Inductive rotation angle sensor and motor-driven airflow control device using the same

一种旋转检测、控制装置的技术,应用在发动机控制、测量装置、采用电/磁装置传递传感构件等方向,能够解决装置变大、氧化、电磁感应作用变弱等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

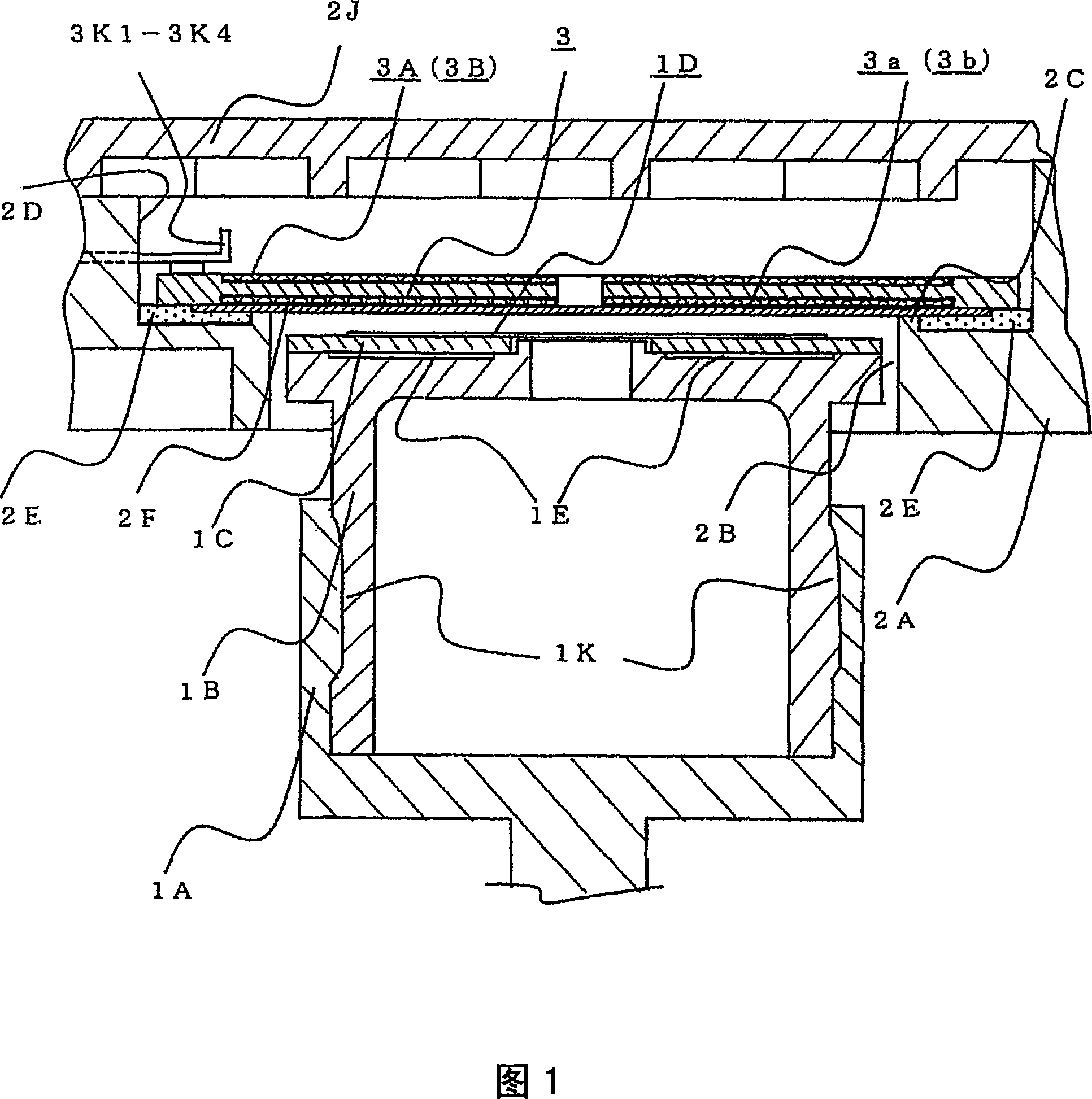

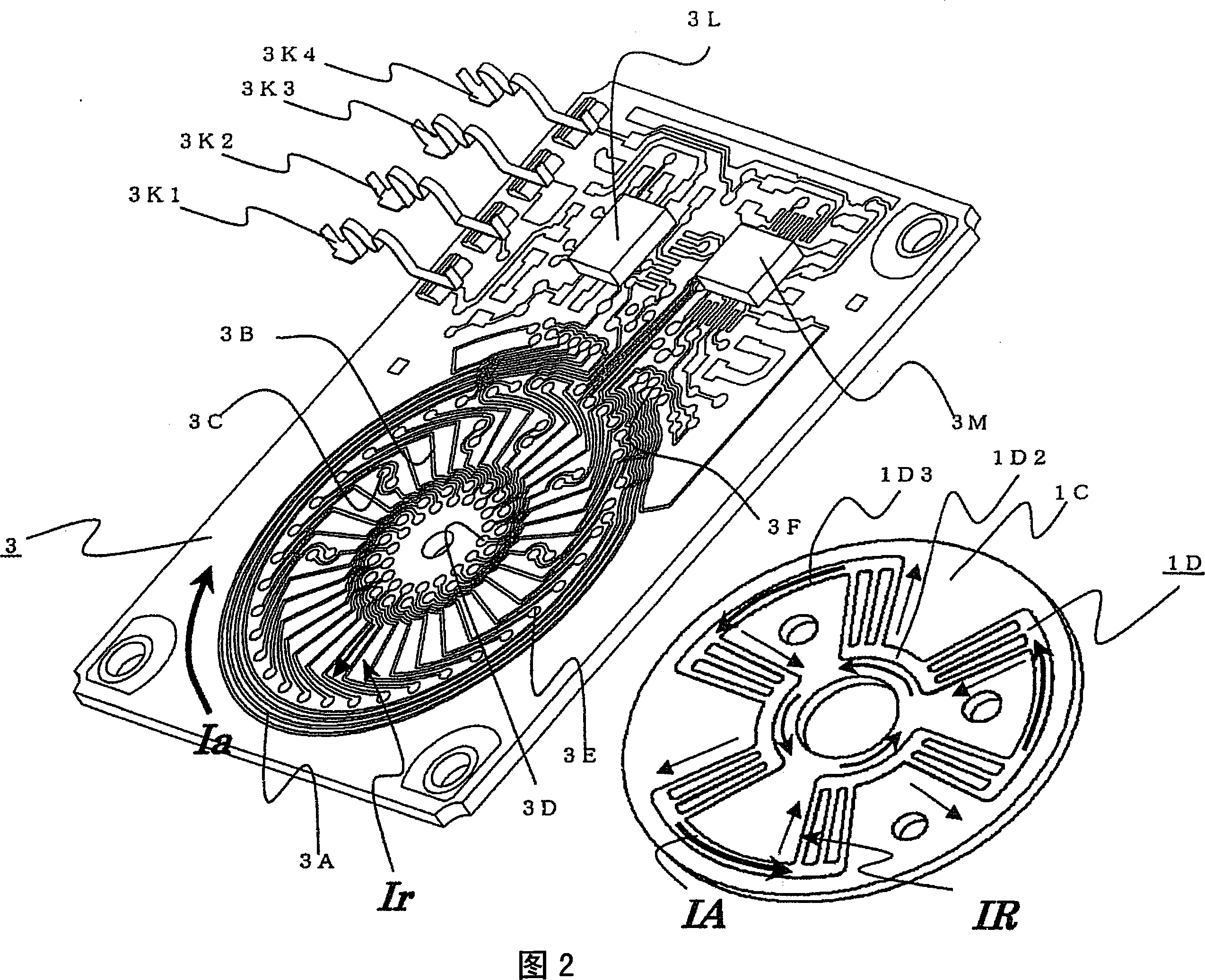

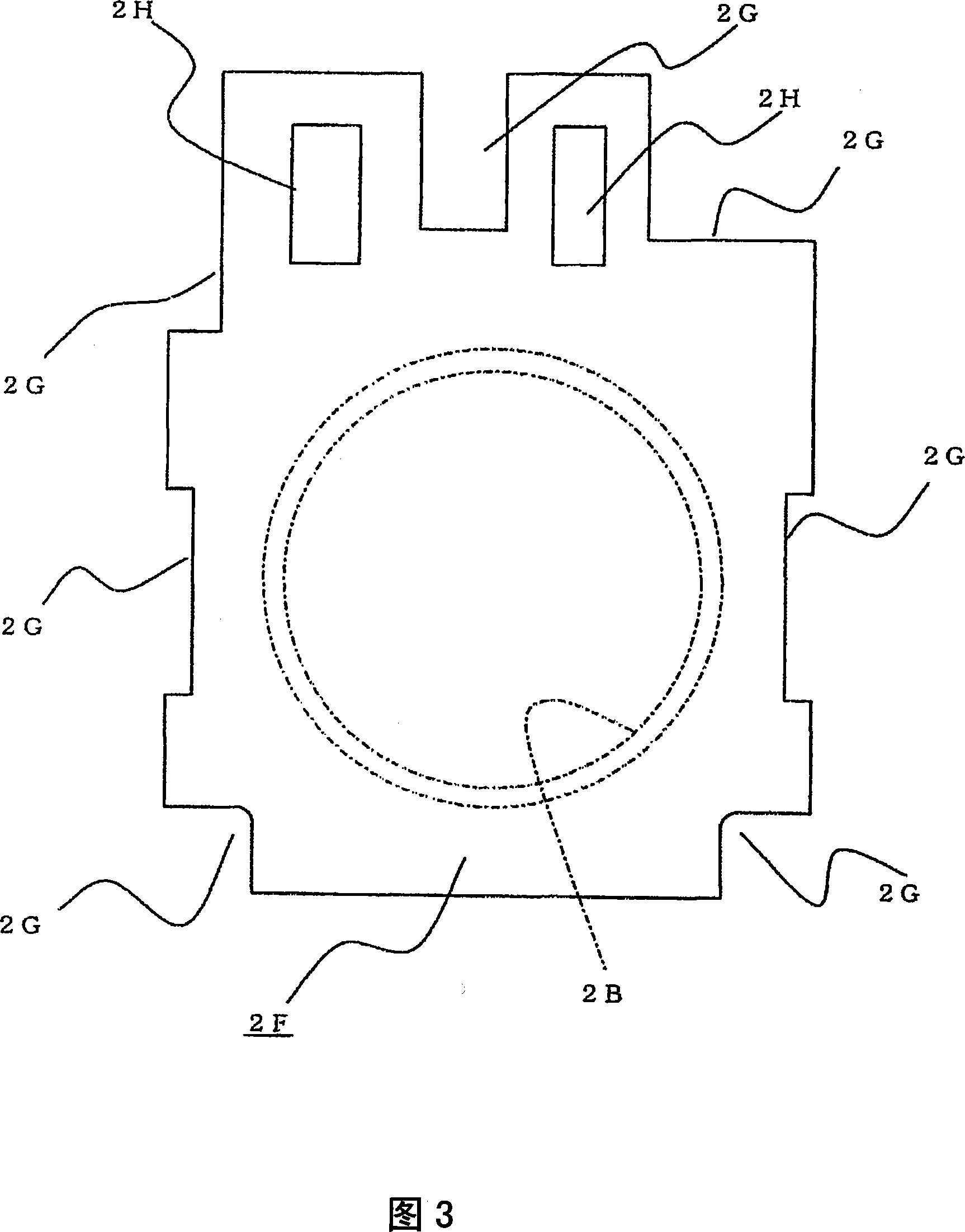

[0043] One embodiment of the rotation angle detecting device of the present invention will be described with reference to FIGS. 1 and 2 .

[0044] As shown in FIG. 1 , a shallow cylindrical (cup-shaped) holder 1B made of a resin molded body is attached to the front end of the rotating shaft 1A. A circular plate 1C made of insulating material is bonded and fixed to the front end surface of the bracket 1B. An annular recess 1E is formed on the front end surface of the holder 1B, and the adhesive flows into the recess 1E, and the disc 1C is placed on the upper surface and bonded. An excitation conductor 1D to be described later is printed on the surface (the surface opposite to the bonding surface) of the circular plate 1C.

[0045] Grooves extending in the axial direction are formed around the cylindrical portion of the bracket 1B, and ridges extending in the axial direction are formed alternately with the grooves on the inner peripheral surface of the rotating body 1A, and the...

Embodiment 2

[0104] An alternative structure of the fixing structure of the fixing substrate 27 will be described with reference to FIG. 10 .

[0105] Positioning pins 36 are provided on the gear cover 25 .

[0106] The positioning pin 36 is provided with a notch 37 , and the diameter of the positioning pin 36 may be larger than the diameter of the installation hole provided on the fixed base 27 .

[0107] By employing this structure, the fixing base plate 27 can be fixed to the gear cover 25 by the resin elastic force of the positioning pin 36 acting on the mounting hole of the fixing base plate 27 .

[0108] On the other hand, a drop prevention pin 38 is provided on the resin cover 29 .

[0109] A hole slightly larger than that of the positioning pin 36 is provided in the anti-dropout pin 38 , and the positioning pin 36 and the anti-dropout pin 38 are coupled by coupling the resin cover 29 to the gear cover 25 .

[0110] There is a certain gap between the anti-dropping pin 38 and the f...

Embodiment 3

[0112] As shown in FIG. 11 , immediately after the gear cover 25 is resin-molded, the gear storage chamber 30 and the substrate mounting space 31 are connected to each other.

[0113] At this connecting portion, the thin resin plate 28 is fixed to the gear cover 25 with an adhesive 33 to close the window hole. Thereby, the gear storage chamber 30 and the board|substrate mounting part space 31 are isolate|segregated. Then, the thin resin plate 28 and the fixed substrate 27 are fixed with the adhesive 33 in the same manner. After connecting the gear cover 25 and electrically connecting the fixed substrate 27 , the resin cover 29 is fixed to the gear cover 25 with an adhesive 33 to block the outside air from the substrate mounting space 31 .

[0114] The above-mentioned embodiment described the method of bonding the thin-walled resin plate 28 to the gear cover 25, but it may also be bonded to the fixed substrate 27, and then the fixed substrate 27 assembled with the thin-walled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com