Patents

Literature

48 results about "Ha coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

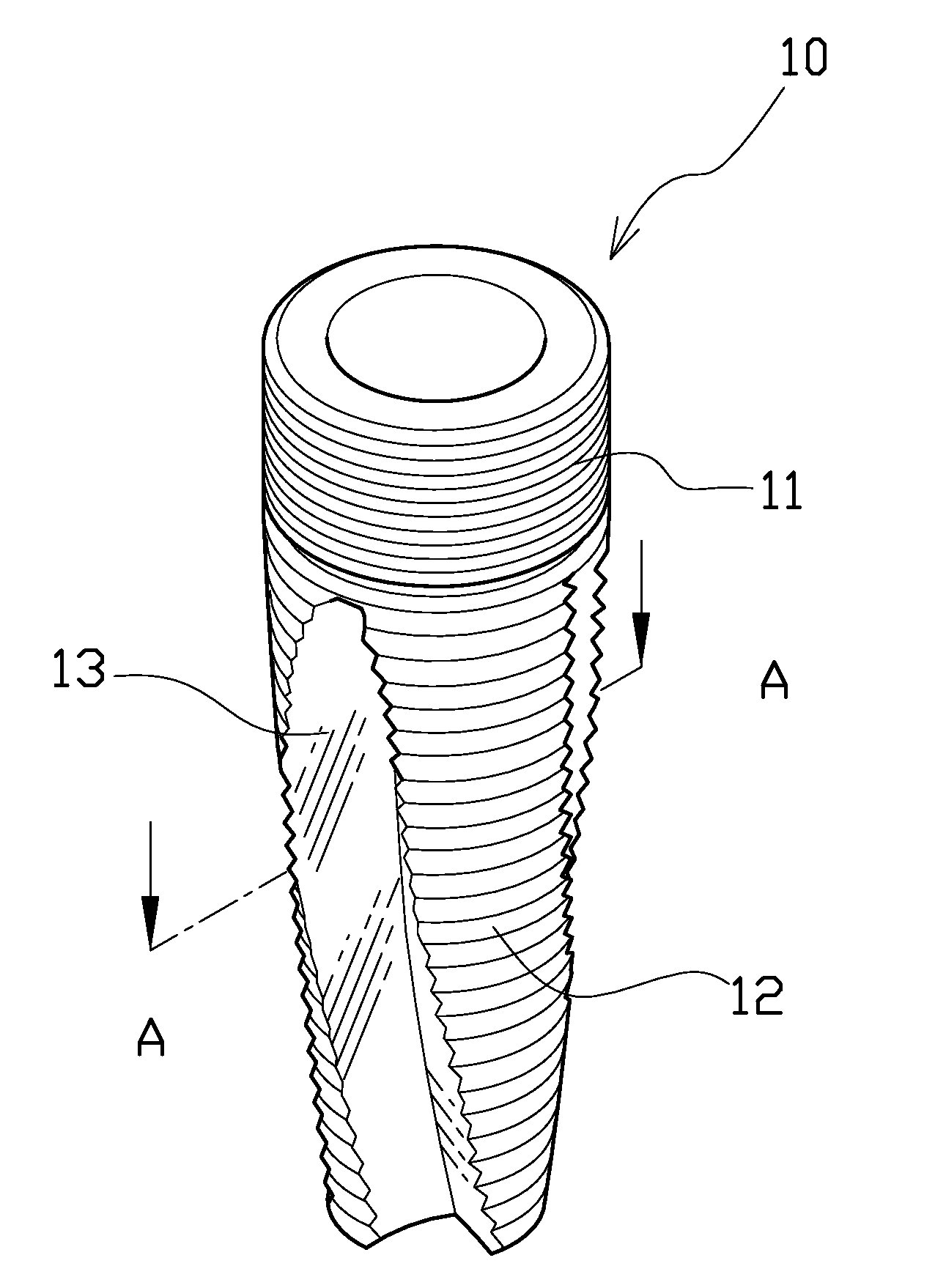

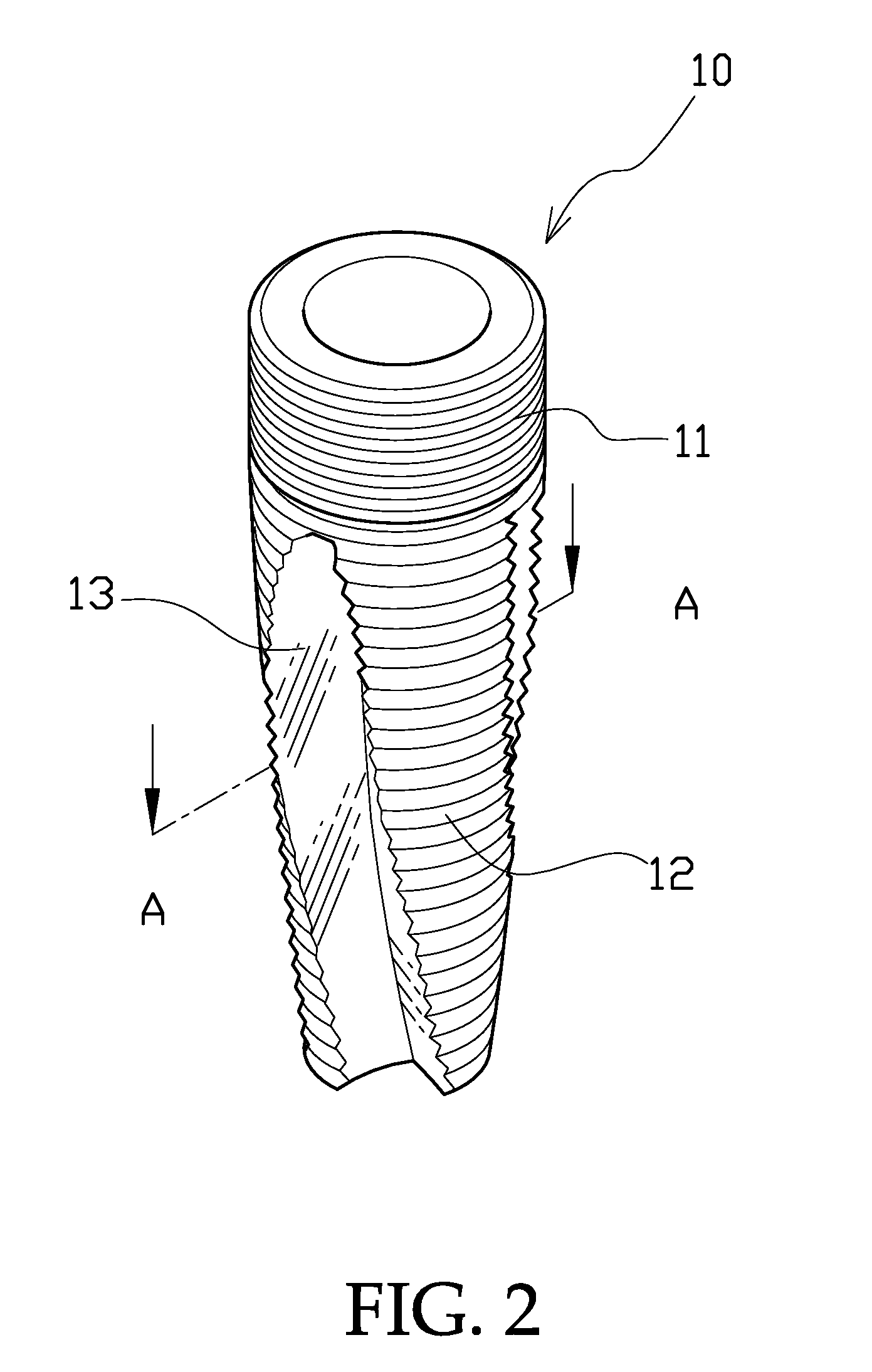

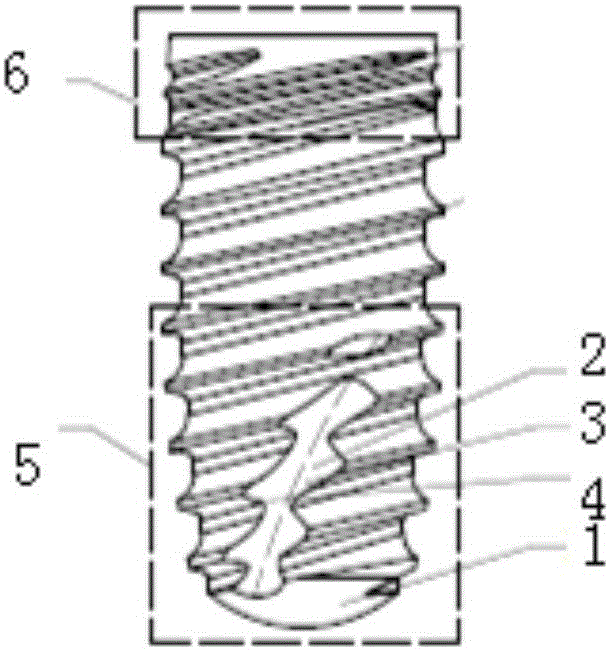

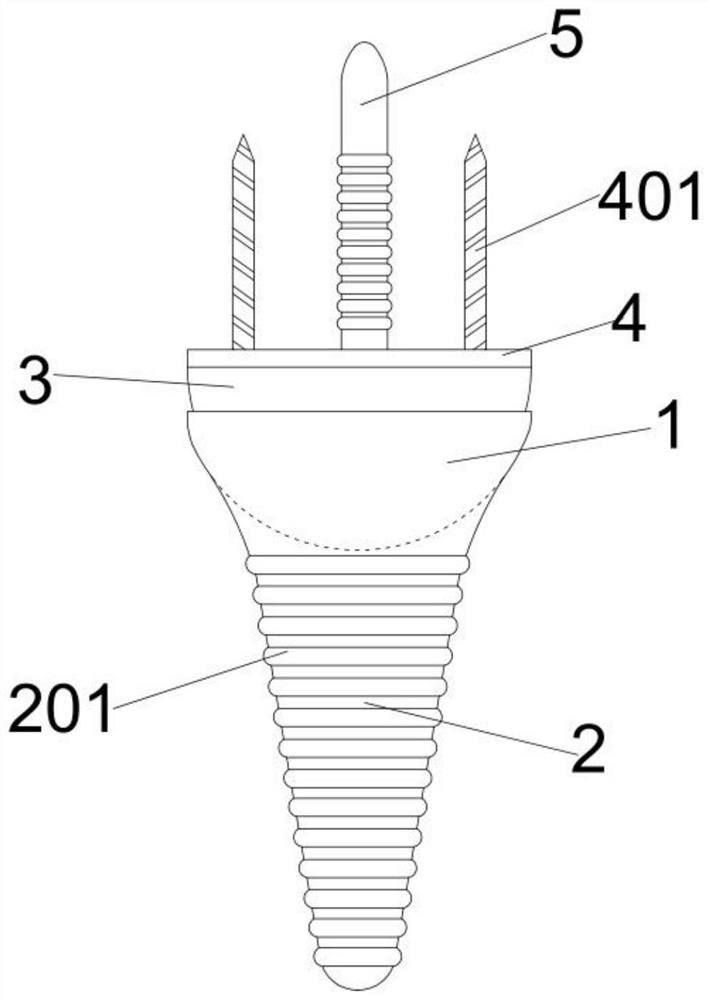

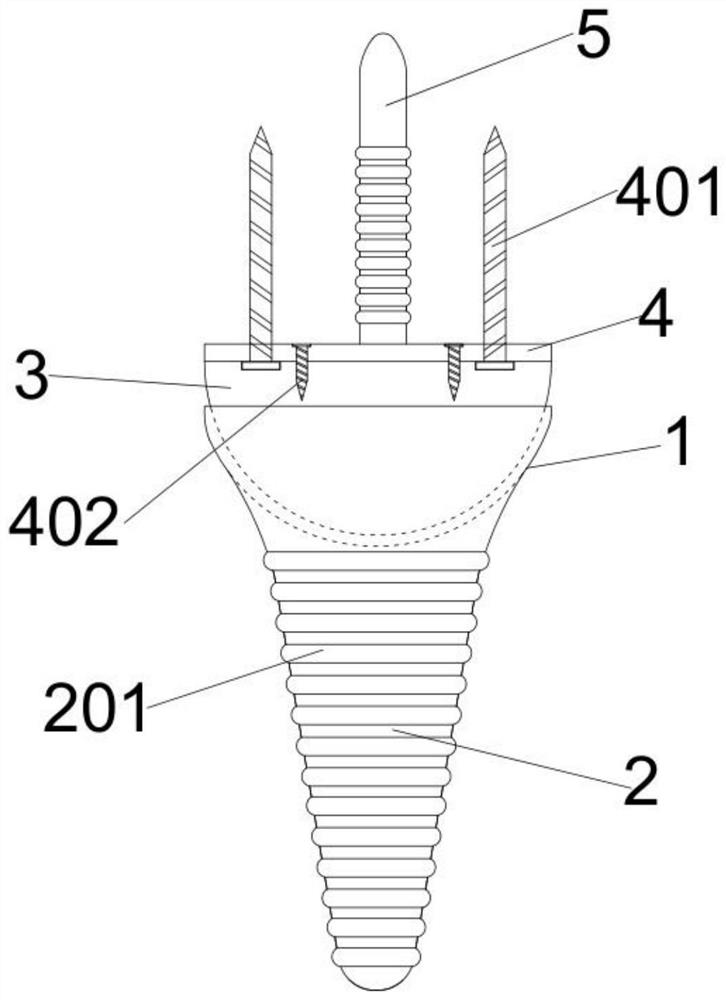

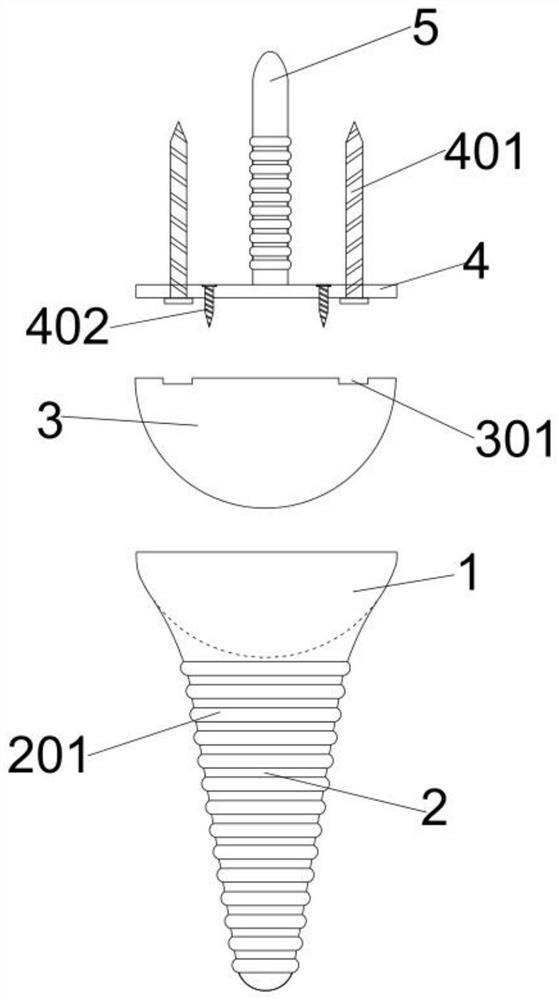

Implant root for tooth implanting

An improved implant root for tooth implanting, a coarse threaded portion of the implant root is formed to have at least two helical treating surfaces each with an HA coating (covered with hydroxyapatite) and each extending in the vertical direction. The areas of the HA coatings can thus be increased in favor of fast growth of a bone of a denture base after implanting into the bone to envelop the implant root; this can shorten the curing process from implanting the implant root to mounting a crown.

Owner:CHEN CHUN LEON

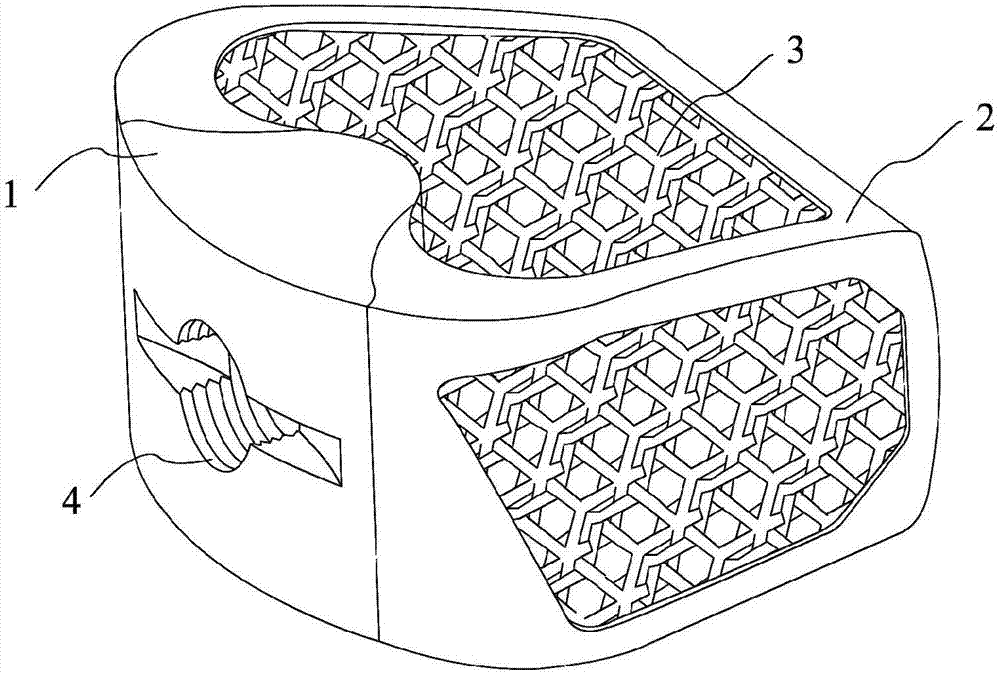

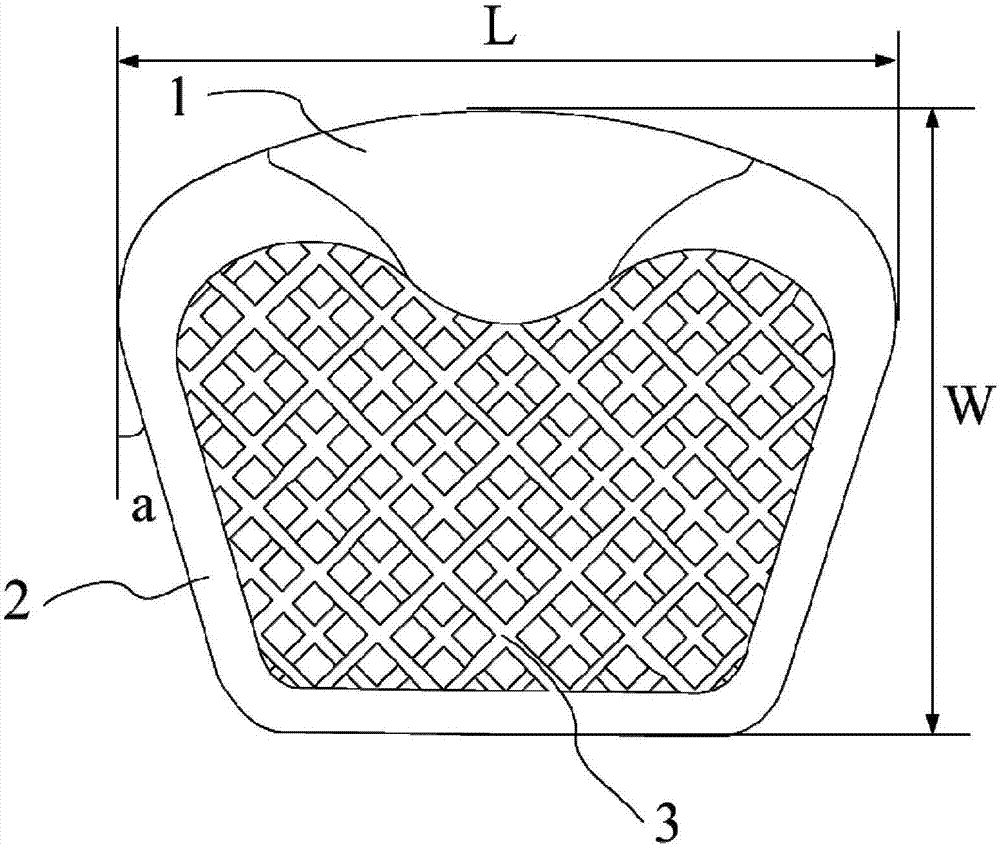

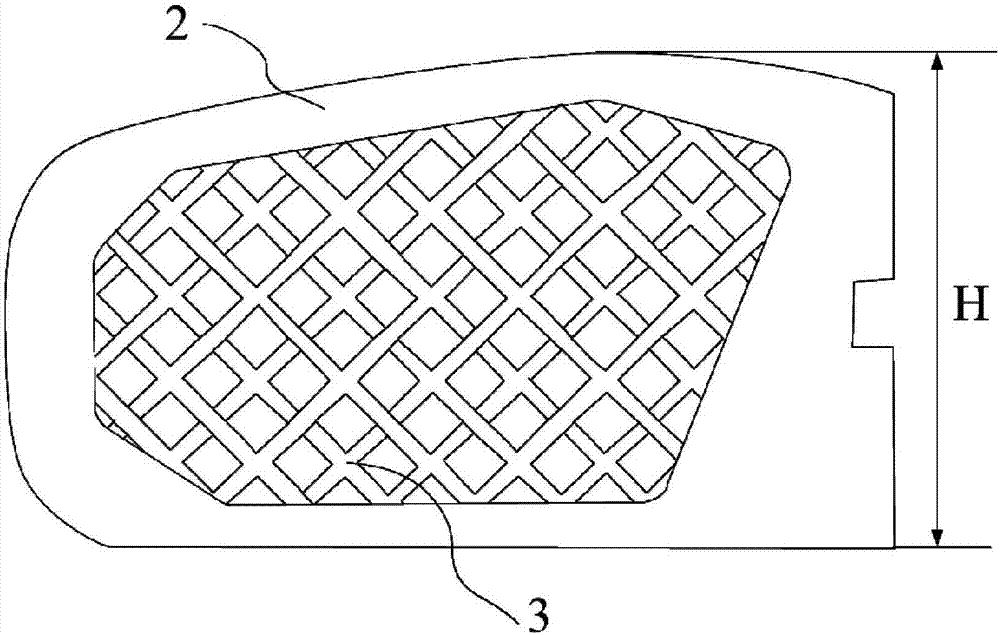

Porous titanium cervical fusion cage with HA coating and preparation method of fusion cage

InactiveCN107349034AReduce the risk of broken armsReduced risk of spinal cord compressionJoint implantsSpinal implantsStress concentrationOsseointegration

The invention discloses a porous titanium cervical fusion cage with a hydroxyapatite (HA) coating and a preparation method of the fusion cage. The fusion cage is composed of an entity framework structure and a porous structure, wherein the entity framework structure is filled with the porous structure. The front portion of the fusion cage is of a structure similar to a bullet head, all edges of the fusion cage are covered with entity smooth titanium alloy thin wall, and the risk that in the implanting process, fusion cage edge small beams are subjected to stress concentration, and arm breaking is caused can be reduced. The central part of the rear portion of the fusion cage is of an arc-shaped entity titanium alloy structure with the thickness being 3 mm or above, and a threaded hole and a groove are machined in the arc-shaped entity titanium alloy structure in a second stage machining mode and used for making the fusion cage connected to an implanting handle during an operation. A thread and the groove can provide a connection mode which is firmer and more reliable than a clamping mode, and implanting is conducted conveniently during the operation. The surfaces of all the small beams of the porous structure of the fusion cage are covered with the hydroxyapatite (HA) coating with the thickness being about 100-500 micrometers, and a more excellent early osseointegration effect can be provided.

Owner:维度(西安)生物医疗科技有限公司 +1

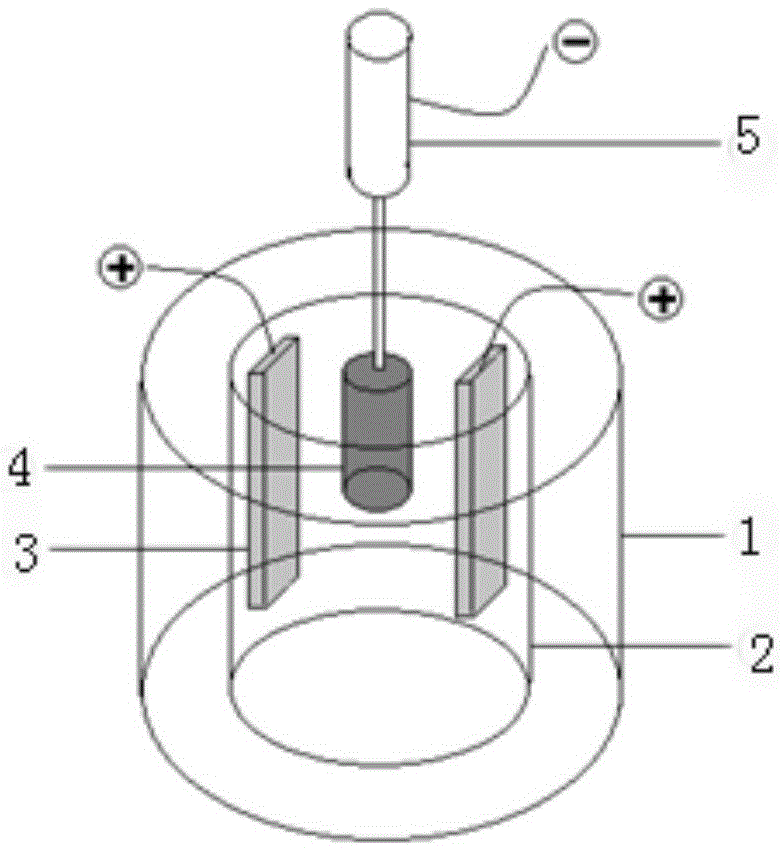

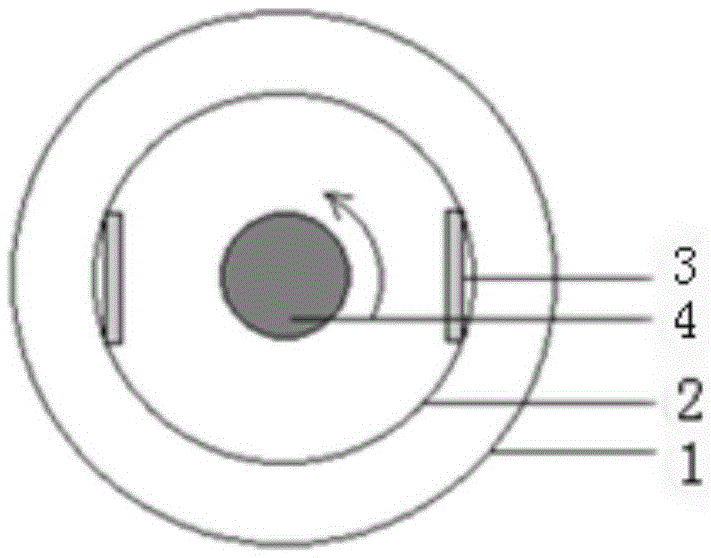

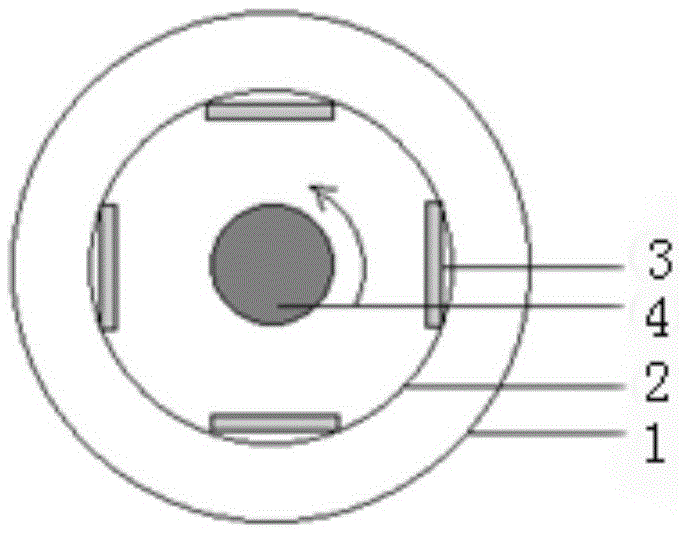

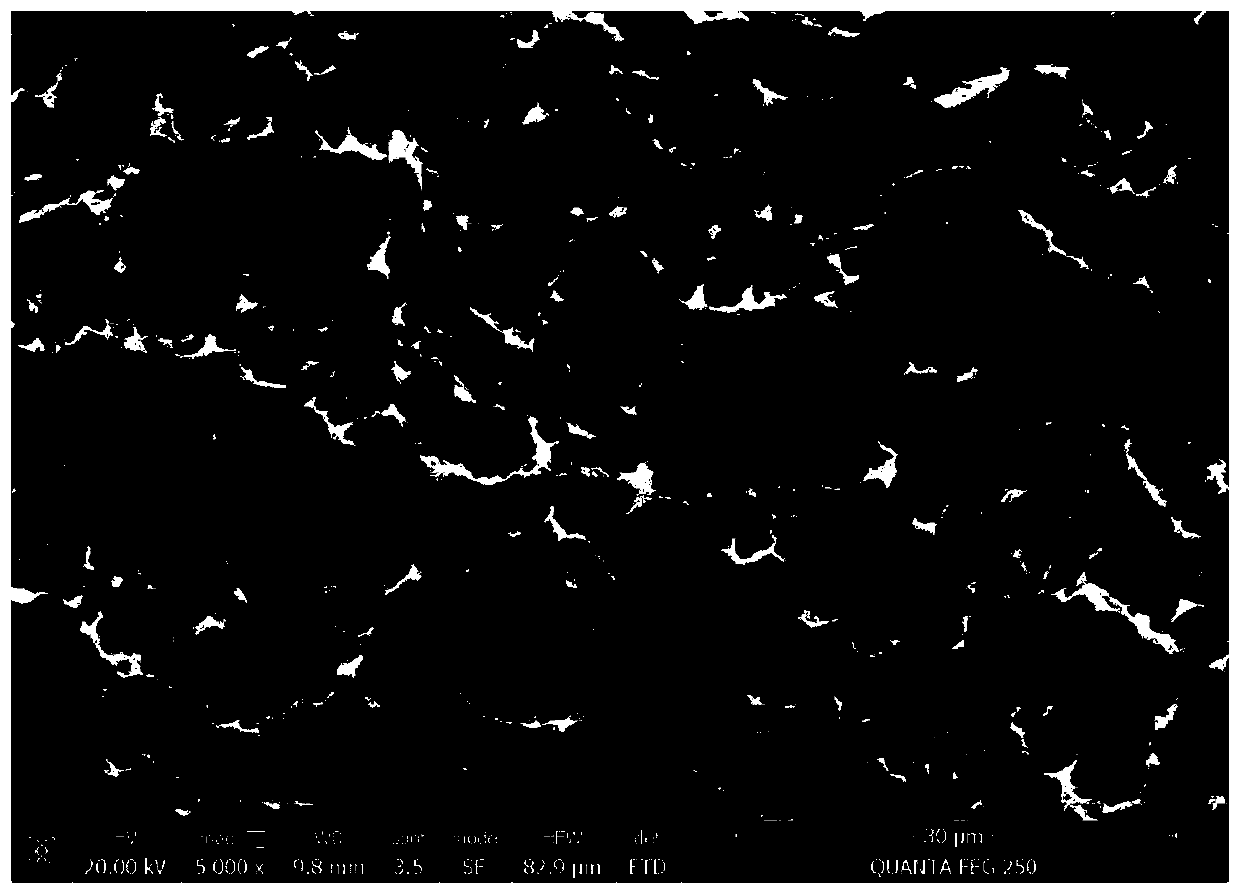

Technology for uniform deposition of HA (hydroxyapatite) coatings on medical porous titanium and titanium alloy

ActiveCN105624753AEfficient preprocessingEffective mechanical grindingElectrolytic inorganic material coatingProsthesisElectrolysisApatite

The invention relates to the field of surface modification treatment of medical materials and particularly discloses a technology for uniform deposition of HA (hydroxyapatite) coatings on medical porous titanium and titanium alloy. The technology for deposition of the HA coatings on the porous titanium and titanium alloy comprises processes including pretreatment of a porous metal base material, preparation of an electroplating solution and electro-deposition. In the pretreatment process, effective mechanical grinding and cleaning treatment can be performed on inner and outer surfaces of porous metal; in the electro-deposition process, HA electro-deposition treatment can be performed on the porous metal by using a rotating electrode electrolysis device, the thickness of diffusion layers on the inner and outer surfaces of the porous metal can be effectively reduced, and the problem that electro-deposition technologies of inner and outer surfaces of a porous structure are not synchronous can be effectively solved under the diffusion mixing controlled condition; uniform HA electro-deposition layers on the inner and outer surfaces of the porous metal are obtained by adjusting the rotating speed.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

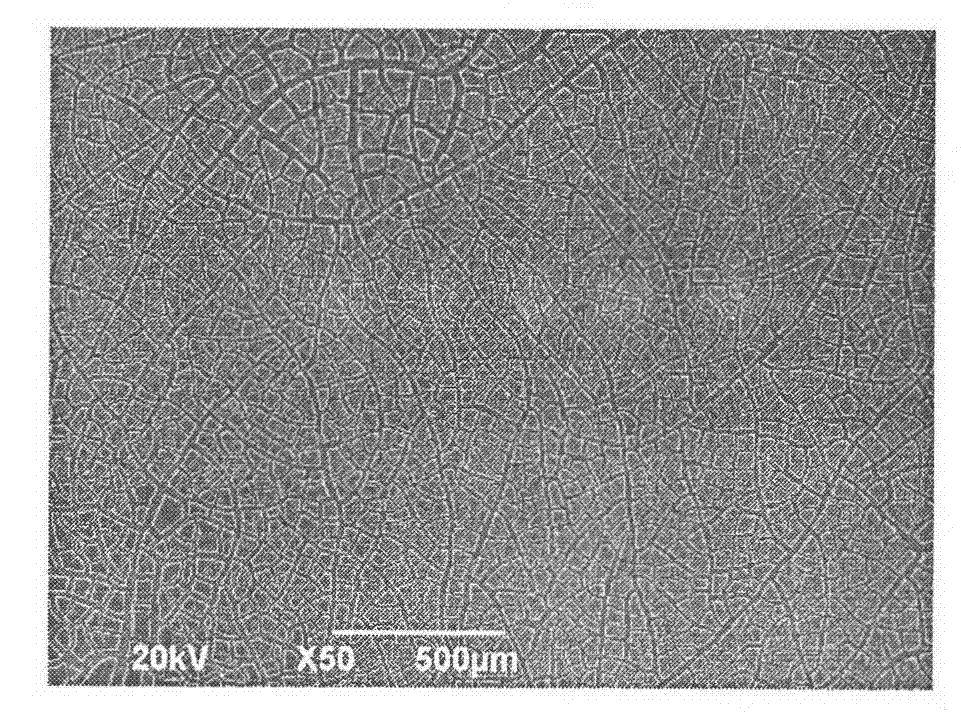

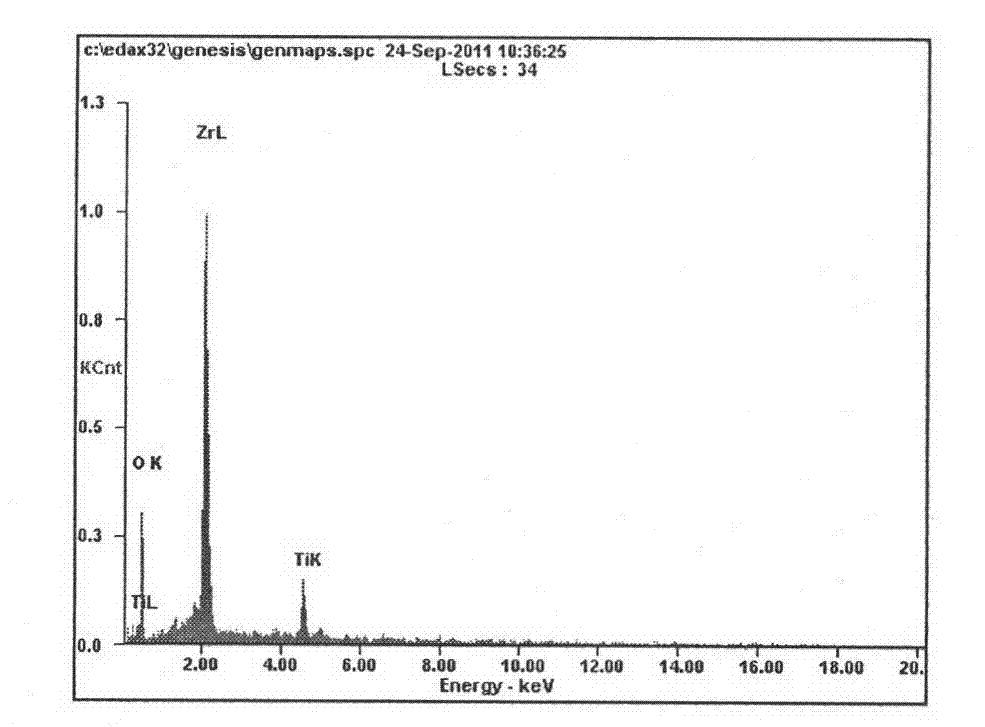

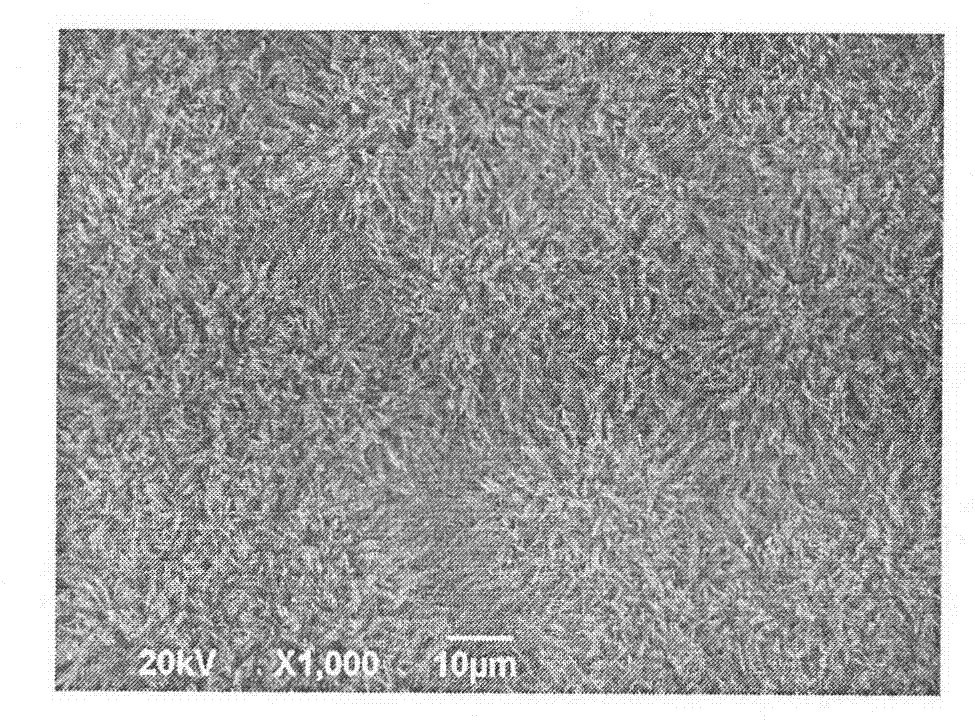

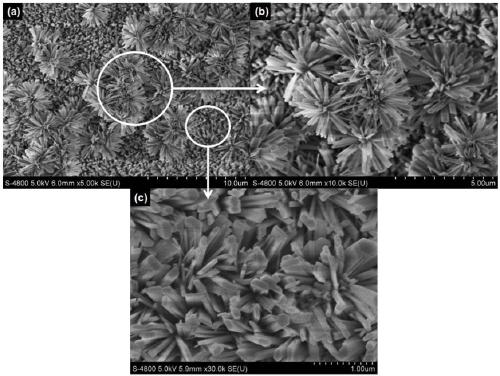

Electrochemical method for preparing citric acid-hydroxyapatite/zirconia transition coating on surface of biomedical titanium

InactiveCN103088383AAlleviate shortcomings such as thermal expansion coefficient mismatchHigh bonding strengthElectrolytic inorganic material coatingDrug biological activityMicron size

The invention discloses an electrochemical method for preparing a citric acid-hydroxyapatite / zirconia transition coating on the surface of biomedical titanium. The electrochemical method comprises the following steps of 1, carrying out electrodeposition in an electrolytic cell with a three-electrode system by based on a biomedical titanium slice as a work electrode, carrying out electrodeposition in a zirconium oxynitrate solution having a certain concentration and a certain pH at an electrodeposition electric current of 11.1mA for 50s to obtain a Zr(OH)4 coating and carrying out electrodeposition in an electrolyte which is composed of calcium nitrate, ammonium dihydrogen phosphate, sodium citrate and hydrogen peroxide and has a certain concentration and a certain pH at an electrodeposition electric current of 0.9mA for 2700s to obtain a citric acid-modified HA(Cit-HA) coating, and 2, carrying out vacuum sintering at a temperature of 450 DEG C to obtain the citric acid-hydroxyapatite / zirconia transition coating. Citric acid radical prolongs a nucleation period of HA crystals. A micron-size chrysanthemum petal shape of the coating is changed into a nano-size needle shape. The HA coating realizes transition from an inner compact layer to an outer loose layer. ZrO2 is used as a transition layer between a titanium matrix and the HA coating, and the Cit-HA / ZrO2 transition coating has high bonding strength with the Ti matrix. A late-stage simulated body fluid immersion experiment proves that the Cit-HA / ZrO2 transition coating has good biological activity.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing staged absorbable ha/acp composite coating on titanium implant surface

InactiveCN102286764AImprove biological activityACP is fastElectrolytic inorganic material coatingProsthesisElectrolytic agentTitanium metal

The invention discloses a method for preparing a staged absorbable HA / ACP composite coating on the surface of a titanium implant. Using platinum as the anode and the metal titanium substrate as the cathode, the two electrodes are first immersed in the container of the electrolyte solution containing the constituent elements of hydroxyapatite, so that the cathodic reduction reaction occurs on the surface of the metal titanium substrate, and thus the surface of the metal titanium substrate First deposit a layer of HA coating; then take out the two electrodes and then immerse them in the container of electrolyte solution containing the constituent elements of amorphous calcium phosphate and stable ions of amorphous calcium phosphate, so that the cathodic reduction reaction continues to occur on the surface of the metal titanium substrate , thereby depositing a layer of ACP coating on the surface of the HA coating, thereby depositing the HA / ACP composite coating on the surface of the metal titanium substrate; after cleaning, removing the electrolyte attached to the surface of the metal titanium substrate, and drying in a drying oven. The composite coating formed by the invention has better biological activity, and can regulate the biological response in the whole process of implant implantation.

Owner:ZHEJIANG UNIV

Preparation method of biological gradient coating on surface of dental implant

InactiveCN103598919AImprove the bonding strength of the interfaceInhibit sheddingDental implantsSolid/suspension decomposition chemical coatingSolubilityApatite

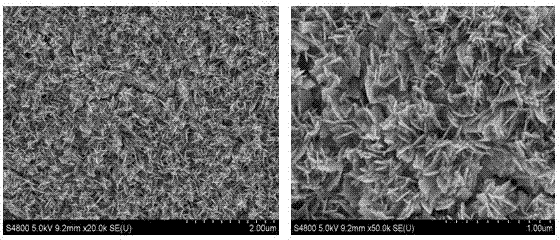

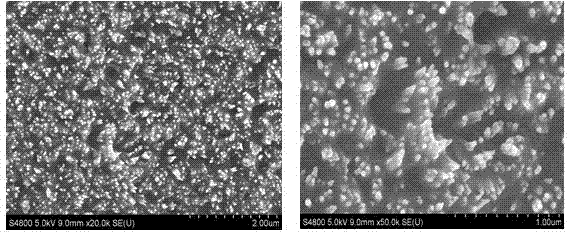

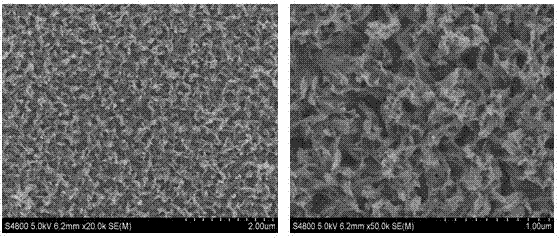

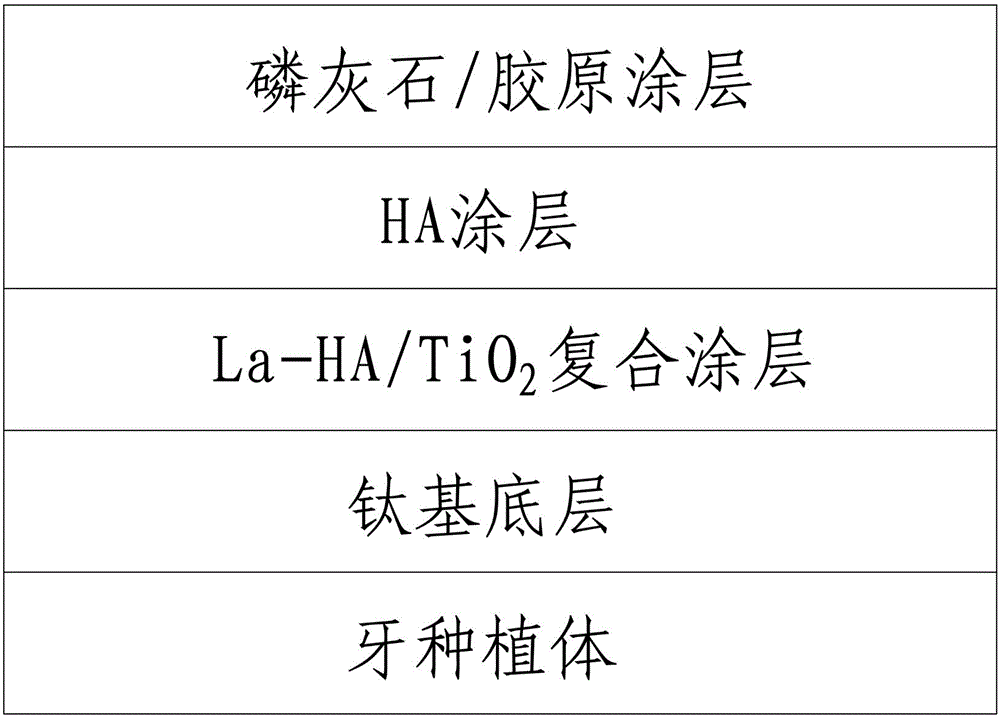

The invention discloses a preparation method of a biological gradient coating on the surface of a dental implant. The method is used for performing operation of the following steps on the dental implant: polishing a titanium sheet by SiC metallographic abrasive paper, cleaning, drying, and setting the dried titanium sheet on the surface of the dental implant to form a titanium substrate layer; preparing an La-HA / TiO2 composite coating on the surface of the titanium substrate layer; preparing an HA coating on the surface of the La-HA / TiO2 composite coating; and setting the dental implant in an apatite / collagen solution containing La, thus forming the apatite / collagen coating on the surface of the dental implant. According to the invention, the La-HA / TiO2 composite coating is prepared on the titanium surface, so that the excessively high solubility of the HA coating is effectively lowered, the problem of instability between original HA and a metal interface is solved, and the chemical stability and the bonding force of the coating are improved; with the novel coating design, the biological activity and the solubility are improved in a gradient way from inside to outside, and the chemical stability and the bonding strength are improved in a gradient way from outside to inside.

Owner:温州医科大学附属口腔医院

Method of fast growing HA biologically active layer from oxidation film on titanium alloy surface by ultraviolet excitation

InactiveCN1908231AImprove hydrophilicityImprove wettabilitySolid state diffusion coatingLiquid/solution decomposition chemical coatingUltravioletTitanium alloy

the invention discloses an oxide-film rapid growing method of HA biological active layer on the ultraviolet laser Ti-alloy surface, which comprises the following steps: (1) oxidizing through heat; (2) irradiating through ultraviolet; (3) allocating soaking liquid of analog; (4) immersing to grow HA coating layer through analogy soaking liquid.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Gradient medical material and preparation method thereof

ActiveCN111235429ALow elastic modulusMaintain use intensity requirementsMolten spray coatingSurgeryHuman bodyAnti bacteria

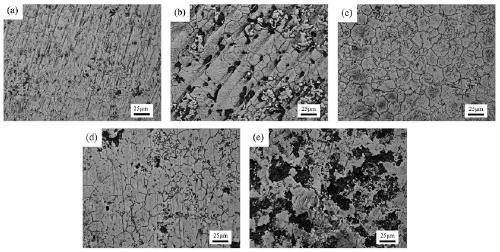

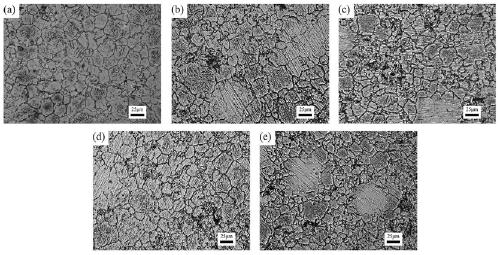

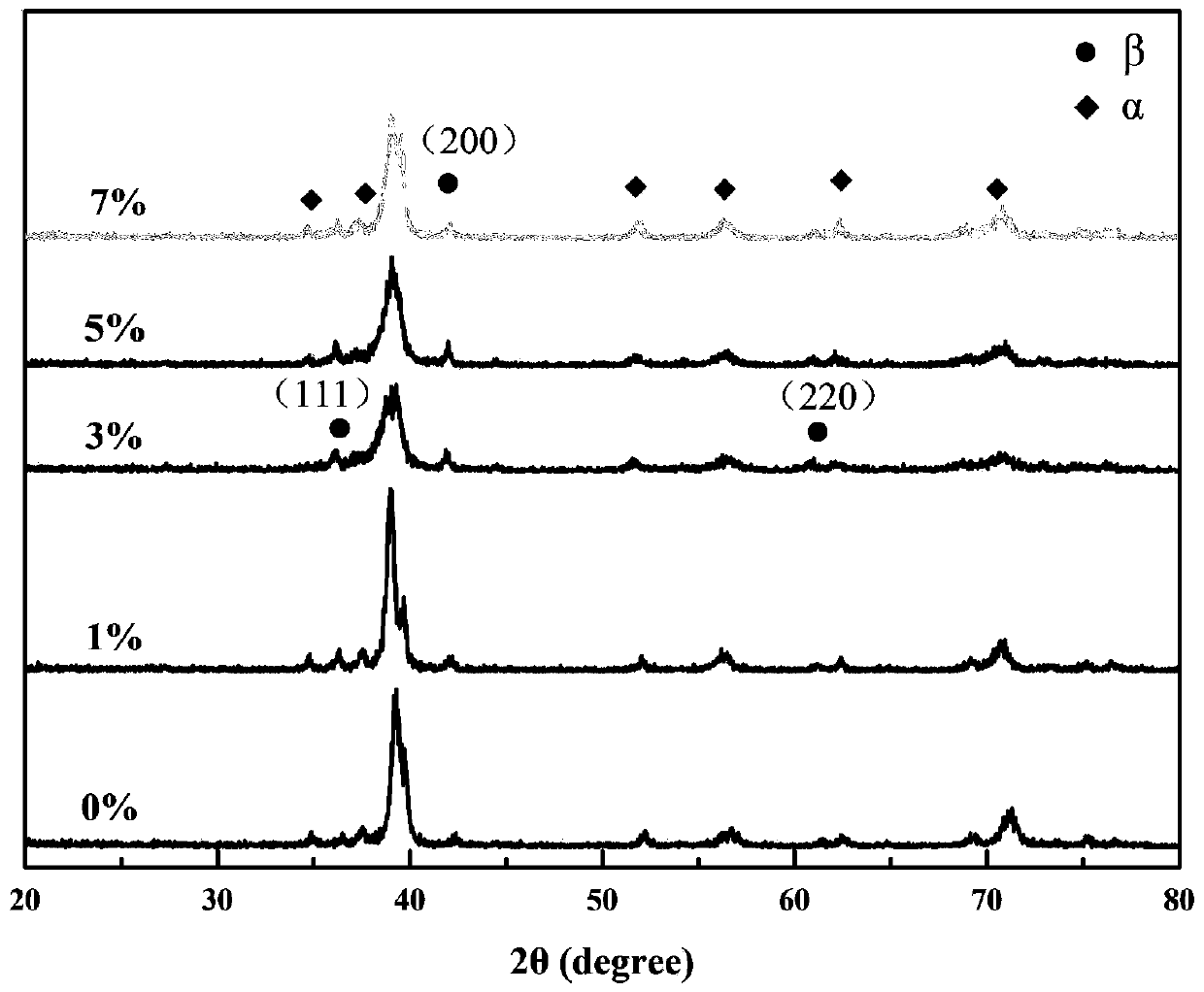

The invention discloses a gradient medical material and a preparation method thereof. An alloy strengthening element Zr and a beta-phase stable element Ta are added on the basis of the ratio of Ti-10Mo-28Nb alloy, and a surface coating of Ti-Mo-Nb-Zr-Ta multicomponent alloy is an HA coating or an HA-Cu-Zn complex coating. Through addition of Zr and Ta, the elasticity modulus of the alloy can be remarkably reduced, the requirement for strength of use inside the body is met, corrosion resistance is improved, and the requirement for implantation of titanium alloy in the human body is further met.A surface coating of Ti-10Mo-28Nb-3Zr-6Ta multicomponent alloy is an HA coating or an HA-Cu-Zn complex coating. The surface of Ti-5Mo-28Nb-3Zr-6Ta alloy is polished; and nanosized oxidation tubes areprepared on the surface of the alloy in an anodic oxidation method, then a layer prepared by elements of hydroxyapatite (HA), copper (Cu) and zinc (Zn) is sprayed to the surfaces of the nanosized oxidation tubes through a plasma spraying technology, and a complex bio-coating is prepared. By the adoption of the gradient medical material, the problems that an existing bone implantation material ishigh in elasticity modulus, poor in biological activity and poor in corrosion resistance and antibacterial property can be solved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

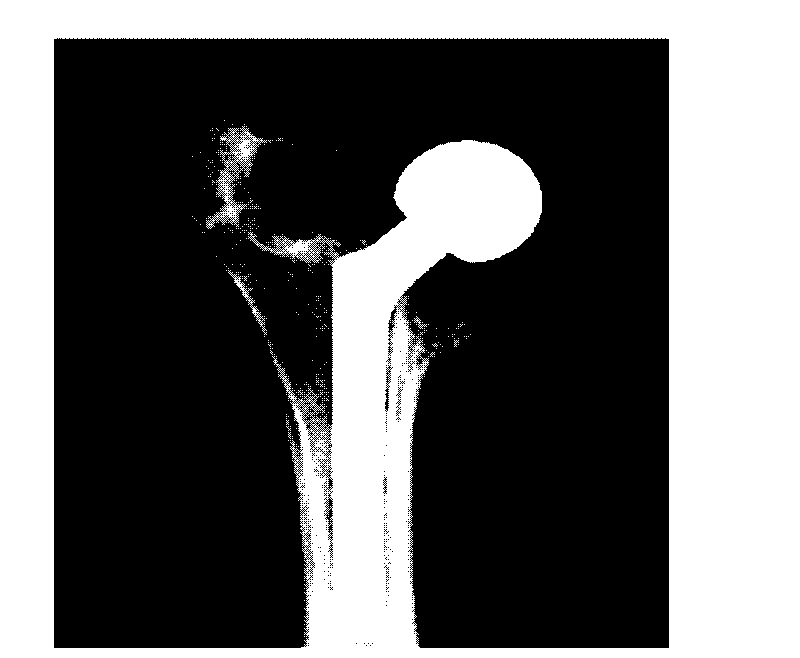

Artificial joint medium layer and method of preparing the same

InactiveCN101279109AImprove adhesionReduce friction lossJoint implantsConductive polymerTissue material

The invention discloses an artificial articulation media layer and a preparation method thereof and relates to an artificial bone tissue material. A media layer with biotic compatibility, biotic degradation and cell inducing activity is formed on the surface of the artificial bone articulation of titanium alloy by compositing hydrogel and conductive polymer. The media layer can be taken as a buffer layer of the surface of the artificial articulation to reduce the loss of artificial articulation surface by friction and also as a framework material for the growth of bone cells and can induce the growth of the bone and facilitate the quick acceptance of the planted artificial articulation by the tissues. The artificial articulation media layer is a laminated structure, including a titanium alloy base layer, a nano hydroxyapatite layer, a biodegradable polyethylene glycol-lactic acid block copolymer layer and a polypyrrole layer with nano structure. An HA coating is constructed on the surface of the titanium alloy and then a hydrogel layer is constructed on the HA coating by adopting optical cross linking or free radical cross linking and finally pyrrole is in situ polymerized on the hydrogel layer, then the titanium alloy decorated with the ploypyrrole / glycol-lactic acid block copolymer / HA media layer is obtained.

Owner:XIAMEN UNIV

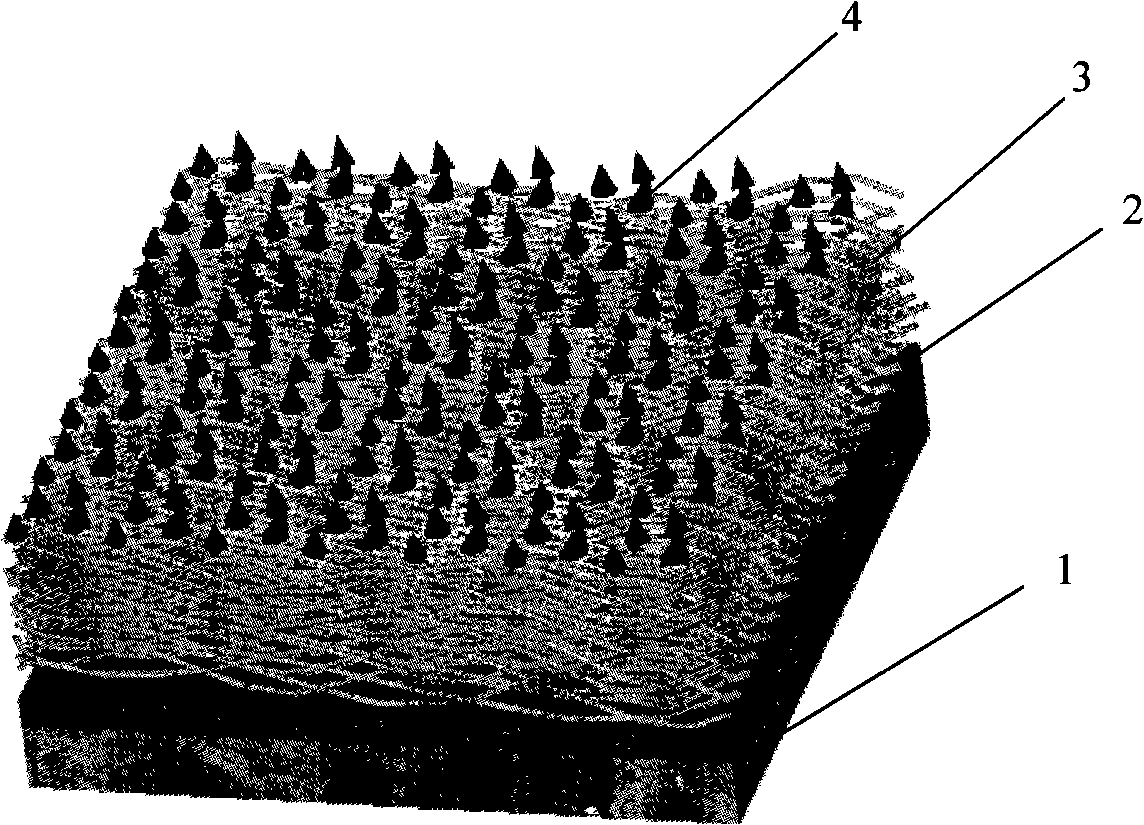

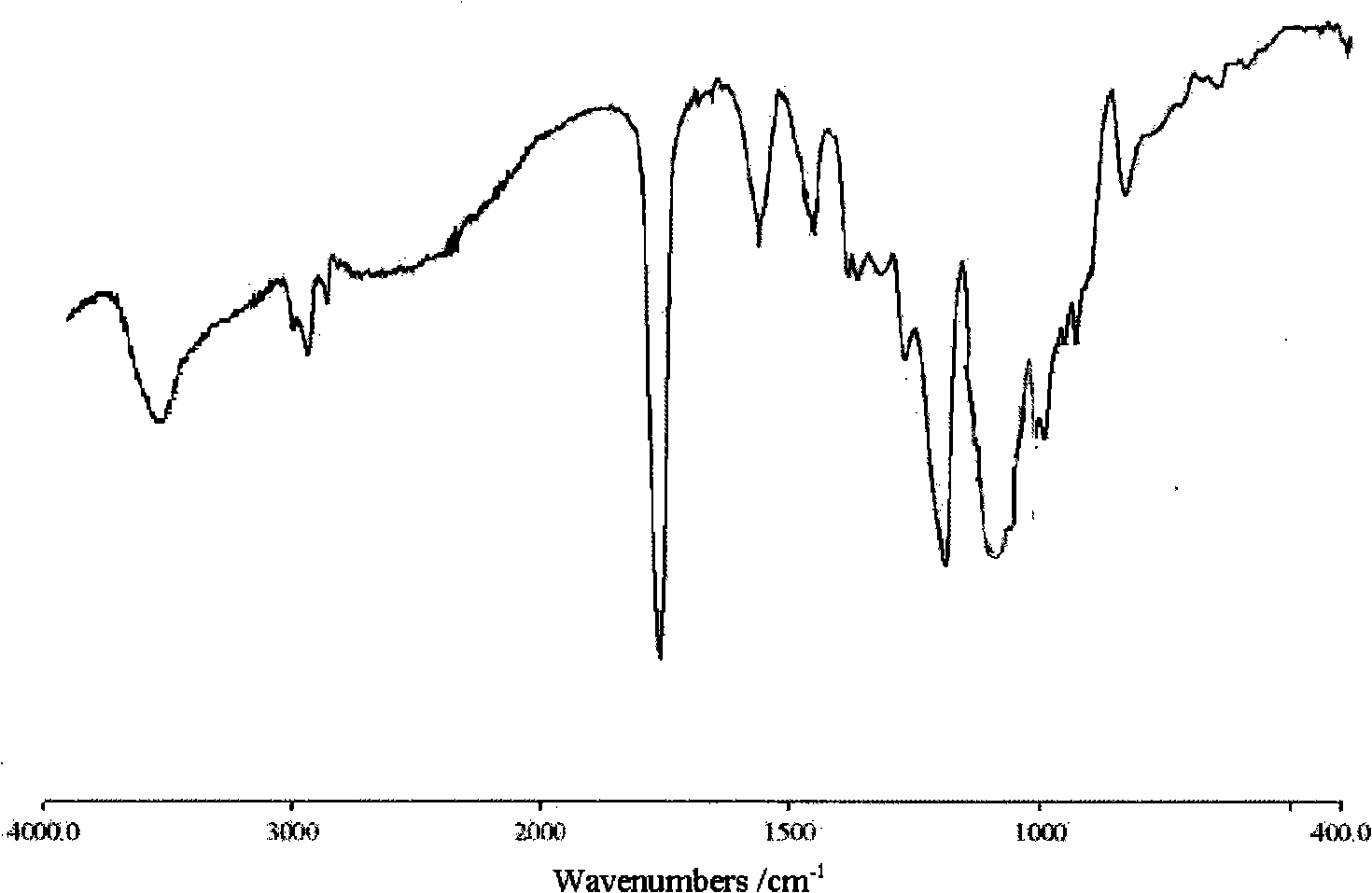

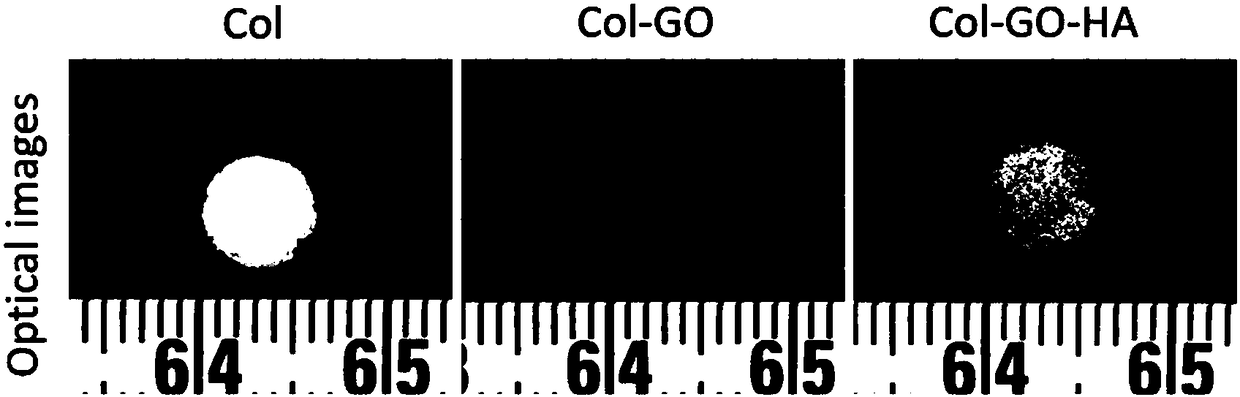

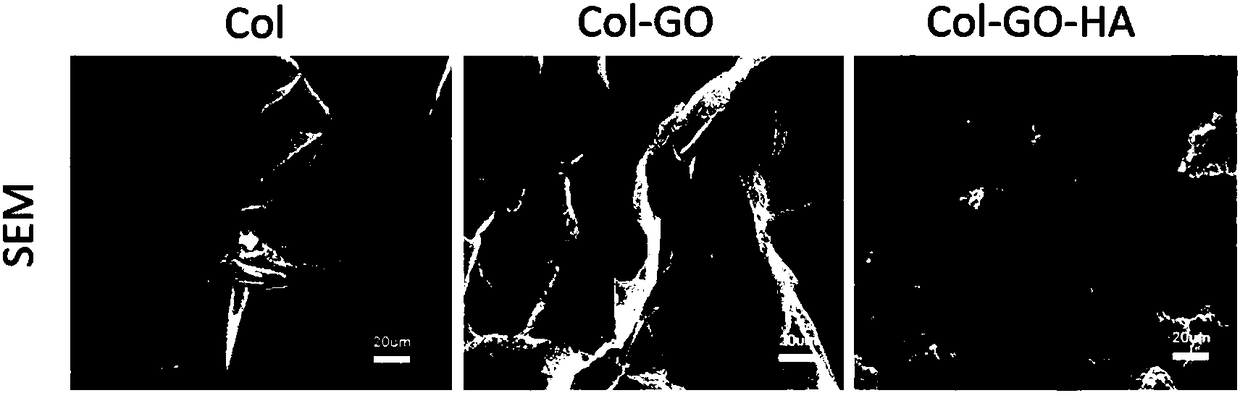

Hydroxylapatite coated collagen-graphene oxide bionic material and preparation method thereof

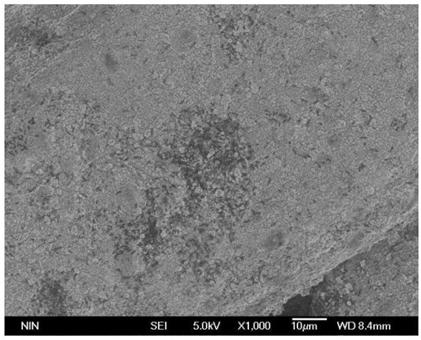

ActiveCN109453430AImprove mechanical propertiesInstitutional stabilityTissue regenerationCoatingsSimulated body fluidApatite

Disclosed is a hydroxylapatite coated collagen-graphene oxide bionic material. The hydroxylapatite coated collagen-graphene oxide bionic material is composed of, by weight percentage, 22.5-30% of typeI collagen, 3-4% of graphene oxide and 66-74% of hydroxylapatite coating. The preparation of the hydroxylapatite coated collagen-graphene oxide bionic material comprises the steps of (1) preparationof a collagen-graphene oxide material, (2) preparation of simulated body fluid, (3) surface HA (hydroxylapatite) coating of the collagen-graphene oxide material through simulated body fluid mineralization. The hydroxylapatite coated collagen-graphene oxide bionic material is controllable in thickness of HA coating, high in mechanical performance, good in biocompatibility and osteo-conductivity andcapable of achieving good bone repair effects.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

Method for depositing bionic hydroxyapatite (HA) on zinc phosphate conversion coating surface

ActiveCN104195531AImprove bindingEvenly distributed holesLiquid/solution decomposition chemical coatingDipotassium hydrogen phosphateWater baths

The invention relates to a method for depositing bionic hydroxyapatite (HA) on a zinc phosphate conversion coating surface, which comprises the following steps: preparing a simulated body fluid, in which the solute concentrations are as follows: 8.035-16.07g / L sodium chloride, 0.355-0.71g / L sodium bicarbonate, 0.225-0.45g / L potassium chloride, 0.231-0.462g / L dipotassium hydrogen phosphate dihydrate, 0.311-0.622g / L magnesium chloride hexahydrate, 39-58.5mL / L 1mol / L hydrochloric acid, 0.292-0.584g / L calcium chloride and 0.072-0.144g / L sodium sulfate; and cleaning a stainless steel sample of which the surface is provided with the zinc phosphate chemical conversion coating, putting the cleaned sample into the simulated body fluid, putting in a 36-38 DEG C thermostatic water bath oscillator, immersing for 0.5-30 days, taking out, cleaning with deionized water, and drying to obtain the HA coating. The composite coating is beneficial to enhancing the corrosion resistance of the stainless steel implant, has excellent biological activity, and implements early healing and long-term stability of the stainless steel implant.

Owner:SHANDONG UNIV

Method for strengthening joint stability by using rhBMP-2 release coating on surface of artificial joint

InactiveCN101721743ABroad compatibilityGood compatibilityCoatingsProsthesisArtificial jointsBone formation

Owner:曲彦隆

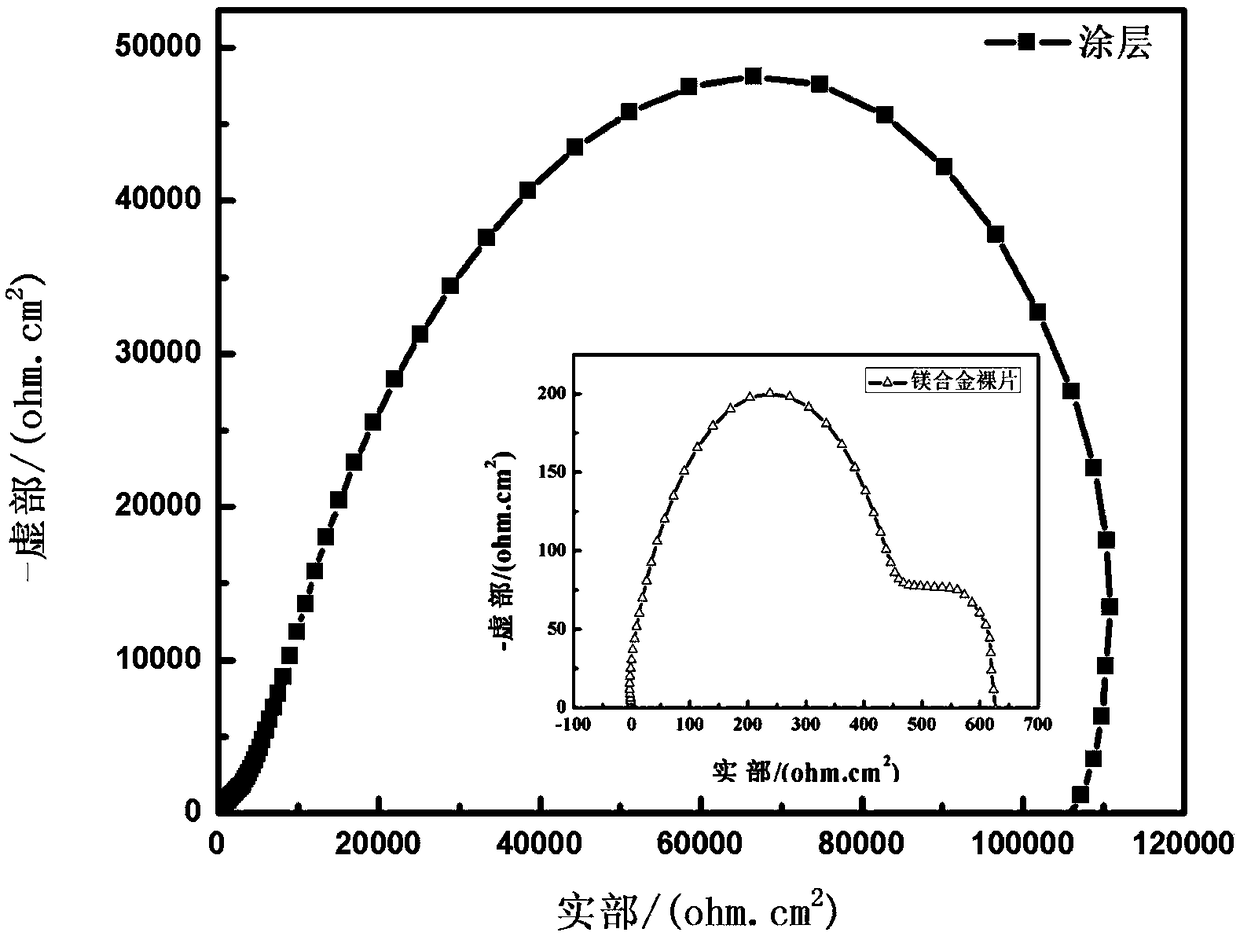

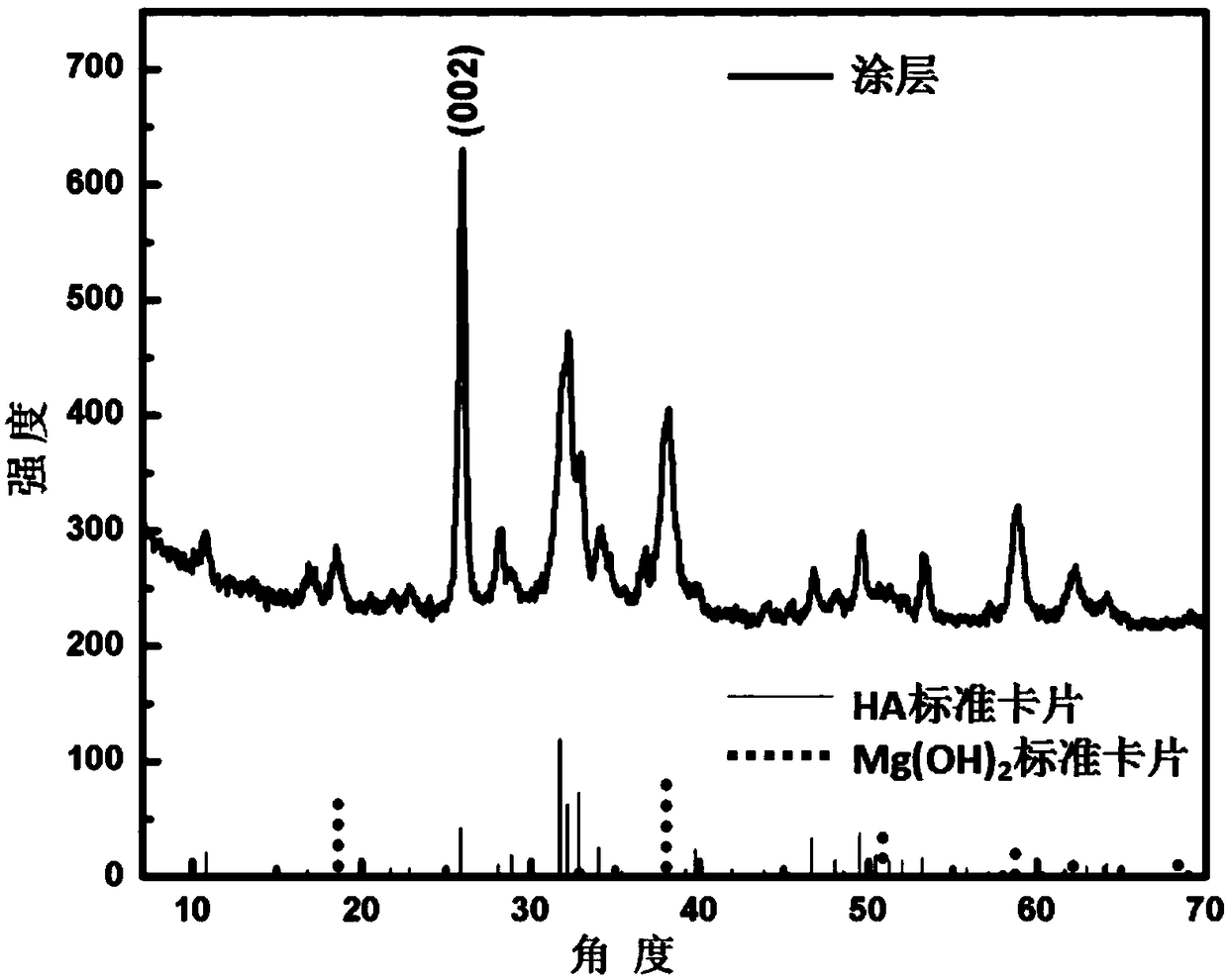

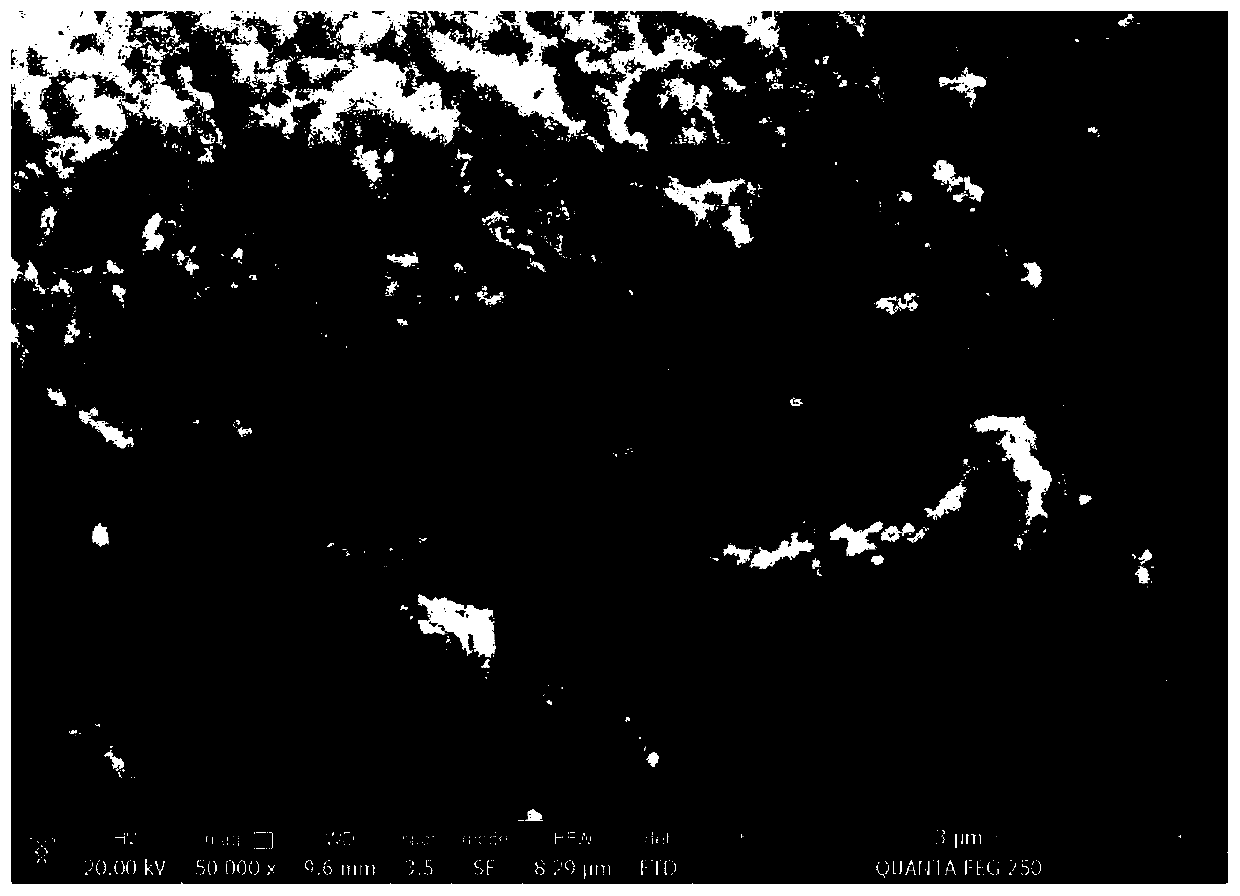

Method for preparing magnesium alloy surface micro-nano structure hydroxyapatite coating through hydrothermal manner

InactiveCN109295438AImprove adhesionPromote growthLiquid/solution decomposition chemical coatingMicro nanoAlcohol

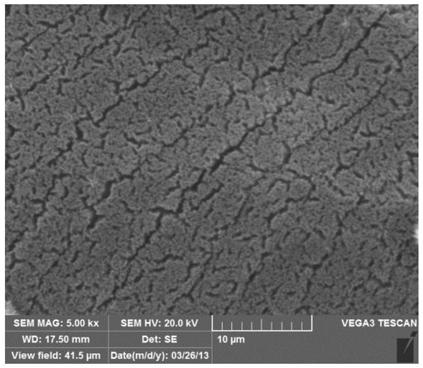

The invention relates to a method for preparing a magnesium alloy surface micro-nano structure hydroxyapatite coating through a hydrothermal manner. Firstly, a magnesium alloy is subject to surface polishing treatment; the magnesium alloy surface is ground, and is subjected to ultrasonic cleaning in sequence in acetone, deionized water and ethyl alcohol, and drying is carried out; the polished magnesium alloy is soaked in an NaOH solution with the concentration being 1-2mol / L, heat preservation is carried out in an oven with the temperature of 60 to 90 DEG C, deionized water is used for cleaning, and drying is carried out; the magnesium alloy sample pre-treated through the NaOH is placed in a high-pressure reaction kettle containing a hydrothermal reaction solution, the reaction kettle isplaced in the oven with the temperature of 100 to 140 DEG C to be subject to heat preservation, after cooling, the sample is taken out, and the sample is cleaned and dried; an HA coating of a micro-nano structure is divided into two layers, the upper layer is of a micro flower-shaped cluster structure composed of nanorods, and through gaps between clusters, it can be seen that the lower layer is of a uniform and compact nanorod structure. The coating has the long-time corrosion resistance, and has the large commercial popularizing value.

Owner:TIANJIN UNIV

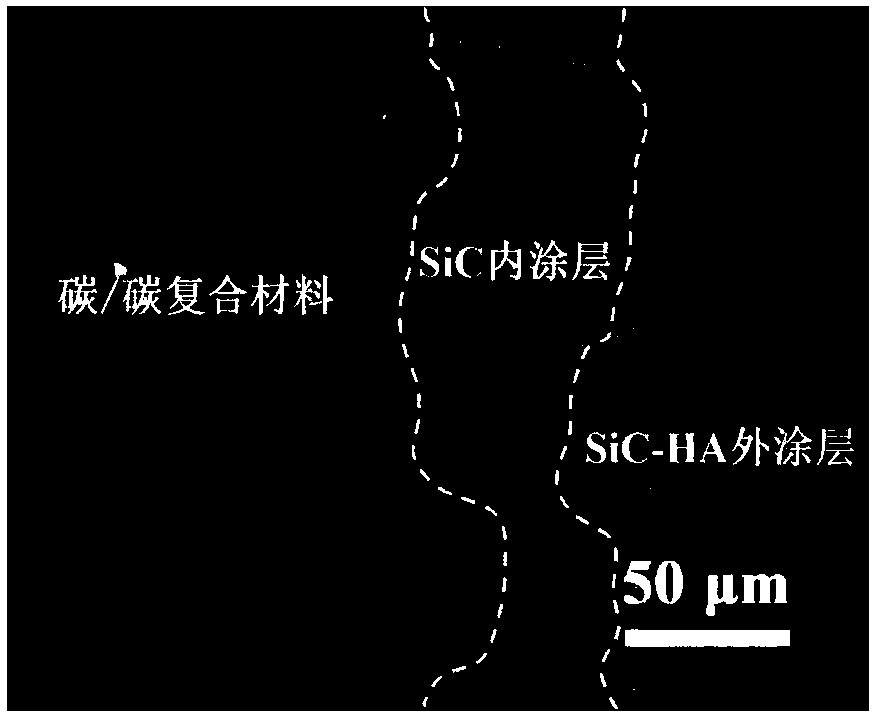

Carbon/carbon composite material modified by silicon carbide and hydroxyapatite gradient coating and preparation method thereof

Owner:NORTHWESTERN POLYTECHNICAL UNIV

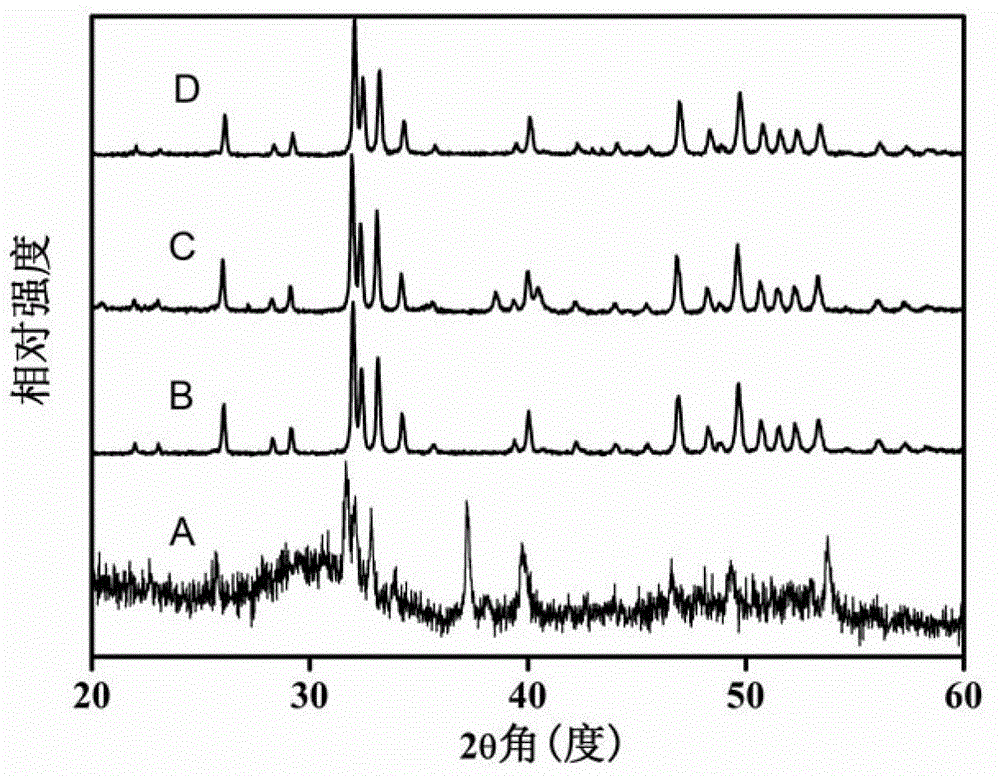

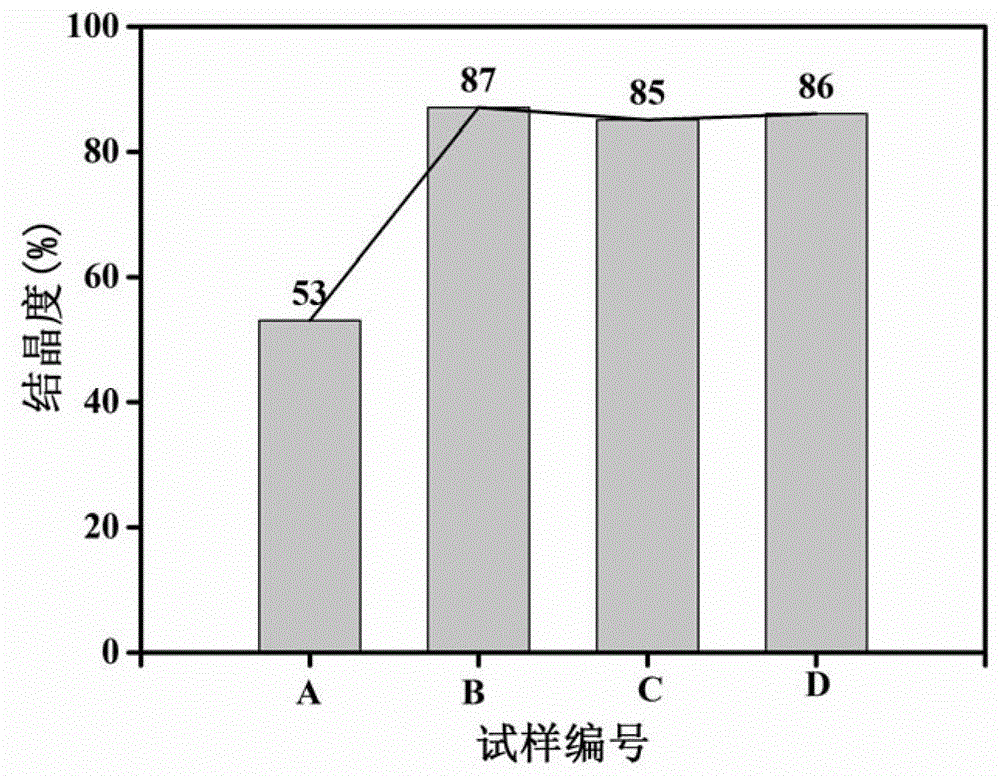

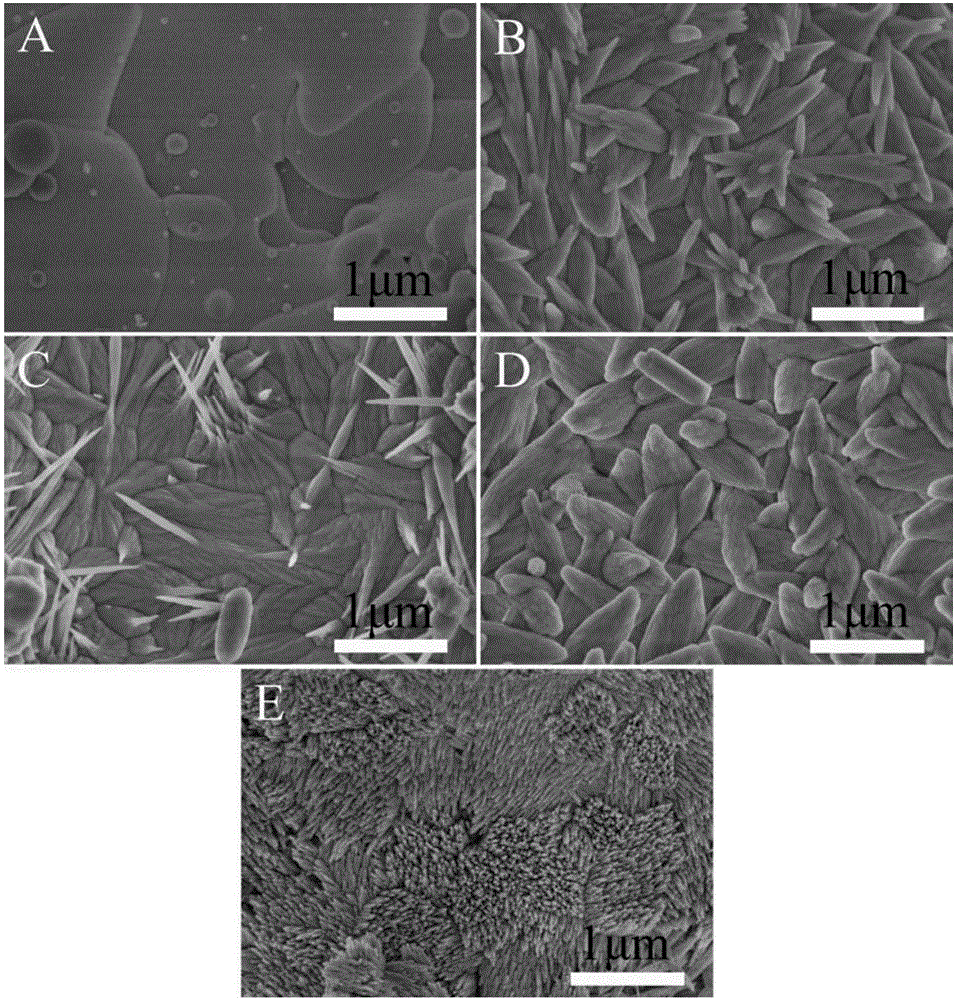

HA (Hydroxyapatite) coating with high degree of crystallinity and nano-structure and preparation method of HA coating

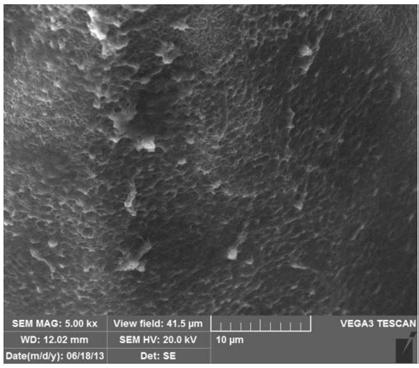

InactiveCN105641741AHigh purityHigh crystallinityMolten spray coatingProsthesisOsseointegrationNano structuring

The invention relates to an HA (Hydroxyapatite) coating with high degree of crystallinity and a nano-structure and a preparation method of the HA coating. The HA coating comprises 95% or above of hydroxyapatite, the degree of crystallinity is 85% or above, and the surface structure of the HA coating comprises the nano-structure. The HA coating has high purity and high degree of crystallinity, so that the problems that the phase decomposition and low degree of crystallinity of the traditional coating cause the coating degradation, and further, the coating falls off, an implant becomes loose, and the like, are solved; meanwhile, the coating has the nano-structure, and can promote the adhesion and proliferation of osteoblasts and the osteogenic differentiation, so that the osseointegration performance of the implant of the HA coating is improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing biomedical alloy HA (hahnium) coating by gelcasting

ActiveCN108273133AGood biocompatibilityImprove mechanical propertiesAdditive manufacturing apparatusTransportation and packagingBiocompatibility TestingAlloy composite

The invention relates to a method for preparing a biomedical alloy HA (hahnium) coating by gelcasting, and belongs to the field of preparation of biological materials by gelcasting. The method is characterized in that a methyl cellulose gel system is centrifugally cast to prepare hydroxyapatite, a transition layer and a biomedical alloy composite coating material, and the exterior of the biomedical metal material is bonded with a hydroxyapatite coating at high efficiency. The biomedical alloy HA coating prepared by the method has the advantages that the biocompatibility is good, the mechanicalproperty is excellent, the corrosion-resistant property is good, and the specific strength is high; a non-poisonous gel system is adopted, the forming property is good, and the bonding strength is high; the technology is simple, the function of near-net forming is realized, the product with complicated shape can be prepared at one time, the utilization rate of material is improved, and the processing cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

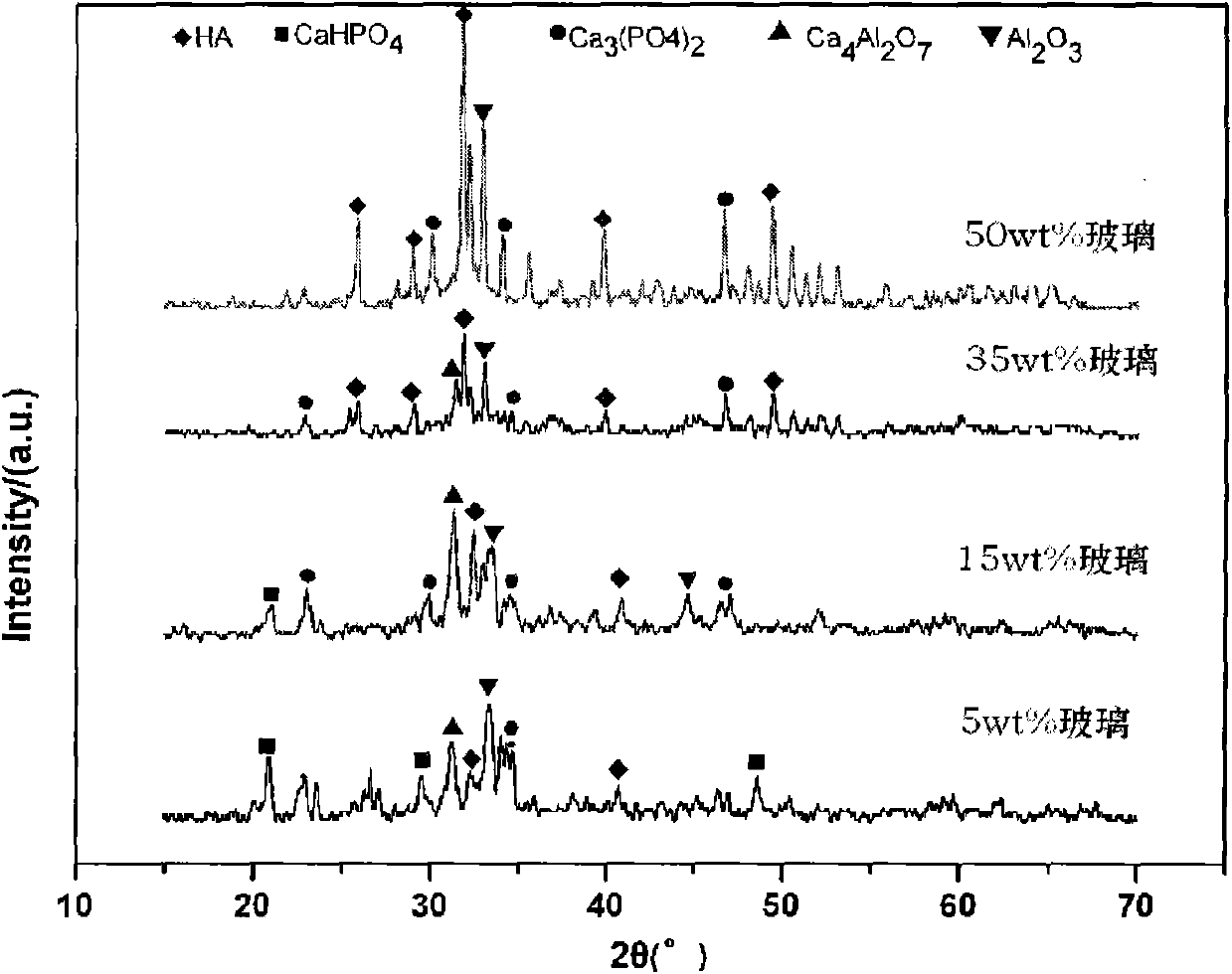

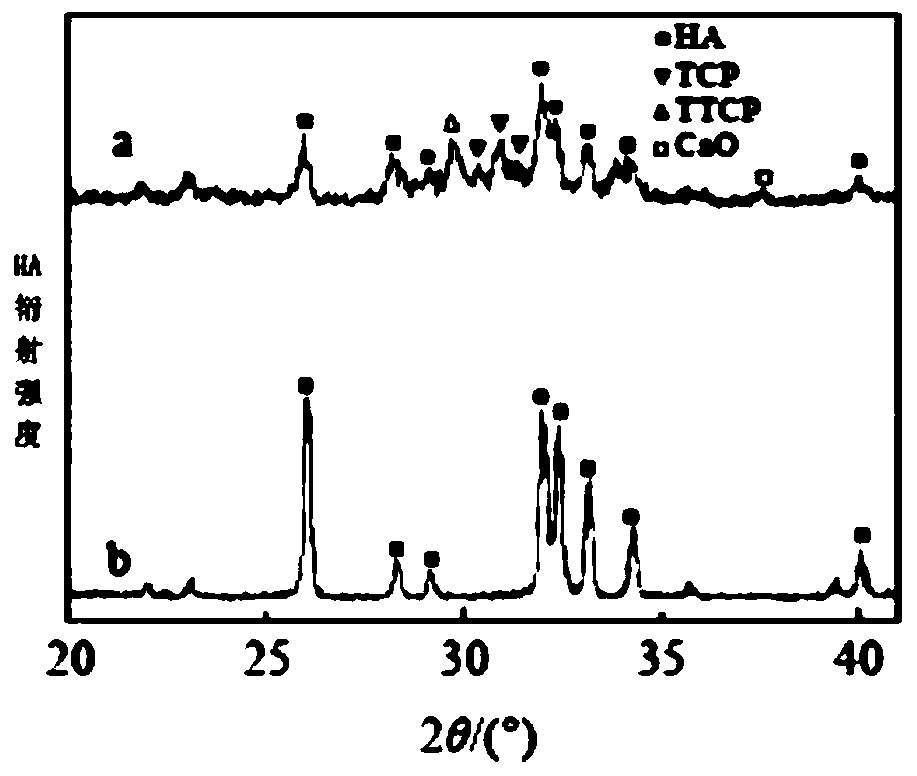

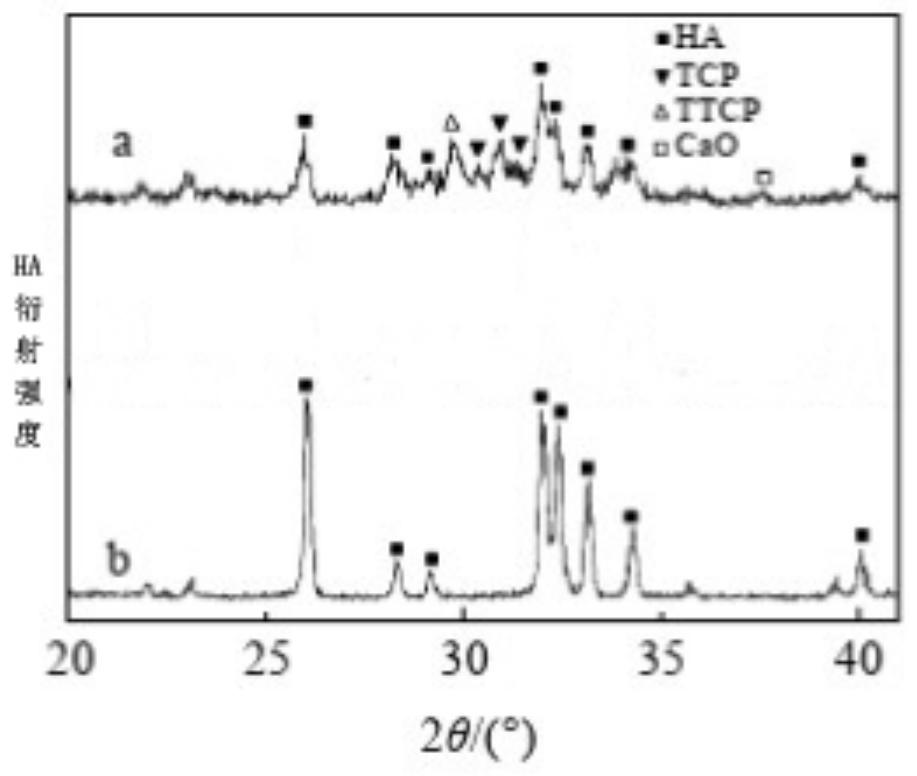

Preparation method of three-phase CaP-glass coating/porous A1203 rack biological composite material

The invention provides a preparation method of a three-phase CaP-glass coating / porous A1203 rack biological composite material, which belongs to the technical field of biological medicinal material preparation and comprises the following steps of: coating a composite coating consisting of biological glass using HA (Hydroxylapatite) and phosphate as base bodies on a porous Al2O3 rack to obtain the combination of good biological performance and mechanical performance; mixing HA powder and biological glass powder with different compositions at different proportions to obtain slurry to be coated on the porous Al2O3 rack; carrying out heat treatment for two hours in air at 800 DEG C; and forming the three-phase CaP-glass coating through generating hydroxylapatite (HA), tertiary calcium phosphate (TCP) and calcium hydrophosphate (DCP) principal crystalline phases in the coating phase. The three-phase CaP-glass coating is tightly, uniformly and closely attached on the Al2O3 rack, the highest combining intensity of the three-phase CaP-glass coating can reach 50MPa and is more than two times of that of the pure HA coating, the growth of the osteoblast on the porous Al2O3 rack coated with the three-phase CaP-glass coating is good, and cells can actively pass the coating to be spread into the porous rack.

Owner:SHAANXI UNIV OF SCI & TECH

Functionalized gradient composite coating on surface of porous titanium alloy and preparation method thereof

The present invention provides a functionalized gradient composite coating on surface of porous titanium alloy. The gradient composite coating successively comprises a porous titanium matrix, a nanoscale activation layer, a precalcification layer, a HA layer and a collagen layer. A preparation method of the composite coating comprises the following steps: (1) an acid treatment is conducted: poroustitanium alloy is soaked in corrosive liquid until the surface presents bright silver-white metallic luster, and the soaking stops; (2) an alkali heat treatment is conducted: the porous titanium alloy is respectively washed with acetone, alcohol and deionized water successively in an ultrasonic cleaning machine, and the porous titanium alloy is put into an alkali solution for treatment; (3) precalcification treatment is conducted: the porous titanium alloy is soaked in a solution of Na2HPO4 and saturated Ca(OH)2; (4) HA coating preparation is conducted: the porous titanium alloy is placed ina test tube containing simulated body fluid and the test tube is put into constant temperature water bath for soaking; and (5) the porous titanium alloy is subjected to high-pressure disinfection andsterilization, drying is conducted, and then the porous titanium alloy is soaked in a water-soluble human collagen solution to obtain the finished product.

Owner:JIANGSU UNIV OF TECH

Preparation method of electro-deposited hydroxyapatite in choline chloride based ionic liquid

ActiveCN108060444AHigh densityImprove biological activityElectrolytic inorganic material coatingTissue regenerationConcentration polarizationApatite

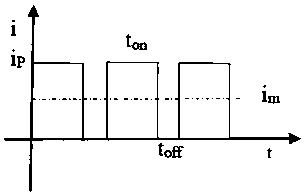

The invention provides a preparation method of ultrasonic-pulse electro-deposited hydroxyapatite (HA) in choline chloride based ionic liquid. According to the technical scheme, the preparation methodcomprises the following steps: taking the choline chloride based ionic liquid as a solvent; adding a compound which contains Ca and P in the solvent according to the quantity relative ratio that the concentration of Ca2+ is 2-50 mmol-L-1, and the concentration of H2PO42- is 1-30 mmol-L-1; and adding 1-10% of an additive H2O2 to prepare an electro-deposited solution of HA. Under an ultrasonic condition, an HA coating is prepared by a one-way positive pulse electrodeposition method. By the preparation method, hydrogen evolution can be relieved effectively, concentration polarization is weakened,and the structural compactness of HA is improved. The preparation method has the advantages of simplicity in operation, easiness in preparation, safety, reliability and the like.

Owner:TIANJIN AGRICULTURE COLLEGE

Method for depositing hydroxyapatite on metal surface and metal implant

InactiveCN110724991AImprove conductivityHigh purityElectrolytic inorganic material coatingPharmaceutical delivery mechanismElectrolytic agentP phosphate

The invention relates to a method for depositing hydroxyapatite on a metal surface and a metal implant. The method for depositing hydroxyapatite on the metal surface comprises the steps that a material substrate is provided; a rough structure is formed on the surface of the metal substrate; an electrolyte is provided; the metal substrate with the surface provided with the rough structure is placedin the electrolyte, and a hydroxyapatite layer is formed on the rough structure through electrochemical deposition; and the electrolyte is prepared with the raw materials of calcium salt, phosphate and hydrogen peroxide. A high-purity and high-crystalline HA coating is formed on the surface of the metal implant which is obtained with the method; and the HA coating has high binding force to the surface of the metal implant, so that the using safety and reliability of the metal implant are improved.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

Method for depositing hydroxyapatite coating on surface of carbon/carbon composite material

InactiveCN109082692AImprove efficiencySimple processElectrolytic inorganic material coatingTissue regenerationCarbon compositesPhosphoric acid

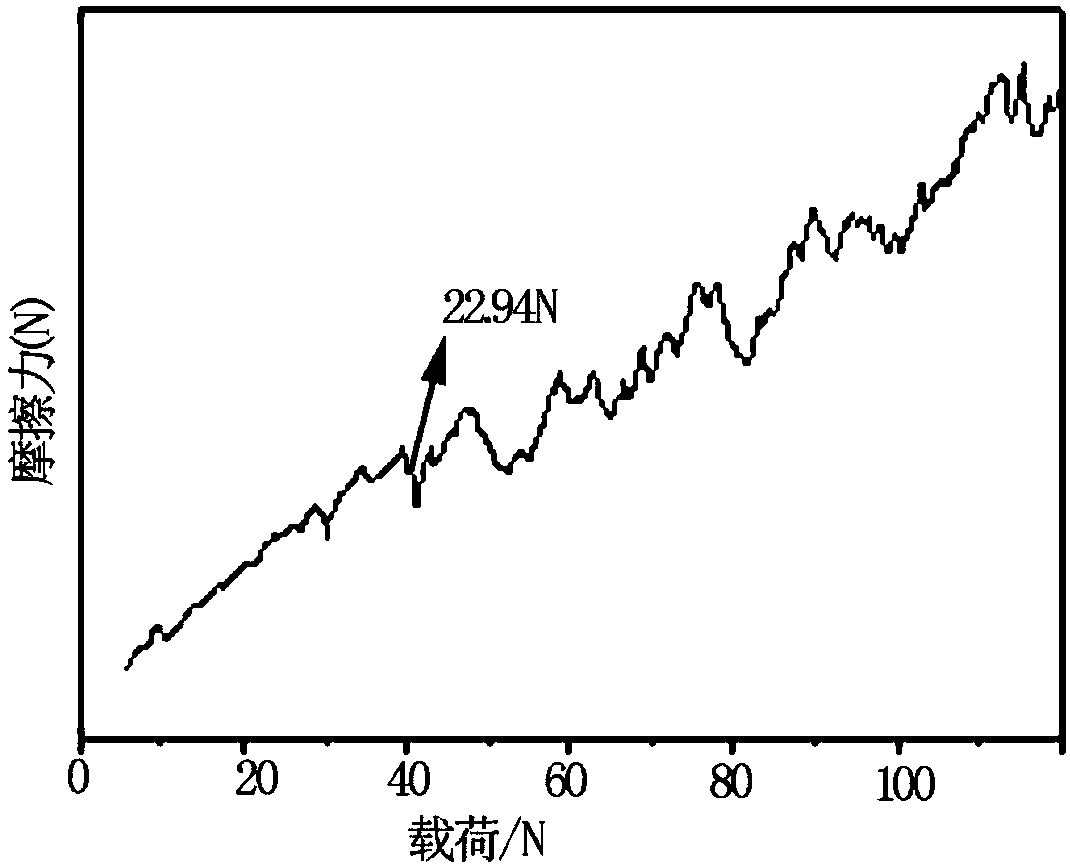

The invention relates to the technical field of carbon / carbon composite materials, and particularly provides a method for depositing a hydroxyapatite coating on the surface of a carbon / carbon composite material. The method at least includes the following steps that S01, the carbon / carbon composite material is used as a cathode, and a mixed solution containing calcium hydroxide, organic acid and phosphoric acid is used as a electrolyte to conduct hydrothermal electrodeposition reaction, so that the surface of the carbon / carbon composite material is deposited with an anhydrous calcium hydrophosphate coating; and S02, the carbon / carbon composite material obtained in the step S01 is placed in an alkali solution to be subjected to hydrothermal treatment, and thus the anhydrous calcium hydrophosphate coating is subjected to in-situ topology to be transformed into the hydroxyapatite coating. According to the method for depositing the hydroxyapatite coating on the surface of the carbon / carboncomposite material, the bonding strength of the prepared HA coating and the C / C composite material reaches no less than 20N, and the shearing strength can reach no less than 75.8 MPa; and the method for depositing the hydroxyapatite coating on the surface of the carbon / carbon composite material has simple process, high efficiency and excellent product performance, can meet the needs of clinical application, and is worthy of being popularized and used.

Owner:SHENZHEN UNIV

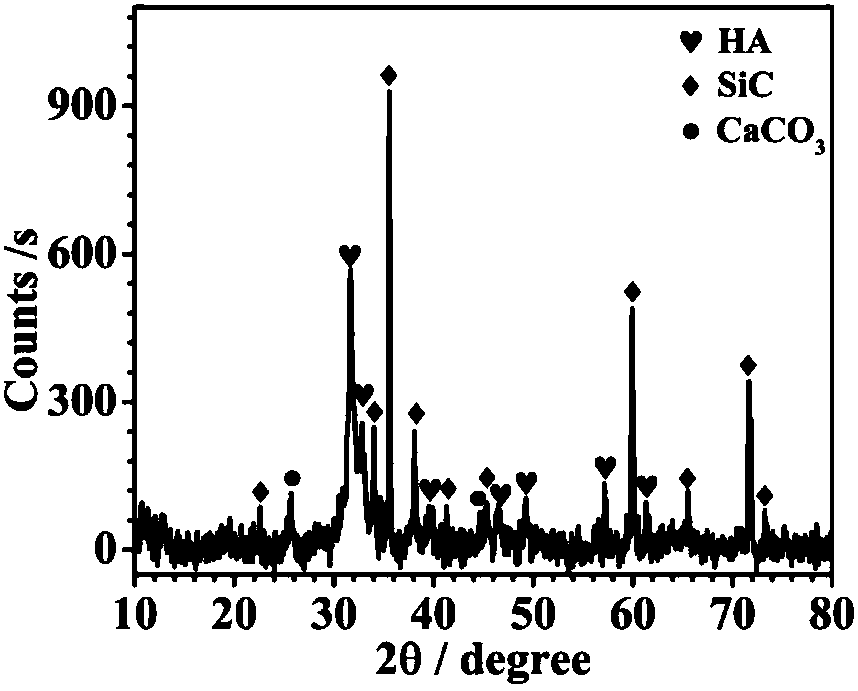

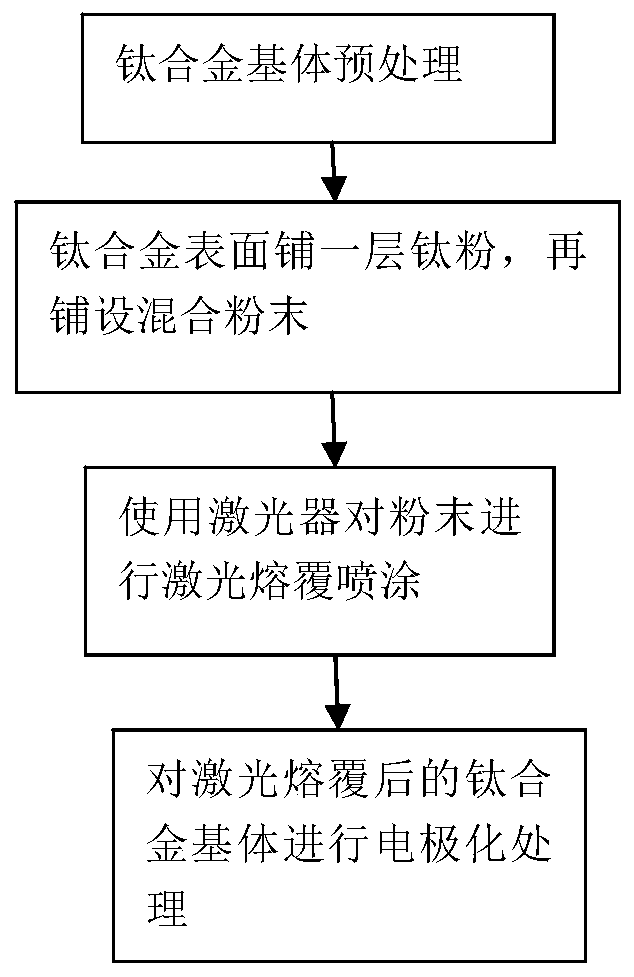

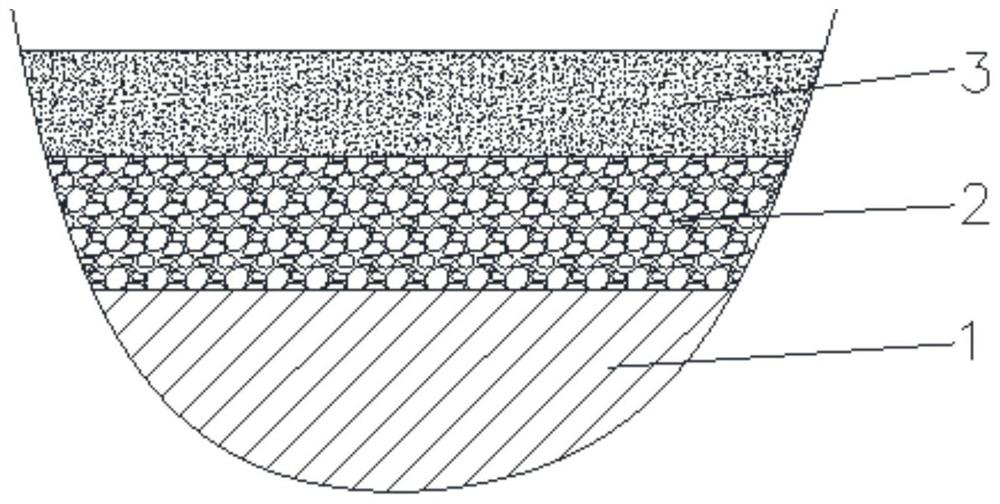

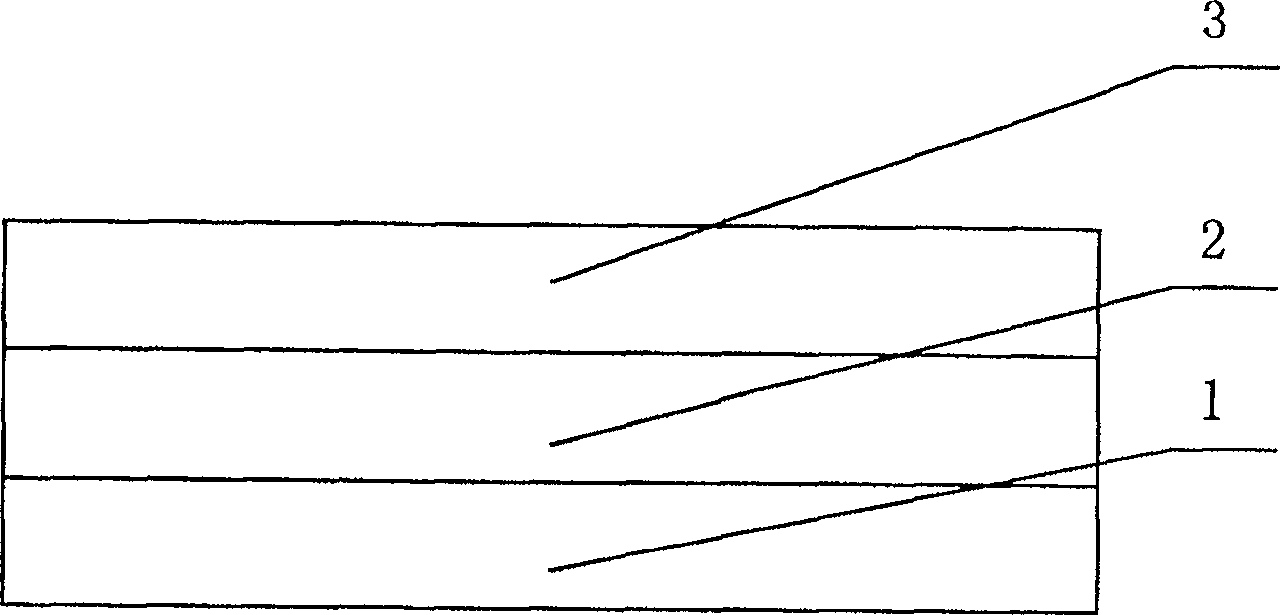

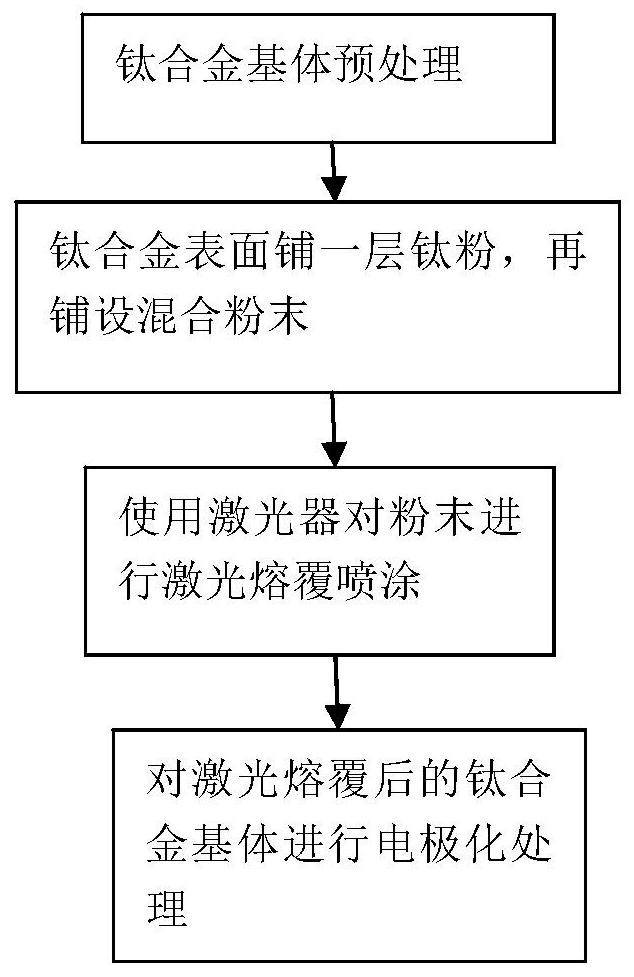

Preparation method of HA coating on surface of titanium alloy matrix

ActiveCN110975006AImprove biological activityIncrease HA contentMetallic material coating processesTissue regenerationMetallurgyHa coating

The invention discloses a preparation method of an HA coating on a surface of a titanium alloy matrix, which belongs to the field of biomedical materials, and comprises the following steps: pretreating the surface of the titanium alloy matrix; spraying spraying powder on the surface of the treated titanium alloy matrix through laser cladding, wherein the spraying powder comprises mixed powder andtitanium powder, and the mixed powder comprises hydroxyapatite powder and calcium carbonate powder; and placing the sprayed titanium alloy matrix into alkali liquor to be subjected to electric polarization treatment. According to the method, the content of HA can be effectively increased, so that the biological activity of the coating is improved.

Owner:锐百顺涂层科技(苏州)有限公司

Implant with high-content and high-stability BMP coating

InactiveCN106725935AIncrease loading capacityImprove bindingDental implantsTissue regenerationAcid etchingBone formation

The invention discloses an implant with a high-content and high-stability BMP active surface coating. A titanium dioxide base layer is arranged on the surface of a titanium-based bottom layer of the implant, and the outer surface of the base layer is alternatively coated by an I type collagen / BMP complex coating with positive charges and an HA coating with negative charges. According the implant with the high-content and high-stability BMP active surface coating disclosed by the invention, a porous coarse surface coated by titanium hydroxyl base is prepared through a surface processing method that a sand blasting technology, an acid etching technology and an alkali heat processing technology are combined; the I type collagen / BMP-2 complex coating with the positive charges and the HA coating with the negative charges are alternatively introduced to the surface repeatedly; thus, load capacity and stability of BMP in the coating are remarkably improved, the BMP can be slowly and continuously released along with degradation of the coating after the implant is implanted into a body, bone formation is promoted, and early bone healing between the implant and peripheral bone tissues is improved.

Owner:DALIAN SANSHENG SCI & TECH DEV

Active HA coating prepared by compounding laser cladding and cold spraying and preparation method of active HA coating

InactiveCN114032543AGood metallurgical bondImprove bindingMolten spray coatingShielding gasPhysical chemistry

The invention belongs to the technical field of medical materials, and particularly relates to a preparation method of an active HA coating prepared by compounding laser cladding and cold spraying, and the preparation method comprises the following steps: 1, removing corrosion on the surface of a titanium alloy base material; 2, drying a first mixed powder and a second mixed powder; 3, clamping the titanium alloy base material; 4, setting inert gas protection, achieving the sealing of the inert gas protection box, injecting argon into the inert gas protection box, and detecting the oxygen content in the inert gas protection box, wherein the oxygen content in the inert gas protection box is kept to be not higher than 100 ppm; 5, preparing a fusion layer through a laser cladding technology, wherein argon serves as powder feeding carrier gas and molten pool shielding gas, remanufacturing forming is conducted in a four-way coaxial powder feeding mode, and the height of the fusion layer is not larger than 1 mm; and 6, preparing a covering layer through a cold spraying technology, and through an electric arc cold spraying technology, allowing a spray gun to conduct movable spraying on the fusion layer.

Owner:JIANGSU UNIV OF TECH

HA/Ti coating

InactiveCN109837576AEasy to operateImprove controllabilityElectrolytic inorganic material coatingSurface oxidationCalcium phosphorus

The invention relates to a HA / Ti coating in the field of medical materials. The HA / Ti coating is prepared through the following steps that A) a titanium plate is treated, wherein a pure titanium plateis ground through a 1200#SiC abrasive paper so as to remove a surface oxidation layer, and then undergoes industrial treatment through an acidic etchant for later use; B) the pure titanium plate treated in the step A) is taken as a cathode, a nickel sheet is used as an anode plate, the coating is prepared through an electrochemical deposition method, an electrolyte is a CaCl2 and Na2HPO4 mixed solution of 10<-4> mol / L, wherein the molar concentration ratio of calcium to phosphorus is 2 to 1, moreover, the pH value is adjusted to be 5.5-7.0, electrochemical deposition is performed under a boiling condition, then the cathode is taken out, and the calcium-phosphorus salt coating is prepared. In the method, an electrochemical hydrogen evolution reaction is an important induction step, necessary OH<-> is provided for the second-step chemical precipitation process, meanwhile, the hydrogen evolution process can also affect the degree of oversaturation of the electrolyte near the surface of the electrode, so that the surface morphology and grain size of the HA coating of the surface of the electrode are further affected, the calcium-phosphorus salt coating prepared on the surface of the titanium plate by adopting the method has good preferred orientation, and can have the relatively good capacity of promoting the growth of hard tissues after being implanted into a living body, moreover, the size of the grain cross section of the calcium-phosphorus salt coating is small, the stability is good, and the morphology of the coating is uniform.

Owner:翁健平

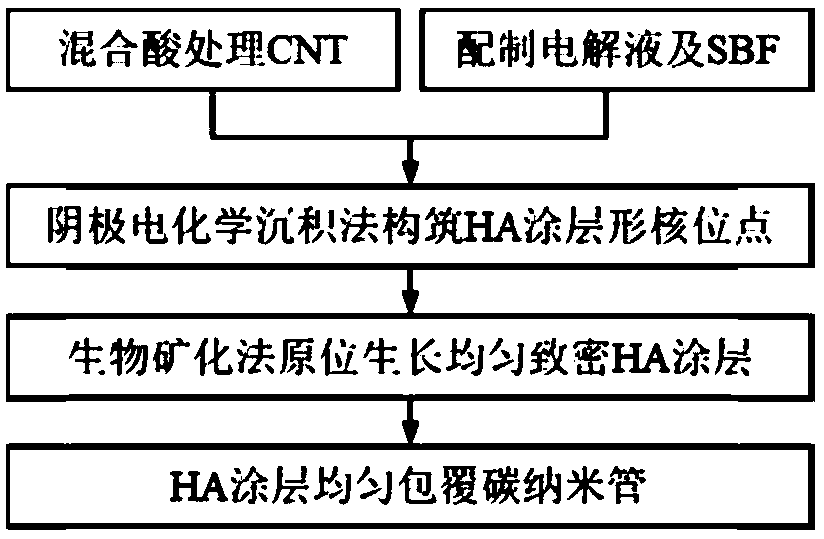

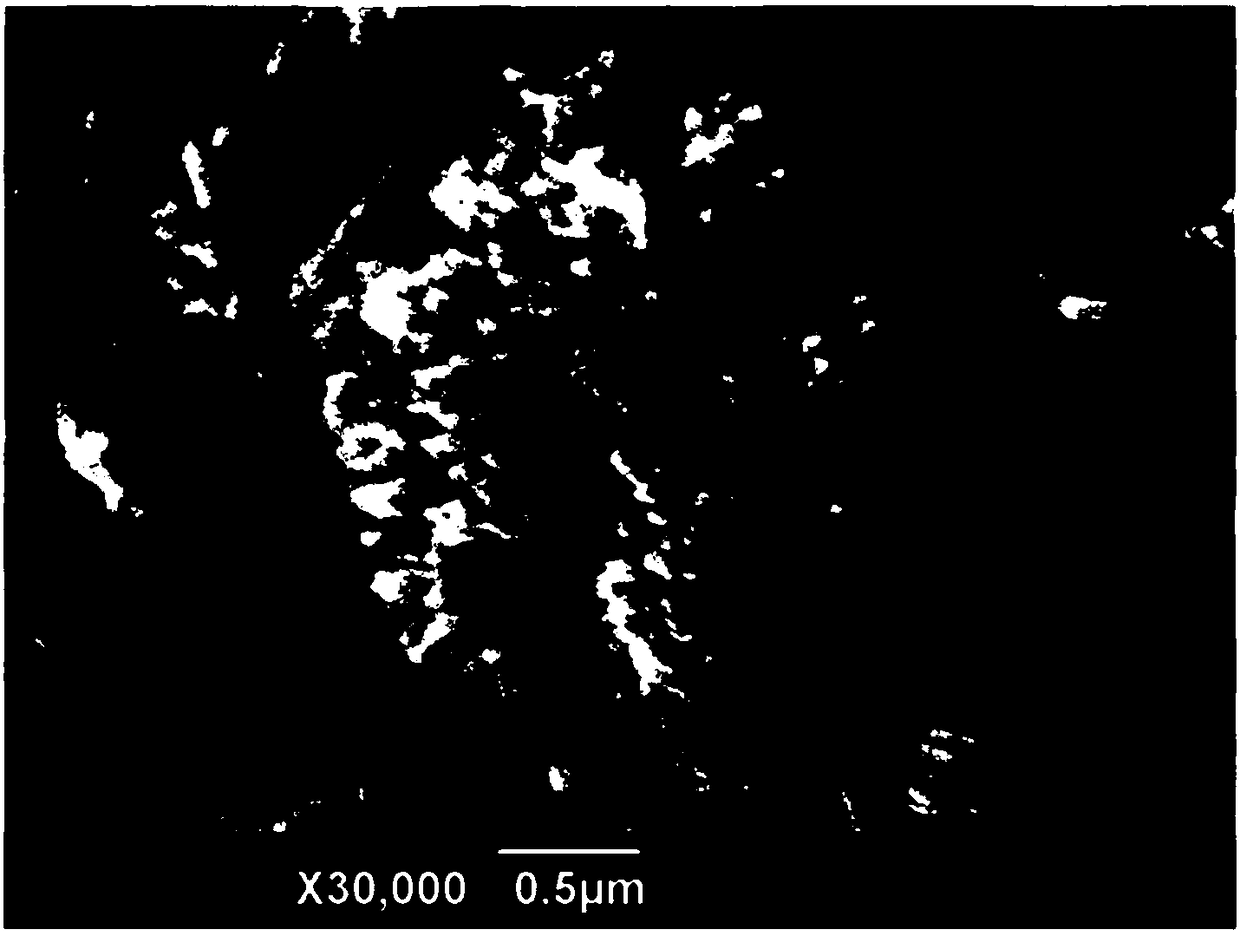

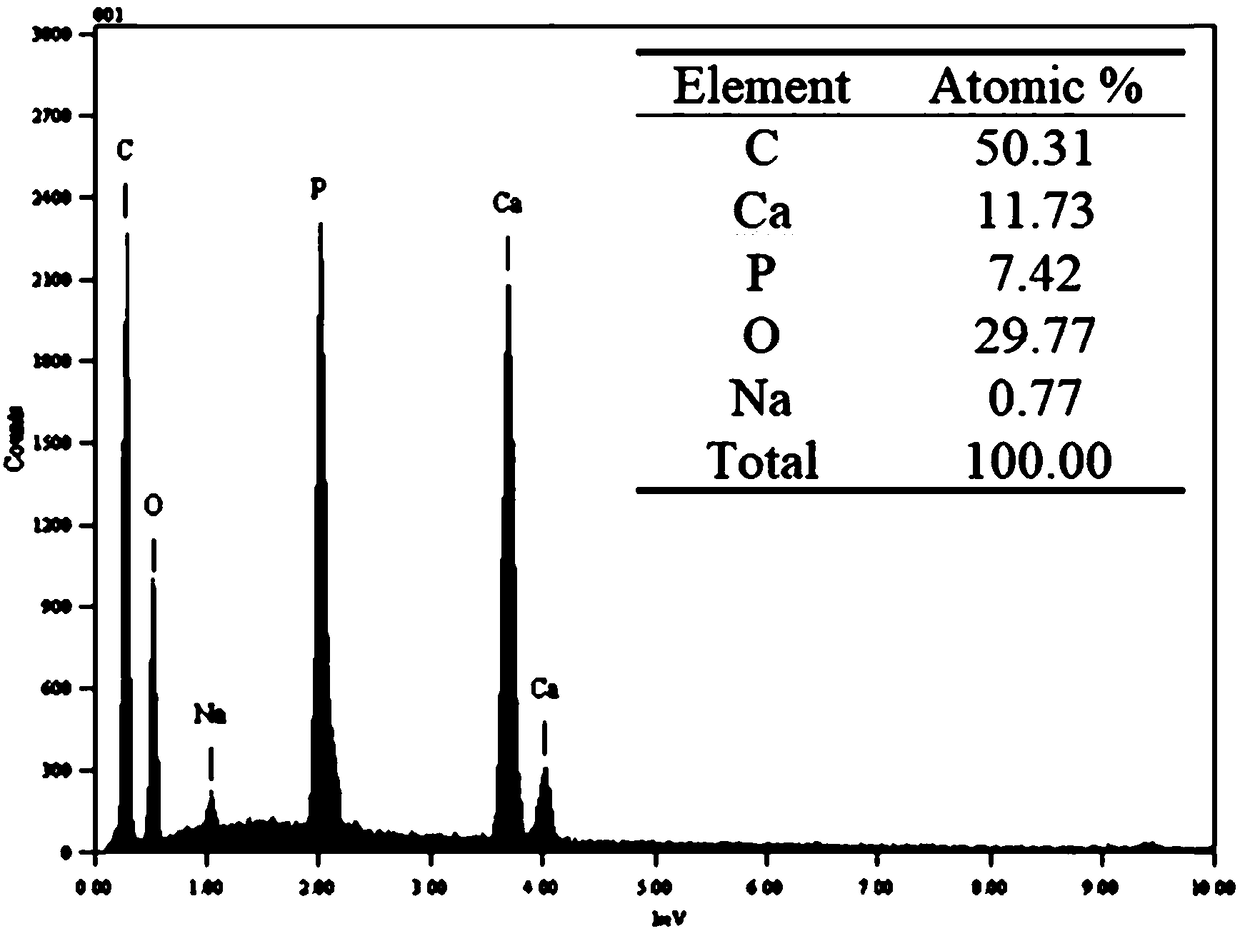

Method for preparing hydroxyapatite coating on surface of carbon nanotube based on electrochemical deposition method and biomineralization method in combined mode

ActiveCN108796572AHigh aspect ratioStrong van der Waals forceElectrolytic inorganic material coatingLiquid/solution decomposition chemical coatingSimulated body fluidHydroxyapatite crystal

The invention discloses a method for preparing a hydroxyapatite coating on the surface of a carbon nanotube based on an electrochemical deposition method and a biomineralization method in a combined mode. The preparation method comprises the following steps that the carbon nanotube is cleaned, acidification treatment is conducted, and the carbon nanotube subjected to acidification treatment is washed and dried; nucleation sites of hydroxyapatite crystal grains are constructed on the surface of the carbon nanotube subjected to acidification treatment through a cathodic electrochemical deposition method; the carbon nanotube with the nanotube sites of the hydroxyapatite crystal grains is washed and dried; a hydroxyapatite coating is grown in situ on the surface of the dried carbon nanotube with the crystal grain nucleation sites through the biomineralization method; and the carbon nanotube with the crystal grain nucleation sites is soaked in a simulated body fluid solution when the dryingprocess is going to be completed. Through the preparation method, the HA coating can be prepared on the surface of the nano-scale CNT, the interface bonding property between the CNT and the HA matrixmaterial can be improved, and thus effect of enhancing the toughness of the CNT on the HA matrix material is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

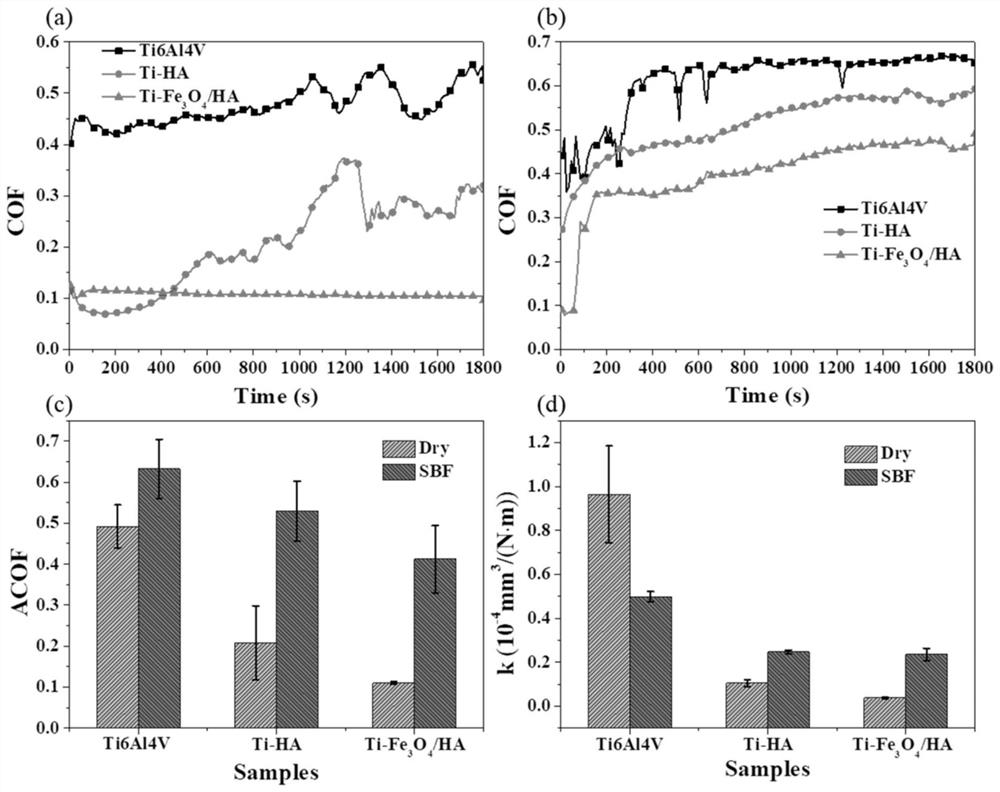

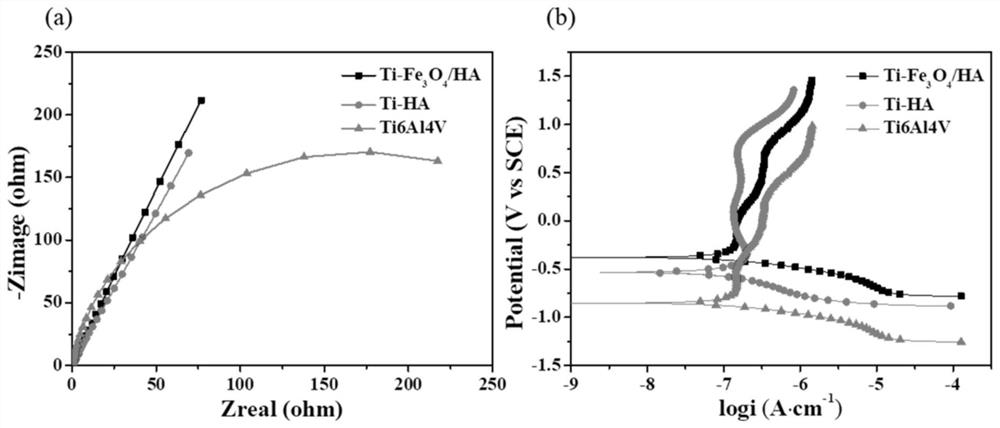

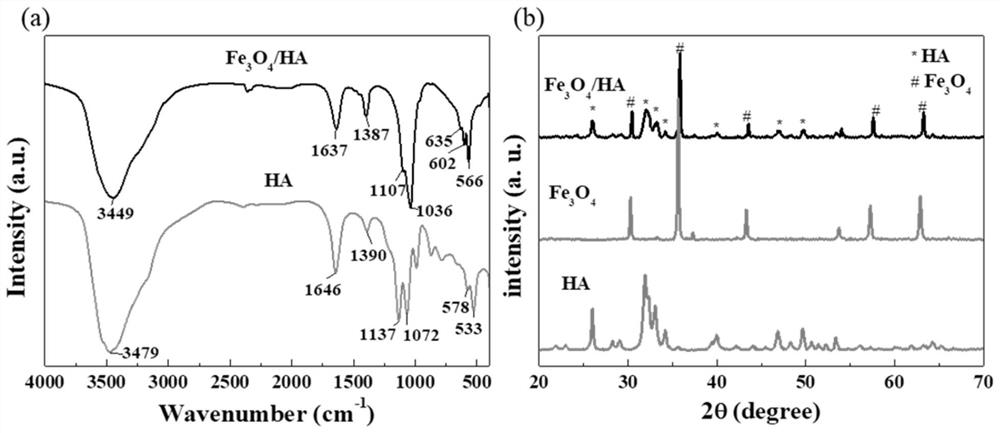

Method for improving biological friction and corrosion resistance of titanium alloy surface

ActiveCN114246978AEasy to buildImprove wear resistanceMetallic material coating processesTissue regenerationMetallurgyHa coating

The invention relates to a method for improving biological friction and corrosion resistance of a titanium alloy surface. The method comprises the following steps: (1) carrying out hydroxylation treatment on the titanium alloy surface; (2) grafting a silane coupling agent and dopamine on the surface of the titanium alloy subjected to hydroxylation treatment; and (3) finally, the Fe3O4 / HA coating is grafted to the titanium alloy, and the method is completed. Compared with the prior art, the method has the advantages that Fe3O4 / HA is grafted on the surface of the titanium alloy through a self-assembly means, so that the biological tribological performance of the titanium alloy is improved, the corrosion resistance of the surface of the titanium alloy is improved, the whole process is simple, and the effect is outstanding.

Owner:SHANGHAI INST OF TECH

Method of fast growing HA biologically active layer from oxidation film on titanium alloy surface by ultraviolet excitation

InactiveCN100467669CImprove hydrophilicityImprove wettabilitySolid state diffusion coatingLiquid/solution decomposition chemical coatingUltravioletTitanium alloy

the invention discloses an oxide-film rapid growing method of HA biological active layer on the ultraviolet laser Ti-alloy surface, which comprises the following steps: (1) oxidizing through heat; (2) irradiating through ultraviolet; (3) allocating soaking liquid of analog; (4) immersing to grow HA coating layer through analogy soaking liquid.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

A kind of preparation method of ha coating on the surface of titanium alloy substrate

ActiveCN110975006BImprove biological activityIncrease HA contentMetallic material coating processesTissue regenerationHa coatingTitanium alloy

The invention discloses a method for preparing an HA coating on the surface of a titanium alloy substrate, which belongs to the field of biomedical materials and comprises the following steps: pretreating the surface of the titanium alloy substrate; spraying spray powder on the treated titanium alloy by laser cladding On the surface of the substrate, the spraying powder includes mixed powder and titanium powder, and the mixed powder includes hydroxyapatite powder and calcium carbonate powder; the sprayed titanium alloy substrate is put into alkaline solution for electric polarization treatment. The invention can effectively increase the content of HA, thereby improving the biological activity of the coating.

Owner:锐百顺涂层科技(苏州)有限公司

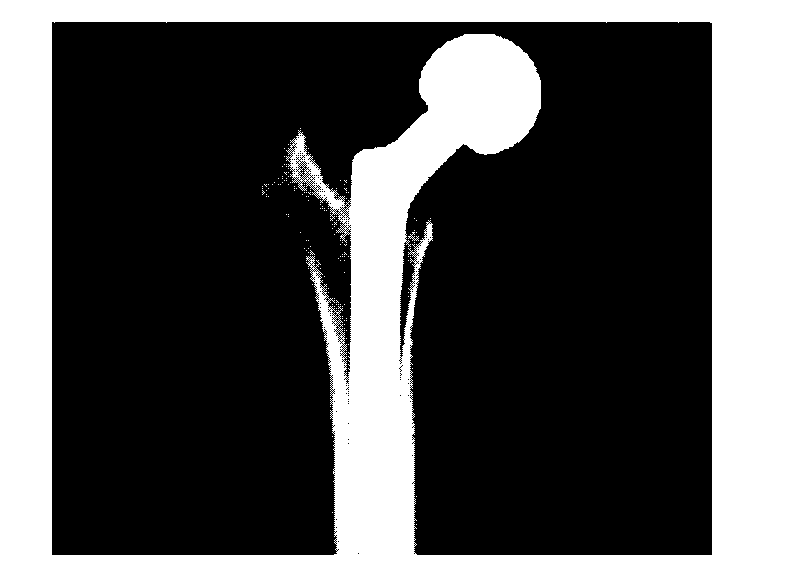

Wrist joint prosthesis with surface hydroxyapatite HA modified microporous titanium

PendingCN114224572APromote osteogenic differentiationEasy to loosenAdditive manufacturing apparatusWrist jointsOsseointegrationEngineering

The invention discloses a wrist joint prosthesis with surface hydroxyapatite HA modified microporous titanium. The wrist joint prosthesis comprises a hemispherical cup, a radial handle, a movable hemisphere, a carpal bone platform and a metacarpal bone fixing handle. Titanium alloy (Ti6Al4V) is used as a material and is integrally manufactured in a laser 3D printing mode, the surface is covered with an HA coating through a plasma spraying technology, the HA coating can ensure that calcium and phosphorus ions are slowly released around the prosthesis, so that cell osteogenic differentiation is promoted, better bone ingrowth is achieved, the problem that middle and long-term prostheses are prone to loosening is solved, and the prosthesis has a good application prospect. Meanwhile, the HA coating can enable the surface of the prosthesis to become rough and can also be coated with an anti-infection coating, so that the prosthesis has antibacterial ability, and the problem that infection is likely to occur in the early stage of replacement is solved; the surface of the prosthesis is designed to be conical circular rings stacked layer by layer, friction force is increased, anti-pullout performance is improved, the surfaces of the radius assembly, the carpal assembly and screws on the two sides are all provided with HA coatings, and therefore better osseointegration is achieved.

Owner:中国人民解放军联勤保障部队第九二〇医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com