Patents

Literature

334 results about "Kyanite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kyanite is typically a blue aluminosilicate mineral, usually found in aluminium-rich metamorphic pegmatites and/or sedimentary rock. Kyanite in metamorphic rocks generally indicates pressures higher than four kilobars. It is commonly found in quartz. Although potentially stable at lower pressure and low temperature, the activity of water is usually high enough under such conditions that it is replaced by hydrous aluminosilicates such as muscovite, pyrophyllite, or kaolinite. Kyanite is also known as disthene, rhaeticite and cyanite.

Preparation method of microporous kyanite-based lightweight insulating refractory material

The invention relates to a preparation method of a microporous kyanite-based lightweight insulating refractory material. The preparation method is realized by comprising the following steps: (1) by taking kyanite, auxiliary materials and a cementing material as raw materials, adding a certain amount of dispersing agent, thickening time control agent and foam stabilizer, premixing, adding a certain amount of water, and mixing to prepare uniform slurry; (2) adding a certain amount of foaming agent in the slurry, mechanically agitating and foaming to prepare uniform foam slurry; (3) injecting the foam slurry into a mould, standing under a room-temperature environment so as to be cued and formed; (4) demoulding a green body, and then drying and sintering to obtain the microporous kyanite-based lightweight insulating refractory material. The prepared microporous kyanite-based lightweight insulating refractory material has the advantages of microfine air bore aperture (20-200mum), low volume density, high porosity, high strength, small sintering line change rate, low thermal conductivity, high usage temperature and the like. The raw materials are mainly kyanite, and other raw materials are common materials in refractory material industry, and are non-toxic and low-cost. The preparation method is simple and is easily controlled for the technology, and is suitable for industrial production.

Owner:ZHENGZHOU UNIV

Refractory castable for desulfurization stirrer

The invention discloses a refractory castable for a desulfurization stirrer, which is prepared by mixing a castable base material and a proper amount of additives, wherein the castable base material comprises the following components in percentage by weight: 26-33% of sintered zirconium mullite, 26-35% of common fused mullite, 5-9% of flint clay, 4-7% of kyanite, 5-10% of superfine bauxite chamotte, 3-5% of fine silicon powder, 3-5% of fine alpha-Al2O3 powder, 5-8% of fine rho-Al2O3 powder, 1.5-3.5% of pure calcium aluminate cement and 1.5-3.5% of dense fine alundum powder. The additives comprise three or more of 1-2% of heat-proof steel fiber, 0-0.15% of polypropylene fiber, 0-0.5% of metallic aluminum powder, 0-0.3% of sodium tripolyphosphate and 0-0.5% of melamine based on the weight of the castable base material. The refractory castable has the advantages of good performance, low cost and wide sources of raw materials. Compared with the prior art, the refractory castable can enable the average service life of KR desulfurization stirrers to be improved by more than 100 times.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Light thermal-shield refractory castable

InactiveCN101792294ALight weightImproved thermal shock stabilitySolid waste managementCapacitanceMullite

The invention relates to a light thermal-shield refractory castable comprising the following components in percentage by weight: 40-60% of light aggregate, 10-20% of capacitance mullite, 5-10% of kyanite powder, 5-10% of high-aluminium clinker powder, 3-8% of silica micro powder, 3-8% of alpha-Al2O3 micro powder, 5-10% of high-aluminium cement, 0.5-10% of high-aluminium refractory fibre containing zirconium, 1.5-4% of thermal-shield steel fibre, 0.1-1% of melamine and 0.05-0.1% of organic anti-explosion fibre, wherein the granularity of the capacitance mullite is less than or equal to 1 mm, both the granularity of the silica micro powder and the granularity of the alpha-Al2O3 micro powder are less than or equal to 5 mu m, and the chemical modified light aggregate is obtained by drying after the light aggregate is dipped in inorganic chemical solution or sol. The light thermal-shield refractory castable of the invention can improve the service life of a furnace roller, lowers production consumption cost, reduces non-working hours caused by exchanging rollers and improves production efficiency.

Owner:武钢集团有限公司

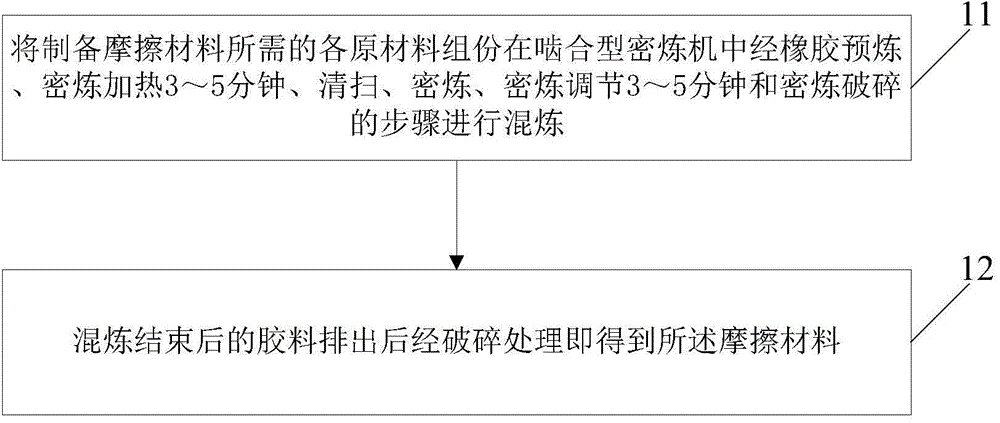

Friction material for brake-shoe of heavy axle-load wagon and preparation method of friction material

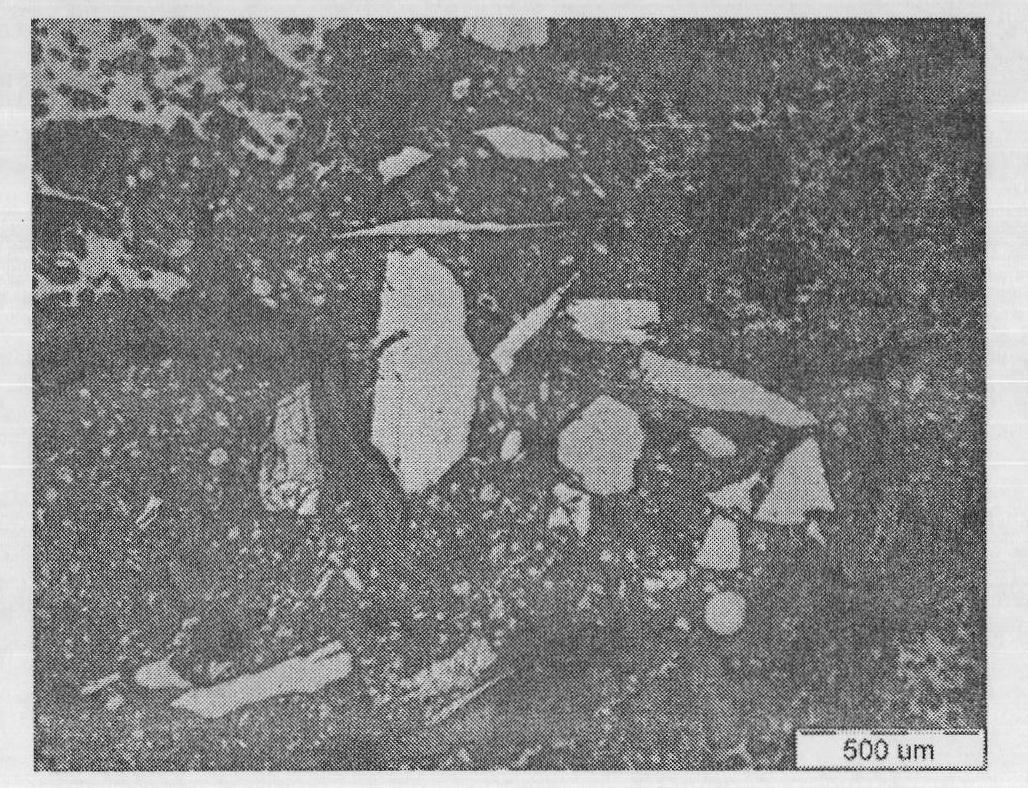

InactiveCN104087245AMeet the friction performanceMeet the mechanicsOther chemical processesFiberKyanite

The invention discloses a friction material for a brake-shoe of a heavy axle-load wagon. The friction material is prepared from the following components in percentage by mass: 6-12 percent of nitrile rubber, 1-4 percent of butadiene styrene rubber, 3-8 percent of A-stage phenolic resin, 0.4-1 percent of insoluble sulfur, 0.1-0.6 percent of an accelerant, 0.1-0.6 part of a curing agent, 2-6 percent of carbon black, 8-18 percent of barite, 1-4 percent of kyanite, 17-40 percent of hybrid fibers, 7-14 percent of magnesium oxide, 2-6 percent of petroleum coke, 2-8 percent of calcium sulfate crystal whiskers, 1-4 percent of molybdenum disulfide, 1-5 percent of crystalline flake graphite, 1-4 percent of artificial graphite, 1-4 percent of mica iron oxide and 1-3 percent of antimony sulfide. The friction material can satisfy the friction performance and mechanical property required by the brake-shoe of the heavy axle-load wagon and can meet the high speed operating requirement on heavy load of the wagon.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

Proppants and Anti-flowback additives made from sillimanite minerals, methods of manufacture, and methods of use

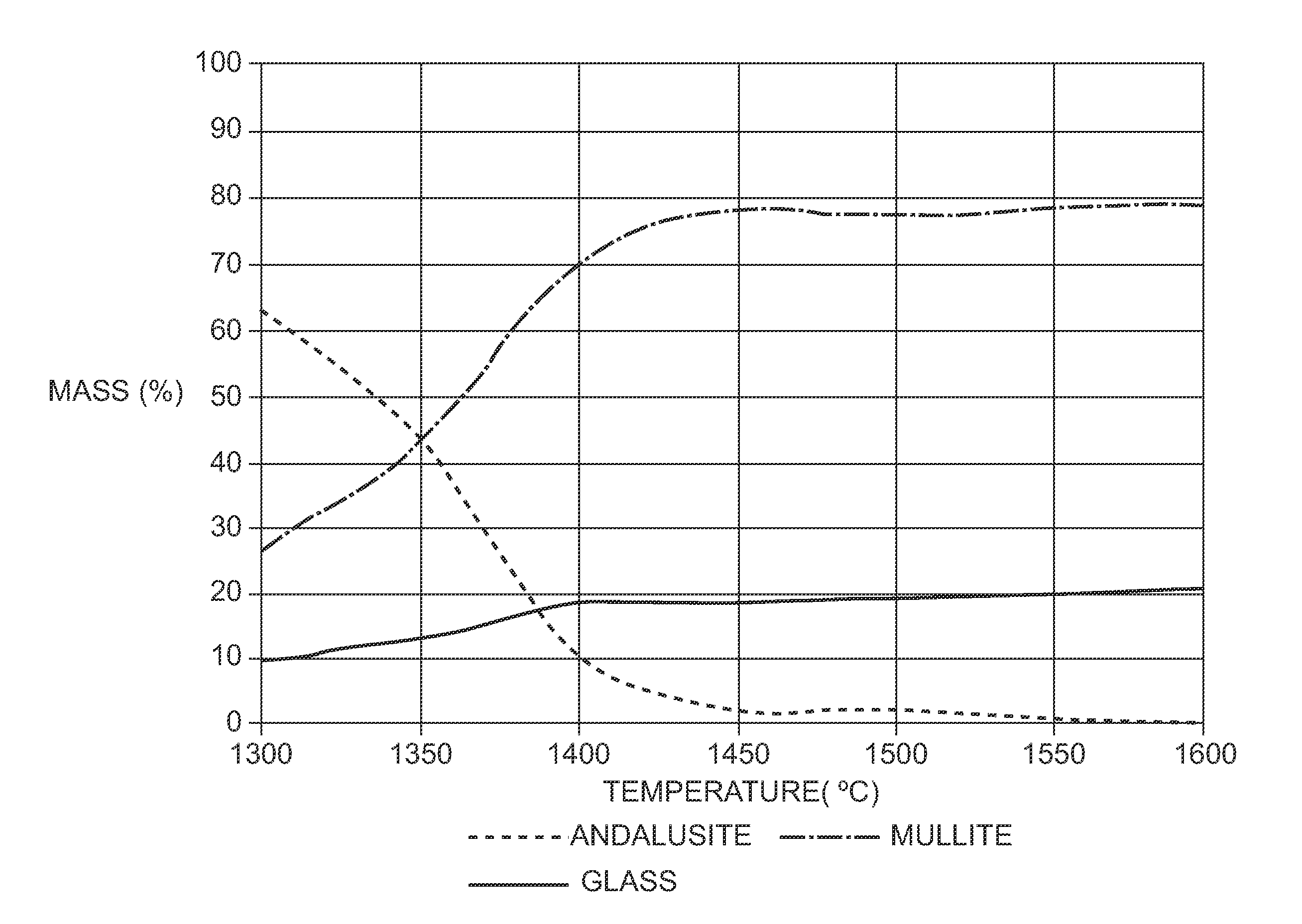

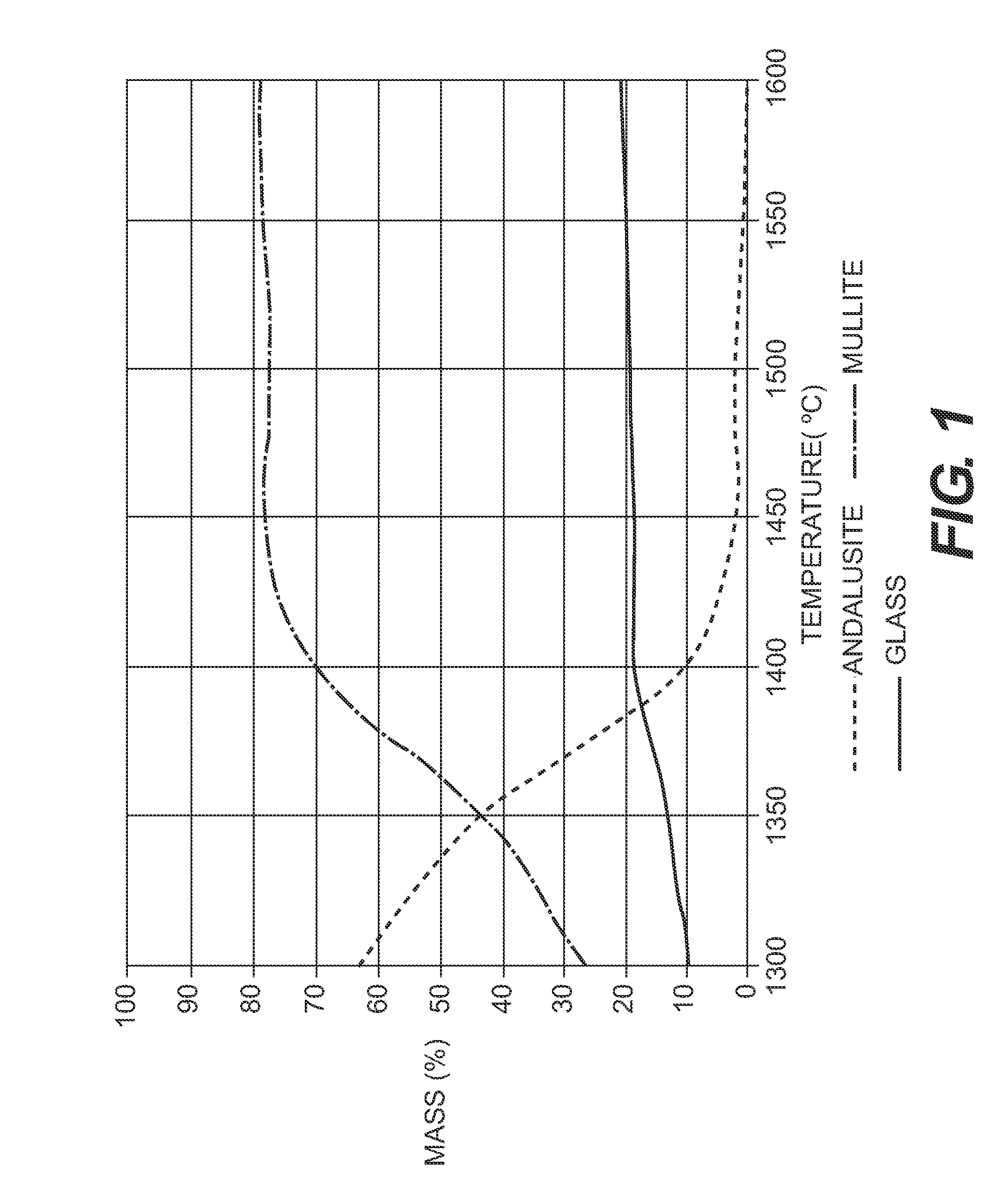

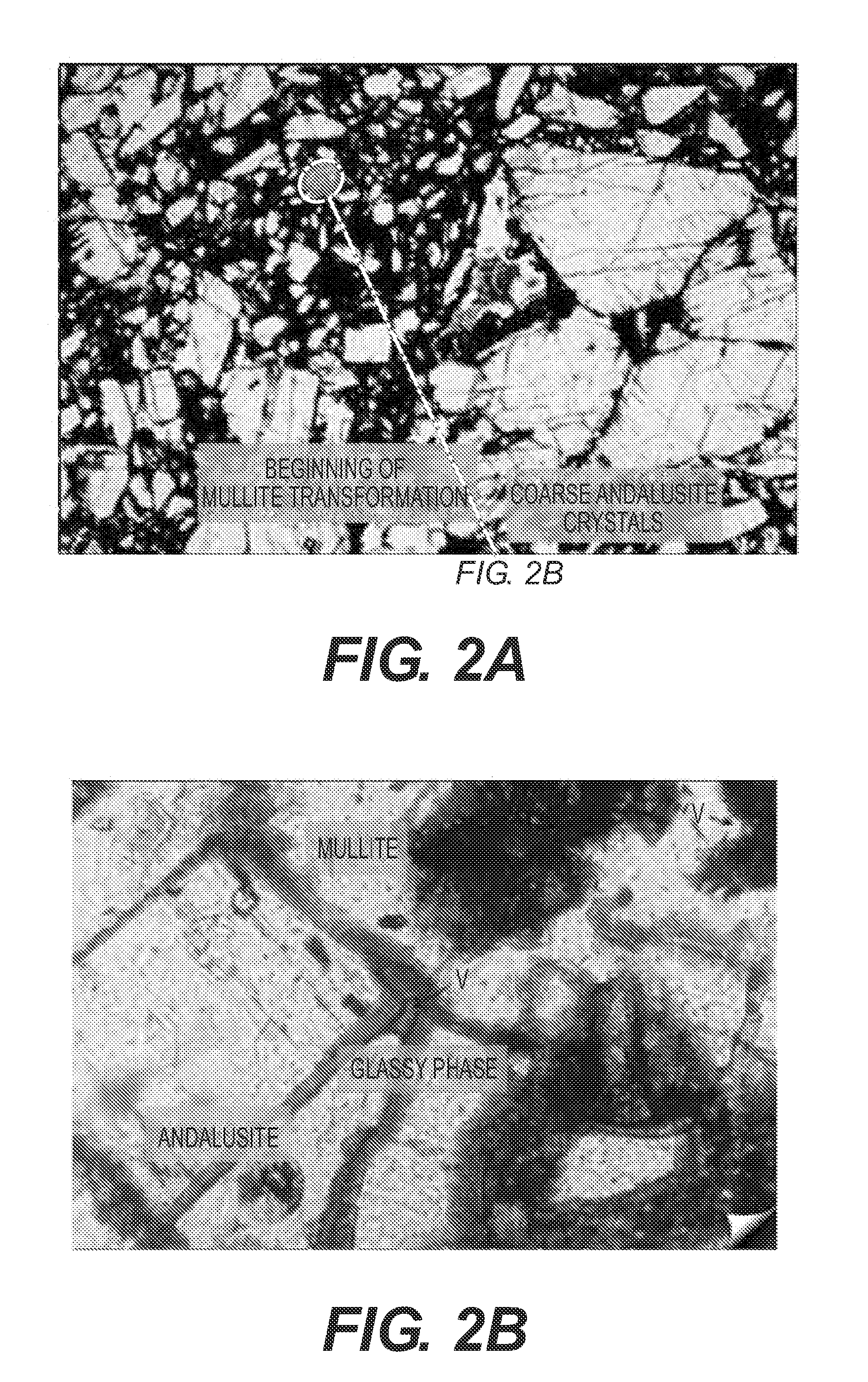

Spherical and rod-shaped proppants and anti-flowback agents made from sillimanite minerals possess high strength and high conductivity. The sillimanite minerals may be selected from the group consisting of kyanite, sillimanite, and andalusite and may be used alone or in combination with other materials, such as bauxite, kaolin, meta-kaolin, pure or technical grade alumina (about 98%-99.9% alumina by weight), alumina-containing slag, zirconia, silica, iron, alkali elements (such as calcium, magnesium, and sodium), and virtually any other mineral containing alumina. The starting material may optionally be milled to achieve better compacity and crush resistance in the final proppant or anti-flowback agent. A fracturing fluid may comprise the rods or spheres alone, or in combination with each other or other proppants or anti-flowback agents of different shapes.

Owner:US CERAMICS LLC

Casting material with thermal insulation function

The invention discloses a casting material with a thermal insulation function. The casting material comprises the following raw materials by weight percent: 25-45% of alumina hollow ball or mullite hollow ball or high-alumina hollow ball or a mixture of more than two mixed according to any ratio, 5-15% of corundum or mullite aggregate, 3-8% of kyanite, 15-35% of corundum or mullite powder, 0.1-3% of asphalt powder, 1-5% of alumina micro powder, 2-5% of silicon oxide micro powder, 5-15% of calcium aluminate cement powder, 0.01-2% of water-soluble phenolic resin powder, 0.01-0.2% of polymer carboxylic acid salt water reducer and the balance of water, wherein the alumina hollow ball or mullite hollow ball or high-alumina hollow ball has the refractoriness being greater than 1700 DEG C and the particle size of 5-1mm; the particle size of the corundum or mullite aggregate is smaller than 1mm; the particle size of the kyanite is smaller than 0.1mm; the particle size of the corundum or mullite powder is smaller than 0.088mm; the weight of the water is 2-7% of total weight of the added raw materials. By adopting the casting material, heat loss of a kiln can be reduced, the strength is not lower than 7.5MPa after drying at 110 DEG C for 24 hours, and the compressive strength is not lower than 15MPa after firing at 1300 DEG C. Thus, maintenance of the kiln is facilitated, the maintenance time is shortened, and energy consumption is reduced.

Owner:武汉钢铁有限公司

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

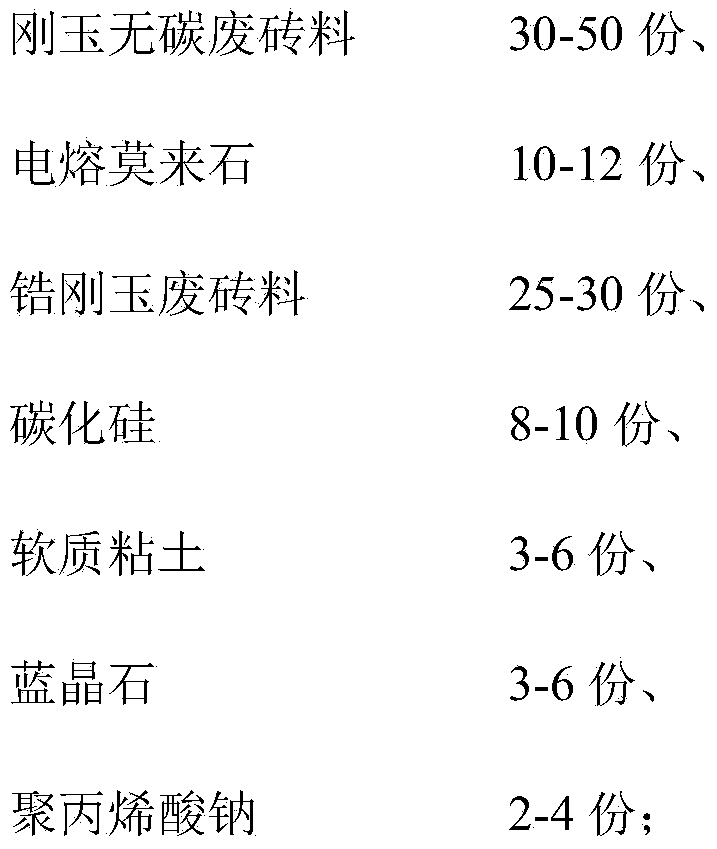

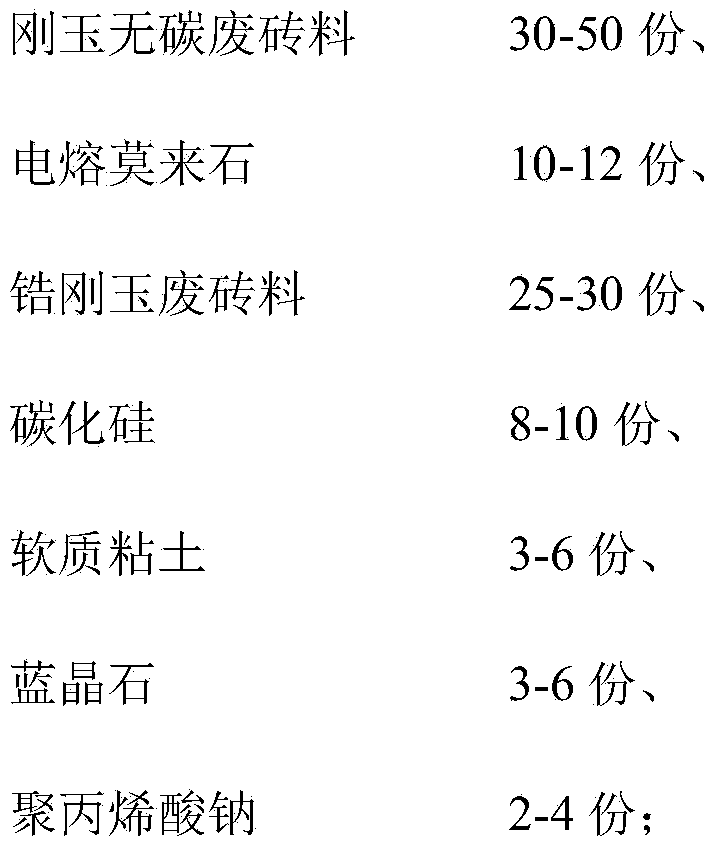

High-temperature protective coating for high-carbon steel billet and application thereof

The invention discloses a high-temperature protective coating for a high-carbon steel billet. The coating comprises a dry powder material and an adhesive. The dry powder material is prepared from the following components in parts by weight: 30-50 parts of corundum carbon-free waste brick materials, 10-12 parts of electro-fused mullite, 25-30 parts of fused alumina zirconia waste brick materials, 8-10 parts of silicon carbide, 3-6 parts of soft clay, 3-6 parts of kyanite and 2-4 parts of sodium polyacrylate. The adhesive is prepared from a solid compound adhesive and a liquid compound adhesive. The dosage of the solid compound adhesive is 3-6% of the total weight of the dry powder material and the dosage of the liquid compound adhesive is 2-4% of the total weight of the dry powder material. The protective coating can be used for directly spraying the hot state billet with the surface temperature of 400-1100 DEG C, and not only has the double functions of preventing oxidization and resisting decarburization, but also has the self-repairing ability, so that the loss of iron scale and the thickness of a decarburized layer in the heating process of the high-carbon steel billet are remarkably reduced, the surface quality of the billet is improved. The production efficiency of a rolling mill is improved, and the production cost is lowered.

Owner:辽宁富城耐火材料(集团)有限公司

Light refractory castable material for heat insulation lining of cast steel plate (CPS) furnace roller

The invention discloses a light refractory castable material for a heat insulation lining of a cast steel plate (CPS) furnace roller. The light refractory castable material comprises the following components by weight percent: 40-50% of light mullite bone material, 5-8% of flint clay with a particle size of 0.1-1mm, 5-7% of kyanite powder, 6-9% of first-class bauxite chamotte with a particle sizeof less than or equal to 180 meshes, 7-9% of silicon micro powder, 5-8% of alpha-Al2O3 micro powder, 10-18% of bauxite cement, 1-4% of refractory fiber, 1-1.5% of spodumene, 0.05-0.154% of sodium hexametaphosphate, 0.05-0.15% of organic water reducing agent, 0.04-0.07% of organic silane coupling agent and 0.013-0.06% of defoaming agent. The refractory castable material has the characteristics of light volume weight, strong high temperature resistance, good mechanical property, good heat insulation property and excellent thermal shock stability performance.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Honeycomb heat accumulator made of silicon carbide-corundum composite materials

ActiveCN101798212ASimple compositionHigh refractorinessChemical industrySmall footprintPetrochemical

The invention relates to a honeycomb heat accumulator made of silicon carbide-corundum composite materials, which comprises the following main raw materials: 20-30wt% of silicon carbide powder, 4-8wt% of zirconia corundum powder, 20-30wt% of corundum powder, 15-20wt% of porzite powder, 15-30wt% of composition of kyanite, andalusite and sillimanite, 4-8wt% of kaolin and 2-5wt% of cellulose powder. The preparation method of the honeycomb heat accumulator comprises the following steps: adding the main raw materials into a ball mill for ball milling; adding stearic acid of which the weight is not greater than 1% of the total weight of the main raw materials for ball milling, and then, sieving to obtain a mixture; respectively adding tung oil of which the weight is not greater than 1% of the weight of the mixture and glycerol of which the weight is not greater than 1% of the weight of the mixture for mixing, aging and vacuum pugmill to form pug segments; carrying out extrusion forming in a mold, and drying; and insulating at the temperature of 1400-1450 DEG C for 4-8 hours, and then, calcining. The honeycomb heat accumulator of the invention has the characteristics of high fire resistance, good thermal shock resistance, strong corrosion resistance, large heat exchange area, small gas flow resistance, high heat accumulating efficiency, small floor space and long service life which can be more than two years, and is widely used for heat accumulating type heating furnaces of black and non-ferrous smelting, thermal power generation, petrochemical industry, ceramics, glass, machining, civil cookers and the like.

Owner:JIANGXI SHINCO ENVIRONMENTAL PROTECTION CO LTD

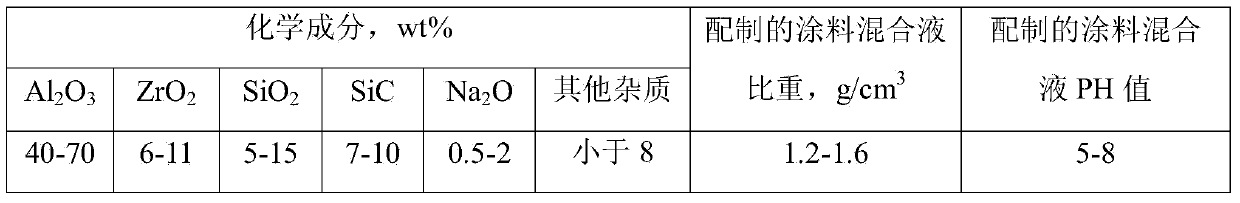

Ore dressing collector and preparation method thereof

The invention discloses an ore dressing collector and a preparation method thereof. The ore dressing collector consists of the following raw materials in percentage by weight: 75 to 80 percent of oleic acid, 3 to 5 percent of surfactant, 5 to 7 percent of N,N-dimethylformamide-dimethyl sulfate, and 10 to 15 percent of chloride. The oleic acid is subjected to electrolytic dissociation and chemicalmodification by the steps of activation, electrolyzation, separation and introduction of an active group so as to form the ore dressing collector with high activity, dispersibility and selectivity. The ore dressing collector is particularly suitable for ore dressing of minerals such as non-metallic fluorite, kyanite, barite, metal white tungsten, hematite reverse flotation and the like, particularly the ore dressing at low temperature (more than or equal to 2 DEG C).

Owner:烟台市富林矿山机械有限公司

Self-reacting alumina-base composite ceramic mold core for fine casting and preparation method thereof

InactiveCN101386546ALow thermal shock resistanceImprove thermal shock resistanceFoundry mouldsFoundry coresComposite ceramicMullite

The invention provides a self-reaction alumina-based composite ceramic core for precision casting, and a preparation method thereof. The composite ceramic core consists of alundum powder, in-situ synthesized aluminum titanate, MgTi2O5 and mullite. The composite ceramic core is prepared from the following raw materials in weight percentage: 70 to 85 percent of alundum powder with different particle sizes, 0 to 2 percent of magnesium oxide powder, 8 to 20 percent of titanium dioxide powder and 6 to 10 percent of kyanite powder, and carbon powder accounting for 1 to 3 percent of the gross mass of the four raw materials is added as an easy-breakdown agent. The method prepares the composite ceramic core through the following steps of mixing, dry-pressing, shaping and firing the raw materials at high temperature. As other raw materials are added to an alumina matrix of the invention, the prepared composite ceramic core has the advantages of good high-temperature chemical stability and thermal stability, low thermal expansion coefficient and small shrinkage factor after sintering, and meets the requirements of a ceramic core for precision casting on room temperature and high temperature strength.

Owner:SOUTH CHINA UNIV OF TECH

Calciclase light heat-insulating refractory material and preparation method thereof

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

High-temperature wear-resistant repairing coating and preparation method thereof

ActiveCN102134164AHigh compressive strengthHigh densityFireproof paintsSpecial surfacesWear resistantZircon

The invention relates to a high-temperature wear-resistant repairing coating and a preparation method thereof, and the coating comprises a material A and a material B with a weight ratio of 70-85:30-15, wherein the material A is prepared by zirconia corundum fine powder, kyanite, aluminium titanates, silicon micropowder, magnesium zircon sand, alumina micropowder, pure calcium aluminate cement, sodium tripolyphosphate, fused calcium chromate, and zinc aluminate gahnite; and the B material is prepared by phosphoric acid, ink-grade aluminium hydroxide, aluminium chloride, yttrium-stabilized zirconium, borax, and a medium-temperature agglutinant. The product has excellent wear resistance, corrosion resistance, erosion resistance, thermal shock stability, and a high caking property; using the product, the running period of a circulating fluidized bed boiler is increased from about 3500 hours to over 18000 hours for accumulating running time; the problem that the boiler liner needs to be repaired and replaced frequently is overcome; human and material resources are saved; and the production efficiency is greatly improved.

Owner:YIXING GUOQIANG FURNACE IND

Light-weight and heat-isolation mullite bricks and preparation method thereof

The invention particularly relates to light-weight and heat-isolation mullite bricks and a preparation method thereof. The technical scheme is that the light-weight and heat-isolation mullite bricks are prepared from the following raw materials in percentage by weight: 40 to 48 percent of flint clay, 14 to 38 percent of kyanite, 6 to 16 percent of clay and 14 to 24 percent of alpha-Al2O3 fine powder, wherein a bonding agent is 15 to 20 percent by weight of the raw materials, and a pore-forming agent is 45 to 60 percent by weight of the raw materials. The preparation method comprises the following steps of firstly mixing the alpha-Al2O3 fine powder with the pore-forming agent, and carrying out wet grinding for 8 to 10 hours to obtain homogenized mud; uniformly stirring the homogenized mud, the flint clay, the kyanite, the clay and the bonding agent; carrying out aging, forming and baking; and preserving the heat at 1,325 to 1,450 DEG C for 3 to 5 hours to obtain the light-weight and heat-isolation mullite bricks. The light-weight and heat-isolation mullite bricks and the preparation method thereof have the advantages of saving resources, being simple in process, and being environmentally-friendly; and the prepared light-weight and heat-isolation mullite bricks are high in heat stability, low in heat conduction coefficient, low in volume density, low in after-burning linear shrinkage ratio, high in compression strength and good in heat insulation and isolation effect.

Owner:WUHAN UNIV OF SCI & TECH

Stemming for taphole of ore hearth and preparation method thereof

The invention relates to stemming for a taphole of an ore hearth and a preparation method thereof. The technical scheme adopted by the stemming disclosed by the invention lies in that the preparation method comprises the following steps of: firstly using 40-60wt% of bauxite, 5-15wt% of kyanite, 10-20wt% of brown fused alumina fine powder, 5-15wt% of chromium oxide fine powder, 5-15wt% of silicon carbide fine powder, 5-10wt% of silicon micro powder, 1-5wt% of titanium oxide fine powder, 1-3wt% of cerium oxide fine powder, 1-3wt% of bentonite fine powder and 1-5wt% of Al2O3 / Si2N2O / SiC / C composite powder as raw materials, additionally adding an oxide additive accounting for 1-5wt% of the raw materials, and pre-mixing the raw materials and the oxide additive for 5-10 minutes in a mixing and grinding machine so as to obtain premix powder; and then adding a retarder accounting for 0.05-0.25wt% of the raw materials and an aluminum dihydrogen phosphate aqueous solution accounting for 7-15wt% of the raw materials to the premix powder, grinding the premix powder, the retarder and the aluminum dihydrogen phosphate aqueous solution for 20-30 minutes in a wet manner, and then performing stemming extrusion and shaping through a stemming extruder so as to obtain the stemming for the taphole of the ore hearth. The stemming for the taphole of the ore hearth prepared by the preparation method disclosed by the invention has the characteristics of being low in cost, high in intensity, excellent in washing resistance and excellent in corrosion resistance.

Owner:湖南立达高新材料有限公司 +1

Mullite light insulating brick and preparation method thereof

The invention relates to a mullite light insulating brick and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps of: by taking the following components by weight percent as raw materials: 30-40 wt% of a flint clay clinker, 20-30wt% of a clay clinker, 20-32wt% of kyanite micro-powder, 2-8 wt% of p-aluminum oxide micro-powder, 1-6wt% of light-burnt calcium oxide and 0.5-2wt% of silicon dioxide micro-powder, adding 20wt% of water and 0.5-2wt% of a water reducing agent, mixing and preparing a slurry; then, adding 0.1-0.5wt% of a foaming agent to prepare foams, stirring, adding 0.5-2 wt% of a gel, 0.1-1wt% of a thermosetting water-soluble high molecular compound and 0.5-2.5wt% of an accelerating agent, stirring, pouring, and molding; and finally, drying for 4-9 hours in a temperature of 30-50 DEG C, demolding, baking for 10-20 hours in a temperature of 60-120 DEG C, and preserving a temperature of 1350-1500 DEG C for 2-12 hours to obtain the mullite light insulating brick. The preparation method is short in de-molding time, short in drying period and environment-friendly; and the product is small in air hole size, uniform in air hole distribution, high in strength, low in volume density and low in heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

Mullite light heat-insulation brick based on kyanite tailings and manufacturing method of brick

InactiveCN103864403AEfficient recyclingAvoid pollutionCeramic materials productionClaywaresBrickMullite

The invention relates to a mullite light heat-insulation brick based on kyanite tailings and a manufacturing method of the brick. According to the adopted technical scheme, the manufacturing method comprises the following steps: mixing 50-85wt% of kyanite tailings, 10-36wt% of plastic clay, 2-18wt% of alpha-Al203 and 1-5wt% of silica powder as raw materials, adding 30-60wt% of pore-forming agent, 0.1-1.4wt% of binding agent and 15-50wt% of water, uniformly mixing, ageing the mixture for 12-24 hours, forming, naturally drying, baking for 10-16 hours at 110 DEG.C, warming to 1300-1550 DEG.C, and preserving heat for 2-8 hours to obtain the mullite light heat-insulation brick based on kyanite tailings. The mullite light heat-insulation brick based on kyanite tailings has the characteristics of being environment-friendly, low in production cost and simple in process; the prepared mullite light heat-insulation brick based on kyanite tailings is high in compression strength, excellent in thermal shock stabilization, low in volume density and low in heat conductivity coefficient, and especially small in variation of re-burning line, and suitable for working surface lining of an industrial furnace.

Owner:WUHAN UNIV OF SCI & TECH +1

Preparation method of high temperature heat storage material

InactiveCN1869146AReduce dosageReduce production energy consumptionMachines/enginesHeat-exchange elementsHigh temperature storageKyanite

The invention relates to high temperature storage material manufacturing method. It includes selecting material, mixing, and preparing. It includes the following steps: using basalt as coarse aggregate, bauxite as fine aggregate, and aluminate cement as cementation agent; and adopting silicon micro-powder, activated alumina powder, natural graphite powder, and kyanite micro-powder as material; mixing them; adding 4-6% water; putting in steel mould and demoulding after 24 hours; setting in water at 20-25 centigrade degree for 72 hours; and baking at 100-120 centigrade degree for 24 hour. The formed material has high all round properties, and can avoid environmental pollution.

Owner:WUHAN UNIV OF TECH

Riser material and production method thereof

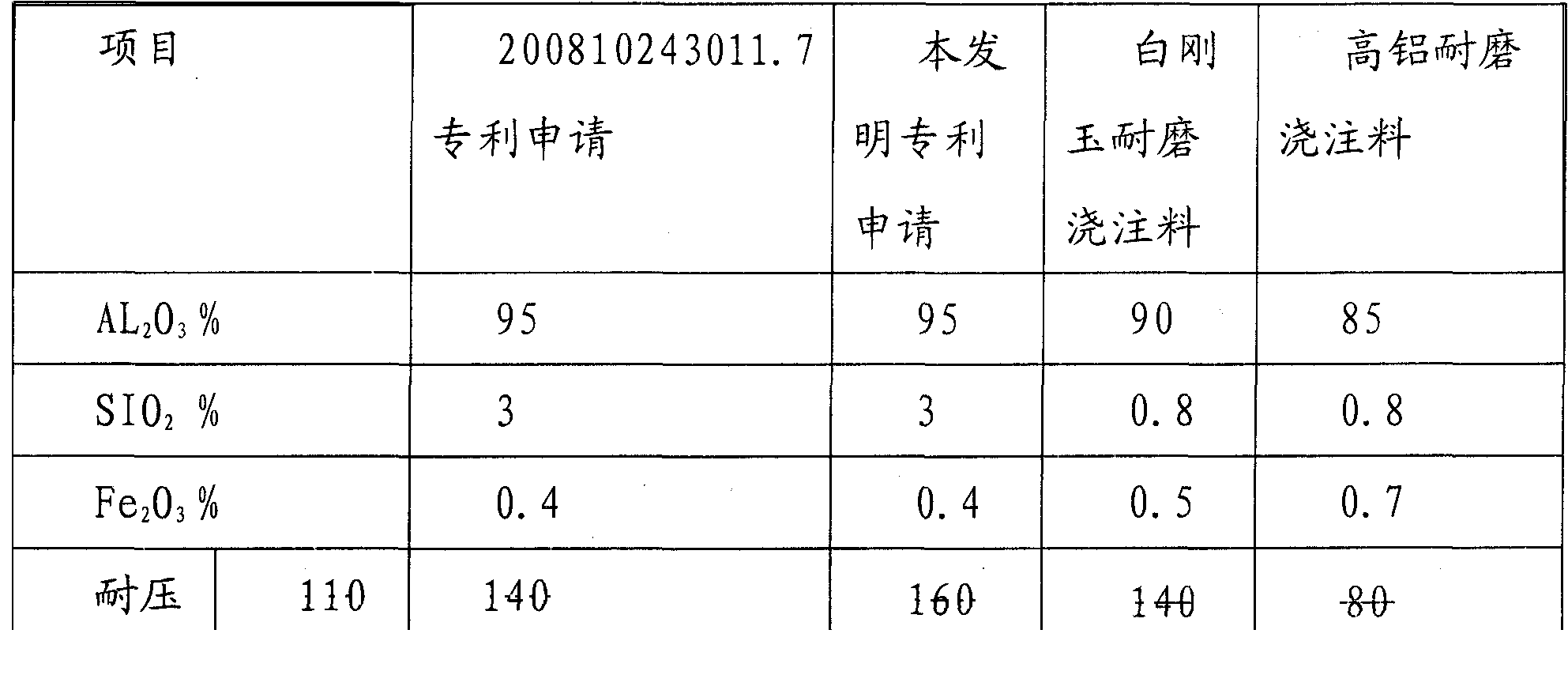

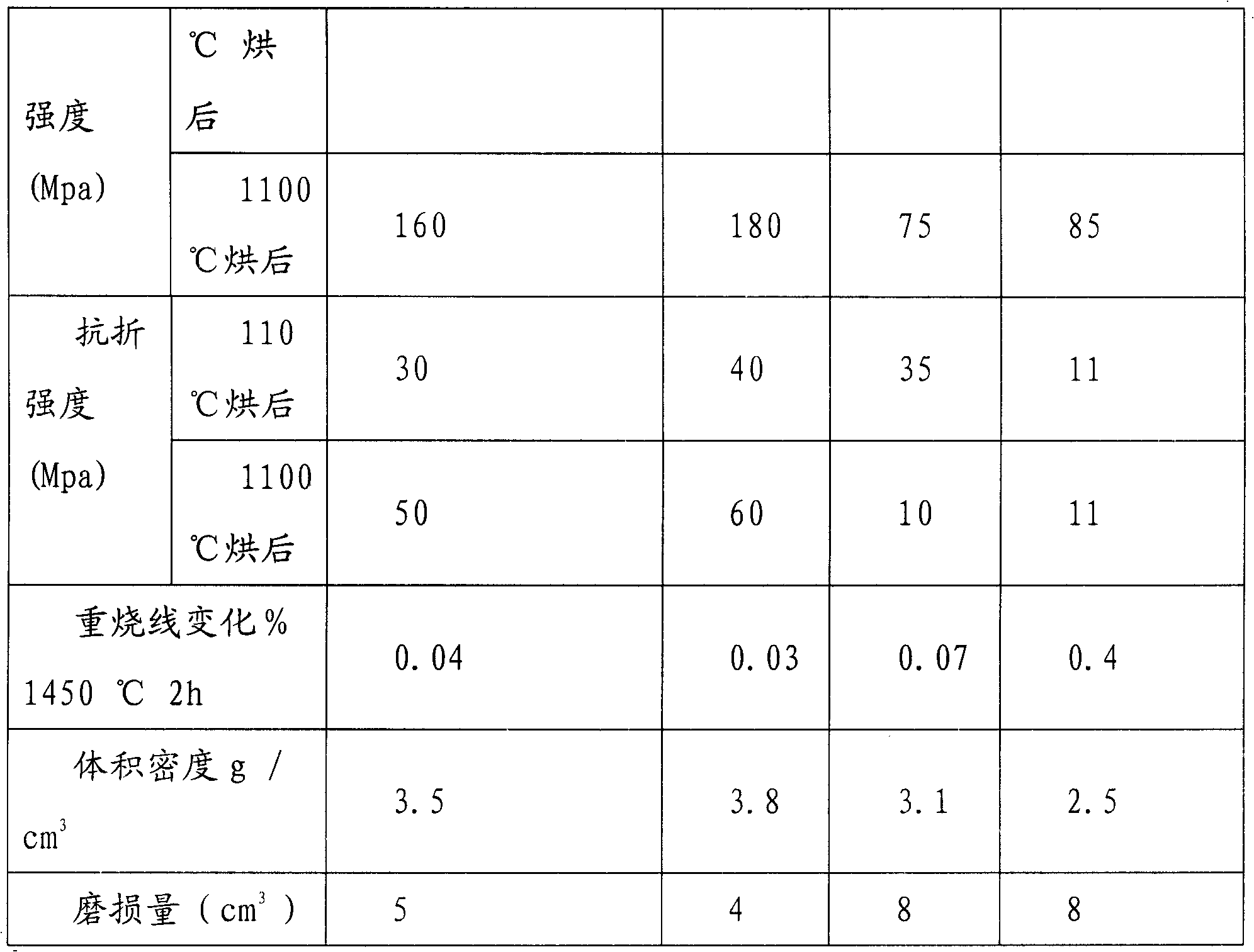

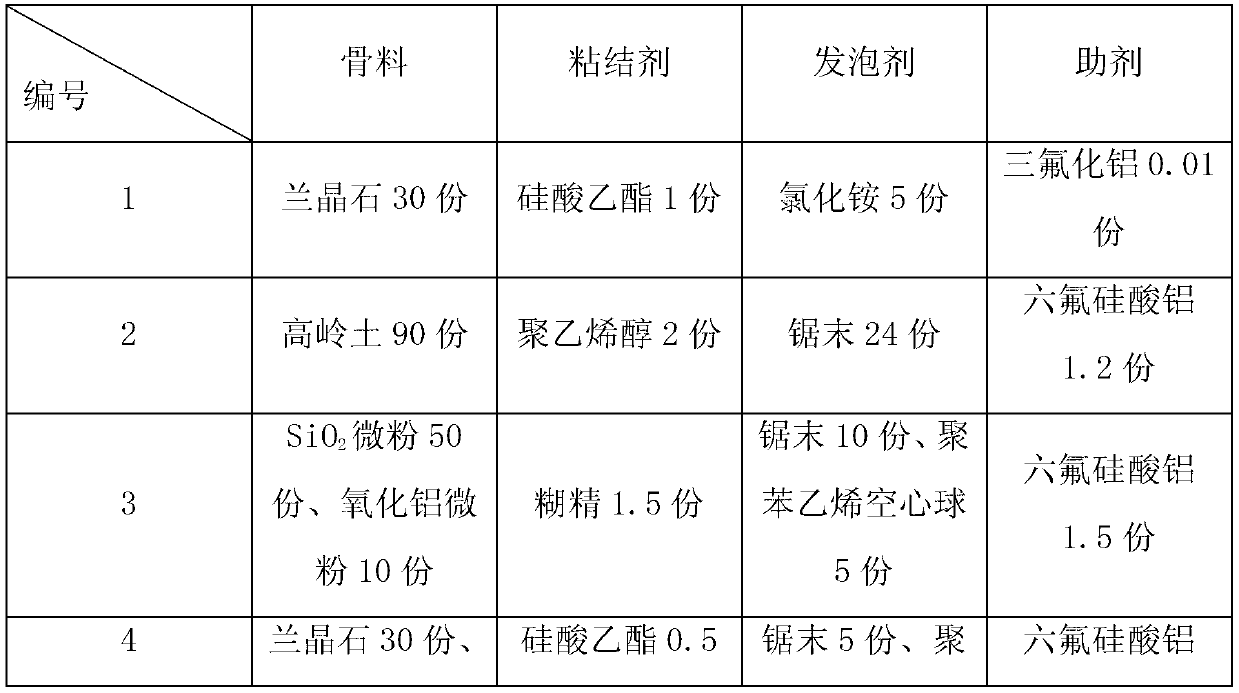

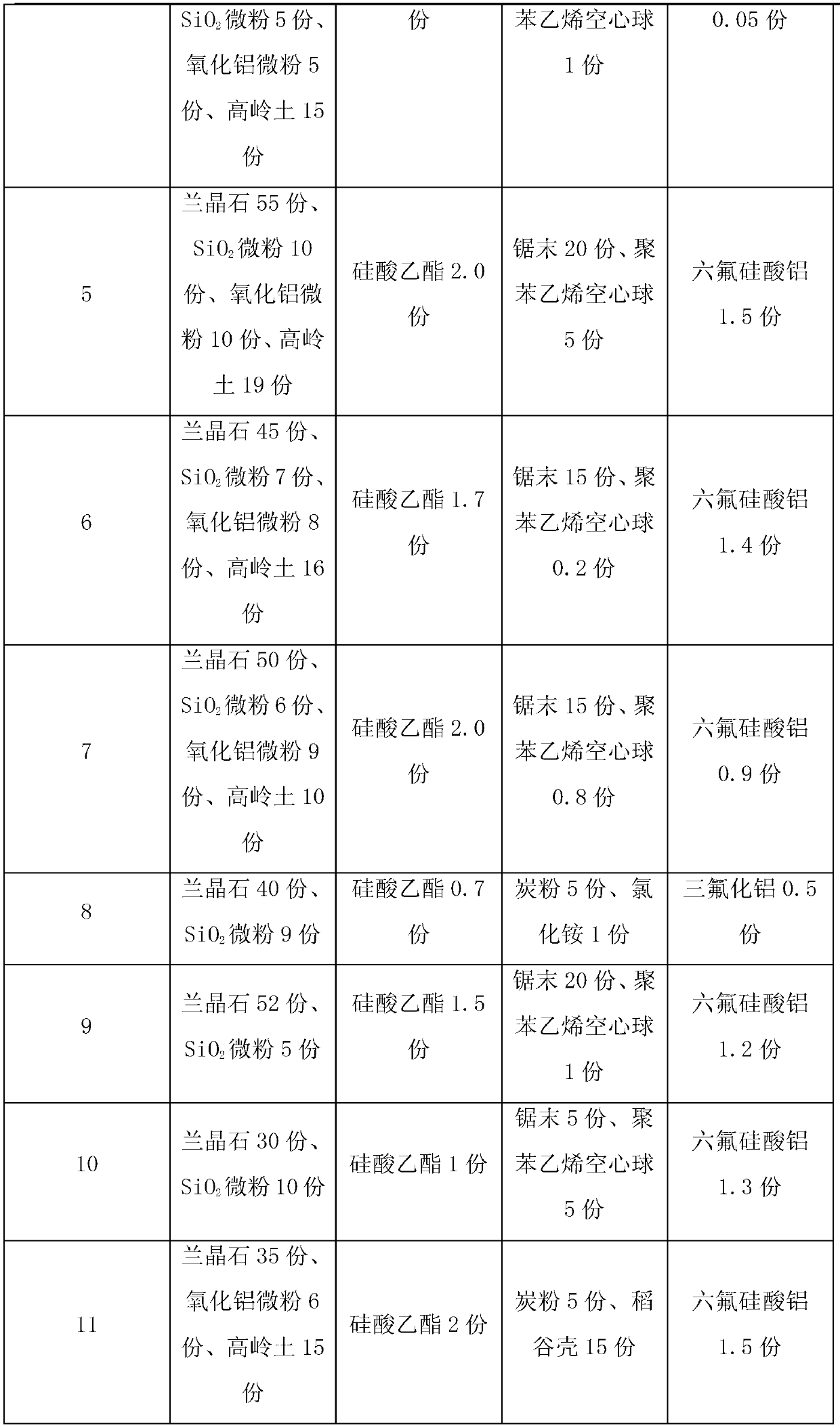

ActiveCN103130523AFoundry Technology Progress GuaranteeGood high temperature performancePolyvinyl alcoholPolystyrene

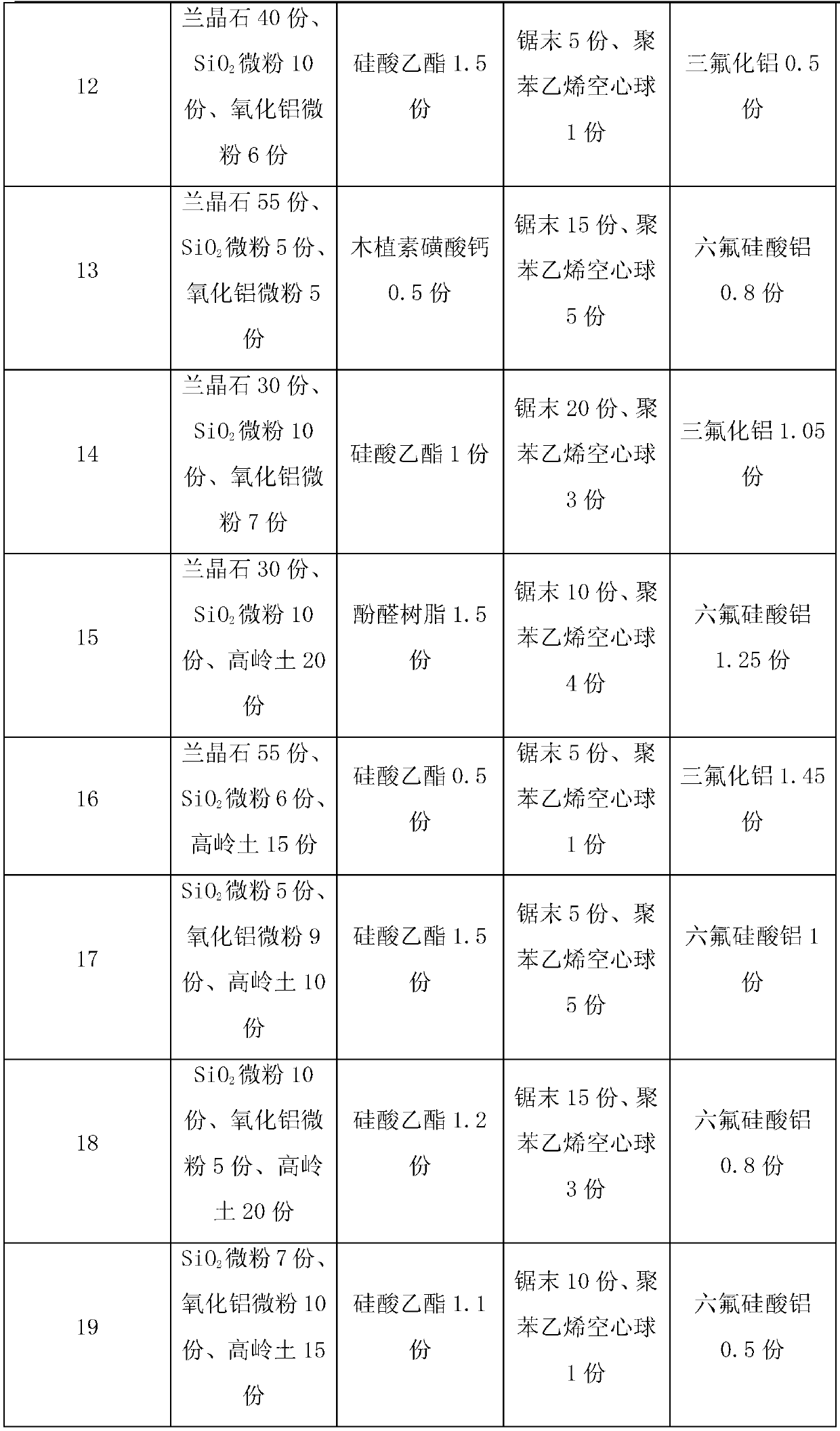

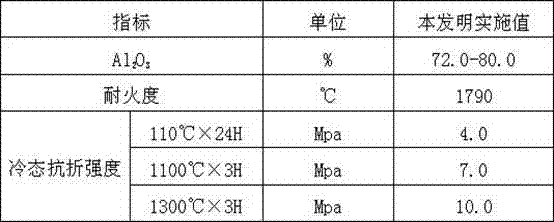

The invention relates to a riser material and a production method thereof, belongs to the technical field of riser materials and aims to provide a riser material applicable to a large casting. The riser material is prepared from the following components in parts by weight: 30-95 parts of aggregate, 0.5-2 parts of binding agent, 5-25 parts of foaming agent and 0.01-1.5 parts of assistant, wherein the aggregate is at least one of kyanite, aluminum oxide micropowder, kaolin and SiO2 micropowder; the binding agent is at least one of ethyl silicate, carboxymethyl cellulose, lignin calcium sulfonate, dextrin, polyvinyl alcohol and phenolic resin; the foaming agent is at least one of sawdust, polystyrene hollow spheres, carbon powder, rice hulls and ammonium chloride; and the assistant is at least one of aluminum trifluoride and aluminum fluosilicate.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Permeable fireproof materials for aluminium refining and process for preparing same

The invention discloses a poromeric fire-proof material and preparing method of refined aluminum, which comprises the following parts: 60-92 percent sintered compact calcium hexaluminate, 8-30 percent auxiliary material and 2.5-5.5 percent binder, wherein the auxiliary material is some or all of board-shaped corundum, electric melting white corundum, mild-clay, quartz, kyanite, chromium hemitrioxide green and zircon. The preparing method comprises the following steps: blending poromeric fire-proof material and binder completely; loading the material in the mould; placing the mould on the vibrating platform; pressurizing on the material at 10-20 ton; vibrating at 3-5 mm amplitude at 5-15 s; sintering at 1400-1700 deg.c.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Preparation method of special inorganic anti-veining additive for casting

ActiveCN104493075AReduce the amount addedReduce manufacturing costFoundry mouldsFoundry coresMicrosphereLithium carbonate

The invention relates to a preparation method of an additive, and in particular relates to a preparation method of a special inorganic anti-veining additive for casting. The method comprises the following steps: respectively sieving iron oxide red and black iron oxide through a sieve of 70mesh; removing oversize materials and remaining the residues on the sieve for later use; respectively sieving spodumene, kyanite and hollow microspheres through a sieve of 30mesh; removing oversize materials and remaining the residues on the sieve for later use; sequentially feeding the sieved raw materials, potassium carbonate and lithium carbonate into a special agitating device according to a technical formula; then starting to agitate for mixing; discharging after mixing. The special inorganic anti-veining additive has the advantages that the addition quantity is small, the influence on the strength of moulding sand is low, the anti-veining effect is good, and the production cost can be effectively decreased.

Owner:共享新材料(山东)有限公司

High-aluminum silicon carbide casting material combined with silica sol

The invention discloses a high-aluminum silicon carbide casting material combined with a silica sol. The high-aluminum silicon carbide casting material is prepared from the following raw materials in parts by weight: 60-80 parts of bauxite with particle size of 8-0mm, 10-15 parts of silicon carbide with particle size of 180-320 meshes, 2-7 parts of alpha-Al2O3 micropowder with particle size less than 0.5mu m, 2-5 parts of kyanite with particle size of 80-120 meshes, 10-15 parts of brown corundum with particle size of 160-200 meshes, 2-5 parts of sodium tripolyphosphate and 5-10 parts of silica sol. The high-aluminum silicon carbide casting material combined with a silica sol has the beneficial effects that: the chemical activity of the silica sol is large; the casting material is easy to sinter; after middle-temperature sintering, the strength of the casting material is not reduced; the property of the casting material is greatly improved at the temperature of 1500 DEG C; the thermal shock stability of the casting material is good; and water cooling can be carried out over forty times at the temperature of 1100 DEG C.

Owner:郑州京华耐火材料实业有限公司

Anti-thermal shock iolite fireproof kiln furniture and preparation method thereof

The invention relates to an anti-thermal shock iolite fireproof kiln furniture and a preparation method thereof. The fireproof kiln furniture comprises the raw materials of 25-37% of a matrix, 50-56% of an aggregate, 4-5% of a sintering agent and 9-14% of a fiber reinforced material, wherein the matrix is composed for 15-25% of kyanite fine powder, 15-25% of kaolin fine powder, 48-69% of and alusite fine powder, and 1-2% of magnesia fine powder, and the aggregate is composed for 60-75% of gangue and 25-40% of high bauxitic clay clinker. In the prepared fireproof material, acicular iolite and cylindrical mullite are interlaced to a net state, the particles are in a free state with uniform size, the matrix and the particles have a certain buffer area, a certain stress is absorbed, and crack dynamic expansion is avoided. An iolite-mullite multiphase is generated in the fireproof product, synchronous increase of flexural intensity and compression strength can be satisfied, and the heat stability of the final product is increased.

Owner:HENAN UNIV OF SCI & TECH

Heat-insulation fireproof coating applied to pre-buried pipe of vacuum cast aluminium alloy casting

The invention discloses a heat-insulation fireproof coating applied to a pre-buried pipe of a vacuum cast aluminium alloy casting. The heat-insulation fireproof coating is prepared from the following components in parts by weight: 20-30 parts of sepiolite powder, 4-6 parts of cationic starch, 4-6 parts of expanded graphite, 1.5-3 parts of chloroplatinic acid, 1-3 parts of industrial alkali, 4-6 parts of modified clay, 4-6 parts of aluminium oxide, 4-6 parts of silicon carbide, 4-6 parts of sodium carboxymethylcellulose, 30-50 parts of deionized water, 1-3 parts of mullite, 1-3 parts of shell, 4-6 parts of sea mud, 1-3 parts of potassium titanate whiskers, 1-3 parts of silicon nitride, 1-3 parts of boron nitride, 1-3 parts of iron carbonate, 1-3 parts of titanium dioxide whiskers, 1-3 parts of magnesium carbonate, 1-3 parts of zinc oxide, 4-6 parts of calcined kaolin, 1-3 parts of white alum and 4-6 parts of kyanite powder. By improving the preparation of the conventional fireproof mud, a pre-buried copper pipe or stainless steel pipe is coated with a layer of fireproof coating with specific thickness; and the effects of insulating heat, preventing softening and preventing a liquid aluminum accommodation copper pipe from entering a pipeline can be implemented.

Owner:CHUZHOU JINNUO INDAL

Water system press-in grouting material used for iron making hot blast heater system and preparation method thereof

ActiveCN102765954ASolve the problem of red furnace shellSolve the Redness ConundrumChemical industryCelluloseSodium phosphates

The invention discloses a water system press-in grouting material used for an iron making hot blast heater system and a preparation method thereof. The material includes the following components by weight: 72-81 parts of bauxite, 5-10 parts of corundum fine powder, 3-6 parts of alpha aluminum micro powder, 1 part to 3 parts of green clay, 1 part to 3 parts of bentonite, 1 part to 3 parts of kyanite, 0.5-1 part of yttrium oxide, 0.5-1 part of lanthanum oxide, 1 part to 2 parts of dextrin, 2-4 parts of silica gel powder, 1 part to 2 parts of silicon powder, 0.5-1 part of carboxymethylcellulose, 0.2-1 part of sodium tripolyphosphate and 0.2-1 part of sodium hexametaphosphate. The water system press-in grouting material adopts a three-grade matching main material, a composite rare earth materials, a composite binding agent and the like, greatly improves compactness, greatly improves normal temperature strength, improves strength constantly with rise of temperature, and is good in heat and shock resistance stability and strong in anti-erosion capability. Pulverization dropping cannot happen after the material is pressed in a furnace lining, and the material can serve as a simple, effective, energy-saving furnace device maintenance material.

Owner:PINGXIANG KEXING FURNACE MATERIAL

Clay light-weight brick and preparation method thereof

InactiveCN103435332ALarge reservesRealize comprehensive utilizationCeramic materials productionCeramicwareBrickPhysical chemistry

The invention relates to a clay light-weight brick and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps of: firstly applying 30-40wt% of kyanite or flint clay, 35-45wt% of coal ash and 15-35wt% of plastic clays as raw materials, additionally adding 35-55wt% of pore-forming agents of the raw materials or 2-4wt% of polystyrene spheres, then additionally adding 6-10wt% of bonding agents of the raw materials, uniformly mixing, granulating, drying, and baking at 120-300 DEG C to prepare clay light-weight aggregates; then applying 10-20wt% of first-stage aggregates, 20-30wt% of second-stage aggregates, 15-25wt% of three-stage aggregates, 15-25wt% of the coal ash, 10-20wt% of the kyanite or the flint clay and 10-20wt% of the plastic clays as mixed materials, additionally adding 40-60wt% of the pore-forming agents of the mixed materials or 2-4wt% of the polystyrene spheres, then additionally adding 5-15wt% of the bonding agents of the mixed materials, uniformly mixing, forming, drying, and keeping temperature at 1200-1400 DEG C for 3-10 hours. The preparation method disclosed by the invention has the advantages of low cost, energy conservation and environmental friendliness; the product prepared through the method disclosed by the invention has the advantages of low volume density, good compressive strength as well as small linear changing rate and low heat conduction coefficient after being burnt.

Owner:WUHAN UNIV OF SCI & TECH

Mullite light heat-insulation brick based on flint clay and preparation method of brick

ActiveCN105503209AEasy to form large-scale industrial productionLow costCeramic materials productionClaywaresFiberBrick

The invention particularly relates to a mullite light heat-insulation brick based on flint clay and a preparation method of the brick. According to the technical scheme, the mullite light heat-insulation brick is prepared from the raw materials of 20-38 wt% of the flint clay, 20-32 wt% of kyanite, 20-32 wt% of clay and 14-26 wt% of alpha-alumina micro powder, and saw dust accounting for 30-50% of the weight of the raw materials, mullite fibers accounting for 5-11% of the weight of the raw materials and a binding agent accounting for 10-35% of the weight of the raw materials are additionally added; the materials are stirred for 6-8 h at room temperature, and then material aging, shaping and natural drying are conducted; an obtained product is baked for 12-24 h at the temperature ranging from 110 DEG C to 210 DEG C, heat preservation is conducted for 2-5 h at the temperature ranging from 1,150 DEG C to 1,450 DEG C, and the mullite light heat-insulation brick based on the flint clay is prepared. The preparation method has the advantages of being low in cost and simple in technology, and the prepared mullite light heat-insulation brick based on the flint clay has the advantages of being low in heat conductivity coefficient, low in volume density, low in linear shrinkage rate after burning and high in compressive strength.

Owner:WUHAN UNIV OF SCI & TECH

Heat-dissipation paint for iron casting surfaces

The invention provides a heat-dissipation paint for iron casting surfaces, relating to the technical field of heat-dissipation paints. The invention is characterized in that the heat-dissipation paint is composed of the following components in parts by weight: 30 parts of water-soluble epoxy resin, 5 parts of kyanite powder, 3 parts of silica sol, 4 parts of zircon flour, 3 parts of aluminum oxide, 5 parts of calcined potash feldspar, 2 parts of xylitol, 2 parts of calcined kaolin, 3 parts of barite powder, 5 parts of large-granule graphite, 50 parts of deionized water 2 parts of hexatitanium crystal whisker, 2 parts of flake graphite, 2 parts of zirconia, 5 parts of modifier, 2 parts of nano anion powder, 2 parts of silicon nitride, 2 parts of chromite powder, 2 parts of boric acid water solution, 1 part of nano titanium dioxide, 2 parts of polyester polyol and 2 parts of slaked lime powder. By adding the modifier into the traditional formula to perform modification treatment, the coated heat-dissipation paint can effectively achieve the effects of radiation and heat dissipation, has the advantages of low cost, low harm to the human body, high coating strength, no crack, no blister, uniform coating and high surface quality.

Owner:NINGGUO WANNAN FITNESS MATERIAL

Environment-friendly cordierite-mullite kiln furniture and preparation method thereof

Environment-friendly cordierite-mullite kiln furniture is prepared from the following raw materials in parts by weight: 25 to 35 parts of waste ceramics, 12 to 22 parts of cordierite-mullite clinker,30 to 45 parts of washing ball clay, 10 to 15 parts of andalusite, 8 to 13 parts of talcum powder, 5 to 15 parts of kyanite, 5 to 12 parts of industrial-alpha-alumina powder. According to the environment-friendly cordierite-mullite kiln furniture disclosed by the invention, a solid matter of a composite material of the environment-friendly cordierite-mullite kiln furniture is prepared by taking the waste ceramics, the cordierite-mullite clinker and the andalusite as aggregates and introducing the washing ball clay, the talcum powder, the kyanite and the industrial-alpha-alumina powder as matrix materials, so that the utilization rate of the waste ceramics is up to 25 to 35 percent, waste of resources is reduced, and the production cost of kiln furniture materials is also reduced; a prepared environment-friendly cordierite-mullite kiln furniture product has the advantages of low density, light weight, high bending strength under a normal temperature, high apparent porosity, good thermalshock stability and good energy-saving performance.

Owner:福建省德化县创捷窑具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com