Net pipe concrete and manufacturing method thereof

A production method and concrete technology, applied in the direction of architecture, building structure, etc., can solve the problems of quality inspection and construction inconvenience, limited use range, difficult installation, etc., achieve quality inspection and construction convenience, optimize physical and mechanical properties, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

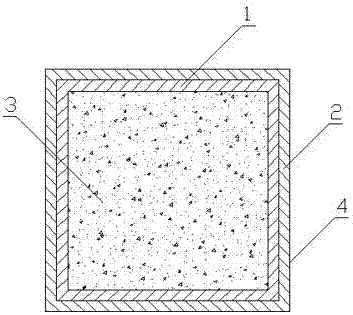

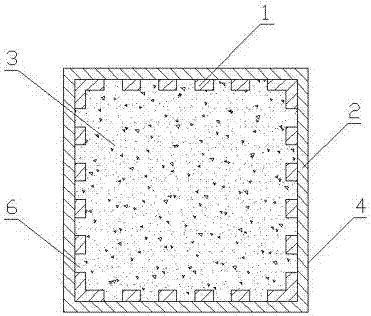

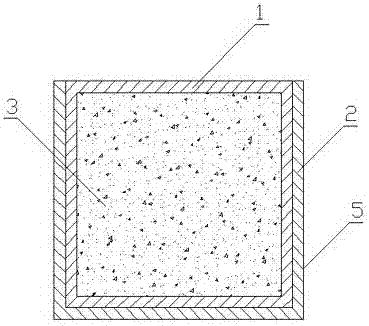

[0040] Such as Figure 1~5 Among them, the mesh concrete includes a hollow mesh tube 1 with holes 6 evenly distributed on the wall of the tube 1, a plate 2 wrapped around the mesh tube 1, and a mesh concrete column 4 or a mesh concrete beam 5 composed of concrete 3 poured in the mesh tube 1.

[0041] among them:

[0042] The network tube 1 is square or round.

[0043] The holes 6 are square holes or round holes, and are evenly distributed along the circumferential and axial directions of the network pipe 1.

[0044] The board 2 is a fiber plastic board.

[0045] The four circumferential sides of the network tube concrete column 4 are bonded to the plate 2 wrapped around the network tube 1.

[0046] The three outer walls of the network tube concrete beam 5 except for the top surface are bonded to the plate 2 covering the network tube 1.

[0047] Reinforcing bars 7 or section steel 8 are arranged in the cavity of the network concrete column 4 or the network concrete beam 5.

[0048] The man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com