3D printing-based bionic artificial tooth and manufacturing method thereof

A 3D printing, bionic tooth technology, applied in dentures, dentistry, implants, etc., can solve the problems of easy loosening and falling off, unstable connection of dentures, inconvenience to patients, etc., to improve wearing comfort, facilitate attachment and growth, and prevent shrinkage and necrosis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

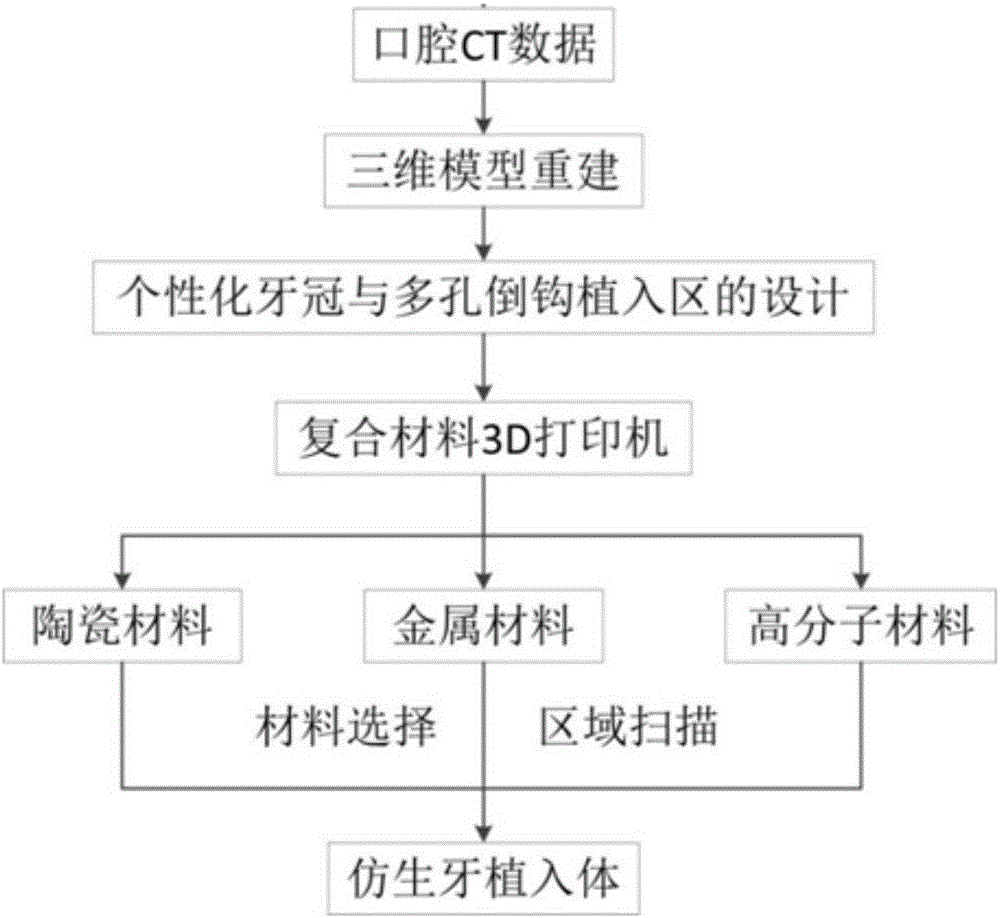

Method used

Image

Examples

Embodiment

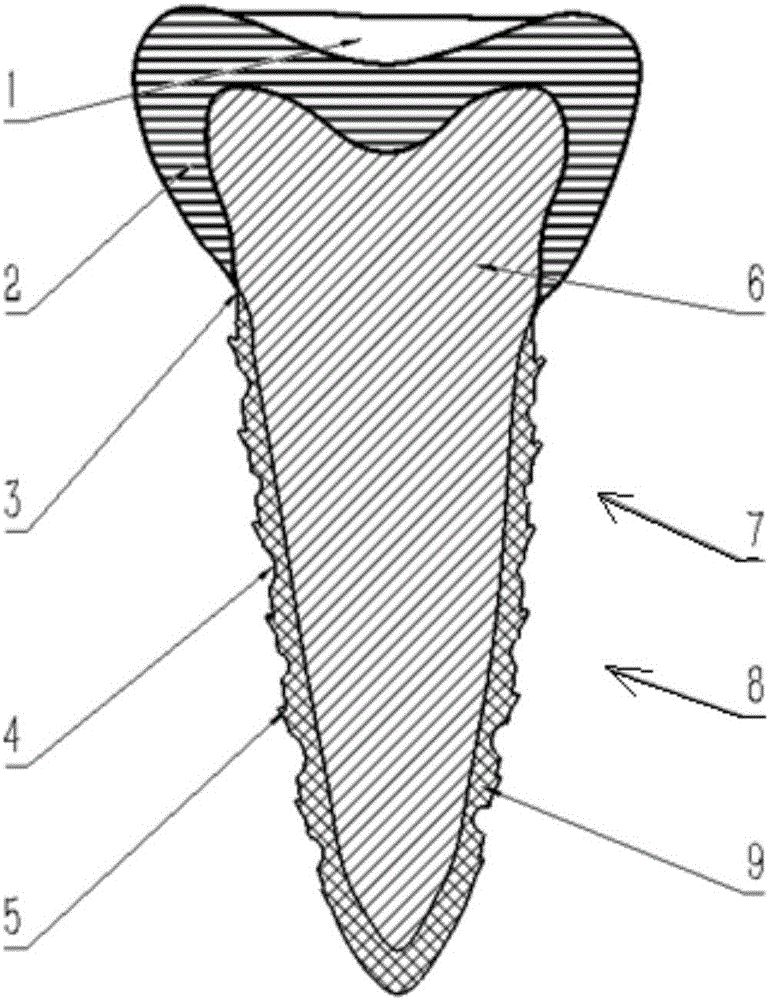

[0035] Such as Figures 1 to 4 shown. The invention discloses a bionic denture (bionic tooth implant) based on 3D printing, which comprises a bionic dentin body 6, a bionic enamel layer 2 coated on the upper end surface of the bionic dentin body 6, and a bionic dentin body coated on the bionic dentin body. The biomimetic cementum layer 9 on the body 6; the biomimetic enamel layer 2 connects to the biomimetic cementum layer 9 through the transition zone 3;

[0036] The outer surface of the biomimetic cementum layer 9 is covered with a microstructure layer.

[0037] The upper part of the bionic enamel layer 2 is a concave structure layer, and the crown curved surface structure layer 1 is arranged on the concave structure layer.

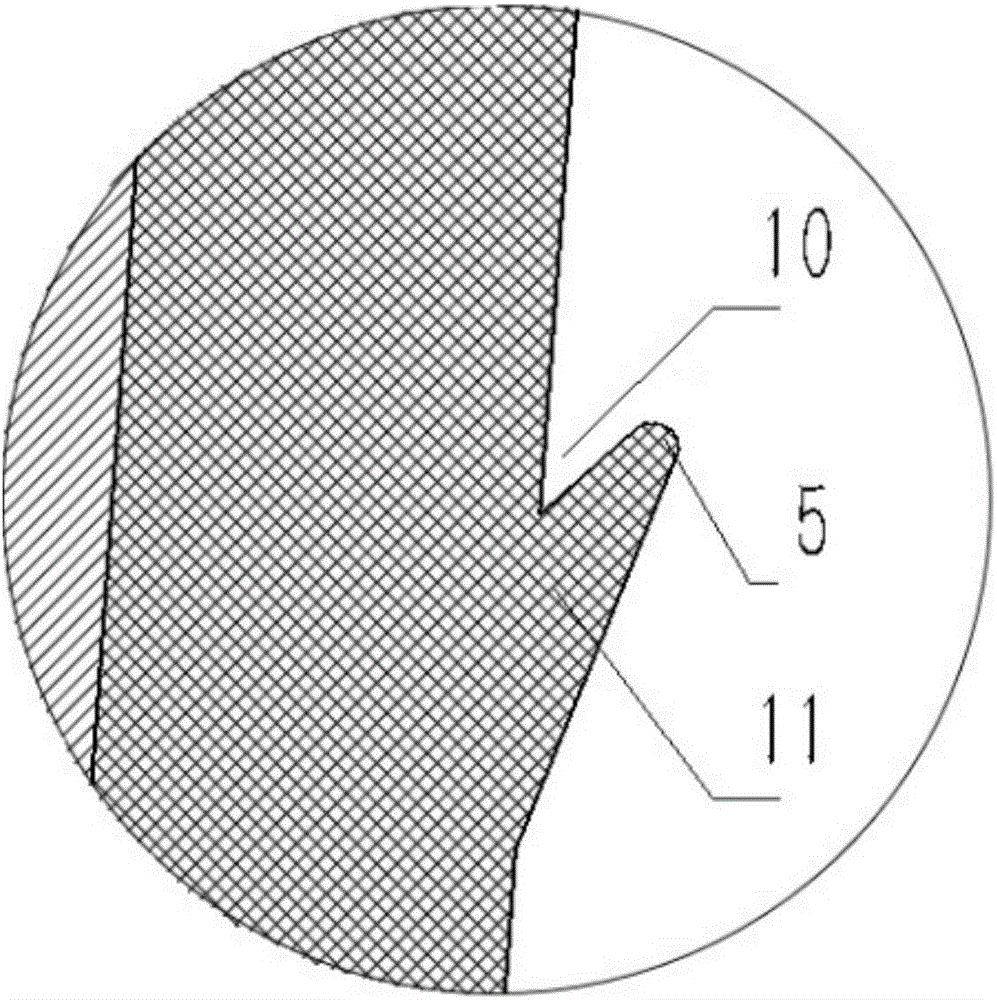

[0038] The microstructure layer includes porous structures 4 and barb structures 5 that are interlaced or irregularly distributed on the biomimetic cementum layer 9 .

[0039] The porous structure 4 is a cone-shaped, honeycomb-shaped, octagon-shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com