Patents

Literature

176 results about "Dental composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

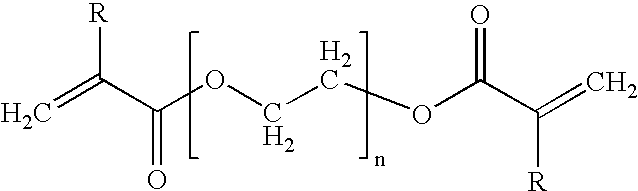

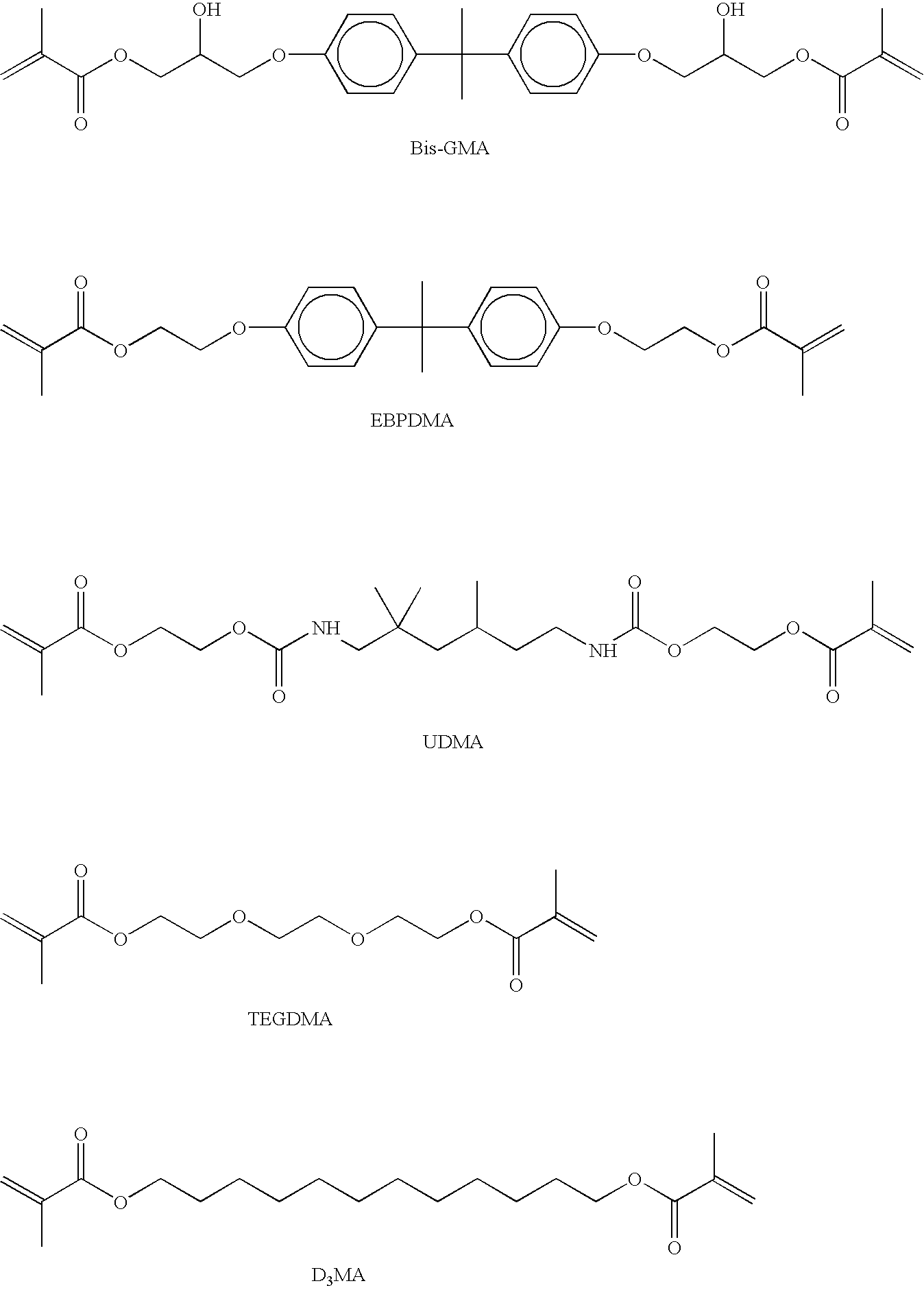

Dental composite resins (better referred to as "resin-based composites" or simply "filled resins") are types of synthetic resins that are used in dentistry as restorative material or adhesives. Dental composite resins have certain properties that will benefit patients according to the patient's cavity. It has a micro-mechanical retention property that makes composite more effective for filling small cavities where amalgam fillings are not as effective and could therefore fall out (due to the macro-mechanical retention property of amalgam). Synthetic resins evolved as restorative materials since they were insoluble, of good tooth-like appearance, insensitive to dehydration, easy to manipulate and reasonably inexpensive. Composite resins are most commonly composed of Bis-GMA and other dimethacrylate monomers (TEGMA, UDMA, HDDMA), a filler material such as silica and in most current applications, a photoinitiator. Dimethylglyoxime is also commonly added to achieve certain physical properties such as flow-ability. Further tailoring of physical properties is achieved by formulating unique concentrations of each constituent.

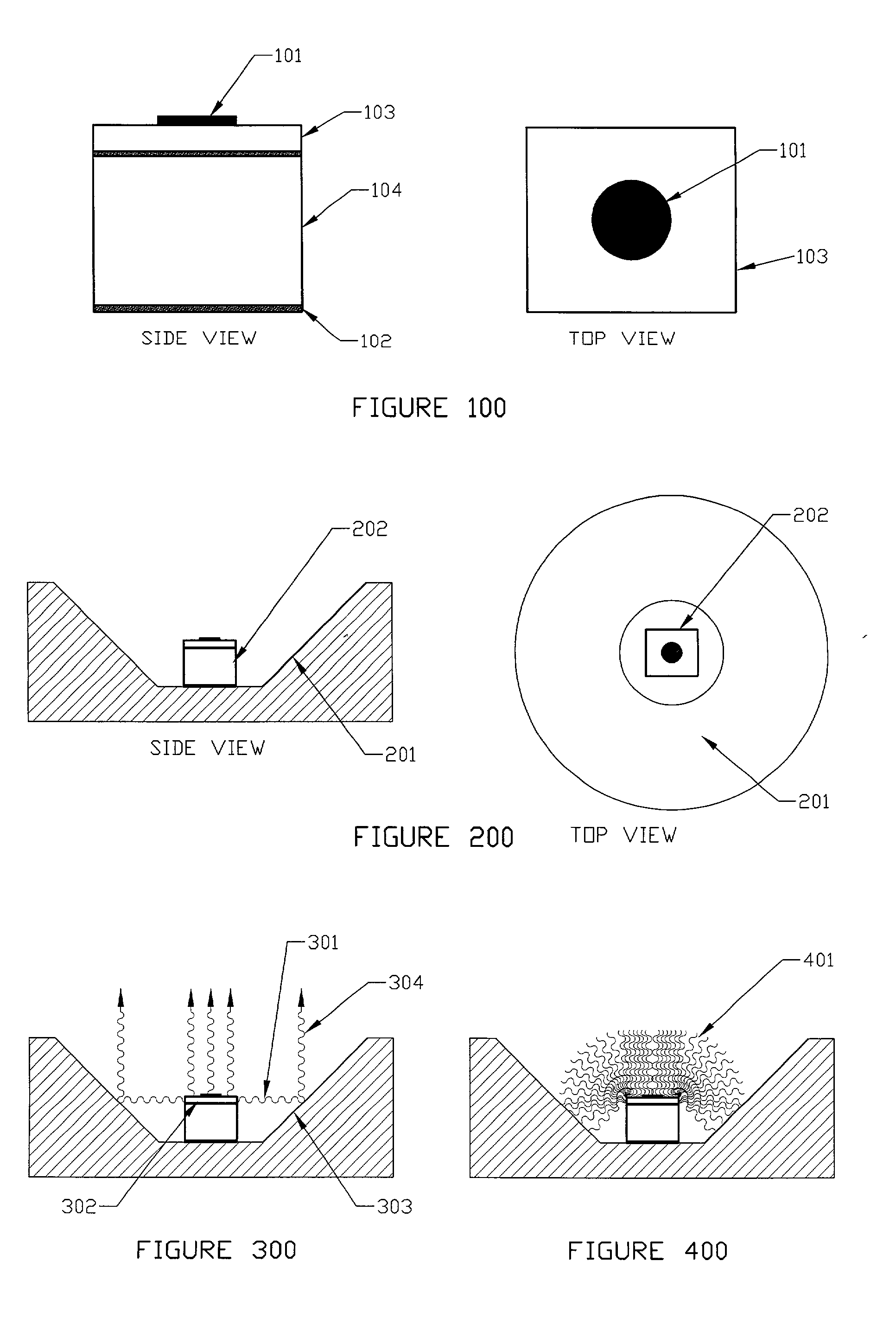

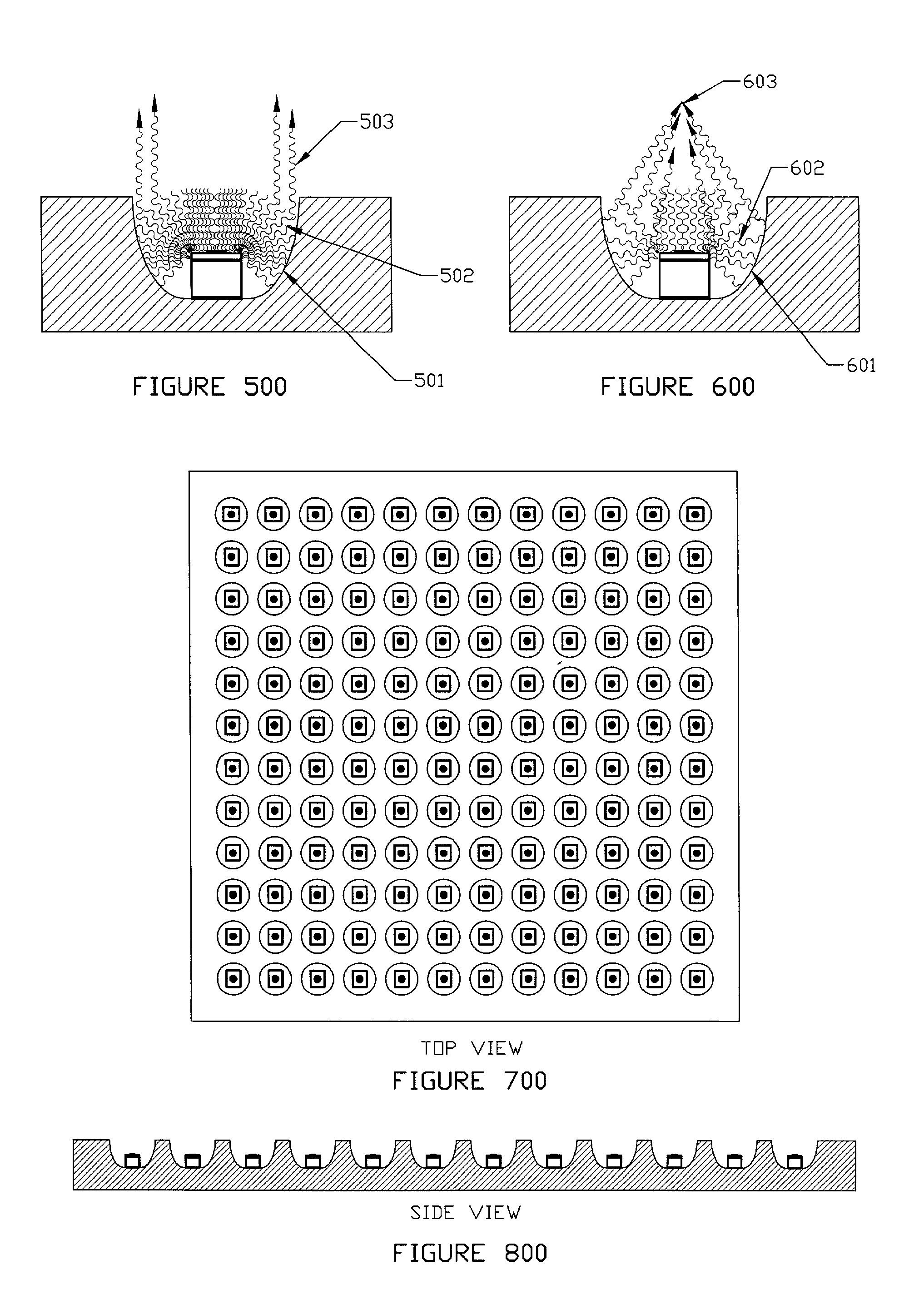

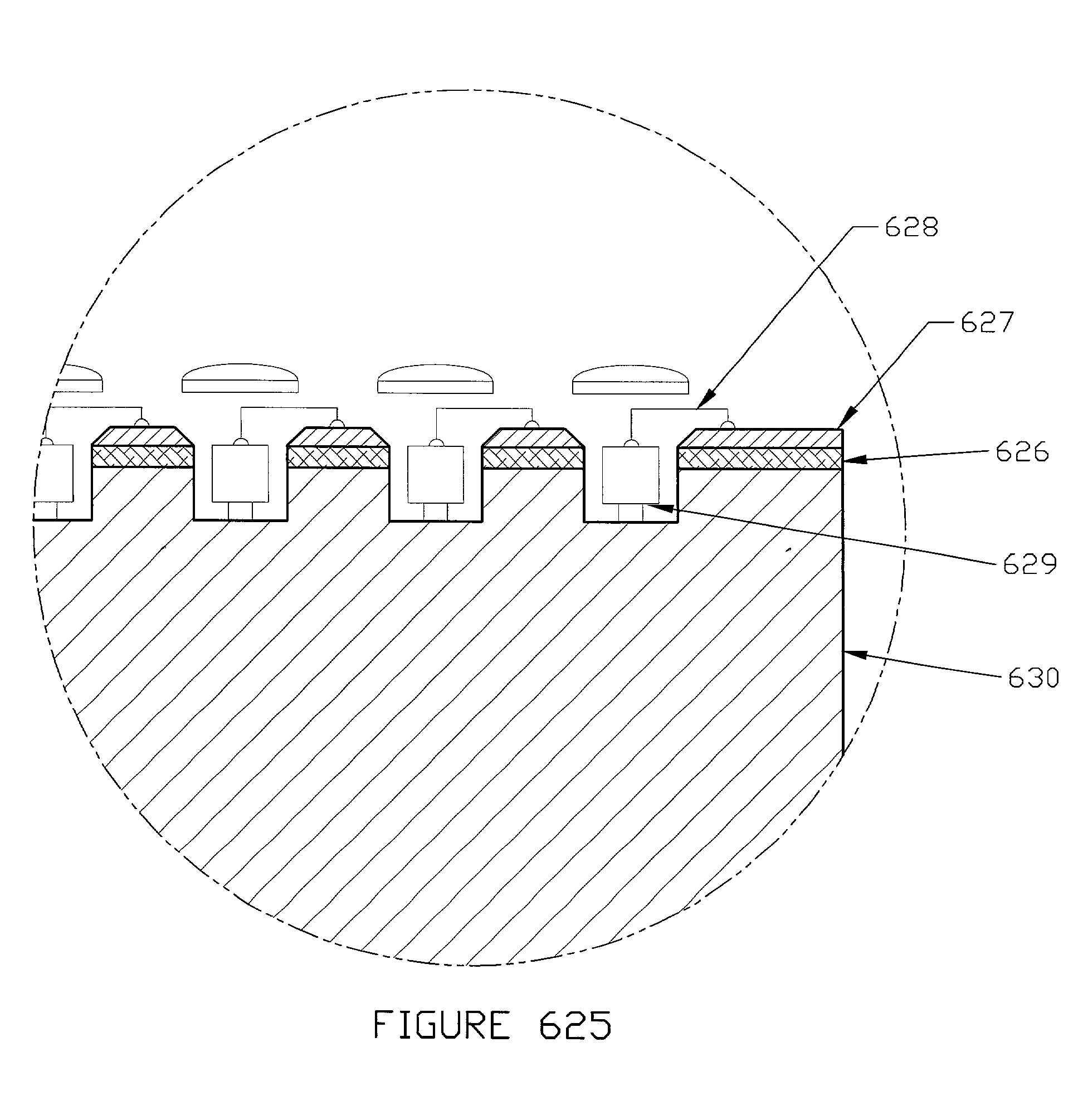

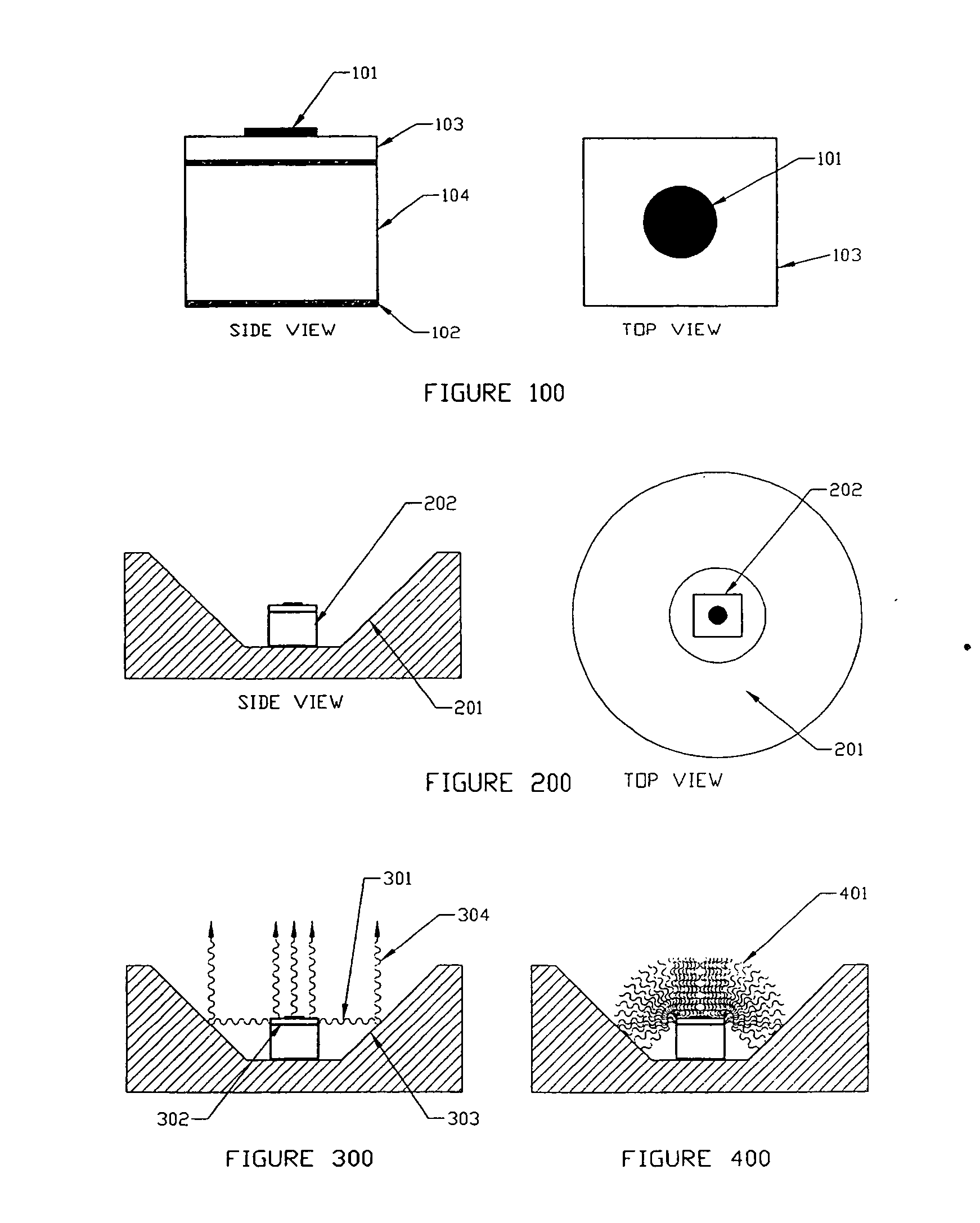

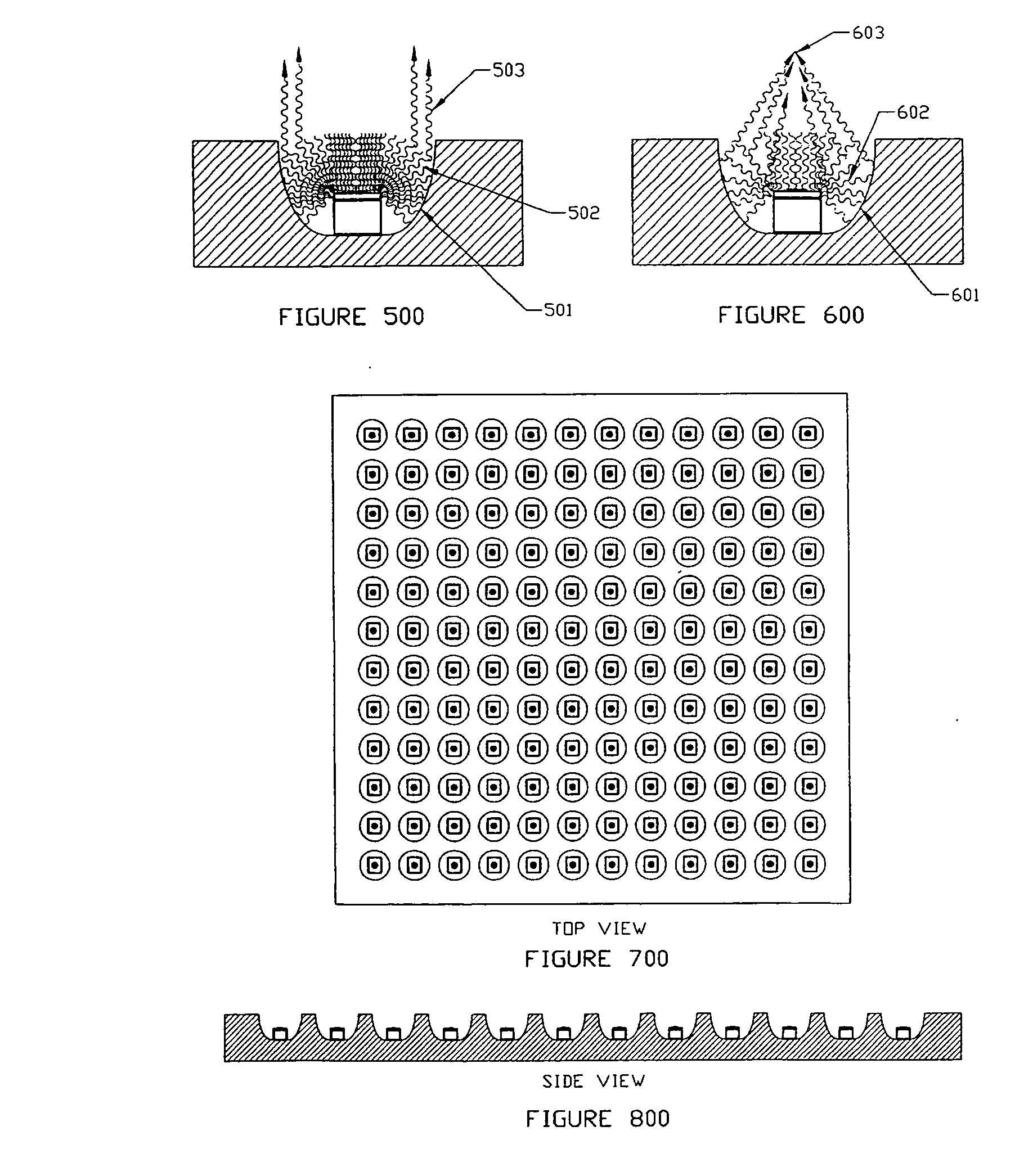

Light emitting diode light source for curing dental composites

InactiveUS20010046652A1Sufficient powerSufficient structurePrinted circuit aspectsSolid-state devicesDental compositeHeat sink

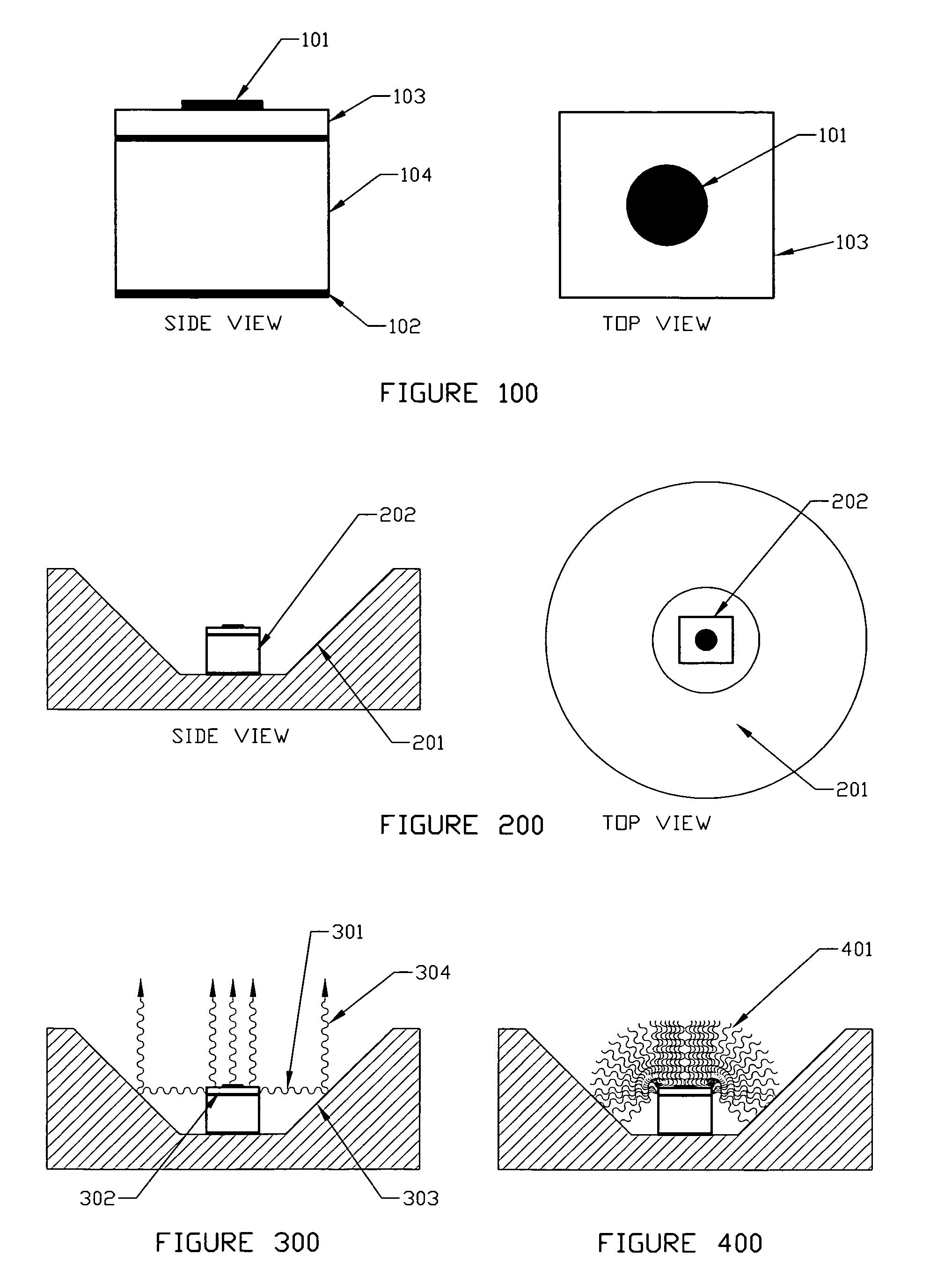

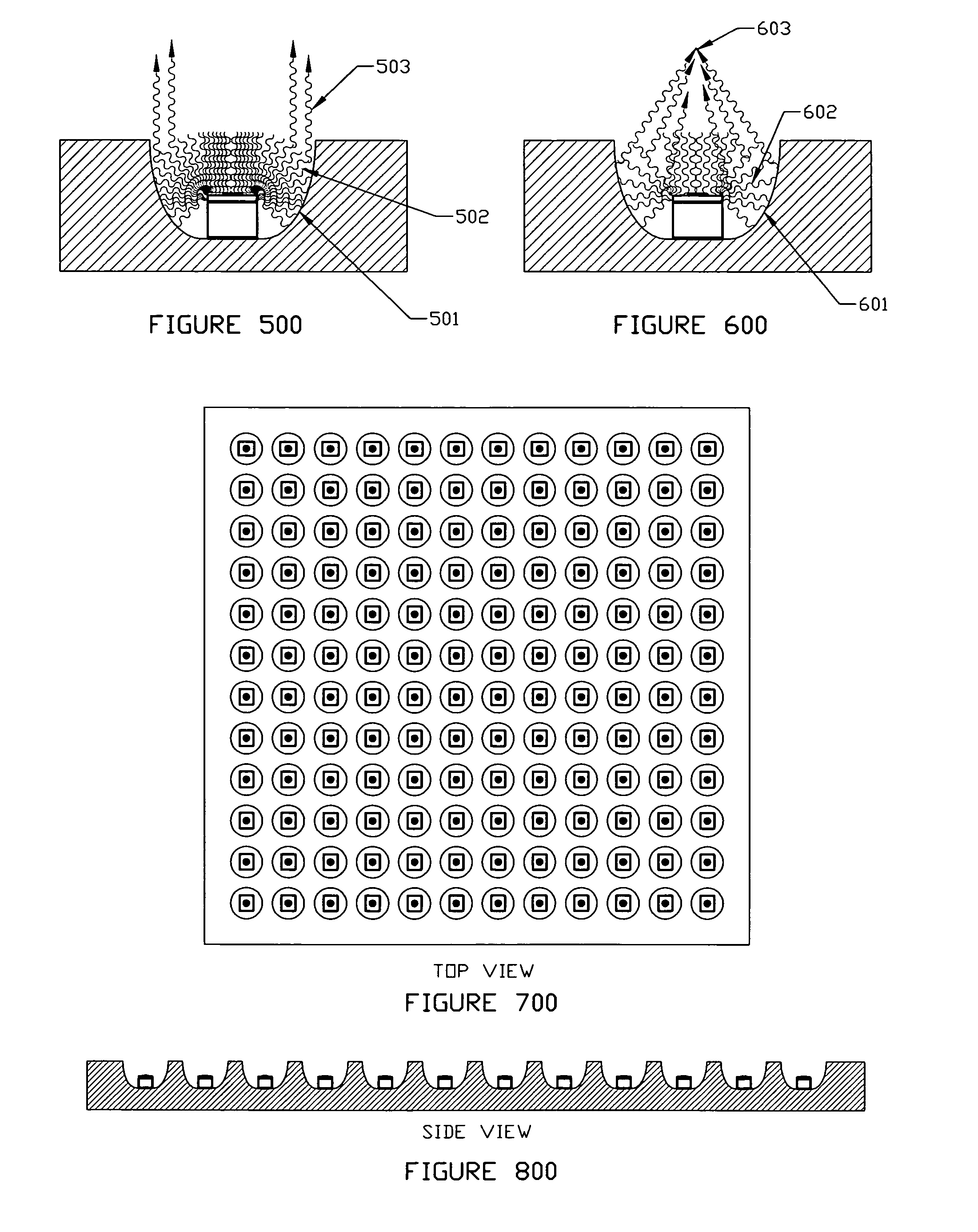

Light Emitting Diode Light Sources for Dental Curing are disclosed. Some embodiments of the invention include structures such as Light Emitting Diode Array(s), heat sink, heat dissipation, heat pipe, and control circuitry are disclosed.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

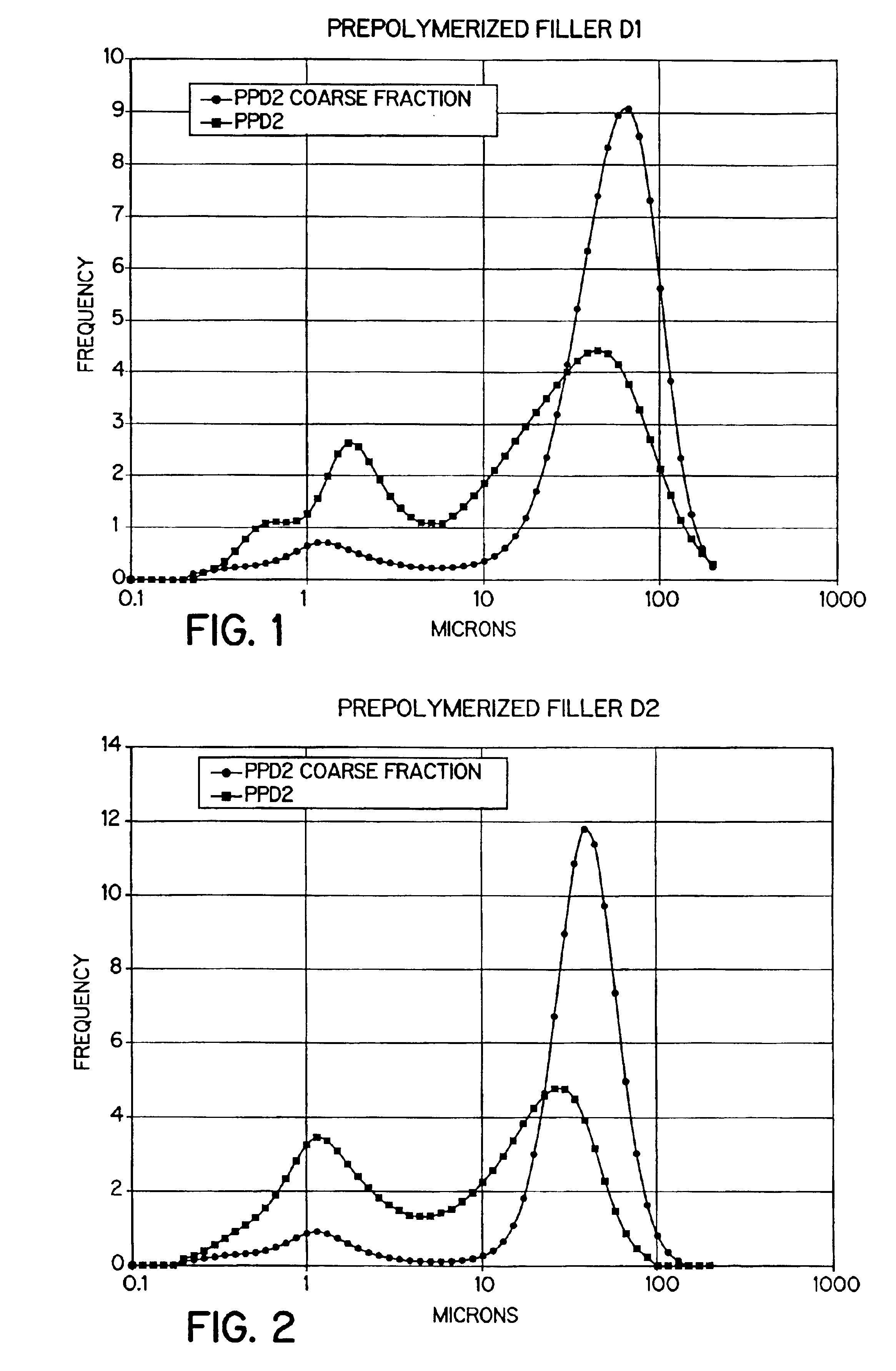

Prepolymerized filler in dental restorative composite

InactiveUS6890968B2High filler loadingReduce Shrinkage ProblemsImpression capsSurgical adhesivesDental compositeUltimate tensile strength

A dental composite having high filler loading and low shrinkage thereby providing good strength and marginal integrity. Through the use of prepolymerized filler particles in combination with a structural filler and a nanofiller, the composite exhibits very low shrinkage and is useful in stress bearing restorations and in cosmetic restorations. The structural filler used is ground to a mean particle size of less than 0.5 μm and the nanofiller has discrete particles of a mean particle size less than 100 nm to improve handling and mechanical characteristics. The prepolymerized filler particles also allow for less viscosity and better handling characteristics of the composite.

Owner:THE KERR

Non-volatile dental compositions containing multifunctional acrylate compounds and lacking an oxygen-inhibited layer

Dental composite formulations containing an initiator and a multiacrylate compound are disclosed. The formulations lack methyl methacrylate, a volatile, irritating, and potentially hazardous material commonly found in dental formulations. The multiacrylate compound has at least three acrylate functionalities per molecule. The formulations cure to form a surface lacking an oxygen inhibition layer. The formulations can be used as dental sealants, dental coatings, and in fingernail / toenail repair applications.

Owner:BISCO

Self-Healing dental restorative formulations and related methods

ActiveUS20110071234A1Improve the immunitySpeeds up (accelerates) a chemical reactionImpression capsDentistry preparationsSelf-healingDecomposition

Dental restorative formulations comprising two additives incorporated into the continuous phase of a dental material. One additive contains a capsule with a radical initiator. The other additive contains a capsule with one or more monomers and a radical accelerator. The dental restorative formulation is applied and polymerized to form a composite. When a disturbance occurs in the dental composite, the capsules of the additives rupture so that the radical accelerator of the second capsule decomposes the radical initiator of the first capsule to polymerize the one or more monomers of the second capsule thereby healing the dental composite. The radical accelerator controls the rate of decomposition of the radical initiator.

Owner:PREMIER DENTAL PRODS

Dental composite materials

A polymerizable dental composition, comprising a polymerizable resin composition; and a filler composition comprising a bound, nanostructured colloidal silica

Owner:PENTRON CLINICAL TECH

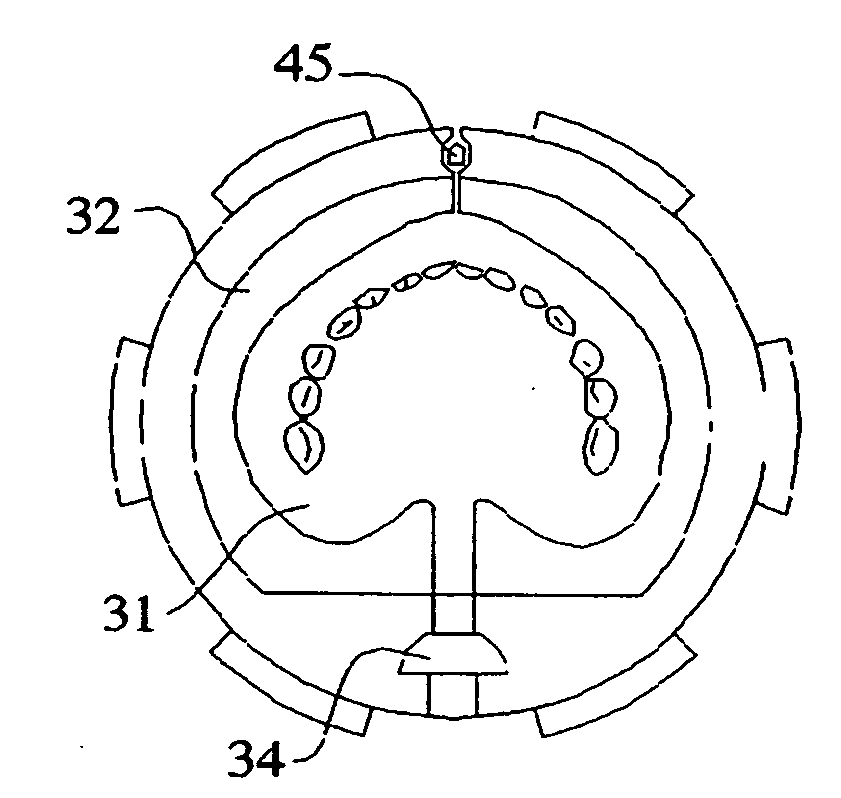

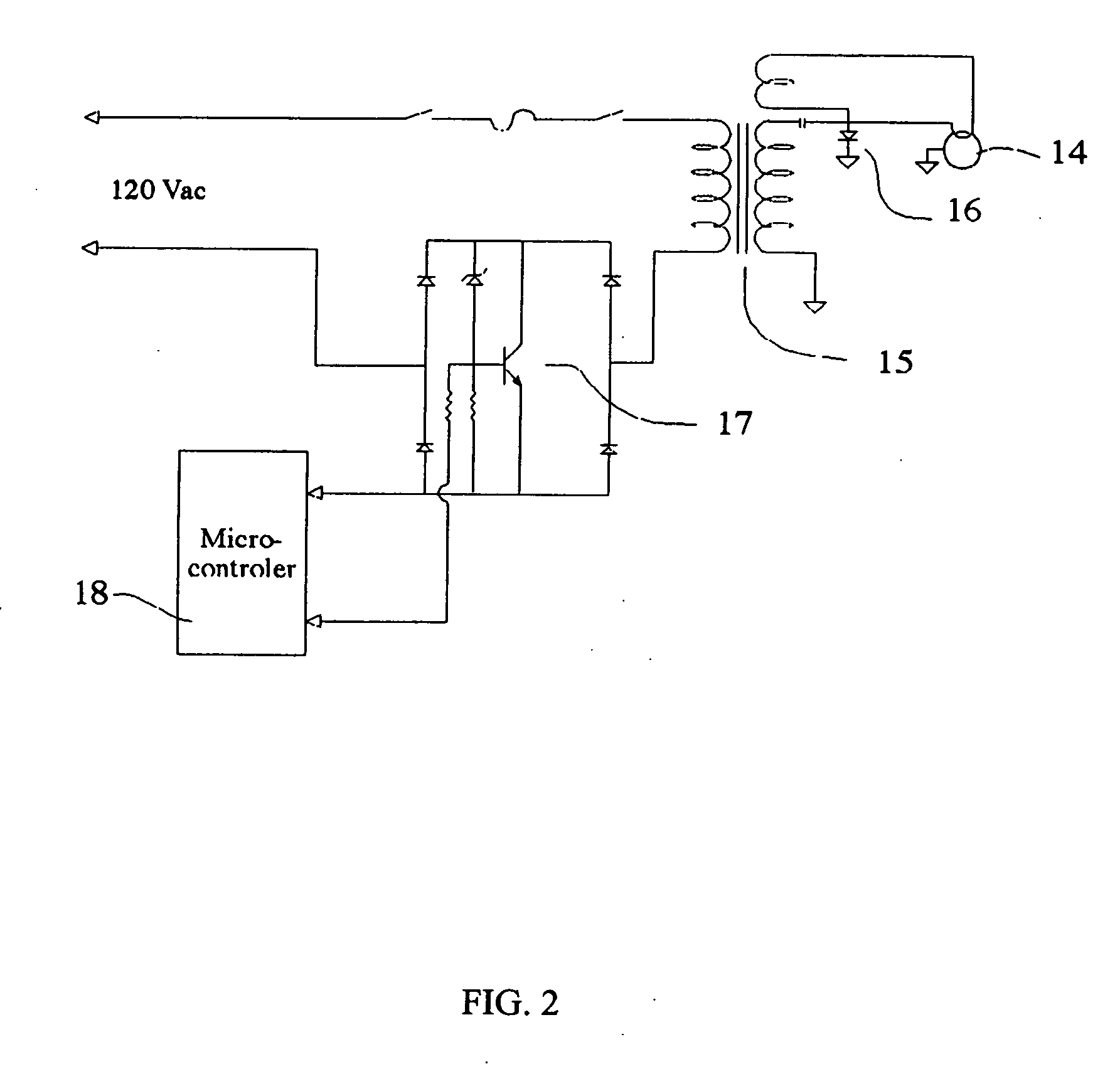

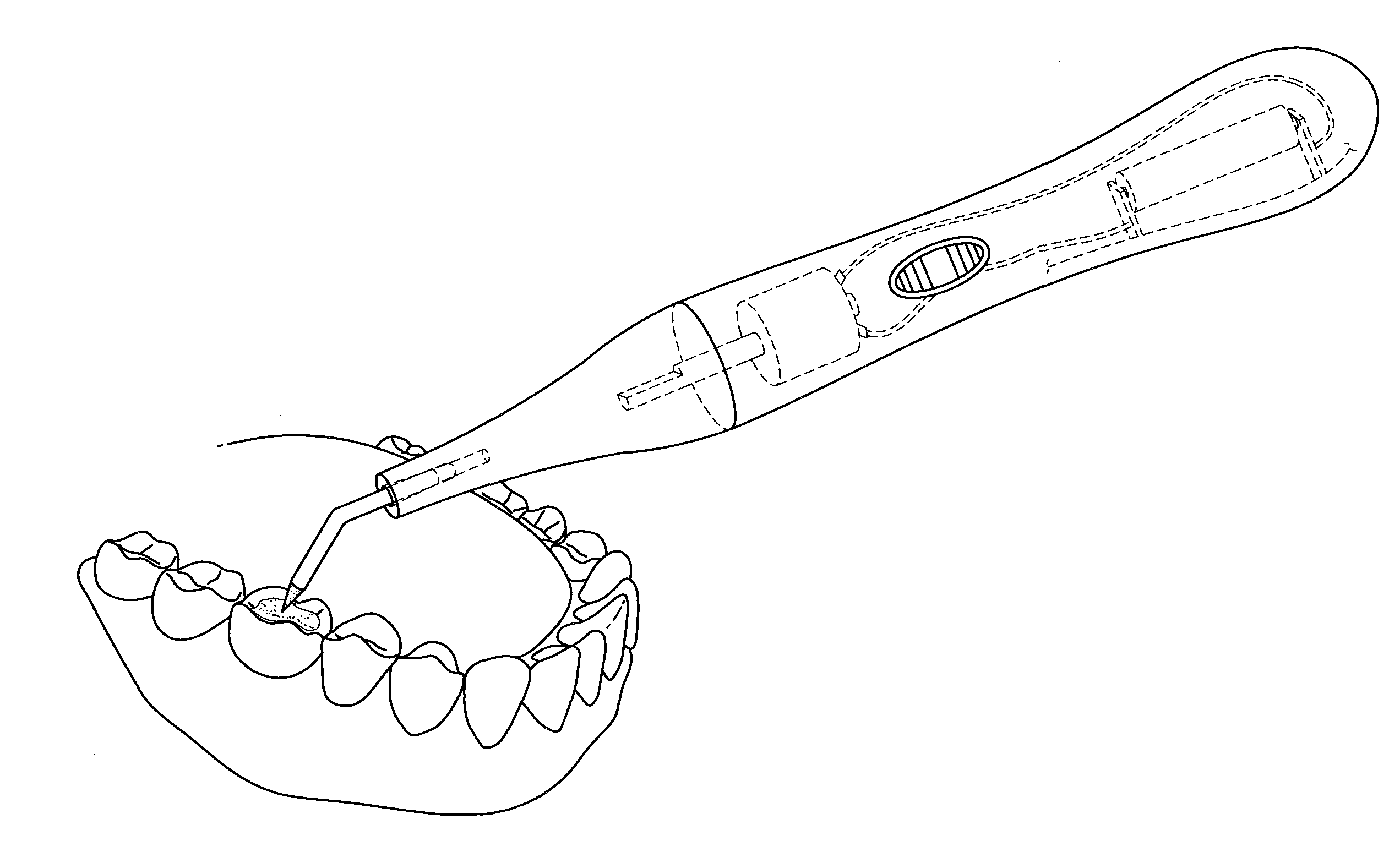

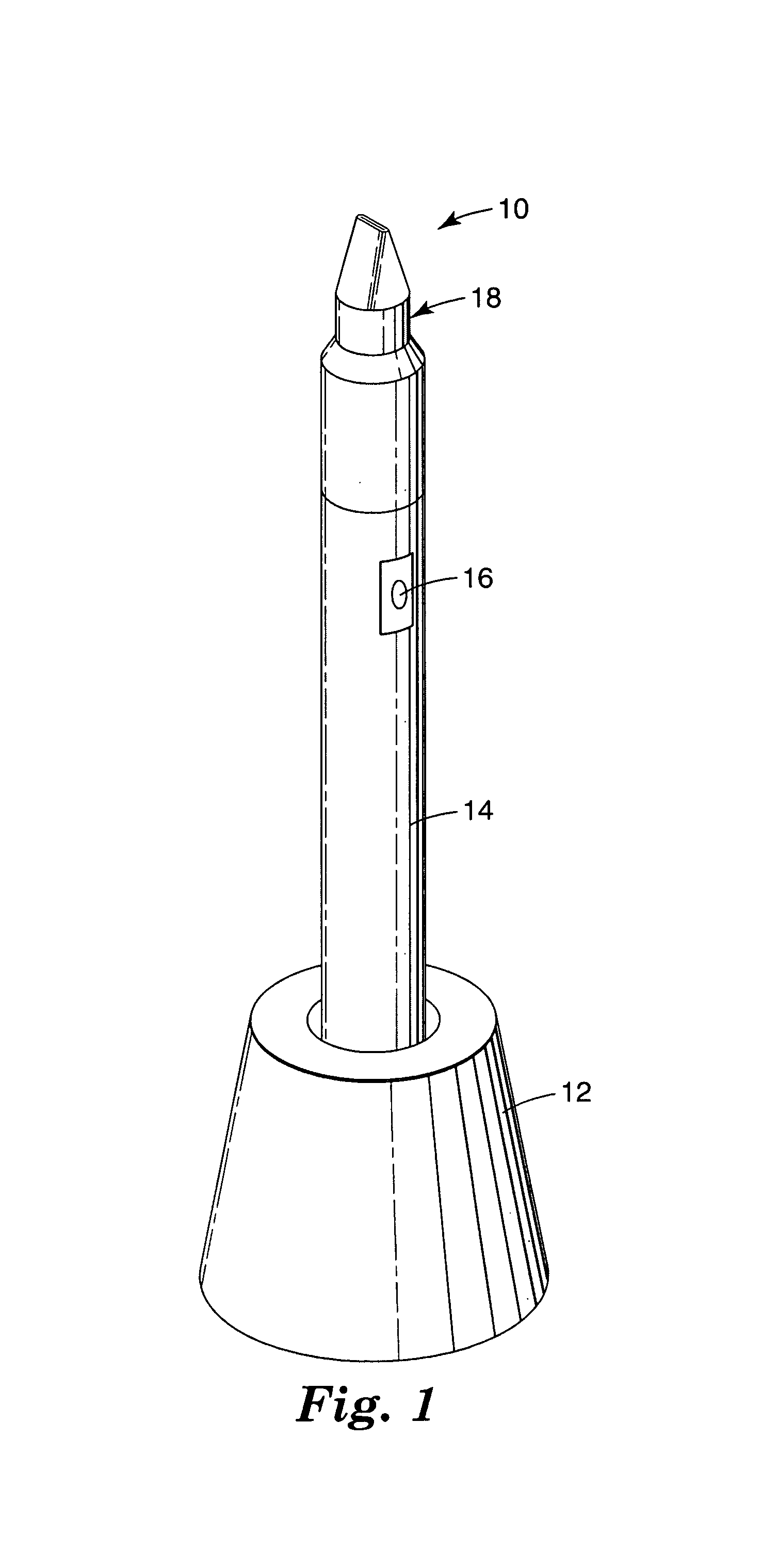

Hand-held microwave polymerization system for dentistry

InactiveUS20050011885A1Improve physical propertiesLess energyTooth crownsOhmic-resistance heatingHand heldEngineering

A hand-held microwave system for intra-oral dentistry utilizes microwave energy to cure polymer materials intra-orally so as to produce dental composites having improved physical characteristics, and also utilizes microwave energy to detect the presence of and to preferentially heat caries or cavities, thereby disinfecting and therapeutically treating the caries in a potentially non-invasive manner. The intra-oral polymerization process can be accomplished with less overall energy and with composite-matrices that maximally absorb the microwave energy so as to reduce heating of adjacent tissue. The antenna of a hand-held version of the intra-oral microwave system is also advantageously designed to detect the presence of and to preferentially heat caries or cavities, thereby disinfecting and therapeutically treating the caries in a potentially non-invasive manner. A method and product by process for the system are also disclosed.

Owner:SEGHATOL MARC +1

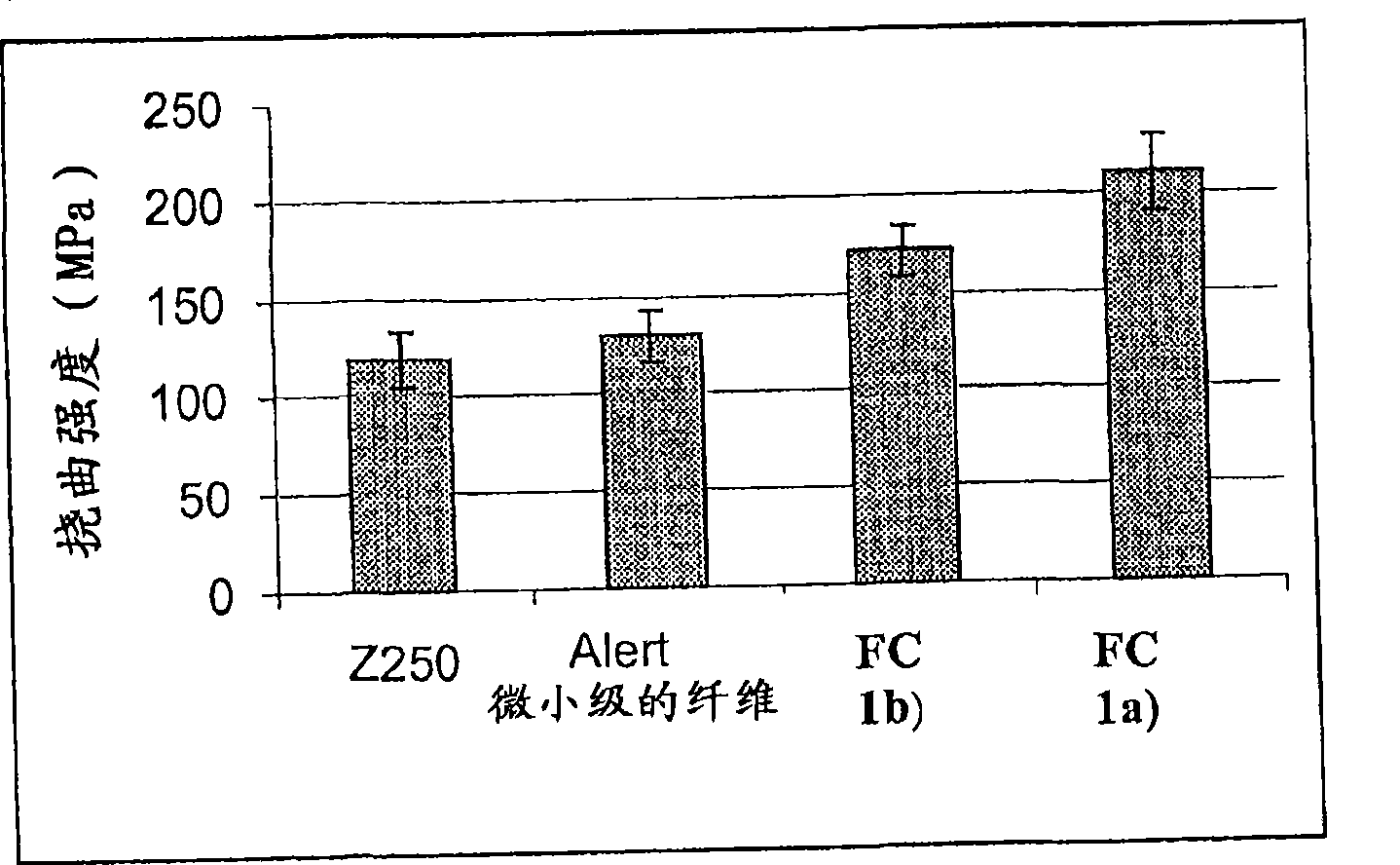

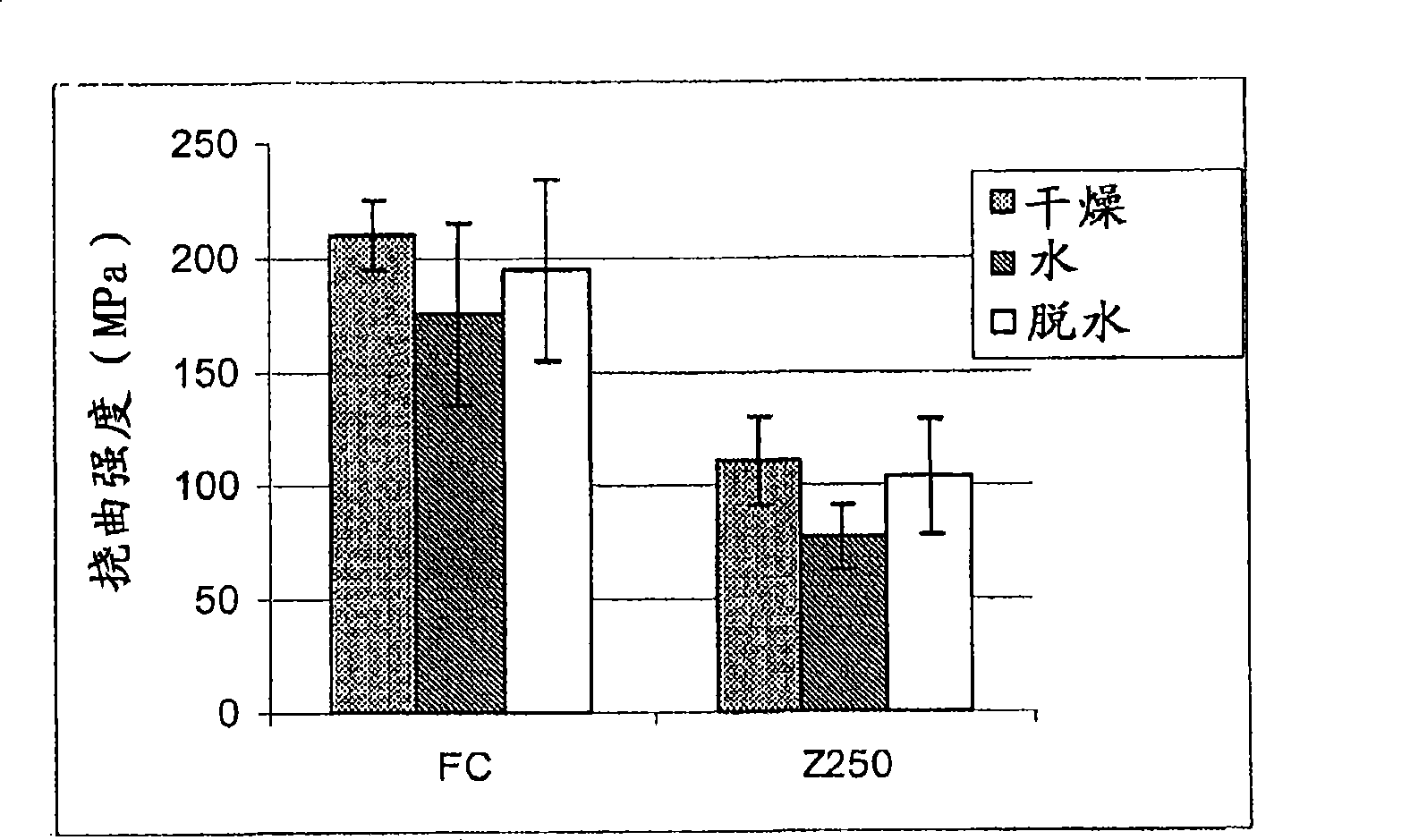

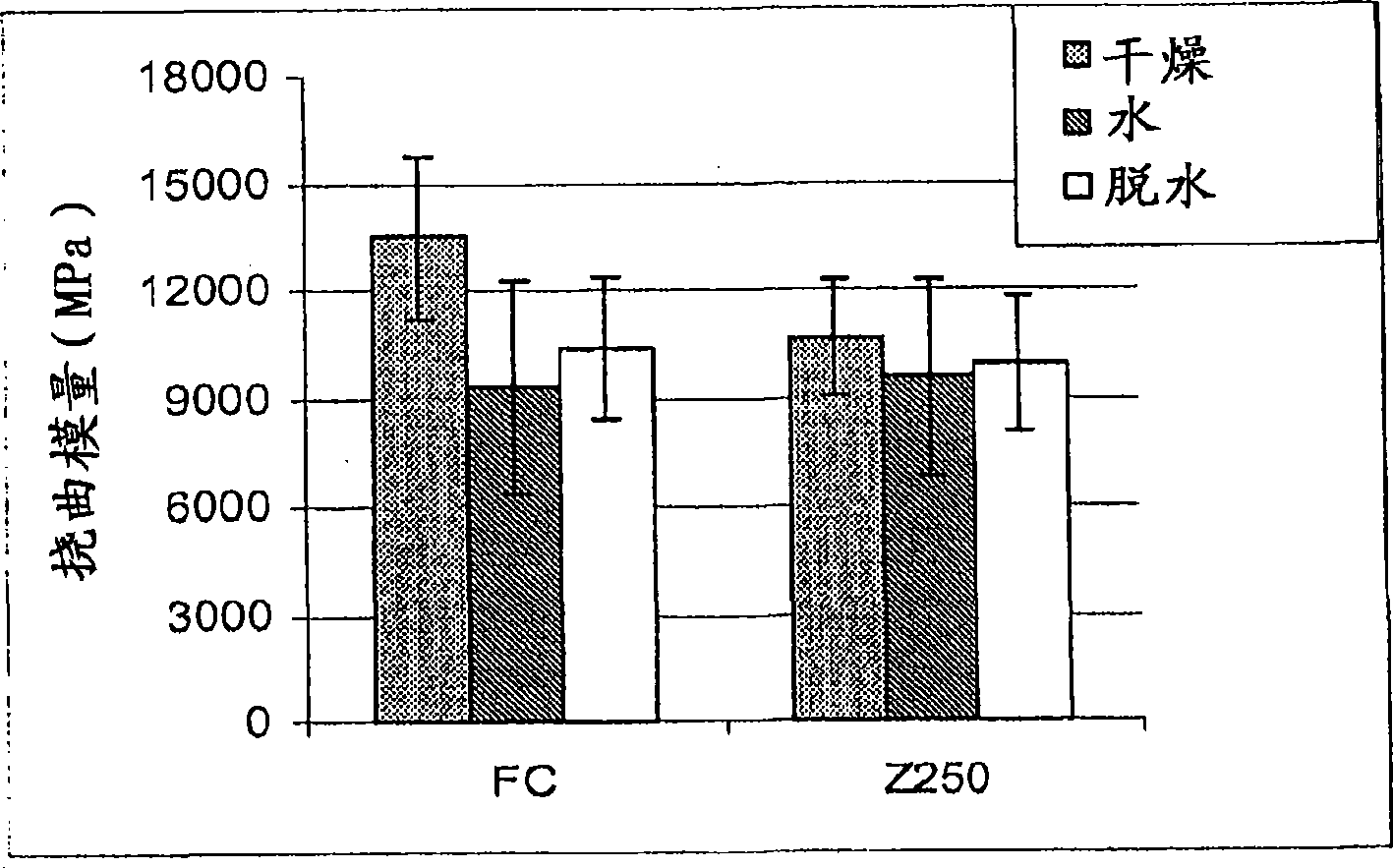

Fiber-reinforced composites and method for the manufacture thereof

The present invention relates to fiber-reinforced composites and a preparation method thereof, particularly application-oriented composites useful in dental and medical applications / appliances, such as fiber reinforced dental composites, and to a method for the manufacture thereof. Particularly the invention concerns random glass fiber-reinforced restorative composite resins with semi-interpenetrating polymer network matrix and their use in dental applications like cavity fillings, core composites, provisional and semi- permanent crown and bridge composite, cements and adhesives.

Owner:STICK TECH OY

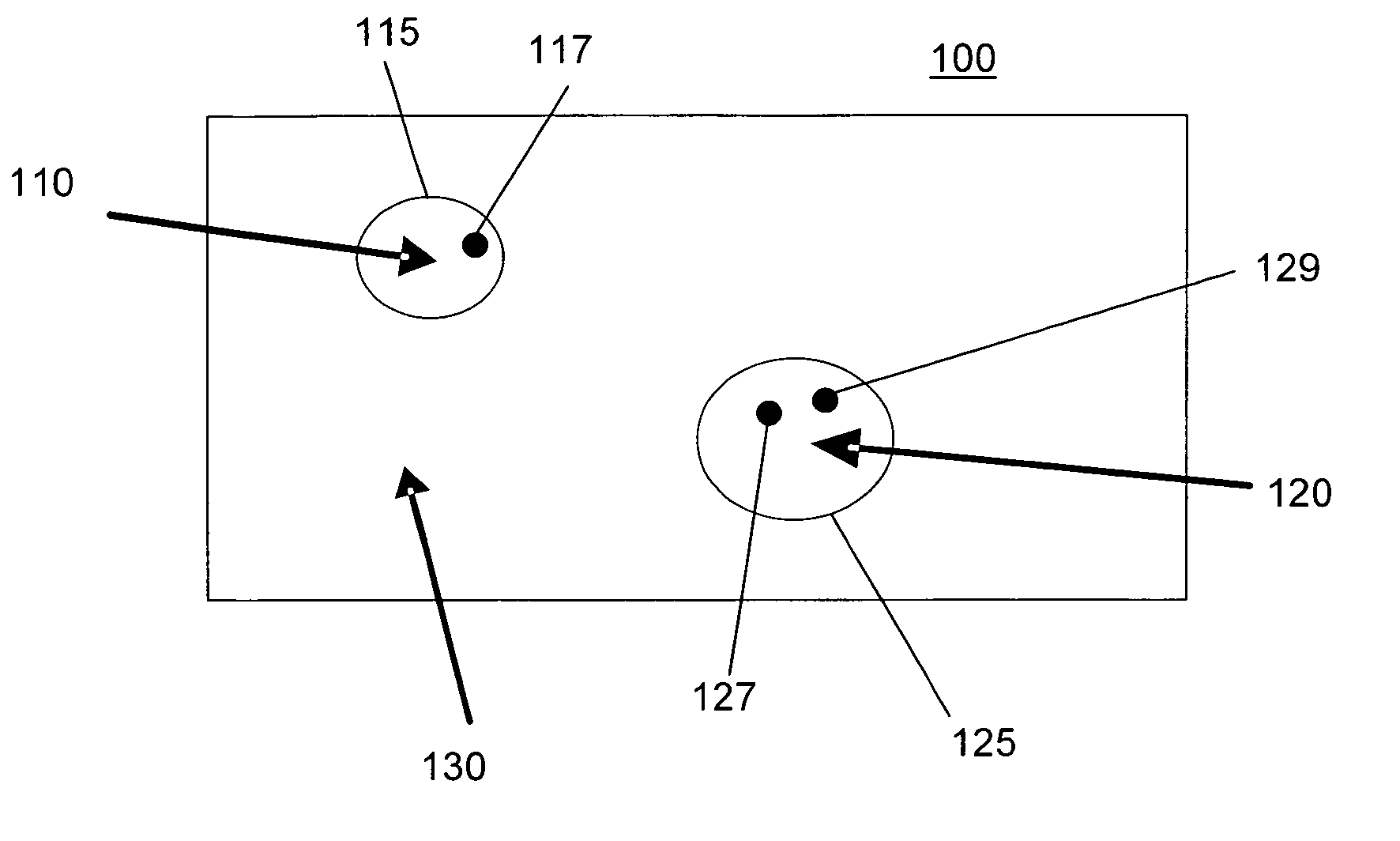

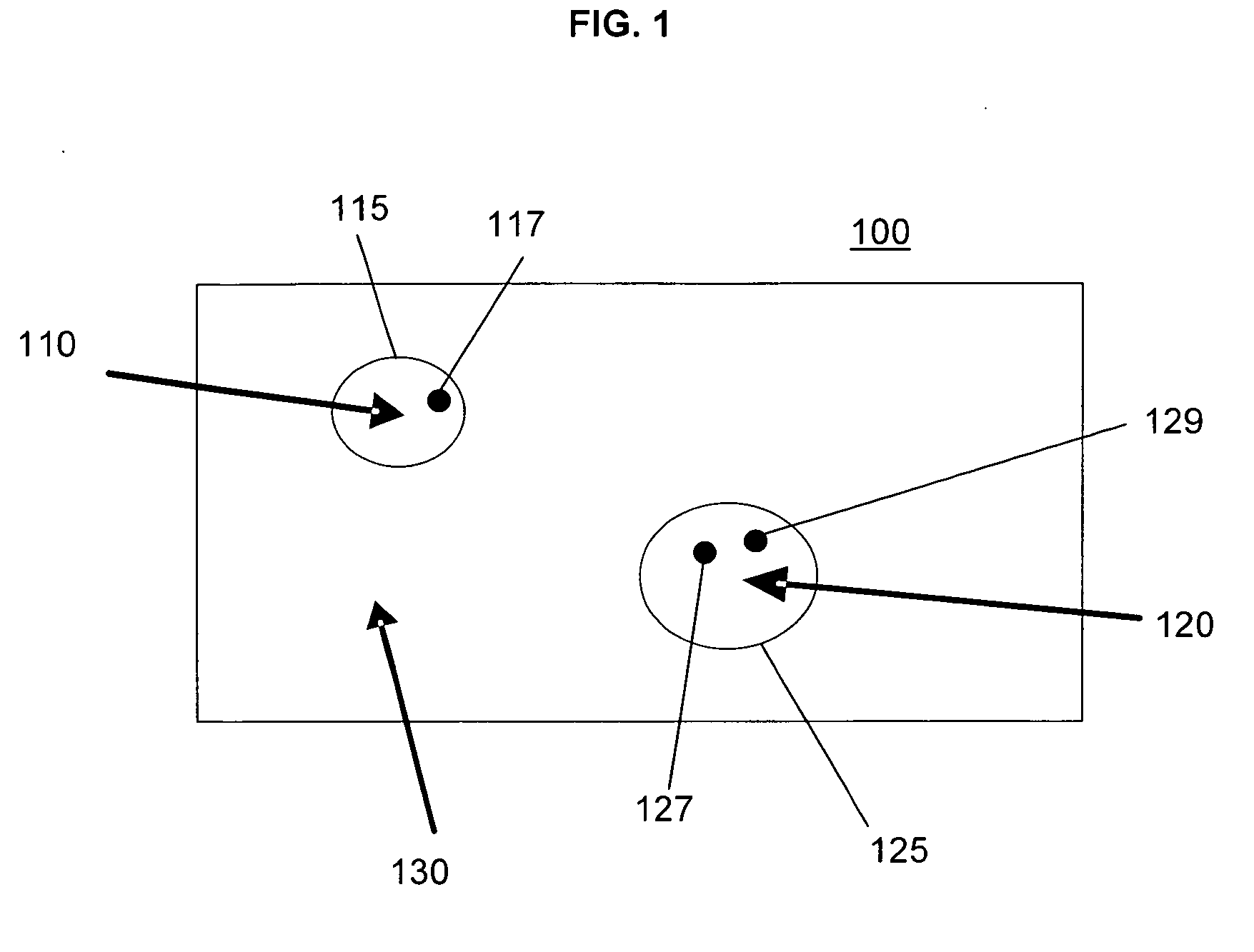

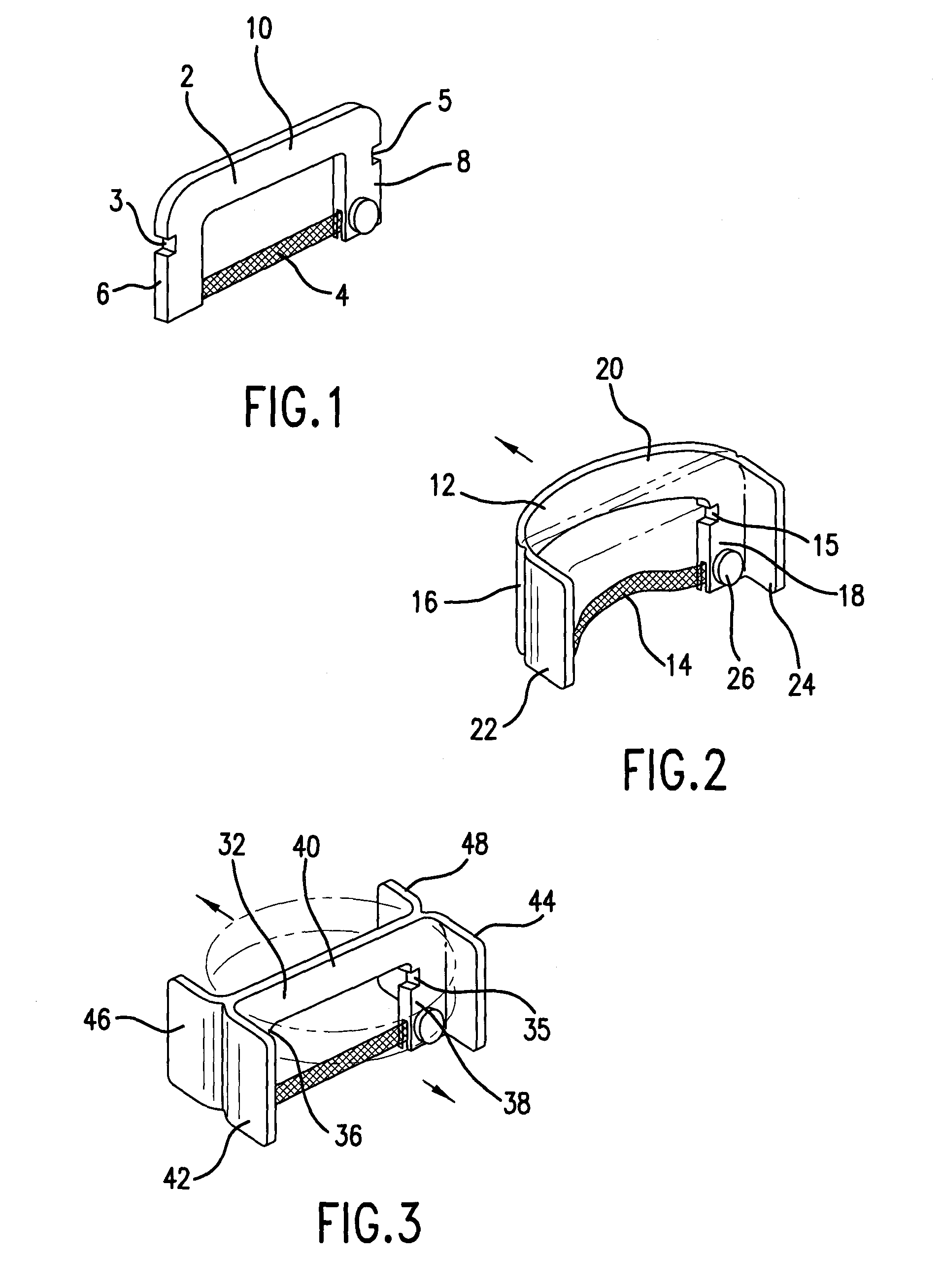

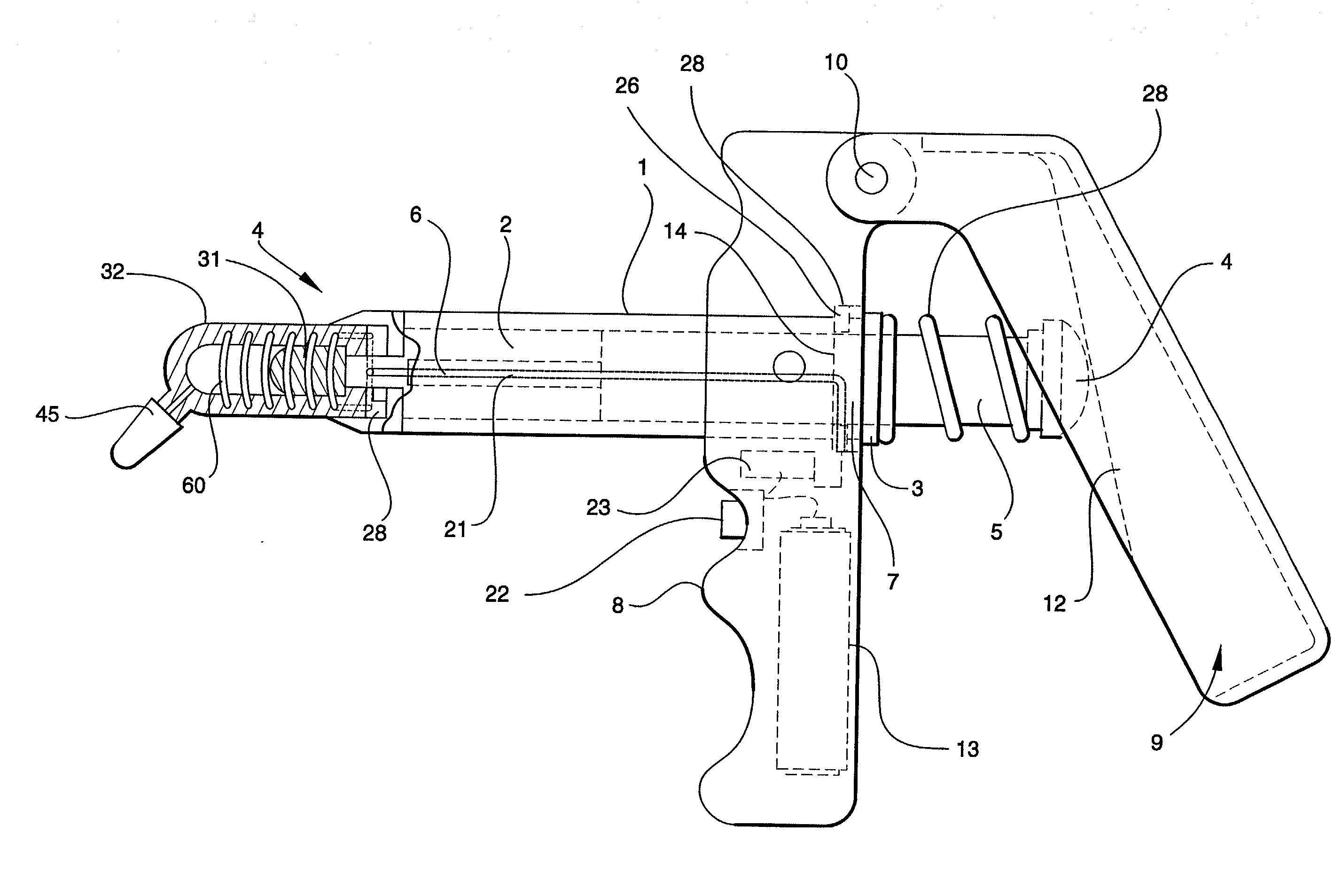

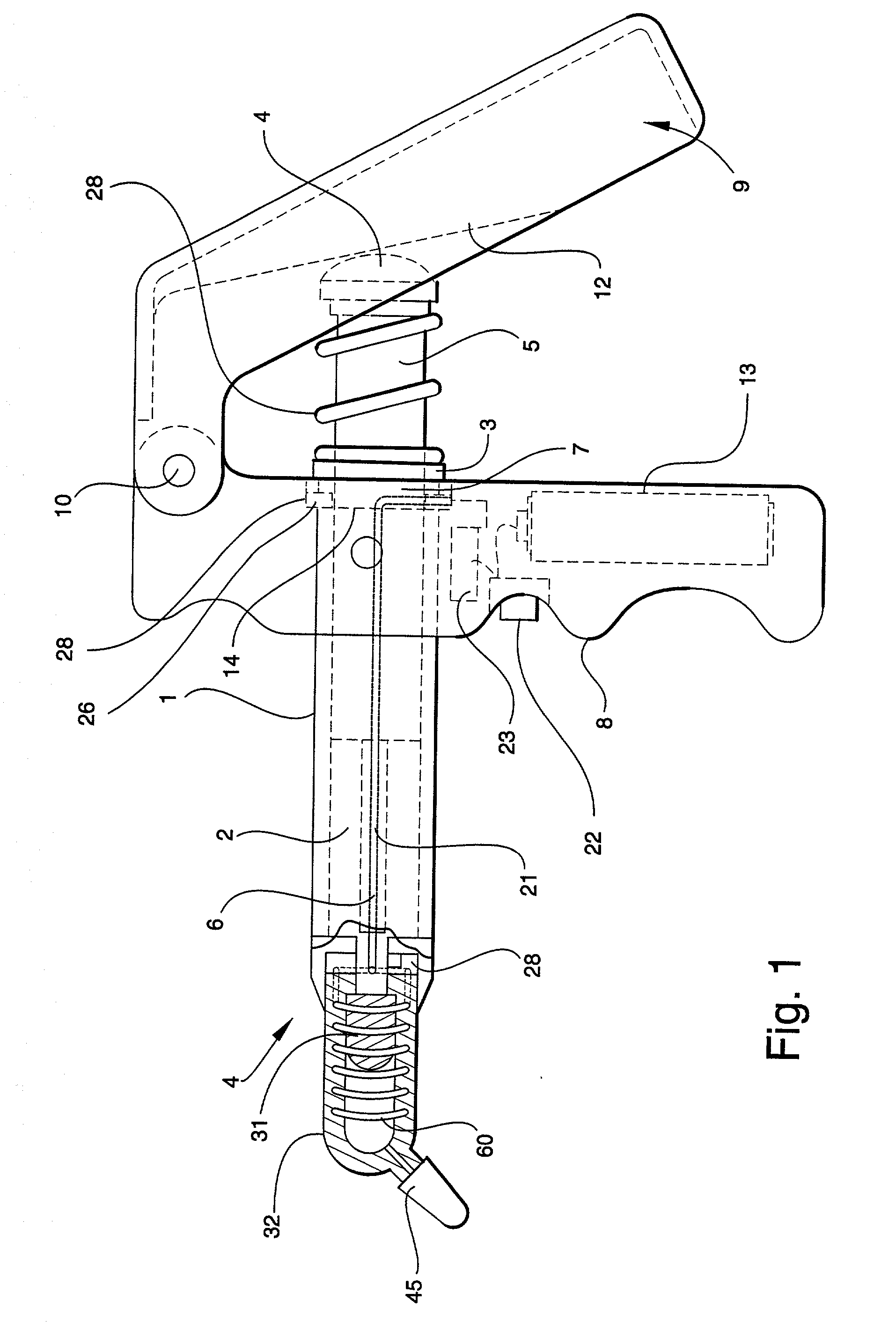

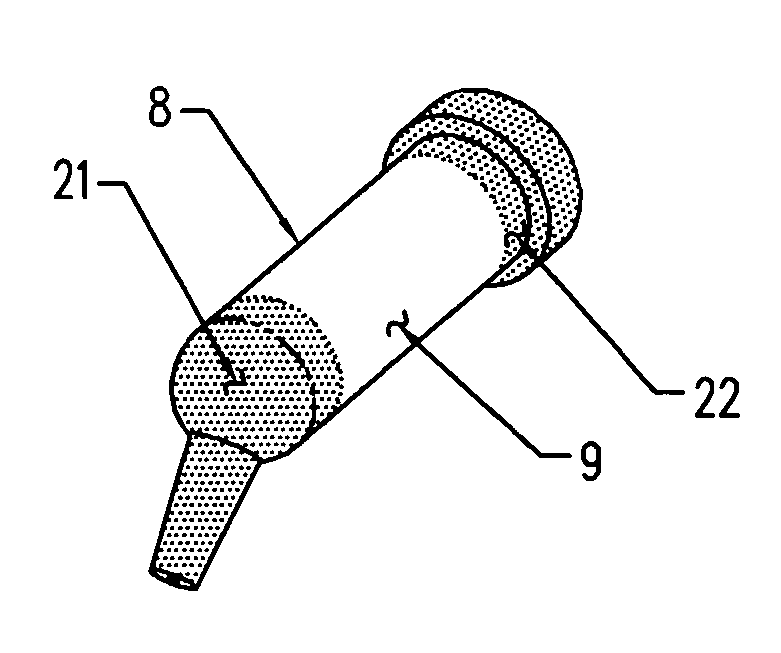

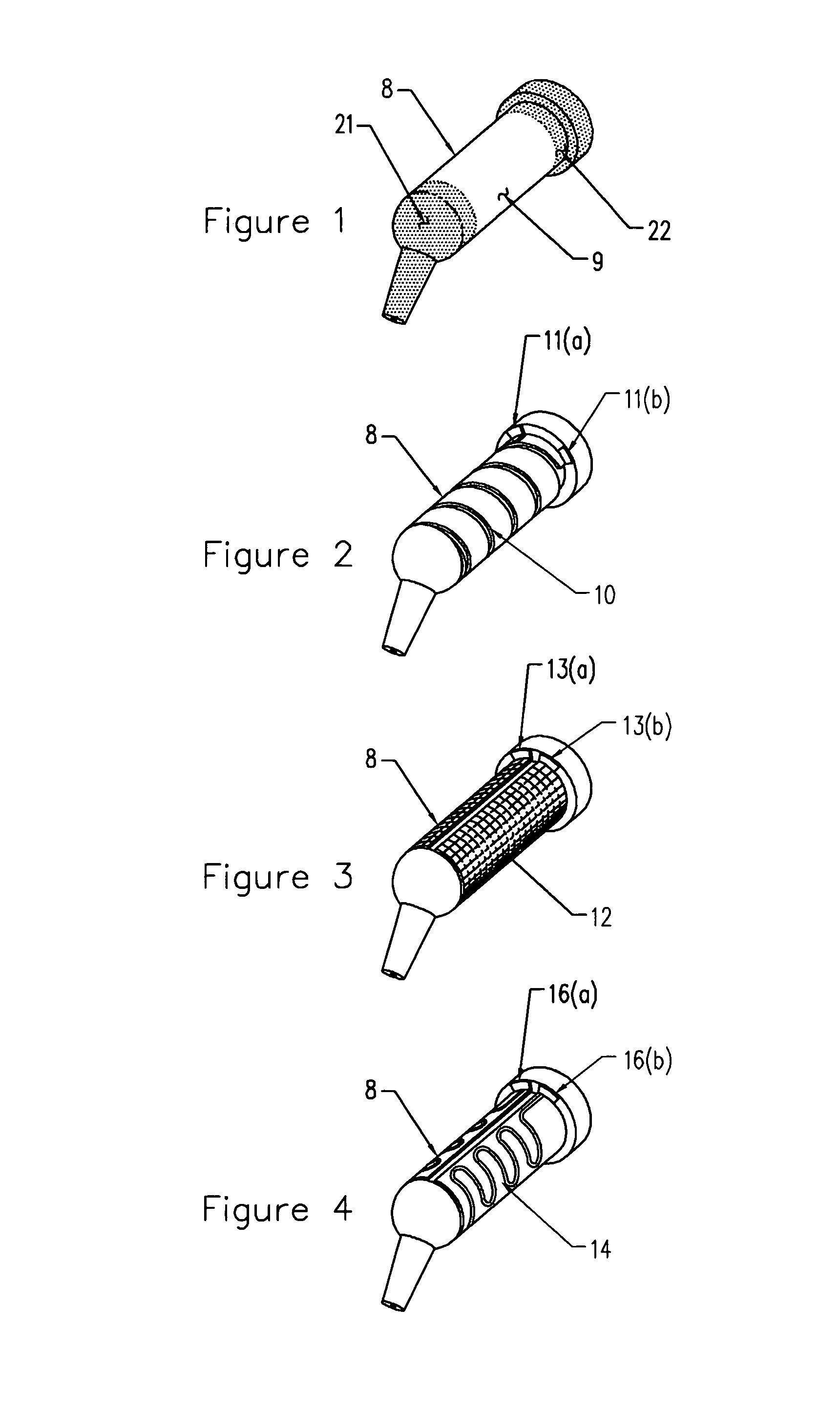

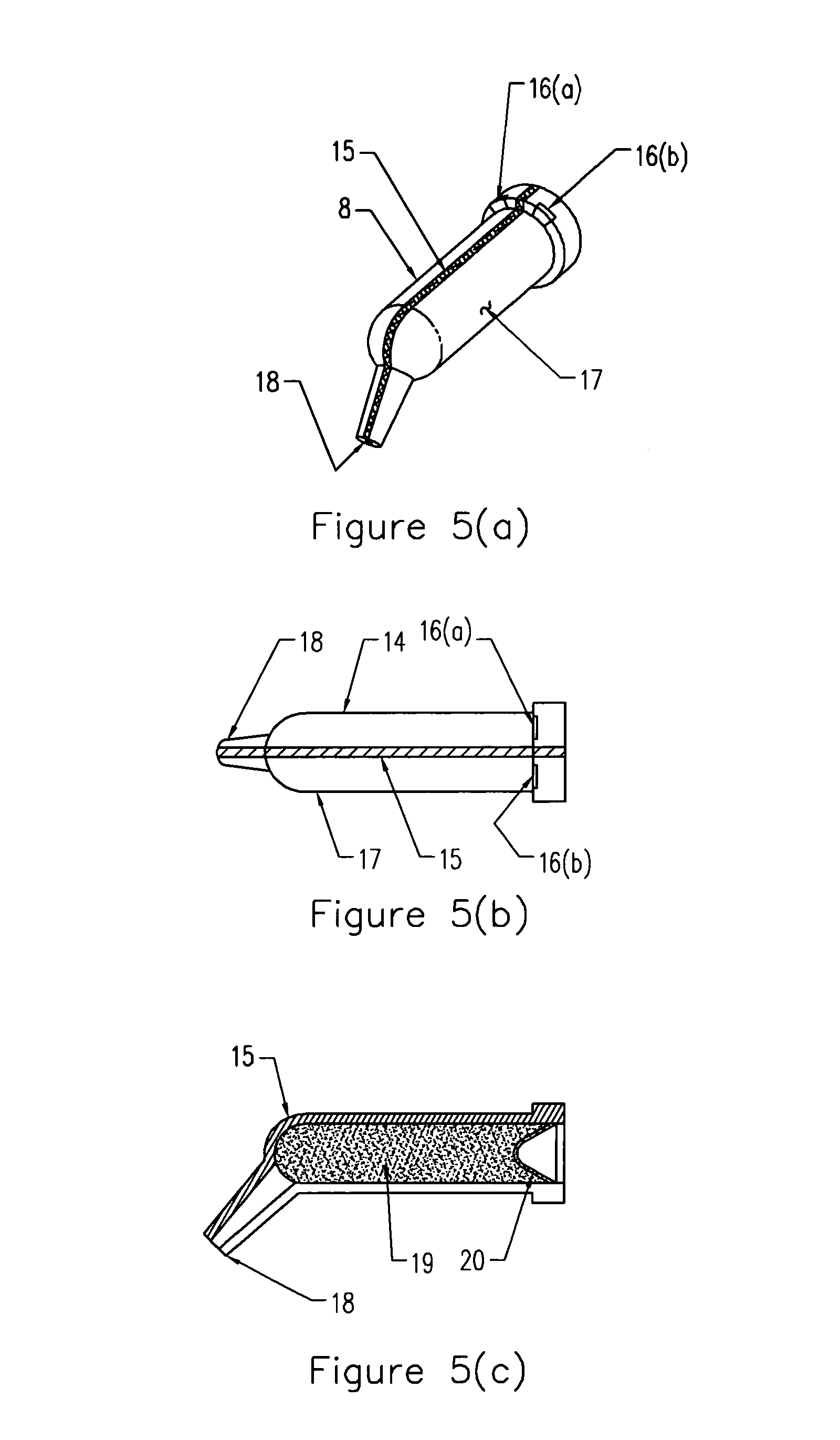

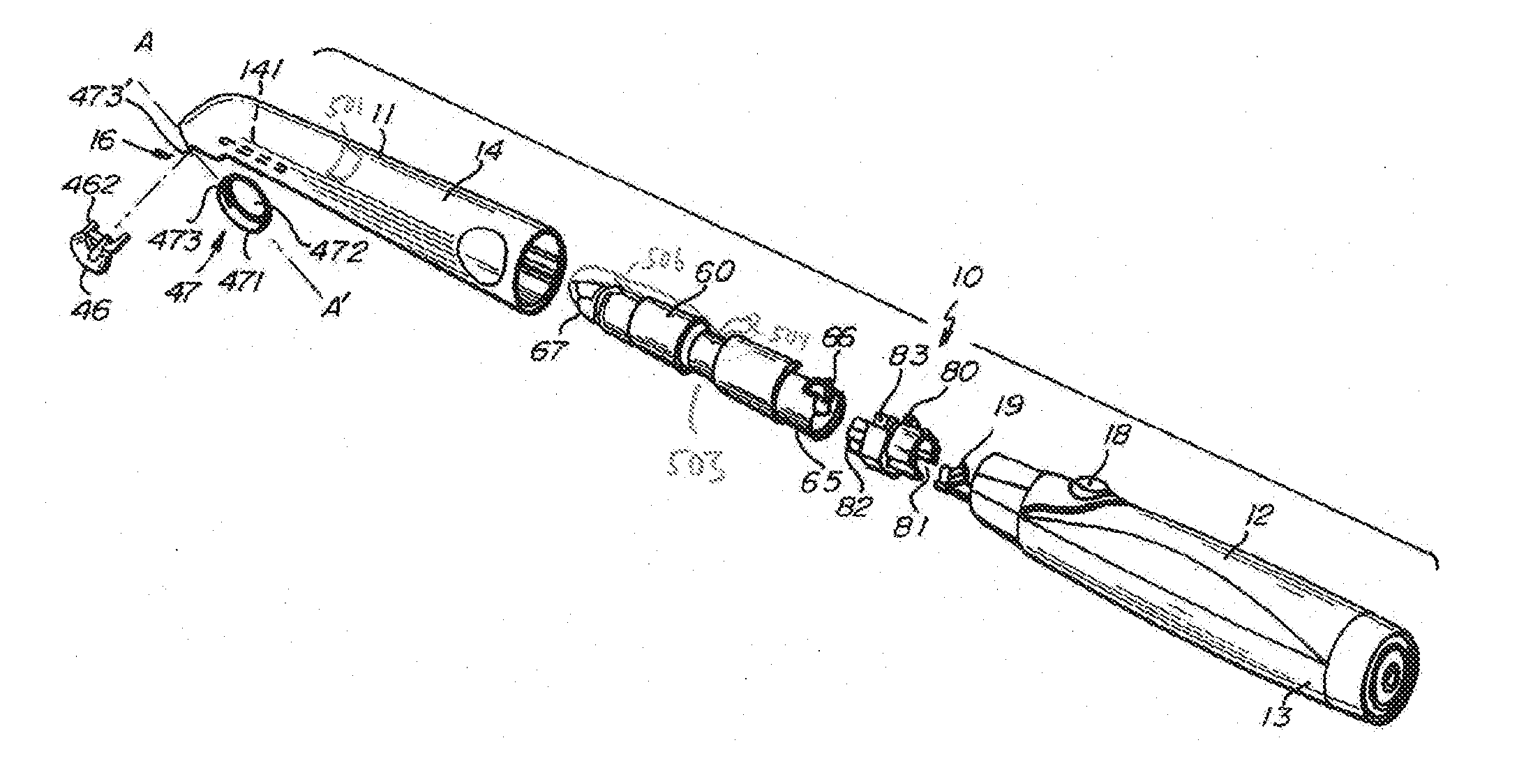

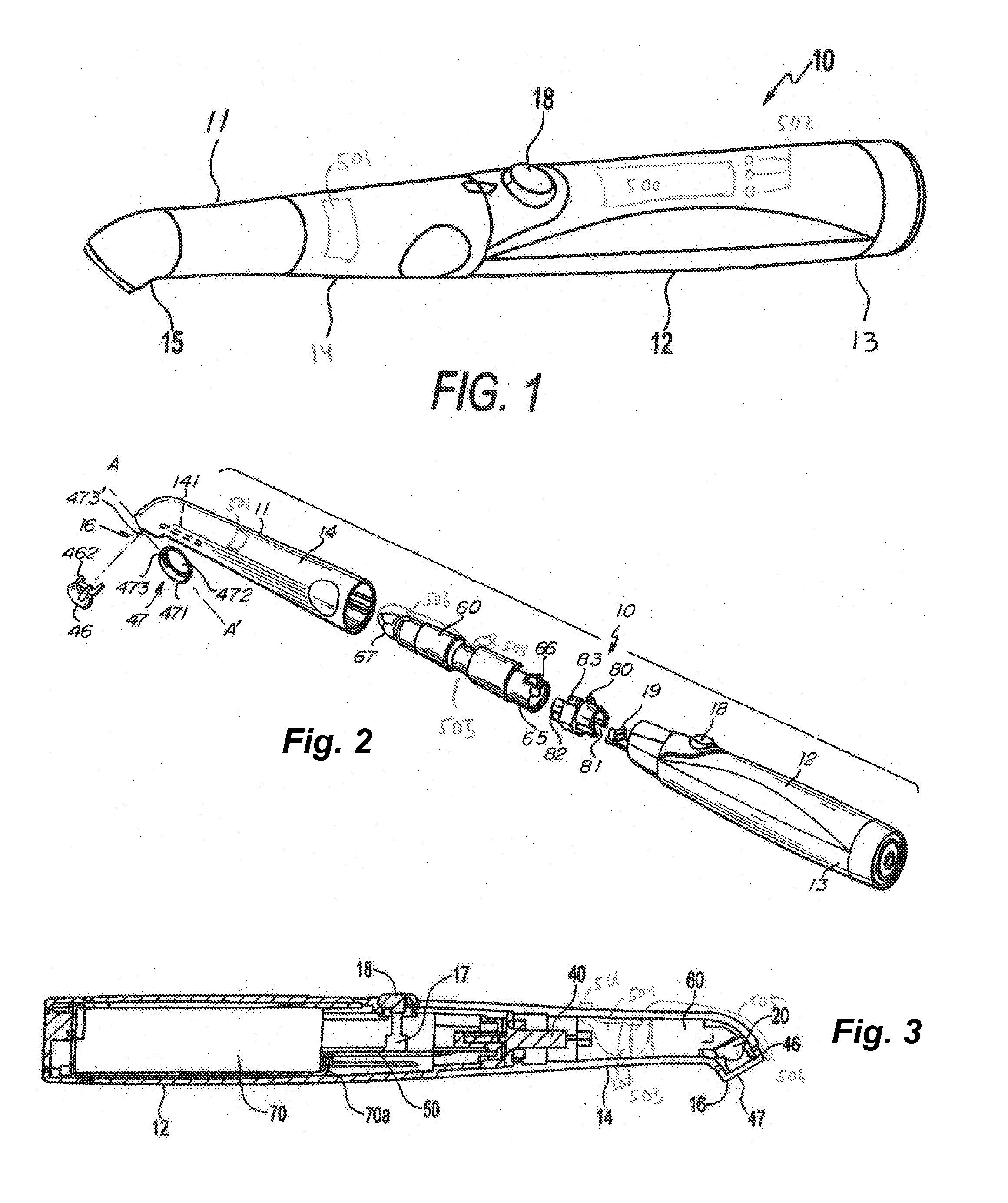

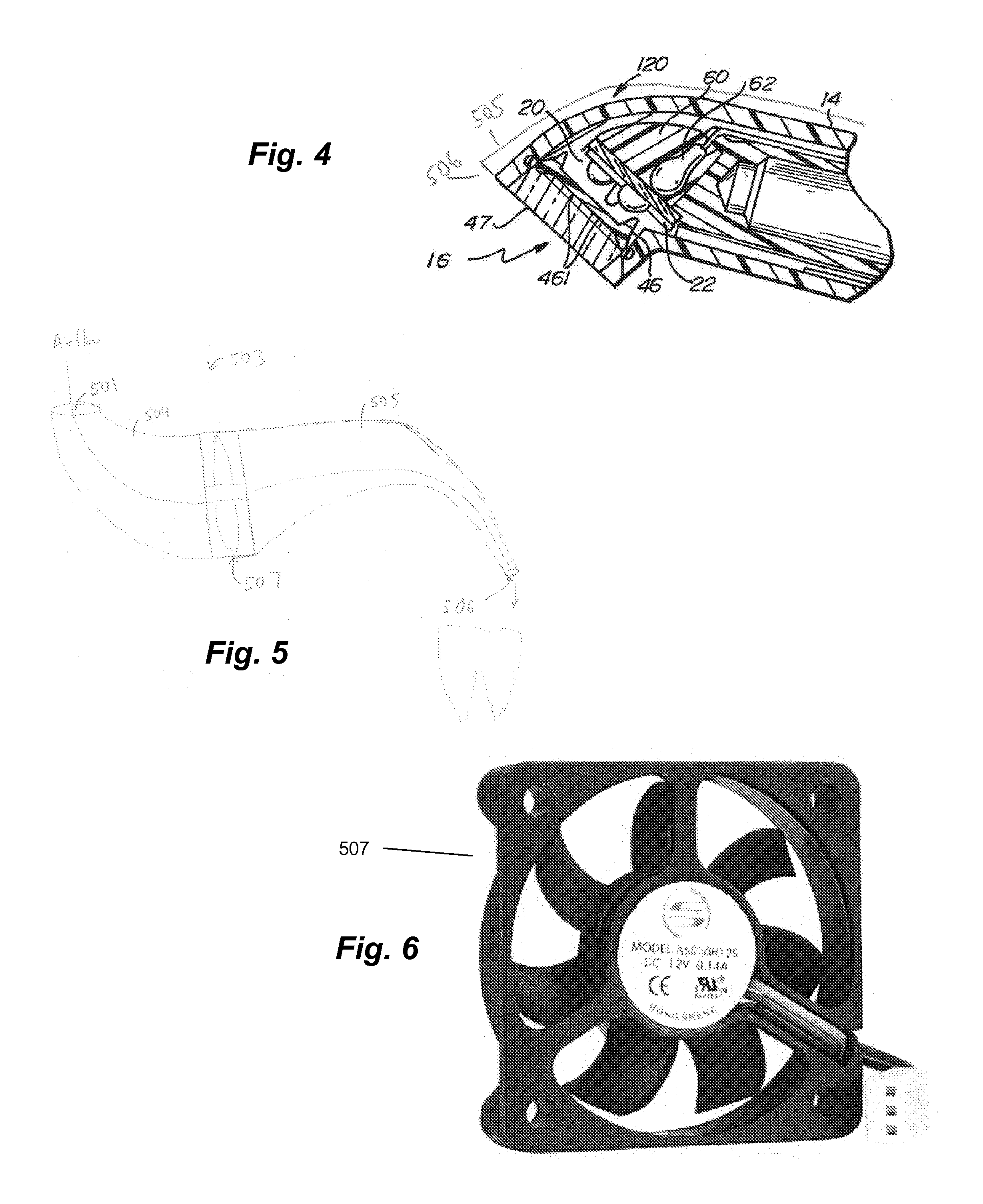

Devices and methods of applying dental composites

InactiveUS20080213731A1Easy to spread evenlyTendency is dullTooth sawsTooth pluggers/hammersDental compositeHand held

A device and method for applying dental composite matter to dental surfaces, such as cavities in teeth, gaps in teeth, or other deformations in tooth surfaces, or other applications to teeth, or appliances and devices used with teeth, such as crowns or inlays / onlays. A hand held powered tool provides oscillation of the composite material after the composite material is grossly applied to the dental surface. The oscillation is at a frequency and amplitude that facilitates uniform spreading of the composite material over the dental surface in a desired pattern, while retarding the tendency of the material to stick to the tool.

Owner:FISHBURNE COTESWORTH

Dental composite restorative material and method of restroring a tooth

InactiveUS20030060532A1Highly packableCosmetic preparationsImpression capsMicrometerDental composite

A dental composite material includes a hardenable resin matrix and a filler component. The filler component includes (a) a first plurality of preferably glass particles having an average particle size of from about 1 to about 10 micrometers; (b) a second plurality of preferably glass particles having an average particle size of from about 0.1 to about 1 micrometers; and, (c) a plurality of filler particles having an average particle size of from about 0.01 to about 0.04 micrometers. A method according to the invention includes compacting a dental composite material into a prepared tooth cavity, wherein the material has a packability index above about 300 g / mm2.

Owner:DENTSPLY RES DEVMENT

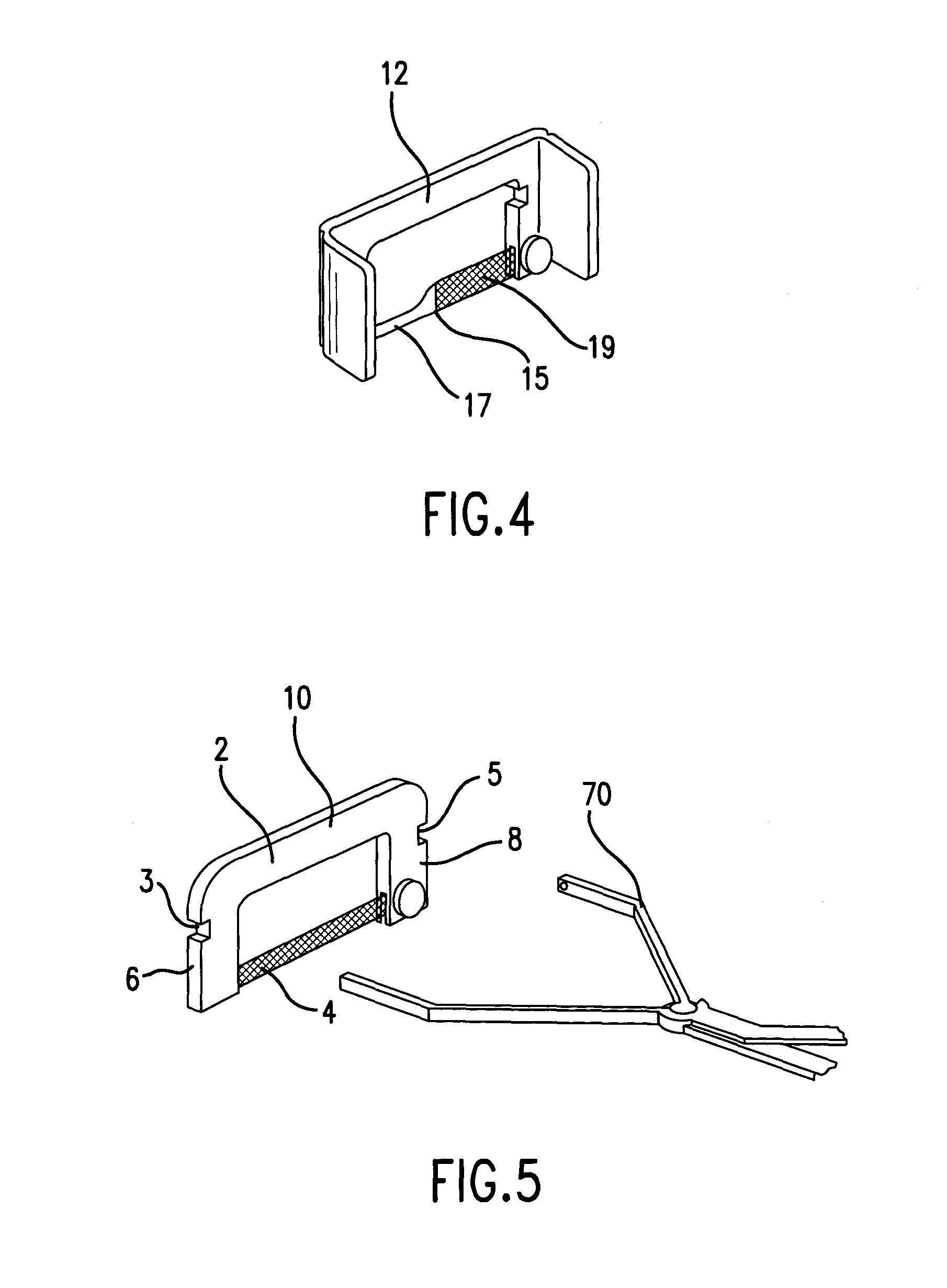

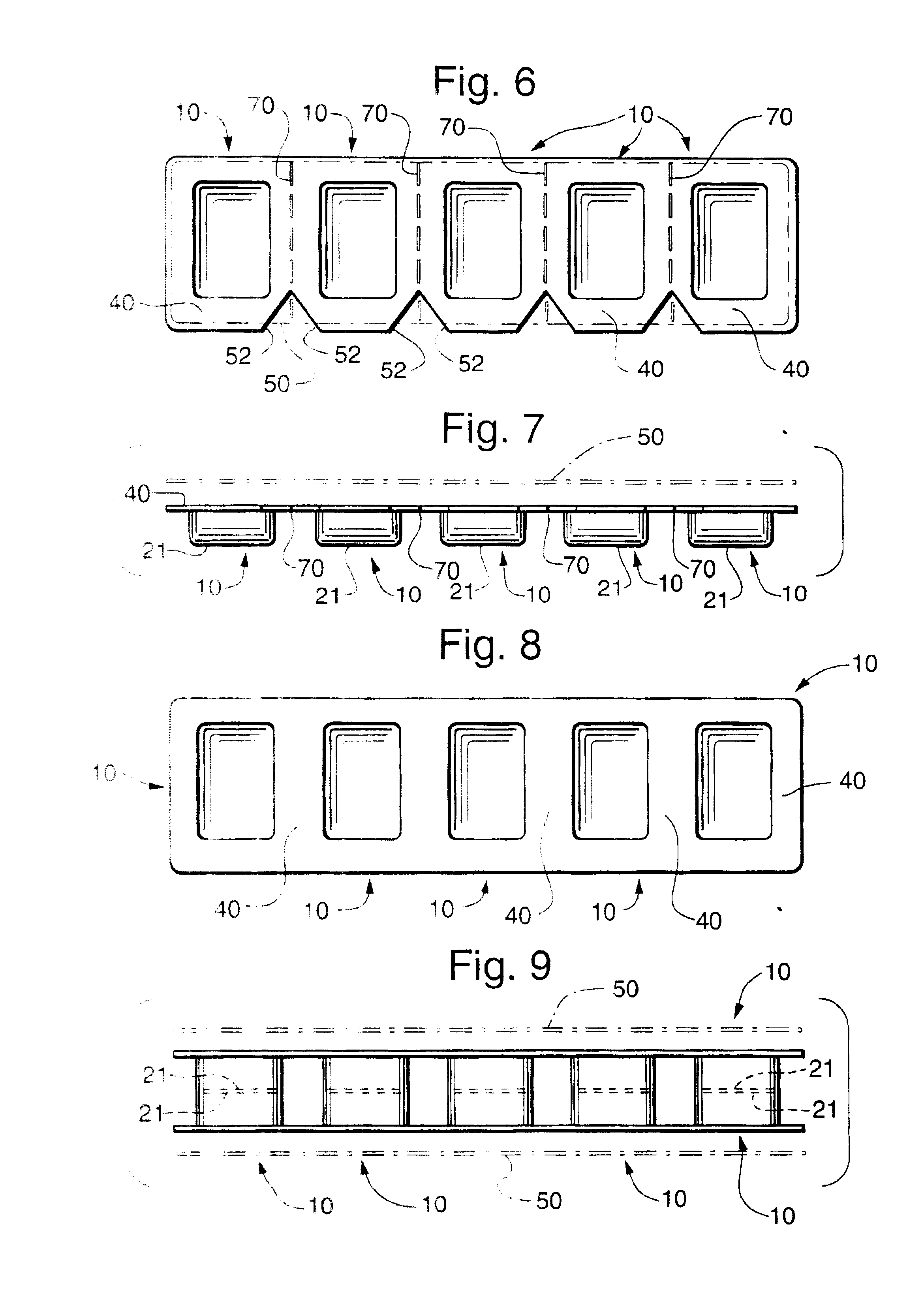

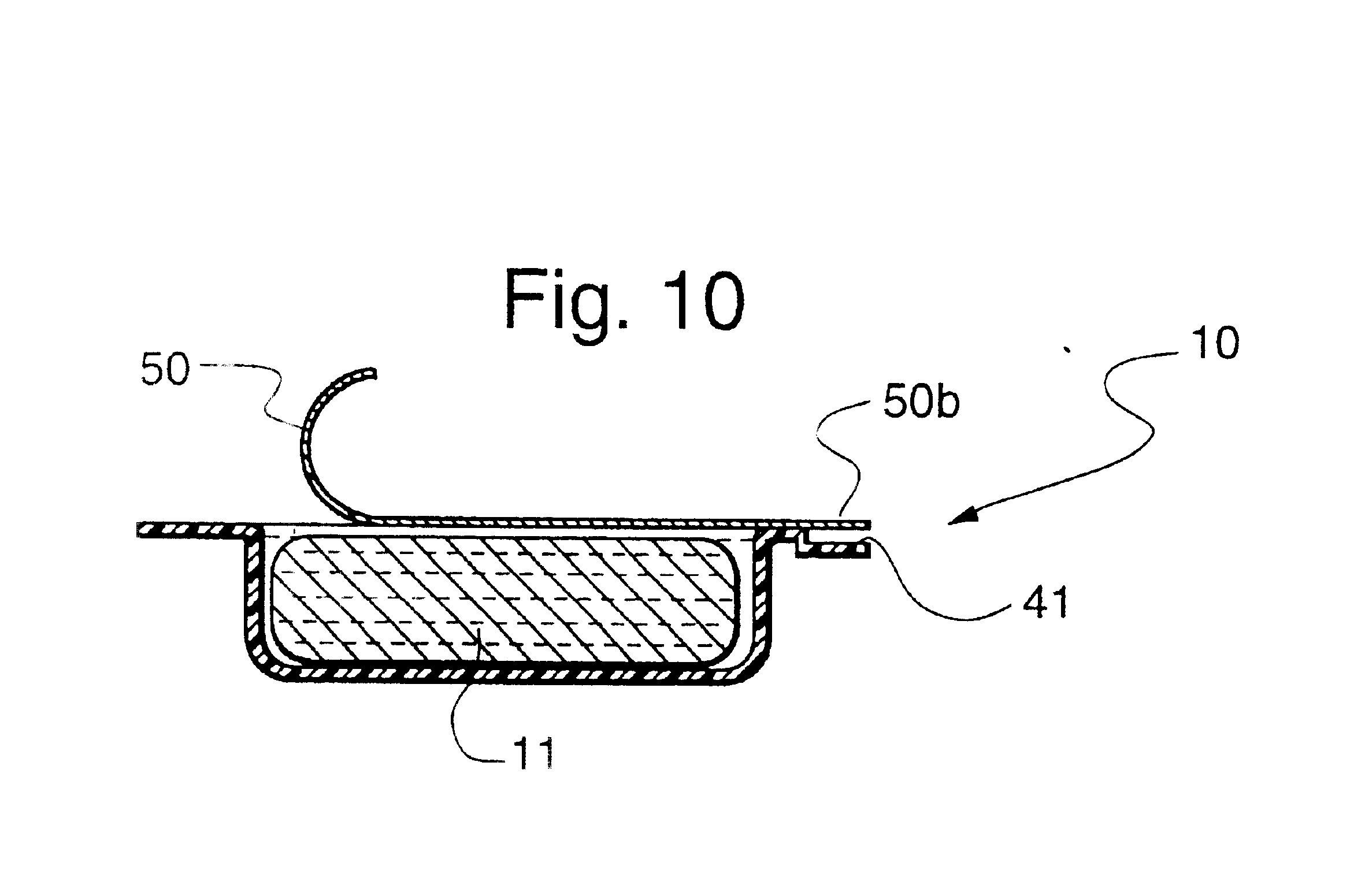

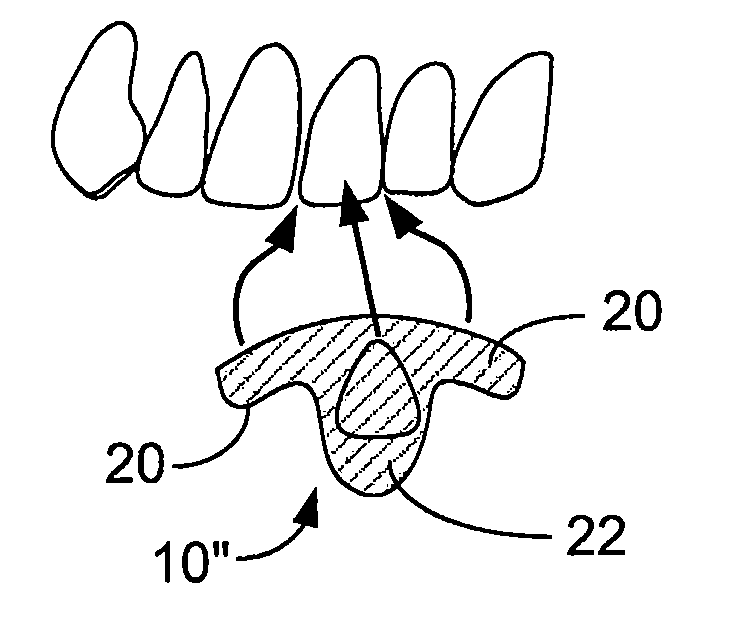

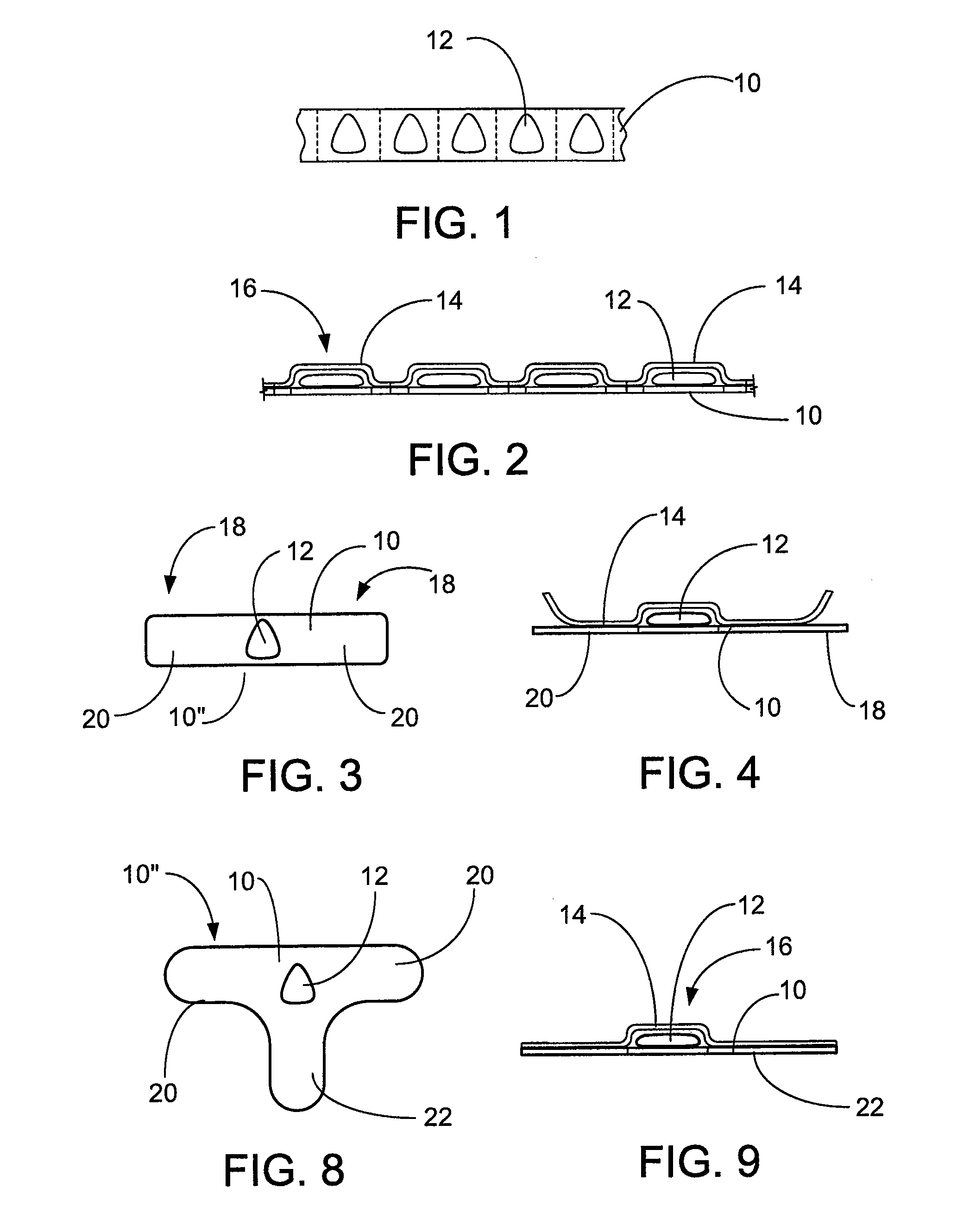

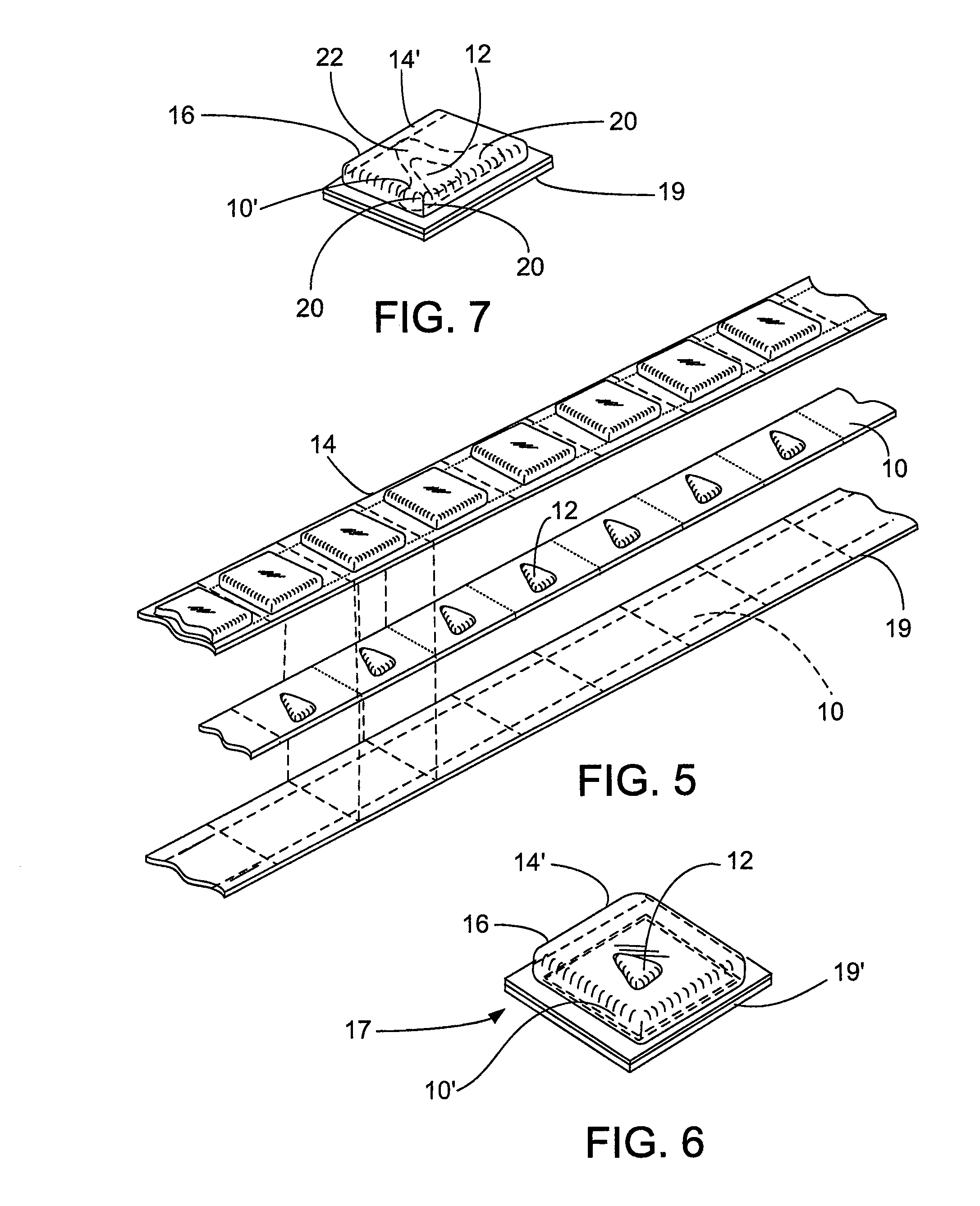

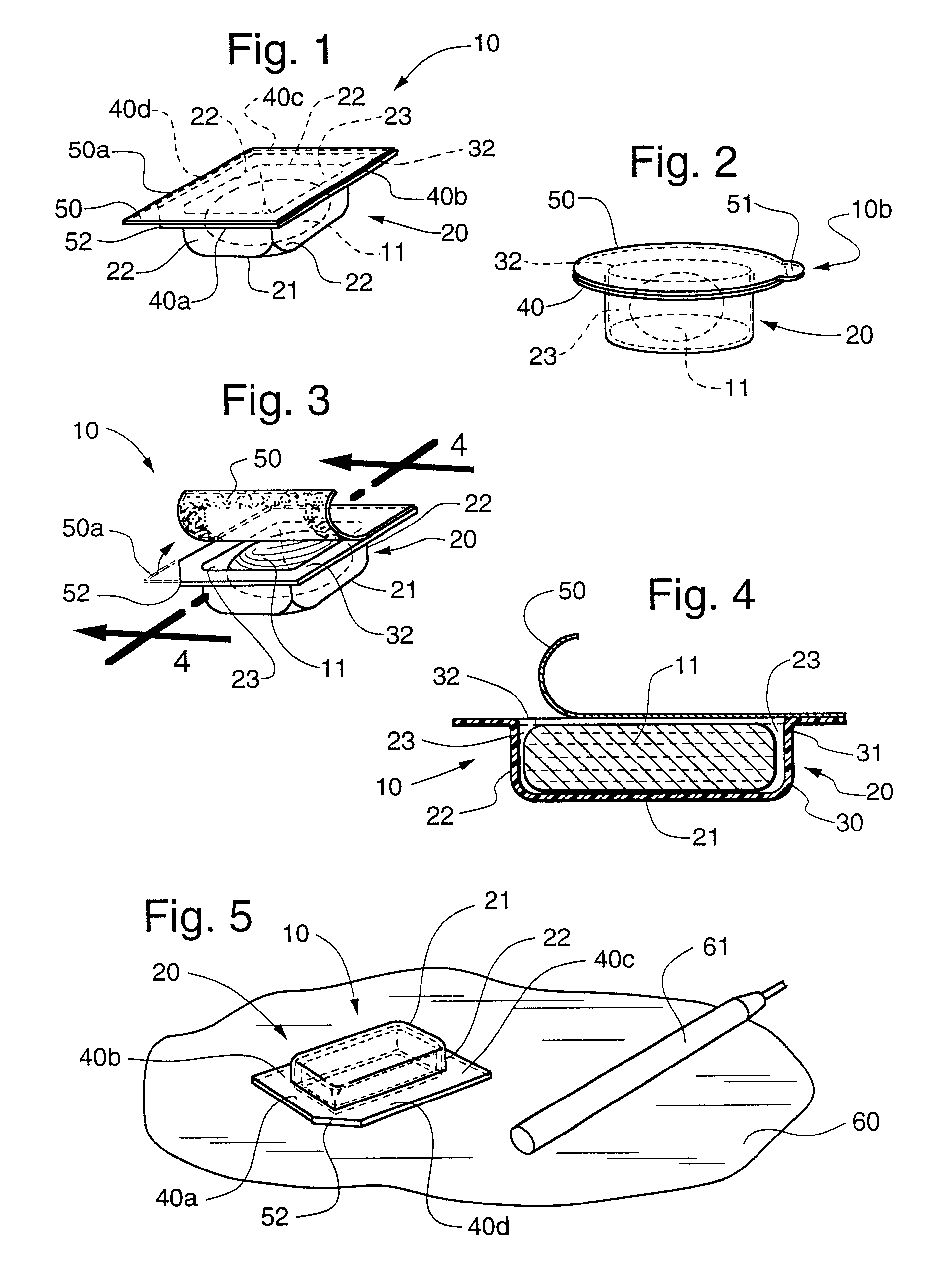

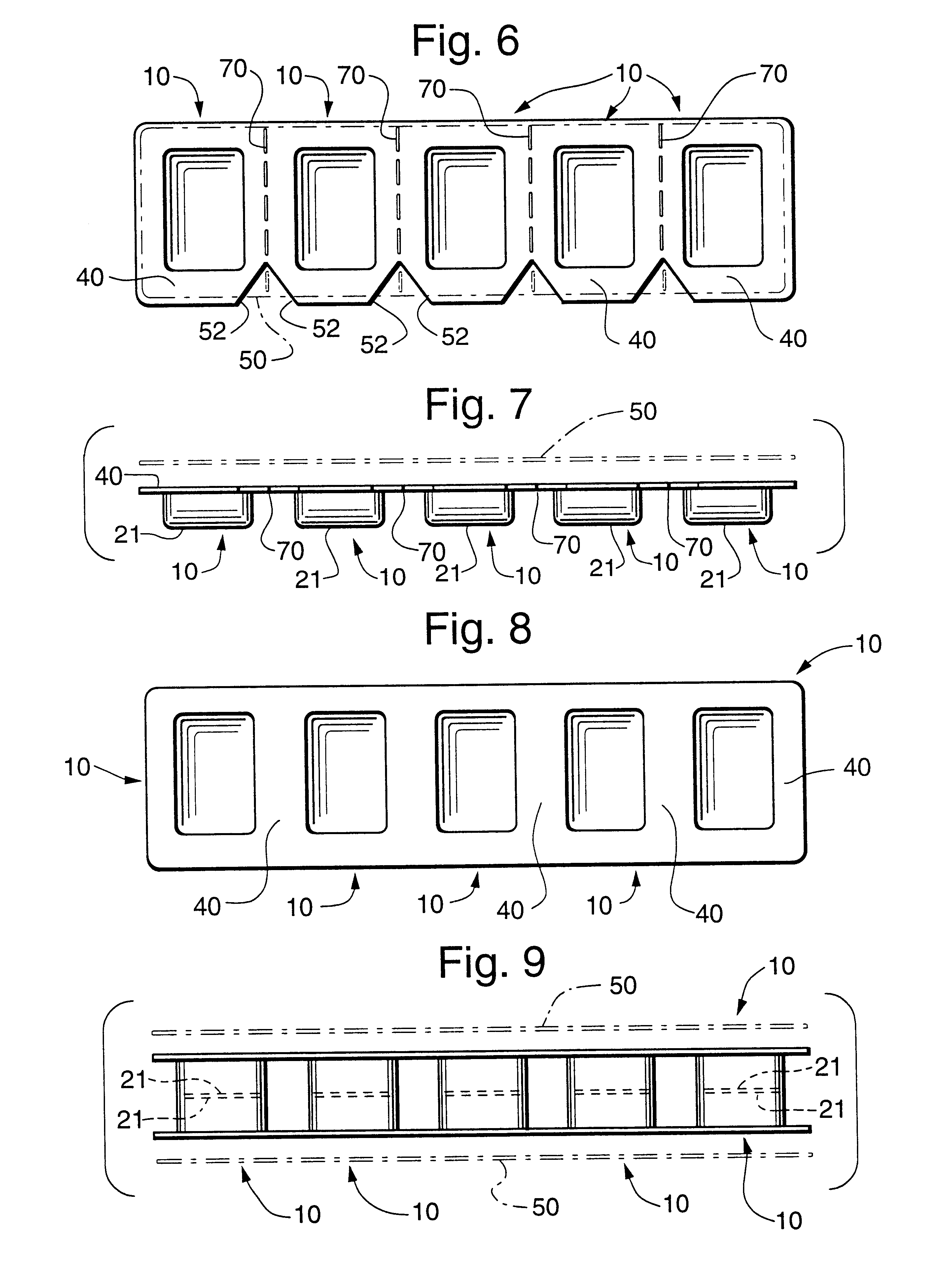

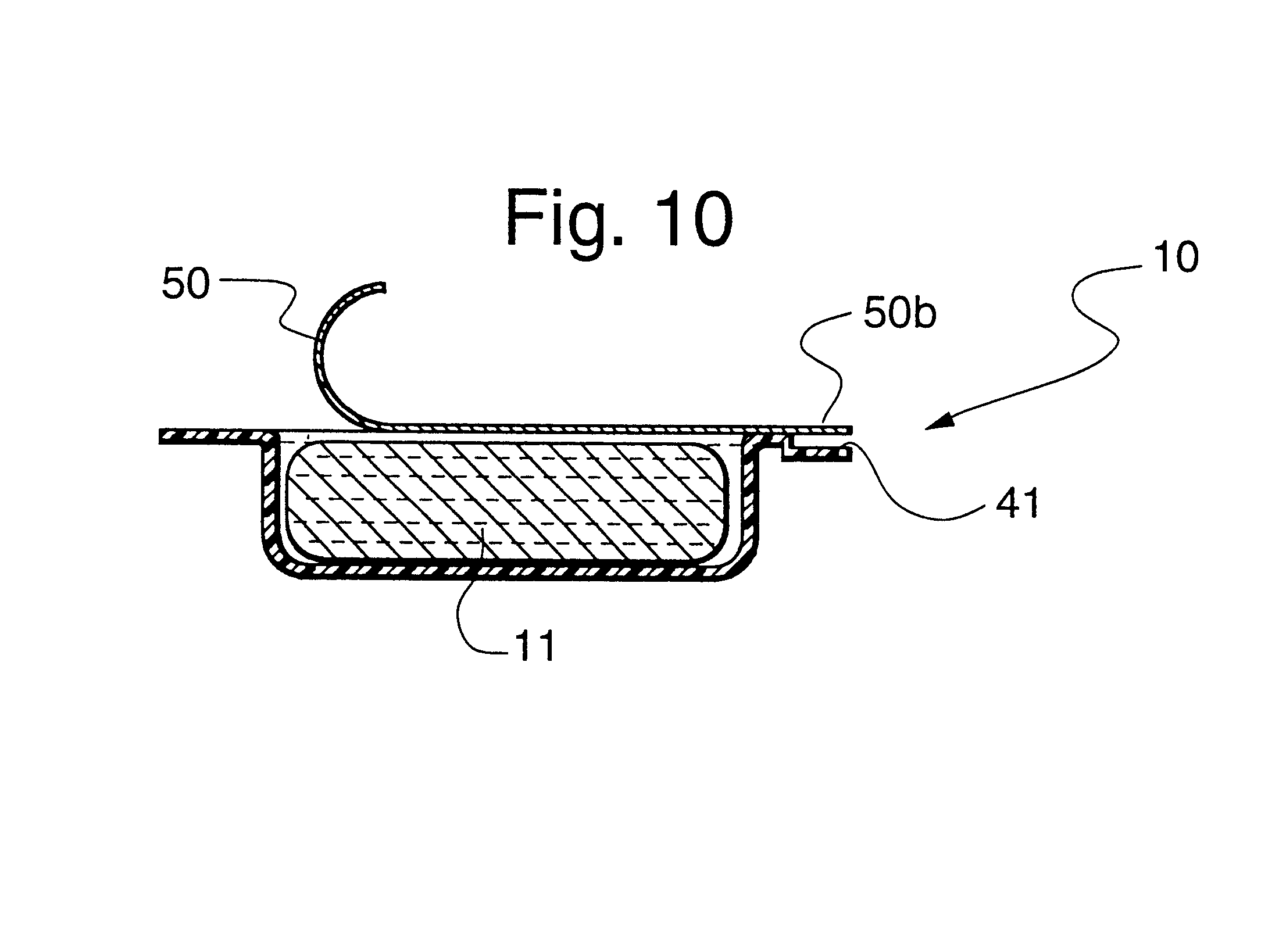

Dental composite delivery system

InactiveUS8197252B1Easy to pasteAvoid excessive accumulationDam holdersTooth clampsDental compositePolymer thin films

A packaged unit of composite for performing an aesthetic restoration. The unit is mounted on a polymeric film carrier material and is covered and sealed with the same or otherwise suitable covering film. The carrier film may be an elongated strip containing serially placed units of composite, each readily separable from the strip for individual usage. This packaging is in light restrictive outer packaging since the preferred unit of composite is of a light-cured material such as bis-GMA. In preferred packaging, the unit dose is singular and applicable to the tooth surface with the film carrier which is adapted with tabs to facilitate handling and the draping or damming of the subject tooth from adjacent teeth to facilitate application of the composite. The composite is then worked, i.e., formed on the tooth with the film intermediate the composite and the customary forming tools. In preferred embodiments, the single unit packaging of composite is mounted on a clear carrier film which includes embrasure tabs for selective insertion in the embrasure between the teeth, and in a further preferred embodiment, the carrier film includes an incisal tab to cover the incisal edge of the tooth. The clear carrier is contained in further outer packaging which limits actinic radiation from reaching the composite.

Owner:HARRISON III LOUIE V

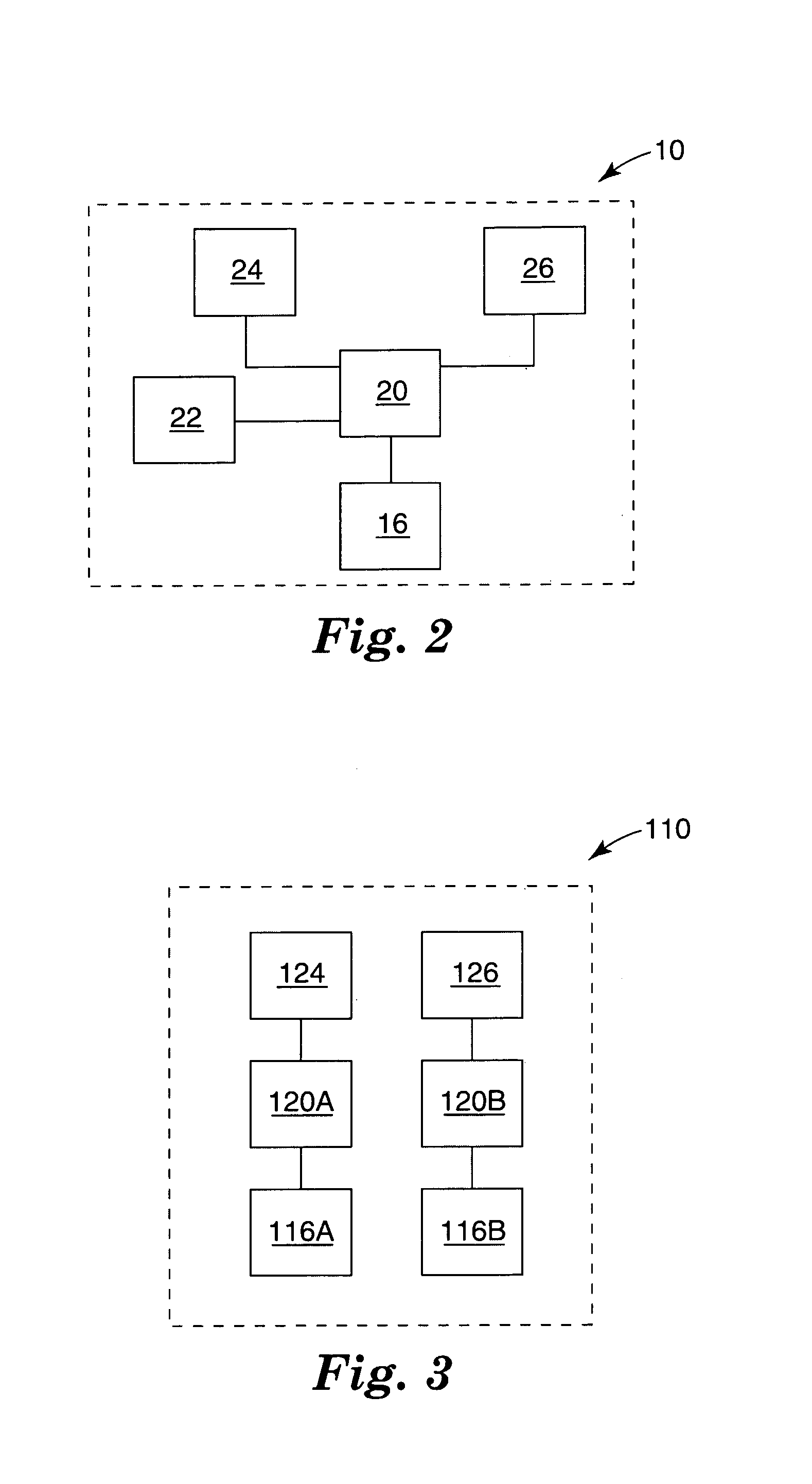

Light emitting diode light source for curing dental composites

InactiveUS20050196720A1Sufficient powerSufficient structureSolid-state devicesDischarge tube main electrodesDental compositeHeat sink

Light Emitting Diode Light Sources for Dental Curing are disclosed. Some embodiments of the invention include structures such as Light Emitting Diode Array(s), heat sink, heat dissipation, heat pipe, and control circuitry are disclosed.

Owner:KONINK PHILIPS ELECTRONICS NV

Filler materials for dental composites

InactiveUS20060241205A1Easy to operateImprove wear resistanceImpression capsDentistry preparationsFilling materialsDentures

A dental composite comprising a reinforcing material in the form of glass flakes. The resulting filler material can be used in dental composites and dental restorations including but not limited to fillings, orthodontic retainers, bridges, space maintainers, tooth replacement appliances, dentures, crowns, posts, jackets, inlays, onlays, facings, veneers, facets, implants, abutments, cements, bonding agents and splints, to provide optimal handling properties, good wear resistance and high strength.

Owner:PENTRON CLINICAL TECH

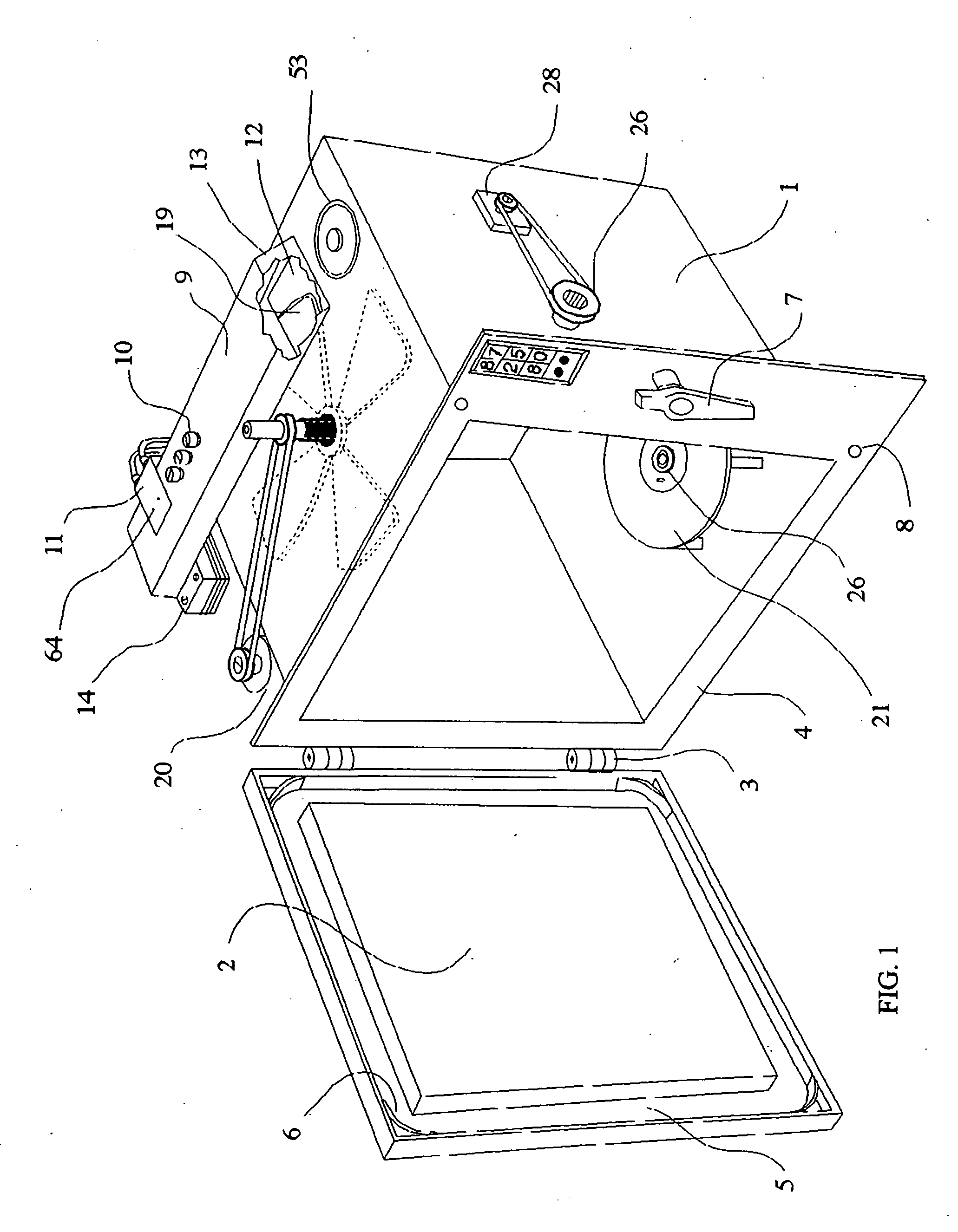

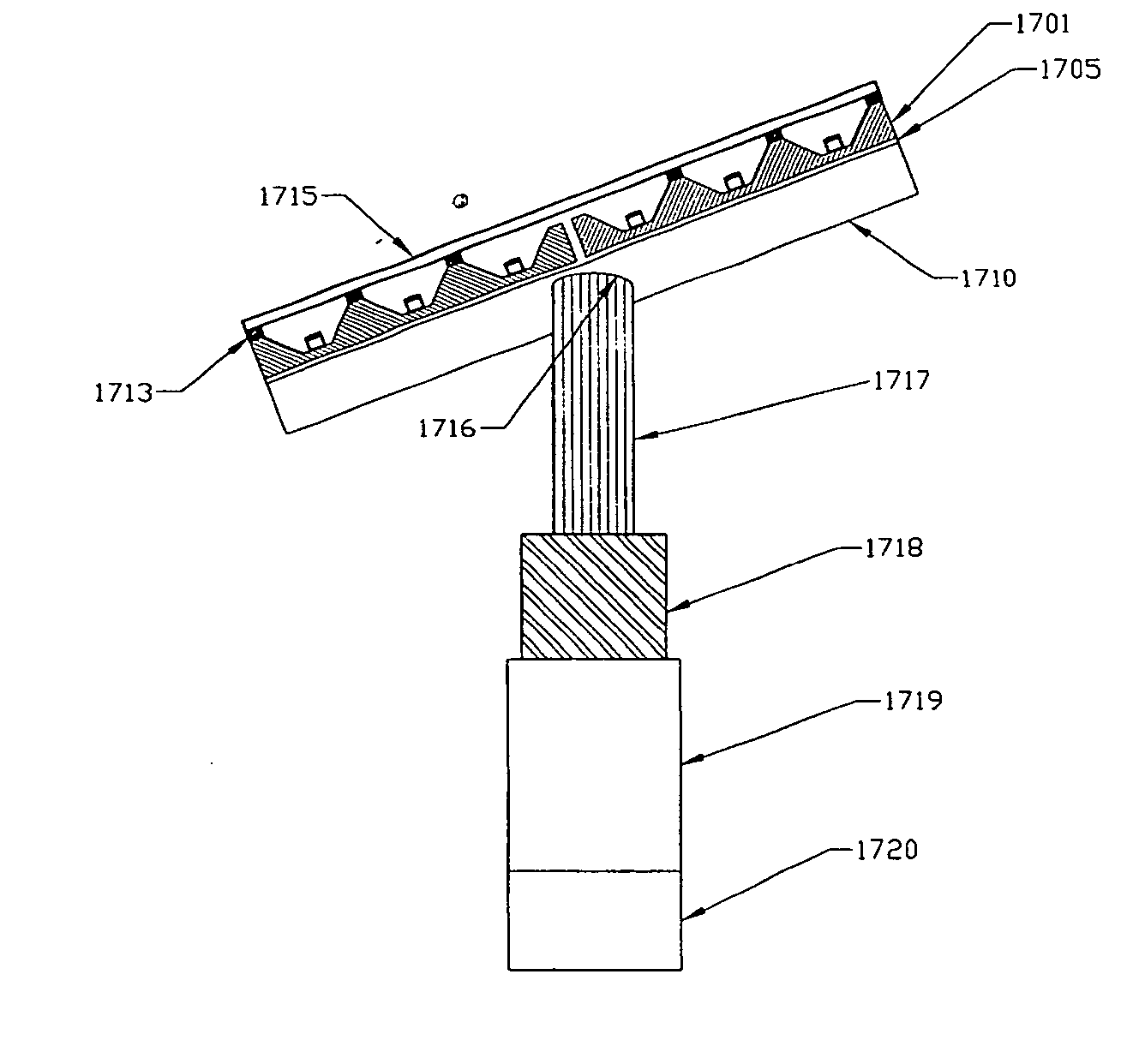

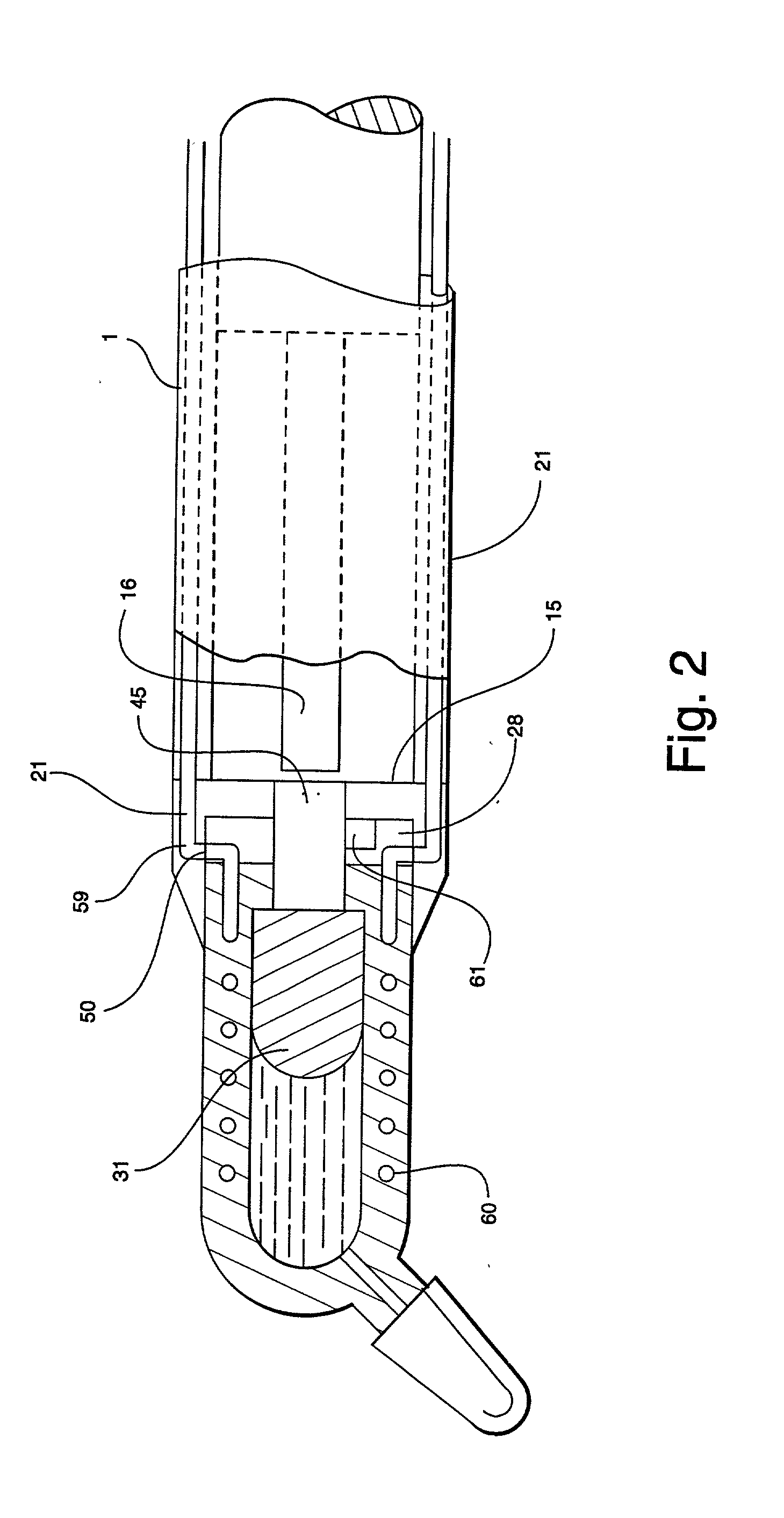

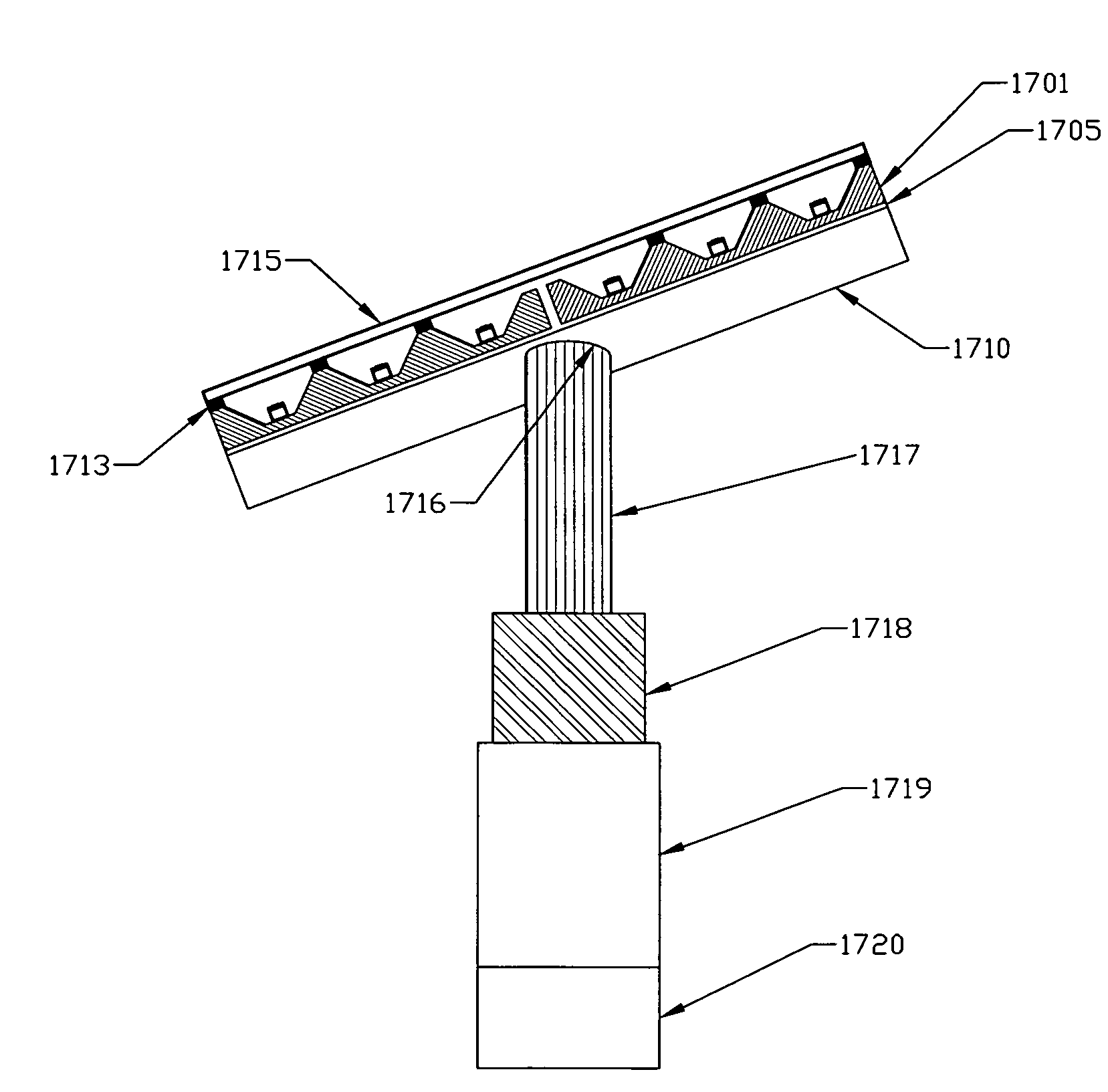

System for dispensing viscous materials

The invention provides for a delivery system where a viscous material such as dental composite is heated by an induction field or by resistance to an electric current. The system comprises at the proximal end a capsule-like cartridge that is self heating. The capsule may be fabricated of any number of heat conducting polymers or doped polymers that are susceptible to induction fields or any material that will heat when an induction current is applied. In the second instance the capsules may have a resistance wire of the appropriate metal or any other material to allow heating of the capsule when a current is applied. In the third instance the capsule may have an induction coil embedded in it's wall combined with any type of metal or other material where this becomes the heating device when current of the appropriate nature is applied. In the fourth instance a thin film or foil may be applied to either the outer surface or the inner surface of the capsule such that when a current is applied the foil or film heats and in so doing heats the capsule and the contents. Coupled with the above described capsule is a delivery device. This hand held device, whether powered manually or electrically forces a shaft to engage a piston embedded within the cartridge to move forward, dispensing the material within the cartridge at it's proximal end. In the manually powered mode, an electrical power source, whether a battery, capacitor discharge or AC / DC current, is used exclusively to activate the various heating methods described above. In the electrically powered mode, a linear stepper motor or other such motor with a proper configuration allows the shaft to engage the piston embedded in the cartridge and allow the material contained within the cartridge to be dispensed at it's proximal end. In the electrically powered configuration the power source described above is used to power the motor as well as the energy to activate the various heating elements described above. In addition where the force needed to extrude the material contained in the capsule, embedded in the device, whether manually or electrically applied to the device, such device may have the induction coil embedded in the barrel extension of the device in such placement as to provide adequate heating of the capsule.

Owner:YOBEL DAN +1

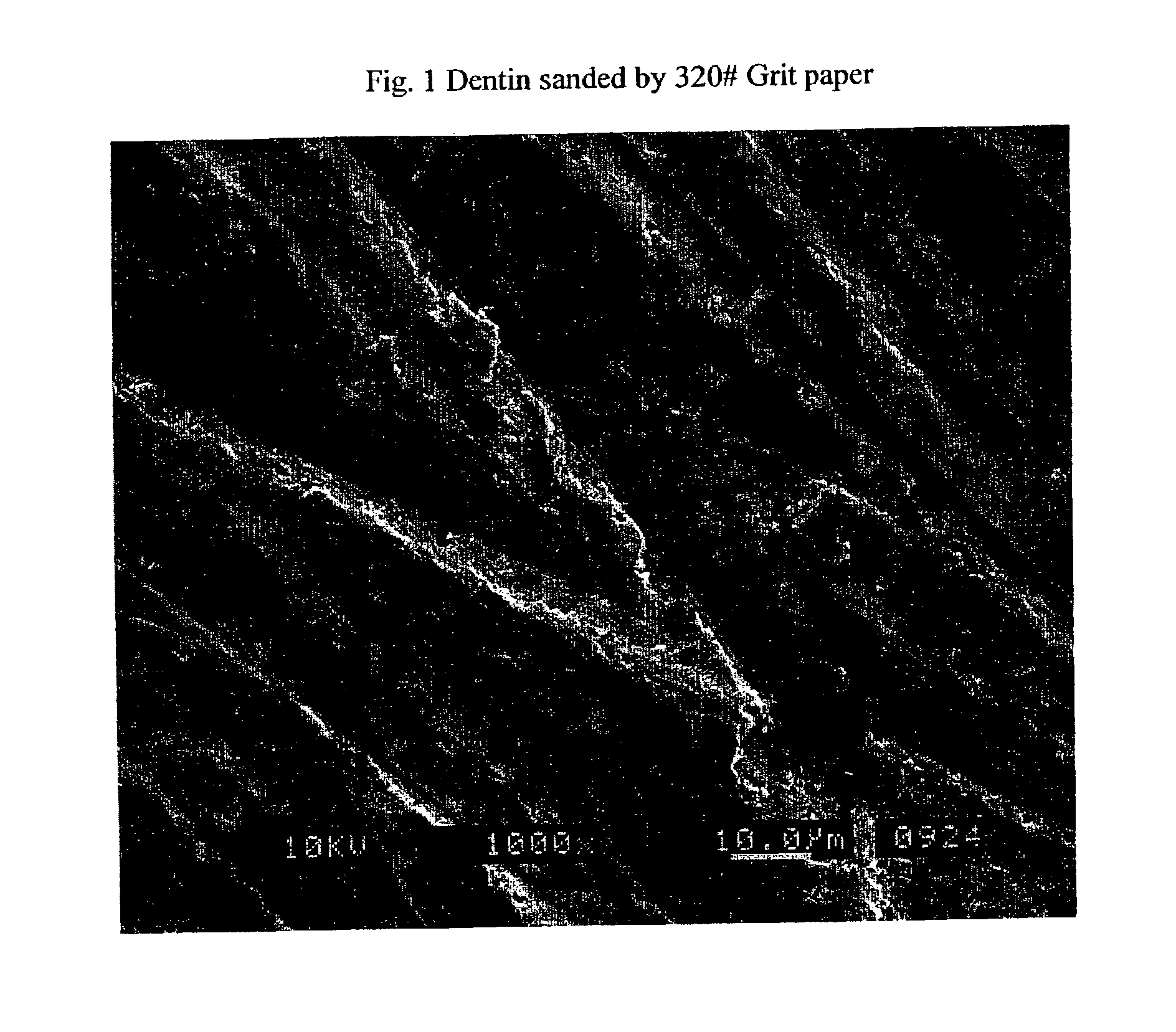

Stable self-etching primer and adhesive bonding resin compositions, systems, and methods

InactiveUS6994551B2High bonding strengthExtended shelf lifeImpression capsTeeth fillingDental AdhesivesTooth enamel

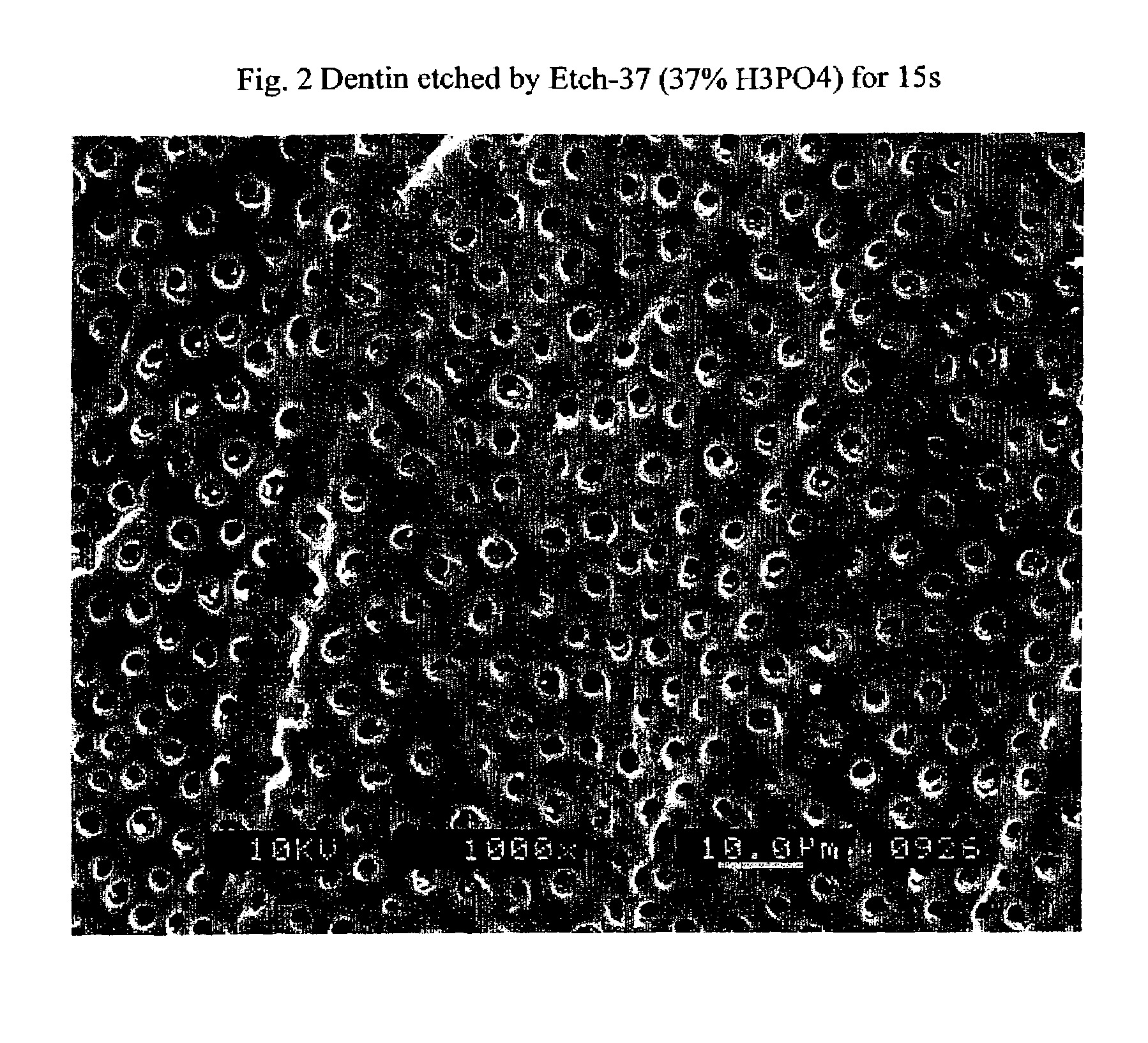

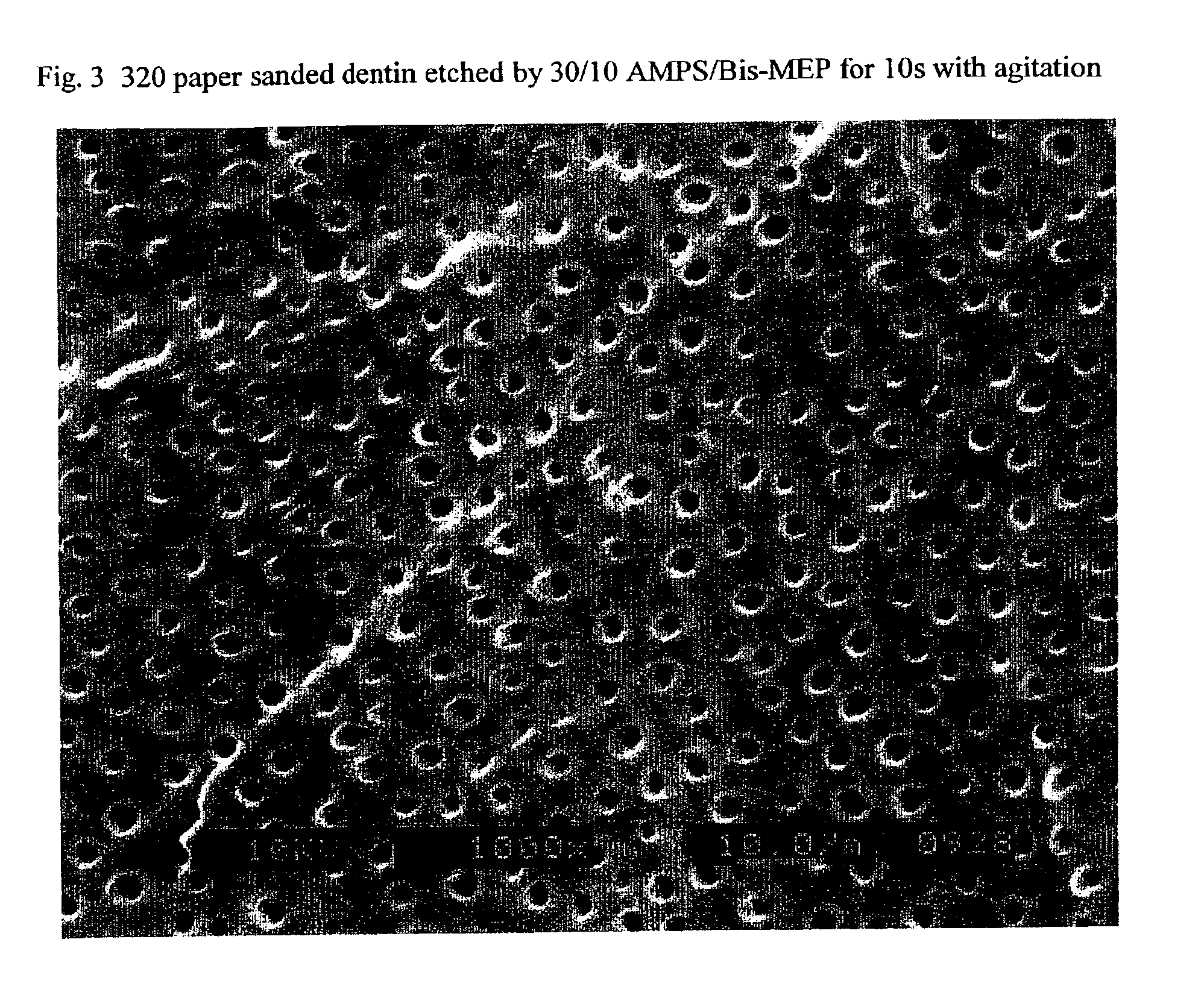

Stable self-etching copolymerizable primer compositions are provided including compounds having a polymerizable ethylenically unsaturated groups and acidic groups, and optionally comonomers and suitable solvents. Such compositions are used in conjunction with dental adhesives to provide one or multi-component dental systems capable of etching or decalcifying tooth dentin and enamel without the need for a separate rinse step. Methods of use of such compositions according to the present invention include application for priming and imparting enhanced adhesion between the primers, adhesives, and the tooth substrates such as dentin or cut or uncut enamel, and subsequently applied dental composites, restoratives or other dental components.

Owner:BISCO

Dental composite restorative material and method of restoring a tooth

InactiveUS6353040B1Highly packableCosmetic preparationsImpression capsRestorative materialDental composite

A dental composite material includes a hardenable resin matrix and a filler component. The filler component includes (a) a first plurality of preferably glass particles having an average particle size of from about 1 to about 10 micrometers; (b) a second plurality of preferably glass particles having an average particle size of from about 0.1 to about 1 micrometers; and, (c) a plurality of filler particles having an average particle size of from about 0.01 to about 0.04 micrometers. A method according to the invention includes compacting a dental composite material into a prepared tooth cavity, wherein the material has a packability index above about 300 g / mm2.

Owner:DENTSPLY RES DEVMENT

Dental compositions containing core-shell polymers with low modulus cores

The invention relates to a dental composite material wherein core-shell polymer compounds are utilized to reduce shrinkage upon polymerization; the invention also relates to a method for producing dental restoration articles with reduced shrinkage; the invention also relates to various dental restorative articles comprising the aforementioned core-shell polymer compounds.

Owner:EI DU PONT DE NEMOURS & CO

Dental curable composition

InactiveUS6933327B2Easy to measureHighly aesthetic appearanceImpression capsSpecial tyresNatural toothFlexural strength

A dental polymerizable and curable composition that can be used as a dental composite restorative featuring excellent handling property at the time of filling, a small contraction upon polymerization, a high bending strength, excellent surface smoothness and wear resistance, and a very good matching of color tone to the natural tooth after restored.

Owner:TOKUYAMA CORP

Dental composite restorative material and method of restoring a tooth

A composite material is provided which, while having an unusually high filler content may be extruded from a dental syringe and remains easily adaptable in the dental cavity. When materials of the present invention are cured, dental restorations are provided which have unusually high surface hardness and yield strength, as well as a low volume shrinkage on curing. This is achieved by use of a mixture of filler particles with a specific size, size range, and size relationship. Such a combination of properties makes the material of the present invention particularly useful for restoring cavities in posterior teeth.

Owner:DENTSPLY DETREY GMBH

Processes for forming dental materials and device

Processes for forming dental materials that include applying a first hardenable dental composition (e.g., a dental adhesive) to a surface followed by applying a second hardenable dental composition (e.g., a dental composite) to the first hardenable dental composition on the surface. The first and second hardenable dental compositions are hardened such that the second hardenable composition is substantially completely hardened prior to complete hardening of the first hardenable composition.

Owner:3M DEUTLAND +1

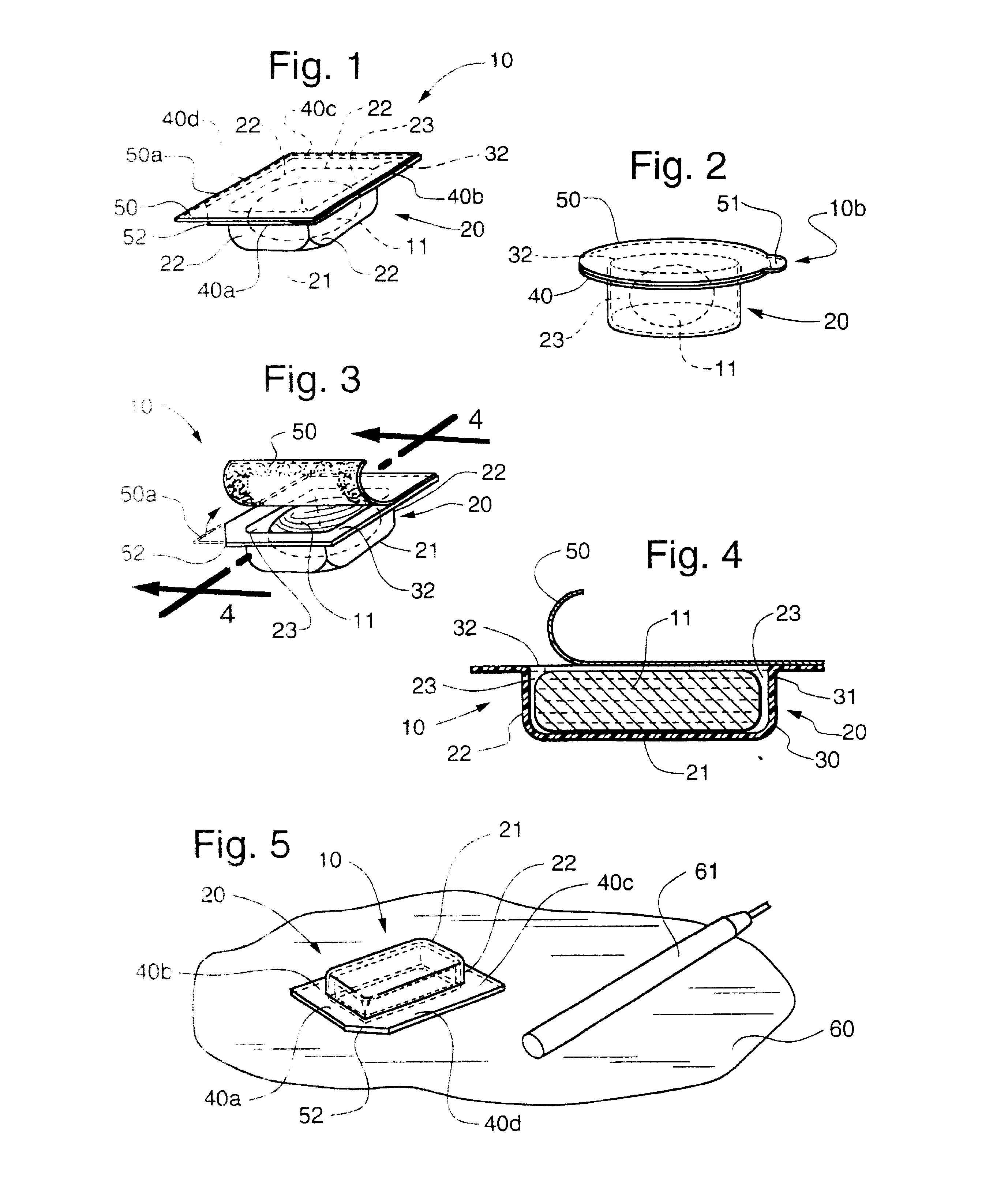

Heated compule

ActiveUS7097452B2Efficient heatingHeating fastLiquid surface applicatorsCapsule deliveryDental compositeDental restoration

Owner:FRIEDMAN JOSHUA

Methods for making provisional and long-term dental crowns and bridges

The invention provides methods of making provisional and long-term dental restorations, particularly dental veneers, crowns and bridges. In one embodiment, the restoration can be fabricated indirectly by a dental laboratory. In another version, a dental practitioner can make the restoration chairside for a patient in a dental office. A polymerizable dental composite material, which is dimensionally shape-stable in its uncured state, is used to make the restoration. A substructure such as a metal coping can be used to support the polymerizable material. The material includes a polymerizable acrylic compound, polymerization initiator system capable of being activated by light or heat, and preferably a filler material. The resulting dental restoration has good aesthetics, mechanical strength, and margins and contacts.

Owner:SUN BENJAMIN JIEMIN +2

Light emitting diode light source for curing dental composites

InactiveUS7320593B2Sufficient powerSufficient structurePrinted circuit aspectsSolid-state devicesDental compositeHeat sink

Owner:KONINK PHILIPS ELECTRONICS NV

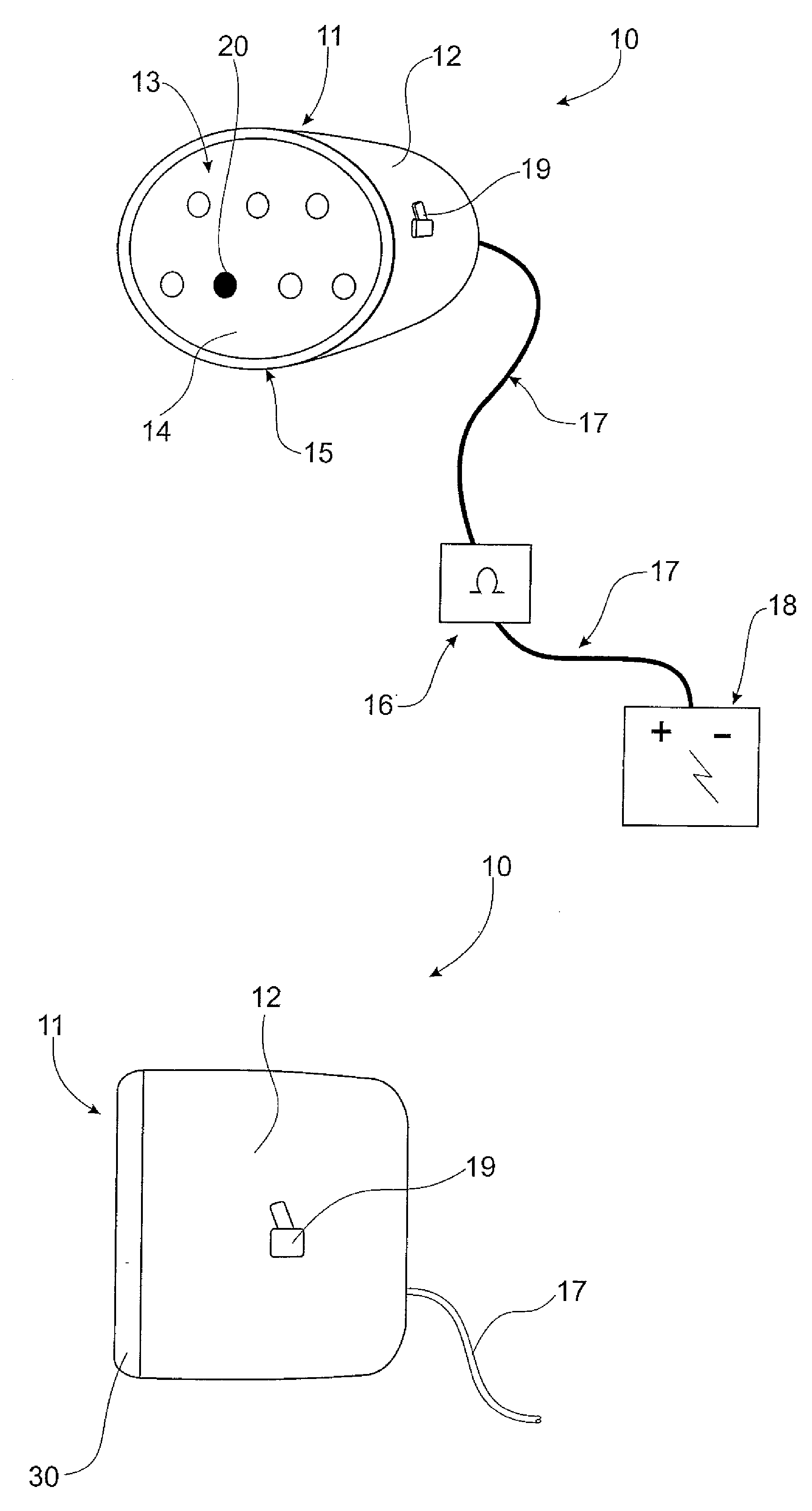

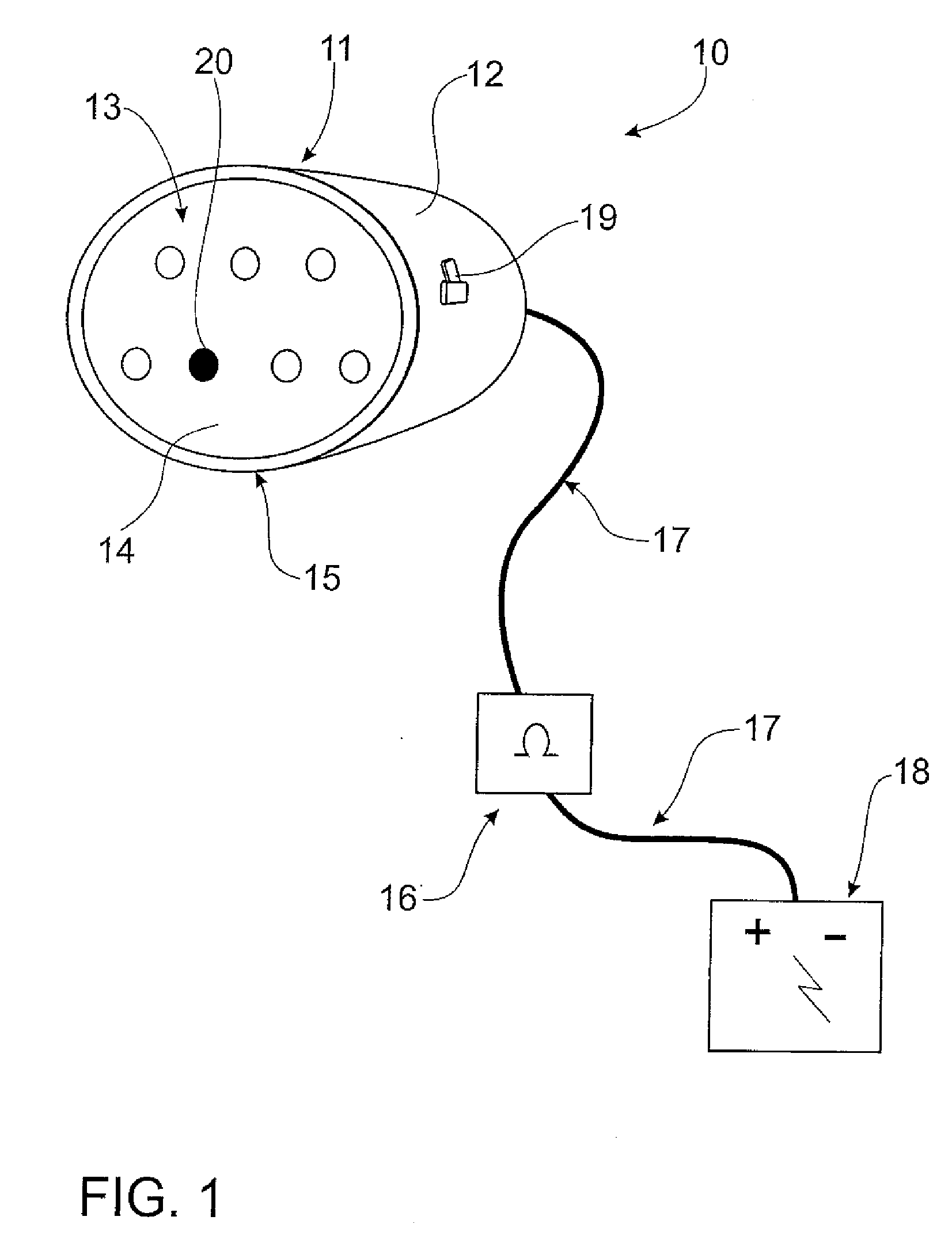

Dental illumination device and method

InactiveUS20080002402A1Reduce light intensityGuaranteed to workPhotometrySurgeryLight equipmentMedicine

A dental illumination device is provided that comprises a plurality of light-emitting diodes capable of emitting light of selected wavelengths that do not activate initiator molecules contained within dental restorative material such as dental composite, or at an intensity which is insufficient to initiate substantial polymerization of the dental restorative material. Typically, the dental illumination device produces light having wavelengths not in a range selected from 400 nm to 500 nm, 350 nm to 470 nm and below 350 nm to 420 nm. The dental illumination device may further comprise a switch that allows the aforementioned wavelengths to be switched off or reduced in intensity as required. The dental illumination device may operate as a stand-alone unit or may be fitted to an existing dental light.

Owner:TOPSTORE

Dental light device with identification means

InactiveUS20130052607A1Extend battery lifeAccurate light intensityDental toolsLight therapyDental compositeIdentification device

This invention relates to a curing light device capable of curing dental composites with a means to blow air. The blown air is directed from the curing light onto the tooth that is exposed to the curing light. The blown air has the effect of cooling the surface of the tooth to maintain patient comfort and efficient curing of dental composites

Owner:DISCUS DENTAL LLC

Self-healing dental composites and related methods

ActiveUS20080300340A1Reduce Shrinkage ProblemsIncrease polymerization rateImpression capsDentistry preparationsSelf-healingMicrosphere

Dental restorative composites having self-healing capabilities to repair discontinuities in the composite are provided. Dental restorative composites according to the present invention include a microsphere that encapsulates a monomer. When a fracture occurs, the microsphere is ruptured and the monomer fills the fracture. Depending on the monomer present in the microsphere, it is polymerized by a polymerization initiator or by an olefin metathesis catalyst present in the dental restorative composite. Self-healing dental restorative composites provide increased resistance to fracturing, and thus remain substantially intact for a longer period of time, preserving the remedial integrity of the dental repair or reconstruction.

Owner:PREMIER DENTAL PRODS

Dental composite restorative material

ActiveUS20130096226A1Small polymerization shrinkageHigh transparencyImpression capsDentistry preparationsRestorative materialResin matrix

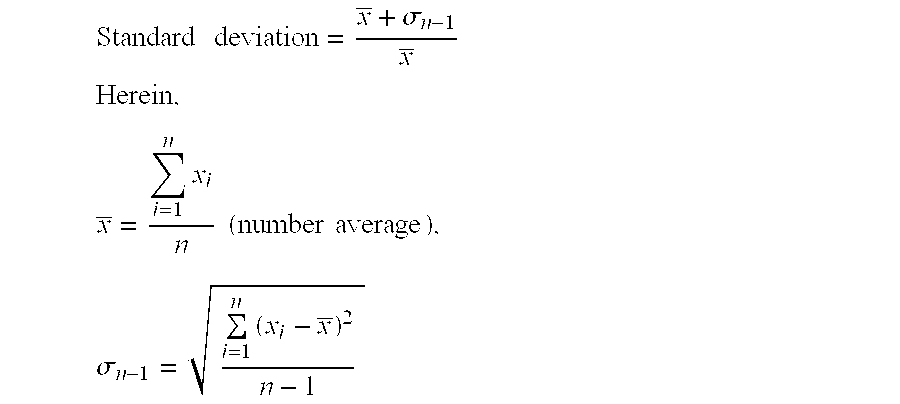

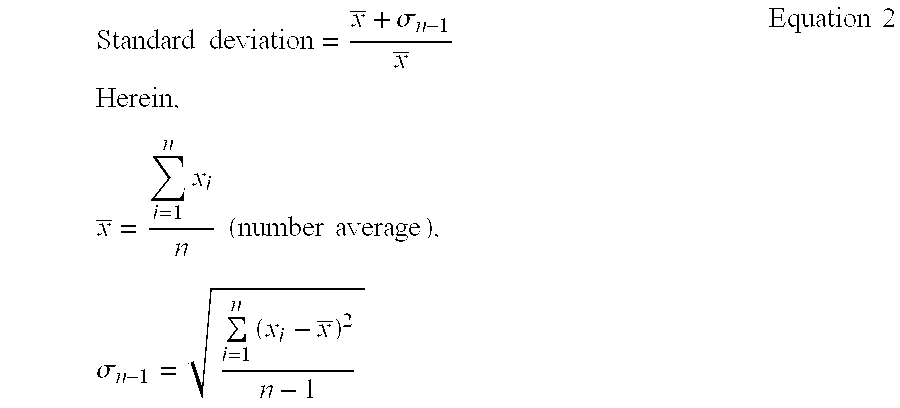

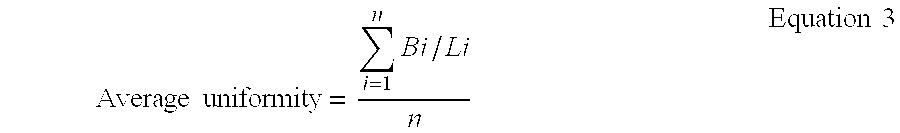

There is provided a dental composite restorative material that has an excellent opalescent effect, no paste stickiness, small polymerization shrinkage during curing and is suitable for the restoration of the incisal edge of a tooth. This dental composite restorative material comprises: (A) a polymerizable monomer, (B) a spherical silica-based particle [I] having an average particle diameter in the range of from 0.1 to 0.5 μm and a standard deviation of particle diameter distribution within 1.30, preferably a silica-titanium group oxide-composite oxide particle, (C) an organic-inorganic composite filler prepared by dispersing the above-described silica-based particle [I] in an organic resin matrix, and (D) a polymerization initiator.

Owner:TOKUYAMA DENTAL CORP

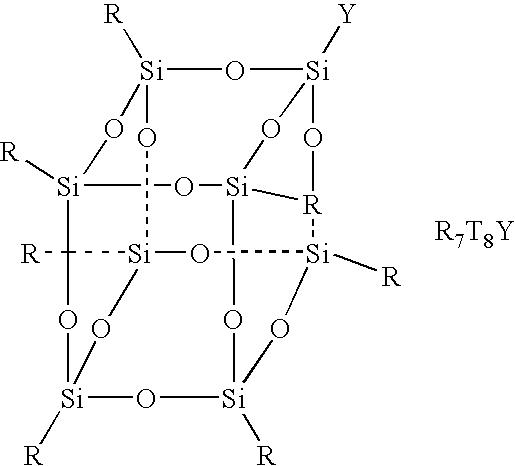

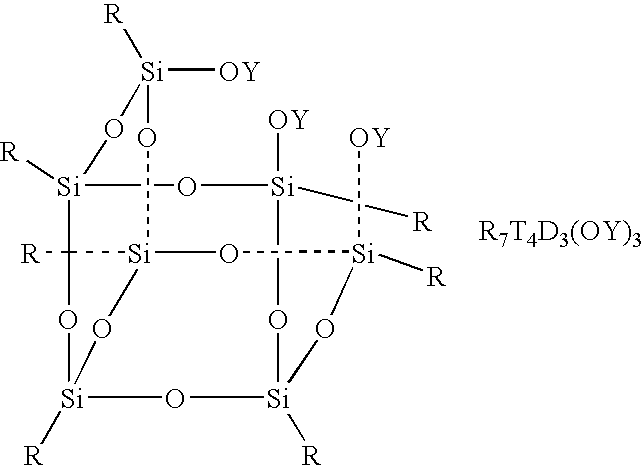

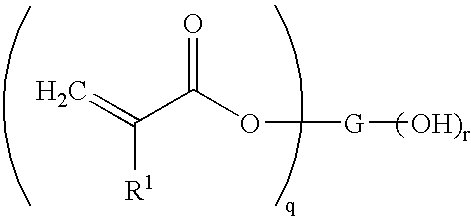

Dental composite materials and method of manufacture thereof

A dental composite material that comprises a polyhedral oligomeric silsesquioxane is disclosed. The dental composite material is useful for a variety of dental materials, treatments, and restorative functions including crown and bridge materials, fillings, adhesives, sealants, luting agents or cements, denture base materials, orthodontic materials and sealants, and other dental restorative materials.

Owner:PENTRON CLINICAL TECH

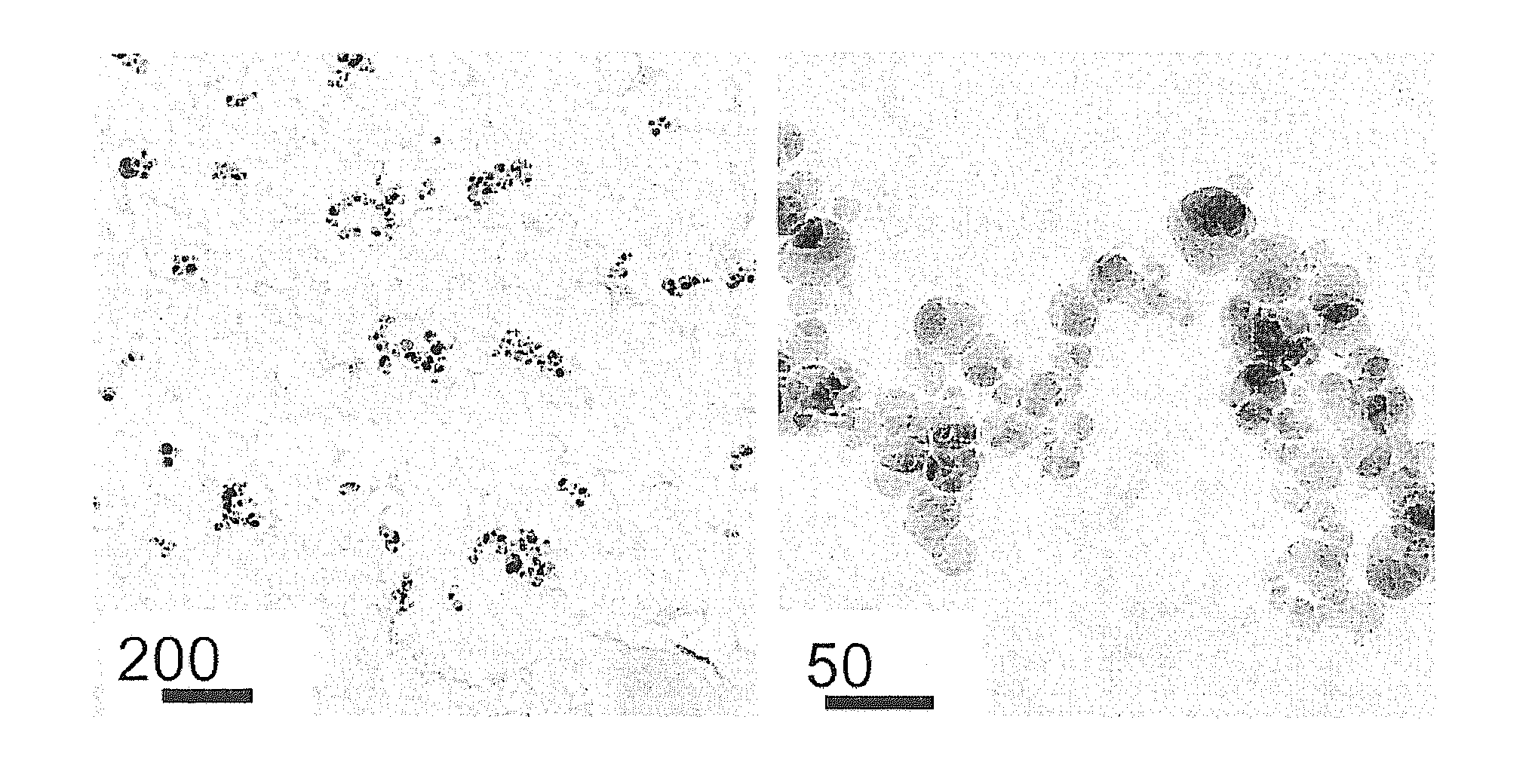

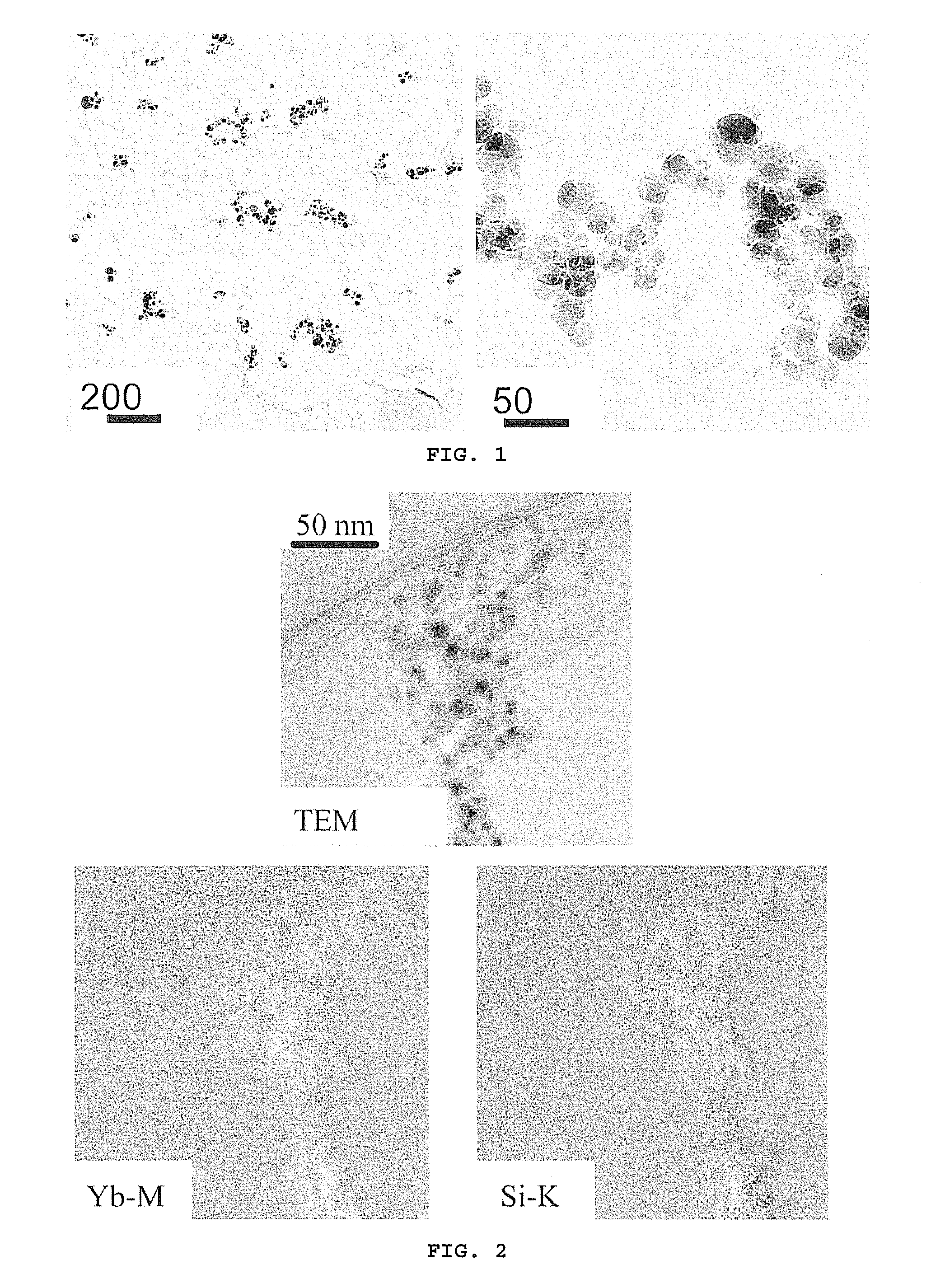

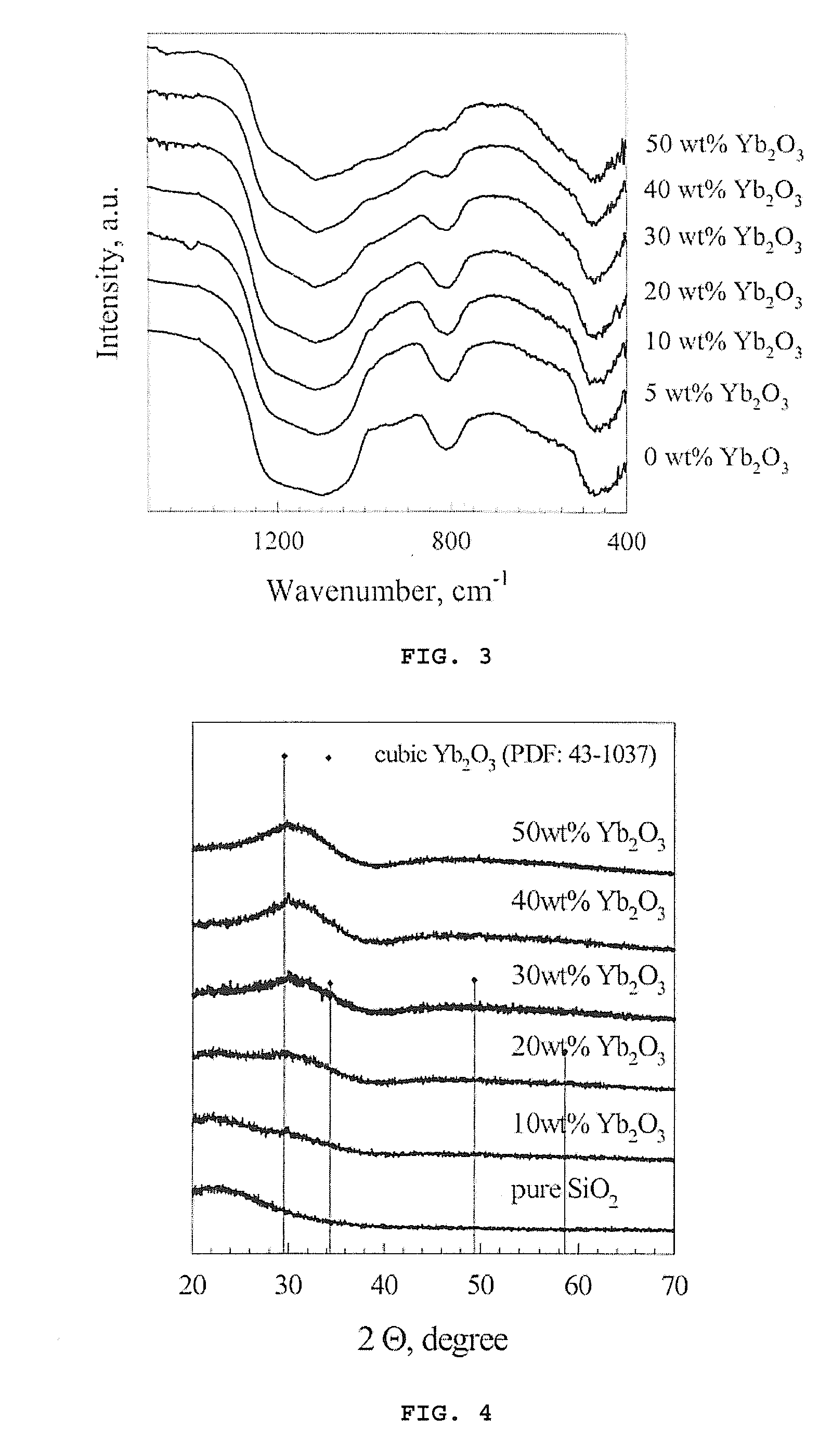

Dental composites based on x-ray-opaque mixed oxides prepared by flame spraying

InactiveUS20080160206A1Low intrinsic colorIncrease coverageImpression capsMolten spray coatingMixed oxideX-ray

The present invention relates to dental composites comprising at least one nanoparticulate mixed oxide (a) of SiO2 with X-ray-opaque metal oxides of one or more elements selected from the group consisting of Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu which has been prepared by flame spraying.

Owner:BURTSCHER PETER +4

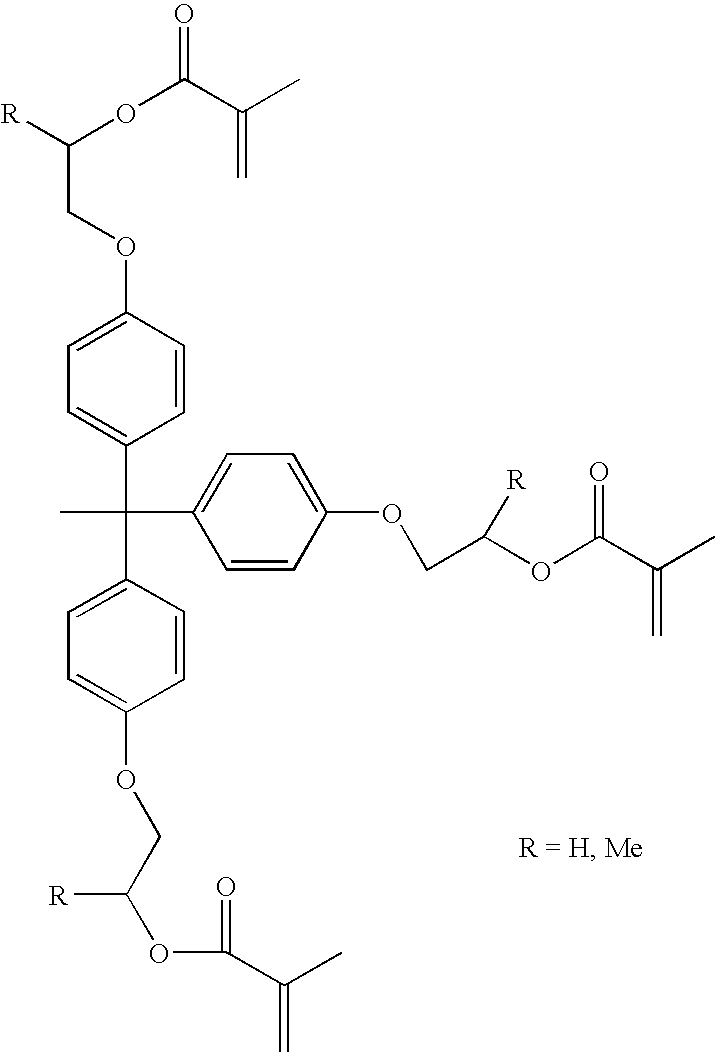

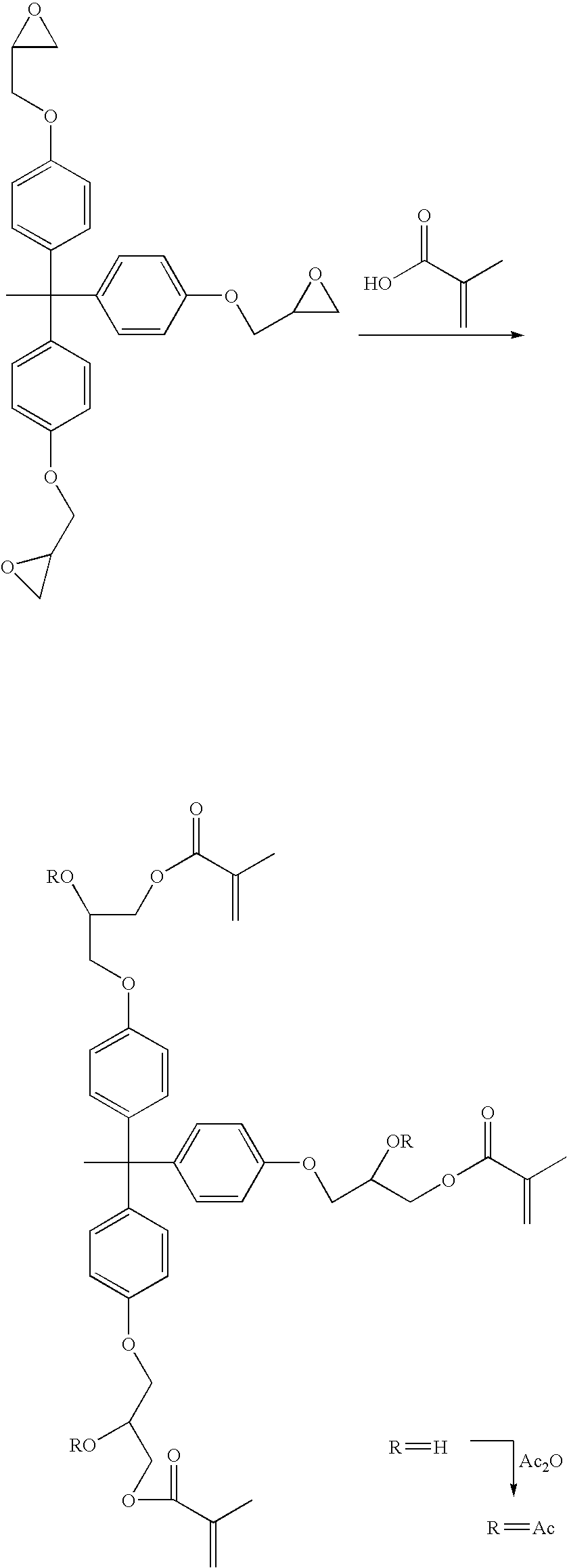

Materials leading to improved dental composites and dental composites made therefrom

This invention relates to composite materials for restorative dentistry. More particularly, it relates to new components for dental composites, which impart an attractive combination of good mechanical properties and low shrinkage.

Owner:EI DU PONT DE NEMOURS & CO

Formulations and composites with reactive fillers

ActiveUS20100069469A1High surface hardnessHigh modulusOrganic active ingredientsBiocideCross-linkAdhesive

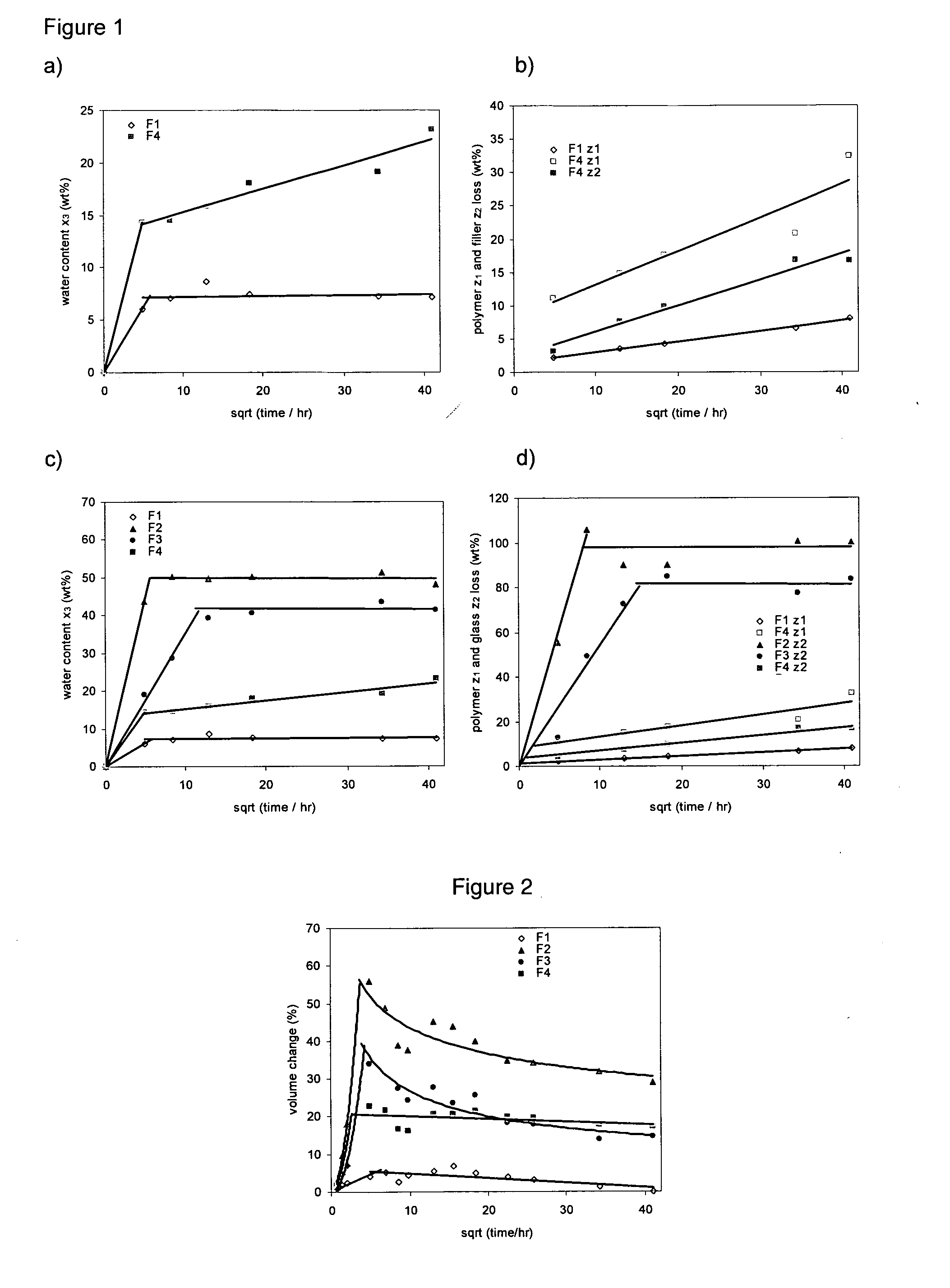

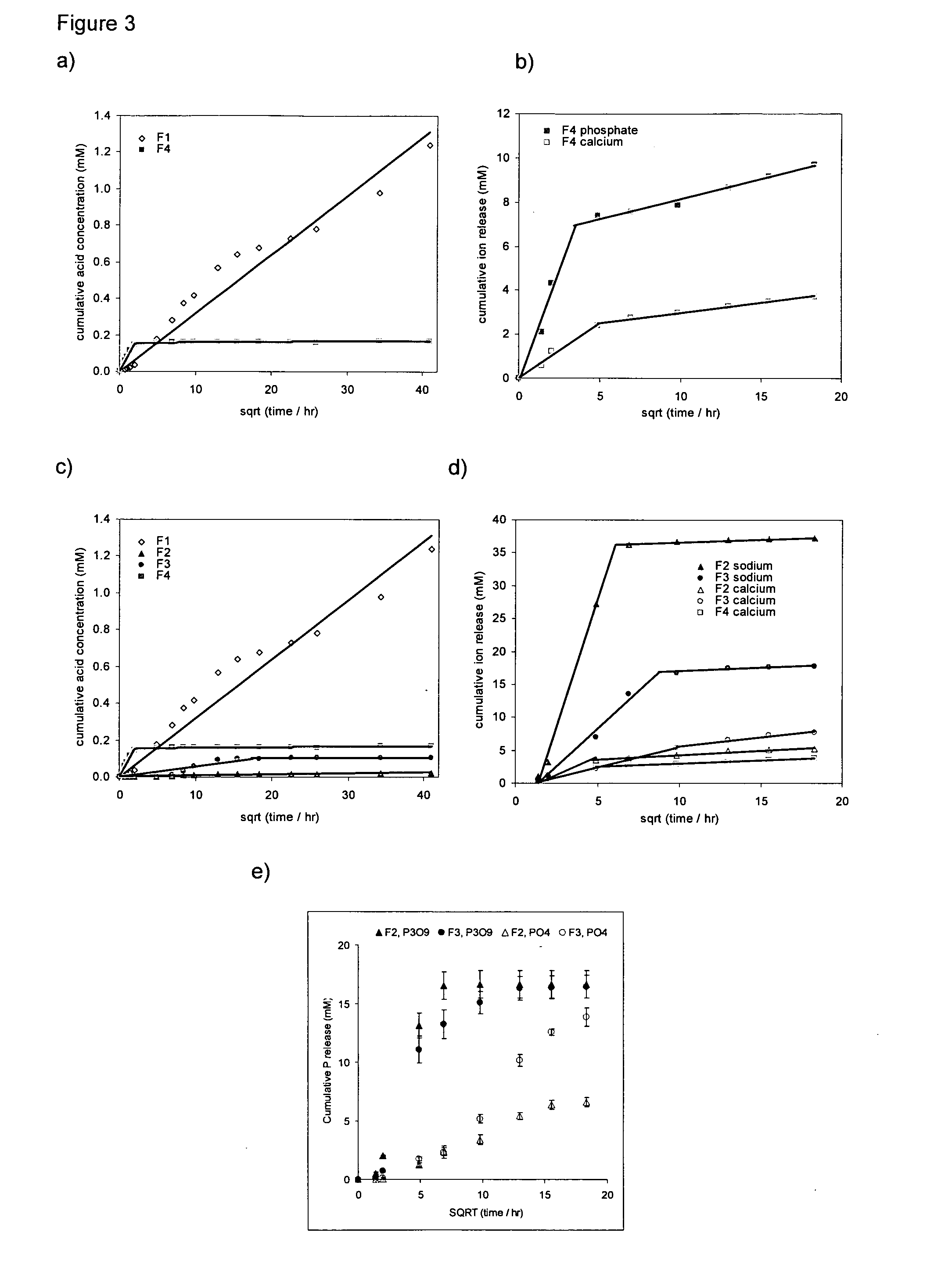

The invention provides composite materials prepared by i) providing a fluid formulation comprising (1) at least one compound capable of polymerisation and / or cross-linking and (2) a water-consuming reactive filler; ii) optionally injecting said formulation into a site of use; iii) polymerising and / or cross-linking said compound, to form a solid polymer matrix (which may be degradable or non-degradable); iv) causing or allowing said filler to react with water absorbed by said polymer matrix, to produce a solid filler material which is dispersed throughout the composite material. The hydration and formation of the solid filler in situ provides desirable properties to the composites, which have utility for dental composites, bone fillers and adhesives and so on. The composite may also be used to release an active ingredient e.g. an antibacterial or DNA.

Owner:UCL BUSINESS PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com