Pre-buried pipeline suitable for pavement shallow layers

A pipeline and pre-embedded technology, applied in pipeline protection, pipeline damage/wear prevention, roads, etc., can solve problems such as pipeline pressure, achieve the effect of satisfying robustness, preventing groundwater infiltration and corrosion, and protecting pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

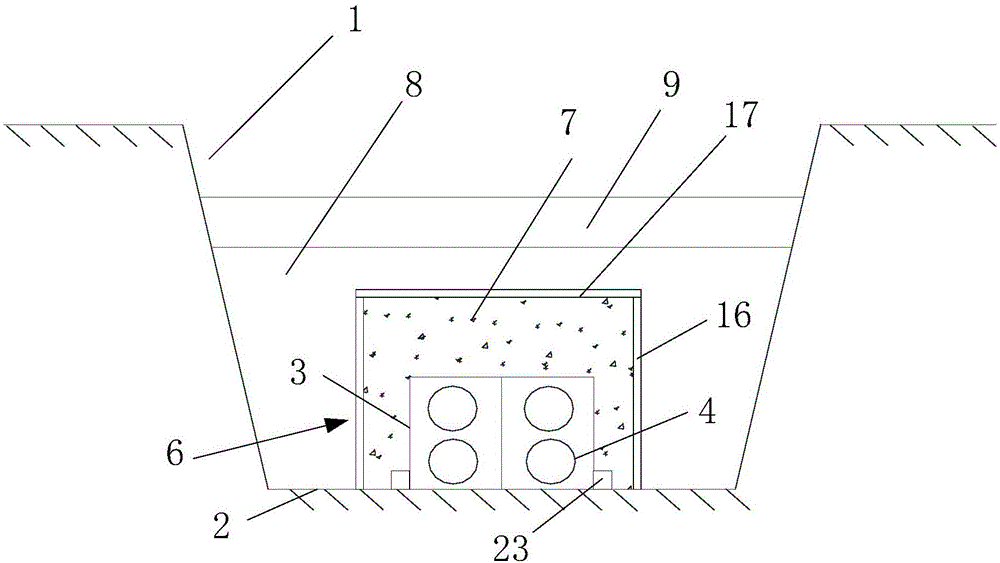

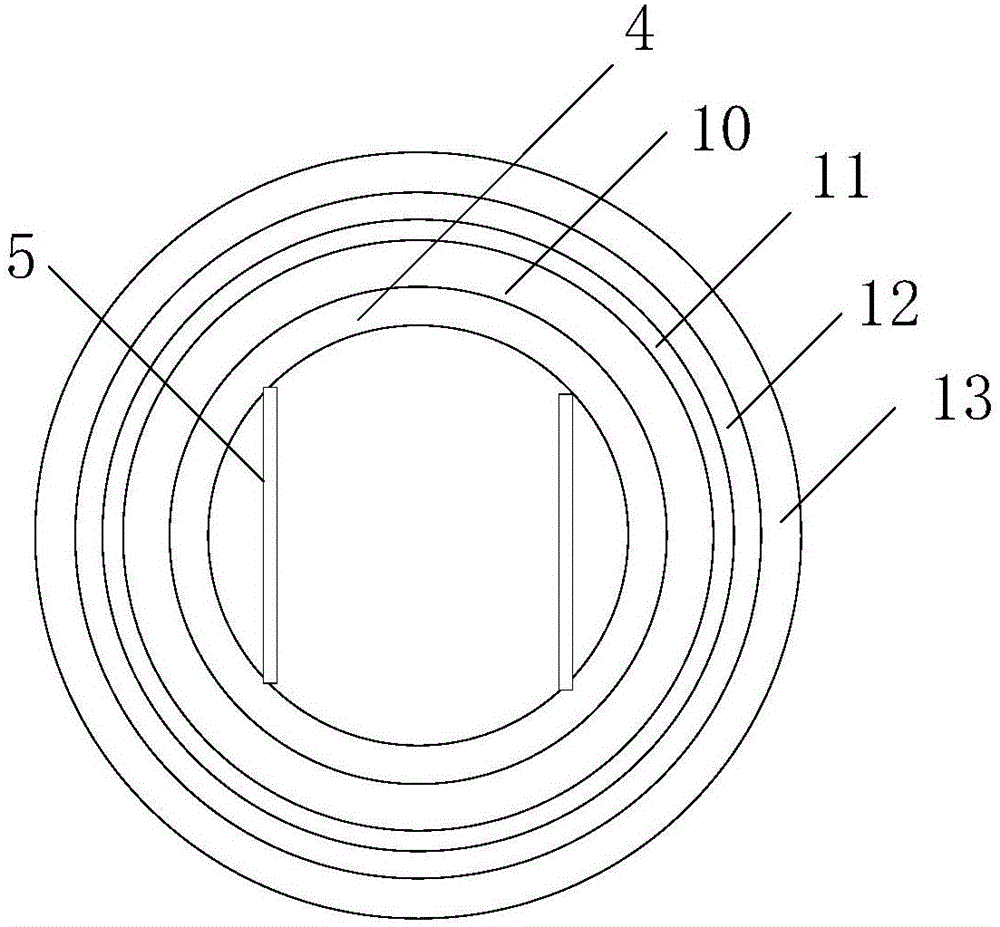

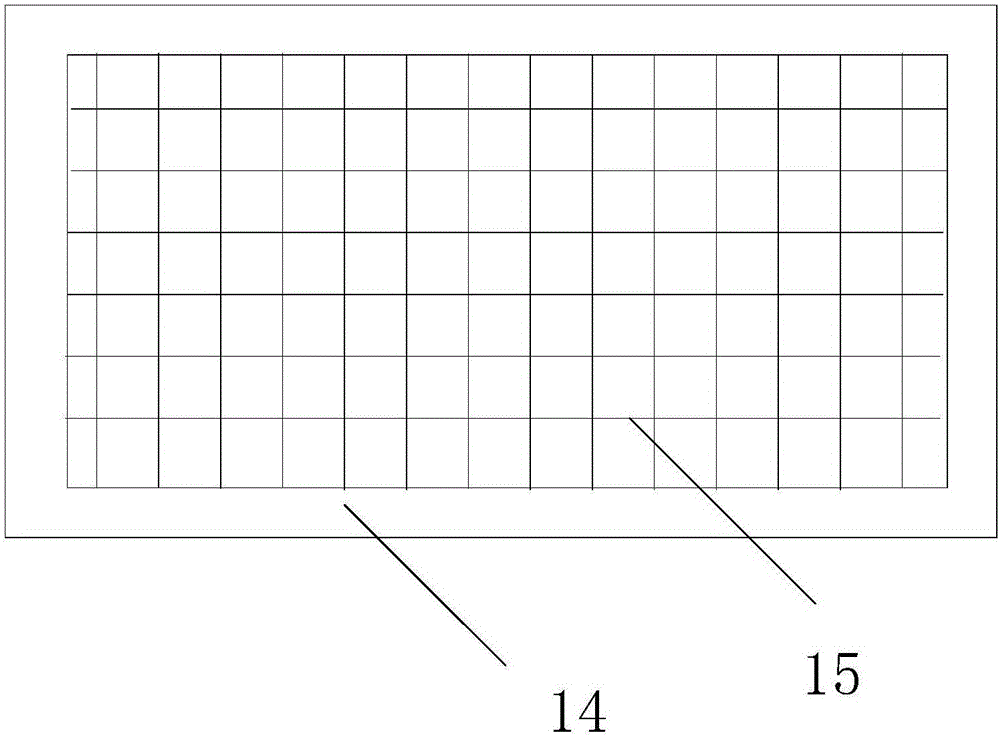

[0061] It is suitable for pre-embedded pipelines in shallow pavement, which includes a pavement pre-embedded groove 1, and a base layer 2 is arranged in the pavement pre-embedded groove 1, and its difference lies in that a pipeline reinforcement component is arranged on the base layer 2 3. Support channels 4 are distributed in the pipeline reinforcement component 3 . In this way, multiple groups of pipelines distributed in the same direction can be laid and protected. Considering the bearing capacity of the support channel 4 for longitudinal stress, the support channel 4 is provided with auxiliary support rods 5, and the upper and lower ends of the auxiliary support rods 5 are aligned with the support channel. 4 The inner walls are in contact.

[0062] A partition assembly 6 is distributed on the periphery of the support channel 4, which can effectively partition the downward water seepage from the surface of the road surface. Thus, an airtight protective space is formed betw...

Embodiment 2

[0074] The pre-embedded pipeline suitable for the shallow layer of the pavement includes a pavement pre-embedded groove 1, and a base layer 2 is arranged in the pavement pre-embedded groove 1. The difference between it and the prior art is that: There is a pipeline reinforcement component 3, and support channels 4 are distributed in the pipeline reinforcement component 3. In this way, multiple groups of pipelines distributed in the same direction can be laid and protected. Considering the bearing capacity of the support channel 4 for longitudinal stress, the support channel 4 is provided with auxiliary support rods 5, and the upper and lower ends of the auxiliary support rods 5 are aligned with the support channel. 4 The inner walls are in contact.

[0075] A partition assembly 6 is distributed on the periphery of the support channel 4, which can effectively partition the downward water seepage from the surface of the road surface. Thus, an airtight protective space is formed...

Embodiment 3

[0087] It is suitable for pre-embedded pipelines in shallow pavement, which includes a pavement pre-embedded groove 1, and a base layer 2 is arranged in the pavement pre-embedded groove 1. Supporting channels 4 are distributed in the reinforcement assembly 3 . Meanwhile, an auxiliary support rod 5 is arranged in the support channel 4 , and the upper and lower ends of the auxiliary support rod 5 are in contact with the inner wall of the support channel 4 . In order to effectively block the downward water seepage of the pavement surface, a partition assembly 6 is distributed around the support channel 4 . Thus, an airtight protective space is formed between the partition assembly 6 and the periphery of the support channel 4 . At the same time, a filling layer 7 is arranged in the protection space. Moreover, in the present invention, a backfill layer 8 is distributed in the pavement embedded groove 1, and a barrier layer 9 is laid on the backfill layer 8.

[0088] At the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com