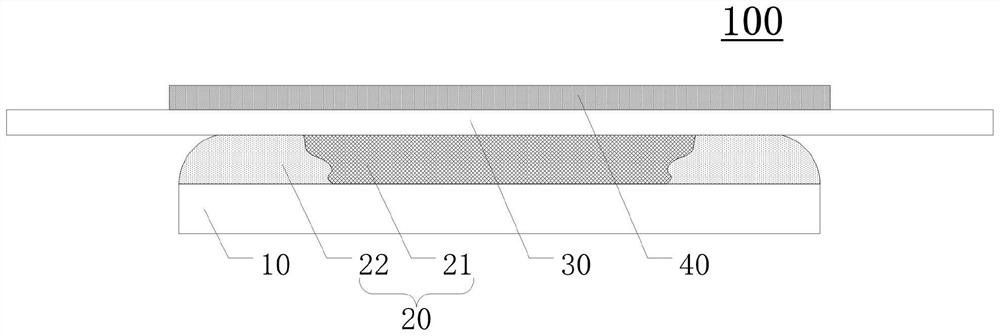

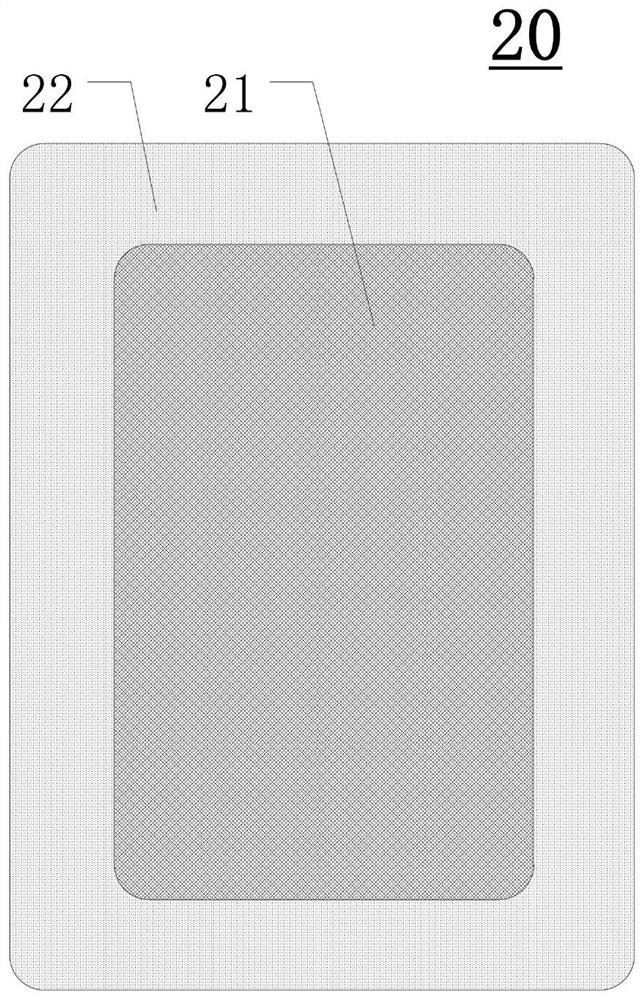

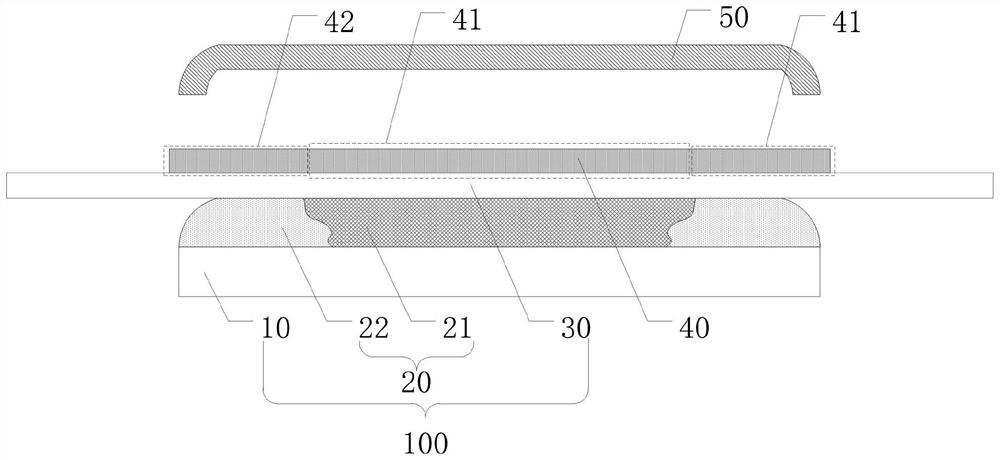

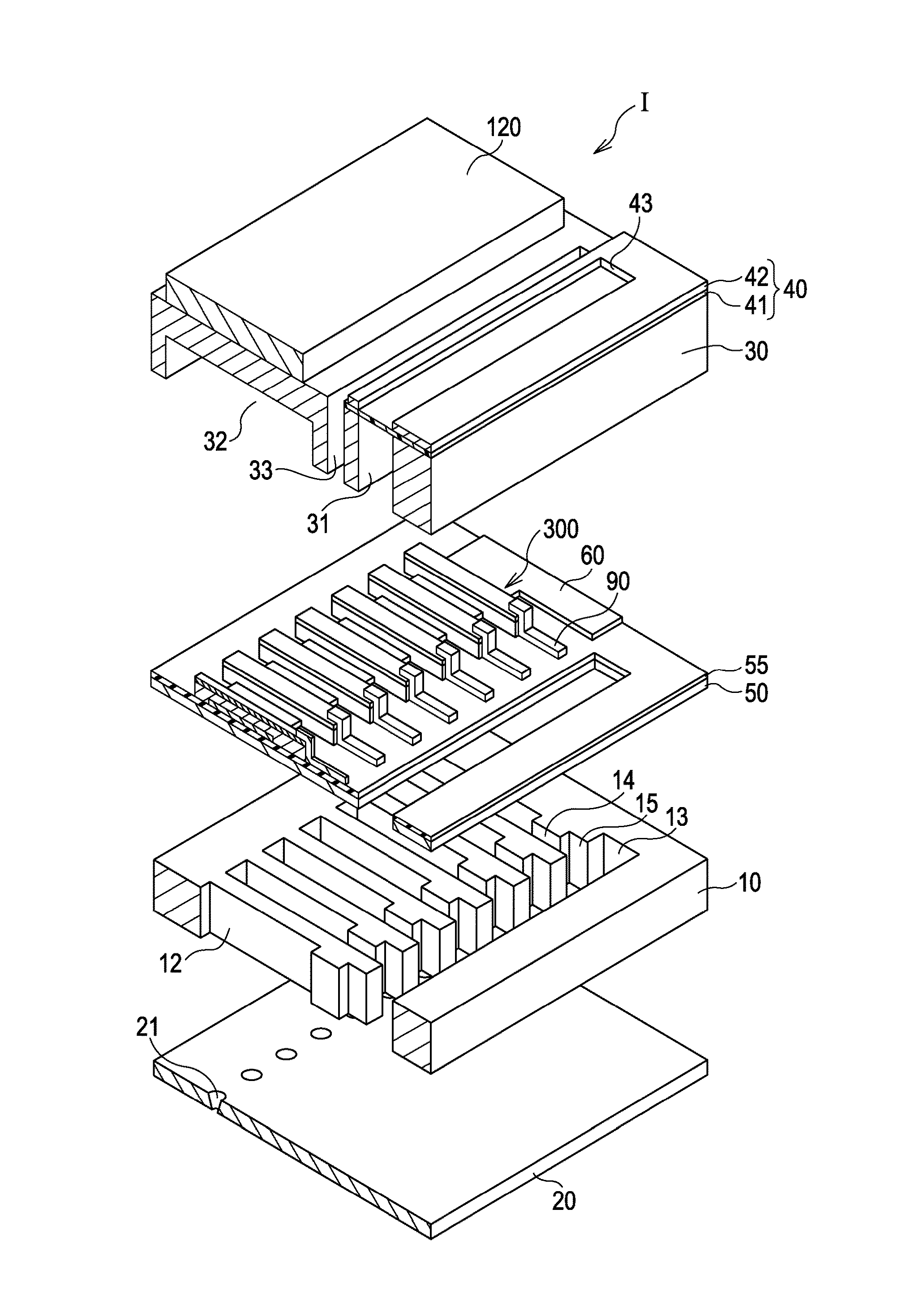

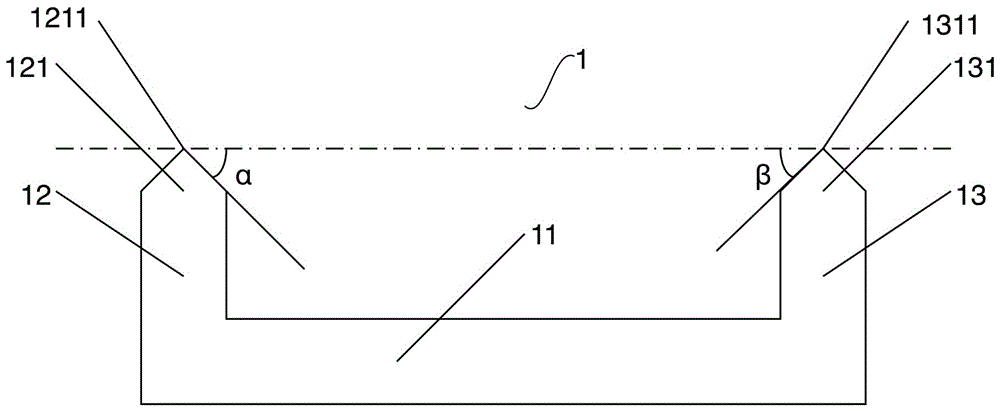

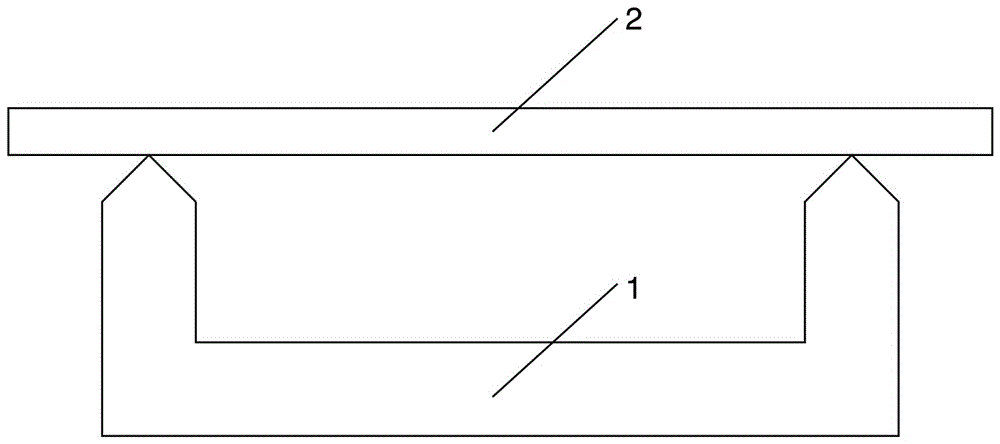

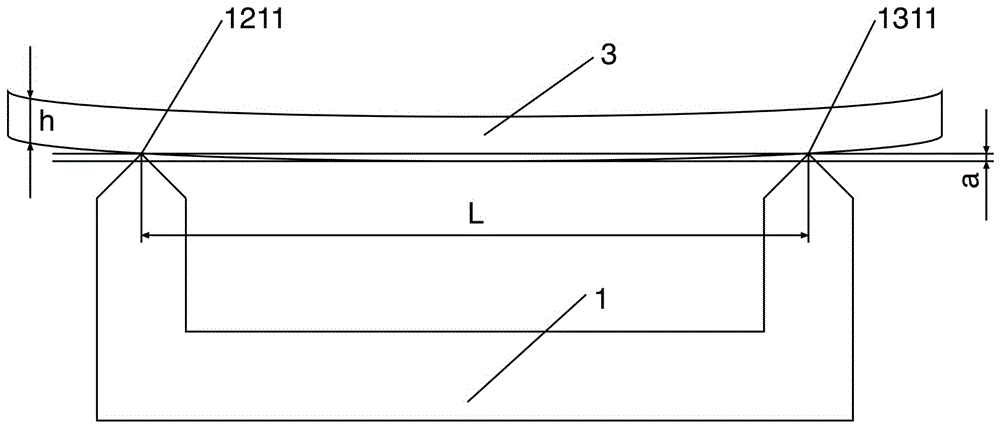

Display panel profiling tool

InactiveCN111899637AGood deformation propertiesReduce stressIdentification meansPhysicsSurface plate

The invention discloses a display panel profiling tool, and belongs to the technical field of display. The display panel profiling tool comprises a first substrate, a profiling layer and a panel fixing layer; the first substrate and the panel fixing layer are arranged on the two sides of the profiling layer respectively in a direction perpendicular to a plane where the first substrate is located;the profiling layer comprises a first part and a second part fixed to the first part; the second part at least partially surrounds the first part; the surface, away from the first substrate, of the first part is a plane; the surface, away from the first substrate, of the second part at least comprises an arc-shaped structure; the density of the first part is greater than that of the second part. Therefore, the second part with the arc-shaped structure has better deformation performance relative to the first part of the plane; in the profiling process of a display panel, the stress borne by thearc-shaped structure of the display panel is correspondingly reduced, then the problems that the stress is concentrated and the arc-shaped structure is broken in the attaching process of the displaypanel and a glass cover plate are solved, and the attaching yield of the display panel can be increased.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Liquid-ejecting head, liquid-ejecting apparatus, piezoelectric element, and method for manufacturing liquid-ejecting head

InactiveUS8567926B2Good deformation propertiesWell formedPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusLiquid jetManganese

A piezoelectric element comprising a first electrode, a piezoelectric layer containing bismuth lanthanum iron and manganese formed above the first electrode, and a second electrode formed above the piezoelectric layer. The piezoelectric layer contains crystals preferentially oriented in a (111) plane.

Owner:SEIKO EPSON CORP

Liquid-ejecting head, liquid-ejecting apparatus, and piezoelectric element

InactiveUS8573755B2Good deformation propertiesPromote formationPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusManganeseX-ray

A piezoelectric element comprising a first electrode, a piezoelectric layer which includes bismuth, lanthanum iron, and manganese and which formed above the first electrode and a second electrode formed above the piezoelectric layer. The integrated intensity of a diffraction peak observed at 20°<2θ<25° is 90% or more of the sum of the integrated intensities of diffraction peaks observed at 20°<2θ<50° in an X-ray powder diffraction pattern of the piezoelectric layer measured at φ=Φ=0°.

Owner:SEIKO EPSON CORP

Road pipeline crossing node protection structure

ActiveCN105088916ASatisfy the articulation positioningAchieve protectionTemporary pavingsArchitectural engineeringStructural engineering

The invention relates to a road pipeline crossing node protection structure, comprising a road pre-embedded groove, which is internally provided with a bearing base course. The road pipeline crossing node protection structure is characterized in that symmetric support assemblies are arranged at two sides of the bearing base course, and corresponding pipeline through holes are formed in the support assemblies; a cover plate is connected to the top ends of the support assemblies and is provided with a separation assembly; the bearing base course is provided with pipeline reinforcing assemblies crossed up and down in a non-horizontal manner, two ends of pipeline reinforcing assembly at the upper layer are connected with the pipeline through holes, and a fill layer is distributed between the pipeline reinforcing assemblies. Therefore, the connection positioning of the pipeline reinforcing assembly at the upper layer can be guaranteed, and crossed pipelines can be protected. Furthermore, external stress from all directions can be absorbed effectively, corrosion caused by underwater infiltration can be prevented, and road pipeline pre-embedding with crossed pipeline layout can be available.

Owner:苏州同尚工程设计咨询有限公司

Foam

ActiveUS20180016195A1Excellent deformation characteristicGood deformation propertiesSound producing devicesCeramicwareAsbestosCompression ratio

A foamed body that is a porous foamed body including inorganic fibers other than asbestos, and having a compressive stress when compressed at normal temperature at a compression ratio of 80% of 0.1 MPa or less and a recovery ratio when compressed at normal temperature at a compression ratio of 80% of 50% or more.

Owner:NICHIAS

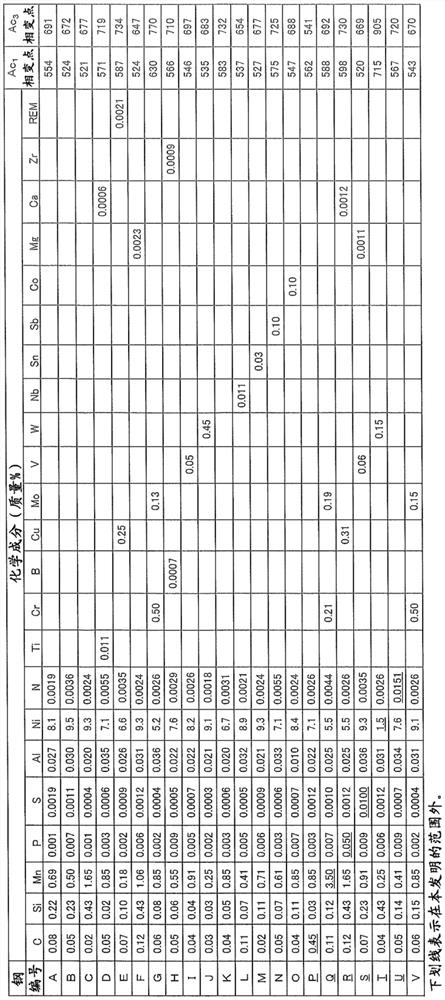

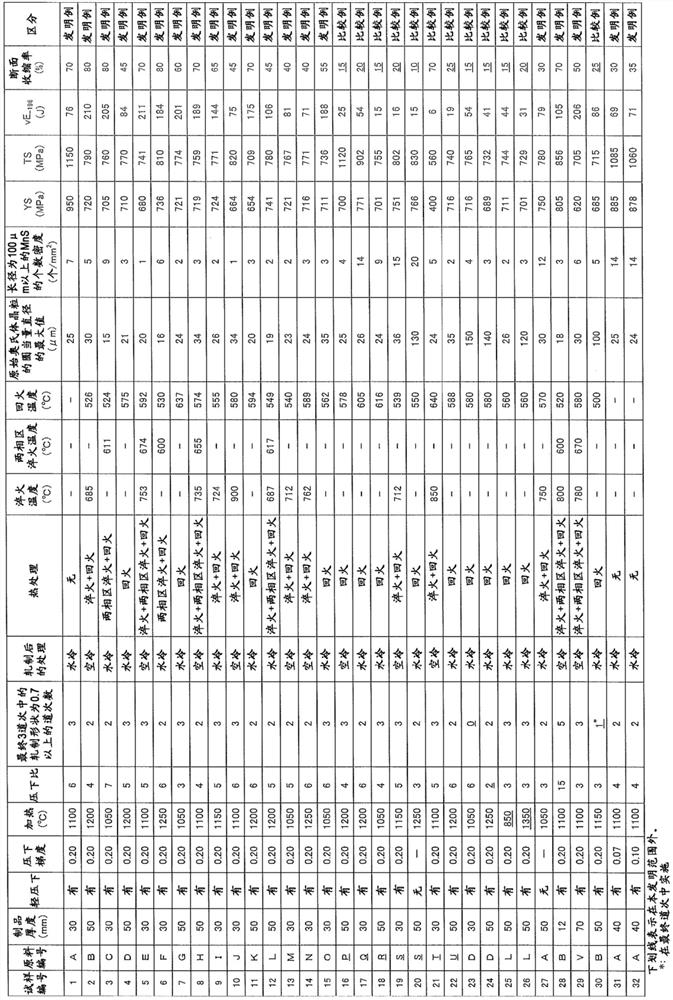

Thick steel sheet and production method therefor

PendingCN113631731AGood deformation propertiesImprove securityFurnace typesMetal rolling arrangementsMetallurgyPhysical chemistry

The purpose of the present invention is to provide a thick steel sheet having excellent deformation characteristics at a center portion in the thickness direction thereof; and a production method therefor. This thick steel sheet is characterized by having a component composition containing, in mass%, 0.01-0.15% of C, 0.01-1.00% of Si, 0.10-2.00% of Mn, 0.010% or less of P, 0.0050% or less of S, 0.002-0.100% of Al, 5.0-10.0% of Ni, and 0.0010-0.0080% of N, the balance being Fe and incidental impurities, and having a tensile reduction of area of 30% or more in the thickness direction thereof at a center portion thereof in the thickness direction.

Owner:JFE STEEL CORP

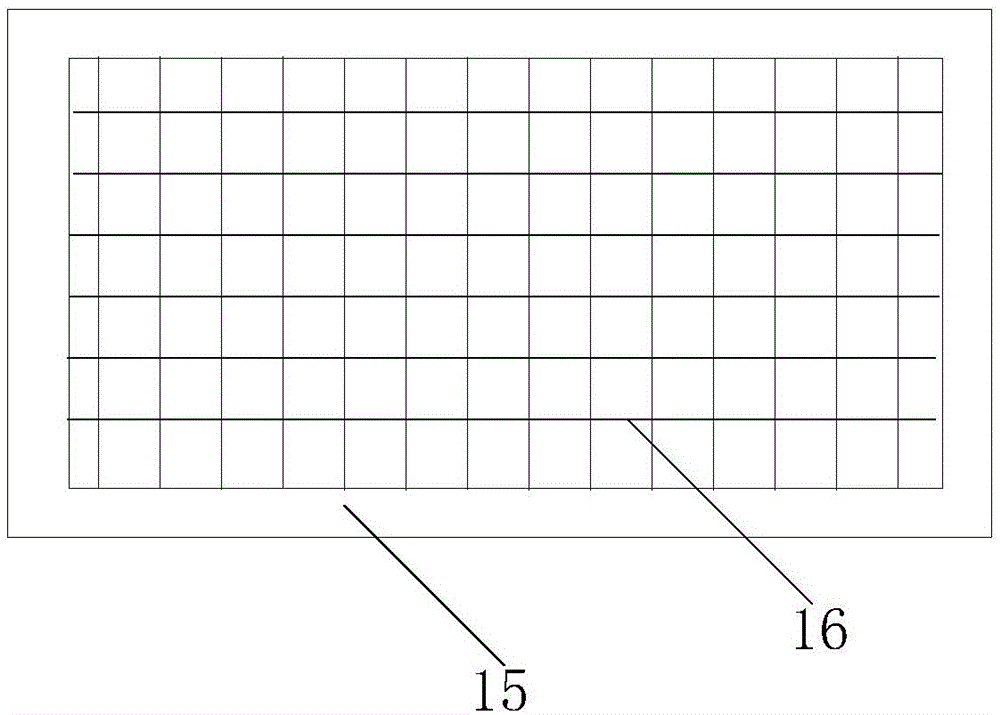

Net pipe concrete and manufacturing method thereof

PendingCN107268790AHigh compressive strengthImproved compression deformation capabilityBuilding constructionsCarrying capacityConcrete beams

The invention relates to a net pipe concrete and further discloses a manufacturing method of the net pipe concrete. The net pipe concrete comprises a hollow net pipe, plates and a net pipe concrete column or a net pipe concrete beam, wherein holes are uniformly distributed in the pipe wall of the net pipe, the net pipe is wrapped with the plates, and the net pipe concrete column or the net pipe concrete beam is formed by pouring concrete in the net pipe. The net pipe concrete is high in bearing capacity, good in deformation characteristic, wide in application range, simple in structure, convenient to construct and capable of saving materials, reducing the cost and achieving building industrialization.

Owner:HENAN UNIV OF URBAN CONSTR

Foam

Owner:NICHIAS CORP

Ceramic sintering deformation test fixture and method for testing ceramic slurry sintering deformation coefficients with same

InactiveCN106404822AEasy to determine spacing when measuringDetermine the spacingInvestigating phase/state changeCeramic sinteringMetallurgy

The invention discloses a ceramic sintering deformation test fixture and a method for testing ceramic slurry sintering deformation coefficients with the same. The ceramic sintering deformation test fixture comprises a base and two supports integrated with the base, wherein tops of the two supports are formed by joining two slopes in opposite slope directions, and ridges are formed at the joints; the ridges of the tops of the two supports are parallel and are parallel to the bottom surface of the base, and the distance between the ridge of the top of each support and the bottom surface of the base is identical to that between the ridge of the top of the other support and the bottom surface of the base. The test method comprises steps as follows: manufacturing a mold, manufacturing a wet blank, performing drying to manufacture a dry blank, placing the dry blank on the supports performing sintering, measuring and calculation and the like. With the adoption of the fixture and the test method, the deformation coefficients of slurry adopting different formulas can be determined, fluctuation of the deformation coefficients due to differences of samples is avoided, and the fixture can be more accurately used for representing deformation characteristics of the slurry and evaluating and comparing different slurry formulas.

Owner:JOMOO KITCHEN & BATHROOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com