Patents

Literature

66 results about "Wet bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sprayable water-based adhesive

InactiveUS20070224395A1Efficient use ofProlong lifeAdhesive processesRoof covering using sealantsWet bondingWater based

Water-based adhesive compositions are improved by the incorporation of hollow polymeric microspheres having outer surfaces coated with one or more barrier materials such as calcium carbonate particles. The adhesive compositions exhibit enhanced rheology, sprayability, drying time, tack and storage stability as compared to analogous adhesives that are not modified with coated hollow polymeric microspheres. Such compositions are useful as both contact adhesives as well as wet bonding one-way adhesives.

Owner:HENKEL IP & HOLDING GMBH

High-temperature-resisting easy collapse molding sand and preparation method thereof

InactiveCN103495693AImprove breathabilityImprove liquidityFoundry mouldsFoundry coresWet bondingSodium metasilicate

High-temperature-resisting easy collapse molding sand is made from, by weight, 240-280 parts of quartz sand, 50-55 parts of lightweight calcium carbonate powder, 20-30 parts of hollow ceramic microspheres, 10-15 parts of hollow glass microspheres, 40-55 parts of aluminum silicate powder, 25-30 parts of titanium dioxide, 35-40 parts of fluorite nano-powder, 30-40 parts of gypsum whisker, 60-70 parts of expanded perlite, 10-15 parts of talcum powder, 2-4 parts of sodium metasilicate, 1-2 parts of glucose powder, 1-2 parts of urea, 1-2 parts of chlorinated paraffin, and a proper amount of water. The materials such as the hollow ceramic microspheres and the hollow glass microspheres are used, so that the molding sand is fine in breathability and fluidity; meanwhile, the lightweight calcium carbonate, the glucose, the urea and the like are used, so that the molding sand is fine in high temperature collapsibility, high dry strength of sand molds, high in wet bonding power, excellent in sticking resistance and applicable to various hardening manners; drying time after CO2 hardening is shortened, and reuse rate of used sand can be increased significantly.

Owner:HEFEI CITY TENVER PRECISION CASTING

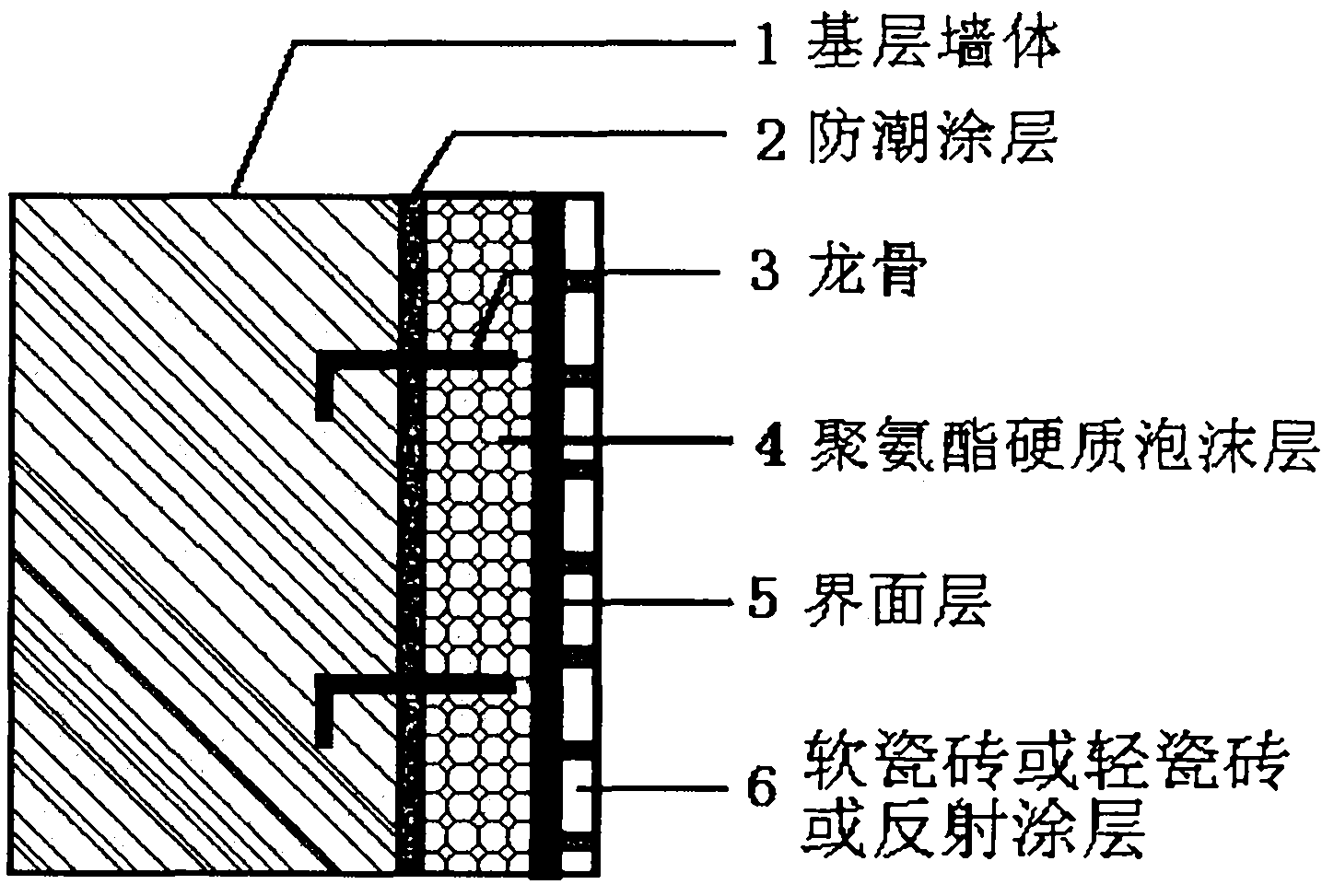

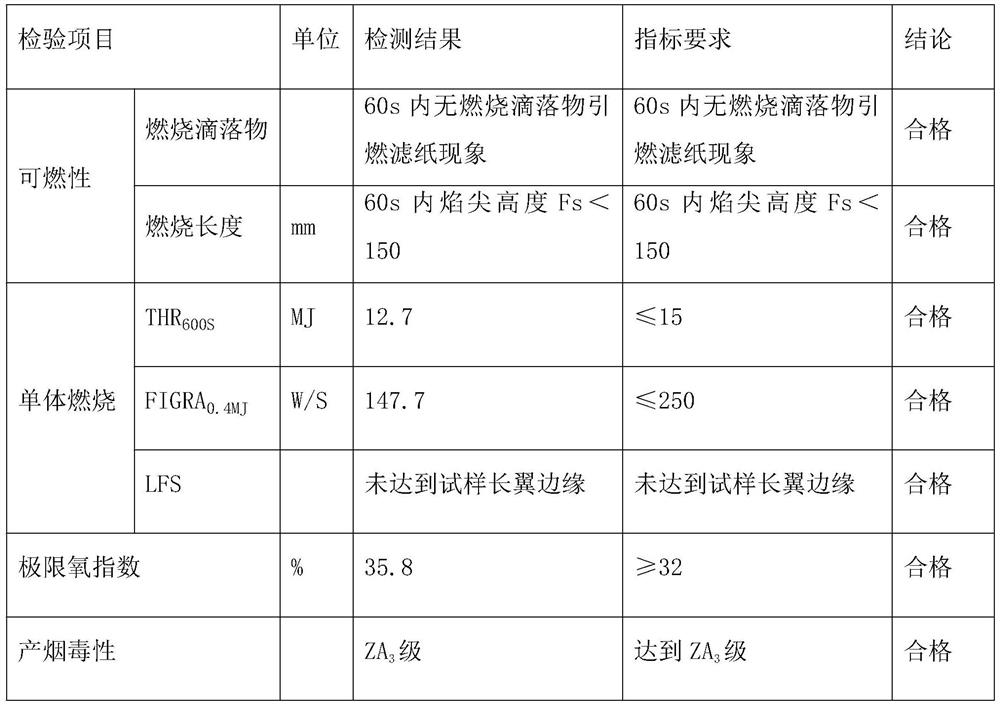

High flame retardant polyurethane rigid foam outer wall thermal insulation system

ActiveCN101956429AMeet the needs of beautificationImprove the problem of shrinkage and collapseHeat proofingBuilding material handlingWet bondingKeel

The invention discloses a high flame retardant polyurethane rigid foam outer wall thermal insulation system. From a basic unit wall provided with a keel and connecting pieces, a prime coat thickening layer, a polyurethane rigid foam layer, an interface layer, and soft tiles, light tiles or a reflective coating are arranged in turn. In the system, the prime coat thickening layer has high adhesion and good wet bonding strength for the basic unit wall and the polyurethane rigid foam; and the high flame retardant polyurethane rigid foam outer wall thermal insulation system is foamed by pure water, and is halogen-free, flame retardant, safe and environment-friendly. The vertical face of the wall is successfully foamed on site, and the polyurethane rigid foam can be directly sprayed and foamed on the basic unit wall which is treated by the prime coat thickening layer, can reach high adhesion to the basic unit wall after 24 to 48 hours, and has the coefficient of thermal conductivity of less than 0.03W / (m.K), the vertical burning reaching V-0 level, and the water absorption of less than 2.5 percent.

Owner:海聚高分子材料科技(广州)有限公司

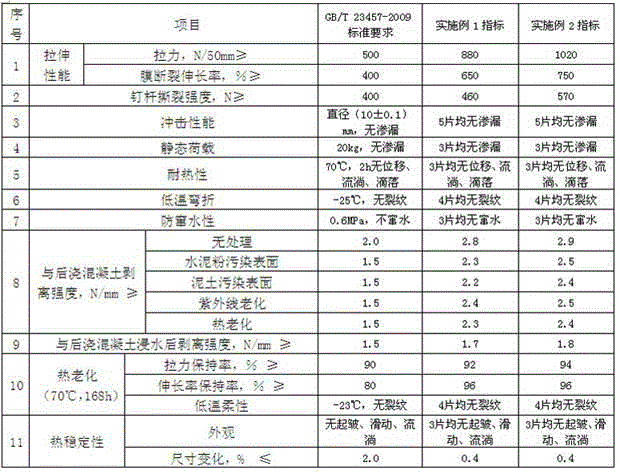

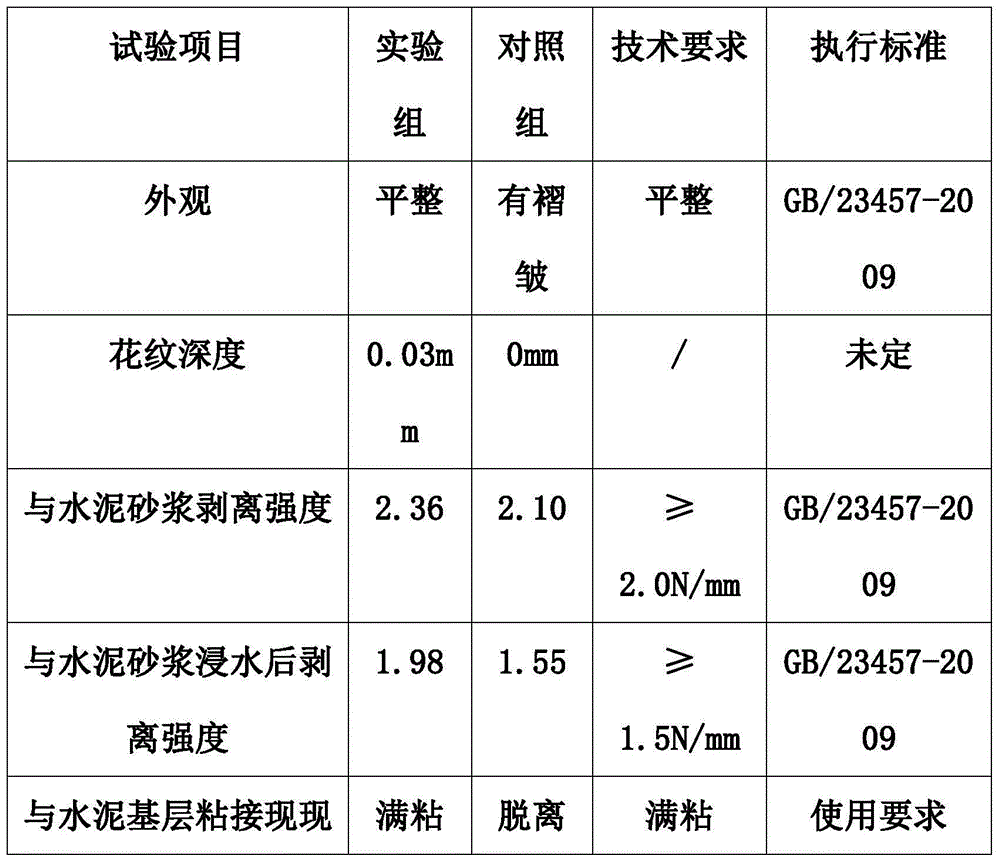

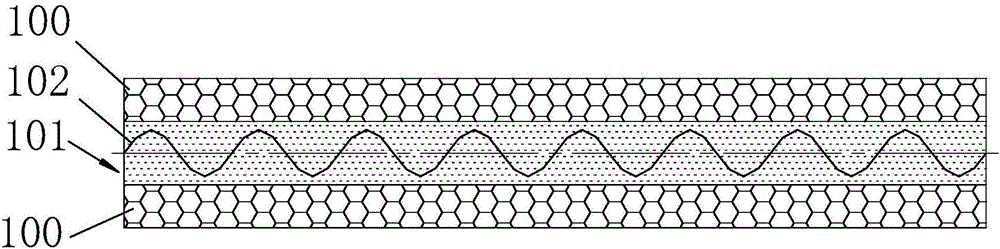

Preparation method of pre-laid waterproof coiled material for concrete mortar bonding construction

ActiveCN104057686ACost efficientObvious cost advantageSynthetic resin layered productsLaminationWet bondingMineral particles

The invention relates to a preparation method of a pre-laid waterproof coiled material for concrete mortar bonding construction. According to the technical scheme, the preparation method comprises the following steps: fully applying an SIS hot-melt pressure-sensitive adhesive to a modified polyethylene plastic waterproof main body layer by virtue of a hot-melt pressure sensitive adhesive coating machine, so as to form an SIS hot-melt pressure-sensitive self-sticking layer, and then coating the hot-melt pressure-sensitive self-sticking layer with a weather resistant mineral grain functional layer with cement reactivity and an anti-sticking isolation membrane positioned on one side of the coiled material. The preparation method has the beneficial effects that (1) a novel wet bonding technique is provided, the coiled material and structural concrete are permanently and organically combined, no water channeling hazards exist between the coiled material and the structural concrete, and the reliability of a waterproof layer is improved; (2) the impact resistant performance and the puncture resistant performance are excellent, and the construction load which directly acts on the pre-laid waterproof coiled material and the impact of a steel skeleton can be born; (3) strong chemical resistance is provided; (4) the construction is convenient, and a leveling blanket is not needed; (5) the waterproof coiled material and a basic layer are in border adhibiting without influence of sedimentation deformation of the basic layer.

Owner:胜利油田大明新型建筑防水材料有限责任公司

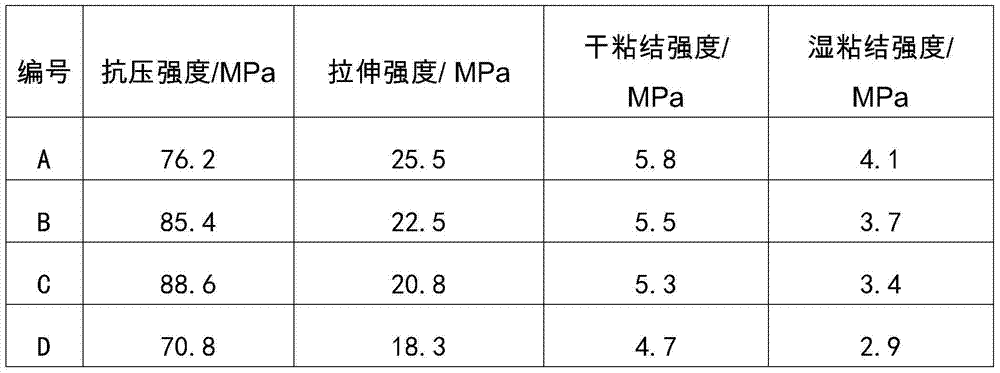

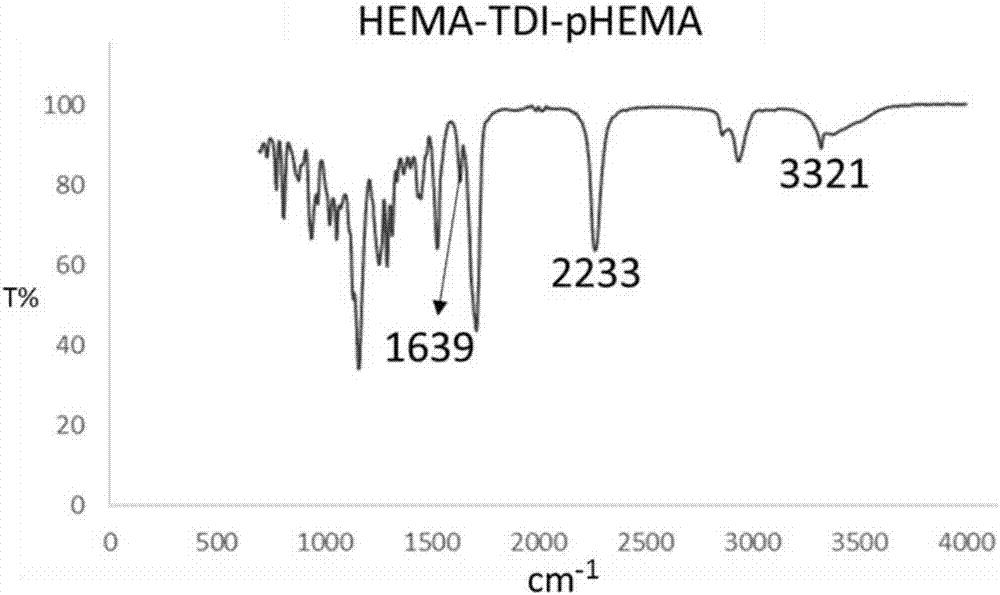

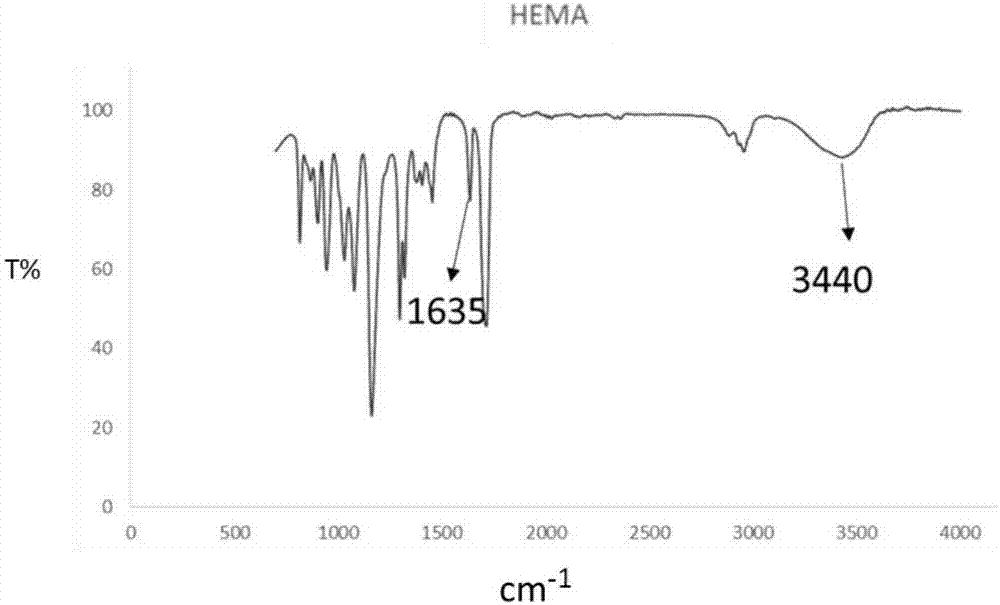

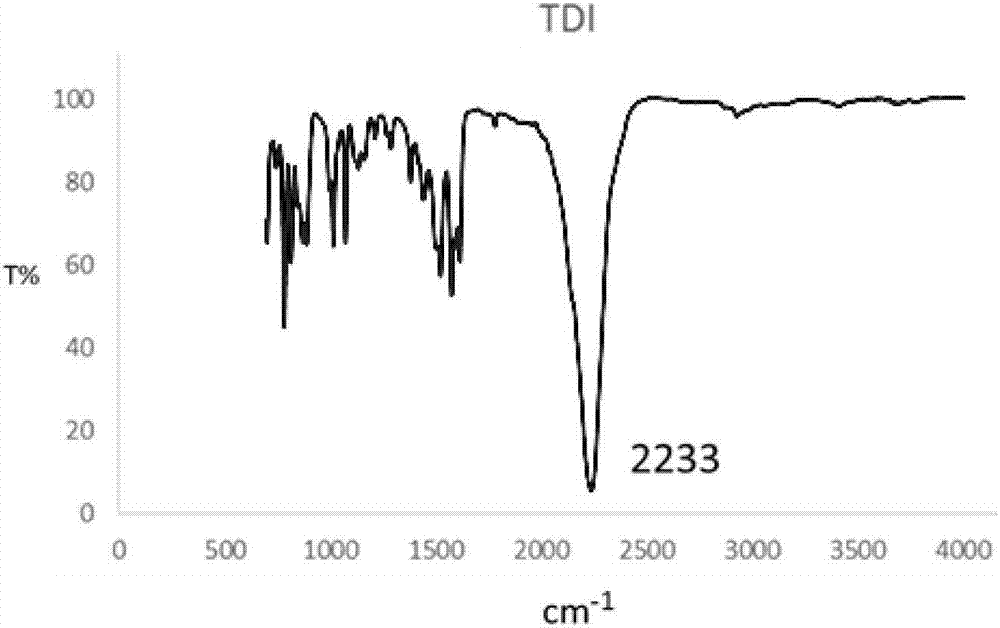

Preparation method of polyurethane modified epoxy resin and grouting material based on resin

The invention provides a preparation method of polyurethane modified epoxy resin. The preparation method comprises the following steps: firstly performing reaction on isocyanate and a hydroxyl group on epoxy resin to obtain polyurethane graft epoxy resin, further terminating isocyanate on the polyurethane graft epoxy resin with monohydric alcohol, and further grafting a polyurethane short branch chain on the epoxy resin by utilizing the unit termination of isocyanate so as to increase the intermolecular distance of the epoxy resin, reduce the intermolecular action force, improve the motion ability of a chain segment and simultaneously realize the effects of reducing viscosity of slurry and toughening; furthermore, a grouting material based on the polyurethane modified epoxy resin provided by the invention can effectively reduce the intermolecular physical crosslinking and realize strong permeability and good toughness; data shows that the compressive strength exceeds 70MPa, the tensile strength is more than 20MPa, the dry bonding strength is more than 5MPa, and the wet bonding strength is more than 3MPa.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

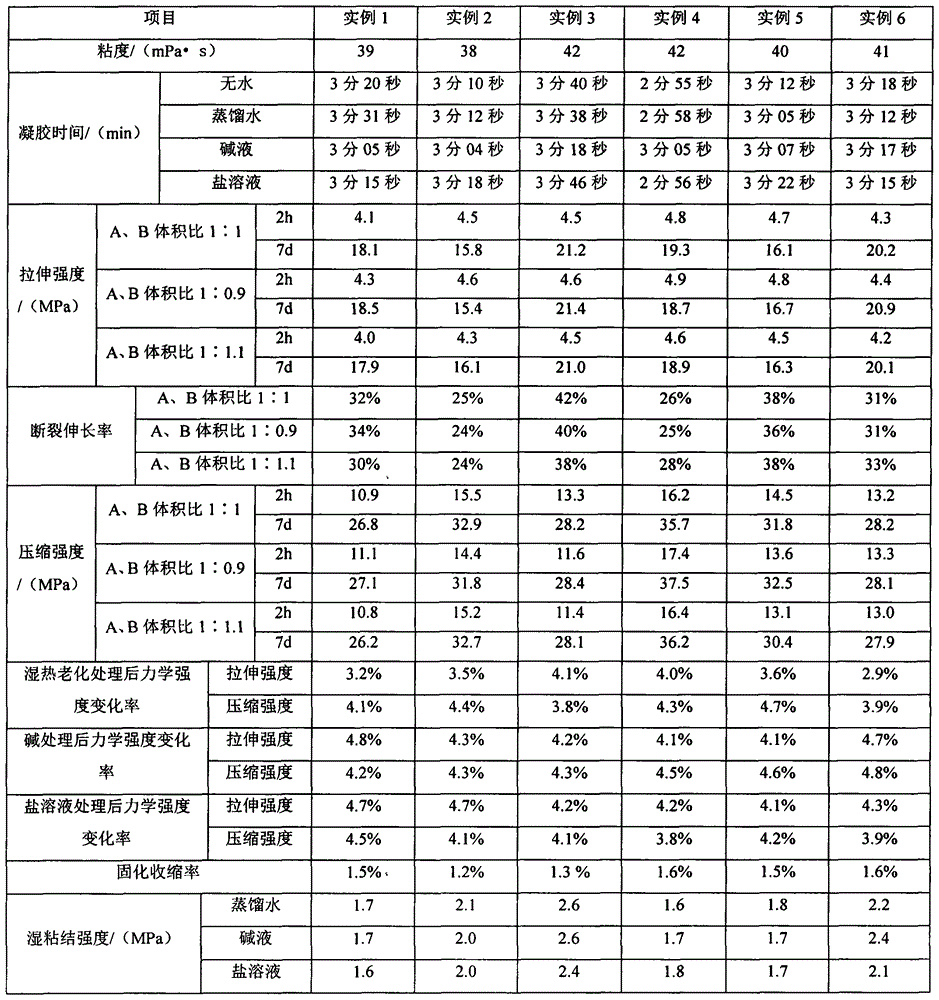

Foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material

The invention provides a foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material. The material is composed of a component A and a component B, wherein the component A comprises isocyanate monomer, isocyanate prepolymer and highly-hydrophobic environment-friendly plasticizer, the component B comprises high-activity polyether polyol, chain-extending cross-linking agent, highly-hydrophobic environment-friendly plasticizer and antioxidant, and a volume ratio of the component A to the component B is 1: 1. The leak-stopping waterproof polyurethane grouting material has low viscosity, is convenient to grout, has the characteristics of no foaming and fast curing and the advantages of good leak-stopping effect, high mechanical strength and wet bonding strength and excellent aging resistance, and is applicable to rapid leak stopping, water prevention and reinforcement of distress in concrete of an underground construction.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

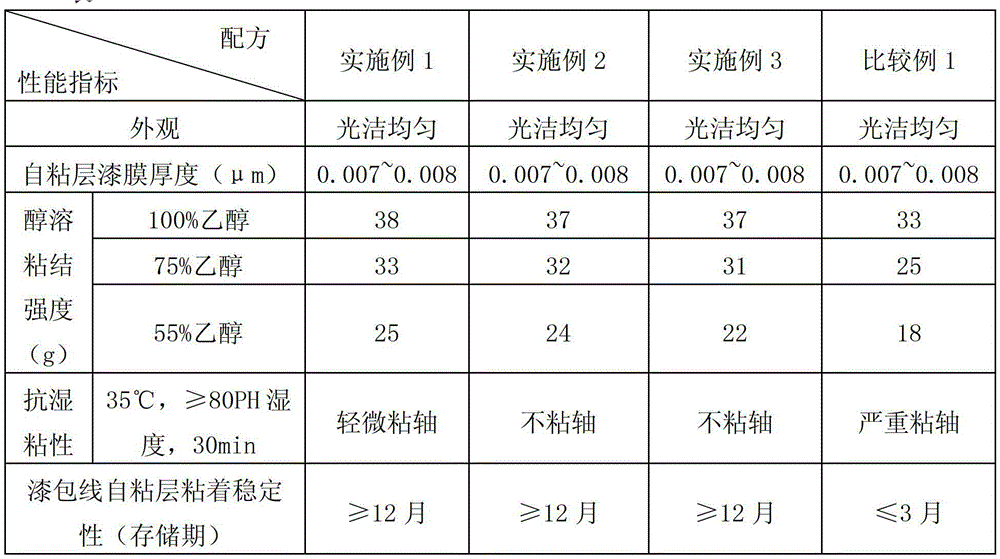

Wet bonding resistant alcohol soluble self-bonded paint and preparation method thereof

ActiveCN103146299AGood compatibilityImprove homogeneityPolyamide coatingsEpoxy resin coatingsWet bondingEpoxy

The invention discloses a wet bonding resistant alcohol soluble self-bonded paint and a preparation method thereof. According to the preparation method, p-cresol, dimethylbenzene and butanol are taken as a mixed solvent, ES-08, IC alcohol-soluble nylon and epoxy resin are taken as the main raw materials, and a lubricant is taken as an addition agent. The alcohol-soluble nylon is added into equipment and is dissolved by the mixed solvent into an intermediate semi-finished product, and the epoxy resin and a certain proportion of lubricant are added for modification and reaction so as to obtain the product. As the epoxy resin with high molecular weight, high softening point and good humidity resistance is taken as the cooperative modified resin of the alcohol-soluble nylon, and a proper proportion of a lubricant and the mixed solvent with gradually steady evaporation property are added for cooperation, so that the wet bonding resistance of the enameled wire self-bonded paint is greatly improved; the prepared product has good homogeneity and storage stability; and chemical components of low chemical activity are adopted for cooperation, so that the production requirement of the product in production process is lowered, and the property of the product is more stable.

Owner:江苏佳禾电子材料有限公司

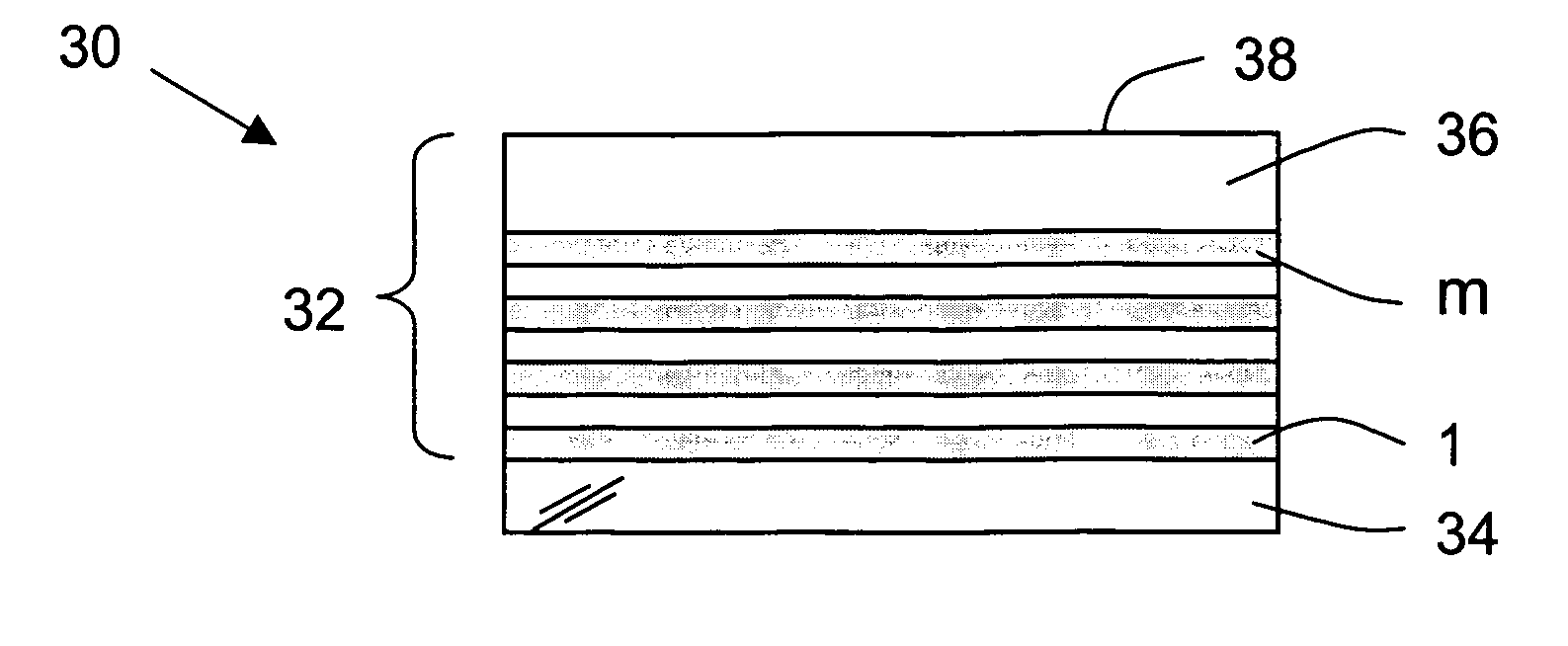

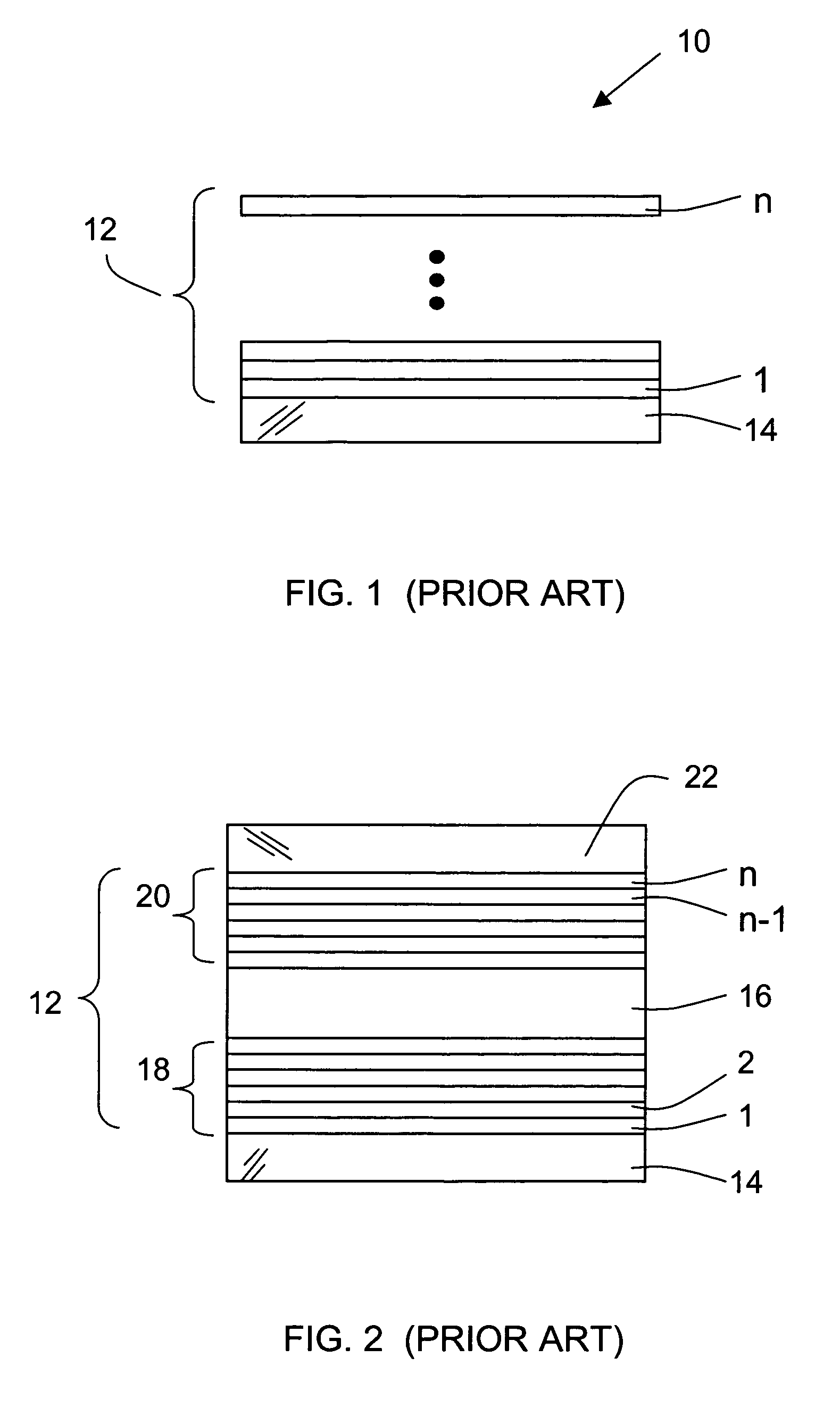

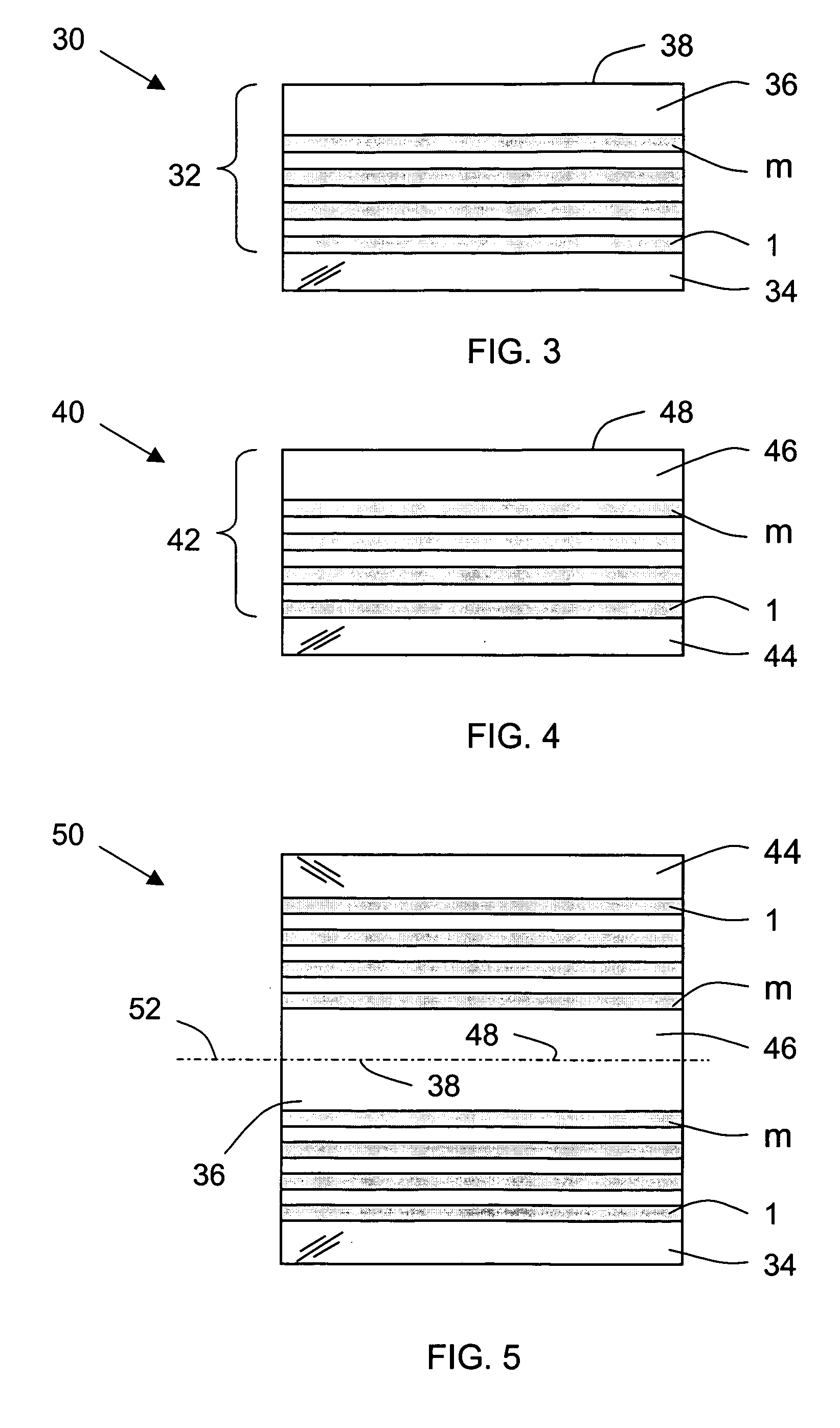

Fabrication of narrow-band thin-film optical filters

InactiveUS7332044B2Attenuation bandwidthDegree of reductionAdhesive processesLamination ancillary operationsWet bondingEngineering

Owner:MEADE INSTRUMENTS

Wood adhesive and preparation method thereof

InactiveCN101824286AWide variety of sourcesHigh bonding strengthDextran adhesivesChitin adhesivesWet bondingAdhesive

Owner:NORTHWEST A & F UNIV

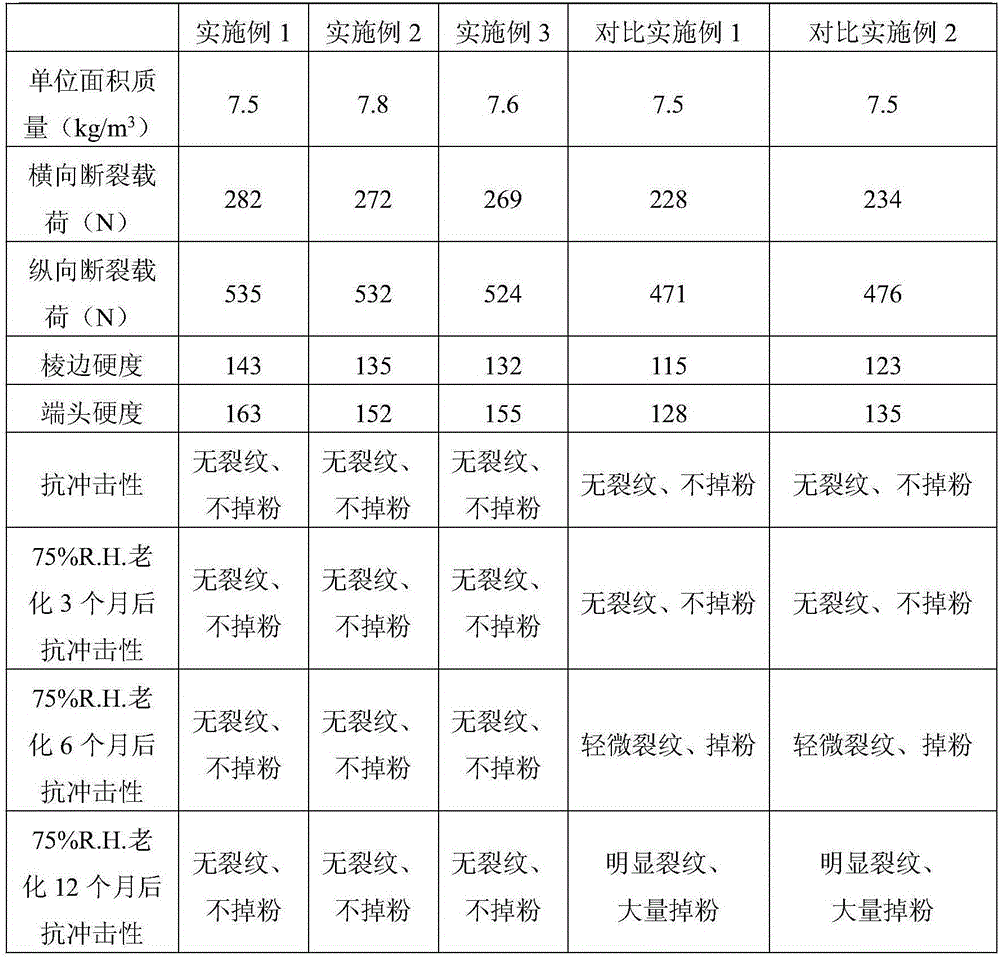

Antimagnetic plasterboard applicable to high-humidity environments and preparation method thereof

InactiveCN106478145AHigh strengthImprove electromagnetic shielding performanceConstruction materialSolid waste managementWet bondingScreening effect

The invention provides antimagnetic plasterboard applicable to high-humidity environments. The antimagnetic plasterboard is mainly prepared from the raw materials, i.e., coir fibers, a foamer, plaster clinker, graphene oxide, a humectant and causticized white clay. According to the antimagnetic plasterboard applicable to the high-humidity environments, the coir fibers and the causticized white clay are added on the basis of the conventional plaster clinker and foamer, so that the waterproof performance of the plasterboard is improved, and a very good wetted bonding effect can be achieved without adding additives such as CMC powder; by adding the graphene oxide, the strength of the plasterboard can be further improved; in order to improve the dispersion effect in the entire system, the humectant is required to be added, and proven by a large number of experiments, a very good dispersion effect can be achieved through adding a small amount of humectant Hyonic PE-100; after basalt fibers are added, the plasterboard has a very good screening effect on electromagnetic waves with the frequency band of 8GHz to 16GHz. The antimagnetic plasterboard applicable to the high-humidity environments, provided by the invention, is low in cost and high in strength, particularly, has very good bonding strength in the high-humidity environments and is free of powder falling in long-term use, and the electromagnetic screening effect is good.

Owner:长兴钦禾建材科技有限公司

Dentin reactive monomer mixture and preparing method, polycarboxylic oligomer and preparing method, and dental composite resin bonding systems

ActiveCN107028770AFacilitated DiffusionImprove adsorption capacityImpression capsDentistry preparationsWet bondingHydrophilic monomer

The invention provides a dentin reactive monomer mixture and a preparing method, a polycarboxylic oligomer and a preparing method, and dental composite resin bonding systems, wherein the dentin reactive monomer mixture and the polycarboxylic oligomer are used for constructing the dental composite resin bonding systems. The invention further provides a single-component dental composite resin bonding systems and a double-component dental composite resin bonding system. The bonding systems overcome the defect that due to the fact that a large number of hydrophilic monomers are introduced into a traditional wet bonding technique, cured resin can be easily degraded by esterase in saliva as the water absorption rate is increased remarkably.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Environment-friendly efficient smoke-suppression additive type flame retardant for wood-based panels

InactiveCN111635714AFix bugsImprove dry and wet bond strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesWet bondingSilanes

The invention discloses an environment-friendly efficient smoke-suppression additive type flame retardant for wood-based panels. The additive type flame retardant is prepared from the following raw materials in parts by weight: 10-80 parts of a phosphate compound, 10-80 parts of a boron-containing compound, 10-80 parts of a nitrogen-containing compound, 10-50 parts of a hydroxide compound and 0.1-10 parts of a silane coupling agent. The additive flame retardant is prepared by synergistic effect of multiple elements of nitrogen, phosphorus and boron, can overcome the defects of the existing soaking type flame retardant, has the advantages of low production cost, high efficiency, convenience in use, good flame retardant and smoke suppression effects, no volatilization, no delay and lasting flame retardance, can improve the dry-wet bonding strength of a finished product plate, and has remarkable economic and social benefits. The environment-friendly efficient smoke-suppression additive type flame retardant is widely suitable for being used in cooperation with fireproof and flame-retardant operation.

Owner:袁志伟

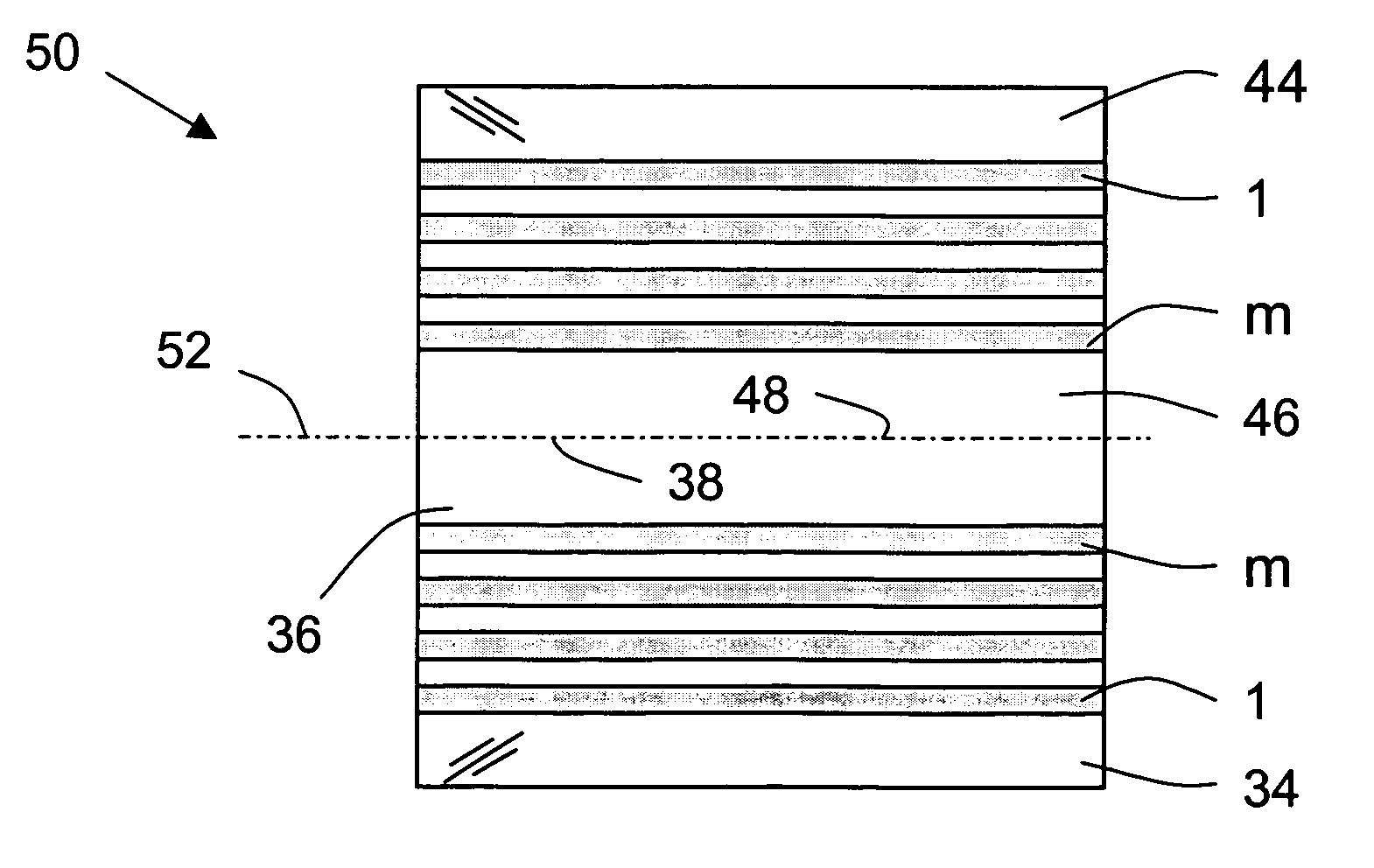

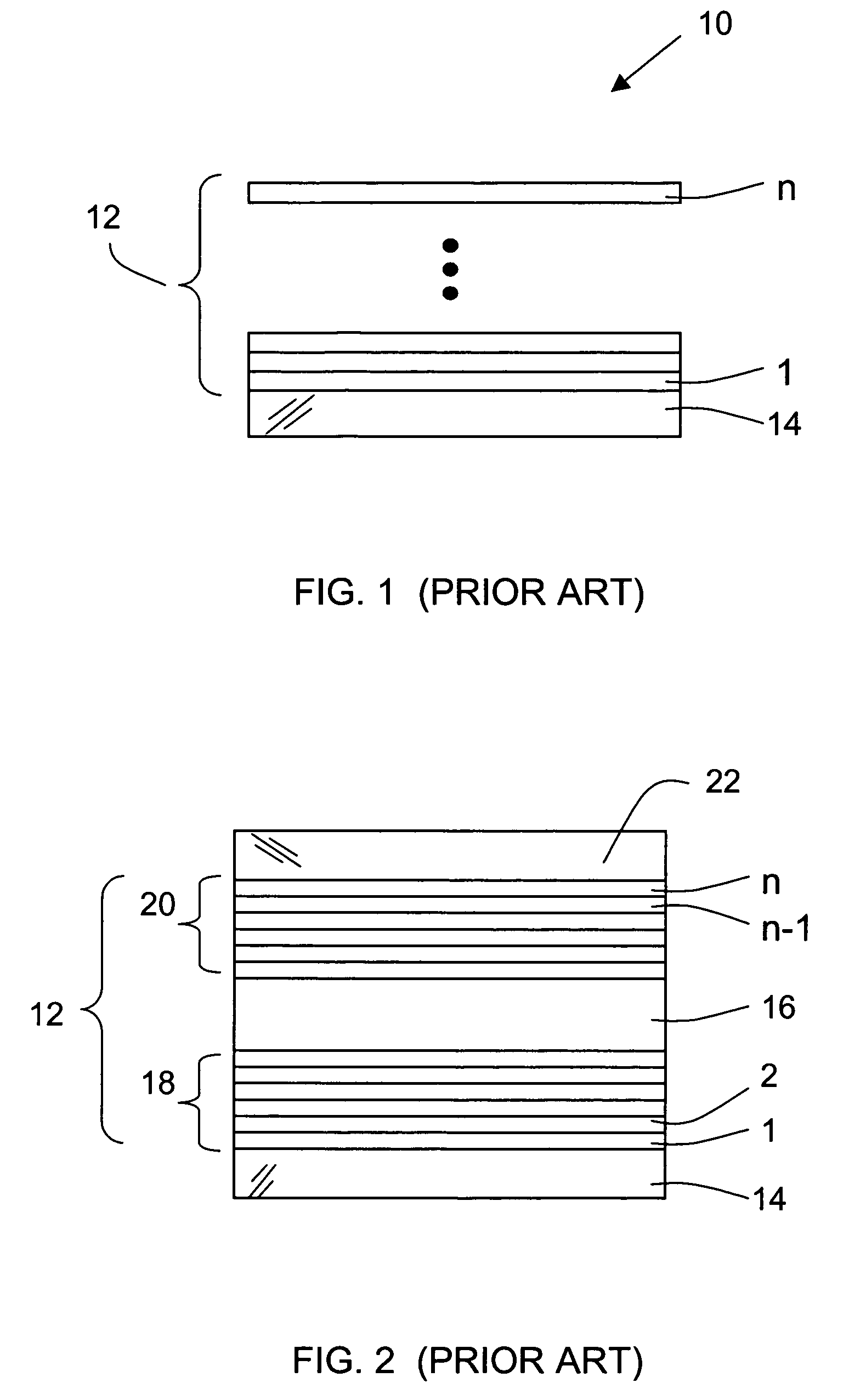

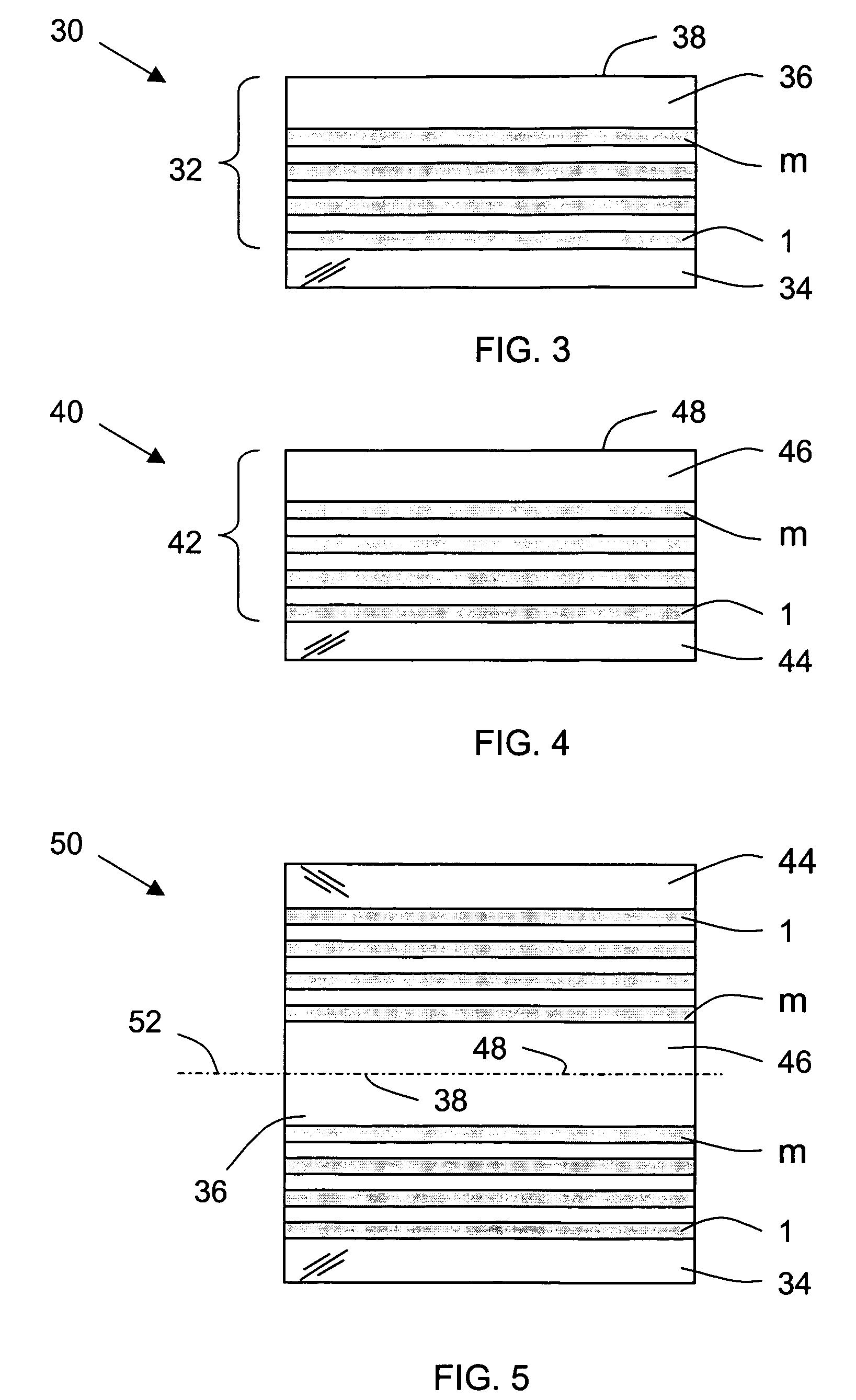

Fabrication of narrow-band thin-film optical filters

InactiveUS20050180015A1Reduced spectral bandwidthAttenuation bandwidthAdhesive processesLamination ancillary operationsWet bondingEngineering

A multi-layer thin-film narrow-band filter is fabricated by a process wherein each half of a symmetric stack is deposited under exact conditions, either successively or contemporaneously. The two halves of the filter structure are then combined and bonded together using a wet bonding process that remains reversible for a period of time sufficient for testing the filter and, if necessary, for separating the two halves to regain access to the spacer layer. Accordingly, the spacer layer may be adjusted to shift the peak wavelength, if necessary, to the precise design specifications for a particular application. After correction, the components of the symmetric filter are bonded again using the same wet process.

Owner:MEADE INSTRUMENTS

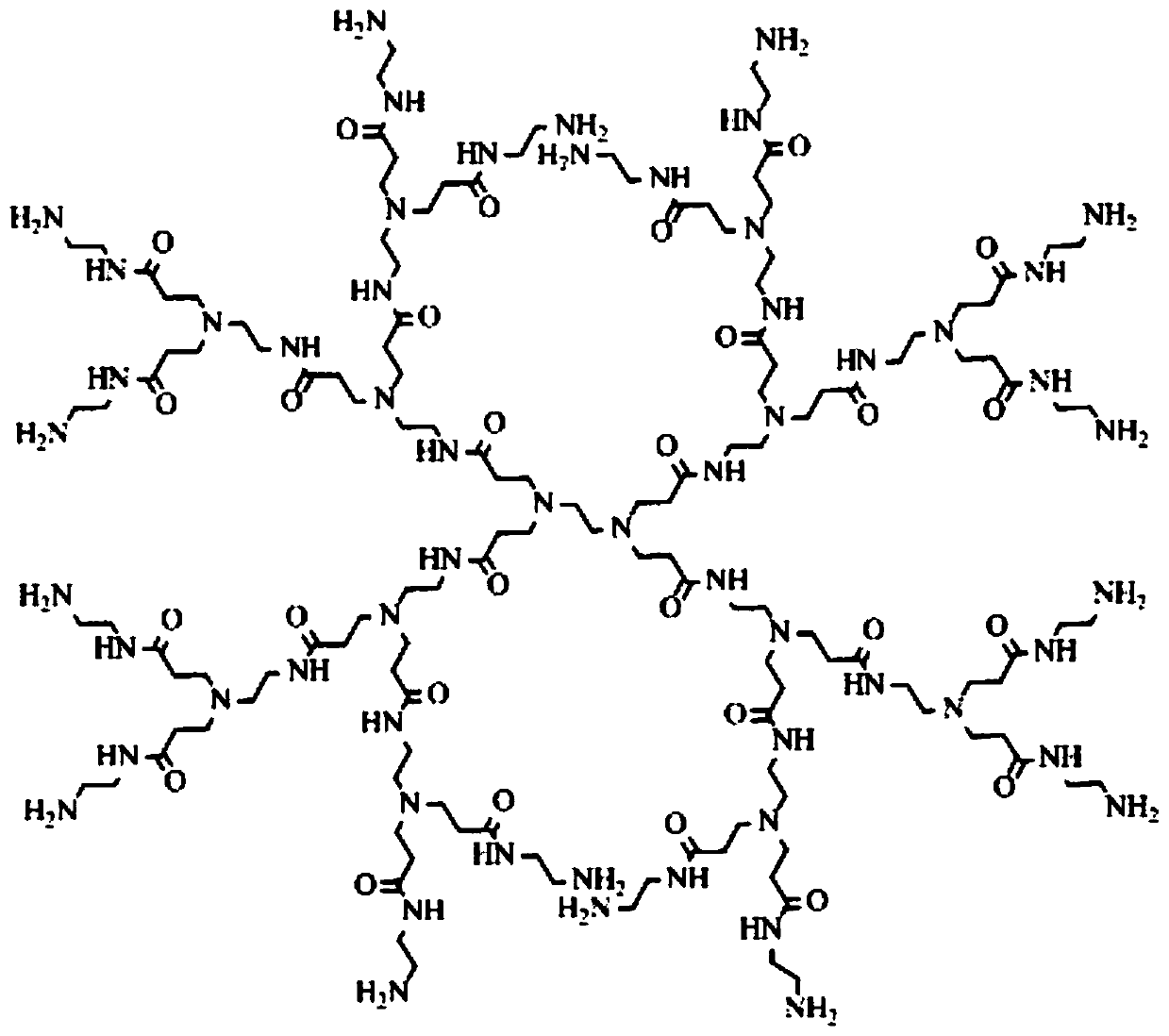

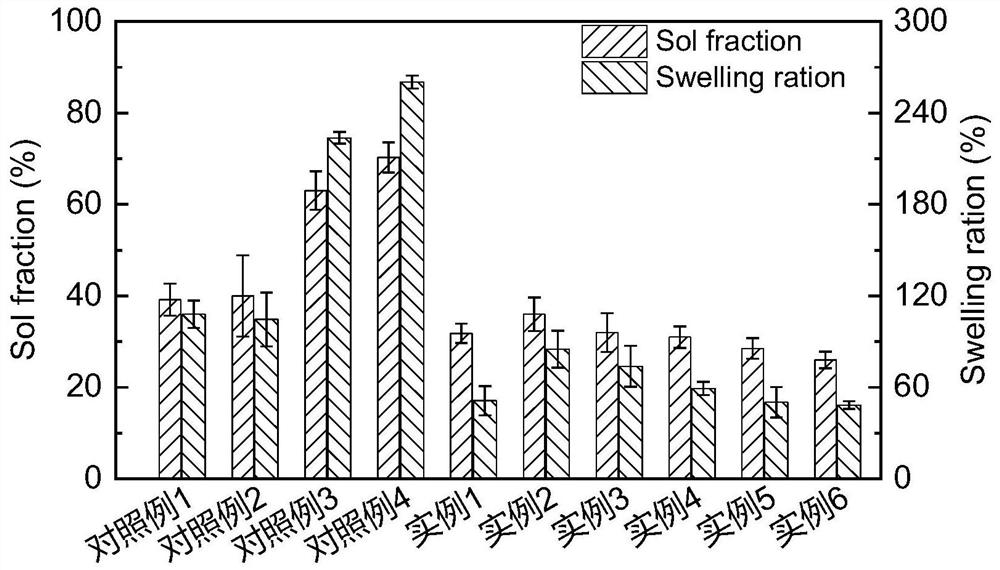

Hyperbranched polyamide modified tannin adhesive, preparation method thereof, plywood and application of the hyperbranched polyamide modified tannin adhesive

InactiveCN106753030AIncrease the degree of cross-linkingImprove completenessMacromolecular adhesive additivesWood veneer joiningWet bondingPolymer science

The invention discloses a hyperbranched polyamide modified tannin adhesive. The hyperbranched polyamide modified tannin adhesive comprises a hyperbranched polyamide solid and tannin powder, wherein the content of the hyperbranched polyamide is 1-6%wt of the content of tannin. The invention also discloses hyperbranched polyamide modified tannin adhesive based plywood, a preparation method of the hyperbranched polyamide modified tannin adhesive, and application of the hyperbranched polyamide modified tannin adhesive in preparation of the plywood. The hyperbranched polyamide modified tannin adhesive provided by the invention utilizes a hyperbranched polymer with a lot of active functional groups as a crosslinking agent to improve the cross-linking degree and polycondensation degree between tannin molecules, thus reaching the purpose of improving the bonding strength and water resistance. Compared with the unmodified adhesive, the hyperbranched polyamide modified tannin adhesive has the advantages that the dry bonding strength is increased by 27% or above, and the wet bonding strength is increased by 33% or above.

Owner:NANJING FORESTRY UNIV

Grouting material for reinforcing and strengthening concrete used underwater

InactiveCN104650790AGood self-emulsifying performanceGood adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesWet bondingEpoxy

The invention relates to a grouting material for reinforcing and strengthening concrete used underwater. The grouting material for reinforcing and strengthening the concrete used underwater is mainly prepared from the following components: 100 parts of epoxy resin, 20-40 parts of diluent and 40-50 parts of a phenolic amine curing agent, wherein the epoxy resin is self-emulsification modified waterborne epoxy resin with the characteristics of a surfactant. The grouting material for reinforcing and strengthening the concrete used underwater has the advantages that compressive strength 7 days after maintenance can reach up to 45.6MPa, wet bonding strength of epoxy mortar and concrete can reach up to 4.08MPa, and the grouting material for reinforcing and strengthening the concrete used underwater is applicable to repairing of the concrete used underwater, can be used for repairing and reinforcing the concrete used underwater and is especially applicable to repairing and reinforcing of an underwater pier column.

Owner:上海颖川佳固信息工程股份有限公司

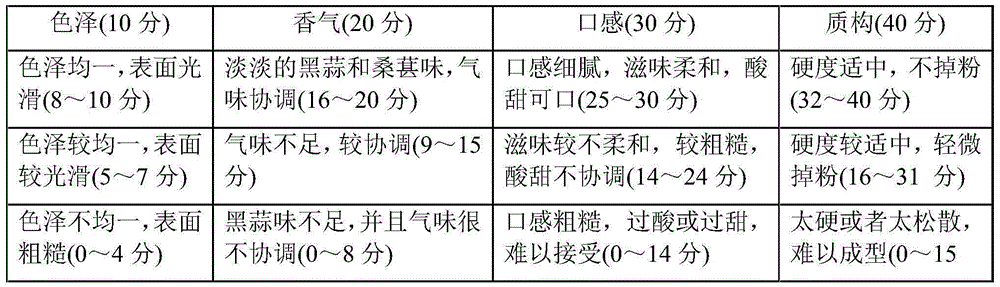

Black garlic and milk chewable tablet and preparation method thereof

The invention discloses a black garlic and milk chewable tablet and a preparation method thereof. The chewable tablet is prepared from the following raw materials in percentage by weight: 12 to 18 percent of black garlic, 6 to 9 percent of blackberries, 6 to 9 percent of black mulberries, 6 to 9 percent of black medlar, 8 to 15 percent of milk powder, 30 to 35 percent of sweetening agent, 9 to 15 percent of wetting bonding agent, 0.5 to 1 percent of acid agent, 4 to 6 percent of filling agent and 0.5 to 1 percent of lubricating agent. The method comprises the process of raw material pretreatment, soft material manufacturing, wet granulating, drying, tabletting, sterilizing, packaging and the like. The black garlic and milk chewable tablet provided by the invention is delicate in taste, fresh and cool in flavor, better in texture and convenient to carry, melts quickly after being chewed in mouth, and the preparation process of the chewable tablet is simple, free of high-heat treatment, and the active ingredients of black food such as the black garlic, the blackberries, the black mulberries, and the black medlar are reserved in maximum, so the demands of consumers on health food are met, and convenience is brought for fast-paced life.

Owner:XUZHOU UNIV OF TECH

Sprayable water-based adhesive

InactiveUS20140113126A1Efficient use ofProlong lifeAdhesive processesSynthetic resin layered productsWet bondingWater based

Water-based adhesive compositions are improved by the incorporation of hollow polymeric microspheres having outer surfaces coated with one or more barrier materials such as calcium carbonate particles. The adhesive compositions exhibit enhanced rheology, sprayability, drying time, tack and storage stability as compared to analogous adhesives that are not modified with coated hollow polymeric microspheres. Such compositions are useful as both contact adhesives as well as wet bonding one-way adhesives.

Owner:HENKEL IP & HOLDING GMBH

Method for rapidly repairing metal crack damage with composite material

The invention relates to the field of composite material cementing repair, in particular to a method for rapidly repairing metal crack damage with a composite material. The method comprises the stepsof first, carrying out surface treatment; second, laying fiber reinforced polymer; third, laying strippable cloth; fourth, placing metal plates with holes; fifth, laying flow distribution net; sixth,laying a t-branch pipe; seventh, connecting a first vacuum equipment; eighth, sealing a vacuum bag; ninth, bonding a thermocouple to the vacuum bag, and laying an electric blanket on the vacuum bag; tenth, laying air-permeable felt on the electric blanket, and placing a vacuum joint on the air-permeable felt; eleventh, adhering sealing rubber strips; twelfth, carrying out vacuum pumping; thirteenth, program setting; fourth, carrying out solidification; and fifth, carrying out finishing. According to the method for rapidly repairing metal crack damage with a composite material, by combining thecharacteristics of a composite material wet bonding metal crack technology and a resin vacuum pouring technology, the resin vacuum pouring technology is used in cooperation when composite material bonding is used to repair metal cracks, the requirements on repair for quickness and convenience are met, and the mechanical property is higher than that of traditional composite material wet bonding repair.

Owner:国营芜湖机械厂

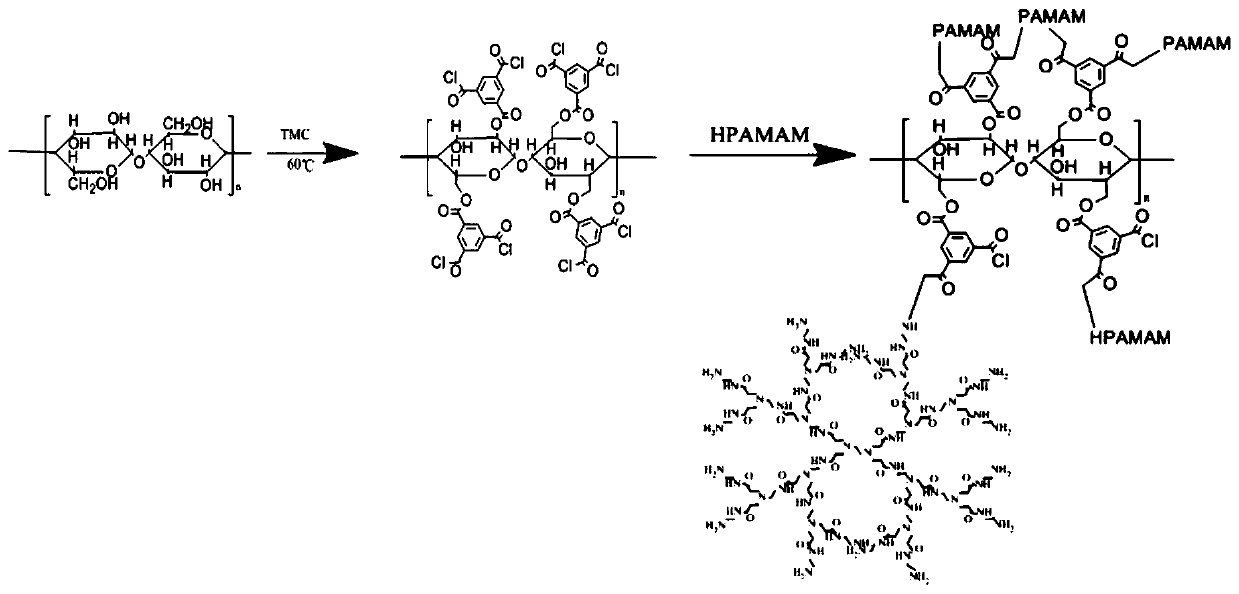

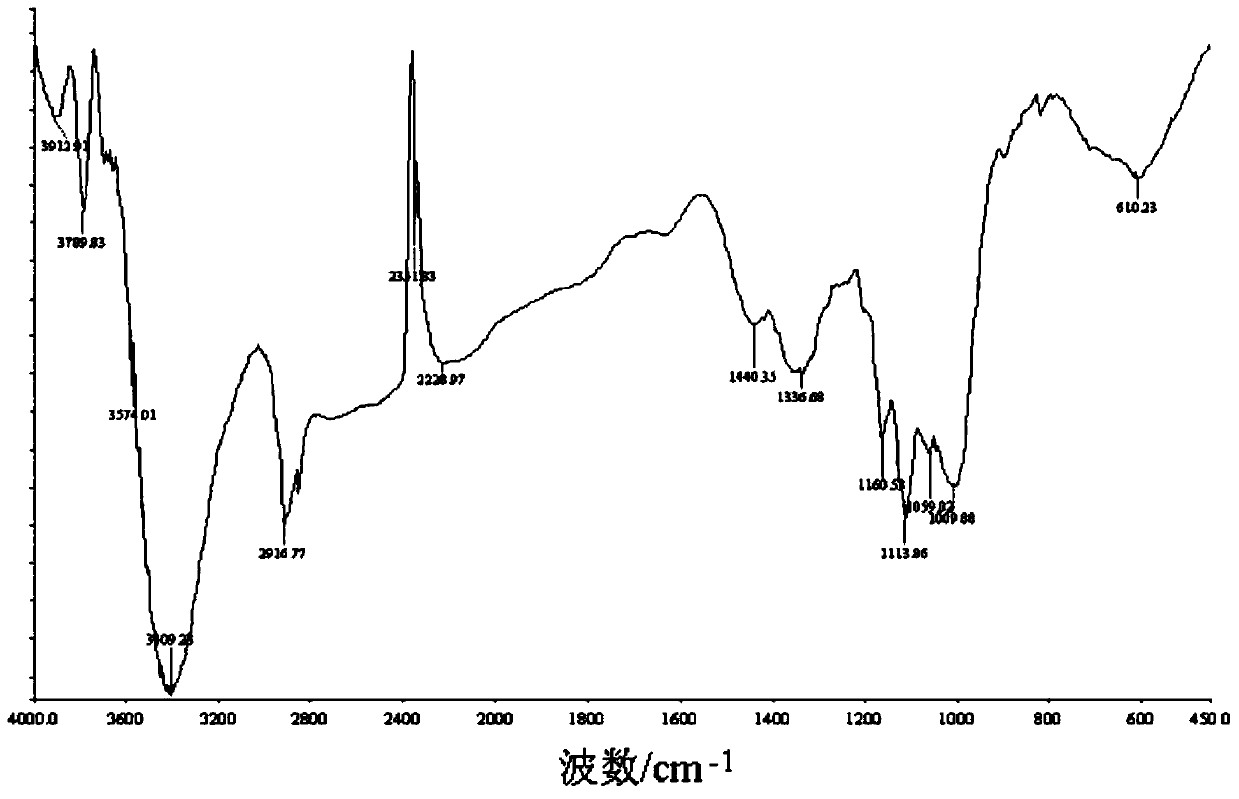

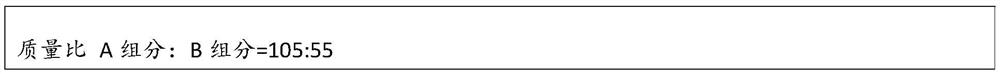

Preparation method and use method of cross-linked hyperbranched amine-modified oxidized starch adhesive for laminated wood

InactiveCN109749661AHas long-lasting adhesive propertiesAvoid corrosionStarch derivtive adhesivesCross-linkWet bonding

The invention discloses a preparation method and a use method of a cross-linked hyperbranched amine-modified oxidized starch adhesive for laminated wood and relates to a starch adhesive applied to thelaminated wood and a use method thereof. The preparation method and the use method of the cross-linked hyperbranched amine-modified oxidized starch adhesive for the laminated wood aim to solve the technical problems that the existing starch adhesive is relatively low in wet bonding strength and is not resistant to water. The preparation method comprises the following steps of I, preparing an oxidized starch adhesive; II, preparing a hyperbranched amine aqueous solution; III, preparing an oxidized starch grafted with trimesoyl chloride; and IV, preparing the cross-linked hyperbranched amine-modified oxidized starch adhesive. The cross-linked hyperbranched amine modified oxidized starch adhesive is uniformly smeared on the inner surface of a surface plate and two surfaces of a core plate byusing a brush, then the surface plate and the core plate are laminated to form a multilayer plate blank, and hot pressing is performed on the multilayer plate blank to finally obtain the multiply plywood. According to the preparation method and the use method of the cross-linked hyperbranched amine-modified oxidized starch adhesive for the laminated wood disclosed by the invention, hyperbranchedamine modification is performed on the oxidized starch adhesive, and then the laminated wood is prepared, the water resistance and the bonding property are improved, the corrosion effect of wood-inhabiting fungi on the laminated wood is inhibited and the service life is prolonged.

Owner:NORTHEAST FORESTRY UNIVERSITY

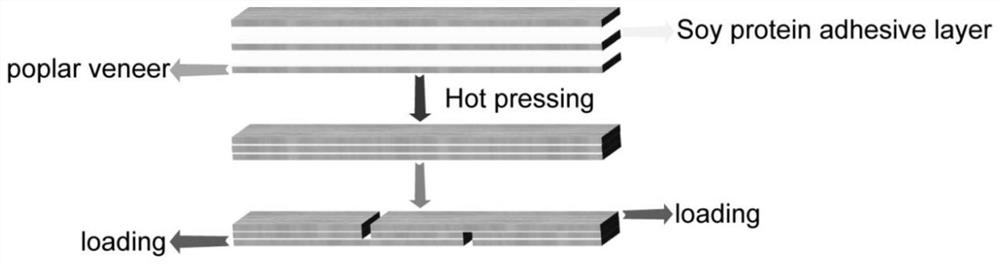

Aldehyde free soybean protein adhesive having multiple network structure and preparation method thereof

ActiveCN110982487ASolve the problem of pollution endangering human healthReduce resource consumptionNon-macromolecular adhesive additivesProtein adhesivesWet bondingAdhesive

The invention relates to an aldehyde free soybean protein adhesive having a multiple network structure. The adhesive comprises following components in parts by weight: 15 to 18 parts of a main agent,85 to 88 parts of a dispersing medium (water), 0.05 to 0.1 part of bromelain, 2 to 3 parts of tannic acid (TA), 0.25 to 0.5 part of zinc sulfate heptahydrate, and 2 to 4 parts of a crosslinking agentnamely 1,2,3-glyceroldiglycidyl ether (PTGE). The adhesive has a triple network structure, has the advantages of proper viscosity, high dry / wet bonding strength, good toughness, good mildew resistantproperty, and can be evenly painted; the performance is stable, and the product quality is stably improved. The invention further relates to a preparation method of the adhesive.

Owner:BEIJING FORESTRY UNIVERSITY

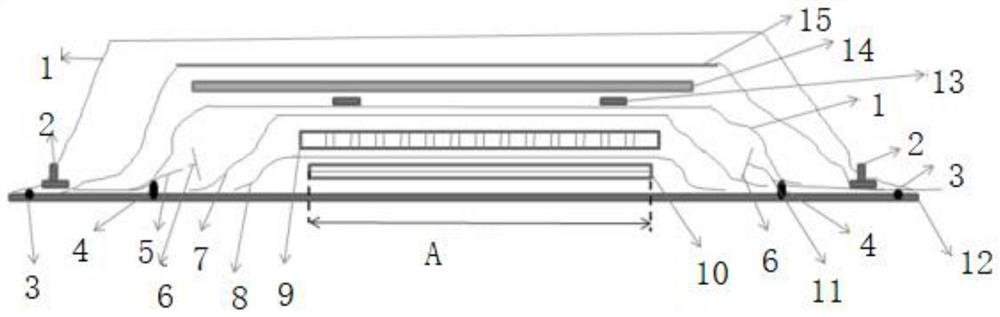

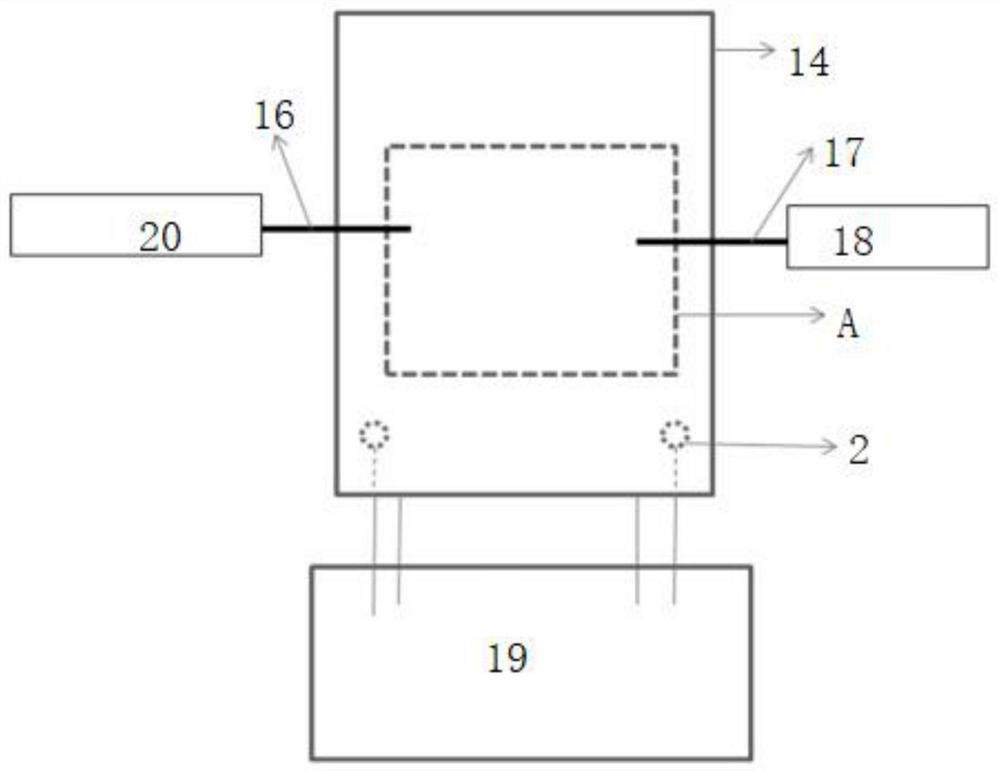

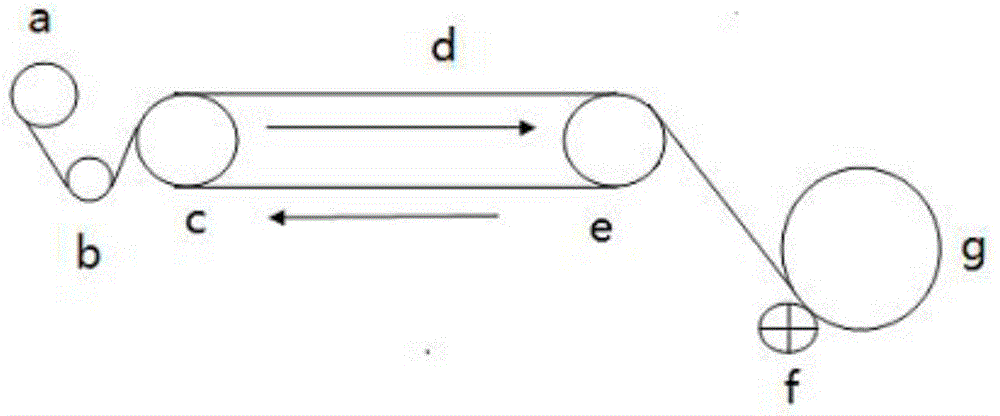

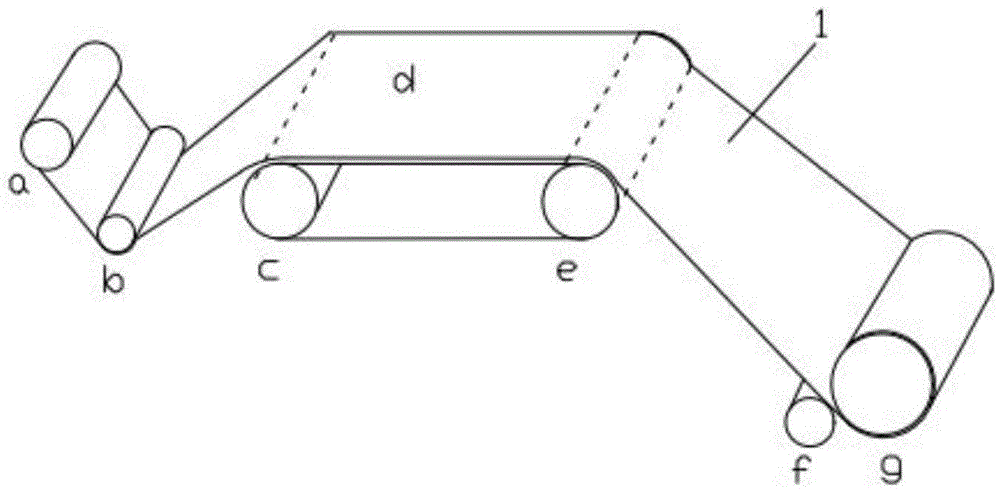

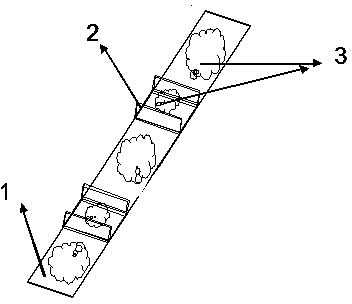

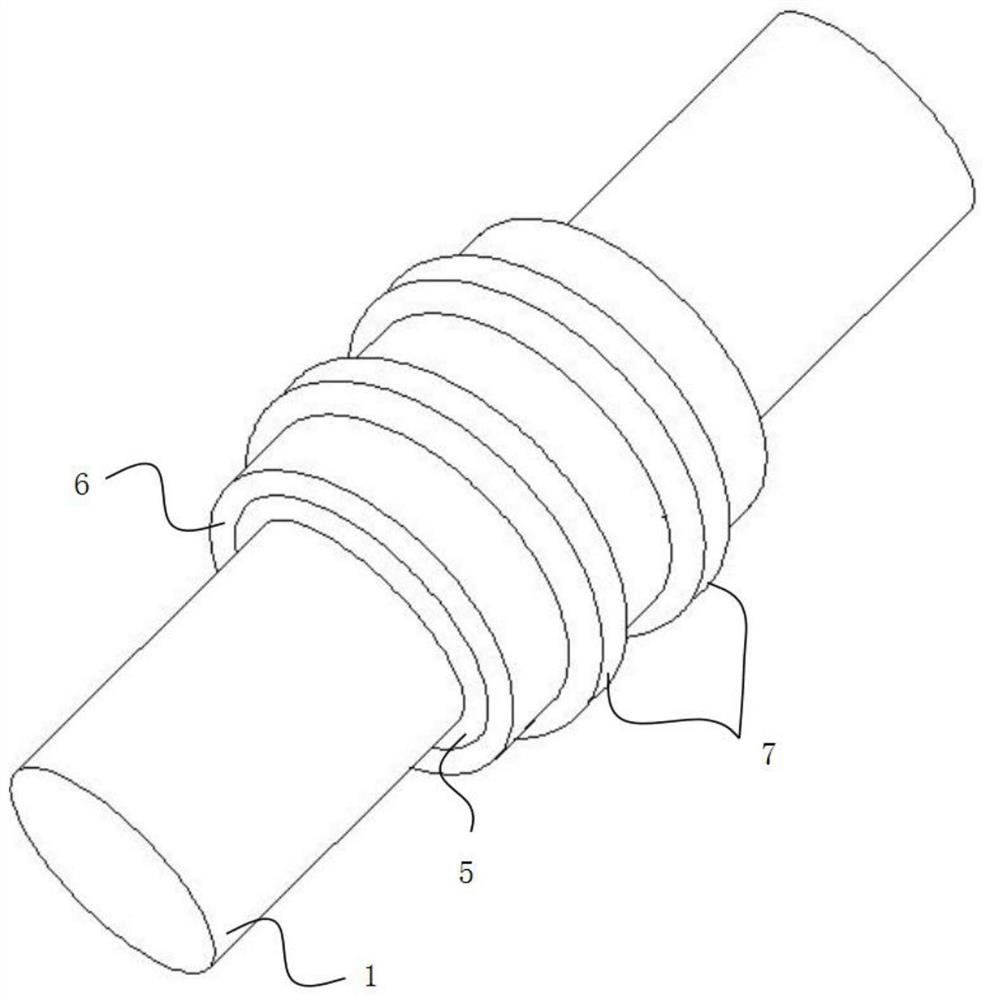

Film covering device for constructing self-adhered coiled material with wet method

InactiveCN104802494AGood lookingHigh bonding strengthLamination ancillary operationsLaminationWet bondingKnurling

The invention relates to a film covering device for constructing a self-adhered coiled material with a wet method. The film covering device comprises a cooling steel belt, a film covering frame, a left driving roller, a right driving roller, a knurling roller and a main driving roller, wherein the left driving roller and the right driving roller are symmetrically arranged respectively on both sides of the cooling steel belt, the left driving roller and the right driving roller are tangent to the cooling steel belt, an oil applying tank is arranged on the cooling steel belt, an isolating film is coated with covering materials by the oil applying tank, the film covering frame is arranged on one side of the left driving roller, the isolating film is wound on the film covering frame, the knurling roller and the main driving roller are arranged on one side of the right driving roller, and the knurling roller and the main driving roller are tangent. According to the film covering device, an original film covering process is changed, an inherent idea is broken, a great effect is achieved at low cost, under the condition that other aspects are not changed, the appearance of the coiled material is improved by the film covering device, and the wet bonding intensity is increased.

Owner:HUIZHOU ORIENTAL YUHONG BUILDING MATERIALS

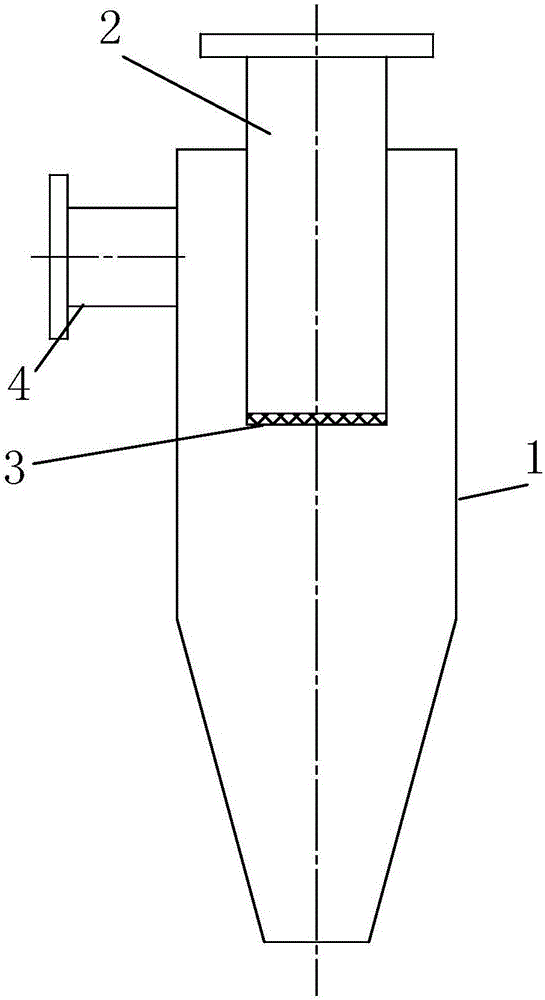

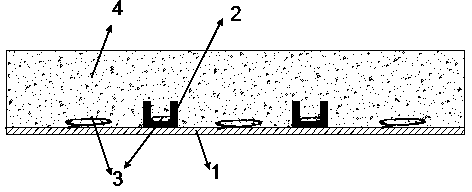

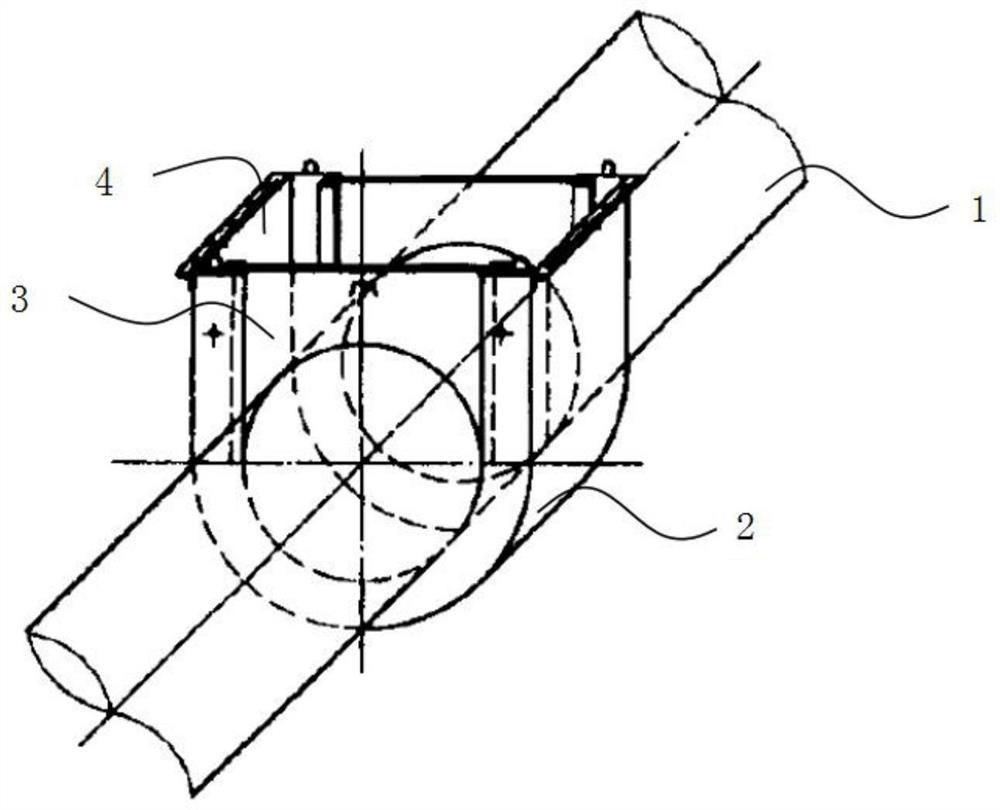

Wet-bonding-proof cyclone separator

InactiveCN106040448AIncrease drynessWet Stick PreventionReversed direction vortexWet bondingElectric heating

The invention provides an anti-humidity and sticking cyclone separator, which comprises an inverted cone-shaped cylinder, an upper air inlet is arranged on the inverted cone-shaped cylinder, and the inverted cone-shaped cylinder has two layers of anti-sticking coatings and the The heating layer sandwiched between the two layers of anti-sticking coatings, the heating layer is equipped with electric heating wires, and also includes a heating device for controlling the operation of the electric heating wires. By setting the heating layer on the inverted cone-shaped cylinder, the inverted cone is further dried. The residual material on the shaped cylinder prevents wet sticking and facilitates the separation of the material from the cyclone separator. The invention has a simple structure and obvious effect, and can further improve the drying degree of the material, which serves multiple purposes.

Owner:扬州日发干燥工程有限公司

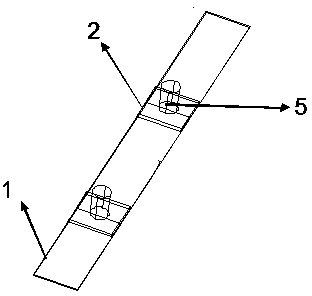

FRP (fiber reinforced plastic) sectional material-concrete combined structure adopting novel combined interface

InactiveCN104234182AIncreased shear capacityImprove carrying capacityBuilding constructionsWet bondingFiber

The invention belongs to the technical field of a concrete structure, and particularly relates to an FRP (fiber reinforced plastic) sectional material-concrete combined structure adopting a novel combined interface. The structure comprises an FRP sectional material template, an FRC shear key, an interface resin layer and concrete, wherein the FRP shear key is arranged on the surface of the FRP sectional material template, the concrete is directly cast on the surface of the FRP sectional material template, and the interface resin layer is arranged among the cast-in-place concrete, the surface of the FRP sectional material template and the FRP shear key. The FRP sectional material-concrete combined structure adopting the novel combined interface provided by the invention has the advantages that the preparing process is simple and convenient, the operation is easy, meanwhile, higher designability is realized, the technical advantages of the existing wet bonding and steel screw bolt shear key are combined, the technical effect is more excellent, the technical defects that the FRP sectional materials and the concrete can easily peel and fall, the steel screw bolt shear key can easily get rusty and the perforation damage to the FRP sectional material can be easily caused can be more effectively overcome, and the popularization and the application of the FRP sectional material-concrete combined structure are favorably realized.

Owner:ZHENGZHOU UNIV

Novel molding sand

PendingCN105170872AImprove breathabilityHigh viscosityFoundry mouldsFoundry coresWet bondingMicrosphere

The invention discloses novel molding sand. The novel molding sand is prepared from, by weight, 120-140 parts of quartz sand, 25-30 parts of bentonite, 10-15 parts of zeolite powder, 5-8 parts of gypsum powder, 2-3 parts of Chinese medicine residues, 1-2 parts of carbon powder, 3-4 parts of modified starch, 15-20 parts of aluminum oxide and 3-5 parts of vitrified microspheres. The novel molding sand is good in breathability, liquidity and high-temperature collapsibility. A sand mold is high in dry strength, high in wet bonding power, and good in anti-adhesive sand capacity, so that machined castings are smooth and glossy in surface, and high in finished product rate. Besides, the novel molding sand is capable of improving the operating environment of personnel, reusing waste and being good for the environment.

Owner:HEFEI CITY TENVER PRECISION CASTING

Method for manufacturing paper straw

ActiveUS20210060890A1High viscosityImprove efficiencyMechanical working/deformationPaper/cardboard articlesWet bondingAdhesive glue

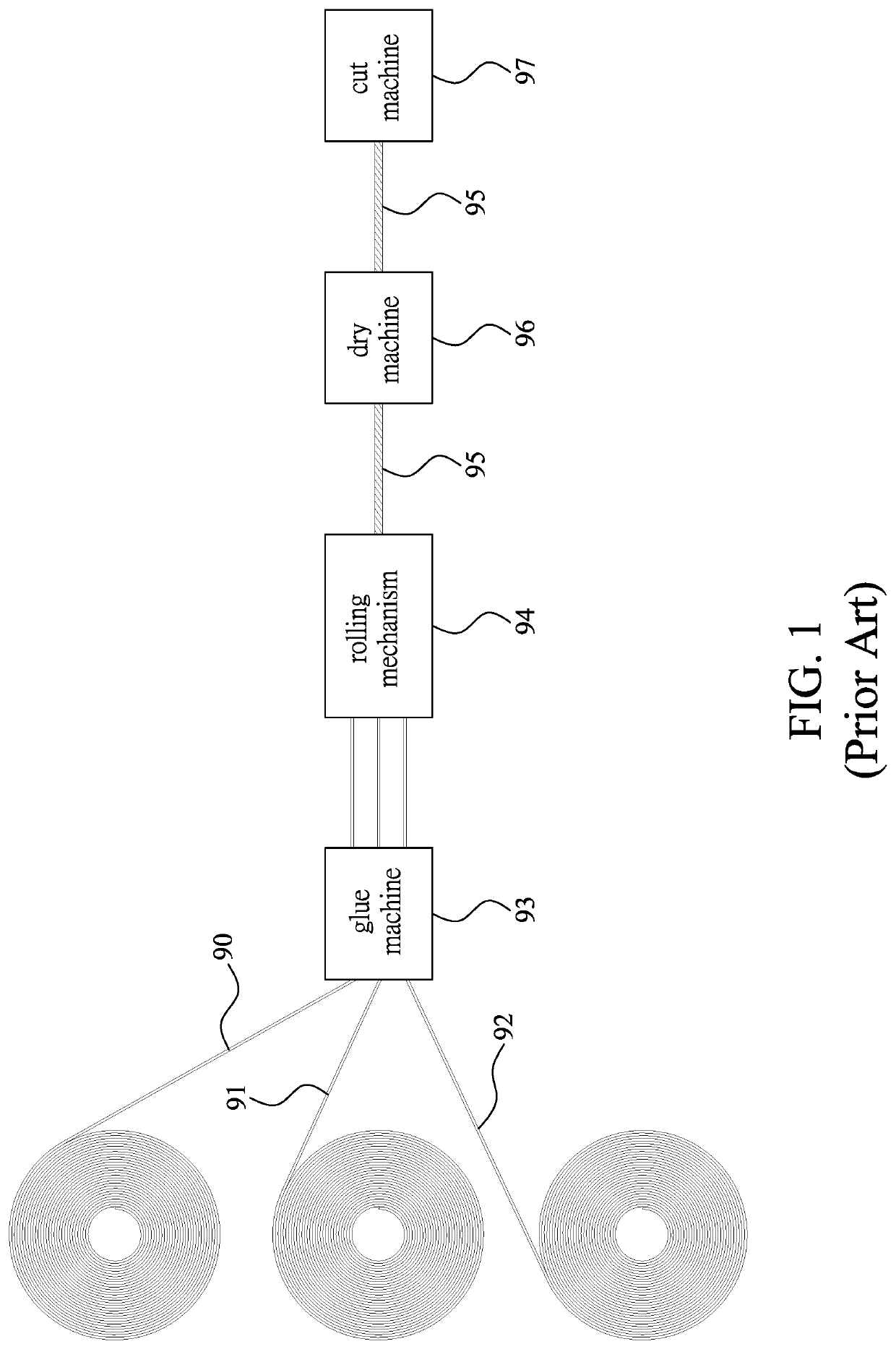

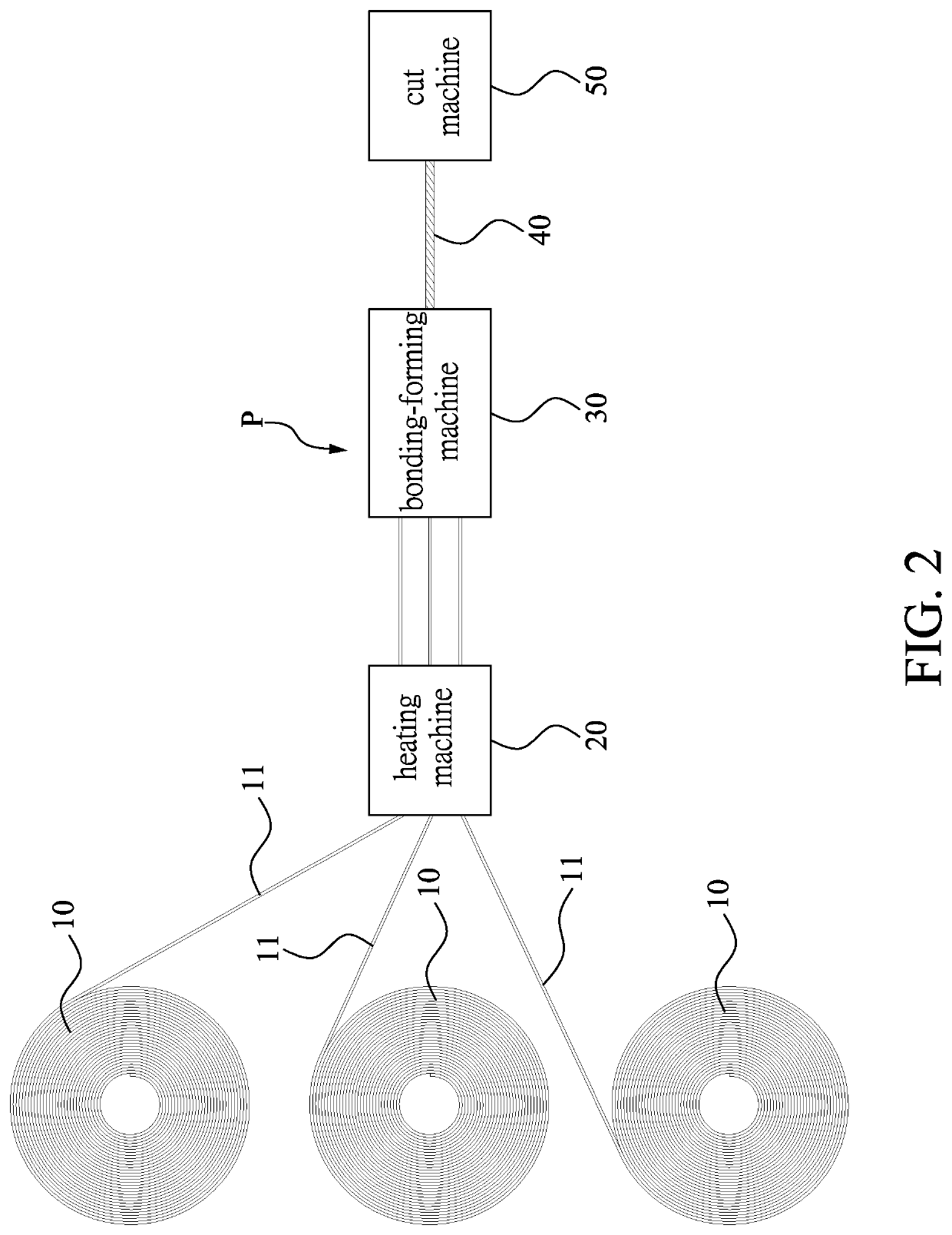

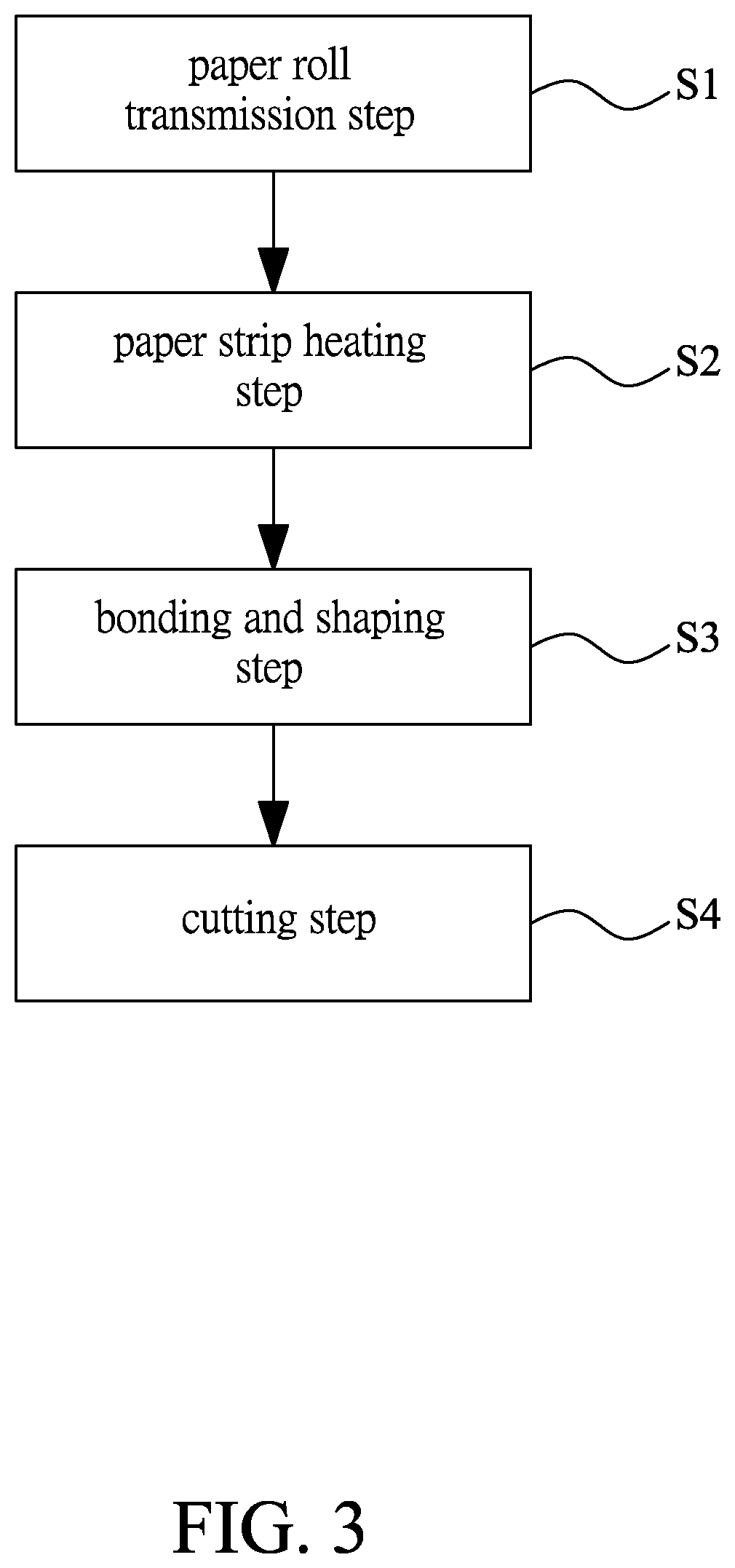

The present invention relates to a method for manufacturing a paper straw, the method comprising: a paper roll transmission step, a paper strip heating step, a bonding and shaping step and a cutting step. Wherein, a plurality of raw paper rolls face a connection position jointly to transmit a raw paper strip, the raw paper strip includes a paper material and a dry hot-melt adhesive. The dry hot-melt adhesive of the raw paper rolls is heated for changing into flow hot-melt adhesive. Then the raw paper rolls is transmitted to the connection position for rolling jointly, and the flow hot-melt adhesives are bounded on another raw paper strip to form a pipe. Finally, the pipe is cut to form at least one paper straw after the pipe exceeds a setting length. The present invention uses dry adhesive to manufacture paper straw, without the excessive glue problem and mold phenomenon of the traditional wet bonding method as well as without an extra dry fixing step of traditional manufacture process, so the productivity will be raised significantly, and the defect rate will be reduced.

Owner:HOU JING SHENG JINGHUA CO LTD

Sprayable Water-Based Adhesive

Water-based adhesive compositions are improved by the incorporation of hollow polymeric microspheres having outer surfaces coated with one or more barrier materials such as calcium carbonate particles. The adhesive compositions exhibit enhanced rheology, sprayability, drying time, tack and storage stability as compared to analogous adhesives that are not modified with coated hollow polymeric microspheres. Such compositions are useful as both contact adhesives as well as wet bonding one-way adhesives.

Owner:HENKEL KGAA

Preparation method of polyurethane modified epoxy resin and grouting material based on the resin

The invention provides a preparation method of polyurethane modified epoxy resin. Firstly, isocyanate is used to react with hydroxyl groups on epoxy resin under certain conditions to obtain polyurethane grafted epoxy resin, and then the polyurethane is grafted with monohydric alcohol. The isocyanate on the grafted epoxy resin is blocked, so that the unit of isocyanate is used to block the epoxy resin, and the polyurethane short chain is grafted on the epoxy resin, so that the distance between the epoxy resin molecules is increased, the intermolecular force is reduced, and the chain is improved. The movement ability of the segment, and at the same time reduce the viscosity of the slurry and toughen the effect; thus the grouting material based on the polyurethane modified epoxy resin of the present invention can effectively reduce the physical crosslinking between molecules, and has strong permeability and good toughness , The data shows that its compressive strength exceeds 70MPa, tensile strength exceeds 20MPa, dry bond strength exceeds 5Mpa, and wet bond strength exceeds 3MPa.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

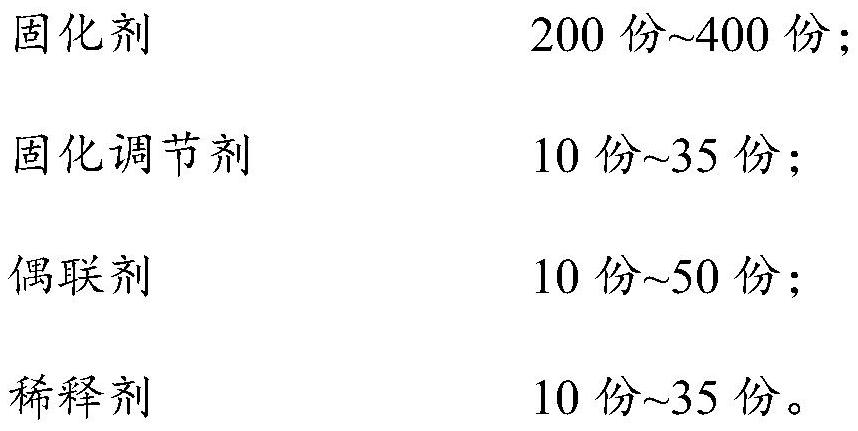

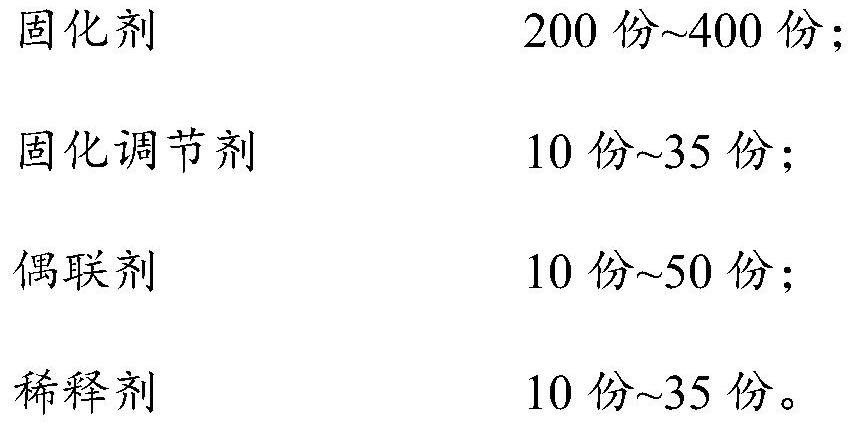

Grouting material, and preparation method and application thereof

The invention discloses a grouting material, and a preparation method and application thereof, and belongs to the technical field of building materials. The grouting material comprises a component A and a component B; the component A is prepared from the raw materials: an epoxy matrix and a reactive diluent; the reactive diluent is at least two of butanediol glycidyl ether, allyl glycidyl ether and butyl glycidyl ether; the component B is prepared from the raw materials: a curing agent, a curing regulator, a coupling agent and a diluent; and the mass ratio of the component A to the component B is 100:(35-60). Due to the synergistic effect of all the components, the grouting material has the following advantages that the initial viscosity is low, the operable time is long, and the dry and wet bonding performance is excellent.

Owner:GUANGZHOU UNIVERSITY

A kind of full bio-based two-component soybean adhesive, preparation method and application thereof

ActiveCN113480970BEasy to operateEasy to implementNon-macromolecular adhesive additivesProtein adhesivesWet bondingAdhesive

The invention discloses a full bio-based two-component soybean adhesive, a preparation method and its application, and belongs to the technical field of wood adhesive preparation, which includes soybean protein mixing main agent A and cross-linking curing agent B, calculated in parts by weight. The soybean protein mixed main agent A includes 20-30 parts of soybean protein powder, 40-70 parts of deionized water, 2-5 parts of alkali, and 4-10 parts of phytic acid. The cross-linking curing agent B includes bio-based cross-linking curing 70-100 parts of agent, 0-30 parts of deionized water. The adhesive prepared by this method has moderate viscosity and good wettability on the wood surface, and can form a strong and dense cross-linked structure on the bonding surface after curing. The adhesive has high dry / wet bonding strength and good thermal stability. The flame retardancy and water resistance of the artificial board prepared by the adhesive are significantly improved, and the practical application performance of the soybean protein adhesive is improved.

Owner:SOUTH CHINA AGRI UNIV

Novel underwater pipeline leakage rapid repair construction method

The invention provides a novel underwater pipeline leakage rapid repair construction method. A U-shaped steel sheath is installed in a to-be-poured area of the leakage pipeline, and polymer resin concrete is poured to achieve rapid repair of leakage of the underwater pipeline. The invention also provides a composition ratio of the polymer resin concrete, including 12 to 20 percent of epoxy resin matrix, 7 to 15 percent of cement, 30 to 40 percent of stone, 0.07 to 0.12 percent of accelerant, 0.07 to 0.12 percent of initiator and the balance of sand, and the polymer resin matrix is a composition of epoxy resin, polyurethane prepolymer, unsaturated polyester and substituted ethylene; the polymer resin concrete can promote interface infiltration so as to obtain good wet bonding strength.

Owner:杭州每步材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com