Patents

Literature

236 results about "Denture base" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

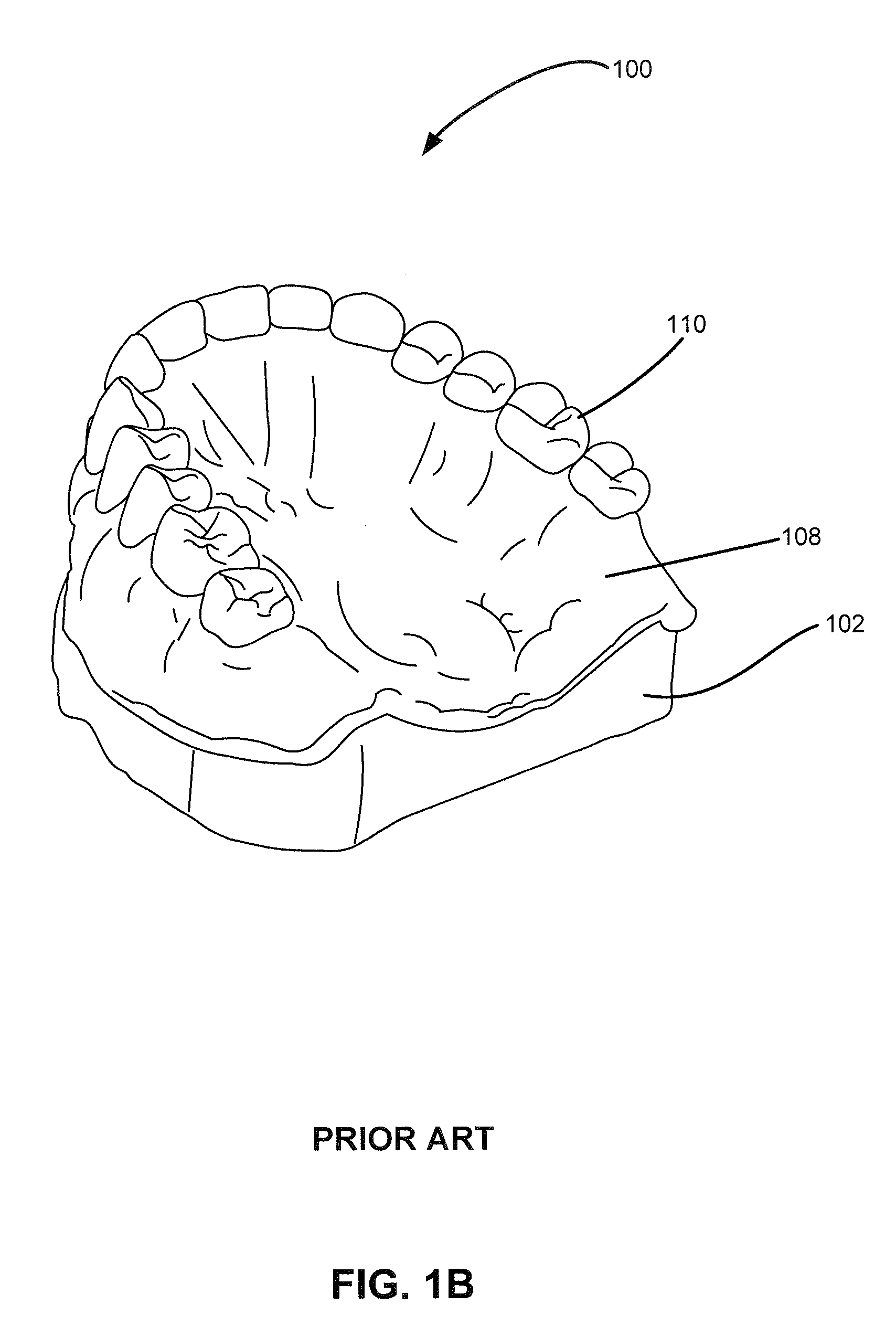

Denture base. the part of a denture that covers the soft tissue of the mouth. It is commonly made of resin or a combination of resins and metal to which artificial teeth are attached. Also called saddle.

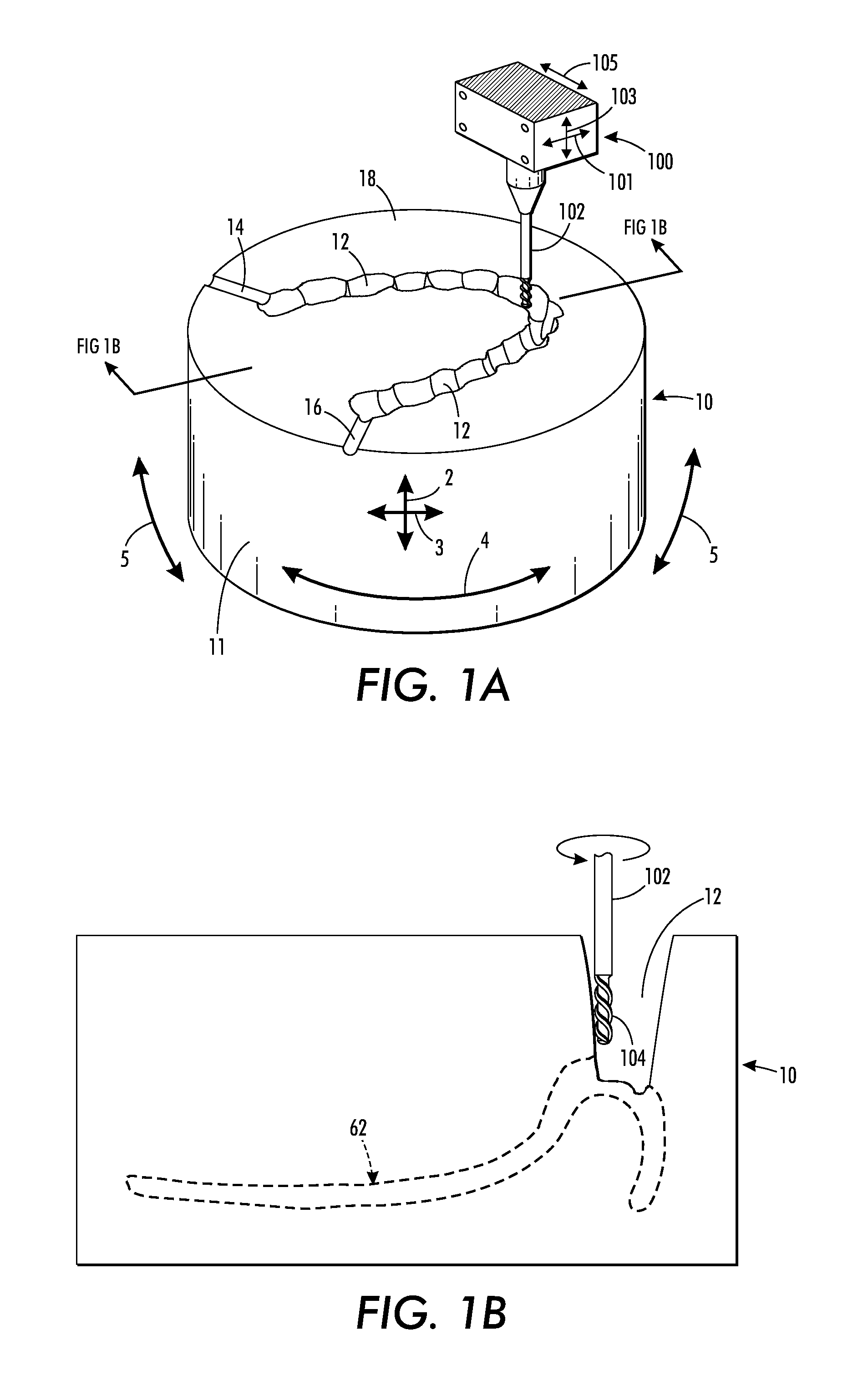

Denture and method and apparatus of making same

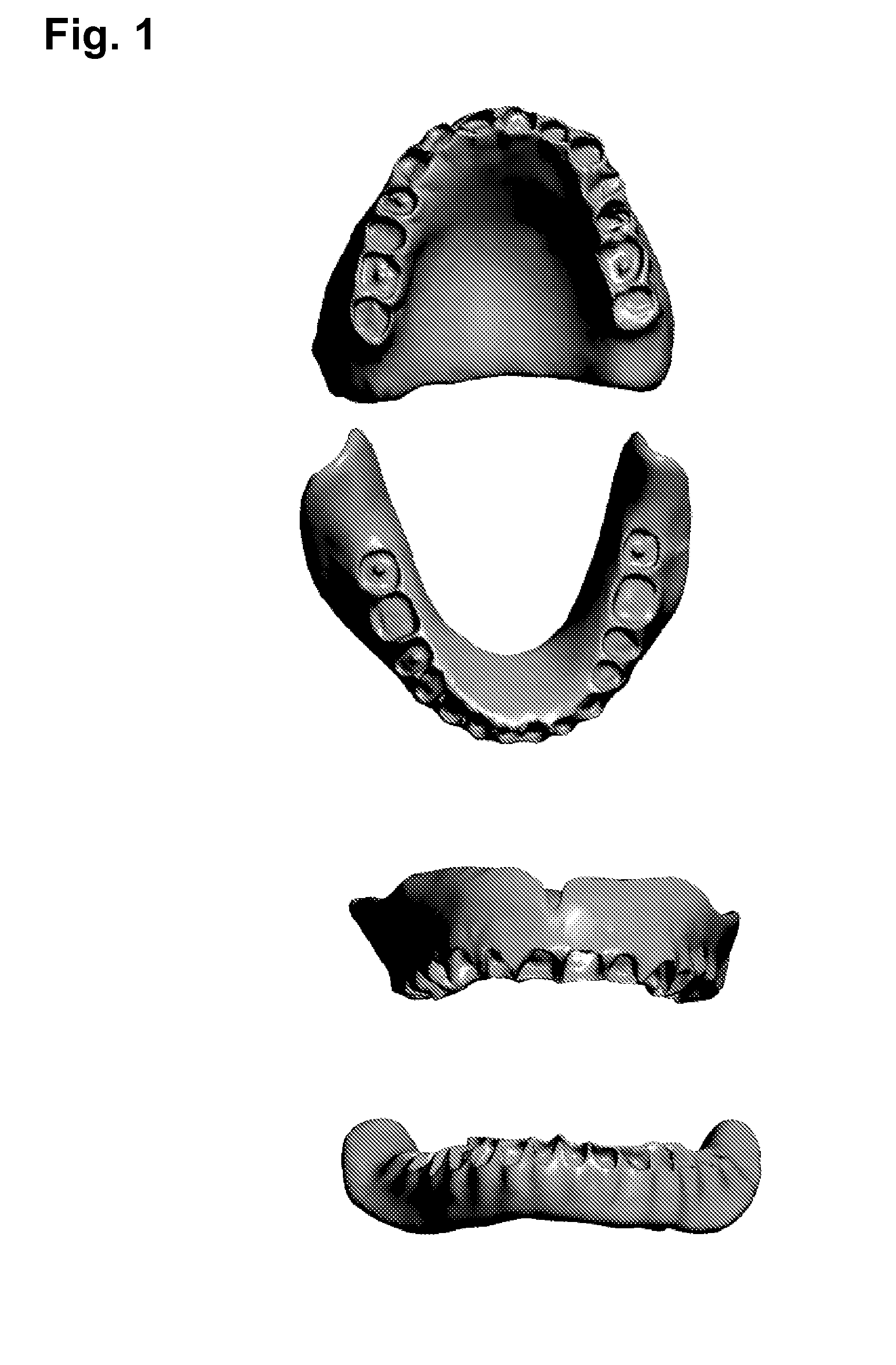

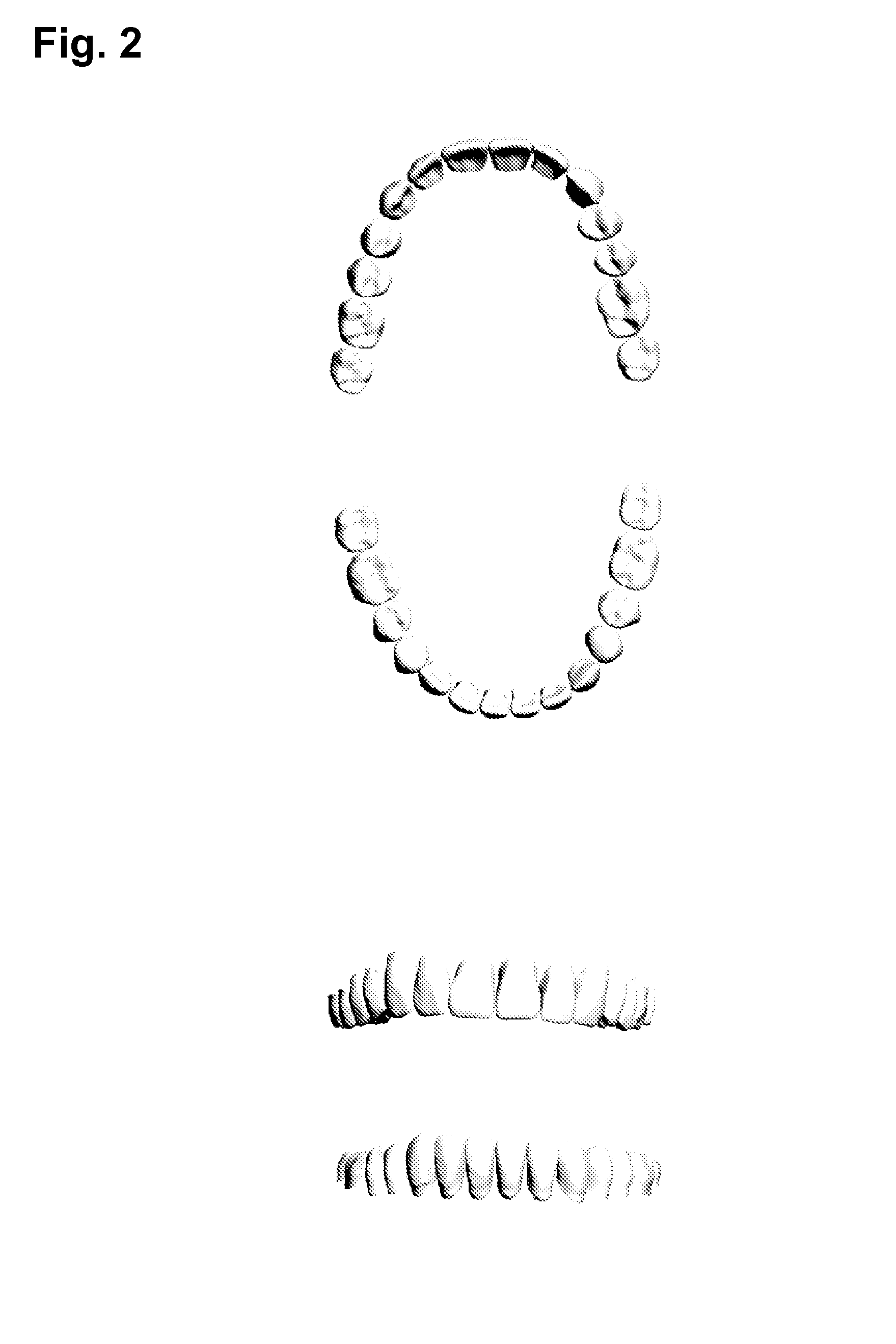

ActiveUS20130101962A1Optimize aestheticOptimize fitImpression capsAdditive manufacturing apparatusNatural toothBody of mandible

Owner:GLOBAL DENTAL SCI

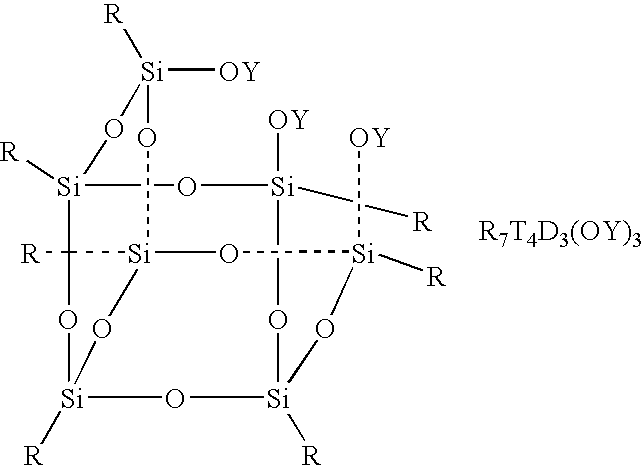

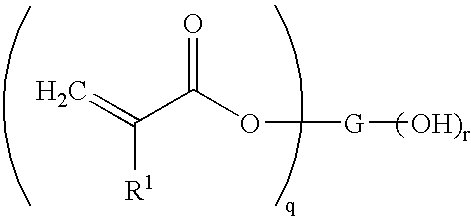

Photo-curable resin compositions and method of using the same in three-dimensional printing for manufacturing artificial teeth and denture base

ActiveUS20140239527A1Simple and easilyLow viscosityAdditive manufacturing apparatusImpression capsMeth-Oligomer

A composition includes a light-curable viscous mixture that includes: 0-50% by weight of a poly(methyl methacrylate) / methyl methacrylate solution; 5-20% by weight of at least one kind of multifunctional aliphatic (meth)acrylate; 5-40% by weight of at least one kind of aliphatic urethane (meth)acrylate oligomer; 25-65% by weight of at least one kind of difunctional bisphenol-A dimethacrylate; 0.1 to 5% by weight of at least one kind of a photoinitiator; 0.05 to 2% by weight of at least one kind of light stabilizer; and 0.1 to 3% by weight of color pigment based on the total weight of the composition.

Owner:DENTCA

Photo-curable resin compositions and method of using the same in three-dimensional printing for manufacturing artificial teeth and denture base

ActiveUS20140167300A1Suitable viscositySuitable curing rateImpression capsAdditive manufacturing apparatusViscous liquidMaterials science

Photo-curable compositions for artificial teeth and denture base and a method for manufacturing denture by a three-dimensional printing system are provided. The compositions include photo-curable organic compounds, surface modified nano-sized inorganic filler, photo-initiator, colorant, and stabilizer. The composition is in a viscous liquid state having 1500-5000 cps at ambient temperature and has a low viscosity of 50-500 cps at jetting temperature or dispensing temperature. The composition also has an excellent curing rate for three-dimensional printing. Using the compositions, denture having a distinctive denture base and a set of artificial teeth can be manufactured via an inkjet type or digital light process type three-dimensional printing according to Computer Aided Design (CAD) data.

Owner:DENTCA

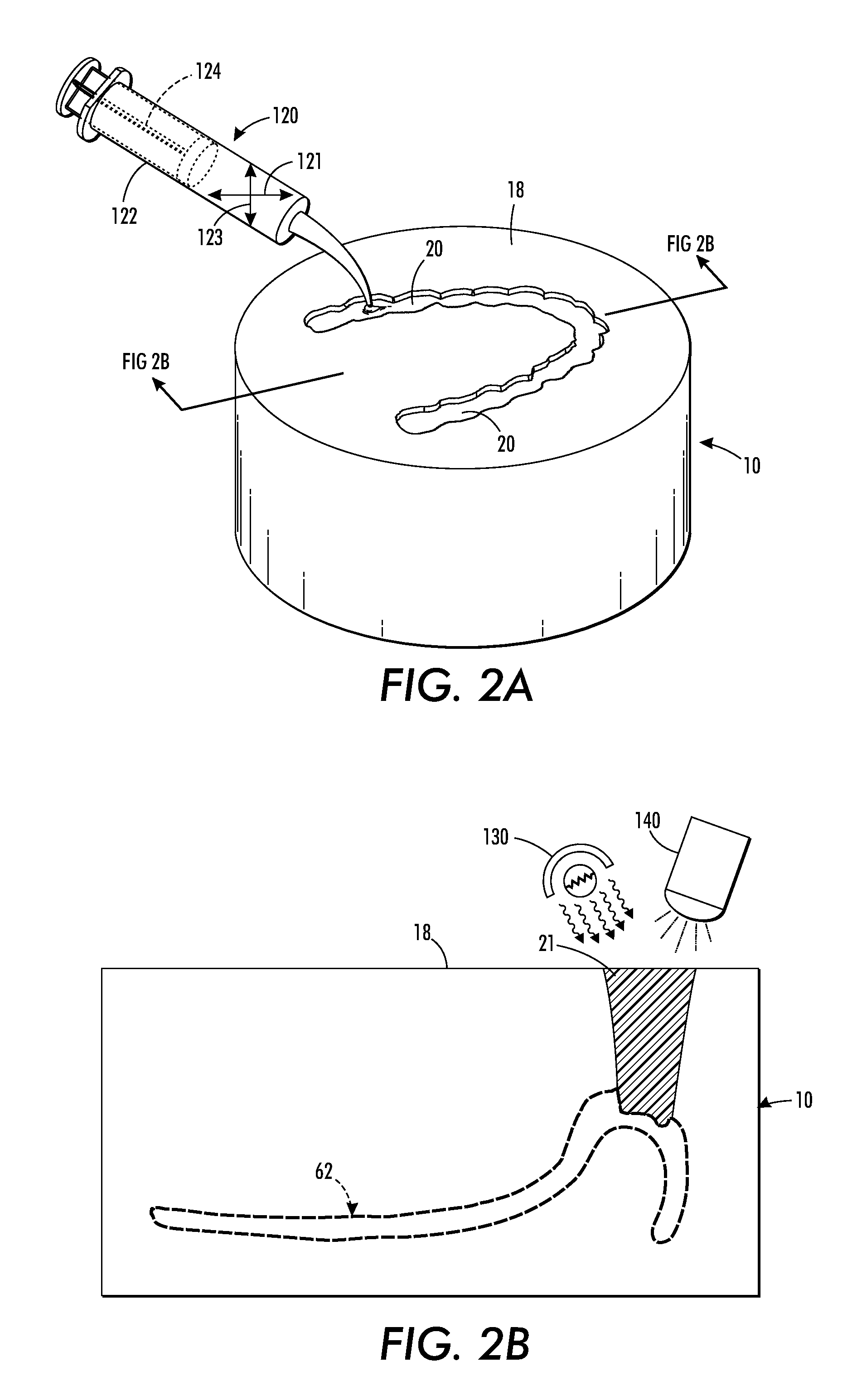

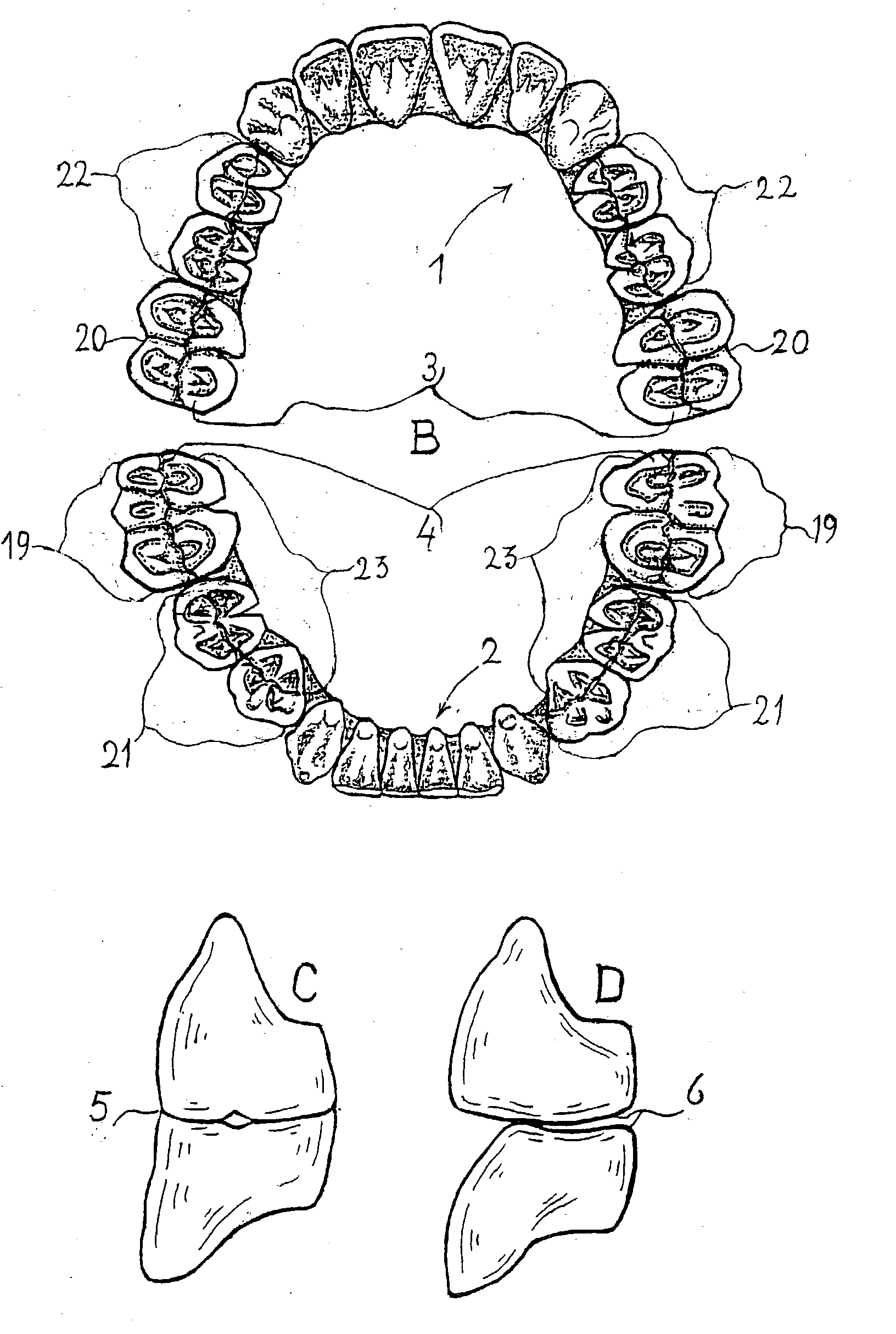

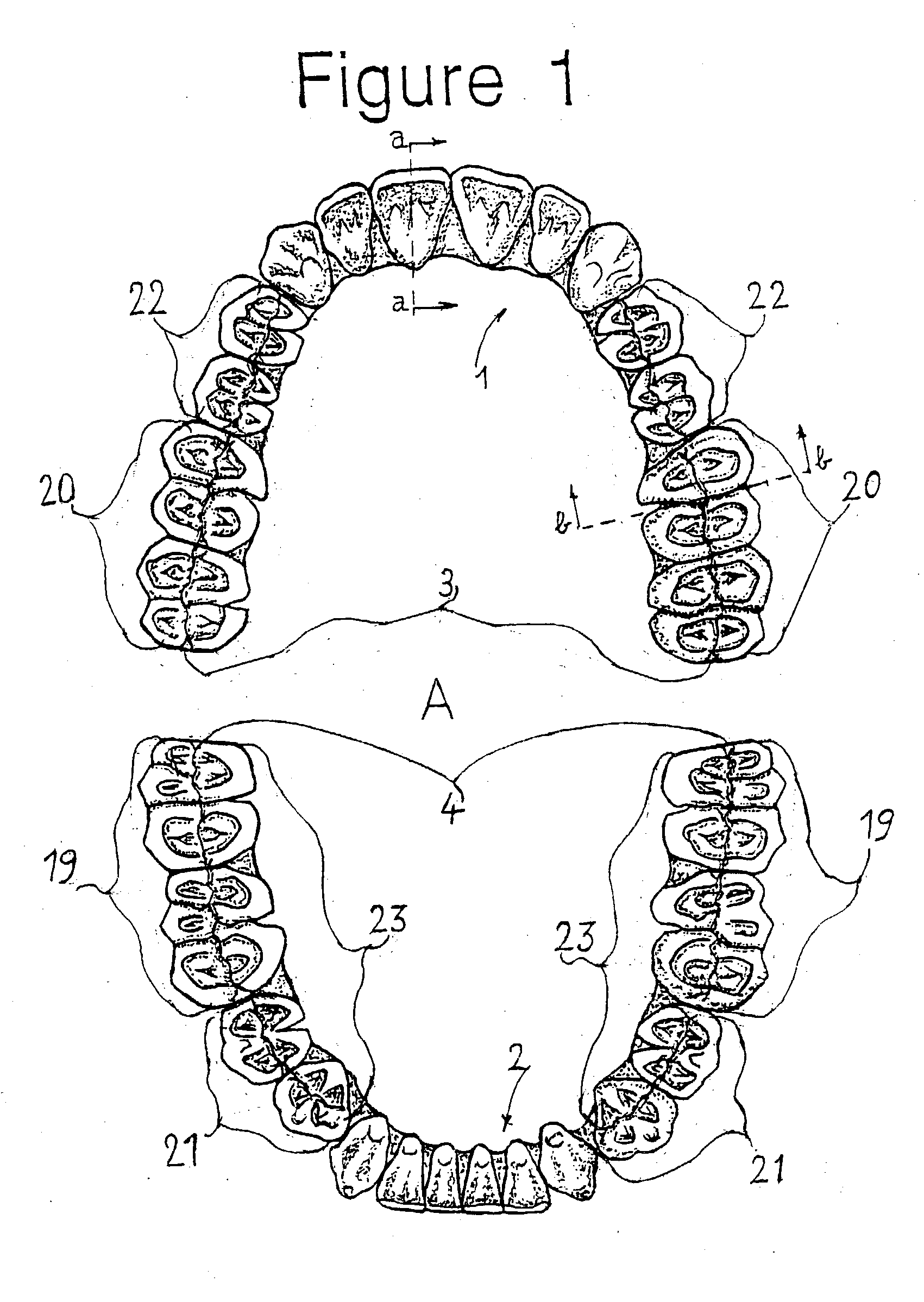

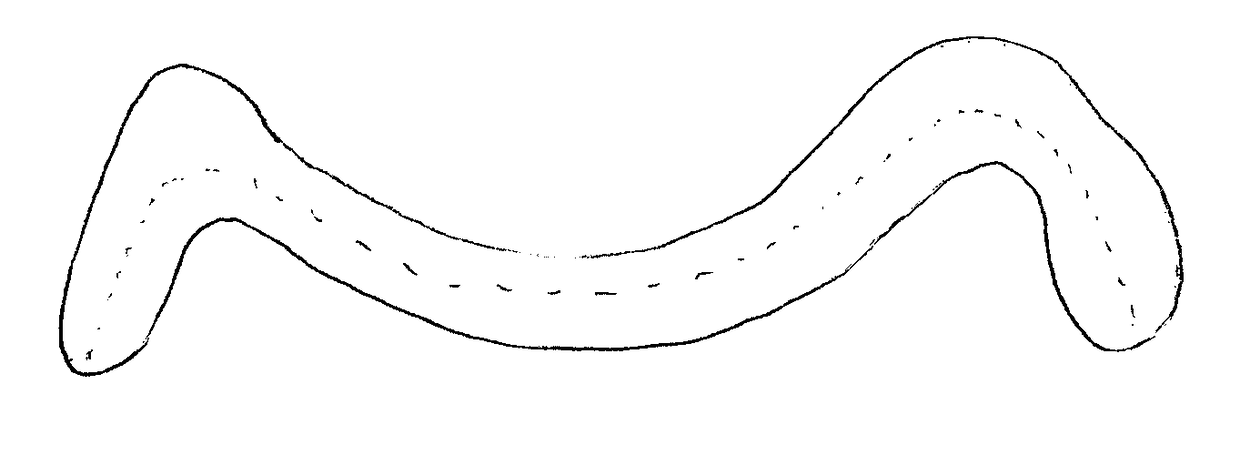

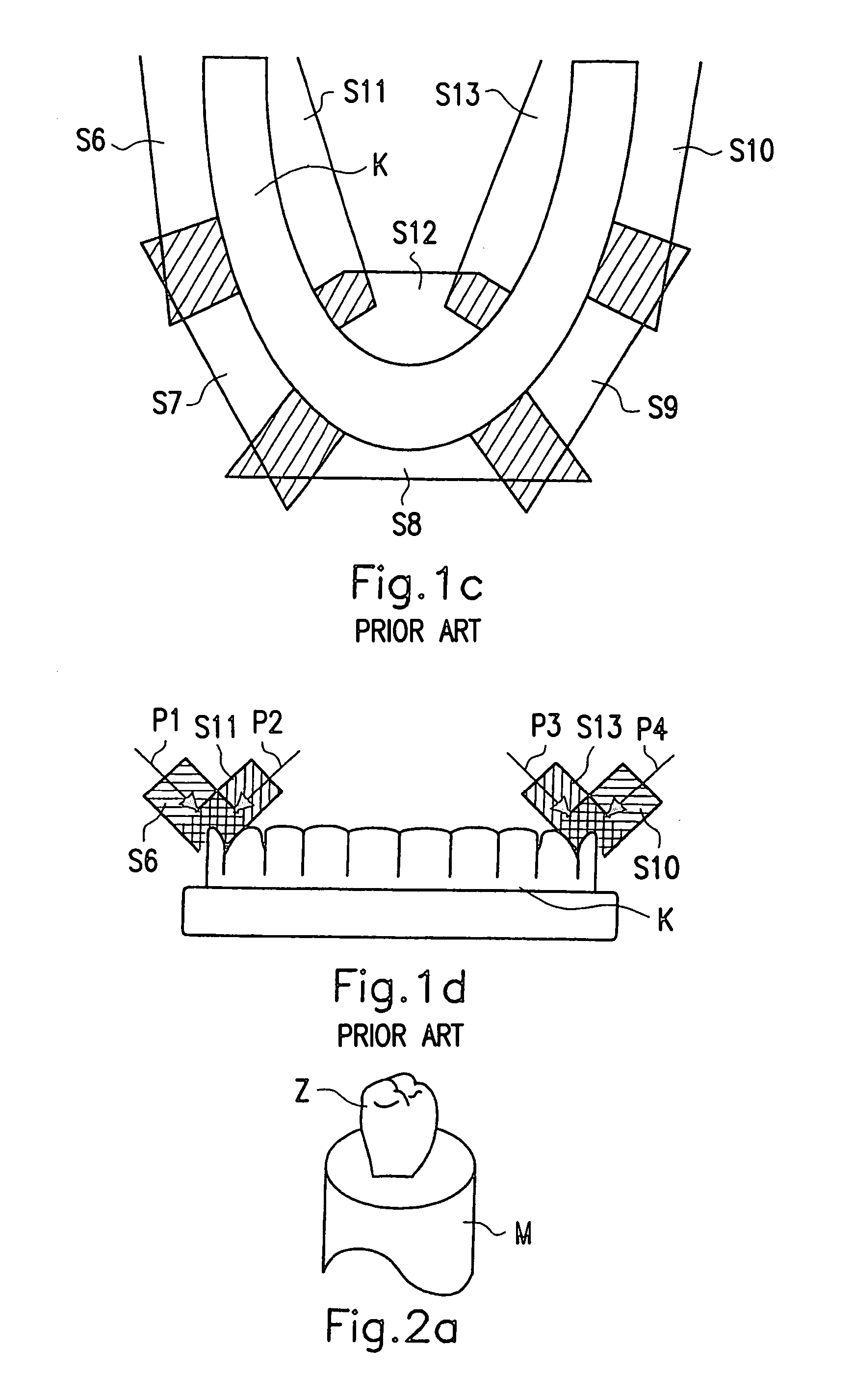

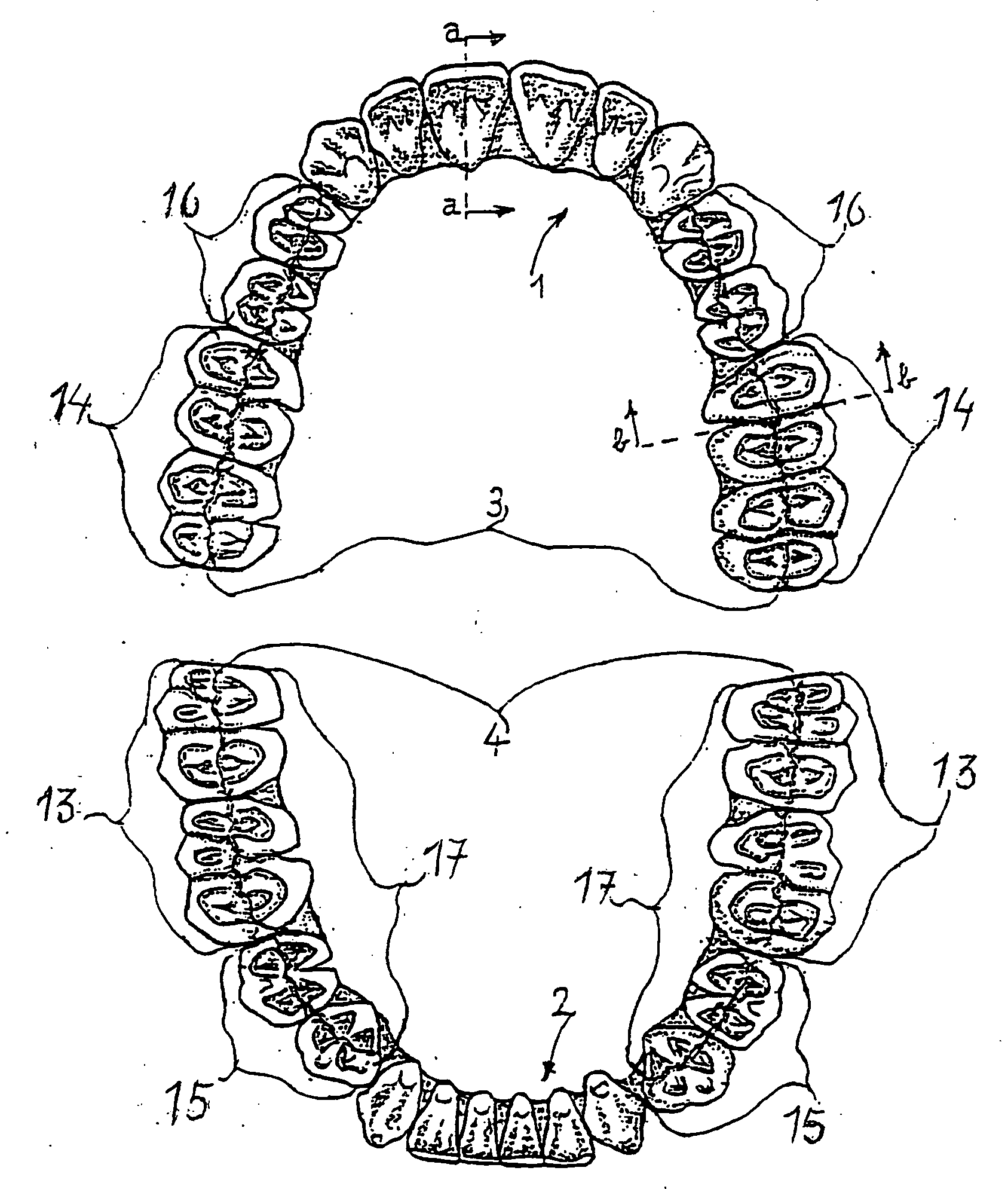

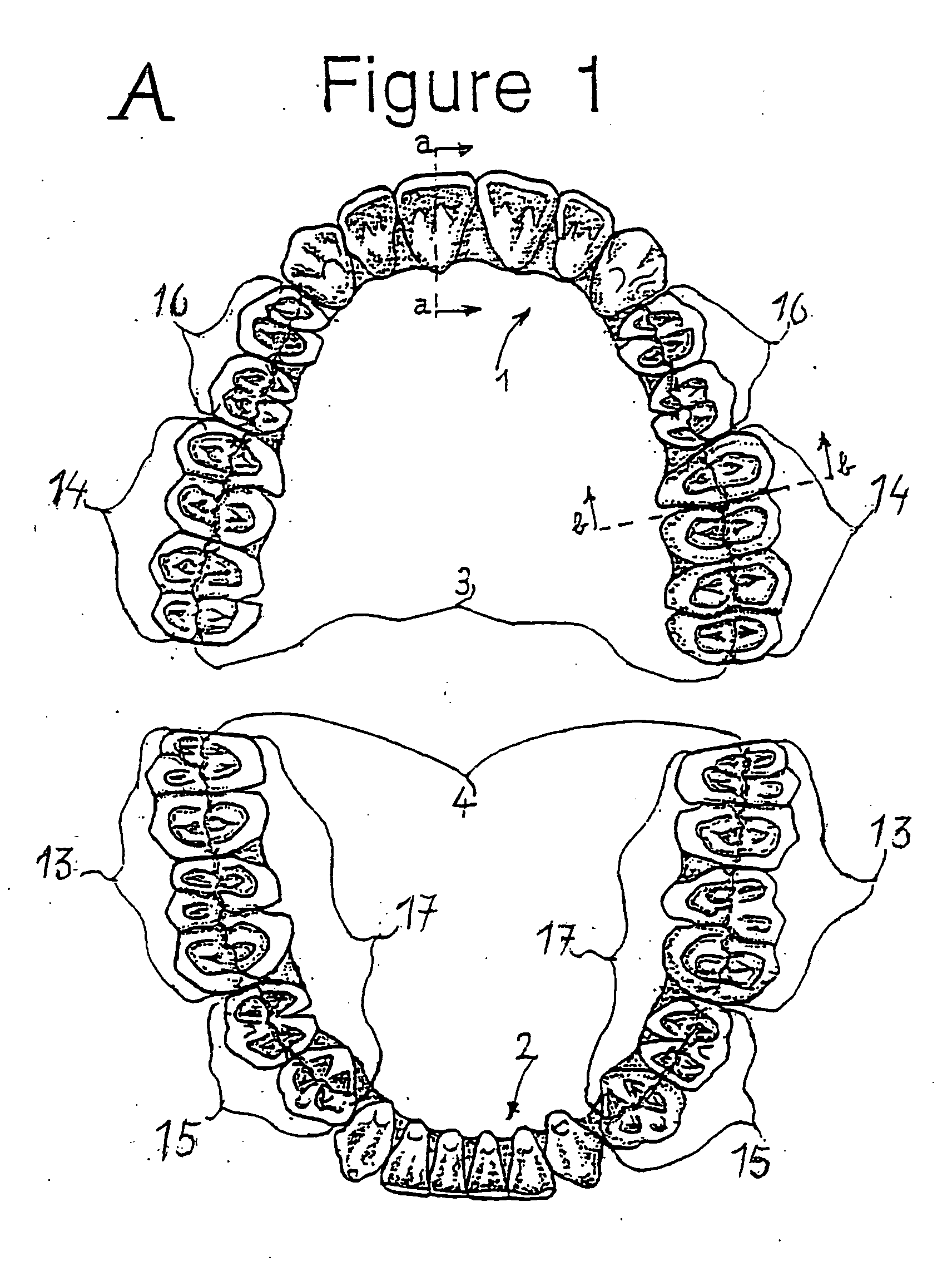

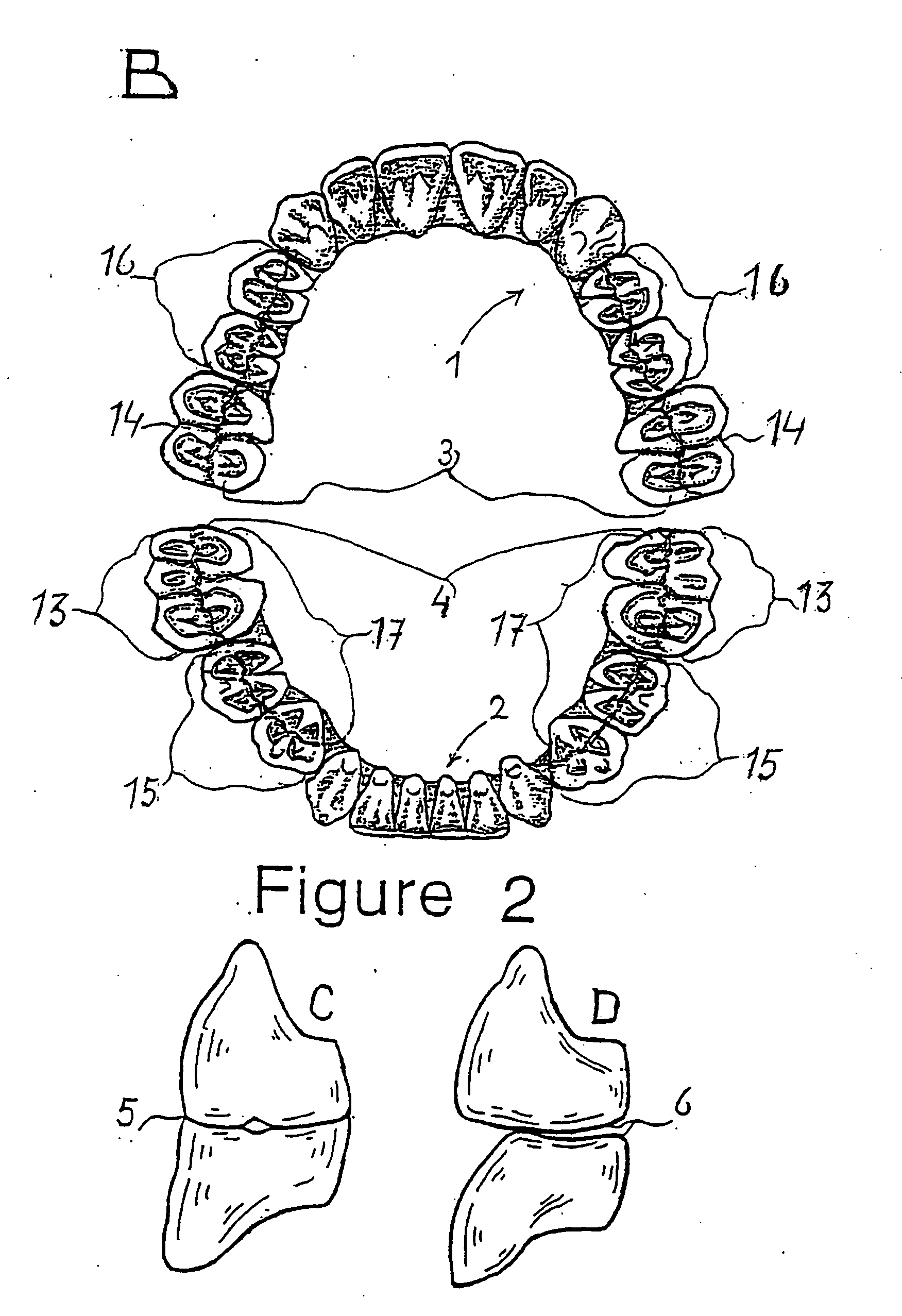

Combination set of denture teeth units for setting-up dentures in balanced articulation

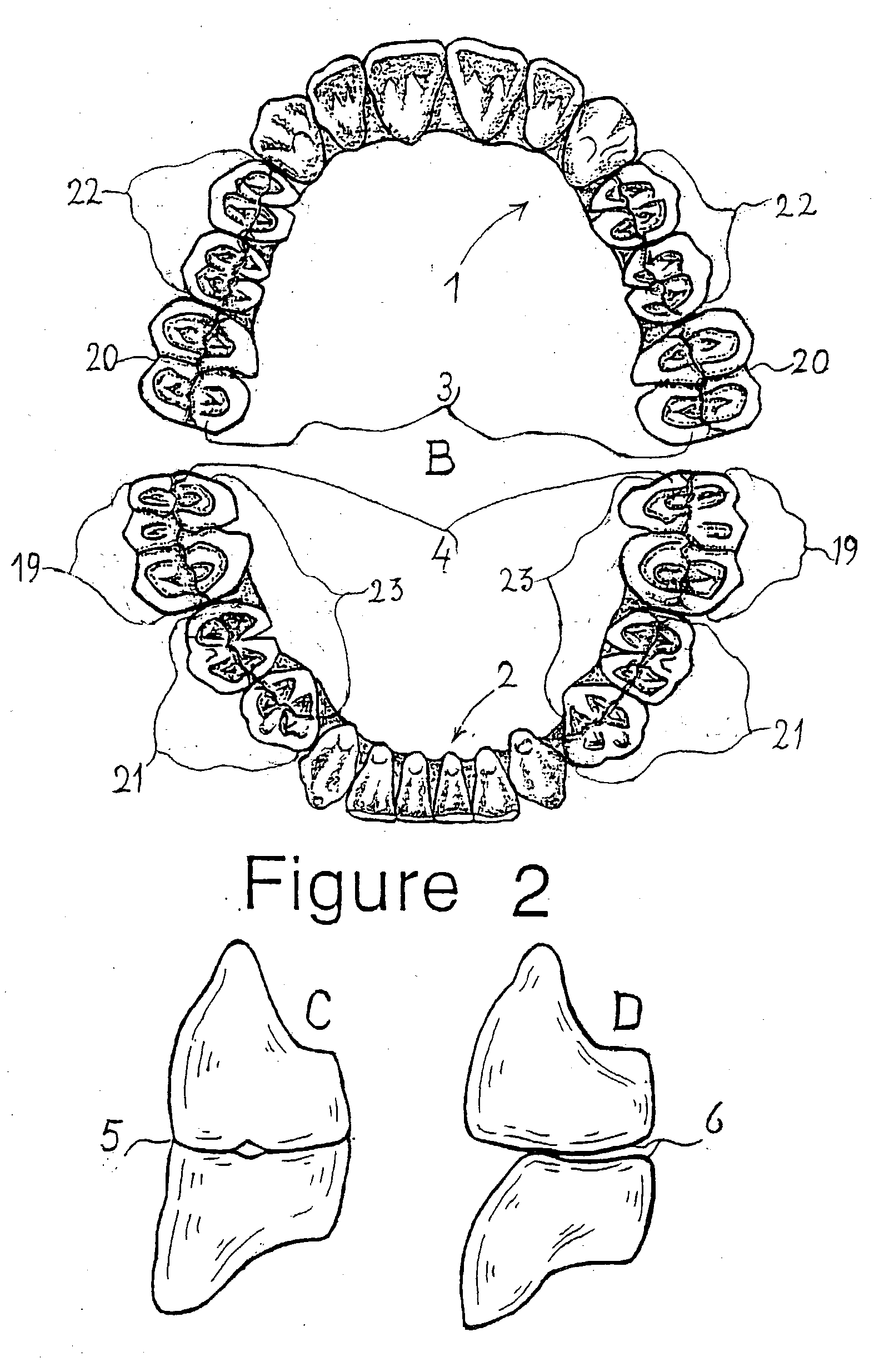

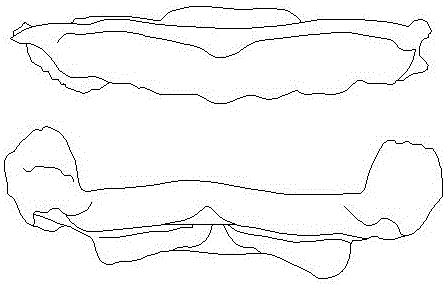

A combination set (FIG. 1, A,B), at least in a medium size or different sizes, includes complete arched denture teeth units (1), (2) preformed without denture base, for setting up denture teeth instantly and adjustable in a full balanced articulation during custom denture work. The set(s) is composed of a complete upper (1) and separate complementary complete lower (2) arched denture teeth unit, each including anterior and posterior denture teeth inter-connected either in a complete (A) or under-extended complete (B) tooth arch at least in an oval form. Each of the units includes a total unitary inter-occlusal bite plane preformed in a corresponding centric occlusion and full balanced articulation. In order to prevent to setting-up denture teeth, one by one in the centric and full balanced articulation, as regularly, hereto the unitary inter-occlusal bite plane is pre-set according to interconnected anterior and posterior denture teeth. While the posterior denture teeth are formed cuspless spheroellipsoidal, conforming a 4 inch (11 cm.) radius, thereby pre-set either in a planar or anterio-posterior or curved sphero-ellipsoidal arrangement including a free centric inter-occlusal contact (FIG. 2) either full (C, 5) or partly (D,6) and a free eccentric bi-lateral balanced articular contact. Having the last molar posterior denture teeth either broader or not than regularly and pre-set without tongue interference to ascertain individually the balanced articular contact. Having the set(s) non-bendable from a durable tooth aesthetic material. The invention includes further a method A for preforming the set(s) from the material by providing a durable economised mould structure and yet a method B for setting up the set(s) in an instant and adjustable full balanced articulation with the provision of an auxiliary set of tools.

Owner:DEQUEKER FRANS A B

Removable denture and method of producing the same

InactiveUS20110236856A1Easy to disassembleIncreased durabilityDental prostheticsDentistryDenture base

A removable denture includes a denture base that is made of ultrahigh molecular weight polyethylene and is formed in a predetermined shape by a molded object of ultrahigh molecular weight polyethylene being cut; and artificial teeth that are arrayed at the denture base.

Owner:NAT UNIV CORP TOKYO MEDICAL & DENTAL UNIV

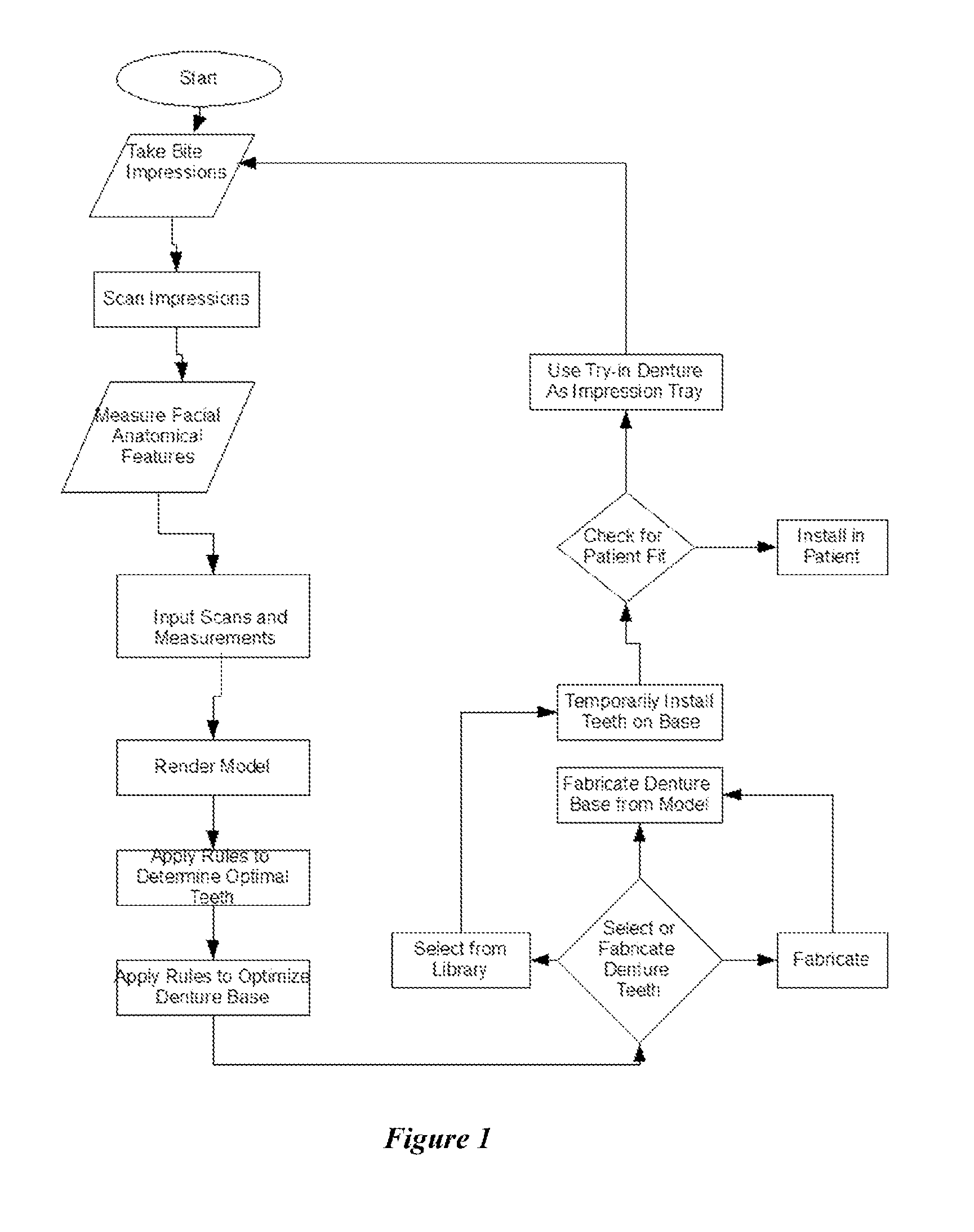

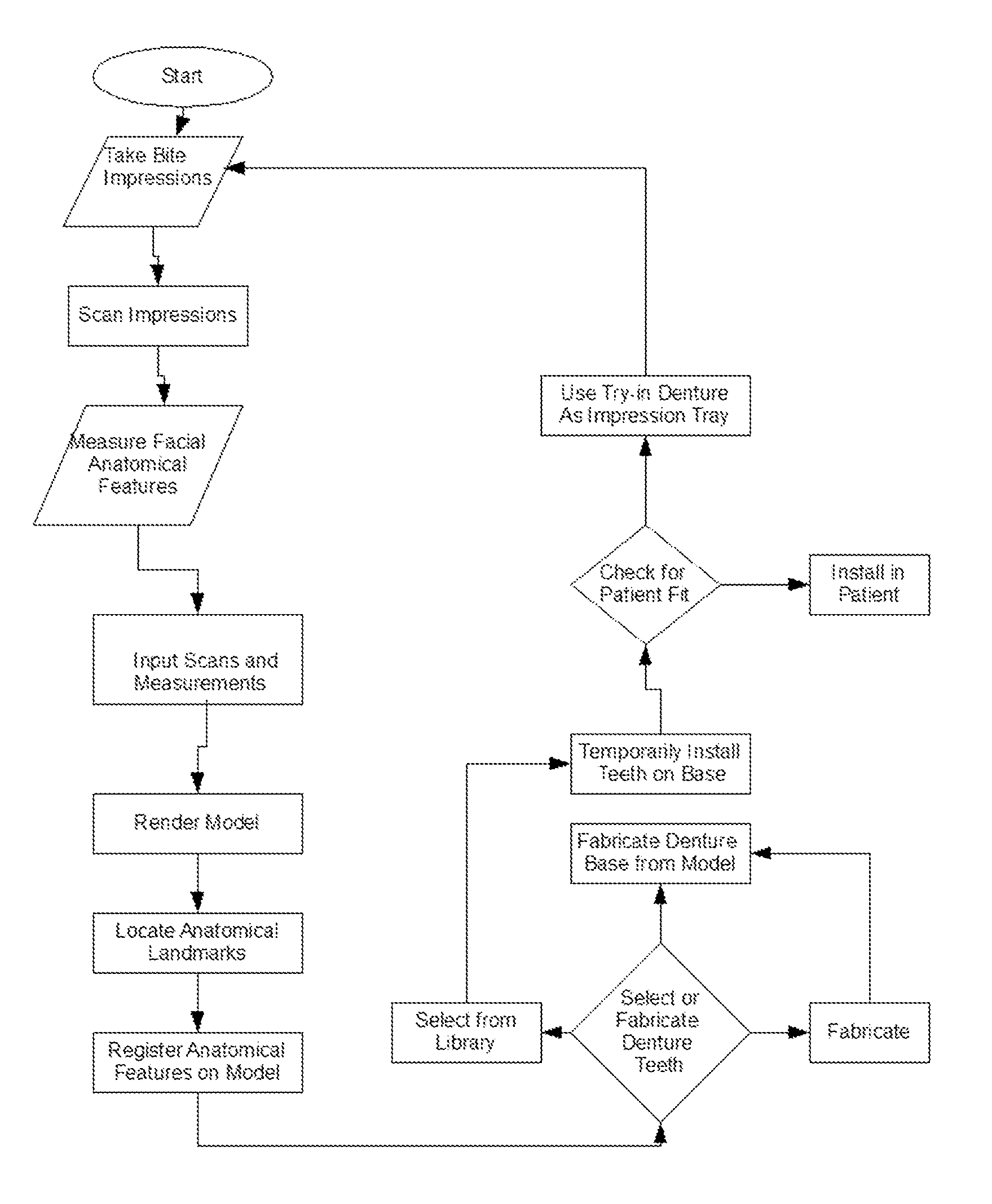

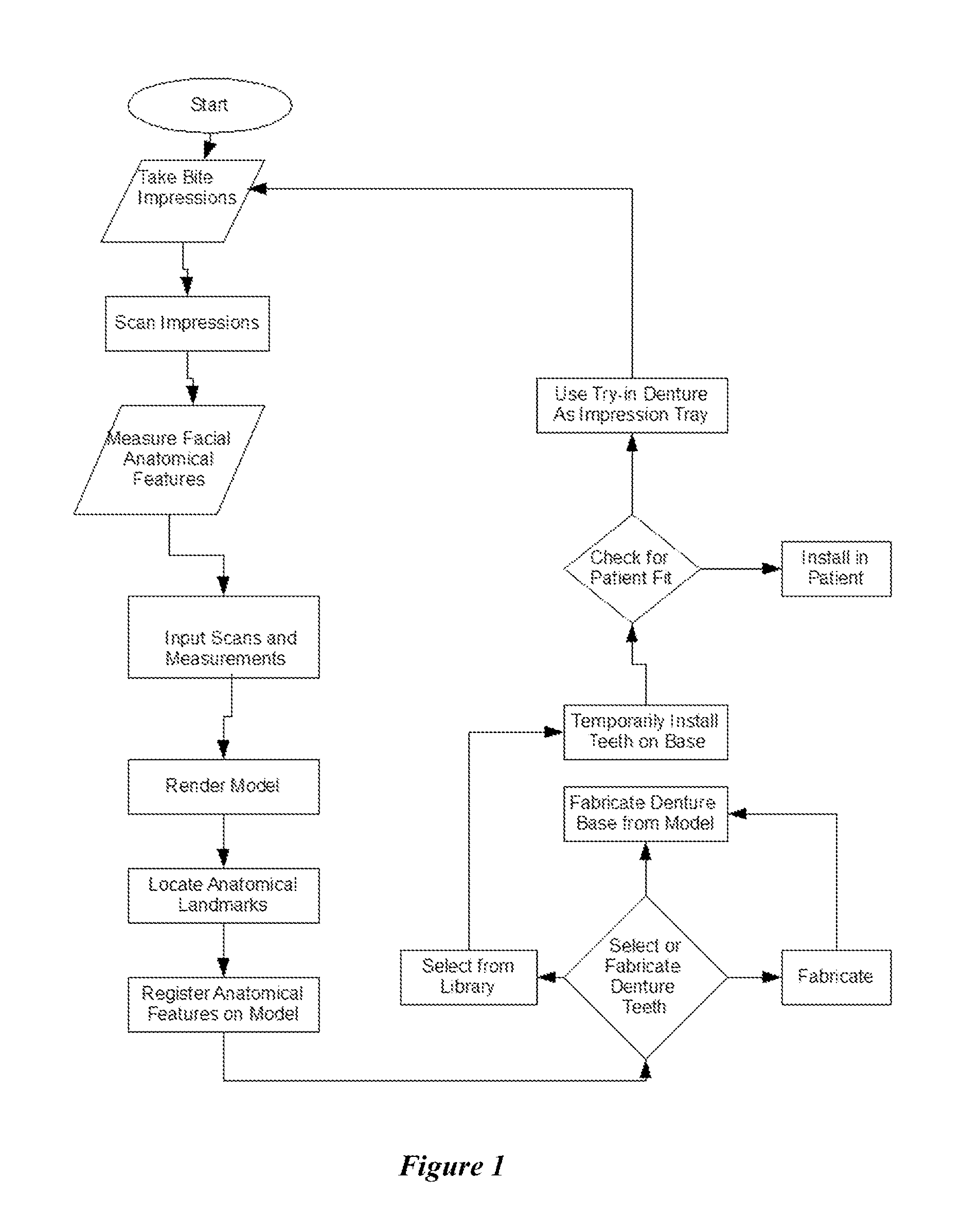

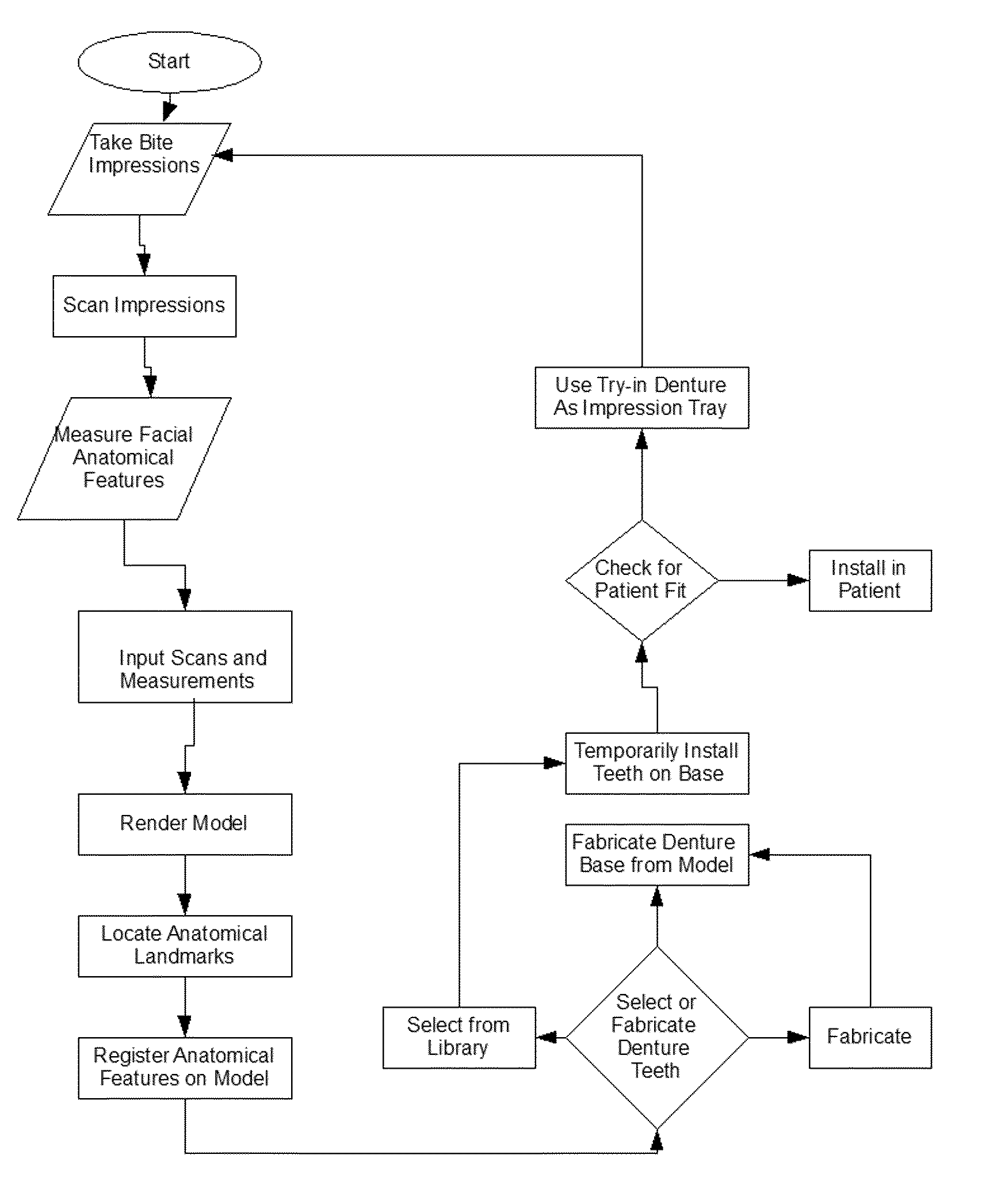

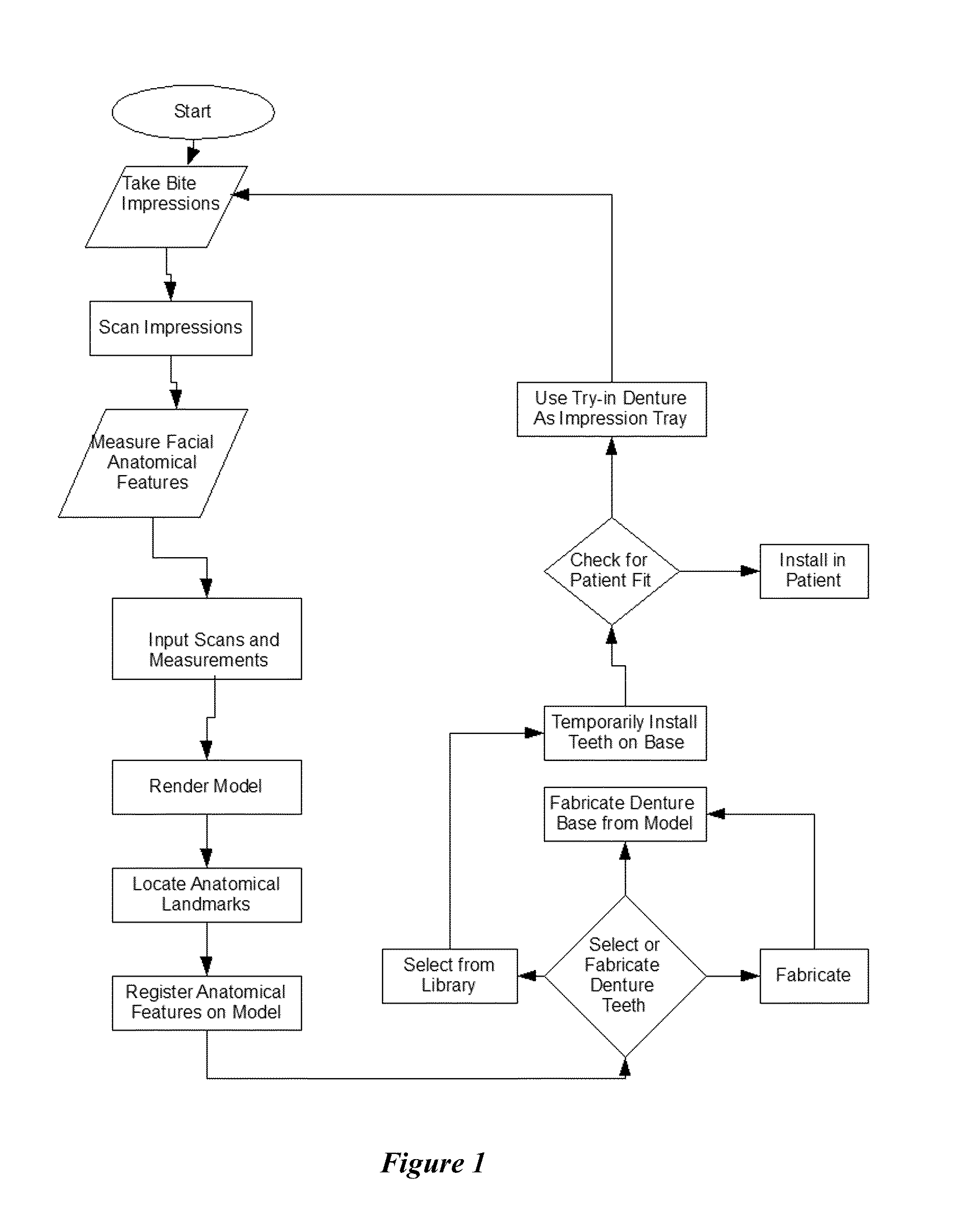

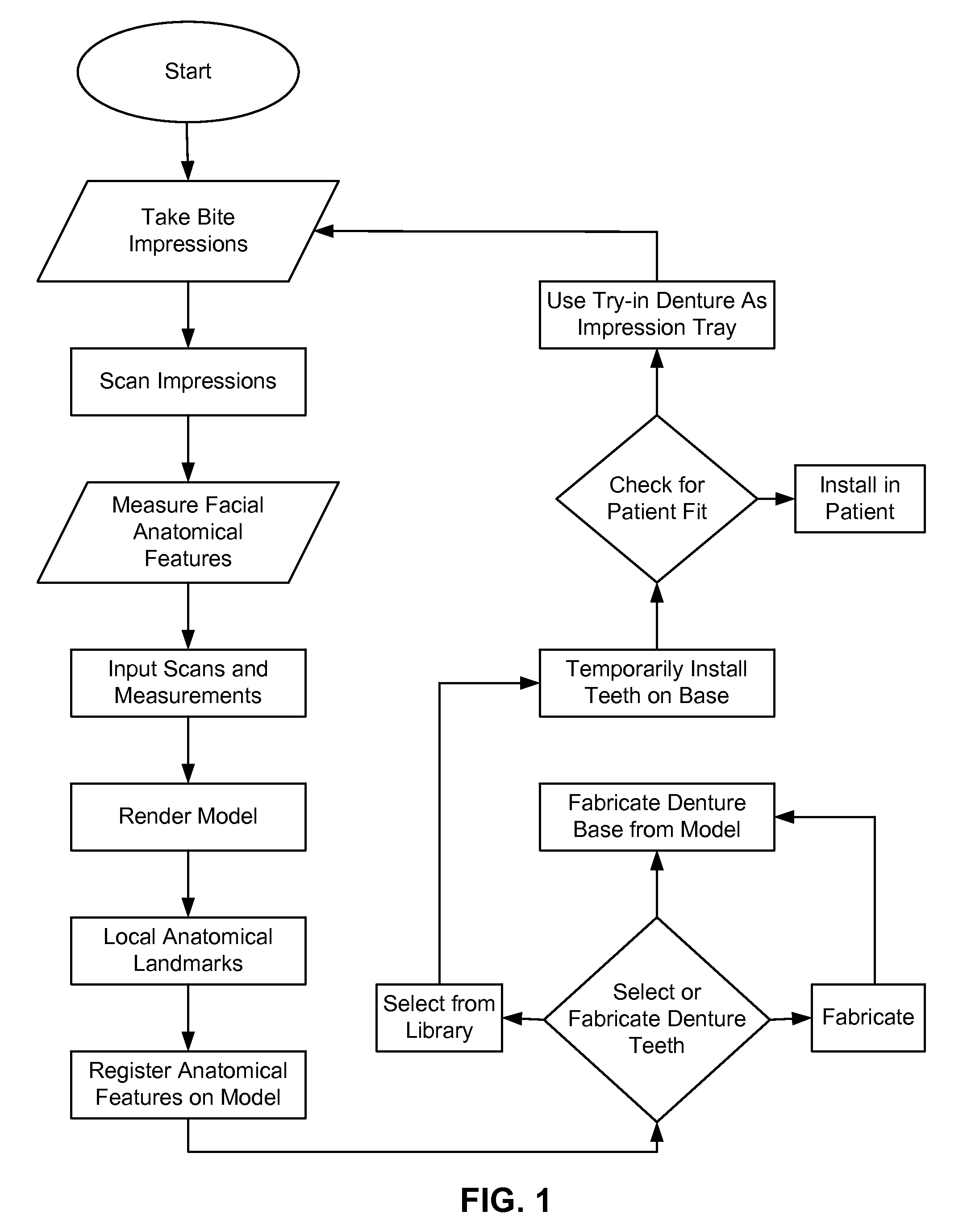

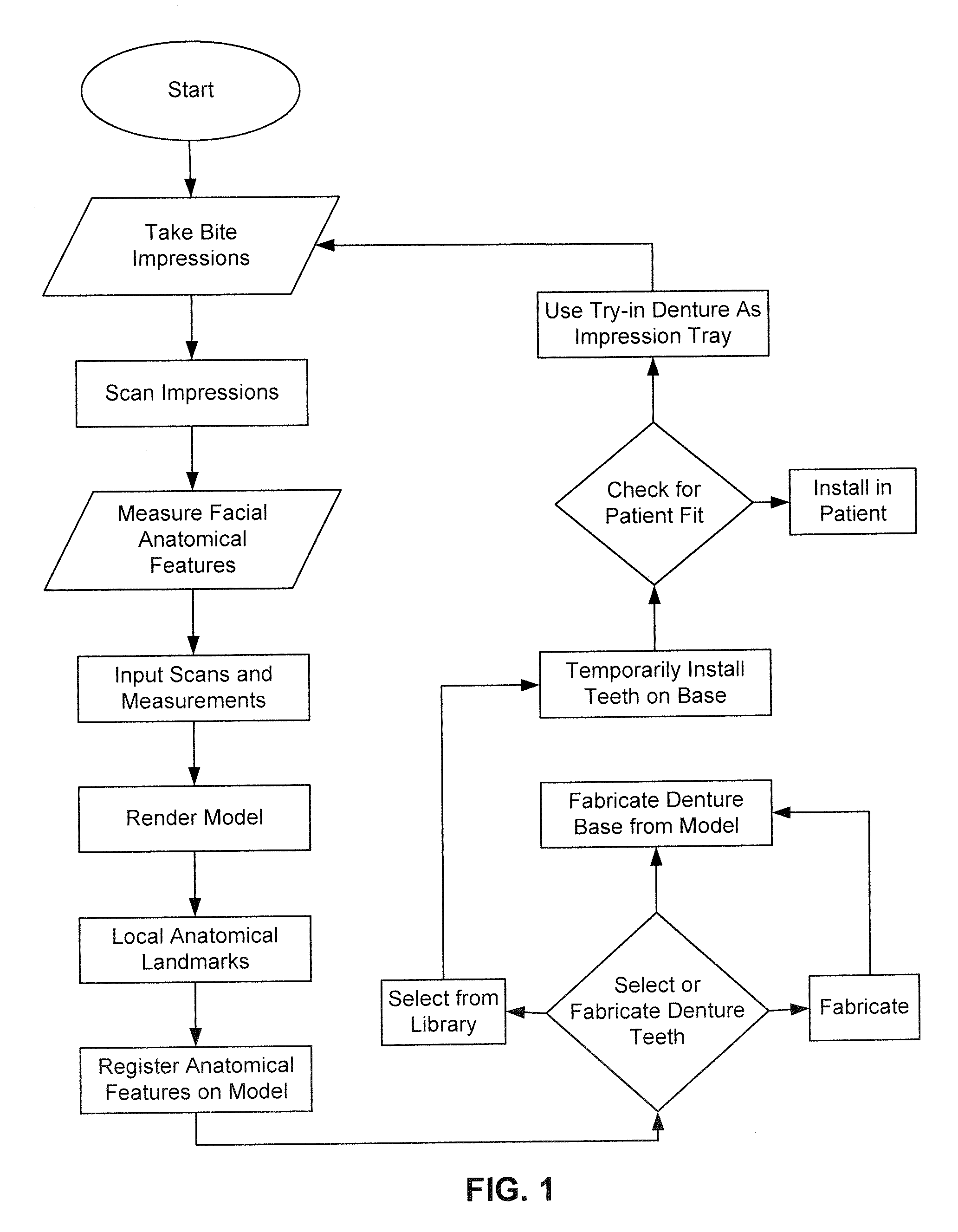

System and process for optimization of dentures

ActiveUS20130218532A1Reduce in quantityGood choiceAdditive manufacturing apparatusMechanical/radiation/invasive therapiesDenturesAnatomical measurement

System and processes for optimal selection of teeth for dentures based on the anatomical measurements and bite impressions of the patient. This information is applied in an iterative manner to rules that balance the anatomical and aesthetic considerations to select the best teeth for a patient. The system may also use this information in an iterative manner to rules that balance the anatomical and aesthetic considerations to design the optimal denture base for the patient as well.

Owner:GLOBAL DENTAL SCI

Three-dimensional fabricating material systems and methods for producing layered dental products

ActiveUS20170360534A1Highly shapeHigh wear resistanceAdditive manufacturing apparatusImpression capsFull denturesDental Product

This invention designs and builds multiple layers (two layers or more) of various dental devices, specifically denture base or denture, where printed multiple layered denture base with teeth cavities to receive artificial denture tooth materials to form final dental devices, such as partial and full dentures. It can also print denture teeth. This invention also designs and prints multiple layers (two layers or more) of denture base with artificial denture teeth to form final dental devices, such as partial and full dentures. A method for manufacturing a layered denture is provided. The invention provides a multiple layered denture base materials for printing a denture base. The invention also provides a multiple layered denture tooth materials for printing artificial denture teeth. Highly shape adjustable or shape memory polymer layer(s) may be used in these multiple layered denture base forms. Different layer of material has different mechanical and physical properties to meet different need, which provide added benefits to the patients, dental professional and dental laboratory.

Owner:DENTSPLY SIRONA INC

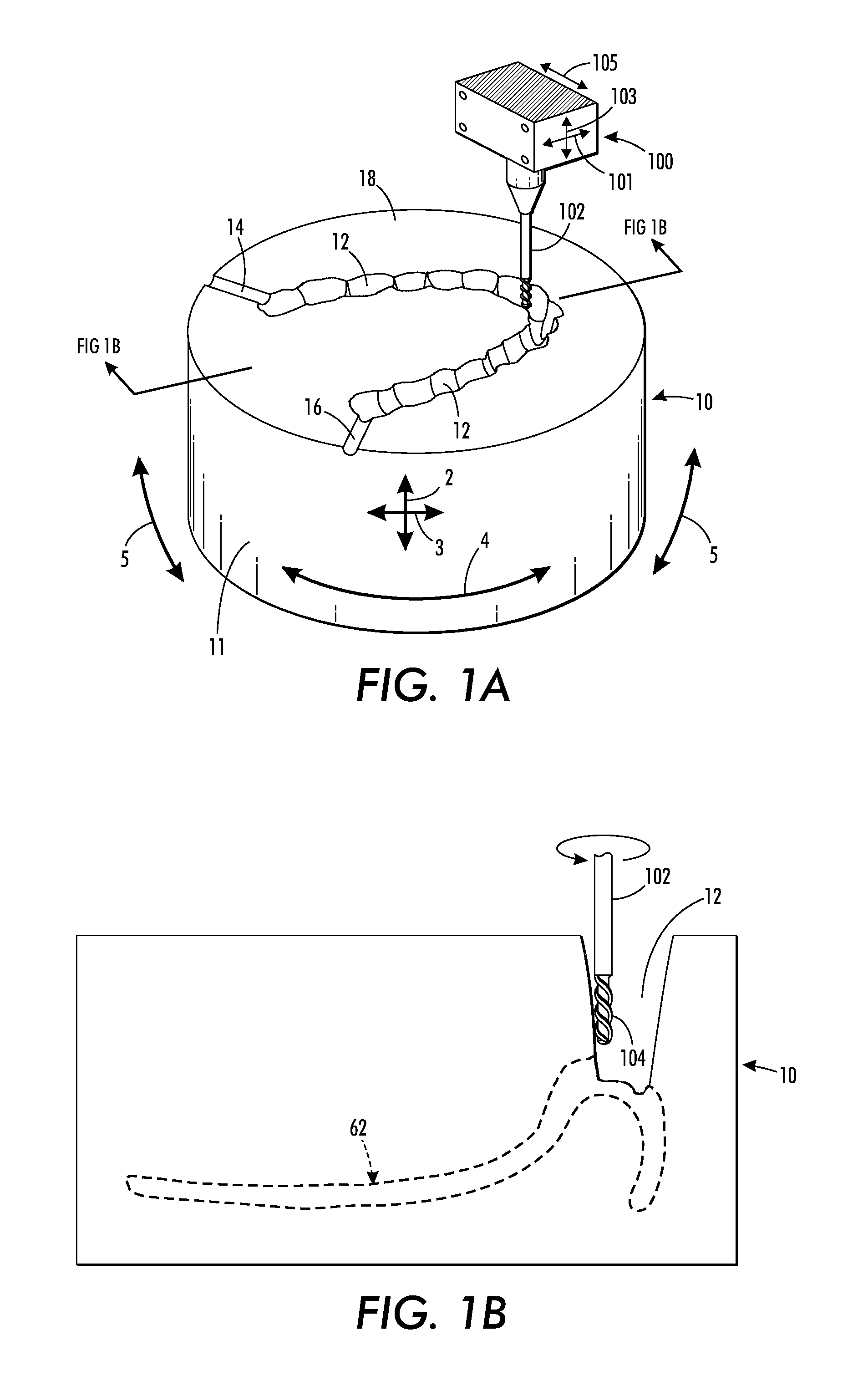

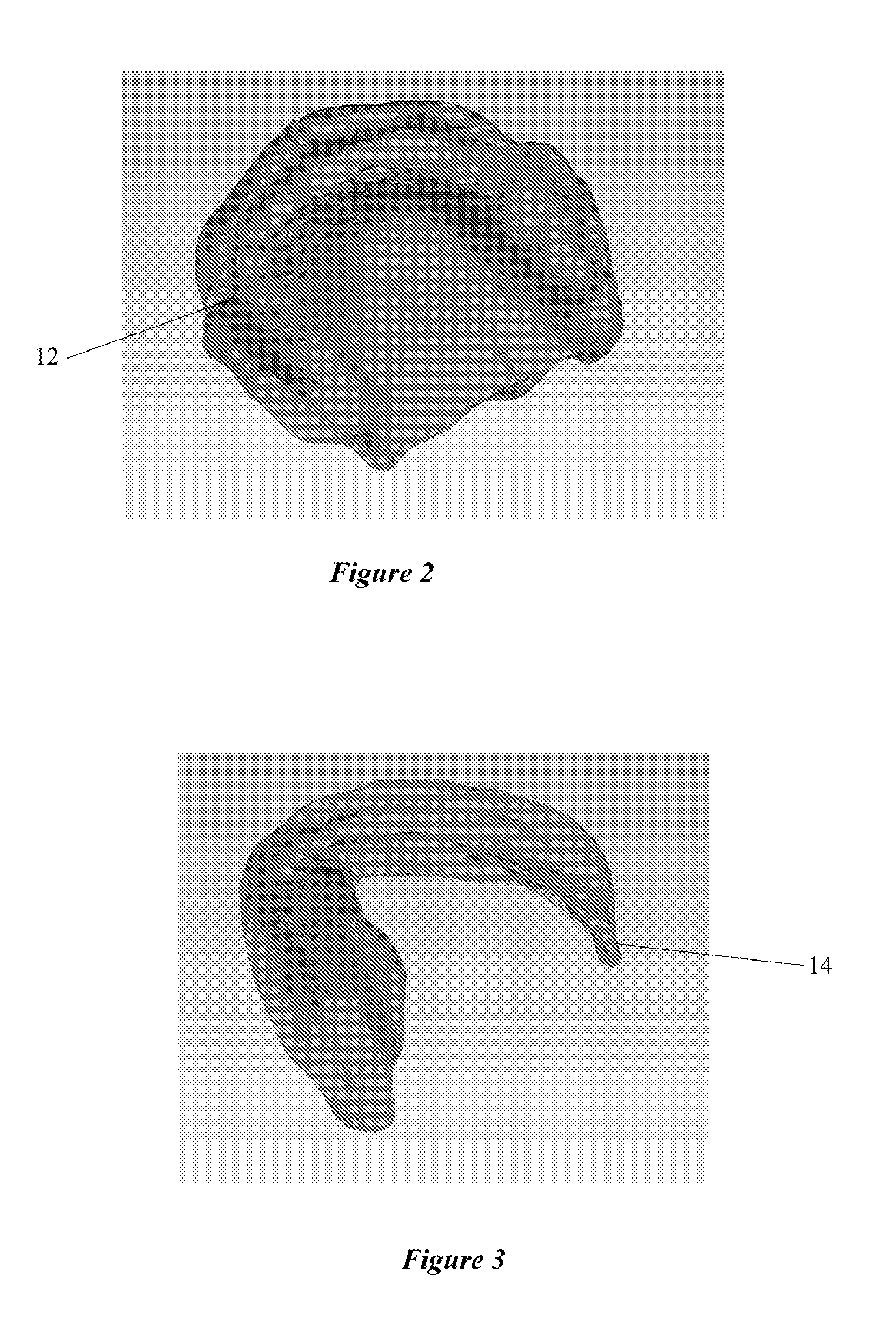

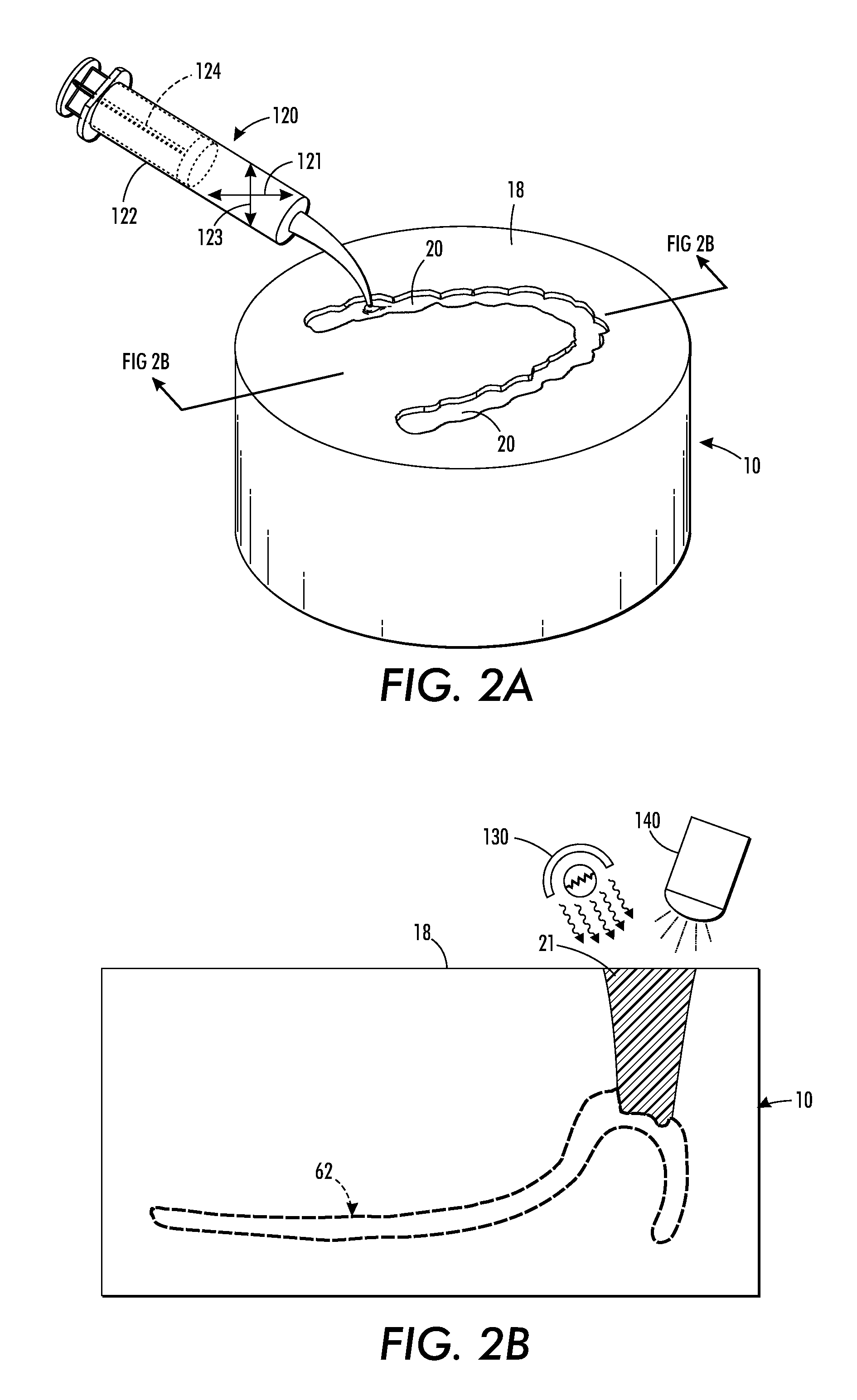

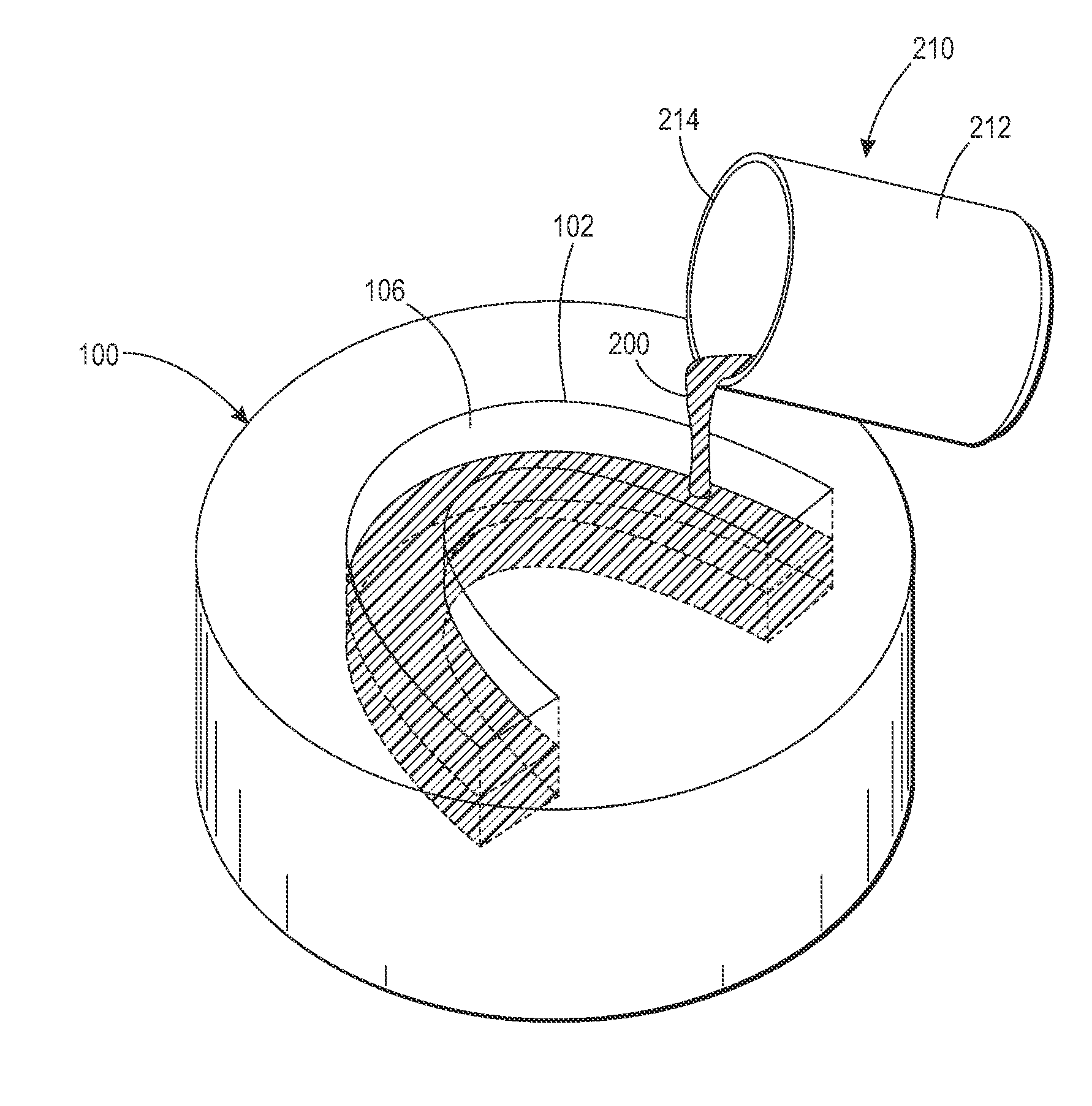

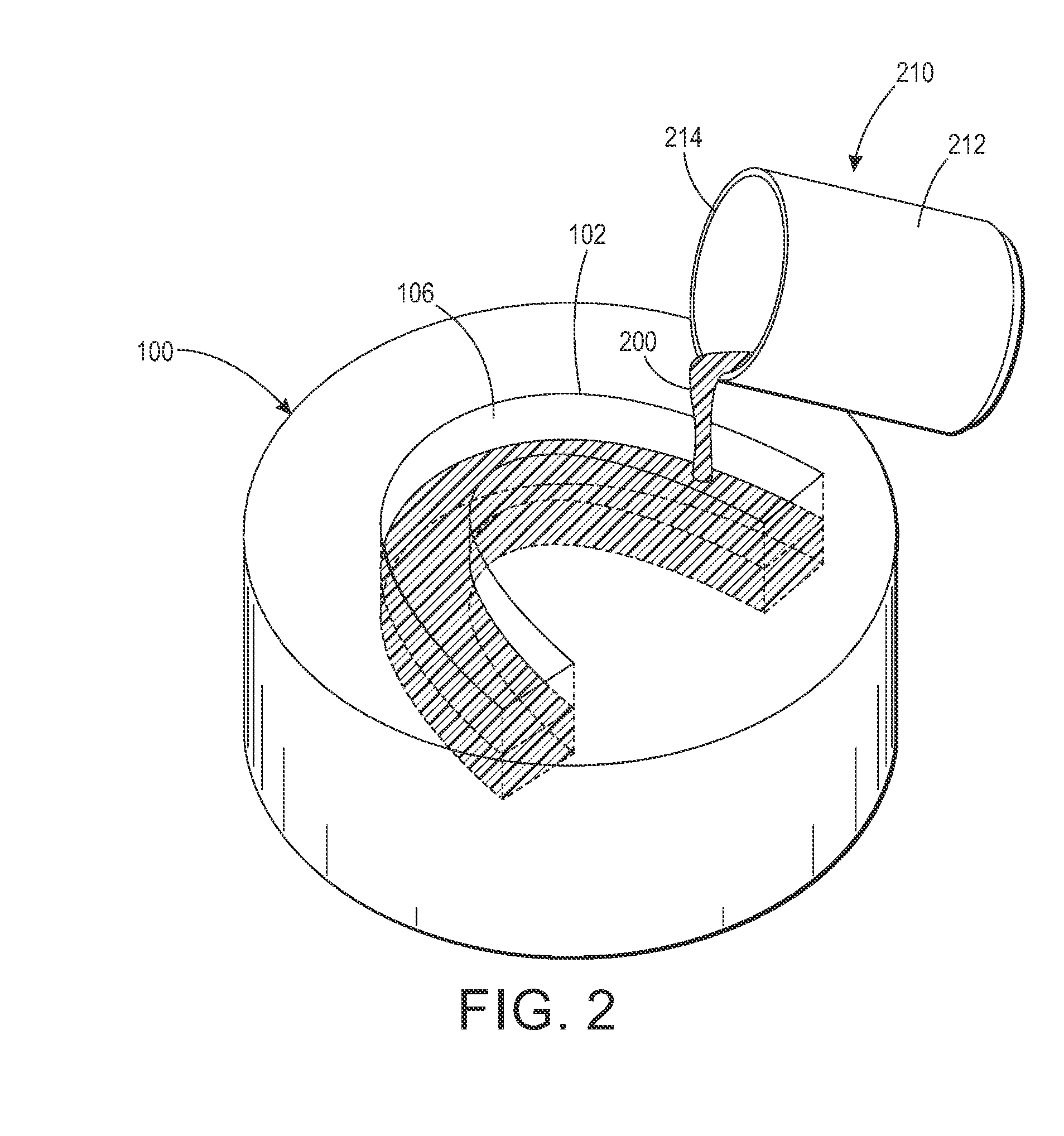

Molded denture and method and apparatus of making same

InactiveUS20160100917A1Reduce the possibilityMinimal number of stepAdditive manufacturing apparatusMechanical/radiation/invasive therapiesDenturesDental cast

A method for making a denture comprising creating three-dimensional models of top denture base, bottom denture base, and denture tooth molds; fabricating the molds by an additive manufacturing process; joining the bottom denture base mold to the top denture base mold to form a denture base mold cavity; injecting fluid synthetic denture base material into the mold cavity and curing the material to form the denture base; removing the bottom denture base mold from the top denture base mold, while leaving the denture base in the top denture base mold; joining the denture tooth mold to the top denture base mold to form a mold cavity defining the shape of denture teeth; and injecting fluid synthetic denture tooth material into the denture teeth mold cavity and curing the material to form the denture teeth joined to the denture base. An apparatus for making the denture is also disclosed.

Owner:GLOBAL DENTAL SCI

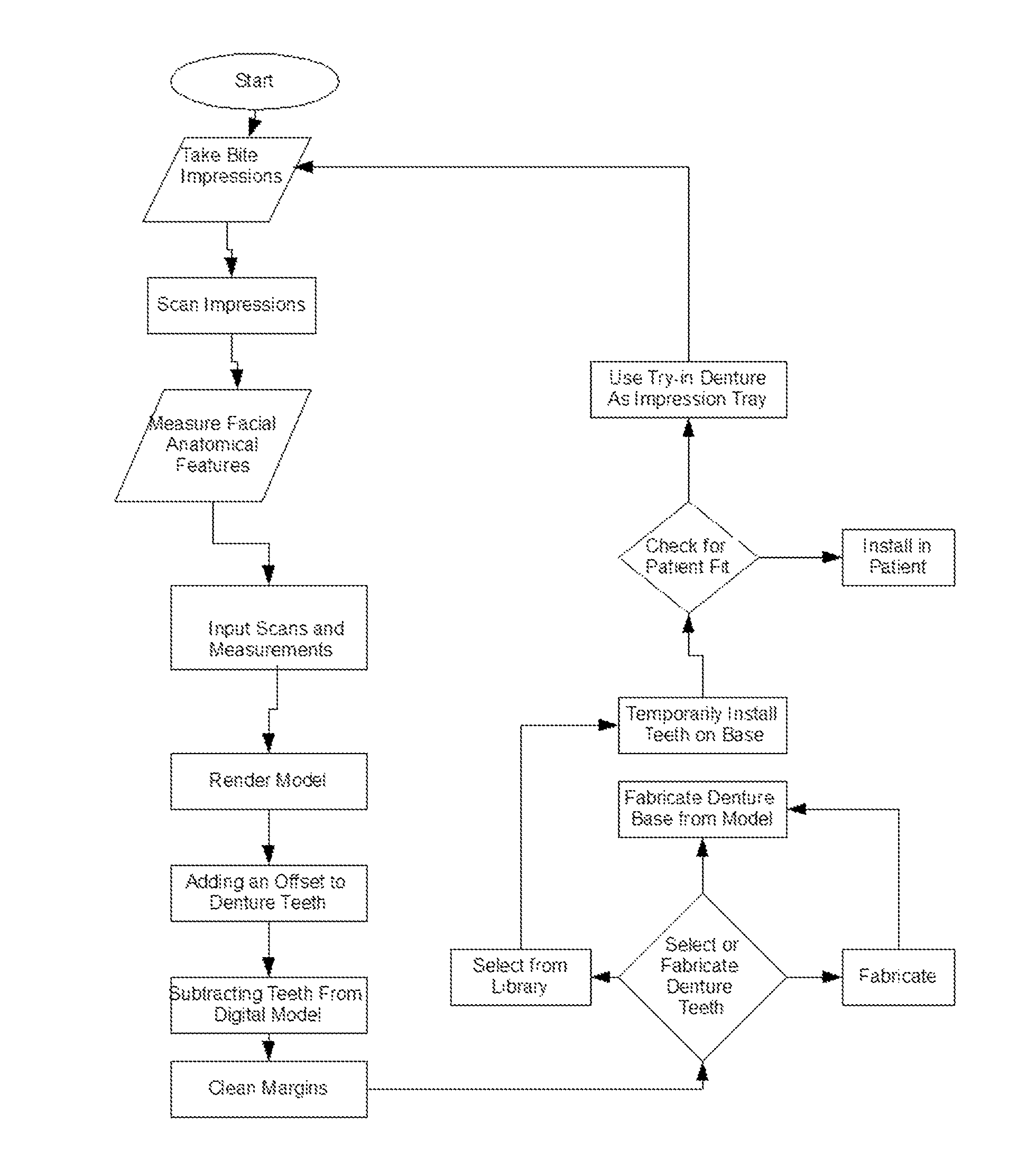

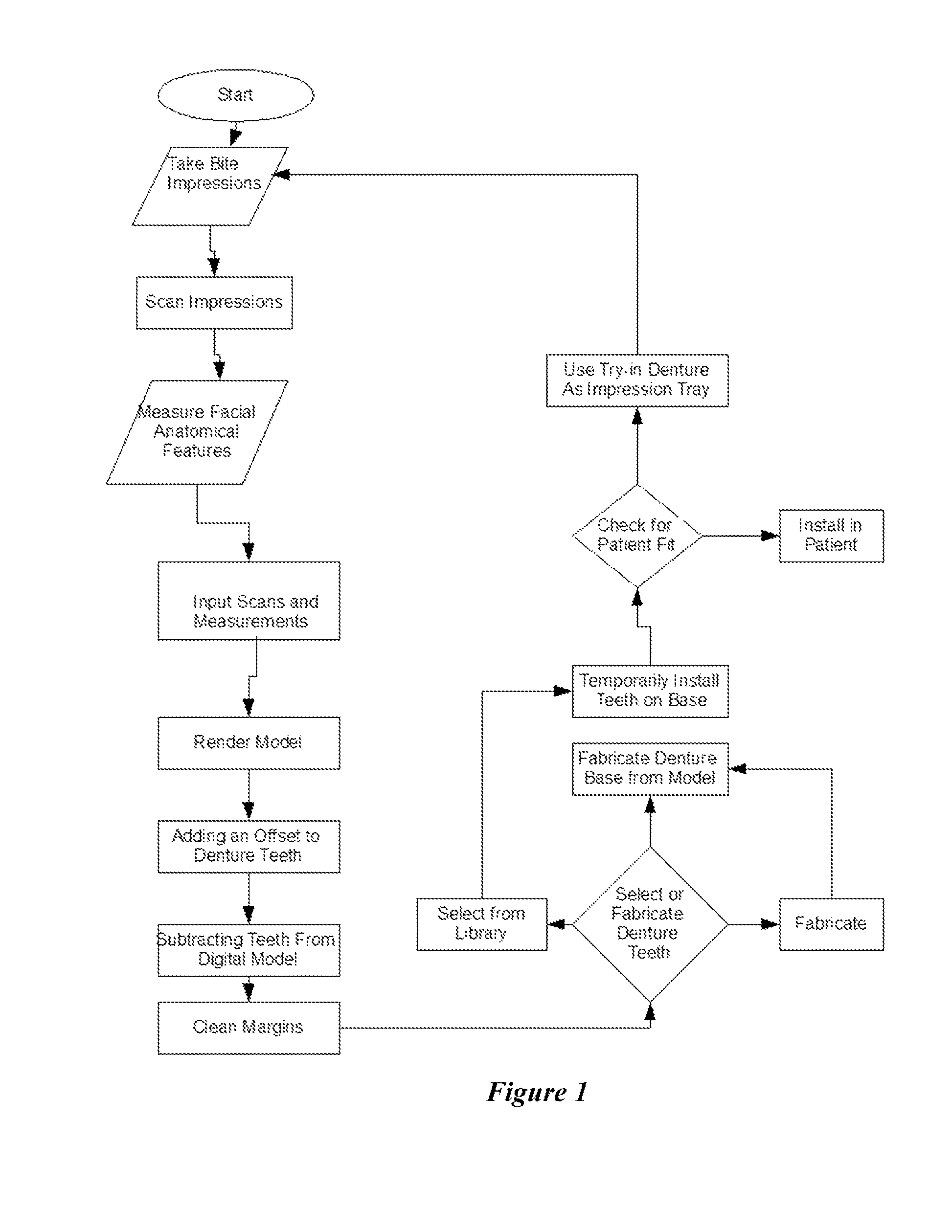

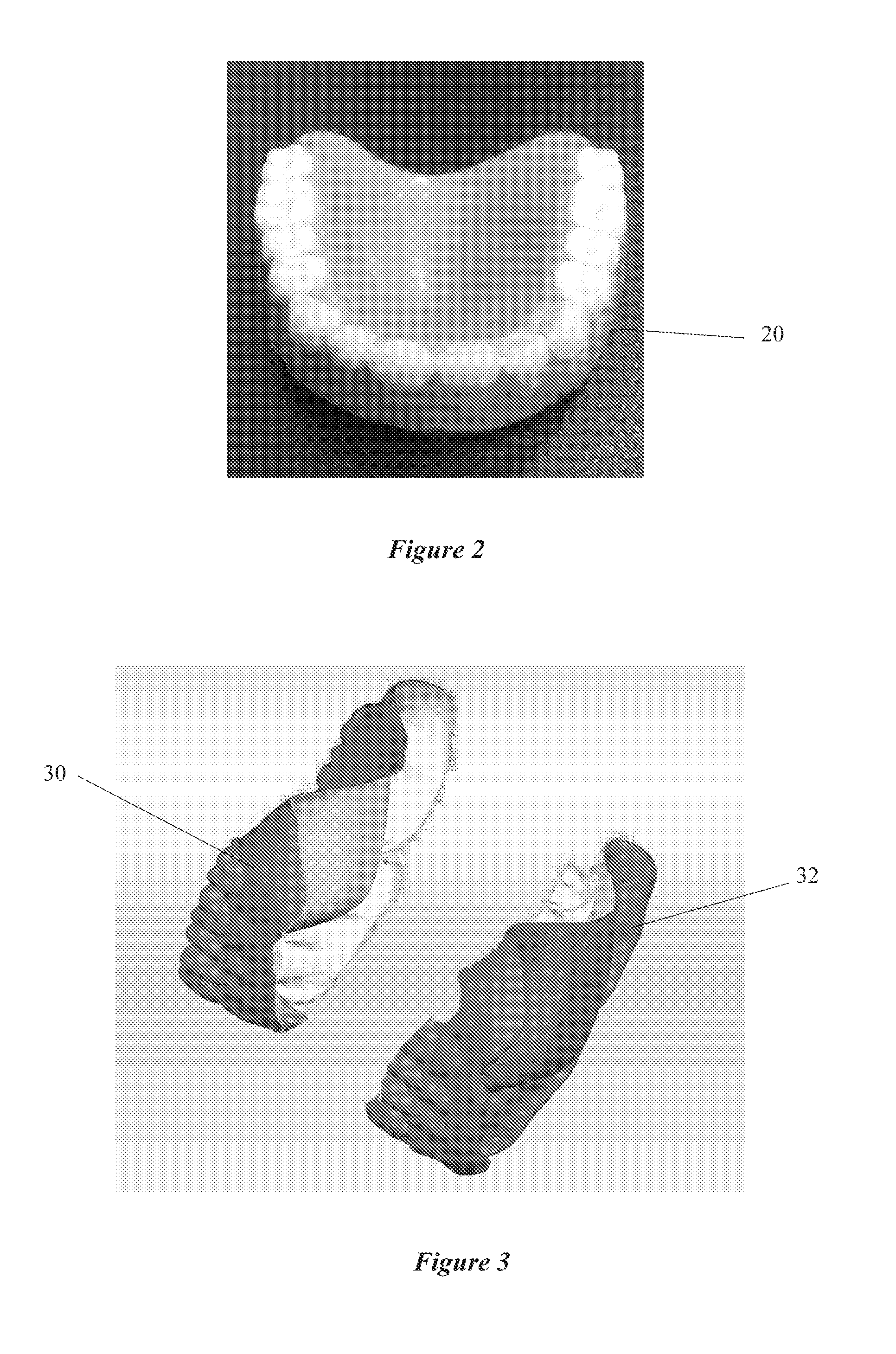

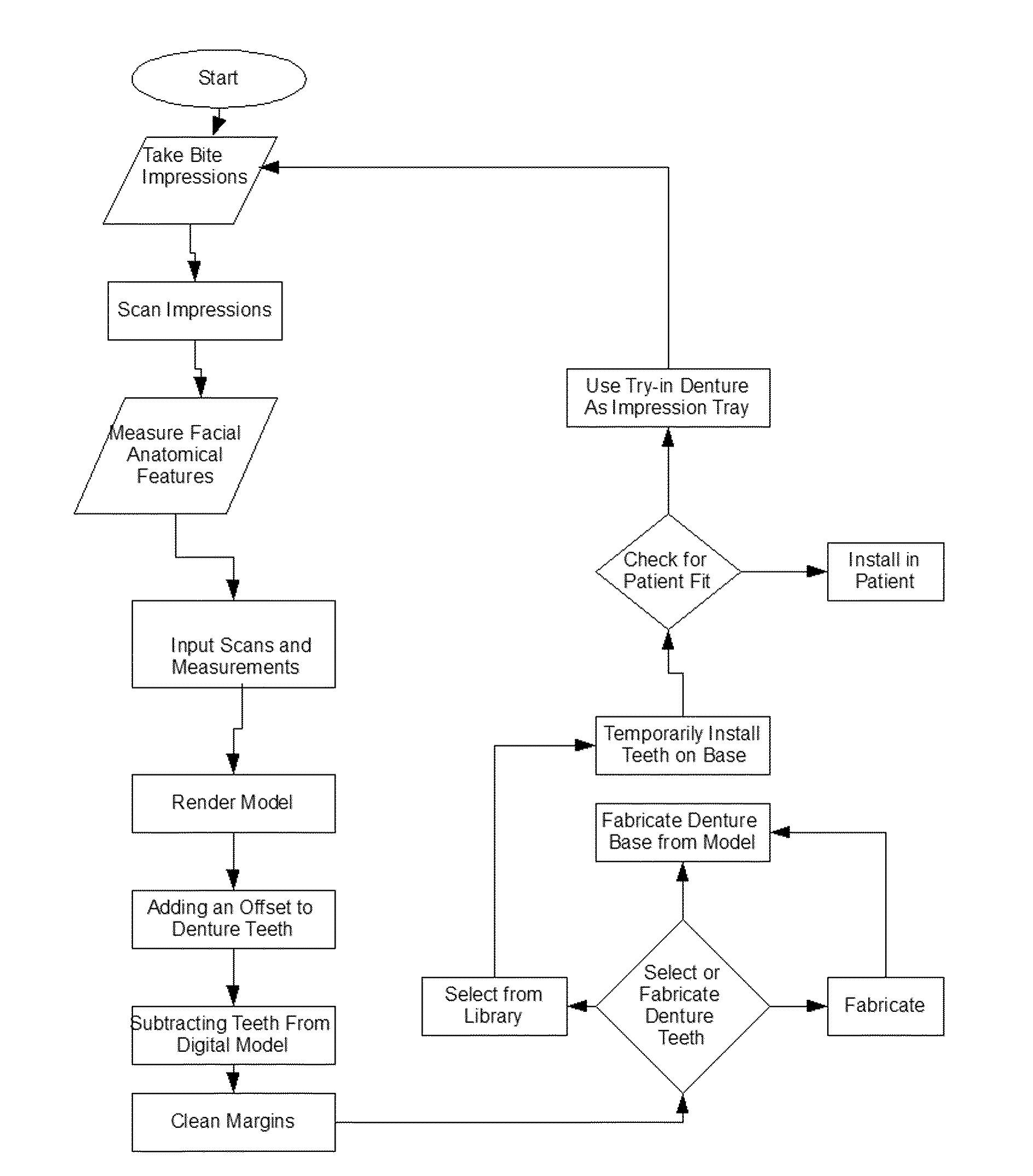

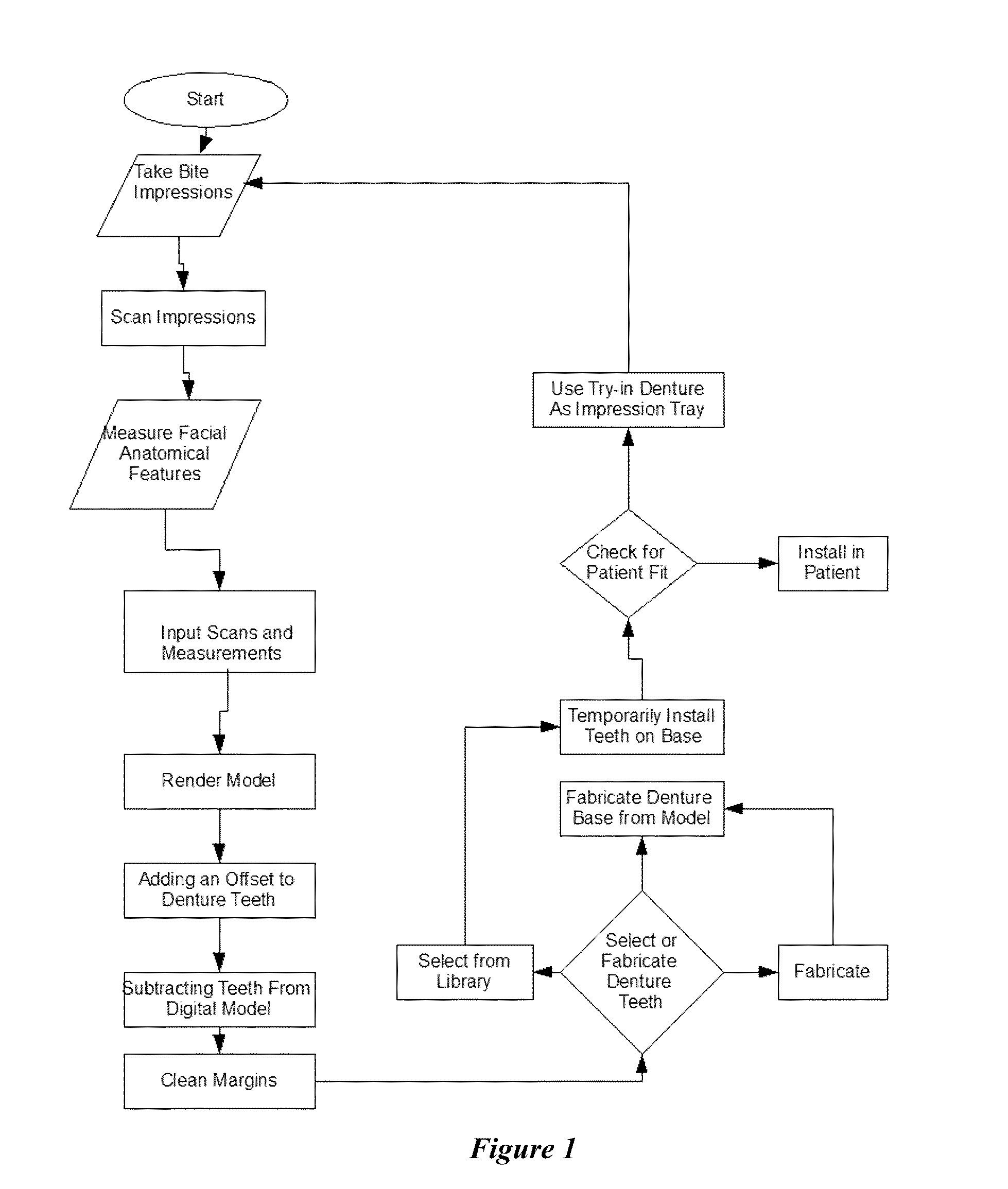

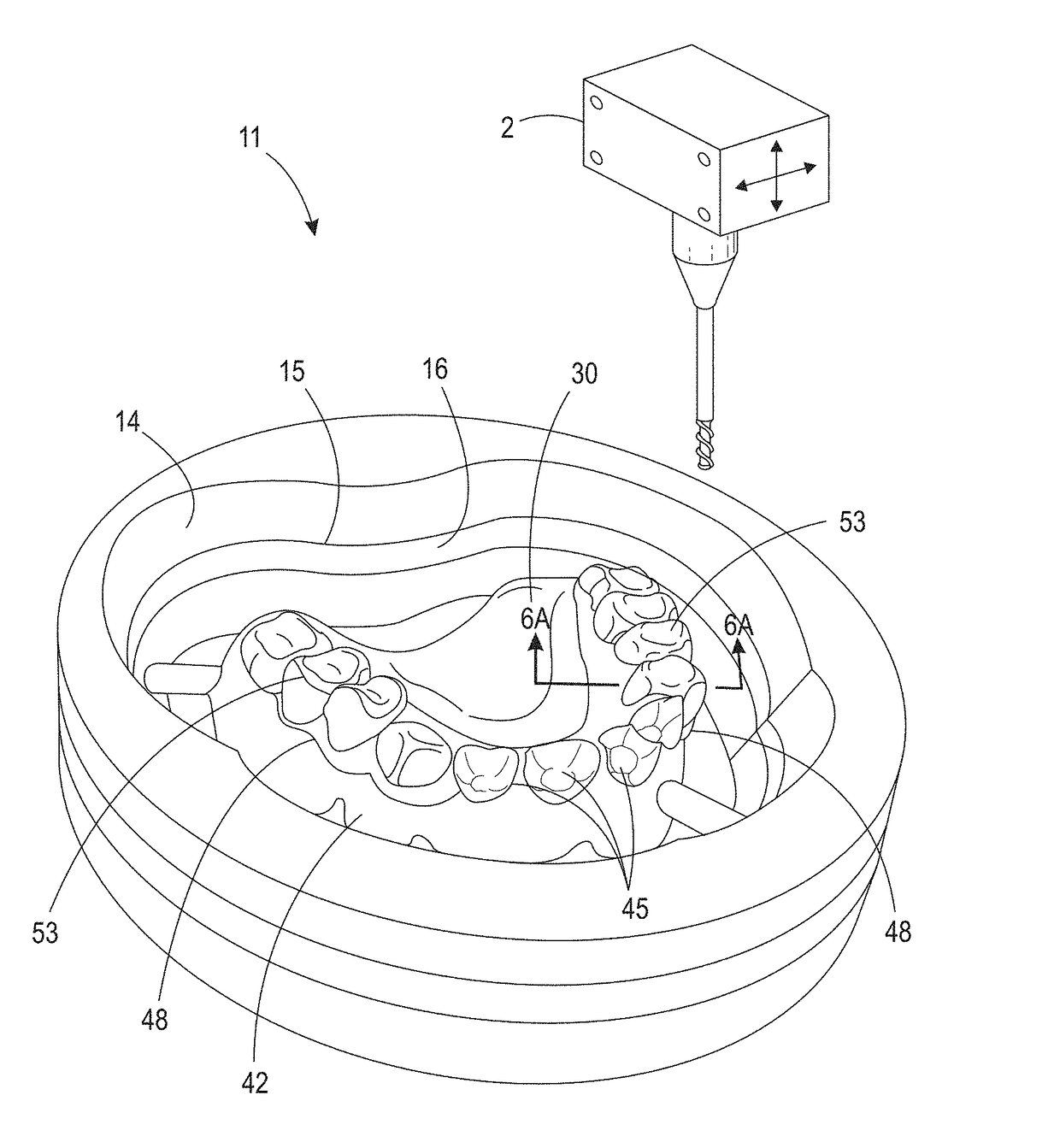

System and process for duplication of dentures

Systems and processes for the duplication of dentures from existing dentures. The interior and exterior of the dentures are scanned and a best fit procedure is used to create a fully digitized denture. The denture teeth are selected from a library that is the closest fit to the original denture teeth. The library teeth are offset a preset distance to compensate for the best fit. The teeth are then subtracted from the digitized denture. The margins of the denture are then cleaned after subtracting the teeth. The denture base is then ready for manufacturing. The teeth are then installed onto the denture base and provided to the patient.

Owner:GLOBAL DENTAL SCI

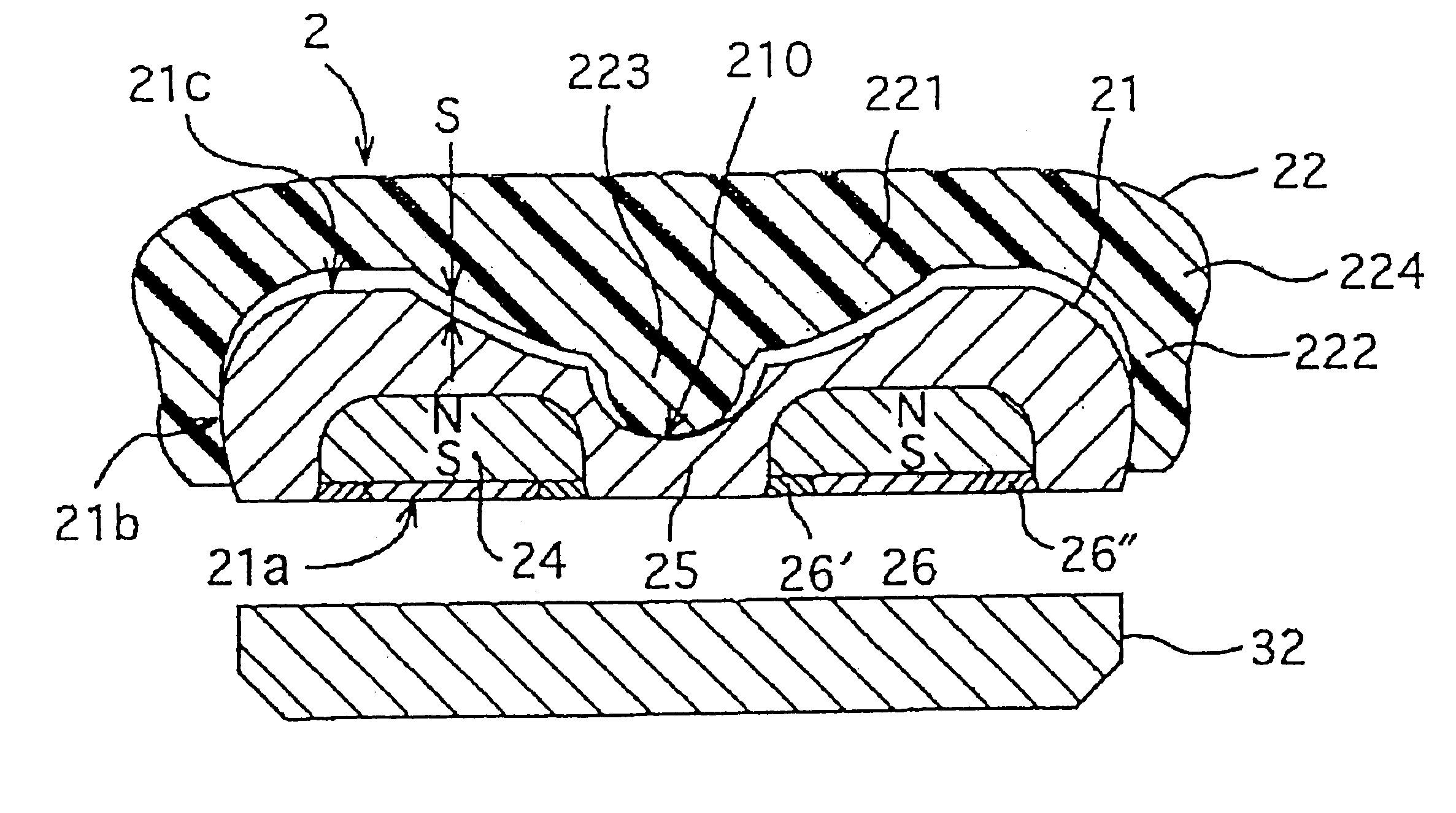

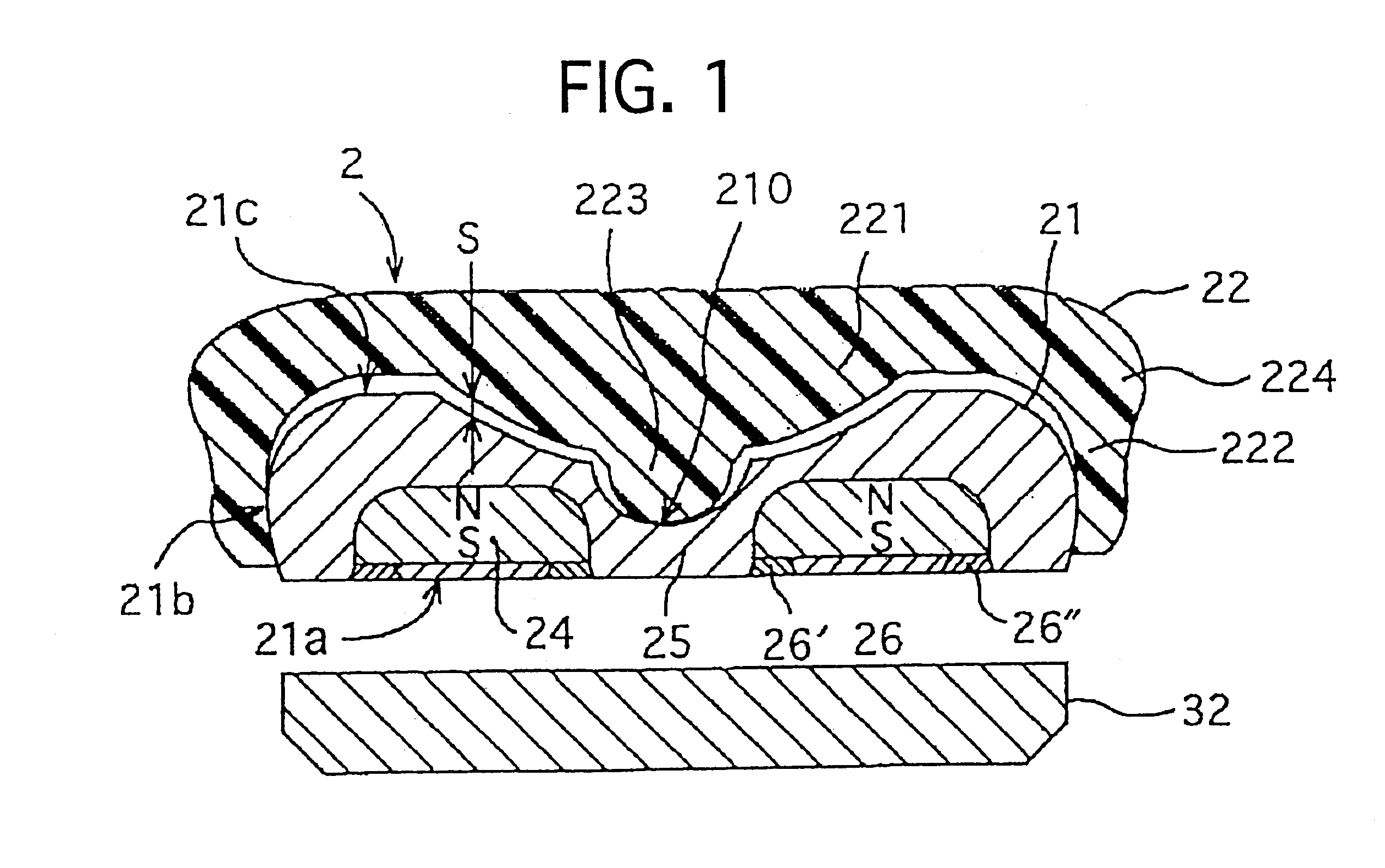

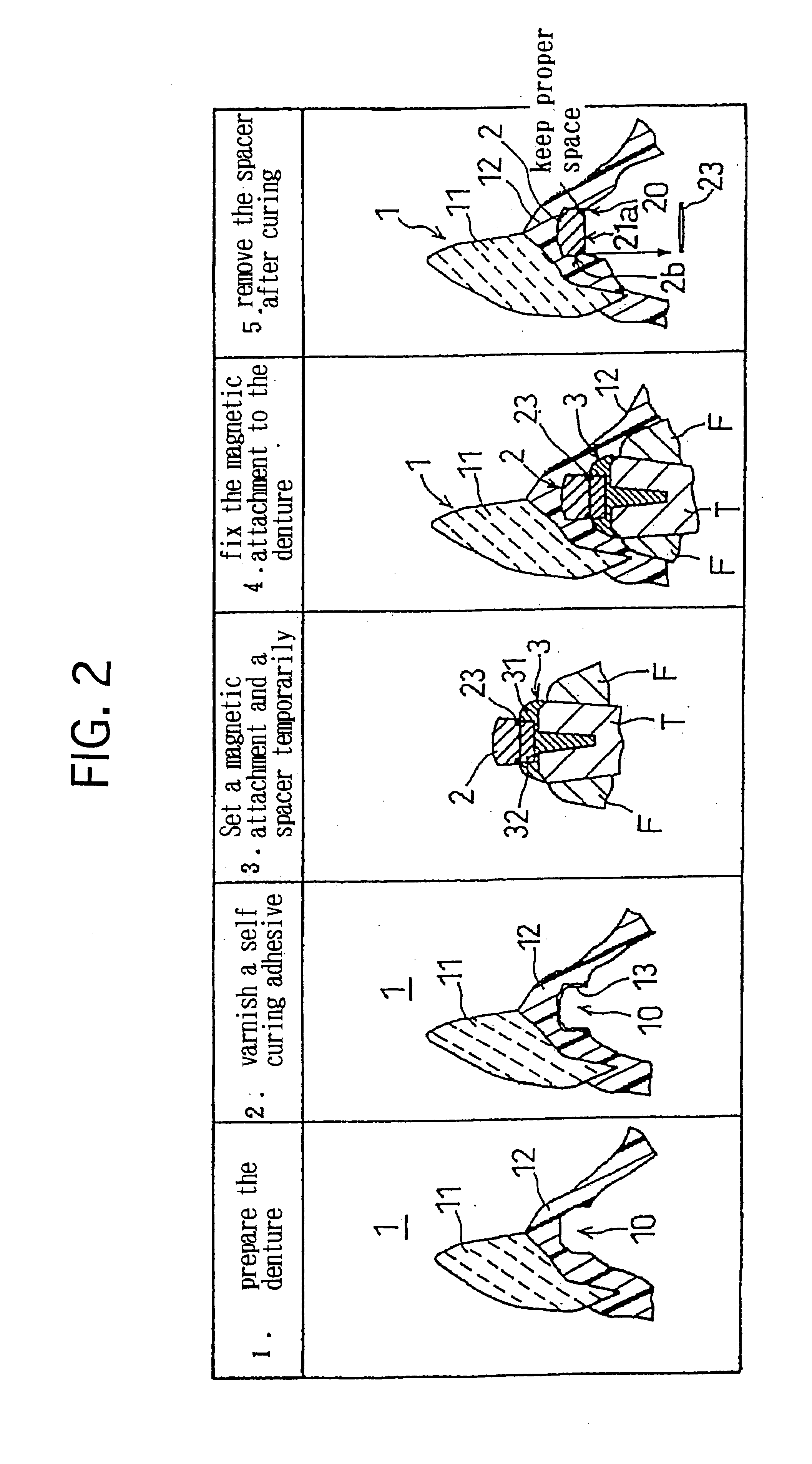

Dental magnetic attachment and its fixing method including spacer

InactiveUS6203325B1Reduce concentrationReducing shaking and rolling motionFastening prosthesisCushioningDentures

A dental magnetic attachment having good cushioning properties against a compressing pressure which makes a denture sink appropriately on biting. The dental magnetic attachment embedded in the denture base for holding the denture in the oral cavity by a magnetic attractive force working with the magnetic assembly and a soft magnetic keeper embedded in the top of the root surface includes a magnetic assembly and a cap covering the top of the magnetic assembly. The magnetic assembly has a hollow in the center of its top. The cap with a button is placed on the magnetic assembly, inserting the button into the hollow to contact to its bottom. On biting, the button is compressed, to be deformed with a shorter thickness and at this time a sleeve formed as a body around the core slides down along the side of the magnetic assembly to reduce the thickness of the dental magnetic attachment. This sliding makes the denture sink uniformly and appropriately. The dental magnetic attachment has good cushioning properties and offers a good feeling to a patient when biting with the denture.

Owner:AICHI STEEL

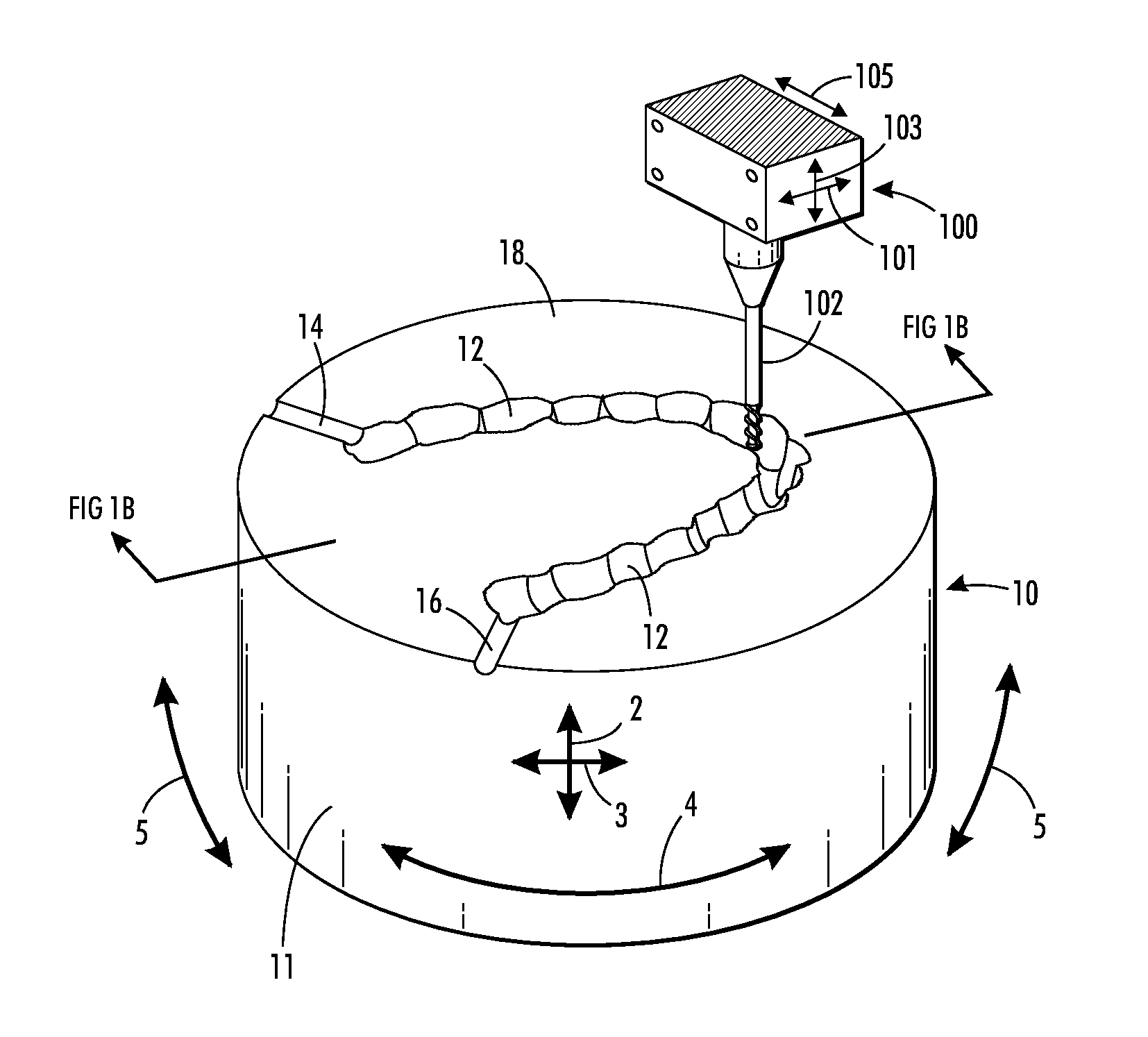

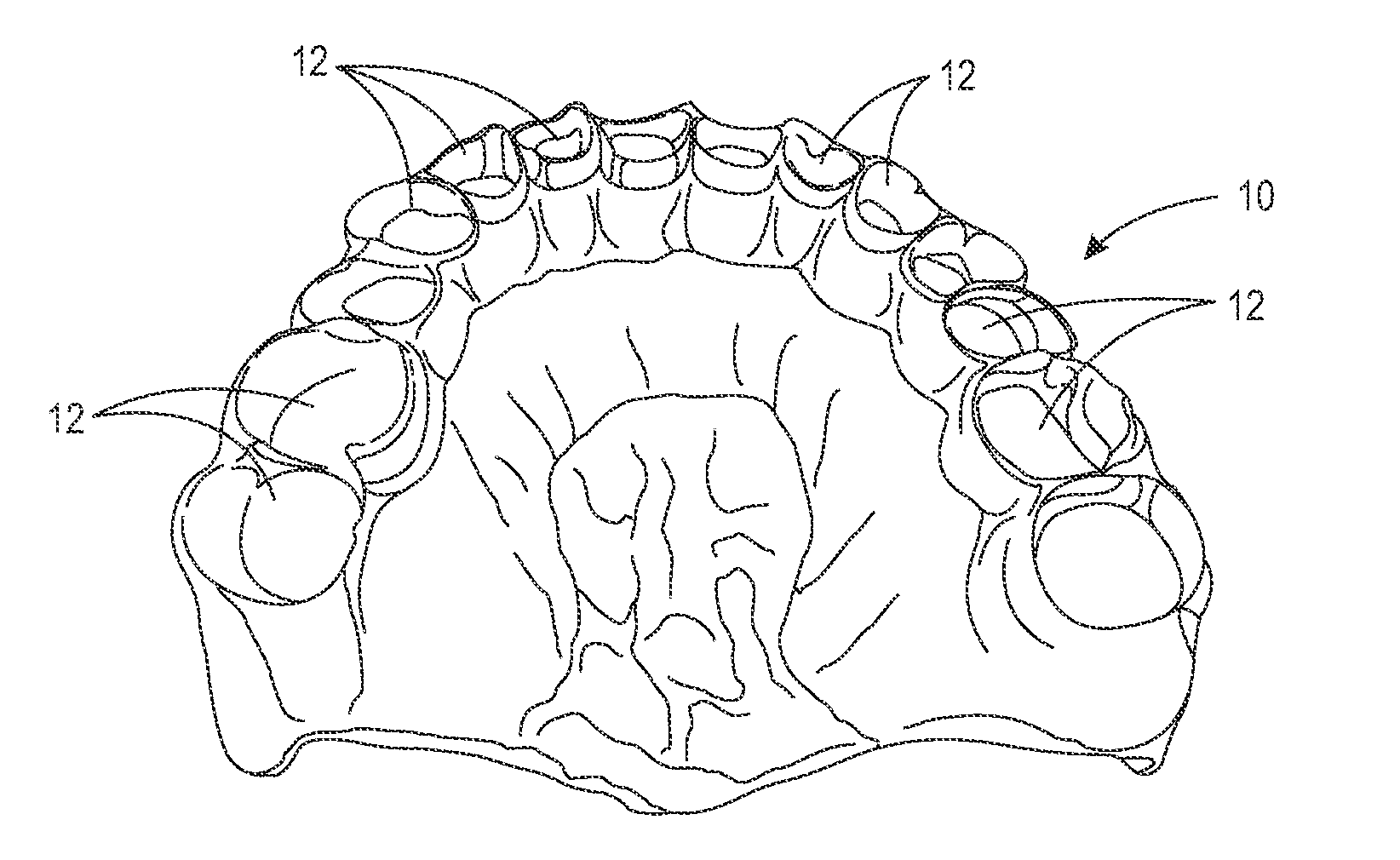

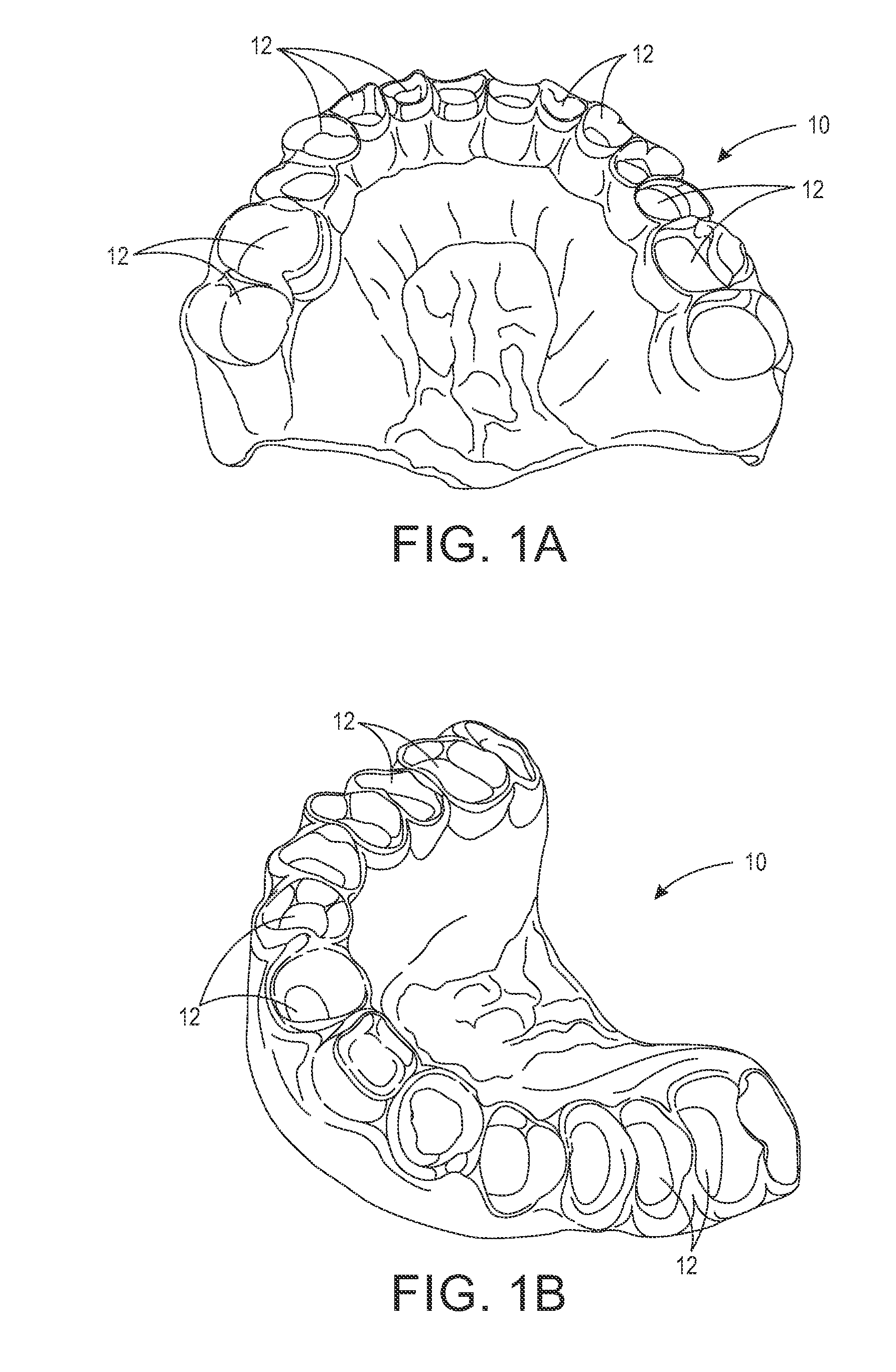

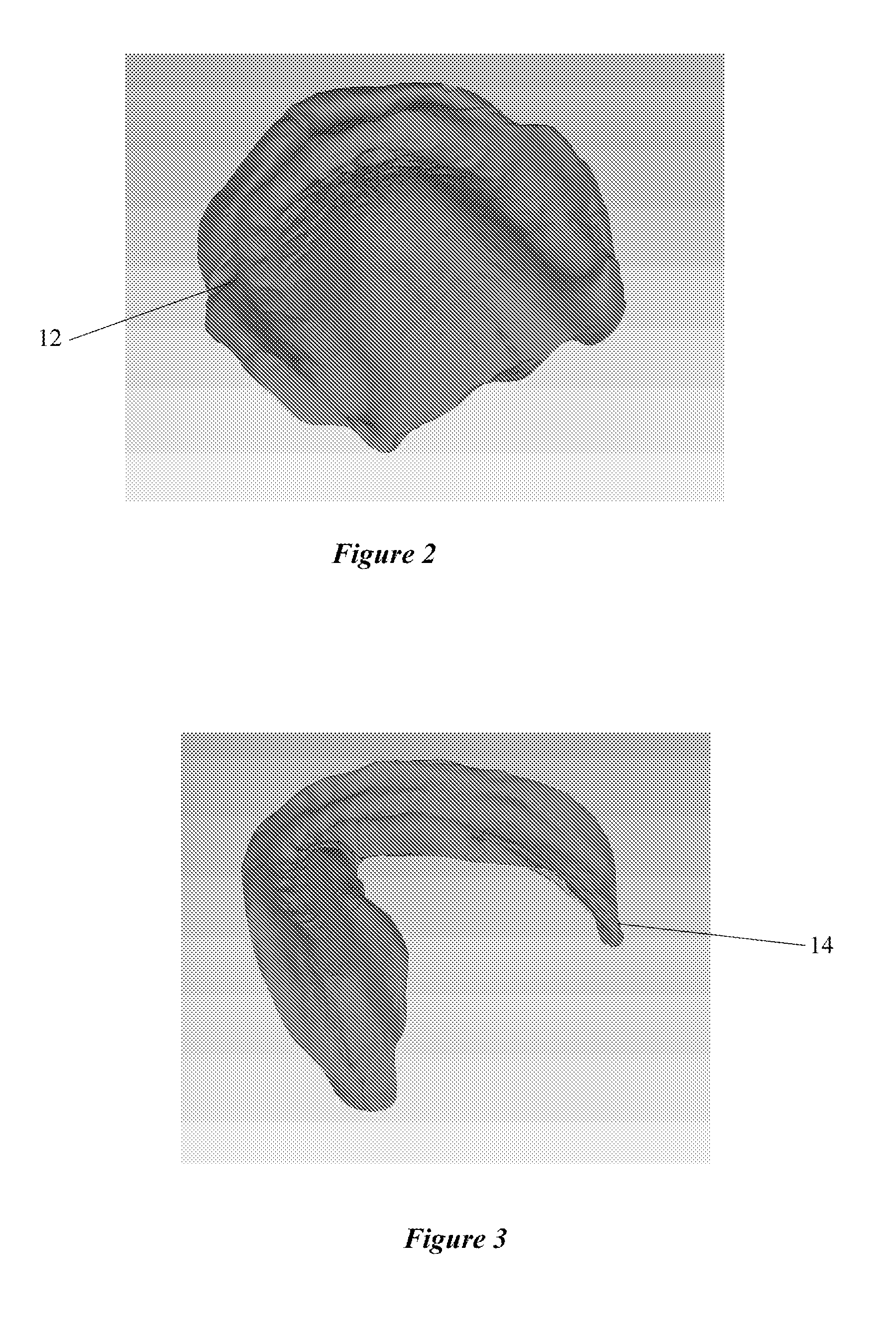

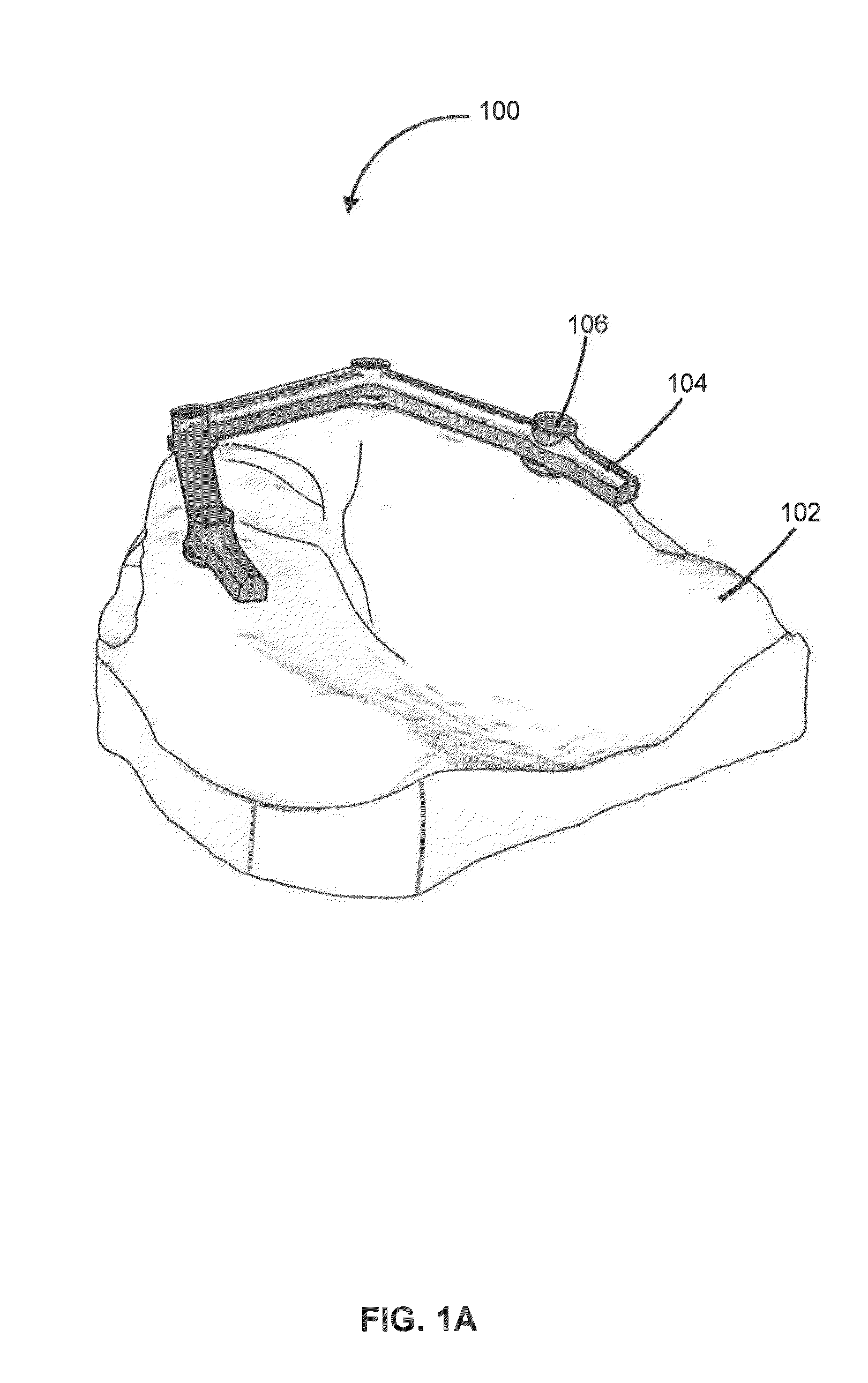

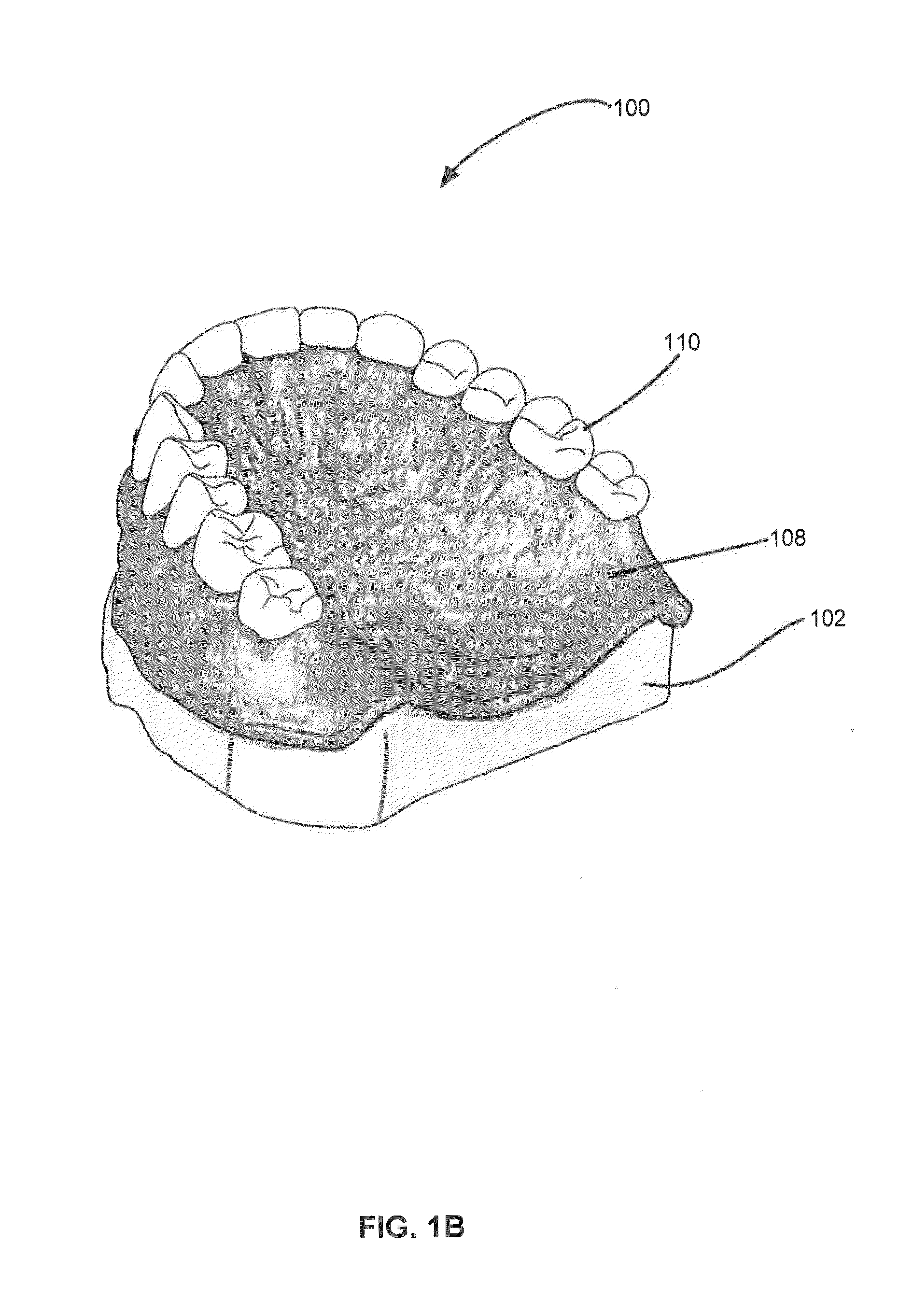

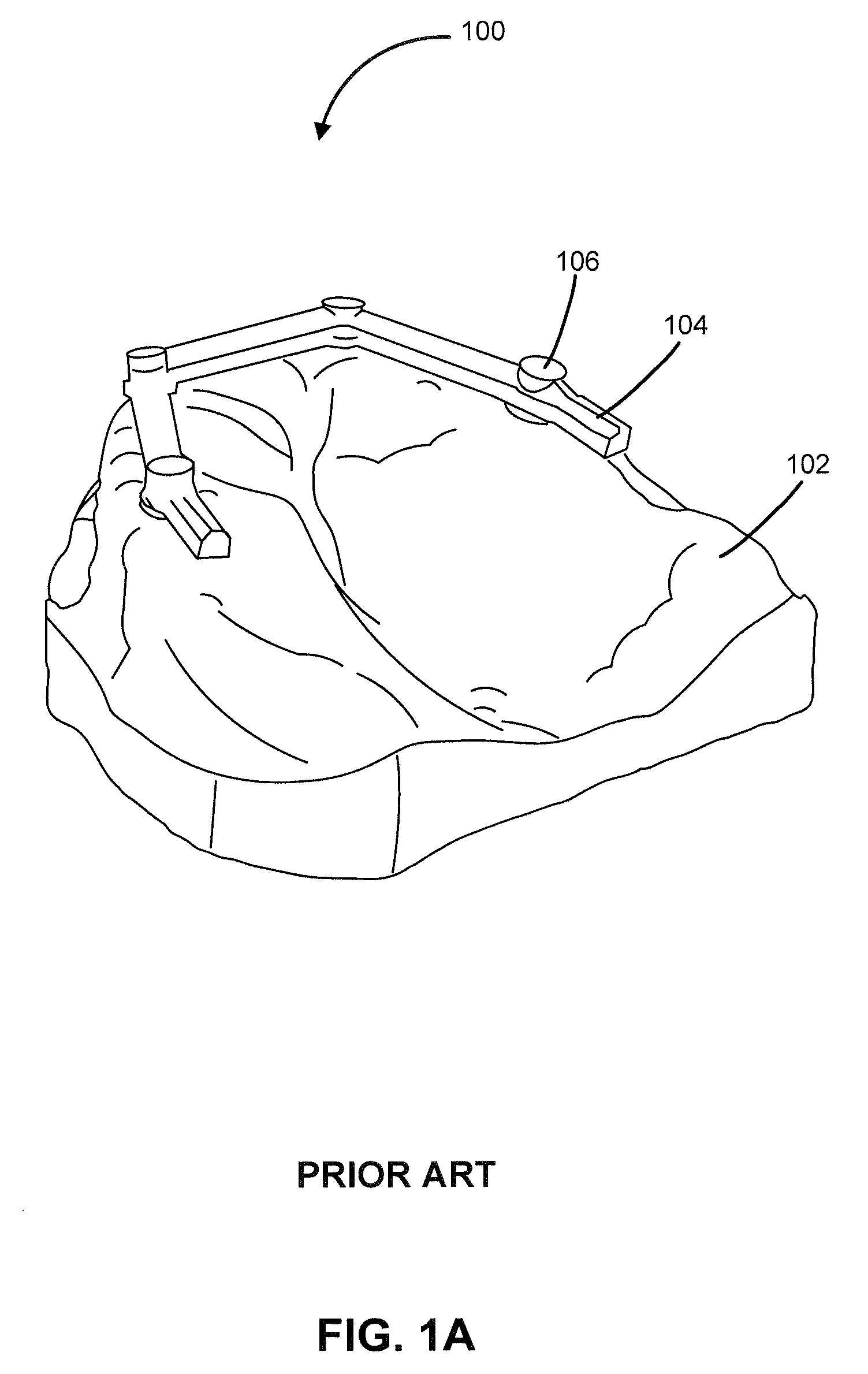

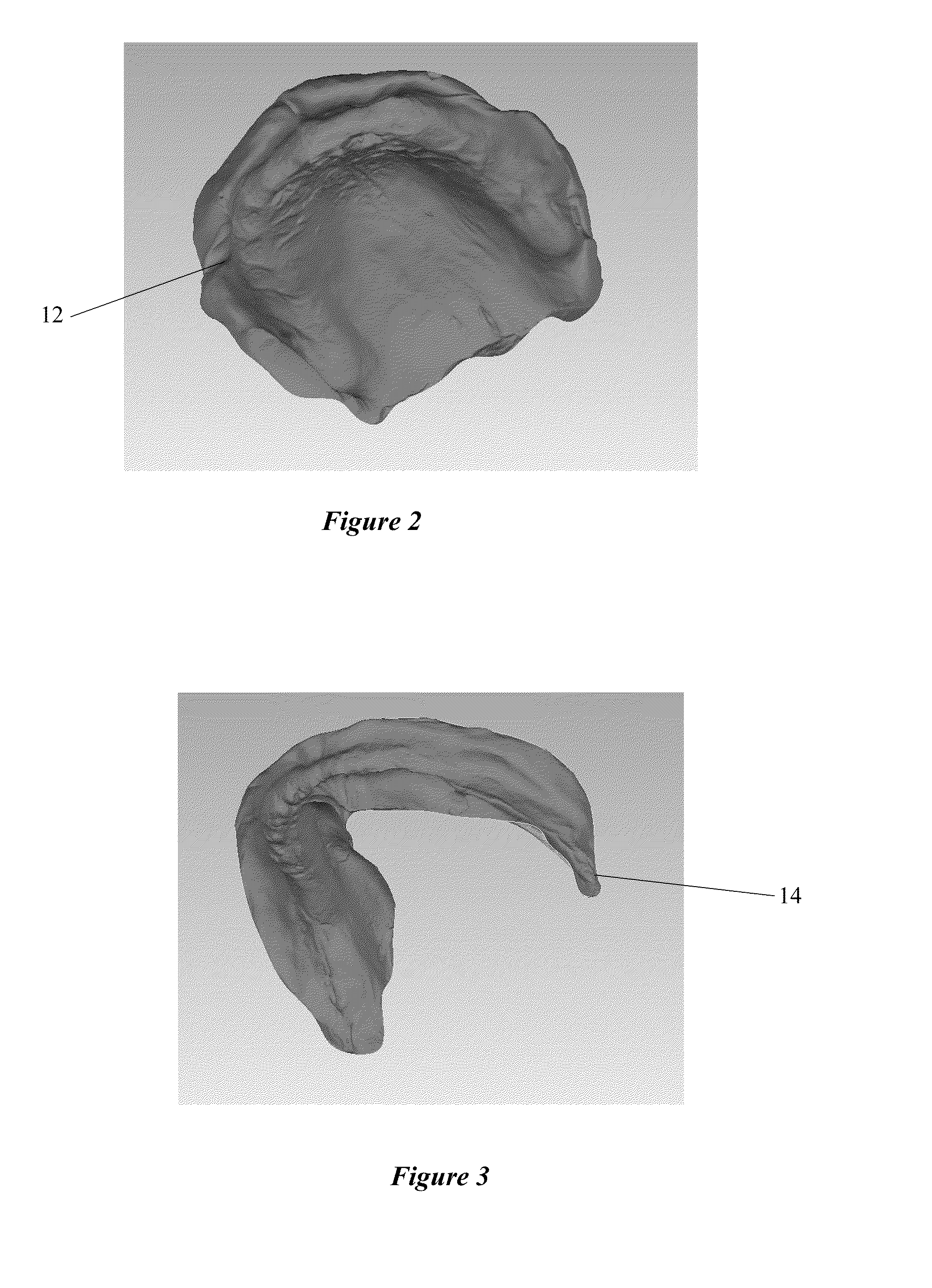

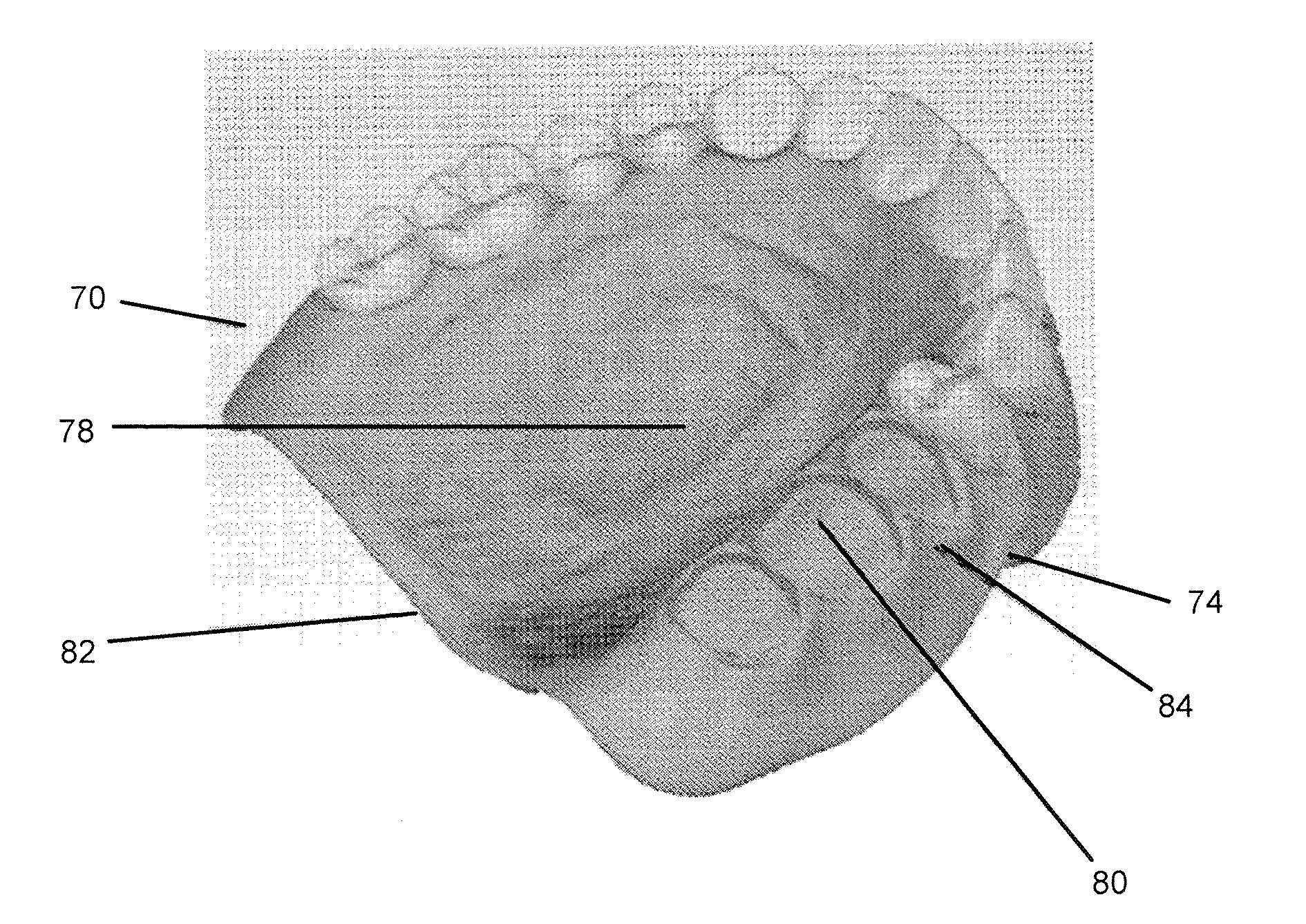

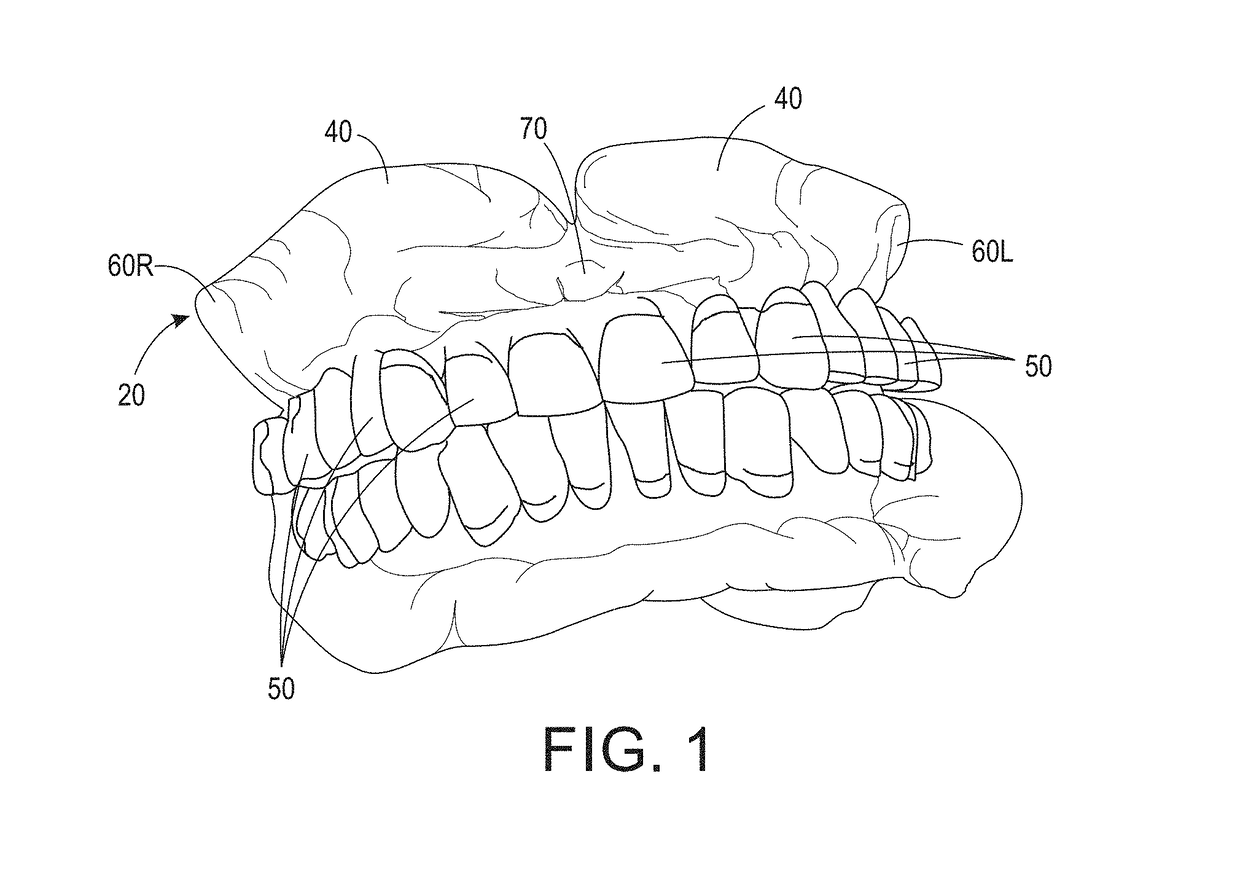

Systems and process for forming anatomical features in dentures

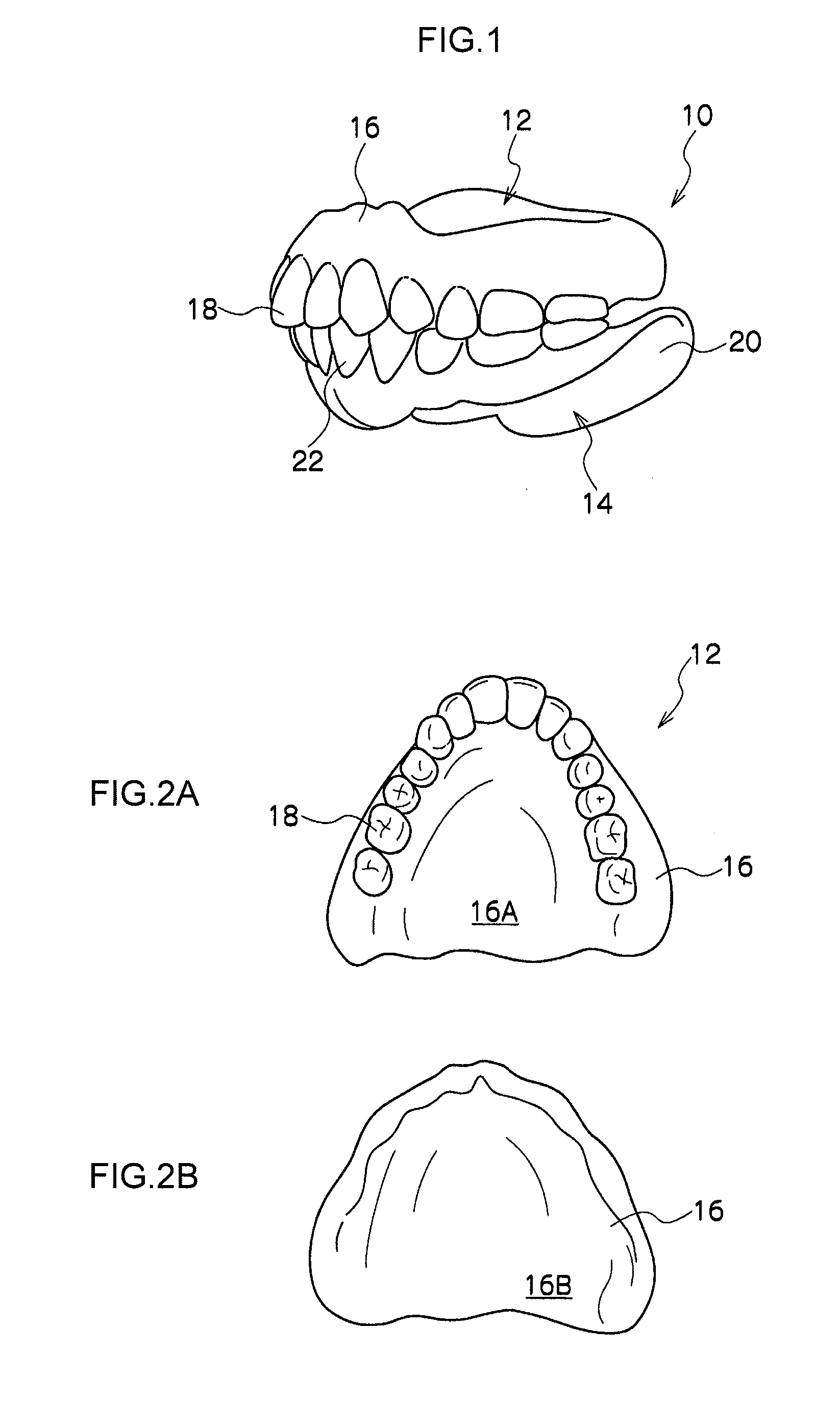

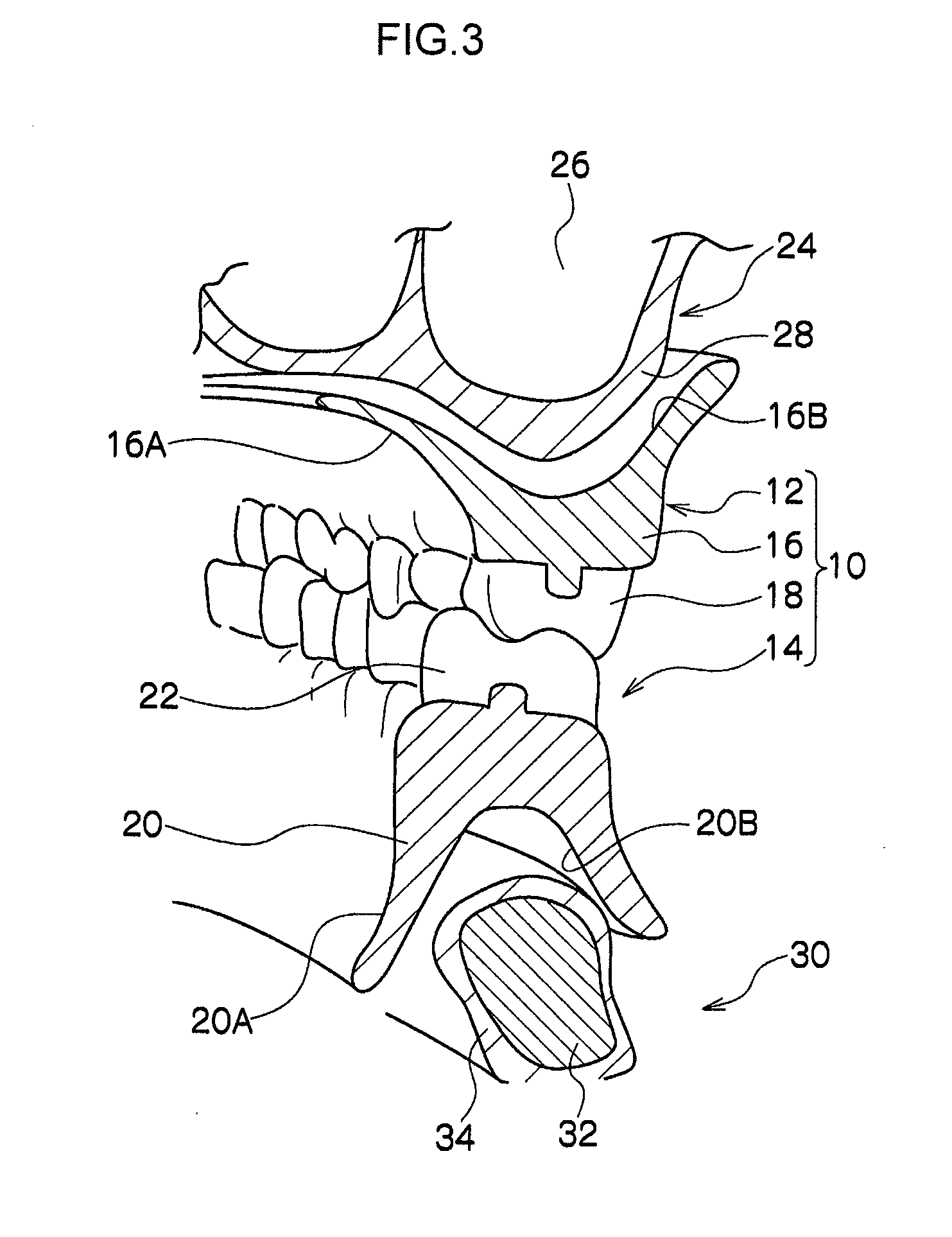

ActiveUS20130216978A1Minimize dislocationImproves comfort and fit and aestheticImpression capsMechanical/radiation/invasive therapiesAnatomical landmarkDentures

The system of a preferred embodiment uses a process whereby a true replication of the patient's jaw structure is created in a digital three dimensional model. This true replication is then used to precisely locate and / or copy the anatomical landmarks of the patient for use in fabricating a denture base for use in a denture for the individual patient. This system is able to create a denture with precisely located features corresponding to the anatomical landmarks of the patient with little manual intervention.

Owner:GLOBAL DENTAL SCI

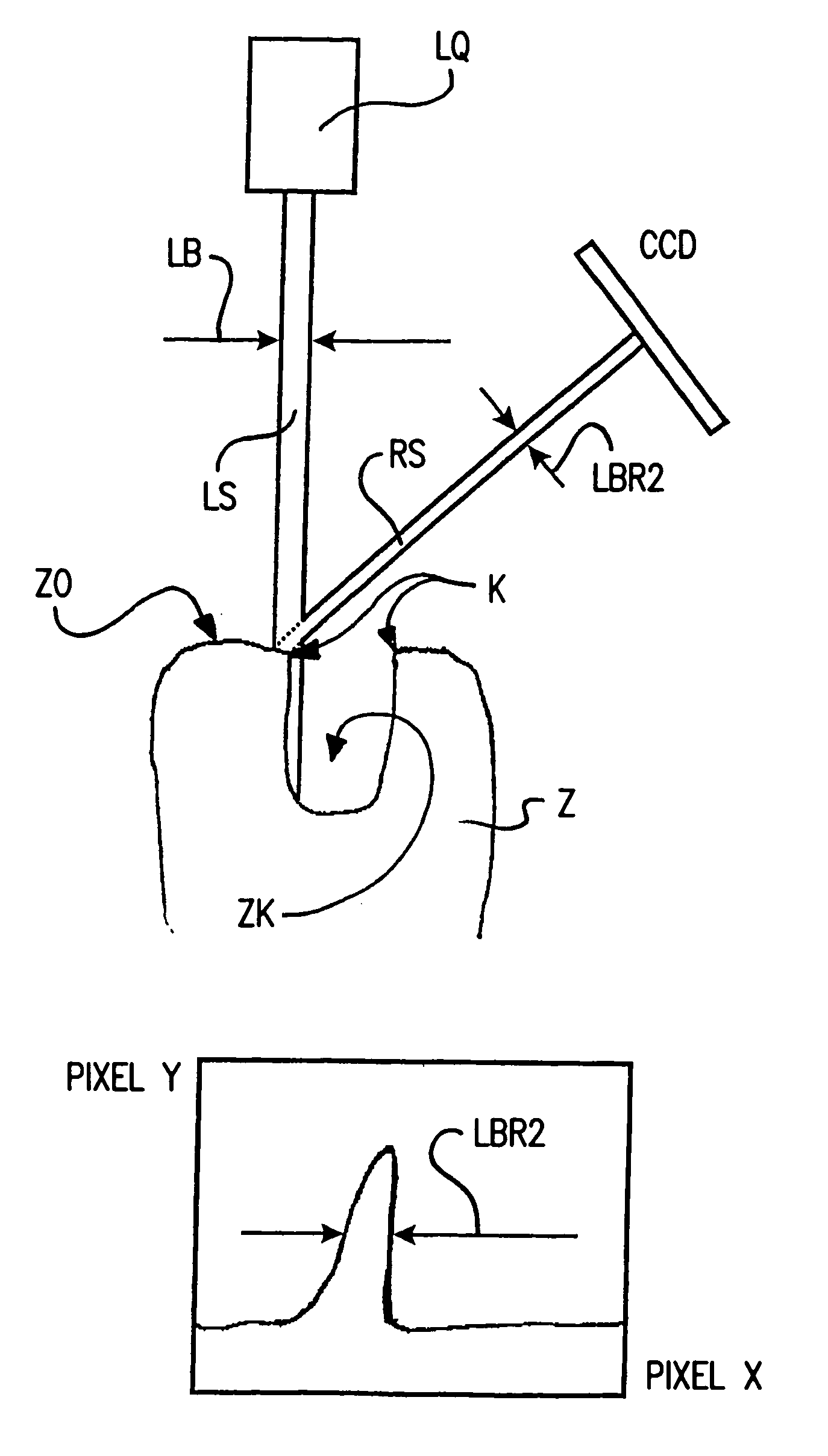

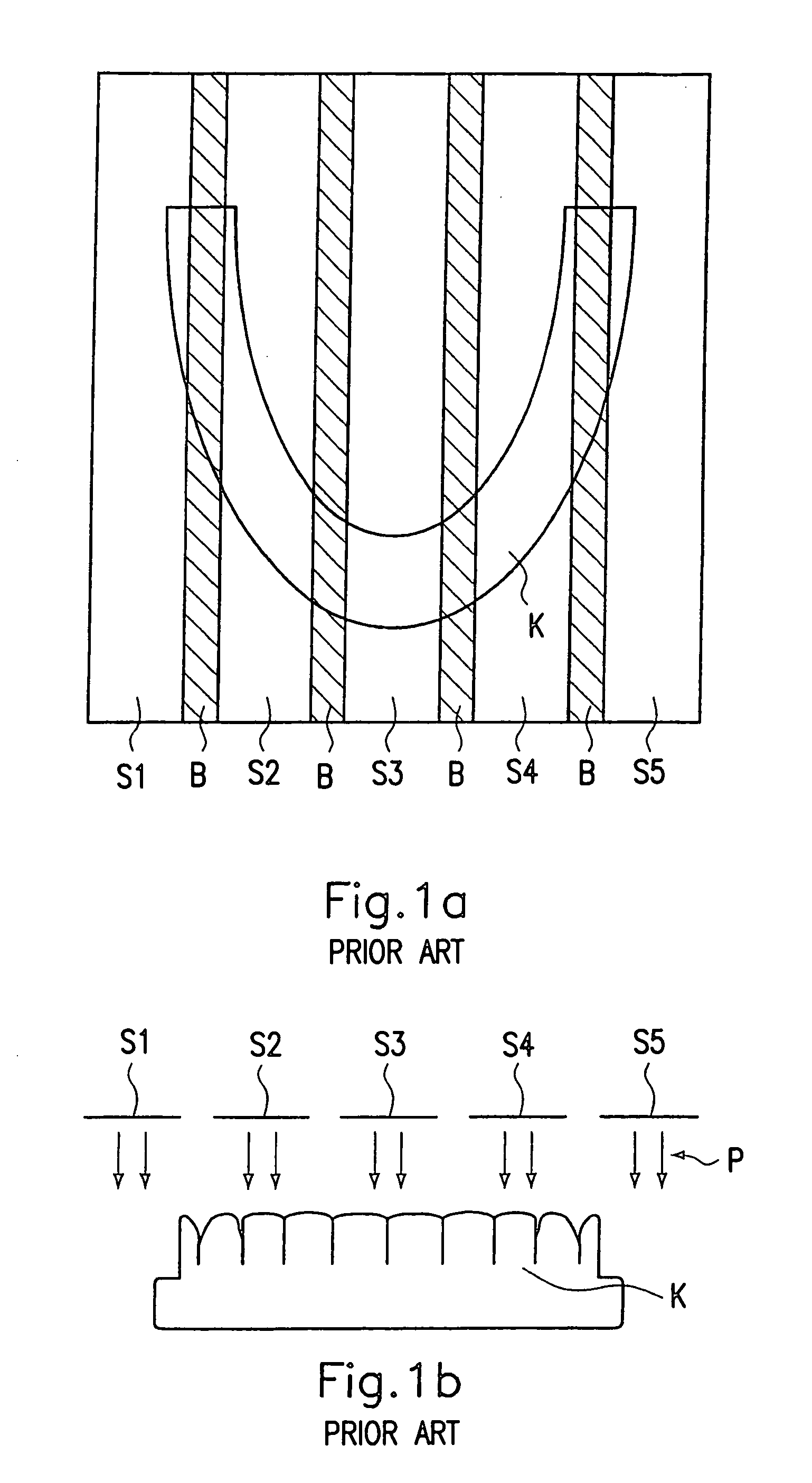

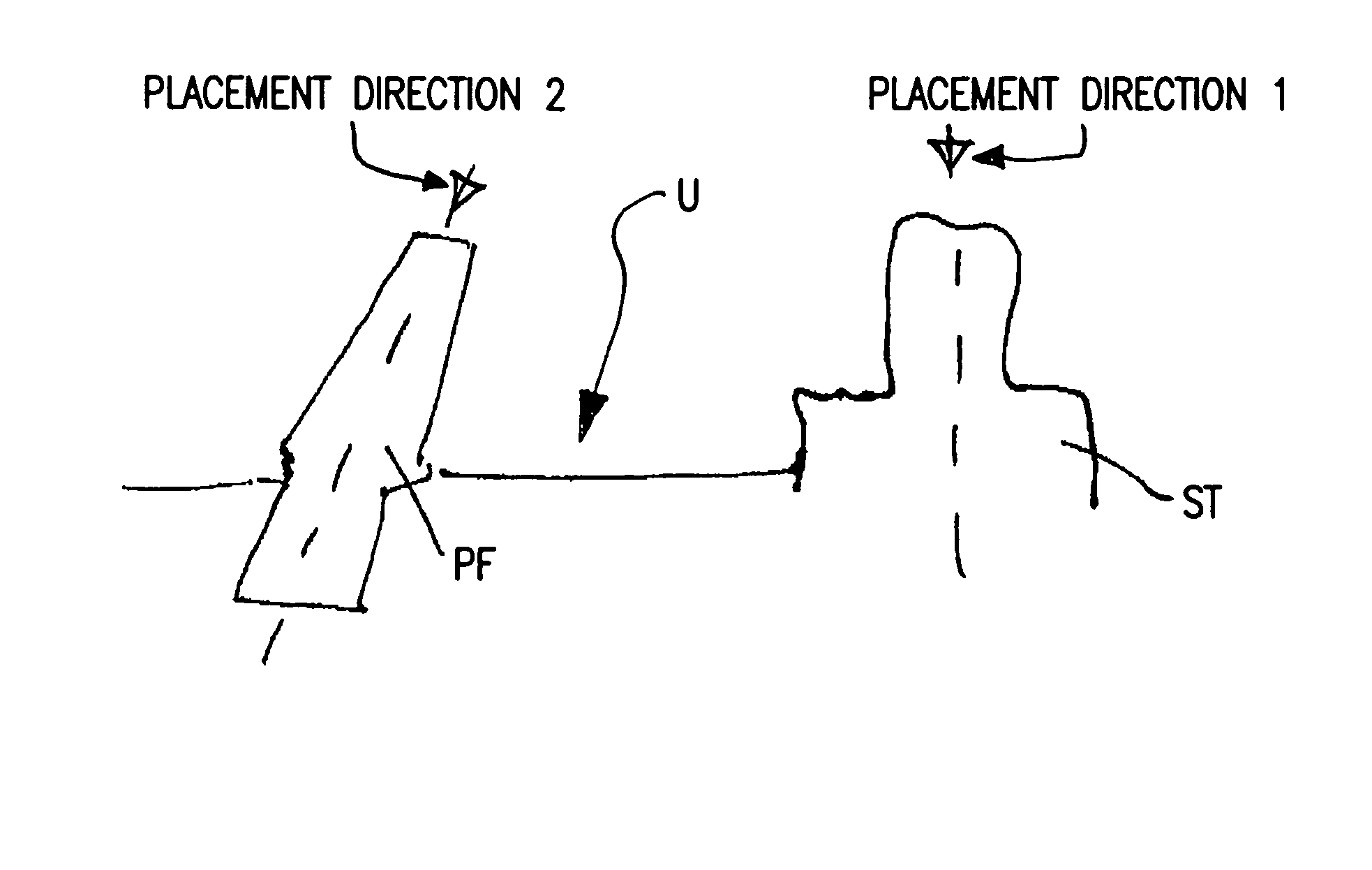

Devices and methods for producing denture parts

Surface mapping and / or generation device is provided, with a device for mapping 3D data of at least one denture base object such as a tooth stump or an implantation abutment, and an environment thereof, as well as with a device for the data-based generation and production of a denture part incorporating the 3D data of the denture base object. Additionally provided are a device for determining and / or defining a placement direction of the denture part that is to be slipped onto the denture base object, and a device for determining and producing a primary part that is to be slipped onto the denture base object before the denture part and that yields a desired placement direction for the denture part which is different from the placement direction that exists for slipping the primary part onto the denture base object. The device for data-based generation and production of a denture part is designed to generate and produce the latter by incorporating the 3D data of the primary part. Surface mapping and / or generation method is provided, wherein 3D data from a denture base object such as a tooth stump or an implantation abutment and an environment thereof are mapped and then, based on this 3D data of the denture base object, a denture part to be slipped thereon is produced. Before production of the denture part, a placement direction of the denture part onto the denture base object is determined or defined. On the basis of this 3D data of the denture base object, a primary part is determined and produced, with which a desired placement direction that differs from the placement direction that exists for slipping the primary part onto the denture base object is created for the denture part. On the basis of the 3D data, the denture part is generated and produced based on data so as to fit when pushed onto the primary part.

Owner:INSTITUT STRAUMANN AG +1

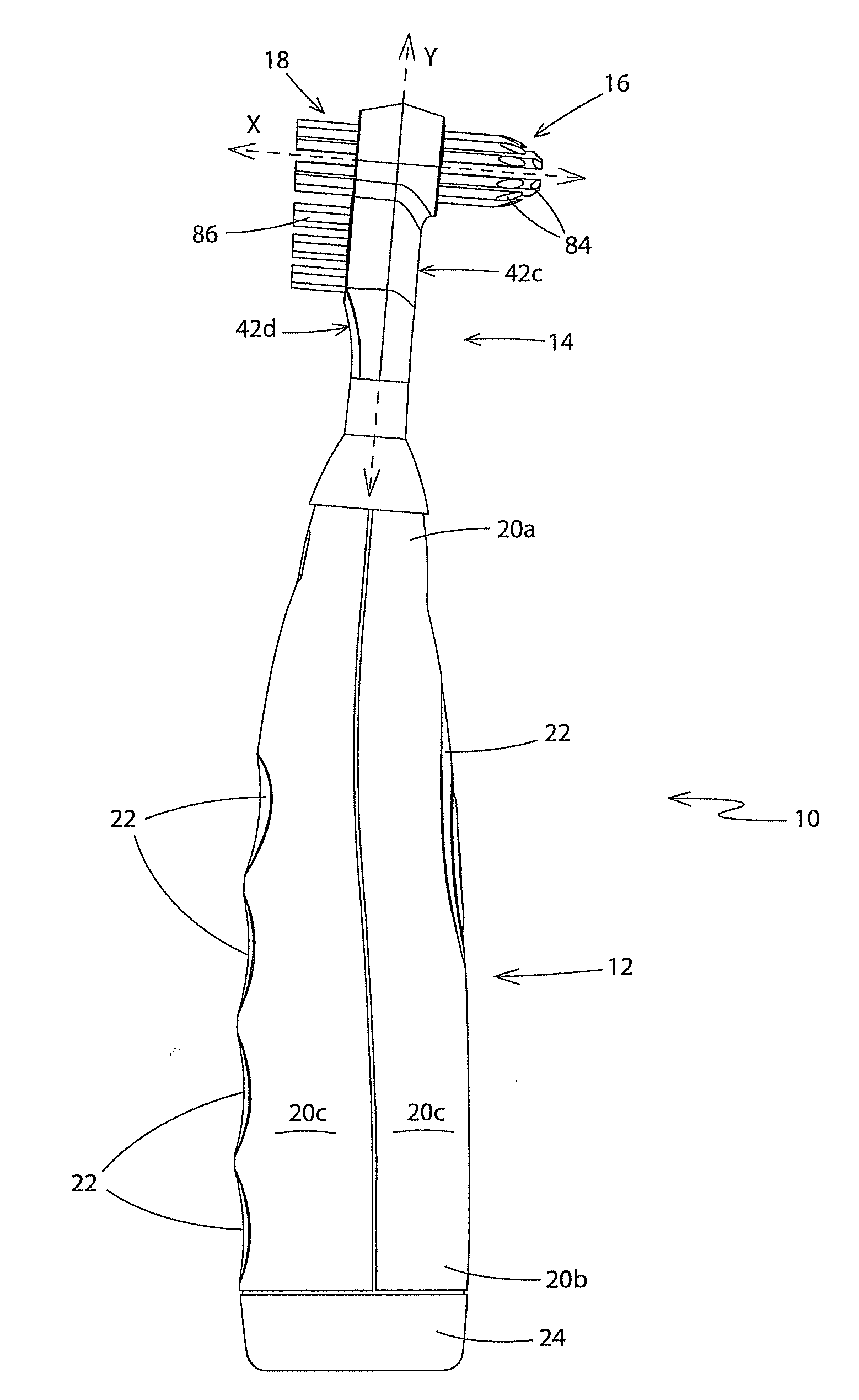

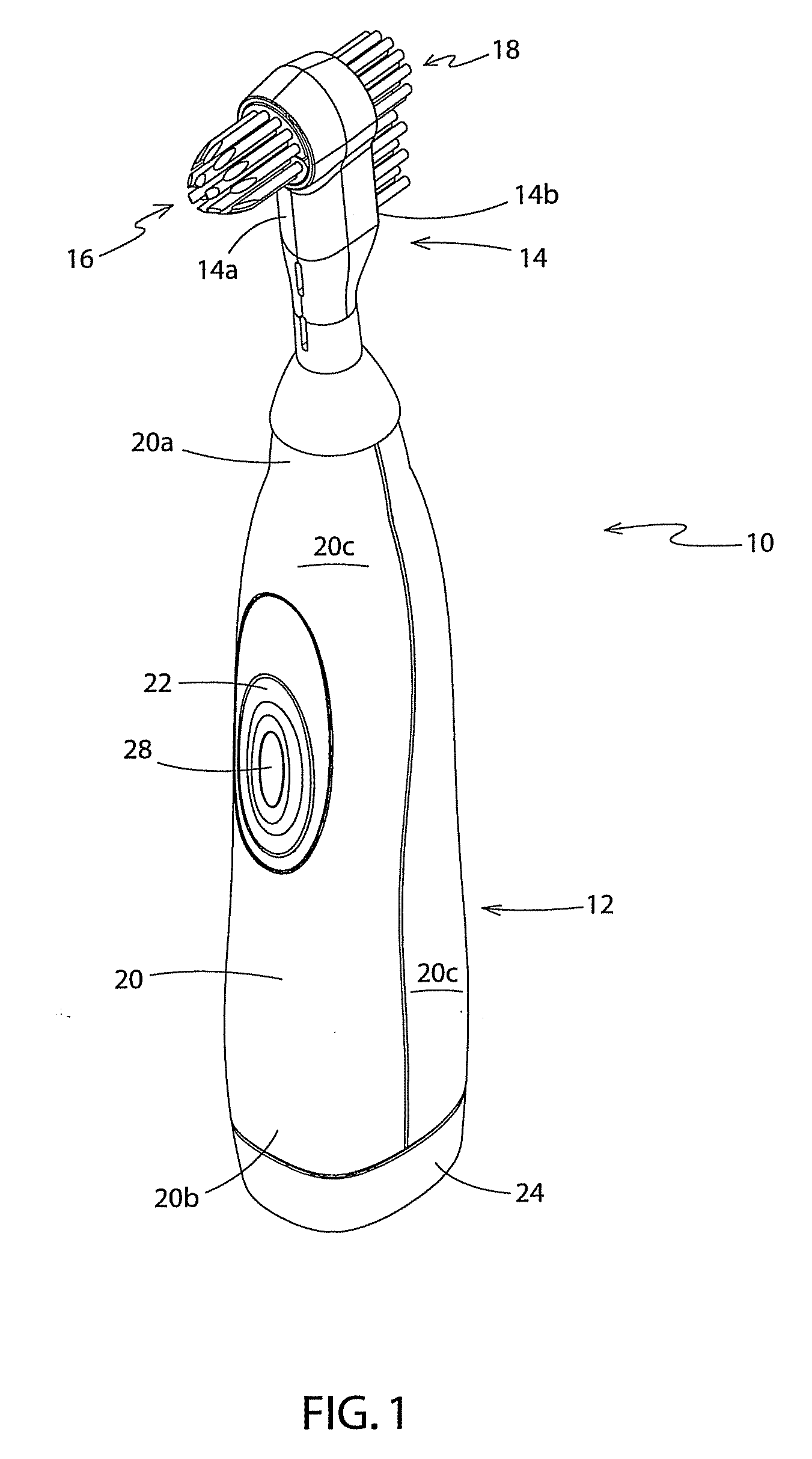

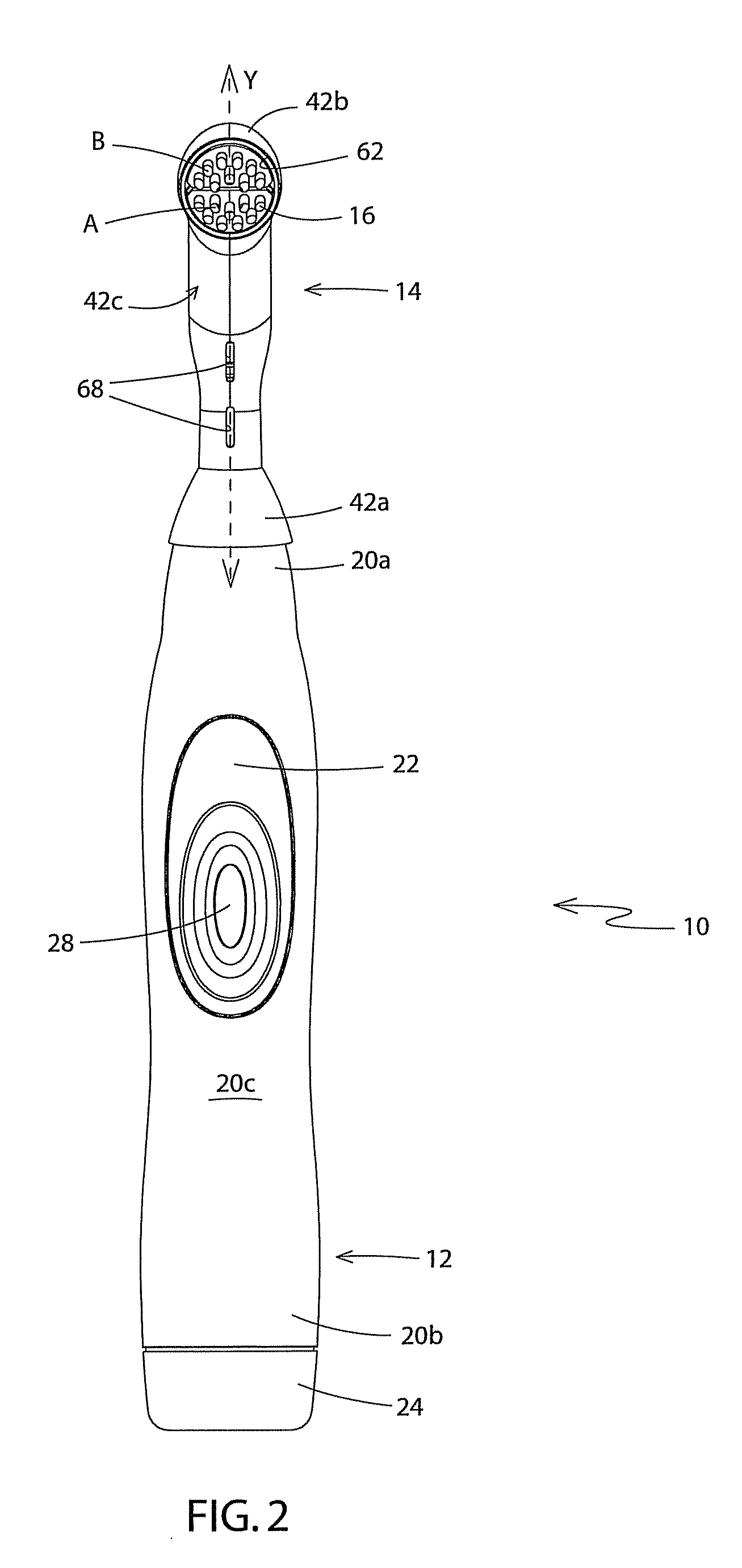

Head for a powered denture brush and a denture brush incorporating the same

A head for a denture brush that is detachably connected to a powered handle and a denture brush incorporating the same. The head includes a housing having a first set of bristles extending outwardly from a first side and a second set of bristles extending outwardly from a second side. The first and second sets of bristles are mounted such that they are movable in response to rotation of a camshaft in the head. Some of bristles on each side of the head may be linearly pulsed toward and away from the housing substantially orthogonally to a longitudinal axis of the head. Additionally, some of the bristles on each side of the head may be rotated about a horizontal axis that is orthogonal to the longitudinal axis.

Owner:HARRISON HYGIENE

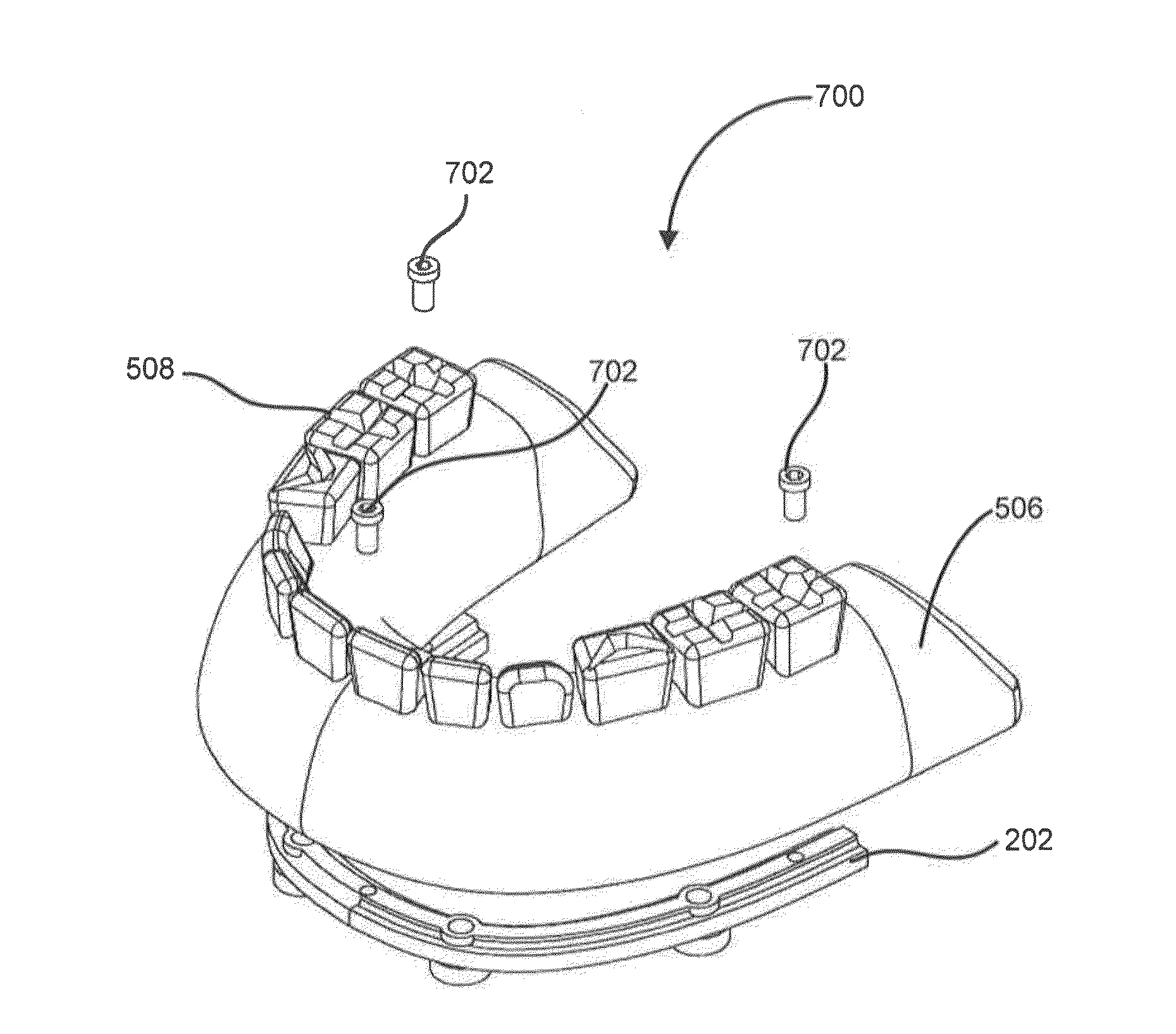

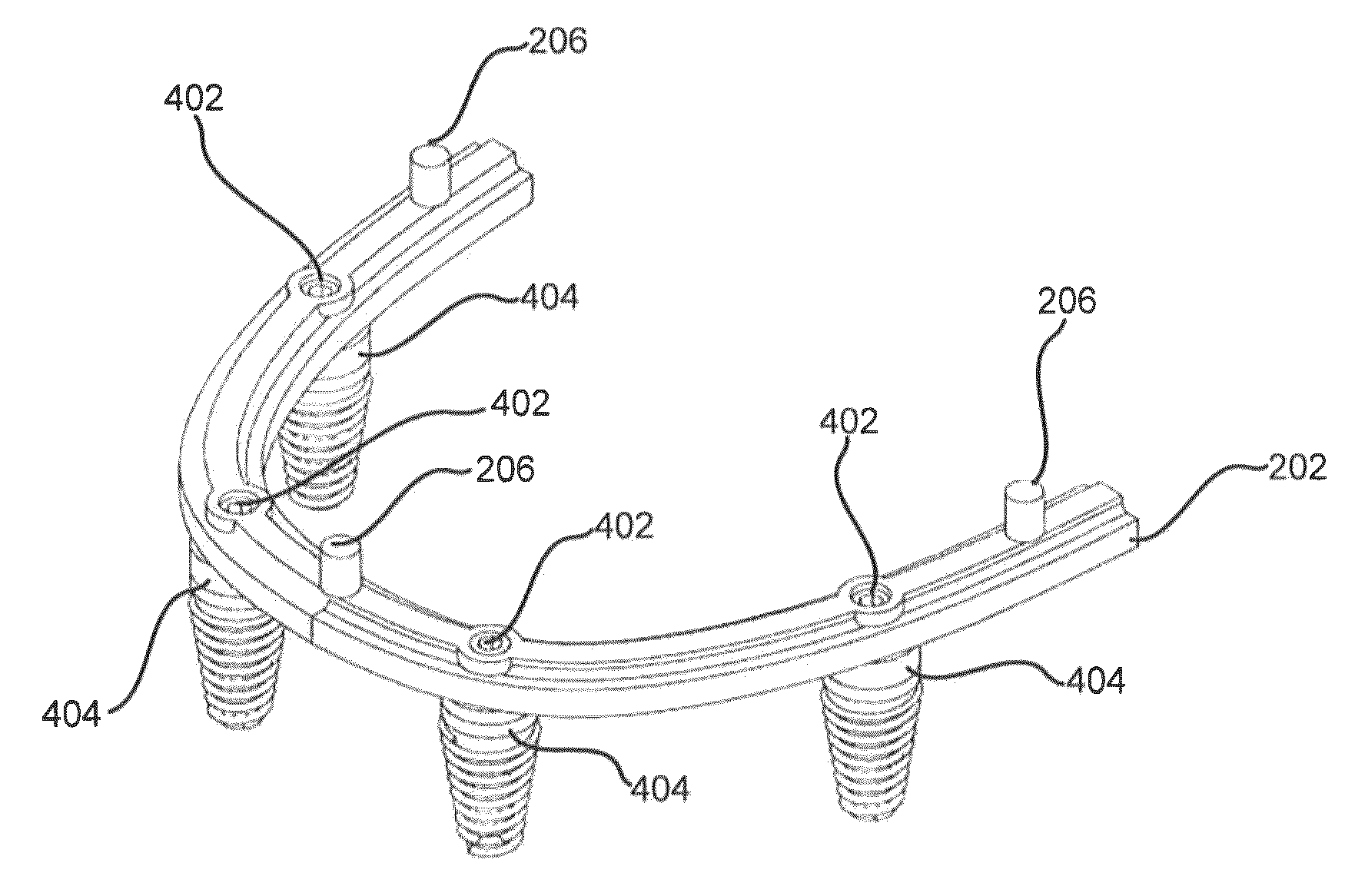

Denture Reference and Registration System

An improved denture system is disclosed. An improved denture system has a support bar and an artificial denture base. The denture base has an oversize cutout and a corresponding cavity and the support bar has a plurality of reference posts which mechanically interface with the corresponding cavity so that the support bar is connected to the artificial denture base and provides reinforcement and stability to the denture system. The shape and position of the reference posts fully constrains the support bar in a fixed position with reference to the denture base. In one embodiment, the denture base snap-fits onto the support bar.

Owner:GLOBAL DENTAL SCI

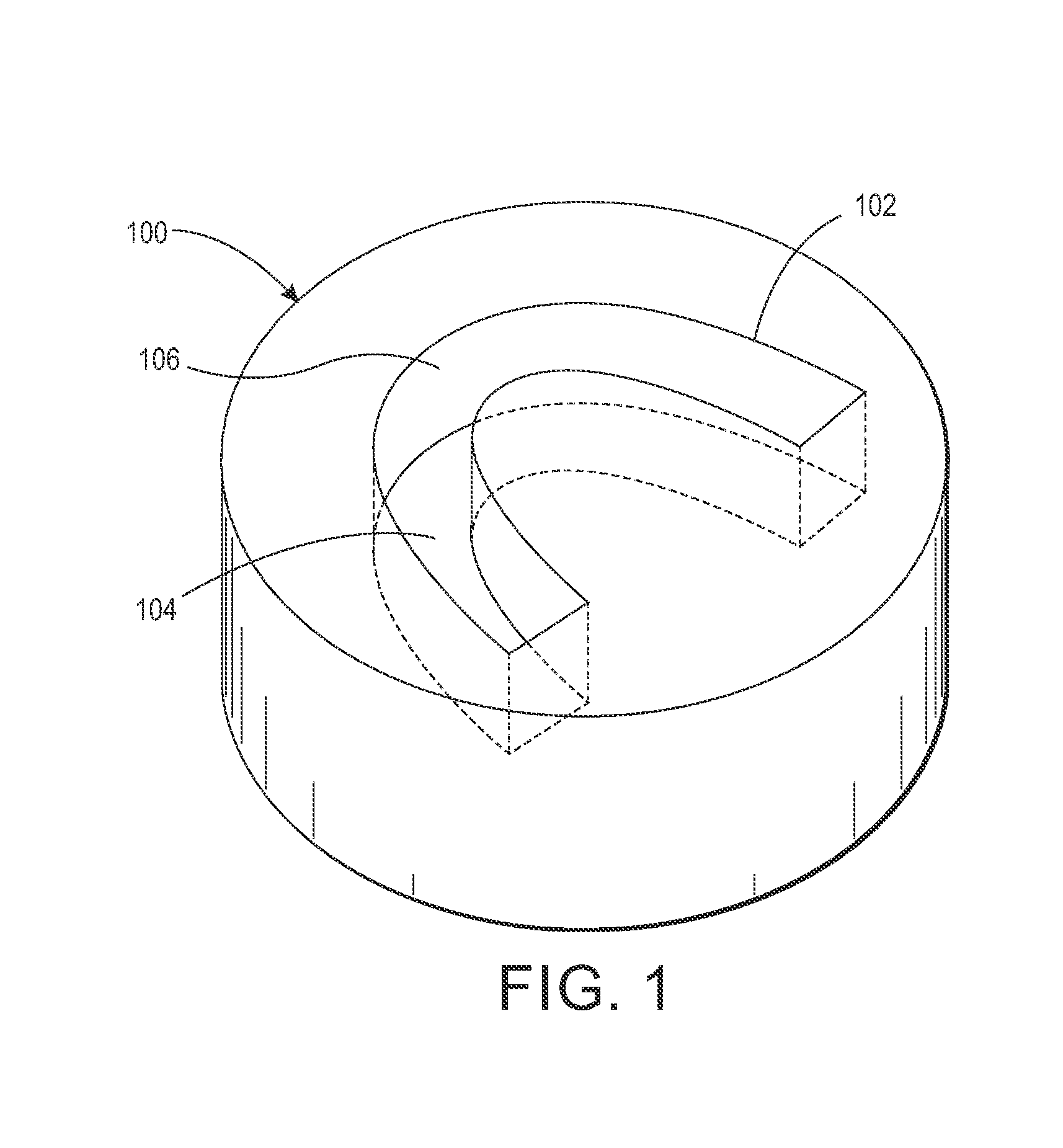

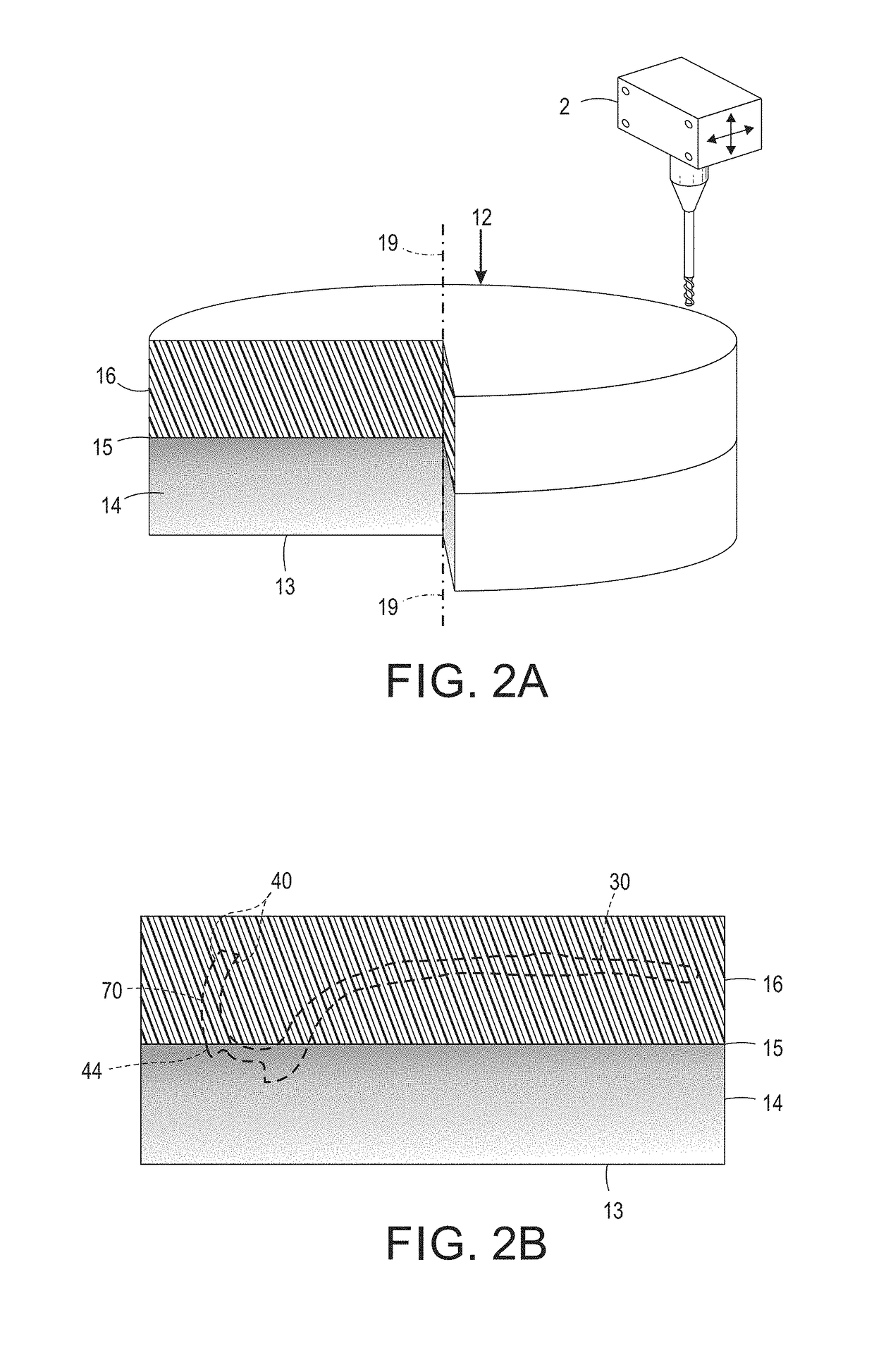

Denture and method and apparatus of making same

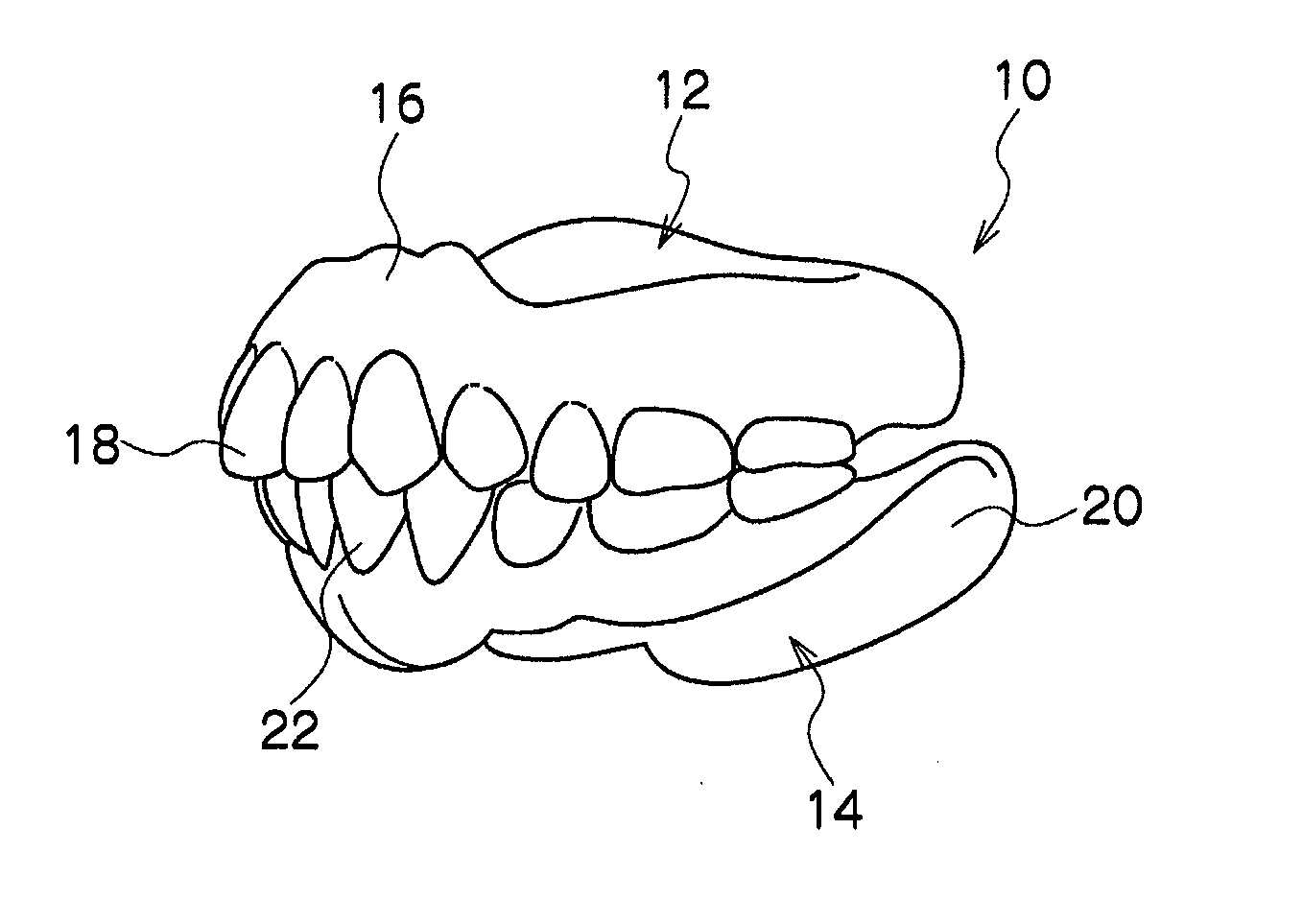

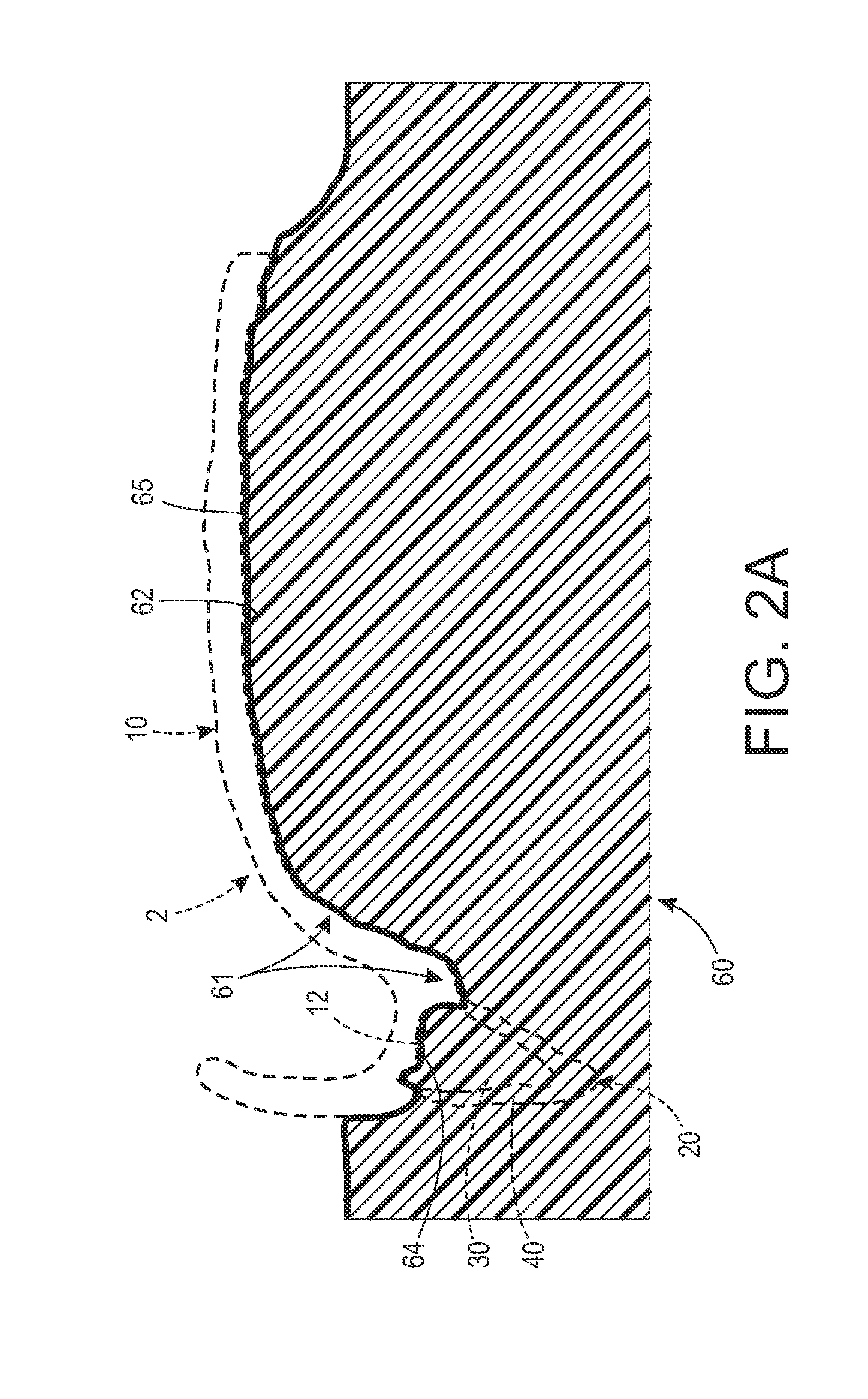

ActiveUS8641938B2Minimal number of stepMinimal manual laborAdditive manufacturing apparatusImpression capsNatural toothDentures

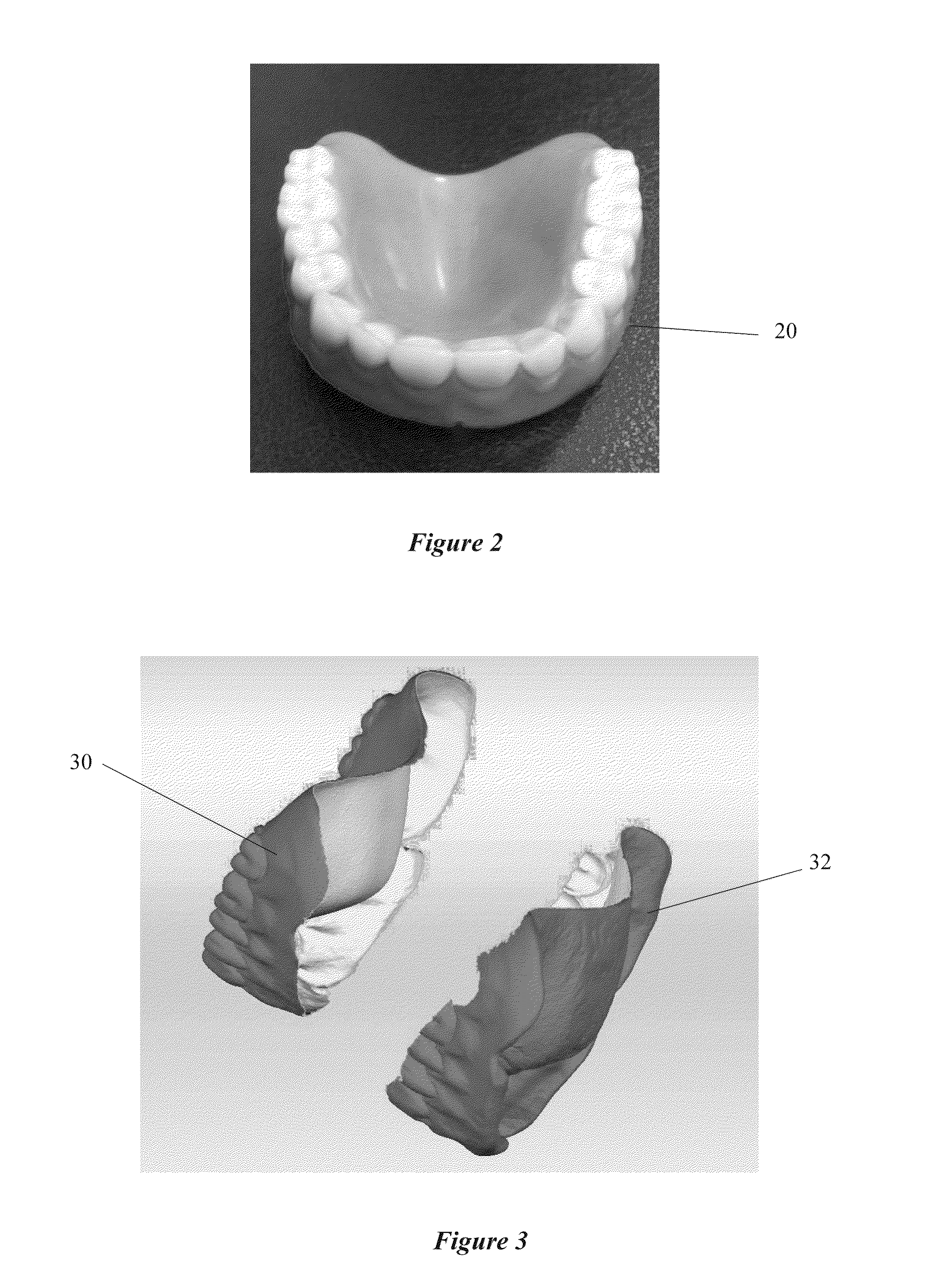

A method for making a denture comprising a base and a plurality of teeth joined thereto. The method comprises forming a first cavity in a block of a denture base material, the first cavity being formed to match the contour of natural teeth as arranged on maxillae or on a mandible; filling the first cavity with a first fluid synthetic tooth material and solidifying the first fluid synthetic tooth material into a first solid synthetic tooth material; removing a portion of the first solid synthetic tooth material to form the plurality of teeth; and removing a portion of the block of denture base material to form the denture base. The steps of the method may be implemented by a computer. An apparatus for making the denture according to certain embodiments of the method, and a denture comprised of a base and artificial teeth are also disclosed.

Owner:GLOBAL DENTAL SCI

Denture reference and registration system

An improved denture system is disclosed. An improved denture system has a support bar and an artificial denture base. The denture base has an oversize cutout and a corresponding cavity and the support bar has a plurality of reference posts which mechanically interface with the corresponding cavity so that the support bar is connected to the artificial denture base and provides reinforcement and stability to the denture system. The shape and position of the reference posts fully constrains the support bar in a fixed position with reference to the denture base. In one embodiment, the denture base snap-fits onto the support bar.

Owner:GLOBAL DENTAL SCI

Systems and Processes for Forming Anatomical Features in Dentures

ActiveUS20150134094A1Function increaseMinimize dislocationImpression capsComputer aided designAnatomical landmarkDentures

The system of a preferred embodiment uses a process whereby a true replication of the patient's jaw structure is created in a digital three dimensional model. This true replication is then used to precisely locate and / or copy the anatomical landmarks of the patient for use in fabricating a denture base for use in a denture for the individual patient. This system is able to to create a denture with precisely located features corresponding to the anatomical landmarks of the patient with little manual intervention.

Owner:GLOBAL DENTAL SCI

Systems and processes for forming anatomical features in dentures

ActiveUS9155599B2Minimize dislocationImproves comfort and fit and aestheticImpression capsMechanical/radiation/invasive therapiesAnatomical landmarkDentures

The system of a preferred embodiment uses a process whereby a true replication of the patient's jaw structure is created in a digital three dimensional model. This true replication is then used to precisely locate and / or copy the anatomical landmarks of the patient for use in fabricating a denture base for use in a denture for the individual patient. This system is able to create a denture with precisely located features corresponding to the anatomical landmarks of the patient with little manual intervention.

Owner:GLOBAL DENTAL SCI

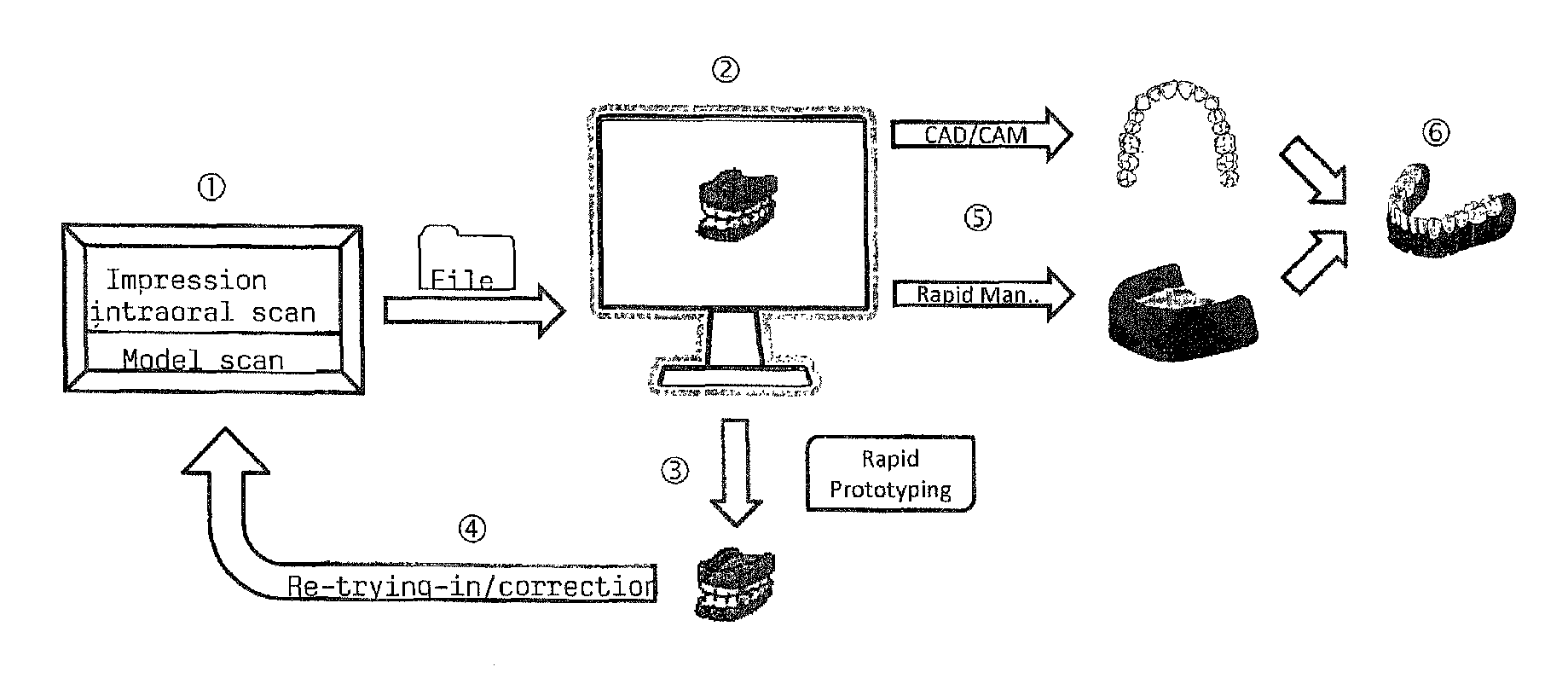

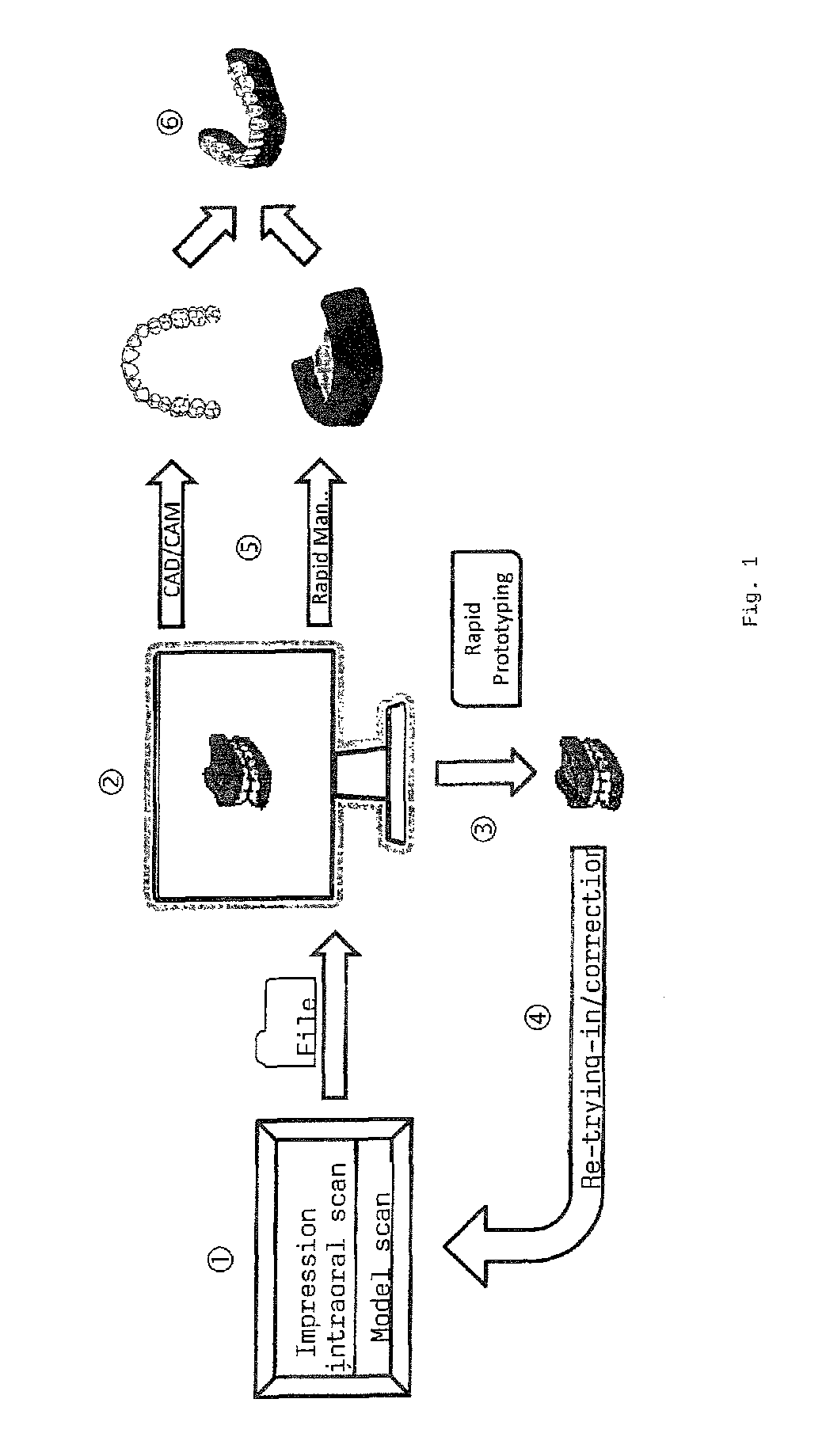

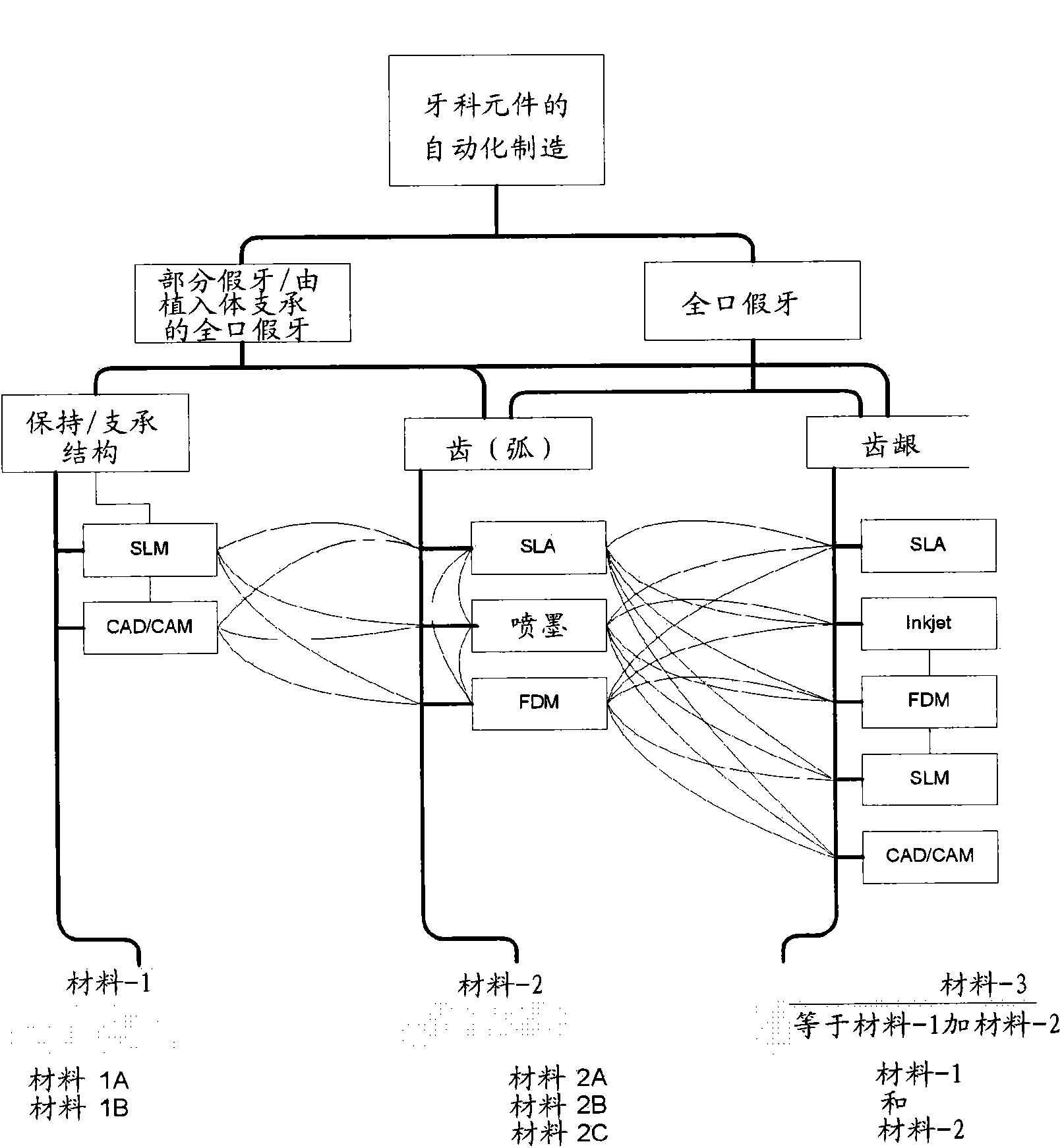

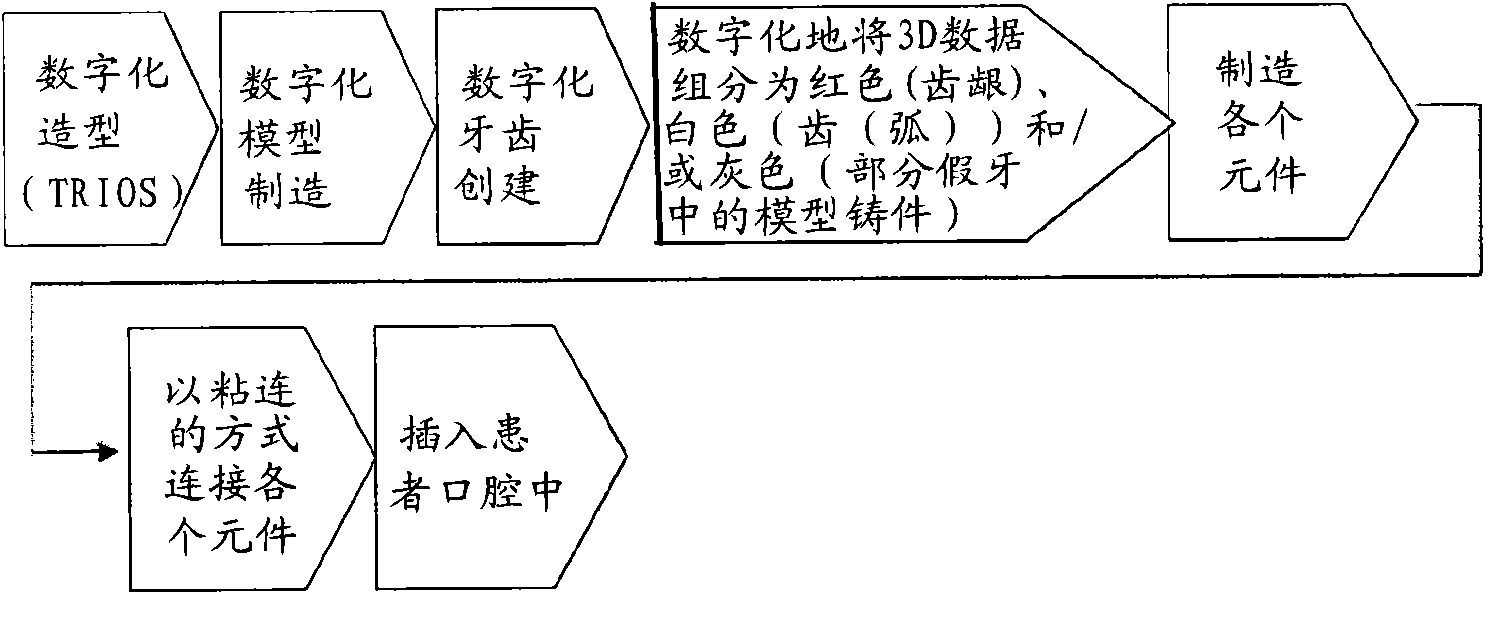

Production of individual dental prostheses via CAD/CAM and rapid manufacturing/rapid prototyping from data of the digital impression

ActiveUS9295534B2Meet the requirementsSimplify the manufacturing processImpression capsAdditive manufacturing apparatusDigital dataDentures

A method for automated manufacture of dentures including providing a digital data set of the individual denture to be produced, a digital separation of the model into dental arch and gingival, producing the dental arch from a ceramic or plastic material using cutting technology, producing the denture base through generative or ablative procedures from predominantly (meth-)acrylate-based plastic materials, connecting the dental arch and gingiva through bonding or joining or a combination of bonding and joining.

Owner:HERAEUS KULZER

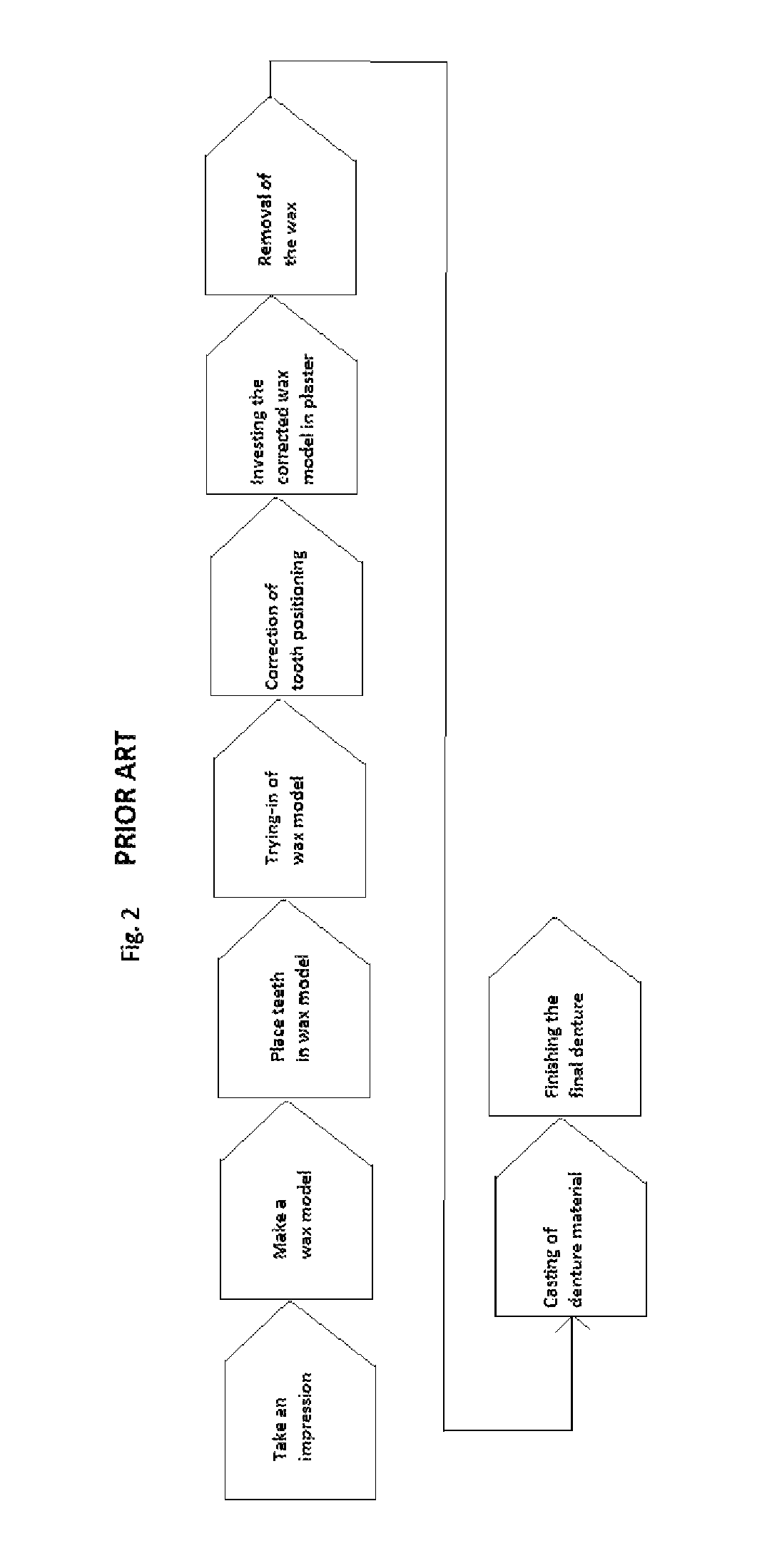

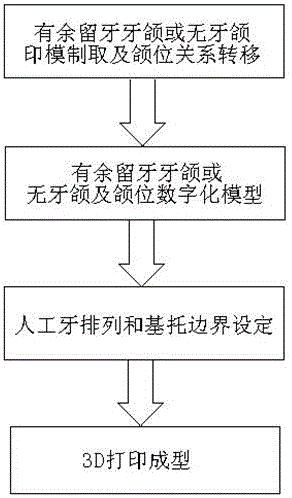

Method for producing immediate complete or half denture based on 3D printing technique

ActiveCN106037967AComfortable to wearSimple preparation steps3D printingDental prostheticsDenture baseBite registration

The invention discloses a method for producing an immediate complete or half denture based on a 3D printing technique. The method comprises the steps of preparing an impression with a remaining tooth jaw or a tooth-free jaw, transferring a jaw position relation, acquiring digital models of the remaining tooth jaw or the tooth-free jaw and the jaw position relation, setting the arrangement and the denture border of artificial teeth of the immediate complete or half denture corresponding to the form of the remaining tooth jaw or the tooth-free jaw and the jaw position relation, invoking data in a preset database, designing the artificial teeth and polishing surfaces of the artificial teeth, regulating the occlusion of the teeth to enable alveolar ridge supporting tissues to bear proper pressure distribution, and manufacturing a three-dimensional model of the immediate complete or half denture by virtue of a photo-healing three-dimensional printing technique in the 3D printing technique. The method has the advantages that the production steps are simple, the production time is short, the precision is high, the denture can be conformably worn by a patient, and meanwhile, the production cost is lowered.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

Systems and processes for forming anatomical features in dentures

ActiveUS9402698B2Minimize dislocationImproves comfort and fit and aestheticImpression capsFastening prosthesisAnatomical landmarkDentures

The system of a preferred embodiment uses a process whereby a true replication of the patient's jaw structure is created in a digital three dimensional model. This true replication is then used to precisely locate and / or copy the anatomical landmarks of the patient for use in fabricating a denture base for use in a denture for the individual patient. This system is able to to create a denture with precisely located features corresponding to the anatomical landmarks of the patient with little manual intervention.

Owner:GLOBAL DENTAL SCI

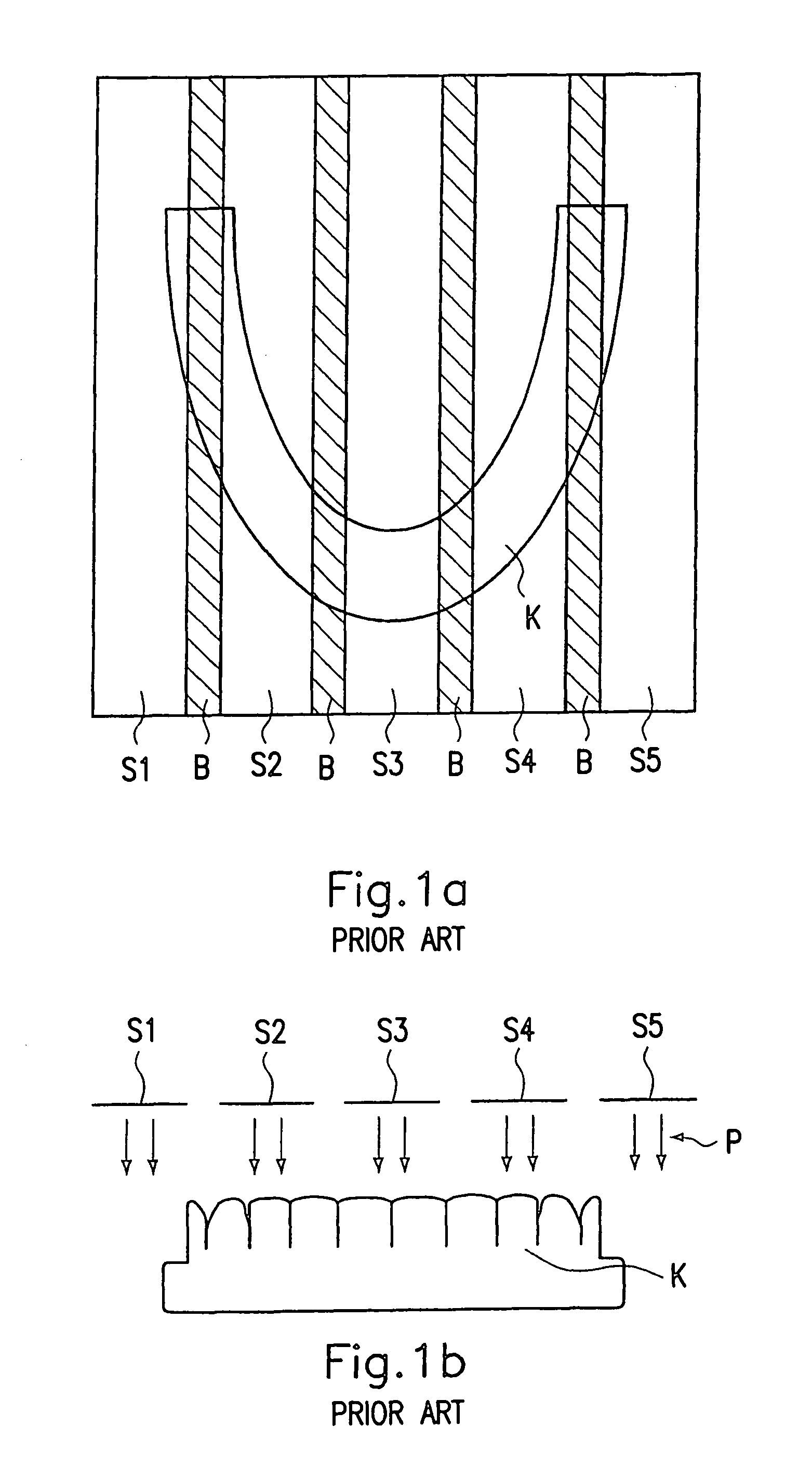

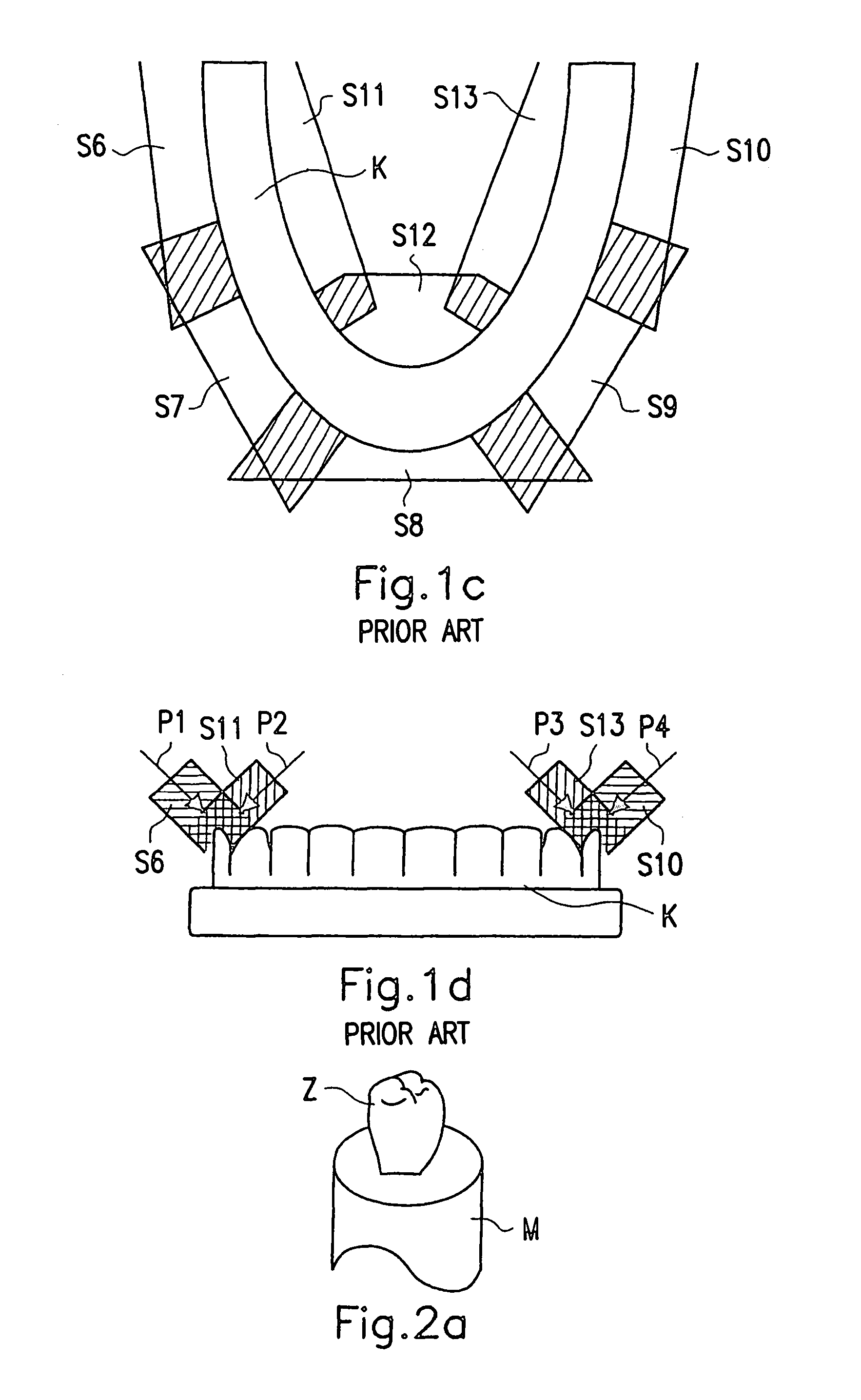

Molding artificial teeth in denture base disc

A method of molding artificial teeth in denture base material comprising forming a U-shaped cavity in a block of denture base material, forming socket cavities in the bottom of the U-shaped cavity, casting a fluid artificial tooth material into the cavities, and causing the fluid tooth material to solidify into solid artificial tooth material while applying pressure. Causing the solidification may include heating the fluid tooth material. The method may include casting a liquid elastomer into a bottom portion of the U-shaped cavity following forming that cavity and prior to the forming the socket cavities, curing the liquid elastomer into a solid elastomeric cushion, and removing the cushion from the U-shaped cavity. Subsequently, the cushion may be inserted into the U-shaped cavity and contacted with the fluid tooth material. A die may then be contacted with the cushion to apply pressure to it and the fluid tooth material during curing.

Owner:GLOBAL DENTAL SCI

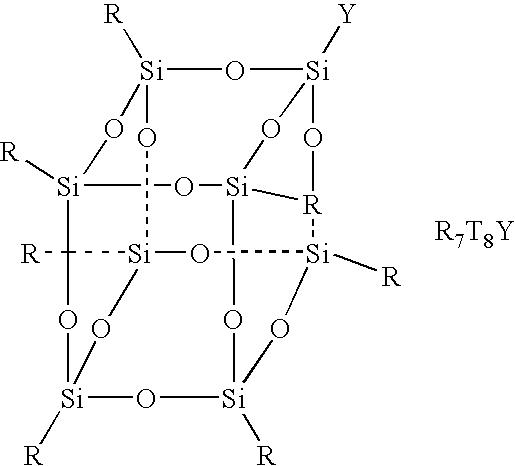

Dental composite materials and method of manufacture thereof

A dental composite material that comprises a polyhedral oligomeric silsesquioxane is disclosed. The dental composite material is useful for a variety of dental materials, treatments, and restorative functions including crown and bridge materials, fillings, adhesives, sealants, luting agents or cements, denture base materials, orthodontic materials and sealants, and other dental restorative materials.

Owner:PENTRON CLINICAL TECH

System and Process for Duplication of Dentures

Owner:GLOBAL DENTAL SCI

Formed denture and method of making same

ActiveUS20180042705A1Efficient and accurateImprove fitArtificial teeth3D printingDenturesDenture base

A method of fabricating a denture, comprising milling a preliminary try-in denture from denture material comprising a layer of denture base material contiguous with a layer of denture tooth material. Denture base material is removed from the block to form a first part of the, labial, buccal, gingival, and flange regions of the denture base to form a preliminary denture. A preliminary mold is created from this preliminary denture. The preliminary denture is then further modified with deformable waxes in gingival and anterior tooth recesses to form a preliminary try-in denture, which is fitted to a patient and adjusted to optimal dimensions. The adjusted try-in denture is then reproduced by further molding methods, producing the final denture.

Owner:GLOBAL DENTAL SCI

Devices and methods for producing denture parts

Surface mapping and / or generation device is provided, with a device for mapping 3D data of at least one denture base object such as a tooth stump or an implantation abutment, and an environment thereof, as well as with a device for the data-based generation and production of a denture part incorporating the 3D data of the denture base object. Additionally provided are a device for determining and / or defining a placement direction of the denture part that is to be slipped onto the denture base object, and a device for determining and producing a primary part that is to be slipped onto the denture base object before the denture part and that yields a desired placement direction for the denture part which is different from the placement direction that exists for slipping the primary part onto the denture base object. The device for data-based generation and production of a denture part is designed to generate and produce the latter by incorporating the 3D data of the primary part. Surface mapping and / or generation method is provided, wherein 3D data from a denture base object such as a tooth stump or an implantation abutment and an environment thereof are mapped and then, based on this 3D data of the denture base object, a denture part to be slipped thereon is produced. Before production of the denture part, a placement direction of the denture part onto the denture base object is determined or defined. On the basis of this 3D data of the denture base object, a primary part is determined and produced, with which a desired placement direction that differs from the placement direction that exists for slipping the primary part onto the denture base object is created for the denture part. On the basis of the 3D data, the denture part is generated and produced based on data so as to fit when pushed onto the primary part.

Owner:INSTITUT STRAUMANN AG +1

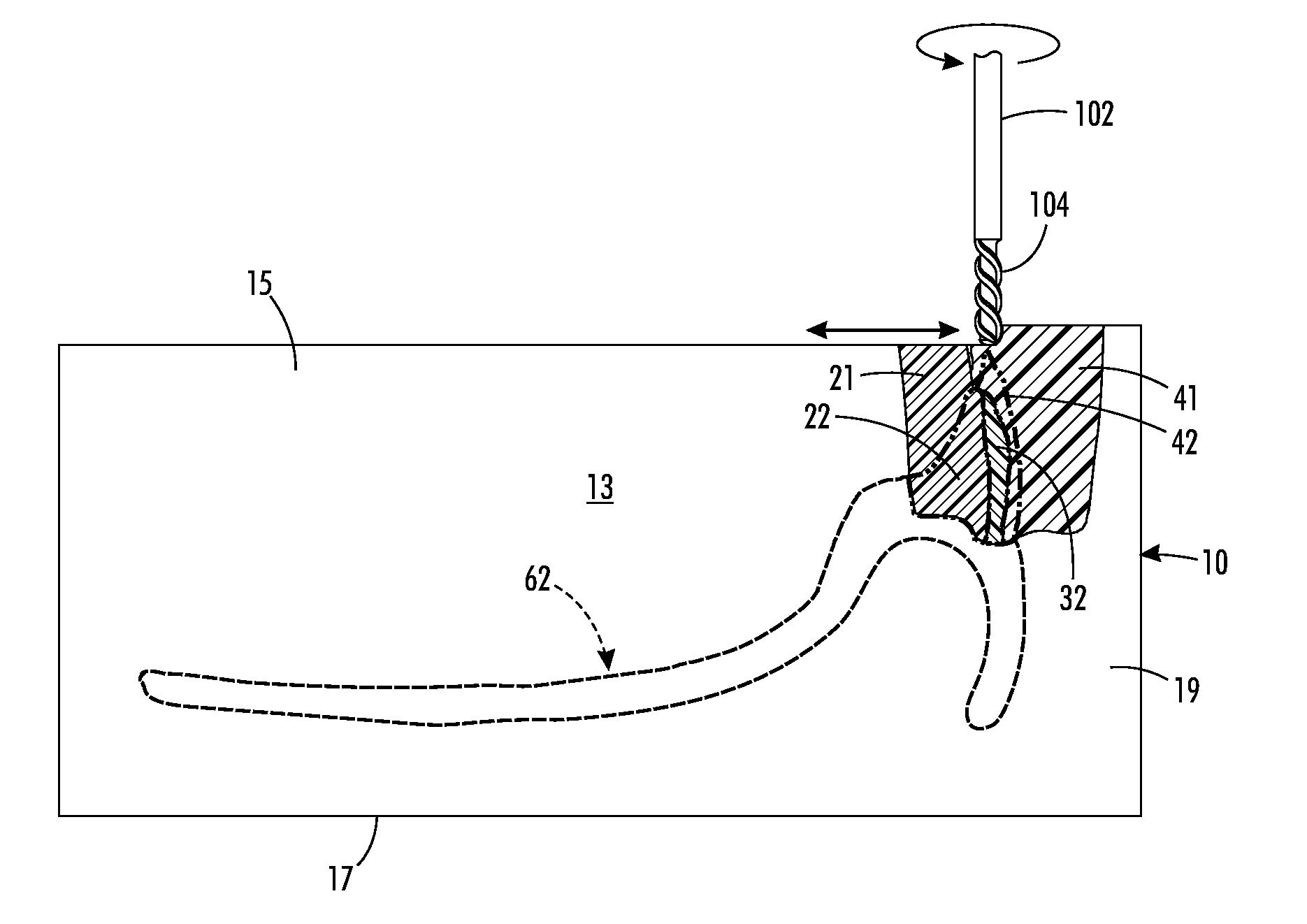

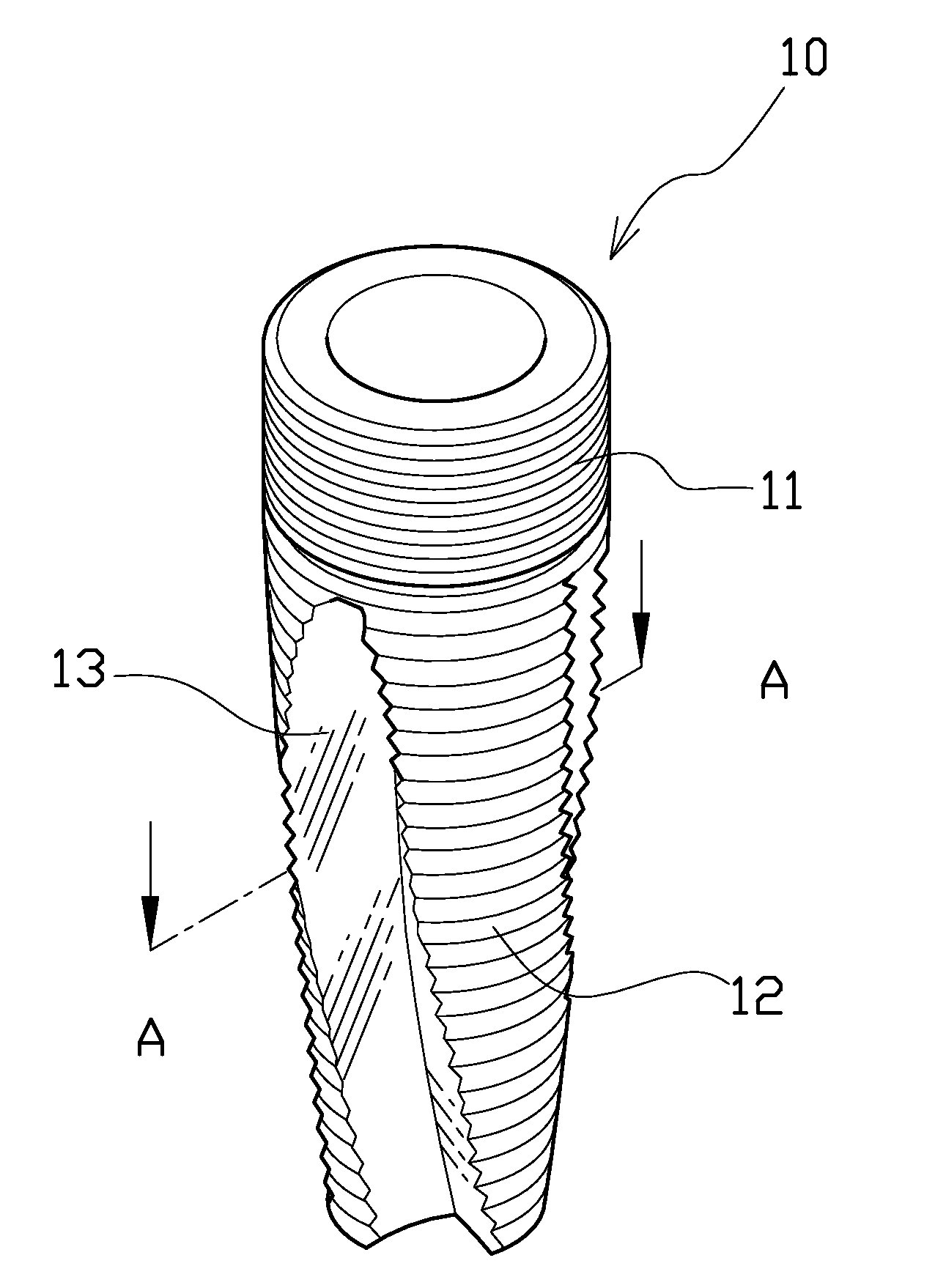

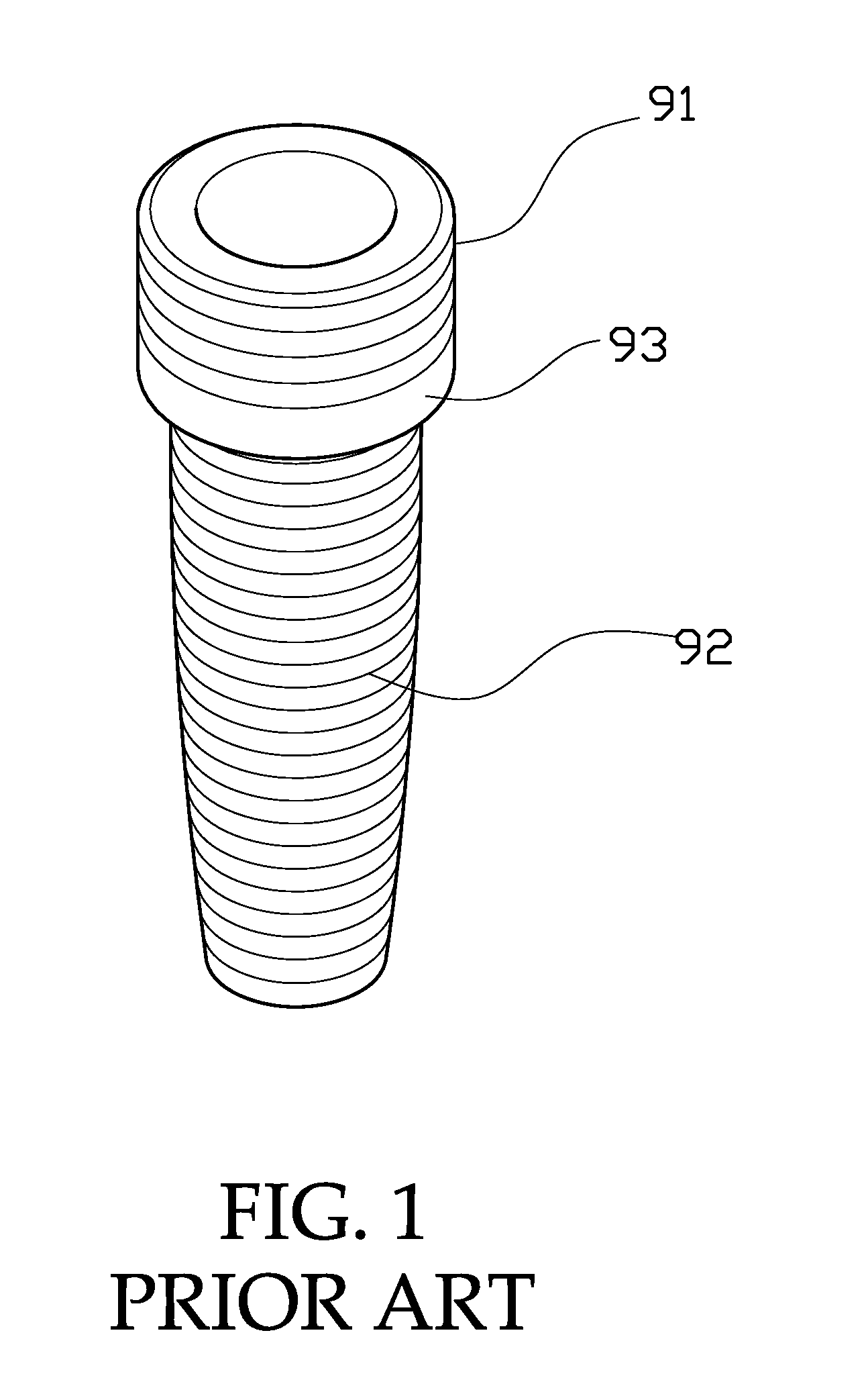

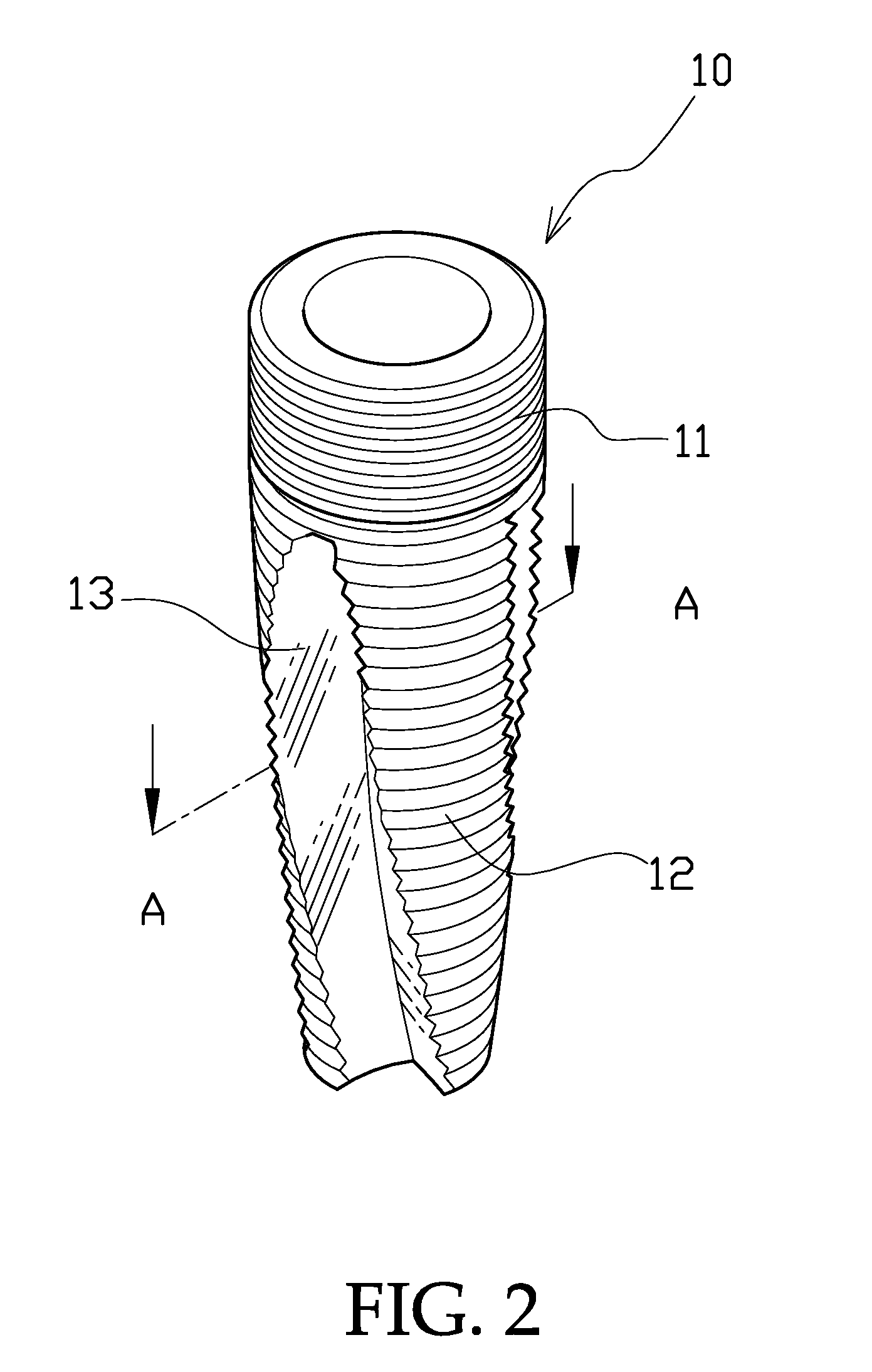

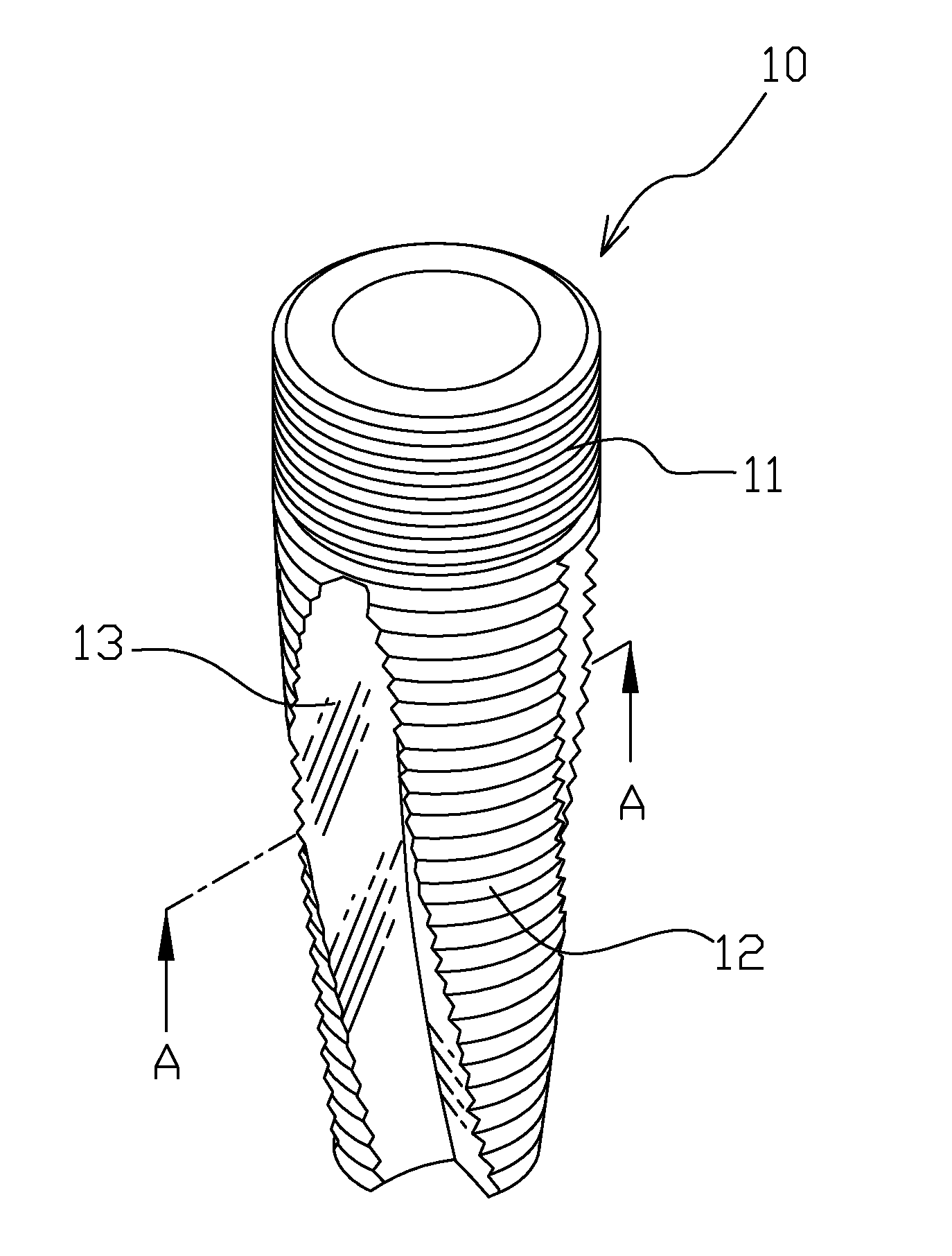

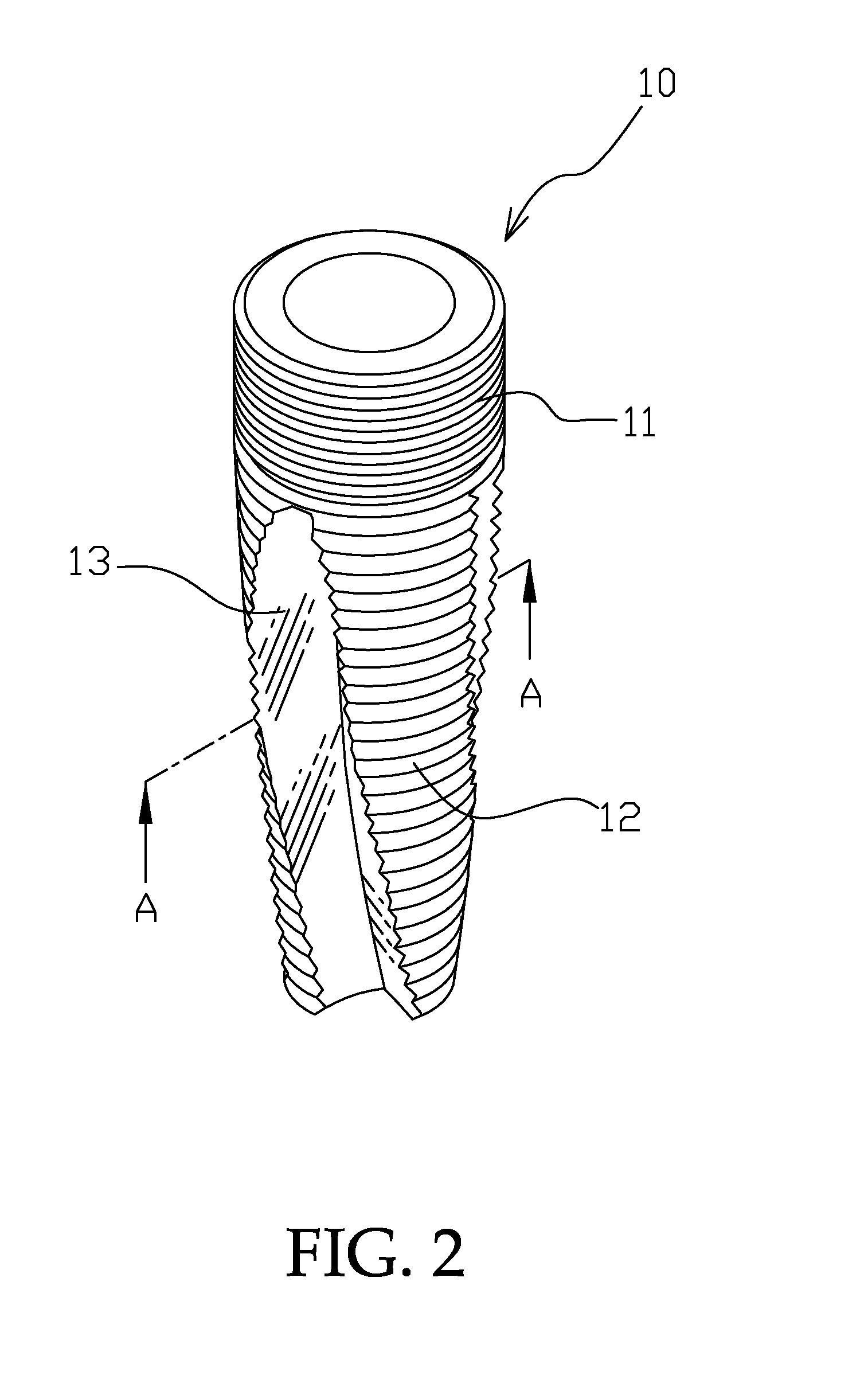

Implant root for tooth implanting

An improved implant root for tooth implanting, a coarse threaded portion of the implant root is formed to have at least two helical treating surfaces each with an HA coating (covered with hydroxyapatite) and each extending in the vertical direction. The areas of the HA coatings can thus be increased in favor of fast growth of a bone of a denture base after implanting into the bone to envelop the implant root; this can shorten the curing process from implanting the implant root to mounting a crown.

Owner:CHEN CHUN LEON

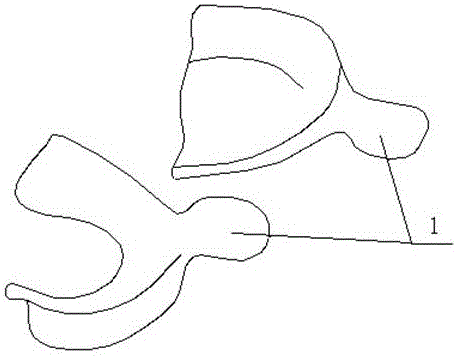

Combination set of artificial teeth units for setting-up dentures in balanced articulation

InactiveUS20060286507A1The result is accurateAvoid difficultyDental prostheticsCentric occlusionDentures

A combination set (FIG. 1, A,B), at least normalized in a medium size or different sizes and forms, includes complete arched artificial teeth units (1), (2) preformed without denture base, for setting up these units (1), (2) in a denture thereby instantly and adjustable in a full balanced articulation during custom denture work. The set(s) is composed of a complete upper (1) and separate complementary complete lower (2) arched artificial teeth unit, each including anterior and posterior artificial teeth inter-connected either in a complete (A) or under-extended complete (B) tooth arch at least in an oval form and restricted occluso-gingival height. Each of the units includes a total unitary inter-occlusal bite plane preformed in a corresponding centric occlusion and full balanced articulation. In order to prevent setting up as regularly denture teeth, one by one in the centric and full balanced articulation, hereto the unitary inter-occlusal bite plane is pre-formed according to interconnected styled artificial anterior and posterior teeth. Thereby the bite plane is formed cuspless sphero-ellipsoidal, conforming a 4 inch (11 cm.) radius, thereby to be set on an oblique planar sphero-ellipsoidal bite occlusal level including a free centric inter-occlusal contact (FIG. 2) either full (C,5) or partly (D,6) and a free eccentric bi-lateral balanced articular contact. Having the last molar posterior artificial teeth either broader or not than regularly and pre-formed without tongue interference to ascertain individually the balanced articular contact. Further the set(s) is non-bendable from a durable tooth aesthetic material.

Owner:DEQUEKER FRANS ARTHUR BENOIT

Implant root for tooth implanting

InactiveUS20110033826A1Increase the areaIncrease spacingDental implantsHydroxyapatite coatingDenture base

An improved implant root for tooth implanting, a coarse threaded portion of the implant root is formed to have at least two helical treated surfaces extending from the bottom to the top of the implant root of the coarse threaded portion each being treated with a roughened coating (for example, covered with a hydroxyapatite coating) and extending in the whole length of the coarse threaded portion and each extending in the vertical direction. The areas of the roughened coatings can thus be increased in favor of fast growth of a bone of a denture base after implanting into the bone to envelop the implant root; this can shorten the curing process from implanting the implant root to mounting a crown.

Owner:CHEN CHUN LEON

Production of dental prostheses via CAD and rapid manufacturing from digitally recorded oral data

ActiveCN103637851AHigh precisionAdditive manufacturing apparatusMechanical/radiation/invasive therapiesDenturesProsthesis

Summary Methods for the production of complete or partial prostheses involve, firstly A) provision of 3D data of the situation in the mouth in the edentulate or partly toothed state; B) digital designing of the denture base for lower and upper jaw each; C) digital positioning of virtual teeth with appropriate occlusion and a tooth shape selected according to aesthetic criteria, in the case of complete prostheses, D1) production of the dental arch using an automated method from the groups of layer-building and of material-removing methods; and D2) production of the denture base using an automated method from the groups of layer-building and of material-removing methods; and, in the case of partial prostheses; D1) production of the dental arch using an automated method from the groups of layer-building and of material-removing methods; and D2) production of the support structures or fastening elements using an automated method from the groups of layer-building and of material-removing methods.

Owner:赫罗伊斯库尔泽有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com