Preparation method of biological gradient coating on surface of dental implant

A dental implant and gradient coating technology, applied in the field of biomedicine, can solve the problems that the coating cannot meet the bonding strength, biological activity and solubility at the same time, and the coating can not meet the clinical needs, so as to enhance chemical stability and bonding force, thermal stress relaxation, and bond strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

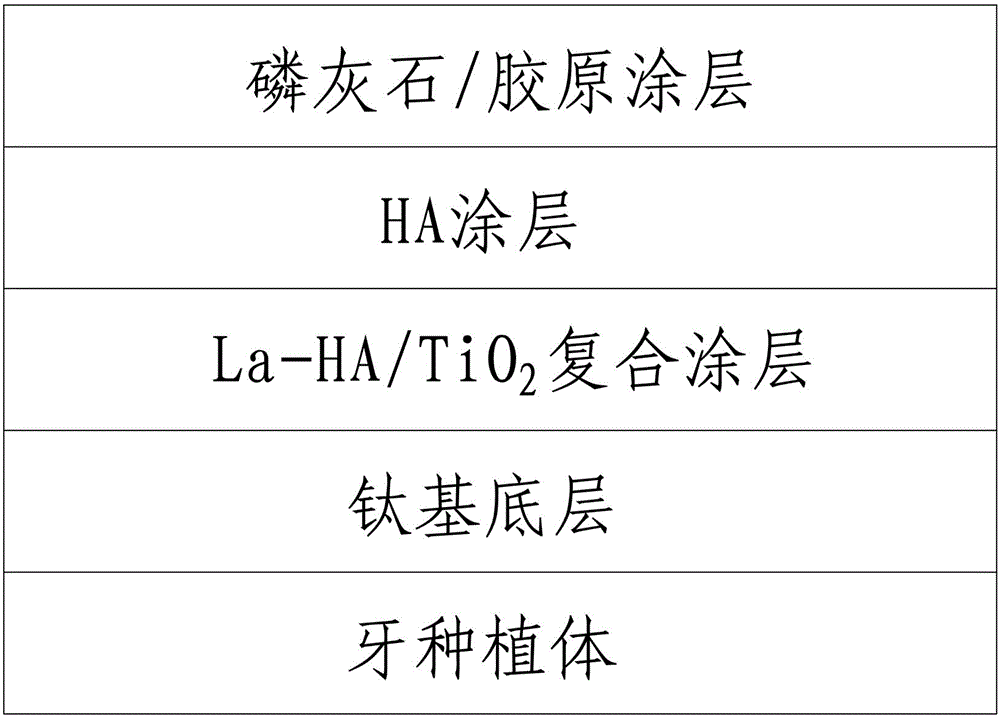

[0030] Such as figure 1 Shown is a specific embodiment of the preparation method of the biogradient coating on the surface of the dental implant of the present invention. This embodiment includes a dental implant, and the following steps are performed on the dental implant:

[0031] In the first step, the titanium sheet is polished with SiC metallographic sandpaper, cleaned and dried, and then placed on the surface of the dental implant to form a titanium base layer;

[0032] The second step is to prepare La-HA / TiO on the surface of the titanium base layer 2 Composite coating, generating gradient TiO 2 / La-HA=(100-x) / x, where x=20~80, the interval of x is 20, that is, the value of x is preferably 20, 40, 60, 80, to realize the gradient of the thermal expansion coefficient and elastic modulus of the coating transition;

[0033] The third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com