Water permeable concrete and pavement construction method

A construction method and concrete technology, which can be applied to coagulating pavements, roads, roads and other directions paved on site, can solve problems such as blocking permeable voids, squares not reaching the level of practical application, and difficulties.

Inactive Publication Date: 2008-10-29

HENAN GUOJI CONSTR GRP +1

View PDF0 Cites 65 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the 1990s, domestic research on permeable concrete pavement materials has begun, but so far, permeable concrete bricks are mainly used to pave sidewalks, while paving roads and squares using domestic materials and construction techniques have not yet reached the level of practical application.

There are the following difficulties when permeable concrete is used in road engineering: (1) It is difficult to ensure a relatively high compressive strength due to the large honeycomb structure inside the permeable concrete; (2) Due to the action of gravity, the cement slurry will Falling into the bottom of the concrete, blocking the water-permeable gap, resulting in a decrease in water-permeability, or even impermeability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

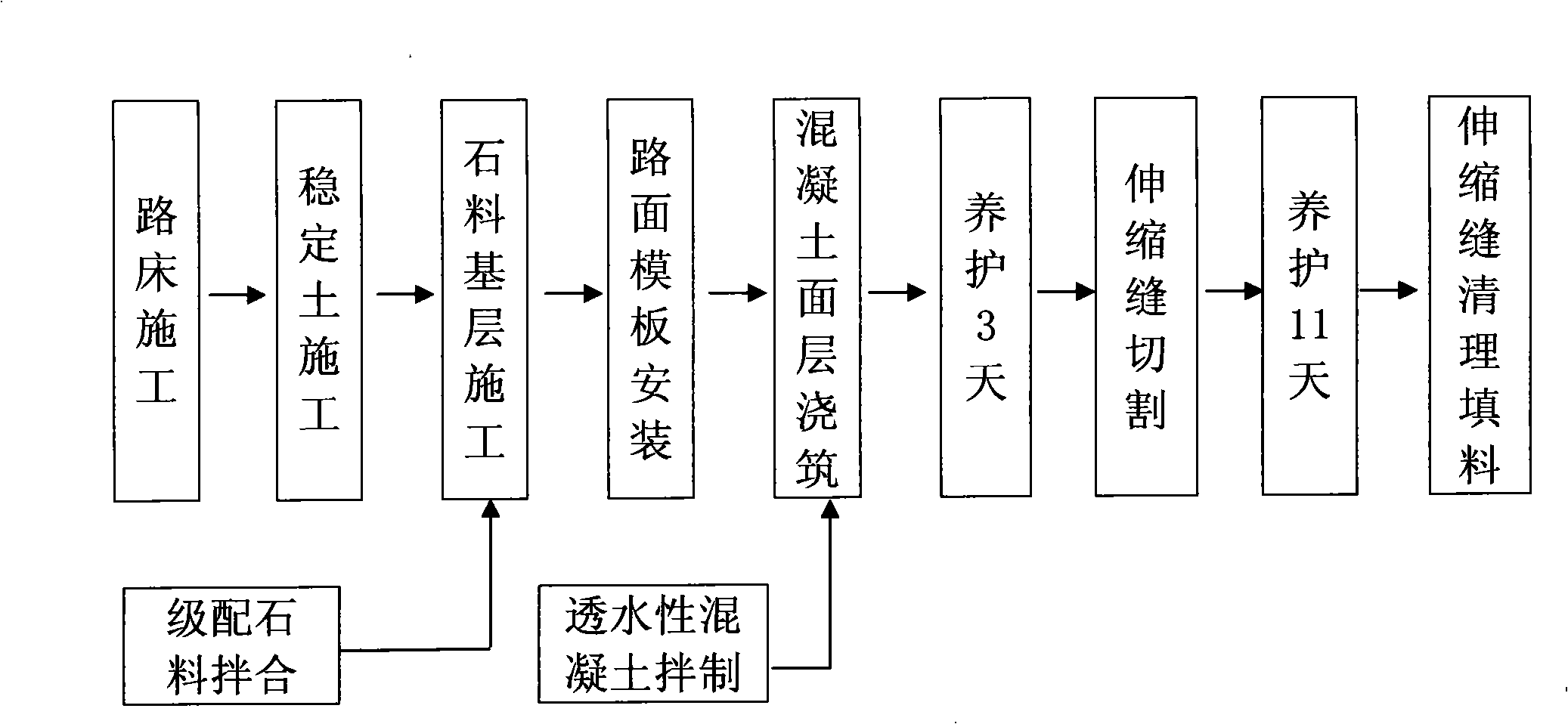

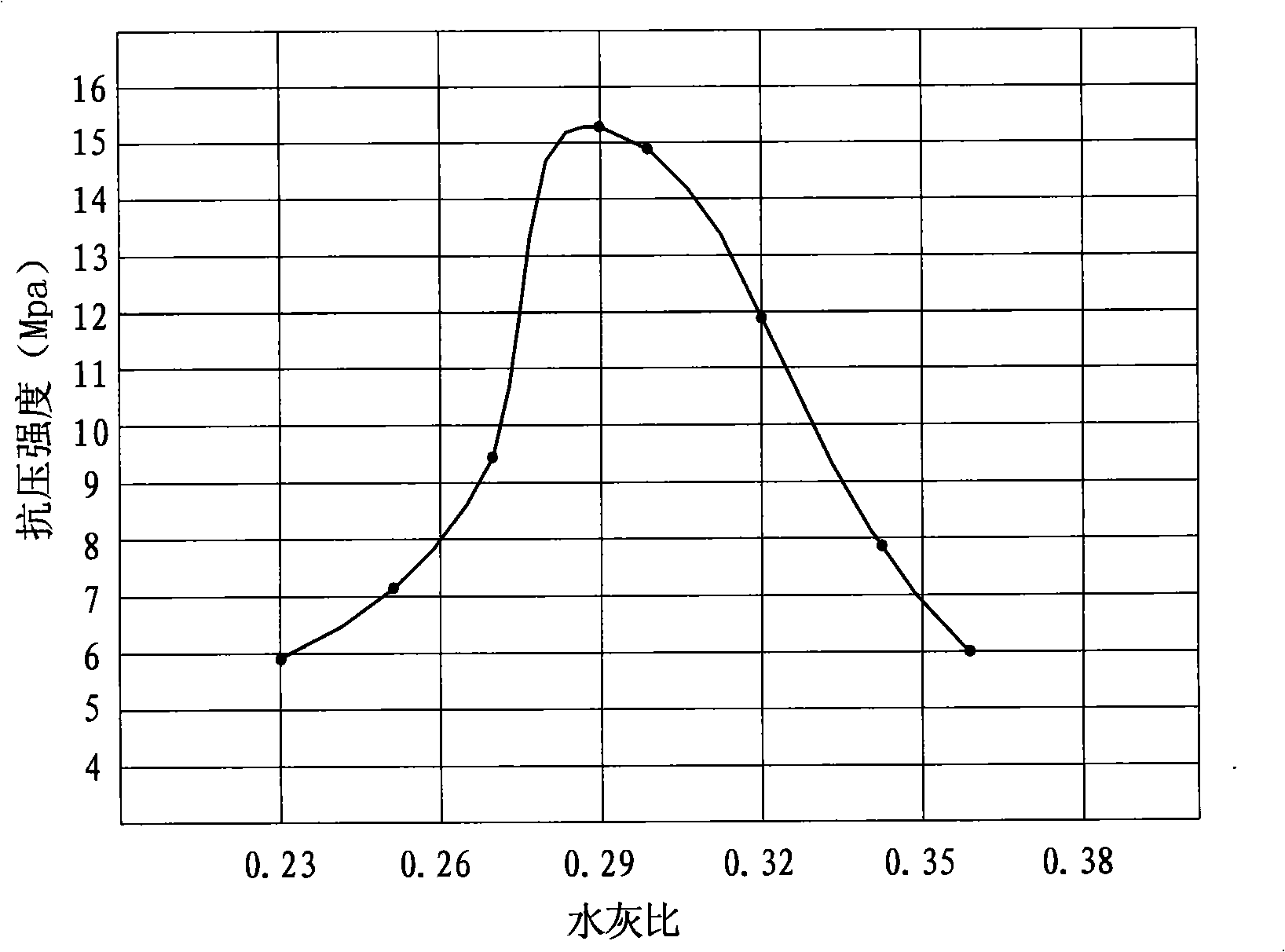

The invention discloses permeable concrete and a pavement construction method. The permeable concrete comprises the following components: 1350 to 1800 parts of broken stones, 90 to 150 parts of water, 300 to 350 parts of cement, 10 to 70 parts of mineral powder, 10 to 70 parts of silicon ash and 0.3 to 7 parts of water reducing agent; if necessary, organic intensifying agent can be added. The construction method comprises the following steps: permeable concrete is mixed, poured and cured, an expansion joint is cut, and the filling and the other processes are performed. Concrete pavement prepared by the method has higher strength and water permeability, and the compression strength can reach or exceed 30 MPa; the flexural strength is above 4 MPa; the coefficient of water permeability is more than or equal to 1 mm / s; the requirements for the permeable concrete pavement can be fully satisfied. The permeable concrete is suitable for the construction of permeable concrete pavement, squares and parking lots; by adopting the method, the consumption of cement is small, the construction is simple, and the method is favorable for being popularized.

Description

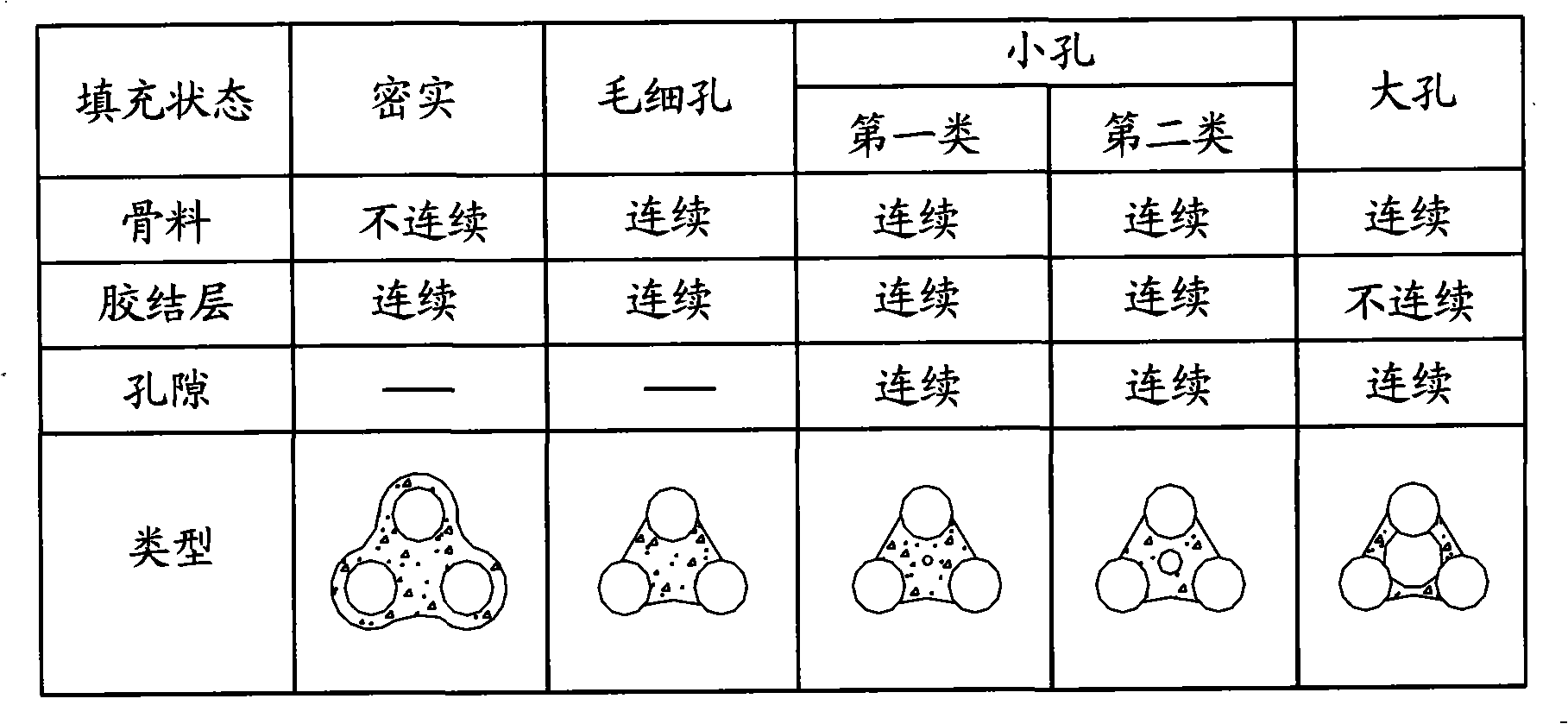

Water-permeable concrete and pavement construction method 1. Technical field: The invention relates to a concrete and a construction method, in particular to a permeable concrete and a road surface construction method. 2. Background technology: Permeable concrete is a kind of porous lightweight concrete made by mixing aggregate, cement and water. It does not contain fine aggregate, and the surface of coarse aggregate is covered with a thin layer of cement paste to bond with each other to form a uniform distribution of pores. The honeycomb structure has the characteristics of air permeability, water permeability and light weight. As an environmental load-reducing concrete, the research and development of permeable concrete has attracted more and more attention. With the development of economy and the acceleration of urban construction, the surface of modern cities is gradually covered by buildings and concrete pavement. Convenient transportation facilities and paved roads...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/00E01C7/14C04B14/02C04B14/04C04B18/12

CPCC04B2201/50C04B2111/0075C04B28/02Y02W30/91C04B14/02C04B18/12C04B18/146C04B2103/302

Inventor 周忠义胡宝刚马宏亮郑建峰李水才郭强赵建国

Owner HENAN GUOJI CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com